Page 1

GRUNDFOS INSTRUCTIONS

S pumps, range 72 - 74 - 78

DIN 50/60 Hz

Service instructions

Page 2

English (GB) Service instructions

Caution

Note

English (GB)

Original service instructions.

CONTENTS

1. Symbols used in this document

2. Servicing S pumps with explosion-proof motors

3. Safety

4. Identification

4.1 Nameplate

4.2 Type key

5. Handling the pump

5.1 Lifting the pump

5.2 Lifting points

5.3 Raising pump to upright position

6. Torques, lubricants and special liquids

6.1 Common torques

6.2 Special torques and lubricants

6.3 Quantities of grease in bearings

6.4 Special liquids

7. Service tools

7.1 Standard tools

7.2 Special tools

7.3 Tightness test tools

7.4 Lifting tools

8. Service

8.1 General information

8.2 Pump cleaning and visual inspection

8.3 Annual maintenance

8.4 Oil check and oil change

8.5 Inspection and adjustment of impeller clearance

9. Dismantling and assembly instructions

9.1 Checking and replacing the cable

9.2 Replacing the terminal board

9.3 Replacing the protection sensors

9.4 Dismantling range 72

9.5 Assembling range 72

9.6 Dismantling range 74

9.7 Assembling range 74

9.8 Dismantling range 78

9.9 Assembling range 78

10. Tightness tests

10.1 Tightness test of stator (submerged)

10.2 Tightness test of terminal box (cable side, submerged)

11. Drawings

11.1 Range 72

11.2 Range 74

11.3 Range 78

11.4 Position numbers and material specification

11.5 Sensor positions

11.6 Electrical connections

Page

10

10

10

10

11

12

13

13

14

17

19

21

23

25

29

30

32

32

32

33

33

42

48

56

58

60

1. Symbols used in this document

Warnin g

If these safety instructions are not observed,

2

3

3

3

3

4

6

6

6

6

7

7

7

7

7

8

8

9

9

9

it may result in personal injury.

Warnin g

These instructions must be observed for

explosion-proof pumps. It is advisable also to

follow these instructions for standard pumps.

Warnin g

If these instructions are not observed, it may lead

to electric shock with consequent risk of serious

personal injury or death.

Warnin g

The surface of the product may be so hot that

it may cause burns or personal injury.

Warnin g

The sound pressure level is so high that hearing

protection must be used.

If these safety instructions are not observed,

it may result in malfunction or damage to the

equipment.

Notes or instructions that make the job easier

and ensure safe operation.

2

Page 3

2. Servicing S pumps with explosion-proof

Note

motors

S pumps, range 72 to 78 have the following explosion protection

classification:

Direct drive, 50 or 60 Hz CE 1180 II2 G Ex bc d IIB T4

72

74, 78

Service work on Ex pumps must be carried out by Grundfos or a

workshop authorised by Grundfos. Violation of this requirement

will invalidate the Ex classification of the pump.

Overhauled and repaired explosion-proof pumps are provided

with a repair plate giving the following information:

• the repair symbol R

• name of registered trade mark of the repairing workshop

• workshop reference number relating to the repair

• date of overhaul or repair.

In case of subsequent repairs, the existing repair plate should be

replaced by a new, updated repair plate and earlier markings

must be recorded.

The repairing workshop must keep records of performed

overhauls and repairs together with records of all previous

overhauls, repairs and possible modifications. Copies of the

repairing workshop’s detailed records should be filed by the

owner or operator together with the original type certificate of the

explosion-proof motor in question.

Frequency converter

drive

Direct drive, 50 or 60 Hz Only on request

Frequency converter

drive

CE 1180 II2 G Ex bc d IIB T3

Only on request

3. Safety

Warning

Pump installation in pits must be carried out by

specially trained persons.

Work in or near pits must be carried out

according to local regulations.

For safety reasons, all work in pits must be supervised by a

person outside the pump pit.

Pits for submersible sewage and wastewater pumps contain

sewage and wastewater with toxic and/or disease-causing

substances. Therefore, all persons involved must wear

appropriate personal protective equipment and clothing, and all

work on and near the pump must be carried out under strict

observance of the hygienic regulations in force.

Warning

Before attempting to lift the pump, make sure the

rated capacity of the lifting equipment (lifting

chain etc.) is adequate for the lifting work.

The rated capacity of the lifting equipment is

stated on the equipment nameplate. The weight

of the pump is stated on the pump nameplate.

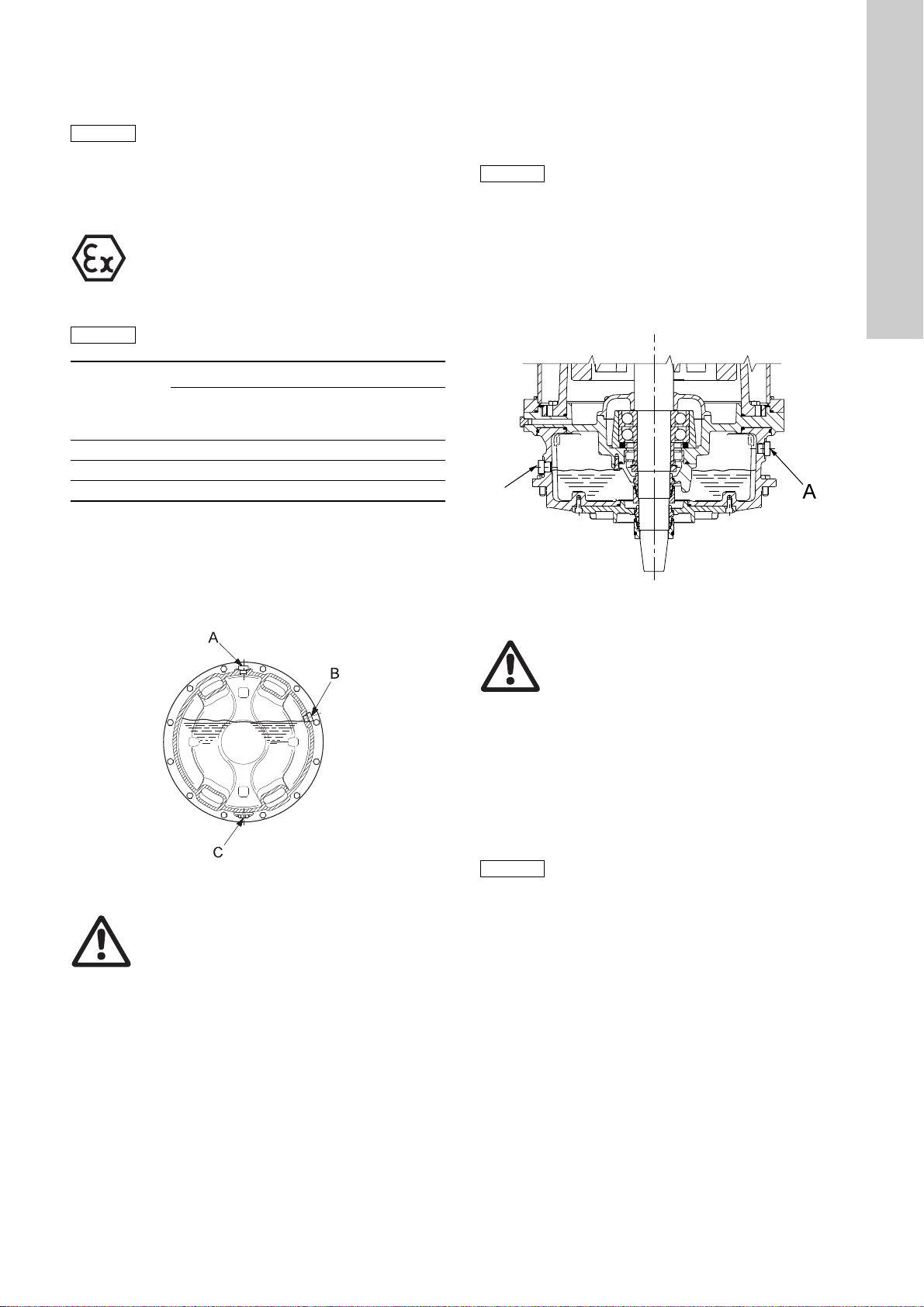

4. Identification

4.1 Nameplate

English (GB)

TM05 8220 2113

Fig. 1 Pump nameplate

All pumps can be identified by means of the nameplate on the

motor top cover, see fig. 1.

Pos. Description

1 Type designation

2 Product number

3 Serial number

4 Maximum head (m)

5 Number of phases

6 Voltage, delta connection

7 Voltage, star connection

8 Rated power input (kW)

9 Power factor (Cos φ)

10 Production code (YYWW)

11 Model

12 Maximum liquid temperature

13 Maximum flow rate (l/s)

14 Enclosure class according to IEC 60529

15 Frequency (Hz)

16 Rated speed

17 Current, delta connection

18 Current, star connection

19 Rated power output P2

20 Insulation class

21 Weight

If a pump has been used for a liquid which is

injurious to health or toxic, the pump will be

classified as contaminated.

If Grundfos is requested to service the pump, Grundfos must be

contacted with details about the pumped liquid, etc., before the

pump is returned for service. Otherwise Grundfos can refuse to

accept the pump.

Possible costs of returning the pump are paid by the customer.

However, any application for service (no matter to whom it may

be made) must include details about the pumped liquid if the

pump has been used for liquids which are injurious to health or

toxic.

3

Page 4

4.2 Type key

English (GB)

All S pumps, range 72, 74 and 78, described in this product guide are identified by the type designation stated in the confirmation of order

and other documentation supplied with the pump.

Please note that the pump type described in this type key is not necessarily available in all variants.

Code Example S 2 .90 .250 .2250 .4 .72 S .C .496 .G .N .D .5 13 .Z

Pump type:

Grundfos sewage and wastewater pump

S

Multi-channel impeller pump installed in a column pipe

ST

Impeller type:

Two-channel

2

Three-channel

3

Four-channel

4

Pump passage:

Maximum solids size [mm]

Pump discharge, S type:

250

Nominal diameter of pump discharge port [mm]

Pump discharge, ST-type:

[ ]

Nominal diameter of column pipe [mm]

Output power, P2:

P2 = Code number from type designation/10 [kW]

Number of poles:

4-pole motor

4

6-pole motor

6

8-pole motor

8

10-pole motor

10

12-pole motor

12

14-pole motor

14

Pump range:

72

72

74

74

78

78

Pressure version:

Super-high

S

High

H

Medium

M

Low

L

Extra-low

E

Super low

F

Installation type:

Submerged installation without cooling jacket

S

Submerged installation with cooling jacket

C

Dry installation with cooling jacket

D

Dry horizontal installation with cooling jacket

H

Impeller diameter (average):

[mm]

Material code for impeller, pump housing and stator housing:

Cast iron impeller, pump housing and stator housing

G

Cast iron pump with stainless steel impeller

Q

Pump version:

Non-explosion-proof pump

N

Pump with explosion-proof motor

Ex

Sensor version:

S pump with built-in SM 113 module. PTC sensors are connected directly to IO 113 or other PTC relay.

