Page 1

66"" GGRRIINNDDEERR

MMOODDEELL GG99771177

IINNSSTTRRUUCCTTIIOONN MMAANNUUAALL

COPYRIGHT ©2000 BY GRIZZLY INDUSTRIAL, INC.

1821 VALENCIA ST., BELLINGHAM, WA 98227

WWAARRNNIINNGG:: NNOO PPOORRTTIIOONN OOFF TTHHIISS MMAANNUUAALL MMAAYY BBEE RREEPPRROODDUUCCEEDD IINN AANNYY SSHHAAPPEE

OORR FFOORRMM WWIITTHHOOUUTT TTHHEE WWRRIITTTTEENN AAPPPPRROOVVAALL OOFF GGRRIIZZZZLLYY IINNDDUUSSTTRRIIAALL,, IINNCC..

MARCH, 2000 PRINTED IN CHINA

ONLINE MANUAL DISCLAIMER

THE INFORMATION IN THIS MANUAL REPRESENTS THE CONFIGURATION OF THE MACHINE AS IT IS CURRENTLY BEING SHIPPED. THE MACHINE

CONFIGURATION CAN CHANGE AS PRODUCT IMPROVEMENTS ARE INCORPORATED. IF YOU OWN AN EARLIER VERSION OF THE MACHINE, THIS

MANUAL MAY NOT EXACTLY DEPICT YOUR MACHINE . CONTACT CUSTOMER SERVICE IF YOU HAVE ANY QUESTIONS ABOUT DIFFERENCES. PRE-

VIOUS VERSIONS ARE NOT AVAILABLE ONLINE.

Page 2

G9717 6" Grinder

-1-

SSaaffeettyy IInnssttrruuccttiioonnss FFoorr PPoowweerr TToooollss

GGEENNEERRAALL SSAAFFEETTYY RRUULLEESS

55.. KKEEEEPP CCHHIILLDDRREENN AANNDD VVIISSIITTOORRSS AAWWAAYY

.

All children and visitors should be kept a

safe distance from work area.

66.. MMAAKKEE WWOORRKK SSHHOOPP CCHHIILLDD PPRROOOOFF

with

padlocks, master switches, or by removing

starter keys.

77.. DDOONN’’TT FFOORRCCEE TTOOOOLL

. It will do the job

better and safer at the rate for which it was

designed.

88.. UUSSEE RRIIGGHHTT TTOOOOLL..

Don’t force tool or

attachment to do a job for which it was not

designed.

11.. KKEEEEPP GGUUAARRDDSS IINN PPLLAACCEE

and in working

order.

22.. RREEMMOOVVEE AADDJJUUSSTTIINNGG KKEEYYSS AANNDD

WWRREENNCCHHEESS

. Form habit of checking to

see that keys and adjusting wrenches are

removed from tool before turning on

..

33.. KKEEEEPP WWOORRKK AARREEAA CCLLEEAANN

. Cluttered

areas and benches invite accidents.

44.. DDOONN’’TT UUSSEE IINN DDAANNGGEERROOUUSS EENNVVIIRROONN--

MMEENNTT

. Don’t use power tools in damp or

wet locations, or where any flammable or

noxious fumes may exist. Keep work area

well lighted.

FFoorr YYoouurr OOwwnn SSaaffeettyy RReeaadd IInnssttrruuccttiioonn MMaannuuaall

BBeeffoorree OOppeerraattiinngg TThhiiss EEqquuiippmmeenntt

IInnddiiccaatteess aann iimmmmiinneennttllyy hhaazzaarrddoouuss ssiittuuaattiioonn wwhhiicchh,, iiff nnoott aavvooiiddeedd,,

WWIILLLL rreessuulltt iinn ddeeaatthh oorr sseerriioouuss iinnjjuurryy..

IInnddiiccaatteess aa ppootteennttiiaallllyy hhaazzaarrddoouuss ssiittuuaattiioonn wwhhiicchh,, iiff nnoott aavvooiiddeedd,,

CCOOUULLDD

rreessuulltt iinn ddeeaatthh oorr sseerriioouuss iinnjjuurryy..

IInnddiiccaatteess aa ppootteennttiiaallllyy hhaazzaarrddoouuss ssiittuuaattiioonn wwhhiicchh,, iiff nnoott aavvooiiddeedd,,

MMAAYY

rreessuulltt iinn mmiinnoorr oorr mmooddeerraattee iinnjjuurryy.. IItt mmaayy aallssoo bbee uusseedd ttoo

aalleerrtt aaggaaiinnsstt uunnssaaffee pprraaccttiicceess..

TThhiiss ssyymmbbooll iiss uusseedd ttoo aalleerrtt tthhee uusseerr ttoo uusseeffuull iinnffoorrmmaattiioonn aabboouutt

pprrooppeerr ooppeerraattiioonn ooff tthhee eeqquuiippmmeenntt..

