Page 1

PNEG-1451

Ladder, Safety Cage and

Platform Assembly for

GSI Hopper Tanks

Installation Manual

PNEG-1451

Date: 03-17-11

Page 2

2 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 3

Table of Contents

Contents

Chapter 1 Introduction ..........................................................................................................................................5

Chapter 2 Safety .....................................................................................................................................................6

Safety Guidelines ...... ... ... .... .................................................................................................................. 6

Safety Instructions ..................... ... .... ............................................. ... ... ... .... ... ... ..................................... 7

Chapter 3 Safety Decals ........................................................................................................................................9

Roof Damage Warning and Disclaimer ................................................................................................. 9

Chapter 4 General Detail Information ................................................................................................................12

Extension Rail Installation ......... ... .... ... ... ... .......................................................................................... 12

Ladder Section Assembly ................................................................................................................... 13

Ladder Standoff Detail ........................................................................................................................ 14

Extension Angle Hole Detail ................................................................................................................ 15

Cage Hoop Bracket Assembly ............................................................................................................ 16

Chapter 5 2.66" Corrugated Commercial Hopper Tank 4-9 Rings ...................................................................20

2.66" Commercial Hopper Tank (NCHT) Ladder and Platform Layout 4-9 Rings ............................... 20

NCHT Ladder, Safety Cage and Platform Instructions 4-9 Rings ....................................................... 22

Eave Starter Bracket Installation .....................................................................................................22

Location of Field Drilled Holes for Eave Ladder Starter Brackets ...................................................23

Eave Starter Bracket and Ladder Assembly with Safety Cage .......................................................24

Eave Adjustable Braces ..................................................................................................................26

Eave Platform Mounting Angle Installation ......................................................................................27

Right Hand Platform and Platform Support Assembly ........................................................................ 28

Eave Safety Cage Hoop Assembly ..................................................................................................... 29

Adapter Assembly Detail ..................................................................................................................... 30

Vertical Supports ................................. ... ... ... .... ... ... ............................................. .... ... ... ...................... 31

32" and 48" Safety Cage .................................. ............................................. ... ... .... ... ... ... ... ................ 31

Access Door Platform Mounting Angle Installation ............................................................................. 32

Left Hand Platform and Platform Support Assembly ........................................................................... 33

Access Door Safety Cage Hoop Assembly ......................................................................................... 34

24"-48" Safety Cage Bell Sections ...................... ... ... .... ... ... ... .... ... ... ... ... ............................................. 35

Ladder Support Detail ......................................................................................................................... 36

Chapter 6 2.66" Corrugated Commercial Hopper Tank 10-22 Rings ...............................................................38

2.66" Commercial Hopper Tank (NCHT) Ladder and Platform Layout 10-22 Rings ........................... 38

NCHT Ladder, Safety Cage and Platform Instructions 10-22 Rings ................................................... 42

Eave Starter Bracket Installation .....................................................................................................42

Location of Field Drilled Holes for Eave Ladder Starter Brackets ...................................................42

Eave Starter Bracket and Ladder Assembly with Safety Cage .......................................................43

Eave Adjustable Braces ..................................................................................................................45

Eave Platform Mounting Angle Installation ......................................................................................46

Right Hand Platform and Platform Support Assembly ........................................................................ 47

Eave Safety Cage Hoop Assembly ..................................................................................................... 48

Adapter Assembly Detail ..................................................................................................................... 49

Vertical Supports ................................. ... ... ... .... ... ... ............................................. .... ... ... ..

48" Safety Cage ........................ ... .... ... ............................................. ... ... .... ......................................... 50

24"-48" Safety Cage Bell Sections ...................... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... ................................ 51

Intermediate Platform Mounting Angle Installation .............................................................................. 52

Location of Field Drilled Holes for Intermediate Ladder Starter Brackets ........................................... 53

.................... 50

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 3

Page 4

Table of Contents

Intermediate Starter Bracket and Ladder Assembly with Safety Cage ............................................... 54

Intermediate and Base Safety Cage Hoop Assembly ......................................................................... 55

Base Platform Mounting Angle Installation ......................................................................................... 56

Location of Field Drilled Holes for Base Ladder Starter Brackets ....................................................... 57

Base Starter Bracket and Ladder Assembly with Safety Cage ........................................................... 58

Access Door Platform Mounting Angle Installation ............................................................................. 59

Left Hand Platform and Platform Support Assembly ........................................................................... 60

Access Door Safety Cage Hoop Assembly ......................................................................................... 61

Ladder Support Detail ...... .... ... ... ... .............................................. ... ... ... ... .... ... ..................................... 62

Chapter 7 4.00" Corrugation Farm Commercial Hopper Tanks (FCHT) 4-6 Rings .........................................64

4.00" Farm Commercial Hopper Tank Ladder and Platform Layout 4-6 Rings ................................... 64

FCHT Ladder, Safety Cage and Platform Instructions 4-6 Rings ....................................................... 66

Eave Starter Bracket Installation .....................................................................................................66

Location of Field Drilled Holes for Eave Ladder Starter Brackets ................................................ ...67

Eave Starter Bracket and Ladder Assembly with Safety Cage .......................................................68

Eave Adjustable Braces ..................................................................................................................70

Eave Platform Mounting Angle Installation ................................... ...................................................71

Right Hand Platform and Platform Support Assembly ........................................................................ 72

Eave Safety Cage Hoop Assembly .................................................................................................73

Adapter Assembly Detail ..................................................................................................................... 74

Vertical Supports ................................................................................................................................. 75

44" and 48" Safety Cage ......................... ............................................................. ............................... 75

Access Door Platform Mounting Angle Installation ............................................................................. 76

Left Hand Platform and Platform Support Assembly ........................................................................... 77

Access Door Safety Cage Hoop Assembly ......................................................................................... 78

24"-48" Safety Cage Bell Sections ...................................................................................................... 79

Ladder Support Detail ...... .... ... ... ... .............................................. ... ... ... ... .... ... ..................................... 80

Chapter 8 4.00" Corrugation Farm Commercial Hopper Tank (FCHT) 7-9 Rings ........... ....................... .........82

4.00" Farm Commercial Hopper Tank (FCHT) Ladder and Platform Layout ...................................... 82

FCHT Ladder, Safety Cage and Platform Instructions 7-9 Rings ....................................................... 83

Eave Starter Bracket Installation .....................................................................................................83

Location of Field Drilled Holes for Eave Ladder Starter Brackets ................................................ ...83

Eave Starter Bracket and Ladder Assembly with Safety Cage .......................................................84

Eave Adjustable Braces ..................................................................................................................86

Eave Platform Mounting Angle Installation ................................... ...................................................87

Eave Platform and Platform Support Assembly .......................... ... ... ... ... .... ... ..................................... 88

Eave Safety Cage Hoop Assembly ................................ ... ... ... .... ... ... ... ... .... ... ... ... ............................... 89

Adapter Assembly Detail ..................................................................................................................... 90

Vertical Supports ................................................................................................................................. 91

48" Safety Cage .................................................................................................................................. 91

24"-48" Safety Cage Bell Sections ...................................................................................................... 92

Access Door/Base Platform Mounting Angle Installation .................................................................... 93

Location of Field Drilled Holes for Base/Access Door Ladder Starter Brackets .................................. 94

Base/Access Door Starter Bracket and Ladder Assembly with Safety Cage ...................................... 95

Access Door Platform and Platform Support Assembly ...................................................................... 96

Base Platform and Platform Support Assembly .......................... ... ... ... ... .... ... ..................................... 97

Access Door/Base Safety Cage Hoop Assembly .... ... .... ............................................. ... ... ... .... ... ... ... .. 98

Access Door/Base Platform Vertical Supports .................................................................................... 99

Ladder Support Detail ...... .... ... ... ... .............................................. ... ... ... ... .... ... ................................... 100

Chapter 9 Warranty ............................................................................................................................................101

4 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 5

1. Introduction

READ THIS MANUAL carefully to learn how to properly use and install equipment. Failure to do so could

result in personal injury or equipment damage.

INSPECT the shipment immediately upon arrival. The customer is responsible for ensuring that all

quantities are correct. The customer should report and note any damage or shortage on the bill of

lading to justify their claim to the transport company.

THIS MANUAL SHOULD BE CONSIDERED a permanent part of your equipment and should be easily

accessible when needed.

This warranty provides you the assurance that the company will back its products when defects appear

within the warranty period. In some circumstances, the company also provides field improvements, often

without charge to the customer, even if the product is out of warranty. Should the equipment be abused,

or modified to change its performance beyond the factory specifications, the warranty will become void

and field improvements may be denied.

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 5

Page 6

2. Safety

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a

hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to

personal injury.

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

DANGER

WARNING

CAUTION

NOTICE

6 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 7

2. Safety

Follow Safety Instructions

Carefully read all safety messages in this manual and

safety signs on your machine. Keep signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from the manufacturer.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machinery in proper working condition.

Unauthorized modifications to the machine may impair

the function and/or safety and affect machine life.

If you do not understand any part of this manual or need

assistance, contact your dealer.

Read and Understand Manual

Install Equipment Properly

This equipment shall be installed in accordance with the

current installation codes and applicable regulations which

should be carefully followed in all cases. Authorities having

jurisdiction should be consulted before installations

are made.

Follow Building Codes

Safety Instructions

Our foremost concern is your safety and the safety of others associated with this equipment. We want to

keep you as a customer. This manual is to help you understand safe operating procedures and some

problems which may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards and precautions

exist, and to inform all personnel associated with the equipment or in the area. Safety precautions may be

required from the personnel. Avoid any alterations to the equipment. Such alterations may produce a very

dangerous situation, where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable

regulations which should be carefully followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 7

Page 8

2. Safety

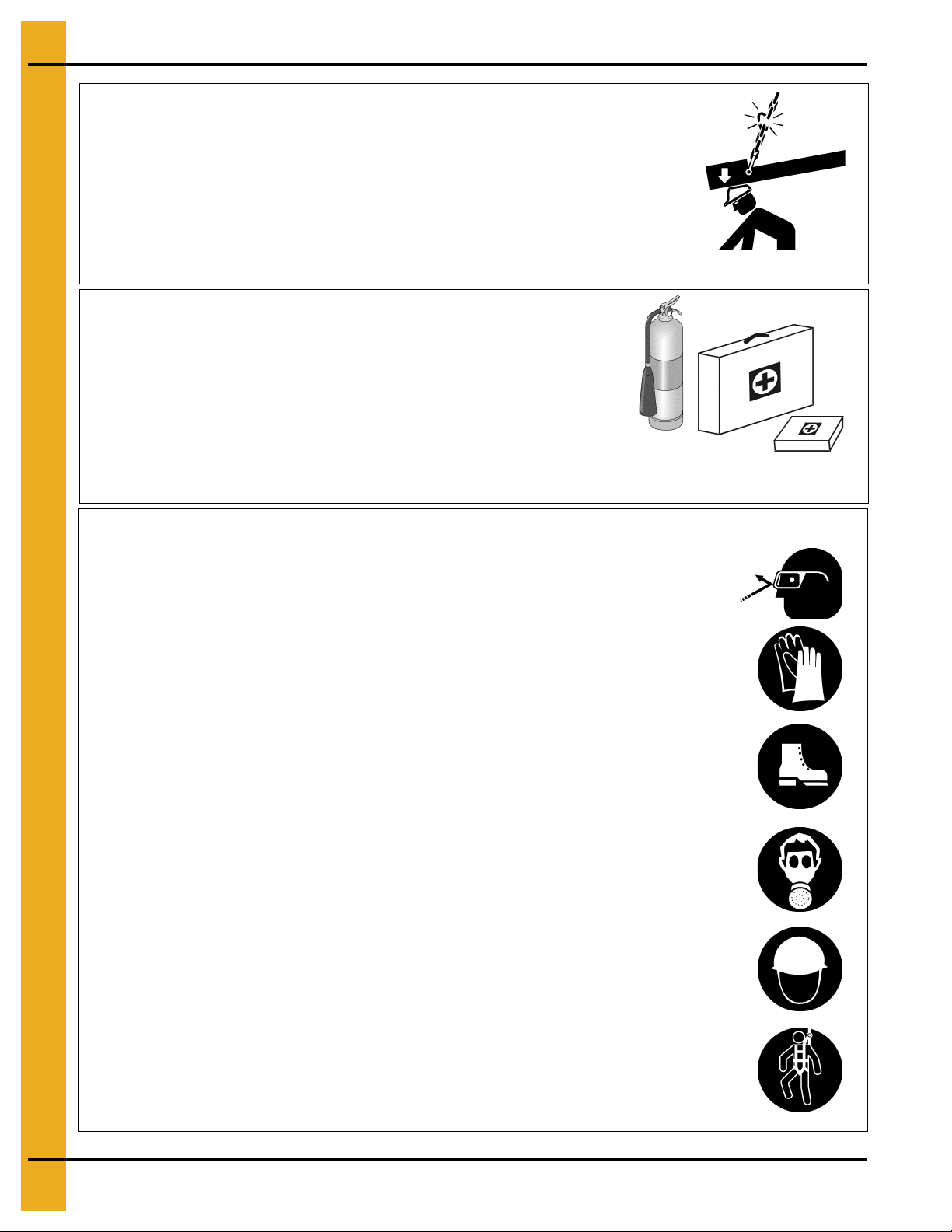

Stay Clear of Hoisted Equipment

Always use proper lifting/hoisting equipment when

assembling or disassembling equipment.

Do not walk or stand under hoisted equipment.

Always use sturdy and stable supports when needed

for installation.

Crush Hazard

Prepare for Emergencies

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital and fire department near your telephone.

Keep Emergency Equipment

Quickly Accessible

Wear Protective Clothing

Wear close fitting clothing and safety equipment appropriate

to the job.

Remove all jewelry.

Long hair should be tied up and back.

Safety glasses should be worn at all times to protect eyes

from debris.

Wear gloves to protect your hands from sharp edges on

plastic or steel parts.

Wear steel toe boots to help protect your feet from falling

debris. Tuck in any loose or dangling shoe strings.

A respirator may be needed to prevent breathing potentially

toxic fumes and dust.

Wear hard hat to help protect your head.

Wear appropriate fall protection equipment when working at

elevations greater than six feet (6').

Eye Protection

Gloves

Steel Toe Boots

Respirator

Hard Hat

Fall Protection

8 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 9

3. Safety Decals

The manufacturer does not warrant any roof damage caused by excess ive v acuum or internal

pressure from fans or other air moving systems. Adequate ventilation and/or “makeup air”

devices should be provided for all powered air handling systems. The manufacturer does not

recommend the use of downward flow systems (suction). Severe roof damage can result from

any blockage of air passages. Running fans durin g high humidity/cold weather conditions can

cause air exhaust or intake ports to freeze.

