Grundfos ALPHA User Manual

GRUNDFOS INSTRUCTIONS

Grundfos ALPHA

Installation and operating instructions

LIMITED WARRANTY

Products manufactured by GRUNDFOS PUMPS CORPORATION (Grundfos) are warranted to the original user only to be free of defects in material and workmanship for a period of 36 months from date of manufacture. Grundfos' liability under this warranty shall be limited to repairing or replacing at Grundfos' option, without charge, F.O.B. Grundfos' factory or authorized service station, any product of Grundfos' manufacture. Grundfos will not be liable for any costs of removal, installation, transportation, or any other charges which may arise in connection with a warranty claim. Products which are sold but not manufactured by Grundfos are subject to the warranty provided by the manufacturer of said products and not by Grundfos' warranty. Grundfos will not be liable for damage or wear to products caused by abnormal operating conditions, accident, abuse, misuse, unauthorized alteration or repair, or if the product was not installed in accordance with Grundfos' printed installation and operating instructions.

To obtain service under this warranty, the defective product must be returned to the distributor or dealer of Grundfos' products from which it was purchased together with proof of purchase and installation date, failure date, and supporting installation data. Unless otherwise provided, the distributor or dealer will contact Grundfos or an authorized service station for instructions. Any defective product to be returned to Grundfos or a service station must be sent freight prepaid; documentation supporting the warranty claim and/or a Return Material Authorization must be included if so instructed.

GRUNDFOS WILL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES, LOSSES, OR EXPENSES ARISING FROM INSTALLATION, USE, OR ANY OTHER CAUSES. THERE ARE NO EXPRESS OR IMPLIED WARRANTIES, INCLUDING MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, WHICH EXTEND BEYOND THOSE WARRANTIES DESCRIBED OR REFERRED TO ABOVE.

Some jurisdictions do not allow the exclusion or limitation of incidental or consequential damages and some jurisdictions do not allow limit actions on how long implied warranties may last. Therefore, the above limitations or exclusions may not apply to you. This warranty gives you specific legal rights and you may also have other rights which vary from jurisdiction to jurisdiction.

2

Grundfos ALPHA

Installation and operating instructions |

4 |

|

Notice d’installation et d’entretien |

11 |

|

Instrucciones de instalación y funcionamiento |

19 |

|

3

CONTENTS

|

|

|

|

Page |

1. |

General |

4 |

||

|

2. |

Shipment inspection |

4 |

|

|

||||

|

3. |

Pumped Liquids |

4 |

|

4. |

Pump installation |

4 |

||

5. |

Changing the control box position |

5 |

||

6. |

Electrical installation |

5 |

||

7. |

Name Plate |

6 |

||

8. |

Control Display |

6 |

||

9. |

Performance & operation modes |

7 |

||

10. |

Fault finding |

8 |

||

11. |

Disposal |

8 |

||

12. |

Technical data |

9 |

||

|

|

|

|

|

Warning

Prior to installation, read these installation and operating instructions. Installation and operation must comply with national, state, and local regulations and accepted codes of good practice.

1. General

Grundfos Alpha is suitable for systems with constant or variable flows where it is desirable to optimize the setting of the pump duty point .

2. Shipment inspection

Examine the components carefully to make sure no damage has occurred to the pump during shipment. Care should be taken to ensure the pump is NOT dropped or mishandled.

•One Grundfos Alpha pump

•One line cord

•Two gaskets

•One installation and operating instructions

•One check valve

•One "Check Valve Installed" sticker

3. Pumped liquids

Warning

The pump must not be used for the transfer of flammable liquids such as

diesel oil, gasoline, and similar liquids. Pump not for pool or marine use.

Clean, thin, non-aggressive and non-explosive liquids, not containing solid particles, fibers or mineral oil.

For glycol usage see Section 10. Review Section 10 for additional liquid information.

4. Pump installation

Warning

Do not energize pump until properly installed.

Risk of electric shock — This pump has not been investigated for use in swimming pool or marine areas.

When making piping connections, be sure to follow piping manufactures recommendations and all code requirements for piping material.

•System should be properly flushed of debris before pump installation.

