Page 1

CarAudio Service Manual

1. Ergänzung / Supplement 1

MCD 36

(G.HF 2800)

MCD 40

(G.HF 2900)

Zusätzlich erforderliche Unterlagen für den Komplettservice

Additionally required Service Documents for the Complete Service

Service

Manual

MCD 36

MCD 40

Materialnr./Part No.

72010 748 3000

Materialnummer/Part Number 72010 748 3100

Änderungen vorbehalten/Subject to alteration • Printed in Germany

E-BS 36 0400 • 9033

http://www.grundig.com

Service

Manual

Sicherheit

Safety

Materialnr./Part No.

72010 800 0000

Grundig Service

Hotline Deutschland...

Technik:

TV

TV

SAT

VCR/LiveCam

HiFi/Audio

Car Audio

Telekommunikation

Planatron

Ersatzteil-Verkauf: ...Mo.-Fr. 8.00-19.00 Uhr

(8.00-22.00 Uhr)

...Mo.-Fr. 8.00-18.00 Uhr

0180/52318-41

0180/52318-49

0180/52318-48

0180/52318-42

0180/52318-43

0180/52318-44

Fax:

Telefon:

Fax:

0180/52318-45

0180/52318-51

0180/52318-99

0180/52318-40

0180/52318-50

Page 2

Allgemeiner Teil / General Section MCD 36 / MCD 40

Es gelten die Vorschriften und Sicherheitshinweise

gemäß dem Service Manual "Sicherheit", Materialnummer 72010 800 0000, sowie zusätzlich die eventuell abweichenden, landesspezifischen Vorschriften!

Dieses Service Manual gilt für die Geräte MCD 36 und MCD 40 ab

folgenden Seriennummern:

MCD 36: 01 00995 0 521 284501

MCD 40: 01 00996 0 521 119801

Für Geräte mit niedrigeren Seriennummern verwenden Sie bitte

das Service Manual mit der Materialnummer 72010 748 3000.

D

Inhaltsverzeichnis

Seite

Allgemeiner Teil ............................ 1 - 2 … 1 - 6

Technische Daten ..................................................................... 1 - 2

Ausbauhinweise ........................................................................ 1 - 3

Steuerungsablauf der Mechanik ............................................... 1 - 6

Schaltpläne und

Druckplatten-Abbildungen ......... 2 - 1 … 2 - 16

Blockschaltplan ......................................................................... 2 - 1

Verdrahtungsplan ...................................................................... 2 - 2

Schaltplan ................................................................................. 2 - 3

Pick-Up-Einheit ......................................................................... 2 - 7

Spannungen .............................................................................. 2 - 8

Druckplatten-Abbildungen ......................................................... 2 - 9

IC-Innen-Beschaltungen ......................................................... 2 - 11

The regulations and safety instructions shall be valid

as provided by the "Safety" Service Manual, part

number 72010 800 0000, as well as the respective

national deviations.

This Service Manual is valid for MCD 36 and MCD 40 from the

following serial numbers on:

MCD 36: 01 00995 0 521 284501

MCD 40: 01 00996 0 521 119801

For sets with lower serial numbers please use the Service Manual

with the part number 72010 748 3000.

GB

Table of Contents

Page

General Section ............................. 1 - 2 … 1 - 6

Technical Data .......................................................................... 1 - 2

Disassembly Instructions .......................................................... 1 - 3

Flowchart of Control Operation of Mechanism .......................... 1 - 6

Circuit Diagrams and

Layout of PCBs ........................... 2 - 1 … 2 - 16

Block Diagram ........................................................................... 2 - 1

Wiring Diagram ......................................................................... 2 - 2

Circuit Diagram ......................................................................... 2 - 3

Pick Up Unit .............................................................................. 2 - 7

Voltages .................................................................................... 2 - 8

Layout of PCBs ......................................................................... 2 - 9

IC Block Diagrams .................................................................. 2 - 11

Explosionszeichnungen

und Ersatzteilliste ......................... 3 - 1 … 3 - 6

Allgemeiner Teil

Messgeräte / Messmittel

Beachten Sie bitte das GRUNDIG Messtechnik-Programm, das Sie

unter folgender Adresse erhalten:

GRUNDIG Instruments Test- und Messsysteme GmbH

Würzburger Str. 150, D-90766 Fürth/Bay

Tel. 0911/703-4118, Fax 0911/703-4130

eMail: instruments@grundig.de; Internet: http://www.grundig.instruments.de

Technische Daten

D/A-Wandler ............................................................................. 1 Bit

Oversampling-Rate ................................................................. 8 fach

Frequenzbereich ........................................................ 20Hz…20kHz

Geräuschspannungsabstand ................................................... 95dB

Gleichlaufschwankung .......................................... unter Meßgrenze

Klirrfaktor (1kHz) .................................................................. 0,008%

Nenn-Ausgangspegel ............................................................. 0,68V

Nenn-Ausgangsimpedanz .......................................................... 1kΩ

Stromaufnahme .................................................................... 400mA

Betriebstemperatur .................................................. -10˚C … +50˚C

Gewicht ca. ................................................................................. 2kg

Abmessungen

(MCD 36) .......................................................... 25 x 6,4 x 16cm

(MCD 40) .......................................................... 25 x 8,1 x 16cm

Exploded Views and

Spare Parts List ............................. 3 - 1 … 3 - 6

General Section

Test Equipment / Aids

Please note the Grundig Catalog "Test and Measuring Equipment"

obtainable from:

Technical Data

D/A Converter ............................................................................ 1Bit

Oversampling Rate ............................................................... 8 times

Frequency Range ...................................................... 20Hz…20kHz

Signal/Noise Ratio ................................................................... 95dB

Wow and Flutter ................................................... immeasurably low

Distortion Factor (1kHz) ....................................................... 0.008%

Nominal Output Level ............................................................. 0.68V

Nominal Output Impedance ....................................................... 1kΩ

Current Consumption ............................................................ 400mA

Operating Temperature ............................................ -10˚C … +50˚C

Weigth approx. ............................................................................ 2kg

Dimensions

(MCD 36) ........................................................... 25 x 6.4 x 16cm

(MCD 40) ........................................................... 25 x 8.1 x 16cm

1 - 2 GRUNDIG Service

Page 3

MCD 36 / MCD 40 Allgemeiner Teil / General Section

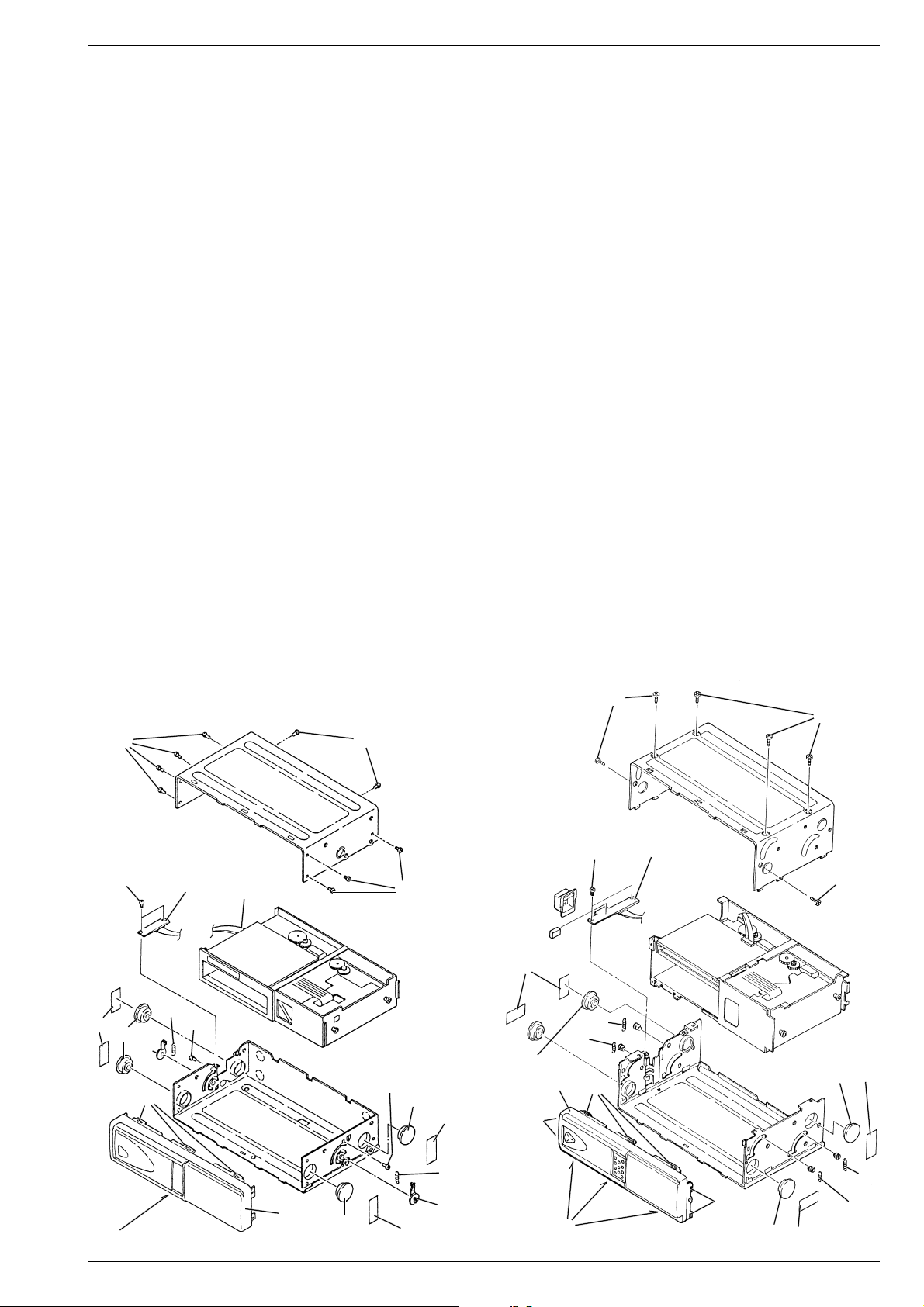

Ausbauhinweise

1a. Zerlegen des Gehäuses (MCD 36)

Gehäuseoberteil abnehmen (Fig. 1a)

- Die 9 Schrauben A herausschrauben.

