Page 1

GRUNDFOS INSTRUCTIONS

75

+

FM

SL1 and SLV pumps

1.5 - 15 hp, 60 Hz

Installation and operating instructions

Page 2

2

Page 3

SL1 and SLV pumps

1.5 - 15 hp, 60 Hz

Installation and operating instructions 4

Instrucciones de instalación y funcionamiento 30

Notice d'installation et de fonctionnement 58

3

Page 4

LIMITED WARRANTY

Products man ufactu red by GR UNDFOS P UMP S CO RPOR ATION (Grundfos) are warrante d

to the original user only to be free of defects in material and workmanship for a period of

24 months from date of installation, but not more t ha n 30 mon ths fr om da te of man uf actu re .

Grundfos' liabilit y under this warra nty sha ll be limite d to repair ing or replaci ng at Gr undfo s'

option, without charge, F.O.B. Grundfos' factory or authorized service station, any product

of Grundfos' manufacture. Grundfo s will not be liable for a ny costs of removal, installation,

transportation, or any other charges which may arise in connection with a warranty claim.

Products which are sold but not manufactured by Grundfos are subject to the warranty

provided by the manufacturer of said products and not by Grundfos' warran ty. Grundfos will

not be liable for damage or wear to products caused by abnormal operating conditions,

accident, abuse, misu se, unauth orized al teration or rep air, or if the product w as not inst all ed

in accordance with Grundfos' printed installation and operating instructions.

To obtain service under this warranty, the defective product must be returned to the

distributor or dealer of Grundfos' products from which it was purchased together with proof

of purchase and installation date, failure date, and supporting installation data. Unless

otherwise provided, the distributor or dealer will contact Grundfos or an authorized service

station for instruction s. Any defectiv e produc t to be returne d to Grundfos or a service st ation

must be sent freight prepaid; documentation supporting the warranty claim and/or a Return

Material Authorization must be included if so instructed.

GRUNDFOS WILL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES, LOSSES, OR EXPENSES ARISING FROM INSTALLATION, USE, OR ANY

OTHER CAUSES. THERE ARE NO EXPRESS OR IMPLIED WARRANTIES, INCLUDING

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, WHICH EXTEND

BEYOND THOSE WARRANTIES DESCRIBED OR REFERRED TO ABOVE.

Some jurisdictions do not allow the exclusion or limitation of incidental or consequential

damages and some jurisdictions do not allow limit actions on how long implied warranties

may last. Therefore, the above limit ati ons or exclu sions m ay not app ly to you . This warran ty

gives you specific legal rights and you may also have other rights which vary from

jurisdiction to jurisdiction.

4

Page 5

Original installation and operating instructions.

Caution

Note

FM

1. Symbols used in this document

CONTENTS

1. Symbols used in this document

2. General description

2.1 Product drawing 6

2.2 Control and monitoring 6

2.3 Applications 6

2.4 Pump selection 6

2.5 Operating conditions 7

3. Delivery and handling

3.1 Transportation 8

3.2 Storage 8

4. Identification

4.1 Nameplate 8

4.2 Type key 9

5. Approvals

5.1 Approval standard s 10

5.2 Explanation to FM approval 10

6. Safety

6.1 Potentially explosive env ironm ents 11

7. Installation

7.1 Submerged installation on auto -cou pling 12

7.2 Free-standing submerged ins tallation o n rin g stand 13

8. Electrical connection

8.1 Wiring diagrams 15

8.2 Pump controllers 18

8.3 Thermal switch, Pt1000 and thermistor 19

8.4 WIO sensor (water-in-oil sensor) 19

8.5 Moisture switch 19

8.6 IO 111 20

8.7 Frequency convert er oper atio n (VFD ) 20

9. Start-up

9.1 General start-up procedure 21

9.2 Operating modes 22

9.3 Direction of rotation 22

10. Maintenance and service

10.1 Inspection 23

10.2 Dismantling the pump 23

10.3 Asse mb ling th e pum p 24

10.4 Oil quantities 25

10.5 Service kits 26

10.6 Contami nate d pumps 26

11. Fault finding

12. Technical data

13. Disposal

10

10

11

14

21

22

27

28

29

Warning

5

5

8

8

If these safety inst ructio ns ar e not obser ved, it

may result in personal injury!

Warning

If these instructions are not observed, it may lead

to electric shock with consequent risk of serious

personal injury or death.

Warning

These instruction s must b e ob served for

explosion-proof pumps. It is advisable also to

follow these instructions for standard pumps.

If these safety inst ructio ns ar e not obser ved, it

may result in malfunction or damage to the

equipment.

Notes or instructio ns tha t make the jo b easi er

and ensure safe operation.

2. General description

This booklet include s inst ruc tions for installa tion, o peratio n an d

maintenance of Grundfos SL1 and SLV submersible sewage and

wastewater pumps with motors of 1.5 to 15 hp (1.1 to 11 kW).

Grundfos SL1 and SLV sewage pum ps ar e de signed for pumping

domestic and indu str ial sew age and wa stewat er.

Two types of pumps are available:

• SL1 sewage pumps with single-cha nnel im peller

• SLV sewage pumps with Vortex impeller.

The pumps can be ins talled on an aut o-coupli ng s ystem or stand

freely on the bott om of a tan k.

Grundfos SL1 and S LV pumps are designed wit h sin gle-chan ne l

and free-flow impel ler, respective ly, to ensure reliable and

optimum operation .

The booklet also include s spe cific in str ucti ons for the explo si onproof pumps.

Warning

Prior to installation, read these installation and

operating instructions. Installation and operation

must comply with local regulations and accepted

codes of good practice.

Warning

The use of this product requires experience with

and knowledge of the product.

Persons with reduced physical, sensory or

mental capabilities must not use this product,

unless they are under supervision or have been

instructed in the use of the product by a person

responsible for their safety.

Children must not use or play with this product.

5

Page 6

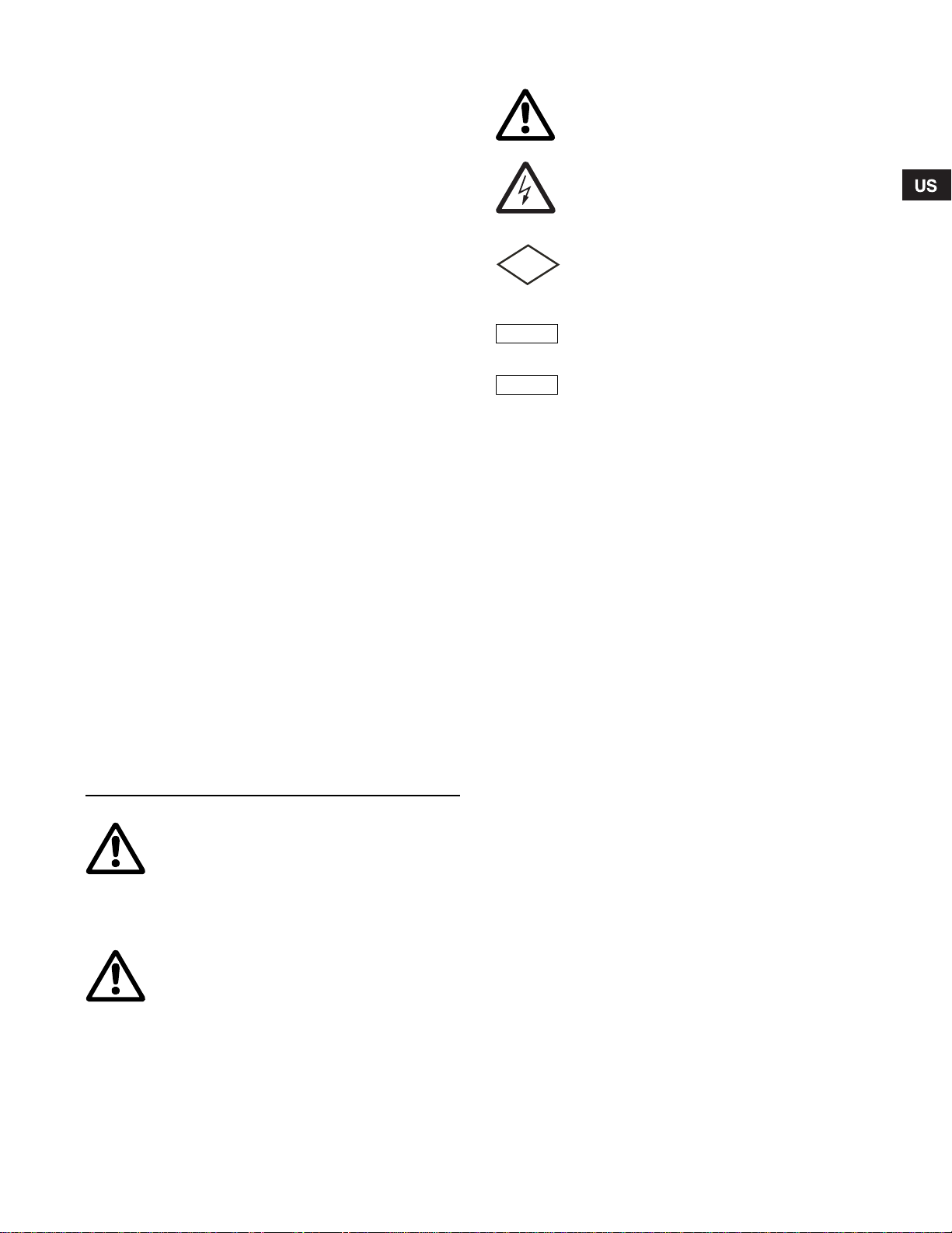

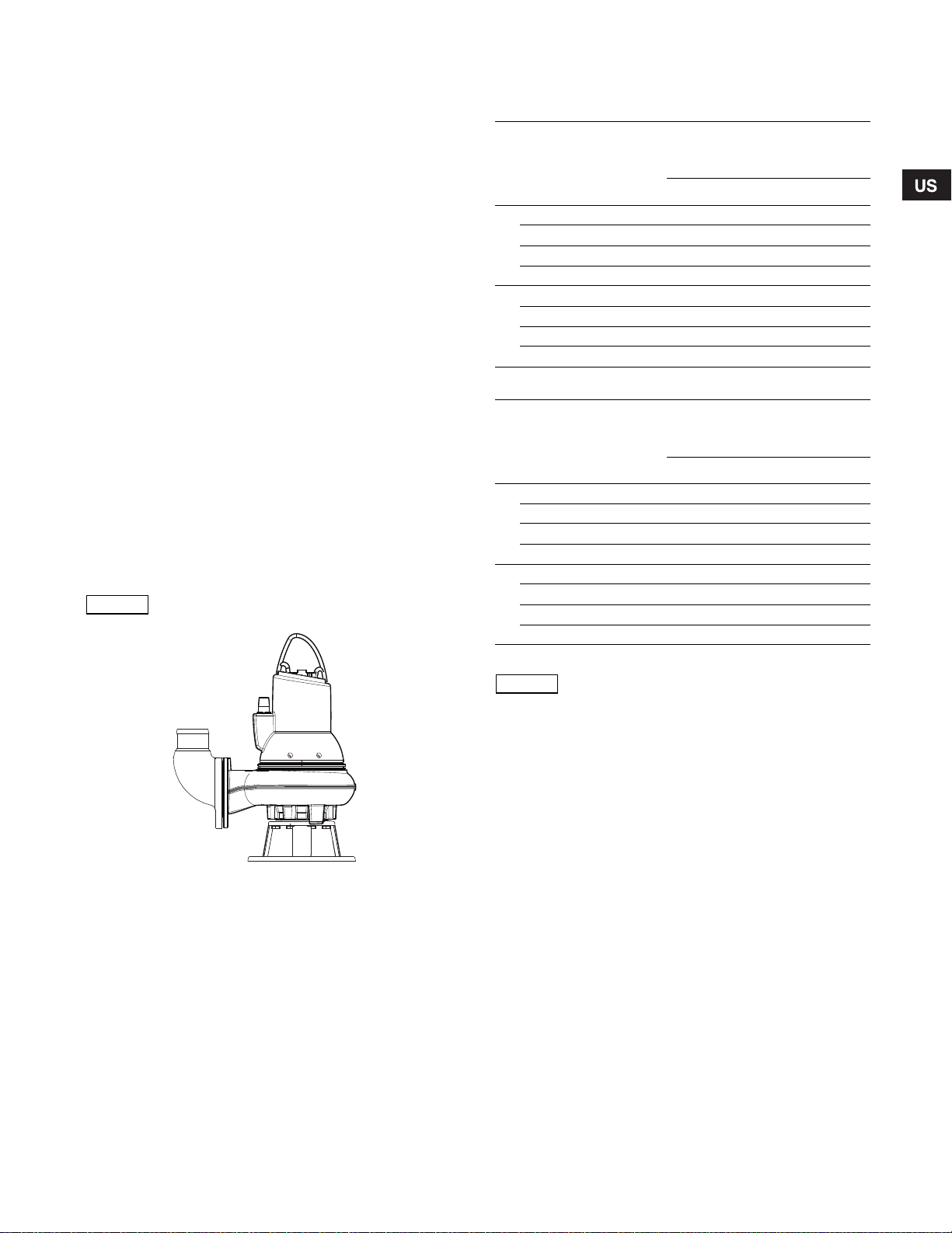

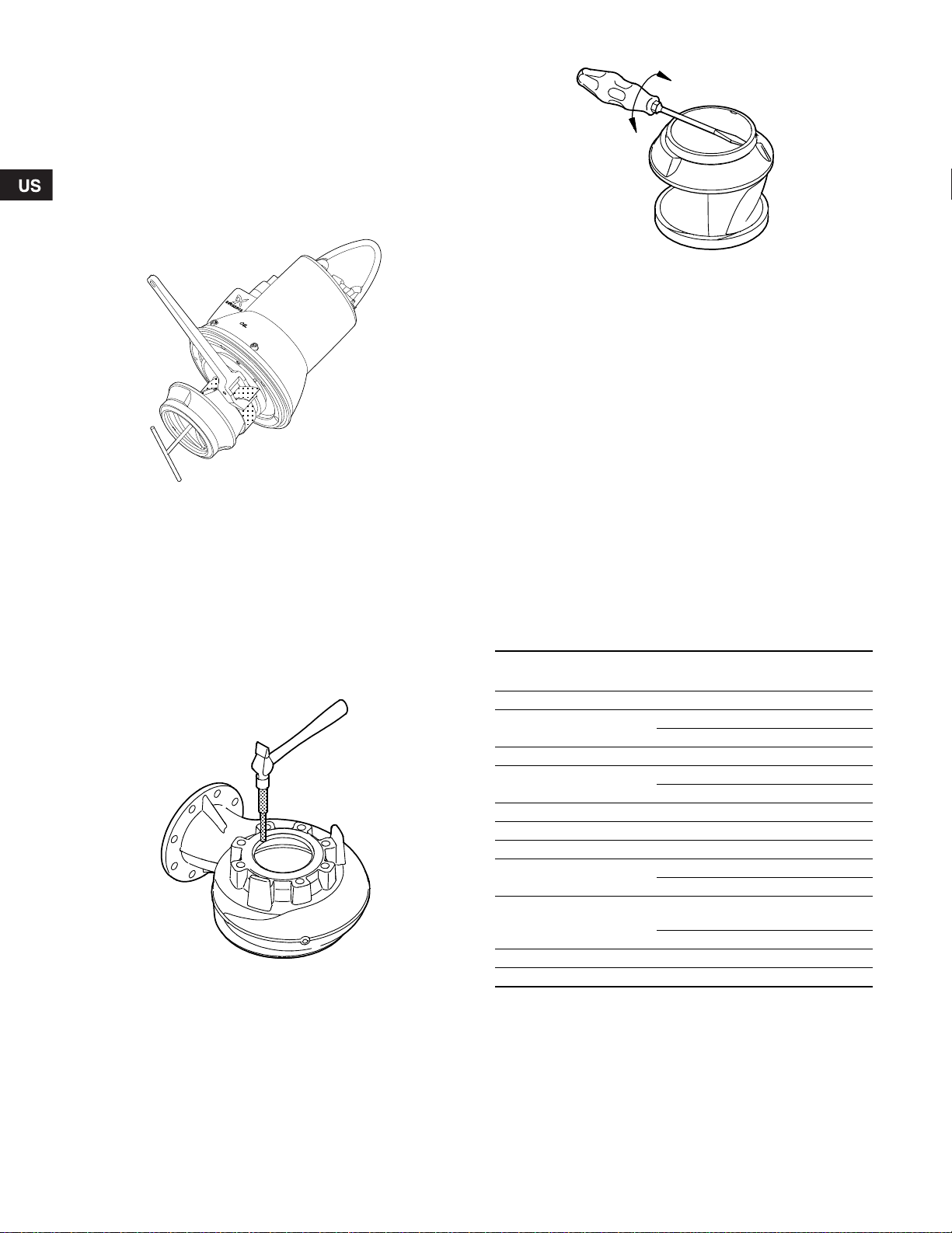

2.1 Product drawing

1

5

2

6

4

3

7

Fig. 1 SL1 pump

Pos. Description

1 Lifting bracket

2 Nameplate

3 Oil screws

4 Discharge flange

5 Cable plug

6 Clamp

7 Pump housing

For further info rmatio n on dimen sions , wei ghts and co mpon en ts,

see pages 86 and 94.

