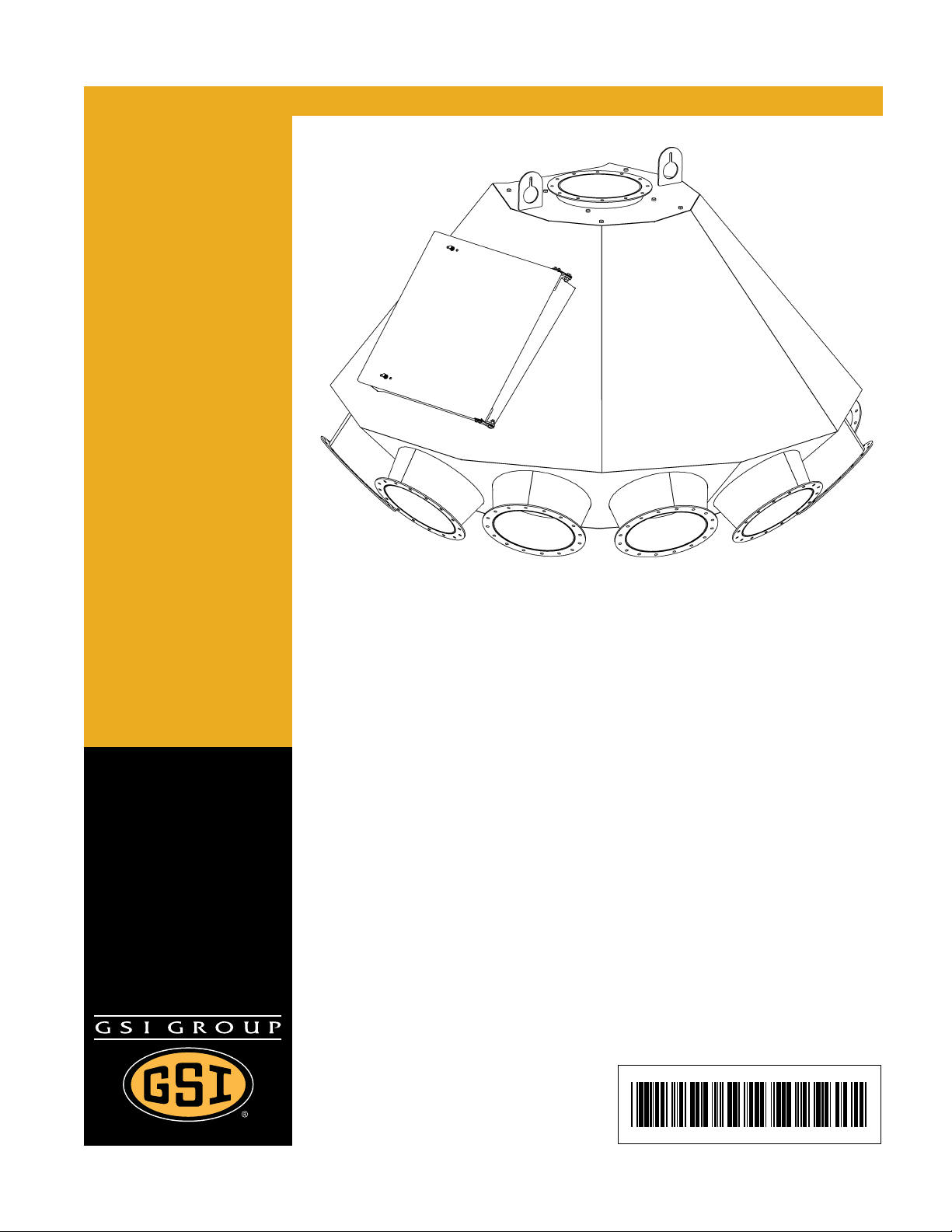

Page 1

PNEG-1385

Farm/Commercial Distributor

Instruction Manual

PNEG-1385

Date: 06-08-12

Page 2

All information, illustrations, photos, and specifications in this manual are based on the latest

information available at the time of publication. The right is reserved to make changes at any

time without notice.

2 PNEG-1385 Farm/Commercial Distributor

Page 3

Table of Contents

Contents

Chapter 1 Introduction ..........................................................................................................................................4

Chapter 2 Safety .....................................................................................................................................................5

Safety Guidelines .................................................................................................................................. 5

Safety Instructions ..................... ... .... .......................................... ... ... ..................................................... 6

Chapter 3 Installation Notes .................................................................................................................................8

Chapter 4 Maintenance ........................................................................................................................................12

Greasing the Bearing .......................................................................................................................... 12

Replacing the Wear Liner .................................................................................................................... 13

Replacing the Brush Mount Assembly ................................................................................................ 14

Chapter 5 Parts List .............................................................................................................................................15

6" 4 Hole, 45° Distributor Assembly (DFB06445G) ............................................................................. 16

6" 6 Hole, 45° Distributor Assembly (DFB06645G) ............................................................................. 18

6" 8 Hole, 45° Distributor Assembly (DFB06845G) ............................................................................. 20

8" 6 Hole, 45° Distributor Assembly (DFB08645G) ............................................................................. 22

8" 8 Hole, 45° Distributor Assembly (DFB08845G) ............................................................................. 24

8" 10 Hole, 45° Distributor Assembly (DFB081045G) ......................................................................... 26

10" 6 Hole, 45° Distributor Assembly - Drawing A (DFB10645G) .......... ............................................. 28

10" 6 Hole, 45° Distributor Assembly - Drawing B (DFB10645G) .......... ............................................. 30

10" 8 Hole, 45° Distributor Assembly (DFB10845G) ........................................................................... 32

10" 10 Hole, 45° Distributor Assembly (DFB101045G) ....................................................................... 34

12" 4 Hole, 45° Distributor Assembly (DFB12445G) ........................................................................... 36

12" 6 Hole, 45° Distributor Assembly (DFB12645G) ........................................................................... 38

12" 8 Hole, 45° Distributor Assembly (DFB12845G) ........................................................................... 40

12" 10 Hole, 45° Distributor Assembly (DFB121045G) ....................................................................... 42

14" 4 Hole, 45° Distributor Assembly (DFB14445G) ........................................................................... 44

14" 6 Hole, 45° Distributor Assembly (DFB14645G) ........................................................................... 46

14" 8 Hole, 45° Distributor Assembly (DFB14845G) ........................................................................... 48

Chapter 6 Warranty ..............................................................................................................................................51

PNEG-1385 Farm/Commercial Distributor 3

Page 4

1. Introduction

Thank you for choosing this product. It is designed to give excellent performance and service for

many years.

This manual covers general information on the distributor installation. Due to the wide variety of field

conditions we cannot cover every aspect of installation. We offer one method for installing equipment but,

rely on the qualified contractor’s experience and techniques. Some conditions and surroundings

do not allow certain practices during the installation of equipment. We can not be responsible for the

installation of the distributor and accessories. We encourage anyone installing, or maintaining this

equipment to thoroughly read this manual before proceeding.

The company is the vendor of the distributor and certain of its optional accessories only, and does not

assume responsibility for the installation. The installation recommendations contained within this manual

are for consideration only.

READ THIS MANUAL carefully to learn how to properly use and install equipment. Failure to do so could

result in personal injury or equipment damage.

INSPECT the shipment immediately upon arrival. The customer is responsible for ensuring that all

quantities are correct. The customer should report and note any damage or shortage on the bill of lading

to justify their claim to the transport company.

THIS MANUAL SHOULD BE CONSIDERED a permanent part of your equipment and should be easily

accessible when needed.

A WARRANTY is provided as part of the company’s support program for customers who use and maintain

their equipment as described in the manual. The warranty is explained on the warranty page located on

the inside back cover of this manual.

This warranty provides you the assurance that the company will back its products when defects appear

within the warranty period. In some circumstances, the company also provides field improvements, often

without charge to the customer, even if the product is out of warranty. Should the equipment be abused,

or modified to change its performance beyond the factory specifications, the warranty will become void

and field improvements may be denied.

4 PNEG-1385 Farm/Commercial Distributor

Page 5

2. Safety

DANGER

WARNING

CAUTION

NOTICE

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a

hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to

personal injury.

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

PNEG-1385 Farm/Commercial Distributor 5

Page 6

2. Safety

Follow Safety Instructions

Carefully read all safety messages in this manual and

safety signs on your machine. Keep signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from the manufacturer.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machinery in proper working condition.

Unauthorized modifications to the machine may impair

the function and/or safety and affect machine life.

If you do not understand any part of this manual or need

assistance, contact your dealer.

Read and Understand Manual

Prepare for Emergencies

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital, and fire department near your telephone.

Keep Emergency Equipment

Quickly Accessible

Safety Instructions

Our foremost concern is your safety and the safety of others associated with this equipment. We want to

keep you as a customer. This manual is to help you understand safe operating procedures and some

problems that may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards, and precautions

exist, and to inform all personnel associated with the equipment or in the area. Safety precautions may be

required from the personnel. Avoid any alterations to the equipment. Such alterations may p roduce a very

dangerous situation where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable

regulations, which should be carefully followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

6 PNEG-1385 Farm/Commercial Distributor

Page 7

2. Safety

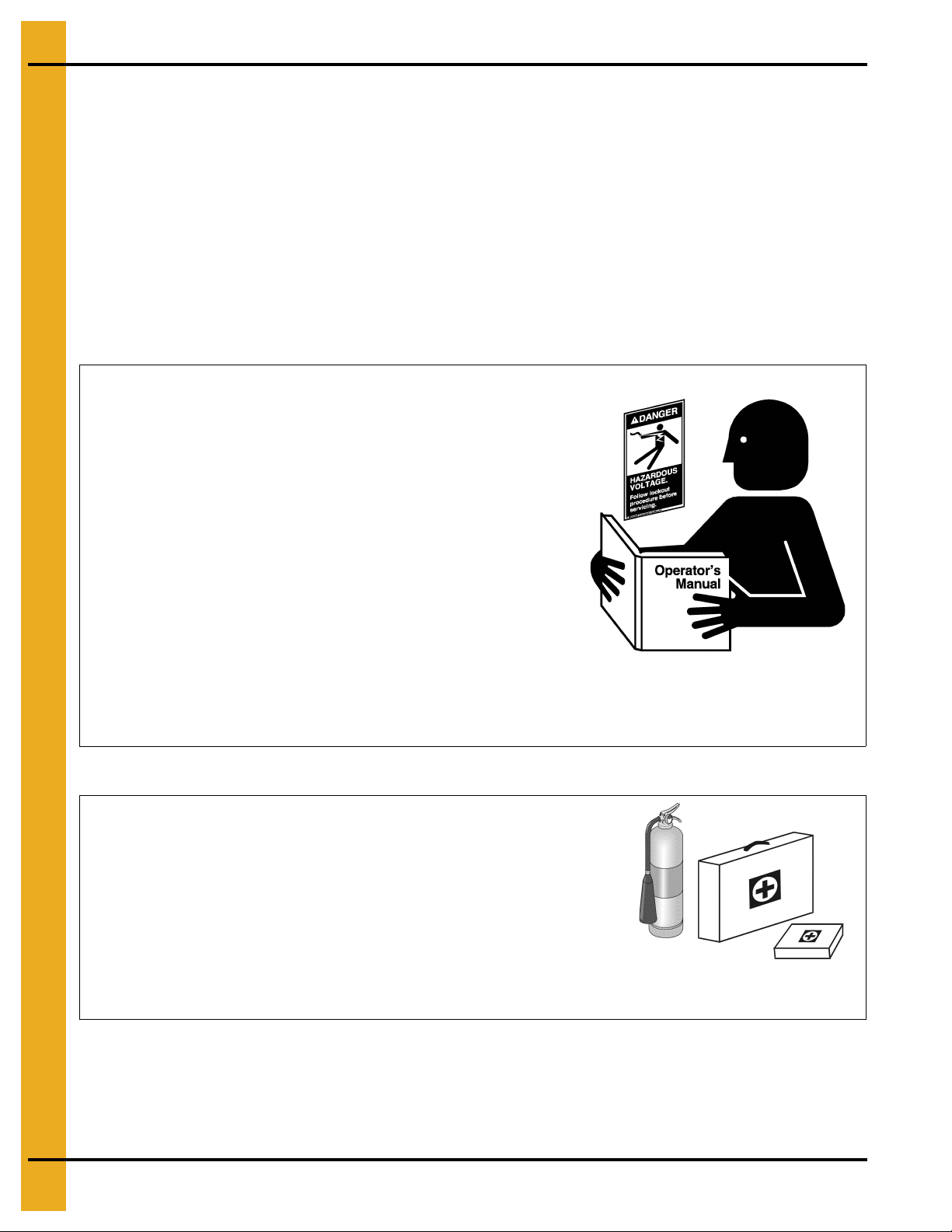

Wear Protective Clothing

Wear close-fitting clothing and safety equipment appropriate

to the job.

