Page 1

SL1 and SLV pumps

1.1 - 11 kW, 50 Hz

Installation and operating instructions

GRUNDFOS INSTRUCTIONS

Page 2

English (GB) Installation and operating instructions

Caution

Note

English (GB)

Original installation and operating instructions

CONTENTS

1. Symbols used in this document

2. General description

2.1 Product drawing

2.2 Control and monitoring

2.3 Applications

2.4 Operating conditions

3. Delivery and handling

3.1 Transportation

3.2 Storage

4. Identification

4.1 Nameplate

4.2 Type key

5. Approvals

5.1 Approval standards

5.2 Explanation to Ex approval

6. Safety

6.1 Potentially explosive environments

7. Installation

7.1 Submerged installation on auto-coupling

7.2 Free-standing submerged installation on ring stand

7.3 Torques for suction and discharge flanges

8. Electrical connection

8.1 Wiring diagrams

8.2 Pump controllers

8.3 Thermal switch, Pt1000 and PTC thermistor

8.4 WIO sensor (water-in-oil sensor)

8.5 Moisture switch

8.6 IO 113

8.7 Frequency converter operation

9. Startup

9.1 General startup procedure

9.2 Operating modes

9.3 Direction of rotation

10. Maintenance and service

10.1 Inspection

10.2 Dismantling the pump

10.3 Assembling the pump

10.4 Oil quantities

10.5 Service kits

10.6 Contaminated pumps

11. Fault finding

12. Technical data

13. Disposal

Page

10

11

13

13

13

13

14

14

15

15

15

16

16

16

17

18

19

19

19

20

21

22

1. Symbols used in this document

Warning

If these safety instructions are not observed, it may

2

2

3

3

3

3

4

4

4

4

4

5

6

6

6

7

7

2. General description

8

This booklet includes instructions for installation, operation and

8

maintenance of Grundfos SL1 and SLV submersible sewage and

9

wastewater pumps with motors of 1.1 to 11 kW. Grundfos SL1

9

and SLV sewage and wastewater pumps are designed for

pumping domestic, municipal and industrial sewage and

wastewater.

Two types of pumps are available:

• SL1 sewage pumps with S-tube impeller

• SLV sewage pumps with SuperVortex, free-flow impeller.

The pumps can be installed on an auto-coupling system or stand

freely on the bottom of a tank.

Grundfos SL1 and SLV pumps are designed with an S-tube and

SuperVortex impeller, respectively, to ensure reliable and

optimum operation.

The booklet also includes specific instructions for the explosionproof pumps.

result in personal injury.

Warning

If these instructions are not observed, it may lead to

electric shock with consequent risk of serious

personal injury or death.

Warning

These instructions must be observed for explosion-

proof pumps. We recommend that you also follow

these instructions for standard pumps.

If these safety instructions are not observed, it may

result in malfunction or damage to the equipment.

Notes or instructions that make the job easier and

ensure safe operation.

Warning

Prior to installation, read these installation and

operating instructions. Installation and operation

must comply with local regulations and accepted

codes of good practice.

Warning

The use of this product requires experience with and

knowledge of the product.

Persons with reduced physical, sensory or mental

capabilities must not use this product, unless they

are under supervision or have been instructed in the

use of the product by a person responsible for their

safety.

Children must not use or play with this product.

2

Page 3

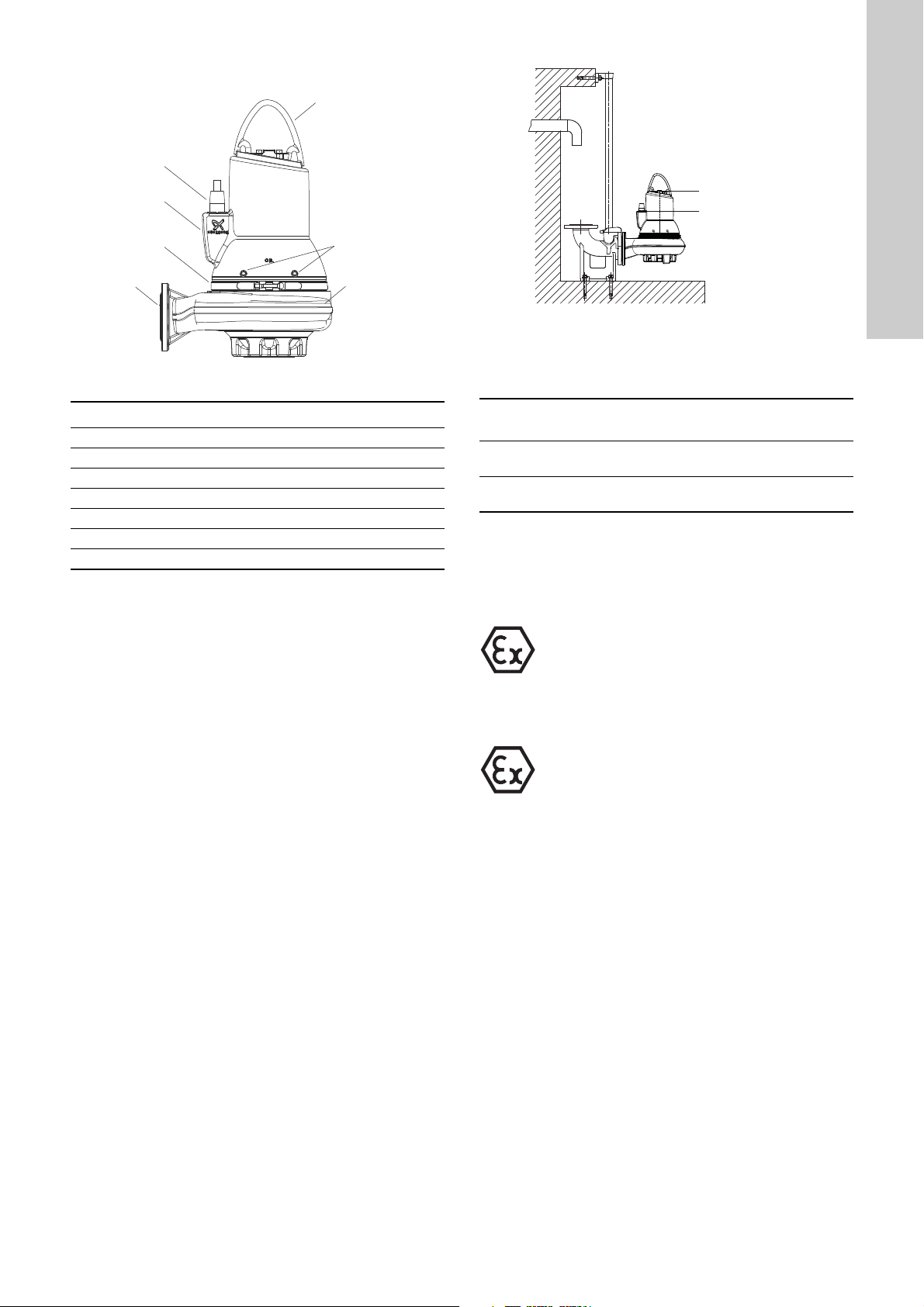

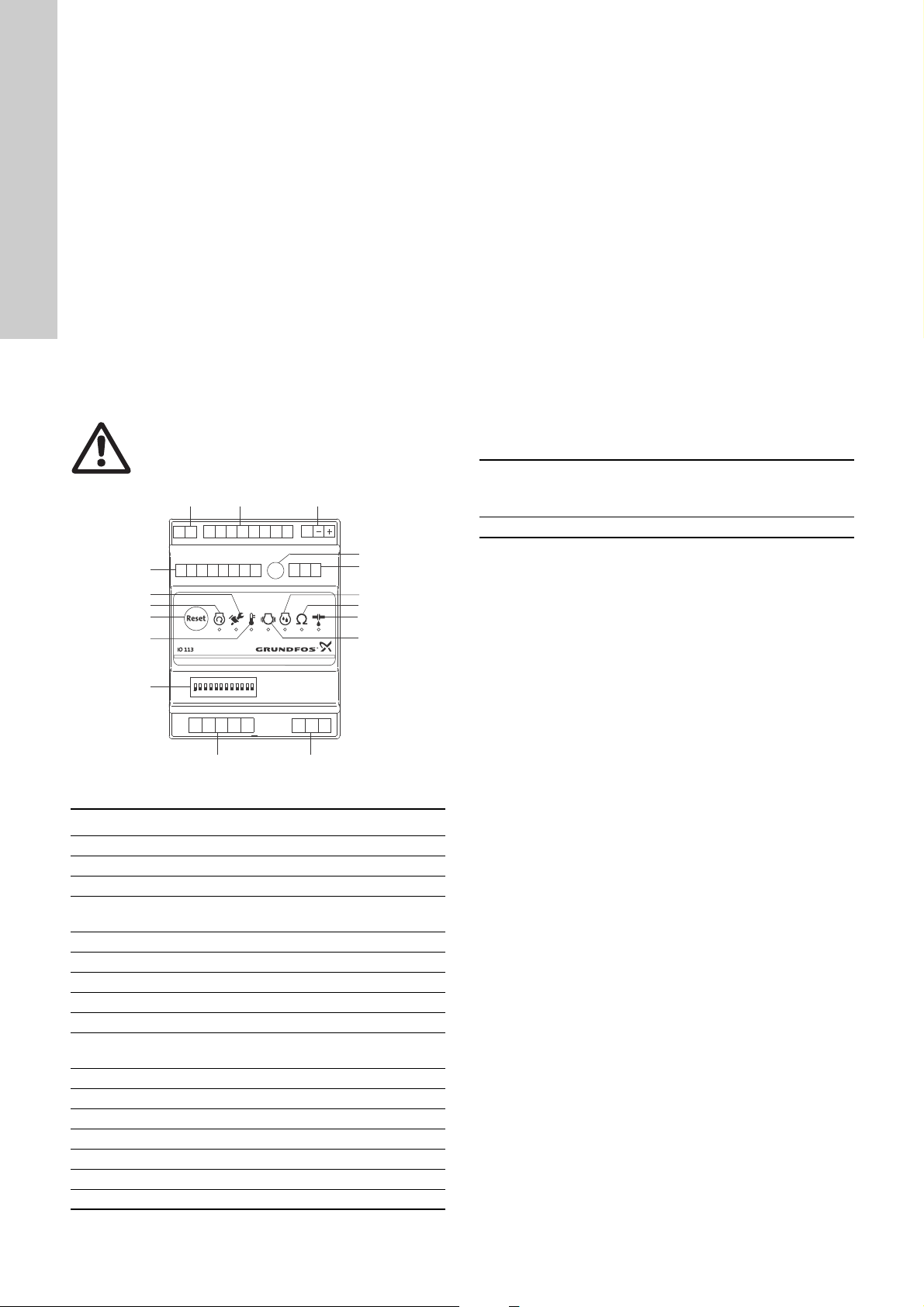

2.1 Product drawing

1

5

2

6

4

3

7

S1 operation

S3 operation

Fig. 1 SL1 pump

Fig. 2 Stop levels

pH value

TM04 2648 0616

SL1 and SLV pumps in permanent installations can be used for

pumping liquids with the following pH values:

English (GB)

TM04 2649 2808

Pos. Description

1 Lifting bracket

2Nameplate

3 Oil screws

4 Discharge flange

5 Cable plug

6Clamp

7 Pump housing

2.2 Control and monitoring

The pumps can be controlled via the Grundfos controllers LC,

LCD and dedicated controls DC and DCD. See section 8.2 Pump

controllers.

Pumps with sensor are supplied together with an IO 113.

See section 8.6 IO 113.

2.3 Applications

SL1 and SLV pumps are designed for pumping these liquids:

• large quantities of drainage and surface water

• domestic wastewater with discharge from toilets

• wastewater with a high content of fibres (SuperVortex impeller)

• municipal and commercial sewage and wastewater.

2.4 Operating conditions

The Grundfos SL1 and SLV pumps are suitable for the following

operating situations:

• S1 operation (continuous operation), the pump must always

be covered by the pumped liquid to the top of the motor.

See fig. 2.

• S3 operation (intermittent operation), the pump must always

be covered by the pumped liquid up to the top of the cable

entry. See fig. 2.

For further information about S1 and S3 operation, see section

9.2 Operating modes.

Pump

type

SL1/SLV Standard

SLV Q

1)

For fluctuating pH values, the range is pH 4 to 14.

Liquid temperature

0 °C - +40 °C.

