GRUNDIG 1999 Technical Annual

TECHNICAL

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

General Part

ANNUAL

1999

Grundig Service

Hotline Germany...

Technical Support:

TV

TV

SAT

VCR/LiveCam

HiFi/Audio

Car Audio

Telecommunication

Planatron

Spare Parts Order Desk: ...Mo.-Fr. 8.00-19.00 hr

Kundendienst Ost, Wittestraße 30 E , 13509 Berlin

Manager: Telefon (0 30) 43 80-320, Telefax (0 30) 43 25-597

e-mail: Siegfried.Heuer@Grundig.de

Kundendienst Nord, Kolumbusstr. 14 , 22113 Hamburg

Manager: Telefon (0 40) 7 33 31-240, Telefax (0 40) 7 33 31-333

e-mail: Werner.Richter@Grundig.de

Kundendienst West, Horbeller Str. 19, 50858 Köln

Manager: Telefon (0 22 34) 95 81-280, Telefax (0 22 34) 95 81-278

e-mail: Juergen.Bubendey@Grundig.de

Kundendienst Süd-West, Dudenstr. 45 - 53, 68167 Mannheim

Manager: Telefon (06 21) 33 76-270, -271, Telefax (06 21) 33 76-250

e-mail: Klaus.Belli@Grundig.de

Kundendienst Süd, Beuthener Str. 65, 90471 Nürnberg

Manager: Telefon (09 11) 7 03-12 69, Telefax (09 11) 7 03-11 27

e-mail: Willi.Geldermann@Grundig.de

(8.00-22.00 hr)

...Mo.-Fr. 8.00-18.00 hr

Fax:

Phone:

Fax:

0180/52318-41

0180/52318-49

0180/52318-48

0180/52318-42

0180/52318-43

0180/52318-44

0180/52318-45

0180/52318-51

0180/52318-99

0180/52318-40

0180/52318-50

Subject to alteration!

This publication, or parts therof, may not be reprinted without permission of the publisher

Publisher: GRUNDIG Vertriebs-GmbH

We would be obliged for any tips and suggestions or criticism which we shall give our attention.

Please send to fax number: ++49 9 11 / 7 03 19 05

Zentralkundendienst; Technische Dokumentation

Technical

Annual 1999

Dear Readers,

In order not to go beyond the limits of a booklet this issues contains

as usual only the latest data and technical changes.

For informations frequently repeated in the past few years please

refer to the previous issues of the Grundig Technical Annual.

Contents:

General Part 1.1

TV Technology 2.1

Video Technology 3.1

Camcorder Technology 4.1

Satellite Reception 5.1

Audio Technology 6.1

Electronic Appliances 7.1

General PartTVVideoCamcorderSATAudio/HiFi

Subject to alteration

Electronic Appliances

Partners help each other

General Part

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

Please help us find hidden faults and return all modules with a brief

description of the fault.

For this purpose, a green fault tag or white adhesive label is enclosed

with all modules (insert cards) delivered by the GRUNDIG service

organisation.

Fehleranhänger für Module / Label tag for modules

Cartellino dei diffeti per i moduli / Fiche suiveuse pour module

Etiqueta de avería bara módulos

Fehler tritt sofort auf / Fault aoccurs immediately / Il difetto compare subito

Le défaut apparaît immédiatement / La avería aparece inmediatamente

Fehler tritt nur zeitweise auf / Fault aoccurs intermittently / Il difetto compare solo

a periodi / Le défaut est intermittent / La avería aparece intermitentemente

Fehler tritt nach ca.

Fault occurs after approx

Il difetto compare dopo ca.

Le défaut apparaî aprés environ

MODULES

FÜR IHR RÜCKABETEIL

FOR RETURNING FAULTY

Bitte unterstützen Sie uns beim Auffinden versteckter Fehler: Versehen

Sie alle Modul-Rückläufer mit vollständig ausgefüllten Fehleranhängern!

Please help us to trace obscure faults: Ensure all modules are returned

with label tag completed!

Collaborate con noi nella ricera deidifetti:

corredate ogni modulo che rimandate indietro dei cartellino

dei diffetti compilato in tutti i suoi punti!

Afin de nous permettre d'améliorer la Qualité de notre service,

nous vous prions de nous renv oyer avec votre module, cette

étiquette dûment renseignée. Merci pour votre collaboration.

Ayúdennos a encontrar las averías ocultas: procuren que cada

módulo devuelto vaya con su etiqueta de a vería para módulos

Thank you very much for your kind assistance.

debidamente relienda!

MODULE DEFECTUEUX

ALLEGARE AL PEZZO CHE

VIENE RIMANDATO INDIETRO

POUR RETOURRNER AVEC LE

La avería aparece tras

Wackelkontakt / intermittent contact / Contatto difettoso

Mauvais contact intermittent / contacto intermitente

Sonstige Fehlererscheinungen: / Other faults: / Altri difetti:

Autres défauts: / Otras averías:

MÓDULOS AVERIADOS

PARA DEVOLUCIÓN DE

...........

Minuten aut

...........

minutes

...........

minuti

...........

minutes de fonctionnement

...........

minutos

Sach-Nr.: 09624-645.03

Grundig Annual 1999 General Part

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

Contents: General Part

Addresses:

Grundig 1.2

Grundig Vertriebs-GmbH 1.2

Grundig Sales Companies (Europe) 1.4

Grundig Overseas Sales Division 1.6

GRUNDIG Division Instruments Test and Measuring Systems

Product Range and Customer Services 1.12

Test and Measuring Instruments 1.13

Service Training Courses for our Customers 1.16

Private Study 1.17

General Information on Safety, MOS, Chip and Laser Technology 1.18

ISDN-Info Tip 1.26

Grundig Universal Remote Controls 1.30

Pinning of Sockets and Plugs 1.35

General Part

Grundig Service 1.1

General Part Grundig Annual 1999

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

GRUNDIG

General Part

General Management

Kurgartenstraße 37, 90762 Fürth

Phone (09 11) 7 03-0, Telefax: (09 11) 70 53 76

Btx: *32700#, http://www.grundig.de

Grundig Vertriebs-GmbH

Sales Centre

Beuthener Str. 41, 90329 Nürnberg

Central Customer Service, Beuthener Str.55, 90471 Nürnberg

Manager: Thomas Kobusch

Phone: 0911/703-1900 Fax: -1903 e-mail: Thomas.Kobusch@Grundig.de

Central Warranty Remuneration/Workshops, Kolumbusstraße 14, 22113 Hamburg

Phone: 0180 / 500 02 95 Fax 0180 / 500 02 96

Manager: Peter Müller

Phone: 0911/703-7708 Fax: -9214 e-mail: Peter.Mueller@Grundig.de

Region Süd, Beuthener Str. 65, 90471 Nürnberg

Sales Manager: Werner Goldstein

Phone: 0911/703-1583 Fax: -1308 e-mail: Werner.Goldstein@Grundig.de

Area Manager (SM deputy): Thomas Baier/Nürnberg

Phone: 0911/703-1240 Fax: -1303 e-mail: Thomas.Baier@Grundig.de

Area Manager: Franz Asbeck/München

Phone: 0911/703-1584 Fax: -1303 e-mail: Franz.Asbeck@Grundig.de

Service Manager: Willi Geldermann

Phone: 0911/703-1269 Fax: -1127 e-mail: Willi.Geldermann@Grundig.de

Region Süd-West, Dudenstr. 45-53, 68167 Mannheim

Sales Manager: Günter Grimm

Phone: 0621/33 76-111 Fax: -115 e-mail: Guenter.Grimm@Grundig.de

Area Manager (SM deputy): Werner Murko/Frankfurt

Phone: 0621/33 76-114 Fax: -115 e-mail: Werner.Murko@Grundig.de

Area Manager: Dietmar Heering/Stuttgart

Phone: 0621/33 76-140 Fax: -115 e-mail: Dietmar.Heering@Grundig.de

Service Manager: Klaus Belli

Phone: 0621/33 76-270/271 Fax: -250 e-mail: Klaus.Belli@Grundig.de

Area Manager Business Systems: Andreas Seidler

Phone: 0621/33 76-170 Fax: -175 e-mail: Andreas.Seidler@Grundig.de

Region West, Horbeller Str. 19, 50858 Köln

Sales Manager: Jürgen Schmitz-Axe

Phone: 0211/20 90-115 Fax: -160 e-mail: Juergen.SchmitzAxe@Grundig.de

Area Manager (SM deputy): Bernd Klüh/Düsseldorf

Phone: 0211/20 90-110 Fax: -160 e-mail: Bernd.Klueh@Grundig.de

1.2 Grundig Service

Grundig Annual 1999 General Part

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

Area Manager: Heinz Kuhl/Dortmund

Tel.: 0211/20 90-120 Fax: -160 e-mail: Heinz.Kuhl@Grundig.de

Service Manager: Jürgen Bubendey

Tel.: 02234/95 81 280 Fax: -278 e-mail: Juergen.Bubendey@Grundig.de

Area Manager Business Systems: Friedhelm Hockenbrink

Tel.: 0231/56 22 53-0 Fax: -20 e-mail:

Region Ost, Wittestr. 30e, 13509 Berlin

Sales Manager: Karl-Heinz Pietsch

Tel.: 030/43 80-399 Fax: -335 e-mail: Karlheinz.Pietsch@Grundig.de

Area Manager (SM deputy): Heinz Fischer/Leipzig

Tel.: 030/43 80-311 Fax: -358 e-mail: Heinz.Fischer@Grundig.de

Area Manager: Klaus Markgraf/Berlin

Tel.: 030/43 80-350 Fax: -335 e-mail: Klaus.Markgraf@Grundig.de

Service Manager: Siegfried Heuer

Tel.: 030/43 80-320 Fax: 43 25 597 e-mail: Siegfried.Heuer@Grundig.de

Area Manager Business Systems: Karlheinz Kretschmar

Tel.: 030/43 80-380 Fax: -385 e-mail:

Region Nord, Kolumbusstr. 14, 22113 Hamburg

Sales Manager: Reinhard Domröse

Tel.: 040/733 31-220 Fax: -201 e-mail: Reinhard.Domroese@Grundig.de

Area Manager (SM deputy): Jens Wilkening/Hannover

Tel.: 0511/90 16-610 Fax: -619 e-mail: Jens.Wilkening@Grundig.de

Area Manager: Jürgen Karlein/Hamburg

Tel.: 040/733 31-202 Fax: -201 e-mail: Juergen.Karlein@Grundig.de

Service Manager: Werner Richter

Tel.: 040/733 31-240 Fax: -333 e-mail: Werner.Richter@Grundig.de

Area Manager Business Systems: Hans Dotter

Tel.: 0511/90 16-717 Fax: -719 e-mail: Hans.Dotter@Grundig.de

General Part

Grundig Service 1.3

General Part Grundig Annual 1999

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

Grundig Sales Companies (Europe)

General Part

S.A. Grundig Belux N. V.

Deltapark Unit 3, Weihoek 3 G, B-1930 Zaventem

Phone: (++32-2) 7 16 04 00, Fax:(++32-2) 7 16 03 80

Grundig Danmark A/S

Lejrvej 19, DK-3500 Vaerloese

Phone: (++45) 44 48 68 22, Fax: (++45) 44 48 62 63, (++45) 44 48 66 67

Grundig Oy

Luoteisrinne 5, SF-02270 Espoo, Finnland

Phone: (++3 58) 98 04 39 10, Fax: (++3 58) 98 04 39 01

Grundig France S. A. S.

5, Boulevard Marcel Pourtout, F-92563 Rueil Malmaison Cedex

Phone: (++33-1) 41 39 26 26, Telex: 0 42-63 45 04, Fax: (++33-1) 47 08 69 48

Grundig UK Limited.

Elstree Way, Borehamwood, Hertfordshire, WD6 1RX, Großbritannien/Great Britain

Phone: (++44-181) 324 94 00, Fax:(++44-181) 324 94 01

Grundig Italiana S. P. A.

Via G. B. Trener 8, I-38100 Trento

Phone: (++39-04 61) 89 31 11, Fax: (++39-04 61) 89 34 08 / 89 32 07 (KD)

Grundig Nederland B. V.

Joan Muyskenweg 22, NL-1096 CJ Amsterdam

Phone: (++31-20) 5 68 15 68, Fax: (++31-20) 5 68 14 06

Grundig Norge AS

Glynitveien 25, Postboks 234, N-1401 Ski

Phone: (++47) 64 87 82 00, Fax: (++47) 64 87 66 10

Grundig Austria Ges. m. b. H.

Breitenfurter Str. 43-45, A-1120 Wien

Phone:(++43-1) 81 11 76 03, Fax: (++43-1) 81 11 77 13

e-mail: pucheggerd@Grundig.co.at

Grundig Portuguesa, Comércio de Artigos Electronicos Lda.

Rua Bento de Jesus Caraça, 17, P-1495 Cruz Quebrada

Phone: (++3 51-1) 4 19 75 70, Fax: (++3 51-1) 4 19 90 83

Grundig Svenska AB

Box 4050, Albygatan 109 D, S-171 04 Solna

Phone: (++46-8) 6 29 85 30, Telex: 0 54-1 99 34, Fax: (++46-8) 6 29 85 70

Grundig (Schweiz) AG

Steinackerstr. 28, CH-8302 Kloten

Phone: (++41-1) 8 15 81 11, Fax: (++41-1) 8 13 52 31

1.4 Grundig Service

Grundig Annual 1999 General Part

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

Grundig España S. A.

Solsonés, 2, Edif. Muntadas (Mas Blau I), E-08820 El Prat de Llobregat (Barcelona)

Phone: (++34-93) 4 79 92 00, Fax: (++34-93) 4 79 92 47

Grundig Ireland Ltd.

2 Waverley Office Park, Old Naas Road, Dublin 12/Eire

Phone: (++3 53-1) 4 50 97 17, Fax: (++3 53-1) 4 50 99 36

Grundig Polska SP. Z.O.O. (Kundendienst)

Ul. Czéstochowska 140, PL - 62-800 Kalisz, Poland

Phone: (++48-62) 7 66 77 70, Fax (++48-62) 7 66 77 72

Grundig Polska SP. Z.O.O.

Ul. Raclawicka 146, PL - 02-117 Warszawa, Poland

Phone: (++48-22) 6 68 62 66, Fax (++48-22) 6 68 62 54,

e-mail: Grundig@ikp.atm.com.pl

Grundig spol. s r.o.

Koperniková 2, CZ - 12 000 Praha 2, Czechia

Phone: (++4 20) 2 - 24 23 90 99, (++4 20) 2 - 24 23 90 81, Fax (++4 20) 2 - 24 23 51 01,

e-mail: Grundig@login.cz

Grundig Slovensko s r.o.

Drienová 3, SK - 821 02 Bratislava, Slovakia

Phone: (++4 21) 7 - 43 41 12 42, (++4 21) 7 - 43 42 94 95, Telefax (++4 21) 7 - 43 41 02 70

e-mail: Grundig@internet.sk

Grundig Magyarország Kft.

Bécsi út 85, H - 1036 Budapest, Hungary

Phone: (++36) 1 - 25 08 142, (++36) 1 - 25 08 143, Fax (++36) 1 - 25 08 144

e-mail: Grundig@ibm.net

Grundig Slovenija d.o.o.

Dunajska 22, Si - 1511 Ljubljana, Slovenia

Phone: (++3 86) 61 - 32 88 79, (++3 86) 61 - 32 88 83, Fax (++3 86) 61 - 32 86 86

e-mail: Marn.Grundig@siol.net

Grundig Hrvatska d.o.o.

Metalceva 5, HR - 10000 Zagreb, Croatia

Phone: (++3 85) 1 - 39 34 06, Fax: (++3 85) 1 - 39 17 78

e-mail: grundig-hrvatska@zg.Phonehr

General Part

Grundig Service 1.5

General Part Grundig Annual 1999

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

Grundig Overseas Sales Division

General Part

General Management:

Kurgartenstraße 37 , 90762 Fuerth / Germany

Phone ++49-911-703-0 , Fax ++49-911-703-7134

e-mail: grundig@gims.grundig.de

E U R O P E

RUSSIA (Regional Office)

Contact Office Moscow Phone: ++7-095-973 3054

Ul. Obrazszova 17 Fax: ++7-095-973 3057

103055 Moscow e-mail: grundig@dol.ru

Distributors in Europe

CYPRUS

Ideal Grafico Ltd. Phone: ++35-72-752 109

14 C Stassinos Ave., Fax: ++35-72-750 943

P.O. Box 4809 e-mail: graphicocy@logos.cy.net

Nicosia 1304

GREECE

ELEX S.A.

