Page 1

PNEG-1702

ETL Listed GSI/FFI Portable

Dryer Manual

Operation Manual

PNEG-1702

Date: 11-27-12

Page 2

Models:

100 Series (Models 108, 112, 114, 116, 118, 120, 122, 126, CFAB190, CFAB270, CFAB320, CFAB370,

CFAB400, CFAB460, CFAB511, CFAB60 1)

1100 Se rie s (Models 1108, 1112, 1114, 1116, 1118, 1120, 1122, 1126, CFAB190, CFAB270, CFAB320,

CFAB370, CFAB400, CFAB460, CFAB510, CFAB511, CFAB601)

1200 Series (Models 1214, 1216, 1218, 1220, 1222, 1226, C2120A, C2122A, C2125A, C2130A,

C2132A, C2140A)

1200S Series (Models 1214S, 1218S, 1220S, 1222S, 1226S, CF2141, CF2181, CF500H,

CF2221, CF650M)

2300 Series (Models 2314, 2318, 2320, 2322, 2326, CF3142, CF3182, CF3202, CF3222, CF3262

2400 Series (Models 2420, 2426, CF1000H, CF1300M)

3400 Series (Models 3414, 3418, 3420, 3422, 3426, CF4143, CF4183, CF4203, CF4223, CF4263)

3600 Series (Models 3620, 3626, CF1500H, CF2000M)

X-Stream Configuration - Uses same model numbers (and components) as listed above. The only

difference is that the fans are pointed in different directions.

2 PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual

Page 3

Table of Contents

Contents

Chapter 1 Introduction ..........................................................................................................................................6

Dryer Operation ..................................................................................................................................... 6

Operating Precautions ..................................................... .......................................... ... ... ... .................. 6

Chapter 2 Safety .....................................................................................................................................................8

Safety Guidelines .................................................................................................................................. 8

Emergency Stop Switch ................................... ... ... ... .... ... ... ... .... ... ... ..................................................... 9

Chapter 3 Decals ..................................................................................................................................................10

Chapter 4 Installation ..........................................................................................................................................14

Transporting/Single Fan ................................... ... ... ... .... ... ... ... .... ......................................... . ............... 14

Location of the Dryer ........................................................................................................................... 15

Foundation .......................................................................................................................................... 15

Supporting the Dryer ........................................................................................................................... 15

Anchor Points ...................................................................................................................................... 15

Wet/Dry Grain ..................................................................................................................................... 15

Electrical Power Supply ...................................................................................................................... 16

Fuel ..................................................................................................................................................... 18

Single Fan Foundation ........................................................................................................................ 22

Chapter 5 Specifications .....................................................................................................................................24

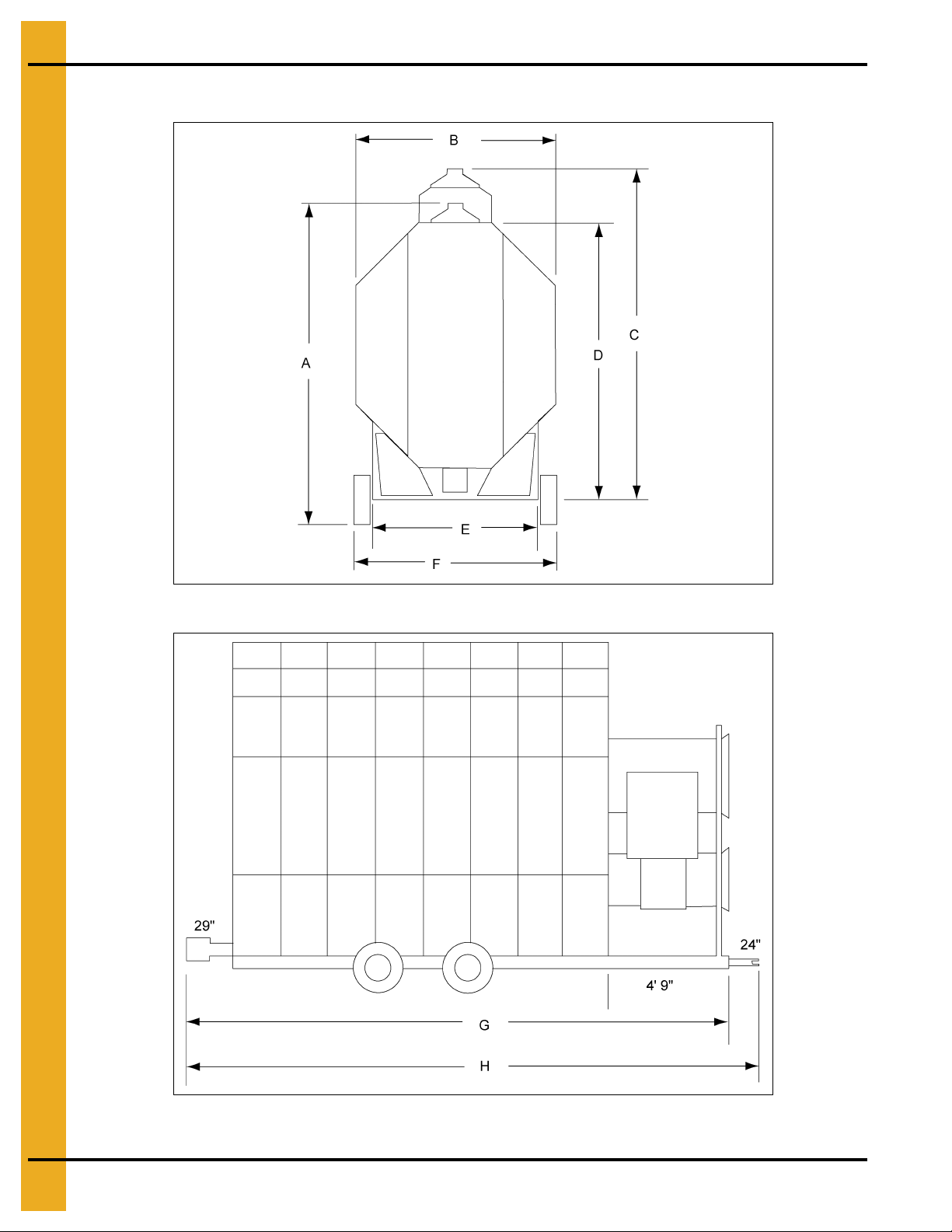

FFI Dimensions ................................................................................................................................... 24

FFI Specifications ................................................................................................................................ 26

GSI Dimensions .................................................................................................................................. 28

GSI Specifications ............................................................................................................................... 30

All Stack Dimensions .......................................................................................................................... 32

All Stack Specifications ....................................................................................................................... 35

Stack Dryer Foundation Specifications ............................................................................................... 39

Chapter 6 Competitor/Dri-Tek Test Firing .........................................................................................................40

Inspect the Metering Rolls ................................................................................................................... 40

Set Control Switches ........................................................................................................................... 41

Electrical Power .................................................................................................................................. 41

Control Power Switch .......................................................................................................................... 41

Power Start Button .............................................................................................................................. 41

Fuel Check .......................................................................................................................................... 41

Load Auger .......................... ... .......................................... .......................................... ......................... 42

1 Speed Operation .............................................................................................................................. 42

Metering Roll Operation ...................................................................................................................... 42

Fan Switch .......................................................................................................................................... 43

Burner Safety ...................................................................................................................................... 43

Burner Test Fire .................................................................................................................................. 43

Staged Batch Check ........................................................................................................................... 45

Stopping Dryer Operation ................................................................................................................... 45

Dryer Shutdown .................................................................................................................................. 45

Emergency .......................................................................................................................................... 45

PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual 3

Page 4

Table of Contents

Chapter 7 Vision Test Firing ...............................................................................................................................46

Dryer Pre-Season Checks .................................................................................................................. 46

Inspect the Metering Rolls ................................................................................................................... 46

Check Control Panel Switches ............................................................................................................ 46

Electrical Power ...................................... ... ... .......................................... .... ... ... .................................. 46

Control Power Switch .......................................................................................................................... 46

Start Switch ......................................................................................................................................... 46

Fuel Check .......................................................................................................................................... 46

Load Auger ................. ... .......................................... ............................................................................ 47

Unload Auto Operation ........................................................................................................................ 47

Unload Manual Operation ................................................................................................................... 47

Meter Roll Operation ........................................................................................................................... 47

Fan Switches ....................................................................................................................................... 48

Burner Safety ...................................................................................................................................... 48

Burner Test Fire .................................................................................................................................. 48

Dryer Shutdown .................................................................................................................................. 50

Emergency .......................................................................................................................................... 50

Chapter 8 Competitor Dryer Operation ..............................................................................................................51

Continuous Flow Operation ........... .... ... ... ... ... .......................................... .... ... ... ... .... ... ... ... ... ............... 51

Full Start-Up Check ............................................................................................................................. 51

Filling the Dryer ................................................................................................................................... 51

Staged Batch Operation ...................................................................................................................... 52

Starting the Dryer ................................................................................................................................ 53

Adjusting the Temperature .................................................................................................................. 54

Full Heat Continuous Flow Operation ................................................................................................. 55

Adjusting the Moisture Control ............................................................................................................ 56

Chapter 9 Vision/Dri-Tek Dryer Operation .........................................................................................................57

Dryer Start-Up and Operation Full Heat Drying .................................................................................. 57

Drying Temperatures .......................................................................................................................... 57

Dryer Shutdown .................................................................................................................................. 57

Initial Setup Parameters ...................................................................................................................... 57

Timer and Delay Settings .................................................................................................................... 57

Setting the Temperatures .............. .... ... ... .......................................... ... ... .... ... ... ... .... ........................... 58

Start-Up ................................... ....................................................... ..................................................... 58

Continuous Flow Drying Mode Using Regulation of Grain Temperature ............................................ 59

Continuous Flow Drying Mode Using Regulation of Moisture: 5 MR SP ............................................. 66

Chapter 10 Vision/Competitor Illustrations .......................................................................................................70

Supply Line (LP Shown) .................................................................................................................... 70

28" and 36" LP Fan/Heater Pipe Train .............................................................................................. 71

40" and 42" LP Fan/Heater Pipe Train .............................................................................................. 72

LP Vaporizer Coil Adjustment ............................................................................................................ 73

NG Fan/Heater Pipe Train ................................................................................................................. 73

Competitor Fan/Heater Control Box .................................................................................................. 74

Vision Fan/Heater Control Box .......................................................................................................... 74

Top Auger Drive .......................................... .... ... ... .......................................... ... .... ........................... 75

Discharge Safety Switch .................................................................................................................... 75

Meter Roll Speed Sensor .................................................................................................................. 76

Vision Upper Control Box .................................................................................................................. 77

Vision Control Panel (Rear) ............................................................................................................... 78

Vision Lower Control Box (Back Panel) ............................................................................................. 79

Competitor Lower Control Box .......................................................................................................... 80

Competitor Rear Control Panel ......................................................................................................... 80

Competitor Upper Control Box .......................................................................................................... 81

4 PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual

Page 5

Table of Contents

Chapter 11 Service ...............................................................................................................................................82

Seasonal Inspection/Service ............................................................................................................. 82

Lubrication Procedure .................................................... ... ... .... ... ... ... ... .... ... ... ................................... 84

Fan Blade Removal and Installation ............................ ................................................ ...................... 85

Fan Motor Removal and Installation .................................................................................................. 86

Heater Parts Removal and Installation .............................................................................................. 86

Metering Roll Servicing ...................................................................................................................... 87

Main Controls .................................................................................................................................... 87

How to Clear a Jammed Meter Roll (All Power “OFF”) ..................................................................... 88

Chapter 12 Competitor/Dri-Tek Schematics and Wiring Diagrams .................................................................89

Competitor/Dri-Tek Single Fan Wiring to Control Box ....................................................................... 89

Competitor/Dri-Tek Lower Switch Panel Wiring .......................................... ... ... .... ............................ 90

Competitor/Dri-Tek Lower Back Panel Wiring ...................... .... ... ... ... ... .... ... ... ... .... ... ... ... ... ................ 92

Competitor/Dri-Tek Upper Control Panel Wiring for Canadian Export .............................................. 94

Competitor/Dri-Tek Upper Control Panel Wiring for Canadian Export

220 Volt 1 Phase and 3 Phase ....................................... ... ... .... ... ... ... ... .... ......................................... 97

Competitor/Dri-Tek Upper Control Panel Wiring for Canadian Export 380, 440, 575 Volt ................ 98

Competitor/Dri-Tek Control Schematic ........................ ... ... ... .... ... ... ... ... .... ... ... ... .... ............................ 99

Competitor/Dri-Tek 220 VAC 1 Phase Power Schematic .................. ... .... ... ... ... .... ... ... ... ... .... ... ... ... . 104

Competitor/Dri-Tek 220 VAC 3 Phase Power Schematic .................. ... .... ... ... ... .... ... ... ... ... .... ... ... ... . 105

Competitor/Dri-Tek 440 VAC 3 Phase Power Schematic .................. ... .... ... ... ... .... ... ... ... ... .... ... ... ... . 106

Competitor/Dri-Tek 575 VAC 3 Phase Power Schematic .................. ... .... ... ... ... .... ... ... ... ... .... ... ... ... . 107

Chapter 13 Vision Schematics and Wiring Diagrams ................ ... ... ... .... ... ... ... ... .... ... ... ..................................108

Fan/Heater Standard ....................................................................................................................... 108

Front Panel . ... ... .... ... ... ... .... ... .......................................... ... ... .................................................... ... ... . 109

Upper Control Box ........................................................................................................................... 131

220 VAC 1 Phase . ... ... ... .... ... ... ... .... .......................................... ... ... ... .............................................. 134

220 VAC 3 Phase . ... ... ... .... ... ... ... .... .......................................... ... ... ... .............................................. 135

440 VAC 3 Phase . ... ... ... .... ... ... ... .... .......................................... ... ... ... .............................................. 136

575 VAC 3 Phase . ... ... ... .... ... ... ... .... .......................................... ... ... ... .............................................. 137

Ladder Diagram ............................................................................................................................... 138

Chapter 14 Warranty ..........................................................................................................................................141

PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual 5

Page 6

1. Introduction

Dryer Operation

Thank you for choosing a GSI/FFI Vision Series Grain Dryers. These units are among the finest

grain dryers ever built; designed to give the excellent operating performance and reliable service for

many years.

This manual describes the installation and operation for all standard production model dryers. These

dryers are available with liquid propane or natural gas fuel supply, 1 phase 230 volt, 3 phase 230 volt,

460 volt, or 575 volt (60 Hz) electrical power.

Our foremost concern is your safety and the safety of others associated with this equipment. We want to

keep you as a customer. This manual is to help you understand safe operating procedures and some

problems which may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards and precautions

exist, and to inform all personnel associated with the equipment or in the area. Safety precautions may be

required from the personnel. Avoid any alterations to the equipment. Such alterations may p roduce a very

dangerous situation where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable

regulations which should be carefully followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

Operating Precautions

READ THESE INSTRUCTIONS BEFORE INSTALLATION AND OPERATION

SAVE FOR FUTURE REFERENCE

1. Read and understand the operating manual before attempting to operate the unit.

2. Keep ALL guards, safety decals, and safety devices in place. NEVER operate dryer while guards

are removed.

3. Keep visitors, children and untrained personnel away from dryer at all times.

4. NEVER attempt to operate the dryer by jumping or otherwise bypassing any safety devices on

the unit.

5. Always set the main power supply disconnect switch to OFF and lock it in the OFF position

using a padlock before performing any service or maintenance work on the dryer or the auxiliary

conveyor equipment.

6. Before attempting to remove and reinstall the fan blade, make certain to read recommended

procedure listed within the SERVICING section on Page 85 of the manual.

7. Keep the dryer and wet holding equipment CLEAN. DO NOT allow fine material to accumulate.

8. Set pressure regulator to avoid excessive gas pressure applied to a burner during ignition and

when burner is in operation. See Page 49 for operating gas pressures. DO NOT exceed maximum

recommended drying temperatures.

