33 334

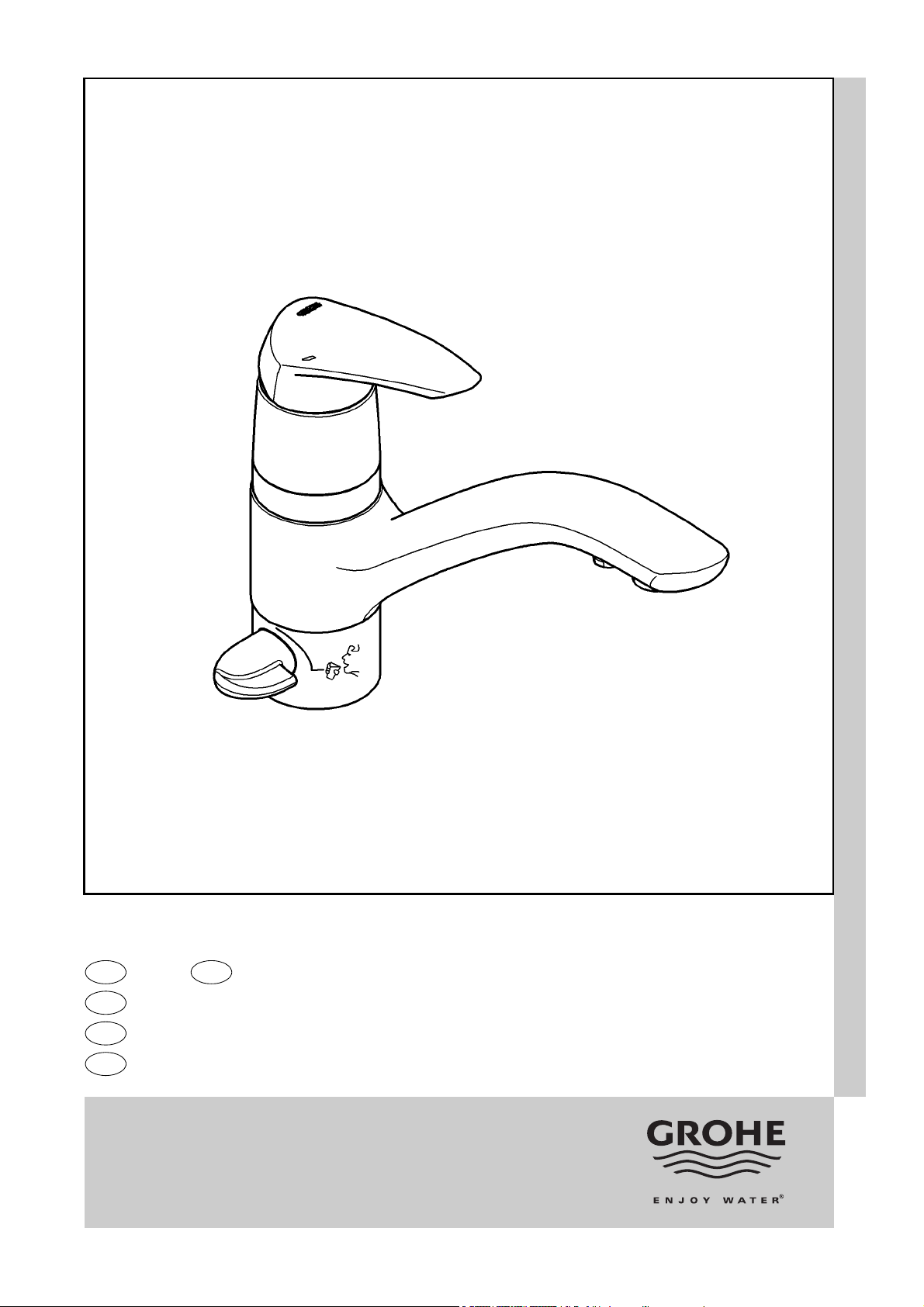

Eurodisc

Eurodisc

.....1

.....1

D

GB

.....1

.....2

F

GB

.....1

F

E

TR

.....3

.....2

.....4

UAE

96.096.031/ÄM 207891/10.06

RUS

I

NL

NL

S

S

DK

DK

.....2

.....5

.....2

.....2

.....3

.....3

.....3

.....3

N

N

FIN

FIN

PL

PL

UAE

UAE

.....3

.....3

.....4

.....4

.....4

.....4

.....4

.....4

GR

GR

CZ

CZ

H

H

P

P

.....5

.....5

.....5

.....5

.....5

.....5

.....6

.....6

TR

TR

SK

SK

SLO

SLO

HR

HR

.....6

.....6

.....6

.....6

.....7

.....7

.....7

.....7

BG

BG

EST

EST

LV

LV

LT

LT

.....7

.....7

.....8

.....8

.....8

.....8

.....8

.....8

.....9

RO

RO

CN

CN

RUS .....9

RUS .....9

.....9

.....9

.....9

Bitte diese Anleitung an den Benutzer der Armatur weitergeben!

Please pass these instructions on to the end user of the fitting.

S.v.p remettre cette instruction à l'utilisateur de la robinetterie!

I

II

GB

Application

Can be used in conjunction with:

• Pressurised storage heaters

• Thermally controlled instantaneous heaters

• Hydraulically controlled instantaneous heaters

Operation with low-pressure displacement water heaters is

not possible.

Specifications

b) Stopcock for drinking water

Tap handle horizontal = valve closed

Turn tap handle counterclockwise = valve opens

Water emerges at the nozzle.

Flow rate limiter

This mixer is fitted with a flow rate limiter, permitting an

infinitely individual variable reduction in the flow rate.

The highest possible flow rate is set by the factory before

despatch.

The use of flow rate limiters in combination with hydraulic

instantaneous water heaters is not recommended.

• Flow pressure

- min. 1 bar

- recommended 1 - 5 bar

• Operating pressure max. 10 bar

• Test pressure 16 bar

If static pressure is greater than 5 bar, fit pressure reducer.

Avoid major pressure differences between hot and cold water

supply.

• Flow rate at 3 bar flow pressure:

- flow straightener approx. 20 l/min

• Temperature

Hot water inlet (maximum): 80 °C

Recommended (energy saving): 60 °C

• Water connection cold - right

hot - left

• Max. clamping length 60mm

Installation

Flush pipes thoroughly.

