Page 1

8", 10", & 12" BE-SAW

Unload Auger

Assembly & Operation Manual

PNEG-1391

Date: 5-5-06

PNEG-1391

Page 2

Model Number of My BE-SAW:

Date Delivered:

Date Installed:

The manufacturer reserves the right to improve its product whenever possible

and practical to do so. We reserve the right to change, improve and modify

products at any time without obligation to make changes, improvements and

modifications on equipment sold previously.

Page 3

TABLE OF CONTENTS

Introduction.............................................................................. 4

BE-SAW Numbering System................................................... 5

Safety ..................................................................................... 6

Decals .................................................................................... 12

Assembly ................................................................................ 14

Assemble Hopper to Incline (8" &10") ............................... 14

Assemble Hopper to Incline (12") ...................................... 16

Assemble Rubber Belting (8", 10", & 12") ......................... 19

Table of Content

Optional Low Profile Hopper (10" & 12") ........................... 20

Incline Tube to Bucket Elevator Boot ................................... 22

BE-SAW Transition ............................................................ 23

Start-Up .................................................................................. 24

Operation ................................................................................ 25

Shutdown ................................................................................ 26

Maintenance ........................................................................... 27

Troubleshooting....................................................................... 29

Parts ....................................................................................... 30

Hardware Location Charts ...................................................... 50

3PNEG-1391 8",10", & 12" BE-SAW Augers

Page 4

Introduction

INTRODUCTION

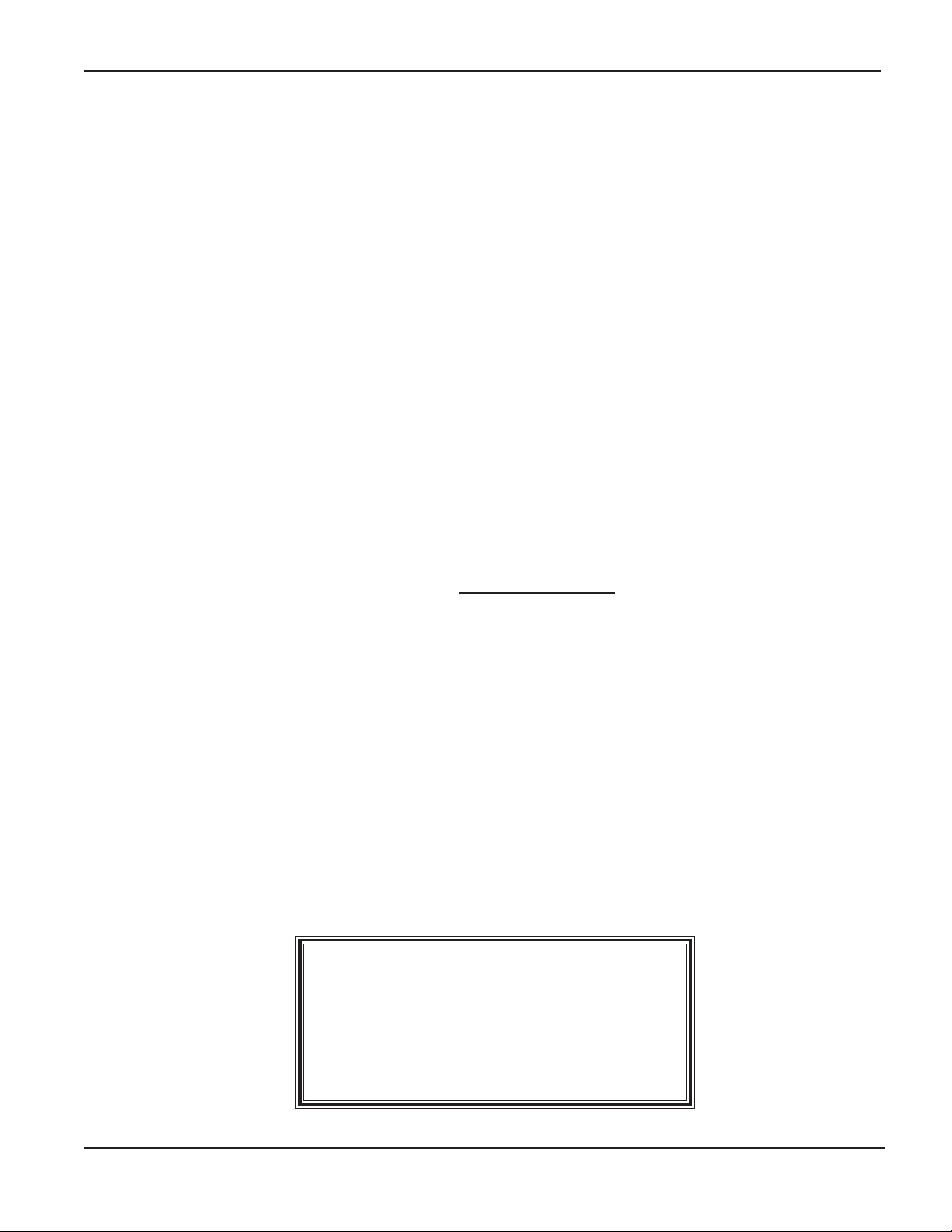

GENERAL OVERVIEW

The Bucket Elevator Swing Away Auger (BE-SAW) is

pimarily used for unloading grain trucks/wagons. The

BE-SAW hopper is placed under the unload chute

and augers the grain to a new location.

The manufacturer reserves the right to improve its

product whenever possible and practical to do so.

We reserve the right to change, improve and modify

products at any time without obligation to make

changes, improvements and modifications on equipment sold previously.

The BE-SAW Augers have been designed and

manufactured to give years of dependable service.

The care and maintenance of this equipment will

effect the satisfaction and service obtained. By

observing the instructions and suggestions we have

recommended, the owner should receive competent

service for many years. If additional information or

assistance should be required, please contact your

dealer or the manufacturer.

CAPACITY

A. The capacities of augers or screw

conveyers varies greatly under varying

conditions. The following factors play a role in

the performance of the auger:

• Speed

• Angle of operation

• Moisture content

• Amounts of foreign matter

• Methods of feeding

• Different materials

B. An auger operating at a 25° incline might

experience 20% less capacity than an auger

operating horizontally. Twenty-five percent

(25%) moisture could cut capacity by as much

as 40% under some conditions.

GENERAL INFORMATION

READ THIS MANUAL carefully to learn how to properly

use and install equipment. Failure to do so could result

in personal injury or equipment damage.

INSPECT the shipment immediately upon arrival. The

Customer is responsible for ensuring that all quantities

are correct. Report any damage or shortages by

recording a detailed description on the Bill of Lading to

justify the Customer’s claim from the Transport Firm.

THIS MANUAL SHOULD BE CONSIDERED a

permanent part of your equipment and should be easily

accessible when needed.

WARRANTY is provided as part of the company’s

support program for customers who use and maintain

their equipment as described in the manual. The

warranty is explained on the warranty page located on

inside back cover.

This warranty provides you the assurance that the

company will back its products where defects appear

within the warranty period. Should the equipment be

abused, or modified to change its performance beyond

the factory specifications, the warranty will become void

and field improvements may be denied.

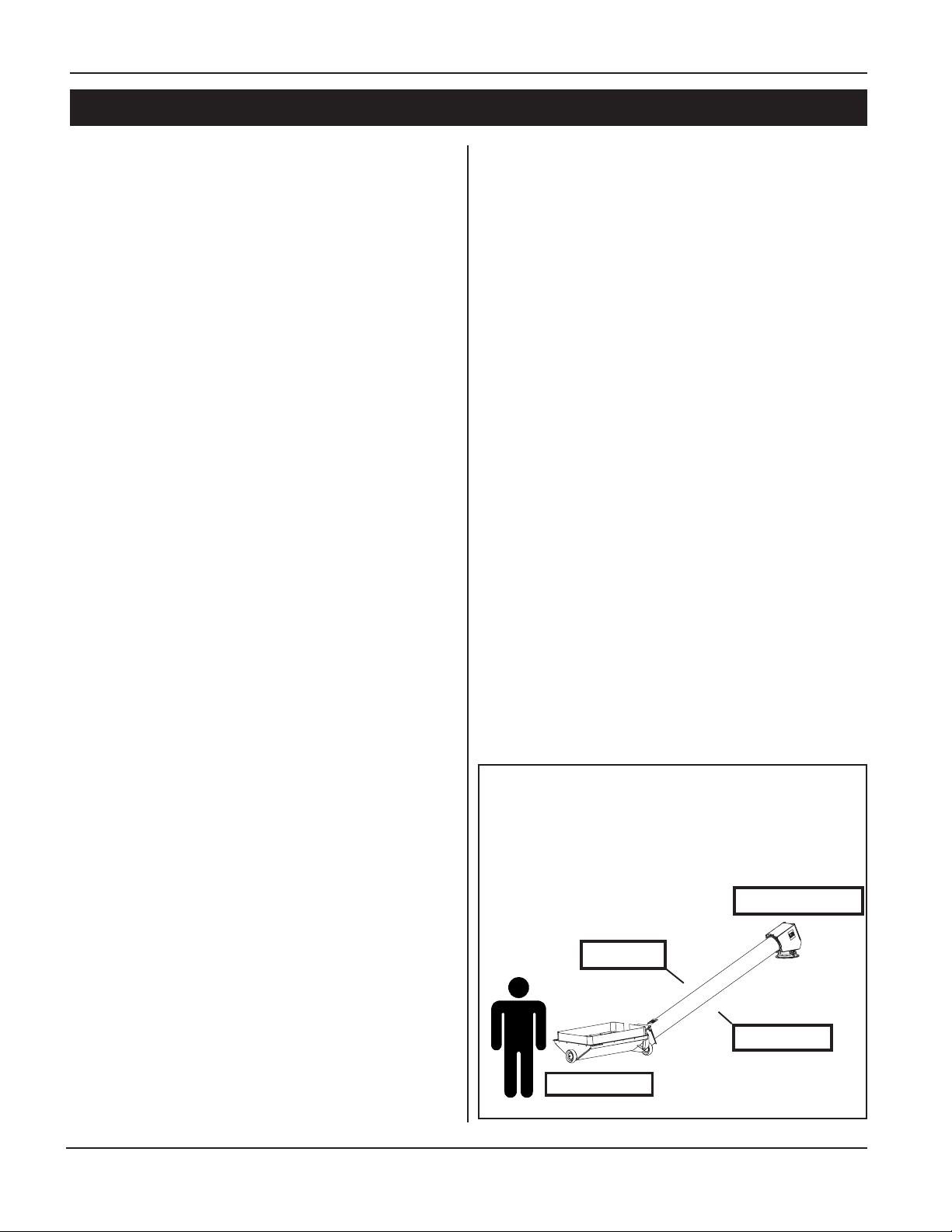

For the purpose of this manual, if you stand at

the intake end of the auger looking towards

the discharge end, your left is the left side of

the auger; your right is the right side of the

auger.

