Page 1

LIVE CAM Service Manual

Livance LC 1150

GMI8500

Zusätzlich erforderliche Unterlagen für den Komplettservice

Additionally required Service Documents for the Complete Service

Service

Manual

Sicherheit

Safety

Materialnr./Part No.

720108000000

Materialnummer/Part Number 7201005408100

Änderungen vorbehalten/Subject to alteration • Printed in Germany

E-BS-SA14 0601

http://www.grundig.com

Grundig Service

Hotline Deutschland...

Technik:

TV

TV

SAT

VCR/LiveCam

HiFi/Audio

Car Audio

Telekommunikation

Planatron

Ersatzteil-Verkauf: ...Mo.-Fr. 8.00-19.00 Uhr

(8.00-22.00 Uhr)

...Mo.-Fr. 8.00-18.00 Uhr

0180/52318-41

0180/52318-49

0180/52318-48

0180/52318-42

0180/52318-43

0180/52318-44

Fax:

Telefon:

Fax:

0180/52318-45

0180/52318-51

0180/52318-99

0180/52318-40

0180/52318-50

Page 2

CONTENTS

Page

1 INTRODUCTION 3

1.1. INTRODUCTION1

1.2. INTRODUCTION2

1.3. FEATURE COMPARISON CHART

2 SERVICE CAUTION

2.1. EEPROM DATA FOR SPARE PARTS OF THE MAIN

C.B.A.

2.2. SERVICE EXTENSION CABLES.

2.3. SET-UP FOR ADJUSTMENT OF TATSUJIN.

3 SERVICE INFORMATION

3.1. SERVICE INFORMATION DISPLAY (GENERAL

DESCRIPTION)

3.2. SERVICE MODE 3 (ERROR CODE DISPLAY)

3.3. INSERTING THE BUTTON-TYPE BATTERY

4 ADJUSTMENT PROCEDURES

4.1. DISASSEMBLY PROCEDURES

4.2. DISASSEMBLY PROCEDURES OF LENS UNIT

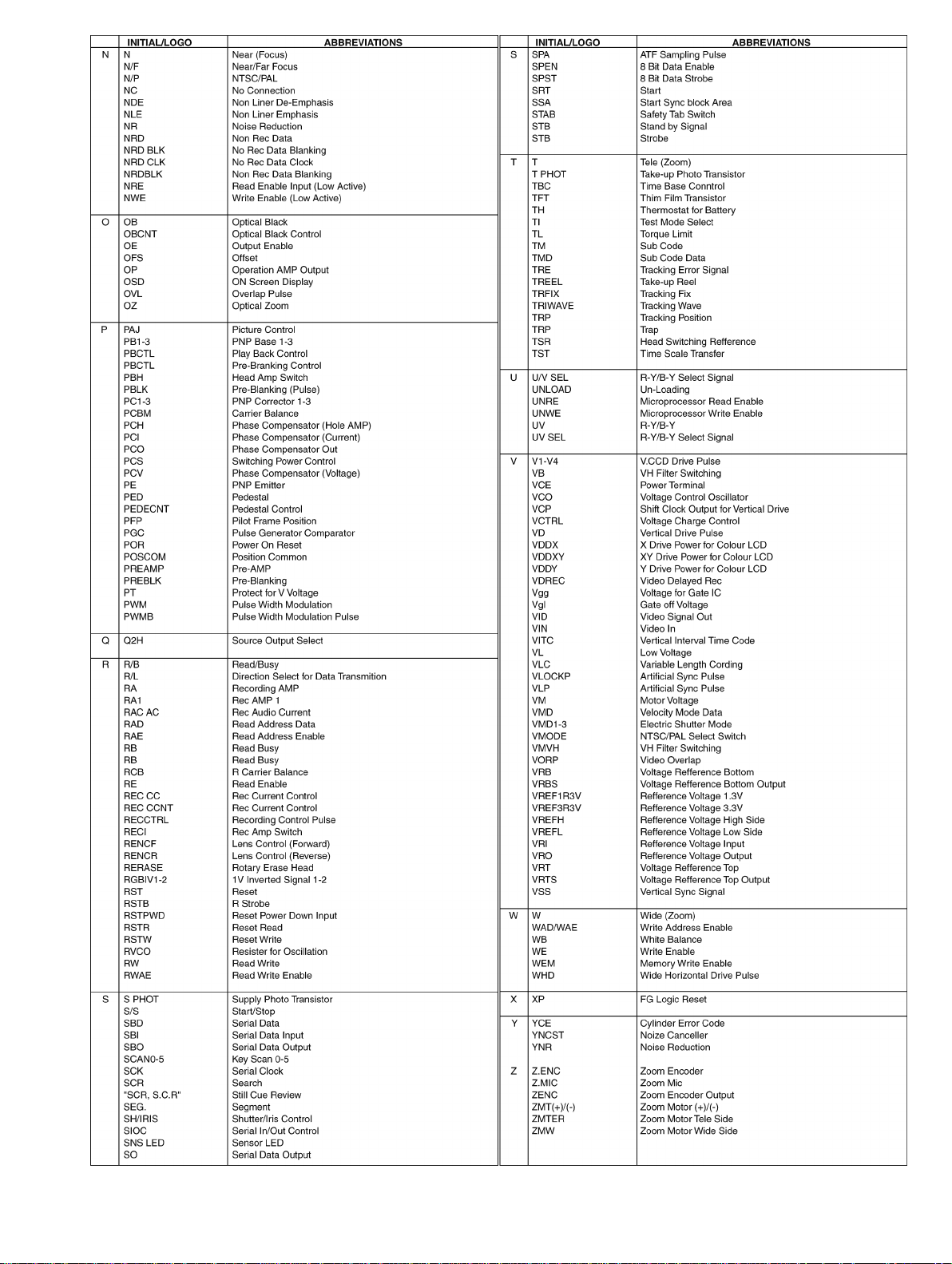

5 ABBREVIATIONS

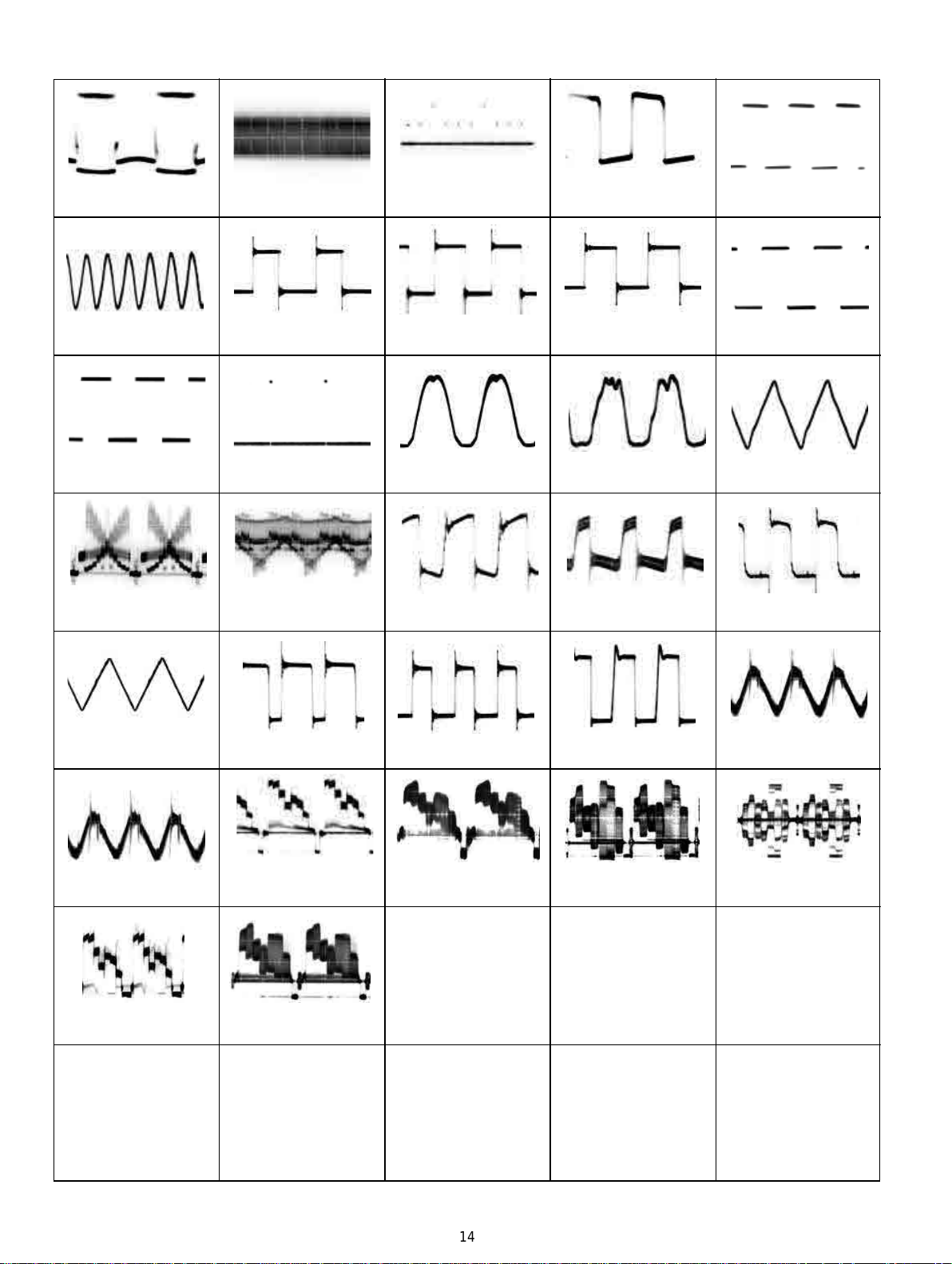

6 WAVEFORM TABLE

7 BLOCK DIAGRAMS

7.1. OVERALL BLOCK DIAGRAM

7.2. BLOCK DIAGRAM OF CONNECTION

7.3. SYSTEM CONTROL& SERVO/ POWER BLOCK

DIAGRAM

7.4. VIDEO BLOCK DIAGRAM

7.5. MONITOR BLOCK DIAGRAM

7.6. CAMERA BLOCK DIAGRAM

8 SCHEMATIC DIAGRAMS

8.1. LENS DRIVE SCHEMATIC DIAGRAM

8.2. CAMERA 1 SCHEMATIC DIAGRAM

8.3. CAMERA 2 SCHEMATIC DIAGRAM

8.4. VIDEO SCHEMATIC DIAGRAM

8.5. SYSTEM CONTROL& SERVO SCHEMATIC DIAGRAM

8.6. AUDIO SCHEMATIC DIAGRAM

8.7. POWER SCHEMATIC DIAGRAM

8.8. SUB SERVO SCHEMATIC DIAGRAM

3

3

3

4

4

4

5

6

6

6

7

8

8

11

12

14

15

15

15

16

18

18

19

21

21

22

23

25

27

30

31

8.9. LCD SCHEMATIC DIAGRAM

8.10. AVS OUT SCHEMATIC DIAGRAM

8.11. MONITOR& SENSOR FLEX. CARD SCHEMATIC

DIAGRAM

8.12. B/W-E.V.F. SCHEMATIC DIAGRAM

8.13. MIC UNIT SCHEMATIC DIAGRAM

8.14. CCD FLEX. CARD SCHEMATIC DIAGRAM

9 CIRCUIT BOARD ASSEMBLIES

9.1. MAIN C.B.A. ADDRESS INFORMATION

9.2. MAIN C.B.A. (COMPONENT SIDE)

9.3. MAIN C.B.A. (FOIL SIDE)

9.4. MONITOR C.B.A.

9.5. MIC UNIT

9.6. B/W-E.V.F. C.B.A.

9.7. CCD FLEX. CARD C.B.A.

10 EXPLODED VIEWS

11 REPLACEMENT PARTS LIST

Page

33

34

34

35

36

36

36

37

37

38

39

40

40

40

40

41

44

Page 3

1 INTRODUCTION

1.1. INTRODUCTION1

This service manual contains technical information which will be allowed service personnel’s to understand and service this model.

Please use part number on the parts list to make order for spare part and do not use reference number on the drawing.

If the circuit is changed or modified, this information will be followed by supplement service manual.

Note 1:

The service manual for Mechanism-Chassis is separated as another one.

Please refer to the following manual for detail of adjustment procedure for Mechanism-Chassis.

Order number for service manual of Mechanism-Chassis : VMD9912044C8

1.2. INTRODUCTION2

Note 1:

Differences are mentioned as follows for VZ9 series.

Description EG EGM

Packing case VPG0H14 VPG0H15

Operating manual VQT9062 VQT9063

Note 2:

Differences are mentioned as follows for VZ10 series.

Description EG EGM

Packing case VPG0H26 VPG0H27

Operating manual VQT9062 VQT9063

Note 3:

Differences are mentioned as follows for VZ10 series.

Description EN ENH ENC

Packing case VPG0H29 VPG0H30 VPG0H31

AC cord VJA0664 VJA0940 VJA0664

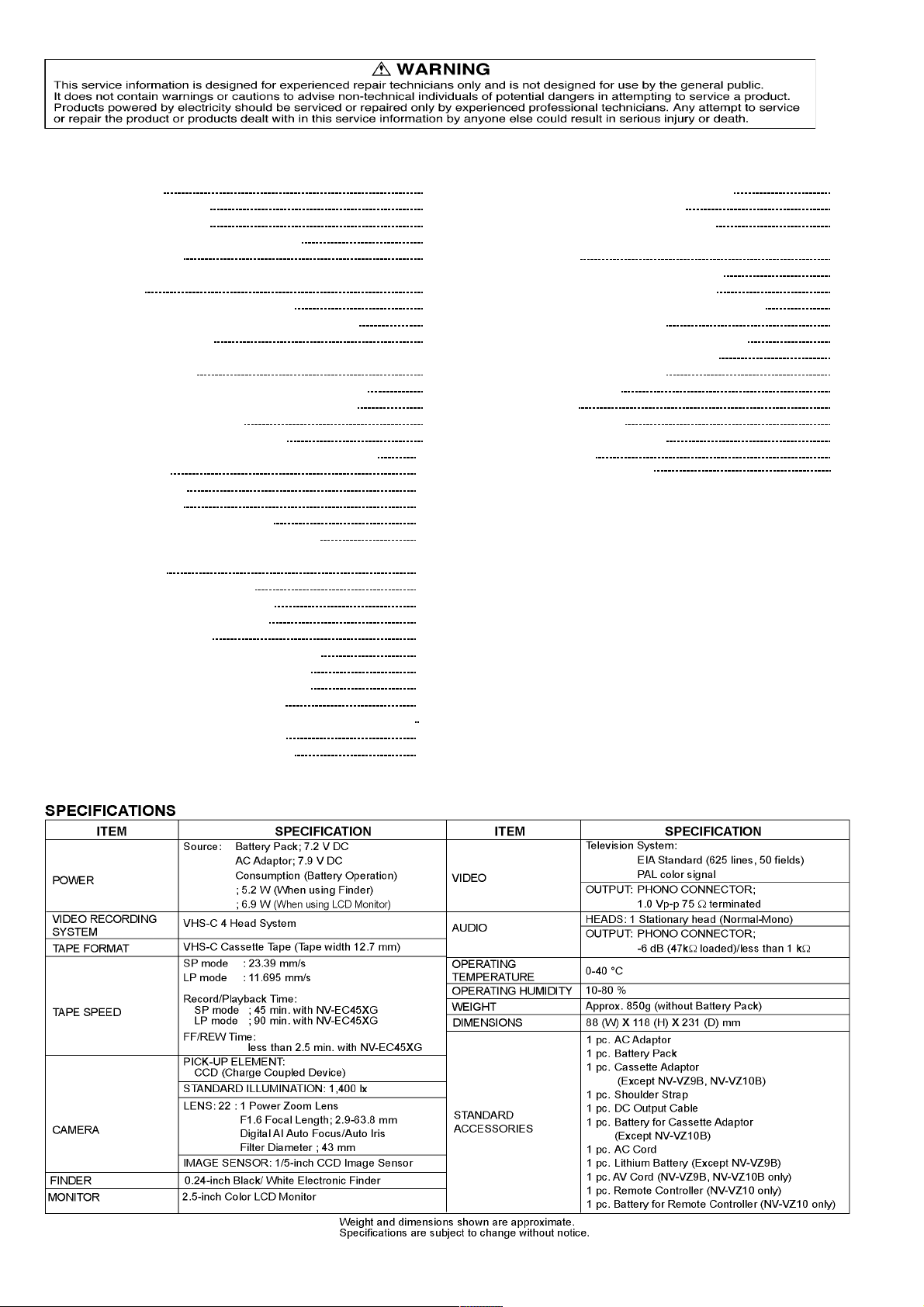

1.3. FEATURE COMPARISON CHART

VZ9 VZ10

EG B EN/EU EG B EN A

CCD CCD Image Sensor 1/5" 1/5" 1/5" 1/5" 1/5" 1/5" 1/5"