Roof Damage Warning and Disclaimer

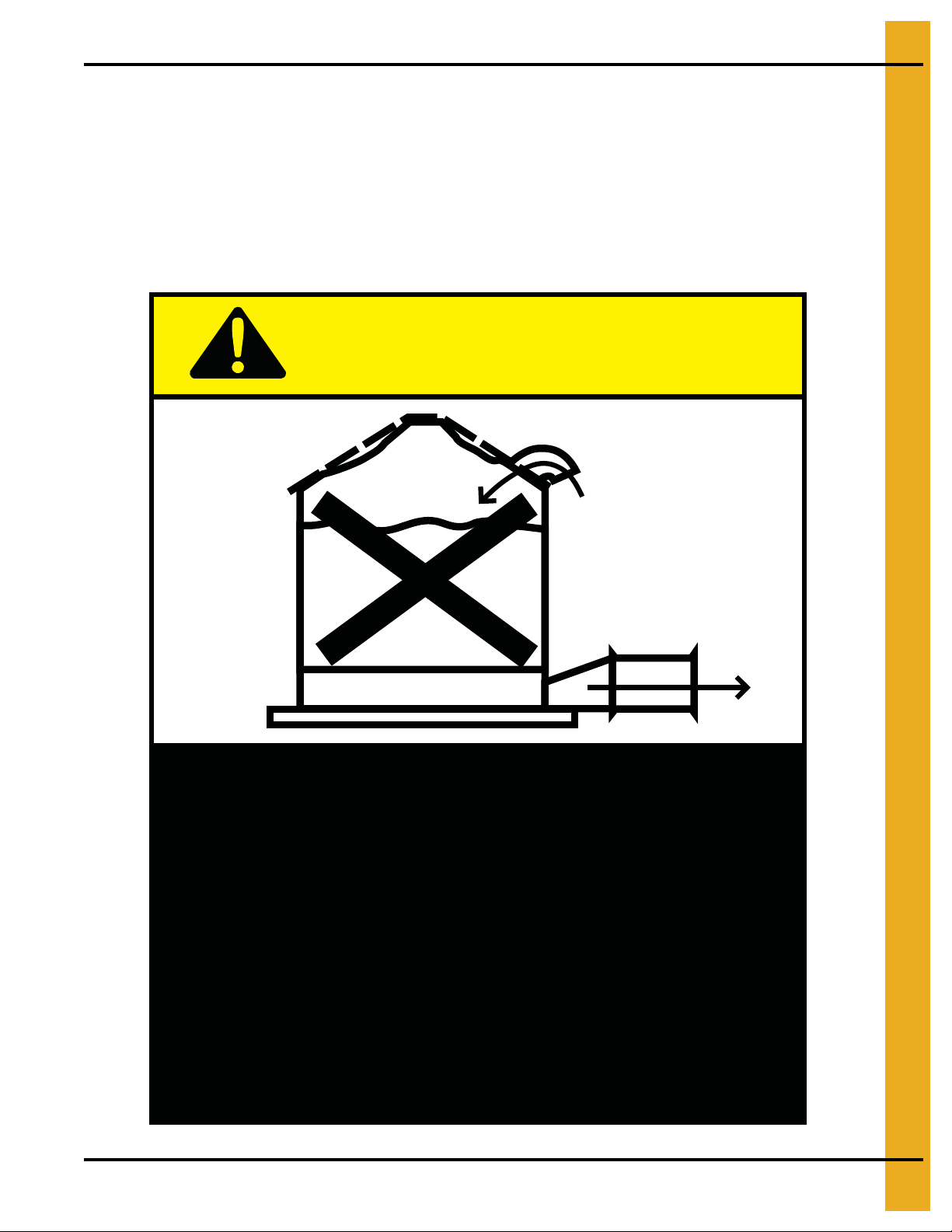

CAUTION!

Excessive vacuum (or pressure) may

damage roof. Use positive aeration

system. Make sure all roof vents are

open and unobstructed. Start roof

fans when supply fans are started.

Do not operate when conditions exist

that may cause roof vent icing.

DC-969

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 9

Page 10

3. Safety Decals

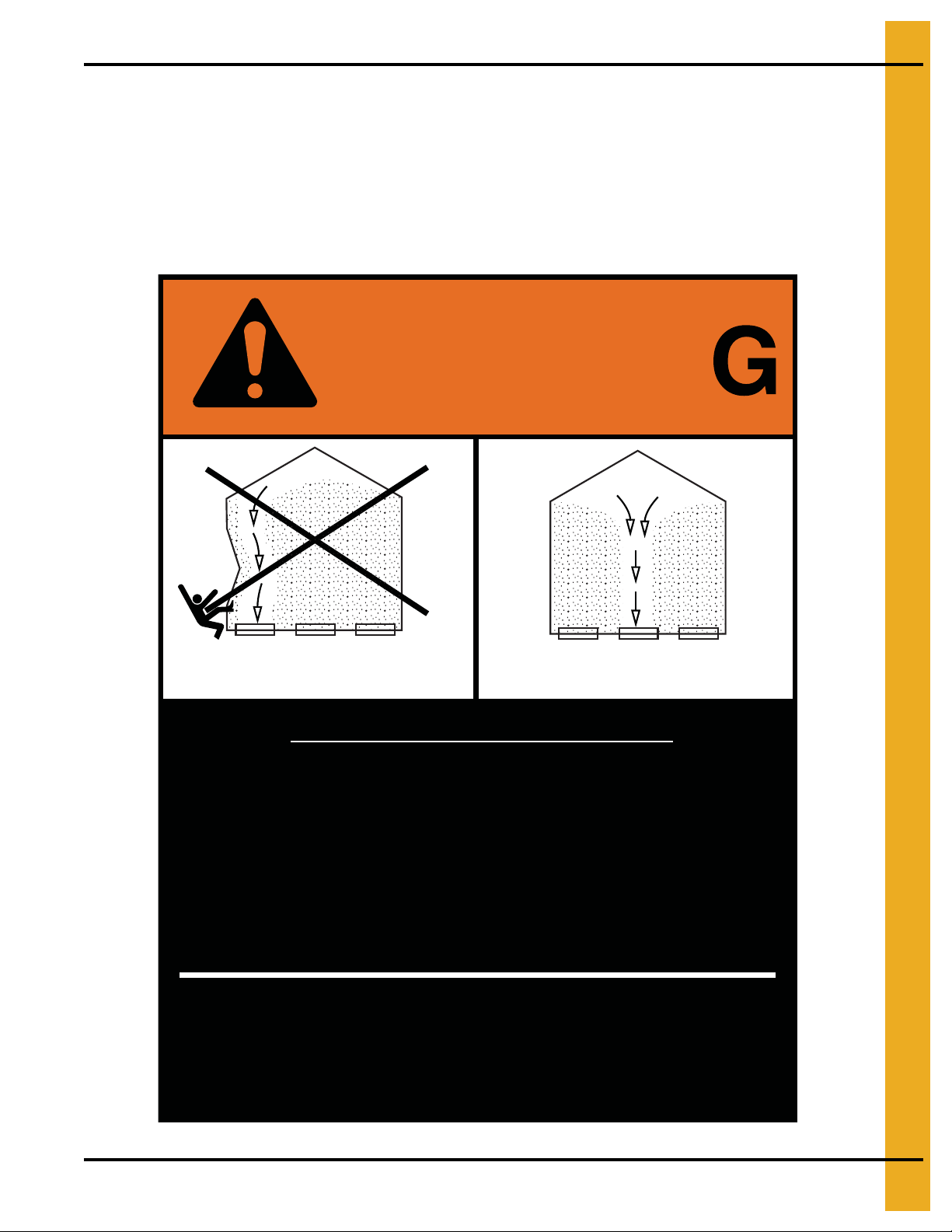

Rotating flighting will

kill or dismember.

Flowing material will

trap and suffocate.

Crusted material will

collapse and suffocate.

Keep clear of all augers.

DO NOT ENTER this bin!

Failure to heed these

warnings will result in

serious injury or death.

If you must enter the bin:

1. Shut off and lock out all power.

2. Use a safety harness and safety line.

3. Station another person outside the bin.

4. Avoid the center of the bin.

5. Wear proper breathing equipment or respirator.

DC-GBC-1A

ATTENTION: The decal shown below should be present on the outside of t he door cover of the 2 ring on

the 24" porthole door cover, and on the roof manway cover. If a decal has been damaged or is missing in

any of these locations, contact the manufacturer for a free replacement decal.

GSI Decals

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 1-217-226-4421

10 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 11

3. Safety Decals

Failure to heed these warnings

could result in serious injury, death,

structural damage or collapse of tank.

1. Use CENTER FLOOR OUTLET ONLY until NO grain

remains above this outlet.

2. Side floor outlets to be used ONLY when above

condition is satisfied.

3. Lock all side floor outlets to avoid accidental

premature use.

4. See manufacturers instructions for proper use of

factory supplied sidedraw (wall) discharge systems.

UNLOADING INSTRUCTIONS:

DC-GBC-2A

WARNIN

DON’T

DO

ATTENTION: The decal shown below should be present on the outside of the door cover of the 2 ring on

the 24" porthole door cover, and on the roof manway cover. If a decal has been damaged or is missing in

any of these locations, contact the manufacturer for a free replacement decal.

