Page 1

SEG AUTOADAPT

Service instructions

GRUNDFOS INSTRUCTIONS

Page 2

Content

1. Symbols used in this document....................................................................................... 4

2. Identification......................................................................................................................4

2.1 Nameplate ........................................................................................................................................4

2.2 Type key...........................................................................................................................................5

3. Service tools...................................................................................................................... 5

3.1 Special tools .....................................................................................................................................5

3.2 Standard tools ..................................................................................................................................6

3.3 Torque tools .....................................................................................................................................6

4. Tightening torques, lubricants and oil ............................................................................. 6

4.1 Tightening torques ............................................................................................................................6

4.2 Lubricants.........................................................................................................................................6

4.3 Oil.....................................................................................................................................................6

5. Dismantling and assembly ............................................................................................... 6

5.1 Position numbers ..............................................................................................................................6

5.2 Before dismantling ............................................................................................................................7

5.3 Before assembly ...............................................................................................................................7

5.4 During assembly ...............................................................................................................................7

5.5 After assembly..................................................................................................................................7

6. Cleaning the pump housing ............................................................................................. 7

7. Grinder system .................................................................................................................. 7

7.1 Dismantling.......................................................................................................................................7

7.2 Assembly..........................................................................................................................................8

8. Impeller.............................................................................................................................. 8

8.1 Dismantling.......................................................................................................................................8

8.2 Assembly..........................................................................................................................................9

9. Oil....................................................................................................................................... 9

9.1 Oil change ........................................................................................................................................9

9.2 Draining of oil ...................................................................................................................................9

9.3 Oil filling............................................................................................................................................9

10. Shaft seal......................................................................................................................... 10

10.1 Dismantling, 0.9 - 1.5 kW................................................................................................................10

10.2 Assembly, 0.9 - 1.5 kW ...................................................................................................................10

10.3 Dismantling, 2.6 - 4 kW...................................................................................................................11

10.4 Assembly, 2.6 - 4 kW......................................................................................................................11

11. Bearings .......................................................................................................................... 12

11.1 Dismantling.....................................................................................................................................12

11.2 Assembly........................................................................................................................................12

12. Electronic unit................................................................................................................. 13

12.1 Dismantling.....................................................................................................................................13

12.2 Assembly........................................................................................................................................14

13. Run capacitor (single-phase pumps)............................................................................. 14

13.1 Dismantling.....................................................................................................................................14

13.2 Assembly........................................................................................................................................14

14. Dry-running sensor......................................................................................................... 14

14.1 Dismantling.....................................................................................................................................14

14.2 Assembly........................................................................................................................................14

15. Level sensor.................................................................................................................... 15

15.1 Dismantling.....................................................................................................................................15

15.2 Assembly........................................................................................................................................15

16. Cable plug........................................................................................................................ 15

16.1 Dismantling.....................................................................................................................................15

16.2 Assembly........................................................................................................................................15

2 / 20

Page 3

17. Supply scable.................................................................................................................. 16

17.1 Dismantling.....................................................................................................................................16

17.2 Assembly........................................................................................................................................16

18. Replacing the electronic unit.......................................................................................... 17

19. Exploded views ...............................................................................................................18

20. Fault finding .................................................................................................................... 19

3 / 20

Page 4

1. Symbols used in this do cument

Caution

Note

Note

Àß56

Made in Tatabánya, Hungary

Type:

96770195

Model:

P.c. Auto Adapt

IP68

Hmax: m Qmax:

P1: kW

l/s

m

kW

A

P2:

Weight: Tmax: °C

Insul.class:

kg

n: Cos φmin

-1

opr.:: μF Hz

~

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Warning

If these safety instruct ions are no t o bser ved, it may re sult in per son al inju ry!

Warning

These instructions must be obse rved f or explosio n-p roof p umps. It is adv isabl e al so t o foll ow

these instructions fo r stan dard pu mps.

If these safety instruct ions ar e not o bser ved, it may re sult in malf unc tio n or d amage to the

equipment!

Notes or instructions that mak e th e job e asier an d ensur e saf e o perati on.

2. Identification

This section shows the nameplate, type key and the codes that can appear in the variant code.

As codes can be combined, a code p osit ion may cont ain mor e than one code (o ne le tter) .

2.1 Nameplate

The nameplate states the operating data and approvals applying to the pump. It is fixed to the side of the stator

housing opposite to the electronic unit.

The additional nameplate supplied with the pump can be fixed close to the pit.

TM04 4459 1309

Fig. 1 Nameplate

Pos. Description Pos. Description

1 Type designation 13 Weight without cable

2 Product number 14 Run capacitor

3 CE mark 15 EN approval

4 ATEX certificate * 16 Ex mark *

5 IEC Ex mark * 17 Maximum installation depth

6 IEC Ex certificate * 18 Maximum flow rate

7 Production code (year and week) 19 Output power

8 Enclosure class to IEC 20 Rated current

9 Maximum head 21 Power factor

10 Rated input power 22 Maximum liquid temperature

11 Number of phases 23 Frequency

12 Rated speed 24 Insulation class

* Only explosion-proof pumps.

