Page 1

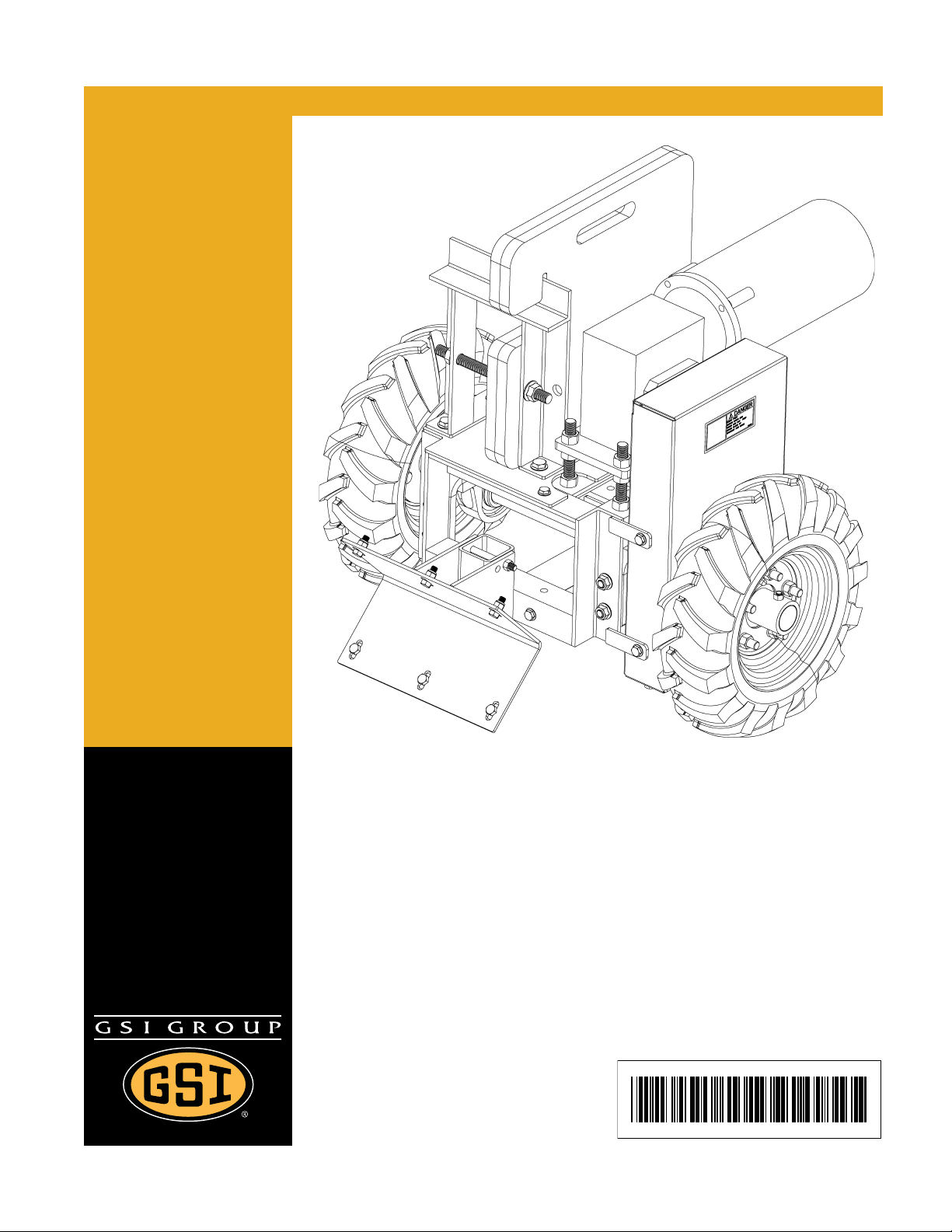

PNEG-1597

Sweep Tractor and Control Panel

Assembly Instructions

Instruction Manual

PNEG-1597

Date: 02-20-13

Page 2

Personnel operating or working around this equipment should read this manual. This manual

must be delivered with equipment to its owner. Failure to read this manual and its safety

instructions is a misuse of the equipment. Any misuse of the equipment may void the warranty.

2 PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions

Page 3

Table of Contents

Contents

Chapter 1 Introduction ..........................................................................................................................................4

General Information .............................................................................................................................. 4

Chapter 2 Safety .....................................................................................................................................................5

Safety Guidelines .................................................................................................................................. 5

Safety Instructions ..................... ... .... .......................................... ... ... ..................................................... 6

Operator Qualifications ....................................................................................... .... ... ... ... ..................... 9

Chapter 3 Safety Decals ......................................................................................................................................10

Chapter 4 Assembly ............................................................................................................................................11

Sweep Tractor Assembly ....................................... ... .... ... ... ... .......................................... ... ................ 11

End Wheel Assembly ... .......................................... ... .... ... ... ... .... ... ...................................................... 21

Sweep Tractor to Shield Assembly ........ ... ... ....................................................................................... 22

Chapter 5 Operation ............................................................................................................................................23

Programming ....................................... ................ ................... ................ ................. ............................ 23

Chapter 6 Control Panel Diagrams ................................. ...................... ....................... .......................................28

Sweep Tractor Control Box Definitions ......................................... ... ... ... .... ... ... ... .... ... ... ... ... .... ............ 28

Commercial Sweep Control Panel .................................. ... .... ......................................... .... ... ... ... ....28

Schematic - Control Panel GCS Sweeps 230V 3 HP (GCSTP2-03) ...............................................29

Schematic - Control Panel GCS Sweeps 230V 5 HP (GCSTP2-05) ...............................................30

Schematic - Control Panel GCS Sweeps 230V 7.5 HP (GCSTP2-75) ............................................31

Schematic - Control Panel GCS Sweeps 230V 10 HP (GCSTP2-10) .............................................32

Schematic - Control Panel GCS Sweeps 460V 3 HP (GCSTP4-03) ...............................................33

Schematic - Control Panel GCS Sweeps 460V 5 HP (GCSTP4-05) ...............................................34

Schematic - Control Panel GCS Sweeps 460V 7.5 HP (GCSTP4-75) ............................................35

Schematic - Control Panel GCS Sweeps 460V 10 HP (GCSTP4-10) .............................................36

Schematic - Control Panel GCS Sweeps 460V 15 HP (GCSTP4-15) .............................................37

Standard Control Panel Assembly 230V 3 Phase .......... ... .... ... ... ... ... .... ... ... ....... ... ... ... ... .... ... ... ... ....38

Standard Control Panel Assembly 460V 3 Phase .......... ... .... ... ... ... ... .... ... ... ....... ... ... ... ... .... ... ... ... ....40

Chapter 7 Parts List .............................................................................................................................................43

Sweep Tractor Parts ........... ... ... ... .... .......................................... ... ... ................................................... 44

Chain Guard Assembly ....................................................................................................................... 46

Drive Motor Assembly ......................................................................................................................... 47

Bearing Stand Assembly ..................................................................................................................... 48

Chapter 8 Warranty ..............................................................................................................................................49

PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions 3

Page 4

1. Introduction

General Information

1. We reserve the right to improve our product whenever possible and practical to do so. We reserve

the right to change, improve and modify products at any time without obligation to make changes,

improvements and modifications on equipment sold previously.

2. The Sweep Tractor has been designed and manufactured to give years of dependable service.

The care and maintenance of this machine will affect the satisfaction and service obtained. By

observing the instructions and suggestions we have recommended, the owner should receive

competent service for many years. If additional information or assistance should be required,

please contact the factory or your local dealer.

3. Receiving Merchandise and Filing Claims

a. When receiving merchandise, it is important to check both the quantity of parts and their

descriptions with the packing list enclosed within each package. All claims for freight damage or

shortage must be made by the consignee within ten (10) days from the date of the occurrence

of freight damage. The consignee should accept the shipment after noting the damage or loss.

For Claims Contact:

GSI Group

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 1-217-226-4421

4 PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions

Page 5

2. Safety

DANGER

WARNING

CAUTION

NOTICE

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a

hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to

personal injury.