- Die 4 Rastnasen 1 ausrasten und die Frontblende 2 nach vorne

abziehen.

- Gehäuseoberteil an der rechten Seite ausrasten, nach links hochklappen und abnehmen.

Gehäuseunterteil abnehmen (Fig. 1a)

- Die 2 Schrauben B herausschrauben und Anschluss-Platte C

abnehmen.

- Die 4 Klebstreifen 8 abziehen und die 4 Dämpfer 7 nach aussen

herausziehen.

- Die Federn 5 und 6 aushängen.

- Gehäuseunterteil abnehmen.

Hebel 4 ausbauen (Fig. 1a)

- Die 2 Schrauben E herausschrauben.

- Die Hebel 4 bis zur Aussparung drehen und nach aussen herausnehmen.

1b. Zerlegen des Gehäuses (MCD 40)

Gehäuseoberteil abnehmen (Fig. 1b)

- Die 6 Schrauben A herausschrauben.

- Die 10 Rastnasen 1 ausrasten und die Frontblende 2 nach vorne

abziehen.

- Gehäuseoberteil an der rechten Seite ausrasten, nach links hochklappen und abnehmen.

Gehäuseunterteil abnehmen (Fig. 1b)

- Die 2 Schrauben B herausschrauben und Anschluss-Platte C

abnehmen.

- Die 4 Klebstreifen 8 abziehen und die 4 Dämpfer 7 nach aussen

herausziehen.

- Die Federn 5 und 6 aushängen.

- Gehäuseunterteil abnehmen.

Disassembly Instructions

1a. Disassembling of the Cabinet (MCD 36)

Removing the upper part of the cabinet (Fig. 1a)

- Undo 9 screws A.

- Disengage 4 catches 1 and pull the front panel 2 towards the

front.

- Detach the top of the cabinet on the right side and raise it towards

the left to remove it.

Removing the bottom part of the cabinet (Fig. 1a)

- Undo 2 screws B and remove the Connection Board C.

- Remove the 4 pieces of adhesive tape 8 and pull out the 4

dampers 7.

- Unhook the springs 5 and 6.

- Remove the bottom part of the cabinet.

Removing the levers 4 (Fig. 1a)

- Undo 2 screws E.

- Turn the levers 4 to the outcut and take them out.

1b. Disassembling of the Cabinet (MCD 40)

Removing the upper part of the cabinet (Fig. 1b)

- Undo 6 screws A.

- Disengage 10 catches 1 and pull the front panel 2 towards the

front.

- Detach the top of the cabinet on the right side and raise it towards

the left to remove it.

Removing the bottom part of the cabinet (Fig. 1b)

- Undo 2 screws B and remove the Connection Board C.

- Remove the 4 pieces of adhesive tape 8 and pull out the 4

dampers 7.

- Unhook the springs 5 and 6.

- Remove the bottom part of the cabinet.

MCD 36

A

B

8

7

4

1

5

C

E

D

A

E

A

7

8

MCD 40

8

7

1

2

5

B

6

1

A

C

A

A

7

8

6

1

7

8

8

4

1

2

1

GRUNDIG Service 1 - 3

Fig. 1a Fig. 1b

7

6

5

Page 4

Allgemeiner Teil / General Section MCD 36 / MCD 40

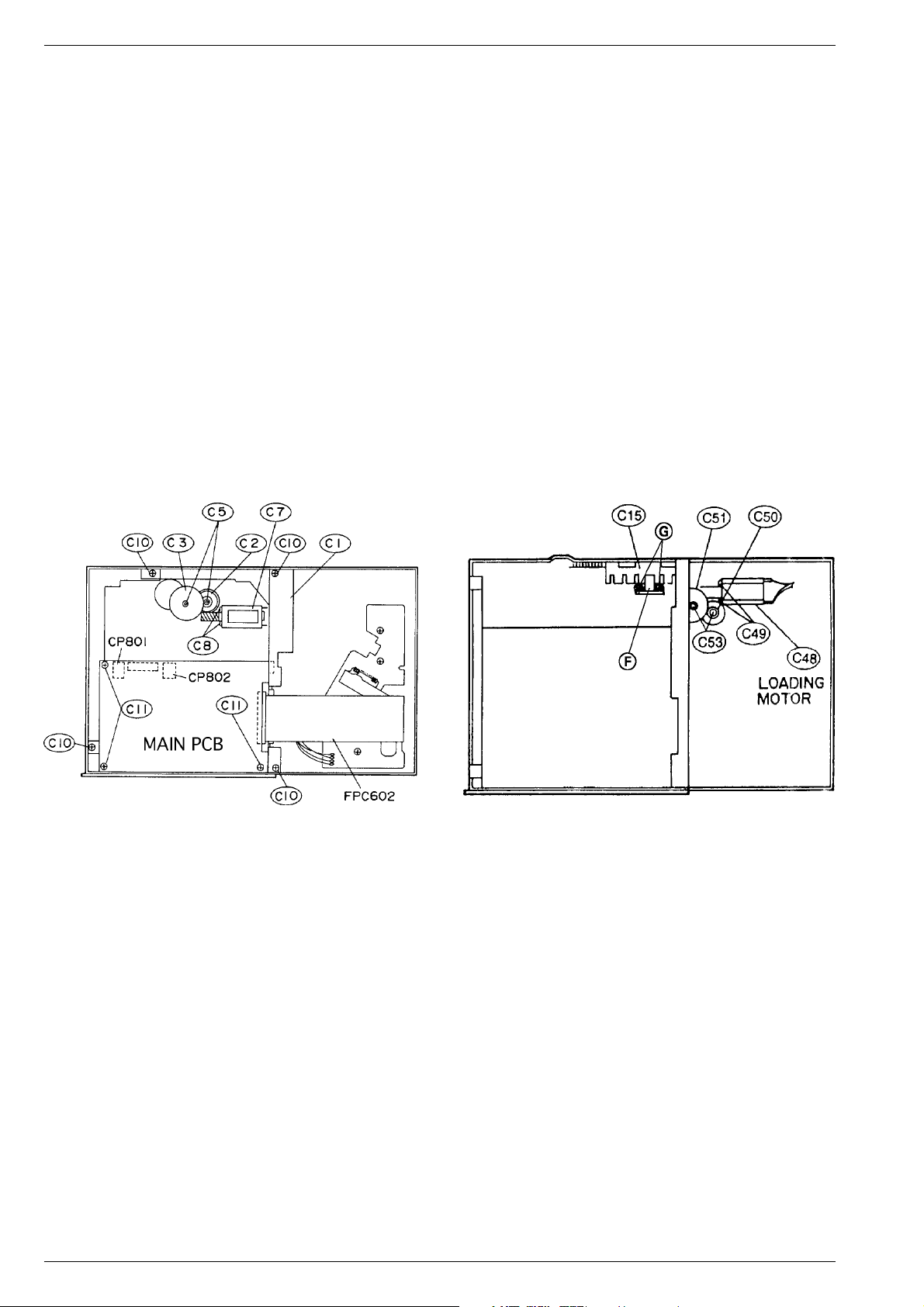

2. Hauptplatte ”MAIN PCB” ausbauen (Fig. 2)

- Gehäuseoberteil abnehmen (Pkt. 1).

- 3 Schrauben C11 herausschrauben.

- Steckverbindungen lösen.

- Leiterplatte herausnehmen.

3. Ausbau des Lift-Motors C7 (Fig. 2)

- Hauptplatte ”MAIN PCB” ausbauen (Pkt 2).

- Kunststoffscheiben C5 abziehen.

- Zahnräder C2 und C3 abnehmen.

- 2 Schrauben C8 herausschrauben.

- Lift-Motor C7 ablöten und herausnehmen.

4. Ausbau des Loading-Motors C48

- Hauptplatte ”MAIN PCB” ausbauen (Pkt 2).

- 4 Schrauben C10 herausschrauben und Magazinschacht-Oberteil

C1 herausnehmen (Fig. 2).

- Kunststoffscheiben C53 abziehen (Fig. 3).

- Zahnräder C50 und C51 herausnehmen (Fig. 3).

- 2 Schrauben C49 herausschrauben (Fig. 3).

- Loading-Motor C48 ablöten und herausnehmen (Fig. 3).

5. Ausbau des Optokopplers J

- Hauptplatte ”MAIN PCB” ausbauen (Pkt 2).

- 4 Schrauben C10 herausschrauben und Magazinschacht-Oberteil

C1 herausnehmen (Fig. 2).

- 2 Schrauben I herausschrauben (Fig. 3).

- Optokoppler J ablöten und herausnehmen.

2. Removing the Main Board (Fig. 2)

- Remove the upper part of the cabinet (para 1).

- Undo 3 screws C11.

- Unplug all connectors.

- Take out the PCB.

3. Removing the Lift Motor C7

- Remove the Main Board (para 2).

- Loosen and remove the plastic washers C5.

- Pull off the gear wheels C2 and C3.

- Undo 2 screws C8.

- Unsolder the Lift Motor C7 and take it out.

