Page 1

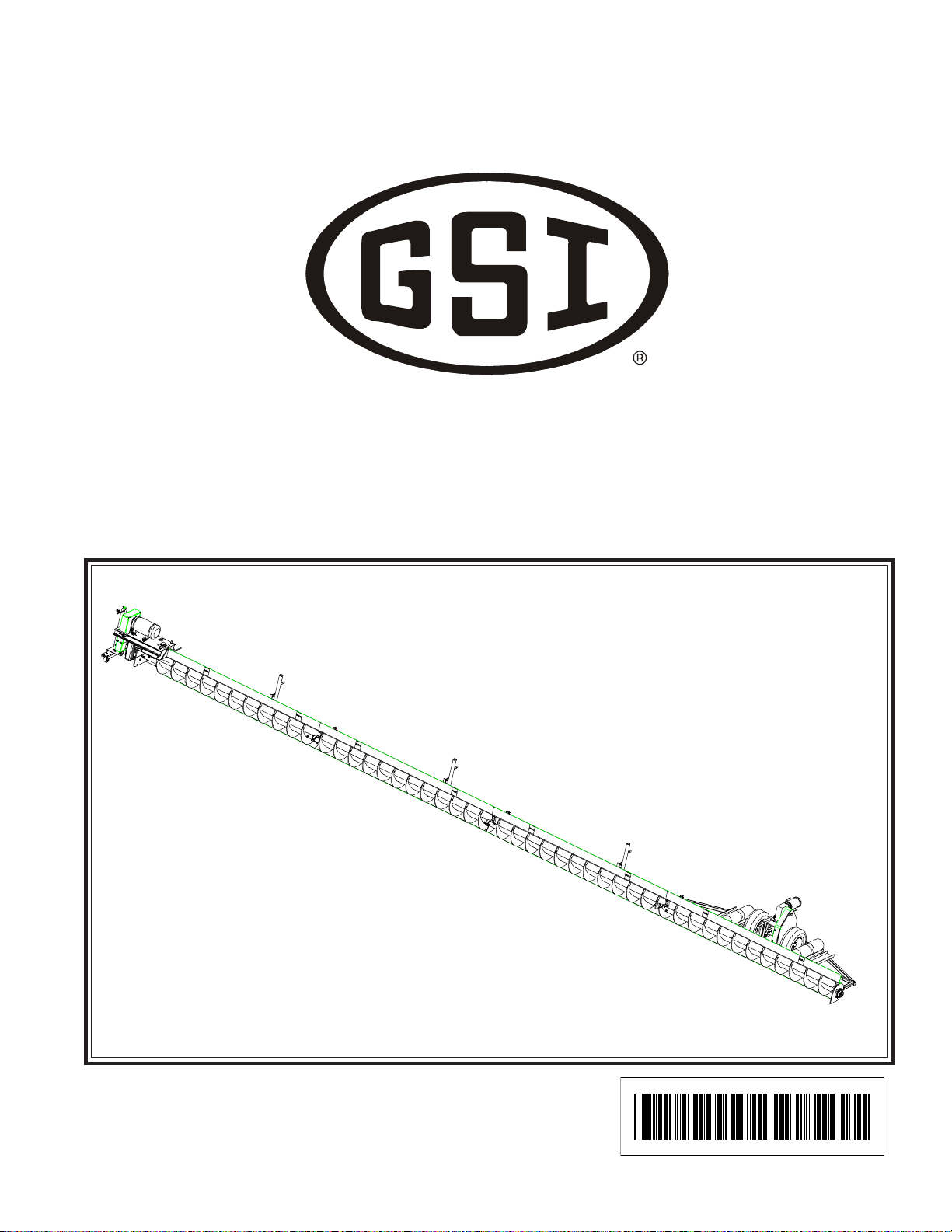

PNEG-1579

12" & 16" Series II Sweep

(Special)

Owner's Manual

06-08-07

PNEG-1579

Page 2

Model Number of My Sweep:

Date Delivered:

Date Installed:

The manufacturer reserves the right to improve it's product whenever

possible and practical to do so. We reserve the right to change, improve

and modify products at any time without obligation to make changes,

improvements and modifications on equipment sold previously.

Page 3

Table of Contents

TABLE OF CONTENTS

Safety ...................................................................................................4-8

Introduction...........................................................................................9-10

Decals..................................................................................................11-14

Operator Qualifications ........................................................................15

General Product Information ................................................................ 16-19

Assembly Section

Back Shield .................................................................................... 20

Flighting .......................................................................................... 22

Hanger Bracket ..............................................................................23

Flange Bearing ...............................................................................24

Gear Reducer................................................................................. 24

Drive Axle & Bearing Support .........................................................25

Reducer Mounting Plate & Reducer ............................................... 27

Key Alignment................................................................................. 27

Tractor Motor ..................................................................................28

Guard Assembly.............................................................................29

Tractor Wheel Assembly ................................................................ 30

Counter Weight ..............................................................................31

Weight Channel Extension Kit........................................................32

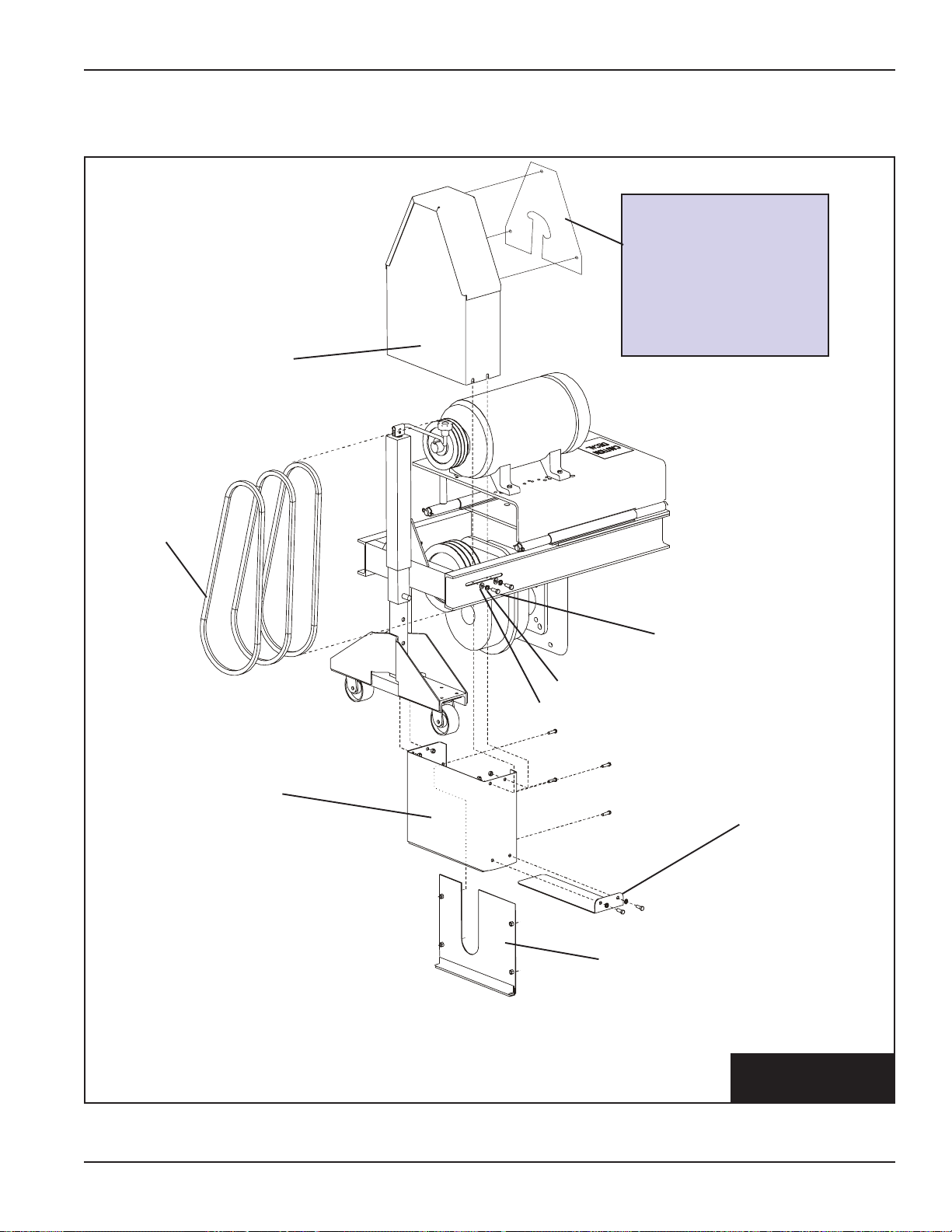

Motor Jack & Base Assembly......................................................... 33

Motor Installation.............................................................................34

Sheave Installation.......................................................................... 35

Electrical Assembly ........................................................................37

Jack Support .................................................................................. 43

Center Pivot.................................................................................... 45

Control Panel.................................................................................. 48

Start-Up................................................................................................50

Operation .............................................................................................52

Shutdown .............................................................................................54

Storage Prep aration .............................................................................54

Maintenance .........................................................................................55

Control Panel Schematics ................................................................... 62

Troubleshooting....................................................................................65

Part Lists..............................................................................................66

Warranty...............................................................................................Inside Back Cover

Personnel operating or working around this equipment should read this

manual. This manual must be delivered with equipment to its owner.

Failure to read this manual and its safety instructions is a misuse of the

equipment. Any misuse of the equipment may void the warranty.

PNEG-720-G2 12" & 16" Series II Sweep

3

Page 4

Safety

SAFETY

GSI equipment is built to provide many years of dependable service to our

customers through durable craftsmanship.

One of the most important aspects of GSI engineering is SAFETY 1

throughout all product lines. At GSI - safety is NO ACCIDENT!

That is why GSI is implementing its SAFETY 1

safety decals, or owner/operator manuals, simply contact GSI, and we will supply

you with them FREE OF CHARGE!

While it is our main goal for GSI to be the world leader in auger manufacturing, it

is always our first priority to keep our customers safe.

If you need any of the above listed safety items or have safety questions, please

contact GSI:

st

program. Should you ever need

st

design

The GSI Group

PO Box 20

1004 E. Illinois Street

Assumption, IL 62510

Ph: 217-226-4421

4 12" & 16" Series II Sweep PNEG-720-G2

Page 5

Safety

SAFETY GUIDELINES

This manual contains information that is important for you, the owner/operator , to know and

understand. This information relates to protecting personal safety and preventing

equipment problems. It is the responsibility of the owner/operator to inform anyone operating

or working in the area of this equipment of these safety guidelines. T o help you recognize this

information, we use the symbols that are defined below . Please read the manual and pay

attention to these sections. Failure to read this manual and it’s safety instructions is a misuse of

the equipment and may lead to serious injury or death.

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid possible

injury or death.

DANGER indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury .

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury .

CAUTION indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury .

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in property damage.

PNEG-720-G2 12" & 16" Series II Sweep

NOTE indicates information about the equipment that you

should pay special attention to.

5

Page 6

Safety

Safety Instructions

GSI’s principle concern is your safety and the safety of others associated with grain handling equipment.

We want to keep you as a customer. This manual is to help you understand safe operating procedures and

some problems which may be encountered by the operator and other personnel.

As owner and/or operator , it is your responsibility to know what requirements, hazards and precautions

exist, and to inform all personnel associated with the equipment or in the area. Safety precautions may be

required from the personnel. Avoid any alterations to the equipment. Such alterations may produce a very

dangerous situation, where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable regulations which should be carefully followed in all cases. Authorities having jurisdiction should be consulted

before installations are made.

OPERATE UNLOAD EQUIPMENT PROPERLY

Make sure ALL equipment is locked in position before operating.

NEVER start equipment until ALL persons are clear of the work area.

Use caution not to hit the auger when positioning the load.

Operate Unload

Be sure all operators are adequately rested and prepared to

perform all functions of operating this equipment.

Untrained operators subject themselves and others to SERIOUS INJURY

or DEA TH. NEVER allow untrained personnel to operate this equipment.

Keep children and other unqualified personnel out of the working area at ALL times.

NEVER allow any person intoxicated or under the influence of alcohol or drugs to operate the equipment.

NEVER work alone. Make sure someone is nearby who is aware of the proper shutdown sequence in

the event of an accident or emergency .

AL W A YS think before acting. NEVER act impulsively around the equipment.

NEVER allow anyone inside a bin, truck or wagon which is being unloaded by an auger or conveyor .

Flowing grain can trap and suffocate in seconds.

Use ample overhead lighting after sunset to light the work area.

Keep area around intake free of obstacles such as electrical cords, blocks, etc. that might trip workers.

Equipment Safely

NEVER drive, stand or walk under the equipment.

AL W A YS lockout ALL power to the equipment when finished

unloading a bin.

Be aware of pinch points. A Pinch point is a narrow area between two surfaces that is likely to trap or

catch objects and so is a potential safety hazard.

6 12" & 16" Series II Sweep PNEG-720-G2

Page 7

FOLLOW SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual and safety

signs on your equipment. Keep signs in good condition.

Replace missing or damaged safety signs. Be sure new

equipment components and repair parts include the current

safety signs. Replacement safety signs are available from the

manufacturer.

Learn how to operate the machine and how to use controls

properly . Do not let anyone operate without instruction.

Keep your machinery in proper working condition. Unauthorized modifications to the machine may impair the function

and/or safety and affect machine life.

If you do not understand any part of this manual and need

assistance, contact your dealer.

Safety

Read and

Understand

Manual.

KEEP HANDS AWAY FROM MOVING PARTS

Keep hands and feet away from auger intake and other moving parts.

Rotating auger can sever a person's limbs or even kill.

Keep hair, loose clothing, and shoestrings away from rot ating and moving

parts. NEVER wear loose fitting clothing when working around augers.

AL WA YS turn of f and lock out all power sources before servicing equipment.

AL W A YS keep belt and chain guards in place during operation.

NEVER attempt to assist machinery operation or to remove trash from equip-

ment while in operation.

OPERATE MOTOR PROPERLY

In an emergency, shut down the power source.

Turn of f and lock out all power sources before performing any maintenance.

Rotating Auger

Do not operate electric motor equipped units until motors are properly

grounded.

Disconnect power on electrical driven units before resetting motor overloads.

Do not repetitively stop and start the drive in order to free a plugged condi-

tion. Jogging the drive in this type of condition can damage the auger and/or

drive components.

PNEG-720-G2 12" & 16" Series II Sweep

Electric

Shock

Hazard.

7

Page 8

Safety

PRACTICE SAFE MAINTENANCE

Understand service procedures before doing work.

Keep area clean and dry.

Never lubricate, service, or adjust machine while it is in

operation. Keep hands, feet, and clothing from rotating

shafts, screws, belts, or other moving equipment.

Keep all parts in good condition and properly installed.

Fix damage immediately. Replace worn or broken

parts. Remove any build up grease, oil, or debris.

WEAR PROTECTIVE CLOTHING

Wear close fitting clothing and safety equipment

appropriate to the job.

Safety glasses should be worn at all times to

protect eyes from debris.

Maintain

Equipment

and Work

Area.

Eye Protection

Gloves

Wear gloves to protect your hands from sharp

edges on plastic or steel parts.

Use a respirator to prevent breathing potentially

toxic fumes and dust.

Wear hard hat and steel toe boots to help

protect your head and toes from falling debris.

Remove all jewelry .

Tuck in any loose or dangling shoe strings.

Long hair should be tied up and back.

PREPARE FOR EMERGENCIES

Be prepared if fire starts.

Steel Toe

Boots

Respirator

Hard Hat

Keep a first aid kit and fire extinguisher handy .

Keep emergency numbers for doctors, ambulance ser-

vice, hospital, and fire department near your telephone.

Keep Emergency Equipment

Quickly Accessible.

8 12" & 16" Series II Sweep PNEG-720-G2

Page 9

Introduction

PRODUCT INTRODUCTION

Congratulations! Your selection of the GSI Series 2 Sweep was a wise investment. It will give you years of

dependable service. The main function of the Series 2 Sweep is to clean out the remaining grain, from the

bin, after all gravity unloading has finished. The GSI Series 2 Sweep is a single pass sweep only. The unit will

only operate in a round grain bin equipped with a center sump in the bin floor. NOTE: The bin manufacturer

should be contacted for their recommendations on your bin’s structural integrity. The following are sweep

criteria recommendations.

ISSUES RECOMMENDATIONS

Flooring

Center Sump Size

The flooring type of choice is concrete. However, the sweep can be

used on a full aeration floor. When installing a sweep on a full aeration floor, the floor manufacturer should be cont acted for proper

recommendations concerning supporting of the floor. It is required to

lay a track, 10 Ga. minimum with slip resistant finish, under the sweep

at the points of contact of the tractor drive tires, and 10 Ga minimum,

under the points of contact of the intermediate jacks over any type of

aeration flooring, both full floor or flush floor aeration. A chart is

included that shows radius dimensions locating the points of contact

between the sweep and the bin floor. The dimensions may be used to

figure the material quantities of track to support the sweep across the

aeration flooring. The track material is not supplied with the sweep

and must be supplied by the installer or purchased from GSI. The

dimensions are approximate and the assembled sweep should be

checked for exact points of contact.

When installing a 12" standard sweep, the minimum recommended

opening is 36" x 36". With a 16" standard sweep, it is 42" x 42". If

installing a sump with collector ring, the opening will be 42" x 42" for

both sweep sizes.

The sump hopper supplied by GSI was designed with sufficient clearance around the collector ring housing to allow grain to gravity flow

thru the hopper and be carried away by the material handling equipment below. 42 3/4" is the maximum opening size to allow rolling

clearance for the casters assembled to the head end jack. If made

smaller, grain flow may be decreased to an unacceptable level.

Number of Intermediate

Sumps.

PNEG-720-G2 12" & 16" Series II Sweep

**Flow of grain is limited to 15,000 BPH when using this sump and

collector ring housing assembly . The collector ring housing extends

22 1/2" down from the floor surface and is approximately 14 1/4" x 14

1/4" in size.

It is recommended to install the intermediate sumps on a maximum of

10’ centers where the sweep will be parked during storage. The extra

sumps will help clean out the grain in front of the sweep reducing the

start-up load. Doing this will save labor dollars and hours of work to

uncover the sweep and can help the sweep during start-up. The

sweep should be parked behind the intermediate sumps with the

sumps on the auger side of the sweep.

9

Page 10

Introduction

Routing the Power Supply

to the Sweep.

Floor Level Tolerance

Bin Roundness Tolerance

Bin Opening Size

Required for Installation

There are three (3) options for routing the power. The most used option is

to run the cords out the door in the sidewall. Another option is to use the

hopper sump with collector ring. This allows the power to be transferred

through a mechanical device in the center sump and does not twist any

cords. This method is popular overseas. Last, is by using the pivot kit,

which routes the power cord through the center sump. Using this kit

requires the sweep to be backed up to the start point after sweeping. The

pivot kit is not the preferred choice due to the cord twisting repeatedly.

The top edge of the sump hopper and the top edge of the "X" brace

support must be level with the floor. The floor must be level within 3/4"

plus or minus, preferably less. Any high or low points must be gradually

sloped. The change in elevation should be no more than 3/4" over 60".

Diameter tolerances are limited by foundation limits and sweep operation as well as structural issues. For 72’ diameter and larger the overall

tolerance would be plus or minus 1 1/4” on the radius, plus or minus 1”

on 42’-66’ diameter bins and plus or minus ¾” on 30’ – 39’ bins.