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment of

these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions 5

Page 6

2. Safety

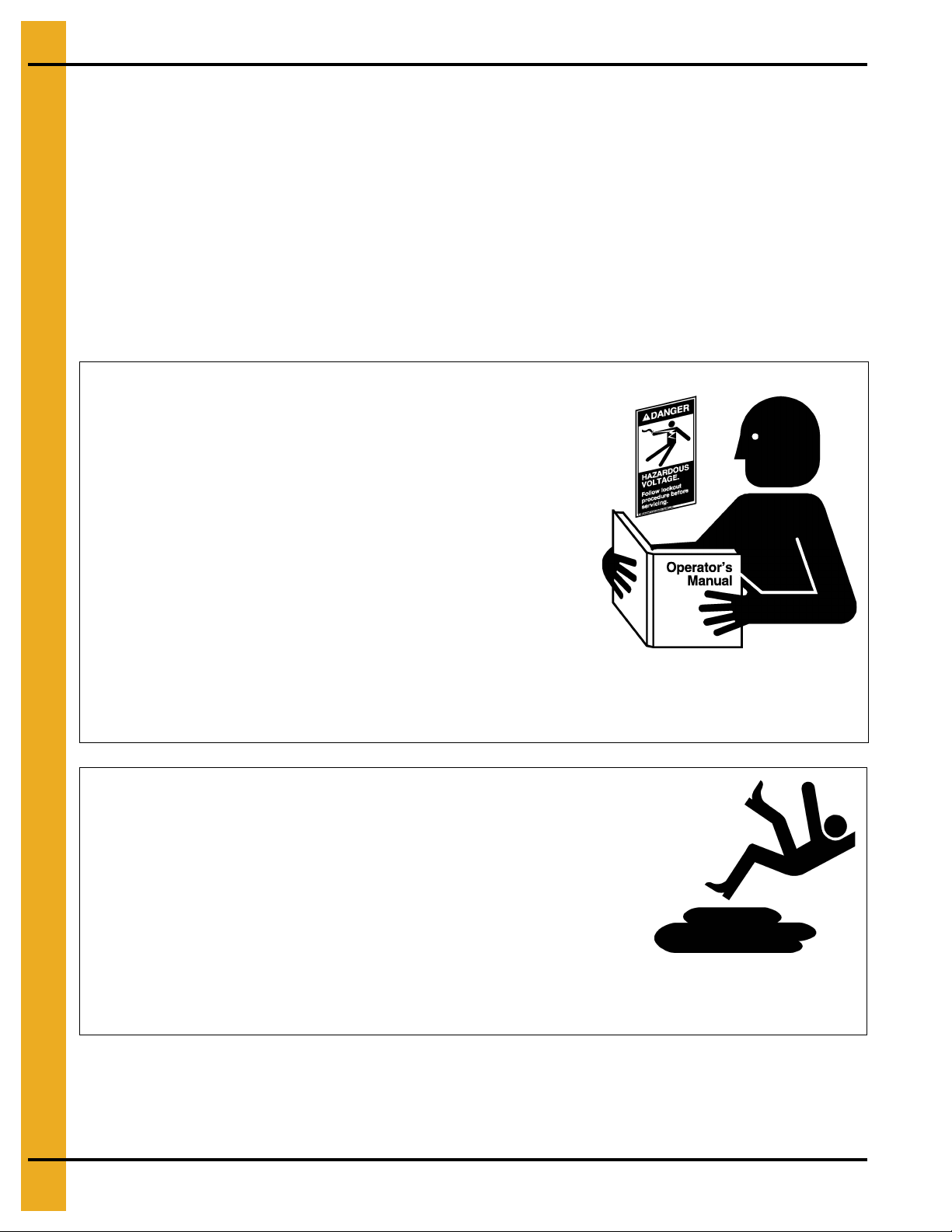

Follow Safety Instructions

Carefully read all safety messages in this manual and

safety signs on your machine. Keep signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from the manufacturer.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machinery in proper working condition.

Unauthorized modifications to the machine may impair

the function and/or safety and affect machine life.

If you do not understand any part of this manual or need

assistance, contact your dealer.

Read and Understand Manual

Practice Safe Maintenance

Understand service procedures before doing work. Keep area

clean and dry.

Never lubricate, service, or adjust machine while it is in operation.

Keep hands, feet and clothing away from rotating parts.

Keep all parts in good condition and properly installed. Fix

damage immediately . Replace worn or broken p arts. Remove any

built up grease oil and debris.

Maintain Equipment

and Work Area

Safety Instructions

Our foremost concern is your safety and the safety of others associated with this equipment. We want to

keep you as a customer. This manual is to help you understand safe operating procedures and some

problems that may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards, and precautions

exist, and to inform all personnel associated with the equipment or in the area. Safety precautions may be

required from the personnel. Avoid any alterations to the equipment. Such alterations may p roduce a very

dangerous situation where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable

regulations, which should be carefully followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

6 PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions

Page 7

2. Safety

Prepare for Emergencies

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital, and fire department near your telephone.

Keep Emergency Equipment

Quickly Accessible

Wear Protective Clothing

Wear close-fitting clothing and safety equipment appropriate

to the job.

Remove all jewelry.

Tie long hair up and back.

Wear safety glasses at all times to protect eyes from debris.

Wear gloves to protect your hands from sharp edges on plastic

or steel parts.

Wear steel-toed boots to help protect your feet from falling

debris. Tuck in any loose or dangling shoestrings.

A respirator may be needed to prevent breathing potentially

toxic fumes and dust.

Wear a hard hat to help protect your head.

Wear appropriate fall protection equipment when working at

elevations greater than six feet (6').

Eye Protection

Gloves

Steel-Toed Boots

Respirator

Hard Hat

Fall Protection

PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions 7

Page 8

2. Safety

Operate Unload Equipment Properly

• Untrained operators subject themselves and others to SERIOUS INJURY

or DEATH. NEVER allow untrained personnel to operate this equipment.

• NEVER work alone.

• Keep children and other unqualified personnel out of the working

area at ALL times. Refer to the Start-Up section of this manual for

diagrams of the work area.

• Make sure ALL equipment is locked in position before operating.

• NEVER start equipment until ALL persons are clear of the work area.

• Keep hands and feet away from the auger intake and other moving parts.

• NEVER attempt to assist machinery operation or to remove trash from equipment while

in operation.

• Be sure all operators are adequately rested and prepared to perform all functions of operating

this equipment.

• NEVER allow any person intoxicated or under the influence of alcohol or drugs to operate

the equipment.

• Make sure someone is nearby who is aware of the proper shut down sequence in the event of an

accident or emergency.

• ALWAYS think before acting. NEVER act impulsively around the equipment.

• NEVER allow anyone inside a bin, truck or wagon which is being unloaded by an auger or

conveyor. Flowing grain can trap and suffocate in seconds.

• Use ample overhead lighting after sunset to light the work area.

• Keep area around intake free of obstacles such as electrical cords, blocks, etc., that might

trip workers.

• NEVER drive, stand or walk under the equipment.

• Use caution not to hit the auger when positioning the load.

• ALWAYS lock out ALL power to the equipment when finished unloading a bin.

• Be aware of pinch points. A pinch point is a narrow area between two surfaces that is likely to trap or

catch objects and so is a potential safety hazard.

Operate Unload

Equipment Safely

8 PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions

Page 9

2. Safety

Operator Qualifications

A. The User/Operator must be competent and experienced to operate auger equipment. Anyone who

works with or around augers must have good common sense in order to be qualified. T hese persons

must also know and meet all other qualifications, such as:

i. Any person who has not read and/or does not understand all operation and safety procedures

is not qualified to operate any auger systems.

ii. Certain regulations apply to personnel operating power machinery. Personnel under the age of

18 years may not operate power machinery, including augers. It is your responsibility, as owner

and/or supervisor, to know what these regulations are in your area or situation.

iii. Unqualified or incompetent persons are to remain out of the work area.

iv. O.S.H.A. (Occupational Safety and Health Administration) regulations state: “At the time of

initial assignment and at least annually thereafter, the employer shall instruct every employee

in the safe operation and servicing of all equipment with which the employee is, or will be

involved”. (Federal Occupational Safety and Health Standards for Agriculture. Subpart D,

Section 1928.57 (a) (6)).

B. As a requirement of O.S.H.A., it is necessary for the employer to train the employee in the safe

operating and safety procedures for this auger. The sign-off sheet is provided for your convenience

and personal record keeping. All unqualified persons are to stay out of the work area at all times. It

is strongly recommended that another qualified person who knows the shut down procedure is in the

area in the event of an emergency.

