Page 1

Parts

Manual

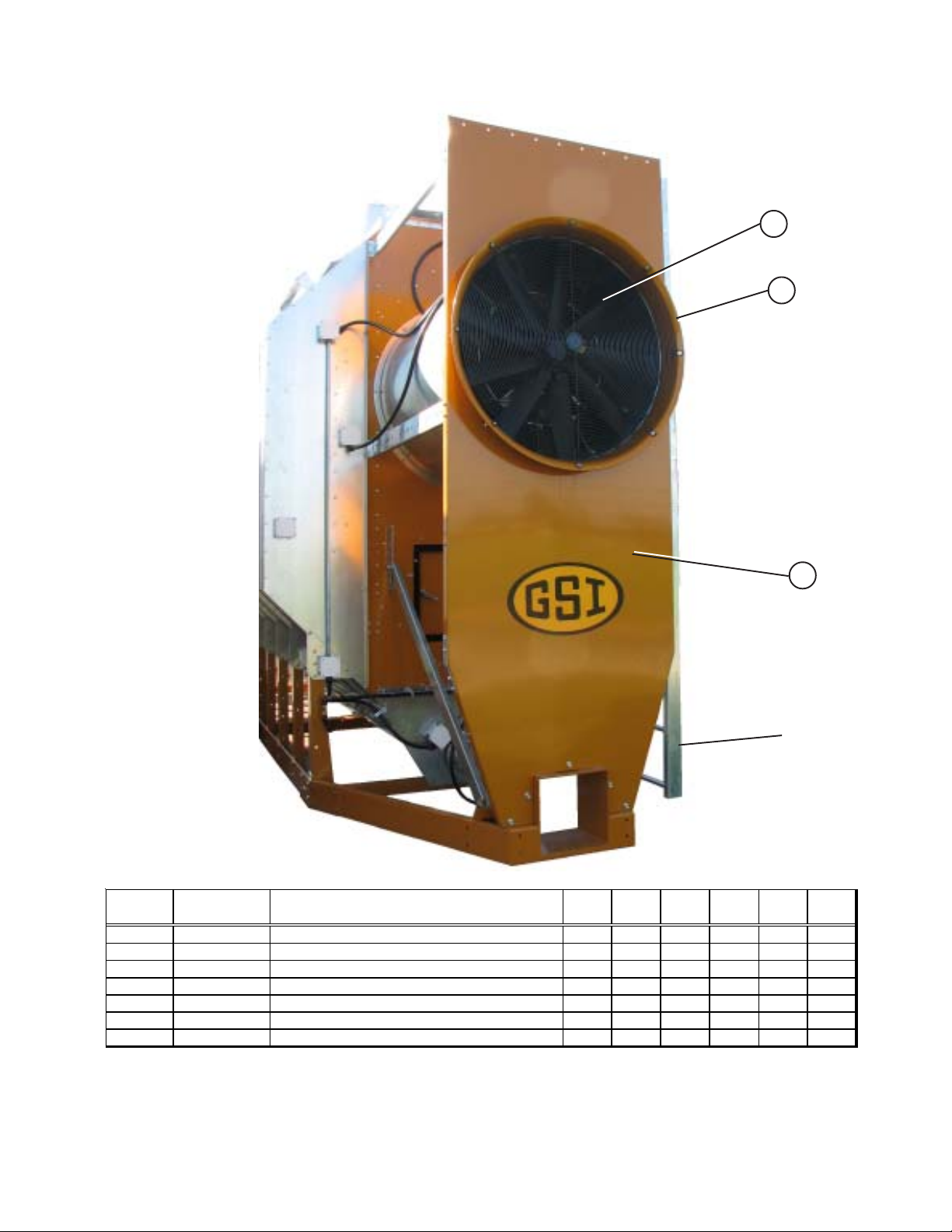

1200 Vision X-Stream

Series Portable Dryers

PNEG-1616

Date: 09-22-10

PNEG-1616

Page 2

2

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 3

T able of Contents

MAIN STRUCTURE ASSEMBL Y .....................................................................................5

FRAME ASSEMBLY.......................................................................................................................................................5

FRAME, LOWER BASKET, AND METERING ROLLS........................................................................................ ........8

PLENUM (INSIDE) SCREENS AND METER ROLL UPPER SHIELD........................................................................12

OUTER SCREENS AND PLENUM DIVIDER............................................................................................... ................14

CLEAN OUT DOORS................................................................................................................ ..................................16

FRONT AND REAR PLENUM END PANELS AND REAR ACCESS DOORS..............................................................18

FAN GUARDS, SUPPOR T PANELS, LADDER ASSEMBLY........................................................................................20

BOTTOM AUGER.......................................................................................................................................................22

TOP AUGER WITH W ET BIN...................................................................................................................................24

AUGER AND METER ROLL DRIVE TRAINS..............................................................26

BOTTOM AUGER DRIVE..........................................................................................................................................26

TOP AUGER DRIVE...................................................................................................................................................28

METER ROLL DRIVE............................................................................................................... ..................................30

F AN HEA TERS.................................................................................................................32

FAN HOUSING ASSEMBLIES......................................................................................................................................32

FAN MOT OR, MOT OR MOUNT, AND FAN BLADE.................................................................................................34

AIR MIXERS..................................................................................................................... ..........................................35

FLAME PROBE, IGNIT OR, AND BURNER ASSEMBLIES........................................................................................36

LP PIPE TRAIN ASSEMBLIES...................................................................................................................................38

NG PIPE TRAIN ASSEMBLIES...................................................................................................................................44

FAN HEATER ORIFICES............................................................................................................ .................................48

LP SUPPLY LINE.......................................................................................................................................................49

NG SUPPLY LINE................................................................................................................. ......................................50

DRYER ELECTRICAL CONDUITS..................................................................................51

UPPER JUNCTION BOX, T OP AUGER MOTOR CONDUIT, AND OPERATOR LIGHT...........................................51

RIGHT AND LEFT GRAIN, AND PLENUM HIGH LIMITS................................................................................... ....52

LOWER JUNCTION BOXES, METER ROLL MOTOR CONDUIT, AND REAR DISCHARGE CONDUIT.................54

AIR SWITCH ASSEMBLY....................................................................................................................................56

CONTROL BOXES..........................................................................................................57

NETWORK CONTROL BOX............................................................................................................ ..........................57

FAN HEATER CONTROL BOX......................................................................................................... ........................58

LOWER CONTROL BOX CONTROL PANEL............................................................................................................60

LOWER CONTROL BOX CONTROL PANEL (INSIDE)...........................................................................................61

LOWER CONTROL BOX BACK PANEL....................................................................................................................62

UPPER CONTROL BOX.............................................................................................................. ...............................63

NOTES................................................................................................................................70

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

3

Page 4

4

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 5

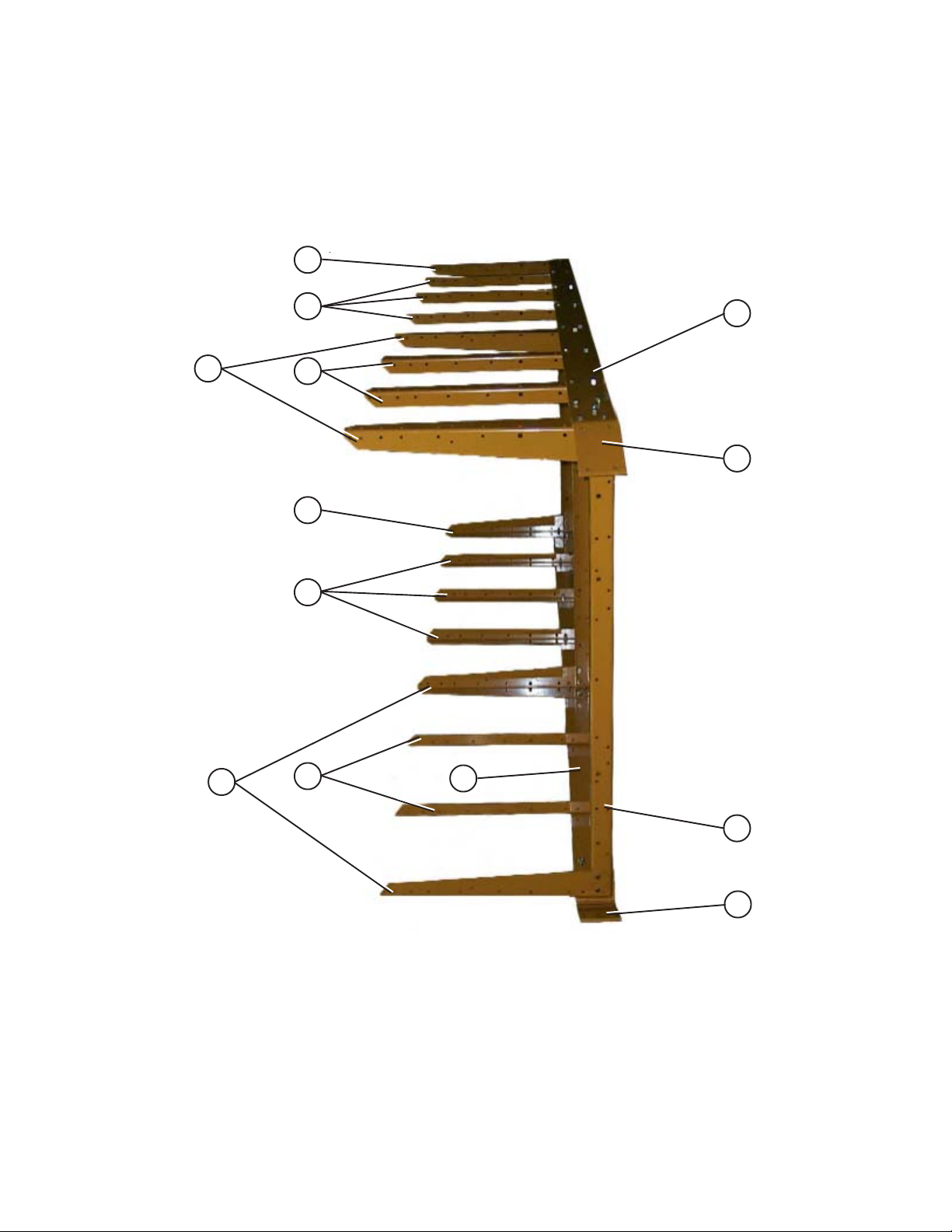

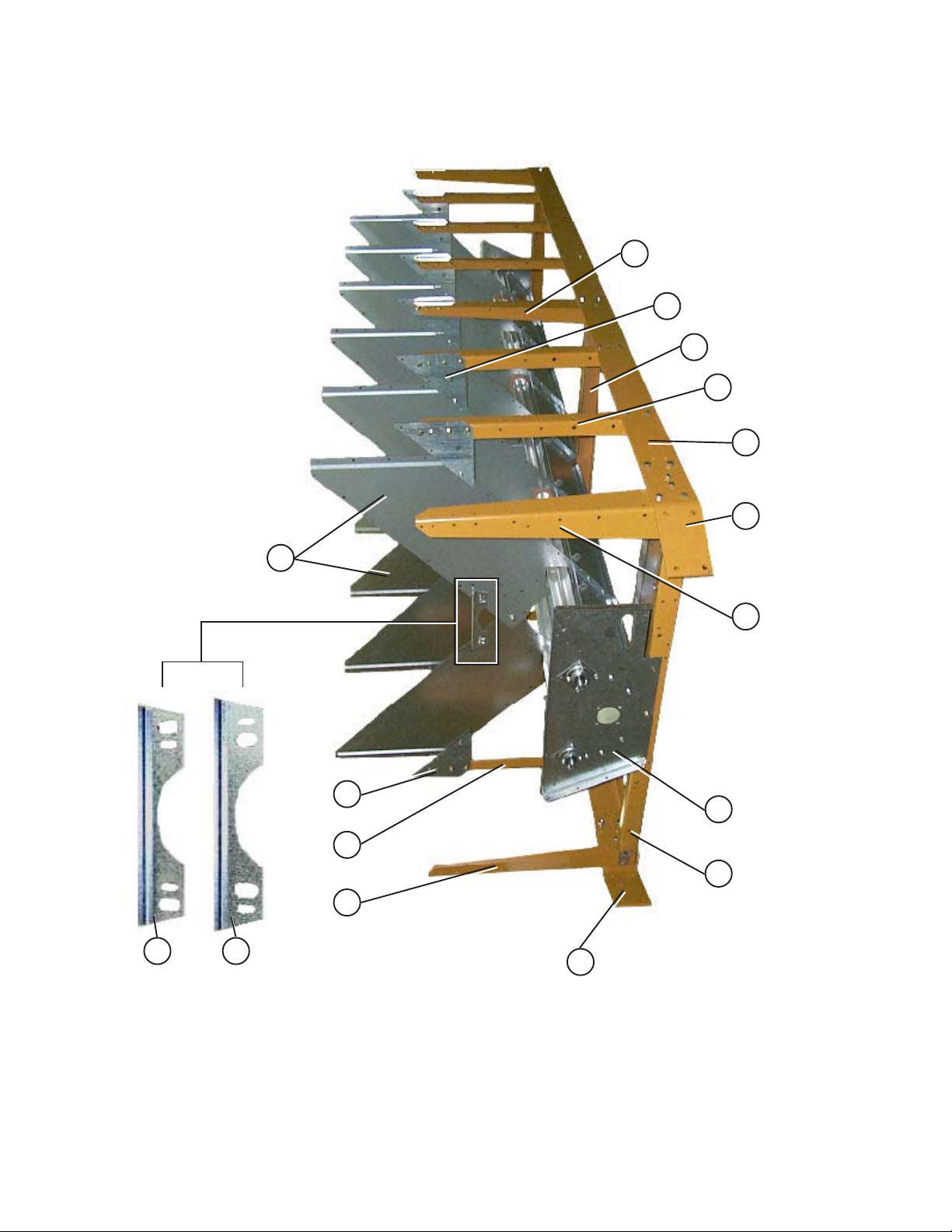

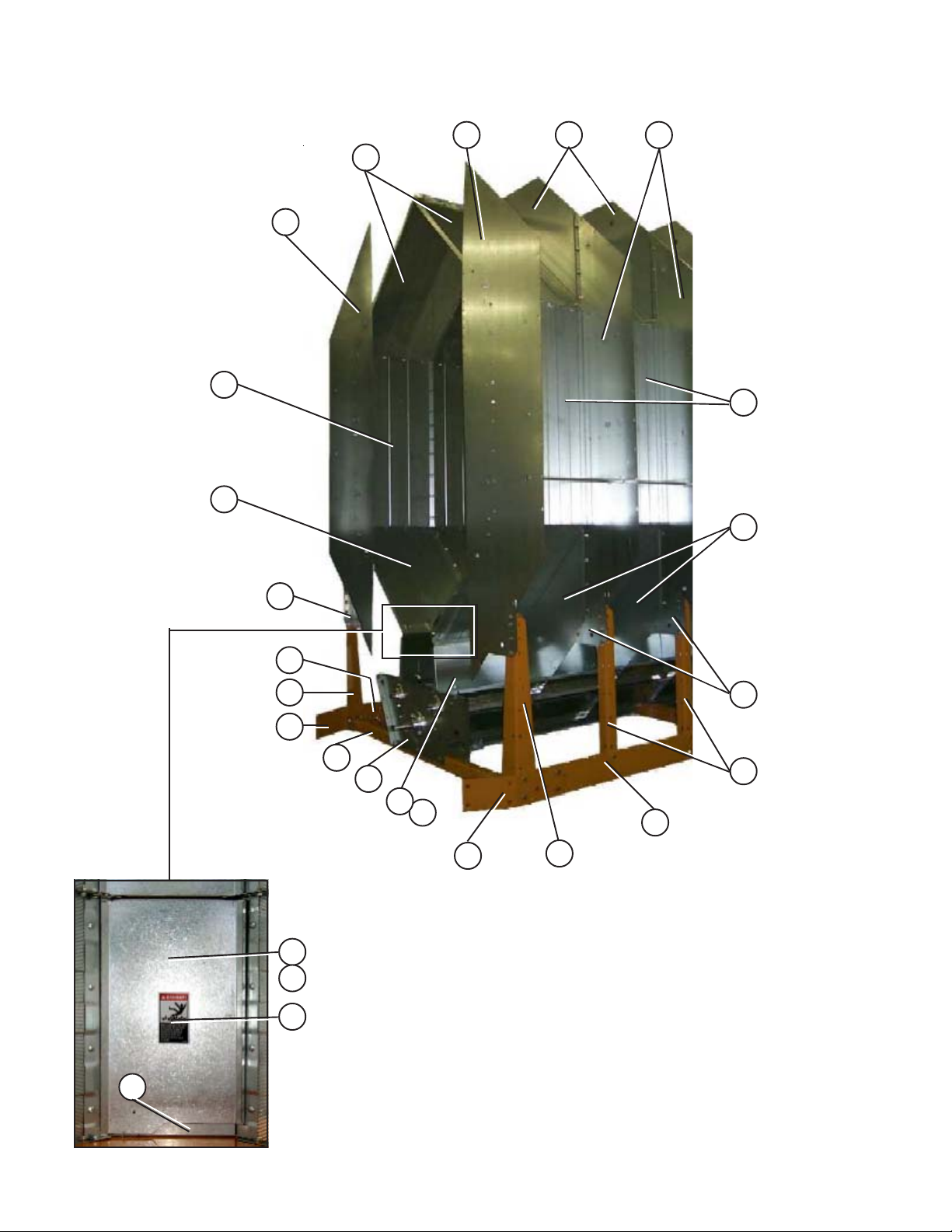

Frame

53

3

553

4a

3

5

4

Frame Assembly (view from fan/heater end with hitch weldment removed).

