Page 1

PNEG-1458

T-Series Tower Dryer

Operation Manual

PNEG-1458

Version: 1.0

Date: 11-07-11

Page 2

All information, illustrations, photos and specifications in this manual are based on the latest

information available at the time of publication. The right is reserved to make changes at any

time without notice.

2 PNEG-1458 T-Series Tower Dryer

Page 3

Table of Contents

Contents

Chapter 1 Safety .....................................................................................................................................................5

Safety Guidelines .................................................................................................................................. 5

Dryer Operation ..................................................................................................................................... 6

Emergency Stop Switch ...................... ... ... ... .... ... ... ... .... ... ..................................................................... 6

Operating Precautions ..................................... ... ... ... .... ... ... ... .... ... ........................................................ 7

Chapter 2 Safety Decals ........................................................................................................................................9

Chapter 3 Specifications .....................................................................................................................................11

Dimensions ......................................................................................................................................... 12

Chapter 4 Dryer Installation ................................................................................................................................15

Dryer Layout ........................................................................................................................................ 15

Liquid Propane (LP) Dryers with Internal Vaporizers .......................................................................... 15

Natural Gas (NG) Dryers ........................... ................ ................. ............ ................. ............................ 15

Central United States Foundation for Dryer Sizes up to 20100 .......................................................... 16

Northern United States Foundation for Dryer Sizes up to 20100 ........................................................ 17

Foundation for 24100 Dryer ................................................................................................................ 18

Fuel Supply ......................................................................................................................................... 19

Electrical Power Supply ...................................................................................................................... 20

Transformers and Wiring Voltage Drop ............................................................................................... 20

Power Supply Disconnect ................................................................................................................... 20

Machine to Earth Grounding ............................................................................................................... 20

Proper Installation of Ground Rod ....................................................................................................... 21

Connecting Auxiliary Conveyors ......................................................................................................... 21

Chapter 5 Operating Controls .............................................................................................................................22

Vision Control Panel Layout ................................................................................................................ 22

Control Power Switch .......................................................................................................................... 22

Fan Switch .......................................................................................................................................... 22

Heater Switch ...................................................................................................................................... 23

Load Auger Switch ....................... .... ... ... ... ... .... ................................................................ ................... 23

Unload Switch ..................................................................................................................................... 23

Outside Light Switch ........................................................................................................................... 23

Start Switch ......................................................................................................................................... 23

Stop Switch ......................................................................................................................................... 23

Chapter 6 Vision Touch Screen Display ........... ... ... ... .... ....................................................................................24

Boot Screen ........................................................................................................................................ 24

Default Operation Screen .................................................................................................................... 24

Setting the Timers ............................................................................................................................... 25

Setting the Temperatures .................................................................................................................... 26

The Setup Screen ............................................................................................................................... 28

Chapter 7 Test Firing ...........................................................................................................................................34

Dryer Pre-Season Checks .................................................................................................................. 34

Inspect the Accutrol Metering System .................... ................ ................ ................. ................ ............ 34

Electrical Power .................................................................................................................................. 34

Control Power Switch .......................................................................................................................... 34

Start Switch ......................................................................................................................................... 34

Fuel Check .......................................................................................................................................... 34

Load Auger .......................... ... ................................................................ .... ... ... ... ................................ 35

Unload Auto Operation ........................................................................................................................ 35

Unload Manual Operation ................................................................................................................... 35

Accutrol Sweep Metering System Operation ...................................................................................... 35

Fan Switch .......................................................................................................................................... 35

Burner Safety ...................................................................................................................................... 35

Burner Test Fire .................................................................................................................................. 35

Dryer Shut Down ................................................................................................................................. 36

Emergency .......................................................................................................................................... 36

PNEG-1458 T-Series Tower Dryer 3

Page 4

Table of Contents

Chapter 8 Dryer Operation ..................................................................................................................................37

Dryer Start-Up and Operation ............................................................................................................. 37

Dryer Shut Down ................................................................................................................................. 37

Initial Setup Parameters ...................................................................................................................... 37

Timer and Delay Settings .................................................................................................................... 37

Setting the Temperatures .............. .... ... ... .................................................................... ... ... .................. 39

Start-Up ................................... ....................................................... ..................................................... 40

Continuous Flow Drying Mode Using Advanced Moisture Control ..................................................... 41

Chapter 9 Drying Time Tables ............................................................................................................................43

Chapter 10 Service ...............................................................................................................................................49

Pre-Seasonal Inspection and Service ............................................................................................... 49

Seasonal Inspection and Service ...................................................................................................... 49

Pre-Season Service Check List ......................................................................................................... 51

End of Season Shut Down Procedure ............................................................................................... 51

Chapter 11 Safety Circuit Shut Down Messages ..............................................................................................53

Fan/Heater Generated Errors ............................................................................................................ 53

Input/Output Generated Errors .......................................................................................................... 55

Master Display Generated Errors ...................................................................................................... 56

Chapter 12 Wiring Diagrams ...............................................................................................................................58

T and F Upper Control Box with Honeywell 220V ..................................................................... ... ... .. 58

T and F Upper Control Box with Honeywell 440V ..................................................................... ... ... .. 61

Field Wiring Bottom Terminal Strip Power Box .................................................................................. 64

Field Wiring Top Terminal Strip Power Box ....................................................................................... 65

Field Wiring Top Terminal Strip Power Box w/ Mod Valve ................................................................ 66

Remote Moisture Box ........................................................................................................................ 67

Fan/Heater Board Wiring ................................................................................................................... 68

Main Input/Output Power Box Wiring ................................................................................................ 69

Burner Control Wiring ............... ... .... ... ... ... ... .... ... ............................................................................... 70

DC Motor Wiring ................................................................................................................................ 71

Fan Contactor and Overload (ACL) ................................................................................................... 72

Fan Contactor Part Winding Starter .................................................................................................. 73

Fan Contactor Soft Starter ............... ................................................................... .... ... ... ... ... ............... 74

Control Box 12 VDC Lamp Wiring ..................................................................................................... 75

Control Box 12 VDC Negative Lamp Wiring ...................................................................................... 76

Control Box 12 VDC Switch Wiring ................................................................................................... 77

Control Box 120V Wiring ................................................................................................................... 78

Control Box Switch Wiring ........ ... .... ... ... .................................................................... ... ... .................. 79

Chapter 13 Warranty ............................................................................................................................................81

4 PNEG-1458 T-Series Tower Dryer

Page 5

1. Safety

DANGER

WARNING

CAUTION

NOTICE

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a

hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to

personal injury.

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

PNEG-1458 T-Series Tower Dryer 5

Page 6

1. Safety

Emergency stop

WARNING

Pushing the Emergency Stop switch does not interrupt the main power to the

upper control box panel.

Dryer Operation

Thank you for choosing a GSI product. It is designed to give excellent performance and service for

many years.

This manual describes the operation for all standard production model dryers. These dryers are available

with liquid propane or natural gas fuel supply and 3 phase 230, 380, 460 or 575 volts (50 Hz or 60 Hz)

electrical power.

Our foremost concern is your safety and the safety of others associated with this equipment. We want to

keep you as a customer. This manual is to help you understand safe operating procedures and some

problems that may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards, and precautions

exist and to inform all personnel associated with the equipment or in the area. Safety precautions may be

required from the personnel. Avoid any alterations to the equipment. Such alterations may p roduce a very

dangerous situation where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable

regulations, which should be carefully followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

Emergency Stop Switch

The Emergency Stop switch is located on the upper control box door. Pushing the Emergency Stop switch

will interrupt the control power and stop all dryer functions.

6 PNEG-1458 T-Series Tower Dryer

Page 7

1. Safety

Keep the dryer clean. Do not allow fine material to accumulate in the plenum

chamber or surrounding the outside of the dryer.

Operating Precautions

READ THESE INSTRUCTIONS BEFORE INSTALLATION AND OPERATION

SAVE FOR FUTURE REFERENCE

1. Read and understand the operations manual before attempting to operate the unit.

2. Keep ALL guards, safety decals and safety devices in place. NEVER operate dryer while guards

are removed.

3. Keep visitors, children and untrained personnel away from dryer at all times.

4. Never attempt to operate the dryer by jumping or otherwise bypassing any safety devices on

the unit.

5. Always set the main power supply disconnect switch to OFF and lock it in the OFF position using

a padlock before performing any service or maintenance work on the dryer or the auxiliary

conveyor equipment.

6. Before attempting to remove and reinstall the fan blade on the models 1050 and 1260, make certain

to contact GSI for the recommended procedure.

7. Keep the dryer and wet holding equipment CLEAN. DO NOT allow fine material to accumulate.

8. On LP fired units, set pressure regulator to avoid excessive gas pressure applied to a burner during

ignition and when the burner is in operation. See Page 20 for operating gas pressures. Do not exceed

maximum recommended drying temperatures.

9.

DO NOT

10. Clean grain is safer and easier to dry. Fine materials can be highly combustible and it also requires

removal of extra moisture.

11. Use CAUTION in working around high-speed fans, gas burner, augers and auxiliary conveyors which

can START AUTOMATICALLY.

12. Be certain that capacities of auxiliary conveyors are matched to dryer metering capacities.

13. DO NOT operate in an area where combustible material will be drawn into the dryer.

14. The operating and safety recommendations in this manual pertain to the common cereal grains as

indicated. When drying any other grain or products, consult the factory for additional

recommendations.

15. Routinely check for any developing gas plumbing leaks.

operate the dryer if any gas leak is detected. Shut down and repair before further operation.

Use Caution in the Operation of this Equipment

This dryer is designed and manufactured with operator safety in mind. However, the very nature of a grain

dryer having a gas burner, high voltage electrical equipment and high speed rotating parts, presents

hazards to personnel which cannot be completely safeguarded against without interfering with the efficient

operation of the dryer and reasonable access to its components.

Use extreme caution in working around high speed fans, gas-fired heaters, augers and auxiliary

conveyors, which may start without warning when the dryer is operating on automatic control.

CAUTION

Continued safe, dependable operation of automatic equipment depends, to a great degree, upon the

owner. For a safe and dependable drying system, follow the recommendations within the Owner’s Manual

and make it a practice to regularly inspect the unit for any developing problems or unsafe conditions.

Take special note of the Operating Precautions before attempting to operate the dryer.

PNEG-1458 T-Series Tower Dryer 7

Page 8

1. Safety

Prepare for Emergencies

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital, and fire department near your telephone.

Keep Emergency Equipment

Quickly Accessible

Wear Protective Clothing

Wear close-fitting clothing and safety equipment appropriate

to the job.

Remove all jewelry.

Tie long hair up and back.

Wear safety glasses at all times to protect eyes from debris.

Wear gloves to protect your hands from sharp edges on plastic

or steel parts.

Wear steel-toed boots to help protect your feet from falling

debris. Tuck in any loose or dangling shoestrings.

A respirator may be needed to prevent breathing potentially

toxic fumes and dust.

Wear a hard hat to help protect your head.

Wear appropriate fall protection equipment when working at

elevations greater than six feet (6').

Eye Protection

Gloves

Steel-Toed Boots

Respirator

Hard Hat

Fall Protection

8 PNEG-1458 T-Series Tower Dryer

Page 9

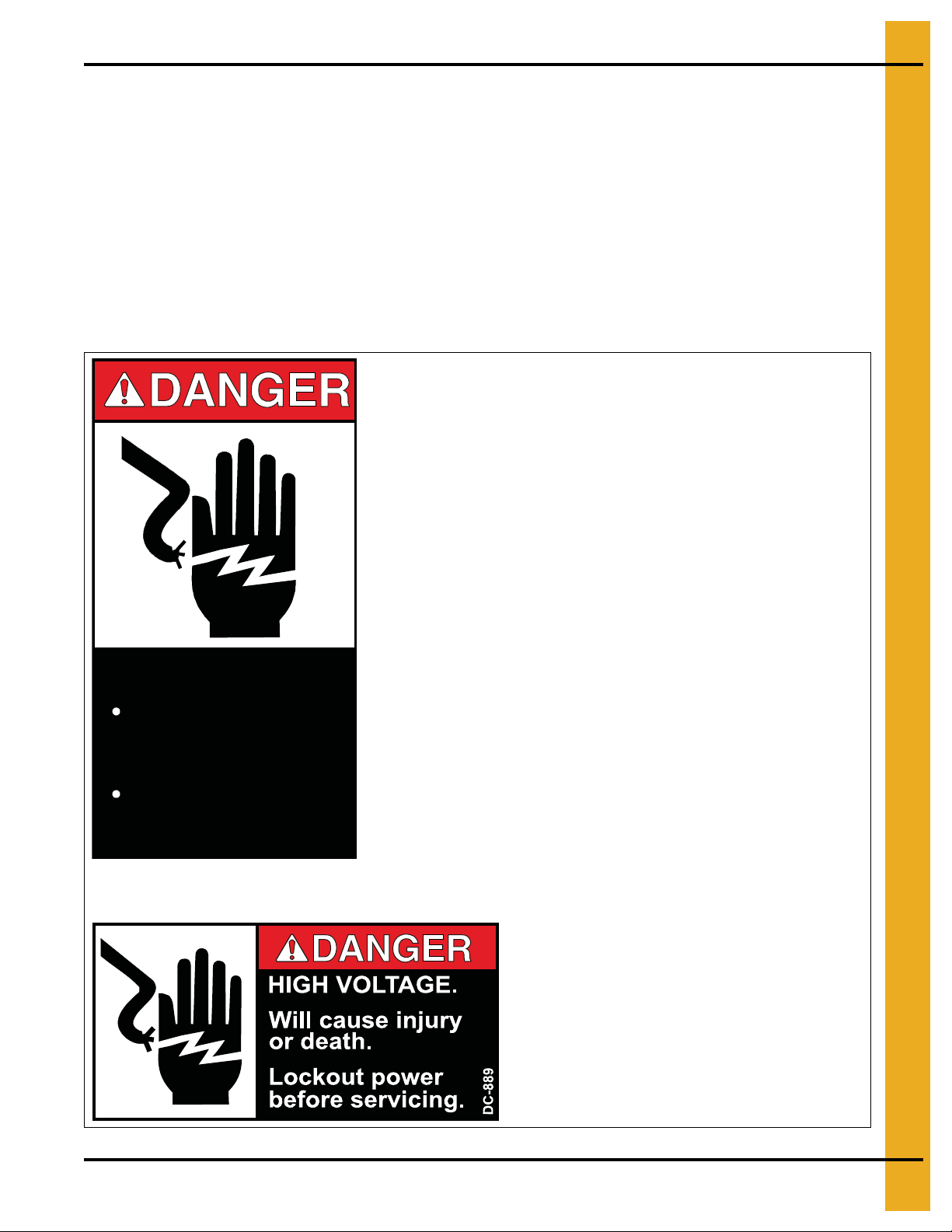

2. Safety Decals

HIGH VOLTAGE.