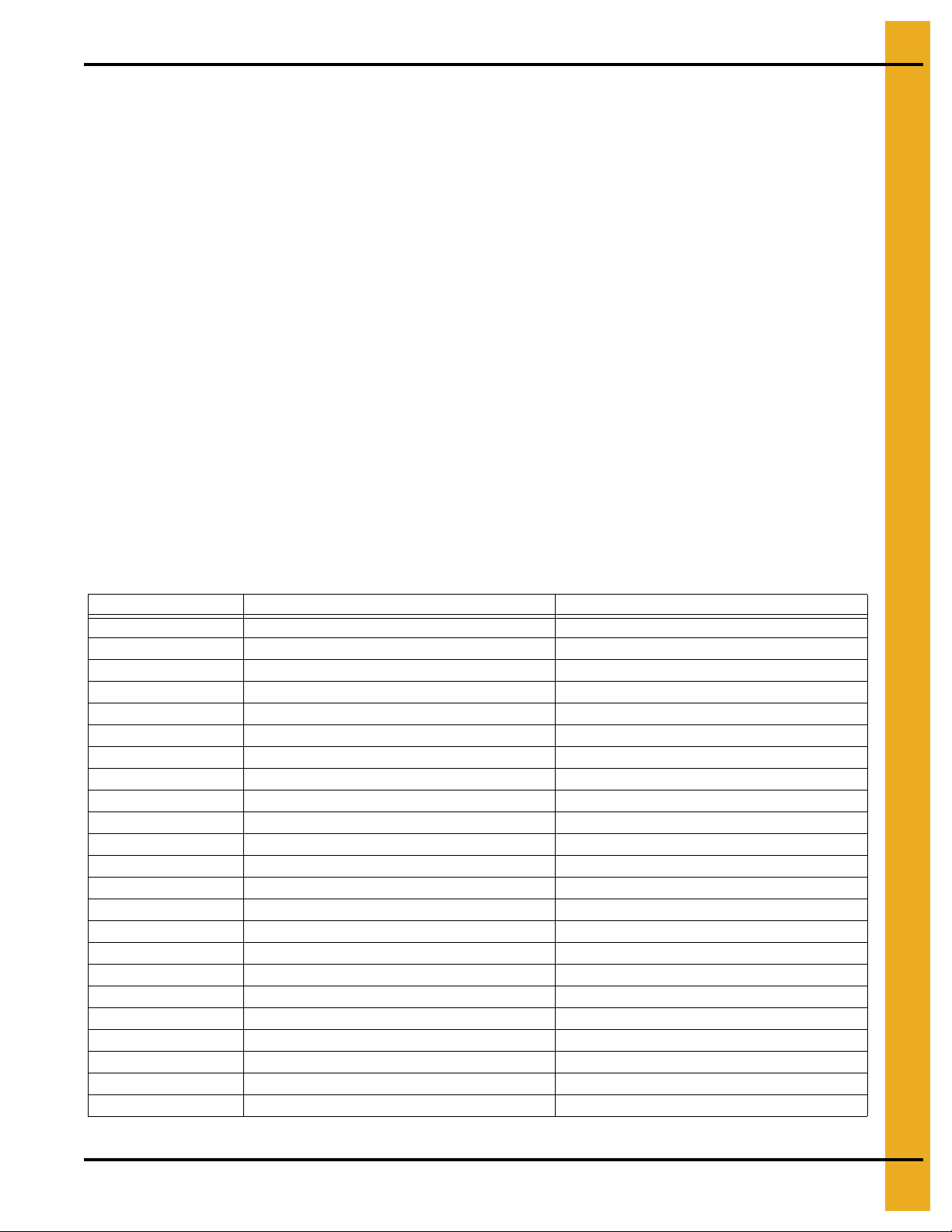

Date Employee Name Supervisor Name

PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions 9

Page 10

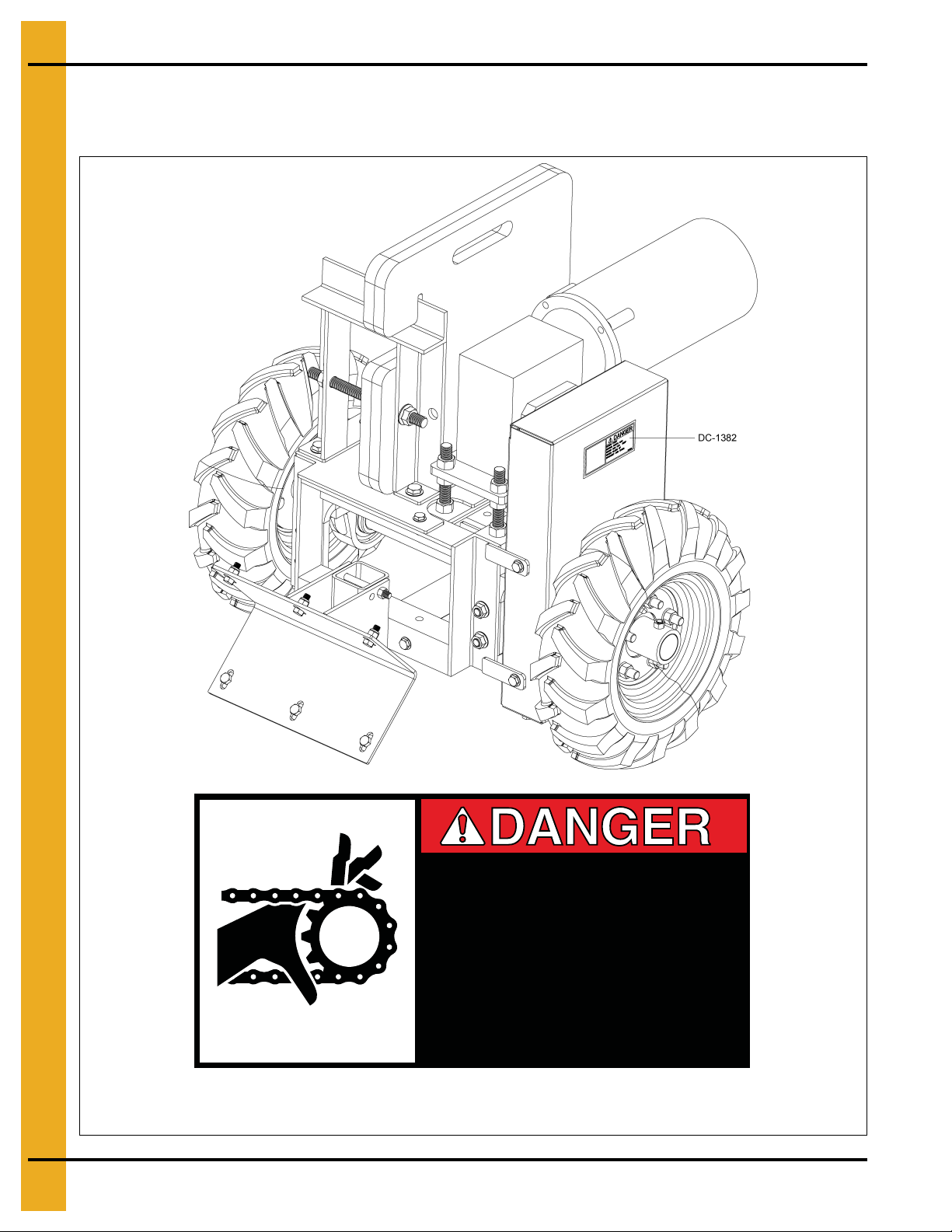

3. Safety Decals

SHEAR POINT

Moving parts can

crush and cut. Keep

hands clear of

sprocket and chain.

DC-1382

DC-1382

Decals located on outside of chain guards.

Check components shown below to ensure that the safety decals are in place and in good co ndition. If a

decal cannot be easily read for any reason or has been painted over, replace it immediately. Contact you r

dealer or the manufacturer to order a replacement decal free of charge.

