Grundfos MAGNA1 25-60, MAGNA1 25-100, MAGNA1 32-40, MAGNA1 25-120, MAGNA1 32-60 Installation And Operating Instructions Manual

...Page 1

MAGNA1

Installation and operating instructions

GRUNDFOS INSTRUCTIONS

Page 2

Declaration of conformity

Declaration of conformity

GB: EC declaration of conformity

We, Grundfos, declare under our sole responsibility that the products

MAGNA1, to which this declaration relates, are in conformity with these

Council directives on the approximation of the laws of the EC member

states:

— Machinery Directive (2006/42/EC).

Standard used: EN 809:1998.

— Low Voltage Directive (2006/95/EC).

Standards used: EN 60335-2-51:2003 and

EN 60950-1:2006/A12:2011.

— EMC Directive (2004/108/EC).

Standards used: EN 55014-1:2006, EN 55014-2:1998,

EN 61800-3-3:2008 and EN 61000-3-2:2006.

— Ecodesign Directive (2009/125/EC).

Circulators:

Commission Regulation Nos 641/2009 and 622/2012.

Applies only to circulators marked with the energy efficiency index

EEI. See the pump nameplate.

Standards used: EN 16297-1:2012 and EN 16297-2:2012.

This EC declaration of conformity is only valid when published as part of

the Grundfos installation and operating instructions (publication number

98091804 0113).

CZ: ES prohlášení o shodě

My firma Grundfos prohlašujeme na svou plnou odpovědnost, že výrobky

MAGNA1, na něž se toto prohlášení vztahuje, jsou v souladu s

ustanoveními směrnice Rady pro sblížení právních předpisů členských

států Evropského společenství v oblastech:

—Směrnice pro strojní zařízení (2006/42/ES).

Použitá norma: EN 809:1998.

—Směrnice pro nízkonapět’ové aplikace (2006/95/ES).

Použité normy: EN 60335-2-51:2003 a EN 60950-1:2006/A12:2011.

—Směrnice pro elektromagnetickou kompatibilitu (EMC)

(2004/108/ES).

Použité normy: EN 55014-1:2006, EN 55014-2:1998,

EN 61800-3-3:2008 a EN 61000-3-2:2006.

—Směrnice o požadavcích na ekodesign (2009/125/ES).

Oběhová čerpadla:

Nařízení Komise č. 641/2009 a 622/2012.

Platí pouze pro oběhová čerpadla s vyznačeným indexem

energetické účinnosti EEI. Viz typový štítek čerpadla.

Použité normy: EN 16297-1:2012 a EN 16297-2:2012.

Toto ES prohlášení o shodě je platné pouze tehdy, pokud je zveřejněno

jako součást instalačních a provozních návodů Grundfos (publikace číslo

98091804 0113).

DE: EG-Konformitätserklärung

Wir, Grundfos, erklären in alleiniger Verantwortung, dass die Produkte

MAGNA1, auf die sich diese Erklärung bezieht, mit den folgenden

Richtlinien des Rates zur Angleichung der Rechtsvorschriften der

EU-Mitgliedsstaaten übereinstimmen:

— Maschinenrichtlinie (2006/42/EG).

Norm, die verwendet wurde: EN 809:1998.

— Niederspannungsrichtlinie (2006/95/EG).

Normen, die verwendet wurden: EN 60335-2-51:2003 und

EN 60950-1:2006/A12:2011.

— EMV-Richtlinie (2004/108/EG).

Normen, die verwendet wurden: EN 55014-1:2006,

EN 55014-2:1998, EN 61800-3-3:2008 und EN 61000-3-2:2006.

— Ökodesign-Richtlinie (2009/125/EG).

Umwälzpumpen:

Verordnung der EU-Kommission Nr. 641/2009 und 622/2012.

Gilt nur für Umwälzpumpen, bei denen das Kennzeichen EEI auf

dem Typenschild aufgeführt ist. EEI steht für Energieeffizienzindex.

Normen, die verwendet wurden: EN 16297-1:2012 und

EN 16297-2:2012.

Diese EG-Konformitätserklärung gilt nur, wenn sie in Verbindung mit der

Grundfos Montage- und Betriebsanleitung (Veröffentlichungsnummer

98091804 0113) veröffentlicht wird.

BG: EC декларация за съответствие

Ние, фирма Grundfos, заявяваме с пълна отговорност, че продуктите

MAGNA1, за които се отнася настоящата декларация, отговарят на

следните указания на Съвета за уеднаквяване на правните

разпоредби на държавите членки на ЕС:

— Директива за машините (2006/42/EC).

Приложен стандарт: EN 809:1998.

— Директива за нисковолтови системи (2006/95/EC).

Приложени стандарти: EN 60335-2-51:2003 и

EN 60950-1:2006/A12:2011.

— Директива за електромагнитна съвместимост (2004/108/EC).

Приложени стандарти: EN 55014-1:2006, EN 55014-2:1998,

EN 61800-3-3:2008 и EN 61000-3-2:2006.

— Директива за екодизайн (2009/125/EC).

Циркулатори:

Наредба No 641/2009 и 622/2012 на Европейската комисия.

Прилага се само за циркулатори, маркирани с индекс за

енергийна ефективност EEI. Вижте табелата с данни на

помпата.

Приложени стандарти: EN 16297-1:2012 и EN 16297-2:2012.

Тази ЕС декларация за съответствие е валидна само когато е

публикувана като част от инструкциите за монтаж и експлоатация на

Grundfos (номер на публикацията 98091804 0113).

DK: EF-overensstemmelseserklæring

Vi, Grundfos, erklærer under ansvar at produkterne MAGNA1 som denne

erklæring omhandler, er i overensstemmelse med disse af Rådets

direktiver om indbyrdes tilnærmelse til EF-medlemsstaternes lovgivning:

— Maskindirektivet (2006/42/EF).

Anvendt standard: EN 809:1998.

— Lavspændingsdirektivet (2006/95/EF).

Anvendte standarder: EN 60335-2-51:2003 og

EN 60950-1:2006/A12:2011.

— EMC-direktivet (2004/108/EF).

Anvendte standarder: EN 55014-1:2006, EN 55014-2:1998,

EN 61800-3-3:2008 og EN 61000-3-2:2006.

— Ecodesigndirektivet (2009/125/EF).

Cirkulationspumper:

Kommissionens forordning nr. 641/2009 og 622/2012.

Gælder kun cirkulationspumper der er mærket med

energieffektivitetsindeks EEI. Se pumpens typeskilt.

Anvendte standarder: EN 16297-1:2012 og EN 16297-2:2012.

Denne EF-overensstemmelseserklæring er kun gyldig når den publiceres

som en del af Grundfos-monterings- og driftsinstruktionen (publikationsnummer 98091804 0113).

EE: EL vastavusdeklaratsioon

Meie, Grundfos, deklareerime enda ainuvastutusel, et tooted MAGNA1,

mille kohta käesolev juhend käib, on vastavuses EÜ Nõukogu

direktiividega EMÜ liikmesriikide seaduste ühitamise kohta, mis

käsitlevad:

— Masinate ohutus (2006/42/EC).

Kasutatud standard: EN 809:1998.

— Madalpinge direktiiv (2006/95/EC).

Kasutatud standardid: EN 60335-2-51:2003 ja

EN 60950-1:2006/A12:2011.

— Elektromagnetiline ühilduvus (EMC direktiiv) (2004/108/EC).

Kasutatud standardid: EN 55014-1:2006, EN 55014-2:1998,

EN 61800-3-3:2008 ja EN 61000-3-2:2006.

— Ökodisaini direktiiv (2009/125/EC).

Ringluspumbad:

Komisjoni määrus nr 641/2009 ja 622/2012.

Rakendub ainult ringluspumpadele, mis on tähistatud

energiatõhususe märgistusega EEI. Vt pumba andmeplaati.

Kasutatud standardid: EN 16297-1:2012 ja EN 16297-2:2012.

Käesolev EL-i vastavusdeklaratsioon kehtib ainult siis, kui see

avaldatakse Grundfosi paigaldus- ja kasutusjuhendi (avaldamisnumber

98091804 0113) osana.

2

Page 3

GR: ∆ήλωση συμμόρφωσης EC

Εμείς, η Grundfos, δηλώνουμε με αποκλειστικά δική μας ευθύνη ότι

τα προϊόντα MAGNA1 στα οποία αναφέρεται η παρούσα δήλωση,

συμμορφώνονται με τις εξής Οδηγίες του Συμβουλίου περί προσέγγισης

των νομοθεσιών των κρατών μελών της ΕΕ:

— Οδηγία για μηχανήματα (2006/42/EC).

Πρότυπο που χρησιμοποιήθηκε: EN 809:1998.

— Οδηγία χαμηλής τάσης (2006/95/EC).

Πρότυπα που χρησιμοποιήθηκαν: EN 60335-2-51:2003 και

EN 60950-1:2006/A12:2011.

— Οδηγία Ηλεκτρομαγνητικής Συμβατότητας (EMC) (2004/108/EC).

— Οδηγία Οικολογικού Σχεδιασμού (2009/125/ΕC).

Αυτή η δήλωση συμμόρφωσης EC ισχύει μόνον όταν συνοδεύει τις

οδηγίες εγκατάστασης και λειτουργίας της Grundfos (κωδικός εντύπου

98091804 0113).

που χρησιμοποιήθηκαν: EN 55014-1:2006,

Πρότυπα

EN 55014-2:1998, EN 61800-3-3:2008 και EN 61000-3-2:2006.

Κυκλοφορητές:

Κανονισμός Αρ. 641/2009 και 622/2012 της Επιτροπής.

Ισχύει μόνο για κυκλοφορητές που φέρουν τον δείκτη ενεργειακής

απόδοσης EEI. Βλέπε πινακίδα κυκλοφορητή.

Πρότυπα που χρησιμοποιήθηκαν: EN 16297-1:2012 και

EN 16297-2:2012.

FR: Déclaration de conformité CE

Nous, Grundfos, déclarons sous notre seule responsabilité, que

les produits MAGNA1, auxquels se réfère cette déclaration, sont

conformes aux Directives du Conseil concernant le rapprochement des

législations des Etats membres CE relatives aux normes énoncées

ci-dessous:

— Directive Machines (2006/42/CE).

Norme utilisée: EN 809:1998.

— Directive Basse Tension (2006/95/CE).

Normes utilisées: EN 60335-2-51:2003 et

EN 60950-1:2006/A12:2011.

— Directive Compatibilité Electromagnétique CEM (2004/108/CE).

Normes utilisées: EN 55014-1:2006, EN 55014-2:1998,

EN 61800-3-3:2008 et EN 61000-3-2:2006.

— Directive sur l'éco-conception (2009/125/CE).

Circulateurs:

Règlement de la Commission Nº 641/2009 et 622/2012.

S'applique uniquement aux circulateurs marqués de l'indice de

performance énergétique EEI. Voir plaque signalétique du

circulateur.

Normes utilisées: EN 16297-1:2012 et EN 16297-2:2012.

Cette déclaration de conformité CE est uniquement valide lors de sa

publication dans la notice d'installation et de fonctionnement Grundfos

(numéro de publication 98091804 0113).

