Page 1

ALPHA1

Variable-speed circulators

Installation and operating instructions

GRUNDFOS INSTRUCTIONS

Listed

3191277

Conforms to ANSI/UL Std. 778

Certified to CAN/CSA Std. C22.2 No. 108

Page 2

Table of contents

ALPHA1

English (US)

Installation and operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Français (CA)

Notice d'installation et de fonctionnement . . . . . . . . . . . . . . . . . . . . . . . 17

Español (MX)

Instrucciones de instalación y operación . . . . . . . . . . . . . . . . . . . . . . . . 31

2

Page 3

English (US) Installation and operating instructions

Original installation and operating

instructions

These installation and operating instructions

describe Grundfos ALPHA1.

Sections 1-5 give the information necessary to

be able to unpack, install and start up the

product in a safe way.

Sections 6-11 give important information about

the product, as well as information on service,

fault finding and disposal of the product.

CONTENTS

Page

1. Limited warranty

2. General information

2.1 Symbols used in this document

3. Receiving the product

3.1 Inspecting the product

3.2 Scope of delivery

4. Installing the product

4.1 Quick installation tips

4.2 Mechanical installation

4.3 Changing the power head position

4.4 Electrical connection

5. Starting up the product

5.1 Venting the pump

5.2 First startup

6. Product introduction

6.1 Product description

6.2 Applications

6.3 Pumped liquids

7. Identification

7.1 Nameplate

7.2 Type key

7.3 Approvals

8. Control functions

8.1 Elements on the control panel

8.2 Display

8.3 Setting the pump

8.4 Pump control

8.5 Pump performance and operating

mode selection

9. Fault finding the product

10. Technical data

10.1 Operating conditions

11. Disposing of the product

Prior to installation, read this

document. Installation and operation

must comply with local regulations

and accepted code

s of good practice.

This appliance can be used by

children aged from 8 years and above

and persons with reduced physical,

sensory or mental capabilities or lack

of experience and knowledge if they

have been given supervision or

instruction concerning the use of the

appliance in a safe way and

understand the hazards involved.

Children must not use or play with the

appliance. Cleaning and user

maintenance shall not be made by

children without supervision.

3

4

4

4

4

1. Limited warranty

4

Products manufactured by Grundfos Pumps

5

Corporation (Grundfos) are warranted to the

original user only to be free of defects in

5

material and workmanship for a period of 30

5

months from date of installation, but not more

6

than 36 months from date of manufacture.

7

Grundfos' liability under this warranty shall be

9

limited to repairing or replacing at Grundfos'

option, without charge, F.O.B. Grundfos' factory

9

or authorized service station, any product of

9

Grundfos manufacture. Grundfos will not be

9

liable for any costs of removal, installation,

9

transportation, or any other charges that may

9

arise in connection with a warranty claim.

10

Products which are sold, but not manufactured

by Grundfos, are subject to the warranty

11

provided by the manufacturer of said products

11

and not by Grundfos' warranty.

11

Grundfos will not be liable for damage or wear to

11

products caused by abnormal operating

12

conditions, accident, abuse, misuse,

12

unauthorized alteration or repair, or if the

product was not installed in accordance with

12

Grundfos' printed installation and operating

12

instructions and accepted codes of good

12

practice. The warranty does not cover normal

wear and tear.

13

To obtain service under this warranty, the

14

defective product must be returned to the

distributor or dealer of Grundfos' products from

16

which it was purchased together with proof of

16

purchase and installation date, failure date and

16

supporting installation data. Unless otherwise

provided, the distributor or dealer will contact

Grundfos or an authorized service station for

instructions. Any defective product to be

returned to Grundfos or a service station must

be sent freight prepaid; documentation

supporting the warranty claim and/or a Return

Material Authorization must be included if so

instructed.

Successful operation depends on

careful attention to the procedures

described in this manual. Keep this

manual for future use.

English (US)

3

Page 4

English (US)

Grundfos will not be liable for any incidental or

consequential damages, losses, or expenses

arising from installation, use, or any other

causes. There are no express or implied

warranties, including merchantability or fitness

for a particular purpose, which extend beyond

those warranties described or referred to above.

Some jurisdictions do not allow the exclusion or

limitation of incidental or consequential

damages and some jurisdictions do not allow

limitations on how long implied warranties may

last. Therefore the above limitations or

exclusions may not apply to you. This warranty

gives you specific legal rights and you may also

have other rights which vary from jurisdiction to

jurisdiction.

Products which are repaired or replaced by

Grundfos or authorized service center under the

provisions of these limited warranty terms will

continue to be covered by Grundfos warranty

only through the remainder of the original

warranty period set forth by the original

purchase date.

2. General information

2.1 Symbols used in this document

DANGER

Indicates a hazardous situation which,

if not avoided, will result in death or

serious personal injury.

WARNING

Indicates a hazardous situation which,

if not avoided, could result in death or

serious personal injury.

CAUTION

Indicates a hazardous situation which,

if not avoided, could result in minor or

moderate personal injury.

The text accompanying the three hazard

symbols DANGER, WARNING and CAUTION

will be structured in the following way:

SIGNAL WORD

Description of hazard

Consequence of ignoring the warning.

- Action to avoid the hazard.

Example

DANGER

Electric shock

Death or serious personal injury

- Switch off the power supply before

starting any work on the product.

Make sure that the power supply

cannot be accidentally switched on.

A blue or grey circle with a white

graphical symbol indicates that an

action must be taken.

A red or grey circle with a diagonal

bar, possibly with a black graphical

symbol, indicates that an action must

not be taken or must be stopped.

If these instructions are not observed,

it may result in malfunction or damage

to the equipment.

Tips and advice that make the work

easier.

3. Receiving the product

3.1 Inspecting the product

Check that the product received is in

accordance with the order.

Check that the voltage and frequency of the

product match the voltage and frequency of the

installation site. See section 7. Identification for

information on the nameplate.

3.2 Scope of delivery

The box contains the following items:

• one Grundfos ALPHA1 pump

• one line cord or terminal box

• two gaskets

• installation and operating instructions

• one check valve

• one "Check Valve Installed" sticker.

4

Page 5

4. Installing the product

WARNING

Pressurized system

Death or serious personal injury

- Before dismantling the pump, drain

the system or close the isolating

valve on either side of the pump

before you remove the screws. The

pumped liquid may be scalding hot

and under high pressure.

DANGER

Electric shock

Death or serious personal injury

- Switch off the power supply before

starting any work on the product.

Make sure that the power supply

cannot be accidentally switched on.

DANGER

Electric shock

Death or serious personal injury

- This pump has not been

investigated for use in swimming

pool or marine areas.

4.1 Quick installation tips

1. To ensure proper venting of your system,

place the pump in "Constant Pressure III"

mode until all air has been removed.

Isolating zones during this process will

ensure proper air removal.

2. For balancing manifold zone(s) applications,

utilizing modes "Constant Pressure I" or

"Constant Pressure II" and only one zone at

a time during balancing will ensure proper

flow rate to each zone.

3. Always review your boiler minimum flow rate

requirements if utilizing the pump as a

primary pump. Select one of the constant

pressure modes for boiler primary pump

applications. You may change hydraulic

selection while pumping. No permanent

damage will occur. In fact, Grundfos

encourages testing the various hydraulic

modes with your hydronic system to ensure

maximum energy savings and comfort level.

4. With zone panel control applications, when

there is a call for heat and power has been

sent to the pump, the pump will remember

and restart from the last duty point and

hydraulic mode.

4.2 Mechanical installation

When making pipe connections, follow the

piping manufacturer's recommendations and all

code requirements for the piping material.

• Flush the system of debris before

installation.

• Insert the check valve if required. See fig. 1.

• Refer to the arrows on the pump housing

indicating the direction of the liquid flow

through the pump.

• Install the pump with horizontal motor shaft.

See fig. 2.

• Fit the two gaskets supplied to the pump

ends.

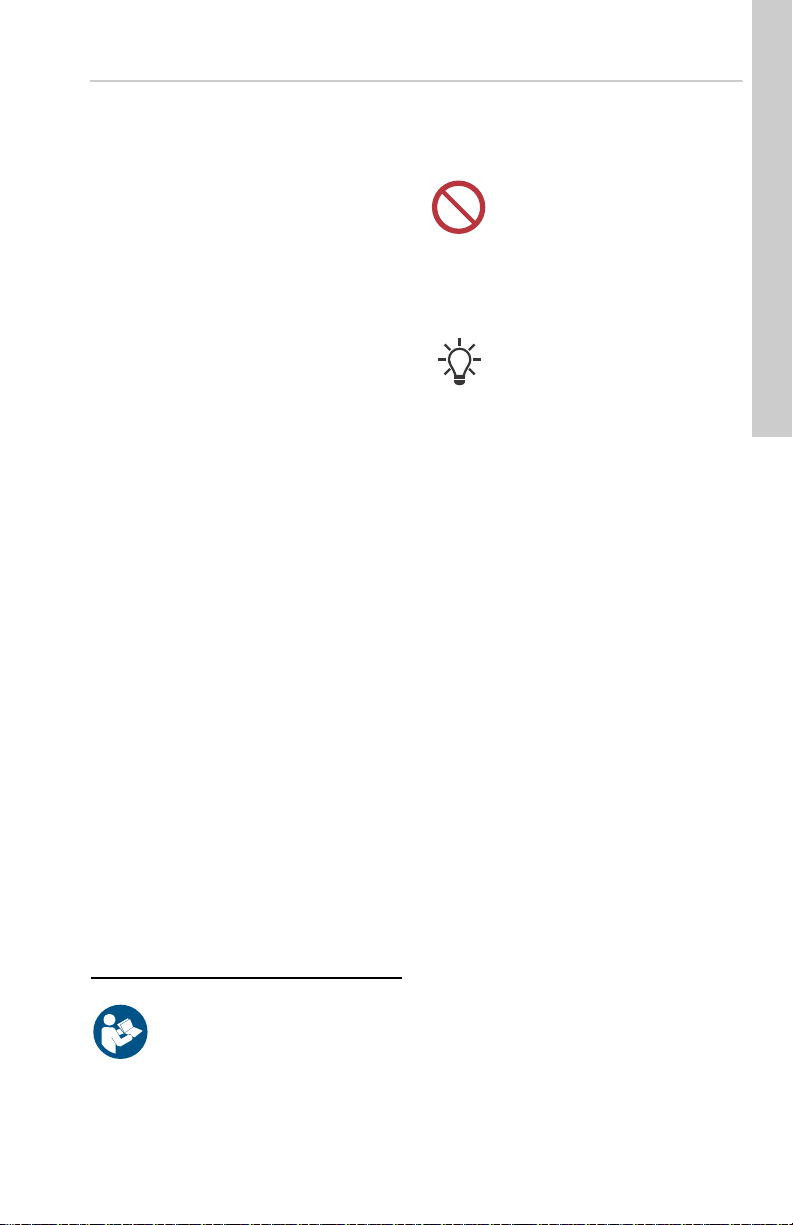

Fig. 1 Check valve installation

Fig. 2 Installation positions

English (US)

TM04 3422 4408

TM06 8959 1417

5

Page 6

English (US)

Power head

orientation A

Power head

orientation B

Power head

orientation C

Power head

orientation D

4.3 Changing the power head position

CAUTION

Hot surface

Minor or moderate personal injury

- Position the pump so that persons

cannot accidentally come into

contact with hot surfaces.