For short periods (maximum 3 minutes) a temperature of up to

+60 °C is permissible (non-Ex versions only).

Ambient temperature

For non-explosion proof pumps, the ambient temperature may

exceed +40 °C for a short period (max. 3 minutes).

Density and viscosity of pumped liquid

When pumping liquids with a density and/or a kinematic viscosity

higher than that of water, use motors with correspondingly higher

outputs.

Flow velocity

We recommend you to keep a minimum flow velocity to avoid

sedimentations in the piping system. Recommended flow

velocities:

• in vertical pipes: 1.0 m/s

• in horizontal pipes: 0.7 m/s

Free spherical passage

From 50 to 100 mm, depending on pump size.

Operating mode

Maximum 20 starts per hour.

Material

variant

Warning

Explosion-proof pumps must never pump liquids of a

temperature higher than +40 °C.

Warning

For explosion-proof pumps, the ambient temperature

on the installation site must be in the range from -20

°C to +40 °C.

For explosion-proof pumps with WIO sensor, the

ambient temperature at the installation site must be

in the range from 0 °C to +40 °C.

Material pH value

Cast-iron impeller and pump

housing

Stainless-steel impeller and

cast-iron pump housing

6.5 - 14

1)

6-14

1)

3

Page 4

3. Delivery and handling

Type: SLV.80.80.110.EX.2.51D

Model: 9687208500000001

P.c. 0845 IP68

44.9 90

40

12.5 11.0

2950 0.89

50

0197

180

22.4-20.8

380-415

3 ~

20 m

Hmax:

Motor:

P1:

Qmax:

Tmax.:

n:

kg

min

kW

V

A

mmh/

3

C

kW

P2:

-1

V

A

Hz Insul.class:

Weight: EN 12050-1

Made in Tatabanya. Hungary

98808079

96771279

3

5

6

9

10

12

8

7

11

17

15

19

13

14

16

22

24

21

23

4

1

2

18

20

25

H

CE0344

II2G

KEMA 08ATEX 0125X

Ex cd llB T4, T3 Gb

&RVij

DK-8850 Bjerringbro, Denmark

English (GB)

The pump may be transported and stored in a vertical or

horizontal position. Make sure that it cannot roll or fall over.

3.1 Transportation

All lifting equipment must be rated for the purpose and checked

for damage before any attempts to lift the pump. The lifting

equipment rating must under no circumstances be exceeded.

The pump weight is stated on the pump nameplate.

3.2 Storage

During long periods of storage, the pump must be protected

against moisture and heat.

Storage temperature: -30 °C - +60 °C

If the pump has been in use, the oil should be changed before

storage.

After a long period of storage, the pump should be inspected

before it is put into operation. Make sure that the impeller can

rotate freely. Pay special attention to the condition of the shaft

seal, O-rings, oil and the cable entry.

4

Warning

Always lift the pump by its lifting bracket or by means

of a fork-lift truck if the pump is fixed on a pallet.

Never lift the pump by means of the motor cable or

the hose/pipe.

Warning

If the pump is stored for more than one year or it

takes a long time before it is put into operation after

the installation, the impeller must be turned at least

once a month.

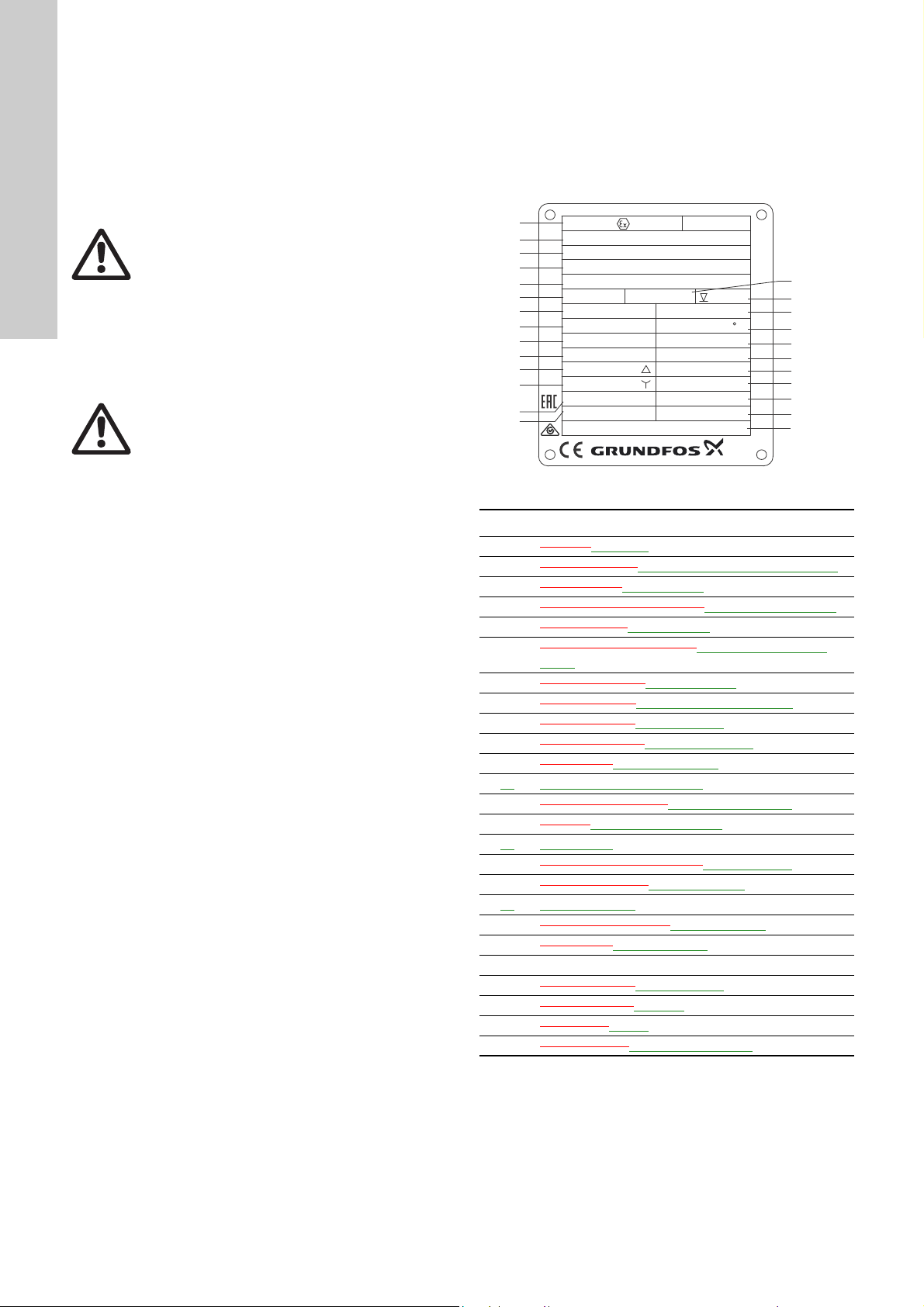

4. Identification

4.1 Nameplate

The nameplate states the operating data and approvals applying

to the pump. The nameplate is fitted to the side of the motor

housing close to the cable entry.

Fix the extra nameplate supplied with the pump to the cable end

in the control cabinet.

TM04 3279 4108

Fig. 3 Nameplate

Pos. Description

1 Ex mark Approvals

2 Type designationExplosion protection certificate No.

3 Model numberEx description

4 Production code (year/week)Pump type designation

5 Maximum headModel number

Maximum installation depth

6

week)

7 Number of phasesEnclosure class

8 Rated voltage, DMaximum installation depth

9 Rated voltage, YMaximum head

10 Rated input powerMaximum flow rate

11 Power factorNumber of phases

12 Maximum liquid temperature

13 Country of production Rated power input P1

14 CE markRated power output P2

15 Rated speed

16 Maximum liquid temperatureCos φ, 1/1-load

17 Maximum flow rateRated voltage, D

18 Rated current, D

19 Enclosure class to IECRated voltage, Y

20 Rated speedRated current, Y

21 Frequency

22 Rated current, D

Insulation class

23 Rated current, YApproval

24 Shaft powerWeight

25 Insulation classCountry of production

Production code (year/

Page 5

4.2 Type key

The pump can be identified by means of the type designation stated on the pump nameplate. See section 4.1 Nameplate.

Code Example SL V .80 .80 .40 .A .Ex .4 .5 .OD .Q

Pump type:

SL

Grundfos wastewater pump

Impeller type:

S-tube impeller

1

SuperVortex (free-flow) impeller

V

Free spherical passage:

50 mm

50

65 mm

65

80 mm

80

100

100

150

Blank

100 mm

Pump discharge:

DN 65

65

DN 80

80

DN 100

DN 150

Motor power, P2 (motor output power P2/10 [kW]):

4 kW

40

Sensor version:

Standard

Sensor version

A

English (GB)

Blank

Ex

2

4

50

0B

0D

1D

0E

1E

Blank

A

B

Blank

Q

Blank

Z

Pump version:

Non-explosion-proof pump (standard)

Explosion-proof pump

Number of poles:

2-pole

4-pole

Frequency:

50 Hz

Voltage and starting method:

3 x 400-415 V, direct-on-line starting

3 x 380-415 V, direct-on-line starting

3 x 380-415 V, star-delta starting

3 x 220-240 V, direct-on-line starting

3 x 220-240 V, star-delta starting

Generation:

1st generation

2nd generation

3rd generation

Pump materials:

Cast-iron impeller, pump housing and motor housing

Stainless-steel impeller, cast-iron pump housing and motor housing

Customisation:

Pump in standard range

Custom-built pump

5

Page 6

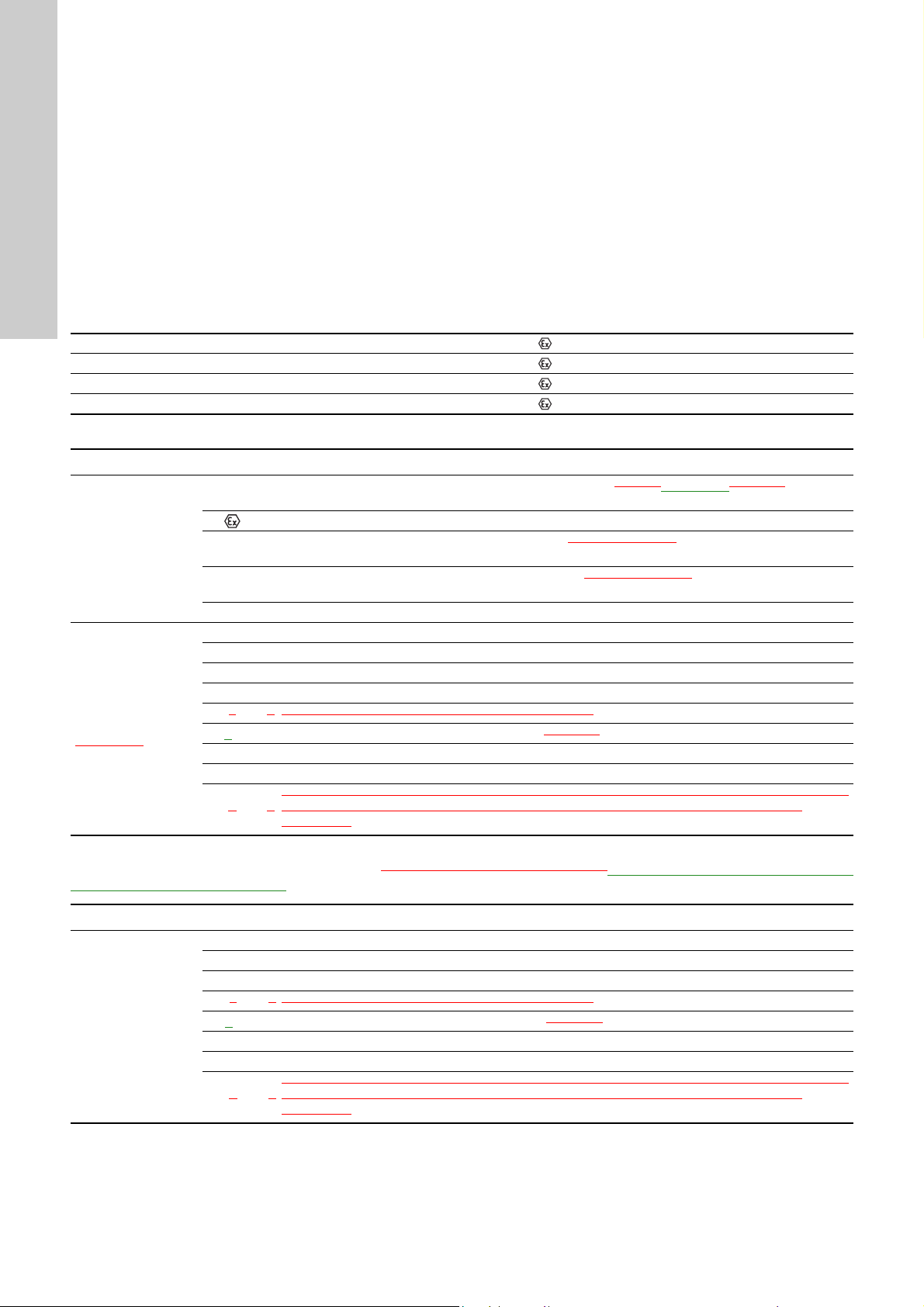

5. Approvals

English (GB)

The SL1 and SLV pumps have been tested by KEMA.

