Page 1

L and B Series Field Installation

Installation Guide for

Centrifugal Dryers

PNEG-1472

Date: 04-18-08

PNEG-1472

Page 2

2 PNEG-1472 L & B Series Field Installation

Page 3

Table of Contents

Contents

Chapter 1 Introduction ........................................................................................................................................ 4

Chapter 2 Safety ..................................................................................................................................................5

Safety Guidelines ............................................................................................................................... 5

Safety Instructions .............................................................................................................................. 6

Chapter 3 Safety Decals ......................................................................................................................................8

Chapter 4 Installation Instructions...................................................................................................................11

Site Selection .................................................................................................................................... 11

Foundation ................................................................................................................................. ...... 11

Legs ..................................... ................ ................ ................ ................ ................ .......................... ... 11

Dryer Assembly Instructions.............................................................................................................. 11

1. Leg Assembly................................................................................................................................ 11

2. Set Dryer Body.............................................................................................................................. 11

3. Set Fan-Heater Module................................................................................................................. 14

4. Fan-Heater Enclosure Assembly... ... ... ... ... .... ... ... .......................................... ... .... ... ... ................... 16

5. Fuel Plumbing Assembly............................................................................................................ ... 22

6. Vaporizer Plumbing Assembly ...................................................................................................... 24

7. Electrical Wiring............................................................................................................................. 26

Chapter 5 Warranty ...........................................................................................................................................29

PNEG-1472 L & B Series Field Installation 3

Page 4

1. Introduction

Thank you for choosing a GSI product. It is designed to provide excellent performance and service for

many years.

This manual describes the start-up of Vision series model dryers. When installed and operated properly

and according to specifications, this unit will provide many years of dependable service.

READ THIS MANUAL carefully to learn how to properly use and install equipment. Failure to do so could

result in personal injury or equipment damage.

INSPECT the shipment immediately upon arrival. The customer is responsible for ensuring that all

quantities are correct. The customer should report and note any damage or shortage on the bill of lading

to justify their claim to the transport company.

THIS MANUAL SHOULD BE CONSIDERED a permanent part of your equipment and should be easily

accessible when needed.

The warranty provides you the assurance that the company will back its products when defects appear

within the warranty period. In some circumstances, the company also provide s field improvements, often

without charge to the customer, even if the product is out of warranty. Should the equipment be abused,

or modified to change its performance beyond the factory specifications, the warranty will be come void

and field improvements may be denied.

4 PNEG-1472 L & B Series Field Installation

Page 5

2. Safety

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in property damage.

NOTE indicates information about the equipment that you

should pay special attention.

PNEG-1472 L & B Series Field Installation 5

Page 6

2. Safety

Safety Instructions

Our foremost concern is your safety and the safety of others associated with this equipment. We want

to keep you as a customer. This manual is to help you understand safe operating procedures and some

problems which may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requ irements, hazards and p recautions

exist, and to inform all personnel associated with the equipment or in the area . Safety precautions may

be required from the personnel. Avoid any alterations to the equipment. Such alterations may produce

a very dangerous situation where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable

regulations which should be carefully followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

Follow Safety Instructions

Carefully read all safety messages in this manual and

safety signs on your machine. Keep signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from the manufacturer.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machinery in proper working condition.

Unauthorized modifications to the machine may impair

the function and/or safety and affect machine life.

If you do not understand any part of this manual or need

assistance, contact your dealer.

Prepare for Emergencies

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital and fire department near your telephone.

Read and Understand Manual

Keep Emergency Equipment

Quickly Accessible

6 PNEG-1472 L & B Series Field Installation

Page 7

Wear Protective Clothing

Wear close fitting clothing and safety equipment appropriate

to the job.

Remove all jewelry.

2. Safety

Eye Protection

Long hair should be tied up and back.

Safety glasses should be worn at all times to protect eyes

from debris.

Wear gloves to protect your hands from sharp edges on

plastic or steel parts.

Wear steel toe boots to help protect your feet from falling

debris. Tuck in any loose or dangling shoe strings.

A respirator may be needed to prevent breathing potentially

toxic fumes and dust.

Wear hard hat to help protect your head.

