Page 1

2 - Leg

Towers

20' to 55' Tall

F/C Series

Chain Loop and

Catwalk Designs

Installation Manual

PNEG-1412

Revision Date: 9-26-05

PNEG-1412

Page 2

2 PNEG-1412 Two Leg Towers

Page 3

TABLE OF CONTENTS

Overview ...............................................................................................4

Tools ......................................................................................................4

Safety....................................................................................................5

Anchor Bolt Layout for Chain Loop Support...........................................6

Anchor Bolt Layout for Catwalk Support.................................................7

Lateral Bracket to Bin for Chain Loop Support................................... 8-9

Lateral Bracket to Bin for Catwalk Support .....................................10-11

Column Section with Bottom Angle Joint - Plan View........................... 13

Pre-Measuring for Alignment .......................................................... 14-15

Lateral Bracket, Bin Bracket, & Backing Plate - Plan Views ............... 16

Diagonal "X" Bracing Configurations................................................... 17

Column Joints without Diagonal “X” Bracing........................................ 18

Column Joints with Diagonal “X” Bracing ....................................... 19-20

Diagonal “X” Bracing - Plan View ........................................................ 21

Straighten Columns & S tand T owers in Place...................................... 22

Catwalk Support Brackets - Plan View................................................ 23

Warranty.....................................................................Inside Back Cover

PNEG-1412 Two Leg Towers 3

Page 4

OVERVIEW

This assembly manual is for 2-Leg Towers for Chain Loop & catwalk support . Be sure and review all

pages before planning foundation work. Depending on application, your foundation could vary .

Choose the anchor bolt layout that fits your design and follow those dimensions for proper layout.

Once all concrete work is done and bins have been erected locate parts and hardware for towers.

Check packing list and count all parts. Report any missing components. Layout and sort parts for

easy identification. Depending on your work environment, these instructions may need to be altered

to fit your needs.

The tower can be assembled flat laying on a level surface and stood upright after all hardware has

been tightened. Make sure tower legs are aligned and straight!

TOOLS

Drift Punches for 3/8" to 1/2" Bolts

3/4" Wrenches & Sockets

Ratchet & Impact Gun

9/16" Wrenches and Sockets

S tring

4 PNEG-1412 Two Leg Towers

Page 5

SAFETY

This equipment shall be installed in accordance with the current installation codes and applicable regulations which should be carefully followed in all cases. Authorities having jurisdiction should be consulted

before installations are made.

PREPARE FOR EMERGENCIES

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service, hospital, and fire department near

your telephone.

WEAR PROTECTIVE CLOTHING

Keep Emergency Equipment

Quickly Accessible.

Wear close fitting clothing and safety equipment

appropriate to the job.

Safety glasses should be worn at all times to

protect eyes from debris.

Wear gloves to protect your hands from sharp

edges on plastic or steel parts.

A respirator may be needed to prevent breathing

potentially toxic fumes and dust.

Wear hard hat and steel toe boots to help

protect your head and toes from falling debris.

Remove all jewelry .

Tuck in any loose or dangling shoe strings.

Long hair should be tied up and back.