The explosion-proof versions hold two examination certificates:

• ATEX (EU): KEMA08ATEX0125X

• IECEX: IECEX KEM08.0039X

Both certificates have been issued by KEMA according to the

ATEX directive.

5.1 Approval standards

The standard variants are approved by LGA (notified body under

the Construction Products Directive) according to EN 12050-1 or

EN 12050-2 as specified on the pump nameplate.

5.2 Explanation to Ex approval

The SL1 and SLV pumps have the following explosion protection

classifications:

Direct-drive pump, without sensor: CE 0344 II 2 G Ex c d IIB T4 Gb

Direct-drive pump, with sensor: CE 0344 II 2 G Ex c d mb IIB T4 Gb

Pump driven by frequency converter, without sensor: CE 0344 II 2 G Ex c d IIB T3 Gb

Pump driven by frequency converter, with sensor: CE 0344 II 2 G Ex c d mb IIB T3 Gb

5.2.1 Europe

Directive/standard Code Description

CE 0344 =

ATEX

Harmonized

European standard

EN 60079-0

5.2.2 Australia

Explosion proof variants for Australia are approved as Ex d IIB T3/T4 Gb or Ex d mb T3/T4 Gb

Ex d mb T3/T4 Gb (with WIO sensor)..

II =

2=

G = Explosive atmosphere caused by gases or vapours.

Ex = The equipment conforms to harmonized European standard.

c Constructional safety according to EN 13463-5:2011 and EN 13463-1:2009.

d = Flameproof enclosure according to EN 60079-1:2007.

mb = Encapsulation according to EN 60079-18:2009.

II

IIB = Classification of gases, see EN 60079-0:2012, Annex A. Gas group B includes gas group A.

T4/T3 = Maximum surface temperature is 135 °C / 200 °C according to EN 60079-0:2012.

Gb = Equipment protection level.

X

CE marking of conformity according to the ATEX directive 94/9/EC

0344 is the number of the notified body which has certified the quality system for ATEX

= Marking of explosion protection.

Equipment group according to the ATEX directive, Annex II, point 2.2

applicable to the equipment in this group.

Equipment category according to the ATEX directive, Annex II, point 2.2

applicable to the equipment in this category.

= Suitable for use in explosive atmospheres (not mines).

The letter X in the certificate number indicates that the equipment is subject to special conditions for

=

safe use. The conditions are mentioned in the certificate and the installation and operating

instructions.

2014/34/EU, Annex X.

.

, defining the requirements

, defining the requirements

Ex d IIB T3/T4 Gb (without WIO sensor) or

Standard Code Description

Ex = Area classification according to AS 2430.1.

d = Flameproof enclosure according to IEC 60079-1:2007.

mb = Encapsulation according to IEC 60079-18:2009.

II

= Suitable for use in explosive atmospheres (not mines).

IEC 60079-0 and

IEC 60079-1

IIB = Classification of gases, see IEC 60079-0:2011, Annex A. Gas group B includes gas group A.

T4/T3 = Maximum surface temperature is 135 °C / 200 °C according to IEC 60079-0:2011.

Gb = Equipment protection level.

The letter X in the certificate number indicates that the equipment is subject to special conditions for

=

X

safe use. The conditions are mentioned in the certificate and the installation and operating

instructions.

6

Page 7

6. Safety

Note

Warning

Pump installation in tanks must be carried out by

specially trained persons.

Work in or near tanks must be carried out according

to local regulations.

Warning

Persons must not enter the installation area when the

atmosphere is explosive.

Warning

It must be possible to lock the mains switch in

position 0. Type and requirements as specified in EN

60204-1, 5.3.2.

For safety reasons, all work in tanks must be supervised by a

person outside the pump tank.

We recommend you to make all maintenance and

service jobs when the pump is placed outside the

tank.

Tanks for submersible sewage and wastewater pumps may

contain sewage or wastewater with toxic and/or disease-causing

substances. Therefore, all persons involved must wear

appropriate personal protective equipment and clothing, and all

work on and near the pump must be carried out under strict

observance of the hygiene regulations in force.

Warning

Make sure that the lifting bracket is tightened before

attempting to lift the pump. Tighten if necessary.

Carelessness during lifting or transportation may

cause injury to personnel or damage to the pump.

6.1 Potentially explosive environments

Use explosion-proof pumps for applications in potentially

explosive environments. See section 5.2 Explanation to Ex

approval.

Warning

SL1 and SLV pumps must under no circumstances

be used to pump explosive, flammable or

combustible liquids.

Warning

The classification of the installation site must be

approved by the local fire-fighting authorities in each

individual case.

Special conditions for safe use of SL1 and SLV

explosion-proof pumps:

1. Make sure the moisture switch and thermal

switches are connected in the same circuit but

have separate alarm outputs (motor stop) in case

of high humidity or high temperature in the motor.

2. Bolts used for replacement must be class A2-70

or better according to EN/ISO 3506-1.

3. Contact the manufacturer for information on the

dimensions of the flameproof joints.

4. The level of pumped liquid must be controlled by

two level switches connected to the motor control

circuit. The minimum level depends on the

installation type and is specified in these

installation and operating instructions.

5. Make sure the permanently attached cable is

suitably mechanically protected and terminated in

a suitable terminal board placed outside the

potentially explosive area.

6. The sewage pumps have an ambient temperature

range of -20 °C to +40 °C and a maximum

process temperature of +40 °C. The minimum

ambient temperature for a pump with a water-inoil sensor is 0 °C.

7. The thermal protection in the stator windings has

a nominal switch temperature of 150 °C and must

guarantee the disconnection of the power supply;

the power supply must be reset manually.

8. The control unit must protect the WIO sensor

against short circuit current of the supply to which

it is connected. The maximum current from the

control unit must be limited to 350 mA.

9. In case of frequency converter usage, the

Maximum surface temperature of the pump can

be 200 °C.

English (GB)

7

Page 8

7. Installation

Caution

Note

Caution

Caution

Caution

Note

English (GB)

Warning

During installation, always support the pump by

means of lifting chains or place it in horizontal

position to secure stability.

Prior to installation, make sure the tank bottom is

even.

Warning

Before beginning the installation, switch off the

power supply and lock the mains switch in position 0

with a padlock to ensure that the power supply

cannot be accidentally switched on.

Any external voltage connected to the pump must be

switched off before working on the pump.

Before beginning installation procedures, carry out these checks:

• Does the pump correspond to order?

• Is the pump suitable for the supply voltage and frequency

available at the installation site?

• Are accessories and other equipment undamaged?

Further details concerning accessories can be found

in the data booklet on SL1, SLV pumps on

www.grundfos.com.

Fix the extra nameplate supplied with the pump to the cable end

in the control cabinet.

All safety regulations must be observed at the installation site,

e.g. the use of blowers for fresh-air supply to the tank.

Prior to installation, check the oil level in the oil chamber.

See section 10. Maintenance and service.

Warning

Do not put your hands or any tool into the pump

suction or discharge port after the pump has been

connected to the power supply, unless the pump has

been switched off by removing the fuses or switching

off the mains switch. Make sure that the power

supply cannot be accidentally switched on.

We recommend to always use Grundfos accessories

to avoid malfunctions due to incorrect installation.

Warning

Only use the lifting bracket for lifting the pump. Do

not use it to hold the pump when in operation.

Installation types

The SL1 and SLV pumps are designed for two installation types:

• submerged installation on auto-coupling

• free-standing submerged installation on ring stand.

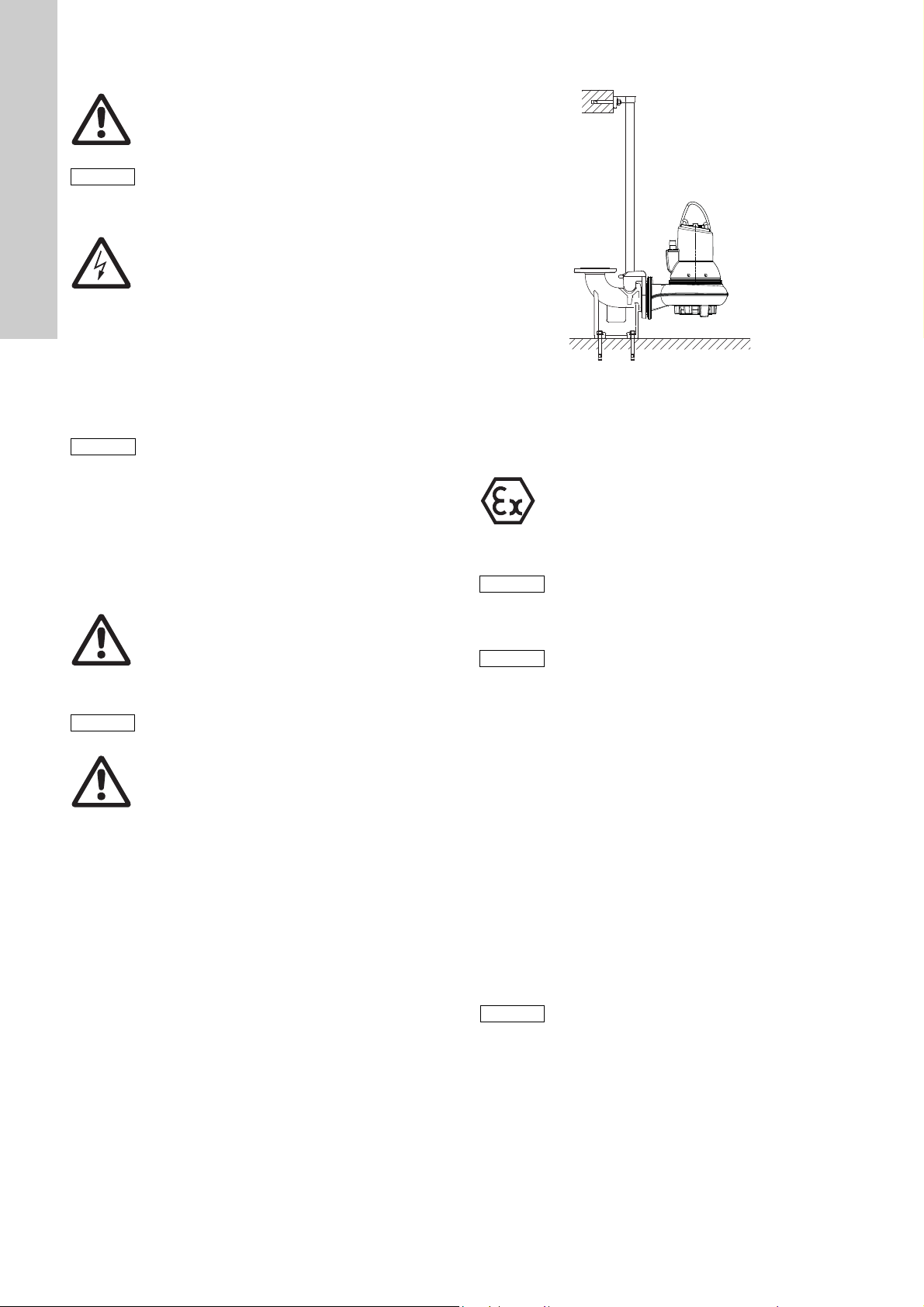

7.1 Submerged installation on auto-coupling

TM04 2650 2808

Fig. 4 Submerged installation on auto coupling

Pumps for permanent installation can be installed on a stationary

auto-coupling guide rail system. The auto-coupling system

facilitates maintenance and service as the pump can easily be

lifted out of the tank.

