Page 1

COPYRIGHT © 2000 BY GRIZZLY INDUSTRIAL, INC.

1821 VALENCIA ST., BELLINGHAM, WA 98227

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

PRINTED IN CHINA

71⁄4

" CIRCULAR SAW

MODEL G9906

INSTRUCTION MANUAL

Page 2

G9906 71⁄4" Circular Saw

-2-

Page 3

-1-

For Your Own Safety Read Instruction Manual

Before Operating This Equipment

Indicates an imminently hazardous situation which, if

not avoided, WILL

result in death or serious injury.

Indicates a potentially hazardous situation which, if

not avoided, COULD

result in death or serious injury.

Indicates a potentially hazardous situation which, if

not avoided, MAY

result in minor or moderate injury.

It may also be used to alert against unsafe practices.

This symbol is used to alert the user to useful information

about proper operation of the equipment.

The purpose of safety symbols is to attract your attention to possible hazardous

conditions. This manual uses a series of symbols and signal words which are

intended to convey the level of importance of the safety messages. The progression of symbols is described below. Remember that safety messages by themselves do not eliminate danger and are not a substitute for proper accident prevention measures.

NOTICE

Safety Instructions For Power Tools

5. KEEP CHILDREN AND VISITORS

AWAY. All children and visitors

should be kept a safe distance from

work area.

6. MAKE WORK SHOP CHILD

PROOF with padlocks, master

switches, or by removing starter

keys.

7. DON’T FORCE TOOL. It will do the

job better and safer at the rate for

which it was designed.

8. USE RIGHT TOOL. Don’t force tool

or attachment to do a job for which it

was not designed.

1. KEEP ALL SAFETY DEVICES IN

PLACE and in working order.

2. REMOVE ADJUSTING KEYS AND

WRENCHES. Form habit of check-

ing to see that keys and adjusting

wrenches are removed from tool

before turning on.

3. KEEP WORK AREA CLEAN.

Cluttered areas and benches invite

accidents.

4. DON’T USE IN DANGEROUS

ENVIRONMENT. Don’t use power

tools in damp or wet locations, or

where any flammable or noxious

fumes may exist. Keep work area

well lighted.

SAFETY

G9906 71⁄4" Circular Saw

Page 4

No list of safety guidelines can be

complete. Every shop environment is

different. Always consider safety

first, as it applies to your individual

working conditions. Use this and

other machinery with caution and

respect. Failure to do so could result

in serious personal injury, damage to

equipment or poor work results.