IT: Dichiarazione di conformità CE

Grundfos dichiara sotto la sua esclusiva responsabilità che i prodotti

MAGNA1, ai quali si riferisce questa dichiarazione, sono conformi alle

seguenti direttive del Consiglio riguardanti il riavvicinamento delle

legislazioni degli Stati membri CE:

— Direttiva Macchine (2006/42/CE).

Norma applicata: EN 809:1998.

— Direttiva Bassa Tensione (2006/95/CE).

Norme applicate: EN 60335-2-51:2003 e

EN 60950-1:2006/A12:2011.

— Direttiva EMC (2004/108/CE).

Norme applicate: EN 55014-1:2006, EN 55014-2:1998,

EN 61800-3-3:2008 e EN 61000-3-2:2006.

— Direttiva Ecodesign (2009/125/CE).

Circolatori:

Regolamento della Commissione N. 641/2009 e 622/2012.

Applicabile solo ai circolatori dotati di indice di efficienza EEI. Vedi la

targhetta identificativa del circolatore.

Norme applicate: EN 16297-1:2012 e EN 16297-2:2012.

Questa dichiarazione di conformità CE è valida solo quando pubblicata

come parte delle istruzioni di installazione e funzionamento Grundfos

(pubblicazione numero 98091804 0113).

ES: Declaración CE de conformidad

Nosotros, Grundfos, declaramos bajo nuestra entera responsabilidad

que los productos MAGNA1, a los cuales se refiere esta declaración,

están conformes con las Directivas del Consejo en la aproximación de

las leyes de las Estados Miembros del EM:

— Directiva de Maquinaria (2006/42/CE).

Norma aplicada: EN 809:1998.

— Directiva de Baja Tensión (2006/95/CE).

Normas aplicadas: EN 60335-2-51:2003 y

EN 60950-1:2006/A12:2011.

— Directiva EMC (2004/108/CE).

Normas aplicadas: EN 55014-1:2006, EN 55014-2:1998,

EN 61800-3-3:2008 y EN 61000-3-2:2006.

— Directiva sobre diseño ecológico (2009/125/CE).

Bombas circuladoras:

Reglamento de la Comisión nº 641/2009 y 622/2012.

Aplicable únicamente a las bombas circuladoras marcadas con

el índice de eficiencia energética IEE. Véase la placa de

características.

Normas aplicadas: EN 16297-1:2012 y EN 16297-2:2012.

Esta declaración CE de conformidad sólo es válida cuando se publique

como parte de las instrucciones de instalación y funcionamiento de

Grundfos (número de publicación 98091804 0113).

HR: EZ izjava o usklađenosti

Mi, Grundfos, izjavljujemo pod vlastitom odgovornošću da je proizvod

MAGNA1, na koji se ova izjava odnosi, u skladu s direktivama ovog

Vijeća o usklađivanju zakona država članica EU:

— Direktiva za strojeve (2006/42/EZ).

Korištena norma: EN 809:1998.

— Direktiva za niski napon (2006/95/EZ).

Korištene norme: EN 60335-2-51:2003 i

EN 60950-1:2006/A12:2011.

— Direktiva za elektromagnetsku kompatibilnost (2004/108/EZ).

Korištene norme: EN 55014-1:2006, EN 55014-2:1998,

EN 61800-3-3:2008 i EN 61000-3-2:2006.

— Direktiva o ekološkoj izvedbi (2009/125/EZ).

Optočne crpke:

Regulativa komisije br. 641/2009 i 622/2012.

Odnosi se samo na optočne crpke označene indeksom energetske

učinkovitosti EEI. Pogledajte natpisnu pločicu crpke.

Korištene norme: EN 16297-1:2012 i EN 16297-2:2012.

Ova EZ izjava o usklađnosti važeća je jedino kada je izdana kao dio

Grundfos montažnih i pogonskih uputa (broj izdanja 98091804 0113).

LV: EK pa z i ņojums par atbilstību prasībām

Sabiedrība GRUNDFOS ar pilnu atbildību dara zināmu, ka produkti

MAGNA1, uz kuriem attiecas šis paziņojums, atbilst šādām Padomes

direktīvām par tuvināšanos EK dalībvalstu likumdošanas normām:

—Mašīnbūves direktīva (2006/42/EK).

Piemērotais standarts: EN 809:1998.

— Zema sprieguma direktīva (2006/95/EK).

Piemērotie standarti: EN 60335-2-51:2003 un

EN 60950-1:2006/A12:2011.

— Elektromagnētiskās saderības direktīva (2004/108/EK).

Piemērotie standarti: EN 55014-1:2006, EN 55014-2:1998,

EN 61800-3-3:2008 un EN 61000-3-2:2006.

— Ekodizaina direktīva (2009/125/EK).

Cirkulācijas sūkņi:

Komisijas Regula Nr. 641/2009 un 622/2012.

Attiecas tikai uz tādiem cirkulācijas sūkņiem, kuriem ir

energoefektivitātes indeksa EEI marķējums. Sk. sūkņa pases datu

plāksnītē.

Piemērotie standarti: EN 16297-1:2012 un EN 16297-2:2012.

Šī EK atbilstības deklarācija ir derī

no GRUNDFOS uzstādīšanas un ekspluatācijas instrukcijām

(publikācijas numurs 98091804 0113).

ga vienīgi tad, ja ir publicēta kā daļa

Declaration of conformity

3

Page 4

Declaration of conformity

LT: EB atitikties deklaracija

Mes, Grundfos, su visa atsakomybe pareiškiame, kad gaminiai MAGNA1,

kuriems skirta ši deklaracija, atitinka šias Tarybos Direktyvas dėl Europos

Ekonominės Bendrijos šalių narių įstatymų suderinimo:

—Mašinų direktyva (2006/42/EB).

Taikomas standartas: EN 809:1998.

—Žemų įtampų direktyva (2006/95/EB).

Taikomi standartai: EN 60335-2-51:2003 ir

EN 60950-1:2006/A12:2011.

— EMS direktyva (2004/108/EB).

Taikomi standartai: EN 55014-1:2006, EN 55014-2:1998,

EN 61800-3-3:2008 ir EN 61000-3-2:2006.

— Ekologinio projektavimo direktyva (2009/125/EB).

Cirkuliaciniai siurbliai:

Komisijos reglamentas Nr. 641/2009 ir 622/2012.

Galioja tik cirkuliaciniams siurbliams, pažymėtiems energijos

efektyvumo indeksu EEI. Žr. siurblio vardinę plokštelę.

Taikomi standartai: EN 16297-1:2012 ir EN 16297-2:2012.

Ši EB atitikties deklaracija galioja tik tuo atveju, kai yra pateikta kaip

"Grundfos" įrengimo ir naudojimo instrukcijos (leidinio numeris 98091804

0113) dalis.

NL: EC overeenkomstigheidsverklaring

Wij, Grundfos, verklaren geheel onder eigen verantwoordelijkheid dat de

producten MAGNA1 waarop deze verklaring betrekking heeft,

in overeenstemming zijn met de Richtlijnen van de Raad in zake de

onderlinge aanpassing van de wetgeving van de EG Lidstaten

betreffende:

— Machine Richtlijn (2006/42/EC).

Gebruikte norm: EN 809:1998.

— Laagspannings Richtlijn (2006/95/EC).

Gebruikte normen: EN 60335-2-51:2003 en

EN 60950-1:2006/A12:2011.

— EMC Richtlijn (2004/108/EC).

Gebruikte normen: EN 55014-1:2006, EN 55014-2:1998,

EN 61800-3-3:2008 en EN 61000-3-2:2006.

— Ecodesign Richtlijn (2009/125/EC).

Circulatiepompen:

Verordening van de Commissie nr. 641/2009 en 622/2012.

Alleen van toepassing op circulatiepompen gemarkeerd met de

energie efficiëntie index EEI. Zie het typeplaatje van de pomp.

Gebruikte normen: EN 16297-1:2012 en EN 16297-2:2012.

Deze EC overeenkomstigheidsverklaring is alleen geldig wanneer deze

gepubliceerd is als onderdeel van de Grundfos installatie- en

bedieningsinstructies (publicatienummer 98091804 0113).

PL: Deklaracja zgodności WE

My, Grundfos, oświadczamy z pełną odpowiedzialnością, że nasze

wyroby MAGNA1, których deklaracja niniejsza dotyczy, są zgodne

z następującymi wytycznymi Rady d/s ujednolicenia przepisów prawnych

krajów członkowskich WE:

— Dyrektywa Maszynowa (2006/42/WE).

Zastosowana norma: EN 809:1998.

— Dyrektywa Niskonapięciowa (LVD) (2006/95/WE).

Zastosowane normy: EN 60335-2-51:2003 oraz

EN 60950-1:2006/A12:2011.

— Dyrektywa EMC (2004/108/WE).

Zastosowane normy: EN 55014-1:2006, EN 55014-2:1998,

EN 61800-3-3:2008 oraz EN 61000-3-2:2006.

— Dyrektywa Ekoprojektowa (2009/125/WE).

Pompy obiegowe:

Rozporządzenie Komisji (WE) Nr 641/2009 oraz 622/2012.

Dotyczy tylko pomp obiegowych oznaczonych sprawnością

energetyczną EEI. Patrz tabliczka znamionowa na pompie.

Zastosowane normy: EN 16297-1:2012 oraz EN 16297-2:2012.

Deklaracja zgodności WE jest ważna tylko i wyłącznie wtedy kiedy jest

opublikowana przez firmę Grundfos i umieszczona w instrukcji montażu i

eksploatacji (numer publikacji 98091804 0113).

HU: EK megfelelőségi nyilatkozat

Mi, a Grundfos, egyedüli felelősséggel kijelentjük, hogy a MAGNA1

termékek, amelyekre jelen nyilatkozik vonatkozik, megfelelnek az

Európai Unió tagállamainak jogi irányelveit összehangoló tanács alábbi

előírásainak:

— Gépek (2006/42/EK).

Alkalmazott szabvány: EN 809:1998.

— Kisfeszültségű Direktíva (2006/95/EK).

Alkalmazott szabványok: EN 60335-2-51:2003 és

EN 60950-1:2006/A12:2011.

— EMC Direktíva (2004/108/EK).

Alkalmazott szabványok: EN 55014-1:2006, EN 55014-2:1998,

EN 61800-3-3:2008 és EN 61000-3-2:2006.

— Környezetbarát tervezésre vonatkozó irányelv (2009/125/EK).

Keringető szivattyúk:

Az Európai Bizottság 641/2009 és 622/2012. számú rendelete.

Kizárólag azokra a keringető szivattyúkra vonatkozik, amelyek

adattábláján szerepel az EEI. energiahatékonysági index.

Alkalmazott szabványok: EN 16297-1:2012 és

EN 16297-2:2012.

Ez az EK megfelelőségi nyilatkozat kizárólag akkor érvényes, ha

Grundfos telepítési és üzemeltetési utasítás (kiadvány szám 98091804

0113) részeként kerül kiadásra.

UA: Декларація відповідності ЄС

Компанія Grundfos заявляє про свою виключну відповідальність за

те, що продукти MAGNA1, на які поширюється дана декларація,

відповідають таким рекомендаціям Ради з уніфікації правових норм

країн - членів ЄС:

— Механічні прилади (2006/42/ЄС).