2.2 Control and monit oring

The pumps can be co ntro lled via the G rund fos Dedic ated

Controls, DC or DCD.

Pumps with sensor ar e supp lied to geth er with a n IO 111 which

can receive sig na ls from the foll owi ng tr ansm itter s:

• water-in-oil-sensor ( WIO sens or) in th e pu mp

• moisture sensor in the motor

• temperature sensor in t he stator win din gs

• winding resistance sensor in the motor.

For further in f orm at ion , se e i nst al l at ion an d o pera ti n g ins t ruct io n s

for the specific sensor.

2.3 Applications

SL1 and SLV pumps are designed for pump ing these liq uid s:

• large quantities of drainage and surf ace water

• domestic wastewater with disc harge from toile ts

• wastewater with a high content of fibres (vor tex imp elle r)

• municipal and commercial sewage a nd was tewat er.

SL1 and SLV pumps are ideal in the following loc ations:

• public buildings

• recidential housing

• industries

• garages

• multi-storey car parks

• vehicle washing tunnels

• restaurants.

The compact design m akes the p umps suitab le for bo th

temporary and pe rma nen t installa tion.

TM04 2648 2808

2.4 Pump selection

The table below shows wh ich pu mp ve rsion to se lect for a

number of liquids:

Impeller type: 1 = single-chann el imp eller, V = free-flow impeller.

Pump passage

Pumped liquid

Drainage water 1 V 1 / V 1 / V

Domestic wastewat er witho ut

discharge from toilets

Domestic wastewat er with

discharge from toilets

Wastewater with a high conten t of

fibres

Industrial wastewater 1 / V 1 / V

Wastewater with gaseous slu dge 1 / V 1 / V

Municipal wastewater 1 / V 1 / V

[Inch (mm)]

2

2.5

(50)

(65)3(80)4(100)

1 V 1 / V 1 / V

VVV

1 / V 1 / V

6

Page 7

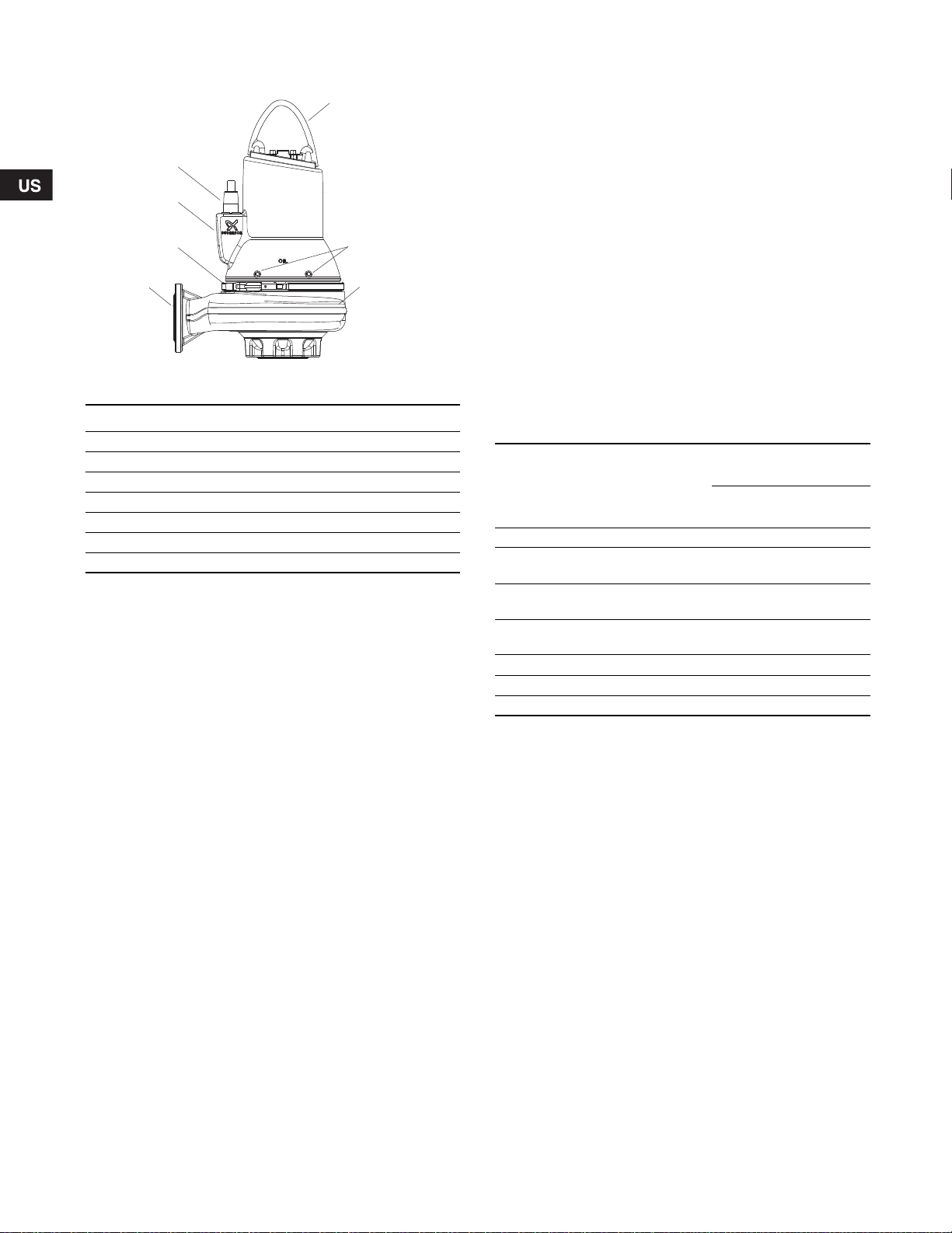

2.5 Operating conditions

S1 operation

S3 operation

FM

FM

Note

Caution

The Grundfos SL 1 and S LV pumps are suitable for th e follo wing

operating situations :

• S1 operation (continuous operation), th e pu mp mu st a lways

be covered by the pu m ped liqu id to t he top of the mot or.

See fig. 2.

• S3 operation (intermittent operation) , the pu mp must alwa ys

be covered by the pu m ped liqu id up t o the top of the c abl e

entry. See fig. 2.

For further info rmatio n ab out S1 a nd S3 o per ation, see s ection

9.2 Operat ing mo des.

Fig. 2 Stop levels

Density and viscosity of pumped liquid

When pumping liqu ids wit h a density and/or a kinematic viscos it y

higher than that of wa t er, use motors w ith correspondingly h ighe r

outputs.

Pumping liquids with high content of solids, fibres etc.

This procedure applies only to vortex impellers.

In very tough applications, and in applications with high content of

solids, fibres, etc. it is advisable to rotate the impeller backwards

a few seconds, before or after each pump cycle.

Do not rotate the impeller in single-channel

impeller pumps backwards.

Flow velocity

It is advisable to keep a minim um f low v elocity to avoid

sedimentations in the pip ing sy stem . Recom men ded flow

velocities:

- in vertical pipes: 2.3 ft/s (0.7 m/s)

- in horizontal pipes: 3.3 ft/s (1.0 m/s)

Installation depth

Maximum 65 ft (20 m) be low liqui d lev el.

Maximum solids s ize

From 2" to 4" (50 to 10 0 mm), depen ding on p ump s ize.

Operating mode

TM04 2649 2808

Maximum 30 s tarts per ho ur.

pH value

SL1 and SLV pumps in permanent installation s can be u sed for

pumping liquids wi th a pH va lue between 4 an d 10.

Liquid temperature

32 °F to +104 °F (0 °C to + 40 °C).

For short perio ds (m axim um 3 m inut es) a temp eratur e of u p to

+140 °F (+60 °C) is permissible ( non-FM versions only).

Warning

Explosion-proof pumps must never pump liquids

of a temperature hi gher than +104 °F (+40 °C).

Ambient temperature

Warning

For explosion-proof pumps, the ambient

temperature on t he inst allat ion site must b e in

the range from -4 °F t o + 104 °F (-20 °C t o +40 °C).

For explosion-proof pumps with WIO sensor, the

ambient temper atu re at the ins talla tion s ite m ust

be in the range from 32 °F to +104 °F

(0 °C to +40 °C).

For non-explosi on proo f pum ps, the ambie nt tem perat ure may

exceed +104 °F (+40 °C) f or a s hort per iod (m ax. 3 m inut es).

7

Page 8

5

4

1

3

6

7

9

10

8

13

11

16

18

15

19

20

23

17

22

24

21

25

12

14

2

3. Delivery and handling

The pump may be tr anspo rte d and sto re d in a vert ical or

horizontal position . Ma ke su re that it ca nno t roll or fall over.

3.1 Transportation

All lifting equipment m ust be r ated for the purpo se and ch ecke d

for damage before any attempts to lift the pump. The lifting

equipment ratin g mus t und er n o circ ums tances be exce ede d.

The pump weight is stated on the pump nameplate.

Warning

Always lift the pump by its lifting bracket or by

means of a fork-lift truck if the pump is fixed on a

pallet. Never lift the pump by means of the motor

cable or the hose/pipe.

4. Identification

4.1 Nameplate

The nameplate states the o peratin g da ta and app rova ls app lyin g

to the pump. The nameplate is fitted to the side of the stator

housing close to the cable e ntry.

Fix the extra nam eplate s upplie d with the pu mp to the cab le en d

in the control box.

3.2 Storage

During long period s of stor age, the pum p mus t be prot ecte d

against moisture and heat.

Storage temperature: -22 °F to +140 °F (- 30 °C to +60 °C)

Warning

If the pumps are sto r ed f o r mo r e th a n o ne year or

it takes a long time before it is put into operation

after the installation, the impeller must be turned

at least once a month.

If the pump has bee n in use , the oil should be cha nged be fore

storage.

After a long period of st orage , the pu mp sh ould be inspec ted

before it is put into operation. Make sure that the impeller can

rotate freely. Pay special attention to the co nditi on of the sh aft

seal, O-rings, oi l and the c abl e entry.

Fig. 3 N amepl ate

Pos. Description

1 FM marking

2 Thermal protected

3 Type designation

4 Serial number

5 Production code (year/week)

6 Maximum ambient tem pera ture

7 Maximum head

8 Maximum flow rate

9 Rated input/output power

10 Ra ted voltage, D

11 Rated voltage, Y

12 Fre qu ency

13 Co untry o f produc tion

14 CSA mark

15 F M ma rk

16 E nclos ure clas s to IE C

17 Maximum installation depth

18 P ower fa ctor

19 Nu mber of pha ses

20 Ra ted spe ed

21 S ervice f actor

22 Full lo ad curr ent, D

23 Full lo ad curr ent, Y

24 Ins ulati on class

25 Weight without cab le

TM04 4187 0909

8

Page 9

4.2 Type key

The pump can be ide ntified by me ans of the type des ignat ion s tated on t he pum p nam eplat e. See se ction 4.1 Nameplate.

Code Example SL 1. 30 .A30. 55. A. Ex. 4. 6. 0H A. Q.

Pump type:

SL

Grundfos wastew ater pum p/s ewag e pu mp

Impeller type:

1

Single-channel impe ller

V

Free-flow impeller ( SuperVortex)

Pump passage. Code numbe r fr om typ e key / 10 [i nch]:

20

2" (50 mm)

25

2.5" (65 m m)

30

3" (80 mm)

40

4" (100 mm)

Pump discharge (d ischa rge po rt in in ch es):

A25

Ansi 2.5" (DN65 )

A30

Ansi 3" (DN80)

A40

Ansi 4" (DN100)

A60

Ansi 6" (DN150)

Motor power. Code number from type key / 10 [hp]

55

5.5 hp = 4.0 kW

Accessories:

[-]

Standard

A

Sensor

Pump version:

[-]

Non-explosion-pro of

Ex

Explosion-proof

Number of poles:

2

2-pole

4

4-pole

Frequency:

6

60 Hz

Voltage and starting method:

0J

3 x 208-230V Δ DOL, (60 Hz)

1J

3 x 208-230V Δ / 460V Y, (60 Hz)

1H

3 x 460V Δ Y/D, (6 0 Hz)

0L

3 x 575V Δ DOL, (60 Hz )

1L

3 x 575V Δ Y/D, (6 0 Hz)

Product generation:

A

1st generation

B

2nd generation

C

3rd generation

Material variant:

[-]

Cast iron impeller, volute and stator housing

Q

Stainless steel impeller

9

Page 10

5. Approvals

Note

FM

Note

Note

Caution

Caution

Caution

Caution

The SL1 and SLV pumps have been approved by CSA and FM, and the explosion-proof versions hold an FM type examination certif ic at e

no.: 3035318.

5.1 Approval standards

These pumps have been app rove d by CS A and FM acc ordi ng to U L778, C22.2 n o. 108 and F M 360 0, FM 3615 an d FM 361 5.80 .

5.2 Explanation to FM approval

The SL1 and SLV pumps have the follo wing ex plos ion p rotec tion clas sif icat ion: Cl ass I, Div ision 1, Gro ups C and D, T4, T3, IP68 .

Standards Code Description

Class I = Explosive atmosphere is caus ed by g as or v apour s.

FM 3600

FM 3615

FM 3615.80

Division 1 = Area classi fica tion

Groups C and D = Classification of gases

T4/T3 = Maximum surface temper atu re is 275 °F (1 35 °C) and 3 92 °F (200 °C)

IP68 = Enclosure class acco rding t o IEC 6 0529.

6. Safety

Warning

Pump installation in tanks must be carried out by

specially trained persons.

Work in or near tanks must be carried out

according to local regulations.

Warning

Persons must not enter the installation area

when the atmospher e is ex plosi ve.

Warning

It must be possible to lock the mains switch in

position 0. Type and requirements as specified in

National Electrical Code and all local codes.

For safety reas on s, all w ork in tanks mu st be super vise d by a

person outside the pump ta nk.

It is advisable to make all maintan ce an d serv ice

jobs when the pump is placed outside the tank.

Tanks for submer sible s ewage and wast ewat er pu mps ma y

contain sewage or wa stew ater wit h to xic an d/or disea se-cau sin g

substances. Therefor e, all per sons involv ed m ust wear

appropriate pers onal pr ote ctive eq uipm ent an d clothi ng, an d all

work on and near the pu mp m ust b e carr ied out u nde r stric t

observance of the hy giene r egu lations in force .

Warning

Make sure that the liftin g br ack et is ti ght ened

before attempting to lift the pump. Tighten if

necessary. Carelessness during lifting or

transportation may cause injury to personnel or

damage to the pump.

The following warnings and notes also appear in a label

(delivered with the pump) . Pla ce th e labe l near t he co ntro l

box.

Warning

To reduce risk of electric shock, see installation

and operating instructions for guidance in proper

installation.

Warning

To reduce risk of electric shock, install only on a

circuit protected by a ground-fault circuit

interrupter (GFCI).

Acceptable for indoor and outdoor use.

Submersible pump.

Provide suitable motor protection based on the

electrical ratings.

Enclosure type 3.

This pump has been tested with water only.

Use wih approved motor protective circuit

breaker matching motor input in full-load

amperes with overloa d el ement (s) se lected or

adjusted in accorda nce with con trol inst ructio ns.

Warning

Risk of electric shoc k. Do not remo ve cab le an d

strain relief. Do not connect conduit to pump.