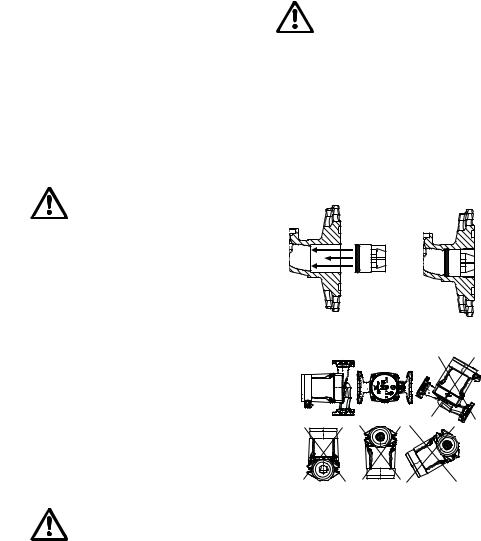

•Insert check valve only if required; see fig. 1.

•Arrows on the pump housing indicate the liquid flow direction through the pump.

•Install the pump with the motor shaft horizontal; See fig. 2.

•Fit the two gaskets supplied to pump ends.

TM 3422 4408

Fig. 1 Check valve installation

TM04 3417 4408

Fig. 2 Installation positions

4

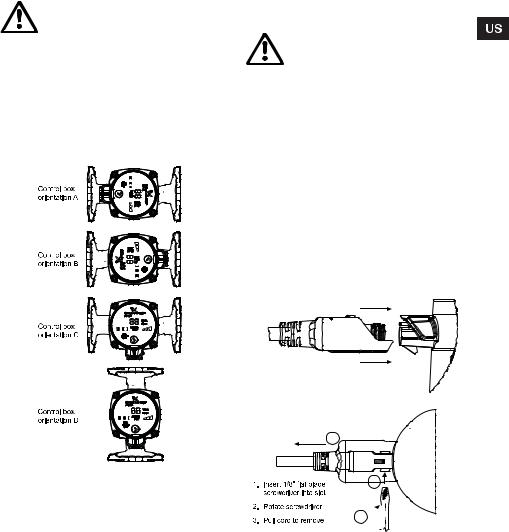

5. Changing the control box position

Warning

Before starting any work on this circulator, make sure electrical supply has been switched off and that it cannot be accidentally switched on.

The control box orientation change should be made before filling the system with fluid.

Pump liquid may be scalding hot and under high pressure.

The control box can be rotated in steps of 90°. Review fig. 3 for possible/permissible positions.

Only use orientations C and D for CSA Enclosure Type 2.

6. Electrical installation

Warning

Risk of electrical shock - This pump is supplied with a grounding conductor and grounding-type attachment plug. To reduce the risk of electric shock, be certain that it is connected only to a properly grounded, grounding-type receptacle in accordance with the National Electric Code and any state, local governing codes and regulations.

All electrical work should be performed by a qualified electrician in accordance with the latest edition of the National Electric Code and state, local codes and regulations.

•The motor of Grundfos Alpha is protected by the electronics in the control box and requires no external motor protection.

•Check that the supply voltage and frequency correspond to the values stated on the pump.

•Only connect the pump to the mains with the cord set supplied; see fig. 4.

•Lights on the control panel indicate that the electrical supply has been switched on.

•Do not modify and only use cord set supplied.

Insert line cord plug onto pump (Side view)

TM04 3418 4408

Fig. 3 Changing the control box position

Procedure:

1. If fluid is present, drain system fluid from pump or isolate system fluid from pump.

2. Loosen 4mm screws and turn the pump head to desired position; see fig. 3.

3. Insert and cross-tighten the screws to 7 ft-lbs torque.

To remove cord plug from pump: |

|

(Bottom view) |

3 |

|

|

|

1 |

2

Fig. 4 Connecting and removing power plug

TM04 3420 4408

5

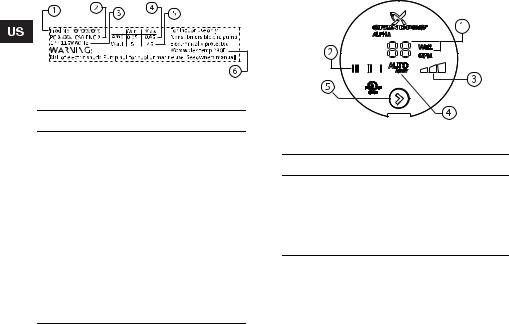

7. Name Plate |

8. Control Display |

Fig. 5 Nameplate

Pos. Description

1Product Number

2Production Code:

