Page 1

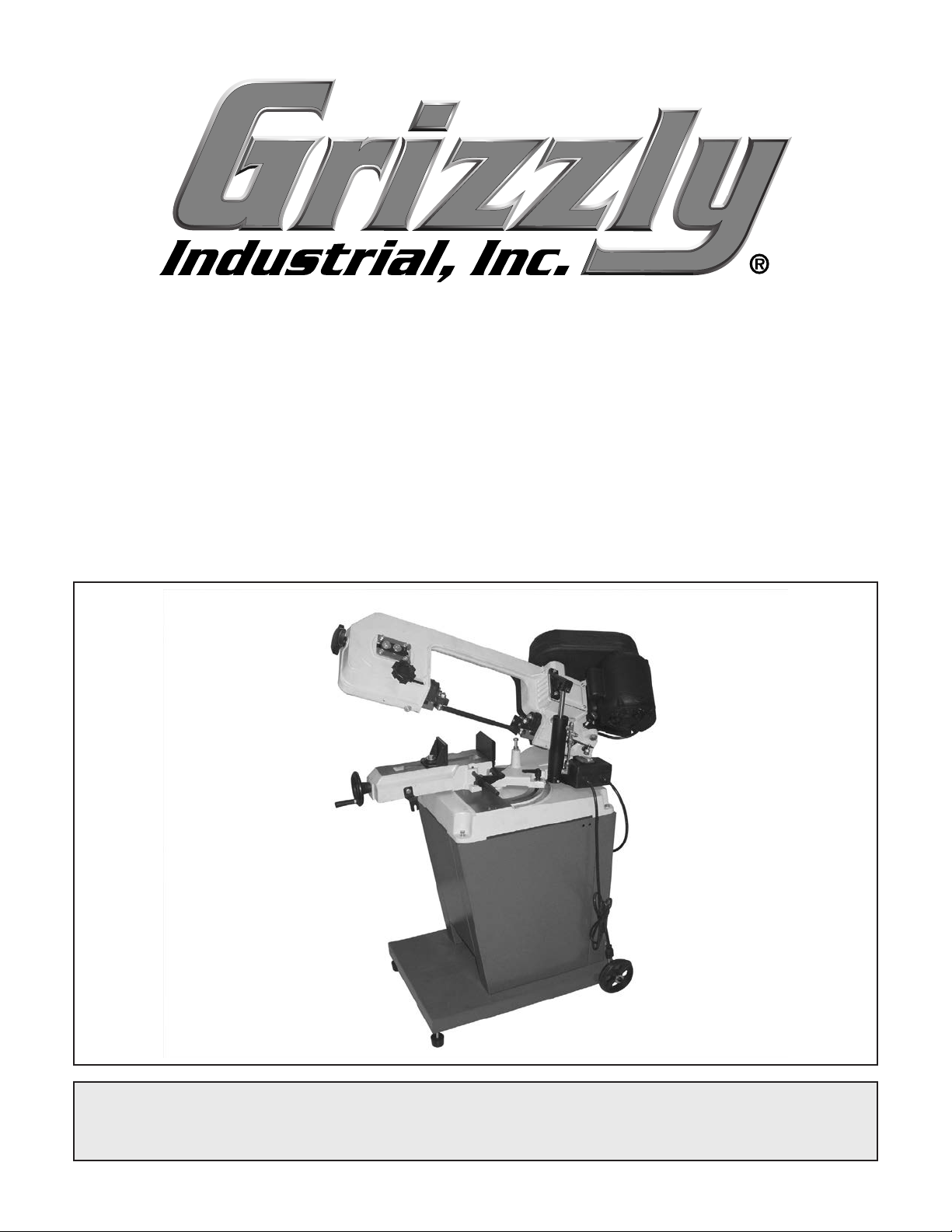

MODEL G9742

5"x 6" METAL-CUTTING

BANDSAW w/ SWIVEL HEAD

OWNER'S MANUAL

(For models manufactured since 11/06)

COPYRIGHT © NOVEMBER, 2005 BY GRIZZLY INDUSTRIAL, INC. REVISED FEBRUARY, 2013 (TS)

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

#PC7670 PRINTED IN CHINA

Page 2

This manual provides critical safety instructions on the proper setup,

operation, maintenance, and service of this machine/tool. Save this

document, refer to it often, and use it to instruct other operators.

Failure to read, understand and follow the instructions in this manual

may result in fire or serious personal injury—including amputation,

electrocution, or death.

The owner of this machine/tool is solely responsible for its safe use.

This responsibility includes but is not limited to proper installation in

a safe environment, personnel training and usage authorization,

proper inspection and maintenance, manual availability and comprehension, application of safety devices, cutting/sanding/grinding tool

integrity, and the usage of personal protective equipment.

The manufacturer will not be held liable for injury or property damage

from negligence, improper training, machine modifications or misuse.

Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State

of California to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

Work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

Page 3

Table of Contents

INTRODUCTION ............................................... 2

Foreword ........................................................ 2

Contact Info.................................................... 2

Machine Data Sheet ...................................... 3

Identification ................................................... 5

SECTION 1: SAFETY ....................................... 6

Safety Instructions for Machinery .................. 6

Additional Safety Instructions for Metal Cutting

Bandsaws ...................................................... 8

SECTION 2: CIRCUIT REQUIREMENTS ........ 9

110/220V Operation ....................................... 9

SECTION 3: SET UP ...................................... 10

Set Up Safety ............................................... 10

Items Needed for Set Up ............................. 10

Unpacking .................................................... 10

Inventory ...................................................... 11

Clean Up ...................................................... 12

Site Considerations ...................................... 12

Cabinet, Wheels & Feet ............................... 13

Squaring Vise to Blade ................................ 15

Chip Tray & Cast Iron Stop.......................... 16

OFF Button Lever ........................................ 16

Pulley Cover................................................. 17

Test Run ...................................................... 18

Recommended Adjustments ........................ 18

SECTION 4: OPERATIONS ........................... 19

Operation Safety .......................................... 19

Blade Speed ................................................ 19

Blade Selection ............................................ 20

Feed Rate .................................................... 21

Blade Guides ............................................... 22

Blade Tension .............................................. 23

Operation Tips ............................................. 23

SECTION 5: ACCESSORIES ......................... 24

SECTION 6: MAINTENANCE ......................... 26

Schedule ...................................................... 26

Cleaning ....................................................... 26

Lubrication ................................................... 26

SECTION 7: SERVICE ................................... 27

Troubleshooting ........................................... 27

Blade Change .............................................. 29

Blade Tracking ............................................. 30

Electrical Components ................................. 31

G9742 Wiring Diagram ................................ 32

Saw Parts Breakdown ................................. 33

Stand Parts Breakdown ............................... 35

Guides & Shafts Parts Breakdown .............. 37

Labels Parts Breakdown .............................. 38

WARRANTY AND RETURNS ........................ 41

Page 4

INTRODUCTION

Foreword

We are proud to offer the Model G9742 5" x 6"

Metal-Cutting Bandsaw with Swivel Head. This

machine is part of a growing Grizzly family of fine

metalworking machinery. When used according

to the guidelines set forth in this manual, you can

expect years of trouble-free, enjoyable operation

and proof of Grizzly’s commitment to customer

satisfaction.

We are pleased to provide this manual with

the Model G9742. It was written to guide you

through assembly, review safety considerations,

and cover general operating procedures. It represents our effort to produce the best documentation possible.

The specifications, drawings, and photographs

illustrated in this manual represent the Model

G9742 as supplied when the manual was prepared. However, owing to Grizzly’s policy of continuous improvement, changes may be made at

any time with no obligation on the part of Grizzly.

For your convenience, we always keep current

Grizzly manuals available on our website at www.

grizzly.com. Any updates to your machine will be

reflected in these manuals as soon as they are

complete. Visit our site often to check for the latest updates to this manual!

Contact Info

If you have any comments regarding this manual,

please write to us at the address below:

C

/O Technical Documentation Manager

We stand behind our machines. If you have any

service questions or parts requests, please call or

write us at the location listed below.

Grizzly Industrial, Inc.

P.O. Box 2069

Bellingham, WA 98227-2069

Grizzly Industrial, Inc.

1203 Lycoming Mall Circle

Muncy, PA 17756

Phone: (570) 546-9663

Fax: (800) 438-5901

E-Mail: techsupport@grizzly.com

Web Site: http://www.grizzly.com

-2-

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

Page 5

MACHINE DATA

SHEET

Customer Service #: (570) 546-9663 · To Order Call: (800) 523-4777 · Fax #: (800) 438-5901

MODEL G9742 5" X 6" METAL-CUTTING BANDSAW W/

SWIVEL HEAD

Product Dimensions:

Weight.............................................................................................................................................................. 150 lbs.

Width (side-to-side) x Depth (front-to-back) x Height............................................................... 39 x 23-3/8 x 54-3/4 in.

Footprint (Length x Width)............................................................................................................... 26-1/2 x 20-1/2 in.

