Page 1

Grundfos ALPHA

Installation and operating instructions

GRUNDFOS INSTRUCTIONS

Page 2

LIMITED WARRANTY

Products manufactured by GRUNDFOS PUMPS CORPORATION (Grundfos) are

warranted to the original user only to be free of defects in material and workmanship

for a period of 36 months from date of manufacture. Grun dfos' liability un der this

warranty shall be limited to repairing or replacing at Grundfos' option, without

charge, F.O.B. Grundfos' factory or authorized service station, any product of

Grundfos' manufacture. Grundfos will not be liable for any costs of removal,

installation, transportation, or any other charges which may arise in connection with

a warranty claim. Products which are sold but not manufactured by Grundfos are

subject to the warranty provided by the manufacturer of said products and not by

Grundfos' warranty. Grundfos will not be liable for damage or wear to products

caused by abnormal operating condition s, accident, abuse, misuse, u nauthorized

alteration or repair, or if the product was not installed in accordance with Grundfos'

printed installation and operating instructions.

To obtain service under this warranty, the defective product must be returned to the

distributor or dealer of Grundfos' products from which it was purchased togeth er

with proof of purchase and installation date, failure date, and supporting installation

data. Unless otherwise provided, the distributor or dealer will contact Grundfos or

an authorized service station for instructions. Any defective product to be returned

to Grundfos or a service station must be sent freight prepaid; documentation

supporting the warranty claim and/or a Return Material Authorization must be

included if so instructed.

GRUNDFOS WILL NOT BE LIABLE FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES, LOSSES, OR EXPENSES ARISING FROM

INST ALLATION, USE, OR ANY OTHER CAUSES. THERE ARE NO EXPRESS OR

IMPLIED WARRANTIES, INCLUDING MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, WHICH EXTEND BEYOND THOSE WARRANTIES

DESCRIBED OR REFERRED TO ABOVE.

Some jurisdictions do not allow the exclusion or limitation of incidental or

consequential damages and some jurisdictions do not allow limit actions on how

long implied warranties may last. Therefore, the above limitations or exclusions may

not apply to you. This warranty gives you specific legal rights and you may also

have other rights which vary from jurisdiction to jurisdiction.

2

Page 3

Grundfos ALPHA

Installation and operating instructions 4

Notice d’installation et d’entretien 11

Instrucciones de instalación y funcionamiento 19

3

Page 4

CONTENTS

1. General 4

2. Shipment inspection 4

3. Pumped Liquids 4

4. Pump installation 4

5. Changing the control box position 5

6. Electrical installation 5

7. Name Plate 6

8. Control Display 6

9. Performance & operation modes 7

10. Fault finding 8

11. Disposal 8

12. Technical data 9

Warnin g

Prior to installation, read these

installation and operating instructions.

Installation and operation must comply

with national, state, and local

regulations and accepted codes of

good practice.

Page

1. General

Grundfos Alpha is suitable for systems with constant

or variable flows where it is desirable to optimize the

setting of the pump duty point .

2. Shipment inspection

Examine the components carefully to make sure no

damage has occurred to the pump during shipment.

Care should be taken to ensure the pump is NOT

dropped or mishandled.

• One Grundfos Alpha pump

• One line cord

• Two gaskets

• One installation and operating instructions

• One check valve

• One "Check Valve Installed" sticker

4. Pump installation

Warnin g

Do not energize pump until properly

installed.

Risk of electric shock — This pump has

not been investigated for use in

swimming pool or marine areas.

When making piping connections, be sure to

follow piping manufactures recommendations

and all code requirements for piping material.

• System should be properly flushed of debris

before pump installation.