Remove all jewelry.

Tie long hair up and back.

Wear safety glasses at all times to protect eyes from debris.

Wear gloves to protect your hands from sharp edges on

plastic or steel parts.

Wear steel-toed boots to help protect your feet from falling

debris. Tuck in any loose or dangling shoestrings.

A respirator may be needed to prevent breathing potentially

toxic fumes and dust.

Wear a hard hat to help protect your head.

Wear appropriate fall protection equipment when working at

elevations greater than six feet (6').

Eye Protection

Gloves

Steel-Toed Boots

Respirator

Hard Hat

Fall Protection

PNEG-1385 Farm/Commercial Distributor 7

Page 8

3. Installation Notes

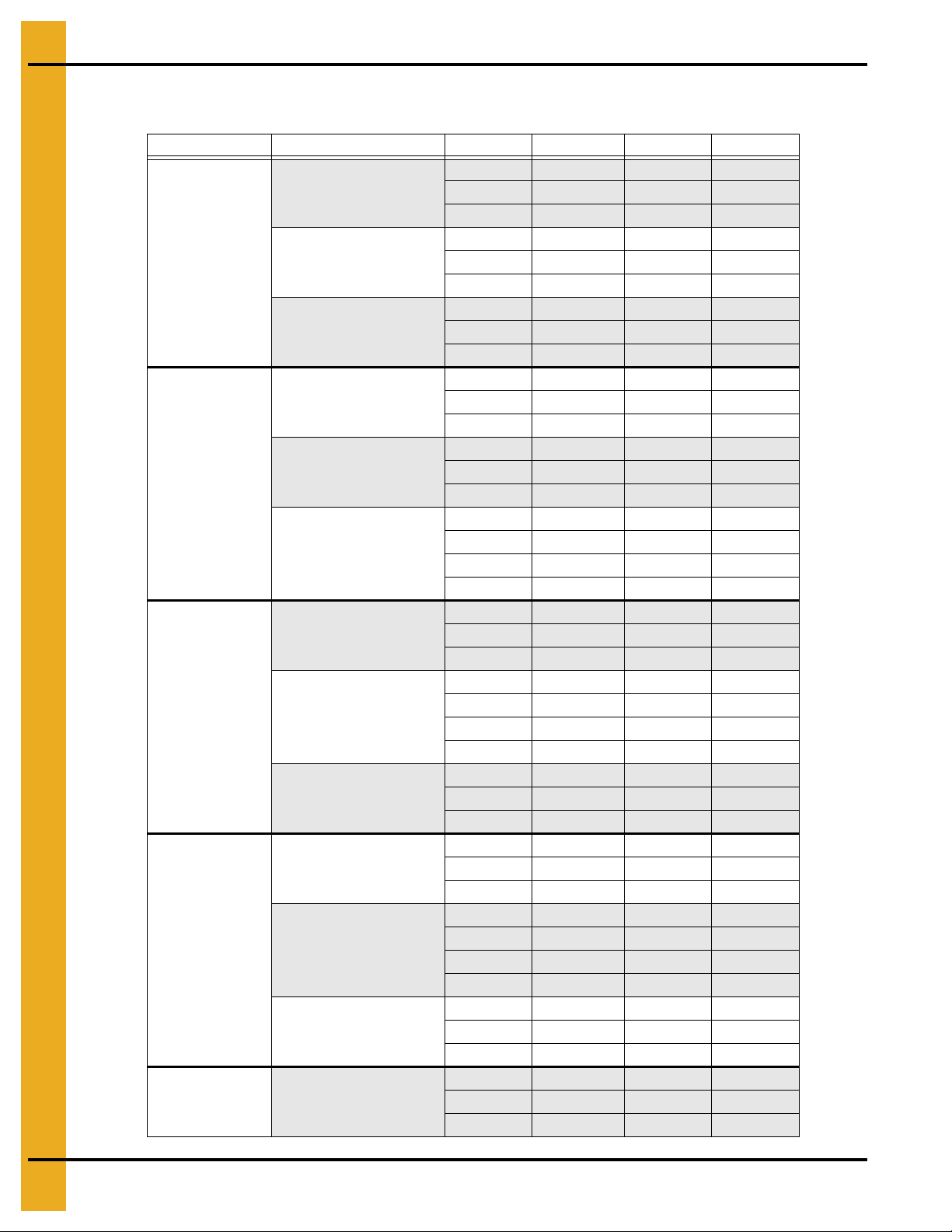

* Sloped transitions are included with the following configurations:

Distributor Offset Transitions for Use with GSI Ladder Packages

Bucket Size Distributor Diameter # Spouts No Offset 1' Offset 2' Offset

4 X

16"

10

24"

30"

36"

42" 14

10

12

10

12

14

10

12

14

6

8

8

6 X

8 X

6 X

8 X

10 X

6 X

8 X

10 X

6X

8X

10 X

6 X

8 X

10 X

4X

6X

8X

10 X

6 X

8 X

10 X

4 X

6 X

8 X

10 X

4 X

6 X

8 X

6X

8X

10 X

4 X

6 X

8 X

10 X

4X

6X

8X

4 X

6 X

8 X

8 PNEG-1385 Farm/Commercial Distributor

Page 9

3. Installation Notes

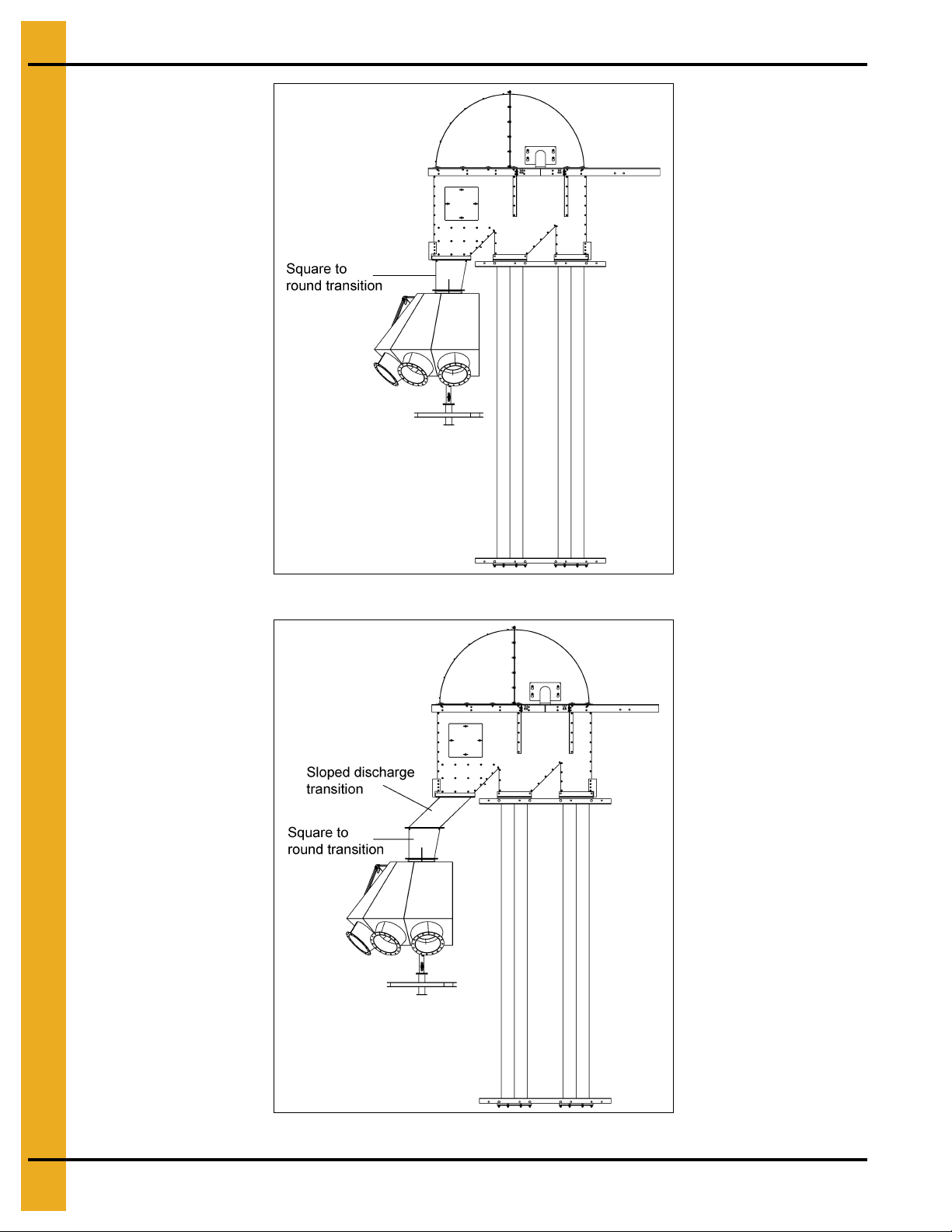

* The offset transition allows clearance between the bucket elevator and the distributor. The transition also

keeps the distributor outlet spouting from interfering with the ladder safety cage. Transitions must be

installed for proper distributor operation. (See Figure 3A and Figure 3B on Page 10.)