Eye Protection

Gloves

Steel Toe

Boots

Respirator

Hard Hat

PNEG-1412 Two Leg Towers 5

Page 6

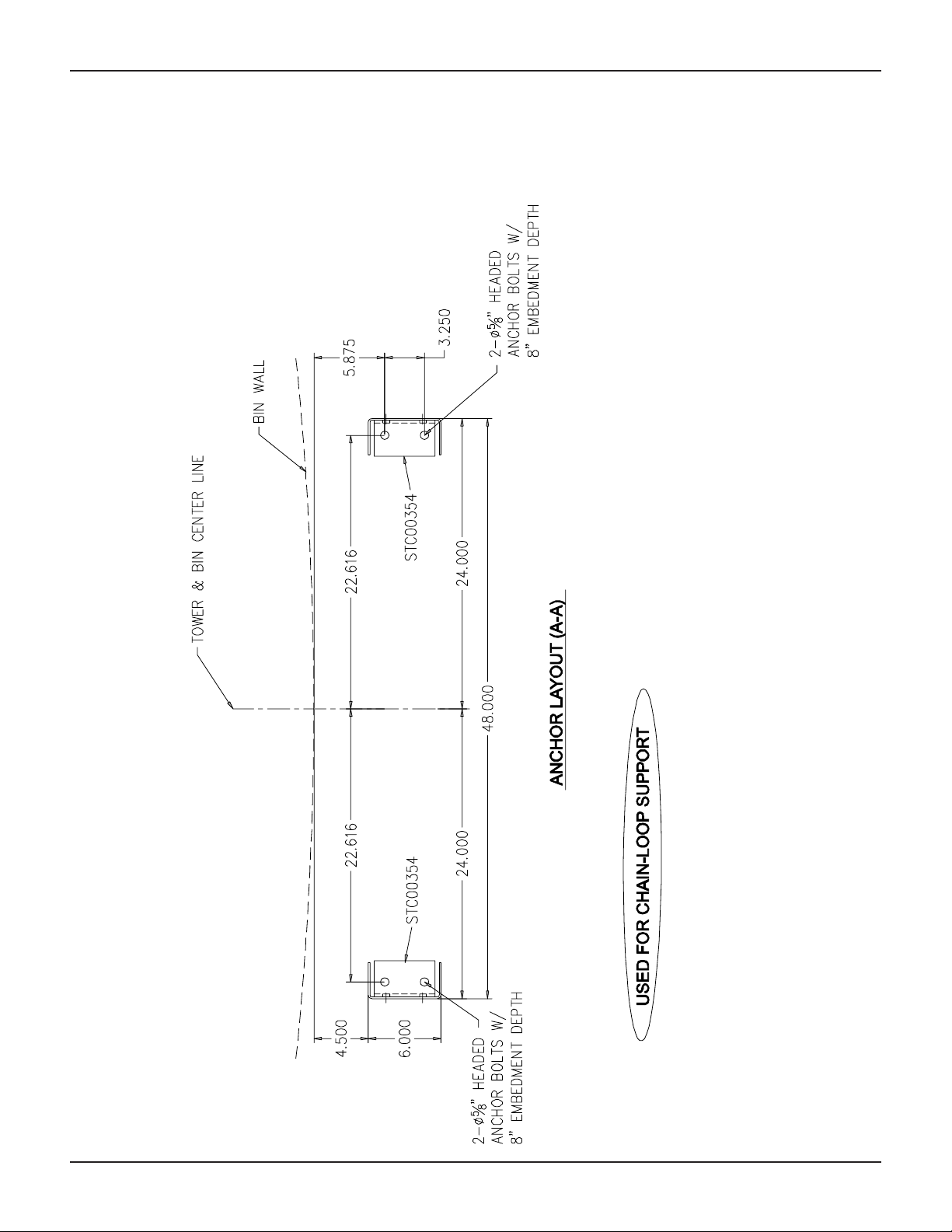

Anchor Bolt Lay out for

Chain-Loop Support

NOTE: Tower & bin

center are the same.