The tail section is the largest piece of a standard Series 2 Sweep. The

dimensions for a 16" tail section are 23 1/2" x 55 1/4". If the bin wall is

not too thick, this unit should fit thru a 23 1/2" x 47" opening. The dimensions for a 12" tail section are 21 1/4" x 51 1/2" Again, if the bin wall is

not too thick the section should fit thru an opening 21 1/2 x 45"

Electrical Requirements

GSI offers a special Knock Down Sweep, uniquely designed for storage

units with small doors. This sweep is broken into 10 main pieces that can

fit through a door as small as 30 1/2" in diameter for 16", 27 1/2" in diameter for 12", or a 20" x 24" rectangular door. The components are then

assembled inside the storage unit.

Electrical controls and wiring should be installed by a qualified electrician. The motor disconnect switches and conductor cables should comply

with the National Electrical and any local codes which may apply.

A main power disconnect switch capable of being locked only in the

OFF position should be used. Disconnect and lock out the power

before servicing the equipment, entering the bin, or resetting the

motor overloads.

The control panel MUST be mounted OUTSIDE the bin near the door. It

must be located so the operator has a full view of the equipment and can

see that all personnel are clear. It must NEVER be installed inside the

bin. The foot switch has to be plugged into the control panel and depressed before the sweep is operational. It has a 10' cord so the sweep

can only be monitored from OUTSIDE the bin. The thermal protection

cord must also be plugged in before the sweep will operate.

10 12" & 16" Series II Sweep PNEG-720-G2

Page 11

DECALS

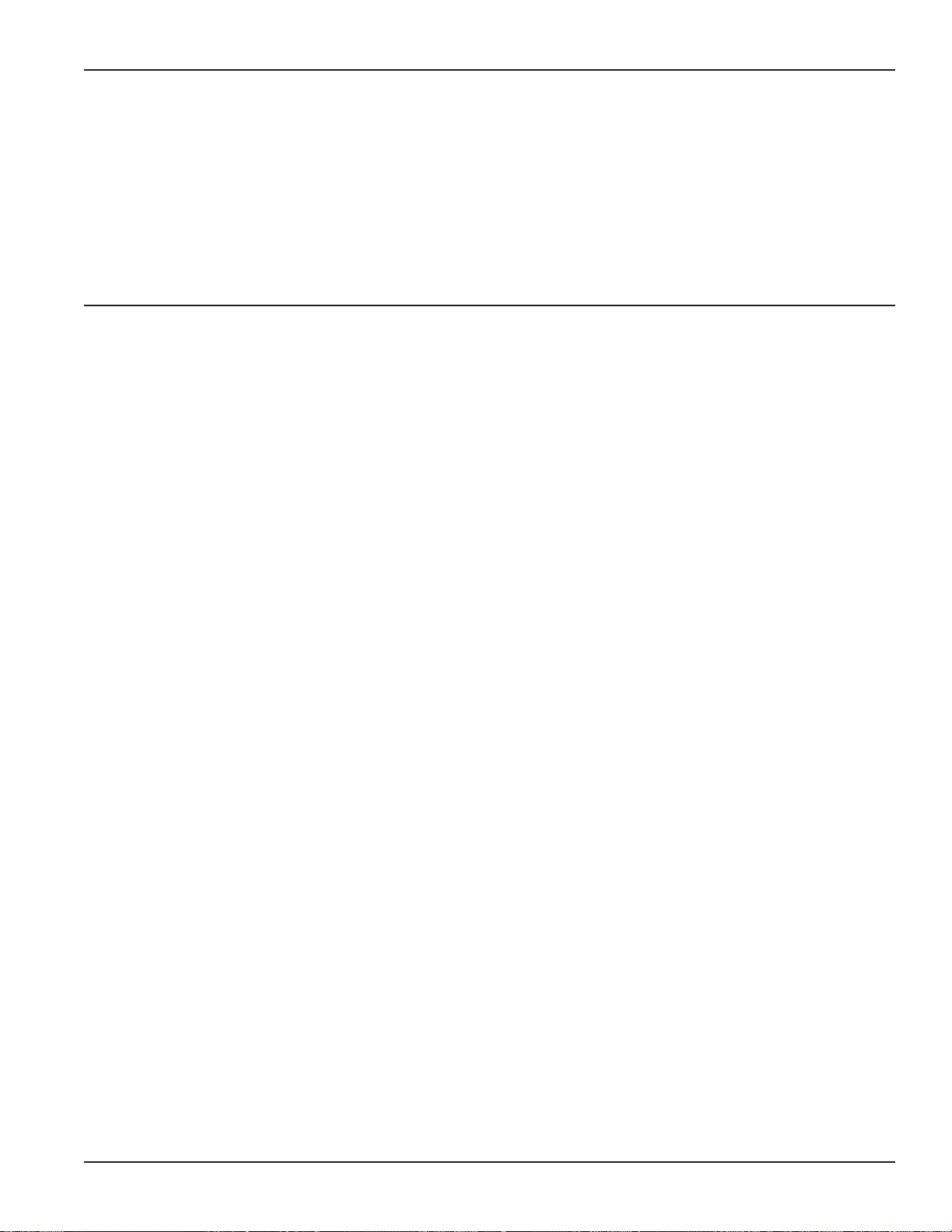

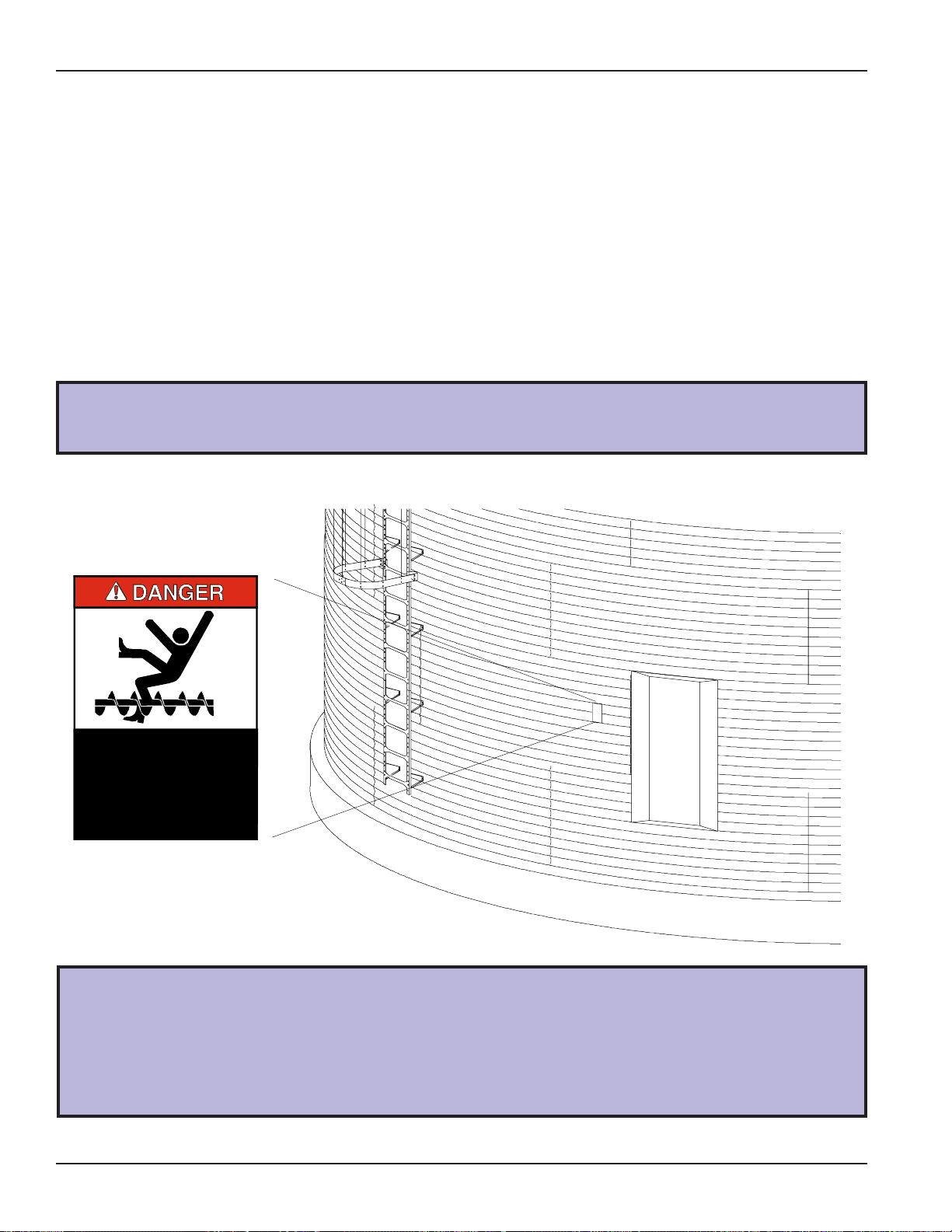

A. The images below show the location of the decals and safety signs which should appear on

the Series II Sweep. (refer to pg. 13-15 for decals)

Decal “E” (DC-994) on

corner of motor mount

Decal “F” (DC-995) on

top of belt guard

Decal “D” (DC-1224) on

corner of motor mount

Decal “C” (DC-1233)

centered on motor mount

Control panel located

outside of bin.

Decals

Decal “D” (DC-1224) on

front corner of control

panel

Decal “I” (DC-834) one (1) per

section centered on back of top

flange

Decal “G” (DC-889) on

corner of motor plate

Decal “B” (DC-1416) two (2) per

section on front of top flange

Decal “A” (DC-1386) on

exterior of chain guard

Please remember safety signs provide important safety information for people working

near bin unloading equipment that is in operation.

Any safety signs that are worn, missing, illegible or painted over should be replaced

immediately. Obtain FREE replacements by contacting GSI.

Decal “G” (DC-889)

three (3) on interior of

control panel

Decal “H” (DC-1382) on

corner of mount plate

PNEG-720-G2 12" & 16" Series II Sweep

11

Page 12

Decals

DECALS (CONT.)

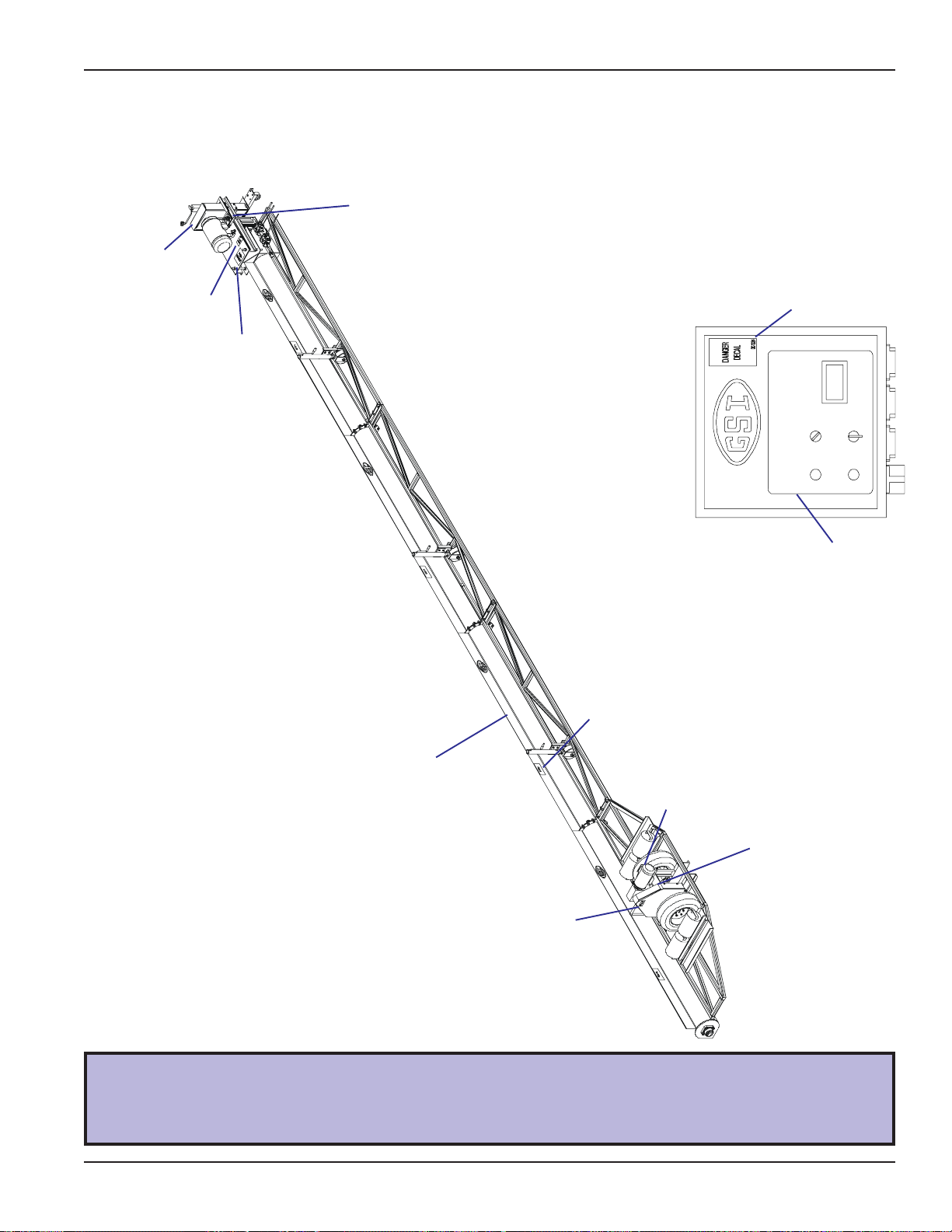

SHEAR POINT

Moving parts can

crush and cut. Keep

hands clear of

sprocket and chain.

Decal “A”

Location: Exterior of chain guard

Size: 2” x 4 1/2”

Part No.: DC-1386

1. READ AND UNDERSTAND THE OPERATOR’S MANUAL

AND ALL SAFETY INSTRUCTIONS.

2. DO NOT OPERATE WHILE UNDER THE INFLUENCE OF

DRUGS OR ALCOHOL.

3. DO NOT OPERATE UNLESS ALL SAFETY EQUIPMENT ,

SWITCHES, GUARDS AND SHIELDS ARE SECURELY IN

PLACE AND OPERATIONAL .

4. ALLOW ONLY TRAINED AUTHORIZED PERSONNEL IN

THE OPERATING AREA.

5. ANY ELECTRICAL WIRING OR SERVICE WORK MUST

BE PERFORMED BY A QUALIFIED ELECTRICIAN. IT MUST

MEET ALL STATE AND LOCAL E LEC TR IC A L CODE S.

Danger Do not put fingers in Auger

6. DO NOT ALLOW CHILDR EN IN THE AREA OF OPERATION.

7. KEEP HANDS, FEET AND CLOTHING AWAY FROM `

MOVING P ART S.

8. DIS C ON N E CT AND LOCK OU T POW ER BEFORE

MAKING ANY ADJUSTMENTS OR PERFORMING ANY

SERVICE WORK.

9. DISCONNECT POWER PRIOR TO RESETTING ANY

MOTOR OVERLOAD.

10. MAKE CERT AI N ALL ELE CT RIC MOT ORS AR E GROUNDED.

11. REPLACE ALL WORN OR DAMAGED LABELS IMMEDIATELY.

DC-1379

Decal “C”

Location: Centered on motor mount

Size: 5 1/2” x 7 3/8”

Part No.: DC-1379

DC-1386

ROTATING AUGER!

• DISCONNECT AND LOCKOUT POWER BEFORE

SERVICING, ADJUSTING OR CLEANING.

• KEEP HANDS, FEET, HAIR AND LOOSE

CLOTHING AWAY FROM ROTATING AUGER AND

MOVING PARTS AT ALL TIMES.

• NEVER REMOVE OR MODIFY GUARDS OR

SHIELDS.

FAILURE TO HEED WILL RESULT IN

SERIOUS INJURY OR DEATH!

DC-1416

Decal “B”

Location: Two (2) per section on

front of top flange

Size: 4 5/16” x 5 7/16”

Part No.: DC-1416

DC-1224

Decal “D”

Location: Corner of motor

mount

Size: 2 7/8” x 5”

Part No.: DC-1224

12 12" & 16" Series II Sweep PNEG-720-G2

Page 13

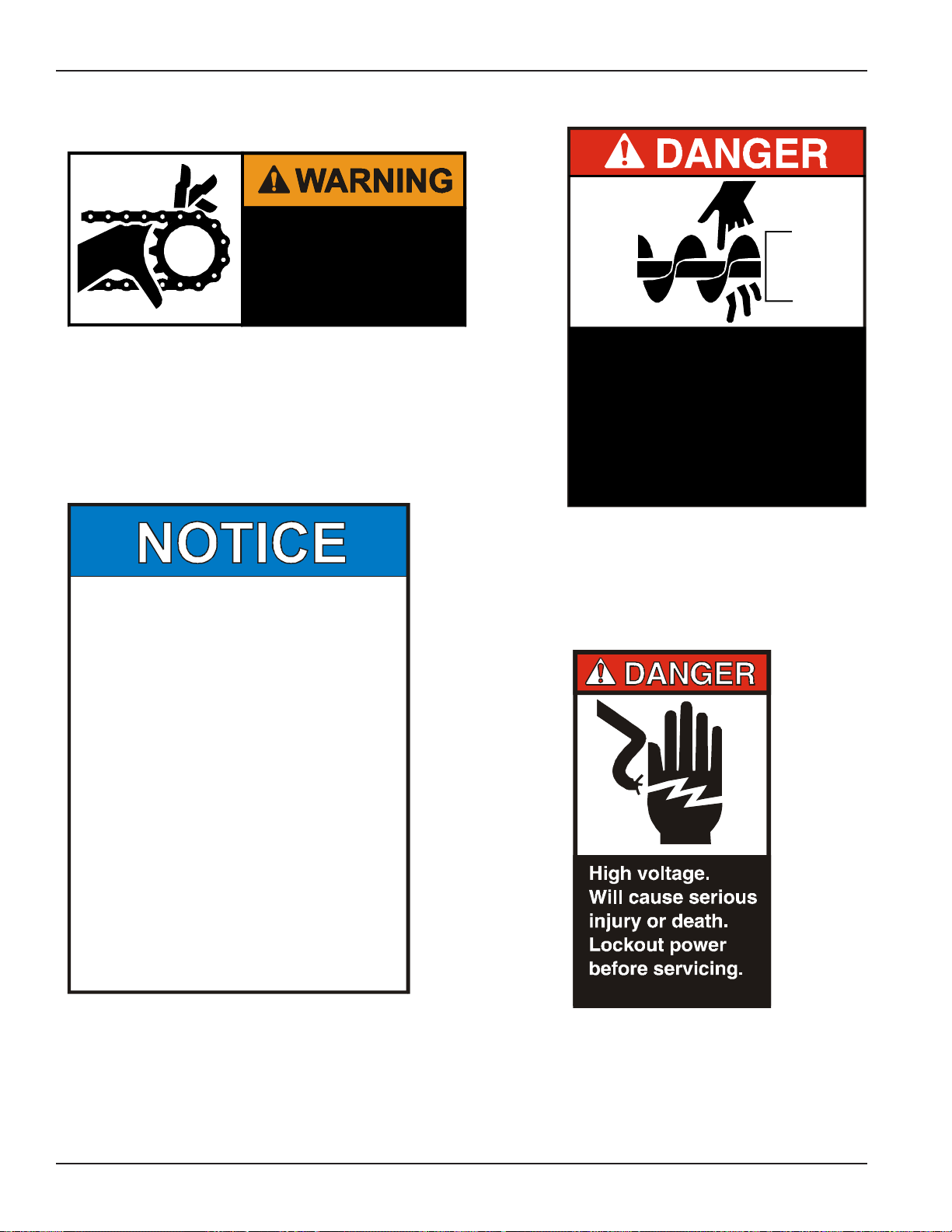

DECALS (CONT.)