4 / 10

Page 5

2.2 Type key

Code Example SE G .40 .11 E .Ex .2 .1 5 02

Type range

SE

G

40

11

Blank

E

Blank

Ex

2

1

Blank

5

02

0B

Blank

A

B

Blank

Grundfos sewage pumps

Impeller type

Grinder system in the pump inlet

Pump outlet

Nominal diameter of pump discharge port [mm]

Output power, P2

P2 = code number from type designation/10 kW

Equipment in pump

Standard

Electronic version with AUTO

Pump version

Non-explosion-proof pump (standard)

Explosion-proof pump

Number of poles

2 poles, n = 3000 min

Number of phases

Single-phase motor

Three-phase motor

Mains frequency

50 Hz

Supply voltage and starting method

230 V, direct-on line starting

400-415 V, direct-on-line starting

Generation

First generation

Second generation

Third generation, etc.

The pumps belonging to the individual generations differ in design, but are similar in terms of power rating.

Materials in pump

Standard materials in pump

-1

, 50 Hz

ADAPT functions

3. Service tools

ABCD

EFGH

IJKL

3.1 Special tools

Pos. Designation For pos. Description

A Puller 49 M24 x 1.5 SV2097

B Spanner for cable nut 181 95043464

Product

number

5 /20

Page 6

3.2 Standard tools

Pos. Designation For pos. Description

C Tool for shaft seal 172 *

D Bit holder D 1/4" SV2011

E Bits kit 188a M8 - 6 mm SV2010

F Screwdrivers Straight slot -

G Punch 44, 49 ∅ 10 -

H Ring/open-end spanner 68 24 mm SV0122

I Hexagon head driver 188a M8 - 6 mm SV0297

J Bearing heater 153, 154 Induction heater -

* Pos. C is included in the shaft seal kit for 0.9 to 1.5 kW pumps.

Product

number

3.3 Torque tools

Pos. Designation For pos. Description

K Torque wrench J 4-20 Nm SV0292

L Ratchet insert tool H 9 x 12 - > 1/2" SV0295

Product

number

4. Tightening torques, lubricants and oil

4.1 Tightening torques

Pos. Designation Dimensions Material Torque [Nm]

161f Screw for capacitor plate M5 x 10 Galvanised steel 3

188a Screw for end cover M10 x 30 A2-70 35

188a Screw for grinder ring M8 x 25 A2-80 16

188a Screw for grinder head M8 x 25 A2-80 20

188a Screw for lifting bracket M8 x 25 A2-80 16

188a Screw for seal ring retainer M8 x 25 A2-80 16

188a Screw for oil chamber M8 x 25 A2-80 16

193 Filling screw M12 x 20 A2-70 16

199 Union nut for cable plug M48 x 1.5 EN 1.4408 30

285b Set screw for dry-running sensor M6 x 18 ISO 898 5

287c Set screw for level sensor M6 x 18 ISO 898 5

Screw for earth lead M5 x 10 Galvanised steel 3

161 Capacitor M8 Galvanised steel 5

4.2 Lubricants

Designation Quantity [kg] Type Product number

O-ring grease 1 Rocol Sapphire Aqua-Sil RM2924

4.3 Oil

Designation Quantity [l] Type Product number

Oil 1 Shell Ondina 917 96001442

5. Dismantling and assemb ly

Warning

Service and dismantling of ele ctr ical part s and repla cement of bea rings must onl y be carri ed

out by Grundfos or an aut hor ised ser vic e worksho p.

5.1 Position numbers

Position numbers of pump parts (digits) refer to exploded views, sectional drawings and parts lists; position

numbers of tools (letters) refer to section 3. Service tools.

6 / 10

Page 7

5.2 Before dismantling

• Disconnect the power supply to the pump.

• Disconnect the power cable in accordance with local regulations.

5.3 Before assembly

• Clean and check all parts.

• Replace defective parts by new parts.

• Order the necessary service kits.

• Always replace gaskets and O-rings when the pump is serviced.

5.4 During assembly

• Lubricate and tighten bolts and nuts according to section 4. Tightening torques, lubricants and oil.

5.5 After assembly

• Test the pump according to test specification No 96076172.

6. Cleaning the pum p housi ng

Warnin g

Beware of the sharp edges on t he impeller, grinder head a nd g rinder ring .

1. Place the pump upside down in a vice (soft jaws). Tighten on lifting bracket (pos. 190).

2. Loosen clamp (pos. 92) holding pump housing (pos. 50) and stator housing (pos. 55) together.

3. Lift pump housing (pos. 50) off stator housing (pos. 55).

4. Remove clamp (pos. 92).

5. Clean the pump housing and the impeller. Grind the surfaces slightly with emery cloth, if necessary.

6. Fit clamp (pos. 92) loosely on stator housing (pos. 55).

7. Lubricate O-ring (pos. 37). See section 4.2 Lubricants.

8. Carefully lower pump housing (pos. 50) down over grinder head (pos. 45) and impeller (pos. 49). Turn the

pump housing so that it engages with the guide pin. The pump discharge must point in the opposite direction

as the electronic unit.

9. Tighten clamp (pos. 92).

10.Check that the grinder head rotates freely and noiselessly.

7. Grinder system

Warnin g

Beware of the sharp edges on t he impeller, grinder head a nd g rinder ring .