Warning

Before beginning installation procedures, make sure

that the atmosphere in the tank is not potentially

explosive.

Make sure that the pipework is installed without the

use of undue force. No loads from the pipework

weight must be carried by the pump. We recommend

the use of loose flanges to ease the installation and

to avoid pipe tension at flanges and bolts.

Do not use elastic elements or bellows in the

pipework; these elements should never be used as a

means to align the pipework.

Proceed as follows:

1. Drill mounting holes for the guide rail bracket on the inside of

the tank and fasten the guide rail bracket provisionally with

two screws.

2. Place the auto-coupling base unit on the bottom of the tank.

Use a plumb line to establish the correct positioning.

Fasten the auto-coupling with expansion bolts. If the bottom of

the tank is uneven, the auto-coupling base unit must be

supported so that it is level when being fastened.

3. Assemble the discharge pipe in accordance with the generally

accepted procedures and without exposing the pipe to

distortion or tension.

4. Place the guide rails on the auto-coupling base unit and adjust

the length of the rails accurately to the guide rail bracket at

the top of the tank.

5. Unscrew the provisionally fastened guide rail bracket.

Insert the upper guide rail bracket into the guide rails.

Fasten the guide rail bracket on the inside of the tank.

The guide rails must not have any axial play as this

would cause noise during pump operation.

6. Clean out debris from the tank before lowering the pump into

the tank.

7. Fit the guide claw to the discharge port of the pump.

8

Page 9

8. Slide the guide claw of the pump between the guide rails and

Note

Note

Caution

lower the pump into the tank by means of a chain secured to

the lifting bracket of the pump. When the pump reaches the

auto-coupling base unit, the pump will automatically connect

tightly.

9. Hang up the end of the chain on a suitable hook at the top of

the tank and in such a way that the chain cannot come into

contact with the pump housing.

10. Adjust the length of the motor cable by coiling it up on a relief

fitting to ensure that the cable is not damaged during

operation. Fasten the relief fitting to a suitable hook at the top

of the tank. Make sure that the cables are not sharply bent or

pinched.

11. Connect the motor cable.

The free end of the cable must not be submerged, as

water may penetrate into the cable .

7.2 Free-standing submerged installation on ring

stand

7.3 Torques for suction and discharge flanges

Grade 4.6 (5) galvanized steel screws and nuts

Pitch

Nominal

diameter

DN 65 145 4 x M16 70 60

DN 80 160 8 x M16 70 60

DN 100 180 8 x M16 70 60

Discharge

DN 150 240 8 x M20 140 120

and suction

Grade A2.50 (AISI 304) steel screws and nuts

Nominal

diameter

DN 65 145 4 x M16 - 60

DN 80 160 8 x M16 - 60

DN 100 180 8 x M16 - 60

Discharge

DN 150 240 8 x M20 - 120

and suction

circle

diameter

[mm]

Pitch

circle

diameter

[mm]

Screws

Screws

Specified torques

rounded off by ± 5

[Nm]

Slightly

oiled

Specified torques

rounded off by ± 5

[Nm]

Slightly

oiled

Well

lubricated

Well

lubricated

English (GB)

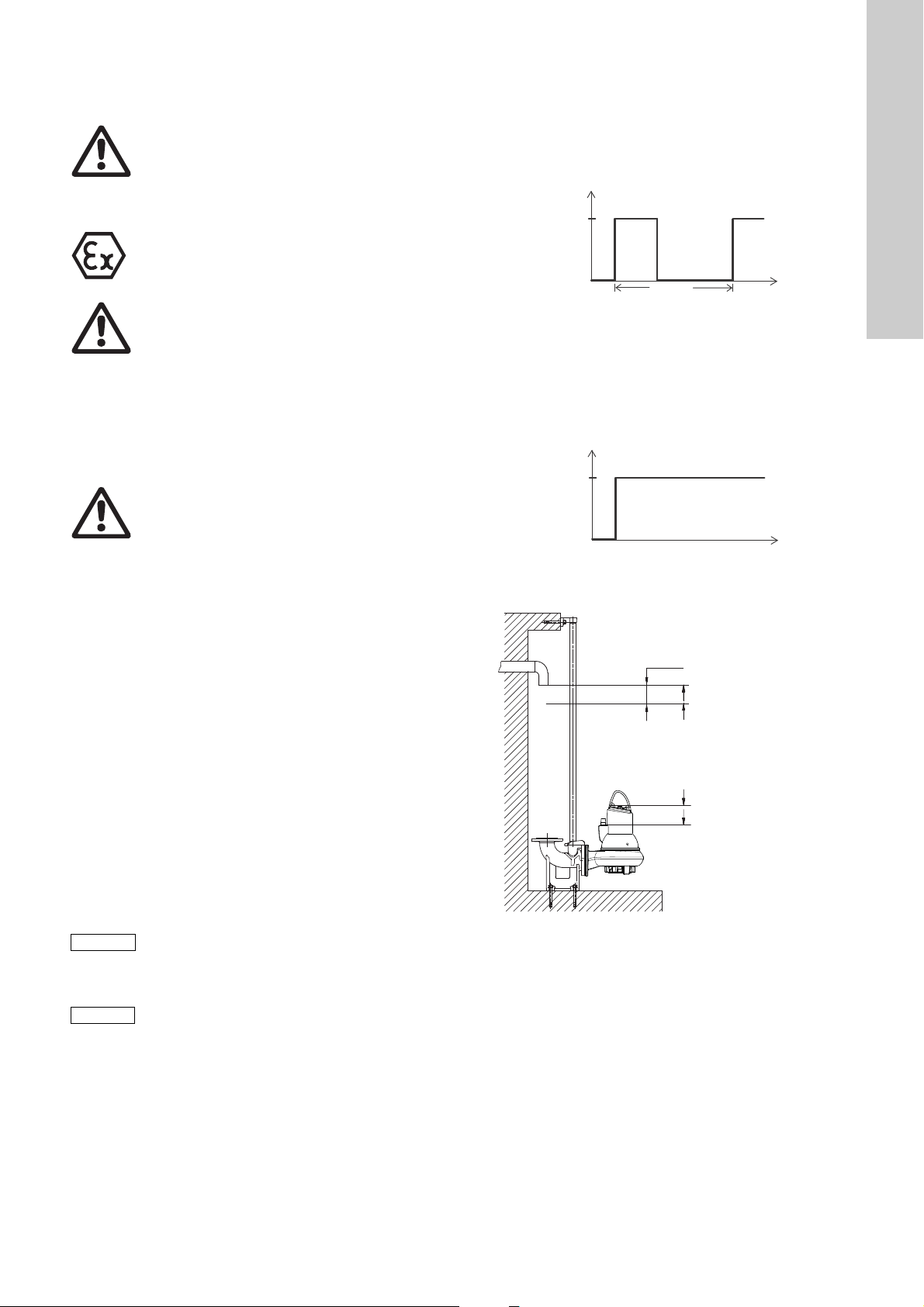

Fig. 5 Free-standing submerged installation on a ring stand

Pumps for free-standing submerged installation can stand freely

on the bottom of the tank. The pump must be installed on a ring

stand. See fig. 5.

The ring stand is available as an accessory.

In order to facilitate service on the pump, fit a flexible union or

coupling to the elbow on the discharge port for easy separation.

If a hose is used, make sure that the hose does not buckle and

that the inside diameter of the hose matches that of the pump

discharge port.

If a rigid pipe is used, fit the union or coupling, non-return valve

and isolating valve in the order mentioned, when viewed from the

pump.

If the pump is installed in muddy conditions or on uneven ground,

support the pump on bricks or a similar support.

Proceed as follows:

1. Fit a 90 ° elbow to the pump discharge port and connect the

discharge pipe/hose.

2. Lower the pump into the liquid by means of a chain secured to

the lifting bracket of the pump. We recommend to place the

pump on a plane, solid foundation. Make sure that the pump is

hanging from the chain and not the cable. Make sure that the

pump is standing securely.

3. Hang up the end of the chain on a suitable hook at the top of

the tank and in such a way that the chain cannot come into

contact with the pump housing.

4. Adjust the length of the motor cable by coiling it up on a relief

fitting to ensure that the cable is not damaged during

operation. Fasten the relief fitting to a suitable hook at the top

of the tank. Make sure that the cable is not sharply bent or

pinched.

5. Connect the motor cable.

The free end of the cable must not be submerged, as

water may penetrate into the cable.

The gasket must be a full face, reinforced paper

gasket like Klingersil C4300. If softer gasket material

is used, torques must be reconsidered.

TM04 2651 2808

9

Page 10

8. Electrical connection

Caution

Caution

Caution

English (GB)

Warning

The pump must not run dry.

An additional level switch must be installed to ensure

that the pump is stopped in case the stop level switch

is not operating.

Warning

Connect the pump to an external mains switch which

ensures all-pole disconnection with a contact

separation according to EN 60204-1, 5.3.2.

It must be possible to lock the mains switch in

position 0. Type and requirements as specified in EN

60204-1, 5.3.2.

The electrical connection must be carried out in

accordance with local regulations.

Warning

The pumps must be connected to a control box with

a motor protection relay with IEC trip class 10 or 15.

Warning

Power supply for motor protection circuit must be low

voltage, Class 2.

See motor protection wiring diagram in section

8.1 Wiring diagrams.

Warning

Pumps for hazardous locations must be connected to

a control box with a motor protection relay with IEC

trip class 10.

Warning

Do not install Grundfos control boxes, pump

controllers, Ex barriers and the free end of the power

cable in potentially explosive environments.

The classification of the installation site must be

approved by the local fire-fighting authorities in each

individual case.

On explosion-proof pumps, make sure that an

external earth conductor is connected to the external

earth terminal on the pump using a secure cable

clamp. Clean the surface of the external earth

connection and mount the cable clamp.

The cross section of the earth conductor must be at

least 4 mm

green.

Make sure that the earth connection is protected

from corrosion.

Make sure that all protective equipment has been

connected correctly.

Float switches used in potentially explosive

environments must be approved for this application.

They must be connected to the Grundfos LC, LCD

108 pump controller via the intrinsically safe LC-Ex4

barrier to ensure a safe circuit.

2

, e.g. type H07 V2-K (PVT 90 °) yellow/

All pumps are supplied with 10 m cable and a free cable end,

except for pumps for Australia which have 15 m cable.

Pumps without sensor must be connected to one of these three

controller types:

• a control box with motor-protective circuit breaker, such as a

Grundfos CU 100

• a Grundfos LC, LCD 107, LC, LCD 108 or LC, LCD 110 pump

controller

• a Grundfos DC, DCD pump controller.

Pumps with sensor must be connected to a Grundfos IO 113

and one of these three controller types:

• a control box with motor-protective circuit breaker, such as a

Grundfos CU 100

• a Grundfos LC, LCD 107, LC, LCD 108 or LC, LCD 110 pump

controller

• a Grundfos DC and DCD pump controller.

Warning

Before installation and the first startup of the pump,

check the condition of the cable visually to avoid

short circuits.

Pumps with WIO sensor

For safe installation and operation of pumps equipped with a

WIO sensor, we recommend to install an RC filter between the

power contactor and the pump.

If an RC filter is installed to avoid any kind of

transients in the installation, the RC filter must be

installed between the power contactor and the pump.

Please note that the following aspects may cause problems in

case of transients in the power supply system:

• Motor power:

– The bigger the motor, the higher the transients.

• Length of motor cable:

– Where power and signal conductors are running in parallel

close to each other, the risk of transients causing

interference between power and signal conductors will

increase with the length of the cable.

• Switchboard layout:

– Power and signal conductors must be physically separated

as much as possible. Close installation can cause

interference in case of transients.

• Supply network "stiffness":

– If a transformer station is located close to the installation,

the supply network may be "stiff" and transient levels will be

higher.

If combinations of the above aspects are present, it may be

necessary to install RC filters for pumps with WIO sensors to

protect against transients.

Transients can be completely eliminated if soft starters are used.

But be aware that soft starters and variable speed drives have

other EMC-related issues that must be taken into consideration.

For more information, see section 8.7 Frequency converter

operation

Warning

If the supply cable is damaged, it must be replaced

by the manufacturer, its service agent or similarly

qualified persons.

Set the motor-protective circuit breaker to the rated

current of the pump. The rated current is stated on

the pump nameplate.

If the pump has an Ex mark on the nameplate, make

sure that the pump is connected in accordance with

the instructions given in this booklet.