G9906 71⁄4" Circular Saw

-2-

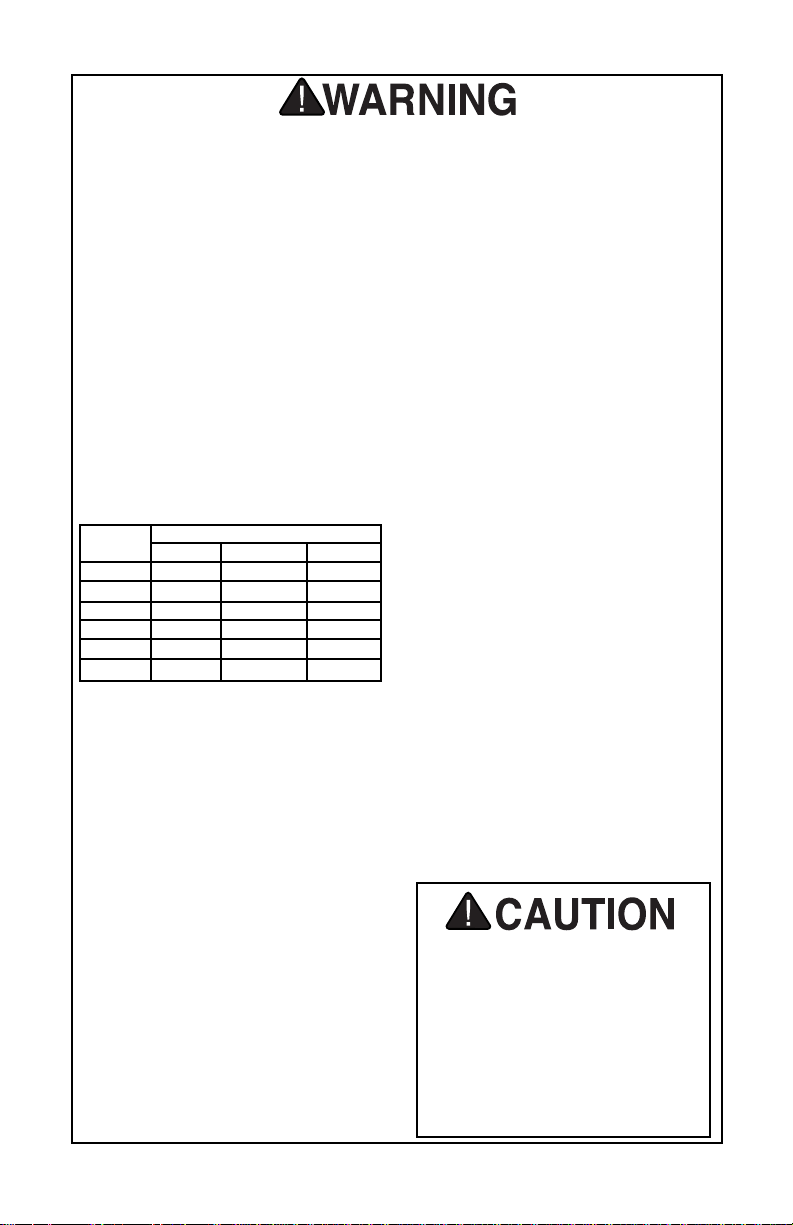

9. USE PROPER EXTENSION CORD

for the tool. Make sure your extension cord is in good condition.

Conductor size should be in accordance with the chart below. The

amperage rating should be listed on

the motor or tool nameplate. An

undersized cord will cause a drop in

line voltage resulting in loss of power

and overheating. Your extension

cord must also contain a ground wire

and plug pin. Always repair or

replace extension cords if they

become damaged.

Minimum Gauge for Extension Cords

10. WEAR PROPER APPAREL. Do not

wear loose clothing, gloves, neckties, rings, bracelets, or other jewelry which may get caught in moving

parts. Non-slip footwear is recommended. Wear protective hair covering to contain long hair.

11. ALWAYS USE SAFETY GLASSES.

Also use face or dust mask if cutting

operation is dusty. Everyday eyeglasses only have impact resistant

lenses, they are NOT safety glasses.

12. SECURE WORK. Use clamps or a

vise to hold work when practical. It’s

safer than using your hand and frees

both hands to operate tool.

13. DON’T OVERREACH. Keep proper

footing and balance at all times.

Safety Instructions For Power Tools

AMP LENGTH

RATING 25ft 50ft 100ft

0-6 18 16 16

7-10 18 16 14

11-12 16 16 14

13-16 14 12 12

17-20 12 12 10

21-30 10 10 No

14. MAINTAIN TOOLS WITH CARE.

Keep tools sharp and clean for best

and safest performance. Follow

instructions for lubricating and

changing accessories.

15. DISCONNECT TOOLS before ser-

vicing and changing accessories,

such as blades, bits, cutters, and

the like.

16. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure

switch is in off position before plugging in.

17. USE RECOMMENDED ACCESSORIES. Consult the owner’s man-

ual for recommended accessories.

The use of improper accessories

may cause risk of injury.

18. CHECK DAMAGED PARTS.

Before further use of the tool, a

guard or other part that is damaged

should be carefully checked to

determine that it will operate properly and perform its intended function.

Check for alignment of moving

parts, binding of moving parts,

breakage of parts, mounting, and

any other conditions that may affect

its operation. A guard or other part

that is damaged should be properly

repaired or replaced.

Page 5

G9906 71⁄4" Circular Saw

-3-

INTRODUCTION

Commentary

Most importantly, we stand behind our

tools. If you have any service questions or

parts requests, please call or write us at

the location listed below.

Grizzly Industrial, Inc.

2406 Reach Road

Williamsport, PA 17701

Phone: (570) 546-9663

Fax: (800) 438-5901

E-Mail: techsupport@grizzly.com

Web Site: http://www.grizzly.com

To operate this, or any power tool,

safely and efficiently, it is essential to

become as familiar with its characteristics as possible. The time you invest

before you begin to use your Model

G9906 will be time well spent. DO NOT

operate this machine until you are

completely familiar with the contents

of this manual. Make sure you read

and understand all of the safety procedures. If you do not understand something, DO NOT operate the machine.