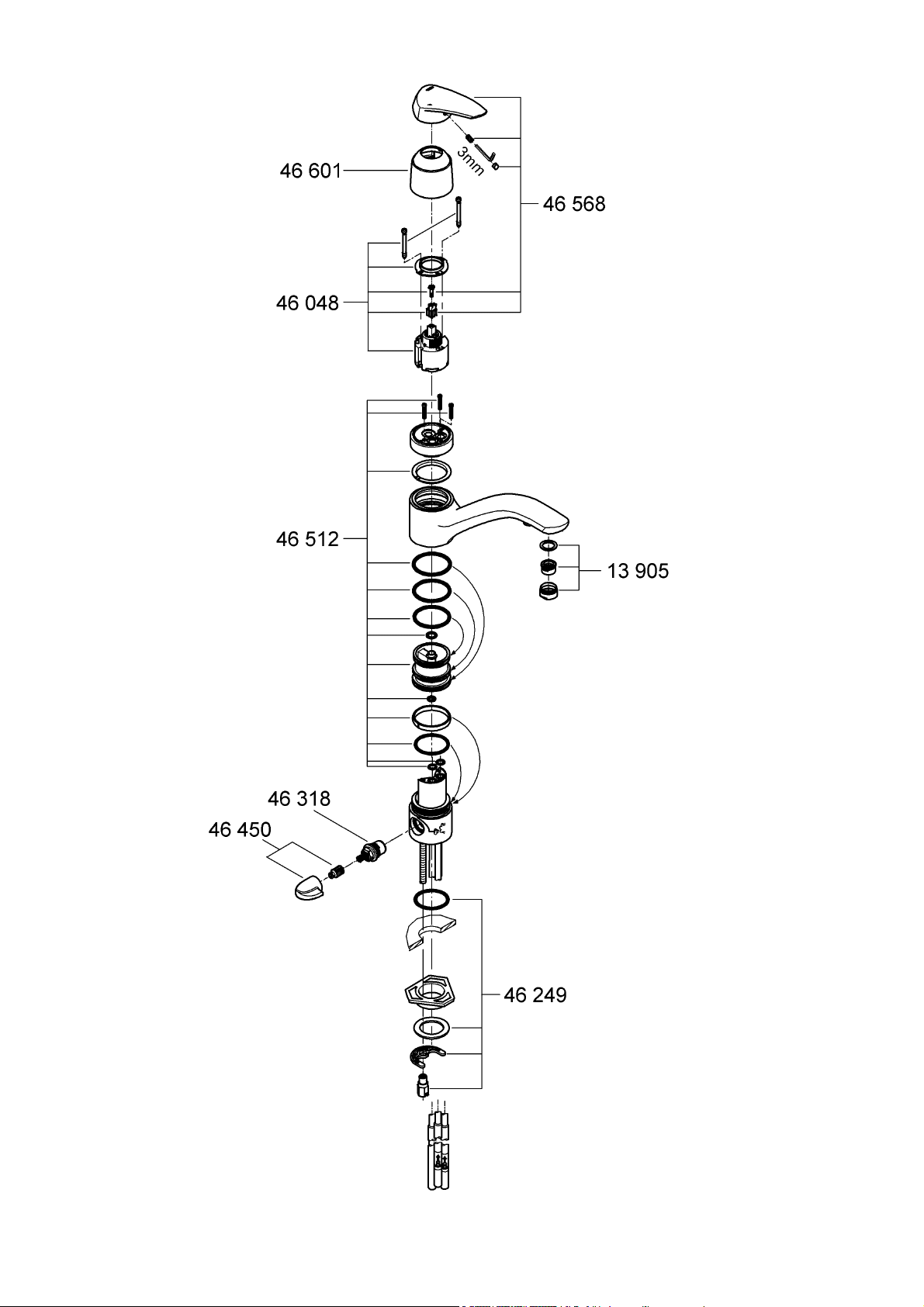

Installation and connection, see fold-out page III, Fig. [1].

Refer to the dimensional drawing on fold-out page I.

Note:

If the support plate (A) is omitted, the clamping length can be

increased by 15mm, see Fig. [1].

Connect sink mixer

The copper pipes must be connected to the service valves,

see Fig. [1].

- Cold-water connection (marked blue) = right

- Hot-water connection (marked red) = left

- Drinking water connection = Ø 10

For commissioning see “maintenance of the cartridge” point 1

to 3, Fig. [2] and [3].

Maintenance

Inspect and clean all parts, replace as necessary and grease

with Grohe special grease.

Shut off hot and cold water supply!

I. Cartridge, see Fig. [3].

1. Lever out plug (B).

2. Loosen set screw (C) with 3mm socket spanner and pull off

lever (D).

3. Unscrew cap (E).

4. Remove screws (G) and detach complete

cartridge (H).

5. Change complete cartridge (H).

Assemble in the reverse order.

Observe the correct installation position.

Make sure that the cartridge seals engage in the grooves on

the housing. Fit screws (G) and tighten evenly and

alternately.

II.Ceramic headpart, see Fig. [4].

1. Remove tap handle (J).

2. Pull off snap insert (K).

3. With a 17mm open-ended spanner, remove ceramic

headpart (L).

4. Replace ceramic headpart (L).

Assemble in the reverse order.