CCD Capacity (Pixels) 450k 450k 450k 450k 450k 450k 450k

LCD

MONITOR

B/W-EVF B/W EVF LCD Monitor 0.24" 0.24" 0.24" 0.24" 0.24" 0.24" 0.24"

SPEED Recording/Playback mode SP SP/LP SP/LP SP SP/LP SP/LP SP/LP

LENS Optical Zoom Ratio x22 x22 x22 x22 x22 x22 x22

DIG.ZOOM Digital Zoom (x45/x100/x250) O/O/O O/O/O O/O/O O/O/O O/O/O O/O/O O/O/O

ACCESSORY Remote controller X X X O O O O

Color LCD Monitor 2.5" 2.5" 2.5" 2.5" 2.5" 2.5" 2.5"

LCD Capacity (Pixels) 112,320 112,320 112,320 112,320 112,320 112,320 112,320

EVF LCD Capacity (Pixels) 76,800 76,800 76,800 76,800 76,800 76,800 76,800

Shortest Image Distance (From 1st Lens) 1.8m 1.8m 1.8m 1.8m 1.8m 1.8m 1.8m

Voice zoom O O O O O O O

AV cord X O X X O X X

3

Page 4

2 SERVICE CAUTION

2.1. EEPROM DATA FOR SPARE PARTS OF THE MAIN C.B.A.

When the Main C.B.A. is replaced, the fixed and average data must be re-installed to EEPROM by Tatsujin kit according to the

suffix for Movie camera.

Then, confirm and/or adjust the VTR and Camera adjustment one by one.

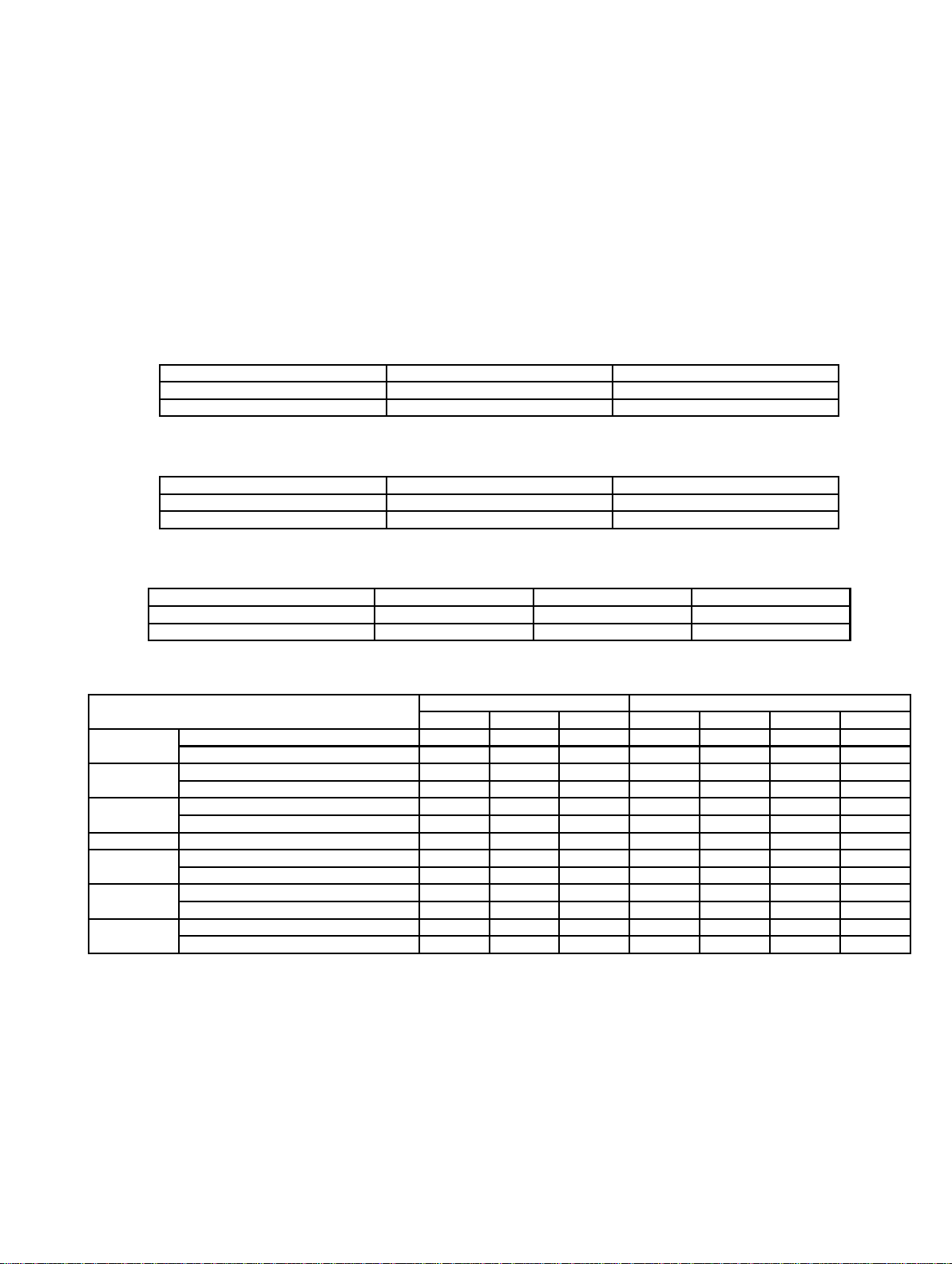

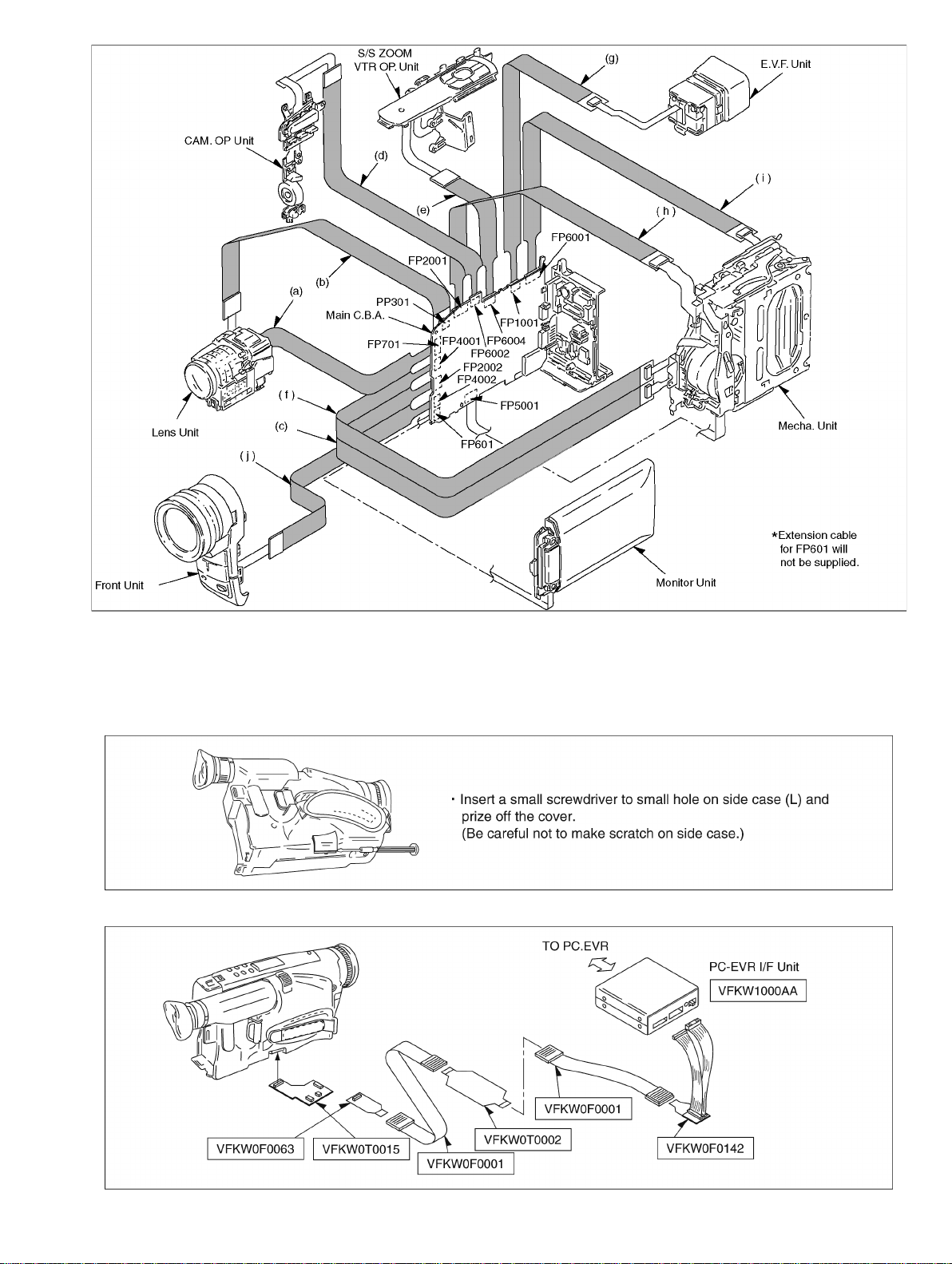

2.2. SERVICE EXTENSION CABLES.

This model is required the following extension cables for all connections.

As a convenient way, please prepare the Rear case U(K4ZZ15000013) as extra to repair easily.

(K4ZZ15000013 can be purchased through service route.)

Ref. Parts No. Pin Part name Connection Q’ty Remarks

(a) VFK1582A2120 21 Flat Cable FP701-Lens Unit 1

(b) VFK1582D1225 12 Flat Cable PP301-Lens Unit 1

(c) VFK1582E0720 7 Flat Cable FP2002-Cylinder 1

(d) VFK1582A1325 13 Flat Cable FP6002-CAM. OP. 1

(e) VFK1582A1625 16 Flat Cable FP6004-S/S ZOOM VTR OP. 1

(f) VFK1582A0920 9 Flat Cable FP4001-A/C Head 1

(g) VFK1582A1025 10 Flat Cable FP1001-EVF 1

(h) VFK1582A1925 19 Flat Cable FP2001-Capstan 1

(i) VFK1582A2125 21 Flat Cable FP6001-Mecha. FPC. 1

(j) VFK1582A1620 16 Flat Cable FP4002-Front 1

NOTE:

New Parts numbers consist 4 blocks. And they has meaning as follows.

How to use extension cables.

4

Page 5

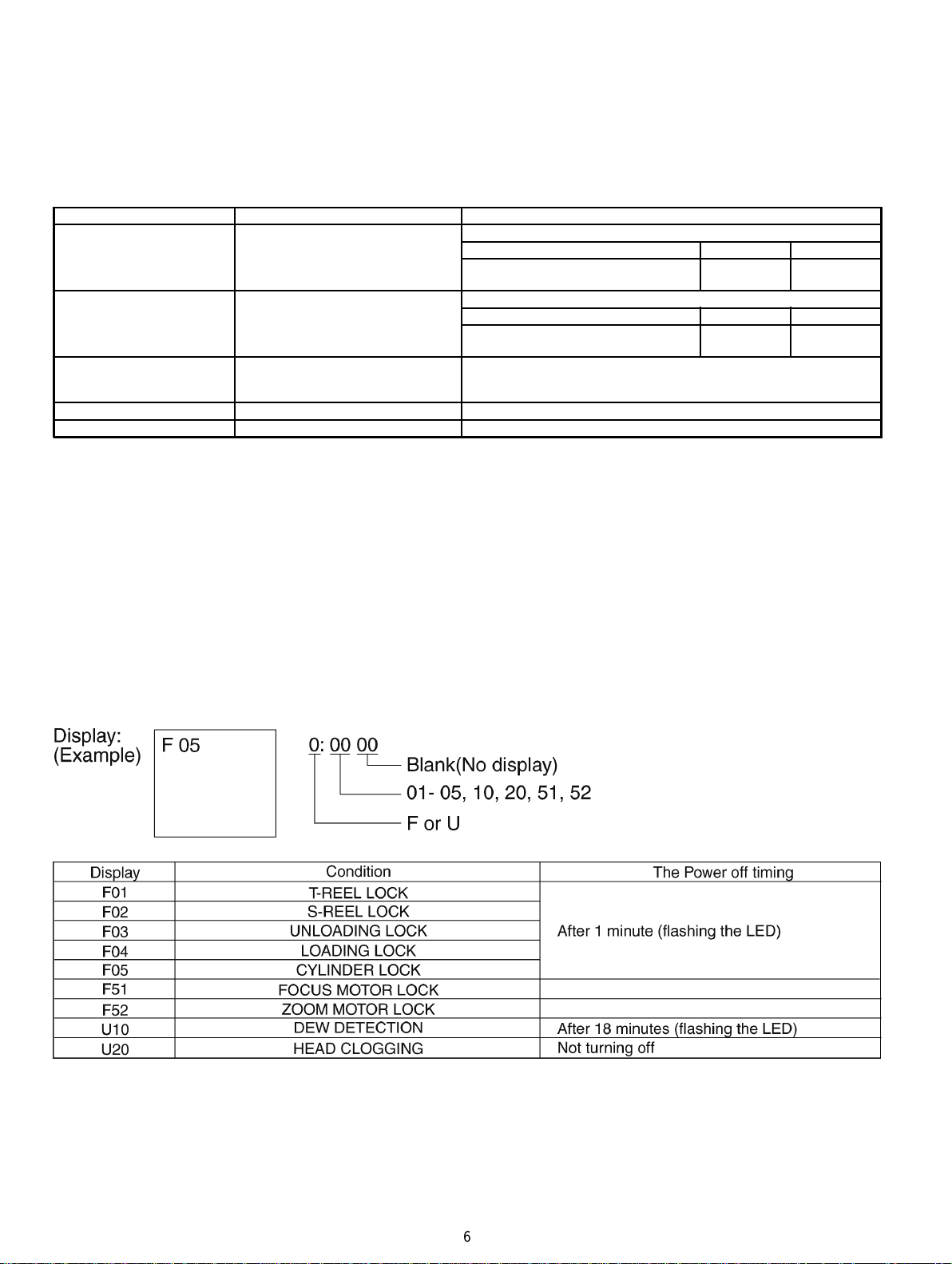

2.3. SET-UP FOR ADJUSTMENT OF TATSUJIN.

For adjustment of“ TATSUJIN“, please open the small cover which is located at bottm of side case(L) using small screwdriver as

follows.

