Grundfos MAGNA1 25-60 N, MAGNA1 25-40 N, MAGNA1 25-80 N, MAGNA1 25-100 N, MAGNA1 25-120 N Installation And Operating Instructions Manual

...

New MAGNA1

Model C

Installation and operating instructions

GRUNDFOS INSTRUCTIONS

English (GB) Installation and operating instructions

English (GB)

Original installation and operating instructions

These installation and operating instructions describe New

MAGNA1 model C.

Sections 1-5 give the information necessary to be able to unpack,

install and start up the product in a safe way.

Sections 6-11 give important information about the product, as

well as information on service, fault finding and disposal of the

product.

CONTENTS

Page

1. General information

1.1 Hazard statements

1.2 Notes

1.3 Symbols on the product

2. Receiving the product

2.1 Inspecting the product

2.2 Scope of delivery

2.3 Lifting the product

3. Installing the product

3.1 Location

3.2 Tools

3.3 Insulating shells

3.4 Mechanical installation

3.5 Electrical connection

4. Starting up the product

4.1 Single-head pump

4.2 Twin-head pump

4.3 Pairing and unpairing twin-head pumps

5. Handling and storing the product

6. Product introduction

6.1 Product description

6.2 Intended use

6.3 Pumped liquids

6.4 Identification

6.5 Radio communication

6.6 Non-return valve

6.7 Closed valve operation

6.8 Accessories

7. Control functions

7.1 Proportional-pressure curve (PP1, PP2 or PP3)

7.2 Constant-pressure curve (CP1, CP2 or CP3)

7.3 Constant curve (I, II or III)

7.4 Overview of the control functions

7.5 Selecting control function

8. Setting the product

8.1 Operating panel

8.2 Setting the control function

8.3 Connecting the pump to Grundfos GO Remote

8.4 Communication, control and monitoring

9. Fault finding the product

9.1 Grundfos Eye operating status

9.2 Resetting a fault indication

9.3 Reading out warning and alarm codes in Grundfos GO

Remote

9.4 Fault finding table

9.5 Warning 77, twin-head pump

10. Technical data

11. Disposing of the product

10

15

15

16

16

17

17

17

17

17

18

18

18

19

19

20

20

20

20

21

22

23

23

23

25

27

28

28

29

29

30

31

32

33

This appliance can be used by children aged from 8

years and above and persons with reduced physical,

sensory or mental capabilities or lack of experience

and knowledge if they have been given supervision

or instruction concerning use of the appliance in a

safe way and understand the hazards involved.

Children shall not play with the appliance. Cleaning

and user maintenance shall not be made by children

without supervision.

1. General information

2

1.1 Hazard statements

2

The symbols and hazard statements below may appear in

3

Grundfos installation and operating instructions, safety

3

instructions and service instructions.

3

3

3

4

5

5

5

5

6

The text accompanying the three hazard symbols DANGER,

WARNING and CAUTION is structured in the following way:

The hazard statements are structured in the following way:

DANGER

Indicates a hazardous situation which, if not avoided,

will result in death or serious personal injury.

WARNING

Indicates a hazardous situation which, if not avoided,

could result in death or serious personal injury.

CAUTION

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate personal injury.

SIGNAL WORD

Description of hazard

Consequence of ignoring the warning.

- Action to avoid the hazard.

Read this document and the quick guide before

installing the product. Installation and operation must

comply with local regulations and accepted codes of

good practice.

2

1.2 Notes

8Nm!

The symbols and notes below may appear in Grundfos

installation and operating instructions, safety instructions and

service instructions.

Observe these instructions for explosion-proof

products.

A blue or grey circle with a white graphical symbol

indicates that an action must be taken.

A red or grey circle with a diagonal bar, possibly with

a black graphical symbol, indicates that an action

must not be taken or must be stopped.

If these instructions are not observed, it may result in

malfunction or damage to the equipment.

2. Receiving the product

2.1 Inspecting the product

Check that the product is in accordance with the order.

Check that the voltage and frequency of the product match the

voltage and frequency of the installation site. See section

6.4.1 Nameplate.

Pumps tested with water containing anticorrosive

additives are taped on the inlet and outlet ports to

prevent residual test water from leaking into the

packaging. Remove the tape before installing the

pump.

2.2 Scope of delivery

2.2.1 Plug-connected single-head pump

English (GB)

Tips and advice that make the work easier.

1.3 Symbols on the product

Check the position of the clamp before you tighten

the clamp. Incorrect position of the clamp will cause

leakage from the pump and damage the hydraulic

parts in the pump head.

Fit and tighten the screw holding the clamp to 8 Nm ±

1 Nm.

Do not apply more torque than specified even though

water is dripping from the clamp. The condensed

water is most likely coming from the drain hole under

the clamp.

TM05 5508 3016TM06 7222 3016

Fig. 1 Plug-connected single-head pump

The box contains the following items:

• MAGNA1 pump

• insulating shells

•gaskets

•quick guide

• safety instructions

• one ALPHA plug.

2.2.2 Plug-connected twin-head pump

Fig. 2 Plug-connected twin-head pump

The box contains the following items:

• MAGNA1 pump

•gaskets

•quick guide

• safety instructions

• two ALPHA plugs.

3

2.2.3 Terminal-connected single-head pump

English (GB)

Fig. 3 Terminal-connected single-head pump

The box contains the following items:

• MAGNA1 pump

• insulating shells

•gaskets

• quick guide

• safety instructions

• box with terminal and cable glands.

2.2.4 Terminal-connected twin-head pump

2.3 Lifting the product

Observe local regulations concerning limits for

manual lifting or handling.

Always lift directly on the pump head or the cooling fins when

handling the pump. See fig. 5.

For large pumps, it may be necessary to use lifting equipment.

Position the lifting straps as illustrated in fig. 5.

TM06 7223 3016TM06 6741 3016

Fig. 4 Terminal-connected twin-head pump

The box contains the following items:

• MAGNA1 pump

•gaskets

• quick guide

• safety instructions

• two boxes with terminal and cable glands.

TM05 5819 3016

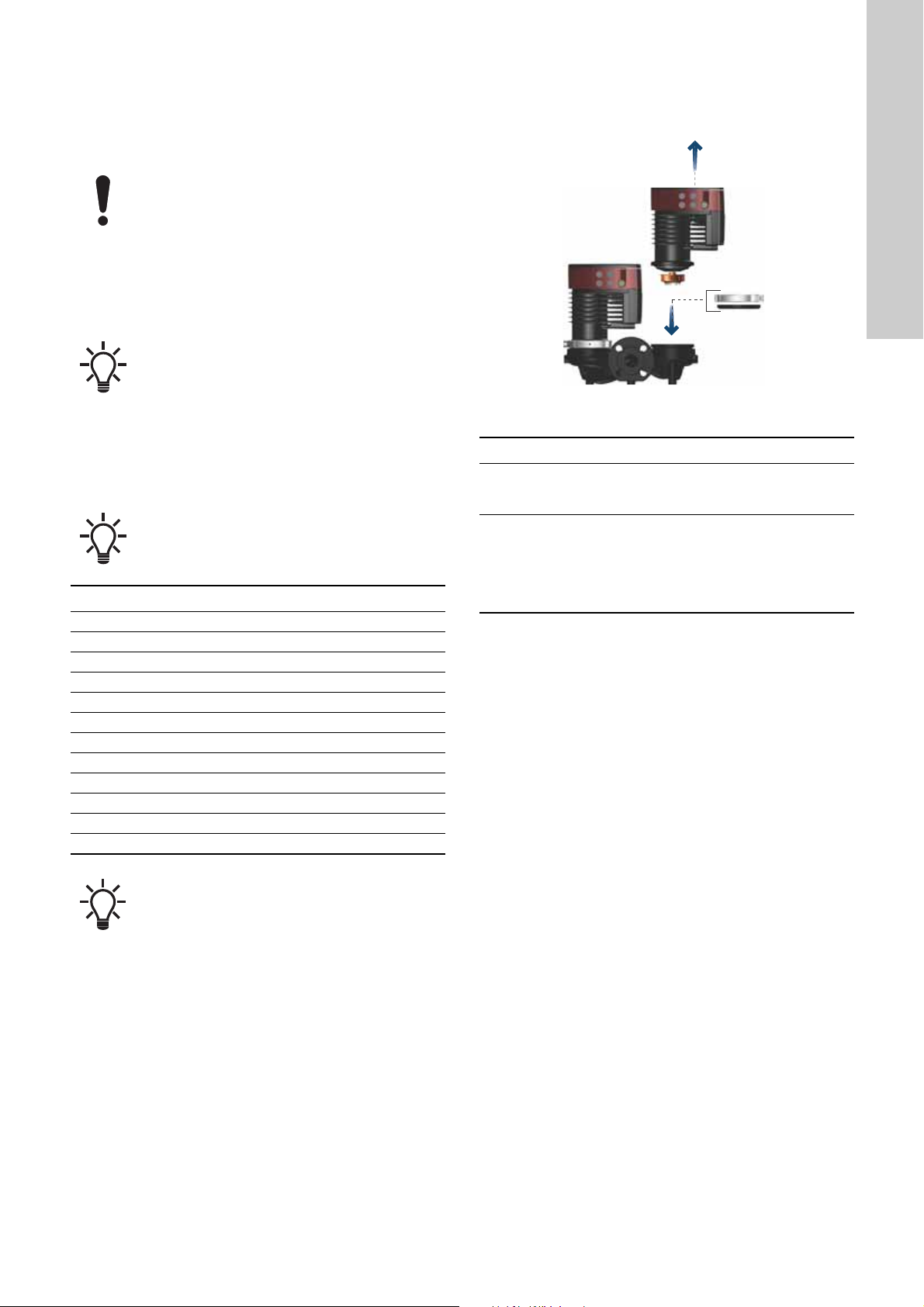

Fig. 5 Correct lifting of the pump

Do not lift the pump head by the control box, i.e. the

red area of the pump. See fig. 6.

