Page 1

Operation

Manual

PNEG-1459

Date: 8-01-2008

L Series Dryer

Operation Manual

PNEG-1459

Page 2

2

PNEG-1459 L Series Operators

Page 3

CONTENTS

INTRODUCTION..................................................................................................................................................4

OPERATING PRECAUTIONS................................................................................................................................................4

SAFETY...............................................................................................................................................................................5

SAFETY ALERT SYMBOL....................................................................................................................................................5

EMERGENCY STOP SWITCH.............................................................................................................................................5

SAFETY DECALS.................................................................................................................................................................5

SPECIFICATIONS.................................................................................................................................................7

DRYER DIMENSIONS...........................................................................................................................................................7

SPECIFICATION CHARTS....................................................................................................................................................8

VISION CONTROL PANEL................................................................................................................................9

CONTROL POWER SWITCH...............................................................................................................................................9

FAN SWITCH........................................................................................................................................................................9

HEATER SWITCH.................................................................................................................................................................9

LOAD AUGER SWITCH.....................................................................................................................................................10

UNLOAD SWITCH..............................................................................................................................................................10

OUTSIDE LIGHT SWITCH.................................................................................................................................................10

START SWITCH...................................................................................................................................................................10

STOP SWITCH.....................................................................................................................................................................10

VISION TOUCH SCREEN DISPLAY...............................................................................................................11

BOOT SCREEN....................................................................................................................................................................11

DEFAULT OPERATION SCREEN......................................................................................................................................11

OPTIONAL OPERATION SCREEN....................................................................................................................................12

SETTING THE TIMERS......................................................................................................................................................13

SETTING THE TEMPERATURES........................................................................................................................................13

THE SETUP SCREEN..........................................................................................................................................................14

VIEWING THE OWNERS MANUALS ON THE DISPLAY SCREEN...............................................................................16

VIEWING THE DRYER SHUTDOWN HISTORY...............................................................................................................16

TEST FIRING.......................................................................................................................................................17

DRYER PRESEASON CHECKS..........................................................................................................................................17

INSPECT THE METERING ROLLS....................................................................................................................................17

ELECTRICAL POWER........................................................................................................................................................17

CONTROL POWER SWITCH..............................................................................................................................................17

START SWITCH..................................................................................................................................................................17

FUEL CHECK......................................................................................................................................................................17

UNLOAD AUTO OPERATION...................................................................................................................................18

UNLOAD MANUAL OPERATION...........................................................................................................................18

METER ROLL OPERATION.......................................................................................................................................18

FAN SWITCHES.........................................................................................................................................................18

BURNER SAFETY.......................................................................................................................................................18

BURNER TEST FIRE...................................................................................................................................................18

DRYER SHUTDOWN..................................................................................................................................................19

EMERGENCY..............................................................................................................................................................19

DRYER OPERATION - START-UP...................................................................................................................20

DRYER OPERATION - BASIC MOISTURE CONTROL............................................................................22

DRYER OPERATION - INTERMEDIATE MOISTURE CONTROL..........................................................26

DRYER OPERATION - ADVANCED MOISTURE CONTROL...................................................................30

DRYING TIME TABLES.....................................................................................................................................36

ILLUSTRATIONS...............................................................................................................................................38

SERVICE..........................................................................................................................................................................44

SEASONAL INSPECTION AND SERVICE.................................................................................................................44

LUBRICATION PROCEDURE....................................................................................................................................45

SUGGESTED LUBRICATION SCHEDULE................................................................................................................45

PROPANE VAPORIZER SEASONAL INSPECTION..................................................................................................46

MAIN CONTROLS......................................................................................................................................................46

HOW TO CLEAR A JAMMED METER ROLL...........................................................................................................46

SAFETY CIRCUIT SHUTDOWN MESSAGES.........................................................................................................47

FAN HEATER GENERATED ERRORS.......................................................................................................................47

INPUT/OUTPUT GENERATED ERRORS................................................................................................................48

MASTER DISPLAY GENERATED ERRORS...............................................................................................................49

WARRANTY....................................................................................................................................................................53

PNEG-1459 L Series Operators

3

Page 4

INTRODUCTION

OPERATING PRECAUTIONS

READ THESE INSTRUCTIONS BEFORE

INSTALLATION and OPERATION.

SAVE FOR FUTURE REFERENCE.

Thank you for choosing a GSI Vision Series grain dryer. These units are among the finest grain dryers ever built;

designed to give you excellent operating performance and reliable service for many years.

This manual describes the installation and operation for all standard production model dryers. These dryers are

available with liquid propane or natural gas fuel supply, single phase 230 volt, three phase 230 or 460 volt (60Hz) electrical

power.

USE CAUTION IN THE OPERATION OF THIS

EQUIPMENT

The design and manufacture of this dryer is directed toward operator safety. However, the very nature of a grain dryer

having a gas burner, high voltage electrical equipment and high speed rotating parts does present a hazard to personnel which

cannot be completely safeguarded against without interfering with efficient operation and reasonable access to components.

Use extreme caution in working around high speed fans, gas-fired heaters, augers and auxiliary conveyors which may

start without warning when the dryer is operating on automatic control.

Continued safe dependable operation of automatic equipment depends, to a great degree, upon the owner. For a safe

and dependable drying system, follow the recommendations within the manual and make it a practice to regularly inspect the

operation of the unit for any developing problems or unsafe conditions.

Take special note of the Operating Precautions listed below before attempting to operate the dryer.

Keep the dryer clean. Do not allow fine material to accumulate in the plenum chamber.

A CAREFUL OPERATOR IS THE BEST INSURANCE AGAINST AN ACCIDENT.

OPERATING PRECAUTIONS

1. Read and understand the operation manual before attempting to operate the unit.

2. Keep ALL guards, safety decals, and safety devices in place. Never operate dryer while guards are removed.

3. Keep visitors, children and untrained personnel away from dryer at all times.

4. Never attempt to operate the dryer by jumping or otherwise bypassing any safety devices on the unit.

5. Always set the main power supply disconnect switch to OFF and lock it in the OFF position using a padlock before

performing any service or maintenance work on the dryer or the auxiliary conveyor equipment.

6. Before attempting to remove and reinstall the fan blade, make certain to read recommended procedure listed within the

SERVICING section of the manual.

7. Keep the dryer and wet holding equipment CLEAN. Do not allow fine material to accumulate.

8. Set pressure regulator to avoid excessive gas pressure applied to a burner during ignition and when burner is in operation.

See page 19 for operating gas pressures. Do not exceed maximum recommended drying temperatures.

9. Do not operate the dryer if any gas leak is detected. Shut down and repair before further operation.

10. Clean grain is safer and easier to dry. Fine material can be highly combustible, and it also requires removal of extra

moisture.

11. Use CAUTION in working around high-speed fans, gas burners, augers, and auxiliary conveyors which can start

automatically.

12. Be certain that capacities of auxiliary conveyors are matched to dryer auger capacities.

13. Do not operate in an area where combustible material will be drawn into the fan.

14. The operating and safety recommendations in this manual pertain to the common cereal grains as indicated. When drying

any other grain or products, consult the factory for additional recommendations.

15. Routinely check for any developing gas plumbing leaks. Check LP vaporizer for contact with burner vanes.

4

PNEG-1459 L Series Operators

Page 5

SAFETY

SAFETY ALERT SYMBOL

The symbol shown is used to call your attention to instructions concerning your personal safety. Watch for this symbol; it points

out important safety precautions. It means "ATTENTION", "WARNING", "CAUTION", and "DANGER". Read the message

and be cautious to the possibility of personal injury or death.

WARNING! BE ALERT!

Personnel operating or working around electric fans should read this manual. This manual must be delivered

with the equipment to its owner. Failure to read this manual and its safety instructions is a misuse of the

equipment.

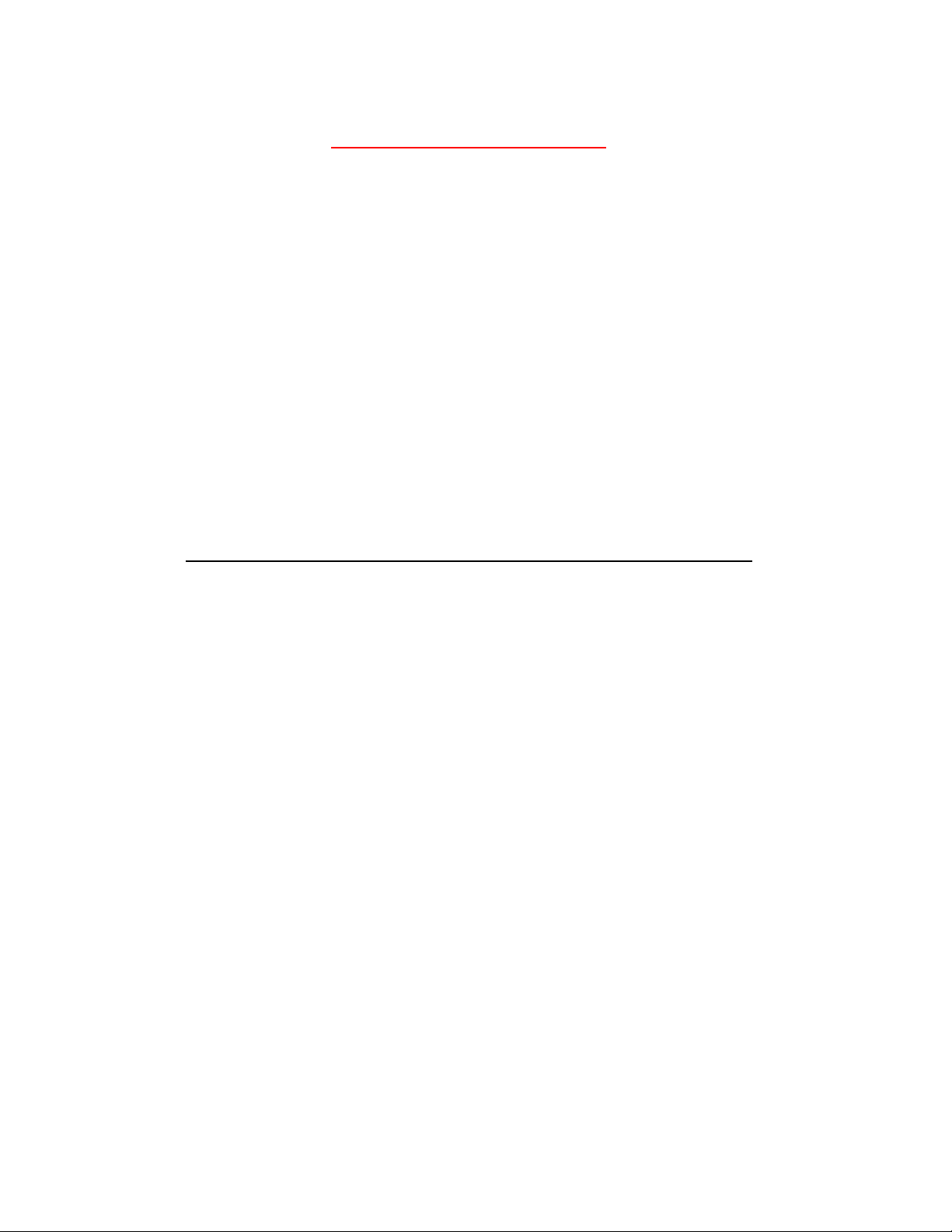

EMERGENCY STOP SWITCH

The emergency stop switch is located on the upper control box door. Pushing the emergency stop switch will interrupt the control

power and stop all dryer functions.

WARNING: Pushing the emergency stop switch does not

interrupt the main power to the upper control box panel.

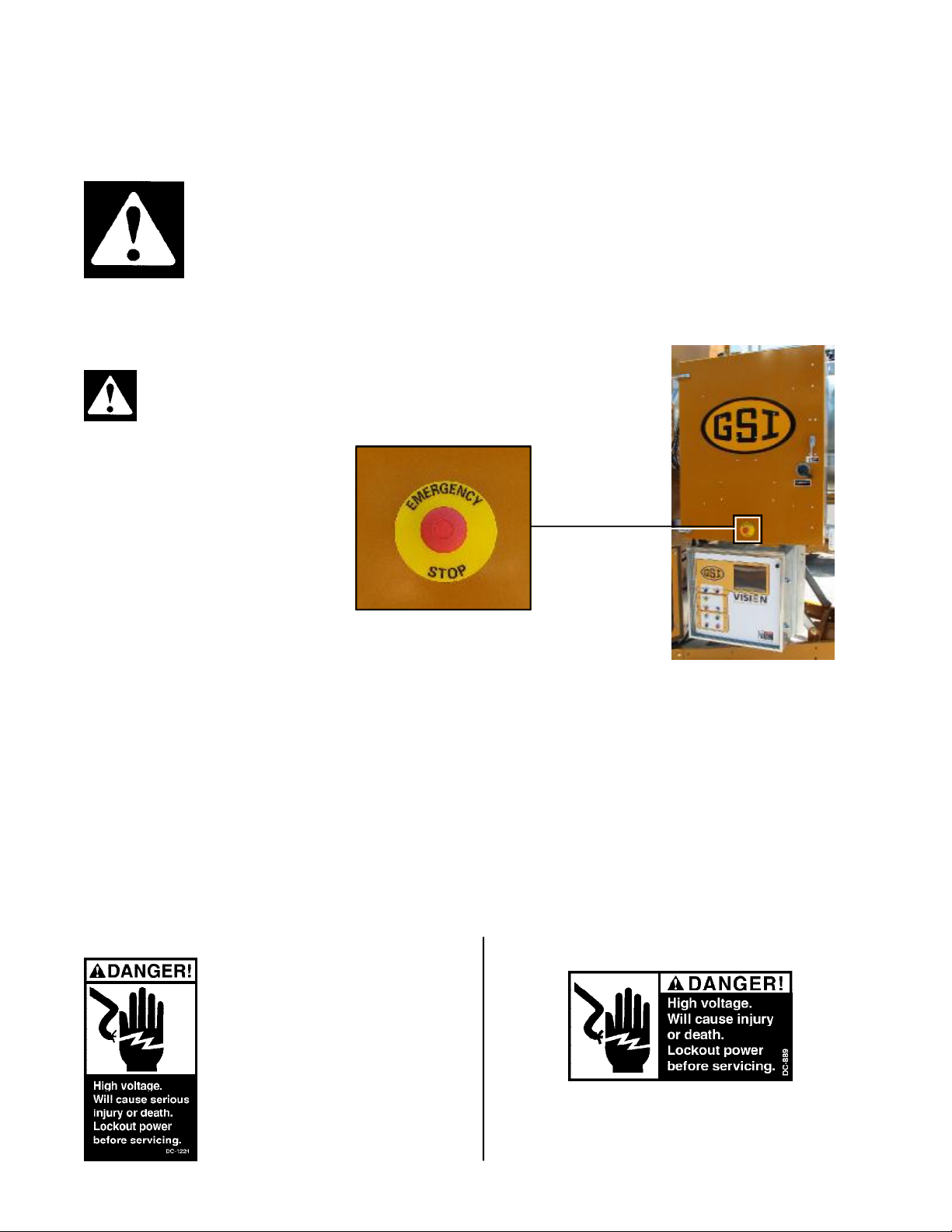

SAFETY DECALS

The GSI Group, Inc. recommends contacting your local power company, and having a representative survey your installation so the

wiring is compatible with their system, and adequate power is supplied to your unit. Safety decals should be read and understood by

all people in the grain handling area.