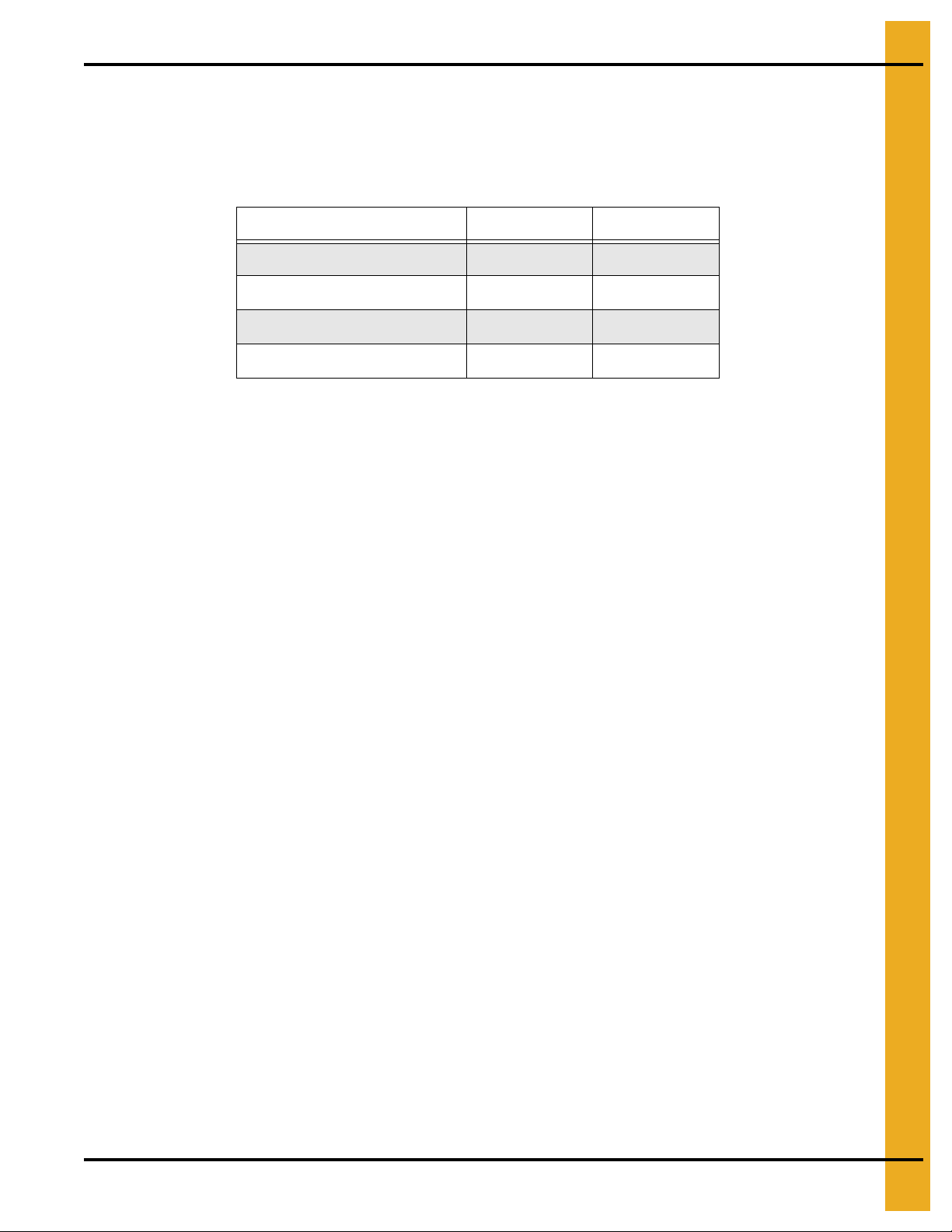

Transition Numbers

Offset Transitions 1' Offset 2' Offset

16" and 24" (AR Construction) GE1612OT-12 GE1612OT-24

16" and 24" (Urethane Lined) GE1612OT-12L GE1612OT-24L

30" and 36" (AR Construction) GE1818OT-12 GE1818OT-24

30" and 36" (Urethane Lined) GE1818OT-12L GE1818OT-24L

NOTE:

Standard offset transitions are hot-dip galvanized finish. Powder coat finish available upo n request.

PNEG-1385 Farm/Commercial Distributor 9

Page 10

3. Installation Notes

Figure 3A

Figure 3B

10 PNEG-1385 Farm/Commercial Distributor

Page 11

3. Installation Notes

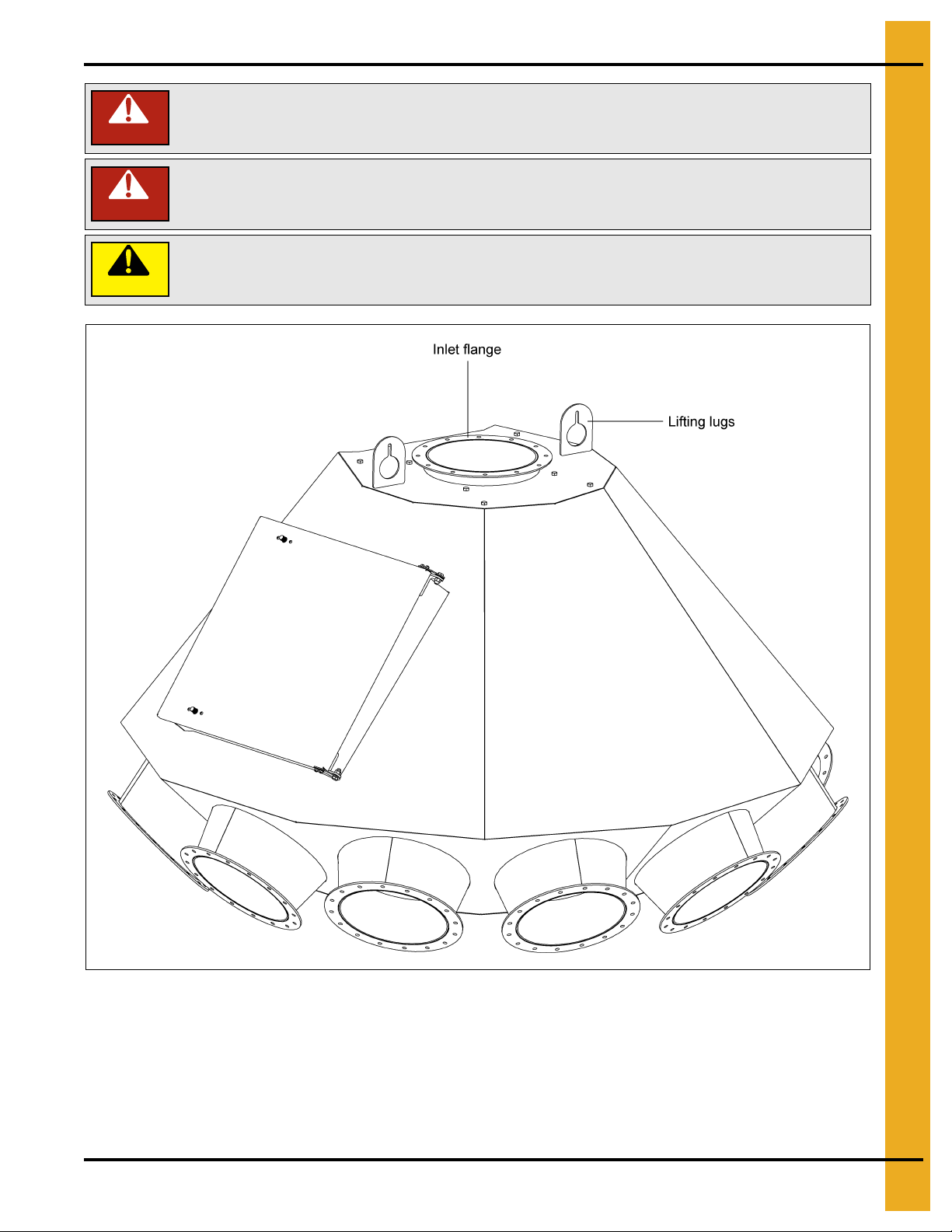

DANGER

If you must get inside of distributor, turn OFF and LOCK OUT all power sources.

DO NOT operate the distributor while inside.

DANGER

Crush hazard. Lifting lugs are to be used for placement only. DO NOT use lifting

lugs for structural support. (See Figure 3C.)

CAUTION

DO NOT use a clamp band when attaching the down spout to the inlet flange.

A bolted connection is required at this point. (See Figure 3C.)

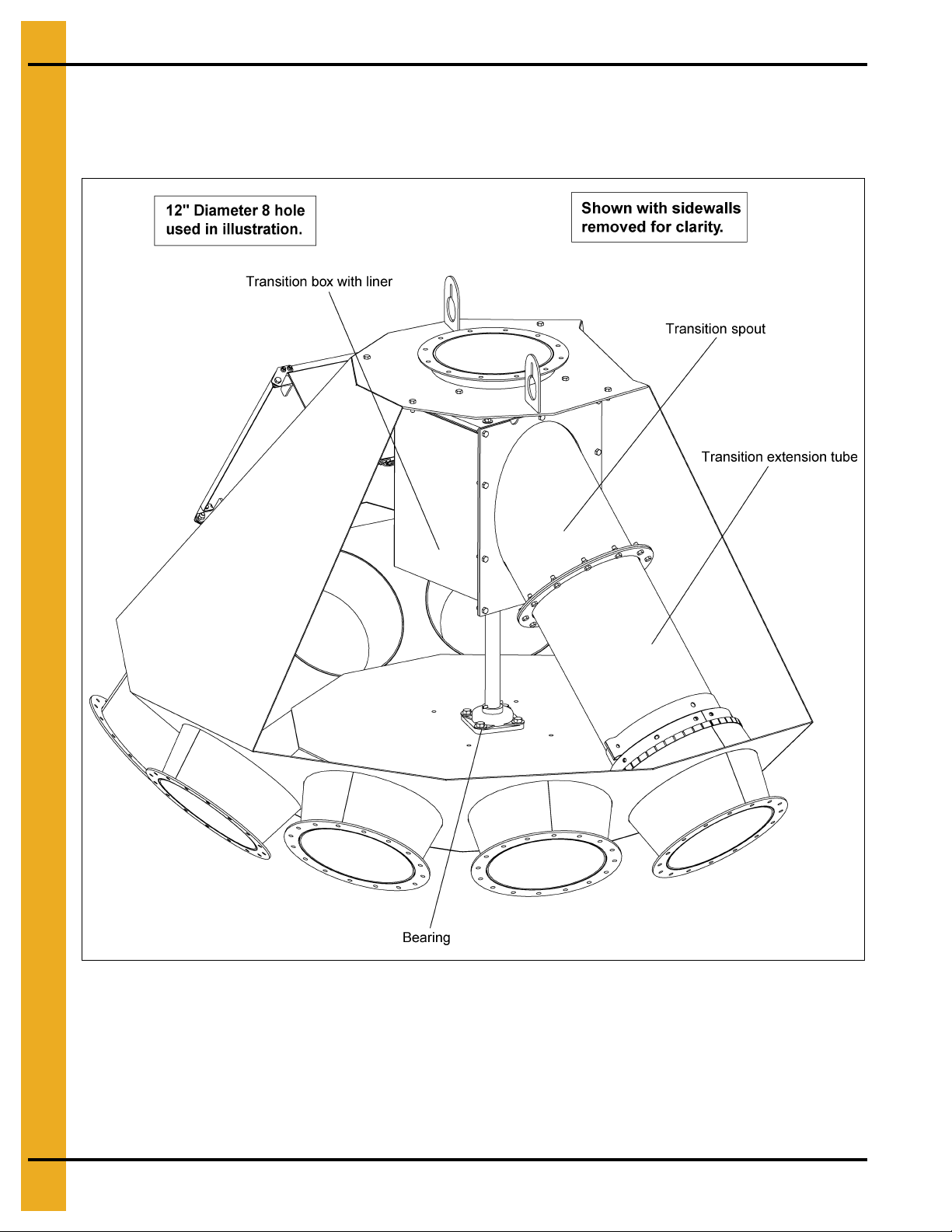

Figure 3C

PNEG-1385 Farm/Commercial Distributor 11

Page 12

4. Maintenance

Greasing the Bearing

The bearing is greased at the factory and is ready for operation. Lubricate annually using a #2 lithium based

grease or equivalent.

(See Figure 4A.)