10 PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions

Page 11

4. Assembly

Sweep Tractor Assembly

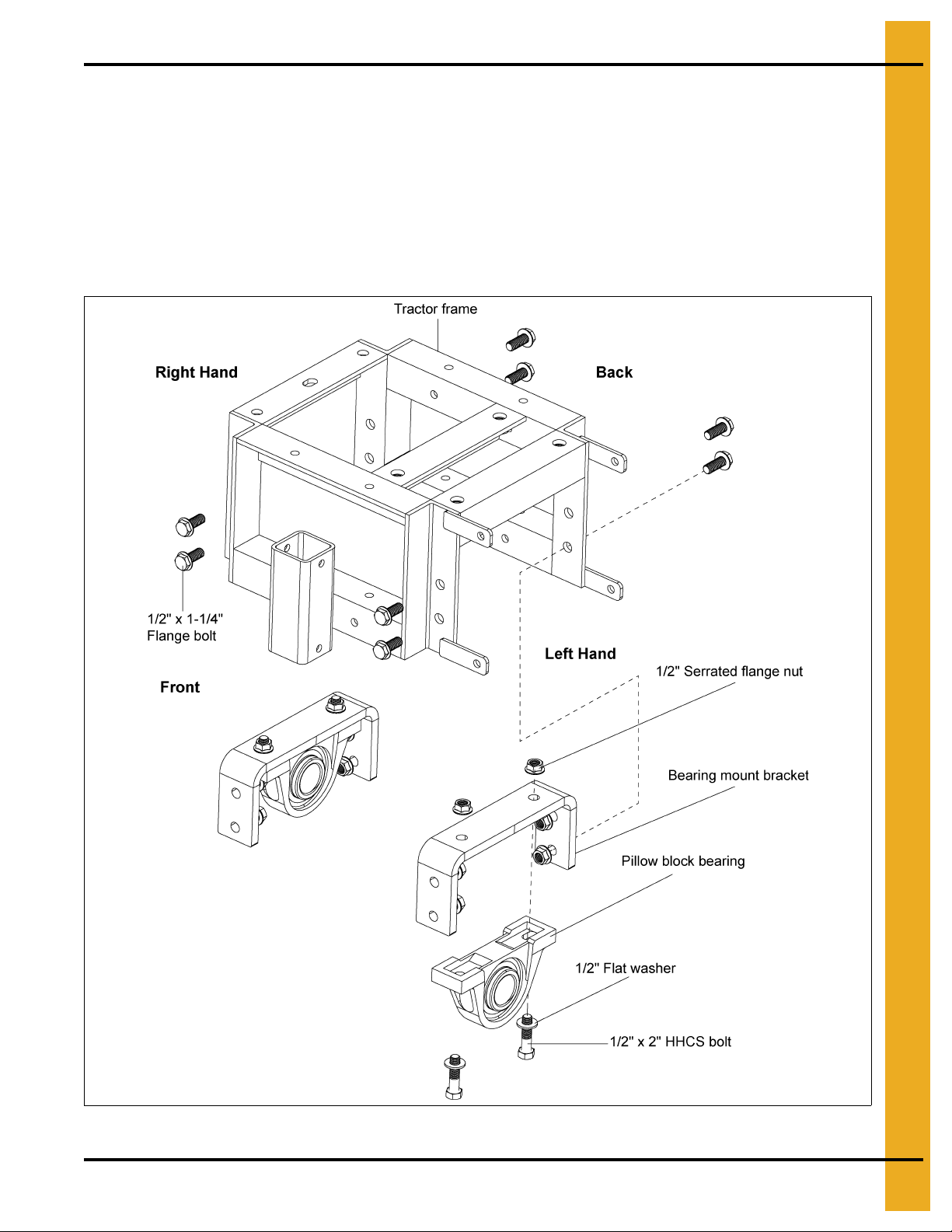

1. Place the tractor frame on plain flat ground.

2. Bolt each pillow block bearing to a bearing mount bracket using two (2) 1/2"-13 x 2" hex head

cap screws, two (2) flat washers and serrated flanged nuts.

3. Bolt each bearing mount bracket to the tractor frame using two (2) 1/2"-13 x 1-1/4" flange bolts and

serrated flanged nuts. (See Figure 4A.)

NOTE: Lock collar flanges for each pillow block bearing must be to the inside of frame.

Figure 4A

PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions 11

Page 12

4. Assembly

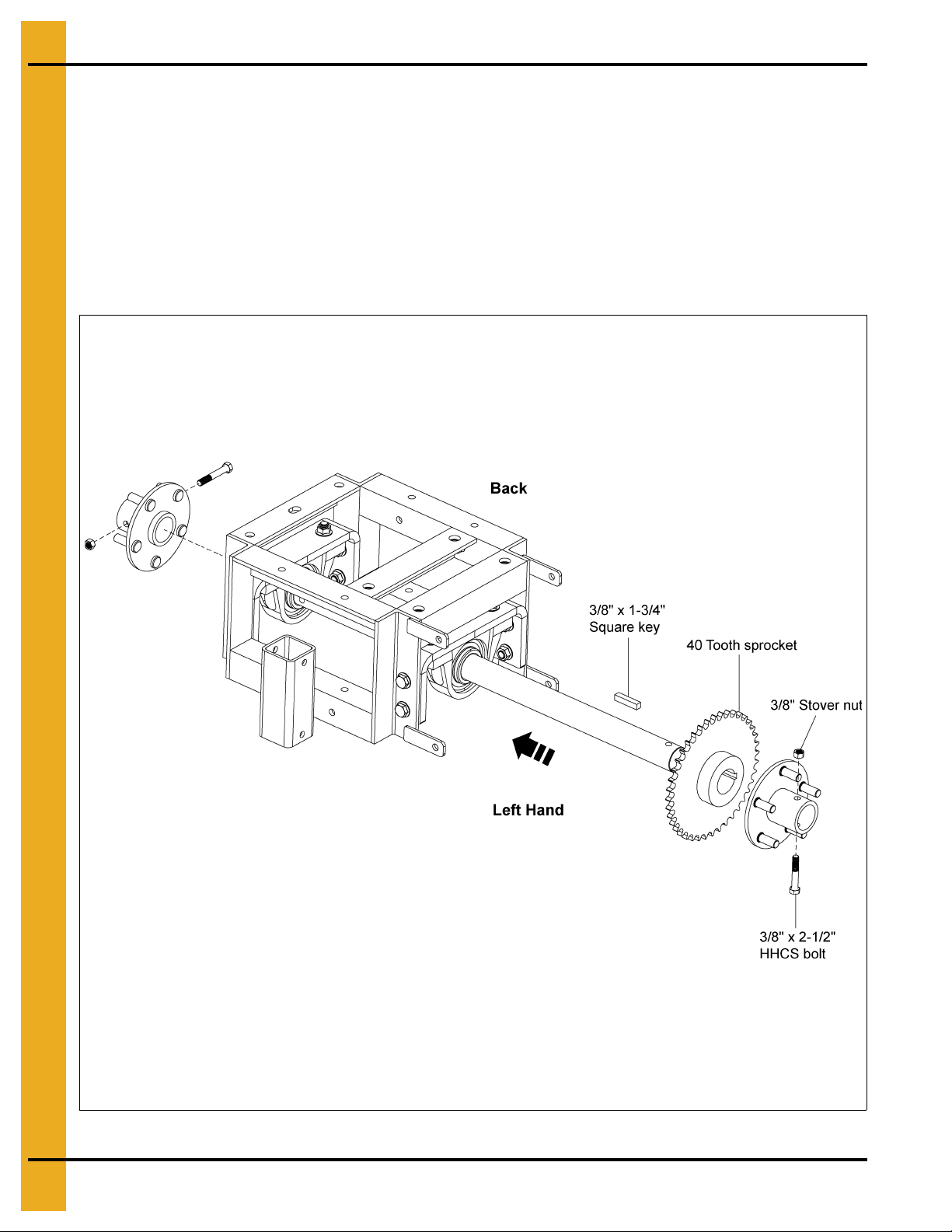

NOTE: Lock collars on inside of frame.

4. Slide the tractor axle through the left side of the pillow block bearing and the lock collars so as to pass

through the right side of the pillow block bearing. Make sure the keyway of the shaft is on the left

hand side of the tractor.

NOTE: Do not tighten the pillow block bearing lock collars yet.

5. Assemble the 40 tooth sprocket to the tractor axle using a 3/8" square x 1-3/4" key. Temporarily

tighten the sprocket to the key and the shaft. Final adjustment of the sprocket placement will occur

after the chain is installed.

6. Mount the wheel hubs to the tractor axle using 3/8"-16 x 2-1/2" hex head cap screws and stover

lock nuts. (See Figure 4B.)

