Page 1

PNEG-1430

6"-6", 6"-8", 8"-8", 8"-10" and

10"-12" 25° Bin Unloader

Assembly and Operation Manual

PNEG-1430

Date: 02-24-12

Page 2

2 PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader

Page 3

Table of Contents

Contents

Chapter 1 Introduction ..........................................................................................................................................4

Chapter 2 Safety .....................................................................................................................................................5

Safety Guidelines .................................................................................................................................. 5

Safety Instructions ..................... ... .... .......................................... ... ... ..................................................... 6

Operator Qualifications ............................................. .... ... ... ... .... ... ... ... ... .... ... ... ... .................................. 9

Chapter 3 Safety Decals ......................................................................................................................................10

Chapter 4 Assembly ............................................................................................................................................12

Attaching the Adapter Plate (for 6"-8", 8"-10" and 10"-12") ................................................................. 12

Assembling Support Stand .................................................................................................................. 12

Attaching Support Stand to Tube ........................................................................................................ 13

Attaching Flights .................................................................................................................................. 13

Installing the Motor Mount Adjuster ..................................................................................................... 14

Installing the Motor Mount Plate .......................................................................................................... 15

Installing the Belt Guard Brackets ....................................................................................................... 16

Installing the Pulley ...... .......................................... ... .... ... .......................................... ... ...................... 17

Tightening the Lock Collar .................................................................................................................. 17

Installing the Motor (Not Provided) ............................ .................... ................... ................ ................... 18

Installing the Belts .................................. ... ... .... ... ... .......................................... ... .... ............................ 18

Installing the Belt Guard ............................... .... ... ... ... .... ... ... ... .... ......................................................... 19

Chapter 5 Motors .................................................................................................................................................20

Electric Drive Motors ........................................................................................................................... 20

Chapter 6 Start-Up ...............................................................................................................................................21

Perform Pre-Start Checks ............................ .... ... .......................................... ... ... ................................ 21

Start the Auger .................................................................................................................................... 22

Chapter 7 Operation ............................................................................................................................................23

Operate the Auger ............................................................................................................................... 23

Chapter 8 Shut Down ...........................................................................................................................................24

Normal Shut Down .............................................................................................................................. 24

Emergency Shut Down ....................................................... ... .... ... ... ... ... .... ... ... ... .... ............................ 24

Storage Preparation ..................................... .... ... .......................................... ... ... .... ............................ 24

Chapter 9 Maintenance ........................................................................................................................................25

Maintain the Auger .............................................................................................................................. 25

Chapter 10 Parts List ...........................................................................................................................................27

6" to 6" 25° Unloader Parts ................................................................................................................ 28

6" to 8" 25° Unloader Parts ................................................................................................................ 30

8" to 8" 25° Unloader Parts ................................................................................................................ 32

8" to 10" 25° Unloader Parts .............................................................................................................. 34

10" to 12" 25° Unloader Parts ............................................................................................................ 36

Chapter 11 Troubleshooting ...............................................................................................................................38

Chapter 12 Warranty ............................................................................................................................................39

PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader 3

Page 4

1. Introduction

READ THIS MANUAL carefully to learn how to properly use and install equipment. Failure to do so could

result in personal injury or equipment damage.

INSPECT the shipment immediately upon arrival. The customer is responsible for ensuring that all

quantities are correct. The customer should report and note any damage or shortage on the bill of

lading to justify their claim to the transport company.

THIS MANUAL SHOULD BE CONSIDERED a permanent part of your equipment and should be easily

accessible when needed.

This warranty provides you the assurance that the company will back its products when defects appear

within the warranty period. In some circumstances, the company also provides field improvements, often

without charge to the customer, even if the product is out of warranty. Should the equipment be abused,

or modified to change its performance beyond the factory specifications, the warranty will become void

and field improvements may be denied.

4 PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader

Page 5

2. Safety

DANGER

WARNING

CAUTION

NOTICE

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a

hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to

personal injury.

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader 5

Page 6

2. Safety

Follow Safety Instructions

Carefully read all safety messages in this manual and

safety signs on your machine. Keep signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from the manufacturer.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machinery in proper working condition.

Unauthorized modifications to the machine may impair

the function and/or safety and affect machine life.

If you do not understand any part of this manual or need

assistance, contact your dealer.

Read and Understand Manual

Operate Motor Properly

To avoid serious injury or death, stay away from unit and make sure

everyone is clear of the equipment before starting or operating

the unit.

All electrical connections should be made in accordance with

the National Electric Code. Be sure equipment and bins are

properly grounded.

Do not operate electric motor equipped units until motors are

properly grounded.

Disconnect power on electrical driven units before resetting

motor overloads.

Do not repetitively stop and start the drive in order to free a plugged

condition. Jogging the drive in this manner can damage the

equipment and/or drive components.

Electric Shock Hazard

Safety Instructions

Our foremost concern is your safety and the safety of others associated with this equipment. We want to

keep you as a customer. This manual is to help you understand safe operating procedures and some

problems that may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards, and precautions

exist, and to inform all personnel associated with the equipment or in the area. Safety precautions may be

required from the personnel. Avoid any alterations to the equipment. Such alterations may p roduce a very

dangerous situation where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable

regulations, which should be carefully followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

6 PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader

Page 7

2. Safety

Prepare for Emergencies

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital, and fire department near your telephone.

Keep Emergency Equipment

Quickly Accessible

Wear Protective Clothing

Wear close-fitting clothing and safety equipment appropriate

to the job.

Remove all jewelry.

Tie long hair up and back.

Wear safety glasses at all times to protect eyes from debris.

Wear gloves to protect your hands from sharp edges on plastic

or steel parts.

Wear steel-toed boots to help protect your feet from falling

debris. Tuck in any loose or dangling shoestrings.

A respirator may be needed to prevent breathing potentially

toxic fumes and dust.

Wear a hard hat to help protect your head.

Wear appropriate fall protection equipment when working at

elevations greater than six feet (6').

Eye Protection

Gloves

Steel-Toed Boots

Respirator

Hard Hat

Fall Protection

PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader 7

Page 8

2. Safety

Operate Unload Equipment Properly

• Untrained operators subject themselves and others to SERIOUS INJURY

or DEATH. NEVER allow untrained personnel to operate this equipment.

• NEVER work alone.

• Keep children and other unqualified personnel out of the working

area at ALL times. Refer to the Start-Up section of this manual for

diagrams of the work area.

• Make sure ALL equipment is locked in position before operating.

• NEVER start equipment until ALL persons are clear of the work area.

• Keep hands and feet away from the auger intake and other moving parts.

• NEVER attempt to assist machinery operation or to remove trash from equipment while

in operation.

• Be sure all operators are adequately rested and prepared to perform all functions of operating

this equipment.

• NEVER allow any person intoxicated or under the influence of alcohol or drugs to operate

the equipment.

• Make sure someone is nearby who is aware of the proper shut down sequence in the event of an

accident or emergency.

• ALWAYS think before acting. NEVER act impulsively around the equipment.