Shipping Dimensions:

Type................................................................................................................................................... Wood Slat Crate

Content........................................................................................................................................................... Machine

Weight.............................................................................................................................................................. 168 lbs.

Length x Width x Height....................................................................................................................... 41 x 18 x 22 in.

Must Ship Upright................................................................................................................................................... Yes

Electrical:

Power Requirement............................................................................................. 110V or 220V, Single-Phase, 60 Hz

Prewired Voltage.................................................................................................................................................. 110V

Full-Load Current Rating...................................................................................................... 7A at 110V, 3.5A at 220V

Minimum Circuit Size.......................................................................................................... 15A at 110V, 15A at 220V

Switch...................................................................................................... Sealed Button Switch w/Automatic Shut-Off

Cord Length............................................................................................................................................................ 6 ft.

Cord Gauge.................................................................................................................................................... 18 AWG

Plug Included.......................................................................................................................................................... Yes

Motors:

Main

Type................................................................................................................. TEFC Capacitor-Start Induction

Horsepower............................................................................................................................................. 1/2 HP

Phase............................................................................................................................................ Single-Phase

Amps...................................................................................................................................................... 7A/3.5A

Speed................................................................................................................................................ 1725 RPM

Power Transfer ............................................................................................................................... V-Belt Drive

Bearings..................................................................................................... Shielded & Permanently Lubricated

Main Specifications:

Operation Info

Blade Speeds......................................................................................................................... 80, 120, 200 FPM

Std. Blade Length................................................................................................................................ 64-1/2 in.

Blade Size Range..................................................................................................................................... 1/2 in.

Head Swivel............................................................................................................................................ 45 deg.

Machine Data Sheet

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

-3-

Page 6

Cutting Capacities

Angle Cuts........................................................................................................................ Right 45, Left 60 deg.

Vise Jaw Depth...................................................................................................................................... 4-3/8 in.

Vise Jaw Height..................................................................................................................................... 2-1/2 in.

Max. Capacity Rectangular Height at 90 Deg.............................................................................................. 5 in.

Max. Capacity Rectangular Width at 90 Deg............................................................................................... 6 in.

Max. Capacity Round at 90 Deg.................................................................................................................. 5 in.

Max. Capacity Rectangular Height at 30 Deg.............................................................................................. 5 in.

Max. Capacity Rectangular Width at 30 Deg............................................................................................... 5 in.

Max. Capacity Round at 30 Deg.................................................................................................................. 5 in.

Max. Capacity Rectangular Height at 45 Deg................................................................................... 2-15/16 in.

Max. Capacity Rectangular Width at 45 Deg......................................................................................... 3-3/4 in.

Max. Capacity Round at 45 Deg............................................................................................................ 3-3/4 in.

Max. Capacity Rectangular Height at 60 Deg....................................................................................... 1-3/4 in.

Max. Capacity Rectangular Width at 60 Deg....................................................................................... 2-3/16 in.

Max. Capacity Round at 60 Deg............................................................................................................ 1-3/4 in.

Construction

Table....................................................................................................................... Precision Ground Cast Iron

Upper Wheel....................................................................................................................... Machined Cast Iron

Lower Wheel....................................................................................................................... Machined Cast Iron

Body..................................................................................................................................................... Cast Iron

Base.......................................................................................... Formed and Welded Steel with Coolant Sump

Wheel Cover............................................................................................................................ Pre-formed Steel

Paint......................................................................................................................................................... Epoxy

Other

Wheel Size................................................................................................................................................. 13 in.

Blade Guides Upper........................................................................................................................ Ball Bearing

Blade Guides Lower........................................................................................................................ Ball Bearing

Table Info

Table Size Length...................................................................................................................................... 12 in.

Table Size Width................................................................................................................................... 4-1/2 in.

Floor To Cutting Area Height..................................................................................................................... 29 in.

Other Specifications:

ISO 9001 Factory .................................................................................................................................................. Yes

Country Of Origin ............................................................................................................................................... China

Warranty ........................................................................................................................................................... 1 Year

Serial Number Location ........................................................................................................ ID Label on Body Frame

Approximate Assembly & Setup Time ........................................................................................................ 30 Minutes

Features:

Control Panel Conveniently Located

Adjustable Hydraulic Downfeed

Quick Release Vise for Rapid Change out of Workpiece

Blade Included

-4-

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

Page 7

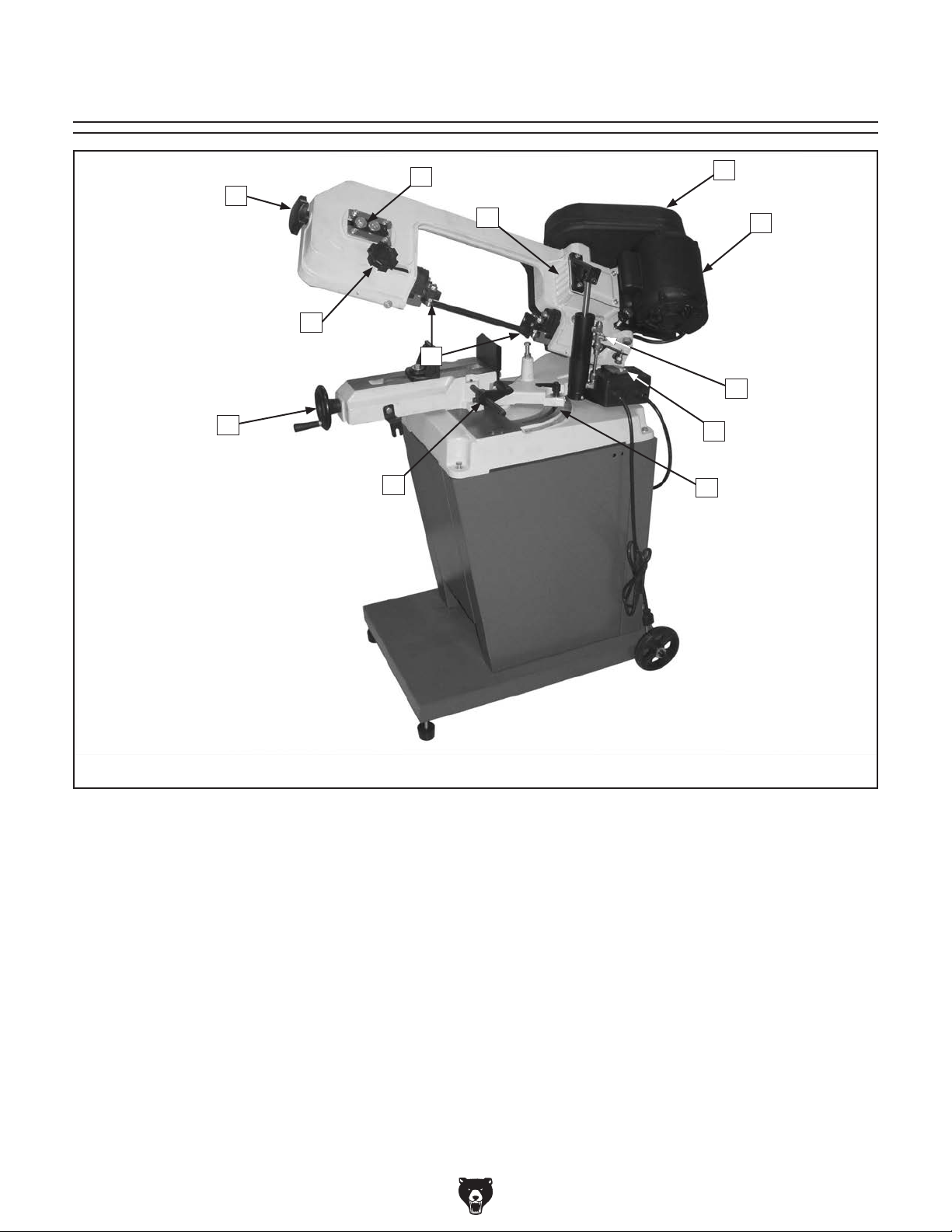

Identification

L

A

K

B

C

J

I

D

E

F

G

H

Figure 1. The Model G9742.

A. Blade Tension Knob

B. Blade Guide Knob

C. Blade Guides

D. Pulley Cover

E. Heavy Duty Motor

F. Hydraulic Cylinder and Feed Rate Dial

G. ON/OFF Push-Button Switch Assembly

H. Table Angle Scale

I. Cast Iron Stop

J. Vise Clamp Handwheel

K. Gear Box

L. Blade Tension Gauge

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

-5-

Page 8

SECTION 1: SAFETY

For Your Own Safety, Read Instruction

Manual Before Operating this Machine

The purpose of safety symbols is to attract your attention to possible hazardous conditions. This

manual uses a series of symbols and signal words intended to convey the level of importance

of the safety messages. The progression of symbols is described below. Remember that safety

messages by themselves do not eliminate danger and are not a substitute for proper accident

prevention measures.

Indicates an imminently hazardous situation which, if not avoided,

WILL result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

COULD result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

MAY result in minor or moderate injury. It may also be used to alert

against unsafe practices.