Discharge End

Left Side

Right Side

Intake End

4

PNEG-1391 8",10", & 12" BE-SAW Augers

Page 5

Introduction

w

w

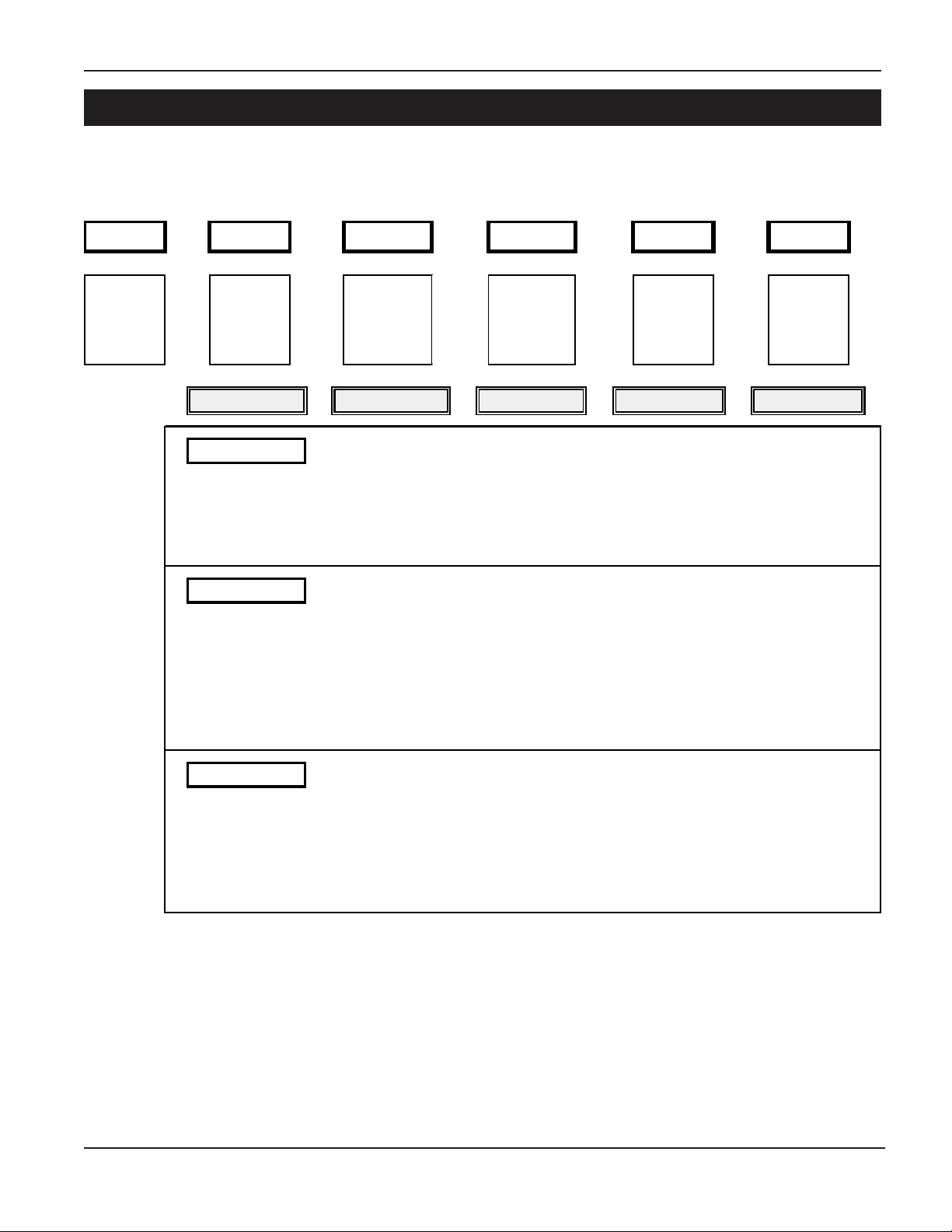

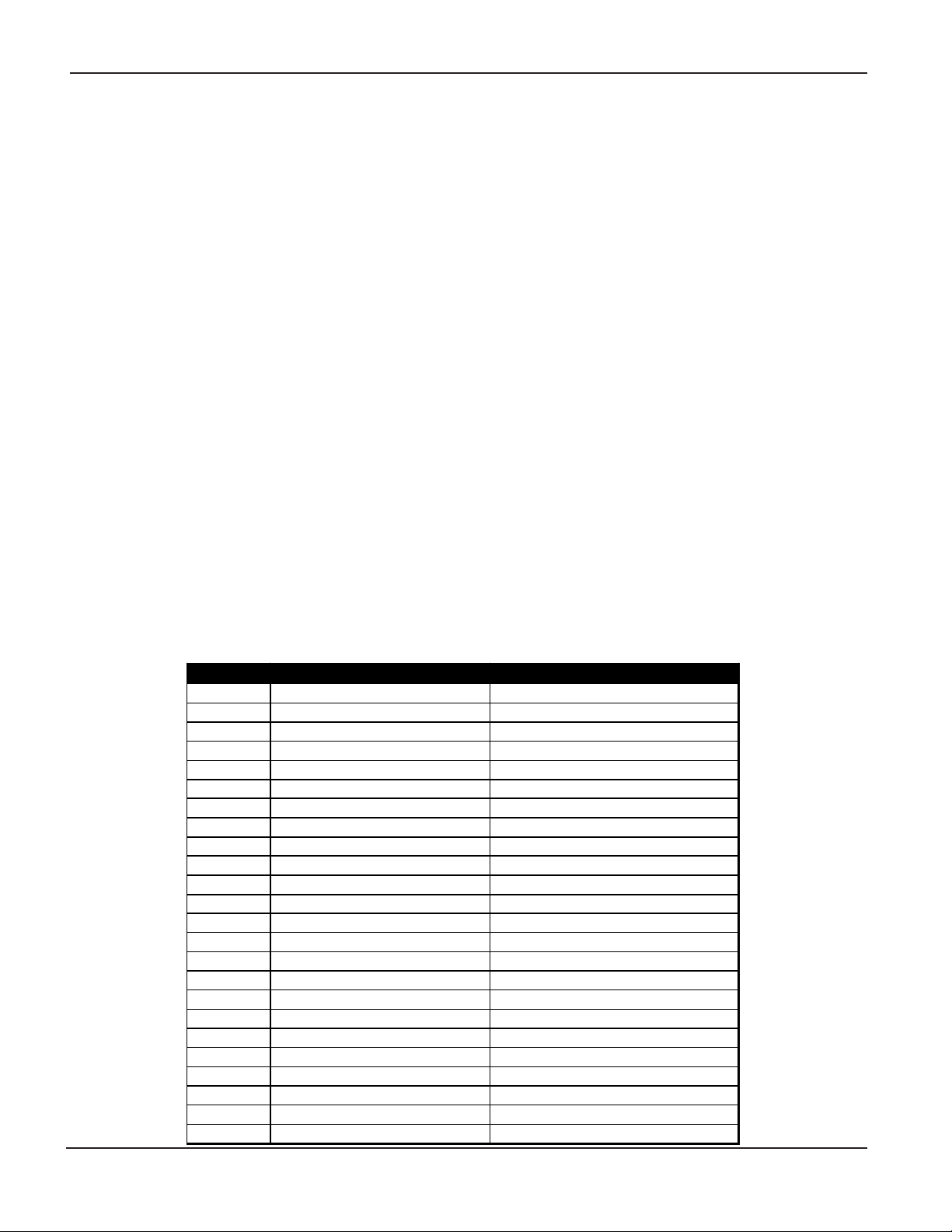

BE-SAW Numbering System

SA XX X XX XX X

Product Diameter Hopper Nominal Capacity Hopper

Line of Profile Length of Flight

Screw of BESAW Thickness

Tube

ChoiceChoi ce Choi ce Choice Choice

08 = 8" Screw

S = Std Profile 10 = 115.875" 15 = 1500 BPH

12 = 144" lg 20 = 2000 BPH

25 = 2500 BPH

30 = 3000 BPH

A = Standa r d

B = 1/4" Thick

10 = 10" Scre

12 = 12" Scre

S = Std Profile 10 = 120" lg 40 = 4000 BPH

13 = 153" lg 50 = 5000 BPH

L = Low-Profile 10 = 115.125"

13 = 148.125"

S = Std Profile 13 = 13' 3" 70 = 7000 BPH A = Standard

15 = 15' 3"

L = Low-Profile 70 = 7000 BPH

12 = 12' 8"

80 = 8000 BPH

A = Standa r d

B = 1/4" Thick14 = 160" lg 56 = 5600 BPH

B = 1/4" Thick

A = Standa r d

B = 1/4" Thick14 = 14' 8" 80 = 8000 BPH

PNEG-1391 8",10", & 12" BE-SAW Augers

5

Page 6

Safety

SAFETY GUIDELINES

This manual contains information that is important for you, the owner/operator, to know and

understand. This information relates to protecting personal safety and preventing

equipment problems. It is the responsibility of the owner/operator to inform anyone

operating or working in the area of this equipment of these safety guidelines. To help you

recognize this information, we use the symbols that are defined below.

Please read the manual and pay attention to these sections. Failure to read this manual

and it’s safety instructions is a misuse of the equipment and may lead to serious injury or death.

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

DANGER indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a potentially

hazardous situation which, if not avoided, may result in property

damage.

NOTE indicates information about the equipment that you

should pay special attention to.

6

PNEG-1391 8",10", & 12" BE-SAW Augers

Page 7

Safety

SAFETY INSTRUCTIONS

GSI’s principle concern is your safety and the safety of others associated with grain handling equipment.

We want to keep you as a customer. This manual is to help you understand safe operating procedures and

some problems which may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards and precautions exist,

and to inform all personnel associated with the equipment. Avoid any alterations to the equipment. Such

alterations may produce a very dangerous situation, where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable regulations which should be carefully followed in all cases. Authorities having jurisdiction should be consulted

before installations are made.

OPERATE UNLOAD EQUIPMENT PROPERLY

Make sure ALL equipment is locked in position before operating.

NEVER start equipment until ALL persons are clear of the work area.

Be sure all operators are adequately rested and prepared to

perform all functions of operating this equipment.

NEVER allow any person intoxicated or under the influence of alcohol or drugs

to operate the equipment.

NEVER work alone.

Make sure someone is nearby who is aware of the proper shutdown sequence in the event of an accident or emergency.

ALWAYS think before acting. NEVER act impulsively around the equipment.

NEVER allow anyone inside a bin, truck or wagon which is being unloaded by

an auger or conveyor. Flowing grain can trap and suffocate in seconds.

Use ample overhead lighting after sunset to light the work area.

Keep area around intake free of obstacles such as electrical cords, blocks,

etc. that might trip workers.

Operate

Unload

Equipment

Safely

NEVER drive, stand or walk under the equipment.

Use caution not to hit the auger when positioning the load.

ALWAYS lockout ALL power to the equipment when finished

unloading a bin.

PNEG-1391 8",10", & 12" BE-SAW Augers

7

Page 8

Safety

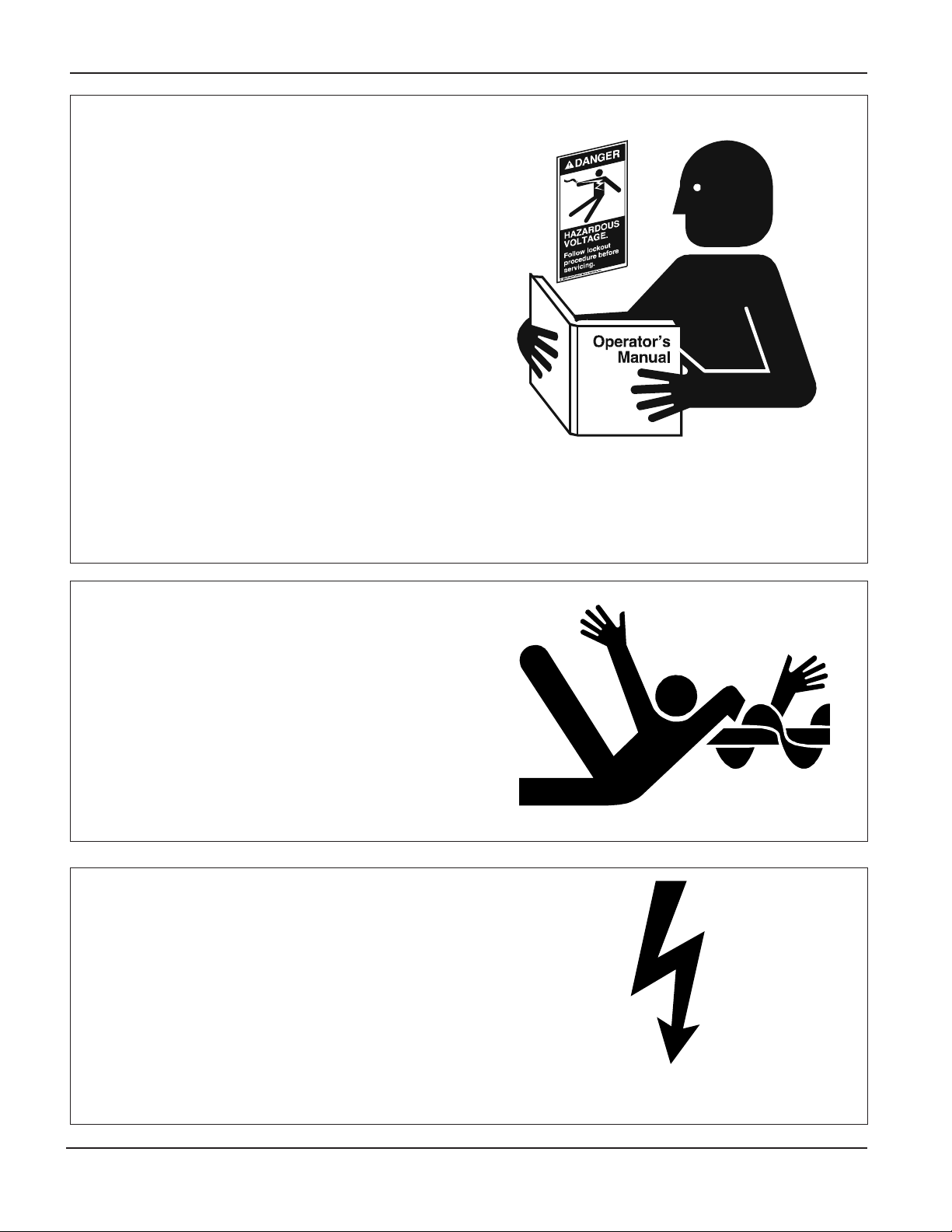

FOLLOW SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual

and on your machine safety signs. Keep signs in

good condition. Replace missing or damaged

safety signs. Be sure new equipment components

and repair parts include the current safety signs.

Replacement safety signs are available from the

manufacturer.

Learn how to operate the machine and how to use

controls properly. Do not let anyone operate without

instruction.

Keep your machinery in proper working condition.

Unauthorized modifications to the machine may

impair the function and/or safety and affect machine

life.

If you do not understand any part of this manual

and need assistance, contact your dealer.

STAY CLEAR OF ROTATING PARTS

Entanglement in rotating augers will cause serious

injury or death.

Keep all shields and covers in place at all times.

Wear close fitting clothing. Stop and lock out power

source before making adjustments, cleaning, or

maintaining equipment.

OPERATE MOTOR PROPERLY

Do not operate electric motor equipped units until

motors are properly grounded.

Disconnect power on electrical driven units before

resetting motor overloads.

Do not repetitively stop and start the drive in order

to free a plugged condition. Jogging the drive in

this type of condition can damage the equipment

and/or motor components.

8

Electric Shock Hazard.

PNEG-1391 8",10", & 12" BE-SAW Augers

Page 9

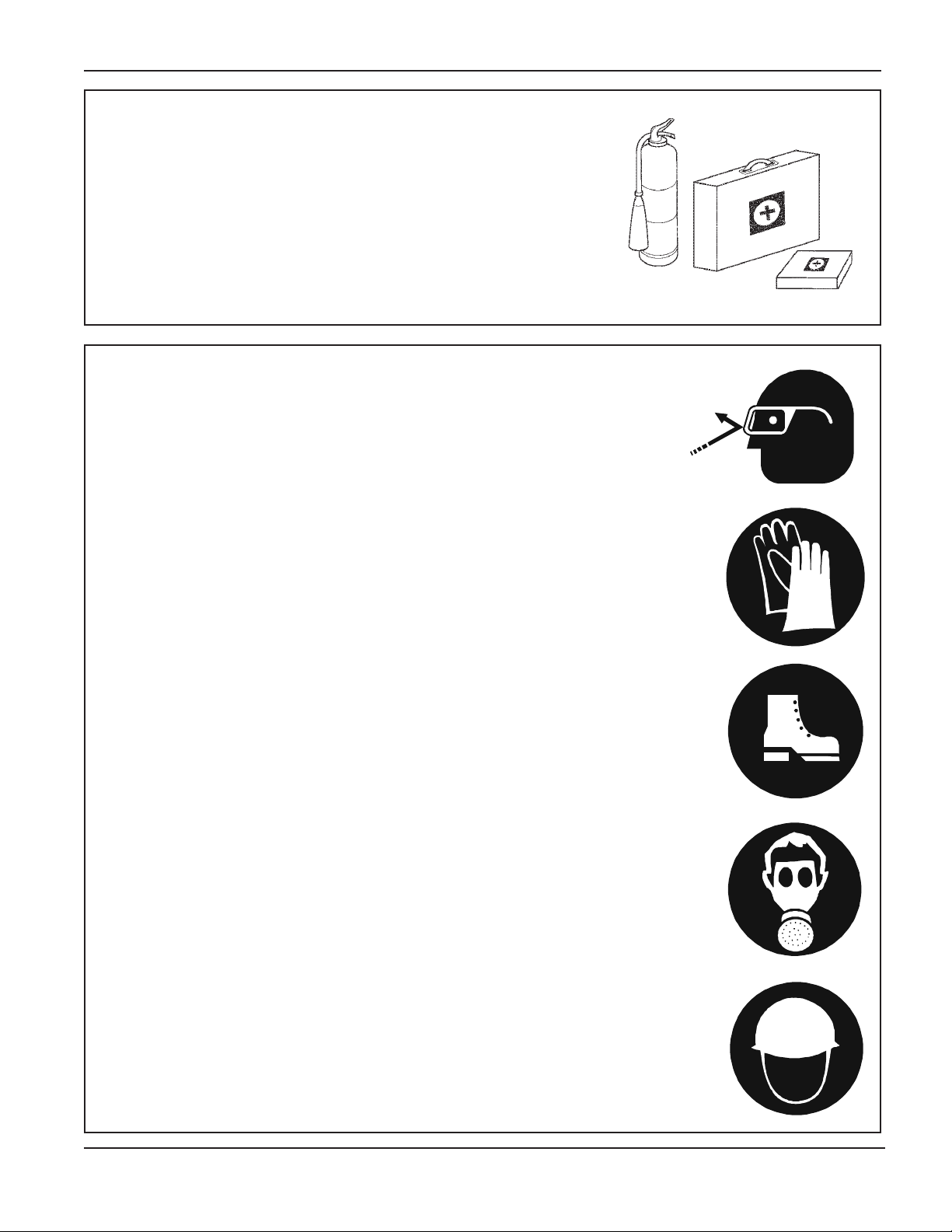

PREPARE FOR EMERGENCIES

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance

service, hospital, and fire department near your

telephone.

WEAR PROTECTIVE CLOTHING

Safety

Wear close fitting clothing and safety equipment

appropriate to the job.

Safety glasses should be worn at all times to

protect eyes from debris.

Wear gloves to protect your hands from sharp

edges on plastic or steel parts.

A respirator may be needed to help prevent

breathing potentially toxic fumes and dust.

Wear hard hat and steel toe boots to help protect

your head and toes from falling debris.

Eye Protection

Gloves

Steel Toe

Boots

PNEG-1391 8",10", & 12" BE-SAW Augers

Respirator

Hard Hat

9

Page 10

Safety

OPERATOR QUALIFICATIONS

A. The User/Operator must be competent and experienced to operate auger equipment. Anyone who

works with or around augers must have good common sense in order to be qualified. These persons

must also know and meet all other qualifications, such as:

1. Any person who has not read and/or does not understand all operation and safety

procedures is not qualified to operate any auger systems.

2. Certain regulations apply to personnel operating power machinery. Personnel under

the age of 18 years may not operate power machinery, including augers. It is your

responsibility, as owner and/or supervisor, to know what these regulations are in your

area or situation.

3. Unqualified or incompetent persons are to remain out of the work area.

4. O.S.H.A. (Occupational Safety & Health Administration) regulations state:

"At the time of initial assignment and at least annually thereafter, the employer shall

instruct every employee in the safe operation and servicing of all equipment with

which the employee is, or will be involved." (Federal Occupational Safety & Health

Standards for Agriculture. Subpart D, Section 19287.57 (a) (6).

B. As a requirement of OSHA, it is necessary for the employer to train the employee in the safe operating

and safety procedures for this auger. We included this sign-off sheet for your convenience and

personal record keeping. All unqualified persons are to stay out of the work area at all times. It is

strongly recommended that another qualified person who knows the shutdown procedure is in the

area in the event of an emergency. A person who has not read this manual and understands all

operating and safety instructions is not qualified to operate the machine.