9.

DO NOT

10. Clean grain is safer and easier to dry. Fine materials can be highly combustible, and it also requires

removal of extra moisture.

11. Use CAUTION in working around high speed fans, gas burners, augers and auxiliary conveyors

which can START AUTOMATICALLY.

6 PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual

operate the dryer if any gas leak is detected. Shutdown and repair before further operation.

Page 7

1. Introduction

CAUTION

Keep the dryer clean. Do not allow fine material to accumulate in the plenum

chamber or surrounding the outside of the dryer.

Operating Precautions (Continued)

12. Make sure that capacities of auxiliary conveyors are matched to dryer metering capacities.

13. DO NOT operate in an area where combustible material will be drawn into the fan.

14. The operating and safety recommendations in this manual pertain to the common cereal grains as

indicated. When drying any other grain or products, consult the factory for additional recommendations.

15. Routinely check for any developing gas plumbing leaks. Check LP vaporizer for contact with

burner vanes.

Use Caution in the Operation of this Equipment

This dryer is designed and manufactured with operator safety in mind. However, the very nature

of a grain dryer having a gas burner, high voltage electrical equipment and high speed rotating parts,

presents hazards to personnel which cannot be completely safeguarded against without interfering with

the efficient operation of the dryer and reasonable access to its components.

Use extreme caution in working around high speed fans, gas-fired heaters, augers and auxiliary

conveyors, which may start without warning when the dryer is operating on automatic control.

Continued safe, dependable operation of automatic equipment depends, to a great degree, upon the

owner. For a safe and dependable drying system, follow the recommendations within the Owner’s Manual

and make it a practice to regularly inspect the unit for any developing problems or unsafe conditions.

Take special note of the Operating Precautions on Page 6 before attempting to operate the dryer.

PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual 7

Page 8

2. Safety

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in property damage.

NOTE indicates information about the equipment that you

should pay special attention.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

Personnel operating or working around electric fans should read this manual. This manual

must be delivered with the equipment to its owner. Failure to read this manual and its

safety instructions is a misuse of the equipment.

WARNING! BE ALERT!

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment of

these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

DANGER

WARNING

CAUTION

NOTICE

8 PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual

Page 9

Emergency Stop Switch

WARNING

Pushing the Emergency Stop switch does not interrupt the main power to the

upper control box panel.

2. Safety

The Emergency Stop switch is located on the upper control box door. Pushing the Emergency Stop switch

will interrupt the control power and stop all dryer functions.

PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual 9

Page 10

3. Decals

DC-1948

Lockout power

before servicing.

Will cause serious

injury or death.

HIGH VOLTAGE.

Vérouillez le

courant avant

l’entretien.

Causera de

sérieuses blessures

ou la mort.

HAUTE TENSION

HIGH VOLTAGE.

Will cause injury

or death.

Lockout power

before servicing.

HAUTE TENSION.

Causera blessure

ou la mort.

Fermez le courant

avant l’entretien.

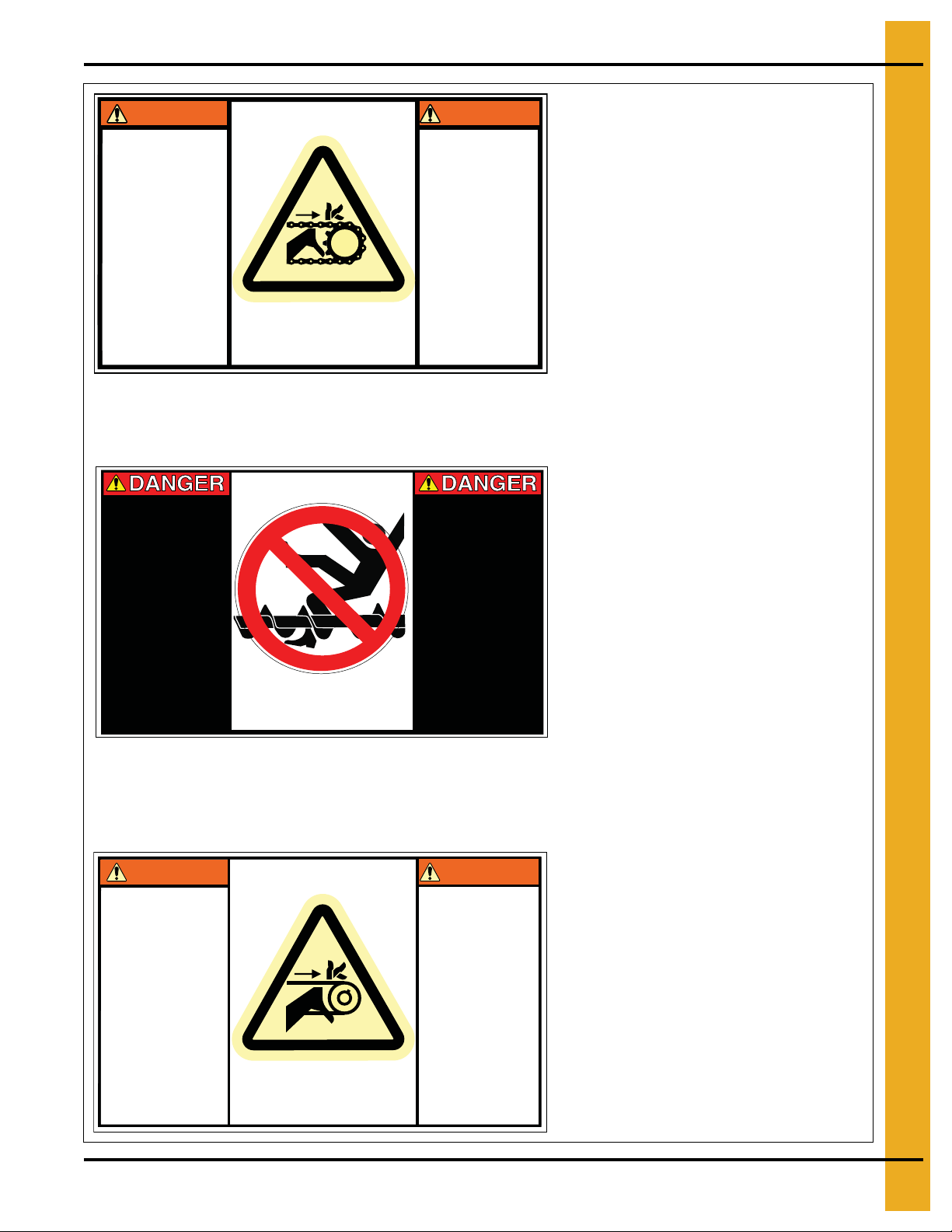

DC-1943

Decal: DC-1943

Decal DC-1943 has two (2)

locations. One inside the

fan/heater control box and

another on the dryer upper control

box door next to the main power

disconnect.

Decal: DC-1948

Decal DC-1948 is located in

two (2) places on the fan/heater

control box. One on the lid and

one on the front of the fan/heater

control box. Another location for

this decal is inside the upper

control box for the dryer.

GSI Group recommends contacting the local power company, and having a representative survey the

installation so the wiring is compatible with their system, and adequate power is supplied to the unit. Safety

decals should be read and understood by all people in the grain handling area.

If a decal is damaged or is missing, contact:

GSI Decals

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 1-217-226-4421

A free replacement will be sent to you.

10 PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual

Page 11

Déplacer des pièces

peut écraser et couper.

Gardez les mains

éloignées. Ne pas faire

fonctionner sans avoir

de gardes en place.

L’omission de faire ceci

pourra résulter à de

sérieuses blessures.

Moving parts can crush

and cut. Keep hands

clear. Do not operate

without guards in place.

Failure to do so could

result in serious injury.

WARNING

AVERTISSEMENT

DC-1945

Rotating auger will

crush and cut. Auto

equipment can start

at anytime. Do not

enter until electric

power is locked in off

position. Failure to do

so will result in

serious injury or

death.

La foreuse tournante

écrasera et coupera.

L’équipement

automatique peut se

mettre en marche en

tout temps. Ne pas

entrer tant que la

puissance

électrique ne soit

fermée à la position

‘arrêt’.

DC-1947

Automatically controlled

belt drive can start at

anytime. Keep hands

clear. Failure to do so

could result in serious

injury.

La conduite

automatiquement

contrôlée de la courroie

peut démarrer à tout

moment. Gardez les

mains éloignées.

L’omission de faire ceci

pourra résulter à de

sérieuses blessures.

WARNING

AVERTISSEMENT

DC-1944

Decal: DC-1945

Decal DC-1945 is located on the bottom auger

belt guard and the front bearing plate (which is

visible when the bottom auger belt guard is

removed). An alternate location would be at the

rear of the dryer for portable dryers equipped

with the Front Discharge Option.

Decal: DC-1944

Decal DC-1944 is located on the bottom auger

belt guard and the front bearing plate (which is

visible when the bottom auger belt guard is

removed). An alternate location would be at the

rear of the dryer for portable dryers equipped with

the

Front Discharge Option

. Another location

for decal DC-1944 is on the top of the auger belt

guard (one on the belt guard cover and one on

the inside belt guard body visible when the belt

guard cover is removed).

Decal: DC-1947

Decal DC-1947 has several different locations.

Two (2) are located on the front end panel

below the fan/heater. Two (2) are located on

the rear end panel below the rear access door.

Two (2) are located on the auger discharge box

(one on the outside top and one on the inside of

the flapper lid next to the discharge mercury

switch). One more of these decals is located

inside the plenum on the rear plenum closure

door just inside the rear access door.

3. Decals

PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual 11

Page 12

3. Decals

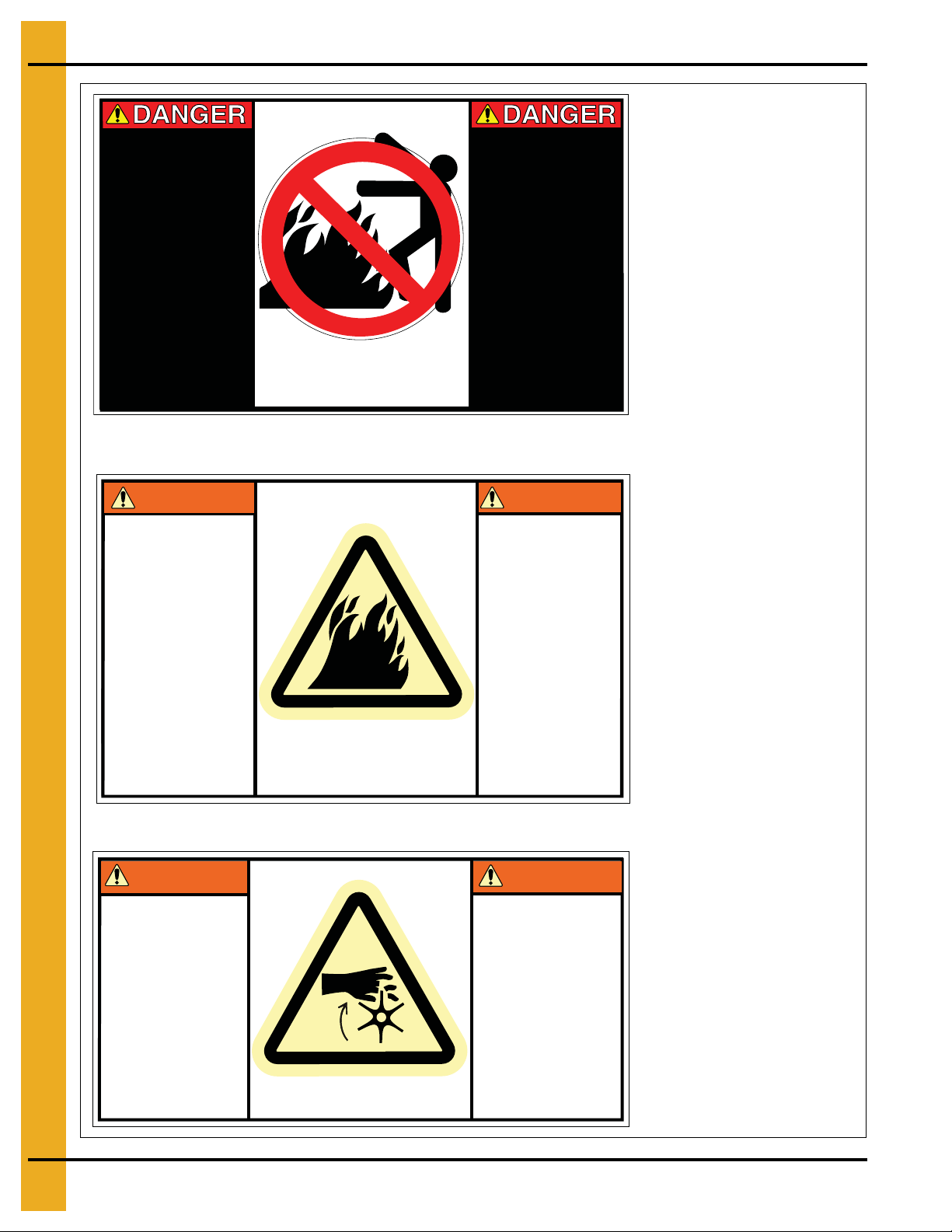

Automatic equipment

can start at anytime.

Do not enter until

fuel is shut off and

electrical power is

locked in off position.

Failure to do so will

result in serious

injury or death.

L’équipement

automatique peut se

mettre en marche en

tout temps. Ne pas

entrer tant que le

courant ne soit pas

coupé, et le courant

électrique fermé à la

position ‘arrêt’.

L’omission de faire

ceci pourra résulter à

de sérieuses

blessures ou la mort.

DC-1946

WARNING

AVERTISSEMENT

DC-1959

Flame and pressure

beyond door can

cause serious injury.

Do not operate with

service door removed.

Keep head and

hands clear.

La flamme et la

pression au-delà de la

porte peuvent causer

des dommages

sérieux. Ne pas faire

fonctionner si la porte

de service est

enlevée. Gardez les

mains et la tête

éloignés.

Decal: DC-1950

Decal DC-1950 is located on each

of the meter roll access doors.

Decal: DC-1946

Decal DC-1946 is located on the

rear plenum access door (inside

and outside).

Decal: DC-1959

Decal DC-1959 is located on

the fan/heater access door.

WARNING

Rotating metering roll.

Equipment can start

automatically. Keep

hands clear. Can cause

serious injury.

Disconnect power

before servicing.

AVERTISSEMENT

Compteur de roulement

tournant. L’équipement

automatique peut se

mettre en marche en

tout temps. - Gardez les

mains éloignées.

Débranchez le courant

avant l’entretien.

DC-1950

12 PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual

Page 13

3. Decals

Hitch pin must be

securely fastened and

no less than 3/4" in

diameter. Failure to

follow installation

instructions may result

in properly damage.

La goupille du crochet

doit être solidement

attachée et pas moins

de 3/4" de diamètre.

L’omission de suivre les

instructions d’installation

peut résulter à du

dommage de propriété.

DC-1954

ATTENTION CAUTION

3/4" MINIMUM

BOLT DIAMETER

SPEED

LIMIT

45

16-17"

Dryer must be towed

empty and in

accordance with

state and provincial

regulations.

Le séchoir doit être

remorqué vide et en

conformité avec les

réglements de l’état

et provinciaux.

HUB TEMPERATURE

TIGHTEN TO

90FT-LBS.

55-60 PSI COLD

CHECK AFTER 50 MILES AND EVERY 200 MILES

050

100

150

200 250

NO GREATER THAN 150°F

150°

DC-1956

ATTENTION CAUTION

Decal: DC-1954

Decal DC-1954 is located on the hitch tongue.

Decal: DC-1956

Decal DC-1956 is located on the hitch tongue.

Decal: DC-1949

Decal DC-1949 is located on

the fan/heater access door.