GSI Decals

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 1-217-226-4421

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 11

Page 12

4. General Detail Information

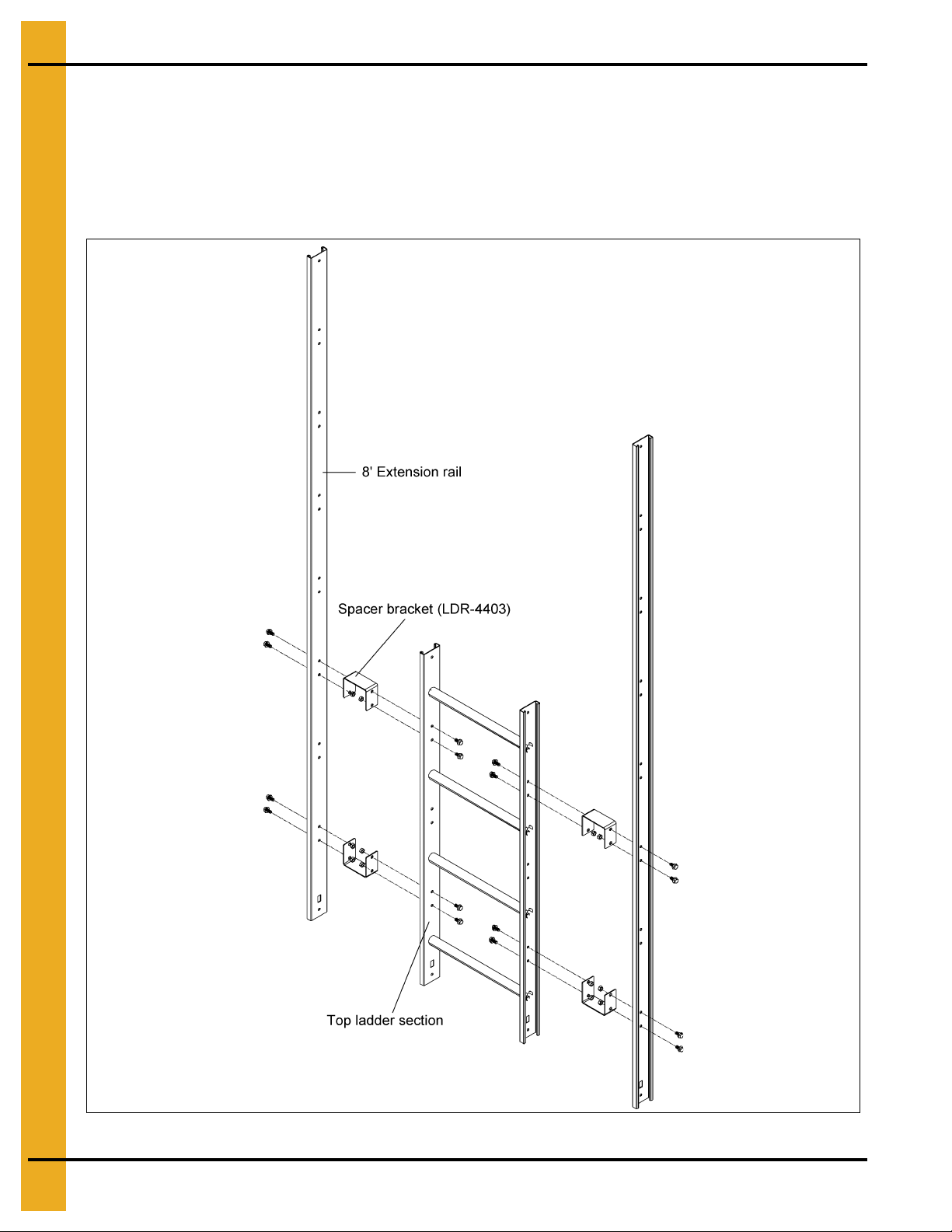

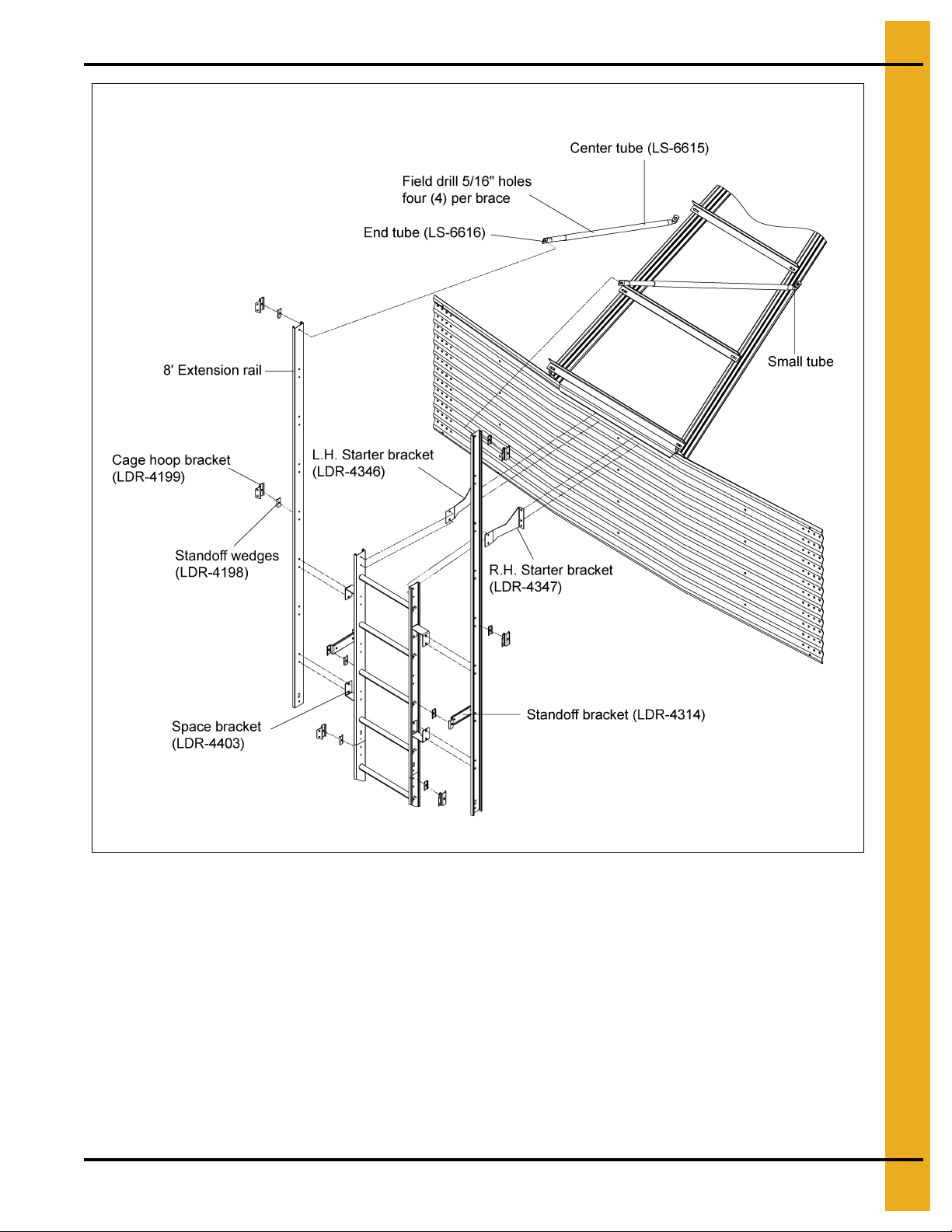

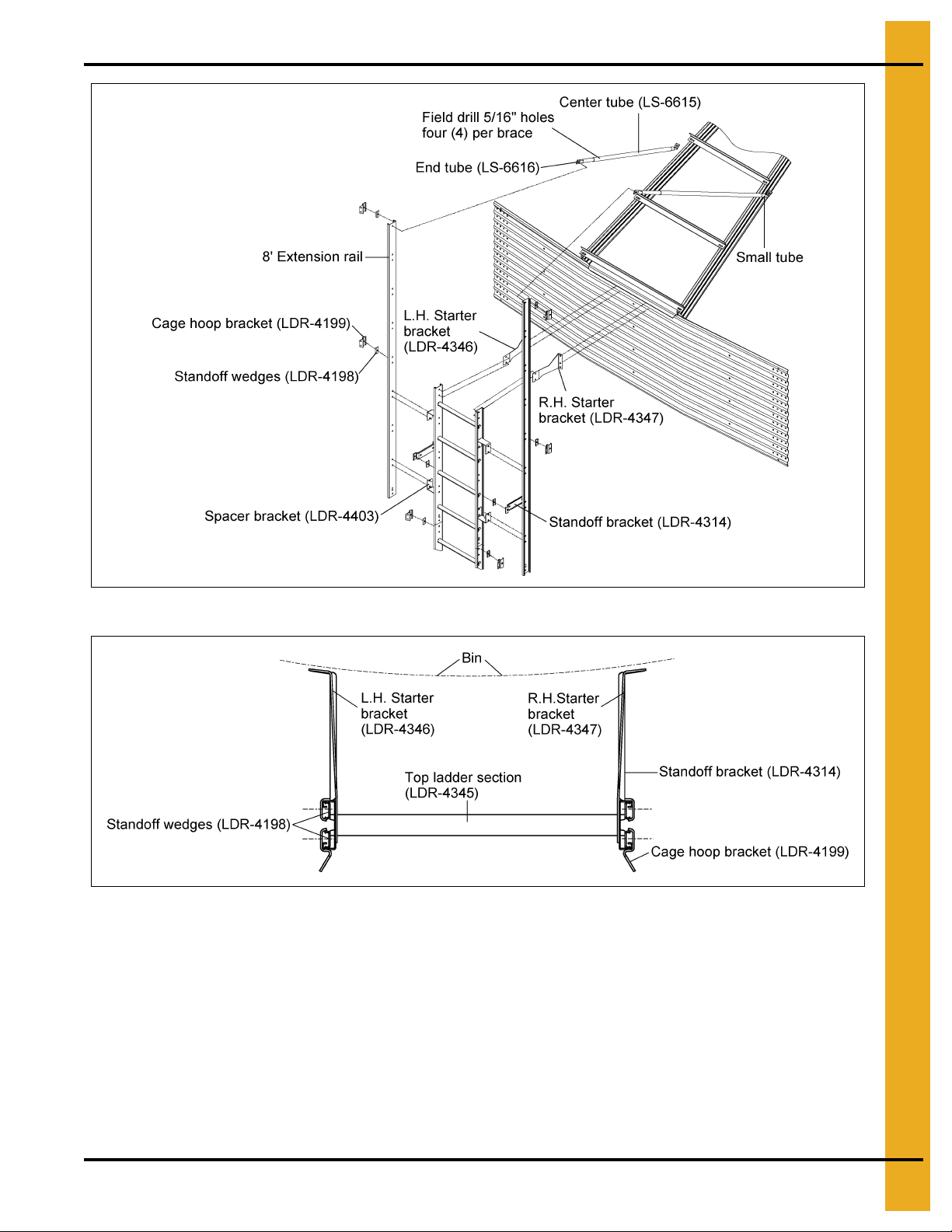

Extension Rail Installation

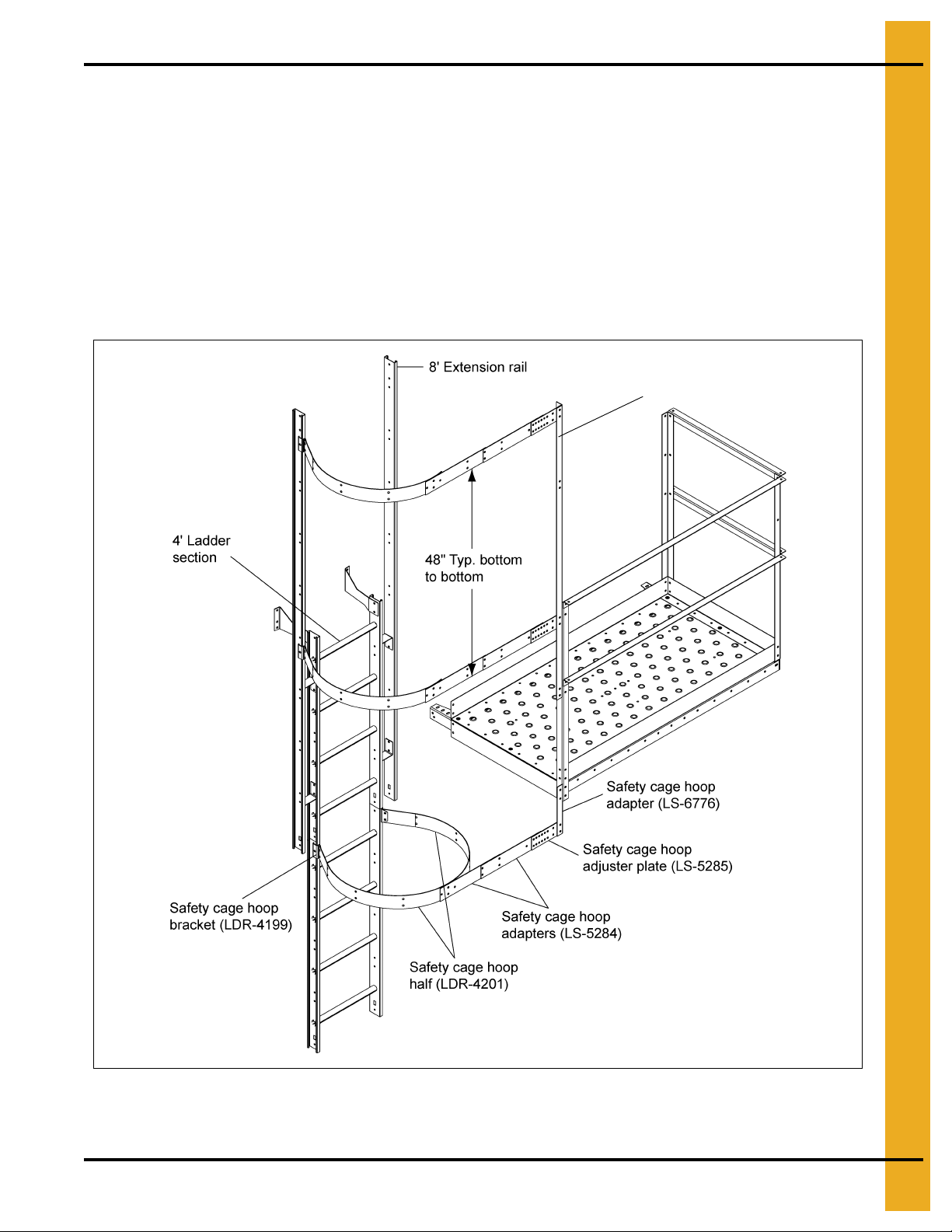

All ladder systems that include a safety cage must also include ladder extension rails attached to the top

four foot (4') ladder section. Start by bolting the spacer brackets through the top and bottom set of holes

in the top ladder section. Then, attach the extension rails to the spacer brackets as shown in Figure 4A.

When installed correctly, the bottom of the extension rail should be flush with the bottom of the top ladder

section. Use 5/16" x 3/4" bin bolts for all connections.

Figure 4A Ladder Extension

12 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 13

4. General Detail Information

Wind rings must be installed in relation to the ladder rungs as

shown here, to insure compliance with O.S.H.A. regulations.

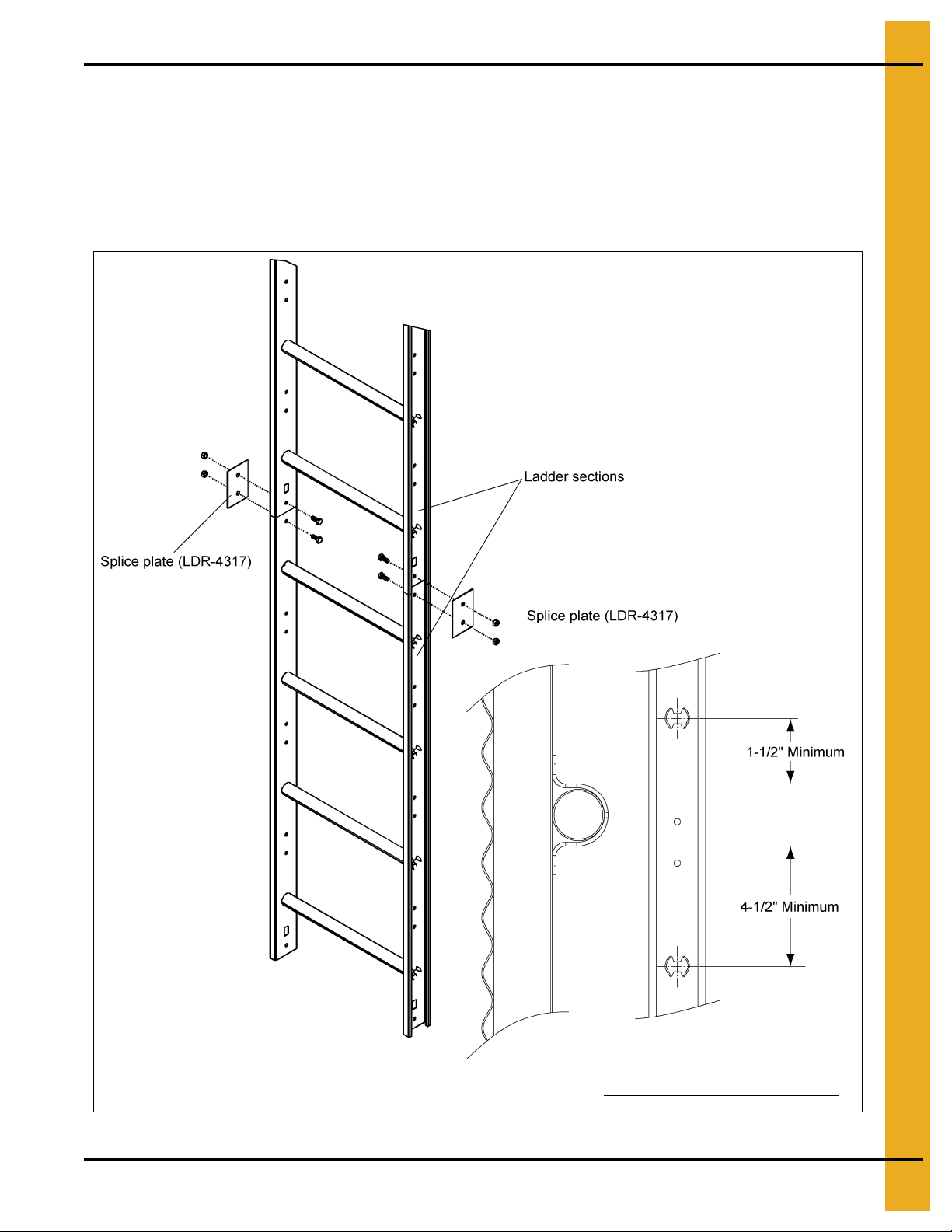

Ladder Section Assembly

Two (2) splice plates (LDR-4317) are required to attach each ladder section. The head of the bolt

should be to the inside of the ladder with the splice plate on the outside as shown in Figure 4B.

Use 5/16" x 3/4" bolts for all connections.

NOTE: With most installations, the last ladder section installed to reach the ground, the base or the

intermediate platform should be cut to fit.

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 13

Figure 4B

Page 14

4. General Detail Information

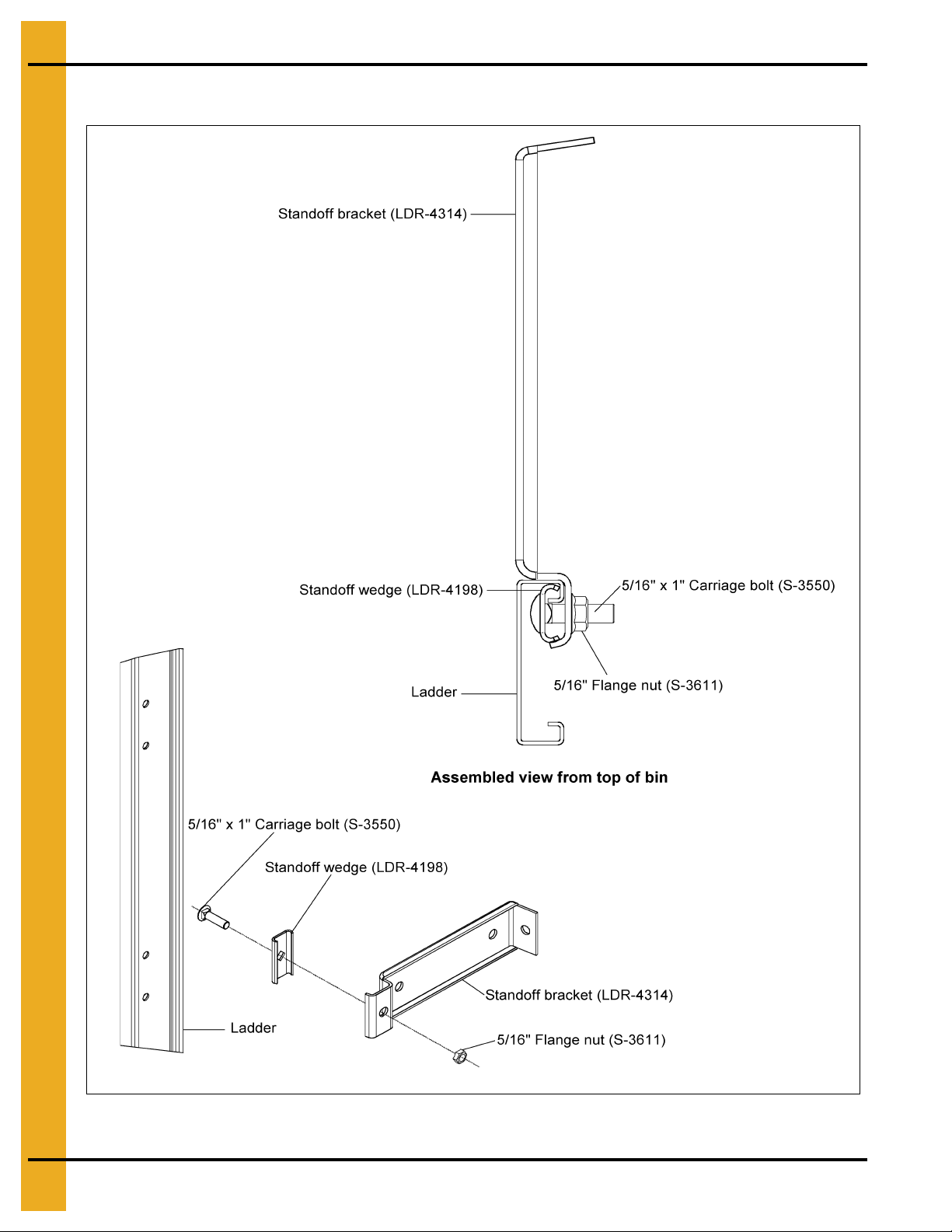

Ladder Standoff Detail

Figure 4C

14 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 15

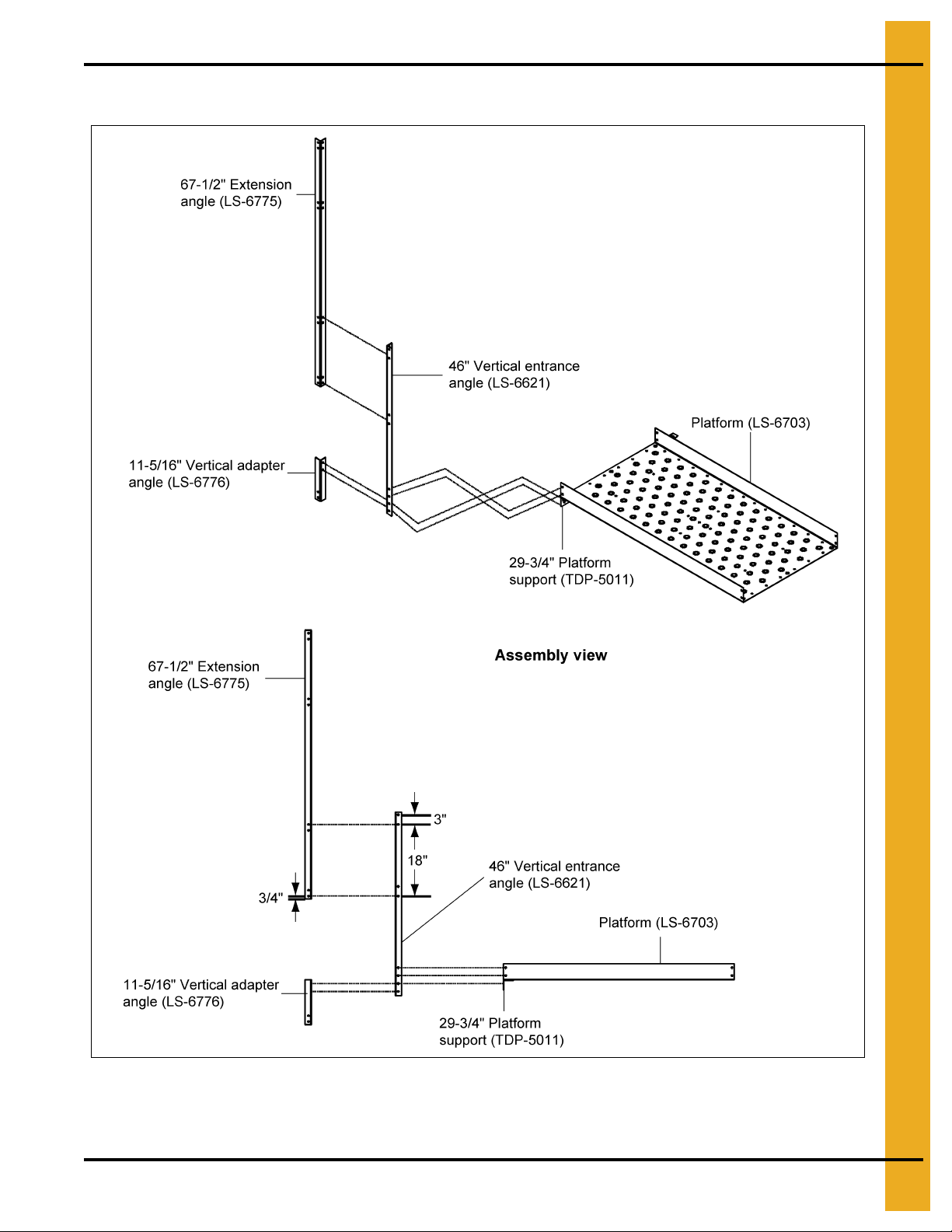

Extension Angle Hole Detail

4. General Detail Information

Figure 4D

NOTE: Platform and platform support shown for reference only. See platform assembly detail on Pa ge 47

for complete installation instructions for these parts.