Date Employer's Signature Employee 's Signature

10

PNEG-1391 8",10", & 12" BE-SAW Augers

Page 11

Y

st

Safety

SAFET

Replace missing guards and shields

FREE OF CHARGE!

Our equipment is built to provide many years of dependable service to our customers

through durable craftsmanship.

One of the most important aspects of our engineering is SAFETY 1

throughout all product lines. Safety is NO ACCIDENT!

That is why we are implementing its SAFETY 1st program. Should you ever need

guards, shields, safety decals, or owner/operator manuals, simply contact us, and

we will supply you with them FREE OF CHARGE!

1

st

design

While it is our main goal to be the world leader in auger manufacturing, it is always

our first priority to keep our customers safe.

If you need any of the above listed safety items or have safety questions, please

contact us:

The GSI Group

PO Box 20

1004 E. Illinois Street

Assumption, IL 62510

Ph: 217-226-4421

PNEG-1391 8",10", & 12" BE-SAW Augers

11

Page 12

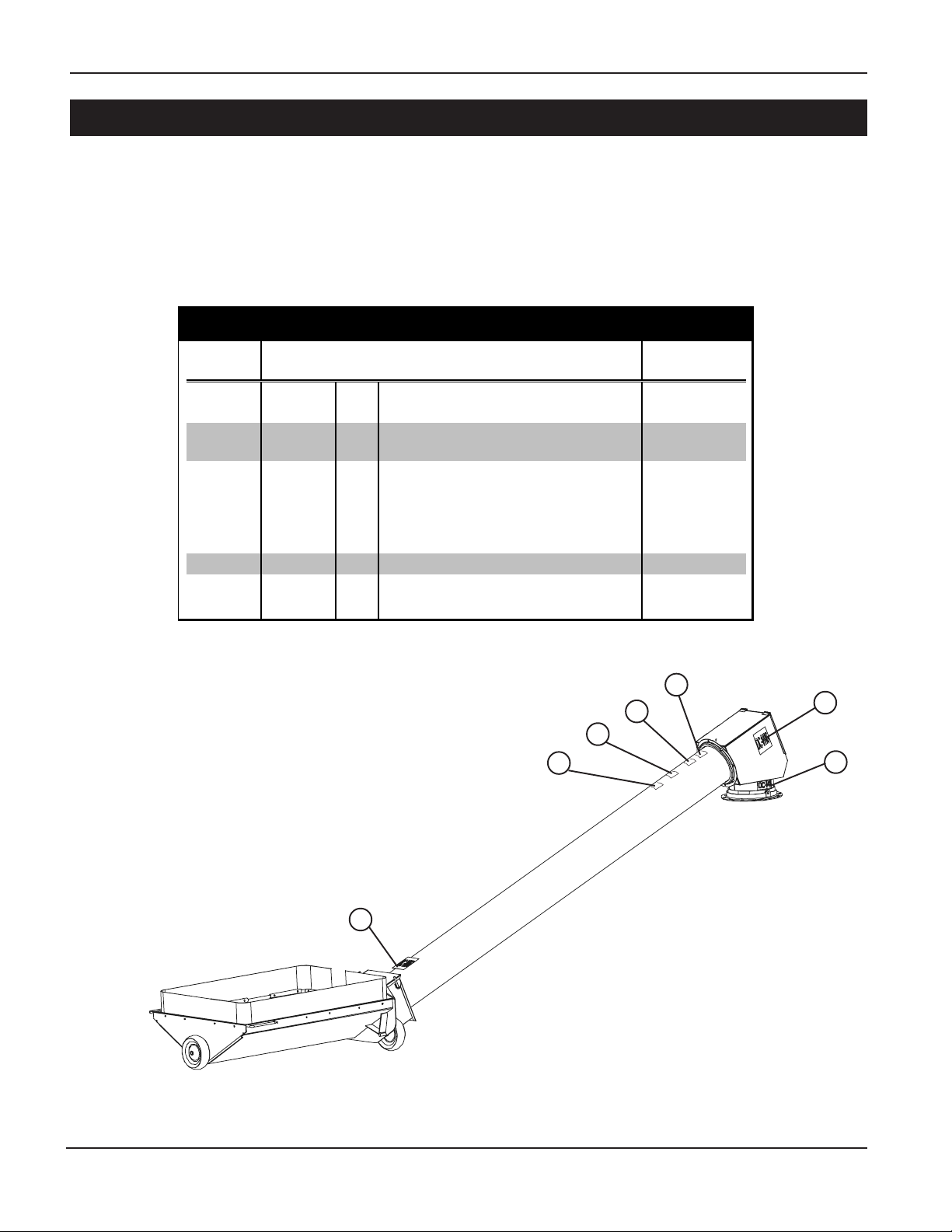

Decals

Safety Decals

The Safety Decals listed below are included with the auger. The following page shows the

locations of the decals on the auger. The following pages show a sample of each decal.

Inspect all decals and replace any that are illegible, worn, or missing. Contact your dealer or

the factory to order replacement decals.

Safety Decals

Ref. # Part # Qty. Description Size

1 DC-1446 1

2 DC-1412 1

3 DC-1416 1

4 DC-1418 1

5 DC-1411 1

Caution—General Statements 1-12

Main Auger Housing)

Danger—Electrocution

Hous ing)

Danger—Rotating Auger

of Tube Near Hopper, On Side of Spout

Head, On Underside of Inlet Hopper, On

Side of Inlet Hopper, On Inlet Hopper

Clean-Out Door)

Safety First

Danger—Shear Point

Hopper)

—(On Main Auger Housing) 4-7/8" x 3-1/2"

(On Main Auger

(On Intake End

(On Front of Inlet

(On

8-1/4" x 4-1/8"

4-1/2" x 5-1/2"

4-1/2" x 2-1/16"

8" x 3-3/8"

3

1

3

2

4

5

3

12

PNEG-1391 8",10", & 12" BE-SAW Augers

Page 13

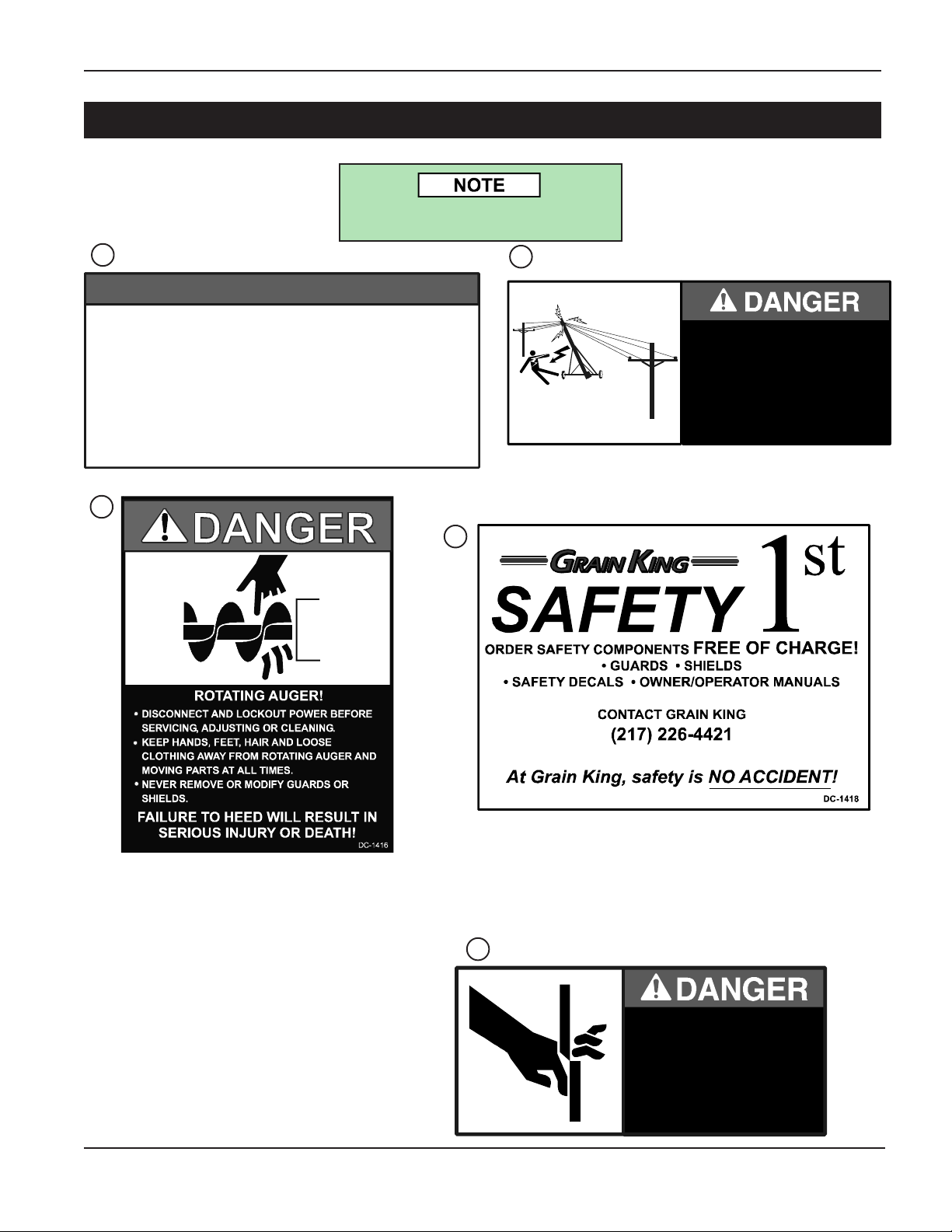

Safety Decals

Decals are not shown actual size.

Decals

1

NOTICE

1. READ AND UNDERSTAND THE INSTALLATION & OPERATION MANUAL AND ALL SAFETY

INSTRUCTIONS BEFORE OPERATING EQUIPMENT.

2. DO NOT OPERATE WHILE UNDER THE INFLUENCE OF DRUGS OR ALCOHOL.

3. DO NOT OPERATE UN LESS ALL SAFET Y EQUIPMENT, SWITCHES, GUARDS AND SHIELDS

ARE SECURELY IN PLACE AND OPERATIONAL.

4. BE SURE EVERYONE IS CLEAR OF THE EQUIPMENT BEFORE ATTEMPTING TO OPERATE

OR MOVING THE MACHINE.

5. ALLOW ONLY TRAINED PERSONNEL IN the OPERATING AREA.

6. KEEP HANDS, FEET, HAIR AND CLOTHING AWAY FROM MOVING PARTS.

7. DI SCONNE CT AND LOCKOU T POWER BEFO RE ADJUSTING OR SERVICIN G.

8. ELECTRICAL WIRING OR SERVICE WORK MUST BE PERFORMED BY A QUALIFIED

ELECTRICIAN. IT MUST MEET ALL STATE AND LOCAL ELECTRICAL CODES.

9. EMPTY AUGER AND LOWER TO TR ANSPORT POSITION BEFORE TRANSPORTIN G.

10. MAKE CERTAIN ALL ELECTRIC MOTORS ARE GROUNDED.

11. NEVER MOVE MACHINE MANUALLY. ALWAYS USE A TOWING VEHICLE.

12. KEEP CHILDREN AWAY FROM WORK AREA AT ALL TIMES.

3

DC-1446

2

ELECTROCUTION!!

STAY CLEAR OF POWER LINES!

• THIS EQUIPMENT IS NOT INSULATED FROM ELECTRIC SHOCK.

• KEEP EQUIPMENT AWAY FROM POWER LINES.

• ELECTROCUTION CAN OCCUR WITH OR WITHOUT DIRECT

CONTACT.

FAILURE TO HEED WILL RESULT

IN SERIOUS INJURY OR DEATH!

DC-1412

4

PNEG-1391 8",10", & 12" BE-SAW Augers

5

SHEAR POINT

KEEP FINGERS, HANDS, HAIR AND

LOOSE CLOTHING AWAY FROM

MOVING PARTS.

FAILURE TO HEED

WILL RESULT IN

SERIOUS INJURY OR DEATH!

DC-1411

13

Page 14

Assembly

8" & 10" Standard Profile Hopper Assembly

1. ASSEMBLE HOPPER 8" & 10" AND INCLINE TUBE (See Figure 1-B)

A. Apply grease to the wheel shafts of the

hopper.

B. Attach the hopper wheels to the wheel shafts

using three (3) 5/8" flat washers and one (1)

3/16" x 1-1/2" cotter pin for each wheel. Note:

One (1) to two (2) washers should be used

as spacers between the hopper and the

wheel. Use one (1) washer between the wheel

and the cotter pin.

C. Use the following hardware to bolt the

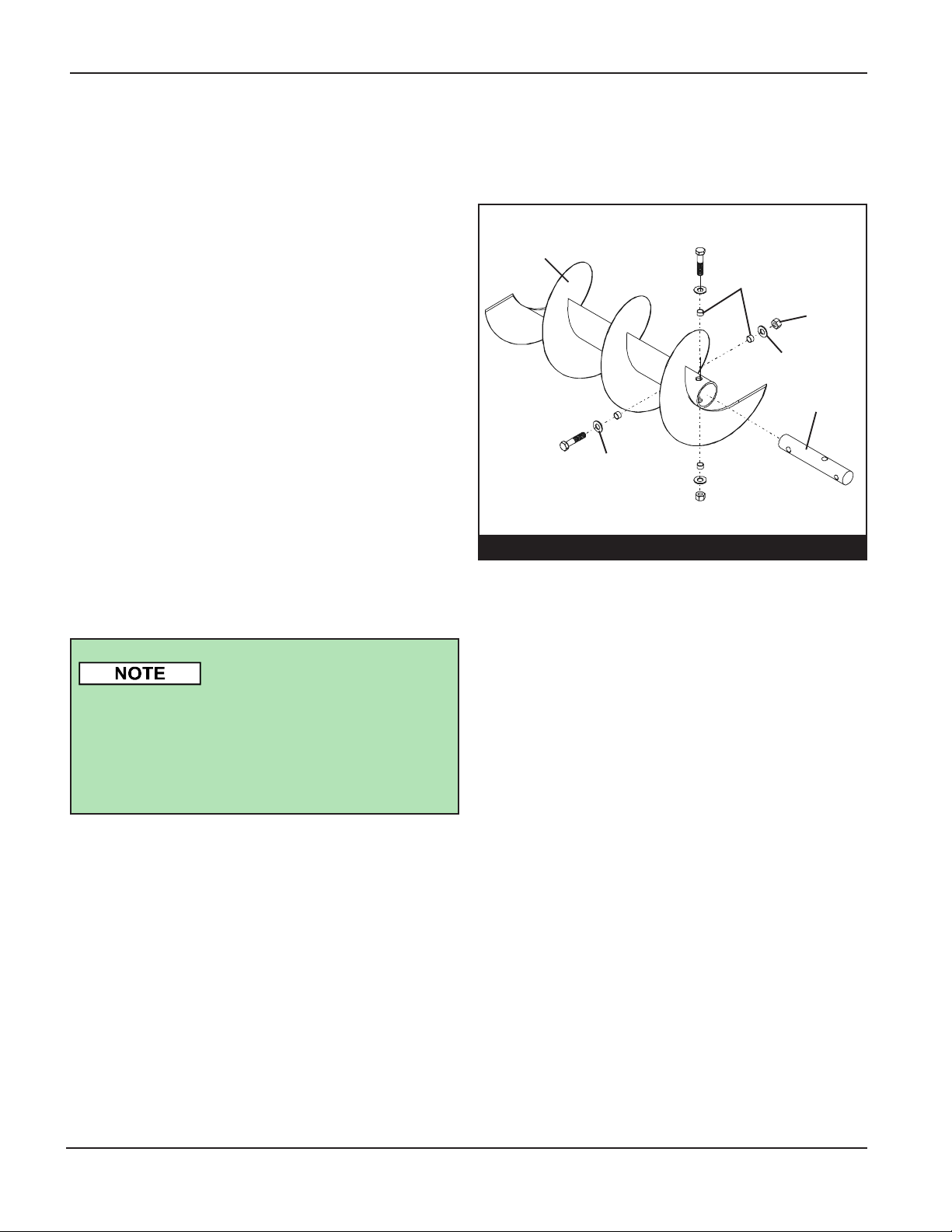

incline tail stub into the incline flight: (See

Figure 1-A)

• Four (4) rubber sleeves

• Two (2) hex head (Grade 5) cap screws:

For 8" models, use 3/8" x 3" long cap

screws. For 10" models, use 7/16" x

3-1/2" long cap screws.