This symbol is used to alert the user to useful information about

NOTICE

proper operation of the machine.

Safety Instructions for Machinery

Safety Instructions for Machinery

OWNER’S MANUAL. Read and understand

this owner’s manual BEFORE using machine.

Untrained users can be seriously hurt.

EYE PROTECTION. Always wear ANSIapproved safety glasses or a face shield when

operating or observing machinery. to reduce

the risk of eye injury or blindness from flying particles Everyday eyeglasses are not

approved safety glasses.

HAZARDOUS DUST. Dust created while using

machinery may cause cancer, birth defects,

or long-term respiratory damage. Be aware of

dust hazards associated with each workpiece

material, and always wear a NIOSH-approved

respirator to reduce your risk.

WEARING PROPER APPAREL. Do not wear

clothing, apparel, or jewelry that can become

entangled in moving parts. Always tie back or

cover long hair. Wear non-slip footwear to avoid

accidental slips which could cause a loss of

workpiece control.

HEARING PROTECTION. Always wear hearing protection when operating or observiing loud

machinery. Extended exposure to this noise

without hearing protection can cause permanent

hearing loss.

MENTAL ALERTNESS. Be mentally alert when

running machinery. Never operate under the

influence of drugs or alcohol, when tired, or when

distracted.

-6-

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

Page 9

SECTION 1: SAFETY

For Your Own Safety, Read Instruction

Manual Before Operating this Machine

The purpose of safety symbols is to attract your attention to possible hazardous conditions. This

manual uses a series of symbols and signal words intended to convey the level of importance

of the safety messages. The progression of symbols is described below. Remember that safety

messages by themselves do not eliminate danger and are not a substitute for proper accident

prevention measures.

Indicates an imminently hazardous situation which, if not avoided,

WILL result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

COULD result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

MAY result in minor or moderate injury. It may also be used to alert

against unsafe practices.

This symbol is used to alert the user to useful information about

NOTICE

proper operation of the machine.

Safety Instructions for Machinery

OWNER’S MANUAL. Read and understand

this owner’s manual BEFORE using machine.

Untrained users can be seriously hurt.

EYE PROTECTION. Always wear ANSIapproved safety glasses or a face shield when

operating or observing machinery. to reduce

the risk of eye injury or blindness from flying particles Everyday eyeglasses are not

approved safety glasses.

HAZARDOUS DUST. Dust created while using

machinery may cause cancer, birth defects,

or long-term respiratory damage. Be aware of

dust hazards associated with each workpiece

material, and always wear a NIOSH-approved

respirator to reduce your risk.

WEARING PROPER APPAREL. Do not wear

clothing, apparel, or jewelry that can become

entangled in moving parts. Always tie back or

cover long hair. Wear non-slip footwear to avoid

accidental slips which could cause a loss of

workpiece control.

HEARING PROTECTION. Always wear hearing protection when operating or observiing loud

machinery. Extended exposure to this noise

without hearing protection can cause permanent

hearing loss.

MENTAL ALERTNESS. Be mentally alert when

running machinery. Never operate under the

influence of drugs or alcohol, when tired, or when

distracted.

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

-7-

Page 10

Additional Safety Instructions for Metal

Cutting Bandsaws

1. BLADE CONDITION. Do not operate with

dull, cracked or badly worn blade. Inspect

blades for cracks and missing teeth before

each use.

2. HAND PLACEMENT. Never position fingers or thumbs in line with the cut. Hands

could be crushed in vise or by falling

machine components.

3. ENTANGLEMENT HAZARDS. Do not

operate this bandsaw without blade guard

in place. Otherwise, loose clothing, jewelry,

long hair and work gloves can be drawn

into working parts.

4. BLADE REPLACEMENT. When replacing

blades, make sure teeth face toward the

workpiece. Wear gloves to protect hands

and safety glasses to protect eyes.

5. WORKPIECE HANDLING. Always support

the workpiece with table, vise, or some

type of support fixture. Flag long pieces

to avoid a tripping hazard. Never hold the

workpiece with your hands during a cut.

6. LOSS OF STABILITY. Unsupported

workpieces may jeopardize machine stability and cause the machine to tip and fall

which could cause serious injury.

7. POWER INTERRUPTION. Unplug machine

after power interruption. Machines without

magnetic switches can start up after power

is restored.

8. FIRE HAZARD. Use EXTREME CAUTION

if cutting magnesium. Using the wrong cutting fluid will lead to chip fire and possible

explosion.

9. CUTTING FLUID SAFETY. Always follow

manufacturer’s cutting fluid safety instructions. Pay particular attention to contact,

contamination, inhalation, storage and disposal warnings. Spilled cutting fluid is a

slipping hazard.

10. ATTENTION TO WORK AREA. Never

leave a machine running and unattended.

Pay attention to the actions of others in the

area to avoid unintended accidents.

11. MAINTENANCE/SERVICE. All inspections, adjustments, and maintenance are

to be done with the machine OFF and the

plug pulled from the outlet. Wait for all

moving parts to come to a complete stop.

12. HEARING PROTECTION & HAZARDS.

Noise generated by blade and workpiece

vibration, material handling, and power

transmission can cause permanent hearing loss over time and interfere with communication and audible signals. Always

wear hearing protection.

13. HOT SURFACES. Due to friction, the

workpiece, chips, and some machine components can be hot enough to burn you.

No list of safety guidelines can be complete. Every shop environment is different. Like all

machines there is danger associated with the Model G9742. Accidents are frequently caused by

lack of familiarity or failure to pay attention. Use this machine with respect and caution to lessen

the possibility of operator injury. If normal safety precautions are overlooked or ignored, serious

personal injury may occur.

-8-

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

Page 11

SECTION 2: CIRCUIT REQUIREMENTS

110/220V Operation

Serious personal injury could occur if you

connect the machine to power before completing the setup process. DO NOT connect

the machine to the power until instructed

later in this manual.

Electrocution or fire could

result if machine is not

grounded and installed in

compliance with electrical

codes. Compliance MUST

be verified by a qualified

electrician!

Power Connection Device

The Model G9742 comes prewired with a NEMA

5-15 plug for connection to power. If you rewire the

motor to 220V, we recommend using the plug and

receptacle shown in Figure 2 for 220V.

GROUNDED

5-15 RECEPTACLE

Grounding Prong

5-15 PLUG

Neutral Hot

GROUNDED

6-15 RECEPTACLE

Current Carrying Prongs

6-15 PLUG

Grounding Prong

Figure 2. Recommended plug types.

5-15 Plug & Outlet

for 110V

6-15 Plug & Outlet

for 220V

NOTICE

The Model G9742 is prewired for 110V operation. If you plan to operate your machine

at 220V, the motor must be rewired (see

Page 32).

Full Load Amperage Draw

Amp Draw at 110V (prewired) ..................7 Amps

Amp Draw at 220V ...............................3.5 Amps

Power Supply Circuit Requirements

You MUST connect your machine to a grounded

circuit that is rated for the amperage given below.

Never replace a circuit breaker on an existing circuit with one of higher amperage without consulting a qualified electrician to ensure compliance

with wiring codes. If you are unsure about the

wiring codes in your area or you plan to connect your machine to a shared circuit, consult

a qualified electrician.

Extension Cords

Using extension cords may reduce the life of the

motor. Instead, place the machine near a power

source. If you must use an extension cord:

• For 110V, use at least a 14 gauge cord that

does not exceed 50 feet in length.

• For 220V, use at least a 14 gauge cord that

does not exceed 50 feet in length.

• The extension cord must have a ground wire

and plug pin.

Minimum Circuit Size (110V) ..................15 Amps

Minimum Circuit Size (220V) ................. 15 Amps

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

-9-

Page 12

SECTION 3: SET UP

Set Up Safety

This machine presents

serious injury hazards

to untrained users. Read

through this entire manual to become familiar with

the controls and operations before starting the

machine!

Wear safety glasses during the entire set up process!

Items Needed for

Set Up

The following items are needed to complete the

set up process, but are not included with your

machine:

Description Qty

• Safety Glasses (for each person) ............... 1

• An Assistant ............................................... 1

• Phillips Head Screwdriver #2 ..................... 1

• Standard Screwdriver #2 ............................ 1

• Hex Wrench 6mm ....................................... 1

• Open-End Wrenches

6, 12, 14, & 19mm ................................ 1 ea.

• Open-End Wrenches

3

⁄8", 7⁄16" & 1⁄2 " ..... 1 ea.

Unpacking

The Model G9742 is a

heavy machine. DO NOT

over-exert yourself while

unpacking or moving

your machine—get assistance.

The Model G9742 was carefully packed to ensure

that it arrives to you safely. If you discover the

machine is damaged after you have signed

for delivery, please immediately call Customer

Service at (570) 546-9663 for advice.

Save the containers and all packing materials for

possible inspection by the carrier or its agent.

Otherwise, filing a freight claim can be difficult.

When you are completely satisfied with the condition of your shipment, you should inventory the

contents.