13th km National Road Phone: ++30-1-80 76 711

14564 Kiffissia Fax: ++30-1-80 76 704

Athens e-mail: elex@acci.gr

ICELAND

Television Center Ltd. Phone: ++354-5-68 90 90

Sidumula 2 Fax: ++354-5-68 03 90

128 Reykjavik e-mail: tel@islandia.is

MALTA

Jokate Group of Co. Ltd. Phone: ++356-22 10 12

Jokate Buildings Fax: ++356-24 31 54

P.O. Box 1

Msida

ROMANIA

SSH Marketing GmbH Phone: ++49-6183-911 32-0

Buchenstraße 15 Fax: ++49-6183-911 32-18

63526 Erlensee / Germany e-mail: ssh_marketing@compuserve.com

TURKEY

Mercansoy A.S. Phone: ++90-212-649 32 96

Yildirim Mah. Fax: ++90-212-537 56 98

Ali Fuat Basgil Cad. 43, Bayrampasa e-mail: infomer@mercansoy.com.tr

34170 Istanbul

1.6 Grundig Service

Grundig Annual 1999 General Part

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

UKRAINE

GR Decision Phone: ++ 38-044-484 4567

Ul. Levanevskovo 5 Fax: ++38-044-484 4584

252058 Kiev

A F R I C A

Distributors in Africa

ALGERIA Phone: ++213-2-63 66 94

E.I.P.EL Fax: ++213-2-61 00 97

14, Rue Khaled Bellagaune ( ex Lulli )

Alger 16000

EGYPT

IEP Int. Electrical Products Phone: ++20-2-261 83 33

1, El Obour Bldg., Salah Salem Fax: ++20-2-261 99 13

Heliopolis

Cairo

EGYPT

IEP Int. Electrical Products Phone: ++20 11 333 414

Lot 240 Fax: ++20 11 333 420

6 October CIty

ETHIOPIA

Cabey Private Limited Phone: ++251-1-613 891, 613 892

Box 18192 Fax: ++251-1-517 953

Addis Ababa

IVORY COAST

Atlantis Electronique Phone: ++225-214 838

RDC CCIA Abidjan Plateau Fax: ++225-218 040

22 BP 1275

Abidjan 22

KENYA

Ardofe Electronics Phone: ++254-2-224 583

Luthuli Avenue Fax: ++254-2-224 449

P.O. Box 30866

Nairobi

MOROCCO

Umareq Phone: ++212-2-30 15 42

43, Bld. Ibn. Tachfine Fax: ++212-2-30 30 03

Casablanca

General Part

Grundig Service 1.7

General Part Grundig Annual 1999

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

NAMIBIA

General Part

Foto Distributors Phone: ++27-11-803 4000

Honeywood Park Fax: ++27-11-803 4047

Humber Street, Woodmead e-mail: isaulco@iafrica.com

P.O. Box 76302

Wendywood 2144

South Africa

SOUTH AFRICA

Specialised Communication Pty. Ltd. Phone: ++27-11-728 1053

33, The Avenue Fax: ++27-11-728 1525

Orchards e-mail: stream@icon.co.za

Johannesburg 2192

TUNISIA

Telectronic S.A. Phone: ++216-1-768 032

KM 14 Borj Tonil Fax: ++216-1-768 361

B.P. 88 Borj Tonil e-mail: alfalah@king.com.tn

2080 Ariana

Tunis

ZIMBABWE

Alliance Co. Phone: ++263-4-707261, 752071

Leopold Takawira Street Fax: ++263-4-704078

P.O. Box 66273 e-mail: alliken@cst.co.zw

Kopje

Harare

A M E R I C A

Distributors in America

USA / CANADA (Distributor for shortwave World Receivers)

Lextronix Inc. Phone: ++1-650-361 16 11

3520 Haven Avenue, Unit L Fax: ++1-650-361 17 24

Redwood City, CA 94063 e-mail: grundig@ix.netcom.com

A S I A

MIDDLE EAST (Regional Office)

Grundig Gulf FZE Phone: ++971-4-838 989

P.O. Box 61012 Fax: ++971-4-838 798

Jebel Ali e-mail: gmeja@emirates.net.ae

Dubai / U.A.E.

1.8 Grundig Service

Grundig Annual 1999 General Part

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

Distributors in Asia

ARMENIA

Zig-Zag Electronics Phone: ++374-2-552 757

Sayat - Nova 20 Fax: ++374-2-151 975

Yerevan 375 001 e-mail: zigzag@arminco.com

AZERBAIJAN

Universal Technics Co. Ltd. Phone: ++994-12-929 732

Ave. Aziz Aliyev 5 Fax: ++994-12-971 134

Baku

BAHRAIN

Yousuf Awadi Group Phone: ++973-214 666

P.O. Box 20004 Fax: ++973- 210 900

Manama

BANGLADESH

Sears Electronics Phone: ++880-2-955 5956, 955 9649

28, Dilkusha C/A, Suite-3 Fax: ++880-2-956 4086

7th Floor e-mail: ati@bdmail.net

Dhaka - 1000

CHINA / HONGKONG

Great Wall Electronics Ltd. Phone: ++852-24 10 86 68

16/F. Riley House Fax: ++852-24 21 12 87, 24 10 87 46

88 Lei Muk Road e-mail: brenda@great-wall.com.hk

Kwai Chung, N.T. / Hongkong

IRAN

PARS Electric Mfg. Co. Phone: ++98-21-602 51 00

563 Azadi Ave. Fax: ++98-21-602 50 95

Tehran - 14

IRAN

Pars Electric Mfg Co. Phone: ++98-21-602 5100

Km9, Jadeh Makhsous Karadj Fax: ++98-21-602 5095

Tehran

ISRAEL

PIRA Ltd. Phone: ++972-3-687 62 30

19, Hatsfira Street Fax: ++972-3-537 47 07

P.O. Box 28085 e-mail: pil0007@ibm.net

67779 Tel Aviv

JORDAN (Distributor for Projects)

Gi.Rho.Ma Co. Phone: ++962-4-619 093, 619 094

Kalbouneh Center Fax: ++962-4-619 733

Prince Moh´d Street e-mail: girhoma@go.com.jo

P.O. Box 639

Amman 11118

Grundig Service 1.9

General Part

General Part Grundig Annual 1999

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

JORDAN (Distributor for Consumer Electronics)

General Part

Hanna Zananiri & Sons Co. Phone: ++962-5-682 386

P.O. Box 842 Fax: ++962-5-672 505

Amman 11118

KUWAIT

Morad Yousuf Behbehani Phone: ++965-481 9734

P.O. Box 146 Fax: ++965-484 4053

13002 Safat e-mail: moradb@ncc.moc.kw

LEBANON

Boulos Freres & Co. Phone: ++961-1-455 071

P.O. Box 1656 Fax: ++961-1-601 240

Hazmieh Boulevard e-mail: boulos@dm.net.lb

Beirut

MALAYSIA

Luxor Electric Corp. Sdn. Bhd. Phone: ++60-3-756 2999

Wisma Luxor, No. 5 Fax: ++60-3-756 5900

Jalan Bersatu 13/4

46200 Petaling Jaya

OMAN

Mushrif Enterprises Phone: ++968-693 620

P.O. Box 1289 Fax: ++968-604 600

Ruwi 112

Sultanate of Oman

OMAN (Distributor for Projects) Phone: ++968-771 1878, 771 6504

Assarain Enterprises LLC Fax: ++968-771 7142

P.O. Box 1475

Ruwi 112

Sultanate of Oman

QATAR

Salam Stores & Studio Phone: ++974-832 050

P.O. Box 121 Fax: ++974-832 103

Doha

SAUDI-ARABIA

Ahmed Ali Badogaish & Co. Phone: ++966-3-864 6786

P.O. Box 65 Fax: ++966-3-898 2585

Al Khobar 31952

SINGAPORE

Asia Radio Singapore Pte. Ltd. Phone: ++65-298 22 11

Asia Radio Building Fax: ++65-383 86 00

39 Mac Taggart Road

Singapore 338084

1.10 Grundig Service

Grundig Annual 1999 General Part

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

SYRIA

Trading & Engineering Center Phone: ++963-11-541 6482

P.O. Box 2053 Fax: ++963-11-541 7031

Damascus

U.A.E.

