Page 1

PNEG-1402

Vision Series Model 1100

Portable Dryers

Parts Manual

PNEG-1402

Date: 03-26-13

Page 2

2 PNEG-1402 Vision Series Model 1100 Portable Dryers

Page 3

Table of Contents

Contents

Chapter 1 Main Structure Assembly ....................................................................................................................4

Frame Assembly ....................................... ... .... ... ... ... ....................................... ... .... ... ... ... ..................... 4

Frame, Auger Trough, Hopper Bulkheads and Metering Rolls ............................................................. 7

Inside (Plenum) Screens and Plenum Closure Doors ......................................................................... 11

Outer Screens and Meter Roll Access Doors ..................................................................................... 13

Clean Out Doors ................................................................................................................................. 15

Front and Rear Plenum End Panels and Rear Access Doors ............................................................ 17

Fan Access Step ................................................................................................................................. 19

Ladder and Fan Assemblies ............................................................................................................... 20

Bottom Auger ...................................................................................................................................... 21

Top Auger with Wet Bin Assembly ...................................................................................................... 23

Chapter 2 Auger and Meter Roll Drive Trains ...................................................................................................26

Bottom Auger Drive ............................................................................................................................. 26

Top Auger Drive .................................................................................................................................. 29

Metering Roll Drive .............................................................................................................................. 31

Chapter 3 Fan/Heaters .........................................................................................................................................33

Fan/Heater Housing Assembly ........ ... ... ... ... .... ... ... ... .......................................... ................................ 33

Fan Motor, Motor Mount and Fan Blade ............................................................................................. 35

Air Mixer Assemblies ........................................................................................................................... 36

Flame Probe, Ignitor and Burner Assemblies .. ... ... ... .... ... ... ... .... ...................................... ... .... ... ... ... ... 37

LP Pipe Train Assemblies ................................................................................................................... 40

NG Pipe Train Assemblies .................................................................................................................. 44

LP Supply Line .................................................................................................................................... 46

NG Supply Line ................................................................................................................................... 47

Chapter 4 Dryer Electrical Conduits ..................................................................................................................48

Upper Junction Box, Top Auger Motor Conduit and Operator Light ................................................... 48

Air Switch Assembly ............................................................................................................................ 49

Right and Left Grain and Plenum High-Limits ..................................................................................... 50

Lower Junction Box, Meter Roll Motor Conduit and Rear Discharge Conduit .................................... 52

Chapter 5 Control Boxes .....................................................................................................................................54

Fan/Heater Electrical Box ......................................... .... ... ... ... .... ... ... ................................................... 54

Control Box Control Panel ............................ .... ... ... ... .... ... ... ... .... ... ... ... ................................................ 56

Lower Control Box Back Panel ........................................................................................................... 57

Control Box Switch Panel (Rear) ........................................................................................................ 58

Upper Control Box ............................................................................................................................... 60

Chapter 6 Warranty ..............................................................................................................................................69

PNEG-1402 Vision Series Model 1100 Portable Dryers 3

Page 4

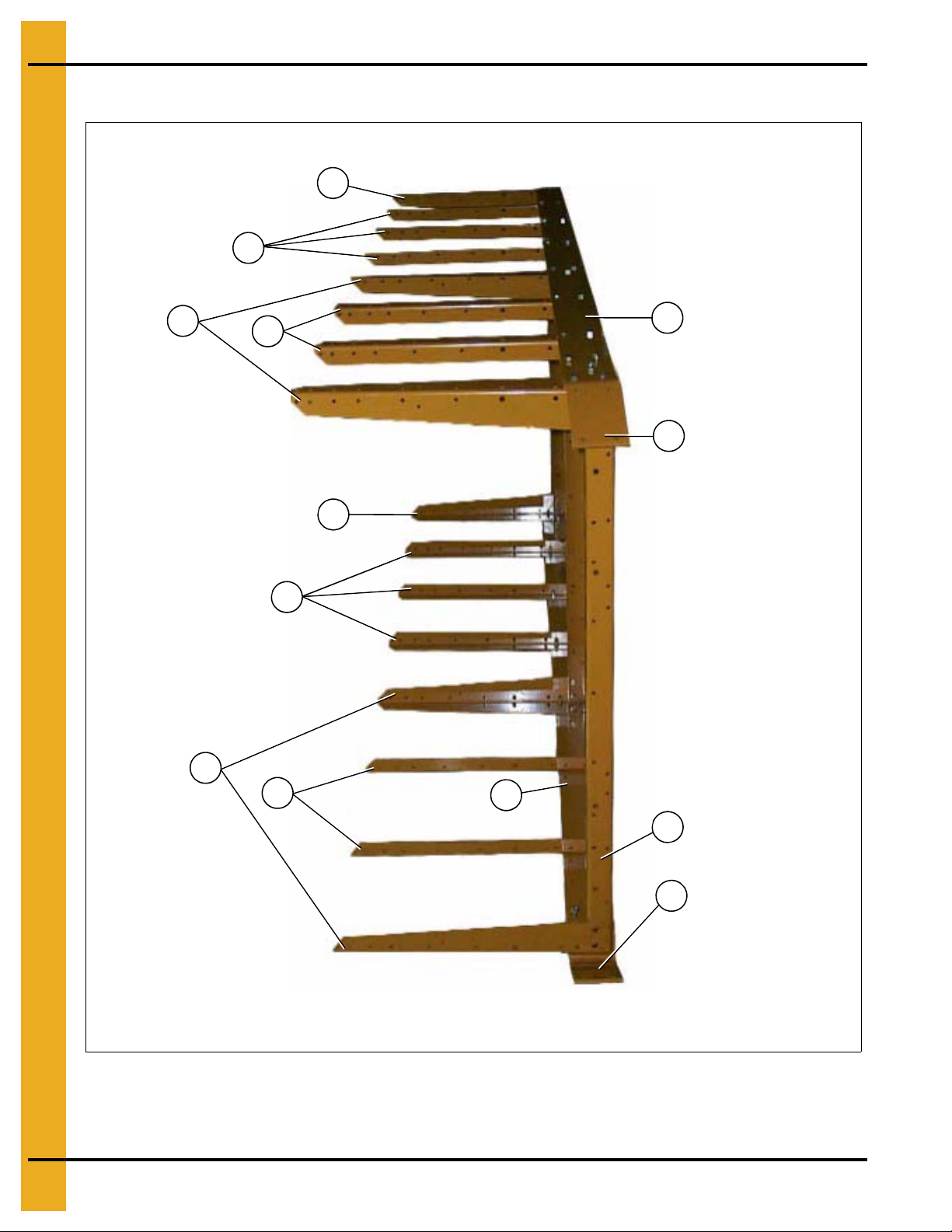

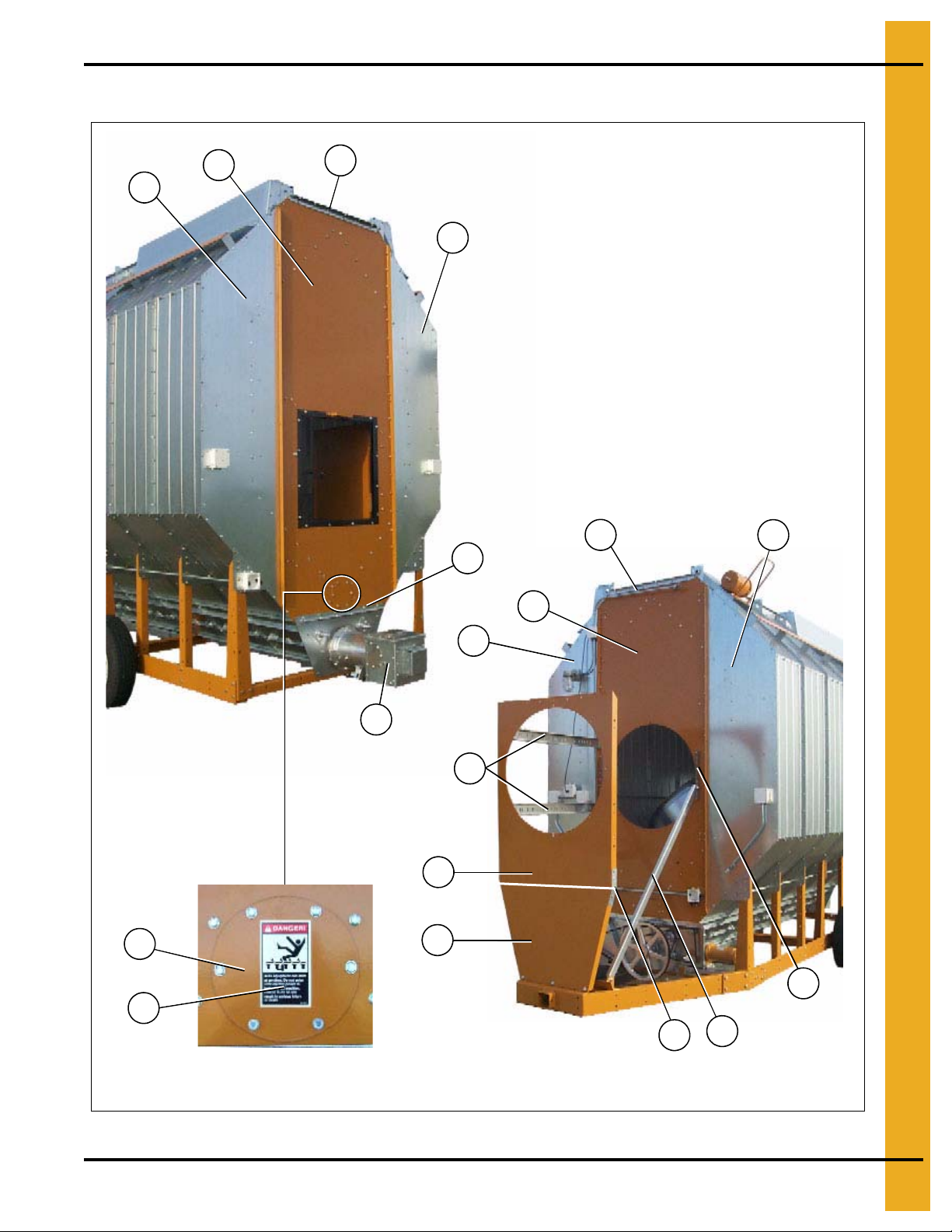

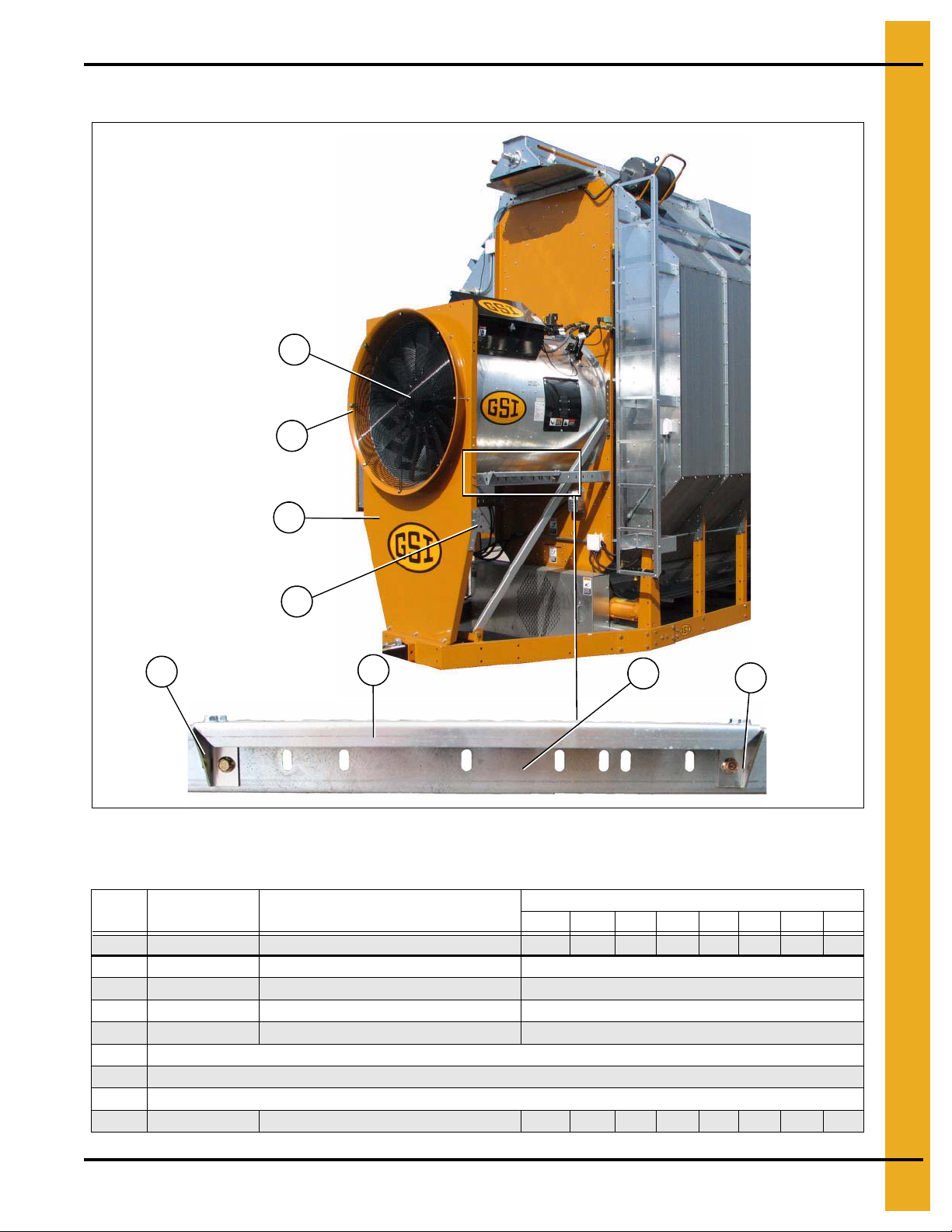

1. Main Structure Assembly

Right side

3

4a

1a

3

2

1

4

5

5

3

5

5

3

The fan/heater end of the dryer is considered by GSI as the front end of the dryer. (The foreground of

this photograph is the front end. Right and left sides are labeled above.)

Left side

Frame Assembly

Figure 1A Frame Assembly (View from fan/heater end with hitch weldment removed.)

NOTE: The parts pointed out on this page are listed on Page 6.

4 PNEG-1402 Vision Series Model 1100 Portable Dryers

Page 5

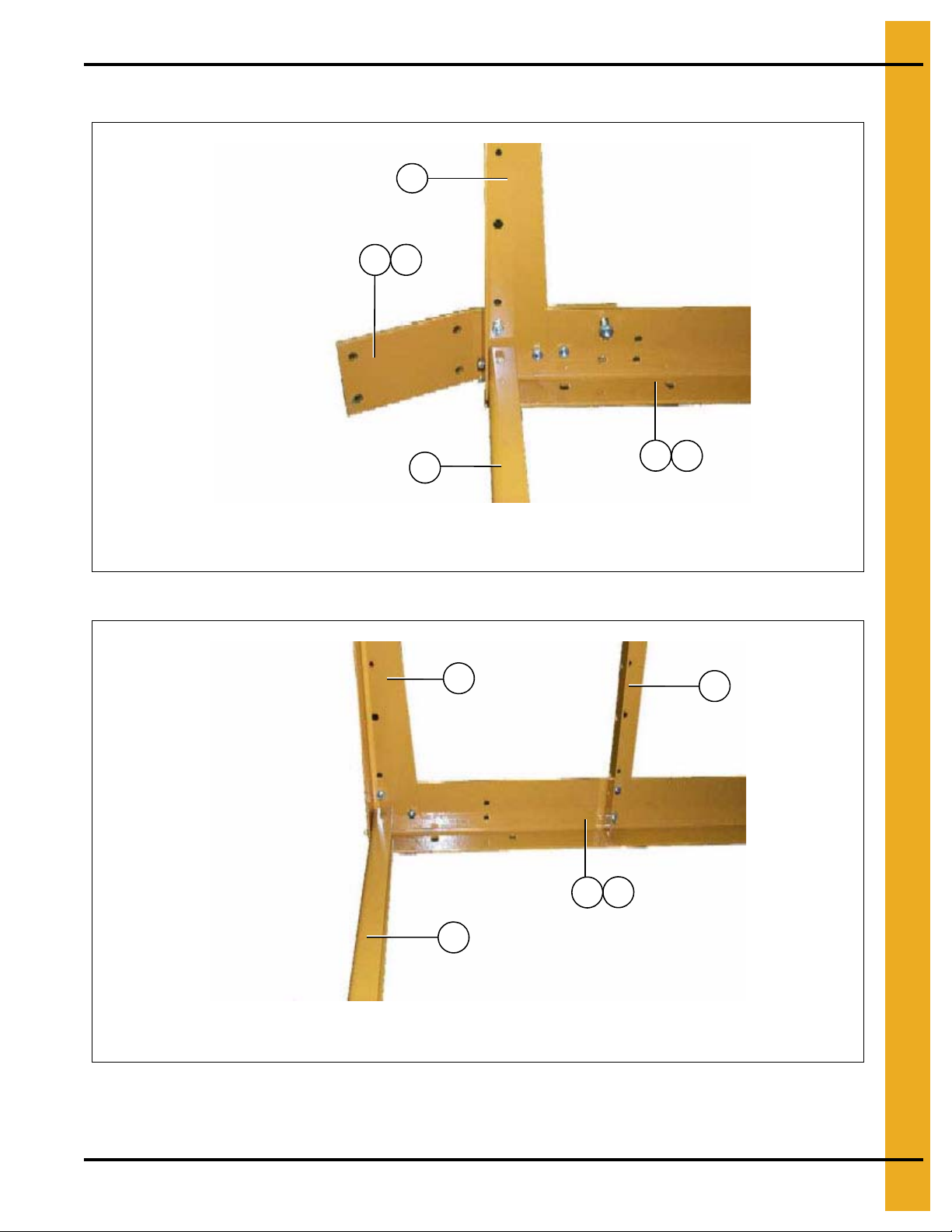

Frame Assembly (Continued)

2

1

1a

NOTE: The right front corner is shown in the photo. For left front corner all parts are the same except for

the hitch bracket (use 1a for the left side), and the frame rail (use 4a for the left side).