• NEVER allow anyone inside a bin, truck or wagon which is being unloaded by an auger or

conveyor. Flowing grain can trap and suffocate in seconds.

• Use ample overhead lighting after sunset to light the work area.

• Keep area around intake free of obstacles such as electrical cords, blocks, etc., that might

trip workers.

• NEVER drive, stand or walk under the equipment.

• Use caution not to hit the auger when positioning the load.

• ALWAYS lock out ALL power to the equipment when finished unloading a bin.

• Be aware of pinch points. A pinch point is a narrow area between two surfaces that is likely to trap

or catch objects and so is a potential safety hazard.

Operate Unload

Equipment Safely

8 PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader

Page 9

2. Safety

Operator Qualifications

A. The User/Operator must be competent and experienced to operate auger equipment. Anyone who

works with or around augers must have good common sense in order to be qualified. T hese persons

must also know and meet all other qualifications, such as:

i. Any person who has not read and/or does not understand all operation and safety procedures

is not qualified to operate any auger systems.

ii. Certain regulations apply to personnel operating power machinery. Personnel under the age of

18 years may not operate power machinery, including augers. It is your responsibility, as owner

and/or supervisor, to know what these regulations are in your area or situation.

iii. Unqualified or incompetent persons are to remain out of the work area.

iv. O.S.H.A. (Occupational Safety and Health Administration) regulations state: “At the time of

initial assignment and at least annually thereafter, the employer shall instruct every employee

in the safe operation and servicing of all equipment with which the employee is, or will be

involved”. (Federal Occupational Safety and Health Standards for Agriculture. Subpart D,

Section 1928.57 (a) (6)).

B. As a requirement of O.S.H.A., it is necessary for the employer to train the employee in the safe

operating and safety procedures for this auger. The sign-off sheet is provided for your convenience

and personal record keeping. All unqualified persons are to stay out of the work area at all times. It

is strongly recommended that another qualified person who knows the shut down procedure is in the

area in the event of an emergency.