DANGER

Electric shock

Death or serious personal injury

- Switch off the power supply before

starting any work on the product.

Make sure that the power supply

cannot be accidentally switched on.

WARNING

Pressurized system

Death or serious personal injury

- Before dismantling the pump, drain

the system or close the isolating

valve on either side of the pump

before you remove the screws. The

pumped liquid may be scalding hot

and under high pressure.

If you change the position of the

power head, fill the system with the

liquid to be pumped or open the

isolating valves.

• Make any change to the power head

orientation before filling the system with

liquid. You can turn the power head in steps

of 90 °.

• See fig. 3 for permissible positions.

• Only use orientations C and D for CSA,

enclosure type 2.

Proceed as follows:

1. If liquid is present, drain the liquid from the

pump or isolate the liquid from the pump.

2. Remove the four socket head cap screws.

3. Turn the pump head to the desired position.

See fig. 3.

4. Cross-tighten the screws to: 7 ft-lbs torque.

Fig. 3 Changing the power head position

TM06 8887 1417

6

Fig. 4 Remove the four socket head cap

screws on the power head to

change the power head position

TM06 8885 1417

Page 7

4.4 Electrical connection

1

2

3

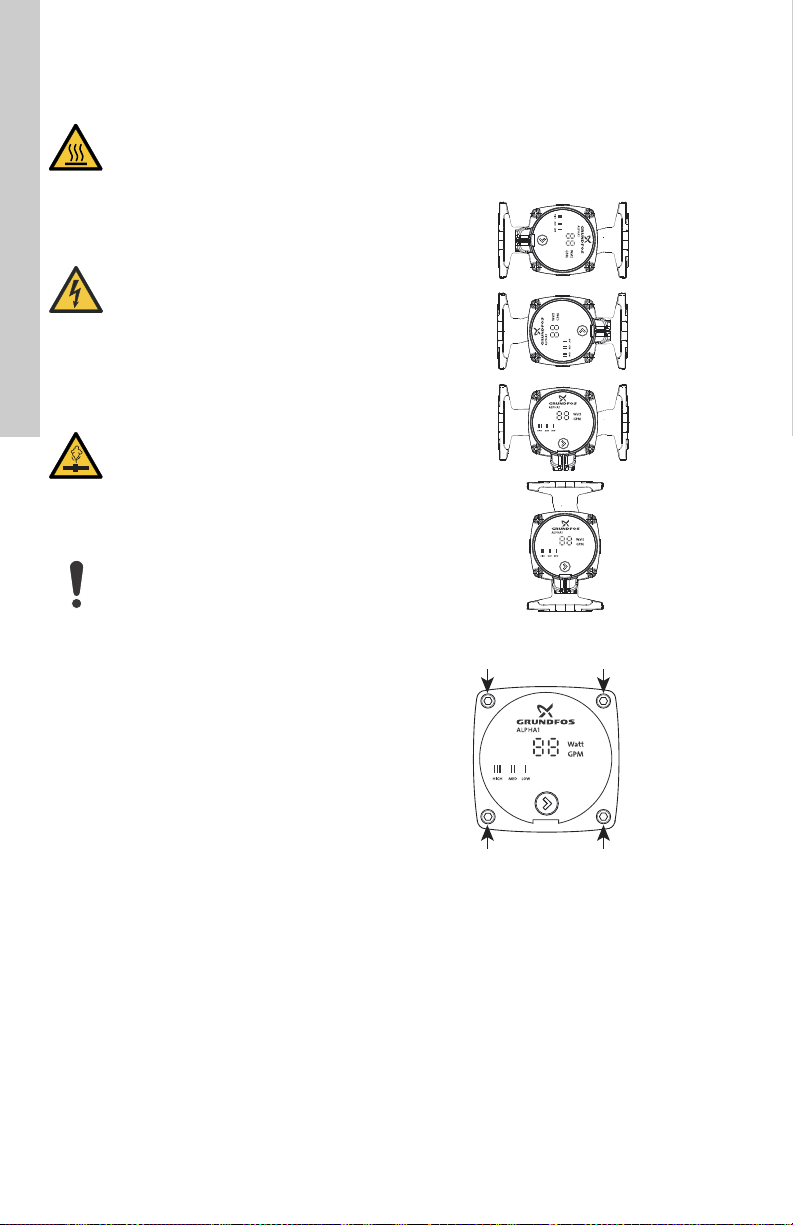

How to remove the cord plug from the

pump (bottom view):

How to insert the line cord plug onto the

pump (side view):

1. Insert a 1/8 in. flat blade

screwdriver into the slot.

2. Twist the screwdriver.

3. Pull the cord to remove it.

DANGER

Electric shock

Death or serious personal injury

- All electrical work must be carried

out by a qualified electrician in

accordance with the latest edition

of the National Electric Code and

state, local codes and regulations.

DANGER

Electric shock

Death or serious personal injury

- Switch off the power supply before

starting any work on the product.

Make sure that the power supply

cannot accidentally switched on.

4.4.1 For pump models with line cord

Follow the procedure as shown in fig. 5.

English (US)

DANGER

Electric shock

Death or serious personal injury

- This pump has not been

investigated for use in swimming

pool or marine areas.

DANGER

Electric shock

Death or serious personal injury

- This pump is supplied with a

grounding conductor and

grounding-type attachment plug. T o

reduce the risk of electric shock, be

certain that it is connected only to a

properly grounded, grounding-type

receptacle in accordance with the

National Electric Code and any

state, local governing codes and

regulations.

• The motor is protected by the electronics in

the control box and requires no external

motor protection.

• Check that the supply voltage and frequency

correspond to the values stated on the

pump.

• Only connect the pump to the power supply

with the line cord or through the terminal box

supplied with the pump; see sections

4.4.1 For pump models with line cord and

4.4.2 For pump models with terminal box.

• Do not modify and only use the line cord

supplied.

• The lights on the control panel indicate that

the electrical supply has been switched on.

Fig. 5 Connecting and removing the power

plug for line cord models

TM04 3420 1010

7

Page 8

English (US)

0.4 in.

(10 mm)

Cable conductor

from the pump

Cable conductor

from the power

supply

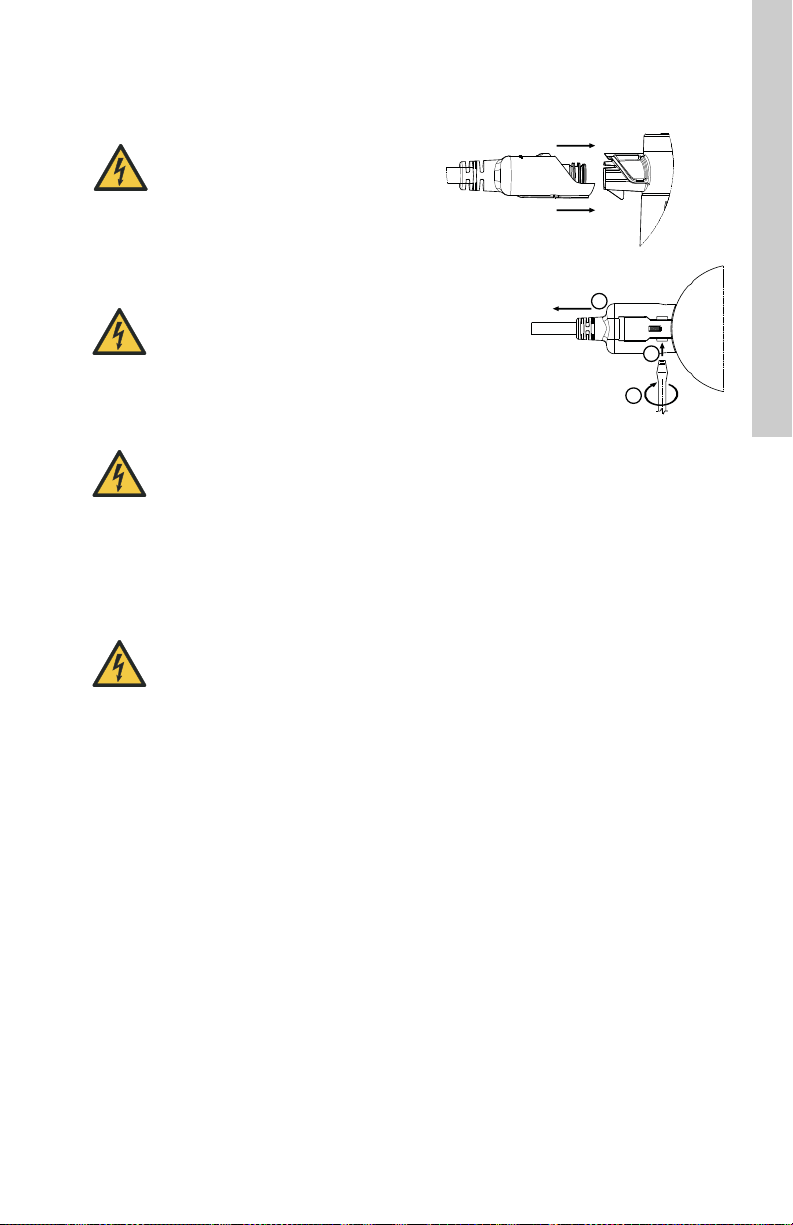

4.4.2 For pump models with terminal box

1. Loosen the terminal box screw from the

terminal box cover.

2. Utilize either conduit port for the wiring

entrance.

3. Wire the plug connector as illustrated in the

section Wiring procedure below, steps 3a3d. Then complete steps 4-7.

Be sure to connect the ground cable

conductor (green) of the pump to the

ground cable conductor of the power

supply.