•1st and 2nd figures = year

•3rd and 4th figures = week

3Voltage (V):

4Rated current (A):

•Min.: Minimum Current (A)

•Max.: Maximum Current (A)

5Input power (W):

•Min.: Minimum Power (W)

•Max.: Maximum Power (W)

6Max. fluid temperature (F)

TM04 3419 4408 |

4408 |

|

TM04 3421 |

Fig. 6 Control display

Pos. Description

1LED showing Watt or flow indicator

2LED indicating fixed speed

3LED indicating constant pressure

4LED AutoADAPT

5Push-button for selection of pump setting

6

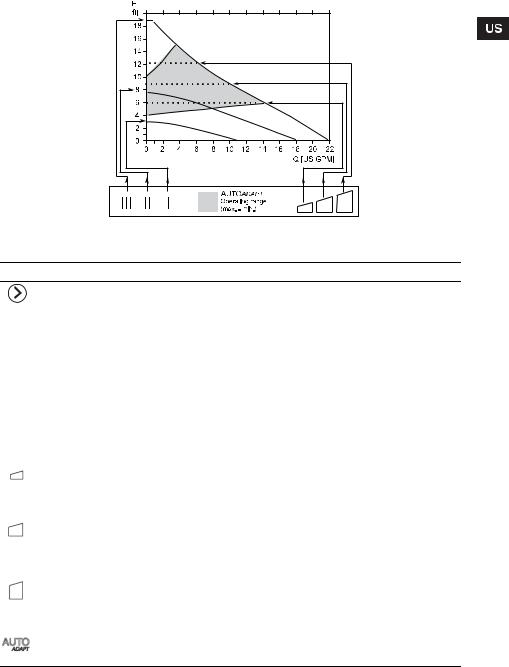

9. Performance* and operation mode selection

*Hydraulic performance without check valve

Pos. Description

•Push-button for selection of pump setting

•Every time the push-button is pressed, the circulator setting is changed

High Fixed Speed

III• Runs at a constant speed and consequently on a constant curve. In Speed III, the pump is set on the maximum curve under all operating conditions. Quick Vent of the pump can be obtained by setting the pump to Speed III for a short period.

Medium Fixed Speed

II• Runs at a constant speed and consequently on a constant curve. In Speed II, the pump is set on the medium curve under all operating conditions.

Low Fixed Speed

I• Runs at a constant speed and consequently on a constant curve. In Speed I, the pump is set on the minimum curve under all operating conditions.

Constant Pressure I

•The duty point of the pump will move left and right along the lowest constant-pressure curve depending on water demand in the system. The pump head (pressure) is kept constant, irrespective of the water demand.

Constant Pressure II

•The duty point of the pump will move left and right along the middle constant-pressure curve depending on water demand in the system. The pump head (pressure) is kept constant, irrespective of the water demand.

Constant Pressure III

•The duty point of the pump will move left and right along the highest constant-pressure curve depending on water demand in the system. The pump head (pressure) is kept constant, irrespective of the water demand.

AutoADAPT (Factory Setting)

•This function controls the pump performance automatically within the defined performance range (shaded area). AutoADAPT will adjust the pump performance to system demands over time.

7

10. Fault finding

Warning

Before starting any work on this circulator, make sure electrical supply has been switched off and that it cannot be accidentally switched on.

Pump liquid may be scalding hot and under high pressure .

Fault |

Control panel |

Remedy |

|

|

|

|

|

1. |

The pump does not run |

LED off |

Check power supply (voltage) and |

|

|

|

circuit breaker. |

|

|

|

Check zone control; voltage, control |

|

|

|

options, and thermostat. |

|

|

|

Check all power connections. |

|

|

|

Damaged circulator / replace. |

|

|

LED on |

Check that the electricity supply falls |

|

|

|

within the specified range. |

|

|

|

Impeller blocked by impurities. |

|

|

"___ ___" |

Requires turning power OFF and back |

|

|

On to pump. |

|

|

|

|

|

2. |

Noise in the system |

LED on |

Install air eliminator. |

|

|

|

Reduce the pump speed. |

|

|

|

Fluid velocities to high; reduce pump |

|

|

|

speed. |

|

|

|

Emitter or piping expanding. |

3. |

Noise in the pump |

LED on |

Let the circulator run, will vent over time. |

|

|

|

Increase the inlet pressure or check the |

|

|

|

air volume in the expansion tank, if |

|

|

|

installed. |

|

|

|

No fluid (dry running). |

|

|

|

Damaged circulator / replace. |

4. |

Insufficient heat |

LED on |

Increase circulator speed or constant |

pressure.