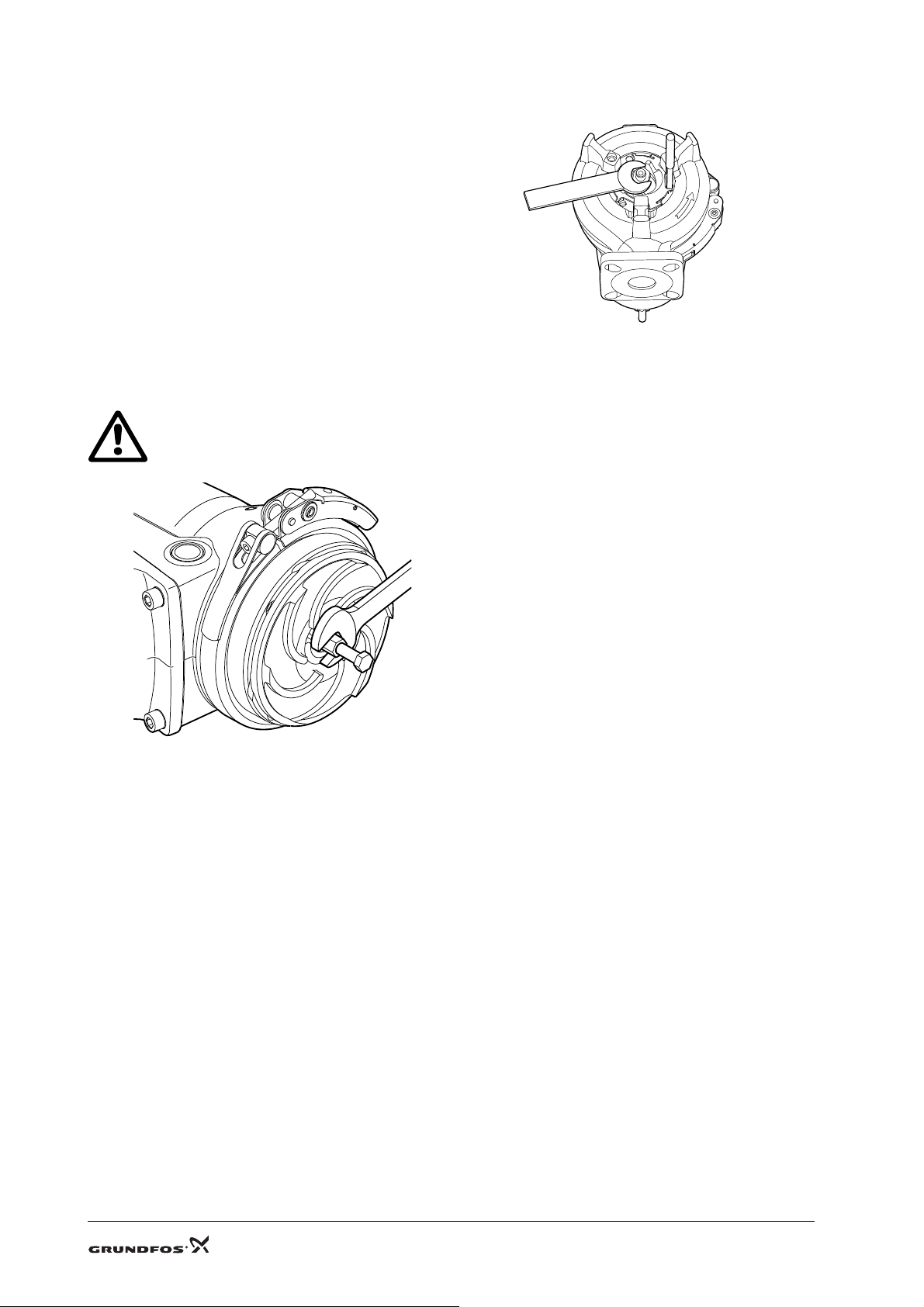

7.1 Dismantling

1. Remove bolt (pos. 188a) in one of the pump feet.

2. Loosen grinder ring (pos. 44) by knocking/turning 15

to 20 ° clockwise.

3. Carefully prise grinder ring (pos. 44) out of the pump

housing with a screwdriver.

Make sure that the grinder ring does not get stuck

against the grinder head!

4. Insert punch (pos. G) into the hole in the pump

housing to hold the impeller.

5. Remove bolt (pos. 188a) in the shaft end and lock

ring (pos. 66).

6. Remove grinder head (pos. 45).

TM04 4480 1509

7 /20

Page 8

7.2 Assembly

1. Fit grinder head (pos. 45). The dogs on the back of

the grinder head must engage with the impeller

holes (pos. 49).

2. Tighten bolt (pos. 188a) in the shaft end. Do not

forget the lock washer.

3. Fit grinder ring (pos. 44).

4. Turn grinder ring (pos. 44) 15 to 20 ° anti-clockwise

until it is tightened.

5. Check that the grinder ring does not touch the

grinder head.

6. Fit and tighten bolt (pos. 188a) in one of the pump

feet. See section 4.1 Tightening torques.

7. Check that the grinder head rotates freely and

noiselessly.

8. Impeller

Warning

Beware of the sharp edges on t he impel ler.

TM04 4481 1509

TM04 6969 1810

Fig. 2 Removing the impeller

8.1 Dismantling

1. Remove the grinder system. See section 7.1 Dismantling.

2. Remove adjusting nut (pos. 68).

3. Fit a puller (pos. A) on the impeller.

4. Loosen the clamp and remove the pump housing.

5. Pull impeller (pos. 49) off the shaft using a puller (pos. A).

6. Remove key (pos. 9a) from the shaft.

7. Clean shaft and key.

8 / 10

Page 9

8.2 Assembly

Note

Note

1. Lubricate key and shaft. See section 4.2 Lubricants.

2. Fit key and impeller. The impeller blades must point away from the stator housing.

3. Fit clamp (pos. 92) loosely on stator housing (pos. 55).

4. Fit adjusting nut (pos. 68) in the impeller.

5. Lubricate O-ring (pos. 37). See section 4.2 Lubricants.

6. Lower pump housing (pos. 50) down over impeller (pos. 49). Turn the pump housing so that it engages with

the guide pin. The pump discharge must point in the opposite direction as the electronic unit.