TM06 7219 3016

Fig. 6 Incorrect lifting of the pump

4

3. Installing the product

0.6 x 3.5

5.0

1.2 x 8.0

TX20

TX10

1

2

3

4

5

6

7

3.1 Location

The pump is designed for indoor installation.

Always install the pump in an dry environment where it will not be

exposed to drops or splashes, for example water, from

surrounding equipment or structures.

As the pump contains stainless-steel parts, it is important that it is

not installed directly in environments, such as:

Indoor swimming pools where the pump would be exposed to the

ambient environment of the pool.

Locations with direct and continuous exposure to a marine

atmosphere.

In rooms where hydrochloric acid (HCl) can form acidic aerosols

escaping from, for example, open tanks or frequently opened or

vented containers.

The above applications do not disqualify for installation of

MAGNA1. However, it is important that the pump is not installed

directly in these environments.

To ensure adequate cooling of the motor and electronics, observe

the following requirements:

• Position the pump in such a way that sufficient cooling is

ensured.

• The ambient temperature must not exceed 40 °C.

3.2 Tools

3.3 Insulating shells

Insulating shells limit the heat loss from the pump housing and

pipes. Insulating shells are available for single-head pumps only.

3.3.1 Heating systems

Insulating shells increase the pump dimensions.

Insulating shells for pumps in heating systems are factory-fitted

with the pump. Remove the insulating shells before you install the

pump. See fig. 8.

Fig. 8 Removing insulating shells from the pump

English (GB)

TM05 5512 3016

Fig. 7 Recommended tools

3.3.2 Cooling systems

Insulating shells for pumps in air-conditioning and cooling

systems, down to -10 °C, are available as accessories and must

be ordered separately. See section 6.8.2 Insulating kits for

air-conditioning and cooling systems.

3.3.3 Insulating the pump

As an alternative to insulating shells, you can insulate the pump

housing and pipes as illustrated in fig. 9.

Do not insulate the control box or cover the operating

panel.

TM05 6472 4712

Pos. Tool Size

1 Screwdriver, straight slot 0.6 x 3.5 mm

2 Screwdriver, straight slot 1.2 x 8.0 mm

3 Screwdriver, torx bit TX10

4 Screwdriver, torx bit TX20

5 Hexagon key 5.0 mm

6 Side cutter

7 Open-end spanner Depending on DN size

TM05 5549 3016

Fig. 9 Insulation of the pump housing and pipe

5

3.4 Mechanical installation

English (GB)

Install the pump so that it is not stressed by the pipes. For

maximum permissible forces and moments from pipe connections

acting on the pump flanges, see page 40.

You can suspend the pump directly in the pipes, provided that the

pipes support the pump.

Twin-head pumps are prepared for installation on a mounting

bracket or base plate.

Step Action Illustration

Arrows on the pump housing indicate the

liquid flow direction through the pump. The

liquid flow direction can be horizontal or

1

vertical, depending on the control-box

position.

Close the isolating valves and make sure

2

that the system is not pressurised during

installation of the pump.

TM05 5513 3812

3 Mount the pump with gaskets in the pipes.

Flanged version:

Fit the bolts, washers and nuts. Use the

correct size of bolts according to the system

4

pressure.

For further information about torques, see

page 40.

TM06 8040 0317

TM05 5515 3812

TM05 5516 3816 TM05 5517 3812

6

3.4.1 Pump positions

A B

C D

Always install the pump with horizontal motor shaft.

• Pump installed correctly in a vertical pipe. See fig. 10, pos. A.

• Pump installed correctly in a horizontal pipe. See fig. 10, pos.

B.

• Do not install the pump with vertical motor shaft. See fig. 10,

pos. C and D.

Fig. 10 Pump installed with horizontal motor shaft

3.4.2 Control box positions

To ensure adequate cooling, make sure that the control box is in

horizontal position with the Grundfos logo in vertical position. See

fig. 11.

English (GB)

TM05 5518 3016

TM05 5522 3016

Fig. 11 Pump with the control box in horizontal position

Twin-head pumps installed in horizontal pipes can be

fitted with an automatic vent, Rp 1/4" thread, in the

upper part of the pump housing if no venting valve is

installed in the system. See fig. 12.

Fig. 12 Automatic vent

TM05 6062 3016

7

3.4.3 Pump head position

English (GB)

If you remove the pump head before installing the pump in the

pipes, pay special attention when fitting the pump head to the

pump housing:

1. Visually check that the floating ring in the sealing system is

centred. See figs 13 and 14.

2. Gently lower the pump head with the rotor shaft and impeller

into the pump housing.

3. Make sure that the contact face of the pump housing and that

of the pump head are in contact before you tighten the clamp.

See fig. 15.

Fig. 13 Correctly centred sealing system

Check the position of the clamp before you tighten it.

Incorrect position of the clamp will cause leakage

from the pump and damage the hydraulic parts in the

pump head. See fig. 15.

TM05 5837 3016

Fig. 15 Fitting the pump head to the pump housing

TM05 6650 3016TM05 6651 3016

Fig. 14 Incorrectly centred sealing system

8

3.4.4 Changing the control box position

8Nm!

5.0

8 Nm5.0

The warning symbol on the clamp holding the pump

head and pump housing together indicates that there

is a risk of personal injury. See specific warnings

below.

CAUTION

Pressurised system

Minor or moderate personal injury

- Pay special attention to any escaping vapour

when loosening the clamp.

CAUTION

Crushing of feet

Minor or moderate personal injury

- Do not drop the pump head when loosening the

clamp.

Fit and tighten the screw holding the clamp to 8 Nm ±

1 Nm. Do not apply more torque than specified even

though water is dripping from the clamp. The

condensed water is most likely coming from the drain

hole under the clamp.

Step Action Illustration

Due to the drain

hole in the stator

housing, position

4

the gap of the

clamp as shown in

step 4a or 4b.

Single-head

pump:

Position the clamp

so that the gap

points towards the

4a

arrow.

It can be in position

3, 6, 9 or 12

o'clock.

English (GB)

TM05 2870 3016

Check the position of the clamp before you tighten

the clamp. Incorrect position of the clamp will cause

leakage from the pump and damage the hydraulic

parts in the pump head.

Step Action Illustration

Loosen the screw

in the clamp that

holds the pump

head and pump

housing together. If

you loosen the

1

screw too much,

the pump head will

be completely

disconnected from

the pump housing.

Carefully, turn the

pump head to the

desired position.

If the pump head is

2

stuck, loosen it with

a light blow of a

rubber mallet.

Place the control

box in horizontal

position so that the

Grundfos logo is in

3

vertical position.

The motor shaft

must be in

horizontal position.

TM05 2918 3016

Twin-head pump:

Position the clamps

so that the gaps

point towards the

4b

arrows.

They can be in

position 3, 6, 9 or

12 o'clock.

TM05 2917 3016

Fit and tighten the

screw holding the

clamp to 8 ± 1 Nm.

TM05 2867 3016

Do not retighten

5

the screw if

condensed water is

dripping from the

clamp.

TM05 2872 3016

Fit the insulating

TM05 5526 3016

shells.

Insulating shells for

pumps in

6

air-conditioning

and cooling

systems must be

ordered separately.

TM05 5529 3016

TM05 5527 3016

9

3.5 Electrical connection

English (GB)

Carry out the electrical connection and protection according to

local regulations.

Check that the supply voltage and frequency correspond to the

values stated on the nameplate.

WARNING

Electric shock

Death or serious personal injury

- Lock the main switch in position 0. Type and

requirements as specified in EN 60204-1, 5.3.2.

WARNING

Electric shock

Death or serious personal injury

- Connect the pump to an external main switch with

a minimum contact gap of 3 mm in all poles.

- Use earthing or neutralisation for protection

against indirect contact.

- If the pump is connected to an electric installation

where an electrical circuit breaker, that is a

voltage sensing ELCB, residual-current device

RCD or residual-current circuit device RCCB, is

used as an additional protection, this circuit

breaker must be marked with the first or both of

the symbols shown below:

• Make sure that the pump is connected to an external main

switch.

• The pump requires no external motor protection.

• The motor incorporates thermal protection against slow

overloading and blocking.

• When switched on via the power supply, the pump starts after

approximately 5 seconds.

3.5.1 Supply voltage

1 x 230 V ± 10 %, 50/60 Hz, PE.

The voltage tolerances are intended for mains-voltage variations.

Do not use the voltage tolerances for running pumps at other

voltages than those stated on the nameplate.

10

3.5.2 Wiring diagrams

External switch

Fuse

RCD/RCCB

L

N

L

N

External switch

Fuse

RCD/RCCB

CNC S/S

S/S CNC

12

Fig. 16 Example of a plug-connected motor with a main switch, backup fuse and additional protection

Fig. 17 Example of a mains-connected motor with a main switch, backup fuse and additional protection

English (GB)

TM05 5277 3016

TM06 8503 0817

Fig. 18 Connection to external control

Pos. Description

1 Plug-connected versions

2 Terminal-connected versions

WARNING

Electric shock

Minor or moderate personal injury

- Separate wires connected to supply terminals,

outputs NC, C and start-stop input from each other

and from the supply by means of reinforced

insulation.