**NOTE: The parts pointed out on this page are listed on page 7.

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

21a

1

Right side Left side

5

Page 6

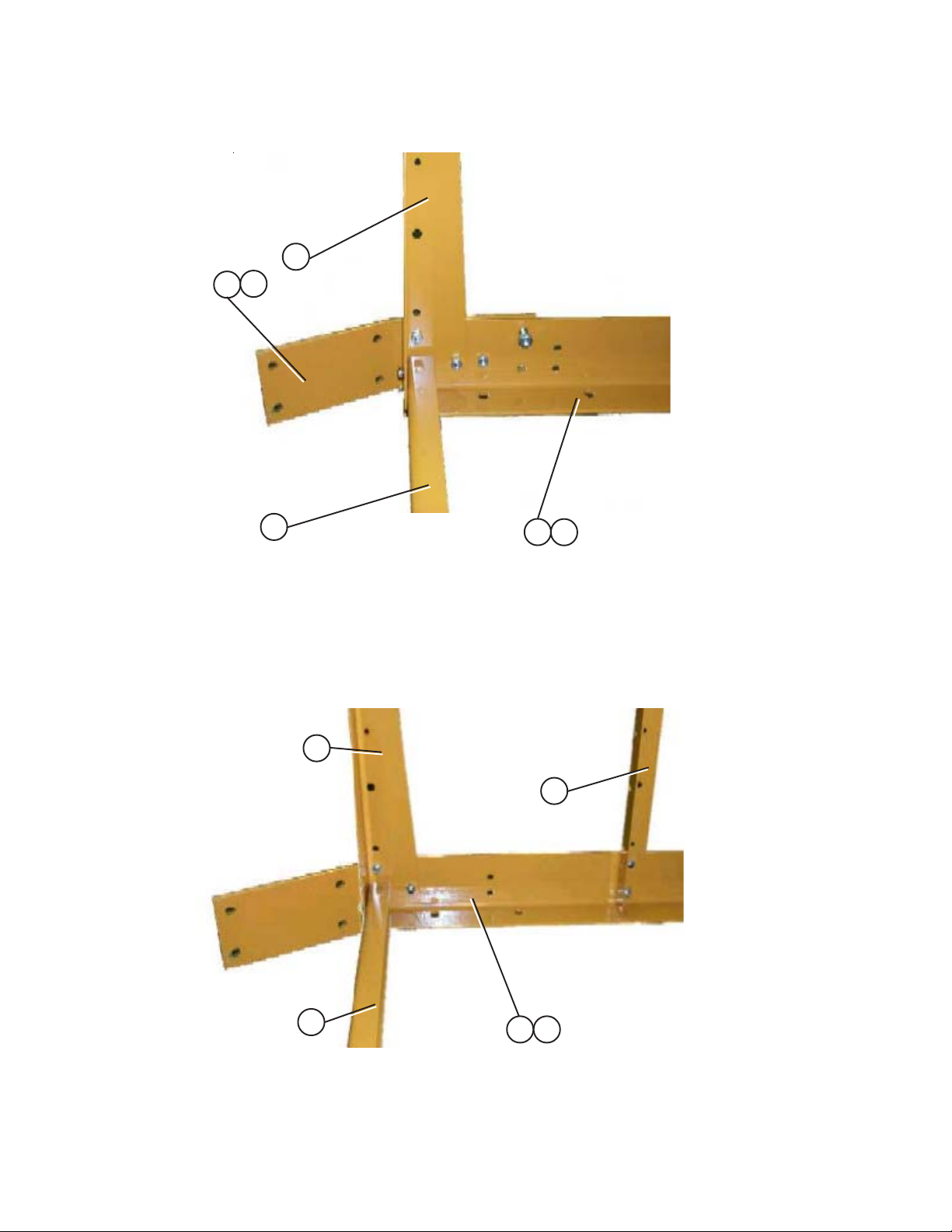

Right front corner of frame.

3

1

1a

Frame

**NOTE: The right front corner is

shown in the photo. For left front

corner all parts are the same

except for the Hitch Bracket (use

1a for the left side), and the Frame

Rail (use 4a for the left side).

2

Left rear corner of frame.

4a

4

3

5

2

6

4

4a

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 7

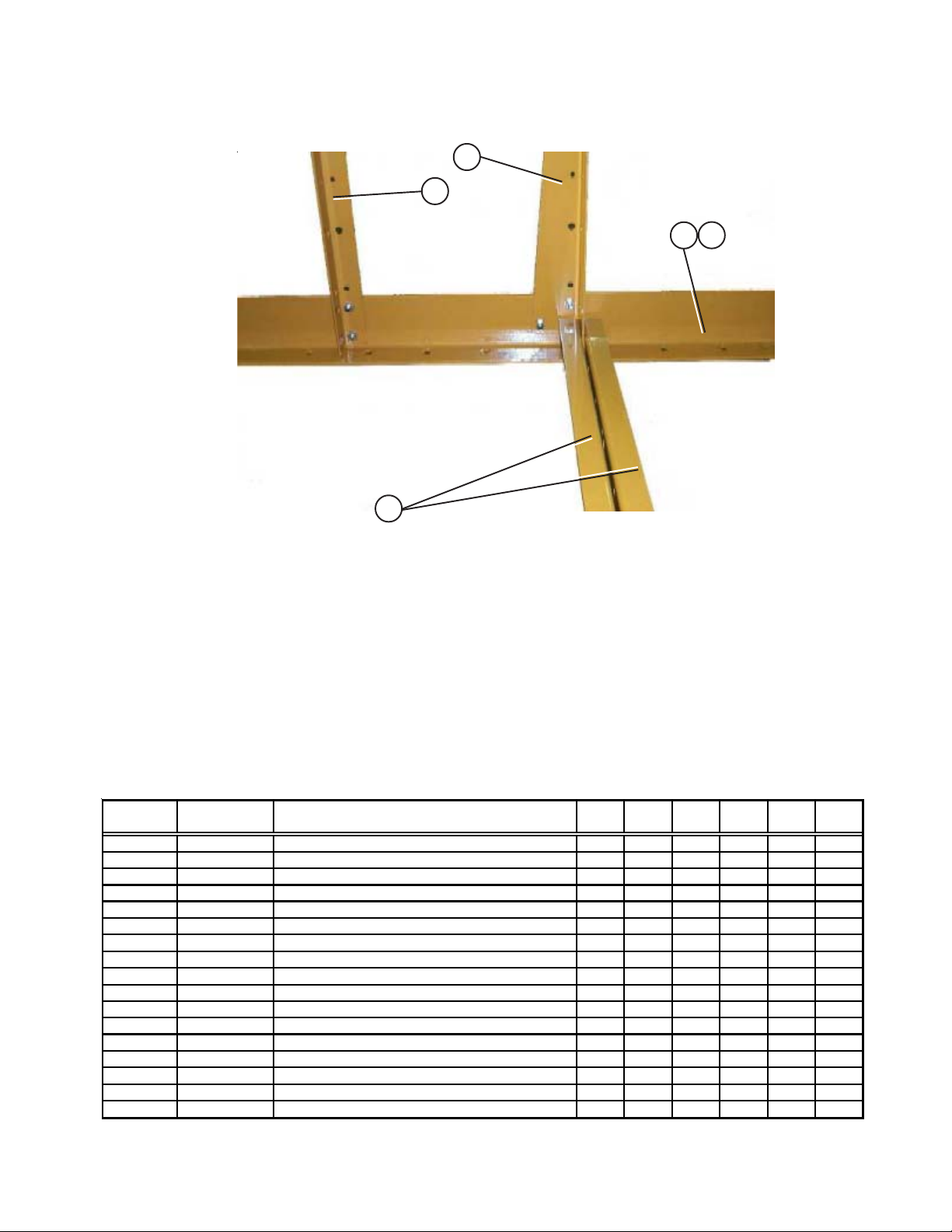

Center cross ties.

Frame

3

5

4 4a

2

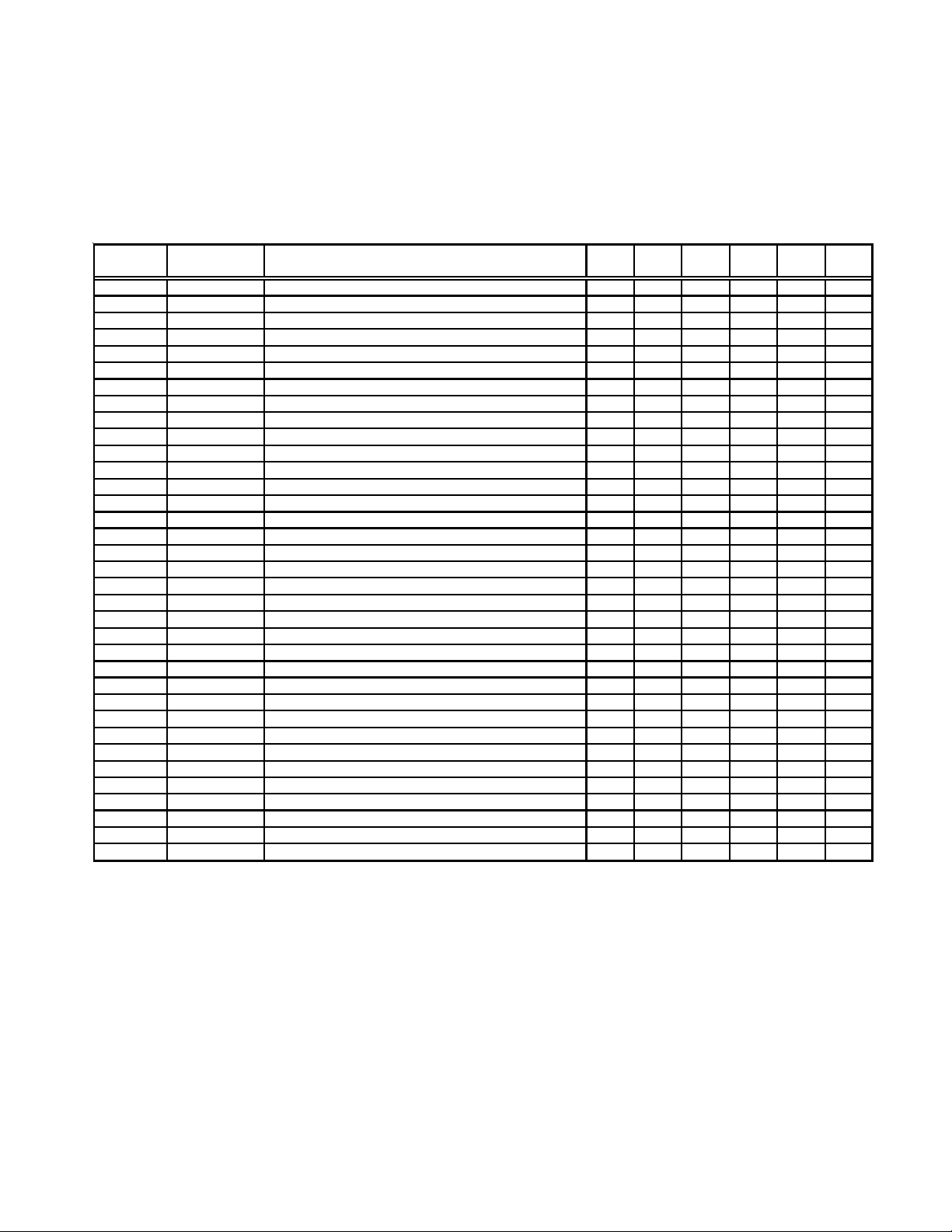

ITEM

NUMBER PART NUMBER

1 D01-0012HITCH BRACKET RIGHT 222222

1a D01-0011HITCH BRACKET LEFT 222222

2 D01-0008FRONT & REAR FRAME TIE CHANNEL 444466

3 D01-0007CORNER LEG PORTABLE DRYER 666688

4 D21-0 01 1- PP FRAME RA I L , 14 ' R IG H T 1

4a D21-0 01 0-PP FRAME RA I L , 14 ' LEFT 1

4 D01-0 53 8- PP FRAME RA I L , 16 ' R IG H T 1

4a D01-0 53 7-PP FRAME RA I L , 16 ' LEFT 1

4 D31-0 04 4- PP FRAME RA I L , 18 ' R IG H T 1

4a D31-0 04 3-PP FRAME RA I L , 18 ' LEFT 1

4 D61-0 00 2- PP FRAME RA I L , 20 ' R IG H T 1

4a D61-0 00 1-PP FRAME RA I L , 20 ' LEFT 1

4 D101- 00 02-PP FRAME RAIL, 22 ' RI G HT 1

4a D101- 00 01 - PP FR AM E RAIL, 22' LEFT 1

4 D71-0 00 1- PP FRAME RA I L , 26 ' R IG H T 1

4a D71-0 00 2-PP FRAME RA I L , 26 ' LEFT 1

5 D01-0005SIDE LEG PORTABLE DRYER 101214161620

DESCRIPTION 1214 1216 1218 1220 1222 1226

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

7

Page 8

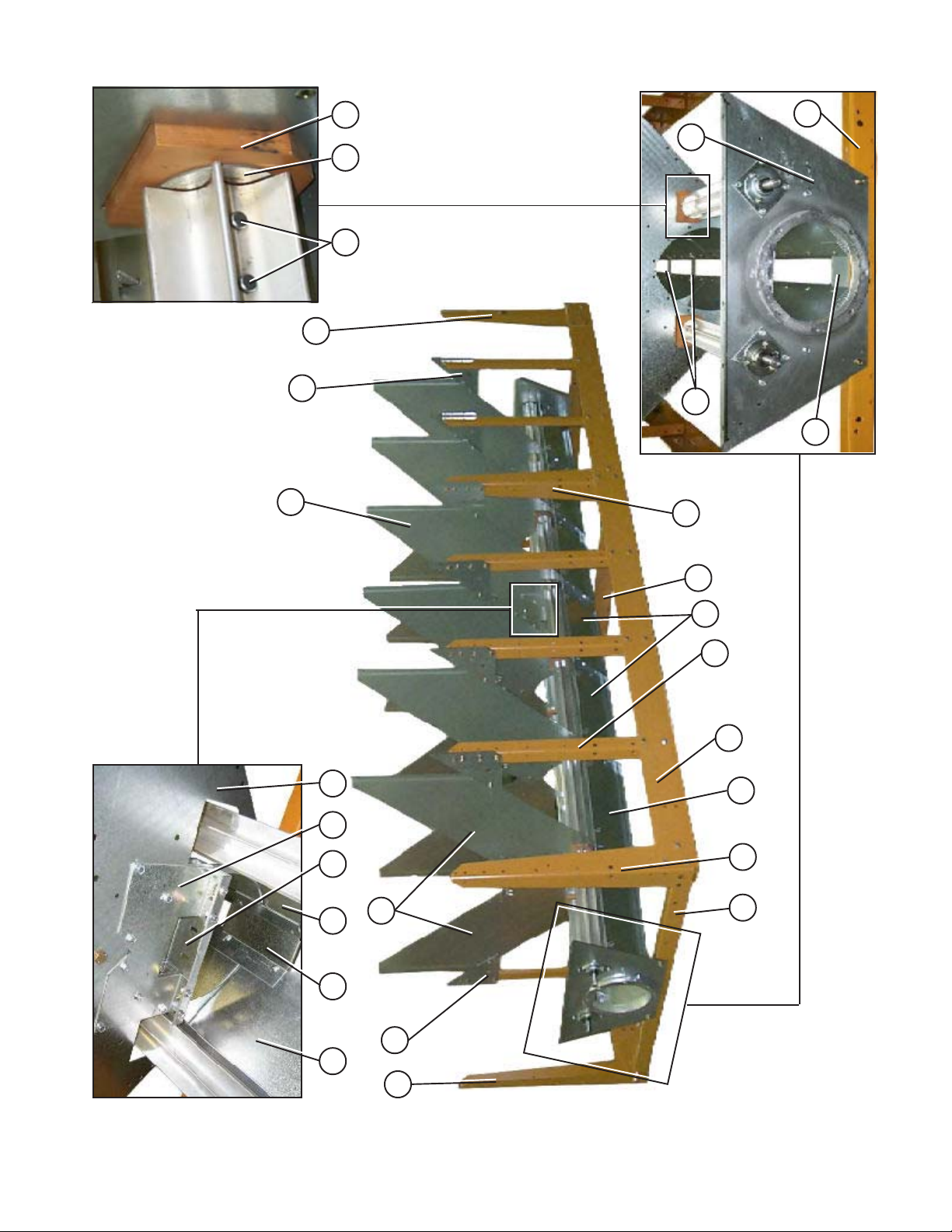

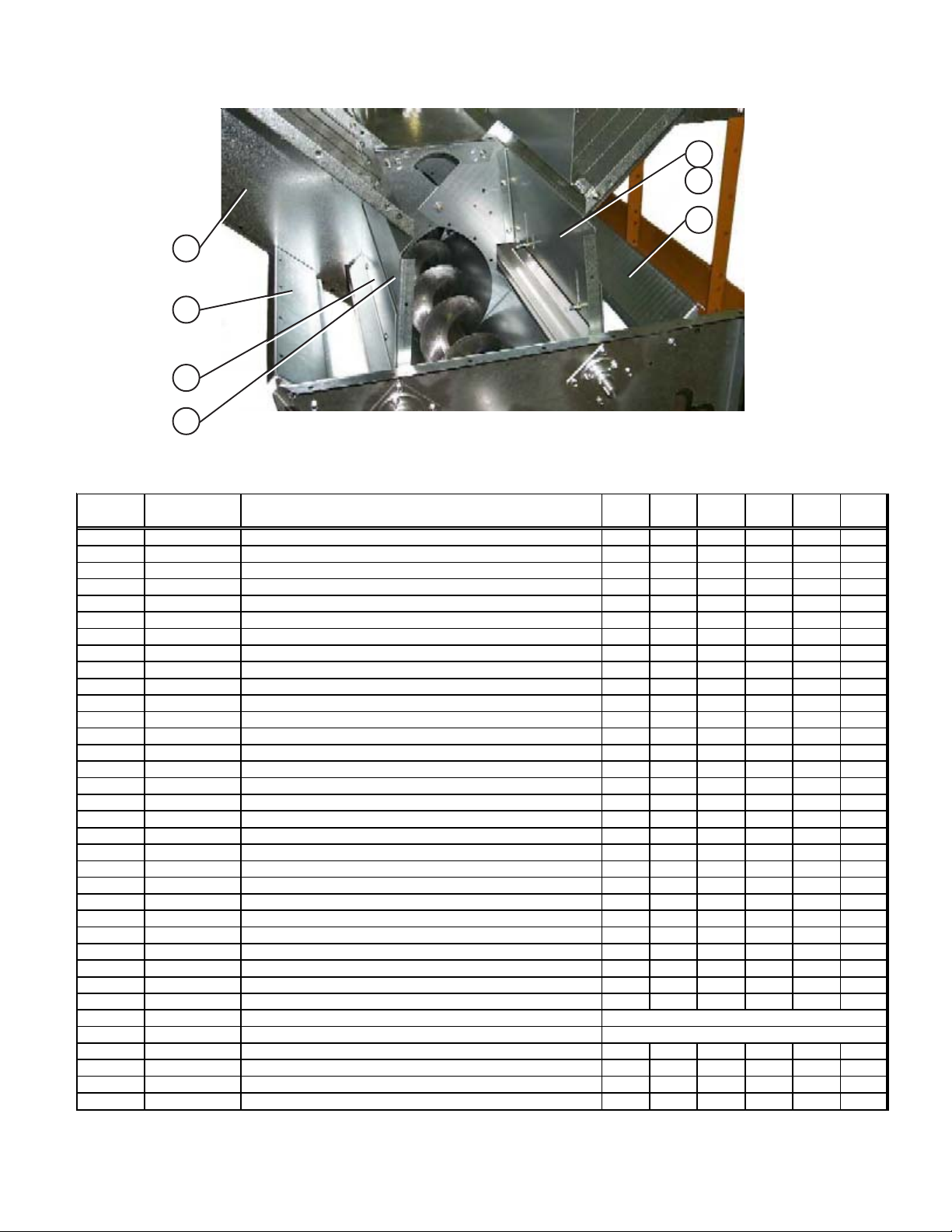

Frame, Auger Trough, & Hopper Bulkheads

6

4

9

5

Dryer frame and lower basket assembly (view from the front

end of the dryer looking down the left side).

1

3

56 4

2

8 116

9 10

7

L.H. and R.H.

distinguish between

door angles. This will

of the plenum closure

Note the hole pattern

**NOTE: The parts pointed out on this page are listed on page 11.

8

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 9

Frame, Auger T rough, & Hopper Bulkheads

Wooden meter roll support

bearing. The meter roll sections

support bearing assembly .

0046) that passes through the

roll splice shaft (part no. D31-

are spliced together with a meter

181716

9

21

6

4

19

20

Discharge bearing plate.