If a decal is damaged or is missing contact:

The GSI Group, Inc.

1004 E. Illinois St.

Assumption, IL 62510

217-226-4421

A free replacement will be sent to you.

Decal: DC-1224

Decal DC-1224 is located in two places on

the fan/heater control box. One on the lid and one

on the front of the fan heater control box. Another location for this decal is inside the upper

control box for the dryer.

Decal: DC-889

Decal DC-889 has two locations. One inside the fan/heater

control box and another on the dryer upper control box door

next to the main power disconnect.

PNEG-1459 L Series Operators

5

Page 6

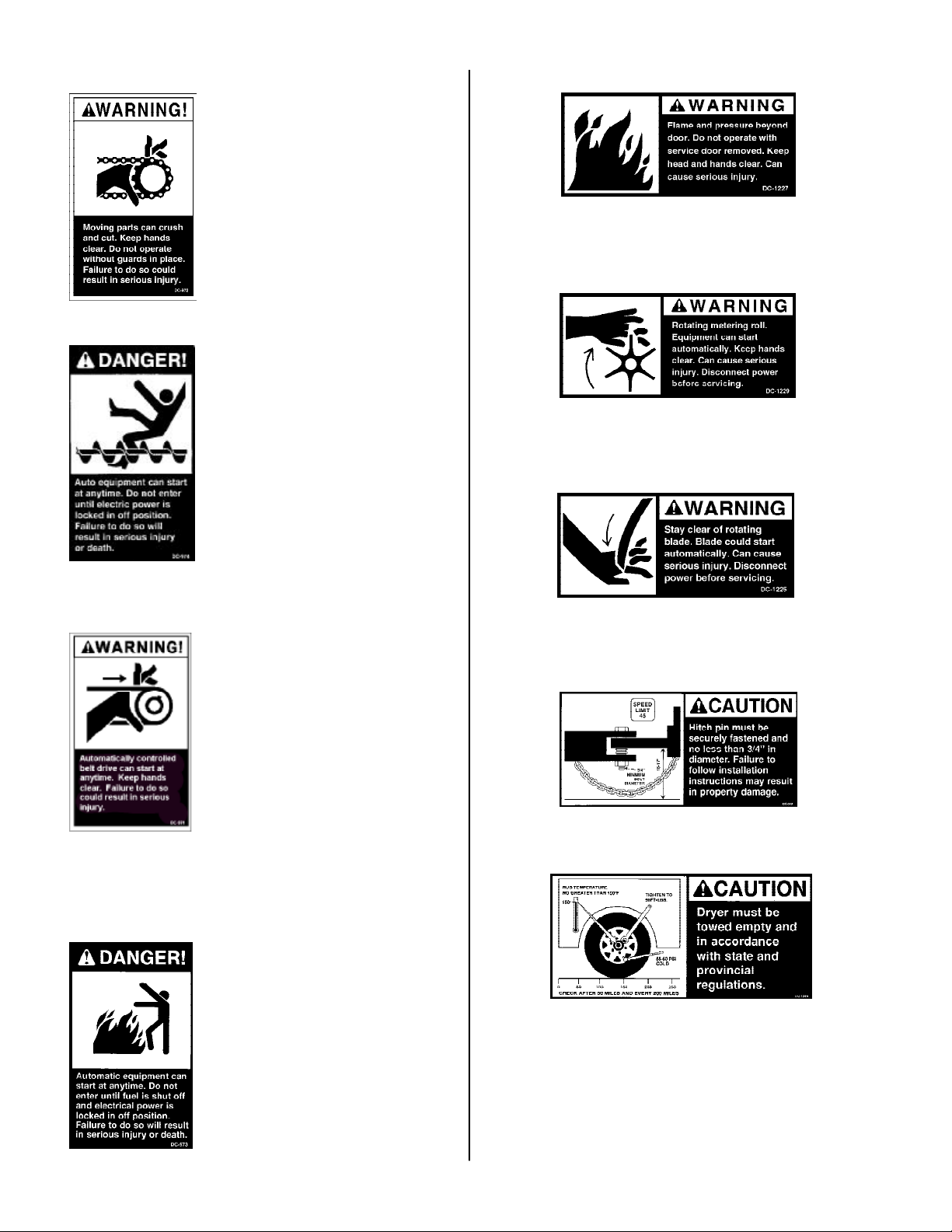

Decal: DC-972

SAFETY

Decal DC-972 is located on the bottom

auger belt guard and the front bearing plate

(which is visible when then bottom auger belt

guard is removed). An alternate location

would be at the rear of the dryer for portable

dryers equipped with the Front Discharge

Option.

Decal: DC-1227

Decal DC-1227 is located on the fan/heater access door.

Decal: DC-1229

Decal: DC-974

Decal: DC-971

Decal DC-974 has several different locations. Two are located on the front end

panel below the fan/heater. Two are located

on the rear end panel below the rear access

door. Two are located on the auger discharge

box (one on the outside top and one on the

inside of the flapper lid next to the discharge

mercury switch). One more of these decals

is located inside the plenum on the rear plenum closure door just inside the rear access

door.

Decal DC-971 is located on the bottom

auger belt guard and the front bearing plate

(which is visible when then bottom auger belt

guard is removed). An alternate location

would be at the rear of the dryer for portable

dryers equipped with the Front Discharge

Option.

Another location for decal DC-971 is

the top auger belt guard (one on the belt guard

cover and one inside on the belt guard body

visible when the belt guard cover is remove).

Decal DC-1229 is located on each of the meter roll access

doors.

Decal: DC-1225

Decal DC-1225 is located on the fan/heater access door.

Decal: DC-388

Decal DC-388 is located on the hitch tongue.

Decal: DC-1249

Decal: DC-973

6

Decal DC-973 is located on the rear ple-

num access door (inside and outside).

Decal DC-1249 is located on the hitch tongue.

PNEG-1459 L Series Operators

Page 7

SPECIFICATIONS

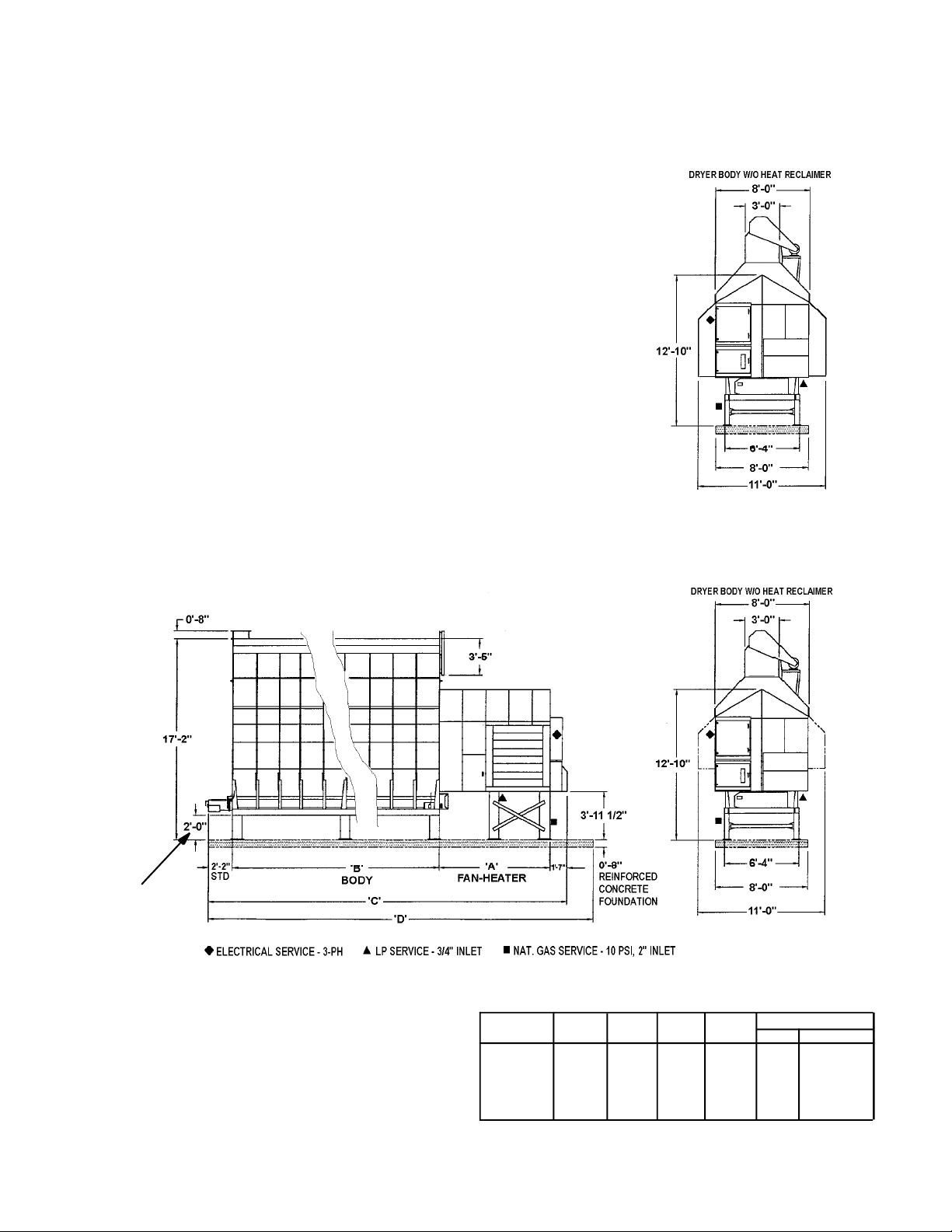

Models 3020L, 4026L, 6034L,

7534L, and 1038L for Dry & Cool:

Designed for drying in the top 2/3 of

the grain column and vacuum cooling

in the lower 1/3 of the grain column,

thus reclaiming the heat in the grain

to preheat the drying air.

Field Conversion: Converter packages are available to permit conversion from Full Heat to Dry & Cool

(pressure or vacuum cooling).

GRAIN COLUMNS: Two 14" galvanized steel grain columns. Solid column dividers every two feet. Grain

movement through columns is controlled by advanced electronic variable speed metering roll drive control.

AUGERS: Automatically controlled

top leveling auger. Bottom auger

unloads grain discharged from metering rolls. Heavy-duty construction.

MOISTURE CONTROL: Automatic

moisture control system uses control

computer to modulate meter roll

speed.

AUTOMATIC CONTROL: Automatic

control of loading, drying, cooling,

and discharge functions. Full safety

control system; automatic shutdown

on wet grain outage, grain Hi-Limit,

and discharge safety shutoff.

Section1: SPECIFICATIONS

SEE

NOTE 1

NOTE 1:

2’ LEG HEIGHT IS STANDARD.

OTHER HEIGHTS ARE AVAILABLE.