Will cause serious

injury or death.

Lockout power

before servicing.

DC-1224

Decal: DC-889

Decal DC-889 has two locations. One inside the

fan/heater control box and another on the dryer upper

control box door next to the main power disconnect.

Decal: DC-1224

Decal DC-1224 is located in two places on the fan/heater control box. One

on the lid and one on the front of the fan heater control box. Another location

for this decal is inside the upper control box for the dryer.

Contact the local power company to have a representative survey the installation to assure the wiring is

compatible with their system and adequate power is supplied to the unit. Safety deca ls should be read and

understood by all people in the grain handling area. Inspect all decals and replace any that are

illegible, worn or missing. Contact your dealer or the factory to order replacement decals.

If a decal is damaged or is missing, contact:

GSI Decals

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 1-217-226-4421

A free replacement will be sent to you.

NOTE: Decals are not shown actual size.

PNEG-1458 T-Series Tower Dryer 9

Page 10

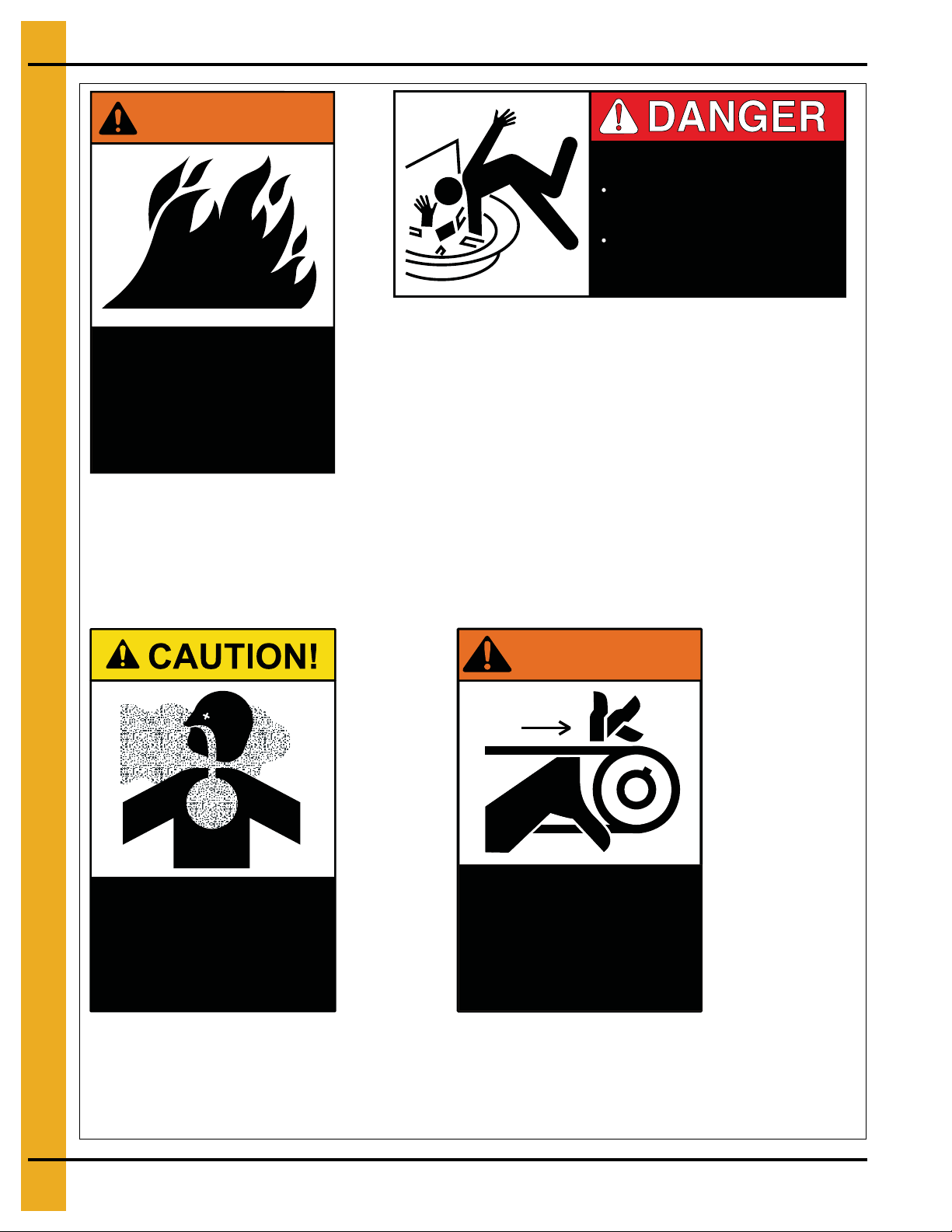

2. Safety Decals

Flame and pressure

beyond door. May

cause serious injury.

Do not enter when

dryer is running.

DC-1061

WARNING!

Decal: DC-1062

Decal DC-1062 is located inside the cooling section of the

dryer on the two access doors to the metering section.

Decal: DC-1063

Decal DC-1063 is located on the louvered

access door to the cooling section of the dryer.

Decal: DC-1064

Decal DC-1064 is located on the louvered access

door to the cooling section of the dryer.

Decal: DC-1061

Decal DC-1061 is located on the outside

of the heat section door.

DO NOT STAND ON DRUM!

Rotating drum will cause

serious injury or death.

Disconnect power before

servicing.

DC-1062

Airborne particles during

operation. May impair

vision and breathing.

Do not enter when

dryer is running.

DC-1063

WARNING!

High speed belt drive

operating overhead.

Can cause serious injury.

Keep head and hands

clear. Do not enter when

dryer is running.

DC-1064

10 PNEG-1458 T-Series Tower Dryer

Page 11

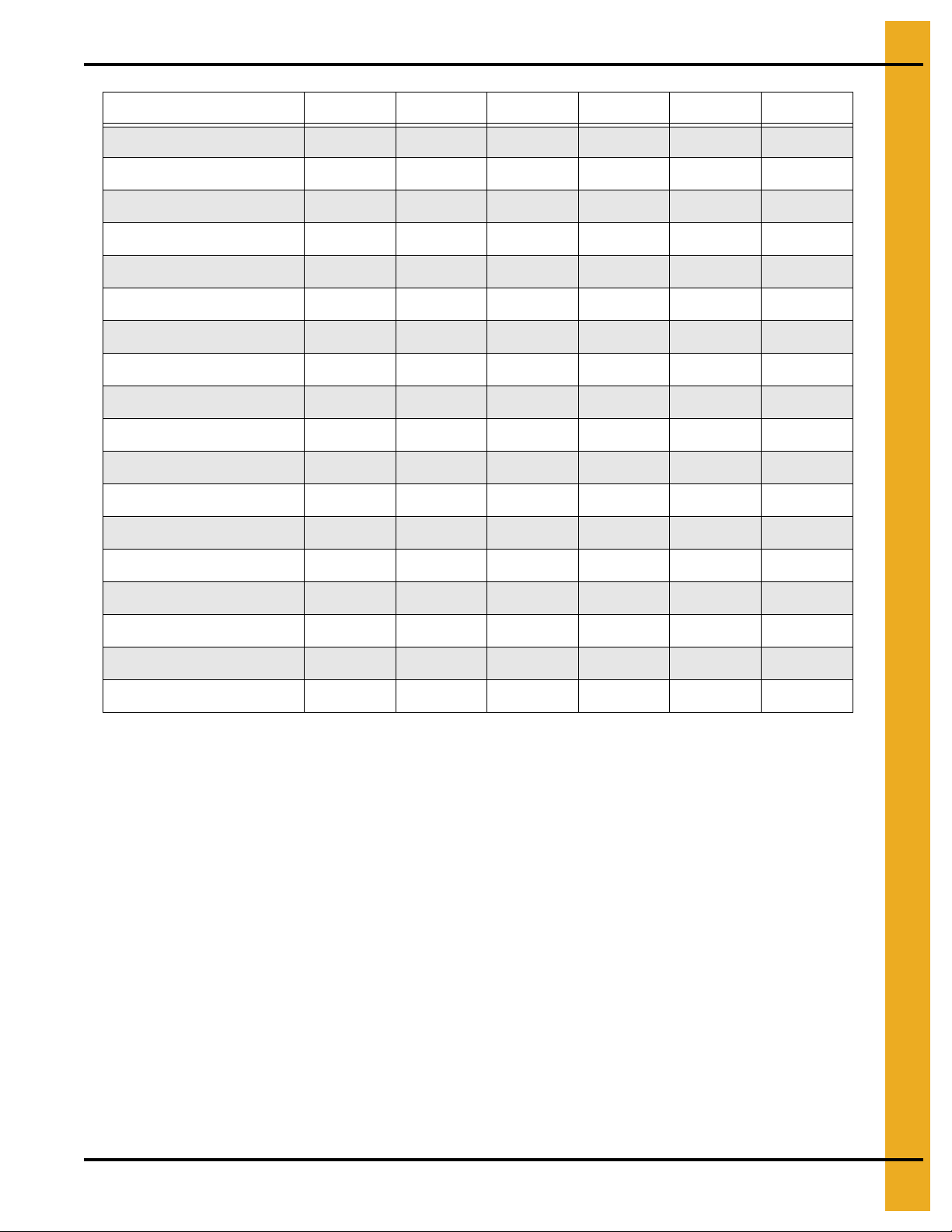

3. Specifications

Models 1050 1260 1575 1875 20100 24100

Blower Size 43" Axial 43" Axial 8490 8542 8542 8600

Blower RPM 1750 1750 1035 856 981 818

Blower HP 50 60 75 75 100 100

Metering HP 1 1 1 1 1 1

Drying CFM 42300 48400 77100 81800 98600 108300

Cooling CFM 14500 17500 38550 40900 49300 54150

Burner Capacity (mBtu) 11100 11100 16654 17669 21298 23393

Average Heat Use (mBtu) 5711 6543 9576 10159 12246 13451

Grain Column 12-3/4" 12-3/4" 12-3/4" 12-3/4" 12-3/4" 12-3/4"

Tower Diameter 12'-0" 12'-0" 12'-0" 12'-0" 12'-0" 12'-0"

Overall Height 45'-8" 52'-4" 59'-0" 69'-0" 75'-8" 85'-8"