Install and Operate Electrical Equipment Properly

Electrical controls should be installed by a qualified electrician

and must meet the standards set by the National Electrical Code

and all local and state codes.

Gloves

Steel Toe Boots

Respirator

Hard Hat

Disconnect and lock out all power sources before installing

wires/cables or servicing equipment.

Electric Shock Hazard

Install and Operate Gas-Fired Equipment Properly

Fuel supply should be installed by a qualified gas

technician and must meet local and state codes for

gaseous fuel supplies.

Disconnect and lock out all fuel sources before

servicing equipment.

PNEG-1472 L & B Series Field Installation 7

Explosive Gases

Page 8

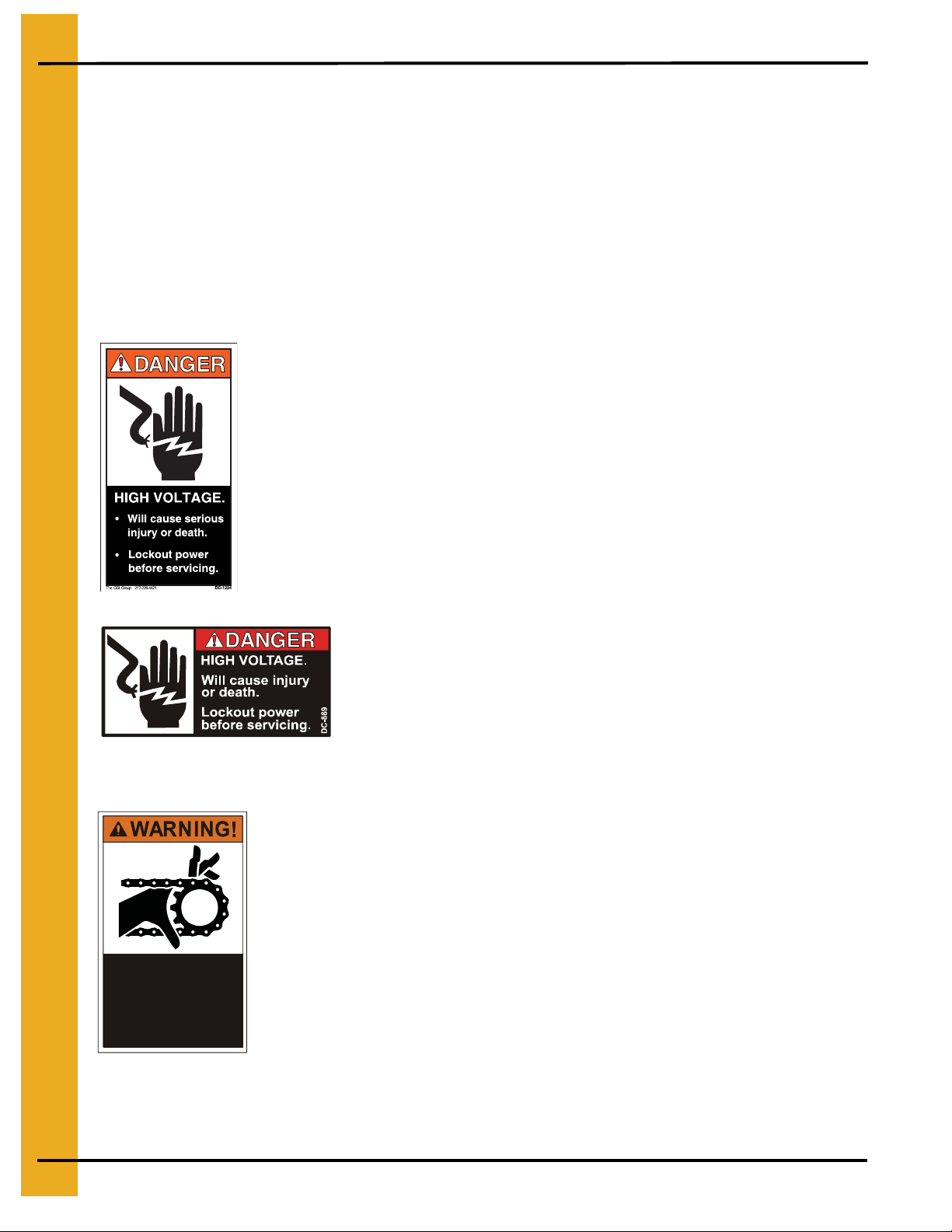

3. SAFETY DECALS

The GSI Group, Inc. recommends contacting your local power company, and having a representative

survey your installation so the wiring is compatible with their system, and adequate power is supplied to

your unit. Safety decals should be read and understood by all people in the grain handling area.