*

ALL MODELS:

DRYER BODY EXPANDS FROM

8’ TO 11’ WITH HEAT RECLAIMER

Fig. 1-1 Centrifugal dryer dimensions

PNEG-1459 L Series Operators

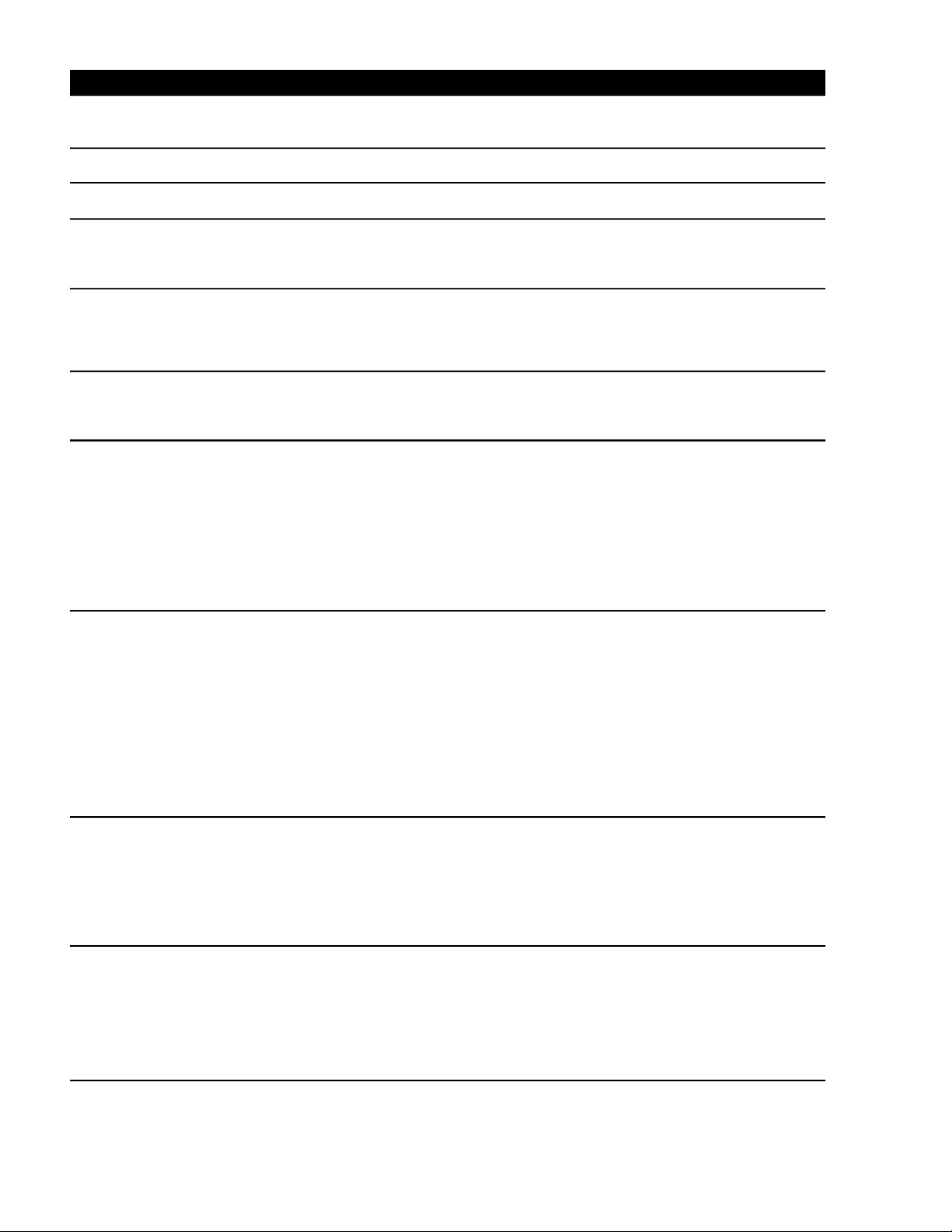

Model

3020L

4026L

6034L

7534L

1038L

‘A'

9'-6"

9'-6"

10'-11"

10'-11"

10'-11"

‘B'

20'-0"

26'-0"

34'-0"

34'-0"

38'-0"

‘C'

33'-3"

39'-3"

48'-8"

48'-8"

52'-8"

‘D'

37'-0"

43'-0"

52'-0"

52'-0"

56'-0"

Leg Pairs Required

Body Fan-Heater

32

42

52

52

52

7

Page 8

SPECIFICATIONS

SPECIFICATIONS CHART

TABLE 1-1 C-2100B SERIES SPECIFICATIONS

Basic Construction

Grain Column by Length

Grain Column Width

Total Holding Capacity

Wet Bin Capacity

Dry Section

Cool Section

Transport Dimensions:

Body Module

Length w/ Hitch

Width

Height

Fan Module

Length

Width

Height

Installed Dimensions

Grain Section Length

Fan-Heater Section

Length

Total Length

Width - w/ Heat

Reclaiming

Max. Width - w/o Heat

Reclaiming

Overall Height

Centrifugal Fan Type

Fan Motor

Burner - Max. Capacity

(Millions)

Top Auger

Capacity

Bottom Auger

2

Capacity

Meter Roll Drive

Electrical Load - Dryer

Only (3-PH)

Drying Capacity Shelled Corn

3

4

Dry & Cool 20-15%

Dry & Cool 25-15%

Full Heat 20-15%

Full Heat 25-15%

3020L

One module

with two zones

20 ft.

14 in.

595 bu.

135 bu.

307 bu.

153 bu.

29'-2"

8'-0"

12'-10"

11'-1"

8'-0"

8'-10"

20'

11'-1"

33'-3"

11'-0"

8'-0"

1

17'-2"

DIDW

30 HP

7 M Btu/Hr.

8", 7.5 HP

2800 BPH

8", 7.5 HP

1360 BPH

3/4 HP, SCR

117A @ 230V

59A @ 460V

595 BPH

350 BPH

945 BPH

550 BPH

4026L

One module

with two zones

26 ft.

14 in.

775 bu.

175 bu.

400 bu.

200 bu.

35'-2"

8'-0"

12'-10"

11'-1"

8'-0"

8'-10"

26'

11'-1"

39'-3"

11'-0"

8'-0"

1

17'-2"

DIDW

40 HP

9 M Btu/Hr.

8", 10 HP

2800 BPH

8", 10 HP

1770 BPH

3/4 HP, SCR

155A @ 230V

78A @ 460V

774 BPH

455 BPH

1220 BPH

720 BPH

6034L

One module

with two zones

34 ft.

14 in.

1010 bu.

229 bu.

521 bu.

260 bu.

43'-2"

8'-0"

12'-10"

12'-6"

8'-0"

8'-10"

34'

12'-6"

48'-9"

11'-0"

11'-0"

1

17'-2"

DIDW

60 HP

12 M Btu/Hr.

8", 10 HP

2800 BPH

8", 10 HP

2315 BPH

3/4 HP, SCR

205A @ 230V

103A @ 460V

1010 BPH

585 BPH

1610 BPH

940 BPH

7534L

One module

with two zones

34 ft.

14 in.

1010 bu.

229 bu.

521 bu.

260 bu.

43'-2"

8'-0"

12'-10"

12'-6"

8'-0"

8'-10"

34'

12'-6"

48'-9"

11'-0"

11'-0"

1

17'-2"

DIDW

75 HP

12 M Btu/Hr.

8", 10 HP

2800 BPH

8", 10 HP

2315 BPH

3/4 HP, SCR

240A @ 230V

120A @ 460V

1070 BPH

620 BPH

1680 BPH

980 BPH

1038L

One module

with two zones

38 ft.

14 in.

1129 bu.

256 bu.

582 bu.

291 bu.

47'-2"

8'-0"

12'-10"

12'-6"

8'-0"

8'-10"

38'

12'-6"

52'-9"

11'-0"

11'-0"

1

17'-2"

DIDW

100 HP

12 M Btu/Hr.

8", 15 HP

2800 BPH

8", 10 HP

2585 BPH

3/4 HP, SCR

310A @ 230V

155A @ 460V

1210 BPH

700 BPH

1900 BPH

1100 BPH

Dryer Specs

8

1.Overall height includes 24" high foundation supports, less 8" hopper.

2.Actual discharge rate is controlled by meter roll speed adjustment, at 5% to 100% of maximum rate.

3.Excludes auxiliary load and unload conveyor equipment.

4.Capacities listed are wet bushels at listed input moisture content and are estimates based on drying

principles, field results, and computer simulation. Variances may occur due to the grain's physiological

factors (kernel size, chemical composition, variety, maturity), excessive fines, adverse weather

conditions, etc.

PNEG-1459 L Series Operators

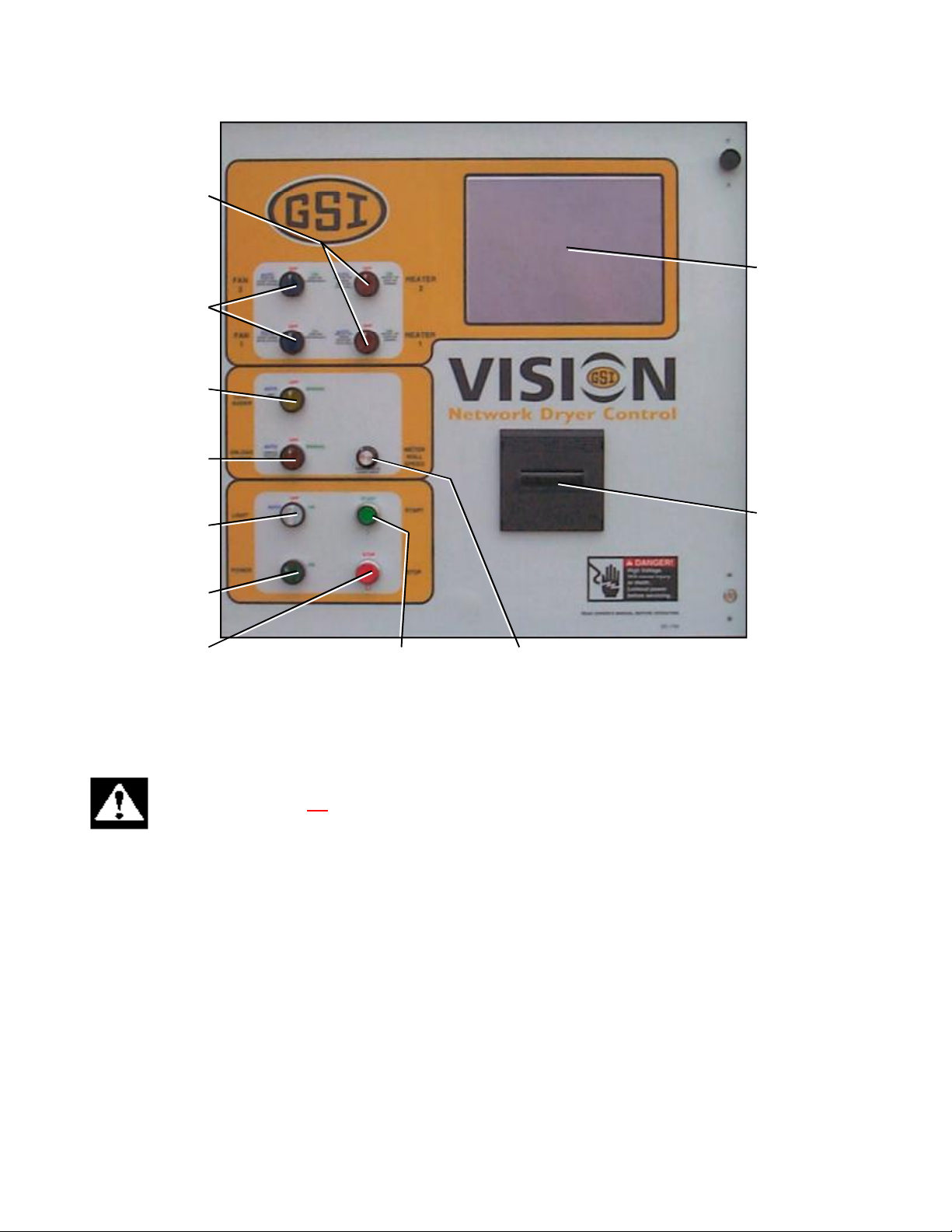

Page 9

Heater Switches

Fan Switches

Load Auger Switch

Unload Auger

Switch

Operator Light

Switch

VISION CONTROL PANEL

Vision Control Panel Layout

Touch Screen

Moisture Manager

Printer (Optional)

Control Power Switch

Stop Switch

Start Switch Meter Roll Speed

CONTROL POWER SWITCH

The control power to energize the Vision Control System is turned on or off with this switch.

Note: This switch does not disconnect the power that is present at the breakers, contactors, transformer(s),

fuses or other electrical components found in the upper and lower control boxes. Turn the Main Disconnect

Handle to the OFF position prior to servicing any of the installed components.

FAN SWITCH

Each fan is turned on or off with this switch. The on position operates the fan continuously during staged batch and continuous

flow modes. The auto position operates the fan in staged batch during the dry and cool cycle but the fan will not operate during

the unload cycle. The switch will light up whenever the air pressure switch is sensing air pressure and the dryer is full of grain.

Note: The bottom fan on your dryer is always Fan 1.

HEATER SWITCH

Each burner is turned on or off with this switch. The auto position operates the burner in staged batch during the dry cycle only.

The on position will operate the burner only when the fan is running. The switch will light up only when the flame sensor

detects the flame.

Note: The bottom burner on your dryer is always Burner 1.

PNEG-1459 L Series Operators

9

Page 10

VISION CONTROL PANEL

LOAD AUGER SWITCH

This is used to select the operation of the fill auger. In both the auto and manual position the load auger will operate if the dryer

is low on grain and will automatically shut off when the dryer is full. In the auto position only the dryer will shut down after a

preset period of time set on the out of grain timer if grain flow is interrupted to the dryer. The load delay is disabled when the

load auger switch is in the manual position. The switch will light whenever the load auger is operating.

Note: If the load auxiliary controls are being used, this switch will also control the operation of the auxiliary equipment.

UNLOAD SWITCH

The unload switch turns the metering rolls and discharge auger on or off, and selects the operation of the metering rolls. In the

manual position the meter rolls will operate in 1 speed only. In the auto position the meter rolls switch to a multi-speed mode

for moisture control operation. The switch will light whenever the load auger is operating.

Note: If the unload auxiliary controls are being used, this switch will also control the operation of the auxiliary equipment.

OUTSIDE LIGHT SWITCH

The dryers outside service light is turned on or off here. It also may be set on auto, which turns the light on while the dryer is

running and off if a shutdown occurs.

START SWITCH

This switch starts and operates the dryer based on switch settings. If other switch settings are in the off position, individual

dryer components can be operated by turning the drying mode switch to continuous flow, pressing the dryer power run button

and then turning on the desired dryer component.