Circulator in proper operating mode.

Check for air; piping, zone(s) and emitter(s).

Check thermostat(s).

Check all valving.

Heat emitter large enough.

Check direction of flow.

Check water temperature from boiler and boiler functions.

Check proper sizing of circulator.

Check T calculation.

11. Disposal

This product or parts of it must be disposed of in an environmentally sound way; please use the public or private waste collection service.

8

12. Technical data

Supply voltage:

1x115V +/-10 %, 60Hz.

Motor protection:

The pump requires no external motor protection.

Enclosure class:

Indoor use only, IP42. CSA Enclosure Type 2.

Insulation class:

F.

Relative air humidity:

Maximum 95 %.

Maximum discharge pressure:

150 psi (10.34 bar).

Inlet pressure:

Liquid temperature |

Min. inlet pressure |

||

|

|

|

|

167 °F |

(75 °C) |

0.75 psi |

(0.05 bar) |

194 °F |

(90 °C) |

4.06 psi |

(0.28 bar) |

230 °F |

(110 °C) |

15.7 psi |

(1.08 bar) |

Sound pressure level:

43 dB (A).

Ambient temperature:

+32 °F (0 °C) to +104 °F (+40 °C).

Liquid temperature:

+36 °F (+2 °C) to +230 °F (+110 °C).

To avoid condensation in the control box and stator, the liquid temperature must always be higher than the ambient temperature.

Ambient |

Liquid temperature |

|

temperature |

|

|

|

|

|

[°F (°C)] |

Min. [°F (°C)] |

Max. [°F (°C)] |

|

|

|

+32 °F |

+36 °F |

+230 °F |

(0 °C) |

(+2 °C) |

(+110 °C) |

+50 °F |

+50 °F |

+230 °F |

(+10 °C) |

(+10 °C) |

(+110 °C) |

+68 °F |

+68 °F |

+230 °F |

(+20 °C) |

(+20 °C) |

(+110 °C) |

+86 °F |

+86 °F |

+230 °F |

(+30 °C) |

(+30 °C) |

(+110 °C) |

+95 °F |

+95 °F |

+194 °F |

(+35 °C) |

(+35 °C) |

(+90 °C) |

+104 °F |

+104 °F |

+158 °F |

(+40 °C) |

(+40 °C) |

(+70 °C) |

In domestic hot-water system, it is recommended to keep the liquid temperature below +149 °F (+65 °C) to

Caution eliminate the risk of lime precipitation.

Maximum glycol concentrations:

50 % glycol @ 36 °F (2 °C).

Hydraulic performance change can be expected.

Watt readings:

Accuracy +/-1 Watt.

Flow indicator:

Provides a relative indication of flow — should not be used in lieu of a flow meter.

Check valve:

Use of check valve may reduce pump hydraulic performance (up to -10%).

Use check valve in parallel pumping applications.

Curve conditions:

Test liquid: Airless water.

Curves apply to a density of 983.2 kg/m3 and a liquid temperature of +140 °F (+60 °C).

All curves show average values and should not be used as guarantee curves. If a specific minimum performance is required, individual measurements must be made.

Curves apply to a kinematic viscosity of 0.474 cSt.

Approximate power usage:

Speed setting |

|

Min. |

Max. |

|

|

|

|

High fixed speed |

III |

39W |

45W |

|

|

|

|

Medium fixed speed |

II |

15W |

30W |

|

|

|

|

Low fixed speed |

I |

5W |

8W |

|

|

|

|

Constant pressure |

|

8W |

45W |

|

|

|

|

Constant pressure |

|

14W |

45W |

|

|

|

|

Constant pressure |

|

22W |

45W |

|

|

|

|

AutoADAPT |

|

5W |

45W |

|

|

|

|

9

Loading...

Loading...