4. Removing the Loading Motor C48

- Remove the Main Board (para 2).

- Undo 4 screws C10 and remove the cover plate of the CD magazine

compartment C1 (Fig. 2).

- Loosen and remove the plastic washers C53 (Fig. 3).

- Pull off the gear wheels C50 and C51 (Fig. 3).

- Undo 2 screws C49 (Fig. 3).

- Unsolder the Lift Motor C48 and take it out (Fig. 3).

5. Removing the Opto Coupler J

- Remove the Main Board (para 2).

- Undo 4 screws C10 and remove the cover plate of the CD magazine

compartment C1 (Fig. 2).

- Undo 2 screws I (Fig. 3).

- Unsolder the Opto Coupler J and take it out.

Fig. 2 Fig. 3

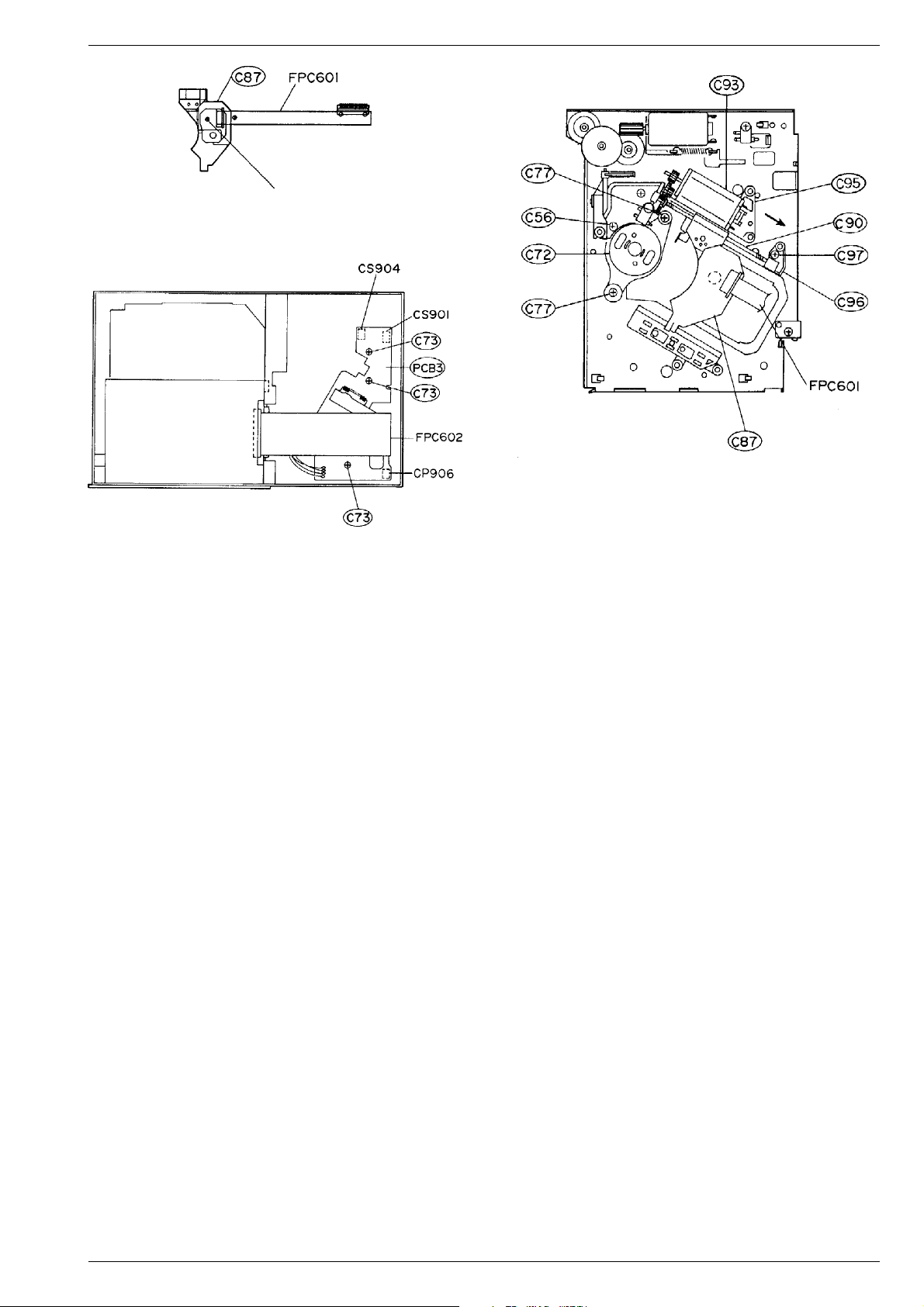

6. CD-Leiterplatte PCB3 und Pick-Up-Einheit C87 ausbauen

-

Wichtig:

Vor dem Ausbau der Pick-Up-Einheit müssen die bei-

den Lötstellen auf der Pick-Up-Einheit kurzgeschlossen werden! (Fig. 4)

- Gehäuse zerlegen (Pkt. 1).

- Steckverbindungen FPC602, CS901, CP904 und CP906 lösen

(Fig. 5).

- 3 Schrauben C73 herausschrauben (Fig. 5).

- Schraube C97 und Schraube C96 herauschrauben (Fig. 6).

- Achse C90 herausziehen (Fig. 6).

- Pick-Up-Einheit herausnehmen.

- Steckverbindung FPC601 lösen (Fig. 4) und CD-Leiterplatte PCB3

herausnehmen.

7. Disc-Motor C72 ausbauen (Fig. 6)

- Pick-Up-Einheit ausbauen (Pkt. 6).

- 2 Schrauben C77 herausschrauben und Disc-Motor herausneh-

men.

6. Removing the CD Board PCB3 and the Pick Up Unit C87

-

Important:

Before removing the Pick Up Unit the two solder tags

on the Pick Up Unit must be connected (Fig. 4).

- Disassemble the cabinet (para 1).

- Unplug the connectors FPC602, CS901, CP904 and CP906 (Fig. 5).

- Undo 3 screws C73 (Fig. 5).

- Undo screws C97 and C96 (Fig. 6).

- Pull out the shaft C90.

- Take out the Pick Up Unit.

- Unplug the connector FPC601 (Fig. 4) and take out the CD Board

PCB3.

7. Removing the Disc Motor C72 (Fig. 6)

- Remove the Pick Up Unit (para 6).

- Undo 2 screws C77 and remove the Disc Motor.

1 - 4 GRUNDIG Service

Page 5

MCD 36 / MCD 40 Allgemeiner Teil / General Section

kurzschliessen

short circuit

Fig. 4

Fig. 6

Fig. 5

GRUNDIG Service 1 - 5

Page 6

Allgemeiner Teil / General Section MCD 36 / MCD 40

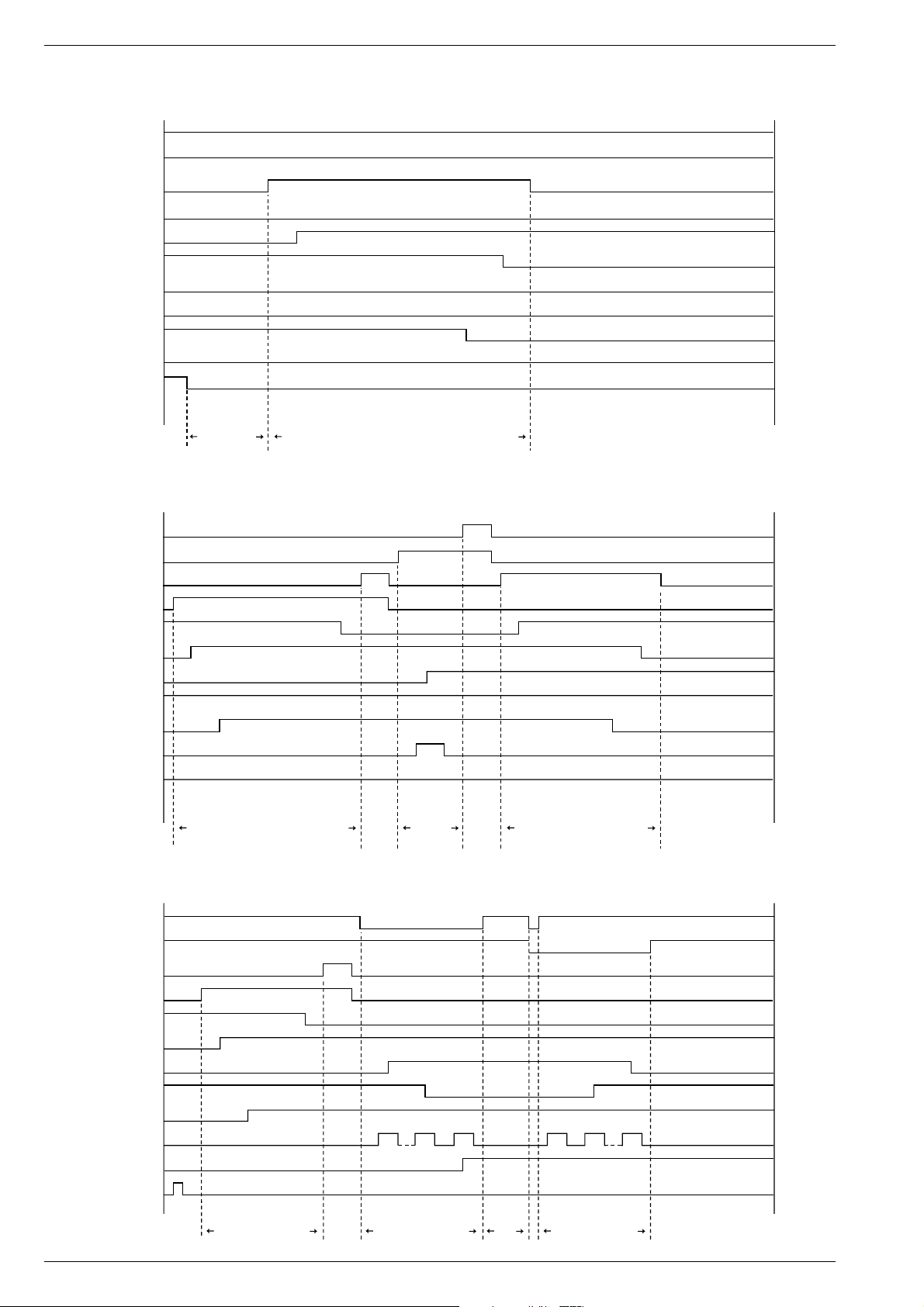

Steuerungsablauf der Mechanik Flowchart of Control Operation of Mechanism

MAGAZIN IN

H

ELV (LIFT) +

ELV (LIFT) -

LOAD +

LOAD -

LOADOUT

CLAMP

UPLIMIT

LOWLIMIT

DISC ON

DISC COUNT

MAG.SW

L

H

L

H

L

H

L

H

L

H

L

H

L

H

L

H

L

H

L

H

L

DISC CHANGE (DISC 1 / 2)