STOP SWITCH

This switch stops all dryer functions. If an automatic dryer shutdown occurs, first determine and correct the cause of the

shutdown. Then, press the dryer power stop button to reset the dryer before restarting.

10

PNEG-1459 L Series Operators

Page 11

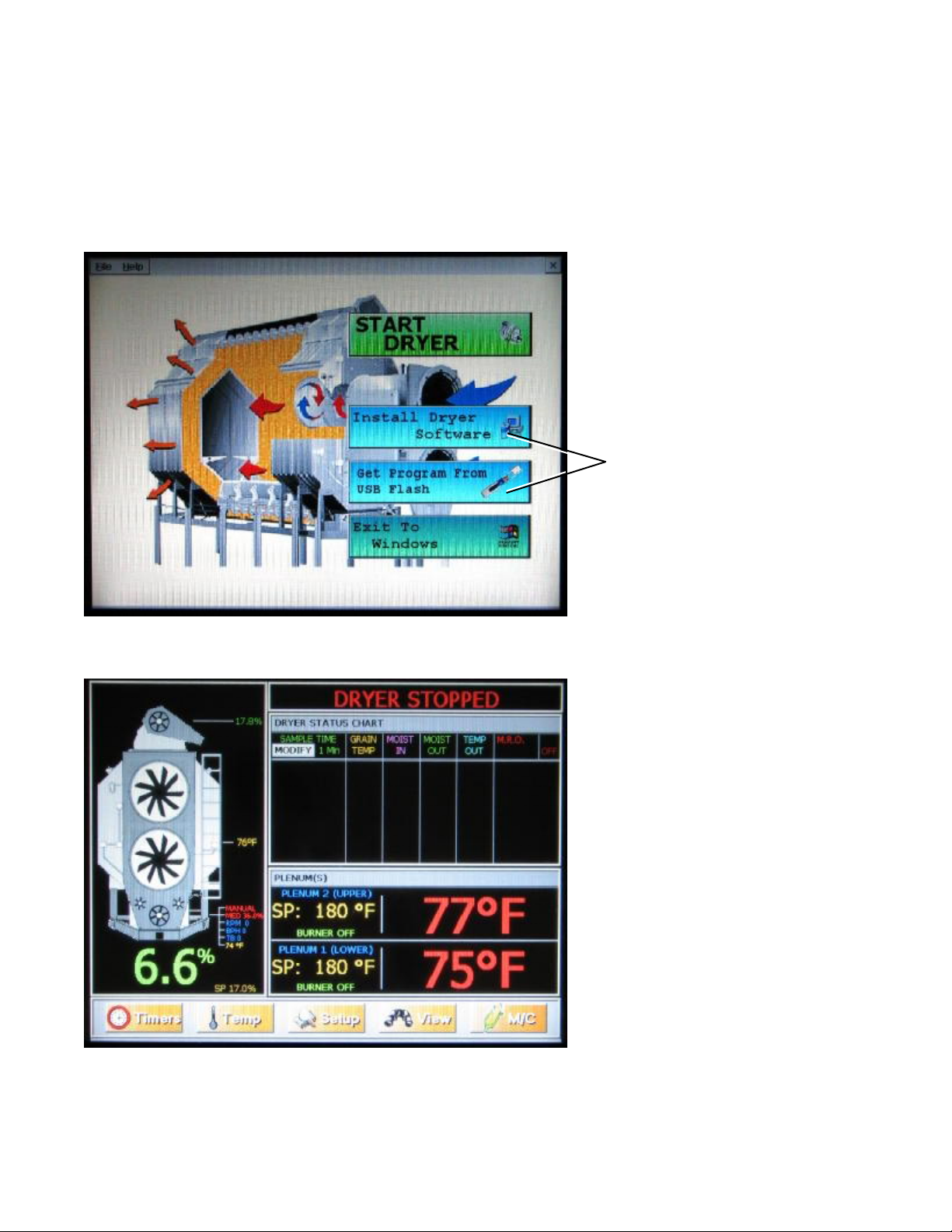

VISION TOUCH SCREEN DISPLAY

THIS SECTION SHOULD BE READ FIRST TO FAMILIARIZE YOURSELF WITH THE VISION CONTROL

COMPUTER. THE DRYER OPERATION SECTION OF THIS MANUAL WILL REFER TO INSTRUCTIONS IN

THIS SECTION.

BOOT SCREEN

With the Power Switch in the on position, pushing the Start Switch will start the Vision computer. The first screen to appear will

be the boot screen (see image above). Notice that there are three “buttons” on the boot screen. The Update / Change Program

and Look For New Program On Flash Card buttons are only used for program updates that may be released at a later date.

Touching the Start Dryer button will display the Default Operation Screen.

These two buttons are used

to update software.

(See PNEG-1506 Vision

Programming Manual)

DEFAULT OPERATION SCREEN

As you can see the Operation Screen is divided

into five sections.

1.) Dryer operation animation: Located on

the left side of the Operation Screen the

operation animation shows the status of the fan/

heaters, load and unload augers and meter rolls.

It will also display the grain temp., moisture

content, M/C setpoint, and bushel counter.

2.) Dryer Status: Located at the very top of

the right side of the Operation Screen the Dryer

Status will tell you if the dryer is stopped,

started, loading, or unloading.

3.) Dryer Status Chart: Located directly

below Dryer Status. This chart will show the

grain temperature, moisture in/out, temperature

out and Meter Roll Output (M.R.O.) over a

period of time.

4.) Plenum(s): Located directly below Dryer

Status Chart. This will show the plenum temperature set point (SP), actual plenum temperature and burner status.

5.) Setup Buttons: Located across the bottom of the Operation Screen. By touching these buttons the timers, temperature set

points, dryer model and moisture control can be set up.

PNEG-1459 L Series Operators

11

Page 12

VISION TOUCH SCREEN DISPLAY

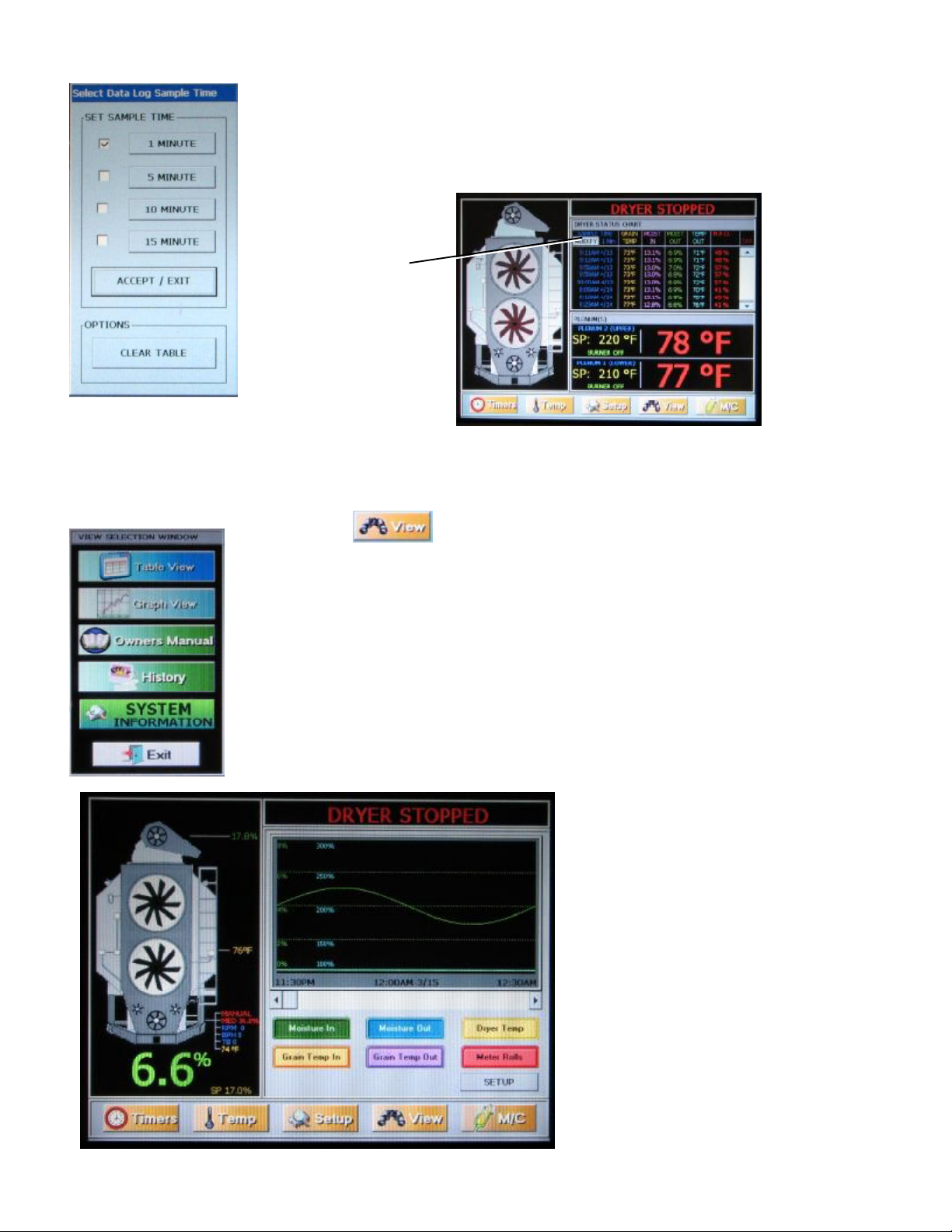

SELECT DATA LOG SAMPLE TIME

Notice the Modify button in the upper left hand side of the Dryer Status Chart. By touching this

button the sample time can be changed from 1 minute to 5, 10 or 15 minutes. Select the desired

sample time and touch Accept/Exit button to exit. Also notice that the chart can be cleared by

selecting the Clear Table button at the bottom.

Modify button

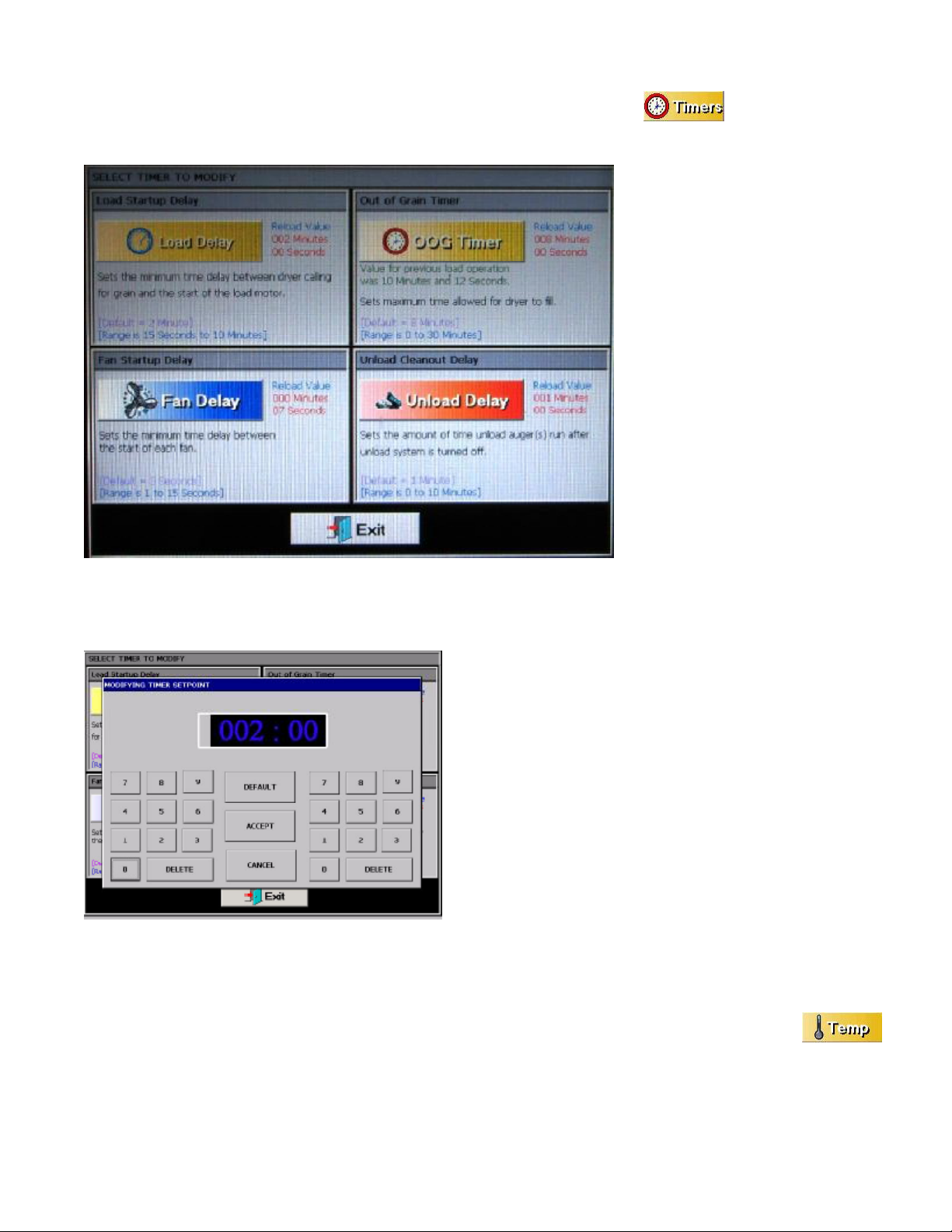

OPTIONAL OPERATION SCREEN

An optional Operation Screen can be selected that shows a graph instead of the chart view.

Touching thebutton at the bottom of the display will bring up the View Selection Window. Notice that you have four selections to choose from.

1.) Table View: This is the Default Operation Screen view (described on previous page).

2.) Graph View: This is the Optional Operation Screen view (shown below).

3.) Owners Manual: This option is described in greater detail on page 16.