Wet Holding (BU) 302 302 302 302 302 302

Heat Holding (BU) 610 756 914 1158 1256 1499

Cool Holding (BU) 219 268 305 354 451 500

Dryer Holding (BU) 1232 1427 1622 1915 2110 2401

Outside Catwalks 0 0 1 2 2 3

BPH (20%-5%) 1000 1200 1500 1800 2000 2400

BPH (25%-15%) 600 720 900 1080 1200 1440

PNEG-1458 T-Series Tower Dryer 11

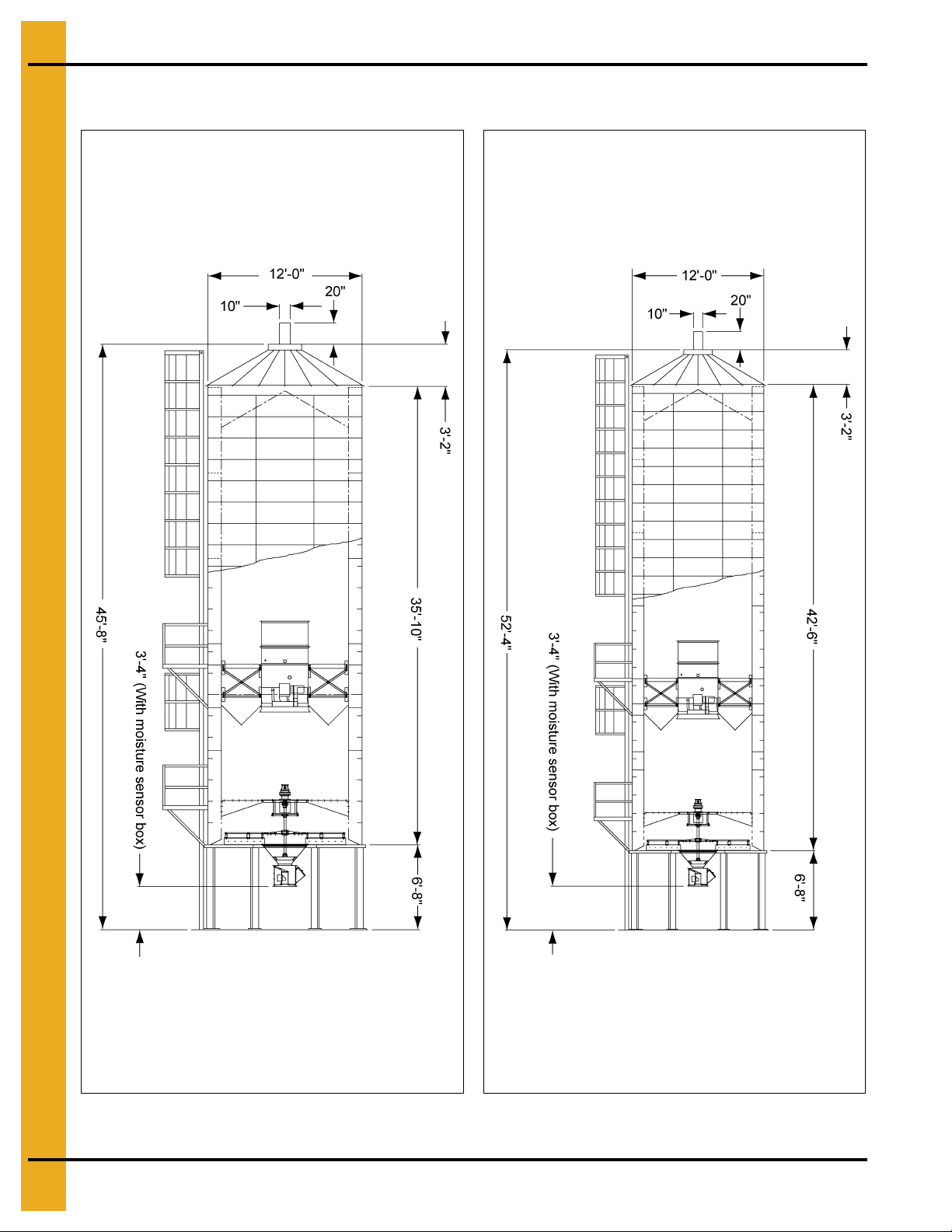

Page 12

3. Specifications

Dimensions

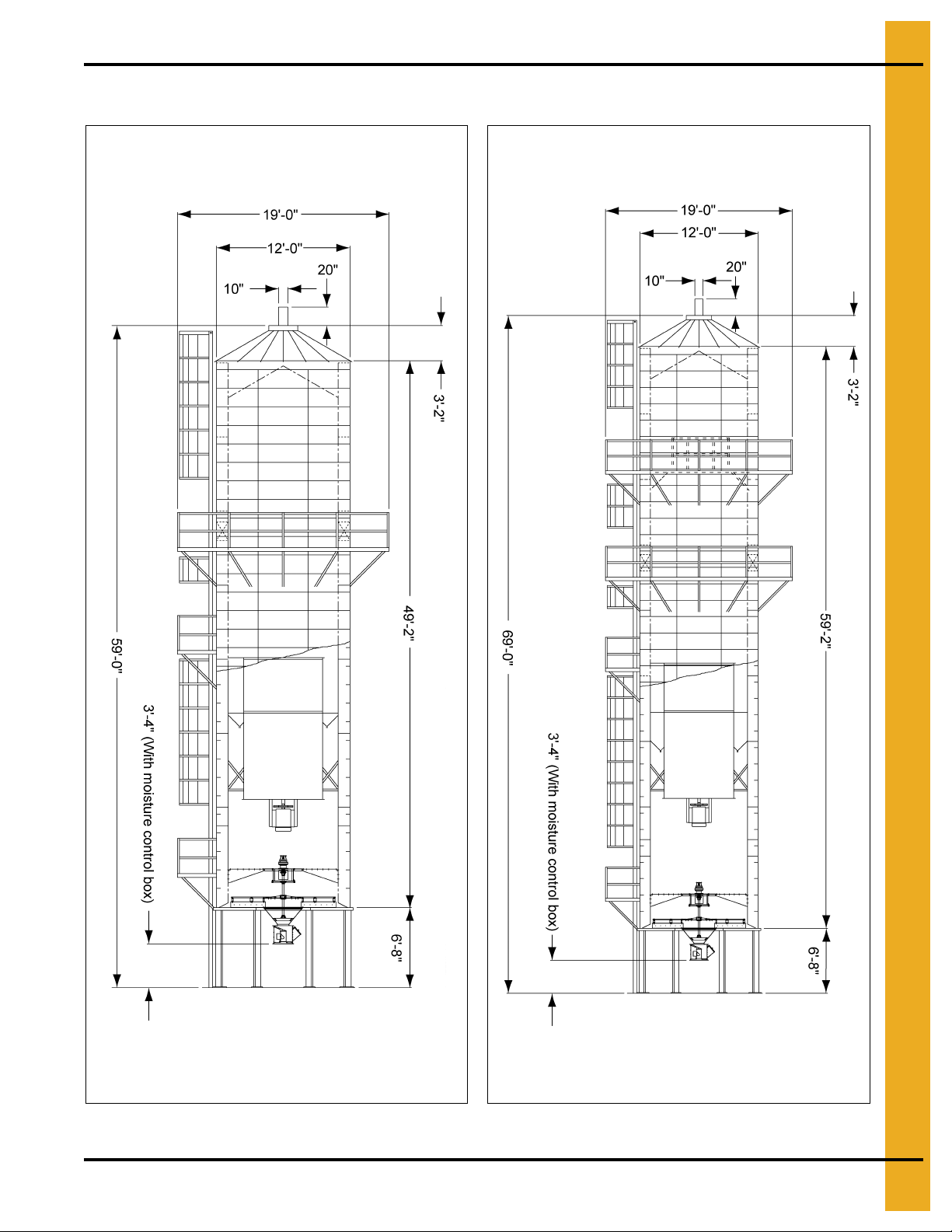

Figure 3A 1050 Figure 3B 1260

12 PNEG-1458 T-Series Tower Dryer

Page 13

Dimensions (Continued)

3. Specifications

Figure 3C 1575 Figure 3D 1875

PNEG-1458 T-Series Tower Dryer 13

Page 14

3. Specifications

Dimensions (Continued)

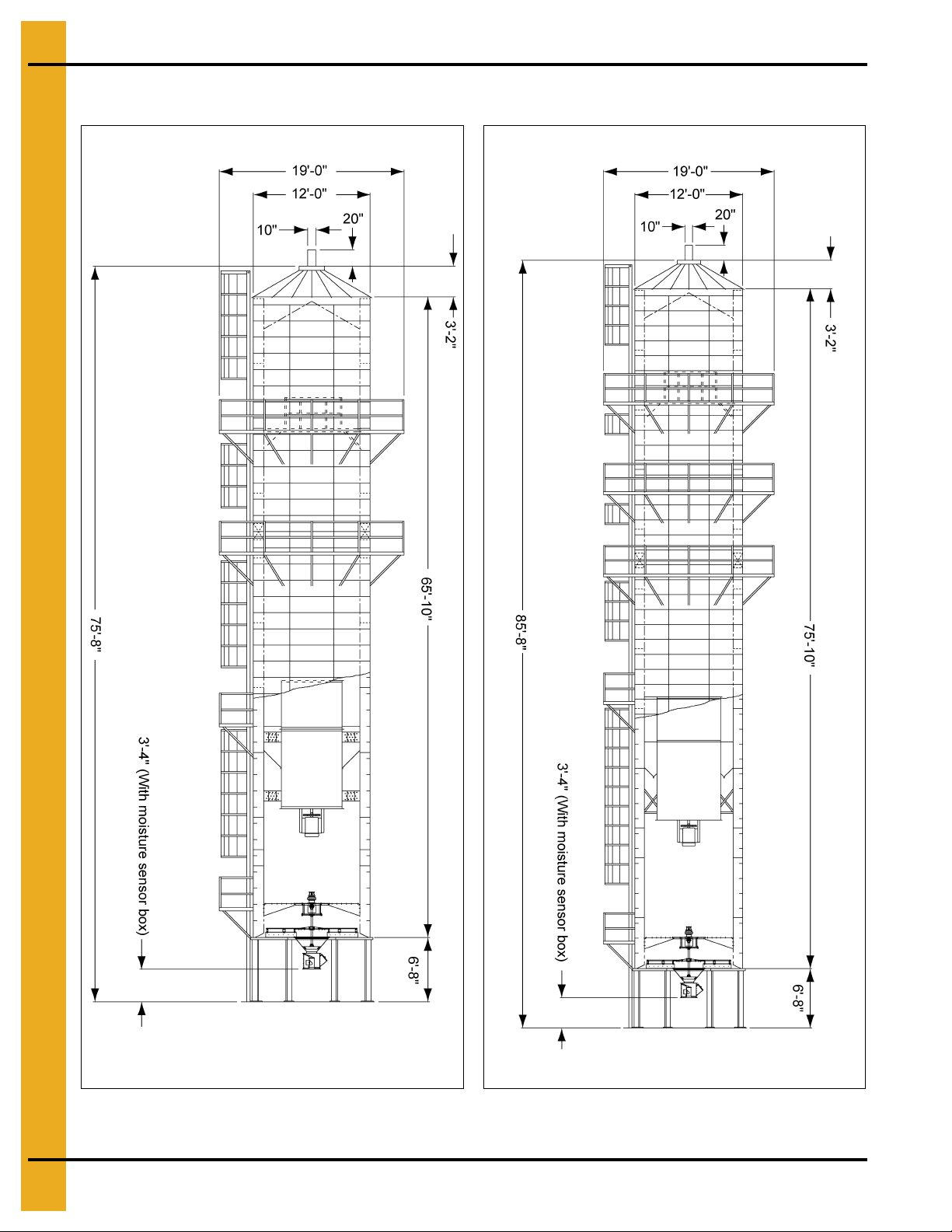

Figure 3E 20100 Figure 3F 24100

14 PNEG-1458 T-Series Tower Dryer

Page 15

4. Dryer Installation

Dryer Layout

System Layout

Consider the grain handling system and location of storage bins and existing conveyors when selecting

dryer site, to facilitate wet grain supply and dry grain discharge to conveyors. Other considerations are

prevailing wind direction, fuel and power supply locations, noise and convenience of control location.

Site Location

The dryer should not be operated inside a building or in any area not permitted by electrical code,

fuel installation regulations or insurance requirements. Do not operate in an area where combustible

material can be drawn into the dryer. Maintain a minimum distance of five feet (5') to other structures.

Refer to dryer specifications on Page 11 and dimensions on Pages 12, 13 and 14.

Foundation

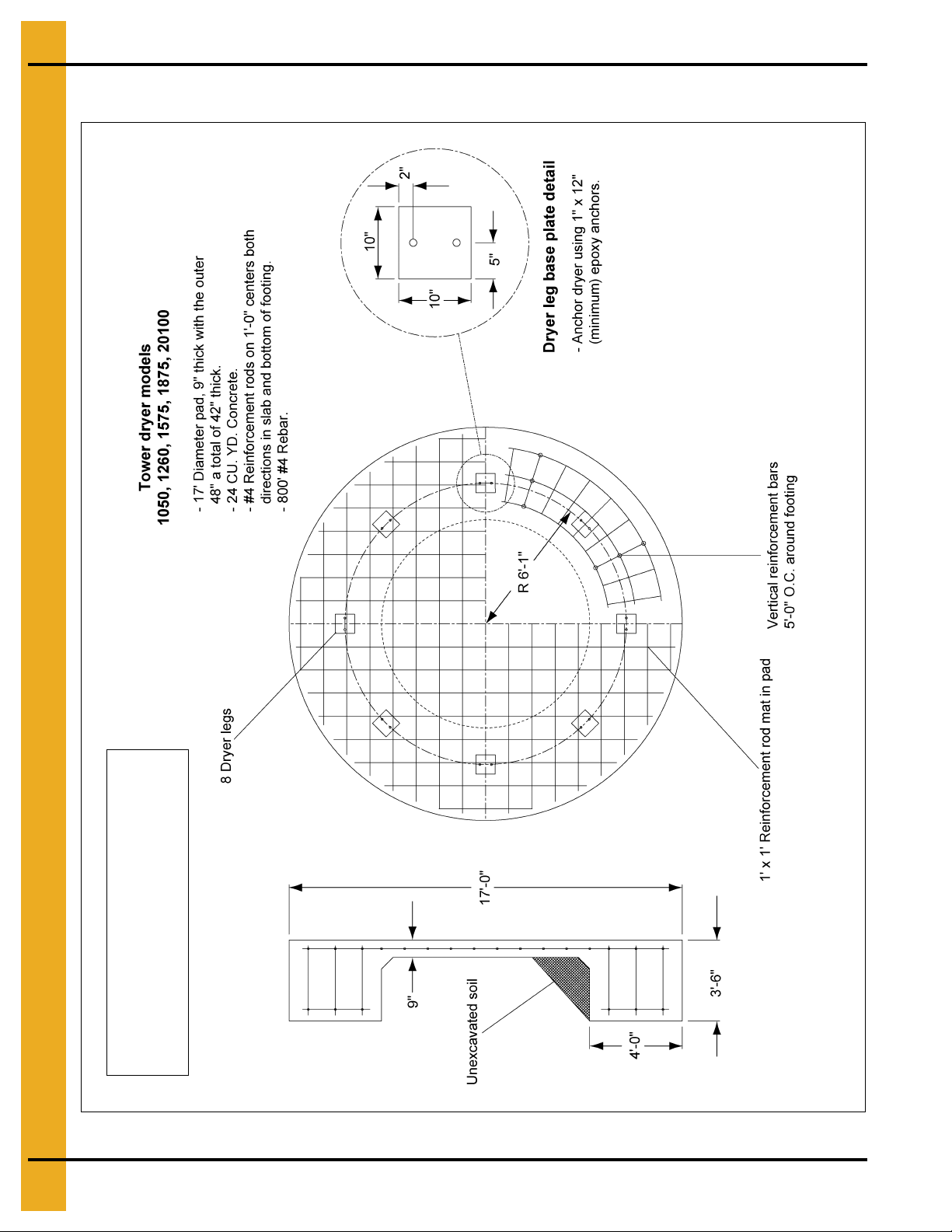

The dryer should be placed on a reinforced concrete slab located in a well drained area. See Figure 4A

on Page 16, Figure 4B on Page 17 and Figure 4C on Page 18 for re commended dryer foundations for soils

with minimum soil bearing pressure of 3000 lbs/ft².