B

S pump without built-in SM 113 module

D

Frequency:

50 Hz

5

60 Hz

6

Voltage and connection:

50 Hz 60 Hz

3 x 400 / 690 V Y/D 3 x 575 / (996) V Y/D

11

3 x 415 / 719 V Y/D

13

3 x 380-400 / 660-690 V Y/D

18

58

1G

3 x 380 / 660 V Y/D 3 x 380 / 660 V Y/D

1H

3 x 460 / (797) V Y/D

1B

3 x 400-415 / 690-719 V Y/D

1D

3 x 380-415 / 660-719 V Y/D

Z Custom-built products

4

Page 5

Type key used for frame size 74 and 78 until 2010. May still be used for spare pumps manufactured later.

Code Example S 2 X 250 4 H 2 5 11 Z

Pump type:

S

Grundfos (or Sarlin) wastewater pump/sewage pump

Impeller type:

Two-channel

2

Three-channel

3

Four-channel

4

Axial Propeller

A

Multi-channel, small pump passage

N

Pump version:

Standard pump

[ ]

In conformity with the ATEX directive

X

Power:

100

Motor power in kW

Number of poles:

2-pole motor

2

4-pole motor

4

6-pole motor

6

8-pole motor

8

10-pole motor

10

12-pole motor

12

14-pole motor

14

Pump generation:

First generation

[ ]

Second generation

A

Third generation

B

Pressure version:

No classification

[ ]

Super high

S

High

H

Medium

M

Low

L

Super extra low

F

Installation type:

Submerged installation without cooling jacket

1

Submerged installation with cooling jacket

2

Dry installation with cooling jacket

3

Submerged installation, portable. Pump without cooling jacket.

4

Submerged installation, portable. Pump with cooling jacket.

5

Dry horizontal installation with base stand and bracket. Pump with cooling jacket

6

Submerged column installation

7

Interchangeability:

No letter indicates full interchangeability of parts and use of the same spare parts catalogue.

[ ]

The letters (A, B, C...) indicate interchangeability of parts between otherwise identical pumps.

A,B,C

Number of phases:

Single-phase

1

Three-phase

[ ]

Frequency:

50 Hz

5

60 Hz

6

Voltage and starting method:

50 Hz 60 Hz

660-690 V Y

06

288-500 V Y/D

10

400-690 V Y/D 460-(796) V Y/D

11

220-380 V Y/D

12

415-(719) V Y/D

13

500-(865) V Y/D

14

380-660 V Y/D

15

Special equipment:

U

Flanges sized according to ANSI specifications

Non-standard parts:

Special diameter in impeller

D

Special length of cable

C

Combination of C and D or other special part

Z

Material code for impeller, pump and stator housing:

R

Stainless steel impeller, pump housing and stator housing, AISI 316 (DIN W.-Nr. 1.4408)

S

Stainless steel impeller and pump housing, AISI 316 (DIN W.-Nr. 1.4408)

Stainless steel impeller, AISI 316 (DIN W.-Nr. 1.4408)

Q

English (GB)

5

Page 6

5. Handling the pump

English (GB)

S pumps, range 78 weigh up to 7800 kg without accessories. It is

therefore very important to use the right lifting equipment.

The pump weight is stated on the pump nameplate. See section

4.1 Nameplate.

5.1 Lifting the pump

All lifting equipment must be rated for the purpose and checked

for damage before any attempt to lift the pump. The lifting

equipment rating must under no circumstances be exceeded.

See section 7.4 Lifting tools.

5.2 Lifting points

Warning

Never lift the pump by the power supply cables.

It may result in electric short-circuit and risk of

electric shock when the pump is connected to the

mains. The cables and cable entry may be

damaged, leading to loss of watertightness and

consequent severe damage to the motor.

5.3 Raising pump to upright position

Warnin g

Make sure that the lifting brackets are tightened

before attempting to lift the pump. Tighten if

necessary. Carelessness during lifting or

transportation may cause injury to personnel or

damage to the pump.

TM03 3034 0208TM03 3035 0208TM03 3036 0208

Fig. 4 Raising the pump to upright position, step 1

Fig. 2 Lifting points, range 72

Fig. 3 Lifting points, range 74 and 78

TM03 4459 0208TM04 6068 4809

Fig. 5 Raising the pump to upright position, step 2

Fig. 6 Raising the pump to upright position, step 3

6

Page 7

6. Torques, lubricants and special liquids

This section shows the screws and nuts that must be tightened to a certain torque and the lubricants to be used.

6.1 Common torques

Dimension M8 M10 M12 M16 M20 M24 M27 M30

Torque [Nm] 20 40 70 170 330 570 820 1120

6.2 Special torques and lubricants

English (GB)

Range Pos. Description Quantity Dimension

74, 78 61a O-ring (primary shaft seal) 2 - - Oil

74, 78 62 O-ring 1 - - Oil

72, 74 67 Screw (impeller) 1 M24 600 Oil

78

All 72a O-ring 1 - - Oil

All 105

72 105 Screw of primary shaft seal 5 - 8 -

74, 8 105 Screw of primary shaft seal 5 - 15 -

All 105b

72, 74 105b Screw of secondary shaft seal 5 - 8 -

78 105b Screw of secondary shaft seal 5 - 15 -

74, 78 153 Angular contact ball bearings 2 - - Unirex S2 / LGHP 2

All 157 O-ring 1 - - Oil

All 157a O-ring 1 - - Oil

All 162 Roller bearings 1 - - Unirex S2 / LGHP 2

All 154 Ball bearing 1 - - Unirex S2 / LGHP 2

All 193 Oil plug 3 R 3/4 55 ± 5 -

74, 78 756 O-ring 1 - - Oil

67 Screw (impeller) 1 M24 160 Oil

67a Screw (fastening plate of impeller) 3 - 170 Oil

O-ring (inside of stationary part) 1 - - Oil

Primary shaft seal (sliding surfaces) 1 - - Silicone spray

O-ring (inside stationary part) 1 - - Oil

Secondary shaft seal (sliding surfaces) 1 - - Silicone spray

Torque

[Nm]

Lubricant

Oils:

Silicone spray Valvoline: 96249498.

Esso Unirex S2: 96248520/SKF LGHP 2 (-).

Motor oil with viscosity grade SAE 10 W 30 or SAE 10 W 40.

6.3 Quantities of grease in bearings

Range Bearing Amount of grease

72

74 2.3 litres

78 4.2 litres

Range Bearing Amount of grease

72

74 1.0 litres

78 1.7 litres

Lower bearings

Upper bearing

2.2 litres

0.28 litres

6.4 Special liquids

Range Pos. Component Liquid

523 Cable gland for WIO Ergo 4307

All

Würth Ergo 4307 or similar (thread-locking compound)

Henkel Loclite 290 or similar (thread-locking compound)

ACC Silicone Silcoset 151 (glue, FM approved).

520d Moisture switch Loclite 290

177 Terminal board Silcoset 151

7

Page 8

7. Service tools

English (GB)

The following sections shows tools for pump service.