3

6

Center hanger bearing support

and cross channel seal plate.

9

12

5

11a

12

3

9 6

4

12 13 12 14 15 3

6

**NOTE: The parts pointed out on this page are listed on page 11.

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Dryer frame and lower basket assembly (view from the rear

end of the dryer looking up the right side).

9

Page 10

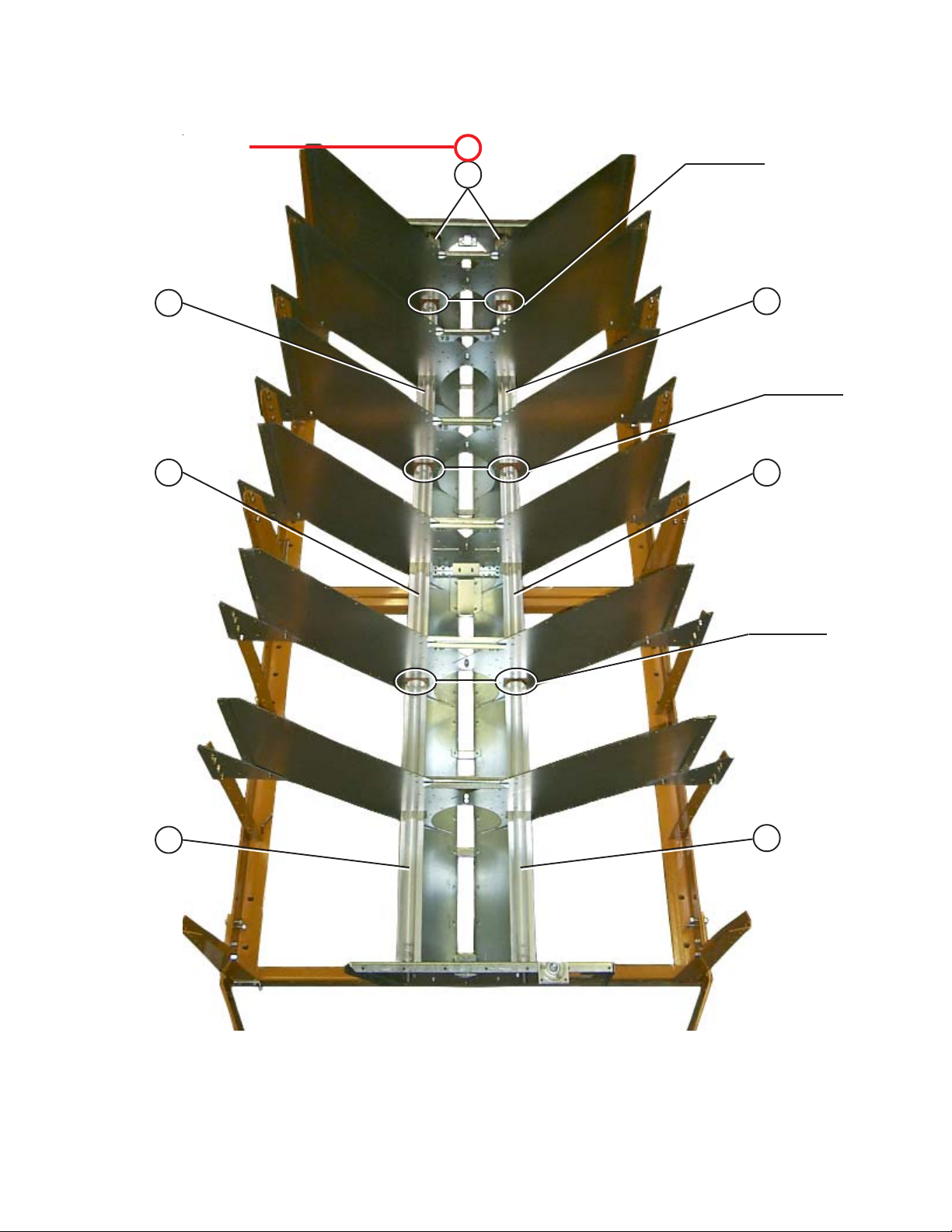

Metering Rolls and their placement in the dryer.

NOTE: Item 22 at the rear of

dryer is a front section

meter roll that is used as a

rear section on 16 and 20

foot dryers only.

Meter Rolls and Their Placement in the Dryer

22

24

Meter Roll

Bearing

See pg. 11

Items 16, 17, 18

23

23

23 23

Items 16, 17, 18

Meter Roll

Bearing

See pg. 11

Items 16, 17, 18

Meter Roll

Bearing

See pg. 11

10

22

22

This end is the front (fan/heater) end of the dryer .

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 11

Meter Rolls and Their Placement in the Dryer

ITEM

NUMBER PART NUMBER

1 D01-1136YPLENUM CLOSURE DOOR ANGLE, RH 67891012

2 D01-1136X PLENUM CLOSURE DOOR ANGLE, LH 7 8 9 10 11 13

3 D01-01 09 HOPPE R B ULKHEAD 12 14 16 18 20 24

4 D01-0004GUSSET PLATE 161820222428

5 D01-0005SIDE LEG 101214161620

6 D01-0007CORNER LEG 666688

7 D01-0011HITCH BRACKET, LH 222222

8 D01-0012HITCH BRACKET, RH 222222

9 D01-0008FRONT & REAR FRAME TIE CHANNEL 444466

10 D01-1374BOTTOM AUGER BEARING PLATE 111111

11 D21-0011-PP F RAME RAIL, 14' RIGHT 1

11 D01-0538-PP F RAME RAIL, 16' RIGHT 1

11 D31-0044-PP F RAME RAIL, 18' RIGHT 1

11 D61-0002-PP F RAME RAIL, 20' RIGHT 1

11 D101-00 02-PP FRAME RAIL , 22' RIGHT 1

11 D71-0001-PP F RAME RAIL, 26' RIGHT 1

11A D21-0010-PP FRAME RAIL, 14' LEFT 1

11A D01-0537-PP FRAME RAIL, 16' LEFT 1

11A D31-0043-PP FRAME RAIL, 18' LEFT 1

11A D61-0001-PP FRAME RAIL, 20' LEFT 1

11A D101-00 01-PP FRAME RAIL , 22' LEFT 1

11A D71-0002-PP FRAME RAIL, 26' LEFT 1

12 D01-0048TROUGH PANEL 141618202226

13 D01-1512PLATE, CROSS CHANNEL SEAL W/TABS 111122

14 D01-1291HANGER BEARING "C" CHANNEL 111122

15 D01-1290HANGER BEARING "J" PLATE 222244

16 D02-0028 CLEVIS PIN 5/16" x 1 3/4" 32 32 40 40 48 56

17 D 31 - 01 48 METER RO LL WA SHER 16 16 20 20 24 28

18 D02-0061METER ROLL SUPPORT BEARING 66881012

19 D01-0177 SUPPORT STRAP 7 8 9 10 11 13

20 D01-1511PLATE, END CHANNEL SEAL W/TAB 222222

21 D31-0120DISCHARGE PLATE 111111

22 D31-0031METER ROLL, FRONT 242422

23 D31-0030METER ROLL, INTERMEDIATE 4466810

24 D31-0029 METER ROLL, REAR 2 2 2 2

DESCRIPTION 1214 1216 1218 1220 1222 1226

The part number list above covers all parts pointed out on pages 8, 9, and 10.

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

11

Page 12

Inside (Plenum) Screens, Plenum Closure Doors

Plenum screens and bulkheads (view from front end).

3B

4

3A

5

6

12

5

16

7

8

10

11

13

14

18

19

12

10

9

7

15

This photograph was taken before the front plenum

end panel and outer screens where installed in order

to get a good view of the inside screens and bulk-

20

20a

heads.

12

21

Plenum closure door. There are two different plenum closure doors. The door

22

shown in the photogragh is the rear plenum closure door and is the rear most

plenum closure door, item no. 20 (just inside the rear access door), all others are

item no. 20a. NOTE: Item 22 is the plenum closure door rear frame angle.

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 13

Meter Roll Upper Shield Assembly

Close up of of meter roll upper shield assembly.

19

18

17

16

17

18

19

ITEM

NUMBER PART NUMBER

1 D31-0055 COLUMN BULK HEAD 12 14 16 18 20 24

2 D01-0101 GARNER BULKHEAD 12 14 16 18 20 24

3A D01-2466COLUMN END PANEL FRONT RIGHT 111111

3B D01-2467COLUMN END PANEL FRONT LEFT 111111

4 D01-0126 SCREEN,PLENUM TOP,GA,094 14 16 1 8 20 22 26

5 D31-0012 SCREEN,PLENUM WALL,GA,094 14 16 18 20 22 26

6 D01-1225 SCREEN,PLENUM BOTTOM,GA,094 14 16 18 20 22 26

7 D01-0004GUSSET PLATE 161820222428

8 D21-0011-PP FRAME RAIL, 14' RIGHT 1

8 D01-0538-PP FRAME RAIL, 16' RIGHT 1

8 D31-0044-PP FRAME RAIL, 18' RIGHT 1

8 D61-0002-PP FRAME RAIL, 20' RIGHT 1

8 D101-0002-PP FRAME RAIL, 22' RIGHT 1

8 D71-0001-PP FRAME RAIL, 26' RIGHT 1

9 D21-0010-PP FRAME RAIL, 14' LEFT 1

9 D01-0537-PP FRAME RAIL, 16' LEFT 1

9 D31-0043-PP FRAME RAIL, 18' LEFT 1

9 D61-0001-PP FRAME RAIL, 20' LEFT 1

9 D101-0001-PP FRAME RAIL, 22' LEFT 1

9 D71-0002-PP FRAME RAIL, 26' LEFT 1

10 D01-0007CORNER LEG PORTABLE DRYER 666688

11 D01-0012HITCH BRACKET RIGHT 222222

12 D01-0011HITCH BRACKET LEFT 222222

13 D01-0008FRONT & REAR FRAME TIE CHANNEL 444466

14 D01-1374BOTTOM AUGER BEARING PLATE 111111

15 D01-0005 SIDE LEG PORTABLE DRYER 10 12 14 16 16 20

16 D01-0109 HOPPER BULKHEAD 12 14 16 18 20 24

17 D01-0050P CONNECTOR SHEET, PERFORATED 14 16 18 20 22 26

*18&19 D01- 11 8 0 METER ROLL UPPER SHIELD ASSY. 14 16 18 20 22 26

18 D01-0431 METER ROLL STRIKE OFF PLATE

19 D01-1226 METER RO LL SHIELD 1995 STYLE

20 D01-1214PLENUM CLOSURE DOOR, REAR 111111

20aD01-1134PLENUM CLOSURE DOOR 67891012

21 DC-974DANGER FOOT IN AUGER DECAL 222222

22 D01-1217PLENUM CLOSURE DOOR REAR FRAME ANGLE 111111

DESCRIPTION 121412161218122012221226

1 PER AS SEMBLY

1 PER AS SEMBLY

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

13

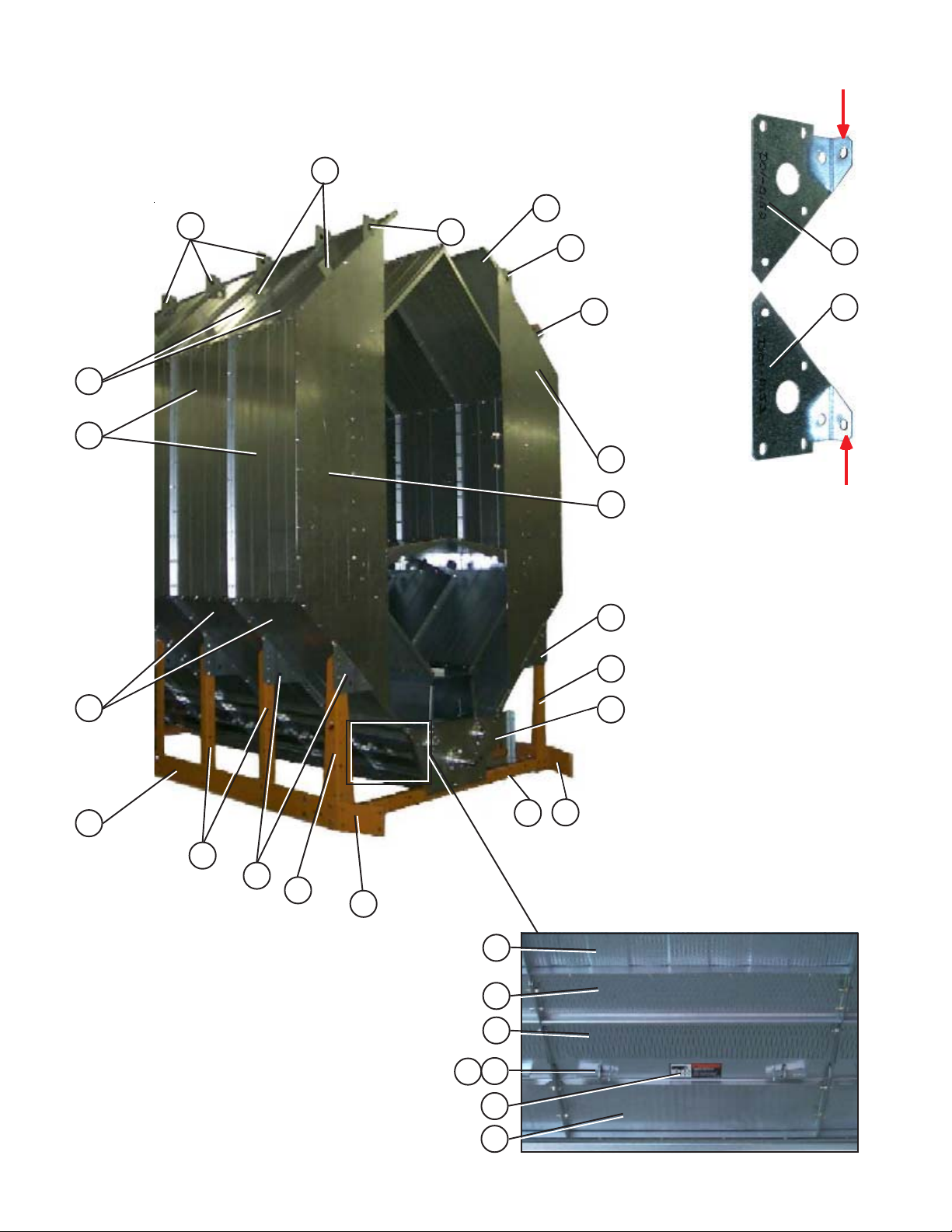

Page 14

Outer Screens, & Meter Roll Access Door

Outer screens (view from front end).

2

*

3

*

4

*3a

3

2

3

3a

4

5

1B

1A

13

14

6

18

*Note: Item 3 is pointing to

the top edge angle gusset.

There are two types of gusset

on the dryer . The photo

above will help distinguish the

difference between the two.

The arrows are pointing to a

tab on the gusset that makes

them different (tabs are

“bent” up in photo). Item 3a

is used in two places only; 1.)

front right of dryer 2.) rear

left of dryer, all others are

item 3.

14

16

11

17

12

13

14

15

Meter roll access door.

6

19

20

22

21

23

24

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 15

Plenum Divider

Plenum divider.

7 8

The photo above and on page 16 was taken before plenum end panels

where installed.

Plenum divider clean-out door.

9

10

9

ITEM

NUMBER PART NUMBER

1A D01-2466COLUMN END PANEL FRONT RIGHT 111111

1B D01-2467COLUMN END PANEL FRONT LEFT 111111

2 D01-0113WALK RAIL MOUNTING BRACKET 182022242832

3 D01-0152 TOP EDGE A NGLE GUSSET - LH 14 16 18 20 22 26

3a D01-0153TOP EDGE ANGLE GUSSET - RH 222222

4 D01-0127SCREEN, ROOF SHEET 141618202226

5 D31-0013SCREEN, OUTSIDE WALL SHEET 141618202226

6 D01-0128SCREEN, HOPPER SHEET 141618202226

7 D31-0032PLENUM DIVIDER: MF: BOTTOM 121416182024

8 D31-0033PLENUM DIVIDER: MF: BOTTOM END 222222

9 D31-0260CLEAN-OUT DOOR GUIDE 444444

10 D31-0259PLENUM DIVIDER CLEAN-OUT DOOR 222222

11 D2 1-0011-PP FRA ME RAIL, 14 ' RIGHT 1

11 D0 1-0538-PP FRA ME RAIL, 16 ' RIGHT 1

11 D3 1-0044-PP FRA ME RAIL, 18 ' RIGHT 1

11 D6 1-0002-PP FRA ME RAIL, 20 ' RIGHT 1

11 D101-0002-PP FRAME RAIL, 22' RIGHT 1

11 D7 1-0001-PP FRA ME RAIL, 26 ' RIGHT 1

12 D01-0005 SIDE LEG PORTABLE DRYER 10 12 14 16 16 20

13 D01-0004GUSSET PLATE 161820222428

14 D01-0007CORNER LEG PORTABLE DRYER 666688

15 D01-0012HITCH BRACKET RIGHT 222222

16 D01-0011HITCH BRACKET LEFT 222222

17 D01-0008FRONT & REAR FRAME TIE CHANNEL 444466

18 D01-1374BOTTOM AUGER BEARING PLATE 111111

19 D01-0050P CONNECTOR SHEET, PERFORATED 14 16 18 20 22 26

20 D01-0045P ACCESS DOOR, PERFORATED 14 16 18 20 22 26

21 D01-0039 DOOR LATCH 28 32 36 40 44 52

22 S-6552 PIN, HAIR CLIP 3/32" 28 32 36 40 44 52

23 DC-1229 DECAL, WARNING METER ROLL ROT. 14 16 18 20 22 26

DESCRIPTION 1214 1216 1218 1220 1222 1226

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

15

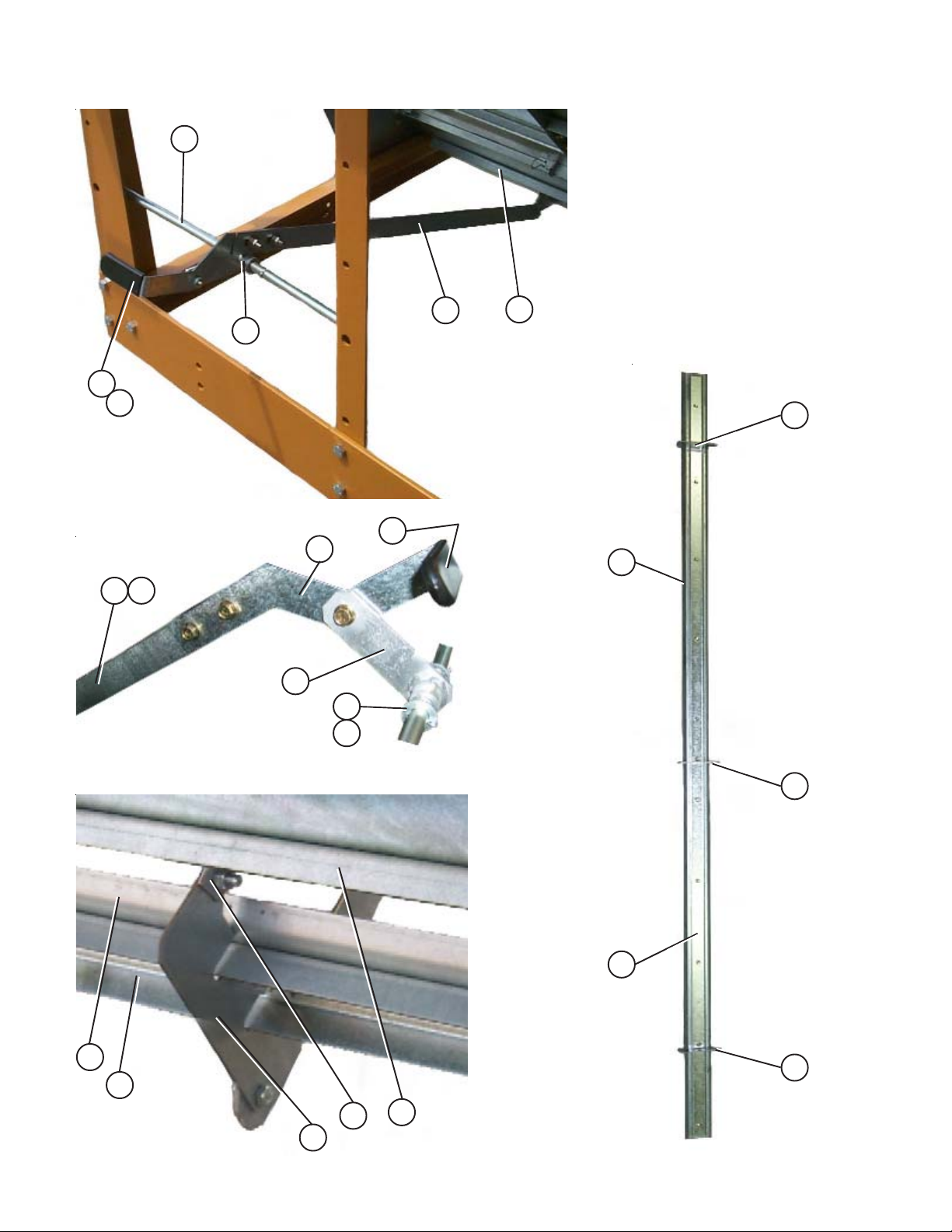

Page 16

Clean Out Doors

Front and rear handle mechanisms (rear shown in photo).