• Four (4) flat washers

IMPORTANT: When tightening nylon locknuts, make

sure they are firmly secured

against the rubber sleeves,

but not so tight that they lay

against the flight tube.

Leave a gap of approximately 1/16".

Flight Connections

Incline

Flight

Flat

Washer

FIGURE 1-A

Rubber Sleeve

Nylon

Locknut

Flat

Washer

Tail Stub

E. Attach the u-joint to the bearing stub in the

hopper using one (1) hex head cap screw and

nylon locknut. For 8" models, use a

5/16" x 2-1/2" long (Grade 5) hex head cap

screw. For 10" models, use a 3/8" x 3" long

(Grade 5) hex head cap screw.

Note: Loosen the hanger bearing hardware

for later adjustment.

D. Attach the u-joint to the incline tail stub using

one (1) hex head cap screw and nylon locknut.

For 8" models, use a 5/16" x 2-1/2" long

(Grade 5) hex head cap screw. For 10"

models, use a 3/8" x 3" long (Grade 5) hex

head cap screw.

14

PNEG-1391 8",10", & 12" BE-SAW Augers

Page 15

8" & 10" Standard Profile Hopper Assembly

1. ASSEMBLE 8" & 10" HOPPER AND INCLINE TUBE (CONT.)

Assembly

F. Attach the lower end of the incline tube to the

front of the flexible swing-out hopper using the

following hardware:

• Two (2) 1/2" x 1-1/4" long (Grade 5) hex

head cap screws

• Four (4) Flat washers

• Nylon locknuts

G. Install the bolt heads onto the inside but DO

NOT tighten completely because the coupler

box must be allowed to pivot.

H. Center hanger bearing on bearing shaft

between hopper flight and u-joint, then tighten.

Swing Out Hopper

Incline Tube

Cover Strap

I. Fasten the hinged cover to the front of the

flexible swing-out hopper using two (2) 5/16"

x 3/4" long (Grade 5) hex head cap screws,

flat washers, and nylon locknuts.

J. Install the cover strap over the lid onto the

3/8" stub, which is welded to the box on the

lower end of the incline tube. Use 3/8" nylon

locknuts to hold the straps on the stud.

IMPORTANT: DO NOT

tighten the locknuts down.

The hinged cover must be

able to slide under the

strap when the incline tube

is tilted at different angles.

5/16" x 3/4" Long (Grade 5) Hex

Head Cap screws, Flatwashers,

and Nylon Locknuts

3/8" Locknuts

Incline

Flight

Hinged

Cover

1/2" x 1-1/4" Long (Grade 5)

Hex Head Cap screw with Flat

Washers and Nylon Locknuts

Note: Install so bolt heads are

on the inside.

The hopper hanger bearing and

bearing stub are preassembled to the

flexible swing-out hopper. In this

assembly drawing, those parts were

exploded away from the hopper to

better show the proper assembly of

the other parts.

Coupler

Box

Rubber Sleeve

U-Joint

8" - 5/16"x 2-1/2"

10" - 3/8" x 3"

PNEG-1391 8",10", & 12" BE-SAW Augers

Hanger

Bearing

Stub

Bearing

FIGURE 1-B

Tail Stub

2 Flat

Washers

Hopper Wheel

Hopper

Hopper Flight

2 Flat

Washers

3/16" x 1-1/2"

Long Cotter Pin

Hopper Wheel

15

Page 16

Assembly

12" Standard Profile Hopper Assembly

The hopper hanger bearing and bearing stub are pre-assembled on the swingaway hopper. Therefore, in the drawings, those parts were exploded away from

the hopper to better show the proper assembly of the other components.

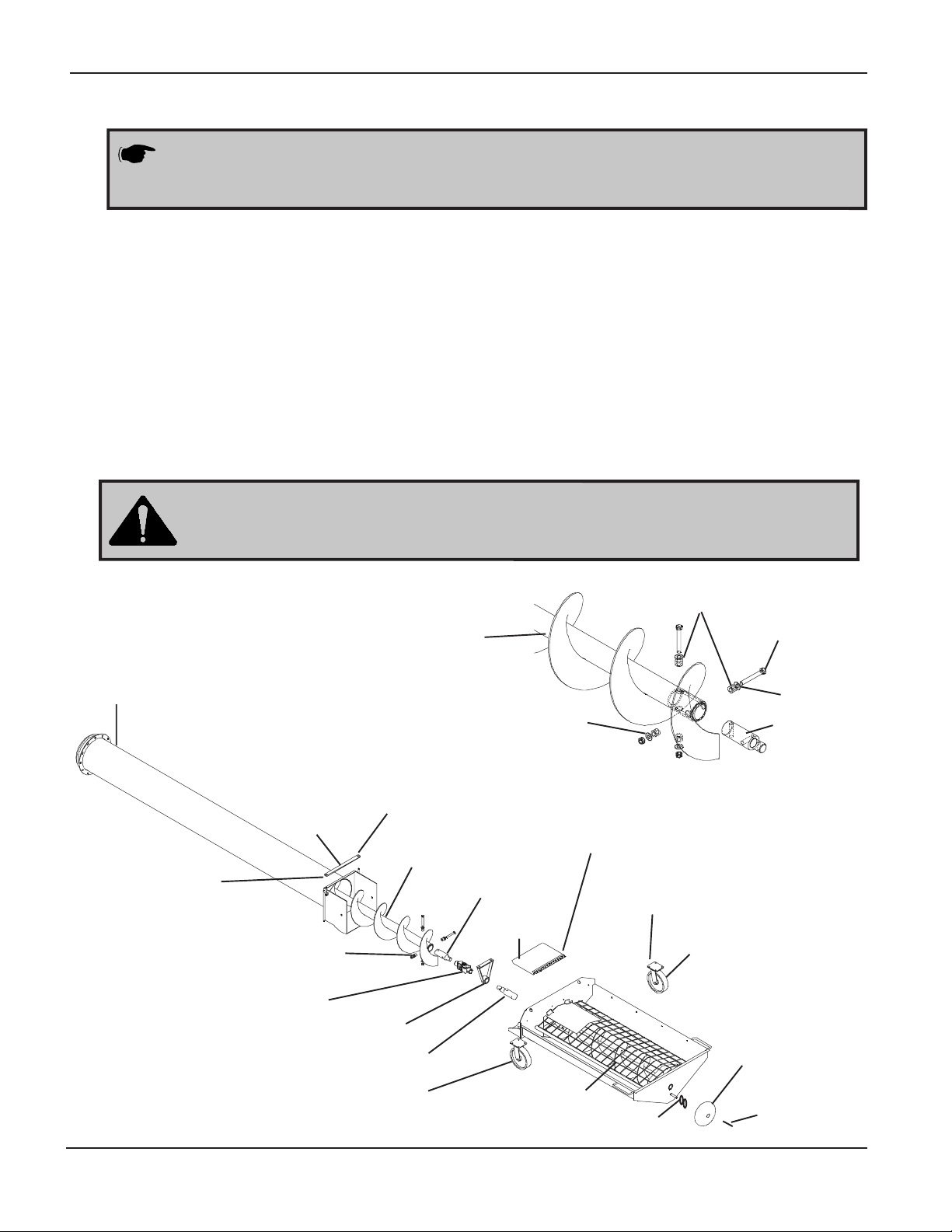

2. ASSEMBLE 12” HOPPER AND INCLINE

TUBE ASSEMBLY

A. Attach the rubber hopper wheel to the back of

the swing-away hopper using two (2) 5/8" flat

washers and 3/16" x 2" cotter pins. (See Fig.

2-B)

B. Fasten two (2) hopper caster wheels to front of

hopper using (4) 3/8" x 1-1/4" long (grade 5) hex

head capscrews and nylon locknuts for each

wheel.

Tighten locknuts so the flat washers are firmly against the rubber sleeves.

DO NOT tighten so tight that the flat washers are against the flight tube.

Leave about 1/16" gap.

INCLINE TUBE

INCLINE

FLIGHT

C. Remove the incline flight from the incline tube.

D. Attach lower end of the incline tube to the front of

the swing-away hopper. Use two (2) 5/8" x

1-1/4" long (grade 5) hex head capscrews, flat

washers, and locknuts.

E. Connect incline tail stub into the incline flight using

four (4) rubber sleeves, two (2) 1/2" x

3-3/4" long (grade 5) hex head capscrews, flat

washers, and nylon locknuts. (See Fig. 2-A)

RUBBER

SLEEVE

LOCKNUT

FLAT

WASHER

FLAT WASHER

TAIL STUB

5/8" X 1 1/4" LONG

(GRADE 5) HEX HEAD

CAPSCREW WITH

FLATWASHWER AND

NYLON LOCKNUTS

NOTE: INSTALL SO

BOLT HEADS ARE ON

THE INSIDE

FIG. 2-B

16

COVER

STRAP

RUBBER SLEEVE

U-JOINT

BEARING HANGER

BEARING STUB

CASTER WHEEL

3/8" LOCKNUT

INCLINE

FLIGHT

TAIL STUB

HOPPER FLIGHT

FIG. 2-A

5/16" X 3/4" LONG (GRADE 5)

HEX HEAD CAPSCREWS,

FLATWASHERS AND NYLON

LOCKNUTS

3/8" X 1 1/4" LONG (GRADE 5)

HEX HEAD CAPSCREW AND

HINGED

COVER

(2) FLAT

WASHERS

NYLON LOCKNUTS

CASTER

WHEEL

HOPPER

WHEEL

3/16" X 2"

LONG

COTTER

PIN

PNEG-1391 8",10", & 12" BE-SAW Augers

Page 17

Assembly

12" Standard Profile Hopper Assembly

2. ASSEMBLE 12” HOPPER AND IN- LINE TUEBE ASSEMBLY (CONT.)

F. Using a 3/8" x 3" long (grade 5) hex head capscrew and nylon locknut, attach the u-joint to the incline

tail stub.

G. Slide the lower end of the inclined flighting (the end with the u-joint fastened) down into the upper end of

the incline tubing. Slide the flighting down until the u-joint is near the swing-away hopper bearing stub.

H. Connect the u-joint on the flighting to the bearing stub in the swing-away hopper using a 3/8" x 3" long

(grade 5) hex head capscrew and nylon locknut.

I. Bolt hinged cover to the front of the swing-away hopper using two (2) 5/16" x 3/4" long (grade 5) hex

head capscrews, flat washers, and nylon locknuts.

DO NOT tighten the nuts down. The hinged cover

MUST be able to slide un-

der the strap when the incline tube is tilted at different angles.

J. Install cover strap over lid onto the 3/8" stub that is welded to the box on the lower end of the incline

tube. Use the 3/8" nylon locknuts to hold the straps onto the stub.

5/8" X 3-1/2" (GRADE 5)

HEX HEAD CAPSCREW

INCLINE FLIGHT

STOP RING

RING

INCLINE TUBE

5/8" LOCKNUT

FIG. 2-C

PNEG-1391 8",10", & 12" BE-SAW Augers

19/32" LONG

SPACER

BUSHING

FLAT WASHER

3/8" X 1 3/4" LONG

(GRADE 5) HEX

HEAD CAPSCREW,

FLAT WASHER AND

LOCKWASHER

17

Page 18

Assembly

12" Standard Profile Hopper Assembly

2. ASSEMBLE 12" HOPPER AND IN-LINE TUBE ASSEMBLY (CONT.)

L. Slide head end of the incline flight onto the spout studs. Secure the incline flight in place by using a

5/8" x 3-1/2" long (grade 5) hex head capscrew with a locknut. (See Fig. 2-C on page 17.)

3/8" X 1 3/4"

LONG HEX

HEAD

CAPSCREW

WELDED TO

SPOUT

STOP RING

WELDED TO

FIG. 2-D

INCLINE

TUBE

M. Slide incline tube onto the back of the downspout, lining up the holes on the incline ring with the bolts

welded onto the down spout. Fasten using eight (8) 19/32" long spacer bushings, eight (8)

3/8" x 1-3/4" long hexhead capscrews, eight (8) flat washers, and eight (8) 3/8" nylon locknuts.

Be sure to install the spacer bushings between the back of the spout and

the ring. After the 3/8" nylon locknuts are tightened, the spout

MUST BE

ABLE TO SWIVEL on the incline tube.

18

PNEG-1391 8",10", & 12" BE-SAW Augers

Page 19

Assembly

3. ASSEMBLE 8", 10", & 12" HOPPER RUBBER BELTING ASSEMBLY

A. Place the rubber belting into the inside of the swing-away hopper.

B. Loosely attach the rubber belting using ten (10) attachment clips and two (2) 1/4” x 1” long hex head

cap screws and nylon locknuts for each clip. The points of the clips should point up and the bolt

heads should be inside the hopper. Use the bolt holes positioned around the upper edge of the

hopper as a guide.

C. Position the belting inside the clips with the belting edge resting on the bolts. As shown on the diagram

on the previous page, the belting should not cover the output end of the hopper. Keep the belting end

within one (1) inch of the clip end.

D. Position the belting evenly around the hopper and through the corners.

E. Tighten the bolts and nuts so that the clip points draw into the belting and the smooth edge of the clips

is in contact with the belting.

Belt Hopper Detail

Attachment

Clips

Rubber

Hopper

Belting

1/4" x 1" Hex Head

Capscrew and Nylon

Locknut

Attachment Clip

1/4" x 1"

Hex Head

Cap

FIGURE 3-B

Rubber

Belting

1/4"

Nut

Hopper

FIG. 3-A

PNEG-1391 8",10", & 12" BE-SAW Augers

Swing-Out

Hopper

19

Page 20

Assembly

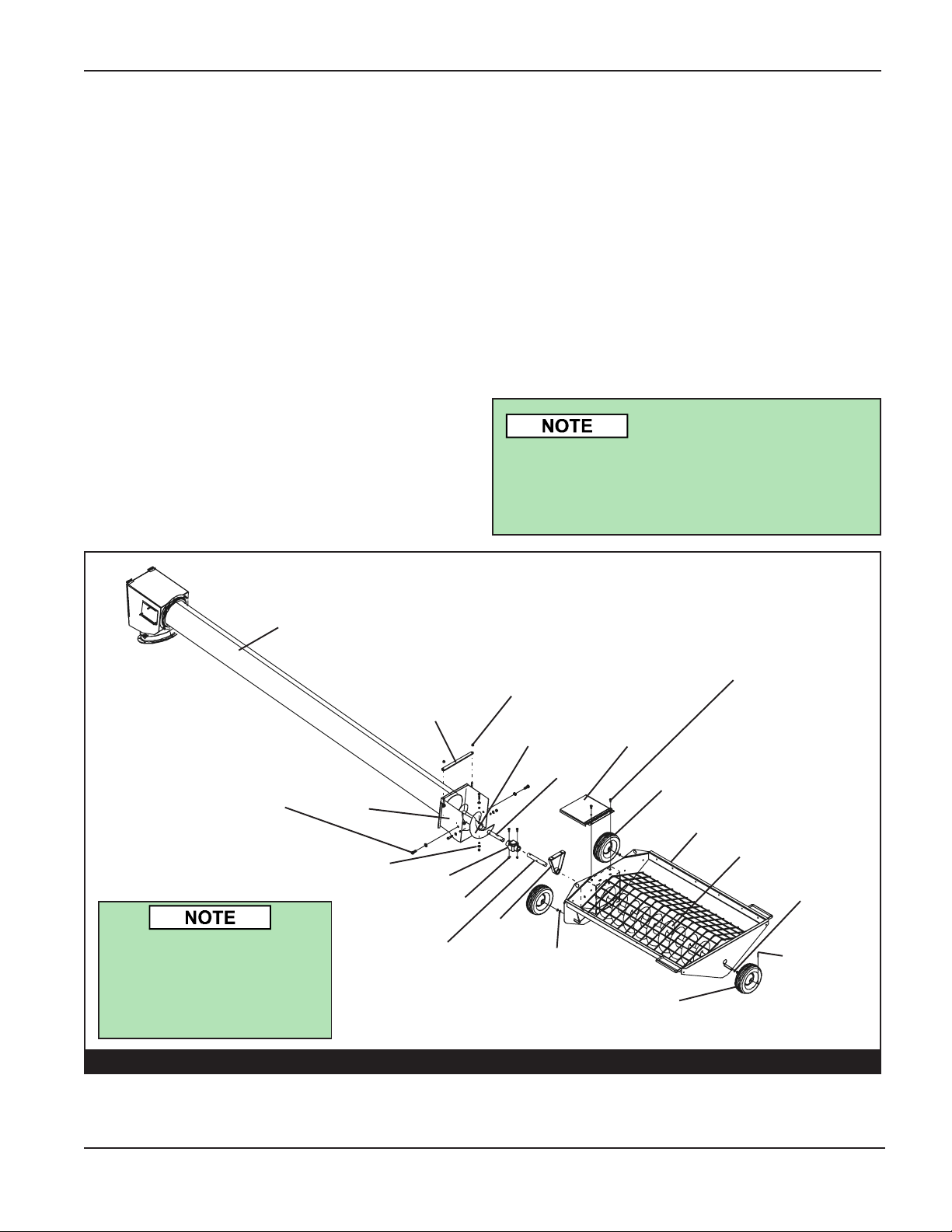

4. OPTIONAL 10" & 12" LOW PROFILE HOPPER ASSEMBLY INSTRUCTIONS (See Figure 4-A)

A. Install the hopper wheels to the hopper using

four (4) 5/8" x 9-3/4" long clevis pins, four (4)

wheel spacer bushings and four (4) 1-1/4"

cotter pins. Install the hopper wheels so the

front wheels are tilted in towards the incline

tube and the rear wheels are tilted away from

the hopper chain guard. Basically, you want

to tilt your wheels so they follow the arc made

when you move the hopper. (See detail 4-B)

There are two installation

heights for the hopper wheels.