Before reinstallation of the tap handle close the headpart (L),

push on snap insert (K) and tap handle (J).

Open cold and hot water supply and check connections

for leakage!

Operation

a) Lever

Pull lever = open (water flow)

Press lever down = closed

Turn lever right = cold water

Turn lever left = hot water

Water emerges at the flow straightener.

1

III. Unscrew and clean flow straightener (13 905), see foldout page II.

Assemble in reverse order.

Replacement parts, see fold-out page II ( * = special

accessories).

Care

For directions on the care of this fitting please refer to the

accompanying Care Instructions.

F

Domaine d'application

Utilisation possible avec

• Accumulateurs sous pression

• Chauffe-eau instantanés à commande thermique

• Chauffe-eau instantanés à commande hydraulique

b) Robinet d'arrêt pour l'eau potable

Poignée d'arrêt à l'horizontale = robinet fermé

Poignée d'arrêt tournée dans le sens

contraire des aiguilles d'une montre = robinet ouvert

De l'eau sort du gicleur.

Un fonctionnement avec des accumulateurs sans pression

(chauffe-eau à écoulement libre) n'est pas possible.

Caractéristiques techniques

• Pression dynamique

- mini. 1 bar

- recommandée 1 à 5 bar(s)

• Pression de service maximale 10 bars

• Pression d'épreuve 16 bars

Installer un réducteur de pression en cas de pression statique

supérieure à 5 bars.