SHEAR POINT

Keep hands clear of moving

parts. Do not operate with

guard removed. Disconnect

and lockout power before

servicing.

Decal “E”

Location: Corner of motor mount

Size: 4 1/2” x 2”

Part No.: DC-994

DC-994

Decals

WARNING

Shear point. Keep hands

clear of moving parts. Do

not o p era te w ith gu a rd

removed. Disconnect

and lockout power before

serv icing.

Decal “F”

Location: Top of belt guard

Size: 4 1/2” x 2”

Part No.: DC-995

DC-995

Decal “G”

Location: Corner of motor plate

Size: 2 13/16” x 1 7/16”

Part No.: DC-889

1. Keep all safety shields and devices in place.

2. Keep hands, feet, hair, loose clothing, and other object s away

from moving parts.

3. Do not operate the machine unless visitors, children, and all other

untrained personnel are well clear of the machine and work area.

4. Stop the machine and lock out power to clean, lubricate, service,

or adjust.

5. Read operation and assembly manual completely before using

equipment.

Rotating flighting

can ki ll or dismember

Failure to head these warnings will

.

result in serious injury or death.

SHEAR POINT

Moving parts can

9

8

8

C

D

crush and cut. Keep

hands clear of

sprocke t an d chai n.

DC-1382

Decal “H”

Location: Corner of mount plate

Size: 4” x 1 3/4”

Part No.: DC-1382

Decal “I”

Location: One (1) per

section centered on back

of top flange

Size: 9” x 3 3/4”

Part No.: DC-834

DC-834

PNEG-720-G2 12" & 16" Series II Sweep

13

Page 14

Decals

DECALS (CONT.)

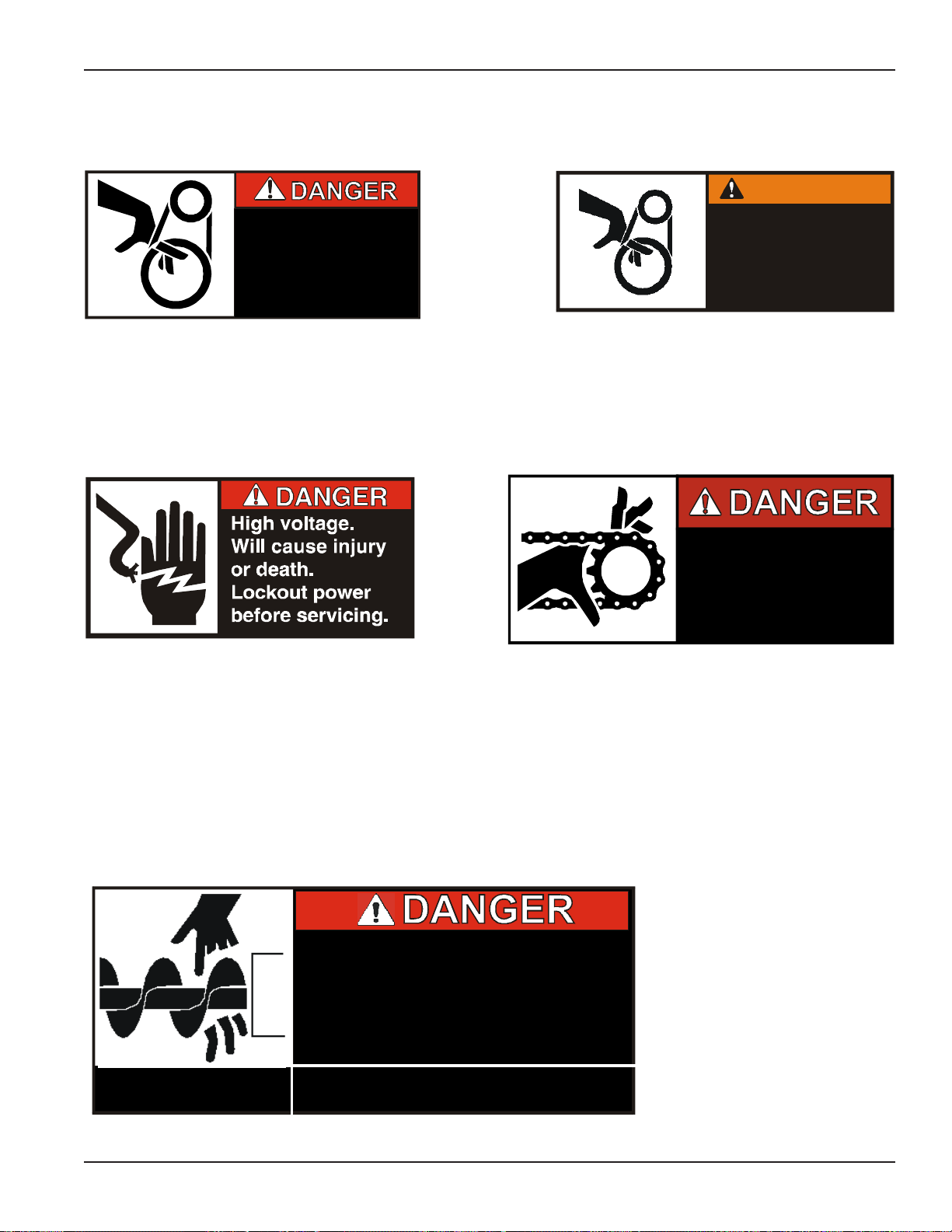

A. DANGER Sign No. DC-1395 was supplied with your bin unloading equipment. This safety sign

should be applied to the side of the bin near the bin opening, so it will be viewed by

people entering into the bin storage building. Do not cover any safety signs or any other

signs that are already there.

B. If the safety sign location suggested is not in full view because of equipment modifications, other

equipment in the area or any reason, then locate the safety sign in a more suitable location.

C. Be certain the surface is clean, dry and free of dirt and oil. Peel paper backing from decals and

stick into place. The adhesive backing will bond on contact.

KEEP CLEAR OF ALL AUGERS AND NEVER ENTER

FAILURE TO DO SO WILL RESULT IN

Please remember, safety signs provide important safety information for people

working near bin unloading equipment that is in operation.

ROTATING FLIGHTING!

THIS BIN IS EQUIPPED WITH GRAIN AUGERS

WHICH CAN KILL OR DISMEMBER.

THIS BIN UNLESS ALL POW ER IS

DISCONNECTED AND LOCKED OUT.

SERIOUS INJURY OR DEATH!

DC-1395

14 12" & 16" Series II Sweep PNEG-720-G2

If the Safety Sign cannot be easily read for any reason or has been painted over,

replace it immediately.

Additional Safety Signs may be obtained free of charge from your dealer, distributor

or ordered from the factory.

Order SAFETY SIGN NO. DC-1395

Page 15

Safety

ploy

)

OPERATOR QUALIFICATIONS.

A. The User/Operator must be competent and experienced to operate auger equipment. Anyone who

works with or around augers must have good common sense in order to be qualified. These

persons must also know and meet all other qualifications, such as:

1. Any person who has not read and/or does not understand all operation and safety instructions is

not qualified to operate any auger systems.

2. Certain regulations apply to personnel operating power machinery. Personnel under the age of

18 years may not operate power machinery , including augers. It is your responsibility, as owner

and/or supervisor, to know what these regulations are in your area or situation.

3. Unqualified or incompetent persons are to remain out of work area.

4. O.S.H.A. (Occupational Safety & Health Administration) regulations state: “At the time of initial

assignment and at least annually thereafter, the employer shall instruct every employee in the

safe operation and servicing of all equipment with which the employee is, or will be involved.”

(Federal Occupational Safety & Health Standards for Agriculture. Sub p art D, Section 19287.57

(a) (6).

B. As a requirement of OSHA, it is necessary for the employer to train the employee in the safe operat-

ing and safety procedures for this auger. W e included this sign-off sheet for your convenience and

personal record keeping. All unqualified people are to st ay out of the work area at all times. It is

strongly recommended that another qualified person who knows the shutdown procedure is in the

area in the event of an emergency . A person who has not read this manual and understands all

operating and safety instructions, is not qualified to operate the machine.

Date Em p loyees Signature

Em

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

ees Nam e (printed

PNEG-720-G2 12" & 16" Series II Sweep

15

Page 16

General Product Information

1. PRODUCT INFORMATION

Attention! This Series 2 Sweep is a single pass sweep. Consult the manufacturer of

your storage tank regarding the requirements or restrictions of the sweeping process.

The manufacturer may require a multiple pass sweep.

A. The Series 2 Sweep includes the following components:

- control panel

- two (2) motors

- motor covers

- motor mount

- auger flighting

- auger backshield assembly

- jack supports

B. The unit will operate only in a round grain bin equipped with a center sump in the bin floor.

NEVER enter a grain bin unless ALL power driven equipment has been shut down.

Disconnect and lockout power before entering the bin or servicing the equipment.

2. GENERAL INFORMATION.

A. GSI reserves the right to improve its product whenever possible and practical to do so. We reserve

the right to change, improve and modify products at any time without obligation to make changes,

improvements and modifications on equipment sold previously.

B. This new bin sweep auger has been engineered and manufactured to give years of dependable

service. The care and maintenance of this equipment will affect the satisfaction and service obtained. By following the instructions and suggestions recommended, the owner should receive

quality service for many years. If additional information or assistance should be required, please

contact GSI.

C. It is important to check both the quantity of parts and their descriptions with the packing list enclosed

within each package. All claims for freight damage or shortage must be made by the consignee

within ten (10) days from the date of the occurrence of freight damage. The consignee should

accept the shipment after noting the damage or loss.

16 12" & 16" Series II Sweep PNEG-720-G2

Page 17

General Product Information

2. GENERAL INFORMATION (CONT. )

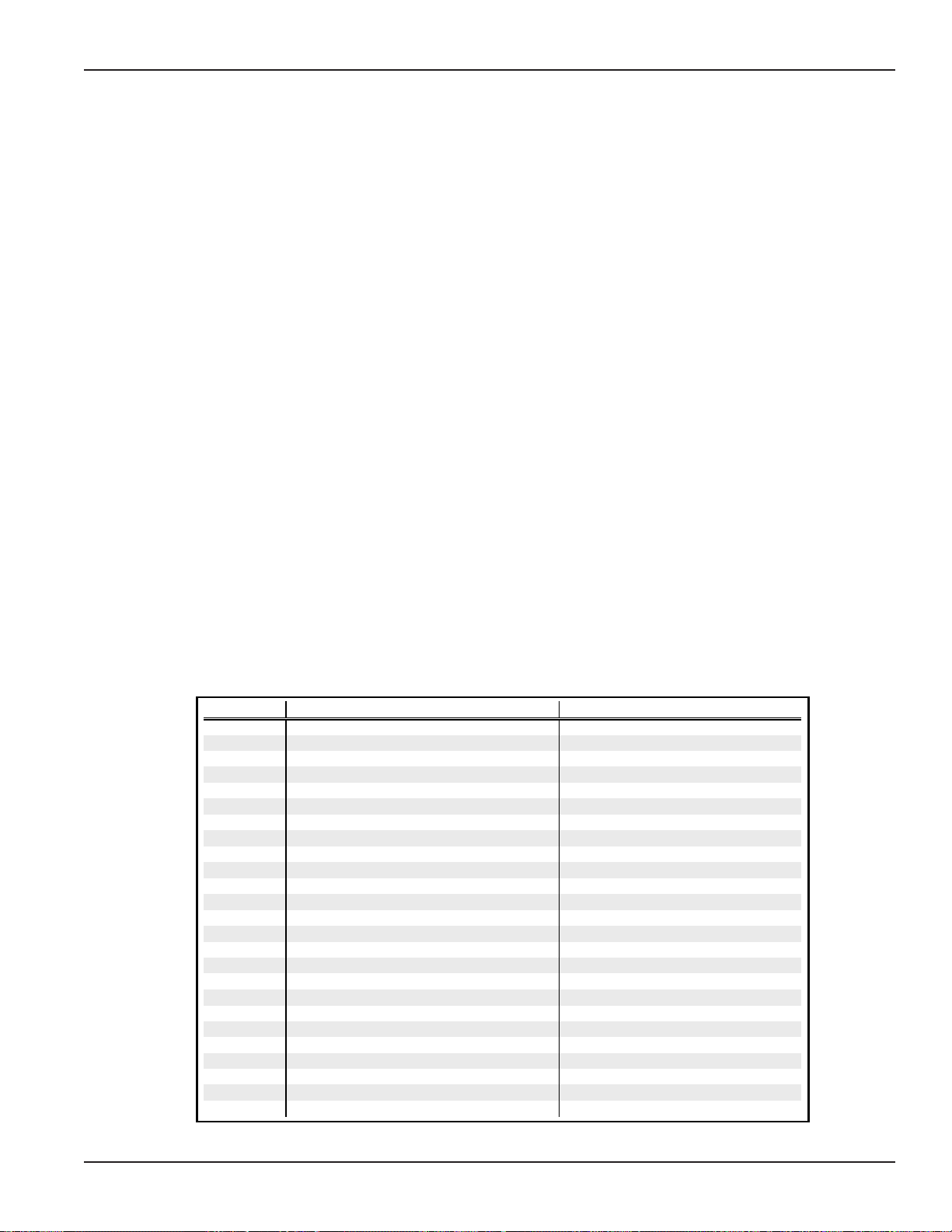

D. The chart below shows radius dimensions locating the points of contact between the sweep and

the bin floor . The dimensions may be used to figure material quantities of track to support the

sweep across the aeration flooring. The track material is not supplied with the sweep and must be

supplied by the installer. The dimensions are approximate and the assembled sweep should be

checked for exact point of contact.

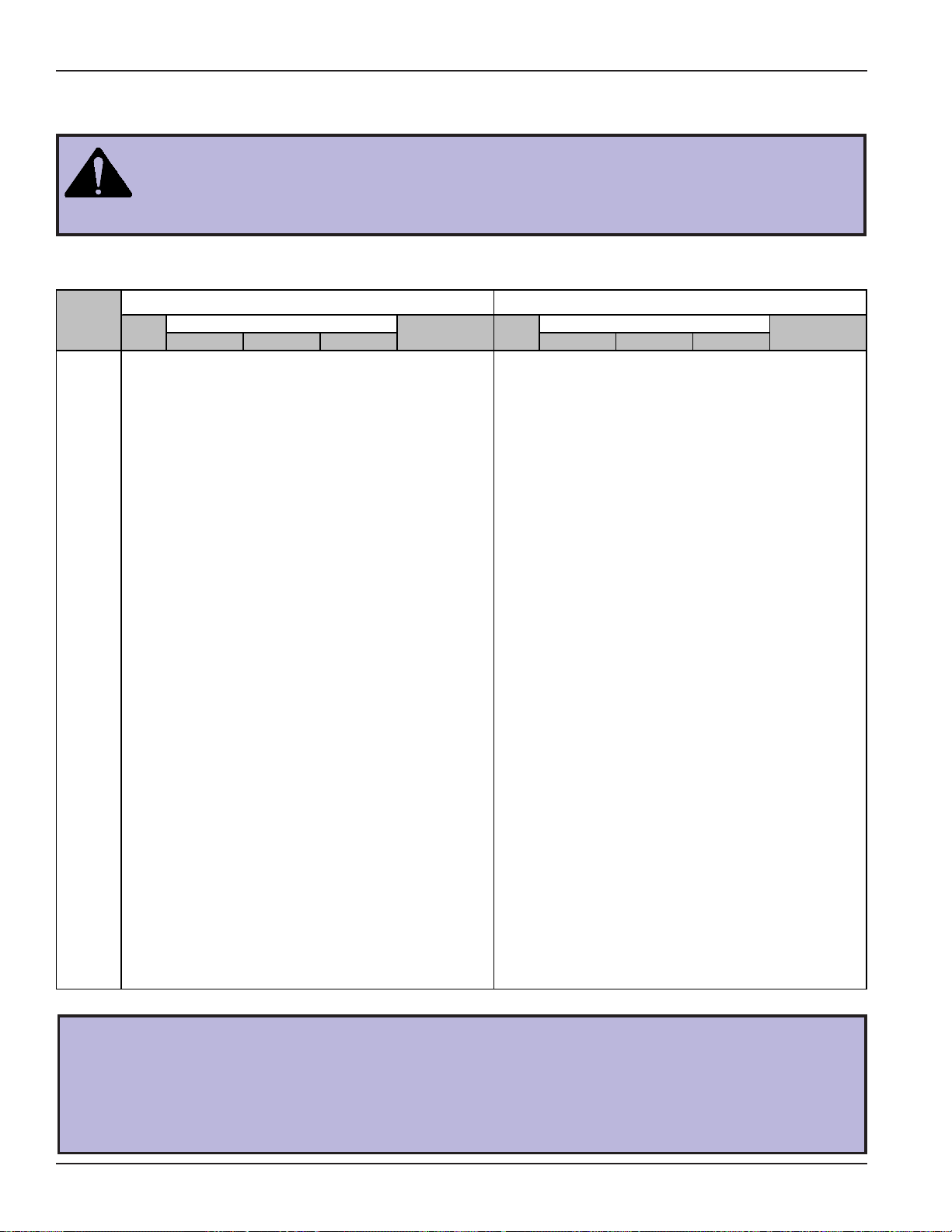

RADIUS DIMENSIONS

Bin Inside Outside End Caster

Dia. Sections Head Inte rm ediate Intermediate Tire Tire 16" Only Extension

36' 2 36'' 109'' 139'' 198''

37' 2 44'' 121'' 151'' 210''

39' 2 52'' 133'' 163'' 222''

40' 2 52'' 133'' 163'' 222''

42' 2 60'' 145'' 175'' 234''

43' 2 64'' 157'' 187'' 246''

45' 2 64'' 157'' 187'' 246''

48' 2 84'' 181'' 211'' 270''

49' 2 84'' 181'' 211'' 270''

51' 2 92'' 193'' 223'' 282''

54' 3 64'' 144'' 217'' 247'' 306''

55' 3 64'' 144'' 217'' 247'' 306''

57' 3 76'' 156'' 229'' 259'' 318''

59' 3 84'' 168'' 241'' 271'' 330''

60' 3 92'' 180'' 253'' 283'' 342''

62' 3 92'' 188'' 265'' 295'' 354''

63' 3 92'' 188'' 265'' 295'' 354''

66' 3 92'' 204'' 289'' 319'' 378''

68' 3 92'' 212'' 301'' 331'' 390''

69' 3 92'' 212'' 301'' 331'' 390''

72' 3 92'' 228'' 325'' 355'' 414''

75' 3 92'' 236'' 337'' 367'' 426''

78' 4 92'' 212'' 288'' 361'' 391'' 450''

80' 4 92'' 220'' 300'' 373'' 403'' 462''

81' 4 92'' 220'' 300'' 373'' 403'' 462''

84' 4 92'' 236'' 324'' 397'' 427'' 486''

87' 4 92'' 236'' 332'' 409'' 439'' 498''

88' 4 92'' 236'' 340'' 421'' 451'' 510''

90' 4 92'' 236'' 348'' 433'' 463'' 522''

91' 4 92'' 236'' 348'' 433'' 463'' 522''

92' 4 92'' 236'' 356'' 445'' 475'' 534''

95' 4 92'' 236'' 364'' 457'' 487'' 546''

98' 4 92'' 236'' 380'' 481'' 511'' 570''

105' 5 92'' 236'' 372'' 469'' 499'' 608''

113' 5 92'' 236'' 380'' 481'' 511'' 656''

120' 5 92'' 236'' 380'' 481'' 511'' 704''

PNEG-720-G2 12" & 16" Series II Sweep

17

Page 18

General Product Information

3. CAPACITIES AND SPECIFICATIONS

Electrical controls and wiring should be installed by a qualified electrician. The motor

disconnect switches and conductor cables should comply with the National Electrical

code and any local codes which apply. Reset and motor starting stations should be

located so the operator can see that all personnel are clear of the equipment.