6 PNEG-1412 Two Leg Towers

Page 7

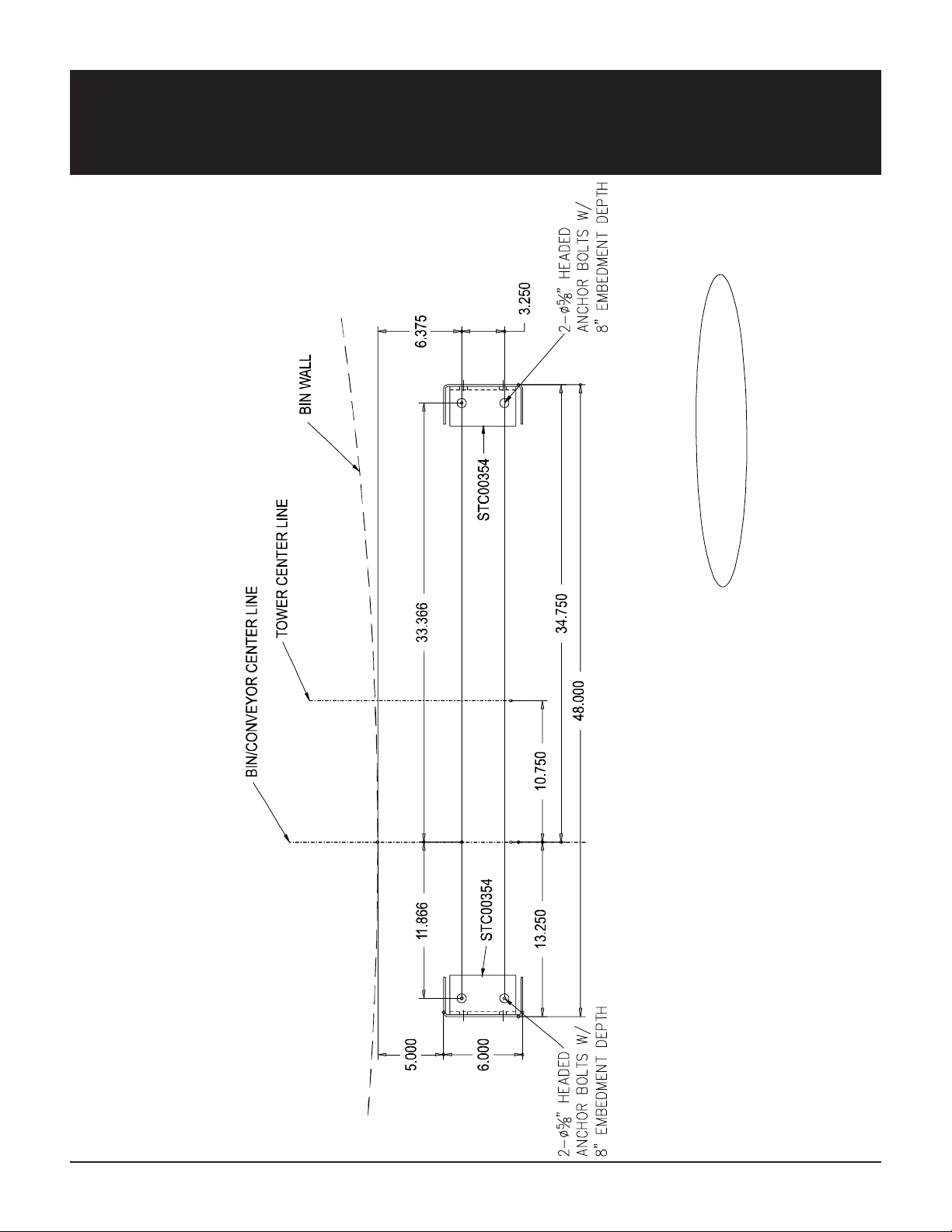

Anchor Bolt Lay out for

Catwalk Support

USED FOR CATWALK SUPPORT

ANCHOR LAYOUT (A-A)

NOTE: Tower Center

is DIFFERENT from

bin center.