The mains supply voltage and frequency are marked on the pump

nameplate. The voltage tolerance must be within - 10 %/+ 10 % of

the rated voltage. Make sure that the motor is suitable for the

power supply available at the installation site.

10

Page 11

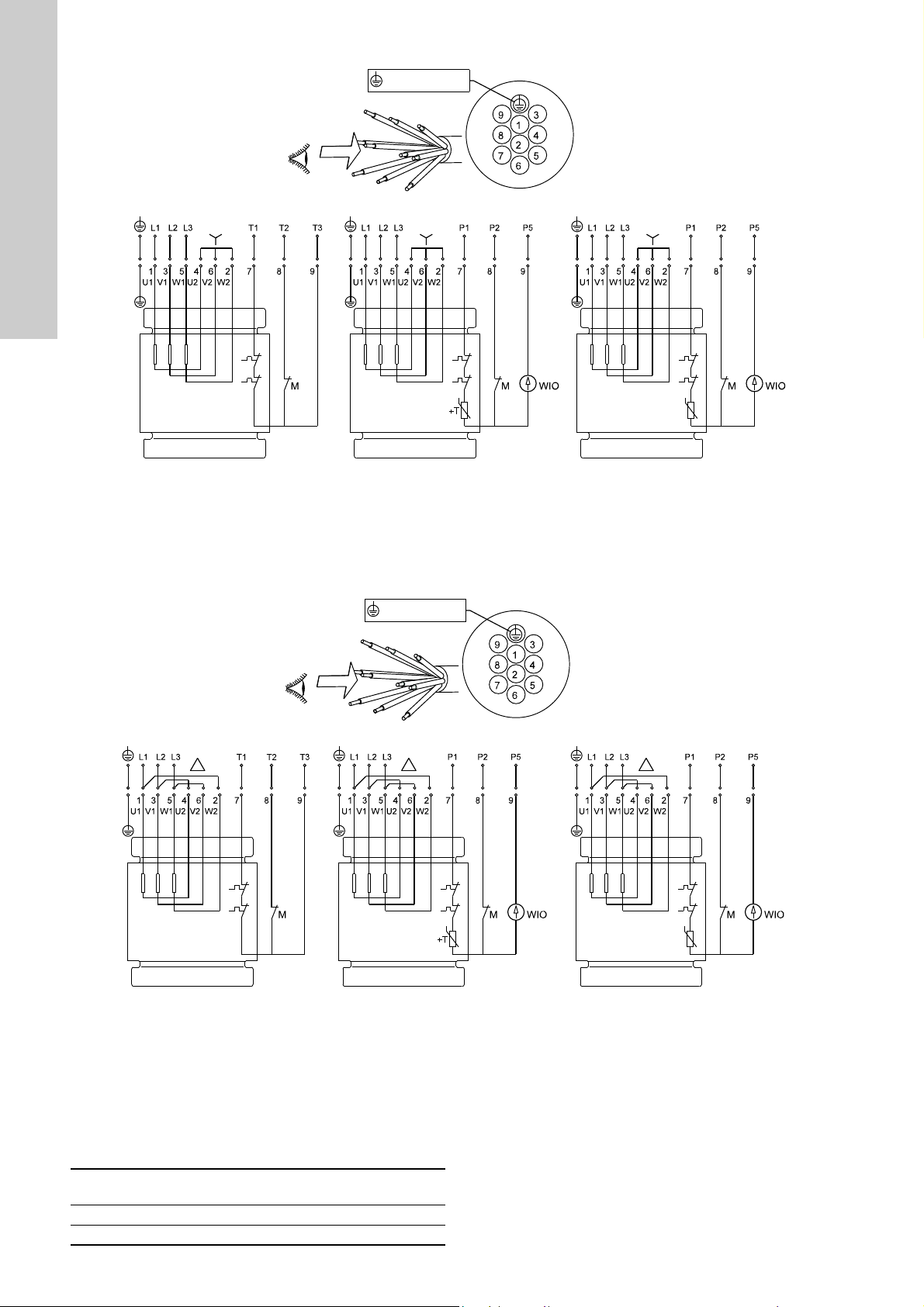

8.1 Wiring diagrams

Standard version

Thermal switch and

moisture switch*

Sensor version

Thermal switch, Pt1000 resistor,

moisture switch and water-in-oil sensor

Sensor version

Thermal switch, PTC thermistor*,

moisture switch and water-in-oil sensor

Yellow/green

* Pumps from 4 kW and up sold in Australia/New Zealand are fitted with a PTC thermistor.

Yellow/green

Standard version

Thermal switch and

moisture switch*

Sensor version

Thermal switch, Pt1000 resistor,

moisture switch and water-in-oil sensor

Sensor version

Thermal switch, PTC thermistor*,

moisture switch and water-in-oil sensor

* Pumps from 4 kW and up sold in Australia/New Zealand are fitted with a PTC thermistor.

The pumps are supplied via either a 7-core cable or a 10-core cable. See fig. 6 for wiring diagrams for 7-core cable connection or figures.

7, 8 and 9 for wiring diagrams for 10-core cable connection. For further information, see the installation and operating instructions for the

selected control box or pump controller.

English (GB)

Fig. 6 Wiring diagram, 7-core cable, DOL

TM04 6884 0314

Fig. 7 Wiring diagram, 10-core cable, star/delta (Y/D)

TM04 6885 0314

11

Page 12

English (GB)

Yellow/green

Standard version

Thermal switch and

moisture switch*

Sensor version

Thermal switch, Pt1000 resistor,

moisture switch and water-in-oil sensor

Sensor version

Thermal switch, PTC thermistor*,

moisture switch and water-in-oil sensor

* Pumps from 4 kW and up sold in Australia/New Zealand are fitted with a PTC thermistor.

Yellow/green

Standard version

Thermal switch and

moisture switch*

Sensor version

Thermal switch, Pt1000 resistor,

moisture switch and water-in-oil sensor

Sensor version

Thermal switch, PTC thermistor*,

moisture switch and water-in-oil sensor

* Pumps from 4 kW and up sold in Australia/New Zealand are fitted with a PTC thermistor.

Fig. 8 Wiring diagram, 10-core cable, star-connected (Y)

TM04 6886 0314

Fig. 9 Wiring diagram, 10-core cable, delta-connected (D)

To find out whether the pump is fitted with a thermal switch or a

PTC thermistor, measure the motor winding resistance. See table

below.

Without cable

Thermal switch < 50 mΩ < 320 mΩ < 390 mΩ

PTC thermistor > 100 mΩ > 370 mΩ > 440 mΩ

12

With 10 m

cable

With 15 m

cable

TM04 6887 0314

Page 13

8.2 Pump controllers

Caution

SL1 and SLV pumps can be connected to the following Grundfos

pump controllers for level control:

LC controllers are for one-pump-installations and LCD controllers

are for two-pump installations.

• LC 107 and LCD 107 with air bells

• LC 108 and LCD 108 with float switches

• LC 110 and LCD 110 with electrodes

• Grundfos DC and DCD.

For further information on controllers, please see the installation

and operation instructions for the selected controller or go to

www.grundfos.com.

8.3 Thermal switch, Pt1000 and PTC thermistor

All SL1 and SLV pumps have thermal protection incorporated in

the stator windings.

Pumps without sensor

Pumps without sensor have a thermal switch or a PTC thermistor.

Via the pump controller safety circuit, the thermal switch will stop

the pump by breaking the circuit in case of overtemperature

(approx. 150 °C). The thermal switch will reclose the circuit after

cooling. For pumps equipped with a PTC thermistor, connect the

thermistor to either the PTC relay or the I/O module to break the

circuit at 150 °C.

The maximum operating current of the thermal switch is 0.5 A at

500 VAC and cos φ 0.6. The switch must be able to break a coil in

the supply circuit.

Pumps with WIO sensor

Pumps with WIO sensor have either a thermal switch and a

Pt1000 sensor or a PTC thermistor in the windings, depending on

the installation site.

Via the pump controller safety circuit, the thermal switch or the

thermistor will stop the pump by breaking the circuit in case of

overtemperature (approx. 150 °C). The thermal switch or the

thermistor will reclose the circuit after cooling.

The maximum operating current of both the Pt1000 and the

thermistor is 1 mA at 24 VDC.

Non-explosion-proof pumps

When closing the circuit after cooling, the thermal protection can

restart the pump automatically via the controller. Pumps from

4 kW and up sold in Australia/New Zealand are fitted with a PTC

thermistor.

Explosion-proof pumps

Warning

The thermal protection of explosion-proof pumps

must not restart the pump automatically.

This ensures protection against overtemperature in

potentially explosive environments. In pumps with

sensor this is done by removing the short circuit

between terminals R1 and R2 in the IO 113. See

Electrical data in the IO 113 installation and

operating instructions.

Warning

The separate motor-protective circuit breaker/

controller must not be installed in potentially

explosive environments.

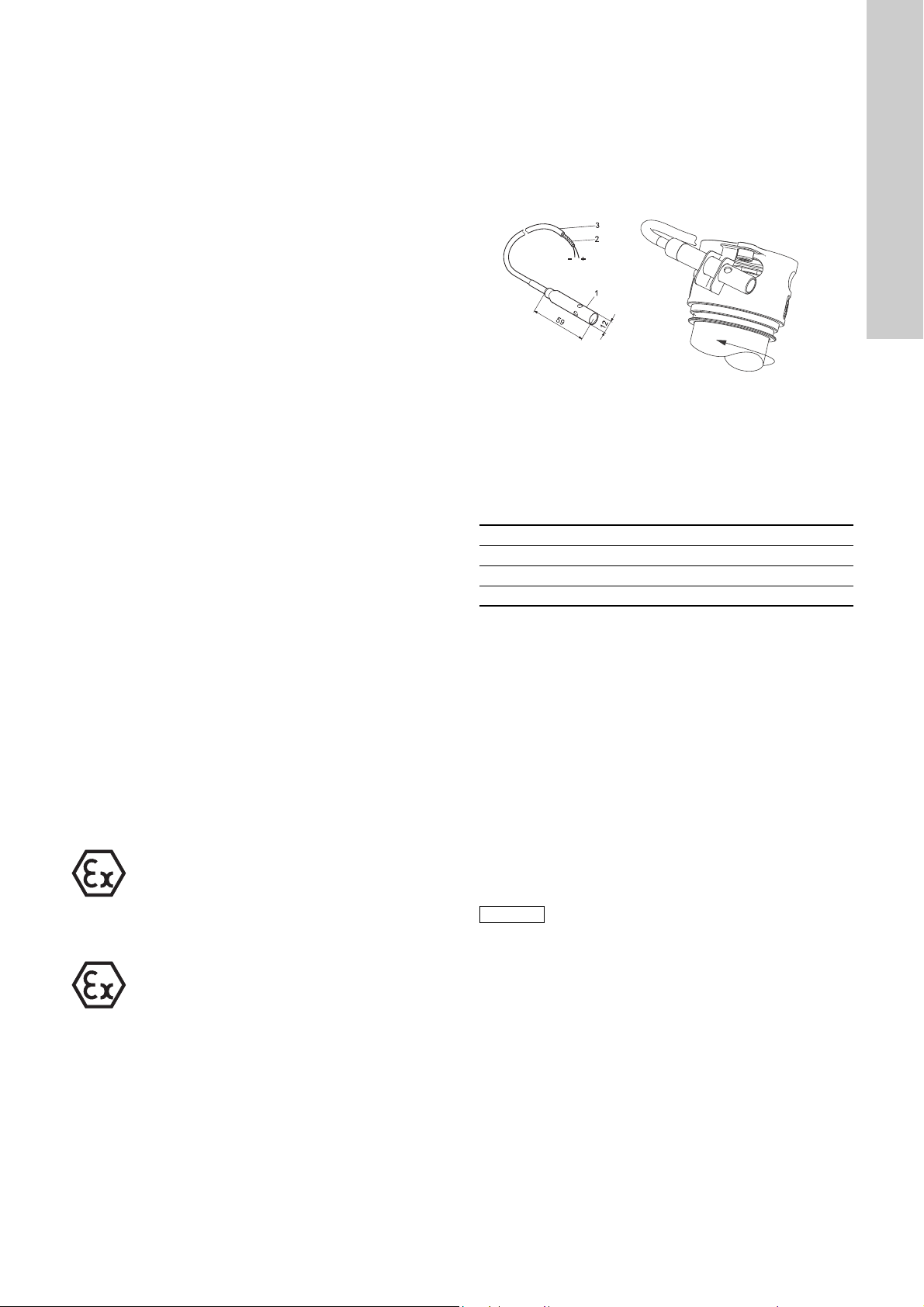

8.4 WIO sensor (water-in-oil sensor)

The WIO sensor measures the water content in the oil and

converts the value into an analogue current signal. The two

sensor conductors are for power supply and for carrying the

signal to the IO 113. The sensor measures the water content from

0 to 20 %. It also sends a signal if the water content is outside the

normal range (warning), or if there is air in the oil chamber

(alarm). The sensor is fitted in a stainless-steel tube for

mechanical protection.