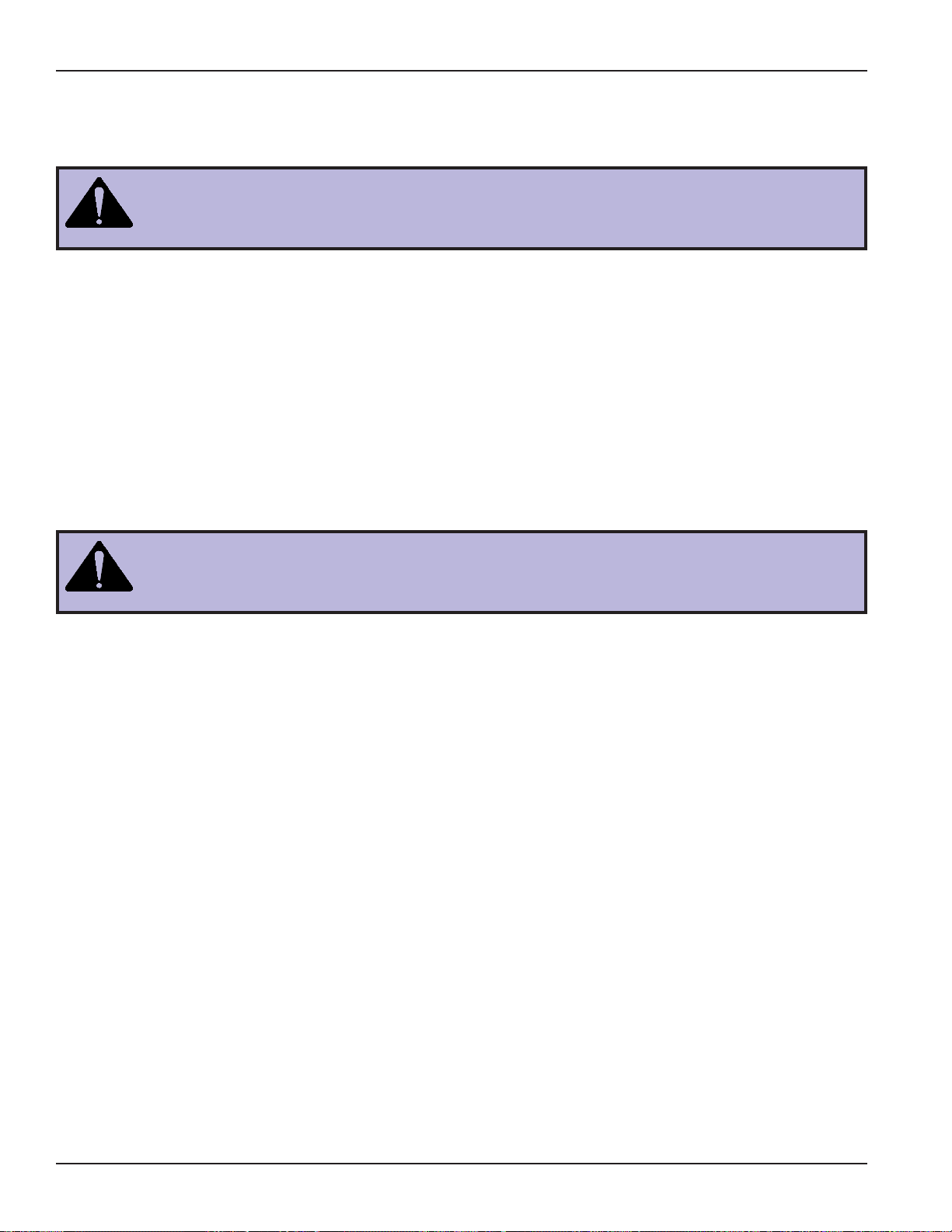

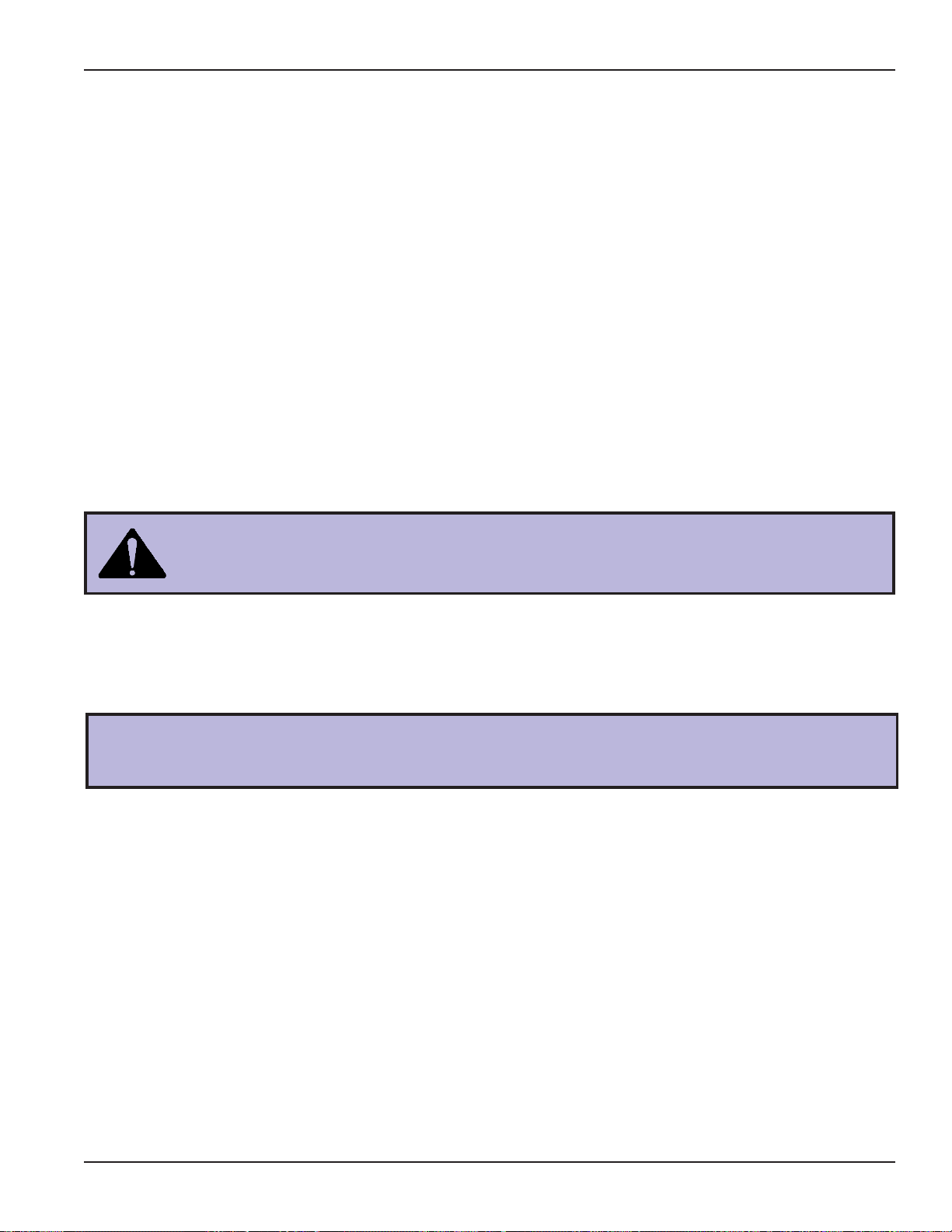

A. Use the chart below to determine the horsepower required.

12" SERI ES I I SWEEP 16" SERI ES I I SWE EP

Bin Drive Length Drive Length

Diameter H.P. 5000/125 6000/155 7000/180 Pivo t to End H.P. 8000/205 9000/230 10000/255 Pivot to End

36' 1 7.5 7.5 7.5 16.79' (5.12m) 2 7.5 7.5 7.5 16.85' (5.14m)

37' 1 7.5 7.5 7.5 17.79' (5.43m) 2 7.5 7.5 7.5 16.85' (5.14m)

39' 1 7.5 7.5 7.5 18.79' (5.73m) 2 7.5 7.5 7.5 17.85' (5.44m)

40' 1 7.5 7.5 7.5 18.79' (5.73m) 2 7.5 7.5 7.5 18.75' (5.72m)

42' 1 7.5 7.5 7.5 19.79' (6.04m) 2 7.5 7.5 10 19.85' (6.05m)

43' 1 7.5 7.5 7.5 20.79' (6.34m) 2 7.5 7.5 10 19.85' (6.05m)

45' 1 7.5 7.5 7.5 20.79' (6.34m) 2 7.5 7.5 10 20.85' (6.36m)

48' 1 7.5 7.5 7.5 22.79' (6.95m) 2 7.5 10 10 22.85' (6.96m)

49' 1 7.5 7.5 7.5 22.79' (6.95m) 2 7.5 10 10 22.85' (6.96m)

51' 1 7.5 7.5 10 23.79' (7.26m) 2 7.5 10 10 23.85' (7.27m)

54' 1 7.5 7.5 10 25.79' (7.86m) 2 10 10 10 25.85' (7.88m)

55' 1 7.5 7.5 10 25.79' (7.86m) 2 10 10 10 25.85' (7.88m)

57' 1 7.5 7.5 10 26.79' (8.17m) 2 10 10 10 26.85' (8.18m)

59' 1 7.5 7.5 10 27.79' (8.47m) 2 10 10 15 27.85' (8.49m)

60' 1 7.5 7.5 10 28.79' (8.78m) 2 10 10 15 28.85' (8.79m)

62' 2 7.5 7.5 10 29.79' (9.08m) 2 10 10 15 29.85' (9.10m)

63' 2 7.5 7.5 10 29.79' (9.08m) 2 10 10 15 29.85' (9.10m)

66' 2 7.5 7.5 10 31.79' (9.69m) 2 10 15 15 31.85' (9.71m)

68' 2 7.5 7.5 10 32.79' (10.00m) 2 10 15 15 32. 85' (10.01m)

69' 2 7.5 7.5 10 32.79' (10.00m) 2 10 15 15 32. 85' (10.01m)

72' 2 7.5 7.5 10 34.79' (10.61m) 2 15 15 15 34. 85' (10.62m)

75' 2 10 10 10 35.79' (10.91m) 2 15 15 15 35.85' (10.93m)

78' 2 10 10 10 37.79' (11.52m) 2 15 15 15 37.85' (11.54m)

80' 2 10 10 10 38.79' (11.83m) 2 15 15 15 38.85' (11.84m)

81' 2 10 10 10 38.79' (11.83m) 2 15 15 15 38.85' (11.84m)

84' 2 10 10 15 40.79' (12.44m) 2 15 15 15 40.85' (12.45m)

87' 2 10 10 15 41.79' (12.74m) 2 15 15 20 41.85' (12.76m)

88' 2 10 10 15 42.79' (13.05m) 2 15 15 20 42.85' (13.06m)

90' 2 10 10 15 43.79' (13.35m) 2 15 15 20 43.85' (13.37m)

91' 2 10 10 15 43.79' (13.35m) 2 15 15 20 43.85' (13.37m)

92' 2 10 10 15 44.79' (13.66m) 2 15 20 20 44.85' (13.67m)

95' 2 10 15 15 45.79' (13.97m) 2 15 20 20 45.85' (13.98m)

98' 2 10 15 15 47.79' (14.57m) 2 15 20 20 47.85' (14.58m)

105' 3 15 15 20 50.79' (15.48m) 3 20 20 20 50.85' (15.50m)

113' 3 15 15 20 54.79' (16.70m) 3 20 20 20 54.85' (16.72m)

120' 3 15 15 20 58.79' (17.92m) 3 20 20 20 58.85' (17.94m)

Due to continual improvements, GSI designs and specifications are subject to change without notice.

Bushel/MT Per Hour H orsepower Bushel/MT Per H our Horsepower

The horsepower recommendations are for augering reasonably dry grain. High moisture

grain (greater than 15%) will require greater power for maximum capacity. The maximum

capacity will be less with high moisture grain than with dry grain.

ALSO NOTE: Sweep drive and carrier wheels require plates or track over aeration flooring for travel and supports not supplied with the sweep unit. Contact your installer or

flooring provider for possible source and details.

18 12" & 16" Series II Sweep PNEG-720-G2

Page 19

General Product Information

3. CAPACITIES AND SPECIFICATIONS (CONT.)

B. A magnetic starter should be used to protect the motor when starting and stopping. It should stop

the motor in case of power interruption, conductor fault, low voltage, circuit interruption or motor

over load. The motor must be restarted manually. Some motors have built-in thermal overload

protection. If this is the type of motor being used, use only those with a manual reset.

C. The motor starting controls must be located outside the bin. They must NEVER be installed on the

Series II auger inside the bin.

D. Disconnect and lockout the power before resetting motor overloads.

E. Disconnect and lockout the power before entering the bin.

F. Disconnect and lockout the power before servicing the equipment.

G. Position the reset and motor starting controls so that the operators have full view of the equipment

There should ALWAYS be two (2) people in the work area.

H. Make sure electric motors are grounded.

A main power disconnect switch capable of being locked only in the OFF position should

be used. It should be locked whenever work is being done on the Series II Sweep.

PNEG-720-G2 12" & 16" Series II Sweep

19

Page 20

Assembly

1. BACK SHIELD ASSEMBLY

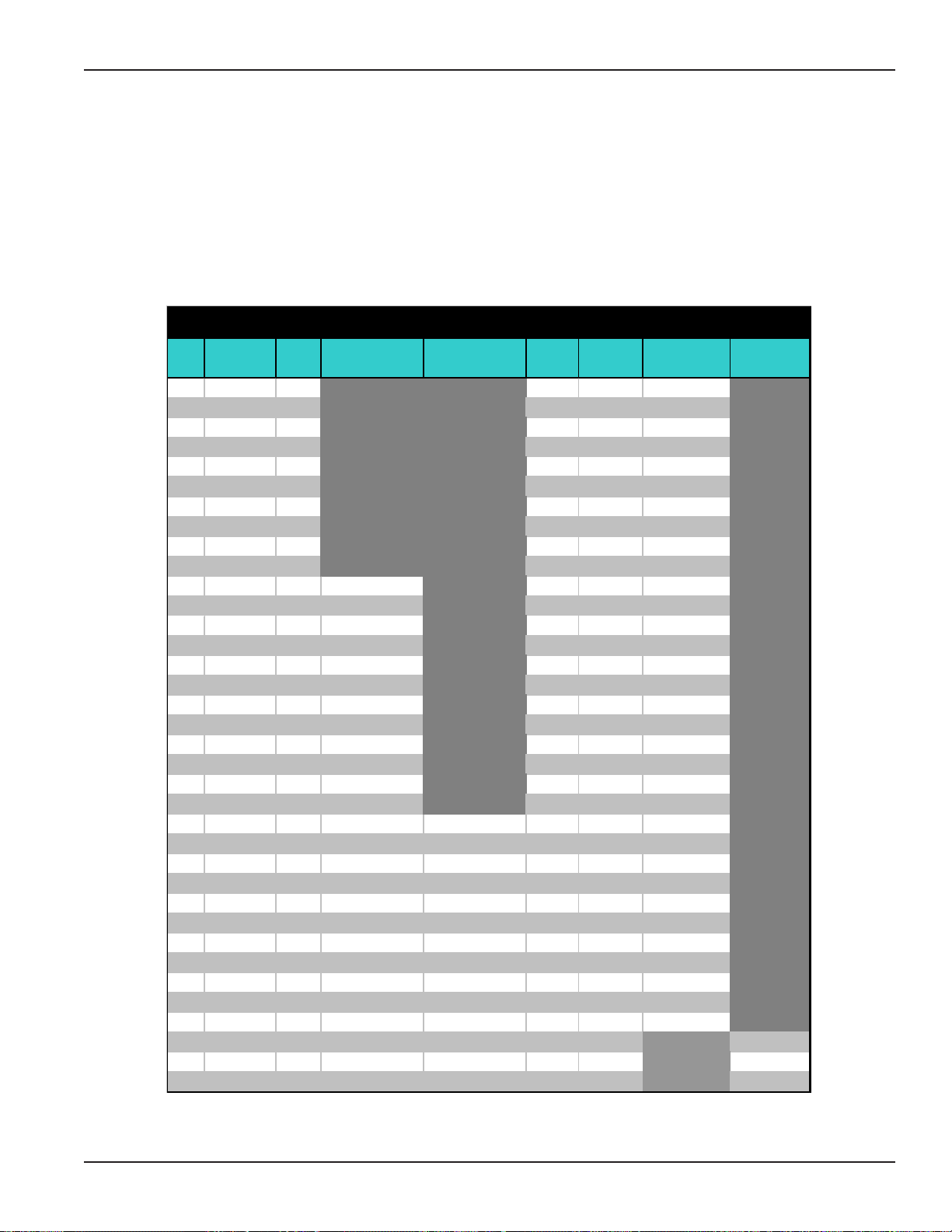

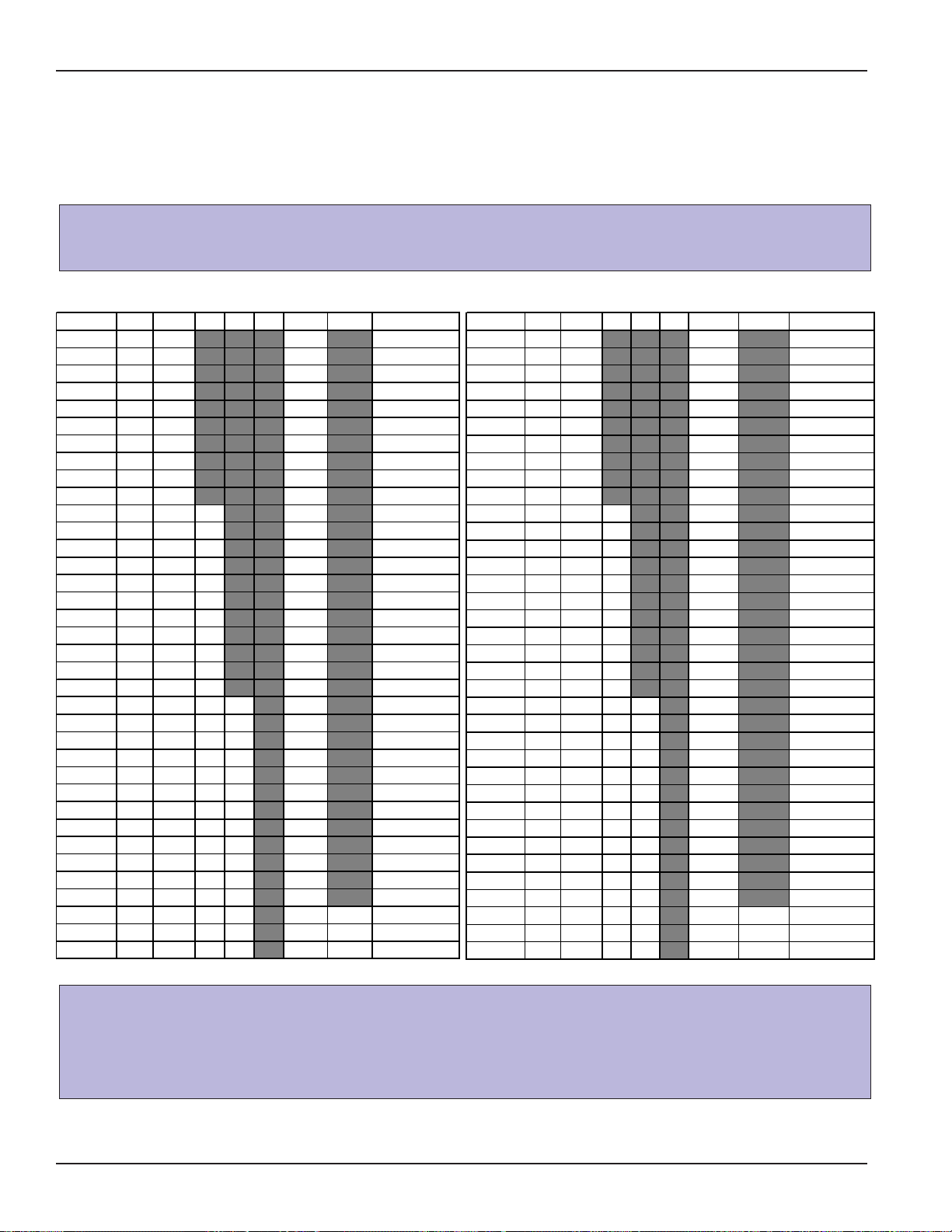

A. The sweep has been broken down into four(4) different section types. The head section,

intermediate section, tail, and extension section.