And then connect the JIG board and TATSUJIN cable as follows.

5

Page 6

3 SERVICE INFORMATION

3.1. SERVICE INFORMATION DISPLAY (GENERAL DESCRIPTION)

· This Movie Camera has SERVICE INFORMATION DISPLAY function which enables quick trouble-shooting.

· The Service Information Display is available with the following prcedures.

· The Service Information is displayed on the EVF and LCD monitor. (There are 4 kinds of SERVICE MODES as follow.)

In the OSD Line Output Mode, the service Information can be displayed even on TV.

MODE NAME FUNCTION How to use.

OSD Line Output Mode Checking the EVF information on the

SERVICE MODE 1 Remaining Battery A/D value.

SERVICE MODE 2 Remaining Voltage A/D value.

SERVICE MODE 3

SERVICE MODE 4

TV monitor

Safety Device

Capstan/Cylinder injuctions.

Mechanism position

Serial key code

ERROR CODE Display After chosing SERVICE MODE 2, push [DATE/TITLE] key.

PG SHIFTER ADJUSTMENT After chosing SERVICE MODE 3, push [DATE/TITLE] key.

NOTE1:

The content of all service modes (service Mode 1 to 4) are the same as previous models.

Please refer to the following Technical Information.

Order number for Technical Information :VMD9512M138

NOTE2:

When an undesirable condition occurs, the power will be turned off except zoom& focus motor lock condition. (Since this

model,“ERROR CODE” is not automatically displayed on the EVF and LCD monitor, even the CAMERA LEDis not flashed.)

By turning on Service Mode 3, it is possible to check what kind of undesirale condition has occurred, even after the ERROR

CODE has disappeared. Because of The ERROR CODE is memorized to EEPROM-IC.

Push the following keys simultaneously more than 2 sec.

FOCUS/SET STOP DATE/TITLE

(SIDE CASE(R)) (TOP PANEL) (SIDE CASE

(L) TOP)

Push the following keys simultaneously more than 2 sec.

COLOR STOP DATE/TITLE

(SIDE CASE(R)) (TOP PANEL) (SIDE CASE

(L) TOP)

After chosing SERVICE MODE 1, push [DATE/TITLE] key.

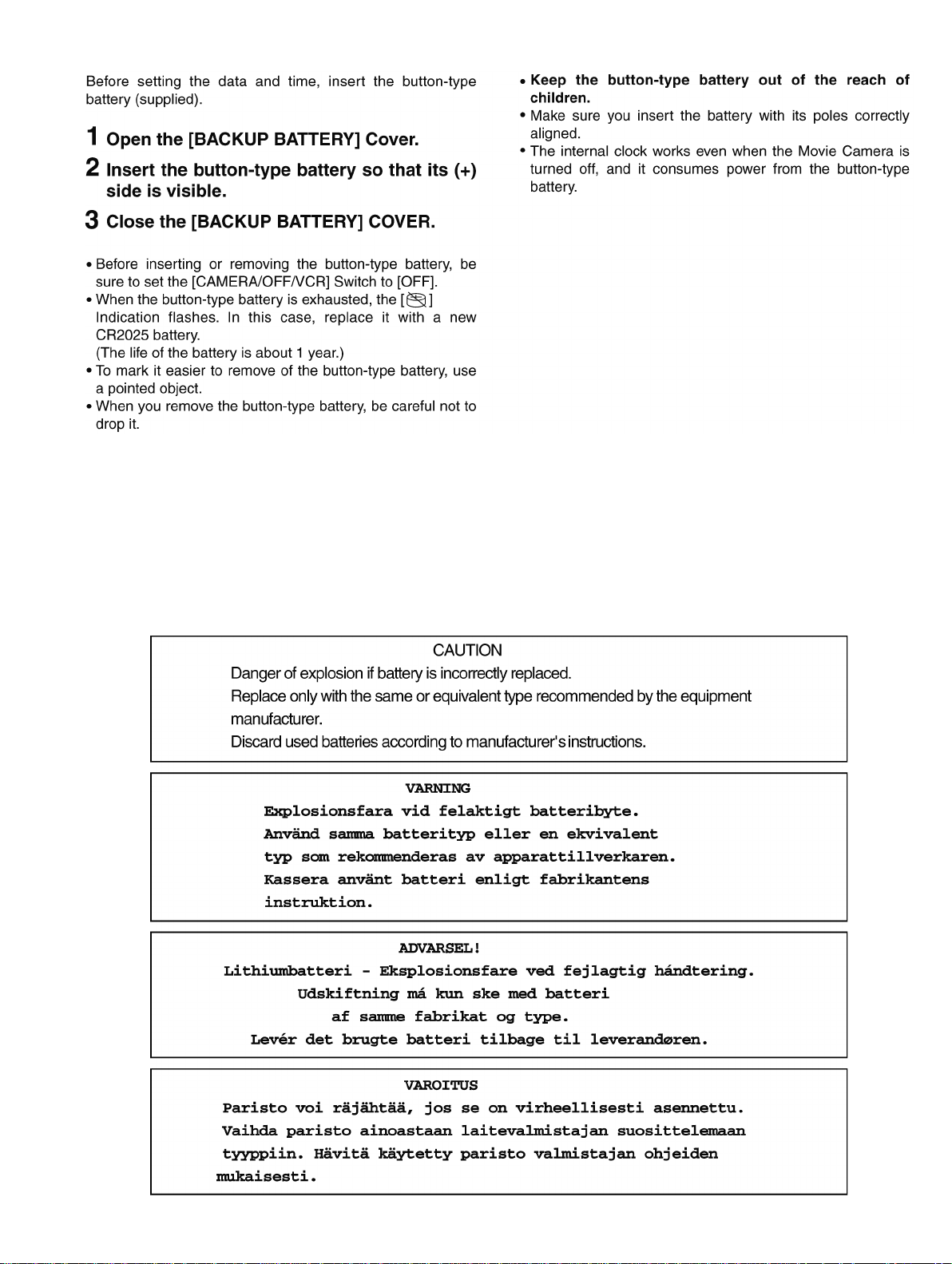

3.2. SERVICE MODE 3 (ERROR CODE DISPLAY)

· ERROR CODE appears on counter display position as follows. (SeeFig.1).

Fig.1

6

Page 7

3.3. INSERTING THE BUTTON-TYPE BATTERY

Note:

The lithium battery is a critical component (Type No.: CR2025 Manufactured by Panasonic.)

It must never be subjected to excessive heat or discharge.

It must therefore only be fitted in equipment designed specifically for its use.

Replacement batteries must be of the same type and manufacture.

They must be fitted in the same manner and location as the original battery, with the correct polarity contacts observed.

Do not attempt to re-charge the old battery or re-use it for any other purpose.

It should be disposed of in waste products destined for burial rather than incineration.

7

Page 8

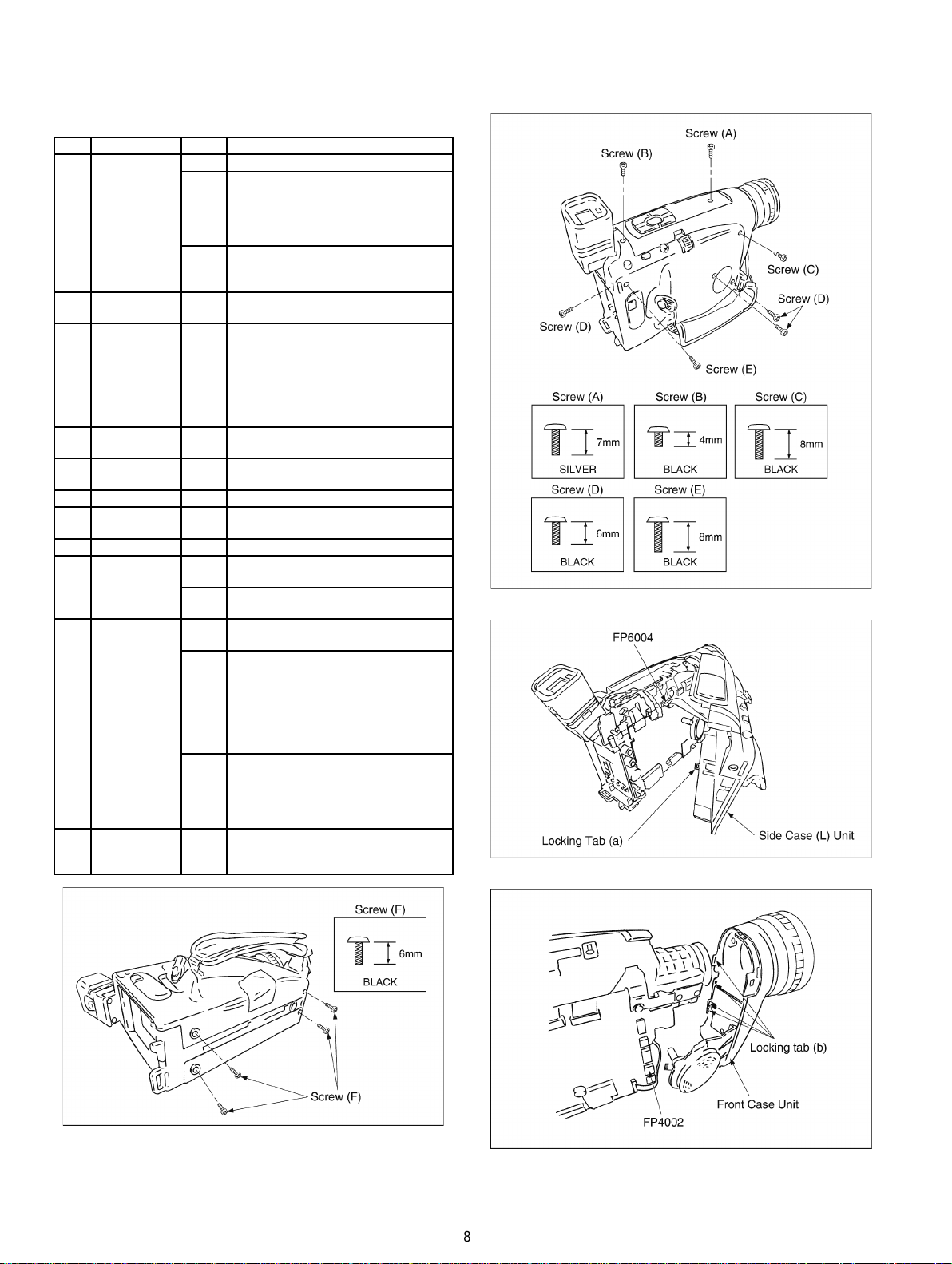

4 ADJUSTMENT PROCEDURES

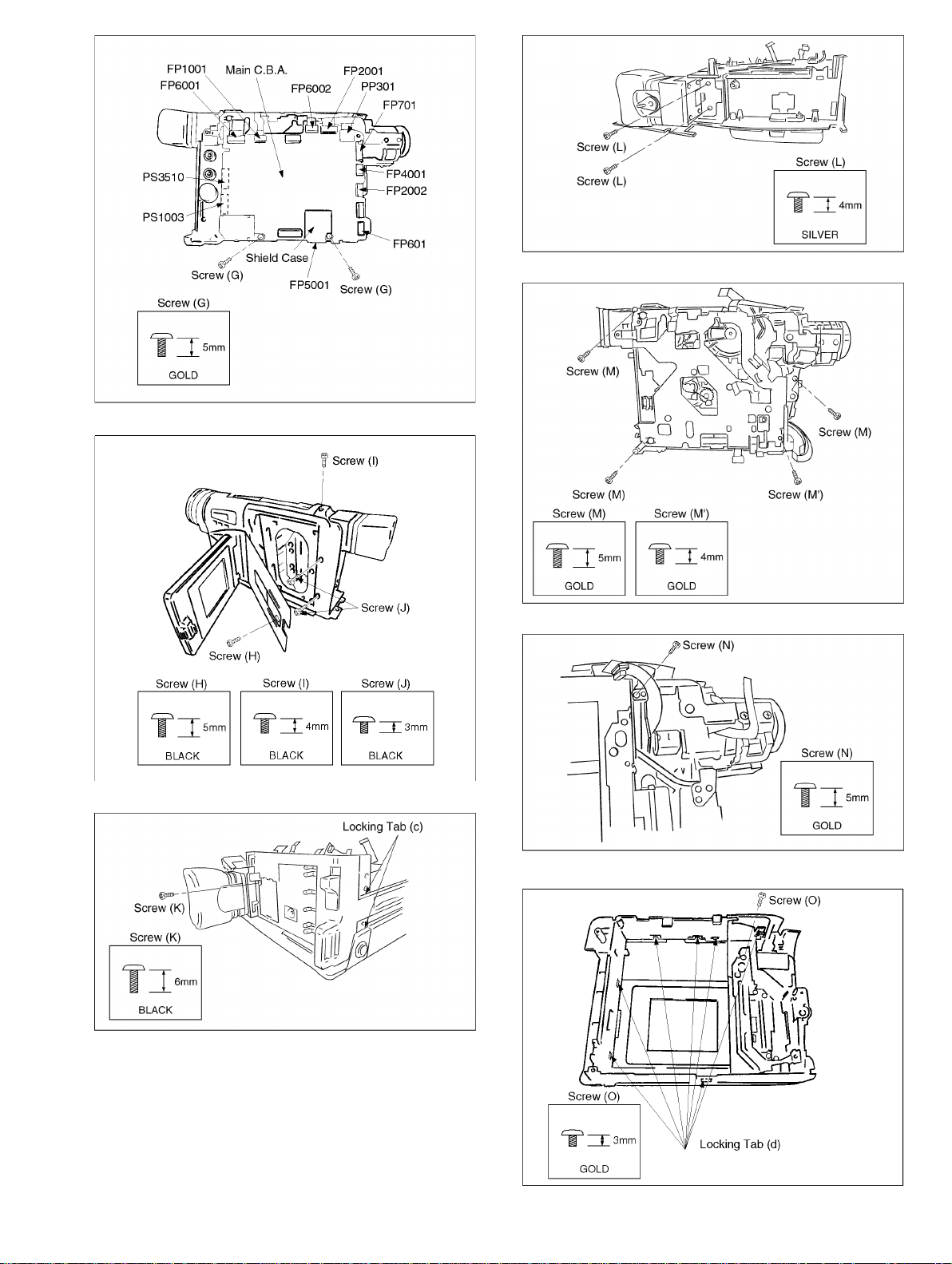

4.1. DISASSEMBLY PROCEDURES

Flow-Chart for Disassembly Procedure

No. Item/Part Fig. Removal (Screw)