WARNING

Stay clear of rotating

blade. Blade could

start automatically.

Can cause serious

injury. Disconnect

power before

servicing.

AVERTISSEMENT

Restez éloigné de la

lame tournante. La

lame peut se mettre

en marche

automatiquement.

Peut causer de

sérieuses blessures.

Vérouillez le courant

avant l’entretien.

DC-1949

PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual 13

Page 14

4. Installation

Tow chain

14"-17" Height

Washers

Locking nut

3/4" Minimum bolt diameter

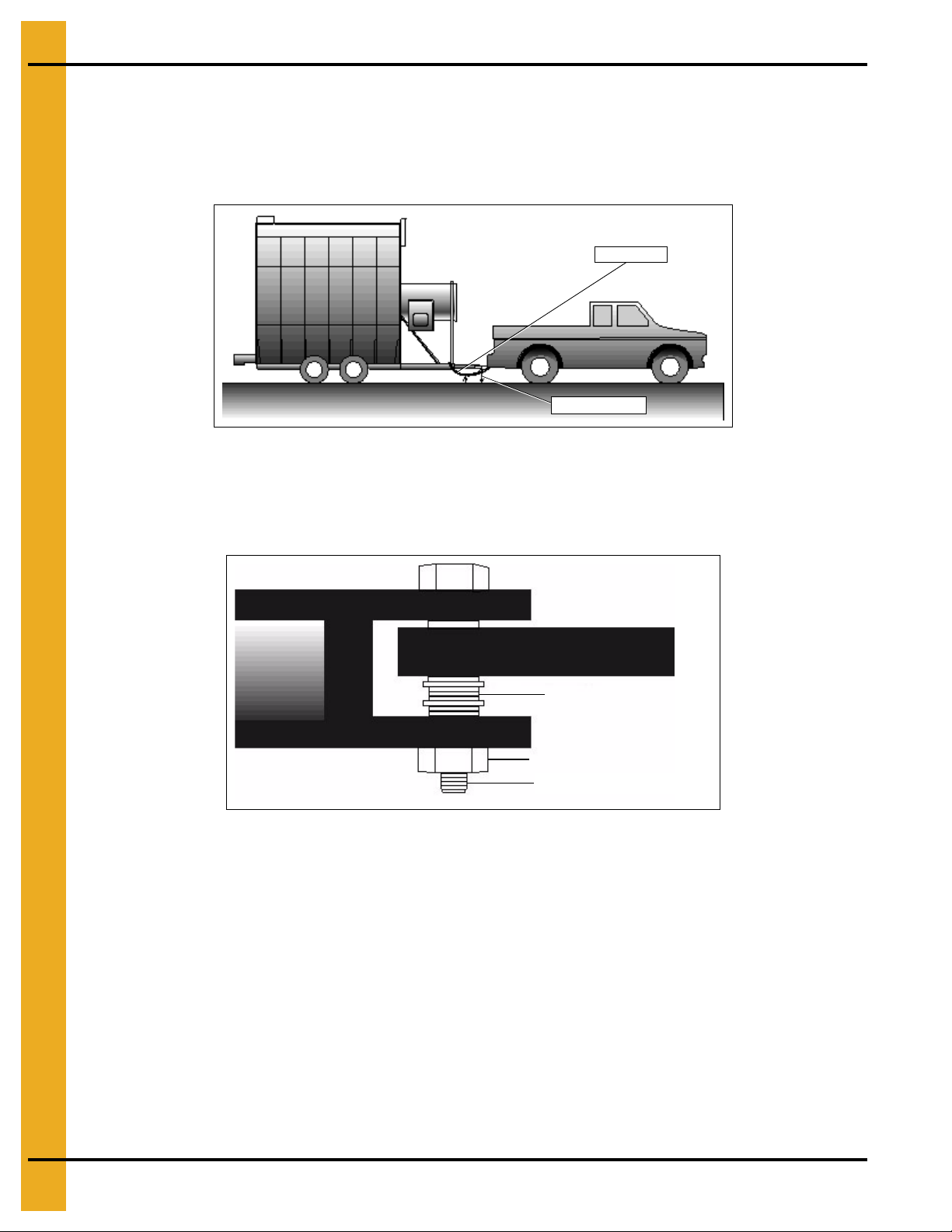

Transporting/Single Fan

The dryer is available with an optional transport kit for transporting the unit by truck or tractor. Make certain

to observe the following safety precautions.

1. Recommended towing hitch height is 14"-17''. (See Figure 4A.)

Figure 4A Use a 14"-17'' Towing Hitch Height and a Safety Chain

2. Hitch bolt must be at least 3/4" in diameter and securely fastened with a locking nut, so it will not

come out during travel and the hitch will not bend. (See Figure 4B.)

3. Be sure to minimize vertical hitch play with washers. (See Figure 4B.)

Figure 4B A 3/4'' Hitch Bolt and Washers Fastened with a Locking Nut

at the Bottom of the Hitch

4. Always use a safety chain. (See Figure 4A.)

5. Dryer must be towed empty and in accordance with applicable state or provincial regulations.

NOTE: NEVER tow dryer with grain or any other material inside of it.

6. Recommended tire pressure is 55-60 PSI (cold).

7. Maximum towing speed is 45 miles per hour or the speed limit, whichever is lower.

8. After the first 50 miles and every 200 miles thereafter, check the following:

a. Dryer wheel hub and spindle temperature immediately after stopping. Temperature should not

exceed 150°F. It may be hot to touch, but not melting lubricant.

b. Wheel lug nuts. They are factory torqued at 115 to 120 ft. lbs. Retighten, if required.

14 PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual

Page 15

4. Installation

Location of the Dryer

When considering the exact location of the dryer, also consider the wet grain supply and dry grain

discharge, as well as the location of storage bins and other grain handling equipment. Do not install

the dryer inside a building or in any other area where not allowed by electrical codes, fuel installation

regulations and/or insurance requirements. Maintain a minimum distance of at least 3' from other

structures, otherwise air flow problems may occur. Do not operate in an area where combustible materials

can be drawn into the fans or where load and unload augers can come in contact with power lines.

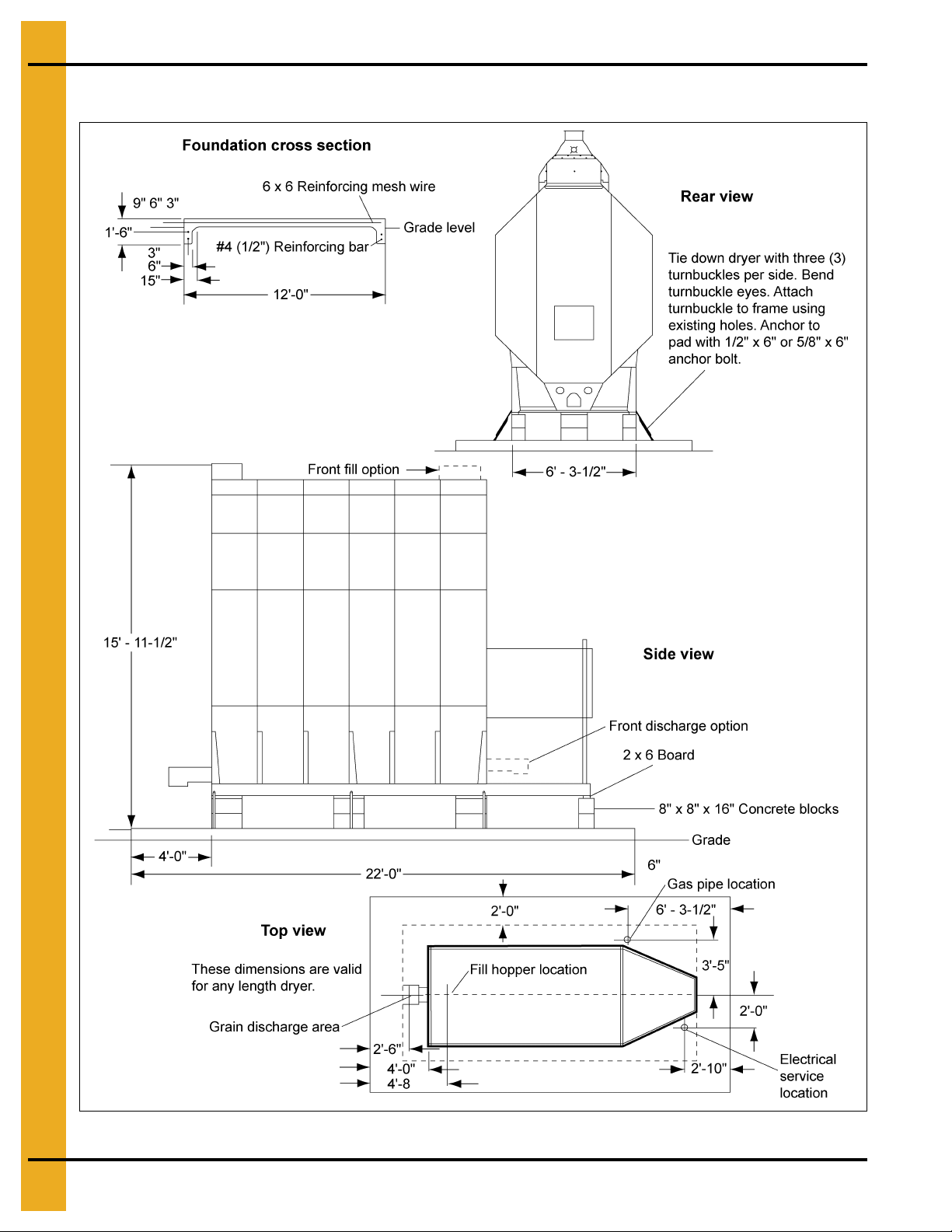

Foundation

A reinforced concrete pad or similar permanent foundation is recommended for dryer stability.

See Pages 22 and 23 for details.

Supporting the Dryer

The wheels are to be used for transporting the dryer only when empty. Before loading any grain into the

dryer, the frame of the unit on each side must be supported. Place concrete blocks on each side, every

6' of the frame, as well as at the hitch mount location with the hitch removed. The blocks must be able to

support the dryer as well as the additional weight of the grain when full. Use shims to provide uniform, level

support for all blocks. The dryer should be at least 16'' off the pad to allow for clean out and the use of

auxiliary grain handling equipment. The hitch tongue should be removed, but the hitch assembly and the

fan support must be left on during operation; they are not part of the transport tie down assembly.

NOTE: Use a minimum of one support per each 6' of basket length on each side.

Anchor Points

Anchor points may be cast into the concrete slab or the dryer may be tied down by cables and turnbuckles

to anchors installed at the edge of the slab. This helps prevent overturn or lateral movement by wind or

other forces.

Wet/Dry Grain

Wet Grain Supply

A wet grain holding bin provides gravity flow to the dryer or loading conveyor. This conveyor may

be electrically connected to the power circuit provided in the main control box. Initially, the dryer will fill

completely. During drying, the top auger will start and stop as required depending upon the dry grain

discharge rate and grain shrinkage to maintain the dryer fill. If the dryer does not fill within the pre-set

time on the out of grain timer (See Vision Manual for instructions on setting this timer), the dryer

will shutdown.

Dry Grain Removal

The dry grain is normally discharged out of the rear end of the dryer. Front discharge is an optional feature.

A take away system needs to be provided to remove grain from the drying system. This conveyor may be

electrically connected to the power circuit provided in the main control box.

PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual 15

Page 16

4. Installation

Electrical Power Supply

Power Supply

An adequate power supply and proper wiring are important factors for maximum performance and long

life of the dryer. Electrical service must be adequate to prevent low voltage da mage to motors and control

circuits. (See Chapter 5 on Pages 24-36.) Power supply for 1 phase models must include a neutral wire.

Transformers and Wiring Voltage Drop

Advise the service representative of the local power supplier that an additional load will be placed on the

line. Check the KVA rating of transformers, considering total horsepower (HP) load. The power supply

wiring, main switch equipment and transformers must provide adequate motor starting and operating

voltage. Voltage drop during motor starting should not exceed 14% of normal voltage. After motor

is running at full speed, it should be within 8% of normal voltage. Check electrical load information

(See Chapter 5 on Pages 24-36)

Power Supply Disconnect

All dryers are equipped with a power disconnect switch in the power box to permit total power shutdown

before opening the power box door, as required for inspection and service. The power disconnect switch

is located on the power box door for quick shutdown.

for HP ratings and maximum amp loads.

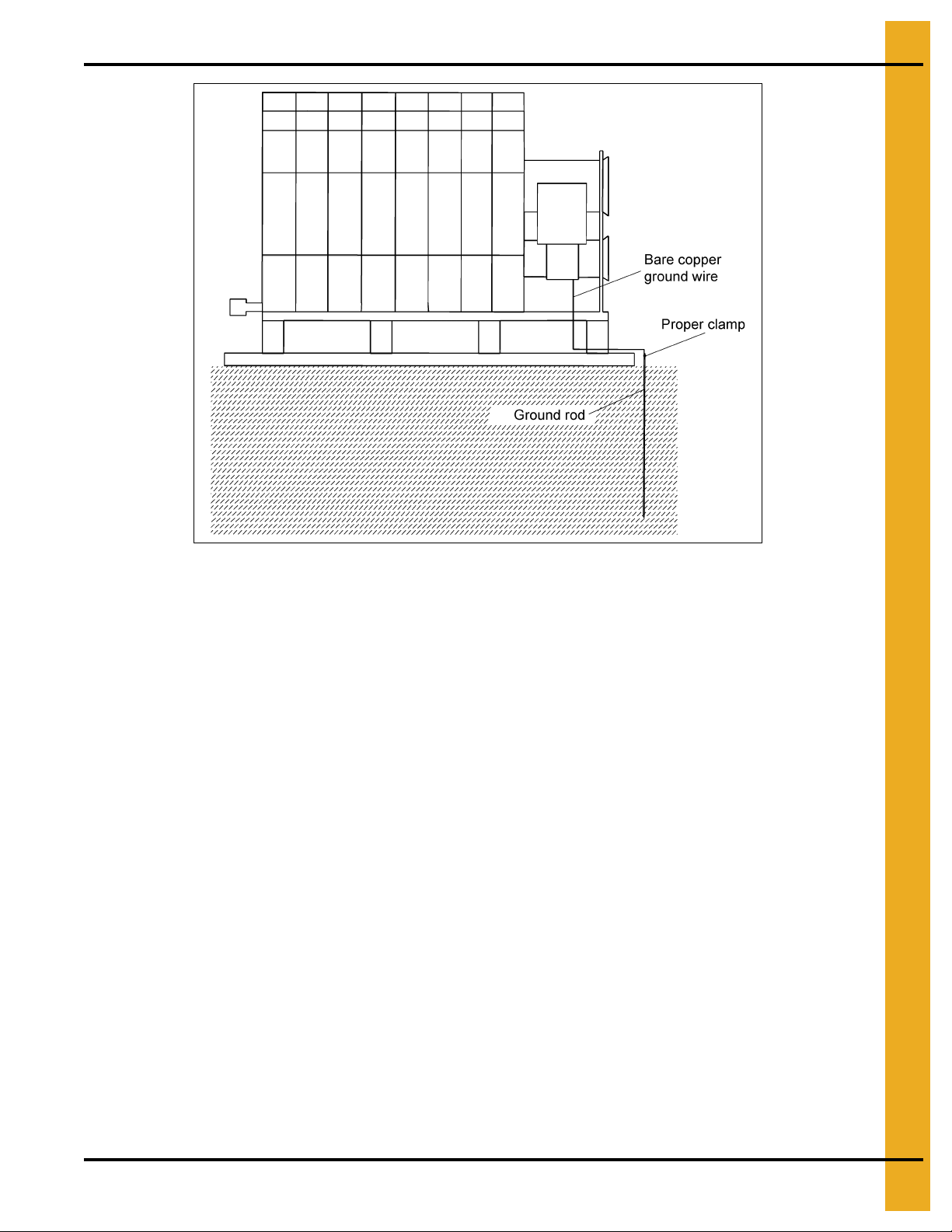

Machine to Earth Grounding

A Machine to Earth Ground Rod must be installed at the dryer. Place the ground rod that co mes standard

within 8' of the dryer and attach it to the dryer control panel with at least a #6 solid, bare, copper ground

wire and the clamp provided. The grounding rod located at the power pole will not provide adequate

grounding for the dryer. Proper grounding will provide additional safety in case of any short and will ensure

long life of all circuit boards, the SCR drive and the ignition system. The ground rod must be in accordance

with local requirements.