Wiring procedure

Step Action Illustration

Strip the ends of the cable conductors as

3a

illustrated.

Align the end of each of the pump's cable

conductors, including any frayed strands,

with the end of the corresponding cable

conductor from the power supply.

3b

Green conductor: ground

Black conductor: line

White conductor: neutral

TM06 8250 4816

TM06 8253 4816

Insert the ends of the cable conductors

into the connector.

3c

Push the cable conductors fully into the

connector.

Twist the connector until you see two

3d

twists in the cable conductors.

4. Slide the terminal box cover over the

terminal box body.

5. Tighten the cross-head screw on the terminal

box to 5 in-lbs.

6. Switch on the power supply.

7. The lights on the control panel will then

indicate that the power supply has been

switched on.

8

TM06 8251 4816

TM06 8252 4816

Page 9

5. Starting up the product

6.2 Applications

Do not start the pump until the system

has been filled with liquid and vented.

The required minimum inlet pressure must be

available at the pump inlet.

5.1 Venting the pump

The pump is self-venting. It needs not to be

vented before startup.

The pump must not run dry.

Air in the pump may cause noise. This noise

ceases after a few minutes running.

You obtain quick venting of the pump by setting

the pump to "Constant Pressure III" for a short

period. How fast the pump is vented depends on

the system size and design.

When you have vented the pump, that is when

the noise has ceased, set the pump according to

the recommendations. See section 8.3 Setting

the pump.

You cannot vent the system through the pump.

5.2 First startup

• The light in the control panel shows that the

power supply has been switched on. See fig.

7.

• Factory setting: Constant Pressure III.

6. Product introduction

DANGER

Explosion hazard

Death or serious personal injury

- Do not use the pump for transfer of

flammable liquids such as diesel

oil, gasoline, and similar liquids.

DANGER

Electric shock

Death or serious personal injury

- This pump has not been

investigated for use in swimming

pool or marine areas.

The ALPHA1 circulator is designed for the

circulation of water in heating systems, domestic

hot-water systems as well as air-conditioning

and cold-water systems.

Cold-water systems are defined as systems

where the ambient temperature is higher than

the temperature of the pumped liquid.

The pump is the best choice for the following

systems:

• underfloor heating systems

• one-pipe systems

• two-pipe systems.

The pump is suitable for the following:

• systems with constant or variable flows

where you want to optimize the setting of the

pump duty point

• systems with variable flow-pipe temperature

• balancing of domestic heating systems.

English (US)

6.1 Product description

The ALPHA1 circulator incorporates a

permanent-magnet motor and differentialpressure control enabling continuous

adjustment of the pump performance to the

actual system requirements.

The pump has a user-friendly front-mounted

control panel. See sections 7. Identification and

8. Control functions.

When you install an ALPHA1, it means:

• Easy installation and startup.

– The pump is easy to install.

You can start the pump, in most cases,

without making any settings.

• High degree of comfort.

• Mini mum noise from valves, etc.

• Low energy consumption.

– Low energy consumption compared to

conventional circulator pumps.

9

Page 10

English (US)

6.3 Pumped liquids

For information about pressures and

temperatures, see section 10. Technical data.

CAUTION

Flammable material

Minor or moderate personal injury

- Do not use the pump for flammable

liquids, such as diesel oil and

petrol.

WARNING

Biological hazard

Death or serious personal injury

- In domestic hot-water systems, the

temperature of the pumped liquid

must always be above 122 °F (50

°C) due to the risk of legionella.

WARNING

Biological hazard

Death or serious personal injury

- In domestic hot-water systems, the

pump is permanently connected to

the mains water. Therefore, do not

connect the pump by a hose.

CAUTION

Corrosive substance

Minor or moderate personal injury

- Do not use the pump for aggressive

liquids, such as acids and

seawater.

In heating systems, the water must meet the

requirements of accepted standards on water

quality in heating systems.

The pump is suitable for the following liquids:

• Thin, clean, non-aggressive and nonexplosive liquids, not containing solid

particles or fibers.

• Cooling liquids, not containing mineral oil.

• Domestic hot water

Maximum: 14 °dH

Maximum: 149 °F (65 °C)

Maximum peak: 158 °F (70 °C).

For water with a higher degree of hardness,

contact Grundfos.

• Softened water.

2

2

/s (10 cSt)

/s (1

The kinematic viscosity of water is 1 mm

cSt) at 68 °F (20 °C). If the pump is used for a

liquid with a higher viscosity, the hydraulic

performance of the pump will be reduced.

Example: 50 % glycol at 68 °F (20 °C) means a

viscosity of approximately 10 mm

and a reduction of the pump performance by

approximately 15 %.

Do not use additives that can or will disturb the

functionality of the pump.

When selecting a pump, take the viscosity of the

pumped liquid into consideration.

For technical data, see section 10. Technical

data.

6.3.1 Glycol

The pump is designed for pumping clean water,

or up to 50/50 mixtures by weight of glycol and

water.

For glycol usage as well as additional liquid

information, see section 10. Technical data.

To prevent the glycol mixture from degrading,

avoid temperatures exceeding the rated liquid

temperature and minimize the operating time at

high temperatures.

It is important to clean and flush the system

before adding the glycol mixture.

To prevent corrosion or precipitation, check the

glycol mixture and maintain it regularly. If further

dilution of the supplied glycol is required, follow

the glycol supplier's instructions.

10

Page 11

7. Identification

3191277

Listed

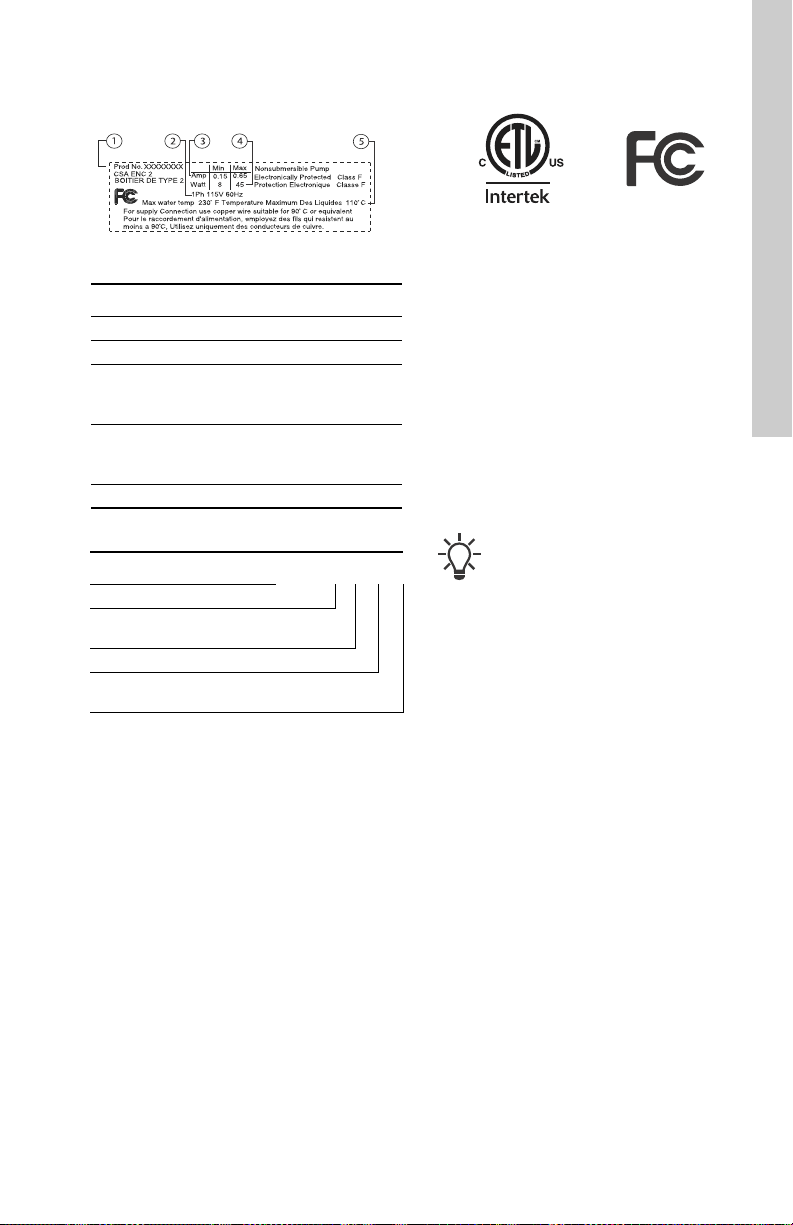

7.1 Nameplate

Fig. 6 Nameplate

Pos. Description

1 Product number

2 Voltage [V]

Rated current [A]:

3

• Min.: Minimum current [A]

• Max.: Maximum current [A]

Input power [W]:

4

• Min.: Minimum power [W]

• Max.: Maximum power [W]

5 Maximum fluid temperature [°F]

7.2 Type key

Example ALPHA1 15 -55 F

Pump type

Nominal diameter (DN) of inlet and

outlet ports [mm]

Maximum head [dm]

Pipe connection

F: Flange

7.3 Approvals

TM06 8960 1417

FCC sections

Section 15.19 (a) 3

This device complies with Part 15 of the FCC

Rules. Operation is subject to the following two

conditions: (1) this device may not cause

harmful interference, and (2) this device must

accept any interference received, including

interference that may cause undesired

operation.

Section 15.21

Any changes or modifications to this equipment

not expressly approved by the party responsible

for compliance could void the user's authority to

operate this equipment void.

Section 15.105 (b)

These limits are designed to provide reasonable

protection against harmful interference in a

residential installation. This equipment

generates, uses and can radiate radio frequency

energy and, if not installed and used in

accordance with the instructions, may cause

harmful interference to radio communications.

However, there is no guarantee that interference

will not occur in a particular installation. If this

equipment does cause harmful interference to

radio or television reception, which can be

determined by turning the equipment off and on,

the user is encouraged to try to correct the

interference by one or more of the following

measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the

• Connect the equipment to an outlet on a

• Consult the dealer or an experienced radio/

Canadian EMC Standard: ICES-003

This class B digital apparatus complies with

Canadian ICES-003.

This equipment has been tested and

found to comply with the limits for a

class B digital device, pursuant to Part

15 of the FCC Rules.

equipment and receiver.

circuit different from that to which the

receiver is connected.

TV technician for help.