4

4a

3

2

5

NOTE: The left rear corner is shown in the photo. For right rear corner all parts are the

same except for the frame rail (use 4 for the right side).

3

4a

4

1. Main Structure Assembly

Figure 1B Right Front Corner of Frame

Figure 1C Left Rear Corner of Frame

PNEG-1402 Vision Series Model 1100 Portable Dryers 5

Page 6

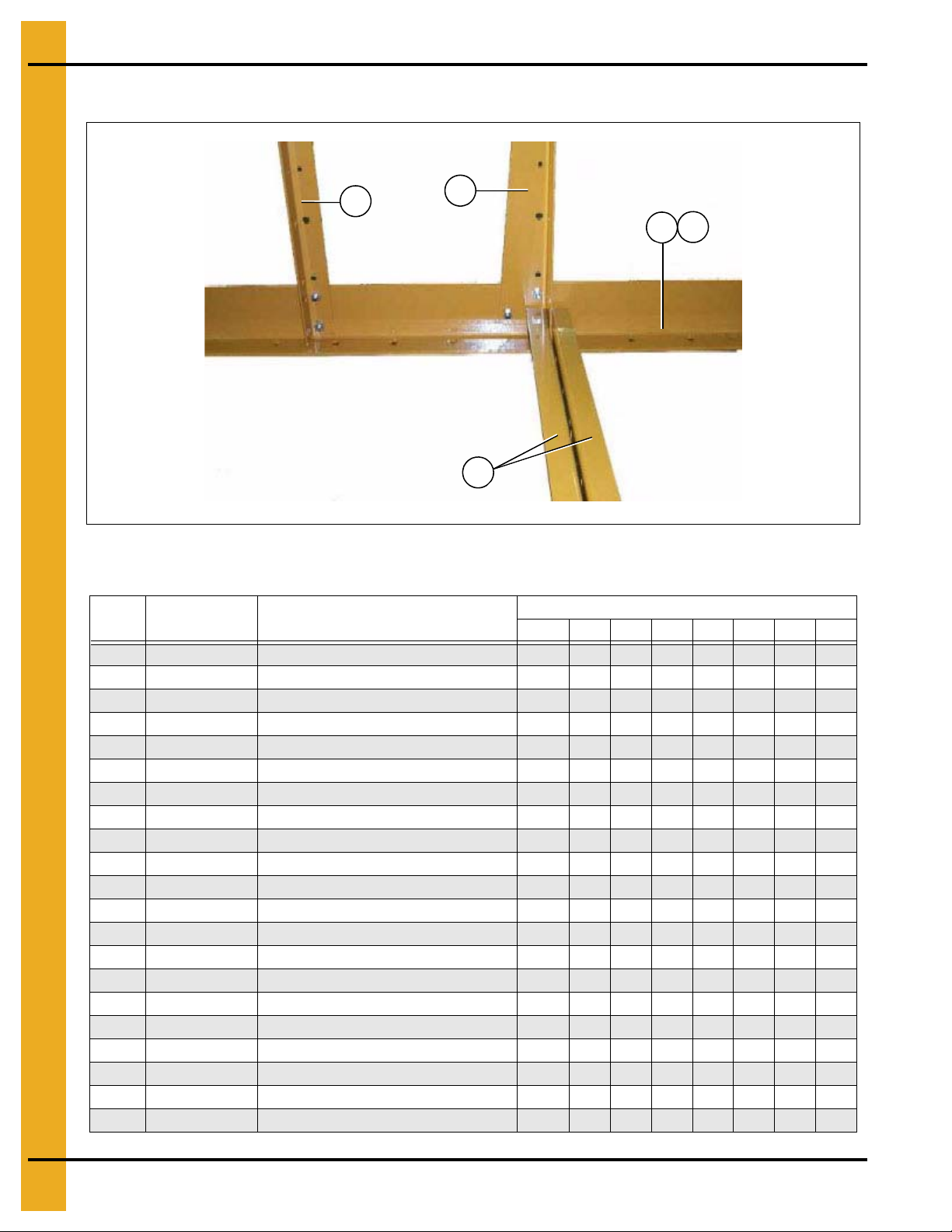

1. Main Structure Assembly

5

3

2

4a

4

Frame Assembly (Continued)

Figure 1D Center Cross Ties

Frame Assembly Parts List (See Figure 1A, 1B, 1C and 1D)

Ref # Part # Description

1 D01-0012 Hitch Bracket Right 1 1 1 1 1 1 1 1

1aD01-0011 Hitch Bracket Left 1 1111111

2 D01-0008 Front and Rear Frame Tie Channel 2 4 4 4 4 4 6 6

3 D01-0007 Corner Leg Portable Dryer 4 6666688

4 D11-0005 Frame Rail, 8' Right 1

4a D11-0004 Frame Rail, 8' Left 1

4 D51-0002 Frame Rail, 12' Right 1

4a D51-0001 Frame Rail, 12' Left 1

4 D21-0011 Frame Rail, 14' Right 1

4a D21-0010 Frame Rail, 14' Left 1

4 D01-0538 Frame Rail, 16' Right 1

4a D01-0537 Frame Rail, 16' Left 1

4 D31-0044 Frame Rail, 18' Right 1

4a D31-0043 Frame Rail, 18' Left 1

4 D61-0002 Frame Rail, 20' Right 1

4a D61-0001 Frame Rail, 20' Left 1

4 D101-0002 Frame Rail, 22' Right 1

4a D101-0001 Frame Rail, 22' Left 1

4 D71-0001 Frame Rail, 26' Right 1

4a D71-0002 Frame Rail, 26' Left 1

5 D01-0005 Side Leg Portable Dryer 6 8 10 12 14 16 16 20

1108T 1112 1114 1116 1118 1120 1122 1126

Qty

6 PNEG-1402 Vision Series Model 1100 Portable Dryers

Page 7

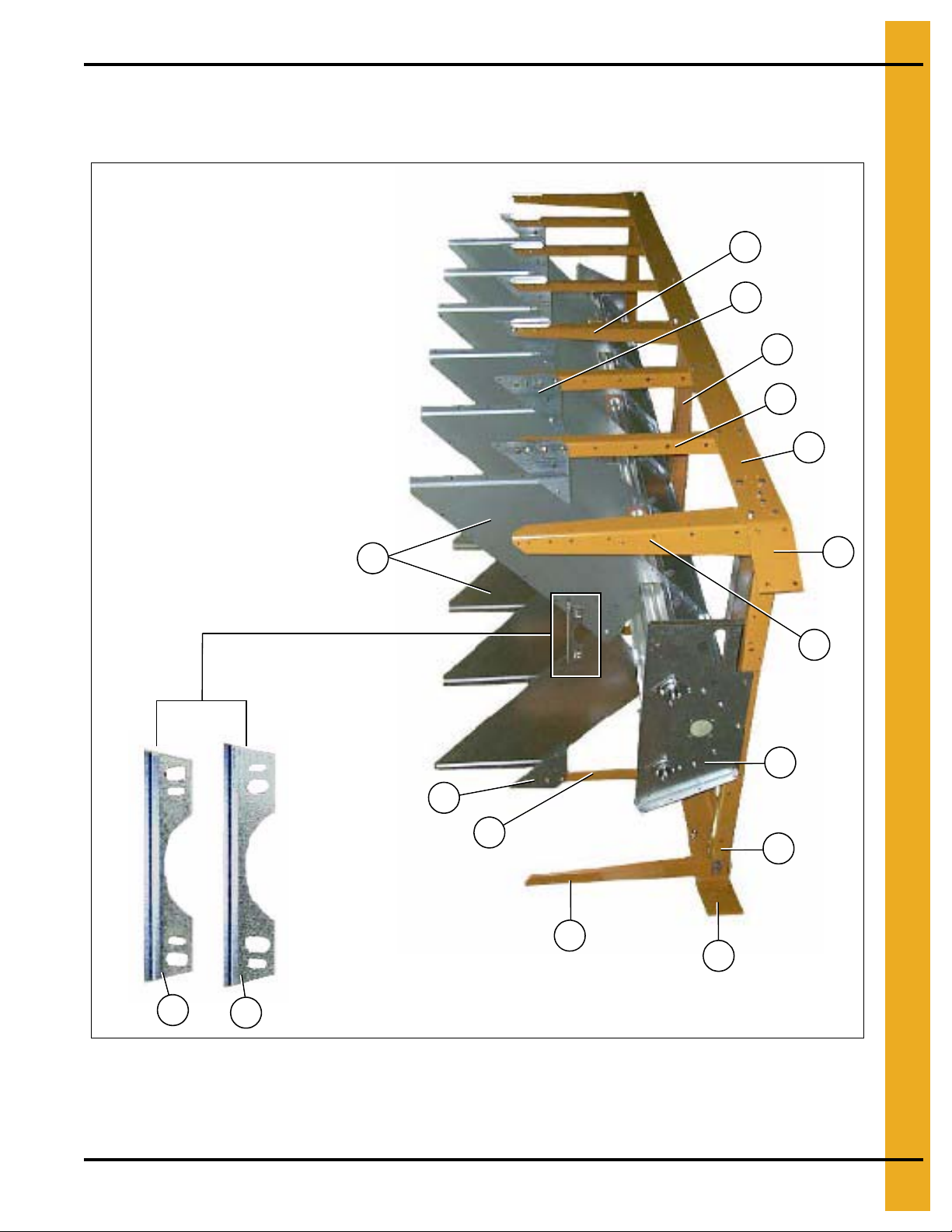

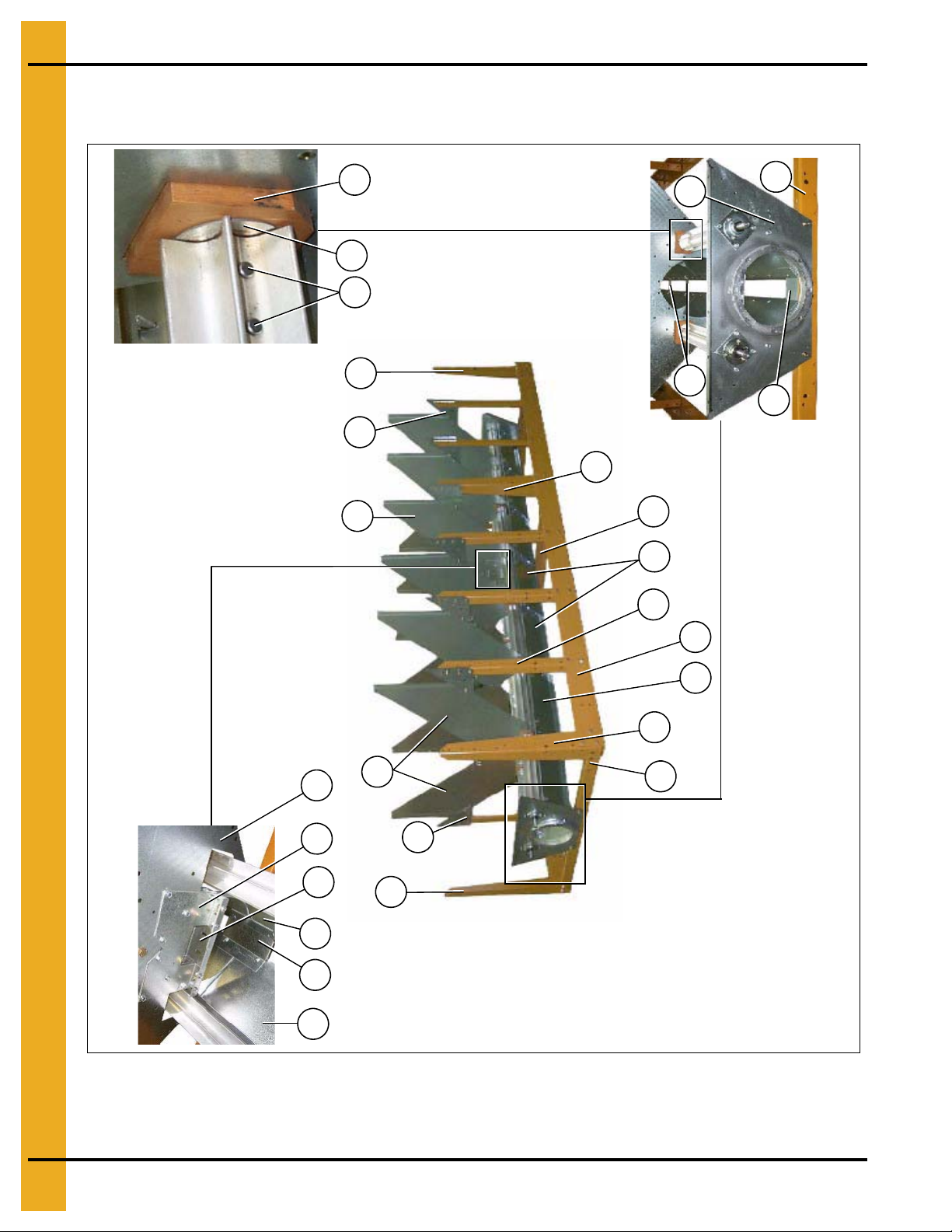

1. Main Structure Assembly

2

1

3

6

4

9

5

11

8

6

4

5

6

7

9

10

NOTE: The hole pattern of the plenum closure door angles.

This will distinguish between L.H. and R.H.

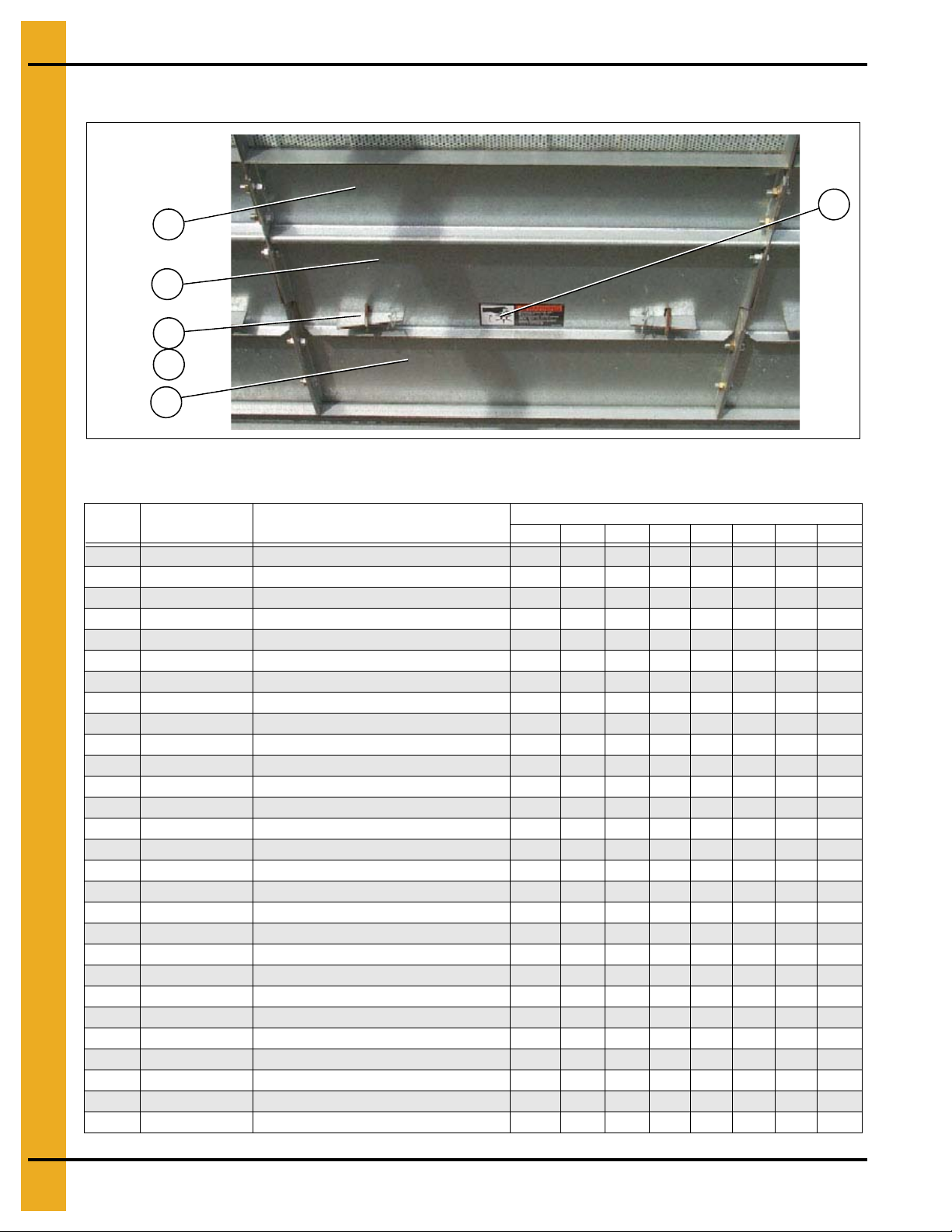

Frame, Auger Trough, Hopper Bulkheads and Metering Rolls

Frame, Auger Trough and Hopper Bulkheads

Figure 1E Dryer Frame and Lower Basket Assembly

(View from the front end of the dryer looking down the left side.)

NOTE: The parts pointed out on this page are listed on Page 10.

PNEG-1402 Vision Series Model 1100 Portable Dryers 7

Page 8

1. Main Structure Assembly

Wooden meter roll support bearing.

The meter roll sections are spliced

together with a meter roll splice shaft

(part #D31-0046) that passes through

the support bearing assembly.

Center hanger bearing

support and cross

channel seal plate.