7. Tighten clamp (pos. 92).

8. Tighten adjusting screw (pos. 68) until impeller (pos. 49) touches the pump housing.

9. Slacken the adjusting nut (pos. 68) by 1/4 turn. The impeller should now be able to rotate freely.

10.Fit the grinder system. See section 7.2 Assembly.

9. Oil

9.1 Oil change

The oil in the oil chamber should be changed at least once a year or after 3000 operating hours. (The number of

operating hours can read by means of a CIU XX2 and an R100 remote control.)

If the oil contains m ore th an 20 % o f wat er, the shaft seal may be d efec tive.

If the shaft seal is replaced, the oil mu st be ch anged . Check the oil af ter one week of oper ation.

Warnin g

When slackening the scre ws of th e oi l chamber, note that p ressur e may have bui lt up in t he

chamber. Do not remove the screws until the pre ssure h as be en f ully r eli eved.

9.2 Draining of oil

1. Remove both oil screws (pos. 193) to allow the oil to drain from the chamber into a container.

2. Lay the pump on the side and turn it to empty the oil chamber.

3. Check the oil for impurities.

4. Clean the pump of spilled oil.

Oil, gaskets and metal par ts must be dis posed of in accorda nce wi th local r egul ati ons.

9.3 Oil filling

1. Pour new oil into the oil chamber. See fig. 3. See table below.

TM04 6970 1810

Fig. 3 Oil filling

Pump

[kW]

0.9 - 1.5 0.17

2.6 - 4.0 0.42

Oil

[l]

Type

Shell Ondina 917

2. Fit and tighten the two oil screws (pos. 193). See section 4.1 Tightening torques.

3. Clean the pump of spilled oil.

9 /20

Page 10

10. Shaft seal

10.1 Dismantling, 0.9 - 1.5 kW

1. Drain the oil. See section 9.2 Draining of oil.

2. Remove the two bolts (pos. 188a) in seal ring retainer (pos. 58) and fit them into the extractor holes.

3. Remove the retainer by means of the two bolts. Cross-tighten the bolts to ensure an even pull.

4. Remove the rotating shaft seal part with two angle screwdrivers. Insert the screwdriver tips behind the shaft

seal.

TM04 6971 1810TM04 6972 1810

Fig. 4 Removing the shaft seal, 0.9 - 1.5 kW

5. Check the shaft where the secondary seal touches the shaft. If there signs of wear, replace the shaft.

6. Carefully loosen bush (pos. 103) from the bearing using two screwdrivers with straight slot and pull it off the

shaft using two angle screwdrivers.

10.2 Assembly, 0.9 - 1.5 kW

1. Check and clean the oil chamber.

2. Fit tool (pos. C) on the shaft.

3. Check O-ring (pos. 102) in bush (pos. 103).

4. Lubricate the shaft end and journal. See section 4.2 Lubricants.

5. Fit bush (pos. 103) and press it home with a piece of pipe.

6. Lubricate O-ring (pos. 107) of the shaft seal. See section 4.2 Lubricants.

7. Fit shaft seal (pos. 105a) with tool (pos. C) from the shaft seal kit.

Fig. 5 Fitting the shaft seal

8. Tighten the two bolts (pos. 188a) in seal ring retainer (pos. 58). See section 4.1 Tightening torques.

9. Fit key and impeller (see section 8.2), grinder head (see section 7.2) and fill the oil chamber with oil (see

section 9.3).

10.Check that the grinder head rotates freely and noiselessly.

10 / 10

Page 11

10.3 Dismantling, 2.6 - 4 kW

1. Remove key (pos. 9a) from the shaft.

2. Remove lock ring (pos. 112).

3. Remove the two bolts in seal ring retainer (pos. 58) and fit them in the extractor holes.

4. Remove seal ring retainer (pos. 58).

5. Insert an angle screwdriver behind the shaft seal and pull the shaft seal off the shaft.

6. Remove O-ring (pos. 102) from the shaft.

7. Remove spacer ring (pos. 153b).

10.4 Assembly, 2.6 - 4 kW.

1. Clean spacer ring (pos. 153b) and its contact surface on the bearing.

2. Fit the distance ring against the bearing.

3. Fit O-ring (pos. 102) in the groove of the shaft. See section 4.2 Lubricants.

4. Fit the shaft seal. The "ears" of the seal must point towards the bearing. The projection of the shaft seal must

engage with the keyway in the shaft.

5. Fit O-ring (pos. 107) in seal ring retainer. See section 4.2 Lubricants.

6. Fit seal ring retainer (pos. 58). Cross-tighten the retainer to ensure that the shaft seal is in the correct position.

7. Press back the shaft seal using a piece of pipe and fit lock ring (pos. 112a) on the shaft. Check that the lock

ring is fitted correctly in the groove.

8. Fit key and impeller (see section 8.2), grinder head (see section 7.2) and fill the oil chamber with oil (see

section 9.3).

9. Check that the grinder head rotates freely and noiselessly.

Fig. 6 Fitting the shaft seal, 2.6 - 4 kW

TM04 7130 1810

11 /20

Page 12

11. Bearings

Warning

Replacement of bearings of E x pu mps must only be car ried ou t b y Gr undfos or a se rvice

workshop authorised by Grundfos .