If a decal is damaged or is missing contact:

The GSI Group, Inc.

1004 E. Illinois St.

Assumption, IL 62510

Ph: (217) - 226 - 4421

A free replacement will be sent to you.

Decal DC-1224 is located in two places on the fan/heater control box.

One on the lid and one on the front of the fan heater control box.

Another location for this decal is inside the upper control box for the

dryer.

Moving parts can crush

and cut. Keep hands

clear. Do not operate

without guards in place.

Failure to do so could

result in serious injury.

DC-972

Decal DC-889 has two locations. One inside the fan/heater

control box and another on the dryer upper control box door

next to the main power disconnect.

Decal DC-972 is located on the bottom auger belt guard and the front

bearing plate (which is visible when then bottom auger belt guard is

removed). An alternate location would be at the rear of the dryer for

portable dryers equipped with the Front Discharge Option.

8 PNEG-1472 L & B Series Field Installation

Page 9

3. Safety Decals

Decal DC-974 has several different locations. Two are located on the

front end panel below the fan/heater. Two are located on the rear end

panel below the rear access door. Two are located on the auger

discharge box (one on the outside top and one on the inside of the

flapper lid next to the discharge mercury switch). One more of these

decals is located inside the plenum on the rear plenum closure door just

inside the rear access door.

WARNING

Automatically controlled

belt drive can start at

anytime. Keep hands

clear. Failure to do so

could result in serious

injury.

DC-971

DANGER!

Automatic equipment can

start at any time. Do not

enter until fuel is shut off

and electrical power is

locked in off position.

Failure to do so will result

in serious injury or death.

DC-973

Decal DC-971 is located on the bottom auger belt guard and the front

bearing plate (which is visible when then bottom auger belt guard is

removed). An alternate location would be at the rear of the dryer for

portable dryers equipped with the Front Discharge Option.

Another location for decal DC-971 is the top auger belt guard

(one on the belt guard cover and one inside on the belt guard body visible

when the belt guard cover is remove).

Decal DC-973 is located on the rear plenum access door

(inside and outside).

Decal DC-1227 is located on the

fan/heater access door.

PNEG-1472 L & B Series Field Installation 9

Page 10

3. Safety Decals

WARNING

Stay clear of rotating

blade. Blade could start

automatically. Can cause

serious injury. Disconnect

power before servicing.

DC-1225

Decal DC-1229 is located on each of the

meter roll access doors.

Decal DC-1225 is located on the fan/heater

access door.

Decal DC-388 is located on the hitch tongue.

Decal DC-1249 is located on the hitch tongue.

10 PNEG-1472 L & B Series Field Installation

Page 11

4. Installation Instructions

Site Selection

Consider the grain handling system and location of storage bins and existing conveyors when selecting

dryer site, to facilitate wet grain supply and dry grain discharge to conveyors. Other considerations are

prevailing wind direction, fuel and power supply locations, noise, and convenience of control location.

Foundation

The dryer should be placed on an 8” reinforced concrete slab located in a well-drained area. The slab

should be large enough to provide working area around the dryer , with a surface elevation consistent with

other parts of the grain handling and storage systems.

Legs

Centrifugal fan dryers are supplied with a standard leg set to support the dryer body 24” high as shown

in Figure 4A (optional 36” or 48” leg sets are availble). The dryer must be anchored to the foundation

with tie-down cables or placing anchor bolts through the leg supports into the fountion.

Dryer Assembly Procedure

Note: The front end of the dryer is defined as the fan-heater end. Left and right sides are as seen when

standing behind the rear of the dryer looking forward.