All wiring to be done in accordance with the Canadian Electrical Code.

16 PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual

Page 17

4. Installation

Figure 4C Installation of a ground rod (standard with dryer purchase) specifically

for the grain dryer is necessary for safety and equipment preservation.

Proper Installation of Ground Rod

The rod should not be driven into dry ground. Follow these instructions for proper installation.

1. Dig a hole large enough to hold one to two (2) gallons of water.

2. Fill hole with water.

3. Insert rod through water and “jab” it into the ground.

4. Continue “jabbing” the rod up and down. This allows the water to work its way into the ground,

allowing it to be completely inserted into the ground. This method of installation also assures good

contact with the surrounding soil, thereby making a proper ground.

5. Connect the bare, copper ground wire to the rod with the proper clamp.

6. Connect ground wire to control panel with the ground lug provided in the control box.

7. Ground wire must not have any breaks or splices. Do not use insulated wire for grounding ap plications.

Connecting Auxiliary Conveyors

The auxiliary load and auxiliary unload augers or conveyors can be wired directly to the dryer. Electrical

load information in Chapter 5 on Pages 24-36 shows the maximum horsepower and amps of auxiliaries

that can be wired to the dryer. If an auxiliary motor is larger than recommended, it must be powered from

a source outside the dryer and must use a separate contactor and overload protection device for each

motor. However, the operation of the auxiliaries can be performed by the control panel.

PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual 17

Page 18

4. Installation

See Fuel Specification

Chart on Page 19 for

recommended line use.

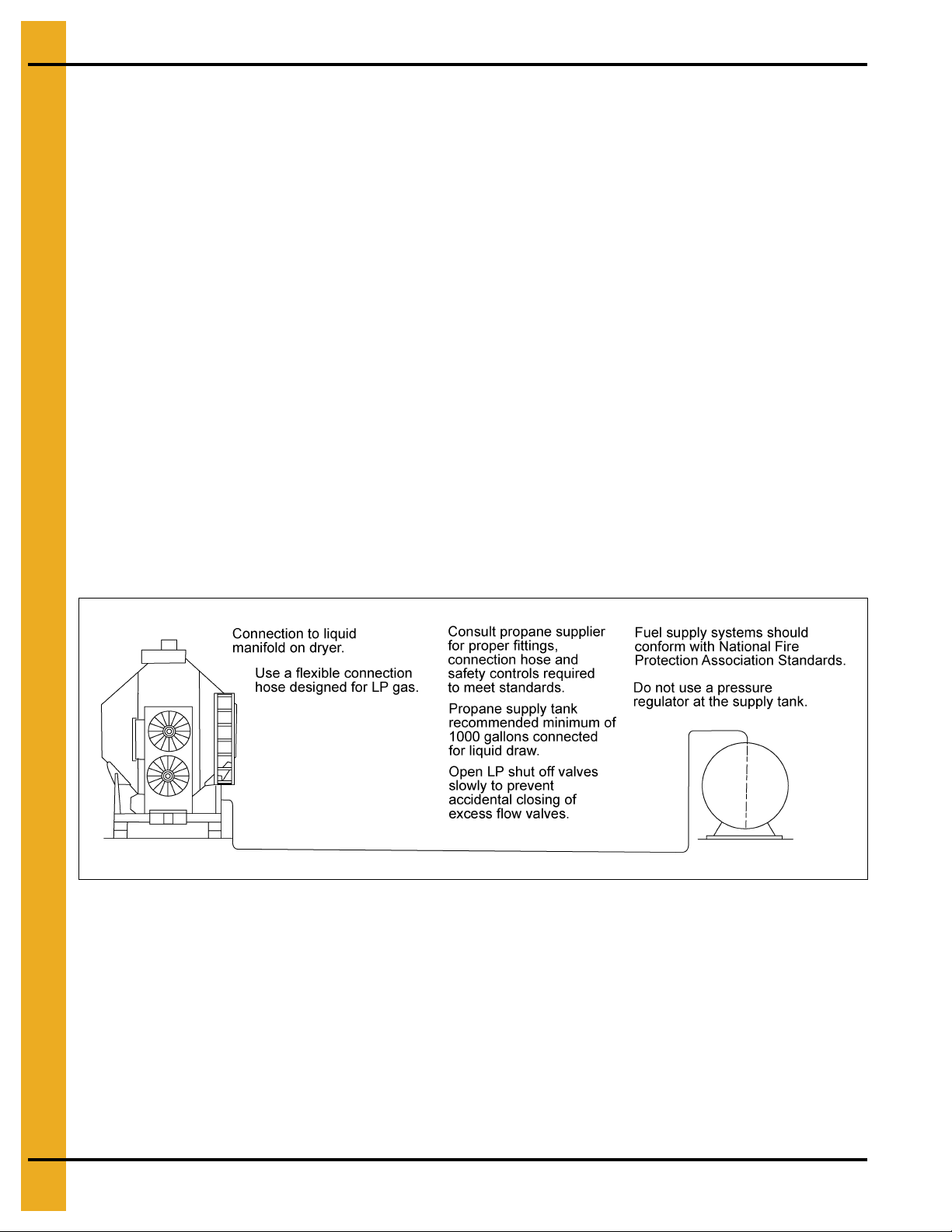

Fuel

Liquid Propane (LP)

Liquid Draw

The dryers have internal vaporizers and are designed to operate on liquid draw from the supply tank. The

tank should be 1000 gallons or larger and should not have a regulator mounted to it. The connection to

the dryer should be with a flexible hose designed for LP gas, See Chart on Page 19 for proper size.

Consult your LP gas dealer for proper fittings, connection hose and safety controls required to meet local

standards and to conform with National Fire Protection Association standards. The piping train on the

dryer includes strainer, pressure relief valve, electronic safety shut off valve (on some models) and a

pressure regulator between the vaporizer and burner.

Ammonia Tanks

Do not use tanks which have previously been used for ammonia or fertilizer solutions. These substances

are extremely corrosive and will damage fuel supply and burner parts.

Oil or Water in Tanks

With liquid draw from the supply tank, any water or oil present in the tank may freeze in the pipe train or

controls causing damage. To make sure the tank is free of moisture, it can be purged with methanol.

Avoid tanks which may contain an accumulation of oil or heavy hydrocarbon from long use on a vapor

withdrawal system.

Figure 4D Grain dryer connected to a liquid propane tank.

“The equipment shall be installed in accordance with the current INSTALLATION CODES FOR GAS

BURNING APPLIANCES AND EQUIPMENT, CAN/CGA-B149.1 and CAN/CGA-B149.2, or applicable

provincial regulations, which should be carefully followed in all cases. Authorities having jurisdiction

should be consulted before installations are made”.

18 PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual

Page 19

4. Installation

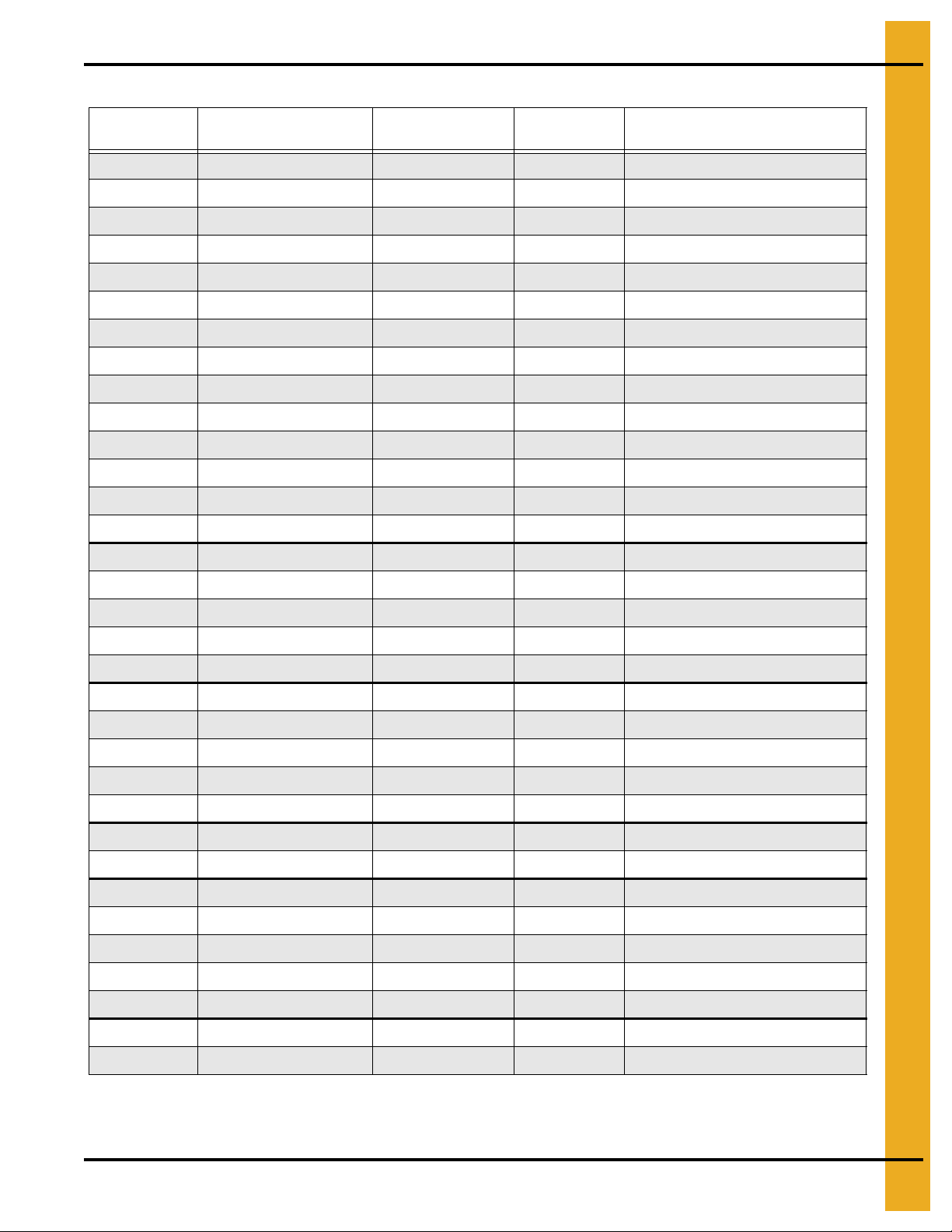

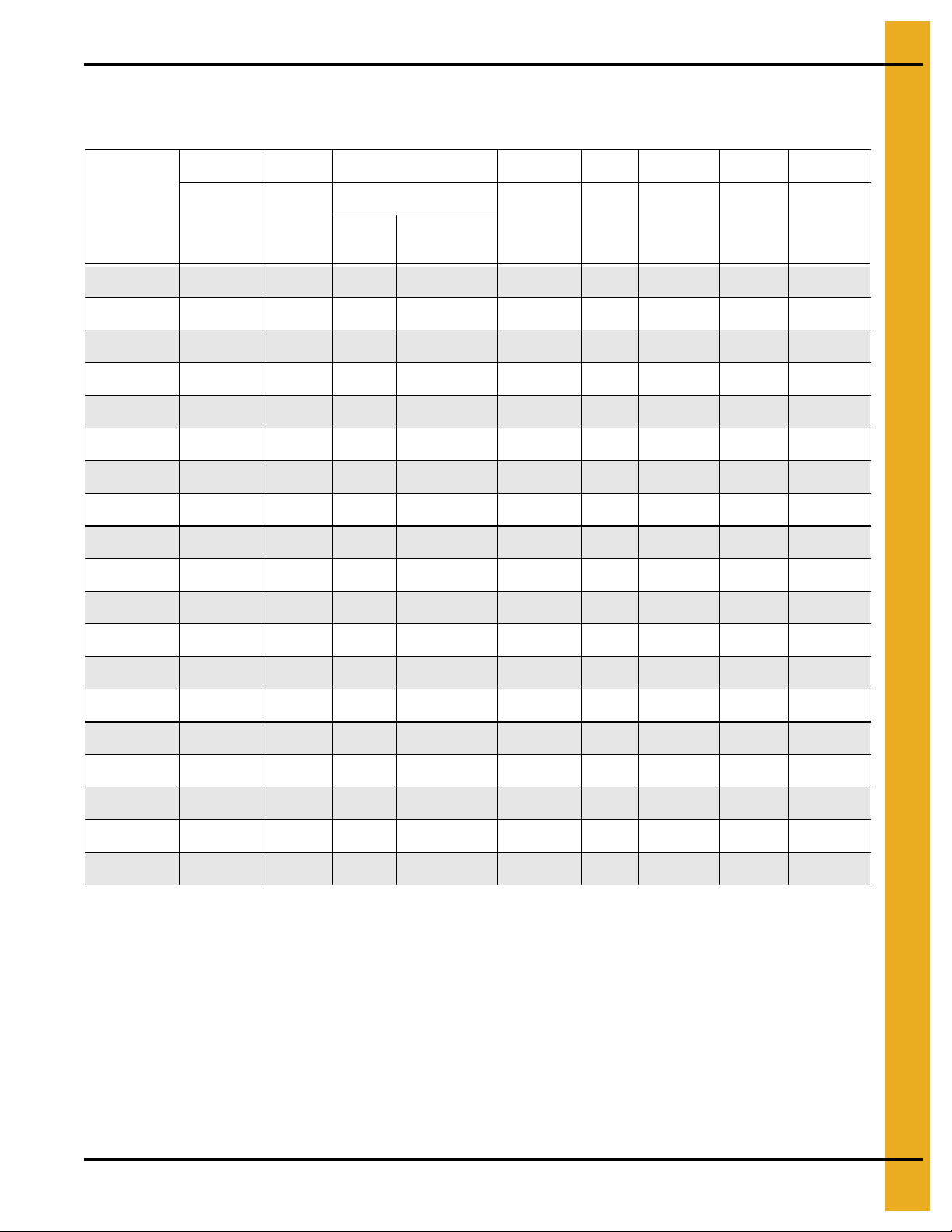

Fuel System Specifications and Recommendations (LP) Liquid Propane

Dryer

Model #

108/1108/190 3,500,000 38 1/2'' 1/4''

112/1112/270 4,500,000 49 1/2'' 21/64"

114/1114/320 5,750,000 63 1/2'' 11/32"

116/1116/370 5,750,000 63 1/2'' 11/32''

118/1118/400 7,000,000 76 1/2'' 3/8"

120/1120/460 7,500,000 82 1/2'' 25/64"

122/1122/511 8,500,000 93 3/4'' 7/16"

126/1126/601 9,500,000 104 3/4'' 29/64"

1214/2120 5,800,000 63 3/4'' (U)9/32" (L)7/32"

1216 6,800,000 74 3/4'' (U)21/64" (L)7/32"

1218/2125 6,800,000 74 3/4'' (U)21/64" (L)7/32"

1220/2130 8,750,000 96 3/4'' (U)11/32" (L)1/4"

1222 10,000,000 109 3/4'' (U)3/8" (L)1/4"

1226/2140 10,500,000 115 3/4'' (U)25/64" (L)1/4"

1214S/2141 7,000,000 76 3/4'' (2)-9/32"

Maximum Heat

Capacity BTU Per Hour

Maximum Fuel Flow

Gals Per Hour

Fuel Line Size* Heater Orifice Drill Size

1218S/2181 9,000,000 98 3/4'' (2)-21/64"

1220S/500H 11,500,000 126 3/4'' (2)-11/32"

1222S/2221 14,000,000 153 3/4'' (2)-3/8"

1226S/650M 15,000,000 164 3/4'' (2)-25/64"

2314/3142 11,750,000 128 3/4'' Top-11/32" Base (2)-1/4"

2318/3182 14,000,000 153 3/4'' Top-3/8" Base (2)-9/32"

2320/3202 16,500,000 180 3/4'' Top-25/64" Base (2)-21/64"

2322/3222 17,500,000 191 3/4'' Top-7/16" Base (2)-21/64"

2326/3262 24,500,000 267 3/4'' Top-29/64" Base (2)-23/64"

2420/1000H 18,000,000 197 3/4'' (4)-21/64"

2426/1300M 26,000,000 284 3/4'' (4)-23/64"

3414/4143 17,500,000 191 3/4'' Top-11/32" Mid-11/32" Base (2)-1/4"

3418/4183 21,000,000 229 3/4'' Top-3/8" Mid-3/8" Base (2)-9/32"

3420/4203 24,000,000 262 3/4'' Top-25/64" Mid-25/64" Base (2)-21/64"

3422/4223 26,000,000 284 3/4'' Top-7/16" Mid-7/16" Base (2)-21/64"

3426/4263 32,000,000 349 3/4'' Top-29/64" Mid-29/64" Base (2)-23/64"

3620/1500H 27,000,000 295 3/4'' (6)-21/64"

3626/2000M 39,000,000 426 3/4'' (6)-23/64"

* The minimum size of the fuel line for distances of 30.48 m (100').

PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual 19

Page 20

4. Installation

See Fuel Specifications Chart on

Page 21 for required pressure and

typical maximum fuel flow rates.

See Fuel Specifications Chart

on Page 21 for recommended

line size.

Natural Gas (NG)

Gas Volume and Pressure

The dryer is designed to operate on natural gas having a heat value of approximately 1000 BTU per cubic

foot. The dryer is equipped with a natural gas supply pipe system connected to the heater solenoid valves.

A regulated pressure of 10 PSI must be provided at the connection to the dryer, with gas available in

sufficient volume to maintain the operating pressure.

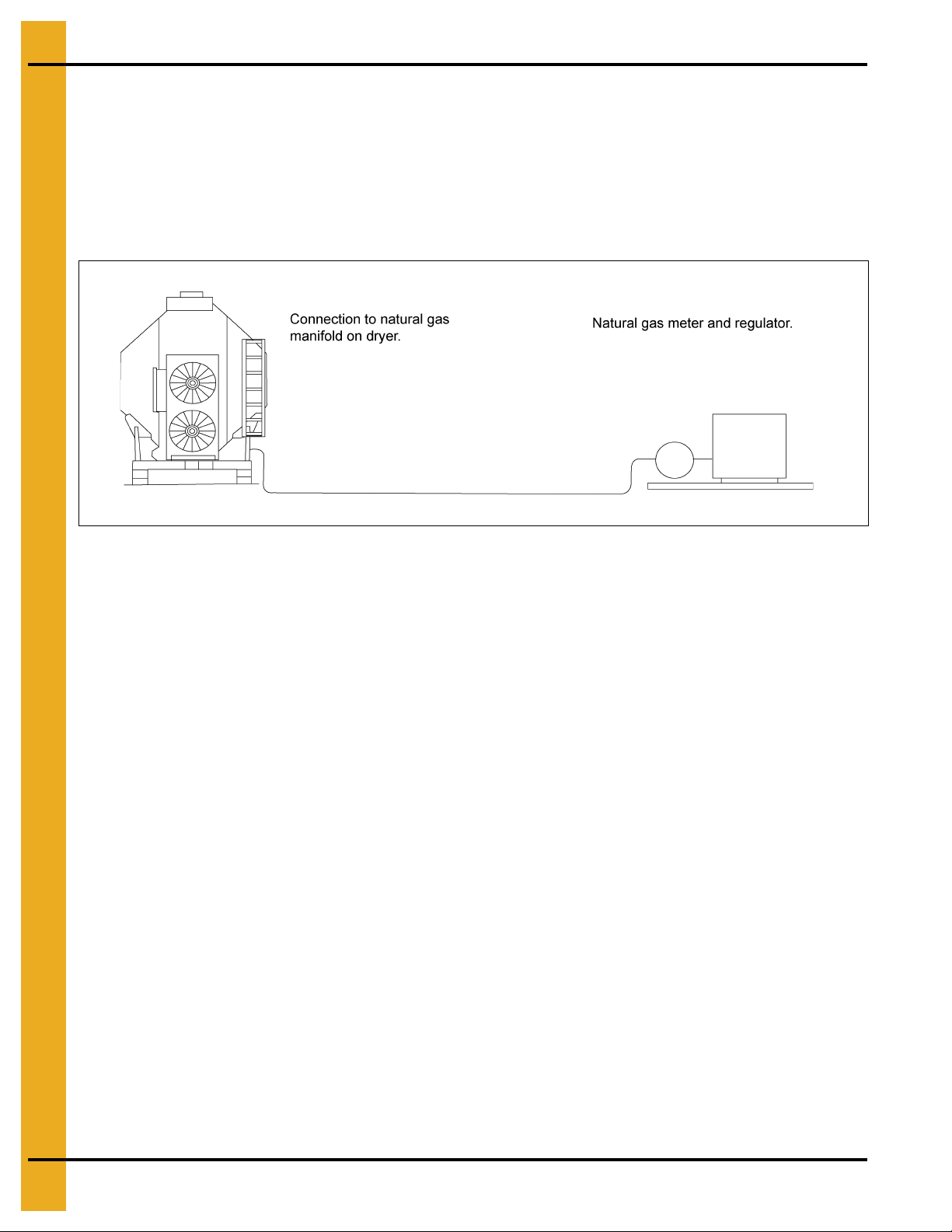

Figure 4E Grain dryer connected to a natural gas supply tank.

“The equipment shall be installed in accordance with the current INSTALLATION CODES FOR GAS

BURNING APPLIANCES AND EQUIPMENT, CAN/CGA-B149.1 and CAN/CGA-B149.2, or applicable

provincial regulations, which should be carefully followed in all cases. Authorities having jurisdiction

should be consulted before installations are made”.

20 PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual

Page 21

4. Installation

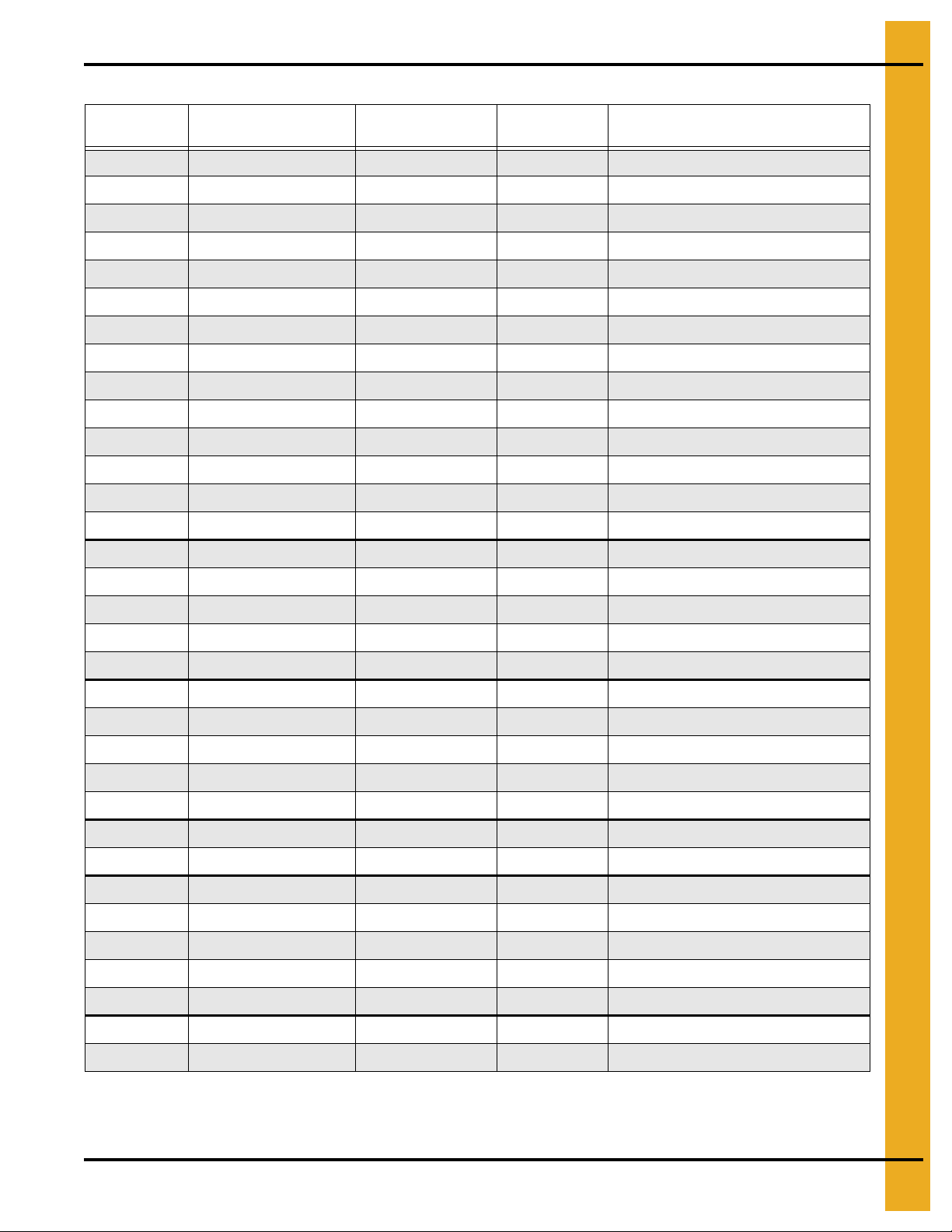

Fuel System Specifications and Recommendations (NG) Natural Gas

Dryer

Model #

108/1108/190 3,500,000 3500 1-1/2'' 3/8"

112/1112/270 4,500,000 4500 1-1/2'' 1/2"

114/1114/320 5,750,000 5750 1-1/2'' 33/64"

116/1116/370 5,750,000 5750 1-1/2'' 33/64"

118/1118/400 7,000,000 7000 2'' 35/64"

120/1120/460 7,500,000 7500 2'' 37/64"

122/1122/511 8,500,000 8500 2'' 19/32"

126/1126/601 9,500,000 9500 2'' 41/64"

1214/2120 5,800,000 5800 1-1/2'' (U)13/32" (L)5/16"

1216 6,800,000 6800 2'' (U)1/2" (L)5/16"

1218/2125 6,800,000 6800 2'' (U)1/2" (L)5/16"

1220/2130 8,750,000 8750 2'' (U)33/64" (L)5/16"

1222 10,000,000 10000 2'' (U)35/64" (L)5/16"

1226/2140 10,500,000 10500 2'' (U)37/64" (L)5/16"

1214S/2141 7,000,000 7000 1-1/2'' (2)-13/32"

Maximum Heat

Capacity BTU Per Hour

Maximum Fuel Flow

Cubic Feet Per Hour

Fuel Line Size* Heater Orifice Drill Size

1218S/2181 9,000,000 9000 1-1/2'' (2)-1/2"

1220S/500H 11,500,000 11500 2'' (2)-33/64"

1222S/2221 14,000,000 14000 2'' (2)-35/64"

1226S/650M 15,000,000 15000 2'' (2)-37/64"

2314/3142 11,750,000 11750 2'' Top-33/64" Base (2)-3/8"

2318/3182 14,000,000 14000 2'' Top-35/64" Base (2)-13/32"

2320/3202 16,500,000 16500 3'' Top-37/64" Base (2)-1/2"

2322/3222 17,500,000 17500 3'' Top-19/32" Base (2)-1/2"

2326/3262 24,500,000 24500 3'' Top-41/64" Base (2)-17/32"

2420/1000H 18,000,000 18000 3'' (4)-1/2"

2426/1300M 26,000,000 26000 3'' (4)-17/32"

3414/4143 17,500,000 17500 3'' Top-33/64" Mid-33/64" Base (2)-3/8"

3418/4183 21,000,000 21000 3'' Top-35/64" Mid-35/64" Base (2)-13/32"

3420/4203 24,000,000 24000 3'' Top-37/64" Mid-37/64" Base (2)-1/2"

3422/4223 26,000,000 26000 3'' Top-19/32" Mid-19/32" Base (2)-1/2"

3426/4263 32,000,000 32000 3'' Top-41/64" Mid-41/64" Base (2)-17/32"

3620/1500H 27,000,000 27000 3'' (6)-1/2"

3626/2000M 39,000,000 39000 3'' (6)-17/32"

* The minimum size of the fuel line for distances of 30.48 m (100').

PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual 21

Page 22

4. Installation

Single Fan Foundation

Figure 4F

22 PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual

Page 23

4. Installation

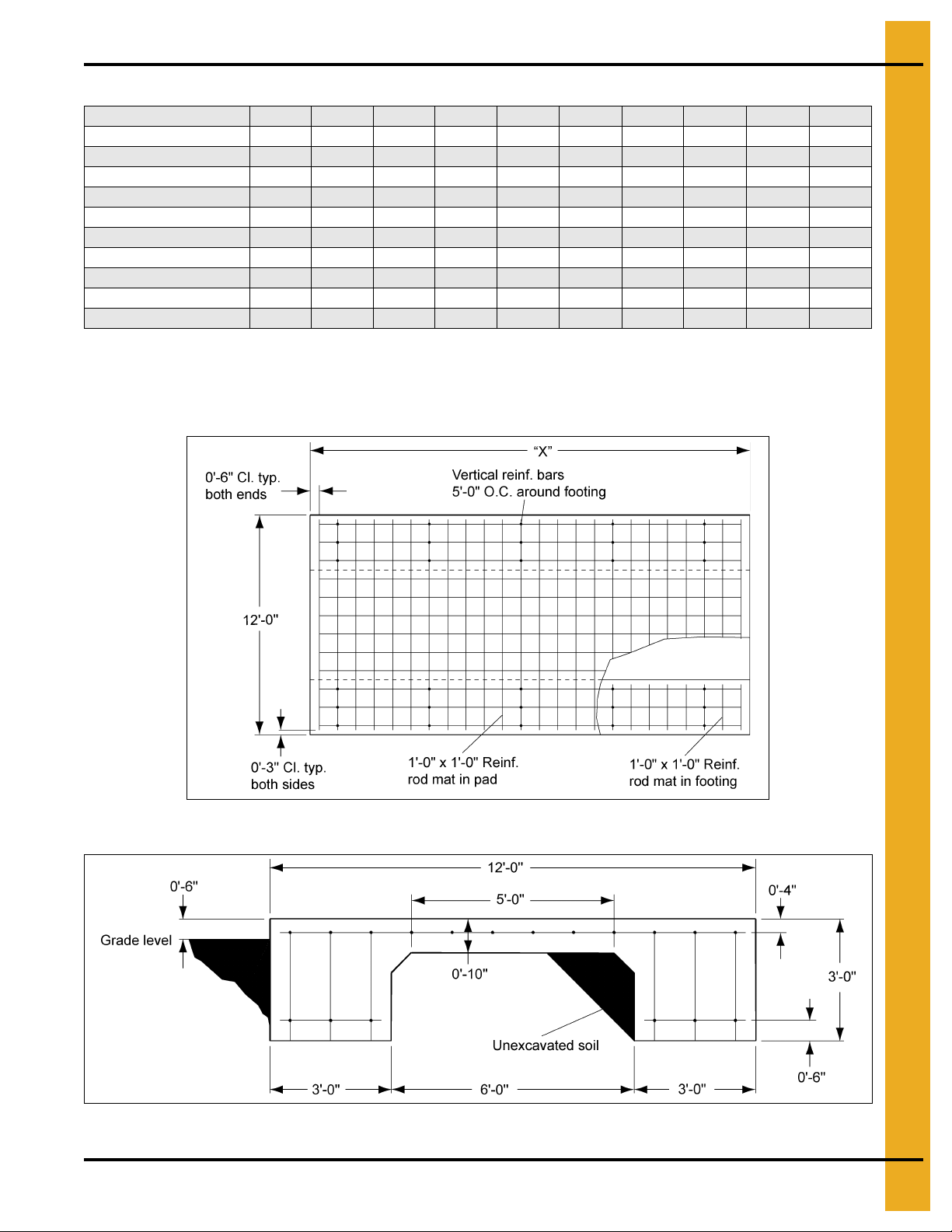

Minimum Bag Mix for Concrete Strength per Model Weight

Dryer Basket Length 6 8 10 12 14 16 18 20 22 26

Concrete Pad Size 12 x 16 12 x 18 12 x 20 12 x 22 12 x 24 12 x 26 12 x 28 12 x 30 12 x 32 12 x 36

Yards Concrete 5.3 5.9 6.5 7.1 7.7 8.3 8.9 9.2 10.1 11.3

Reinforcing Rods 20" each

Wire Mesh Sq. Ft. 192 216 240 264 288 312 336 360 384 432

Steel Legs (Minimum) 8 8 10 10 12 12 14 14 16 18

Anchors 4 4 4 6 6 6 8 8 8 10

Blocks 10 14 14 18 18 18 22 22 26 30

Foot of 2 x 6 10 14 14 18 18 18 22 22 26 30

Turnbuckles 4 4 4 6 6 6 8 8 8 10

Estimated Man Hours 8 10 12 14 18 18 20 22 24 28

Quantities are approximate and requirements may vary due to site elevations.