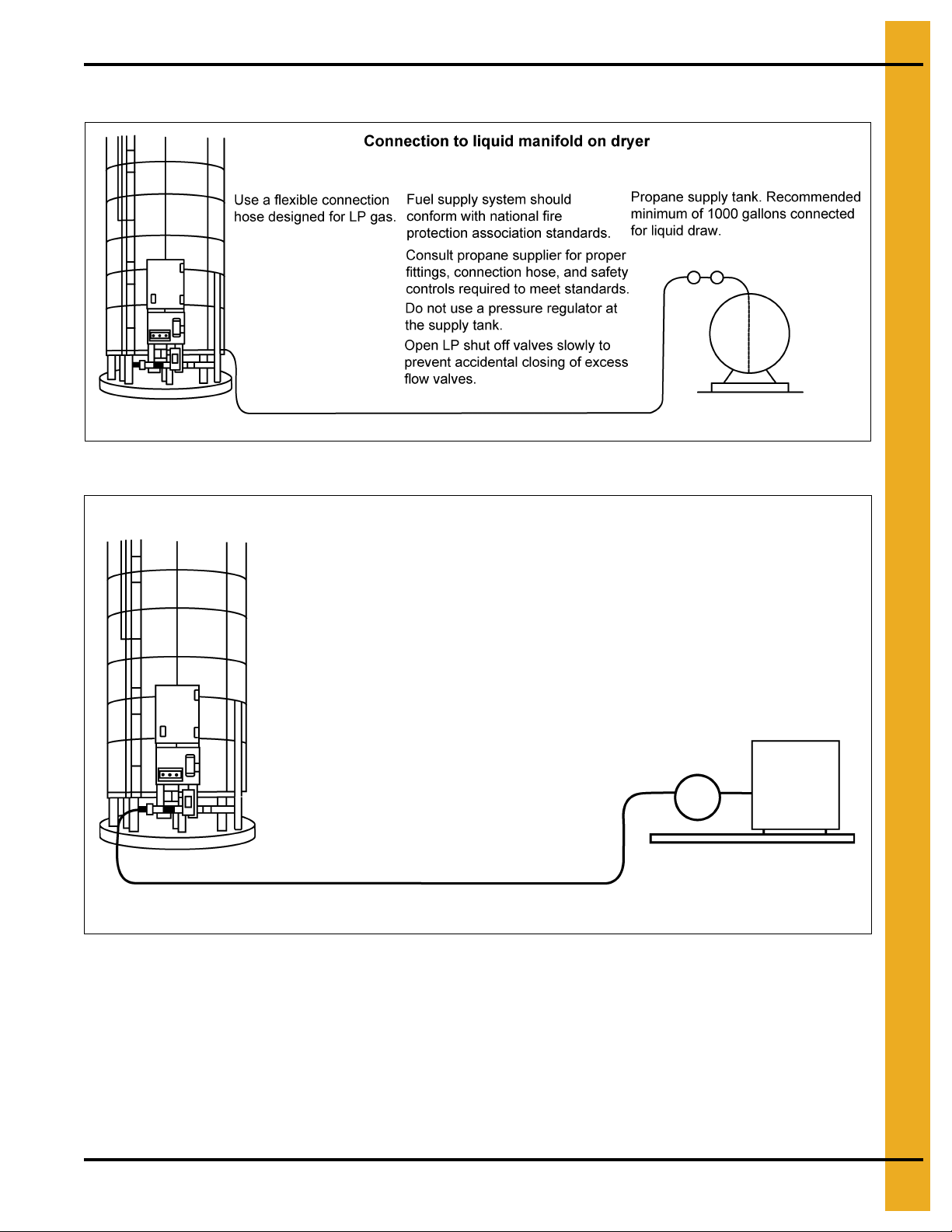

Liquid Propane (LP) Dryers with Internal Vaporizers

Liquid Draw

The dryer is designed to operate on liquid propane, with liquid draw from the supply tank. A piping

system is provided on the dryer, including strainer, pressure relief valve and manual shut off valve.

(See Figure 4D on Page 19.)

Ammonia Tanks

Do not use propane supply tanks which have previously contained ammonia or fertilizer solutions.

These substances are extremely corrosive and damaging to fuel supply and burner parts.

Oil or Water in Tanks

With liquid draw from the supply tank, any water present in the tank may freeze in the piping and con trols

in cold weather. To ensure that tanks are free of moisture, the usual precautio n is to purge with methanol.

Avoid tanks which may contain an accumulation of oil or heavy hydrocarbons from long use on a vapor

withdrawal system.

Natural Gas (NG) Dryers

Gas Volume and Pressure

The dryer is designed to operate on natural gas having a heat value of about 1000 BTU per cubic foot.

The dryer is equipped with a natural gas supply pipe system connected to the heater solenoid valves.

A regulated pressure of 10 PSI must be provided at the connection to the dryer, with gas available in

sufficient volume to maintain operating pressure. (See Figure 4E on Page 19.)

PNEG-1458 T-Series Tower Dryer 15

Page 16

4. Dryer Installation

NOTES:

1. Foundation design based on net soil bearing

pressure of 3000 PSF.

2. Site shall be free of any debris or vegetation

and well drained.

3. All reinforcing steel to be A-615 grade 40

deformed bars.

Concrete specifications

Compressive strength @ 28 days - - 4000 PSI

Minimum cement content - - 6 sacks/yard

Maximum slump - - 4" ± 1"

Central United States Foundation for Dryer Sizes up to 20100

Figure 4A

16 PNEG-1458 T-Series Tower Dryer

Page 17

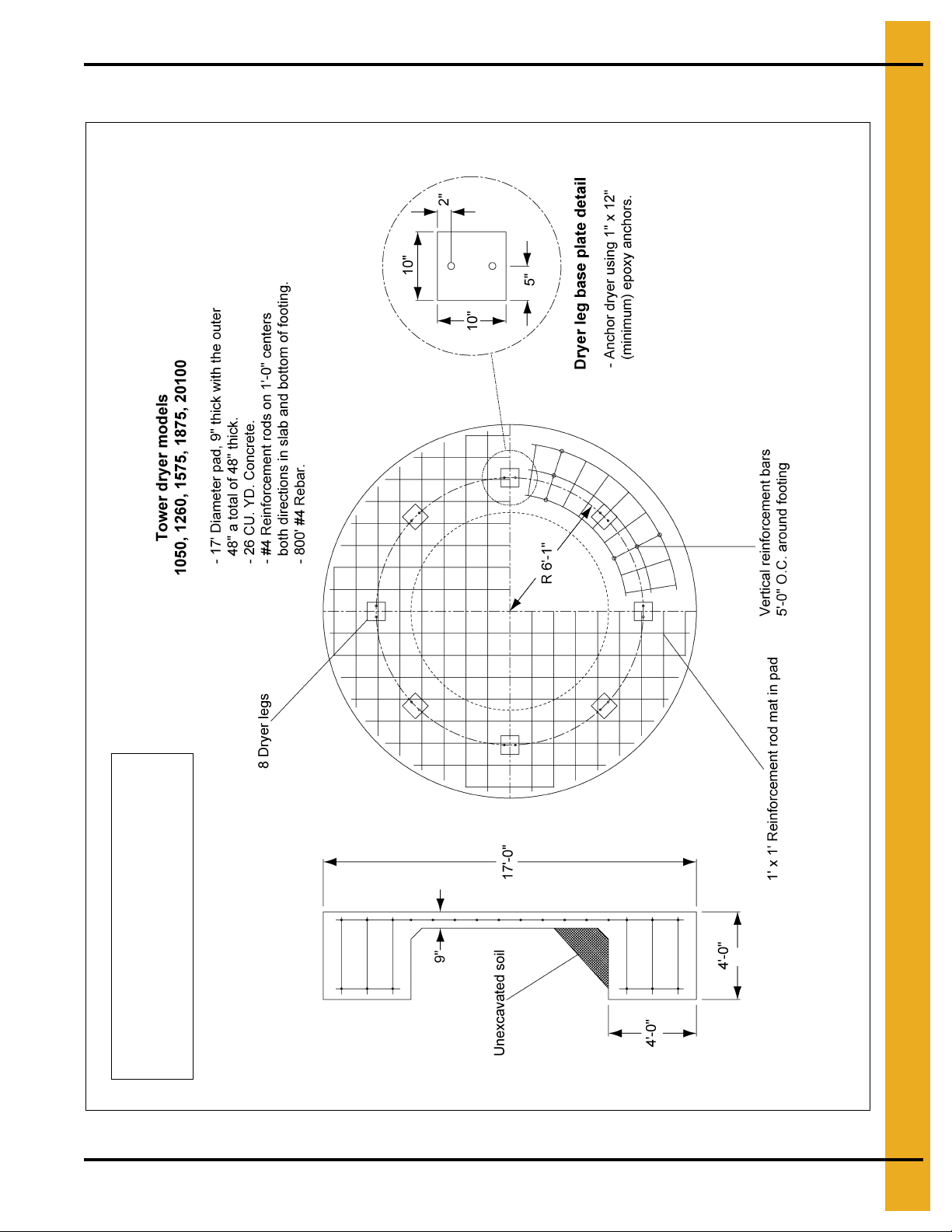

4. Dryer Installation

NOTES:

1. Foundation design based on net soil bearing

pressure of 3000 PSF.

2. Site shall be free of any debris or vegetation

and well drained.

3. All reinforcing steel to be A-615 grade 40

deformed bars.

Concrete specifications

Compressive strength @ 28 days - - 4000 PSI

Minimum cement content - - 6 sacks/yard

Maximum slump - - 4" ± 1"

Northern United States Foundation for Dryer Sizes up to 20100

Figure 4B

PNEG-1458 T-Series Tower Dryer 17

Page 18

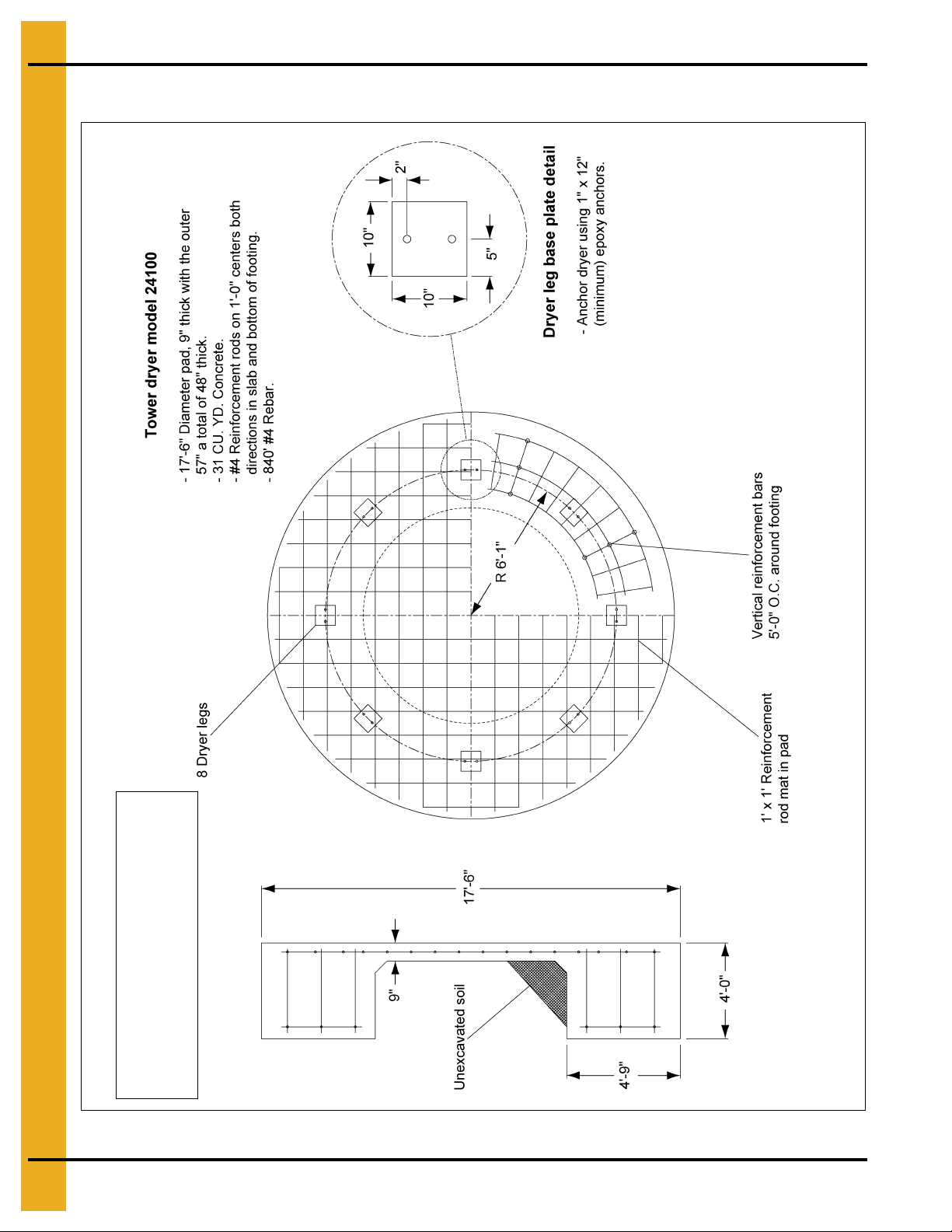

4. Dryer Installation

NOTES:

1. Foundation design based on net soil bearing

pressure of 3000 PSF.

2. Site shall be free of any debris or vegetation

and well drained.

3. All reinforcing steel to be A-615 grade 40

deformed bars.

Concrete specifications

Compressive strength @ 28 days - - 4000 PSI

Minimum cement content - - 6 sacks/yard

Maximum slump - - 4" ± 1"

Foundation for 24100 Dryer

Figure 4C

18 PNEG-1458 T-Series Tower Dryer

Page 19

Fuel Supply

See Table on Page 20

for recommended

line size.

Connection to natural gas manifold on dryer

See Table on Page 20 for

recommended line size.

Natural gas meter and regulator. See Table

on Page 20 for required pressure and

typical maximum fuel flow rates.