English (US)

11

Page 12

English (US)

3

4

2

1

PC XXXX

8. Control functions

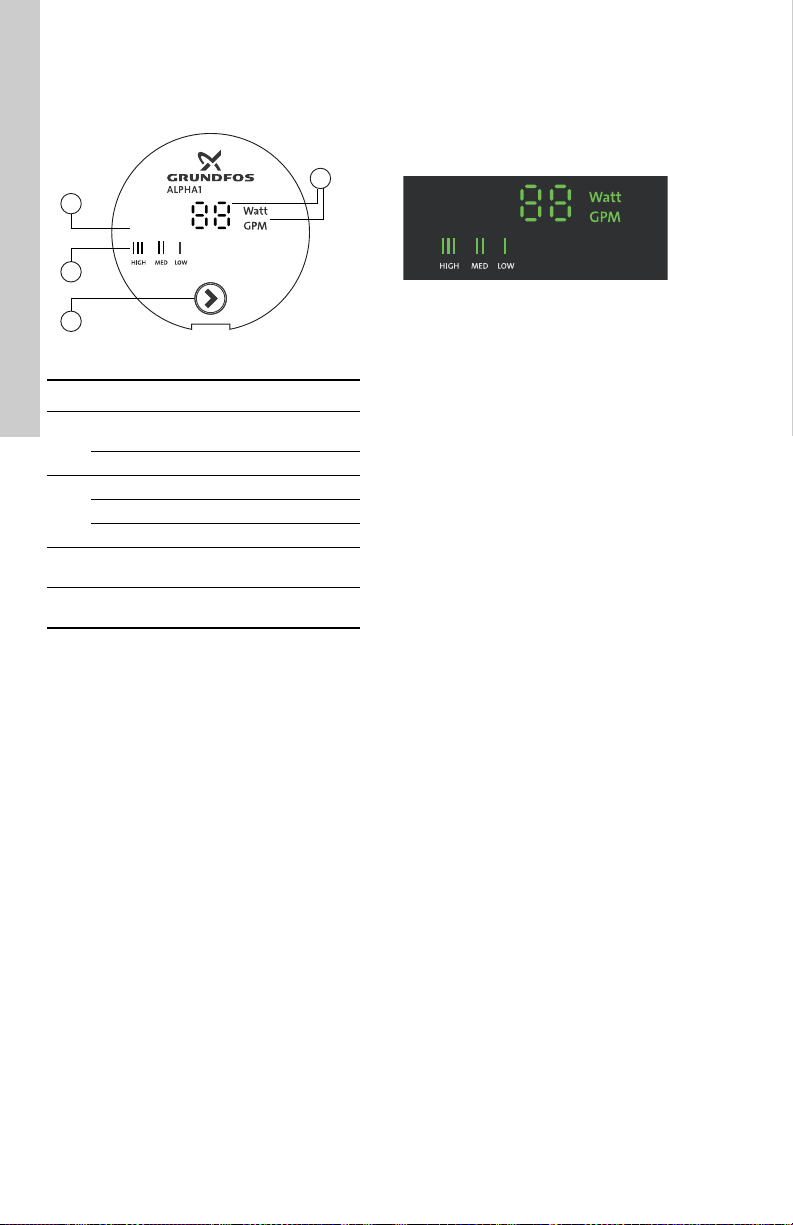

8.1 Elements on the control panel

Fig. 7 Control panel

Pos. Description

Display showing the power

consumption in watt or the flow

1

Light field indicating high and low flow

Production code:

2

• 1st and 2nd figures: year

• 3rd and 4th figures: week

Light field indicating constant pressure

3

setting

Push-button for selection of pump

4

setting

8.2 Display

The display (1) is on when you have switched on

the power supply.

The display shows the actual pump power

consumption in watt (integer) or the actual flow

during operation.

If a fault is indicated, correct the fault and reset

the pump by switching the power supply off and

on.

If the pump impeller is rotated, for example

when filling the pump with water, sufficient

energy can be generated to light up the display

even if the power supply has been switched off.

Light field indicating high and low flow

• The light field blinks for low flow

– If the flow is lower than 1 gpm, the light

field alternately flashes between "0" and

"1" randomly.

• The light field shows HI for high flow

– If the flow is higher than 12 gpm, the light

field shows "HI" on user interface.

8.2.1 Light fields indicating the pump setting

The pump has optional performance settings

which you can select with the push-button. See

fig. 7.

The pump setting is indicated by light fields in

the display. See fig. 8.

Fig. 8 Light fields

For more information about the function of the

TM06 8878 1417

settings, see section 9. Fault finding the product.

8.3 Setting the pump

You can change the pump setting by pressing

the push-button.

8.3.1 Factory default setting

The pump's factory default setting is the

Constant Pressure III setting.

8.3.2 Changing from recommended to alternative pump setting

Heating systems are "slow" systems that cannot

be set to the optimum operation within minutes

or hours.

However, if the recommended pump setting in

some applications does not give the desired

distribution of heat in the rooms of the house,

you can change to an alternative pump setting.

8.4 Pump control

See section 8.5 Pump performance and

operating mode selection.

Constant-pressure control

In this control mode, a constant differential

pressure across the pump is maintained,

irrespective of the flow.

See also sections 8. Control functions and

8.3 Setting the pump.

TM06 8893 1417

12

Page 13

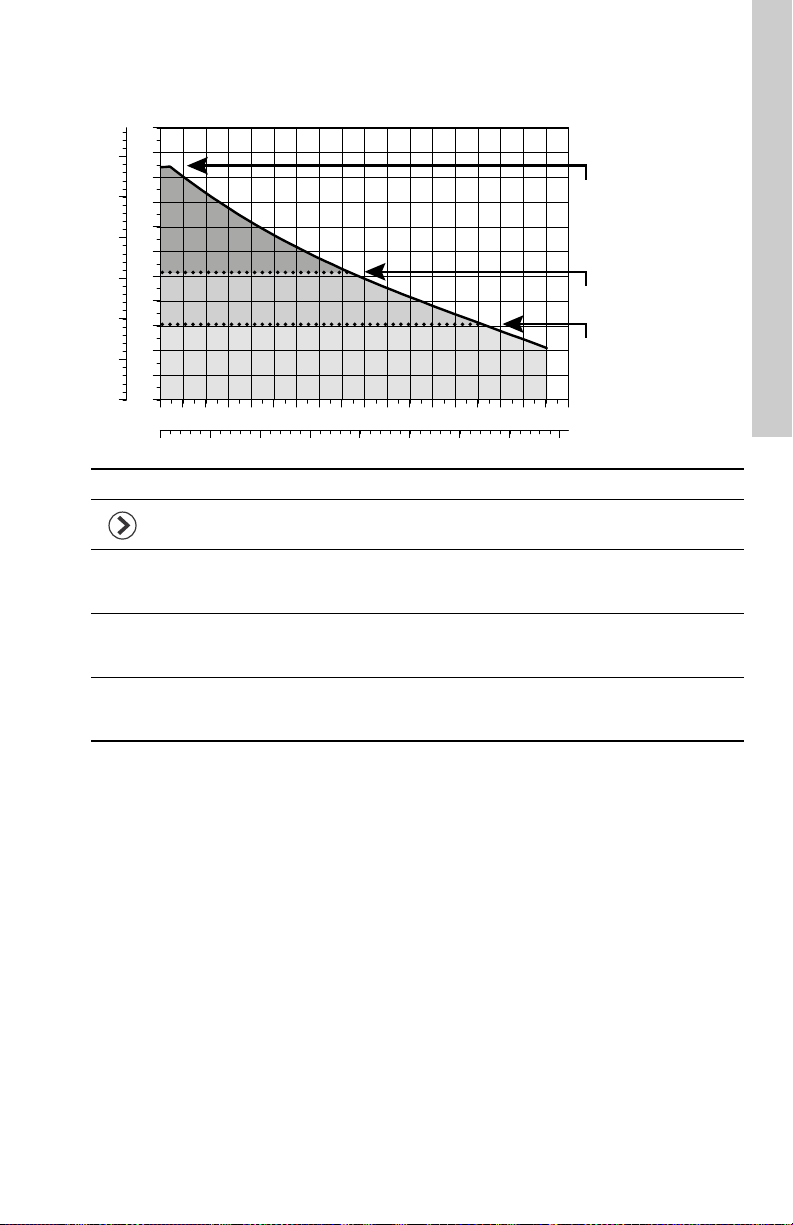

8.5 Pump performance and operating mode selection

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Q [US GPM]

0

2

4

6

8

10

12

14

16

18

20

[ft]

H

0

1

2

3

4

5

6

[m]

H

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0

Q [m³/h]

Constant Pressure III

Constant Pressure II

Constant Pressure I

17 18

The hydraulic performance shown is without check valve.

Pos. Description

• Push-button for selection of pump setting

• Every time you press the push-button, the circulator setting is changed.

Constant pressure III

III

• The duty point of the pump will move left and right along the highest constant-pressure

curve depending on the water demand in the system.

Constant pressure II

II

• The duty point of the pump will move left and right along the middle constant-pressure

curve depending on the water demand in the system.

Constant pressure I

I

• The duty point of the pump will move left and right along the lowest constant-pressure

curve depending on the water demand in the system.

English (US)

TM06 8910 1417

13

Page 14

English (US)

9. Fault finding the product

DANGER

Electric shock

Death or serious personal injury

- Switch off the power supply before

starting any work on the product.

Make sure that the power supply

cannot be accidentally switched on.

Fault Control panel Remedy

1. The pump

does not

run.

2. Noise in

the system

3. Noise in

the pump

The light field is

off.

The light field is

on.

___ ___" a) Supply voltage is too

"

The light field is

on.

The light field is

on.

a) The pump is not

connected to the

power supply.

b) The circuit breaker

has tripped.

c) The pump is

defective.

a) Supply voltage is too

high.

b) The rotor is blocked

by impurities.

low.

a) There is air in the

system.

b) The flow is too high. Reduce the pump speed.

c) Thermal expansion

of system

components.

a) There is air in the

pump.

b) The inlet pressure is

too low.

c) No liquid (dry

running).

d) The pump is

defective.

WARNING

Pressurized system

Death or serious personal injury

- Before dismantling the pump, drain

the system or close the isolating

valve on either side of the pump

before you remove the screws. The

pumped liquid may be scalding hot

and under high pressure.

Connect the pump to the power

supply.

Cut in the circuit breaker.

Replace the pump.

Check that the power supply falls

within the specified range.

Remove the impurities.

Switch the power off and on.

Check for air, locked rotor and/or

voltage.

Correct the power supply.

Install an air eliminator.

Check the mounting brackets for

the pipes.

Secure loose mounting brackets.

Let the pump run, as it will vent

over time.

Install an air eliminator.

Increase the inlet pressure.

