Page 1

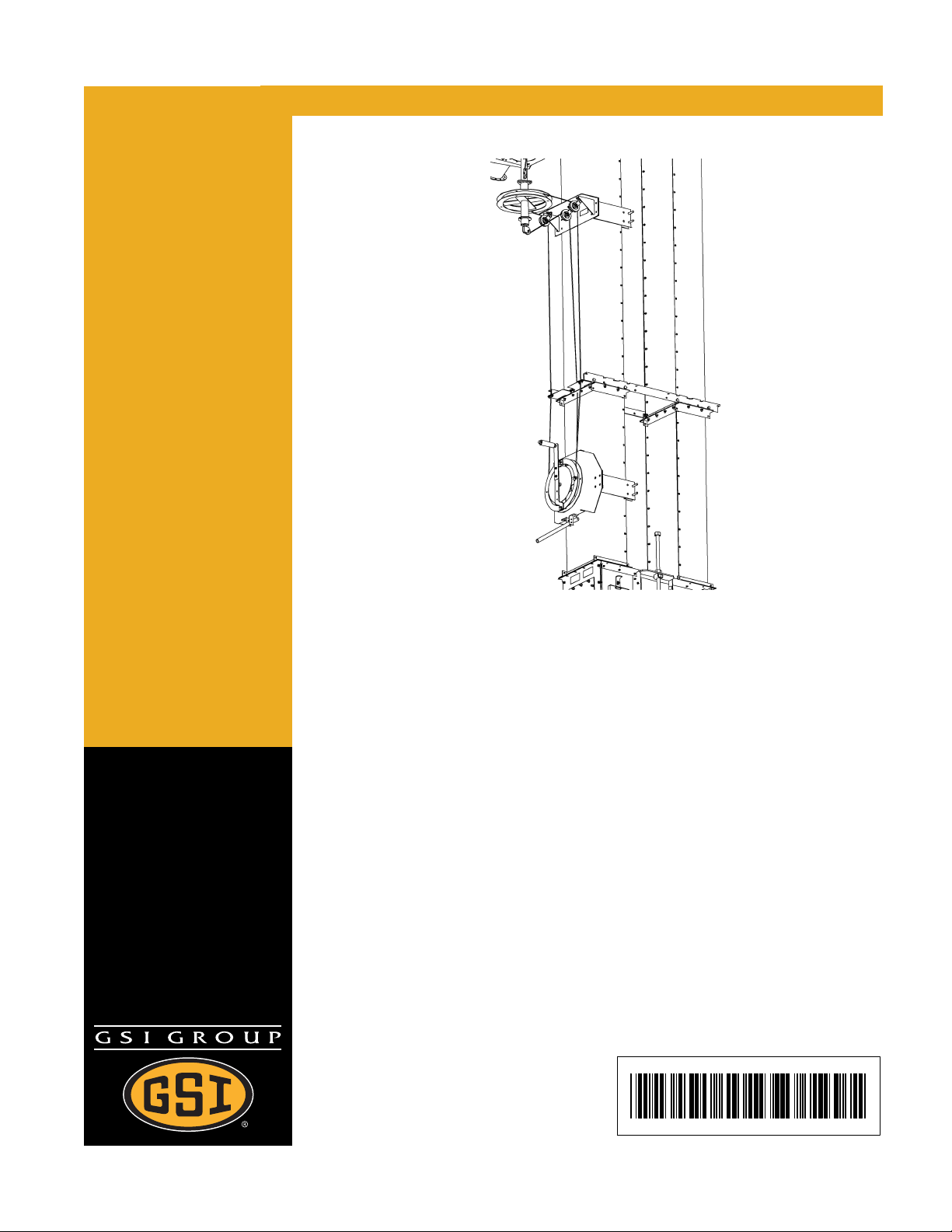

Farm/Commercial

Distributor Cable Control

Installation Manual

PNEG-1375

Date: 05-08-07

PNEG-1375

Page 2

Equipment Information

Use of the Equipment Information page will help you identify your equipment in the case that

you need call your dealer or installer. This information should be filled out and kept on record.