Стандарти, що застосовувалися: EN 809:1998.

— Низька напруга (2006/95/ЄС).

Стандарти, що застосовувалися: EN 60335-2-51:2003 та

EN 60950-1:2006/A12:2011.

— Електромагнітна сумісність (2004/108/ЄС).

Стандарти, що застосовувалися: EN 55014-1:2006,

EN 55014-2:1998, EN 61800-3-3:2008 та EN 61000-3-2:2006.

— Директива з

Циркулятори:

Регламент Комісії № 641/2009 та 622/2012.

Застосовується тільки для циркуляторів, позначених індексом

енергоефективності EEI. Див. заводську табличку на насосі.

Стандарти, що застосовувалися: EN 16297-1:2012 та

EN 16297-2:2012.

Ця декларація відповідності ЄС дійсна тільки в тому випадку, якщо

публікується як частина інструкцій Grundfos з монтажу та

експлуатації (номер публікації 98091804 0113).

екодизайну (2009/125/ЄС).

PT: Declaração de conformidade CE

A Grundfos declara sob sua única responsabilidade que os produtos

MAGNA1, aos quais diz respeito esta declaração, estão em

conformidade com as seguintes Directivas do Conselho sobre

a aproximação das legislações dos Estados Membros da CE:

— Directiva Máquinas (2006/42/CE).

Norma utilizada: EN 809:1998.

— Directiva Baixa Tensão (2006/95/CE).

Normas utilizadas: EN 60335-2-51:2003 e

EN 60950-1:2006/A12:2011.

— Directiva EMC (compatibilidade electromagnética) (2004/108/CE).

Normas utilizadas: EN 55014-1:2006, EN 55014-2:1998,

EN 61800-3-3:2008 e EN 61000-3-2:2006.

— Directiva de Concepção Ecológica (2009/125/CE).

Circuladores:

Disposição Regulamentar da Comissão n.º 641/2009 e 622/2012.

Aplica-se apenas a circuladores marcados com o Índice de

Eficiência Energética EEI. Ver chapa de características do

circulador.

Normas utilizadas: EN 16297-1:2012 e EN 16297-2:2012.

Esta declaração de conformidade CE é apenas válida quando publicada

como parte das instruções de instalação e funcionamento Grundfos

(número de publicação 98091804 0113).

4

Page 5

RU: Декларация о соответствии ЕС

Мы, компания Grundfos, со всей ответственностью заявляем, что

изделия MAGNA1, к которым относится настоящая декларация,

соответствуют следующим Директивам Совета Евросоюза об

унификации законодательных предписаний стран-членов ЕС:

— Механические устройства (2006/42/ЕС).

Применявшийся стандарт: EN 809:1998.

— Низковольтное оборудование (2006/95/EC).

Применявшиеся стандарты: EN 60335-2-51:2003 и

EN 60950-1:2006/A12:2011.

— Электромагнитная совместимость (2004/108/EC).

Применявшиеся стандарты: EN 55014-1:2006,

EN 55014-2:1998, EN 61800-3-3:2008 и EN 61000-3-2:2006.

— Директива по экологическому проектированию

энергопотребляющей продукции (2009/125/EC).

Циркуляционные насосы

Постановление Комиссии № 641/2009 и 622/2012.

Применяется только по отношению к циркуляционным насосам,

промаркированным и имеющим индекс энергоэффективности

EEI. См. фирменную табличку насоса.

Применявшиеся стандарты: EN 16297-1:2012 и

EN 16297-2:2012.

Данная декларация о соответствии ЕС имеет силу только в случае

публикации в составе инструкции по монтажу и эксплуатации на

продукцию производства компании Grundfos (номер публикации

98091804 0113).

:

SK: Prehlásenie o konformite ES

My firma Grundfos prehlasujeme na svoju plnú zodpovednost’, že výrobky

MAGNA1, na ktoré sa toto prehlásenie vzt’ahuje, sú v súlade s

ustanovením smernice Rady pre zblíženie právnych predpisov členských

štátov Európskeho spoločenstva v oblastiach:

— Smernica pre strojové zariadenie (2006/42/ES).

Použitá norma: EN 809:1998.

— Smernica pre nízkonapät’ové aplikácie (2006/95/ES).

Použité normy: EN 60335-2-51:2003 a EN 60950-1:2006/A12:2011.

— Smernica pre elektromagnetickú kompatibilitu (2004/108/ES).

Použité normy: EN 55014-1:2006, EN 55014-2:1998,

EN 61800-3-3:2008 a EN 61000-3-2:2006.

— Smernica o ekodizajne (2009/125/ES).

Obehové čerpadlá:

Nariadenie Komisie č 641/2009 a 622/2012.

Platí iba pre obehové čerpadlá s vyznačeným indexom energetickej

účinnosti EEI. Viď typový štítok čerpadla.

Použité normy: EN 16297-1:2012 a EN 16297-2:2012.

Toto prehlásenie o konformite ES je platné iba vtedy, ak je zverejnené

ako súčasť montážnych a prevádzkových pokynov Grundfos (publikácia

číslo 98091804 0113).

RS: EC deklaracija o usaglašenosti

Mi, Grundfos, izjavljujemo pod vlastitom odgovornošću da je proizvod

MAGNA1, na koji se ova izjava odnosi, u skladu sa direktivama Saveta

za usklađivanje zakona država članica EU:

— Direktiva za mašine (2006/42/EC).

Korišćen standard: EN 809:1998.

— Direktiva niskog napona (2006/95/EC).

Korišćeni standardi: EN 60335-2-51:2003 i

EN 60950-1:2006/A12:2011.

— EMC direktiva (2004/108/EC).

Korišćeni standardi: EN 55014-1:2006, EN 55014-2:1998,

EN 61800-3-3:2008 i EN 61000-3-2:2006.

— Direktiva o ekološkom projektovanju (2009/125/EC).

Cirkulacione pumpe:

Propis Komisije br. 641/2009 i 622/2012.

Odnosi se samo na cirkulacione pumpe označene indeksom

energetske efikasnosti EEI. Pogledajte natpisnu pločicu pumpe.

Korišćeni standardi: EN 16297-1:2012 i EN 16297-2:2012.

Ova EC deklaracija o usaglašenosti važeća je jedino kada je izdata kao

deo Grundfos uputstava za instalaciju i rad (broj izdanja 98091804 0113).

RO: Declaraţie de conformitate CE

Noi, Grundfos, declarăm pe propria răspundere că produsele MAGNA1,

la care se referă această declaraţie, sunt în conformitate cu aceste

Directive de Consiliu asupra armonizării legilor Statelor Membre CE:

— Directiva Utilaje (2006/42/CE).

Standard utilizat: EN 809:1998.

— Directiva Tensiune Joasă (2006/95/CE).

Standarde utilizate: EN 60335-2-51:2003 şi

EN 60950-1:2006/A12:2011.

— Directiva EMC (2004/108/CE).

Standarde utilizate: EN 55014-1:2006, EN 55014-2:1998,

EN 61800-3-3:2008 şi EN 61000-3-2:2006.

— Directiva Ecodesign (2009/125/CE).

Circulatorii:

Regulamentul Comisiei nr. 641/2009 şi 622/2012.

Se aplică numai pompelor de circulație marcate cu indexul de

eficiență energetică EEI. Vezi plăcuța de identificare a pompei.

Standarde utilizate: EN 16297-1:2012 şi EN 16297-2:2012.

Această declarație de conformitate CE este valabilă numai când este

publicată ca parte a instrucțiunilor Grundfos de instalare şi utilizare

(număr publicație 98091804 0113).

SI: ES izjava o skladnosti

V Grundfosu s polno odgovornostjo izjavljamo, da so naši izdelki

MAGNA1, na katere se ta izjava nanaša, v skladu z naslednjimi

direktivami Sveta o približevanju zakonodaje za izenačevanje pravnih

predpisov držav članic ES:

— Direktiva o strojih (2006/42/ES).

Uporabljena norma: EN 809:1998.

— Direktiva o nizki napetosti (2006/95/ES).

Uporabljeni normi: EN 60335-2-51:2003 in

EN 60950-1:2006/A12:2011.

— Direktiva o elektromagnetni združljivosti (EMC) (2004/108/ES).

Uporabljeni normi: EN 55014-1:2006, EN 55014-2:1998,

EN 61800-3-3:2008 in EN 61000-3-2:2006.

— Eco-design direktiva (2009/125/ES).

Črpalke:

Uredba Komisije št. 641/2009 in 622/2012.

Velja samo za obtočne črpalke označene z indeksom energetske

učinkovitosti EEI. Poglejte napisno ploščico črpalke.

Uporabljeni normi: EN 16297-1:2012 in EN 16297-2:2012.

ES izjava o skladnosti velja samo kadar je izdana kot del Grundfos

instalacije in navodil delovanja (publikacija številka 98091804 0113).

FI: EY-vaatimustenmukaisuusvakuutus

Me, Grundfos, vakuutamme omalla vastuullamme, että tuotteet

MAGNA1, joita tämä vakuutus koskee, ovat EY:n jäsenvaltioiden

lainsäädännön yhdenmukaistamiseen tähtäävien Euroopan neuvoston

direktiivien vaatimusten mukaisia seuraavasti:

— Konedirektiivi (2006/42/EY).

Sovellettu standardi: EN 809:1998.

— Pienjännitedirektiivi (2006/95/EY).

Sovellettavat standardit: EN 60335-2-51:2003 ja

EN 60950-1:2006/A12:2011.

— EMC-direktiivi (2004/108/EY).

Sovellettavat standardit: EN 55014-1:2006, EN 55014-2:1998,

EN 61800-3-3:2008 ja EN 61000-3-2:2006.

— Ekologista suunnittelua koskeva direktiivi (2009/125/EY).

Kiertovesipumput:

Komission asetus (EY) N:o 641/2009 ja 622/2012.

Koskee vain kiertovesipumppuja, jotka on merkitty

energiatehokkuusindeksillä EEI. Ks. pumpun tyyppikilpi.

Sovellettavat standardit: EN 16297-1:2012 ja EN 16297-2:2012.

Tämä EY-vaatimustenmukaisuusvakuutus on voimassa vain, kun se

julkaistaan osana Grundfosin asennus- ja käyttöohjeita (julkaisun numero

98091804 0113).

Declaration of conformity

5

Page 6

Declaration of conformity

Àß56

SE: EG-försäkran om överensstämmelse

Vi, Grundfos, försäkrar under ansvar att produkterna MAGNA1, som

omfattas av denna försäkran, är i överensstämmelse med rådets direktiv

om inbördes närmande till EU-medlemsstaternas lagstiftning, avseende:

— Maskindirektivet (2006/42/EG).

Tillämpad standard: EN 809:1998.

— Lågspänningsdirektivet (2006/95/EG).

Tillämpade standarder: EN 60335-2-51:2003 och

EN 60950-1:2006/A12:2011.

— EMC-direktivet (2004/108/EG).

Tillämpade standarder: EN 55014-1:2006, EN 55014-2:1998,

EN 61800-3-3:2008 och EN 61000-3-2:2006.