TM06 9106 4517 - TM06 8060 0717

Make sure that the fuse is dimensioned according to

the nameplate and local regulations.

Connect all cables in accordance with local

regulations.

Make sure that all cables are heat-resistant up to 75

°C.

Install all cables in accordance with EN 60204-1 and

EN 50174-2:2000.

11

3.5.3 Connection to the power supply, plug-connected

17 mm

12 mm

7 mm

Ø 5.5 - 10 mm

Max. 1.5 mm

2

Click

Click

Click

x 3

Max 0.8 x 4

English (GB)

versions

Step Action Illustration

Step Action Illustration

Fit the cable gland

and plug cover to

the cable. Strip the

1

cable conductors

as illustrated.

Connect the cable

2

conductors to the

power supply plug.

Bend the cable

with the cable

3

conductors

pointing upwards.

7

TM05 5538 3216

Disassembling the plug

Step Action Illustration

TM05 5539 3812

TM05 5540 3812

1

2

Insert the power

supply plug into

the male plug in

the pump control

box.

TM07 1417 1618

Loosen the cable

gland and remove

it from the plug.

TM05 5545 3812

Pull off the plug

cover while

pressing on both

sides.

Pull out the

conductor guide

4

plate and throw it

away.

Click the plug

5

cover onto the

power supply plug.

Screw the cable

6

gland onto the

power supply plug.

TM05 5546 3812

Loosen the cable

TM05 5541 3812

conductors one by

one by pressing a

3

screwdriver gently

into the terminal

clip.

TM05 5547 3812

TM05 5542 3812

The plug has now

been removed

4

from the power

supply plug.

TM05 5543 3812

TM05 5548 3812

12

3.5.4 Connection to the power supply, terminal-connected

1 x 230 V

7 mm

20 mm

7 mm

25 mm

Min. Ø 7 mm

Max. Ø 14 mm

version

Step Action Illustration

Step Action Illustration

Remove the

front cover from

the control box.

1

Do not remove

the screws from

the cover.

Locate the

power supply

plug and cable

gland in the

2

small cardboard

box supplied

with the pump.

Connect the

3

cable gland to

the control box.

Connect the

cable

conductors to

6

English (GB)

the power

supply plug.

TM05 5530 3016

TM06 8053 0717

Insert the power

supply plug into

7

the male plug in

the control box.

TM06 8049 0717

TM06 8054 0717

Tighten the

cable gland.

8

Refit the front

cover.

TM06 8050 0717

Pull the power

4

cable through

the cable gland.

Strip the cable

5

conductors as

illustrated.

TM06 8061 0717

TM06 8051 0717

TM06 8052 0717

13

3.5.5 Connecting the digital input 3.5.6 Connecting the fault relay output

English (GB)

Step Action Illustration

Remove the front

cover from the

control box.

1

Do not remove the

screws from the

cover.

Locate the digital

2

input terminal

connector.

Pull the cable

through a cable

gland, M16, and

connect the cable

conductors to the

digital input

terminal

connector.

3

See section

8.4.1 Digital input

(Start/Stop) for

instructions on

how to connect

the cable to the

terminal.

Step Action Illustration

Remove the front

cover from the

control box.

1

Do not remove the

screws from the

cover.

TM05 5530 3016

Locate the fault

2

relay output cover

and remove it.

Pull the cable

TM06 8017 8517 0817

through a cable

gland, M16, and

connect the cable

conductors to the

fault relay output

terminal

connector.

3

See section

8.4.2 Fault relay

output for

instructions on

how to connect

the cable to the

terminal.

TM06 8516 0817

TM05 5530 3016

TM06 8056 0817

TM06 8057 0817

Refit the front

4

cover to the

control box.

Refit the fault

4

relay output cover.

TM06 8058 0717

TM06 8059 0717

Refit the front

5

cover to the

control box.

TM06 8059 0717

14

4. Starting up the product

1 x 230 V ± 10 %

ϝ0/60 Hz

1 / On

0 / Off

4.1 Single-head pump

In order to protect the electronics, the number of

starts and stops must not exceed four times per

hour.

Do not start the pump until the system has been filled with liquid

and vented. Furthermore, the required minimum inlet pressure

must be available at the pump inlet. See section 10. Technical

data.

The pump is self-venting through the system, and the system

must be vented at the highest point.

Step Action Illustration

English (GB)

1

Switch on the power supply to the pump.

The pump starts after approximately 5 seconds.

2 Operating panel at first startup.

The pump has been factory-set to the intermediate

proportional-pressure curve.

3

Select the control mode according to the system

application by pressing the button . See section

7. Control functions and 8. Setting the product.

TM07 0033 3917

TM05 5551 3016

TM05 5551 3016

15

4.2 Twin-head pump

5 sec.

=

5 sec.

=

English (GB)

4.3.2 Unpairing

Step Action Illustration

Make sure that both pump heads are powered on.

The pumps are paired from factory. When switching on the power

supply, the heads will establish connection, which is indicated by

a green light in the centre of Grundfos Eye. Please allow

approximately 5 seconds for this to happen.

If one of the pump heads is turned off, the pump with power will

show a yellow indicator light, warning 77, see section 9. Fault

finding the product. In that case, power up the switched off pump.

Once both pumps are on, the pumps will establish connection and

the warning deactivates.

See sections 8.4.1 Digital input (Start/Stop), 8.4.2 Fault relay

output and 8.4.3 Twin-head pump function for additional

twin-head pump setup options.

4.3 Pairing and unpairing twin-head pumps

The pumps are paired from factory, however, it can be useful to

know how to pair the system e.g. for service purposes.

The pumps can also be unpaired.

When you have paired the pumps, you must wait 10

seconds before unpairing.

4.3.1 Pairing

The master pump head is the one from which you

initiate the pairing.

Push and hold the

button on any of

the two pump

1

heads for 5

seconds.

The light in the

centre of Grundfos

Eye will disappear.

2

The system has

been deactivated.

TM06 8521 1017

TM06 8522 1017

Step Action Illustration

Push and hold the

button on the

pump you wish to

assign as the

master pump for 5

1

seconds.

The centre of

Grundfos Eye on

both pumps will

begin to flash.

Push the button

on the other pump

2

to assign this as

the slave pump.

The centre of both

Grundfos Eye

indicator lights are

alight and

3

constant.

The two pumps

are now paired.

TM06 8524 1017

TM06 8525 1017

16

TM06 8527 1017

5. Handling and storing the product

Max. 95 % RH

IPX4D

If the pump is not used during periods of frost, add

antifreeze or let the pump run in regular intervals to

prevent frost bursts.

Observe local regulations concerning limits for

manual lifting or handling.

Always lift directly on the pump head or the cooling fins when

handling the pump. For large pumps, it may be necessary to use

lifting equipment. See section 2.3 Lifting the product.

6. Product introduction

6.1 Product description

Grundfos MAGNA1 is a complete range of circulator pumps with

integrated controller enabling adjustment of pump performance to

the actual system requirements. In many systems, this reduces

the power consumption considerably, reduces noise from

thermostatic radiator valves and similar fittings and improves the

control of the system.

You can set the desired head on the operating panel.

6.2 Intended use

The pump is designed for circulating liquids in the following

systems:

• heating systems

• domestic hot-water systems

• air-conditioning and cooling systems.

You can also use the pump in the following systems:

• ground-source heat-pump systems

• solar-heating systems.

6.3.1 Glycol

You can use the pump for pumping water-ethylene-glycol

mixtures up to 50 %.

Example of a water-ethylene-glycol mixture:

Maximum viscosity: 50 cSt ~ 50 % water and 50 % glycol mixture

at -10 °C.

The pump has a power-limiting function that protects it against

overload.

The pumping of glycol mixtures affects the maximum curve and

reduces the performance, depending on the

water-ethylene-glycol mixture and the liquid temperature.

To prevent the glycol mixture from degrading, avoid temperatures

exceeding the rated liquid temperature and minimise the

operating time at high temperatures.

Clean and flush the system before you add the glycol mixture.

To prevent corrosion or lime precipitation, maintain the glycol

mixture regularly. If further dilution of the supplied glycol is

required, follow the glycol supplier's instructions.

Additives with a density or kinematic viscosity higher

than water reduces the hydraulic performance.

English (GB)

6.3 Pumped liquids

The pump is suitable for thin, clean, non-aggressive and

non-explosive liquids, not containing solid particles or fibres that

may attack the pump mechanically or chemically.

In heating systems, the water must meet the requirements of

accepted standards on water quality in heating systems, for

example the German standard VDI 2035.

The pump is also suitable for domestic hot-water systems.

We strongly recommend that you use stainless-steel pumps in

domestic hot-water applications to avoid corrosion.

In domestic hot-water systems, we recommend that you use the

pump only for water with a degree of hardness lower than

approximately 14 °dH.

In domestic hot-water systems, we recommend that you keep the

liquid temperature below 65 °C to eliminate the risk of lime

precipitation.

TM06 8055 0717

Fig. 19 Pumped liquids

Observe local regulations regarding pump-housing

material.

Do not pump aggressive liquids.

Do not pump flammable, combustible or explosive

liquids.