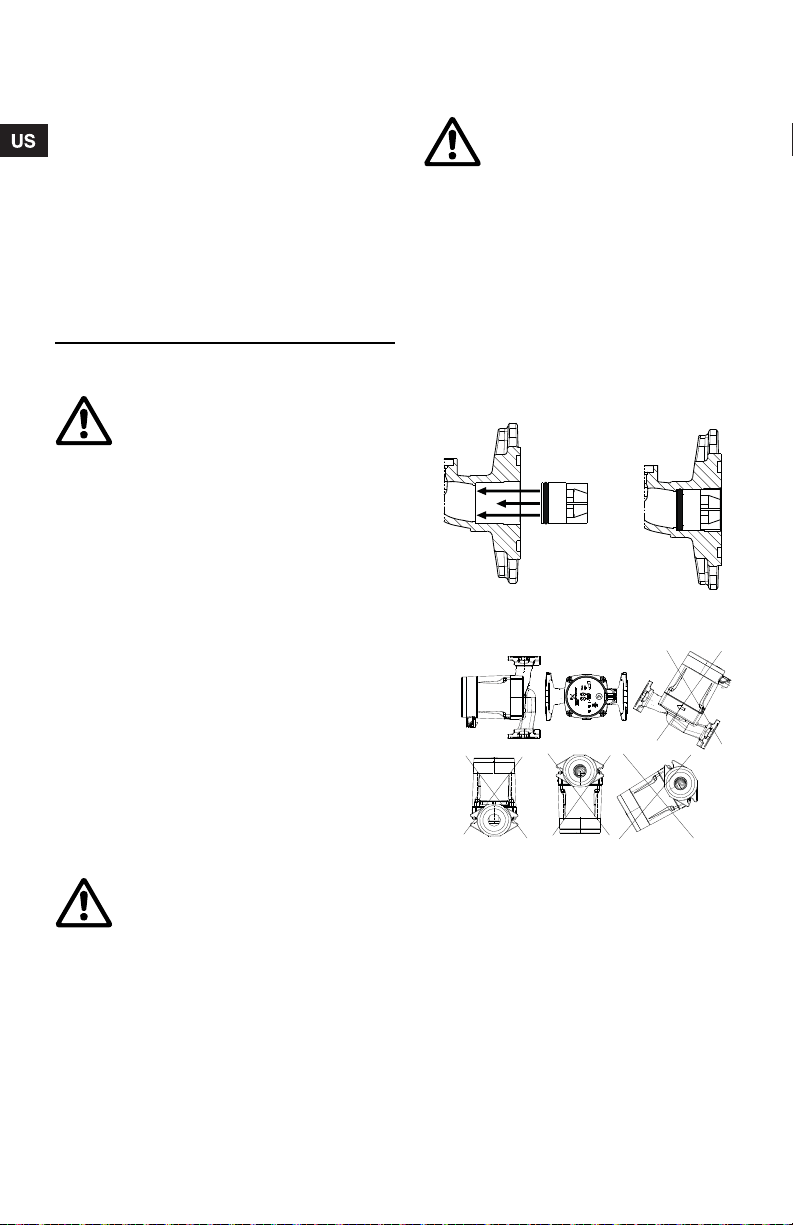

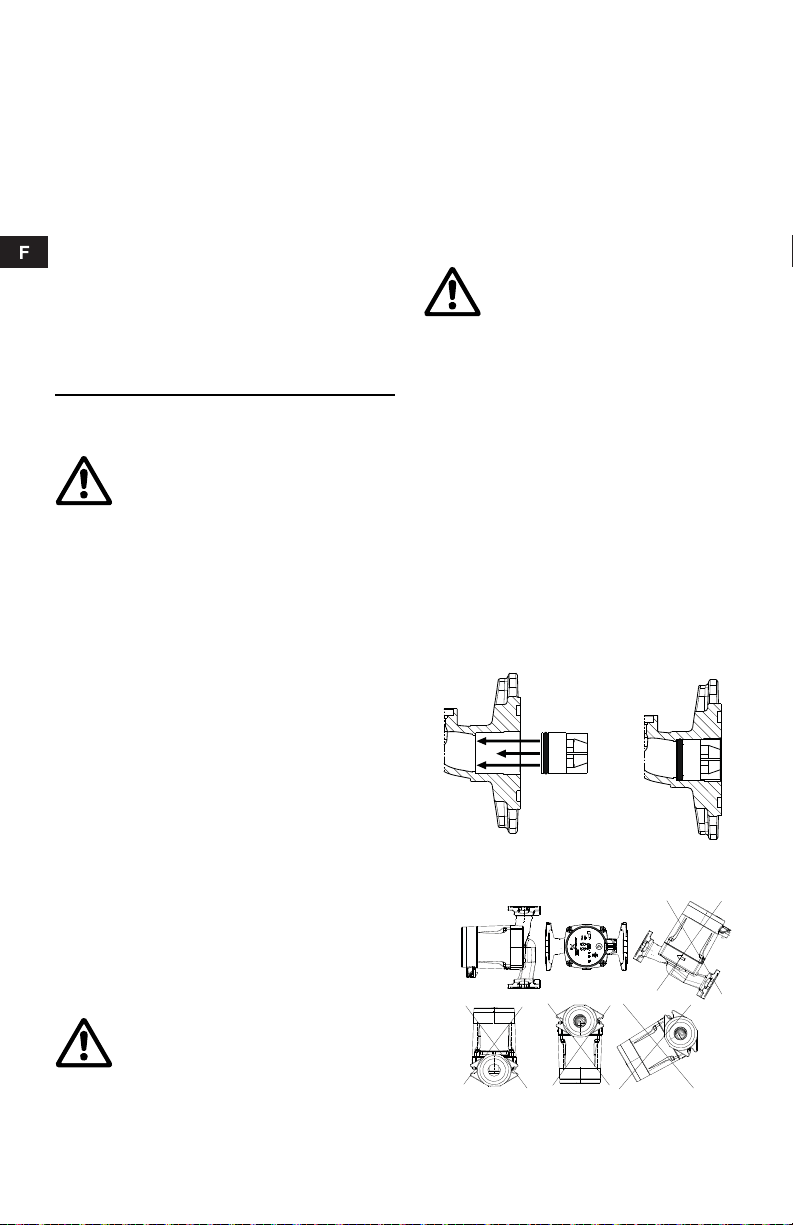

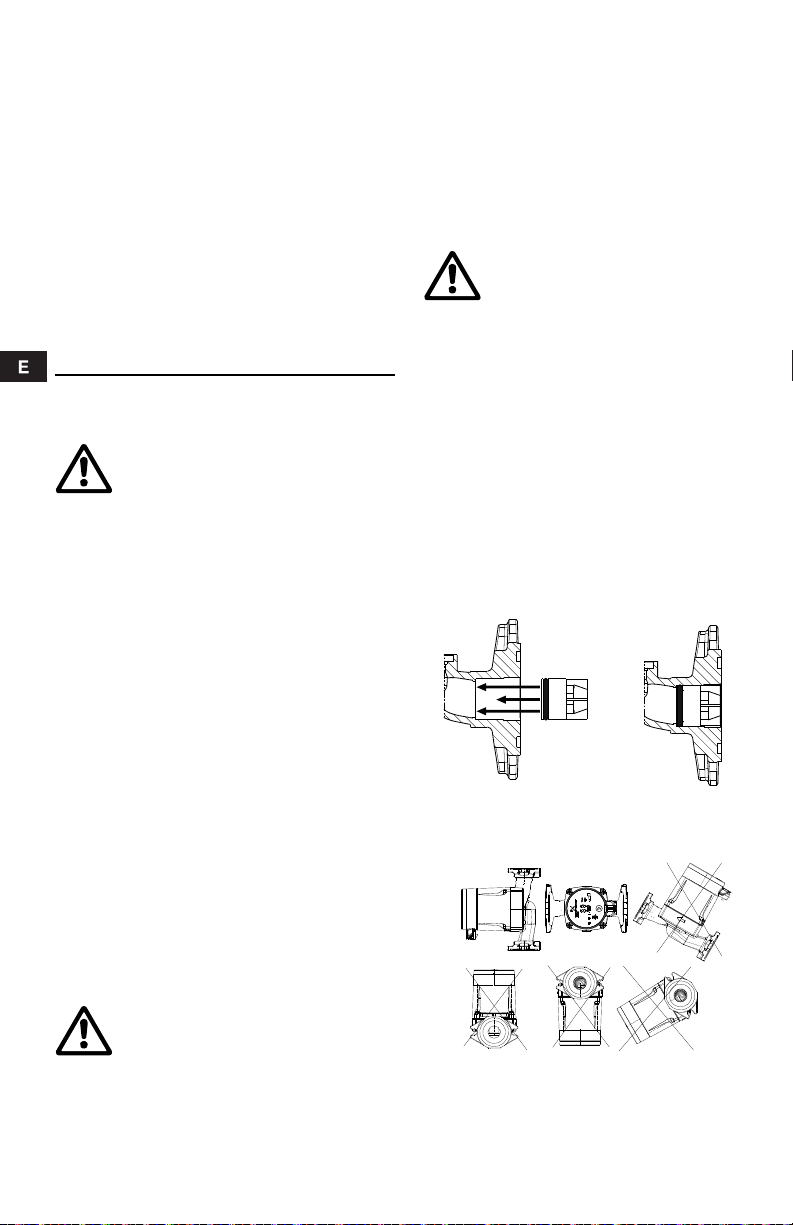

• Insert check valve only if required; see fig. 1.

• Arrows on the pump housing indicate the liquid

flow direction through the pump.

• Install the pump with the motor shaft horizontal;

See fig. 2.

• Fit the two gaskets supplied to pump ends.

Fig. 1 Check valve installation

TM 3422 4408TM04 3417 4408

3. Pumped liquids

Warnin g

The pump must not be used for the

transfer of flammable liquids such as

diesel oil, gasoline, and similar liquids.

Pump not for pool or marine use.

Clean, thin, non-aggressive and non-explosive

liquids, not containing solid particles, fibers or

mineral oil.

For glycol usage see Section 10. Review Section 10

for additional liquid information.

4

Fig. 2 Installation positions

Page 5

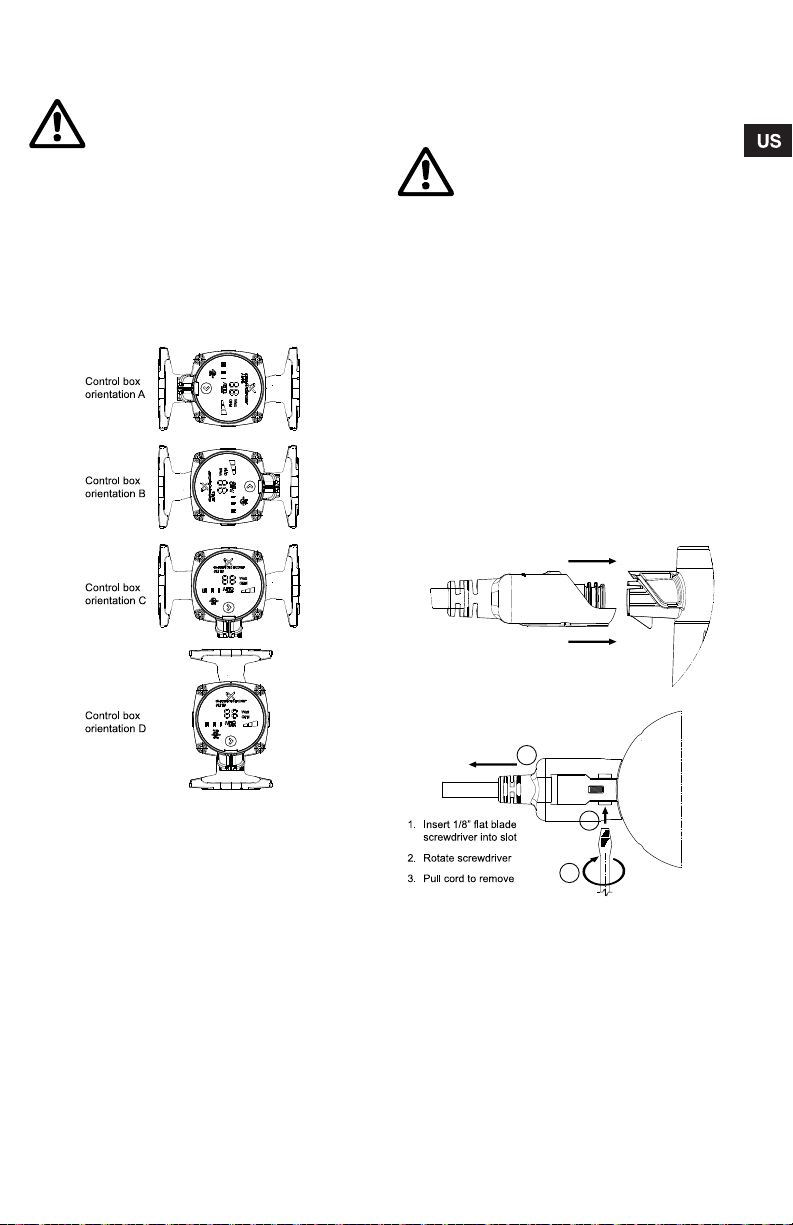

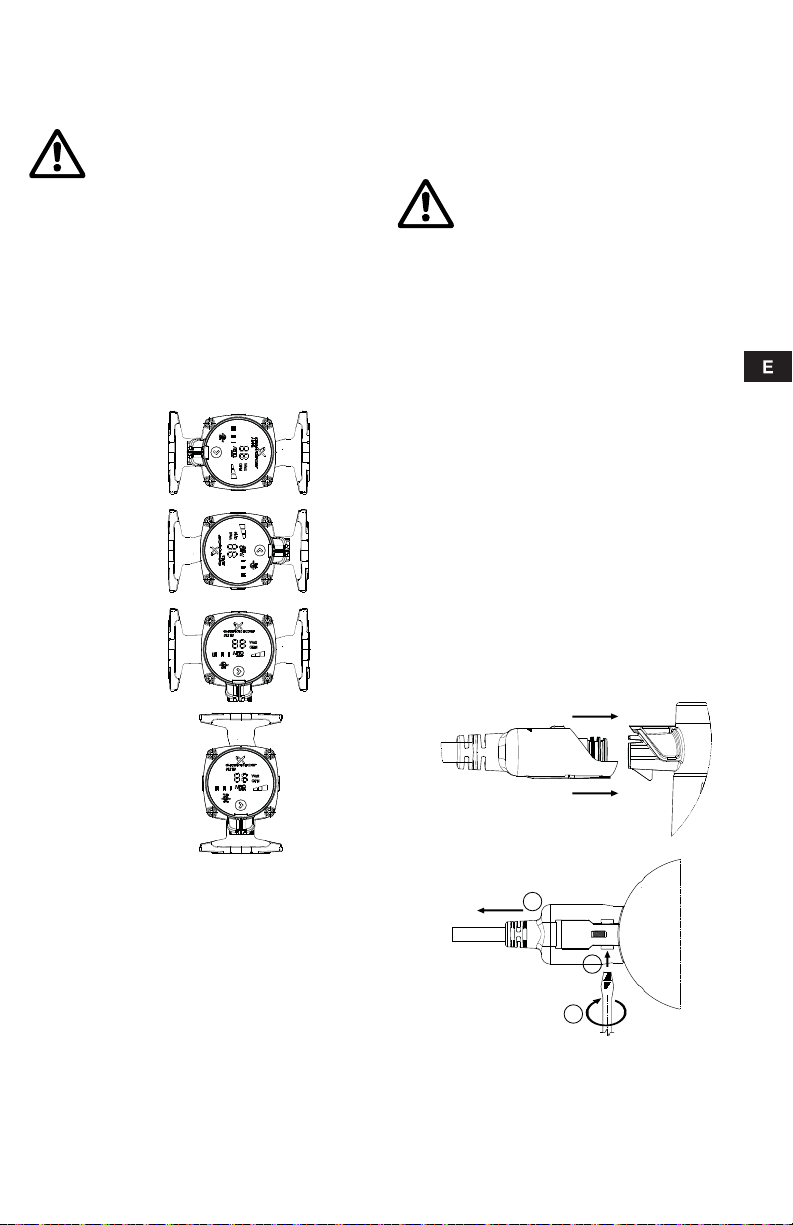

5. Changing the control box position

Insert line cord plug onto pump

To remove cord plug from pump:

1

2

3

(Side view)

(Bottom view)

Warnin g

Before starting any work on this

circulator, make sure electrical supply

has been switched off and that it cannot

be accidentally switched on.

The control box orientation change should be made

before filling the system with fluid.

Pump liquid may be scalding hot and under high

pressure.

The control box can be rotated in steps of 90°.

Review fig. 3 for possible/permissible positions.

Only use orientations C and D for CSA Encl os ur e

Type 2.