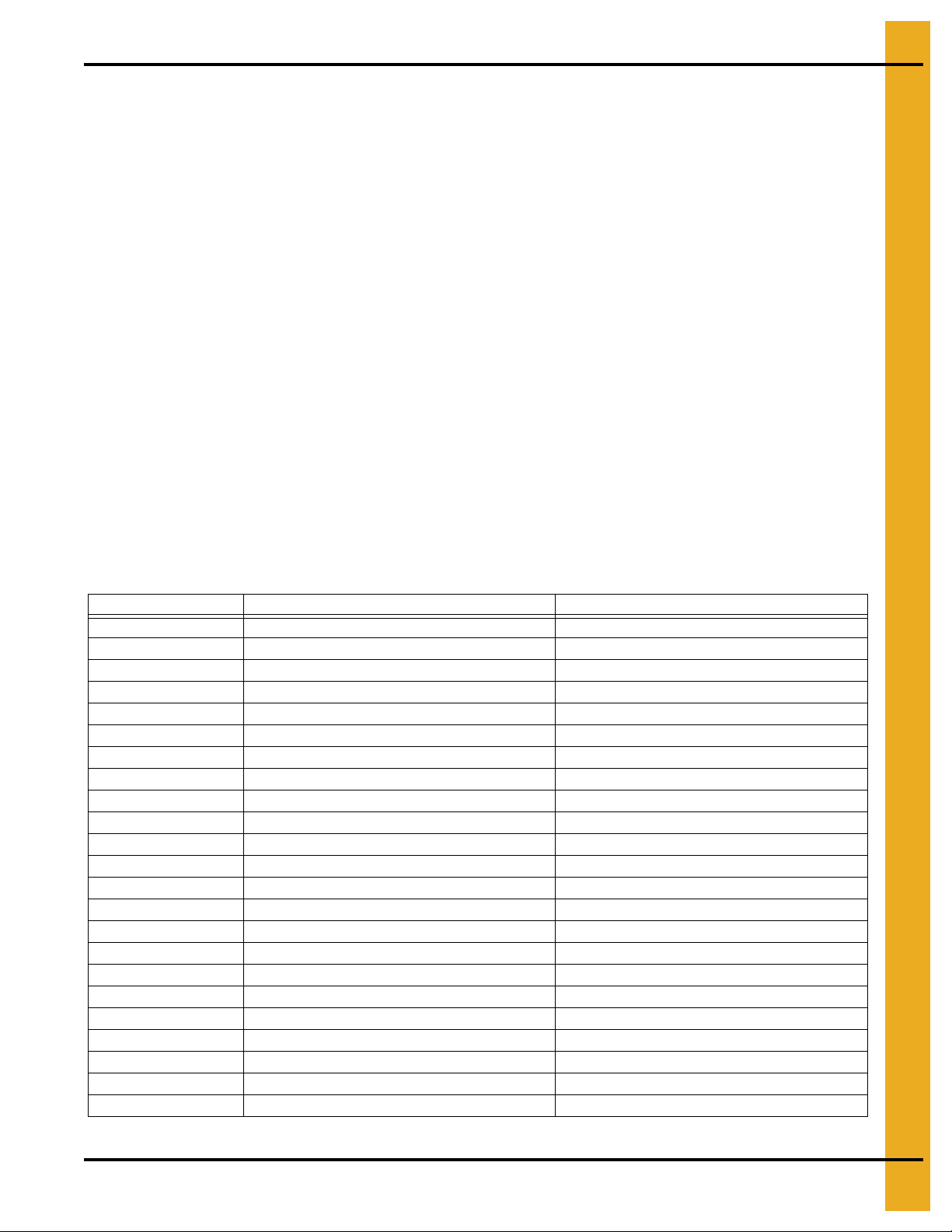

Date Employee Name Supervisor Name

PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader 9

Page 10

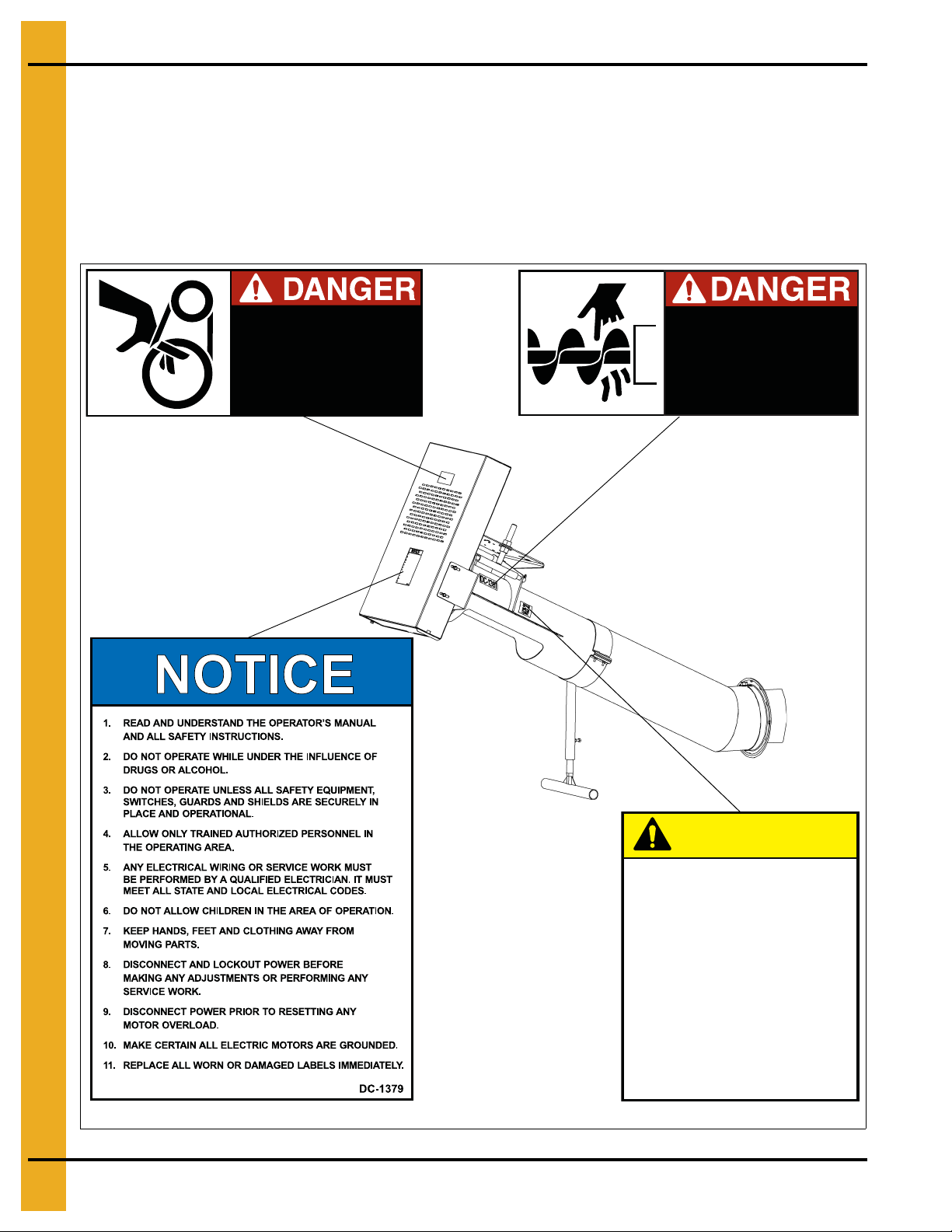

3. Safety Decals

DC-994

DC-1381

DC-1234

DC-1379

SHEAR POINT

Keep clear of rotating auger and

moving parts.

Do not remove or modify guards.

Disconnect and lock out power

before servicing.

Failure to do so will result in

serious INJURY or DEATH.

DC-1381

SHEAR POINT

Keep hands clear of moving

parts. Do not operate with

guard removed. Disconnect

and lockout power before

servicing.

DC-994

Check components shown below to ensure that the safety decals are in place and in good co ndition. If a

decal cannot be easily read for any reason or has been painted over, replace it immediately. Contact you r

dealer or the manufacturer to order a replacement decal free of charge.

Contact:

The GSI Group

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 1-217-226-4421

CAUTION

FAILURE TO PROPERLY SELECT,

INSTALL OR MAINTAIN AN AUGER, ITS

DRIVE OR OTHER COMPONENTS CAN

RESULT IN DANGEROUS OPERATION.

THIS EQUIPMENT IF IMPROPERLY

SELECTED, INSTALLED OR

MAINTAINED MAY FAIL AND COULD

RESULT IN SERIOUS INJURY OR

PROPERTY DAMAGE.

CHECK PRODUCT LITERATURE AND

EQUIPMENT MANUFACTURER’S

LITERATURE OR CALL THE FACTORY

FOR FURTHER INFORMATION.

10 PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader

DC-1234

Page 11

3. Safety Decals

A. DANGER Sign No. DC-1395 was supplied with your bin unloading equipment. This safety sign

should be applied to the side of the bin near the bin opening, so it will be viewed by people

entering into the bin storage building. Do not cover any safety signs or any other signs that are

already there.

B. If the safety sign location suggested is not in full view because of equipment modifications, other

equipment in the area or any reason, then locate the safety sign in a more suitable location.

C. Be certain the surface is clean, dry and free of dirt and oil. Peel paper backing from decals and stick

into place. The adhesive backing will bond on contact.

NOTE: Please remember, safety signs provide important safety information for people working near bin

unloading equipment that is in operation.

NOTE: If the Safety Sign cannot be easily read for any reason or has been painted over, replace it

immediately. Additional Safety Signs may be obtained free of charge from your dealer, distributo r

or ordered from the factory.