1 Side Case (L)

Unit

2 Front Case

Unit

3 Main C.B.A. Fig.5 2-Screw (G)

4 Cassette

Cover Unit

5 Rear Case

Unit

6 EVF Unit Fig.8 2-Screws (L)

7 Mechanism

Unit

8 Lens Unit Fig.10 1-Screw (N)

9 Main Frame

Unit

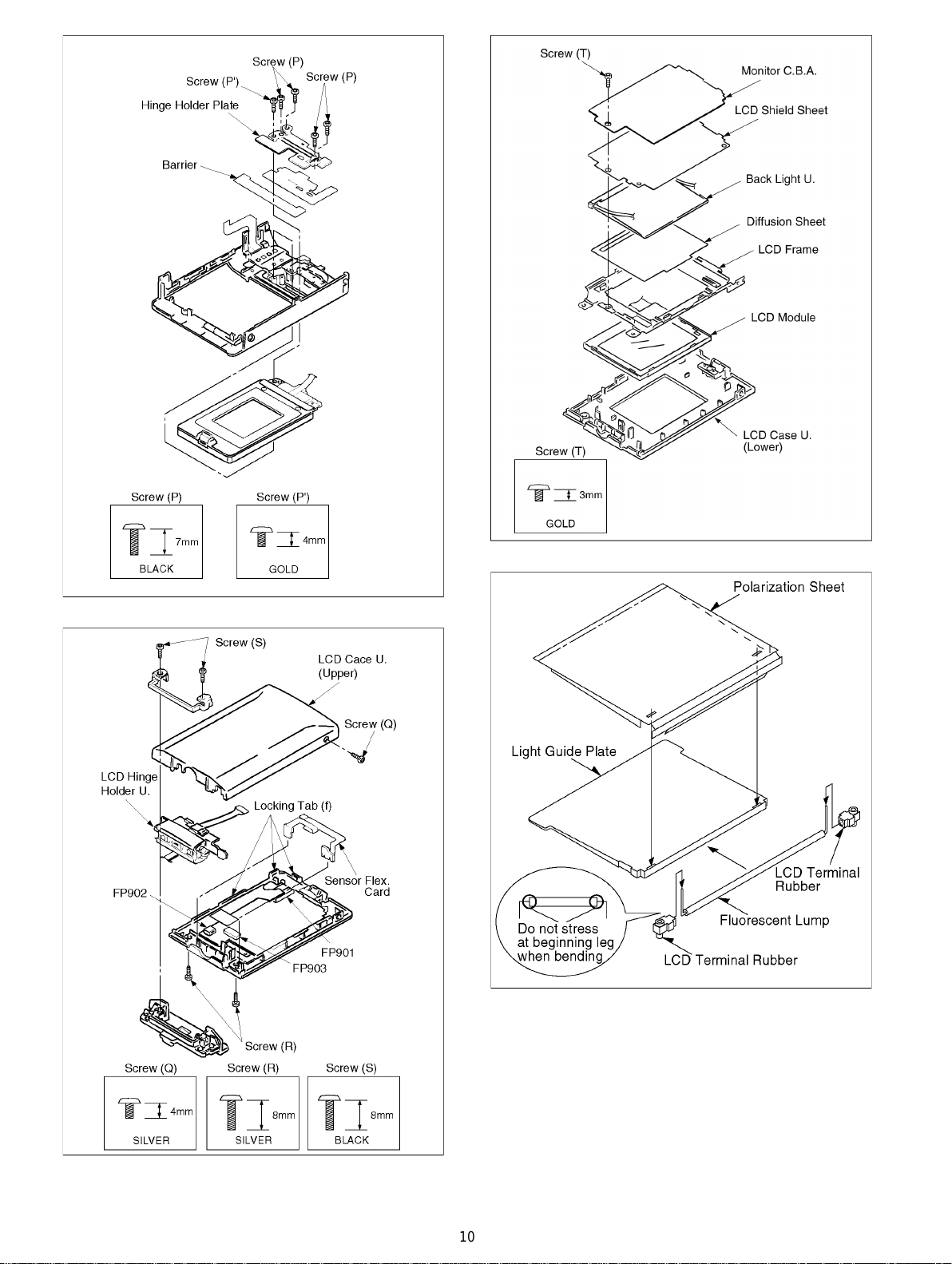

10 LCD Unit Fig.12 Remove the Barrier.

11 Back light Unit Fig.15 Remove the Polarization Sheet.

Fig.1 4-Screws (F)

Fig.2 1-Screw (A)

1-Screw (B)

1-Screw (C)

3-Screws (D)

1-Screw (E)

Fig.3 Locking Tab (a)

Slightly open the Side Case (L) Unit.

Disconnect FP6004.

Fig.4 4-Locking Tabs (b)

Disconnect FP4002.

Remove the Shield Case.

Disconnect the following connectors.

FP6002, FP2001, PP301, FP701,

FP4001, FP2002, FP601, FP5001,

FP6001, FP1001, FP4002, PS3510,

PS1003

Fig.6 1-Screw (H)

Fig.7 1-Screw (K)

2-Locking Tabs (c)

Fig.9 3-Screws (M)

1-Screw (M’)

Fig.6 1-Screw (I)

2-Screws (J)

Fig.11 1-Screw (O)

7-Locking Tabs (d)

1-Screw (P’), 4-Screws (P)

Fig.13 1-Screw (Q)

2-Screws (R)

3-Locking Tabs (f)

Remove the LCD Case (Upper) U.

Disconnect FP901, FP902 and FP903.

2-Screws (S)

Remove the LCD Hinge Holder U.

Fig.14 1-Screw (T)

Remove the Monitor C.B.A., Back Light

U., LCD Shield Sheet, Diffusion Sheet,

LCD Frame, LCD Module, LCD Case

(Lower) U.

Remove the LCD Terminal Rubber and

Fluorescent Lump.

Fig.2

Fig.3

Fig.1

Fig.4

8

Page 9

Fig.5

Fig.8

Fig.9

Fig.6

Fig.7

Fig.10

Fig.11

9

Page 10

Fig.12

Fig.14

Fig.15

Fig.13

10

Page 11

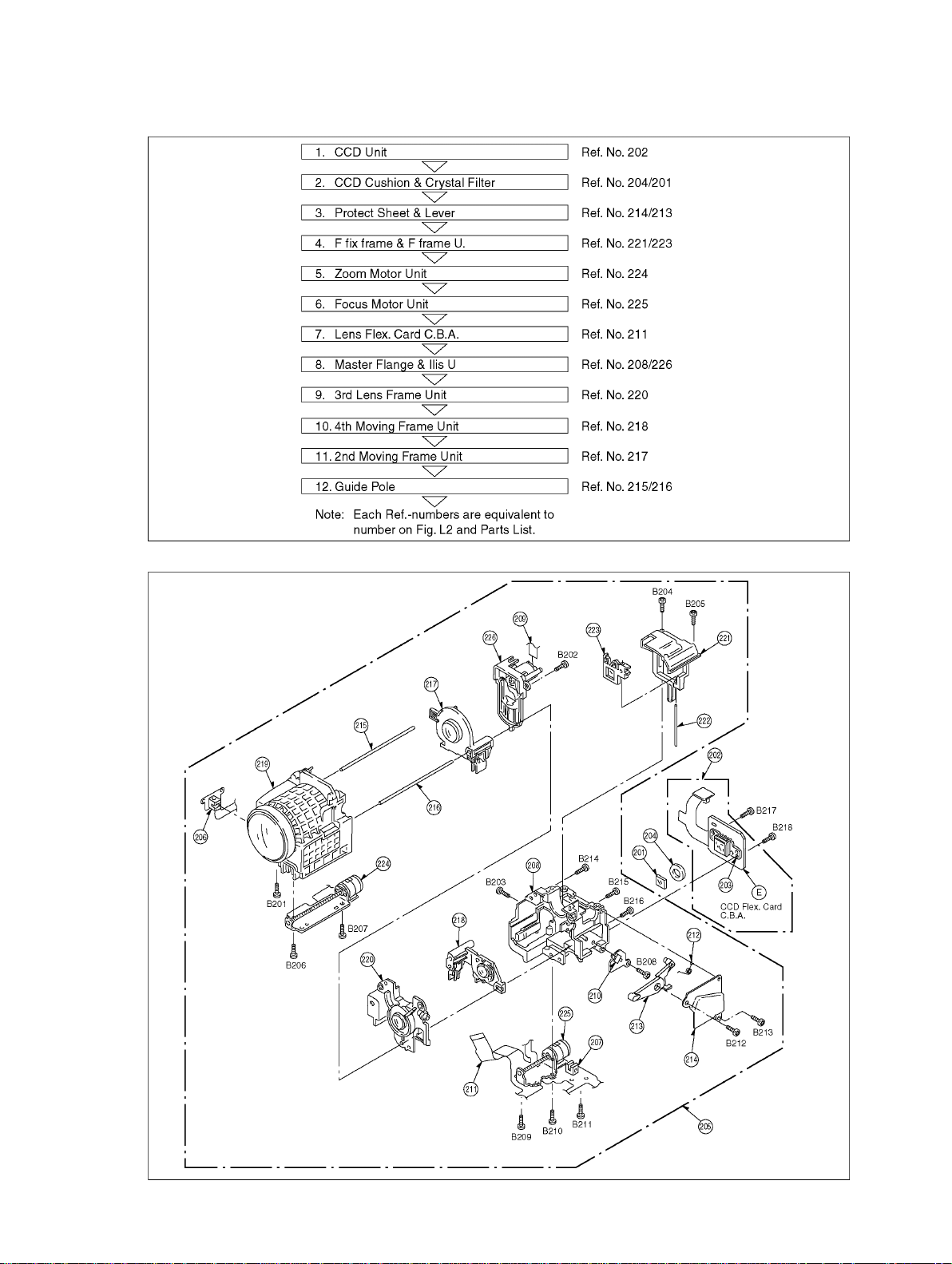

4.2. DISASSEMBLY PROCEDURES OF LENS UNIT

· The following flowchart describes order or steps for removing the lens units and certain printed circuit boards in order to make

access to the item needing service.

· To reassemble the unit follow the steps in reverse order.

Fig. L1

Fig. L2

11

Page 12

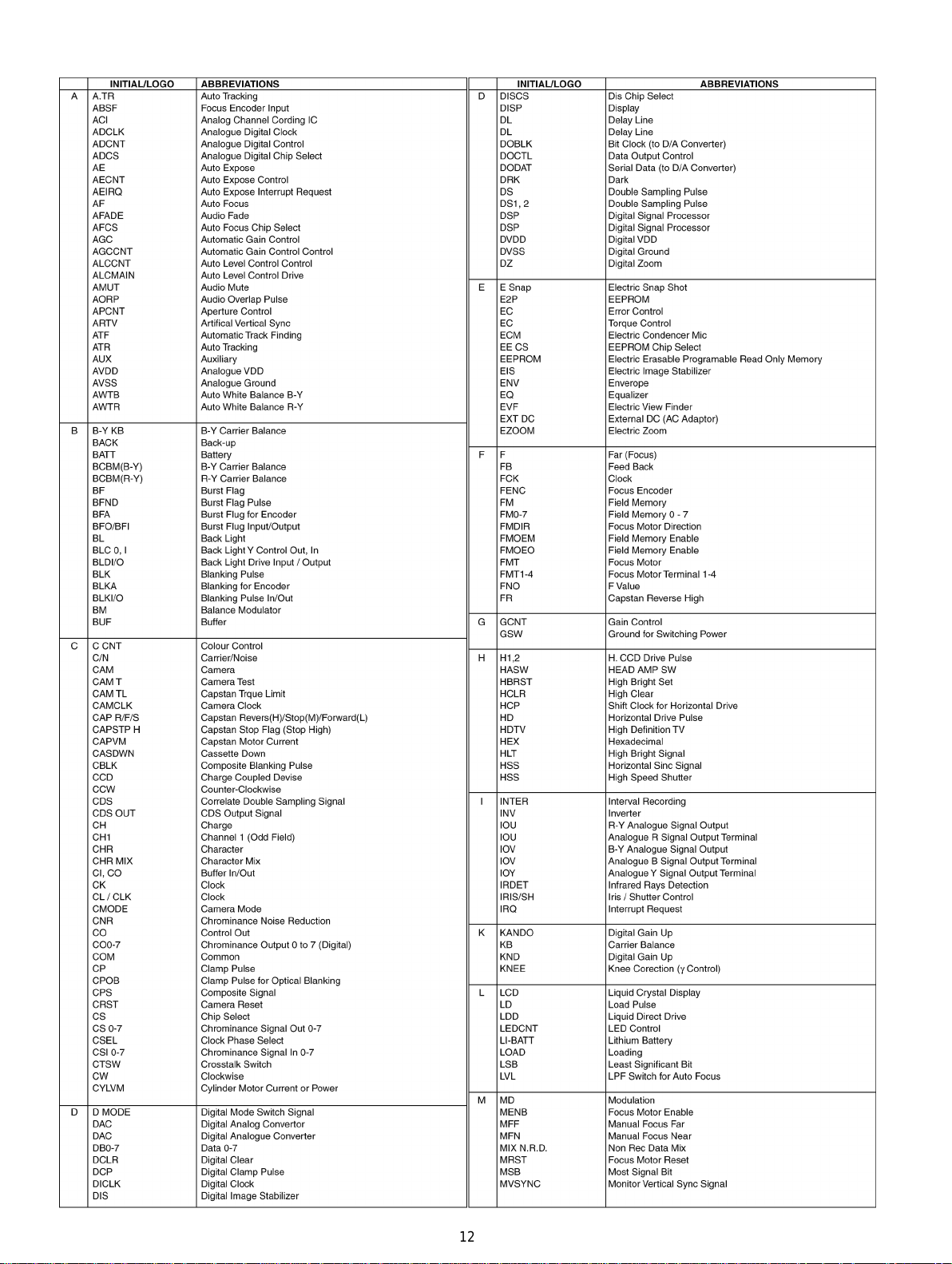

5 ABBREVIATIONS

12

Page 13

13

Page 14

6 WAVEFORM TABLE

IC701-12, 14 POWER ON

6.0 Vp-p (5msec./div.)

ZOOM MOTOR DRIVING

IC6003-66 STOP

2.6 Vp-p (50nsec./div.)

IC6003-159, IC2001-27 REC/PLAY

3.0 Vp-p (1msec./div.)

IC302-10 STOP

1.2 Vp-p (20µsec./div.)

GRAY SCALE

IC5001-47 PLAY

0.2 Vp-p (2msec./div.)

COLOR BAR

IC6003-144, IC2001-40 REC/PLAY

5.2 Vp-p (1µsec./div.)

IC6003-174 STOP

5.4 Vp-p (0.5µsec./div.)

IC302-26 STOP

0.6 Vp-p (20µsec./div.)

GRAY SCALE

IC5001-8

3.0 Vp-p (20msec./div.)

COLOR BAR

IC6003-145 REC/PLAY

5.4 Vp-p (1µsec./div.)

IC2001-59, 61, 63 REC/PLAY

2.8 Vp-p (1msec./div.)

IC1001-9 STOP

1.0 Vp-p (1µsec./div.)

IC6003-35 FF/REW

2.2 Vp-p (50msec./div.)

IC6003-155, IC2001-26 REC/PLAY

3.0 Vp-p (10msec./div.)

IC2001-52, 53, 54 REC/PLAY

2.8 Vp-p (20msec./div.)

IC1001-11 STOP

1.4 Vp-p (1µsec./div.)

IC6003-36 FF/REW

3.0 Vp-p (20msec./div.)

IC6003-157, IC2001-25 REC/PLAY

3.0 Vp-p (0.2msec./div.)

IC2001-21 REC/PLAY

0.6 Vp-p (0.5µsec./div.)

IC1001-15 STOP

1.3 Vp-p (1µsec./div.)

IC1001-27 STOP

0.6 Vp-p (1µsec./div.)

Q1062-4 STOP

0.2 Vp-p (1µsec./div.)

IC401-85 REC

1.0Vp-p (20µsec./div.)