1. Leg Assembly

The standard leg support package shipped with this dryer is used to support the dryer frame at 24” high.

Three to five pairs of 24” leg assemblies are used under the dryer body depending on model, and two

pairs of 47.5” leg assemblies are used under the fan-heater module.

Assemble the 24” leg sets using item #2 leg weldment, item #3 cross beam 73.25” long, and item #5

triangular gusset using hardware items A and B. Snug the hardware hand-tight but do not torque until

positioned under dryer. Be sure to assemble the cross beam with the “C” channel opening facing down.

See Figure 4A.

Assemble the 47.5” legs in a similar manner using item #1 leg weldment and item #4 cross be am 64.5”

long. Be sure to orient legs so that the .25” dia. hole in the outer leg flange is 2.5” from the bottom. Set

the 47.5” legs approximately 57.5” apart on models 6034L (C2160B), 7534L (C2175B), 1038L

(C21100B), or 40.75” on models 3020L (C2130B), and 4026L (C2140B), then assemble (4) item #6

diagonal leg brace as shown. Only hand tighten hardware at this point.

2. Set Dryer Body Module

The dryer body may be placed on the dryer foundation by rolling it into position on its transports or by

using the supplied crane brackets for lifting. The wet bin must be assembled first. See wet bin assembly

manual (PNEG-1273) included in the dryer’s literature pack.

PNEG-1472 L & B Series Field Installation 11

Page 12

4. Installation Instructions

Figure 4A Support legs.

Table 1: Leg Package

415-2895-1 Leg Package for 20’ Dryer X

415-2894-4 Leg Package for 26’ Dryer X

415-2790-4 Leg Package for 34’ & 38’ Dryer X

Item Part No. Description Qty Qty Qty

1 410-1048-9 Leg Weldment LSP 24” 6 8 10

2 401-1160-1 Cross Beam LSP 74.25” 3 4 5

3 401-1156-9 Triangular Gusset LSP 20 24 28

4 410-1793-0 Leg Weldment LSP 47.5” 4 4 4

5 401-3912-3 Cross Beam LSP 64.5” 2 2 2

6 401-4025-3 Brace, Diagonal LSP 64” 4 4 -

6 401-3956-0 Brace, Diagonal LSP 77.5” - - 4

A S-9062 Bolt, FLNGS 1/2-13x1-1/4 ZN Grade 5 150 178 206

B S-8506 Nut, FLANGWZ 1/2-13 ZN 150 178 206

12 PNEG-1472 L & B Series Field Installation

Page 13

4. Installation Instructions

If the dryer is to be set using a crane, a four point crane sling with a 10 ft minimum length must be used

to prevent excessive side pull on the crane brackets. The crane and sling should be sized to lift a

minimum of:

1. 3020L (C2130B) - 9,500 lbs

2. 4026L (C2140B) - 12,500 lbs

3. 6034L (C2160B) - 16,000 lbs

4. 7534L (C2175B) - 16,000 lbs

5. 1038L (C21100B) - 17,900 lbs

When the dryer is in position, place the 24” leg support assemb lies evenly under the dryer as shown in

Figure 4A. Attach the legs using hardware items A and B , then lower the dryer body weight onto the

supports. Level and shim the dryer legs as required so that each leg is sharing the weight of the dryer.

The leg support assembly hardware can now be tightened.

The dryer body transport kit should now be removed. This includes the drop axle weldments and

wheels, hitch welment (6), hitch brace support (13), hitch brackets (8 & 9), hitch diagonal braces (11 &

12), and diagonal attaching channels (10). See Figure 4B.

Figure 4B Remove transport items.

PNEG-1472 L & B Series Field Installation 13

Page 14

4. Installation Instructions

3. Set Fan-Heater Module

The fan-heater module will require a crane to set into position. Crane lifting brackets are supplied on

this module. A four-point crane sling with a minimum length of 10 ft must be used to prevent excessive

side pull on the crane brackets. The crane and sling should be sized to lift a minimum of 4,000 lbs for

the 3020L (C2130B) and 4026L (C2140B) models or 6,000 lbs for 6034L (C2160B), and 7534L

(C2175B) models, or 9,000 lbs for 1038L (C21100B) models.