1

3

2

4

5

*Note: Items 9, 10, & 11 together create the

clean out door assembly. There are three

different clean out door assemblies that are used

on GSI Network dryers:

1.) 3 column clean out door assy. (D51-0077).

Item 8a on the part no. listing (pg 17).

2.) 4 column clean out door assy. (D11-0032).

Item 8b on the part no. listing (pg 17).

3.) 5 column clean out door assy. (D01-0349).

13

Item 8c on the part no. listing (pg 17).

A 5 column clean out door assy (D01-0349) is

shown in the photograph below.

11

Clean out door handle mechanism.

3a

3

2

Clean out door hinge.

5

4

9

6

7

11

10

16

9

11

10

12

13

11

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 17

Clean Out Doors

Center handle mechanisms (this handle mechanism stradles the center cross channels).

14

3a

1a

14

3a 11

4

2

5

14

ITEM

NUMBER

1 D01-0264 PIVOT ROD 25.188" 2 2 2 2 2 2

1a D31-0162 PIVOT ROD 49.62 5" 1 1 1 1 2 2

2 D01-0296LINKAGE BAR WELDMENT 444466

3 D01-0261LINKAGE BAR, 37" LONG 222222

3a D01-0293 LINKAGE BAR, 30" LONG 2 2 2 2 4 4

4 D01-0294 CLEAN OUT DOOR HANDLE 4 4 4 4 6 6

5 S-4378PLASTIC GRIP 444466

6 S-248 WASH ER , FLAT 3/ 8 U SS ZN 8 8 8 8 1 2 12

7 S-7241 COTTER PIN, 1/8 x 1 1/4 8 8 8 8 12 12

8a D51-0077 CL EA N OUT DOOR ASSY , 3 C O LUMN 1 1

9 D21-000 5 CLEAN OU T D O O R, 67 "

10 D21-0012 SUPPORT CHANNEL , CLEAN OUT DOOR

11 D01-0308 CLEAN OUT DOOR HINGE

8b D11-0032 CL EA N OUT DOOR ASSY , 4 C O LUMN 1 2 1 2 2

9 D31-002 1 CLEAN OU T D O O R, 91 "

10 D31-0130 SUPPORT CHANNEL , CLEAN OUT DOOR

11 D01-0308 CLEAN OUT DOOR HINGE

8c D01-0349 CLEAN OUT DOOR ASSY, 5 CO LUMN 1 2 1

9 D01-018 0 CLEAN OU T D O O R, 11 5"

10 D01-0307 SUPPORT CHANNEL , CLEAN OUT DOOR

11 D01-0308 CLEAN OUT DOOR HINGE

12 D01-0175 HIN GE BRACKET 4 5 5 6 6 7

13 D01-0 18 1 CLEAN O UT EXT E N SION, 11 9.75" 2 4 2

13 D31-0023 CLEAN OUT EXTENSION, 90.75" 2 4 2 4 4

13 D21-0006 CLEAN OUT EXTENSION, 66.75" 2 2

14 D01-0299 PIVOT ROD BRACKET 3 3 3 3 6 6

PART

NUMBER

DESCRIPTION 121412161218122012221226

1 PER ASSEMBLY

1 PER ASSEMBLY

2 PER ASSEMBLY

1 PER ASSEMBLY

1 PER ASSEMBLY

2 PER ASSEMBLY

1 PER ASSEMBLY

1 PER ASSEMBLY

3 PER ASSEMBLY

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

17

Page 18

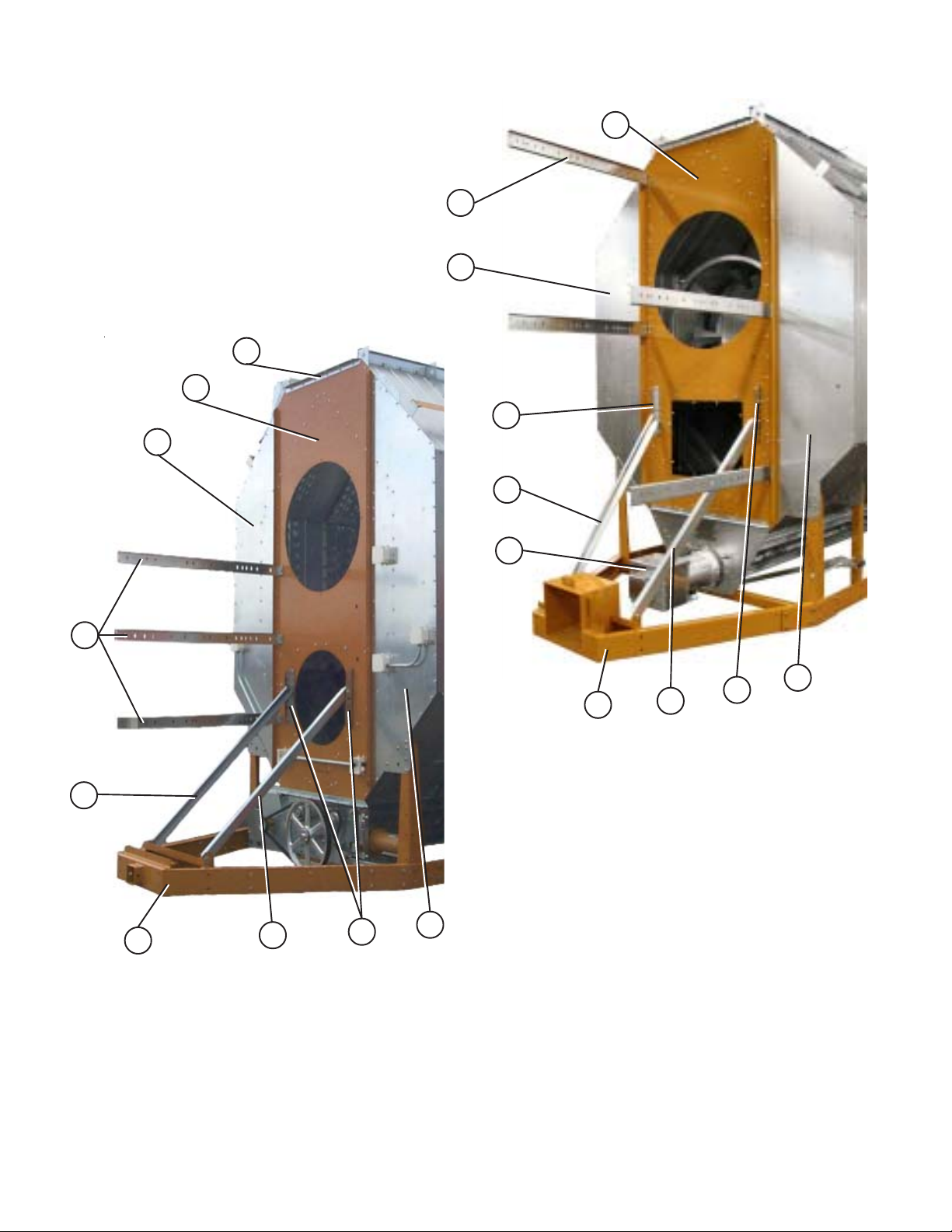

Front & Rear Plenum End Panels, & Upper & Lower Rear Access Doors

Front end panels & support arms.

3

4

1A

Rear end panels & support arms.

2

5

1D

8

6A

24

5

7A

6

7

6

8

1B

6A

8

1C

18

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 19

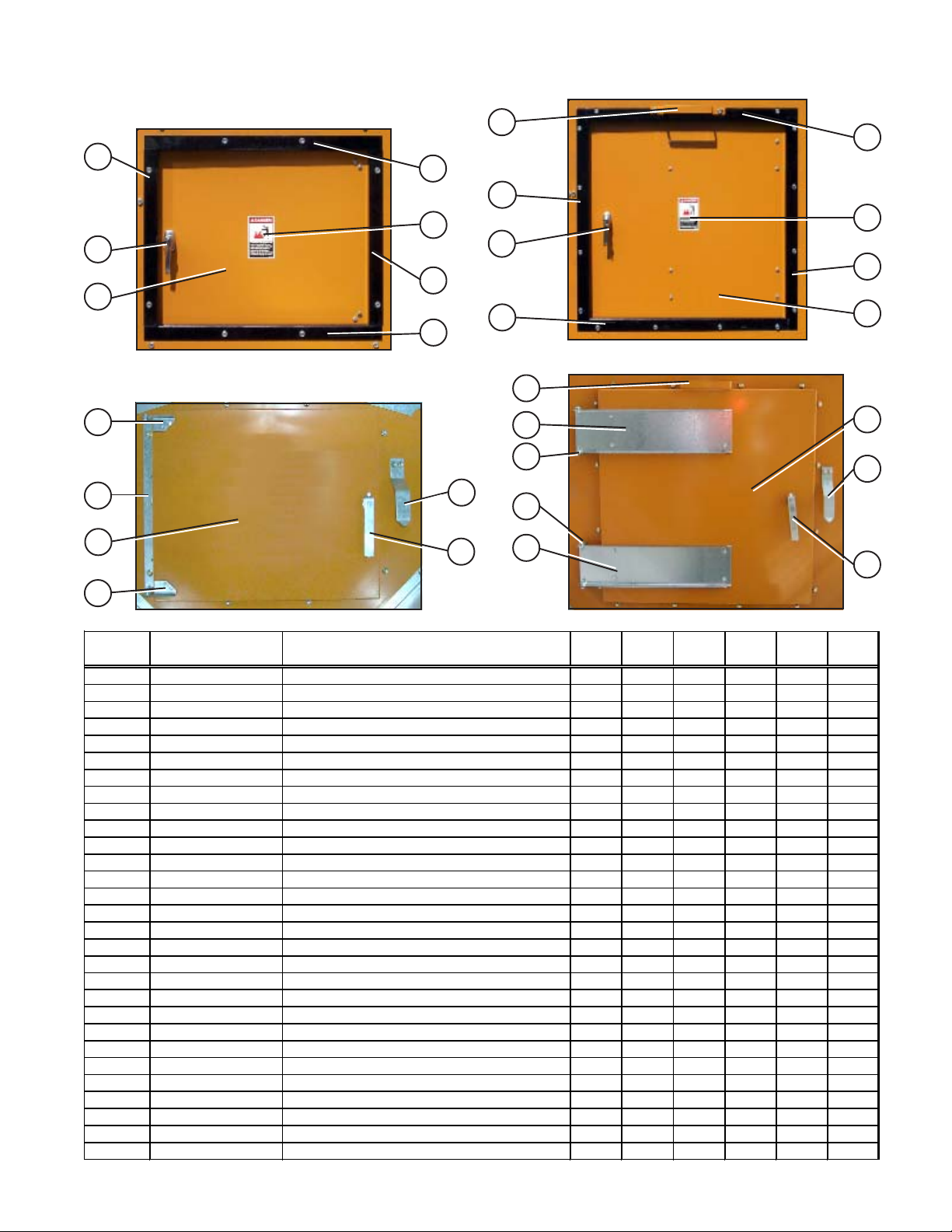

Front & Rear Plenum End Panels, & Upper & Lower Rear Access Doors

Upper plenum access door.

Lower plenum access door.

9

10

12

Lower plenum access door (inside).

17

18

12

14

15

11

15

13

13

10

15

9

15

16

11

Upper plenum access door (inside).

14

22

23

21

23

20

22

16

21

20

19

ITEM

NUMBER PART NUMBER

1A D01-2466COLUMN END PANEL FRONT - RH 111111

1B D01-2467COLUMN END PANEL FRONT - LH 111111

1C D01-2476COLUMN END PANEL REAR - RH 111111

1D D01-2477COLUMN END PANEL REAR - LH 111111

2 D01-2402-Y REAR END PANEL 28-40 OPP FA N 1

2 D01-2431-Y REAR END PANEL 28-42 OPP FA N 1 1

3 325-1688-2TOP ANGLE BRKT FRONT & REAR 222222

4 D01-2401-OC FRONT END PA NEL 28" OPP FA N 1 1 1 1

5 D51 -00 2 2 SUPPORT, CO NTROL PANEL 10 10 10 10 10 10

6 D31-0082FRONT DIAGONAL SUPPORT CHANNEL 222222

6A D01-0778DIAGONAL SUPPORT CHANNEL, 5' 222222

7 D01-0029HITCH WELDMENT 111111

7A D01-0029HITCH WELDMENT REAR 111111

8 D31-0129DIAGONAL SUPPORT ANGLE 444444

9 D01-0395SQUARE DOOR SIDE BRKT 222222

10 D03-0512DOOR HANDLE LOCKING 222222

11 D01-0396SQUARE DOOR TOP/BOTTOM BRKT 222222

12 D01-0394SQUARE REAR ACCESS DOOR 111111

13 DC-973 DECAL, DANGER FIRE HAZARD 222222

14 D01-1783-YASSIST HANDLE, 29" SQ. DOOR 222222

15D01-1782-BLKFRAME ANGLE, 29" SQ. DOOR 444444

16 D01-1781-YDOOR, 29" SQUARE 111111

17 D31-0297REAR DOOR HINGE, TOP 111111

18 D31-0161HINGE BRACKET 111111

19 D31-0296REAR DOOR HINGE, BOTTOM 111111

20 D01-1792LATCH BAR 222222

21 D01-0397LATCH BRACKET 222222

22 401-4669-8REAR ACC. DOOR HINGE, DOOR HALF 222222

23 401-4630-0HINGE BRACKET 222222

DESCRIPTION 1214 1216 1218 1220 1222 1226

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

19

Page 20

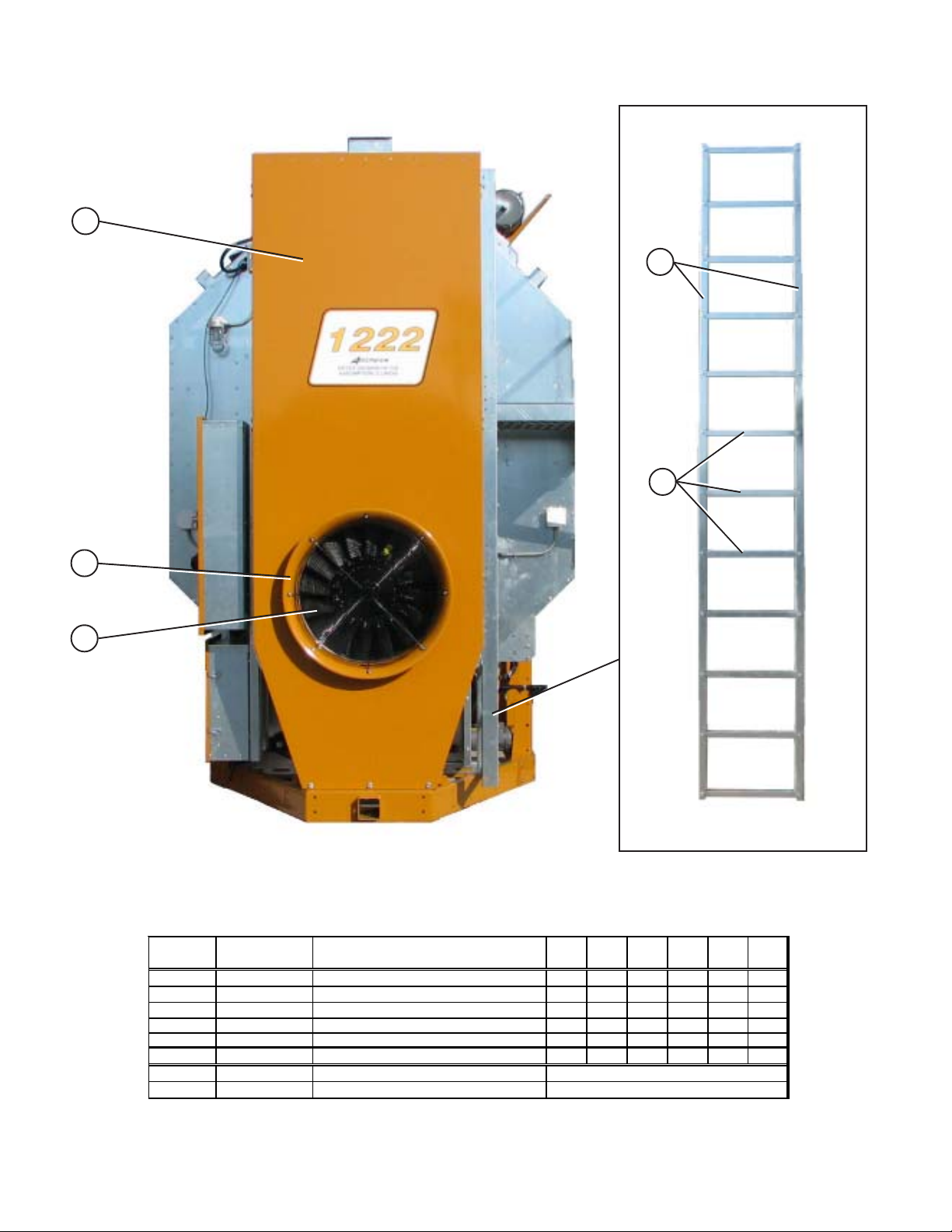

Fan Guards, Support Panels, Ladder Assembly

1

4

5

2

3

ITEM

NUMBER PART NUMB ER

1 D01-2400-Y SUPPORT PANEL-FRONT 28 OPP FA N

2 F-7062-Y VENTURI: 26" 1 1 1

2 F-7060-Y VENTURI: 28" 1 1 1

3 CD-0 575 GRILL GUARD: CD- 26 1 1 1

3 CD-0 576 GRILL GUARD: CD- 28 1 1 1

4-5 410-1577-7 LA DDER ASSEMBLY - 10' 7" 2 2 2 2 2 2

4 D0 1 -191 9 L ADDER RA IL 1 2 RUNG UNIVERSA L

5 D6 1 -009 6 L ADDER RUNG

DESCRIPTION 1214 1216 1218 1220 1222 1226

111

2/A S SEMBLY

12/ASSEMBLY

20

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 21

Fan Guards, Support Panels, Ladder Assembly

1

2

3

Ladder

Assembly

shown on page

ITEM

NUMBER PART NUMBER

1 CD-0544 GRILL GUARD: 36" 1 1 1

1 CD-0547 GRILL GUARD: 40 & 42" 1 1 1

2 CD-054 3-Y VENTURI: 36" 1 1 1

2 CD-054 5-Y VENTURI: 40" 1

2 CD-054 6-Y VENTURI: 42" 11

3 D01-2403-Y REA R FA N SUPPORT 40" OPP FAN 1

3 D01-2432-Y REA R FA N SUPPORT 42" OPP FAN 1 1

DESCRIPTION 1214 1216 1218 1220 1222 1226

20.