4.) History: This option is described in greater detail on page 16.

5.) System Information: Touching this button will display the current software version your dryer

is running, and the time and date.

Touch the Graph View button then touch the

Exit button. The Optional Operation Screen

will appear. Notice that the Dryer Status Chart

and the Plenum(s) sections have been replaced

by the graph view (see image below). You can

choose what the graph will display by touching

any of the colored buttons under the graph (i.e.

Moisture In, Moisture Out, Dryer Temperature,

Grain Temperature In, Grain Temperature Out

and Meter Rolls).

Touching these buttons once will display them

on the graph, and touching them again will

remove them from the graph.

12

The Setup button will bring up the Graph

Setup Window and allow you to choose the

length of time (1, 2, 4 or 8 hours) for the

horizontal scale.

PNEG-1459 L Series Operators

Page 13

VISION TOUCH SCREEN DISPLAY

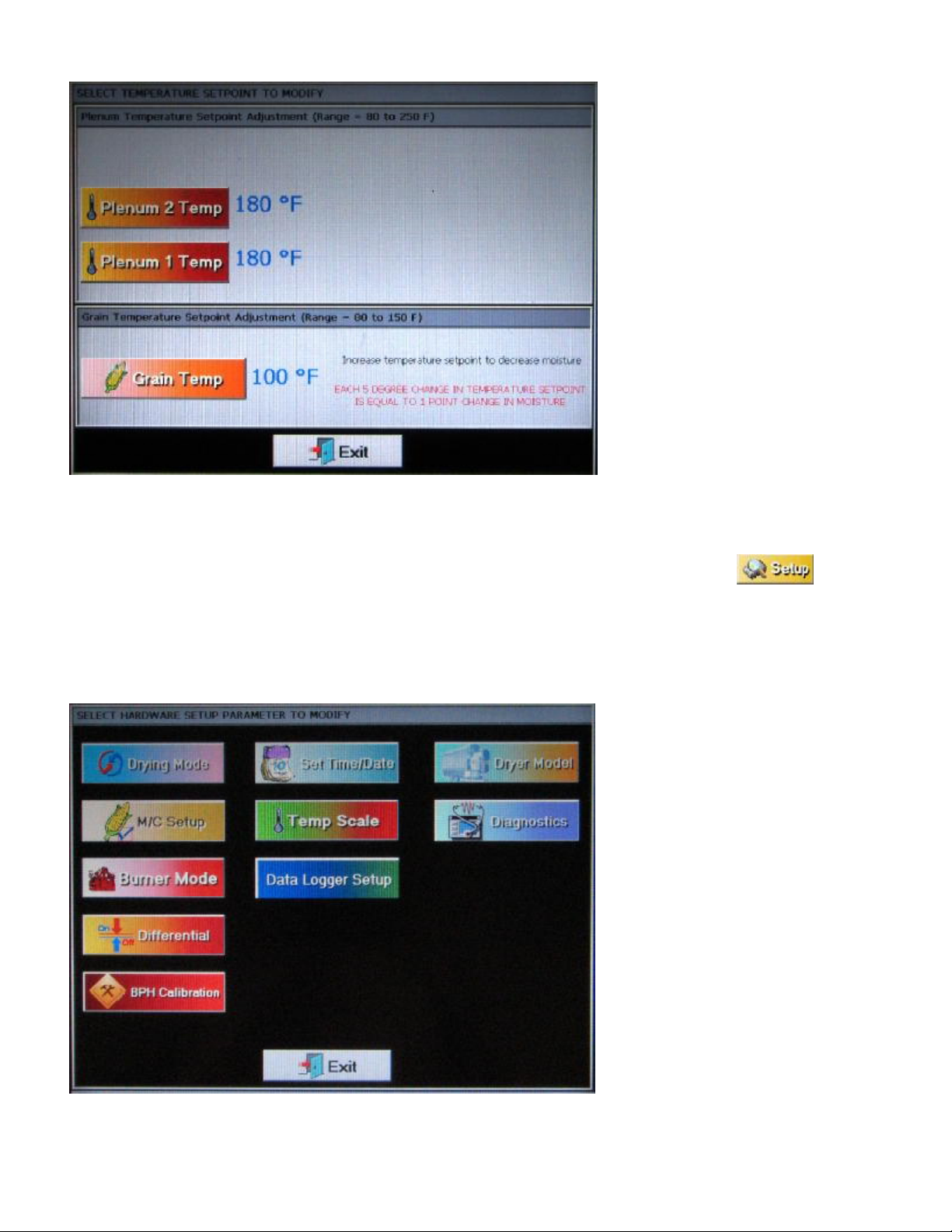

SETTING THE TIMERS

Setting the timers for the dryer is a simple procedure. To set the timers touch the buttonat the bottom of

Operation Screen. A new screen will appear called the Select Timers to Modify screen (shown on the left). As you can see there

are 4 timers that you can modify:

1.) Load Delay: (Default setting - 2

minutes)This delay is used to delay the

starting of the load auger when the

dryer is unloading to prevent the load

auger from cycling to often. The load

delay is active only when the load auger

switch in the auto position.

2.) Out of Grain (OOG) Timer:

(Default setting - 8 minutes)The OOG

timer should be set to the maximum

time it takes for your dryer to refill

during continuous or batch drying

modes. Note that the computer will

display the time required to fill your

dryer on the previous load operation to

aid you in setting an accurate time. If

the dryer runs out of grain while the

load auger switch is in the auto position, the OOG timer automatically shuts

off the dryer after the period of time

preset on the timer.

3.) Fan Delay: (Default setting - 3 seconds) The Fan Sequence Delay timer controls the amount of time between each fan startup to reduce the dryer start-up amperage.

4.) Unload Delay: (Default setting - 1 minute)The Unload Delay

timer is used to control the amount of time the unload auger runs

after the metering rolls stop to allow the unload auger to clean itself

out.

To setup a timer touch the button of the timer you wish to modify.

The Modify Timer Setpoint screen will then be displayed (see

image at left). Note that there are two number pads on this modify

screen. The left number pad is used to modify the minutes and the

right number pad will modify the seconds. Touching the Default

button will automatically set the timer to the default setpoint for

that timer. The Accept button will save the timer setpoint displayed

in the time display. Touching Cancel will exit the Modify Timer

Setpoint screen without saving any changes and the timer will stay

at the currently saved setpoint.

Once you have the timer setpoints set touching the Exit button at the bottom of the Modify Timer Setpoint screen will return you

to the Operation Screen.

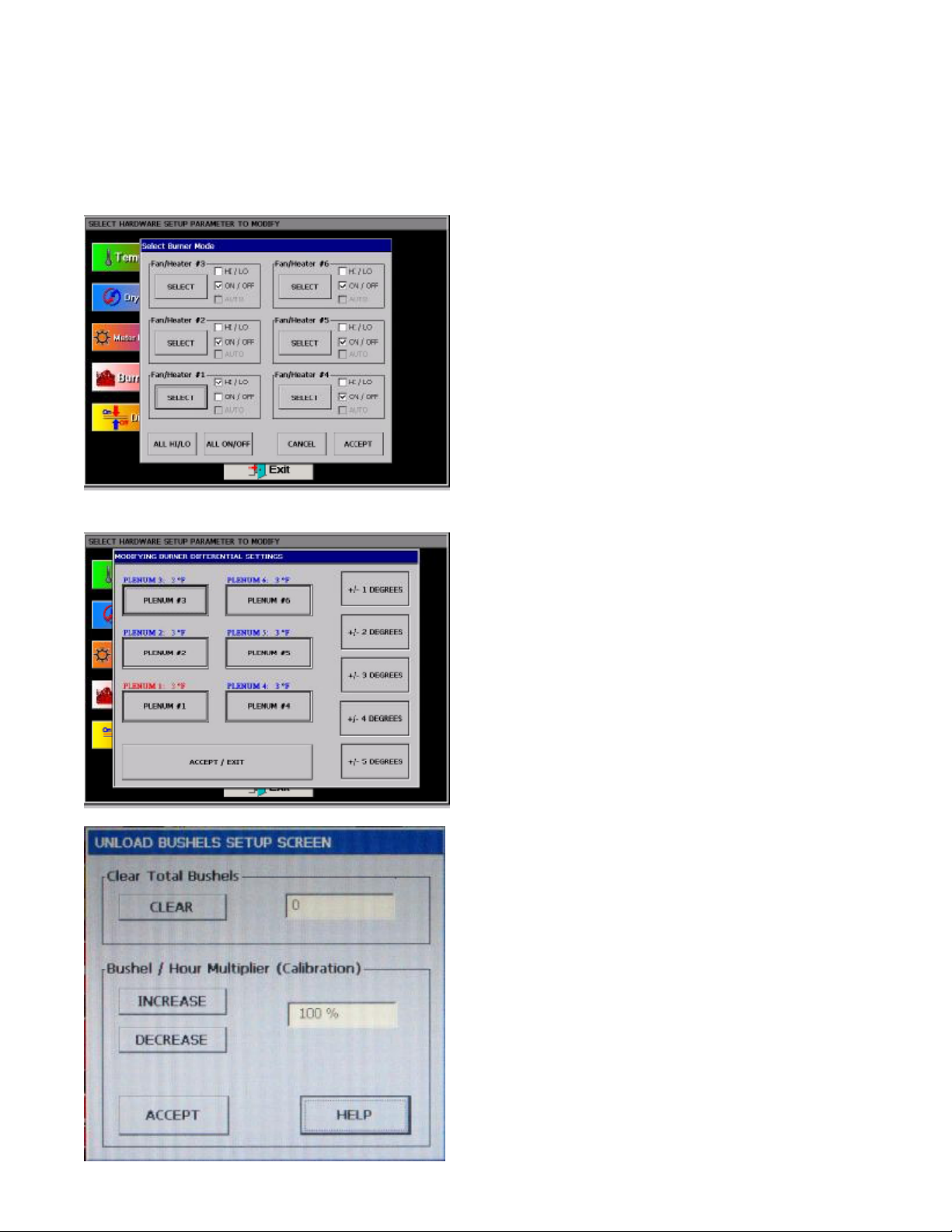

SETTING THE TEMPERATURES

Setting the temperature setpoints for the dryer is a simple procedure. To adjust the temperture setpoints touch the

button at the bottom of Operation Screen. A new screen will appear called the Select Temperature Setpoint to Modify screen

(shown at the top of the next page). As you can see you modify the setpoint for each of the plenums by touching the desired

plenum button.

NOTE: Plenum one is the bottom plenum and plenum two is the top plenum for a two fan dryer. Use plenum one for a single

fan dryer.

PNEG-1459 L Series Operators

13

Page 14

VISION TOUCH SCREEN DISPLAY

The plenum temperature setpoint range

is 80oF - 250oF, and the current temperature setpoint for each plenum is displayed next to the corresponding

plenum button.

The grain temperature setpoint range is

80oF - 150oF, and the current temperature setpoint for the grain temperature is

displayed next to the Grain Temp.

button.

Modifying a temperature setpoint is

much like setting a timer described on

the previous page. Touch the desired

button of the setpoint you wish to

change. The Modify Temperature

Setpoint screen will appear. Enter the

desired temperature using the displayed

number pad then touch the Accept

button. Touching the Exit button at the

bottom of the Select Temperature Setpoint to Modify screen will return you to the Operators Screen.

THE SETUP SCREEN

The Setup Screen will allow you to setup other parameters of your dryer. To use the Setup Screen touch thebutton. The Select Hardware Setup Parameter To Modify screen will now be displayed. As you can see there several different

parameters that can be modified on this screen:

1.) Drying Mode: Touching the Drying Mode button will display the Select Drying Mode window. Touch the desired drying

mode button (Continuous Flow or Staged Batch). A check mark is displayed next to the currently selected drying mode.

2.) Set Time/Date: Touching the Set

Time/Date button will display the Set

Time/Date window. Use the up and

down buttons to change each of the

parameters for date and time. Touch

Accept / Exit to save settings and return

to the Select Hardware Parameter To

Modify screen.

3.) Dryer Model: Touching the Dryer

Model button will display the Dryer

Hardware Setup window. In order for

your dryer operate properly the following items must be entered correctly:

a) Number Fan/Heaters

b) Load System

c) Dryer Length (ft.)

d) Number Modules

e) Fuel

Touch the select button until a check

mark appears next to the parameter

corresponding to your dryer model.

4.) M/C Setup: The M/C Setup operations are described in greater detail in the dryer operation section of this manual.

14

PNEG-1459 L Series Operators

Page 15

VISION TOUCH SCREEN DISPLAY

5.) Temp Scale: Touch the Temp. Scale button to choose either English units or SI units temperature scales. Depending what

temperature scale you now operating in touching this button will display a popup window asking if you want to switch to SI

(Celsius, metric tons, etc..) or English units (Fahrenheit, bushels, etc..)

6.) Diagnostics: The Diagnostics operations are described in greater detail in the service section of this manual.

7.) Burner Mode: Touching the Burner Mode button will display

the Select Burner Mode screen (see image at left).

NOTE: The bottom fan heater on a two fan dryer is always fan

heater one.

The Select Burner Mode screen will allow the operator to select

the type of burner operation for each burner. In the HI/LO mode

the burner will switch from high heat to low heat when the plenum

temperature setpoint has been reached. In the ON/OFF mode the

burner will shut off when the upper temperature setpoint has been

reached. To select either the HI/LO or ON/OFF modes touch the

Select button for the fan heater you wish to change. Touching the

All HI/LO button will set all burners to HI/LO mode and touching

All ON/OFF will set all burners to ON/OFF mode. Touch the

Accept button to save any changes and return to the setup screen

or touch Cancel to return to setup screen without saving any

changes to the burner modes.