Model #: ____________________________

Serial #: _____________________________

RPM: _______________________________

Head Pulley Dia.: _____________________

Discharge Height: _____________________

Horsepower: _________________________

Spout Dia.: __________________________

# of Spouts: __________________________

Date Purchased: _____________________

Dealer Name and Phone #: _____________

___________________________________

___________________________________

___________________________________

2 PNEG-1375 Farm/Commercial Distributor Cable

Page 3

Table of Contents

Contents

Chapter 1 Introduction ...................................................................................................................... 4

Chapter 2 Safety .................................................................................................................................. 5

Safety Guidelines ................................................................................................................ 5

Sign-off Sheet ..................................................................................................................... 8

Chapter 3 Decal Locations ................................................................................................................. 9

Chapter 4 Part Identification ............................................................................................................ 10

Distributor Cable Control Farm/Commercial ..................................................................... 10

Distributor Hardware ......................................................................................................... 10

10" Bucket Elevator ........................................................................................................... 10

16" - 36" Bucket Elevator .................................................................................................. 10

Chapter 5 Installation ...................................................................................................................... 11

Installation of Cable Wheel & Coupler Connector ............................................................. 11

Connector Pulley Assembly .............................................................................................. 12

Cable Guide Location ........................................................................................................ 13

Upper Cable Guide Assembly ........................................................................................... 14

Control Handle Installation ................................................................................................ 16

Lower Cable Wheel Assembly .......................................................................................... 17

Cable Guides .................................................................................................................... 19

Cable Installation ............................................................................................................... 20

Chapter 6 Warranty ........................................................................................................................... 23

PNEG-1375 Farm/Commercial Distributor Cable Control 3

Page 4

1. INTRODUCTION

Thank you for choosing this product. It is designed to give excellent performance and service for

many years.

This manual covers general information on the distributor cable control installation. Due to the

wide variety of field conditions we cannot cover every aspect of installation. We offer one method

for installing equipment but, rely on your qualified contractor’s experience and techniques. Some

conditions and surroundings do not allow certain practices during the installation of equipment.

We cannot be responsible for the installation of the distributor and accessories. We encourage

anyone installing or maintaining this equipment to thoroughly read this manual before

proceeding.

The company is the vendor of the distributor and certain of its optional accessories only and does

not assume responsibility for the installation. The installation recommendations contained within

this manual are for consideration only.

READ THIS MANUAL carefully to learn how to properly use and install this equipment. Failure

to do so could result in personal injury or equipment damage.

INSPECT the shipment immediately upon arrival. The Customer is responsible for ensuring that

all quantities are correct. Report any damage or shortages by recording a detailed description

on the Bill of Lading to justify the Customer’s claim from the Transport Firm. Our responsibility

for damage to the equipment ends with acceptance by the delivering carrier. Save all paperwork

and documentation furnished with any of the equipment.

THIS MANUAL SHOULD BE CONSIDERED a permanent part of your equipment and should be

easily accessible when needed.

A WARRANTY is provided as part of the company’s support program for customers who use and

maintain their equipment as described in the manual. The warranty is explained on the Warranty

page located on the inside back cover of this manual.

This warranty provides you the assurance that the company will back its products where defects

appear within the warranty period. Should the equipment be abused or modified to change its

performance beyond the factory specifications, the warranty will become void.

Note: All information, illustrations, photos and specifications in this manual are based on

the latest information available at the time of publication. The right is reserved to

make changes at any time without notice.

4 PNEG-1375 Farm/Commercial Distributor Cable Control

Page 5

E

T

S

A

2

.

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and

understand. This information relates to protecting personal safety and preventing equipment

problems. It is the responsibility of the owner/operator to inform anyone operating or working in

the area of this equipment of these safety guidelines. To help you recognize this information, we

use the symbols that are defined below. Please read the manual and pay attention to these

sections. Failure to read this manual and it’s safety instructions is a misuse of the equipment and

may lead to serious injury or death.

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

F

Y

DANGER

WARNING

CAUTION

CAUTION

NOTE

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury.

CAUTION used without the safety alert symbol indicates

a potentially hazardous situation which, if not avoided,

may result in property damage.

NOTE indicates information about the equipment that

you should pay special attention to.

PNEG-1375 Farm/Commercial Distributor Cable Control 5

Page 6

2. SAFETY

Follow Safety Instructions

Carefully read all safety messages in this manual and

on your machine safety signs. Keep signs in good

condition. Replace missing or damaged safety signs.