6. Electrical installation

Warnin g

Risk of electrical shock - This pump is

supplied with a grounding conductor

and grounding-type attachment plug.

To reduce the risk of electric shock, be

certain that it is connected only to a

properly grounded, grounding -type

receptacle in accordance with the

National Electric Code and any state,

local governing codes and regulations.

All electrical work should be performed by a qualified

electrician in accordance with the latest edition of the

National Electric Code and state, local codes and

regulations.

• The motor of Grundfos Alpha is protected by the

electronics in the control box and requires no

external motor protection.

• Check that the supply voltage and frequency

correspond to the values stated on the pump.

• Only connect the pump to the mains with the cord

set supplied; see fig. 4.

• Lights on the control panel indicate that the

electrical supply has been switched on.

• Do not modify and only use cord set supplied.

Fig. 3 Changing the control box position

Procedure:

1. If fluid is present, drain system fluid from pump or

isolate system fluid from pump.

2. Loosen 4mm screws and turn the pump head to

desired position; see fig. 3.

3. Insert and cross-tighten the screws to 7 ft-lbs

torque.

TM04 3418 4408

TM04 3420 4408

Fig. 4 Connecting and removing power plug

5

Page 6

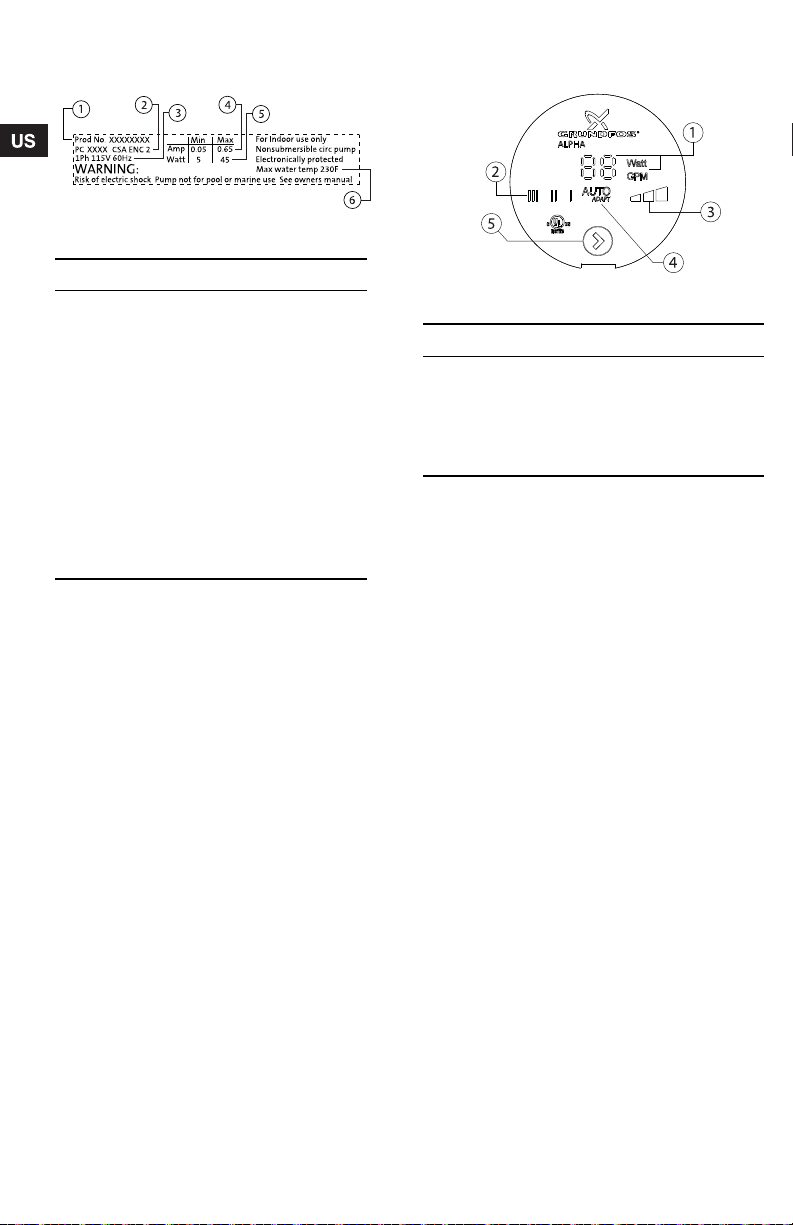

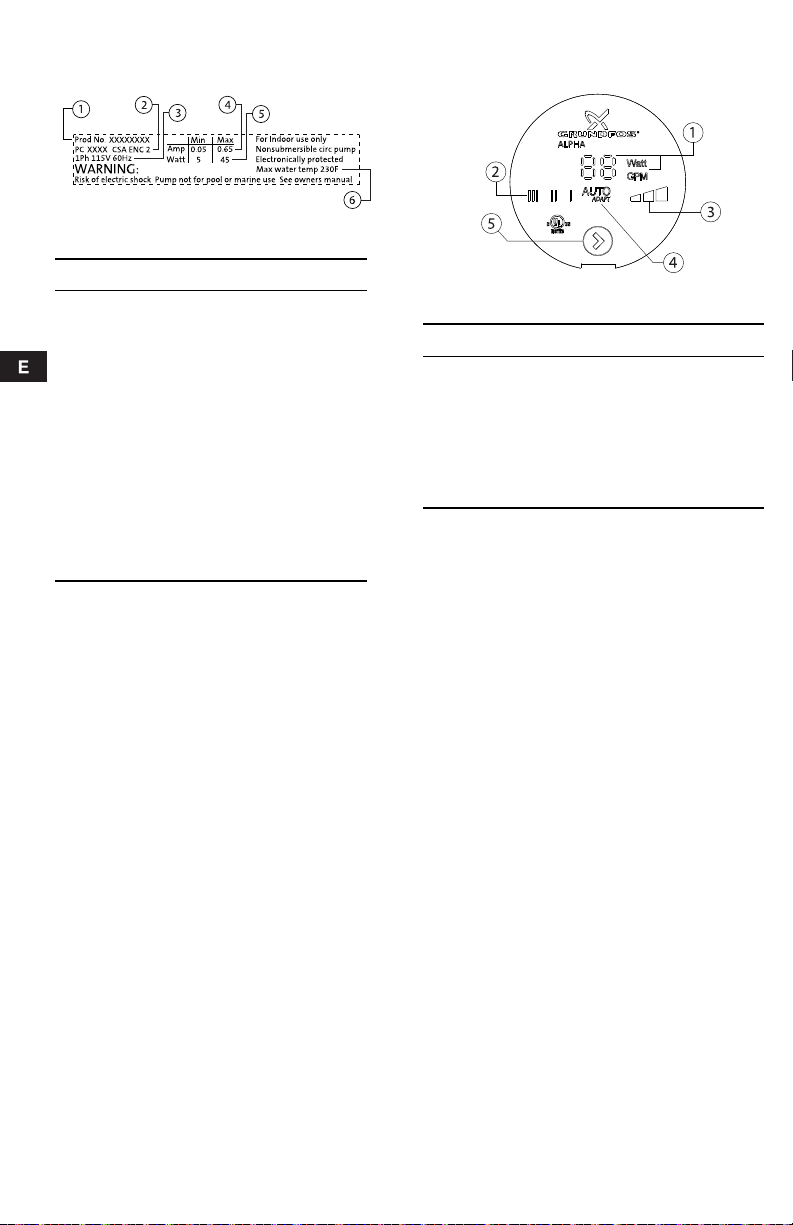

7. Name Plate

Fig. 5 Nameplate

8. Control Display

TM04 3419 4408

Pos. Description

1 Product Number

2 Production Code:

• 1st and 2nd figures = year

• 3rd and 4th figures = week

3 Voltage (V):

4 Rated current (A):

• Min.: Minimum Current (A)

• Max.: Maximum Current (A)

5 Input power (W):

• Min.: Minimum Power (W)

• Max.: Maximum Power (W)