Warning

Risk of electric shock

This pump has not been approved for use in

swimming pools or marine areas.

10

Page 11

6.1 Potentially expl osiv e en vironmen ts

FM

FM

FM

Caution

Note

Caution

Use explosion-pr oof pum ps for a pplica tions in p oten tially

explosive envi ronm ents. Se e sec tion 5.2.

Warning

SL1 and SLV pumps must under no

circumstances pump combustible liquids.

Warning

The classification of the i nstall atio n site mus t be

approved by the local fire-fighting authorities in

each individual case .

Special conditions for safe use of SL1 and SLV

explosion-proof pumps:

1. Make sure the mo istu re sw itch es and th erma l

switches are connected in the same circuit but

have separate alarm outputs (motor stop) in case

of high humidity or high temperature in the motor.

2. Bolts used for replac emen t mu st be class A2- 70

or better according to EN/ISO 3506-1.

3. Contact the manufacturer for information on the

dimensions of the flameproof joints.

4. The level of pump ed liquid must be co ntro lled by

two level switches connected to the moto r control

circuit. The minimu m le vel de pen ds on the

installation type and is specified in these

installation and operat ing ins truct ions .

5. Make sure the perm anently attache d cable is

suitably mechanically pro tec t ed and term i na te d in

a suitable terminal boar d plac ed outside t he

potentially explosive area.

6. The sewage pumps have an ambient temperature

range of -4 °F to +104 °F (-20 °C to +40 °C) and a

maximum process temper atu re of +104 °F

(+40 °C). The mininmum ambient tem perature for

a pump with a water-in-oil sensor is 32 °F (0 °C).

7. The thermal protection in the stator windings has

a nominal switch temperature of 302 °F (150 °C)

and must guarant ee the d isc onne ctio n of the

power supply; th e powe r supp ly m ust be res et

manually.

8. The control unit mu st pro tect t he W IO sensor

against short circuit cur re nt of the supply to which

it is connected. T he ma xi mum curr ent fro m th e

control unit must be limited to 35 0 mA.

7. Installation

Warning

During installation, always support the pump by

means of lifting chains or place it in hor izontal

position to secure stability.

Prior to installation, make sure the tank bottom is

even.

Warning

Before beginning the installation, switch off the

power supply and lock the mains switch in

position 0.

Any external voltage connected to the pump must

be switched off before working on the pump.

Before beginn ing installat ion pr oced ures , carry out th ese ch eck s:

• Does the pump correspond to ord er?

• Is the pump suitable for the supp ly volta ge and f requ ency

available at the installatio n sit e?

• Are accessories and other eq uipme nt un dama ged?

Further details concerning accessories can be

found in the product guide SL1, SLV pumps on

www.grundfos.com.

Fix the extra nam eplate s upplie d with the pu mp to the cab le en d

in the control box.

All safety regulations must be observed at the installation site,

e.g. the use of blow ers for fre sh-a ir supp ly to th e tank.

Prior to installation, check the o il level in th e oil ch amber.

See section 10. Maintenance and service.

Warning

Do not put your hands or any tool into the pump

suction or discharge port after the pump has

been connected to the power supply, unless the

pump has been switched off by removing the

fuses or switching off the mains switch. It must

be ensured that the power supply cannot be

accidentally switche d o n.

We recommend to alwa ys us e Grund fos

accessories to avoid malfunctions due to

incorrect installation.

Warning

Only use the lifting bracket for lifting the pump.

Do not use it to hold the pump when in operation.

Installation types

The SL1 and SLV pumps are designe d for two in stallation typ es:

• submerged installation on auto-coupling

• free-standing submerged installat ion on ring stand.

11

Page 12

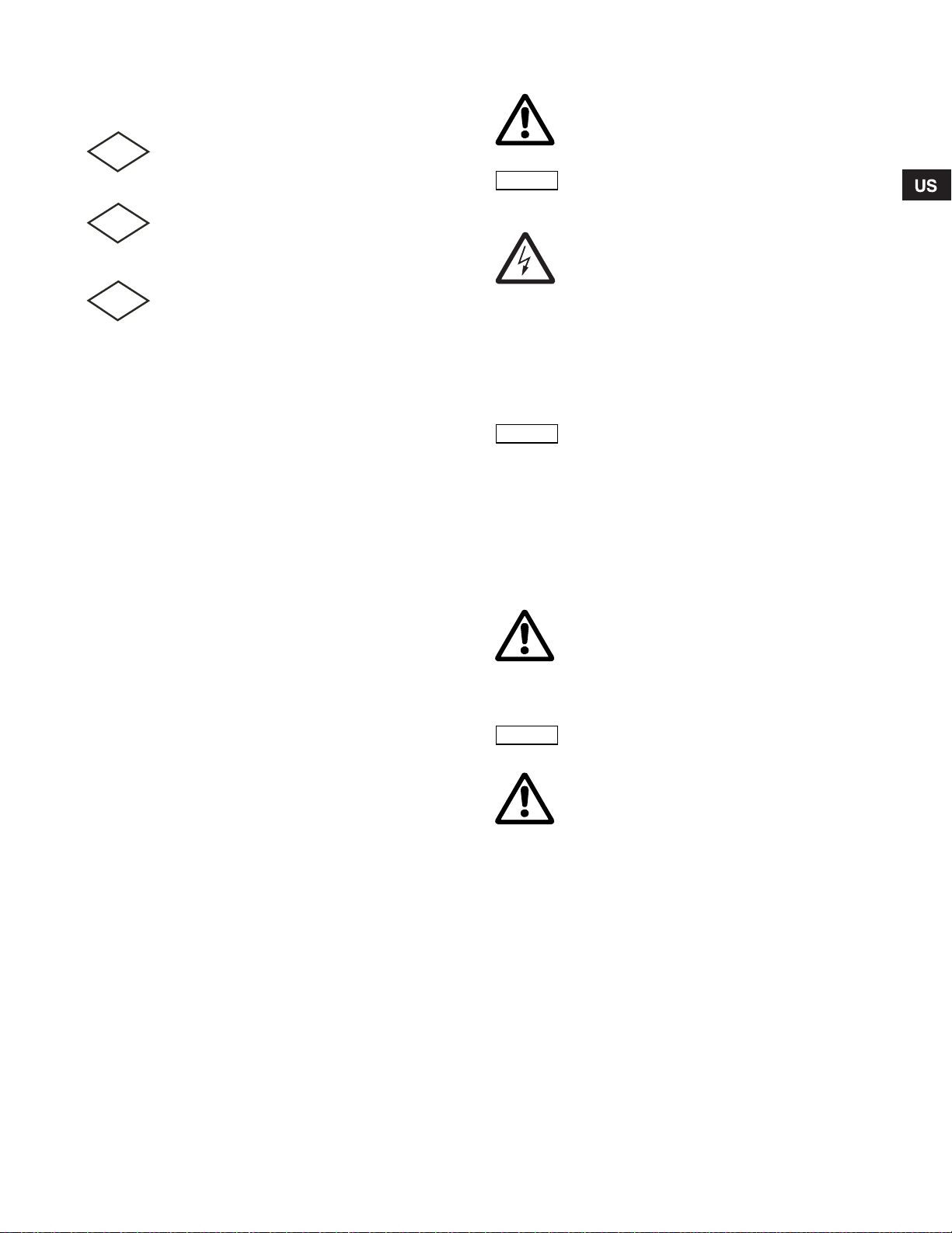

7.1 Submerged installation on auto -coupli ng

Caution

Caution

Note

Note

FM

Pumps for perm anent installation ca n b e i nstalled on a stationary

auto-coupling guide rail system. The auto-coupling system

facilitates mainte nance and se rv ice as t he pum p can easily be

lifted out of the tank. See fig. 4.

Warning

Before beginning installation procedures, make

sure that the atmos ph ere in the tan k is not

potentially explosive.

Make sure that the pipework is installed without

the use of undue force. No loads from the

pipework weight must be carried by the pump.

We recommend the use of loose flanges to ease

the installation and to avoid pipe tension at

flanges and bolts.

Do not use elastic elements or bellows in the

pipework; these elements should never be used

as a means to align th e pipe work .

Proceed as follows :

1. Drill mounting holes for the guid e rail br acket on the inside of

the tank and fasten the g uide rail br acke t pro visionall y w ith

two screws.

2. Place the auto-coup ling bas e unit on th e botto m of th e tank.

Use a plumb line to establis h the corr ect p osition ing. Fa ste n

the auto-coupling with ex pansion bol ts, If the botto m of th e

tank is uneven, the auto-coupling base unit must be supported

so that it is level when b eing fas tene d.

3. Assemble the discharge pipe in accordance with the generally

accepted procedu res an d w ithout expos ing th e pipe t o

distortion or tension.

4. Place the guide rails on the auto-coupling base unit and adjust

the length of the rails ac cura tely to the g uide rail br acke t at

the top of the tank.

5. Unscrew the pro visio nally f asten ed g uide ra il br acke t. In sert

the upper guide rai l brac ket in to the g uid e rails . Fast en t he

guide rail bracket on the ins id e of the tank.

The guide rails must not have any axial play as

this would cause noise during pump operation.

6. Clean out debris from the tank b efore low eri ng the pu mp int o

the tank.

7. Fit the guide claw to the discharge port of the pump.

8. Slide the guide claw of the pum p b etween t he gui de rails and

lower the pump into th e tank by mean s of a ch ain secu red to

the lifting bracket of the pum p. Wh en the pump reaches the

auto-coupling base unit, the pump w ill autom atically conn ect

tightly.

9. Hang up the end of th e chain on a sui table hoo k a t the top o f

the tank and in such a wa y tha t the c hai n cann ot co me int o

contact with the pump ho using.

10.Adjust th e length of the motor c able by coiling it up on a r eli ef

fitting to ensure that the cable is not damaged during

operation. Fasten th e r elief fitting to a suitable hook at th e t op

of the tank. Make sure tha t the c ables are not s harply bent or

pinched.

11.Connect the motor cable.

The free end of the cable must not be submerged,

as water may pen etrat e into the ca bl e.

TM04 2650 2808

Fig. 4 Sub merg ed insta llatio n on auto coupli ng

12

Page 13

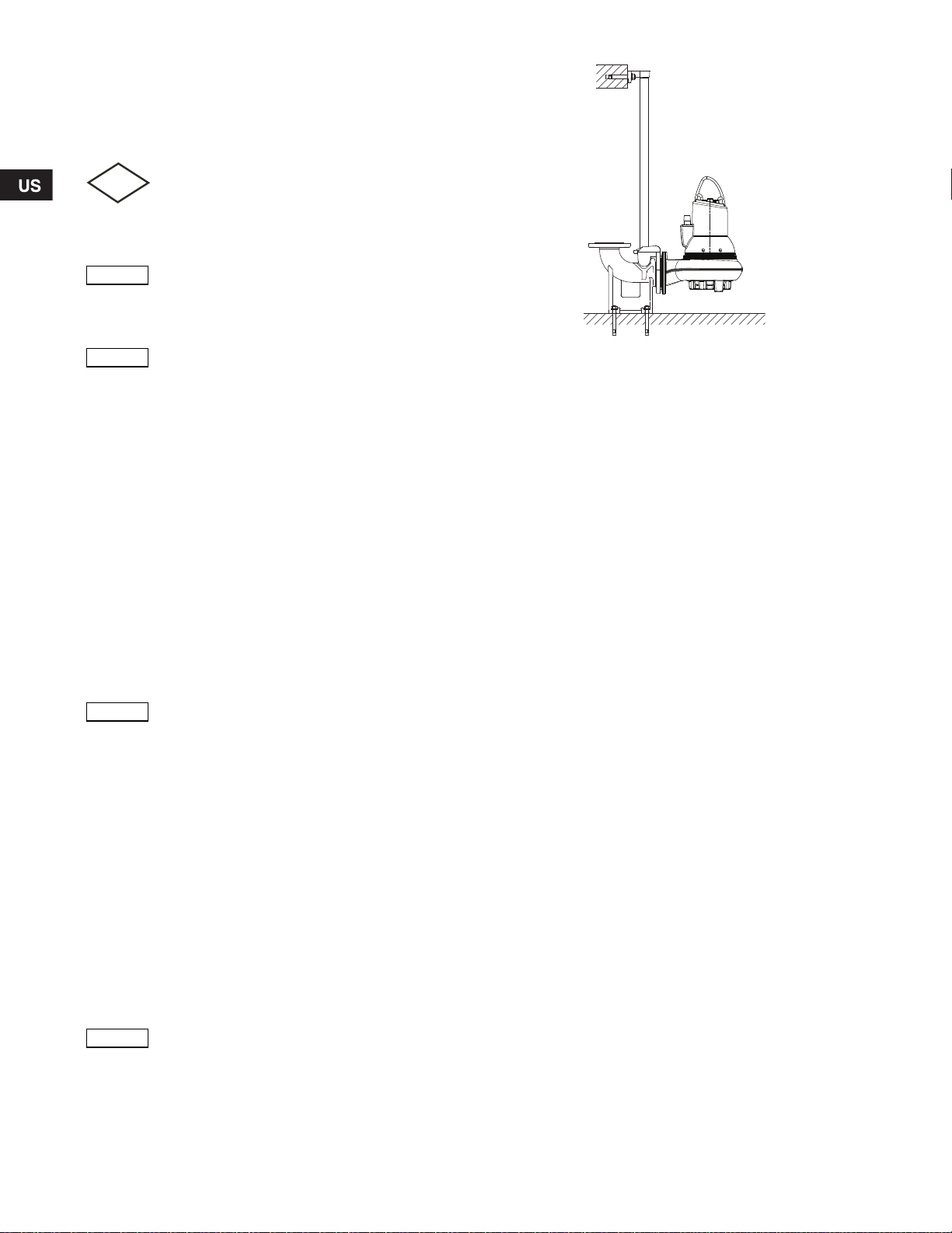

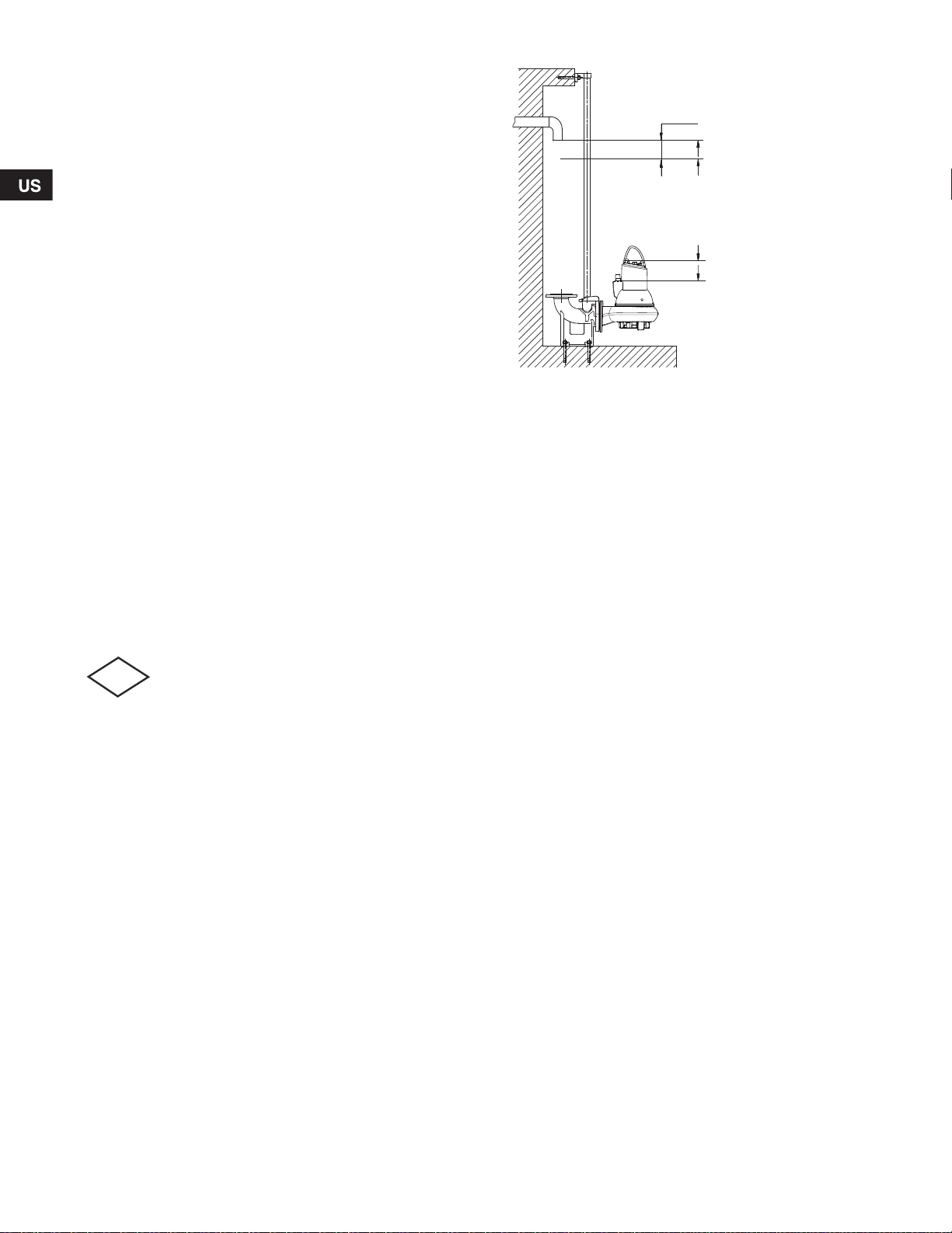

7.2 Free-standing submerged installation on ring stand

Note

Caution

Pumps for free-standin g s ubme rged in stallatio n c an stand fre ely

on the bottom of the tank. The pump must be installed on a ring

stand. See fig. 5.