Eviter les différences de pression importantes entre le

raccordement d'eau chaude et celui d'eau froide!

• Débit à une pression dynamique de 3 bars:

- Régulateur de jet à tamis 20 l/min env.

• Température

Arrivée d'eau chaude: 80 °C maxi.

Recommandée pour une économie d'énergie: 60 °C

• Raccordement

d'eau froide-à droite

d'eau chaude - à gauche

• Prise 60mm maxi.

Installation

Purger les tuyauteries.

Montage et raccordement, voir volet III, fig. [1].

Tenir compte de la cote du schéma sur le volet I.

Remarque:

Il est possible d'augmenter la prise de 15mm en supprimant la

plaque de stabilisation (A), voir fig. [1].

Raccorder la robinetterie

Monter les tubes en cuivre sur les robinets d'équerre, voir

fig. [1].

Limiteur de débit

Ce mitigeur est équipé d'un limiteur de débit. Celui-ci permet

une limitation, individualisée et en continu, du débit. Le débit

maximal est préréglé en usine.

L'utilisation du limiteur de débit est déconseillée avec des

chauffe-eau instantanés à commande hydraulique.

Pour l'activer, voir "Maintenance de la cartouche", points 1 à 3,

fig. [2] et [3].

Maintenance

Contrôler toutes les pièces, les nettoyer, les remplacer si

nécessaire et les graisser avec de la graisse spéciale pour

robinetterie.

Fermer l'arrivée d'eau chaude et d'eau froide.

I. Cartouche, voir fig. [3].

1. Retirer le capot (B) en faisant levier.

2. Dévisser la tige filetée (C) avec une clé Allen

de 3mm et déposer le levier (D).

3. Dévisser le capuchon (E).

4. Desserrer les vis (G) et retirer entièrement la cartouche (H).

5. Remplacer la cartouche complète (H).

Le montage s'effectue dans l'ordre inverse.

Respecter la position de montage.

Veiller à ce que les joints de la cartouche s'engagent

correctement dans les logements du corps de robinetterie.

Insérer les vis (G) et les serrer uniformément et en

alternance.

II.Tête à disques en céramique, voir fig. [4].

1. Enlever la poignée d'arrêt (J).

2. Retirer l'insert encliquetable (K).

3. Dévisser la tête à disques en céramique (L) à l'aide d'une

clé plate de 17mm.

4. Remplacer la tête à disques en céramique (L).

- Raccordement d'eau froide (repère bleu) = droite

- Raccordement d'eau chaude (repère rouge) = gauche

- Raccordement d'eau potable = Ø de 10

Ouvrir l'arrivée d'eau froide et d'eau chaude et vérifier

l'étanchéité des raccordements.

Utilisation

a)Levier

Tirer le levier = ouvert (écoulement d'eau)

Abaisser le levier = fermé

Diriger le levier vers la droite = eau froide

Diriger le levier vers la gauche = eau chaude

De l'eau sort du régulateur de jet à tamis.

Le montage s'effectue dans l'ordre inverse.

Avant le montage de la poignée d'arrêt, fermer la

tête (L), encliqueter l'insert encliquetable (K) et monter la

poignée d'arrêt (J).

III. Dévisser et nettoyer le régulateur de jet à

tamis (13 905) voir volet II.

Le montage s'effectue dans l'ordre inverse.

Pièces de rechange, voir volet II ( * = accessoires en option).

Entretien

Les indications relatives à l'entretien de cette robinetterie

figurent sur la notice jointe à l'emballage.

2

UAE

1

10

3

TR

Kullanım sahası

Aşağıda belirtilenlerle kullanılması mümkündür:

•Basınçlı hidroforlarla

• Termik kumandalı ısıtıcılarla

• Hidrolik kumandalı ısıtıcılarla

b) İçme suyu için kapama valfi

Yatay açma kapama kolu = Valf kapalı

Açma kapama kolunu saat

yönünün tersine çevirin = Valf açar

Su, ağız parçasından dışarı akar.

Basınçsız kaplarla (açık sıcak su hazırlayıcı) işletmek mümkün

değildir.

Teknik Veriler

•Akış basıncı

- en az 1 bar

- tavsiye edilen 1 - 5 bar

• İşletme basıncı maks. 10 bar

• Kontrol basıncı 16 bar

Statik basıncın 5 barın üzerinde olması durumunda, bir basınç

düşürücü takılmalıdır.