11.1 Dismantling

1. Remove the grinder system (see section 7.1), drain oil (see section 9.2) and remove the shaft seal (see

section 10.1).

2. Remove the four bolts in the oil chamber (pos. 155).

3. Remove the oil chamber with rotor shaft (pos. 172) and bearings (pos. 153).

4. Refit bolt (pos. 188a) in the shaft end to protect the shaft end thread.

5. Press the shaft out of the bearing in the oil chamber using a hydraulic press.

6. Remove N-end bearing (pos. 154) from the shaft with a puller.

11.2 Assembly

Fig. 7 Fitting the bearing in the

oil chamber

TM04 6984 1810

Fig. 8 Position of oil chamber

on rotor shaft

TM04 6974 1810

Fig. 9 Fitting the oil chamber

on the rotor shaft

1. Clean the bearing surface of the oil chamber, and heat the oil chamber to approx. 100 °C using a bearing

heater (pos. J).

2. Fit the cold bearing (pos. 153) into the heated oil chamber (pos. 155) and let the oil chamber cool. See fig. 7.

3. Place the shaft in a vertical position and place the oil chamber on the shaft. See fig. 8.

4. Press the bearing and oil chamber home on the shaft using a piece of pipe and a hydraulic press. Press only

on the inner bearing ring. See fig. 8.

TM04 6975 1810

12 / 10

Page 13

12. Electronic unit

Caution

12.1 Dismantling

1. Clean the pump around the electronic unit to protect the electronic parts from dirt when opening the electronic

unit.

2. Lay the pump on the side with the level sensor upwards. See fig. 10.

3. Remove the four bolts (pos. 188a) and place the electronic unit next to the pump.

Take care not to disconnect wires.

TM04 6976 1810TM04 6977 1810TM04 6978 1810

Fig. 10 Correct opening of electronic unit

4. Place the electronic unit on a block or similar support. See fig. 11.

Fig. 11 Electronic unit on block

5. Place the pump in a vertical position. See fig. 12.

Fig. 12 Pump in vertical position

6. Remove O-ring (pos. 90b) from the electronic unit.

7. Clean the contact surfaces of the stator housing and the electronic unit, and the O-ring groove.

13 /20

Page 14

12.2 Assembly

Caution

1. Lubricate O-ring (pos. 90b) and the contact surfaces of the stator housing and electronic unit. See section

4.2 Lubricants.

2. Fit the O-ring in the stator housing.

3. Place the wires in the hollow space and fit the electronic unit on the stator housing.

Take care that the wires are not pinc hed bet we en the s tat or hou sing and ele ctroni c un it.

4. Tighten the four bolts (pos. 188a). See section 4.1 Tightening torques.

5. Connect the supply cable. See section 17.2 Assembly.

13. Run capacitor (single-phas e pumps)

13.1 Dismantling

1. Open the electronic unit. See section 12.1 Dismantling.

2. Disconnect the capacitor wire from the electronic unit.

3. Remove the Pt1000 plug from the PC board.

4. Remove the earth lead from bracket (pos. 161c).

5. Remove the capacitor bracket with capacitor from the stator housing.

13.2 Assembly

1. Fix the capacitor wire on the PC board.

2. Fit the earth lead on the new bracket.

3. Fit the new Pt1000 sensor.

4. Fit the electronic unit. See section 12.2 Assembly.

14. Dry-running sen sor

14.1 Dismantling

1. Open the electronic unit. See section 12.1 Dismantling.

2. Remove the sensor wire from the PC board.

3. Remove set screw (pos. 285b).

4. Press the sensor out of the stator housing with a screwdriver. The sensor must not be reused.

5. Clean the sensor hole.

14.2 Assembly

1. Lubricate and fit O-rings (pos. 285a). See section 4.2 Lubricants.

2. Lubricate the sensor hole. See section 4.2 Lubricants.

3. Press the sensor home in the stator housing.

4. Connect the sensor wire to the PC board.

5. Fit a new set screw. See section 4.1 Tightening torques.

6. Fit the electronic unit. See section 12.2 Assembly.

14 / 10

Page 15

15. Level sensor

Caution

15.1 Dismantling

1. Open the electronic unit. See section 12.1 Dismantling.

2. Remove the sensor wire from the PC board.

3. Remove set screw (pos. 287c).

4. Press the sensor out of the electronic unit.

5. Clean the sensor hole.

15.2 Assembly

1. Lubricate and fit O-ring (pos. 287b). See section 4.2 Lubricants.

2. Lubricate the sensor hole. See section 4.2 Lubricants.

3. Press the sensor home in the electronic unit.

4. Connect the sensor wire to the PC board.

5. Fit a new set screw. See section 4.1 Tightening torques.

6. Fit the electronic unit. See section 12.2 Assembly.

16. Cable plug

16.1 Dismantling

1. Open the electronic unit. See section 12.1 Dismantling.

2. Remove the earth lead screw and the washer.

3. Remove the two plugs from the electronic unit.

4. Press in the three barbs and press the cable plug out of the electronic unit.

5. Clean the cable entry.

16.2 Assembly

1. Press the cable plug into the cable entry.

Take care not to damage the three bar bs .