17

6.4 Identification

English (GB)

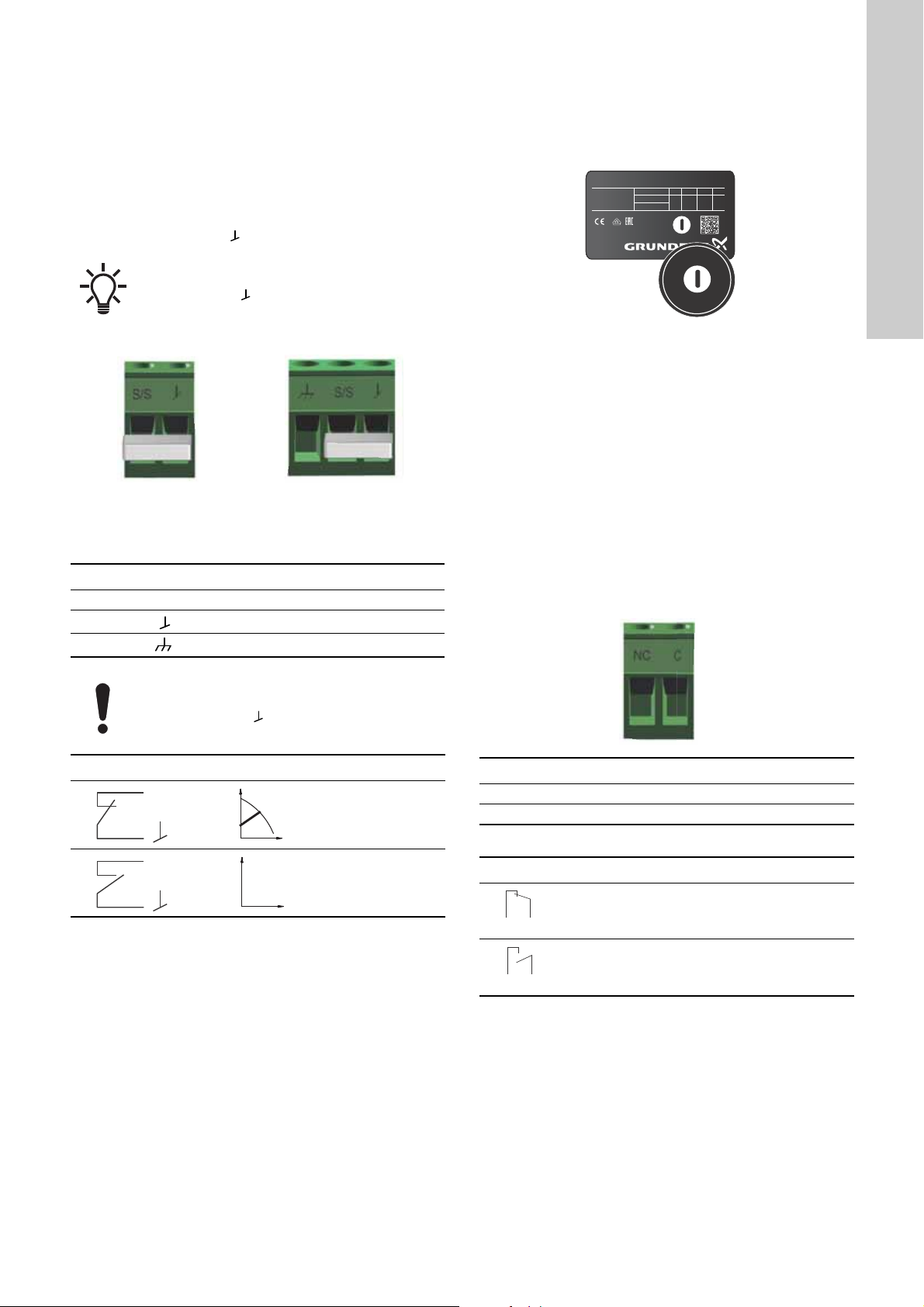

6.4.1 Nameplate

Fig. 20 Example of a nameplate

Pos. Description

1 Product name

2 Model

3 Production code, PC, year and week*

4 Serial number

5 Product number

6 Country of manufacture

7 Enclosure class

8 Energy Efficiency Index, EEI

9 Part, according to EEI

10 Temperature class

11 Minimum current [A]

12 Maximum current [A]

13 Minimum power [W]

14 Maximum power [W]

15 Maximum system pressure

16 Voltage [V] and frequency [Hz]

17 QR code

18 CE mark and approvals

19 Manufacturer's name and address

* Example of production code: 1326. The pump was produced in

week 26, 2013.

6.4.2 Type key

Code Example MAGNA1 D 80 -120 (F) (N) 360

Type range

MAGNA1

D Twin-head pump

Nominal diameter (DN) of inlet

and outlet ports [mm]

TM05 5561 3812

Maximum head

[dm]

Pipe connection

Threaded

Flange

F

Pump housing material

Cast iron

Stainless steel

N

Port-to-port length [mm]

6.5 Radio communication

MAGNA1 single-head pumps are designed for infrared

communication (IR) with Grundfos GO Remote, while MAGNA1

twin-head pumps can also communicate via radio.

6.6 Non-return valve

If a non-return valve is fitted in the pipe system, ensure that the

set minimum outlet pressure of the pump is always higher than

the closing pressure of the valve. See fig. 22. This is especially

important in proportional-pressure control mode with reduced

head at a low flow rate.

Fig. 22 Non-return valve

TM05 3055 0912

Fig. 21 Production code on the packaging

18

TM06 6692 2216

6.7 Closed valve operation

MAGNA1 pumps can operate at any speed against a closed valve

for several days without damage to the pump. However, Grundfos

recommends to operate at the lowest possible speed curve to

minimize energy losses. There are no minimum flow

requirements.

Do not close inlet and outlet valves simultaneously,

always keep one open when the pump is running.

Media- and ambient temperatures must never

exceed the specified temperature range.

6.8 Accessories

6.8.1 Insulating shells for heating systems

Insulating shells are available for single-head pumps only and are

supplied with the pump.

Insulating shells increase the pump dimensions.

6.8.2 Insulating kits for air-conditioning and cooling systems

Insulating shells for pumps in air-conditioning and cooling

systems, down to -10 °C, are available as accessories and must

be ordered separately. A kit consists of two shells made of

polyurethane and a self-adhesive seal to ensure tight assembly.

Insulating shells increase the pump dimensions. The

dimensions of the insulating shells for pumps in

air-conditioning and cooling systems differ from

those of the insulating shells for pumps in heating

systems.

Pump type Product number

MAGNA1 25-40/60/80/100/120 (N) 98538852

MAGNA1 32-40/60/80/100/120 (N) 98538853

MAGNA1 32-40/60/80/100 F (N) 98538854

MAGNA1 32-120 F (N) 98164595

MAGNA1 40-40/60 F (N) 98538855

MAGNA1 40-80/100 F (N) 98164597

MAGNA1 40-120/150/180 F (N) 98164598

MAGNA1 50-60/80 F (N) 98164599

MAGNA1 50-100/120/150/180 F (N) 98164600

MAGNA1 65-40/60/80/100/120/150 F (N) 98538839

MAGNA1 80-60/80/100/120 F 98538851

MAGNA1 100-40/60/80/100/120 F 98164611

6.8.3 Blanking flanges

A blanking flange is used to blank off the opening when one of the

pump heads of a twin-head pump is removed for service to

enable uninterrupted operation of the other pump.

Fig. 23 Position of a blanking flange

Pump type Product number

MAGNA1 D 25-40/60/80/100/120

MAGNA1 D 32-40/60/80/100 (F)

MAGNA1 D 40-40/60 F

MAGNA1 D 32-120 F

MAGNA1 D 40-80/100/120/150/180 F

MAGNA1 D 50-60/80/100/120/150/180 F

MAGNA1 D 65-40/60/80/100/120/150 F

MAGNA1 D 80-60/80/100/120 F

MAGNA1 D 100-40/60/80/100/120 F

6.8.4 Counterflanges

Counterflange kits consist of two flanges, two gaskets and bolts

and nuts, making it possible to install the pump in any pipes. See

New MAGNA1 model C data booklet, Accessories section, for the

right dimension and product number.

98159373

98159372

English (GB)

TM06 8518 0817

The insulating kit also fits stainless-steel versions

(N).

19

6.8.5 Grundfos GO Remote

PP3

PP2

PP1

Q

H

Q

H

CP3

CP2

CP1

Q

H

English (GB)

MAGNA1 single-head pumps are designed for infrared

communication (IR) with Grundfos GO Remote, while MAGNA1

twin-head pumps can also communicate via radio.

The radio communication between the pump and

Grundfos GO Remote is encrypted to protect against

misuse.

In order to communicate with Grundfos GO Remote via infrared,

you need an add-on module. Two variants are available as

described in the following.

MI 204

MI 204 is an add-on module with built-in infrared and radio

communication. You can use MI 204 in conjunction with an Apple

iPhone or iPod with Lightning connector.

Fig. 24 MI 204

Supplied with the product:

• Grundfos MI 204

• sleeve

• quick guide

• charger cable.

MI 301

MI 301 is a module with built-in infrared and radio

communication. Use MI 301 in conjunction with an Android or

iOS-based smart device with a Bluetooth connection. MI 301 has

a rechargeable Li-ion battery and must be charged separately.

7. Control functions

Factory setting: Intermediate proportional-pressure

curve, referred to as PP2.

7.1 Proportional-pressure curve (PP1, PP2 or PP3)

Proportional-pressure control adjusts the pump performance to

the actual flow rate demand in the system, but the pump

performance follows the selected performance curve, PP1, PP2

or PP3. See fig. 26 where PP2 has been selected.

Fig. 26 Three proportional-pressure curves and settings

TM05 7704 1513TM05 3890 1712

The selection of the right proportional-pressure setting depends

on the characteristics of the system in question and the actual

flow rate demand.