Before setting the fan-heater module, the following instructions should be followed.

• Remove any parts or packages shipped on or in the fan-heater or dryer body modules.

• If the dryer is equipped with a vaporizer for LP fuel, locate the vaporizer coil and vaporizer

support bracket and place them inside the dryer body upper plenum.

• Check to see that the mating faces of the dryer body and fan-heater module are clear of

conduits, sensors, or bolts which may interfere with the mating of the two modules.

• Place the 47.5” leg set on the foundation approx. 6 ft in front of the dryer body module.

The fan-heater module may now be lifted onto the leg set. Position the module so that the front wall of

the fan-heater module is flush with the front flange of the front legs. Using the 1/2”-13 hardware supplied

with the legs, attach the leg to the module through the two inside holes of each leg weldment. Note that

the fan-heater module should still be a few feet away from the dryer body at this point. Tighten all leg

hardware at this time.

Locate the fan-heater module hardware package and be prepared to install the 5/16” flanged or 5/16”

self tapping hardware. Make another visual inspection of the dryer and fan-heater mating surfaces for

any interferences, then lift the fan-heater with its leg sets attached into place to mate with the dryer body.

Aligning the holes in the rear floor frame channel of the fan-heater module with the holes in the front dryer

body gusset plates is the most convenient place to check for correct positioning (see Figure 4D). Install

hardware in these holes to maintain alignment, then shim and level the fan-heater module leg as

required to align and install hardware in the vertical rows of attaching holes and the row of hardware

down the roof slope.

14 PNEG-1472 L & B Series Field Installation

Page 15

4. Installation Instructions

Figure 4C Dryer dimensions - 6034L (C2160B) shown.

PNEG-1472 L & B Series Field Installation 15

Page 16

4. Installation Instructions

Figure 4D Alignment of Fan-Heater Module to Body Module.

4. Fan-Heater Enclosure Assembly (6034L, 7534L, 1038L, C2160B, C2175B,

C21100B)

The 6034L (C2160B), 7534L (C2175B), and 1038L (C21100B) model fan-heater enclosures are ship ped

unassembled to the module in order to maintain an 8 ft shipping width. Field assemble following these

steps and refer to Figures 4E, 4F, 4G, and 4H.

1. Remove the louver assemblies from their shipping placement on the fan-heater module and discard

the shipping brackets.

2. Locate (6) floor frame extension channels (item #1 401-3914-9) and insert them inside the fan

module frame channels (see Figures 4E). Note that the fan-heater floor hardware will need to

be removed then reinstalled after channels are in place. Attach using the self tapping 5/16”

hardware (S-7221).

3. Locate items #4 (401-3910-7) and #5 (401-3911-5) reclaimer floor panels and position in place over

the floor frame extension channels. Attach using self tapping 5/16” hardware (S-7221).

4. Install items #9 (401-3910-9), #10 (401-3908-1), and #11 (401-3997-4) as shown. From this step

on it is highly recommended that the hardware be installed only loosley, allowing the wall

sheets to move slightly for aligning parts.

5. Install items #26 (401-3944-6) and #17 (401-3943-8) reclaimer end panels as shown in Figure 4E.

6. Install items #8 (401-3915-6), #2 (401-3941-2), and #3 (401-3942-0) fan reclaimer side panels

shown in Figure 4E. Note that the side panels should slip under the roof panels on the fan-

16 PNEG-1472 L & B Series Field Installation

Page 17

4. Installation Instructions

heater module.

7. Install (2) item #13 (401-3850-5) outer roof frame channels as shown in Figure 4E.

8. Install (2) item #15 (401-3945-3) reclaimer roof panels as shown in Figure 4E.

9. Install (2) item #7 louver assemblies with the adjusting screw located at the bottom. Untie the

adjusting screw and feed it through the hole located in the reclaimer floor panel. It will be

necessary to remove them reinstall the handle weldment in order to do this.

10.Install (2) item #14 (401-3998-2) fan reclaimer side panels-short, (2) item #12 (401-3968-5)

sidewall braces, (2) item #18 (401-3996-6) door frame channeld, (2) item #6 (401-3995-8) fanheater access doors and door latches as shown in Figure 4E.