Al Gurg Electronics Phone: ++971-4-376 804

P.O. Box 325 Fax: ++971-4-365 167

Dubai / U.A.E. e-mail: gurgtyre@emirates.net.ae

TAIWAN R.O.C.

GRE Trading Phone: ++886 2 705 22 60

P.O. Box 26-1182 Fax: ++886 2 755 23 93

11 F. No. 602, Tun Hua South e-mail: a0947782@ms8.hinet.net

Taipai

YEMEN

Ghamdan General Trading Phone: ++967-1-279 143

P.O. Box 10932 Fax: ++967-1-237 715

T.R. 10932 e-mail: ggti@y.net.ye

Sana´a

YEMEN

General Electronics Phone: ++967-1-269 098

P.O. Box 18105 Fax: ++967-1-269 097

Had Street

Sana´a

A U S T R A L I A

Distributors of Australia

AUSTRALIA

Southern Cross Electric Pty. Ltd. Phone: ++61-2-97 50 31 66

26-30 Kent Street Fax: ++61-2-97 59 66 21

Belmore NSW 2192 e-mail: sce1@ozemail.com.au

Sydney

General Part

O C E A N I A

Distributors of Oceania

NEW ZEALAND

Sound Group Holdings Ltd. Phone: ++64-9-415 66 80

Unit B / 3 Rothwell Ave. Fax: ++64-9-415 66 83

Albany P.O. Box 302-106 e-mail: bob@soundgroup.co.nz

North Harbour Post Centre

Auckland

Grundig Service 1.11

General Part Grundig Annual 1999

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

General Part

Product Range and Customer Services

Test and Measuring Instruments

Laboratory and Service PN 400-F Programmable Power Supply

Measuring Instuments PN 400-R Programmable Power Supply

Video Measuring PPE 400 PALplus Studio Encoder

Instruments PPE 600 PALplus Studio Decoder

Antenna Measuring MSK 33 Combination Measuring Receiver

Instruments SK 33/G Combination Measuring Receiver

Accessories Connection cables

1.12 Grundig Service

PN 300 Programmable Power Supply

PN 200 Programmable Power Supply

UZ 2500 Universal Counter

UZ 2400 Universal Counter

RF 1000 RF Millivolt Meter

Adapter Analog -> RS-232 C

RLC 300 Automatic RLC Meter

RLC 100 Automatic RLC Meter

RLC 200 Automatic RLC Meter

DM 100 Digital Multimeter

FG 100 Function Generator

AFG 100 Arbitrary Function Generator

TG 100 Low Distortion Generator

MV 100 LF Millivolt Meter

digimess®

soft-workshop

Software-Set for

SC 600System Controller

19"-Adapter single expert MA 19-1

19"-Adapter dual compact MA 19-2

19"-Adapter single compact MA 19-3

Enclosure Top Line

Adapter RS-232 C -> IEEE 488.2

MO 32 Dual Channel Oscilloscope

MO 30 Dual Channel Oscilloscope

SO 100 Digital Storage Oscilloscope

S 100 S Operating and User Software

VG 1100 Professional Video Generator

VTG 700 Video Transmission Generator

MSK 33/Q Combination Measuring Receiver

ME 100 Combination Measuring Receiver

MSK 23 Level Measuring Receiver

MSK 23/V Level Measuring Receiver

probes and adapters

oscilloscope accessories

Bags

Internet: http://www.grundig-instruments.de

digimess®

-Instruments

Grundig AG

Geschäftsbereich Instruments

Test- und Meßsysteme

Würzburger Str. 150

D-90766 Fürth

Tel.: 0911 / 703-4118

Fax: 0911 / 703-4130

eMail: instruments@grundig.de

Grundig Annual 1999 General Part

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

Division Instruments

Test and Measuring Systems

Communication Measuring Instruments

Austria Claus Grothusen OHG Phone: + 43-662-4 33 68 80

Australia Rhode & Schwarz pty. Ltd. Phone: + 61-2-97 48 01 55

Belgium Air-Parts B.V. Phone: + 31-172-422-455

Czech Republic DOVATRON CZECH a.s. Phone: + 420-5-41 12 28 35

Denmark Erik Blichfeld A/S Phone: + 45-75 56 70 00

Denmark Witronic A/S Phone: + 45-36 72 20 00

Egypt Phillips Egypt Phone: + 20-2-3 49 09 22

Finland PEREL OY Phone: + 358-19-8 71 11

France Salies S.A. Phone: + 33-1-69 20 40 10

Hong Kong GEC Hong Kong Phone: + 852-29 19 82 82

Indonesia GAE PT Guna Electro Phone: + 62-21-5 65 50 10

Ireland Vann Draper Electronics Limited Phone: + 44-116-2 77 14 00

Israel Kanion Phone: + 972-3-9 22 12 87

Italy Delo Instruments Phone: + 39-2-90 72 24 41

Saalachstr. 40 Fax: + 43-662-43 60 04

5019 Salzburg

63 Parramatta Fax: + 61-2-97 48 18 36

Silverwater N.S.W. 21 41

Kalkovenweg 12 Fax: + 31-172-421-022

NL - 2401 LK Alphen aan den Rijn

Purkynova 99 Fax: + 420-5-41 21 20 85

61245 Brno

Essen 27 Fax: + 45-75 56 70 07

6000 Kolding

Road Roskildevej 308 Fax: + 45-36 72 04 40

2610 Rqdovre

10, Abdel Rahman El Rafei St. Fax: + 20-2-3 49 21 42

Mohandesin

P.O. Box 242 Dokki

Cairo

Torpankatu 28 Fax: + 358-19-8 71 15 00

05800 Hyvinkää

65-67, Avenue Jean Jouräs Fax: + 33-1-69 20 36 04

91122 Palaiseau

CC Wu Building Fax: + 852-28 34 57 73

302-308 Hennessy Road

Wanchai

P.O. Box 15 GPO

JI. Terusan Arjuna 50 Fax: + 62-21-5 65 50 30

Jakarta Barat 11510

Unit 5, Premier Works Fax: + 44-116-2 77 39 45

Canal Street

South Wingston

Leicester LE 18 2 PL

8 Mikhaelis St. Fax: + 972-3-9 22 07 51

Kiryat-Arie

P.O.B. 3783 Petah-Tikva

49130

Via Piemonte, 14 Fax: + 39-2-90 72 27 42

20090 Fizzonasco Pieve E. (Mi)

General Part

Grundig Service 1.13

General Part Grundig Annual 1999

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

Japan Matsushita Electric Phone: + 81-3-54 04 88 43

General Part

Luxembourgh Air-Parts B.V. Phone: + 31-172-422-455

Netherlands Air-Parts B.V. Phone: + 31-172-422-455

Norway Grundig Norge A/S Phone: + 47-64 87 82 00

Poland Lamium sp.c. Phone: + 48-32-2 79 49 37

Portugal Grundig Portugesa Phone: + 351-141-9 75 70

Singapore Gold Lite Pte. Ltd. Phone: + 65-2 73 04 87

South Africa Tek Test cc Phone: + 27-11-972-60 05

South Korea Whain Systech Co., LTD. Phone: + 82-2-571-57 11

Sweden Ferner Electronics AB Phone: + 46-8-7 60 83 60

Sweden Polystar AB Phone: +46-8-6 08 28 28

Switzerland Erivision AG Phone: + 41-62-3 91 11 34

Switzerland Grundig Schweiz AG Phone: + 41-1-8 15 81 11

Taiwan Precision International Phone: + 886-2-9 99 08 50

Thailand Schmidt Scientific (Thailand) Ltd. Phone: + 662-643-13 30-9

Industrial Co. Ltd. Fax: + 81-3-54 04 88 49

Corporate International

Trade Division

32nd Floor, World Trade Center Buildg.