8.) Differential: Touching the Differential button will display the

Modify Burner Differential Settings screen (see image at left).

Adjusting the burner differential settings allows the operator to

keep the plenum temperature within a certain range. For example:

If you have the temperature setpoint at 180 degrees and you select

+/- 3 degrees as the burner differential, then the burner will switch

to low heat at 183 degrees and back to high heat at 177 degrees.

To modify a burner differential setting first touch the plenum

button you wish to modify, then select one of the five differential

setting button on the right side of the Modify Burner Differential

Settings screen. Touch the Accept / Exit button to save settings

and return to the Select Hardware Setup Parameter To Modify

screen.

9.) BHP Calibration: Touching the BHP Calibration button will

display the Unload Bushels Setup screen (see image at left). As

you can see the bushel counter can be cleared by touching the

CLEAR button. However if the bushel counter is out of calibration

it can be calibrated by touching the INCREASE and DECREASE

buttons.

Example: If you ran 1000 bushels through the dryer but the

bushel counter on the dryer reads 900 bushels then touch the

DECREASE button until the calibration reads 90%, or if you ran a

1000 bushels and the counter reads 1100 bushels then touch the

INCREASE button until the calibration reads 110%.

PNEG-1459 L Series Operators

When you are finished with the calibration or clearing the bushel

counter touch the ACCEPT button to return to the Hardware Setup

Parameter screen.

15

Page 16

VISION TOUCH SCREEN DISPLAY

10.) Meter Roll Reverse: Touch the Meter Roll Reverse button to reverse the metering rolls. Reversing the metering rolls aids

in cleaning out the fine material that builds up over the course of the drying season. Just touching this button will toggle

between normal meter roll operation and reversed meter roll operation.

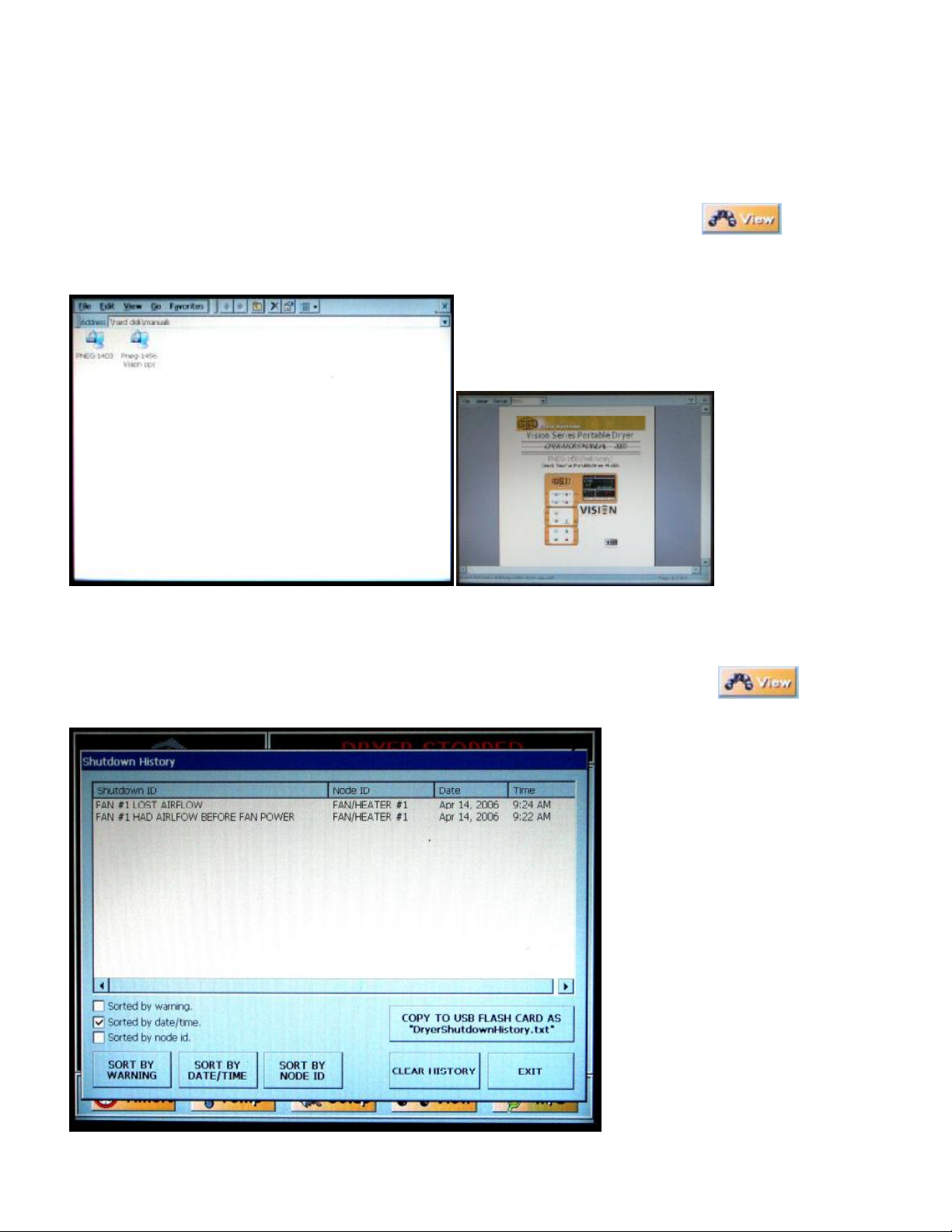

VIEWING THE OWNERS MANUALS ON THE DISPLAY SCREEN

The operators and parts manuals can be viewed on the display screen. To view a manual touch thebutton.

When the View Selection Window appears touch the Owners Manual button. A new display will appear called an explorer

window (shown below). The explorer window will show the manuals that are stored in the computer memory. In this case they

are PNEG-1403 (2 Fan Vision Parts), and PNEG-1456 (1 & 2

Fan Vision Operators). To select a manual to view you must

“double tap” the desired manual icon. Much like double

clicking a mouse on your computer. Once selected it may take

a few seconds for the manual to be displayed. Once the manual

is displayed use the scroll bars on the right to scroll through the

pages of the manual.

To exit the manual

and return to the

Operation Screen

touch the X button in

the upper right corner

of the screen.

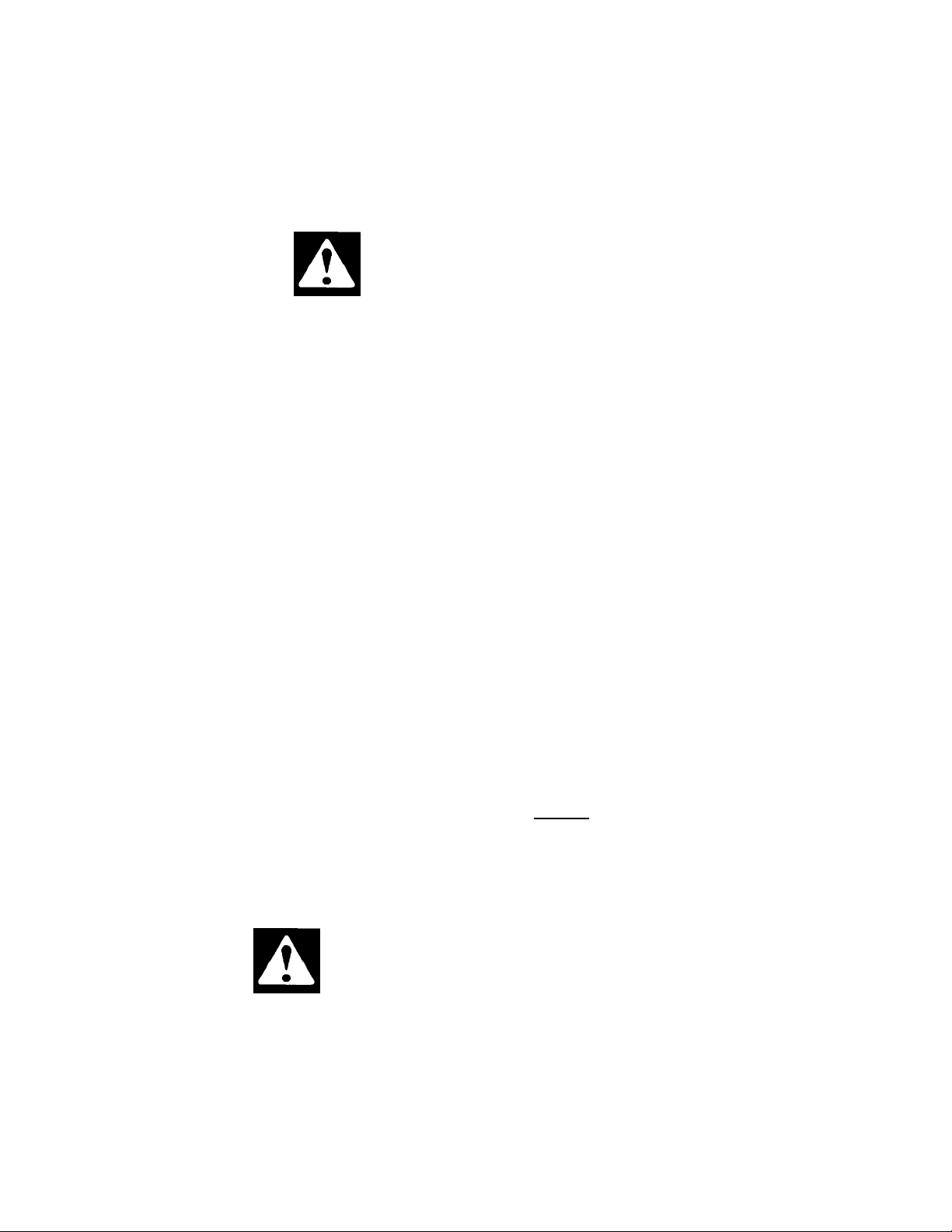

VIEWING THE DRYER SHUTDOWN HISTORY

The dryer will keep track of all safety shutdown warnings. To view the Shutdown History touch thebutton.

When the View Selection Window appears touch the History button. A new window called Shutdown History will appear. A list

of all shutdown warnings are listed.

This list can be sorted by:

1.) Warning

2.) Date/Time

3.) Node

by touching any of the three sort by

buttons.

The whole list can be copied to a USB

flash drive and transferred to a personal

computer as a text file by touching the

Copy To USB Flash Card button.

The list can also be cleared to start a

new list by touching the Clear History

button.

To return to the Operators Screen touch

the Exit button.

16

PNEG-1459 L Series Operators

Page 17

TEST FIRING

DRYER PRESEASON CHECKS

This section gives a series of checks to be carried out on the dryer before starting for the first time in the drying

season. If any of the checks fail to produce the stated result, you should consult your dealer.

YOU SHOULD NOT ATTEMPT TO USE THE DRYER UNLESS ALL THE PRE-START CHECKS HAVE

BEEN SUCCESSFULLY COMPLETED.

BEFORE ATTEMPTING TO

OPERATE THE DRYER MAKE SURE ALL SAFETY SHIELDS ARE IN PLACE, ALL BOT-

TOM CLEAN OUT AND REAR ACCESS DOORS ARE CLOSED AND ALL PERSONNEL ARE

CLEAR OF THE DRYER

INSPECT THE METERING ROLLS

Open all metering roll access doors and inspect each compartment for any bolts, nuts or other foreign material, that may

cause possible jamming of the metering rolls.

CHECK CONTROL PANEL SWITCHES

Before applying electrical power to the dryer, be sure that all switches on the dryer control panel are in the OFF position.

ELECTRICAL POWER

Turn on the electrical power supply to the dryer, set all circuit breakers to on, including the safety disconnect handle mounted

on front of the dryer power panel.

CONTROL POWER SWITCH

Turn the control power switch to on. At this point the controller will lock out all other dryer functions. Once the Boot

Screen appears (see page 12), touch the START DRYER button and the dryer will perform a safety circuit check. If a fault is

found, the cause will be displayed on the Main Screen. If all are found safe, the controller will supply power to the electronic

fuel shut-off valve (Maxon), if so equipped, and the start switch will light up, indicating that the dryer is ready to be started.

START SWITCH

Push the dryer start switch, and all the selector switches on the control panel will be activated.

FUEL CHECK

If using LP gas, make sure the tank has plenty of fuel and that the tank does not have a regulator mounted on the liquid line.

Slowly open the main fuel supply valve at the tank. Then, open the electronic shut off valve (Maxon valve), if so equipped, or

open the manual shut off valve on the dryer to allow fuel flow to the dryer.

If using natural gas, make sure an adequate supply is available. Turn on the valve along the supply line. Then, open the electronic shut off valve (Maxon valve). Inspect all gas lines and connections for possible leaks.

Any gas leaks must be fixed immediately!

LOAD AUGER

With the grain supply shut off, quickly bump the load auger switch to manual, and see if the load auger rotates clockwise as

viewed from the drive end, or counterclockwise if the dryer is a front load model. If the wet grain supply auxiliary is wired to

the dryer it should also rotate in the correct direction at this time.

Turn the load auger switch to the auto position. The top auger and wet grain supply auxiliary should run for eight (8) min-

PNEG-1459 L Series Operators

17

Page 18

TEST FIRING

utes, and then the dryer will shutdown leaving the safety shutdown message (out of grain warning) displayed. Press the dryer

power stop button to reset the panel, then press the start button.

UNLOAD AUTO OPERATION

To check auto operation place the unload switch in the auto setting. Turn the meter roll dial until the meter rolls start rotating. The bottom auger should rotate counterclockwise as viewed from the drive end. The meter roll drive motor should rotate clockwise as viewed from the drive end of the gear box. If the dry grain take away auxiliary is wired to the dryer, it

should start and rotate in the proper direction.