Figure 4B

12 PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions

Page 13

4. Assembly

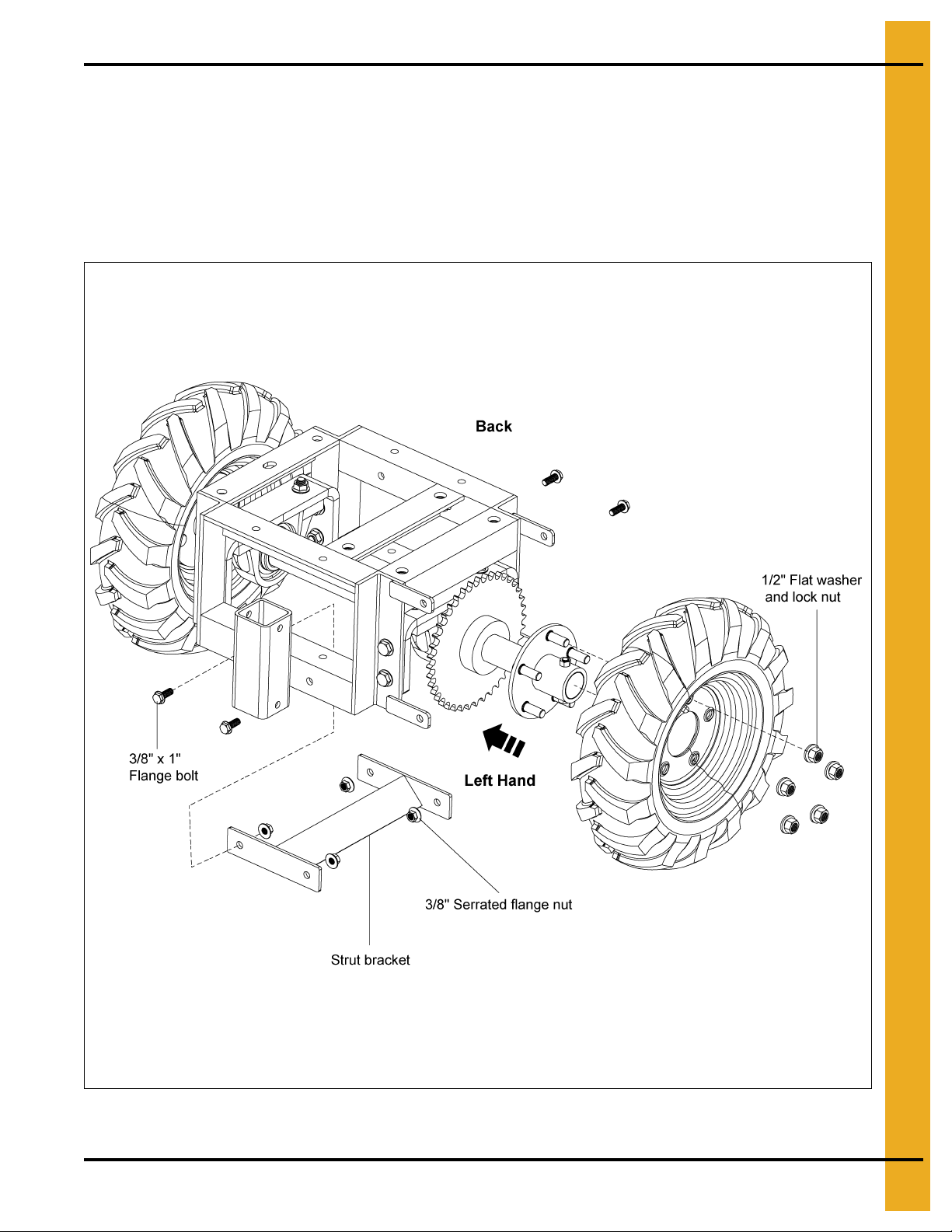

7. Assemble the tire and wheel assemblies securely to the wheel hubs using five (5) 1/2" flat washers

and lock nuts.

NOTE: Remove the screws or nails that are present in the tires to contain the foam in the tires when

they are made. The treads of the tires should be in the forward direction. Figure 4C shows

the proper orientation of the tire and wheel assemblies.

8. Assemble the strut bracket to the tractor frame using four (4) 3/8"-16 x 1" flange bolts and serrated

flange nuts. (See Figure 4C.)

Figure 4C

PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions 13

Page 14

4. Assembly

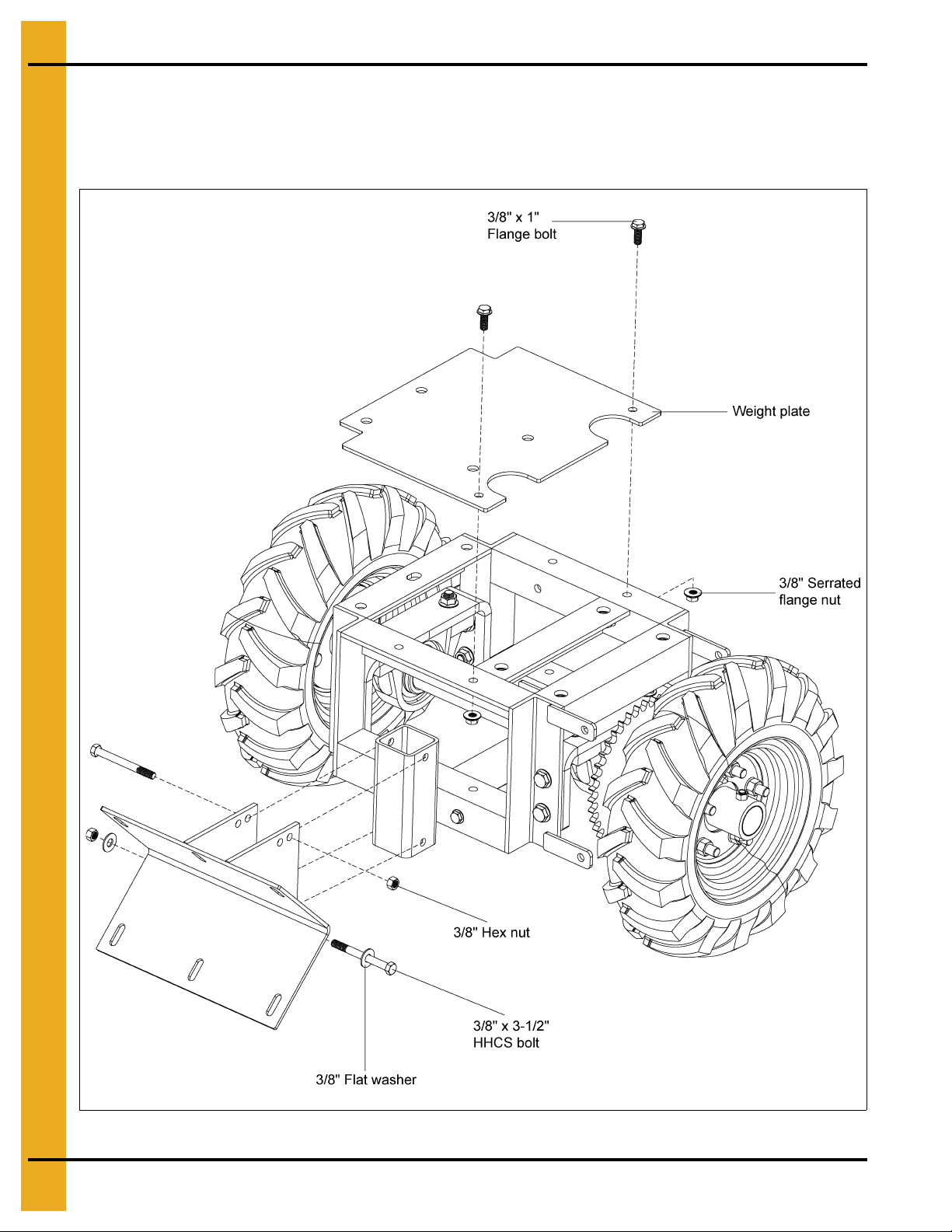

9. Bolt the shield bracket to the front of the tractor frame using two (2) 3/8"-16 x 3-1/2" hex head

cap screws, two (2) flat washers (only on the bottom slot of the bracket) and hex nuts.

10. Attach the weight plate to the tractor frame using two (2) 3/8"-16 x 1" flange bolts and serrated

flange nuts. (See Figure 4D.)