Fig. 10 WIO sensor

8.4.1 Fitting the WIO sensor

Fit the sensor next to one of the shaft seal openings. See fig. 10.

The sensor must be tilted into the motor's direction of rotation to

ensure that oil is led into the sensor. Make sure that the sensor is

submerged in the oil.

8.4.2 Technical data

Input voltage: 12-24 VDC

Output current: 3.4 - 22 mA

Power input: 0.6 W

Ambient temperature: 0-70 °C

See also the installation and operating instructions for IO 113 on

www.grundfos.com.

8.5 Moisture switch

All pumps are fitted with a moisture switch as standard with the

moisture switch being connected via the supply cable, see

section 8. Electrical connection, and connected to a separate

circuit breaker.

The moisture switch is positioned in the bottom of the motor.

If there is moisture in the motor, the switch will break the circuit

and send a signal to the IO 113.

The moisture switch is non-reversing and must be replaced after

use.

The moisture switch is connected to the monitoring cable, and it

must be connected to the safety circuit of the separate pump

controller. See section 8. Electrical connection.

The motor-protective circuit breaker of the pump

controller must include a circuit which automatically

disconnects the power supply in case the protective

circuit for the pump is opened.

English (GB)

TM04 5238 2909 - TM03 1164 1105

13

Page 14

English (GB)

PET1 T2

G1 A1 G2 A2 K1 K2 R1 R2

D1 D2D3 D4 D5 D6D7 D8

P1 P2 P3 P4 P5

AYB

I1 I2 I3

ON DIP

12345678910

11 12

12 3

4

5

6

7

8

9

1011

12

13

14

16

15

17

8.6 IO 113

IO 113 provides an interface between a Grundfos wastewater

pump equipped with sensors and the pump controller(s).

The most important sensor status information is indicated on the

front panel.

One pump can be connected to one IO 113 module.

Together with the sensors, the IO 113 provides a galvanic

isolation between the motor voltage in the pump and the

connected controller(s).

IO 113 can do the following as standard:

• Protect the pump against overheating.

• Monitor the status of these items:

– motor winding temperature

– leakage (WIO)

– moisture in pump.

• Measure the stator insulation resistance.

• Stop the pump in case of alarm.

• Remotely monitor the pump via RS-485 communication

(Modbus or GENIbus).

• Control the pump via a frequency converter.

Warning

IO 113 must not be used for purposes other than

those specified above.

Fig. 11 IO 113 module

Pos. Description

1 Terminals for alarm relay

2 Terminals for analog and digital inputs and outputs

3 Terminals for supply voltage

Potentiometer for setting the warning limit of stator

4

insulation resistance

5 Terminals for RS-485 for GENIbus or Modbus

6 Indicator light for moisture measurement

7 Indicator light for stator insulation resistance

8 Indicator light for leakage (WIO)

9 Indicator light for vibration in pump

Terminals for measurement of stator insulation

10

resistance

11 Terminals for connection of pump sensors

12 DIP switch for configuration

13 Indicator light for motor temperature

14 Button for resetting alarms

15 Indicator light for motor running

16 Indicator light for service

17 Terminals for digital outputs

8.7 Frequency converter operation

All SL1/SLV pump types are designed for frequency converter

operation to keep the energy consumption at a minimum.

To avoid the risk of sedimentation in the pipes, we recommend

that you operate the speed-controlled pump at a flow rate above

1 m/s.

For frequency converter operation, please observe the following

information:

• Requirements must be fulfilled. See section

8.7.1 Requirements.

• Recommendations ought to be fulfilled. See section

8.7.2 Recommendations.

• Consequences should be considered. See section

8.7.3 Consequences.

8.7.1 Requirements

• The thermal protection of the motor must be connected.

• Minimum switching frequency: 2.5 kHz.

• Peak voltage and dU/dt must be in accordance with the table

below. The values stated are maximum values supplied to the

motor terminals. The cable influence has not been taken into

account. See the frequency converter data sheet regarding the

actual values and the cable influence on the peak voltage and

dU/dt.

Maximum repetitive peak

voltage

[V]

850 2000

• If the pump is an Ex-approved pump, check if the Ex certificate

of the specific pump allows the use of a frequency converter.

• Set the frequency converter U/f ratio according to the motor

data.

• Local regulations/standards must be fulfilled.

8.7.2 Recommendations

Before installing a frequency converter, calculate the lowest

allowable frequency in the installation in order to avoid zero flow.

• Do not reduce the motor speed to less than 30 % of rated

speed.

• Keep the flow velocity above 1 m/sec.

• Let the pump run at rated speed at least once a day in order to

TM05 1881 3811

prevent sedimentation in the piping system.

• Do not exceed the frequency indicated on the nameplate.

In this case there is risk of motor overload.

• Keep the motor cable as short as possible. The peak voltage

will increase with the length of the motor cable. See data sheet

for the frequency converter used.

• Use input and output filters on the frequency converter.

See data sheet for the frequency converter used.

• Use screened motor cable if there is a risk that electrical noise

can disturb other electrical equipment. See data sheet for the

frequency converter used.

8.7.3 Consequences

When operating the pump via a frequency converter, please be

aware of these possible consequences:

• The locked-rotor torque will be lower. How much lower will

depend on the frequency converter type. See the installation

and operating instructions for the frequency converter used for

information on the locked-rotor torque available.

• The working condition of bearings and shaft seal may be

affected. The possible effect will depend on the application.

The actual effect cannot be predicted.

• The acoustic noise level may increase. See the installation

and operating instructions for the frequency converter used for

advice as to how to reduce the acoustic noise.

Maximum dU/dt

U

400 V

N

[V/μ sec.]

14

Page 15

9. Startup

Note

Caution

Operation

Stop

6 min.4 min.

10 min.

P

t

P

t

Operation

Stop

Start

Stop S1 operation

Alarm

Min. 10 cm

Stop S3 operation

Warning

Before starting work on the pump, make sure that the

fuses have been removed or the mains switch has

been switched off. Make sure that the power supply

cannot be accidentally switched on.

Make sure that all protective equipment has been

connected correctly.

The pump must not run dry.

Warning

The pump must not be started if the atmosphere in

the tank is potentially explosive.

S3, intermittent operation:

Operating mode S3 means that within 10 minutes the pump must

be in operation for 4 minutes and stopped for 6 minutes.

See fig. 12.

In this operating mode, the pump is partly submerged in the

pumped liquid, i.e. the liquid level reaches at minimum the top of

the cable entry on the motor housing. See fig. 2.

English (GB)

Warning

It may lead to personal injuries or death to open the

clamp while the pump is operating.

9.1 General startup procedure

This procedure applies to new installations as well as after

service inspections if startup takes place some time after the

pump was placed in the tank.

1. Remove the fuses and check that the impeller can rotate

freely. Turn the impeller by hand.

Warning

The impeller can have sharp edges - wear protective

gloves.

2. Check the condition of the oil in the oil chamber. See also

section 10.1 Inspection.

3. Check that the system, bolts, gaskets, pipework and valves

etc. are in correct condition.

4. Mount the pump in the system.

5. Switch on the power supply.

6. Check whether the monitoring units, if used, are operating

satisfactorily.

7. For pumps with WIO sensor, switch on the IO 113 and check

that there are no alarms or warnings. See section 8.6 IO 113.

8. Check the setting of air bells, float switches or electrodes.

9. Check the direction of rotation. See section 9.3 Direction of

rotation.

10. Open the isolating valves, if fitted.

11. Check that the liquid level is above the motor for S1 operation

and above the cable entry for S3 operation. See fig. 14. If the

minimum level is not reached do not start the pump.

12. Start the pump and let the pump run briefly, and check if the

liquid level is falling.

13. Observe if the discharge pressure and input current are

normal. If not there might be air trapped inside the pump.

TM04 4527 1509TM04 4528 1509TM04 2654 2808

Fig. 12 S3, intermittent operation

S1, continuous operation:

In this operating mode, the pump can operate continuously

without being stopped for cooling. See fig. 13. Being completely

submerged, the pump is sufficiently cooled by the surrounding

liquid. See fig. 2.

Fig. 13 S1, continuous operation

Trapped air can be removed from the pump housing

by tilting the pump by means of the lifting chain when

the pump is in operation.

In case of abnormal noise or vibrations from the

pump, other pump failure or power supply failure or

water supply failure, stop the pump immediately. Do

not attempt to restart the pump until the cause of the

fault has been found and the fault corrected.

After one week of operation or after replacement of the shaft seal,

check the condition of the oil in the chamber. For pumps without

sensor, this is done by taking a sample of the oil. See section

10. Maintenance and service for procedure.

Every time the pump has been removed from the tank, go through

the above procedure when starting up again.

9.2 Operating modes

The pumps are designed for intermittent operation (S3).

When completely submerged, the pumps can also operate

continuously (S1).

Fig. 14 Start and stop levels

Make sure that the effective volume of the tank does not become

so low that the number of starts per hour exceeds the maximum

permissible number.

15

Page 16

9.3 Direction of rotation

Note

English (GB)

The pump may be started for a very short period

without being submerged to check the direction of

rotation.

Check the direction of rotation before starting up the pump.

An arrow on the motor housing indicates the correct direction of

rotation. Correct direction of rotation is clockwise when viewed

from above.

Checking the direction of rotation

The direction of rotation should be checked in the following way

every time the pump is connected to a new installation.

Procedure

1. Let the pump hang from a lifting device, e.g. the hoist used for

lowering the pump into the tank.

2. Start and stop the pump while observing the movement (jerk)

of the pump. If connected correctly, the pump will rotate

clockwise, i.e. it will jerk counter-clockwise. See fig. 15.

3. If the direction of rotation is wrong, interchange any two of the

phases in the power supply cable. See fig. 6 or 8.

10. Maintenance and service

Warning

During maintenance and service, including

transportation to service workshop, always support

the pump by means of lifting chains or place it in

horizontal position to secure stability.

Warning

Before starting work on the pump, make sure that the

fuses have been removed or the mains switch has

been switched off. Make sure that the power supply

cannot be accidentally switched on.

Make sure that all protective equipment has been

connected correctly.

Warning

Before starting work on the pump, make sure that the

mains switch has been locked in position 0.

All rotating parts must have stopped moving.

Warning

Maintenance work on explosion-proof pumps must

be carried out by Grundfos or a service workshop

authorized by Grundfos.

However, this does not apply to the hydraulic

components, such as pump housing, impeller, etc.

Warning

The cable must only be replaced by Grundfos or a

service workshop authorized by Grundfos.

Before carrying out maintenance and service, make sure that the

pump has been thoroughly flushed with clean water. Rinse the

pump parts in water after dismantling.

Fig. 15 Jerk direction

10.1 Inspection

Pumps running normal operation should be inspected every

3000 operating hours or at least once a year. If the pumped liquid

TM04 2657 2808

is very muddy or sandy, inspect the pump at shorter intervals.

Check the following points:

• Power consumption

See pump nameplate.

• Oil level and oil condition

When the pump is new or after replacement of the shaft seal,

check the oil level and water content after one week of

operation. If there is more than 20 % extra liquid (water) in the

oil chamber, the shaft seal is defective. The oil should be

changed after 3000 operating hours or once a year.

Use Shell Ondina 919 oil or similar type.

See section 10.2.1 Oil change.

• Cable entry

Make sure that the cable entry is watertight (visual inspection)

and that the cable is not sharply bent and/or pinched.

• Pump parts

Check impeller, pump housing, etc. for possible wear.

Replace defective parts.

See section 10.2.2 Removing the pump housing and impeller.

16

Page 17

• Ball bearings

Note

Note

Note

Oil filling/venting

Check the shaft for noisy or heavy operation (turn the shaft by

hand). Replace defective ball bearings.

A general overhaul of the pump is usually required in case of

defective ball bearings or poor motor function. This work must

be carried out by Grundfos or a service workshop authorized

by Grundfos.

Warning

Defective bearings may reduce the Ex safety.