The ring stand is availa ble as a n acce sso ry.

In order to facilitate service on the pump , fit a flexible un ion or

coupling to the elb ow o n the d ischa rge po rt f or eas y se paratio n.

If a hose is used, make s ure t hat th e hose doe s not buck le and

that the inside diam eter of the hose m atche s tha t of th e pum p

discharge port.

If a rigid pipe is used, fit the union or co upling, non-return v alv e

and isolating valve in the order mentioned, when viewed from the

pump.

If the pump is installed in muddy conditions or on uneven ground,

support the pump on br icks or a sim ilar s uppor t.

Proceed as follows :

1. Fit a 90 ° elbow to the pump disch arge p ort a nd con nect the

discharge pipe/hose .

2. Lower the pump into the liquid by means of a chain secured to

the lifting bracket of the pump. We recommend to place the

pump on a plane, solid foundation. Make sure that the pump is

hanging from the chai n and not the cable. Make sure that the

pump is standing se cure ly.

3. Hang up the end of the c hain on a suitabl e hook at the top of

the tank and in such a way that the c hain c annot c ome int o

contact with the pump hous ing.

4. Adjust the length of the motor cable by coiling it up on a relief

fitting to ensure that the cable is not damaged during operation.

Fasten the relief fitting to a suitable hook at the top of the tank.

Make sure that the cable is not sharply bent or pinched.

5. Connect the motor cable.

The free end of the cable must not be submerged,

as water may pen etrat e into the ca bl e.

7.3 Tightening torques for su ctio n and d ischa rge

flanges

Grade 4.6 (5) ga lvani zed st eel screw s an d nuts

Specified tightening torques

DN DC Screw

2½" 5½" 4xM16 50 (70) 45 (60)

3" 6" 8xM16 50 (70) 45 (60)

4" 7½" 8xM 16 50 (70) 45 (60)

Suction

6" 9½" 8x M20 100 (140) 90 (120 )

2½" 5½" 4x5/8" UNC 50 (70) 45 (60)

3" 6" 8x5/8" UNC 50 (70) 45 (60)

4" 7½" 8x5/8" UNC 50 (70 ) 45 (60)

Discharge

6" 9½" 8x3/4" UNC 90 (120) 80 (100)

Grade A2.50 (AISI 304) steel screws and nuts

DN DC Screw

2½" 5½" 4xM16 - 45(60)

3" 6" 8xM16 - 45( 60 )

4" 7½" 8xM 16 - 45(60)

Suction

6" 9½" 8xM 20 - 90(120)

2½" 5½" 4x 5/8" U NC - 45(60)

3" 6" 8x5/8" UNC - 45(60)

4" 7½" 8x5/8" UNC - 45(60)

Discharge

6" 9½" 8x3/4 UNC - 80(100)

rounded off by +/- 5

[ft.lbs (Nm)]

Slightly oiled Well lubricated

Specified tightening torques

rounded off by +/- 5

[ft.lbs (Nm)]

Slightly oiled Well lubricated

Fig. 5 Fr ee-stand ing sub mer ged ins tallation o n a ring stand

The gasket must be a full face, reinforced paper

gasket like Klingersil C4300 . If sof ter gask et

material is used, torques must be reconsidered.

TM04 2651 2808

13

Page 14

8. Electrical connection

Caution

Caution

FM

FM

FM

Warning

Connect the pump to an external mains switch

which ensures all-pole disconnection with a

contact separation according to National

Electrical Code and all local codes.

It must be possible to lock the mains switch in

position 0. Type and requirements as specified in

National Electrical Code and all local codes.

The electrical connection must be carried out in

accordance with lo cal reg ulat ions.

Warning

The pumps must be connected to a control box

with a motor protection relay with IEC trip class

10 or 15.

Warning

Pumps for hazardous locations must be

connected to a control box with a motor

protection relay with I EC tri p clas s 10.

See “Motor protection wiring diagram” on

page 17.

Warning

Do not install Grundfos control boxes, pump

controllers, Ex barriers and the free end of the

power cable in potentially explosive

environments.

The classification of the i nstall atio n site mus t be

approved by the local fire-fighting authorities in

each individual case .

On explosion-proof pumps, make sure that an

external earth lead is connected to the external

earth terminal on the pump using a secure cable

clamp. Clean the s urface of th e exte rnal ea rth

connection and mount the cable clamp.

The earth lead must be minimum AWG 12 type

RHH, RHW, RHW-2 or similar, rated for 600 V and

min. 194 °F (90 °C), yellow /gree n.

Make sure that the earth co nnect ion i s prot ected

from corrosion.

Make sure that all protective equipment has been

connected correctly.

Float switches us ed in po tenti al ly explo sive

environments must be approved for this

application. They must be connected to the

Grundfos Dedicated Controls, DC or DCD, via an

intrinsically safe barrier to ensure a safe circuit.

The mains supply voltage and frequency are marked on the pump

nameplate. The voltage tolerance must be within - 10 %/+ 10 % of

the rated voltage. Make sure that the motor is suitable for the

power supply available at the in stallation site .

As standard, all pumps are supplied with 33 ft (10 m) cable and a

free cable end.

Pumps without sensor must be connected to:

• a control box with motor-prot ecti ve cir cuit br ea ker, such as a

Grundfos DC, DCD pump controller

Pumps with sensor mus t be con nected to:

• a Grundfos IO 111

• a control box with motor-prot ecti ve cir cuit br ea ker, such as a

Grundfos DC, DCD pump controller

Warning

Before installation and the first start-up of the

pump, check the condition of the cable visually to

avoid short circuits.

Warning

If the supply cable is damaged, it must be

replaced by the manufacturer, its service agent or

similarly qualified persons.

Set the motor-pr otec tive circ uit br eake r to t he

rated current of the pump + 15% Service factor.

The rated current is stated on the pump

nameplate.

If the pump has an Ex mark on the nameplate,

make sure that the pump i s conn ected in

accordance with th e ins truct ions given i n this

booklet.

14

Page 15

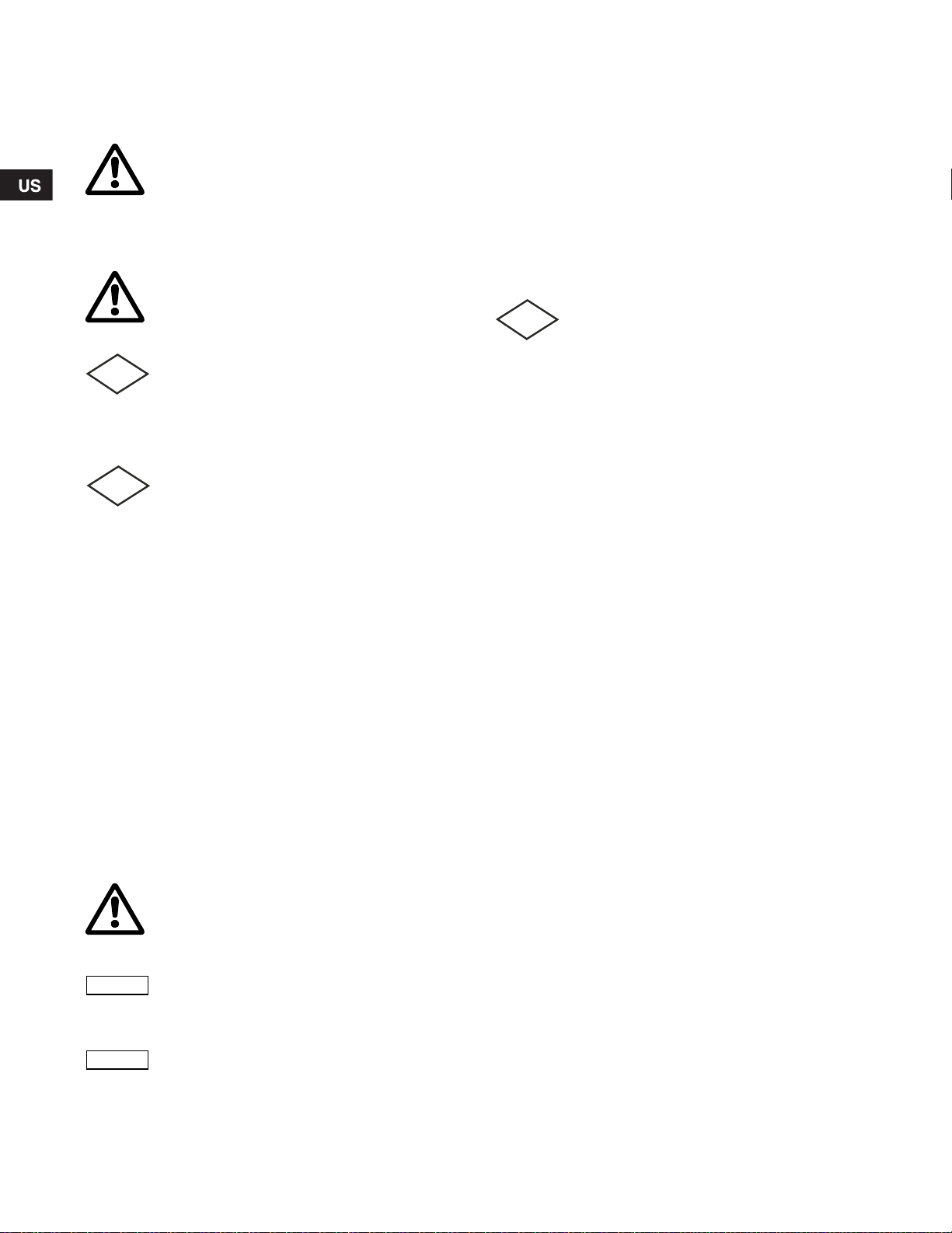

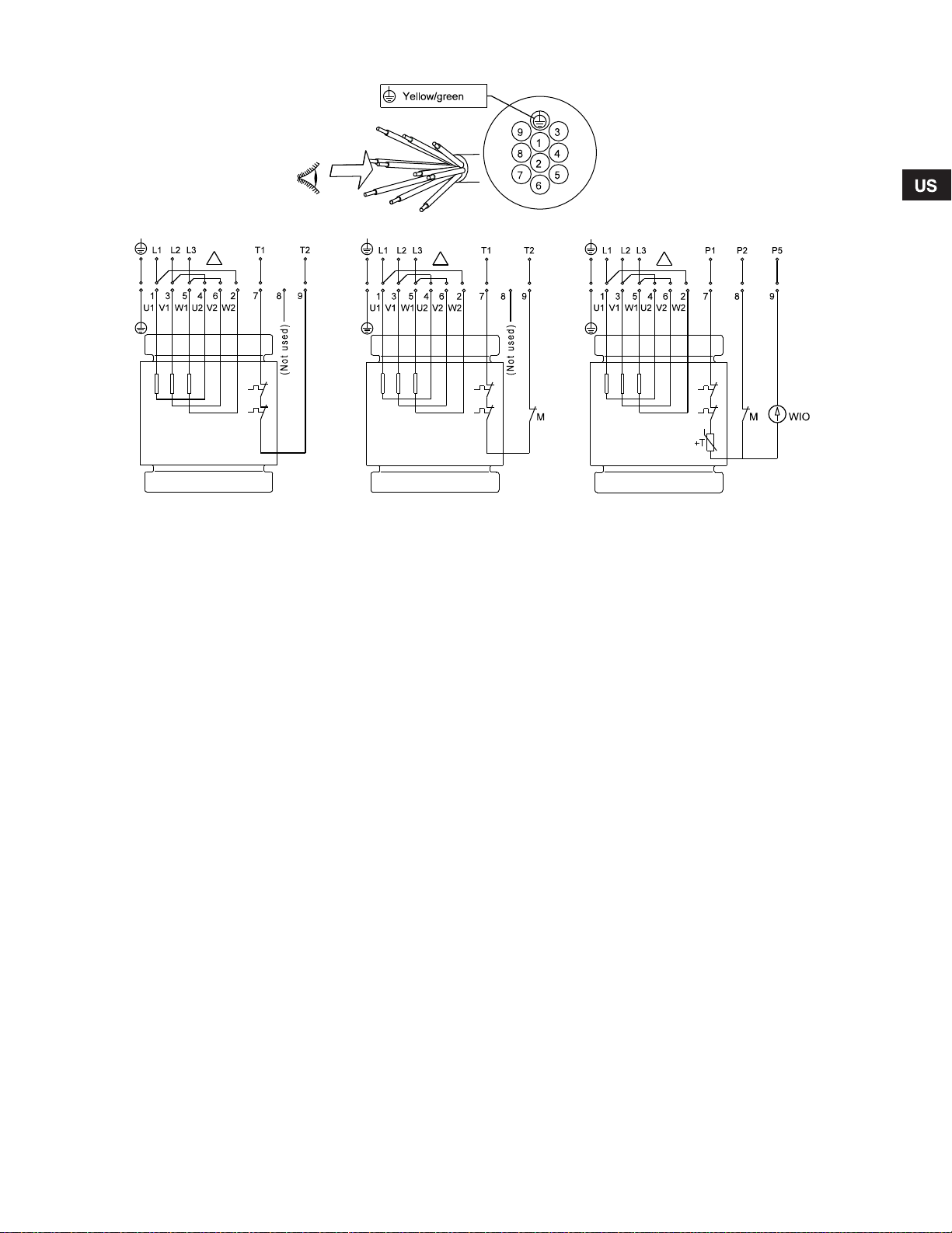

8.1 Wiring diagrams

Standard version

Thermal switches

CSA approved

Ex. version

Thermal switch and moisture switc h

CSA and FM appr oved

Sensor version

Thermal switch and PT1000 resistor

Moisture switch and water -in-oil se nsor

CSA approved, wi th/witho ut F M app rova l

The pumps are supp lied via eithe r a 7-w ire cable o r a 10-w ir e cable . Se e fig. 6 for wiring diag ram s for 7- wire c able co nne ction or figs. 7,

8 and 9 for wiring diag ram s for 10-wir e cabl e conn ec tion. Fo r fur ther inf orm atio n, se e the insta llatio n and op erat ing ins tru ctions for the

selected control box or pump controller.