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 15

Page 16

4. General Detail Information

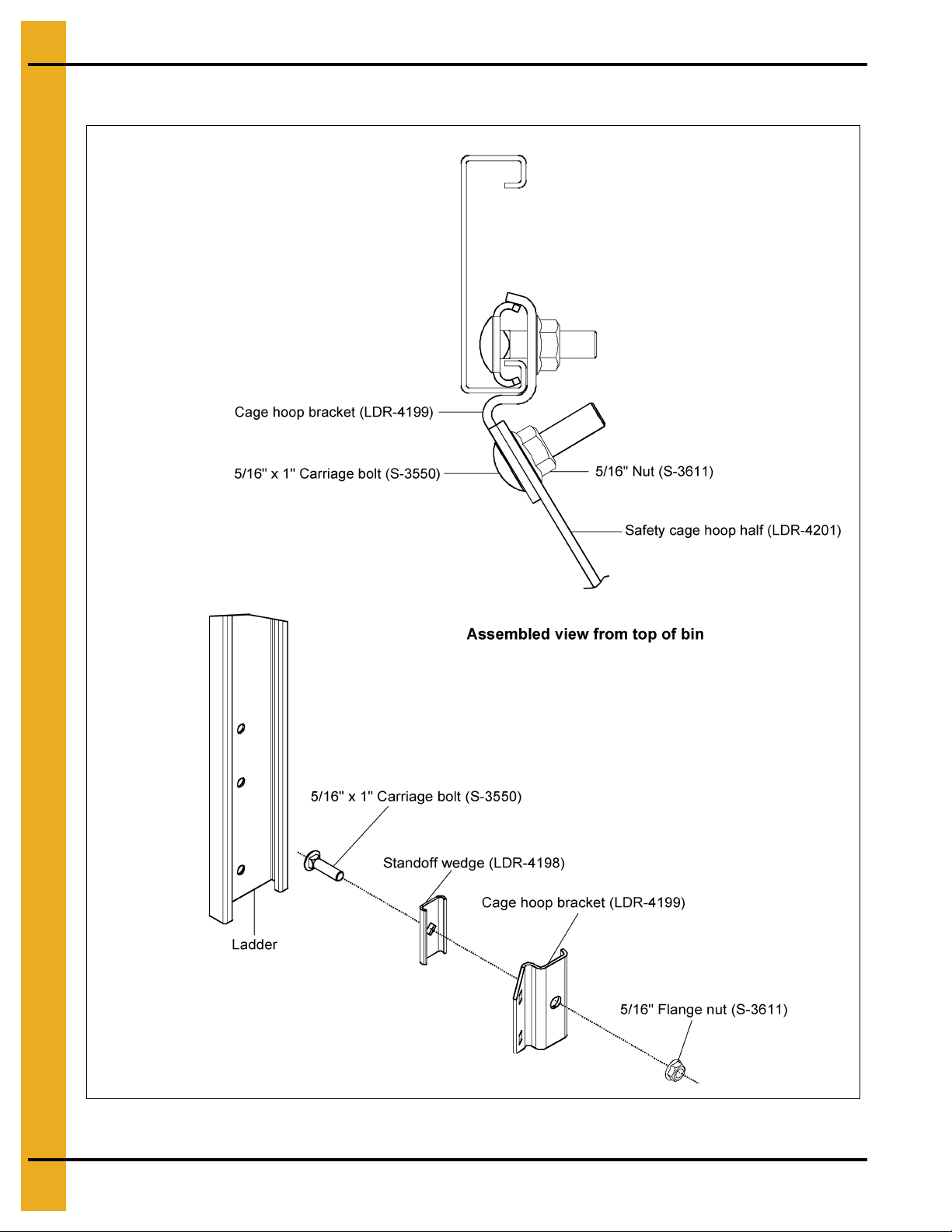

NOTE: Leave bolt loose until cage

hoop half has been attached.

Cage Hoop Bracket Assembly

Figure 4E

16 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 17

4. General Detail Information

Figure 4F

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 17

Page 18

NOTES

18 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 19

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 19

2.66" Corrugated

Commercial Hopper

Tank 4-9 Rings

®

Page 20

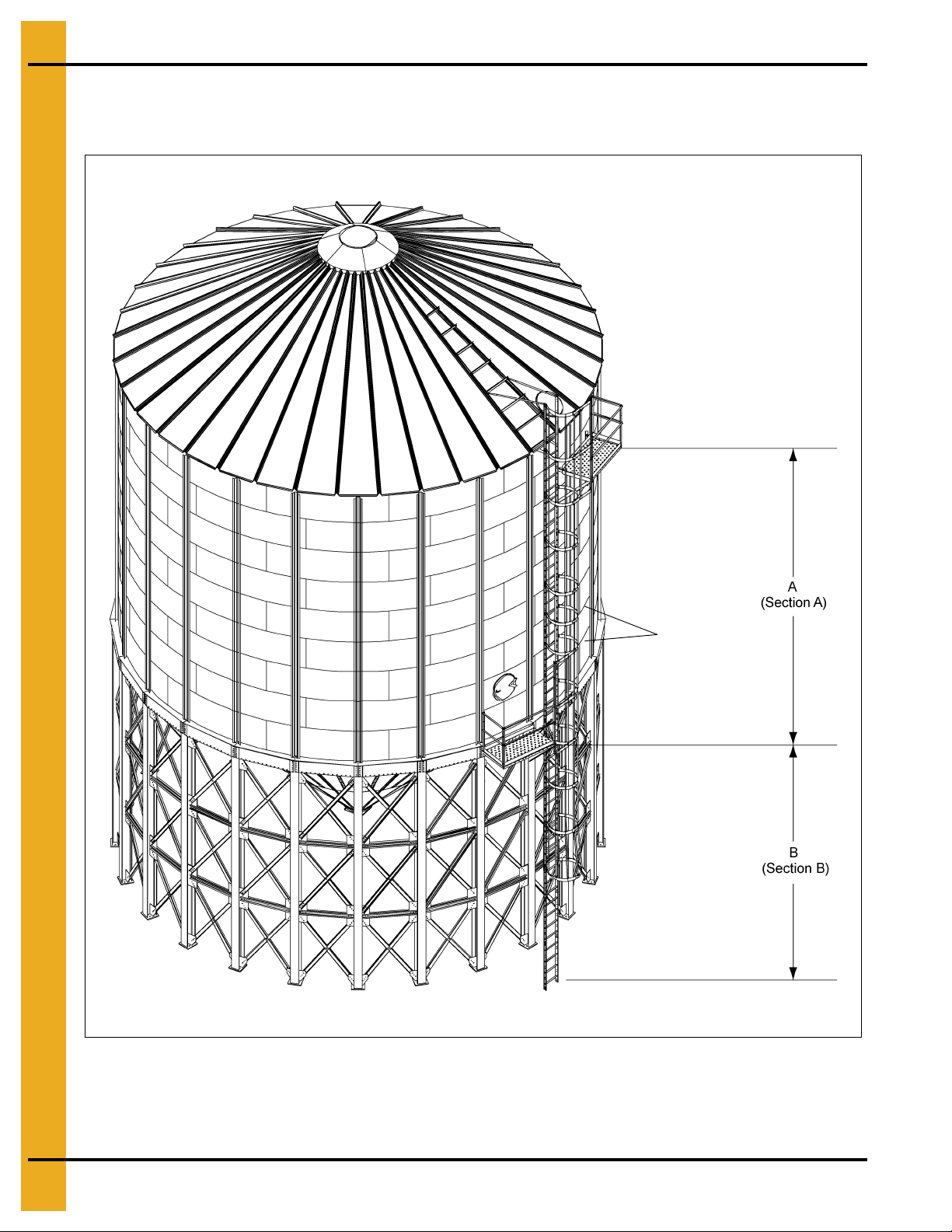

5. 2.66" Corrugated Commercial Hopper Tank 4-9 Rings

32" Safety cage

sections (See note

on page 21.)

2.66" Commercial Hopper Tank (NCHT) Ladder and Platform

Layout 4-9 Rings

Figure 5A 9 Rings

See Page 21 for platform locations and section listings.

20 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 21

5. 2.66" Corrugated Commercial Hopper Tank 4-9 Rings

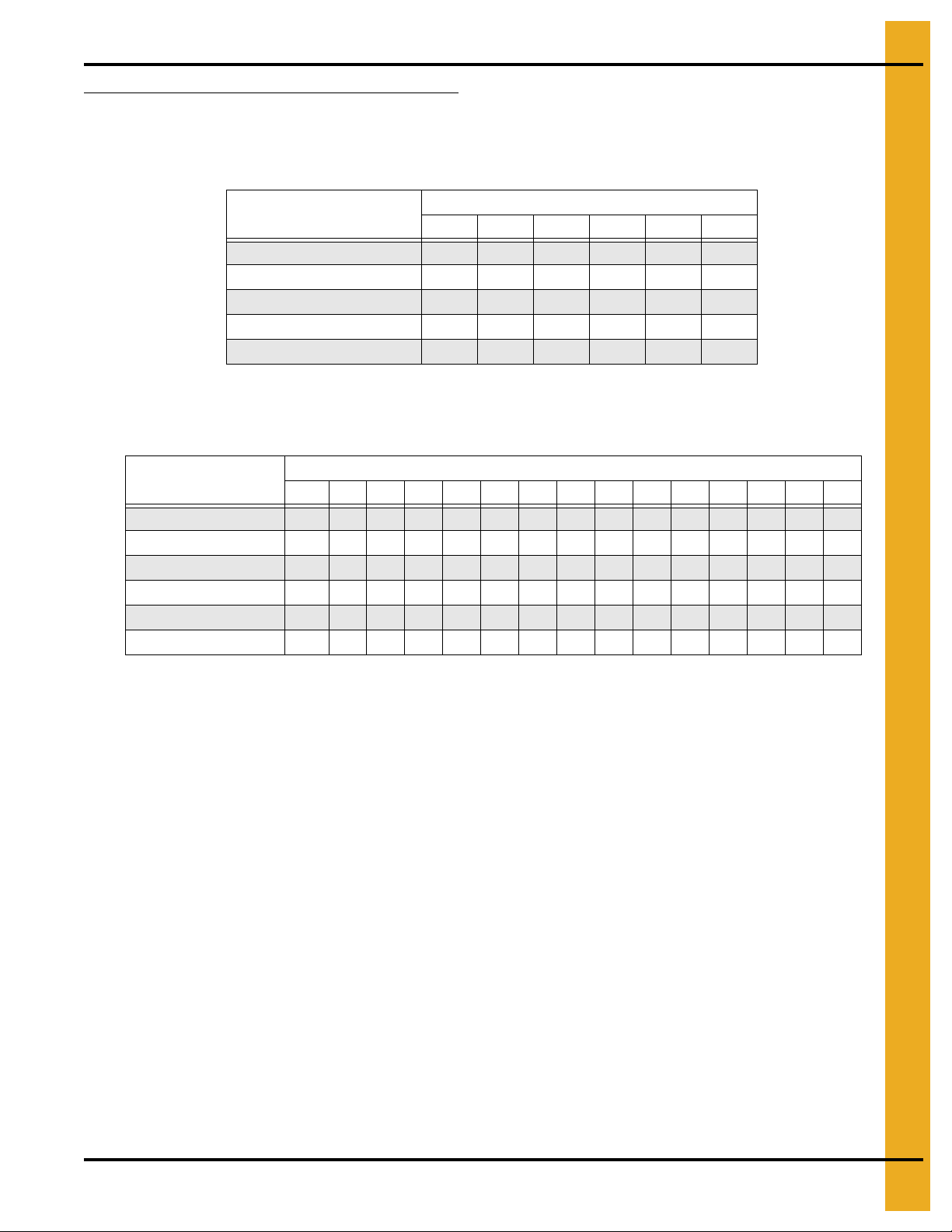

Ladder, Safety Cage and Platform Location Chart

For Section A, find the proper ring grain bin and use the number of ladders and safety cages indicated.

See Chart below (Section A). For Section B, find the proper diameter grain bin and hopper slope, then use

the number of ladders and safety cages indicated. See Chart below (Section B).

Rings

456789

Platform Located in Ring: 2 2 2 2 2 2

4' Ladder Section 3 4 4 5 6 6

Safety Cage 32" Section 0 1 2 0 1 2

Safety Cage 48" Section 000222

Section A

Dimension A 96" 128" 160" 192" 224" 256"

NOTE: The 32" safety cage section must be installed in Section A of the ladder system. DO NOT install

the 32" verticals in the eave or access door safety cage hoop assembly. The eave and access door

safety cage hoop assembly use the 48" verticals.

Diameter

12' 12' 15' 15' 18' 18' 21' 21' 24' 27' 27' 30' 30' 36' 36'

Hopper Slope: 45 60 45 60 45 60 45 60 45 40 45 40 45 40 45

4' Ladder Section 4 55657576566767

Bell Safety Cage 0 1 0 1 1 1 1 1 1 1 1 1 1 1 1

Safety Cage 48" Section0 00101020010112

Section B

Bell Safety Cage Size N/A 24" N/A 24" 24" 48" 48" 24" 48" 48" 24" 48" 48" 48" 48"

Dimension B 91" 128" 108" 167" 128" 198" 144" 229" 162" 142" 179" 156" 195" 187" 236"

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 21

Page 22

5. 2.66" Corrugated Commercial Hopper Tank 4-9 Rings

NCHT Ladder, Safety Cage and Platform Instructions 4-9 Rings

All grain bin packages, from 4 ring to 9 ring and 12' to 35' diameter, contain the correct components for

assembly. Read and follow the complete instructions for correct placement of parts. Be sure and use the

charts to determine the appropriate number and size parts to be used based upon the number of rings in

the bin. Failure to do so may result in an improper fit or shortage of parts. Pay particular attention to the

location of ladders and platforms as they relate to the other equipment and structures in the area.

Eave Starter Bracket Installation

Correct placement of the eave ladder starter bracket is critical to assure proper fit of all ladder co mponents

and to assure the correlation is correct between the platforms for proper installation of the access door

platform. If the eave starter brackets are mislocated, standard installation of the access door platform will

not be possible.