PNEG-1412 Two Leg Towers 7

Page 8

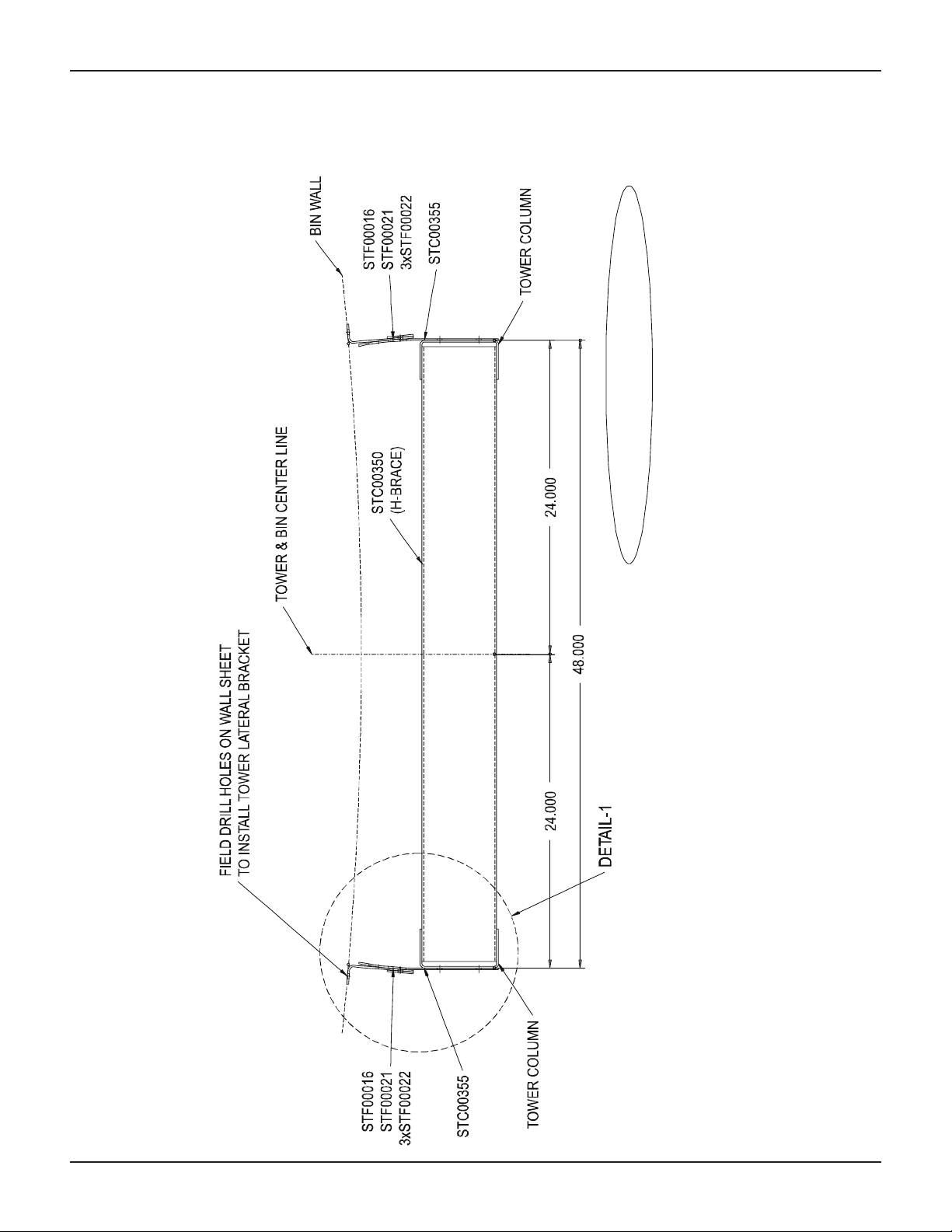

Lateral Brack et to Bin for

Chain Loop Support

USED FOR CHAIN-LOOP SUPPORT

TOWER PLAN (B-B)

NOTE: Tower & bin

center are the same.

8 PNEG-1412 Two Leg Towers

Page 9

Lateral Brack et to Bin for

Chain-Loop Support

USED FOR CHAIN-LOOP SUPPORT

NOTE: Tower & bin

center are the same.

FRONT VIEW

PNEG-1412 Two Leg Towers 9

SIDE VIEW

Page 10

Lateral Brack et to Bin for

Catwalk Support

USED FOR CATWALK SUPPORT

TOWE R PLAN (B-B)

NOTE: Tower Center

is DIFFERENT from

bin center.