11.All attaching hardware may now be tightened.

PNEG-1472 L & B Series Field Installation 17

Page 18

4. Installation Instructions

Figure 4E Fan-Heater enclosure layout.

18 PNEG-1472 L & B Series Field Installation

Page 19

4. Installation Instructions

Table 2: Fan-Heater Enclosure Parts

Item Part No. Description Qty

1 401-3914-9 CHANNEL - FLOOR FRAME EXT 6

2 401-3941-2 PANEL - FAN RECLAIMER - FRONT SIDE - RH 1

3 401-3942-0 PANEL - FAN RECLAIMER - FRONT SIDE - RH 1

4 401-3910-7 PANEL - RECLAIMER FLOOR - RH 1

5 401-3911-5 PANEL - RECLAIMER FLOOR - LH 1

6 401-3995-8 DOOR FAN-HEATER ACCESS 2

7 415-2808-4 LOUVER ASSY 2

8 401-3915-6 PANEL - FAN RECLAIMER SIDE 2

9 401-3909-9 PANEL - LOWER RECLAIMER - LH 1

10 401-3908-1 PANEL - LOWER RECLAIMER - RH 1

11 401-3997-4 PANEL - UPPER RECLAIMER CLOSURE 2

12 401-3968-5 CHANNEL - SIDE WALL BRACE 2

13 401-3850-5 CHANNEL - OUTER ROOF FRAME 2

14 401-3998-2 PANEL FAN RECLAIMER SIDE SHORT 2

15 401-3945-3 PANEL - RECLAIMER - ROOF 6

16 401-3944-6 PANEL - RECLAIMER END - LH 1

17 401-3943-8 PANEL - RECLAIMER END - RH 1

18 401-3996-6 CHANNEL DOOR FRAME 4

19 025-1112-9 DOOR LATCH 2

A S-7221 SCREW, SMSAB 5/16 x 3/4 HWH GR2 B S-3611 NUT, FLANGWZ 5/16-18 ZN YDP C S-6606 BOLT, FLNGS 5/16-18 x 3/4 ZN GR5 -

PNEG-1472 L & B Series Field Installation 19

Page 20

4. Installation Instructions

Figure 4F Louver adjusting screw.

20 PNEG-1472 L & B Series Field Installation

Page 21

4. Installation Instructions

Figure 4G Fan-Heater enclosure side view.

PNEG-1472 L & B Series Field Installation 21

Page 22

4. Installation Instructions

Figure 4H Door assembly.

22 PNEG-1472 L & B Series Field Installation

Page 23

4. Installation Instructions

5. Fuel Plumbing Assembly

The fuel inlet manifold assembly has been shipped pre-assembled. LP model dryers also include a

vaporizer plumbing assembly and will require assembly. Use a teflon paste pipe sealer on fuel pipe

threads.

The fuel manifold assembly should be assembled as follows:

1. Install support bracket 401-3946-1 on the underside of the front frame channel of the fan-heater

module directly beneath the existing plumbing on the fan-heater module using 5/16” bolt (S-6606)

and 5/16” nut (S-3611). See Figure 4I.

2. Install connecting pipe assembly D04-0419 to lower pipe coupler on the fan-heater module.

Secure connecting pipe to bracket installed in step 1 with U-bolt (090-1485-3).

3. Install support bracket 401-3946-1 loosely to the manifold assembly next to the Maxon valve with

U-bolt (090-1485-3). See Figure 4I. Lift the manifold assembly in place and connect the union.

Adjust the support bracket so that it lines up with the holes in the support leg and install using 5/

16” bolts (S-6606) and 5/16” nuts (S-3611).

4. Now fully tighten the union that was connected in step 3.

5. Install conduit assembly D04-0483 to the unilet “T” on the 2 inch valve. Connect the white wire to

one lead of each valve. Connect the black/white wire to the remaining lead of the 1 inch valve.

Connect the brown/white wire to the remaining lead of the 2 inch valve.

6. Install the pressure gauges as shown in Figure 4I. Use a teflon paste pipe sealer on fuel pipe

threads.