For the shortest hopper

profile, use the upper set of

holes. Also use the holes to

angel the wheels by using

opposite holes.

B. Fasten the U- Joint to the incline tail stub us-

ing one 3/8" x 3" long (grade 5) HHCS and

stover nut.

C. Connect the U-Joint to the power shaft in the

swing-out hopper using one (1) 3/8" x 3" long

(grade 5) HHCS and stover nut.

G. Low Profile Swing-Out Hopper Rubber

Belting Assembly (See Figure 4-A)

1. Install the rubber belting into the inside of

the swing out hopper. Use ten (10) long

and four (4) short attachment clips to install

the belting. Two (2) 1/4" x 1" long hex head

capscrews and nylon locknuts are used

for each clip. Loosely attach each clip with

grip teeth of clips up and with bolt heads

inside the hopper. Use bolt holes

positioned around upper edge of hopper.

2. Set the belting inside the clips with the

belting edge resting on the bolts. (See

Figure 4-C) The belting does not go

completely across the output end of the

hopper. The belting is notched to

accommodate the center guard support

at the rear of the hopper. Begin installing

the belting at this point and work each way

toward the hopper discharge. Keep the

belting end within one inch of the clip end.

Position the belting evenly around the

hopper and through the corners.

D. Fasten the lower end of the incline tube to the

front of the swing away hopper. Use two 1/2"

x 1-1/2" long (grade 5) HHCS, flat washers,

and nylon locknuts.

Install bolt heads to the

inside and DO NOT tighten

completely. The coupler

box must be able to pivot.

E. Bolt hopper lid to the front of the swing out

hopper using three (3) 5/16" x 3/4" long (grade

5) HHCS flat washers, and nylon locknuts.

F. Install lid strap onto 3/8" stubs welded onto

lower end of incline tube. Hold the straps on

the stud with 3/8" nylon locknuts.

Do NOT tighten the nuts

down. The lid straps must

be allowed to slide when

the incline tube is tilted at

different angles.

3. Tighten the bolts and nuts to where the

clip points draw into the belting and the

smooth edge of the clips is in contact with

the belting.

Belt Hopper Detail

Hopper

Attachment Clip

1/4" Nylon

Locknut

1/4" x 1"

Hex Head Cap

Hopper

FIGURE 4-C

20

PNEG-1391 8",10", & 12" BE-SAW Augers

Page 21

Low Profile Hopper - 10" & 12" Only

Assembly

1/4" X 1" LONG HHCS

AND LOCKNUT

COTTER PIN

LONG

CLIP

5/8" X 9-3/4"

CLEVIS PIN

SHORT

CLIP

SPACER BUSHING

WHEELS

5/16" X 3/4" LONG HHCS,

FLAT WASHERS, AND

NYLON LOCKNUTS

HOPPER LID

U-JOINT

RUBBER

BELT

3/8" LOCKNUT

LID STRAP

3/8" X 3" LONG

(GRADE 5) BOLT

& STOVER NUT

INCLINE

TUBE

1/2" X 1-1/2"

LONG (GRADE 5)

HHCS AND

NYLON LOCKNUT

Angle Hopper Wheels

HOPPER

PNEG-1391 8",10", & 12" BE-SAW Augers

FIGURE 4-A

HOPPER PATH

ANGLED WHEELS

FIGURE 4-B

21

Page 22

Assembly

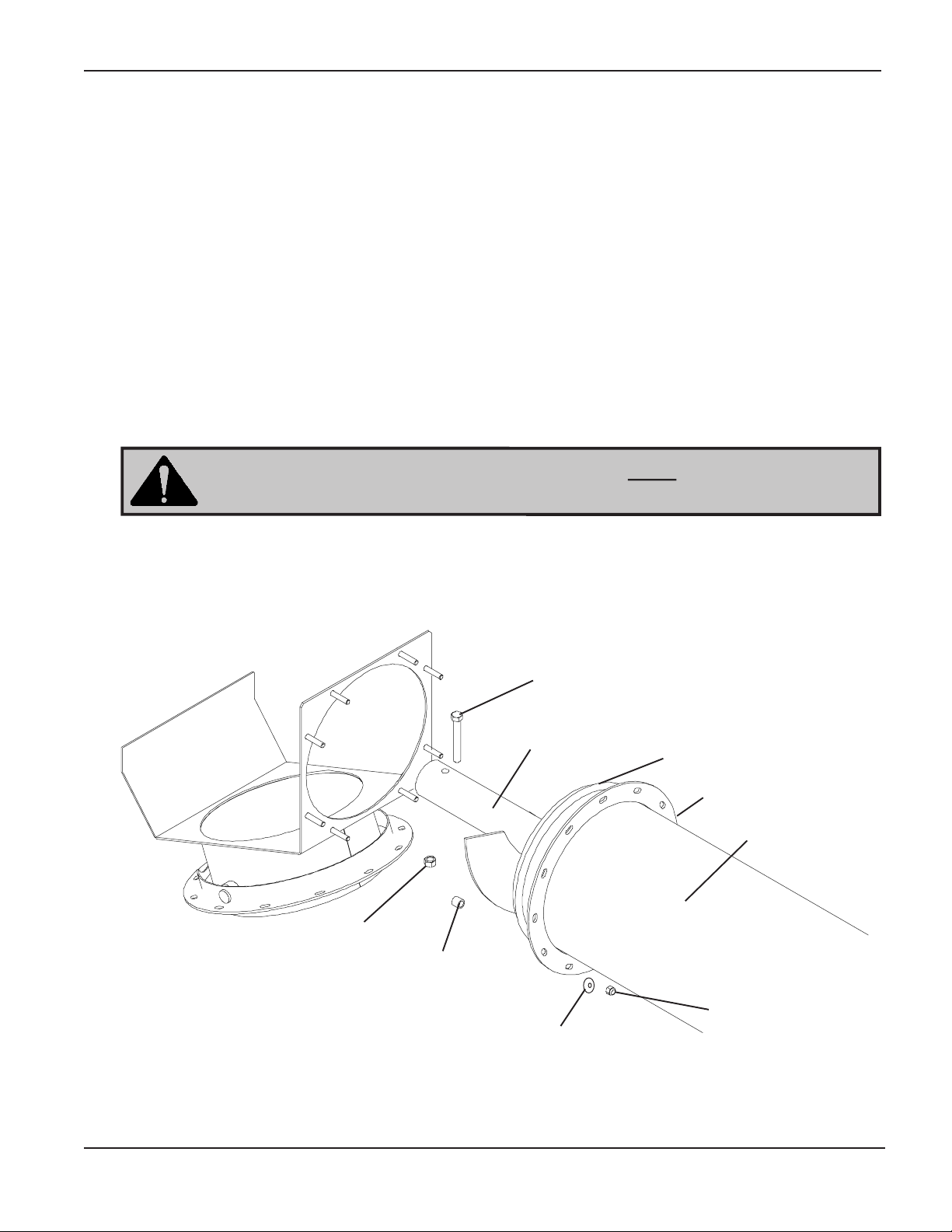

5. ASSEMBLE 8", 10", OR 12" INCLINE TUBE TO BUCKET ELEVATOR BOOT (See Figure 5)

A. Attach Transition* to B.E. Boot using 3/8"-16 x 1"

HHCS bolts, 3/8" lock washers, & 3/8"-16 Hex nuts.

B. Use a sling to lift the downspout end of the incline

tube assembly and position it directly over the transition opening.

C. Completely lower the tube until the spout flange

sits flat on top of the transition.

D. Install the spout flange to the top of the main inlet

hopper using four (4) 2" O.D. flat washers and 3/

8" nylon locknuts. The incline tube spout should

rotate on the top of the main inlet hopper.

*See next page for transition information.

22

Swivel Spout

Weldment

Tube

Weldment

3/8" Nylock

Nut

3/8"

Washer

Transition

3/8"-16 x 1 HHCS

3/8" Lock Washer

3/8" Hex Nut

Bucket Elevator Boot

PNEG-1391 8",10", & 12" BE-SAW Augers

Page 23

Assembly

Di

BE-SAW Transition

The GSI BESAW was designed to mate with GSI bucket elevators from 16" to 42" in size and capacities

from 1500 to 8000 BPH. Due to the large quantity of boot hoppers available for these bucket elevators, it

would be impossible for GSI to offer a transition assembly that would fit all the possible combinations of

BESAWs and bucket elevators. Since the BESAW requires special mounting components to swivel, after

April 1, 2006 each BESAW shipped from our facilities will include a BESAW Swivel Plate Assembly. The

swivel assembly is made up of a square plate with the attachment bolts welded to it. It already has the

appropriate sized hole bored in it to allow the flow of material. The swivel hardware is also included.

Swivel Plate Assembly

When fabricating the mounting transition, the top of this plate should be from 6" to 8" above the mounting

flange of the bucket elevator boot hopper. The center of the large hole should be a sufficient distance away

from the bucket elevator trunk to allow the BESAW chain guard to clear and the BESAW to swivel. An

example of a transition is shown below.

mension varies

due to the angle

of operation.

PNEG-1391 8",10", & 12" BE-SAW Augers

23

Page 24

Start-Up

1. DESIGNATE WORK AREA

A. Before starting the auger, establish the

designated work areas. Figure 6 below shows

where boundaries should be established.

B. Mark off the designated work areas using

colored nylon or plastic rope as portable

barriers.

RULES FOR SAFE WORK AREA

Under no circumstances should persons not

involved in the operation of the auger be

allowed to trespass into the designated work

area. It is the duty of ALL operators to

ensure that children and/or other persons

stay out of the work areas. Should anyone

not involved in the operation trespass into

the work area or into a hazard area, the

operator should immediately shutdown the

auger.

It is the responsibility of ALL operators to

ensure that the work area has secure

footing, and is clean and free of debris and

tools that might cause accidental tripping or

falling. The operator is also responsible for

keeping the work area clean and orderly

during operation of the auger.

Overhead Wires:

Keep Away!

Auger Intake

Area: Keep Out!

2. INSPECT THE AUGER

A. After your new auger is delivered and assem-

bly is complete, and before each use, you

must inspect the auger.

B. Be sure that ALL guards listed in the assem-

bly instructions are in place, secured, and functional.

Walking Surface: Is it

slippery? Are there things

that might trip you?

BE-SAW Auger

Wagon

or Truck

Work Area: Authorized

Personnel Only

FIGURE 6

C. Check ALL safety decals. Replace any that

are worn, missing, or illegible. A list of decals

found on the auger is included in the front of

this manual. You may obtain decals from your

dealer or order direct from the factory.

D. Ensure that ALL fasteners are tight.

24

E. Ensure that the inspection covers are in place.

PNEG-1391 8",10", & 12" BE-SAW Augers

Page 25

1. OPERATION RECOMMENDATIONS

Operation

A. One person must be in a position to monitor

the operation of the auger at ALL times. That

person should visually inspect the auger

before and during operation and be alert to

any unusual vibrations, noises, and the

loosening of any fasteners.

B. For smoother start-ups, keep the auger from

operating totally filled. This will also help

ensure efficient operation.

C. To avoid excessive wear, do not operate the

auger empty for any length of time.

D. You must “break-in" a screw conveyor when

it is new and at the beginning of each season.

Refer to Step 2 for instructions.

Be certain to close ALL the cleanout doors in the main auger head

before operating the auger.

The operator should not add

power before viewing the entire

work area and checking that ALL

personnel are clear of the designated work areas.

The operator should be alert to

any unusual vibrations or noises

that might indicate a need for

service or repair during the initial

start-up and break-in period.

The operator should regulate the

grain flow into the auger by controlling the amount of grain fed to

the hopper.

Be certain that ALL safety shields

and devices remain in place

during operation.

Ensure that hands, feet, and

clothing are kept away from moving parts.

Lockout the power source whenever the equipment must be

serviced or adjusted.

2. START-UP AND BREAK-IN

A. Any auger that is new or has set idle for a

season needs to go through a “break-in"

period.

B. Run the auger at partial capacity until several

hundred bushels of grain have been augered

and the flighting assembly and tube are

polished.

PNEG-1391 8",10", & 12" BE-SAW Augers

Do not stop or start the auger

under load because the auger has

a tendency to “freeze up," especially if the flight and tube have

not become well polished.

25

Page 26

Shutdown

1. NORMAL SHUTDOWN

A. Make sure that the hopper and auger are

empty before shutting down the unit.

B. Before the operator leaves the work area, the

power source should be locked out, as

described on below.

2. INTERMITTENT OPERATION SHUTDOWN

A. During intermittent operations such as batch

drying, give careful consideration to the size

of auger to use. Using a larger diameter auger

and reducing its load level is far better than

subjecting a smaller diameter auger to high

loads. An auger that is kept from absolute filling

will start-up easier and convey more efficiently.

3. EMERGENCY SHUTDOWN

WARNING: Precaution should be

made to prevent anyone from

operating the auger when the operator is absent from the work area.

The operator must stop the auger

and turn off the power source any

time he/she must leave the work

area, or service/adjust the auger.

IMPORTANT: Do not stop and

restart the auger when it is fully

loaded. This may damage the

auger.

A. If you have to immediately shutdown the auger

under load, be sure to disconnect and

lockout the power source.

B. Remove as much grain from the hoppers and

auger that you can before restarting.

C. Never attempt to restart the auger when it is

full.

D. When as much grain as possible has been

cleared from the hoppers and the auger,

reconnect the power source and clear the

remaining grain gradually.

4. LOCKOUT

A. To lockout the auger, stop the auger and turn

off the power supply.

B. The operator should lockout the SAW auger

in the following situations:

• Anytime the operator leaves the work

area, such as after shutdown.

• Anytime the operator services or adjusts

the auger.

IMPORTANT: Starting the auger

under load may result in damage to

the auger. Such damage is considered abuse of the equipment.

26

PNEG-1391 8",10", & 12" BE-SAW Augers

Page 27

1. LUBRICATION GUIDELINES

Maintenance

A. Check and service the auger frequently to

ensure economical and efficient operation of

your auger. Maintaining regular and correct

lubrication is key to proper maintenance. Infrequent or incorrect lubrication can result in

reduced efficiency, excessive wear, and needless downtime.

B. Refer to the drawing below to identify the parts

that need lubrication and the lubrication

frequency.