20

21

9

6

4

3

6

9

12

5

11a

12

6

9

6

4

3

3

15

14

12

13

19

Discharge bearing plate

12

18

17

16

Frame, Auger Trough, Hopper Bulkheads and Metering

Rolls (Continued)

Figure 1F Dryer Frame and Lower Basket Assembly

(View from the rear end of the dryer looking up the ri ght side.)

NOTE: The parts pointed out on this page are listed on Page 10.

8 PNEG-1402 Vision Series Model 1100 Portable Dryers

Page 9

1. Main Structure Assembly

Meter roll bearing

Ref #16, 17 and 18

on Page 10.

This end is the front (fan/heater) end of the dryer.

NOTE: Ref #22 at the rear of dryer is a front section meter roll

that is used as a rear section on 16 and 20 feet dryers only.

22

24

23

23

22

22

23

23

Meter roll bearing

Ref #16, 17 and 18

on Page 10.

Meter roll bearing

Ref #16, 17 and 18

on Page 10.

Metering Rolls and their Placement in the Dryer

PNEG-1402 Vision Series Model 1100 Portable Dryers 9

Figure 1G

Page 10

1. Main Structure Assembly

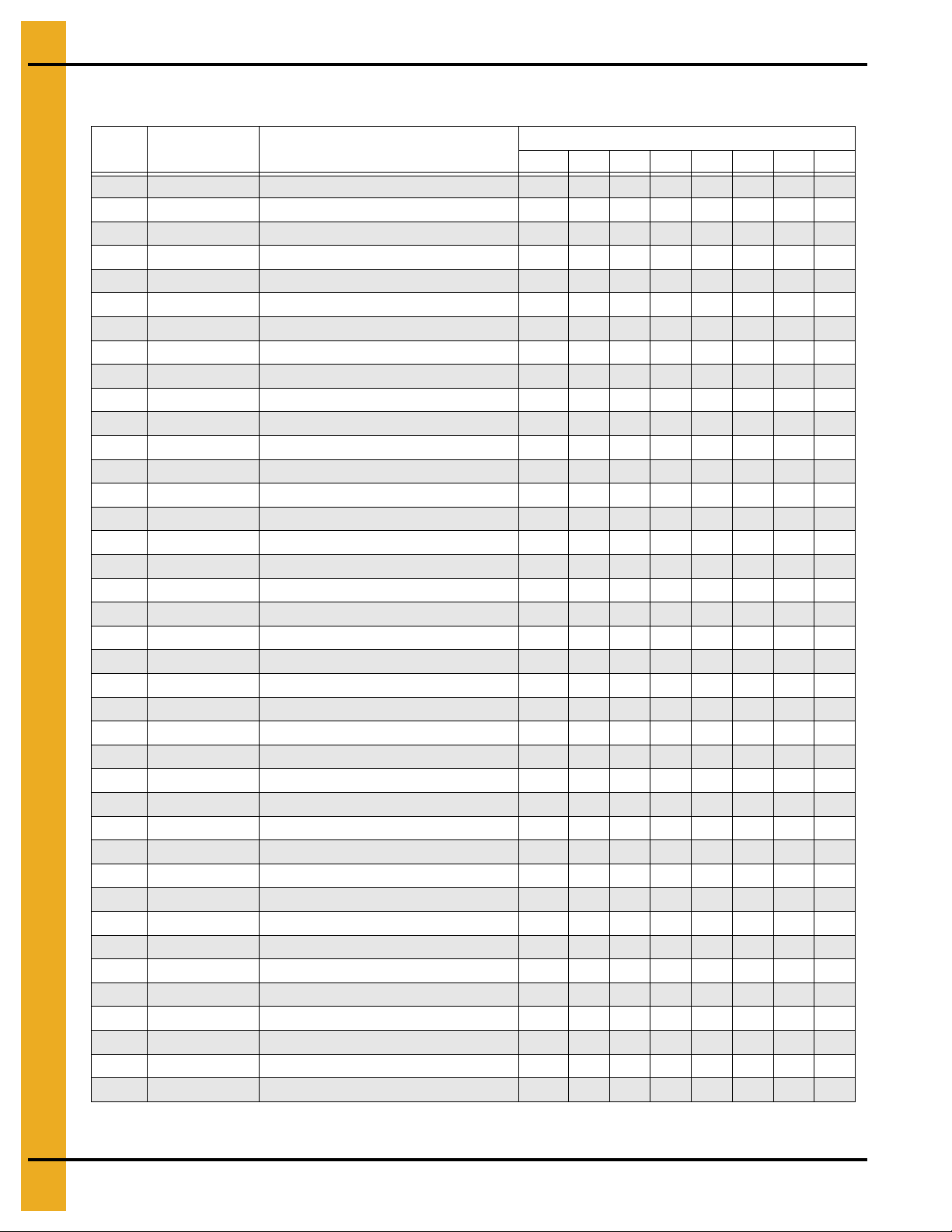

Frame, Auger Trough, Hopper Bulkheads and Metering Rolls Parts List

(See Figure 1E, 1F, and 1G)

Ref # Part # Description

1 D01-1136Y Plenum Closure Door Angle, R.H. 3 5 6 7 8 9 10 12

2 D01-1136X Plenum Closure Door Angle, L.H. 4 6 7 8 9 10 11 13

3 D01-0109 Hopper Bulkhead 6 10 12 14 16 18 20 24

4 D01-0004 Gusset Plate 10 14 16 18 20 22 24 28

5 D01-0005 Side Leg 6 8 10 12 14 16 16 20

6 D01-0007 Corner Leg 4 6 6 6 6 6 8 8

7 D01-0011 Hitch Bracket, L.H. 1 1 1 1 1 1 1 1

8D01-0012 Hitch Bracket, R.H. 1 1111111

9 D01-0008 Front and Rear Frame Tie Channel 2 4 4 4 4 4 6 6

10 D01-2435 Front Bearing Plate 2008 4" Meter Rolls 1 1 1 1 1 1 1 1

11 D11-0005 Frame Rail, 8' Right 1

11 D51-0002 Frame Rail, 12' Right 1

11 D21-0011 Frame Rail, 14' Right 1

11 D01-0538 Frame Rail, 16' Right 1

11 D31-0044 Frame Rail, 18' Right 1

11 D61-0002 Frame Rail, 20' Right 1

11 D101-0002 Frame Rail, 22' Right 1

11 D71-0001 Frame Rail, 26' Right 1

11a D11-0004 Frame Rail, 8' Left 1

11a D51-0001 Frame Rail, 12' Left 1

11a D21-0010 Frame Rail, 14' Left 1

11a D01-0537 Frame Rail, 16' Left 1

11a D31-0043 Frame Rail, 18' Left 1

11a D61-0001 Frame Rail, 20' Left 1

11a D101-0001 Frame Rail, 22' Left 1

11a D71-0002 Frame Rail, 26' Left 1

12 D01-0048 Trough Panel 8 12 14 16 18 20 22 26

13 D01-1512 Plate, Cross Channel Seal w/ Tabs 1 1 1 1 1 2 2

14 D01-1291 Hanger Bearing “C” Channel 1 1 1 1 1 2 2

15 D01-1290 Hanger Bearing “J” Plate 2 2 2 2 2 4 4

16 D02-0028 Clevis Pin 5/16" x 1-3/4" 16 24 32 32 40 40 48 56

17 D31-0148 Meter Roll Washer 8 12 16 16 20 20 24 28

18 D02-0061 Meter Roll Support Bearing 2 4 6 6 8 8 10 12

19 D01-0177 Support Strap 4 6 7 8 9 10 11 13

20 D01-1511 Plate, End Channel Seal w/ Tab 2 2 2 2 2 2 2 2

21 D01-2434 Discharge Plate 2008 4" Meter Roll 1 1 1 1 1 1 1 1

22 D31-0031 Meter Roll, Front 4 4 2 4 2 4 2 2

23 D31-0030 Meter Roll, Intermediate 2 4 4 6 6 8 10

24 D31-0029 Meter Roll, Rear 2 2 2 2

1108T 1112 1114 1116 1118 1120 1122 1126

Qty

The part number list above covers all parts pointed out on Pages 7, 8 and 9.

10 PNEG-1402 Vision Series Model 1100 Portable Dryers

Page 11

1. Main Structure Assembly

20a

This photograph was taken before the front plenum end panel and

outer screens were installed in order to get a good view of the inside

screens and bulkheads.

Plenum closure door. There are two (2) different plenum closure

doors. The door shown in the photograph is the rear plenum closure

door and is the rear most plenum closure door, Ref #20 (just inside

the rear access door), all others are Ref #20a. NOTE: Ref #22 is the

plenum closure door rear frame angle.

20

21

4

3

6

7

10

11

13

14

18

12

10

9

15

7

16

1

2

22

5

8

3

5

19

Inside (Plenum) Screens and Plenum Closure Doors

Plenum Screens and Bulkheads (View from Front End)

PNEG-1402 Vision Series Model 1100 Portable Dryers 11

Figure 1H

Page 12

1. Main Structure Assembly

16

18

17

19

18

17

19

Meter Roll Upper Shield Assembly

Figure 1I Close Up of Meter Roll Upper Shield Assembly

Plenum (Inside) Screens and Meter Roll Upper Shield Parts List (See Figure 1H and 1I)

Ref # Part # Description

1 D31-0055 Column Bulkhead 6 10 12 14 16 18 20 24

2 D01-0101 Garner Bulkhead 6 10 12 14 16 18 20 24

3 D31-0307 Column End Panel 4 4 4 4 4 4 4 4

4 D01-0126 Screen, Plenum Top, Gauge, 094 8 12 14 16 18 20 22 26

5 D31-0012 Screen, Plenum Wall, Gauge, 094 8 12 14 16 18 20 22 26

6 D01-1225 Screen, Plenum Bottom, Gauge, 094 8 12 14 16 18 20 22 26

7 D01-0004 Gusset Plate 10 14 16 18 20 22 24 28

8 D11-0005 Frame Rail, 8' Right 1

8 D51-0002 Frame Rail, 12' Right 1

8 D21-0011 Frame Rail, 14' Right 1

8 D01-0538 Frame Rail, 16' Right 1

8 D31-0044 Frame Rail, 18' Right 1

8 D61-0002 Frame Rail, 20' Right 1

8 D101-0002 Frame Rail, 22' Right 1

8 D71-0001 Frame Rail, 26' Right 1

9 D11-0004 Frame Rail, 8' Left 1

9 D51-0001 Frame Rail, 12' Left 1

9 D21-0010 Frame Rail, 14' Left 1

9 D01-0537 Frame Rail, 16' Left 1

9 D31-0043 Frame Rail, 18' Left 1

9 D61-0001 Frame Rail, 20' Left 1

9 D101-0001 Frame Rail, 22' Left 1

9 D71-0002 Frame Rail, 26' Left 1

10 D01-0007 Corner Leg Portable Dryer 4 6 6 6 6688

11 D01-0012 Hitch Bracket Right 1 1 1 1 1 1 1 1

12D01-0011 Hitch Bracket Left 1 1111111

13 D01-0008 Front and Rear Frame Tie Channel 2 4 4 4 4 4 6 6

14 D01-2435 Front Bearing Plate 2008 4" Meter Rolls 1 1 1 1 1111

15 D01-0005 Side Leg Portable Dryer 6 8 10 12 14 16 16 20

16 D01-0109 Hopper Bulkhead 6 10 12 14 16 18 20 24

17 D01-0050 Connector Sheet 8 12 14 16 18 20 22 26

*18 and 19 D01-1180 Meter Roll Upper Shield Assembly 8 12 14 16 18 20 22 26

18 D01-0431 Meter Roll Strike Off Plate 1/Assembly

19 D01-1226 Meter Roll Shield 1995 Style 1/Assembly

20 D01-1214 Plenum Closure Door, Rear 1 1 1 1 1 1 1 1

20a D01-1134 Plenum Closure Door 4 6 7 8 9 10 12 14

21 DC-974 Danger Foot In Auger Decal 2 2 2 2 2 2 2 2

22 D01-1217 Plenum Closure Door Rear Frame Angle 1 1 1 1 1111

*Ref #18 and Ref #19 together make up the meter roll upper shield assembly.

1108T 1112 1114 1116 1118 1120 1122 1126

Qty

12 PNEG-1402 Vision Series Model 1100 Portable Dryers

Page 13

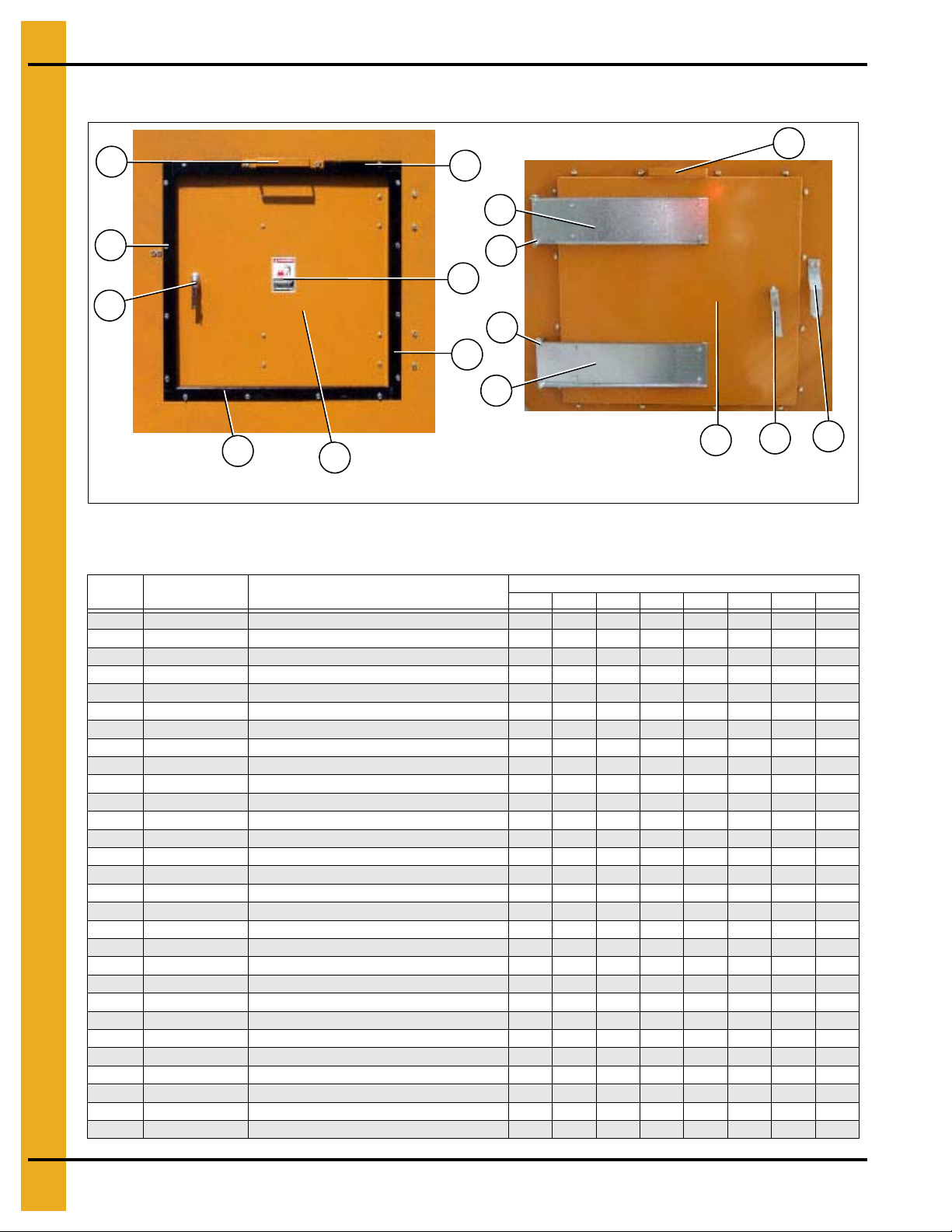

Outer Screens and Meter Roll Access Doors

*

*

See Figure 1K on Page 14

*NOTE: Ref #3 is pointing to the top edge angle gusset. There are two (2) types of gusset on the dryer. The photo on top

right will help distinguish the difference between the two. The arrows are pointing to a tab on the gusset that makes them

different (tabs are “bent” up in photo). Ref #3a is used in two (2) places only; 1) front right of dryer 2) rear left of dryer, all

others are Ref #3.

3a

3

4

1

9

10

14

12

11

10

7

5

4

2

3a

2

3

*

6

3

8

9

13

1. Main Structure Assembly

PNEG-1402 Vision Series Model 1100 Portable Dryers 13

Figure 1J Outer Screens (View from front end.)