Setup times do not include site preparation and pouring concrete pad.

6 6 7 7 7 8 8 8 9 10

All Stack Dimensions

Figure 4G Foundation Plan View

Figure 4H Foundation Cross Section

PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual 23

Page 24

5. Specifications

FFI Dimensions

Figure 5A

Figure 5B

24 PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual

Page 25

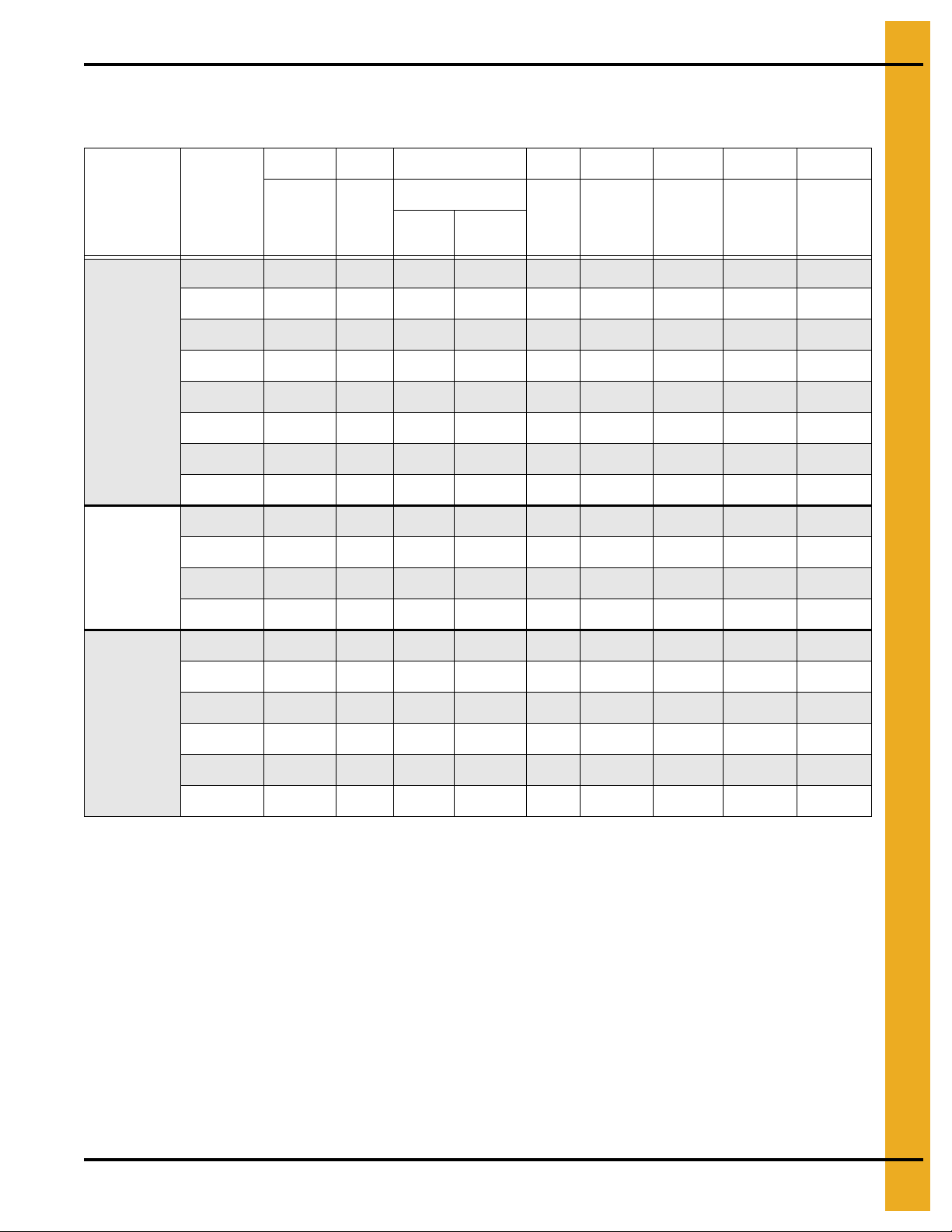

Single Module FFI Transport and Installation Dimensions

Values are Valid for Transportation of Stack Modules

AB C DE F G H

5. Specifications

1 Fan CFAB

Series Dryers

2 Fan CFAB

Series Dryers

Dryer

Basket

190T (8') 11' 11" 8' 13' 11' 6" 10' 3" 6' 5" 8' 17' 2" 19' 2"

270 (12') 13' 5" 8' 14' 6" 13' 11' 9" 6' 5" 8' 19' 2" 21' 2"

320 (14') 13' 5" 8' 14' 6" 13' 11' 9" 6' 5" 8' 21' 2" 23' 2"

370 (16') 13' 5" 8' 14' 6" 13' 11' 9" 6' 5" 8' 23' 2" 25' 2"

400 (18') 13' 5" 8' 14' 6" 13' 11' 9" 6' 5" 8' 25' 2" 27' 2"

460 (20') 13' 5" 8' 14' 6" 13' 11' 9" 6' 5" 8' 27' 2" 29' 2"

511 (22') 13' 5" 8' 14' 6" 13' 11' 9" 6' 5" 8' 29' 2" 31' 2"

601 (26') 13' 5" 8' 14' 6" 13' 11' 9" 6' 5" 8' 33' 2" 35' 2"

320 (14') 13' 5" 8' 8" 14' 6" 13' 11' 9" 6' 5" 8' 21' 2" 23' 2"

410 (18') 13' 5" 8' 8" 14' 6" 13' 11' 9" 6' 5" 8' 25' 2" 27' 2"

510 (22') 13' 5" 8' 8" 14' 6" 13' 11' 9" 6' 5" 8' 29' 2" 31' 2"

600 (26') 13' 5" 8' 8" 14' 6" 13' 11' 9" 6' 5" 8' 33' 2" 35' 2"

2120 (14') 13' 5" 8' 14' 6" 13' 11' 9" 6' 5" 8' 21' 2" 23' 2"

Transport

Height

Installed

Width

Installed Height

Standard

Bin

Top

Height

w/o Wet

Bin

Frame

Width

Transport

Width

Installed

Length

Transport

LengthWet

C2100A

Series Dryers

2122 (16') 13' 5" 8' 14' 6" 13' 11' 9" 6' 5" 8' 23' 2" 25' 2"

2125 (18') 13' 5" 8' 14' 6" 13' 11' 9" 6' 5" 8' 25' 2" 27' 2"

2130 (20') 13' 5" 8' 14' 6" 13' 11' 9" 6' 5" 8' 27' 2" 29' 2"

2132 (22') 13' 5" 8' 14' 6" 13' 11' 9" 6' 5" 8' 29' 2" 31' 2"

2140 (26') 13' 5" 8' 14' 6" 13' 11' 9" 6' 5" 8' 33' 2" 35' 2"

PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual 25

Page 26

5. Specifications

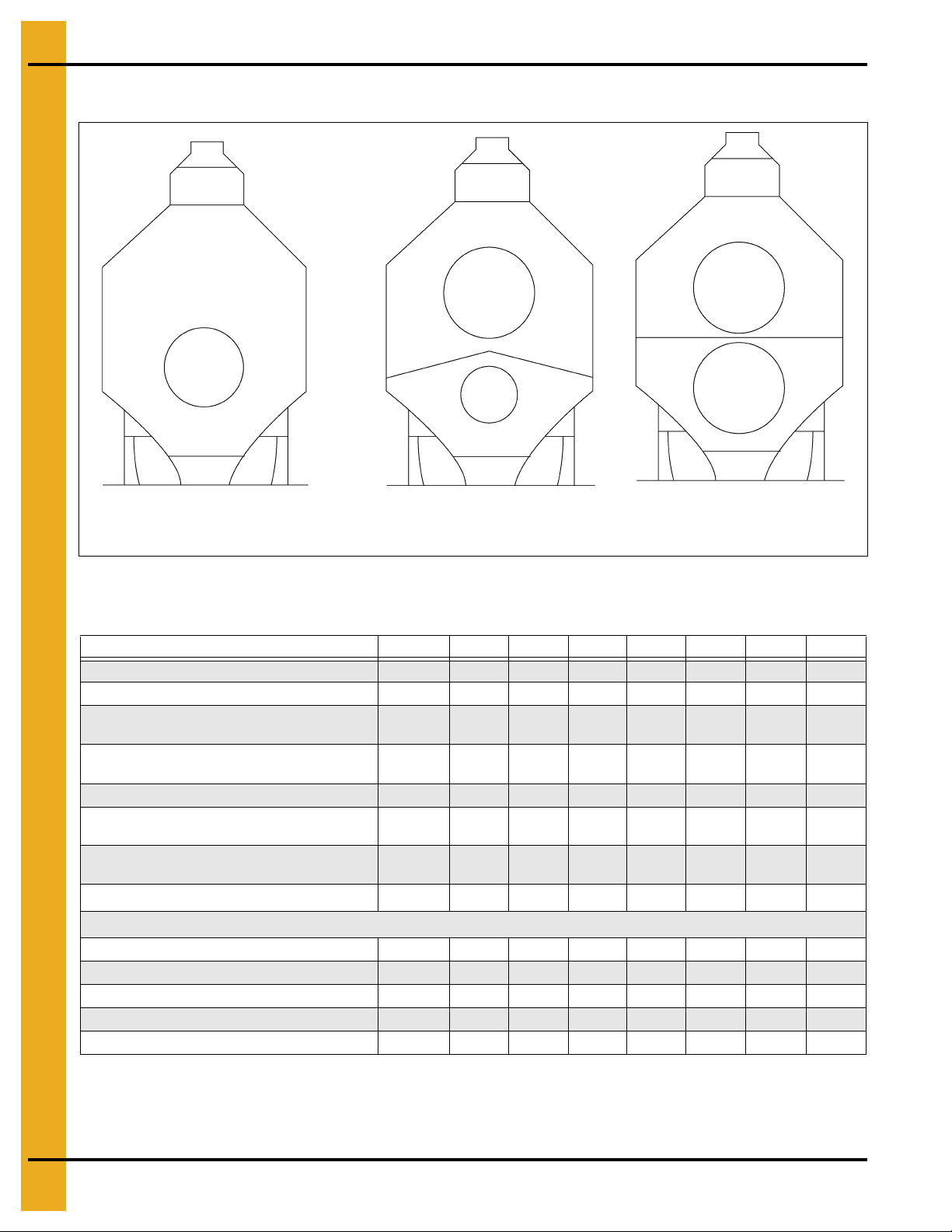

1 Fan CFAB profile

2 Fan CFAB profil e

C2100A profile

FFI Specifications

Figure 5C

1 Fan CFAB Specifications

CFAB 190 8'CFAB 270

Total Holding Capacity (Bushels) 216 294 357 436 509 565 622 735

Grain Column Holding Capacity (Bushels) 186 25 7 300 376 414 460 506 598

Fan

Top Auger

Capacity (BHP) 925 1150 1800 2800 2800 2800 2800 2800

Bottom Auger

Meter Roll Drive

Capacity - Maximum Rate1 (BHP)

Electrical Load (Fans, Top and Bottom Augers2)

1 Phase, 220 Volt 77 96 100 108 - - - -

36"

10-13 HP

8" Dia.

2 HP

8" Dia.

1.5 HP

SCR,

3/4 HP

1120 1680 1960 2240 2520 2800 3080 3640

12'

36"

15 HP

8" Dia.

2 HP

8" Dia.

2 HP

SCR,

3/4 HP

CFAB 320

14'

40"

15 HP

8" Dia.

5 HP

8" Dia.

3 HP

SCR,

3/4 HP

CFAB 370

16'

40"

15 HP

8" Dia.

5 HP

8" Dia.

3 HP

SCR,

3/4 HP

CFAB 400

18'

42"

20 HP

8" Dia.

5 HP

8" Dia.

3 HP

SCR,

3/4 HP

CFAB 460

20'

42"

25 HP

8" Dia.

7.5 HP

8" Dia.

5 HP

SCR,

3/4 HP

CFAB 511

22'

42"

30 HP

8" Dia.

7.5 HP

8" Dia.

5 HP

SCR,

3/4 HP

CFAB 601

26'

42"

40 HP

8" Dia.

10 HP

8" Dia.

7.5 HP

SCR,

3/4 HP

3 Phase, 220 Volt 44 52 56 65 95 107 114 150

3 Phase, 440 Volt 22 26 28 33 46 53 57 75

1

Actual discharge rate is controlled by meter roll speed adjustment, at 5% to 100% of maximum rate.

2

Excludes auxiliary load and unload conveyor equipment.

26 PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual

Page 27

2 Fan CFAB Specifications

5. Specifications

CFSA 320

14'

CFSA 410

18'

CFSA 510

22'

CFSA 600

26'

Total Holding Capacity (Bushels) 357 459 622 735

Grain Column Holding Capacity (Bushels) 300 386 506 598

Fans 28" 10-13 HP (2) 28" 10-13 HP (2) 36" 15 HP (2) 39" 20 HP (2)

Top Auger

8" Dia.

5 HP

8" Dia.

5 HP

8" Dia.

7.5 HP

8" Dia.

10 HP

Capacity (BHP) 1800 1800 2800 2800

Bottom Auger

Meter Roll Drive

Capacity - Maximum Rate

1

(BHP)

8" Dia.

3 HP

SCR,

3/4 HP

1960 2520 3080 3640

8" Dia.

3 HP

SCR,

3/4 HP

8" Dia.

5 HP

SCR,

3/4 HP

8" Dia.

7.5 HP

SCR,

3/4 HP

Electrical Load (Fans, Top and Bottom Augers2)

1 Phase, 220 Volt 136 156 217 3 Phase, 220 Volt 72 92 127 166

3 Phase, 440 Volt 36 46 63 83

1

Actual discharge rate is controlled by meter roll speed adjustment, at 5% to 100% of maximum rate.

2

Excludes auxiliary load and unload conveyor equipment.