Figure 4D

14 PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions

Page 15

4. Assembly

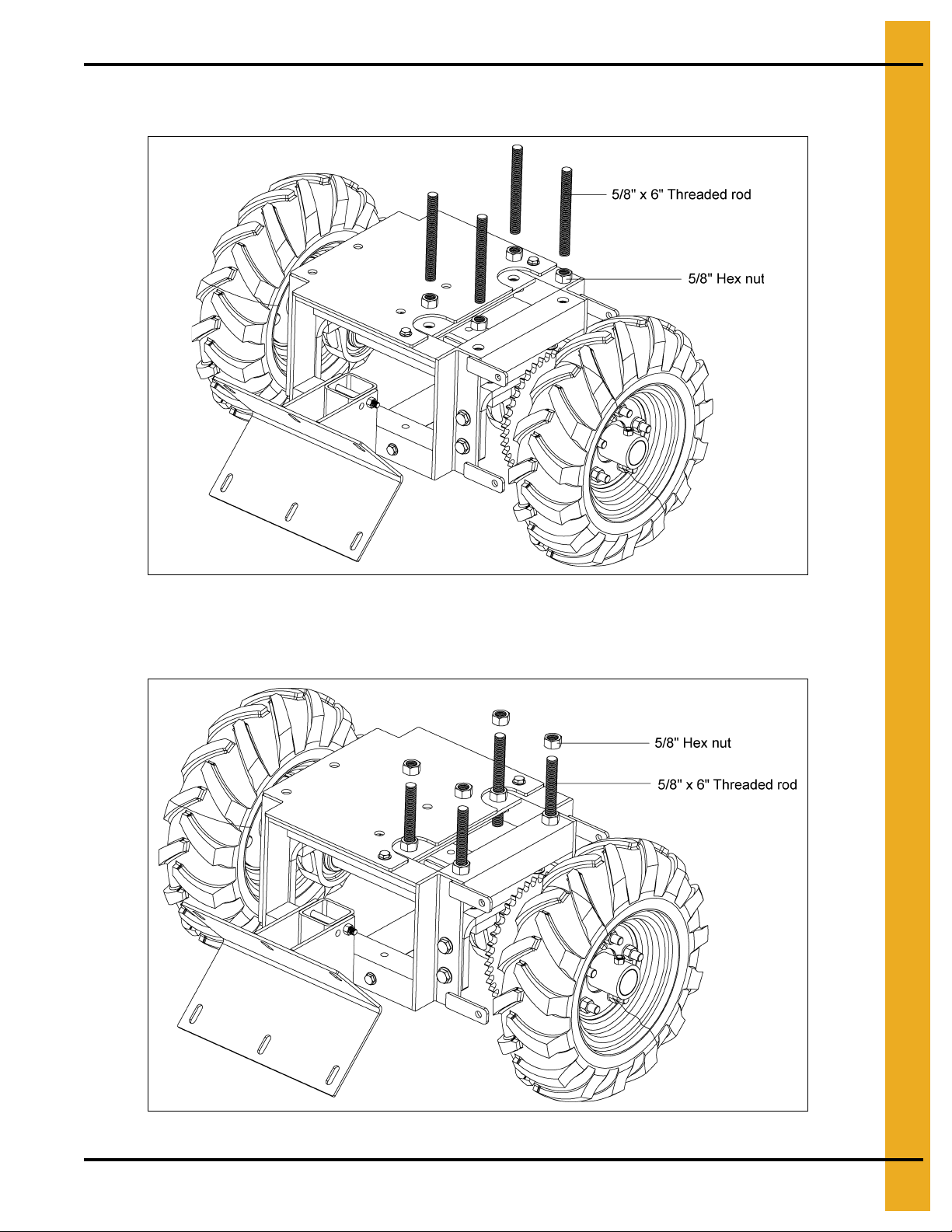

11. Bolt the four (4) 5/8"-11 x 6" threaded rods to the tractor frame using one 5/8"-11 hex nut for

each rod. (See Figure 4E.)

Figure 4E

12. Place one 5/8"-11 hex nut onto each rod in a temporary position. These will hold the motor plate in

place. (See Figure 4F.)

Figure 4F

PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions 15

Page 16

4. Assembly

13. Mount the drive assembly to the gearbox plate using four (4) 3/8"-16 x 1" flange bolts. Place the

gearbox plate and motor assembly over the threaded rods, resting on the hex nuts. (See Figure 4G.)

Figure 4G

16 PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions

Page 17

4. Assembly

14. Mount the gearbox plate and motor assembly to the 5/8"-11 x 6" threaded rod installed to the tractor

frame using four (4) 5/8"-11 hex nuts.

15. Attach the weight stand to the weight plate and tractor frame with four (4) 1/2"-13 x 1-1/4" flange bolts

and serrated flange nuts. (See Figure 4H.)

Figure 4H

PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions 17

Page 18

4. Assembly

16. Assemble the 13 tooth sprocket to the motor shaft using a 1/4" square x 1" key.

17. Install the roller chain around both sprockets. Adjust the position each sprocket or the tractor axle

(if necessary) to correctly align the chain.

18. Tighten all the sprocket set screws.

19. Tension the roller chain as required by adjusting the nuts on the 5/8"-11 x 6" threaded rods.

(See Figure 4I.)

NOTE: Tighten both pillow block bearing lock collars at this time.

Figure 4I

18 PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions

Page 19

4. Assembly

20. Install the top chain guard assembly to the tractor frame using four (4) 3/8"-16 x 1" flange bolts.

Slide the bottom chain guard assembly through the slot on the top chain guard and secure it with a

3/8"-16 x 3/4" flange bolt. (See Figure 4J.)

Figure 4J

PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions 19

Page 20

4. Assembly

21. Mount the weights to the weight stand using one 5/8"-11 x 8-1/2" threaded rod and three (3) flange

nuts and one flat washer. (See Figure 4K.)

NOTE: Install the weights against the left hand of the weig ht stand so the weight is in the middle of

the tractor assembly. The weight stand can be reversed so that the weights hang over the

front of the frame, if necessary. Adjust the weights to the inside of the frame to center the

weight on the frame when the weight stand is reversed as described above.

Figure 4K

20 PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions

Page 21

4. Assembly

End Wheel Assembly

NOTE: If installing sweep tractor to an existing sweep, the current end wheel components must

be removed.

1. Connect the stub shaft into the sweep flight using a 5/8"-11 x 4" hex head cap screw and

5/8" stover nut.

2. Install the bearing stand assembly onto the stub shaft and bolt it to the sweep shield using two (2)

3/8" x 3" carriage bolts, flat washers and nylock nuts.

3. Install the end wheel and collar onto the end of the stub shaft. Pin the collar in place with a

1/2" x 3-1/2" hex head cap screw and prevailing torque lock nut. (See Figure 4L.)

Figure 4L End Wheel Assembly

PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions 21

Page 22

4. Assembly

All electrical wiring shall be installed by a qualified electrician and must meet the

standards set by the National Electric Code and all local and state codes.

Sweep Tractor to Shield Assembly

1. Position sweep tractor against the sweep shield approximately 3' from the end wheel.

2. Use the bracket on the sweep tractor to mark the location where the holes need to be drilled into the

sweep shield.

3. The bolts that attach the sweep bracket to the tractor frame may need to be a djusted so t hat he ight

and angle of the sweep back shield and the shield bracket are matched.

4. After marking the hole locations, drill six (6) 7/16" holes and attach the sweep tractor to the back

shield using six (6) 3/8" x 1" hex head cap screws, flat washers and nylock nuts.

5. Install electric wiring for motor and controls. (See Figure 4M.)

CAUTION

Figure 4M Sweep Tractor to Shield Assembly

22 PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions

Page 23

5. Operation

Programming

Control Panel Calibration

Observe the tractor drive motor nameplate and the auger drive motor nameplate.

Record the full load amp (FLA) value for the specific voltage on each motor.

Auger drive motor full load amps: ____

Tractor drive motor full load amps: ____

Unlock and open the control panel.

Adjust the FLA dial screw on the tractor drive motor contactor (M2) and the auger drive motor

contactor (M1) so that the indicator arrowhead is set slightly higher than the full load amp value listed

on the nameplates.

Tractor drive motor contactor (M1) FLA adjustment dial: ____

Auger drive motor (M2) FLA adjustment dial value: ____

Close and lock the control panel.

Initial Display Setup

NOTE: If no keys are activated for 2 minutes, the display returns to the default state without saving any

configuration changes. At each value, after 5 seconds of inactivity, a description of the current

state will scroll across the display.

NOTE: Pressing and hold OK will return to the previou s menu or return to the default state without saving

the changed values or parameters.

Press OK on the display unit.

(IN) should be displayed on the unit.

Press or on the display unit until (CURR) is shown (not VOLT, POTM or TEMP).

Press OK.

(RANG) should be displayed on the unit.

Press or on the display unit until 4-20 is shown (not 0-20).

Press OK.

(DEC.P) should be displayed on the unit.

Press or on the display unit until 11.11 is shown (not 1111, 111.1, 1.111 or .1111).

Press OK.

PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions 23

Page 24

5. Operation

(DI.LO) should be displayed on the unit.

Press or on the display unit until 0 is shown.

Press OK.

(DI.HI) should be displayed on the unit.

The DI.HI value will match the amperage range selection switch value on the current transducer

(30, 60 or 90). Refer part # AS-0736 on Page 39.

Press or on the display unit until the correct value is shown.

Press OK repeatedly until “-----” is displayed. This indicates the programming described above has

been saved.

Make sure no individual is inside the bin.

Make sure the sweep will not contact any obstruction and cause damage.

Have an employee observe the sweep from outside the bin, through the open door.

Have another employee operate the control panel.

Switch the Run Mode switch so that Manual is selected (not Auto).

Switch the Manual Mode switch to idle (not reverse or forward).

Press the Start button on the control panel.

NOTE: If any dama ge is observed or there is abnormal operation of the sweep, shut it down immediately.

There are three (3) ways to accomplish this. 1) Remove the pressure on the safety foot switch.

2) Press the Stop button on the control panel. 3) Press in on the Enable/Disable button so that it

collapses appropriately. Switch the disconnect switch on the panel to OFF (not ON). Lock out the

panel before entering the bin to service the sweep.

Observe the no load amps (NLA) displayed on the meter on the front of the panel.

Auger drive motor no load amps: ____

The tractor motor operation (forward and stop) in automatic is dictated by the amp reading on the auger

drive motor.

The tractor drive motor is meant to shut off (idle) when the Auger Drive Motor reaches 90% of the

nameplate FLA.

90% of full load amps: ____

The tractor motor is meant to reactivate (forward) when the auger drive motor reaches 110% of the no load

amps (amperage observed when the auger flight turns freely in absence of grain).

110% of no load amps: ____

24 PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions

Page 25

5. Operation

Final Display Setup

NOTE: If no keys are activated for 2 minutes, the display returns to the default state without saving any

configuration changes. At each value, after 5 seconds of inactivity, a description of the current

state will scroll across the display.

Press OK repeatedly until RELU is displayed on the unit.

Press or on the display unit until DISP is shown (not PERC).

Press OK.

REL1 should be displayed on the unit.

Press or on the display unit until SET is shown (not SKIP or OFF).

Press OK.

