Page 1

KBIC SCR Control Kit

Installation Manual

PNEG-1587

Date: 01-18-08

PNEG-1587

Page 2

2 PNEG-1587 KBIC SCR Control Kit Installation

Page 3

Table of Contents

Contents

Chapter 1 Introduction ........................................................................................................................................ 4

Read these Instructions before Installation and Operation ................................................................ 4

Chapter 2 Installation .......................................................................................................................................... 6

Replacing the Woods Board ......................... .... ... ... ... .... ... ... ... .... ... ... .................................................. 6

Chapter 3 Adjusting SCR Motor Speed .............................................................................................................8

Maximum Potentiometer Adjustment ................................................................................................. 8

Minimum Potentiometer Adjustment ... ... ... ... .... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ..... 8

Chapter 4 Warranty .............................................................................................................................................9

PNEG-1587 KBIC SCR Control Kit Installation 3

Page 4

1. Introduction

Read these Instructions before Installation and Operation

To reduce the risk of electrical shock or damage to electrical components, turn

OFF and lock out the main power supply before performing any service or

maintenance work on the dryer.

KBIC Control Kit

The KBIC control kit is a service replacement package for the discontinued Woods SCR control boards

installed on Farm Fans dryers from 1990 to 2007.

The KBIC kit supersedes previous SCR kits and contains the necessary p arts for replacing the following

SCR control boards:

1. 415-3621-0 SCR CONTROL 1 HP-WOODS W/54

2. 415-4563-3 SCR CONTROL 1/3 HP-WOODS W/54

3. 415-3019-7 SCR CONTROL 3/4 HP-WOODS

4. 415-2302-8 SCR CONTROL 3/4 HP-WOODS W/54

5. SCR-003 SCR CONTROL KIT WOODS

6. 056-1580-2 SCR MOTOR CONTROL-WOODS

Beginning in 1990, the Woods SCR board was installed on all new CMS-H, CMS-J, and M-Series dryers.

As of July, 1992, the Woods SCR board was installed on all new CF/AB and CF/SA series dryers.

KBIC Parts List (Part # D03-0104R1/3 or D03-0104R3/4)