Fig. 6 Wiring diagram, 7-wire cable, DOL

TM04 6689 0710

15

Page 16

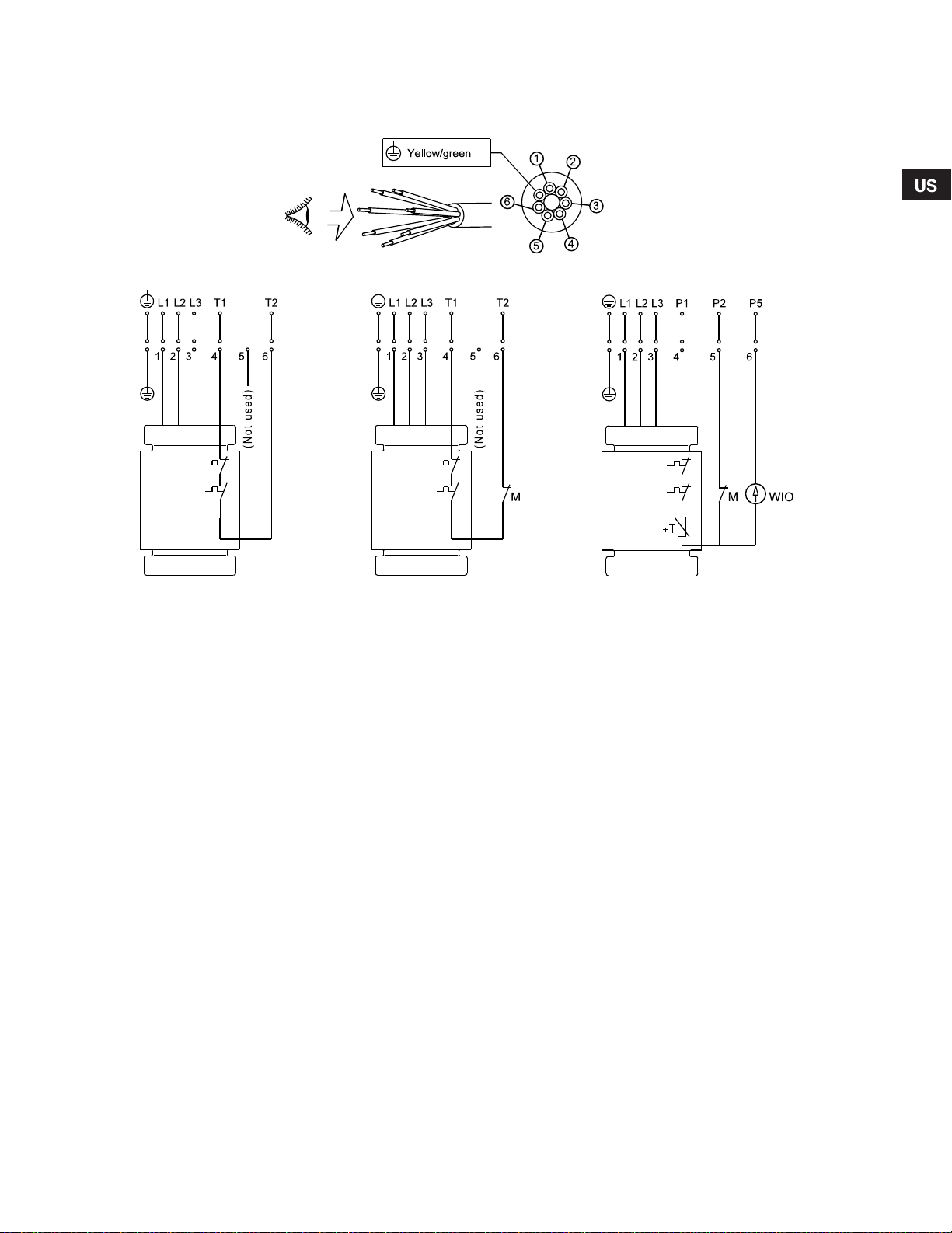

Fig. 7 Wir ing dia gram , 10-wir e cabl e, Star / Delta (Y/D)

Standard version

Thermal switches

CSA approved

Ex. version

Thermal switch and moisture switch

CSA and FM approved

Sensor version

Thermal switch an d PT100 0 res isto r

Moisture switch and water-in-oil sensor

CSA approved, with/wi thou t FM ap prov al

Standard version

Thermal switches

CSA approved

Ex. version

Thermal switch and m oisture sw itch

CSA and FM appro ve d

Sensor version

Thermal switch and PT10 00 resist or

Moisture switch and water- in-oil sensor

CSA approved, with/ wit hout FM app roval

TM04 6690 0710

Fig. 8 Wir ing dia gram , 10-wir e cabl e, Star connected (Y )

16

TM04 6691 0710

Page 17

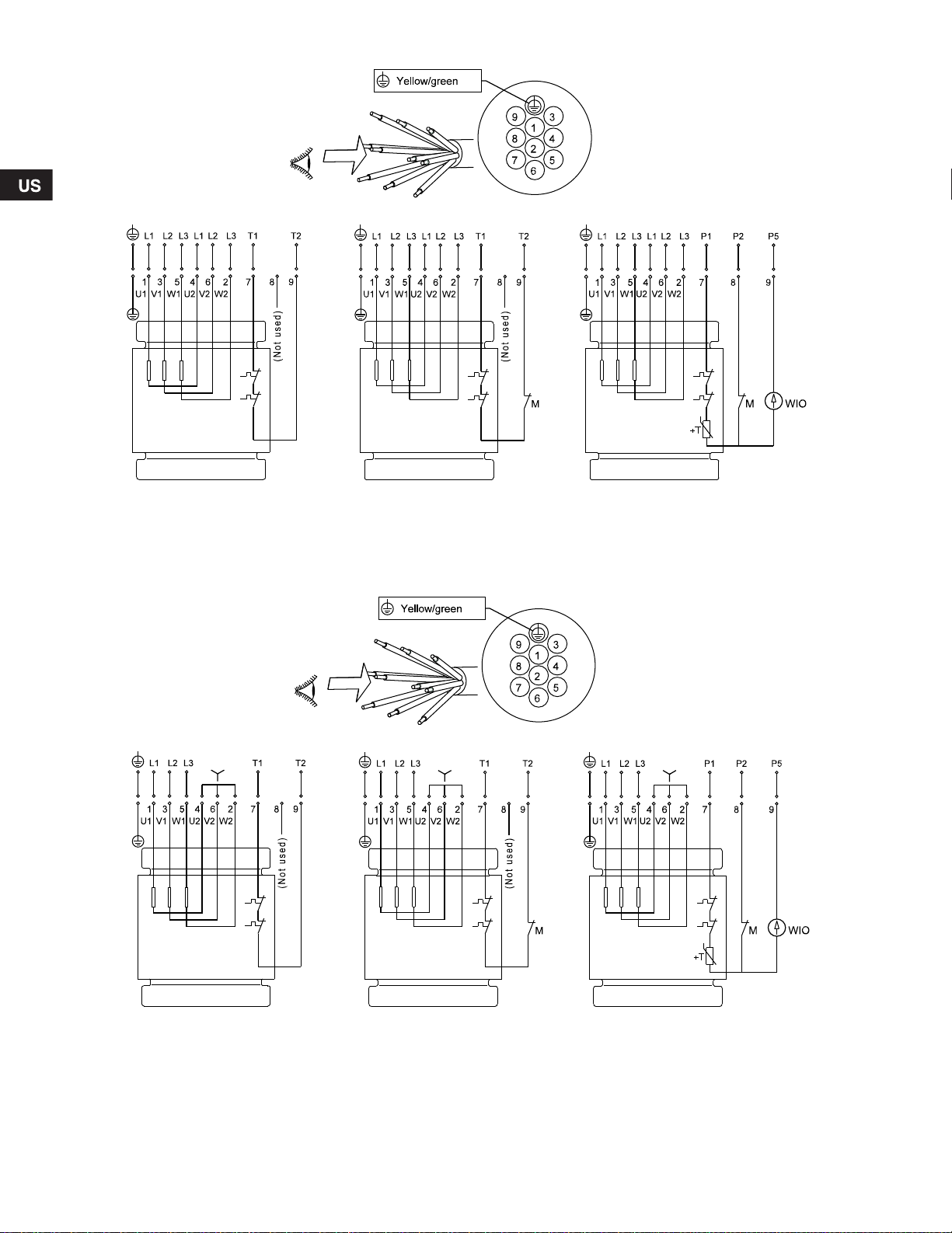

Fig. 9 Wir ing dia gram , 10-wir e cabl e, De lta conn ected ( D)

Standard version

Thermal switches

CSA approved

Ex. version

Thermal switch and moisture switc h

CSA and FM appr oved

Sensor version

Thermal switch and PT1 000 resis tor

Moisture switch and water-in -oil se nsor

CSA approved, with /with out FM appro va l

TM04 6692 0710

Fig. 10 Motor protec tion wiring diagra m

TM04 7168 1710

17

Page 18

8.2 Pump contro lle rs

FM

Start

Stop S1 operation

Alarm

Min. 4 Inch (100 mm)

Stop S3 operation

SL1 and SLV pumps can be connected to a se parate Gru ndfos

Dedicated Contr ols for level c ontrol. Dedic ated Co ntro ls are

available as accessories:

• type DC for one-pump installation s

• type DCD for two-pump install ation s.

The Dedicated Co ntro ls syste m starts/s tops the SL1 an d SLV

pumps by means of one of the following transmitters:

• float switches

• pressure sensors

• ultrasonic sensors.

Furthermore, it is possible to control the water level by both float

switches and an an alo g pressu re sens or or u ltrason ic sensor.

Optionally, the controller can co ntrol a m ixer. The Dedica ted

Controls system c an be ex tend ed wit h an IO 111 module per

pump (for SL1 an d SLV pumps with built-in sens or).

When installing the level switc hes, ob serve the follow ing poi nts:

• To prevent air intake and vibration s in stall the stop level

switch in such a way that the pump is stopped before the

liquid level is lowere d below the top of the c able ent ry.

• In tanks with one pump, install the start level switch in such a

way that the pump is started a t the requ ire d level ; how ever,

the pump must alway s be starte d befo re the liq uid level

reaches the bottom inlet pipe to the tank.

• In tanks with two pumps, the start level switc h for pump 2

must start the pump before the liquid level reache s the bottom

inlet pipe to the tank, and the start level switch for pump 1

must start this pump correspondingly earlier.

• If installed, always install the high-level alarm switch about

4" (100 mm) above the s tart lev el switc h; how ever, the alarm

must always be given b efor e the liqu id lev el rea ches t he

bottom inlet pipe to the tank.

For further inform atio n, see t he ins tallation a nd o peratin g

instructions for the pump controller selected.

Warning

The pump must not run dry.

An additional level switch must be installed to

ensure that the pump is stopped in c ase the stop

level switch is not operating.

The pump must be stopped when the liquid level

reaches the top of the cable entry.

Float switches us ed in po tenti al ly explo sive

environments must be approved for this

application. They must be connected to the

Grundfos Dedicated controls, DC or DCD, via an

intrinsically safe barrier to ensure a safe circuit.

TM04 2654 2808

Fig. 11 Start and stop levels

Make sure that the effe ctive vo lume of the tank doe s no t beco me

so low that the numb er of starts per hou r e xcee ds th e max imum

permissible nu mber. See section 9 .2 Operating modes .

18

Page 19

8.3 Thermal switch, Pt100 0 and th ermisto r

FM

FM

Note

Caution

All SL1 and SLV pumps have thermal prot ectio n incor pora ted in

the stator windings.

Pumps without sensor

Pumps without se ns or hav e a th erma l sw itch .

Via the pump controller s afety c ir cu it, the thermal switch will stop

the pump by break ing t he circui t in ca se of over tem peratu re

(approx. 302 °F (150 °C)). The ther mal switc h will reclo se the

circuit after cooling.

The maximum oper ating curr ent o f the ther mal s witch is 0.5 A at

500 V A C an d cos ϕ 0.6. The switch must be able to break a coil in

the supply circui t.

Pumps with sensor

Pumps with sensor have eithe r a the rma l sw itch and a P t100 0

sensor or a thermis tor (P TC) in t he win ding s, depe ndi ng on t he

installation site.

Via the pump controller safety circuit, the thermal switch or the

thermistor will stop the pu mp by br eakin g the circu it in case of

overtemperatur e (approx. 302 °F ( 150 °C). The thermal switch or

the thermistor will reclose the c ircu it after cooling.

The maximum op erat ing cu rrent of bo th the Pt1 000 and the

thermistor is 1 mA at 2 4 VDC.

Non-explosion-proof pumps

When closing the circ uit after co oling, the th erma l protec tion can

restart the pump auto matic ally vi a the c ontrol ler.

Explosion-proof pumps

Warning

The thermal protection of explosion-proof pumps

must not restart the pump automatically. This

ensures protection against overtemperature in

potentially explosive environments. In pumps

with sensor this is done by removing the shortcircuit between terminals R1 and R2 in the IO 111.

See Electrical data in the IO 111 installation and

operating instructions.

Warning

The separate motor-protective circuit breaker/

control box must not be installed in potentially

explosive environm ents.

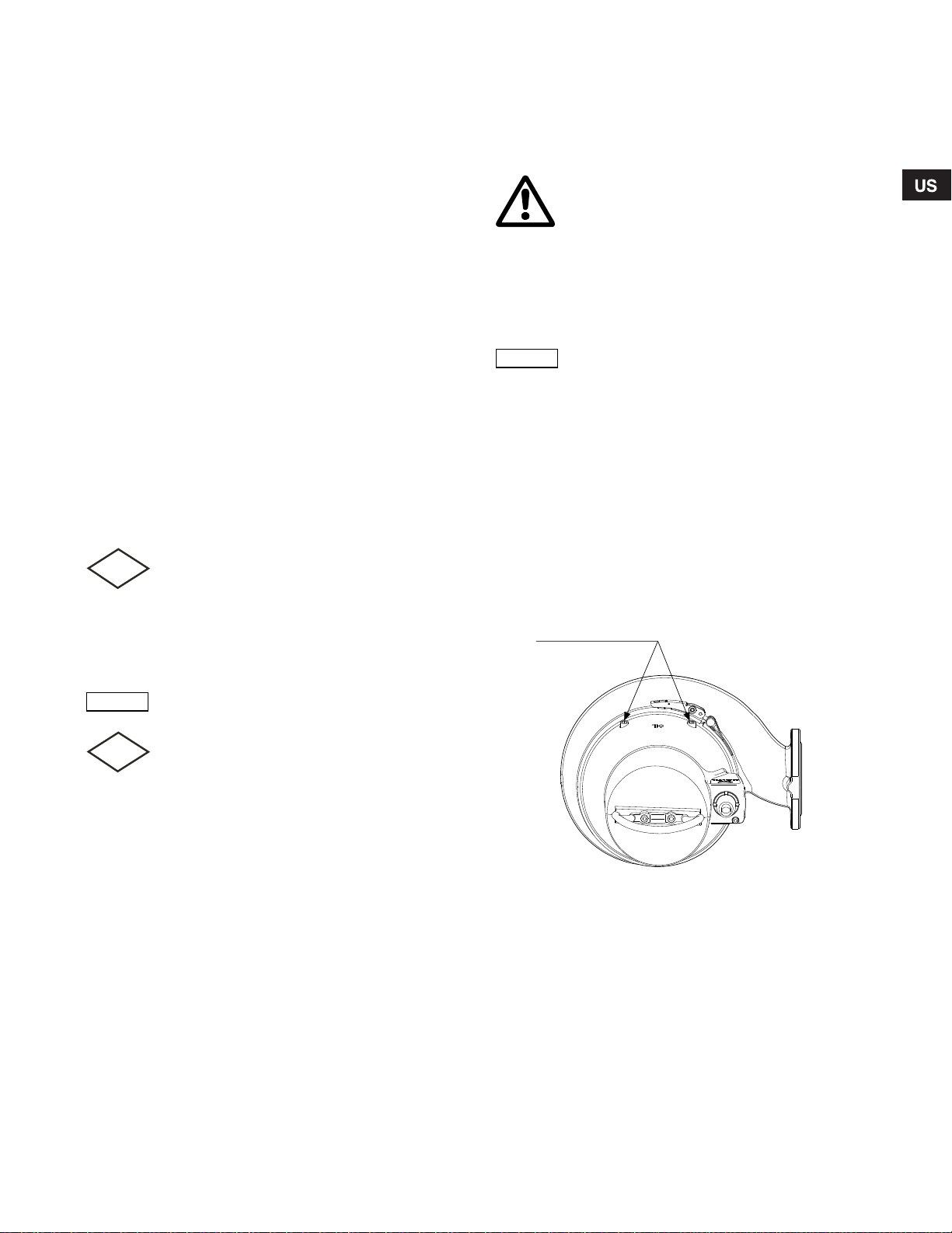

8.4 WIO sensor (water-in-oil sensor )

The WIO sensor measures the water content in the oil and

converts the value into an analo g c urrent signa l. The t wo se nsor

leads are for power supp ly a nd for c arry ing th e si gnal to t he

IO 111. The sensor measur es the w ater conten t from 0 to 2 0 %.

sIt also sends a sig nal i f the wa ter con tent is outside the no rma l

range (warning), or if the re is a ir in th e oil cha mber (alar m). The

sensor is fitte d in a s tai nles s s te el tube for mechan ica l protection.