10 PNEG-1412 Two Leg Towers

Page 11

Lateral Brack et to Bin for

Catwalk Support

USED FOR CATWALK SUPPORT

NOTE: Tower Center

is DIFFERENT from

bin center.

FRONT/ BACK VIEW

PNEG-1412 Two Leg Towers 11

SIDE VIEW

Page 12

Assemble Bottom Angle Joints to Columns

1. S tart assembly by taking the 2 bottom columns (STC00348 -5' or STC00349 -10' depending on

height of tower) and attaching Bottom Angle Joint (STC00354) using (4) 1/2" x 1 HHCS bolts and (4)

1/2" hex nuts. (See Figure 1.) Note: Angles go to inside of leg channel.

Columns

(STC00348 - 10')

or

(STC00349 - 5')

Columns

(STC00348 - 10')

or

(STC00349 - 5')

1/2" Hex Nut

(S-3729)

1/2" Hex Nut

(S-3729)

Figure 1

1/2" x 1" HHCS Bolts

(S-4492)

Bottom Angle Joint

(STC00354)

Bottom Angle Joint

(STC00354)

12 PNEG-1412 Two Leg Towers

Page 13

FRONT/BACK VIEW SIDE VIEW

Bottom Column Sections with Bottom Angle Joints

PNEG-1412 Two Leg Towers 13

Page 14

Pre-Measuring for Alignment

This step is to locate the placement

of the bin bracket. All bin bracket

bolts must line up on the “hill” of the

corrugation. If this “pre-measuring” is

done correctly , no adjustments

should be needed to align holes on

hills after the tower is lifted into

place.

ATTACHING LATERAL

BRACKET, BIN BRACKET, &

BACKING PLATE TO COLUMNS.

1. Align holes & attach lateral brackets (STC00355) to top of bottom

columns using (2) 1/2" x 1" bolts, (2)

1/2" flat washers, & (2) 1/2" hex nuts

for each column. NOTE: Bolt heads

go to inside of column. Do not

fully tighten bolts. (See Figure 2.)

Lateral Bracket

(STC00355)

1/2" Flat Washer

(S-2120)

Column

1/2" x 1" HHCS Bolt

(S-4492)

1/2" Hex Nut

(S-3729)

Figure 2

2. Attach bin brackets (STF00016)

and backing plates (STF00021) to

lateral brackets using (3) 3/8" x 1"

HHCS bolts, (3) spacers, (6) washers, and (3) hex nuts as shown in

Figure 3 for each column. NOTE:

Bolts should be placed in the

bottom half of the bin bracket

slots. Fasten only finger tight to

allow bin to settle.

Bin Bracket

(STF00016)

3/8" Hex Nut

(S-456)

Figure 3

Backing Plate

(STF00021)

3/8" Flat Washer

(S-248)

NOTE: These bolts are to be finger tight only and

should be placed in the bottom half of the slot.

3/8" Flat Washer

(S-248)

3/8" S pacer

(STF00022)

Bin Bracket SLOTS

3/8" x 1" HHCS Bolt

(S-8671)

Lateral Bracket

(STC00355)

Column

14 PNEG-1412 Two Leg Towers

Page 15

Pre-Measuring for Alignment (cont.)

3. T ake columns and set on foundation so anchor bolts go through angle

joints. The bin bracket bolt holes

should line up on the “hills” of the

corrugation. (See Figure 4.) NOTE:

Do not attach to bin, this is for

alignment only .

4. If holes do not line up on the “hills”

of the corrugation, then you need to

remove the LATERAL BRACKET

(STC00355) from the column and reattach it to the column using the slots

in the lateral bracket. (See Figure 4.)

Then adjust the lateral bracket up or

down in the slots to line the holes in

BIN BRACKET (STF00016) on the

“hills” of the corrugation. Then fully

tighten lateral bracket bolts.