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

21

Page 22

Bottom Auger (view from center of dryer to the

forward end).

Bottom Auger

Bottom Auger (view from center of dryer to the

rear end).

1

2

2

3

2

4

Bottom Auger center bearing and support. Bottom Auger rear bearing.

22

8 75 7 6

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 23

Bottom Auger

A

A

A

A

A

A

9-19

D01-0481-MS

DISCHARGE BOX ASSEMBLY

11111

1

19

D01-046

DISCHARGE TOP FLAPPER

NOT SHOWN

D31-0079

DISCHARGE AUGER WELDMENT

11111

1

Y

Y

Rear Discharge Box. Auger bearing.

18 19

17

20

9

10

16

11

12

ITEM

NUMBER PART NUMBER

1 D01-1214 PLENUM CLOSURE DOOR, REAR 1 11111

2 D01-1134 PLENUM CLOSURE DOOR 6 7 8 9 10 12

3 D21-0017

3 D01-0607

3 D31-0092

3 D31-0092

4 D31-0267

4 D61-0184

5 D01-1290 HANGER BEARING BOTTOM J-PLATE 2 22244

6 D01-1291 HANGER BEARING BOTTOM C-CHANNEL 1 11122

7 D01-1246 HANGER BEARING ASSEMBLY (SHORT) 2 22233

8 D31-0076 SHAFT, AUGER SPLICE 2 22233

9 D01-1884 DISCHARGE WELDMENT

10 D01-1886 MOIST. SAMPLER TUBE COVER PLATE

11 D01-0405 GRAIN SAMPLER ASSEMBLY

12 D01-1752 DISCHARGE SIDE COVER

13 D01-1751 DISCHARGE SICE PANEL MC

14 D31-0298 DISCHARGE SIDE PANEL

15 D01-1885 MOIST. SAMPLER COVER PLATE

16 D01-1650 R EAR AUGER BEARING SHIELD

17 D31-0299 D ISCHARGE BOX BEARING PLATE

18 D01-0466 DISCHARGE TOP PANEL

20 D32-0001 FLANGETTE BEARING 1 11111

21 D31-0005 SHAFT, TOP & BOT AUGER STUB 1 11111

UGER BOTTOM FRONT WELDMENT 1 1

UGER BOTTOM FRONT WELDMENT 1

UGER BOTTOM FRONT WELDMENT 1 1

UGER BOTTOM FRONT WELDMENT (116 3/8" LONG) 1

UGER BOTTOM REAR WELDMENT 1 1 1 2 2

UGER BOTTOM REAR WELDMENT (117 7/8" LONG) 1

7

13 14 15

DESCRIPTION 1214 1216 1218 1220 1222 1226

21

1/ASSEMBL

1/ASSEMBLY

1/ASSEMBLY

1/ASSEMBLY

1/ASSEMBLY

1/ASSEMBLY

1/ASSEMBLY

1/ASSEMBLY

1/ASSEMBLY

1/ASSEMBLY

1/ASSEMBL

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

23

Page 24

T op Auger With Wet Bin Assembly

Top Auger with wet bin (switch paddle end).

6

5

2

1

1

43

7

9

13 14

14a

8

1

3

10

11

12

26

9

24

Top Auger (fill end).

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 25

T op Auger With Wet Bin Assembly

Top Auger bearing support. Top Auger bearing support (inside view).

PART

17

7

21

22

20

23

24

7

25

19

DESCRIPTION 1214 1216 1218 1220 1222 1226

16

15

10 21 22 18

ITEM

NUMBER

1 D01-1521 WET BIN SIDE, 4 'SID E GALV. PERF 4 2 4 2 4

1 D01-1522WET BIN SIDE,6'SIDE GALV. PER 246466

2 D01-0103MERCURY SWITCH SHAFT 111111

3 D21-0003 TOP EDGE ANGLE 71.875" 2 2

3 D31-0004 TOP EDGE ANGLE 95.875" 2 4 2 4 4

3 D01-0168 TOP EDGE ANGLE 11 9.875" 2 4 2

3a D31-0003TOP EDGE ANGLE SPLICE 222244

5 D01-0147TOP AUGER HOUSING HINGE L.H. 222222

6 D01-0167MERCURY SWITCH PADDLE WELDMENT111111

7 D21 -00 15 AUGER TOP FR ONT WELDME N T 1 1

7 D01-0608 AUGER TOP FRONT WLDT 16'BASKET 1

7 D31 -00 91 AUGER TOP FR ONT WELDME N T 1 1 1

7 D31-0267 AU GER TOP & BOTTO M WELDMENT 1 1 1 2 2

7 D61 - 0184 AUGER WELDMENT 117 7/ 8" 1

8 D01-0148TOP AUGER HOUSING HINGE R.H. 222222

9 D01-1525WET BIN END 222222

10 D21-0002 TOP AUGER TROUGH SIDE/6' 2 2

10 D31-0010 TOP AUGER TROUGH SIDE/8' 2 4 2 4 4

10 D01-0161 TOP AUGER TROUGH SIDE/10' 2 4 2

11 D01-1650REAR AUGER BEARING COVER 111111

12 D31-0028TOP AUGER HOUSING END 222222

13 D32-0001BEARING 1 1/2" DIA W/FLANGETTE 222222

14 D31-0090SHAFT, TOP AUGER FRONT 111111

14a D31-0005SHAFT, TOP AUGER STUB REAR 111111

15 D01-1123TOP AUGER COVER, 30.25" 111111

15 D01-1124TOP AUGER COVER, 24.25" 345757

15 D01-1125TOP AUGER COVER, 20.25" 222244

16 D31-0015TOP AUGER BEARING SUPPORT 111122

17 D31-0011CENTER STABILIZER BEAM 111122

18 D31-0009GUSSET ATTACH BRACKET 222244

19 D31-0001CENTER HANDRAIL GUSSET L.H. 222244

20 D31-0002CENTER HANDRAIL GUSSET R.H. 222244

21 D21-0001-Y HAND RAIL-SUPPORT,1"EMTX71.75" 2 2

21 D31-0006-Y HAND RAIL SUPPORT,1"EMTX95.75" 2 4 2 4 4

21 D01-0151-Y HAND RAIL, 1"EMT X119.75"LONG 2 4 2

22 D01-0140HANGER BRACKET-HANDRAIL GALV. 161616162424

23 D31-0008TOP AUGER TROUGH SPLICE 222244

24 D01-1245TOP AUGER BEARING HANGER ASSY. 111122

25 D31-0076SHAFT, AUGER SPLICE 111122

26 D01-0156TOP AUGER HOUSING CHANNEL 222222

NUMBER

16

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

25

Page 26

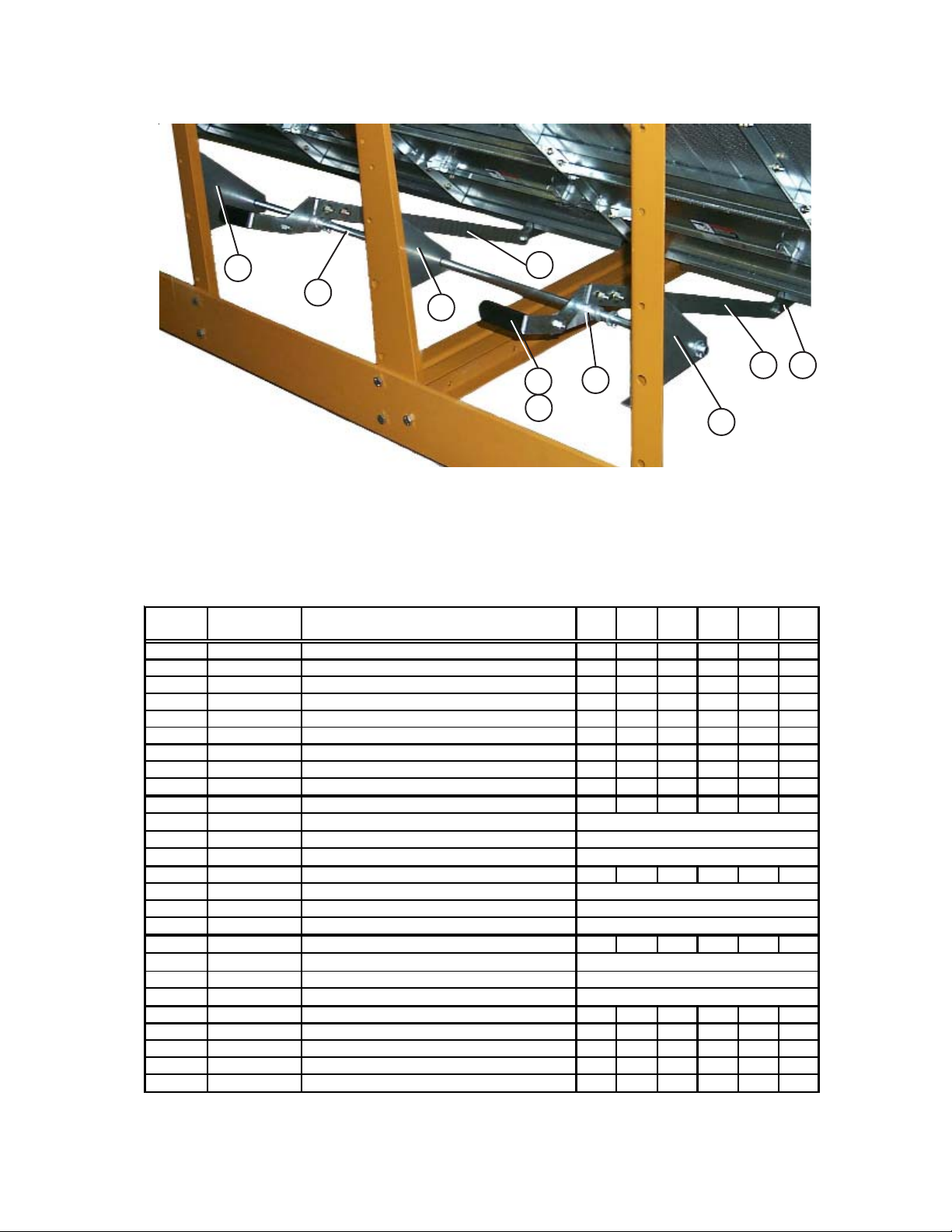

Bottom Auger drive components

Bottom Auger Drive

1

2

3

4

5

11

11

9

10

8

7

6

Bottom Auger motor and motor mount.

12

13

Rear drive tension adjustment.

13

18

16

17

Forward drive tension adjustment.

5

13

14

16

15

6

4

26

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 27

Bottom Auger Drive

Bottom auger and metering roll drive guard.

21

22

19

20

ITEM

NUMBER PART NUMB ER

1 D01-1376 BOTTOM FRONT ANGLE BRACKET 111111

2 MHC00490BELT-V BX82 222222

3 2818-2 SHEAVE 2GR 3.35Dx1 1/8" 1 1 1

3 D62-0003 SHEAVE 2GR 4.25Dx1 3/8" 1 1 1

4 D01-0012 HITCH BRACKET, RIGHT 111111

5 D01-1373 BELTGUARD, UNLOAD MOTOR SHROUD 111111

6 D01-0029 HITCH WELDMENT 111111

7 D01-0011 HITCH BRACKET, LEFT 111111

8 D01-1374 BOTTOM AUGER BEA RING PLA TE 111111

9 D03-0304 SHEAVE 2GR 20" GRIPBELT 111111

10 D32-0019 BUSHING Q1-1 1/2" SPLIT TAPER 111111

11 D01-0065 SPACER, BEARING SHIELD 222222

*12 D03-1109 MOTOR 5HP 1PH 1800RPM 1 1 1

12 500-3 MOTOR 5HP 3PH 1800RPM 1 1 1

*12 D03-1010 MOTOR 7.5HP 1PH 1800RPM 1

12 712-3 MOTOR 7.5HP 3PH 1800RPM 1 1

12 1000-3 MOTOR 10HP 3PH 1800RPM 1

13 D01-0081 MOTOR MOUNT - BOTTOM AUGER 111111

14 D01-0008 FRONT & REAR FRA ME TIE CHANNEL 444466

15 D01-0007 CORNER LEG 666688

16 D01-0017 MOTOR ADJUSTMENT BRACKET 222222

17 D21-0011 FRAME RAIL, 14' R.H. 1

17 D01-0538 FRAME RAIL, 16' R.H. 1

17 D31-0044 FRAME RAIL, 18' R.H. 1

17 D61-0002 FRAME RAIL, 20' R.H. 1

17 D101-0 00 2 F RAME RAIL, 22' R. H. 1

17 D71-0002 FRAME RAIL, 26' R.H. 1

18 D01-0016 MOTOR MOUNT SUPPORT BRACKET 111111

19 D01-1372 BELTGUARD, UNLOAD FRONT SHIELD 111111

20 PR-331PEAK CAP HANDLE 222222

21 DC-971DECAL, BELT DRIVE WARNING 222222

22 DC-972DECAL, CHAIN WARNING 222222

*ITEM 12, PART Nos D03-1109 & D03-1010 ARE SINGLE PHASE MOTORS

DESCRIPTION 1214 1216 1218 1220 1222 1226

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

27

Page 28

T op Auger Drive

1

6

1

2

3

Belt guard upper mount.

4

5

Top Auger drive components.

Top Auger belt guard cover.

28

12

13

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 29

T op Auger Drive

7

8

9

10

11

T op Auger motor and motor mount.

ITEM

NUMBER PA RT NUMBER

1 D01-0453 TOP AUGER BELTGARD BODY 1 11111

2 D52-0001 SHEAVE 2GR 16" GRIPBELT 1 11111

3 D32-0019 BUSHING Q1-1 1/2" SPLIT TAPER 1 11111

4 D01-0464 BELT- V BX97 2 22222

5 2818-2 SHEA VE 2GR 3.35Dx1 1/8" BORE 1 1 1

5 D62-0003 SHEAVE 2GR 4.25Dx1 3/8" 1 1 1

6 D01-0155 MOUNTING BRACKET-BELT GD SPCR 1 11111

7 D01-0424 DRY ER TOP HAND HOLD 1 11111

* 8 D03-1109 MOTOR 5HP 1PH 1800RPM 1 1 1

8 500-3 MOTOR 5HP 3PH 1800RPM 1 1 1

* 8 D03-1010 MOTOR 7.5HP 1PH 1800RPM 1

8 712-3 MOTOR 7.5HP 3PH 1800RPM 1 1

8 1000-3 MOTOR 10HP 3PH 1800RPM 1

9 D01-0173 TOP MOTOR MOUNT WELDMENT 1 11111

10 D01-0465 TURNBUCKLE 1/2 " X 6" PLA TED 1 11111

11 D01-0170 ANCHOR BRACKET-MOTOR MOUNT 1 11111

12 D01-0452-Y TOP AUGER BELTGUARD COVER OCHR 1 11111

13 DC-971DECAL, BELT DRIVE WARNING 222222

*ITEM 8, PART Nos D03-1109 & D03-1010 ARE SINGLE PHASE MOTORS

DESCRIPTION 1214 1216 1218 1220 1222 1226

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

29

Page 30

Metering Roll Drive

SCR Motor/Reduction drive and motor mount assembly .

1

7

2

34 5 6

8

Meter roll drive train components.

12

9

14

17

15

9

14

10

11

8

12

13

14

16

30

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 31

Metering Roll Drive

Front meter roll bearing. Rear meter roll bearing.

18

19

20

ITEM

NUMBER PART NUMBER

1 D01-0007CORNER LEG PORTABLE DRYER 666688

2 D21 -0010 FRAME RAIL, 14' LEF T 1

2 D01 -0537 FRAME RAIL, 16' LEF T 1

2 D31 -0043 FRAME RAIL, 18' LEF T 1

2 D61 -0001 FRAME RAIL, 20' LEF T 1

2 D101-0001 FRAME RAIL, 22 ' LE F T 1

2 D71 -0002 FRAME RAIL, 26' LEF T 1

3 D01-0016MOTOR MOUNT SUPPORT BRACKET 111111

4 D01-0081MOTOR MOUNT 111111

5 D01-0704SCR MOTOR GEARBOX MOUNT 111111

6 D01-0008FRONT & REAR FRAME TIE CHANNEL 444466

7 D03-0232MOTOR 3/4 HP DC W/GEAR BOX 50:1 111111

8 D01-1374BOTTOM AUGER BEARING PLATE 111111

9 D02-0029SPROCKET 40H30 222222

10 D31-0316FRONT BOTTOM AUGER SHAFT 111111

11 D32-0001FLANGETTE BEARING 1 1/2" 222222

12 D01-0196SPROCKET IDLER ASSEMBLY 222222

13 D03-0257SPROCKET 4015 x 7/8" BORE W/KEYWAY 111111

14 S-9168KEY SQ. 1/4" x 1" 333333

15 S-6290 CHAIN #40 ROLL ER CHA IN 6ft 6ft 6ft 6ft 6ft 6ft

16 D02-0031#40 CHAIN CONNECTING LINK 111111

17 DC-972DECAL, CHAIN WARNING 222222

18 D01-0003ADAPTOR PLATE 444444

19 GK1583FLANGETTE BEARING 1", W/LOCK COLLAR 444444

20 D01-0006METER ROLL DRIVE SHAFT (front) 222222

21 D01-0272METER ROLL SHAFT STUB (rear) 222222

DESCRIPTION 1214 1216 1218 1220 1222 1226

18

19

21

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

31

Page 32

Fan Heater Housing Assembly

Fan Heater housing assembly. 26” & 28” burner support and

collector cup.

1

2

3

10a

9a

9

10

36”-42” burner support and collector cup.