We are proud to offer the Grizzly Model

G9906 Circular Saw. The Model G9906 is

part of a growing Grizzly family of fine

power tools. When used according to the

guidelines set forth in this manual, you can

expect years of trouble-free, enjoyable

operation and proof of Grizzly’s commitment to customer satisfaction.

The Model G9906 is a 71⁄4" electric circular

saw that is capable of a wide variety of

operations. An 18-tooth carbide tipped

blade driven by a 1 HP motor at 4600

RPM makes the toughest cutting job a

simple task. Blade depth can be easily

adjusted using the graduated scale, and

the blade can be tilted for bevel cuts up to

45°. The saw can be equipped with various blades used to cut through wood,

plastic and concrete. A number of blades

for the Model G9906 saw are available

through the Grizzly catalog.

We are pleased to provide this manual

with the Model G9906. It was written to

encourage safety considerations and

guide you through general operating procedures and maintenance. It represents

our effort to produce the best documentation possible.

The specifications, details, and photographs in this manual represent the

Model G9906 as supplied when the manual was prepared. However, owing to

Grizzly’s policy of continuous improvement, changes may be made at any time

with no obligation on the part of Grizzly. If

you have any comments regarding this

manual, please write to us at the address

below:

Grizzly Industrial, Inc.

C

/O Technical Documentation

P.O. Box 2069

Bellingham, WA 98227-2069

Page 6

-4-

G9906 71⁄4" Circular Saw

Before You Start

Cutting Depth and

Adjustment

Setting the Edge Guide

OPERATIONS

The Model G9906 was specifically

designed for cutting wood, plastic

and concrete. Do not modify and/or

use this machine for any other purpose. Modifications or improper use

of this tool will void the warranty. If

you are confused about any aspect

of this machine, DO NOT use it until

you have answered all your questions. Serious personal injury may

occur.

Dust

Port

Angle

Gauge

Edge Guide

Set Knob

Retractable

Blade Guard

Please take the time to familiarize yourself

with the controls of your new saw. Below

are listed the names of controls and features found on the saw. Please refer to

Fig. 1

FIG 1

1. Loosen the silver knob to the left and

below the hand grip.

2. Pull or push the saw base to expose

more or less saw blade.

3. To check the depth of cut, compare

the blade depth to the workpiece

thickness and adjust saw base until

approximately 1⁄4" of the blade is

exposed past the thickness of the

workpiece.

4. Tighten the lock knob.

Adjust saw base so that approximately 1⁄4" of the blade is exposed past the

thickness of the workpiece to help

avoid potential kick-back.

1. Loosen the edge guide set knob

located on the top leading edge of

the saw base.

2. Insert the edge guide in the slot just

below the retaining screw.

3. Slide the edge guide until it is inserted through a slot provided on the left

hand side of the saw base.

4. Determine the width of cut needed

for your project and slide the edge

guide using the scale provided.

5. Tighten the edge guide set knob.

Always double check the distance

between the tip of the blade to the

inside edge of the edge guide. Blade

thicknesses can very, causing the

scale on the edge guide to read inaccurately.

Page 7

G9906 71⁄4" Circular Saw

-5-

OPERATIONS, CONT’D

Like all power tools, there is danger

associated with the Model G9906.

Accidents are frequently caused by

lack of familiarity or failure to pay

attention. Use this tool with respect

and caution to lessen the possibility of

operator injury. If normal safety precautions are overlooked or ignored,

serious personal injury may occur.

Avoid kickback hazards! If saw motor

stalls during cut release the trigger

immediately. Determine the cause of

the problem and rectify before continuing cut.

Guide Notches

Setting the Blade Angle

Operating the Saw

The saw is provided with two guide notches for either 45° or 90° cuts. These are

located on the leading edge of the saw

base. The notches are used for following a

line through a cut. It should be noted that

these are provided for one blade thickness.

Blades without carbide teeth or with carbide teeth that are thinner or thicker may

render the guide notches inaccurate.

1. Loosen the black angle locking

knobs located at the leading and

trailing edge of the saw base.

2. Rotate the saw base until the index

pointer is at the desired angle and

tighten knobs.

3. For best results always check the

blade angle with a protractor or angle

guide before making a cut. Make a

test cut into scrap lumber and check

the angle of the cut. Readjust as necessary.

1. Ensure the blade is secure.

2. Grasp the hand grip with one hand.

Use the hand you would use most

often: if you are right handed use the

right.