Part # Description Qty

D03-0106 SCR Contactor 15 Amp 1

D03-0013-BRK DIN Rail Mount, 3.9" 1

D03-0711M SCR Drive Board Base Unit 1

DC-1859 Decal, 3A 250V Fuse Repl. Label 1

PNEG-1587 KBIC Control Kit Instructions 1

HH-1462 Wire Nuts 2

WR-16 BLK Wire, 16 Gauge Stranded Black MTW 4

WR-18 YLW Wire, 18 Gauge Stranded Yellow MTW 3

WR-18 WHT Wire, 18 Gauge Stranded White MTW 3

D03-0712-1/3 SCR Drive Board for 1/3 HP Motor 1

D03-0712-3/4 SCR Drive Board for 3/4 HP Motor 1

4 PNEG-1587 KBIC SCR Control Kit Installation

Page 5

1. Introduction

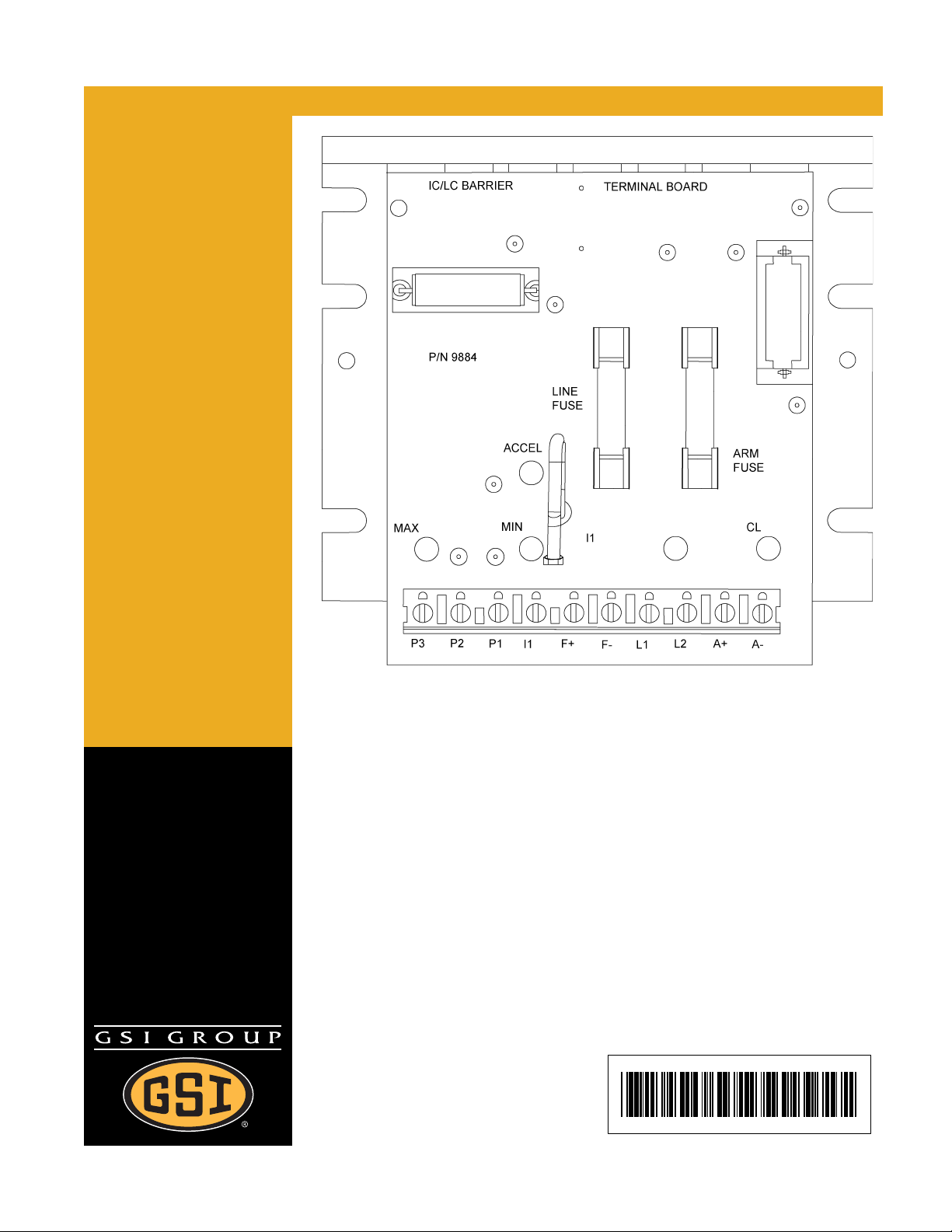

Figure 1A KBIC SCR Board

Figure 1B Woods SCR Board (Discontinued)

PNEG-1587 KBIC SCR Control Kit Installation 5

Page 6

2. Installation

Replacing the Woods Board

1. Disconnect the power to the circuit.

2. For ease of re-connection, record the colors and terminal numbers of all wires leading to the Woods

board. Disconnect wiring and remove board. Mount the KBIC board in approximately the same

location, oriented as shown in Figure 1A on Page 5. Note that additional holes must be drilled into

the mounting surface using a 9/64" drill bit. Try to keep power terminal L 1 and L2 in approximately

the same location as before to help prevent the need for longer wire lengths.

3. Mount the DIN Rail (D03-0013-BRK) next to the KBIC board if possible using a 9/64" drill bit. Use

the self tapping screws to secure the DIN Rail to the panel. Snap the SCR contactor (D03-0106)

onto the DIN Rail.

4. Reconnect the wires as follows:

Previous Woods Terminal New KBIC Terminal Previous Woods T erminal New KBIC Terminal

L1 T1 of SCR Contactor 1 P1

L2 T3 of SCR Contactor 2 P2

F1 F+ 3 P3

F2 F- 6 N.C. See text in Step 8

A1 A+ 7 N.C. See text in Step 7

A2 A

5. Strip the end of the supplied black 16 gauge wire and connect it to the wire between the L1 terminal

of the SCR contactor and the L1 terminal of the KBIC board. Now strip and connect a wire to the

L3 terminal of the SCR contactor and the L2 terminal of the KBIC board.

6. Connect the supplied white 18 gauge wire to the A2 terminal of the SCR contactor. Connect the

other end to any available AC neutral connection. This is usually a white wire labeled with a

number 2 at its connection point.

7. Connect the wire (See Figure 2A on Page 7) that was connected to terminal 7 on the Woods board

to the A1 terminal of the SCR contactor. If additional wire length is required, use part of the supplied

yellow 18 gauge wire and wire nut (HH-1462).

8. Connect the wire that was connected to terminal 6 to the supplied yellow 18 gauge wire using the

supplied wire nut (HH-1462) and the other end to a fused 110 VAC power sou rce. You can use any

connection that wire number 3 or number 27 is connected to.

6 PNEG-1587 KBIC SCR Control Kit Installation

Page 7

2. Installation

Figure 2A Wiring Diagram for all FFI Dryers

The board is ready to be calibrated unless the drye r is equipped with a Vari-Trol “VM” (Honeywell digital

type control), in which case the following additional step is required before calibration.

• If the dryer has a Honeywell Vari-Trol control and an Auto-Range module, connect the red wire

(#54) attached to the KBIC board to the terminal 1 of the Auto-Range module base. If this wire was

not present on your Woods board, please remove the wire with wire cutters.

PNEG-1587 KBIC SCR Control Kit Installation 7

Page 8

3. Adjusting SCR Motor Speed

Maximum Potentiometer Adjustment

With dryer unload circuit energized, set the SCR Speed Control knob on the ASC panel to 100%. Using

a small blade screwdriver, adjust the maximum potentiometer to obtain 155 VDC across the DC motor

armature terminals A+ and A- on the KBIC board. (NOTE: Some early M-Series dryers were designed

to operate with a 175 VDC armature voltage. Consult the factory if there is any question regarding these

early models.)