ELV (LIFT) +

ELV (LIFT) -

LOAD +

LOAD -

LOADOUT

CLAMP

UPLIMIT

LOWLIMIT

DISC ON

DISC COUNT

MAG.SW

H

L

H

L

H

L

H

L

H

L

H

L

H

L

H

L

H

L

H

L

H

L

0.6sec

1.5sec

(DISC UNLOADING)

1.5sec

(DISC LOADING)

0.2sec

(ELV DOWN)

1.5sec

(DISC LOADING)

MAG EJECT(DISC 1 PLAY)

ELV (LIFT) +

ELV (LIFT) -

LOAD +

LOAD -

LOADOUT

CLAMP

UPLIMIT

LOWLIMIT

DISC ON

DISC COUNT

MAG.SW

EJECT

H

L

H

L

H

L

H

L

H

L

H

L

H

L

H

L

H

L

H

L

H

L

H

L

1.5sec

(DISC UNLOADING)

1101110 1

2.5sec

(ELV DOWN)

2sec

3.0sec

(ELV UP)

1 - 6 GRUNDIG Service

Page 7

MCD 36 / MCD 40 Schaltpläne und Druckplattenabbildungen / Circuit Diagrams and Layout of PCBs MCD 36 / MCD 40 Schaltpläne und Druckplattenabbildungen / Circuit Diagrams and Layout of PCBs

LD

OPTICAL

PICK UP

Q601

SWITCH

DISC MOTOR

FEED MOTOR

IC651 DRIVER

IC650

SERVO

CONTROLLER

IC601

DIGITAL SIGNAL

PROCESSOR

&

DAC

VRMDGND

Vcc

VREF

COM

PD1

PD2EFF+F–T+T–

CLUMP

DISC

ON

D101

Q901

D910

DISC

COUNT

BUFFER

LOADING

MOTOR

IC950

MOTOR

DRIVER

IC806

MOTOR

DRIVER

ELEVATOR

MOTOR

IC807

LOAD

LOW

UP

INSIDE

MAG.IN

M

M

M

M

F+

F–

F+

T–

SP+

SP–

SL+

SL–

T IN

LDS

LDD

CLK

4.2M

X OUT

X IN

TD

FD

SPD

SLD

SL+

SL–

DRF

CE

DAT

CL

SQ OUT

WRQ

LOAD+

LOAD–

ELV+

FEM+

FEM–

DRF

RWC

COIN

CQCK

SQ OUT

WRQ

DS

RESET

ELV–

DS RESET

F IN

SPD

IN

SLD

IN

DISC ON

CLUMP

DISC COUNT

MAG. SW

LOWUPINSIDE

LOAD

FIN2

SLI

RCHO

EFMO

X601

SWITCH

Q803,804,950

Q900

Q805

REGULATOR

DIN

REGULATOR

+12V

+8V

D5V

L.P.F.

IC701

L.P.F.

IC701

Q801,802

IC801

␣ -COM

IC803

IC802

IC804

RESET

BATTERY

SWITCH

DETECT

U+5V

EFMI

CLV+

CLV–

V/P

HFL

TOFF

TGU

TP+

/CQCK

COIN

RWC

TP–

LCHO

RF SW

CLV+

CLV–

SLOF

HFL

TOFF

TGL

DATA 1

DATA 0

BATT

Acc

CD+B

RESET

POWER

TP+

TP–

FIN1EF

2

4

1

6

7

3

5

8

S

PICKUP

FPC FPC602 FPC602

MAIN

12A/L

VC

VCC

11

10

9

7

6

5

4

3

2

1

13

14

15

16

8NC

11

10

9

8

7

6

5

4

3

2

1

12

13

14

15

14

15

14

15

1

2

3

4

5

6

7

8

9

10

11

12

13

1

2

3

4

5

6

7

8

9

10

11

12

13

F-

F+

NL

F

VC

VCCLDGNDVRMDEPD1

PD2T+T-

29

30

16

17

18

19

20

21

22

23

24

25

26

27

28

DOWN

GND

LM+

LM-

CLAMP

LOAD0

DION

LED

SL-

SL+

SP-

SP+

GND

INSIDE

UP

29

30

16

17

18

19

1

CS901

DISC LED

D901

LOAD MOTOR

CLAMP SW

FEED MOTOR

DISC MOTOR

INSIDE SW

LOAD SW

Q901

DISK ON

2

3

4

4

3

4

3

2

1

2

1

2

1

3

2

1

3

2

1

2

1

4

3

2

1

20

21

22

23

24

25

26

27

28

2

1

CS501

CP501 CP801

MAG SW

ELV MOTOR

DISC CHG

D910 LED

CP802

B.UP

3

4

5

213

213

4

5

6

7

2

1

CS505

3

4

5

6

8

7

8

9

2

1

2

1

EM+

EM-

DISC.C

GND

LED

MAG.SW

GND

3

4

5

6

7

8

9

ACC

B.UP.1

B.UP

CD+B

BUS

GND

R-CH

SGND

L-CH

CONNECT

PHOTO

CS602 CS602

SENSOR

SENSOR

SWITCH

CP906 CS906

UP SW

LOW SW

Q901 : PT4850F

D901 : SLR-989A

D910 : GP1S51V

CD

FPC603

S

Schaltpläne und Druckplatten-Abbildungen / Circuit Diagrams and Layout of PCBs

Blockschaltplan / Block Diagram

Verdrahtungsplan / Wiring Diagram

GRUNDIG Service GRUNDIG Service

Page 8

Schaltpläne und Druckplattenabbildungen / Circuit Diagrams and Layout of PCBs MCD 36 / MCD 40

A: 2ms

5

: 50mV9: 500mV

VC™

MODE: Forward Search

VC™

5

9

Schaltpläne und Druckplattenabbildungen / Circuit Diagrams and Layout of PCBs MCD 36 / MCD 40

Schaltplan / Circuit Diagram

MODE: Play

VC™

A: 500ns

1

: 500mV

LED DRIVER

MODE: Play

1

VC™

VC™

A: 1ms

5

: 50mV6: 50mV

5

6

MODE: Play

VC™

VC™

A: 1ms

2

: 50mV3: 50mV

2

3

MODE: Play

VC™

VC™

A: 200∝s

7: 50mV 8: 50mV

7

8

MODE: Focus Search

VC™

A: 100ms

4: 50mV

4

5

VC

2

34

6

SERVO CONTROL

7

8

1

9

DEFECT

COMPARATOR

SWITCH

DEFECT

COMPARATOR

DSP & D/A

MUTE

REGULATOR

MUTE

SERVO DRIVER

SWITCH

MUTE

GRUNDIG Service GRUNDIG Service

2 - 42 - 3

Page 9

MCD 36 / MCD 40 Schaltpläne und Druckplattenabbildungen / Circuit Diagrams and Layout of PCBs MCD 36 / MCD 40 Schaltpläne und Druckplattenabbildungen / Circuit Diagrams and Layout of PCBs

REGULATOR

EJECT

MODE

SWITCH

SWITCH

SWITCH

INVERTER

MOTOR

DRIVER

LC66566B-4K60

CONTROL

MICRO COMPUTER

SWITCH

DETECTOR

DETECTOR

SWITCH

REGULATOR

REGULATOR

REGULATOR

MOTOR

DRIVER

GRUNDIG Service GRUNDIG Service2 - 5 2 - 6

Page 10

Schaltpläne und Druckplattenabbildungen / Circuit Diagrams and Layout of PCBs MCD 36 / MCD 40