4-1, Hamamatsu-Cho, 2-chome, Minato Ku

Tokyo 105

Kalkovenweg 12 Fax: + 31-172-421-022

NL - 2401 LK Alphen aan den Rijn

Kalkovenweg 12 Fax: + 31-172-421-022

NL - 2401 LK Alphen aan den Rijn

Postboks 234 Fax: + 47-64 87 66 10

1401 Ski

ul. Toszecka 101/3 Fax: + 48-32 2 79 49 37

44-100 Gliwice

Rua Bento de Jesus Caraca, Fax: + 351-141-9 90 83

17, Cruz Quebrada

1495 Lisboa

Blk 211 Henderson Road Fax: + 65-2 73 50 06

Henderson Industrial Park

# 08-03

Singapore 159552

28 van Loggerenberg Avenue Fax: + 27-11-972-60 05

Norkem Park

Kempton Park 1618

3F Iljeong Building, 425-2 Fax: + 82-2-571-57 14

Togok-Dong, Kangnam-Ku

Seoul

Vedestavägen 15 Fax: + 46-8-7 60 83 41

17526 Järfälla

Dalhemsvägen 23 Fax: +46-8-7 11 44 45

14146 Huddinge

Im Moos 13 Fax: + 41-62-3 91 48 19

4710 Balsthal

Steinackerstraße 28 Fax: + 41-1-8 13 52 31

8302 Kloten

Corp. PIC Fax: + 886-2-9 99 15 22

P.O. Box 03-15

Sanchung City

241 Taipei

Government Housing Fax: + 662-643-13 40-1

Bank Bldg.

212 Rama 9 Rd., Huay Kwang

Bangkok 10320

Thailand

1.14 Grundig Service

Grundig Annual 1999 General Part

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

UK Vann Drapper Electronics Limited Phone: + 44-116-2 77 14 00

Unit 5, Premier Works Fax: + 44-116-2 77 39 45

Canal Street

South Wigston

Leicester LE 18 2PL

Automotive Measuring Instruments

Austria T.A.C. LUCAV Phone: + 43-662-43 75 01-43

Brazil NAHUEL Indl. E Coml. LTDA Phone: + 55-11-7467-133

China SHENZHEN WANTONG Phone: + 86-755-6 89 18 85

Czech Republic UNIVER, spol. s.r.o. Phone: + 420-436-2 33 81

Hungary T.A.G. HUNGARIA Phone: + 36-23-33 80 42

Norway a.s. Fartskriver Phone: + 47-22-64 58 60

Portugal GRUBER LDA. Phone: + 35-11-2 74 76 79

Spain EDAGYAM S.L. Phone: + 349-8180-3339

Switzerland W. Luginbühl AG Phone: + 41-62-8 93 24 24

USA Gemini Technologies AG Phone: + 925-254-2755

Moserstr. 39 Fax: + 43-662-43 75 01-39

5020 Salzburg

Rua Pedro Alexandrino No. 205 Fax: + 55-11-7467-181

J.D. Portinari, Diadema

Sao Paulo

MOTOR-CAR TECHNOLOGY Fax: + 86-755-6 67 92 95

DEVELOPMENT CO., LTD

5/F 19 # Yan Shan RD.

SheKou / ShenZhen

People Republic of China (PRC)

Preperska 1809 Fax: + 420-436-2 12 72

511 01 Turnov

DEPO Pf. 23. Fax: + 36-23-33 80 43

2046 Törökbalint

Persveien 32 Fax: + 47-22-65 83 50

P.B. 78, Oekern

05078 Oslo

Rua Oliveira Martins, Fax: + 35-11-2 73 27 83

10-5°D

P-2810 Feijo

Francelos s/n Fax: + 349-8180-3555

15911 Rois

(La Coruna)

Bruneggerstr. 45 Fax: + 41-62-8 93 37 05

5103 Möriken

5 Donald Drive, Orinda Fax: + 925-253-8646

CA. 94563 USA

General Part

Grundig Service 1.15

General Part Grundig Annual 1999

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

SERVICE TRAINING COURSES for our Customers

General Part

We train you in intensive courses in the GRUNDIG after-sales service division in Nürnberg

as well as in one-day regional training courses.

We deal with all current questions on product technology in the fields of television, satellite

reception, video, digital audio, and communications.

For detailed information on these courses please see the technical training booklet which is

available on request from your competent GRUNDIG contact partner.

________________________________________________________________________

Training with Training Film Cassettes

GRUNDIG offers a training film titled “Servicing made easy - Training by Video” designed for private study

and practical application in the field of servicing which has proven very well. The present offer of video

cassettes comprises:

Training Film: Video VHS (2 x 4/1600) Part No.:72007 744 6000

Flow converter power supply • sequence and motor control • servo control/ATF • video signal path •

chroma signal path • mechanical adjustments • length ca. 90 minutes.

Training Film: Video VHS (VS 200/220) Part No.:72007 744 7000

Diagnosis • power supply • sequence and motor control • servo control • video and chroma signal path •

mechanical adjustments • length ca. 110 minutes.

Training Film: Television Compact Universal Chassis Part No.:72007 744 8000

Switched mode power supply• transistor line output stages 90/110 degrees • east/west modulator • multistandard reception • viewdata retrofitting • length ca. 55 minutes.

Training Film: Video VHS (VS 310, 320, 380 HiFi) Part No.:72007 744 9000

Diagnosis • service works on drive mechanism• adjustments and mechanical settings • repair hints •

functional characteristics of electrical modules • length ca.110 minutes.

Training Film: The Horizontal TV Chassis Part No.:72007 744 9500

Line power supply • multi-standard reception • transistor line output stages 90/110 dregrees • viewdata and

PC connecting instructions • satellite receiver • satellite reception • adjustment of the paraboloidal reflector

• service hints • length ca. 60 minutes.

Training Film: Video VHS (VS 340/400) Part No.:72007 744 9700

Circuitry and mechanics • length ca. 90 minutes.

Training Film: Video VS 540 HiFi Part No.:72007 744 9800

Circuitry and mechanics • length ca. 80 minutes.

Training Film: STP 300 Satellite System Part No.:72007 744 6100

Installation of the satellite system STP 300 • length ca. 30 minutes.

Training Film: Highspeed Video Drive Mechanism HSD Part No.:72007 744 8100

Dismantling and re-assembling the drive mechanism • replacement of wearing parts • replacement of the

headwheel and the CTL head • adjustment of the tape run, tracking position and head gap position

indicator • length ca. 30 minutes.

(in English) 72007 744 9100

(in Italian) 72007 744 9200

1.16 Grundig Service

Grundig Annual 1999 General Part

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

Private Study with Service Training Manuals

The following training manuals can be ordered for private study against payment of a fee:

TV Engineering

Service Training Language Part Number

CUC 6360/6365/7300 D 72010 350 0000

Digi IV/ 100Hz Technique D 72010 350 0500

Pal+ System Principles D 72010 350 1000

Digi Basic D 72010 350 1500

Digi Basic GB 72010 350 1600

Digi Basic ++ D 72010 350 1700

Digi 6 / CUC 1842 D 72010 350 3000

Digi 6 / CUC 1842 GB 72010 350 3100

CUC 2000/2010/2030 D 72010 350 3500

CUC 2000/2010/2030 GB 72010 350 3600

Digi Basic 3 (deliverable ca. 03/99) D 72010 350 3700

Planatron (deliverable ca. 07/99) D 72010 350 3800

Video Engineering:

Service Training Language Part Number

GV 400 and similar D 72010 525 1000

GV 500 and similar D 72010 525 1500

GV 540/560 HiFi and similar D 72010 525 2000

HSD Drive Mechanism D 72010 525 2500

GV 640 and similar D 72010 528 9000

GV 640 and similar GB 72010 528 9100

GV 670-690 D 72010 528 9300

GV 670-690 (deliverable ca. 4/99) GB 72010 528 9400

GV 7000 D 72010 531 4000

GV 7000 GB 72010 531 4100

Principles of Digital-Video DV D 72010 532 3500

MPEG Principles Digital-Video (deliverable ca. 02/99) D 72010 534 4000

General Part

Audio/HiFi Engineering:

Service Training Language Part Number

Principles of Audio Engineering D 72010 749 5000

FM Tuner T11 / T1000 D 72010 749 5500

CD Player CD11 / CD12 D 72010 749 6000

DAB Principle (deliverableca. 02/99) D 72010 749 6500

Telecommunications Engineering:

Service Training Language Part Number

Telecommunications Principles D 72010 749 7000

Grundig Service 1.17

General Part Grundig Annual 1999

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

© General Instructions for Safety, MOS, Chip and Laser Technology

General Part

© ü ç

This Service Manual covers the safety regulations which must be observed

when carrying out repairs.