— Ekodesigndirektivet (2009/125/EG).

Cirkulationspumpar:

Kommissionens förordning nr 641/2009 och 622/2012.

Gäller endast cirkulationspumpar märkta med

energieffektivitetsindex EEI. Se pumpens typskylt.

Tillämpade standarder: EN 16297-1:2012 och EN 16297-2:2012.

Denna EG-försäkran om överensstämmelse är endast giltig när den

publiceras som en del av Grundfos monterings- och driftsinstruktion

(publikation nummer 98091804 0113).

CN: EC 产品合格声明书

我们格兰富在我们的全权责任下声明,产品 MAGNA1,即该合格证所指之

产品,符合欧共体使其成员国法律趋于一致的以下欧共理事会指令:

— 机械设备指令 (2006/42/EC)。

所用标准 : EN 809:1998。

— 低电压指令 (2006/95/EC)。

所用标准 : EN 60335-2-51:2003 和 EN 60950-1:2006/A12:2011。

— 电磁兼容性指令 (2004/108/EC)。

所用标准 : EN 55014-1:2006, EN 55014-2:1998, EN 61800-3-3:2008

和 EN 61000-3-2:2006。

— 生态化设计指令 (2009/125/EC)。

循环泵:

委员会规定第 641/2009 和 622/2012 号。

仅适用于具有节能指标 (EEI)标志的循环泵。 见水泵铭牌。

所用标准 : EN 16297-1:2012 和 EN 16297-2:2012。

本EC合格性声明仅在作为格兰富安装与操作指导手册 (出版号98091804

0113)的一部分时有效。

KO: EC 적합성 선언

Grundfos 에서는 자사의 단독 책임에 따라 이 선언과 관련된 MAGNA1 제

품이 EC 회원국 법률에 기반한 다음 이사회 지침을 준수함을 선언합니다:

– 기계류 지침 (2006/42/EC).

사용된 표준 : EN 809:1998.

– 저전압 지침 (2006/95/EC).

사용된 표준 : EN 60335-2-51:2003 및

EN 60950-1:2006/A12:2011.

– EMC 지침 (2004/108/EC).

사용된 표준 : EN 55014-1:2006, EN 55014-2:1998,

EN 61800-3-3:2008 및 EN 61000-3-2:2006.

– 에코디자인 지침 (2009/125/EC).

순환 펌프 :

위원회 규정 번호 641/2009 및 622/2012.

순환펌프에의 적용은 에너지 효율 지수 EEI. 를 획득 한 경우 가능하며

, EEI 정보는 펌프 명판을 참고하시기 바랍니다.

사용된 표준 : EN 16297-1:2012 및 EN 16297-2:2012.

본 EC 인증은 그런포스에서 인쇄 배포한 설치 가이드 및 작업 매뉴얼에 포

함되어 발행되었을 경우에만 유효합니다 (발행 번호 98091804 0113).

TR: EC uygunluk bildirgesi

Grundfos olarak bu beyannameye konu olan MAGNA1 ürünlerinin, AB

Üyesi Ülkelerin kanunlarını birbirine yaklaştırma üzerine Konsey

Direktifleriyle uyumlu olduğunun yalnızca bizim sorumluluğumuz altında

olduğunu beyan ederiz:

— Makineler Yönetmeliği (2006/42/EC).

Kullanılan standart: EN 809:1998.

—Düşük Voltaj Yönetmeliği (2006/95/EC).

Kullanılan standartlar: EN 60335-2-51:2003 ve

EN 60950-1:2006/A12:2011.

— EMC Diretifi (2004/108/EC).

Kullanılan standartlar: EN 55014-1:2006, EN 55014-2:1998,

EN 61800-3-3:2008 ve EN 61000-3-2:2006.

— Çevreye duyarlı tasarım (Ecodesign) Yönetmeliği (2009/125/EC).

Sirkülasyon pompaları:

641/2009 ve 622/2012 sayılı Komisyon Yönetmeliği.

Yal nızca enerji verimlilik endeksi (EEI) ile işaretlenen sirkülasyon

pompaları için geçerlidir. Pompa üzerindeki bilgi etiketine bakın.

Kullanılan standartlar: EN 16297-1:2012 ve EN 16297-2:2012.

İşbu EC uygunluk bildirgesi, yalnızca Grundfos kurulum ve çalıştırma

talimatlarının (bası m numarası 98091804 0113) bir parçası olarak

basıldığı takdirde geçerlilik kazanmaktad

ır.

JP: EC 適合宣言

Grundfosは、 そ の責任の下 に 、 MAGNA1製品がEC加盟諸国の法規に関

連す る、 以下の評議会指令 に適合している こと を宣言します :

‒ 機械指令 (2006/42/EC)。

適用規格 :EN809:1998。

‒ 低電圧指令 (2006/95/EC)。

適用規格 :EN60335-2-51:2003およびEN60950-1:2006/A12:2011。

‒ EMC指令 (2004/108/EC)。

適用規格 :EN55014-1:2006,EN55014-2:1998,EN61800-3-3:2008

お よびEN61000-3-2:2006。

‒ エコデザイン指令 (2009/125/EC)。

循環ポ ン プ :

委員会規定No641/2009および622/2012。

エネルギー効率指数EEI. ( ポンプ銘板参照 ) のマ ーク付き循環ポンプ

のみに適用。

適用規格 :EN16297-1:2012およびEN16297-2:2012。

こ のEC適合宣言は、 グル ン ド フォス取扱説明書 (出版番号98091804

0113) の一部に 掲載される場合のみ有効 です。

Bjerringbro, 7th December 2012

Jan Strandgaard

Technical Director

Grundfos Holding A/S

Poul Due Jensens Vej 7

8850 Bjerringbro, Denmark

Person authorised to compile technical file and

empowered to sign the EC declaration of conformity.

Декларация о соответствии на территории РФ

Насосы серии MAGNA1 сертифицированы в системе ГОСТ Р.

Сертификат соответствия:

№ РОСС DK.АЯ56.B43661, срок действия до 24.04.2014 г.

Истра, 1 октября 2012 г.

Касаткина В. В.

Руководитель отдела качества,

экологии и охраны труда

ООО Грундфос Истра, Россия

143581, Московская область,

Истринский район,

дер. Лешково, д.188

6

Page 7

English (GB) Installation and operating instructions

Caution

Note

Original installation and operating instructions.

CONTENTS

1. Symbols used in this document

2. General information

2.1 Applications

2.2 Pumped liquids

2.3 Operating conditions

2.4 Frost protection

2.5 Insulating shells

2.6 Non-return valve

2.7 Nameplate

2.8 Tools

3. Mechanical installation

3.1 Lifting the pump

3.2 Installing the pump

3.3 Positioning

3.4 Control box positions

3.5 Changing the control box position

4. Electrical installation

4.1 Supply voltage

4.2 Connection to the power supply

4.3 ALPHA-plug version

4.4 Connection diagrams

5. First start-up

6. Settings

7. Control panel

7.1 Elements on the control panel

7.2 Grundfos Eye

7.3 Light fields indicating the pump setting

8. Overview of settings

8.1 Pump setting

9. Selection of control mode

10. Fault finding

10.1 Grundfos Eye operating status

10.2 Resetting of fault indications

11. Accessories

11.1 Insulating kits for air-conditioning and cooling systems

11.2 Blanking flanges

11.3 Counter flanges

11.4 Adapter for various port-to-port lengths

12. Technical data

13. Disposal

Page

10

10

11

11

11

12

12

13

14

14

14

15

16

17

18

18

18

18

18

19

20

21

22

22

22

23

23

23

24

27

30

30

1. Symbols used in this document

Warnin g

If these safety instructions are not observed,

7

8

8

8

9

9

9

9

it may result in personal injury.

Warnin g

If these instructions are not observed, it may lead

to electric shock with consequent risk of serious

personal injury or death.

Warnin g

The surface of the product may be so hot that it

may cause burns or personal injury.

Warnin g

Risk of dropping objects which may cause

personal injury.

Warnin g

Escaping vapour involves the risk of personal

injury.

If these safety instructions are not observed,

it may result in malfunction or damage to the

equipment.

Notes or instructions that make the job easier

and ensure safe operation.

English (GB)

Warning

Prior to installation, read these installation and

operating instructions. Installation and operation

must comply with local regulations and accepted

codes of good practice.

Warning

The use of this product requires experience with

and knowledge of the product.

Persons with reduced physical, sensory or

mental capabilities must not use this product,

unless they are under supervision or have been

instructed in the use of the product by a person

responsible for their safety.

Children must not use or play with this product.

7

Page 8

2. General information

Note

English (GB)

The Grundfos MAGNA1 is a complete range of circulator pumps

with integrated controller enabling adjustment of pump

performance to the actual system requirements. In many

systems, this will reduce the power consumption considerably,

reduce noise from thermostatic radiator valves and similar fittings

and improve the control of the system.

The desired head can be set on the pump control panel.

2.1 Applications

The Grundfos MAGNA1 is designed for circulating liquids in the

following systems:

• heating systems

• air-conditioning and cooling systems.

The pump can also be used in the following systems:

• ground source heat pump systems

• solar-heating systems.

2.2 Pumped liquids

The pump is suitable for thin, clean, non-aggressive and

non-explosive liquids, not containing solid particles or fibres that

may attack the pump mechanically or chemically.

In heating systems, the water should meet the requirements of

accepted standards on water quality in heating systems, for

example the German standard VDI 2035.

2.2.1 Glycol

The pump can be used for pumping water/glycol mixtures up to

50 %.

Example of a water/ethylene glycol mixture:

Maximum viscosity: 50 cSt ~ 50 % water/50 % ethylene glycol

mixture at -10 °C.

The pump has a power-limiting function that protects against

overload.

The pumping of glycol mixtures will affect the max. curve and

reduce the performance, depending on the water/ethylene glycol

mixture and the liquid temperature.

To prevent the ethylene glycol mixture from degrading, avoid

temperatures exceeding the rated liquid temperature and

minimise the operating time at high temperatures.

It is important to clean and flush the system before the ethylene

glycol mixture is added.

To prevent corrosion or lime precipitation, check and maintain the

ethylene glycol mixture regularly. If further dilution of the supplied

ethylene glycol is required, follow the glycol supplier's

instructions.

Additives with a density and/or kinematic

viscosity higher than those/that of water will

reduce the hydraulic performance.

TM05 5509 3812TM05 5510 3812

Fig. 1 Pumped liquids (flanged version)

Fig. 2 Pumped liquids (threaded version)

Warning

Do not use the pump for flammable liquids, such

as diesel oil and petrol.

Warning

Do not use the pump for aggressive liquids, such

as acids and seawater.

8

Page 9

2.3 Operating conditions

Caution

Note

1

2

3

4

Note

Note

Fig. 3 Operating conditions

2.3.1 Liquid temperature

See fig. 3, pos. 1.

Continuously: -10 to +110 °C.

2.3.2 System pressure

See fig. 3, pos. 2.

The maximum permissible system pressure is stated on the pump

nameplate. See fig. 6.

2.3.3 Test pressure

The pumps can withstand test pressures as indicated in

EN 60335-2-51. See below.