2. Check that three barbs have engaged with the electronic unit.

3. Connect the two plugs to the PC board.

4. Fix the earth lead with the screw. Do not forget to fit the washer.

5. Fit the electronic unit. See section 12.2 Assembly. Do not forget to fit O-ring (pos. 26a) for the cable plug.

15 /20

Page 16

17. Supply scable

17.1 Dismantling

1. Slacken union nut (pos. 199) anti-clockwise with hook spanner (pos. B).

2. Insert two screwdrivers into the groove and prise the supply cable out of the cable entry. See fig. 13.

TM04 6983 1810

Fig. 13 Removing the supply cable

3. If the cable is to be reused, the flash path gap and plastic pin on the supply cable must not be damaged when

the cable is removed.

4. Check the cable for damage.

5. Remove O-ring (pos. 26a) from the cable entry, for instance with a pair of pincers.

6. Remove O-ring (pos. 198) from the supply cable and clean the groove.

7. If a new supply cable is not fitted, the cable entry must be covered to protect the cable entry from dirt.

17.2 Assembly

1. Clean the cable entry, union nut and supply cable.

2. Lubricate O-ring (pos. 198) and fit it on the supply cable.

3. Fit O-ring (pos. 26a) at the bottom of the cable entry.

4. Insert the supply cable into the cable entry. The pin must engage with the cable plug.

5. Lubricate union nut (pos. 199). See section 4.2 Lubricants.

6. Hold the supply cable with one hand and tighten the union nut with a hook spanner (pos. B).

16 / 10

Page 17

18. Replacing the e lectron ic unit

Caution

Caution

1. Open the electronic unit. See section 12. Electronic unit.

2. Remove the wires of the dry-running sensor, Pt1000 sensor and capacitor (single-phase pumps) as well as

the earth lead.

3. Cut the motor leads between the electronic unit and the stator housing in the middle.

4. Remove the level sensor (see section 15.) and cable plug (see section 16.) from the old electronic unit and fit

them in the new one.

5. Remove approximately 60 mm of the insulating sheath of the cable from the new electronic unit so that

approximately 75 mm of the three leads are stripped.

6. Cut away 5, 30 and 55 mm of the three leads from the electronic unit and from the stator housing so that the

joints are displaced from each other. See fig. 14. If for instance 5 mm of the red lead from the electronic unit

are cut away, 55 mm of the red lead from the stator housing must be cut away.

7. Strip the three leads from the electronic unit and from the stator housing with a cable stripper.

Do not use side-cutt ing plie rs , as th ere is a r isk of pull ing th e le ads o ut of the sta tor h ousi ng.

8. Pull a new 16 mm insulation sheath over the original insulating sheath of the motor leads. See fig. 15.

9. Pinch connectors on the three leads with a crimping tool.

The leads must be connect ed so t hat the col ours f rom th e el ectr onic un it and th e stator

housing match.

10.Grab the leads on each side of the connector and pull a little to check the joints.

11.Carefully pull the new insulating sheath over the joints and fix it with a cable clip.

TM04 6979 1810

Fig. 14 Leads with connectors Fig. 15 Insulating sheath on the three leads

12.Connect the wires from the dry-running sensor, Pt1000 sensor and capacitor (single-phase pumps) as well as

the earth lead.

13.Fit the electronic unit. See section 17.2 Assembly.

TM04 6980 1810

17 /20

Page 18

19. Exploded views

Fig. 16 SEG, 0.9 - 1.5 kW

TM04 4486 2210

18 / 10

Page 19

Fig. 17 SEG, 2.6 - 4 kW

Subject to alterations.

20. Fault finding

Warnin g

Remove all fuses, or switch off th e main swit ch befo re fau lt cor rectio n. Make su re th at t he

power supply cannot be acciden tal ly s witch ed on.

All rotating parts must h ave s top ped moving.

Warnin g

All regulations applying to pumps installed in potentially explosive environments must be observed.

No work must be carried out in potent iall y exp losi ve atmosp her e.

Fault Cause Remedy

Motor does not start.

Supply failure; short-circuit; earth-leakage fault in

cable or motor winding.

19 /20

Have the cable and motor checked and

repaired by a qualified electrician.

TM04 5062 2109

Page 20

Argentina

Bombas GRUNDFOS de Argentina S.A.

Ruta Panamericana km. 37.500 Lote 34A

1619 - Garin

Pcia. de Buenos Aires

Phone: +54-3327 414 444

Telefax: +54-3327 411 111

Australia

GRUNDFOS Pumps Pty. Ltd.

P.O. Box 2040

Regency Park

South Australia 5942

Phone: +61-8-8461-4611

Telefax: +61-8-8340 0155

Austria

GRUNDFOS Pumpen Vertrieb Ges.m.b.H.

Grundfosstraße 2

A-5082 Grödig/Salzburg

Tel.: +43-6246-883-0

Telefax: +43-6246-883-30

Belgium

N.V. GRUNDFOS Bellux S.A.

Boomsesteenweg 81-83

B-2630 Aartselaar

Tél.: +32-3-870 7300

Télécopie: +32-3-870 7301

Belorussia

Представительство ГРУНДФОС в

Минске

220123, Минск,

ул. В. Хоружей, 22, оф. 1105

Тел.: +(37517) 233 97 65,

Факс: +(37517) 233 97 69

E-mail: grundfos_minsk@mail.ru

Bosnia/Herzegovina

GRUNDFOS Sarajevo

Trg Heroja 16,

BiH-71000 Sarajevo

Phone: +387 33 713 290

Telefax: +387 33 659 079

e-mail: grundfos@bih.net.ba

Brazil

BOMBAS GRUNDFOS DO BRASIL

Av. Humberto de Alencar Castelo Branco,

630

CEP 09850 - 300

São Bernardo do Campo - SP

Phone: +55-11 4393 5533

Telefax: +55-11 4343 5015

Bulgaria

Grundfos Bulgaria EOOD

Slatina District

Iztochna Tangenta street no. 100

BG - 1592 Sofia

Tel. +359 2 49 22 200

Fax. +359 2 49 22 201

email: bulgaria@grundfos.bg

Canada

GRUNDFOS Canada Inc.