Lubrication Locations

Flexible Swing-Out Hopper U-Joints:

Lubricate 10 Hour Intervals

NEVER perform maintenance on the

auger unless all safety shields and

devices are in place. Replace any

that are damaged or lost. Do not

clean, adjust, or lubricate any part of

a machine that is in operation.

PNEG-1391 8",10", & 12" BE-SAW Augers

FIGURE 7

27

Page 28

Maintenance

2. FLEXIBLE SWING-OUT HOPPER FLIGHT U-JOINT LUBRICATION

A. A u-joint connects the hopper and the inclined

flight at the hopper elbow. Lubricate the flight

u-joint at approximately ten (10) hour intervals

using SAE multipurpose type grease.

B. To lubricate the u-joint, first remove the cover

strap.

C. Raise the hinged cover.

D. Lubricate the grease zerk if necessary.

E. Close the cover and replace the cover strap

before operating the unit.

Swing Out Hopper U-Joint Lubrication

WARNING: The hinge cover

must be closed and the strap

properly installed before

operating the unit.

Cover Strap

Hopper Flight

Bronze

Tail Flight

Bearing

3. MAIN AUGER HEAD BEARING

MAINTENANCE

A. The main auger head bearing is a self-

aligning, sealed ball bearing. It requires

lubrication daily during operation.

B. Although no adjustment needs to be made

to the bearing, ensure that it is firmly

fastened.

FIGURE 8

4. BRONZE FLIGHT BEARINGS MAINTENANCE

Hinged Cover

Incline Flight

Bronze Bearing

U-Joint

A. Bronze with graphite flight bearings support

the swing-away hopper flight. The bearings

require no lubrication.

B. If the bronze bearing spins inside the retainer,

replace it with a new one.

C. Remove the old bronze bearing and press in

the new one.

C. Be certain that the setscrews in the lock

collar are tight against the shaft, securing the

lock collar firmly to the shaft.

28

PNEG-1391 8",10", & 12" BE-SAW Augers

Page 29

Troubleshooting

Problem

1. THE AUGER IS

VIBRATING.

2. CAPACITY IS TOO LOW.

3. THE AUGER PLUGS.

Possible Cause

A. Damage can occur to the auger

flighting, causing noise. Damage

usually is caused from foreign

material being run through the

auger.

A. There may not be enough grain

reaching the auger.

B. The auger is moving too slowly.

A. The auger may be "jamming"

because too much grain is

reaching the auger.

Solution

A1. It may be necessary to remove

the flighting for inspection.

A1. Make sure the intake has not

bridged over, restricting flow.

The flighting at the intake should

be covered with grain for maximum capacity.

B1. Check the auger speed. Low

capacity will result from speeds

slower than recommended.

A1. Decrease the amount of grain the

auger is gathering.

4. DRIVELINE SHEAR BOLT

SHEARS FREQUENTLY.

B. The grain may be wet.

C. The auger may be jammed with

foreign material.

D. The discharge end may be

plugged.

A. Grain may be flowing too

quickly into the ground hopper.

B. The discharge of grain from the

main auger may be restricted.

B1. If wet grain or other hard-to-move

material is being augered,

reduce the amount of grain

being fed into the swing-away

hopper.

C1. Remove any foreign material in

the auger.

D1. Unplug any plugs at the

discharge end of the auger.

A1. Reduce the flow rate of grain into

the ground hopper.

B1. Inspect auger intake and

discharge areas for damage.

PNEG-1391 8",10", & 12" BE-SAW Augers

29

Page 30

Parts

8" & 10" BE-SAW HOPPER COMPONENTS

8" & 10" SWING A WAY HOPPER COMPONENTS

Ref # Part # Description

1 GK1490 Flexible Swing Away Hopper W eldment for 8"

GK1491 Flexible Swing Away Hopper Weldment for 10"

2 GK6484 Hopper Flight Weldment with Tail Stub for 8" (3/16" Flighting)

GK6485 Hopper Flight Weldment with Tail Stub for 8" (1/4" Flighting)

GK6487 Hopper Flight Weldment with Tail Stub for 10" (3/16" Flighting)

GK6488 Hopper Flight Weldment with Tail Stub for 10" (1/4" Flighting)

3 GK1360 Lid with Hinge for 8"

GK1361 Lid with Hinge for 10"

4 GK1560 Bearing Stub for 8" (1" x 7 1/4" Long)

GK1487 Bearing Stub for 10" (1 1/4" x 8" Long)

5 GK1357 Bearing Hanger Weldment with Bearing for 8" (1" Bore)

GK1359 Bearing Hanger Weldment with Bearing for 10" (1 1/4" Bore)

6 GK1362 Rubber Mat

7 GK1482 Rubber Mat Strap

8 GK1526 Hopper Wheel

9 GK1266 U-Joint for 8" (1" Bore x 5" Long)

GK1483 U-Joint for 10" (1 1/4" Bore x 5" Long)

10 GK1559 Incline Flight Tail Stub for 8" (1" x 6" Long)

GK1484 Incline Flight Tail Stub for 10" (1 1/4" x 5 3/4" Long)

11 GC10634 Tube - 08" x 116" Std Incline Tube Assembly

11 GK6968 Tube - 08" x 144" Std Incline Tube Assembly

11 GC10685 Tube - 10" x 120" Std Incline Tube Assembly

11 GC10445 Tube - 10" x 160" Std Incline Tube Assembly

12 GK6980 Screw - 08" x 7" Pitch x 9' 8"

12 GK6981 Screw - 08" x 7" Pitch x 12' 0"

12 GK6950 Screw - 10" x 9" Pitch x 10' 0"

12 GK6952 Screw - 10" x 9" Pitch x 13' 4"

15 GC10324 Swivel Spout W eldment for 8"

GC10385 Swivel Spout W eldment for 10"

17 GK1534 Rubber Sleeve for 8"

GK1535 Rubber Sleeve for 10"

18 GK2265 Cover Strap for 8"

GK1358 Cover Strap for 10"

19 GK1550 Incline Flight to Tail Stub-Stub Bolt Kit for 8"

GK1536 Incline Flight to Tail Stub-Stub Bolt Kit for 10"

30 PNEG-1391 8",10", & 12" BE-SAW Augers

Page 31

15

Parts

8" & 10" BE-SAW HOPPER COMPONENTS

6

18

3

22

23

12

11

22

10

7

5

8

9

4

8

22

2

24

24

17

1

8

8

12

Connecting Components

8" Standard Flight Mounted on 1.90" O.D. Tubing

10" Standard and Heavy Flighting Mounted on 2 3/8" O.D. Tubing

8" 10"

Ref. # Part # Part # Description

22 S-8316 -- Connecting Bolt 7/16"-14 x 3" HHCS Zinc YDP Gr 8 (8" Upper )

S-7249 -- Connecting Bolt 3/8"-16 x 3 " HHCS Zinc YDP Gr 5 (8" Lower )

-- S-8314 Connecting Bolt 1/2"-13 x 3-1/2 " HHCS Zinc Gr 8 (10" Upper)

-- S-9185 Connecting Bolt 7/16"-14 x 3-1/2 " HHCS Zinc YDP Gr 8 (10" Lower)

23 S-8317 S-8317 7/16"-14 ZN GrC Stover Type Locknut (10" Upper) & (8" Upper)

-- S-8315 1/2"-13 ZN GrC Stover Type Locknut (10" Upper)

S-7383 -- 3/8"-16 ZN Locknut (8" Lower)

24 S-248 -- 3/8" Flat Washer - USS Zinc GR2 (8" Lower)

-- S-8320 7/16" Flat Washer - USS Zinc (10" Lower)

31PNEG-1391 8",10", & 12" BE-SAW Augers

Page 32

Parts

12" BE-SAW HOPPER COMPONENTS

12" SWING A WAY HOPPER COMPONENTS

Ref No. Part No. Description

1 GK4255 Hopper

2 GK4256 Hopper Flight Weldment 3/16

GK4257 Hopper Flight Weldment 1/4"

3 GK4144 Lid w/Hinge

4 GK4254 Bearing Hanger Stub

5 GK4253 Bearing Hanger

N/S GK1303 Bronze Bushing 1.875" O.D. x 11/2" I.D. (in bearing hanger)

6 GK4289 Rubber Mat

7 GK4258 Rubber Mat Strap

8 GK1526 Rubber Wheel w/Steel Pin

9 GK1291 U-Joint (1 1/4" bore x 7") (12N)

10 GK4102 Shaft: Incline Flight Stub

11 Incline Tube Weldment

GC10574 Standard Tube 13' 3" Nominal

GC10577 Standard Tube 15' 3" Nominal

12 Incline Flight

GK7007 w/7ga Flighting X 15' Nominal

GK7008 w/7ga Flighting X 17' Nominal

15 GC10503 12" Swivel Spout W eldment

17 S-7509 W asher, Flat 1/2"

18 GK1535 Rubber Sleeve

19 S-8315 Nut, Lock 1/2-13

20 GK3833 Lid Cover Strap

21 S-8400 Bolt HHCS 1/2" - 13 x 3 3-4" Long Zinc Coated Grade 5

24 S-8251 Nut, Lock 3/8-16

25 GK4292 Spacer Bushing for Swivel Spout to Incline Tube

26 GK4147 Wheel: 8" Caster

32 PNEG-1391 8",10", & 12" BE-SAW Augers

Page 33

12" BE-SAW HOPPER COMPONENTS

8

26

Parts

12

21

10

7

1

2

5

4

9

26

18

17

19

11

6

6

3

20

15

Swing-Out Hopper Illustration

25

33PNEG-1391 8",10", & 12" BE-SAW Augers

Page 34

Parts

10" LOW-PROFILE HOPPER COMPONENTS

10" Low Profile Hopper Component

Ref. # Part # Description

1 GK5813 Swing Away Hopper with Bushing

2 GK5811 Flight 7" O.D. x 7 Ga.

GK5825 Flight 7" O.D. x 1/4".

3 GK5820 1" x 9" Intake Shaft

4 GK6954 1.25" x 60-15/16" Drive Shaft

5 GK5810 Hanger Bearing

6 GK1049 2 Hole Flange Bearing w/ 1" Bore & Lock Collar

7 GK1330 2 Hole Flange Bearing w/ 1.25" Bore & Lock Collar

8 GK1021 15 Tooth Sprocket 1.25" Bore

9 GK1110 22 Tooth Sprocket 1.00" Bore # 50 w/ Keyway

10 GK5821 Chain Guard

11 GK5900 Spacer Bushing 1.25" x .083" x .875"

12 GK1701 13 Tooth Idler Sprocket #50 x 5/8" Bore

14 GK6393 # 50 Roller Chain

13 GK5965 Spacer Bushing .843" x .109" x 1.00"

15 GK1483 U-Joint for 10" (1.25" bore x 5" long)

16 GK5857 Clevis Pin 5/8" x 9-3/4"

17 GK5817 Wheel 10" Dia. X 3.25" Wide

18 GK5815 Hopper Lid W eldment

19 GK5814 Lid Strap

20 GK5822 .125" x 6" x 161" Rubber Mat

21 GK1482 9.875" Rubber Mat Strap

22 GK5824 4.875" Rubber Mat Strap

23 GK6858 Screw - 10" X 9" Pitch x 10'-1 15/16"

24 GC10691 Tube - 10" x 120" Lo-Pro Incline Tube Assy

23 GK6959 Screw - 10" X 9" Pitch x 12'-10 15/16"

24 GC10437 Tube - 10" x 153" Lo-Pro Incline Tube Assy

25 GC10386 10" Swivel Spout Assembly

28 GK6394 Wheel Spacer Bus hing

34 PNEG-1391 8",10", & 12" BE-SAW Augers

Page 35

10" LOW-PROFILE HOPPER COMPONENTS

Parts

35PNEG-1391 8",10", & 12" BE-SAW Augers

Page 36

Parts

12" LOW-PROFILE HOPPER COMPONENTS

12" LOW PROFILE SWING A WAY HOPPER

Ref # Pa rt # Description

1 GK5813 Swing Away Hopper w/Bushing

2 GK5811 Flight 7" O.D. x 7 ga

GK5825 Flight 7" O.D. x 1/4"

3 GK5820 1" x 9" Intake Shaft

4 GK5812 1.25" x 57" Drive Shaft

5 GK5810 Hanger Bearing

6 GK1049 2 Hole Flange Bearing w/1" Bore & Lock Collar

7 GK1330 2 Hole Flange Bearing w/1.25" Bore & Lock Collar

8 GK1021 15 Tooth Sprocket 1.25" Bore

9 GK1014 15 Tooth Sprocket 1.00" Bore

10 GK5821 12" Chain Guard

11 GK5900 Spac er Bushing 1.25" x . 083" x .875"

12 GK5823 #50 Roller Chain

13 GK1701 13 Tooth Idler Sprocket #50 x 5/8" Bearing

14 GK5965 Spac er Bushing .843" x . 109" x 1.00"

15 GK5819 CV Joint 1.25" x 8.875"

16 GK5857 Clevis Pin 5/8" x 9 3/4"

17 GK5817 W heel 10" Dia x 3.25" W ide

18 GK5815 Hopper Lid W eldment

19 GK5814 Lid Strap

20 GK5822 .125" x 6" x 161" Rubber Mat

21 GK1482 9.875" Rubber Mat Strap

22 GK5824 4.875" Rubber May Strap

23 GK7007 12" Incline Flight Assembly 7 Ga. X 15' Nominal

GK7008 12" Incline Flight Assembly 7 Ga. X 17' Nominal

24 GC10580 12" Incline Tube Assembly 12' 8" Nominal

GC10583 12" Inc line Tube Assembly 14' 8" Nominal

25 GC10503 12" Swivel Spout Assembly

28 GK6394 W heel Spacer Bushing

36 PNEG-1391 8",10", & 12" BE-SAW Augers

Page 37

12" LOW-PROFILE HOPPER COMPONENTS

Parts

37PNEG-1391 8",10", & 12" BE-SAW Augers

Page 38

Parts

8" BE-SAW DRIVE COMPONENTS

Drive Components for BESAW

8" Auger

460 V & 220 V 60 Hz Operation

Capacity Item # Qty Description Specification Part No.

1 1 Motor - 182T 3hp/460V/3PH 60HZ 300-3

OR 1 Motor - 184T 3hp/220V/1PH 60HZ 300-1

2 4 Bolt-Hex Hd 3/8"-16 x 1 1/2" S-7515

3 4 Washer-Lock 3/8" Split S-1054

4 4 Nut-Hex 3/8-16 S-456

8 1 Key 1/4" sq x 3" S-8276

1450 BPH

1800 BPH

2200 BPH

2900 BPH

Capacity Item # Qty Description Specification Part No.

1450 BPH

1800 BPH

2200 BPH

2900 BPH

5 1 Sheave-Drv 2gr B 3.0"OD x 1 1/8" PT0563

6 1 Sheave-Drvn 2gr B 18.4"OD x sk GK2567

7 1 Bushing SK-1 1/4" GC07674

N/S 2 Belt BX65 MHC00743

5 1 Sheave-Drv 2gr B 3.0"OD x 1 1/8" PT0563

6 1 Sheave-Drvn 2gr B 1 5"OD x 1.25" GK1869

7 Not Used

N/S 2 Belt BX58 PT1179

5 1 Sheave-Drv 2gr B 3.0"OD x 1 1/8" PT0563

6 1 Sheave-Drvn 2gr B 12"OD x 1 1/4" GK1335

7 Not Used

N/S 2 Belt BX52 020-1034-6

5 1 Sheave-Drv 2gr B 4"OD x 1 1/8" 4018-2

6 1 Sheave-Drvn 2gr B 12"OD x 1 1/4" GK1335

7 Not Used

N/S 2 Belt BX54 MHC00949

380V 50 Hz Operation

1 1 Motor - 182T 3hp/380V/3PH 50HZ 300-3-50

2 4 Bolt-Hex Hd 3/8"-16 x 1 1/2" S-7515

3 4 Washer-Lock 3/8" Split S-1054

4 4 Nut-Hex 3/8-16 S-456

8 1 Key 1/4" sq x 3" S-8276

5 1 Sheave-Drv 2 GR A3.0B3.4-1210 MHC00760

Bushing 1210 - 1 1/8 MHC00144

6 1 Sheave-Drvn 2gr B 18.4"OD x sk GK2567

7 1 Bushing SK-1 1/4" GC07674

N/S 2 Belt BX65 MHC00743

5 1 Sheave-Drv 2 GR A3.0B3.4-1210 MHC00760

Bushing 1210 - 1 1/8 MHC00144

6 1 Sheave-Drvn 2gr B 1 5"OD x 1.25" GK1869

7 Not Used

N/S 2 Belt BX58 PT1179

5 1 Sheave-Drv 2 GR A3.0B3.4-1210 MHC00760

Bushing 1210 - 1 1/8 MHC00144

6 1 Sheave-Drvn 2gr B 12"OD x 1 1/4" GK1335

7 Not Used

N/S 2 Belt BX52 020-1034-6

5 1 Sheave-Drv 2 GR A4.0B4.4-1610 MHC01118

Bushing 1610 - 1 1/8 MHC00035

6 1 Sheave-Drvn 2gr B 12"OD x 1 1/4" GK1335

7 Not Used

N/S 2 Belt BX54 MHC00949

38 PNEG-1391 8",10", & 12" BE-SAW Augers

Page 39

10" BE-SAW DRIVE COMPONENTS

Drive Components for BESAW

10" Auger

460 V & 220 V 60 Hz Operation

Capacity Item # Qty Description Specification Part No.