• PN 6: 7.2 bar

• PN 10: 12 bar

• PN 6/10: 12 bar

• PN 16: 19.2 bar.

During normal operation, the pump should not be used at higher

pressures than those stated on the nameplate. See fig. 6.

Pumps tested with water containing anti-corrosive additives are

taped on the suction and discharge ports to prevent residual test

water from leaking into the packaging. Remove the tape before

installing the pump.

The pressure test has been made with water containing

anti-corrosive additives at a temperature of +20 °C.

2.3.4 Ambient temperature

See fig. 3, pos. 3.

0 to +40 °C.

The control box is air-cooled. Therefore, it is important that the

maximum permissible ambient temperature is not exceeded

during operation.

During transport: -30 to +55 °C.

2.3.5 Sound pressure level

See fig. 3, pos. 4.

The sound pressure level of the pump is lower than 43 dB(A).

2.5 Insulating shells

Insulating shells are available for single-head pumps only.

Limit the heat loss from the pump housing and

pipework.

The heat loss from the pump and pipework can be reduced by

insulating the pump housing and the pipework. See fig. 4.

• Insulating shells for pumps in heating systems are supplied

with the pump.

• Insulating shells for pumps in air-conditioning and cooling

systems (down to -10 °C) are available as accessories and

must be ordered separately. See section 11.1 Insulating kits

for air-conditioning and cooling systems.

The fitting of insulating shells will increase the pump dimensions.

Pumps for heating systems are factory-fitted with

insulating shells. Remove the insulating shells

TM05 5511 3812

before installing the pump.

Fig. 4 Insulating shells

2.6 Non-return valve

If a non-return valve is fitted in the pipe system (fig. 5), ensure

that the set minimum discharge pressure of the pump is always

higher than the closing pressure of the valve. This is especially

important in proportional-pressure control mode (reduced head at

low flow). The first non-return valve is included in the pump

setting as the minimum setpoint is 1.0 metre.

Fig. 5 Non-return valve

English (GB)

TM05 5512 3812TM05 3055 0912

2.4 Frost protection

If the pump is not used during periods of frost,

necessary steps must be taken to prevent frost

bursts.

Additives with a density and/or kinematic

viscosity higher than those/that of water will

reduce the hydraulic performance.

9

Page 10

2.7 Nameplate

1.2 x 8.0 TX200.6 x 3.5 5.0

1

2

3

4

5

6

7

English (GB)

The pump nameplate provides the following information:

Fig. 6 Example of nameplate

Pos. Description

1 Product name

2 Model

3 Production code (year and week)

4 Serial number

5 Product number

6 Country of manufacture

7 Enclosure class

8 Energy Efficiency Index (EEI)

9 Part (according to EEI)

10 Temperature class

11 Minimum current [A]

12 Maximum current [A]

13 Minimum power [W]

14 Maximum power [W]

15 Maximum system pressure

16 Voltage [V] and frequency [Hz]

17 QR (Quick Response) code

18 CE mark and approvals

TM05 5561 3812

2.8 Tools

Fig. 7 Recommended tools

Pos. Tool Size

1 Screwdriver, straight slot 1.2 x 8.0 mm

2 Screwdriver, straight slot 0.6 x 3.5 mm

3 Screwdriver, torx bit TX20

4 Hexagon key 5.0 mm

5 Open-end spanner Depending on DN size

6 Side cutter

7 Pipe wrench

Only used for pumps with

unions

TM05 6472 4712

10

Page 11

3. Mechanical installation

Caution

3.1 Lifting the pump

Warning

Observe local regulations setting limits for

manual lifting or handling.

Always lift directly on the pump head or the cooling fins when

handling the pump. See fig. 8.

For large pumps, it may be ncessary to use lifting equipment.

Position the lifting straps as illustrated in fig. 8.

3.2 Installing the pump

The MAGNA1 is designed for indoor installation.

The MAGNA1 pump range includes both flanged and threaded

versions. These installation and operating instructions apply to

both versions, but give a general description of flanged versions.

If the versions differ, the threaded version will be described

separately.

The pump must be installed in such a way that it is not stressed

by the pipework. The maximum permissible forces and moments

from pipe connections acting on the pump flanges or threaded

connections can be found on page 34.

The pump may be suspended direct in the pipes, provided that

the pipework can support the pump.

Twin-head pumps are prepared for installation on a mounting

bracket or base plate (pump housing with M12 thread).

To ensure adequate cooling of motor and electronics, observe the

following requirements:

• Position the pump in such a way that sufficient cooling is

ensured.

• The ambient temperature must not exceed +40 °C.

Step Action Illustration

English (GB)

Fig. 8 Correct lifting of pump

Do not lift the pump head by the control box

(red area of the pump). See fig. 9.

Arrows on the pump housing

indicate the liquid flow direction

through the pump. The liquid

1

flow direction can be horizontal

TM05 5513 3812TM05 5514 3812

or vertical, depending on the

control box position.

TM05 5819 4112

Mount the pump with gaskets in

2

the pipework.

TM05 5515 3812

Flanged version:

Fit bolts and nuts. Use the right

size of bolts according to system

pressure.

For recommended tightening

torque for the bolts used in the

3

TM05 5516 3816 TM05 5517 3812

flanged connection,

see page 34.

Threaded version:

Tighten the union nuts.

TM05 5819 4112

Fig. 9 Incorrect lifting of pump

11

Page 12

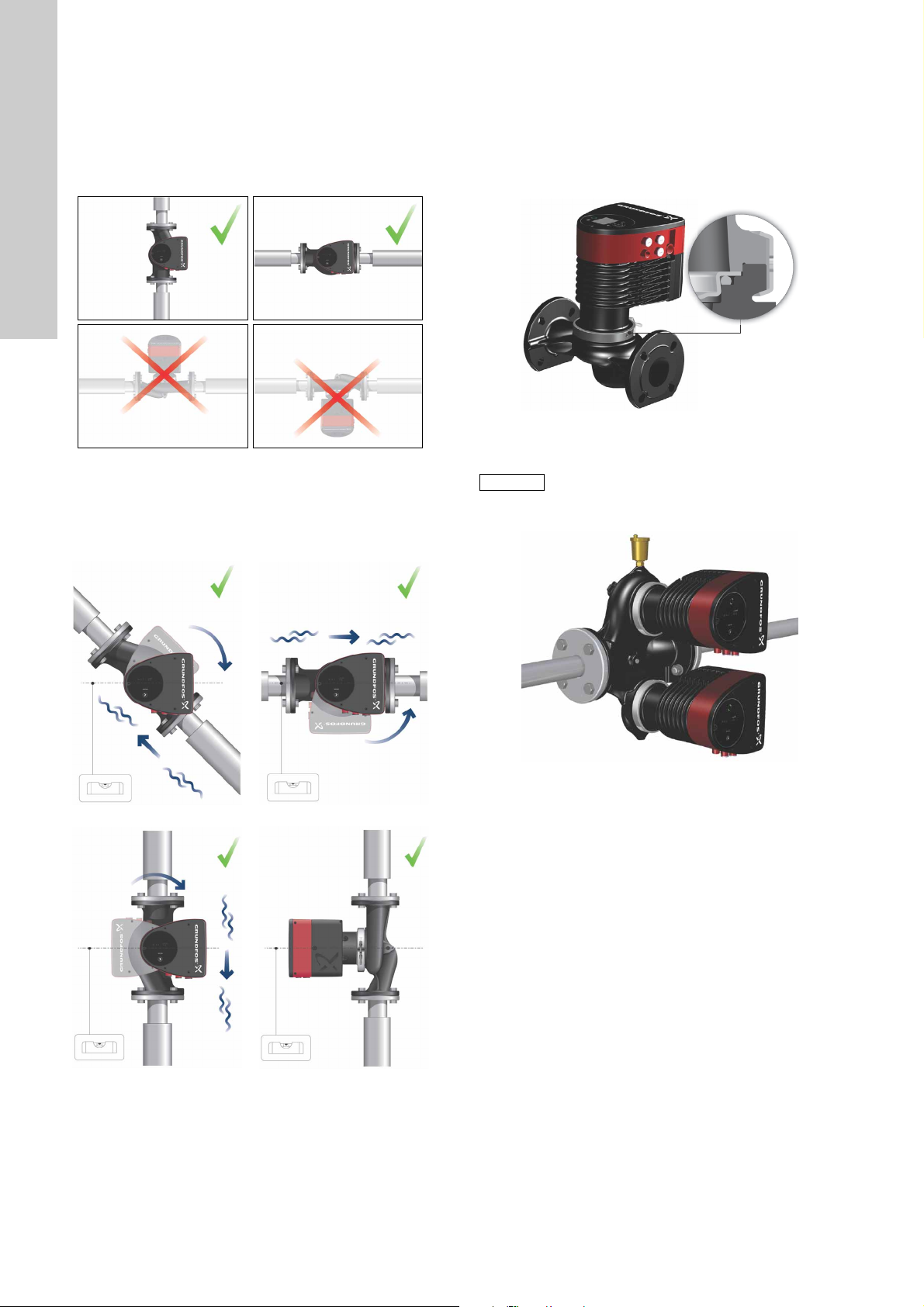

3.3 Positioning

AB

CD

Caution

English (GB)

Always install the pump with horizontal motor shaft.

• Pump installed correctly in a vertical pipe. See fig. 10, pos. A.

• Pump installed correctly in a horizontal pipe. See fig. 10,

pos. B.

• Do not install the pump with vertical motor shaft. See fig. 10,

pos. C and D.