• O-rings and similar parts

During service/replacement, make sure that the grooves for

the O-rings as well as the seal faces have been cleaned

before the new parts are fitted. Grease O-rings and recesses

before assembly.

Filling with oil

1. Turn the pump so that the oil filling holes are placed opposite

to each other, pointing upwards.

English (GB)

Do not reuse rubber parts.

Warning

Explosion-proof pumps must be checked by an

authorized Ex workshop once a year.

10.2 Dismantling the pump

See www.grundfos.com for service videos.

10.2.1 Oil change

After 3000 operating hours or once a year, change the oil in the

oil chamber as described below.

If the shaft seal has been replaced, the oil must be changed.

Warning

When loosening the screws of the oil chamber, note

that pressure may have built up in the chamber. Do

not remove the screws until the pressure has been

fully relieved.

Draining of oil

1. Place the pump on a plane surface with one oil screw pointing

downwards.

2. Place a suitable container (approx. 1 litre), for instance made

of transparent plastic material, under the oil screw.

Used oil must be disposed of in accordance with

local regulations.

3. Remove the lower oil screw.

4. Remove the upper oil screw.

If the pump has been in operation for a long period of time, if

the oil is drained off shortly after the pump has been stopped,

and if the oil is greyish white like milk, it contains water. If the

oil contains more than 20 % water, it is an indication that the

shaft seal is defective and must be replaced. If the shaft seal

is not replaced, the motor will be damaged.

If the quantity of oil is smaller than the quantity stated in

section 10.4 Oil quantities, the shaft seal is defective.

5. Clean the faces for the gaskets for oil screws.

TM04 6477 0616TM04 6476 0410

Fig. 16 Oil filling holes

2. Pour oil into the chamber.

For oil quantity, see section 10.4 Oil quantities.

3. Fit the oil screws with new gaskets.

10.2.2 Removing the pump housing and impeller

For position numbers, see pages 29 and 30.

Procedure

1. Loosen the clamp (pos. 92).

2. Remove the screw (pos. 92a) using your fingers.

3. Remove the pump housing (pos. 50) by inserting two

screwdrivers between the cooling jacket and the pump

housing.

4. Remove the screw (pos. 188a). Hold the impeller with a strap

wrench.

Fig. 17 Removing the impeller

5. Loosen the impeller (pos. 49) with a light blow on the edge.

Pull it off.

6. Remove the key (pos. 9a) and the spring for impeller

(pos. 157).

17

Page 18

10.2.3 Removing the seal ring and wear ring

English (GB)

Procedure

1. Turn the pump housing upside-down.

2. Knock the seal ring (pos. 46) out of the pump housing using a

punch.

Fig. 18 Removing the seal ring

3. Clean the pump housing where the seal ring was fitted.

4. Remove the wear ring (pos. 49c) using a screwdriver.

Fig. 19 Removing the wear ring

5. Clean the impeller where the wear ring was fitted.

10.2.4 Removing the shaft seal

Procedure

1. Remove the screws (pos. 188).

2. Remove the cover for oil chamber (pos. 58) using a puller.

3. Remove the screws (pos. 186).

4. Remove the shaft seal (pos. 105) using the puller.

5. Remove the O-ring (pos. 153b).

Procedure (pump with WIO sensor)

1. Remove the screws (pos. 188).

2. Remove the cover for oil chamber (pos. 58) using a puller.

3. Remove the screws (pos. 186).

4. Remove the sensor (pos. 521) and holder (pos. 522) from the

shaft seal.

5. Remove the shaft seal (pos. 105) using the puller.

6. Remove the O-ring (pos. 153b).

10.3 Assembling the pump

10.3.1 Tightening torques and lubricants

Pos. Designation Quantity Dim.

92a Screw 1 12 ± 2

118 a Scr ew 2

174 Screw 1 4 ± 1

181 Union nut 1

186 Screw 2 7 + 2-0

182 Screw 4 20 ± 2

187 Screw 4 20 ± 2

188 Screw 2

188a Screw 2

TM02 8420 5103TM02 8422 5103

193 Screw 2 16 ± 2

O-rings All Rocol

Rocol Sapphire Aqua-Sil, product number RM2924 (1 kg).

Shell Ondina 919, product number 96001442 (1 l)

10.3.2 Fitting the shaft seal Procedure

1. Fit and lubricate the O-ring (pos. 153b) with oil.

2. Slide the shaft seal (pos. 105) gently over the shaft.

3. Fit and tighten the screws (pos. 186).

4. Fit and lubricate the O-ring (pos. 107) in the cover for oil

chamber (pos. 58) with oil.

5. Fit the cover for oil chamber.

6. Fit and tighten the screws (pos. 188).

Procedure (pump with WIO sensor)

1. Fit and lubricate the O-ring (pos. 153b) with oil.

2. Slide the shaft seal (pos. 105) gently over the shaft.

3. Fit the holder (pos. 522) and sensor (pos. 521) with one of the

screws (pos. 186).

4. Fit the second screw and tighten both screws (pos. 186).

5. Fit and lubricate the O-ring (pos. 107) in the cover for oil

chamber (pos. 58) with oil.

6. Check that the sensor is positioned correctly. See section

8.4.1 Fitting the WIO sensor and fig. 10. This is of special

importance in horizontal pumps.

7. Fit the cover for oil chamber.

8. Fit and tighten the screws (pos. 188).

M10 30 ± 3

7-pole 50 ± 5

10-pole 75 ± 5

M10 30 ± 3

M10 50 + 5-0

M12 75 ± 5

Torque

[Nm]

M8 20 ± 2

M8 20 ± 2

Lubricant

18

Page 19

10.3.3 Fitting the seal ring and wear ring

Note

Note

Procedure

1. Lubricate the seal ring (pos. 46) with soapy water.

2. Place the seal ring in the pump housing.

3. Knock the seal ring home in the pump housing using a punch

or a wooden block.

Fig. 20 Fitting the seal ring

4. Place the wear ring (pos. 49c) on the impeller.

5. Knock the wear ring home using a wooden block.

10.4 Oil quantities

The table shows the quantity of oil in the oil chamber of SL1 and

SLV pumps. Oil type: Shell Ondina 919.

Power

[kW]

2.2 0.6

3.0 0.6

4.0 1.0

2-pole

TM02 8421 5103TM02 8423 5103

4-pole

Used oil must be disposed of in accordance with

local regulations.

6.0 1.0

7.5 1.0

9.2 1.2

11. 0 1 .2

1.1 0.6

1.3 0.6

1.5 0.6

2.2 0.6

3.0 1.0

4.0 1.0

5.5 1.0

7.5 1.2

Oil quantity

[l]

English (GB)

Fig. 21 Fitting the wear ring

10.3.4 Fitting the impeller and pump housing

Procedure

1. Fit the spring (pos. 157) and the key (pos. 9a).

Keep the key in position while the impeller is fitted.

2. Fit the impeller (pos. 49).

3. Fit the washer (pos. 66) and the screw (pos. 188a).

4. Tighten the screw (pos. 188a) to 75 Nm. Hold the impeller

with the strap wrench.

5. Mark the position of the pin on the pump housing.

6. Mark the position of the pin hole on the oil chamber.

7. Fit and lubricate the O-ring (pos. 37) with oil.

8. Fit the pump part in the pump housing (pos. 50).

9. Fit the clamp (pos. 92).

10. Tighten the screw (pos. 92a) to 12 Nm.

11. Check that the impeller rotates freely and without drag.

10.5 Service kits

For service kits for SL1, SLV, see www.grundfos.com or Service

Kit Catalogue.

10.6 Contaminated pumps

If a pump has been used for a liquid which is

injurious to health or toxic, the pump will be classified

as contaminated.

If Grundfos is requested to service the pump, Grundfos must be

contacted with details about the pumped liquid, etc. before the

pump is returned for service. Otherwise Grundfos can refuse to

accept the pump for service.

Possible costs of returning the pump are to be paid by the

customer.

However, any application for service (no matter to whom it may

be made) must include details about the pumped liquid if the

pump has been used for liquids which are injurious to health or

toxic.

Before a pump is returned, it must be cleaned in the best possible

way before it is returned.

Service instruction and service video can be found on

www.grundfos.com.

19

Page 20

11. Fault finding

Note

English (GB)

Warning

Before attempting to diagnose any fault, make sure

that the fuses have been removed or the mains

switch has been switched off. Make sure that the

power supply cannot be accidentally switched on.

All rotating parts must have stopped moving.

Fault Cause Remedy

1. Motor does not start.

Fuses blow or motorprotective circuit breaker trips

immediately.

Caution: Do not start again!

2. Pump operates, but motorprotective circuit breaker trips

after a short while.

3. The thermal switch of the

pump trips after a short while.

4. Pump operates at belowstandard performance and

power consumption.

5. Pump operates, but gives no

liquid.

6. High power consumption

(SLV).

7. Noisy operation and excessive

vibrations (SL1).

8. Pump clogged. a) The liquid contains large particles. Select a pump with a larger size of passage.

* Applies only to pumps with sensor and with IO 113.

Warning

All regulations applying to pumps installed in

potentially explosive environments must be

observed.

Make sure that no work is carried out in potentially

explosive atmosphere.

For pumps with sensor, start fault finding by checking

the status on the IO 113 front panel.

See installation and operating instructions for IO 113.

a) Supply failure; short circuit; earth-leakage

fault in cable or motor winding.

b) Fuses blow due to use of wrong type of

fuse.

c) Impeller blocked by impurities. Clean the impeller.

d) Air bells, float switches or electrodes out of

adjustment or defective.

e) Moisture in the stator housing (alarm).

The IO 113 interrupts the supply voltage.*

f) The WIO sensor is not covered by oil

(alarm). The IO 113 interrupts the supply

voltage.*

g) Stator insulation resistance too low.* Reset alarm on IO 113, see installation and

a) Low setting of thermal relay in motor-

protective circuit breaker.

b) Increased current consumption due to

large voltage drop.

c) Impeller blocked by impurities.

Increased current consumption in all three

phases.

d) Wrong direction of rotation. Check the direction of rotation and possibly

a) Too high liquid temperature. Reduce the liquid temperature.

b) Too high viscosity of the pumped liquid. Dilute the pumped liquid.

c) Wrong electrical connection. (If the pump

is star-connected to a delta connection,

the result will be very low undervoltage).

a) Impeller blocked by impurities. Clean the impeller.

b) Wrong direction of rotation.

a) Discharge valve closed or blocked. Check the discharge valve and possibly open and/

b) Non-return valve blocked. Clean the non-return valve.

c) Air in pump. Vent the pump.

a) Wrong direction of rotation. Check the direction of rotation and possibly

b) Impeller blocked by impurities. Clean the impeller.

a) Wrong direction of rotation. Check the direction of rotation and possibly

b) Impeller blocked by impurities. Clean the impeller.

b) A float layer has formed on the surface of

the liquid.

Have the cable and motor checked and repaired by

a qualified electrician.

Fit fuses of the correct type.

Readjust or replace the air bells, float switches or

electrodes.

Replace the O-rings, the shaft seal and moisture

switch.

Check, and possibly replace, the shaft seal, fill up

with oil and reset the IO 113.

operating instructions for IO 113.

Set the relay in accordance with the specifications

on the nameplate.

Measure the voltage between two motor phases.

Tolerance: - 10 %/+ 6 %. Reestablish correct

voltage supply.

Clean the impeller.

interchange any two of the phases in the incoming

supply cable. See section 9.3 Direction of rotation.

Check and correct the electrical installation.

Check the direction of rotation and possibly

interchange any two of the phases in the incoming

supply cable. See section 9.3 Direction of rotation.

or clean it.

interchange any two of the phases in the incoming

supply cable. See section 9.3 Direction of rotation.

interchange any two of the phases in the incoming

supply cable. See section 9.3 Direction of rotation.

Install a mixer in the tank.

20

Page 21

12. Technical data

Supply voltage

• 3 x 380-415 V - 10 %/+ 10 %, 50 Hz

• 3 x 400-415 V - 10 %/+ 10 %, 50 Hz.

Enclosure class

IP68. According to IEC 60529.

Insulation class

H (180 °C).

Operating pressure

All pump housings have a cast-iron PN 10 discharge flange.

Dimensions

Discharge flanges are DN 65, DN 80, DN 100 or DN 150

according to EN 1092-2.

Pump curves

Pump curves are available via the internet on

www.grundfos.com.

The curves are to be considered as a guide. They must not be

used as guarantee curves.