1 1 Motor - 184T 5hp/460V/3PH 60HZ 500-3

OR 1 Motor - 184T 5hp/220V/1PH 60HZ 500-1

2 4 Bolt-Hex Hd 3/8"-16 x 1 1/2" S-7515

3 4 Washer-Lock 3/8" Split S-1054

4 4 Nut-Hex 3/8-16 S-456

8 1 Key 3/8" sq x 3" S-9181

4000 BPH

4600 BPH

5600 BPH

5 1 Sheave-Drv 2gr B 3.5"OD x 1 1/8" PT0567

6 1 Sheave-Drvn 2gr B 18.4"OD x sk GK2567

7 1 Bushing SK-1 1/2" GK4248

N/S 2 Belt BX66 MHC00616

5 1 Sheave-Drv 2gr B 4"OD x 1 1/8" 4018-2

6 1 Sheave-Drvn 2gr B 18.4"OD x sk GK2567

7 1 Bushing SK-1 1/2" GK4248

N/S 2 Belt BX66 MHC00616

5 1 Sheave-Drv 2gr B 4"OD x 1 1/8" 4018-2

6 1 Sheave-Drvn 2gr B 15"OD x 1 1/2" GK2567

7 Not Used

N/S 2 Belt BX60 MHC00028

Parts

380 V 50 Hz Operation

Capacity Item # Qty Description Specification Part No.

1 1 Motor - 184T 5hp/380V/3PH 50HZ 500.3-50

2 4 Bolt-Hex Hd 3/8"-16 x 1 1/2" S-7515

3 4 Washer-Lock 3/8" Split S-1054

4 4 Nut-Hex 3/8-16 S-456

8 1 Key 3/8" sq x 3" S-9181

4000 BPH

4600 BPH

5600 BPH

5 1 Sheave-Drv 2 GR A3.4B3.8-1610 MHC00499

Bushing 1610 - 1 1/8 MHC00035

6 1 Sheave-Drvn 2gr B 18.4"OD x sk GK2567

7 1 Bushing SK-1 1/2" GK4248

N/S 2 Belt BX66 MHC00616

5 1 Sheave-Drv 2 GR A4.0B4.4-1610 MHC01118

Bushing 1610 - 1 1/8 MHC00035

6 1 Sheave-Drvn 2gr B 18.4"OD x sk GK2567

7 1 Bushing SK-1 1/2" GK4248

N/S 2 Belt BX66 MHC00616

5 1 Sheave-Drv 2 GR A4.0B4.4-1610 MHC01118

Bushing 1610 - 1 1/8 MHC00035

6 1 Sheave-Drvn 2gr B 15"OD x 1 1/2" GK2567

7 Not Used

N/S 2 Belt BX60 MHC00028

39PNEG-1391 8",10", & 12" BE-SAW Augers

Page 40

Parts

12" BE-SAW DRIVE COMPONENTS

Drive Components for BESAW

12" Auger

460V 3PH 60Hz Operation

Ca pa city Ite m # Q ty De scription S pe cifi ca tion Pa rt No .

1 1 Motor - 213T 7 1/2hp/460V/3PH 60HZ 712-3

2 4 Bolt-Hex Hd 3/8"-16 x 1 1/2" S-7515

3 4 Washer-Lock 3/8" Split S -1054

4 4 Nut-Hex 3/8-16 S-456

8 1 Key 3/8" sq x 3" S-9181

7000 BPH 5 1 Sheave-Drv 3gr B 3.5"OD x 1 3/8" ID PT0588

6 1 Sheave-Drvn 3gr B 18.4"OD x SK GK 2570

7 1 B ushing S K -1 1/2" GK 4248

N/S 3 B elt B X73 017-1498-9

8000 BPH 5 1 Sheave-Drv 3gr A3.4B 3.8 SH GK6994

1 Bushing SH 1 3/8" GC07383

6 1 S heave-Drvn 3gr B 18.4"OD x SK GK 2570

7 1 B ushing S K -1 1/2" GK 4248

N/S 3 B elt B X73 017-1498-9

220V 1 PH 60 Hz Operation

Ca pa city Ite m # Q ty De scription S pe cifi ca tion Pa rt No .

1 1 M otor - 215 7 1/2hp/460V /3P H 60HZ 712-3

2 4 B olt-Hex Hd 3/8"-16 x 1 1/2" S-7515

3 4 W asher-Lock 3/8" Split S -1054

4 4 Nut-Hex 3/8-16 S-456

8 1 K ey 3/8" sq x 3" S -9181

7000 BPH 5 1 Sheave-Drv 3 GR 3.5"O.D. X 1 1/8" ID PT0587

6 1 S heave-Drvn 3gr B 18.4"OD x SK GK 2570

7 1 B ushing S K -1 1/2" GK 4248

N/S 3 B elt B X73 017-1498-9

8000 BPH 5 1 Sheave-Drv 3 GR A3.4B3.8 - SH GK 6994

1 Bushing Bushing SH x 1 1/8" Bore MHC00649

6 1 S heave-Drvn 3gr B 18.4"OD x SK GK 2570

7 1 B ushing S K -1 1/2" GK 4248

N/S 3 B elt B X73 017-1498-9

380V 3PH 50Hz Operation

Ca pa city Ite m # Q ty De scription S pe cifi ca tion Pa rt No .

1 1 M otor - 213T 7 1/2hp/380V/3PH 50HZ 712-3-50

2 4 B olt-Hex Hd 3/8"-16 x 1 1/2" S-7515

3 4 W asher-Lock 3/8" Split S -1054

4 4 Nut-Hex 3/8-16 S-456

8 1 K ey 3/8" sq x 3" S -9181

7000 BPH 5 1 Sheave-Drv 3 GR A3.6B4.0-1610 M HC00778

1 Bushing Bushing 1610 - 1 3/8 CE-00594

6 1 S heave-Drvn 3gr B 18.4"OD x SK GK 2570

7 1 B ushing S K -1 1/2" GK 4248

N/S 3 B elt B X73 017-1498-9

8000 BPH 5 1 Sheave-Drv 3 GR A4.2B4.6-1610 GC10714

Bushing 1610 - 1 3/8 CE -00594

6 1 S heave-Drvn 3gr B 18.4"OD x SK GK 2570

7 1 B ushing S K -1 1/2" GK 4248

N/S 3 B elt B X73 017-1498-9

40 PNEG-1391 8",10", & 12" BE-SAW Augers

Page 41

8", 10", & 12" BE-SAW DRIVE COMPONENTS

1

5

Parts

2

6

3

4

8

7

41PNEG-1391 8",10", & 12" BE-SAW Augers

Page 42

Parts

8" & 8" & 10" SWIVEL SPOUT COMPONENTS

8" Swivel Spout Assembly

Ref # Part # Qty. Description

1 GC10324 1 Swivel Spout Weldment

2 DC-1416 2 Danger Rotating Auger Decal

3 GC10340 2 Swivel Pin for Motor Mount 8 & 10"

4 GC10325 1 Motor Mount Plate

5 GC10338 1 Hinged Motor Mount Swing Adjuster

6 S-7835 2 Washer Flat 1" USS Zinc

7 S-240 2 Nut, Hex 1"-8 Zinc Grade 5

8 DC-1411 1 Decal - Shear Point

9 GK1017 1 Four Bolt Flange Bearing 1 1/4" w/Lock collar

10 GK1331 1 Shaft: Drive 1 1/4" x 10 1/2" Long

11 S-236 4 Lock Washer 1/2"

12 S-3729 4 Hex Nut 1/2"-13 Plated Grade 5

13 S-8312 4 Cotter Pin 3/16" dia x 1 1/2" Long

14 GK1571 1 Snap Fastener

15 S-8325 1 Screw MS #8 x 1/2 RHP ZN

16 S-6551 1 Washer Lock Split #8 Med ZN

17 S-6525 1 Nut Hex #8-32 ZN

10" Swivel Spout Assembly

Ref # Part # Qty. Description

1 GC10385 1 Swivel Spout Weldment

2 DC-1416 2 Danger Rotating Auger Decal

3 GC10340 2 Swivel Pin for Motor Mount 8 & 10"

4 GC10325 1 Motor Mount Plate

5 GC10338 1 Hinged Motor Mount Swing Adjuster

6 S-7835 2 Washer Flat 1" USS Zinc

7 S-240 2 Nut, Hex 1"-8 Zinc Grade 5

8 DC-1411 1 Decal - Shear Point

9 GK1343 1 Four Bolt Flange Bearing 1 1/2" w/Lock collar

10 GK1289 1 Shaft: Drive 1 1/2" x 11 1/2" Long

11 S-236 4 Lock Washer 1/2"

12 S-3729 4 Hex Nut 1/2"-13 Plated Grade 5

13 S-8312 4 Cotter Pin 3/16" dia x 1 1/2" Long

14 GK1571 1 Snap Fastener

15 S-8325 1 Screw MS #8 x 1/2 RHP ZN

16 S-6551 1 Washer Lock Split #8 Med ZN

17 S-6525 1 Nut Hex #8-32 ZN

42 PNEG-1391 8",10", & 12" BE-SAW Augers

Page 43

8" & 10" SWIVEL SPOUT COMPONENTS

Parts

12

10

11

4

3

9

1

7

6

5

6

7

3

13

14

2

8

15

16

17

43PNEG-1391 8",10", & 12" BE-SAW Augers

Page 44

Parts

12" SWIVEL SPOUT COMPONENTS

12" Swivel Spout Assembly

Ref # Part # Qty. Description

1 GC10502 1 Swivel Spout Weldment

2 DC-1416 2 Danger Rotating Auger Decal

3 GC10509 2 Swivel Pin for Motor Mount 12"

4 GC10504 1 Motor Mount Plate

5 GC10508 1 Hinged Motor Mount Swing Adjuster

6 S-7835 2 Washer Flat 1" USS Zinc

7 S-240 2 Nut, Hex 1"-8 Zinc Grade 5

8 DC-1411 2 Decal - Shear Point

9 GK2004 1 Four Bolt Flange Bearing 2" w/Lock collar

10 GK2006 1 Shaft: Drive 2" to 1 1/2" x 12" Long

N/S GC10419 1 Belt Guard (Not Shown)

12 S-8349 4 Hex Nut 5/8-11 Plated Grade 5

13 S-8312 4 Cotter Pin 3/16" dia x 1 1/2" Long

14 GK1571 1 Snap Fastener

15 S-8325 1 Screw MS #8 x 1/2 RHP ZN

16 S-6551 1 W asher Lock Split #8 Med ZN

17 S-6525 1 Nut Hex #8-32 ZN

44 PNEG-1391 8",10", & 12" BE-SAW Augers

Page 45

13

Parts

12" SWIVEL SPOUT COMPONENTS

5

4

7

6

6

7

3

10

3

2

14

9

8

15

16

12

17

1

45PNEG-1391 8",10", & 12" BE-SAW Augers

Page 46

Parts

BESAW SWIVEL ATTACHMENT PARTS

A swivel plate assembly is supplied with each BESAW

The swivel plate is used as the top plate of the customer supplied

transition assembly

8" BESAW 10" BESAW

Ref Part # Qty. Description Ref Part # Qty. Description

1 GC11649 1 Swvl Plt. Asy W/Bolt Kit 1 GC11645 1 Swvl Plt. Asy W/Bolt Kit

2 GC11646 1 Bolt Kit 2 GC11646 1 Bolt Kit

3 GC11650 1 Swvl Plt Weldment 3 GC11647 1 Swvl Plt Weldment

4 GK1532 4 3/8" Washer for Swivel 4 GK1532 4 3/8" Washer for Swivel

5 S-7383 4 3/8-16 Nylock Nut 5 S-7383 4 3/8-16 Nylock Nut

12" BESAW

Ref Part # Qty. Description

1 GC11652 1 Swvl Plt. Asy W/Bolt Kit

2 GC11646 1 Bolt Kit

3 GC11653 1 Swvl Plt Weldment

4 GK1532 4 3/8" Washer for Swivel

5 S-7383 4 3/8-16 Nylock Nut

Use the following hardware 6 S-7520

to attach the customer supplied 7 S-1054

transition to GSI bucket elevators 8 S-456

46 PNEG-1391 8",10", & 12" BE-SAW Augers

3/8"-16 x 1" HHCS

3/8" Lock Washer

3/8"-16 Hex Nut

Page 47

TRANSITION TO BUCKET ELEVATOR

Parts

5

4

3

6

7

8

47PNEG-1391 8",10", & 12" BE-SAW Augers

Page 48

Parts

10" BELT GUARD COMPONENTS

10" Belt Gua rd Parts

Ref. # Pa rt # Qty. Description

1 GC08972 1 Belt Guard Back Plate - 18" Sheave

2 GC04677 2 Hinge: .125" x 2" x .063" x 2" Bk

3 GC08983 1 Plast ic 18" Guard

4 DC-995 1 Decal - Warning Shear Point

5 DC-1379 1 Decal Notice

6 DC-994 1 Danger Shear Point

7 99-0026 2 Clip 1/4"-20 Tinnerman Nut

8 S-6674 2 Screw 1/4"-20 x 1/2" THS

9 S-7060 8 Rivet 3/16" x 1/2" (#64)

4

3

2

1

5

9

6

7

8

48 PNEG-1391 8",10", & 12" BE-SAW Augers

Page 49

Parts

HARDWARE LOCATION

CHARTS

49PNEG-1391 8",10", & 12" BE-SAW Augers

Page 50

Parts

HARDWARE LOCATION CHARTS

8" Std Profile BESAW

SAW BOP: 08" STD HPR GC10480

SAW, BOLT KIT: 08" STD HPR GC10481

GSI P/N Qty Description Where Used

PB-005 1 Bag Plastic 5" x 7" x 3 Mil.