4. Dryer Installation

Figure 4D Liquid Propane (LP) Fuel Supply

PNEG-1458 T-Series Tower Dryer 19

Figure 4E Natural Gas (N) Fuel Supply

Page 20

4. Dryer Installation

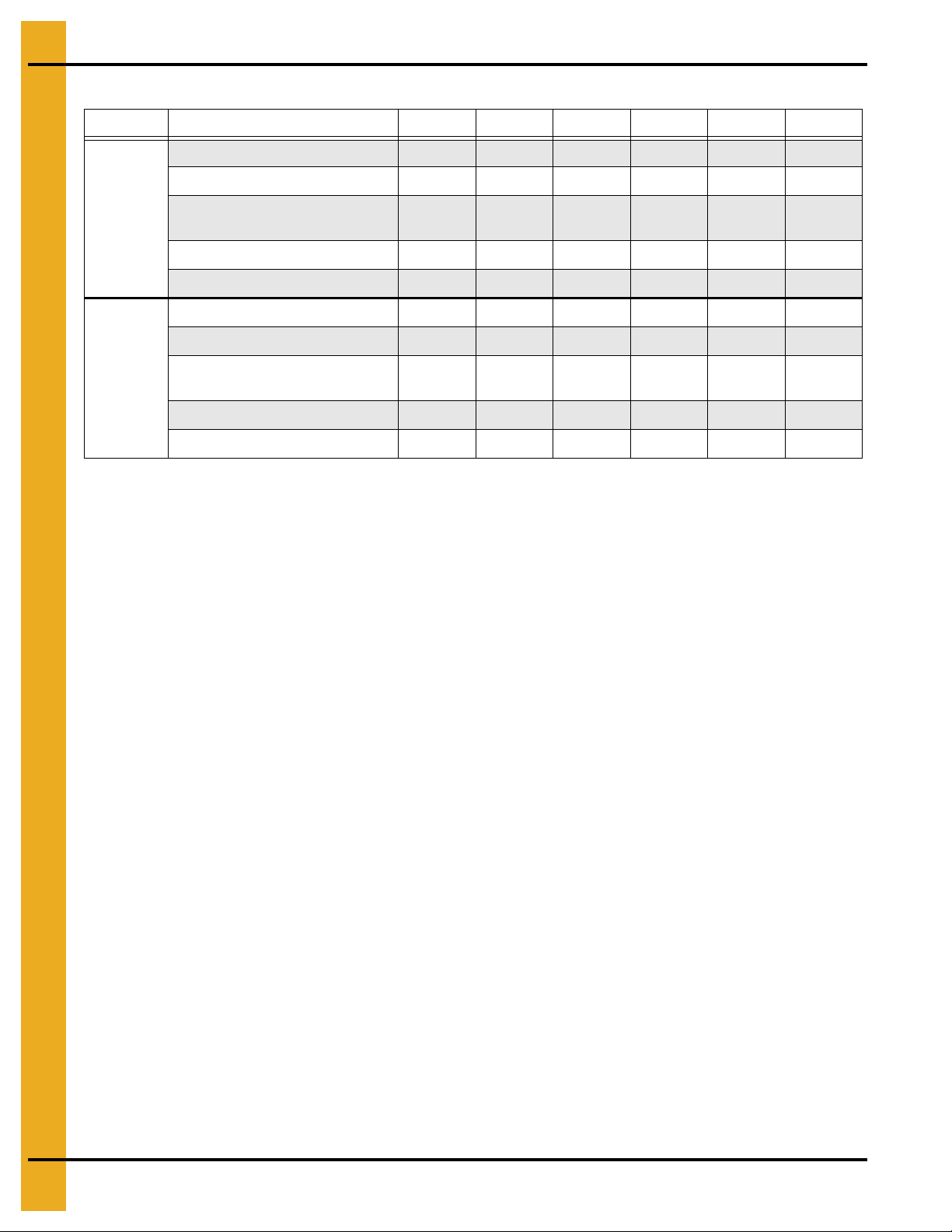

Burner Capacity (Btu/Hr)¹ 11100000 11100000 16654000 17669000 21298000 23393000

Maximum Fuel Usage (Gal/Hr) 121 121 182 193 233 255

Fuel System Recommendations

1050 1260 1575 1875 20100 24100

Liquid

Propane

Natural

Gas

¹Burner capacity for fuel line sizing. Actual average fuel usage is typically 50%-60% of the burner capacity.

Recommended Liquid

Line Size (>100')

Fuel Train Orifice Size (inch) 0.625" 0.625" 0.7187" 0.787" 0.781" 0.781"

Pressure Regulator Setting (PSI) 9 9 9 9 9 9

Burner Capacity (Btu/Hr) 11100000 11100000 16654000 17669000 21298000 23393000

Maximum Fuel Usage (Cu Ft/Hr) 11100 11100 16654 17669 21298 23393

Recommended Liquid

Line Size (>100')

Fuel Train Office Size (inch) 0.7187" 0.7187" 0.8125" 0.875" 1.000" 1.000"

Regulated Supply Pressure (PSI) 10 10 10 10 10 10

3/4" 3/4" 3/4" 1" 1" 1"

2" 2" 2-1/2" 2-1/2" 2-1/2" 2-1/2"

Electrical Power Supply

An adequate power supply and proper wiring are important factors for maximum performance and long

life of the dryer. Electrical service must be adequate enough to prevent low voltage damage to motors and

control circuits.

Transformers and Wiring Voltage Drop

Advise the service representative of the local power supplier that an additional load will be placed on the

line. Check on KVA rating of transformers, considering total horsepower load. The power supply wiring,

main switch equipment and transformers must provide adequate motor starting and operating voltage.

Voltage drop during motor starting should not exceed 14% of normal voltage and a fter motor is running at

full speed it should be within 8% of normal voltage.

Power Supply Disconnect

All dryers are equipped with a power disconnect switch in the power box to permit total power shut down

before opening the power box door, as required for inspection and service. The power disconnect switch

is located on the power box door for quick shut down.

Machine to Earth Grounding

It is very important that a machine to earth ground rod be installed at the dryer. Place the ground rod that

comes standard, within eight feet (8') of the dryer and attach it to the dryer control panel with a t least a #6

solid, bare, copper ground wire and the clamp provided. The grounding rod located at the power pole will

not provide adequate grounding for the dryer. The proper grounding will provide additional safety

in case of any short and will ensure long life of all circuit boards, SCR drive and the ignition system.

The ground rod must be in accordance with local requirements.

20 PNEG-1458 T-Series Tower Dryer

Page 21

4. Dryer Installation

Proper Installation of Ground Rod

It is not recommended that the rod be driven into dry ground. Follow these instructions for

proper installation.

1. Dig a hole large enough to hold one to two (2) gallons of water.

2. Fill hole with water.

3. Insert rod through water and jab it into the ground.

4. Continue jabbing the rod up and down. The water will work its way down the hole, making it possible

to work the rod completely into the ground. This method of installation assures good contact with the

surrounding soil, making a proper ground.

5. Connect the bare, copper ground wire to the rod with proper clamp.

6. Connect ground wire to control panel with the ground lug provided in the control box.

7. Ground wire must not have any breaks or splices. Insulated wire is not recommended for

grounding applications.

Connecting Auxiliary Conveyors

The auxiliary load and auxiliary unload augers or conveyors can be wired directly to the dryer. The

maximum horsepower of auxiliaries that can be wired to the dryer is 10 horsep ower. If an auxiliary motor

is larger than what is recommended, then it must be powered from a source outside the dryer and must

use a separate contractor and overload protection device for each motor. However, the operation of the

auxiliaries can be performed by the control panel.

It is recommended that you contact the local power company and have a representative survey the

installation to see that the wiring is compatible with their system and that adequate power is supplied

to the unit. Remember that the only thing connected to the recommended service amps should be the

grain dryer. Standard electrical safety practices and codes should be used. (Refer to National Electrical

Code Standard Handbook by National Fire Protection Association.) A qualified electrician should make all

electrical wiring installations.

PNEG-1458 T-Series Tower Dryer 21

Page 22

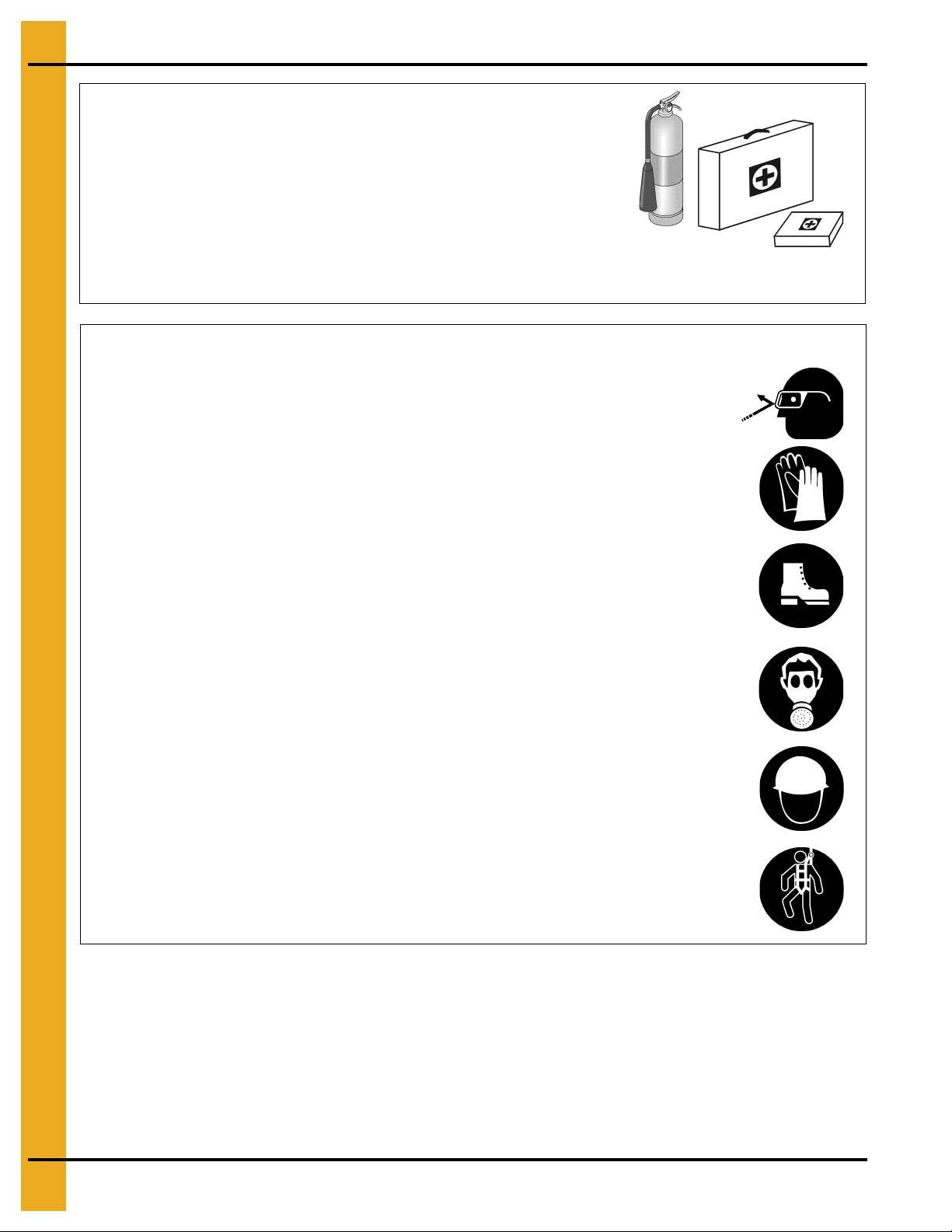

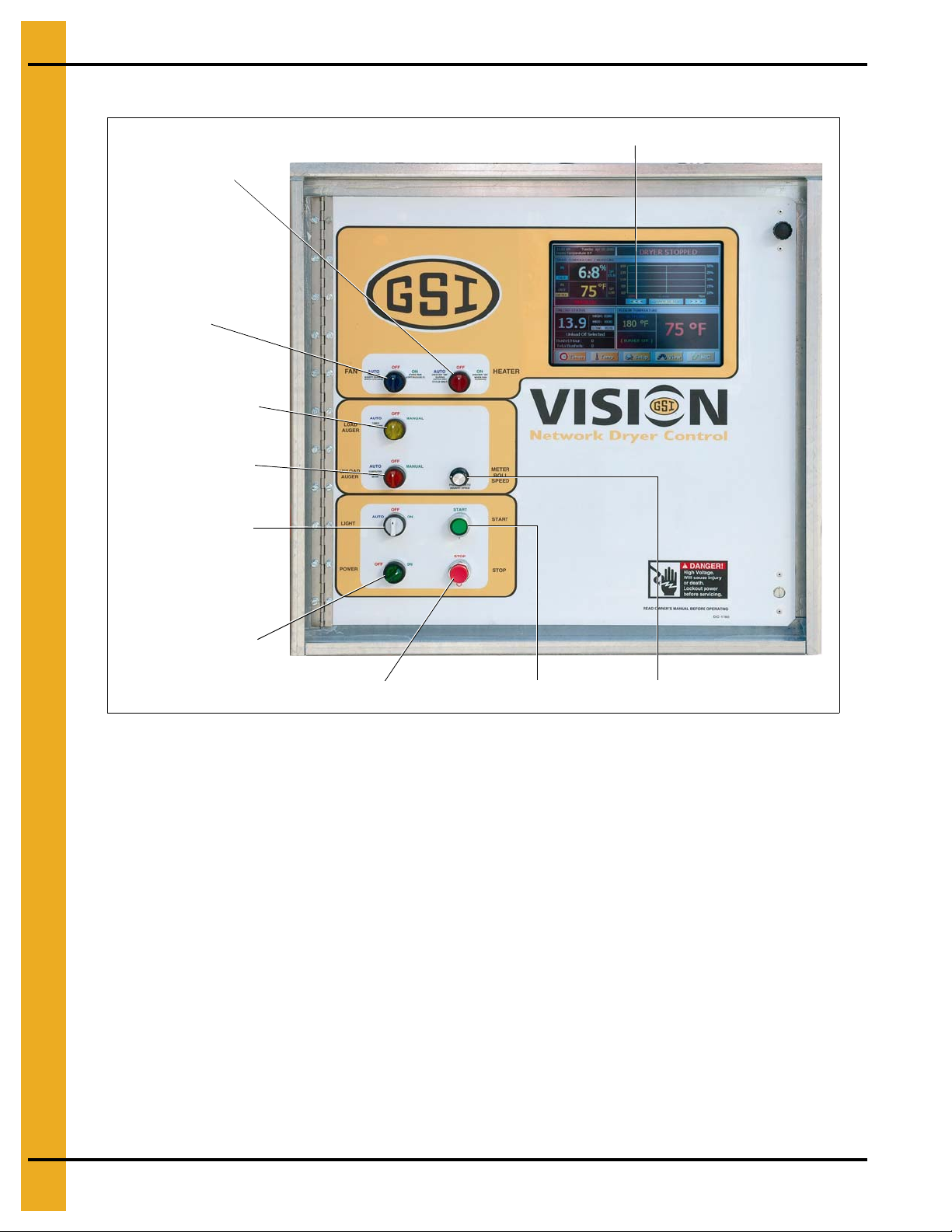

5. Operating Controls

Heater switch

Fan switch

Load auger switch

Unload auger switch

Operator light switch

Control power switch

Stop switch

Start switch

Meter roll speed

Touch screen

Vision Control Panel Layout

Figure 5A

The vision control system is a state of the art dryer controller used on several GSI drying products. The

vision control can operate any dryer in either a batch or a continuous flow mode. Therefore, all operating

instructions for the T-Series dryer describes continuous flow operation only.

Control Power Switch

The vision control system is turned ON or OFF with this switch.

NOTE: This switch does NOT disconnect the power that is present at the breakers, contractors,

transformers, fuses or other electrical components found in the control or power box. Turn the main

disconnect handle located on the power box to the OFF position prior to servicing any of the

installed components.

Fan Switch

The fan is turned ON or OFF with this switch. Turning the switch to the ON position will turn the fan ON.