Order SAFETY SIGN NO. DC-1395

PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader 11

Page 12

4. Assembly

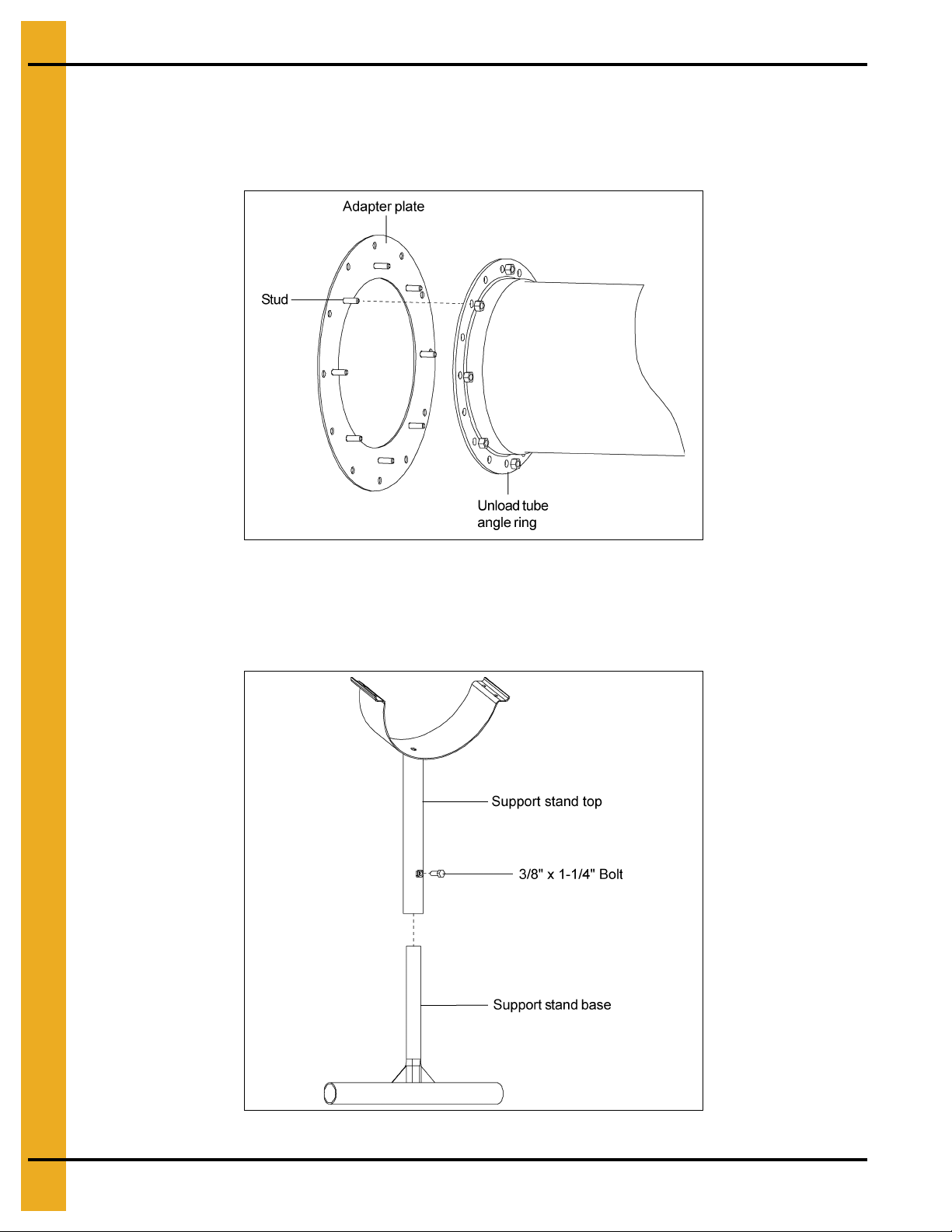

Attaching the Adapter Plate (for 6"-8", 8"-10" and 10"-12")

1. Align studs on adapter plate with the holes on the unload tube’s angle ring.

2. Insert studs through the holes and fasten using nuts from tube end plate. (See Figure 4A.)

Figure 4A

Assembling Support Stand

1. Insert support stand base into support stand top and secure with 3/8" x 1-1/4" bolt. (See Figure 4B.)

Figure 4B

12 PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader

Page 13

4. Assembly

(See Chart for Bolt Sizes on Page 16.)

Attaching Support Stand to Tube

1. Place support stand and half band around tube and secure together with 5/16" bolts and serrated

flange nuts. (See Figure 4C.)

Figure 4C

Attaching Flights

1. Pull bin unload flight out of unload tube approximately one foot (1').

2. Remove bearing connecting stub bolts and nuts from connecting stub.

3. Position 25° unloader assembly in-line with bin tube.

4. Align holes in unload flight with holes in bearing connecting stub and slide flight onto stub.

5. With holes aligned, secure with bearing connecting stub bolts and nuts that were removed in Step 2.

(See Figure 4D.)

PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader 13

Figure 4D

Page 14

4. Assembly

Installing the Motor Mount Adjuster

1. Place motor mount adjuster between the head plate and back plate on the discharge tube.

2. Insert pivot rod through the tube plates and motor mount adjuster. Secure in place with two (2)

3/16" x 2" cotter pins. (See Figure 4E.)

Figure 4E

14 PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader

Page 15

4. Assembly

Installing the Motor Mount Plate

1. Secure one of the motor mount adjustment nuts and one of the motor mount adjustment washers

approximately 3/4" of the way down the motor mount adjuster’s threaded shaft.

2. Once the nut and washer are secure, slip the motor mount plate over the a djuster and align the pivot

holes with the pivot tube. (See Figure 4F.)

Figure 4F

3. Slide the motor mount pivot rod through the pivot tube on the discharge tube.

4. When the pivot rod begins to extend through the pivot tube, install the spacers BETWEEN the back

plate and the inner face of the motor mount plate. (See Figure 4G.)

Figure 4G

5. Secure pivot rod with two (2) 3/16" x 2" cotter pins.

NOTE: The number of spacers will vary depending on size of unloader.

PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader 15

Page 16

4. Assembly

(See Chart for Bolt Sizes.)

Installing the Belt Guard Brackets

1. Align the holes on the bearing plate with the slots on the belt guard mounting brackets.

2. Secure the brackets with proper bolts, flat washers and serrated flange nuts. (See Chart below and

Figure 4H.)

Figure 4H

Belt Guard Mounting Bracket Bolt

Part # Bolt Size Description

S-1 196 6" to 6", 6" to 8" and 8" to 8" 5/16"-18 x 1" Grade 5 Bolt

S-2071 8" to 10" and 10" to 12" 3/8"-16 x 1-1/4" Grade 5 Bolt

NOTE: DO NOT tighten the bolts completely. The brackets will need to be rotated to align the slot in the

belt guard with the shafts on the motor and flight.

16 PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader

Page 17

4. Assembly

Installing the Pulley

1. Place and position the key into the keyway located on the drive shaft.

2. Place the pulley onto the drive shaft with the set screw side of the pulley facing away from the bearing

plate. (See Figure 4I.) Position the pulley so that it is as close to the lock collar as possible, but

without touching it.

3. Once the pulley is appropriately positioned, tighten the set screw with a hex head wrench to secure

it to the drive shaft. (See Figure 4I.)

Figure 4I

Tightening the Lock Collar

1. Use a punch and hammer to drive the lock collar clockwise or in the same direction as the shaft

rotation. Once the lock collar is set in place, use a hex head wrench to tighten the lock collar by

tightening the set screw.

NOTE: If the lock collar is not turned far enough, the set screw will not lock it into place.

PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader 17

Page 18

4. Assembly

Installing the Motor (Not Provided)

1. Attach the motor to the motor mount plate using appropriate bolts, lock washers and hex nuts.

(See Motor Bolt Chart below.)

2. Install pulley onto motor shaft making sure that it is aligned with the flight pulley. It may be necessary

to move spacers to gain shaft alignment. (See Figure 4J.)

Installing the Belts

1. Place the belts on the pulleys.

Figure 4J

Motor Bolt Chart

Motor Size Hex Bolt Size Qty

56

5/16"-18 x 1-1/4" 4143T

145T

182T

184T

3/8"- 16 x 1-1/4" 4

213T

215T

254T

1/2"-13 x 1-3/4" 4

256T

2. Screw the lower motor mount adjustment nut upward, thereby raising the motor mount plate and

putting tension on the belts.

3. Once the desired tension is reached, tighten the upper motor mount adjustment nut down onto the

motor mount plate to lock it into place. (See Figure 4K on Page 19.)

18 PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader

Page 19

4. Assembly

Installing the Belt Guard

1. With the belts properly tensioned, remove the bottom belt guard cover and slip belt guard down over

motor shaft.

2. Bolt the belt guard to the belt guard mounting brackets. Note that the brackets should still be loose

at this time.

3. Align the motor shaft and the flight drive shaft in the belt guard’s slot, making sure that the belt guard

DOES NOT contact either pulley or shaft and tighten down the belt guard mounting brackets to the

bearing plate. (See Figure 4K.)