3. Grasp the stabilizing hand grip with

the other hand.

4. Place the leading edge of the saw on

the edge of the board to be cut. Align

the guide notch to a reference line or

the edge guide to the end of the

board.

5. Ensure the blade will not contact the

board during start up by pulling saw

away from the edge of the board.

6. Pull the trigger to activate the saw.

7. Slowly feed saw through the cut.

8. Let go of the trigger when finished

with the cut.

Page 8

G9906 71⁄4" Circular Saw

-6-

OPERATIONS, CONT’D

MAKE SURE SAW IS UNPLUGGED!

1. Rotate the blade guard clockwise to

reveal the blade.

2. While holding the blade guard open,

place the saw onto a secure surface

engaging the blade teeth onto the

surface.

3. While maintaining downward pressure on the saw, remove the retaining

screw and washer from the center of

the blade.

4. Note the orientation of the teeth. They

are pointed toward the leading edge

base of the saw. Be careful to avoid

touching the saw teeth and slip the

blade out of the saw.

5. Ensuring the teeth on the new blade

are in the correct orientation, slide the

blade into the slot on the bottom edge

of the closed blade guard.

6. Carefully center the blade over the

arbor and replace the washer and

retaining screw.

7. Tighten the retaining screw in the

same manner as it was removed.

Saw blades are sharp. Use care when

handling. Blades may cut or nick fingers or hands causing lacerations,

disfigurement or disability.

Changing Blades

Page 9

G9906 71⁄4" Circular Saw

-7-

Guidelines and Tips

Maintenance

OPERATING TIPS AND

MAINTNENACE

Before starting saw, insure the

wrench has been removed from the

arbor. If not removed, the wrench

could be propelled into the air and

may cause serious personal injury.

Avoid overloading the saw. Always use

sharp saw blades. Do not apply

excessive pressure to the saw while

using. If the speed drops abnormally,

decrease pressure immediately. If

the blade stops abruptly or becomes

jammed, release the trigger at once.

Ensure the safety of the workplace.

Clear the work area of all parts and

debris that may cause injury by flying

objects. Securely fix the object to be

sawn in a vise or otherwise clamp to

avoid injury. Do not attempt to hold

workpiece by hand.

Inspect the saw before use. Run the saw

before using to ensure all parts are

running smoothly and there are no

abnormal sounds or sparks. If any

defect is found, have unit serviced.

Match your feed rate to the material.

Use a lower rate of feeding the saw

through the material when cutting

hard materials. In softer material

such as drywall or soft woods, you

can feed the saw faster.

Know your worksite. Only saw as deep

as necessary. Check behind walls for

for wires, other electrical hazards, or

plumbing.

Keep the saw free from dirt and grease.

Operating this equipment has the

potential to propel debris into the air

which can cause eye injury. Always

wear safety glasses or goggles when

operating equipment. Be certain the

safety glasses you wear meet the

appropriate standards of the

American National Standards

Institute (ANSI).

Disassembly and improper reassembly of this device can result in electrical shock danger. Always have this

device serviced by an qualified electrical repair technician. Serious injury

will result.

Page 10

NOTES

Page 11

G9906 71⁄4" Circular Saw

-9-

NOTES

Page 12

G9906 71⁄4" Circular Saw

-10-

Grizzly Industrial, Inc. warrants every product it sells for a period of 1 year to the original

purchaser from the date of purchase. This warranty does not apply to defects due directly

or indirectly to misuse, abuse, negligence, accidents, repairs or alterations or lack of maintenance. This is Grizzly’s sole written warranty and any and all warranties that may be

implied by law, including any merchantability or fitness, for any particular purpose, are hereby limited to the duration of this written warranty. We do not warrant or represent that the

merchandise complies with the provisions of any law or acts unless the manufacturer so

warrants. In no event shall Grizzly’s liability under this warranty exceed the purchase price

paid for the product and any legal actions brought against Grizzly shall be tried in the State

of Washington, County of Whatcom.

We shall in no event be liable for death, injuries to persons or property or for incidental, contingent, special, or consequential damages arising from the use of our products.

To take advantage of this warranty, contact us by mail or phone and give us all the details.

We will then issue you a “Return Number’’, which must be clearly posted on the outside as

well as the inside of the carton. We will not accept any item back without this number. Proof

of purchase must accompany the merchandise.