C2100A Specifications

C2120A

14'

Total Holding Capacity (Bushels) 375 436 490 544 599 708

Grain Column Holding Capacity

(Bushels)

Fans

Top Auger

322 376 415 460 517 600

28" 10-13 HP/

28" 10-13 HP

8" Dia.

5 HP

Capacity (BHP) 1800 2800 2800 2800 2800 2800

Bottom Auger

Meter Roll Drive

Capacity - Maximum Rate

1

(BHP)

8" Dia.

3 HP

SCR,

3/4 HP

1960 2240 2520 2800 3080 3640

Electrical Load (Fans, Top and Bottom Augers2)

1 Phase, 220 Volt 146 187 187 - - 3 Phase, 220 Volt 92 96 96 135 144 154

3 Phase, 440 Volt 46 48 48 68 72 77

1

Actual discharge rate is controlled by meter roll speed adjustment, at 5% to 100% of maximum rate.

C2122A

16'

28" 10-13 HP/

36" 15 HP

8" Dia.

5 HP

8" Dia.

3 HP

SCR,

3/4 HP

C2125A

18'

28" 10-13 HP/

36" 15 HP

8" Dia.

5 HP

8" Dia.

3 HP

SCR,

3/4 HP

C2130A

20'

28" 10-13 HP/

39" 20 HP

8" Dia.

7.5 HP

8" Dia.

5 HP

SCR,

3/4 HP

C2132A

22'

28" 10-13 HP/

42" 20 HP

8" Dia.

7.5 HP

8" Dia.

5 HP

SCR,

3/4 HP

C2140A

26'

28" 10-13 HP/

42" 25 HP

8" Dia.

10 HP

8" Dia.

7.5 HP

SCR,

3/4 HP

2

Excludes auxiliary load and unload conveyor equipment.

PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual 27

Page 28

5. Specifications

GSI Dimensions

Figure 5D

Figure 5E

28 PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual

Page 29

5. Specifications

Single Module GSI Transport and Installation Dimensions

Values are Valid for Transportation of Stack Modules

AB C DEFGH

Dryer

Basket

1108T/108T 13' 5'' 8' 14' 6'' 13' 11' 9' ' 6' 5'' 8' 15' 2'' 17' 2''

1112/112 13' 5'' 8' 14' 6'' 13' 11' 9'' 6' 5'' 8' 19' 2'' 21' 2''

1114/114 13' 5'' 8' 14' 6'' 13' 11' 9'' 6' 5'' 8' 21' 2'' 23' 2''

1116/116 13' 5'' 8' 14' 6'' 13' 11' 9'' 6' 5'' 8' 23' 2'' 25' 2''

1118/118 13' 5'' 8' 14' 6'' 13' 11' 9'' 6' 5'' 8' 25' 2'' 27' 2''

1120/120 13' 5'' 8' 14' 6'' 13' 11' 9'' 6' 5'' 8' 27' 2'' 29' 2''

1 122/122 13' 5'' 8' 14' 6'' 13' 11' 9'' 6' 5'' 8' 29' 2'' 31' 2''

1126/126 13' 5'' 8' 14' 6'' 13' 11' 9'' 6' 5'' 8' 33' 2'' 35' 2''

1214 13' 5'' 8' 14' 6'' 13' 11' 9'' 6' 5' ' 8' 21' 2'' 23' 2''

1216 13' 5'' 8' 14' 6'' 13' 11' 9'' 6' 5'' 8' 23' 2'' 25' 2''

1218 13' 5'' 8' 14' 6'' 13' 11' 9'' 6' 5' ' 8' 25' 2'' 27' 2''

1220 13' 5'' 8' 14' 6'' 13' 11' 9'' 6' 5'' 8' 27' 2'' 29' 2''

Transport

Height

Installed

Width

Installed Height

Wet Bin

Standard

Top

Height w/o

Wet Bin

Frame

Width

Trans-

port

Width

Installed

Length

Transport

Length

1222 13' 5'' 8' 14' 6'' 13' 11' 9'' 6' 5' ' 8' 29' 2'' 31' 2''

1226 13' 5'' 8' 14' 6'' 13' 11' 9'' 6' 5'' 8' 33' 2'' 35' 2''

1214S 13' 5'' 8' 8'' 14' 6'' 13' 11' 9'' 6' 5'' 8' 21' 2'' 23' 2''

1218S 13' 5'' 8' 8'' 14' 6'' 13' 11' 9'' 6' 5'' 8' 25' 2'' 27' 2''

1220S 13' 5'' 8' 8'' 14' 6'' 13' 11' 9'' 6' 5'' 8' 27' 2'' 29' 2''

1222S 13' 5'' 8' 8'' 14' 6'' 13' 11' 9'' 6' 5'' 8' 29' 2'' 31' 2''

1226S 13' 5'' 8' 8'' 14' 6'' 13' 11' 9'' 6' 5'' 8' 33' 2'' 35' 2''

PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual 29

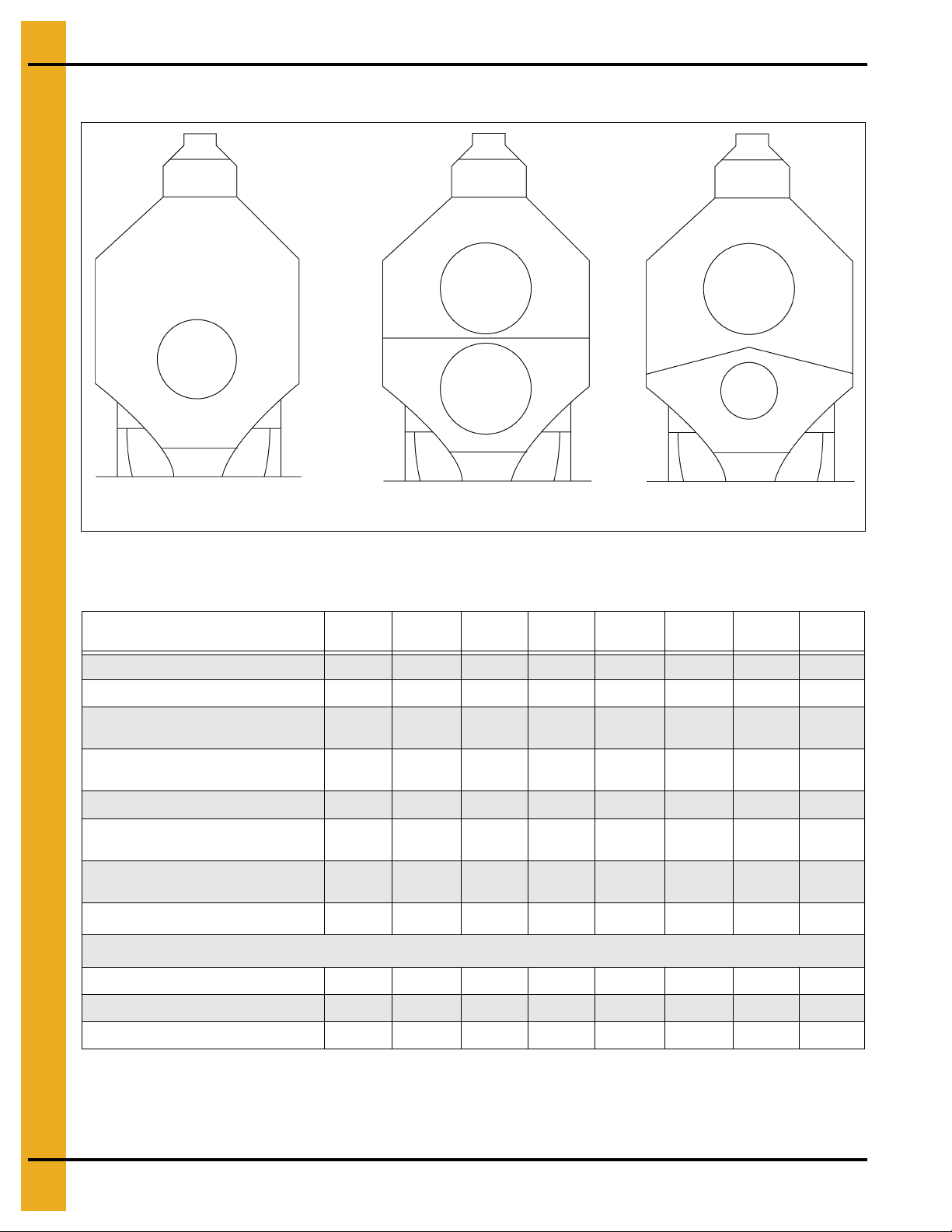

Page 30

5. Specifications

1100 Series profile

1200 Series profile

1200S Series profile

GSI Specifications

Figure 5F

1100 Series Dryer Specifications

1108T/108 1112/112 1114/114 1116/116 1118/118 1120/120 1122/122 1126/126

Total Holding Capacity (Bushels) 190 327 381 436 490 544 599 708

Grain Column Holding Capacity (Bushels) 160 282 329 376 423 470 517 611

Fan

Top Auger

Capacity (BHP) 2900 2900 3800 3800 3800 3800 3800 3800

Bottom Auger

Meter Roll Drive

1

Capacity - Maximum Rate

Electrical Load (Fans, Top and Bottom Augers2)

1 Phase, 220 Volt 63 85 98 108 - - - 3 Phase, 220 Volt 42 50 56 65 80 104 114 150

3 Phase, 440 Volt 21 25 28 33 40 52 57 75

3 Phase, 575 Volt 18 20 23 27 32 42 46 61

3 Phase, 380 Volt 22 33 36 44 49 68 75 88

1

Actual discharge rate is controlled by meter roll speed adjustment, at 5% to 100% of maximum rate.

2

Excludes auxiliary load and unload conveyor equipment.

(BHP)

36''

10-13 HP

8'' Dia.

2 HP

8'' Dia.

1-1/2 HP

SCR,

3/4 HP

1120 1680 1960 2240 2520 2800 3080 3640

36''

15 HP

8'' Dia.

2 HP

8'' Dia.

1-1/2 HP

SCR,

3/4 HP

40''

15 HP

8'' Dia.

5 HP

8'' Dia.

3 HP

SCR,

3/4 HP

40''

15 HP

8'' Dia.

5 HP

8'' Dia.

5 HP

SCR,

3/4 HP

42''

20 HP

8'' Dia.

5 HP

8'' Dia.

5 HP

SCR,

3/4 HP

42''

25 HP

8'' Dia.

7-1/2 HP

8'' Dia.

7-1/2 HP

SCR,

3/4 HP

42''

30 HP

8'' Dia.

7-1/2 HP

8'' Dia.

7-1/2 HP

SCR,

3/4 HP

42''

40 HP

8'' Dia.

10 HP

8'' Dia.

10 HP

SCR,

3/4 HP

30 PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual

Page 31

5. Specifications

1200 Series Dryer Specifications

1214 1216 1218 1220 1222 1226

Total Holding Capacity (Bushels) 381 436 490 544 599 708

Grain Column Holding

Capacity (Bushels)

Fan

Top Auger

Capacity (BHP) 3800 3800 3800 3800 3800 3800

Bottom Auger

Meter Roll Drive SCR, 3/4 HP SCR, 3/4 HP SCR, 3/4 HP SCR, 3/4 HP SCR, 3/4 HP SCR, 3/4 HP

1

Capacity - Maximum Rate

(BHP)

Electrical Load (Fans, Top and Bottom Augers2)

1 Phase, 220 Volt 142 156 156 172 - 3 Phase, 220 Volt 92 99 99 112 126 150

3 Phase, 440 Volt 47 50 50 57 63 75

3 Phase, 575 Volt 37 42 42 47 52 61

3 Phase, 380 Volt 50 61 61 70 75 90

1

Actual discharge rate is controlled by meter roll speed adjustment, at 5% to 100% of maximum rate.

2

Excludes auxiliary load and unload conveyor equipment.

329 376 423 470 517 611

26'' 10-13 HP

36'' 10-13 HP

8'' Dia.

5 HP

8'' Dia.

5 HP

26'' 10-13 HP

36'' 15 HP

8'' Dia.

5 HP

8'' Dia.

5 HP

26'' 10-13 HP

36'' 15 HP

8'' Dia.

5 HP

8'' Dia.

5 HP

28'' 10-13 HP

40" 15 HP

8'' Dia.

7-1/2 HP

8'' Dia.

7-1/2 HP

28'' 10-13 HP

42'' 20 HP

8'' Dia.

7-1/2 HP

8'' Dia.

7-1/2 HP

1960 2240 2520 2800 3080 3640

28'' 10-13 HP

42'' 25 HP

8'' Dia.

10 HP

8'' Dia.

10 HP

1200S Series Dryer Specifications

1214S 1218S 1220S 1222S 1226S

Total Holding Capacity (Bushels) 381 490 544 599 708

Grain Column Holding Capacity (Bushels) 329 423 470 517 611

Fan

Top Auger

28'' 10-13 HP

(2)

8'' Dia.

5 HP

Capacity (BHP) 3800 3800 3800 3800 3800

Bottom Auger

8'' Dia.

5 HP

Meter Roll Drive SCR, 3/4 HP SCR, 3/ 4 HP SCR, 3/4 HP SCR, 3/4 HP SCR, 3/4 HP

Capacity - Maximum Rate

1

(BHP)

1960 2520 2800 3080 3640

Electrical Load (Fans, Top and Bottom Augers2)

1 Phase, 220 Volt 142 142 186 186 3 Phase, 220 Volt 93 93 118 118 180

3 Phase, 440 Volt 47 47 60 60 90

3 Phase, 575 Volt 40 33 48 48 72

3 Phase, 380 Volt 50 50 80 80 115

1

Actual discharge rate is controlled by meter roll speed adjustment, at 5% to 100% of maximum rate.

2

Excludes auxiliary load and unload conveyor equipment.

36'' 10-13 HP

(2)

8'' Dia.

5 HP

8'' Dia.

5 HP

36'' 15 HP

(2)

8'' Dia.

7-1/2 HP

8'' Dia.

7-1/2 HP

36'' 15 HP

(2)

8'' Dia.

7-1/2 HP

8'' Dia.

7-1/2 HP

40'' 25 HP

(2)

8'' Dia.

10 HP

8'' Dia.

10 HP

PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual 31

Page 32

5. Specifications

“X” - Varies with dryer length (See Chart on Page 33.)

All Stack Dimensions

Figure 5G Example of Stack Dryer Footprint

Figure 5H Side View - 2 Module Stack Dryer

32 PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual

Page 33

All Stack Dimensions (Continued)

“X” - Varies with dryer length (See chart below)

5. Specifications

Figure 5I Stack Dryer Dimension (Side View - 3 Module Stack Dryer)

Dryer Installed Length (1, 2 and 3 Module Stacks)

PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual 33

Basket Length Installed Length

14 23' 10"

18 27' 10"

20 29' 10"

22 31' 10"

26 35' 10"

Page 34

5. Specifications

End View - 2 Module Stack Dryer

End View - 3 Module Stack Dryer

All Stack Dimensions (Continued)

Figure 5J

34 PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual

Page 35

All Stack Specifications

Total Holding Capacity (Bushels) 731 940 1044 1149 1304

Grain Column Holding Capacity (Bushels) 679 873 970 1067 1261

Fans

Top Auger 8" Dia. 5 HP 8" Dia. 5 HP 8" Dia. 7.5 HP 8" Dia. 7.5 HP 8" Dia. 10 HP

Capacity (BHP) 3800 3800 3800 3800 3800

Bottom Auger 8" Dia. 5 HP 8" Dia. 5 HP 8" Dia. 7.5 HP 8" Dia. 7.5 HP 8" Dia. 10 HP

Meter Roll Drive SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP

Capacity - Maximum Rate¹ (BHP) 1960 2520 2800 3080 3640

Electrical Load (Fans, Top and Bottom Augers²)

1 Phase, 220 Volt 226 - - - 3 Phase, 220 Volt 121 132 182 192 282

3 Phase, 440 Vo lt 61 66 91 96 141

3 Phase, 575 Volt 49 53 73 77 113

1

Actual discharge rate is cont rolled by meter roll speed adjustment, at 5% to 100% of maximum rate.