-10-

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

Page 13

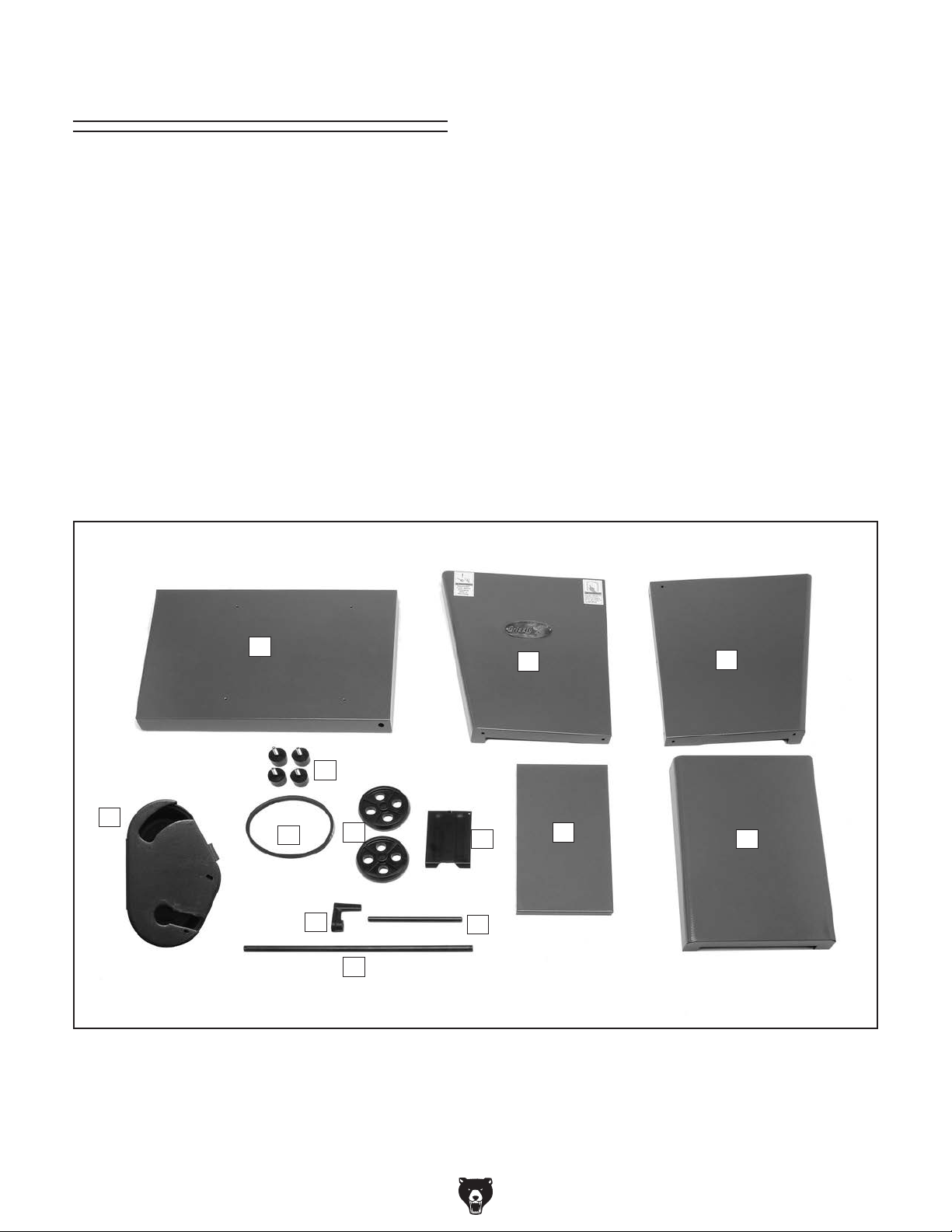

Inventory

After all the parts have been removed from the

box, you should have the following items:

Box 1: (Figure 3) Qty

A. Base ........................................................... 1

B. Front Panel ................................................. 1

C. Rear Panel.................................................. 1

D. Right Panel ................................................. 1

E. Left Panel ................................................... 1

F. Ch ip Tr ay .................................................... 1

G. Feet ............................................................ 4

H. Wheels ....................................................... 2

I. Axle ............................................................ 1

J. Work Stop Shaft ......................................... 1

K. Work Stop ................................................... 1

L. Belt Cover ................................................... 1

M. V-Belt .......................................................... 1

Assembly Hardware:

—Hex Wrench 4mm ................................... 1

3

—Hex Bolt

⁄8 -16 x 1" .................................. 2

—Hex Bolt M8-1.25 x 30 ............................ 4

—Flat Washer 17mm (Wheels) .................. 4

—Flat Washer 8mm ................................... 4

1

—Cotter Pin

—Hex Nut

—Flat Washer

⁄8 x 1 (Wheels) ...................... 2

3

⁄8 -16 (Feet) ............................... 4

3

⁄8 ........................................ 1

—Phillips Head Screw M6-1 x 12 ............. 16

1

—Flat Washer

—Hex Bolt

—Sheet Metal Screw

⁄4 ...................................... 18

1

⁄4 x 20 x 1⁄2 " ............................. 2

1

⁄4-10 x 5⁄16" ............... 1

In the event that any nonproprietary parts are

missing (e.g. a nut or a washer), we would be

glad to replace them, or for the sake of expediency, replacements can be obtained at your local

hardware store.

A

B

C

G

L

M

H

K

F

J

E

D

I

Figure 3. G9742 Loose parts inventory.

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

-11-

Page 14

Clean Up

Site Considerations

The unpainted surfaces are coated with a waxy

oil to prevent corrosion during shipment. Remove

this protective coating with a solvent cleaner or

degreaser, such as shown in Figure 4. For thorough cleaning, some parts must be removed.

For optimum performance, clean all moving

parts or sliding contact surfaces. Avoid chlo-

rine-based solvents, such as acetone or brake

parts cleaner that may damage painted surfaces. Always follow the manufacturer’s instructions

when using any type of cleaning product.

Gasoline and petroleum

products have low flash

points and can explode

or cause fire if used to

clean machinery. DO

NOT use these products

to clean the machinery.

Floor Load

Refer to the Machine Data Sheet for the weight

and footprint specifications of your machine.

Some floors may require additional reinforcement

to support both the machine and operator.

Working Clearances

Consider existing and anticipated needs, size of

material to be processed through each machine,

and space for auxiliary stands, work tables or

other machinery when establishing a location for

your new machine. See Figure 5 for the minimum

working clearances.

Many cleaning solvents

are toxic if inhaled.

Minimize your risk by only

using these products in a

well ventilated area.

G2544—Solvent Cleaner & Degreaser

A great product for removing the waxy shipping

grease from your machine during clean up.

23 3⁄8"

39"

Figure 5. Minimum working clearances.

Unsupervised children and

visitors inside your shop

could cause serious personal injury to themselves.

Lock all entrances to the

shop when you are away and

DO NOT allow unsupervised

children or visitors in your

shop at any time!

Figure 4. Cleaner/degreaser available from

Grizzly.

-12-

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

Page 15

Cabinet, Wheels &

Feet

This bandsaw is shipped with four rubber feet

with posts and two wheels with an axle. It is your

option to install four rubber feet if you do not

need to move the bandsaw, or install the axle

and wheels if you need to move the bandsaw

re g ul arly.

Components and Hardware Needed: Qty

Base .................................................................. 1

Front Panel ........................................................ 1

Rear Panel ......................................................... 1

Right Panel ........................................................ 1

Left Panel .......................................................... 1

Ramp ................................................................. 1

Feet ................................................................... 4

Wheels............................................................... 2

Axle ................................................................... 1

—Flat Washers 17mm ................................ 4

—Cotter Pins .............................................. 2

—Hex Nuts

—Phillips Head Screw M6-1 x 12 ............. 16

—Flat Washer

—Hex Bolt M8-1.25 x 30 ............................ 4

—Flat Washer 8mm ................................... 4

3

⁄8 -16 ........................................ 4

1

⁄4 ...................................... 16

Figure 6. Installing wheels and feet.

5. Position the base on the floor, and adjust the

feet until the base is level and is stable.

6. Tighten the hex nuts against the base to lock

the feet in position.

7. Position the front and rear panels on the

base and install the panels to the base with

four M6-1 x 12 Phillips head screws and flat

washers (see Figure 7).

To install the wheels, feet, and the cabinet:

1. At the end of the base with the axle holes,

insert the axle into the base (see Figure 6).

2. Slide a 17mm flat washer and wheel onto

each end of the axle, followed by another

washer and cotter pin.

3

3. Thread a

4. Thread the two rubber feet into the base (see

Figure 6).

⁄8-16 hex nut on both feet.

Figure 7. Front and rear panels installed.

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

-13-

Page 16

8. Position the left panel between the front

and rear panels, and secure it in place with

six M6-1 x 12 Phillips head screws and flat

washers (see Figure 8).

Figure 8. Left Panel installed.

9. Position the right panel between the front

and rear panel, and secure it in place with six

M6-1 x 12 Phillips head screws and flat washers (see Figure 9).