Page 14

1. Main Structure Assembly

18

17

19

16

20

15

Outer Screens and Meter Roll Access Doors (Continued)

Figure 1K Meter Roll Access Door

Outer Screens and Meter Roll Access Doors Parts List (See Figure 1J and 1K)

Ref # Part # Description

1 D31-0307 Column End Panel 4 4 4 4 4 4 4 4

2 D01-0113 Walk Rail Mounting Bracket 10 16 18 20 22 24 28 32

3 D01-0152 Top Edge Angle Gusset - L.H. 8 12 14 16 18 20 22 26

3a D01-0153 Top Edge Angle Gusset - R.H. 2 2 2 2 2 2 2 2

4 D01-0127 Screen, Roof Sheet 8 12 14 16 18 20 22 26

5 D31-0013 Screen, Outside Wall Sheet 8 12 14 16 18 20 22 26

6 D01-0128 Screen, Hopper Sheet 8 12 14 16 18 20 22 26

7 D11-0005 Frame Rail, 8' Right 1

7 D51-0002 Frame Rail, 12' Right 1

7 D21-0011 Frame Rail, 14' Right 1

7 D01-0538 Frame Rail, 16' Right 1

7 D31-0044 Frame Rail, 18' Right 1

7 D61-0002 Frame Rail, 20' Right 1

7 D101-0002 Frame Rail, 22' Right 1

7 D71-0001 Frame Rail, 26' Right 1

8 D01-0005 Side Leg Portable Dryer 6 8 10 12 14 16 16 20

9 D01-0004 Gusset Plate 10 14 16 18 20 22 24 28

10 D01-0007 Corner Leg Portable Dryer 4 6 6 6 6 6 8 8

11 D01-0012 Hitch Bracket Right 1 1 1 1 1 1 1 1

12 D01-0011 Hitch Bracket Left 1 1 1 1 1 1 1 1

13 D01-0008 Front and Rear Frame Tie Channel 2 4 4 4 4 4 6 6

14 D01-2435 Front Bearing Plate 2008 4" Meter Rolls 1 1 1 1 1 1 1 1

15 D01-0050 Connector Sheet 8 12 14 16 18 20 22 26

16 D01-0045 Access Door 8 12 14 16 18 20 22 26

17 D01-0039 Door Latch 16 24 28 32 36 40 44 52

18 S-6552 Pin, Hair Clip 3/32" 16 24 28 32 36 40 44 52

19 DC-1229 Decal, Warning Meter Roll Rot. 8 12 14 16 18 20 22 26

20 D01-0048 Trough Panel Weldment 8 12 14 16 18 20 22 26

1108T 1112 1114 1116 1118 1120 1122 1126

Qty

14 PNEG-1402 Vision Series Model 1100 Portable Dryers

Page 15

Clean Out Doors

5

3a

7

NOTE: Ref #9, 10 and 1 1 together create the clean out

door assembly. There are three (3) different clean out

door assemblies that are used on GSI Network dryers:

1) 3 Column clean out door assembly (D51-0077). Ref #8a

on the part # listing (Page 16).

2) 4 Column clean out door assembly (D11-0032). Ref #8b

on the part # listing (Page 16).

3) 5 Column clean out door assembly (D01-0349). Ref #8c

on the part # listing (Page 16).

A 5 column clean out door assembly (D01-0349) is shown in

the photograph above.

1

4

2

13

3

4

2

6

5

9

10

11

12

13

9

11

11

11

Clean out door hinge

Front and rear handle mechanisms (rear shown in photo)

Clean out door handle mechanism

10

3

1. Main Structure Assembly

PNEG-1402 Vision Series Model 1100 Portable Dryers 15

Figure 1L

Page 16

1. Main Structure Assembly

5

14

1a

14

3a

4

2

14

3a

11

Clean Out Doors (Continued)

Figure 1M Center Handle Mechanisms (This handle mechanism

straddles the center cross channels.)

Clean Out Doors Parts List (See Figure 1L and 1M)

Qty

Ref # Part # Description

1 D01-0264 Pivot Rod 25-3/16" 2 2 2 2 2 2 2 2

1a D31-0162 Pivot Rod 49-5/8" 1 1 1 1 1 2 2

2 D01-0296 Linkage Bar Weldment 2 4 4 4 4 4 6 6

3 D01-0261 Linkage Bar, 37" Long 2 2 2 2 2 2 2 2

3a D01-0293 Linkage Bar, 30" Long 2 2 2 2 2 4 4

4 D01-0294 Clean Out Door Handle 2 4 4 4 4 4 6 6

5 S-4378 Plastic Grip 2 4 4 4 4 4 6 6

6 S-248 Flat Washer, 3/8" USS ZN 4 8 8 8 8 8 12 12

7 S-7241 Cotter Pin, 1/8" x 1-1/4" 4 8 8 8 8 8 12 12

8a D51-0077 Clean Out Door Assembly, 3 Column 2 1 1

9 D21-0005 Clean Out Door, 67" 1/Assembly

10 D21-0012 Support Channel, Clean Out Door 1/Assembly

11 D01-0308 Clean Out Door Hinge 2/Assembly

8b D11-0032 Clean Out Door Assembly, 4 Column 1 1 2 1 2 2

9 D31-0021 Clean Out Door, 91" 1/Assembly

10 D31-0130 Support Channel, Clean Out Door 1/Assembly

11 D01-0308 Clean Out Door Hinge 2/Assembly

8c D01-0349 Clean Out Door Assembly, 5 Column 1 2 1

9 D01-0180 Clean Out Door, 115" 1/Assembly

10 D01-0307 Support Channel, Clean Out Door 1/Assembly

11 D01-0308 Clean Out Door Hinge 3/Assembly

12 D01-0175 Hinge Bracket 2 4 4 5 5 6 6 7

13 D01-0181 Clean Out Extension, 119-3/4" 2 4 2

13 D31-0023 Clean Out Extension, 90-3/4" 2 2 4 2 4 4

13 D21-0006 Clean Out Extension, 66-3/4" 4 2 2

14 D01-0299 Pivot Rod Bracket 3 3 3 3 3 6 6

1108T 1112 1114 1116 1118 1120 1122 1126

16 PNEG-1402 Vision Series Model 1100 Portable Dryers

Page 17

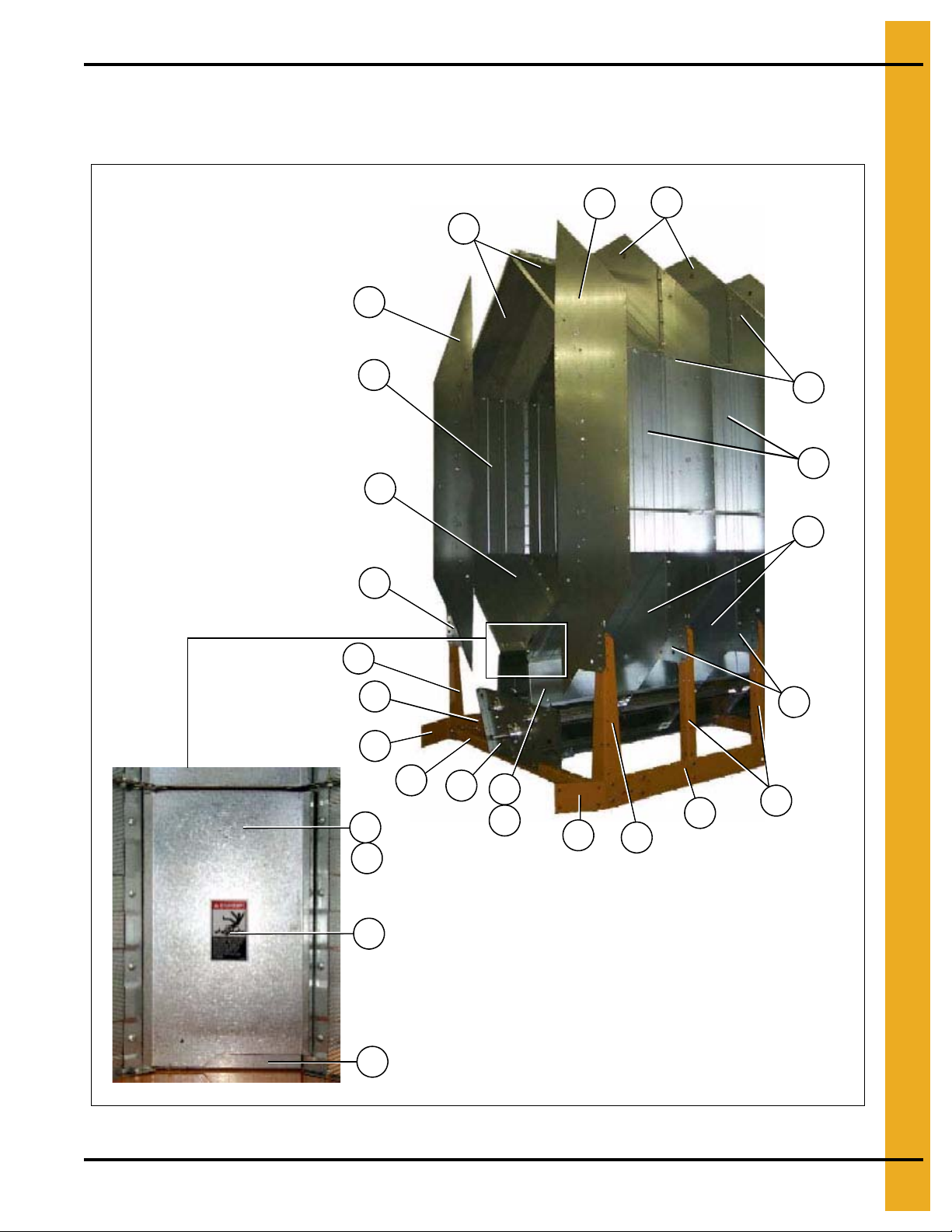

1. Main Structure Assembly

1b

1a

2

3

1c

3

4

1d

5

6

7

8

11

12

3

9

10

Front end panels and

support arms

Aspirator end cap

Rear plenum

end panels

22

Front and Rear Plenum End Panels and Rear Access Doors

PNEG-1402 Vision Series Model 1100 Portable Dryers 17

Figure 1N

Page 18

1. Main Structure Assembly

15

16

13

14

16

16

17

16

21

21

20

15

20

17

18

19

Rear access door

Rear access door (inside)

Rear Access Doors

Figure 1O

Front and Rear Plenum End Panels and Rear Access Doors Parts List (See Figure 1N and 1O)

Ref # Part # Description

1a D01-2477 Column End Panel - L.H. Rear Grain Dryers 1 1 1 1 1 1 1 1

1b D01-2476 Column End Panel - R.H. Rear Grain Dryers 11111111

1c D01-2467 Column End Panel - L.H. Front Grain Dryers 1 1 1 1 1 1 1 1

1d D01-2466 Column End Panel - R.H. Front Grain Dryers 11111111

2 D01-2259-Y Rear Panel Single Fan, Ochre 1 1 1 1 1 1 1 1

3325-1688-2 Top Angle Bracket Front and Rear 22222222

4 D01-2232-Y Front End Panel 1-36", Ochre 1 1

4 D01-2235-Y Front End Panel 1-40", Ochre 1 1

4 D01-2238-Y Front End Panel 1-42", Ochre 1 1 1 1

5 D51-0022 Support, Control Panel 33333333

6 D01-2542-Y Panel, Short Fan Support 1-36" Fan, Ochre 1 1

6 D01-2543-Y Panel, Short Fan Support 1-40" Fan, Ochre 1 1

6 D01-2545-Y Panel, Short Fan Support 1-42" Fan, Ochre 1 1 1 1

7 D51-0021 Stiffener, Front Fan Support 22222222

8 D01-0062 Front Diagonal Support Channel 2 2 2 2 2 2 2 2

9 D31-0129 Diagonal Support Angle 22222222

10 D01-0481-MS Rear Discharge Box Assembly 1 1 1 1 1 1 1 1

11 D01-1510 Aspirator End Cap 11111111

12 DC-974 Decal, Danger Foot in Auger 1 1 1 1 1 1 1 1

13 D03-0512 Door Handle Locking 11111111

14 DC-973 Decal, Danger Fire Hazard 1 1 1 1 1 1 1 1

15 D01-1783-Y Assist Handle, 29" Square Door 22222222

16 D01-1782-BLK Frame Angle, 29" Square Door 4 4 4 4 4 4 4 4

17 D01-1781-Y Door, 29" Square 11111111

18 D01-1792 Latch Bar 1 1 1 1 1 1 1 1

19 D01-0397 Latch Bracket 11111111

20 401-4669-8 Rear Access Door Hinge, Door Half 2 2 2 2 2 2 2 2

21401-4630-0 Hinge Bracket 22222222

22 D01-2537-Y Base, Fan Support - Standard, Ochre 1 1 1 1 1 1 1 1

1108T 1112 1114 1116 1118 1120 1122 1126

Qty

18 PNEG-1402 Vision Series Model 1100 Portable Dryers

Page 19

Fan Access Step

6

5

7

8

1

3

2

4

1. Main Structure Assembly

Figure 1P

Ref # Part # Description

1-4 D01-1198 Fan Access Step Kit 1 1 1 1 1 1 1 1

1 D01-1168 Fan Access Step L.H. Mount 1/Kit

2 D01-1166 Fan Access Step 1/Kit

3 D51-0022 Support, Control Panel 1/Kit

4 D01-1167 Fan Access Step R.H. Mount 1/Kit

5 See Ref #5 on Page 20

6 See Ref #6 on Page 20

7 See Ref #7 on Page 20

8 D51-0021 Stiffener, Front Fan Support 2 2 2 2 2 2 2 2

Fan Access Step Parts List

1108T 1112 1114 1116 1118 1120 1122 1126

Qty

PNEG-1402 Vision Series Model 1100 Portable Dryers 19

Page 20

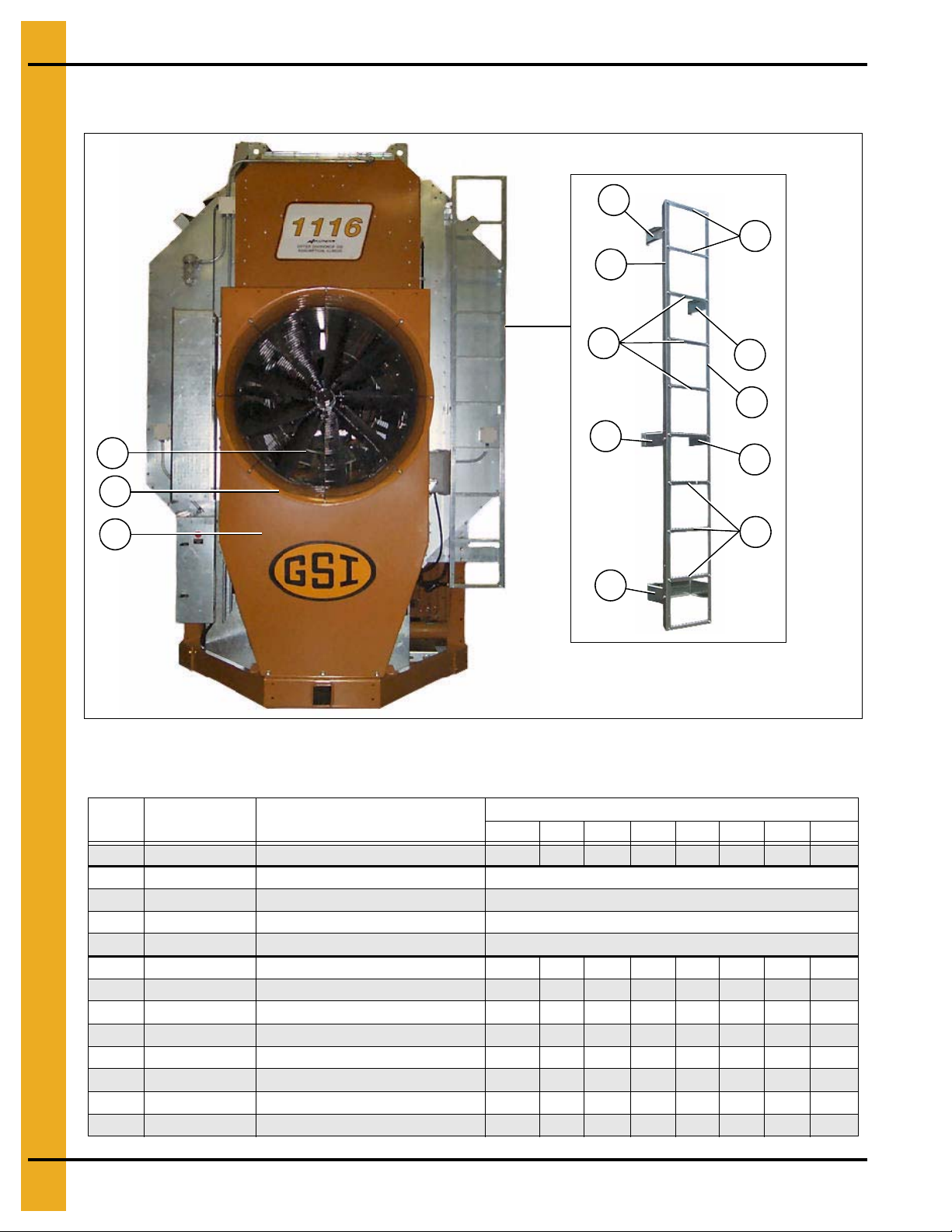

1. Main Structure Assembly

Front and rear ladder assembly

1

2

3

1

4

1

2

1

3

3

5

6

7

Ladder and Fan Assemblies

Figure 1Q

Ladder and Fan Assembly Parts List

Ref # Part # Description

1-4 D31-0293 Ladder Assembly, Tall Profile 1 1 2 2 2 2 2 2

1 D01-1012 Ladder Bracket 4/Assembly

2 D31-0020 Ladder Rail 2/Assembly

3 D01-0112 Ladder Rung 10/Assembly

4 D01-0114 Ladder Lower Bracket 1/Assembly

5 CD-0544 Grill Guard: 36" 1 1

5 CD-0547 Grill Guard: 40" and 42" 1 1 1 1 1 1

6 CD-0543-Y Venturi: 36" Ochre 1 1

6 CD-0545-Y Venturi: 40" Ochre 1 1

6 CD-0546-Y Venturi: 42" Ochre 1 1 1 1

7 D51-0007 Front Fan Support 1-36" 1 1

7 D01-1458 Front Fan Support 1-40" 1 1

7 D51-0132 Front Fan Support 1-42" 1 1 1 1

1108T 1112 1114 1116 1118 1120 1122 1126

Qty

20 PNEG-1402 Vision Series Model 1100 Portable Dryers

Page 21

Bottom Auger

Bottom auger center bearing and support

Bottom auger rear bearing

2

1

5

7

6

Bottom auger

(View from center of dryer to the forward end.)

Bottom auger

(View from center of dryer to the rear end.)