For further information, see section 7.4 Overview of the control

functions and 7.5 Selecting control function.

7.2 Constant-pressure curve (CP1, CP2 or CP3)

Constant-pressure control adjusts the pump performance to the

actual flow rate demand in the system, but the pump performance

follows the selected performance curve, CP1, CP2 or CP3. See

fig. 27 where CP1 has been selected.

TM05 5555 3812TM05 5556 3812TM05 5557 3812

Fig. 27 Three constant-pressure curves and settings

Fig. 25 MI 301

The selection of the right constant-pressure setting depends on

the characteristics of the system in question and the actual flow

Supplied with the product:

• Grundfos MI 301

• battery charger

• quick guide.

Product numbers

Grundfos GO variant Product number

Grundfos MI 204 98424092

rate demand.

For further information, see section 7.4 Overview of the control

functions and 7.5 Selecting control function.

7.3 Constant curve (I, II or III)

At constant-curve operation, the pump runs at a constant speed,

independently of the actual flow rate demand in the system. The

pump performance follows the selected performance curve, I, II

or III. See fig. 28 where II has been selected.

Grundfos MI 301 98046408

Together with the Grundfos GO module, you will need to

download the Grundfos GO Remote app, which is available in

Apple App Store and Google Play.

For function and connection to the pump, see the separate

installation and operating instructions for the desired type of

Grundfos GO setup.

Fig. 28 Three constant-curve settings

The selection of the right constant-curve setting depends on the

characteristics of the system in question.

For further information, see section 7.4 Overview of the control

functions and 7.5 Selecting control function.

20

7.4 Overview of the control functions

Q

III

II

I

H

PP3

CP3

CP2

PP1

CP1

PP2

English (GB)

Fig. 29 Control function in relation to system requirements

Setting Pump curve Function

PP1

PP2

PP3

CP1

CP2

CP3

III Speed III

II Speed II

I Speed I

Lowest proportional-pressure

curve

Intermediate

proportional-pressure curve

Highest

proportional-pressure curve

Lowest constant-pressure

curve

Intermediate

constant-pressure curve

Highest constant-pressure

curve

The duty point of the pump will move up or down on the lowest proportional-pressure curve,

depending on the flow rate demand.

The head is reduced at falling flow rate demand and increased at rising flow rate demand.

The duty point of the pump will move up or down on the intermediate proportional-pressure

curve, depending on the flow rate demand.

The head is reduced at falling flow rate demand and increased at rising flow rate demand.

The duty point of the pump will move up or down on the highest proportional-pressure curve,

depending on the flow rate demand.

The head is reduced at falling flow rate demand and increased at rising flow rate demand.

The duty point of the pump will move out or in on the lowest constant-pressure curve,

depending on the flow rate demand in the system.

The head is kept constant, irrespective of the flow rate demand.

The duty point of the pump will move out or in on the intermediate constant-pressure curve,

depending on the flow rate demand in the system.

The head is kept constant, irrespective of the flow rate demand.

The duty point of the pump will move out or in on the highest constant-pressure curve,

depending on the flow rate demand in the system.

The head is kept constant, irrespective of the flow rate demand.

The pump runs on a constant curve which means that it runs at a constant speed.

At speed III, the pump is set to run on the maximum curve under all operating conditions.

You obtain quick venting of the pump by setting the pump to speed III for a short period.

The pump runs on a constant curve which means that it runs at a constant speed.

At speed II, the pump is set to run on the intermediate curve under all operating conditions.

The pump runs on a constant curve which means that it runs at a constant speed.

At speed I, the pump is set to run on the minimum curve under all operating conditions.

TM05 2778 3617

21

7.5 Selecting control function

Q

H

Q

H

Q

H

English (GB)

System application Select this control mode

Systems with relatively large pressure losses in the distribution pipes and in air-conditioning and cooling

systems.

• Two-pipe heating systems with thermostatic valves and the following:

– very long distribution pipes

– strongly throttled pipe-balancing valves

– differential-pressure regulators

– large pressure losses in those parts of the system through which the total quantity of water flows, for

example a boiler, a heat exchanger and a distribution pipe up to the first branching.

• Primary circuit pumps in systems with large pressure losses in the primary circuit.

• Air-conditioning systems with the following:

– heat exchangers, fan coils

– cooling ceilings

– cooling surfaces.

Systems with relatively small pressure losses in the distribution pipes.

• Two-pipe heating systems with thermostatic valves and the following:

– dimensioning for natural circulation

– small pressure losses in those parts of the system through which the total quantity of water flows,

for example a boiler, a heat exchanger and a distribution pipe up to the first branching or modified to

a high differential temperature between the flow pipe and the return pipe, for example district

heating.

• Underfloor heating systems with thermostatic valves.

• One-pipe heating systems with thermostatic valves or pipe-balancing valves.

• Primary circuit pumps in systems with small pressure losses in the primary circuit.

Operation according to the maximum or minimum curve, like an uncontrolled pump:

• Use the maximum-curve mode in periods in which a maximum flow rate is required. This operating

mode is for instance suitable for hot-water priority in domestic hot-water systems.

• Use the minimum-curve mode in periods in which a minimum flow rate is required.

Proportional pressure

Constant pressure

Constant curve

22

8. Setting the product

1

3

4

2

5

8.1 Operating panel

CAUTION

Hot surface

Minor or moderate personal injury

- To avoid burns only touch the operating panel.

Fig. 30 Operating panel

8.2 Setting the control function

The pump has nine control functions, see section 7. Control

functions. Select the control function by pressing the push-button

on the operating panel, see fig. 30, pos. 5. The control function is

indicated by eight different light fields in the display.

Button

presses

0

1

2

3

4

TM06 9078 3617

5

Active light fields Description

Intermediate

proportional-pressure

curve, referred to as

PP2, factory setting

Highest

proportional-pressure

curve, referred to as PP3

Lowest

constant-pressure curve,

referred to as CP1

Intermediate

constant-pressure curve,

referred to as CP2

Highest

constant-pressure curve,

referred to as CP3

Constant curve III

English (GB)

The operating panel on the pump comprises the following:

Pos. Description

Infrared receiver for Grundfos GO.

1

Plug-connected versions.

Grundfos Eye.

2

See section 9.1 Grundfos Eye operating status.

Infrared receiver for Grundfos GO.

3

Terminal-connected versions.

LEDs indicate the control function.

4

See section 8.2 Setting the control function.

5 Push-button for selection of a control function.

6

7

8

Constant curve II

Constant curve I

Lowest

proportional-pressure

curve, referred to as PP1

23

8.2.1 Adjusting the proportional pressure using Grundfos GO

English (GB)

Remote

The setpoint of the proportional-pressure curve can be adjusted

using Grundfos GO Remote.

Adjusting the proportional pressure is only possible

in proportional pressure mode.

Step Action Illustration

Choose

"Settings" in the

Grundfos GO

1

Remote

dashboard.

Step Action Illustration

Use the arrows

on the top right

of the screen, or

slide the

setpoint

3

indicator up and

down to adjust

the setpoint.

Press "OK".

When the pump

receives the

setpoint from

Grundfos GO

Remote, the

proportional-pre

4

ssure symbol on

the pump lights

TM06 8584 0817

up - none of the

level indicators

lights up.

For instructions on how to connect the pump to Grundfos GO

Remote, see section 8.3 Connecting the pump to Grundfos GO

Remote.

TM06 8582 0817

Choose

"Setpoint" in the

2

"Settings"

menu.

TM06 8583 0817

24

8.3 Connecting the pump to Grundfos GO Remote

IR

Plug-connected versions

Terminal-connected

versions

Min. 30 cm

IR

Max. 15 °

Max. 15 °

3

2

5

6

7

1

4

MAGNA1 single-head pumps are designed for infrared

communication (IR) with Grundfos GO Remote, while MAGNA1

twin-head pumps can also communicate via radio.

Before connecting to Grundfos GO Remote

To use Grundfos GO Remote together with MAGNA1 make sure

to have the following ready:

• For IR communication: A Grundfos GO add-on module, which

is available as an accessory. See section 6.8.5 Grundfos GO

Remote. See the separate installation and operating

instructions for the desired type of Grundfos GO setup.

• The Grundfos GO Remote app downloaded to your smart

device. Grundfos GO Remote is available in Apple App Store

and Google Play.

Connecting to Grundfos GO Remote

To connect to Grundfos GO Remote, do as follows:

1. For IR communication: Establish a connection between the

Grundfos GO add-on module and your smart device. See the

separate installation and operating instructions.

2. Open the Grundfos GO Remote app and select either IR or

radio communication depending on the pump type and chosen

communication method. Make sure to point Grundfos GO at

the receiver placed left or right to Grundfos Eye depending on

your pump model. See fig. 31.

8.3.1 Using Grundfos GO Remote

English (GB)

TM06 8584 0817

Fig. 32 Grundfos GO Remote dashboard

Pos. Description

1 Information about the connected product.

Grundfos Eye reflecting the current operating status of

2

the pump.

In a multipump system: Icon indicating if Grundfos GO

3

is connected to the master or slave pump.

When connected to a single pump: The field is empty.

4 The actual, measured head (pressure).

5 The power consumption of the pump.

Main menu. See section 8.3.2 "Status" menu,

6

8.3.3 "Settings" menu and 8.3.4 "Alarms and warnings"

menu.

"Disconnect": Disconnects Grundfos GO from the

TM06 9081 3617TM06 7653 0718

pump.