UNLOAD MANUAL OPERATION

To check manual operation move the unload switch to the manual position. Turn the meter roll dial until the meter rolls start

rotating. The bottom auger should rotate counterclockwise as viewed from the drive end. The meter roll drive motor should

rotate clockwise as viewed from the drive end of the gear box. If the dry grain take away auxiliary is wired to the dryer, it

should start and rotate in the proper direction.

METER ROLL OPERATION

To check the meter roll operation turn the knob clockwise, and the meter roll speed should increase. Turning the knob counterclockwise will decrease the speed. When the meter rolls are set to maximum (1000) the meter roll speed should be 17.5

RPM for 8” (20 cm) discharge augers. Make sure the drive chain tension is properly adjusted and all sections of the meter

rolls rotate. Turn the unload switch off after these checks are complete. The bottom auger will continue to run for 60 seconds (default clean out delay setting) after the switch is turned off to allow for clean out.

Note: Due to the nature of the DC drive motor used on the meter rolls, it is possible for the brushes inside the motor

to become corroded if the dryer has not been operated for several months. This will cause the meter rolls not to function. To fix this problem, use a rubber mallet or a piece of wood to tap the DC drive motor. The shock is usually all

the motor needs to start working again. You should not have any more problems with this during the rest of your

drying season.

FAN SWITCHES

Momentarily turn each fan switch to on and observe the fan rotation. The fan should run counterclockwise. Sometimes on

three phase models all motors will run backwards. They can easily be reversed by interchanging two of the three power supply wires. All power should be switched and locked off before attempting to reverse the connections. Reverse the two outside wires, L1 and L3, and leave the middle one in the same position.

BURNER SAFETY

To check the burner safety function, first make sure the main gas valve is off. Turn the fan switch on and allow the fan to

start. Then, turn the heater switch on for that fan. The dryer will shut down after 20 seconds. The safety message, “Ignition

Failure Fan #” will appear. Reset the dryer and repeat for the other fan/heater(s).

BURNER TEST FIRE

To perform this test the dryer will need to be full of grain or the air switch need to be disabled. Test fire each burner by starting the fan. Turn on the fuel supply then, turn the burner switch to on and the burner should ignite after a short purge delay

of approximately 10 seconds. Gas pressure should be shown on the gauge. At this time adjust the plenum set point to 200°F

(93°C), causing the burner to operate on hi-fire. Observe the gas pressure on the gauge, and lower the plenum set point until

it causes the burner to cycle into lo-fire. When the plenum temperature set point is met, the gas pressure should show a noticeable drop, indicating that the cycle solenoid is closed and the burner is being supplied with less gas through the cycle solenoid bypass port. At this time set the hi-fire and lo-fire pressure settings. Use the pressure regulator (for LP models) or the

supply line ball valve (for nat. gas models) for hi-fire and the ball valve on the lo-fire bypass line for lo-fire (see images on page

39 for help). The computer should cycle the burners between high and low, approximately 1 to 3 times per minute.

Only use pressure required to obtain desired temperature.

18

PNEG-1459 L Series Operators

Page 19

TEST FIRING

Approximate settings should be:

LP GasHi-Fire 6-15 PSI (41-102 kPa)

Lo-Fire 2-6 PSI (14-41 kPa)

Natural GasHi-Fire 6-10 PSI (41-69 kPa)

Lo-Fire 1-3 PSI (7-20 kPa)

If the burner remains on hi-fire and does not cycle, increase the regulator setting on the propane models, or the supply valve

on the natural gas models in order to reach the plenum set point. If the burner remains in lo-fire and does not cycle, slightly

decease gas pressure with the lo-fire adjustment screw on the cycle solenoid. If the gas pressure is decreased too much a

popping or fluttering sound will be heard. This popping and fluttering should not be allowed to continue or damage to the

burner will occur. Also, anytime the high pressure side is adjusted, the low pressure side needs to be checked. Repeat the test

for each fan/heater unit.

Note: If the flame sensor fails to detect a burner flame or is defective and signals a dryer shutdown all systems will shut

down except for the blower motor. This is to prevent wear on the blower motor curcuit from repeated start ups and shut downs.

DRYER SHUTDOWN

To shut down the dryer,

1. Close the fuel supply valve at the tank or valve along the fuel line.

2. If the burner is operating, let the dryer run out of fuel, and it will shut down automatically due to loss of flame.

3. Close the fuel valve at the dryer, and press the dryer power stop button.

4. Turn off the control power.

5. Turn off the safety disconnect handle on the front of the power box, and turn off the main power to the dryer.

EMERGENCY

In case of emergency push the dryer stop button or the emergency stop button. This will interrupt power to the control panel

and the fan, burner and all augers will stop immediately.

PNEG-1459 L Series Operators

19

Page 20

DRYER OPERATION - START-UP

DRYER START-UP AND OPERATION

FULL HEAT DRYING

Full Heat Operation

With this type of drying, the grain is discharged hot, with no cooling. Drying capacity is substantially higher with FULL HEAT

than the DRY AND COOL process.

Final Moisture

From 1 to 3% apparent moisture is usually removed in the cooling process, so hot shelled corn is removed from the dryer at

about 17% moisture if the final desired moisture content is 15%.

DRYING TEMPERATURES

Shelled Corn

For shelled corn with an initial moisture content of 25-30%, the recommended maximum drying temperature is 220-240o F (104116o C) for the top fan and 170-190o F (77-88o C) for the bottom fan.

Small Grain

For drying small grain (wheat, oats, milo), 150o F (66o C) is suggested.

Soybeans

Drying temperatures are critical in drying rice and soybeans. A temperature of 130o F (54o C) is recommended to keep grain

temperature low.

Drying Efficiency

The general rule for obtaining the highest drying efficiency is to use the highest possible drying temperatures which will not

adversely affect grain quality.

DRYER SHUTDOWN

Cooling Hot Grain

If the dryer is to be shut down while filled with grain, it is recommended that hot grain be cooled for 10 to 15 minutes, especially in cold weather, to prevent water vapor condensation and possible freezing of such condensate following shut down.

INITIAL SETUP PARAMETERS

Turn the control power switch to on. When the Boot Screen appears touch the START DRYER button. The computer will run a

quick check of the system network after which the Operation Screen will appear.

TIMER AND DELAY SETTINGS

Setting the timers for the Vision Dryer is a simple procedure. To set the timers touchthe button at the bottom

of Operation Screen. A new screen will appear called the Select Timers to Modify screen (see page 13 for instructions on how

to set the timer and delays).

SETTING THE TEMPERATURES

Setting the temperature setpoints for the dryer is a simple procedure. To adjust the temperture setpoints touch the

button at the bottom of Operation Screen. A new screen will appear called the Select Temperature Setpoint to Modify screen

(see page 13 for instructions on how to set the temperatures).

START-UP

Start-up Procedure

At the beginning of each harvest and before filling the dryer with grain make sure to inspect the dryer for rodent damage, proper

belt and chain tension and missing or damaged safety shields. Test operate the dryer using the pre start check procedures.

1.Before attempting to operate the dryer make sure that all safety shields are in place, all plenum bottom closure panel doors

are closed, all rear access doors are closed and all personnel are clear of the grain dryer and grain handling machinery.

2.Turn all selector switches on the control panel to the off position.

20

PNEG-1459 L Series Operators

Page 21

DRYER OPERATION - START-UP

3.Turn on the electrical power supply to the dryer, and move the safety disconnect handle mounted on the dryer’s upper

power box to on.

4.Turn the control power switch to on. The switch will light up. The control computer will boot up. At this point the controller will lock out all other dryer functions. Once the boot screen appears, touch the Start Dryer button and the dryer will perform

its safety circuit checks. If a fault is found the cause will be displayed on the Display screen (touch screen). If all safeties do not

detect a problem the controller will allow the electronic fuel shutoff valve (Maxon) to be manually opened, if so equipped. The

dryer is ready to be started.

5.Move the load auger switch to manual, and push the dryer start switch. The top auger will immediately start, and the load

auger switch will light up. If additional loading equipment is wired to the dryer it will also start immediately.

6.When the dryer is full of grain the top auger will stop automatically, and any auxiliary loading equipment wired to the dryer

will also stop.

The dryer is now ready to begin drying grain. There are three moisture control options to use in the dryer operation:

1.) Dryer Operation - Basic Moisture Control (page 22)

2.) Dryer Operation - Intermediate Moisture Control (page 26)

3.) Dryer Operation - Advanced Moisture Control (page 30)

PNEG-1459 L Series Operators

21

Page 22

DRYER OPERATION - BASIC MOISTURE CONTROL

CONTINUOUS FLOW DRYING MODE USING BASIC MOISTURE CONTROL

Full Heat-Continuous Flow Operation

This section begins with step 7 and it is assumed that steps 1 through 6 in the start-up procedure described on page 20 & 21

have been completed.

7.Touch the SETUP button at the bottom of the Dryer Operation screen. Once the Hardware Parameter screen is displayed

touch the DRYING MODE button. When the Select Drying Mode window appears touch the CONTINUOUS FLOW button to

select continuous flow drying mode. Then touch the EXIT button and return to the Hardware Parameter screen. Touch the M/C

SETUP button. When the Moisture Control Selection window appears select the BASIC : REGULATION OF GRAIN TEMPERATURE : 2 MR SETPOINTS moisture control option. Touch the EXIT button and return to the Dryer Operation screen.

8.Make sure the UNLOAD switch is OFF.

9.Open the main fuel supply valve on the tank if using LP gas, or the valve in the fuel supply line if using natural gas. Turn on

the Maxon electric shut off valve, if so equipped, or open the manual shut off valve to allow fuel flow to the dryer.

10. The dryer should already be filled with grain. Turn the LOAD AUGER switch to the AUTO position. In both the auto and

manual positions, the dryer grain level switch will automatically keep the dryer full of grain. In the auto position the dryer will

shut down after a preset time period using the out of grain timer.

11.Turn each FAN switch to ON. The fan will start, and the switch will light up when air pressure is detected.

12.Start each burner by turning the HEATER switch to ON. After purging for approximately 10 seconds the burner will fire,

and the heater switch will light up. This indicates that the flame sensing circuit is sensing burner flame. For information concerning burner adjustment see the Dryer pre start checks section of this manual. Set the plenum temperature setpoints to 180 oF.

13.Look in the Drying Charts section starting on page 36 for the FULL HEAT chart settings that correspond to your model of

dryer. You will see the settings for (Initial Moisture) (Moisture Removed) (Approx. Dry Time) (1 Speed) (2 Speed Low) (2

Speed High) pick the line that has your initial starting moisture. These are the settings we will be referring to during this start up

procedure.

14.Run the fan(s) and heater(s) for about 10% longer than the (APPROX. DRYING TIME) required for the moisture you are

trying to dry.

15.Take the remaining number of burners to be started, divide that into the total drying time required, working up, start each

burner that many minutes apart. Run them about 10% longer than the (APPROX. DRYING TIME) total required for the

moisture you are trying to dry.

16.Example: 10% removal would be about 54 minutes, 15% removal would be about 76 minutes and 20% removal would be

about 100 minutes. Add 10 minutes to insure that the grain is dry.

17.After the time in step 14 turn the UNLOAD AUGER switch to MANUAL and set the METER ROLL SPEED, (MANUAL

SPEED). To do this push on the Meter Roll Adjustment knob. When the Modify Meter Roll Setpoints window appears (see

image below) turn the Meter Roll Adjustment knob until the speed indicator is set to the speed suggested for 1 SPEED. Grain

should begin to run at this time. Run time for this is about 10% longer than the (APPROX. DRYING TIME) required for the

moisture you are trying to dry. This allows the moisture in the dryer to reach an even gradient top to bottom without having any

highs or lows in it. It will however, over dry some of the grain.

22

PNEG-1459 L Series Operators

Page 23

DRYER OPERATION - BASIC MOISTURE CONTROL

18.Increase the drying temperature to 190 deg. F for single fans or for multiple fan dryers set the heat chambers 30 to 60

degrees apart. Hottest at the top, most cool at the bottom (see Setting Temperatures on page 14).

19.DO NOT TRY TO ADJUST THE DRYER FOR MOISTURE DURING THIS PROCESS OR YOU WILL ESTABLISH

HIGH AND LOW SWINGS IN THE MOISTURE CONTROL. IT WILL TAKE SEVERAL HOURS TO WORK ITSELF

OUT.

20.After the run time in step 17 you are ready to set up the moisture control. Turn the UNLOAD switch to AUTO. Push the

Meter Roll Adjustment knob. When the Modify Meter Roll Setpoints window appears (see image at top of next page) check

that Two Speed is selected. Set the low speed by pushing the Meter Roll Speed Adjustment knob until the Low Speed Indicator

is red and then turn the knob to the desired low speed setting. When low speed is set push the Meter Roll Adjustment knob until

the High Speed Indicator is red then turn knob to the desired high speed setting (IMPORTANT: THE HIGH SPEED SET-

TING MUST BE A HIGHER VALUE THAN THE LOW SPEED). Touch the ACCEPT/EXIT button and return to the Dryer

Check two speed

operation

Operation screen.

21.Now that the UNLOAD AUGER switch is in the AUTO position the moisture control is active. Now touch the M/C button

at the bottom of the Dryer Operation screen. When the Modify Temperature Setpoint window appears set the temperature to

about 105o F (see image below). Let the dryer run on these settings before trying to adjust moisture or meter roll settings. These

settings will not have your grain moisture adjusted exactly where you want it, but will be a good place to start initially. A little

different moisture at the bottom of the storage bin is not usually a problem as long as you have full floor aeration.

M/C button

22.After the run time in step 21 you are ready to adjust the moisture control, and the meter roll speeds if required. Each time

you make an adjustment to the moisture control it will take about the time shown in the drying charts to see the results of this

adjustment. For every 5 degrees change in temperature, moisture will change by 1 point.