Check the air volume in the

expansion tank, if this is installed.

(Pressure leaks in the system can

lead to cavitation.)

Ensure the system has been filled

with liquid and vented.

Open the isolating valves.

Replace the pump.

14

Page 15

Fault Control panel Remedy

4. Insufficient

heat

The light field is

on.

a) The pump

performance is set

too low.

b) The thermostat is set

too low or is not

working.

c) Air or gas in the

system.

d) The valves are

sticking.

e) Wrong direction of

flow.

f) The boiler is not

working properly.

g) The pump

performance is not

adequate for the

application.

h) The pump

performance is not

adequate for the

application.

Increase the pump's constant

pressure setting.

Check to see if the circulator is in

the proper operating mode.

Check the thermostat to ensure

that it is set to the desired

temperature and is working.

Replace the batteries in the

thermostat.

Vent the air or gas from the system

by allowing the pump to run, as it

will vent over time.

Install an air eliminator.

If necessary rework the piping.

Make sure all valves are in good

working order, that is remove lime

deposits.

See the direction of flow arrow

marked on the pump.

Reinstall the pump to correct the

direction of flow.

Check the water temperature from

the boiler and check the boiler

functions.

Repair the boiler if required.

Check for proper sizing of the

circulator and other system

components.

Check the T calculation.

English (US)

15

Page 16

English (US)

10. Technical data

10.1 Operating conditions

Supply voltage

1 x 115 V, + 10 %/- 10 %, 60 Hz.

Motor protection

The pump requires no external motor protection.

Enclosure class

Indoor use only, IP42.

CSA enclosure type 2.

Insulation class

F.

Relative humidity

Maximum 95 %.

Maximum outlet pressure

150 psi (10.34 bar).

Inlet pressure

Liquid

temperature

167 °F (75 °C) 0.75 psi (0.05 bar)

194 °F (90 °C) 4.06 psi (0.28 bar)

230 °F (110 °C) 15.7 psi (1.08 bar)

Sound pressure level

43 dB (A).

Ambient temperature

32 °F (0 °C) to 104 °F (40 °C).

Liquid temperature

36 °F (2 °C) to 230 °F (110 °C).

To avoid condensation in the control box and

stator, the liquid temperature must always be

higher than the ambient temperature.

Ambient

temperature

[°F (°C) ]

32 (0) 36 (2) 230 (110)

50 (10) 50 (10) 230 (110)

68 (20) 68 (20) 230 (110)

86 (30) 86 (30) 230 (110)

95 (35) 95 (35) 194 (90)

104 (40) 104 (40) 158 (70)

Liquid temperature

Minimum

[°F (°C)]

Minimum

inlet pressure

Maximum

[°F (°C) ]

Glycol

Maximum glycol concentrations with clean

water:

50 % glycol @ 36 °F (2 °C).

Hydraulic performance change can be expected.

Watt readings

Accuracy: ± 1 Watt.

Flow indicator

Provides a relative indication of flow - must not

be used in lieu of a flow meter.

Check valve

Use of a check valve may reduce pump

hydraulic performance (up to - 10 %).

Use a check valve in parallel pumping

applications.

Curve conditions

Test liquid: Airless water.

Curves apply to a density of 983.2 kg/m

liquid temperature of 140 °F (60 °C).

All curves show average values and must not be

used as guarantee curves. If a specific minimum

performance is required, individual

measurements must be made.

Curves apply to a kinematic viscosity of 0.474

cSt.

Approximate power usage

Speed

setting

Constant

pressure

Constant

pressure

Constant

pressure

Minimum Maximum

III 39 W 45 W

II 14 W 45 W

I 8 W 45 W

3

and a

11. Disposing of the product

This product or parts of it must be disposed of in

an environmentally sound way:

1. Use the public or private waste collection

service.

2. If this is not possible, contact the nearest

Grundfos company or service workshop.

Subject to alterations.

16

In domestic hot water systems, keep

the liquid temperature below 149 °F

(65 °C) to eliminate the risk of lime

precipitation.

Page 17

Français (CA) Notice d'installation et de fonctionnement

Traduction de la version anglaise originale

La présente notice d'installation et d'utilisation

décrit la pompe Grundfos ALPHA1.

Les paragraphes 1 à 5 fournissent les informations nécessaires pour déballer, installer et

démarrer le produit en toute sécurité.

Les paragraphes 6 à 11 donnent des informations importantes sur le produit, ainsi que sur la

maintenance, le dépannage et la mise au rebut.

SOMMAIRE

Page

1. Garantie limitée

2. Informations générales

2.1 Symboles utilisés dans cette notice

3. Réception du produit

3.1 Inspection du produit

3.2 Livraison

4. Installation du produit

4.1 Conseils d'installation rapide

4.2 Installation mécanique

4.3 Modification de la position de la tête

de pompe

4.4 Connexion électrique

5. Mise en service du produit

5.1 Purge de la pompe

5.2 Première mise en service

6. Introduction au produit

6.1 Description du produit

6.2 Applications

6.3 Liquides pompés

7. Identification

7.1 Plaque signalétique

7.2 Désignation

7.3 Approbations

8. Fonctions de régulation

8.1 Composition du panneau de commande

8.2 Affichage

8.3 Réglage de la pompe

8.4 Régulation de la pompe

8.5 Sélection mode de fonctionnement et

rendement

9. Détection des défauts de fonctionnement

10. Caractéristiques techniques

10.1 Conditions de fonctionnement

11. Mise au rebut du produit

Avant de procéder à l'installation, lire

attentivement cette notice. L'installa-

ion et le fonctionnement doivent être

t

conformes à la réglementation locale

et aux règles de bonne pratique en

vigueur.

Ce produit peut être utilisé par des

enfants âgés d'au moins 8 ans, et par

des personnes ayant des capacités

physiques, sensorielles ou mentales

limitées ou dénuées d'expérience ou

de connaissances, si elles sont correctement supervisées, ou si des instructions relatives à l'utilisation du produit en toute sécurité leur ont été

données, et si les risques encourus

ont été appréhendés. Les enfants ne

sont pas autorisés à utiliser ce produit

ni à jouer avec. Le nettoyage et

17

18

18

18

18

18

19

19

19

1. Garantie limitée

Les produits fabriqués par Grundfos Pumps Cor-

20

poration (Grundfos) sont garantis, uniquement

21

pour l'utilisateur initial, exempts de défauts de

23

matériaux et de fabrication pour une période de

23

30 mois à compter de la date d'installation, mais

au plus 36 mois à compter de la date de fabrica-

23

tion. Dans le cadre de cette garantie, la respon-

23

sabilité de Grundfos se limite à la réparation ou

23

au remplacement, à la convenance de

23

Grundfos, sans frais, FOB de l'usine Grundfos

24

ou d'un atelier de maintenance autorisé, de tout

produit de fabrication Grundfos. Grundfos

25

n'assume aucune responsabilité quant aux frais

25

de dépose, d'installation, de transport ou pour

25

toute autre charge pouvant survenir en relation

25

avec une réclamation au titre de la garantie.

26

Les produits vendus mais non fabriqués par

Grundfos sont couverts par la garantie fournie

26

par le fabricant des dits produits et non par la

garantie de Grundfos.

26

Grundfos n'est responsable ni des dommages ni

26

de l'usure des produits causés par des condi-

26

tions d'exploitation anormales, un accident, un

abus, une mauvaise utilisation, une altération ou

27

une réparation non autorisée, ou par une installation du produit non conforme aux notices d'ins-

28

tallation et de fonctionnement imprimées de

30

Grundfos, ainsi qu'aux codes de bonnes pratiques communément acceptés. La garantie ne

30

couvre pas l'usure normale.

30

Pour bénéficier de la garantie, il faut renvoyer le

produit défectueux au distributeur ou au revendeur de produits Grundfos chez qui il a été

acheté, accompagné de la preuve d'achat, de la

date d'installation, de la date du dysfonctionnement ainsi que des données concernant l'installation. Sauf disposition contraire, le distributeur

ou le revendeur contactera Grundfos ou un atelier de maintenance autorisé pour obtenir des

l'entretien ne doivent pas être effectués par des enfants sans surveillance.

Un bon fonctionnement dépend de

l'attention particulière accordée aux

procédures décrites dans ce manuel.

Conservez ce manuel pour une utilisation future.

Français (CA)

17

Page 18

Français (CA)

instructions. Tout produit défectueux renvoyé à

Grundfos ou à un atelier de maintenance doit

être expédié port payé ; la documentation relative à la déclaration de demande de garantie et

à une autorisation de retour de matériel éventuelle doit être jointe, si elle est demandée.

Grundfos n'assume aucune responsabilité en

cas de dommages indirects ou consécutifs, de

pertes ou de dépenses résultant de l'installation,

de l'utilisation ou de toute autre cause. Il n'existe

aucune garantie, explicite ni implicite, y compris

la qualité marchande ou l'adéquation pour un

usage particulier, en dehors des garanties

décrites ou mentionnées ci-dessus. Certaines

juridictions n'autorisent pas l'exclusion ou la

limitation des dommages indirects ou consécutifs, et certaines juridictions ne permettent pas

de limiter la durée des garanties implicites. Il se

peut donc que les limitations ou exclusions mentionnées ci-dessus ne soient pas applicables

dans votre cas. Cette garantie vous donne des

droits légaux spécifiques. Il se peut que vous

ayez également d'autres droits qui varient d'une

juridiction à l'autre.

Les produits qui sont réparés ou remplacés par

Grundfos ou par atelier de maintenance autorisé, en vertu des dispositions de ces conditions

de garantie limitée, continueront à être couverts

par la garantie Grundfos uniquement pendant le

reste de la période de garantie initialement fixée

à la date d'achat d'origine.

2. Informations générales

2.1 Symboles utilisés dans cette notice

DANGER

Indique une situation dangereuse qui,

si elle n'est pas évitée, entraînera des

blessures graves ou la mort.

AVERTISSEMENT

Indique une situation dangereuse qui,

si elle n'est pas évitée, peut entraîner

des blessures graves ou la mort.

PRÉCAUTIONS

Indique une situation dangereuse qui,

si elle n'est pas évitée, peut entraîner

des blessures légères ou modérées.

Le texte qui accompagne les trois symboles

DANGER, AVERTISSEMENT et PRUDENCE

est structuré de la façon suivante :

Exemple

DANGER

Choc électrique

Blessures graves ou mort

- Avant toute intervention sur le produit, couper l'alimentation électrique. S'assurer que l'alimentation

électrique ne risque pas d'être

branchée accidentellement.