TThhee ppuurrppoossee ooff ssaaffeettyy ssyymmbboollss iiss ttoo aattttrraacctt yyoouurr aatttteennttiioonn ttoo ppoossssiibbllee hhaazzaarrddoouuss ccoonnddiittiioonnss.. TThhiiss mmaann--

uuaall uusseess aa sseerriieess ooff ssyymmbboollss aanndd ssiiggnnaall wwoorrddss wwhhiicchh aarree iinntteennddeedd ttoo ccoonnvveeyy tthhee lleevveell ooff iimmppoorrttaannccee ooff

tthhee ssaaffeettyy mmeessssaaggeess.. TThhee pprrooggrreessssiioonn ooff ssyymmbboollss iiss ddeessccrriibbeedd bbeellooww.. RReemmeemmbbeerr tthhaatt ssaaffeettyy mmeessssaaggeess

bbyy tthheemmsseellvveess ddoo nnoott eelliimmiinnaattee ddaannggeerr aanndd aarree nnoott aa ssuubbssttiittuuttee ffoorr pprrooppeerr aacccciiddeenntt pprreevveennttiioonn mmeeaass--

uurreess..

NNOOTTIICCEE

Page 3

G9717 6" Grinder

-2-

99.. UUSSEE PPRROOPPEERR EEXXTTEENNSSIIOONN CCOORRDD

. Make

sure your extension cord is in good condition. Conductor size should be in accordance with the chart below. The amperage

rating should be listed on the motor or tool

nameplate. An undersized cord will cause

a drop in line voltage resulting in loss of

power and overheating. Your extension

cord must also contain a ground wire and

plug pin. Always repair or replace extension cords if they become damaged.

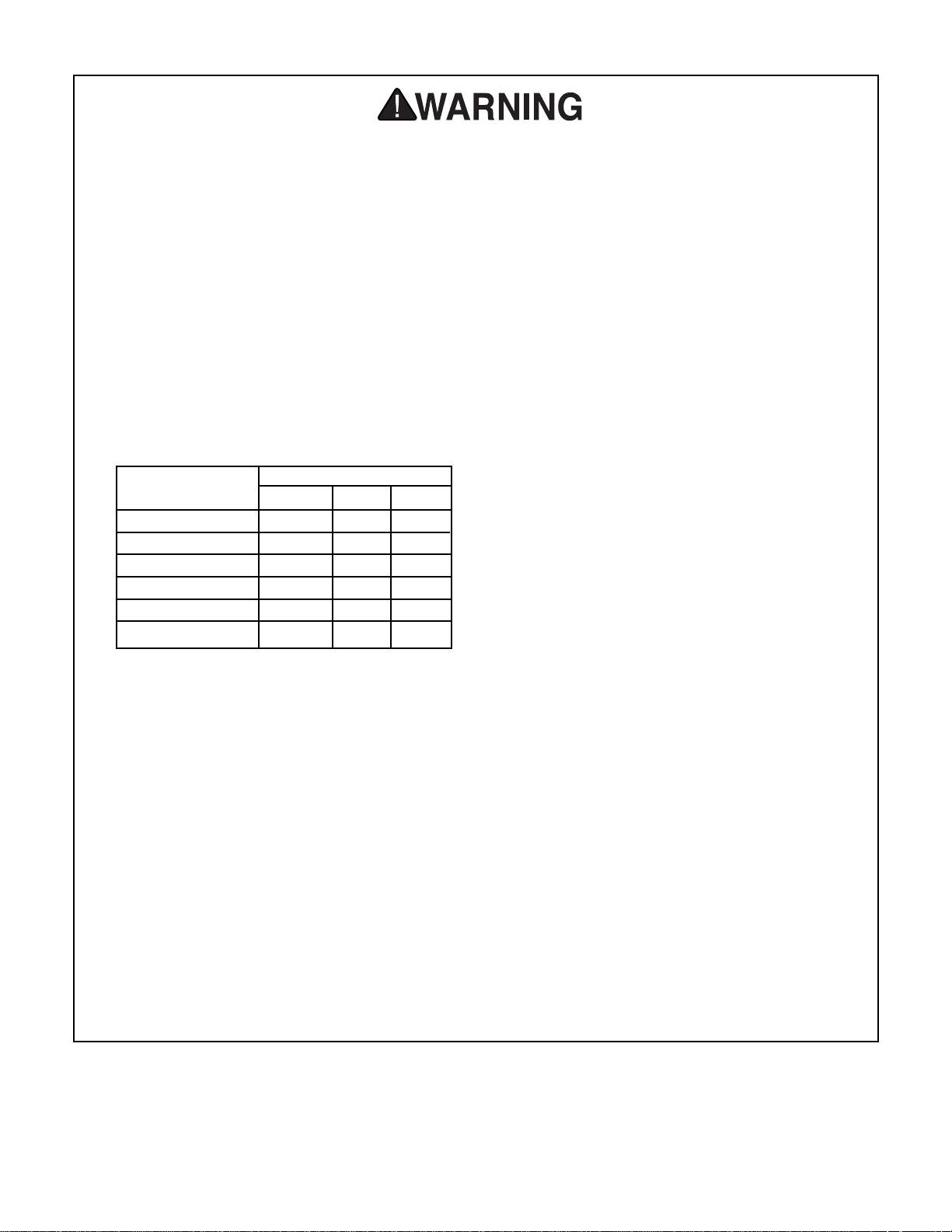

Minimum Gauge for Extension Cords

1100.. WWEEAARR PPRROOPPEERR AAPPPPAARREELL..