S-7383 4 3/8-16 Nylock Nut Tube Ring to Head Assy

S-8317 2 Nut Stover 7/16-14 Zn Gr C Flight to Head Shaft

S-8316 2 Bolt HHCS 7/16 - 14 x 3 Zn GR8 Fli ght to Head Shaft

GK1534 4 Bus hing: Rubber 11/16x3/8x5/8"L Flight to Tail S haft

S-7383 2 Nut Nylock 3/8-16 Zn Gr 5 Flight to Tail Shaft

S-248 4 W asher Flat 3/8 USS Zn Flight to Tail S haft

S-

7249 2 Bolt HHCS 3/ 8-16 x 3 Zn GR5 Flight to Tail S haft

GK1559 1 Tail Shaft Flight to Tail Shaft

GK1526 3 Wheels Wheels to Hopper

S-858 9 W asher Flat 5/8" Wheels to Hopper

S-8312 3 Cotter Pin 3/16" x 1 1/2" lg Wheels to Hopper

GK1266 1 U-Joint U-Joint to t ail Shaft

S-7076 2 Bolt HHCS 5/16"-18 x 2 1/2" GR 5 U-Joint to tail Shaft

S-7382 2 Nut Nylock 5/16-18 U-Joint to tail Shaft

S-7534 2 Bolt HHCS 1/2" x 1 1/4" Screw Tube to Hopper

S-2121 4 W ashers Flat 1/2" Sc rew Tube to Hopper

S-8260 2 Nut Nylock 1/2"-13 Screw Tube to Hopper

GK1360 1 Hinged Cover Hinged Cover to Hopper

S-4275 2 Bolt HHCS 5/16-18 x 3/4" Hinged Cover to Hopper

S-845 2 W asher Flat 5/16 Hinged Cover to Hopper

S-7382 2 Nut Nylock 5/16-18 Hinged Cover to Hopper

GK2265 1 Cover Strap Cover Strap to Tube

S-7383 2 Nut Nylock 3/8"-16 Cover Strap to Tube

GK1362 1 Rubber Belting (151.5" LG) Rubber Belting to Hopper

GK1482 10 Attachment Clips Long Rubber Belting t o Hopper

S-6998 20 Bolt HHCS 1/ 4" x 1" Rubber Belting to Hopper

S-7025 20 Nut Nylock 1/4" Rubber Belting to Hopper

GK1482 10 Attachment Clips Long Rubber Belting t o Hopper

S-6998 20 Bolt HHCS 1/4" x 1" Rubber Belting to Hopper

S-7025 20 Nut Nylock 1/4" Rubber Belting to Hopper

50 PNEG-1391 8",10", & 12" BE-SAW Augers

Page 51

HARDWARE LOCATION CHARTS

10" Std Profile BESAW

SAW BOP: 10" STD HPR GC10454

SAW, BOLT KIT: 10" STD HPR GC10452

GSI P/N Qty Description Where Used

PB-005 1 Bag Plastic 5" x 7" x 3 Mil.

S-7383 4 3/8-16 Nylock Nut Tube Ring to Head Assy

S-8315 2 Nut Stover 1/2"-13 Zn Gr C Flight to Head Shaft

S-8314 2 Bolt HHCS 1/2"-13 x 3-1/2 Zn GR8 Flight to Head Shaft

GK1535 4 Bus hing: Rubber 7/8x1/2x5/8"L Flight to Tail Shaft

S-8317 2 Nut Stover 7/16-14 Zn Gr C Flight to Tail S haft

S-8320 4 W asher Flat 7/16 USS Zn Flight to Tail Shaft

S-9185 2 Bolt HHCS 7/16-14x3-1/ 2 Zn GR8 Flight to Tail Shaft

GK1484 1 Tail Shaft Flight to Tail Shaft

Parts

GK1526 3 Wheels Wheels to Hopper

S-858 9 W asher Flat 5/8" Wheels to Hopper

S-8312 3 Cotter Pin 3/16" x 1 1/2" lg Wheels to Hopper

GK1483 1 U-Joint U-Joint to t ail Shaft

S-7249 2 Bolt HHCS 3/8" x 3" GR 5 U-Joint to t ail Shaft

S-7383 2 Nut Nylock 3/8" U-Joint to tail Shaft

S-7534 2 Bolt HHCS 1/2" x 1 1/4" Screw Tube to Hopper

S-2121 4 W ashers Flat 1/2" Sc rew Tube to Hopper

S-8260 2 Nut Nylock 1/2"-13 Screw Tube to Hopper

GK1361 1 Hinged Cover Hinged Cover to Hopper

S-4275 2 Bolt HHCS 5/16-18 x 3/4" Hinged Cover to Hopper

S-845 2 W asher Flat 5/16 Hinged Cover to Hopper

S-7382 2 Nut Nylock 5/16-18 Hinged Cover to Hopper

GK1358 1 Cover Strap Cover Strap to Tube

S-7383 2 Nut Nylock 3/8"-16 Cover Strap to Tube

GK1362 1 Rubber Belting (151.5" LG) Rubber Belting to Hopper

GK1482 10 Attachment Clips Long Rubber Belting t o Hopper

S-6998 20 Bolt HHCS 1/4" x 1" Rubber Belting to Hopper

S-7025 20 Nut Nylock 1/4" Rubber Belting to Hopper

51PNEG-1391 8",10", & 12" BE-SAW Augers

Page 52

Parts

HARDWARE LOCATION CHARTS

10" Low Profile BESAW

SAW BOP: 10" Lo Pro HPR GC10455

SAW, BOLT KIT: 10" Lo Pro HPR GC10453

GSI P/N Qty Description Where Used

PB-005 1 Bag Plastic 5" x 7" x 3 Mil.

S-7383 4 3/8-16 Nylock Nut Tube Ring to Head Assy

S-8315 2 Nut Stover 1/2"-13 Zn Gr C Flight to Head Shaft

S-8314 2 Bolt HHCS 1/2"-13 x 3-1/2 Zn GR8 Flight to Head Shaft

GK1535 4 Bus hing:Rubber 7/8x1/2x5/8"L Flight to Tail Shaft

S-8317 2 Nut Stover 7/16-14 Zn Gr C Flight to Tail Shaft

S-8320 4 W asher Flat 7/16 USS Zn Flight to Tail Shaft

S-9185 2 Bolt HHCS 7/16-14x3-1/2 Zn GR8 Flight to Tail Shaft

GK1484 1 Tail Shaft Flight to Tail Shaft

GK5817 4 Wheels Wheels to Hopper

GK5857 4 Pin 5/8" x 9 3/4" lg W/.125 Hole Wheels to Hopper

S-7241 4 Cott er Pin 1/8 " x 1 1/ 4" lg Wheels to Hopper

GK6394 4 Bus hing:Whl Spcr;1.06x.125x.50 Wheels to Hopper

GK5819 1 U-Joint U-Joint to tail Shaft

S-7249 2 Bolt HHCS 3/8"-16 x 3" GR 5 U-Joint to tail Shaft

S-8251 2 Nut Stover 3/8"-16 U-Joint to tail Shaft

S-8760 2 Bolt HHCS 1/2"-13 x 1 1/2" Screw Tube to Hopper

S-2120 4 W ashers Flat 1/2" SAE Screw Tube to Hopper

S-8260 2 Nut Nyloc k 1/2"-13 Screw Tube to Hopper

GK5815 1 Hinged Cover Hinged Cover to Hopper

S-8072 3 Bolt HHCS 5/16-18 x 3/4" Hinged Cover to Hopper

S-1937 3 W asher Flat 5/16 Hinged Cover to Hopper

S-7382 3 Nut Nyloc k 5/16-18 Hinged Cover to Hopper

GK5814 1 Cover Strap Cover Strap to Tube

S-7383 2 Nut Nyloc k 3/8"-16 Cover Strap to Tube

GK5822 1 Rubber Belting (EA 161" lg) Rubber Belt ing t o Hopper

GK1482 10 Attachment Clips Long Rubber Belting to Hopper

GK5824 4 At tachment Clips Short Rubber Belting to Hopper

S-6998 28 Bolt HHCS 1/4" x 1" Rubber Belting t o Hopper

S-7025 28 Nut Nylock 1/4" Rubber Belting to Hopper

52 PNEG-1391 8",10", & 12" BE-SAW Augers

Page 53

HARDWARE LOCATION CHARTS

12" Low Profile BESAW

SAW BOP: 12" LOPRO HPR GC10587

SAW, BOLT KIT: 12" LOPRO HPR GC10588

GSI P/N Qty Description Where Used

GK5817 4 Wheels Wheels to Hopper

GK5857 4 Pin 5/8" x 9 3/4" lg W/. 125 Hole W heels t o Hopper

S-7241 4 Cotter Pin 1/8 " x 1 1/4" lg Wheels to Hopper

GK6394 4 Bus hing: Whl Spcr;1.06x.125x .50 Wheels to Hopper

GK5822 1 Rubber Belt ing (EA 161" lg) Rubber Belting to Hopper

GK1482 10 Attachment Clips Long Rubber Belting to Hopper

GK5824 4 At tachment Clips Short Rubber Belting to Hopper

S-6998 28 Bolt HHCS 1/4" x 1" Rubber Belting to Hopper

S-7025 28 Nut Nylock 1/4" Rubber Belting to Hopper

Parts

GK5815 1 Hinged Cover Hinged Cover to Hopper

S-8072 3 Bolt HHCS 5/16-18 x 3/4" Hinged Cover to Hopper

S-1937 3 W asher Flat 5/16 Hinged Cover to Hopper

S-7382 3 Nut Nylock 5/16-18 Hinged Cover to Hopper

GK5814 1 Cover Strap Cover Strap to Tube

S-7383 2 Nut Nylock 3/8"-16 Cover Strap to Tube

S-8760 2 Bolt HHCS 1/2"-13 x 1 1/2" S c rew Tube to Hopper

S-2120 4 W ashers Flat 1/2" SAE Screw Tube to Hopper

S-8260 2 Nut Nylock 1/2"-13 Screw Tube to Hopper

GK5819 1 U-Joint U-Joint to t ail Shaft

S-7249 2 Bolt HHCS 3/8"-16 x 3" GR 5 U-Joint to tail Shaft

S-8251 2 Nut Stover 3/8"-16 U-Joint to tail Shaft

GK1535 4 Bus hing: Rubber 7/8x1/2x5/8"L Flight to Tail Shaft

S-8315 2 Nut Stover 1/2-13 Zn Gr C Flight to Tail Shaft

S-2121 4 W asher Flat 1/2" Flight to Tail Shaft

S-8400 2 Bolt HHCS 1/2-13 X 3-3/4 Zn GR5 Flight to Tail Shaft

GK4102 1 Tail Shaft Flight to Tail Shaft

S-8606 2 Nut Stover 5/8"- 11 Zn Gr C Flight to Head Shaft

S-7011 2 Bolt HHCS 5/8"- 11 x 3-1/2 Zn GR8 Flight to Head Shaft

GK4292 8 Spac er Bus hing Tube Ring to Head Assy

S-7409 8 W asher Flat 3/8" Tube Ring to Head Assy

S-7383 8 3/8-16 Nylock Nut Tube Ring to Head Assy

PB-008 1 Bag Plastic 7" x 8" x 3 Mil.

53PNEG-1391 8",10", & 12" BE-SAW Augers

Page 54

Parts

HARDWARE LOCATION CHARTS

12" Low Profile BESAW

SAW BOP: 12" LOPRO HPR GC10587

SAW, BOLT KIT: 12" LOPRO HPR GC10588

GSI P/N Qty Description Where Used

GK5817 4 Wheels Wheels to Hopper

GK5857 4 Pin 5/8" x 9 3/4" lg W/.125 Hole Wheels to Hopper

S-7241 4 Cott er Pin 1/8 " x 1 1/ 4" lg Wheels to Hopper

GK6394 4 Bus hing:Whl Spcr;1.06x.125x.50 Wheels to Hopper

GK5822 1 Rubber Belting (EA 161" lg) Rubber Belt ing t o Hopper

GK1482 10 Attachment Clips Long Rubber Belting to Hopper

GK5824 4 At tachment Clips Short Rubber Belting to Hopper

S-6998 28 Bolt HHCS 1/4" x 1" Rubber Belting t o Hopper

S-7025 28 Nut Nylock 1/4" Rubber Belting to Hopper

GK5815 1 Hinged Cover Hinged Cover to Hopper

S-8072 3 Bolt HHCS 5/16-18 x 3/4" Hinged Cover to Hopper

S-1937 3 W asher Flat 5/16 Hinged Cover to Hopper

S-7382 3 Nut Nyloc k 5/16-18 Hinged Cover to Hopper

GK5814 1 Cover Strap Cover Strap to Tube

S-7383 2 Nut Nyloc k 3/8"-16 Cover Strap to Tube

S-8760 2 Bolt HHCS 1/2"-13 x 1 1/2" Screw Tube to Hopper

S-2120 4 W ashers Flat 1/2" SAE Screw Tube to Hopper

S-8260 2 Nut Nyloc k 1/2"-13 Screw Tube to Hopper

GK5819 1 U-Joint U-Joint to tail Shaft

S-7249 2 Bolt HHCS 3/8"-16 x 3" GR 5 U-Joint to tail Shaft

S-8251 2 Nut Stover 3/8"-16 U-Joint to tail Shaft

GK1535 4 Bus hing:Rubber 7/8x1/2x5/8"L Flight to Tail Shaft

S-8315 2 Nut Stover 1/2-13 Zn Gr C Flight to Tail Shaft

S-2121 4 W asher Flat 1/2" Flight to Tail Shaft

S-8400 2 Bolt HHCS 1/2-13 X 3-3/4 Zn GR5 Flight to Tail Shaft

GK4102 1 Tail Shaft Flight to Tail Shaft

S-8606 2 Nut Stover 5/8"- 11 Zn Gr C Flight to Head Shaft

S-7011 2 Bolt HHCS 5/8"- 11 x 3-1/2 Zn GR8 Flight to Head Shaft

GK4292 8 Spac er Bushing Tube Ring to Head Assy

S-7409 8 W asher Flat 3/8" Tube Ring to Head Assy

S-7383 8 3/8-16 Nylock Nut Tube Ring to Head Assy

PB-008 1 Bag Plastic 7" x 8" x 3 Mil.

54 PNEG-1391 8",10", & 12" BE-SAW Augers

Page 55

WARRANTY

THE COMPANY WARRANTS ALL PRODUCTS MANUFACTURED TO BE FREE OF DEFECTS IN MATERIAL

AND WORKMANSHIP UNDER NORMAL USAGE AND CONDITIONS FOR A PERIOD OF TWELVE (12)

MONTHS AFTER RETAIL SALE TO THE ORIGINAL END USER OF SUCH PRODUCTS. OUR ONLY

OBLIGATION IS, AND PURCHASER'S SOLE REMEDY SHALL BE TO REPAIR OR REPLACE, AT THE

COMPANY'S OPTION AND EXPENSE, PRODUCTS THAT, IN THE MANUFACTURERS SOLE JUDGEMENT,

CONTAIN A MATERIAL DEFECT DUE TO MATERIALS OR WORKMANSHIP. ALL DELIVERY AND SHIPMENT

CHARGES TO AND FROM THE FACTORY WILL BE PURCHASER'S RESPONSIBILITY. EXPENSES

INCURRED BY OR ON BEHALF OF THE PURCHASER WITHOUT PRIOR WRITTEN AUTHORIZATION

FROM AN AUTHORIZED EMPLOYEE OF THE COMPANY SHALL BE THE SOLE RESPONSIBILITY OF THE

PURCHASER.

EXCEPT FOR THE ABOVE EXPRESS LIMITED WARRANTIES, THE COMPANY MAKES NO WARRANTY

OF ANY KIND, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION, WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR USE IN CONNECTION WITH (i)

PRODUCT MANUFACTURED OR SOLD BY THE COMPANY OR (ii) ANY ADVICE, INSTRUCTION,

RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESENTATIVE OR EMPLOYEE

OF THE COMPANY REGARDING OR RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT,

SUITABILITY FOR A PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCT OR PRODUCTS.

IN NO EVENT SHALL THE COMPANY BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, INCLUDING, WITHOUT LIMITATION, LOSS OF ANTICIPATED PROFITS OR

BENEFITS. PURCHASER'S SOLE AND EXCLUSIVE REMEDY SHALL BE LIMITED TO THAT STATED

ABOVE, WHICH SHALL NOT EXCEED THE AMOUNT PAID FOR THE PRODUCT PURCHASED. THIS

WARRANTY IS NOT TRANSFERABLE AND APPLIES ONLY TO THE ORIGINAL PURCHASER. WE SHALL

HAVE NO OBLIGATION OR RESPONSIBILITY FOR ANY REPRESENTATIVE OR WARRANTIES MADE BY

OR ON BEHALF OF ANY DEALER, AGENT OR DISTRIBUTOR OF THE COMPANY.

THE COMPANY ASSUMES NO RESPONSIBILITY FOR FIELD MODIFICATIONS. MODIFICATIONS TO THE

PRODUCT NOT SPECIFICALLY COVERED BY THE CONTENTS OF THIS MANUAL WILL NULLIFY ANY

PRODUCT WARRANTY THAT MIGHT HAVE BEEN OTHERWISE AVAILABLE. THE USE OF OUR