The manufacturers reserve the right to change specifications at any time because they constantly strive to achieve better quality equipment. We make every effort to ensure that our

products meet high quality and durability standards and we hope you never need to use this

warranty.

Please feel free to write or call us if you have any questions about the machine or the manual.

Grizzly Industrial, Inc.

2406 Reach Road

Williamsport, PA 17701

Phone: (570) 546-9663

Fax: (800) 438-5901

E-Mail:

techsupport@grizzly.com

Web Site: http://www.grizzly.com

Thank you again for your business and continued support. We hope to serve you again

soon.

WARRANTY AND RETURNS

Page 13

G9906 71⁄4" Circular Saw

-11-

Name__________________________________________________________

Street__________________________________________________________

City____________________State________Zip_________

Phone Number____________E-Mail___________________FAX____________

Model # G9906 Circular Saw Order #_______________________

The following information is given on a voluntary basis. It will be used for marketing purposes to help

us develop better products and services. Of course, all information is strictly confidential.

WARRANTY CARD

9. How many of the machines checked above are

Grizzly? ____________

10. Which portable/hand held power tools do you own?

Check all that apply.

___Belt Sander ___Orbital Sander

___Biscuit Joiner ___Palm Sander

___Circular Saw ___Portable Planer

___Detail Sander ___Saber Saw

___Drill/Driver ___Reciprocating Saw

___Miter Saw ___Router

___Other_________________________________

11. What machines/supplies would you like Grizzly

Industrial to carry?

___12" Table Saw ___Radial Arm Saw

___12" Jointer ___Panel Saw

___Brass Hardware ___Lumber

___Paint & Finishing Supplies

___Contractor’s Supplies

___Combination Planer/Jointer

___Other_________________________________

12. What new accessories would you like Grizzly

Industrial to carry?

___Builders Hardware ___Hand Tools

___Fasteners

___Wood Components

___Other_________________________________

13. What other companies do you purchase your tools

and supplies from?

_________________________________________

_________________________________________

_________________________________________

14. Do you think your purchase represents good value?

___Yes ___No

15. Would you recommend Grizzly to a friend?

___Yes ___No

16. Would you allow us to use your name as a reference for Grizzly customers in your area? Note: We

never use names more than three times.

___Yes ___No

17.Comments:________________________________

_________________________________________

_________________________________________

_________________________________________

1. How did you learn about us?

___Advertisement ___Friend

___Catalog ___Card Deck

___World Wide Web

___Other__________________________

2. What is your annual household income?

___$20,000-$29,999 ___$60,000-$69,999

___$30,000-$39,999 ___$70,000-$79,999

___$40,000-$49,999 ___$80,000-$89,999

___$50,000-$59,999 ___$90,000 +

3. What is your age group?

___20-29 ___50-59

___30-39 ___60-69

___40-49 ___70 +

4. How long have you been a woodworker?

___0 - 2 Years ___8 - 20 Years

___2 - 8 Years ___20+ Years

5. How would you rank your woodworking skills?

___Simple ___Advanced

___Intermediate ___Master Craftsman

6. What stationary woodworking tools do you own?

Check all that apply.

___Air Compressor ___Panel Saw

___Band Saw ___Planer

___Drill Press ___Power Feeder

___Drum Sander ___Radial Arm Saw

___Dust Collector ___Shaper

___Spindle Sander ___Jointer

___Table Saw ___Lathe

___Mortiser ___Wide Belt Sander

___Horiz.Boring Machine

___Vacuum Veneer Press

___Other______________________________

7. How many of your woodworking machines are

Grizzly? _____________

8. Which benchtop tools do you own? Check all

that apply.

___1"x42" Belt Sander ___6" - 8" Grinder

___5" - 8" Drill Press ___Mini Lathe

___8" Table Saw ___8" - 10" Bandsaw

___Scroll Saw ___Disc/Belt Sander

___Spindle/Belt Sander ___Mini Jointer

___10"-12"Thickness Planer

___Other______________________________

Page 14

G9906 71⁄4" Circular Saw

-12-

FOLD ALONG DOTTED LINE

GRIZZLY INDUSTRIAL, INC.

P.O. BOX 2069

BELLINGHAM, WA 98227-2069

TAPE ALONG EDGES--PLEASE DO NOT STAPLE

Name________________________________

Street________________________________

City______________State______Zip_______

Send a Grizzly Catalog to a friend:

Loading...

Loading...