COLOR BAR

Q1001-2 STOP

11.8 Vp-p (1µsec./div.)

IC801-5 STOP (B/W EVF)

1.0 Vp-p (20µsec./div.)

COLOR BAR

FP801-6 STOP

0.6Vp-p (20µsec./div.)

COLOR BAR

Q1003-4 STOP

12.0 Vp-p (1µsec./div.)

IC3301-25 REC/PLAY

3.5Vp-p (20µsec./div.)

COLOR BAR

Q1004-2 STOP

18.0 Vp-p (1µsec./div.)

IC3301-20 REC

1.8Vp-p (20µsec./div.)

COLOR BAR

Q1061-4 ST

OP

0.2 Vp-p (1µsec./div.)

IC401-80 REC

0.6Vp-p (20µsec./div.)

COLOR BAR

14

Page 15

7 BLOCK DIAGRAMS

7.1. OVERALL BLOCK DIAGRAM

CAP

LOAD

MOTOR

7.2. BLOCK DIAGRAM OF CONNECTION

SENSOR

FLEX. C.B.A.

FP901

VJS3320B024

FP902

VJS3931B006

SPEAKER

AV JACK

D/D

CYLINDER

IC5001

(REC/PLAY HEAD AMP)

REC Y/C

PB Y/C

IC3301

(VIDEO)

E2SBI/O

(SERIAL DATA)

IC6008

(EEPROM)

X6001

(16MHz)

IC2001

(CAP/CYL/LOADING DRIVE)

CYL FG/PG

CYL CTL

CAP CTL

CAP FG

LOAD CTL

IC6003

(SYSTEM CTL,SERVO,DSP,SIS &AF

MICROPROCESSOR)

VTR OP.

CAMERA OP.

LCD

LENS U.

CAPSTAN

VJP3358A012

PP301

VJS3931B019

FP2001

FP701

VJS3319B021

A/C HEAD

FP4001

VJS3931B009

C.B.A.

MONITOR

FP2002

VJS3931B019

FP903

VJS3971B027

VJP3331B002

P6802

FP4002

VJS3931B016

MIC UNIT

FP6801

VJS3498A016

FP601

VJS3971B027

LCD

X301

(45.0625MHz)

PWM

IC401

(DSP/WB/AF/SIS/ZOOM/DNR/TBC/VIDEO/DA)

CDS IN

PB Y/C

IC302(AD)

(CDS/AGC)

CCD

(1/5")

H1/H2/R

V1-V4/SUB

IC315

(V DRIVE)

LENS

IRIS

(RESET,ENABLE,CLK,CW/CCW)

ZOOM MOTOR CTL

FOCUS MOTOR CTL

(RESET,ENABLE,CLK,CW/CCW)

IC701

(AF/ZOOM DRIVE)

CAM.OP.U.

VJS3930B013

FP6002

VTR.OP.U.

VJS3930B016

FP6004

VJS3931B010

FP1001

MECHA. FPC

VJS3931B021

FP6001

VJS4297B010

FP803

B/W E.V.F.

VJS4365B020

FP802

LCD

MAIN C.B.A.

PS3510

VJS4005B004

VIDEO

REAR CASE U.

AUDIO

PS1003

VJS4005B006

PP3001

EVR

DC JACK

VJS2959B013

FP5001

K1KA40A00110

CYLINDER

15

Page 16

7.3. SYSTEM CONTROL& SERVO/ POWER BLOCK DIAGRAM

TO

SYSTEM/CAMERA/

SUB SERVO

TO

SYSTEM/VIDEO/AUDIO/

MIC/CAMERA/

SP DRIVE/AVS OUT

TO

SP DRIVE

TO

VIDEO/AUDIO

TO

EVF

TO

BACK LIGHT

TO

LCD

TO

LCD

TO

VIDEO/CAMERA/

AUDIO

TO

SYSTEM

TO

CAMERA

TO

SUB SERVO

TO

SUB SERVO

NOREG

REG 4.8V

SPEAK 5V

ST 4.8V

EVF 5V

BL 5V

LCD 5V

LCD 3V

REG 3V

REG 3V

REG 3V

CAP VM

TRI WAVE

QR1002

QR1701

QR1803

QR1801

BL CTL

MONI CTL

L1008

L1015

L1006

QR1061

BUFFER

Q1008

L1014

L1014

L1004

QR1003

L1003

121

2

EVF CTL

Q1002

L1007

21

L1061

12

L1002

21

(SWITCHING 4.8V)

Q1001

ERROR VOLTAGE

INPUT TERMINAL

1

Q1003

(SWITCHING 3V)

4

21

ERROR VOLTAGE

INPUT TERMINAL

2

Q1061

(SWITCHING CAP VM)

4

21

ERROR VOLTAGE

INPUT TERMINAL

3

L1001

OUT1

11

IN1+

30

3

OUT2

9

IN2+

1

3

27

VCC

14

OUT3

15

IN3+

22

4P SOCKET

LI-ION BATT.

LI BATT.

REAR CASE UNIT

IC1001(SWITCHING REGURATOR)

CT

PWM

COMPARATOR

&BUFFER

ERROR

AMP

PWM

COMPARATOR

&BUFFER

ERROR

AMP

PWM

COMPARATOR

&BUFFER

ERROR

AMP

VOLTAGE

CTL

CH1

TRI-WAVE

OSC

VOLTAGE

CTL

CH2

VOLTAGE

CTL

CH3

IC6003

(SYSTEM CONTROL & SERVO MICROPROCESSOR)

NC

SW

-

+

D

T

-

+

-

+

REFERENCE

VOLTAGE

PS1003

4

PS1003

1

PS1003

2

PS1003

3

PS1003

6

IN1-

IN2-

V.REF

CTL2

IN3-

VCC

TO

IC6002-14

QR1001

SWITCHING

NOREG

25

31

2

26

23

21

QR6009

Q6007

QR6012

90

BATT D

97

BATT T

17

BAT

76

POWER ON

105

104

B REF AD

109

CP ON

H

BATT AD

211

VTRSBT

213

VTRSBO

214

VTRSBI

154

ADCS

118

TM1M

135

XON/H

H

RESET

60

15

VDDH

31

VDDB

VDDB

49

PVDD

55

VDDH

67

VDDH

85

AVDD

109

VDDH

140

VDDH

186

VDDH

212

23

CAS DOWN

75

SENSOR LED

101

SPHT AD

TAKE-UP REEL PULSE

H

SUPPLY REEL PULSE

16

14

TO IC404-3

TO IC404-1

IC6009

RESET

21

Q6003,QR6005

LED DRIVE

IC6002

(RTC/REG/RESET)

SCLK

6

7

SIO

5

CS

1

/INT

OSC IN

OSC OUT

VDD

FP6001

19

FP6001

7

FP6001

16

FP6001

17

FP6001

3

FP6001

2

FP6001

6

FP6001

5

2

3

LITHIUM

BATTERY

8

CASSETTE DOWN SW

SUPPLY

PHOTO TR.

X6002

T REEL

SENSOR

S REEL

SENSOR

SENSOR

LED

TO

CAMERA

TO

CAMERA

TO

LCD

TO

LCD

CAM 15V

CAM -8V

MONI 12V

MONI -15V

Q1808

Q1812

QR1802

Q1802

Q1808

Q1804

Q1809

T1001

2

7

53

1

CL1003

2

1

3

Q1004

(POWER CONTROL)

16

X6001

65

66

151

69

123

OSC1

OSC2

EVF CTL

BL CTL

MONI CTL

E2BST

E2SBO

E2SBI

E2PCS

E2R/B

TO

CAMERA

IC6008

(EEPROM)

194

195

196

188

185

2

CK

3

SI

4

SO

1

CS

7

R/B

A

B

Page 17

:CAPSTAN SERVO SPEED LOOP

:CAPSTAN SERVO PHASE LOOP

:CYLINDER SERVO SPEED LOOP

:CYLINDER SERVO PHASE LOOP

SYSTEM CTL

SECTION

SUB SERVO

SECTION

IC2001

(CAP/CYL/LOADING MOTOR DRIVE)

VTR OP.U.

SEARCH+

FF

CAMERA OP.U.

SET

SEARCHREW

MENU

FADE

STOP

PROG

AE

REC

BLC

PLAY

STORE

ZOOM

WT

DEW SENSOR

WB

PAUSE

S/S

DATA/TITLE

EJECT

POWER/VCR/CAM

MF/TRACKING

COLOUR

FP6004

1

FP6004

2

FP6004

3

FP6004

4

FP6004

5

FP6004

6

FP6004

7

FP6004

8

FP6004

9

FP6004

10

FP6004

12

FP6004

14

FP6004

16

FP6002

13

FP6002

12

FP6002

11

FP6002

10

FP6002

9

FP6002

8

FP6002

7

FP6002

6

FP6002

5

FP6002

4

FP6002

3

FP6002

2

FP6002

1

96

ZM-AD

102

DEW-AD

113

SUBREC

92

KEY1

8

S/S

70

DATA/TITLE

119

EJECT SW

115

VTR PER

120

POWER SW

95

VR1

VR2

100

182

CAMLED

184

VCRLED

183

EFFECT LED

181

SISLED

5

AUTOLED

91

KEY0

PB

H

EE

H

AUDIO MUTE

L

AUDIO FADE

L

DELAY REC

H

R ERASE ON

H

SAFETY TAB

CYLINDER

DRIVE CLOCK

L

CYLINDER ON

CYLINDER FG

CYLINDER PG

CYLINDER TORQUE

H

LINE

FACT MODE

REMOTE CTL

TALLY

HASW

H

LP

FROM

POWER

78

77

74

142

88

86

22

174

175

159

155

145

66

20

152

72

133

125

TRI WAVE

FP6001

18

TO

VIDEO

QR6050

(S TAB :ON)

SAFETY SW

CL6207

CL6206

CL6012

FROM/TO

VIDEO

QR2001

TRIWAVE

21

CAP SW

18

H

DRIVE CLOCK

19

CYLINDER ON

14

FG

27

PG

26

CYLINDER EC

6

22

VCC

L

+

-

AMP

ACTIVE COIL

SWITCHING

LOGIC

FG AMP

COMPARATOR

PG AMP

COMPARATOR

DIRECTION

LOGIC

DIRECTION

DETECTOR

SLOPE

ADDITION

DIRECTION

SWITCHING

CYL VM

DRIVE

TRANSISTOR

CONTROL

CAP VM

DRIVE

TRANSISTOR

CONTROL

DD CYLINDER MOTOR

N

FROM

5

POWER

FP2002

MAIN COIL 1

4

FP2002

MAIN COIL 2

59

61

63

28

29

31

30

FROM

43

POWER

54

55

5

FP2002

3

FP2002

6

FP2002

1

FP2001

12,13

FP2001

7,8

FP2001

1,2

MAIN COIL 3

MAIN COIL 1

MAIN COIL 2

MAIN COIL 3

N

S

N

S

FG

PG

S

M3

M1

M2

M3

M1

M2

N

S

DD CAPSTAN MOTOR

N

S

M1

N

S

S

N

M2

S

M1

N

M3

S

M2

M1

N

M3

S

N

S

M2

M3

M2

N

M1

S

M3

N

52

FP2001

19

LHM

TORQUE LIMIT

CAP SW

CAPSTAN FG

11

144

12

CL6014

Q6002

BUFFER

QR6014

84

157

CL6208

TO

POWER

CAPSTAN R /S /F

CAPSTAN TORQUE

C

1

2

3

MODE SW

FROM/TO

VIDEO

A

B

FP6001

11

FP6001

10

FP6001

9

FP6001

8

149

71

13

10

134

143

138

103

POS-COM

POS-1

POS-2

POS-3

H.SW

ENVGAIN

VORP

ENV AD

CAPSTAN R/S/F

36

CAPSTAN TORQUE

40

TORQUE LIMIT

41

FG

25

MATRIX

LIMITER

FG AMP

COMP.