4. Once the brackets are tightened, slide the bottom cover back into place and secure with supplied bolt.

Figure 4K

PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader 19

Page 20

5. Motors

WARNING

Electrical controls and wiring should be installed by a qualified electrician. The

motor disconnect switches and conductor cables should comply with the

National Electrical Code and any local codes which apply. Reset and motor

starting stations should be located so that the operator can see that all personnel

are clear of the equipment.

WARNING

Disconnect and lock out power before resetting motor overloads. Make certain

electric motors are grounded.

Electric Drive Motors

A. Knowing the bin size and the length of flighting to be used in the unloading tube is necessary to

determine how much horsepower is required for the job.

B. Use the Chart below to determine the size of motor required. Use a larger motor when encountering

high moisture or when high capacity is required.

25°

Horsepower

6" 2 2 3 3 3 3 5 5 - 8" 3 3 5 5 5 7-1/2 7-1/2 7-1/2 7-1/2 7-1/2

10" - - - 5 5 7-1/2 7-1/2 7-1/2 10 10

15' 18' 21' 24' 27' 30' 33' 36' 42' 48'

Grain Bin Diameter

NOTE: For high capacity or high moisture, use one size larger motor.

LONGER BELT NOTE: Longer belts may be required when using larger framed motors due to high

capacity or high moisture applications.

C. The following horsepower recommendations are for augering relatively dry grain. Use an electric

motor of the proper size that operates at 1750 RPM. Motor pulleys are not furnished with the auger.

D. A magnetic starter should be used for the operator’s protection and for the protection of the motor.

This helps to protect the operator against accidental re-start caused by power interruption, conductor

fault, low voltage, circuit interruption or motor overload. Therefore, the motor must be restarted

manually. If using a motor with built-in thermal overload protection, make sure this type of motor has

a manual reset.

20 PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader

Page 21

6. Start-Up

Failure to perform any or all of these pre-start checks may cause damage to the

equipment and/or cause SERIOUS INJURY or DEATH to those in the work area.

Failure to perform any or all of these pre-start checks may also be a misuse of the

equipment. Any misuse of the equipment may void the warranty.

ALWAYS keep ALL guards and shields in place, until all the power is

disconnected and locked out.

DANGER

WARNING

Make certain ONLY trained operators are in the work area before operating or

moving the machine. Two (2) people must always be in a position where the

operation of the equipment can be monitored.

Perform Pre-Start Checks

DANGER

A. Make sure ALL belts are tensioned properly.

B. Make sure ALL shields are in place and that the belt(s) and pulley(s) are able to move freely.

C. Inspect the drive unit for any problems or potential problems.

D. Be aware of any emergency shut down procedures. Two (2) people must always be in a position

where the operation of the equipment can be monitored.

E. Before starting the auger for the first time, make sure that all parts are assembled correctly according

to the instructions in this manual.

PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader 21

Page 22

6. Start-Up

CAUTION

DO NOT start or stop the auger while it is under load. Doing so may cause the

auger to jam.

Failures may occur if the auger is run full before it has been “polished” during the

“break-in” period.

CAUTION

NEVER operate the auger empty. Operating augers empty for any length of time

will cause excessive wear.

NEVER operate the auger at speeds higher than recommended. Auger flight speed

in excess of recommended speed causes excessive wear.

CAUTION

Be aware of any unusual vibration or noises during the initial start-up and

“break-in” period. If anything unusual is detected, immediately shut down the

auger and disconnect and lock out the power supply before servicing.

CAUTION

Start the Auger

A. Start the auger.

B. Run the auger through a “break-in” period if it is being used for the first time or for the first time of

the season.

C. Polish the flighting by running the auger at partial capacity until it is smooth, before attempting

to run it at full capacity.

22 PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader

Page 23

7. Operation

WARNING

Be alert for any unusual vibrations, noises and the loosening of any fasteners. If

anything unusual is detected, immediately shut down the auger, disconnect and

lock out the power source before servicing.

Operate the Auger

NOTE: The auger capacity can fluctuate greatly under varying conditions. Moisture content, different

commodities, amount of foreign matter and speeds all play a part in the performance of the auger.

For example, 25% moisture may cut capacity by as much as 40% under some conditions.

A. Make certain there are at least two (2) people in the work area to monitor operations at all times.

B. Visually inspect the auger periodically during operation.

C. Consideration should be given to the proper size auger for a batch drying or any intermittent type

operations. When augers are stopped and re-started under full load, it may result in damage to the

auger. Using a larger diameter auger and reducing its load level is generally preferable to subjecting

a smaller diameter auger to big loads. If an auger is kept from absolute filling, it will make start-up

easier and it will convey more efficiently.

PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader 23

Page 24

8. Shut Down

NEVER start the equipment under load. Doing so may cause damage. This type of

damage is considered a misuse of the equipment. Any misuse of the equipment

may void the warranty.

Normal Shut Down

A. Before shutting down the unit, be sure the hoppers and augers are empty.

B. Disconnect and lock out the power source before leaving the work area.

Emergency Shut Down

A. Know how to shut down the auger in case of an emergency.

B. Do not re-start the auger when it is under load.

C. Close the bin well control gates.

D. Re-connect and unlock the power source.

E. Clear the auger gradually until there is no grain and there are no obstructions.

CAUTION

Storage Preparation

A. Close all wells to the discharge auger.

B. Be sure the unload tube is empty.

C. Shut down the auger.

D. Make sure all fasteners are tight.

24 PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader

Page 25

9. Maintenance

ALWAYS shut down and disconnect the power supply before adjusting,

servicing or cleaning the equipment.

Maintain the Auger

DANGER

A. Use caution when repairing or replacing equipment parts.

B. Make sure ALL decals are legible and tightly attached to th e auger. If necessary, replace them FREE

OF CHARGE by contacting your dealer or the manufacturer.

C. Ensure that ALL electric motors, etc., are operating at the proper speed.

D. Maintain proper adjustments on the belt(s).

E. Mount controls for any electric motors at a safe distance from the machine and in a location

accessible in case of an emergency.

F. Make sure ALL electrical wiring is not damaged and that it meets proper wiring codes.

G. Make sure ALL components are in good working condition before use.

H. Check the auger flighting to make sure it is in good working condition.

I. Check the internal bearing bracket, bearing and universal joint to make sure they are in good

working condition.

J. Grease bearing at least two (2) times each season.

PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader 25

Page 26

NOTES

26 PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader

Page 27

1. 6" to 6" 25° Unloader Parts - (See Pages 28-29.)

2. 6" to 8" 25° Unloader Parts - (See Pages 30-31.)

3. 8" to 8" 25° Unloader Parts - (See Pages 32-33.)

4. 8" to 10" 25° Unloader Parts - (See Pages 34-35.)

5. 10" to 12" 25° Unloader Parts - (See Pages 36-37.)