2

3

4

8

7

2

1. Main Structure Assembly

PNEG-1402 Vision Series Model 1100 Portable Dryers 21

Figure 1R

Page 22

1. Main Structure Assembly

19

Auger bearing

Rear discharge box

9

10

11

12

14

15

18

17

16

21

20

13

Bottom Auger (Continued)

Bottom Auger Parts List (See Figure 1R and 1S)

Figure 1S

Ref # Part # Description

1 D01-1214 Plenum Closure Door, Rear 1 1 1 1 1 1 1 1

2 D01-1134 Plenum Closure Door 3 5 6 7 8 9 10 12

3 D01-1819 Bottom Auger 8' 1

3 D21-0017 Auger Bottom Front 1 1 1

3 D01-0607 Auger Bottom Front 1

3 D31-0092 Auger Bottom Front 1 1

3 D31-0092 Auger Bottom Front (116-3/8" Long) 1

4 D01-0801 Auger Bottom Rear 12' 1

4 D31-0267 Auger Bottom Rear 1 1 1 2 2

4 D61-0184 Auger Bottom Rear (117-7/8" Long) 1

5 D01-1290 Hanger Bearing Bottom J-Plate 2 2 2 2 2 4 4

6 D01-1291 Hanger Bearing Bottom C-Channel

7 D01-1246 Hanger Bearing Assembly (Short) 2 2 2 2 2 3 3

8 D31-0076 Shaft, Auger Splice 2 2 2 2 2 3 3

9-19 D01-0481-MS Discharge Box Assembl y 1 1 1 1 1 1 1 1

9 D01-1884 Discharge Weldment 1/Assembly

10 D01-1886 Moisture Sampler Tube Cover Plate 1/Assembly

11 D01-0405 Grain Sampler Assembly 1/Assembly

12 D01-1752 Discharge Side Cover 1/Assembly

13 D01 -1751 Discharge Side Panel MC 1/Assembly

14 D31-0298 Discharge Side Panel 1/Assembly

15 D01-1885 Moisture Sampler Cover Plate 1/Assembly

16 D01-1650 Rear Auger Bearing Shield 1/Assembly

17 D31-0299 Discharge Box Bearing Plate 1/Assembly

18 D01-0466 Discharge Top Panel 1/Assembly

19 D01-0467 Discharge Top Flapper 1/Assembly

20 D32-0001 Flangette Bearing 1 1 1 1 1 1 1 1

21 D31-0005 Shaft, Top and Bottom Auger Stub 1 1 1 1 1 1 1 1

N/S D31-0079 Discharge Auger Weldment 1 1 1 1 1 1 1 1

22 PNEG-1402 Vision Series Model 1100 Portable Dryers

1108T 1112 1114 1116 1118 1120 1122 1126

1111122

Qty

Page 23

Top Auger with Wet Bin Assembly

Top auger with wet bin (switch paddle end)

1

1

2

3

4

6

5

7

8

9

3

1

13

14a

14

9

12

11

10

26

Top auger (fill end)

1. Main Structure Assembly

PNEG-1402 Vision Series Model 1100 Portable Dryers 23

Figure 1T

Page 24

1. Main Structure Assembly

Top auger bearing support

Top auger bearing support (inside view)

25

15

16

17

10

21

22

18

19

20

22

21

7

7

23

24

16

Top Auger with Wet Bin Assembly (Continued)

Figure 1U

24 PNEG-1402 Vision Series Model 1100 Portable Dryers

Page 25

1. Main Structure Assembly

Top Auger with Wet Bin Assembly Parts List (See Figure 1T and 1U)

Ref # Part # Description

1 D01-1521 Wet Bin Side, 4' Side Galv. Perf. 4 4 2 4 2 4

1 D01-1522 Wet Bin Side, 6' Side Galv. Perf. 4 2 4 6 4 6 6

2 D01-0103 Mercury Switch Shaft 1 1 1 1 1 1 1 1

3 D21-0003 Top Edge Angle 71-7/8" 4 2 2

3 D31-0004 Top Edge Angle 95-7/8" 2 2 4 2 4 4

3 D01-0168 Top Edge Angle 119-7/8" 24 2

3a D31-0003 Top Edge Angle Splice 2 2 2 2 2 4 4

4325-1688-2 Angle Bracket 2 2222222

5 D01-0147 Top Auger Housing Hinge L.H. 2 2 2 2 2 2 2 2

6 D01-0167 Mercury Switch Paddle Weldment 1 1 1 1 1 1 1 1

7 D01-0811 Auger Top W eldment 8' Basket 1

7 D21-0015 Auger Top Front Weldment 1 1 1

7 D01-0608 Auger Top Front W eldment 16' Basket 1

7 D31-0091 Auger Top Front Weldment 1 1 1

7 D01-0801 Auger Top/Bot tom Rear Weldment 12' Basket 1

7 D31-0267 Auger Top and Bot tom Weldment 1 1 1 2 2

7 D61-0184 Auger Weldment 117-7/8" 1

8 D01-0148 Top Auger Housing Hinge R.H. 2 2 2 2 2 2 2 2

9 D01-1525 Wet Bin End 2 2 2 2 2 2 2 2

10 D21-0002 Top Auger Trough Side/6' 2 2

10 D31-0010 Top Auger Trough Side/8' 2 2 4 2 4 4

10 D01-0161 Top Auger Trough Side/10' 2 4 2

11 D01-1650 Rear Auger Bearing Cover 1 1 1 1 1 1 1 1

12 D31-0028 Top Auger Housing End 2 2 2 2 2 2 2 2

13 D32-0001 Bearing 1-1/2" Diameter w/ Flangette 2 2 2 2 2 2 2 2

14 D31-0090 Shaft, Top Auger Front (with Keyway) 1 1 1 1 1 1 1 1

14a D31-0005 Shaft, Top Auger Stub Rear 1 1 1 1 1 1 1 1

15 D01-1123 Top Auger Cover, 30-1/4" 1 1 1 1 1 1 1 1

15 D01-1124 Top Auger Cover, 24-1/4" 2 2 3 4 5 7 5 7

15 D01-1125 Top Auger Cover, 20-1/4" 2 2 2 2 2 4 4

16 D31-0015 Top Auger Bearing Support 1 1 1 1 1 2 2

17 D31-0011 Center Stabilizer Beam 1 1 1 1 1 2 2

18 D31-0009 Gusset Attach Bracket 2 2 2 2 2 4 4

19 D31-0001 Center Handrail Gusset L.H. 2 2 2 2 2 4 4

20 D31-0002 Center Handrail Gusset R.H. 2 2 2 2 2 4 4

21 D21-0001-Y Hand Rail Support, 1" EMT x 71-3/4" 4 2 2

21 D31-0006-Y Hand Rail Support, 1" EMT x 95-3/4" 2 4 2 4 4

21 D01-0151-Y Hand Rail, 1" EMT x 119-3/4" Long 2 2 4 2

22 D01-0140 Hanger Bracket-Handrail Galv. 8 16 16 16 16 16 24 24

23 D31-0008 Top Auger Trough Splice 2 2 2 2 2 4 4

24 D01-1245 Top Auger Bearing Hanger Assembly 1 1 1 1 1 2 2

25 D31-0076 Shaft, Auger Splice 1 1 1 1 1 2 2

1108T 1112 1114 1116 1118 1120 1122 1126

Qty

PNEG-1402 Vision Series Model 1100 Portable Dryers 25

Page 26

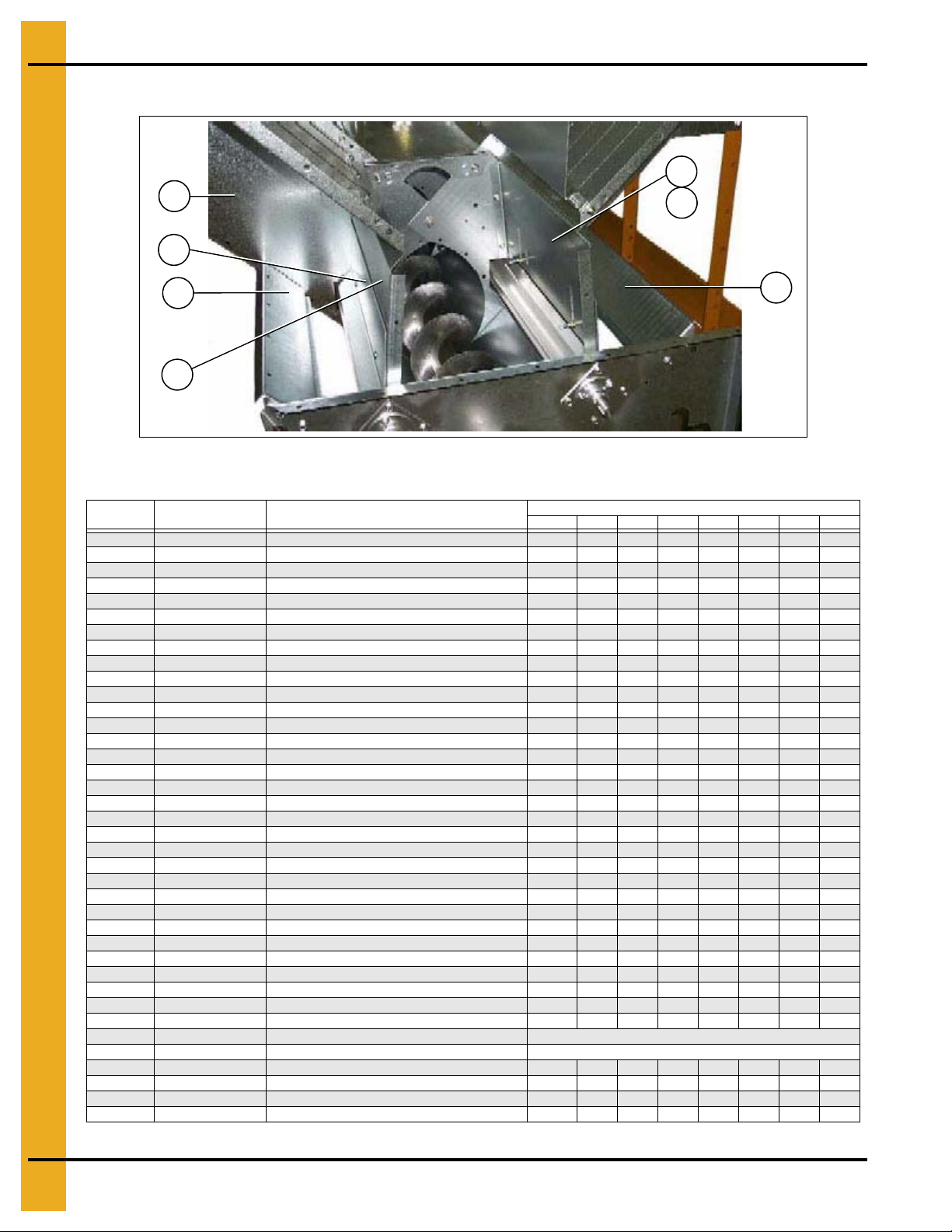

2. Auger and Meter Roll Drive Trains

1

2

3

4

11

5

9

8

7

6

11

12

13

5

16

6

4

15

14

13

13

18

16

17

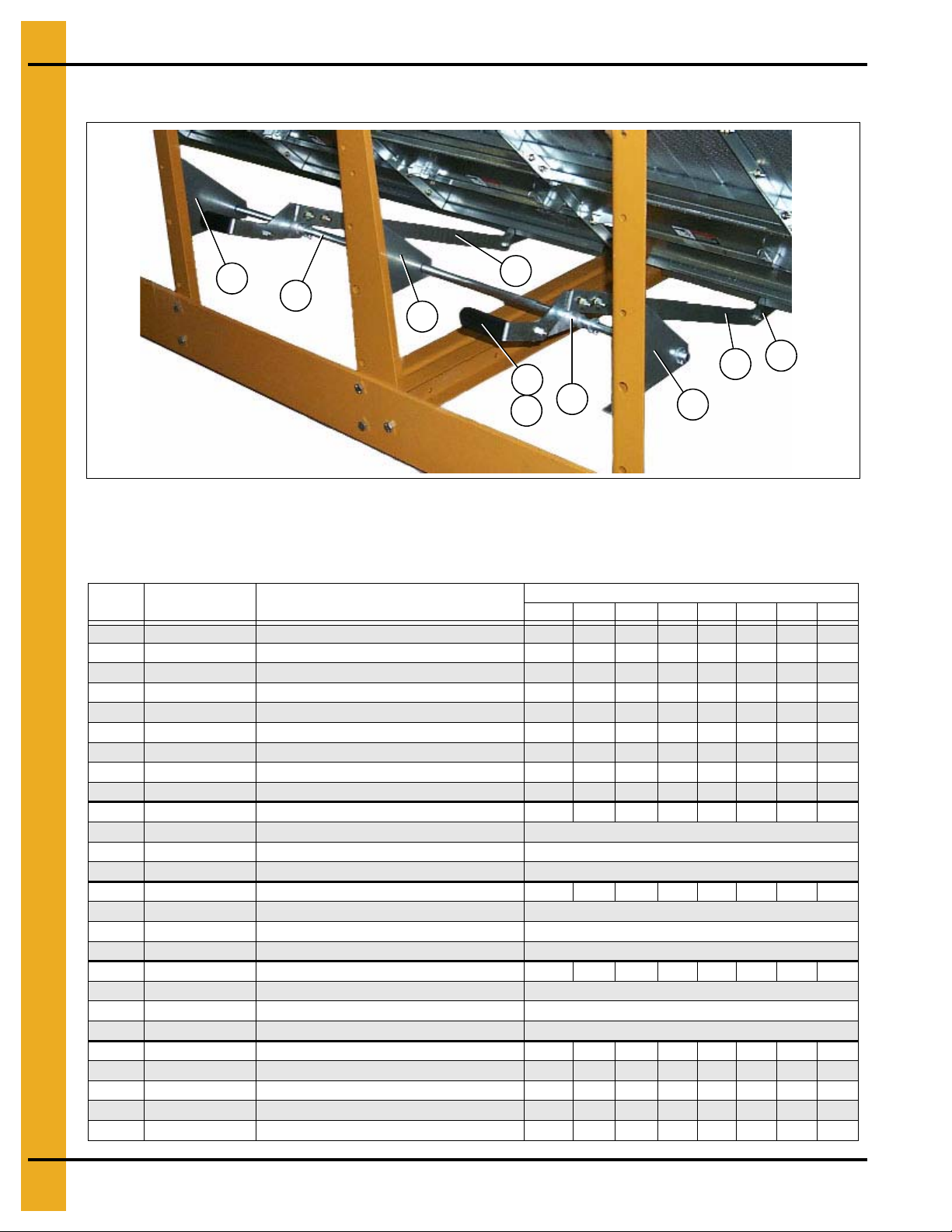

Bottom auger drive components

Bottom auger motor and motor mount

Forward drive tension adjustment

Rear drive tension adjustment

10

Bottom Auger Drive

Figure 2A

26 PNEG-1402 Vision Series Model 1100 Portable Dryers

Page 27

Bottom Auger Drive (Continued)

20

21

19

22

2. Auger and Meter Roll Drive Trains

Figure 2B Bottom Auger and Metering Roll Drive Guard

PNEG-1402 Vision Series Model 1100 Portable Dryers 27

Page 28

2. Auger and Meter Roll Drive Trains

Bottom Auger Drive Parts List (See Figure 2A and 2B)

Ref # Part # Description

1 D01-1376 Bottom Front Angle Bracket 1 1 1 1 1 1 1 1

2 D02-0067 V-Belt BX85 2 2

2 MHC00490 V-Belt BX82 2 2 2 2 2 2

3 D02-0056 Sheave 2 Grade 3.35D x 5/8" Bore 1

3 D03-0174 Sheave 2.5D x 7/8" Bore 1

3 2818-2 Sheave 2 Grade 3.35D x 1-1/8" 1 1 1

3 D62-0003 Sheave 2 Grade 4.25D x 1-3/8" 1 1 1

4 D01-0012 Hitch Bracket, Right 1 1 1 1 1 1 1 1

5 D01-1373 Belt Guard, Unload Motor Shroud 1 1 1 1 1 1 1 1

6 D01-0029 Hitch Weldment 1 1 1 1 1 1 1 1

7 D01-0011 Hitch Bracket, Left 1 1 1 1 1 1 1 1

8 D01-2435 Front Bearing Plate 2008 4" Meter Rolls 1 1 1 1 1 1 1 1

9 D03-0304 Sheave 2 Grade 20" Gripbelt 1 1 1 1 1 1 1 1

10 D32-0019 Bushing Q1 - 1-1/2" Split Taper 1 1 1 1 1 1 1 1

11 D01-0065 Spacer, Bearing Shield 2 2 2 2 2 2 2 2

*12 100-1 Motor 1 HP 1 PH 1800 RPM 1

12 100-3 Motor 1 HP 3 PH 143T 1750 TEFC 1

*12 D03-1106 Motor 1-1/2 HP 1 PH 1800 RPM 1

12 112-3 Motor 1-1/2 HP 3 PH 1800 RPM 1

*12 D03-1109 Motor 5 HP 1 PH 1800 RPM 1 1 1

12 500-3 Motor 5 HP 3 PH 1800 RPM 1 1 1

*12 D03-1010 Motor 7-1/2 HP 1 PH 1800 RPM 1

12 712-3 Motor 7-1/2 HP 3 PH 1800 RPM 1 1

12 1000-3 Motor 10 HP 3 PH 1800 RPM 1

13 D01-0081 Motor Mount - Bottom Auger 1 1 1 1 1 1 1 1

14 D01-0008 Front and Rear Frame Tie Channel 2 4 4 4 4 4 6 6

15 D01-0007 Corner Leg 6 6 6 6 8 8

16 D01-0017 Motor Adjustment Bracket 2 2 2 2 2 2

17 D11-0005 Frame Rail, 8' R.H. 1

17 D51-0002 Frame Rail, 12' R.H. 1

17 D21-0011 Frame Rail, 14' R.H. 1

17 D01-0538 Frame Rail, 16' R.H. 1

17 D31-0044 Frame Rail, 18' R.H. 1

17 D61-0002 Frame Rail, 20' R.H. 1

17 D101-0002 Frame Rail, 22' R.H. 1

17 D71-0002 Frame Rail, 26' R.H. 1

18 D01-0016 Motor Mount Support Bracket 1 1 1 1 1 1 1 1

19 D01-1372 Belt Guard, Unload Front Shield 1 1 1 1 1 1 1 1

20 PR-331 Peak Cap Handle 2 2 2 2 2 2 2 2

21 DC-971 Decal, Belt Drive Warning 2 2 2 2 2 2 2 2

22 DC-972 Decal, Chain Warning 2 2 2 2 2 2 2 2

*Ref #12, Part #D03-1109 and D03-1010 are single phase motors.