Use the charts below to determine the number of sections and the section sizes

required for the length of sweep to be used.

12" Series II Sweep Sections

Bin Dia. Sec. Head Int. Int. Int. Tail Ex t. Pivot to End

36' 2 52 149.5 16.79'

37' 2 64 149.5 17.79'

39' 2 76 149.5 18.79'

40' 2 76 149.5 18.79'

42' 2 88 149.5 19.79'

43' 2 100 149.5 20.79'

45' 2 100 149.5 20.79'

48' 2 124 149.5 22.79'

49' 2 124 149.5 22.79'

51' 2 136 149.5 23.79'

54' 3 100 60 149.5 25.79'

55' 3 100 60 149.5 25.79'

57' 3 112 60 149.5 26.79'

59' 3 124 60 149.5 27.79'

60' 3 136 60 149.5 28.79'

62' 3 136 72 149.5 29.79'

63' 3 136 72 149.5 29.79'

66' 3 136 96 149.5 31.79'

68' 3 136 108 149.5 32.79'

69' 3 136 108 149.5 32.79'

72' 3 136 132 149.5 34.79'

75' 4 136 144 60 149.5 40.79'

78' 4 136 108 60 149.5 37.79'

80' 4 136 120 60 149.5 38.79'

81' 4 136 120 60 149.5 38.79'

84' 4 136 144 60 149.5 40.79'

87' 4 136 144 72 149.5 41.79'

88' 4 136 144 84 149.5 42.79'

90' 4 136 144 96 149.5 43.79'

91' 4 136 144 96 149.5 43.79'

92' 4 136 144 108 149.5 44.79'

95' 4 136 144 120 149.5 45.79'

98' 4 136 144 144 149.5 47.79'

105' 5 136 144 132 144 53.5 50.79'

113' 5 136 144 144 144 89.5 54.79'

120' 5 136 144 144 144 137.5 58.79'

16" Series II Sweep Sections

Bin Dia . S ec. Head Int. Int. In t. Tai l Ext. P ivot to End

36' 2 52 150.25 16.85'

37' 2 52 150.25 16.85'

39' 2 64 150.25 17.85'

40' 2 76 150.25 18.85'

42' 2 88 150.25 19.85'

43' 2 88 150.25 19.85'

45' 2 100 150.25 20.85'

48' 2 124 150.25 22.85'

49' 2 124 150.25 22.85'

51' 2 136 150.25 23.85'

54' 3 100 60 150.25 25.85'

55' 3 100 60 150.25 25.85'

57' 3 112 60 150.25 26.85'

59' 3 124 60 150.25 27.85'

60' 3 136 60 150.25 28.85'

62' 3 136 72 150.25 29.85'

63' 3 136 72 150.25 29.85'

66' 3 136 96 150.25 31.85'

68' 3 136 108 150.25 32.85'

69' 3 136 108 150.25 32.85'

72' 3 136 132 150.25 34.85'

75' 4 136 144 60 150.25 40.85'

78' 4 136 108 60 150.25 37.85'

80' 4 136 120 60 150.25 38.85'

81' 4 136 120 60 150.25 38.85'

84' 4 136 144 60 150.25 40.85'

87' 4 136 144 72 150.25 41.85'

88' 4 136 144 84 150.25 42.85'

90' 4 136 144 96 150.25 43.85'

91' 4 136 144 96 150.25 43.85'

92' 4 136 144 108 150.25 44.85'

95' 4 136 144 120 150.25 45.85'

98' 4 136 144 144 150.25 47.85'

105' 5 136 144 132 144 54.25 50.85'

113' 5 136 144 144 144 90.25 54.85'

120' 5 136 144 144 144 138.25 58.85'

The section sizes are total length given in inches. The head section has 8" sub-

tracted from the shield length due to the pivot pipe location.

The 12" tail section has 5-1/2" added to the shield length due to the end shaft length.

The 16" tail section has 6-1/4" added to the shield length due to the end shaft length.

20 12" & 16" Series II Sweep PNEG-720-G2

Page 21

Assembly

1. BACK SHIELD ASSEMBLY (CONT.)

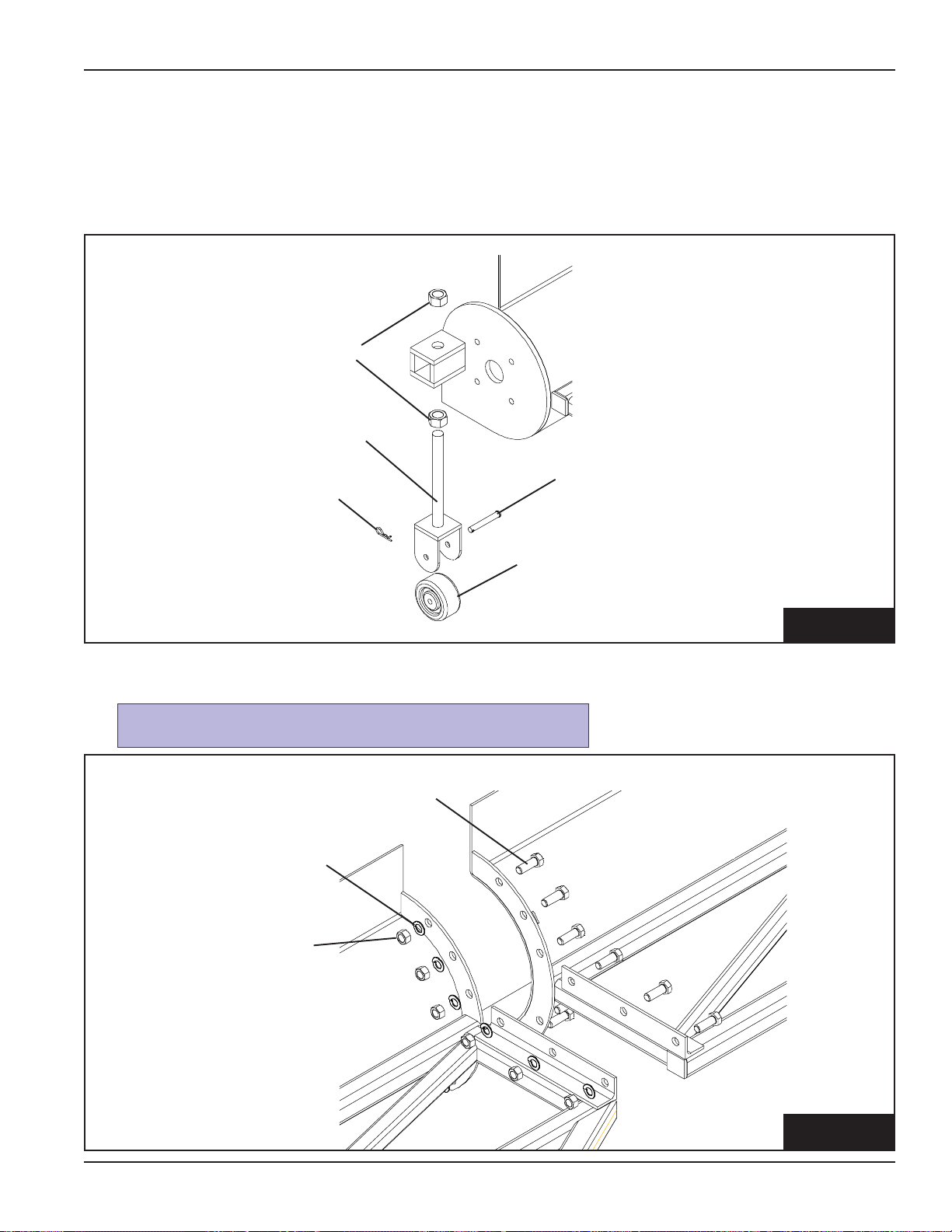

B. (All 16" Models and 12" Models with extensions) Assemble the caster assembly using the

1/2" x 3-1/2" clevis pin and 1/8" pin clip.

C. Attach the end caster assembly to the end of the tail section using two (2) 1"-8 hex nuts.

1"-8 hex nut

end caster assembly

1/2" x 3-1/2" clevis pin

1/8" pin clip

end caster

FIG. 1-C

D. Use eight (8) 5/8"-11 x 1-3/4" grade 8 hex bolts, lock washers, and hex nuts at each section connection.

The bolts MUST be inst alled as shown below.

5/8"-11 x 1-3/4" hex bolt

5/8" lockwasher

5/8"-11 hex nut

PNEG-720-G2 12" & 16" Series II Sweep

FIG. 1-D

21

Page 22

Assembly

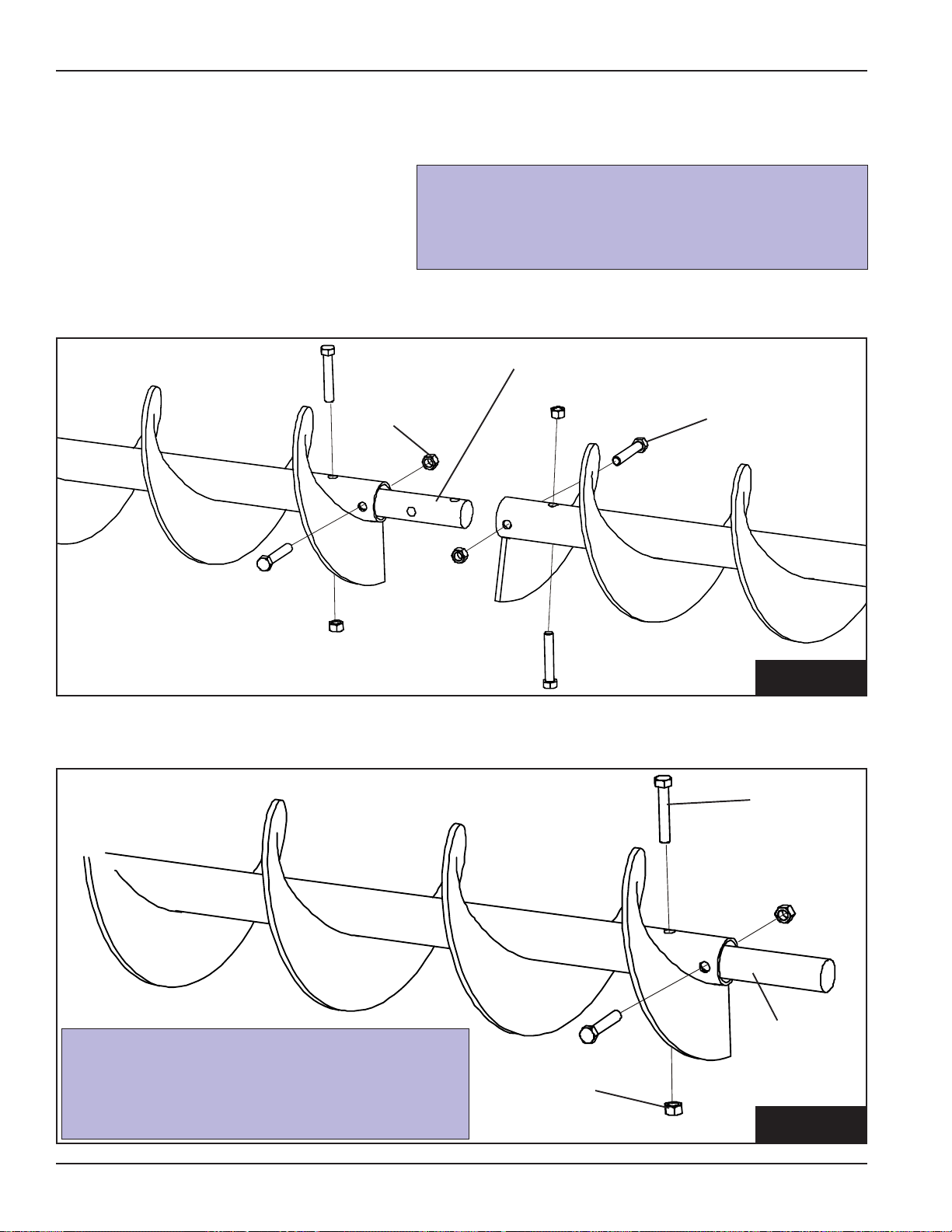

2. FLIGHTING ASSEMBLY

A. Layout the flight sections in order of

assembly starting with the head flight

working towards the tail flight.

B. Using the connecting stubs, bolt the

flight sections together with hex bolts

and lock nuts. Make sure the flight ends

are in time with each other .

lock nut

12" 2" x 11 1/2" Connecting Stub

Four (4) 5/8"-11 x 3 1/2" Hex Bolts

16" 3" x 13" Connecting Stub

Four (4) 3/4"-10 x 5 1/2" Hex Bolts

connecting stub

hex bolt

FIG. 2-B

C. Slide the end stub through the bearing plate on the tail section and into the tail flight securing it with hex

bolts and lock nuts.

hex

bolt

end

12" 2" x 12" End Stub

Two (2) 5/8"-11 x 3-1/2" Hex Bolts

16" 3" x 14 7/8" End Stub

Two (2) 3/4"-10 x 5-1/2" Hex Bolts

lock nut

stub

FIG. 2-C

22 12" & 16" Series II Sweep PNEG-720-G2

Page 23

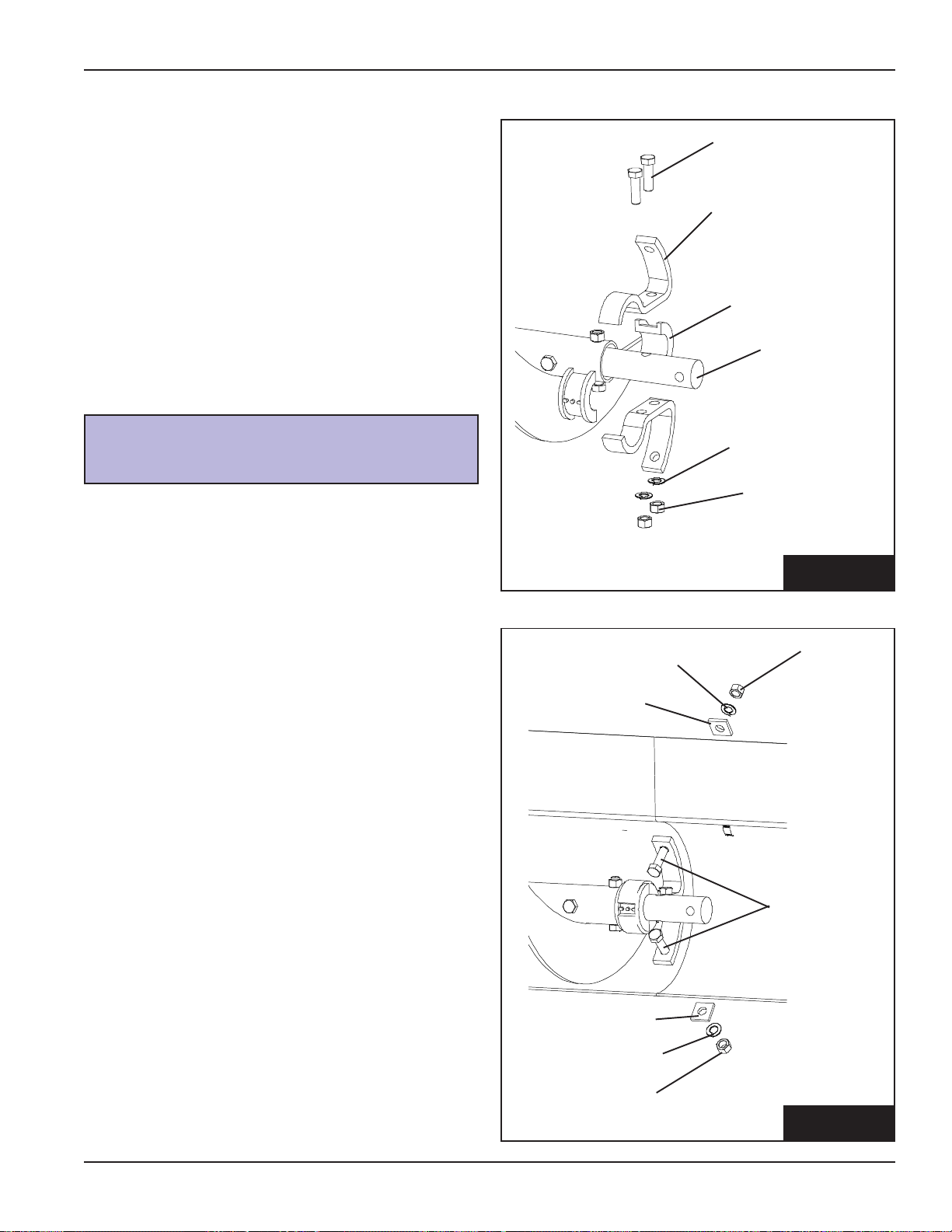

3. HANGER BRACKET ASSEMBLY

A. Bolt the nylon bearings and hanger brack-

ets to the connecting stubs using hex bolts,

lockwashers, and hex nuts.