"Refresh": Retrieves current data from the pump.

7

"Reports": Wizard creating a report with the pump's

current operating status and settings.

"Help": Guides you through the app.

When using Grundfos GO in a multipump setup and

choosing "system view", Grundfos Eye, pos. 2, fig.

32, will indicate the system's operating status and not

the status of the pump itself. See section

9.1.1 Multipump system operating indications.

Fig. 31 Establishing a connection between Grundfos GO and

MAGNA1 via infrared communication

25

8.3.2 "Status" menu

1

3

2

English (GB)

The "Status" menu gives an overview of the pump's current

operating status. To access the menu, connect the pump to

Grundfos GO. See section 4.3 Pairing and unpairing twin-head

pumps, and choose the "Status" menu from the dashboard.

8.3.3 "Settings" menu

The "Settings" menu allows you to:

• Adjust the proportional pressure, see section 8.2.1 Adjusting

the proportional pressure using Grundfos GO Remote for

instructions.

• Configure the Warning 77 relay setting, see section

9.5.1 Activating and deactivating the fault relay for

instructions.

Fig. 33 "Status" menu

Pos. Description

The accumulated energy consumption. This cannot be

1

reset.

The amount of time the product has been operating.

2

This is an accumulated value that cannot be reset.

The total number of times the pump has been started

3

since installation.

status menu 1 - status menu 2

Fig. 34 "Settings" menu

8.3.4 "Alarms and warnings" menu

This menu lets you read out alarm codes and text. A log history of

previous alarms and warnings is also available.

Fig. 35 "Alarms and warnings" menu with alarm

TM06 8583 0817

Alarm_Warning

For more information on warnings and alarms, see section

9. Fault finding the product.

You can also reach the menu by tapping Grundfos

Eye on the dashboard, see pos. 2, fig. 32.

26

8.4 Communication, control and monitoring

S/S

Q

H

S/S

Q

H

XXXXXXXXXXXXXXXXXXXXXXXX

P/N: XXXXXXXX

S/N: XXXXXXXX

PC: XXXX

Model: X

IP XXX TF XXX

Grundfos Holding A/S, DK - 8850 Bjerringbro, Denmark

((,;;;3DUW;

Made in Germany

0LQ

0D[

;;;

;;

XXXX

XXXX;;;

I1 [A] P

1 [W] MPa

12

NC C

12

NC C

MAGNA1 enables external control and monitoring via the

Start/Stop input, see section 8.4.1 Digital input (Start/Stop), and

the fault relay output, see section 8.4.2 Fault relay output, on

both single and twin-head pumps. In addition, the wireless

communication feature in twin-head pumps lets you use the pump

without an external controller, see section 8.4.3 Twin-head pump

function.

8.4.1 Digital input (Start/Stop)

To use the digital input, connect the control wires to terminals

Start/Stop (S/S) and frame ( ).

If no external on and off switch is connected,

maintain the jumper between terminals Start/Stop

(S/S) and frame ( ).This connection is the factory

setting.

A

Fig. 36 Digital input in the control box

A: Plug-connected versions

B: Terminal-connected versions

Contact symbol Function

S/S Start/Stop

B

Frame connection

Cable shield

Digital input on twin-head pumps

The Start/Stop input operates on system level, meaning that if the

master pump head receives a stop signal, the system stops.

As a main rule the digital input is only effective on the master,

which is why it is important to know which pump is assigned as

the master, see fig. 37.

Fig. 37 Identifying the master pump head on the nameplate

For redundancy purposes, the digital input can be used

concurrent on the slave pump head. However, as long as the

master is powered up, the input on the slave will be ignored. In

the event of power loss on the master, the digital input of the

slave will take over. When the master pump head is back on, the

master takes over and controls the slave.

8.4.2 Fault relay output

It is possible to use the relay output as part of a control strategy

TM06 9107 4617 - TM06 9080 3617

or for monitoring. For example, if the pump experiences a fault,

the fault relay sends a signal to the controller, which will

subsequently trigger further events depending on your chosen

strategy. In order to use the fault relay output, follow the

instructions in fig. 38.

The relay can be used for outputs up to 250 V and 2 A.

Factory settings of the relay:

English (GB)

TM06 8063 0817TM06 9107 4617

Plug-connected versions, pos. A, fig. 36:

When using a shielded cable, connect the shield in

the frame terminal ( ) together with the frame

connection cord.

Start/Stop

Normal duty

Stop

For instructions on how to connect to the Start/Stop input, see

section 3.5.5 Connecting the digital input.

Contact symbol Function

NC Normally closed

C Common

The functions of the fault relay are as shown in the table:

Fault relay Alarm signal

Not activated:

• The power supply has been switched off.

• The pump has not registered a fault.

Activated:

• The pump has registered a fault or there is a

wirebreak.

Fig. 38 Fault relay output table

For instructions on how to connect to the fault relay output, see

section 3.5.6 Connecting the fault relay output.

Fault relay output in twin-head pumps

The fault relay output on each pump head operates

independently, meaning that if a fault occurs in one of the pumps

its respective relay is triggered.

27

8.4.3 Twin-head pump function

English (GB)

The twin-head pump function allows you to use twin-head pumps

without an external controller, as the two pump heads

communicate via wireless connection.

Operating mode

The pumps are operating in alternating mode, meaning that only

one pump is running at a time. The two pumps change from one

pump to the other every 24 hours with a tolerance of ± 0,5 % per

day.

To control the twin-head pump via the digital Start/Stop input, see

section 8.4.1 Digital input (Start/Stop).

To monitor the twin-head pump via the fault relay output, see

section 3.5.6 Connecting the fault relay output.

9. Fault finding the product

9.1 Grundfos Eye operating status

Grundfos Eye is on when you switch on the power supply.

Grundfos Eye is an indicator light providing information about the

actual pump status. A fault is indicated by a yellow or red

indicator light in Grundfos Eye on the operating panel and in

Grundfos GO Remote.

The indicator light flashes in different sequences and provides

information about the following:

Grundfos Eye Indication Cause Operational state

No lights are on. The power is off. The pump is not running.

Two opposite green indicator lights

running in the direction of rotation of the

pump.

Two opposite green indicator lights are

permanently on.

One yellow indicator light running in the

direction of rotation of the pump.

One yellow indicator light is permanently

on.

Two opposite red indicator lights flashing

simultaneously.

If the pump impeller is rotated, for example when

filling the pump with water, sufficient energy may be

generated to light up the operating panel even if the

power supply has been switched off.

The power is on. The pump is running.

The power is on. The pump has stopped.

Warning. See section 9. Fault

finding the product.

Warning. See section 9. Fault

finding the product.

Alarm. See section 9. Fault

finding the product.

The pump is running.

The pump has stopped.

The pump has stopped.

28

9.1.1 Multipump system operating indications

B

A

When connecting Grundfos GO Remote to a multipump setup

and choosing "system view", Grundfos GO Remote will indicate

the system's operating status and not the status of the pump

itself. Therefore the indicator light in Grundfos GO Remote might

differ from the indicator light shown on the pump's operating

panel. See the table below.

Grundfos Eye,

master pump

Green Green Green

Green or yellow Yellow or red Yellow

Yellow or red Green or yellow Yellow

Red Red Red

Grundfos Eye,

slave pump

Grundfos Eye,

Grundfos GO

Remote

9.2 Resetting a fault indication

To reset a fault indication, eliminate the fault cause, see section

9.4 Fault finding table, and reset the pump by pressing the button

on the pump. If the pump does not revert to normal duty, the fault

cause is not eliminated.

If the fault disappears by itself, the fault indication is automatically

reset.

A fault can also be reset by using Grundfos GO Remote. See

section 9.3 Reading out warning and alarm codes in Grundfos

GO Remote.

CAUTION

Pressurised system

Minor or moderate personal injury

- Before dismantling the pump, drain the system or

close the isolating valve on either side of the

pump. The pumped liquid may be scalding hot and

under high pressure.

WARNING

Electric shock

Death or serious personal injury

- Switch off the power supply for at least 3 minutes

before you start any work on the product. Lock the

main switch in position 0. Type and requirements

as specified in EN 60204-1, 5.3.2.

WARNING

Electric shock

Death or serious personal injury

- Make sure that other pumps or sources do not

force flow through the pump even if the pump is

stopped.

If the power cable is damaged, it must be replaced

by the manufacturer, the manufacturer's service

partner or a similarly qualified person.

9.3 Reading out warning and alarm codes in Grundfos GO Remote

To read out alarm codes and text, connect the pump to Grundfos

GO Remote and navigate to the "Alarms and warnings" menu.

Grundfos Eye in the dashboard indicates the warning or alarm.

Step Action Illustration

A. Select the

"Alarms and

warnings" menu

from the

dashboard,

1

B. You can also

reach the menu by

tapping Grundfos

Eye.

The "Alarms and

warnings" menu

shows the current

alarm code and

text. A log history

of previous alarms

and warnings is

also available.

2

When the fault is

corrected, reset

the alarm by

pressing the

"Reset alarm"

button.

When connecting Grundfos GO to one of the pumps

of a twin-head pump, Grundfos GO reads out alarm

codes and texts for that pump. If you want to see

alarms and warnings for the other pump, connect to

this instead.

An overview of warnings and alarms is also available in section

9.4 Fault finding table.

For instructions on how to connect the pump to Grundfos GO, see

section 8.3 Connecting the pump to Grundfos GO Remote.