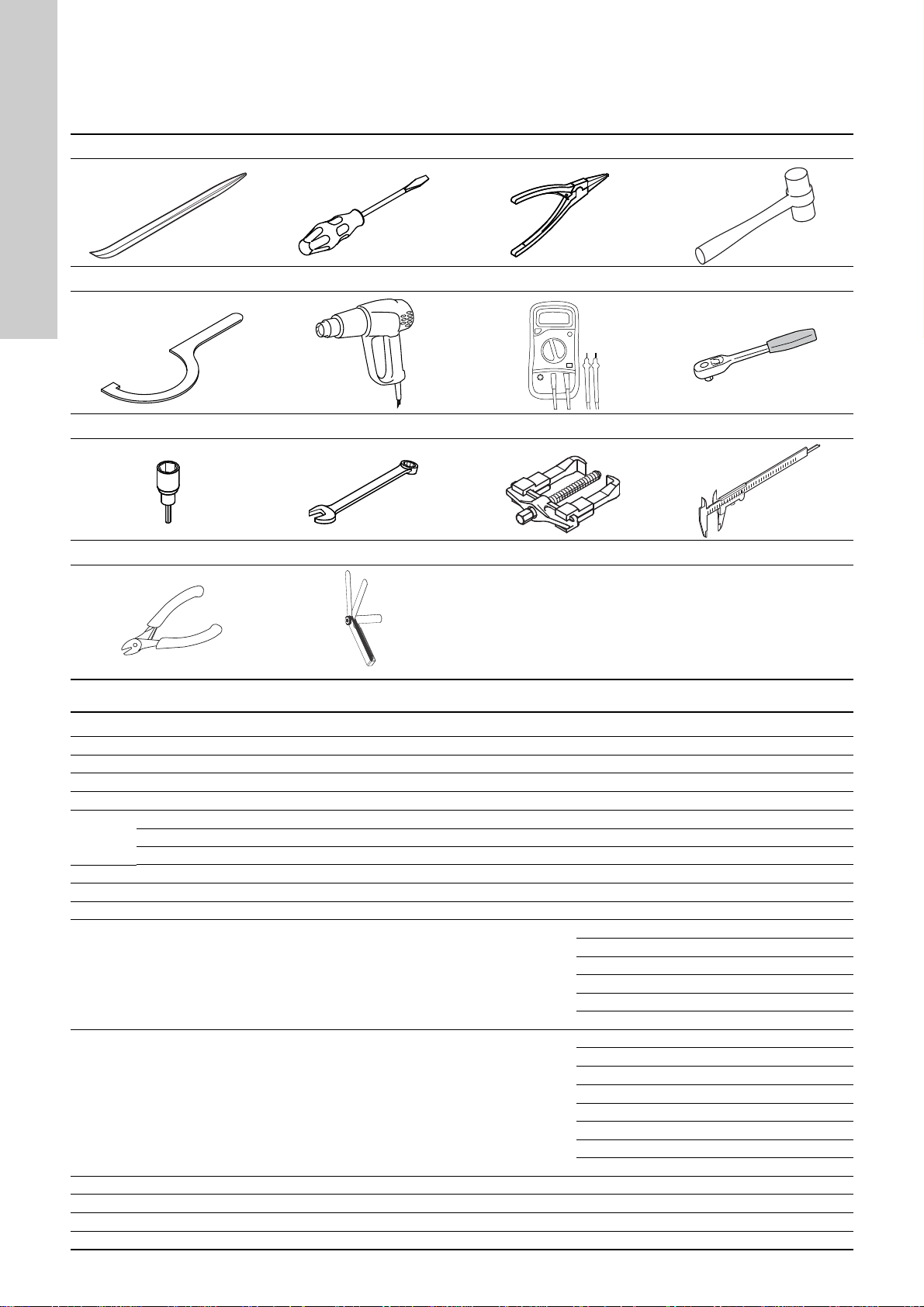

7.1 Standard tools

ABCD

EFGH

IJKL

MN

Standard tools

Pos. Range Designation Description Part number

A All Pinch bar - SV5201

B All Screwdriver Straight slot C All Lock-ring pliers - SV2014

D All Plastic hammer - SV0349

72 Hook spanner (Walter) 120-130 mm -

E

F All Warm-air heater - G All Multimeter - H All Ratchet handle 1/2" - 96777072

I All Hexagon head driver

J All Ring/open-end spanner

K All Puller for bearing - SV0335

L All Sliding gauge 0-150 mm SV0307

M All Cable pliers - N All Feeler gauge - -

74 Hook spanner (SKF) HN22 78 Impact spanner (TMFN) 30-40 -

4 mm SV0414

M6 - 5 mm SV0296

M8 - 6 mm SV0297

M10 - 8 mm SV0298

M12 - 10 mm SV0299

M16 - 12 mm - 1/2" SV0394

8 mm SV0273

10 mm SV0083

12 mm SV0274

16 mm SV0185

20 mm 24 mm SV0122

27 mm SV0084

30 mm SV0073

8

Page 9

7.2 Special tools

OPQR

STUV

Special tools

Pos. Range Designation Description Part number

O All Torque wrench - P 74 Seal assembly tool (PUR127) Roplan 85 mm 96242908

Q 74 Seal assembly tool (PUR128) Roplan 95 mm 96242909

R 78 Seal assembly tool (PUR129) Roplan 110 mm 96242910

S 78 Seal assembly tool (PUR130) Roplan 110 mm 96242911

T 74 Seal assembly tool (PUR131) Roplan 100 mm 96242912

U 78 Seal assembly tool (PUR132) Roplan 120 mm 96242913

V 72 Seal assembly tool (PUR133) Roplan 65 mm 96255372

English (GB)

7.3 Tightness test tools

WXY

BAR

Tightness test tools

Pos. De sig n atio n Description Part number

W Pressure gauge --

X Test plug (KOE045)

Y Test plug (KOE171) Connector R3/4 96061213

Connector M3\8-24 UNF F-ISO

228-G 3\8M

96061209

7.4 Lifting tools

AA BB CC DD

Lifting tools

Pos. De sig n atio n Description Part number

AA Eyebolt with rotating swivel Range 74 and 78 BB Shackle All CC Eye bolt All DD Lifting clamp Range 78 98253177

9

Page 10

8. Service

Note

English (GB)

8.1 General information

Warning

Before starting work on the pump, make sure that

the mains switch has been locked in position 0.

All rotating parts must have stopped moving.

Warning

Except for replacement/dismantling of bearings,

all other service work must be carried out by

Grundfos or an authorised service workshop.

Service must be carried out by specially trained persons.

Before carrying out maintenance and service, it must be ensured

that the pump has been thoroughly flushed with clean water.

Rinse the pump parts with water after dismantling.

Before assembly:

• Clean and check all parts.

• Replace defective parts with new parts.

• Order the necessary service kits.

• Gaskets and O-rings should always be replaced when the

pump is overhauled.

During assembly:

• Lubricate and tighten screws and nuts to correct torque as

stated in section.

8.2 Pump cleaning and visual inspection

A simple maintenance measure is to clean the pumps at regular

intervals. The pumps may be cleaned on site at the pumping

station when lifted up from the wet pit. Hose down the pump

externally using a high-pressure jet cleaner (maximum pressure

100 bar). Caked dirt on the motor must be removed to ensure

good heat conductivity. A mild detergent approved for disposal

into the sewage system may be used. The pumps may be

scrubbed, using a soft brush, if necessary.

Visual inspection of the pump should include search for cracks or

other external damage. Inspect the lifting bracket and lifting chain

for wear and corrosion. Inspect the pump cable for cracks or

lacerations in the sheath, kinks or other damage. Inspect visible

parts of the cable entry for cracks and for being firmly connected

to the motor top cover. Check all visible screws and tighten, if

necessary.

The air vent valve at the top of the cooling jacket may be removed

and cleaned, if necessary. Clean the vent hole before refitting the

valve after cleaning.

8.3 Annual maintenance

Pumps in normal operation should be inspected once a year.

If the pumped liquid is very muddy or sandy, check the pump at

shorter intervals.

The following points should be checked:

• Power consumption

See section 4.1 Nameplate.

• Oil level and oil condition

See section 8.4 Oil check and oil change.

• Cable entry

Make sure that the cables are not sharply bent or pinched.

Replace the cables if necessary.

See section 9.1 Checking and replacing the cable.

• Sensors

Make sure that sensor are working. Replace the sensors if

necessary.

See section 9.3 Replacing the protection sensors

• Impeller clearance

Check the impeller clearance.

See section 8.5 Inspection and adjustment of impeller

clearance.

• Pump parts

Check the pump housing, etc. for possible wear.

Replace defective parts.

• Ball bearings

Check the shaft for noisy or heavy operation (turn the shaft by

hand). Replace defective ball bearings.

A general overhaul of the pump is usually required in case of

defective ball bearings or poor motor function. This work must

be carried out by an authorized service workshop.

Warnin g

On Ex pumps, the ball bearings must only be

replaced by an authorised Ex workshop.

• O-rings and similar parts

During service / replacement, it must be ensured that the

grooves for O-rings and seal faces have been cleaned before

the new parts are fitted.

Used rubber parts must not be reused.

10

Page 11

8.4 Oil check and oil change

Note

Note

Note

Note

B

The oil chamber is filled with oil acting as lubricant and coolant for

both mechanical shaft seals.

Check the oil regularly to avoid damage and

breakdown of the pump.

Low oil level may indicate that the upper mechanical shaft seal is

defective. Contact an authorized service workshop for further

overhaul of the pump and repair, if required.

Warning

Lack of oil may cause overheating and damage of

the mechanical shaft seals. The WIO sensor in

the oil chamber will trip the alarm if the oil quality

is poor or there is not enough oil in the oil

chamber.

Use oil with viscosity grade SAE 10 W 30 or SAE

10 W 40.

Oil quantity

4. If the oil needs to be changed, remove screw C and allow all

the oil to drain from the chamber into the container. Pour an

oil sample into a glass container and observe the condition of

the oil.

Clear oil can be reused.

Emulsified oil must be changed and disposed of.

Used oil must be disposed of in accordance with

local regulations.

5. Replace the O-rings, refit screw C and tighten securely.

Fill the oil chamber with oil to the correct level. Refit screws A

and B and tighten securely.

Upright position

Proceed as follows:

1. Identify the screws A, B and C and their positions relative to

each other. See fig. 7.

English (GB)

Range

72 25 litres 18.5 litres 25 litres

74 - 20 litres 25 litres

78 - 80 litres 80 litres

The oil in the oil chamber can be changed with the pump in either

horizontal or upright position.

Horizontal position

Proceed as follows:

1. Place the pump in such a position that inspection screw A is

pointing upwards.

Fig. 7 Pump with inspection screw A upwards

Warning

When slackening the screw A of the oil chamber,

note that pressure may have built up in the

chamber. Do not remove the screw until the

pressure has been fully relieved!

2. Place a clean container under the pump to collect all the

drained-off oil. Remove screw B and observe the oil level.

3. Check the oil level and take an oil sample to inspect the

condition of the oil. The oil becomes greyish white like milk if it

contains water. In normal operation a small leakage through

the mechanical shaft seals is expected to happen, but if the

water content in the oil is high, this may be the result of a

defective shaft seal. The oil should be changed if it contains

water.

Installation type

S C and D ST

Fig. 8 Correct oil level of upright pump

Warnin g

When slackening the screw A of the oil chamber,

note that pressure may have built up in the

chamber. Do not remove the screw until the

pressure has been fully relieved!

2. Proceed as above and use screw B again for indication of the

level of oil in the oil chamber. See fig. 8.

3. When the pump is upright, the oil has to be pumped out of the

oil chamber. Use a suction pump with a flexible suction hose

that can be inserted deep into the oil chamber.

4. Pump out the oil using all the screw holes in turns so as to

reach all sections of the interior of the oil chamber. Collect the

drained oil in a clean container.

TM03 1628 2705

5. Replace the O-rings, refit screw C and tighten securely.

Fill the oil chamber with oil to the correct level. Refit screws A

and connecting block B and tighten securely.

Used oil must be disposed of in accordance with

local regulations.