6 Max. fluid temperature (F)

TM04 3421 4408

Fig. 6 Control display

Pos. Description

1 LED showing Watt or flow indicator

2 LED indicating fixed speed

3 LED indicating constant pressure

4 LED AutoADAPT

5 Push-button for selection of pump setting

6

Page 7

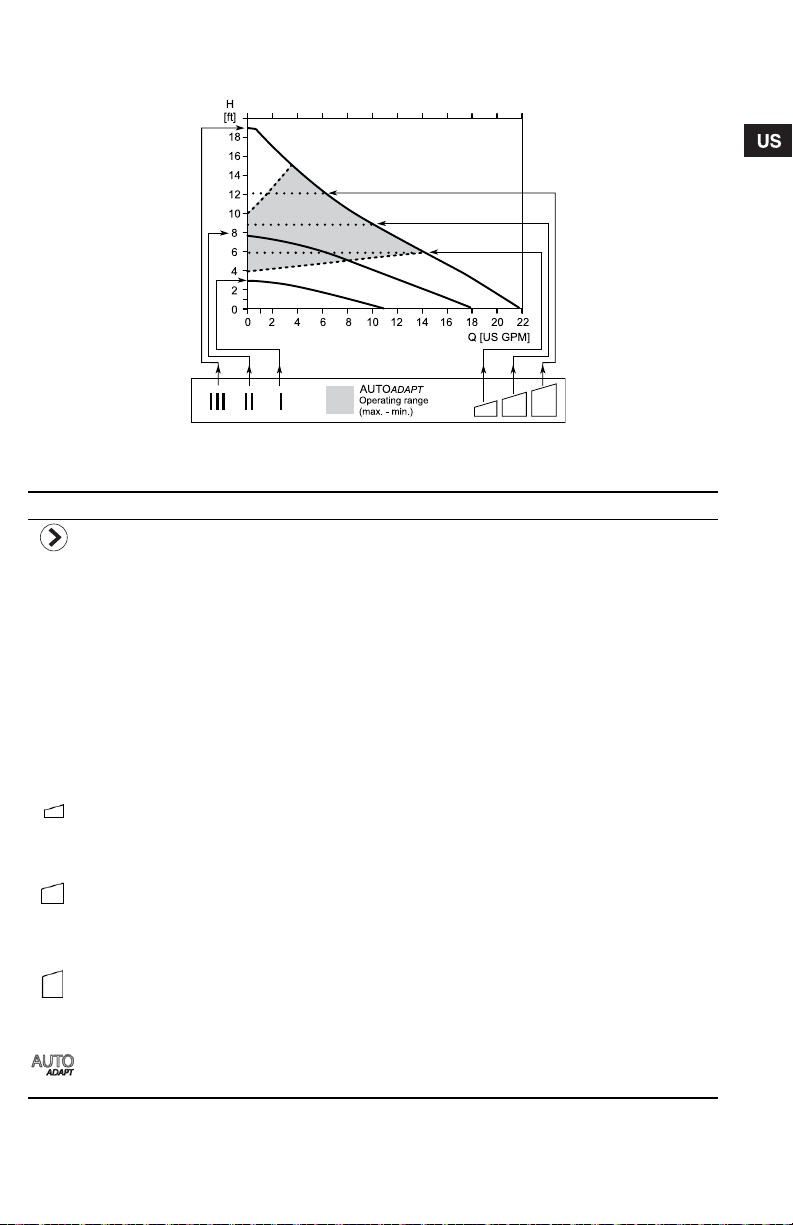

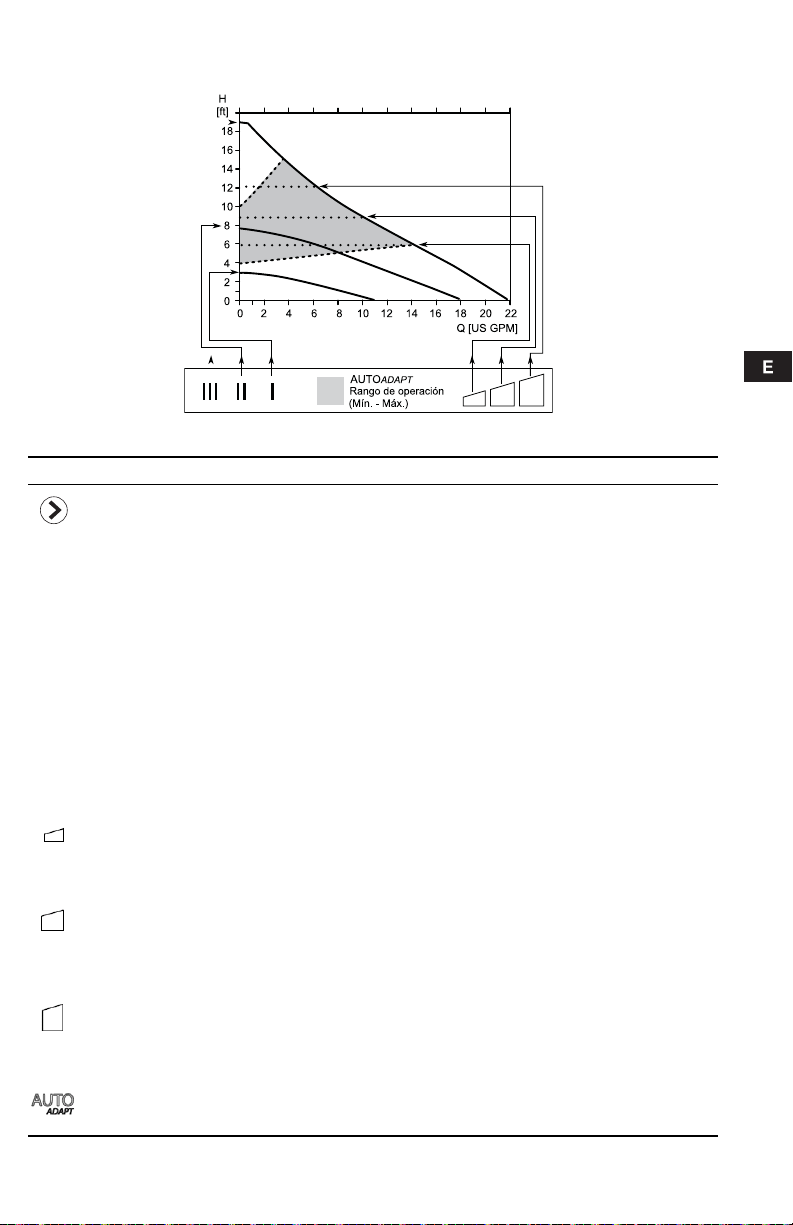

9. Performance* and operation mode s election

*Hydraulic performance without check valve

Pos. Description

• Push -button for selection of pump setting

• Ever y time the push-button is pressed, the circulator setting is changed

High Fixed Speed

• Runs at a constant speed and consequently on a constant curve. In Speed III, the pump is set

III

on the maximum curve under all operating conditions. Quick Vent of the pump can be obtained

by setting the pump to Speed III for a short period.

Medium Fixed Speed

II

• Runs at a constant speed and consequently on a constant curve. In Speed II, the pump is set on

the medium curve under all operating conditions.

Low Fixed Speed

I

• Runs at a constant speed and consequently on a constant curve. In Speed I, the pump is set on

the minimum curve under all operating conditions.

Constant Pressure I

• The duty point of the pump will move left and right along the lowest constant-pressure curve

depending on water demand in the system. The pump head (pressure) is kept constant,

irrespective of the water demand.

Constant Pressure II

• The duty point of the pump will move left and right along the middle constant-pressure curve

depending on water demand in the system. The pump head (pressure) is kept constant,

irrespective of the water demand.

Constant Pressure III

• The duty point of the pump will move left and right along the highest constant-pressure curve

depending on water demand in the system. The pump head (pressure) is kept constant,

irrespective of the water demand.

AutoADAPT (Factory Setting)

• This function controls the pump performance a utomatica lly w ithin the define d perfor mance

range (shaded area). AutoADAPT will adjust the pump performance to system demands over

time.

7

Page 8

10. Fault finding

Warning

Before starting any work on this circulator, make sure electrical supply has been

switched off and that it cannot be accidentally switched on.

Pump liquid may be scalding hot and under high pressure.

Fault Control panel Remedy

1. The pump does not run LED off Check power supply (voltage) and

LED on Check that the electricity supply falls

___ ___"

"

2. Noise in the system LED on Install air eliminator.

3. Noise in the pump LED on Let the circulator run, will vent over time.

4. Insufficient heat LED on Increase circulator speed or constant

circuit breaker.

Check zone control; voltage, control

options, and thermostat.

Check all power connections.

Damaged circulator / replace.

within the specified range.

Impeller blocked by impurities.

Requires turning power OFF and back

On to pump.

Reduce the pump speed.

Fluid velocities to high; reduce pump

speed.

Emitter or piping expanding.

Increase the inlet pressure or check the

air volume in the expansion tank, if

installed.

No fluid (dry running).

Damaged circulator / replace.

pressure.

Circulator in proper operating mode.

Check for air; piping, zone(s) and

emitter(s).

Check thermostat(s).

Check all valving.

Heat emitter large enough.

Check direction of flow.

Check water temperature from boiler

and boiler functions.

Check proper sizing of circulator.

Check ΔT calculation.

11. Disposal

This product or parts of it must be disposed of in an

environmentally sound way; please use the public or

private waste collection service.

8

Page 9

12. Technical data

Caution

Supply voltage:

1x115V +/-10 %, 60Hz.

Motor protection:

The pump requires no external motor protection.

Enclosure class:

Indoor use only, IP42.

CSA Enclosure Type 2.

Insulation class:

F.

Relative air humidity:

Maximum 95 %.

Maximum discharge pressure:

150 psi (10.34 bar).

Inlet pressure:

Liquid temperature Min. inlet pressure

167 °F (75 °C) 0.75 psi (0.05 bar)

194 °F (90 °C) 4.06 psi (0.28 bar)

230 °F (110 °C) 15.7 psi (1.08 bar)

Sound pressure level:

43 dB (A).

Ambient temperature:

+32 °F (0 °C) to +104 °F (+40 °C) .

Liquid temperature:

+36 °F (+2 °C) to +230 °F (+110 °C).

To avoid condensation in the control box and stator,

the liquid temperature must always be higher than

the ambient temperature.

Ambient

temperature

[°F (°C) ]

+32 °F

(0 °C)

+50 °F

(+10 °C)

+68 °F

(+20 °C)

+86 °F

(+30 °C)

+95 °F

(+35 °C)

+104 °F

(+40 °C)

Liquid temperature

Min. [°F (°C)] Max. [°F (°C)]

+36 °F

(+2 °C)

+50 °F

(+10 °C)

+68 °F

(+20 °C)

+86 °F

(+30 °C)

+95 °F

(+35 °C)

+104 °F

(+40 °C)

+230 °F

(+110 °C)

+230 °F

(+110 °C)

+230 °F

(+110 °C)

+230 °F

(+110 °C)

+194 °F

(+90 °C)

+158 °F

(+70 °C)

In domestic hot-water system, it is

recommended to keep the liquid

temperature below +149 °F (+65 °C) to

eliminate the risk of lime precipitation.

Maximum glycol concentrations:

50 % glycol @ 36 °F (2 °C).

Hydraulic performance change can be expected.

Watt readings:

Accuracy +/-1 Watt.

Flow indicator:

Provides a relative indication of flow — should not

be used in lieu of a flow meter.

Check valve:

Use of check valve may reduce pump hydraulic

performance (up to -10%).

Use check valve in parallel pumping applications.

Curve conditions:

Test liquid: Airless water.

Curves apply to a density of 983.2 kg/m

3

and a

liquid temperature of +140 °F (+60 °C).

All curves show average values and should not be

used as guarantee curves. If a specific minimum

performance is required, individual measurements

must be made.

Curves apply to a kinematic viscosity of 0.474 cSt.

Approximate power usage:

Speed setting Min. Max.

High fixed speed III 39W 45W

Medium fixed speed II 15W 30W

Low fixed speed I 5W 8W

Constant pressure 8W 45W

Constant pressure 14W 45W

Constant pressure 22W 45W

AutoADAPT 5W 45W

9

Page 10

12.1 Approvals:

Subject to alterations.

FCC Sections:

Section 15.19 (a) 3:

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference,

and (2) this device must accept any interference

received, including interference that may cause

undesired operation.

Section 15.21:

Any changes or modifications to this equipment not

expressly approved by the party responsible for

compliance could void the user's authority to operate

this equipment.