4

5

6

7

8

32

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 33

y

y

Fan Heater Housing Assembly

BOTTOM FANS T OP FANS

ITEM

NUMBER PART NUMBER

1 D01-1995 WRAPPER, 26" FAN HEATER 1

1 D01-1996 WRAPPER, 28" FAN HEATER 1

1 D01-1963 WRAPPER, 36" FAN HEATER 1 1

1 D01-1997 WRAPPER, 40" FAN HEATER 1

1 D01-1964 WRAPPER, 42" FAN HEATER 1 1

2 D01-0 651 STRAI GHTE NING VANE, 26" F/H 11

2 D01-0 529 STRAI GHTE NING VANE, 28" F/H 11

2 D01-1452STRAIGHTENING VANE, 36-42" F/H 1111111111

3 D01-0528 INNER CAN, 26" & 28" F/H 1 1

3 D01-1480 INNER CAN, 36" F/H 1 1

3 D01-1479 INNER CAN, 40" F/H 1

3 D01-1451 INNER CAN, 42" F/H 11

4 401-5759-6-BACCESS DOOR-GALV FAN BLACK 1 111111

5 069-1303-2SIGHT GLASS 1 111111

6 DC-1224DECAL, DANGER HI-VOLTAGE 1111111

7 DC-1225DECAL, WARNING ROTATING BLADE 1111111

8 DC-1227DECAL, WARNING FIRE 1111111

9 HF-986 COLLECTOR CUP, 26" FAN HEATER 1

9 HF-983 COLLECTOR CUP, 28" FAN HEATER 1

9a D01-1484 COLLECTOR CUP, 36" FAN HEATER 1 1

9a D01-1485 COLLECTOR CUP, 40" FAN HEATER 1

9a TF-1217 COLLECTOR CUP, 42" FAN HEATER 1 1

10 HF-978 SUPPORT PLATE, 26" FAN HEATER 1

10 HF-7092 SUPPORT PLATE, 28" FAN HEATER 1

10a D01-1482 SUPPORT BRACKET, 36" FAN HEATER 1 1

10a D01-1483 SUPPORT BRACKET, 40" FAN HEATER 1

10a TF-1216 SUPPORT BRACKET, 42" FAN HEAT ER 1 1

DESCRIPTION 2612 2812 3612 3615 4015 4220 4225

Matching the right size fan heater to the model number of the dryer .

Top Fan (F an 2)

er Model No.

Dr

Fan Heater

1214 1216 1218 1220 1222 1226

36", 10 - 12 hp (3612) x

36", 10 - 16 hp (3615) x x

40", 10 - 16 hp (4015) x

42", 20 hp (4220) x

42", 25 hp (4225) x

Botto m Fa n (Fan 1)

er Model No.

Dr

Fan Heater

26", 10 - 12 hp (2612) x x x

28", 10 - 12 hp (2812) x x x

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

1214 1216 1218 1220 1222 1226

33

Page 34

Fan Motor , Motor Mount, & Fan Blade

Fan motor and motor mount. Fan blade and bushing.

1 2 3 4

FAN HEATER;

(Dia., HP)

26" 12Hp

28" 12Hp

36" 12Hp

36" 15Hp

40" 15Hp

42" 20Hp

42" 25Hp

ITEM NUBER

1

2

3

4

1 MOTOR MOUNT D01-0530 D01-0530 D01-0530 D01-0530 D01-0530

2 MOTOR CD-0110 CD-0239 CD-0239 CD-0239 D03-0193

3 FAN BLADE D03-0302 D03-0302 D03-0302 D03-0302 D03-0302

4 BUSHING PT0778 PT0778 PT0778 PT0778 PT0778

1 MOTOR MOUNT D01-1478 D01-1478 D01-1478 D01-1478 D01-1478

NOT SHOWN MOTOR MOUNT ADAPTER CD-0233 CD-0233 CD-0233 CD-0233 CD-0233

2 MOTOR CD-0110 CD-0239 CD-0239 CD-0239 CH-6819

3 FAN BLADE D01-0468 D01-0468 D01-0468 D01-0468 D01-0468

4 BUSHING FH-1009 FH-1009 FH-1009 FH-1009 FH-1009

1 MOTOR MOUNT D01-1478 D01-1478 D01-1478 D01-1478 D01-1478

2 MOTOR 002-1073-2 CH-1050 CH-1050 CH-1050 CH-6820

3 FAN BLADE D82-0002 D82-0002 D82-0002 D82-0002 D82-0002

4 BUSHING FH-1009 FH-6963 FH-6963 FH-6963 FH-6963

1 MOTOR MOUNT D01-1481 D01-1481 D01-1481 D01-1481 D01-1481

2 MOTOR CD-0571 CH-1050 CH-1050 CH-1050 CH-6820

3 FAN BLADE D03-0567 D03-0567 D03-0567 D03-0567 D03-0567

4 BUSHING GC03810 GC03810 GC03810 GC03810 GC03810

1 MOTOR MOUNT N/A D01-1453 D01-145 3 D01-145 3 D01 - 14 53

2 MOTOR N/A CH-1051 CH-1051 CH-1051 2000-3-5

3 FAN BLADE N/A D01-0470 D01-0470 D01- 0470 D01-0470

4 BUSHING N/A GC03810 GC03810 GC03810 GC03810

1 MOTOR MOUNT N/A D01-1474 D01-147 4 D01-147 4 D01 - 14 74

2 MOTOR N/A C-2049 C-2049 C-2049 CH-6692

3 FAN BLADE N/A D01-0471 D01-0471 D01- 0471 D01-0471

4 BUSHING N/A CE-00617 CE-00617 CE-00617 CE-00617

DESCRIPTION

MOTOR MOUNT D01-0530 D01-0530 D01-0530 D01-0530 D01-0530

MOTOR CD-0110 CD-0239 CD-0239 CD-0239 D03-0193

FAN BLADE D03-0301 D03-0301 D03-0301 D03-0301 D03-0301

BUSHING PT0778 PT0778 PT0778 PT0778 PT0778

220V 1Ph 208V 3Ph 220V 3Ph 440V 3Ph 575V Ph

PART NUMBER

34

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 35

Air Mixer Assemblies

Air mixer assemblies (36” air mixer shown in photo).

1

1a

2

ITEM

NUMBER

1-2 D01-0969 AIR MIX ER AS SE M BLY, 26" 1

1 D01-0968 AIRMIXER CAN, 26" x 15" LONG

1a D01-0967 AIRMIXER CAN, 26" x 8" SHORT

2 CD-0228 SMALL DIA. CAN AIR MIXER VANE

1-2 D01-0955 AIR MIX ER AS SE M BLY, 28" 1

1 D01-0951 AIRMIXER CAN, 28" x 15" LONG

1a D01-0950 AIRMIXER CAN, 28" x 8" SHORT

2 CD-0228 SMALL DIA. CAN AIR MIXER VANE

1-2 CD-0113 AIR MIXER ASSEMBLY, 36" 1

1&1a D01-1303 AIRMIXER CAN, 36" W/ACCESS

2 CD-0083 A IR MIXER VANE

1-2 CD-0117 AIR MIXER ASSEMBLY, 40" 1

1&1a D01-1218 AIRMIXER CAN, 40" W/ACCESS

2 CD-0083 A IR MIXER VANE

1-2 CD-0118 AIR MIXER ASSEMBLY, 42" 1

1&1a CD-0192 AIRMIXER CAN, 42"

2 CD-0083 A IR MIXER VANE

PART

NUMBER

DESCRIPTION

26"

F/H

28"

36"

F/H

F/H

1/ASSEMBLY

1/ASSEMBLY

6/ASSEMBLY

1/ASSEMBLY

1/ASSEMBLY

6/ASSEMBLY

2/ASSEMBLY

8/ASSEMBLY

2/ASSEMBLY

8/ASSEMBLY

2/ASSEMBLY

8/ASSEMBLY

40"

F/H

42"

F/H

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

35

Page 36

Flame Probe, Ignitor , and Burner Assemblies

(

8

1

2

Ignitor

3

Flame probe

9

10

Items 9 and 10 are used in LP Fan/Heaters only.

ITEM PART No. DESCRIP TION 2612 2812 3615 4015 4220 4225 4230 4240

10 CD-0414 VAPORIZOR COIL 26 28" 3 WRAP 1 1

10 HF- 7207 VAPORIZ ER COIL 36-42 " 10-17H P 1 1 1

10 HF-7251 VAPORIZER 3/4" 3 WRAP 36-42" 1 1

10 HF-7319 VAPOR COIL

SPIRAL) 42" 40HP 1

Burner housing high

limit switch.

7

6

5

4

36

11 12 13 14 15

28” Fan heater burner assembly.

26” Fan heater burner assembly.

16

17

18

19

22

20

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

21

Page 37

Flame Probe, Ignitor , and Burner Assemblies

r

36” Fan heater burner assembly. 40” &42” Fan heater burner assembly.

23

28

31

24

2725

ITEM PART NUMBER

1-3 TF-1559-N FLAME PROBE ASSY NETWK 1 1 1 1 1

1 HH-7025 BOOT 8MM SILICONE 90DEGREE

2 THH-4179 FLAME SENSOR 6" LONG ROD

3 CD-0187 FLAME SENSOR BRACKET

4-8 TF-1558 IGNITOR ASSEMBLY 1 1 1 1 1

4 HF-7204 DUAL PROBE IGNITOR BRACKET

5 D01-0878 IGNITOR AIR DEFLECTOR ANGLE

6 HF-7201 IGNITOR HALF CLAMP

7 CD-0238 IGNITOR FLAME

8 TF-1876 IGNITION WIRE ASSY (includes both wires)

9 HH-7054 CONE 26/28" BURNER S.S. 1 1

9 HH-7056 CONE 36/42" BURNER S.S. 1 1 1

10

11 THH-4064 UNILET TYPE LRL CONDUITBX1/2" 1 1 1 1 1

12 027-1006-9 THERMOSTAT - HI LIMIT 200F AUT 1 1 1 1 1

13 D01-1473 HOUSING HI LIMIT PLATE 1 1 1 1 1

14 No Numbe

15 TFC-0076 NEOPRENE GASKE T, CO NDUI T BODY 1 1 1 1 1

16-18 BA-26 26" BURNER ASSEMBLY 1

16 HF-992 26" DIVERTER WELDMENT

17 HH-3934 BURNER GU N M ACHINE D 26 "

18 HH-1179 FLAME SPREADER 26"

19-22 BA-28 28" BURNER ASSEMBLY 1

19 HF-7629 DIVERTER WELDME NT 28"

20 THF-3144 FLAME SPREADER 28"

21 THF-3141 HEATER GUN MACHINED 28"

22 THF-3113 28" DIVERTER BRACKET

23-27 BA-36 36" BURNER ASSEMBLY 1

23 THF-3038 DIVERTER BRACKET 36" & 40"

24 THF-3038P DIVERTER BRACKET 36" & 40" PERFED

25 THF-3039 DIVERTER BRACKET 36" & 40" W/HOLE

26 THF-3057 FLAME SPREADER 36-42"

27 CD-0091 BURNER WELDMENT CD 36" & 40"

28-31 BA-40-2 40" BURNER ASSEMBLY 1

28 CD-0448P DIVERTER BRACKET 42" PERFD

29 CD-0448 DIVERTER BRACKET 42"

30 CD-0208 BURNER WELDMENT CD 42"

31 THF-3057 FLAME SPREADER 36-42"

28-31 BA-42 42" BURNER ASSEMBLY 1

28 CD-0448P DIVERTER BRACKET 42" PERFD

29 CD-0448 DIVERTER BRACKET 42"

30 CD-0208 BURNER WELDMENT CD 42"

31 THF-3057 FLAME SPREADER 36-42"

LID FOR LRL CONDUIT BOX IS PART OF ITEM 11

DESCRIPTION

SEE CHART ON PAGE 36

2926

26" F/H 28" F/H 36" F/H 40" F/H 42" F/H

1/ASSEMBLY

1/ASSEMBLY

1/ASSEMBLY

1/ASSEMBLY

1/ASSEMBLY

2/ASSEMBLY

2/ASSEMBLY

1/ASSEMBLY

NOT APPLICABLE

1/ASSEMBLY

1/ASSEMBLY

1/ASSEMBLY

1/ASSEMBLY

1/ASSEMBLY

1/ASSEMBLY

1/ASSEMBLY

3/ASSEMBLY

4/ASSEMBLY

1/ASSEMBLY

1/ASSEMBLY

1/ASSEMBLY

4/ASSEMBLY

4/ASSEMBLY

1/ASSEMBLY

1/ASSEMBLY

4/ASSEMBLY

4/ASSEMBLY

1/ASSEMBLY

1/ASSEMBLY

30

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

37

Page 38

LP Pipe T rain Assemblies

26” & 28” Fan heater LP pipe train assembly.

24 25 26

1

11

2 3 4 5 6 7 8 9

10

4

23 24

21

22

18

191720

26” & 28” Vaporizer coil connection and adjustment

brackets.

1213

14

121617

15

2

11

38

29

27

28

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 39

LP Pipe T rain Assemblies

ITEM

NUMBER PART NUMBER

1 THH-4120 ELBOW, 3/4" - 90 DEG SCH 40 * 1

2 THH-4121 NIPPLE , 3/ 4" CLOSE SCH 40 2 2

3 007-1048-3 BALL VALVE, 3/4" W/LEVER HANDLE 1 1

4 THH-4125 NIP PL E, 3/4" x 2 SCH 40 2 2

5 THH-4154 TEE, 3/4" x 3/4" x 1/4" SC H 40 1 1

6 HH-2984 GUAGE , P RESSUR E 0- 3 0# LP 1 1

7 THH-4136 NIP PL E, 3/4" x 3" SCH 40 1 1

8 056 -2223-8 VALVE , S O LE N O ID 3/4"NPT 115V DIN 1 1

9 056 -2228-7 VALVE , S O LE N O ID 3/4"NPT 115V BYP 1 1

10 THH-4066 ELBOW 3/4-90 STREET SCH 40 1 1

11 THH-4149 ELBOW, 3/4"-1/2" REDUCER SCH 40 2 1

12 HH - 20 29 NIPP L E , 1/2" x 1 1/2" SCH 40 2 2

13 HH-1453 TEE, 1/2" x 1/2" x 1/2" SCH 40 1 1

14 HH-7013 SWITCH SCREW-IN VAPOR HI-LIMI T 1 1

15 THH-4 07 1 ELBOW 1/2"-90 S CH 40 1 1

16 TFC-0 02 3- 5 0 R EG U L A T O R , 1/2" NPT 50PSI 1 1

17 D07-001 9 N IPPLE, 1/2" x 1 1/ 2" SC H 80 2 2

18 031-10 08-7 PRESSUR E R ELIEF VALVE 300 P S I 1 1

19 HH-4846 TEE, 1/2" x 1/2" x 1/4" SCH 80 1 1

20 HH-1251 STRAINER, 1/2" "Y" SC H 80 1 1

21 HH-1 932 ELBOW, 1/2" PIPE - 1/2" FLARE BRASS 1 1

22 T FC - 0 095 HOSE, 1/ 2" x 24" LP GAS 2 2

23 TF-1227 PI PETRAIN BR A C KET FOR 36 & 42" 1 1

24 326-10 47-9 U-BOLT 5/ 16 - 18 X 1-3/8 X 2-3/16 3 3

25 401-5503-8 PLUMBG MTG BRKT 1 1

26 401-5255-5 PLUMBG MTG BASE BRKT 1 1

27 HH-4847 ELBOW, 1/2"-90 SCH 80 2 2

28 D01-2217 VAPORIZER SUPPORT PLATE BLACK 1

29 41 0- 1 78 3- 1 - B VAPORIZER ADJUSTIN G WELD 1/ 2" 1

DESCRIPTION

26" FAN 28" FAN

1

1

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

39

Page 40

36” Fan heater LP pipe train assembly.

1

2 3 4 5 6 7 8 9

LP Pipe T rain Assemblies

24 25 26

10

4

23 24

21

22

18

191720

36” Vaporizer coil connection and adjustment brackets.

1213

14

121617

15

2

11

40

29

27

28

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 41

LP Pipe T rain Assemblies

ITEM

NUMBER

1 THH-4120 ELBOW, 3/4" - 90 DEG SCH 40 1

2 THH-4121 NIPPLE, 3/4" CLOSE SCH 40 2

3 00 7- 1048-3 BALL VALV E, 3/4" W/L EVER HAND L E 1

4 THH-4125 NIPPLE, 3/4" x 2 SCH 40 2

5 THH-4154 TEE, 3/4" x 3/4" x 1/4" SCH 40 1

6 HH-2984 GUAGE, PRESSURE 0-30# LP 1

7 THH-4136 NIPPLE, 3/4" x 3" SCH 40 1

8 05 6- 2223-8 VALVE, SO LENOID 3/4"NP T 11 5V DIN 1

9 05 6- 2228-7 VALVE, SO LENOID 3/4"NP T 11 5V BYP 1

10 THH-4066 ELBOW 3/ 4-90 ST REE T SCH 40 1

11 THH-4149 ELBOW, 3/4"-1/2" REDUCER SCH 40 1

12 HH-2029 NIPPLE, 1/2" x 1 1/2" SCH 40 2

13 HH-1453 TEE, 1/2" x 1/2" x 1/2" SCH 40 1

14 HH-7013 SWI TCH SCRE W-IN VAPOR HI-LIM IT 1

15 THH- 4 071 ELBOW 1/2"-9 0 SC H 40 1

16 TF C - 00 23 - 50 REGULA T O R , 1/2" NPT 50PSI 1

17 D07 - 00 19 NIPPLE, 1/2" x 1 1/2" S C H 80 2

18 031- 1 00 8- 7 PRESS UR E R ELIEF VALVE 30 0PSI 1

19 HH-4846 TEE, 1/2" x 1/2" x 1/4" SCH 80 1

20 HH-1251 STRAINER , 1/2" "Y" SCH 80 1

21 HH-1932 ELBOW, 1/2" PIPE - 1/2" FLARE BRASS 1

22 TFC-00 95 HOSE , 1/2" x 24" LP GA S 2

23 TF-1227 PI PE TR A IN BR A CKET FOR 36 & 42" 1

24 326- 1 04 7- 9 U-BOLT 5/16-18 X 1-3/ 8 X 2-3 / 1 6 3

25 401-5503-8 PLUMBG MTG BRKT 1

26 401-5255-5 PLUMBG MTG BASE BRKT 1

27 HH-4847 ELBOW, 1/2"-90 SC H 80 2

28 D01-2217 VAPO RI ZE R SU PP OR T PLATE BLACK 1

29 410-1783-1-B VAPORIZER ADJUSTING WELD 1/2" 1

PART NUMBER DESCRI PT ION 36" LP F/ H

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

41

Page 42

40” & 42” LP pipe train assemblies.

1

LP Pipe T rain Assemblies

24 25

23

2

1

10

232

23

22

17 19

4

5

6

7

40” & 42” with 20hp and smaller motors vaporizer coil

connection and adjustment brackets.

8

1312

12

1617182021

14

15

40” & 42” with 25hp and larger motors vaporizer

coil connection and adjustment brackets.