10. Parts List

PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader 27

Page 28

10. Parts List

6" to 6" 25° Unloader Parts

28 PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader

Page 29

6" to 6" 25° Unloader Parts List

Ref # Part # Description

2 GK5706 1" x 7-7/8" Bearing Connecting Stub

3 S-6762 3/8"-16 x 2-1/2" Grade 5 Bearing Connecting Stub Bolt

4 S-8251 3/8"-16 Bearing Connecting Stub Stover Nut

5 S-8397 5/16" x 1-3/4" U-Joint Rolled Pin

7 GC06392 Hanger Bearing

8 GK1267 1" x 6" Connecting Stub

9 GK1266 1" Bore x 5" Long U-Joint

10 S-7886 5/8"-11 x 1-3/4" Grade 8 Hanger Bearing Bolt

11 S-3208 5/8" Hanger Bearing Lock Washer

12 GK7072 6" 25° Unload Tube Assembly

13 S-2741 5/16"-18 x 1-1/2" Grade 5 Stand Connecting Band Bolt

14 GK1 122 6" x 4" 12 Gauge Half Band

15 S-866 3/4" Motor Mount Adjustment Flat Washer

16 S-234 3/4"-10 Motor Mount Adjustment Hex Nut

17 GK7052 Motor Mount Plate

18 GK7060 Motor Mount Adjustment Weldment

20 S-6994 3/16" x 2" Cotter Pin

21 GK7058 Motor Mount Plate Pivot Rod

23 GK7005 Belt Guard

24 GK1321 12" Diameter x 1" Bore 2 Belt Sheave

25 S-4513 1/4" x 2" Sheave Key

26 GK7062 Belt Guard Mounting Brackets

27 S-1196 5/16"-18 x 1" Grade 5 Belt Guard Mounting Bracket Bolt

28 S-845 5/16" Belt Guard Mounting Bracket Flat Washer

29 S-9065 3/8"-16 x 1" Grade 5 Bolt

30 S-3611 5/16"-18 Bearing Plate Serrated Flange Nut

31 GK2825 Support Stand Top

32 GK1277 Support Stand Base

33 S-3611 5/16"-18 Serrated Flange Nut

34 S-6762 3/8"-16 x 2-1/2" Grade 5 Flight Connection Bolt

35 GK2025 1" x 10" Drive Shaft

36 S-8251 3/8"-16 Flight Connection Stover Nut

37 S-860 7/16"-14 Bearing Hex Nut

38 S-7014 7/16" Bearing Lock Washer

39 GK1049 1" Two (2) Hole Flange with Lock Collar (Bearing with Flange)

40 S-1196 5/16"-18 x 1" Grade 5 Bearing Plate Bolt

41 GK7061 Bearing Plate

42 S-3886 7/16"-14 x 1-1/4" Grade 5 Bearing Bolt

43 GK2827 6" 25° Weldment Discharge Flight

44 S-2071 3/8"-16 x 1-1/4" Grade 5 Bolt

45 GK1323 B48 V-Belt

10. Parts List

PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader 29

Page 30

10. Parts List

6" to 8" 25° Unloader Parts

30 PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader

Page 31

6" to 8" 25° Unloader Parts List

Ref # Part # Description

1 GK1280 Adapter Plate

2 GK7241 1" x 8-1/2" Bearing Connecting Stub

3 S-6762 3/8"-16 x 2-1/2" Grade 5 Bearing Connecting Stub Bolt

4 S-8251 3/8"-16 Bearing Connecting Stub Stover Nut

5 S-8397 5/16" x 1-3/4" U-Joint Rolled Pin

7 GC06394 Hanger Bearing

8 GK1267 1" x 6" Connecting Stub

9 GK1266 1" Bore x 5" Long U-Joint

10 S-7886 5/8"-11 x 1-3/4" Grade 8 Hanger Bearing Bolt

1 1 S-3208 5/8" Hanger Bearing Lock Washer

12 GK7073 8" 25° Unload Tube Assembly

13 S-2741 5/16"-18 x 1-1/2" Grade 5 Stand Connecting Band Bolt

14 GK1059 8" x 4" 12 Gauge Half Band

15 S-7835 1" Motor Mount Adjustment Flat Washer

16 S-240 1"-8 Motor Mount Adjustment Hex Nut

17 GK6986 Motor Mount Plate

18 GK6942 Motor Mount Adjustment Weldment

19 GK7012 Motor Mount Adjustment Pivot Rod

20 S-6994 3/16" x 2" Cotter Pin

21 GK7013 Motor Mount Plate Pivot Rod

22 GK7014 Pivot Spacer Tube

23 GK7005 Belt Guard

24 GK1335 12" Diameter x 1-1/4" Bore 2 Belt Sheave

25 S-4513 1/4" x 2" Sheave Key

26 GK7006 Belt Guard Mounting Brackets

27 S-1196 5/16"-18 x 1" Grade 5 Belt Guard Mounting Bracket Bolt

28 S-845 5/16" Belt Guard Mounting Bracket Flat Washer

29 S-9065 3/8"-16 x 1" Grade 5 Bolt

30 S-3611 5/16"-18 Bearing Plate Serrated Flange Nut

31 GK1278 Support Stand Top

32 GK1277 Support Stand Base

33 S-3611 5/16"-18 Serrated Flange Nut

34 S-8316 7/16"-14 x 3" Grade 8 Flight Connection Bolt

35 GK1331 1-1/4" x 10-1/2" Drive Shaft

36 S-8317 7/16"-14 Flight Connection Stover Nut

37 S-7510 1/2"-13 Bearing Hex Nut

38 S-236 1 / 2" B ea ri n g Lock Washer

39 GK1330 1-1/4" Two (2) Hole Flange with Lock Collar (Bearing with Flange)

40 S-1196 5/16"-18 x 1" Grade 5 Bearing Plate Bolt

41 GK6987 Bearing Plate

42 S-8760 1/2"-13 x 1-1/2" Grade 5 Bearing Bolt

43 GK1268 8" 25° Weldment Discharge Flight

44 S-2071 3/8"-16 x 1-1/4" Grade 5 Bolt

45 GK1952 B50 V-Belt

10. Parts List

PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader 31

Page 32

10. Parts List

8" to 8" 25° Unloader Parts

32 PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader

Page 33

8" to 8" 25° Unloader Parts List

Ref # Part # Description

2 GK1283 1-1/4" x 7-7/8" Bearing Connecting Stub

3 S-8316 7/16"-14 x 3" Grade 5 Bearing Connecting Stub Bolt

4 S-8317 7/16"-14 Bearing Connecting Stub Stover Nut

5 S-8397 5/16" x 1-3/4" U-Joint Rolled Pin

7 GC06394 Hanger Bearing

8 GK1267 1" x 6" Connecting Stub

9 GK1266 1" Bore x 5" Long U-Joint

10 S-7886 5/8"-11 x 1-3/4" Grade 8 Hanger Bearing Bolt

11 S-3208 5/8" Hanger Bearing Lock Washer

12 GK7073 8" 25° Unload Tube Assembly

13 S-2741 5/16"-18 x 1-1/2" Grade 5 Stand Connecting Band Bolt

14 GK1059 8" x 4" 12 Gauge Half Band

15 S-7835 1" Motor Mount Adjustment Flat Washer

16 S-240 1 "-8 Motor Mount Adjustment Hex Nut

17 GK6986 Motor Mount Plate

18 GK6942 Motor Mount Adjustment Weldment

19 GK7012 Motor Mount Adjustment Pivot Rod

20 S-6994 3/16" x 2" Cotter Pin

21 GK7013 Motor Mount Plate Pivot Rod

22 GK7014 Pivot Spacer T ube

23 GK7005 Belt Guard

24 GK1335 12" Diameter x 1-1/4" Bore 2 Belt Sheave

25 S-4513 1/4" x 2" Sheave Key

26 GK7006 Belt Guard Mounting Brackets

27 S-1196 5/16"-18 x 1" Grade 5 Belt Guard Mounting Bracket Bolt

28 S-845 5/16" Belt Guard Mounting Bracket Flat Washer

29 S-9065 3/8"-16 x 1" Grade 5 Bolt

30 S-3611 5/16"-18 Bearing Plate Serrated Flange Nut

31 GK1278 Support Stand Top

32 GK1277 Support Stand Base

33 S-3611 5/16"-18 Serrated Flange Nut