Section 15.105 (b):

NOTE: This equipment has been tested and found

to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection

against harmful interference in a residential

installation. This equipment generates, uses, and

can radiate radio frequency energy and, if not

installed and used in accordance with the

instructions, may cause harmful interference to radio

communications. However, there is no guarantee

that interference will not occur in a particular

installation. If this equipment does cause harmful

interference to radio or television reception, which

can be determined by turning the equipment off and

on, the user is encouraged to try to correct the

interference by one or more of the following

measures;

• Reorient or relocated the receiving antenna.

• Increase the separation between the equipment

and receiver.

• Connect the equipment into an outlet on a circuit

different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV

technician for help.

Canadian EMC Standard:

ICES-003

This Class B digital apparatus complies with

Canadian ICES-003.

10

Page 11

GARANTIE LIMITÉE

Les produits fabriqués par GRUNDFOS PUMPS CORPORATION (Grundfos) sont

garantis à l'acheteur initial contre tous défauts de matériaux et vices de fabrication

pendant une période de 36 mois à compter de la date de fabrication. La

responsabilité de Grundfos au titre de la présente garantie est limitée à la

réparation ou au remplacement de tout produit fabriqué par Grundfos, à la

discrétion de ce dernier, sans frais, franco à bord de l'usine de Grundfos ou d'un

centre de service autorisé. Grundfos ne sera pas tenu responsab le de s frais

associés à l'enlèvement, à l'installation ou au transport, ou de toute autre dépense

relative à une demande au titre de la garantie. Les produits vendus par Grundfos

mais qui ne sont pas fabriqués par ce dernier sont soumis à la garantie proposée

par le fabricant et ne sont pas couverts par la garantie de Grundfos. Grundfos ne

sera pas tenu responsable des dégâts ou de l'usure des produits causés par une

utilisation anormale, un accident, un abus, un mauvais emploi, une modification ou

une réparation non autorisée, ou si le produit n'a pas été installé conformément aux

instructions d'installation et d'utilisation de Grundfos.

Pour obtenir un service au titre de la présente garantie, le produit défectueux doit

être renvoyé au distributeur ou au détaillant des produits Grundfos auprès duquel

il a été acheté, et il doit être accompagné d'une preuve d'achat et de la date de

l'installation et de la défaillance, ainsi que des pièces justificatives relatives à

l'installation. Saut indication contraire, le distributeur ou le détaillant entrera en

contact avec Grundfos ou avec un centre de service autorisé pour connaître la

marche à suivre. Tout produit défectueux doit être renvoyé fret payé d'avance à

Grundfos ou à un centre de service; les documents justifiant la demande au titre de

la garantie et l'autorisation de renvoi du produit doivent être inclus suivant les

instructions.

GRUNDFOS NE SERA PAS TENU RESPONSABLE DES DOMMAGES

ACCESSOIRES OU CONSÉCUTIFS, DES PERTES OU DES DÉPENSES

DÉCOULANT DE L'INSTALLATION OU DE L'UTILISATION DU PRODUIT OU DE

TOUTE AUTRE CAUSE. AUCUNE GARANTIE EXPRESSE OU IMPLICITE, Y

COMPRIS LES GARANTIES DE QUALITÉ MARCHANDE OU D'ADAPTATION À

UN USAGE PARTICULIER, N'EST FORMULÉE AU-DELÀ DES GARANTIES

DÉCRITES OU MENTIONNÉES CI-DESSUS.

Certaines juridictions n'autorisent pas les exclusions ou les limitations des

dommages accessoires ou consécutifs, et d'autres juridictions ne permettent pas

de limitations relatives à la durée des garanties implicites. Par conséquent, il se

peut que les limitations ou les exclusions ci-dessus ne s'appliquent pas à votre cas.

La présente garantie vous accorde des droits spécifiques, et il se peut que vous

ayez d'autres droits pouvant varier d'une juridiction à l'autre.

11

Page 12

CONTENU

1. Généralités 12

2. Vérification de l'envoi 12

3. Liquides pompés 12

4. Installation de la pompe 12

5. Modification de la position du boîtier de

commande 13

6. Installation électrique 13

7. Plaque signalétique 14

8. Affichage des commandes 14

9. Modes de performance et de

fonctionnement 15

11. Détection des défaillances 16

12. Élimination 16

10. Données techniques 17

Avertissement

Lisez les présentes instructions

d'installation et d'utilisation avant toute

installation. L'installation et le

fonctionnement doivent répondre à

l'ensemble des règlements nationaux,

provinciaux et locaux et des codes de

bonne pratique acceptés.

Página

1. Généralités

Grundfos Alpha est adaptée aux systèmes à débit

constant ou variable et sert à optimiser le réglage du

point de fonctionnement de la pompe.

2. Vérification de l'envoi

Examinez les composants attentivement pour vous

assurer que la pompe n'a pas été abîmée pendant le

transport. Prenez soin de NE PAS faire tomber la

pompe et de ne pas la manipuler de façon

inadéquate.

• Une pompe Grundfos Alpha

• Un cordon d'alimentation

• Deux joints d'étanchéité

• Un exemplaire des instructions d'installation et

d'utilisation

• Un clapet anti-retour

• Un autocollant indiquant "clapet anti-retour

installé"

Liquides propres, clairs, non agressifs et non

explosifs, ne contenant pas de particules solides, de

fibres ou d'huile minérale.

Pour l'utilisation avec le glycol, se reporter à la

rubrique nº 10. Lisez la rubrique nº 10 pour obtenir

des renseignements complémentaires sur les

liquides.

4. Installation de la pompe

Avertissement

Ne mettez pas la pompe sous tension

avant qu'elle ne soit installée de façon

adéquate.

Risque de choc électrique : cette

pompe n'a pas été évaluée pour une

utilisation dans une piscine ou en

milieu marin.

Lorsque vous procédez au raccordement des

tuyaux, assurez-vous de suivre les

recommandations du fabricant des tuyaux et de

respecter toutes les exigences des codes relatifs aux

matériaux de canalisation.

Il est nécessaire d'éliminer tous les résidus pouvant

se trouver dans le système avant l'installation de la

pompe.

Installez uniquement le clapet anti-retour en cas de

besoin; se reporter au schéma 1.

Les flèches situées sur le corps de la pompe

indiquent la direction du débit du liquide passant à

travers la pompe.

Installez la pompe en orientant l'axe du moteur de

façon horizontale; se reporter au schéma 2.

Installez les deux joints d'étanchéité fournis à la

pompe fin.

Fig. 1 Installation du clapet anti-retour

TM 3422 4408TM04 3417 4408

3. Liquides pompés

Avertissement

La pompe ne doit pas être utilisée pour

transférer des liquides inflammables

tels que le carburant diesel, l'essence

et les liquides similaires.

La pompe n'est pas destinée à une

utilisation dans une piscine ou en

milieu marin.

12

Fig. 2 Options d'installation

Page 13

5. Modification de la position du

Position A

Position B

Position C

Position D

Insérer fiche du cordon secteur sur la pompe

Pour enlever le cordon fiche de pompe :

1

2

3

VUE LATÉRALE

VIEW DU BAS

1. Insert 1 / 8 " lame de

tournevis plat dans la fente

2. Tourner le tournevis

3. Tirez le cordon à supprimer

boîtier de commande

Avertissement

Avant de commencer à travailler sur ce

circulateur, assurez-vous que

l'alimentation électrique est coupée et

qu'elle ne peut pas être rétablie par

accident.

La modification de l'orientation du boîtier de

commande doit être effectuée avant de remplir le

système de liquide.

Il se peut que le liquide de la pompe soit bouillant et

sous haute pression.

Le boîtier de commande peut être tourné par paliers

de 90 º.

Se reporter au schéma 3 pour connaître les positions

possibles et acceptables.

Utilisez uniquement les positions C et D pour les

boîtiers CSA de type 2.

6. Installation électrique

Avertissement

Risque d'électrocution - Cette pompe

est fournie avec un conducteur de terre

et une fiche de branchement de type

mise à la terre. Pour réduire le risque

d'électrocution, assurez-vous qu'elle

n'est branchée que dans une prise de

type mise à la terre correctement mise

à la terre conformément au Code

national de l'électricité et aux codes et

aux règlements provinciaux et locaux.

• Tous les travaux électriques doivent être

effectués par un électricien professionnel

conformément à la dernière édition du Code

national de l'électricité et aux codes et règlements

municipaux et des États.

• Le moteur de la pompe Grundfos Alpha est

protégé par les composants électroniques du

boîtier de commande et ne nécessite pas de

protection externe.

• Vérifiez que la tension et la fréquence de

l'alimentation correspondent aux valeurs

indiquées sur la pompe.

• Raccordez la pompe uniquement au réseau

principal à l'aide du jeu de cordons fourni; se

reporter au schéma 4.

• Les voyants du panneau de commande indiquent

que l'alimentation électrique est allumée.

• N'apportez pas de modifications et utilisez

uniquement le jeu de cordons fourni.

Fig. 3 Modification de la position du boîtier de

commande

5.1 Procédure:

1. En cas de présence de liquide, faites couler le

fluide du système hors de la pompe ou isolez

celui-ci de la pompe.

2. Desserrez les vis de 4 mm et tournez la tête de la

pompe sur la position désirée; se reporter au

schéma 3.

3. Remettez les vis et serrez-les en croisé en

applicant 7 pi-lbs de torsion.

TM04 3418 4408

Fig. 4 Connexion et retrait de la fiche

d'alimentation

TM04 3420 4408

13

Page 14

7. Plaque signalétique

Fig. 5 Placa de identificación

8. Affichage des commandes

TM04 3419 4408

Pos. Descripción

1 Numéro de produit :

2 Code de production :

• 1er et 2ème chiffres = année

• 3ème et 4ème chiffres = semaine

3 Tension (V) :

4 Courant nominal (A) :

• Min. : courant minimal (A)

• Max . : courant maximal (A)

5 Alimentation d'entrée (W) :

• Min. : puissance m inimale (W)

• Max. : puissance maximale (W)

6 Température maximale du fluide (ºF)

Fig. 6 Affichage des commandes

Pos. Descripción

LED indiquant le relevé des watts ou

1

l'indicateur de flux

2 LED indiquant la vitesse fixe

3 LED indiquant la pression constante

4 LED de la fonction AutoADAPT

Bouton-poussoir de sélection du réglage de

5

la pompe

TM04 3421 4408

14

Page 15

9. Sélection des modes de performance* et de fonctionnement

*Performance hydraulique sans le clapet anti-retour

Pos. Descripción

• Bouton-pousso ir de sélection du réglage de la pompe

• À chaque fois que vous appuyez sur le bouton, le réglage du circulateur change.