22 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 23

5. 2.66" Corrugated Commercial Hopper Tank 4-9 Rings

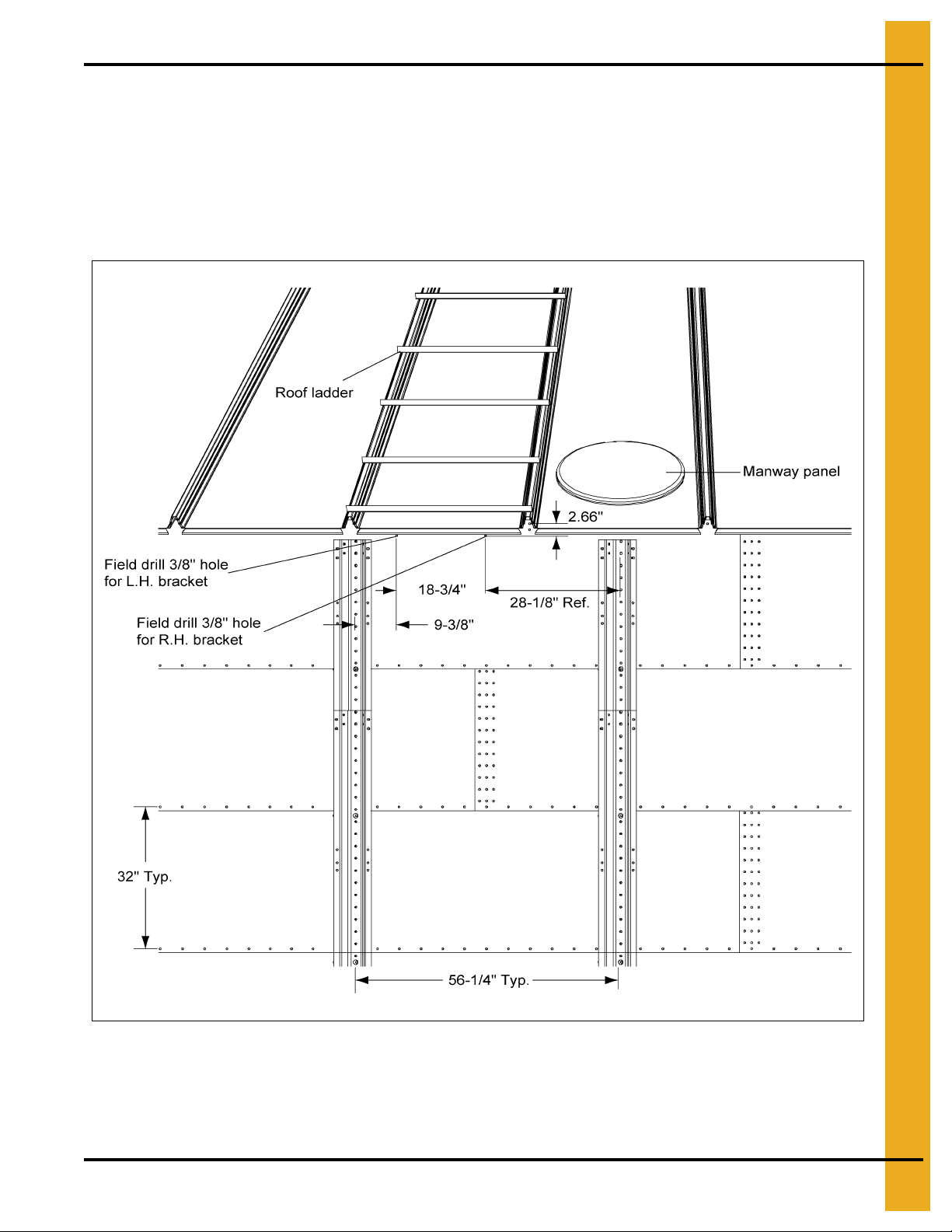

Location of Field Drilled Holes for Eave Ladder Starter Brackets

The starter brackets must be located directly below the roof ladder. Before the starter brackets can be

installed, two (2) 3/8" holes must be field drilled 2.66" below and directly in line with the top row of

pre-punched horizontal holes. The first hole, required for the left hand starter bracket, must be located

9-3/8" from the center of the stiffener to the center of the hole as shown in Figure 5B. The second

hole, required for the right hand bracket, must be located 18-3/4" from the center of the first hole. Refer to

Figure 5B for the proper location of the two (2) 3/8" field drilled holes required to install the starter brackets.

Figure 5B

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 23

Page 24

5. 2.66" Corrugated Commercial Hopper Tank 4-9 Rings

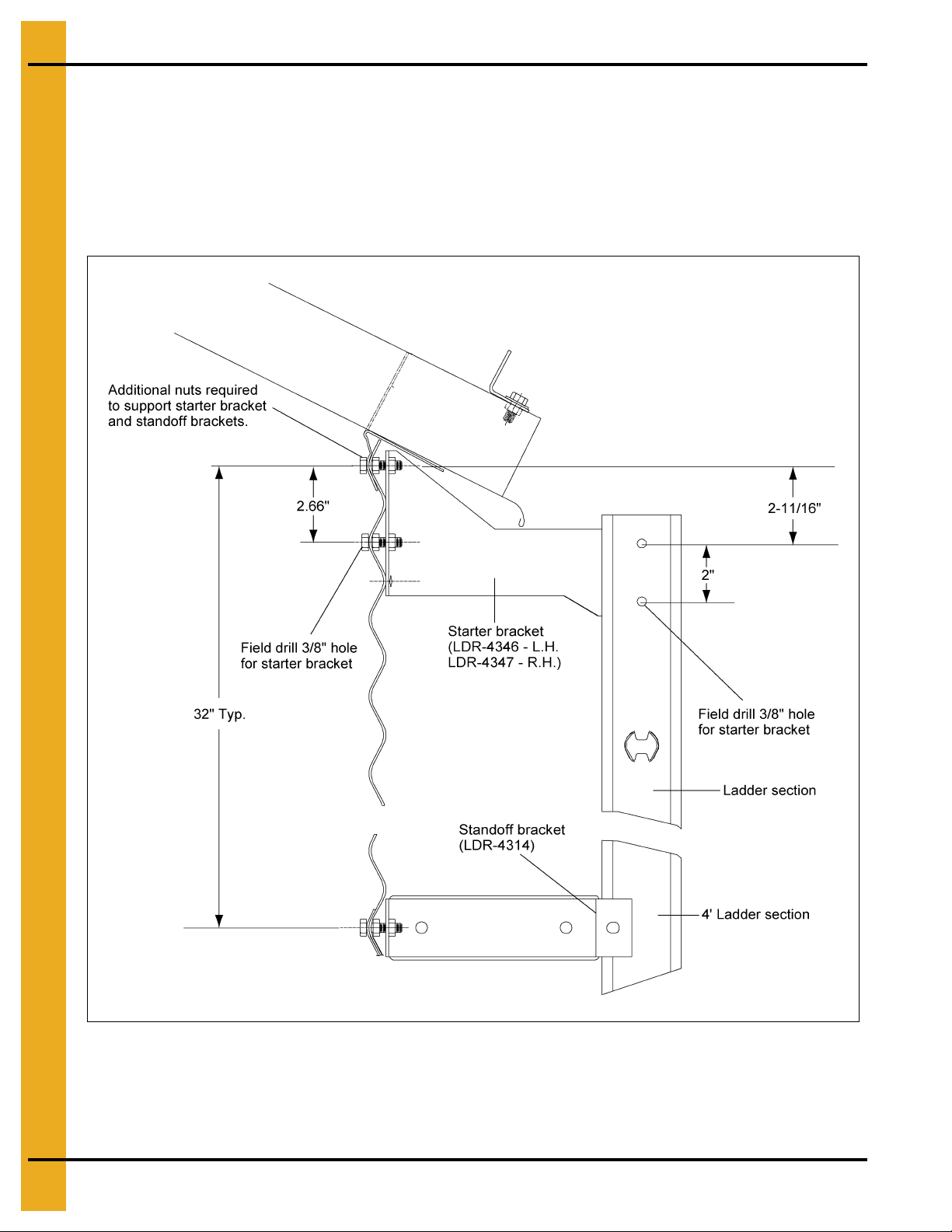

Eave Starter Bracket and Ladder Assembly with Safety Cage

Once the two (2) 3/8" holes have been field drilled, attach the starter brackets to the sidewall as shown in

Figure 5C. Check the top ladder section to make sure the ladder rung dimples are to the top. Attach starter

brackets to the top of the ladder. See Figure 4B on Page 13 for the pro per installation of addit ional ladder

sections required. Standoff brackets must be installed on the ladder sections an d attached to the sidewall

at each horizontal seam and repeated every 32". Use 5/16" x 3/4" bin bolts for all connections. It is also

necessary to field drill a 3/8" hole on the ladder section for each starter bracket (L.H. and R.H.).

Figure 5C

NOTE: Refer to general detail information on Page 12 for additional d etails for sta ndoff bracket to ladde r

assembly and also, 8' extension rail installation (omitted in detailed figure above for clarity).

24 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 25

5. 2.66" Corrugated Commercial Hopper Tank 4-9 Rings

Figure 5D

Figure 5E Ladder and Bracket as Viewed from Top of Bin

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 25

Page 26

5. 2.66" Corrugated Commercial Hopper Tank 4-9 Rings

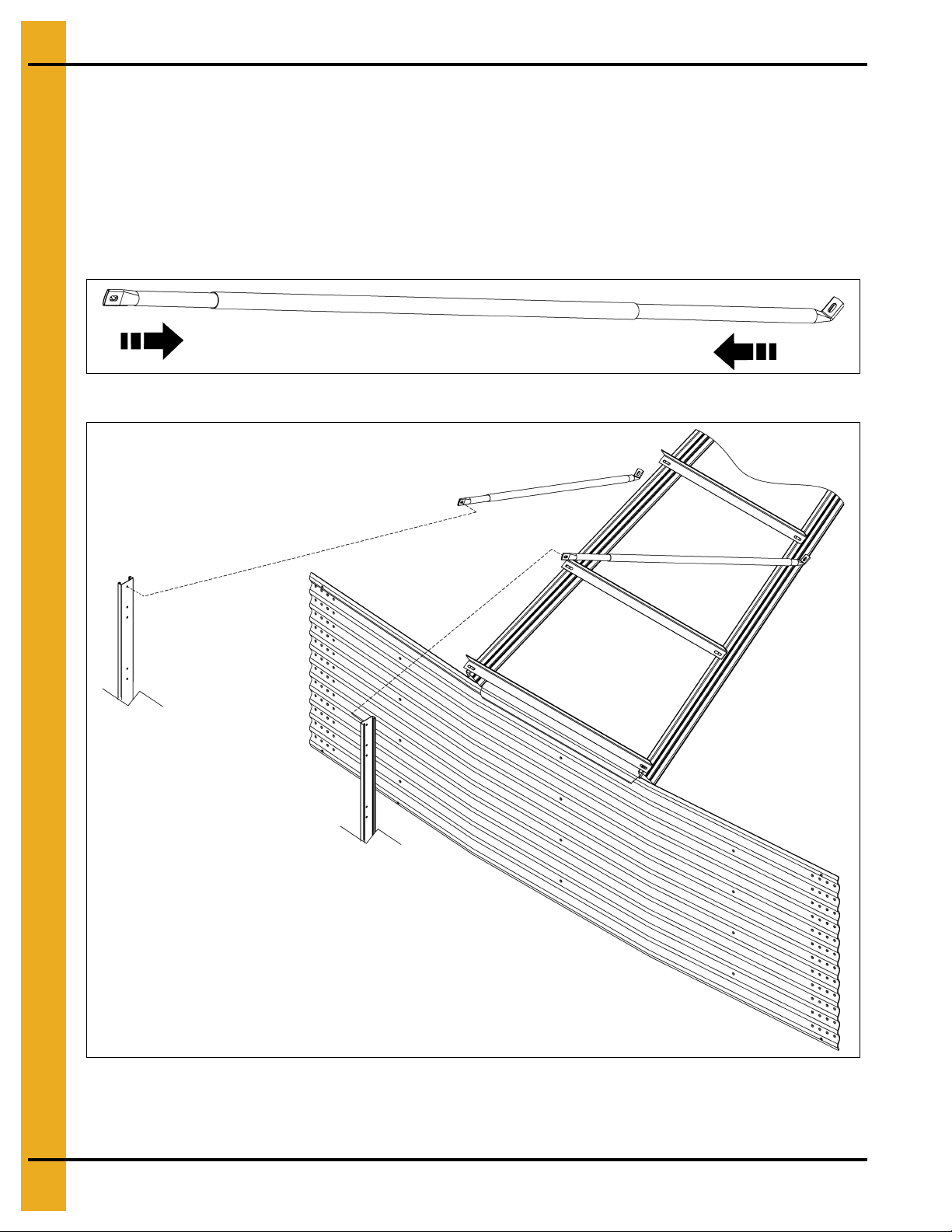

Eave Adjustable Braces

The eave adjustable braces must be attached at this time. An eave adjustable brace is comprised of

one large diameter tube and two (2) smaller diameter tubes. (See Figure 5F.) Slide the smaller tubes

inside the larger tubes and attach one smaller tube to the top of the ladder extension rail. Adjust the other

smaller tube so the bottom of the flattened tube reaches the roof panel. Field drill four (4) 5/16" holes

through both large and small tubes and bolt together using 1/4" x 1-1/2" bolts and nuts. This will prevent

the adjustable braces from slipping. (See Figure 5G.)

NOTE: Refer to Page 24 for proper location of ladder starter brackets.

Figure 5F

Figure 5G

NOTE: Refer to Figure 4A on Page 12 for additional details for standoff bracket to ladder assembly and

cage hoop bracket to ladder.

26 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 27

5. 2.66" Corrugated Commercial Hopper Tank 4-9 Rings

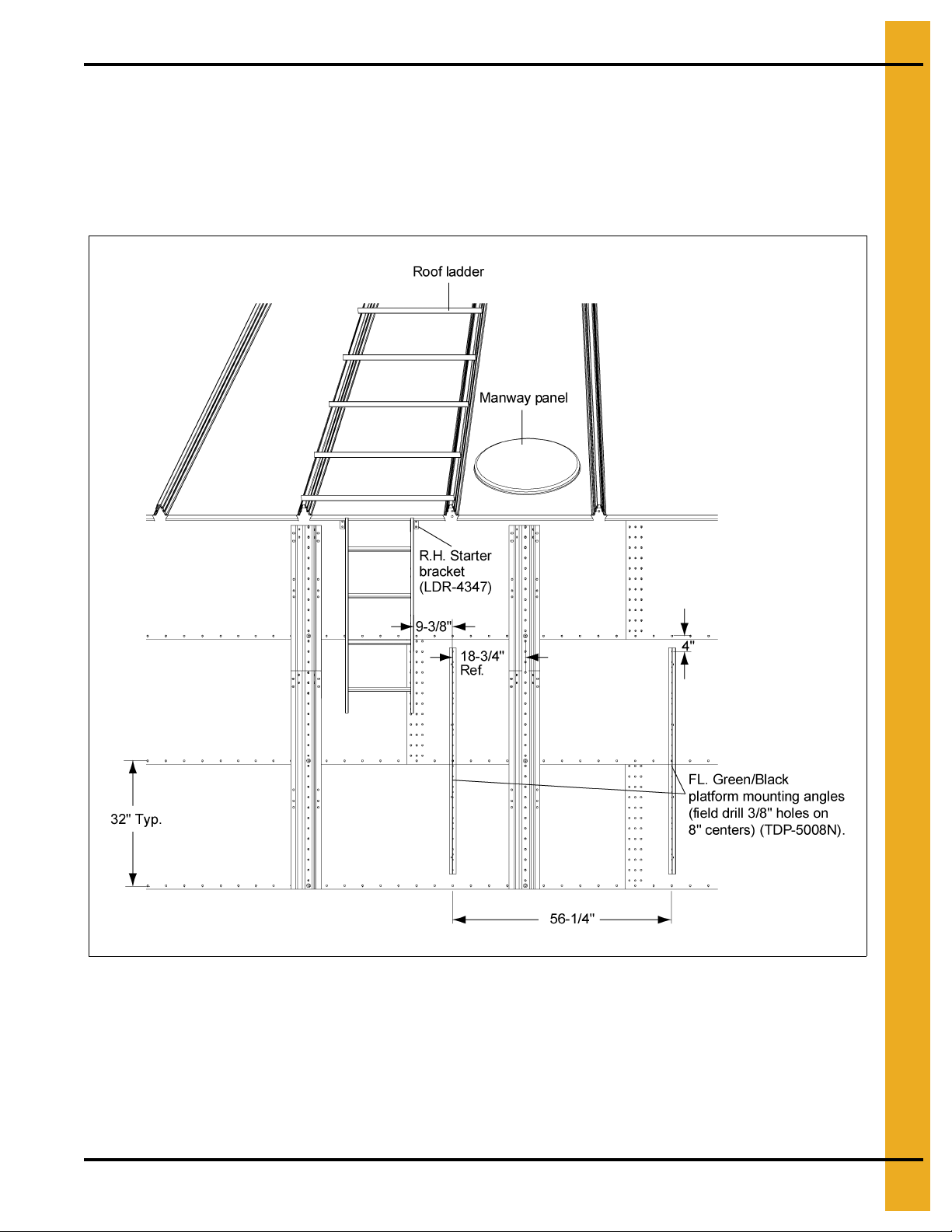

Eave Platform Mounting Angle Installation

Figure 5H shows the location of the platform mounting angles. Each angle must be mounted starting

4" below the top horizontal seam of the second ring with the first mounting angle offset 9-3/8" from the

right hand starter bracket. The second mounting angle must be located 56-1/4" from the first mounting

angle. The dimensions and locations of these angles are critical for proper fit of all parts. Using the platform

mounting angels as guides, field drill 3/8" holes in the sidewall every 8". (See Figure 5H.)