IC601

IC

IC

PIN

12345678910111213141516

0 0 1.5 0 1.6 5 0.3 0 0/5

1.4/3.3

0 0/5 0 0 0 0/5

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

05000/50/55000000 0

33 34 35 36 37 38 39 40 41 42 43

44

48

0 HiZ 0 5 2.2 0 0 2.2 5 0 5 -1/5 0/5

49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64

0/5 0/5 0 0/5 0/5 0/5 0/5 4.8 0/5 4.8 0

-1.5/6.5 -0.6/5.4

000

0

45

0/5460

0/5

IC806

PIN

12345678910

0 11.5 HiZ HiZ 0 HiZ 11.5 HiZ 7.8 0

IC

IC950

PIN

12345678910

0 11.5 HiZ HiZ 0 HiZ 11.5 HiZ 7.8 0

IC

IC681

PIN

12345678

0.1 3 2.2 0 2.2 2.2 0.1 5

IC

IC701

PIN

12345678

2.5 2.5 2.5 0 2.5 2.5 2.5 7.5

47

0/5

PIN

B

3.8

0

0.1

8.2

0

0

0

0.6

0

0.9

12.6

4.3

8.4

0.8

Q601

Q681

Q682

Q700

Q701

Q702

Q703

Q801

Q802

Q803

Q804

Q805

Q900

Q950

C

2

2.2

2.2

11.5

0

0

0

0

4.8

11.8

11.5

HiZ

11.5

0.9

E

4.5

0

0

7.5

0

0

0

0

4.8

0

13.2

4.8

7.8

0

IC650

IC

PIN

12345678910111213141516

2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.3

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

2.5 2.6 2.5 2.5 2.5 0 2.4 2.4 2.4 2.5 2.9 2.5 2.6 0

33 34 35 36 37 38 39 40 41 42 43

44

48

0500/50000/5

1.4/3.5

2.4 2.7

2.5

HiZ

49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64

0

-0.6/5.4

0/5 4.8 0/5 4.9 HiZ 5 2.5 2.5 2.6 2.7 2.2 3.8 0.2 5

2.3

45

0

46

2.5

2.3

47

2.5

IC801

IC

PIN

12345678910111213141516

4.800000000050.14.80

0/4.5

HiZ

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

0000

0/4.5

0 0 1.9

1.2/3.6

4.7 4.8 0 0 0

33 34 35 36 37 38 39 40 41 42 43

44

48

00000001.71.93.73.7

4.8

0

49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64

5 4.8 0 4.8 4.8 4.8 0 4.8 0/5 4.8 0/5 0/5 0 0/5 0 4.4

3.6

45

0

46

0

0

47

4.9

IC651

IC

PIN

12345678910111213141516

7.8 2.5 2.5 2.5 2.5 2.8 0 0 7.8 7.8 3.4 4.1 3.5 3.9 3.7 3.7

17 18 19 20 21 22 23 24 25 26 27 28

3.3 4 7.8 HiZ 0 2.5 2.5 0.8 2.3 2.5 2.6 2.5

IC

IC

IC

IC

IC804

PIN

12345

HiZ 0 0 4.7 4.7

IC

IC807

PIN

12345

HiZ 4.6 0 0 5

IC802

PIN

123

13.2 5.4 0.4

IC803

PIN

123

4.8 8.2 0

IC805

PIN

123

11.5 5 0

Schaltpläne und Druckplattenabbildungen / Circuit Diagrams and Layout of PCBs MCD 36 / MCD 40

Schaltplan Pick-Up-Einheit / Circuit Diagram Pick Up Unit

Spannungen / Voltages (gemessen bei UB = 14V bei PLAY / measured with UB = 14V at PLAY)

2 - 7 2 - 8

GRUNDIG Service GRUNDIG Service

Page 11

MCD 36 / MCD 40 Schaltpläne und Druckplattenabbildungen / Circuit Diagrams and Layout of PCBs MCD 36 / MCD 40 Schaltpläne und Druckplattenabbildungen / Circuit Diagrams and Layout of PCBs

Druckplatten-Abbildungen / Layout of PCBs

GRUNDIG Service GRUNDIG Service2 - 9 2 - 10

Page 12

Schaltpläne und Druckplattenabbildungen / Circuit Diagrams and Layout of PCBs MCD 36 / MCD 40

PIN

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

DESCRIPTION

Pickup photo-diode connecting pin. Forms RF signal by addition to FIN1 pin,and FE signal by

subtraction.

Pickup photo-diode connecting pin.

Pickup photo-diode connecting pin. Forms TE signal by subtraction from F pin.

Pickup photo-diode connecting pin.

Pin for inputting DC constituent of TE signal.

Pin for connecting gain setting resistence of TE signal to TE pin.

TE signal output pin.

TES(TRACK ERROR SENCE) comparator input pin. Band pass TE signal, and input.

Input pin for shock detection.

Constant setting pin at the time of tracking gain.

Pin for connecting high pass elimination condensor of servo.

Pin for constituting tracking phase compensation constant between TD and VR pin.

Pin for setting tracking phase compensation.

Pin for setting tracking jump signal (kick pulse) amplitude.

Tracking control signal output pin.

Focusing control signal output pin.

Pin for constituting focussing phase compenstion constant between FD and FA pin.

Pin for constituting focussing phase compensation constant between FA- and FE- pin.

Pin for constituting focussing phase compensation constant between FA and FE pin.

FE signal output pin.

Pin for connecting FE signal gain setting resistance to TE pin.

GND for analog signal.

Signal end output of CV+ and CV- pin input signal

.

Connecting pin for spindle phase compensation constant together with SPD pin.

Spindle control signal output pin.

Connecting pin for sled phase compensation constant.

Sled control signal output pin.

Input pin for sled delivery signal from micro computer.

Input pin for sled delivery signal from micro computer.

Input pin for tracking jump signal from DSP.

Input pin for tracking jump signal from DSP.

Input pin for tracking gain control signal from DSP.Gain low in case of TGL="H".

Input pin for tracking off control signal from DSP.Off in case of TOFF="H".

Output pin of TES signal to DSP.

(HIGH FREQENCY LEVEL) is used to judge whether main beam is located

above pit or above mirror.

Sled servo off control input pin.

Input pin for CLV error signal from DSP.

Input pin for CLV error signal from DSP.

RF output pin.

Pin for setting RF gain and EFM signal 3T compensation constant together with RFSM pin.

(SLICE LEVEL CONTROL) is output pin for controlling data slice level by RF waveshape DSP.

Input pin for controlling data slice level by DSP.

GND pin digital system.

For Focs Smoosing capacita output pin.

Tracking Balance control pin.

NO CONNECT.

Output pin for detecting disc defect.

Standard clock input pin. DSP 4.23MHz is input.

Micro computer command clock input pin.

Micro computer command data input pin.

(DEFECT RF) RF level detecting output.

Micro computer command chip enable input pin.

Spindle amplifier input.

Connecting pin for gain setting resistance at the time of spindle 12cm mode.

PORT NAME

FIN2

FIN1

E

F

TB

TE-

TE

TESI

SCI

TH

FIN1

TA

TD-

TD

JP

TO

FD

FD-

FA

FA-

FE

FE-

AGND

SP

SPI

SPG

SP-

SPD

SLEQ

SLD

SL-

SL+

JP-

JO+

TGL

TOFF

TES

HFL

SLOF

CV-

CV+

RFSM

RFS-

SLC

SLI

DGND

FSC

TBC

NC

DEF

CLK

CL

DAT

CE

DRF

55

56

57

58

59

60

61

62

63

64

Focs serch select pin.

VCC pin for servo system and digital system.

Connection pin for standard voltage capacitor.

Standard voltage output pin.

Pin for setting constant at the time of detecting disc defect.

Pin for connecting condensor for RF signal peak hold.

Pin for connecting condensor for RF signal bottom hold.

APC circuit output pin.

APC circuit input pin.

RF system VCC pin.

FSS

VCC2

REF1

VR

LF2

PH1

BH1

LDD

LDS

VCC1

Schaltpläne und Druckplattenabbildungen / Circuit Diagrams and Layout of PCBs MCD 36 / MCD 40

IC-Innen-Beschaltungen / IC Block Diagrams

NJM2100M

–INPUT

+INPUT

V

IN

GND

VDD

VSS

2,6

3,5

S-81250HG-RD

V

REF

1

S-8054HN

2

7

OUT32

OUT1

FIN2

FIN1

TB

TE–

TE

TESI

SCH

TH

TA

TD–

TD

JP

TO

FD

8

V+

1,7

OUTPUT

4

V–

VCC1

LDS

LDD

BHI

PHI

64 63 62 61 60 59 58 57 56 55 54 53 - 50 49

APC

RF DET

1

BAL

VCA

VCA

2

I/V

E

3

F

4

5

6

TE

7

8

9

T.SERVO &

T.LOGIC

10

11

12

13

F.SERVO &

F.LOGIC

14

15

16

17 18 19 20 2122 23 24 25 26 27 28 29 30 31 32

FA

FA–FEFE–

FD–

LF2VRREF1

VCC2NCDRFCEDATCLCLK

REF

LA9240MS

∝-COM

INTERFACE

SPINDLE

SERVO

SP

SPI

AGND

SP–

SPG

SLC

RF

AMP

SLED SERVO

SLD

SPD

SLEQ

LA 9240 MS

DEF

48

NC

47

NC

46

NC

45

DGND

44

SLI

43

SLC

42

RFS–

41

RFSM

40

CV+

39

CV–

38

SLOF

37

HFL

36

TES

35

TOFF

34

TGL

33

JP+

JP–

SL–

SL+

GRUNDIG Service GRUNDIG Service

2 - 122 - 11

Page 13

MCD 36 / MCD 40 Schaltpläne und Druckplattenabbildungen / Circuit Diagrams and Layout of PCBs MCD 36 / MCD 40 Schaltpläne und Druckplattenabbildungen / Circuit Diagrams and Layout of PCBs