NOTE:

DO NOT use slots in BIN

BRACKET (STF00016) for adjust-

ment. Bolts holding lateral bracket, bin

bracket, & backing plate need to stay

in the bottom half of the slot to allow

the bin to settle. These bolts should

only be finger tight or damage may

occur to the bin.

3/8" x 1" HHCS Bolt

(S-8671)

“Hills” of

Corrugation

Bin Bracket

(STF00016)

Figure 4

Bin Bracket

(top hole)

(STF00016)

3/8" Hex Nut

(S-456)

Backing Plate

(STF00021)

LATERAL

BRACKET

SLOTS

Lateral Bracket

(STC00355)

5. T o make sure the next set of lateral

brackets, bin brackets, & backing

plates, line up on the “hills” of the

corrugation, measure form the top

120'

hole of the previously installed bin

bracket to the top hole on the bin

bracket being installed. The holes

should measure 120" apart. If they do

not, then adjust the lateral bracket

being installed following step #4

above, until the holes measure 120"

apart. (See Figure 5.) Repeat this

Bin Bracket

(top hole)

(STF00016)

step for all bin brackets as the columns are installed.

Figure 5

PNEG-1412 Two Leg Towers 15

Page 16

Top & Side Views

SIDE VIEW TOP VIEW

Lateral Bracket, Bin Bracket, & Backing Plate

16 PNEG-1412 Two Leg Towers

Page 17

Diagonal “X” Bracing Configurations

“X”-Bracing is to be used in all upper sections of a tower.

All 20’-25’-30’ Tall Towers should all be “X”-braced, except for

the lower 10’ that is not “x” braced. (See examples above.)

All 35’ and taller towers should all be “X”-braced, except for

the lower 15’ that is not “X”-braced. (See examples above.)

PNEG-1412 Two Leg Towers 17

Page 18

Column Joints without Diagonal “X” Bracing

1. Place next columns on top of bottom columns.

2. Fasten top column to lateral brackets

(STC00355) using (2) 1/2" x 1" bolts, washers, &

hex nuts for each column. (See Figure 6.)

3. Align flange joint plates (STC00353) with holes

in columns and attach using (6) 1/2" x 1" HHCS

bolts & hex nuts. NOTE: Bolt heads go to inside

of channel. Skip top hole in bottom channel

until next step. DO NOT fully tighten bolts.

4. Attach “H” channel braces (STC00350) to the

inside of the columns and the flange joint plates

using (2) 1/2" x 1" HHCS bolts and hex nuts for

each column. (See Figure 6.)

1/2" Flat

Washer

(S-2120)

1/2" Hex Nut

(S-3729)

Bin Bracket

(STF00016)

Backing Plate

(STF00021)

1/2" x 1"

HHCS Bolt

(S-4492)

Lateral Bracket

(STC00355)

1/2" x 1" HHCS Bolt

(S-4492)

1/2" Hex Nut

(S-3729)

“H” Channel Brace

(STC00350)

Flange Joint Plate

(STC00353)

Figure 6

Column

18 PNEG-1412 Two Leg Towers

Page 19

Column Joints with Diagonal “X” Bracing

Review Diagonal “X” Bracing Configurations on

page 17 and determine the proper layout for your

bin diameter . Diagonal bracing covers 5' of

vertical height, additional “H” braces are to be

installed at these increments.

1. T o inst all diagonal bracing, align columns on

top of each other and fasten together using a web

plate (STC00352), (4) 1/2" x 1" HHCS bolts and

1/2" hex nuts for each column. NOTE: Bolt

heads go to inside of column. (See Figure 7.)

2. Using top hole, attach flange joint plates

(STC00353) to columns using (2) 1/2" x 1"

HHCS bolts & hex nuts for each column as

shown.