1108T 1112 1114 1116 1118 1120 1122 1126

Qty

28 PNEG-1402 Vision Series Model 1100 Portable Dryers

Page 29

Top Auger Drive

1

2

4

12

13

Top auger belt guard cover

Belt guard upper mount

Top auger drive components

3

5

14

1

6

2. Auger and Meter Roll Drive Trains

Figure 2C

PNEG-1402 Vision Series Model 1100 Portable Dryers 29

Page 30

2. Auger and Meter Roll Drive Trains

8

7

10

11

9

Top Auger Drive (Continued)

Figure 2D Top Auger Motor and Motor Mount

Top Auger Drive Parts List (See Figure 2C and 2D)

Ref # Part # D escription

1 D01-0453 Top Auger Belt Guard Body 1 1 1 1 1 1 1 1

2 D52-0001 Sheave 2 Grade 16" Gripbelt 1 1 1 1 1 1 1 1

3 D32-0019 Bushing Q1 - 1-1/2" Split Taper 1 1 1 1 1 1 1 1

4 D01-0464 V-Belt BX97 2 2 2 2 2 2 2 2

5 D03-0174 Sheave 2.5D x 7/8" Bore 1 1

5 2818-2 Sheave 2 Grade 3.35D x 1-1/8" Bore 1 1 1

5 D62-0003 Sheave 2 Grade 4.25D x 1-3/8" 1 1 1

6 D01-0155 Mounting Bracket - Belt Guard Spacer 1 1 1 1 1 1 1 1

7 D01-0424 Dryer Top Hand Hold 1 1 1 1 1 1 1 1

*8 D03-1107 Motor 2 HP 1 PH 1800 RPM 1 1

8 200-3 Motor 2 HP 3 PH 1800 RPM 1 1

*8 D03-1109 Motor 5 HP 1 PH 1800 RPM 1 1 1

8 500-3 Motor 5 HP 3 PH 1800 RPM 1 1 1

*8 D03-1010 Motor 7-1/2 HP 1 PH 1800 RPM 1

8 712-3 Motor 7-1/2 HP 3 PH 1800 RPM 1 1

8 1000-3 Motor 10 HP 3 PH 1800 RPM 1

9 D01-0173 Top Motor Mount Weldment 1 1 1 1 1 1 1 1

10 D01-0465 Turnbuckle 1/2" x 6" Plated 1 1 1 1 1 1 1 1

11 D01-0170 Anchor Bracket - Motor Mount 1 1 1 1 1 1 1 1

12 D01-0452-Y Top Auger Belt Guard Cover Ochr 1 1 1 1 1 1 1 1

13 DC-971 Decal, Belt Drive Warning 2 2 2 2 2 2 2 2

14 FH-4429-1 Latch 3 3 3 3 3 3 3 3

*Ref #8, Part #D03-1107, D03-1109 and D03-1010 are single phase motors.

1108T 1112 1114 1116 1118 1119 1122 1126

Qty

30 PNEG-1402 Vision Series Model 1100 Portable Dryers

Page 31

Metering Roll Drive

Meter roll drive train components

8

7

1

3

4

2

6

5

15

16

14

9

10

11

8

13

14

12

12

17

9

14

SCR Motor/reduction drive and motor mount assembly

2. Auger and Meter Roll Drive Trains

Figure 2E

PNEG-1402 Vision Series Model 1100 Portable Dryers 31

Page 32

2. Auger and Meter Roll Drive Trains

Front meter roll bearing

Rear meter roll bearing

18

18

19

21

19

20

Metering Roll Drive (Continued)

Figure 2F

Metering Roll Drive Parts List (See Figure 2E and 2F)

Ref # Part # Description

1 D01-0007 Corner Leg Portable Dryer 4 6 6 6 6 6 8 8

2 D11-0004 Frame Rail, 8' Left 1

2 D51-0001 Frame Rail, 12' Left 1

2 D21-0010 Frame Rail, 14' Left 1

2 D01-0537 Frame Rail, 16' Left 1

2 D31-0043 Frame Rail, 18' Left 1

2 D61-0001 Frame Rail, 20' Left 1

2 D101-0001 Frame Rail, 22' Left 1

2 D71-0002 Frame Rail, 26' Left 1

3 D01-0016 Motor Mount Support Bracket 1 1 1 1 1111

4 D01-0081 Motor Mount 1 1 1 1 1 1 1 1

5 D01-0704 SCR Motor Gear Box Mount 1 1 1 1 1111

6 D01-0008 Front and Rear Frame Tie Channel 2 4 4 4 4 4 6 6

7D03-0232 Motor 3/4 HP DC w/ Gear Box 50:1 1 1111111

8 D01-2435 Front Bearing Plate 2008 4" Meter Rolls 1 1 1 1 1 1 1 1

9D02-0029 Sprocket 40H30 2 2222222

10 D31-0316 Front Bottom Auger Shaft 1 1 1 1 1 1 1 1

11 D32-0001 Flangette Bearing 1-1/2" 2 2 2 2 2222

12 D01-0196 Sprocket Idler Assembly 2 2 2 2 2 2 2 2

13 D03-0257 Sprocket 4015 x 7/8" Bore w/ Keyway 1 1 1 1 1111

14 S-9168 Key Square 1/4" x 1" 3 3 3 3 3 3 3 3

15 S-6290 Chain #40 Roller Chain 6' 6' 6' 6' 6' 6' 6' 6'

16 D02-0031 #40 Chain Connecting Link 1 1 1 1 1 1 1 1

17DC-972 Decal, Chain Warning 2 2222222

18 D01-0003 Adaptor Plate 4 4 4 4 4 4 4 4

19 GK1583 Flangette Bearing 1", w/ Lock Collar 4 4 4 4 4444

20 D01-0006 Meter Roll Drive Shaft (Front) 2 2 2 2 2 2 2 2

21D01-0272 Meter Roll Shaft Stub (Rear) 2 2222222

Qty

1108T 1112 1114 1116 1118 1120 1122 1126

32 PNEG-1402 Vision Series Model 1100 Portable Dryers

Page 33

Fan/Heater Housing Assembly

36" and 42" Burner support and collector cup

1

3

10

9

Fan/Heater housing assembly

4

5

8

7

6

2

3. Fan/Heaters

Figure 3A

PNEG-1402 Vision Series Model 1100 Portable Dryers 33

Page 34

3. Fan/Heaters

Fan/Heater Housing Assembly Parts List (See Figure 3A)

Ref # Part # Description

3615 4015 4220 4225 4230 4240

1 D01-1963-6 Wrapper, 36" Fan/Heater 1

1 D01-1997-6 Wrapper, 40" Fan/Heater 1

1 D01-1964-6 Wrapper, 42" Fan/Heater 1 1 1 1

2 D01-1452 Straightening Va ne, 36-42" Fan/Heater 11 11 11 11 11 11

3 D01-1480 Inner Can, 36" Fan/Heater 1

3 D01-1479 Inner Can, 40" Fan/Heater 1

3 D01-1451 Inner Can, 42" Fan/Heater 1 1 1 1

4 401-5759-6-B Access Door - Galv. Fan Black 1 11111

5 069-1303-2 Sight Glass 1 1 1 1 1 1

6DC-1224 Decal, Danger High-Voltage 1 11111

7 DC-1225 Decal, Warning Rotating Blade 1 1 1 1 1 1

8DC-1227 Decal, Warning Fire 1 11111

9 D01-1484 Collector Cup, 36" Fan/Heater 1

9 D01-1485 Collector Cup, 40" Fan/Heater 1

9 TF-1217 Collector Cup, 42" Fan/Heater 1 1 1 1

Qty

10 D01-1482 Support Bracket, 36" Fan/Heater 1

10 D01-1483 Support Bracket, 40" Fan/Heater 1

10TF-1216 Support Bracket, 42" Fan/Heater 1111

Matching the right size fan/heater to the model number of the dryer.

Figure 3B

34 PNEG-1402 Vision Series Model 1100 Portable Dryers

Page 35

Fan Motor, Motor Mount and Fan Blade

Fan blade and bushing

Fan motor and motor mount

1

2

4

3

Figure 3C

3. Fan/Heaters

Fan/Heater

(Diameter, HP)

36" 15 HP

40" 15 HP

42" 20 HP

42" 25 HP

42" 30 HP

42" 40 HP

Fan Motor, Motor Mount and Fan Blade Parts List

Ref #

1 D01-1478 D01-1478 D01-1478 D01-1478 D01-1478 Motor Mount

2 002-1073-2 CH-1050 CH-1050 CH-1050 CH-6820 Motor

3 D82-0002 D82-0002 D82-0002 D82-0002 D82-0002 Fan Blade

4 FH-1009 FH-6963 FH-6963 FH-6963 FH-6963 Bushing

1 D01-1481 D01-1481 D01-1481 D01-1481 D01-1481 Motor Mount

2 CD-0571 CH-1050 CH-1050 CH-1050 CH-6820 Motor

3 D03-0567 D03-0567 D03-0567 D03-0567 D03-0567 Fan Blade

4 GC03810 GC03810 GC03810 GC03810 GC03810 Bushing

1 N/A D01-1453 D01-1453 D01-1453 D01-1453 Motor Mount

2 N/A CH-1051 CH-1051 CH-1051 2000-3-5 Motor

3 N/A D01-0470 D01-0470 D01-0470 D01-0470 Fan Blade

4 N/A GC03810 GC03810 GC03810 GC03810 Bushing

1 N/A D01-1474 D01-1474 D01-1474 D01-1474 Motor Mount

2 N/A C-2049 C-2049 C-2049 CH-6692 Motor

3 N/A D01-0471 D01-0471 D01-0471 D01-0471 Fan Blade

4 N/A CE-00617 CE-00617 CE-00617 CE-00617 Bushing

1 N/A D01-1474 D01-1474 D01-1474 D01-1474 Motor Mount

2 N/A TFH-2011 TFH-2011 TFH-2011 CH-6917 Motor

3 N/A D01-0472 D01-0472 D01-0472 D01-0472 Fan Blade

4 N/A CE-00617 CE-00617 CE-00617 CE-00617 Bushing

1 N/A D01-1475 D01-1475 D01-1475 D01-1475 Motor Mount

2 N/A CH-6848 CH-6848 CH-6848 CH-6887 Motor

3 N/A D01-0473 D01-0473 D01-0473 D01-0473 Fan Blade

4 N/A PT0784 PT0784 PT0784 PT0784 Bushing

220V 1 PH 208V 3 PH 220V 3 PH 440V 3 PH 575V 3 PH

Part #

Description

PNEG-1402 Vision Series Model 1100 Portable Dryers 35

Page 36

3. Fan/Heaters

1a

2

1

Air Mixer Assemblies

Figure 3D Air Mixer Assemblies (36'' Air mixer shown in photo.)

Air Mixer Assemblies Parts List

Ref # Part # Description 36'' F/H 40'' F/H 42'' F/H

1-2 CD-0113 Air Mixer Assembly, 36" 1

1 and 1a D01-1303 Air Mixer Can, 36" w/ Access 2/Assembly

2 CD-0083 Air Mixer Vane 8/Assembly

1-2 CD-0117 Air Mixer Assembly, 40" 1

1 and 1a D01-1218 Air Mixer Can, 40" w/ Access 2/Assembly

2 CD-0083 Air Mixer Vane 8/Assembly

1-2 CD-0118 Air Mixer Assembly, 42" 1

1 and 1a CD-0192 Air Mixer Can, 42" 2/Assembly

2 CD-0083 Air Mixer Vane 8/Assembly

36 PNEG-1402 Vision Series Model 1100 Portable Dryers

Page 37

Flame Probe, Ignitor and Burner Assemblies

Ignitor

Ignitor and flame probe assemblies

9

10

3

1

2

4

6

7

8

Flame probe

Ref #9 and 10 are used in LP fan/heaters only.

5

3. Fan/Heaters

Figure 3E

Ref # Part # Description 3615 4015 4220 4225 4230 4240

10 HF-7207 Vaporizer Coil 36-42" 10-17 HP 1 1 1

10 HF-7251 Vaporizer 3/4" 3 Wrap 36-42" 1 1

10 HF-7319 Vaporizer Coil (Spiral) 42" 40 HP 1

PNEG-1402 Vision Series Model 1100 Portable Dryers 37

Flame Probe, Ignitor and Burner Assemblies Parts List

Page 38

Burner housing high-limit switch

16

17

18

19

20

21

22

24

40'' and 42" Fan/Heater burner assembly

36" Fan/Heater burner assembly

23

14

15

12

11

13

3. Fan/Heaters

Flame Probe, Ignitor and Burner Assemblies (Continued)

38 PNEG-1402 Vision Series Model 1100 Portable Dryers

Figure 3F

Page 39

3. Fan/Heaters

Flame Probe, Ignitor and Burner Assemblies Parts List (See Figure 3E and 3F)

Ref # Part # Description 36'' F/H 40'' F/H 42'' F/H

1-3 TF-1559-N Flame Probe Assembly Network 1 1 1

1 HH-7025 Boot 8 mm Silicone 90° 1/Assembly

2 THH-4179 Flame Sensor 6" Long Rod 1/Assembly

3 CD-0187 Flame Sensor Bracket 1/Assembly

4-8 TF-1558 Ignitor Assembly 1 1 1

4 HF-7204 Dual Probe Ignitor Bracket 1/Assembly

5 D01-0878 Ignitor Air Deflector Angle 1/Assembly

6 HF-7201 Ignitor Half Clamp 2 /Assembl y

7 CD-0238 Ignitor Flame 2/Assembly

8 TF-1876 Ignition Wire Assembly (Includes Both Wires) 1/Assembly

9 HH-7056 Cone 36/42" Burner S.S. 1 1 1

10 See Chart on Page 37

11 THH-4064 Unilet Type LRL Conduit Box 1/2" 1 1 1

12 027-1006-9 Thermostat - High-Limit 200°F AUT 1 1 1

13 D01-1473 Housing High-Limit Plate 1 1 1

14 No Number Lid for LRL Conduit Box is Part of Ref #11 Not Applicable

15 TFC-0076 Neoprene Gasket, Conduit Body 1 1 1

16-20 BA-36 36" Burner Assembly 1

16 THF-3038 Diverter Bracket 36" and 40" 3/Assembly

17 THF-3038P Diverter Bracket 36" and 40" Perfed 4/Assembly

18 THF-3039 Diverter Bracket 36" and 40" w/ Hole 1/Assembly

19 THF-3057 Flame Spreader 36-42" 1/Assembly

20 CD-0091 Burner Weldment CD 36" and 40" 1/Assembly

21-24 BA-40-2 40" Burner Assembly 1

21 CD-0448P Diverter Bracket 42" Perfed 4/Assembly

22 CD-0448 Diverter Bracket 42" 4/Assembly

23 CD-0208 Burner Weldment CD 42" 1/Assembly

24 THF-3057 Flame Spreader 36-42" 1/Assembly

21-24 BA-42 42" Burner Assembly 1

21 CD-0448P Diverter Bracket 42" Perfed 4/Assembly

22 CD-0448 Diverter Bracket 42" 4/Assembly

23 CD-0208 Burner Weldment CD 42" 1/Assembly

24 THF-3057 Flame Spreader 36"-42" 1/Assembly

PNEG-1402 Vision Series Model 1100 Portable Dryers 39

Page 40

3. Fan/Heaters

36" Vaporizer coil connection and adjustment brackets

23

24

18

2

3

4

7

8

10

4

9

11

2

14

15

16

22

21

28

29

27

12

13

12

36" Fan/Heater LP pipe train assembly

25 26

24

1

5

6

17

19

17

20

LP Pipe Train Assemblies

Figure 3G

40 PNEG-1402 Vision Series Model 1100 Portable Dryers

Page 41

3. Fan/Heaters

36" Fan/Heater LP Pipe Train Assemblies Parts List (See Figure 3G)

Ref # Part # Description 36" LP F/H

1 THH-4120 Elbow, 3/4" - 90° SCH 40 1

2 THH-4121 Nipple, 3/4" Close SCH 40 2

3 007-1048-3 Ball Valve, 3/4" w/ Lever Handle 1

4 THH-4125 Nipple, 3/4" x 2 SCH 40 2

5 THH-4154 Tee, 3/4" x 3/4" x 1/4" SCH 40 1

6 HH-2984 Gauge, Pressure 0-30# LP 1

7 THH-4136 Nipple, 3/4" x 3" SCH 40 1

8 056-2223-8 Valve, Solenoid 3/4" NPT 115V Din 1

9 056-2228-7 Valve, Solenoid 3/4" NPT 115V Bypass 1

10 THH-4066 Elbow, 3/4" - 90° Street SCH 40 1

11 THH-4149 Elbow, 3/4" - 1/2" - 90° Reducer SCH 40 1

12 HH-2029 Nipple, 1/2" x 1-1/2" SCH 40 2

13 HH-1453 Tee, 1/2" x 1/2" x 1/2" SCH 40 1

14 HH-7013 Switch Screw-In Vapor High-Limit 1

15 THH-4071 Elbow, 1/2" - 90° SCH 40 1

16 TFC-0023-50 Regulator, 1/2" NPT 50 PSI 1

17 D07-0019 Nipple, 1/2" x 1-1/2" SCH 80 2

18 031-1008-7 Pressure Relief Valve 300 PSI 1

19 HH-4846 Tee, 1/2" x 1/2" x 1/4" SCH 80 1

20 HH-1251 Strainer, 1/2" “Y” SCH 80 1

21 HH-1932 Elbow, 1/2" - 90° Pipe - 1/2" Flare Brass 1

22 TFC-0095 Hose, 1/2" x 24" LP Gas 2

23 TF-1227 Pipe Train Bracket for 36" and 42" 1

24 326-1047-9 U-Bolt 5/16"-18 x 1-3/8" x 2-3/16" 3

25 401-5503-8 Plumbing Mounting Bracket 1

26 401-5255-5 Plumbing Mounting Base Bracket 1

27 HH-4847 Elbow, 1/2" - 90° SCH 80 2

28 D01-2217 Vaporizer Support Plate Black 1

29 410-1783-1-B Vaporizer Adjusting Weldment 1/2" 1

Ref # Part # Description Orifice Size

N/S CD-0150 Orifice For 36" Fans W/15 HP Motors 0.328"

PNEG-1402 Vision Series Model 1100 Portable Dryers 41

Page 42

3. Fan/Heaters

40'' and 42'' with 20 HP and smaller

motors vaporizer coil connection

and adjustment brackets.