12" Two (2) 5/8"-11 x 2" Hex Bolts

16" Two (2) 1/2"-13 x 2 1/4" Hex Bolts

Assembly

hex bolt

hanger bracket

nylon bearing

connecting

stub

lockwasher

hex nut

B. Bolt the hanger brackets to the back

shields using two (2) 5/8"-1 1 x 2"

hex bolts, two (2) square washers, two

(2) lockwashers, and two (2) hex nuts.

5/8" lockwasher

square washer

square washer

FIG. 3-A

5/8"-1 1

hex nut

5/8"-11x 2"

hex bolt

PNEG-720-G2 12" & 16" Series II Sweep

5/8" lockwasher

5/8"-11 hex nut

FIG. 3-B

23

Page 24

Assembly

4. FLANGE BEARING ASSEMBLY

A. Slide the flange bearing onto the end stub and bolt it to the end plate using hex bolts, lockwashers,

and hex nuts.

12" Sweep 2" Flange Bearing

16" Sweep 3" Flange Bearing

Do not tighten the set screws on the bearing at this time. This can be done after

the gear reducer is installed.

Caster assembly only used on all 16" sweeps & 12" sweeps with

extensions.

Four (4) 1/2"-13 x 2-1/2" Hex Bolts

Four (4) 3/4"-10 x 3-1/2" Hex Bolts

(16" Shown.)

lockwasher

hex nut

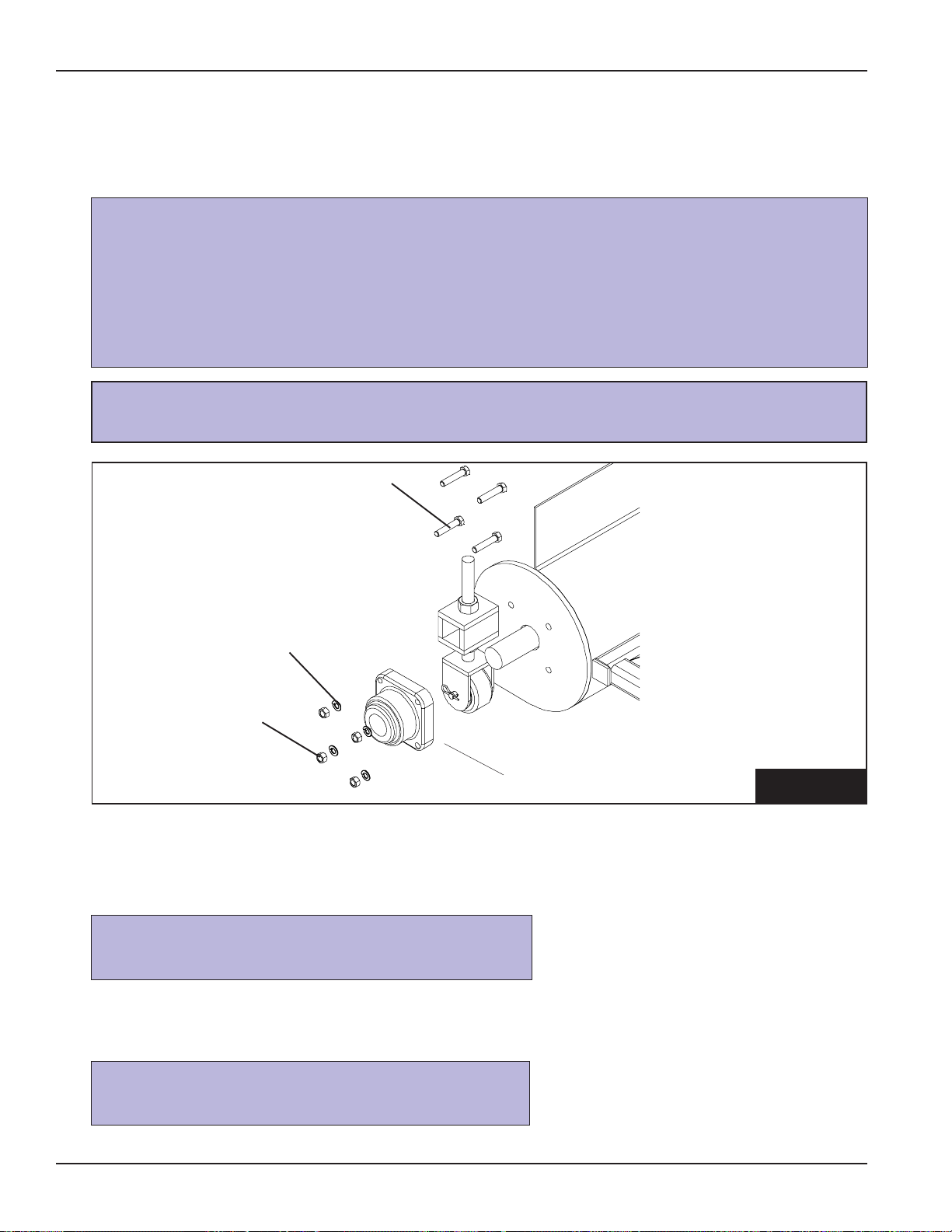

5. GEAR REDUCER ASSEMBLY

A. Slide the output shaft of the reducer through the end plate of the head section and into the end of

the head flight and secure it the shafts with hex bolts and lock nuts. (See Figure 5)

hex bolt

flange bearing

FIG. 4

B. Bolt the reducer to the end plate of the head section using hex bolts, flat washers, & lockwashers,

24 12" & 16" Series II Sweep PNEG-720-G2

12" Two (2) 5/8"-11 x 3-1/2" Hex Bolts

16" Two (2) 3/4"-10 x 5-1/2" Hex Bolts

supplied with the reducer . (See Figure 5)

12" Four (4) 5/8"-11 x 2-1/2" Hex Bolts

16" Four (4) 3/4"-10 x 2-3/4" Hex Bolts

Page 25

5. GEAR REDUCER ASSEMBLY (CONT.)

The input shaft of the reducer MUST be to

the top of the reducer. Refer to the owner's

manual supplied with the reducer for proper

vent plug, fill plug, and drain plug locations.

input

shaft

hex nut

Assembly

gear reducer

flat washers

FIG. 5

The gear reducer is NOT filled with oil from the factory . For gear reducer

specifications and oil fill recommendations, refer to the lubrication section of

this manual.

6. DRIVE AXLE ASSEMBLY & BEARING SUPPORT

A. Loosen set screws on bearings.

B. Replace standard grease zerks with 90°

grease zerks on both bearings. Make sure

the 90° grease zerk is turned as shown in Fig.

6-B, so the zerks are accessible from the

center of the tractor drive stand.

hex bolt

lock nut

hex bolt

Bearings

C. Slide the axle assembly between the legs of

the tractor drive stand as shown in Fig 6-C.

Bearing

90°

Grease

Zerk

PNEG-720-G2 12" & 16" Series II Sweep

FIG. 6-B

Axle Assembly

Tractor Drive

Stand Legs

FIG. 6-C

25

Page 26

Assembly

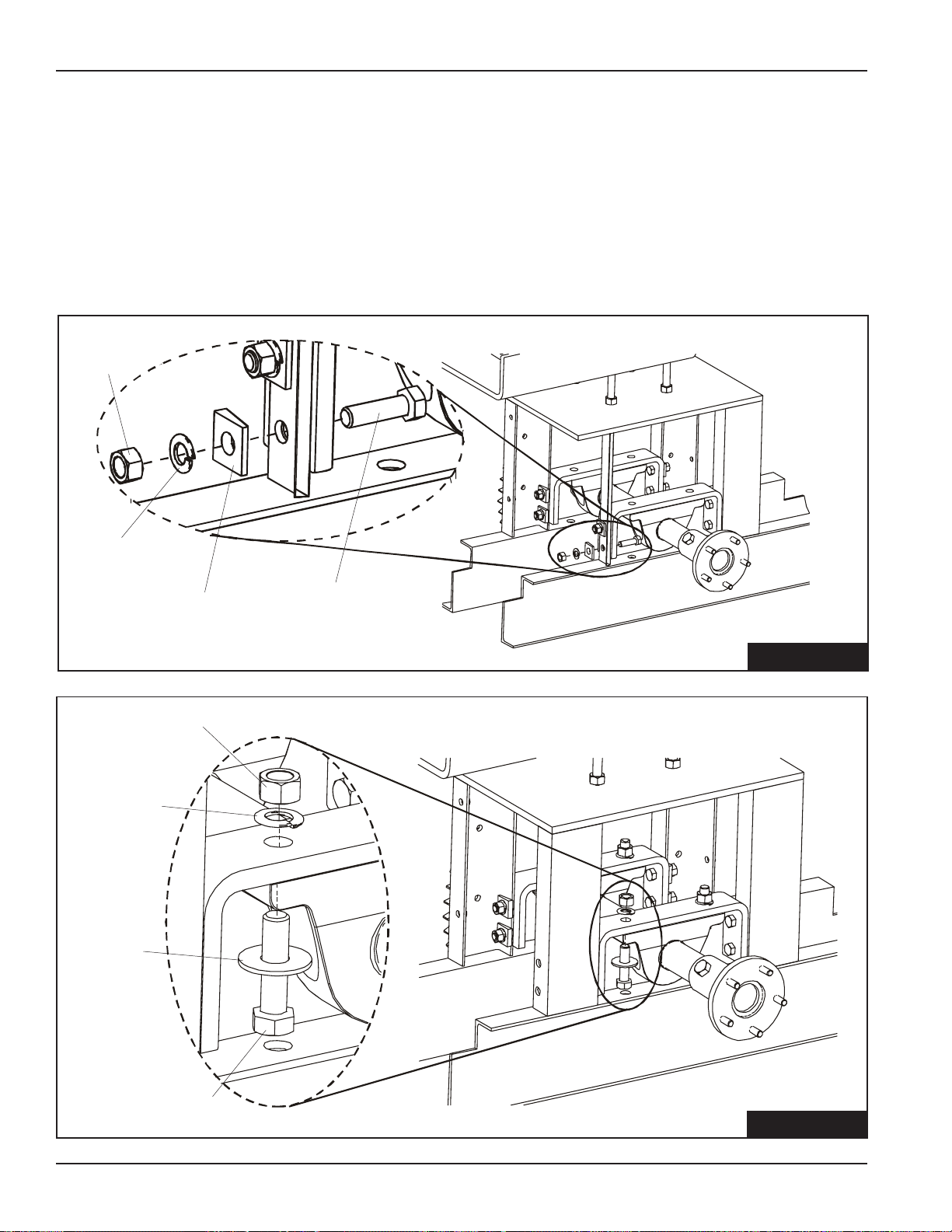

6. DRIVE AXLE ASSEMBLY & BEARING SUPPORT (CONT.)

D. Rotate the pillow block bearings until the bases

are facing up. (See Fig 6-C)

E. Bolt the bearing support brackets to the legs of

the tractor drive stand using ½" x 1 ¾" bolts,

½" lock washers, ½" bevel washers, and ½"

hex nuts. (See Fig. 6-E)

1/2" Hex

Nuts

1/2" Lock

Washers

1/2" Bevel

1/2" x 1-3/4" Bolts

Washers

F. Attach pillow block bearings to the bearing

brackets using 5/8" x 2 ½" bolts, 5/8" lock and

flat washers, and 5/8" hex nuts. (See Fig 6-F)

G. Tighten set screws on pillow block bearings.

H. Tighten all hardware.

5/8" Hex Nut

5/8" Lock

Washer

5/8" Flat

Washer

5/8" x 2-1/2" Bolt

FIG. 6-E

FIG. 6-F

26 12" & 16" Series II Sweep PNEG-720-G2

Page 27

Assembly

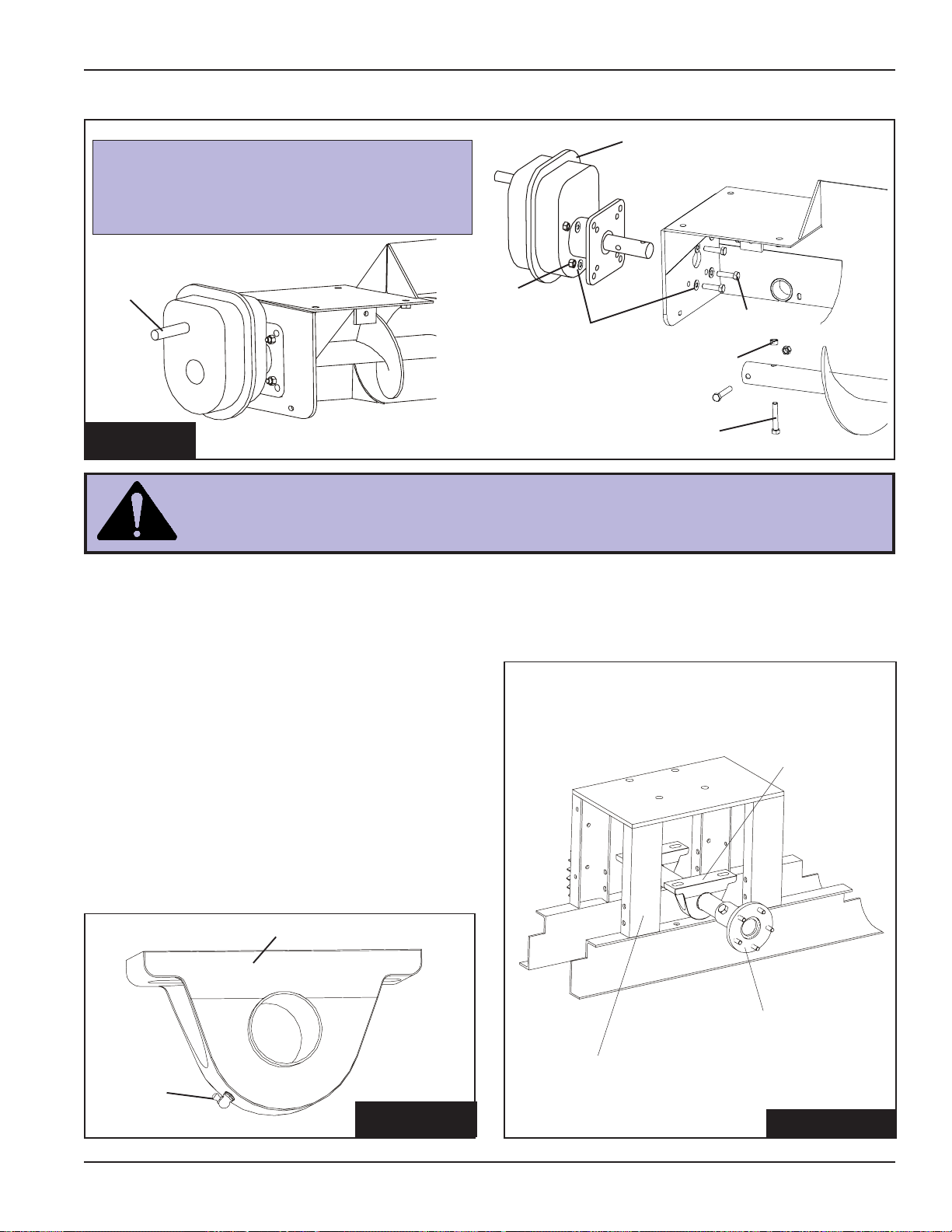

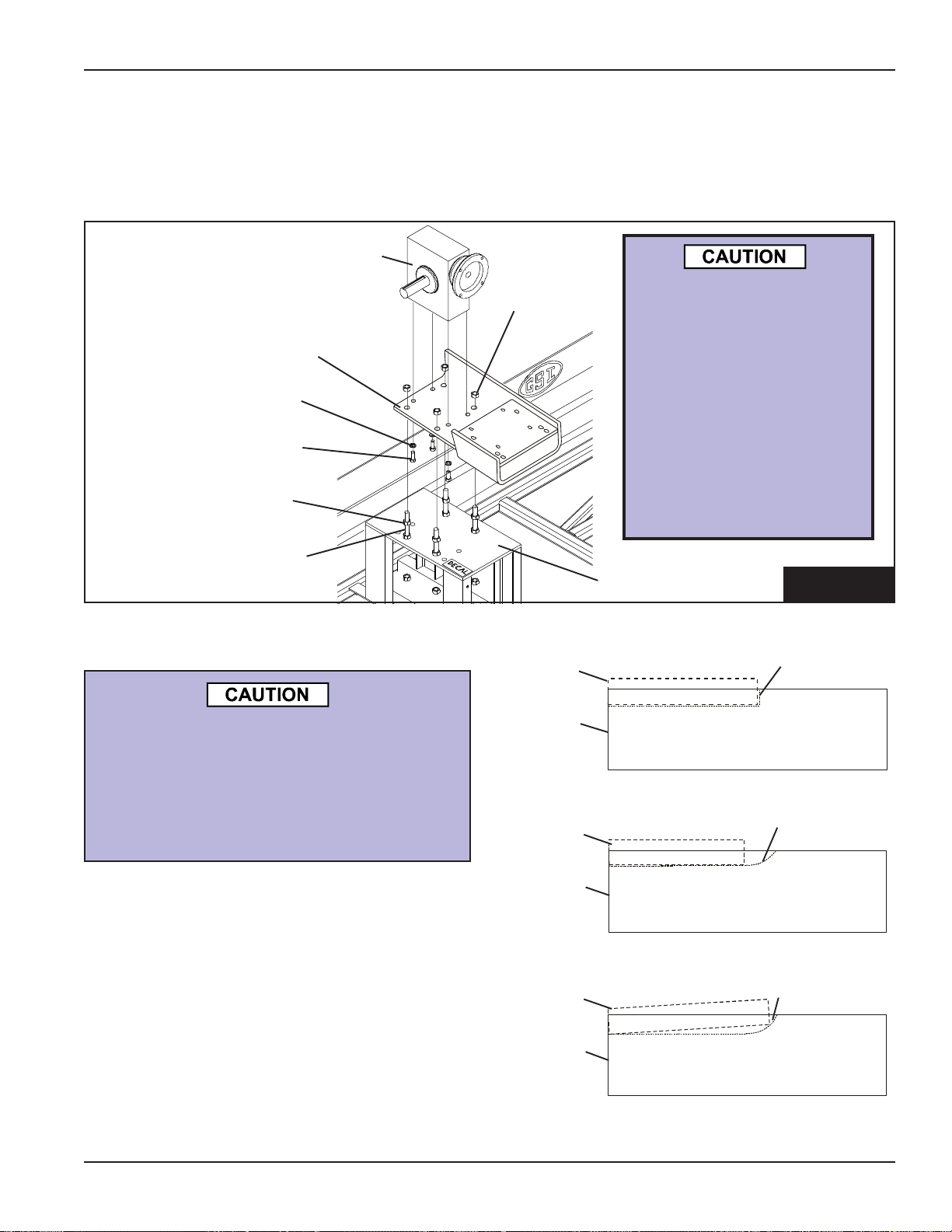

7. INSTALL REDUCER MOUNTING PLATE & REDUCER

A. Attach the C-Face reducer to the mounting plate using four (4) 1/2"-13 x 1-1/4" hex bolts and

lockwashers.

B. Fasten the mounting plate to the tail section plate using four (4) 5/8"-1 1 x 6" all-thread rods and

sixteen (16) hex nuts. Adjust the mounting plate as close as possible to the tail section plate.