30

9

2

11

42

26

31

27

28

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

30

27

29

Page 43

LP Pipe T rain Assemblies

40 & 42" LP F/H

ITEM

NUMBER PA RT NUMBER

1 THH-4115 ELBOW, 1" -90 DEG SCH 40 2 2

2 007-1104-4 NIPPLE, CLOSE 1" 4 4

3 007-1296-8 BALL VALVE, 1" WITH LEVER HANDLE 1 1

4 007-1106-9 TEE, 1" x 1" x 3/4" 1 1

5 D07-0027 REDUCER, 3/4"-1/4" HEX BUSHING 1 1

6 HH-2984 PRESSURE GUAGE, 0-30# LP 1 1

7 T H H -4037 N IPPLE, 1" x 2 1/2" SC H 40 1 1

8 056-2224- 6 VA LV E , SOLEN O ID 1" N PT 115V DIN 1 1

9 056-2230- 3 VA LV E , SOLEN O ID 1" N PT 115V BY P A S S 1 1

10 007-1242- 2 NIPPLE, 1" x 2" S CH 40 1 1

11 007-1288- 5 ELB OW, 1" - 1/ 2" SC H 40 1 1

12 HH-2029 NIPPLE, 1/2" x 1 1/2" SCH 40 2 2

13 HH-1453 TEE, 1/2" x 1/2 " x 1/2" SCH 40 1 1

14 HH-7 013 SWITCH SCRE W-IN VAPOR HI-LIM IT 1 1

15 T H H- 40 71 ELBOW 1/2" - 9 0 S CH 40 1 1

16 TF C - 00 23 - 50 REGULATO R , 1/2" NPT - CSA 50PSI 1 1

17 D07-0019 NIPPLE , 1/2" x 1 1/2" S C H 80 2 2

18 HH-4846 TEE, 1/2" x 1/2 " x 1/4" SCH 80 1 1

19 031-1008- 7 PRE S SURE REL I E F VALVE 30 0 PSI 1 1

20 HH-1251 STRAINER, 1/ 2" " Y" SC H 80 1 1

21 HH-1932 ELBOW, 1/2" PIPE - 1/2" FLARE BRASS 1 1

22 TF-1227 PIPE TRAIN BRACKE T FO R 36 & 42" 1 1

23 326-1047- 9 U-BO L T 5/16-18 X 1-3/8 X 2-3/1 6 3 3

24 401-5503-8 PLUMBG MTG BRKT 1 1

25 401-5255-5 PLUMBG MTG BASE BRKT 1 1

26 HH-4847 ELBOW, 1/2" - 90DEG SHC 80 2 *

27 D01-2217 VAPORIZER SUPP O RT PL AT E BL ACK 1 1

28 410-1783-1-B VAPORIZER ADJUSTIN G WELD 1/2" 1 *

29 D01-2 220 VAPORIZ ER ADJUSTING WELD 3/4" * 1

30 007-193 0-2 REDUCER, BELL 3/4" - 1/2" SCH 80 * 2

31 HH-1082 ELBOW, 1/2"-90 DEG STREET SCH 80 * 2

DESCRIPTION

W/ 15 & 20 Hp

MOTORS

40 & 42" LP F/H

W/ 25 Hp &

LARGER

MOTORS

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

43

Page 44

NG Pipe Train Assemblies

26” & 28” Fan heater NG pipe train assembly.

12 13 14

1 2 3 4 5 6 7 8

1A

10

4

9

2

11

ITEM

NUMBER PART NU MBER

1 THH- 41 49 ELB O W, 3/4" - 1/ 2" R ED U CER SCH 40 1

1A T HH - 41 20 ELB OW, 3/ 4" -9 0 SC H 40 1

2 THH-4121 NIP PLE, 3/4" CLOSE SCH 4 0 2 2

3 007- 10 48 - 3 BALL VALVE, 3/4" W/LEV E R H AN DLE 1 1

4 THH- 41 25 NIPPLE, 3/4" x 2" SCH 40 2 2

5 THH-4154 TEE, 3/4" x 3/4" x 1/4" SCH 40 1 1

6 D08-0022 GAUGE, PRESSURE 0-15# 1 1

7 THH- 41 36 NIPPLE, 3/4" x 3" SCH 40 1 1

8 056-2223-8 VALVE , SO LENOID 3/ 4" N PT 115V DI N 1 1

9 056-2228-7 VALVE , SO LENOID 3/ 4" N PT 115V B YP 1 1

10 THH-4066 ELBOW, 3/4" x 90 DEG STREET SCH 40 1 1

11 0 07-1307 -3 ELBO W, 1 - 3/4" RE D UC ER SCH 40 1 1

12 326-1047-9 U-BOL T 5/16-1 8 X 1-3/8 X 2-3/16 2 2

13 401-5503-8 PLUMBG MTG BRKT 1 1

14 401-52 55 -5 PLUMBG MTG BASE BRKT 1 1

DESCRIPTION

26" FANS 28" FANS

44

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 45

NG Pipe Train Assemblies

36” Fan heater NG pipe train assembly.

12 13 14

1

2

8

7

2 3 2 4

7 9

5

6

10

11

ITEM

NUMBER

10 0 56-2230 - 3 VALV E, SOLEN O ID 1" NPT 115V W/BY P 1

11 THH-4164 ELBOW, 1"-90 DEG. STREE T SCH 40 1

12 3 26-1047 - 9 U-BOLT 5/16-18 X 1-3/8 X 2-3/16 2

13 401-5503-8 PLUMBG MTG BRKT 1

14 401-5255-5 PLUMBG MTG BASE BRKT 1

PART NUMBER DESCRIPTION 36" FAN

1 007-1307-3 ELBOW, 1" - 3/4" 1

2 007-1104-4 N IPPLE, CLOSE 1" 3

3 007-1296-8 BALL VALVE, 1" W/LEVER HANDLE 1

4 007-1106-9 TEE, 1" x 1" x 3/ 4" 1

5 D07-002 7 R EDUCE R, 3/4" - 1/4 " HEX BUSHING 1

6 D08-0 022 GAUGE, PRESS URE 0-1 5# 1

7 007-1242-2 NIPPLE, 1" x 2" SCH 40 2

8 THH-4115 ELBOW, 1"-90 D EG. SCH 40 1

9 056-22 24 - 6 VALV E, SOLEN O ID 1" N P T 11 5V DIN 1

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

45

Page 46

NG Pipe Train Assemblies

40” & 42” Fan heater NG pipe train assembly.

11 12 13

1

2

1

7

2 3 2 4

7 9

5

6

10

8

46

ITEM

NUMBER PART NUMBER

1 THH-4115 ELBOW, 1" - 90 DEG SCH 40 2

2 007-1104-4 N IPPLE, CLOSE 1" 3

3 007-1296-8 BALL VALVE, 1" W/LEVER HANDLE 1

4 007-1106-9 TEE, 1" x 1" x 3/4" 1

5 D07-002 7 REDUCER, 3/4" - 1/4" HEX BUSHING 1

6 D08-0 022 GAUGE, PRESS URE 0-1 5# 1

7 007-1242-2 NIPPLE, 1" x 2" SCH 40 2

8 THH-4 164 ELBOW, 1"-90 DEG. STREE T SCH 40 1

9 056-2224-6 VALVE, SOLENOID 1"NPT 115V DIN 1

10 0 56-2230 -3 VALV E, SOLE NO I D 1" N PT 115V W/BY P 1

11 326-1047-9 U-BOLT 5/16-18 X 1-3/8 X 2-3/16 2

12 401-5503-8 PLUMBG MTG BRKT 1

13 401-5255-5 PLUMBG MTG BASE BRKT 1

DESCRIPTION

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

40" & 42" FANS

Page 47

Fan Heater Orifices

LIQUID PROPANE ORIFICES

FAN HEATER ORIFICE SIZE PART NUMBER

26"12hp .2188" HF-7087

PIPE FOR 26" FAN HEATER ORIFICE

HF-7587

28"12hp .25" THF-3241

36"12hp .2813" THF-3242

36"15hp .3281" CD-0150

40"15hp .3438" THF-3058

42"20hp .375" THF-3247

42"25hp .3906" THF-3249

NATURAL GAS ORIF ICES

FAN HEATER ORIFICE SIZE PART NUMBER

26"12hp .3125" HF-7099

PIPE FOR 26" FAN HEATER ORIFICE

HF-7587

28"12hp .375" THF-3140

36"12hp .4063" THF-3243

36"15hp .5" THF-3244

40"15hp .5156" THF-3246

42"20hp .5469" THF-3248

42"25hp 0.5781 THF-3250

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

47

Page 48

LP Supply Line

Front LP supply line.

1

Rear LP supply line.

8

14

13

2

12

5

11

2

6

7

3

4

5

8

ITEM N o. PAR T No.

1 HH-7088

2 THH-4058 TEE, 1/2" x 1 /2" x 1/2" SCH 80 3

2A HH-1932 ELBOW, 1/2"PIPE/1/2"FLARE BRASS 1

3 HH-3854 NIPPLE, 1/2" x 6" SCH 80 2

4 HH-4847 ELBOW, 1/2"-90 SCH 80 3

5 D07-0019 NIPPLE, 1/2" x 1 1/2" SCH 80 5

6 HH-1376 VALVE, VAPORIZER S HUT-OFF 2

7 HH-4846 TEE, 1/2" x 1/2" x 1/4" SCH 80 1

8 TFC-0027 VALVE, 1/4" NPT 250 PSI RELIEF 3

9 HH-1251 STRAINER, "Y" SCH 80 1

10 D87-0001 NIPPLE, 1/2" x 55" SCH 80 1

11 D01-2408 NIPPLE, 1/2"X98" SCH80 1

12 TFC-0100 VALVE, 1/2" NPT SOLENOID LP W/DIN 2

13 D07-0023 NIPPLE, 1/2" x 3" SCH 80 2

14 007-126 5-3 RDCR 1/2-1/4 BELL SCH80 2

NOT SHOWN 006-1353-9 CORD ASSEMBL Y FOR SUPPLY LINE LIQUID SOLENOID 2

3

9

NIPPLE, 1/2" x 31" SCH 80

DESCRIPTION

10

LP SUPPLY

LINE

1

4

5

6

48

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 49

NG Supply Line

1

1

19

D51-0045

CARRIER BRACKET, 1.5" PIPING

1

1

1 2

1a 2a

Natural gas fuel supply line.

3

3b

4

5

6

7

8

3

13

14

15

16

2a

Supply line mounting brackets.

1a

2

1

17

18

19

3 2 9

ITEM NUMBER

11

10

a

2 D08-0009 NI PP LE 1 1/2" CLOSE SCH 40 3 3

2a THH-4117 NIPPLE 1" CLOSE SCH 40 2 2

3 D08-0011 ELBOW 1 1/2"-90 SCH 40 3 3

3a THH-41 15 ELB O W, 1" x 90 D EG SC H 40 1 1

4 HH-7070 NIPPLE 1 1/2"x5 4" SC H 40 1

4 HH-7076 NIPPLE 1 1/2"x6 0" SC H40 1

5 D3 8-0001 TEE 1 1/2 " x1 1/2"x1" S CH 40 1 1

6 D01-0763 NIPPLE 1 1/2"x31-1/2" SCH40 1

6 HH-7069 NIPPLE 1 1/2"x2 8" SC H 40 1

7 D08-0010 UNION 1 1/2" FEMALE SCH 40 1 1

8 HH-7068 NIPPLE 1 1/2"x2 4" SC H 40 1 1

9 031-1063-2 SHUT-OFF VALVE 1 1/2IN 1 1

10 HH-7067 NIPPLE 1 1/2"x9" SCH 40 1 1

11 D08-0015 STRNR 1 1/ 2" Y SC H 80 1 1

12 D67-0007 PLUG 3/4" SQUARE 1 1

13 D08-0007 RDCR, 1 1/2" x 1" HEX BUSHING 1 1

14 007-1104-4 NIPPLE, CLOSE 1" 2 2

15 007-11 05 - 1 UN IO N 1" FEMALE SCH 40 2 2

16 033-1007-5 GAS HOSE 1" NPT MALE BOTH ENDS 2 2

17 D31-0074 G AS MANIFOLD MOUNTING BRKT 3 3

18 S-6643 CONDUIT HANGER 1 1/2 3 3

12

PART

NUMBER

D08-0008 VALVE 1 1/2"NPT B-COCK SHUTOFF 1 1

TFC-0093 VALV E 1" NPT BRONZE BALL 1 1

DESCRIPTION

1214-

1218

1220-

1226

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

49

Page 50

Upper junction box.

Upper Juntion Box, T op Auger Motor Conduit, & Operator Light

Top auger motor conduit.

1

11 10 1 2

3

Operator light.

2

9

4 5 6

Fill switch assembly (installed).

7

9

10

1

11

2

8

12

15

Fill switch assembly (opened).

13

14

Items 9 - 14 are components of the mercury

switch box assembly (fill switch assembly) part

no. D01-0192.

ITEM No. DESCRIPTION PART No.

1 CONDUIT 1/2" EMT METALLIC D03-0057

2 CONNECTOR 1/2" EMT COMPRESSION D03-0054

3 CLAMP 1/2" CONDUIT HH-1096

4 CONNECTOR 1/2" EMT TO SEALTITE D03-0075

5 SEALTITE PVC 1 /2" FH-7039

6 ELBOW 1/2" 90 DE G REE PVC WITH FH-7052

7 LAMP 90 DEGREE W/JUNC.BOX D03-0117

8 BULB, 100W 130V ROUGH SERVICE D03-0575

9 ENCLOSUR E 4x4x2.5 WHITE PVC FH-69 72

10 CONNECTOR 1/2" FH-1310

11 WIRE 18/2 TYP E SJ OW -A BL ACK WR-182SJ OW A

12 MOUNTING PLATE WLDMNT, TILT BX D01-0358

13 TILT SWI TC H 6- D EG. 6" LE A DS D03-0 010-DC

14 CLIP TILT SWITCH SPD-2098

15 TILT SWITCH SHAFT D01-0103

50

9

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 51

Air switch assembly (part # D01-0672).

Air Switch Assembly

Air switch assembly (internal parts).

3

1

Upper air switch assembly (installed).

10

11

7

9

2

8

4 5 6

Lower air switch assembly (installed).

12

10

1-9

ITEM

No. PART No.

1-9 D0 1-0 672 AIR SWITCH ASSE MBLY 2/DRYER

1D01-0671

2 D01-0670 AIR SWITCH BOX FACE PLATE 1/ASSEMBLY

3 DC-1103

4 D03-0177 GROMMET, 11/16" ID x 1" OD 1/ASSEMBLY

5 HF-7227

6 HF-7228 BUSHING, 1/4" - 1/8" HEX 1/ASSEMBLY

7 HF-7226

8 HF- 7 22 9 ELBOW, 1/8" - 90 SC H 40 1/ASSE MB LY

9 D03- 0167 AIR PRESSURE SW I TCH 1/ASSEMBLY

AIR SWI TCH BOX CONDUIT HALF

DECAL, AIR PRESSURE ADJUSTMENT

COUPLING, 1/4" ST D BLA CK ST EEL

NIPP LE, 1/8" C LOSE

ITEM No. DES CRIP TI ON PART No.

10 CONDUIT, 3/8" SE ALTI TE FH -7038

11 CONNECTOR, 3/8" x 90 F H-7050

12 CONNECTOR, 3/8" STRAI GHT FH-7049

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

1-9

DESCRIPTION

12

QUANTITY

2/ASSEMBLY

1/ASSEMBLY

1/ASSEMBLY

2/ASSEMBLY

10

51

Page 52

Right grain high

limit

Upper plenum high limit thermostat.

Right & Left Grain and Plenum High Limits

Upper plenum

high limit

Lower plenum

high limit

Left grain high

limit

3

5

Lower plenum high limit thermostat.

6

7

1

Grain temperature thermister. There are

2 thermisters in each (right & left) grain

high limit thermostat assemblies.

2

4

8

Right & left grain high limit thermostat.

1

1

2

9

3

52

3

7

5

4

6

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 53

Right & Left Grain and Plenum High Limits

g

y)

(

)

g

y)

(

)

(

)

(

)

g

Upper plenum high limit thermostat conduit.

11 13 14 15

10

12

Lower plenum high limit thermostat conduit.

ITEM No. DESCRIPTION PART No.

1 HIGH LIMIT MOUNTING BRACKET D01-0254

2

2

3 ENCLOSURE 4x4x2.5 WHITE PVC FH-6972

4 SEALTITE PVC 3/8" FH-7038

5 ELBOW 3/8" 90 DEGREE PVC W/NUT FH-7050

6 CONDUIT 1/2" EMT METALLIC D03-0057

7 CONNECTOR 1/2" EMT COMPRESSION D03-0054

8 GRAIN TEMP THERMISTOR SER2000 D03-0258

9

9

10 CONDUIT BODY, LL TYPE D03-0375

11 PLENUM THERMISTOR BOLT HF-7236

12 COVER ALUMINUM, CONDUIT BODY TFC-0075

13 PIPE SCH 40 1/2" DM60001

14 CLAMP, BEAM 1/2" GT3-0241

15 CLAMP 1/2" CONDUIT HH-1096

the followin

not shown conduit 1/2" emt metallic D03-0057

not shown

not shown

not shown

plenum-thermostat 10' 300de

PLENUM-THERMOSTAT 24' 300DEG

rain therm o hi-lmt 10' 210deg (for 14' dryers onl

GRAIN THERMO HI-LMT 24' 210DEG

components m ake up the grain high limit conduits that run through the grain columns. The conduit assemblies are not shown in

connector 1/2" emt compressio n

coupler 1/2" emt compression

enclosure 4x4x2.5 white pvc (as of 2003 a 4x4 enclosure has be en added to th ese assemlies and is mounted

on the rear column end panels into which thr grain high limit thermostat conduits now terminate.)

(for 14' dryers onl

for dryers that are 16' an d l o nger

for dryers that are 16' an d l o nger

the photos.

2/conduit; 1 at each end of the dryer.

couples the lengths of 1/2" em t

D03-0004

D03-0377

D03-0005

D03-0378

D03-0054

D33-0002

FH-6972

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

53

Page 54

Lower Junction Box, Meter Roll Motor Conduit, Rear Discharge Conduit

Lower junction box (left).Lower junction box (right).

5

3

7

1 2 3 4

Meter roll motor conduit connection.

6

7

Conduit to

Meter Roll

Motor

(see photo

below)

4

6

5

2

1 8 10

Conduit to Meter Roll Speed

Sensor & Rear Discharge

Switch

(see photos below & on next

page)

1

8

9

2

1

Meter roll speed sensor and rear discharge switch conduit. This

is a photo of the front section of the conduit that runs through

the gussets on the left side of the dryer.

14

13

12

1

11

Rear discharge switch conduit at rear

left gusset where 1/2” EMT conduit

terminates.

14 13

Coupler for 1/2” EMT conduit.

54

14 15 14

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 55

Lower Junction Box, Meter Roll Motor Conduit, Rear Discharge Conduit

Rear discharge switch conduit at rear left gusset.

Meter roll speed sensor.

16

17

18

19

2

1

11

1

7

Rear discharge switch (open to show tilt switch).

11 17

20

8

24

9

23

21

ITEM No. DESCRIPTION PART No.