PNEG-1459 L Series Operators

23

Page 24

DRYER OPERATION - BASIC MOISTURE CONTROL

Dry and Cool-Continuous Flow Operation

This section begins with step 7 and it is assumed that steps 1 through 6 in the start-up procedure described on page 22 have been

completed.

7.Touch the SETUP button at the bottom of the Dryer Operation screen. Once the Hardware Parameter screen is displayed

touch the DRYING MODE button. When the Select Drying Mode window appears touch the CONTINUOUS FLOW button to

select continuous flow drying mode. Then touch the EXIT button and return to the Hardware Parameter screen. Touch the M/C

SETUP button. When the Moisture Control Selection window appears select the BASIC : REGULATION OF GRAIN TEMPERATURE : 2 MR SETPOINTS moisture control option. Touch the EXIT button and return to the Dryer Operation screen.

8.Make sure the UNLOAD switch is OFF.

9. Open the main fuel supply valve on the tank if using LP gas, or open the fuel supply line if using natural gas. Turn on the

Maxon electric shut off valve, if so equipped, or open the manual shut off valve to allow fuel flow to the dryer.

10. The dryer should already be filled with grain. Turn the LOAD AUGER switch to the AUTO position. In both the auto and

manual positions, the dryer grain level switch will automatically keep the dryer full of grain. In the auto position the dryer will

shut down after a preset time period on the out of grain timer.

11.Turn each FAN switch to ON. The fan will start, and the switch will light up when air pressure is detected.

12.Start each burner by turning the HEATER switch to ON. After purging for approximately 10 seconds the burner will fire,

and the heater switch will light up. This indicates that the flame sensing circuit is sensing burner flame. For information concerning burner adjustment see the Dryer pre start checks section of this manual. Set the plenum temperature setpoints to 180 oF.

13.Look in the Drying Charts section starting on page 36 for the DRY AND COOL chart settings that correspond to your

model of dryer. You will see the settings for (Initial Moisture) (Moisture Removed) (Approx. Dry Time) (1 Speed) (2 Speed

Low) (2 Speed High) pick the line that has your initial starting moisture. These are the settings we will be referring to during

this start up procedure.

14.Run the bottom fan(s) and heater(s) (to be used for cooling later) for about 20 minutes. This will start the bottom drying so

we can cool it before we begin to discharge grain.

15.Take the remaining number of burners to be started, divide that into the total drying time required, working up, start each

burner that many minutes apart. Run them about 10% longer than the (APPROX. DRYING TIME) total required for the

moisture you are trying to dry.

16.Example: 10% removal would be about 60 minutes, 15% removal would be about 85 minutes, and 20% removal would be

about 110 minutes. Add 10 minutes to insure that the grain is dry.

17.20 minutes before the required drying time is finished turn the bottom heater OFF but let the fan run and cool this section

for about . Set the upper plenum thermostats to the decreed temperature (190°-230°F).

18.Turn the UNLOAD AUGER switch to MANUAL and set the METER ROLL SPEED, (MANUAL SPEED). To do this push

on the Meter Roll Adjustment knob. When the Modify Meter Roll Setpoints window appears turn the Meter Roll Adjustment

knob until the speed indicator is set to the speed suggested for 1 SPEED (see image below). Grain should begin to run at this

time. Run time for this is about 10% longer than the (APPROX. DRYING TIME) required for the moisture you are trying to

dry. This allows the moisture in the dryer to reach an even gradient top to bottom without having any highs or lows in it. It will

however, over dry some of the grain a little.

24

PNEG-1459 L Series Operators

Page 25

DRYER OPERATION - BASIC MOISTURE CONTROL

19.DO NOT TRY TO ADJUST THE DRYER FOR MOISTURE DURING THIS PROCESS OR YOU WILL ESTABLISH

HIGH AND LOW SWINGS IN THE MOISTURE CONTROL. IT WILL TAKE SEVERAL HOURS TO WORK ITSELF

OUT.

20.After the run time in step 18 you are ready to set up the moisture control. Turn the UNLOAD switch to AUTO. Push the

Meter Roll Adjustment knob. When the Modify Meter Roll Setpoints window appears check that Two Speed is selected (see

image below). Set the low speed by pushing the Meter Roll Speed Adjustment knob until the Low Speed Indicator turns red and

then turning the knob to the desired low speed setting. When low speed is set push the Meter Roll Adjustment knob until the

High Speed Indicator turns red then turn knob to the desired high speed setting (IMPORTANT: THE HIGH SPEED SETTING

MUST BE A HIGHER VALUE THAN THE LOW SPEED). Touch the ACCEPT/EXIT button and return to the Dryer

Operation screen.

21.Now that the UNLOAD AUGER switch is in the AUTO position the moisture control is active. Now touch the M/C button

at the bottom of the Dryer Operation screen. When the Modify Temperature Setpoint window appears set the temperature to

about 130o F (see image below). Let the dryer run on these settings before trying to adjust moisture or meter roll settings. These

settings will not have your grain moisture adjusted exactly where you want it, but will be a good place to start initially. A little

different moisture at the bottom of the storage bin is not usually a problem as long as you have full floor aeration.

22.After the run time in step 21, you are ready to adjust the moisture control and the meter roll speeds if required. Each time

you make an adjustment to the moisture control it will take about the time shown in drying charts to see the results of this

adjustment. For every 5 degrees change in temperature, moisture will change by 1 point.

PNEG-1459 L Series Operators

25

Page 26

DRYER OPERATION - INTERMEDIATE MOISTURE CONTROL

CONTINUOUS FLOW DRYING MODE USING INTERMEDIATE MOISTURE CONTROL

Full Heat-Continuous Flow Operation

This section begins with step 7 and it is assumed that steps 1 through 6 in the start-up procedure described on page 22 have been

completed.

7.Touch the SETUP button at the bottom of the Dryer Operation screen. Once the Hardware Parameter screen is displayed

touch the DRYING MODE button. When the Select Drying Mode window appears touch the CONTINUOUS FLOW button to

select continuous flow drying mode. Then touch the EXIT button and return to the Hardware Parameter screen.

8.Touch the M/C SETUP button. When the Moisture Control Selection window appears select the INTERMEDIATE :

REGULATION OF MOISTURE : 3 SPEED moisture control option. Now touch the EXTENDED SETUP button. When the

Set Unload Rate Limits window appears set the MAXIMUM Unloading Rate to a value lower than the rated BPH of any

auxiliary unloading equipment connected to the dryer. Next set the MINIMUM Unloading Rate. The minimum unloading rate

is used so that any auxiliary unloading equipment does run empty. By setting a minimum unloading rate the dryer unloading

system will never completely stop. This saves wear and tear on any auxiliary unloading equipment. Once the values have been

changed to the desired rate, press the “ACCEPT” button.

Intermediate: Regulation

of Moisture: 3 MR

Setpoints button

Extended Setup button:

Touching this button

will bring up the SETTING UNLOAD RATE

LIMITS window

Set Max. Unload Rate

Set Min. Unload Rate

26

PNEG-1459 L Series Operators

Page 27

DRYER OPERATION - INTERMEDIATE MOISTURE CONTROL

9.You should now be back in the Moisture Control Selection window. Touch the BIN # / GRAIN TYPE button. When the

Storage Parameters window appears select the type of grain that is to be dried and select the storage bin to be used (The bin

number is for reference only and has nothing to do with the control of moisture). Then touch the EXIT button and return to the

Moisture Control Selection window.

10.The printer can also be enabled or disabled by touching the PRINTER SETUP button. After you have made your selection,

press the exit button to accept and exit.

Printer Setup

Bin # / Grain Type

Calibrate Sensors

11.You will also see a button to calibrate the moisture sensors. Do not calibrate the sensors at this time.

12.Now press the exit button at the bottom of the screen and return to the Dryer Operation screen.

The setup is almost complete and you are now ready to begin drying using the Intermediate moisture control system. The

following steps start the flow of grain through your dryer, and finish setting up the moisture control.

13.Make sure the UNLOAD switch is OFF.

14.Open the main fuel supply valve on the tank if using LP gas, or the valve in the fuel supply line if using natural gas. Turn on

the Maxon electric shut off valve, if so equipped, or open the manual shut off valve to allow fuel flow to the dryer.

15. The dryer should already be filled with grain. Turn the LOAD AUGER switch to the AUTO position. In both the auto and

manual positions, the dryer grain level switch will automatically keep the dryer full of grain. In the auto position the dryer will

shut down after a preset time period using the out of grain timer.

16.Look in the Drying Charts section starting on page 36 for the FULL HEAT chart settings that correspond to your model of

dryer. You will see the settings for (Initial Moisture) (Moisture Removed) (Approx. Dry Time) (1 Speed) (2 Speed Low) (2

Speed High) pick the line that has your initial starting moisture. These are the settings we will be referring to during this start up

procedure.

17.Turn each FAN switch to ON. The fan will start, and the switch will light up when air pressure is detected.

18.Start each burner by turning the HEATER switch to ON. After purging for approximately 10 seconds the burner will fire,

and the heater switch will light up. This indicates that the flame sensing circuit is sensing burner flame. For information

concerning burner adjustment see the Dryer pre start checks section of this manual. Set the plenum temperature setpoints to

180 oF.

PNEG-1459 L Series Operators

27

Page 28

DRYER OPERATION - INTERMEDIATE MOISTURE CONTROL

19.Run the fan(s) and heater(s) for about 10% longer than the (APPROX. DRYING TIME) required for the moisture you are

trying to dry.

20.Example: 10% removal would be about 54 minutes, 15% removal would be about 76 minutes and 20% removal would be

about 100 minutes. Add 10 minutes to insure that the grain is dry.

21.After the time in step 19 turn the UNLOAD AUGER switch to MANUAL. and set the METER ROLL SPEED, (MANUAL

SPEED). Remember that Manual is a true Manual operation, with no moisture control. The meter rolls will run at the speed that

you select using the Meter Roll Speed Encoder. To do this push on the Meter Roll Adjustment knob. When the Modify Meter

Roll Setpoints window appears turn the Meter Roll Adjustment knob until the speed indicator is set to the speed suggested for

1 SPEED. Grain should begin to run at this time. Run time for this is about 10% longer than the (APPROX. DRYING TIME)

required for the moisture you are trying to dry. This allows the moisture in the dryer to reach an even gradient top to bottom

without having any highs or lows in it. It will however, over dry some of the grain a little.

22.After the run time in step 21 begin to test the moisture content with a Moisture Tester you consider to be accurate. Test at

least 3 samples for accuracy. Having determined the average discharge moisture, you may now calibrate the incoming and

outgoing moisture sensors on the dryer. To do this you will need to press the SETUP button again and return to the Hardware

Parameter screen. Press the M/C SETUP button and then press the CALIBRATE MOISTURE SENSORS button. The Moisture

Sensor Calibration window will appear (see image below). Follow the example below to adjust the dryer to your moisture tester.

Example: Your moisture tester gives you an average moisture of 17% but the moisture sensor on the dryer is reading

18.3%. You would then calibrate the dryers moisture sensor (-1.3%), that would make the moisture screen read 17% the same

as your moisture tester.

Calibrate sensors by

touching the arrow

buttons.

28

PNEG-1459 L Series Operators

Page 29

DRYER OPERATION - INTERMEDIATE MOISTURE CONTROL

23.Once the moisture reading at the discharge is where you want it to be, turn the UNLOAD switch to AUTO.

24.Now that the UNLOAD AUGER switch is in the AUTO position the INTERMEDIATE MOISTURE CONTROL is active.

Now touch the M/C button at the bottom right of the Dryer Operation screen. When the Moisture Setpoint window appears set

the moisture setpoint to the output moisture you desire. Let the dryer run on these settings before trying to adjust moisture or

meter roll settings.

25.The dryer will immediately switch to the intermediate 3 speed moisture control. If you press the meter roll knob you will

now notice that there are three different meter roll speeds. The computer has automatically set the low and high speed setpoints

to 15% above and below the middle speed. The middle speed is the same as the manual speed that you had entered when staging

the grain for the correct exiting moisture content.

How the Intermediate Moisture Control Works

The controller continuously monitors the moisture coming in and out of the dryer, and the column grain temperature at the end

of the drying section. However, the control action is based on the dry sensor at the outlet of the dryer. If the moisture coming out

of the dryer is not right at the target, the controller will speed up or slow down the unload accordingly. How the meter rolls react

depends on the setpoint and the actual moisture coming out of the dryer. So long as the outgoing moisture is 3 tenths above or

below the setpoint, the meter rolls run on the middle speed. Once the moisture begins to drift from the setpoint by over 3 tenths

above or below the setpoint, the speed will automatically switch between middle and low, or middle and high speed. This is a

very fast response and will bring grain back towards the set point quickly.

The controller does not have enough information of the grain in the dryer in the first pass after the dryer is started. It controls the

dryer by using the manual speed setting as the starting point. In other words, the manual speed setting is most responsible for the

first pass of drying. Therefore, set the manual unloading speed as close as it should be for the grain currently in the dryer before

switching to moisture control mode. The manual speed setting does not have to be adjusted after the moisture control is

activated.

PNEG-1459 L Series Operators

29

Page 30

DRYER OPERATION - ADVANCED MOISTURE CONTROL

CONTINUOUS FLOW DRYING MODE USING ADVANCED MOISTURE CONTROL

Full Heat-Continuous Flow Operation

This section begins with step 7 and it is assumed that steps 1 through 6 in the start-up procedure described on page 22 have been

completed.

7.Touch the SETUP button at the bottom of the Dryer Operation screen. Once the Hardware Parameter screen is displayed

touch the DRYING MODE button. When the Select Drying Mode window appears touch the CONTINUOUS FLOW button to

select continuous flow drying mode. Then touch the EXIT button and return to the Hardware Parameter screen.