Fig. 10 Pump installed with horizontal motor shaft

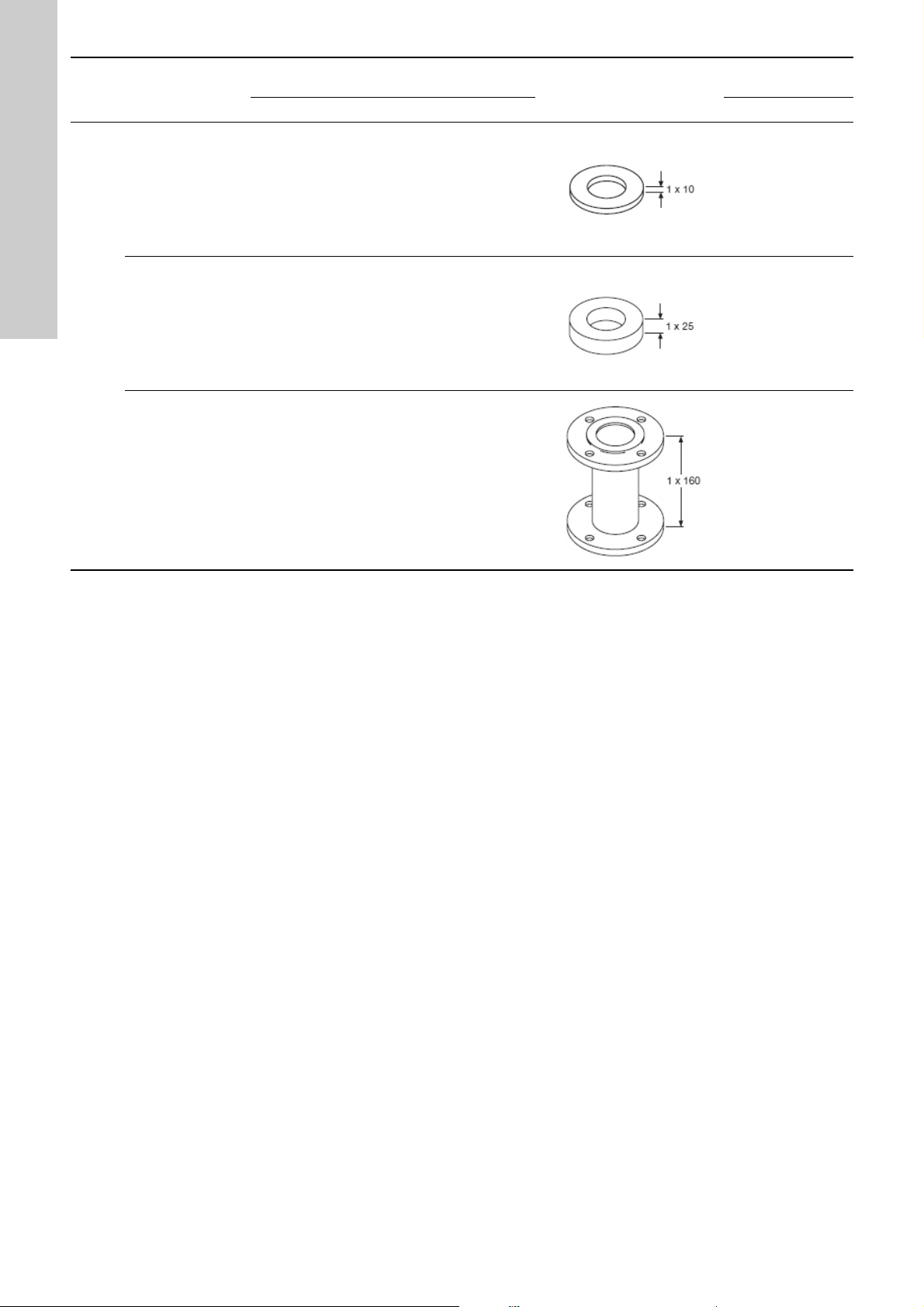

3.4 Control box positions

To ensure adequate cooling, the control box must be in horizontal

position with the Grundfos logo in vertical position. See fig. 11.

If the pump head is removed before the pump is installed in the

pipework, pay special attention when fitting the pump head to the

pump housing:

1. Gently lower the pump head with rotor shaft and impeller into

the pump housing.

2. Make sure that the contact face of the pump housing and that

of the pump head are in contact before the clamp is tighened.

See fig. 12.

TM05 5837 4112

Fig. 12 Fitting the pump head to the pump housing

TM05 5518 3812

Twin-head pumps installed in horizontal pipes

must be fitted with an automatic air vent (Rp 1/4)

in the upper part of the pump housing.

See fig. 13.

TM05 5519 3812

TM05 5521 3812

Fig. 11 Pump with control box in horizontal position

TM05 6062 4412

Fig. 13 Automatic air vent

TM05 5520 3812

TM05 5522 3812

12

Page 13

3.5 Changing the control box position

Caution

Warning

The warning symbol on the clamp holding the

pump head and pump housing together indicates

that there is a risk of personal injury . See speci fic

warnings below.

Warning

When loosening the clamp, do not drop the pump

head.

Twin-head pump.

Position the clamps so that the

gaps point towards the arrows.

4c

They can be in position 3 or

9o’clock.

English (GB)

TM05 2917 0612 - TM05 2873 0612

Warning

Risk of escaping vapour.

Step Action Illustration

Loosen the screw in the clamp

holding the pump head and

pump housing together.

Warn ing: If the screw is

1

loosened too much, the pump

head will be completely

disconnected from the pump

housing.

Carefully rotate the pump head

to the desired position.

If the pump head is stuck,

2

loosen it with a light blow of a

rubber mallet.

Place the control box in

horizontal position so that the

Grundfos logo is in vertical

3

position. The motor shaft must

be horizontal.

Due to the drain hole in the

stator housing, position the gap

4

of the clamp as shown in step

4a, 4b, 4c, 4d or 4e.

Twin-head pump.

Note: The gap of the clamp can

also be in position 6 o’clock for

the following pump sizes:

4d

• DN 65

• DN 80

• DN 100.

TM05 2897 1912

Threaded single-head pump.

4e

The gap of the clamp can be in

position 3, 6, 9 or 12 o’clock.

TM05 2867 0612

TM05 5528 3812

Fit and tighten the screw

TM05 5526 3812

holding the clamp to 8 ± 1 Nm.

Note: Do not retighten the

5

screw if condensed water is

dripping from the clamp.

TM05 2872 0612

Fit the insulating shells.

TM05 5527 3812

Note: Insulating shells for

pumps in air-conditioning and

6

cooling systems must be

ordered separately.

TM05 5529 3812

Do not insulate the control box or cover the

control panel.

Flanged single-head pump.

Position the clamp so that the

gap points towards the arrow.

4a

It can be in position 3 or

9o’clock.

Flanged single-head pump.

Note: The gap of the clamp can

also be in position 6 o’clock for

the following pump sizes:

4b

• DN 65

• DN 80

• DN 100.

TM05 2870 0612

TM05 2918 0612 - TM05 2871 0612

TM05 5549 3812

Fig. 14 Insulation of pump housing and pipework

TM05 2899 1912

13

Page 14

4. Electrical installation

Note

English (GB)

Carry out the electrical connection and protection according to

local regulations.

Check that the supply voltage and frequency correspond to the

values stated on the nameplate.

Warning

Switch off the power supply before making

connections.

Warning

The pump must be connected to an external

mains switch with a minimum contact gap of

3 mm in all poles.

Earthing or neutralisation must be used for

protection against indirect contact.

If the pump is connected to an electric

installation where an earth leakage circuit

breaker (ELCB) is used as an additional

protection, this circuit breaker must trip when

earth fault currents with DC content (pulsating

DC) occur.

The earth leakage circuit breaker must be marked

with the first or both of the symbols shown

below:

Connect the cable

3

gland to the

control box.

Pull the power

supply cable

4

through the cable

gland.

Strip the cable

5

conductors as

illustrated.

TM05 5532 3812

TM05 5533 3812

• The pump must be connected to an external mains switch.

• The pump requires no external motor protection.

• The motor incorporates thermal protection against slow

overloading and blocking.

• When switched on via the power supply, the pump will start

pumping after approx. 5 seconds.

The number of starts and stops via the power

supply must not exceed four times per hour.

4.1 Supply voltage

1 x 230 V ± 10 %, 50/60 Hz, PE.

The voltage tolerances are intended for mains voltage variations.

They should not be used for running pumps at other voltages than

those stated on the nameplate.

4.2 Connection to the power supply

Step Action Illustration

Remove the front

cover from the

control box.

Note: Do not

1

remove the

screws from the

cover.

Locate the power

supply plug and

cable gland in the

2

small paper bag

supplied with the

pump.

TM05 5534 3812

Connect the cable

6

conductors to the

power supply plug.

TM05 5535 3812

Insert the power

supply plug into

the male plug in

7

the pump control

box.

TM05 5536 3812

TM05 5530 3812

Tighten the cable

gland.

8

Refit the front

cover.

TM05 5537 3812

TM05 5531 3812

14

Page 15

4.3 ALPHA-plug version

Max. 1.5 mm

2

12 mm

∅5.5 - 10 mm

7 mm

17 mm

4.3.1 Assembling the plug

Step Action Illustration

Fit the cable gland

and plug cover to

the cable.

1

Strip the cable

conductors as

illustrated.

Connect the cable

conductors to the

2

power supply

plug.

Bend the cable

with the cable

3

conductors

pointing upwards.

Insert the power

supply plug into

the male plug in

7

the pump control

box.

TM05 5538 3812

4.3.2 Disassembling the plug

Step Action Illustration

Loosen the cable

1

TM05 5539 3812

gland and remove

it from the plug.

English (GB)

TM05 5544 3812

TM05 5545 3812

4

5

6

Pull out the

conductor guide

plate and throw it

away.

Click the plug

cover onto the

power supply

plug.

Screw the cable

gland onto the

power supply

plug.

Pull off the plug

cover while

2

TM05 5540 3812

pressing on both

sides.

TM05 5546 3812

Loosen the cable

conductors one by

one by pressing a

TM05 5541 3812

3

screwdriver gently

into the terminal

clip.

TM05 5547 3812

TM05 5542 3812

The plug has now

been removed

4

from the power

supply plug.

TM05 5543 3812

TM05 5548 3812

15

Page 16

4.4 Connection diagrams

External switch

Fuse

(min. 10 A, time lag)

ELCB

External switch

Fuse

(min. 10 A, time lag)

ELCB

Note

English (GB)

Fig. 15 Example of terminal connection, 1 x 230 V ± 10 %, 50/60 Hz, PE

Fig. 16 Example of ALPHA plug connection, 1 x 230 V ± 10 %, 50/60 Hz, PE

TM03 2397 3712TM05 5277 3712

All cables used must be connected in accordance

with local regulations.

16

Page 17

5. First start-up

Caution

Do not start the pump until the system has been filled with liquid

and vented. Furthermore, the required minimum inlet pressure

must be available at the pump inlet. See section 12. Technical

data.

The system cannot be vented through the pump. The pump is

self-venting.

The discharge valve must be opened immediately

after start-up of the pump. Otherwise the

temperature of the pumped liquid may become

too high and cause damage to the equipment.

Step Action Illustration

English (GB)

1

Note: When switched on, the pump will start after approx.

5 seconds.

2 Control panel at first start-up.

The pump has been factory-set to the intermediate

Switch on the power supply to the pump.

3

proportional-pressure curve.

Select the control mode according to the system

application.

TM05 5550 3812

TM05 5551 3812

TM05 5551 3812

17

Page 18

6. Settings

Note

Note

1

2

3

English (GB)

7. Control panel

7.3 Light fields indicating the pump setting

The pump has nine optional performance settings which can be

selected with the push-button. See fig. 17, pos. 3.

The pump setting is indicated by eight light fields in the display.

See fig. 17, pos. 2.

7.1 Elements on the control panel

Fig. 17 Control panel

The control panel on the pump comprises the following:

Pos. Description

Grundfos Eye operating status.

1

See section 7.2 Grundfos Eye.

Eight light fields indicating the pump setting.

2

See section 7.3 Light fields indicating the pump

setting.

3 Push-button for selection of pump setting.

7.2 Grundfos Eye

The Grundfos Eye is on when the power supply has been

switched on. See fig. 17, pos. 1.

The Grundfos Eye is an indicator light providing information about

the actual pump status.

The indicator light will flash in different sequences and provide

information about the following:

• power on/off

• pump alarms.

The function of the Grundfos Eye is described in section

10.1 Grundfos Eye operating status.

Faults preventing the pump from operating

properly (for example blocked rotor) are

indicated by the Grundfos Eye. See section

10.1 Grundfos Eye operating status.

If a fault is indicated, correct the fault and reset the pump by

switching the power supply off and on.