Be sure new equipment components and repair parts

include the current safety signs. Replacement safety

signs are available from the manufacturer.

Learn how to operate the machine and how to use

controls properly. Do not let anyone operate without

instruction. Keep children and other unqualified out of

the working area of ALL times.

Keep your machinery in proper working condition.

Unauthorized modifications to the machine may

impair the function and/or safety and affect machine

life.

If you do not understand any part of this manual and

need assistance, contact your dealer.

Read and Understand Manual

Prepare for Emergencies

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance

service, hospital and fire department near your

telephone.

Keep Emergency

Equipment Quickly Accessible

6 PNEG-1375 Farm/Commercial Distributor Cable Control

Page 7

Wear Protective Clothing

Wear close fitting clothing and safety equipment appropriate to the job.

Safety glasses should be worn at all times

to protect eyes from debris.

2. SAFETY

Eye Protection

Wear gloves to protect your hands from

sharp edges on plastic or steel parts.

Wear steel toe boots to help protect your

toes from falling debris.

A respirator may be needed if a hog house

has poor ventilation. Waste fumes can be

toxic.

Remove all jewelry.

Tuck in any loose or dangling shoe strings.

Long hair should be tied up and back.

Gloves

Steel Toe Boots

Respirator

Hard Hat

Wear hard hat to help protect your head.