TM04 6924 1210

11

Page 12

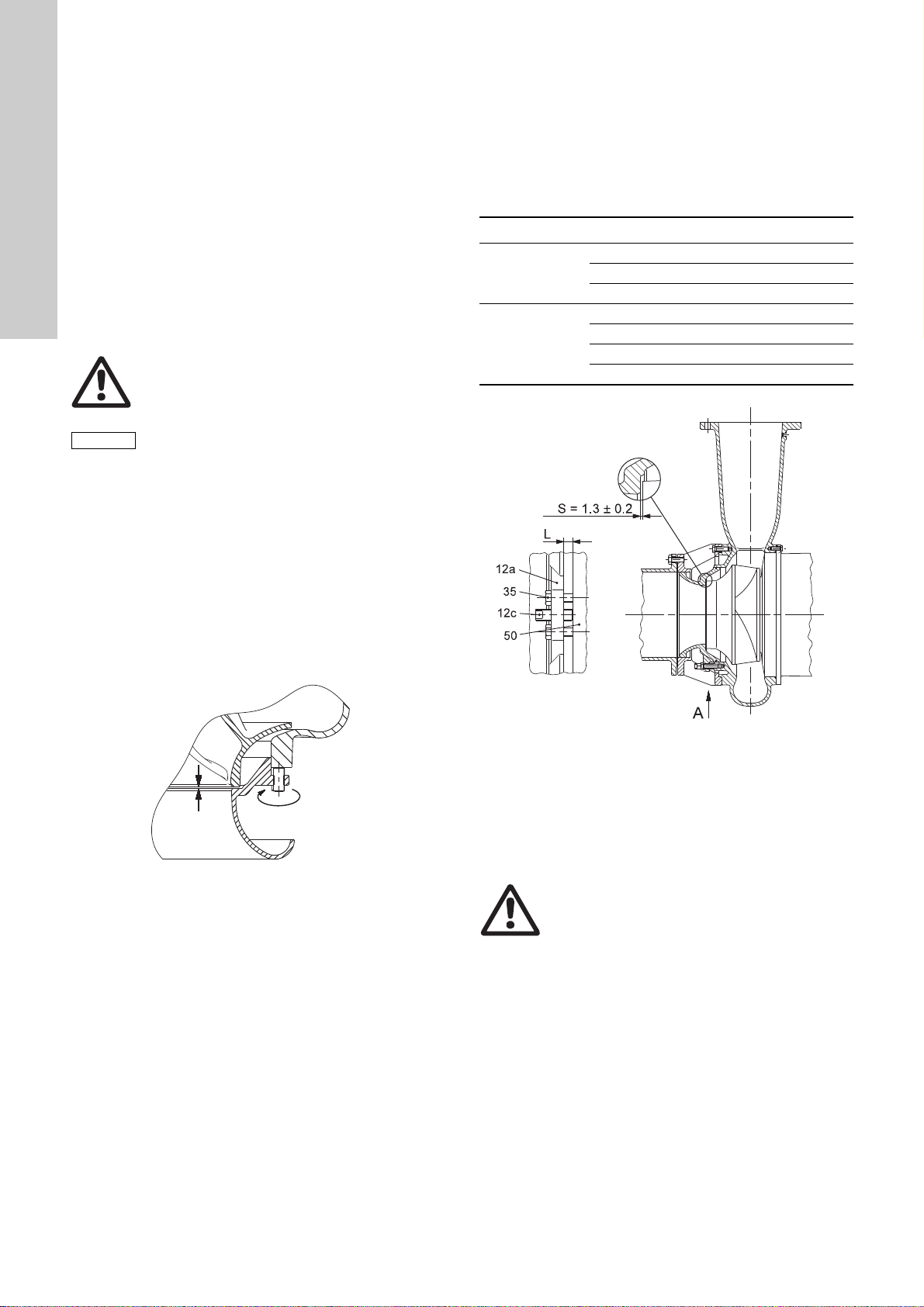

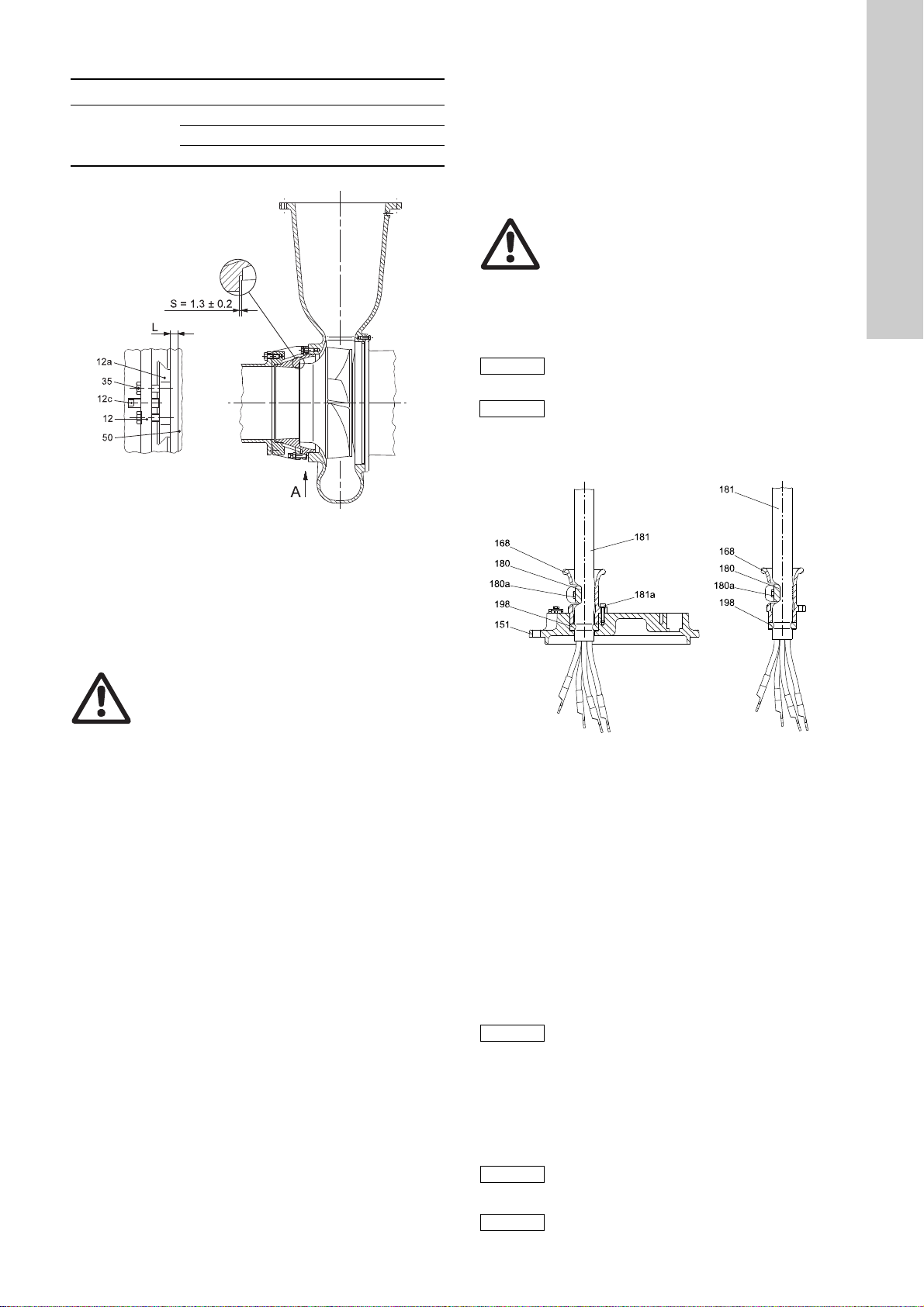

8.5 Inspection and adjustment of impeller clearance

Note

View from direction A

English (GB)

Position numbers of parts (digits) refer to section 11. Drawings

and section 11.4Position numbers and material specification.

The correct impeller clearance is 1.3 mm ± 0.2 mm.

The clearance should be reset if it is 2.0 mm or more.

The method for resetting the clearance is different for dryinstalled pumps, type D, and submersible pumps, types S and C.

For dry-installed pumps there are two methods. All methods are

described here.

8.5.1 Submersible pumps, installation types S, C and ST

Submersible pumps have a separate adjustable pump suction

cover which may be shaped as a suction bell. When the pump is

installed or withdrawn, locate the six fastening screws of the

suction cover and the three set screws.

Use a feeler gauge (N) to check the clearance between the

impeller and the suction cover all around the perimeter of the

suction opening. See fig. 9.

Warning

Never work under a pump when it is hanging

from hoist!

Before adjusting the clearance, clean the gap

between impeller and suction cover.

If the clearance needs adjustment proceed as follows:

1. Slacken all fastening screws (35) and set screws between

suction cover and pump housing.

2. Use a rubber mallet to tap the suction cover to close the

clearance.

3. Open the clearance to specified value by turning the three set

screws (12c).

4. Check that the clearance is uniform around the perimeter of

the suction opening.

5. Tighten the fastening screws (35) and check that the

clearance is stable.

6. Turn the impeller (49) by hand and check at several points.

8.5.2 Dry-installed pumps, installation types D and H

The impeller clearance can be inspected and set with the pump

installed on the pump stand and connected to the pipework.

In these pumps, the suction cover is located between pump

housing and outer connection flange on the suction side of the

pump.

Depending on the construction, there are two ways to set the

impeller clearance.

Method 1

Range Pump types

S2.90.xxx.xxxx.x.xxx.

72 and 74

S2.100.xxx.xxxx.x.xxx.

S3.135.600.xxxx.x.xxx.

S3.115.xxx.xxxx.x.xxx.

78

S3.130.xxx.xxxx.x.xxx.

S3.145.xxx.xxxx.x.xxx.

S4.135.xxx.xxxx.x.xxx.

Fig. 9 Impeller clearance, installation types S, C and ST

Fig. 10 Impeller clearance, installation types D and H,

method 1

These pump types have threaded holes for the fastening screws

(35) of the suction cover (12a) in the pump housing (50) as shown

in fig. 10. Set the impeller (49) clearance as follows:

1. Slacken the three set screws (12c) and close the impeller

TM03 3362 0506

clearance "S" by tightening the six fastening screws (35)

diagonally to move the suction cover evenly.

Warnin g

Do not use too much force when tightening the

fastening screws as this may damage the

bearings. The movement is usual 1 to 3 mm.

2. Measure the distance "L" between suction cover and pump

housing at three points, next to the set screws, using feeler

gauges or callipers and make a note of the distance.

3. Slacken the fastening screws and draw back the suction cover

by 1.3 mm ± 0.2 mm using the three set screws (approx. one

150 ° turn of an M27 set screw) and the distance "L" as

reference.

4. Tighten all fastening screws and check that the distance "L" at

the three reference points is stable on the new value.

TM03 3073 0206

12

Page 13

Method 2

View from direction A

Note

Caution

Note

Note

Note

Range Pump types

S3.110.xxx.xxxx.x.xxx.

72 and 74

S3.120.xxx.xxxx.x.xxx.

S3.135.500.xxxx.x.xxx.

Fig. 11 Impeller clearance, installation type D and H, method 2

9. Dismantling and assembly instructions

Position numbers of parts (digits) refer to section 11. Drawings

and section 11.4 Position numbers and material specification,

and position numbers of tools (letters) refer to section 7. Service

tools.

9.1 Checking and replacing the ca ble

Make sure that the cables are not sharply bent or pinched and

that the cable sheath has no visual defects.

Warnin g

In case of repairs, always use original service

parts from the manufacturer.

Cable change

There are two different methods of changing the cables.

Both methods are described here.

Do not disassemble the cable entry unless you

are going to replace it.

Disconnecting the cables will shorten them

significantly.

9.1.1 Change of cable without adapter flange, method A

TM03 3074 0206

English (GB)

These pump types have threaded holes in the suction cover (12a)

for the fastening screws (35) as shown in fig. 11. Set the impeller

clearance as follows:

1. Slacken the six fastening screws (35) and close the impeller

clearance "S" by tightening the three set screws (12C).

Tighten the screws diagonally to move the suction cover

evenly.

Warning

Do not use too much force when tightening the

fastening screws as this may damage the

bearings. The movement is usual 1 to 3 mm.

2. Measure the distance "L" between suction cover and pump

housing at three points, next to the set screws, using feeler

gauges or callipers and make a note of the distance.

3. Slacken the set screws and draw back the suction cover by

1.3 mm ± 0.2 mm using the six fastening screws (approx. one

270 ° turn of an M12 fastening screw) and the distance "L" as

reference.

4. Tighten all set screws and check that the distance "L" at the

three reference points is stable on the new value.