3. Attach (8) diagonal braces (STC00351) to

inside of both right and left columns and flange

joint plates using (8) 1/2" x 1" HHCS bolts and

hex nuts. One set of four braces go above H

Channel Brace (STC00350) and one set goes

below . (See Figure 7.) NOTE: Diagonal braces

are located on both front and back flanges.

4. Attach “H” Channel Brace (STC00350) to both

left and right columns and flange joint plates

(STC00353) using (4) 1/2" x 1" HHCS bolts and

nuts for each column. (See Figure 7.)

Flange Joint Plate

(STC00353)

1/2" Hex Nut

(S-3729)

1/2" Hex Nut

(S-3729)

Column

Web Plate

(STC00352)

1/2" x 1"

HHCS Bolt

(S-4492)

“H” Channel Brace

(STC00350)

Diagonal “X”

Brace

(STC00351)

Flange Joint Plate

(STC00353)

Diagonal “X”

Brace

(STC00351)

1/2" Hex Nut

(S-3729)

Column

Figure 7

PNEG-1412 Two Leg Towers 19

Page 20

Column Joints with Diagonal “X” Bracing (cont.)

Diagonal “X”

5. For “X” Bracing where a lateral bracket

is used instead of a web plate, see

Figure 8.

6. Install an “H” Channel Brace

(STC00350) to the top of the columns

and “X” bracing as shown using (4) 1/2" x

1" HHCS bolts and nuts. (See Figure 9.)

3/8" S pacer

(STF00022)

3/8" Hex

Nut (S-456)

3/8" Flat

Washer

(S-248)

Brace (STC00351)

3/8" x 1"

HHCS Bolt

(S-8671)

1/2" x 1"

HHCS

Bolt

(S-4492)

1/2" x 1"

HHCS Bolt

(S-4492)

“H” Channel Brace

(STC00350)

Diagonal “X” Brace

(STC00351)

Bin Bracket

(STF00016)

Figure 8

1/2" Flat

Washer

(S-2120)

Backing Plate

(STF00021)

1/2" Hex Nut

(S-3729)

Lateral Bracket

(STC00355)

1/2" x 1"

HHCS Bolt

(S-4492)

1/2" Hex Nut

(S-3729)

Column

1/2" Hex Nut

(S-3729)

Column

Figure 9

20 PNEG-1412 Two Leg Towers

Page 21

Diagonal “X” Bracing

PNEG-1412 Two Leg Towers 21

FRONT/BACK VIEW SIDE VIEW

Page 22

Straighten Columns and Stand Towers in Place

1. St art with one column and run a string from top to bottom, align all joints and straighten. T ighten all

hardware. Repeat process for both columns. NOTE:

bin bracket & backing plate to the lateral bracket. These bolts need to be finger tight only to

allow bin to settle.

2. When assembly is complete and hardware tightened. St and tower assembly upright and set in

place over anchor bolts. All bin brackets holes should line up on the hills of the corrugation. Field drill

through bin brackets into hills of corrugation and bolt the tower bin brackets to bin sidewall using

3/8" x 1" HHCS bolts & hex nuts. NOTE: Bolt heads go on outside of bin.

DO NOT tighten hardware that connects the

22 PNEG-1412 Two Leg Towers

Page 23

Catwalk Support Br ackets

DETAIL-2

SIDE VIEW TOP VIEW

PNEG-1412 Two Leg Towers 23

Page 24

NOTES

24 PNEG-1412 Two Leg Towers

Page 25

The GSI Group, Inc. Warranty

THE GSI GROUP, INC. (“GSI”) WARRANTS ALL PRODUCTS WHICH IT MANUFACTURES TO

BE FREE OF DEFECTS IN MATERIAL AND WORKMANSHIP UNDER NORMAL USAGE AND

CONDITIONS FOR A PERIOD OF 12 MONTHS AFTER RETAIL SALE TO THE ORIGINAL END

USER. THE PURCHASER’S SOLE REMEDY AND GSI’S ONLY OBLIGATION SHALL BE TO

REPAIR OR REPLACE, AT GSI’S OPTION AND EXPENSE, PRODUCTS THAT, IN GSI’S SOLE

JUDGMENT, CONTAIN A MATERIAL DEFECT DUE TO MATERIALS OR WORKMANSHIP.