Vitesse fixe élevée

Fonctionne à vitesse constante et par conséquent avec une courbe constante. En mode de

III

vitesse III, la pompe est réglée sur une courbe maximale pour toutes les conditions de

fonctionnement. L'évacuation rapide de la pompe peut être effectuée en réglant celle-ci sur le

mode de vitesse III pendant un court instant.

Vitesse fixe moyenne

Fonctionne à vitesse constante et par conséquent avec une courbe constante. En mode de

II

vitesse II, la pompe est réglée sur une courbe moyenne pour toutes les conditions de

fonctionnement.

Vitesse fixe basse

Fonctionne à vitesse constante et par conséquent avec une courbe constante. En mode de

I

vitesse I, la pompe est réglée sur une courbe minimale pour toutes les conditions de

fonctionnement.

Pression constante I

Le point de fonctionnement de la pompe oscillera vers la gauche et vers la droite à côté de la

courbe de pression constante la plus basse en fonction de la quantité d'eau requise par le

système. La tête de la pompe (pression) demeure constante, quelle que soit la demande en eau.

Pression constante II

Le point de fonctionnement de la pompe oscillera vers la gauche et vers la droite à côté de la

courbe de pression constante moyenne en fonction de la quantité d'eau requise par le système.

La tête de la pompe (pression) demeure constante, quelle que soit la demande en eau.

Pression constante III

Le point de fonctionnement de la pompe oscillera vers la gauche et vers la droite à côté de la

courbe de pression constante la plus élevée en fonction de la quantité d'eau requise par le

système. La tête de la pompe (pression) demeure constante, quelle que soit la demande en eau.

Fonction AutoADAPT (réglage en usine)

Ce mode commande le fonctionnement de la pompe automatiquement à l'intérieur de la fourchette

de rendement établie (zone d'ombre dans le graphique ci-dessus). AutoADAPT ajuste des

performances de la pompe en fonction des besoins du système avec le temps.

15

Page 16

10. Détection des défaillances

Avertissement

Avant de commencer à travailler sur ce circulateur, assurez-vous que l'alimentation

électrique est coupée et qu'elle ne peut pas être rétablie par accident.

Il se peut que le liquide de la pompe soit bouillant et sous haute pression.

Défaillance Panneau de commande Solution

1. La pompe ne fonctionne

pas

2. Bruit dans le système LED allumée Installez un purgeur d'air.

3. Bruit dans la pompe LED allumée Laissez le circulateur fonctionner; il se

4. Chaleur insuffisante LED allumée Augmentez la vitesse du circulateur ou

LED éteinte Vérifiez l'alimentation électrique

LED está encendido LED al lumée Vérifiez q ue l'alimentation

___ ___"

"

(tension) et le disjoncteur.

Vérifiez la commande des zones, la

tension, les options de commande et le

thermostat.

Vérifiez l'ensemble des raccords à

l'alimentation.

Circulateur endommagé : à remplacer.

électrique se situe dans l'échelle

indiquée.

Tête de pompe bloquée par des

impuretés.

Pour lancer le pompage, il faut couper

l'alimentation et la rallumer.

Réduisez la vitesse de la pompe.

Vitesse du fluide trop élevée; réduisez la

vitesse de la pompe.

Émetteur ou tuyau s'agrandissant.

déchargera après un certain temps.

Augmenter la pression d'entrée ou

vérifiez le volume d'air dans le réservoir

d'expansion si celui-ci est installé.

Aucun fluide (écoulement sec).

Circulateur endommagé : à remplacer.

la pression constante.

Circulateur en mode de fonctionnement

adéquat.

Vérifiez la présence d'air, les tuyaux, les

zones et les émetteurs.

Vérifiez le(s) thermostat(s).

Vérifiez toutes les soupapes.

Vérifiez que l'émetteur de chaleur est

suffisamment grand.

Vérifiez la direction du débit.

Vérifiez la température de l'eau à partir

du chauffe-eau et vérifiez les fonctions

de ce dernier.

Vérifiez que le format du circulateur est

approprié.

Vérifiez le calcul du ΔT.

11. Élimination

Ce produit ou ses composants doivent être éliminés

dans le respect de l'environnement;

16

veuillez recourir aux services publics ou privés de

récupération des déchets.

Page 17

12. Données techniques

Tension de l'alimentation :

1 × 115 V +/-10 %, 60 Hz.

Protection du moteur :

La pompe ne nécessite pas de protection externe

du moteur.

Classification du boîtier :

Usage à l'intérieur uniquement, IP42.

Boîtier CSA de type 2.

Classification de l'isolant électrique :

F.

Humidité relative de l'air :

95 % maximum.

Pression de décharge maximale :

150 psi (10,34 bars).

Pression d'entrée :

Température

du liquide

167 °F (75 °C) 0,75 psi (0,05 bar)

194 °F (90 °C) 4,06 psi (0,28 bar)

230 °F (110 °C) 15,7 psi (1,08 bar)

Niveau de pression sonore :

43 dB (A).

Température ambiante :

De +32 °F (0 °C) à +104 °F (+40 °C).

Température du liquide :

De +36 °F (2 °C) à +230 °F (+110 °C).

Pour éviter toute condensation dans le boîtier de

commande et dans le stator, la température du

liquide doit toujours être supérieure à la température

de l'air.

Température

ambiante

[°F (°C) ]

+32 °F

(0 °C)

+50 °F

(+10 °C)

+68 °F

(+20 °C)

+86 °F

(+30 °C)

+95 °F

(+35 °C)

+104 °F

(+40 °C)

Min. [°F (°C)] Max. [°F (°C)]

Pression d'entrée

minimale

Température du liquide

+36 °F

(+2 °C)

+50 °F

(+10 °C)

+68 °F

(+20 °C)

+86 °F

(+30 °C)

+95 °F

(+35 °C)

+104 °F

(+40 °C)

+230 °F

(+110 °C)

+230 °F

(+110 °C)

+230 °F

(+110 °C)

+230 °F

(+110 °C)

+194 °F

(+90 °C)

+158 °F

(+70 °C)

Précaution : Dans les réseaux de

distribution d'eau domestique, il est

recommandé de maintenir la

température du liquide en dessous de

+149 °F (+65 °C) afin d'éviter tout risque

de précipitation des minéraux.

Concentrations maximum de glycol :

50 % de glycol à 36 °F (2 °C).

Des changements de la performance hydraulique

peuvent se produire.

Relevé des watts :

Précision +/-1 watt.

Flux indicateur :

Fournit une indication relative de flux — ne doit

pas être utilisé à la place d'un indicateur de flux.

Clapet anti-retour :

L'utilisation d'un clapet anti-retour peut réduire les

performances du système hydraulique de la

pompe (jusqu'à -10 %).

Utilisez le clapet anti-retour en même temps que

d'autres fonctions de pompage.

Conditions de la courbe :

Liquide d'essai : eau sans air.

Les courbes s'appliquent à une densité de 983,2

kg/m3 et à une température du liquide de +140 °F

(+60 °C).

Toutes les courbes indiquent des valeurs

moyennes et leur précision ne doit pas être

considérée comme étant garantie. En cas de

besoin d'une performance minimale spécifique, il

faut effectuer un relevé individuel.

Les courbes s'appliquent à une viscosité

cinématique de 0,474 cSt.

Consommation électrique approximative :

Réglage de la

vitesse

Vitesse fixe élevée III 39W 45W

Vitesse fixe

moyenne

Vitesse fixe basse I 5W 8W

Pression constante 8W 45W

Pression constante 14W 45W

Pression constante 22W 45W

Fonction

AutoADAPT

Mín. Máx.

II 15W 30W

5W 45W

Sous réserve de modifications.

17

Page 18

Certifications:

Articles de la FCC:

Article 15.19 (a) 3:

Ce dispositif est conforme à la partie 15 du

règlement de la FCC. Le fonctionnement est soumis

aux deux conditions suivantes: (1) ce dispositif ne

doit pas causer d'interférence préjudiciable, et (2) ce

dispositif doit accepter toute interférence reçue, y

compris l'interférence pouvant provoquer un

mauvais fonctionnement.

Article 15.21:

Tout changement apporté à ce dispositif qui n'a pas

été expressément approuvé par la partie

responsable de la conformité pourrait annuler

l'autorisation de l'utilisateur de faire fonctionner ce

dispositif.

Article 15.105 (b):

REMARQUE: cet équipement a été testé et reconnu

conforme aux limites imposées aux appareils

numériques de classe B en vertu de la Partie 15 du

règlement de la FCC. Ces limites sont conçues pour

fournir une protection raisonnable contre le

brouillage préjudiciable dans le cadre d'une

installation à usage domestique. Ce dispositif

génère, utilise et peut rayonner de l'énergie de radiofréquence et, s'il n'est pas installé et utilisé

conformément aux instructions, peut provoquer une

interférence préjudiciable aux communications radio.

Il n'existe cependant aucune garantie qu'un

équipement particulier ne sera pas victime

d'interférence. Si ce dispositif provoque une

interférence préjudiciable à la réception des

émissions radio ou de télévision, ce que l'on peut

déterminer en mettant l'appareil hors tension puis de

nouveau sous tension, il est recommandé à

l'utilisateur de tenter de pallier à ce problème au

moyen d'une ou plusieurs des mesures suivantes:

• Orienter l'antenne réceptrice différemment ou la

changer de place.

• Augmenter la distance séparant le dispositif du

récepteur.

• Connecter le dispositif à une prise sur un circuit

différent de celui sur lequel est branché le

récepteur.

• Obtenir de l'aide auprès du revendeur ou d'un

technicien radio/TV expérimenté.

Norme canadienne concernant la CEM:

NMB-003

Cet appareil numérique de classe B est conforme à

la NMB-003 canadienne.