It is to be regarded as a supplement to all Service Manuals which will be

issued in future without these safety regulations.

Preserve this Service Manual carefully and observe the instructions given

in it for product liability.

Please observe also all additional national safety regulations!

Contents

Safety Instructions .........................................................................................1.19

Safety Standard Compliance .........................................................................1.19

Electrical Safety after Repairs........................................................................1.20

Important Advice and Safety Tests relevant to Service Repairs ....................1.21

Important Safety Instructions .........................................................................1.21

Laser Safety ...................................................................................................1.23

Safety Advice for Lithium Batteries ................................................................1.24

Handling of MOS Chip Components ..............................................................1.24

MOS Soldering Instructions ...........................................................................1.24

CHIP Technology ...........................................................................................1.25

1.18 Grundig Service

Page

Grundig Annual 1999 General Part

!

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

Safety Instructions

The products identified in Service Manuals were manufactured to meet strict Quality and Safety Standards. It is

imperative that the Safety Standards are observed when carrying out repairs to ensure that the product always

conforms to IEC 65 or VDE Regulations and the harmonised National Safety Regulations, eg. Low Voltage Directive

(73/23/EEC), the Low Voltage Electrical Equipment (Safety) Regulations, 1989 (UK) and the Electricity at Work

Regulations, 1989 (UK) before it is returned to the owner.

This symbol:

is used to identify components which conform to IEC or VDE Guidelines! When these require replacement, for

continued compliance and protection, use only the original components specified in the Service Manual (List of Spare

Parts). For continued protection against the risk of fire, the type and rating of fuses (nominal value, characteristic

and rupturing rating) used as replacements must be as specified by the Standards!

After any repair, it is imperative that the Leakage Current and/or Insulation Resistance is checked as described in

this Safety Manual. If the result of the check indicates that the product does not conform, the user / owner must be

notified in writing. If the user / owner requests that the product is to be returned in a defective condition, the written

warning must draw notice to the risks.

In all cases:

– The mains plug and the fuse fitted (UK) must be checked and any defect found corrected.

– The mains lead, and any other connecting leads, must be checked for damage and defects rectified.

Check the insulation!

– The functional reliability of all tension relief and bending protection bushes provided in the product must be

checked and defects rectified.

– For continued safety compliance, safety determining parts in the product must not be damaged or evidently

unsuitable. This is especially valid for insulators and insulating parts.

– Use specified parts only. For components and assemblies marked with the Safety Symbol ! the original

specified spare parts only are strictly to be used.

– Use, if applicable, only information published in Grundig Technical Bulletins or in the Grundig Infotip System.

– Thermally loaded solder pads and those passing large currents, known by experience to cause a risk, must be

thoroughly cleaned and re-soldered.

– Ensure that the ventilation openings are not obstructed or contaminated with dust.

– Ensure the proper disposal of exhausted batteries and accumulators (hazardous waste - environmental

protection!)

– For all receivers, ensure that the aerial system conforms to BSI CP 6330:1983 (UK).

– Maintain records of all checks, remedial action and disposals.

General Part

Safety Standard Compliance

After repairing a product which originally conformed to the Safety Class II (double insulated), the Insulation

Resistance and / or Leakage Current with the product switched on must be checked to VDE 0701 or to the National

Safety Regulations quoted above.

The products covered by these Instructions conform to the Safety Class II, as identified by the symbol:

Warning: After repairs are carried out to parts within this product, the Safety Instructions given in VDE 0701

(Repair Instructions) and / or VDE 0860 / IEC 65 / EN 60065 (Product Specification) must be

observed.

!

Components conforming to IEC or VDE Approval Specification! For replacement purposes, use parts with

the same specification only!

MOS Observe the requirements when handling MOS Components!

Grundig Service 1.19

General Part Grundig Annual 1999

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

Electrical Safety after repairs

General Part

According to the Product Liability Laws, the Manufacturer is responsible for ensuring that the product presents no

danger to the user when used correctly. This risk is especially important with products which are operated from the

mains voltage supply. To ensure that safety parameters are maintained especially after repairs have been carried

out, it is imperative that the product is tested as specified in a recognised Test Procedure.

1. Products conforming to Safety Class I (earthed, Symbol )

Earth lead Test.

Check that the earth lead performs its function by using a Continuity Tester. For this integrity of the connection

(conduction of current) from the protection lead contact in the plug to all metal parts that can be touched, with the

product switched on and with it switched off, must be proved. A maximum of 0.3Ω is permitted for the resistance of

a connecting lead with a length of up to 5 metres.

2. Products conforming to Safety Class II (insulated, Symbol )

Insulating resistance measurements as specified in VDE 0701/Part 200.

The insulation resistance between all electrical functioning stages and metallic cabinet parts that can be touched

must be proved.

Measurement of the Insulation Resistance to VDE 0701

Connect an Insulation Test Meter (U

all other functional parts (aerial and connecting sockets, buttons, decorative trims, screws, etc.) made from metal

or metal alloy. The product is fault free if:

Note: The Insulation Resistance in some Safety Class II products can be < 2MΩ, depending upon

construction and the value of discharge resistors. In these cases, the Leakage Current is significant

and must be checked.

= 500V DC) to both mains poles simultaneously and between the cabinet and

test

R

> 2MΩ at U

isol

Measuring time: > 1s

= 500V DC

test

Measurement of the Leakage Current to VDE 0701

Connect a Leakage Current Meter (U

and all other functional parts (aerial and connecting sockets, buttons, decorative trims, screws, etc.) made from metal

or metal alloy. The product is fault free if:

*

As, at the time of preparing these Safety Instructions, there is no British Standard Institute Standard that

is equivalent to VDE 0701, use a test voltage of 240V AC.

• For testing to VDE 0701 / IEC 65 / BS 415 etc. we recommend that the measurements are carried out using the

PAC 500, PAT 1000, PAT 2000, Metratester 4/5 or suitable equipment. These can be obtained from:

e.g. Seaward Electronic Ltd e.g. Gossen-Metrawatt GmbH

Bracken Hill, South West Ind Est Thomas-Mann-Str. 16-20

Peterlee D-90471 Nürnberg

Co Durham

SR8 2JJ

Telephone: 0191-5863511

I

leak

Measuring time: > 1s

= 220V AC*) to both mains poles simultaneously and between the cabinet

test

< 1mA at U

= 220V AC*

test

Note: Models quoted may be superceded with new models with the passage of time.

• The PAC provides an initial indication of a "pass" or "fail" and is also suitable for mobile (field service) use, and

the PAT units are designed for in-house use and for the maintenance of records and other professional uses and

are compatible with most PC systems.

• If the safety of the product is not proven because:

– a repair and full restoration is not physically or economically possible

– or if the user / owner requests that repairs are not to be carried out,

the user / owner must be given a written warning of the risk!

• Observe the conditions given in the "Safety Instructions" section.

1.20 Grundig Service

Grundig Annual 1999 General Part

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

Important Advice and Safety Tests relevant to Service Repairs

– Service repairs must be carried out only by qualified personnel.

– Observe the VDE and National Safety Regulations as applicable.

– Operate line / mains powered units via an isolating transformer.

– Connect external aerials via an aerial isolating element.

– After repair, activate all protective circuits put out of operation.

– Before complete re-assembly of the unit restore the wiring to the original condition.

– Wear the protective clothing as required for repairs on picture tubes.

– Discharge the picture tube before dismantling it.