PNEG-1375 Farm/Commercial Distributor Cable Control 7

Page 8

2. SAFETY

Sign-off Sheet

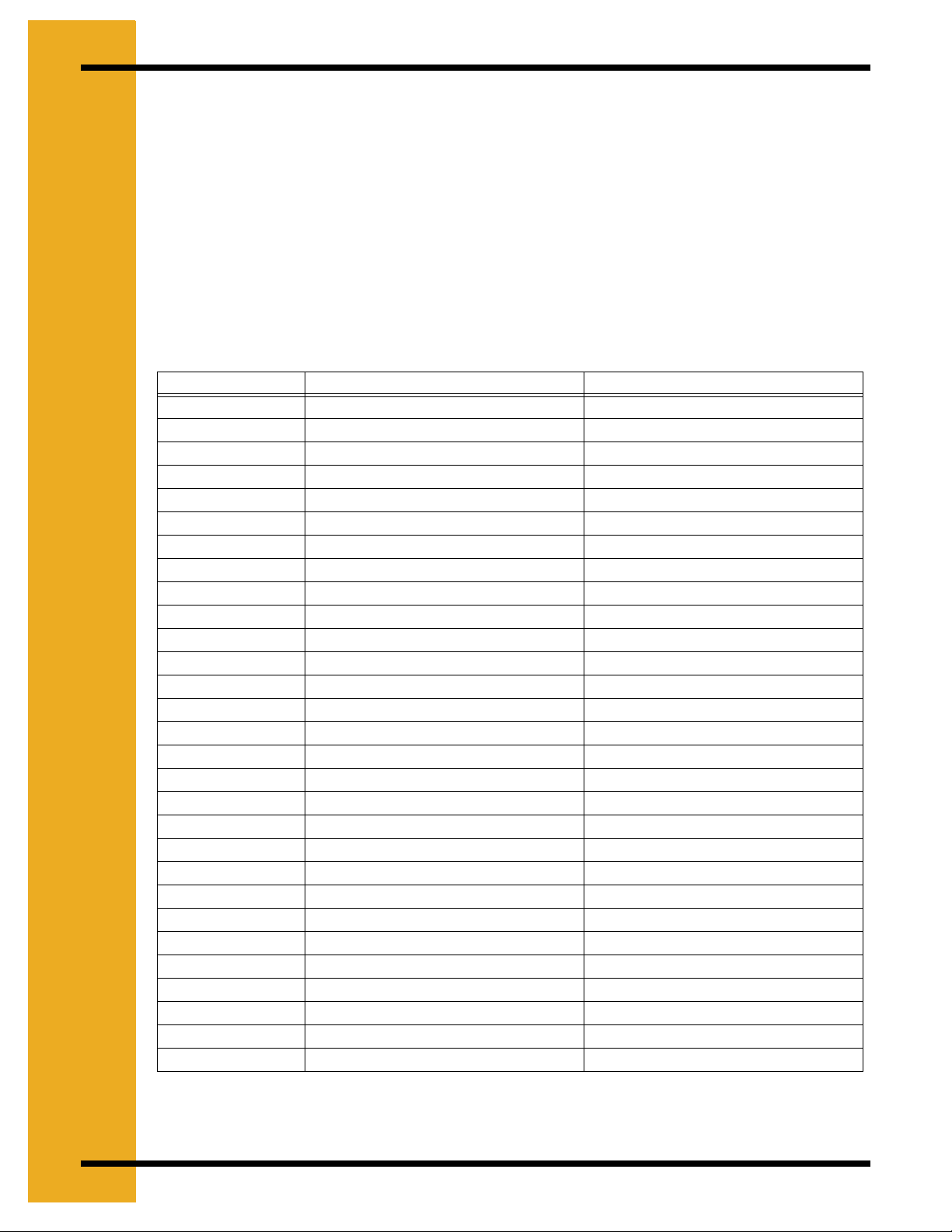

Employer/Employee Training Sign-off Sheet

The principal concern of the company is your safety and the safety of others associated with

grain handling equipment. It is the responsibility of the buyer to make this manual available to

the person or persons involved with this equipment.

As owner and/or operator, it is your responsibility to know what requirements, hazards and

precautions exist and to inform all personnel associated with the equipment or who are in the

area. Failure to read this manual is a misuse of the equipment.

We have included this Sign-off Sheet for you and your staff to use in the training process on

installation and operation of the equipment described in this manual. Read the entire manual,

sign off and date on Chart below.

Date Employees Name (printed) Employee’s Signature

1

2

3

4

5

6

7

8

9

10

11

12

13

14

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

8 PNEG-1375 Farm/Commercial Distributor Cable Control

Page 9

O

N

A

C

T

A

L

E

3

.

Install safety decals on components as shown below. Always insure that safety decals are in

place and in good condition. If a decal cannot be easily read for any reason or has been painted

over, replace it immediately. Contact your dealer or the manufacturer to order a replacement

decal free of charge.

C

D

O

L

S

I

WARNING

SHEAR POINT

Keep hands clear of

drum and cables.

Disconnect and lockout

power before servicing.

DC-857

DC-857

PNEG-1375 Farm/Commercial Distributor Cable Control 9

Page 10

4. PART IDENTIFICATION

Note: Cable is not supplied with cable control. 3/16" aircraft cable is recommended.

Distributor Cable Control Farm/Commercial

FC-DCG

Part # Description Qty

1636DCG Trunk Clamp Assy. 16" - 36" PLTFRM 2

B24C Drive Crate, 24" Inside Cube 1

DFB0388 HD Cable Guide Assy.Top 1

FC-DCG-HDW Hardware, Dist.Cable Guide F/C 1

GSB-0006 Spacer, Bottom Guide 1

GSB-0030 Control Handle 1

GSB-0031 Control Handle Brackets 2

GSB-0045 Connector - Pulley Assembly 1

GSB-0049 Cable Wheel Assembly, Bottom 1

FC-DCG-XL

Part # Description Qty

1636DCG Trunk Clamp Assy. 16" - 36" PLTFRM 2

B42C Drive Crate, 42" x 40" x 24"T ID 1

DFB0388 HD Cable Guide Assy.Top 1

DFB0406 XL Cable Wheel Assy, Bottom 1

DFB0407 XL Control Handle Brackets 2

FC-DCG-HDW Hardware, Dist.Cable Guide F/C 1

GSB-0006 Spacer, Bottom Guide 1

GSB-0030 Control Handle 1

GSB-0045 Connector - Pulley Assembly 1

Distributor Hardware

Part # Description Qty

S-8762 Clamp 3/16" Cable 8

S-7521 Bolt 3/8"-16 x 1-1/2" 3

S-968 3/8"-16 Whiz Nut 3

S-1146 Bolt HHCS 5/16-18 x 1 ZN GR2 6

S-3611 Nut Flangewz 5/16" ZN 6

S-3729 Nut Hex 1/2"-13 ZN YDP GR5 20

S-7329 Bolt HHCS 5/16-18 x 2 ZN GR2 1

S-7382 Nut Nylock 5/16-18 ZN GR5 1

S-8268 Bolt HHCS 1/2-13 x 2 ZN GR8 16

10" Bucket Elevator

Part # Description Qty

GSB-10174 Clamp Band 4

16" - 36" Bucket Elevator

Part # Description Qty

DSP16002 Clamp Band 4

DSP16005 Clamp Rod Weldment 2

FC-DCG-HDW

GSB-10DCG

1636 DCG

10 PNEG-1375 Farm/Commercial Distributor Cable Control

Page 11

I

O

T

N

L

L

A

A

T

I

N

5

Installation of Cable Wheel & Coupler Connector

Once the distributor has been installed the installation of the cable controls can begin. First install