7. The Natural Gas supply line may now be installed. NG should be supplied at a regulated pressure

of 10 psi. If the fuel supply is liquid propane, see the following instructions for vaporizer plumbing

installation. If an external vaporizer is used, a propane vapor supply line regulated to 10 psi may

be installed at this time.

PNEG-1472 L & B Series Field Installation 23

Page 24

4. Installation Instructions

Figure 4I Fuel manifold installation.

24 PNEG-1472 L & B Series Field Installation

Page 25

4. Installation Instructions

6. Vaporizer Plumbing Assembly (LP models only)

The vaporizer plumbing assembly is installed as follows (LP models only). Refer to Fig ures 4J, 4K, and

4L.

1. Install the vaporizer assembly and vaporizer support bracket into dryer heating plenum.

2. Starting from the vaporizer, assemble the pipe subassemblies. Fully tighten all pipe joints as you

proceed. Use a teflon paste pipe sealer on fuel pipe threads.

3. See installation Step 7, Electrical Wiring, for attaching and wiring vaporizer conduit assembly.

4. The liquid propane supply line may now be attached. Propane should be supplied at tank pressure

to the vaporizer plumbing inlet ball valve.

Figure 4J Vaporizer plumbing for 3020L (C2130B), and 4026L (C2140B).

PNEG-1472 L & B Series Field Installation 25

Page 26

4. Installation Instructions

Figure 4K Vaporizer plumbing for 6034L (C2160B), and 7534L (C2175B).

Figure 4L Vaporizer plumbing for 1038L (C21100B).

26 PNEG-1472 L & B Series Field Installation

Page 27

4. Installation Instructions

7. Electrical Wiring

The dryer modules are shipped with the wiring as complete as possible within each module. The

following wiring must be completed in the field when mating the dryer body with the fan-heater module.

1. Load Motor - The rear-fill load auger motor conduit is shipped attached to the fan-heater module

roof. Remove the conduit shipping ties and attach the conduit junction box to the upper right hand

side of the front dryer panel using (4) self-tapping screws. Route the flex conduit to the unload

motor and wire motor for the appropriate supply voltage. Attach the Fill Switch box to the Fill

Paddle shaft. Connect the SJO cord to orange and yellow wires inside the Top Auger Conduit

junction box.

2. Unload Motor - The conduit for the unload motor is found tied to the rear fan-heater frame channel

under the module. Route the flex conduit to the unload motor and wire motor for the appropriate

supply voltage.

3. SCR Motor - The conduit for the SCR motor is found tied to the rear fan-heater frame channel under

the module. Route the flex conduit to the SCR motor and wire motor.

4. Sensors - Find the flex conduit tied to the right side of the dryer body module and route to the Upper

Control Box and connect wires to the terminal strip as shown in Figure 4M.

5. Maxon Valve and Fuel Manifold - Route these two conduit to the Upper Control Box and connect

the Maxon valve wires to the lower terminal strip at the gray and white terminals labeled for the

Maxon valve. Connect fuel manifold wire to the upper terminal strip as shown in Figure 4M.

6. Liquid Solenoid Valve and Vapor Hi-Limit - If the dryer is equipped with a LP vaporizer the

Vaporizer Conduit must be assembled to the Vapor Hi-Limit Thermostat and the Liquid Solenoid

Valve. Connect the thermostat and valve in series and route the conduit to the upper control box.

Connect wire to the appropriate terminals as shown in Figure 4M.

PNEG-1472 L & B Series Field Installation 27

Page 28

4. Installation Instructions

Figure 4M Upper control box terminal wiring.

28 PNEG-1472 L & B Series Field Installation

Page 29

7. Warranty

The GSI Group, Inc. Warranty

THE GSI GROUP, INC. (GSI) WARRANTS ALL PRODUCTS WHICH IT MANUFACTURES TO BE

FREE OF DEFECTS IN MATERIAL AND WORKMANSHIP UNDER NORMAL USAGE AND

CONDITIONS FOR A PERIOD OF 12 MONTHS AFTER RETAIL SALE TO THE ORIGINAL END USER.