C-Face Reducer

The gear reducer is NOT

hex nut

reducer

mounting plate

lockwasher

1/2"-13 x 1 1/4" hex bolt

hex nut

filled with oil from the

factory . For gear reducer specifications

and oil fill recommendations, refer to the owners manual supplied

with the reducer or the

lubrication information

in the maintenance

section of this manual.

5/8" x 6" all-thread rod

8-A. KEY ALIGNMENT

All keys should be parallel to the drive

shaft. If the key is not straight (parallel)

the gearbox quill sleave will crack.

THIS TYPE OF DAMAGE IS NOT

COVERED BY WARRANTY.

1. Place key in keyway on drive shaft.

2. Make sure key is flat (parallel to drive shaft) in

keyway as in Figure 8A-1 and 8A-2. NOT like

Figure 8A-3.

Key

Drive

Shaft

Key

Drive

Shaft

Key

tail section plate

FIG. 7

Keyway

FIGURE 8A-1

Key correctly positioned in a straight routed

keyway . (Profiled keyway)

Keyway

FIGURE 8A-2

Key correctly positioned in a scalloped

routed keyway. (Sled runner keyway)

Keyway

3. Line up keyway on shaft with keyway on reducer

and insert shaft into motor . (See Figure 8A-4 on

page 30.)

PNEG-720-G2 12" & 16" Series II Sweep

Drive

Shaft

FIGURE 8A-3

Key INCORRECTLY positioned in a

scalloped routed keyway. DO NOT install

key in this position.

27

Page 28

Assembly

Keyway on Reducer

Keyway on Drive Shaft

Key

FIGURE 8A-4

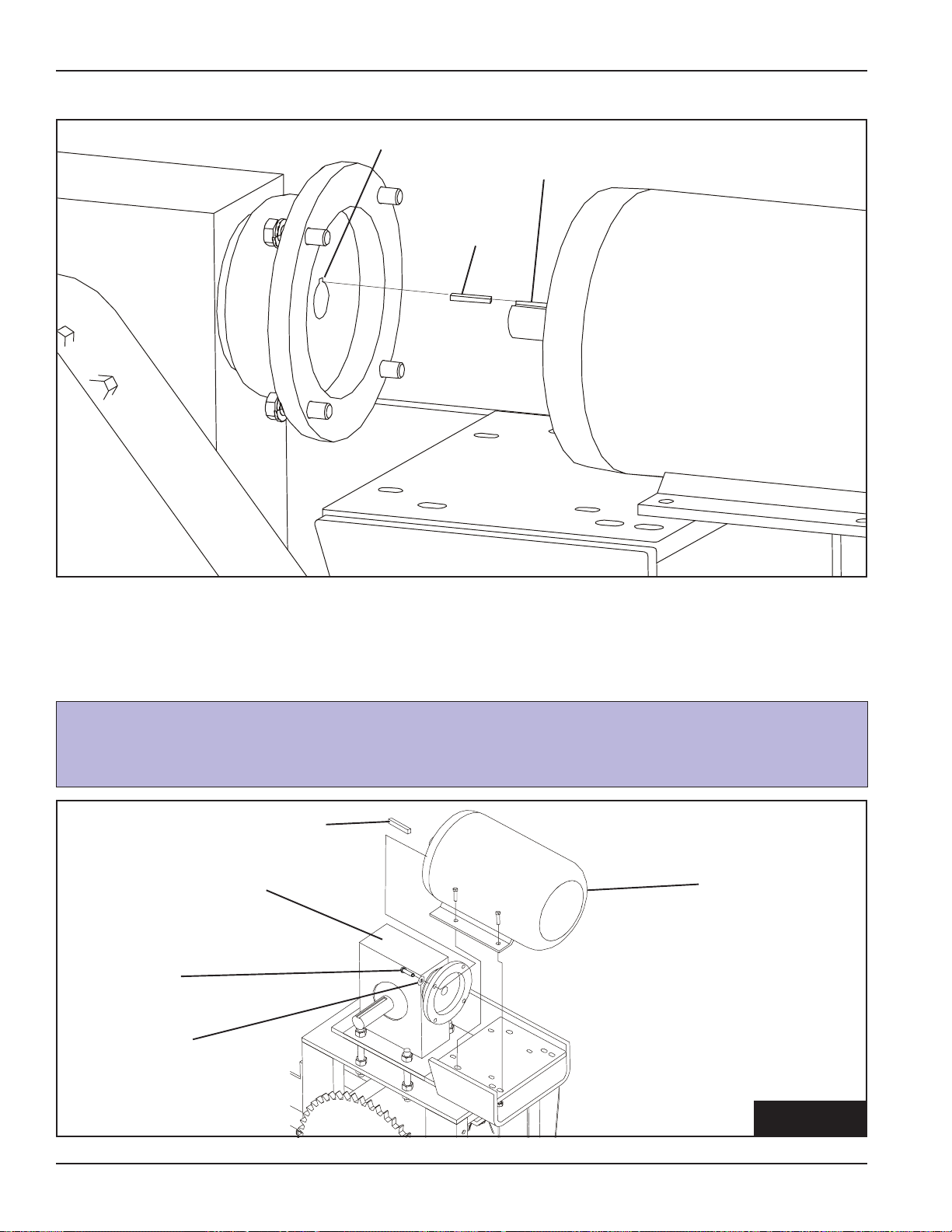

8-B. INSTALL TRACTOR DRIVE MOTOR

A. Bolt the C-Face motor to the reducer using hex bolt s, lockwashers, and a key .

(See note below for bolt size.)

56C Frame Four (4) 3/8"-16 x 1 1/4" Hex Bolts & 3/16" x 3/16" x 1" Key

143TC Frame Four (4) 3/8"-16 x 1 1/4" Hex Bolts & 3/16" x 3/16" x 1" Key

182TC Frame Four (4) 1/2"-13 x 1 1/4" Hex Bolts & 1/4" x 1/4" x 1" Key

key

C-Face Reducer

hex bolt

motor

lockwasher

FIG. 8-B

28 12" & 16" Series II Sweep PNEG-720-G2

Page 29

Assembly

9. GUARD ASSEMBLY

A. Slide the Chain Guard Top Seal (GC11978) over the Gear Reducer Output Shaf t before installing any

other components. Fig. TD1

Slide Seal on

Reducer Shaft

Before Installing

Upper Guard Plate

FIG. TD1

B. Attach the Guard Plate to the Tractor Drive Stand Legs using 3/8" bolts, lockwashers, and hex nuts

before attaching the Drive Sprocket (See Fig TD2)

C. Remove the Wheel Hub Assembly on the sprocket side only

Attach Guard Plate

to T ractor Drive

Stand Legs

Use 3/8"-16 Bolts, 3/8"-16 Lock

Washers and 3/8" Hex Nuts

Remove Wheel Hub

Assembly this Side Only

FIG. TD2

PNEG-1579 12" & 16" Series II Sweep Special

29

Page 30

Assembly

9. GUARD ASSEMBLY - (CONT.)

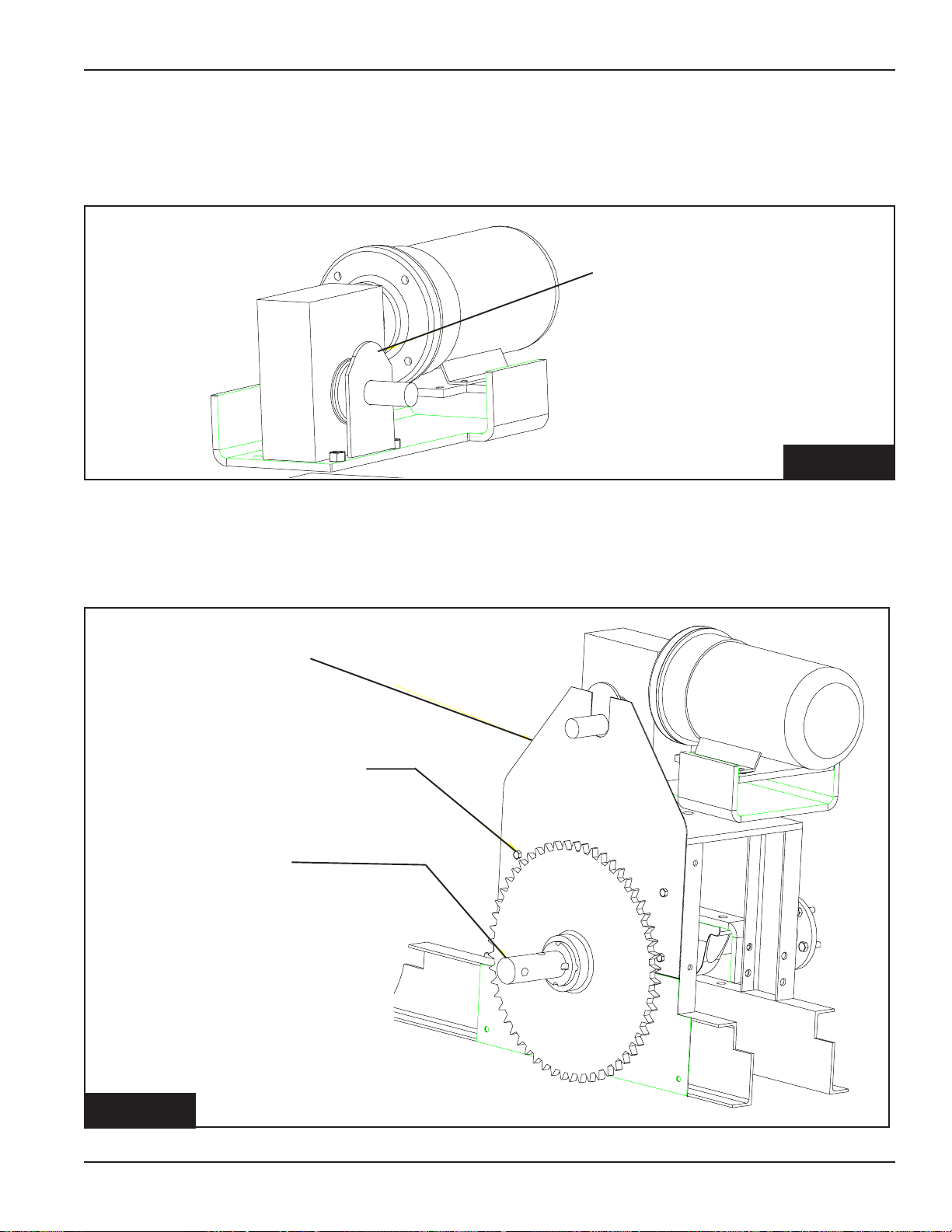

D. Slide the twelve tooth drive sprocket, bushing and key (see the key chart for your key size) onto the

output shaft of the reducer, making sure both sprockets line up. (See Fig TD3 & TD4)

Wedging forces in the bushing saw slot, such as that exerted by a narrow

edged regular screw driver, may damage or break the bushing. This damage

would not be covered under the GSI Warranty

Assemble 12 Tooth Sprocket,

Bushing and key to Gear Reducer

Output Shaft

To Assemble the Inner Lower Shaf t

Seal, this Sprocket and Bushing

May Have to be Loosened and

Moved Out of the Way

FIG. TD3

KEY CHART

1 HP - 5/16" x 2" Key

2 HP - 3/8" x 3-3/4" Key

3 HP - 3/8" x 3" Key

29-A

FIG. TD4

12" & 16" Series II Sweep Special PNEG-1579

Page 31

Assembly

9. GUARD ASSEMBLY - (CONT.)

E. Slide the Dust Seal Clips over the studs welded to the Guard Plate, capturing the Upper Shaft Seal.

F. Lock the Dust Seal Clips into position by tightening the 3/8 hex nuts.

Reducer not shown in this view. Removed for

Illustrational Purposes Only .

Slide Seal on Reducer Shaft

Before Installing Sprocket

Attach the Dust Seal Clips

with3/8 Hex Nuts

FIG. TD5

G. Attach the Inner Bottom Drive Shaf t Seal (GC11974) to the Guard Plate using 3/8-16 x 1 1/4" bolts, hex

nuts and flat washers. This seal is designed to fit tight around the Drive Axle Shaft. (See Figure TD6)

PNEG-1579 12" & 16" Series II Sweep Special

29-B

Page 32

Assembly

9. GUARD ASSEMBLY - (CONT.)

Attach the Inner

Bottom Drive Shaft

Seal to the Guard Plate

Use 3/8"-16 Bolts, Hex

Nuts, and Flat W ashers

for Attachment

FIG. TD6

G. Move the Bottom S procket back into position and lock in place. Make sure the sprockets are lined up

as in FIG TD4.

H. Install the Chain

Chain Tension-The chain should be installed fairly tight with only a small amount of slack. New chains

will loosen up slightly as the joints seat themselves, causing initial elongation. After the first operation, it

is advisable to tighten the chain.

I. Assemble the Bottom Chain Guard Trap to the Bottom Chain Guard Weldment using 1/2" x 3" HHCS

bolts, 1/2" split lock washers and 1/2" hex nuts

J. Attach the Bottom Chain Guard W eldment to the Tractor Drive St and using 3/8"-16 x 1 1/4" HHCS

bolts, 3/8" split lock washers and 3/8"-16 hex nuts.

29-C

12" & 16" Series II Sweep Special PNEG-1579

Page 33

9. GUARD ASSEMBLY - (CONT.)

Assembly

Bottom

Chain Guard

Weldment

1/2" x 3"

HHCS Bolt

Bottom Chain

FIG. TD7

K. Attach the Top Chain Guard (GC11984) to the T ractor Drive Stand using 3/8"-16 x 1" bolts, 3/8" split

lock washers and 3/8"-16 hex nuts.Attach the Top Chain Guard (GC1 1984) to the Tractor Drive Stand

using 3/8"-16 x 1" bolts, 3/8" split lock washers and 3/8"-16 hex nuts.

Guard Trap

3/8" x 1-1/4"

HHCS Bolt

1/2" Hex Nut

1/2" Split

Lock Washer

Top Chain Guard

Assembly (GC1 1984)

Bottom Chain Guard

Weldment (GC1 1991)

FIG. TD8

PNEG-1579 12" & 16" Series II Sweep Special

3/8"-16 x

1-1/4" bolt,

lock

washer,

and 3/8"

hex nut

29-D

Page 34

Assembly

9. GUARD ASSEMBLY - (CONT.)

L. Reinstall the Wheel Hub Assembly that was removed during step #C above. Leave the inner bolt out

until after the seals are put into place.

M. Slide the Inner Bottom Drive Shaft Seal (GC1 1986) halves over the studs welded to the Top Chain

Guard.

N. Slide the Outer Bottom Drive Shaft Seal (GC11985) halves over the studs welded to the Top Chain

Guard and on top of the Inner Bottom Drive Shaft Seal halves.

O. Lock the Bottom Drive Shaft Seals into position using 3/8" flat washers and 3/8"-16 hex nuts.

Install the Inner

Drive Shaft Seal

(Large Hole) First

Install the Outer

Drive Shaft Seal

(Smaller Hole)

on T op of the

Inner Seal

Lock into

position with

3/8" washers

and 3/8"-16

hex nuts

Reinstall wheel

hub assembly

FIG. TD9

29-E

12" & 16" Series II Sweep Special PNEG-1579

Page 35

NOTES

Assembly

PNEG-1579 12" & 16" Series II Sweep Special

29-F

Page 36

Assembly

10. TRACTOR WHEEL ASSEMBLY

A. Assemble the tires to the drive axle assembly using ten (10) 7/16" lockwashers, and hex nuts.

(See Fig 10)

NOTE: Tires go on backwards as shown.

Rotation

Direction

of Tires

7/16"

lockwashers

drive axle

7/16" hex nuts

FIG. 10

30 12" & 16" Series II Sweep PNEG-720-G2

Page 37

Assembly

11-A. COUNTER WEIGHT PLACEMENT

A. Place the equal number of counter weights each side of the drive assembly on the six inch (6")

channels that are welded to the tail section.

Caution! Use proper lifting procedures and equipment when lifting counter weights

(175 pounds each).

PNEG-720-G2 12" & 16" Series II Sweep

counter

weight

6" channels

FIG. 11-A

31

Page 38

Assembly

11-B. CHANNEL EXTENSION KIT FOR SWEEPS USED IN 72' DIA.

BINS & LARGER

A. 72' sweeps and larger need an extension kit installed.

B. Attach the center weight weldments to the adjustable center weight channel using eight (8) 1/2" x

1-1/4" bolts, split lockwashers, & hex nuts. The adjustable center weight has three sets of holes

for the center weight weldments so you can adjust the weights accordingly. (See Fig. 11-B1)

C. Place assembly on top of the back tail section, around the tires. The end of the adjustable center

weight should be placed under the tail frame. (See Fig. 11-B2)

D. Fasten assembly to tail section using two (2) 3/8" x 2-7/16" u-bolts, four (4) 3/8" lockwashers, &

four (4) 3/8" hex nuts.

T ail Frame

Center Weight

Weldment

Adjustable Center

Weight Channel

U-Bolts

FIG. 11-B1

Center Weight Weldment

U-Bolts

T ail Frame

32 12" & 16" Series II Sweep PNEG-720-G2

Adjustable Center

Weight Channel

FIG. 11-B2

Page 39

Assembly

12. MOTOR JACK AND BASE ASSEMBLY

A. Attach the Motor Mount Base Assembly to the Head Section using four (4) 3/4"x 2"bolts, lock washers

and hex nuts. (See Fig 12)

B. Attach the Motor Jack Assembly to the Motor Mount Base Assembly using four (4) 1/2"-13 x 1-1/2" bolts,

1/2" flat washers and 1/2" hex nuts.

1/2" x 1-1/2"

bolts

1/2" flat washer

1/2" hex nuts

Motor Jack

Assembly

Motor Mount

Base Assembly

3/4" x 2" bolts

Head Section

PNEG-720-G2 12" & 16" Series II Sweep

3/4" lock washer

3/4" hex nuts

FIG. 12

33

Page 40

Assembly

13. MOTOR INSTALLATION

A. Level the T op Plate Assembly by adjusting

the 1" nuts and washers on the adjustment

rods. (See Fig 13)

B. Line up the end face of the shafts as closely

as possible before bolting motor to mounting plate. (See Fig 13-A)

C. Fasten the motor to the motor mount using

hex bolts, lockwashers, and hex nuts.

(See Motor Bolt Chart for bolt sizes.)

Motor Bolt Chart

Mot or Size Hex Bolt Si ze Qt y.

213T 3/8"-16 x 1-1/ 4" 4

215T 3/8"-16 x 1-1/ 4" 4

254T 1/2"-13 x 1-3/ 4" 4

256T 1/2"-13 x 1-3/ 4" 4

284T 1/2"-13 x 1-3/ 4" 4

286T 1/2"-13 x 1-3/ 4" 4

Top Plate

Assembly

motor

motor bolt

(see chart

for size)

Line Up

Face of

Shafts

BEFORE

bolting

motor.

adjustment rod

1" hex nut

1" flat

washer

FIG. 13-A

FIG. 13

34 12" & 16" Series II Sweep PNEG-720-G2

Page 41

Assembly

13. MOTOR INSTALLATION - (CONT.)

D. Insert the upper belt guard seal (Slider) GC12024 into the track on the belt guard fill plate (GC12023.)

Insert Slider (GC12024) into

track on belt guard fill plate

assembly (GC12023)

FIG. 13D

E. Install the Slider/fill plate assembly over the motor shaft before mounting the motor

sheave and bushing.