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

Initial setting input terminal for changer 1 or 2 switching

Play mode output H:play mode

Load/spindle motor switching signal output

No connection

No connection

No connection

No connection

No connection

Disc clamp finish SW input

Elevator upper limit SW input

Elevator lower limit SW input

Magazine detection SW input

CD mode signal output

No connection

Status data output

No connection

No connection

No connection

No connection

No connection

Command data input

Connection to ground

Ground

Ceramic oscillator connection terminal for system clock

Ceramic oscillator connection terminal for system clock

Reset signal input

Battery LOW detection input

No connection

No connection

Main & servo system power supply ON/OFF output

No connection

No connection

No connection

Pickup moving-inside signal output

Pickup moving-outside signal output

Output to move a tray in the direction out of magazine with loading motor

Output to move a tray in the direction into magazine with loading motor

No connection

No connection

Reference voltage for TH1

Reference voltage for TH2

Temperature sensor ON signal input

Temperature sensor OFF signal input

Acc ON/OFF detection signal input

Disc detection photo transistor signal input

Magazine eject key signal input

Focus OK signal input

No connection

Elevator position detection pulse input

Initial setting input terminal for 6 discs changer or 10 discs changer

Mute signal output

Reset signal for DSP(LC78622E)

Magazine tray detection SW input

Inner circle limit detection SW input

No connection

Power supply (+5V)

Interface with DSP(LC78622E)

Interface with DSP(LC78622E)

Interface with DSP(LC78622E)

Interface with DSP(LC78622E)

Elevator moving-down signal output

Interface with DSP(LC78622E)

Elevator moving-up signal output

Stand by position cancellation signal input

MODE

PLAY

LD/SP

NC

NC

NC

NC

NC

CLAMPSW

UPLIMIT

LOWLIMIT

MAGZSW

CD+B

NC

DATAOUT

NC

NC

NC

NC

NC

DATAIN

TEST

VSS

OSC1

OSC2

RESET

BATT

NC

NC

POWER

NC

NC

NC

FEM-

FEM+

LOAD+

LOAD-

NC

NC

VREF0

VREF1

TH1

TH2

ACC

DISCON

EJECT

DRF

NC

DISCCOUNT

6/10CD

MUTE

DSPRST

LOADOUT

INSIDESW

NC

VDD

SQOUT

COIN

CQCK

WRQ

ELV-

RWC

ELV+

STBY

I

O

O

O

O

O

O

O

I

I

I

I

O

O

O

O

O

O

O

O

I

I

I

I

O

O

O

O

O

O

O

O

O

O

O

O

I

I

I

I

I

I

I

I

O

I

I

O

O

I

I

O

I

O

O

I

O

O

O

I

PIN I/O

DESCRIPTION

PORT NAME

IC-PST9138N

BA5941FP

GRUNDIG Service GRUNDIG Service

28 27 26 25 24 23 22

1234567

5

4

2

Vcc

V OUT

SUB

CO1

+

–

OP1

–

+

GND

1

NC

3

10k 10k

13.3k

13.3k

20 19 18 17 16 15

21

Vcc

LEVEL

SHIFT

13.3k

LEVEL

SHIFT

10k 10k

13.3k

MUTE

VccVcc

8 9 10 11 12 13 14

LC66566B-4K60

26

22

24

25

64

SYSTEM

CONTROL

RAM STACK

(512W)

E

D D

M

P P

SP

R

H L

FLAG

D D

P P

X Y

Z

C

EA

ALU

46

47

42

43

44

45

38

~

41

34

~

37

30

~

33

PE

PRESCALER

PD

MPX

PC

PB

PA

INTERRUPT

CONTROL

P0 P1 P2 P3 P4 P5 P6 P7 P8 P9

48~51 52~55 57~60 61~64 1~4 5~8 9~12 13~16 17~20 21,27~29

MPX

MPX

TIMER

0

TIMER

1

LEVEL

SHIFT

LEVEL

SHIFT

SERIAL I/O 0

SERIAL I/O 1

RAM

(12K/16IK)

PC

62

57

58

59

60

61

21

27

29

10

11

12

63

LC 66566 B-4K60

~

9

2 - 13 2 - 14

Page 14

Schaltpläne und Druckplattenabbildungen / Circuit Diagrams and Layout of PCBs MCD 36 / MCD 40

PIN DESCRIPTION

Defect detect signal (DEF) input terminal.

PLL Input terminal for testing . Pulldown resistance is self-contained.

Phase comparison output terminal for outer VCO control.

Power supply terminal for self-contained VCO. Normally 0V.

Resistance connecting terminal for PDO output current adjustment.

Earthing terminal for self-contained VCO. Normally 5V.

For VCO range frequency adjustment.

Input terminal for testing. Pulldown resistance is self-contained.

Output terminal for spindle servo control. Accelerates when CLV+ is "H", slows down when CLV- "H".

Output terminal for automatic switchover monitor by rough servo/phase control. "H" causes rough servo, "L" phases control mode.

Input terminal for track detecting signal. Schmidt input.

Input terminal for tracking error signal. Schmidt input.

Output terminal for tracking OFF.

Output terminal for tracking gain switchover, "L" raises gain.

Output terminal for track jump.When JP+ is "H", accelerates at the time of outer track direction jump, or slows down at the time

of inner track direction jump.

Output terminal for synchronous signal detection. When synchronous signal detected from EFM signal and synchronous signal

occurring inside correspond "H".

Earthing terminal for digital system.

Input / output terminal.

Clock monitoring terminal for EFM data playback. At the time of phase lock, 4.3218MHz.

Output terminal for deemphasis monitor. At the time of "H", deemphasis disc is in playback.

C2 Frag output.

Digital Out output terminal.

Input terminal for testing. Pulldown resistance is self-contained.

Input terminal for testing. Pulldown resistance is self-contained.

Not connected

For 1 bit DAC Mute output terminal.

Power supply terminal for L channel.

L channel output terminal.

Earthing terminal for L channel. Normally 0V.

Earthing terminal for R channel. Normally 0V.

R channel output terminal.

Earthing terminal for R channel. Normally 0V.

Mute output terminal.

Connecting terminal for 16.9344MHz crystal oscillator.

Earthing terminal for crystal oscillation. Normally 0V.

Output terminal for synchronous signal of sub-code block.

Terminal for monitoring C1,C2, single, double correction.

Output terminal for sub-code P,Q,R,S,T,U,W.

Output terminal for synchronous signal of sub-code frame. When sub-code is in standby, "= L".

Output terminal for 7.35kHz synchronous signal which is divided frequency from crystal oscillation.

Output terminal for sub-code Q output standby.

Input terminal for read/write control.

Sub-code Q output terminal.

Input terminal for command from micro computer.

Input terminal for command input intake clock,or sub-code offtake clock from SQOUT. Schmidt input.

Chip reset input terminal. When power is supplied, changeover to "L" once.

Input terminal for testing. Open (Normally "L" output).

16.9344MHz output terminal. But outputs 33.8688MHz, only in case of quadruple speed playback mode.

4.2336MHz output terminal.

Input terminal for testing. Pulldown resistance is self-contained.

Chip select input terminal. Pulldown resistance is self-contained.

Input terminal for testing. Pulldown resistance is self-contained.

Input terminal for sub-code readout clock. Schmidt input.

PORT

NAME

DEFI

TAI

PDO

VVSS

ISET

VVDD

FR

VSS

EFMO

EFMIN

TEST2

CLV+

CLV-

V/P

HFL

TES

TOFF

TGL

JP+

JPPCK

FSEQ

VDD

CONT1

CONT2

CONT3

CONT4

CONT5

EMPH

C2F

DOUT

TEST3

TEST4

NC

MUTEL

LVDD

LCHO

LVSS

RVSS

RCHO

RVDD

MUTER

XVDD

XOUT

XIN

XVSS

SBSY

EFLG

PW

SFSY

SBCK

FSX

WRQ

RWC

SQOUT

COIN

CQCK

RES

TST11

16M

4.2M

TEST5

CS

TEST1

I/O

I

I

O

-

AI

-

AI

-

O

I

I

O

O

O

I

I

O

O

O

O

O

O

I/O

I/O

I/O

I/O

I/O

O

O

O

I

I

-

O

-

O

-

-

O

-

O

-

O

I

-

O

O

O

O

I

O

O

I

O

I

I

I

O

O

O

I

I

I

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

Power supply terminal for crystal oscillation. Normally 5V.

Earthing terminal for digital system. Normally 0V.

For slice

level control

EFM signal reverse output terminal.

EFM signal input terminal.

Schaltpläne und Druckplattenabbildungen / Circuit Diagrams and Layout of PCBs MCD 36 / MCD 40

L78M05T

Over

current

protection

amp

PDD

1SET

STANDARD

PORTS

CONT1

Output path

Heat protection

FR

CONT3

CONT2

INTPUT

IN1

IN2

SQOUT

1

GND

2

TA8409F

STANDBY

10

1

PROTECTION

LC78622ED

1

DEFI

EFMIN

10

FSEQ

22

CLV+

12

CLV–

13

V/P

14

PW

49

SBCK

51

SBSY

47

SFSY

50

63

CS

53

WRQ

55

57

CQCK

56

COIN

54

RWC

Start

circuit

Refer-

ence

voltage

V

CC

2

Difference

HEAT

EFMO

VVDD

VVSS

9 6 4 3 5 7 21 2 596411323362 23 8

SLICE

LEVEL

CONTROL

SYNC

DETECTION

EFM

DEMODULATION

CLV

DIGITAL

SERVO

SUB CODE

SEPARATION

Q-CRC

∝-COM

INTERFACE

SERVO

COMMAND

HFL

TES

TOFF

VCO CLOCK

OSCILLATION

CLOCK CONTROL

JP–

JP+

TGL

RES

Current

limit

PCK

TAI

C1C2 ERROR

DETECTION

CORRECTION

FLAG

PROCESSING

EFLG

EMPH

CONT5

CONT4

3

OUTPUTOUTPUT

V

S

7

5

GND

TST11

TEST1

TEST2

TEST3

2kx8BIT

RAM

XTAL

TIMING

GENERATOR

16M

4.2M

FSX

XVSS

VREF

TEST4

TEST5

XIN

XOUT

V OUT1

V IN1-

V IN1+

GND

V

REF

9

OUT1

8

M

3

OUT2

VDD

VSS

ADDRESS

GENERATOR

MUTE

DIGITAL

OUT

DIGITAL

ATTENUATOR

4 TIMES OVER SAMPLING

DIGITAL FILTER

1bit DAC

L.P.F

XVDD

RVSS

RVDD

MUTE R

RCHO

LCHO

LA6393M

1

2

3

4

30

31

34

36

38353740424139434445524667604829282726252418581920171615

LVSS

LVDD

MUTE L

LC 78622 ED

VCC

8

V OUT2

7

V IN2-

6

V IN2+

5

C2F

DOUT

NC

GRUNDIG Service GRUNDIG Service

2 - 162 - 15

Page 15

MCD 36 / MCD 40

Explosionszeichnungen und Ersatzteillisten / Exploded Views and Spare Parts Lists

MCD 36

1

GRUNDIG Service

Page 16

Explosionszeichnungen und Ersatzteillisten / Exploded Views and Spare Parts Lists

MCD 36

2

3 - 2

Page 17

GRUNDIG Service

Ersatzteilliste

Spare Parts List

1 / 2000

POS. NR. ABB. MATERIAL-NR. ANZ. BEZEICHNUNG DESCRIPTION

POS. NO. FIG. PART NUMBER QTY.