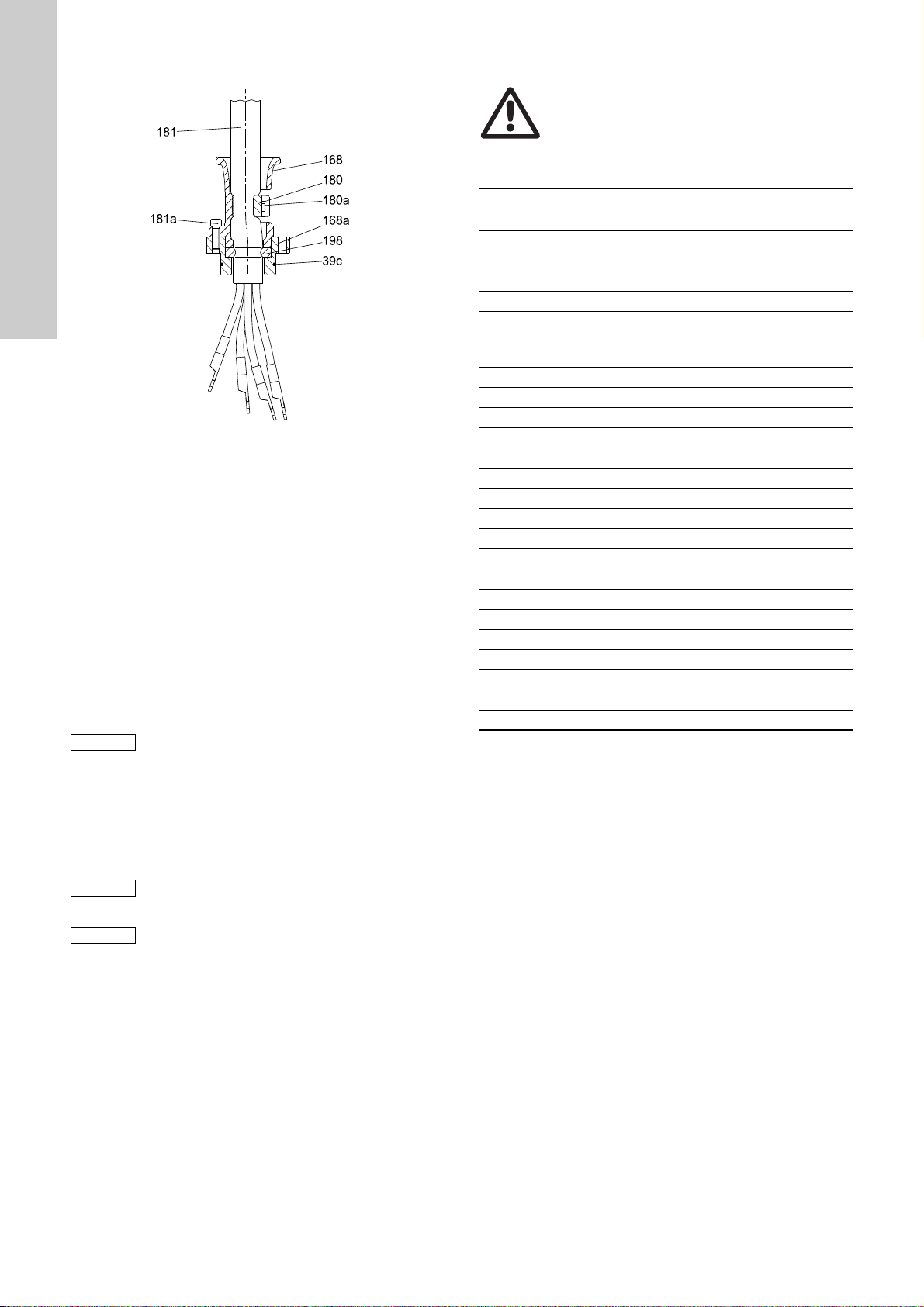

TM05 6812 5212 - TM05 6813 5212

Fig. 12 Cable entry without adapter flange attached to motor

top cover (left) and cable entry (right)

Disconnecting the old cable

1. Remove the screws (180a). See fig. 12.

2. Remove the cable clamp (180).

3. Remove the screws (181a).

4. Pull the cable out of motor top cover/terminal box (151/164a).

5. Remove the cable entry (168) including the rubber seal (198)

from the cable (181).

6. Remove the rubber seal (198) from the cable entry (168).

Connecting the new cable

1. Slide cable entry (168) on to cable.

2. Slide rubber seal (198) on to cable.

Make sure that the washer is below the rubber

seal and fitted against the cable entry.

Not all rubber seals include the washer

(especially pumps manufactured before 2010).

3. Fit the cable entry to the motor top cover/terminal box (151/

164a) with screws (181a).

4. Fit the cable clamp (180a) to the cable entry (168) with screws

(180a).

To prepare a new cable (length of leads, cable

clips, cable markings, etc.), please use the old

cable as reference.

Connect according to the wiring diagram.

13

Page 14

9.1.2 Change of cable with adapter flange, method B

Note

Note

Note

English (GB)

9.2 Replacing the terminal board

Warnin g

Do not change the terminal board unless it is

damaged or it is absolutely necessary.

Please note that the position numbers below refer exclusively to

the replacing of the terminal board.

Fig. 13 Cable entry with adapter flange

Disconnecting the old cable

1. Disconnect the cables from the terminal box (164a).

2. Remove the screws (180a). See fig. 13.

3. Remove the cable clamp (180).

4. Remove the screws (183).

5. Pull out the cable including adapter flange (168a), rubber seal

(198) and cable entry (168).

6. Remove the screws (181a).

7. Pull out the adapter flange (168a).

8. Pull out the cable entry (168) including the rubber seal (198).

9. Remove the rubber seal (198) from the cable entry (168).

Connecting the new cable

1. Slide cable entry (168) on to cable.

2. Slide rubber seal (198) on to cable.

Make sure that the washer is below the rubber

seal and fitted against the cable entry.

3. Slide adapter flange (168a) on to cable.

4. Fit the screws (181a).

5. Fit the cable clamp (180a) on the cable entry (168) with

screws (180a).

6. Fit the cable to motor top cover/terminal box (151/164a).

To prepare a new cable (length of leads, cable

clips, cable markings, etc.), please use the old

cable as reference.

Pos. Description Dimension

1 Copper stud bolt* - 2Sleeve - 3 Washer plate (round) - 4 Plastic bar - -

Washer plate

5

(rectangular)

--

6 Washer plate (square) - 7 Locking plate (round) - 8 Locking plate (square) - -

TM05 6811 5211

9Brass bolt M8 10 Brass screw M12 12

11 Brass nut M8 20

12 Brass nut M12 16

13 Brass nut M16 40

14 Brass nut M20 60

15 Spring washer M8 16 Spring washer M10 17 Spring washer M12 18 Spring washer M16 19 Washer plate M24 20 O-ring 12.0 x 3 21 O-ring 19.2 x 3 22 O-ring 24.0 x 3.53 23 O-ring 34.2 x 3.53 24 Glue (Silcoset 151) - -

* Range 74 pumps manufactured between 1995 and 1997 may

have brass stud bolts.

Torque

[Nm]

Connect according to the wiring diagram.

14

Page 15

9.2.1 Range 72

Tightening torque 16 Nm

Cable side

Stator side

Note

Note

Threaded joint, threads

engaged > 5 mm

Glued joints, shortest path

through joint > 10 mm

Upper bearing

bracket

Creepage distance > 16 mm

Tightening

torque 16 Nm

Cable side

Stator side

Threaded joint, threads

engaged > 5 mm

S pumps, range 72, have two types of terminal board, standard

and Ex. Changing method for both types are described here.

Standard terminal board, method 1

Fig. 14 Standard terminal board, range 72

Dismantling the terminal board

1. Remove the brass nuts (12) and the spring washers (10) from

cable side. See fig. 14.

2. Release the locking of the brass nuts (12) on the stator side

by bending down the tabs of the locking plates (8).

Remove the brass nuts (12) and the plates (8).

3. Remove the washers (3 and 5) including the O-rings (20).

4. Remove the plastic bars (4) including O-rings (22) from both

sides.

5. Remove the copper stud bolts (1) including sleeves (2).

Assembling the terminal board

1. Fit the copper stud bolts (1) into the sleeves (2) and fit them to

the bottom of the upper bearing bracket (61c).

2. Fit the O-rings (22) around the sleeves (2).

3. Fit the plastic bars (4).

4. Fit the washers (3 and 5) including O-rings (20) to the copper

stud bolts (1) on the both sides. Fit the locking plates (8) and

brass nuts (12) on the stator side. Bend one tab of the locking

plates (8) against the nuts (12) to lock the nuts.

5. Connect according to the wiring diagram, use spring washers

(10) and brass nuts (12).

Ex terminal board, method 2

TM05 6798 5212

Fig. 15 Ex terminal board, range 72

Dismantling the terminal board

Warnin g

Ex terminal board parts have been glued

together. You might need to use more force in

removing than normally.

Ex terminal board parts cannot be reused.

1. Remove the brass nuts (12) and the spring washers (17).

Disconnect the cables from both cable and stator sides.

See fig. 15.

2. Release the locking of the brass nuts (12) on the stator side

by bending down the tabs of the locking plates (8).

3. Remove the washers (5) including the O-rings (20).

4. Remove the copper stud bolts (1) including washers (3).

5. Remove the sleeves (2).

Upper bearing bracket (61c) must be cleaned

carefully before assembly.

Assembling the terminal board

1. Fit the copper stud bolts (1) into sleeves (2) and fit them to the

bottom of the upper bearing bracket (61c).

Use glue, such as Silcoset 151.

2. Apply glue to the bottom of the plastic bars (4) and fit to upper

bearing bracket (61c) on the cable side.

3. Apply glue to the bottom of the washers (3) and fit them to the

plastic bars (4).

4. Fit the O-rings (22) around the sleeves (2) on the stator side.

5. Fit the plastic bars (4) on the upper bearing bracket (61c) on

the stator side. Fit the locking plates (8) and brass nuts (12).

Lock the nuts by bending one tab of locking plates (8) towards

the brass nuts (12).

6. Connect according to the wiring diagram, use spring washers

(17) and brass nuts (12).

English (GB)

TM05 6799 5212

15

Page 16

9.2.2 Range 74 and 78

Stator side

Stator side

English (GB)

For S pumps, range 74 and 78, there are two main types of

terminal board depending on pump manufacturing year and

model. Changing methods for all are described here.

Pumps manufactured between 1995 and 1997

Fig. 16 Terminal board for pumps manufactured between 1995

and 1997, range 74 and 78

Dismantling the terminal board

1. See fig. 16.

2. Disconnect the cables from cable side by removing nuts (11),

bolts (9), washer plates (5) and spring washers (15).

3. Disconnect the cables from stator side by removing nuts (13)

and spring washers (18).

4. Remove the nuts (13) and locking plates (7).

5. Remove the plastic bars (4) and washers (3).

6. Remove washers (19).

7. Remove the copper stud bolts (1) and sleeves (2) including Orings (21 and 23).

Assembling the terminal board

1. Fit the O-rings (21 and 23) and lubricate with silicone spray

2. Fit the copper stud bolts (1) in the sleeves (2) fit them to wall.

3. Fit washers (3 and 19).

4. Fit the plastic bars (4).

5. Fit the washers (7) and nuts (13).

6. Connect the cables on the stator side according to the wiring

diagram. Use brass nuts (13) and washers (18).

7. Connect the power cables on the cable side according to the

wiring diagram. Use brass bolts (9), nuts (1) and washers (5

and 15).