2

Excludes auxiliary load and unload conveyor equipment.

Total Holding Capacity (Bushels) 731 940 1044 1149 1304

Grain Column Holding Capacity (Bushels) 679 873 970 1067 1261

Fans

Top Auger 8" Dia. 5 HP 8" Dia. 5 HP 8" Dia. 7.5 HP 8" Dia. 7.5 HP 8" Dia. 10 HP

Capacity (BHP) 3800 3800 3800 3800 3800

Bottom Auger 8" Dia. 5 HP 8" Dia. 5 HP 8" Dia. 7.5 HP 8" Dia. 7.5 HP 8" Dia. 10 HP

Meter Roll Drive SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP

Capacity - Maximum Rate¹ (BHP) 1960 2520 2800 3080 3640

Electrical Load (Fans, Top and Bottom Augers²)

1 Phase, 220 Volt 244 244 - - 3 Phase, 220 Volt 138 138 196 196 308

3 Phase, 440 Vo lt 69 69 98 98 154

3 Phase, 575 Volt 55 55 78 78 123

1

Actual discharge rate is cont rolled by meter roll speed adjustment, at 5% to 100% of maximum rate.

2

Excludes auxiliary load and unload conveyor equipment.

5. Specifications

14' 18' 20' 22' 26'

28" 10-13 HP

40" 15 HP

14' 18' 20' 22' 26'

28" 10-13 HP

28" 10-13 HP

36" 10-12 HP

42" 20 HP

36" 10-13 HP

36" 10-13 HP

36" 15 HP

42" 25 HP

36" 15 HP

36" 15 HP

36" 15 HP

42" 30 HP

36" 15 HP

36" 15 HP

40" 25 HP

42" 40 HP

40" 25 HP

40" 25 HP

14' 18' 20' 22' 26'

Total Holding Capacity (Bushels) 1074 1381 1534 1688 1995

Grain Column Holding Capacity (Bushels) 1022 1314 1460 1606 1898

Fans

Top Auger 8" Dia. 5 HP 8" Dia. 5 HP 8" Dia. 7.5 HP 8" Dia. 7.5 HP 8" Dia. 10 HP

Capacity (BHP) 3800 3800 3800 3800 3800

Bottom Auger 8" Dia. 5 HP 8" Dia. 5 HP 8" Dia. 7.5 HP 8" Dia. 7.5 HP 8" Dia. 10 HP

Meter Roll Drive SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP

Capacity - Maximum Rate¹ (BHP) 1960 2520 2800 3080 3640

Electrical Load (Fans, Top and Bottom Augers²)

1 Phase, 220 Volt 286 - - - 3 Phase, 220 Volt 143 176 232 262 358

3 Phase, 440 Vo lt 72 88 116 131 179

3 Phase, 575 Volt 58 70 93 105 143

1

Actual discharge rate is cont rolled by meter roll speed adjustment, at 5% to 100% of maximum rate.

2

Excludes auxiliary load and unload conveyor equipment.

40" 15 HP

40" 15 HP

42" 20 HP

42" 20 HP

42" 25 HP

42" 25 HP

42" 30 HP

42" 30 HP

42" 40 HP

42" 40 HP

PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual 35

Page 36

5. Specifications

All Stack Specifications (Continued)

Total Holding Capacity (Bushels) 1074 1381 1534 1688 1995

Grain Column Holding Capacity (Bushels) 1022 1314 1460 1606 1898

14' 18' 20' 22' 26'

Fans

Top Auger 8" Dia. 5 HP 8" Dia. 5 HP 8" Dia. 7.5 HP 8" Dia. 7.5 HP 8" Dia. 10 HP

Capacity (BHP) 3800 3800 3800 3800 3800

Bottom Auger 8" Dia. 5 HP 8" Dia. 5 HP 8" Dia. 7.5 HP 8" Dia. 7.5 HP 8" Dia. 10 HP

Meter Roll Drive SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP

Capacity - Maximum Rate¹ (BHP) 1960 2520 2800 3080 3640

Electrical Load (Fans, Top and Bottom Augers²)

1 Phase, 220 Volt 304 - - - 3 Phase, 220 Volt 160 182 246 266 384

3 Phase, 440 Volt 80 91 123 133 192

3 Phase, 575 Volt 64 73 98 106 154

1

Actual discharge rate is control led by meter roll speed adjustment, at 5% to 100% of maximum rate.

2

Excludes auxiliary load and unload conveyor equipment.

Total Holding Capacity (Bushels) 1074 1381 1534 1688 1995

Grain Column Holding Capacity (Bushels) 1022 1314 1460 1606 1898

28" 10-13 HP

40" 15 HP

14' 18' 20' 22' 26'

36" 10-13 HP

42" 20 HP

36" 15 HP

42" 25 HP

36" 15 HP

42" 30 HP

40" 25 HP

42" 40 HP

Fans 28" 10-13 HP 36" 10-13 HP 36" 15 HP 36" 15 HP 40" 25 HP

Top Auger 8" Dia. 5 HP 8" Dia. 5 HP 8" Dia. 7.5 HP 8" Dia. 7.5 HP 8" Dia. 10 HP

Capacity (BHP) 3800 3800 3800 3800 3800

Bottom Auger 8" Dia. 5 HP 8" Dia. 5 HP 8" Dia. 7.5 HP 8" Dia. 7.5 HP 8" Dia. 10 HP

Meter Roll Drive SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP

Capacity - Maximum Rate¹ (BHP) 1960 2520 2800 3080 3640

Electrical Load (Fans, Top and Bottom Augers²)

1 Phase, 220 Volt 340 340 - - 3 Phase, 220 Volt 194 194 274 274 436

3 Phase, 440 Volt 97 97 137 137 218

3 Phase, 575 Volt 78 78 110 110 174

1

Actual discharge rate is control led by meter roll speed adjustment, at 5% to 100% of maximum rate.

2

Excludes auxiliary load and unload conveyor equipment.

36 PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual

Page 37

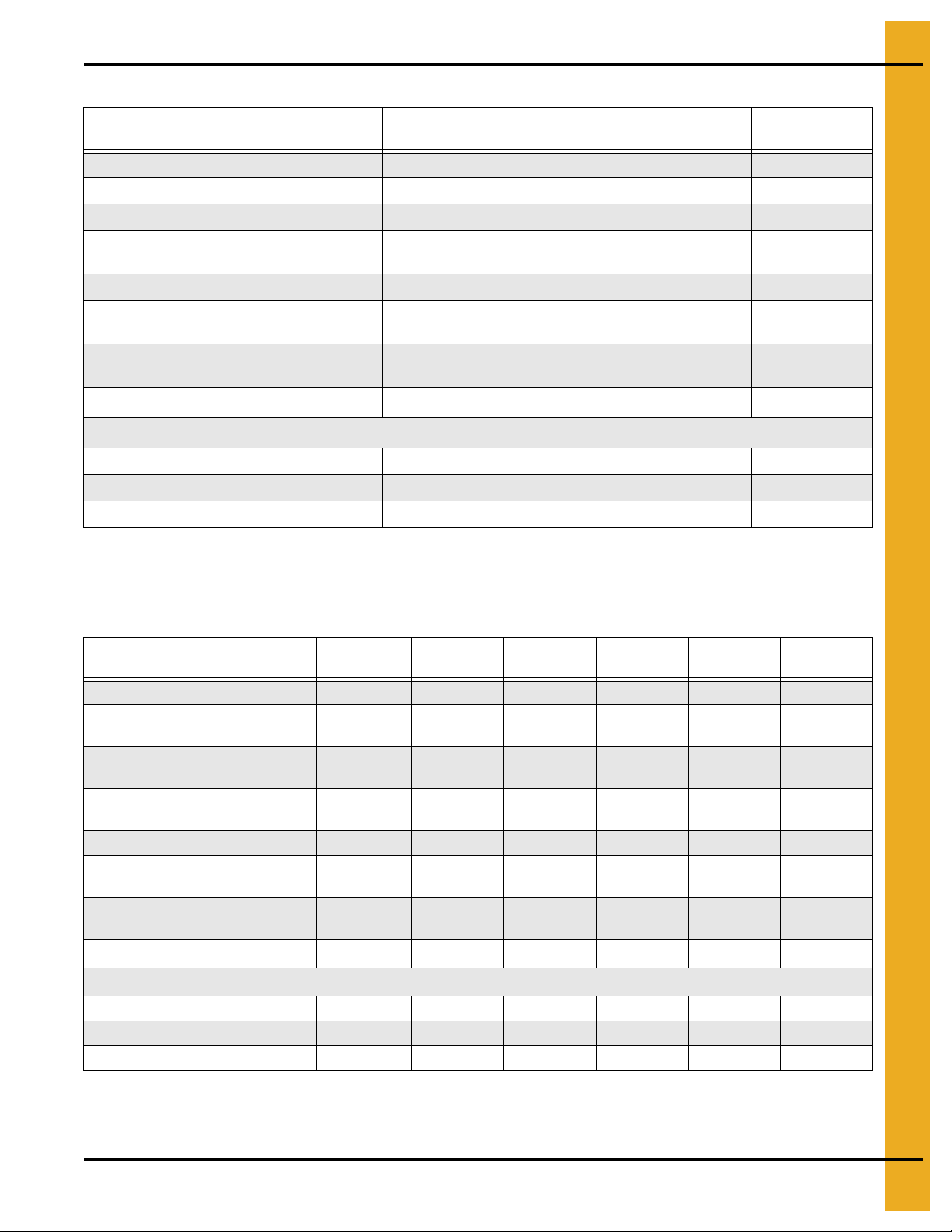

All Stack Specifications (Continued)

5. Specifications

Figure 5K

A BCD

14' 23'-1-1/2" 2'-2" 14'-0" 4'-8" 16" Min. 11'-2" 4'-9-3/4" 0'-8" 8'-0" 23'-9-1/2" 10'-0" 6'-4"

18' 27'-1-1/2" 2'-2" 18'-0" 4'-8" 16" Min. 11'-2" 4'-9-3/4" 0'-8" 8'-0" 23'-9-1/2" 10'-0" 6'-4"

20' 29'-1-1/2" 2'-2" 20'-0" 4'-8" 16" Min. 11'-2" 4'-9-3/4" 0'-8" 8'-0" 23'-9-1/2" 10'-0" 6'-4"

22' 31'-1-1/2" 2'-2" 22'-0" 4'-8" 16" Min. 11'-2" 4'-9-3/4" 0'-8" 8'-0" 23'-9-1/2" 10'-0" 6'-4"

26' 35'-1-1/2" 2'-2" 26'-0" 4'-8" 16" Min. 11'-2" 4'-9-3/4" 0'-8" 8'-0" 23'-9-1/2" 10'-0" 6'-4"

1

E

FGHJLMN

1. A 12" thick reinforced concrete foundation and 16" pedestal (min.) are required. See bulletin

FL-02-2 for details. 32" Thick pedestal required for heat reclaimer option (see bulletin FL-03-2

for details).

2. Approximate location of standard service platform shown. See bulletin SP-02-2 for details.

For information on optional catwalk, see bulletin CATH-01-5.

3. For safety cage information, refer to bulletin SC-01-2.

PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual 37

Page 38

5. Specifications

H

G

L

D

E

B

C

A

J

K

N

F

14'-0"

SEE

NOTE 2

2'-8"-REAR SAFETY CAGE

SEE NOTE 3

7'-9"-SAFETY

PLATFORM

13'-0"-OPTIONAL

CATWALK

SEE

NOTE 1

All Stack Specifications (Continued)

Figure 5L

A BCD

14' 23'-1-1/2" 2'-2" 14'-0" 4'-8" 16" Min. 11'-2" 4'-9-3/4" 0'-8" 8'-0" 3'-0" 23'-9-1/2" 6'-4"

18' 2 7' - 1-1/2" 2'-2" 18'-0" 4'-8" 16" Min. 11'-2" 4'-9-3/4" 0'-8" 8'-0" 3'-0" 23'-9-1/2" 6'-4"

20' 29'-1-1/2" 2'-2" 20'-0" 4'-8" 16" Min. 11'-2" 4'-9-3/4" 0'-8" 8'-0" 3'-0" 23'-9-1/2" 6'-4"

22' 3 1' - 1-1/2" 2'-2" 22'-0" 4'-8" 16" Min. 11'-2" 4'-9-3/4" 0'-8" 8'-0" 3'-0" 23'-9-1/2" 6'-4"

26' 35'-1-1/2" 2'-2" 26'-0" 4'-8" 16" Min. 11'-2" 4'-9-3/4" 0'-8" 8'-0" 3'-0" 23'-9-1/2" 6'-4"

E

1

FGHJKLN

1. A 12" thick reinforced concrete foundation and 16" pedestal (min.) are required. See bulletin

FL-02-2 for details. 32" Thick pedestal required for heat reclaimer option (see bulletin FL-03-2

for details).

2. Approximate location of standard service platform shown. See bulletin SP-02-2 for details.

For information on optional catwalk, see bulletin CATH-01-5.

3. For safety cage information, refer to bulletin SC-01-2.

38 PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual

Page 39

Stack Dryer Foundation Specifications

Stack Dryer Foundation

Basket Length 14 18 20 22 26

5. Specifications

Concrete Pad Size (12' x “X”)

Concrete (Cubic Yards) 20-3/4 24-1/4 26 27-1/2 31

#4 Rebar (Feet)

Anchors

1

10" Depth with 36" wide x 36" deep footings along ea c h si de.

2

#4 Reinforcing rods on 1"-0" centers. Both dire c t io ns in slab and bottom of footing.

3

Use 3/4" x 9-5/8" minimum anchors with epoxy. GSI part #: Anchor (GTC-0003) epoxy (GTC-0004).

3

²

¹

Minimum soil bearing capacity = 2000 PSF.

Concrete specifications:

• Compressive strength at 28 days - 4000 PSI.

• Minimum cement content - 6 sacks/yard.

• Maximum slump - 4" ± 1".

12 x 24 12 x 28 12 x 30 12 x 32 12 x 36

900 1060 1140 1220 1400

16 20 22 24 28

PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual 39

Page 40

6. Competitor/Dri-Tek Test Firing

CAUTION

Before attempting to operate the dryer make sure all safety shields are in place, all

bottom clean-out and rear access doors are closed and all personnel are clear of

the dryer.

Before the dryer is filled, thoroughly inspect the unit and check the operation of the dryer as follows.

Inspect the Metering Rolls

Figure 6A 4" Meter Roll

Figure 6B 7" Meter Roll

Open all metering roll access doors and inspect each compartment for any bolts, nuts or other foreign

material, that may cause possible jamming of the metering rolls.

40 PNEG-1702 ETL Listed GSI/FFI Portable Dryer Manual

Page 41

Set Control Switches

Moisture Control Switch OFF

Moisture Control Thermostat 200°

Load Switch OFF

Unload Switch OFF

Fan Switch OFF

Burner Switch OFF

Out of Grain Timer 1 MINUTE (Reset to 8 Minutes after testing)

Load Delay 30 SECONDS

Unload Delay 30 SECONDS

Metering Roll Speed LOW AND HIGH SPEED SETTINGS PUT ON ZERO

Dry Timer 60 MINUTES

Cool Timer 20 MINUTES

6. Competitor/Dri-Tek Test Firing

Unload Timer 10 MINUTES

Mode Switch CONTINUOUS FLOW

Electrical Power

Turn ON the electrical power supply to the dryer. Set all circuit breakers to ON, including the safety

disconnect handle mounted on front of the dryer’s power panel.

Control Power Switch

Turn the Control Power switch to ON. The switch light comes on. “GSI” and the software version will

appear. At this point, the controller will lock out all other dryer functions and the dryer will perform its safety

circuit check. If a fault is found, the cause will be displayed on the LCD. If all safeties are safe, the controller