18

Page 19

GARANTÍA LIMITADA

Se garantiza únicamente al usuario original de los productos fabricados por

GRUNDFOS PUMPS CORPORATION (Grundfos), durante un período de 36

meses contados a partir de la fecha de fabricación, que estos no presentarán

defectos de material ni de mano de obra. La responsabilidad de Grundfos en virtud

de esta garantía queda limitada a la reparación o al cambio, a opción de Grundfos,

sin cargo alguno, en condiciones F .O.B., fábrica de Grundfos o estación de servicio

autorizada. Grundfos no tendrá responsabilidad alguna por gastos de remoción, de

instalación, o de transportación, ni por los cargos que surjan en relación con

reclamos bajo la garantía. Los productos que Grundfos venda pero que no sean

fabricados por esta empresa, están sujetos a la garantía que ofrezca el fabricante

de tales productos y no a la garantía de Grundfos. Grundfos no será responsab le

por daños o desgaste que se produzcan en los productos debido a condiciones de

funcionamiento anormales, accidentes, maltrato, uso indebido, modificaciones o

reparaciones no autorizadas, o instalaciones que no se realicen de conformidad

con las instrucciones impresas de instalación y de funcionamiento de Grundfos.

A fin de obtener servicio bajo la garantía, debe devolver el producto al distribuidor

de Grundfos o a la tienda minorista donde lo adquirió, acompañado del

comprobante de venta y así como de información acerca de la fecha de instalación,

de la fecha en que se produjo el mal funciona miento, y de lo s datos

complementarios sobre la instalación. Salvo que se disponga lo contrario, el

distribuidor o la tienda minorista se comunicará con Grundfos o con una estación

de servicio autorizada para solicitar instrucciones. Los productos defectuosos que

se devuelvan a Grundfos o a una estación de servicio autorizada deben ser

enviados con el porte pagado, acompañados de la documentación que sustente el

reclamo de garantía, así como del documento de autorización de devolución de

materiales en caso de que se exija.

GRUNDFOS NO SERÁ RESPONSABLE POR DAÑOS, PÉRDIDAS O GASTOS

CONCOMITANTES O SECUNDARIOS, PROVENIENTES DE LA INSTALACIÓN,

DEL USO, O DE CUALESQUIER OTRAS CAUSAS. NO SE OTORGAN

GARANTÍAS EXPRESAS O IMPLÍCITAS, COMO LA DE LA IDONEIDAD DEL

PRODUCTO PARA SU COMERCIALIZACIÓN O PARA ALGÚN PROPÓSITO EN

PARTICULAR, QUE AMPLÍEN LAS GARANTÍAS DESCRITAS O A LAS QUE SE

HACE REFERENCIA MÁS ARRIBA.

En algunas jurisdicciones no se permiten exclusiones o limitaciones en cuanto a

daños concomitantes o secundarios y en algunas jurisdicciones no se permite

acciones que limiten el plazo de vigencia de las garantías implícitas. Por lo tanto,

es posible que las limitaciones arriba señaladas no sean aplicables en su caso.

Esta garantía le otorga derechos específicos de efecto jurídico; es posible que,

además, usted tenga otros derechos que varíen de una jurisdicció n a otra.

19

Page 20

ÍNDICE

1. Información general 20

2. Inspección del envío 20

3. Líquidos bombeados 20

4. Instalación de la bomba 20

5. Cambio de posición

de la caja de control 21

6. Instalación eléctrica 21

7. Placa de identificación del producto 22

8. Pantalla de control 22

9. Modos de rendimiento y

de funcionamiento 23

10. Localización de fallas 24

11. Eliminación 24

12. Datos técnicos 25

Advertencia

Antes de la instalación, lea estas

instrucciones y las instrucciones de

funcionamiento La instalación y el

modo de funcionamiento deben

ajustarse a lo estipulado por

reglamentos nacionales, estatales y

locales, así como por los códigos

aceptados de buenas prácticas.

Página

1. Información general

La bomba Alpha de Grundfos es adecuada para los

sistemas con flujos constantes o variables en los

que sea necesario optimizar la configuración del

punto de funcionamiento de la bomba.

Líquidos limpios, no espesos, no agresivos, no

explosivos, que no contengan partículas sólidas,

fibras ni aceite mineral.

Para usarla con glicol lea la sección 10. Lea

información adicional sobre el líquido en la sección

10.

4. Instalación de la bomba

Advertencia

No conecte la bomba al suministro

eléctrico hasta que esté debidamente

instalada.

Riesgo de descarga eléctrica: Esta

bomba no ha sido diseñada para usarla

en piscinas de natación ni en zonas

marinas.

Para hacer conexiones de tuberías, recuerde que

debe seguir las recomendaciones del fabricante de

los tubos y observar todos los requisitos señalados

en los códigos para materiales de tuberías.

Antes de la instalación de la bomba, debe evacuarse

adecuadamente todo escombro en el sistema.

Introduzca la válvula de retención sólo si es

necesario; vea la fig. 1.

Las flechas de la caja de la bomba indican la

dirección del flujo del líquido al pasar por la bomba.

Instale la bomba con el eje del motor horizontal; vea

la fig. 2.

Instale las dos juntas incluyen a la bomba termina.

2. Inspección del envío

Examine cuidadosamente las piezas para verificar

que la bomba no haya sufrido daño durante el

transporte. Debe tener cuidado para EVITAR dejar

caer o maltratar la bomba.

• Una bomba Alpha de Grundfos

• Un cable eléctrico

• Dos empaquetaduras

• Un manual de instrucciones de instalación y de

funcionamiento

• Una válvula de retención

• Una etiqueta que dice: “La válvula de retención

está instalada”

3. Tipo de líquidos que puede bombear

Advertencia

La bomba no se debe usar para

transferir líquidos inflamables, como

petrodiesel, gasolina o líquidos

similares.

La bomba no es para usarla en piscinas

ni en actividades marineras.

20

TM 3422 4408TM04 3417 4408

Fig. 1 Revise la in stalación de la v álvula de

retención

Fig. 2 Posiciones de instalación

Page 21

5. Cambio de la posición de l a ca ja de

Posición A

Posición B

Posición C

Posición D

control

Advertencia

Antes de iniciar cualquier trabajo en esta

bomba de circulación, verifique que haya

apagado el suministro eléctrico y que

éste no pueda encenderse

accidentalmente.

El cambio de la orientación de la caja de control

debe hacerse antes de llenar el sistema con el

fluido.

El líquido de la bomba puede estar sumamente

caliente y bajo alta presión.

La caja de control se puede girar en pasos de 90°.

Examine la fig. 3 para ver las posiciones posibles/

adecuadas.

Use las orientaciones C y D únicamente para el

recinto CSA de tipo 2.

6. Instalación eléctrica

Advertencia

Riesgo de descarga eléctrica - Esta

bomba viene con un conductor de

puesta a tierra y con un enchufe con

dispositivo de conexión a tierra. Para

reducir el riesgo de descarga eléctrica,

verifique que esté enchufado

únicamente en un tomacorriente con

dispositivo de conexión a tierra y

debidamente conectado a tierra, de

conformidad con el código nacional

para instalaciones eléctricas y con los

códigos y reglamentos estatales y

locales correspondientes.

• Los trabajos en las instalaciones eléctricas deben

ser realizados por electricistas calificados, de

conformidad con la más reciente edición del

Código Nacional de Electricidad y de los códigos

y reglamentos estatales y locales.

• El motor de la bomba Alpha de Grundfos está

protegido por las piezas electrónicas que se

encuentran dentro de la caja de control; el motor

no necesita de protección externa.

• Verifique que el voltaje y a la frecuencia de la

corriente de suministro correspondan a los

valores señalados en la bomba.

• Conecte la bomba únicamente al suministro

eléctrico únicamente con el juego de cables que

se suministra; vea la fig. 4.

• Las luces del tablero de control indican que se ha

vuelto a encender el suministro eléctrico.

• Use únicamente el cordón eléctrico que viene con

la bomba, y no lo modifique.

Fig. 3 Cambio de la posición de la caja de

control

5.1 Procedimiento:

1. Si contiene líquido, drene la bomba del líquido del

sistema o aísle el líquido de la bomba.

2. Afloje los tornillos de 4 mm y gire el cabezal de la

bomba a la posición que desee; vea la fig. 3.

3. Introduzca los tornillos y apriételos en forma

entrecruzada hasta un par de torsión de 7 pies-lb.

VISTA DE PERFIL

Inserte el cable en la línea de la bomba

(Side view)

TM04 3418 4408

VISTA INFERIOR

Para quitar el enchufe del cordón de la bomba:

3

1

1. Inserte 1 / 8" de hoja plana

destornillador en la ranura

2. Gire el destornillador

3. Tire de la cuerda para extraerlo

Fig. 4 Cómo conectar y desconectar el enchufe

eléctrico

2

TM04 3420 4408

21

Page 22

7. Placa de identificación del producto

Fig. 5 Placa de identificación

8. Pantalla de control

TM04 3419 4408

Pos. Descripción

1 Número de producto:

2 Código de producción:

• 1o y 2o dígito = año

• 3o y 4o dígito = sem ana

3Voltaje (V):

4 Corriente nominal (A):

• Mín.: Corriente mínima (A)

• Máx.: Corriente máxima (A)

5 Potencia de entrada (W):

• Mín.: Potencia mínima (W)

• Máx.: Potencia máxima (W)

6 Temperatura máxima del líquido (F)

Fig. 6 Pantalla de control

Pos. Descripción

El LED que indica la lectura de vatios o

1

indicador de flujo

2 El LED que indica la velocidad fija

3 El LED que indica la presión constante

4 LED AutoADAPT

Botón pulsador para elegir la configuración

5

de funcionamiento de la bomba

TM04 3421 4408

22

Page 23

9. Elección del modo de rendim iento* y fu ncio namie nto

*Rendimiento hidráulico sin la válvula de retención

Pos. Descripción

• Botón pulsa dor para elegir la configuración de funcionamiento de la bomba.

• Cada vez que se oprime el botón pulsador, se cambia la configuración de la bomba de

circulación

Velocidad alta fija

Funciona a velocidad constante y, por consiguiente, en una curva constante. En el nivel de

III

velocidad III, la bomba está configurada en la curva máxima bajo todas las condiciones de

funcionamiento. Se puede obtener una ventilación rápida configurando la bomba a la velocidad III

por un período corto.