Get assistance when

lifting this machine.

Otherwise, you can

severely injure yourself!

10. With the help of an assistant or a hoisting

device, place the bandsaw onto the cabinet.

11. Secure the bandsaw to the cabinet with four

M8-1.25 x 30 hex bolts and 8mm flat washers

(see Figure 10).

Figure 9. Installing right panel.

Figure 10. Attaching bandsaw to cabinet.

-14-

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

Page 17

Shipping Strap &

Squaring Vise to

Stop Adjustment

To ensure that your bandsaw arrives without

damage to the hinge system, a shipping strap

was installed. After removing the shipping strap,

you will have to make a series of adjustments,

beginning with the feed stop bolt.

To remove the shipping strap and adjust the

feed stop bolt:

1. Remove the shipping strap hex bolt and

strap with a 12mm wrench (see Figure 11).

Note: Keep this shipping strap in the event that

you must transport or ship the bandsaw.

2. Adjust the feed stop bolt and jam nut with a

14mm wrench (Figure 12), so the bandsaw

blade teeth are just below the table surface

when the cut is complete.

Blade

To ensure that your bandsaw will make cuts that

match the degree scale, you must make sure to

square the vise to the blade.

To square the vise to the blade:

1. Rotate the headstock until the pointer reads

"0" on the tabletop scale, and tighten the

headstock lock lever so the headstock stays

indexed at zero.

2. Using a 6mm wrench, loosen the two cap

screws that hold the vise to the table (see

Figure 13).

Square

Headstock

Lock Lever

Figure 11. Removing shipping strap.

Figure 12. Feed stop bolt.

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

Figure 13. Squaring vise to blade, headstock,

and table scale.

3. Using a small machinists square, adjust the

vise so it is square to the blade.

4. Tighten the two cap screws, so the vise and

blade are square with one another.

-15-

Page 18

Chip Tray & Cast

Iron Stop

The chip tray directs small workpieces into a bucket when the cut is complete. The cast iron stop

allows you to repeat cuts at the same length.

OFF Button Lever

After you have removed the shipping strap and

have adjusted the headstock stop bolt, you must

adjust the OFF button lever stop bolt, so the

bandsaw shuts OFF automatically when a cut is

complete.

To install the chip tray and cast iron stop:

1. Position the chip tray as shown in Figure 14

if you choose to use this accessory.

Chip tray

Figure 14. Chip tray installed.

2. Insert the stop rod approximately 3⁄4" into the

saw until the end of the rod is just flush with

the inside casting surface.

To set the OFF button lever stop bolt:

1. With the headstock in the complete down

position, loosen the 12mm stop bolt and jam

nut (see Figure 16).

Stop Bolt and

Jam Nut

OFF Button

Figure 16. OFF button lever and stop bolt.

3. Using the 4mm hex wrench, tighten the set

screw shown in Figure 15.

Set Screw

Set Screw

Figure 15. Installing stop rod.

4. Slide the cast iron stop onto the stop rod

and tighten the set screw.

2. Push down on the OFF button lever so the

button is completely depressed.

3. While keeping the lever depressed, use your

fingertips to turn the stop bolt until the head

touches the lever.

1

4. Back off the stop bolt

jam nut.

⁄3 turn and tighten the

-16-

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

Page 19

Pulley Cover

When opened, the pulley cover gives you access

to change the pulley ratio so the bandsaw can cut

at one of three speeds.

ENTANGLEMENT

HAZARD! You MUST

install the pulley cover

before operating!

Otherwise, severe injury

may occur.

To install the pulley cover:

4. Loosen the belt tension knob enough to

install the belt on the appropriate pulley that

will give the required blade speed. Refer to

Blade Speed on Page 19 for blade speed

selections.

5. Adjust the belt tension knob (Figure 18), so

the belt has

the center, and close the cover.

1

⁄4" deflection when pressed in

1. UNPLUG THE BANDSAW!

2. Position and rotate the pulley cover into

place as shown in Figure 17.

1

3. Install the two

ers that secure the pulley cover.

⁄4-20 x 1⁄2" hex bolts and wash-

Belt Tension

Knob

Figure 18. Belt tension knob.

Figure 17. Positioning the pulley cover.

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

-17-

Page 20

Test Run

Recommended

Adjustments

Projectiles thrown from

the machine could cause

serious eye injury. Wear

safety glasses during

assembly and operation.

Starting the machine:

1. Read the entire instruction manual.

2. Make sure all tools and foreign objects have

been removed from the machine.

3. Put on safety glasses and secure loose

clothing or long hair.

4. Raise the bandsaw by the handle.

5. Start the bandsaw while keeping your finger

near the ON/OFF switch at all times during the test run. The bandsaw should run

smoothly with little or no vibration.

The adjustments listed below have been performed at the factory. However, because of

the many variables involved with shipping, we

recommend that you at least verify the following

adjustments to ensure the adjustments remain

unchanged.

Step-by-step instructions on verifying these

adjustments can be found in SECTION 6:

MAINTENANCE on Page 26 and SECTION 7:

SERVICE on Page 27.

Factory adjustments that should be verified:

1. Blade Tracking (Page 30).

2. Squaring Vise to Blade (Page 15).

3. Blade Guides (Page 22).

— If you suspect any problems, immediately

stop the bandsaw and correct before continuing.

—If you need any help with your bandsaw

call our Tech Support at (570) 546-9663.

-18-

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

Page 21

SECTION 4: OPERATIONS

Operation Safety

Damage to your eyes, lungs, and ears could

result from using this machine without

proper protective gear. Always wear safety

glasses, a respirator, and hearing protection

when operating this machine.

Loose hair and clothing could get caught in

machinery and cause serious personal injury. Keep

loose clothing and long

hair away from moving

machinery.

NOTICE

If you have never used this type of machine

or equipment before, WE STRONGLY RECOMMEND that you read books, trade magazines, or get formal training before beginning any projects. Regardless of the content in this section, Grizzly Industrial will

not be held liable for accidents caused by

lack of training.

Blade Speed

The Model G9742 has these three blade speeds:

80, 120, and 200 FPM.

To change blade speeds:

1. UNPLUG THE BANDSAW!

2. Determine the best speed for your cut. The

table in Figure 19 is provided as a basic

guideline. Material thickness and the type of

blade used will factor into FPM selection.

Material Feet Per Minute

(FPM)

Aluminum 250

Plastics 800

Brass (soft) 500

Carbon Tool Steel 100-150

Cast Iron 100-150

Cold Rolled Steel 150-200

High Speed Steel 90-125

Malleable Iron 150-200

Hard Rubber 150-200

Figure 19. Blade speed table.

3. Slacken the V-belt and position it for the

desired FPM (see Figure 20).

80

120

200

Motor Pulley

Wheel Pulley

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

Figure 20. V-belt positions in FPM.

4. Tension the V-belt as described in the Pulley

Cover section on Page 17.

-19-

Page 22

Blade Selection

The chart below is a basic starting point for choosing blade type based on teeth per inch (TPI) for

variable tooth pitch blades and for standard raker

type bimetal blades/HSS blades. However, for

exact specifications of bandsaw blades, contact

the blade manufacturer.

Here are some general rules of thumb with

respect to bandsaw blade use.

• At least three teeth must contact the metal

at any phase of the cut. Otherwise, the teeth

can load up with metal, fracture, and break

off. If the TPI is too high, the teeth can load

up with material and overheat, damaging the

blade.

• For a faster but rougher cut, use a blade with

a lower TPI and a higher feed rate.

• For a slower but smoother cut, use a blade

with more TPI and a lower feed rate.

To select the correct blade TPI:

1. Measure the material thickness. This mea-

surement is the length of cut taken from

where the tooth enters the workpiece, sweeps

through, and exits the workpiece.

2. Refer to the "Material Thickness" row of the

blade selection chart in Figure 21, and read

across to find the workpiece thickness you

need to cut.

3. Refer to the "Shape" of metal and "Material

Type" columns, and find the shape and

material to be cut.

4. In the applicable row, read across to the right

and find the box where the row and column

intersect. Listed in the box is the minimum

TPI recommended for the variable tooth pitch

blades, and the TPI for bimetal raker blades

in parentheses.

TOOTH SELECTION

mm

50

inch

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 192½ 3½

75 100 150 200 250 300 350 400

3/4

4/6

5/8

3/4

3/4

4/6

2/3

2/3 1.4/2.5

CUTTING SPEED RATE RECOMMENDATION

Material

Carbon

Steel

Angle

Steel

Thin

Tube

Aluminum

Alloy

Copper

Alloy

Speed FPM

(M/Min)

196~354

(60) (108)

180~220

(54) (67)

180~220

(54) (67)

220~534

(67) (163)

229~482

(70) (147)

Material Material Material

Tool Steel

High-Speed

Tool Steel

Cold-Work

Tool Steel

Hot-Work

Tool Steel

Oil-Hardened

Tool Steel

Speed FPM

(M/Min)

203

(62)

75~118

(25) (36)

95~213

(29) (65)

203

(62)

203~213

(62) (65)

Alloy

Steel

Mold Steel

Water

Hardened

Tool Steel

Stainless

Steel

CR Stainless

Steel

1.4/2.5

Speed FPM

(M/Min)

111~321

(34) (98)

246

(75)

242

(75)

85

(26)

85-203

(26) (62)

2/3

1.5/.8

Free Machining

Stainless Steel

Gray

Cast Iron

Ductile

Austenitic

Cast Iron

Malleable

Cast Iron

Plastics

450

1.5/.8

Speed FPM

(M/Min)

150~203

(46) (62)

108~225

(33) (75)

65~85

(20) (26)

321

(98)

220

(67)

-20-

Figure 21. Blade selection chart.