English (GB)

Dashboard_With_Alarm

Alarm_Warning

29

9.4 Fault finding table

English (GB)

Warning and alarm

codes

"Pump communication

fault" (10)

Alarm

"Forced pumping" (29)

Alarm

"Undervoltage" (40, 75)

Alarm

"Blocked pump" (51)

Alarm

High motor temperature

(64)

Alarm

Internal fault (72 and

155)

Alarm

"Overvoltage" (74)

Alarm

Comm. fault, twin-head

pump (77)

Warning

Internal fault (84 and

85)

Warning

Fault

Communication fault between

different parts of the

electronics.

Other pumps or sources force

flow through the pump even if

the pump is stopped and

switched off.

The supply voltage to the

pump is too low.

The pump is blocked. Yes

The temperature in the stator

windings is too high.

Internal fault in the pump

electronics.

Irregularities in the voltage

supply can cause alarm 72.

The supply voltage to the

pump is too high.

The communication between

pump heads was disturbed or

broken.

Fault in the pump electronics. - Contact Grundfos Service, or replace the pump.

Automatic reset

and restart?

Yes

Yes

Yes

No Contact Grundfos Service, or replace the pump.

Yes

Yes

-

Corrective actions

Replace the pump, or contact Grundfos Service.

Check if the pump is running in turbine operation. See code

(29) "Forced pumping".

Switch off the pump on the main switch. If the light in

Grundfos Eye is on, the pump is running in forced-pumping

mode.

Check the system for defective non-return valves and

replace the valves, if necessary.

Check the system for correct position of non-return valves.

Make sure that the power supply is within the specified

range.

Dismantle the pump, and remove any foreign matter or

impurities preventing the pump from rotating. Check the

water quality to eliminate the risk of lime precipitation.

There might be turbine flow in the application that forces a

flow through the pump.

Contact Grundfos Service, or replace the pump.

Make sure that the power supply is within the specified

range.

Make sure that the second pump head is powered on or

connected to the power supply.

30

9.5 Warning 77, twin-head pump

A yellow Grundfos Eye in a twin-head pump system often means

that the two heads have lost connection to each other, warning

77. This is often intermittent and caused by external disturbance,

or because one of the heads has lost power.

The warning is shown immediately and triggers the fault relay

after one hour. If communication is re-established, the warning is

automatically reset.

9.5.1 Activating and deactivating the fault relay

It is possible to choose whether warning 77 should trigger the

fault relay or not. This is done in Grundfos GO. For instructions

on how to connect the pump to Grundfos GO, see section

8.3 Connecting the pump to Grundfos GO Remote.

Step Action Illustration

Choose

"Settings" in the

Grundfos GO

1

Remote

dashboard.

Step Action Illustration

By default the

fault relay

setting is

activated.

To disable the

3

setting, choose

"Do not activate

relay".

Press "OK".

English (GB)

MAGNA1_warning77

Choose

2

"Warning 77

relay settings".

TM06 8584 0817

TM06 8583 0817

31

10. Technical data

English (GB)

Supply voltage

1 x 230 V ± 10 %, 50/60 Hz, PE.

Motor protection

The pump requires no external motor protection.

Enclosure class

IPX4D (EN 60529).

Insulation class

F.

Relative humidity

Maximum 95 %.

Ambient temperature

0 to 40 °C.

During transport: -40 to +70 °C.

Temperature class

TF110 (EN 60335-2-51).

Liquid temperature

Continuously: -10 to +110 °C.

Stainless steel pumps in domestic hot-water systems:

In domestic hot-water systems, we recommend that you keep the

liquid temperature below 65 °C to eliminate the risk of lime

precipitation.

Maximum system pressure

The actual inlet pressure and the pump pressure

against a closed valve must be lower than the

maximum permissible system pressure.

The maximum permissible system pressure is stated on the pump

nameplate:

PN 6: 6 bar or 0.6 MPa

PN 10: 10 bar or 1.0 MPa

PN 16: 16 bar or 1.6 MPa.

Test pressure

The pumps can withstand test pressures as indicated in EN

60335-2-51.

• PN 6: 7.2 bar

• PN 10: 12 bar

• PN 6/10: 12 bar

• PN 16: 19.2 bar.

During normal operation, do not use the pump at higher

pressures than those stated on the nameplate. See fig. 20.

The pressure test has been made with water containing

anti-corrosive additives at a temperature of 20 °C.

Minimum inlet pressure

The following relative minimum inlet pressure must be available

at the pump inlet during operation to avoid cavitation noise and

damage to the pump bearings.

The values in the table below apply to single-head

pumps and twin-head pumps in single-head

operation.

Liquid temperature

Single-head pumps

DN

25-40/60/80/100/120 0.10 / 0.01 0.35 / 0.035 1.0 / 0.10

32-40/60/80/100/120 0.10 / 0.01 0.35 / 0.035 1.0 / 0.10

32-120 F 0.10 / 0.01 0.20 / 0.020 0.7 / 0.07

40-40/60 F 0.10 / 0.01 0.35 / 0.035 1.0 / 0.10

40-80/100/120/150/180 F 0.10 / 0.01 0.50 / 0.05 1.0 / 0.10

50-60/80 F 0.10 / 0.01 0.40 / 0.04 1.0 / 0.10

50-100/120 F 0.10 / 0.01 0.50 / 0.05 1.0 / 0.10

50-150/180 F 0.70 / 0.07 1.20 / 0.12 1.7 / 0.17

65-40/60/80/100/120/150 F 0.70 / 0.07 1.20 / 0.12 1.7 / 0.17

80-60/80/100/120 F 0.50 / 0.05 1.00 / 0.10 1.5 / 0.15

100-40/60/80/100/120 F 0.70 / 0.07 1.20 / 0.12 1.7 / 0.17

In the case of twin-head operation, increase the required relative

inlet pressure by 0.1 bar or 0.01 MPa compared to the stated

values for single-head pumps or twin-head pumps in single-head

operation.

The relative minimum inlet pressures apply to pumps installed up

to 300 metres above sea level. For altitudes above 300 metres,

increase the required relative inlet pressure by 0.01 bar or 0.001

MPa per 100 metres altitude. The pump is only approved for an

altitude of maximum 2000 metres above sea level.

Sound pressure level

The sound pressure level of the pump is dependent on the power

consumption. Levels are determined in accordance with ISO

3745 and ISO 11203, method Q2.

Pump size Max. dB(A)

25-40/60/80/100/120

32-40/60/80/100/120

40-40/60

50-40

32-120 F

40-80/100

50-60/80

65-40/60

80-40

40-120/150/180

50-100/120/150/180

65-80/100/120

80-60/80

100-40/60

65-150

80-100/120

100-80/100/120

Leakage current

The mains filter will cause a leakage current to earth during

operation. The leakage current is less than 3.5 mA.

Power factor

The terminal-connected versions have a built-in active

power-factor correction which gives a cos φ from 0.98 to 0.99.

The plug-connected versions have a built-in passive power-factor

correction with coil and resistors which ensure that the current

drawn from the grid is in phase with the voltage and that the

current is approximately sinusoidal which gives a cos φ from 0.55

to 0.98.

75 °C 95 °C 110 °C

Inlet pressure

[bar] / [MPa]

39

45

50

55

32

11. Disposing of the product

This product has been designed with focus on the disposal and

recycling of materials. The following average disposal values

apply to all variants of MAGNA1 pumps:

• 85 % recycling

• 10 % incineration

• 5 % depositing.

Dispose of this product or parts of it in an environmentally sound

way according to local regulations.

See also end-of-life information on

www.grundfos.com/product-recycling.

WARNING

Magnetic field

Death or serious personal injury

- Persons with pacemakers disassembling this

product must exercise care when handling the

magnetic materials embedded in the rotor.

English (GB)

33

Appendix

D1

G

L6

L1

B6

B4

L5

B7

B2

H3

H2

B1

H1

H4

B1

G

D1

L5

B3 H3

H1

L1

L7

B5 B4H2

M3

Appendix 1

1. Dimensions, threaded versions

Fig. 1 Single-head pump dimensions, threaded version

TM06 9948 3717

Pump type

Dimensions [mm] [inch]

L1 L5 L6 B1 B2 B4 B6 B7 H1 H2 H3 H4 D1 G

MAGNA1 25-40 (N) 180 158 190 58 111 69 90 113 54 142 196 71 25 1 1/2

MAGNA1 25-60 (N) 180 158 190 58 111 69 90 113 54 142 196 71 25 1 1/2

MAGNA1 25-80 (N) 180 158 190 58 111 69 90 113 54 142 196 71 25 1 1/2

MAGNA1 25-100 (N) 180 158 190 58 111 69 90 113 54 142 196 71 25 1 1/2

MAGNA1 25-120 (N) 180 158 190 58 111 69 90 113 54 142 196 71 25 1 1/2

MAGNA1 32-40 (N) 180 158 190 58 111 69 90 113 54 142 196 71 32 2

MAGNA1 32-60 (N) 180 158 190 58 111 69 90 113 54 142 196 71 32 2

MAGNA1 32-80 (N) 180 158 190 58 111 69 90 113 54 142 196 71 32 2

MAGNA1 32-100 (N) 180 158 190 58 111 69 90 113 54 142 196 71 32 2

MAGNA1 32-120 (N) 180 158 190 58 111 69 90 113 54 142 196 71 32 2

Fig. 2 Twin-head pump dimensions, threaded version

34

TM07 0068 4117

2. Dimensions, flanged versions

D4

D2

D1

B1

H1 H2

H3

H4B4

B6 B7

L5

L6

L1

B2

D5

D3

D3

Pump type

Dimensions [mm] [inch]