2941 Brighton Road

Oakville, Ontario

L6H 6C9

Phone: +1-905 829 9533

Telefax: +1-905 829 9512

China

GRUNDFOS Pumps (Shanghai) Co. Ltd.

50/F Maxdo Center No. 8 XingYi Rd.

Hongqiao development Zone

Shanghai 200336

PRC

Phone: +86-021-612 252 22

Telefax: +86-021-612 253 33

Croatia

GRUNDFOS CROATIA d.o.o.

Cebini 37, Buzin

HR-10010 Zagreb

Phone: +385 1 6595 400

Telefax: +385 1 6595 499

www.grundfos.hr

Czech Republic

GRUNDFOS s.r.o.

Čajkovského 21

779 00 Olomouc

Phone: +420-585-716 111

Telefax: +420-585-716 299

Denmark

GRUNDFOS DK A/S

Martin Bachs Vej 3

DK-8850 Bjerringbro

Tlf.: +45-87 50 50 50

Telefax: +45-87 50 51 51

E-mail: info_GDK@grundfos.com

www.grundfos.com/DK

Estonia

GRUNDFOS Pumps Eesti OÜ

Peterburi tee 92G

11415 Tallinn

Tel: + 372 606 1690

Fax: + 372 606 1691

Finland

OY GRUNDFOS Pumput AB

Mestarintie 11

FIN-01730 Vantaa

Phone: +358-3066 5650

Telefax: +358-3066 56550

France

Pompes GRUNDFOS Distribution S.A.

Parc d’Activités de Chesnes

57, rue de Malacombe

F-38290 St. Quentin Fallavier (Lyon)

Tél.: +33-4 74 82 15 15

Télécopie: +33-4 74 94 10 51

Germany

GRUNDFOS GMBH

Schlüterstr. 33

40699 Erkrath

Tel.: +49-(0) 211 929 69-0

Telefax: +49-(0) 211 929 69-3799

e-mail: infoservice@grundfos.de

Service in Deutschland:

e-mail: kundendienst@grundfos.de

Greece

GRUNDFOS Hellas A.E.B.E.

20th km. Athinon-Markopoulou Av.

P.O . B o x 71

GR-19002 Peania

Phone: +0030-210-66 83 400

Telefax: +0030-210-66 46 273

Hong Kong

GRUNDFOS Pumps (Hong Kong) Ltd.

Unit 1, Ground floor

Siu Wai Industrial Centre

29-33 Wing Hong Street &

68 King Lam Street, Cheung Sha Wan

Kowloon

Phone: +852-27861706 / 27861741

Telefax: +852-27858664

Hungary

GRUNDFOS Hungária Kft.

Park u. 8

H-2045 Törökbálint,

Phone: +36-23 511 110

Telefax: +36-23 511 111

India

GRUNDFOS Pumps India Private Limited

118 Old Mahabalipuram Road

Thoraipakkam

Chennai 600 096

Phone: +91-44 2496 6800

Indonesi a

PT GRUNDFOS Pompa

Jl. Rawa Sumur III, Blok III / CC-1

Kawasan Industri, Pulogadung

Jakarta 13930

Phone: +62-21-460 6909

Telefax: +62-21-460 6910 / 460 6901

Ireland

GRUNDFOS (Ireland) Ltd.

Unit A, Merrywell Business Park

Ballymount Road Lower

Dublin 12

Phone: +353-1-4089 800

Telefax: +353-1-4089 830

Italy

GRUNDFOS Pompe Italia S.r.l.

Via Gran Sasso 4

I-20060 Truccazzano (Milano)

Tel.: +39-02-95838112

Telefax: +39-02-95309290 / 95838461

Japan

GRUNDFOS Pumps K.K.

Gotanda Metalion Bldg., 5F,

5-21-15, Higashi-gotanda

Shiagawa-ku, Tokyo

141-0022 Japan

Phone: +81 35 448 1391

Telefax: +81 35 448 9619

Korea

GRUNDFOS Pumps Korea Ltd.

6th Floor, Aju Building 679-5

Yeoksam-dong, Kangnam-ku, 135-916

Seoul, Korea

Phone: +82-2-5317 600

Telefax: +82-2-5633 725

Latvia

SIA GRUNDFOS Pumps Latvia

Deglava biznesa centrs

Augusta Deglava ielā 60, LV-1035, Rīga,

Tālr.: + 371 714 9640, 7 149 641

Fakss: + 371 914 9646

Lithuania

GRUNDFOS Pumps UAB

Smolensko g. 6

LT-03201 Vilnius

Tel: + 370 52 395 430

Fax: + 370 52 395 431

Malaysia

GRUNDFOS Pumps Sdn. Bhd.

7 Jalan Peguam U1/25

Glenmarie Industrial Park

40150 Shah Alam

Selangor

Phone: +60-3-5569 2922

Telefax: +60-3-5569 2866

México

Bombas GRUNDFOS de México S.A. de

C.V.