0001.000 1 75954 033 2900 GEH-VORDERTEIL CABINET FRONT

0002.000 1 75952 038 0200 GEH-OBERTEIL CABINET TOP

0003.000 1 75954 033 3100 GEHAEUSE BODEN HOUSING BOTTOM

0004.000 1 75952 038 0400 2 HEBEL LEVER

0005.000 1 75952 038 0500 FEDER, LINKS SPRING LEFT

0006.000 1 75952 038 0600 FEDER, RECHTS SPRING RIGHT

0007.000 1 75952 038 0700 4 DAEMPFUNG DAMPING

0008.000 1 75952 038 0800 4 ABDECKUNG COVER

0009.000 1 75952 038 0900 KAPPE CAP

0012.000 19772 196 0000 CD-WECHSLERKABEL CD CHANGER CABLE

0015.000 75952 038 6500 MAGAZIN KPL. MCD30 MAGAZINE CPL.

0050.000 75953 506 0100 HALTERUNG LINKS UND RECHTS HOLDER LEFT AND RIGHT

C002.000 2 75952 038 1600 ZAHNRAD A GEAR WHEEL A

C003.000 2 75952 038 1700 ZAHNRAD B GEAR WHEEL B

C004.000 2 75952 038 1800 ZAHNRAD C GEAR WHEEL C

C005.000 2 75952 038 7600 2 SCHEIBE WASHER

C006.000 2 75952 038 7700 SCHEIBE WASHER

C007.000 2 75954 033 0200 MOTOR KPL./DC MOTOR CPL./DC

C023.000 2 75955 019 0600 SPEZIAL SCHEIBE SPECIAL WASHER

C030.000 2 75955 019 0600 SPEZIAL SCHEIBE SPECIAL WASHER

C031.000 2 75954 033 3000 ZAHNRAD, D GEAR WHEEL D

C048.000 2 75952 038 1900 MOTOR KPL./DC MOTOR KPL./DC

C050.000 2 75954 033 0400 ZAHNRAD, LA GEAR LA

C051.000 2 75954 033 0500 ZAHNRAD, LB GEAR WHEEL LB

C052.000 2 75952 038 2300 ZAHNRAD G GEAR WHEEL G

C053.000 2 75954 033 0900 3 SPEZIAL SCHEIBE SPECIAL SCREW

C067.000 2 75953 506 0600 SCHALTER SWITCH

C072.000 2 75955 019 0800 MOTOR MONTIERT KPL MOTOR ASSY

C078.000 2 75953 506 0600 SCHALTER SWITCH

C080.000 2 75954 033 4200 HEBEL, DISC LEVER, DISC

C087.000

C092.000 2 75955 019 1000 ZAHNRAD GEAR WHEEL

C093.000 2 75955 019 1100 MOTOR DC MOTOR DC

C094.000 2 75955 019 1200 GETRIEBE MOTOR GEAR MOTOR

C110.000 2 75952 038 1300 ZAHNRAD H GEAR WHEEL H

C130.000 2 75953 506 0600 SCHALTER SWITCH

C134.000 2 75954 033 3400 BLENDE KPL PANEL CPL

C147.000 2 75955 019 0500 ROLLE ROLLER

C150.000 2 75955 019 0700 FEDER STOPPER SPRING STOPPER

1

CAR AUDIO

MATERIAL-NR. / PART NO.: 91833 581 5100

BESTELL-NR. / ORDER NO.: G.HF 28-00 SCHWARZ/BLACK

d©

72008 848 9900 MCD 36 TAUSCHGERAET MCD 36 EXCHANGE SET

S2 75955 019 0900 LASEREINHEIT LASER UNIT

72010 744 7500 BEDIENUNGSANLEITUNG OPERATING INSTRUCTIONS

72010 748 3000 SERVICE MANUAL MCD 36 D/GB SERVICE MANUAL MCD 36 D/GB

72010 748 3100 SERVICE MANUAL MCD 36 D/GB SERVICE MANUAL MCD 36 D/GB

D/GB/F/I/P/E/NL/DK/S/FIN D/GB/F/I/P/E/NL/DK/S/FIN

1. ERGAENZUNG SUPPLEMENT 1

MCD 36

POS. NR. MATERIAL-NR. BEZEICHNUNG

POS. NO. PART NUMBER DESCRIPTION

D 00681 75981 299 9600 SMD DIODE MA 152 K

D 00700 75952 041 5400 Z DIODE DZD 8.2 Y

D 00803 75952 022 0600 DIODE DCC 010

D 00805 75987 356 2200 SMD DIODE MA 152 WA

D 00806 75981 299 9600 SMD DIODE MA 152 K

D 00807 75981 299 9600 SMD DIODE MA 152 K

D 00808 75981 299 9600 SMD DIODE MA 152 K

D 00809 75955 019 2400 DIODE DAN202K

D 00810 75955 019 1900 DIODE DAN217

D 00811 75981 299 9600 SMD DIODE MA 152 K

D 00812 75955 019 2400 DIODE DAN202K

D 00814 75955 019 1700 Z DIODE MELF RLZ6,8B

D 00900 75955 019 1400 Z DIODE MELF RLZ8,2B

D 00901 75952 041 7500 LE DIODE SLR 989 A

D 00910 75952 041 8500 OPTOKOPPLER GP 1S 5V

D 00950 75955 019 1500 Z DIODE MELF RLZJ11B

IC 00601 75955 019 2100 IC LC78622ED

IC 00650 75954 505 1900 IC LA9240ML

IC 00651 75954 062 2800 IC BA 5941FP

IC 00681 75950 022 1900 SMD IC LA 6393 M MFP 8

IC 00701 75955 019 2200 IC NJM2100M

IC 00801 75955 019 2000 IC LC66566B-4K60

IC 00802 75952 041 4500 IC S 81250 HG-RD-T2

IC 00803 75952 041 5700 IC S 8054 HN-CB

IC 00804 75954 033 1500 IC PST9138N

IC 00805 75955 019 1300 IC L78M05TL

IC 00806 75955 019 1600 IC TA8409F

IC 00807 75952 041 7900 SMD IC TC 7 S 04 F

IC 00950 75955 019 1600 IC TA8409F

PCB 00002 75954 033 3200 BUCHSE KPL M.LP

PCB 00006 75955 019 2300 SCHALTER MONTIERT KPL

Q 00601 75954 033 2100 SMD-TRANS. 2 SA 1338-5

Q 00681 75987 433 8800 TRANS.DTC 114 YK DTC114YK

Q 00682 75987 433 8800 TRANS.DTC 114 YK DTC114YK

Q 00700 75952 023 0900 SMD TRANS. 2 SC 2412 K-R

Q 00701 75952 041 4200 SMD TRANS. 2 SA 1341

Q 00702 75952 023 1000 SMD TRANS. DTC 114 TK

Q 00703 75952 023 1000 SMD TRANS. DTC 114 TK

Q 00801 75952 041 9300 SMD TRANS. 2 SC 2812-6

Q 00802 75987 459 6100 TRANS.-WIDERST.UN 2114 UN

Q 00803 75952 041 6300 SMD TRANS. DTC 124 XK

Q 00804 75952 041 6400 TRANS. 2 SB 1202 S

Q 00805 75953 501 4600 SMD-TRANS. 2 SA 1179 M6

Q 00900 75952 041 6400 TRANS. 2 SB 1202 S

Q 00901 75952 041 8000 FOTO-DIODE PT 4850 F

Q 00950 75952 041 6300 SMD TRANS. DTC 124 XK

SW 00801 75955 019 1800 TAKTSCHALTER 1P-1T/EJECT

SW 00802 75954 033 1600 SCHIEBESCHALTER/MODE

TH 00801 75952 041 8200 NTC CS 20123 BH 102 KCTH1

X 00601 75953 506 2900 QUARZ 16,9344 MHZ

X 00801 75952 041 7900 SMD IC TC 7 S 04 F

POS. NR. MATERIAL-NR. BEZEICHNUNG

POS. NO. PART NUMBER DESCRIPTION

MCD 36 / MCD 40

ÄNDERUNGEN VORBEHALTEN / SUBJECT TO ALTERATION

Es gelten die Vorschriften und Sicherheitshinweise

gemäß dem Service Manual "Sicherheit", Mat.-Nummer 72010 800 0000, sowie zusätzlich die eventuell

abweichenden, landesspezifischen Vorschriften!

