Continuous Workstation Monitors

Model CM400 Series

Instruction Manual

2470-2474 Manatee Avenue East

Bradenton, Florida 34208

Toll Free 877-GND-ZERO (463-1376)

Direct Phone 941-751-7581

Fax 1-941-751-7586

Email sales@gndzero.com

http:/ / www.gndzero.com

Contents

1 Description

CM400 Series 1

2 Installation

Installation Instructions 2

Installation Diagrams 4

Maintenance 6

3 Operation

Wrist Strap Indications 6

Bench System Ground Indications 6

4 Specifications 7

5 Parts Included List 8

6 Service and Warranty 9

Service and Warranty

Ground Zero Electrostatics provides a limited warranty for the

Model CM2015. All new products are guaranteed to be free from

defects in material and workmanship for a period of one (1) year

from the date of shipment. Liability is limited to servicing (after

evaluating, repairing or replacing) any product returned to

Ground Zero Electrostatics. The company does not war-rant

damage due to misuse, neglect, alteration or accident. In no

event shall Ground Zero Electrostatics be liable for collateral or

consequential damages.

To receive service under warranty, please contact Ground Zero

Electrostatics Technical Support.

About Ground Zero Electrostatics

Since 1998, Ground Zero Electrostatics has helped electronic

manufacturing facilities to protect their products and processes

from the many serious problems associated with static electricity.

Ground Zero Electrostatics offers a wide range of unique and

outstanding products to detect, protect, eliminate and monitor

electrostatic charges. Our products are integral components of an

effective static control program.

9

Product Specifications

Dimensions/Weight

CM400 0.88” H x 1.75” W x 1.25” D

(2.24 x 4.45 x 3.18 cm)

7.4 oz.

CM410 1.00” H x 2.40” W x 2.30” D

(2.54 x 6.10 x 5.84 cm)

7.8 oz

CM420 1.00” H x 4.00” W x 2.40” D

(2.54 x 10.16 x 6.10 cm)

12.4 oz

Mounting Mounting materials included

Power Supply

Input 120VAC—60hz

Output 12VDC, 200mA

Audible Alarm 10 beeps (max); 5 seconds

Adjustment No adjustments required

Parts Included List

1. CM400 series workstation monitor

2. CM420 only: Two (2) remote terminals boxes

3. Plug-in Power Supply (12-15 Volts DC, 200 mA, 2.1mm

center positive output)

4. CM410 and CM420 Only: Velcro or Mounting Bracket

5. CM400 only: Two (2) mounting screws

8

Description

Monitors: CM400 Series

Continuously verifying the integrity of the ground system is

critical to an effective ESD protection program. Using specialized

impedance sensing technology, the CM400, CM410 and CM420

single wire monitoring products continuously check the total

ground loop, including the operator, the wrist band and the coil

cord. The systems are compatible with most wrist straps. Units

are tested to NIST traceable standards and require no user

adjustments.

Reliable, Repeatable Results

Accuracy and reliability are improved with the impedance

technology incorporated into our constant monitors. False alarms

disappear and adjustments are not necessary. Powered and

grounded by an AC adapter, the system is fully automatic and

begins sensing when a coil cord is plugged into the unit. A green

light indicates a safe connection and a red light and audible alarm

communicate an unsafe connection.

Continuous Monitors pay for themselves

ESD-S1.1 notes that it is not necessary to test wrist straps daily

when using constant monitoring systems. Higher value-added

products especially benefit from the certainty of continuous

monitoring. The CM400, CM410 and CM420 are perfect solutions

for assuring workstation grounding protection.

1

Installation

1. Remove all items from carton and confirm you have

received all items contained in the “Parts Included List.”

located on Page 8.

2. Choose a location on the work station to mount the

monitor where LED lights are visible and alarm can be

heard by operators. Frequently, monitors are mounted

toward the front edge of workstation or under an eye level

shelf.

NOTE: CM410 and CM420 have an optional requirement

for a Common Point ground

3. Mount monitor securely to workstation using the included

screws, Velcro, or stainless steel bracket included with

monitor model. Refer to installation diagrams located on

Page 4 and 5

NOTE: For CM420 installation move to Step 4 for all other

monitors skip to Step 5.

4. CM420 Only: To install remote wrist strap monitors,

locate a convenient location for operators and mount with

included screws. Frequently remote monitors are mounted

on the underside of work bench near the front edge

5. CM410 and CM420 ONLY: Plug wire from the Common

Point Ground in the banana jack labeled “Bench System

Ground” on back of the monitor.

2

Product Specifications

Performance Specifications

Wrist strap open circuit voltage 0.7 VDC, +0.1VDC @ < 2mA

Mat open circuit voltage 5.0—7.5 VDC

Alarm indicators Visual, audible

(green: safe, red: unsafe)

Alarm set point

Wrist strap 38 to 87pF (human body);

with 1 megohm wrist strap

resistance

Mat 6.5 megohm

Unit monitoring capabilities

CM400 One wrist strap/person

CM410 One wrist strap + mat

CM420 Two wrist straps + mat

CAL400 NIST Calibrated Periodic

verification tool for

CM400

CAL410 NIST Calibrated Periodic

verification tool for

CM410

CAL420 NIST Calibrated Periodic

verification tool for

CM420

7

Operation

Wrist strap monitor operation

Monitoring begins when the coiled cord of the wrist strap is

plugged into the monitor or remote jack. The status of a wrist

strap resistance is indicated by a the tricolor LED and audible

Alarm:

Stand-by indication.