Pumps manufactured after 1997

Fig. 17 Terminal board for pumps manufactured 1997 and

later, range 74 and 78

Dismantling the terminal board

1. See fig. 17.

TM05 6817 0113

2. Disconnect the cables from the cable side by removing nuts

(10) and spring washers (17).

3. Disconnect cables from the stator side by removing nuts (13)

and spring washers (18).

4. Release the locking of the nuts (14) by bending down the tabs

of the locking plates (8).

5. Remove the nuts (14).

6. Remove the locking plates (8) and washers (6).

7. Remove the copper stud bolts (1), washer plates (19) and

sleeves (2) including O-rings (21 and 23).

Assembling the terminal board

1. Fit the O-rings (21 and 23) and lubricate with silicone spray.

2. Fit the plastic bars (4) to the wall in the terminal box.

3. Fit the copper stud bolts (1) including sleeves (2) and washers

(19).

4. Fit the washers (6) and the locking plates (8).

5. Fit the nuts (14) and tighten with a torque of 60 Nm.

6. Lock the nuts (14) by bending up one tab of the washers (8).

7. Connect the cables on the stator side according to the wiring

diagram.

8. Connect the cables on the cable side according to the wiring

diagram.

TM05 6818 0113

16

Page 17

9.3 Replacing the protection sensors

Spade connectors

Mounting screw and lock

washer

Screw

Mounting bracket

Caution

Pt100 in stator

Pt100 in upper bearing

9.3.1 Moisture switch

The pumps can have up to three moisture switches, two in the

terminal box (164a) and one on the lower bearing bracket (155).

The changing method is the same, no matter where the switch is

placed.

Warning

Do not touch the head of the moisture switch with

wet or oily hands. Moisture on the sensor head

before installation will cause false measuring

values.

Fig. 18 Moisture switch on lower bearing bracket

Removing the moisture switch

1. Disconnect the spade connectors from the switch.

2. Remove the mounting screw and lock washer from the

mounting bracket. Remove the switch from the base of the

terminal box/upper bearing bracket (164a/61c).

3. Remove the screw.

4. Remove the switch from the mounting bracket.

Fitting new moisture switch

5. Fit the moisture switch to the mounting bracket.

6. Fit the screw to attach the switch to the mounting bracket.

7. Fit the mounting bracket including the switch on the base with

the mounting screw and the lock washer.

8. Connect the spade connectors.

9. Connect the wires according to the wiring diagram.

See section 11.6 Electrical connections.

9.3.2 Pt100 sensor in upper bearing bracket

Fig. 19 Pt100 in upper bearing and in stator

Removing Pt100

1. Cut the wire of the Pt100 sensor right next to sensor.

2. Drill out the sensor from the upper bearing bracket (61c).

Fitting new Pt100

3. Dip the sensor head in glue and insert it into the hole in the

upper bearing bracket (61c).

TM05 6578 4912

4. Connect according to the wiring diagram. See section

11.6 Electrical connections.

9.3.3 Pt100 sensor on the stator

Removing Pt100

1. Cut the wire of the Pt100 sensor right next to sensor and

remove the wire. See fig. 19.

2. Leave the old sensor on the stator (48).

Fitting new Pt100

Warnin g

Make sure that the wire of new sensor is

protected by a protection sleeve.

3. Glue the sensor on to stator windings (48).

4. Connect according to the wiring diagram. See section

11.6 Electrical connections.

English (GB)

TM05 6476 4812

17

Page 18

9.3.4 Pt100 sensor in lower bearing bracket

Quick connector

59a

155

Glue point of Pt100

155

WIO sensor

Connecting

block

155

English (GB)

Pt100 in lower bearing bracket can be fitted in three places

depending on pump manufacturing year. In pumps manufactured

before 2012, sensors are fitted to the locking ring (59a) and lower

bearing bracket (155). See fig. 20. One sensor can be fitted to the

lower bearing bracket (155), but in a different place, see fig. 21.

There are two methods for changing the sensors, and both

methods are described here.

Method A

Removing Pt100

1. See fig. 21. Pull out the sensor using a pair of tongs.

2. Clean the sensor hole carefully.

Fitting new Pt100 sensor in the lower bearing bracket

3. Insert the sensor into the hole in the lower bearing bracket

(155).

4. Spread glue around the sensor end, see fig. 21.

5. Connect according to the wiring diagram. See section

11.6 Electrical connections.

9.3.5 Water-In-Oil sensor (WIO)

Fig. 20 Pt100 sensor positions in the lower bearings

Removing Pt100

1. See fig. 20. Cut the wire of the Pt100 right next to the sensor.

2. Drill out the sensor from the locking ring/bearing bracket (59a/

155).

3. Clean the area with pressurised air.

Fitting new Pt100

4. Dip the whole sensor in the glue and insert it into the hole in

locking ring/bearing bracket (59a/155).

5. Apply a small amount of glue to root of sensor to make sure

that it sticks.

6. Connect according to the wiring diagram. See section

11.6 Electrical connections.

Method B

TM05 6470 4812TM05 6471 4812

TM05 6099 4512

Fig. 22 Water-In-Oil sensor (WIO)

Removing the WIO sensor

1. See section 9.4.10 Removing the rotor.

2. Remove the sensor from the bracket on lower bearing bracket

(155).

3. Open the cable gland.

4. Remove the wires from the connecting block.

5. Pull the sensor cable out through the cable entry in the lower

bearing bracket.

Fitting new WIO sensor

1. Fit the sensor in the bracket.

2. Put the sensor cable up through the cable entry in the lower

bearing bracket.

3. Tighten the cable gland.

4. Cut the cable to a suitable length and connect the wires to the

connecting block. Connect according to the wiring diagram.

See section 11.6 Electrical connections.

Fig. 21 Pt100 in lower bearing bracket on pumps

manufactured after 2010

18

Page 19

9.4 Dismantling range 72

Note

190

164a

173

173b

61c

178

176a

176

164

176c

166

157a

177a

055

759

760

154

177

61c

183

157

For position numbers, see section 11.1 Range 72.

Warning

Maintenance and service work on explosion

proof pumps must be carried out by Grundfos or

a service workshop authorised by Grundfos.

9.4.1 Removing the impeller and pump housing

Before dismantling, support the pump from lifting

bracket with hoist and beneath the discharge

flange with wedges.

1. Remove the outer screws (26).

2. Lift the pump including the impeller (49) and intermediate ring

(1) out of the pump housing (50). Use wedges, if necessary.

3. Remove the O-ring (39a).

4. Place the motor with impeller in horizontal position on for

instance a stable trestle.

5. Remove the O-ring (37b).

6. Support the impeller with a lifting strap, board and hoist to

prevent movement.

7. Bend out the locking tab in the cap (66) and loosen the

impeller screw (67) but do not remove the screw yet.

8. Remove the impeller (49), use wedges, if necessary.

9. Remove the impeller screw (67), the O-ring (67b), the cap

(66) and the O-ring (62a).

10. Remove the impeller (49).

11. Remove the key (9a).

9.4.2 Draining the oil

1. See section 8.4 Oil check and oil change

9.4.3 Removing the primary shaft seal

1. See section 9.4.1 Removing the impeller and pump housing.

2. See section 9.4.2 Draining the oil.

3. Loosen the set screws in the shaft seal (105) and remove the

rotating part.

4. Gently remove the stationary ring of the shaft seal (105).

9.4.4 Removing the terminal box

Fig. 23 Terminal box, range 72

1. See section 9.4.3 Removing the primary shaft seal

2. Place the motor in vertical position on for instance a stable

trestle (shaft downwards).

3. Remove the screws (166). See fig. 23.

4. Remove the terminal box cover (164) including O-ring (165).

5. Remove the screws (173) and locking plate (173b).

6. Disconnect the power cable wires (181) from the terminal

board (177) on upper bearing bracket (61c).

7. Disconnect protection sensor cables from the terminal block

(176a). Do not disconnect the control cable wires from the

terminal block.

8. Straighten the corners of the locking plate (173b) and remove

the screws (173) and the locking plate.

9. Disconnect the control cable (252) earth conductors.

10. Remove the outer screws (178).

11. Lift off the terminal box (164a).

9.4.5 Removing the cooling jacket

1. Remove the screws (150a).

2. Remove the cooling jacket (150c) using a hoist by lifting from

the lifting eyes on both sides of the cooling jacket.

Remove the O-rings (37a and 157b).

9.4.6 Removing the upper bearing bracket

Fig. 24 Upper bearing bracket, range 72

1. See section 9.4.4 Removing the terminal box.

2. See section 9.4.5 Removing the cooling jacket.

3. Remove the screws (183) and fit them in the holes in the

upper bearing bracket (61c).

4. Loosen the bearing bracket by driving the four screws (183)

against the end of the stator housing. Screws will push the

bearing bracket up from the stator housing (55).

5. Pull the upper bearing bracket (61c) approximately 20 cm out

of the stator housing.

6. Disconnect the sensor cables from the terminal board (177)

under upper bearing bracket (61c).

7. Disconnect the cables by removing the screws and locking

plates from the terminal board (177) under the upper bearing

bracket. See fig. 24.

8. Remove the upper bearing bracket (61c) including O-rings

(157a and 157) from the stator housing (55).

9. Remove the moisture absorbing bag (760) from the protection

ring (759).

10. Remove the protection ring (759) including protection sleeve

(177a).

9.4.7 Removing the upper bearing

1. See section 9.4.6 Removing the upper bearing bracket

2. Gently heat up the inner ring of the roller bearing and remove

TM05 6770 5112

the bearing (154) with a bearing puller (K).

English (GB)

TM05 6769 5112

19

Page 20

9.4.8 Removing the shaft seal housing

Note

105b058 272184

055

Note

English (GB)

9.4.11 Removing the lower bearings

1. See section 9.4.10 Removing the rotor.

2. See fig. 26. Disconnect the cable gland (523) in the lower

bearing bracket cover.

3. Disconnect the bearing sensor and remove the cable gland

from the upper bearing bracket cover (60).

4. Remove the screws (182b) and remove upper bearing bracket

cover (60) of the lower bearing bracket. Leave the cover lying

against the stator windings.

5. Loosen and remove the screws (182a).

6. Remove the lower bearing bracket cover (59) of the lower

bearing bracket and remove the O-ring (109).

7. Remove the lock nut (270), lock washer (271) and angle ring

(269).

8. Remove the lower bearing bracket (155) using a hoist.

Fig. 25 Removing the shaft seal housing, range 72

1. See section 9.4.3 Removing the primary shaft seal.

2. Place the motor in horizontal position on for instance a stable

trestle or other support.

3. Remove the vent pipe (272) from the stator housing (55).

4. Secure the shaft seal housing (58) with the lifting strap and

remove screws (184).

5. Remove the shaft seal housing (58) including the vent pipe

(272).

9.4.9 Removing the secondary shaft seal

1. See section 9.4.8 Removing the shaft seal housing.

2. Loosen the set screws in the secondary shaft seal (105b).

Remove the rotating and stationary parts of the shaft seal

(105b).