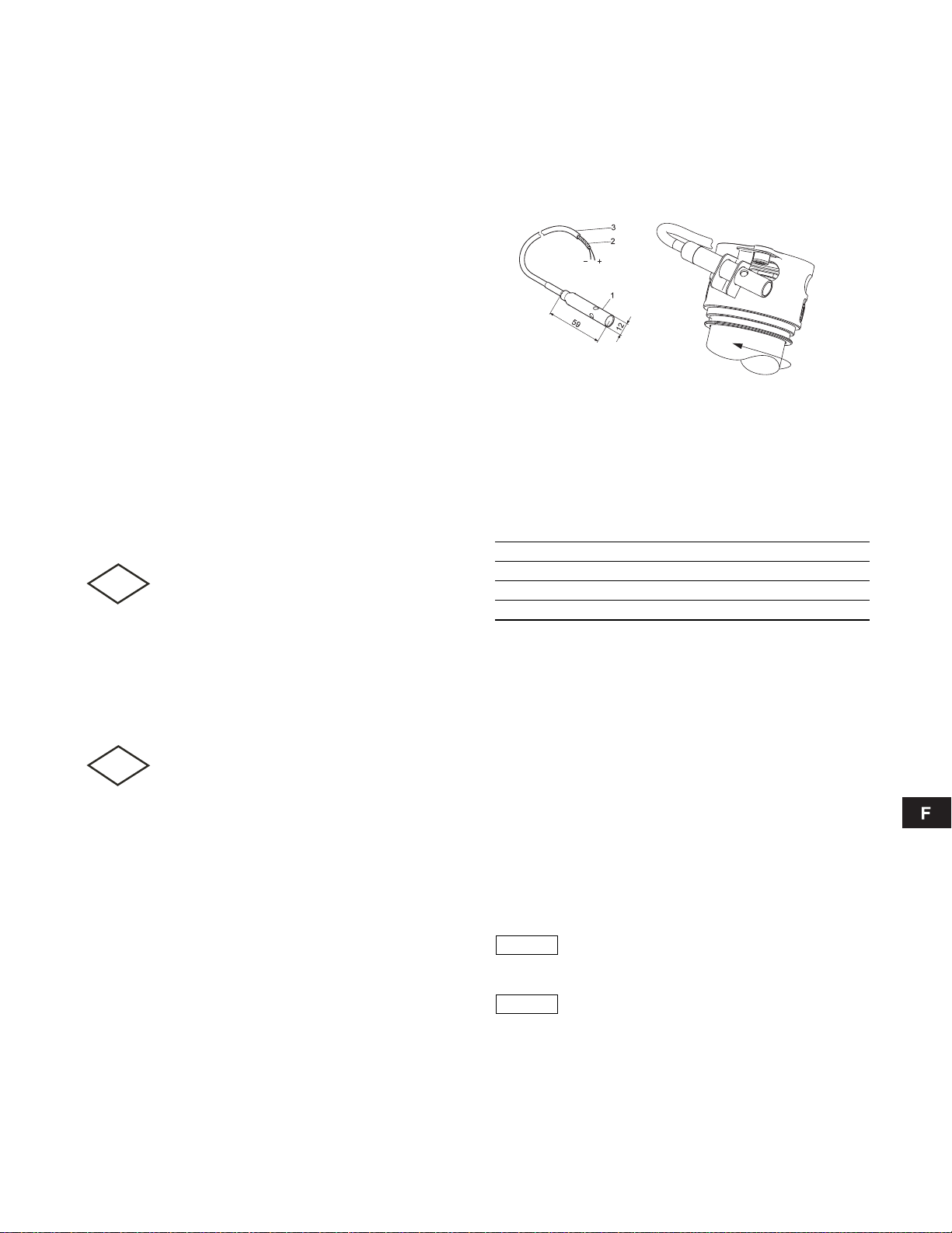

TM04 5238 2909/ TM03 1164 1105

Fig. 12 WIO sensor

8.4.1 Fitting the WI O sen sor

Fit the sensor next to one of t he shaft se al openin gs. See fig. 12.

The sensor must be tilted into the motor’s direction of rotation to

ensure that oil is led into the sensor. Make sure that the sensor is

submerged in the oil.

8.4.2 Technical data

Input voltage: 12-24 VDC

Output current: 3.4 - 22 mA

Power input: 0.6 W

Ambient temperat ure: 32 to 15 8 °F (0 to 70 °C)

See also the installati on and o peratin g ins truct ions for IO 111 on

www.grundfos.com.

8.5 Moisture switch

All FM approved moto rs ar e fitt ed wit h a moist ure swit ch as

standard, with the moisture switch being connected via the supply

cable. See 8. Electrical connection. The moisture switch must be

connected to a separate circuit breaker.

The moisture switch is positioned in the bottom of the motor. If there

is moisture in the motor, the switch will break the circuit and send a

signal to the IO 111.

The moisture switc h is non -rev ersin g and m ust be r ep laced a fter

use.

On sensor motors the moisture switc h is connected in ser ies wit h

the thermal switch an d con nect ed to th e mon itori ng cab le, and it

must be connected to the safety circuit of the separate pump

controller. See section 8. Electrical connect ion.

There is no moisture switch in CSA versions

without sensor.

The motor-protective circuit breaker of the pump

controller must include a circuit which

automatically disconnects the power supply in

case the protective circuit for t he pum p is

opened.

19

Page 20

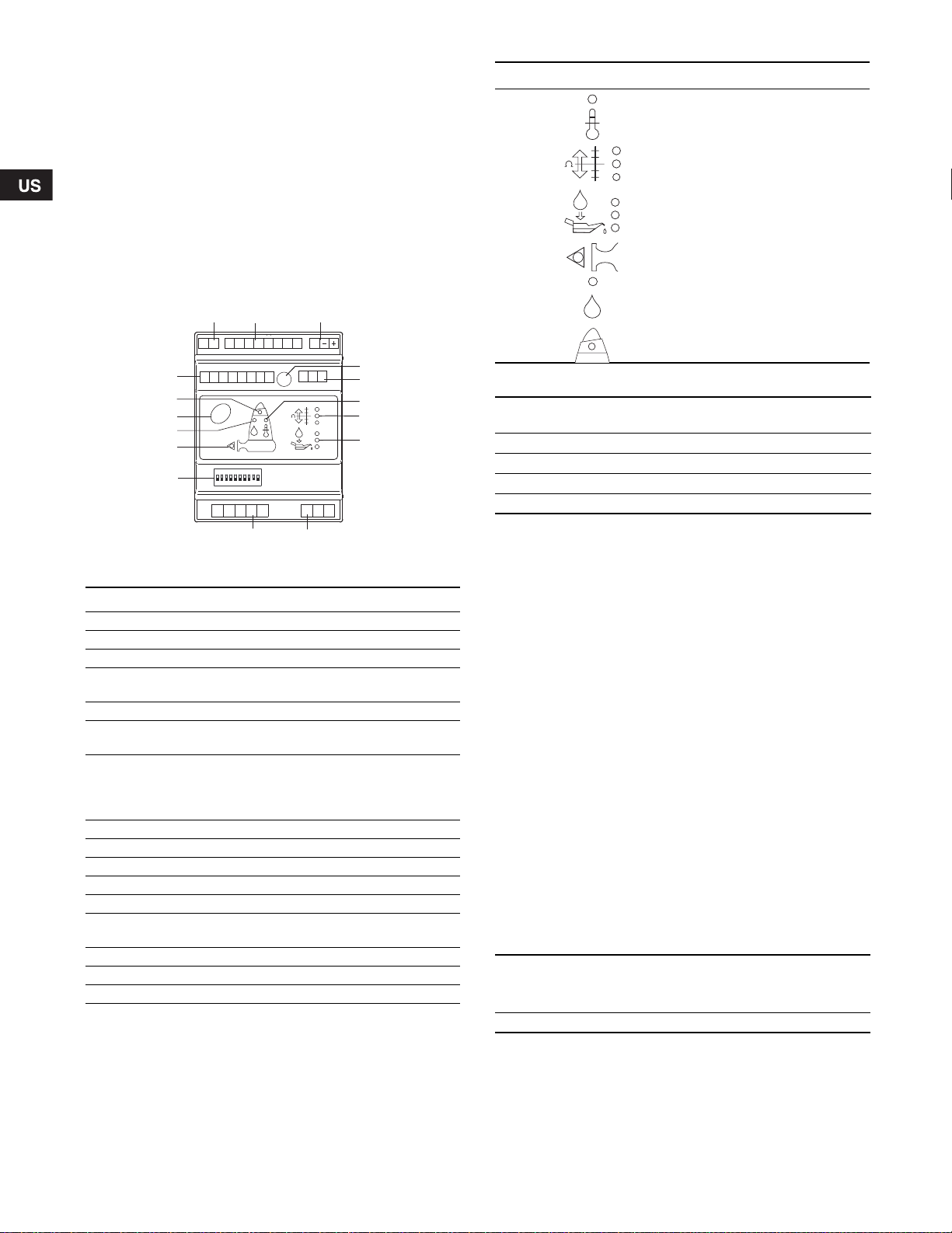

8.6 IO 111

Reset

PET1 T2

G1 A1 G2 A2 K1 K2 R1 R2

D1D2 D3D4 D5 D6 D7 D8

P1 P2 P3 P4 P5

AYB

I1 I2 I3

ON DIP

12345678910

12 3

910

4

5

6

7

8

11

12

15

16

13

14

The IO 111 forms interface betw een a Grund fos sew ag e or

wastewater pump with an alog an d digital sen sors and t he pum p

controller. The most importa nt se nsor data are indica ted on the

front panel.

One pump can be conn ec ted to a n IO 111.

Together with the sensors, the IO 111 forms a galvanic separation

between the motor voltag e in the pump and th e contr oller

connected.

IO 111 can distinguish between two categories of fault:

•Alarm: The pump stops. The fault is serious, such as too

high motor t em perature.

•Warning: The pump does not stop. The fault is not serious,

such as too much water in the oil.

Pos. Symbol Description

6 Stator temperature

7 Stator insulation resistance

8 Water in oil chamber

12 Pump running

13 Moisture in motor

15 Pump fault

8.6.1 Technical data

Fig. 13 IO 111

Pos. Description

1 Terminal for alarm relay

2 Terminal for analog and digital inputs and outpu ts

3 Terminal for supply voltage (24 VAC/24 VDC)

Potentiometer for setting the warn ing limit of stator

4

insulation resistance

5 Terminal for RS485

Red indicator light. Alar m in ca se of too h igh m oto r

6

temperature.

Indicator lights for s tator insula tion r esista nce.

Green = ok.

7

Yellow = warnin g.

Red = alarm.

8 Indicator lights for measurement of water in oil

9 Terminal for measurement of stator insul ation resi stance

10 Terminal for connection of pump se nsor s

11 DIP sw itch fo r configuration

12 Green indicator light. On when th e pu mp is r unning .

Red indicator light. On in case of mois ture in the moto r

13

(alarm).

14 Button for reset of alarm

15 Yellow indicator light. On in case of pum p fa ult (war nin g).

16 Terminal for digital outputs

20

Supply voltage:

24 VAC - 10 %/+ 10 %, 50 and 60 Hz

24 VDC - 10 %/+ 10 %

Input current: Min. 0.5 A; max. 8 A

Power input: Max. 5 W

Ambient temperature: -13 °F to 149 °F (-25 °C to +65 °C)

Enclosure class: IP20

For further information, see installation and operating instructions

TM03 0691 0505

for IO 111.

8.7 Frequency converter ope rat ion (V FD )

In principle, all thre e-ph ase m otor s can be con nected to a

frequency conv ert er.

However, frequency converter opera tion w ill often ex pose the

motor insulati on s y st e m to a heavier load and cause the m ot or t o

be more noisy tha n usua l due to harm on ic frequ enc y cu rrents

caused by voltage peak s.

In addition, larg e motor s driven via a freque ncy c on verter wil l be

loaded by bearing curr ents.

For frequency co nv erter o perat ion, pleas e obse rv e the fo llowi ng

information:

Requirements must be ful filled .

Recommendations ought to be fulfille d.

Consequences sh oul d be con sider ed.

8.7.1 Requirements

• The thermal protection of the mot or m ust be c onnec ted .

• Peak voltage and dU/dt must be in accordanc e with the table

below. The values stated are maximum value s supp lied to the

motor terminals. The c ab le infl uence has no t been taken int o

account. See the frequency converter data sheet regarding the

actual values and the cable influence on t h e peak voltage and

dU/dt.

Maximum repeti tive p eak

voltage

(V)

850 2000

• If the pump is an FM-approv ed pum p, check if the FM

certificate of the spec ific pump allows the use o f a freq uenc y

converter.

• Set the frequency converter U/f ratio according to the motor data.

• Local regulations/standards mu st be fulfille d.

Maximum dU/dt

U

400 V

N

(V/μ sec.)

Page 21

8.7.2 Recommen datio ns

FM

Note

Caution

Before installing a frequen cy conv erter, calculate the lowes t

allowable frequency in the installation in order to avoid zero flow.

• Do not reduce the motor s peed t o less than 30 % of rated

speed.

• Keep the flow velocity above 1 m/sec.

• Let the pump run at rated speed at least once a day in order to

prevent sedimentation in the p iping sy stem .

• Do not exceed the frequency ind ica ted o n the nam eplat e.

In this case there is risk of mot or ov erload .

• Keep the motor cable as sh ort as p ossib le. The pea k voltage

will increas e wit h the length of the mo tor cab le. Se e dat a shee t

for the frequency con vert er us ed.

• Use input and output filters on th e fre quenc y con verter.

See data sheet for t he f reque ncy c onve rter us ed .

• Use screened motor cable if there is a risk that electrical noise

can disturb other ele ctr ical equ ipme nt. See da ta shee t for the

frequency conve rte r used .

8.7.3 Consequences

When operating th e pu mp via a fre quenc y con vert er, please be

aware of th es e poss ble consequence s :

• The locked-rotor torque will be lower. How much lower wi ll

depend on the frequ ency co nv erter t ype. S ee th e installati on

and operating instructions for the frequency converter used for

information on the lo cked -rot or torq ue availab le.

• The working condition of bear ings an d shaft seal may be

affected. The possible effect will depe nd on the a pplica tion.

The actual effect cann ot be pre dict ed.

• The acoustic noise level may incre ase. Se e the installa tion

and operating instructions for the frequency converter used for

advice as to how to reduce the acoustic noise.

9.1 General start-up procedure

This procedure appli es to new installa tions as well as after

service inspection s if start -up takes place som e tim e after th e

pump was placed in the tank.

1. Remove the fuses an d ch eck that the im p eller can r otate

freely. Turn the impeller by hand.

Warning

The impeller can have sharp edges - wear

protective gloves.

2. Check the condition of t he oil in the oil cham ber. See also

section 10 .1 I nspec tion .

3. Check that the sys tem, bolts, gask ets, pipe wo rk and valve s

etc. are in correc t co nditio n.

4. Mount the pump in the system.

5. Switch on the power su pply.

6. Check whether the monito rin g units, if us ed, are ope ra ting

satisfactorily.

7. For pumps with sensor, switch on the IO 111 and check that

there are no alarms or w ar nings . See sectio n 8.6 IO 111.

8. Check the setting of ai r be lls, flo at sw itches or elec trode s.

9. Check the direction of rotation. See section 9.3 Direc tio n of

rotation.

10.Ope n the isol ating va lves, if f itted.

11.Check that the liquid level is above the motor for S1 operation

and above the cable en try for S3 o per ation. See fi g. 11. If the

minimum level is n ot re ached do not start t he pum p.

12.Start the pump an d let th e pump run briefl y, and check if the

liquid level is falling.

13.Obs erve if the dis cha rge pr essu re an d inpu t curre nt ar e

normal. If not there mig ht be air tr apped ins ide the pu mp .