Figure 4A

12 PNEG-1385 Farm/Commercial Distributor

Page 13

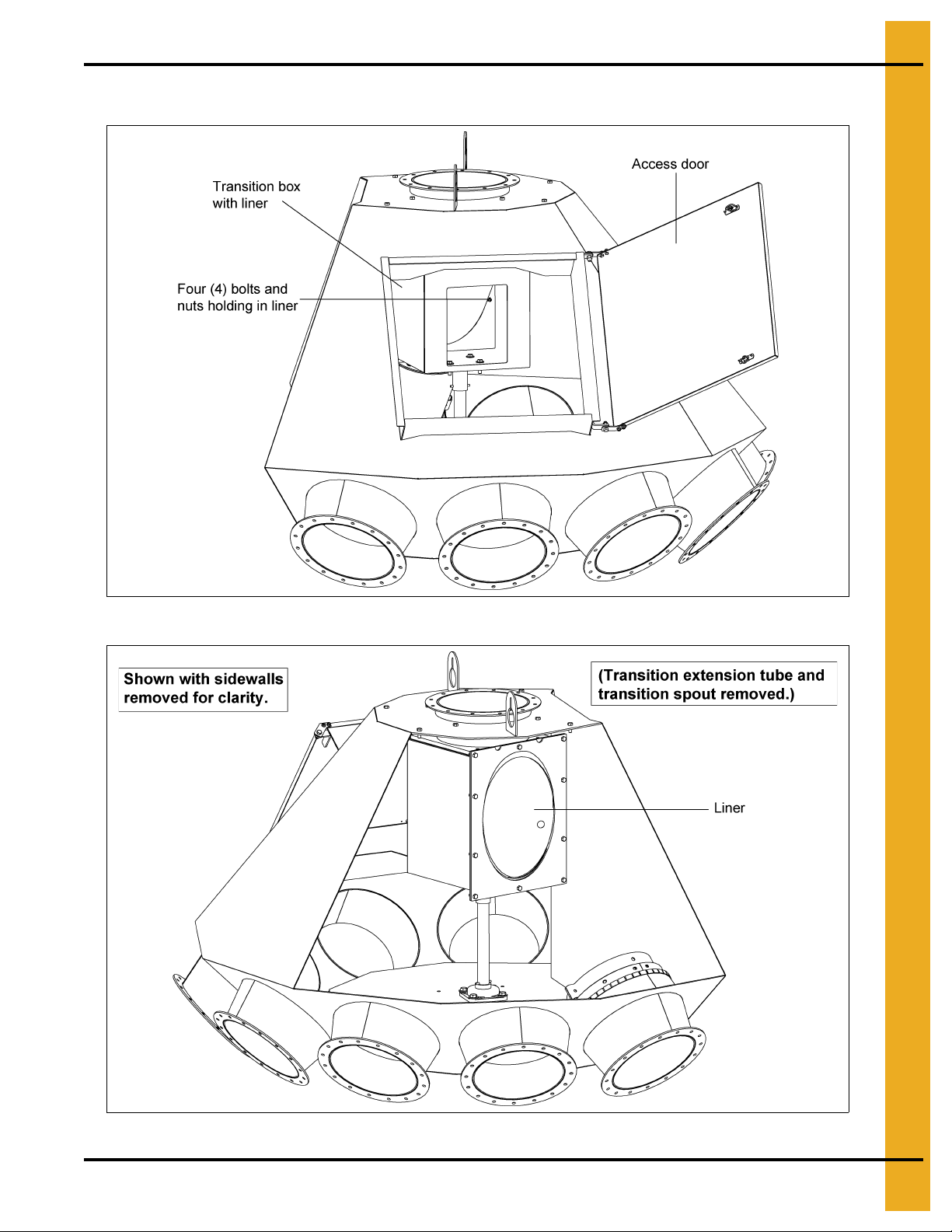

Replacing the Wear Liner

4. Maintenance

Figure 4B

Figure 4C

PNEG-1385 Farm/Commercial Distributor 13

Page 14

4. Maintenance

Replacing the Wear Liner (Continued)

Position the spouting near the door. Remove the transition extension tube. (See Figure 4A on Page 12.)

Remove the transition spout. (See Figure 4A on Page 12.) Reverse the transition box which will allow

access to the hardware holding the liner in. (See Figure 4B on Page 13). Replace the old liner with the

new liner. (See Figure 4C on Page 13.) Replace the transition spout and transition extension tube.

Replacement Liner Numbers

6" - DFB0368, 8" - DFB0183, 10" - DFB0051, 12" - DFB0121, 14" - DFB0268

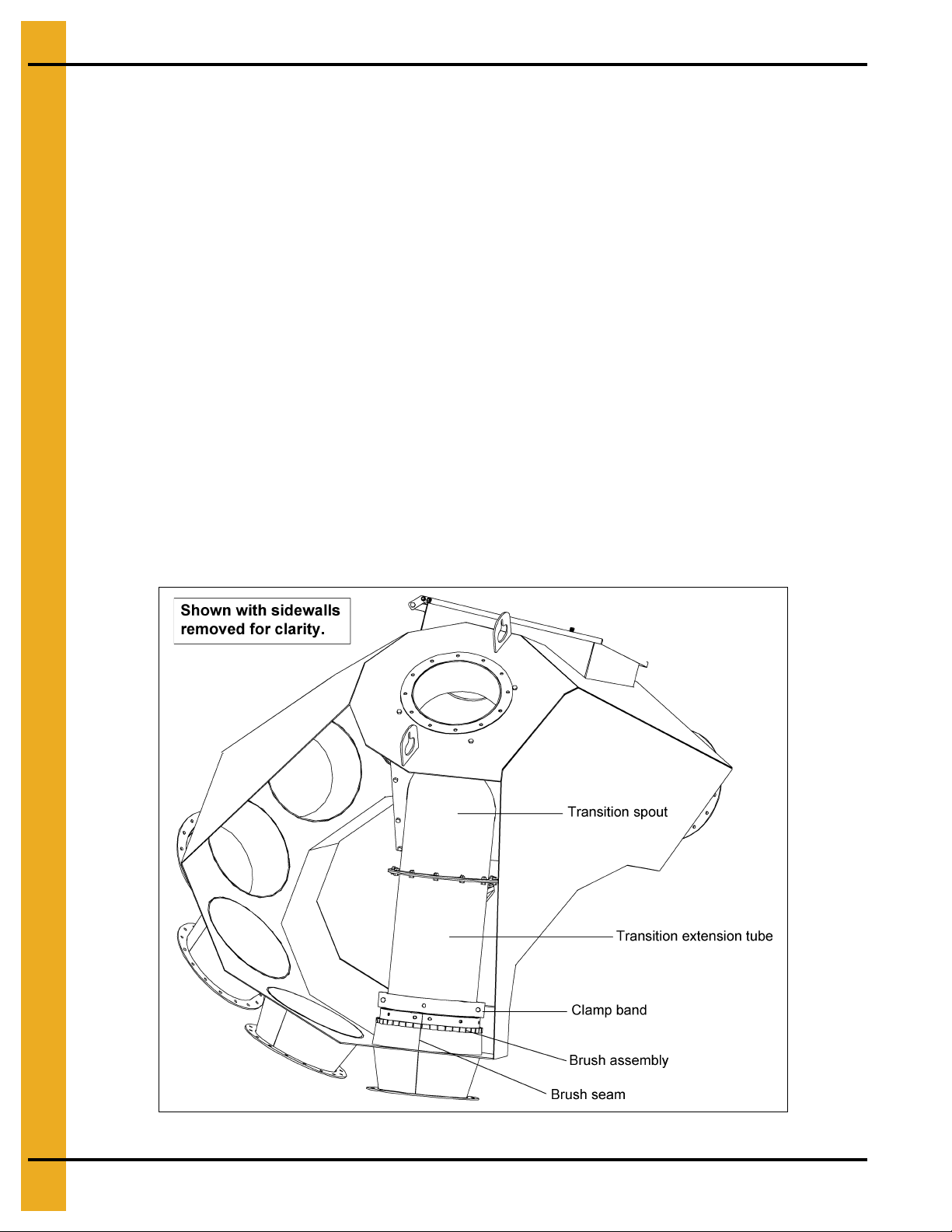

Replacing the Brush Mount Assembly

Position the spouting near the door. Remove the transition extension tube. (See Figure 4D.) Loosen the

clamp band and remove old brush assembly from the transition extension tube. Replace the new brush

assembly onto transition extension tube and tighten in place using the clamp band. Replace the transition

extension tube/brush assembly.

NOTE: Make sure the seam of the brush assembly is facing towards the top as shown in Figure 4D.

The brush bristles should be somewhat snug against the spout wall. Operate the spout to all

outlets to ensure proper alignment and clearance.

Replacement Brush Assembly Numbers

6" - DFB0374, 8" - DFB0189, 10" - DFB0060, 12" - DFB0127, 14" - DFB0274

Figure 4D

14 PNEG-1385 Farm/Commercial Distributor

Page 15

1. 6" 4 Hole, 45° Distributor Assembly (DFB06445G)

2. 6" 6 Hole, 45° Distributor Assembly (DFB06645G)

3. 6" 8 Hole, 45° Distributor Assembly (DFB06845G)

4. 8" 6 Hole, 45° Distributor Assembly (DFB08645G)

5. 8" 8 Hole, 45° Distributor Assembly (DFB08845G)

6. 8" 10 Hole, 45° Distributor Assembly (DFB081045G)

7. 10" 6 Hole, 45° Distributor Assembly - Drawing A (DFB10645G)

8. 10" 6 Hole, 45° Distributor Assembly - Drawing B (DFB10645G)

9. 10" 8 Hole, 45° Distributor Assembly (DFB10845G)

5. Parts List

10. 10" 10 Hole, 45° Distributor Assembly (DFB101045G)

11. 12" 4 Hole, 45° Distributor Assembly (DFB12445G)

12. 12" 6 Hole, 45° Distributor Assembly (DFB12645G)

13. 12" 8 Hole, 45° Distributor Assembly (DFB12845G)

14. 12" 10 Hole, 45° Distributor Assembly (DFB121045G)

15. 14" 4 Hole, 45° Distributor Assembly (DFB14445G)

16. 14" 6 Hole, 45° Distributor Assembly (DFB14645G)

17. 14" 8 Hole, 45° Distributor Assembly (DFB14845G)