1 SEALTITE PVC 3 /8" FH- 7 038

2 CONNECTOR PVC 3/8" 45' W/ NUT F-6913

3 ELBOW 3/8" 90 DE G REE PVC W/NUT FH-7050

4 STRAIGHT PVC W/LOCKNUT 3/8" FH-7049

5 FITT ING COMPRE SS ION 1/ 2" TO BOX D03-0054

6 CONDUIT 1/2" EMT D03-0057

7 ENCLOSURE 4x4x2.5 WHITE PVC FH-6972

8 CONNECTOR 1/2" FH-1310

9 WIRE 18 /2 TYP E SJ OW -A BL ACK WR-182 SJ OW A

10 RDCR 3/4"X1/2"HEX BUSHING D07-0028

11 ELBOW 3/8" 90 DEGREE PVC W/NUT FH-7050

12 CONNECTOR 3/8" LI Q UID-TITE TO 1/2" EMT D03-0060

13 CONNECTOR 1/2" EMT COMPRESSION D03-0054

14 CONDUIT 1/2" EMT METALLIC D03-0057

15 COUPLER 1/2" EMT COMPRES SI O N D33-0002

16 SPEED SENSOR BOX BRACKET D01-0462

17 SCR METER ROLL SPEED SE NSOR D01-0527

18 DISCONNECT .187 FEM HH-7046

19 METERING ROLL TIMING GEA R ASS B D01-0687

20 DISCHARGE SWITCH MOUNTING PLATE D01-1105

21 COVER ALUMINUM, CONDUIT BODY TFC-0075

22 CLIP, TILT SWITCH SPD-2098

23 TILT SWITCH D03-0010-DC

24 CONDUIT BODY, LL TYPE D03-0375

22

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

55

Page 56

Fan Heater Electrical Box

8

15 16 17 18 9

19 2017 181615 191

22

21

4

13 10 32

7 5

9 6 11 1214

A detailed view of the heater board.

13

23

26

23

14

56

24 25

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 57

Fan Heater Electrical Box

ITEM

NUMBER

not shown D01-1992 CONT R OL BOX LID 1

1 D01-2105 CONTROL BOX BACK PANEL 1

2 D01-2106 CONTROL LEFT SIDE 1

3 D01-2107 CONTROL BOX RIGHT SIDE 1

4 D01-2110 CONTROL BOX FRONT PANEL 1

5 D03-0696 CONTROL BOX LATCH 1

6 D01-2108 CONTROL BOX BASE 1

7 006-1389-3 NYLON BUSHIN G - 2" DIA 1

8 D01-2111 CONTROL BOX WALL 1

9 E160-1137 GROUND LUG, #TA-2 2

10 HH-1105 NYLON BUSHING - 11/16" ID 3

11 HF-4624 FENWAL FLAME DETECTION BOARD 1

12 D01-2109 FENWAL BOARD BRACKET 1

13 D01-1981 MOUNTING BRKT HEATER BOARD 1

14 D01-0730 TOUCH CNTRL FAN/ HTR PCB ASM 1

15 D03-0013 DIN RAI L MOUNTING 39.3 7" LONG 0.45

16 D01-0531 TERMINAL - BLOCK ENTRELEC 4MM 28

17 D01-0532 TERMINAL - BLANK END PROTECTOR 11

18 D01-0534 TE RMINAL - ENTREL EC GROUND BLOCK 1

19 D01-0533 TERMINAL - ENTRELEC END STOP 8

20 D03-0511 POINTS, AUXILLARY FOR IEC 1

21

22

23 E240-1148 CONNECTOR 4 PIN .200 PCB PLUG 2

24 D01-0460 TERM STRIP 10 POSITION 1

25 E240-1155 CONNECTOR 3 PIN .200 PCB PLUG 1

26 E240-1154 CONNECTOR 5 PIN .200 PCB PLUG 1

PART

NUMBER

DESCRIPTION

SEE CHART BELOW FOR PART NUMBERS

SEE CHART BELOW FOR PART NUMBERS

ALL FAN

HEATERS

ITEM

NUMBER

DESCRIPTION

21 OVERLOAD D03-0483 D03-0482 D03-0482 D03-0476 D03-0475

22 CONTACTOR D03-0495 D03-0494 D03-0494 D03-0492 D03-0490

21 OVERLOAD D03-0485 D03-0483 D03-0483 D03-0477 D03-0478

22 CONTACTOR D03-0497 D03-0494 D03-0494 D03-0492 D03-0491

21 OVERLOAD D03-0485 D03-0483 D03-0483 D03-0478 D03-0478

22 CONTACTOR D03-0497 D03-0494 D03-0494 D03-0491 D03-0491

21 OVERLOAD N/A D03-0484 D03-0484 D03-0480 D03-0479

22 CONTACTOR N/A D03-0495 D03-0495 D03-0492 D03-0492

21 OVERLOAD N/A D03-0485 D03-0485 D03-0482 D03-0479

22 CONTACTOR N/A D03-0496 D03-0496 D03-0494 D03-0492

10-12 HP FAN MOTORS (2612, 2812, 3612 FAN HEATERS)

220V 1Ph 208V 3Ph 220V 3Ph 440V 3Ph 575V 3Ph

10-16 HP FAN MOTORS (3615 FAN HEATERS)

220V 1Ph 208V 3Ph 220V 3Ph 440V 3Ph 575V 3Ph

10-16 HP FAN MOTORS (4015 FAN HEATERS)

220V 1Ph 208V 3Ph 220V 3Ph 440V 3Ph 575V 3Ph

20 HP FAN MOTORS (4220 FAN HEATERS)

220V 1Ph 208V 3Ph 220V 3Ph 440V 3Ph 575V 3Ph

25 HP FAN MOTORS (4225 FAN HEATERS)

220V 1Ph 208V 3Ph 220V 3Ph 440V 3Ph 575V 3Ph

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

57

Page 58

Control Box Control Panel

Vision control panel (front).

1

13

2

14

3

4

5

6

11

12

7

8 9 10

ITEM NUMBER

1 HINGE 1-1/6 X 19GA X 72IN S S 111-1001- 2

2 SWITCH 3 POS. SELECTOR RED D01-0447

3 SWITCH 3 POS. SELECTOR BLUE D01-0449

4 3 POS . SE LECT OR SWITCH YELLOW D01-0579

5 SWI TCH 3 POS. SEL ECT O R AMBER D01-0445

6 SWITCH 3 POS. SELECTOR WHITE D03-0182

7 SWI TCH 2 POS. SEL ECT O R GREEN D01-0446

8 SWITCH START N.O.(ILLUMINATED) D03-0017

9 SWITCH STOP BLOCK ( RED) D03 -0020

10 KNO B, AUGAT #PK-70B-1/4 E115-1060

11 SWITCH MOUNTING PLA TE 2F 401-5794- 5-2

12 DECAL, VISION CONTROL 2 FAN DC-1781

13 LATCH, SOUTHCO SLOTTED TF-1519

14 TOUCH CONTROL TOUCH SCREEN D0 3-0746

15 GSI MOI ST URE CONTROL PRINTER D03-0734PRNT

DESCRIPTION PART NUMBER

15

13

58

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 59

Lower Control Box Back Panel

Lower control box back panel.

9

13

14

1

4

5

6

7

8

5

Emergency stop switch

(outside).

10

2

11

Emergency stop switch

(inside).

12

10

3

15

ITEM

NUMBER

1

2

3

4 DIN RAIL, TERMINA L BLOCK MOUNT ING MISC. D03-0013

5 TERMINAL - ENTREL EC END STOP MISC. D01-0533

6 TERMINAL - ENTRELEC GROUND BLOCK MISC. D01-0534

7 TE RMINAL - BLOCK ENTRELEC 4MM MISC. D01-05 31

8 TE RMINAL - END PROTECTO R MISC. D01-0532

9 F IL TE R RFI "B" SE RIES CONTROL D 03-0181

10 EMERGENCY STO P SWITCH SA FE TY TF-1279

11 DECAL, EMERGENCY STOP MISC. DC-1317

12 BLOCK, CONTACT N/C SAFETY D63-0013

13 WIRE TIE ANCHOR MISC. D02-0039

14 WIRE TIE , 5" PA NDUIT MISC. D03- 0247

15 VISION MOISTURE CONTROL BOARD ASSEMBLY CONTROL D03-0725-C

LOWER CONTROL BOX BACK PA NEL MISC. D01-0486

VISION CONTROL 12 VDC POWE R SUPP LY CONTROL D03-0742-C

TOUCH CONTROL 5 VDC POWER SUPPLY CONTROL D03-0754-C

DESCRIPTION CIRCUIT PART NUMBER

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

59

Page 60

Vision control panel (rear).

1

9

2

3

Control Box Switch Panel (Rear)

A more

detailed parts

breakdown

of the display

& computer

is shown on

next page.

4

1A

5

7

8

7

Detailed view of a two

position switch.

ITEM NUMBER

1 SPRING LATCH SOUTHCO W/BLK KN MISC. TFH-2046

1A LATCH, SOUTHCO SLOTTED MISC. TF-1519

2 SWITCH MOUNTING PLAT E 2 F MISC . 401-5794-2

3 GSI MOISTURE CONTROL PRINTER CONTROL D03-0734PRNT

4 TAKE-UP MOTOR SUPPORT BRACKET MISC. 602E155BKT

5 PRINTER-PAPER TAKE-UP MIS C. 60 2E15 5

6 SCR POTENTIOMETER 10K CONTROL D03-0595

7 BLOCK, CONTACT N/O CONTROL D6 3-0006

8 BLOCK, LIGHT 12/24/120V LAMPS CONTROL D01-0455

9 TOUCH CNTRL DISP. I/O PCB COMP CONTROL D03-0723-C

DESCRIPTION CIRCUIT PART NUMBER

Detailed view of a single

position switch.

6

7

8

60

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

Page 61

Control Box Switch Panel (Rear)

Vision control computer (cover removed).

1

2

3

4

6

7

5

Vision control computer cover.

8

9

ITEM NUMBER

1 TOUCH CONTROL FRONT PANEL D03-0763FRNT

2 TOUCH CONTROL INTERNAL PLATE D03-0763PLT

3 TOUCH CNTRL USB CABLE D03-0753TUSB

4 TOUCH CNTRLR PCB (DRYERS) D03-0753TC

5 TOUCH CNTRL CPU ASM(DRYERS) D03-0753

6 TOUCH CNTRL DISPLAY INVERTE R D03-0744

7 TOUCH CNTRL DISP. I/O PCB COMP D03-0723-C

8 FAN COOLING FOR D03-0763-ASY D03-0763- FAN

9 TOUCH CONTROL BACK COVER D03-0763BACK

DESCRIPTION PART NUMBER

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

61

Page 62

Upper Control Box

Upper control box power distrbution panel.

34

1

6

33

2

3

7

32

8

4

9

5

10

11

12

13

14

15

31

30

29

28

27

26

25

62

16

24

17

19 21

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

2018

22 23

Page 63

Upper Control Box Components Part Numbers

ITEM

NUMBER

1 POWER BOX BOCK PANEL N/A D01-0480 D01-0480 D01-0480 D01-0480 D01-0480

2 OVERLOAD LOAD D03-0487 D03-0477 D 03-0475 D03-0473 D03-0472

3 OVERLOAD LOAD AUX. D03-0482 D03-0480 D03-0479 D03-0475 D03-0475

4 OVERLOAD UNLOAD D03-0487 D03-0477 D03-0475 D03-0473 D03-0472

5 OVERLOAD UNLOAD AUX. D03-0482 D03-0480 D03-0479 D03-0475 D03-0475

6 CONTACTOR LOAD D03-0492 D03-0491 D03-0490 D03-0488 D03-0488

7 CONTACTOR LOAD AUX. D03-0494 D03-0493 D03-0492 D03-0490 D03-0489

8 CONTACTOR UNLOAD D03-0492 D03-0491 D03-0490 D03-0488 D03-0488

9 CONTACTOR UNLOAD AUX. D03-0494 D03-0493 D03-0492 D03-0490 D03-0489

10 TERMINAL-BLOCK ENTRELEC 4MM CONTROL D01-0531 D01-0531 D01-0531 D01-0531 D01-0531

11 TERMINAL-BLANK END PROTECTOR CONTROL D01-0532 D01-0532 D01-0532 D01-0532 D01-0532

12 TERMINAL-ENTRELEC END STOP CONTROL D01-0533 D01-0533 D01-0533 D01-0533 D01-0533

13 TERMINAL-ENTRELEC GRND BLOCK CONTROL D01-0534 D01-0534 D01-0534 D01-0534 D01-0534

14 RELAY, 3PDT 120V RH3B-U IDEC CONTROL HF-7203 HF-7203 HF-7203 HF-7203 HF-7203

15 RELAY BASE, 3PDT CONTROL 07097555 070975553 07097555 07097555 07097555

16 TRANSFORMER CONTROL FH-3807 FH-3807 FH-3807 FH-3807 FH-3807

17 TERMINAL GROUND BAR GROUND 006-1184-8 006-1184-8 006-1184-8 006-1184-8 006-1184-8

18 DRYER I/O PCB ASM COMP VISION CONTROL D03-0736-C D03-0736-C D03-0736-C D03-0736-C D03-0736-C

19 SCR CONTACTOR 15 AMP 3 POLE METER ROLL D03-0106 D03-0106 D03-0106 D03-0106 D03-0106

20 BREAKER, 3 AMP 3 POLE DELAYED METER ROLL D03-0660-34 D03-0660-34 D03-0660-34 D03-0660-34 D03-0660-34

21 BREAKER 6 AMP 1 POLE 110VAC CONTROL D03-0661 D03-0661 D03-0661 D03-0661 D03-0661

22 SCR DRIVE BOARD BASE UNIT METER ROLL D03-0711 D03-0711 D03-0711 D03-0711 D03-0711

23 SCR ISOLATED TERMINAL BOARD METER ROLL D03-0592 D03-0592 D03-0592 D03-0592 D03-0592

24 POWER BOX CATCH ANGLE, BOTTOM N/A D01-0550 D01-0550 D01-0550 D01-0550 D01-0550

25 MAIN BREAKER POWER D01-0504 D01-0503 D01-0503 D03-0271 D03-0175

26 SCR RESISTOR PLUG-IN 3/4HP180V METER ROLL D33-0001 D33-0001 D33-0001 D33-0001 D33-0001

27 BREAKER UNLOAD AUX. D03-0460 D03-0461 D03-0461 D03-0545 D03-0395

28 BREAKER UNLOAD D03-0460 D03-0453 D03-0451 D03-0389 D03-0531

29 DISTRIBUTION BLOCK POWER D03-0300 D03-0293 D03-0293 D35-0001 D35-0001

30 BREAKER LOAD AUX. D03-0460 D03-0461 D03-0461 D03-0545 D03-0395

31 BREAKER LOAD D03-0460 D03-0453 D03-0451 D03-0389 D03-0531

32 BREAKER FAN 1 D03-0510 D03-0461 D03-0461 D03-0546 D03-0532

33 BREAKER FAN 2 D03-0466 D03-0461 D03-0465 D03-0529 D03-0532

34 POWER BOX CATCH ANGLE, TOP N/A D01-0551 D01-0551 D01-0551 D01-0551 D01-0551

DESCRIPTION CIRCUIT

220V 1Ph 208V 3Ph 220V 3Ph 440V 3Ph 575V 3Ph

1214 PART NUMBER

PNEG-1616 1200 VISION X-STREAM PARTS MANUAL

63

Page 64

Upper Control Box Component Part Numbers

ITEM

NUMBER

1 POWER BOX BOCK PANEL N/A D01-0480 D01-0480 D01-0480 D01-0480 D01-0480

2 OVERLOAD LOAD D03-0487 D03-0477 D03-0475 D03-0473 D03-0472

3 OVERLOAD LOAD AUX. D03-0482 D03-0480 D03-0479 D03-0475 D03-0475

4 OVERLOAD UNLOAD D03-0487 D03-0477 D03-0475 D03-0473 D03-0472

5 OVERLOAD UNLOAD AUX. D03-0482 D03-0480 D03-0479 D03-0475 D03-0475

6 CONTACTOR LOAD D03-0492 D03-0491 D03-0490 D03-0488 D03-0488

7 CONTACTOR LOAD AUX. D03-0494 D03-0493 D03-0492 D03-0490 D03-0489

8 CONTACTOR UNLOAD D03-0492 D03-0491 D03-0490 D03-0488 D03-0488

9 CONTACTOR UNLOAD AUX. D03-0494 D03-0493 D03-0492 D03-0490 D03-0489

10 TERMINAL-BLOCK ENTRELEC 4MM CONTROL D01-0531 D01-0531 D01-0531 D01-0531 D01-0531

11 TERMINAL-BLANK END PROTECTOR CONTROL D01-0532 D01-0532 D01-0532 D01-0532 D01-0532

12 TERMINAL-ENTRELEC END STOP CONTROL D01-0533 D01-0533 D01-0533 D01-0533 D01-0533

13 TERMINAL-ENTRELEC GRND BLOCK CONTROL D01-0534 D01-0534 D01-0534 D01-0534 D01-0534

14 RELAY, 3PDT 120V RH3B-U IDEC CONTROL HF-7203 HF-7203 HF-7203 HF-7203 HF-7203

15 RELAY BASE, 3PDT CONTROL 07097555 070975553 07097555 07097555 07097555

16 TRANSFORMER CONTROL FH-3807 FH-3807 FH-3807 FH-3807 FH-3807

17 TERMINAL GROUND BAR GROUND 006-1184-8 006-1184-8 006-1184-8 006-1184-8 006-1184-8

18 DRYER I/O PCB ASM COMP VISION CONTROL D03-0736-C D03-0736-C D03-0736-C D03-0736-C D03-0736-C

19 SCR CONTACTOR 15 AMP 3 POLE METER ROLL D03-0106 D03-0106 D03-0106 D03-0106 D03-0106

20 BREAKER, 3 AMP 3 POLE DELAYED METER ROLL D03-0660-34 D03-0660-34 D03-0660-34 D03-0660-34 D03-0660-34

21 BREAKER 6 AMP 1 POLE 110VAC CONTROL D03-0661 D03-0661 D03-0661 D03-0661 D03-0661

22 SCR DRIVE BOARD BASE UNIT METER ROLL D03-0711 D03-0711 D03-0711 D03-0711 D03-0711

23 SCR ISOLATED TERMINAL BOARD METER ROLL D03-0592 D03-0592 D03-0592 D03-0592 D03-0592

24 POWER BOX CATCH ANGLE, BOTTOM N/A D01-0550 D01-0550 D01-0550 D01-0550 D01-0550

25 MAIN BREAKER POWER D01-0504 D01-0475 D01-0503 D03-0271 D03-0175

26 SCR RESISTOR PLUG-IN 3/4HP180V METER ROLL D33-0001 D33-0001 D33-0001 D33-0001 D33-0001

27 BREAKER UNLOAD AUX. D03-0464 D03-0461 D03-0461 D03-0545 D03-0395

28 BREAKER UNLOAD D03-0460 D03-0453 D03-0451 D03-0389 D03-0531

29 DISTRIBUTION BLOCK POWER D03-0300 D03-0293 D03-0293 D35-0001 D35-0001

30 BREAKER LOAD AUX. D03-0464 D03-0461 D03-0461 D03-0545 D03-0395

31 BREAKER LOAD D03-0460 D03-0453 D03-0451 D03-0389 D03-0531

32 BREAKER FAN 1 D03-0510 D03-0461 D03-0461 D03-0546 D03-0395

33 BREAKER FAN 2 D03-0466 D03-0468 D03-0465 D03-0529 D03-0395