9. Start-up

Warning

Before starting work on the pump, make sure that

the fuses have been removed or the mains switch

has been switched off. It must be ensured that

the power supply cannot be accidentally

switched on.

Make sure that all protective equipment has been

connected correctly.

The pump must not run dry.

Warning

The pump must not be started if the atmosphere

in the tank is potentially explosive.

Warning

It may lead to personal injuries or death to open

the clamp while the pump is operating.

Trapped air can be removed from the pump

housing by tilting the pump by means of the

lifting chain when the pump is in operation.

In case of abnormal noise or vibrations from the

pump, other pump failure or power supply failure

or water supply failure, stop the pump

immediately. Do not attempt to restart the pump

until the cause of the fault has been found and

the fault corrected.

After one week of operation or after replacement of the shaft seal,

check the conditio n of the oil in th e cham ber. For pumps with out

sensor, this is done by taking a sample of the o il, Se e sec tion

10. Maintenance and service for procedure.

Every time the pump has been removed from the tank, go through

the above procedure whe n starting u p ag ain.

21

Page 22

9.2 Operating modes

Note

Operation

Stop

6 min.4 min.

10 min.

P

t

P

t

Operation

Stop

FM

The pumps are desig ned f or int ermi ttent ope ra tion (S 3).

When com pletely s ub merg ed, the pumps c an also op erate

continuously (S1).

S3, intermittent operation:

Operating mode S3 m ean s th at wit hin 10 minutes the pu mp m us t

be in operation for 4 minu tes a nd stop ped for 6 minutes .

See fig. 14.

In this operating mod e, the p ump is partly subm erged in the

pumped liquid, i.e . the liqu id leve l re aches at minim um t he t op of

the cable entry on the stator hous ing . See fig. 2.

Fig. 14 S3, intermittent operation

S1, continuous operation:

In this operating mod e, the p ump c an oper ate con tinu ously

without being stopp ed fo r cool ing. See fig. 15. Bein g com pletely

submerged, the pu mp is sufficien tly c ooled b y the surr oundin g

liquid. See fig. 2.

Fig. 15 S1, continuo us ope ration

9.3 Direction of rotation

The pump may be started for a very short period

without being submerged to check the direction

of rotation.

Check the direct ion of rotatio n be fore star ting up the pump .

An arrow on the stator housing indicates the correct direction of

rotation. Correct dir ection o f rotation is cloc kwis e when v iew ed

from above.

Checking the direction of rotation

The direction of ro tation sh oul d be che cked in the followi ng way

every time the pump is connected to a new installation.

Procedure

1. Let the pump hang from a lifting dev ic e, e.g. the hoist used for

lowering the pump into the tank.

2. Start and stop the pump while obse rving the m ovem ent (jerk)

of the pump. If conn ected c orrec tly, the pump will rotate

clockwise, i.e. it will jerk counter- clockw ise. See fig. 16 .

3. If the direction of r otatio n is wr ong, interchange any t wo of the

phases in the power supply ca ble . See f ig. 6, 7 o r 8, 9.

TM04 4527 1509

Fig. 16 Jerk direction

10. Maintenance and service

Warning

During maintenance and service, including

transportation to service workshop, always

support the pump by means of lifting chains or

place it in horizontal position to secure stability.

Warning

Maintenance work on explosion-proof pumps must

be carried out by FM approved service centres.

However, this does not apply to the hydraulic

TM04 4528 1509

Before carrying out maintenance and servic e, it m us t b e ensured

that the pump has b een th orou ghly flus hed wit h cle an wat er.

Rinse the pump parts in wate r afte r disman tling .

components, such as pump housing, impeller, etc.

Warning

The cable must only be replaced by Grundfos or

a service workshop authorized by Grundfos.

Warning

Before starting work on the pump, make sure that

the fuses have been removed or the mains switch

has been switched off. It mus t be en sured tha t

the power supply cannot be accidentally

switched on.

Make sure that all protective equipment has been

connected correctly.

Warning

Before starting work on the pump, make sure that

the mains switch has been locked in position 0.

All rotating parts must have stopped moving.

TM04 2657 2808

22

Page 23

10.1 Inspection

Note

FM

FM

Note

Oil filling/venting

Pumps running no rmal o perat ion s hould be inspe cted ever y

3000 operating hours or at least once a year. If the pumped liquid

is very muddy or sandy, inspect the pump at shorter intervals.

Check the following p oints:

• Power consumption

See pump nameplate.

• Oil level and oil condition

When the pump is new or after replacement of the shaft seal,

check the oil level and water content after one week of operation.

If there is more than 20 % extra liquid (water) in the oil chamber,

the shaft seal is defective. The oil should be changed after

3000 operating hours or once a year.

Use Shell Ondina 917 oil or similar type.

See section 10.2.1 Oil change.

• Cable entry

Make sure that the cable entry is watertight (visual inspection)

and that the cable is not sh arply bent and/o r pinc hed.

• Pump parts

Check impeller, pump housing, etc. for possible wear.

Replace defect ive parts.

See section 10.2.2 Remo ving the pump housin g and im peller .

• Ball bearings

Check the shaft for no isy or heavy operation (tu rn the shaft by

hand). Replace defec tive ba ll bea rings .

A general overhaul of t he pum p is usua lly requir ed in c ase of

defective ball be arings or poor motor f un cti o n. T hi s work must

be carried out by Gru nd fos or a s ervi ce wor ksho p aut horized

by Grundfos.

Warning

Defective bearings may reduce the explosion

protection.

• O-rings and similar parts

During service/repl acem ent, it m ust be e ns ured tha t the

grooves for the O- rings as wel l as the seal face s h ave be en

cleaned before the new parts are fitted. Grease O-rings and

recesses bef ore asse mb ly.

10.2 Dismantling th e pump

10.2.1 Oil change

After 3000 operating hou rs or once a year, change the oil in t he

oil chamber as de scribe d be low.

If the shaft seal has be en rep laced , th e oil mu st be chang ed.

Warning

When loosening the screws of the oil chamber,

note that pressure may have built up in the

chamber. Do not remove the screw s unt il the

pressure has been f ully reli eved.

Draining of oil

1. Place the pump on a plane surface with one oil screw poin t ing

downwards.

2. Place a suitable container (approx. 1 litre), for instance made

of transparent plastic ma ter ial, un der the o il scr ew.

Used oil must be disposed of in accordance with

local regulations.

3. Remove the lower oil scre w.

4. Remove the upper o il scre w.

If the pump has been in ope ration for a lo ng p eriod of time , if

the oil is drained off shortly after the pump has been stopped,

and if the oil is greyish white like milk, it co ntains water. If the

oil contains more than 20 % water, it is an indication that the

shaft seal is defective and must be re placed . If the sh aft seal

is not replaced, the motor w ill be damag ed .

If the quantity of oil is sma ller than the q uantit y stated in

section 10.4 Oil quantities, t he s haft seal i s defec tive.

5. Clean the faces for the gaskets for oil screws.

Filling with oil

1. Turn the pump so that the oil filling holes are place d oppo site

to each other, pointing upwards.

Do not reuse rubber parts.

Warning

Explosion-proof pumps must be checked by an

FM approved servic e cen tre on ce a yea r.

TM04 6477 0410

Fig. 17 Oil filling holes

2. Pour oil into the chamber.

For oil quantity, see section 10.4 Oil qua ntities.

3. Fit the oil screws with new gaskets.

23

Page 24

10.2.2 Removing the pump housing and impeller

For position num bers , se e pages 94 and 95.

Procedure

1. Loosen the clamp ( pos. 92) .

2. Remove the screw us ing yo ur fin gers .

3. Remove the pump housing (pos. 50) by inserting two screwdrivers between the stator ho using and th e pum p hous ing.

4. Remove the screw (p os. 188 a). H old th e impe ller with a str ap

wrench.

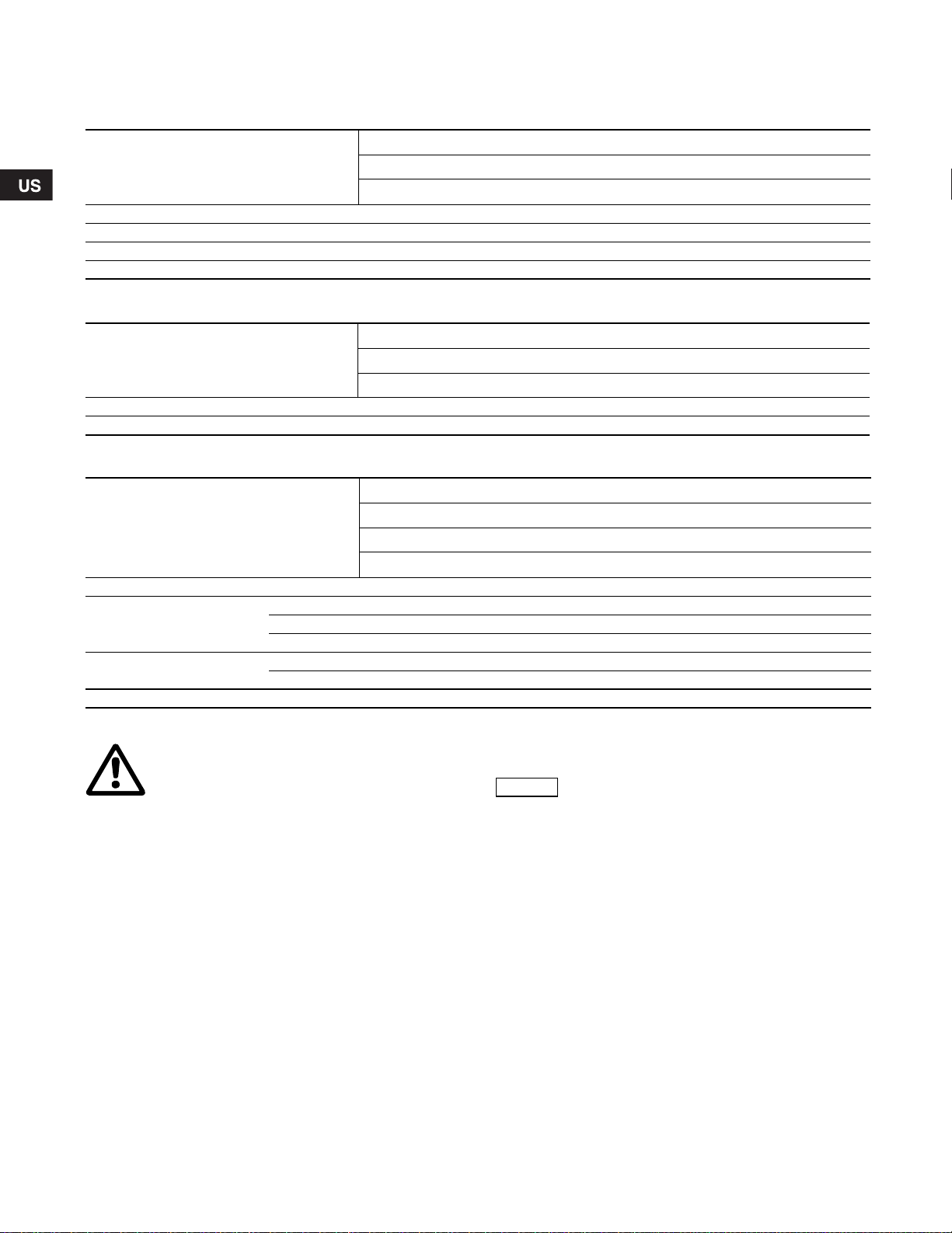

Fig. 18 Removing the im peller

5. Loosen the impeller (po s. 4 9) wit h a light blo w on the edge .

Pull it off.

6. Remove the key (pos . 9a) and the s pring for im peller

(pos. 157).

10.2.3 Removing t he se al ring an d we ar ring

Procedure

1. Turn the pump housing upside -dow n.

2. Knock the seal ring (p os. 4 6) out of the pump hou sing us ing a

punch.

Fig. 19 Removing th e seal ring

3. Clean the pump hous ing whe re the se al r ing was fitted.

4. Remove the wear ri ng (pos . 49 c) us ing a sc rewd riv er.

Fig. 20 Removing th e wear ring

5. Clean the impeller where the wear ring wa s fitted.

10.2.4 Removing t he sha ft seal

Procedure

1. Remove the screws (po s. 188) .

2. Remove the cover for o il ch ambe r (pos . 58 ) using a puller.

3. Remove the screws (po s. 186) .

4. Remove the shaft seal (p os. 105) using the pu ller.

5. Remove the O-ring (pos . 15 3b).

Procedure (pump with sensor)

1. Remove the screws (po s. 188) .

TM04 6477 0410TM02 8420 5103

2. Remove the cover for o il ch ambe r (pos . 58 ) using a puller.

3. Remove the screws (po s. 186) .

4. Remove the sensor (pos . 521 ) and h olde r (pos. 522) from the

shaft seal.

5. Remove the shaft seal (p os. 105) using the pu ller.

6. Remove the O-ring (pos . 15 3b).

10.3 Assembling the pump

10.3.1 Tightening torques and lubricants

Desig-

Pos.

nation

Quantity Dim.

92a Screw 1 8.85 ± 1.5 (12 ±2)

118a Screw 2

M8 14.75 ± 1.5 (20 ±2)

M10 22. 15 ± 2.2 (3 0 ±3)

174 Screw 1 2.95 ± 0.74 (4 ±1)

181 Union nut 1

7-pole 3 6.88 ± 3. 7 (50 ± 5)

10-pole 55.32 ± 3 .7 (75 ± 5)

186 Screw 2 5.2 + 1.5-0 (7 +2-0)

182 Screw 4 14.75 ± 1. 5 (20 ± 2)

187 Screw 4 14.75 ± 1. 5 (20 ± 2)

188 Screw 2

188a Screw 2

M8 14.75 ± 1.5 (20 ±2)

M10 22. 13 ± 2.2 (3 0 ±3)

M10

M12 55. 32 ± 3.7 (7 5 ±5)

193 Screw 2 11.8 ± 1.5 (16 ±2)

O-rings All Rocol

Rocol Sapphire Aq ua-S il, pro duct nu mber RM29 24 (1 k g).

Shell Ondina 917, pro du ct num ber 960 01442 (1 l)

Torque

[ft-lb (Nm)]

36.88 + 3.7- 0

(50 +5-0)

TM02 8422 5103

Lubri-

cant

24

Page 25

10.3.2 Fitting t he sha ft seal

Note

Procedure

1. Fit and lubricate the O- ring (p os. 153b) with oi l.

2. Slide the shaft seal (pos. 105) gent ly ove r the sh aft.

3. Fit and tighten the sc rews (pos . 186).

4. Fit and lubricate th e O-rin g (p os. 107 ) in the c over fo r oil

chamber (pos. 58 ) with oil.

5. Fit the cover for o il cham ber.

6. Fit and tighten the sc rews (pos . 188).

Procedure (pump with sensor)

1. Fit and lubricate the O- ring (p os. 153b) with oi l.

2. Slide the shaft seal (pos. 105) gent ly ove r the sh aft.

3. Fit the holder (pos. 522) and s ens or (po s. 521) with one of the

screws (pos. 186).

4. Fit the second screw and tighten both screws (pos. 186).

5. Fit and lubricate th e O-rin g (p os. 107 ) in the c over fo r oil

chamber (pos. 58 ) with oil.

6. Check that the sensor is positioned c or rec t ly, see 8.4.1 Fit tin g

the WIO sens or a nd fig. 12. This is of spec ial importanc e in

horizontal pumps.

7. Fit the cover for o il cham ber.

8. Fit and tighten the sc rews (pos . 188).

10.3.3 Fitting the seal ring and wear ring

Procedure

1. Lubricate the seal rin g (p os. 46) with soapy water.

2. Place the seal ring in the pu mp ho using .

3. Knock the seal ring hom e in the pump h ousin g using a pu nch

or a wooden block.

10.3.4 Fitting the impeller and pump housing

Procedure

1. Fit the spring (pos. 15 7) and the k ey (po s. 9a).

Keep the key in position while the impeller is fitted.

2. Fit the impeller (pos . 49).

3. Fit the washer (p os. 66) and the scr ew (pos. 18 8a ).

4. Tighten the screw (pos. 188a) to 55 ft-lb (75 Nm). Hold the

impeller with the str ap wren ch.