Figure 5H

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 27

Page 28

5. 2.66" Corrugated Commercial Hopper Tank 4-9 Rings

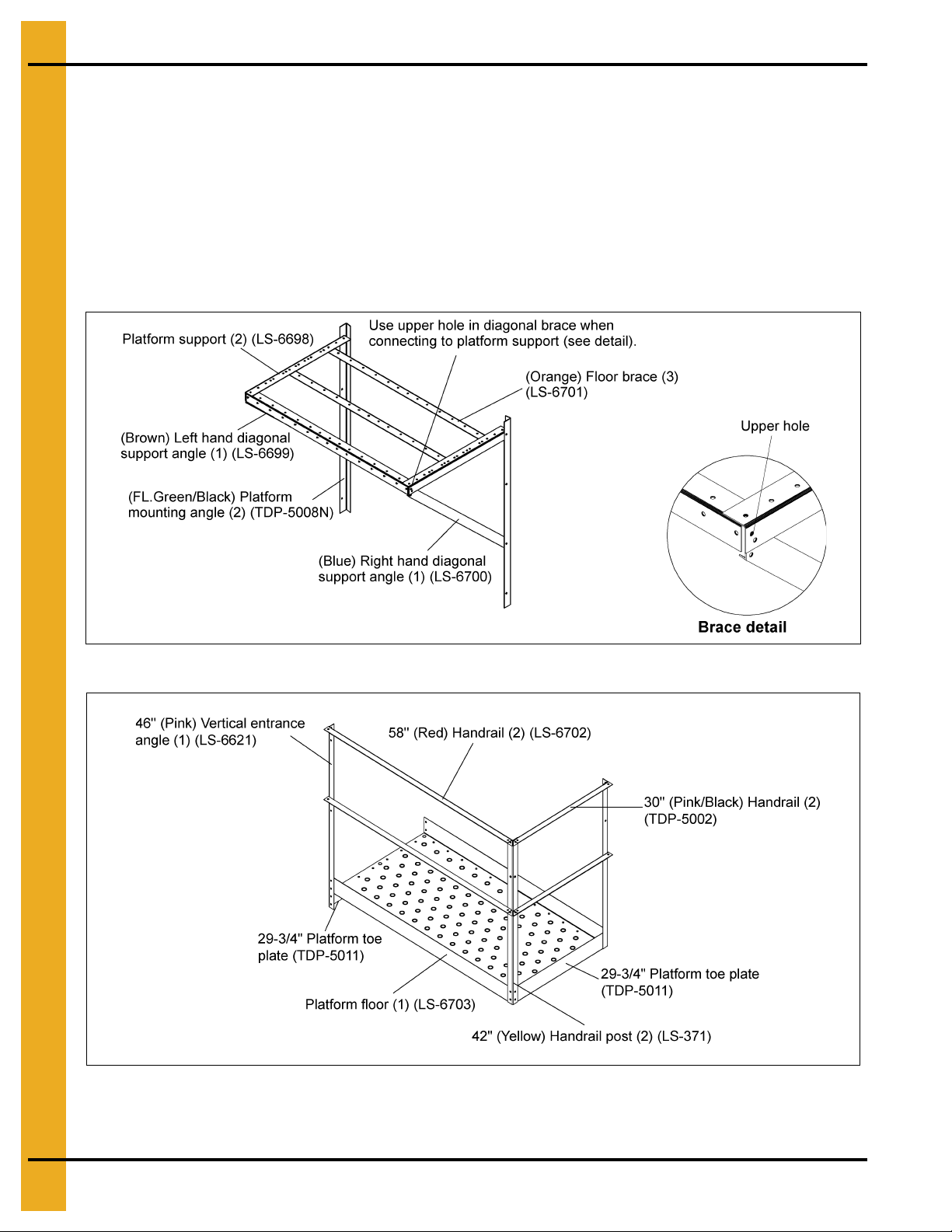

Right Hand Platform and Platform Support Assembly

NOTE:

Assemble the platform support frame using 5/16" x 3/4" truss head bolts and nuts. (See Figure 5I.) Wh en

attaching the platform mounting angles to the sidewall, locate the mounting angles according to the

instructions on previous pages. Align holes on the platform floor with the holes on the platform supports

and bolt together using 5/16" x 3/4" truss head bolts and nuts. Attach platform toe plates at the same time

as attaching the platform floor. The vertical entrance angle bolts to the platform floor, toe plate and

platform support. The handrail post bolts to the platform floor and toe plate as shown in Figure 5J.

Mount the platform supports on the bin first. Next, assemble the platform floor onto the support

frame. Do not tighten platform support to floor brace bolts until the floor and toe plates are secure.

Figure 5I Right Hand Platform Support Assembly

Figure 5J Right hand platform

28 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 29

5. 2.66" Corrugated Commercial Hopper Tank 4-9 Rings

67-1/2" Extension angles (LS-6775)

(See extension angle hole detail

on Page 15 for proper installation.)

Eave Safety Cage Hoop Assembly

Before attaching any pieces to the ladders or platform, some pre-assembly is required. Attach two (2)

safety cage brackets to the 8' extension rail and one safety cage bracket to the second 4' ladder section

as shown in Figure 5K. Bolt the safety cage hoop adjuster plates onto the extension angle as shown in

Figure 5K. Using the proper configuration depending on the bin diameter (see adapter assembly detail

on Page 30), bolt the safety cage hoop adapters together and attach to the safety cage hoop halves.

Be sure to use the 5/16" x 3/4" bolt with the head of the bolt to the inside of the safety cage. Bolt these

assemblies to the safety cage brackets and hoop adjuster plates (See connection detail on Page 30 for

proper hole location). Tighten bolts as you go. The bottom asse mbly requires two (2) hoop halves and will

be positioned just below the platform as shown in Figure 5K. Use the safety cage hoop adjuster angle to

secure the two (2) hoop half assemblies to the vertical entrance angle on the platform assembly.

NOTE: 48" Vertical supports removed in Figure 5K for clarity.

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 29

Figure 5K

Page 30

5. 2.66" Corrugated Commercial Hopper Tank 4-9 Rings

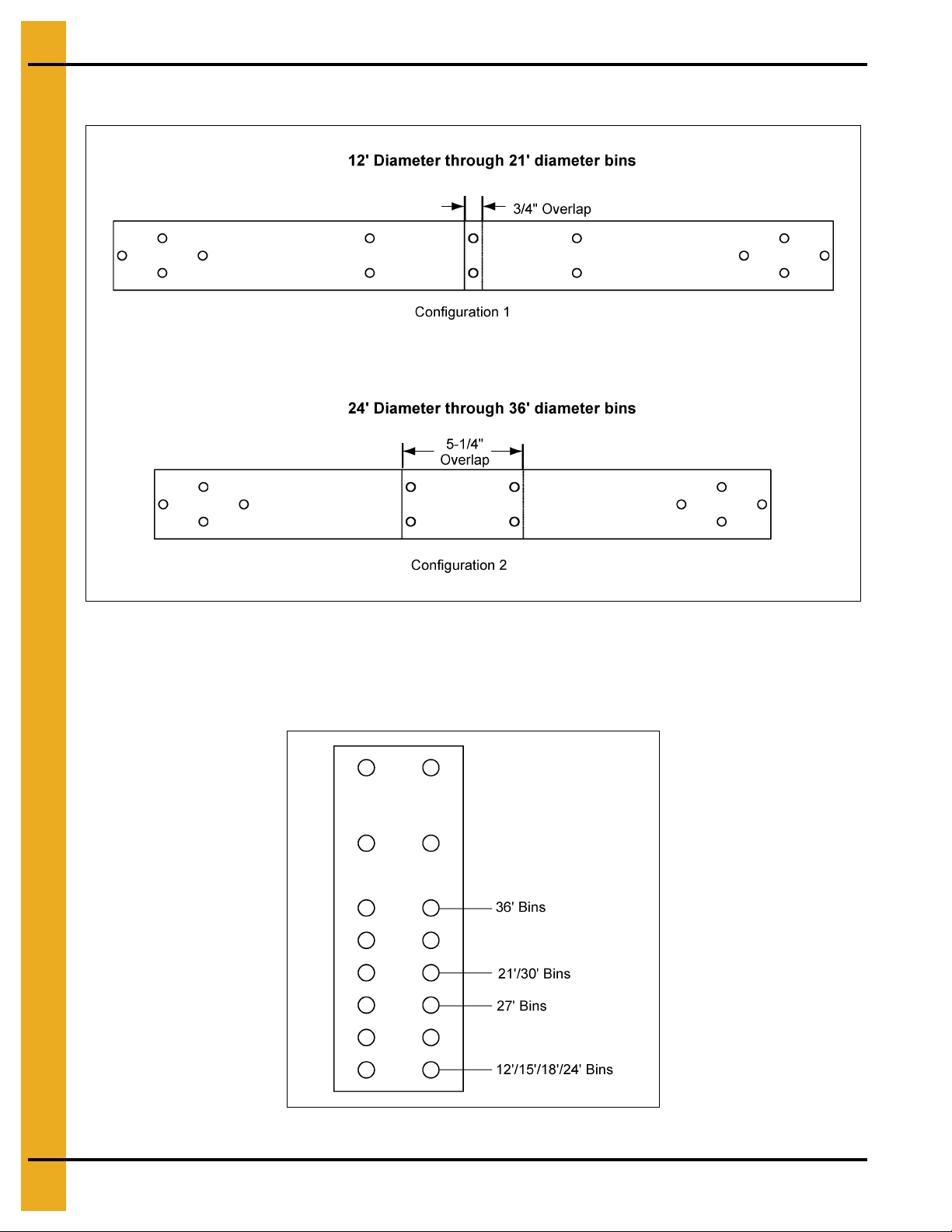

Adapter Assembly Detail

Connection Detail

Use

Figure 5M

to determine the proper holes to use when attaching the hoop adapter to the adjuster plate.

Figure 5L

Figure 5M

30 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 31

5. 2.66" Corrugated Commercial Hopper Tank 4-9 Rings

Vertical Supports

After all three (3) hoop assemblies

are in place, attach the 48" vertical

supports from hoop assembly to hoop

assembly, as shown in Figure 5N.

This requires ten (10) supports, five (5)

between each set of hoops. The second

set of vertical supports must be bent at

the flat area to allow for the tapering

of the bottom hoop assembly. Use

5/16" x 3/4" bolts (unless otherwise

noted) with the head of the bolt to the

inside of the safety cage.

Figure 5N Vertical Supports

32" and 48" Safety Cage

Attach the vertical support pieces to the existing hoop halves using the 5/16" x 3/4" bolts and nuts (with

the heads on the inside of the cage). Fasten two (2) hoop halves together and bolt to other end of vertical

supports. Attach cage hoop brackets to ladder, Refer to Figure 5K on Page 29 for proper attachment.

Once cage hoop brackets have been installed, attach cage hoop halves and tighten bolts. Repeat

installation for each safety cage required.

Figure 5O 32" Safety Cage

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 31

Figure 5P 48" Safety Cage

Page 32

5. 2.66" Corrugated Commercial Hopper Tank 4-9 Rings

Access Door Platform Mounting Angle Installation

Figure 5Q

32 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 33

5. 2.66" Corrugated Commercial Hopper Tank 4-9 Rings

Left Hand Platform and Platform Support Assembly

NOTE: Mount the platform mounting angles on the columns first. Next, assemble the platform floor onto

the support frame. Do not tighten platform support to floor brace bo lts until the floor and toe plates

are secure.

Assemble the platform support frame using 5/16" x 3/4" truss head bolts and nuts. Align holes on the

platform floor with the holes on platform supports and bolt together using 5/16" x 3/4" truss head bolts and

nuts. Attach platform toe plates at the same time as attaching the platform floor. Vertical entrance angle

bolts to the platform floor, toe plate and platform support. Handrail post b olts to the pla tform floor and toe

plate as shown in Figure 5S.

Figure 5R Left Hand Platform Support Assembly

Figure 5S Left Hand Platform

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 33

Page 34

5. 2.66" Corrugated Commercial Hopper Tank 4-9 Rings

Left hand platform

assembly (See Page 32

for assembly details.)

Extension angle (LS-6775) (See general detail

information on Page 12 for proper installation.)

32" Safety cage assemblies shown

for reference only. See Page 32 for

installation details.

Access Door Safety Cage Hoop Assembly

Before attaching any pieces to the ladder or platform, some pre-assembly is required. Attach the safety

cage brackets to the ladder section.

onto the extension angle as shown in

adapters and safety cage hoop half together using the proper holes, based upon the bin diameter.

(See Page 30.)

Be sure to use the 5/16" x 3/4" bolt with the head of the bolt to the inside of the safety

cage. Bolt this assembly to the safety cage bracket and hoop adjuster plate, tighten as you go. The bottom

assembly requires two (2) hoop halves and will be positioned just below the platform as shown in

Use the safety cage hoop adjuster angle to secure the two (2) hoop half assemblies to the vertical entrance

angle on the platform assembly. To finish the installation, secure the access door platform assembly to the

existing safety cage assembly using the safety cage hoop adapters as shown in

NOTE: See Pages 31 and 35 for vertical supports, safety cage installation an d bell safety cage installation

details to complete the ladder assembly.

(See Figure 5K on Page 29.)

Figure 5T

. For the middle hoop assembly, bolt the safety cage hoop

Bolt the safety cage hoop adjuster plates

Figure 5T

Figure 5T

.

.

Figure 5T

34 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 35

5. 2.66" Corrugated Commercial Hopper Tank 4-9 Rings

24"-48" Safety Cage Bell Sections

Attach the vertical supports to the hoop half assembly from the final safety cage installation using

5/16" x 3/4" bolts and nuts (with the heads on the inside of the cage). Assemble the special bell safety

cage hoop halves and attach to other end of vertical supports. The vertical support must be bent at the flat

area to allow for the angle of the bell section. Attach the safety cage brackets to the ladder as shown in

the Figure 5K on Page 29. Once the safety cage brackets are installed, attach the bell safety cage hoop

half assembly to the safety cage brackets and tighten bolts.

NOTE: The safety cage bell section is to be used at the poi nt of termination of the safety cage an d should

be just above the concrete (generally 7' to 8').

Figure 5U 24" Bell

Figure 5V 48" Bell

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 35

Page 36

5. 2.66" Corrugated Commercial Hopper Tank 4-9 Rings

Ladder Support Detail

The ladder must be secured to the hopper support columns with ladder standoff brackets using support

channels and ladder brackets as shown in Figure 5W.