Turning the switch to the OFF position turns the fan OFF. The light inside the switch will illuminate

whenever the air pressure sensor senses air movement through the fan. (NOTE: The fan AUT O position

is not used.)

22 PNEG-1458 T-Series Tower Dryer

Page 23

5. Operating Controls

Heater Switch

The burner is turned ON or OFF with this switch. Turning the switch to the ON position will start the

burner ignition sequence if the fan is also running. Turning the switch to the OFF position turns the

burner OFF. The light inside of the switch will illuminate only when the flame sensor detects the burner

flame. (NOTE: The heater AUTO position is not used.)

Load Auger Switch

This switch is used to select the operation of the wet fill conveyor. In both the AUTO and the MANUAL

positions, the wet fill conveyor will operate if the dryer is low on grain and will automatically shut off

when the dryer is full. In the AUTO position only, the dryer will automatically shut down should the dryer

go low on grain. The time period between the dryer going low on grain and the actual shut down is

determined by the setting on the out of grain timer. In the MANUAL position, the out of grain timer is

deactivated. The MANUAL switch position should be used for initially filling the dryer. The AUTO switch

position should be used during normal dryer operation. The switch will illuminate whenever the load auger

is operating.

Unload Switch

The Unload switch turns the accutrol metering system and the unload conveyor ON or OFF and also

selects the operation of the metering system. In the MANUAL position, the metering system operates

at the speed set by the Metering Roll Speed Rotary switch. In the AUTO position, the metering system

switches to a multi-speed operation controlled by the automatic moisture control. The switch will illuminate

whenever the unload auger is operating.

Outside Light Switch

The service light is turned ON or OFF with this switch. In the AUTO position, the light is turned ON

while the dryer is running automatically and turns OFF if a shut down occurs. In the ON position, the light

is turned ON.

Start Switch

This switch starts and operates the dryer. If all of the above Dryer Operational switches are in the OFF

position, each component can be turned ON by turning the component switch to the ON position after the

run switch has been pressed. Or, if the Operational switches are preset to their ON position, the vision

controls will sequentially start the various dryer components after the run switch is pressed.

Stop Switch

This switch stops all dryer functions except the blower. If the Blower switch is in the ON position, the blower

will continue to run for 15 minutes. If you desire the blower to be OFF, simply turn the Blower switch to the

OFF position. If an automatic dryer shut down occurs, first determine and correct the cause of the shut

down. Then press the Dryer Power Stop button to reset the dryer before restarting.

PNEG-1458 T-Series Tower Dryer 23

Page 24

6. Vision Touch Screen Display

These two (2) buttons are

used to update software.

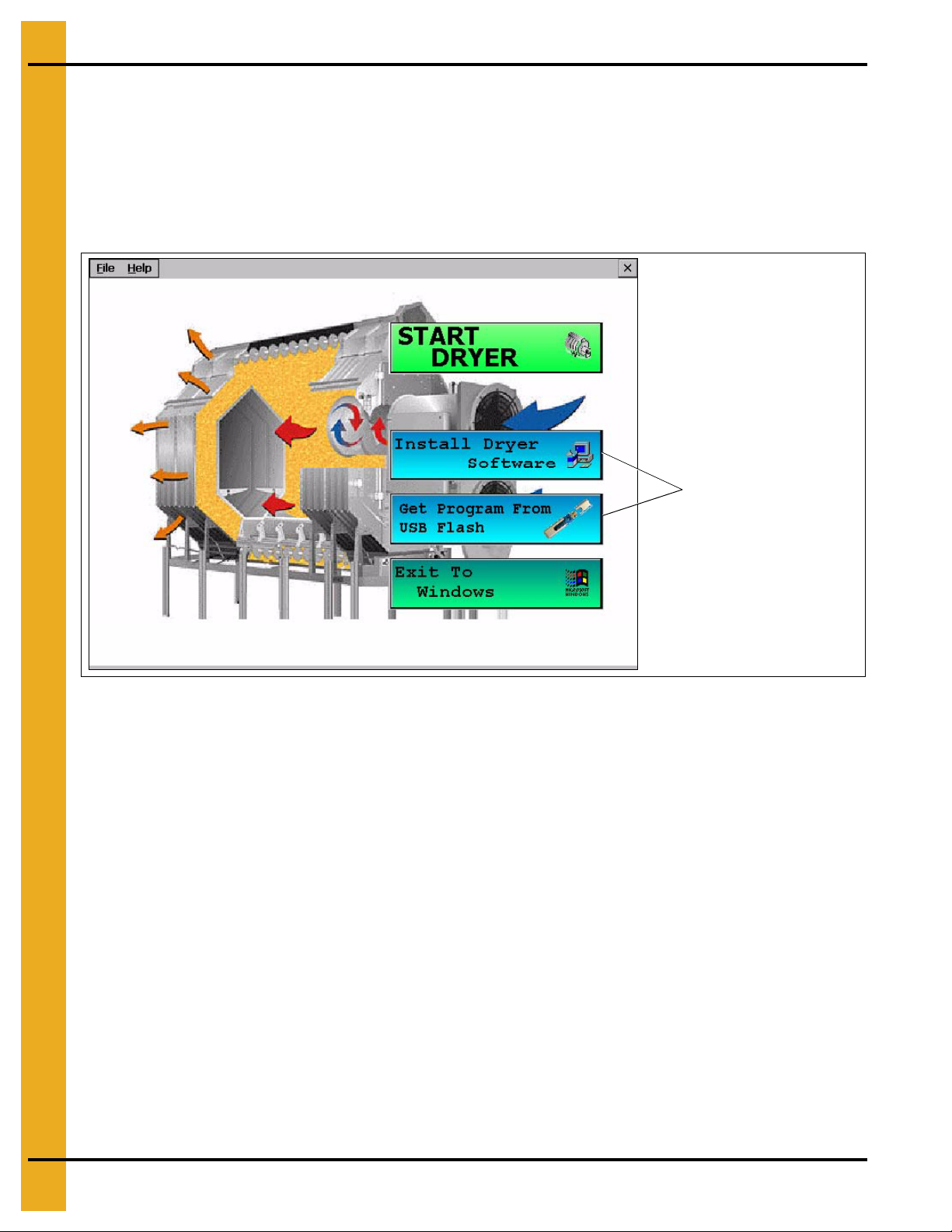

Boot Screen

With the Power switch in the ON position, pushing the Start switch will start the Vision computer. The first

screen to appear will be the Boot screen. (See Figure 6A.) Notice that there are four (4) “buttons” on the

Boot screen. Install Dryer Software and Get Program From USB Flash buttons are only used for program

updates that may be released at a later date. Touching the Start Dryer button will display the Default

Operation screen. Touching the Exit To Windows button will close down the dryer program and take you

to the Windows CE Operating System.

Figure 6A

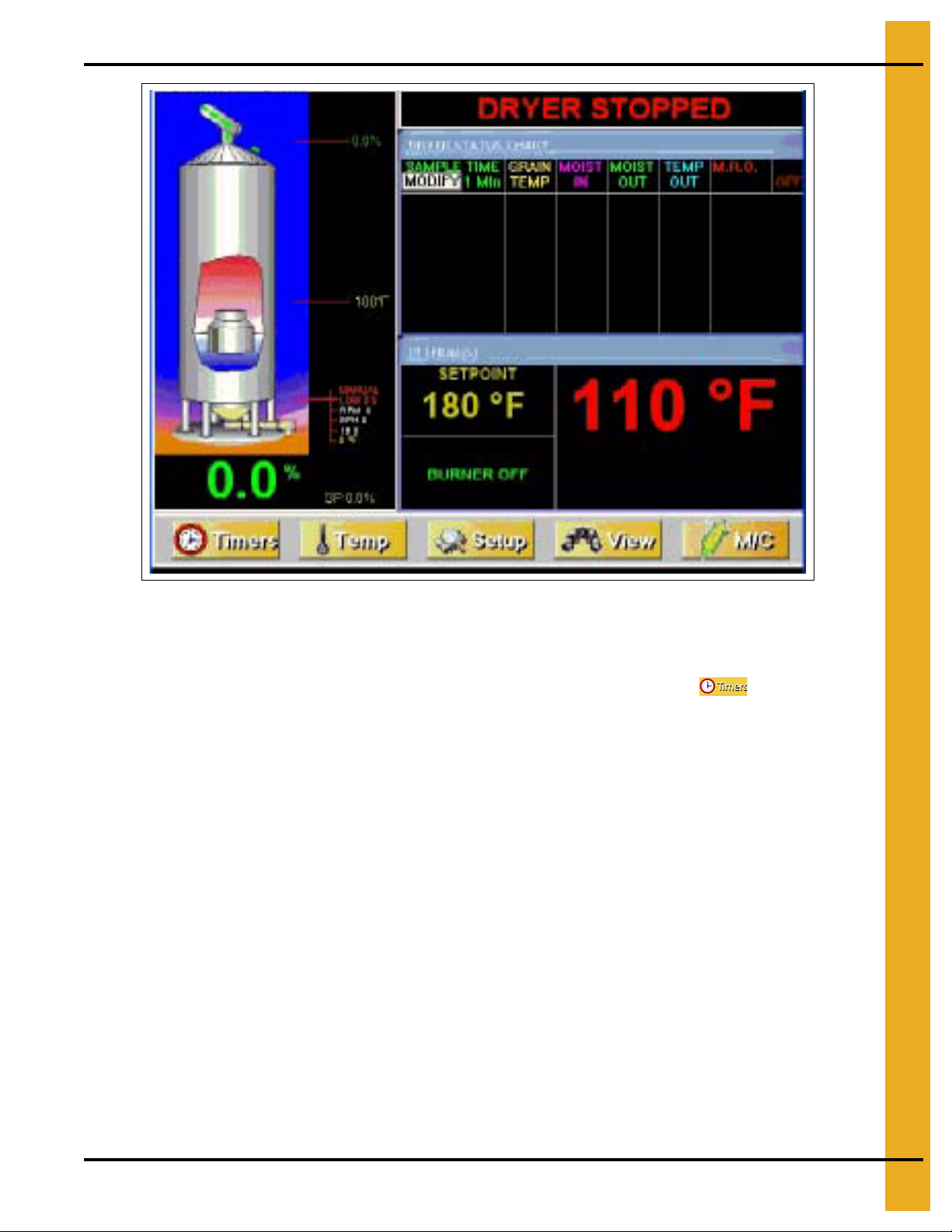

Default Operation Screen

As you can see the Operation screen is divided into five (5) sections.

1. Dryer operation animation: Located on the left side of the Operation screen the operation animation

shows the status of the fan/heaters, load and unload augers and meter rolls. It will also display the

grain temperature, moisture content, M/C set point and bushel counter.

2. Dryer status: Located at the very top of the right side of the Operation screen the dryer status

will tell you if the dryer is stopped, started, loading or unloading.

3. Dryer status chart: Located directly below dryer status. This chart will show the grain temperature,

moisture in/out, temperature out and M.R.O. over a period of time.

4. Plenum: Located directly below dryer status chart. This will show the plenum temperature

set point (SP), actual plenum temperature and burner status.

5. Setup buttons: Located across the bottom of the Operation screen. By touching these buttons

the timers, temperature set points, dryer model and moisture control can be set up.

24 PNEG-1458 T-Series Tower Dryer

Page 25

6. Vision Touch Screen Display

Figure 6B

Setting the Timers

Setting the timers for the dryer is a simple procedure. To set the timers, touch the button at the

bottom of Operation screen. A new screen will appear called the Select Timers to Modify screen.

(See Figure 6C on Page 26.) As you can see there are five (5) timers that you can modify:

1. Load delay: This delay is used to delay the starting of the load conveyor when the dryer is unloading

to prevent the load conveyor from cycling to often.

2. Out of grain (OOG) timer: The OOG timer should be set to the maximum time it takes for the dryer

to refill. Note that the computer will display the time required to fill the dryer on the previous load

operation to aid you in setting an accurate time. If the dryer runs out of grain while the Load Auger

switch is in the AUTO position, the OOG timer automatically shuts off the dryer after the period of

time preset on the timer.

3. Fan delay timer: The fan sequence delay timer.

4. Cool down timer: The cool down timer is used to set the amount of time the fan is to run, after a

non-heat related shut down. Setting to 0 will cause an immediate shut down on a warning. The range

is from 0 to 20 minute.

5. Unload delay timer: The unload delay timer is used to control the amount o f time the unloa d auger

runs after the metering system stops to allow the unload auger to clean itself out.

PNEG-1458 T-Series Tower Dryer 25

Page 26

6. Vision Touch Screen Display

Operation screen for setting timers

Modifying timer set point

Figure 6C

To setup a timer touch the button of the timer you wish to modify. The Modify Timer Set Point screen

will then be displayed. (See Figure 6C.) Note that there are two (2) number pads on this Modify screen.

The left number pad is used to modify the minutes and the right number pad will modify the seconds.

Touching the Default button will automatically set the timer to the default set point for that timer. The

Accept button will save the timer set point displayed in the time display. Touching Cancel will exit the

Modify Timer Set Point screen without saving any changes and the timer will stay at the currently

saved set point.

Once you have the timer set points set touching the Exit button at the bottom of the Modify Timer

Set Point screen will return you to the Operation screen.

Setting the Temperatures

Setting the plenum temperature set point for the dryer is a simple procedure. To adjust the plenum

temperature touch the button at the bottom of Operation screen. A new screen will appear called

the Select Temperature Set Point to Modify screen. (See Figure 6D on Page 27.)

26 PNEG-1458 T-Series Tower Dryer

Page 27

6. Vision Touch Screen Display

Figure 6D

The plenum temperature set point range is 80°F-250°F and the current temperature set point for each

plenum is displayed next to the corresponding Plenum button.

The grain temperature set point range is 80°F-150°F and the current temperature set point for the grain

temperature is displayed next to the Grain Temperature button.

Modifying a temperature set point is much like setting a timer described on Page 25. Touch the desired

button of the set point you wish to change. The Modify Temperature Set Point screen will appear. Enter

the desired temperature using the displayed number pad then touch the Accept button. Tou ching the Exit

button at the bottom of the Select Temperature Set Point to Modify screen will return you to the

Operators screen.

PNEG-1458 T-Series Tower Dryer 27

Page 28

6. Vision Touch Screen Display

The Setup Screen

The Setup screen will allow you to setup other parameters of the dryer. To use the Setup screen touch the

button. The Select Hardware Setup Parameter to Modify screen will now be displayed. As you can

see there several different parameters that can be modified on this screen:

Figure 6E

1. Drying mode: Touching the Drying Mode button will display the Select Drying Mode window.

Continuous flow will be the only option for Tower Dryers.