Minimum Potentiometer Adjustment

Set the SCR Speed Control knob on the ASC panel at the 10% setting. Adjust the minimum potentiometer

to obtain 15.5 VDC across the DC motor armature terminal A+ and A-.

Recheck the maximum potentiometer setting and readjust if necessary. Repeat and readjust the

minimum potentiometer if necessary. Rechecking the maximum and minimum potentiometer settings

once should be sufficient.

8 PNEG-1587 KBIC SCR Control Kit Installation

Page 9

4. Warranty

The GSI Group Warranty

THE GSI GROUP (GSI) WARRANTS ALL PRODUCTS WHICH IT MANUFACTURES TO BE FREE OF

DEFECTS IN MATERIAL AND WORKMANSHIP UNDER NORMAL USAGE AND CONDITIONS FOR

A PERIOD OF 12 MONTHS AFTER RETAIL SALE TO THE ORIGINAL END USER. THE

PURCHASER’S SOLE REMEDY AND GSI’S ONLY OBLIGATION SHALL BE TO REPAIR OR

REPLACE, AT GSI’S OPTION AND EXPENSE, PRODUCTS THAT, IN GSI’S SOLE JUDGMENT,

CONTAIN A MATERIAL DEFECT DUE TO MATERIALS OR WORKMANSHIP. ALL DELIVERY AND

SHIPMENT CHARGES TO AND FROM GSI’S FACTORY WILL BE PURCHASER’S RESPONSIBILITY.

EXPENSES INCURRED BY OR ON BEHALF OF THE PURCHASER WITHOUT PRIOR WRITTEN

AUTHORIZATION FROM AN AUTHORIZED EMPLOYEE OF GSI SHALL BE THE SOLE

RESPONSIBILITY OF THE PURCHASER.

EXCEPT FOR THE LIMITED WARRANTY EXPRESSED ABOVE, GSI MAKES NO FURTHER

WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION,

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR USE IN

CONNECTION WITH (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (II) ANY ADVICE,

INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT,

REPRESENTATIVE OR EMPLOYEE OF GSI REGARDING OR RELATED TO THE CONFIGURATION,

INSTALLATION, LAYOUT, SUITABILITY FOR A PARTICULAR PURPOSE, OR DESIGN OF SUCH

PRODUCTS.

GSI SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES, INCLUDING, WITHOUT LIMITATION, LOSS OF ANTICIPATED PROFITS OR BENEFITS.

PURCHASER’S SOLE AND EXCLUSIVE REMEDY IS AS SET FORTH IN THE LIMITED WARRANTY

EXPRESSED ABOVE, WHICH SHALL NOT EXCEED THE AMOUNT PAID FOR THE PRODUCT

PURCHASED. THIS WARRANTY IS NOT TRANSFERABLE AND APPLIES ONLY TO THE ORIGINAL

PURCHASER. GSI SHALL HAVE NO OBLIGATION OR RESPONSIBILITY FOR ANY

REPRESENTATIONS OR WARRANTIES MADE BY OR ON BEHALF OF ANY DEALER, AGENT OR

DISTRIBUTOR OF GSI.

GSI ASSUMES NO RESPONSIBILITY FOR CLAIMS RESULTING FROM ERECTION DEFECTS OR

UNAUTHORIZED MODIFICATIONS TO PRODUCTS WHICH IT MANUFACTURED. MODIFICATIONS

TO PRODUCTS NOT SPECIFICALLY DELINEATED IN THE MANUAL ACCOMPANYING THE

EQUIPMENT AT INITIAL SALE WILL NULLIFY THE PRODUCT WARRANTY THAT MIGHT HAVE

BEEN OTHERWISE AVAILABLE.

THE FOREGOING WARRANTY SHALL NOT EXTEND TO PRODUCTS OR PARTS WHICH HAVE

BEEN DAMAGED BY NEGLIGENT USE, MISUSE, ALTERATION OR ACCIDENT. THIS WARRANTY

EXTENDS SOLELY TO ONLY PRODUCTS MANUFACTURED BY GSI. THIS WARRANTY IS

EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES EXPRESS OR IMPLIED. GSI RESERVES

THE RIGHT TO MAKE DESIGN OR SPECIFICATION CHANGES AT ANY TIME.

PRIOR TO INSTALLATION, PURCHASER HAS THE RESPONSIBILITY TO COMPLY WITH ALL

FEDERAL, STATE AND LOCAL CODES WHICH MAY APPLY TO THE LOCATION AND

INSTALLATION OF PRODUCTS MANUFACTURED OR SOLD BY GSI.

PHLEGAL: #1832020 v1 (139LG01!.DOC) (revised Decembe r 2005)

PNEG-1587 KBIC SCR Control Kit Installation 9

Page 10

This equipment shall be installed in accordance with

the current installation codes and applicable

regulations which should be carefully followed in all

cases. Authorities having jurisdiction should be

consulted before installations are made.

Copyright © 2007 by GSI Group

Printed in the USA

GSI Group

1004 E. Illinois St.

Assumption, IL 62510-0020

Phone: 1-217-226-4421

Fax: 1-217-226-4420

www.gsiag.com

Loading...

Loading...