THE PURCHASER’S SOLE REMEDY AND GSI’S ONLY OBLIGATION SHALL BE TO REPAIR OR

REPLACE, AT GSI’S OPTION AND EXPENSE, PRODUCTS THAT, IN GSI’S SOLE JUDGMENT,

CONTAIN A MATERIAL DEFECT DUE TO MATERIALS OR WORKMANSHIP. ALL DELIVERY AND

SHIPMENT CHARGES TO AND FROM GSI’S FACTORY WILL BE PURCHASER’S RESPONSIBILITY.

EXPENSES INCURRED BY OR ON BEHALF OF THE PURCHASER WITHOUT PRIOR WRITTEN

AUTHORIZATION FROM AN AUTHORIZED EMPLOYEE OF GSI SHALL BE THE SOLE

RESPONSIBILITY OF THE PURCHASER.

EXCEPT FOR THE LIMITED WARRANTY EXPRESSED ABOVE, GSI MAKES NO FURTHER

WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION,

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

OR USE IN CONNECTION WITH (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (II) ANY

ADVICE, INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT,

REPRESENTATIVE OR EMPLOYEE OF GSI REGARDING OR RELATED TO THE CONFIGURATION,

INSTALLATION, LAYOUT, SUITABILITY FOR A PARTICULAR PURPOSE, OR DESIGN OF

SUCH PRODUCTS.

GSI SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES, INCLUDING, WITHOUT LIMITATION, LOSS OF ANTICIPATED PROFITS OR BENEFITS.

PURCHASER’S SOLE AND EXCLUSIVE REMEDY IS AS SET FORTH IN THE LIMITED WARRANTY

EXPRESSED ABOVE, WHICH SHALL NOT EXCEED THE AMOUNT PAID FOR THE PRODUCT

PURCHASED. THIS WARRANTY IS NOT TRANSFERABLE AND APPLIES ONLY TO THE ORIGINAL

PURCHASER. GSI SHALL HAVE NO OBLIGATION OR RESPONSIBILITY FOR ANY

REPRESENTATIONS OR WARRANTIES MADE BY OR ON BEHALF OF ANY DEALER, AGENT OR

DISTRIBUTOR OF GSI.

GSI ASSUMES NO RESPONSIBILITY FOR CLAIMS RESULTING FROM ERECTION DEFECTS OR

UNAUTHORIZED MODIFICATIONS TO PRODUCTS WHICH IT MANUFACTURED. MODIFICATIONS

TO PRODUCTS NOT SPECIFICALLY DELINEATED IN THE MANUAL ACCOMPANYING THE

EQUIPMENT AT INITIAL SALE WILL NULLIFY THE PRODUCT WARRANTY THAT MIGHT HAVE

BEEN OTHERWISE AVAILABLE.

THE FOREGOING WARRANTY SHALL NOT EXTEND TO PRODUCTS OR PARTS WHICH HAVE

BEEN DAMAGED BY NEGLIGENT USE, MISUSE, ALTERATION OR ACCIDENT. THIS WARRANTY

EXTENDS SOLELY TO ONLY PRODUCTS MANUFACTURED BY GSI. THIS WARRANTY IS

EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES EXPRESS OR IMPLIED. GSI RESERVES

THE RIGHT TO MAKE DESIGN OR SPECIFICATION CHANGES AT ANY TIME.

PRIOR TO INSTALLATION, PURCHASER HAS THE RESPONSIBILITY TO COMPLY WITH ALL

FEDERAL, STATE AND LOCAL CODES WHICH MAY APPLY TO THE LOCATION AND

INSTALLATION OF PRODUCTS MANUFACTURED OR SOLD BY GSI.

PHLEGAL: #1832020 v1 (139LG01!.DOC) (revised December 2005)

PNEG-1472 L & B Series Field Installation 29

Page 30

This equipment shall be installed in accordance with

the current installation codes and applicable

regulations which should be carefully followed in all

cases. Authorities having jurisdiction should be

consulted before installations are made.

Copyright © 2008 by GSI Group

Printed in the USA

GSI Group

1004 E. Illinois St.

Assumption, IL 62510-0020

Phone: 1-217-226-4421

Fax: 1-217-226-4420

www.grainsystems.com

Loading...

Loading...