2. M/C Setup: The M/C Setup operations are described in greater detail in the dryer opera tion section

on Page 37 of this manual.

3. Unload parameters: Touching the Unload Parameters button will present a screen where you will

edit you maximum and minimum unload rates.

Figure 6F

28 PNEG-1458 T-Series Tower Dryer

Page 29

6. Vision Touch Screen Display

4. Plenum temperature manager: Touching the plenum temperature manager will display a

Configuration screen that will allow you to turn this feature ON or OFF. Also, a Configuration section

is presented so that the user can edit the behavior of this option.

Figure 6G

5. Burner mode: Touching the Burner Mode button will display the Select Burner Mode screen.

(See Figure 6H.) Tower dryer burner mode should always be set to ALL HIGH\LOW.

Figure 6H

PNEG-1458 T-Series Tower Dryer 29

Page 30

6. Vision Touch Screen Display

6. Calibrate moisture sensor: Touching this butto n will display the Configuration screen to adjust the

offset for wet and dry moisture and temperature.

7.

Extended setup:

Figure 6I

Touching this button will display a setup menu with extended features and options.

Figure 6J

30 PNEG-1458 T-Series Tower Dryer

Page 31

6. Vision Touch Screen Display

1. Diagnostics: The Diagnostics operations are described in greater detail in the service section

on Page 49 of this manual.

2. Differential: Touching the Differential button will display the Modify Burner Differential

Settings screen. (See Figure 6K.) Adjusting the burner differential settings allows the

operator to keep the plenum temperature within a certain range. For example: If you have the

temperature set point at 180° and you select ± 3° as the burner differential, then the burner will

switch to low heat at 183° and back to high heat at 177°. To modify a burner differential setting

first touch the Plenum button you wish to modify, then select one of the five (5) differential

setting button on the right side of the Modify Burner Differential Settings screen. Touch the

Accept/Exit button to save settings and return to the Select Hardware Setup Parameter to

Modify screen. NOTE: Tower dryer only have plenum #1.

Figure 6K

3. Printer setup: This section only applies if the dryer is equipped with a printer.

Figure 6L

PNEG-1458 T-Series Tower Dryer 31

Page 32

6. Vision Touch Screen Display

4. BPH Calibration: Touching the BHP Calibration button will display the Unload Bushels Setup

screen. (See Figure 6M.) As you can see the bushel counter can be cleared by touching the

Clear button. However if the bushel counter is out of calibration it can be calibrated by touching

the Increase and Decrease buttons.

Example: If you ran 1000 bushels through the dryer but the bushel counter on the dryer reads

900 bushels then touch the Decrease button until the calibration reads 90% or if you ran a

1000 bushels and the counter reads 1100 bushels then touch the Increase button until the

calibration reads 110%.

When you are finished with the calibration or clearing the bushel counter touch the Accept

button to return to the Hardware Setup Parameter screen.

Figure 6M

5. Set Time/Date: Touching the Set Time/Date button will display the Set Time/Date window.

Use the up and down buttons to change each of the parameters for date and time. Touch

Accept/Exit to save settings and return to the Select Hardware Parameter to Modify screen.

Figure 6N

32 PNEG-1458 T-Series Tower Dryer

Page 33

6. Vision Touch Screen Display

6. Temperature scale: Touch the Temperat ure Scale button to choose either English units or SI

units temperature scales. Depending what temperature scale you now operating in touching

this button will display a pop-up window asking if you want to switch to SI (celsius, metric tons,

etc.,) or English units (fahrenheit, bushels, etc.).

7. Dryer model: Touching the Dryer Model button will display the Dryer Hardware Setup window.

In order for the dryer operate properly the following items must be entered correctly: model

number and fuel type. Touch the select button until a check mark appears next to the

parameter corresponding to the dryer model.

Figure 6O

8. Data logger setup: Touching this button will display a dialogue box which will allow you

to turn this option ON. Also, you will have the option to delete the log file or copy it to a

USB thumb drive.

9. User saved defaults: Pressing this button will prompt you to save the current dryer settings

as the default settings for the system.

PNEG-1458 T-Series Tower Dryer 33

Page 34

7. Test Firing

WARNING

Before attempting to operate the dryer make sure all safety shields are in place,

all access doors are closed and all personnel are clear of the dryer.

Any gas leaks must be fixed immediately.

Dryer Pre-Season Checks

This section gives a series of checks to be carried out on the dryer before starting for the first time in the

drying season. If any of the checks fail to produce the stated result, you should consult your dealer.

You should not attempt to use the dryer unless all the pre-start checks have been successfully completed.

Inspect the Accutrol Metering System

Open the two (2) access doors and inspect the accutrol sweep metering system to ensure that the system

is free of foreign material.

Electrical Power

Turn ON the electrical power supply to the dryer, set all circuit breakers to ON, including the safety

disconnect handle mounted on front of the dryer power panel.

Control Power Switch

Turn the Control Power switch to ON. At this point the controller will lock out all other dryer functions.

Once the Boot screen appears (See Page 24), touch the Start Dryer button and the dryer will perform

a safety circuit check. If a fault is found, the cause will be displayed on the Main screen. If all are found

safe, the Start switch will illuminate, indicating that the dryer is ready to be started.

Start Switch

Push the Dryer Start switch and all the selector switches on the control panel will be activated.

Fuel Check

If using LP gas, make sure the tank has plenty of fuel and that the tank does not have a regulator mounted

on the liquid line. Slowly open the main fuel supply valve at th e tank. Then, open the manual shut off valve

on the dryer to allow fuel flow to the dryer.

If using natural gas, make sure an adequate supply at 10 PSI of pressure is available. Turn ON the valve

along the supply line. Inspect all gas lines and connections for possible leaks.

WARNING

34 PNEG-1458 T-Series Tower Dryer

Page 35

7. Test Firing

Load Auger

With the grain supply shut off, quickly bump the Load Auger switch to manual and check all filling

equipment for proper rotation.

Turn the Load Auger switch to the AUTO position. The filling equipment should run for eight (8) minutes

and then the dryer will shut down leaving the safety shut down message (out of grain warning) disp layed.

Press the Dryer Power Stop button to reset the panel, then press the Start button.

Unload Auto Operation

To check auto operation place the Unload switch in the AUTO setting. Check unload equipment for

proper rotation.

Unload Manual Operation

To check manual operation move the Unload switch to the MANUAL position. Check unload equipment

for proper rotation.

Accutrol Sweep Metering System Operation

To check the metering operation turn the knob clockwise and the metering speed should increase.

The metering system should be turning clockwise when viewed from above. Turning the knob

counterclockwise will decrease the speed. When the meter system is set to maximum (1000) the meter

roll speed should be 2.4 RPM. Turn the Unload switch OFF after t hese checks are comple te. The bottom

auger will continue to run for 60 seconds (default clean out delay setting) after the switch is turned OFF to

allow for clean out.

Fan Switch

Momentarily turn the Fan switch to ON and observe the fan for rotation.

Burner Safety

To check the burner safety function, first make sure the main gas valve is OFF. Turn the Fan switch ON

and allow the fan to start. Then, turn the Hea ter switch ON. The dryer will go through a 15 seconds purse

time follower by a 10 seconds ignition time. The dryer will them shut down. The safety message, “Ignition

Failure Fan #” will appear.

Burner Test Fire

Test fire the burner by starting the fan. Adjust the plenum temperature set point to 140°F (60°C). Turn ON

the fuel supply them, turn the Burner switch to ON. After the 15 seconds purge time, manually latch the

electronic shut off valve (maxon valve) during the ignition time. The burner should illuminate and the

plenum temperature will start to increase. Adjust the High-Fire adjustment valve so that the burner

pressure gauge reads 25-30 ounces of pressure. (See Figure 7A on Page 36.) When the plenum

temperature reaches the set point, the cycle solenoid will close. Adjust the Low-Fire valve so that the

burner pressure gauge reads 6-8 ounces of pressure. The computer should cycle the burne r between high

and low 3 to 4 times a minute. If, during normal operation, the burner remains on High-Fire or the dryer

does not get to operating temperature, slightly open the High-Fire valve. If the burner stays on

Low-Fire and does not cycle, slightly close the Low-Fire valve.

PNEG-1458 T-Series Tower Dryer 35

Page 36

7. Test Firing

Dryer Shut Down

To shut down the dryer,

1. Close the fuel supply valve at the tank or valve along the fuel line.

2. If the burner is operating, let the dryer run out of fuel and it will shut down automatically due to loss

of flame.

3. Close the fuel valve at the dryer and press the Dryer Power Stop button.

4. Turn OFF the control power.

5. Turn OFF the safety disconnect handle on the front of the power box and turn OFF the main power

to the dryer.

Emergency

In case of emergency push the Dryer Stop button or the Emergency Stop button. This will interrupt power

to the control panel and the fan, burner and all augers will stop immediately.

Figure 7A

36 PNEG-1458 T-Series Tower Dryer

Page 37

8. Dryer Operation

Dryer Start-Up and Operation

Drying Temperatures

Shelled Corn

For shelled corn with an initial moisture content of 20%-30%, the recommended drying temperature

is 210°F-220°F (93°C-104°C). For lower initial moisture content, lower drying temperatures in the

180°F-200°F (82°C-93°C) range.

Small Grain

For drying small grain (wheat, oats, barley, milo), 150°F (66°C) is suggested.

Soybeans

Drying temperatures are critical in drying soybeans. A temperature of 130°F (54°C) is recommended to

keep grain temperature low.

Drying Efficiency

The general rule for obtaining the highest drying efficiency is to use the highest possible drying

temperatures which will not adversely affect grain quality.

Dryer Shut Down

Cooling Hot Grain

If the dryer is to be shut down while filled with grain, it is recommended that hot grain be cooled for

10 to 15 minute, especially in cold weather, to prevent water vapor condensation a nd possible freezing of

such condensate following shut down.

Initial Setup Parameters

Turn the Control Power switch to ON. When the Boot screen appears touch the Start Dryer button. The

computer will run a quick check of the system network after which the Operation screen will appear.

Timer and Delay Settings

Setting the timers for the vision dryer is a simple procedure. To set the timers touch the button

at the bottom of Operation screen. A new screen will appear called the Select Timers to Modify screen.

(See Figure 8A on Page 38.) As you can see there are five (5) timers that you can modify:

1. Load timer

2. Out of grain (OOG) timer

3. Fan delay timer

4. Cool down timer

5. Unload delay timer

PNEG-1458 T-Series Tower Dryer 37

Page 38

8. Dryer Operation

1. Load delay: This delay is used to delay the starting of the load auge r when the dryer is unloading t o

prevent the load auger from cycling to often.

2. Out of grain (OOG) timer: The OOG timer should be set to the maximum time it takes for the

dryer to refill during continuous or batch drying modes. Note that the Vision computer will display the

time required to fill the dryer on the previous load operation to aid you in setting an accurate time. If

the dryer runs out of grain while the Load Auger switch is in the AUTO position, the OOG timer

automatically shuts off the dryer after the period of time preset on the timer. NOTE: The time it took

to load the dryer for the previous load operation is displayed directly below the OOG button in

green letters.

3. Fan delay timer: The fan sequence delay timer is not used on 1 fan dryers.

4. Cool down timer: The cool down timer is used to control the amount of time the fan will continue to

run on a non heat related shut down. To set the time, touch the Cool Down Timer button and

enter the minutes and seconds you wish for the fan to run. Entering Zero in for minutes and seconds

will cause the fan to stop immediately on a shut down warning. NOTE: Pressing the Stop button will

override the cool down mode and cause an immediate shut down of the fans.

5. Unload delay timer: The unload delay timer is used to control the amount of time the unload auger

runs after the metering rolls stop to allow the unload auger to clean itself out.

Figure 8A

To setup a timer touch the button of the timer you wish to modify. The Modify Timer Set Point screen

will then be displayed. (See Figure 8B on Page 39.) Note that there are two (2) number pads on this

Modify screen. The left number pad is used to modify the minutes and the right number pad will modify

the seconds. Touching the Default button will automatically set the timer to the default set point for that

timer. The Accept button will save the timer set point displayed in the time display. Touching cancel will

exit the Modify Timer Set Point screen without saving any changes and the timer will stay at the currently

saved set point.

Once you have the timer set points set touching the Exit button at the bottom of the Modify Timer

Set Point screen will return you to the Operation screen.

38 PNEG-1458 T-Series Tower Dryer

Page 39

Figure 8B

8. Dryer Operation

Setting the Temperatures

Setting the temperature set points for the dryer is a simple procedure. To adjust the temperature

set points touch the button at the bottom of Operation screen. A new screen will appear called the

Select Temperature Set Point to Modify screen. (See Figure 8C.) As you can see you modify the set point

for the plenum by touching the Plenum 1 Temperature button.

The plenum temperature set point range is 80°F-250°F and the current temperature set point for each

plenum is displayed next to the corresponding Plenum button.

Figure 8C

PNEG-1458 T-Series Tower Dryer 39

Page 40

8. Dryer Operation

The grain temperature set point range is 80°F-150°F and the current temperature set point for the grain

temperature is displayed next to the Grain Temperature button.

Modifying a temperature set point is much like setting a timer described on Page 25. Touch the desired

button of the set point you wish to change. The Modify Temperature Set Point screen will appear. Enter

the desired temperature using the displayed number pad then touch the Accept button. Touching the

Exit button at the bottom of the Select Temperature Set Point to Modify screen will return you to the

Operators screen.

Start-Up

Start-Up Procedure

At the beginning of each harvest and before filling the dryer with grain make sure to inspect the dryer for

rodent damage, proper belt tension and missing or damaged safety shields. Test operate the dryer using

the pre-start check procedures.

1. Before attempting to operate the dryer make sure that all safety shields and access doors are in place

and closed and all personnel are clear of the grain dryer and grain handling machinery.

2. Turn all selector switches on the control panel to the OFF position.

3. Turn ON the electrical power supply to the dryer and move the safety disconnect handle mounted on

the dryer’s power box to ON.

4. Turn the Control Power switch to ON. The switch will illuminate. The vision control computer will boot

up. At this point the controller will lock out all other dryer functions. Once the Boot screen appears,

touch the Start Dryer button and the dryer will perfo rm its safety circuit checks. If a fault is found the

cause will be displayed on the Display screen (Touch screen). If all safeties do not detect a problem.