Do not wear

loose clothing, gloves, neckties, rings,

bracelets, or other jewelry which may get

caught in moving parts. Non-slip footwear

is recommended. Wear protective hair

covering to contain long hair.

1111.. AALLWWAAYYSS UUSSEE SSAAFFEETTYY GGLLAASSSSEESS..

Also

use face or dust mask if cutting operation

is dusty. Everyday eyeglasses only have

impact resistant lenses, they are NOT

safety glasses.

1122.. SSEECCUURREE WWOORRKK..

Use clamps or a vise to

hold work when practical. It’s safer than

using your hand and frees both hands to

operate tool.

LLEENNGGTTHH

AAMMPP RRAATTIINNGG 2255fftt 5500fftt 110000fftt

0-6 18 16 16

7-10 18 16 14

11-12 16 16 14

13-16 14 12 12

17-20 12 12 10

21-30 10 10 No

SSaaffeettyy IInnssttrruuccttiioonnss FFoorr PPoowweerr TToooollss

1133.. DDOONN’’TT OOVVEERRRREEAACCHH..

Keep proper footing

and balance at all times.

1144.. MMAAIINNTTAAIINN TTOOOOLLSS WWIITTHH CCAARREE..

Keep

tools sharp and clean for best and safest

performance. Follow instructions for lubricating and changing accessories.

1155.. DDIISSCCOONNNNEECCTT TTOOOOLLSS

before servicing

and changing accessories, such as blades,

bits, cutters, and the like.

1166.. RREEDDUUCCEE TTHHEE RRIISSKK OOFF UUNNIINNTTEENNTTIIOONN--

AALL SSTTAARRTTIINNGG..

Make sure switch is in off

position before plugging in.

1177.. UUSSEE RREECCOOMMMMEENNDDEEDD AACCCCEESSSSOORRIIEESS..

Consult the owner’s manual for recommended accessories. The use of improper

accessories may cause risk of injury.

1188.. CCHHEECCKK DDAAMMAAGGEEDD PPAARRTTSS..

Before further use of the tool, a guard or other part

that is damaged should be carefully

checked to determine that it will operate

properly and perform its intended function.

Check for alignment of moving parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that

may affect its operation. A guard or other

part that is damaged should be properly

repaired or replaced.

1199.. NNEEVVEERR LLEEAAVVEE TTOOOOLL RRUUNNNNIINNGG UUNNAATT--

TTEENNDDEEDD.. TTUURRNN PPOOWWEERR OOFFFF..

Don’t

leave tool until it comes to a complete stop.

Page 4

G9717 6" Grinder

-3-

AAddddiittiioonnaall SSaaffeettyy IInnssttrruuccttiioonnss FFoorr GGrriinnddeerrss

NNoo lliisstt ooff ssaaffeettyy gguuiiddeelliinneess ccaann bbee ccoommpplleettee..

EEvveerryy sshhoopp eennvviirroonnmmeenntt iiss ddiiffffeerreenntt.. AAllwwaayyss

ccoonnssiiddeerr ssaaffeettyy ffiirrsstt,, aass iitt aapppplliieess ttoo yyoouurr iinnddii--

vviidduuaall wwoorrkkiinngg ccoonnddiittiioonnss.. UUssee tthhiiss aanndd ootthheerr

mmaacchhiinneerryy wwiitthh ccaauuttiioonn aanndd rreessppeecctt.. FFaaiilluurree ttoo

ddoo ssoo ccoouulldd rreessuulltt iinn sseerriioouuss ppeerrssoonnaall iinnjjuurryy,,

ddaammaaggee ttoo eeqquuiippmmeenntt oorr ppoooorr wwoorrkk rreessuullttss..

OOppeerraattiinngg tthhiiss eeqquuiippmmeenntt hhaass tthhee ppootteennttiiaall ttoo

pprrooppeell ddeebbrriiss iinnttoo tthhee aaiirr wwhhiicchh ccaann ccaauussee eeyyee

iinnjjuurryy.. AAllwwaayyss wweeaarr ssaaffeettyy ggllaasssseess oorr ggoogggglleess

wwhheenn ooppeerraattiinngg eeqquuiippmmeenntt.. EEvveerryyddaayy ggllaasssseess

oorr rreeaaddiinngg ggllaasssseess oonnllyy hhaavvee iimmppaacctt rreessiissttaanntt

lleennsseess,, tthheeyy aarree nnoott ssaaffeettyy ggllaasssseess.. BBee cceerrttaaiinn

tthhee ssaaffeettyy ggllaasssseess yyoouu wweeaarr mmeeeett tthhee aapppprroo--

pprriiaattee ssttaannddaarrddss ooff tthhee AAmmeerriiccaann NNaattiioonnaall

SSttaannddaarrddss IInnssttiittuuttee ((AANNSSII))..