PNEG-1385 Farm/Commercial Distributor 15

Page 16

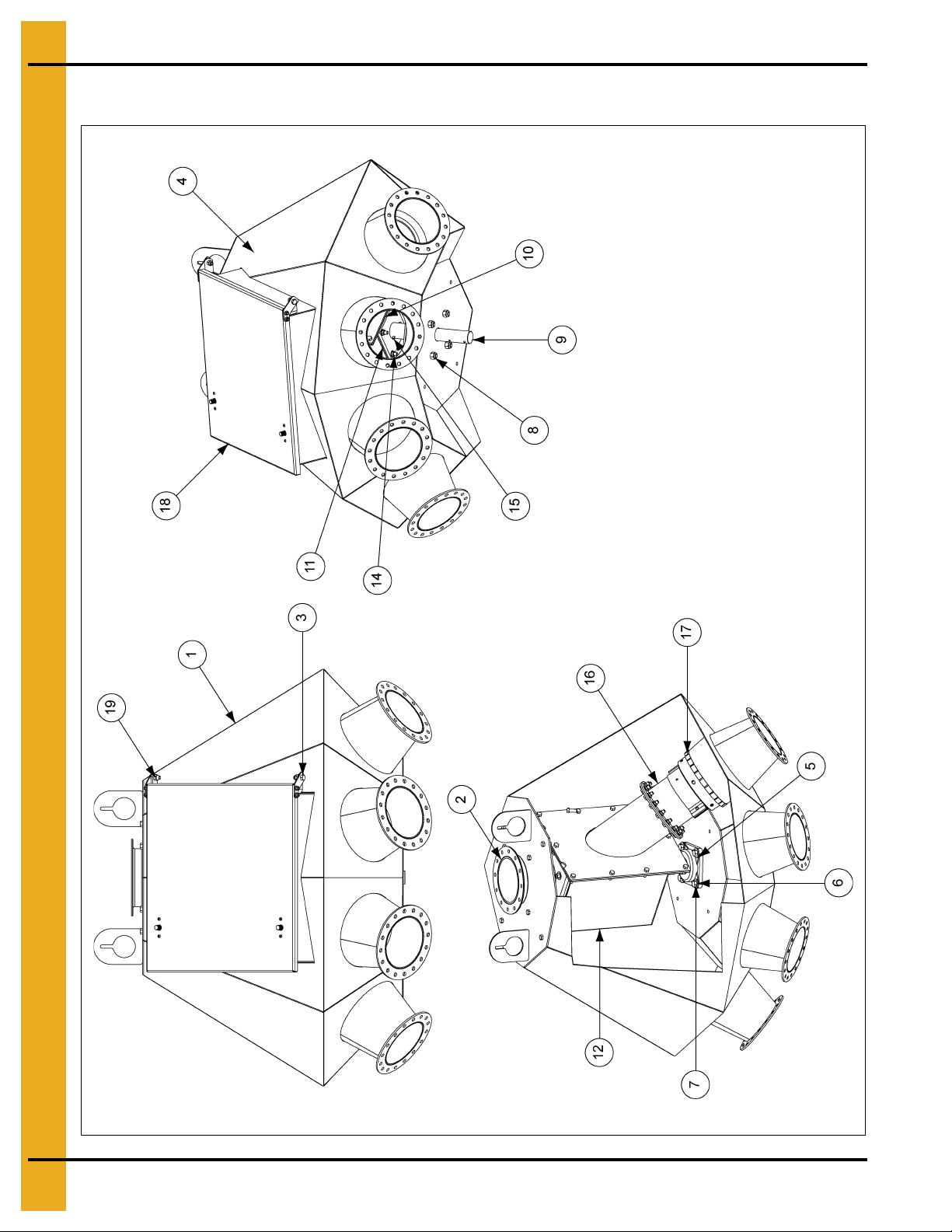

5. Parts List

NOTE: Side panels and door removed for viewing internal parts.

NOTE: Ref #13 flat washer 3/8" x 7/16" I.D. x 1" O.D. YDP (S-248) (6) is

only used in the following places: Four (4) in the transition box (Ref #12).

Two (2) on the door hinge (Ref #18).

NOTE: Ref #19 nylock nut 3/8"-16 ZN grade 5 (S-7383) (2). These should

only be used on the door hinge.

6" 4 Hole, 45° Distributor Assembly (DFB06445G)

16 PNEG-1385 Farm/Commercial Distributor

Page 17

5. Parts List

6" 4 Hole, 45° Distributor Assembly (DFB06445G) Parts List

Ref # Part # Description Qty

1 DFB0424G 6" 4 Hole Body Weldment Distributor 1

2 DFB0422 Inlet Sleeve Weldment 1

3 S-7469 Bolt, HHCS 3/8"-16 x 1" ZN Grade 5 26

4 S-968 Flange Nut 3/8"-16 ZN Grade 5 Wide Flange 28

5 KD-PBA0003 Bearing, 1-1/2" 4 Bolt 1

6 S-2120 Flat Washer 1/2" SAE ZN 4

7 S-8760 Bolt, HHCS 1/2"-13 x 1-1/2" ZN Grade 5 4

8 S-8260 Nylock Nut 1/2"-13 ZN Grade 5 4

9 DFB0210 Index Shaft 1

10 DFB0040 Transition Box Support Weldment 1

11 DFB0043 Plate, Transition Box Spacer 2

12 DFB0361 6" Transition Box with Liner 1

13 S-248 Flat Washer 3/8" x 7/16" I.D. x 1" O.D. YDP 6

14 S-7515 Bolt, HHCS 3/8"-16 x 1-1/2" Grade 5 4

15 S-9288 Spring Pin 1/4" x 2-1/2" Plain Steel Slotted Rolled 3

16 DFB0420 6" 6 Hole Transition Tube Extension Weldment 1

17 DFB0374 Brush/Mount Assembly - 6" 1

18 DFB0032G Door/Hinge Bracket Assembly 1

19 S-7383 Nylock Nut 3/8"-1 6 ZN Gra de 5 2

PNEG-1385 Farm/Commercial Distributor 17

Page 18

5. Parts List

NOTE: Side panels removed for viewing internal parts.

NOTE: Ref #13 flat washer 3/8" x 7/16" I.D. x 1" O.D. YDP (S-248) (6) is only

used in the following places: Four (4) in the transition box (Ref #12). Two (2)

on the door hinge (Ref #18).

NOTE: Ref #19 nylock nut 3/8"-16 ZN grade 5 (S-7383) (2). These should

only be used on the door hinge.

6" 6 Hole, 45° Distributor Assembly (DFB06645G)

18 PNEG-1385 Farm/Commercial Distributor

Page 19

5. Parts List

6" 6 Hole, 45° Distributor Assembly (DFB06645G) Parts List

Ref # Part # Description Qty

1 DFB0408G 6" 6 Hole Body Weldment Distributor 1

2 DFB0422 6" 6 Hole Inlet Sleeve Weldment 1

3 S-7469 Bolt, HHCS 3/8"-16 x 1" ZN Grade 5 26

4 S-968 Flange Nut 3/8"-16 ZN Grade 5 Wide Flange 28

5 KD-PBA0003 Bearing, 1-1/2" 4 Bolt 1

6 S-2120 Flat Washer 1/2" SAE ZN 4

7 S-8760 Bolt, HHCS 1/2"-13 x 1-1/2" ZN Grade 5 4

8 S-8260 Nylock Nut 1/2"-13 ZN Grade 5 4

9 DFB0210 Index Shaft 1

10 DFB0040 Transition Box Support Weldment 1

11 DFB0043 Plate, Transition Box Spacer 2

12 DFB0361 6" Transition Box with Liner 1

13 S-248 Flat Washer 3/8" x 7/16" I.D. x 1" O.D. YDP 6

14 S-7515 Bolt, HHCS 3/8"-16 x 1-1/2" Grade 5 4

15 S-9288 Spring Pin 1/4" x 2-1/2" Plain Steel Slotted Rolled 3

16 DFB0420 6" 6 Hole Transition Tube Extension Weldment 1

17 DFB0374 Brush/Mount Assembly - 6" 1

18 DFB0032G Door/Hinge Bracket Assembly 1

19 S-7383 Nylock Nut 3/8"-1 6 ZN Gra de 5 2

PNEG-1385 Farm/Commercial Distributor 19

Page 20

5. Parts List

NOTE: Side panels removed for viewing internal parts.

NOTE: Ref #14 flat washer 3/8" x 7/16" I.D. x 1" O.D. YDP (S-248) (6) is

only used in the following places: Four (4) in the transition box (Ref #12).

Two (2) on the door hinge (Ref #18).

NOTE: Ref #19 Nylock nut 3/8"-16 ZN grade 5 (S-7383) (2). These should

only be used on the door hinge.

6" 8 Hole, 45° Distributor Assembly (DFB06845G)

20 PNEG-1385 Farm/Commercial Distributor

Page 21

5. Parts List

6" 8 Hole, 45° Distributor Assembly (DFB06845G) Parts List

Ref # Part # Description Qty

1 DFB0347G 6" 8 Hole Body Weldment Distributor 1

2 DFB0381 6" 8 Hole Inlet Sleeve Weldment 1

3 S-7469 Bolt, HHCS 3/8"-16 x 1" ZN Grade 5 26

4 S-968 Flange Nut 3/8"-16 ZN Grade 5 Wide Flange 28

5 KD-PBA0003 Bearing, 1-1/2" 4 Bolt 1

6 S-2120 Flat Washer 1/2" SAE ZN 4

7 S-8760 Bolt, HHCS 1/2"-13 x 1-1/2" ZN Grade 5 4

8 S-8260 Nylock Nut 1/2"-13 ZN Grade 5 4

9 DFB0360 Index Shaft 6" 8 Hole Distributor 1

10 DFB0040 Transition Box Support Weldment 1

11 DFB0043 Plate, Transition Box Spacer 2

12 DFB0361 6" Transition Box with Liner 1

13 S-9288 Spring Pin 1/4" x 2-1/2" Plain Steel Slotted Rolled 3

14 S-248 Flat Washer 3/8" x 7/16" I.D. x 1" O.D. YDP 6

15 S-7515 Bolt, HHCS 3/8"-16 x 1-1/2" Grade 5 4

16 DFB0372 6" 8 Hole Transition Tube Extension Weldment 1

17 DFB0374 Brush/Mount Assembly - 6" 1

18 DFB0032G Door/Hinge Bracket Assembly 1

19 S-7383 Nylock Nut 3/8"-1 6 ZN Gra de 5 2

PNEG-1385 Farm/Commercial Distributor 21

Page 22

5. Parts List

NOTE: Side panels and door removed for viewing internal parts.

NOTE: Ref #14 flat washer 3/8" x 7/16" I.D. x 1" O.D. YDP (S-248) (6) is

only used in the following places: Four (4) in the transition box (Ref #12).

Two (2) on the door hinge (Ref #18).

NOTE: Ref #19 nylock nut 3/8"-16 ZN grade 5 (S-7383) (2). These should

only be used on the door hinge.

8" 6 Hole, 45° Distributor Assembly (DFB08645G)

22 PNEG-1385 Farm/Commercial Distributor

Page 23

5. Parts List

8" 6 Hole, 45° Distributor Assembly (DFB08645G) Parts List

Ref # Part # Description Qty

1 DFB0199G 8" 6 Hole Body Weldment Distributor 1

2 DFB0196 8" Inlet Sleeve Weldment Distributor 1

3 S-7469 Bolt, HHCS 3/8"-16 x 1" ZN Grade 5 26

4 S-968 Flange Nut 3/8"-16 ZN Grade 5 Wide Flange 28

5 KD-PBA0003 Bearing, 1-1/2" 4 Bolt 1

6 S-2120 Flat Washer 1/2" SAE ZN 4

7 S-8760 Bolt, HHCS 1/2"-13 x 1-1/2" ZN Grade 5 4

8 S-8260 Nylock Nut 1/2"-13 ZN Grade 5 4

9 DFB0210 Index Shaft 8" 6 Hole Distributor 1

10 DFB0040 Transition Box Support Weldment 1

11 DFB0043 Plate, Transition Box Spacer 2

12 DFB0176 8" Transition Box with Liner 1

13 S-248 Flat Washer 3/8" x 7/16" I.D. x 1" O.D. YDP 6

14 S-7515 Bolt, HHCS 3/8"-16 x 1-1/2" Grade 5 4

15 S-9288 Spring Pin 1/4" x 2-1/2" Plain Steel Slotted Rolled 3

16 DFB0211 8" 6 Hole Transition Tube Extension Weldment 1

17 DFB0189 Brush/Mount Assembly - 8" 1

18 DFB0032G Door/Hinge Bracket Assembly 1

19 S-7383 Nylock Nut 3/8"-1 6 ZN Gra de 5 2

PNEG-1385 Farm/Commercial Distributor 23

Page 24

5. Parts List

NOTE: Side panels removed for viewing internal parts.