5. Mark the position of the pi n on the pu mp hou si ng.

6. Mark the position of the pi n ho le on th e oil ch ambe r.

7. Fit and lubricate the O -ring (p os. 3 7) with oi l.

8. Fit the stator housing in the pum p hous ing (po s. 50 ).

9. Fit the clamp (pos. 92 ).

10.Tighten the s crew to 6 ft-lb (8 N m ).

11.Che ck tha t the im pe ller rotat es free ly and w ithou t dra g.

10.4 Oil quantities

The table shows the qu antity of oil in t he oil ch ambe r of S L1 and

SLV pumps. Oil type: Shell Ondina 917.

2-pole

4-pole

Power

[hp (kW)]

3.0 (2.2) 20.3 (0.6)

4.0 (3.0) 20.3 (0.6)

5.5 (4.0) 33.8 (1.0)

8.0 (6.0) 33.8 (1.0)

10.0 (7.5) 33.8 (1.0)

12.5 (9.2) 40.6 (1.2)

15.0 (11) 40.6 (1.2)

1.5 (1.1) 20.3 (0.6)

1.8 (1.3) 20.3 (0.6)

2.0 (1.5) 20.3 (0.6)

3.0 (2.2) 20.3 (0.6)

4.0 (3.0) 33.8 (1.0)

5.5 (4.0) 33.8 (1.0)

7.5 (5.5) 33.8 (1.0)

10.0 (7.5) 40.6 (1.2)

Oil quantity

[oz (l])

Fig. 21 Fitting the seal ring

4. Place the wear ring (po s. 49c) on th e impe ller.

5. Knock the wear ring ho me us ing a wo oden blo ck.

Fig. 22 Fitting the wear rin g

Used oil must be disposed of in accordance with

TM02 8421 5103TM02 8423 5103

local regulations.

25

Page 26

10.5 Service kits

Note

The following ser vice kits are availa ble for al l SL1, SLV pumps and can be orde red as re quired

10.5.1 Impeller fitting kit

2-pole: 3.0 - 5.5 hp (2.2 - 4.0 kW) 8.0 - 15.0 hp ( 6.0 - 11 kW )

Pos. Descr iptio n

9a Key 1 1

66 Washer 1 1

157 Corrugated spring 1 1

188a Screw 1 1

10.5.2 Wear ring kit (SL1)

Pos. Description

46 Seal ring 1 1 1

49c Wear ring 1 1 1

10.5.3 Shaft seal kit

Pos. Description

105 Shaft seal cartridge 1 1

4.3 x 0.12 inch (110 x 3 mm) 1

107 O-ring

153b O-ri ng

157 Corrugated spring 1 1

For position num bers , se e pages 94 and 95.

Warning

The cable must only be replaced by Grundfos or

a service workshop authorized by Grundfos.

For service parts not show n in the above table, cons ult

www.grundfos.com WebCAPS, Service.

Examples of se rvic e parts:

• cable

• pump housing

• impeller

• bearings

• shaft/rotor

•clamp

•stator

• motor complete, both standard a nd FM .

5.3 x 0.12 inch (134.5 x 3 mm) 1 1

6.3 x 0.12 inch (160 x 3 mm) 1

0.67 x 0.09 inch (1 7.0 x 2. 4 mm ) 1

1.1 x 0.08 inch (28 x 2 mm) 1

4-pole: 1.5 - 3.0 hp (1.1 - 2.2 kW) 4.0 - 10.0 hp (3.0 - 7.5 kW )

Kit no: 96102365 96102366

Free passage: 2" ( ∅ 50) 3" ( ∅ 80) 4 " ( ∅ 100)

Rubber type: NBR NBR NBR

Kit no: 96102362 96102363 96102364

2-pole: 3.0 - 5.5 hp (2.2 - 4.0 kW) 8.0 - 15.0 hp (6.0 - 11 kW)

4-pole: 1.5 - 3.0 hp (1.1 - 2.2 kW) 4.0 - 10.0 hp (3.0 - 7.5 kW)

Rubber type: NBR NBR

Kit no: 96102360 96102361

10.6 Contaminated pumps

If a pump has been used for a liquid which is

injurious to health or toxic, the pump will be

classified as conta minat ed.

If Grundfos is requested to service the pump, Grundfos must be

contacted with details about the pum ped liq uid, e tc. befo re th e

pump is returned for service. Otherwise Grundfos can refuse to

accept the pump for service.

Possible costs of re tur ning t he pum p are t o be paid by the

customer.

However, any application for se rvice (n o matt er to who m it may

be made) must incl ude d etails abou t the pum p ed liquid if the

pump has been used for liq uids w hich ar e injur ious to he alth or

toxic.

Before a pump is returned, it must be cleaned in the best possible

way before it is ret urned .

Service instru ctio n and se rvic e vide o ca n be foun d on

www.grundfos.com.

26

Page 27

11. Fault finding

FM

Note

Warning

Before attempting to diagnose any fault, make sure that the fuses have been removed or the mains switch has been

switched off. It must be ensured that the power supply cannot be accidentally switched on.

All rotating parts must have stopped moving.

Warning

All regulations applying to pumps installed in potentially explosive environments must be observed.

It must be ensured that no work is carried out in potentially explosive atmosphere.

For pumps with sensor, start fault finding by checking the status on the IO 111 front panel.

See installation and operating instructions for IO 111.

Fault Cause Remedy

1. Motor does not

start.

Fuses blow or

motor-protecti ve

circuit breaker

trips out

immediately.

Caution: Do not

start again!

2. Pump operates,

but motorprotective circ uit

breaker trips out

after a short while.

3. The thermal switch

of the pump trips

out after a short

while.

4. Pump operates at

below-standard

performance and

power

consumption.

5. Pump operates,

but gives no liquid.

6. High power

consumption

(SLV).

7. Noisy operation

and excessive

vibrations (SL1).

8. Pump clogged. a) T he liqui d co ntai ns larg e pa rticle s. Select a pump with a la rger size o f passa ge.

* Applies only to pum ps w ith sens or and with IO 111.

a) Supply failur e; short-circuit; earth- leak age fault in

cable or motor w inding.

b) Fuses blow du e to us e of w rong ty pe of fuse . Fit fuses of the correc t type .

c) Impeller blocked by impurities. Clean the impeller.

d) Air bells, float switc hes or electr odes o ut of

adjustment or defe ctive.

e) Moisture in the stat or ho using (alar m).*

The IO 111 interrup ts the suppl y volt age.

f) The WIO sensor is not covered by oil (alarm).*

The IO 111 interrup ts the suppl y volt age.

g) *Stator insula tion res ista nce too low. Reset ala rm on IO 111. See installation and ope rati ng

a) Low setting of thermal relay in motor-protec tive

circuit breake r.

b) Increased cur rent cons umptio n du e to large

voltage drop.

c) Impeller blocked by impurit ies. Incre ase d cur rent

consumption in all thr ee phas es.

d) Wrong direction of rotation. Check the direction of rotation and possibly interchange

a) Too high liquid temperature. Reduce the liquid temperature.

b) Too high visc osity o f the pum ped li quid . Dilute the pumped liquid.

c) Wrong electrical connectio n. (I f the pump is sta r-

connected to a delta connection, the result will be

very low undervo ltage ).

a) Impeller bloc ked by impu ritie s. Clean the impeller.

b) Wrong directi on of rot ation.

a) Discharge va lve close d or blo cked . Check the d ischa rge v alve an d poss ibl y open and/o r

b) Non-return valve block ed. Clean the non-retur n valv e.

c) Air in pump. Vent the pump.

a) Wrong direction of rotation. Check the direction of rotation and possibly interchange

b) Impeller bloc ked by impu ritie s. Clean the impeller.

a) Wrong direction of rotation. Check the direction of rotation and possibly interchange

b) Impeller bloc ked by impu ritie s. Clean the impeller.

b) A float layer has formed on the surface of the liquid. I nstall a mixer i n the tank.

Have the cable and m oto r che cked and repaired by a

qualified electricia n.

Readjust or replac e the air bells, float switche s or

electrodes.

Replace the O-rin gs , th e sh aft seal and moisture sw itch.

Check, and possibly repla ce, the sh aft seal, fill up with

oil and reset the I O 111.

instructions for IO 111.

Set the relay in accordance with the sp ecification s on

the nameplate.

Measure the voltage between two moto r phases.

Tolerance: -10 %/+ 6 %. Reestablish corr ect volt ag e supp ly.

Clean the impeller.

any two of the phase s in t he inco mi ng sup ply ca ble.

See section 9. 3 D irec tion o f rotation.

Check and corr ect the ele ctr ical in stallation .

Check the direction of rotation and poss bly interchange

any two of the phase s in t he inco mi ng sup ply ca ble.

See section 9. 3 D irec tion o f rotation.

clean it.

any two of the phase s in t he inco mi ng sup ply ca ble.

See section 9. 3 D irec tion o f rotation.

any two of the phase s in t he inco mi ng sup ply ca ble.

See section 9. 3 D irec tion o f rotation.

27

Page 28

12. Technical data

Supply voltage

• 3 x 208 V - 10 %/+ 10 %, 60 Hz

• 3 x 230 V - 10 %/+ 10 %, 60 Hz

• 3 x 380 V - 10 %/+ 10 %, 60 Hz

• 3 x 460 V - 10 %/+ 10 %, 60 Hz

• 3 x 575 V - 10 %/+ 10 %, 60 Hz

Enclosure class

IP68. According to IEC 60529.

Insulation class

H (356 °F (180 °C)).

Operating pressure

All pump housings h ave a c ast iron A NSI 10 d isc harg e flan ge.

Dimensions

Discharge flange s are A NSI 2.5" , ANSI 3", ANS I 4" or A NSI 6".

2-pole motor Cable connection

Pump curves

Pump curves ar e availa ble via the in tern et on

www.grundfos.com.

The curves are to be c onsid ered as a g uide. T hey mus t not be

used as guarante e cu rves.

Test curves for the s upplied pum p are availa ble on re qu est.

It must be ensure d tha t the pu mp does n ot op era te outsid e the

recommended ope rat ing ran ge dur ing n ormal op era tion .

Pump noise emission < 70 dBA

• Sound power measurements were c arried ou t acc ordin g to

ISO 3743.

• Sound power was calculated at a distan ce of 1 m etre

accord in g to ISO 11203.

The sound pressur e level o f th e pump is lo wer tha n the li mi ting

values stated in the E C Coun cil D irecti ve 200 6/42 /EC rel ating to

machinery.

Power P

[hp (kW)]

2

Power P

[hp (kW)]

1

Voltage

[V]

Starti ng method

Thermal

protection

Cable cross-section

[AWG (mm²)]

Conductors/pins

3.0 (2.2) 3.9 (2.8) 3 x 460 Y/D Thermal switch 14 (2.5) 10/10

3.0 (2.2) 3.9 (2.8) 3 x 575 Y/D Thermal switch 14 (2.5) 10/10

3.0 (2.2) 3.9 (2.8) 3 x 208-230 / 3 x 460 Dual voltage (DOL) Thermal switch 14 (2. 5 ) 10/10

4.0 (3.0) 3.9 (3.8) 3 x 460 Y/D Therm al switch 14 (2. 5) 10/10

4.0 (3.0) 3.9 (3.8) 3 x 575 Y/D Therm al switch 14 (2. 5) 10/10

4.0 (3.0) 3.9 (3.8) 3 x 208-230 / 3 x 460 Dual voltage (DOL) Thermal switch 1 4 (2.5 ) 10/10

5.5 (4.0) 6.6 (4.9) 3 x 460 Y/D Therm al switch 14 (2. 5) 10/10

5.5 (4.0) 6.6 (4.9) 3 x 575 Y/D Therm al switch 14 (2. 5) 10/10

5.5 (4.0) 6.6 (4.9) 3 x 208-230 / 3 x 460 Dual voltage (DOL) Thermal switch 1 4 (2.5 ) 10/10

7.5 (5.5) 8.6 (6.4) 3 x 460 Y/D Therm al switch 14 (2. 5) 10/10

7.5 (5.5) 8.6 (6.4) 3 x 575 Y/D Therm al switch 14 (2. 5) 10/10

7.5 (5.5) 8.6 (6.4) 3 x 208-230 / 3 x 460 Dual voltage (DOL) Thermal switch 1 4 (2.5 ) 10/10

8.0 (6.0) 9.4 (7.0) 3 x 460 Y/D Therm al switch 14 (2. 5) 10/10

8.0 (6.0) 9.4 (7.0) 3 x 575 Y/D Therm al switch 14 (2. 5) 10/10

8.0 (6.0) 9.4 (7.0) 3 x 208-230 / 3 x 460 Dual voltage (DOL) Thermal switch 1 4 (2.5 ) 10/10

10 (7.5) 11.7 (8.7) 3 x 460 Y/D Thermal switch 14 (2.5 ) 10/10

10 (7.5) 11.7 (8.7) 3 x 575 Y/D Thermal switch 14 (2.5 ) 10/10

10 (7.5) 11.7 (8.7) 3 x 208-230 / 3 x 460 Dual voltage (DOL) Thermal switch 14 (2.5) 10/10

12.5 (9.2) 14.1 (10.5) 3 x 460 Y/D Thermal switch 14 (2.5) 10/10

12.5 (9.2) 14.1 (10.5) 3 x 575 Y/D Thermal switch 14 (2.5) 10/10

12.5 (9.2) 14.1 (10.5) 3 x 208-230 / 3 x 460 Dual voltage (DOL) Therm al switch 14 (2. 5 ) 10/10

15 (11) 16.9 (12.6) 3 x 460 Y/D Thermal switch 14 (2.5) 10/10

15 (11) 16.9 (12.6) 3 x 575 Y/D Thermal switch 14 (2.5) 10/10

15 (11) 16.9 (12.6) 3 x 208-230 / 3 x 460 Dual voltage (DOL) Thermal switch 14 (2 .5) 10/10

The resistance in the supply cable depends on the cable diameter.

Resistance per metre of cable: AWG 16 (1.5 mm

Resistance per metre of cable: AWG 14 (2.5 mm

2

) = 0.013 OHM - CSA/FM

2

) = 0.00830 OHM - CSA/FM

28

Page 29

4-pole motor Cable connection

Subject to alterations.

Power P

[hp (kW)]

2

Power P

[hp (kW)]

1

Voltage

[V]

Starting method

Thermal

protection

Cable cross-section

2

]

[mm

Conductors/

pins

1.5 (1.1) 2.0 (1.5) 3 x 575 Y/D Thermal switch 16 (1.5) 10/10

1.5 (1.1) 2.0 (1.5) 3 x 575 DOL Thermal switch 16 (1.5) 7/7

1.5 (1.1) 2.0 (1.5) 3 x 208-230 DOL Thermal switch 16 (1.5) 7/7

1.5 (1.1) 2.0 (1.5) 3 x 208-230 / 3 x 460 Dual voltage (DOL) Thermal switch 14 (2.5) 10/10

1.8 (1.3) 2.3 (1.7) 3 x 575 Y/D Thermal switch 16 (1.5) 10/10

1.8 (1.3) 2.3 (1.7) 3 x 575 DOL Thermal switch 16 (1.5) 7/7

1.8 (1.3) 2.3 (1.7) 3 x 208-230 DOL Thermal switch 16 (1.5) 7/7

1.8 (1.3) 2.3 (1.7) 3 x 208-230 / 3 x 460 Dual voltage (DOL) Thermal switch 14 (2.5) 10/10

2.0 (1.5) 2.5 (1.9) 3 x 575 Y/D Thermal switch 16 (1.5) 10/10

2.0 (1.5) 2.5 (1.9) 3 x 575 DOL Thermal switch 16 (1.5) 7/7

2.0 (1.5) 2.5 (1.9) 3 x 208-230 DOL Thermal switch 16 (1.5) 7/7

2.0 (1.5) 2.5 (1.9) 3 x 208-230 / 3 x 460 Dual voltage (DOL) Thermal switch 14 (2.5) 10/10

3.0 (2.2) 3.6 (2.7) 3 x 460 Y/D Thermal switch 14 (2.5) 10/10

3.0 (2.2) 3.6 (2.7) 3 x 575 Y/D Thermal switch 14 (2.5) 10/10