SETP should be displayed on the unit.

Press or on the display unit the 90% of FLA value is shown.

Press OK.

ACT1 should be displayed on the unit.

Press or on the display unit until INCR is shown (not DECR).

Press OK.

HYS1 should be displayed on the unit.

For this control panel hysteresis (HYS1) is measured as the different between 90% of full load amps and

110% of no load amps.

90% of full load amps: ____ minus 110% of no load amps: ____

Press or on the display unit until the correct value is shown.

Press OK.

ERR1 should be displayed on the unit.

Press or on the display unit until DEAC is shown (not HOLD, ACTI or NONE).

Press OK.

ON.DE should be displayed on the unit.

Press or on the display unit until 0 is shown.

Press OK.

PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions 25

Page 26

5. Operation

OF.DE should be displayed on the unit.

Press or o the display unit until 20 is shown.

Press OK.

REL2 should be displayed on the unit.

Press or on the display unit until OFF is shown (not SET or SKIP).

Press OK.

E.PAS should be displayed on the unit.

Press or on the display unit until NO is shown.

Press OK.

This function will allow the values that were entered to be locked.

NOTE: Using a password will stop access to the menu and parameters. There are two (2) levels of

password protection. Passwords between 0000 and 4999 allow access to the fast set point

adjustment and relay test. (Using this password stops access to all other parts of the menu.)

Passwords between 5000 and 9999 stop access to all parts of the menu, fast set point adjustment

and relay test. (Current set point is still shown.) By using the master password 2008, all

configuration menus are available.

If you select NO, press OK.

If you select YES, N.PAS will be displayed. Press or on the display unit until your password is shown.

Press OK. Document this password.

The password will be necessary if there needs to be changes to many of the configuration values.

26 PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions

Page 27

NOTES

PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions 27

Page 28

6. Control Panel Diagrams

Sweep Tractor Control Box Definitions

Commercial Sweep Control Panel

28 PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions

Page 29

6. Control Panel Diagrams

Schematic - Control Panel GCS Sweeps 230V 3 HP (GCSTP2-03)

PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions 29

Page 30

6. Control Panel Diagrams

Schematic - Control Panel GCS Sweeps 230V 5 HP (GCSTP2-05)

30 PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions

Page 31

6. Control Panel Diagrams

Schematic - Control Panel GCS Sweeps 230V 7.5 HP (GCSTP2-75)

PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions 31

Page 32

6. Control Panel Diagrams

Schematic - Control Panel GCS Sweeps 230V 10 HP (GCSTP2-10)

32 PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions

Page 33

6. Control Panel Diagrams

Schematic - Control Panel GCS Sweeps 460V 3 HP (GCSTP4-03)

PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions 33

Page 34

6. Control Panel Diagrams

Schematic - Control Panel GCS Sweeps 460V 5 HP (GCSTP4-05)

34 PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions

Page 35

6. Control Panel Diagrams

Schematic - Control Panel GCS Sweeps 460V 7.5 HP (GCSTP4-75)

PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions 35

Page 36

6. Control Panel Diagrams

Schematic - Control Panel GCS Sweeps 460V 10 HP (GCSTP4-10)

36 PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions

Page 37

6. Control Panel Diagrams

Schematic - Control Panel GCS Sweeps 460V 15 HP (GCSTP4-15)

PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions 37

Page 38

6. Control Panel Diagrams

Standa rd Control Panel Assembly 230V 3 Phase

38 PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions

Page 39

6. Control Panel Diagrams

Standard Control Panel Assembly 230V 3 Phase Parts List

Qty

Ref # Part # Description

1 C-8711 Transformer 1 1 1 1

2GC20176Ground Bar Kit 1111

3 AS-0736 Current Transducer 1 1 1 1

4 GC20170 Manual Starter Terminal Block 2222

5 GC20184 Auger Motor Starter and Protector 1 1 1 1

6 GC20186 Auger Motor Starter and Protector 1 - - 6 GC20187 Auger Motor Starter and Protector - 1 - 6 GC20188 Auger Motor Starter and Protector - - 1 6 GC20189 Auger Motor Starter and Protector - - - 1

7 056-1942-4 Auger Relay 1 - - 7 056-1949-9 Auger Relay - 1 - 7 056-1969-7 Auger Relay - - 1 -

GCSTP2-03 GCSTP2-05 GCSTP2-75 GCSTP2-10

3 HP 5 HP 7.5 HP 10 HP

7 056-1941-6 Auger Relay - - - 1

8GC20168Reverse Contactor 1111

9 GC20169 Starter Cable Busbar 1 1 1 1

PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions 39

Page 40

6. Control Panel Diagrams

Standa rd Control Panel Assembly 460V 3 Phase

40 PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions

Page 41

6. Control Panel Diagrams

Standard Control Panel Assembly 460V 3 Phase Parts List

Qty

Ref # Part # Description

1 C-871 1 Transformer 1 1 1 1 1

2 GC20176 Ground Bar Kit 1 1 1 1 1

3 AS-0736 Current Transducer 1 1 1 1 1

4 GC20170 Manual Starter Terminal Block 2 2 2 2 2

5 GC20185 Motor Starter and Protector 1 1 1 1 1

6 GC20190 Auger Motor Starter and Protector 1 - - - 6 D03-0964 Auger Motor Starte r and Protector - 1 - - 6 GC20186 Auger Motor Starter and Protector - - 1 - 6 GC20187 Au ger Motor Starter and Protector - - - 1 6 GC20188 Auger Motor Starter and Protector - - - - 1