The regulations and safety instructions shall be valid

!

as provided by the "Safety" Service Manual, part

number 72010 800 0000, as well as the respective

( ! )

national deviations.

ÄNDERUNGEN VORBEHALTEN / SUBJECT TO ALTERATION

Page 18

Explosionszeichnungen und Ersatzteillisten / Exploded Views and Spare Parts Lists

MCD 40

1

3 - 4

Page 19

MCD 36 / MCD 40

MCD 40

2

GRUNDIG Service

Page 20

3 - 6

1

Ersatzteilliste

Spare Parts List

4 / 2000

POS. NR. ABB. MATERIAL-NR. ANZ. BEZEICHNUNG DESCRIPTION

POS. NO. FIG. PART NUMBER QTY.

72008 849 9900 MCD 40 TAUSCHGERAET MCD 40 EXCHANGE SET

0001.000 1 75954 033 2200 GEH-VORDERTEIL HOUSING FRONT

0002.000 1 75954 033 2300 GEH-OBERTEIL CABINET TOP

0003.000 1 75954 033 2400 GEHAEUSE BODEN HOUSIN BOTTOM

0004.000 1 75954 033 2500 HEBEL LEVER

0005.000 1 75954 033 2600 FEDER LINKS SPRING LEFT

0006.000 1 75954 033 2700 ZUGFEDER RECHTS ZUG-SPRING RIGHT

0008.000 1 75952 038 0800 ABDECKUNG COVER

0009.000 1 75954 033 2200 GEH-VORDERTEIL HOUSING FRONT

0010.000 1 75952 038 0900 KAPPE COP

0012.000 19772 196 0000 CD-WECHSLERKABEL CD CHANGER CABLE

0015.000 75954 033 0100 MAGAZIN KPL. MAGAZINE CPL.

0050.000 75954 033 3600 HALTERUNG LINKS U. RECHTS HOLDER LEFT AND RIGHT

C002.000 2 75952 038 1600 ZAHNRAD A GEAR WHEEL A

C003.000 2 75952 038 1700 ZAHNRAD B GEAR WHEEL B

C004.000 2 75952 038 1800 2 ZAHNRAD C GEAR WHEEL C

C005.000 2 75952 038 7600 SCHEIBE WASHER

C006.000 2 75952 038 7700 SCHEIBE WASHER

C007.000 2 75954 033 0200 MOTOR KPL. MOTOR CPL.

C017.000 2 75955 019 0600 3 SPEZIAL SCHEIBE SPECIAL WASHER

C028.000 2 75954 033 0300 ZAHNRAD, PLATTE GEAR BOARD

C039.000 2 75953 506 0600 SCHALTER SWITCH

C044.000 2 75955 019 0600 2 SPEZIAL SCHEIBE SPECIAL WASHER

C048.000 2 75952 038 1900 MOTOR KPL. MOTOR KPL.

C050.000 2 75954 033 0400 ZAHNRAD, LA GEAR LA

C051.000 2 75954 033 0500 ZAHNRAD, LB GEAR WHEEL LB

C052.000 2 75952 038 2300 ZAHNRAD G GEAR WHEEL G

C053.000 2 75954 033 0900 3 SPEZIAL SCHEIBE SPECIAL SCREW

C067.000 2 75953 506 0600 SCHALTER SWITCH

C072.000 2 75955 019 0800 MOTOR MONTIERT KPL MOTOR ASSY

C078.000 2 75953 506 0600 SCHALTER SWITCH

C080.000 2 75954 033 4200 HEBEL, DISC LEVER, DISC

C087.000

S 2 75955 019 0900 LASEREINHEIT LASER UNIT

C092.000 2 75955 019 1000 ZAHNRAD GEAR WHEEL

C093.000 2 75955 019 1100 MOTOR DC MOTOR DC

C094.000 2 75955 019 1200 GETRIEBE MOTOR GEAR MOTOR

C096.000 2 75954 033 3700 MITNEHMER DRIVER/CARRIER

C106.000 2 75955 019 0600 2 SPEZIAL SCHEIBE SPECIAL WASHER

C110.000 2 75952 038 1300 ZAHNRAD H GEAR WHEEL H

C130.000 2 75955 019 0600 SPEZIAL SCHEIBE SPECIAL WASHER

C134.000 2 75954 033 3900 BLENDE KPL. MASK CPL

72010 744 8000 BEDIENUNGSANLEITUNG OPERATING INSTRUCTIONS

72010 748 3000 SERVICE MANUAL MCD 36 D/GB SERVICE MANUAL MCD 36 D/GB

72010 748 3100 SERVICE MANUAL MCD 36 D/GB SERVICE MANUAL MCD 36 D/GB

d©

D/GB/F/I/P/E/NL/DK/S/FIN D/GB/F/I/P/E/NL/DK/S/FIN

1. ERGAENZUNG SUPPLEMENT 1

CAR AUDIO

MATERIAL-NR. / PART NO.: 91833 781 5100

BESTELL-NR. / ORDER NO.: G.HF 29-00

MCD 40

POS. NR. MATERIAL-NR. BEZEICHNUNG

POS. NO. PART NUMBER DESCRIPTION

CS 00505 75954 033 4000 DIN BUCHSE KPL.

D 00681 75955 019 2500 DIODE MA152K

D 00700 75952 041 5400 Z DIODE DZD 8.2 Y

D 00803 75952 022 0600 DIODE DCC 010

D 00805 75987 356 2200 SMD DIODE MA 152 WA

D 00806 75981 299 9600 SMD DIODE MA 152 K

D 00807 75981 299 9600 SMD DIODE MA 152 K

D 00808 75981 299 9600 SMD DIODE MA 152 K

D 00809 75955 019 2400 DIODE DAN202K

D 00810 75955 019 1900 DIODE DAN217

D 00811 75981 299 9600 SMD DIODE MA 152 K

D 00812 75955 019 2400 DIODE DAN202K

D 00814 75955 019 1700 Z DIODE MELF RLZ6,8B

D 00900 75955 019 1400 Z DIODE MELF RLZ8,2B

D 00901 75952 041 7500 LE DIODE SLR 989 A

D 00910 75952 041 8500 OPTOKOPPLER GP 1S 5V

D 00950 75955 019 1500 Z DIODE MELF RLZJ11B

FPC 00602 75954 033 3800 FLEXPRINTLEITUNG FBC602

IC 00601 75955 019 2800 IC LC78622ED-U

IC 00650 75954 505 1900 IC LA9240ML

IC 00651 75954 062 2800 IC BA 5941FP

IC 00681 75955 019 2900 IC LA6393ML

IC 00701 75955 019 2200 IC NJM2100M

IC 00801 75955 019 2700 IC LC66566B-4L33

IC 00802 75952 041 4500 IC S 81250 HG-RD-T2

IC 00803 75952 041 5700 IC S 8054 HN-CB

IC 00804 75954 033 1500 IC PST9138N

IC 00805 75955 019 1300 IC L78M05TL

IC 00806 75955 019 1600 IC TA8409F

IC 00807 75952 041 7900 SMD IC TC 7 S 04 F

IC 00950 75955 019 1600 IC TA8409F

PCB 00002 75954 033 3500 ANSCHLUSSBUCHSE KPL

PCB 00006 75954 033 1400 SCHALTER

Q 00601 75954 033 2100 SMD-TRANS. 2 SA 1338-5

Q 00681 75987 433 8800 TRANS.DTC 114 YK DTC114YK

Q 00700 75952 023 0900 SMD TRANS. 2 SC 2412 K-R

Q 00701 75952 041 4200 SMD TRANS. 2 SA 1341

Q 00702 75952 023 1000 SMD TRANS. DTC 114 TK

Q 00703 75952 023 1000 SMD TRANS. DTC 114 TK

Q 00801 75952 041 9300 SMD TRANS. 2 SC 2812-6

Q 00802 75987 459 6100 TRANS.-WIDERST.UN 2114 UN

Q 00803 75952 041 6300 SMD TRANS. DTC 124 XK

Q 00804 75952 041 6400 TRANS. 2 SB 1202 S

Q 00805 75953 501 4600 SMD-TRANS. 2 SA 1179

Q 00900 75955 019 2600 TRANS 2SD1802-S

Q 00901 75952 041 8000 FOTO-DIODE PT 4850 F

Q 00950 75952 041 6300 SMD TRANS. DTC 124 XK

SW 00801 75955 019 1800 TAKTSCHALTER 1P-1T

SW 00802 75954 033 1600 SCHIEBESCHALTER

TH 00801 75952 041 8200 NTC CS 20123 BH 102 KCTH1

X 00601 75953 506 2900 QUARZ 16,9344 MHZ

X 00801 75952 041 7900 SMD IC TC 7 S 04 F

POS. NR. MATERIAL-NR. BEZEICHNUNG

POS. NO. PART NUMBER DESCRIPTION

Explosionszeichnungen und Ersatzteillisten / Exploded Views and Spare Parts Lists

ÄNDERUNGEN VORBEHALTEN / SUBJECT TO ALTERATION

Es gelten die Vorschriften und Sicherheitshinweise

gemäß dem Service Manual "Sicherheit", Mat.-Nummer 72010 800 0000, sowie zusätzlich die eventuell

abweichenden, landesspezifischen Vorschriften!

The regulations and safety instructions shall be valid

!

as provided by the "Safety" Service Manual, part

number 72010 800 0000, as well as the respective

( ! )

national deviations.

ÄNDERUNGEN VORBEHALTEN / SUBJECT TO ALTERATION

Loading...

Loading...