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

Page 23

Feed Rate

The speed at which the saw blade will cut through

a workpiece is controlled by blade type and feed

rate.

The feed rate is controlled by the valve lever and

feed rate dial on the hydraulic cylinder shown in

Figure 22.

To set the feed rate:

1. Raise the headstock and turn the valve lever

sideways (horizontally).

2. Clamp the workpiece in the table vise.

3. Move the headstock and blade a few inches

above the workpiece.

4. With the correct saw blade installed and

blade speed selected, turn the saw ON.

Valve Lever

Feed Rate Dial

Figure 22. Bandsaw feed rate control.

Turning the valve lever in-line with the piping (as

shown in the Figure 22) opens it up, which allows

the fluid to circulate and allows the head to move.

Turning the valve lever sideways or perpendicular

to the pipiing closes it, which locks the headstock

in place.

The feed rate dial controls the amount of fluid that

circulates around the hydraulic cylinder, which in

turn, controls the speed that it moves.

5. Slowly rotate the feed rate dial to a conservative feed rate until the saw begins to cut the

workpiece.

6. Observe the chips that exit the cut, and

increase or decrease the feed rate according

to the chip characteristics (see Figure 23).

Chips are width

of tooth, thin and

curled, and silvery:

Optimum speed and

feed rate.

Chips are silvery,

thin, small, or

powdery: Increase

feed rate.

Chips are large,

curled, blue or

brown, or smoking:

Decrease feed rate.

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

Figure 23. Reading chips.

-21-

Page 24

Blade Guides

UNPLUG the bandsaw

power cord, and NEVER

adjust the blade guides

while the saw blade is

moving!

The blade guide side bearings support and twist

the blade straight so the blade will enter the

workpiece perpendicular to the table surface. The

blade guide support bearings prevent blade twist

by stopping the blade from being pushed back

during a cut. Both adjustments are critical for correct saw operation (see Figure 24).

Guide Bearing

Adjustment

Hex Bolt

Side Bearing

Eccentric and

Jam Nut

Blade Guide Support Bearing

Side Bearing

Eccentric

and Jam Nut

Figure 25. Blade guide adjustments.

4. Adjust the blade guide housing so the sup-

port bearing rests against the rear of the

blade (see Figure 24).

5. Using a 14mm wrench, loosen the outer side

bearing eccentric jam nuts.

6. Using a 12mm wrench, rotate the side bearing eccentrics until the bearings have a bearing-to-blade clearance of 0.000" to 0.001".

The bearings must not pinch the blade and

the blade needs to be perpendicular to the

table.

Guide Bearing

Adjustment Hex Bolt

Blade Guide

Side Bearing

Figure 24. Blade guide adjustment locations.

To adjust the guide bearings:

Note: Make sure the blade is tensioned and

tracks correctly before you adjust the blade guide

bearings. Refer to Blade Tension and Blade

Tracking on Pages 23 and 30 for further instructions.

1. UNPLUG THE BANDSAW!

2. Let the bandsaw headstock park in the full

down position.

3. Using a 12mm wrench, loosen the guide

bearing adjustment hex bolt (see Figure 25).

7. Tighten the jam nuts, loosen the lock knob,

and slide the blade guide close to the

workpiece so the blade is supported and will

not twist during the cut (see Figure 26).

Lock Knob

Figure 26. Blade guide position lock knob.

-22-

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

Page 25

Blade Tension

Proper blade tension is essential to long blade life,

straight cuts, and efficient cutting.

Two major signs that you do not have proper

blade tension are: 1) the blade stalls in the cut and

slips on the wheels, and 2) the blade frequently

breaks from being too tight.

To tension the blade on the bandsaw:

1. Make sure the blade is tracking properly.

2. UNPLUG THE BANDSAW!

• Let the blade reach full speed before engaging the workpiece. Never start a cut with the

blade in contact with the workpiece (see

Figure 27).

• Chips should be curled and silvery. If the

chips are thin and powder like, increase your

feed rate.

• Burned chips indicate a need to reduce your

blade speed.

• Wait until the blade has completely stopped

before removing the workpiece from the vise,

and avoid touching the cut end—it could be

very hot!

3. Slide the blade guides as far apart as they

will go, then tighten them down again.

4. Turn the tension knob clockwise to tighten

the blade, or counterclockwise to loosen the

blade.

Note: To fine tune blade tension, use a

blade tensioning gauge, like the one found in

SECTION 5: ACCESSORIES on Page 24.

Please follow the instructions included with

your gauge and the blade manufacturer's

recommendations on blade tension.

Operation Tips

The following tips will help you safely and effectively operate your bandsaw, and help you get the

maximum life out of your saw blades.

• Support long pieces so they won't fall when

cut, and flag the end to alert passers-by of

potential danger.

• Adjust the blade guides as close as possible

to the workpiece to minimize side-to-side

blade movement.

• Use coolant when possible to increase blade

life.

Work Stop

Tips for horizontal cutting:

• Use the work stop to quickly and accurately

cut multiple pieces of stock to the same

length.

• Clamp the material firmly in the vise jaws to

ensure a straight cut through the material,

and use the positive lock to speed production.

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

Figure 27. Typical proper starting position.

-23-

Page 26

ACCESSORIES

SECTION 5: ACCESSORIES

G5107— 64 -1/ 2 x 1/2 x .025 10 TPI Raker

G5108—64-1/2 x 1/2 x .025 14 TPI Raker

G5109—64-1/2 x 1/2 x .025 18 TPI Raker

G5110—64-1/2 x 1/2 x .025 24 TPI Raker

G5111—64-1/2 x 1/2 x .025 6-10 Variable Pitch

G5112—64-1/2 x 1/2 x .025 8-12 Variable Pitch

G5113 — 6 4 -1 / 2 x 1/2 x .025 10-14 Variable Pitch

G5114 — 6 4 -1/ 2 x 1/2 x .025 14-18 Variable Pitch

G5115 — 64 -1/ 2 x 1/2 x .025 20-24 Variable Pitch

®

Power Tw ist

H9815—A

A smart upgrade for any machine that uses

V-belts. These link belts provide smooth running

with less vibration, heat, and noise than solid

belts. Power Twist

in minutes to any size—just add or remove sections to fit your needs. Once you use a link belt,

you'll like it so much you'll want to convert all your

machines!

V-Belts

1

⁄2" x 4'

®

V-Belts can be customized

Figure 28. Blades.

H5408—Blade Tensioning Gauge

The Blade Tensioning Gauge ensures long blade

life, reduced blade breakage, and straight cutting

by indicating correct tension. A precision dial indicator provides you with a direct readout in PSI.

Figure 29. H5408 blade tensioning gauge.

Figure 30. Power Twist® V-Belt.

T20640—Machinery’s Handbook

For more than 90 years, this handbook has been

the benchmark by which machinists’ and engineering texts have been judged. Includes a wealth

of information on mathematics, mechanics, measurements, and materials. A must have for the

amateur or professional.

-24-

Figure 31. Machinery’s Handbook.

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

Page 27

G5618—Deburring Tool w/ 2 Blades

G5619—Extra Aluminum Blades

G5620—Extra Brass and Cast Iron Blade

The quickest tool for smoothing freshly machined

metal edges. Comes with two blades—one for

steel/aluminum and one for brass/cast iron.

Figure 32. G5618 deburring tool.

T20501—Face Shield Crown Protector 4"

T20502—Face Shield Crown Protector 7"

T20503—Face Shield Window

T20448—Economy Clear Safety Glasses

T20452—"Kirova" Anti-Reflective Glasses

T20456—"Dakura" Clear Safety Glasses

®

H0736—Shop Fox

Safety Glasses

These glasses meet ANSI Z87.1-2003 specifications. Buy extras for visitors or employees. You

can't be too careful with shop safety!

G7615—Oil Can w/Steel Nozzle

G7616—Oil Can w/Plastic Nozzle

G7617—Oil Can w/Flexible Plastic Nozzle

Whether you’re lubricating cutting tools or maintaining machinery in top operating condition, you’ll

appreciate these High Pressure Oil Cans. Each

can holds 5 ounces of oil and has a trigger activated, high pressure pump.

Figure 34. High pressure oil cans.

G9256—6" Dial Caliper

G9257—8" Dial Caliper

G9258—12" Dial Caliper

These traditional dial calipers are accurate to

0.001" and can measure outside surfaces, inside

surfaces, and heights/depths. Features stainless

steel, shock resistant construction and a dust

proof display.