11.. AALLWWAAYYSS WWEEAARR

a face shield and/or safe-

ty goggles.

22.. SSEECCUURREE TTHHIISS GGRRIINNDDEERR

firmly to a

benchtop or stand.

33.. NNEEVVEERR UUSSEE AA GGRRIINNDDIINNGG WWHHEEEELL

which

has evidence of cracking or chips. “Ring

Check” the wheel to test its integrity (See

Page 9 for checking procedure).

44.. UUSSEE OONNLLYY PPRROOPPEERRLLYY SSIIZZEEDD WWHHEEEELLSS

which have the right bore size and overall

diameter.

55.. DDRREESSSS TTHHEE GGRRIINNDDIINNGG WWHHEEEELL

when its

surface becomes rutted or uneven.

Replace the wheel if the wear or damage

becomes excessive.

66.. AALLLLOOWW TTHHEE WWHHEEEELL TTOO AATTTTAAIINN FFUULLLL

SSPPEEEEDD

before introducing the workpiece.

77.. AALLWWAAYYSS UUSSEE TTHHEE SSAAFFEETTYY SSHHIIEELLDDSS

AANNDD TTOOOOLL RREESSTT

when grinding. The

shields prevent sparks from flying, and the

tool rest provides a firm rest on which to

position the workpiece.

88.. NNEEVVEERR GGRRIINNDD SSMMAALLLL SSTTOOCCKK..

Do not

attempt to grind or sharpen anything which

can’t be adequately supported by the tool

rest. Use clamping pliers or a similar holder

when grinding parts which can’t be easily

held by hand.

99.. GGRRIINNDDIINNGG CCRREEAATTEESS SSPPAARRKKSS

, make

sure your work area is free of combustible

materials.

1100.. AAVVOOIIDD OOVVEERRHHEEAATTIINNGG TTHHEE WWOORRKK--

PPIIEECCEE..

Excessive prolonged grinding on a

workpiece can heat it to the point of being

dangerously hot. Keep a water reservoir

handy when grinding to quench hot parts.

Overheating can also change the metallurgical properties of your part.

1111.. NNEEVVEERR SSTTIICCKK AANN OOBBJJEECCTT AAGGAAIINNSSTT TTHHEE

WWHHEEEELL TTOO SSTTOOPP TTHHEE WWHHEEEELL RROOTTAA--

TTIIOONN..