TM05 5553 3812

Fig. 18 Factory setting, PP2

Button

presses

0

Active light fields Description

Intermediate

proportional-pressure

curve, referred to as PP2

1

Highest

proportional-pressure

curve, referred to as PP3

2

TM05 5552 3812

3

Lowest

constant-pressure curve,

referred to as CP1

Intermediate

constant-pressure curve,

referred to as CP2

4

Highest

constant-pressure curve,

referred to as CP3

5

6

7

8

Constant curve/constant

speed III

Constant curve/constant

speed II

Constant curve/constant

speed I

Lowest

proportional-pressure

curve, referred to as PP1

If the pump impeller is rotated, for example when

filling the pump with water, sufficient energy can

be generated to light up the control panel even if

the power supply has been switched off.

18

Page 19

8. Overview of settings

III

II

I

H

PP3

CP3

CP2

PP1

CP1

PP2

Q

English (GB)

Fig. 19 Pump setting in relation to pump performance

Setting Pump curve Function

Lowest

PP1

PP2

PP3

CP1

CP2

CP3

III Speed III

II Speed II

I Speed I

proportional-pressure

curve

Intermediate

proportional-pressure

curve

Highest

proportional-pressure

curve

Lowest constant-pressure

curve

Intermediate

constant-pressure curve

Highest

constant-pressure curve

The duty point of the pump will move up or down on the lowest proportional-pressure curve,

depending on the heat demand. See fig. 19.

The head (pressure) is reduced at falling heat demand and increased at rising heat demand.

The duty point of the pump will move up or down on the intermediate proportional-pressure

curve, depending on the heat demand. See fig. 19.

The head (pressure) is reduced at falling heat demand and increased at rising heat demand.

The duty point of the pump will move up or down on the highest proportional-pressure curve,

depending on the heat demand. See fig. 19.

The head (pressure) is reduced at falling heat demand and increased at rising heat demand.

The duty point of the pump will move out or in on the lowest constant-pressure curve,

depending on the heat demand in the system. See fig. 19.

The head (pressure) is kept constant, irrespective of the heat demand.

The duty point of the pump will move out or in on the intermediate constant-pressure curve,

depending on the heat demand in the system. See fig. 19.

The head (pressure) is kept constant, irrespective of the heat demand.

The duty point of the pump will move out or in on the highest constant-pressure curve,

depending on the heat demand in the system. See fig. 19.

The head (pressure) is kept constant, irrespective of the heat demand.

The pump runs on a constant curve which means that it runs at a constant speed.

In speed III, the pump is set to run on the max. curve under all operating conditions.

See fig. 19.

Quick venting of the pump can be obtained by setting the pump to speed III for a short

period.

The pump runs on a constant curve which means that it runs at a constant speed.

In speed II, the pump is set to run on the intermediate curve under all operating conditions.

See fig. 19.

The pump runs on a constant curve which means that it runs at a constant speed.

In speed I, the pump is set to run on the min. curve under all operating conditions.

See fig. 19.

TM05 2777 0512

19

Page 20

8.1 Pump setting

Q

H

PP3

PP2

PP1

Q

H

Q

H

CP3

CP2

CP1

Q

H

English (GB)

Constant curve/constant speed (I, II or III)

At constant-curve/constant-speed operation, the pump runs at a

constant speed, independent of the actual flow demand in the

system. The pump performance follows the selected performance

curve, I, II or III. See fig. 23 where II has been selected.

See section 9. Selection of control mode for further information.

Fig. 20 Selection of pump setting for system type

Factory setting: Intermediate proportional-pressure curve,

referred to as PP2.

Proportional-pressure curve (PP1, PP2 or PP3)

Proportional-pressure control adjusts the pump performance to

the actual heat demand in the system, but the pump performance

follows the selected performance curve, PP1, PP2 or PP3.

See fig. 21 where PP2 has been selected. See section

9. Selection of control mode for further information.

Fig. 21 Three proportional-pressure curves/settings

The selection of the right proportional-pressure setting depends

on the characteristics of the heating system in question and the

actual heat demand.

Constant-pressure curve (CP1, CP2 or CP3)

Constant-pressure control adjusts the pump performance to the

actual heat demand in the system, but the pump performance

follows the selected performance curve, CP1, CP2 or CP3.

See fig. 22 where CP1 has been selected.

See section 9. Selection of control mode for further information.

TM05 5554 3812TM05 5555 3812TM05 5556 3812

Fig. 23 Three constant-curve/constant-speed settings

The selection of the right constant-curve/constant-speed setting

depends on the characteristics of the heating system in question.

TM05 5557 3812

Fig. 22 Three constant-pressure curves/settings

The selection of the right constant-pressure setting depends on

the characteristics of the heating system in question and the

actual heat demand.

20

Page 21

9. Selection of control mode

Q

H

Q

H

Q

H

System application Select this control mode

In systems with relatively large pressure losses in the distribution pipes and in air-conditioning and cooling

systems.

• Two-pipe heating systems with thermostatic valves and

– very long distribution pipes

– strongly throttled pipe balancing valves

– differential-pressure regulators

– large pressure losses in those parts of the system through which the total quantity of water flows

(for example boiler, heat exchanger and distribution pipe up to the first branching).

• Primary circuit pumps in systems with large pressure losses in the primary circuit.

• Air-conditioning systems with

– heat exchangers (fan coils)

– cooling ceilings

– cooling surfaces.

In systems with relatively small pressure losses in the distribution pipes.

• Two-pipe heating systems with thermostatic valves and

– dimensioned for natural circulation

– small pressure losses in those parts of the system through which the total quantity of water flows

(for example boiler, heat exchanger and distribution pipe up to the first branching) or

– modified to a high differential temperature between flow pipe and return pipe

(for example district heating).

• Underfloor heating systems with thermostatic valves.

• One-pipe heating systems with thermostatic valves or pipe balancing valves.

• Primary circuit pumps in systems with small pressure losses in the primary circuit.

The pump can also be set to operate according to the max. or min. curve, like an uncontrolled pump:

• The max. curve mode can be used in periods in which a maximum flow is required. This operating

mode is for instance suitable for hot-water priority.

• The min. curve mode can be used in periods in which a minimum flow is required. This operating

mode is for instance suitable for manual night setback.

Proportional pressure

Constant pressure

Constant curve

English (GB)

21

Page 22

10. Fault finding

Caution

English (GB)

Warning

Before dismantling the pump, drain the system or close the isolating valve on either side of the pump. The pumped

liquid may be scalding hot and under high pressure.

10.1 Grundfos Eye operating status

Grundfos Eye Indication Cause

No lights on.

Two opposite green indicator lights running in the

direction of rotation of the pump.

Two opposite red indicator lights flashing

simultaneously.

Power off.

Pump not running.

Power on.

Pump running.

Alarm.

Pump stopped.

10.2 Resetting of fault indications

A fault indication can be reset in one of the following ways:

• When the fault cause has been eliminated, the pump will revert to normal duty.

• If the fault disappears by itself, the fault indication will automatically be reset.

Fault

Other pumps or sources force flow through

the pump even if the pump is stopped. There

will be light in the display even if the power

supply has been switched off.

Supply voltage to the pump too low. Yes Check that the power supply is within the specified range.

The pump is blocked. No

No water at the pump inlet or the water

contains too much air.

Internal fault in the pump electronics. Yes

Supply voltage to the pump too high. Yes Check that the power supply is within the specified range.

Automatic reset and

restart?

Yes

No

Corrective actions

Check the system for defective non-return valves and replace,

if necessary.

Check the system for correct position of non-return valves,

etc.

Dismantle the pump, and remove any foreign matter or

impurities preventing the pump from rotating.

Prime and vent the pump before a new start-up. Check that

the pump is operating correctly. If not, replace the pump, or

call GRUNDFOS SERVICE for assistance.

Replace the pump, or call GRUNDFOS SERVICE for

assistance.

If the power supply cable is damaged, it must be replaced by the manufacturer, the manufacturer’s service partner or

a similarly qualified person.

22

Page 23

11. Accessories

Note

11.1 Insulating kits for air-conditioning and cooling systems

Single-head pumps for air-conditioning and cooling systems can

be fitted with insulating shells. A kit consists of two shells made of

polyurethane (PUR) and a self-adhesive seal to ensure tight

assembly.

The dimensions of the insulating shells for

pumps in air-conditioning and cooling systems

differ from those of the insulating shells for

pumps in heating systems.

Pump type Product number

MAGNA1 25-40/60/80/100/120 98354534

MAGNA1 32-40/60/80/100 98354535

MAGNA1 32-40/60/80/100 F 98354536

MAGNA1 32-120 F 98063287

MAGNA1 40-40/60 F 98354537

MAGNA1 40-80/100 F 98063288

MAGNA1 40-120/150/180 F 98145675

MAGNA1 50-40/60/80 F 98063289

MAGNA1 50-100/120/150/180 F 98145676

MAGNA1 65-40/60/80/100/120/150 F 96913593

MAGNA1 80-40/60/80/100/120 F 98134265

MAGNA1 100-40/60/80/100/120 F 96913589

English (GB)