T20502

T20452

T20503

T20448

T20456

H0736

Figure 33. Our most popular eye protection.

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

Figure 35. Grizzly® dial calipers.

-25-

Page 28

SECTION 6: MAINTENANCE

Always disconnect power

to the machine before

performing maintenance.

Failure to do this may

result in serious personal injury.

Schedule

For optimum performance from your machine,

follow this maintenance schedule and refer to any

specific instructions given in this section.

Daily Check

• Loose mounting bolts.

• Damaged saw blade.

• Worn or damaged wires.

• Any other unsafe condition.

• Clean after each use.

• Proper blade tension.

Monthly Check

• Lubricate vise screw.

• Check V-Belt for wear.

Lubrication

The gearbox and all bearings are sealed and permanently lubricated so no scheduled lubrication is

needed. However, you must periodically lubricate

adjustment locations and bare metal surfaces.

Refer to Figure 36 for lubrication points.

Lubricate the following areas listed below:

A. Blade Tension Mechanism: Open the main

blade guard, and drop a few drops of oil on

the tension knob lead screw.

B. Blade and Guides: Drop a few drops of

light machine oil on the blade and the blade

guides daily.

C. Gear Box: Is packed with grease and should

only be changed if you suspect contamination has entered.

D. Table and Machined Surfaces: Keep bare

metal surfaces rust-free with regular applications of products like SLIPIT®. For long term

storage you may want to consider products

like Boeshield T-9™.

Annual Check

• Inspect gear lubrication.

Cleaning

Cleaning the Model G9742 is relatively easy.

Keeping metal chips away from bandsaw mechanisms is important to making sure that your

bandsaw lasts a long time. Use a shop vacuum

or brush off metal chips frequently.

-26-

E. Vise Lead Screw: Drop a few drops of light

machine oil on the vise lead screw weekly.

A

E

D

Figure 36. Lubrication points.

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

B

C

Page 29

SECTION 7: SERVICE

Review the troubleshooting and procedures in this section to fix your machine if a problem develops. If you

need replacement parts or you are unsure of your repair skills, then feel free to call our Technical Support

at (570) 546-9663.

Troubleshooting

Motor & Electrical

Symptom Possible Cause Possible Solution

Machine does not start

or a breaker trips.

Machine stalls or is

underpowered.

Machine has vibration

or noisy operation.

1. Plug/receptacle is at fault or wired incorrectly.

2. Start capacitor is at fault.

3. Wall fuse/circuit breaker is blown/tripped.

4. Motor connection wired incorrectly.

5. Power supply is at fault/switched OFF.

6. Motor ON/OFF switch is at fault.

7. Wiring is open/has high resistance.

8. Motor is at fault.

1. Wrong blade for the workpiece material.

2. Wrong workpiece material.

3. Feed rate/cutting speed too fast for task.

4. Blade is slipping on wheels.

5. Low power supply voltage.

6. Motor bearings are at fault.

7. Plug/receptacle is at fault.

8. Motor connection is wired incorrectly.

9. Motor has overheated.

10. Motor is at fault.

1. Motor fan is rubbing on fan cover.

2. Blade is at fault.

3. Gearbox is at fault.

4. Wrong blade & too slow of speed.

1. Test for good contacts; correct the wiring.

2. Test/replace if faulty.

3. Ensure correct size for machine load; replace

weak breaker.

4. Correct motor wiring connections.

5. Ensure hot lines have correct voltage on all

legs and main power supply is switched ON.

6. Replace faulty ON/OFF switch.

7. Check for broken wires or disconnected/

corroded connections, and repair/replace as

necessary.

8. Test/repair/replace.

1. Use blade with correct properties for your type

of cutting.

2. Use metal with correct properties for your type

of cutting.

3. Decrease feed rate/cutting speed.

4. Adjust blade tracking and tension.

5. Ensure hot lines have correct voltage on all

legs.

6. Test by rotating shaft; rotational grinding/loose

shaft requires bearing replacement.

7. Test for good contacts; correct the wiring.

8. Correct motor wiring connections.

9. Clean off motor, let cool, and reduce

workload.

10. Test/repair/replace.

1. Replace dented fan cover; replace loose/

damaged fan.

2. Replace/resharpen blade.

3. Rebuild gearbox for bad gear(s)/bearing(s).

4. Change blade and or speed.

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

-27-

Page 30

Bandsaw Operations

SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION

Machine is loud when

cutting or bogs down in

the cut.

Blades break often. 1. Blade is not tensioned correctly.

Blade dulls prematurely. 1. The cutting speed is too fast.

Blade wears on one side. 1. The blade guides are worn or mis-

Teeth are ripping from the

blade.

The cuts are crooked. 1. The feed pressure is too high.

1. Excessive feed rate.

2. The blade TPI is too great, or the

material is too coarse.

2. The workpiece is loose in the vise.

3. The feed or cut speed is wrong.

4. The blade TPI is too great, or the

material is too coarse.

5. The blade is rubbing on the wheel

flange.

6. The bandsaw is being started with

the blade resting on the workpiece.

7. The guide bearings are

misaligned, or the blade is rubbing

on the wheel flange.

8. The blade is too thick, or the

blades are of low quality.

2. The blade TPI is too coarse.

3. The blade feed pressure is too

light.

4. The workpiece has hard spots,

welds, or scale is on the material.

5. The blade is twisted.

6. The blade is slipping on the

wheels.

adjusted.

2. The blade guide slide bracket is

loose.

3. The wheels are out of alignment.

1. The feed pressure is too heavy

and the blade speed is too slow; or

the blade TPI is too coarse for the

workpiece.

2. The workpiece is vibrating in the

vise.

3. The blade gullets are loading up

with chips.

2. The guide bearings are out of

adjustment, or too far away from

the workpiece.

3. The blade tension is low.

4. The blade is dull.

5. The blade speed is wrong.

1. Refer to Feed Rate on Page 21, or Changing

Blade Speed on Page 19, and adjust as required.

2. Refer to Blade Selection on Page 20 and adjust as

required.

1. Check to see that blade is not excessively tight or

too loose.

2. Clamp the workpiece tighter, or use a jig to hold the

workpiece.

3. Refer to Feed Rate on Page 21, or Changing

Blade Speed on Page 19, and adjust as required.

4. Refer to Blade Selection on Page 20 and adjust as

required.

5. Refer to Blade Tracking on Page 30, and adjust as

required.

6. Start bandsaw and then slowly lower the headstock

by setting the feed rate.

7. Refer to Blade Tracking on Page 30, or Blade

Guides on Page 22 and adjust as required.

8. Use a higher quality blade.

1. Refer to Changing Blade Speed on Page 19, and

adjust as required.

2. Refer to Blade Selection on Page 20 and adjust as

required.

3. Refer to Feed Rate on Page 21, and adjust as

required.

4. Increase the feed pressure, and reduce the cutting

speed.

5. Replace the blade.

6. Refer to Blade Tension on Page 23, and adjust as

required.

1. Refer to Blade Guides on Page 22 and replace or

adjust.

2. Tighten the blade guide bracket.

3. Refer to Blade Tracking on Page 30, and adjust as

required.

1. Refer to Blade Selection on Page 20 and decrease

the feed pressure. Refer to Feed Rate on Page 21,

and adjust as required.

2. Re-clamp the workpiece in the vise, and use a jig if

required.

3. Use a coarser-tooth blade.

1. Refer to Feed Rate on Page 21, and adjust as

required.

2. Refer to Blade Guides on Page 22 and replace or

adjust.

3. Refer to Blade Tension on Page 23, and adjust as

required.

4. Refer to Changing the Blade on Page 29 and

replace the blade.

5. Refer to Changing Blade Speed on Page 19, and

adjust as required.

-28-

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

Page 31

Blade Change

Blades should be changed when they become

dull, damaged, or when you are using materials

that require a blade of a certain type or tooth

count.

To change the bandsaw blade:

1. UNPLUG THE BANDSAW!

2. Hold the headstock, unattach the feed cyl-

inder by removing the cap screw, then raise

the headstock to the full vertical position (see

Figure 37).

4. Loosen the tension knob and slip the blade

off of the wheels.

5. Install the new blade through both blade

guide bearings, as shown in Figure 39, and

around the bottom wheel.

Figure 39. Typical blade installation.

Feed Cylinder

Cap Screw

Figure 37. Disengaging the feed cylinder.

3. Push the safety stop in, use a screwdriver

to remove the upper and lower blade guide

guards, and loosen the blade guides (see

Figure 38).

Safety

Stop

Figure 38. Blade guide guards and fasteners.

Blade

Guide

Guards

6. Hold the blade around the bottom wheel with

one hand and slip it around the top wheel with

the other hand, keeping the blade between

the blade guide bearings.

Note: It is sometimes possible to flip the

blade inside out, in which case the blade will

be installed in the wrong direction. Check to

make sure the blade teeth are facing toward

the workpiece, as shown in Figure 39, after

mounting on the bandsaw. Some blades will

have a directional arrow as a guide.