Test curves for the supplied pump are available on request.

Make sure that the pump does not operate outside the

recommended operating range during normal operation.

Pump noise emission < 70 dB(A)

• Sound power measurements were carried out according to

ISO 3743.

• Sound power was calculated at a distance of 1 metre

according to ISO 11203.

The sound pressure level of the pump is lower than the limiting

values stated in the EC Council Directive 2006/42/EC relating to

machinery.

English (GB)

2-pole motor Cable connection

Power P

[kW]

Power P

2

1

[kW]

Voltage

[V]

Starting

method

Thermal protection

Cable cross section

[mm

2

]

2.2 2.8 3 x 380-415 DOL Thermal switch 1.5 7/7

2.2 2.8 3 x 380-415 Y/D Thermal switch 1.5 10/10

2.2 2.8 3 x 400-415 DOL Thermal switch 1.5 7/7

3 3.8 3 x 380-415 DOL Thermal switch 1.5 7/7

3 3.8 3 x 380-415 Y/D Thermal switch 1.5 10/10

3 3.8 3 x 400-415 DOL Thermal switch 1.5 7/7

4 4.8 3 x 380-415 Y/D Thermal switch 2.5 10/10

4 4.8 3 x 400-415 DOL Thermistor 2.5 7/10

6.0 7.1 3 x 380-415 Y/D Thermal switch 2.5 10/10

6.0 7.1 3 x 400-415 DOL Thermistor 2.5 7/10

7.5 8.9 3 x 380-415 Y/D Thermal switch 2.5 10/10

7.5 8.9 3 x 400-415 DOL Thermistor 2.5 7/10

9.2 10.5 3 x 380-415 Y/D Thermal switch 2.5 10/10

9.2 10.5 3 x 400-415 DOL Thermistor 2.5 7/10

11 12.6 3 x 380-415 Y/D Thermal switch 2.5 10/10

11 12.6 3 x 400-415 DOL Thermistor 2.5 7/10

The supply cable resistance depends on the cable diameter.

2

Resistance per running metre of cable: 1.5 mm

Resistance per running metre of cable: 2.5 mm

= 0.012 Ω.

2

= 0.007 Ω.

Conductors /

plug pins

21

Page 22

English (GB)

Power P

[kW]

Power P

2

1

[kW]

4-pole motor Cable connection

Voltage

[V]

1.1 1.5 3 x 380-415 DOL Thermal switch 1.5 7/7

1.1 1.5 3 x 400-415 DOL Thermal switch 1.5 7/7

1.3 1.8 3 x 380-415 DOL Thermal switch 1.5 7/7

1.3 1.8 3 x 400-415 DOL Thermal switch 1.5 7/7

1.5 2.1 3 x 380-415 DOL Thermal switch 1.5 7/7

1.5 2.1 3 x 400-415 DOL Thermal switch 1.5 7/7

2.2 2.9 3 x 380-415 DOL Thermal switch 1.5 7/7

2.2 2.9 3 x 380-415 Y/D Thermal switch 1.5 10/10

2.2 2.9 3 x 400-415 DOL Thermal switch 1.5 7/7

3 3.7 3 x 380-415 DOL Thermal switch 1.5 7/7

3 3.7 3 x 380-415 Y/D Thermal switch 1.5 10/10

3 3.7 3 x 400-415 DOL Thermal switch 2.5 7/7

4 4.9 3 x 380-415 Y/D Thermal switch 2.5 10/10

4 4.9 3 x 400-415 DOL Thermistor 2.5 7/10

5.5 6.5 3 x 380-415 Y/D Thermal switch 2.5 10/10

5.5 6.5 3 x 400-415 DOL Thermistor 2.5 7/10

7.5 9.0 3 x 380-415 Y/D Thermal switch 2.5 10/10

7.5 9.0 3 x 400-415 DOL Thermistor 2.5 7/10

The supply cable resistance depends on the cable diameter.

Resistance per running metre of cable: 1.5 mm

Resistance per running metre of cable: 2.5 mm

Starting method Thermal protection

2

= 0.012 Ω.

2

= 0.007 Ω.

Cable cross section

[mm

2

]

Conductors /

plug pins

13. Disposal

This product or parts of it must be disposed of in an

environmentally sound way:

1. Use the public or private waste collection service.

2. If this is not possible, contact the nearest Grundfos company

or service workshop.

Subject to alterations.

22

Page 23

Appendix 1

1. Dimensions and weights

1.1 Pumps without accessories

Appendix

TM04 2793 0616

23

Page 24

Appendix

Pump type A C D E F H DN1 Dc1 D1n-D∅1 DN2 Dc2 D2n-D∅2

SL1.50.65.22.2 641 366 171 216 321 93 65 145 4 x M16 65 145 4 x 18 86

SL1.50.65.30.2 641 366 171 216 321 93 65 145 4 x M16 65 145 4 x 18 89

SL1.50.65.40.2 677 407 200 227 379 93 65 145 4 x M16 65 145 4 x 18 115

SL1.50.80.22.2 641 366 171 216 321 100 65 145 4 x M16 80 160 8 x 18 87

SL1.50.80.30.2 641 366 171 216 321 100 65 145 4 x M16 80 160 8 x 18 90

SL1.50.80.40.2 677 407 200 227 379 100 65 145 4 x M16 80 160 8 x 18 116

SL1.80.80.15.4 682 435 171 272 347 100 100 180 8 x M16 80 160 8 x 18 95

SL1.80.80.22.4 682 435 171 272 347 100 100 180 8 x M16 80 160 8 x 18 107

SL1.80.80.30.4 711 505 200 319 397 118 100 180 8 x M16 80 160 8 x 18 137

SL1.80.80.40.4 748 505 200 319 397 118 100 180 8 x M16 80 160 8 x 18 142

SL1.80.80.55.4 755 505 200 319 397 118 100 180 8 x M16 80 160 8 x 18 149

SL1.80.80.75.4 818 530 217 328 423 118 100 180 8 x M16 80 160 8 x 18 193

SL1.80.100.15.4 682 435 171 272 347 112 100 180 8 x M16 100 180 8 x 19 96

SL1.80.100.22.4 682 435 171 272 347 112 100 180 8 x M16 100 180 8 x 19 108

SL1.80.100.30.4 726 505 200 319 397 118 100 180 8 x M16 100 180 8 x 19 139

SL1.80.100.40.4 748 505 200 319 397 118 100 180 8 x M16 100 180 8 x 19 143

SL1.80.100.55.4 755 505 200 319 397 118 100 180 8 x M16 100 180 8 x 19 150

SL1.80.100.75.4 818 530 217 328 423 118 100 180 8 x M16 100 180 8 x 19 194

SL1.100.100.40.4 754 541 200 320 438 115 150 240 8 x M20 100 180 8 x 22 155

SL1.100.100.55.4 762 541 200 320 438 115 150 240 8 x M20 100 180 8 x 22 161

SL1.100.100.75.4 827 541 217 312 462 115 150 240 8 x M20 100 180 8 x 22 202

SL1.100.150.40.4 755 541 200 320 440 143 150 240 8 x M20 150 240 8 x 22 157

SL1.100.150.40.4 755 541 200 320 440 143 150 240 8 x M20 150 240 8 x 22 157

SL1.100.150.55.4 762 541 200 320 440 143 150 240 8 x M20 150 240 8 x 22 163

SL1.100.150.75.4 827 541 217 306 472 143 150 240 8 x M20 150 240 8 x 22 204

SLV.65.65.22.2 684 396 171 246 321 102 80 160 8 x M16 65 145 4 x 18 88

SLV.65.65.30.2 684 396 171 246 321 102 80 160 8 x M16 65 145 4 x 18 91

SLV.65.65.40.2 718 456 200 276 380 106 80 160 8 x M16 65 145 4 x 18 117

SLV.65.80.22.2 685 397 171 247 321 103 80 160 8 x M16 80 160 8 x 18 89

SLV.65.80.30.2 685 397 171 247 321 103 80 160 8 x M16 80 160 8 x 18 92

SLV.65.80.40.2 718 455 200 276 379 106 80 160 8 x M16 80 160 8 x 18 117

SLV.80.80.11.4 711 409 171 241 339 109 80 160 8 x M16 80 160 8 x 18 94

SLV.80.80.13.4 711 409 171 241 339 109 80 160 8 x M16 80 160 8 x 18 94

SLV.80.80.15.4 711 409 171 241 339 109 80 160 8 x M16 80 160 8 x 18 94

SLV.80.80.110.2 782 489 217 293 413 123 80 160 8 x M16 80 160 8 x 18 183

SLV.80.80.22.4 711 409 171 241 339 109 80 160 8 x M16 80 160 8 x 18 106

SLV.80.80.40.4 748 460 200 267 393 109 80 160 8 x M16 80 160 8 x 18 134

SLV.80.80.60.2 751 456 200 276 380 104 80 160 8 x M16 80 160 8 x 18 140

SLV.80.80.75.2 751 456 200 276 380 104 80 160 8 x M16 80 160 8 x 18 140

SLV.80.80.92.2 782 489 217 293 413 123 80 160 8 x M16 80 160 8 x 18 183

SLV.80.100.11.4 711 407 171 241 337 109 80 160 8 x M16 100 180 8 x 18 95

SLV.80.100.13.4 711 407 171 241 337 109 80 160 8 x M16 100 180 8 x 18 95

SLV.80.100.15.4 711 407 171 241 337 109 80 160 8 x M16 100 180 8 x 18 95

SLV.80.100.110.2 782 499 217 303 413 123 80 160 8 x M16 100 180 8 x 18 184

SLV.80.100.22.4 711 407 171 241 337 109 80 160 8 x M16 100 180 8 x 18 107

SLV.80.100.40.4 748 458 200 267 391 109 80 160 8 x M16 100 180 8 x 18 135

SLV.80.100.60.2 751 466 200 286 380 108 80 160 8 x M16 100 180 8 x 18 141

SLV.80.100.75.2 751 466 200 286 380 108 80 160 8 x M16 100 180 8 x 18 141

SLV.80.100.92.2 782 499 217 303 413 123 80 160 8 x M16 100 180 8 x 18 184

SLV.100.100.30.4 737 457 200 277 380 134 100 180 8 x M16 100 160 8 x 18 125

SLV.100.100.40.4 759 457 200 277 380 134 100 180 8 x M16 100 160 8 x 18 130

SLV.100.100.55.4 766 457 200 277 380 134 100 180 8 x M16 100 160 8 x 18 136

SLV.100.100.75.4 842 490 217 294 413 145 100 180 8 x M16 100 180 8 x 22 179

Weight

[kg]

24

Page 25

1.2 Pumps with ring stand

Appendix

TM04 2795 0616

25

Page 26

Appendix

Pump type V1 V2 V3 V4 V5 V6 V7 V∅

SL1.50.65.22.2 771 339 130 325 270 491 65 18

L1.50.65.30.2 771 339 130 325 270 491 65 18

SL1.50.65.40.2 807 341 130 325 270 519 65 18

SL1.50.80.22.2 771 339 130 325 270 496 80 18

SL1.50.80.30.2 771 339 130 325 270 496 80 18

SL1.50.80.40.2 807 341 130 325 270 525 80 18

SL1.80.80.15.4 812 364 130 355 300 567 80 19

SL1.80.80.22.4 812 364 130 355 300 567 80 19

SL1.80.80.30.4 841 390 130 355 300 623 80 19

SL1.80.80.40.4 878 390 130 355 300 623 80 19

SL1.80.80.55.4 885 390 130 355 300 623 80 19

SL1.80.80.75.4 948 390 130 355 300 648 80 19

SL1.80.100.15.4 812 369 130 355 300 591 100 19

SL1.80.100.22.4 812 369 130 355 300 591 100 19

SL1.80.100.30.4 856 395 130 355 300 647 100 19

SL1.80.100.40.4 878 395 130 355 300 647 100 19

SL1.80.100.55.4 885 395 130 355 300 647 100 19

SL1.80.100.75.4 948 395 130 355 300 672 100 19

SL1.100.100.40.4 941 445 186 450 400 711 100 22

SL1.100.100.55.4 948 445 186 450 400 711 100 22

SL1.100.100.75.4 1.013 445 186 450 400 706 100 22

SL1.100.150.40.4 941 555 186 450 400 807 150 22

SL1.100.150.40.4 941 555 186 450 400 807 150 22

SL1.100.150.55.4 948 555 186 450 400 807 150 22

SL1.100.150.75.4 1.013 555 186 450 400 803 150 22