Figure 5W

Tank Diameter Hopper Slope No. of Support Channels Hopper Ladder Brackets

12' 45 3 6

12' 60 4 8

15' 45 3 6

15' 60 5 10

18' 45 4 8

18' 60 6 12

21' 45 4 8

21' 60 7 14

24' 45 5 10

27' 40 4 8

30' 40 4 8

36' 40 5 10

36' 45 7 14

36 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 37

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 37

2.66" Corrugated

Commercial Hopper

Tank 10-22 Rings

®

Page 38

6. 2.66" Corrugated Commercial Hopper Tank 10-22 Rings

2.66" Commercial Hopper Tank (NCHT) Ladder and Platform

Layout 10-22 Rings

Figure 6A 17 Rings

38 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 39

6. 2.66" Corrugated Commercial Hopper Tank 10-22 Rings

Ladder, Safety Cage and Platform Location Chart

For Section A through C, find the proper ring grain bin and use the number of ladders and safety cages

as shown in the Chart below. For Section D, find the proper diameter grain bin and hopper slope and use

the number of ladders and safety cages as shown in the Chart on Page 41.

Rings

10 11 12 13 14 15 16 17 18 19 20 21 22

Platform Located in Ring: 2 2 2 2 2 2 2 2 2 2 2 2 2

4' Ladder Section 56678891046667

Bell Safety Cage 1 1 1 1 1 1 1 1 1 1 1 1 1

Section A

Safety Cage 48" Section1223445602223

Bell Safety Cage Size 48" 24" 48" 48" 24" 48" 48" 24" 48" 48" 48" 48" 48"

Dimension A 192" 224" 256" 288" 320" 352" 384" 416" 160" 256" 256" 256" 288"

Platform Located in Ring: 8 9 10 11 12 13 14 15 16 17 18 19 20

4' Ladder Section 4444444444444

Bell Safety Cage 0 0 0 0 0 0 0 0 0 0 0 0 0

Section B

Safety Cage 48" Section0000000000000

Dimension B 96" 96" 96" 96" 96" 96" 96" 96" 96" 96" 96" 96" 96"

Platform Located in Ring: 7 10 10 10 11

4' Ladder Section 8 7 8 8 8

Bell Safety Cage 1 1 1 1 1

Safety Cage 48" Section 3 2 2 3 3

Section C

Bell Safety Cage Size 48" 24" 48" 48" 48"

Dimension C 288" 224" 256" 288" 288"

Diameter

12' 12' 15' 15' 18' 18' 21' 21' 24' 27' 27' 30' 30' 36' 36'

Hopper Slope: 45 60 45 60 45 60 45 60 45 40 45 40 45 40 45

4' Ladder Section 4 55657576566767

Bell Safety Cage 0 1 0 1 1 1 1 1 1 1 1 1 1 1 1

Safety Cage 4' Section 0 00101020010112

Section D

Bell Safety Cage Size N/A 24" N/A 24" 24" 48" 48" 24" 48" 48" 24" 48" 48" 48" 48"

Dimension D 91" 128" 108" 167" 128" 198" 144" 229" 162" 142" 179" 156" 195" 187" 236"

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 39

Page 40

6. 2.66" Corrugated Commercial Hopper Tank 10-22 Rings

2.66" Commercial Hopper T ank (NCHT) Ladder and Plat form Layout

10-22 Rings (Continued)

Figure 6B 22 Rings

40 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 41

6. 2.66" Corrugated Commercial Hopper Tank 10-22 Rings

Ladder, Safety Cage and Platform Location Chart

For Section A through C, find the proper ring grain bin and use the number of ladders and safety cages

as shown in the Chart below. For Section D, find the proper diameter grain bin and hopper slope and use

the number of ladders and safety cages as shown in the Chart on Page 41.

Rings

10 11 12 13 14 15 16 17 18 19 20 21 22

Platform Located in Ring: 2 2 2 2 2 2 2 2 2 2 2 2 2

4' Ladder Section 56678891046667

Bell Safety Cage 1 1 1 1 1 1 1 1 1 1 1 1 1

Section A

Safety Cage 48" Section1223445602223

Bell Safety Cage Size 48" 24" 48" 48" 24" 48" 48" 24" 48" 48" 48" 48" 48"

Dimension A 192" 224" 256" 288" 320" 352" 384" 416" 160" 256" 256" 256" 288"

Platform Located in Ring: 8 9 10 11 12 13 14 15 16 17 18 19 20

4' Ladder Section 4444444444444

Bell Safety Cage 0 0 0 0 0 0 0 0 0 0 0 0 0

Section B

Safety Cage 48" Section0000000000000

Dimension B 96" 96" 96" 96" 96" 96" 96" 96" 96" 96" 96" 96" 96"

Platform Located in Ring: 7 10 10 10 11

4' Ladder Section 8 7 8 8 8

Bell Safety Cage 1 1 1 1 1

Safety Cage 48" Section 3 2 2 3 3

Section C

Bell Safety Cage Size 48" 24" 48" 48" 48"

Dimension C 288" 224" 256" 288" 288"

Diameter

12' 12' 15' 15' 18' 18' 21' 21' 24' 27' 27' 30' 30' 36' 36'

Hopper Slope: 45 60 45 60 45 60 45 60 45 40 45 40 45 40 45

4' Ladder Section 4 55657576566767

Bell Safety Cage 0 1 0 1 1 1 1 1 1 1 1 1 1 1 1

Safety Cage 4' Section 0 00101020010112

Section D

Bell Safety Cage Size N/A 24" N/A 24" 24" 48" 48" 24" 48" 48" 24" 48" 48" 48" 48"

Dimension D 91" 128" 108" 167" 128" 198" 144" 229" 162" 142" 179" 156" 195" 187" 236"

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 41

Page 42

6. 2.66" Corrugated Commercial Hopper Tank 10-22 Rings

NCHT Ladder, Safety Cage and Platform Instructions 10-22 Rings

All grain bin packages, from 10 ring to 22 ring and 12' to 36' diameter, contain the correct components for

assembly. Be sure and use the charts to determine the appropriate number and size parts to be used

based upon the number of rings in the bin. Read and follow the complete instructions for correct placement

of parts. Failure to do so may result in an improper fit or shortage of parts. Pay particular attention to the

location of ladders and platforms as they relate to the equipment and other structures in the area.

Eave Starter Bracket Installation

Correct placement of the eave ladder starter bracket is critical to assure proper fit of all ladder parts and

also to assure the correlation between the platforms is correct for proper installation of the access door

platform. If the eave starter brackets are mislocated, standard installation of the access door platform will

not be possible.

Location of Field Drilled Holes for Eave Ladder Starter Brackets

The starter brackets must be located directly below the roof ladder. Before the starter brackets can be

installed, two (2) 3/8" holes must be field drilled 2.66" below and directly in line with the top row of

pre-punched horizontal holes. The first hole, required for the left hand starter bracket, must be located

9-3/8" from the center of the stiffener to the center of the hole. The second hole, required for the

right hand bracket, must be located 18-3/4" from the center of the first hole. Refer to Figure 6C for the

proper location of the two (2) 3/8" field drilled holes required to install the starter brackets.

Figure 6C

42 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 43

6. 2.66" Corrugated Commercial Hopper Tank 10-22 Rings

Eave Starter Bracket and Ladder Assembly with Safety Cage

Once the two (2) 3/8" holes have been field drilled, attach the starter brackets to the sidewall as shown in

Figure 6D. Check the top ladder section to make sure the ladder rung dimples are to the top. Attach starter

brackets to the top of the ladder. It will be necessary to field drill a 3/8" hole in the ladder section for the

starter bracket as well. (See Figure 6F on Page 44.) See F igure 4B on Page 13 for the proper installation

of additional ladder sections required. Standoff brackets must be installed on the ladder sections and

attached to the sidewall at each horizontal seam and repeated every 32". Use 5/16" x 3/4" bin bolts for

all connections.

Figure 6D

NOTE: Refer to Figure 4A on Page 12 for additional details for standoff bracket to ladder assembly and

8' extension rail installation (omitted in detailed image above for clarity).

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 43

Page 44

6. 2.66" Corrugated Commercial Hopper Tank 10-22 Rings

Figure 6E

NOTE: Refer to Figure 6D on Page 43 for proper location of ladder starter brackets.

Figure 6F Ladder and Brackets as Viewed from Top of Bin

44 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 45

6. 2.66" Corrugated Commercial Hopper Tank 10-22 Rings

Eave Adjustable Braces

The eave adjustable braces must be attached at this time. An eave adjustable brace is comprised of one

large diameter tube and two (2) smaller tubes. (See Figure 6G.) Slide the smaller tubes inside the larger

tubes and attach one smaller tube to the top of the ladder extension rail. Adjust the other smaller tube so

the bottom of the flattened tube reaches the roof panel. Field drill four (4) 5/16" holes through both large

and small tubes and bolt together using 1/4" x 1-1/2" bolts and nuts. This prevent the adjustable braces

from slipping. (See Figure 6H.)

NOTE: Refer to Page 43 for proper location of ladder starter brackets.

Figure 6G

Figure 6H

NOTE: Refer to Figure 4A on Page 12 for additional details for standoff bracket to ladder assembly and

cage hoop bracket to ladder.

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 45

Page 46

6. 2.66" Corrugated Commercial Hopper Tank 10-22 Rings

Eave Platform Mounting Angle Installation

Figure 6I shows the location of the platform mounting angles. Each angle must be mounted starting

4" below the top horizontal seam of the second ring with the first mounting angle offset 9-3/8" from the

right hand starter bracket. The second mounting angle must be located 56-1/4" from the first mounting

angle. The dimensions and locations of these angles are critical for proper fit of all parts. Using the platform

mounting angels as guides, field drill 3/8" holes in the sidewall every 8". (See Figure 6I.)

Figure 6I

46 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 47

6. 2.66" Corrugated Commercial Hopper Tank 10-22 Rings

Right Hand Platform and Platform Support Assembly

NOTE: Mount the platform supports on the bin first. Next, assemble the platform floor onto the support

frame. Do not tighten platform support to floor brace bolts until the floor and toe plates are secure.

Assemble the platform support frame using 5/16" x 3/4" truss head bolts and nuts. (See Figure 5I

on Page 28.) When attaching the platform mounting angles to the sidewall, locate the mounting angles

according to the instructions on previous pages. Align holes on the platform floor with the holes on the

platform supports and bolt together using 5/16" x 3/4" truss head bolts and nuts. Attach platform toe plates

at the same time as attaching the platform floor. The vertical entrance angle bolts to the platform floor,

toe plate and platform support. The handrail post bolts to the platform floor and toe plate as shown

in Figure 6K.

Figure 6J Right Hand Platform Support Assembly

Figure 6K Right Hand Platform

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 47

Page 48

6. 2.66" Corrugated Commercial Hopper Tank 10-22 Rings

67-1/2" Extension angles (LS-6775)

(See extension angle hole detail

on Page 15 for proper installation.)

Eave Safety Cage Hoop Assembly

Before attaching any pieces to the ladders or platform, some pre-assemb ly is required. Attach two (2) safety

cage brackets to the 8' extension rail and one safety cage bracket to the second 4' ladder section a s shown

in

Figure 6L

Using the proper configuration depending on the bin diameter (see adapter assembly detail

bolt the safety cage hoop adapters toge ther and attach to the safety cage hoop halves. Be sure to use the

5/16" x 3/4" bolt with the head of the bolt to the inside of the safety cage. Bolt thes e assemblies to the safety

cage brackets and hoop adjuster plates. (See conne ction detail

bolts as you go. The bottom assembly requires two (2) hoop halves and will be positioned just below the

platform as shown in

assemblies to the vertical entrance angle on the platform assembly.

. Bolt the safety cage hoop adjuster plates onto the extension angle as shown in

Figure 6L

on Page 49

. Use the safety cage hoop adjuster angle to se cure the two (2) hoop half

for proper hole location.) Tighten

Figure 6L

on Page 49

.

),

Figure 6L

NOTE: 48" Vertical supports removed in Figure 6L for clarity.

48 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 49

6. 2.66" Corrugated Commercial Hopper Tank 10-22 Rings

Adapter Assembly Detail

Connection Detail

Use

Figure 6N

to determine the proper holes to use when attaching the hoop adapter to the adjuster plate.

Figure 6M 18' Diameter through 21' Diameter Bins

Figure 6N

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 49

Page 50

6. 2.66" Corrugated Commercial Hopper Tank 10-22 Rings

Vertical Supports

After all three (3) hoop assemblies are

in place, attach the 48" vertical supports

from hoop assembly to hoop assembly,

as shown in Figure 6O. This requires

ten (10) supports, five (5) between each

set of hoops. The second set of vertical

supports must be bent at the flat area

to allow for the tapering of the bottom

hoop assembly. Use 5/16" x 3/4" bolts

(unless otherwise noted) with the

head of the bolt to the inside of the

safety cage.

48" Safety Cage

Attach the vertical support pieces to the

existing hoop halves above using the

5/16" x 3/4" bolts and nuts (with the

heads on the inside of the cage). Fasten

two (2) hoop halves together and bolt to

other end of vertical supports. Attach

cage hoop brackets to ladder (See

general detail information on Page 12

for proper attachment.) Once cage hoop

brackets have been installed, attach cage

hoop halves and tighten bolts. Repeat

installation for each safety cage required.

Figure 6O Vertical Supports

Figure 6P 48" Safety Cage

50 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 51

6. 2.66" Corrugated Commercial Hopper Tank 10-22 Rings

24"-48" Safety Cage Bell Sections

Attach the vertical supports to the hoop half assembly from the final safety cage installation using

5/16" x 3/4" bolts and nuts (with the heads on the inside of the cage). Assemble the special bell safety

cage hoop halves and attach to other end of vertical supports. The vertical support will have to be bent at

the flat area to allow for the angle of the bell section. Attach the safety cage brackets to the ladder as

shown in the general detail information on Page 12. Once the safety cage brackets are installed, attach

the bell safety cage hoop half assembly to the safety cage brackets and tighten bolts.

NOTE: The safety cage bell section is to be used at the poi nt of termination of the safety cage an d should

be just above the intermediate or base platform (generally 7' to 8').

Figure 6Q 24" Bell

Figure 6R 48" Bell

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 51

Page 52

6. 2.66" Corrugated Commercial Hopper Tank 10-22 Rings

Refer to chart on

page 41 for distance

between platform

mounting angles

(Section A) and ring

location (Section C).

Eave platform mounting

angles shown for reference

only. (See Page 38 for

installation details.)

Intermediate Platform Mounting Angle Installation

For bins with 18-22 rings, an intermediate platform is required. Figure 6S shows the location of the

intermediate platform mounting angles. Each angle must be mounted starting 4" below the top horizontal

seam of the ring specified in the Chart on Page 41, with the first mounting angle directly in line with the left

hand eave mounting angle. The second mounting angle must be located 56-1/4" to the left of the first

mounting angle. Pay careful attention when installing these angle s. The dimensions and locations of these

angles are critical to assure proper fit of all parts. Using the platform mounting angels as guides, field drill

3/8" holes in the sidewall every 8". (See Figure 6I on Page 46.)

Figure 6S

52 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 53

6. 2.66" Corrugated Commercial Hopper Tank 10-22 Rings

Intermediate

platform mounting

angles. (See Page 52

for proper installation.)

Location of Field Drilled Holes for Intermediate Ladder

Starter Brackets

Before installing the starter brackets, field drill two (2) 3/8" holes located 2.66" below and directly in

line with the top horizontal seam holes located in the third ring up from the intermediate platform mounting

angles. The first hole, required for the right hand starter bracket, must be located 9-3/8" from the center of

the left hand intermediate platform mounting angle to the center of the hole. The second hole, required for

the left hand bracket, must be located 18-3/4" from the center of the first hole. Refer to Figure 6T for the

proper location of the two (2) 3/8" field drilled holes required to install the starter brackets.