L1 L5 L7 B1 B3 B4 B5 H1 H2 H3 D1 G M3

MAGNA1 D 32-40 180 158 35 58 400 179 221 54 142 196 32 2 1/4

MAGNA1 D 32-60 180 158 35 58 400 179 221 54 142 196 32 2 1/4

MAGNA1 D 32-80 180 158 35 58 400 179 221 54 142 196 32 2 1/4

MAGNA1 D 32-100 180 158 35 58 400 179 221 54 142 196 32 2 1/4

Fig. 3 Single-head pump dimensions, plug-connected versions, flanged version

Appendix

TM07 0067 4117

Pump type

Dimensions [mm]

L1 L5 L6 B1 B2 B4 B6 B7 H1 H2 H3 H4 D1 D2 D3 D4 D5

MAGNA1 32-40 F (N) 220 158 220 58 111 69 100 110 65 142 207 82 32 76 90/100 140 14/19

MAGNA1 32-60 F (N) 220 158 220 58 111 69 100 110 65 142 207 82 32 76 90/100 140 14/19

MAGNA1 32-80 F (N) 220 158 220 58 111 69 100 110 65 142 207 82 32 76 90/100 140 14/19

MAGNA1 32-100 F (N) 220 158 220 58 111 69 100 110 65 142 207 82 32 76 90/100 140 14/19

MAGNA1 40-40 F (N) 220 158 220 58 111 69 105 105 65 156 221 83 40 84 100/110 150 14/19

MAGNA1 40-60 F (N) 220 158 220 58 111 69 105 105 65 156 221 83 40 84 100/110 150 14/19

35

Appendix

B2

L5

L1

L6

B4

B6 B7

H4

H1

B1

H2

H3

D4

D2

D3

D5

D1

PN 6

PN 10/16

Fig. 4 Single-head pump dimensions, terminal-connected versions, flanged version

TM05 5276 3512

Pump type

Dimensions [mm]

L1 L5 L6 B1 B2 B4 B6 B7 H1 H2 H3 H4 D1 D2 D3 D4 D5

MAGNA1 32-120 F (N) 220 204 216 84 164 73 106 116 65 301 366 86 32 76 90/100 140 14/19

MAGNA1 40-80 F (N) 220 204 220 84 164 73 106 128 65 304 369 83 40 84 100/110 150 14/19

MAGNA1 40-100 F (N) 220 204 220 84 164 73 106 128 65 304 369 83 40 84 100/110 150 14/19

MAGNA1 40-120 F (N) 250 204 220 84 164 73 106 128 65 304 369 83 40 84 100/110 150 14/19

MAGNA1 40-150 F (N) 250 204 220 84 164 73 106 128 65 304 369 83 40 84 100/110 150 14/19

MAGNA1 40-180 F (N) 250 204 220 84 164 73 106 128 65 304 369 83 40 84 100/110 150 14/19

MAGNA1 50-60 F (N) 240 204 240 84 164 73 127 127 71 304 374 97 50 102 110/125 165 14/19

MAGNA1 50-80 F (N) 240 204 240 84 164 73 127 127 71 304 374 97 50 102 110/125 165 14/19

MAGNA1 50-100 F (N) 280 204 240 84 164 73 127 127 72 304 376 97 50 102 110/125 165 14/19

MAGNA1 50-120 F (N) 280 204 240 84 164 73 127 127 72 304 376 97 50 102 110/125 165 14/19

MAGNA1 50-150 F (N) 280 204 240 84 164 73 127 127 72 304 376 97 50 102 110/125 165 14/19

MAGNA1 50-180 F (N) 280 204 240 84 164 73 127 127 72 304 376 97 50 102 110/125 165 14/19

MAGNA1 65-40 F (N) 340 204 296 84 164 73 133 133 74 312 386 94 65 119 130/145 185 14/19

MAGNA1 65-60 F (N) 340 204 296 84 164 73 133 133 74 312 386 94 65 119 130/145 185 14/19

MAGNA1 65-80 F (N) 340 204 296 84 164 73 133 133 74 312 386 94 65 119 130/145 185 14/19

MAGNA1 65-100 F (N) 340 204 296 84 164 73 133 133 74 312 386 94 65 119 130/145 185 14/19

MAGNA1 65-120 F (N) 340 204 296 84 164 73 133 133 74 312 386 94 65 119 130/145 185 14/19

MAGNA1 65-150 F (N) 340 204 296 84 164 73 133 133 74 312 386 94 65 119 130/145 185 14/19

MAGNA1 80-60 F 360 204 310 84 164 73 163 163 96 318 413 115 80 128 150/160 200 19

MAGNA1 80-80 F 360 204 310 84 164 73 163 163 96 318 413 115 80 128 150/160 200 19

MAGNA1 80-100 F 360 204 310 84 164 73 163 163 96 318 413 115 80 128 150/160 200 19

MAGNA1 80-120 F 360 204 310 84 164 73 163 163 96 318 413 115 80 128 150/160 200 19

MAGNA1 100-40 F 450 204 396 84 164 73 178 178 103 330 433 120 100 160 170 220 19

MAGNA1 100-60 F 450 204 396 84 164 73 178 178 103 330 433 120 100 160 170 220 19

MAGNA1 100-80 F 450 204 396 84 164 73 178 178 103 330 433 120 100 160 170 220 19

MAGNA1 100-100 F 450 204 396 84 164 73 178 178 103 330 433 120 100 160 170 220 19

MAGNA1 100-120 F 450 204 396 84 164 73 178 178 103 330 433 120 100 160 170 220 19

36

Fig. 5 Twin-head pump dimensions, plug-connected versions, flanged version

L5

H3

L1

B6 B6

B7

D2

D4

D5

D3

D3

M3

M

L4

L2L3

B3 H1 B5 B4H2

B1

D1

L7

D4

Appendix

TM07 0069 4117

Pump type

MAGNA1 D

32-40 F

MAGNA1 D

32-60 F

MAGNA1 D

32-80 F

MAGNA1 D

40-40 F

MAGNA1 D

40-60 F

MAGNA1 D

40-80 F

Dimensions [mm]

L1 L2 L3 L4 L5 L7 B1 B3 B4 B5 B6 B7 H1 H2 H3 D1 D2 D3 D4 D5 M

220 73 120 85 158 35 58 400 179 221 130 260 69 142 211 32 76 90/100 140 14/19 12

220 73 120 85 158 35 58 400 179 221 130 260 69 142 211 32 76 90/100 140 14/19 12

220 73 120 85 158 35 58 400 179 221 130 260 69 142 211 32 76 90/100 140 14/19 12

220 53 140 60 158 15 58 452 211 241 130 260 76 156 232 40 84 100/110 150 14/19 12

220 53 140 60 158 15 58 452 211 241 130 260 76 156 232 40 84 100/110 150 14/19 12

220 53 140 60 204 15 84 502 210 294 130 260 76 303 379 40 84 100/110 150 14/19 12

37

Appendix

Fig. 6 Twin-head pump dimensions, terminal-connected versions, flanged version

TM05 5275 3512

Pump type

MAGNA1 D

32-120 F

MAGNA1 D

40-80 F

MAGNA1 D

40-100 F

MAGNA1 D

40-120 F

MAGNA1 D

40-150 F

MAGNA1 D

40-180 F

MAGNA1 D

50-40 F

MAGNA1 D

50-60 F

MAGNA1 D

50-80 F

MAGNA1 D

50-100 F

MAGNA1 D

50-120 F

MAGNA1 D

50-150 F

MAGNA1 D

50-180 F

MAGNA1 D

65-40 F

MAGNA1 D

65-60 F

MAGNA1 D

65-80 F

MAGNA1 D

65-100 F

MAGNA1 D

65-120 F

MAGNA1 D

65-150 F

MAGNA1 D

80-40 F

MAGNA1 D

80-60 F

MAGNA1 D

80-80 F

Dimensions [mm]

L1 L2 L3 L4 L5 L7 B1 B3 B4 B5 B6 B7 H1 H2 H3 D1 D2 D3 D4 D5 M

220 97 90 50 204 50 84 502 210 294 130 260 68 300 368 32 76 90/100 140 14/19 12

220 53 140 60 204 15 84 502 210 294 130 260 76 303 379 40 84 100/110 150 14/19 12

220 53 140 60 204 15 84 502 210 294 130 260 76 303 379 40 84 100/110 150 14/19 12

250 58 155 75 204 0 84 512 220 294 130 260 69 303 372 40 84 100/110 150 14/19 12

250 58 155 75 204 0 84 512 220 294 130 260 69 303 372 40 84 100/110 150 14/19 12

250 58 155 75 204 0 84 512 220 294 130 260 69 303 372 40 84 100/110 150 14/19 12

240 48 160 45 204 45 84 515 221 294 130 260 75 304 379 50 102 110/125 165 14/19 12

240 48 160 45 204 45 84 515 221 294 130 260 75 304 379 50 102 110/125 165 14/19 12

240 48 160 45 204 45 84 515 221 294 130 260 75 304 379 50 102 110/125 165 14/19 12

280 175 75 75 204 0 84 517 223 294 130 260 75 304 379 50 102 110/125 165 14/19 12

280 175 75 75 204 0 84 517 223 294 130 260 75 304 379 50 102 110/125 165 14/19 12

280 175 75 75 204 0 84 517 223 294 130 260 75 304 379 50 102 110/125 165 14/19 12

280 175 75 75 204 0 84 517 223 294 130 260 75 304 379 50 102 110/125 165 14/19 12