Page 5

G9717 6" Grinder

-4-

SSEECCTTIIOONN 22:: CCIIRRCCUUIITT RREEQQUUIIRREEMMEENNTTSS

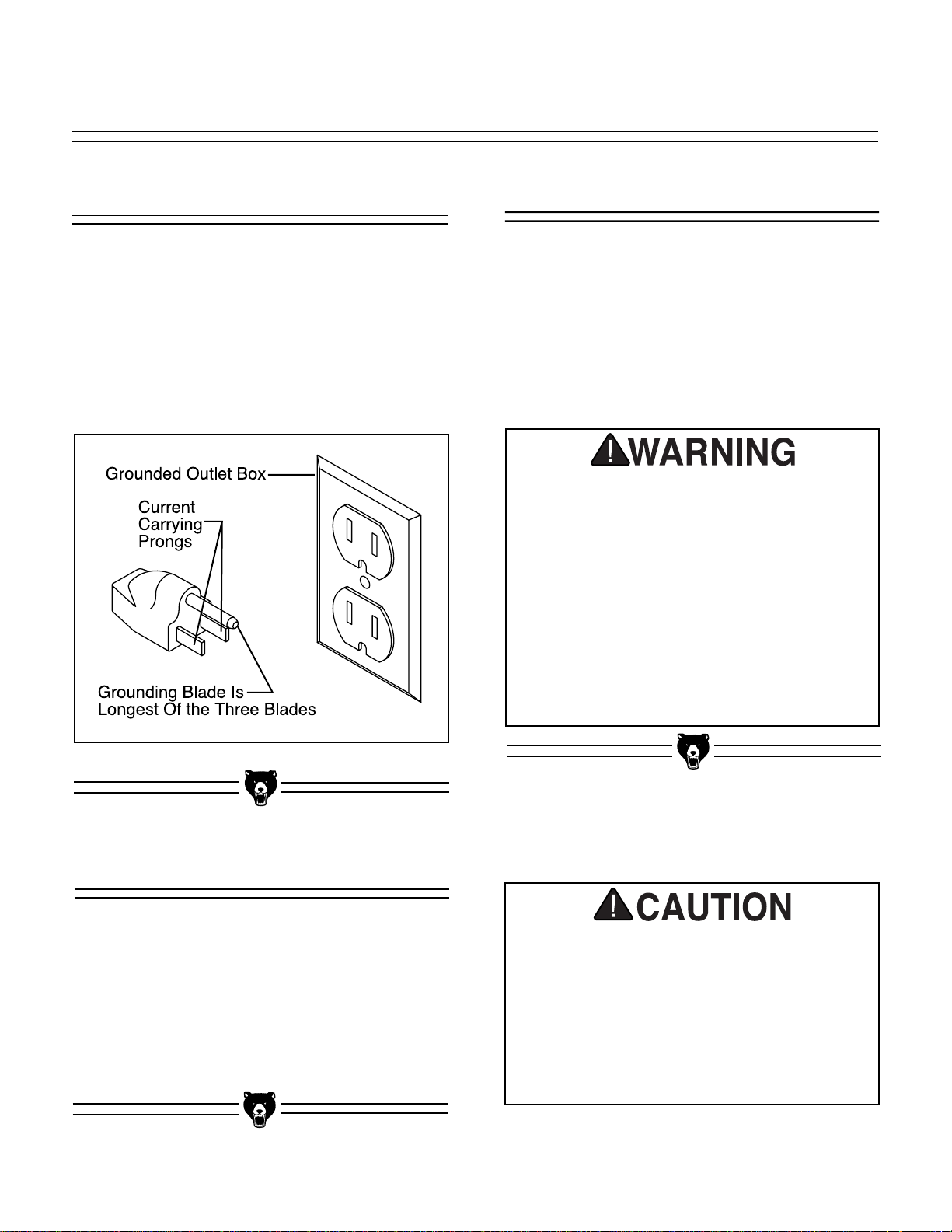

111100VV OOppeerraattiioonn

The motor supplied with the G9717 must be operated at 110V. Use an outlet configuration as

shown in

FFiigguurree 11..

Under normal use, the motor

draws approximately 2-3 amps @ 110V. We recommend a 15 amp circuit breaker for 110V operation. This should be satisfactory for normal use,

while providing enough protection against motor

damage caused by power surges.

FFiigguurree 11..

Typical 110V plug and outlet.

Should it be necessary to use an extension when

operating at 110V, make sure the cord is rated

Hard Service (grade S) or better. Refer to the

chart in Section 1: Safety Instructions to determine the minimum gauge for the extension cord.

The extension cord must also contain a ground

wire and plug pin. Always repair or replace extension cords when they become worn or damaged.

EExxtteennssiioonn CCoorrddss

TThhiiss eeqquuiippmmeenntt mmuusstt bbee ggrroouunnddeedd..

Please

ensure that this machine is continuously

grounded from the motor to the machine frame

and then to a known ground. Verify that any

existing electrical outlet and circuit you intend

to plug into is actually grounded. If it is not, it

will be necessary to run a separate 12 A.W.G.

copper grounding wire from the outlet to a

known ground. Under no circumstances should

the grounding pin from any three-pronged plug

be removed.

SSeerriioouuss ppeerrssoonnaall iinnjjuurryy mmaayy

ooccccuurr..

GGrroouunnddiinngg

In the event of an electrical short, grounding

reduces the risk of electric shock by providing a

path of least resistance to disperse electric current. This tool is equipped with a power cord having an equipment-grounding conductor.

SSeeee

FFiigguurree 11..

The outlet must be properly installed

and grounded in accordance with all local codes

and ordinances.

WWee hhaavvee ccoovveerreedd ssoommee bbaassiicc eelleeccttrriiccaall

rreeqquuiirreemmeennttss ffoorr tthhee ssaaffee ooppeerraattiioonn ooff yyoouurr

SSuurrffaaccee GGrriinnddeerr.. TThheessee rreeqquuiirreemmeennttss aarree nnoott

nneecceessssaarriillyy ccoommpprreehheennssiivvee.. YYoouu mmuusstt bbee ssuurree

tthhaatt yyoouurr ppaarrttiiccuullaarr eelleeccttrriiccaall ccoonnffiigguurraattiioonn

ccoommpplliieess wwiitthh llooccaall aanndd ssttaattee ccooddeess.. EEnnssuurree

ccoommpplliiaannccee bbyy cchheecckkiinngg wwiitthh yyoouurr llooccaall mmuunniicc--

iippaalliittyy oorr aa lliicceennsseedd eelleeccttrriicciiaann..

Page 6

G9717 6" Grinder

-5-

SSEECCTTIIOONN 33:: GGEENNEERRAALL IINNFFOORRMMAATTIIOONN

To operate this, or any power tool, safely and

efficiently, it is essential to become as familiar

with its characteristics as possible. The time

you invest before you begin to use your Model

G9717 will be time well spent. DO NOT operate this machine until you are completely familiar with the contents of this manual. Make sure

you read and understand all of the safety procedures. If you do not understand something,

DDOO NNOOTT

operate the machine.