If the wrist strap is removed or not being worn but is still plugged

into monitor, an audible alarm will sound for 7-10 seconds, and

the “OP” (operator) led will be will be blink RED.

Normal indication.

For normal operating resistance “OP” led will be GREEN.

High alarm.

If the operator wrist strap is plugged into the remote and

resistance is higher than maximum, the “OP” led will be RED and

audible alarm will sound.

Bench System Ground (BSG) operation

If unit is equipped with (BSG) monitoring capabilities, monitoring

begins when the coiled cord of the Common Point Ground is

plugged into the (BSG) jack. The status of a (BSG) resistance is

indicated by a the tricolor LED and audible Alarm:

Normal (BSG) indication.

For normal operating resistance led will be GREEN.

High (BSG) alarm.

If GND resistance is higher than maximum limit, led will be RED

and audible alarm will sound.

6

Installation Cont.

6. Insert the power cord into the inlet labeled “POWER” on

the back of unit and connect the AC adapter to a proper

power source.

NOTE: For CM420 installation move to Step 6 for all other

monitors skip to Step 7.

7. CM420 ONLY: Plug the first wrist strap’s coiled cord into

the banana jack labeled “LEFT WRIST STRAP” or “RIGHT

WRIST STRAP” on the back of the monitor. Re-peat

process with second wrist strap using remaining jack. The

“Operator” lights on the front the of unit should turn

GREEN when wrists straps are placed around the wrist.

8. CM400 and CM410 ONLY: Plug the wrist strap’s coiled

cord into the banana jack on the front of the monitor. The

“Operator” lights on the front the of unit should turn

GREEN when wrists straps are placed around the wrist.

NOTE: If wrists strap LED lights do not turn green when wrist

strap is placed on wrist, touch the wrist strap to the Common

Point Ground. If LED light turns green the wrist strap was not

making good contact with the operators wrist.