The slider and the fill plate

assembly fit over motor

shaft as shown

FIG. 13E

PNEG-1579 12" & 16" Series II Sweep Special

34-A

Page 42

Assembly

NOTES

34-B

12" & 16" Series II Sweep Special PNEG-1579

Page 43

Assembly

14. SHEAVE INSTALLATION

Warning! To ensure that the drive is not unexpectedly started, turn off and

lock out or tag out the power source before proceeding. Failure to observe

these precautions could result in bodily injury .

A. Loosely bolt the bushing and large sheave together with the screws provided with the bushing.

B. Slide the bushing and large sheave onto the auger gear reducer input shaft with a key . (See Fig. 14-A)

Wedging forces in the bushing saw

slot, such as that exerted by a

narrow edged regular screw driver ,

may damage or break the bushing.

This damage would not be covered

under the GSI warranty .

key

bushing

large sheave

input shaft

FIG. 14-A

C. Loosely bolt the bushing and small sheave together with the screws provided with the bushing.

D. Slide the bushing and small sheave onto the motor shaft with a key. (See Fig. 14-B)

output shaft

key

bushing

small sheave

PNEG-720-G2 12" & 16" Series II Sweep

FIG. 14-B

35

Page 44

Assembly

14. SHEAVE INSTALLATION (cont.)

E. Align the sheaves with a straight edge to assure proper alignment and tighten the screws

on the bushings.

F. Carefully install the belts.

Adjust the all-thread nuts on the motor mount to attain correct belt tension while

making sure the motor mount is level on both rods. This will also affect sheave

alignment.

G. Assemble the bottom belt guard assembly. Attach the belt guard back plate assembly (GC12028) to

the belt guard bottom shell assembly (GC09764) using 3/8-16 x 1 HHCS and 3/8 lock washers.

Belt guard bottom

shell assembly

Bottom belt

guard bottom

plate

Bottom belt

guard back

plate assembly

36

FIG. 14G

12" & 16" Series II Sweep Special PNEG-1579

Page 45

Assembly

14. SHEAVE INSTALLATION (cont.)

H. Attach the bottom belt guard assembly to the motor mount frame with 3/8-16 x 1 HHCS, 3/8 flat

washers and 3/8 lock washers. Do not tighten the 3/8 HHCS as the assembly will be adjusted after

the top cover is attached.

Sheave, bushing

and belts not

shown for clarity

Loosely attach the

bottom belt guard

assembly to the

motor mount frame

with 3/8"-16 x 1

HHCS, 3/8" flat

washers and 3/8"

lock washers

I . Attach both the bottom belt guard seals (GC12026 an GC12027) around the reducer shaft and to the

bottom belt guard assembly using 3/8-16 x 1 HHCS, 3/8 flat washers and 3/8 lock washers.

Do not tighten these

bolts until the belt

guard top assembly

is mounted.

FIG. 14H

Attach both belt guard

bottom seals to the bottom

belt guard assembly

Attach using 3/8"-16 x 1"

HHCS, 3/8" flat washers

and 3/8" lock washers

PNEG-1579 12" & 16" Series II Sweep Special

FIG. 14I

36-A

Page 46

Assembly

14. SHEAVE INSTALLATION (cont.)

J. Slide the belt guard top assembly over the lower belt guard assembly attachment bolts. Att ach the

belt guard top assembly to the fill plate using 3/8-16 x 1 HHCS, 3/8 flat washers and 3/8 lock washers. Slide the complete belt guard assembly as close to the motor as possible without allowing the

sheaves or the belt to rub the steel guard. Tighten the belt guard attachment bolt s.

Slide belt guard top

assembly over lower belt

guard assembly

attachment bolts

Attach the top belt assembly

to the belt guard fill plate

assembly with 3/8"-16 x 1"

HHCS, 3/8" flat washers

and 3/8" lock washers

Slide the belt guard as close to

motor as possible without

allowing sheaves or belt to rub

front of guard. Tighten the bolts.

FIG. 14J

36-B

12" & 16" Series II Sweep Special PNEG-1579

Page 47

14. SHEAVE INSTALLATION (cont.)

top belt guard

Assembly

This is a guard plate

made specific for

your motor size.

Attach using 3/8"

bolts, washers, and

lock washers.

belts

bottom belt guard

3/8"-16 x 1" hex bolt

lockwasher

flat washer

Belt Guard

Bottom Pan

Belt Guard

Bottom Back

Plate

PNEG-1579 12" & 16" Series II Sweep Special

FIG. 14K

36-C

Page 48

Assembly

NOTES

36-D

12" & 16" Series II Sweep Special PNEG-1579

Page 49

15. ELECTRICAL ASSEMBLY

Caution! All electrical wiring and service work must be performed by a qualified

electrician and must meet all State and Local electrical codes.

Assembly

A. Place the 3/4" rigid conduit in order starting with the head section

and working towards the tail or extension section.

B. Connect the rigid conduit together using one (1) 3/4" conduit

coupling between each piece of conduit.

See the chart for the correct size of conduit to the corresponding sweep size.

FIG. 15-B

3/4" rigid

conduit

3/4" conduit

coupling

3/4" rigid

conduit

Sweep Section Conduit Sizes

Bin 10' Conduit Other

Diameter Pieces Pieces

36' N/A 1 @ 9'

37' 1 N/A

39'-40' 1 1 @ 1'

42' 1 1 @ 2'

43'-45' 1 1 @ 3'

48'-49' 1 1 @ 5'

51' 1 1 @ 6'

54'-55' 1 1 @ 8'

57' 1 1 @ 9'

59' 2 N/A

60' 2 1 @ 1'

62'-63' 2 1 @ 2'

66' 2 1 @ 4'

68'-69' 2 1 @ 5'

72' 2 1 @ 7'

75' 2 1 @ 8'

78' 3 N/A

80'-81' 3 1 @ 1'

84' 3 1 @ 3'

87' 3 1 @ 4'

88' 3 1 @ 5'

90'-91' 3 1 @ 6'

92' 3 1 @ 7'

95' 3 1 @ 8'

98' 4 N/A

105' 3 1 @ 9'

113'-120' 4 N/A

PNEG-720-G2 12" & 16" Series II Sweep

37

Page 50

Assembly

15. ELECTRICAL ASSEMBLY (cont.)

C. Connect the 3/4" x 48" liquid-tight flex conduit to the drive end of the 3/4" rigid conduit

using one (1) 3/4" conduit coupling and one (1) 3/4" liquid-tight flex conduit coupling.

1. Thread a 3/4" conduit coupling onto the 3/4" rigid conduit.

2. Thread a 3/4" flex conduit coupling body onto the 3/4" conduit coupling.

3 Slide a 3/4" flex conduit coupling cap onto the 3/4" flex conduit followed by a plastic ring.

4. Thread a steel ring into the 3/4" flex conduit.

5. Thread the 3/4" flex conduit coupling cap onto the 3/4" flex conduit coupling body.

3/4" flex

conduit

steel ring

3/4" flex conduit

coupling body

3/4" flex conduit

coupling cap

3/4" conduit

coupling

plastic ring

3/4" rigid

conduit

FIG. 15-C

38 12" & 16" Series II Sweep PNEG-720-G2

Page 51

Assembly

15. ELECTRICAL ASSEMBLY (cont.)

D. Attach the 3/4" x 12" liquid-tight flex conduit to the other end of the rigid conduit using one (1) 3/4"

conduit coupling and one (1) 3/4" liquid-tight flex conduit coupling.

E Connect the two (2) junction boxes together using the 1" x 4 3/4" conduit nipple.

F. Connect the 3/4" x 12" liquid-tight flex conduit to the left junction box using one (1) 3/4" liquid-tight

flex conduit coupling and one (1) 1" to 3/4" reducer bushing.

G. Attach the 3/4" x 40" liquid-tight flex conduit to the right junction box using one (1) 3/4" liquid-tight

flex conduit coupling and one (1) 1" to 3/4" reducer bushing.

3/4" flex conduit

coupling

right junction box

3/4" x 40"

flex conduit

1" to 3/4" reducer

bushing

reducer

bushing

1" x 4 3/4" conduit

3/4" flex conduit

3/4" x 12"

coupling

left junction box

flex conduit

H. Feed each of the six (6) 14 AWG stranded wires through the 3/4" rigid conduit assembly and cut

them off, leaving six inches (6") at both the left junction box and drive motor.

nipple

FIG. 15-G

I . Feed each of the six (6) 10 A WG stranded wires cord through the 3/4" x 40" liquid tight flex conduit

and cut four (4) of them off, leaving six inches (6") at both the right junction box and auger motor .

Cut the 10 A WG blue and yellow wires longer so they can be connected to the 14 AWG blue and

yellow wires in the left junction box.

PNEG-720-G2 12" & 16" Series II Sweep

39

Page 52

Assembly

15. ELECTRICAL ASSEMBLY (cont.)

J. Place the 3/4" rigid conduit assembly onto the back frame of the sweep between the connecting

angle and connecting flange.

3/4" rigid

conduit

connecting

flange

connecting

angle

FIG. 15-J

K. Fasten the junction boxes to the mounting plate using two (2) 3/8"-16 x 1 3/8" u-bolts, four (4)

lockwashers, and hex nuts.

junction box

3/8" x 1-3/8"

u-bolt

mounting

plate

lockwasher

hex nut

FIG. 15-K

40 12" & 16" Series II Sweep PNEG-720-G2

Page 53

Assembly

15. ELECTRICAL ASSEMBLY (cont.)

L. Attach the 3/4" rigid conduit assembly to the sweep using the 5/16"-18 x 3/4" studs welded to the

sweep using 1" conduit clamps, lockwashers, and hex nuts.

M . Run the 14 A WG stranded

wires into the drive motor

and fasten the 3/4" x 48"

liquid-tight flex conduit to the

motor using one (1) 3/4"

liquid-tight flex conduit

coupling. Some motors may

require a reducer bushing

not supplied with the sweep.

Connect the leads as required.

N. Run the 10 AWG stranded

wires into the auger motor

and fasten the 3/4" x 40"

liquid-tight flex conduit to the

motor using one (1) 3/4"

liquid-tight flex conduit

coupling. Some motors may

require a reducer bushing

not supplied with the sweep.

Connect the leads as required.

5/16" hex nut

5/16" lockwasher

1" conduit clamp

5/16"-18 x 3/4"

stud

3/4" rigid conduit

FIG. 15-L

O. Tractor Drive:

Slide a 5/8" to 3/4" cord connector six inches (6") onto one (1) end of the 14 AWG/4 wire cords and

fasten it to the junction box using one (1) 1" to 3/4" reducer bushings. Connect the leads as required.

Sweep Drive all 12" and 16" under 105 Model:

Slide a 5/8" to 3/4" cord connector six inches (6") onto one (1) end of the 10 AWG/4 wire cords and

fasten it to the junction box using one (1) 1" to 3/4" reducer bushings. Connect the leads as required.

Sweep Drive all 16" 105 Model and over:

Slide a 5/8" to 3/4" cord connector six inches (6") onto one (1) end of the 8 AWG/4 wire cords and

fasten it to the junction box using one (1) 1" to 3/4" reducer bushings. Connect the leads as required.

P. Slide a 1/2" to 5/8" cord connector six inches (6") onto the end of the 14 A WG/3 wire cord and

fasten it to the junction box using one (1) 1" to 3/4" reducer bushings. Connect the leads as

required.

Q. Use the plugs provided with the junction boxes to close the holes not being used.

PNEG-720-G2 12" & 16" Series II Sweep

If you are using the pivot kit, skip to page 47 and refer to step "17A".

41

Page 54

Assembly

15. ELECTRICAL ASSEMBLY (CONT.)

5/8" to 3/4" cord connector

for: 10 AWG/4 wire cord

(HBL2431SW)

3/4" to 7/8" cord connector

for: 8 A WG/4 wire cord

(HBL2431SW)

14 A WG/4 wire cord

(HBL2431SW)

14 A WG/3 wire cord

(CS8165C)

1" to 3/4"

reducer

bushing

1/2" to 5/8" cord

connector body

rubber

grommet

plastic

ring

1/2" to 5/8" cord

connector cap

FIG. 15-R

R. Assemble the cord plugs to the other end of each cord. The 14 AWG/4 wire cord requires the

"HBL2431SW" plug. The 10 AWG/4 and 8 AWG/4 wire cord requires the "CS8165C" plug. The

14 A WG/3 wire cord requires the "HBL2311SW" plug.

The plugs are different for each cord and MUST be assembled correctly. This is

done so the cords can not be plugged into the control panel incorrectly.

S. Mount the control panel outside the bin near the door .

The control panel MUST be mounted OUTSIDE the bin near the door. The

foot switch has to be plugged into the control panel and depressed before

the sweep is operational. It has a 10' cord so the sweep can only be monitored from OUTSIDE the bin.

42 12" & 16" Series II Sweep PNEG-720-G2

Page 55

16. JACK SUPPORT ASSEMBLY

Assembly

All Current Pr oduction and Old Style 12"

Jack Support (See fig. 16-A & 16-C)

A. Attach one (1) caster wheel to the jack caster

B. Locate the 2" x 2" x 12" tube to the right of each

C. Attach the jack caster assembly to the jack

D. Bolt the jack assembly to the jack mount as-

Be sure to use the spanner bushings, supplied with the caster wheels, between the

caster and the caster plate on each side. (12" Sweeps Only.)

assembly using one (1) 3/4" x 5-1/2" hex bolt,

lockwasher , and hex nut.

connecting angle and fasten the jack mount

assembly to the sweep frame using one (1) jack

mount plate, four (4) 1/2"-13 x 3-3/4" hex bolts,

lockwashers, and hex nuts.

assembly using one (1) pin.

sembly using four (4) 1/2"-13 x 2" hex bolts,

lockwashers, and hex nuts.

All Old Style 16" Jack Support (See fig.

16A & 16-C)

A. Attach one (1) caster wheel to the jack caster

assembly using one (1) 3/4" x 5-1/2" hex bolt,

lockwasher, and hex nut.

B. Locate the 2" x 2" x 12" tube to the right of each

connecting angle and fasten the jack mount

assembly to the sweep frame using one (1) jack

mount plate, four (4) 1/2"-13 x 3-3/4" hex bolts,

lockwashers, and hex nuts.

C. Attached 16" Jack Caster Assembly to the

swivel caster wheel using four (4) 1/2" x 1-1/2"

HHCS bolts, lockwashers, & hex nuts.

D. Attach the jack caster assembly to the jack

assembly using one (1) pin.

jack

assembly

1/2" x 2"

hex bolt

3/8" x 2 3/4"

safety snap pin

E. Bolt the jack assembly to the jack mount as-

sembly using four (4) 1/2"-13 x 2" hex bolts,

lockwashers, and hex nuts.

CURRENT PRODUCTION SWEEP SHOWN

Connecting

Angle

jack mount

assembly

Tubes cut away

for clarity .

jack mount

plate

1/2" x 3-3/4"

hex bolt

PNEG-720-G2 12" & 16" Series II Sweep

FIG. 16-C

43

Page 56

Assembly

FIG. 16-A

12" JACK SUPPORT

16" JACK SUPPORT

AFTER 11-01-04

jack assembly

1/2" x 1-1/2"

HHCS

jack truss

jack mount plate

jack mount

assembly

pin

3/4" x 5-1/2"

caster wheel

1/2" x 3-3/4" HHCS

sweep jack

caster

assembly

1/2" x 1-1/2"

HHCS

jack assembly

jack truss

1/2" x 3-3/4"

HHCS

jack mount

assembly

jack mount plate

pin

OLD STYLE 16"

JACK SUPPORT

BEFORE 11-01-04

44 12" & 16" Series II Sweep PNEG-720-G2

sweep jack

caster assembly

swivel

caster

Page 57

17. CENTER PIVOT INSTALLATION

Assembly

If you are only running the cords across the floor, you may skip step 17A and go

to step 17B.

A. Center Pivot With Pivot Kit

1. Use the pivot assembly supplied with the sweep pivot kit and cut it to fit, if needed.

The center pipe of the pivot assembly MUST be in the center of the bin. If it

is not, the sweep could hit the bin wall.

2. Feed the multi-conductor cord through the hole in the back of the sweep head section leaving

five feet (5') of cord outside the hole.

PNEG-720-G2 12" & 16" Series II Sweep

multi-conductor cord

(Leave 5' of cord outside of hole.)

FIG. 17-A2

45

Page 58

Assembly

17. CENTER PIVOT INSTALLATION (cont.)

3. Feed the power cord through the pivot tube.

4. Align the hole in the backshield with the pivot tube and push the sweep onto the pivot tube.

5. Connect the pivot plate to the backshield using two (2) 1/2"-13 x 1-3/4" hex bolts, flat washers,

lockwashers, and hex nuts.

6. Fasten the pivot rod to the backshield and pivot plate using two (2) 1/2"-13 x 2" hex bolts,

lockwashers, and hex nuts.

7. Screw the 45 degree grease fitting into the pivot assembly pipe.

1/2"-13 x 2" hex bolt

hex nut

lockwasher

1/2"-13 x 1 3/4" hex bolt

pivot rod

flat washer

pivot tube

pivot plate

cord

pivot assembly

45 degree

grease fitting

multi-conductor

cord

FIG. 17-A3

46 12" & 16" Series II Sweep PNEG-720-G2

Page 59

17. CENTER PIVOT INSTALLATION (cont.)

9. Connect the 1" x 48" liquid-tight flex conduit to the pivot tube using one (1) 1" conduit coupling and

one (1) 1" liquid-tight flex conduit coupling.

10. Connect the 1" x 48" liquid-tight flex conduit to one of the junction boxes using one (1) 1" liquidtight flex conduit coupling. Connect the leads as required.

Assembly

1" flex conduit

coupling

1" x 48" flex

pivot tube

conduit

1" conduit

coupling

11. The customer is to provide proper power cord protection between the pivot assembly and the

sump transition.

12. The multi-conductor power cord can be connected with the 14 AWG/3 wire, 14 AWG/4 wire, and

10 AWG/4 wire cords in an explosion proof junction box .

13. Use the plugs provided with the junction box to close the holes not being used.

14. Assemble the cord plugs to the other end of each of the cords. The 14 AWG/4 wire cord requires

the "HBL2431SW" plug. The 8AWG/4 & the 10 AWG/4 wire cord requires the "CS8165C" plug.

The 14 A WG/3 wire cord requires the "HBL2311SW" plug.

FIG. 17-A9

The plugs are different for each cord and MUST be assembled correctly. This

is done so the cords can not be plugged into the control panel incorrectly.

PNEG-720-G2 12" & 16" Series II Sweep

47

Page 60

Assembly

17. CENTER PIVOT INSTALLATION (cont.)

B. Center Pivot For Standard Sweep

The center pivot for a standard sweep must be supplied by the customer.

The following are requirements for installation.

The pivot pin MUST be in the center of the bin. If it is not, the sweep

could hit the bin wall.

1. The cross braces must be 1/2" steel plate.

2. The pivot pin must be 1-1/2" diameter steel bar and extend approximately 4" above floor

elevation.

18. CONTROL PANEL SETUP