NOTE: Ref #17 flat washer 3/8" x 7/16" I.D. x 1" O.D. YDP (S-248) (6) is

only used in the following places: Four (4) in the transition box (Ref #12).

T wo (2) on the door hinge (Ref #16).

NOTE: Ref #18 nylock nut 3/8"-16 ZN grade 5 (S-7383) (2). These should

only be used on the door hinge.

8" 8 Hole, 45° Distributor Assembly (DFB08845G)

24 PNEG-1385 Farm/Commercial Distributor

Page 25

5. Parts List

8" 8 Hole, 45° Distributor Assembly (DFB08845G) Parts List

Ref # Part # Description Qty

1 DFB0161G 8" 8 Hole Body Weldment Distributor 1

2 DFB0196 8" Inlet Sleeve Weldment Distributor 1

3 S-7469 Bolt, HHCS 3/8"-16 x 1" ZN Grade 5 26

4 S-968 Flange Nut 3/8"-16 ZN Grade 5 Wide Flange 28

5 KD-PBA0003 Bearing, 1-1/2" 4 Bolt 1

6 S-2120 Flat Washer 1/2" SAE ZN 4

7 S-8760 Bolt, HHCS 1/2"-13 x 1-1/2" ZN Grade 5 4

8 S-8260 Nylock Nut 1/2"-13 ZN Grade 5 4

9 DFB0175 Indexing Shaft 8" 8 Hole Distributor 1

10 DFB0040 Transition Box Support Weldment 1

11 DFB0043 Plate, Transition Box Spacer 2

12 DFB0176 8" Transition Box with Liner 1

13 S-9288 Spring Pin 1/4" x 2-1/2" Plain Steel Slotted Rolled 3

14 DFB0187 8" 8 Hole Transition Tube Extension Weldment 1

15 DFB0189 Brush/Mount Assembly - 8" 1

16 DFB0032G Door/Hinge Bracket Assembly 1

17 S-248 Flat Washer 3/8" x 7/16" I.D. x 1" O.D. YDP 6

18 S-7383 Nylock Nut 3/8"-16 ZN Grade 5 2

19 S-7515 Bolt, HHCS 3/8"-16 x 1-1/2" Grade 5 4

PNEG-1385 Farm/Commercial Distributor 25

Page 26

5. Parts List

NOTE: Side panels removed for viewing internal parts.

NOTE: Ref #17 flat washer 3/8" x 7/16" I.D. x 1" O.D. YDP (S-248) (6) is

only used in the following places: Four (4) in the transition box (Ref #11).

Two (2) on the door hinge (Ref #16).

NOTE: Ref #18 nylock nut 3/8"-16 ZN grade 5 (S-7383) (2). These should

only be used on the door hinge.

8" 10 Hole, 45° Distributor Assembly (DFB081045G)

26 PNEG-1385 Farm/Commercial Distributor

Page 27

5. Parts List

8" 10 Hole, 45° Distributor Assembly (DFB081045G) Parts List

Ref # Part # Description Qty

1 DFB0213G 8" 10 Hole Body Weldment Dist ri bu to r 1

2 DFB0196 8" Inlet Sleeve Weldment Distributor 1

3 S-7469 Bolt, HHCS 3/8"-16 x 1" ZN Grade 5 26

4 S-968 Flange Nut 3/8"-16 ZN Grade 5 Wide Flange 28

5 KD-PBA0003 Bearing, 1-1/2" 4 Bolt 1

6 S-2120 Flat Washer 1/2" SAE ZN 4

7 S-8760 Bolt, HHCS 1/2"-13 x 1-1/2" ZN Grade 5 4

8 S-8260 Nylock Nut 1/2"-13 ZN Grade 5 4

9 DFB0226 Indexing Shaft 8" 10 Hole Distributor 1

10 DFB0040 Transition Box Support Weldment 1

11 DFB0043 Plate, Transition Box Spacer 2

12 DFB0176 8" Transition Box with Liner 1

13 S-9288 Spring Pin 1/4" x 2-1/2" Plain Steel Slotted Rolled 3

14 DFB0227 8" 10 Hole Transition Tube Extension Weldment 1

15 DFB0189 Brush/Mount Assembly - 8" 1

16 DFB0032G Door/Hinge Bracket Assembly 1

17 S-248 Flat Washer 3/8" x 7/16" I.D. x 1" O.D. YDP 6

18 S-7383 Nylock Nut 3/8"-16 ZN Grade 5 2

19 S-7515 Bolt, HHCS 3/8"-16 x 1-1/2" Grade 5 4

PNEG-1385 Farm/Commercial Distributor 27

Page 28

5. Parts List

NOTE: See DBF10645G Drawing B on Page 30 for further

detail instruction.

NOTE: Side panels removed for viewing internal parts.

NOTE: Ref #11 flat washer 3/8" x 7/16" I.D. x 1" O.D. YDP (S-248) (6) is

only used in the following places: Four (4) in the transition box (Ref #16).

Two (2) on the door hinge (Ref #3).

NOTE: Ref #10 nylock nut 3/8"-16 ZN grade 5 (S-7383) (2). These

should only be used on the door hinge.

10" 6 Hole, 45° Distributor Assembly - Drawing A (DFB10645G)

28 PNEG-1385 Farm/Commercial Distributor

Page 29

5. Parts List

10" 6 Hole, 45° Distributor Assembly - Drawing A (DFB10645G) Parts List

Ref # Part # Description Qty

1 DFB0001G 10" 6 Hole Body Weldment Distributor 1

2 DFB0035 10" Inlet Sleeve Weldment Distributor 1

3 DFB0032G Door/Hinge Bracket Assembly 1

4 K D-PBA0003 Bearing, 1-1/2" 4 Bolt 1

5 S-7469 Bolt, HHCS 3/8"-16 x 1" ZN Grade 5 26

6 S-968 Flange Nut 3/8"-16 ZN Grade 5 Wide Flange 28

7 S-2120 Flat Washer 1/2" SAE ZN 4

8 S-8760 Bolt, HHCS 1/2"-13 x 1-1/2" ZN Grade 5 4

9 S-8260 Nylock Nut 1/2"-13 ZN Grade 5 4

10 S-7383 Nylock Nut 3/8"-16 ZN Grade 5 2

11 S-248 Flat Washer 3/8" x 7/16" I.D. x 1" O.D. YDP 6

12 DFB0045 Indexing Shaft 10" 6 Hole Distributor 1

13 S-9288 Spring Pin 1/4" x 2-1/2" Plain Steel Slotted Rolled 3

14 DFB0040 Transition Box Support Weldment 1

15 DFB0043 Plate, Transition Box Spacer 4

16 DFB0015 10" Transition Box with Liner 1

17 S-7515 Bolt, HHCS 3/8"-16 x 1-1/2" Grade 5 4

18 DFB0024 10" 6 Hole Transition Tube Extension Weldment 1

19 DFB0060 Brush/Mount Assembly - 10" 1

PNEG-1385 Farm/Commercial Distributor 29

Page 30

5. Parts List

10" 6 Hole, 45° Distributor Assembly - Drawing B (DFB10645G)

30 PNEG-1385 Farm/Commercial Distributor

Page 31

5. Parts List

10" 6 Hole, 45° Distributor Assembly - Drawing B (DFB10645G) Parts List

Ref # Part # Description Qty

1 DFB0001G 10" 6 Hole Body Weldment Distributor 1

2 DFB0035 10" Inlet Sleeve Weldment Distributor 1

3 DFB0032G Door/Hinge Bracket Assembly 1

4 K D-PBA0003 Bearing, 1-1/2" 4 Bolt 1

5 S-7469 Bolt, HHCS 3/8"-16 x 1" ZN Grade 5 26

6 S-968 Flange Nut 3/8"-16 ZN Grade 5 Wide Flange 28

7 S-2120 Flat Washer 1/2" SAE ZN 4

8 S-8760 Bolt, HHCS 1/2"-13 x 1-1/2" ZN Grade 5 4

9 S-8260 Nylock Nut 1/2"-13 ZN Grade 5 4

10 S-7383 Nylock Nut 3/8"-16 ZN Grade 5 2

11 S-248 Flat Washer 3/8" x 7/16" I.D. x 1" O.D. YDP 6

12 DFB0045 Indexing Shaft 10" 6 Hole Distributor 1

13 S-9288 Spring Pin 1/4" x 2-1/2" Plain Steel Slotted Rolled 3

14 DFB0040 Transition Box Support Weldment 1

15 DFB0043 Plate, Transition Box Spacer 4

16 DFB0015 10" Transition Box with Liner 1

17 S-7515 Bolt, HHCS 3/8"-16 x 1-1/2" Grade 5 4

18 DFB0024 10" 6 Hole Transition Tube Extension Weldment 1

19 DFB0060 Brush/Mount Assembly - 10" 1

PNEG-1385 Farm/Commercial Distributor 31

Page 32

5. Parts List

NOTE: Side panels removed for viewing internal parts.

NOTE: Ref #14 flat washer 3/8" x 7/16" I.D. x 1" O.D. YDP (S-248) (6) is

only used in the following places: Four (4) in the transition box (Ref #11)

T wo (2) on the door hinge (Ref #18).

NOTE: Ref #19 nylock nut 3/8"-16 ZN grade 5 (S-7383) (2). These should

only be used on the door hinge.

10" 8 Hole, 45° Distributor Assembly (DFB10845G)

32 PNEG-1385 Farm/Commercial Distributor

Page 33

5. Parts List

10" 8 Hole, 45° Distributor Assembly (DFB10845G) Parts List

Ref # Part # Description Qty

1 DFB0063G 10" 8 Hole Body Weldment Distributor 1

2 K D-PBA0003 Bearing, 1-1/2" 4 Bolt 1

3 S-2120 Flat Washer 1/2" SAE ZN 4

4 S-8760 Bolt, HHCS 1/2"-13 x 1-1/2" ZN Grade 5 4

5 S-8260 Nylock Nut 1/2"-13 ZN Grade 5 4

6 DFB0035 10" Inlet Sleeve Weldment Distributor 1

7 S-7469 Bolt, HHCS 3/8"-16 x 1" ZN Grade 5 26

8 S-968 Flange Nut 3/8"-16 ZN Grade 5 Wide Flange 28

9 DFB0142 Index Shaft 10" 8 Hole Distributor 1

10 DFB0040 Transition Box Support Weldment 1

11 DFB0043 Plate, Transition Box Spacer 2

12 DFB0015 10" Transition Box with Liner 1

13 S-9288 Spring Pin 1/4" x 2-1/2" Plain Steel Slotted Rolled 3

14 S-248 Flat Washer 3/8" x 7/16" I.D. x 1" O.D. YDP 6

15 S-7515 Bolt, HHCS 3/8"-16 x 1-1/2" Grade 5 4

16 DFB0079 10" 8 Hole Transition Tube Extension Weldment 1

17 DFB0060 Brush/Mount Assembly - 10" 1

18 DFB0032G Door/Hinge Bracket Assembly 1

19 S-7383 Nylock Nut 3/8"-1 6 ZN Gra de 5 2

PNEG-1385 Farm/Commercial Distributor 33

Page 34

5. Parts List

NOTE: Side panels and door removed for viewing internal parts.

NOTE: Ref #14 flat washer 3/8" x 7/16" I.D. x 1" O.D. YDP (S-248) (6) is

only used in the following places: Four (4) in the transition box (Ref #13.)