The dryer is ready to be started.

5. Move the Load Auger switch to MANUAL and push the Dryer Start switch. The fill conveyor will

immediately start and the Load Auger switch will illuminate. If additional loading equipment is wired

to the dryer it will also start immediately.

6. When the dryer is full of grain the fill conveyor will stop automatically and any auxiliary loading

equipment wired to the dryer will also stop.

The dryer is now ready to begin drying grain. See Page 41 for advanced moisture control dryer operation.

40 PNEG-1458 T-Series Tower Dryer

Page 41

8. Dryer Operation

Moisture button

Maximum grain

temperature button

V a ri ab le button

Continuous Flow Drying Mode Using Advanced Moisture Control

Full Heat Continuous Flow Operation

This section begins with Step 7 and it is assumed that Step 1 through Step 6 in the start-up procedure

described on Page 40 have been completed.

7. Touch the Setup button at the bottom of the Dryer Operation screen. Once the Hardware Parameter

screen is displayed, touch the Drying Mode button. NOTE: Tower Dryers are always operated in the

continuous flow mode. Press the Accept button and return to the Hardware Parameter screen.

8. Touch the M/C Setup button. When the Moisture Control Selection window appears select the

MOISTURE then VARIABLE moisture control option. Then set the maximum grain temperature

under the Safety Parameters group. Now touch the Setup button then the Unload Parameters button.

When the Unload Parameters window appears, set the % (percent) MAXIMUM Unloading Rate to a

value slightly lower than the maximum unload rate of the unloading equipment. (NOTE: This

percentage will need to be experimentally found by manually operating the dryer unload at various

unload rates to determine the maximum unload rate which the equipment can handle.) Set the

MINIMUM unloading rate at 10%. Once these values have been determined, touch the Accept/Exit

button. In this screen, you also have the option of automatically adjusting the drying temperature

downward if the automatic moisture control continuously calls for an unload rate which is higher than

the maximum unload rate. To select this option, turn the Plenum Temperature Manager to the “ON”

position. (See Page 28 under the Setup screen.) You have the option of controlling the frequency at

which the plenum temperature will be adjusted (time between possible steps) and the size of each

temperature change for each step (size of temperature steps). These settings will be a trial and error

adjustment that will be made based on the site of the unload equipment. Initially, the step time should

be “15 MINUTE” and the size of the temperature step should be “AUTO”. If drying conditions ch ange

after the plenum temperature manager has lowered the drying temperature, the plenum t emperature

will also re-increase the drying temperature.

PNEG-1458 T-Series Tower Dryer 41

Figure 8D

Page 42

8. Dryer Operation

9. Now touch the Setup button >> Extended Setup button >> Printer Setup. When the Storage

Parameters window appears select the type of grain that is to be dried and select the storage bin to

be used (the bin number is for reference only and has nothin g to do with the control of moisture). The

optional printer can also be enabled or disabled by touching the Printer Setup button. After you have

made the selection, touch the Exit button to accept and exit.

10. You will also see a button to calibrate the moisture sensors. Do not calibrate the sensors at

this time.

11. Now touch the Exit button at the bottom of the screen and return to the Dryer Operation screen.

The setup is almost complete and you are now ready to begin drying grain using the variable

moisture control system. The following steps start the flow of grain through the dryer and finish

setting up the moisture control.

12. Make sure the Unload switch is OFF.

13. Open the main fuel supply valve on the tank if using LP gas or the valve in the fuel supply line if using

natural gas.

14. The dryer should already be filled with grain. Turn the Load Auger switch to the AUTO position. In

both the AUTO and MANUAL positions, the Dryer Grain Level switch will automatically keep the

dryer full of grain. In the AUTO position, the dryer will shut down after a preset time period using the

out of grain timer.

15. Look in the drying reference tables section on Pages 43-48 for the chart settings that correspond to

the model of dryer. Pick the initial moisture content and the drying temperature to select an initial

unload rate.

16. Turn the Fan switch to ON. The fan will start and the switch will illuminate when air pressure

is detected.

17. Start the burner by turning the Heater switch to ON. After purging for approximately 15 second

the burner will fire and the Heater switch will illuminate. This indicates that the flame sensing circuit

is sensing burner flame. For information concerning burner adjustment see the dryer pre-start checks

section on Page 34 of this manual.

18. If the dryer is filled with wet corn, run the fan/heater 6 minute/point of moisture to be removed before

starting the unload.

42 PNEG-1458 T-Series Tower Dryer

Page 43

9. Drying Time Tables

Reference Setting Table -- 1050

(Corn)

Moisture

In Out

17% 15% 71 83 95

18%15%546372

19% 15% 44 51 58

20%15%374350

21% 15% 32 38 43

22%15%293338

23% 15% 25 30 34

24%15%232630

25% 15% 20 24 27

26%15%182124

27% 15% 16 19 22

28%15%151720

29% 15% 13 15 18

30%15%121416

32% 15% 10 12 13

35% 15% 8 9 11

170 F

% Unload Rate

190 F

% Unload Rate

210 F

% Unload Rate

(Wheat, Barley, Milo)

Moisture

In Out

15% 13% 50 59 70

16%13%384453

17% 13% 31 36 43

18%13%263137

19% 13% 23 27 32

20%13%202428

21% 13% 18 21 25

23%13%141720

25% 13% 11 13 16

140 F

% Unload Rate

155 F

% Unload Rate

175 F

% Unload Rate

(Soybeans)

Moisture

In Out

15% 13% 57 66 74

16%13%434955

17% 13% 35 40 45

18%13%303438

19% 13% 26 29 33

120 F

% Unload Rate

130 F

% Unload Rate

140 F

% Unload Rate

20%13%232629

21% 13% 20 23 26

23%13%161821

25% 13% 13 15 17

PNEG-1458 T-Series Tower Dryer 43

Page 44

9. Drying Time Tables

Moisture

In Out

17% 15% 85 99 -18% 15% 65 75 86

19% 15% 53 61 69

20% 15% 44 51 60

21% 15% 38 45 51

22% 15% 35 39 45

23% 15% 30 36 40

24% 15% 27 31 36

25% 15% 24 29 32

26% 15% 22 25 29

27% 15% 19 23 26

28% 15% 18 20 24

29% 15% 16 18 21

30% 15% 14 17 19

32% 15% 12 14 15

35% 15% 10 11 13

Reference Setting Table -- 1260

(Corn)

170 F

% Unload Rate

190 F

% Unload Rate

210 F

% Unload Rate

(Wheat, Barley, Milo)

Moisture

In Out

15% 13% 60 70 83

16% 13% 45 53 63

17% 13% 37 43 51

18% 13% 31 37 44

19% 13% 27 32 38

20% 13% 24 28 33

21% 13% 21 25 30

23% 13% 17 20 24

25% 13% 14 16 19

140 F

% Unload Rate

155 F

% Unload Rate

175 F

% Unload Rate

(Soybeans)

Moisture

In Out

15% 13% 68 78 88

16% 13% 51 58 65

17% 13% 41 47 53

18% 13% 35 40 45

19% 13% 31 35 39

20% 13% 27 31 35

21% 13% 24 28 31

23% 13% 19 22 25

25% 13% 15 18 20

120 F

% Unload Rate

130 F

% Unload Rate

140 F

% Unload Rate

44 PNEG-1458 T-Series Tower Dryer

Page 45

9. Drying Time Tables

Reference Setting Table -- 1575

(Corn)

Moisture

In Out

17% 15% -- -- -18% 15% 89 -- -19% 15% 72 85 97

20%15%627282

21% 15% 53 62 71

22%15%475563

23% 15% 42 49 56

24%15%374450

25% 15% 33 40 45

26%15%303540

27% 15% 27 31 36

28%15%242832

29% 15% 22 26 29

30%15%202326

32% 15% 17 19 22

35%15%131517

170 F

% Unload Rate

190 F

% Unload Rate

210 F

% Unload Rate

(Wheat, Barley, Milo)

Moisture

In Out

15% 13% 83 97 -16%13%637387

17% 13% 51 60 71

18%13%445160

19% 13% 38 44 53

20%13%333946

21% 13% 30 35 41

23%13%242833

25% 13% 19 22 26

140 F

% Unload Rate

155 F

% Unload Rate

175 F

% Unload Rate

(Soybeans)

Moisture

In Out

15% 13% 95 -- -16%13%718191

17% 13% 57 66 74

18%13%495663

120 F

% Unload Rate

130 F

% Unload Rate

140 F

% Unload Rate

19% 13% 43 49 55

20%13%384348

21% 13% 33 38 43

23%13%273134

25% 13% 24 24 28

PNEG-1458 T-Series Tower Dryer 45

Page 46

9. Drying Time Tables

Moisture

In Out

17% 15% 92 -- -18% 15% 69 81 92

19% 15% 56 66 75

20% 15% 48 56 64

21% 15% 42 48 56

22% 15% 37 43 49

23% 15% 33 38 43

24% 15% 29 34 39

25% 15% 26 30 35

26% 15% 23 27 31

27% 15% 21 24 28

28% 15% 19 22 25

29% 15% 17 20 23

30% 15% 15 18 21

32% 15% 13 15 17

35% 15% 10 12 14

Reference Setting Table -- 1875

(Corn)

170 F

% Unload Rate

190 F

% Unload Rate

210 F

% Unload Rate

(Wheat, Barley, Milo)

Moisture

In Out

15% 13% 65 76 90

16% 13% 49 57 68

17% 13% 40 47 55

18% 13% 34 40 47

19% 13% 29 34 41

20% 13% 26 30 36

21% 13% 23 27 32

23% 13% 18 21 26

25% 13% 15 17 21

140 F

% Unload Rate

155 F

% Unload Rate

175 F

% Unload Rate

(Soybeans)

Moisture

In Out

15% 13% 74 84 95

16% 13% 55 63 71

17% 13% 45 51 57

18% 13% 38 43 49

120 F

% Unload Rate

130 F

% Unload Rate

140 F

% Unload Rate

19% 13% 33 38 43

20% 13% 29 34 38

21% 13% 26 30 34

23% 13% 21 24 27

25% 13% 17 19 21

46 PNEG-1458 T-Series Tower Dryer

Page 47

9. Drying Time Tables

Reference Setting Table -- 20100

(Corn)

Moisture

In Out

17% 15% -- -- -18% 15% 79 92 -19% 15% 65 75 86

20%15%556473

21% 15% 48 56 64

22%15%424956

23% 15% 37 44 50

24%15%333944

25% 15% 30 35 40

26%15%273136

27% 15% 24 28 32

28%15%222529

29% 15% 19 23 26

30%15%182124

32% 15% 15 17 20

35%15%121416

170 F

% Unload Rate

190 F

% Unload Rate

210 F

% Unload Rate

(Wheat, Barley, Milo)

Moisture

In Out

15% 13% 74 87 -16%13%566578

17% 13% 46 53 63

18%13%394554

19% 13% 34 39 47

20%13%303541

21% 13% 27 31 37

23%13%212529

25% 13% 17 20 24

140 F

% Unload Rate

155 F

% Unload Rate

175 F

% Unload Rate

(Soybeans)

Moisture

In Out

15% 13% 85 97 -16%13%637281

17% 13% 51 58 66

18%13%445056

120 F

% Unload Rate

130 F

% Unload Rate

140 F

% Unload Rate

19% 13% 38 43 49

20%13%343843

21% 13% 30 34 38

23%13%242731

25% 13% 19 22 25

PNEG-1458 T-Series Tower Dryer 47

Page 48

9. Drying Time Tables

Moisture

In Out

17% 15% -- -- -18% 15% 91 -- -19% 15% 74 86 99

20% 15% 63 73 84

21% 15% 55 64 73

22% 15% 48 56 64

23% 15% 43 50 57

24% 15% 38 44 51

25% 15% 34 40 45

26% 15% 31 36 41

27% 15% 27 32 37

28% 15% 25 29 33

29% 15% 22 26 30

30% 15% 20 24 27

32% 15% 17 20 22

35% 15% 13 16 18

Reference Setting Table -- 24100

(Corn)

170 F

% Unload Rate

190 F

% Unload Rate

210 F

% Unload Rate

(Wheat, Barley, Milo)

Moisture

In Out

15% 13% 85 99 -16% 13% 64 75 89

17% 13% 52 61 73

18% 13% 44 52 62

19% 13% 39 45 54

20% 13% 34 40 47

21% 13% 30 36 42

23% 13% 27 28 37

25% 13% 19 23 27

140 F

% Unload Rate

155 F

% Unload Rate

175 F

% Unload Rate

(Soybeans)

Moisture

In Out

15% 13% 97 -- -16% 13% 72 82 92

17% 13% 58 67 75

18% 13% 50 57 64

120 F

% Unload Rate

130 F

% Unload Rate

140 F

% Unload Rate

19% 13% 43 50 56

20% 13% 38 44 49

21% 13% 34 39 44

23% 13% 27 31 35

25% 13% 22 25 28

48 PNEG-1458 T-Series Tower Dryer

Page 49

10. Service

Pre-Seasonal Inspection and Service

The dryer is made of weather-resistant material and is designed to require minimum service. However,

each season we recommend the following items be checked befo re the unit is used and any damaged or

questionable parts replaced. These checks will help eliminate possible failures and assure dependable

operation of the equipment.

1. Shut off electrical power. Open power box and control box and inspect for moisture, rodent damage

or accumulated foreign material present. Inspect and tighten any loose terminal connections.

Replace any damaged or deteriorated wiring.

2. Lubricate the blowers, motors and metering system as outlined in the lubrication table on Page 52.

3. Check blower belts for proper tension.

4. Inspect and clean the burner. Visually check that no holes in the stainless steel air mixing plates are

plugged. If burner ports are plugged, clear them with a piece of wire or a drill bit. (NOTE: Pre-2002

model dryers require a #47 drill bit.)

5. Check electrical connections at both the flame rod and spark plug. Clean spark ignitor and flame rod.

Replace if necessary.

6. Check drain valve on gas train to ensure that there is no water in the gas train. Valve should always

be open when the dryer is not being used. Ensure that drain valve is closed prior to dryer operation.

7. Check the discharge area to ensure that the area is cleaned of stalks and old grain. Inspect the

sweeps for excessive wear.

IMPORTANT: The covers to the discharge sections on the tower dryers must be in place and