9.4.10 Removing the rotor

TM05 6768 5112TM05 6802 5212

The outer ring of the roller bearing and the rolls

will be removed together with the bearing

bracket.

9. Collect the springs (153a).

10. Check that the pin (59b) is attached to the lower bearing

bracket.

11. Gently heat up the inner ring of the roller bearing (162) and

remove the ring from the shaft.

12. Gently heat up the outer ring of the roller bearing (162) and

remove the ring from the lower bearing bracket (155).

13. Remove the supporting ring (197) from the shaft.

14. Heat the locking ring (59a) to 200 °C and remove it.

15. Remove the angular contact ball bearings (153) from the

shaft.

16. Remove the upper bearing bracket cover (60) of the lower

bearing bracket from the shaft.

Fig. 26 Rotor, range 72

1. See section 9.4.9 Removing the secondary shaft seal.

2. Remove the screws (184a).

3. Pull the rotor (172) with the lower bearing bracket (155)

approximately 15 cm out of the stator housing to be able to

disconnect the sensors from the connecting block.

Support the rotor by placing boards between the

stator housing and the rotor.

4. Disconnect the sensors from the connecting block.

5. Remove the rotor and place it in vertical position (shaft

upwards) on for instance a stable trestle.

20

Page 21

9.5 Assembling range 72

Note

2

52.2 ± 0.5

56 ± 0.5

68 ± 0.5

Assembly tool PUR133

∅ 80.4

∅ 85

O-rings

9.5.1 Fitting the lower bearings

1. Place the motor in vertical position on for instance a stable

trestle (shaft seal upwards).

2. Fill the upper bearing bracket cover (60) with grease and fit

the cover on the rotor. See section 6.3 Quantities of grease in

bearings.

3. Grease the angular contact ball bearings (153). Fill only 50 %

of the free space of the bearings.

4. Heat up the greased angular contact ball bearings (153) to

120 °C and fit them on the shaft. For the angular contact

bearing to absorb the axial forces, the bearing must be fitted

so that the large surface of the inner ring is resting on the

bearing shoulder of the shaft and the large surface of the

outer ring is resting on the locking ring (59a).

5. Heat the locking ring (59a) to 180 °C and fit it on the bearings

(153).

6. Fit the springs (153a) in the holes of the locking ring.

7. Fit the supporting ring (197) on the rotor.

8. Heat the inner ring of roller bearing (162) to 120 °C and fit it

on the rotor.

9. Fit the outer ring of roller bearing (162) on to the lower bearing

bracket (155).

10. Grease the roller bearings (162). Fill only 50 % of the free

space of the bearings.

11. Check that the pin (59b) and the Pt100 sensor are fitted on

the lower bearing bracket (155).

12. Fit the lower bearing bracket (155) on the rotor.

13. Fit the angle ring (269), lock washer (271) and nut (270) on

the rotor.

Check that the locking ring and the outer ring of

the bearings can be rotated without any

disturbances.

14. Bend one wing of the lock washer (271) into the notch of lock

nut (270).

15. Fit the O-ring (109) in the groove of the lower bearing bracket

(155).

16. Fit the lower bearing bracket cover (59) on the lower bearing

bracket (155) with screws (182a).

17. Fit the upper bearing bracket cover (60) on the lower bearing

with screws (182b).

9.5.2 Fitting the rotor

1. Fit the O-ring (72) on the lower bearing bracket (155).

2. Lower the rotor with shaft into the stator (55), leaving a space

of approximately 20 cm.

3. Connect the sensor connecting block.

4. Complete the fitting of the rotor/shaft.

5. Fit the screws (184a).

9.5.3 Fitting the secondary shaft seal

English (GB)

TM05 6278 4612

Fig. 27 Fitting the secondary shaft seal, range 72

1. Place the motor in horizontal position on for instance a stable

trestle.

2. Clean the shaft.

3. Fit the O-ring on the stationary part of the secondary shaft

seal (105b).

4. Fit the O-ring inside the stationary part of the secondary shaft

seal (105b).

5. Lubricate the moving parts with silicone spray.

6. Fit the stationary part of the secondary shaft seal (105b) on

the shaft and press it home (V). See fig. 27.

7. Tighten the set screws in the secondary shaft seal (105b) with

a torque of 8 Nm.

8. Check the setup length (2 mm) and the assembly length (56 ±

0.5 mm) of the secondary seal (L).

9.5.4 Fitting the shaft seal housing

1. Fit the O-ring (72a) on the lower bearing bracket (155).

2. Fit the O-ring (37c) in the groove of the shaft seal housing

(58).

3. Secure the shaft seal housing (58) including the air went pipe

with the lifting strap and fit it to the stator housing (55).

4. Fit the screws (184).

5. Attach the air went pipe (272) on the stator housing (55).

9.5.5 Fitting the upper bearing

1. Place the motor in vertical position on for instance a stable

trestle (shaft seal downwards).

2. Heat the upper bearing (154) to 120 °C and fit on the shaft.

3. Grease the upper bearing (154). Fill only 50 % of the free

space of the bearing with grease. See section 6.3 Quantities

of grease in bearings.

21

Page 22

9.5.6 Fitting the upper bearing bracket

Note

Note

Note

2

61.2 ± 0.5

65 ± 0.5

77 ± 0.5

Assembly tool PUR133

∅75

∅80

O-rings

English (GB)

1. Check that the protection sleeves are placed against the

protection ring (759).

2. Take the stator cables and protection sensor cables trough the

protection sleeves.

3. Fit the protection ring (759) to the stator housing (55).

4. Fit the upper bearing bracket (61c) into the stator housing

(55), leaving a space of approximately 20 cm.

5. Fit the O-ring (157) to the upper bearing bracket (61c).

6. Connect the stator wires to the terminal board (177) according

to the wiring diagram. Fit the wires, spring washers and

screws. Tighten the screw with a torque of 16 Nm.

7. Connect the protection sensor wires according to the wiring

diagram.

8. Fit the moisture absorbing bag (760) to the protection ring

(759).

Upper bearing bracket must be closed within one

hour after the new moisture absorbing bag has

been exposed to atmospheric humidity.

9. Complete the fitting of the upper bearing bracket and fit

screws (183).

10. See section 10.1 Tightness test of stator (submerged).

9.5.7 Fitting the cooling jacket

This section applies only to pumps with cooling

jacket.

1. Fit the O-ring (37a) on the lower bearing bracket (155).

2. Fit the O-ring (157b) in the groove of the stator housing (55).

3. Fit the cooling jacket (150c) by lifting with a hoist from the

lifting eyes on both sides of the cooling jacket.

4. Fit the screws (150a).

9.5.8 Fitting the terminal box

1. Fit the O-ring (157a).

2. Fit the terminal box (164a) on the stator housing using a hoist.

3. Fit the screws (178).

4. Connect the power cable earth conductors on the upper

bearing bracket (61c) with locking plate (173b) and screws

(173). Bend one corner of the locking plate towards the screw.

5. Connect the protection sensor cables coming from the motor

side to the terminal block (176a).

6. Connect the power cables to the terminal board (177) with

spring washers and screws.

7. Fit the O-ring (165) to the terminal box cover (164).

8. Fit the terminal box cover (164) including the O-ring (165) to

the terminal box (164a).

9. See section 10.2 Tightness test of terminal box (cable side,

submerged).

9.5.9 Fitting the primary shaft seal

TM05 6277 4612

Fig. 28 Fitting the primary shaft seal, range 72

1. Place the motor in horizontal position on for instance a stable

trestle.

2. Make sure that the shaft is clean and smooth.

3. Lubricate the sliding surfaces with silicone spray.

4. Fit the O-ring on the stationary part of the primary shaft seal

(105).

5. Fit the stationary part on the primary seal (105) on the shaft.

6. Check that the O-ring is fitted inside the rotating part of the

primary shaft seal.

7. Fit the rotating part of the primary shaft seal on the shaft and

press it home (V). See fig. 28.

8. Tighten the set screws in the primary shaft seal (105) with a

torque of 8 Nm.

9. Check the setup length (2 mm) and the assembly length (65 ±

0.5 mm) of the primary shaft seal (L).

10. See section 10.1.1 Tightness test of shaft seal housing

(submerged).

Tightness of complete motor must be verified

through a submersion test.

22

Page 23

9.5.10 Oil filling

Note

Note

Note

Note

Cable side

Stator side

1. See section 8.4 Oil check and oil change.

9.5.11 Fitting the impeller and the pump housing

1. Fit the key (9a).

2. Lubricate the cone of the shaft slightly.

3. Fit the O-ring (62a) in the groove of the cap (66). Lubricate the

O-ring.

4. Fit the O-ring (67b) in the groove of screw (67). Lubricate the

thread and the screw head slightly.

5. Support the impeller (49) with a hoist and fit it to the lower

bearing bracket (155).

6. Fit the cap (66) including O-ring (62a) and the screw (67)

including O-ring (67b). Tighten the screw with a torque of 570

Nm.

The new impeller may be higher than the old

impeller, so open the impeller clearance before

fitting the pump housing.

7. Place the motor in vertical position on for instance a stable

trestle (shaft seal downwards).

8. Fit the O-ring (37).

9. Mount the motor on the pump housing.

10. Fit the outer screws (26) and tighten them.

11. Check the impeller clearance. See section 8.5 Inspection and

adjustment of impeller clearance.

9.6 Dismantling range 74

For position numbers, see section 11.2 Range 74.

Warning

Maintenance and service work on explosion

proof pumps must be carried out by Grundfos or

a service workshop authorised by Grundfos.

9.6.1 Removing impeller and pump housing

9.6.3 Removing the primary seal

1. See section 9.6.1 Removing impeller and pump housing.

2. See section 9.6.2 Draining the oil.

3. Loosen the set screws in the shaft seal (105) and remove the

rotating part.

4. Gently remove the stationary ring of the shaft seal (105).

Lever the stationary ring out of the shaft seal by

inserting screwdrivers in positions 0 °, 90 °, 180 °

and 270 °.

9.6.4 Removing the motor top cover

English (GB)

Before dismantling, support the pump unit from

the lifting bracket with hoist and beneath the

discharge flange with wedges.

1. Remove the outer screws (26).

2. Lift the pump including the impeller (49) out of the pump

housing (50) using a hoist. Use wedges, if necessary.

3. Place the motor with impeller in horizontal position on for

instance a stable trestle.

4. Remove the O-ring (37b).

5. Support the impeller with a lifting strap, board and hoist to

prevent movement.

6. Bend out the locking tab in the cap and loosen the impeller

screw (67), but do not remove the screw yet.

7. Remove the impeller (49), use wedges if necessary.

8. Remove the impeller screw (67), the cap (66) and the O-ring

(62a).

9. Remove the impeller (49).

10. Remove the key (9a).

9.6.2 Draining the oil

11. See section 8.4 Oil check and oil change.

TM05 6804 5212

Fig. 29 Terminal box, range 74

1. Remove the screws (166) from the terminal box cover (164)

on the cable side. See fig. 29.