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 53

Figure 6T

Page 54

6. 2.66" Corrugated Commercial Hopper Tank 10-22 Rings

Intermediate Starter Bracket and Ladder Assembly with

Safety Cage

After drilling the two (2) 3/8" holes, attach the starter brackets to the sidewall as shown in Figure 6U. Check

the top ladder section to make sure the ladder rung dimples are to the top surface and attach to the starter

brackets using the holes located 1" from the top of the ladder. See general detail information on Page 12

for proper installation of additional ladder sections required. Standoff brackets must be installed on the

ladder sections and attached to the sidewall at each horizontal seam (repeating every 32") until reaching

the base platform. (Use 5/16" x 3/4" bin bolts for all connections.) In add ition to the two (2) field drilled holes

in the sidewall for the starter bracket, it is also be necessary to field drill a 3/8" hole in the ladder section

for the starter bracket. Refer to the section in these instructions that references the location of the

base platforms.

Figure 6U

54 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 55

6. 2.66" Corrugated Commercial Hopper Tank 10-22 Rings

Right hand platform assembly

(See Page 47 for assembly details.)

LS-6775 Extension angles

(See general detail information

on Page 12 for proper installation.)

Vertical entrance angle (See

platform assembly on Page 47.)

Cage hoop bracket (See general

detail information on Page 12 for

proper installation.)

Intermediate and Base Safety Cage Hoop Assembly

Before attaching any pieces to the ladders or platform, some pre-assembly is required. Attach the safety

cage brackets to the ladder section. (See general detail information on Page 12.) Bolt the safety cage hoop

adjuster plates onto the extension angle as shown in Figure 6V. Bolt the safety cage hoop adapters

and safety cage hoop halves together using the proper holes based on the diameter of the grain bin.

(See Page 49.) Be sure to use the 5/16" x 3/4" bolt with the head of the bolt to the inside of the safety cage.

Bolt these assemblies to the safety cage brackets and hoop adjuster plates, tighten bolts as you go. The

bottom assembly requires two (2) hoop halves and will be positioned just below the platform as shown in

Figure 6V. Use the safety cage hoop adjuster angle to secure the two (2) hoop half assemblies to the

vertical entrance angle on the platform assembly.

NOTE: See Pages 50 and 51 for vertical supports, safety cage and bell cage installation details to

complete the intermediate ladder assembly.

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 55

Figure 6V

Page 56

6. 2.66" Corrugated Commercial Hopper Tank 10-22 Rings

Eave mounting brackets (10-17 rings)

or intermediate mounting brackets

(18-22 rings) shown for reference only.

See Page 52 for installation details.

Base Platform Mounting Angle Installation

Figure 6W shows the location of the base platform mounting angles. Each angle must be mounted starting

4" below the top horizontal seam of the third ring from the bottom of the tank with the first mounting angle

directly in line with the left hand eave or intermediate mounting angle (if applicable). The second mounting

angle must be located 56-1/4" to the left of the first mounting angle. Pay careful attention when installing

these angles. The dimensions and locations of these angles are critical to assure proper fit of all parts and

integration with the access door platform.

Figure 6W

56 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 57

6. 2.66" Corrugated Commercial Hopper Tank 10-22 Rings

Base platform

mounting angles.

See Page 56 for

installation details.

Location of Field Drilled Holes for Base Ladder Starter Brackets

Before installing the starter brackets, field drill two (2) 3/8" holes 2.66" below and directly in line with the

top horizontal seam holes located in the sixth ring from the bottom of the tank. The first hole, for the

right hand starter bracket, must be located 9-3/8" from the cen ter of the left ha nd base platform mounting

angle to the center of the hole. The second hole, for the left hand bracket, must be located 18-3/4" from

the center of the first hole. Refer to Figure 6X for the proper location of the two (2) 3/8" field drilled holes

required to install the starter brackets.

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 57

Figure 6X

Page 58

6. 2.66" Corrugated Commercial Hopper Tank 10-22 Rings

Base Starter Bracket and Ladder Assembly with Safety Cage

Once the two (2) 3/8" holes have been field drilled, attach the starter brackets to the sidewall as shown in

Figure 6Y. Check the top ladder section to make sure the ladder rung dimples are to the top. Attach to the

starter brackets using the holes located 1" from the top of the ladder. It will also be necessary to field drill

a 3/8" hole in the ladder section. Drill this hole 2" below the pre-drilled hole 1" from the top of the ladder.

(See Figure 6Y.) See general detail information on Page 12 for proper installation of additional ladder

sections required. Now, standoff brackets must be installed on the ladder sections and attached to the

sidewall at each horizontal seam and repeated every 32" until reaching the bottom of the tank. Use

5/16" x 3/4" bin bolts for all connections.

NOTE: See Page 55 for safety cage hoop assembly, Page 47 for platform assembly and Page 50 for

vertical support installation. DO NOT install any safety cages or safety cage bells at this time. The

access door platform assembly must be installed first.

Figure 6Y

58 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 59

6. 2.66" Corrugated Commercial Hopper Tank 10-22 Rings

Access Door Platform Mounting Angle Installation

Figure 6Z

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 59

Page 60

6. 2.66" Corrugated Commercial Hopper Tank 10-22 Rings

Left Hand Platform and Platform Support Assembly

NOTE: Mount the platform mounting angles supports on the column first. Next, assemble the platfo rm floor

onto the support frame. Do not tighten platform support to floor brace bolts until the floor and toe

plates are secure.

Assemble the platform support frame using 5/16" x 3/4" truss head bolts and nuts. Align holes on the

platform floor with the holes on platform supports and bolt together using 5/16" x 3/4" truss head bolts and

nuts. Attach platform toe plates at the same time as attaching the platform floor. The vertical entrance

angle bolts to the platform floor, toe plate and platform support. The handrail post bolts to the platform floor

and toe plate as shown in Figure 6AB.

Figure 6AA Left Hand Platform Support Assembly

Figure 6AB Left Hand Platform

60 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 61

6. 2.66" Corrugated Commercial Hopper Tank 10-22 Rings

Extension angle (LS-6775)

(See general detail information

on Page 12 for proper installation.)

Base platform safety cage assembly shown for

reference only. See Page 59 for installation details.

Left hand platform

assembly (See Page 60

for assembly details.)

Access Door Safety Cage Hoop Assembly

Before attaching any pieces to the ladder or platform, some pre-assembly is required. Attach the safety

cage brackets to the ladder section. (See general detail information

instructions.) Bolt the safety cage hoop adjuster plates onto the extension angle as shown in

For the middle hoop assembly, bolt the safety cage hoop adapters and safety cage hoop half together using

the proper holes, based upon the bin diameter.

(See Page 49.)

head of the bolt to the inside of the safety cage. Bolt this assembly to the safety cage bracket and hoop

adjuster plate, tighten as you go. The bottom assembly requires two (2) hoop halves and will be positioned

just below the platform as shown in

Figure 6AC

. Use the safety cage hoop adjuster angle to secure the

two (2) hoop half assemblies to the vertical entrance angle on the platform assembly. To finish the

installation, secure the access door platform assembly to the base platform assembly using the safety cage

hoop adapters as shown in

Figure 6AC

.

NOTE: See Pages 50 and 51 for vertical support, safety cage and bell cage installation details to complete

the ladder assembly.

on Page 12

for proper installation

Figure 6AC

Be sure to use the 5/16" x 3/4" bolt with the

.

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 61

Figure 6AC

Page 62

6. 2.66" Corrugated Commercial Hopper Tank 10-22 Rings

Ladder Support Detail

The ladder must be secured to the hopper support columns with ladder standoff brackets using support

channels and ladder brackets as shown in Figure 6AD.

Figure 6AD

T ank Diameter Hopper Slope # of Support Channels Hopper Ladder Brackets

12' 45 3 6

12' 60 4 8

15' 45 4 8

15' 60 6 12

18' 45 4 8

18' 60 7 14

21' 45 5 10

21' 60 8 16

24' 45 5 10

27' 40 5 10

30' 40 5 10

36' 40 6 12

36' 45 8 16

62 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 63

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 63

4.00" Corrugated

Farm-Com Hopper

Tanks (FCHT)

4-6 Rings

®

Page 64

7. 4.00" Corrugation Farm Commercial Hopper Tanks (FCHT) 4-6 Rings

44" Safety cage

see note below.

4.00" Farm Commercial Hopper Tank Ladder and Platform Layout

4-6 Rings

Figure 7A 6 Rings

NOTE: The 44" safety cage sections must be installed in Section A of th e ladder system. DO NOT install

the 44" verticals in the eave or access door safety cage hoop assembly.

64 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 65

7. 4.00" Corrugation Farm Commercial Hopper Tanks (FCHT) 4-6 Rings

Ladder, Safety Cage and Platform Location Chart

For Section A, find the proper ring grain bin and use the number of ladders and safety cages. See Chart

below (Section A). For Section B, find the proper diameter grain bin and hopper slope and use the number

of ladders and safety cages. See Chart below (Section B).

Rings

456

Platform Located in Ring: 1 1 1

4' Ladder Section 3 4 5

Bell Safety Cage 0 0 0

44" Safety Cage 0 1 2

Section A

Bell Safety Cage Size 0 0 0

Dimension A 96" 140" 184"

Rings

18' 21' 24'

Hopper Slope: 45 45 45

4' Ladder Section 6 6 7

Bell Safety Cage 1 1 1

Safety Cage 48" Section 1 1 1

Section B

Bell Safety Cage Size 24" 48" 48"

Dimension B 176" 192" 204"

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 65

Page 66

7. 4.00" Corrugation Farm Commercial Hopper Tanks (FCHT) 4-6 Rings

FCHT Ladder, Safety Cage and Platform Instructions 4-6 Rings

All grain bin packages, from 4 ring to 6 ring and 18' to 24' diameter, contain the correct components for

assembly. Read and follow the complete instructions for correct placement of parts. Be sure and use the

charts to determine the appropriate number and size parts to be used based upon the number of rings in

the bin. Failure to do so may result in an improper fit or shortage of parts. Pay particular attention to the

location of ladders and platforms as they relate to the equipment and other structures in the area.

Eave Starter Bracket Installation

Correct placement of the eave ladder starter bracket is critical to assure proper fit of all ladder co mponents

and to assure the correlation is correct between the platforms for proper installation of the access door

platform. If the eave starter brackets are mislocated, standard installation of the access door platform will

not be possible.

66 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 67

7. 4.00" Corrugation Farm Commercial Hopper Tanks (FCHT) 4-6 Rings

Location of Field Drilled Holes for Eave Ladder Starter Brackets

The starter brackets must be located directly below the roof ladder. Before the starter brackets can be

installed, two (2) 3/8" holes must be drilled 4" below and directly in line with the top row of pre-punched

horizontal holes. The first hole, for the left hand starter bracket, must be located 9-3/8" from the cen ter of

the stiffener to the center of the hole. The second hole, for the right hand bracket, must be located

18-3/4" from the center of the first hole. Refer to Figure 7B for the proper location of the two (2) 3/8" field

drilled holes required to install the starter brackets.

Figure 7B

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 67

Page 68

7. 4.00" Corrugation Farm Commercial Hopper Tanks (FCHT) 4-6 Rings

Eave Starter Bracket and Ladder Assembly with Safety Cage

Once the two (2) 3/8" holes have been field drilled, attach the starter brackets to the sidewall as shown in

Figure 7C. Check the top ladder section to make sure the ladder rung dimples are to the top. Attach starter

brackets to the top of the ladder. It will also be necessary to field drill a 3/8" hole on the ladder section for

the starter bracket. Field drill this hole 2" below the pre-drilled hole that is 1" from the top of the ladder.

See general detail information on Page 12 for the proper installation of additional ladder sections required.

Standoff brackets must be installed on the ladder sections and attached to the sidewall at each horizontal

seam and repeated every 44". Use 5/16" x 3/4" bin bolts for all connections.

Figure 7C

NOTE: Refer to general detail information on Page 12 for additional d etails for sta ndoff bracket to ladde r

assembly and also, 8' extension rail installation (omitted in detail for clarity).

68 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 69

7. 4.00" Corrugation Farm Commercial Hopper Tanks (FCHT) 4-6 Rings

Figure 7D

Figure 7E Ladder and Brackets as Viewed from top of Bin

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 69

Page 70

7. 4.00" Corrugation Farm Commercial Hopper Tanks (FCHT) 4-6 Rings

Eave Adjustable Braces

The eave adjustable braces must be attached at this time. An eave adjustable brace is comprised of one

larger diameter tube and two (2) smaller tubes. (See Figure 7F.) Slip the smaller tubes inside the larger

tubes and attach one smaller tube to the top of the ladder extension rail. Adjust the other smaller tube so

the bottom of the flattened tube reaches the roof panel. Field drill four (4) 5/16" holes through both large

and small tubes and bolt together using 1/4" x 1-1/2" bolts and nuts. This prevent the adjustable braces

from slipping. (See Figure 7G.)

NOTE: Refer to Page 68 for proper location of ladder starter brackets.

Figure 7F

Figure 7G

NOTE: Refer to general detail information on Page 12 for additional d etails for sta ndoff bracket to ladde r

assembly and cage hoop bracket to ladder.

70 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 71

7. 4.00" Corrugation Farm Commercial Hopper Tanks (FCHT) 4-6 Rings

Eave Platform Mounting Angle Installation

Figure 7H shows the location of the platform mounting angles. Each angle must be mounted starting

8" above the top horizontal seam of the second ring with the first mounting angle offset 9-3/8" from the

right hand starter bracket. The second mounting angle must be located 56-1/4" from the first mounting

angle. The dimensions and locations of these angles are critical for proper fit of all parts. Using the platform

mounting angels as guides, field drill 3/8" holes in the sidewall every 8". (See Figure 7H.)

Figure 7H

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 71

Page 72

7. 4.00" Corrugation Farm Commercial Hopper Tanks (FCHT) 4-6 Rings

Right Hand Platform and Platform Support Assembly

NOTE: Mount the platform supports on the bin first. Next, assemble the platform floor onto the support

frame. Do not tighten platform support to floor brace bolts until the floor and toe plates are secure.

Assemble the platform support frame using 5/16" x 3/4" truss head bolts and nuts. When attaching the

platform mounting angles to the sidewall, locate the mounting angles according to the instructions on

previous pages. Align holes on the platform floor with the holes on platform supports and bolt together

using 5/16" x 3/4" truss head bolts and nuts. Attach platform toe plates at the same time as attaching the

platform floor. The vertical entrance angle bolts to the platform floor, toe plate and platform support.

The handrail post bolts to the platform floor and toe plate as shown in Figure 7I.

Figure 7I Right Hand Platform

Figure 7J Right Hand Platform Support Assembly

72 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 73

7. 4.00" Corrugation Farm Commercial Hopper Tanks (FCHT) 4-6 Rings

67-1/2" Extension angles (LS-6775)

(See extension angle hole detail on

Page 15 for proper installation.)

Eave Safety Cage Hoop Assembly

Before attaching any pieces to the ladders or platform, some pre-assembly is required. Attach two (2)

safety cage brackets to the 8' extension rail and one safety cage bracket to the second 4' ladder section

as shown in Figure 7K. (See Page 48 for assembly details.) Bolt the safety cage hoop adjuster plates onto

the extension angle as shown. Using the proper configuration depending on the bin diameter (see adapter

assembly detail on Page 74), bolt the safety cage hoop adapters together and attach to the safety cage

hoop halves. Be sure to use the 5/16" x 3/4" bolt with the head of the bolt to the inside of the safety cage.

Bolt these assemblies to the safety cage brackets and hoop adjuster plates. (See connection detail

on Page 74 for proper hole location.) Tighten bolts as you go. The bott om assembly requires two (2) hoop

halves and will be positioned just below the platform as shown in Figure 7K. Use the safety cage hoop

adjuster angle to secure the two (2) hoop half assemblies to the vertical entrance angle on the

platform assembly.

NOTE: 48" Vertical supports removed in Figure 7K for clarity.

PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks 73

Figure 7K

Page 74

7. 4.00" Corrugation Farm Commercial Hopper Tanks (FCHT) 4-6 Rings

Adapter Assembly Detail

Figure 7L 18' Diameter through 21' Diameter Bins

Connection Detail

Use Figure 7M to determine the proper holes to use when attaching the hoop adapter to the adjuster plate.

Figure 7M

74 PNEG-1451 Ladder, Safety Cage and Platform for Hopper Tanks

Page 75

7. 4.00" Corrugation Farm Commercial Hopper Tanks (FCHT) 4-6 Rings

Vertical Supports

After all three (3) hoop assemblies

are in place, attach the 48" vertical