Un cercle bleu ou gris autour d'un pictogramme blanc indique qu'il faut agir.

Un cercle rouge ou gris avec une

barre diagonale, éventuellement avec

un symbole graphique noir, indique

qu'une mesure ne doit pas être prise

ou doit être arrêtée.

Le non-respect de ces consignes peut

entraîner des dysfonctionnements ou

endommager l'équipement.

Conseils et astuces pour faciliter les

opérations.

3. Réception du produit

3.1 Inspection du produit

Vérifier que le produit reçu est conforme à la

commande.

Vérifier que la tension et la fréquence du produit

correspondent à celles du site d'installation.

Pour plus d'informations sur la plaque signalétique, voir paragraphe 7. Identification.

3.2 Livraison

L'emballage contient les éléments suivants :

• une pompe Grundfos ALPHA1 ;

• un cordon d'alimentation ou une boîte de

raccordement ;

• deux joints ;

• des notices d'installation et de fonctionnement ;

• un clapet antiretour ;

• un autocollant "Clapet anti-retour installé".

18

TERME

DESIGNALEMENT

Description du danger

Conséquence de la non-observance

de l'avertissement.

- Mesures pour éviter le danger.

Page 19

4. Installation du produit

AVERTISSEMENT

Système sous pression

Blessures graves ou mort

- Avant de démonter la pompe, purger l'installation ou fermer le robinet

d'arrêt de chaque côté de la pompe

avant de retirer les vis. Le liquide

pompé peut être bouillant et sous

haute pression.

DANGER

Choc électrique

Blessures graves ou mort

- Avant toute intervention sur le produit, couper l'alimentation électrique. S'assurer que l'alimentation

électrique ne risque pas d'être

branchée accidentellement.

DANGER

Choc électrique

Blessures graves ou mort

- Cette pompe n'est pas homologuée

pour une utilisation en piscine ou

dans les zones marines.

4.1 Conseils d'installation rapide

1. Pour assurer une ventilation adéquate de

votre système, placez la pompe en mode

"Constant Pressure III" jusqu'à ce que l'air

soit éliminé. Pendant ce processus, les

zones d'isolation permettront d'assurer une

élimination adéquate de l'air.

2. Pour équilibrer les applications de zones de

manifold, l'utilisation des modes "Constant

Pressure I" ou "Constant Pressure II" et

d'une seule zone à la fois (pendant l'équilibrage) assure que le débit est approprié

pour chaque zone.

3. Pour utiliser la pompe comme pompe primaire, toujours examiner les exigences de

débit minimum de la chaudière. Sélectionner

un des modes de pression constante pour

les applications de pompes primaires de la

chaudière. Vous pouvez modifier la sélection

hydraulique pendant le pompage. Aucun

dommage permanent ne se produira. En fait,

Grundfos encourage à tester les différents

modes hydrauliques avec votre système

hydronique, pour garantir un maximum

d'économie d'énergie et de niveau de

confort.

4. Avec les applications de commande du panneau de zone, lorsqu'un appel pour de la

chaleur et de l'énergie est envoyé à la

pompe, celle-ci mémorise le dernier point de

service et le mode hydraulique en cours, et

elle redémarrera à partir de ceux-ci.

4.2 Installation mécanique

Lors des raccords de tuyauterie, veuillez suivre

les recommandations du fabricant de tuyaux et

toutes les exigences du code pour la tuyauterie.

• Rincer les débris du système avant l'installation.

• Installer un clapet antiretour si cela est

nécessaire. Voir fig. 1.

• Veuillez vous référer aux flèches sur le corps

de pompe indiquant le sens de circulation du

liquide dans la pompe.

• Installer la pompe avec l'arbre du moteur à

l'horizontale. See fig. 2.

• Monter les deux joints fournis aux extrémités

de la pompe.

Fig. 1 Installation du clapet antiretour

Fig. 2 Positions d'installation

Français (CA)

TM04 3422 4408

TM06 8959 1417

19

Page 20

Français (CA)

Tête de

pompe orientation A

Tête de

pompe orientation B

Tête de

pompe orientation C

Tête de pompe

orientation D

4.3 Modification de la position de la tête de pompe

PRÉCAUTIONS

Surface chaude

Blessure mineure ou modérée

- Veiller à ce que la pompe soit positionnée de telle manière que personne ne puisse entrer accidentellement en contact avec les surfaces

chaudes.

DANGER

Choc électrique

Blessures graves ou mort

- Avant toute intervention sur le produit, couper l'alimentation électrique. S'assurer que l'alimentation

électrique ne risque pas d'être

branchée accidentellement.

AVERTISSEMENT

Système sous pression

Blessures graves ou mort

- Avant de démonter la pompe, purger l'installation ou fermer le robinet

d'arrêt de chaque côté de la pompe

avant de retirer les vis. Le liquide

pompé peut être bouillant et sous

haute pression.

Si vous modifiez la position de la tête

de pompe, remplir l'installation avec le

liquide à pomper et ouvrir les robinets

d'arrêt.

• Effectuer toute modification de l'orientation

de la tête de pompe avant de remplir le système de liquide. Vous pouvez tourner la tête

de pompe par rotations de 90 °.

• Voir fig. 3 pour les positions autorisées.

• Pour les boîtiers de protection électrique de

type 2 (CSA), utiliser uniquement les orientations C et D.

Procédure :

1. Si du liquide est présent, purger la pompe ou

isoler le liquide de la pompe.

2. Retirer les quatre vis à tête creuse.

3. Tourner la tête de pompe dans la position

requise. Voir fig. 3.

4. Serrer les vis en croix au couple de 7 lb-pi.

Fig. 3 Modification de la position de la tête

Fig. 4 Retirer les quatre vis à tête creuse

de pompe

sur la tête de pompe pour changer

la position de la tête de pompe

TM06 8887 1417

TM06 8885 1417

20

Page 21

4.4 Connexion électrique

1

2

3

Pour retirer la fiche du cordon de la

pompe (vue de dessous) :

Pour insérer la fiche du cordon d'alimentation dans la pompe (vue latérale) :

1. Insérer un tournevis à

lame plate de 1/8 po dans

la fente.

2. Tourner le tournevis.

3. Tirer sur le cordon pour le

retirer.

DANGER

Choc électrique

Blessures graves ou mort

- Toutes les installations électriques

doivent être effectuées par un électricien qualifié conformément à la

version la plus récente du Code

national de l'électricité, aux codes

nationaux et locaux, ainsi qu'aux

réglementations locales.

DANGER

Choc électrique

Blessures graves ou mort

- Avant toute intervention sur le produit, couper l'alimentation électrique. S'assurer que l'alimentation

électrique ne risque pas d'être

branchée accidentellement.

DANGER

Choc électrique

Blessures graves ou mort

- Cette pompe n'est pas homologuée

pour une utilisation en piscine ou

dans les zones marines.

DANGER

Choc électrique

Blessures graves ou mort

- Cette pompe est fournie avec un

conducteur de mise à la terre et

une fiche de fixation de mise à la

terre. Afin de réduire le risque de

choc électrique, ne relier la pompe

que sur un boîtier électrique correctement relié à la terre, conformément au Code national de l'électricité, aux codes nationaux et locaux,

ainsi qu'aux réglementations

locales.

• Le moteur est protégé par l'électronique du

boîtier de commande et ne nécessite aucune

protection moteur externe.

• Vérifier que la tension d'alimentation et la

fréquence correspondent aux valeurs indiquées sur la plaque signalétique de la

pompe.

• Ne raccorder la pompe à l'alimentation électrique qu'avec le cordon d'alimentation ou

par la boîte de raccordement fournis avec la

pompe ; voir sections 4.4.1 Pour les modèles

de pompes avec cordon d'alimentation et

4.4.2 Pour les modèles de pompes avec

boîte de raccordement.

• Utiliser uniquement le cordon d'alimentation

fourni et n'y apporter aucune modification.

• Les voyants sur le panneau de commande

indiquent que l'alimentation électrique a été

activée.

4.4.1 Pour les modèles de pompes avec

cordon d'alimentation

Suivre la procédure indiquée en fig. 5.

Fig. 5 Raccordement et débranchement

de la fiche d'alimentation pour les

modèles à cordon d'alimentation

Français (CA)

TM04 3420 1010

21

Page 22

Français (CA)

0,4 po

(10 mm)

Conducteur de

câble de la

pompe

Conducteur de

câble de l'alimentation électrique

4.4.2 Pour les modèles de pompes avec boîte de raccordement

1. Desserrer la vis de la boîte de raccordement

du couvercle de cette dernière.

2. Utiliser l'un ou l'autre des ports de conduit

pour l'entrée du câblage.

3. Fixer le connecteur mâle comme illustré au

paragraphe Procédure de câblage ci-dessous, étapes 3a-3d. Effectuer ensuite les

étapes 4 à 7.

S'assurer de brancher le conducteur

de câble de mise à la terre (vert) de la

pompe au conducteur de câble de

mise à la terre de l'alimentation électrique.

Procédure de câblage

Étape Action Illustration

Dénuder les extrémités des conducteurs

3a

de câble comme indiqué dans l'illustration.

Aligner l'extrémité de chacun des conducteurs de câble de la pompe, y compris les

brins effilochés, avec l'extrémité du

conducteur de câble correspondant de

3b

l'alimentation électrique.

Conducteur vert : terre

Conducteur noir : ligne

Conducteur blanc : neutre

TM06 8250 4816

TM06 8253 4816

Insérer les extrémités des conducteurs du

câble dans le connecteur.

3c

Pousser les conducteurs de câble complètement dans le connecteur.

Tourner le connecteur jusqu'à ce que les

3d

deux torsions soient visibles dans les

conducteurs de câble.

4. Glisser le couvercle de la boîte de raccorde-

ment sur celle-ci.

5. Serrer la vis à tête croisée sur la boîte de

raccordement à 5 lb-po.

22

6. Mettre l'alimentation électrique sous tension.

7. Les voyants sur le panneau de commande

indiquent que l'alimentation électrique a été

activée.

TM06 8251 4816

TM06 8252 4816

Page 23

5. Mise en service du produit

6.2 Applications

Ne jamais démarrer la pompe avant

que l'installation n'ait été remplie de

liquide et purgée.

La pression d'aspiration minimale requise doit

être disponible à l'entrée de la pompe.

5.1 Purge de la pompe

La purge de la pompe est automatique. La

pompe n'a pas besoin d'être purgée avant la

mise en service.

La pompe ne doit pas fonctionner à

sec.