– When handling picture tubes avoid mechanical shocks to the tube (risk of implosion).

ü ç

Important Safety Instructions

Attention: Please observe the applicable safety requirements according to VDE 0701 (concerning repairs) and

MOS Observe MOS components handling instructions when servicing!

Attention: This appliance can only be operated from AC mains of 120V/60 Hz. Also observe the information given

• Read Instructions – All the safety and operating instructions should be read before the appliance is operated.

• Retain Instructions – The safety and operating instructions should be retained for future reference.

• Heed Warnings – All warnings on the appliance and in the operating instructions should be adhered to.

• Follow Instructions – All operating and user instructions should be followed.

• Water and Moisture – The appliance should not be used near water – for example, near a bathtub, washbowl,

• Wall or Ceiling Mounting – The appliance should be mounted to wall or ceiling only as recommended by the

• Ventilation – The appliance should be situated so that its location or position does not interfere with its proper

VDE 0860 / IEC 65 / EN 60065 (concerning type of product)!

V

!

D E

Components to IEC or VDE guidelines! Only use components with the same specifications for

replacement!

on the rear of the set.

V

!

D E

CAUTION – FOR CONTINUED PROTECTION AGAINST RISK OF FIRE REPLACE ONLY WITH

SAME TYPE FUSES!

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS

APPLIANCE TO RAIN OR MOISTURE.

The lightning flash with arrowhead symbol, within an equilateral triangle, is intended to alert the user to the

presence of uninsulated "dangerous voltage", within the product's enclosure that may be of sufficient

magnitude to constitute a risk of electric shock to persons.

!

The exclamation point within an equilateral triangle is intended to alert the user to the presence of important

operating and maintenance (servicing) instructions in the literature accompanying the appliance.

This product was designed and manufactured to meet strict quality and safety standards. There are,

however, some installation and operation precautions which you should be particularly aware of.

kitchen sink, laundry tub, in a wet basement, or near a swimming pool, and the like.

manufacturer.

ventilation. For example, the appliance should not be situated on a bed, sofa, rug, or similar surface that may

obstruct the flow of air through the ventilation openings.

General Part

Grundig Service 1.21

General Part Grundig Annual 1999

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

• Heat – The appliance should be situated away from heat sources such as radiators, heat registers, stoves,

General Part

or other appliances (including amplifiers) that produce heat.

• Power Sources – The appliance should be connected to a power supply only of the type given above or as

marked on the appliance.

• Power-Cord Protection – Power-supply cords should be routed so that they are not likely to be walked on or

pinched by items placed upon or against them, paying particular attention to cords at plugs, convenience

receptacles, and the point where they exit from the appliance.

• Cleaning – The appliance should be cleaned only as recommended by the manufacturer.

• x1 Power Lines – An outdoor antenna should be located away from power lines.

• x2 Outdoor Antenna Grounding – If an outside antenna is connected to the receiver, be sure the antenna system

is grounded so as to provide some protection against voltage surges and built up static voltages. Section 810

of the National Electrical Code, ANSI / NFPA No. 70-1984, provides information with respect to proper

grounding of the mast and supporting structure, grounding of the lead-in wire to the antenna discharge unit,

size of the grounding conductors, location of antenna discharge unit, connection to grounding electrodes, and

requirements for the grounding electrode.

• Nonuse Periods – The power cord of the appliance should be unplugged from the outlet when left unused for

a long period of time.

• Object and Liquid Entry – Care should be taken so that objects do not fall and liquids are not spilled into the

enclosure through openings.

• Damage Requiring Service – The appliance should be serviced by qualified service personnel when: The

power-supply cord or the plug has been damaged; or objects have fallen, or liquid has been spilled into the

appliance; or the appliance has been exposed to rain; or the appliance does not appear to operate normally

or exhibits a marked change in performance; or the appliance has been dropped, or the enclosure damaged;

or the batteries have been damaged.

• Servicing – the user should not attempt to service the appliance beyond that described in the operating

instructions. All other servicing should be referred to qualified service personnel.

Items x1 and x2 apply only to receivers, tuners and TV sets.

1.22 Grundig Service

Grundig Annual 1999 General Part

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

LASER Safety

The MOS safety requirements must be met because many components, particularly the laser diode, are very

sensitive to static electricity.

The pick-up unit incorporates many precision components and should therefore be protected against high

temperatures, high humidity, strong magnetic fields, mechanical shocks and dust.

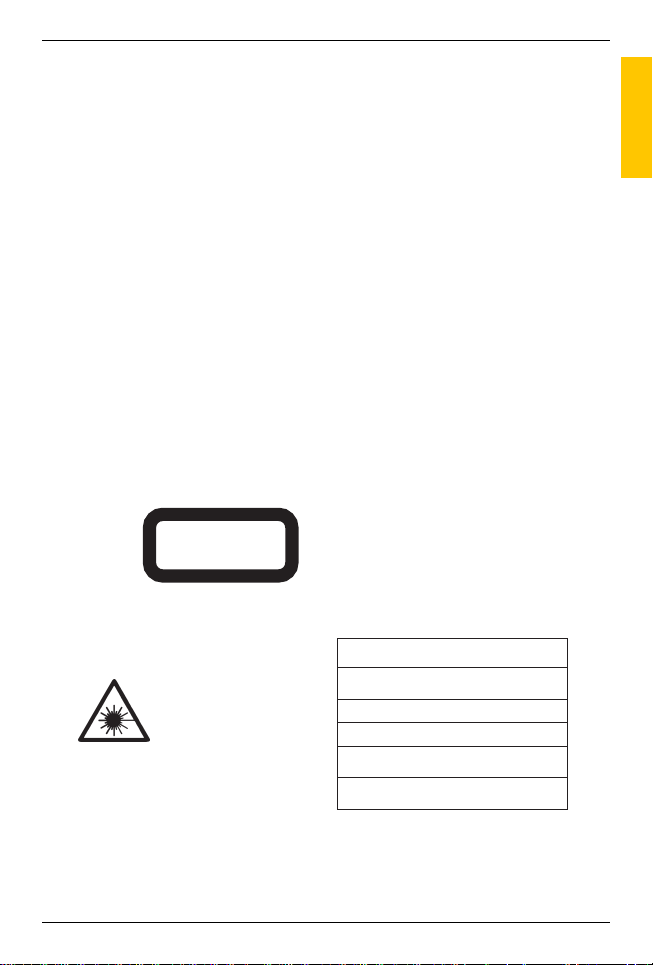

– The CD Player belongs to the category of products with a low-power LASER.

– According to DIN VDE 0837 or IEC 825 it is a Class 1 LASER meaning that the output power limits are determined

by the design. The LASER DIODE must not be operated outside the pick-up since the output power increases

by many times (Class 3B) and will cause injuries to the eye. In this case the use of LASER protective goggles

is strictly recommended.

– Due to the lens system of the LASER pick-up the focal point of the LASER light is about 1.5mm above the focus

lens. The focal point is located low enough to allow the LASER to be looked at with unprotected eyes.

– Avoid looking at the LASER using external optical means such as, for example, a magnifying glass because the

focal point will be projected onto the retina and may cause injuries to the eye.

– The LASER light appears on the focus lens of the pick-up as a dark-red spot when looking at the optical system

at an angle, preferably at low ambient brightness.

– By placing a sheet of transparent paper onto the focus lens the LASER spot is projected onto the back of the sheet

and is well perceivable.

In general, built-in safety locks ensure that the LASER does not operate with an open disc compartment

cover. In consideration of the above instructions, the special safety locks can be made ineffective and

the LASER will be visible as a small red spot.

Safety Standard Classes for the LASER (according to DIN IEC 825 / VDE 0837)

Class 1

Not dangerous for the human eye. Maximum output power eg: at 700nm…69µW.

General Part

CLASS 1

LASER PRODUCT

Class 3 B

Dangerous for the human eye and, in special cases, for

the skin. Maximum radiation power up to 0.5W.

FALLS ERFORDERLICH

IF APPLICABLE

HVIS NØDVENDIG

HVIS DET KREVES

The output of laser light from a CD pick-up unit

corresponds to Class 1. If the laser diode is

operated outside pick-up unit, this corresponds to

operation under Class 3 B.