7 056-1948-1 Auger Relay 1 1 - - 7 056-1942-4 Auger Relay - - 1 - -

GCSTP4-03 GCSTP4-05 GCSTP4-75 GCSTP4-10 GCSTP4-15

3 HP 5 HP 7.5 HP 10 HP 15 HP

7 056-1969-7 Auger Relay - - - 1 1

8 GC20168 Reverse Contactor 1 1 1 1 1

9 GC20169 Starter Cable Busbar 1 1 1 1 1

PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions 41

Page 42

NOTES

42 PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions

Page 43

1. Sweep Tractor Parts

2. Chain Guard Assembly

3. Drive Motor Assembly

4. Bearing Stand Assembly

7. Parts List

PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions 43

Page 44

7. Parts List

Sweep Tractor Parts

44 PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions

Page 45

7. Parts List

Sweep Tractor Parts List

Ref # Part # Description Ref # Part # Description

1 GK7714 Tractor Frame 30 GK7725 5/8"-11 x 8-1/2" Threaded Rod

2 GK7716 Bearing Mounting Bracket 31 S-9259 5/8"-11 Serrated Flange Nut Zinc

3 S-9062

4 S-8506 1/2"-13 Serrated Flange Nut Zinc 33 S-858 5/8" Flat Washer USS Zinc

5 017-1486-4 Bearing: 1-5/8" Bore Pillow Block

6 S-2120 1/2" Flat Washer SAE Zinc

7 S-781 1 1/2"-13 x 2" HHCS Bolt Zinc Grade 5 GK4975

8 GK7724

9 S-9179 3/8" Square x 1-3/4" Key 36 S-248 3/8" Flat Washer YDP

10 GK7715 Tractor Axle 37 S-7469 3/8"-16 x 1" HHCS Bolt Zinc Grade 5

11 GK7718 Wheel Hub 38 S-7383 3/8"-16 Nylock Nut Zinc Grade 5

12 S-6762 3/8"-16 x 2-1/2" Hex Bolt Zinc Grade 5

13 S-8251 3/8"-16 Stover Nut Zinc Grade C GK80166 Stub Shaft - GCS8-10

14 S-8260 Nylock Nut 1/2"-13 ZN Grade 5 GK4952 Stub Shaft - GCS10-12 and GCS12-14

15 GK7748

16 GK80116 Strut Bracket GK4951 Stub Collar - GCS10-12 and GCS12-14

17 S-9065 3/8"-16 x 1" Flange Bolt Zinc Grade 5

18 S-968

19 GK80115 Weight Support Plate GK6457 End Wheel with Bearing - GCS10-12

20 GC03552 5/8"-11 x 6" Threaded Rod GK4954 End Wheel with Bearing - GCS12-14

21 S-4110 5/8"-11 Hex Nut Zinc Grade 5

22 GK7883 Roller Chain, #50, 61 Pitch GK1954 Bea r ing Stand Assembly - GCS8-10

23 D32-0015 Roller Chain Connecting Link, #50 GK2047 Bearing Stand Assembly - GCS10-12

24 GK4978

25 S-9168 1/4" Square x 1" Key

GK4985

GK7828

GK5481

26

GK6387

GK7720

GK6827

27 GK7719 Drive Assembly Plate

28 GK80029 Chain Guard Assembly

29 GK80117 Weight Bracket 47 S-8055 3/8"-16 x 3" Carriage Bolt Zinc Grade 5

1/2"-13 x 1-1/4" Flange Bolt Zinc

Grade 5

Sprocket, #50, 40 Tooth, 1-5/8" Bore,

Type B

Tire and Wheel: 4.80-8 5-Lug,

Foam Filled

3/8"-16 Wide Serrated Flange Nut Zinc

Grade 5

Sprocket, #50, 13 Tooth, 1-1/8" Bore,

Type B

Drive Motor Assembly - 1 PH, 60 Hz,

1 15/230V, TEFC

Drive Motor Assembly - 1 PH, 60 Hz,

115V/208V-230V, XPFC

Drive Motor Assembly - 3 PH, 60 Hz,

230V/460V, TEFC

Drive Motor Assembly - 3 PH, 60 Hz,

208V-230V/460V, XPFC

Drive Motor Assembly - 3 PH, 60 Hz,

575V, XPFC

Drive Motor Assembly - 3 PH, 50 Hz,

220V/380V/460V, TEFC

32 GK7717 Tractor Weight - 50 Lbs.

GK80172 Shield Bracket - GCS6-8

GK80173 Shield Bracket - GCS8-10

34

35 S-8989 3/8"-16 x 3-3/4" HHCS Bolt Zinc Grade 5

GK80165 Stub Shaft - GCS6-8

39

GK80163 Stub Collar - GCS6-8

40

GK80164 Stub Collar - GCS8-10

GK80161 End Wheel with Bearing - GCS6-8

GK80162 End Wheel with Bearing - GCS8-10

41

GK2107 Bearing Stand Assembly - GCS6-8

42

GK80084 Bearing Stand Assembly - GCS12-14

S-8314 1/2"-13 x 3-1/2" HHCS Bolt YDP Grade 8

43

S-7372

S-8315

44

S-8317 Stover Nut 7/16"-14 ZN Grade C - GCS6

S-7893 5/8"-11 x 4" HHCS Bolt YDP Grade 8

45

S-8316

S-8606 5/8"-11 Stover Nut Zinc Grade C

46

S-8317 Stover Nut 7/16"-14 ZN Grade C - GCS6

Shield Bracket - GCS10-12 and

GCS12-14

Bolt, HHCS 7/16"-14 x 2-1/2" ZN Grade 8

- GCS6

1/2"-13 Prevailing Torque Lock Nut Zinc

Grade C

Bolt, HHCS 7/16"-14 x 3 ZN YDP Grade 8

- GCS6

PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions 45

Page 46

7. Parts List

Chain Guard Assembly

Chain Guard Assembly Parts List

Ref # Part # Description

1 GK7712 Chain Guard Top Assembly

2 GK7713 Chain Guard Bottom Assembly

3 S-9067 3/8"-16 x 3/4" Flange Bolt Zinc Grade 5

46 PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions

Page 47

Drive Motor Assembly

7. Parts List

Drive Motor Assembly Parts List

Ref # Part # Description

1 GK4987 Worm Gear Reducer, 60:1, 56C, LO, S23

2 CFDL3504M Motor - 1/2 HP, 1 PH, 60 Hz, 1725 RPM, 115/230V, TEFC, 56C

2 FLX-4021-1PH Motor - 1/2 HP, 1 PH, 60 Hz, 1725 RPM, 115/208-230V, XPFC, 56C

2 FLX-3547 Motor - 1/2 HP, 3 PH, 60 Hz, 1725 RPM, 230/460V, TEFC, 56C

2 FLX-4021 Motor - 1/2 HP, 3 PH, 60 Hz, 1725 RPM, 208-230/460V, XPFC, 56C

2 012-3E-575XP Motor - 1/2 HP, 3 PH, 60 Hz, 1725 RPM, 575V, XPFC, 56C

2 002-1408-0 Motor - 1/2 HP, 3 PH, 50 Hz, 1725 RPM, 220/380/460V, TEFC, 56C

3 S-1054 3/8" Split Lock Washer Zinc

4 S-7469 3/8"-16 x 1" HHCS Bolt Zinc Grade 5

PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions 47

Page 48

7. Parts List

Bearing Stand Assembly

Bearing Stand Assembly Parts List

Ref # Part # Description

1 GK1626 Bearing Stand - GCS8

1 GK1679 Bearing Stand - GCS10

1 GK2049 Bearing Stand - GCS12

1 GK2172 Bearing Stand - GCS14

2 GK1680 Bearing Stand Bearing Assembly - GCS8

2 GK1955 Bearing Stand Bearing Assembly - GCS10

2 GK2050 Bearing Stand Bearing Assembly - GCS12

2 GK2163 Bearing Stand Bearing Assembly - GCS14

3 S-7837 7/16"-14 x 1-1/2" HHCS Bolt Zinc Grade 5

4 S-8317 Stover Nut 7/16" -14 ZN Grade C

48 PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions

Page 49

8. Warranty

9101239_1_CR_rev7.DOC (revised July 2009)

GSI Group, LLC Limited Warranty

The GSI Group, LLC (“GSI”) warrants products which it manufactures to be free of defects in materials and workmanship

under normal usage and conditions for a period of 12 months after sale to the original end-user or if a foreign sale,

14 months from arrival at port of discharge, whichever is earlier. The end-user’s sole remedy (and GSI’s only obligation)

is to repair or replace, at GSI’s option and expense, products that in GSI’s judgment, contain a material defect in materials

or workmanship. Expenses incurred by or on behalf of the end-user without prior written authorization from the GSI

Warranty Group shall be the sole responsibility of the end-user.

Warranty Extensions:

The Limited Warranty period is extended for the following products:

Product Warranty Period

Performer Series Direct Drive Fan Motor 3 Years

AP Fans and Flooring

Cumberland

Feeding/Watering

Systems

Grain Systems Grain Bin Structural Design 5 Years

Grain Systems

Farm Fans

Zimmerman

All Fiberglass Housings Lifetime

All Fiberglass Propellers Lifetime

Feeder System Pan Assemblies 5 Years **

Feed Tubes (1-3/4" and 2.00") 10 Years *

Centerless Augers 10 Years *

Watering Nipples 10 Years *

Portable and Tower Dryers 2 Years

Portable and Tower Dryer Frames and

Internal Infrastructure †

5 Years

* Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 25%

5 to 7 years - end-user pays 50%

7 to 10 years - end-user pays 75%

** Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 50%

† Motors, burner components

and moving parts not included.

Portable dryer screens included.

Tower dryer screens not included.

GSI further warrants that the portable and tower dryer frame and basket, excluding all auger and auger drive components,

shall be free from defects in materials for a period of time beginning on the twelfth (12

and continuing until the sixtieth (60

th

) month from the date of purchase (extended warranty period). During the extended

th

) month from the date of purchase

warranty period, GSI will replace the frame or basket components that prove to be defective under normal conditions

of use without charge, excluding the labor, transportation, and/or shipping costs incurred in the performance of this

extended warranty.

Conditions and Limitations:

THERE ARE NO WARRANTIES THAT EXTEND BEYOND THE LIMITED WARRANTY DESCRIPTION SET FORTH

ABOVE. SPECIFICALLY, GSI MAKES NO FURTHER WARRANTY OF ANY KIND, EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OR USE IN CONNECTION WITH: (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (II) ANY ADVICE,

INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESENTA TIVE OR

EMPLOYEE OF GSI REGARDING OR RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY

FOR A PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCTS.

GSI shall not be liable for any direct, indirect, incidental or consequential damages, including, without limitation, loss of

anticipated profits or benefits. The sole and exclusive remedy is set forth in the Limited Warranty, which shall not exceed

the amount paid for the product purchased. This warranty is not transferable and applies only to the original end-user. GSI

shall have no obligation or responsibility for any representations or warranties made by or on behalf of any dealer, agent

or distributor.

GSI assumes no responsibility for claims resulting from construction defects or unauthorized modifications to products

which it manufactured. Modifications to products not specifically delineated in the manual accompanying the equipment at

initial sale will void the Limited Warranty.

This Limited Warranty shall not extend to products or parts which have been damaged by negligent use, misuse, alteration,

accident or which have been improperly/inadequately maintained. This Limited Warranty extends solely to products

manufactured by GSI.

Prior to installation, the end-user has the responsibility to comply with federal, state and local codes which apply to the

location and installation of products manufactured or sold by GSI.

PNEG-1597 Sweep Tractor and Control Panel Assembly Instructions 49

Page 50

This equipment shall be installed in accordance with

the current installation codes and applicable

regulations, which should be carefully followed in all

cases. Authorities having jurisdiction should be

consulted before installations are made.

Copyright © 2013 by GSI Group

Printed in the USA

GSI Group

1004 E. Illinois St.

Assumption, IL 62510-0020

Phone: 1-217-226-4421

Fax: 1-217-226-4420

www.gsiag.com

CN-303144

Loading...

Loading...