34 S-8316 7/16"-14 x 3" Grade 8 Flight Connection Bolt

35 GK1331 1-1/4" x 10-1/2" Drive Shaft

36 S-8317 7/16"-14 Flight Connection Stover Nut

37 S-7510 1/2"-13 Bearing Hex Nut

38 S-236 1/2" Bearing Lock Washer

39 GK1330 1-1/4" Two (2) Hole Flange with Lock Collar (Bearing with Flange)

40 S-1196 5/16"-18 x 1" Grade 5 Bearing Plate Bolt

41 GK6987 Bearing Plate

42 S-8760 1/2"-13 x 1-1/2" Grade 5 Bearing Bolt

43 GK1268 8" 25° Weldment Discharge Flight

44 S-2071 3/8"-16 x 1-1/4" Grade 5 Bolt

45 GK1952 B50 V-Belt

10. Parts List

PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader 33

Page 34

10. Parts List

8" to 10" 25° Unloader Parts

34 PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader

Page 35

8" to 10" 25° Unloader Parts List

Ref # Part # Description

1 GK1298 Adapter Plate

2 GK7240 1-1/4" x 9" Bearing Connecting Stub

3 S-8316 7/16"-14 x 3" Grade 5 Bearing Connecting Stub Bolt

4 S-8317 7/16"-14 Bearing Connecting Stub Stover Nut

5 S-7245 3/8" x 2-1/2" U-Joint Rolled Pin

7 GC06396 Hanger Bearing

8 GK1290 1-1/4" x 6-1/2" Connecting Stub

9 GK1291 1-1/4" Bore x 7" Long U-Joint

10 S-7886 5/8"-11 x 1-3/4" Grade 8 Hanger Bearing Bolt

1 1 S-3208 5/8" Hanger Bearing Lock Washer

12 GK7074 10" 25° Unload Tube Assembly

13 S-2741 5/16"-18 x 1-1/2" Grade 5 Stand Connecting Band Bolt

14 GK1301 10" x 4" 12 Gauge Half Band

15 S-7835 1" Motor Mount Adjustment Flat Washer

16 S-240 1"-8 Motor Mount Adjustment Hex Nut

17 GK6986 Motor Mount Plate

18 GK6942 Motor Mount Adjustment Weldment

19 GK7012 Motor Mount Adjustment Pivot Rod

20 S-6994 3/16" x 2" Cotter Pin

21 GK7013 Motor Mount Plate Pivot Rod

22 GK7014 Pivot Spacer Tube

23 GK7005 Belt Guard

24 GK1345 15" Diameter x 1-1/2" Bore 2 Belt Sheave

24 GK1304 15" Diameter x 1-1/2" Bore 3 Belt Sheave

25 S-9181 3/8" x 3" Sheave Key

26 GK7018 Belt Guard Mounting Brackets

27 S-2071 3/8"-16 x 1-1/4" Grade 5 Belt Guard Mounting Bracket Bolt

28 S-248 3/8" Belt Guard Mounting Bracket Flat Washer

29 S-9065 3/8"-16 x 1" Grade 5 Bolt

30 S-968 3/8"-16 Bearing Plate Serrated Flange Nut

31 GK1300 Support Stand Top

32 GK1277 Support Stand Base

33 S-3611 5/16"-18 Serrated Flange Nut

34 S-8316 7/16"-14 x 3" Grade 8 Flight Connection Bolt

34 S-8314 1/2"-13 x 3-1/2" Grade 8 Flight Connection Bolt

35 GK1289 1-1/2" x 11-1/2" Drive Shaft

36 S-8317 7/16"-14 Flight Connection Stover Nut

36 S-8315 1/2"-13 Flight Connection Stover Nut

37 S-7510 1/2"-13 Bearing Hex Nut

38 S-236 1/2" Bearing Lock Washer

39 GK1343 1-1/2" Four (4) Hole Flange with Lock Collar (Bearing with Flange)

40 S-7469 3/8"-16 x 1" Grade 5 Bearing Plate Bolt

41 GK7017 Bearing Plate

42 S-8760 1/2"-13 x 1-1/2" Grade 5 Bearing Bolt

43 GK6396 10" 25° Weldment Discharge Flight

44 S-2071 3/8"-16 x 1-1/4" Grade 5 Bolt

45 GK1346 B57 V-Belt

10. Parts List

PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader 35

Page 36

10. Parts List

10" to 12" 25° Unloader Parts

36 PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader

Page 37

10" to 12" 25° Unloader Parts List

Ref # Part # Description

1 GK2013 Adapter Plate

2 GK7242 1-1/2" x 9" Bearing Connecting Stub

3 S-8314 1/2"-13 x 3-1/2" Grade 5 Bearing Connecting Stub Bolt

4 S-8315 1/2"-13 Bearing Connecting Stub Stover Nut

5 S-7245 3/8" x 2-1/2" U-Joint Rolled Pin

6 S-9169 1/4" x 1-1/2" U-Joint Square Key

7 GC06398 Hanger Bearing

8 GK2008 1-1/4" to 2" x 6-1/2" Connecting Stub

9 GK2009 1-1/4" Bore with Key Way x 7" Long (U-Joint)

10 S-869 3/4"-10 x 2" Grade 8 Hanger Bearing Bolt

11 S-233 3/4" Hanger Bearing Lock Washer

12 GK7075 12" 25° Unload Tube Assembly

13 S-7149 5/16"-18 x 1-3/4" Grade 5 Stand Connecting Band Bolt

14 GK2014 12" x 4" 12 Gauge Half Band

15 S-7835 1" Motor Mount Adjustment Flat Washer

16 S-240 1 "-8 Motor Mount Adjustment Hex Nut

17 GK6986 Motor Mount Plate

18 GK6942 Motor Mount Adjustment Weldment

19 GK7012 Motor Mount Adjustment Pivot Rod

20 S-6994 3/16" x 2" Cotter Pin

21 GK7013 Motor Mount Plate Pivot Rod

22 GK7014 Pivot Spacer T ube

23 GK7068 Belt Guard

24 GK1345 15" Diameter x 1-1/2" Bore 2 Belt Sheave

24 GK1304 15" Diameter x 1-1/2" Bore 3 Belt Sheave

25 S-9181 3/8" x 3" Sheave Key

26 GK7065 Belt Guard Mounting Brackets

27 S-2071 3/8"-16 x 1-1/4" Grade 5 Belt Guard Mounting Bracket Bolt

28 S-248 3/8" Belt Guard Mounting Bracket Flat Washer

29 S-9065 3/8"-16 x 1" Grade 5 Bolt

30 S-968 3/8"-16 Bearing Plate Serrated Flange Nut

31 GK2011 Support Stand Top

32 GK1277 Support Stand Base

33 S-3611 5/16"-18 Serrated Flange Nut

34 S-8345 5/8"-11 x 4" Grade 5 Flight Connection Bolt

35 GK2006 2" x 12" Drive Shaft

36 S-8606 5/8"-11 Flight Connection Stover Nut

37 S-4110 5/8"-11 Bearing Hex Nut

38 S-3208 5/8" Bearing Lock Washer

39 GK2004 2" Four (4) Hole Flange with Lock Collar (Bearing with Flange)

40 S-7469 3/8"-16 x 1" Grade 5 Bearing Plate Bolt

41 GK7064 Bearing Plate

42 S-8399 5/8"-11 x 2" Grade 5 Bearing Bolt

43 GK2001 12" 25° Weldment Discharge Flight

44 S-2071 3/8"-16 x 1-1/4" Grade 5 Bolt

45 GK-2546 B62 V-Belt

10. Parts List

PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader 37

Page 38

11. Troubleshooting

Problem Possible Cause Solution

Auger vibration

Low capacity

Auger plugs

1. Drive belt may be overtightened, putting head

stub and flight in a bind. Damage can occur to

the auger flighting, thus causing noise. Damage

usually is caused from foreign material having

been run through the auger.

1. The auger may not be getting enough grain.

2. The auger is moving too slowly.

1. The auger may be getting too much grain,

causing “jamming” inside the housing.

2. The motor may be too small or wired improperly.

3. The grain may be wet.