+

+

40

35

34

44

45

49

46

50

51

FP2001

18

FP2001

6

FP2001

11

FP2001

9

FP2001

5

FP2001

3

FP2001

16

FP2001

14

FP2001

10

FP2001

4

FP2001

15

HALL

IC1

FG

HALL

HALL

IC3

IC2

17

Page 18

7.4. VIDEO BLOCK DIAGRAM

QR3310

Q5003

FE

FROM

2

1

FP5001

FP5001

35

FE

ROTARY ERASE

DRIVE

5

IC5001

(REC/PLAY HEAD AMP)

2

EE/

VV/

TRICK

SP/LP

AGC

TRAP

C3305,C3306

L3303

53 48 46 44 56

IC3301

(VIDEO SIGNAL PROCESSOR)

VTR SYNC

REC Y CTL

SYSTEM CTL

H

RE ON

26

33

CT.SW

CTL

3

VV

DET

ENV

DET

HPF

EE

YNR

29

IC3302

Q5001

(HEAD SW)

2

Y

G.CTL

2

41

C

Y

RF

AGC

LIM

FM

DEM

SUB

LPF

VV

HPF

HSS

16

11

FILTER

4

1

5

3

6

24

19

20

CT.SW

MIX

EE

VV

LIM

EE

LIM

DOC

CCD

LPF

GCA

27

9

FROM

IC6001

H

H

EE

LP

QR3309

QR3308

QR3311

:VIDEO MAIN SIGNAL PATH IN PLAYBACK MODE

:VIDEO MAIN SIGNAL PATH IN REC MODE

ST 4.8V

REC C CTL

C

G.CTL

4

NIL

5

FP5001

23

36

FM

MODFODET

MAIN

EMPH

EE

NLDE

MAIN

VV

NC

DET

HEAD R1

W/D

LPF

VV

4

FP5001

H.SW

AGC

47

CLIP

EE

AGC

Y+C

20

CAMERA Y IN

HEAD R2

10

FP50019FP5001

21

HEAD

BPF

Y

CLP

ATT

P.B:Y

REC:Y+C

Y/C

C

MUTE

AMP

25

VIDEO OUT

7.5. MONITOR BLOCK DIAGRAM

IC6001

HEAD L1

6

FP5001

H.A.SW

AMP

VV

VV

EE

VV EE

EE

MIX

C

1

30

ART

FP5001

16

629KHz

LPF

BURST

UP

4.43

BPF

COMB

AMP

PAL

NTSC

3

7

11

FP5001

H.SW

49

PHASE

ROTATION

MAIN

BM

BURST

DOWN

MESECAM

12

HEAD L2

FP5001

1/4

CCD

PAL

14

IC3302

12

14

ID

EE

BPF

10

FILTER

ACC

F.DET

1/40

SUB

1/4

VCO

X2

DET

ACC

16

5

Q5002

(HEAD SW)

11

CT.SW

BM

KILLER

VV

4

1

2

6

3

13

18

17

CT.SW

CT.SW2

CT.SW1

CT.SW3

CT.SW4

HA.SW

H.SW

LOGIC

8

7

+

SIDE

LOCK

FH

AFCAFC

VV EE

VXO

82 77 79

EE

VV

EE

VV

SP

LP

4.43MHz

FROM

H SW

H

D REC

VIDEO HEAD CTL

:VIDEO MAIN SIGNAL PATH

MONITOR LCD PANEL

SOURCE DRIVE CIRCUIT

STH2

(SOURCE STRAT PULSE2)

OEH

(SOURCE ENABLE)

STH1

(SOURCE STRAT PULSE1)

23

12

FP901

FP901

FP901

A

E

F

VIDEO-R

24

FP901

GHI

15

VIDEO-G

FP901

ABCD

DEV

20 21 22 29 30 31 32

H COUNTER

PH-SET

M.N KILLER

H SYNC(E)

LATCH

495150

HSS VCO

48

IC901(LCD DRIVE)

LOAD

NON REC DATA

COM

TERMINAL

LCD

CELL

GATE

VIDEO-B

CPH1

(SAMPLING1)

CPH2

(SAMPLING2)

CPH3

20

21

17

16

FP901

FP901

FP901

C

D

J

54

POS

H DEC

PHASE

SHIFT

RGB SW

(8 bit 16ch D/A for EVR)

DEC

CL DL

SHIFT-RES

SCLK

SOURCE

GATE

LINE

TFT

DRIVE

CIRCUIT

(SAMPLING3)

STV2

(GATE STRAT PULSE2)

STV1

(GATE STRAT PULSE1)

OEV

(GATE ENABLE)

U/D

CPV

(GATE SCAN CLOCK)

5

6

3

7

19

FP901

FP901

B

K

43373534282726

FP901

MNO

L

FP901

FP901

L

MNO

POS

V DEC

COUST

DOSY

OSD

S/H

CONTRAST

CLAMP

MATRIX

+

CCA

DL

CLAMP

TRAP

59

63

AMP

Q602

LCD

VIDEO

LINE

(SCAN SW)

R/L

(SCAN SW)

4

FP901

FP901

J

P

BLACK DEC

BRIGHT

GEA

PAL SW

B.P.F.

Q2H

13

FP901

K

EFG

+

+

GAMMA

EXT/INT

PAL CU

ACC

SW

22

-

-

18

+

-

+

-

LTN

L.P.F.

DL

HILL DET

ACC DET

-

+

FLAT

APC DET

2

H

-

DEV AMP

DEMOD

X901

4.43MHz

17

+

1- 4 GENE

VXO

3

P

I

MAGNET

MAGNET

CHIP

CHIP

SIDE CASELCD PANEL

16

QR902

Q901

HALL

IC

5

FP902

FP903

FP601

ON/OFF:OPEN/CLOSE

H

Q901

(OPEN :ON)

QR905

18

17

FP903

11

12

FP601

IC6003-21

IC6003-206

HALL

IC

LCD PANEL SIDE CASE

2

FP902

L

(FACEF :OFF)

ON/OFF:

FACTING FORWARD/NORMAL

FROM

POWER

FROM

CAMERA

TO

CAMERA

FROM

CAMERA

TO

LCD/

MONITOR

FROM

IC6001

FROM

CAMERA

FROM

SYSTEM

FROM

CTL

FROM

CAMERA

FROM

SYSTEM

CTL.

VIDEO

TO

SYSTEM

CTL.

18

Page 19

7.6. CAMERA BLOCK DIAGRAM

CCD UNIT

PS291

3

PS291

8

PS291

9

PS291

10

PS291

11

PS291

12

1012 1113

9

V3

V4 V2 V1

8

CCD IMAGE SENSOR

2

H1 H2

76

-8V

+15V

1

3

Q291

BUFFER

4

PS291

PS291

PS291

PS291

PS291

2

1

5

4

6

LENS UNIT

ZOOM

ENCODER

HALL

SENSOR

IRIS

IRIS

MOTOR

ZOOM LENS

ZOOM

MM

MOTOR

FOCUS LENS

FOCUS

MOTOR

FOCUS

ENCODER

PP301

3

PP301

8

PP301

9

PP301

10

PP301

11

PP301

12

PP301

2

PP301

1

PP301

5

PP301

4

PP301

6

H2

H1

R

FROM

POWER

SECTION

FROM

POWER

SECTION

FP701

FP701

FP701

FP701

FP701

FP701

FP701

18

FP701

21

FP701

20

FP701

13

FP701

11

FP701

10

FP701

FP701

12

FP701

16

FP701

15

FP701

14

FP701

17

8

2

3

5

6

4

9

18

17

26

ALC MAIN

HALL OUT(+)

HALL OUT(-)

HALL IN(+)

HALL IN(-)

FOCUS ENCODER

LED CTL

ZOOM ENCODER

FMT1

FMT2

FMT3

FMT4

ZMT1

ZMT2

ZMT3

ZMT4

IC315

(CCD DRIVE)

1

3

5

IC302(CDS/AGC/AD)

CDS AGC

V REF

GEN.

DS2 DS1

VBOT VTOP

30 31 19 18

DS2

DS1

Q704

AMP

FROM EVR

SUB

10

V4

12

CH2

13

V3

14

V2

9

CH1

8

V1

7

KNEE BUFF

D/A

SDATA

123

IC706

2

3

7

IC711

3

2

7

QR701

LED

DRIVE

IC701(MOTOR DRIVE)

24

A1

30

B2

26

A2

28

B1

16

C1

D2

10

C2

14

D1

12

PWMB

CSNSCK

44 40 39

+

+

+

-

+

-

TO AUDIO

TO VIDEO

TO SP-DRIVE

SPK VOL

TVOL CLV

WVOL CRE

Y CTL

TVOL

HALL

GAIN

1

6

5

1

5

6

RESET

OSCIN

SCLK

SDATA

LATCH

VD

EXTZ

EXTF

HALL

38

36

35

34

33

32

31

22

10

43

42

41

37

38

BIAS

IC401(DSP)

AIN

40

VRT

38

VRB

42

DS1

139

DS2

140

H2

143

H1

142

R

141

SUB

9

V4

6

CH2

8

V3

5

V2

4

CH1

7

V1

3

X401

18

OSC

19

VREFC

76

IC6008(EEPROM)

A/D

CONVERTER

(CG)

CLOCK

GEN.(2)

4FCK

OSC

CG1

CS

CK

SI

SO

R/B

PWM

129

1

2

3

4

7

FCK

8bit AD OUT

VD

DCP

FH2

HD

HCLR

2FCK

FCK

FCKU

2FCK

2FCKU

ADCLK

E2SBT E2SBO

10 11

AF Y

DSP MICON INTERFACE

RE

60

59 72

91

51

53 39

RE WE

LED

ZENC

CNT

WE

DSP Y

DSP C

BEND

114

BEND

0LUX

CNT

AF

DRRST

5

DB-DIS

Y/C

D.S.P

POWER

DOWN V1V2 CGCS

148

187

PDN

CSN

188

E2PCS

194

E2SBT

195

E2SBO

196

E2SBI

185

E2R/B

FENC

189 190 172 131

DIS

AF

DATA

-

50 58

41

AD0-AD8

ZOOM

DATA

-

AF

DRSBTF-CLK

48

70

12

117

29

V1V2 CGCS

AF

DRSBI

202201169

SSG

AF

DRCS

R/W

R/W

47

18

ZOOM.Y

ZOOM.C

SYNC,BA

CBLK,ID

FP

IC404

(OSD)

AF

DRVD

31

VTRSBT

:VIDEO MAIN SIGNAL PATH

ENC.Y

ENC

FGP

FTG

FROM

CHARA.IN

CG

2/3

VD

FCK

66 68

8

14 19 20 13

EXD

RD VD HD

CLKCSDATA NRD1

123

211 204 213

OSDCS

VTRSBO

DMPPOF

OKH

DSPRST

DMCS

AF

AF

DREXF

DREXZ

127128

IC6003

ENC.C

DMY

HD

SIDEI

6264 65

67

RDBLK

NRD

BLK NRD

17 15 18

NRD

NRD BLK

NRD1

28

27

87

192

SYSTEM CONTROL & SERVO

MICOROPROCESSOR

DAC

DAC

FCKO

125

DM CHR

85

80

63

TO EVF

TO LCD

AMP MIX

IC413

(DIGITAL MEMORY)

5

FCK

9

DMY

46

SDTI

45

SCLK

VD

12

HD

11

PREP

48 44

DMCHR

CS

C RST

OKH

8

47

4

SYSTEM CONTROL SECTION

Q405 Q404

TO

VIDEO

19

Page 20

20

Page 21

8 SCHEMATIC DIAGRAMS

8.1. LENS DRIVE SCHEMATIC DIAGRAM

TO

POWER

NOREG

1

AF GND

2

CL702

TO

VIDEO

IRIS OPEN

G

F

6

TO

CAMERA2

1

2

6

TO

SYSTEM

92

85

86

87

88

89

90

91

84

REG 4.8V

REG 3V

CAM GND

AF DR EX Z

AF DR RST

AF DR 4M

AF DR SBT

AF DR SB0

AF DR CS

AF DR VD

AF DR EX F

O LUX SW

C713

0.1

R717 56

R706

100K

L703

G1C100K00023

C705

0.1

R703

100K

C712

0.1

C711

F2H1C470A001

6.9

3.9

4.6

Q704

2SC2712GR

(AMP)

R745 10K

R716 1K

C719

1000P

4.7 2.1 2.1

VCC

+

-

1234

R709 10K

R718 22K

R743

D1BB75010002

5678

+

2.02.02.0

GND

IC706

NJM2115V

C702 0.22

R722

1500

R701

4.7

-

3.0

38 37 36 35 34 33 32 31 30 29 28 27 26 25 24 23 22 21 20

E

RESET OSCIN

1/N

D

OSC

SELECTOR

1 3456789

C

R712 10K

TO

LENS FLEX.

FP701

LED CONT

Z ENC

F ENC VCC

F ENC

B

A

ZM T4

ZM T1

ZM T2

ZM T3

O LUX SW

FM T4

FM T1

FM T2

FM T3

ALC MAIN(-)

ALC CTL(-)

HALL IN(+)

HALL OUT(-)

HALL IN(-)

HALL OUT(+)

ALC MAIN(+)

ALC CTL(+)

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1.5

3.0

3.0

3.0

0

OSCOUT

COSC FILA FILB FILC FILD VREF

2

0.3

C709

0.01

PULSE GENERATER

EVR1 EVR2

CURRENT SET

FILTER

FILTER

0.3

0.1

C704 0.1

C701 100P

SCLK

SDATA LATCHVDEXTZ

EVR1 EVR2

CURRENT SET

FILTER

FILTER

0.2

0.2

C706 0.1

C707 0.1

R714

1K

C708 0.1

0.1

0.7

0

0.8

7.0

B2

FBBB1VM2

H BRIDGE 2ch

+-

+

-+

X2

VDD VM3

0.3

2.9

H BRIDGE 2ch

D2

FBDD1VM4

10 11 12 13 14 15 16 17 18 19

0

7.0

0.1

R704

4.7

0

0.7

0

A2

H BRIDGE 1ch

7.0

0.1

R702

4.7

0.9

FBAA1VM1

+-

++

+

+-

H BRIDGE 1ch

C2

FBC

0

R705

4.7

7.0

2.9

EXTF EXP3 PGND

EXTOUT

SELECTOR

SERIAL-PARARELLE

DECODER

C1

-

0

IC701

UPD16878GS

(MOTOR DRIVE)

-

R726

C703

0.01

680

R735 12K

EXP0 EXP1 EXP2LGND

-

R708

47K

-

R711

47K

R728

10K

1.0

R734 12K

R729 33K

R784

2200

R782

1200

4.8

R736

680K

R781

1K

0.7

Q781

2SA1832FY

(LED DRIVE)

C721

6800P

0.8 0.3 0.3

VCC

+

-

1234

R730

8200

R732

27K

5678

+

GND

0.60.62.7

R727 27K

R737 680K R740 120K

R733

560K

R731

68K

R707

100

2.4

2.4

QR701

RN1102F

(LED DRIVE)

IC711

NJM2143R

0

0

R713

2200

R738

150K

0.7

0

0.7

0

R723 D1BB2200A010

R761

D1BB2201A010

R715

10K

Q780

B1ABMD000004

(LED DRIVE)

321

0

0

R780

15

Q782

2SA1036

(SWITCHING NOREG)

6.9

0

6.9

R785

2200

2.7

QR782

RN1103F

(INV.)

TO

VIDEO

FNO

TO

CAMERA2

PWM(A)

V REF

V REF

TO

CAMERA1

HALL BIAS

HALL GAIN

TO

SYSTEM

Z ENC

LED CNT

ABSF

O LUX CNT

R783

15

0

TO

AUDIO

IR NOREG

IR LED OUT

5

4

3

L

5

H

29

30

94

96

95

93

7

8

NOTE:DO NOT USE ANY PART NUMBER SHOWN ON THIS SCHEMATIC DIAGRAM FOR

ORDERING.WHEN YOU ORDER A PART,PLEASE REFER TO PARTS LIST.

1234

NOTE:THE MEASUREMENT MODE OF THE DC VOLTAGE ON THIS DIAGRAM IS STOP MODE.

56789

21

10 11

Page 22

8.2. CAMERA 1 SCHEMATIC DIAGRAM

TO

CAMERA2

SUB

1

2

CH2

3

CH1

4

V4

5

V3

6

F

E

D

C

7

8

9

10

11

12

13

14

15

16

TO

AUDIO

17

TO

LCD

18

TO

POWER

19

20

V2

V1

AD Y IN

REG 3V

DS2

DS1

FCK

CPOB

E2 SBO

E2 SBT

PWM(B)

T VOL

BGA VCO

B LEVEL

Y GAIN

L305 G1C100KA0019

VSS

DAO0

1.3

37

DAO1

1.8

38

DAO2

0.7

39

DAO3

0.8

40

DAO4

2.9

41

DAO5

0

42

DAO6

0.8

43

DAO7

2.5

44

DAO8

45

DAO9

2.5

46

DAO10

1.5

47

DAO11

1.6

48

PGA

PGA

PGA

EVRDAC 0-11

KNEE DAC

SERIAL

REGISTER

SDATA

123456789

3.0

2.9

VDD

+

SCK

2.9

R201 0

2.9

CLP

CSN

3.0

0.1

OBP

RSTN

2.9

1.4

MCK

TEST0

-

0.3

SHR

CDS

OBP DAC

TEST1

-

0.3

SHD

TEST2

-

2.9

VDD

VDD

2.9

BUFFKNEE

VSS

CLAMP

VSS

C319

0.015

1.1

1.9

VOS

CAMIN

+

BUFF

AOUT

VOB

10 11 12

0.9

0.7

C325

0.1

1.8

252627282930313233343536

REFIN

VREF/

IREF

GEN.