ALL DELIVERY AND SHIPMENT CHARGES TO AND FROM GSI’S FACTORY WILL BE

PURCHASER’S RESPONSIBILITY. EXPENSES INCURRED BY OR ON BEHALF OF THE

PURCHASER WITHOUT PRIOR WRITTEN AUTHORIZATION FROM AN AUTHORIZED

EMPLOYEE OF GSI SHALL BE THE SOLE RESPONSIBILITY OF THE PURCHASER.

EXCEPT FOR THE LIMITED WARRANTY EXPRESSED ABOVE, GSI MAKES NO FURTHER

WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION,

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR

USE IN CONNECTION WITH (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (ii) ANY

ADVICE, INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT,

REPRESENTATIVE OR EMPLOYEE OF GSI REGARDING OR RELATED TO THE

CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY FOR A PARTICULAR PURPOSE,

OR DESIGN OF SUCH PRODUCTS.

GSI SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, INCLUDING, WITHOUT LIMITATION, LOSS OF ANTICIPATED

PROFITS OR BENEFITS. PURCHASER’S SOLE AND EXCLUSIVE REMEDY IS AS SET FORTH

IN THE LIMITED WARRANTY EXPRESSED ABOVE, WHICH SHALL NOT EXCEED THE

AMOUNT PAID FOR THE PRODUCT PURCHASED. THIS WARRANTY IS NOT

TRANSFERABLE AND APPLIES ONLY TO THE ORIGINAL PURCHASER. GSI SHALL HAVE

NO OBLIGATION OR RESPONSIBILITY FOR ANY REPRESENTATIONS OR WARRANTIES

MADE BY OR ON BEHALF OF ANY DEALER, AGENT OR DISTRIBUTOR OF GSI.

GSI ASSUMES NO RESPONSIBILITY FOR CLAIMS RESULTING FROM ERECTION DEFECTS

OR UNAUTHORIZED MODIFICATIONS TO PRODUCTS WHICH IT MANUFACTURED.

MODIFICATIONS TO PRODUCTS NOT SPECIFICALLY DELINEATED IN THE MANUAL

ACCOMPANYING THE EQUIPMENT AT INITIAL SALE WILL NULLIFY THE PRODUCT

WARRANTY THAT MIGHT HAVE BEEN OTHERWISE AVAILABLE.

THE FOREGOING WARRANTY SHALL NOT EXTEND TO PRODUCTS OR PARTS WHICH

HAVE BEEN DAMAGED BY NEGLIGENT USE, MISUSE, ALTERATION OR ACCIDENT. THIS

WARRANTY EXTENDS SOLELY TO ONLY PRODUCTS MANUFACTURED BY GSI. THIS

WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES EXPRESS OR

IMPLIED. GSI RESERVES THE RIGHT TO MAKE DESIGN OR SPECIFICATION CHANGES AT

ANY TIME.

PRIOR TO INSTALLATION, PURCHASER HAS THE RESPONSIBILITY TO COMPLY WITH

ALL FEDERAL, STATE AND LOCAL CODES WHICH MAY APPLY TO THE LOCATION AND

INSTALLATION OF PRODUCTS MANUFACTURED OR SOLD BY GSI.

PHLEGAL: #1832020 v1 (139LG01!.DOC) (revised December 2005)

Page 26

This Equipment shall be installed in accordance

with the curr ent installation codes and applicable

regulations which should be carefully followed in

all cases. Authorities having jurisdiction should be

consulted before installation occurs.

Copyright © 2005 by The GSI Group

Printed in the USA

1004 East Illinois Street

Assumption, IL 62510

217-226-4421 Phone

800-800-5329 F AX

Loading...

Loading...