CCoommmmeennttaarryy

We are proud to offer the Grizzly Model G9717

6" Grinder. This Grinder is part of a growing

Grizzly family of fine metalworking machinery.

When used according to the guidelines set forth

in this manual, you can expect years of troublefree, enjoyable operation and proof of Grizzly’s

commitment to customer satisfaction.

The Model G9717 is intended for home and

hobby-type use. It features a

1

⁄3 HP, 110V motor,

two 6" grinding wheels, one 60 grit and one 30

grit. Eye shields and tool rests are included to

ensure safe operation of the wheels.

Replacement wheels with a 6" diameter and a 1⁄2"

bore are available through the Grizzly catalog.

We are also pleased to provide this manual with

the Model G9717. It was written to guide you

through assembly, review safety considerations,

and cover general operating procedures. It represents our effort to produce the best documentation possible. If you have any comments regarding this manual, please write to us at the address

below:

Grizzly Industrial, Inc.

C

/O Technical Documentation

P.O. Box 2069

Bellingham, WA 98227-2069

Most importantly, we stand behind our machines.

If you have any service questions or parts

requests, please call or write us at the location

listed below.

The specifications, drawings, and photographs

illustrated in this manual represent the Model

G9717 as supplied when the manual was prepared. However, owing to Grizzly’s policy of continuous improvement, changes may be made at

any time with no obligation on the part of Grizzly.

Whenever possible, though, we send manual

updates to all owners of a particular tool or

machine. Should you receive one, we urge you to

insert the new information with the old and keep

it for reference.

Grizzly Industrial, Inc.

1203 Lycoming Mall Circle

Muncy, PA 17756

Phone:(570) 546-9663

Fax:(800) 438-5901

E-Mail: techsupport@grizzly.com

Web Site: http://www.grizzly.com

Page 7

G9717 6" Grinder

-6-

SSEECCTTIIOONN 44:: AASSSSEEMMBBLLYY

TTooooll RReesstt

The Tool Rest provides a surface which can be

used to support the workpiece during grinding.

Certain types of grinding may require jigs or

accessories to assure the proper angle of the

piece against the wheel.

The Tool Rest assembles to the inboard side of

the Wheel Guard. Use two (2) hex bolts and lockwashers inserted through the rest support and

thread into the tapped holes. Repeat this installation for the opposite side wheel. The Tool Rest

can be adjusted in and out by loosening these

bolts. Always retighten before beginning grinding

operations.

EEyyee SShhiieelldd

The Eye Shield should be positioned between the

grinding wheel and the operator’s face during

grinding. This lessens the possibility for sparks or

metal bits to go flying directly at the operator.

The Eye Shield has a clear plastic panel which is

attached to a support bracket. Thread the long

Phillips

®

head screw through the bracket, then

through the shield, and then through the other

side of the bracket. Use a nut and lockwasher,

but leave it loose enough so the angle of the Eye

Shield can be adjusted.

Attach the support bracket to the top end of the

wheel rim guard with a Phillips

®

head screw, flat

washer and lockwasher into the tapped hole.

Note that there is a slot in the support bracket

which allow adjusting the Eye Shield up and

down.

Repeat the Eye Shield installation for the opposite side wheel.

FFiigguurree 22..

Tool rest installed.

FFiigguurree 33..

Eye shield in operating position.

Page 8

G9717 6" Grinder

-7-

MMoouunnttiinngg ttoo BBeenncchh

NNootteess

The grinder base has two holes directly under the

wheel shaft. These holes can be used to mount

the grinder to a workbench, table top, or other

solid surface. Since grinding does develop a lot of

force, it is best to mount the grinder solidly before

using. If you wish for the grinder to remain

portable, it can be temporarily clamped to a table.

Just make certain no part of the clamping device

interferes with the wheels or the tool rests.

Page 9

G9717 6" Grinder

-8-

OOppeerraattiioonn ooff tthhiiss eeqquuiippmmeenntt hhaass tthhee ppootteennttiiaall

ttoo pprrooppeell ddeebbrriiss iinnttoo tthhee aaiirr wwhhiicchh ccaann ccaauussee

eeyyee iinnjjuurryy.. AAllwwaayyss wweeaarr ssaaffeettyy ggllaasssseess oorr ggoogg--

gglleess wwhheenn ooppeerraattiinngg eeqquuiippmmeenntt.. EEvveerryyddaayy

ggllaasssseess oorr rreeaaddiinngg ggllaasssseess oonnllyy hhaavvee iimmppaacctt

rreessiissttaanntt lleennsseess,, tthheeyy aarree nnoott ssaaffeettyy ggllaasssseess..

BBee cceerrttaaiinn tthhee ssaaffeettyy ggllaasssseess yyoouu wweeaarr mmeeeett

tthhee aapppprroopprriiaattee ssttaannddaarrddss ooff tthhee AAmmeerriiccaann

NNaattiioonnaall SSttaannddaarrddss IInnssttiittuuttee ((AANNSSII))..