the cable wheel. This cable wheel mounts to the control pipe coming from the bottom of the

distributor using (3) 3/8"-16 x 1-1/2" Bolts (S-7521) and (3) 3/8-16 whiz nuts (S-968).

S

.

Figure 5A

PNEG-1375 Farm/Commercial Distributor Cable Control 11

Page 12

5. INSTALLATION

Connector Pulley Assembly

The next piece to install is the connector-pulley assembly (GSB-0045). This piece mounts to the

Top Cable Wheel Weldment as shown in Figure 5B. These are fastened together using (2)

5/16" x 1" bolts and whiz nuts, supplied in the hardware package (FC-DCG-HDW).

Figure 5B

12 PNEG-1375 Farm/Commercial Distributor Cable Control

Page 13

5. INSTALLATION

Cable Guide Location

Next locate the upper cable guide assembly (DFB0388). The location on the trunking is

determined by the height of the cable wheel. The cable must run in-line from the cable wheel to

the sheaves in the cable guide assembly. This location is shown in Figure 5C. For cable

installation see page 18.

Note: Cable is not supplied with cable control. The company recommends 3/16" aircraft

cable.

Figure 5C

PNEG-1375 Farm/Commercial Distributor Cable Control 13

Page 14

5. INSTALLATION

Upper Cable Guide Assembly

Once the location of the upper cable guide assembly is determined it must be fastened to the

trunking. The assembly of the clamp band and upper cable guide assembly (DFB0388) is shown

in the Figure 5D & Figure 5E. The 1/2" x 2" bolts and nuts that fasten the clamp bands to the

upper cable guide assembly are provide in the hardware package (FC-DCG-HDW). These

clamp bands vary depending on what size leg you have. Refer to the Table below to see what

clamp bands should be used.

Note: Use caution when tightening hardware, DO NOT overtighten and collapse trunking.

Figure 5D Trunking Removed for Clarity

Pulley Dia. Clamp Band Qty

10" GSB10174 2

Figure 5E Trunking Removed for Clarity

16", 24", 30" & 36" Pulleys Part # Qty

Clamp Band DSP16002 2

Clamp w/Rod Weldment DSP16005 1

14 PNEG-1375 Farm/Commercial Distributor Cable Control

Page 15

5. INSTALLATION

Control Handle Installation

Once the upper assembly has been installed, the control handle needs to be assembled to the

lower cable wheel assembly. There are two brackets (GSB-0031) that mount to the bottom of the

lower cable wheel assembly (GSB-0049). These brackets are fastened with 5/16" x 1" bolts and

whiz nuts. The control handle (GSB-0030) is then mounted between the brackets using the

second hole in the control handle and the end hole on the brackets. This is fastened using

5/16" x 2" bolt and lock nut. The hardware required is located in (FC-DCG-HDW). This assembly

is shown in Figure 5F.

Figure 5F

PNEG-1375 Farm/Commercial Distributor Cable Control 15

Page 16

5. INSTALLATION

Lower Cable Wheel Assembly

Once the control handle has been assembled the lower cable wheel can be installed. The

location of the lower cable wheel assembly (GSB-0049) is decided by where the operator will be

positioned. Once the desired height has been determined for the lower cable wheel, it must be

fastened to the trunking. The assembly of the lower cable wheel and clamp bands are shown in

Figure 5G & Figure 5H. The 1/2" x 2" bolts and nuts to fasten clamp bands to the lower cable

wheel are provided in the hardware package (FC-DCG-HDW). These clamp bands vary

depending on what size leg you have. Refer to Table on Page 14 to see what clamp bands

should be used.

Note: Use caution when tightening hardware, do not overtighten and collapse trunking.