4. The auger may be jammed with foreign material.

5. The discharge end may be plugged.

1. It may be necessary to remove the flighting

for inspection.

2. Adjust the drive belt to the proper tension.

1. Check that the intake has not bridged over,

restricting flow. The exposed flighting at the

auger intake should be covered with grain to

achieve maximum capacity.

2. Check the auger speed. Speeds slower than the

recommended speed will result in low capacity.

1. Decrease the amount of grain the auger

is gathering.

2. If the motor is a newer lightweight aluminum

type, the next larger size should be considered.

3. If wet grain or other hard-to-move material is

being augured, use a larger size motor than

recommended for normal use.

4. Be sure there is no foreign material in the auger

such as sacks, tarp corners, etc.

5. Make sure the discharge end of the auger is not

plugged. A plug of the discharge end will cause

an auger plug.

38 PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader

Page 39

12. Warranty

9101239_1_CR_rev7.DOC (revised July 2009)

GSI Group, LLC Limited Warranty

The GSI Group, LLC (“GSI”) warrants products which it manufactures to be free of defects in materials and workmanship

under normal usage and conditions for a period of 12 months after sale to the original end-user or if a foreign sale,

14 months from arrival at port of discharge, whichever is earlier. The end-user’s sole remedy (and GSI’s only obligation)

is to repair or replace, at GSI’s option and expense, products that in GSI’s judgment, contain a material defect in materials

or workmanship. Expenses incurred by or on behalf of the end-user without prior written authorization from the GSI

Warranty Group shall be the sole responsibility of the end-user.

Warranty Extensions:

The Limited Warranty period is extended for the following products:

Product Warranty Period

Performer Series Direct Drive Fan Motor 3 Years

AP Fans and Flooring

Cumberland

Feeding/Watering

Systems

Grain Systems Grain Bin Structural Design 5 Years

Grain Systems

Farm Fans

Zimmerman

All Fiberglass Housings Lifetime

All Fiberglass Propellers Lifetime

Feeder System Pan Assemblies 5 Years **

Feed Tubes (1-3/4" and 2.00") 10 Years *

Centerless Augers 10 Years *

Watering Nipples 10 Years *

Portable and Tower Dryers 2 Years

Portable and Tower Dryer Frames and

Internal Infrastructure †

5 Years

* Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 25%

5 to 7 years - end-user pays 50%

7 to 10 years - end-user pays 75%

** Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 50%

† Motors, burner components

and moving parts not included.

Portable dryer screens included.

Tower dryer screens not included.

GSI further warrants that the portable and tower dryer frame and basket, excluding all auger and auger drive components,

shall be free from defects in materials for a period of time beginning on the twelfth (12

and continuing until the sixtieth (60

th

) month from the date of purchase (extended warranty period). During the extended

th

) month from the date of purchase

warranty period, GSI will replace the frame or basket components that prove to be defective under normal conditions

of use without charge, excluding the labor, transportation, and/or shipping costs incurred in the performance of this

extended warranty.

Conditions and Limitations:

THERE ARE NO WARRANTIES THAT EXTEND BEYOND THE LIMITED WARRANTY DESCRIPTION SET FORTH

ABOVE. SPECIFICALLY, GSI MAKES NO FURTHER WARRANTY OF ANY KIND, EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OR USE IN CONNECTION WITH: (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (II) ANY ADVICE,

INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESENTA TIVE OR

EMPLOYEE OF GSI REGARDING OR RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY

FOR A PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCTS.

GSI shall not be liable for any direct, indirect, incidental or consequential damages, including, without limitation, loss of

anticipated profits or benefits. The sole and exclusive remedy is set forth in the Limited Warranty, which shall not exceed

the amount paid for the product purchased. This warranty is not transferable and applies only to the original end-user. GSI

shall have no obligation or responsibility for any representations or warranties made by or on behalf of any dealer, agent

or distributor.

GSI assumes no responsibility for claims resulting from construction defects or unauthorized modifications to products

which it manufactured. Modifications to products not specifically delineated in the manual accompanying the equipment at

initial sale will void the Limited Warranty.

This Limited Warranty shall not extend to products or parts which have been damaged by negligent use, misuse, alteration,

accident or which have been improperly/inadequately maintained. This Limited Warranty extends solely to products

manufactured by GSI.

Prior to installation, the end-user has the responsibility to comply with federal, state and local codes which apply to the

location and installation of products manufactured or sold by GSI.

PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader 39

Page 40

This equipment shall be installed in accordance with

the current installation codes and applicable

regulations, which should be carefully followed in

all cases. Authorities having jurisdiction should be

consulted before installations are made.

Copyright © 2012 by GSI Group

Printed in the USA

GSI Group

1004 E. Illinois St.

Assumption, IL 62510-0020

Phone: 1-217-226-4421

Fax: 1-217-226-4420

www.gsiag.com

CN-206585

Loading...

Loading...