Boulevard TLC No. 15

Parque Industrial Stiva Aeropuerto

Apodaca, N.L. 66600

Phone: +52-81-8144 4000

Telefax: +52-81-8144 4010

Netherlands

GRUNDFOS Netherlands

Veluwezoom 35

1326 AE Almere

Postbus 22015

1302 CA ALMERE

Tel.: +31-88-478 6336

Telefax: +31-88-478 6332

e-mail: info_gnl@grundfos.com

New Zealand

GRUNDFOS Pumps NZ Ltd.

17 Beatrice Tinsley Crescent

North Harbour Industrial Estate

Albany, Auckland

Phone: +64-9-415 3240

Telefax: +64-9-415 3250

Norway

GRUNDFOS Pumper A/S

Strømsveien 344

Postboks 235, Leirdal

N-1011 Oslo

Tlf.: +47-22 90 47 00

Telefax: +47-22 32 21 50

Poland

GRUNDFOS Pompy Sp. z o.o.

ul. Klonowa 23

Baranowo k. Poznania

PL-62-081 Przeźmierowo

Tel: (+48-61) 650 13 00

Fax: (+48-61) 650 13 50

Portugal

Bombas GRUNDFOS Portugal, S.A.

Rua Calvet de Magalhães, 241

Apartado 1079

P-2770-153 Paço de Arcos

Tel.: +351-21-440 76 00

Telefax: +351-21-440 76 90

România

GRUNDFOS Pompe România SRL

Bd. Biruintei, nr 103

Pantelimon county Ilfov

Phone: +40 21 200 4100

Telefax: +40 21 200 4101

E-mail: romania@grundfos.ro

Russia

ООО Грундф ос

Росси я, 109544 Москва, ул. Школьная

39

Тел. (+7) 495 737 30 00, 564 88 00

Факс (+7) 495 737 75 36, 564 88 11

E-mail grundfos.moscow@grundfos.com

Serbia

GRUNDFOS Predstavništvo Beograd

Dr. Milutina Ivkovića 2a/29

YU-11000 Beograd

Phone: +381 11 26 47 877 / 11 26 47 496

Telefax: +381 11 26 48 340

Singapore

GRUNDFOS (Singapore) Pte. Ltd.

24 Tuas West Road

Jurong Town

Singapore 638381

Phone: +65-6865 1222

Telefax: +65-6861 8402

Slovenia

GRUNDFOS d.o.o.

Šlandrova 8b, SI-1231 Ljubljana-Črnuče

Phone: +386 1 568 0610

Telefax: +386 1 568 0619

E-mail: slovenia@grundfos.si

South Africa

Corner Mountjoy and George Allen Roads

Wilbart Ext. 2

Bedfordview 2008

Phone: (+27) 11 579 4800

Fax: (+27) 11 455 6066

E-mail: lsmart@grundfos.com

Spain

Bombas GRUNDFOS España S.A.

Camino de la Fuentecilla, s/n

E-28110 Algete (Madrid)

Tel.: +34-91-848 8800

Telefax: +34-91-628 0465

Sweden

GRUNDFOS AB

Box 333 (Lunnagårdsgatan 6)

431 24 Mölndal

Tel.: +46(0)771-32 23 00

Telefax: +46(0)31-331 94 60

Switzerland

GRUNDFOS Pumpen AG

Bruggacherstrasse 10

CH-8117 Fällanden/ZH

Tel.: +41-1-806 8111

Telefax: +41-1-806 8115

Taiwan

GRUNDFOS Pumps (Taiwan) Ltd.

7 Floor, 219 Min-Chuan Road

Taichung, Taiwan, R.O.C.

Phone: +886-4-2305 0868

Telefax: +886-4-2305 0878

Thailand

GRUNDFOS (Thailand) Ltd.

92 Chaloem Phrakiat Rama 9 Road,

Dokmai, Pravej, Bangkok 10250

Phone: +66-2-725 8999

Telefax: +66-2-725 8998

Turkey

GRUNDFOS POMPA San. ve Tic. Ltd. Sti.

Gebze Organize Sanayi Bölgesi

Ihsan dede Caddesi,

2. yol 200. Sokak No. 204

41490 Gebze/ Kocaeli

Phone: +90 - 262-679 7979

Telefax: +90 - 262-679 7905

E-mail: satis@grundfos.com

Ukraine

ТОВ ГРУНДФОС УКРАЇНА

01010 Київ, Вул. Московська 8б,

Тел.:(+38 044) 390 40 50

Фах.: (+38 044) 390 40 59

E-mail: ukraine@grundfos.com

United Arab Emirates

GRUNDFOS Gulf Distribution

P.O. Box 16768

Jebel Ali Free Zone

Dubai

Phone: +971-4- 8815 166

Telefax: +971-4-8815 136

United Kingdom

GRUNDFOS Pumps Ltd.

Grovebury Road

Leighton Buzzard/Beds. LU7 8TL

Phone: +44-1525-850000

Telefax: +44-1525-850011

U.S.A.

GRUNDFOS Pumps Corporation

17100 West 118th Terrace

Olathe, Kansas 66061

Phone: +1-913-227-3400

Telefax: +1-913-227-3500

Usbekistan

Представительство ГРУНДФОС в

Ташкенте

700000 Ташкент ул.Усма на Носира 1-й

тупик 5

Теле фо н: (3712) 55-68-15

Факс: (3712) 53-36-35

Addresses revised 11.06.2010

97727298 0710

GB

20 / 20

20

Loading...

Loading...