Soğuk ve sıcak su bağlantıları arasında yüksek basınç

farklılıklarından kaçının!

• 3 bar akış basıncında debi:

- Elek püskürtme regülatörü yakl. 20 l/dak

•Isı

Sıcak su girişi: maks. 80 °C

Enerji tasarrufu için tavsiye edilen: 60 °C

• Su bağlantısı soğuk - sağ

sıcak - sol

•Bağlantı uzunluğu maks. 60mm

Montaj

Boruları su ile temizleyin.

Montaj ve bağlantı, bkz. katlanır sayfa III, şekil [1].

Katlanır sayfa I’deki ölçülere dikkat edin.

Açıklama:

Stabilizasyon plakasını (A) çıkartarak bağlantı

uzunluğunu 15mm artırabilirsiniz, bkz. þekil [1].

Lavabo bataryasının bağlanması

Bakır boruları köşe valflerine monte edin, bkz. şekil [1].

Akım sınırlayıcısı

Bu armatür bir akım sınırlayıcısı ile donatılmıştır. Böylece

kademesiz olarak tekil akış miktarının (debi) sınırlanması

mümkündür. Üretici tarafından mümkün olan en fazla akışa

ayarlanmıştır.

Hidrolik kumandalı ısıtıcıların kullanılması durumunda,

akım sınırlayıcının montajı tavsiye edilmez.

Faal hale getirmek için “Kartuşun bakımı” işlemlerine

madde 1’den 3’e kadar bakın, şekil [2] ve [3].

Bakım

Bütün parçaları kontrol edin, temizleyin, gerekirse değiştirin ve

özel armatür gresi ile gresleyin.

Soğuk ve sıcak su girişini kapatın!

I. Kartuş, bkz. þekil [3].

1. Tapayı (B) çıkartın.

2. Setuskuru (C) 3mm’lik alyen anahtarla çözün ve

kolu (D) çekin.

3. Başlığı (E) sökün.

4. Cıvataları (G) sökün ve kartuşu (H) komple alın.

5. Kartuşu (H) kpl. değiştirin.

Montaj ters sıralamayla yapılır.

Montaj pozisyonuna dikkat edin.

Kartuş contalarının gövdedeki yuvalarına oturmasına dikkat

edin. Cıvataları (G) takın ve değişkenli olarak aynı ayarda

sıkın.

II.Seramik üst parça, bkz. şekil [4].

1. Açma kapama kolunu (J) çekerek çıkarın.

2. Ara tutucuyu (K) çekin.

3. Seramik üst parçayı (L) 17mm’lik düz anahtar ile sökün.

4. Seramik-üst parçasını (L) gerekirse değiştirin.

Montaj ters sıralamayla yapılır.

-Soğuk su bağlantısı (Mavi işaretli) = sağ

-Sıcak su bağlantısı (Kırmızı işaretli) = sol

- İçme suyu bağlantısı = Ø 10

Soğuk ve sıcak su girişlerini açın ve tüm bağlantıların

sızdırmaz olup olmadığını

kontrol edin!

Kullanma

a)Açma kapama kolu

Kolu çekin = açık (Su akışı)

Kolu aşağı bastırın = kapalı

Kolu sağ tarafa çevirin = Soğuk su

Kolu sol tarafa çevirin = Sıcak su

Su, elek püskürtme regülatöründen dışarı akar.

Açma kapama kolunun montajından önce üst parçayı (L)

kapatın, ara parçayı (K) ve açma kapama kolunu (J) yatay

pozisyonda takın.

III. Elek püskürtme regülatörünü (13 905) sökün ve

temizleyin, bkz. katlanır sayfa II.

Montaj aksi yönde sıra ile yapılır.

Yedek parçalar, bkz. katlanır sayfa II ( * = Özel aksesuar).

Bakım

Bu armatürün bakımı ile ilgili gerekli açıklamalar için lütfen

birlikte verilen bakım talimatına başvurunuz.

4

RUS

Область применения

Эксплуатация возможна с:

• накопителями, работающими под давлением

• прямоточными водонагревателями

• с термическим и гидравлическим управлением

Эксплуатация с безнапорными открытыми

водонагревателями не предусмотрена.