7. When the blade is around both wheels,

adjust the position so the back of the blade is

against the shoulder of the wheels.

8. Tighten the tension knob as tight as necessary so the blade will not slip on the wheels

during start up.

9. Spin the wheel by hand until the blade

resumes the previous tracking.

—If the tracking needs to be adjusted, refer

to the Tracking procedure in the next section.

—If the tracking is fine, proceed to Blade

Tension on Page 23.

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

-29-

Page 32

10. Reinstall the blade guards, and adjust the

blade guides as described in Blade Guides

on Page 22

7. Adjust the tracking set screw with a 4mm hex

wrench as shown in Figure 40, then tighten

the cap screw loosened in Step 5.

11. Re-attach the feed cylinder.

Blade Tracking

The blade tracking has been properly set at

the factory. The tracking will rarely need to be

adjusted if the bandsaw is used properly.

To adjust the blade tracking on the bandsaw:

1. UNPLUG THE BANDSAW!

2. Raise the headstock and lock it in place by

pushing in the safety stop knob.

3. Remove both blade guide assemblies.

4. Open the wheel access cover.

5. Loosen, but do not remove the lower cap

screw in the blade wheel tilting mechanism

(Figure 40).

—Tightening the set screw will move the

blade closer to the shoulder of the wheel.

—Loosening the set screw will move the

blade away from the shoulder.

8. Tension the blade.

9. Spin the wheel by hand and observe how the

blade tracks on the wheel.

—If the blade tracks along the shoulder of

the wheel (without rubbing), the blade is

tracking properly and this adjustment is

completed.

—If the blade drifts away from the shoulder

of the wheel or hits the shoulder, repeat

Steps 5-8.

10. Replace the blade guard and blade guide

assemblies.

11. Adjust the blade guides as needed. Refer to

Blade Guides on Page 22

Tracking

Set Screw

Lower Cap Screw

Figure 40. Adjusting tracking set screw.

6. Relax the blade tension.

-30-

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

Page 33

Electrical Components

Figure 41. Capacitor

Figure 42. Switch wiring right-hand view.

Figure 43. Switch wiring rear view.

Figure 44. Switch wiring left-hand view.

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

-31-

Page 34

220 Wiring

G9742 Wiring Diagram

Disconnect power from

machine before performing

any electrical service. Failure

to do this will result in a

shock hazard leading to

injury or death.

110V

Power Supply

Load

Hot

Neutral

Neutral

Green

Green

White

Black

Paddle

Switch

220V

Power Supply

Ground

Ground

110V

Connection

Green

Neutral

White

Black

Hot

Bandsaw Motor

Electrical Box

220V

Red

Red

Black

Black

Gray

Gray

Yellow

Yellow

Motor

Motor

Bandsaw Motor

Capacitor Cover

Wire number

Wire Color

1 = Black

2 = Yellow

3 = Red

4 = Gray

Capacitor

Capacitor

-32-

Load

Hot

White

Black

Neutral

Hot

Ground

Ground

Green

Paddle

Switch

Connection

Green

Hot

White

Black

Hot

Bandsaw Motor

Electrical Box

Capacitor

Capacitor

Motor

Motor

Bandsaw Motor

Capacitor Cover

Red

Black

Black

Gray

Yellow

Yellow

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

Red

Gray

Wire number

Wire Color

1 = Black

2 = Yellow

3 = Red

4 = Gray

Page 35

Saw Parts Breakdown

75

101

100

80

79

75

109

108

101-1

182

35

50

72

89

31

112

104

103

109

81

83

100

72

73

93

92

120

2

123

84

134

71

98

8

133

1

11

97

8

12

320

35

102

132

201

76

200

199

66

35

132-1

102

97

59

11

58

3

48

51

50

71-1

198

113

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

-33-

Page 36

Saw Parts List

REF PART # DESCRIPTION REF PART # DESCRIPTION

1 PB07 HEX BOLT 5/16-18 X 3/4 92 P9742092 GEAR BOX GASKET

2 PN05 HEX NUT 1/4-20 93 P9742093 COVER

3 PW06 FLAT WASHER 1/4 97 PS08M PHLP HD SCR M5-.8 X 12

8 PW07 FLAT WASHER 5/16 98 P9742098 KNOB 5/16-18 X 45

11 PB03 HEX BOLT 5/16-18 X 1 100 PS23 PHLP HD SCR 8-32 x 1/4

12 PN02 HEX NUT 5/16-18 101 P9742101 WORM GEAR PULLEY

31 PB03 HEX BOLT 5/16-18 X 1 101-1 PSS38 SET SCREW 5/16-18 X 5/8

35 PLW04 LOCK WASHER 3/8 102 PLW01 LOCK WASHER 5/16

48 PS06 PHLP HD SCR 10-24 X 3/8 103 P9742103 BLADE TENSION SLIDING PLATE

50 PB07 HEX BOLT 5/16-18 X 3/4 104 PSS38 SET SCREW 5/16-18 X 5/8

51 PW07 FLAT WASHER 5/16 108 P9742108 SHAFT BLOCK

58 P9742058 KNOB 1/4-20 X 5/8 109 P9742109 BLADE TENSION SLIDING GUIDE

59A P9742059A BLADE BACK SAFETY COVER V2.11.06 112 PVA22 V-BELT A-22 4L220

66 P9742066 KNOB 3/8-16 X 1-1/4 113 G5109 BLADE 64-1/2 X 1/2 X.025

71 P9742071 BLADE WHEEL FRONT 120 P9742120 BUSHING 19 X 17 X 7

71-1 PSS17 SET SCREW 5/16-18 X 5/16 123 PB05 HEX BOLT 1/4-20 X 3/4

72 P9742072 BEARING COVER 132 P9742132 SAFETY GUARD RIGHT

73 PK23M KEY 5 X 5 X 25 133 PS06 PHLP HD SCR 10-24 X 3/8

75 PB02 HEX BOLT 1/4-20 X 5/8 134 P9742134 WIRE CLAMP

76 P9742076 SWITCH CUT OFF TIP 182 PW07 FLAT WASHER 5/16

79 P9742079 BLADE TENSION ADJ KNOB 198 PR05M EXT RETAINING RING 15MM

80 P9742080 COMPRESSION SPRING 199 PB03 HEX BOLT 5/16-18 X 1

81 P9742081 BODY FRAME 200 PSB04 CAP SCREW 1/4-20 X 1/2

83 PB41 HEX BOLT 1/2-12 X 1-1/2 201 PN02 HEX NUT 5/16-18

84 P9742084 MOTOR MOUNT PLATE 320 PB58 HEX BOLT 3/8-16 X 2

89 P9742089 OIL SEAL

-34-

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

Page 37

Stand Parts Breakdown

27

85-2

28

194

85-1

307

196V2

111

126

85-3

85-4

305V2

124

302V2

301V2

126

125

313

312

86-1

86

303V2

314

16

74

312

308

311

44

85

319

310

309

318

322

320

11

304

315

50

321

338

51

324

54

325

323

17

328

329

362

363

255

258

254

262

259

263

261

256

257

330A-1

21

19

20

334

359

366

316

300

367

368

364

363

361

330A

333

9

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

-35-

Page 38

Stand Parts List

REF PART # DESCRIPTION REF PART # DESCRIPTION

9 P9742009 WHEEL 302A P9742302A VISE JAW BRACKET-FRONT V2.01.08

11 PB03 HEX BOLT 5/16-18 X 1 303A P9742303A VICE JAW BRACKET-REAR V2.01.08

16 P9742016 MOTOR CABLE 304 P9742304 SWIVEL BASE UPPER

17 P9742017 PIVOTING ROD 305A P9742305A BRACKET W/NUT V2.01.08

19 P9742019 WORK STOP 306 P9742306 ACME NUT

20 PSS17 SET SCREW 5/16-18 X 5/16 307A P9742307A ACME SCREW V2.01.08

21 P9742021 STOCK STOP ROD 1/2 X 216 308 P9742308 BUSHING

27 P9742027 HANDWHEEL HANDLE 309 PLW01 LOCK WASHER 5/16

28 P9742028 HANDWHEEL 310 PSB30 CAP SCREW 5/16-18 X 1/2

44 P9742044 POWER CABLE 311 PB07 HEX BOLT 5/16-18 X 3/4

50 PB07 HEX BOLT 5/16-18 X 3/4 312 PW07 FLAT WASHER 5/16

51 PW07 FLAT WASHER 5/16 313 PB12 HEX BOLT 5/16-18 X 1-1/4

54 P9742054 PIVOT 314 PSS03 SET SCREW 1/4-20 X 3/8

74 PK12M KEY 5 X 5 X 30 315 P9742315 POSITIONING RING

85 P9742085 MOTOR 1/2 HP 316 PN06 HEX NUT 1/2-12

85-1 P9742085-1 MOTOR FAN COVER 318 PB27 HEX BOLT 1/2-13 X 2-1/2

85-2 P9742085-2 MOTOR FAN 319 PN08 HEX NUT 3/8-16