2. Remove the terminal box cover (164) from the terminal box

(164a) including the O-ring (165).

3. Disconnect the control cable wires (252) from the terminal

block. See fig. 30.

4. Remove the screws and the spring washers from the terminal

block bracket.

5. Remove the terminal block including the bracket. Leave the

terminal block and bracket suspended from wires coming

through the partition wall.

The terminal block is connected to the protection

sensor wires coming through the partition wall.

6. Remove the brass nuts and the spring washers from the

terminal board (177) on the cable side. Disconnect the power

cables (181).

23

Page 24

English (GB)

Note

252 181

Terminal block

Terminal block

bracket

Partition wall of

terminal box

177

Earth conductor

Brass nut and

spring washer

Cable side

Screw and

locking plate

Stator side

181

Note

Caution

Note

Fig. 30 Terminal block in terminal box, cable side

7. Bend down the corner of the locking plate, remove the screws

and the plate.

8. Disconnect the earth conductors of the power cable (181).

9. Support the lifting bracket (190) with a hoist, remove screws

(190b) and remove the lifting bracket.

10. Support the cables with a hoist.

11. Remove the screws (183).

12. Remove the motor top cover (151).

13. Remove the O-ring (157a).

In order to change the cables, see section 9.1 Checking and

replacing the cable.

9.6.5 Removing the cooling jacket

This section applies only to pumps with cooling

jacket.

1. See section 9.6.4 Removing the motor top cover.

2. Place the motor in vertical position on for instance a stable

trestle (shaft seal downwards).

3. Remove the screws (150a).

Step 4 applies only to pumps with a locking ring.

4. Remove the locking ring (754) with a hoist.

5. Remove the cooling jacket (150c) by lifting the pump with a

hoist from the lifting eyes on both sides of the cooling jacket.

6. Remove the O-rings (37a and 157b).

9.6.6 Removing the terminal box

1. See section 9.6.4 Removing the motor top cover.

2. See section 9.6.5 Removing the cooling jacket.

3. Remove the screws (166) from the terminal box cover (164)

on the stator side. See fig. 31.

4. Remove the terminal box cover (164) including the O-ring

(165) from the terminal box (164a).

5. Disconnect the protection device cables from the terminal

block.

The terminal block is connected to the protection

sensor wires coming through the partition wall.

6. Disconnect the power cables (181) from the terminal board

(177) by removing the hexagon head screws (10) and

washers (11).

7. Remove the screws (178a or 178 in models without

intermediate ring).

8. Remove the terminal box (164a) including the intermediate

ring (755) using a hoist.

Lift the terminal box carefully to avoid damage to

TM06 0655 0614

the cables.

Step 9 applies only to pumps with intermediate ring.

9. Remove the O-ring (756) from the intermediate ring (755).

9.6.7 Removing the upper bearing

1. Heat up (max. 110 °C) the inner ring of the roller bearing and

pull off the bearing including the bearing housing (61).

2. Remove the circlip (61b).

3. Remove the O-rings (61a) from the outer wall of the bearing

housing (61).

4. Turn the bearing housing (61) so that the roller bearing (154)

is underneath it. Gently heat up (max. 110 °C) the bearing

housing (61) and remove the roller bearing (154).

9.6.8 Removing the shaft seal housing

1. Place the motor in vertical position on for instance a stable

trestle (shaft seal upwards).

2. Remove the screws (184).

3. Remove the shaft seal housing (58) with a hoist. If the

connection is tight, knock gently with a rubber hammer to

ease the separation.

9.6.9 Removing the secondary shaft seal

1. Loosen the set screws in the secondary shaft seal (105b).

2. Carefully remove the rotating part of the shaft seal (105b).

3. Gently remove the stationary ring of the shaft seal (105b).

Lever the stationary ring out of the shaft seal by

inserting screwdrivers in positions 0 °, 90 °, 180 °

and 270 °.

Fig. 31 Terminal box (without motor top cover), range 74

24

TM05 6803 5212

Page 25

9.6.10 Removing the rotor

Note

Note

Note

Note

Note

Note

1. Remove the screws (184a).

2. Loosen the lower bearing bracket (155) from the stator

housing (58) by pushing components apart from each other

with bolts. Lift the rotor (172) at the same time, but no higher

than approximately 10 cm out of the stator housing.

3. Secure lower bearing bracket with boards, and disconnect the

connecting block.

4. Remove the rotor assembly and place it in vertical position

(shaft upwards) on for instance a stable trestle.

9.6.11 Removing the lower bearings

Fig. 32 Rotor, range 74

1. Remove the screws (182b). See fig. 32.

2. Separate the upper bearing bracket cover (60) from the lower

bearing bracket by pushing components apart from each other

with bolts (182b). Leave the cover on to stator wings.

3. Remove the screws (182a).

4. Remove the lower bearing bracket cover (59).

5. Remove the O-ring (109).

6. Bend the tab of the lock washer (271) out of the notch in the

lock nut (270).

7. Remove the lock nut (270), lock washer (271) and angle ring

(269).

8. Remove the lower bearing bracket (155) with a hoist and

remove O-ring (72a).

The outer ring of roller bearing and the rolls will

be removed together with the bearing bracket.

9. Remove the outer ring of roller bearing from lower bearing

bracket by lightly tapping the outer wall of the bearing.

10. Remove the springs (153a).

11. Gently heat up the roller race of the bearing (162) and remove

it.

12. Remove the supporting ring (197).

13. Heat the locking ring (59a) up to 200 °C to loosen it.

Remove the ring.

14. Remove the angular contact ball bearings (153) from the

shaft.

9.7 Assembling range 74

9.7.1 Fitting the lower bearings

1. Place the rotor in vertical position (shaft upwards) on for

instance a stable trestle.

2. Grease the angular contact ball bearings (153) and the roller

bearing (162). Fill only 50 % of the free space of the bearings.

See section 6.3 Quantities of grease in bearings.

3. Fill the bottom of the upper bearing bracket cover (60) with

grease and fit it on the shaft.

Step 4 applies only to pumps that have a labyrinth seal.

4. Heat the labyrinth seal (60a) up to 120 °C and fit it on the

shaft.

5. Heat the greased angular contact ball bearing (153) up to 120

°C and fit it on the shaft.

6. Fit the supporting ring (197) on the shaft.

7. Heat the inner ring of the roller bearing (162) up to 120 °C and

fit it on the shaft.

Let rotor and bearing cool down before

continuing.

8. Heat the locking ring (59a) up to 180 °C and fit it on the shaft.

Let rotor and bearing cool down before

continuing.

9. Fit the six springs (153a) in the locking ring (59a).

10. Fit the roller bearing (162) on the lower bearing bracket (155).

11. Make sure that the pin (59b) is inserted in the hole in the lower

bearing bracket (155). Fit the lower bearing bracket (155) on

the shaft.

12. Fit the angle ring (269) on the rotor.

13. Fit the lock washer (271) on the rotor. Make sure that the tab

TM05 6805 5212

of the inner ring fits into the notch of the shaft.

14. Fit the lock nut (270) on the rotor and tighten it (E).

Check that the bearings rotate smoothly without

any significant play. Adjust if necessary.

15. Bend one tab of the lock washer (271) into the notch of the

lock nut (270).

16. Grease the roller bearing (162). Fill only 50 % of the free

space of the bearing.

17. Fit the O-ring (109) into to the groove of the lower bearing

(155).

18. Fill the bottom of the lower bearing bracket cover (59) with

grease and fit it on the rotor with screws (182a).

19. Lift the upper bearing bracket cover (60) up against the lower

bearing bracket (155) using boards. Fit the screws (182b) and

tighten so that the components are pulled together.

Make an electrical test of sensors attached to

lower bearing bracket.

English (GB)

Angular contact ball bearings might need to be

cut in two to remove them.

15. Remove the upper bearing bracket cover (60).

25

Page 26

9.7.2 Fitting the rotor

Caution

Note

Note

Note

Caution

Note

Stationary part of the secondary shaft seal

Assembly tool PUR131

Assembly tool PUR127

O-ring

English (GB)

1. Lift up the rotor with a hoist and fit O-ring (72).

2. Lower the rotor/shaft into the stator housing (55), leaving

approximately 10 cm open. Secure rotor/stator with boards

between stator housing (55) and lower bearing bracket (155).

3. Connect the sensor connecting block.

4. Remove the boards and complete the fitting of the rotor/shaft.

Pull protection sensor wires tight as the rotor is lowered down.

5. Fit the screws (184a).

Older models only have two bolts between stator

housing and lower bearing bracket. In these

models, secure the assembly of the two

components with four pairs of bolts and nuts.

9.7.3 Fitting the upper bearing

1. Place the motor in vertical position (shaft downwards) on for

instance a stable trestle.

2. Grease the upper bearing (154). Fill only 50 % of the free

space of the bearing. See section 6.3 Quantities of grease in

bearings.

3. Heat the bearing housing (61) up to 120 °C. Fit the upper

bearing (154) in the bearing housing (61).

4. Fit the circlip (61b) in the bearing housing (C).

5. Heat bearing housing and bearing up to 120 °C and fit them

on the shaft.

Let the bearing housing and bearing cool down

before continuing.

6. Fit and lubricate the O-rings (61a).

7. Fill up the bearing with grease.

9.7.4 Fitting the terminal box

1. Fit and lubricate the O-ring (756).

2. Fit the terminal box (164a) including the intermediate ring

(755) on the stator housing (55). Guide the cables out of the

stator side of the terminal box.

3. Fit the screws (178a)

If the intermediate ring is not included on the

pump, fit the terminal box to stator housing with

screws (178).

4. Connect the protection sensor cables to terminal block

according to the wiring diagram. See section 11 .6 Electrical

connections.

5. Fit the stator cables to the terminal board (177) with spring

washers and nuts. Tighten the nuts with a torque of 40 Nm.

Connect according to the wiring diagrams. See section 11.6

Electrical connections.

9.7.5 Fitting the secondary shaft seal

TM05 6175 4512

Fig. 33 Fitting the stationary part of the secondary shaft seal,

range 74

1. Place the motor in horizontal position on for instance a stable

trestle.

2. Make sure that the shaft is clean and smooth.

3. Fit and lubricate the O-ring on the stationary part of the

secondary shaft seal (105b).

4. Fit the stationary part of the secondary shaft seal (105b) and

press it home (P and T). See fig. 33.

Make sure that the pin in lower bearing bracket

cover (59) fits into the notch of the stationary

part.

Test the electrical circuits.

6. Fit the moisture absorbing bag (760) in the terminal box

(164a).

The terminal box must be closed within one hour

after the new moisture absorbing bag has been

exposed to atmospheric humidity.

7. Lubricate and fit the O-ring (165) to the terminal box cover

(164).

8. Fit the terminal box cover (164) on the terminal box (164a)

with screws (166).

26

Page 27