L'air se trouvant dans la pompe peut engendrer

du bruit. Ce bruit doit normalement cesser au

bout de quelques minutes de fonctionnement.

Pour obtenir une purge rapide de la pompe, la

régler sur "Constant Pressure III" pendant une

courte période. La rapidité de purge de la

pompe dépend de la taille et de la conception de

l'installation.

Lorsque vous avez purgé la pompe, á savoir

lorsque le bruit a cessé, régler la pompe en

fonction des recommandations. Voir paragraphe 8.3 Réglage de la pompe.

Vous ne pouvez pas purger l'installation par la

pompe.

5.2 Première mise en service

• Le voyant situé sur le panneau de commande

indique la mise sous tension. Voir fig. 7.

• Réglage en usine : "Constant Pressure III".

6. Introduction au produit

6.1 Description du produit

La pompe ALPHA1 est équipée d'un moteur à

aimant permanent et d'une régulation de la pression différentielle permettant l'ajust ement continuel

du rendement de la pompe en fonction des

besoins réels de l'installation.

La pompe dispose d'un panneau de commande

convivial monté sur la face avant. Voir paragraphes 7. Identification et 8. Fonctions de régula-

tion.

L'installation d'une pompe ALPHA1 signifie :

• Une installation et une mise en service faciles.

– La pompe est facile à installer.

Elle peut être démarrée sans effectuer de

réglage, dans la plupart des cas.

• Un confort de haut niveau.

• Moins de bruit dans les vannes, etc.

• Une faible consommation d'énergie.

– Faible consommation d'énergie par rapport

aux pompes de circulation traditionnelles.

DANGER

Risque d'explosion

Blessures graves ou mort

- Ne pas utiliser la pompe pour le

transfert de liquides inflammables

tels que le carburant diesel,

l'essence et les liquides similaires.

DANGER

Choc électrique

Blessures graves ou mort

- Cette pompe n'est pas homologuée

pour une utilisation en piscine ou

dans les zones marines.

La pompe ALPHA1 est conçue pour la circulation de l'eau dans les installations de chauffage,

dans les installations d'eau chaude sanitaire,

ainsi que dans les installations d'eau froide et de

climatisation.

Les installations d'eau froide sont définies

comme des installations dans lesquelles la température ambiante est supérieure à la température du liquide pompé.

La pompe est le choix idéal dans les installations suivantes :

• installations de chauffage par le sol ;

• installations mono-tubes ;

• installations bi-tubes.

La pompe est conçue pour :

• les installations à débits constants ou

variables dans lesquelles vous souhaitez

optimiser le réglage du point de consigne de

la pompe ;

• les systèmes fonctionnant à des températures variables ;

• l'équilibrage des installations d'eau chaude

sanitaire.

Français (CA)

23

Page 24

Français (CA)

6.3 Liquides pompés

Pour des informations sur les pressions et les

températures, voir paragraphe

10. Caractéristiques techniques.

PRÉCAUTIONS

Matériau inflammable

Blessure mineure ou modérée

- Ne pas utiliser la pompe pour les

liquides inflammables, tels que le

carburant diesel et l'essence.

AVERTISSEMENT

Danger biologique

Blessures graves ou mort

- Dans les installations d'eau chaude

sanitaire, la température du liquide

pompé doit toujours être supérieure

à 122 °F (50 °C) pour éviter tout

risque de transmission de la légionelle.

AVERTISSEMENT

Danger biologique

Blessures graves ou mort

- Dans les installations d'eau chaude

sanitaire, la pompe est reliée en

permanence au réseau d'alimentation. Par conséquent, ne pas relier

la pompe par un tuyau flexible.

PRÉCAUTIONS

Substance corrosive

Blessure mineure ou modérée

- Ne pas utiliser la pompe pour les

liquides agressifs tels que l'acide et

l'eau de mer.

Dans les installations de chauffage, la qualité de

l'eau doit être conforme aux normes de qualité

reconnues pour l'eau dans les installations de

chauffage.

La pompe est conçue pour les liquides suivants :

• liquides clairs, non agressifs et non explosifs, ne contenant ni particules solides ni

fibres ;

• liquides de refroidissement ne contenant

aucune huile minérale ;

• eau chaude sanitaire ;

maximum : 14 °dH ;

maximum : 149 °F (65 °C) ;

pointe maximale : 158 °F (70 °C).

Pour l'eau ayant un degré de dureté supérieur, veuillez contacter Grundfos ;

• eau adoucie.

La viscosité cinématique de l'eau est de

2

/s (1 cSt) à 68 °F (20 °C). Si la pompe est

1 mm

utilisée pour un liquide dont la viscosité est plus

élevée, le rendement hydraulique en sera réduit.

Exemple : 50 % de glycol à 68 °F (20 °C) correspond à une viscosité d'environ 10 mm

cSt) et à une réduction du rendement de la

pompe d'environ 15 %.

Ne pas utiliser d'additifs qui peuvent perturber le

fonctionnement de la pompe.

Prendre en compte la viscosité du liquide pompé

lors de la sélection de la pompe.

Pour les spécifications techniques, voir paragraphe 10. Caractéristiques techniques.

6.3.1 Glycol

La pompe est conçue pour pomper de l'eau

claire ou des mélanges allant jusqu'à 50/50 en

poids de glycol et d'eau.

Pour l'utilisation du glycol ainsi que des informations sur les liquides supplémentaires, voir le

paragraphe 10. Caractéristiques techniques.

Pour prévenir la dégradation du mélange de glycol, éviter les températures supérieures à la

température nominale du liquide et minimiser le

temps de fonctionnement à hautes températures.

Bien nettoyer et rincer le système avant d'ajouter le mélange de glycol.

Vérifier régulièrement l'état du mélange glycol

pour prévenir la corrosion et la précipitation. S'il

est nécessaire de diluer davantage le glycol,

suivre les instructions du fournisseur de glycol.

2

/s (10

24

Page 25

7. Identification

3191277

Enregistré

7.1 Plaque signalétique

Fig. 6 Plaque signalétique

Pos. Description

1 Code article

2 Tension [V]

Intensité nominale [A] :

3

• Min. : Intensité minimale [A ]

• Max. : Intensité maximale [A]

Puissance absorbée [W] :

4

• Min. : Puissance minimale [W]

• Max. : Puissance maximale [W]

5 Température maximale du fluide [°F]

7.2 Désignation

Exemple ALPHA1 15 -55 F

Type de pompe

Diamètre nominal (DN) des orifices

d'aspiration et de refoulement [mm]

Hauteur maximale [dm]

Raccordement de la tuyauterie

F : Bride

7.3 Approbations

TM06 8960 1417

Sections FCC

Section 15.19 (a) 3

Cet appareil est conforme à la section 15 de la

réglementation FCC. Son fonctionnement est

soumis aux deux conditions suivantes : 1) cet

appareil ne doit pas provoquer d'interférences

nuisibles, et 2) il doit accepter toute interférence

reçue, y compris les interférences qui peuvent

causer un mauvais fonctionnement.

Section 15.21

Tout changement ou modification apporté à cet

équipement qui n'est pas expressément

approuvé par la partie responsable de la conformité peut annuler l'autorisation d'utiliser cet

équipement.

Section 15.105 (b)

Ces limites sont conçues pour fournir une protection raisonnable contre les interférences nuisibles dans une installation résidentielle. Cet

équipement génère, utilise et peut émettre de

l'énergie de fréquences radio et, s'il n'est pas

installé et utilisé conformément aux instructions,

peut causer des interférences nuisibles aux

communications radio. Cependant, il n'est pas

garanti que des interférences ne se produiront

pas dans une installation particulière. Si cet

équipement provoque des interférences nuisibles à la réception de la radio ou de la télévision, ce qui peut être déterminé en allumant et

en éteignant l'équipement, l'utilisateur est

encouragé à essayer de corriger l'interférence

en prenant une ou plusieurs des mesures suivantes :

• réorienter ou déplacer l'antenne de

• augmenter la séparation entre l'équipement

• brancher l'équipement á une prise sur un cir-

• consulter le revendeur ou un technicien

Norme EMC canadienne : ICES-003

Cet appareil numérique de classe B est

conforme à la norme canadienne ICES-003.

Cet équipement a été testé et déclaré

conforme aux limites d'un appareil

numérique de classe B, conformément à la partie 15 des règles de la

FCC.

réception ;

et le récepteur ;

cuit différent de celui auquel le récepteur est

connecté ;

radio/TV expérimenté pour obtenir de l'aide.

Français (CA)

25

Page 26

Français (CA)

3

4

2

1

PC XXXX

8. Fonctions de régulation

8.1 Composition du panneau de

commande

Fig. 7 Panneau de commande

Pos. Description

Affichage indiquant la consommation

électrique en watt ou le débit

1

Champ lumineux indiquant le niveau du

débit (haut et bas)

Code de production :

2

• 1er et 2e chiffres : année

• 3e et 4e chiffres : semaine

Champ lumineux indiquant le réglage

3

d'une pression constante

Bouton-poussoir pour la sélection du

4

réglage de la pompe

8.2 Affichage

L'affichage (1) est allumé lorsque l'appareil est

sous tension.

L'affichage indique la consommation électrique

en watt (nombres entiers) ou le débit réel pendant le fonctionnement.

Si une erreur est indiquée, corriger celle-ci et

réinitialiser la pompe en coupant et en réactivant

l'alimentation électrique.

En cas de rotation du rotor de la pompe, par

exemple lors du remplissage d'eau, une quantité

d'énergie suffisante peut être générée pour allumer l'affichage, même si l'alimentation électrique a été coupée.

Champ lumineux indiquant le niveau du débit

(haut et bas)

• Le champ lumineux clignote pour un faible

débit.

– Si le débit est inférieur à 1 gpm, le champ

lumineux clignote en alternance entre "0" et

"1", de manière aléatoire.

• Le champ lumineux affiche HI pour un débit

élevé.

– Si le débit est supérieur à 12 gpm, le champ

lumineux affiche "HI" sur l'interface utilisateur.

26

8.2.1 Champs lumineux indiquant le réglage de la pompe

La pompe a des réglages de rendement en

option que vous pouvez sélectionner avec le

bouton-poussoir. Voir fig. 7.

Les réglages de la pompe sont indiqués sur

l'écran par des champs lumineux. Voir fig. 8.

Fig. 8 Champs lumineux

Pour plus d'informations sur la fonction des

TM06 8878 1417

réglages, voir paragraphe 9. Détection des

défauts de fonctionnement.

8.3 Réglage de la pompe

Vous pouvez modifier le réglage de la pompe en

appuyant sur le bouton-poussoir.