DDOO NNOOTT mmaakkee aaddjjuussttmmeennttss wwhhiillee tthhee ggrriinnddeerr iiss

rruunnnniinngg.. EEnnssuurree tthhaatt tthhee sswwiittcchh iiss ooffff,, ppoowweerr iiss

ddiissccoonnnneecctteedd aanndd mmoovviinngg ppaarrttss hhaavvee ssttooppppeedd

bbeeffoorree mmaakkiinngg aaddjjuussttmmeennttss.. FFaaiilluurree ttoo ccoommppllyy

ccoouulldd rreessuulltt iinn sseerriioouuss iinnjjuurryy oorr eelleeccttrriiccaall sshhoocckk

hhaazzaarrdd..

SSEECCTTIIOONN 55:: OOPPEERRAATTIIOONNSS

SSttaarrttiinngg aanndd SSttooppppiinngg

Once assembly has been completed, the G9717

Grinder is ready for use in the shop.

The switch is located on the front of the grinder.

To turn the grinder “ON”, push the right hand side

of the rocker switch, to turn it “OFF”, push the left

hand side of the switch. Always make sure the

wheels come up to full speed before introducing

the workpiece to the wheel.

When mounting a new wheel, or when there is

any concern about wheel integrity, stand away

from the line of rotation of the wheel and then turn

the wheel “ON”. If there is a potential problem it

will generally occur when the wheel is first started.

Aluminum oxide and silicon carbide wheels are

marked in a somewhat uniform manner by all the

major manufacturers. Understanding these markings will help you understand the capabilities of

various wheels. Always refer to the manufacturer’s grinding recommendations when selecting a

wheel for your project.

The basic format for wheel numbering is:

PPrreeffiixx AAbbrraassiivvee GGrriitt GGrraaddee BBoonndd

TTyyppee SSiizzee TTyyppee

3366 AA 6600 LL VV

The most common abrasive types used are A for

Aluminum Oxide and C for Silicon Carbide, and

occasionally SG for seeded gel. The prefix is the

manufacturer’s designation for a particular type.

The grit size is a number referring to the size of

the abrasive grain in the wheel. The lower the

number the coarser the wheel - 10 is a very

coarse wheel for roughing and 220 is usually the

upper range for fine finish work.

Grade is an indication of the hardness of the

wheel, with A being softest to Z the hardest.

Bond Type refers to the type of bonding material

used to hold the abrasive material. Most general

purpose wheels will have a V indicating Vitrified

clay is used, providing a high strength and good

porosity. The other most common is B for resin

where synthetic resins are used. These are used

to grind cemented carbide and ceramic materials

There may be other numbers inserted which

have meaning for a particular type of wheel.

Refer to the manufacturer’s technical data for a

complete explanation.

WWhheeeell SSeelleeccttiioonn

Page 10

G9717 6" Grinder

-9-

WWhheeeell MMoouunnttiinngg

Before mounting any wheel, check it for integrity

by performing a “ring check”. Balance the wheel

on one finger, then lightly tap the rim of the wheel

with a piece of wood such as the handle of a

hammer. The wheel should have a ringing or

harmonic type of sound. If it responds with a dull

thud it may indicate that the wheel has cracks. Do

not use a wheel which is suspected of having

cracks, or if there are visual chips, nicks or dents

in the wheel surface. These discontinuities can

lead to wheel failure where the wheel flies apart

at operating speed. Always be sure to use a

wheel which is rated for operating at speeds

equal to or greater than 3450 RPM.

The wheel guard assembly must be removed in

order to mount or dismount a grinding wheel.

11

. Remove the three Phillips

®

head screws

and nuts which go through the outer guard.

22..

Remove the outer guard and rim guard.

SSeeee FFiigguurree 44..

FFiigguurree 44..

Wheel guard components.

FFiigguurree 55..

Grinding wheel assembly.

NNEEVVEERR aasssseemmbbllee aa ggrriinnddiinngg wwhheeeell oonn tthhee

aarrbboorr wwiitthhoouutt ppaappeerr oorr ffiibbeerr ddiissccss bbeettwweeeenn tthhee

wwhheeeell aanndd tthhee ffllaannggee.. OOmmiittttiinngg tthhee ddiissccss ccaann

ppuutt uunndduuee ssttrreessss oonn tthhee wwhheeeell ccaauussiinngg iitt ttoo

ccrraacckk aanndd ppoossssiibbllyy ffllyy aappaarrtt.. AALLWWAAYYSS ““rriinngg

cchheecckk”” aa wwhheeeell bbeeffoorree aasssseemmbbllyy ttoo mmaakkee cceerr--

ttaaiinn iitt iiss ssoouunndd wwiitthh nnoo ccrraacckkss oorr ffllaawwss..

33..

Use a

3

⁄4" or 19mm open end wrench on the

nut which holds the wheel on the arbor.