40'' and 42'' with 25 HP and larger

motors vaporizer coil connection

and adjustment brackets.

1

24

25

10

1

2

9

2

12

23

22

19

21

20

17

17

18

16

14

15

27

28

29

27

30

30

31

13

12

40" and 42" LP pipe train assemblies

11

23

2

3

2

5

6

4

7

8

26

LP Pipe Train Assemblies (Continued)

42 PNEG-1402 Vision Series Model 1100 Portable Dryers

Figure 3H

Page 43

40" and 42" LP Pipe Train Assemblies Parts List (See Figure 3H)

3. Fan/Heaters

40" and 42'' LP F/H

Ref # Part # Description

1 THH-4115 Elbow, 1" - 90° SCH 40 2 2

2 007-1104-4 Nipple, Close 1" 4 4

3 007-1296-8 Ball Valve, 1" with Lever Handle 1 1

4 007-1106-9 Tee, 1" x 1" x 3/4" 1 1

5 D07-0027 Reducer, 3/4"-1/4" Hex Bushing 1 1

6 HH-2984 Pressure Gauge, 0-30# LP 1 1

7 THH-4037 Nipple, 1" x 2-1/2" SCH 40 1 1

8 056-2224-6 Valve, Solenoid 1" NPT 115V Din 1 1

9 056-2230-3 Valve, Solenoid 1" NPT 115V Bypass 1 1

10 007-1242-2 Nipple, 1" x 2" SCH 40 1 1

11 007-1288-5 Elbow, 1-1/2" - 90° SCH 40 1 1

12 HH-2029 Nipple, 1/2" x 1-1/2" SCH 40 2 2

13 HH-1453 Tee, 1/2" x 1/2" x 1/2" SCH 40 1 1

14 HH-7013 Switch Screw-In Vapor High-Limit 1 1

15 THH-4071 Elbow, 1/2" - 90° SCH 40 1 1

16 TFC-0023-50 Regulator, 1/2" NPT - CSA 50 PSI 1 1

17 D07-0019 Nipple, 1/2" x 1-1/2" SCH 80 2 2

18 HH-4846 Tee, 1/2" x 1/2" x 1/4" SCH 80 1 1

19 031-1008-7 Pressure Relief Valve 300 PSI 1 1

20 HH-1251 Strainer, 1/2" “Y” SCH 80 1 1

21 HH-1932 Elbow, 1/2" - 90° Pipe - 1/2" Flare Brass 1 1

22 TF-1227 Pipe Train Bracket for 36" and 42" 1 1

23 326-1047-9 U-Bolt 5/16"-18 x 1-3/8" x 2-3/16" 3 3

24 401-5503-8 Plumbing Mounting Bracket 1 1

25 401-5255-5 Plumbing Mounting Base Bracket 1 1

26 HH-4847 Elbow, 1/2" - 90° SCH 80 2 *

27 D01-2217 Vaporizer Support Plate Black 1 1

28 410-1783-1-B Vaporizer Adjusting Weldment 1/2" 1 *

29 D01-2220 Vaporizer Adjusting Weldment 3/4" * 1

30 007-1930-2 Reducer, Bell 3/4"-1/2" SCH 80 * 2

31 HH-1082 Elbow, 1/2" - 90° Street SCH 80 * 2

w/ 15 and

20 HP Motors

40" and 42'' LP F/H

w/ 25 HP and Larger

Motors

Ref # Part # Description Orifice Size

N/S THF-3058 Orifice for 40" Fans W/15 HP Motors 0.344"

N/S THF-3247 Orifice for 42" Fans W/20 HP Motors 0.375"

N/S THF-3249 Orifice for 42" Fans W/25 HP Motors 0.391"

N/S THF-3059 Orifice for 42" Fans W/30 HP Motors 0.438"

N/S THF-3252 Orifice for 42" Fans W/40 HP Motors 0.453"

PNEG-1402 Vision Series Model 1100 Portable Dryers 43

Page 44

3. Fan/Heaters

7

11

10

8

2

5

6

4

7

2

3

2

1

9

13 14

12

NG Pipe Train Assemblies

Figure 3I 36" Fan/Heater NG Pipe Train Assembly

36" Fan/Heater NG Pipe Train Assembly Parts List

Ref # Part # Description 36'' Fan/Heater

1 007-1307-3 Elbow, 1-3/4" - 90° 1

2 007-1104-4 Nipple, Close 1" 3

3 007-1296-8 Ball Valve, 1" w/ Lever Handle 1

4 007-1106-9 Tee, 1" x 1" x 3/4" 1

5 D07-0027 Reducer, 3/4"-1/4" Hex Bushing 1

6 D08-0022 Gauge, Pressure 0-15# 1

7 007-1242-2 Nipple, 1" x 2" SCH 40 2

8 THH-4115 Elbow, 1" - 90° SCH 40 1

9 056-2224-6 Valve, Solenoid 1" NPT 115V Din 1

10 056-2230-3 Valve, Solenoid 1" NPT 115V w/ Bypass 1

11 THH-4164 Elbow, 1" - 90° Street SCH 40 1

12 326-1047-9 U-Bolt 5/16"-18 x 1-3/8" x 2-3/16" 2

13 401-5503-8 Plumbing Mounting Bracket 1

14 401-5255-5 Plumbing Mounting Base Bracket 1

Ref # Part # Description Orifice Size

N/S THF-3244 Orifice for 36 " Fans W/15 HP Motors 0.500"

44 PNEG-1402 Vision Series Model 1100 Portable Dryers

Page 45

NG Pipe Train Assemblies (Continued)

12

13

1

10

7

1

2

11

8

2

3

2

5

6

4

7

9

3. Fan/Heaters

Figure 3J 40" and 42" Fan/Heater NG Pipe Train Assembly

40" and 42" Fan/Heater NG Pipe Train Assembly Parts List

Ref # Part # Descrip tion 40'' and 42'' F/H

1 THH-4115 Elbow, 1" - 90° SCH 40 2

2 007-1104-4 Nipple, Close 1" 3

3 007-1296-8 Ball Valve, 1" w/ Lever Handle 1

4 007-1106-9 Tee, 1" x 1" x 3/4" 1

5 D07-0027 Reducer, 3/4"-1/4" Hex Bushing 1

6 D08-0022 Gauge, Pressure 0-15# 1

7 007-1242-2 Nipple, 1" x 2" SCH 40 2

8 THH-4164 Elbow, 1" - 90° Street SCH 40 1

9 056-2224-6 Valve, Solenoid 1" NPT 115V Din 1

10 056-2230-3 Valve, Solenoid 1" NPT 115V w/ Bypass 1

11 326-1047-9 U-Bolt 5/16"-18 x 1-3/8" x 2-3/16" 2

12 401-5503-8 Plumbing Mounting Bracket 1

13 401-5255-5 Plumbing Mounting Base Bracket 1

Ref # Part # Description Orifice Size

N/S THF-3246 Orifice for 40" Fans W/15 HP Motors 0.516"

N/S THF-3248 Orifice for 42" Fans W/20 HP Motors 0.547"

N/S THF-3250 Orifice for 42" Fans W/25 HP Motors 0.578"

N/S THF-3251 Orifice for 42" Fans W/30 HP Motors 0.594"

N/S THF-3253 Orifice for 42" Fans W/40 HP Motors 0.641"

PNEG-1402 Vision Series Model 1100 Portable Dryers 45

Page 46

3. Fan/Heaters

Ref # Part # Description 1108T-1112 1114-1126

1 TFC-0027 Valve 1/4" NPT 250 PSI 2 2

2 THH-4144 Reducer 1/2" x 1/4" Bell SCH 80 1 1

3 D01-1186 Nipple, 1/2" x 21" SCH 80 1 1

4 TFC-0100 Valve, 1/2" NPT Sol w/ Din 1 1

5 D07-0019 Nipple, 1/2" x 1-1/2" SCH 80 2 2

6 THH-4058 Tee 1/2" x 1/2" x 1/2" SCH 80 1 1

7 D01-1185 Nipple, 1/2" x 67" SCH 80 1 1

8 HH-4847 Elbow, 1/2" - 90° SCH 80 1 1

9 007-1747-0 Pipe Plug, 1/4" 1 1

10 D07-0023 Nipple, 1/2" x 3" SCH 80 1 1

11 HH-1376 Valve, Vaporizer Shut Off 1 1

12 HH-3854 Nipple, 1/2" x 6" SCH 80 1 1

13 HH-4846 Tee 1/2" x 1/2" x 1/4" SCH 80 1 1

14 HH-1251 Strainer, 1/2" “Y” SCH 80 1 1

8

14

10

12

9

1

5

13

5

6

7

3

11

4

1

2

LP Supply Line

Figure 3K

46 PNEG-1402 Vision Series Model 1100 Portable Dryers

Page 47

NG Supply Line

17

15

1

9

7

3

8

10

3

4

2

3

11

12

13

14

Supply line mounting brackets

1

16

1

2

5

6

3. Fan/Heaters

Figure 3L

NG Supply Line Parts List

Ref # Part # Description 1108T-1112 1114-1126

1 D08-0011 Elbow, 1-1/2" - 90° SCH 40 2 3

2 D08-0008 Valve, 1-1/2" NPT B-Cock Shut Off 1 1

3 D08-0009 Nipple, 1-1/2" Close SCH 40 2 2

4 HH-7077 Nipple, 1-1/2" x 55" SCH 40 1 1

5 D08-0010 Union 1-1/2" Female SCH 40 1 1

6 D01-0763 Nipple, 1-1/2" x 31-1/2" SCH 40 1 N/A

6 HH-7074 Nipple, 1-1/2" x 34" SCH 40 N/A 1

7 031-1063-2 Shut Off Valve 1-1/2" 1 1

8 HH-7067 Nipple, 1-1/2" x 9" SCH 40 1 1

9 D67-0007 Plug 3/4" Square 1 1

10 D08-0015 Strainer 1-1/2" “Y” SCH 80 1 1

11 D08-0007 Reducer 1-1/2" x 1" Hex Bushing 1 1

12 007-1104-4 Nipple, Close 1" 1 1

13 007-1105-1 Union 1" Female SCH 40 1 1

14 033-1007-5 Gas Hose 1" NPT Male Both Ends 1 1

15 D31-0074 Gas Manifold Mounting Bracket 6 6

16 S-6643 Conduit Hanger 1-1/2" 3 3

17 D51-0045 Carrier Bracket, 1-1/2" Piping 1 1

PNEG-1402 Vision Series Model 1100 Portable Dryers 47

Page 48

4. Dryer Electrical Conduits

Upper junction box

Fill switch assembly (installed)

Operator light

Top auger motor conduit

Fill switch assembly (opened)

5

1

4

5

12

10

11

7

2

10

2

9

Ref #9-15 are components of the mercury

switch box assembly (fill switch assembly)

part #D01-0192.

3

6

1

15

9

2

9

1

8

14

13

11

Upper Junction Box, Top Auger Motor Conduit and Operator Light

Figure 4A

Ref # Part # Description

1 D03-0057 Conduit 1/2" EMT Metallic

2 D03-0054 Connector 1/2" EMT Compression

3 HH-1096 Clamp 1/2" Conduit

4 D03-0075 Connector 1/2" EMT to Sealtite

5 FH-7039 Sealtite PVC 1/2"

6 FH-7052

7 D03-0117

8 D03-0575 Bulb, 100W 130V Rough Service

9 FH-6972 Enclosure 4 x 4 x 2-1/2 White PVC

10 FH-1310 Connector 1/2"

11 WR-182SJOWA Wire 18/2 Type Sjow - A Black

12 D01-0358 Mounting Plate Weldment, Mercury Box

13 D03-0010-DC

14 SPD-2098 Clip Tilt Switch

15 D01-0103 Tilt Switch Shaft

Upper Junction Box, Top Auger Motor Conduit and Operator Light Parts List

48 PNEG-1402 Vision Series Model 1100 Portable Dryers

Elbow, 1/2" - 90

Lamp 90° w/ Junction Box

° PVC with Lock Nut

Tilt Switch 6° 6" Leads

Page 49

Air Switch Assembly

Air switch assembly (D01-0672)

Air switch assembly (installed)

Air switch assembly (internal parts)

1

3

2

9

4

5

6

8

7

10

12

1-9

11

10

4. Dryer Electrical Conduits

Ref # Part # Description Qty

1-9 D01-0672 Air Switch Assembly 1/Dryer

1 D01-0671 Air Switch Box Conduit Half 2/Assembly

2 D01-0670 Air Switch Box Face Plate 1/Assembly

3 DC-1103 Decal, Air Pressure Adjustment 1/Assembly

4 D03-0177 Grommet, 11/16" I.D. x 1" O.D. 1/Assembly

5 HF-7227 Coupling, 1/4" Std Black Steel 1/Assembly

6 HF-7228 Bushing, 1/4"-1/8" Hex 1/Assembly

7 HF-7226 Nipple, 1/8" Close 2/Assembly

8 HF-7229 Elbow, 1/8" - 90° SCH 40 1/Assembly

9 D03-0167 Air Pressure Switch 1/Assembly

Figure 4B

Air Switch Assembly Parts List

Ref # Part # Description

10 FH-7038 Conduit, 3/8" Sealtite

11 FH-7050 Connector, 3/8" x 90°

12 FH-7049 Connector, 3/8" Straight

PNEG-1402 Vision Series Model 1100 Portable Dryers 49

Page 50

4. Dryer Electrical Conduits

Right grain high-limit

Plenum high-limit

Left grain high-limit

Plenum high-limit thermostat

Grain temperature thermistor. There are two (2) thermistors in

each (right and left) grain high-limit thermostat assemblies.

8

11

7

10

9

Left grain high-limit

thermostat enclosure

8

3

6

8

5

7

1

3

2

4

Right and left grain high-limit thermostat

4

Right grain and plenum high-limit

thermostat enclosures

1

7

Right and Left Grain and Plenum High-Limits

Figure 4C

50 PNEG-1402 Vision Series Model 1100 Portable Dryers

Page 51

4. Dryer Electrical Conduits

Plenum high-limit thermostat conduit

13

12

15

16

14

11

Right and Left Grain and Plenum High-Limits (Continued)

Figure 4D

Right and Left Grain and Plenum High-Limits Parts List (See Figure 4C and 4D)

Ref # Part # Description

1 D01-0254 High-Limit Mounting Bracket

2 D03-0004 Plenum Thermostat 10' 300° (for 14' Dryers Only)

2 D03-0377 Plenum Thermostat 24' 300° (for Dryers that are 16' and Longer)

3 FH-6972 Enclosure 4 x 4 x 2-1/2 White PVC

4 FH-7038 Sealtite PVC 3/8"

5 FH-7050 Elbow, 3/8" - 90° PVC w/ Nut

6 D03-0005 Grain Thermostat High-Limit 10' 210° (for 14' Dryers Only)

6 D03-0378 Grain Thermostat High-Limit 24' 210° (for Dryers that are 16' and Longer)

7 D03-0054 Connector 1/2" EMT Compression

8 D03-0057 Conduit 1/2" EMT Metallic

9 D03-0258 Grain Temperature Thermistor Ser2000

10 D03-0060 Connector 3/8" Liquid-tite to 1/2" EMT

11 HH-1096 Clamp 1/2" Conduit

12 D03-0375 Conduit Body, LL Type

13 TFC-0075 Cover Aluminum, Conduit Body

14 HF-7236 Plenum Thermistor Bolt

15 DM60001 Pipe SCH 40-1/2"

16 GT3-0241 Clamp, Beam 1/2"

The following components make up the grain high-limit conduits that run through the grain columns. The conduit assemblies are not

shown in the photos.

N/S D03-0057 Conduit 1/2" EMT Metallic

N/S D03-0054 Connector 1/2" EMT Compression (2/Conduit; 1 at Each End of the Dryer)

N/S D33-0002 Coupler 1/2" EMT Compression (Couples the Lengths of 1/2" EMT)

Enclosure 4 x 4 x 2-1/2 White PVC (As of 2003 a 4 x 4 enclosure has been added to these assemblies

N/S FH-6972

and is mounted on the rear column end panels into which the grain high-limit thermostat conduits

now terminate.)

PNEG-1402 Vision Series Model 1100 Portable Dryers 51

Page 52

4. Dryer Electrical Conduits

Lower junction box (left)

Rear discharge switch conduit at rear left gusset

where 1/2" EMT conduit terminates.

Conduit to meter roll speed sensor and

rear discharge switch. (See photos below

and on Page 53.)

Meter roll speed sensor and rear discharge

switch conduit. This is a photo of the front

section of the conduit that runs through the

gussets on the left side of the dryer.

Meter roll motor conduit connection

Lower junction box (right)

1

4

7

5

6

6

5

4

3

2

2

8

1

9

10

8

1

11

1

1

13

12

14

14

14

15

Coupler for 1/2" EMT conduit

7

14

13

Conduit to meter roll

motor. (See Meter

roll motor conduit

connection below.)