Figure 5G Trunking Removed for Clarity

Figure 5H Trunking Removed for Clarity

16 PNEG-1375 Farm/Commercial Distributor Cable Control

Page 17

5. INSTALLATION

Cable Guides

To help keep the cable in-line from the upper assembly to lower assembly intermediate cable

guides need to be installed. The quantity of the intermediate cable guides is determined by the

height of the leg. The company recommends that they be installed every 20 feet. These

intermediate cable guides (GSB-0022) are fastened at the trunking joints using the same

hardware as the joint. The Assembly shows how the intermediate cable guides are located on

the trunk joints (See Figure 5I). For cable installation see page 18.

Note: Cable is not supplied with cable control. The company recommends 3/16" aircraft

cable.

Figure 5I

PNEG-1375 Farm/Commercial Distributor Cable Control 17

Page 18

5. INSTALLATION

Cable Installation

There is more than one way to install the cable for the cable control. We recommend that you

rely on your qualified contractor’s experience and techniques for cable installation. Below is an

example of one method of installation.

You will need two cables:

Cable 1, Spout Position Cable:

This cable is used to turn the spout. It should be long enough to reach from the Upper Control

Wheel to the Lower Control Wheel assembly. This can be determined by the vertical distance

between the two wheels and the horizontal distance from the side of the trunking to the center

of the Upper Control Wheel. (See Figure 5J for formula) Multiply this distance x 2 to account for

the distance up and back down. Add 26' to this distance to account for 2½ wraps around the

Upper and Lower Control Wheels (Approximately 3'-9" per wrap plus an extra 2 wraps allowance

for possible error. 7 wraps total = 26')

Spout Position Cable Length Formula: (A + B x 2) + 26' = Cable

Note: Cable is not supplied with cable control. The company recommends 3/16" aircraft

cable.

1

Length

Figure 5J

18 PNEG-1375 Farm/Commercial Distributor Cable Control

Page 19

5. INSTALLATION

When installing, mark the center of the cable. Start at the Upper Control Wheel. Feed the cable

into the holes in the side of the control wheel (as shown in Figure 5K) until the center of the cable

is between the two holes in the side. Wrap each end of the cable one full wrap around wheel.

Figure 5K

Run both ends of the cable through the cable guides (See Figure 5L), continue down through the

intermediate cable guides along trunking (See Figure 5M on Page 20), down to the lower cable

wheel. Wrap each end of the cable 1 full wrap and then cable clamp both ends

(See Figure 5N on Page 21).

Cable 2, Spout Release Cable:

This cable is used to release the index trigger so that the spout can be turned. This cable should

be able to reach from the control handle at the bottom side of the lower control wheel

(See Figure 5M on Page 20), up over the center pulley of the cable guide assembly, under the

connector pulley assembly, and tie off at the index trigger (See Figure 5L). Allow some extra

cable to be able to tie off at both ends.

Figure 5L

PNEG-1375 Farm/Commercial Distributor Cable Control 19

Page 20

5. INSTALLATION

Spout Position

Cable

Intermediate

Cable Guide

Spout Release

Cable

Lower Control

Wheel

Control Hanlde

Figure 5M

20 PNEG-1375 Farm/Commercial Distributor Cable Control

Page 21

5. INSTALLATION

Figure 5N

PNEG-1375 Farm/Commercial Distributor Cable Control 21

Page 22

5. INSTALLATION

Calibrating the Distributor Spout and the Lower Cable Control Wheel

1. Place the discharge spout index trigger to the far right as shown in Figure 5O.

2. Using the Index Number Decal (Decal part number DC-1799), peel off one of the numbers

(numbered 1 through 10) and place on the Spout Decal Plate in front of the Spout Position

Arrow (See Figure 5N on Page 21).

3. Move to the next spout by pulling up on the Control Handle to disengage the Index Trigger

while rotating the Lower Cable Control Wheel counter-clockwise.

4. Repeat Step 2 & 3 until all spouts have been labeled on the Spout Decal Plate.

Figure 5O

22 PNEG-1375 Farm/Commercial Distributor Cable Control

Page 23

6

W

.