8.3.1 Réglage usine par défaut

Le réglage en usine par défaut de la pompe est

le réglage "Constant Pressure III".

8.3.2 Changement du réglage recommandé pour un autre réglage de la pompe

Les installations de chauffage sont des systèmes "lents" qui ne peuvent pas être réglés

rapidement sur un fonctionnement optimal.

Cependant, si, pour certaines applications, le

réglage recommandé de la pompe ne fournit pas

la répartition de chaleur nécessaire dans les

pièces de la maison, vous avez la pos sibilité de

modifier le réglage de la pompe.

8.4 Régulation de la pompe

Voir paragraphe 8.5 Sélection mode de fonction-

nement et rendement.

Régulation en pression constante

Sous ce mode de régulation, une pression différentielle constante est maintenue à travers la

pompe, sans tenir compte du débit.

Voir paragraphes 8. Fonctions de régulation et

8.3 Réglage de la pompe.

TM06 8893 1417

Page 27

8.5 Sélection mode de fonctionnement et rendement

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Q [US GPM]

0

2

4

6

8

10

12

14

16

18

20

[ft]

H

0

1

2

3

4

5

6

[m]

H

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0

Q [m³/h]

Constant Pressure III

Constant Pressure II

Constant Pressure I

17 18

Le rendement hydraulique est affiché sans clapet antiretour.

Pos. Description

• Bouton-poussoir pour la sélection du réglage de la pompe ;

• À chaque pression sur le bouton-poussoir, le réglage de la pompe est modifié.

Constant pressure III

III

• Le point de consigne de la pompe variera à gauche et à droite sur la courbe de pression constante la plus élevée, en fonction de la demande d'eau dans l'installation.

Constant pressure II

II

• Le point de consigne de la pompe variera à gauche et à droite sur la courbe de pression constante intermédiaire, en fonction de la demande d'eau dans l'installation.

Constant pressure I

I

• Le point de consigne de la pompe variera à gauche et à droite sur la courbe de pression constante la plus faible, en fonction de la demande d'eau dans l'installation.

Français (CA)

TM06 8910 1417

27

Page 28

Français (CA)

9. Détection des défauts de fonctionnement

DANGER

Choc électrique

Blessures graves ou mort

- Avant toute intervention sur le produit, couper l'alimentation électrique. S'assurer que l'alimentation

électrique ne risque pas d'être

branchée accidentellement.

Défaut de

fonctionnement

1. La pompe

ne fonctionne pas.

2. Bruit dans

l'installation.

3. Bruit dans

la pompe.

Panneau de

commande

Le champ lumineux est éteint.

Le champ lumineux est allumé.

"___ ___" a) Tension d'alimenta-

Le champ lumineux est allumé.

Le champ lumineux est allumé.

AVERTISSEMENT

Système sous pression

Blessures graves ou mort

- Avant de démonter la pompe, purger l'installation ou fermer le robinet

d'arrêt de chaque côté de la pompe

avant de retirer les vis. Le liquide

pompé peut être bouillant et sous

haute pression.

Solution

a) La pompe n'est pas

correctement branchée à l'alimentation

électrique.

b) Le disjoncteur s'est

déclenché.

c) La pompe est défec-

tueuse.

a) La tension d'alimen-

tation est trop élevée.

b) Le rotor est obstrué

par des impuretés. Enlever les impuretés.

tion trop basse.

a) Il y a de l'air dans

l'installation.

b) Le débit est trop

élevé.

c) Expansion ther-

mique des composants de l'installation.

a) Il y a de l'air dans la

pompe.

b) La pression d'aspira-

tion est trop faible.

c) Pas de liquide

(marche à sec).

d) La pompe est défec-

tueuse.

Raccorder la pompe à l'alimentation électrique.

Couper le disjoncteur.

Remplacer la pompe.

Vérifier que l'alimentation élec-

trique se situe dans la plage spécifiée.

Désactiver et réactiver l'alimentation électrique.

Vérifier l'air, le rotor bloqué et la

tension.

Brancher l'alimentation électrique.

Installer un purgeur d'air.

Réduire la vitesse de la pompe.

Vérifier les supports de montage

de la tuyauterie.

Fixer les supports de fixation desserrés.

Laisser fonctionner la pompe, car

elle se purgera avec le temps.

Installer un purgeur d'air.

Augmenter la pression d'aspiration.

Vérifier le volume d'air présent

dans le réservoir d'expansion (s'il

est installé). (Les fuites de pression dans le système peuvent

entraîner une cavitation.)

S'assurer que l'installation est

pleine de liquide et correctement

purgée.

Ouvrir les robinets d'arrêt.

Remplacer la pompe.

28

Page 29

Défaut de

fonctionnement

4. Chaleur

insuffisante

Panneau de

commande

Le champ lumineux est allumé.

a) Le rendement de la

pompe est trop

faible.

b) Le thermostat est

réglé trop bas ou ne

fonctionne pas.

c) Air ou gaz dans l'ins-

tallation.

d) Les clapets sont col-

lés.

e) Sens d'écoulement

erroné.

f) La chaudière ne

fonctionne pas correctement.

g) Le rendement de la

pompe n'est pas

adapté à l'application.

h) Le rendement de la

pompe n'est pas

adapté à l'application.

Solution

Augmenter le réglage de la pression constante de la pompe.

Vérifier si la pompe est réglée

selon le bon mode de fonctionnement.

S'assurer que le thermostat fonctionne et qu'il est réglé à la température désirée. Remplacer les piles

dans le thermostat.

Purger l'air ou le gaz dans l'installation en laissant la pompe fonctionner, car elle se purgera avec le

temps.

Installer un purgeur d'air.

Si nécessaire, modifier la tuyauterie.

S'assurer que tous les clapets sont

en bon état de fonctionnement, éliminer les dépôts de calcaire si

nécessaire.

Voir la flèche de direction de

l'écoulement marquée sur la

pompe.

Réinstaller la pompe pour corriger

le sens d'écoulement.

Vérifier la température de l'eau de

la chaudière et vérifier les fonctions de celle-ci.

Si nécessaire, réparer la chaudière.

Vérifier le dimensionnement correct de la pompe et des autres

composants de l'installation.

Vérifier le calcul T.

Français (CA)

29

Page 30

Français (CA)

10. Caractéristiques techniques

10.1 Conditions de fonctionnement

Tension d'alimentation

1 x 115 V, + 10 %/- 10 %, 60 Hz.

Protection moteur

La pompe ne nécessite aucune protection

moteur externe.

Indice de protection

Utilisation à l'intérieur uniquement, IP42.

Boîtier CSA de type 2.

Classe d'isolation

F.

Humidité relative

Maximum 95 %.

Pression de refoulement maximale

150 psi (10,34 bar).

Pression d'entrée

Température

du liquide

167 °F (75 °C) 0,75 psi (0,05 bar)

194 °F (90 °C) 4,06 psi (0,28 bar)

230 °F (110 °C) 15,7 psi (1,08 bar)

Niveau de pression sonore

43 dB (A).

Température ambiante

32 °F (0 °C) à 104 °F (40 °C).

Température du liquide

36 °F (2 °C) à 230 °F (110 °C).

Pour éviter la condensation dans le boîter de

commande et le stator, la température du liquide

doit toujours être supérieure à la température

ambiante.

Température

ambiante

[°F (°C) ]

32 (0) 36 (2) 230 (110)

50 (10) 50 (10) 230 (110)

68 (20) 68 (20) 230 (110)

86 (30) 86 (30) 230 (110)

95 (35) 95 (35) 194 (90)

104 (40) 104 (40) 158 (70)

Température du liquide

Minimum

[°F (°C)]

Pression

d'admission

minimale

Maximum

[°F (°C) ]

Glycol

Concentrations maximales de glycol avec de

l'eau claire :

50 % glycol @ 36 °F (2 °C).

Une variation du rendement hydraulique peut

survenir.

Wattmètre

Précision : ± 1 watt.

Indicateur de débit

Fournit une indication relative du débit - ne doit

pas être utilisé à la place d'un débitmètre.

Clapet antiretour

L'utilisation d'un clapet antiretour peut réduire le

rendement hydraulique de la pompe (jusqu'à

- 10 %).

Utiliser un clapet antiretour dans les applications

de pompage parallèle.

Validité des courbes

Liquide testé : eau désaérée.

Les courbes s'appliquent à une densité de 983,2

3

et à une température de liquide de 140 °F

kg/m

(60 °C).

Toutes les courbes sont des valeurs moyennes

et ne doivent être utilisées qu'à titre indicatif. Si

une courbe de rendement minimale spécifique

est requise, des mesures individuelles doivent

être effectuées.

Les courbes sont indiquées pour une viscosité

cinématique de 0,474 cSt.

Consommation approximative de puissance

Réglage de

la vitesse

Pression

constante

Pression

constante

Pression

constante

Minimum Maximum

III 39 W 45 W

II 14 W 45 W

I 8 W 45 W

11. Mise au rebut du produit

Ce produit ou des parties de celui-ci doit être mis

au rebut tout en préservant l'environnement :

1. Utiliser le service local public ou privé de collecte des déchets.

2. Si ce n'est pas possible, envoyer ce produit à

Grundfos ou au réparateur agréé Grundfos le

plus proche.

Nous nous réservons tout droit de modifications.

30

Dans les installations d'eau chaude

sanitaire, il est recommandé de garder

une température de liquide inférieure

à 149 °F (65 °C) afin d'éliminer le

risque de précipitation du calcaire.

Page 31

Español (MX) Instrucciones de instalación y operación

Traducción de la versión original en inglés

Estas instrucciones de instalación y operación

describen la gama ALPHA1 de Grundfos.

Las secciones 1-5 proporcionan la información

necesaria para desempacar, instalar y poner en

marcha el producto de manera segura.

Las secciones 6-11 contienen información

importante acerca del producto, su mantenimiento, la búsqueda de fallas y su eliminación.

CONTENIDO

Página

1. Garantía limitada

2. Información general

2.1 Símbolos utilizados en este documento

3. Recepción del producto

3.1 Inspección del producto

3.2 Contenido del paquete

4. Instalación del producto

4.1 Consejos para una instalación rápida

4.2 Instalación mecánica

4.3 Cambio de la posición del cabezal de

potencia

4.4 Conexión eléctrica

5. Arranque del producto

5.1 Venteo de la bomba

5.2 Arranque inicial

6. Introducción de producto

6.1 Descripción del producto

6.2 Aplicaciones

6.3 Líquidos bombeados

7. Identificación

7.1 Placa de características