Технические данные

• Давление воды:

- мин.1 бар

- рекомендуется 1 - 5 бар

• Рабочее давление макс. 10 бар

• Испытательное давление 16 бар

При давлении в водопроводе более 5 бар рекомендуется

установить редуктор давления.

Необходимо избегать больших перепадов давлений в

подсоединениях холодной и горячей воды.

• Расход при давлении воды 3 бар:

- аэратор прибл. 20 л/мин.

• Температура:

горячей воды на входе (макс.) 80 °C

Рекомендуется (экономия энергии)60 °C

• Подключение воды холодная - справа

горячая - слева

• Макс. длина зажима 60мм

Установка

Тщательно промыть трубопроводы.

Установка и подключение, см. складной лист III, рис. [1].

Учитывайте при этом данные на чертеже с размерами на

складном листе I.

Примечание:

Отказавшись от использования стабилизирующей

пластины (А) можно увеличить длину зажима на 15мм,

см. рис. [1].

Подключение смесителя для мойки

Медная подводка должна быть подсоединена к угловым

вентилям, см. рис. [1].

- Подключение холодной воды

(синяя маркировка)= справа

- Подключение горячей воды

(красная маркировка)= слева

- Подключение питьевой воды = Ø 10

Открыть подачу холодной и горячей воды, проверить

соединения на герметичность!

Обслуживание

a) Рычаг

Поднять рычаг = открыто (поток воды)

Опустить рычаг вниз = закрыто

Отвести рычаг вправо = холодная вода

Отвести рычаг влево = горячая вода

Вода течет из аэратора.

б) Запорный клапан для питьевой воды

Ручка клапана

в горизонтальном положении = клапан закрыт

Поворот ручки клапана

против часовой стрелки = клапан открывается

Вода течет из форсунки.

Регулятор расхода

Настоящий смеситель снабжен регулятором расхода. Тем

самым, возможно индивидуальное бесступенчатое

ограничение расхода.

На заводе-изготовителе установлен максимальный

уровень расхода.

Регулятор расхода не рекомендуется использовать в

системе с гидравлическими проточными

водонагревателями.

Для приведения в действие – см. “Техобслуживание

картриджа”, пункты 1 - 3, рис. [2] и [3].

Техническое обслуживание

Все детали проверить, очистить, при необходимости

заменить и смазать специальной смазкой для

арматуры Grohe.

Перекрыть подачу горячей и холодной воды!

I. Картридж, см. рис. [3].

1. Вынуть пробку (В).

2. Ослабить установочный винт (С) при помощи торцевого

гаечного ключа на 3мм и снять рычаг (D).

3. Отвинтить колпачок (Е).

4. Отвинтить винты (G) и снять картридж в сборе (H).

5. Заменить картридж в сборе (Н).

Монтаж производится в обратной последовательности.

Соблюдать монтажное положение.

Необходимо следить за тем, чтобы уплотнения картриджа

вошли в выточки корпуса. Ввинтить винты (G) и

поочередно равномерно затянуть их до отказа.

II. Керамическая кран-букса, см. рис. [4].

1. Снять ручку клапана (J).

2. Снять фиксатор (K).

3. Вывинтить керамическую кран-буксу (L) гаечным ключом

на 17мм.

4. Снять керамическую кран-буксу (L).

Монтаж производится в обратной последовательности.

Перед переустановкой ручки клапана закрыть

кран-буксу (L), установить фиксатор (K) и ручку

клапана (J).

III. Вывинтить и прочистить аэратор Sistra (13 905), см.

складной лист II.

Монтаж производится в обратной последовательности.

Запасные части, см складной лист II ( * = Специальные

принадлежности).

Уход

Указания по уходу за настоящим изделием приведены в

прилагаемой инструкции по уходу.

5

RUS

Однорычажный смеситель

Комплект поставки 33 334

смеситель для мойки X

излив

отведенный душ

Контргайка X

пружина

Техническое руководство X

Инструкция по уходу X

Вес нетто, кг 4,45

Дата изготовления: см. маркировку на изделии

Срок эксплуатации согласно гарантийному талону.

Изделие сертифицировано.

Grohe AG, Германия

1

3

D

C

3m

m

B

E

A

G

13mm

2

H

4

2

,

5

m

m

K

L

J

m

m

7

1

2

,

5

m

m

III

Loading...

Loading...