COUT

-

C328 0.1

C322 0.1

PGA

VCLP

NC

IBIAS

VSS

VDD

VBOT

VTOP

VCOM

NC

PBYIN

NC

PBCIN

C314

1

R316 0

IC302

C5ZBZ0000005

(CDS/AGC/AD)

1.8

24

23

1.2

22

21

2.9

20

0.6

19

2.0

18

1.1

17

16

-

15

14

-

13

C320

F3F0J1060005

C321

F3F0J1060005

C317

0.1

R309

4700

C318

0.1

R301

6200

0.7

R302

10K

3.3 0.9 1.5

0.9 1.5

R312

1500

C312

0.01

R308

100K

2.8

10

ISUB

NC

-

IC315

MN31121SA

(CCD DRIVE)

1.5

Q304

2SA1832FY

(MUTE)

R313 560 R315 330

C326

22P

456

Q303

B1HFCFE00001

(AMP)

321

D301

MA2J11100L

R310

R311

100K

100K

0.1

2.8

0.1

2.8

-0.3

V2

CH1

V1

LEVEL

CONVERTER

LEVEL

CONVERTER

LEVEL

CONVERTER

LEVEL

CONVERTER

LEVEL

CONVERTER

CH2

V4 V3

1211 13 14 15 16 17 18 19 20

2.6

2.8

2.6

VCC

LEVEL

CONVERTER

LEVEL

CONVERTER

GND

V1Ø

3 STATE

VH

15.1

VM13

DRIVER

3 STATE

V3Ø V4Ø

-7.4

-0.3

V2Ø

DRIVER

-7.5

VM24

:VIDEO MAIN SIGNAL PATH

TO

POWER

CAM 15V

CAM -8V

Q301

15.0

2SC4627

(AMP)

1.7

1.9

C305

12P

R303

2200

C311

0.1

-7.9

-7.9

213456789

VL

OSUB

VHH

15.1

C310

0.1

R304 270

R305 0

R306 0

R307 100

C306 0.01

C307

F2H1A101A001

R219

3.3M

TO

CCD

PP301

1

OUT

2

15V

3

SUB

Ø

H1

4

Ø

H2

5

Ø

R

6

7

PW

8

Ø

V4

9

Ø

V3

10

Ø

V2

11

Ø

V1

12

PT

TO

LENS DRIVE

HALL BIAS

HALL GAIN

TO

CAMERA2

CLV

TO

VIDEO

C CTL

TO

SYSTEM

CSN

27

28

TO

PS291

29

30

31

17

78

TO

B

TO

CAMERA2

V REF

21

22

23

24

25

26

A

H

V REF

L

CG 3.3V

H1

H2

R PULSE

1234

NOTE:DO NOT USE ANY PART NUMBER SHOWN ON THIS SCHEMATIC DIAGRAM FOR

ORDERING.WHEN YOU ORDER A PART,PLEASE REFER TO PARTS LIST.

NOTE:THE MEASUREMENT MODE OF THE DC VOLTAGE ON THIS DIAGRAM IS STOP MODE.

56789

AUDIO

SPK VOL

TO

VIDEO

Y CTL

32

16

10

22

Page 23

8.3. CAMERA 2 SCHEMATIC DIAGRAM

TO

LENS DRIVE

1

REG 4.8V

2

REG 3V

3

V REF

L

4

PWM(A)

5

V REF

H

6

CAM GND

TO

G

POWER

7

REG 3V

8

REG 4.8V

9

CAM GND

F

C429

4700P

IC403

S817A33ANB

(REG 3.3V)

1

2

A

B

C

D

E

F

G

H

I

J

4

3.34.8

3

3.0

GND

VDD

TO

E

SYSTEM

AD0

55

AD1

56

AD2

57

AD3

58

AD4

59

AD5

60

AD6

61

AD7

62

AD8

63

ALE

64

R W

72

52

WE

53

RE

BEND

1

V1V2

D

C

B

2

65

3

68

67

74

73

77

66

75

51

54

69

4

5

49

71

76

70

50

6

TO

LCD

10

11

TO

POWER

12

CG CS

ENC RST

REF25

OK

H

E2 SBT

E2 SBO

DM CS

DM PROF

P DOWN

DSP RST

OSD V SPL

SYS VD

ART V

H

SCR

CAM TEST

V CLK

OSD CS

V DATA

OSD RST

UCOM 3V

LCD NRD

LCD NRD BK

OSD IN

R446 1K

R448

2200

R449

2200

R450

4700

R451

3900

C427

0.01

BEND

V1V2

U1

U2

AD0

AD1

AD2

AD3

AD4

AD5

AD6

AD7

AD8

ALE

R W

WE

RE

25

26

27

28

29

GND

30

3.0

VDD

31

32

33

34

35

36

FI

GND

VDD

OKH

37 38 39 40 41 42 43 44 45 46 47 48

3.0

R438

100

SCLK

0

2.9 3.0 3.0 3.0

A

123456789

SDTI

131415161718192021222324

2.9

VD

12

2.7

HD

11

10

2.9

DMY

9

0

DMCHR

8

3.0

VDD

7

GND

6

1.4

FCK

5

3.0

C RST

4

3.0

RST

3

2

1

CS

PREP

IC413

MN7E002B2S1

(DIGITAL MEMORY)

C485

F2H0J470A003

C483

0.01

R413

1K

2.9

0

R437

10K

D401

MA111

U5

C435

0.01

10

GND

TEST

LD

11 12 13 14 15 16 17 18 19 20

-

0

QR402

RN2107F

(SCR :ON)

H

0

0

R406

3300

1.4

-

XD

EXD

RDBLKRDNRD BLK

0

0

2.9

QR401

RN2103F

(SCR:ON)

2.8

C417

1500P

R444

10K

R445

10K

2.7

CMDCT

0

2.9

3.0

2.7

2.9

2.6

123456789

TCL

VDD

NRD1

-

0

CS

DATA

OSD

0

54

2.9 2.8

CLK

IC404

C1AB00001328

(OSD)

VD

HD

2.9

2.7

2.92.9

QR404

B1GFCFNN0011

(VD BUFFER)

321

R436

1500

U4

10 11

K

L

M

N

O

P

Q

R

S

T

U

V

23

Page 24

:VIDEO MAIN SIGNAL PATH

A

B

C

D

E

F

G

H

LB404

R414

J0JCC0000060

0

I

J

K

L

M

N

O

P

Q

2.8

QR405

RN1104F

(SWITCHING)

R

S

T

U

V

12 13 14 15 16 17 18 19 20 21 22

0

CL414

C424

0.01

R434 100

R403 1K

R404 1K

R440

10K

L401

G1C220K00013

C423

0.01

CL401

CL402

R W

ALE

AD8

AD7

AD6

AD5

AD4

AD3

AD2

AD1

AD0

RE

WE

V1V2

BEND

C414

1000P

C422

0.01

R420

2200

C402

F3F0J1060005

C463

0.01

2.9

2.0

2.9

0.9

0.6

2.9

2.9

0.2

0.2

0.1

0.1

0.2

0.3

0.2

0.2

3.0

3.0

2.9

2.8

2.7

1.4

2.8

-

0

-

0

-

0

0

0

0

0

0

LB402

J0JCC0000060

2.9

VDD

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

GND

VDDAD

VRT

VCCAD

AIN

VSSAD

VRB

GNDAD

GND

VDD

HD

R/W

ALE

REF25

DB8

DB7

DB6

DB5

DB4

DB3

DB2

DB1

DB0

RD

WR

AFMCK

DMY

DMCHR

OSDVD

OSDHD

FCK23

SIDEI

CHRAI

HSW

V1V2

VD

BEND

GND

VDD

73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99

2.9

0

CL413

0

2FCK

SCAN1

0.7

C408 0.01

CL412

0

TA7

VREFC

2.0

C405 1

C431

0.01

CL411

000

TA6

BIASC

2.9

C425

L407

12P

G1C2R2J00006

C420

ENCRST

IREFY

0.7

RANTST

AOUTY

TEST4

VSSDAY

1000P

TEST3

VCCDAY

2.9

1.8

C4041C433

CL410

CL409

CL408

CL406

CL405

CL404

000

TA3

TA4

TA5

VCCDAC

VSSDAC

AOUTC

-

0.3

R408

47K

R409

C438

0.01

12K

U3 U6 U1 U2 U5 U6U3

3.0

TA0

TA1

TA2

IREFC

VDDDA

GNDDA

-

2.9

NOTE:DO NOT USE ANY PART NUMBER SHOWN ON THIS SCHEMATIC DIAGRAM FOR

ORDERING.WHEN YOU ORDER A PART,PLEASE REFER TO PARTS LIST.

TEST2

BIASY

2.9

VDD

VREFY

1.6

0.01

X402 H0J450500002

R415

R421

680

1M

1.3

1.3

XI

XO

GND

SCAN2

PBH

CMPSH

0

3.0

CL403

R423

1K

TEST1

POR

-

510/590

OSDMODE

3.0

C432

15P

2.9

VDDCG

GNDCG

PBSYNCIIEWE

-

0.2

C415

0.01

3.0

-

CSCG

R459

3300

2.9

-

2.0

101112131415161718192021222324252627282930313233343536

SDTCG

RSTW

-

R424 120K

V3

V3

FMYI5

V2

0.1

V2

FMYI6

-

R425

D1BB91020002

V1

0.1

V1

FMYI7

-

R477

D1BB47020003

C418

1

V4

CH1

CH2

SUB

2.9

2.9

2.9

2.8

2.8

V4

CH1

CH2

SUB

SCLKCG

FMYI0

FMYI1

FMYI2

FMYI3

100 101 102 103 104 105 106 107 108

-

R476 10K

R402 1K

R405

1K

FMYI4

-

-

-

-

NOTE:THE MEASUREMENT MODE OF THE DC VOLTAGE ON THIS DIAGRAM IS STOP MODE.

-

CPOB

VDD

2.9

IC401

F712524CPBW

0.6

(DSP)

123456789

PBLK

GNDCG

144

H2

143

H1

142

R

141

DS2

140

DS1

139

VDDS

138

GNDCG

137

GND

136

VDD

135

TB7

134

TB6

133

TB5

132

TB4

131

TB3/BLK

130

PWM

129

OE

128

RE

127

RSTR

126

FCKO

125

FMYO0

124

FMYO1

123

FMYO2

122

FMYO3

121

FMYO4

120

FMYO5

119

FMYO6

118

FMYO7

117

FMCO0

116

FMCO1

115

FMCO2

114

FMCO3

113

FMCI3

112

FMCI2

111

FMCI1

110

FMCI0

109

GND

SUB

CH2

CH1

V4

V3

V2

V1

H2

H1

R PULSE

DS2

DS1

1.5

H2

1.8

H1

0.7

R PULSE

0.2

DS2

0.2

DS1

3.3

2.9

1.4

1.4

1.4

1.4

1.4

2.9

-

-

-

1.4

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

R458 470

R470 1K

R480 2200

R481 4700

R482 10K

CL407

R479

820

C430 1

R417

2700

R412

4700

L403

ELJFA390JB

R416

D1BB10020004

R428

D1BB39010002

R427

D1BB62000001

C413

0.01

R433

150

C403

33P

C439

0.01

1.3

Q404

2SA1774HR

(MIX)

R418

1500

C436

22P

1.9

R419

D1BB9100A010

0.7

L408

G1C220JA0010

C437

47P

IC405

TC7SH04FU

R422

820

2.9

123

1.4 1.4

0.7 1.3

1.3 0.7

C440

22P

R430

4700

0

R431

0

45

C434

F3F0J1060005

456

Q405

B1HDCFA00001

(AMP)

321

U4

TO

CAMERA1

REG 3V

V REF

PWM(B)

V REF

AD Y IN

E2 SBT

E2 SBO

SUB

CH2

CH1

V4

V3

V2

V1

H2

H1

R PULSE

DS2

DS1

CG 3.3V

CPOB

CLV

FCK

TO

VIDEO

V REF

V REF

4.43MHz

SYS VD

VTR SYNC

TO

VIDEO

VTR 4.8V

CAM Y/C IN

L DATA

9

22

L

16

21

H

8

15

14

1

2

3

4

5

6

7

25

24

26

10

11

23

13

31

12

L

9

H

8

13

7

14

10

11

12

24

Page 25

8.4. VIDEO SCHEMATIC DIAGRAM

R3338

TO

SYSTEM

24

RE ON

1

2

3

4

5

6

H

ENV DET

GAIN CTL

ART V

V HEAD CTL

D REC

H

H SW

LP

H

EE

H

S TAB

RESET

L

CAM TEST

HA SW

FACT MODE

EVR SBO

EVR SBI

EVR CAM CL

PB

H

R

B

G

POL

FNO

IRIS OPEN

42

28

20

27

G

25

23

26

110

21

111

44

29

43

113

112

114

22

TO

LCD

F

TO

LENS DRIVE

A10

A11

A12

A13

A14

A15

A16

A17

A18

A20

A21

A1

A2

A3

A4

B1

B2

A5

A6

A7

A8

A9

A25

QR3309

RN1104F

(INV.)

0

(3.3)

E

TO CAMERA2

SYS VD

7

V REF

8

H

V REF

9

L

VTR 4.8V

10

CAM Y/C IN

11

12

L DATA

13

4.43MHz

14

VTR SYNC

TO

AVS OUT

VTR 4.8V

15

D

TO

CAMERA1

16

Y CTL

17

C CTL

C

TO

SYSTEM

P DOWN

45

A22

A23

A24

A26

B4

B5

B6

B7

B8

R3005

3300

R3017

1800

3.1

(0)

QR3002

RN1103

(INV.)

B

TO

POWER

Y IN1

18

REG 4.8V

19

REG 3V

20

A

ANA GND

21

B9

0

QR3303

RN1104

(SWITCHING)

Q3001

2SB1219

SWITCHING

REG 4.8V

4.1

(4.8)

0

(4.8)

QR3308

RN2103F

(SWITCHING)

4.6

QR3311

RN2103F

(SWITCHING)

QR3310

RN1104F

(INV.)