3

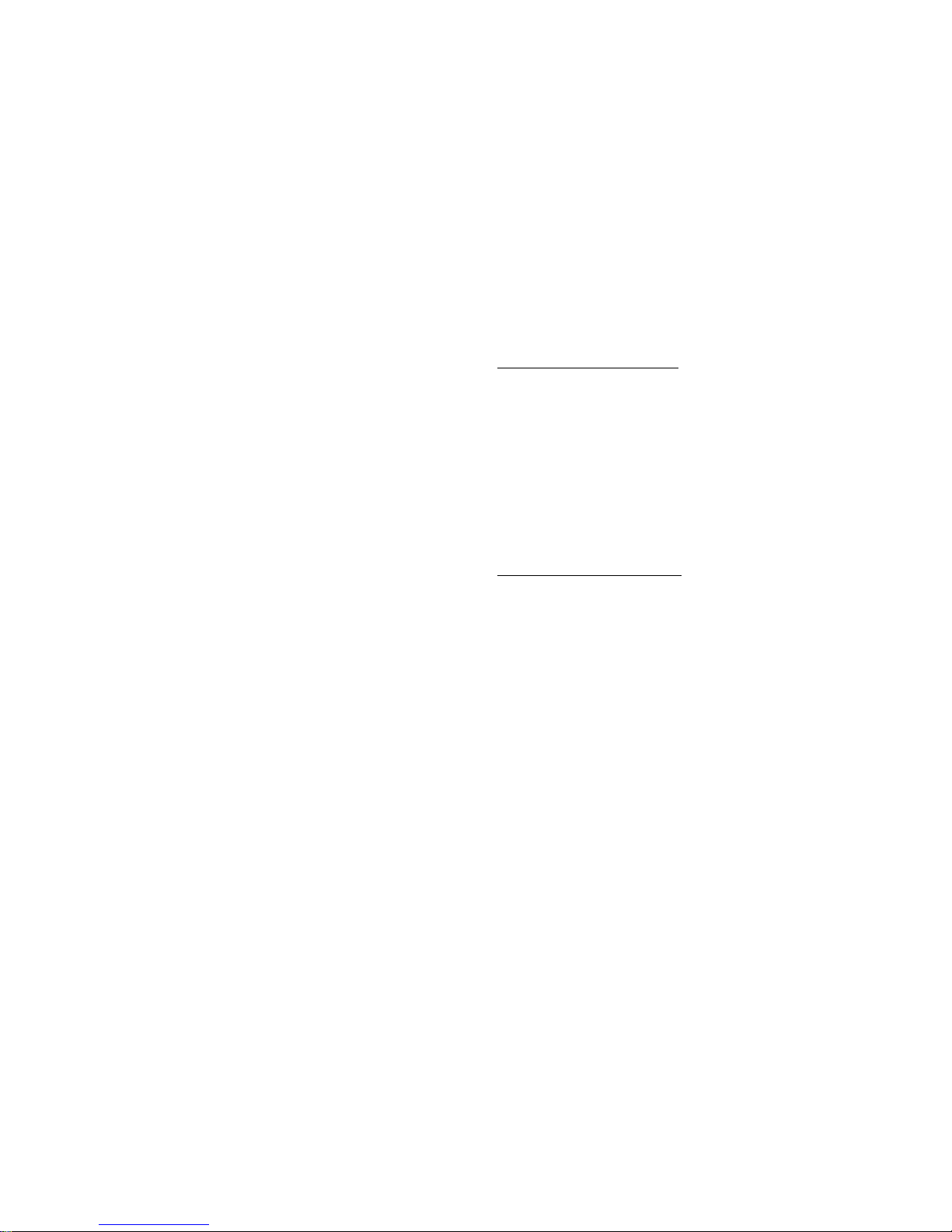

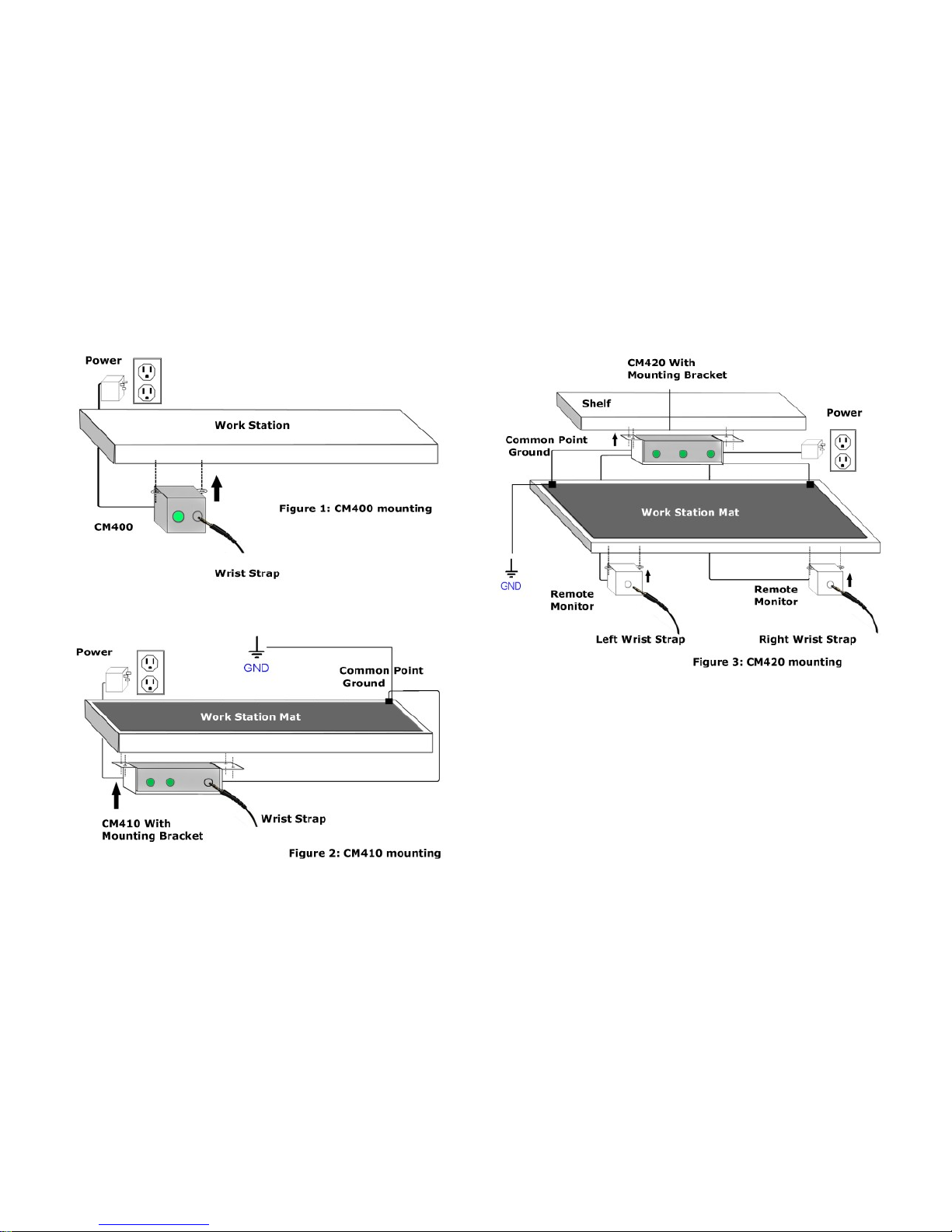

Installation Diagrams

4

Installation Diagrams Cont.

CALIBRATION AND PERIODIC TESTING:

Alarm resistance limits are set by the precision resistors in-side

the tester and never need calibration. You can verify proper

operation of the monitor by periodically testing monitor with an

NIST traceable resistance limit comparator box from Ground Zero

Electrostatics, from the Cal 400 Series.

5

Loading...

Loading...