A

R

T

Y

N

A

R

Warranty

THE GSI GROUP, INC. (GSI) WARRANTS ALL PRODUCTS WHICH IT MANUFACTURES TO

BE FREE OF DEFECTS IN MATERIAL AND WORKMANSHIP UNDER NORMAL USAGE AND

CONDITIONS FOR A PERIOD OF 12 MONTHS AFTER RETAIL SALE TO THE ORIGINAL

END USER. THE PURCHASER’S SOLE REMEDY AND GSI’S ONLY OBLIGATION SHALL BE

TO REPAIR OR REPLACE, AT GSI’S OPTION AND EXPENSE, PRODUCTS THAT, IN GSI’S

SOLE JUDGMENT, CONTAIN A MATERIAL DEFECT DUE TO MATERIALS OR

WORKMANSHIP. ALL DELIVERY AND SHIPMENT CHARGES TO AND FROM GSI’S

FACTORY WILL BE PURCHASER’S RESPONSIBILITY. EXPENSES INCURRED BY OR ON

BEHALF OF THE PURCHASER WITHOUT PRIOR WRITTEN AUTHORIZATION FROM AN

AUTHORIZED EMPLOYEE OF GSI SHALL BE THE SOLE RESPONSIBILITY OF THE

PURCHASER.

EXCEPT FOR THE LIMITED WARRANTY EXPRESSED ABOVE, GSI MAKES NO FURTHER

WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION,

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR

USE IN CONNECTION WITH (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (I) ANY

ADVICE, INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN

AGENT, REPRESENTATIVE OR EMPLOYEE OF GSI REGARDING OR RELATED TO THE

CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY FOR A PARTICULAR

PURPOSE, OR DESIGN OF SUCH PRODUCTS.

GSI SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, INCLUDING, WITHOUT LIMITATION, LOSS OF

ANTICIPATED PROFITS OR BENEFITS. PURCHASER’S SOLE AND EXCLUSIVE REMEDY

IS AS SET FORTH IN THE LIMITED WARRANTY EXPRESSED ABOVE, WHICH SHALL NOT

EXCEED THE AMOUNT PAID FOR THE PRODUCT PURCHASED. THIS WARRANTY IS NOT

TRANSFERABLE AND APPLIES ONLY TO THE ORIGINAL PURCHASER. GSI SHALL HAVE

NO OBLIGATION OR RESPONSIBILITY FOR ANY REPRESENTATIONS OR WARRANTIES

MADE BY OR ON BEHALF OF ANY DEALER, AGENT OR DISTRIBUTOR OF GSI.

GSI ASSUMES NO RESPONSIBILITY FOR CLAIMS RESULTING FROM ERECTION

DEFECTS OR UNAUTHORIZED MODIFICATIONS TO PRODUCTS WHICH IT

MANUFACTURED. MODIFICATIONS TO PRODUCTS NOT SPECIFICALLY DELINEATED IN

THE MANUAL ACCOMPANYING THE EQUIPMENT AT INITIAL SALE WILL NULLIFY THE

PRODUCT WARRANTY THAT MIGHT HAVE BEEN OTHERWISE AVAILABLE.

THE FOREGOING WARRANTY SHALL NOT EXTEND TO PRODUCTS OR PARTS WHICH

HAVE BEEN DAMAGED BY NEGLIGENT USE, MISUSE, ALTERATION OR ACCIDENT. THIS

WARRANTY EXTENDS SOLELY TO ONLY PRODUCTS MANUFACTURED BY GSI. THIS

WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES EXPRESS OR

IMPLIED. GSI RESERVES THE RIGHT TO MAKE DESIGN OR SPECIFICATION CHANGES

AT ANY TIME.

PRIOR TO INSTALLATION, PURCHASER HAS THE RESPONSIBILITY TO COMPLY WITH

ALL FEDERAL, STATE AND LOCAL CODES WHICH MAY APPLY TO THE LOCATION AND

INSTALLATION OF PRODUCTS MANUFACTURED OR SOLD BY GSI.

PHLEGAL: #1832020 v1 (139LG01!.DOC) (revised December 2005)

PNEG-1375 Farm/Commercial Distributor Cable Control 23

Page 24

This equipment shall be installed in accordance with

the current installation codes and applicable

regulations which should be carefully followed in all

cases. Authorities having jurisdiction should be

consulted before installations are made.

Internet: http://www.grainsystems.com

Copyright © 2007 by the GSI Group

Printed in the USA

GSI Group, Inc.

1004 E. Illinois St.

Assumption, IL 62510-0020

Phone: 1-217-226-4421

Fax: 1-217-226-4420

Loading...

Loading...