VARNING!

OM APPARATEN ANVÄNDS PÅ SÄTT ÄN I

DENNA BRUKSANVISNING SPECIFICERATS, KAN ANVÄNDAREN

UTSÄTTAS FOR OSYNLIG LASERSTRÅLNING,

SOM ÖVERSKRIDER GRÄNSEN FOR LASERKLASS 1.

Grundig Service 1.23

LUOKAN 1 LASERLAITE

KLASS 1 LASER APPARAT

VORSICHT – UNSICHTBARE LASERSTRAHLUNG TRITT AUS,

WENN DECKEL GEÖFFNET UND WENN SICHERHEITSVERRIEGELUNG

ÜBERBRÜCKT IST. NICHT DEM STRAHL AUSSETZEN.

CAUTION – INVISIBLE LASER RADIATION

WHEN OPEN AND INTERLOCKS DEFEATED.

AVOID EXPOSURE TO BEAM.

ADVARSEL – UNSYNLIG LASERSTRALING NAR DEKSEL APENS

UNNGA EKSPONERING FOR STRALEN.

ADVARSEL – UNSYNLIG LASER STRÅLING VED ÅBNING.

UNDGÅ UDSETTELSE FOR STRÅLING.

VARNING – OSYNLIG LASER STRÅLNING NÄR

DENNA DEL ÄR ÖPPAND OCH SPÄRREN ÄR URKOPPLAD.

BETRAKTA EJ STRÅLEN.

VARO – AVETTAESSA JA SUOJALUKITUS OHITETTAESSA

OLET ALITTIINA NÄKYMÄTTÖMÄLLE

LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

VAROITUS!

LAITTEEN KÄYTTÄMINEN MUULLA KUIN TÄSSÄ

KÄYTTOOHJEESA MAINITULLA TAVALLA SAATTAA

ALTISTAA KÄYTTÄJÄN TURVALLISUUSLUOKAN I

YLITTÄVÄLLE NÄKYMÄTTOMÄLLE LASERSATEILYLLE.

General Part Grundig Annual 1999

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

Safety Advice for Lithium Batteries

General Part

Warning! Lithium Batteries:

Incorrectly used lithium batteries (excessive heat, reversed connection of terminals, short circuit) represent a danger

of explosion!

Lithium batteries must be replaced only by the original spare part (see Spare Parts List).

Please observe the appropriate disposal regulations for exhausted lithium batteries.

Adversel!

Lithiumbatteri. Eksplosionsfare ved fejlagtig håndtering. Udskiftning må kun ske med batteri af samme fabrikat og

type. Levér det brugte batteri tilbage til leverandøren.

s

Varning

Eksplosionsfara vid felaktigt batteribyte. Ånvänd samma batterityp eller en ekvivalent typ som rekommenderas av

apparattillverkaren.

Kassera använt batteri enligt fabrikantens instruktion.

ß

Varoitus

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

Handling of MOS Chip Components

Circuits containing MOS devices require special and careful handling to protect them from damage by static charges.

Static charges can build up on all highly insulated plastics, can be transferred to persons wearing clothes and shoes

made from synthetic materials and from them to the MOS devices.

Protection circuits in the inputs and outputs of MOS devices provide only a limited degree of protection and this is

due to their reaction time.

Please observe the following instructions to protect these components from damage by static charges:

1. Retain MOS components in their conductive packages until they are required for use. MOS components must

never be stored or transported in Styroper materials or in plastic magazines.

2. Personnel handling MOS components must first discharge any electrostatic charge on their body or clothing by

touching a grounded object.

3. Handle the MOS device by the body and do not touch the terminals / pins.

4. Use earthed instruments only for testing and processing purposes.

5. Removal of, or making contact with, MOS ICs fitted into sockets must only be carried out with the operating voltage

disconnected.

6. Circuits containing p-channel MOS components must not be connected to positive voltages (with reference to

the substrate connection VSS).

MOS Soldering Instructions

• Use mains-isolated low-voltage soldering irons only.

• Maximum soldering period is 5 sec with a soldering iron temperature of 300°C to 400°C.

1.24 Grundig Service

Grundig Annual 1999 General Part

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

CHIP Technology

Soldering and unsoldering of CHIP components

– Use only low-voltage soldering irons with temperature control.

– Permissible soldering temperatures are approx. 240°C up to max. 300°C.

– Keep the soldering period as short as possible.

– Keep the CHIP components in their original packages until they are used to avoid oxidation of the end contacts.

– Do not touch CHIP components with bare hands.

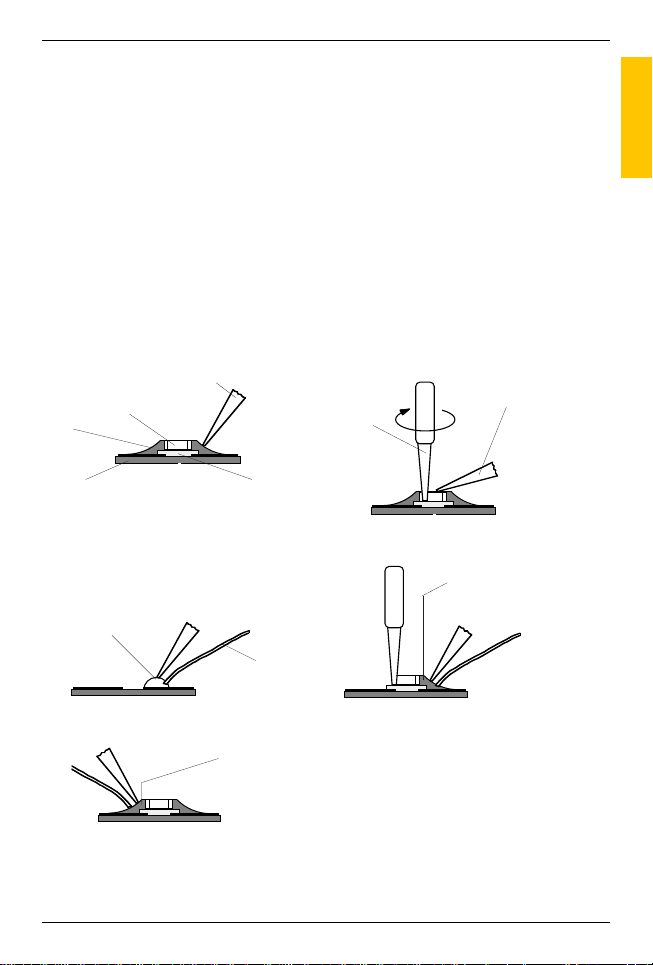

Unsoldering of CHIP components

1. step: Clean the CHIP soldering point with a solder wick (Fig. 1).

2. step: Warm up the ends of the CHIP or the whole CHIP component and remove the CHIP from the adhesive by

turning it without application of force so that the tracks beneath the CHIP do not break (Fig. 2).

Attention! Never use unsoldered CHIPS again!

Soldering of CHIP components

3. step: Remove any remaining residues from the soldering point. Then apply a bead of solder (Fig. 3).

4. step: Place the CHIP onto the soldering point, then center and fix it (Fig. 4).

5. step: Solder the free end of the CHIP and resolder the first soldering point after it has cooled (Fig. 5).

The conductive layer may be broken.

General Part

Tip of soldering iron

P.C.B.

Fixing point

Chip

Adhesive

Solder

Joint 2

Solder

Fig. 1 Fig. 2

Fig. 3 Fig. 4

Fig. 5

More detailed information on the SMD soldering technology is given in the service brochure

"SMD Soldering Technology" – d – obtainable under the part no. 72008-499.98.

Grundig Service 1.25

Tweezers

Tip of soldering iron

Joint 1

General Part Grundig Annual 1999

TV

Video

Camcorder

SAT

Audio/HiFi

Electronic Appliances

General Part

ISDN - InfoTip

The common

Service Communication System in the

Entertainment Electronics Industry!

GRUNDIG and members of the industrial

association of entertainment electronics within

the ZVEI (Central Association of the

Electrotechnical Industry) offer the specialised

dealers

"ISDN-Info Tip"

as a future-orientated communication system.

1.26 Grundig Service

Loading...

Loading...