Lower Junction Box, Meter Roll Motor Conduit and Rear Discharge

Conduit

52 PNEG-1402 Vision Series Model 1100 Portable Dryers

Figure 4E

Page 53

4. Dryer Electrical Conduits

Rear discharge switch conduit

at rear left gusset

7

1

2

20

8

9

24

23

22

21

16

17

18

19

11

1

7

1

11

Meter roll speed sensor

Rear discharge switch (open to show mercury switch)

Lower Junction Box, Meter Roll Motor Conduit and Rear Discharge

Conduit (Continued)

Figure 4F

Lower Junction Box, Meter Roll Motor Conduit and Rear Discharge Conduit Parts List

(See Figure 4E and 4F)

Ref # Part # Description

1 FH-7038

2 F-6913 Connector PVC 3/8" 45' w/ Nut

3 FH-7050 Elbow, 3/8" - 90° PVC w/ Nut

4 FH-7049 Straight PVC w/ Lock Nut 3/8"

5 D03-0054 Fitting Compression 1/2" to Box

6 D03-0057 Conduit 1/2" EMT

7 FH-6972 Enclosure 4 x 4 x 2-1/2 White PVC

8 FH-1310 Connector 1/2"

9 WR-182SJOWA Wire 18/2 Type Sjow - A Black

10 D07-0028 Reducer 3/4" x 1/2" Hex Bushing

11 FH-7050 Elbow, 3/8" - 90° PVC w/ Nut

12 D03-0060 Connector 3/8" Liquid-tite to 1/2" EMT

13 D03-0054 Connector 1/2" EMT Compression

14 D03-0057 Conduit 1/2" EMT Metallic

15 D33-0002 Coupler 1/2" EMT Compression

16 D01-0462 Speed Sensor Box Bracket

17 D01-0527 SCR Meter Roll Speed Sensor

18 HH-7046 Disconnect 0.187 Fem

19 D01-0687 Metering Roll Timing Gear Assembly

20 D01-1105 Discharge Switch Mounting Plate

21 TFC-0075 Cover Aluminum, Conduit Body

22 SPD-2098 Clip, Tilt Switch

23 D03-0010-DC Tilt Switch

24 D03-0375 Conduit Body, LL Type

Sealtite PVC 3/8"

PNEG-1402 Vision Series Model 1100 Portable Dryers 53

Page 54

5. Control Boxes

A detailed view of the heater board

15

8

16 17

18

9

19

20

22

21

4

13

5

7

9

6

3

12

10

14

23

26

25

24

13

23

11

1

15

16

17 18

19

2

14

Fan/Heater Electrical Box

Figure 5A

54 PNEG-1402 Vision Series Model 1100 Portable Dryers

Page 55

5. Control Boxes

Fan/Heater Electrical Box Parts List (See Figure 5A)

Ref # Part # Description All Fan/Heaters

N/S D01-1992 Control Box Lid 1

1 D01-2105 Control Box Back Panel 1

2 D01-2106 Control Left Side 1

3 D01-2107 Control Box Right Side 1

4 D01-2110 Control Box Front Panel 1

5 D03-0696 Control Box Latch 1

6 D01-2108 Control Box Base 1

7 006-1389-3 Nylon Bushing - 2" Diameter 1

8 D01-2111 Control Box Wall 1

9 E160-1137 Ground Lug, #TA-2 2

10 HH-1105 Nylon Bushing - 11/16" I.D. 3

11 HF-4624 Fenwal Flame Detection Board 1

12 D01-2109 Fenwal Board Bracket 1

13 D01-1981 Mounting Bracket Heater Board 1

14 D01-0730 Touch Control Fan/Heater PCB ASM 1

15 D03-0013 Din Rail Mounting 39.37" Long 0.45

16 D01-0531 Terminal - Block Entrelec 4 mm 28

17 D01-0532 Terminal - Blank End Protector 11

18 D01-0534 Terminal - Entrelec Ground Block 1

19 D01-0533 Terminal - Entrelec End Stop 8

20 D03-0511 Points, Auxillary for IEC 1

21 (See Chart below for Part Numbers)

22 (See Chart below for Part Numbers)

23 E240-1148 Connector 4 Pin 0.200 PCB Plug 2

24 D01-0460 Term Strip 10 Position 1

25 E240-1155 Connector 3 Pin 0.200 PCB Plug 1

26 E240-1154 Connector 5 Pin 0.200 PCB Plug 1

Ref # Description 10-12 HP Fan Motors (3612 Fan/Heaters)

220V 1 PH 208V 3 PH 220V 3 PH 380V 3 PH 440V 3 PH 575V 3 PH

21 Overload D03-0483 D03-0482 D03-0482 D03-0476 D03-0476 D03-0475

22 Contactor D03-0495 D03-0494 D03-0494 D03-0490 D03-0492 D03-0490

10-16 HP Fan Motors (3615, 4015 Fan/Heaters)

220V 1 PH 208V 3 PH 220V 3 PH 380V 3 PH 440V 3 PH 575V 3 PH

21 Overload D03-0485 D03-0483 D03-0483 D03-0479 D03-0477 D03-0478

22 Contactor D03-0497 D03-0494 D03-0494 D03-0492 D03-0492 D03-0491

20 HP Fan Motors (4220 Fan/Heaters)

220V 1 PH 208V 3 PH 220V 3 PH 380V 3 PH 440V 3 PH 575V 3 PH

21 Overload N/A D03-0484 D03-0484 D03-0480 D03-0480 D03-0479

22 Contactor N/A D03-0495 D03-0495 D03-0493 D03-0492 D03-0492

25 HP Fan Motors (4225 Fan/Heaters)

220V 1 PH 208V 3 PH 220V 3 PH 380V 3 PH 440V 3 PH 575V 3 PH

21 Overload N/A D03-0485 D03-0485 D03-0482 D03-0482 D03-0479

22 Contactor N/A D03-0497 D03-0496 D03-0494 D03-0494 D03-0492

30 HP Fan Motors (4230 Fan/Heaters)

220V 1 PH 208V 3 PH 220V 3 PH 380V 3 PH 440V 3 PH 575V 3 PH

21 Overload N/A D03-0487 D03-0485 D03-0483 D03-0530 D03-0481

22 Contactor N/A D03-0498 D03-0497 D03-0494 D03-0494 D03-0494

40 HP Fan Motors (4240 Fan/Heaters)

220V 1 PH 208V 3 PH 220V 3 PH 380V 3 PH 440V 3 PH 575V 3 PH

21 Overload N/A 056-2276-6 056-2276-6 D03-0484 D03-0483 D03-0482

22 Contactor N/A 056-2275-8 056-2275-8 D03-0495 D03-0495 D03-0494

PNEG-1402 Vision Series Model 1100 Portable Dryers 55

Page 56

5. Control Boxes

Vision control panel (front)

6

3

5

4

7

12

15

13

11

8

9 10

16

1

2

14

Control Box Control Panel

Figure 5B

Control Box Control Panel Parts List

Ref # Part # Description

1 111-1001-2 Hinge 1-1/6" x 19 Gauge x 72" SS

2 D01-0447 Switch 3 Position Selector Red

3 D01-0449 Switch 3 Position Selector Blue

4 D01-0579 Switch 3 Position Selector Yellow

5 D01-0445 Switch 3 Position Selector Amber

6 D03-018 2 3 Position Selector Switch White

7 D01-0446 Switch 2 Position Selector Green

8 D03-001 7 Switch Start N.O. (Illuminated)

9 D03-0020 Switch Stop Block (Red)

10 E115-1060 Knob, Augat #PK-70B-1/4

10 D03-0595 Screen, SCR Digital Encoder 31 Position Push Button Hi\Low Used On

11 401-5794-5-1 Switch Mounting Plate 1 Fan

12 DC-1780 Decal, Vision Control 1 Fan

13 TF-1519 Latch, Southco Slotted

14 TFH-2046 Spring Latch Southco w/ Black Knob

15 D03-0746 Touch Control Touch Screen

16 D03-0734PRNT GSI Moisture Control Printer

56 PNEG-1402 Vision Series Model 1100 Portable Dryers

Page 57

Lower Control Box Back Panel

Lower control box back panel

1

4

5

6

8

5

2

3

9

14

13

15

Emergency stop

switch (outside)

Emergency stop

switch (inside)

11

12

10

10

7

5. Control Boxes

Figure 5C

Lower Control Box Back Panel Parts List

Ref # Part # Description Circuit

1 D01-0486 Lower Control Box Back Panel Misc.

2 D03-0742-C Vision Control 12 VDC Power Supply Control

3 D03-0754-C Touch Control 5 VDC Power Supply Control

4 D03-0013 Di n Rail, Terminal Block Mounting Misc.

5 D01-0533 Terminal - Entrelec End Stop Misc.

6 D01-0534 Terminal - Entrelec Ground Block Misc.

7 D01-0531 Terminal - Block Entrelec 4 mm Misc.

8 D01-0532 Terminal - End Protector Misc.

9 D03-0181 Filter RFI “B” Series Control

10 TF-1279 Emergency Stop Switch Safety

11 DC-1317 Decal, Emergency Stop Misc.

12 D63-0013 Block, Contact N/C Safety

13 D02-0039 Wire Tie Anchor Misc.

14 D03-0247 Wire Tie, 5" Panduit Misc.

15 D03-0725-C Vision Moisture Control Board Assembly Control

PNEG-1402 Vision Series Model 1100 Portable Dryers 57

Page 58

5. Control Boxes

A more detailed parts breakdown of

the display and computer

is shown on Page 59.

Detailed view of a single

position switch

Vision control panel (rear)

1

1a

2

4

3

6

Detailed view of a two

position switch

5

7

8

7

7

8

9

Control Box Switch Panel (Rear)

Figure 5D

Control Box Switch Panel (Rear) Parts List

Ref # Part # Description Circuit

1 TFH-2046 Spring Latch Southco w/ Black Knob Misc.

1a TF-1519 Latch, Southco Slotted Misc.

2 401-5794-5-1 Switch Mounting Plate 1 Fan Misc.

3 D03-0734PRNT GSI Moisture Control Printer Control

4 602E155BKT Take-up Motor Support Bracket Misc.

5 602E155 Printer-paper Take-Up Misc.

6 D03-0595 SCR Potentiometer 10K Control

7 D63-0006 Block, Contact N/O Control

8 D01-0455 Block, Light 12/24/120V Lamps Control

9 D03-0723-C Touch Control Display I/O PCB Computer Control

58 PNEG-1402 Vision Series Model 1100 Portable Dryers

Page 59

Control Box Switch Panel (Rear)

1

2

3

4

5

7

6

8

9

Vision control computer (cover removed)

Vision control computer cover

5. Control Boxes

Figure 5E

Control Box Switch Panel (Rear) Parts List

Ref # Part # Description

1 D03-0763FRNT Touch Control Front Panel

2 D03-0763PLT Touch Control Internal Plate

3 D03-0753TUSB Touch Control USB Cable

4 D03-0753TC Touch Controller PCB (Dryers)

5 D03-0753 Touch Control CPU Assembly (Dryers)

6 D03-0744 Touch Control Display Inverter

7 D03-0723-C Touch Control Display I/O PCB Computer

8 D03-0763-FAN Fan Cooling for D03-0763 - Assembly

9 D03-0763BACK Touch Control Back Cover

PNEG-1402 Vision Series Model 1100 Portable Dryers 59

Page 60

5. Control Boxes

7

1

3

4

5

2

10

13

12

11

15

16

14

18

17

19

20

21

23

24

22

32

31

29

28

27

26

25

30

8

6

7

9

Upper Control Box

Figure 5F Upper Control Box Power Distribution Panel

60 PNEG-1402 Vision Series Model 1100 Portable Dryers

Page 61

5. Control Boxes

Upper Control Box Component Part Numbers (Continued)

1108T Upper Control Box Component Parts List (See Figure 5F)

Ref #

220V 1 PH 208V 3 PH 220V 3 PH 440V 3 PH 575V 3 PH

1 D01-0480 D01-0480 D01-0480 D01-0480 D01-0480 Power Box Bock Panel N/A

2 D03-0473 D03-0473 D03-0472 D03-0471 D03-0543 Overload Load

3 D03-0482 D03-0479 D03-0477 D03-0474 D03-0473 Overload Load Aux.

4 D03-0473 D03-0472 D03-0471 D03-0541 D03-0541 Overload Unload

5 D03-0482 D03-0479 D03-0477 D03-0474 D03-0473 Overload Unload Aux.

6 D03-0488 D03-0488 D03-0488 D03-0488 D03-0488 Contactor Load

1108T Part #

Description Circuit

7 D03-0494 D03-0492 D03-0491 D03-0489 D03-0489 Contactor Load Aux.

8 D03-0488 D03-0488 D03-0488 D03-0488 D03-0488 Contactor Unload

9 D03-0494 D03-0492 D03-0491 D03-0489 D03-0489 Contactor Unload Aux.

10 D01-0531 D01-0531 D01-0531 D01-0531 D01-0531 Terminal - Block Entrelec 4 mm Control

11 D01-0532 D01-0532 D01-0532 D01-0532 D01-0532 Terminal - Blank End Protector Control

12 D01-0533 D01-0533 D01-0533 D01-0533 D01-0533 Terminal - Entrelec End Stop Control

13 D01-0534 D01-0534 D01-0534 D01-0534 D01-0534 Terminal - Entrelec Ground Block Control

14 HF-7203 HF-7203 HF-7203 HF-7203 HF-7203 Relay, 3 PDT 120V RH3B-U IDEC Control

15 07097555 070975553 07097555 07097555 07097555 Relay Base, 3 PDT Control

16 FH-3807 FH-3807 FH-3807 FH-3807 FH-3807 Transformer Control

17 006-1184-8 006-1184-8 006-1184-8 006-1184-8 006-1184-8 Terminal Ground Bar Ground

18 D03-0736-C D03-0736-C D03-0736-C D03-0736-C D03-0736-C Dryer I/O PCB Assembly Computer Vision Control

19 D03-0106 D03-0106 D03-0106 D03-0106 D03-0106 SCR Contactor 15 Amp 3 Pole Meter Roll

20 D03-0660-34 D03-0660-34 D03-0660-34 D03-0660-34 D03-0660-34 Breaker, 3 Amp 3 Pole Delayed Meter Roll

21 D03-0661 D03-0661 D03-0661 D03-0661 D03-0661 Breaker 6 Amp 1 Pole 110 VAC Control

22 D03-0104-3/4 D03-0104-3/4 D03-0104-3/4 D03-0104-3/4 D03-0104-3/4 SCR Drive Board Assembly 3/4 HP DC Meter Roll

23 D01-0550 D01-0550 D01-0550 D01-0550 D01-0550 Power Box Catch Angle, Bottom N/A

24 D01-0494 D01-0499 D01-0499 D01-0613 D03-0533 Main Breaker Power

25 D33-0001 D33-0001 D33-0001 D33-0001 D33-0001 SCR Resistor Plug-In 3/4 HP 180V Meter Roll

26 D03-0464 D03-0459 D03-0457 D03-0528 D03-0531 Breaker Unload Aux.

27 D03-0300 D03-0293 D03-0293 D35-0001 D35-0001 Distribution Block Power

28 D03-0379 D03-0380 D03-0380 D03-0389 D03-0541 Breaker Unload

29 D03-0464 D03-0459 D03-0457 D03-0528 D03-0531 Breaker Load Aux.

30 D03-0448 D03-0380 D03-0380 D03-0389 D03-0531 Breaker Load

31 D03-0510 D03-0461 D03-0461 D03-0546 D03-0532 Breaker Fan

32 D01-0551 D01-0551 D01-0551 D01-0551 D01-0551 Power Box Catch Angle, Top N/A

PNEG-1402 Vision Series Model 1100 Portable Dryers 61

Page 62

5. Control Boxes

Upper Control Box Component Part Numbers (Continued)

1112 Upper Control Box Component Parts List (See Figure 5F)

Ref #

220V 1 PH 208V 3 PH 220V 3 PH 440V 3Ph 575V 3Ph

1 D01-0480 D01-0480 D01-0480 D01-0480 D01-0480 Power Box Bock Panel N/A

2 D03-0475 D03-0473 D03-0473 D03-0471 D03-0471 Overload Load

3 D03-0482 D03-0479 D03-0477 D03-0474 D03-0473 Overload Load Aux.

4 D03-0473 D03-0473 D03-0472 D03-0471 D03-0543 Overload Unload

5 D03-0482 D03-0479 D03-0477 D03-0474 D03-0473 Overload Unload Aux.

6 D03-0490 D03-0489 D03-0488 D03-0488 D03-0488 Contactor Load

7 D03-0494 D03-0492 D03-0491 D03-0489 D03-0489 Contactor Load Aux.

8 D03-0488 D03-0488 D03-0488 D03-0488 D03-0488 Contactor Unload

9 D03-0494 D03-0492 D03-0491 D03-0489 D03-0489 Contactor Unload Aux.

10 D01-0531 D01-0531 D01-0531 D01-0531 D01-0531 Terminal - Block Entrelec 4 mm Control

11 D01-0532 D01-0532 D01-0532 D01-0532 D01-0532 Terminal - Blank End Protector Control

12 D01-0533 D01-0533 D01-0533 D01-0533 D01-0533 Terminal - Entrelec End Stop Control

13 D01-0534 D01-0534 D01-0534 D01-0534 D01-0534 Terminal - Entrelec Ground Block Control

14 HF-7203 HF-7203 HF-7203 HF-7203 HF-7203 Relay, 3 PDT 120V RH3B-U IDEC Control

15 07097555 070975553 07097555 07097555 07097555 Relay Base, 3 PDT Control

1112 Part #

Description

Circuit

16 FH-3807 FH-3807 FH-3807 FH-3807 FH-3807 Transformer Control

17 006-1184-8 006-1184-8 006-1184-8 006-1184-8 006-1184-8 Terminal Ground Bar Ground

18 D03-0736-C D03-0736-C D03-0736-C D03-0736-C D03-0736-C Dryer I/O PCB Assembly Computer Vision Control

19 D03-0106 D03-0106 D03-0106 D03-0106 D03-0106 SCR Contactor 15 Amp 3 Pole Meter Roll