Two (2) on the door hinge (Ref #18).

NOTE: Ref #19 nylock nut 3/8"-16 ZN grade 5 (S-7383) (2). These should

only be used on the door hinge.

10" 10 Hole, 45° Distributor Assembly (DFB101045G)

34 PNEG-1385 Farm/Commercial Distributor

Page 35

5. Parts List

10" 10 Hole, 45° Distributor Assembly (DFB101045G) Parts List

Ref # Part # Description Qty

1 DFB0143G 10" 10 Hole Body Weldment Distributor 1

2 K D-PBA0003 Bearing, 1-1/2" 4 Bolt 1

3 S-2120 Flat Washer 1/2" SAE ZN 4

4 S-8760 Bolt, HHCS 1/2"-13 x 1-1/2" ZN Grade 5 4

5 S-8260 Nylock Nut 1/2"-13 ZN Grade 5 4

6 DFB0035 10" Inlet Sleeve Weldment Distributor 1

7 S-7469 Bolt, HHCS 3/8"-16 x 1" ZN Grade 5 26

8 S-968 Flange Nut 3/8"-16 ZN Grade 5 Wide Flange 28

9 DFB0144 Index Shaft 10" 10 Hole Distributor 1

10 DFB0040 Transition Box Support Weldment 1

11 DFB0043 Plate, Transition Box Spacer 2

12 S-9288 Spring Pin 1/4" x 2-1/2" Plain Steel Slotted Rolled 3

13 DFB0015 10" Transition Box with Liner 1

14 S-248 Flat Washer 3/8" x 7/16" I.D. x 1" O.D. YDP 6

15 S-7515 Bolt, HHCS 3/8"-16 x 1-1/2" Grade 5 4

16 DFB0093 10" 10 Hole Transition Tube Extension Weldment 1

17 DFB0060 Brush/Mount Assembly - 10" 1

18 DFB0032G Door/Hinge Bracket Assembly 1

19 S-7383 Nylock Nut 3/8"-1 6 ZN Gra de 5 2

PNEG-1385 Farm/Commercial Distributor 35

Page 36

5. Parts List

NOTE: Side panels removed for viewing internal parts.

NOTE: Ref #17 flat washer 3/8" x 7/16" I.D. x 1" O.D. YDP (S-248) (6) is

only used in the following places: Four (4) in the transition box (Ref #12).

on the door hinge (Ref #18).

NOTE: Ref #18 nylock nut 3/8"-16 ZN grade 5 (S-7383) (2). These should

only be used on the door hinge.

12" 4 Hole, 45° Distributor Assembly (DFB12445G)

36 PNEG-1385 Farm/Commercial Distributor

Page 37

5. Parts List

12" 4 Hole, 45° Distributor Assembly (DFB12445G) Parts List

Ref # Part # Description Qty

1 DFB0230G 12" 4 Hole Body Weldment Distributor 1

2 DFB0136 12" Inlet Sleeve Weldment Distributor 1

3 S-7469 Bolt, HHCS 3/8"-16 x 1" ZN Grade 5 22

4 S-968 Flange Nut 3/8"-16 ZN Grade 5 Wide Flange 24

5 KD-PBA0003 Bearing, 1-1/2" 4 Bolt 1

6 S-2120 Flat Washer 1/2" SAE ZN 4

7 S-8760 Bolt, HHCS 1/2"-13 x 1-1/2" ZN Grade 5 4

8 S-8260 Nylock Nut 1/2"-13 ZN Grade 5 4

9 DFB0158 Index Shaft 12" 6 Hole Distributor 1

10 DFB0040 Transition Box Support Weldment 1

11 DFB0043 Plate, Transition Box Spacer 2

12 DFB0114 12" Transition Box with Liner 1

13 S-9288 Spring Pin 1/4" x 2-1/2" Plain Steel Slotted Rolled 3

14 DFB0159 12" 6 Hole Transition Tube Extension Weldment 1

15 DFB0127 Brush/Mount Assembly - 12" 1

16 DFB0146G Door/Hinge Bracket Assembly 12" 1

17 S-248 Flat Washer 3/8" x 7/16" I.D. x 1" O.D. YDP 6

18 S-7383 Nylock Nut 3/8"-16 ZN Grade 5 2

19 S-7515 Bolt, HHCS 3/8"-16 x 1-1/2" Grade 5 4

PNEG-1385 Farm/Commercial Distributor 37

Page 38

5. Parts List

NOTE: Side panels removed for viewing internal parts.

NOTE: Ref #17 flat washer 3/8" x 7/16" I.D. x 1" O.D. YDP (S-248) (6) is

only used in the following places: Four (4) in the transition box (Ref #12).

Two (2) on the door hinge (Ref #12).

NOTE: Ref #18 nylock nut 3/8"-16 ZN grade 5 (S-7383) (2). These should

only be used on the door hinge.

12" 6 Hole, 45° Distributor Assembly (DFB12645G)

38 PNEG-1385 Farm/Commercial Distributor

Page 39

5. Parts List

12" 6 Hole, 45° Distributor Assembly (DFB12645G) Parts List

Ref # Part # Description Qty

1 DFB0147G 12" 6 Hole Body Weldment Distributor 1

2 DFB0136 12" Inlet Sleeve Weldment Distributor 1

3 S-7469 Bolt, HHCS 3/8"-16 x 1" ZN Grade 5 22

4 S-968 Flange Nut 3/8"-16 ZN Grade 5 Wide Flange 24

5 KD-PBA0003 Bearing, 1-1/2" 4 Bolt 1

6 S-2120 Flat Washer 1/2" SAE ZN 4

7 S-8760 Bolt, HHCS 1/2"-13 x 1-1/2" ZN Grade 5 4

8 S-8260 Nylock Nut 1/2"-13 ZN Grade 5 4

9 DFB0158 Index Shaft 12" 6 Hole Distributor 1

10 DFB0040 Transition Box Support Weldment 1

11 DFB0043 Plate, Transition Box Spacer 2

12 DFB0114 12" Transition Box with Liner 1

13 S-9288 Spring Pin 1/4" x 2-1/2" Plain Steel Slotted Rolled 3

14 DFB0159 12" 6 Hole Transition Tube Extension Weldment 1

15 DFB0127 Brush/Mount Assembly - 12" 1

16 DFB0146G Door/Hinge Bracket Assembly 12" 1

17 S-248 Flat Washer 3/8" x 7/16" I.D. x 1" O.D. YDP 6

18 S-7383 Nylock Nut 3/8"-16 ZN Grade 5 2

19 S-7515 Bolt, HHCS 3/8"-16 x 1-1/2" Grade 5 4

PNEG-1385 Farm/Commercial Distributor 39

Page 40

5. Parts List

NOTE: Side panels removed for viewing internal parts.

NOTE: Ref #17 flat washer 3/8" x 7/16" I.D. x 1" O.D. YDP (S-248) (6) is

only used in the following places: Four (4) in the transition box (Ref #12).

Two (2) on the door hinge (Ref #16).

NOTE: Ref #18 nylock nut 3/8"-16 ZN grade 5 (S-7383) (2). These

should only be used on the door hinge.

12" 8 Hole, 45° Distributor Assembly (DFB12845G)

40 PNEG-1385 Farm/Commercial Distributor

Page 41

5. Parts List

12" 8 Hole, 45° Distributor Assembly (DFB12845G) Parts List

Ref # Part # Description Qty

1 DFB0100G 12" 8 Hole Body Weldment Distributor 1

2 DFB0136 12" Inlet Sleeve Weldment Distributor 1

3 S-7469 Bolt, HHCS 3/8"-16 x 1" ZN Grade 5 22

4 S-968 Flange Nut 3/8"-16 ZN Grade 5 Wide Flange 24

5 KD-PBA0003 Bearing, 1-1/2" 4 Bolt 1

6 S-2120 Flat Washer 1/2" SAE ZN 4

7 S-8760 Bolt, HHCS 1/2"-13 x 1-1/2" ZN Grade 5 4

8 S-8260 Nylock Nut 1/2"-13 ZN Grade 5 4

9 DFB0145 Index Shaft 12" 8 Hole Distributor 1

10 DFB0040 Transition Box Support Weldment 1

11 DFB0043 Plate, Transition Box Spacer 2

12 DFB0114 12" Transition Box with Liner 1

13 S-9288 Spring Pin 1/4" x 2-1/2" Plain Steel Slotted Rolled 3

14 DFB0125 12" 8 Hole Transition Tube Extension Weldment 1

15 DFB0127 Brush/Mount Assembly - 12" 1

16 DFB0146G Door/Hinge Bracket Assembly 12" 1

17 S-248 Flat Washer 3/8" x 7/16" I.D. x 1" O.D. YDP 6

18 S-7383 Nylock Nut 3/8"-16 ZN Grade 5 2

19 S-7515 Bolt, HHCS 3/8"-16 x 1-1/2" Grade 5 4

PNEG-1385 Farm/Commercial Distributor 41

Page 42

5. Parts List

NOTE: Side panels removed for viewing internal parts.

NOTE: Ref #12 Flat washer 3/8" x 7/16" I.D. x 1" O.D. YDP (S-248) (6) is

only used in the following places: Four (4) in the transition box (Ref #11).

Two (2) on the door hinge (Ref #18).

NOTE: Ref #19 nylock nut 3/8"-16 ZN grade 5 (S-7383) (2). These

should only be used on the door hinge.

12" 10 Hole, 45° Distributor Assembly (DFB121045G)

42 PNEG-1385 Farm/Commercial Distributor

Page 43

5. Parts List

12" 10 Hole, 45° Distributor Assembly (DFB121045G) Parts List

Ref # Part # Description Qty

1 DFB0331G 12" 10 Hole Body Weldment Distributor 1

2 K D-PBA0003 Bearing, 1-1/2" 4 Bolt 1

3 S-2120 Flat Washer 1/2" SAE ZN 4

4 S-8760 Bolt, HHCS 1/2"-13 x 1-1/2" ZN Grade 5 4

5 S-8260 Nylock Nut 1/2"-13 ZN Grade 5 4

6 S -7469 Bolt, HHCS 3/8"-16 x 1" ZN Grade 5 22

7 DFB0344 Index Shaft 12" 10 Hole Distributor 1

8 DFB0040 Transition Box Support Weldment 1

9 DFB0043 Plate, Transition Box Spacer 2

10 S-9288 Spring Pin 1/4" x 2-1/2" Plain Steel Slotted Rolled 3

11 DFB0114 12" Transition Box with Liner 1

12 S-248 Flat Washer 3/8" x 7/16" I.D. x 1" O.D. YDP 6

13 S-7515 Bolt, HHCS 3/8"-16 x 1-1/2" Grade 5 4

14 S-968 Flange Nut 3/8"-16 ZN Grade 5 Wide Flange 24

15 DFB0136 12" Inlet Sleeve Weldment Distributor 1

16 DFB0345 12" 10 Hole Transition Tube Extension Weldment 1

17 DFB0127 Brush/Mount Assembly - 12" 1

18 DFB0146G Door/Hinge Bracket Assembly 12" 1

19 S-7383 Nylock Nut 3/8"-1 6 ZN Gra de 5 2

PNEG-1385 Farm/Commercial Distributor 43

Page 44

5. Parts List

NOTE: Side panels removed for viewing internal parts.

NOTE: Ref #17 flat washer 3/8" x 7/16" I.D. x 1" O.D. YDP (S-248) (6) is

only used in the following places: Four (4) in the transition box (Ref #12).