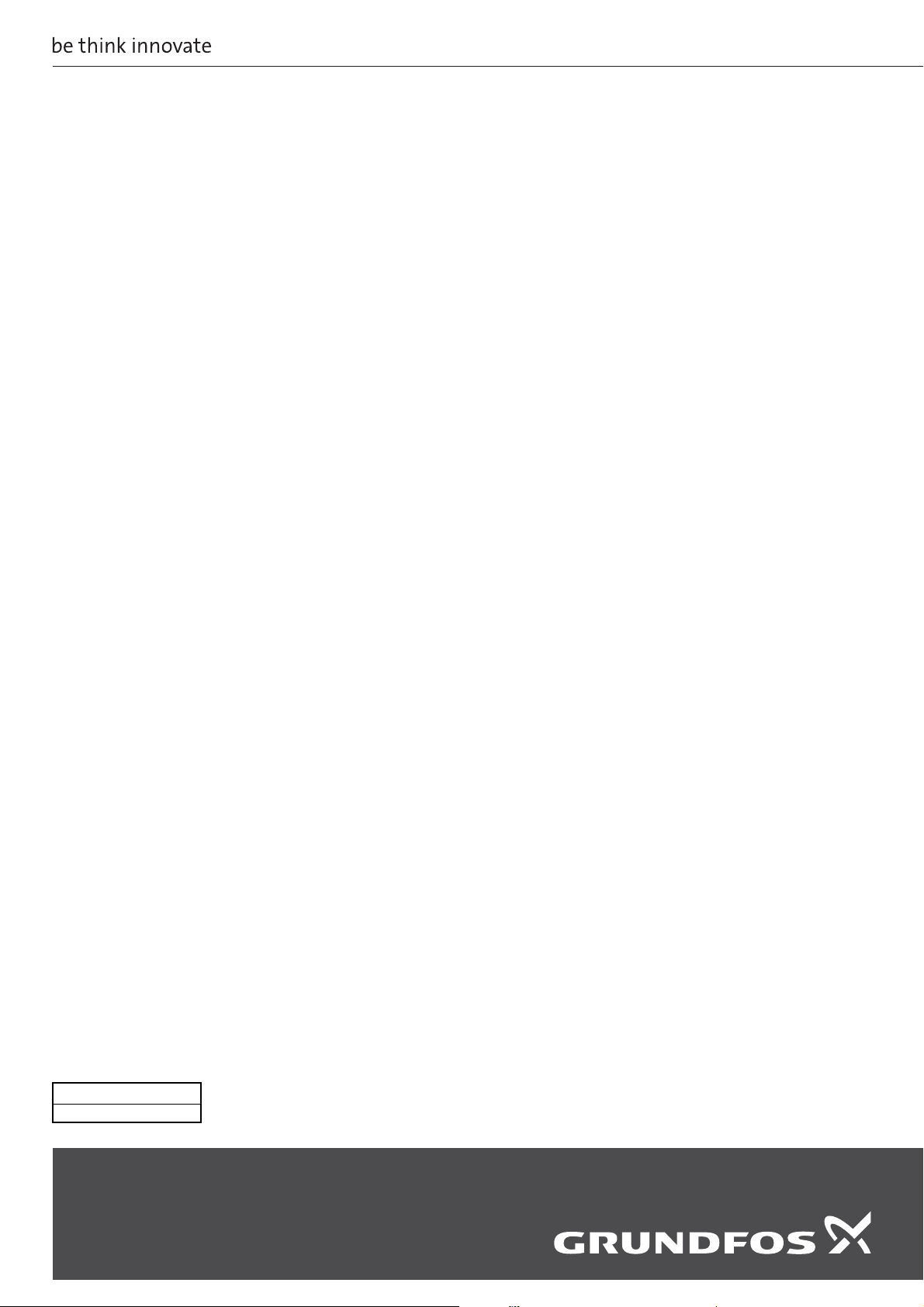

11.2 Blanking flanges

A blanking flange is used to blank off the opening when one of the

pumps of a twin-head pump is removed for service to enable

uninterrupted operation of the other pump.

Fig. 24 Position of blanking flange

Pump type Product number

MAGNA1 25-40/60/80/100/120

MAGNA1 32-40/60/80/100 (F)

MAGNA1 40-40/60 F

MAGNA1 32-120 F

MAGNA1 40-/80/100/120/150/180 F

MAGNA1 50-40/60/80/100/120/150/180 F

MAGNA1 65-40/60/80/100/120/150 F

MAGNA1 80-40/60/80/100/120 F

MAGNA1 100-40/60/80/100/120 F

98159373

98159372

TM05 5525 3812

23

Page 24

11.3 Counter flanges

ø19

ø140

ø100

ø78

Rp 1

¼

Threaded For welding

ø19

ø150

ø110

ø88

Rp 1

½

Threaded For welding

ø19

ø165

ø125

ø102

Rp 2

Threaded For welding

ø19

ø185

ø145

ø122

Rp 2½

Threaded For welding

Threaded For welding

English (GB)

Cast-iron pumps

A counter-flange kit consists of two stainless-steel flanges, two gaskets of asbestos-free material IT 200 and the required number of bolts

and nuts.

Counter flange Pump type Description

Threaded 10 bar Rp 1 1/4 539703

For welding 10 bar

MAGNA1

DN 32

Threaded 16 bar Rp 1 1/4 539703

TM03 0478 5204

For welding 16 bar

Threaded 10 bar Rp 1 1/2 539701

For welding 10 bar

MAGNA1

DN 40

Threaded 16 bar Rp 1 1/2 539701

TM03 0479 5204

For welding 16 bar

Threaded 10 bar Rp 2 549801

For welding 10 bar

MAGNA1

DN 50

Threaded 16 bar Rp 2 549801

Rated pressure

(EN 1092-2)

Pipework

connection

32 mm,

nominal

32 mm,

nominal

40 mm,

nominal

40 mm,

nominal

50 mm,

nominal

Product

number

539704

539704

539702

539702

549802

Rp 3

ø19

ø138

ø160

ø200

TM03 0480 5204

MAGNA1

TM03 0481 5204

MAGNA1

TM03 0482 5204

DN 65

DN 80

For welding 16 bar

50 mm,

nominal

549802

Threaded 10 bar Rp 2 1/2 559801

For welding 10 bar

65 mm,

nominal

559802

Threaded 16 bar Rp 2 1/2 559801

For welding 16 bar

65 mm,

nominal

559802

Threaded 6 bar Rp 3 569902

For welding 6 bar

80 mm,

nominal

569901

Threaded 10 bar Rp 3 569802

For welding 10 bar

80 mm,

nominal

569801

Threaded 16 bar Rp 3 569802

For welding 16 bar

80 mm,

nominal

569801

24

Page 25

Counter flange Pump type Description

Threaded For welding

ø19

ø140

ø100

ø78

Rp 1

¼

Threaded For welding

ø19

ø150

ø110

ø88

Rp 1

½

Threaded For welding

ø19

ø165

ø125

ø102

Rp 2

Threaded For welding

ø19

ø185

ø145

ø122

Rp 2½

Threaded For welding

Threaded 6 bar Rp 4 579901

Rated pressure

(EN 1092-2)

Pipework

connection

Product

number

Rp 4

ø19

For welding 6 bar

100 mm,

nominal

579902

Threaded 10 bar Rp 4 579801

MAGNA1

ø158

ø180

ø220

TM03 0483 5204

DN 100

For welding 10 bar

Threaded 16 bar Rp 4 579801

For welding 16 bar

100 mm,

nominal

100 mm,

nominal

579802

579802

Stainless-steel pumps

A counter-flange kit consists of two bronze flanges, two gaskets of asbestos-free material IT 200 and the required number of bolts and

nuts.

Counter flange Pump type Description

Rated pressure

(EN 1092-2)

Pipework

connection

Product

number

Threaded 10 bar Rp 1 1/4 96427029

MAGNA1

For welding 10 bar

32 mm,

nominal

96427030

DN 32

Threaded 16 bar Rp 1 1/4 96427029

English (GB)

TM03 0478 5204

MAGNA1

TM03 0479 5204

MAGNA1

TM03 0480 5204

MAGNA1

TM03 0481 5204

DN 40

DN 50

DN 65

For welding 16 bar

32 mm,

nominal

96427030

Threaded 10 bar Rp 1 1/2 539711

For welding 10 bar

40 mm,

nominal

539712

Threaded 16 bar Rp 1 1/2 539711

For welding 16 bar

40 mm,

nominal

539712

Threaded 10 bar Rp 2 549811

For welding 10 bar

50 mm,

nominal

549812

Threaded 10 bar Rp 2 1/2 559811

For welding 10 bar

65 mm,

nominal

559812

25

Page 26

English (GB)

ø19

ø200

ø160

ø138

Rp 3

Threaded For welding

Threaded For welding

Counter flange Pump type Description

Threaded 6 bar Rp 3 96405735

Rated pressure

(EN 1092-2)

Pipework

connection

Product

number

Rp 4

ø19

ø158

ø180

ø220

MAGNA1

TM03 0482 5204

MAGNA1

TM03 0485 5204

DN 80

DN 100

For welding 6 bar

80 mm,

nominal

569911

Threaded 10 bar Rp 3 569812

For welding 10 bar

80 mm,

nominal

569811

Threaded 6 bar Rp 4 96405737

Threaded 10 bar Rp 4 96405738

26

Page 27

11.4 Adapter for various port-to-port lengths

DN Type

A40-30 1 x 30 - - - -

40

A40-70 1 x 70 - - 100 110

A50-10 1 x 10 90 102 - 125

Height

[mm]

Diameter

[mm]

Pitch circle diameter

[mm]

Adapter

Product number

PN 6 PN 10 PN 6 PN 10 PN 6 PN 10

96281076 96608515

TM05 4372 2212

539921 539721

TM05 4373 2212

549921 549821

TM05 4374 2212

English (GB)

A50-20 1 x 20 90 102 - -

50

A50-40 1 x 40 - - - -

A50-50 1 x 50 90 102 - -

A50-60 1 x 60 - - 110 125

549922 549822

TM05 4375 2212

96281077 96608516

TM05 4376 2212

549923 549823

TM05 4377 2212

549924 549824

TM05 4378 2212

27

Page 28

English (GB)

DN Type

Height

[mm]

Diameter

[mm]

Pitch circle diameter

[mm]

Adapter

Product number

PN 6 PN 10 PN 6 PN 10 PN 6 PN 10

A65-10 1 x 10 110 122 - -

A65-25 1 x 25 110 122 - -

65

A65-160 1 x 160 - - 130 145

559921 559821

TM05 4379 2212

559922 559822

TM05 4380 2212

559923 559823

TM05 4381 2212

28

Page 29

DN Type

A80-10 1 x 10 127 138 150 160

Height

[mm]

Diameter

[mm]

Pitch circle diameter

[mm]

Adapter

Product number

PN 6 PN 10 PN 6 PN 10 PN 6 PN 10

569921 569821

TM05 4382 2212

English (GB)

A80-15 1 x 15 127 138 - -

A80-20 1 x 20 127 138 - -

A80-25 1 x 25 127 138 - -

80

A80-40 1 x 40 127 138 - -

569922 569822

TM05 4383 2212

569923 569823

TM05 4384 2212

569924 569824

TM05 4385 2212

569925 569825

A80-50 1 x 50 127 138 - -

A80-140 1 x 140 - - 150 160

100 A100-50 2 x 25 - - - -

TM05 4386 2212

569926 569826

TM05 4387 2212

569927 569827

TM05 4388 2212

96545610 96545610

TM05 4389 2212

29

Page 30

12. Technical data

Note

Note

English (GB)

Supply voltage

1 x 230 V ± 10 %, 50/60 Hz, PE.

Motor protection

The pump requires no external motor protection.

Enclosure class

IPX4D (EN 60529).

Insulation class

F.

Relative air humidity

Maximum 95 %.

Ambient temperature

0 to +40 °C.

During transport: -30 to +55 °C.

Temperature class

TF110 (EN 60335-2-51).

Liquid temperature

Continuously: -10 to +110 °C.

System pressure

The maximum permissible system pressure is stated on the pump

nameplate:

PN 6: 6 bar / 0.6 MPa

PN 10: 10 bar / 1.0 MPa

PN 16: 16 bar / 1.6 MPa.

Minimum inlet pressure

The following relative minimum inlet pressure must be available

at the pump inlet during operation to avoid cavitation noise and

damage to the pump bearings.

The relative minimum inlet pressures apply to pumps installed up

to 300 metres above sea level. For altitudes above 300 metres,

the required relative inlet pressure must be increased by

0.01 bar / 0.001 MPa per 100 metres altitude. The MAGNA1

pump is only approved for an altitude of 2000 metres above sea

level.

EMC (electromagnetic compatibility)

EN 55014-1:2006, EN 55014-2:1998, EN 61800-3-3:2008 and

EN 61000-3-2:2006.

Sound pressure level

The sound pressure level of the pump is lower than 43 dB(A).

Leakage current

The pump mains filter will cause a discharge current to earth

during operation. I

Power factor

The MAGNA1 has a built-in PFC (Power Factor Control) which

gives a cos φ from 0.98 to 0.99, i.e. very close to 1.

leakage

< 3.5 mA.

13. Disposal

This product has been designed with focus on the disposal and