0

4.8

4.7

(0)

4.6

4.7

(0)

4.7

R3325

47K

2.2

(4.6)

0.7

4.7

4.7

IC3301

AN3501NFBP

VIDEO SIGNAL

PROCESSOR

C3358 0.01

R3327 D1BB2400A010

C3336 0.01

C33371R3332

2200

R3328

22K

C3338

1

C3339 0.01

CL3302

CL3302

C3355 0.01

C3356

R3319

0.1

47K

C3335

0.01

NC

-

NC

-

65

NC

-

66

4.7

67

NAVCC

NC

-

68

NA MUTE IN

4.7

69

NC

-

70

2.3

1/2

71

VCC

NC

-

72

NC

-

73

FVCO

0.6

74

VCO

75

GND

ACC/CK

/OUT

-

76

RECAFC/

PBAPC

2.1

77

2FSC

OUT

-

78

SIDE

LOCK

DET

2.1

79

3.58XTAL

2.3

80

C GND

81

X TAL IN

2.6

82

NC

-

83

2.3

(2.9)

RECAPC

84

C3359

F2H0J470A003

C3307

0.01

R3308

D1BB3601A010

L3308

2.3

-

NC

PB IN

+

VV/

MUTE

AGC

DET

1/4

ROTARY

BURST

DOWN

VV

EE

FH

VCO

FH

PC

DET

OUTCVCC1

4.7

(4.2)

L3306

G1C470KA0019

82u

C3303 27P

-

NC

FH

TRAP

SP ON

EE

(AUDIO) (VIDEO)

SUB

1/40

BM

SIDE

LOCK

+

AFC

LP/

TRICK

SP

4.43

BPF

NTSC

*PAL

CK

OFF

C

VCXC2

4.7

-

NC

MBDCDET

2.8

R3301 1K

-

NC

GND(A)

EE

SLP

ON

ON

EE ON

LP/SLP

ON

MUTE

VCO

FODET

4.2

+

VV

T

L

-1

1/4

VV

EE

DET

BPF

X2

VXO

EE

VV

CIN

VV/TRICK

PB C

123456789

2.0

2.2

(4.6)

C3357 0.01

R3306

D1BB30000002

-.0.7

NC

ID

FDET

EE

VV

ACC

BM

EEVV

ACC DET

F ACCHF ACC

0

2.3

C3333 0.1

R3322

22K

B11 B12 B13

4.8

LP/M

VVVVEE

EE

BURST

UP

COMB

AMP

ACC

DET

L

0

C3331 0.1

1K

C3301

820P

R3305 1200

R3312

D1BB33010002

0.9

(0)

3.8

(4.7)

4.43MHz

M.DE.EM.

EMP.E

M.DE.EM.

EMP.C

SUB

LPF

DEM

D-LIM

DO

ENV

DOP

4PHASE

SELECT

DP

APC

DET

NOR

KILLER

629

LPF

SECAM

CCD

BPF

PAL

FROM COMB

CK DET

10 11 12 13 14 15 16 17 18 19 20 21

4.4

2.6

(0.1)

C3330 0.1

C3329 0.01

C3332 0.01

PB NTSC OFF

DET

NOR

TOCOMB

1.9

C3328 0.01

YEXTPBFM

SECDET1

3.0

(1.9)

CL6018

R3314 470

VV

EE

AGC

SECAM

C3361 0.01

ATT

VV

EE

3.0

(1.9)

L3302 12u

R3307 47K

PAL/M

TRAP1

TRAP2

CK OFF

VV

EE

NC

NLE

NLDE

MAIN

LPF

SECDET2

1.6

C3362 0.01R3323 150K

A5

1.7

1.2

SQPB

ROTARY

RFPEAKING/

CLAMP

3

LIM HPF

DET

CLAMP

4

HSS DET

SYNC DIT

0

(1.3)

C3327 0.01

B6

C3310 18PC3311 82P

4.8

LIM HPF

VV

EE

Y/C

MIX

T

L

HSS OUT

AGC DET

1.7

(2.2)

R3333 1K

R3335

1500

RF VCC

W/D

CLIP

CLAMP

1

CLAMP

2

2.0

R3309 1.2M

R3310

D1BB30000002

R3336

3300

2.5

2.5

PS/N

PS/IN

-+

RF

AGC

Y/C

MIX

2FSC

MOD

VV

EE

DOP

GCA

MUTE

LINE IN

2.0

(2.9)

C3326

F2H1C100A001

B14

L3303

G1C220JA0010

C3305

R3311

1500

C3312

0.01

C3360

3.1

(2.7)

434445464748495051525354555657585960616263

RF AGC OUT

DET

VV

EE

TEST1

NOR

+

-

YNR

PROCESS

CCD

LPF

0

(4.7)

L3305

G1C470KA0019

F3F0J1060005

RFGND

PB RF IN

TUNER/L

REC FM IN

FO DET

CLAMP3

ME/W/C

ME/VVEDIT

YNR DET

ARTV

TOCCD

V GND

FROMCCD

CLAMP4

V OUT

CLAMP2

CLAMP1

AGCDET

Y VCC

R3040

D1BB4301A010

C3323 0.01

R3041

D1BB33010002

MOD

OUT

CCD

ID

NC

2.5

PS/P

FO

DET

YNR

MIX

NOR

DO

VREG

TUNORIN

2.6

(2.8)

C3325

F2H0J470A003

B4 B5

68P

4264

2.6

(3.2)

41

1.0

40

0.7

39

4.8

38

1.4

(2.1)

37

2.2

36

2.5

(2.2)

35

0.7

(2.0)

34

0.7

(2.0)

33

2.4

(3.8)

32

2.2

31

0.4

30

1.9

29

28

1.9

27

2.3

26

2.5

(2.1)

25

2.5

24

2.5

23

3.1

22

Q3302

2SA1832FY

C3306

10P

R3334 100K

C3352

F2H1C100A001

C3315 0.1

R3320 2200 C3316 0.01

C3317

F2H1C100A001

C3318 0.1

C3319 0.01

C3320 0.1

C3321 0.01

C3322 F2H1C100A001

R3042

1800

1.6

1.0

C3340

F2H0J470A003

(AMP)

A4

D3303

MA111

R3317

47K

Q3303

2SC4738FY

(AMP)

R3346

2200

CL3003

R3001 560 C3001 68P

L3001

82u

C3304 22P

R3316

D1BB1001A010

0

B15

4.7

1.6

CL3303

R3318

D1BB2200A010

R3350

1200

R3351

1K

2.6

L3005

120u

C3007

470P

C3354 820P

C3353 220P

L3320

G1C330JA0010

Q3320

2SA1832FY

(AMP)

2.1

R3003 2200

C3002

22P

R3002

1K

R3004

680

B9

C3380

39P

A

B

C

D

E

F

G

H

I

J

K

L

123456789

25

10 11

M

Page 26

R5001

10

C5012

0.01

:VIDEO MAIN SIGNAL PATH IN PLAYBACK MODE:VIDEO MAIN SIGNAL PATH IN REC MODE

TO

B17

B14

B19

B15

A10

A16

A21

A20

A18

A23

A17

A22

A13

B11

A12

A11

A24

A15

POWER

EVF ADJ

ST 4.8V

TO

AVS OUT

V OUT

V IC OUT

TO

AUDIO

CTL OUT

A OUT

MIC IN

TO EVR

PP3001

1

TL5002

2

TL5002

3

GND

4

V ENV

5

MIC IN

6

ANA Y OUT

7

A OUT

8

FACT MODE

9

CTL OUT

10

B

11

12

IRIS OPEN

13

FNO

14

POL

15

16

V REF

17

G

18

VD

19

CAM CLK

20

CK DET

21

22

SBI

23

SBO

24

GND

25

V REF

26

POL

27

A7

A8

A9

A6

RESET

28

R

29

REG 5V

30

31

CAM TEST

32

HA SW

33

V OUT

34

S TAB

35

EVF ADJ

36

LINE

37

LINE IN

38

GND

39

TL5001

40

TL5001

TO

CYLINDER UINT

FP5001

RE(F)

1

RE(S)

2

GND

3

R1(F)

4

R1(S)

5

L1(F)

6

L1(S)

7

GND

8

R2(F)

9

R2(S)

10

L2(F)

11

L2(S)

12

GND

13

TO FRAME GND

22

23

24

25

26

27

28

H

L

L

H

21 22

A

B

C

D

E

F

G

H

I

J

K

L

A25 A14

R3313

0

L5001

G1C101K00021

NOTE: DO NOT USE ANY PART NUMBER SHOWN ON THIS SCHEMATIC DIAGRAM FOR

M

12 13

:AUDIO MAIN SIGNAL PATH IN REC MODE :AUDIO MAIN SIGNAL PATH IN PLAYBACK MODE

4.7

4.7

(0)

QR3301

RN2103F

SWITCHING

REG 4.8V

2.6

(3.3)

Q3301

2SA1832FY

(AMP)

C3313 0.01

B17

B18

R3326

1K

(4.7)

(3.9)

0

(2.4)

R3302

330

ORDERING. WHEN YOU ORDER A PART, PLEASE REFER TO PARTS LIST.

QR3302

RN1103F

(INV.)

3.0

(0)

L3309

G1C471J00002

L3304

G1C470KA0019

0

C3314

0.027

R3303 1K

C5018

F3F0J1060005

L5003

G1C470KA0019

L5002

G1C470KA0019

C5021

0.01

C5020

0.01

C5019

1

A1

IC5001

AN3355FHP

REC/PLAY

HEAD AMP

A2

A3

C5016

F3F0J1060005

C5014

F3F0J1060005

L3307

G1C470KA0019

C3349

1.8

0.01

C3350

4700P

R3331

820

3.1

R5008

4.7

C5022

R5007

0.1

560

R5005

D1BB1102A010

2.5

AT OUT

(1.7)

37

AT

DET

1.9

38

AT

1.2

CTL

(2.3)

39

VCC4

4.8

40

AT IN

0

41

2.9

VCC3

42

3.0

(0)

PB

H

43

-

N.C.

44

-

N.C.

45

1.9

AGC DET

(2.4)

46

1.9

AGC OUT

(2.4)

47

GND

48

R5004 3300

NOTE: THE MEASUREMENT MODE OF THE DC VOLTAGE IN THE BRAKETS( )ON THIS DIAGRAM IS

RECORD MODE.(SP MODE)

4.8

4.8

(4.2)

GND

AT

DET

GCA

HA

OUT

2.0

(3.3)

B19 B18

0

(4.8)

Q5003

2SA812

ROTARY

ERASE DRIVE

0.6

4.8

(4.2)

FEFO

FE OUT

FE

C

AMP

DET

Y CTL

Y IN

2.6

1.5

C5023

0.01

B7 B8 B2 B1

-

0

(3.0)

N.C.

FEH

HSW

Y

GCR

MIX

C

GCR

C CTL

C IN

2.6

2.2

C5015

0.01

-

N.C.

MA1

MA3

MA2

MA4

+

VCC1

2.9 0(2.8)

C5041

100P

-

N.C.

V-LOGIC

H

D.REC

14 15 16 17 18 19 20

A26

C3348

0.01

R3345

47K

R3344 47K

-

2.3

(0)

(0)

FSCIN

PLLFIL

YOUT

YOB

9

2.2

(0)

1.8

(0)

C3344 0.01

-

-

N.C.

N.C.

+

+-

REC

SW

HEAD

CTL

987654321

0.1

1.7

SW

YIN

10.0

(0)

C3343 0.01

0

(2.4)

PB

ON

-

+

+

-

VCC2

4.8

C5011 0.01

GND

VGG

(0)

4.7

C3342 0.1

0.4

(2.3)

CT

0.5

(2.3)

(0)

VCC

NC

2.3

-

B13 B12

C5009

0.01

1.4

(0)

252627282930313233343536

DMP13

CT SW1

-

SW4

DMP24

121110

1.4

(0)

GND

CIN

(0)

RA1+

RA3+

RA2+

RA4+

C5010

0.01

R5003

68

HA1/

RA1-

GND

HA3/

RA3-

SW3

SW2

HA2/

RA2-

GND

HA4/

RA4-

4.7

(0)

VCC

VOB

16.2

(0)

C3351 0.01

R5002

68

0

(2.4)

24

0.6

(2.2)

23

22

0.6

(2.2)

21

0.5

(2.4)

CT

20

0

(2.4)

19

0

(2.4)

18

0.5

(2.3)

CT

17

0

(2.2)

16

15

0.6

(2.3)

14

0.6

(2.5)

13

12345678

GND

COUT

16151413121110

3.1

(0)

C3341 0.01

C3347

0.01

IC3302

TL8850AF

(FILTER)

LB5001

VLP0319A241

LB5003

VLP0319A241

LB5002

VLP0319A241

LB5004

VLP0319A241

C5001

0.01

C5003

0.01

C5004

0.01

C3345

F2H0J470A003

C5002

0.01

Q5002

XN4501

(HEAD SW)

L5004

G1C470KA0019

0.5

0

(2.4)

123

Q5001

XN4501

(HEAD SW)

654

0

(2.4)

C5005

27P

C5007

27P

C5006

27P

C5008

27P

0

(2.5)

123

654

0

(2.5)

THE MEASUREMENT MODE OF THE DC VOLTAGE OUT OF THE BRACKETS

ON THIS DIAGRAM IS PLAYBACK MODE.

0

0.5

(2.4)

(2.3)

0.5

(2.3) 0(2.4)

0

(2.3)

(2.4)

0.5

(2.3) 0(2.4)

26

Page 27

8.5. SYSTEM CONTROL& SERVO SCHEMATIC DIAGRAM

G

F

E

D

C

B

A

TO

CAMERA2

BEND

1

2

V1V2

3

ENC RST

TO

CAMERA2

4

ART V

5

SCR

6

UCOM 3V

TO

LCD

7

UP DN

8

LOAD

9

LCD EVF

L/R

10

11

FACE F

12

LCD BL

TO

AUDIO

13

A MUTE

14

TALLY

15

REMOTE CTL

16

LP

17

REC CTL

18

A FADE

19

SYS GND

TO

VIDEO

20

ART V

21

S TAB

22

PB

23

H SW

24

RE ON

25

D REC

26

LP

27

V HEAD CTL

28

GAIN CTL

29

HA SW

TO

SUB SERVO

30

M1

31

M2

TO

AUDIO

32

D REC

A25 A26

R6021

R6004

R6023

R6006

QR6003

RN1711R

(CAM LED

DRIVE)

R6007

470K

Q6004

2SC4738FY

(INV.)

R6072

39K

QR6002

UN911EJ

(REG)

IC6002

S3514AEFSTB

(RTC)

470K

CL6024

IC6008

AK6480AM

(EEP ROM)

CL6017

CL6003

CL6002

CL6001

K20

470K

470K

470K

54

R6033

82

54

(VCR LED

DRIVE)

R/B

VDD

CS

CK

1234

8765

SID

VDD

/INT

1234

X6002

H0J27200051

C6034

9P

CIN

/SCK

COUT

CL6022

R6029

R6042

22K

R6043

68K

30K

CL6102

QR6005

RN2103F

(SNS LED DRIVE)

45

QR6050

RN1704R

S TAB

:ON

H

R6059

47K

R6046

1M

C6027

R6058

1

18K

(EFFECT LED

DRIVE)

4

IC6009

S80825ANNP

(RESET)

IC6011

XC62FP3002PR

(REG 3V)

GND

IN

123

OUT

C6011

1000P

R6061

1M

R6040

150

23

1

QR6013

RN2111F

(P ON :ON)

L

QR6007