T wo (2) on the door hinge (Ref #16).

NOTE: Ref #18 nylock nut 3/8"-16 ZN grade 5 (S-7383) (2). These should

only be used on the door hinge.

Not Shown:

Hardware for outlet liner fastening:

Elevator bolt 1/4"-20 x 1" ZN grade 2 (S-8213) (16)

Flange nut 1/4"-20 ZN (S-7215) (16)

14" 4 Hole, 45° Distributor Assembly (DFB14445G)

44 PNEG-1385 Farm/Commercial Distributor

Page 45

5. Parts List

14" 4 Hole, 45° Distributor Assembly (DFB14445G) Parts List

Ref # Part # Description Qty

1 DFB0315G 14" 4 Hole Body Weldment Distributor 1

2 DFB0313 Inlet Sleeve Weldment 1

3 S-7469 Bolt, HHCS 3/8"-16 x 1" ZN Grade 5 22

4 S-968 Flange Nut 3/8"-16 ZN Grade 5 Wide Flange 24

5 KD-PBA0003 Bearing, 1-1/2" 4 Bolt 1

6 S-2120 Flat Washer 1/2" SAE ZN 4

7 S-8760 Bolt, HHCS 1/2"-13 x 1-1/2" ZN Grade 5 4

8 S-8260 Nylock Nut 1/2"-13 ZN Grade 5 4

9 DFB0326 Index Shaft 14" 4 Hole Distributor 1

10 DFB0040 Transition Box Support Weldment 1

11 DFB0043 Plate, Transition Box Spacer 2

12 DFB0261 14" Transition Box with Liner 1

13 S-9288 Spring Pin 1/4" x 2-1/2" Plain Steel Slotted Rolled 3

14 DFB0327 14" 4 Hole Transition Extension Tube Assembly 1

15 DFB0274 Brush/Mount Assembly - 14" 1

16 DFB0288P Door/Hinge Bracket Assembly 14" 1

17 S-248 Flat Washer 3/8" x 7/16" I.D. x 1" O.D. YDP 6

18 S-7383 Nylock Nut 3/8"-16 ZN Grade 5 2

19 S-7515 Bolt, HHCS 3/8"-16 x 1-1/2" Grade 5 4

20 DFB0296 Outlet Cone Liner 14" Distributor 4

PNEG-1385 Farm/Commercial Distributor 45

Page 46

5. Parts List

NOTE: Side panels removed for viewing internal parts.

Not Shown:

Hardware for outlet liner fastening:

Elevator bolt 1/4"-20 x 1" ZN grade 2 (S-8213) (24)

Flange nut 1/4"-20 ZN (S-7215) (24)

NOTE: Ref #13 flat washer 3/8" x 7/16" I.D. x 1" O.D. YDP (S-248) (6) is

only used in the following places: Four (4) in the transition box (Ref #10).

on the door hinge (Ref #18).

NOTE: Ref #19 nylock nut 3/8"-16 ZN grade 5 (S-7383) (2). These

should only be used on the door hinge.

14" 6 Hole, 45° Distributor Assembly (DFB14645G)

46 PNEG-1385 Farm/Commercial Distributor

Page 47

5. Parts List

14" 6 Hole, 45° Distributor Assembly (DFB14645G) Parts List

Ref # Part # Description Qty

1 DFB0298G 14" 6 Hole Body Weldment Distributor 1

2 S -7469 Bolt, HHCS 3/8"-16 x 1" ZN Grade 5 22

3 KD-PBA0003 Bearing, 1-1/2" 4 Bolt 1

4 S-2120 Flat Washer 1/2" SAE ZN 4

5 S-7811 Bolt, HHCS 1/2"-13 x 2" ZN Grade 5 4

6 S-8260 Nylock Nut 1/2"-13 ZN Grade 5 4

7 DFB0308 Index Shaft 14" 6 Hole Distributor 1

8 DFB0040 Transition Box Support Weldment 1

9 DFB0043 Plate, Transition Box Spacer 2

10 DFB0261 14" Transition Box with Liner 1

11 S-9288 Spring Pin 1/4" x 2-1/2" Plain Steel Slotted Rolled 3

12 DFB0312 14" 6 Hole Transition Extension Tube Assembly 1

13 S-248 Flat Washer 3/8" x 7/16" I.D. x 1" O.D. YDP 6

14 S-7515 Bolt, HHCS 3/8"-16 x 1-1/2" Grade 5 4

15 S-968 Flange Nut 3/8"-16 ZN Grade 5 Wide Flange 24

16 DFB0274 Brush/Mount Assembly - 14" 1

17 DFB0313 14" 6 Hole Inlet Sleeve Weldment 1

18 DFB0288G Door/Hinge Bracket Assembly 14" 1

19 S-7383 Nylock Nut 3/8"-1 6 ZN Gra de 5 2

20 DFB0296 Outlet Cone Liner 14" Distributor 6

PNEG-1385 Farm/Commercial Distributor 47

Page 48

5. Parts List

NOTE: Side panels removed for viewing internal parts.

Not Shown:

Hardware for outlet liner fastening:

Elevator bolt 1/4"-20 x 1" ZN grade 2 (S-8213) (32)

Flange nut 1/4"-20 ZN (S-7215) (32)

NOTE: Ref #16 Flat washer 3/8" x 7/16" I.D. x 1" O.D. YDP (S-248) (6) is

only used in the following places: Four (4) in the transition box (Ref #12).

on the door hinge (Ref #18).

NOTE: Ref #19 nylock nut 3/8"-16 ZN grade 5 (S-7383) (2). These

should only be used on the door hinge.

14" 8 Hole, 45° Distributor Assembly (DFB14845G)

48 PNEG-1385 Farm/Commercial Distributor

Page 49

5. Parts List

14" 8 Hole, 45° Distributor Assembly (DFB14845G) Parts List

Ref # Part # Description Qty

1 DFB0246G 14" 8 Hole Body Weldment Distributor 1

2 DFB0282 14" Inlet Sleeve Weldment Distributor 1

3 S-7469 Bolt, HHCS 3/8"-16 x 1" ZN Grade 5 22

4 S-968 Flange Nut 3/8"-16 ZN Grade 5 Wide Flange 24

5 KD-PBA0003 Bearing, 1-1/2" 4 Bolt 1

6 S-2120 Flat Washer 1/2" SAE ZN 4

7 S-7811 Bolt, HHCS 1/2"-13 x 2" ZN Grade 5 4

8 S-8260 Nylock Nut 1/2"-13 ZN Grade 5 4

9 DFB0287 Index Shaft 14" 8 Hole Distributor 1

10 DFB0040 Transition Box Support Weldment 1

11 DFB0043 Plate, Transition Box Spacer 2

12 DFB0261 14" Transition Box with Liner 1

13 S-9288 Spring Pin 1/4" x 2-1/2" Plain Steel Slotted Rolled 3

14 DFB0293 14" 8 Hole Transition Extension Tube Assembly 1

15 DFB0274 Brush/Mount Assembly - 14" 1

16 S-248 Flat Washer 3/8" x 7/16" I.D. x 1" O.D. YDP 6

17 S-7515 Bolt, HHCS 3/8"-16 x 1-1/2" Grade 5 4

18 DFB0288G Door/Hinge Bracket Assembly 14" 1

19 S-7383 Nylock Nut 3/8"-1 6 ZN Gra de 5 2

20 DFB0296 Outlet Cone Liner 14" Distributor 8

PNEG-1385 Farm/Commercial Distributor 49

Page 50

NOTES

50 PNEG-1385 Farm/Commercial Distributor

Page 51

6. Warranty

9101239_1_CR_rev7.DOC (revised July 2009)

GSI Group, LLC Limited Warranty

The GSI Group, LLC (“GSI”) warrants products which it manufactures to be free of defects in materials and workmanship

under normal usage and conditions for a period of 12 months after sale to the original end-user or if a foreign sale,

14 months from arrival at port of discharge, whichever is earlier. The end-user’s sole remedy (and GSI’s only obligation)

is to repair or replace, at GSI’s option and expense, products that in GSI’s judgment, contain a material defect in materials

or workmanship. Expenses incurred by or on behalf of the end-user without prior written authorization from the GSI

Warranty Group shall be the sole responsibility of the end-user.

Warranty Extensions:

The Limited Warranty period is extended for the following products:

Product Warranty Period

Performer Series Direct Drive Fan Motor 3 Years

AP Fans and Flooring

Cumberland

Feeding/Watering

Systems

Grain Systems Grain Bin Structural Design 5 Years

Grain Systems

Farm Fans

Zimmerman

All Fiberglass Housings Lifetime

All Fiberglass Propellers Lifetime

Feeder System Pan Assemblies 5 Years **

Feed Tubes (1-3/4" and 2.00") 10 Years *

Centerless Augers 10 Years *

Watering Nipples 10 Years *

Portable and Tower Dryers 2 Years

Portable and Tower Dryer Frames and

Internal Infrastructure †

5 Years

* Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 25%

5 to 7 years - end-user pays 50%

7 to 10 years - end-user pays 75%

** Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 50%

† Motors, burner components

and moving parts not included.

Portable dryer screens included.

Tower dryer screens not included.

GSI further warrants that the portable and tower dryer frame and basket, excluding all auger and auger drive components,

shall be free from defects in materials for a period of time beginning on the twelfth (12

and continuing until the sixtieth (60

th

) month from the date of purchase (extended warranty period). During the extended

th

) month from the date of purchase

warranty period, GSI will replace the frame or basket components that prove to be defective under normal conditions

of use without charge, excluding the labor, transportation, and/or shipping costs incurred in the performance of this

extended warranty.

Conditions and Limitations:

THERE ARE NO WARRANTIES THAT EXTEND BEYOND THE LIMITED WARRANTY DESCRIPTION SET FORTH

ABOVE. SPECIFICALLY, GSI MAKES NO FURTHER WARRANTY OF ANY KIND, EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OR USE IN CONNECTION WITH: (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (II) ANY ADVICE,

INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESENTA TIVE OR

EMPLOYEE OF GSI REGARDING OR RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY

FOR A PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCTS.

GSI shall not be liable for any direct, indirect, incidental or consequential damages, including, without limitation, loss of

anticipated profits or benefits. The sole and exclusive remedy is set forth in the Limited Warranty, which shall not exceed

the amount paid for the product purchased. This warranty is not transferable and applies only to the original end-user. GSI

shall have no obligation or responsibility for any representations or warranties made by or on behalf of any dealer, agent

or distributor.

GSI assumes no responsibility for claims resulting from construction defects or unauthorized modifications to products

which it manufactured. Modifications to products not specifically delineated in the manual accompanying the equipment at

initial sale will void the Limited Warranty.

This Limited Warranty shall not extend to products or parts which have been damaged by negligent use, misuse, alteration,

accident or which have been improperly/inadequately maintained. This Limited Warranty extends solely to products

manufactured by GSI.

Prior to installation, the end-user has the responsibility to comply with federal, state and local codes which apply to the

location and installation of products manufactured or sold by GSI.

PNEG-1385 Farm/Commercial Distributor 51

Page 52

This equipment shall be installed in accordance with

the current installation codes and applicable

regulations, which should be carefully followed in

all cases. Authorities having jurisdiction should be

consulted before installations are made.

Copyright © 2012 by GSI Group

Printed in the USA

GSI Group

1004 E. Illinois St.

Assumption, IL 62510-0020

Phone: 1-217-226-4421

Fax: 1-217-226-4420

www.gsiag.com

CN-204909

Loading...

Loading...