Velocidad mediana fija

Funciona a velocidad constante y, por consiguiente, en una curva constante. En el nivel de

II

velocidad II, la bomba está configurada en la curva mediana bajo todas las condiciones de

funcionamiento.

Velocidad baja fija

Funciona a velocidad constante y, por consiguiente, en una curva constante. En el nivel de

I

velocidad I, la bomba está configurada en la curva mínima bajo todas las condiciones de

funcionamiento.

Presión constante I

El punto de funcionamiento de la bomba se mueve hacia la izquierda y hacia la derecha junto con

la curva de presión constante más baja, dependiendo de la demanda de ag ua en el sistema. La

presión del cabezal de la bomba se mantiene constante, independientemente de la demanda de

agua.

Presión constante II

El punto de funcionamiento de la bomba se mueve hacia la izquierda y hacia la derecha junto con

la curva de presión constante mediana, dependiendo de la demanda de agua en el sistema. La

presión del cabezal de la bomba se mantiene constante, independientemente de la demanda de

agua.

Presión constante III

El punto de funcionamiento de la bomba se mueve hacia la izquierda y hacia la derecha junto con

la mayor curva de presión constante mediana, dependiendo de la demanda de agua en el

sistema. La presión del cabezal de la bomba se mantiene constante, independientemente de la

demanda de agua.

Función AutoAdapt (Configuración de fábrica)

Esta función controla automáticamente el rendimiento de la bomba, dentro de los límites de

rendimiento señalados, ajustando automáticamente el rendimiento de la bomba a la demanda del

sistema durante el período de funcionamiento (área sombreada del gráfico de la curva).

23

Page 24

10. Localización de fallas

Advertencia

Antes de iniciar cualquier trabajo en esta bomba de circulación, verifique que haya apagado

el suministro eléctrico y que éste no pueda encenderse accidentalmente.

El líquido de la bomba puede estar sumamente caliente y bajo alta presión.

Falla Tablero de control Remedio

1. La bomba no funciona El LED está apagado Revisar el suministro eléctrico (voltaje) y

LED está encendido Verifique que el suministro eléctrico

___ ___"

"

2. Hay ruido en el sistema El LED está encendido Instale un filtro de aire.

3. Hay ruido en la bomba El LED está encendido Deje funcionando la bomba de

4. Calor insuficiente El LED está encendido Aumente la velocidad de la bomba de

el cortacircuitos.

Revise el control de zonas: voltaje,

opciones de control y termostato.

Revise todas las conexiones eléctricas.

Bomba de circulación dañada /

cámbiela.

corresponda a los límites especificados.

El rotor está bloqueado por impurezas.

Es necesario apagar y volver a

encender la bomba.

Disminuya la velocidad de la bomba.

La velocidad del líquido es demasiado

elevada, reduzca la velocidad de la

bomba.

El emisor o la tubería se expanden.

circulación, se ventilará con el tiempo.

Aumente la presión de entrada o revise

el volumen de aire en el tanque de

expansión, si está instalado.

No hay líquido (funciona en vacío).

Bomba de circulación dañada /

cámbiela.

circulación o la presión constante.

Verifique que el modo de

funcionamiento de la bomba de

circulación sea el adecuado.

Revise el suministro de aire; tuberías,

zona(s) y emisor(es).

Revise el (los) termostato(s).

Revise todas las válvulas.

El emisor de calor es suficientemente

grande.

Revise la dirección del flujo.

Revise la temperatura del agua de la

caldera y las funciones de la caldera.

Verifique que el tamaño de la bomba de

circulación sea el adecuado.

Revise los cálculos ΔT.

11. Eliminación

Este producto o sus piezas deben ser eliminados de

una manera adecuada para el medio ambiente; use

24

el servicio público o privado de recolección de

basura.

Page 25

12. Datos técnicos

Voltaje del suministro eléctrico:

1 x 115 V +/-10 %, 60 Hz.

Protección del motor:

El motor de la bomba no requiere de protección

externa.

Clase de caja:

Únicamente para uso en interiores, IP42.

Caja CSA, de tipo 2.

Clase de aislamiento:

F.

Humedad relativa del aire:

Máxima 95 %.

Presión de descarga máxima:

150 lb./pulg.2 (10.34 bar).

Presión de entrada:

Temperatura

del líquido

167 °F (75 °C) 0.75 lb./pulg.2 (0.05 bar)

194 °F (90 °C) 4.06 lb./pulg.2 (0.28 bar)

230 °F (110 °C) 15.7 lb./pulg.2 (1.08 bar)

Nivel de presión sonora:

43 dB (A).

Temperatura ambiente:

+32 °F (0 °C) a +104 °F (+40 °C).

Temperatura del líquido:

+36 °F (+2 °C) a +230 °F (+110 °C).

Para evitar la condensación en la caja de control y

en el núcleo de la bobina, la temperatura del líquido

debe ser siempre mayor que la temperatura

ambiente.

Temperatura

ambiente

[°F (°C) ]

+32 °F

(0 °C)

+50 °F

(+10 °C)

+68 °F

(+20 °C)

+86 °F

(+30 °C)

+95 °F

(+35 °C)

+104 °F

(+40 °C)

Temperatura del líquido

Min. [°F (°C)] Max. [°F (°C)]

(+10 °C)

(+20 °C)

(+30 °C)

(+35 °C)

+104 °F

(+40 °C)

+36 °F

(+2 °C)

+50 °F

+68 °F

+86 °F

+95 °F

Presión mínim

de entrada

+230 °F

(+110 °C)

+230 °F

(+110 °C)

+230 °F

(+110 °C)

+230 °F

(+110 °C)

+194 °F

(+90 °C)

+158 °F

(+70 °C)

Precaución: Se recomienda que, en los

sistemas domésticos de agua caliente,

se mantenga la temperatura del líquido

por debajo de los +149 °F (+65 °C), para

evitar el riesgo de precipitación de

óxido de calcio.

Concentraciones máximas de glicol:

50 % glicol a 36 °F (2 °C).

Se puede esperar un cambio en el rendimiento

hidráulico.

Lecturas en vatios:

Precisión: +/-1 vatio.

Indicador de flujo:

Proporciona una indicación del flujo — no debe

utilizarse en lugar de un indicador de flujo.

Válvula de retención:

El usar la válvula de retención puede reducir el

rendimiento hidráulico de la bomba (en hasta un

10%).

Use la válvula de retención en instalaciones de

bombeo en paralelo.

Condiciones de la curva:

Líquido de prueba: Agua sin aire.

Las curvas corresponden a una densidad de

983.2 kg/m3 y a una temperatura del líquido de

+140 °F (+60 °C).

Todas las curvas muestran valores promedios y

no deben emplearse como curvas garantizadas.

Si se necesita un rendimiento mínimo específico,

deben efectuarse mediciones individuales.

Las curvas corresponden a una viscosidad

cinética de 0.474 cSt.

Consumo aproximado de electricida d:

Velocidad Mín. Máx.

Velocidad alta fija III 39W 45W

Velocidad mediana

fija

Velocidad baja fija I 5W 8W

Presión constante 8W 45W

Presión constante 14W 45W

Presión constante 22W 45W

AutoADAPT 5W 45W

II 15W 30W

Sujeto a alteraciones.

25

Page 26

Aprobaciones:

Artículos de la FCC (o Comisión federal para las

comunicaciones):

Artículo 15.19 (a) 3:

Este dispositivo cumple con lo señalado en la parte

15 del reglamento de la FCC. La autorización para

hacer funcionar este aparato está sujeta a las dos

siguientes condiciones: (1) este dispositivo no debe

producir interferencia nociva, y (2) este dispositivo

debe ser capaz de aceptar cualquier tipo de

interferencia que reciba, incluso la que pueda

producir efectos no deseados en su funcionamiento.

Artículo 15.21:

Todo cambio o modificación que se realice a este

equipo sin autorización expresa de la parte

responsable por su cumplimiento con las normas

oficiales, puede ser motivo para invalidar la facultad

del usuario para hacer funcionar este equipo.

Artículo 15.105 (b ):

NOTA: Este equipo ha sido sometido a pruebas que

han demostrado que cumple con los límites para los

dispositivos digitales de clase B, de conformidad con

lo señalado en la parte 15 del reglamento de la FCC.

Estos límites han sido fijados para ofrecer protección

razonable contra la interferencia nociva en

instalaciones domésticas. Este equipo genera,

emplea y puede emitir energía de radiofrecuencia y,

si no se instala y emplea de conformidad con las

instrucciones, puede producir interferencia nociva a

las comunicaciones por radio. Sin embargo, no

existe garantía de que no se producirá interferencia

en alguna instalación en particular. En caso de que

este equipo produzca interferencia nociva a la

recepción de transmisiones por radio o por

televisión, lo que puede determinarse apagando el

equipo y volviéndolo a encender, se insta al usuario

a que trate de corregir el problema, tomando las

siguientes medidas:

• Cambiar la orientación o la ubicación de la

antena receptora.

• Aumentar la distancia que separa el equipo del

receptor.

• Conectar el equipo en un tomacorriente de un

circuito diferente de aquel en que se encuentra

conectado el receptor.

• Consultar con distribuidor o con un técnico

experto en radio y televisión.

Norma canadiense para compatibilidad

electromagnética:

ICES-003

Este aparato digital de Clase B cumple con las

estipulaciones de la norma canadiense ICES-003.

26

Page 27

U.S.A.

GRUNDFOS Pumps Corporation

17100 West 118th Terrace

Olathe, Kansas 66061

Phone: +1-913-227-3400

Telefax: +1-913-227-3500

Canada

GRUNDFOS Canada Inc.

2941 Brighton Road

Oakville, Ontario

L6H 6C9

Phone: +1-905-829-9533

Telefax: +1-905-829-9512

México

Bombas GRUNDFOS de México

S.A. de C.V.

Boulevard TLC No. 15

Parque Industrial Stiva

Aeropuerto

Apodaca, N.L.C.P. 66600

Phone: +52-81-8144-4000

Telefax: +52-81-8144-4010

Addresses revised 22.09.2005

Page 28

Being responsible is our foundation

Thinking ahead makes it possible

Innovation is the essence

L-AL-TL-001

New 0309

www.grundfos.com

US

Loading...

Loading...