Hold the wheel from turning with the other

hand. Note that the wheel on the left hand

side of the machine is a left hand thread, so

loosening it will require turning it clockwise.

44

. Remove the outer wheel flange and the

paper disc.

55..

Pull the wheel free from the arbor. There

will also be a paper disc and a wheel flange

on the back side of the wheel. Always make

certain there is a paper or fiber disc

between the wheel flanges and the wheel

itself, this helps to spread the rotational

forces across the inner area of the wheel.

SSeeee FFiigguurree 55..

66..

Mount the new wheel in the reverse order.

First a wheel flange, a paper disc, the

wheel, a paper disc, a wheel flange and

finally the nut itself. Tighten the nut snugly

but do not over tighten. Over tightening can

crack the wheel.

77..

Run a new wheel for at least 1-2 minutes

while standing clear of the line of rotation.

If a wheel does have defects it will generally fail as soon as it gets up to full speed

.

Page 11

G9717 6" Grinder

-10-

SSEECCTTIIOONN 66:: MMAAIINNTTEENNAANNCCEE

Make a habit of inspecting your Grinder each

time you use it. Check for the following conditions

and repair or replace when necessary:

11..

Loose mounting bolts.

22..

Worn switch.

33..

Worn or damaged cords and plugs.

44..

Damaged Grinding Wheel.

55..

Any other condition that could hamper the

safe operation of this machine.

GGeenneerraall

GGrriinnddiinngg WWhheeeellss

The grinding wheel should be inspected before

every use. Use the ring check method noted in

the Grinding Wheel section in Operations to verify the structural integrity. If using coolant during

grinding, always run the wheel for 5-10 minutes

at the end of the operation to remove any coolant

from the wheel. Take care in storing grinding

wheels to keep them free from potential damage

by being dropped, or having other items drop on

them.

Replace the wheel when the wheel diameter is

reduced to 4". Operating at anything less than

this diameter does not allow the proper alignment

of the Tool Rest and the Eye Shield.

Depending on the type of grinding you do, the

grinding wheel may require periodic dressing.

There are several different types of wheel dressing devices available on the market. Use a suitable diamond or silicon carbide stick type dresser. Sweep it smoothly and evenly several times

across the face of the wheel. Dressing restores

the abrasive quality of the wheel surface, plus it

will bring the wheel edge back to a square form.

Refer to the instructions which accompany your

dressing accessory for complete detail on wheel

dressing.

LLuubbrriiccaattiioonn

The Model G9717 features factory-sealed bearings. A sealed bearing requires no lubrication

during its lifetime. Should a bearing fail, your

grinder will probably develop a noticeable rumble,

which will increase when the machine is put

under load. If the bad bearing is not replaced, it

will eventually seize - possibly doing damage to

other parts of the machine. Bearings are standard

sizes and can be replaced through Grizzly.

Page 12

G9717 6" Grinder

-11-

This section covers the most common processing problems encountered in grinding and what to do about

them. Do not make any adjustments until grinder is unplugged and moving parts have come to a complete

stop.

TTRROOUUBBLLEESSHHOOOOTTIINNGG

SSYYMMPPTTOOMM

Motor will not start.

Motor will not start; fuses or

circuit breakers blow.

Motor overheats.

Motor stalls (resulting in

blown fuses or tripped circuit).

Machine slows when operating.

Wavy condition on surface

of workpiece.

Lines on surface of workpiece.

Burning spots or cracks in

the workpiece.

Wheel dulls quickly, grit falls

off.

Wheel clogs and workpiece

shows burn marks.

PPOOSSSSIIBBLLEE CCAAUUSSEE

1. Low voltage.

2. Open circuit in motor or loose

connections.

1. Short circuit in line cord or plug.

2. Short circuit in motor or loose

connections.

3. Incorrect fuses or circuit breakers in power line.

1. Motor overloaded.

2. Air circulation through the motor

restricted.

1. Short circuit in motor or loose

connections.

2. Low voltage.

3. Incorrect fuses or circuit breakers

in power line.

4. Motor overloaded.

Depth of cut too great.

1. Machine vibrating.

2. Workpiece not being held firmly.

3. Wheel face uneven.

4. Wheel is too hard.

1. Impurity on wheel surface.

2. Workpiece not being held tightly.

1. Improper type of grinding wheel.

2. Improper feed rate.

3. Coolant required.

1. Depth of cut too great.

2. Wheel is too soft.

3. Wheel diameter too small.

4. Bad wheel dress.

5. Defective wheel bonding.

1. Wheel is too hard.

2. Feed rate too slow.

3. Bad wheel dress.

4. Coolant required.

CCOORRRREECCTTIIVVEE AACCTTIIOONN

1. Check power line for proper voltage.

2. Inspect all lead connections on motor for loose or open connections.

1. Inspect cord or plug for damaged insulation and shorted wires.

2. Inspect all connections on motor for loose or shorted terminals or

worn insulation.

3. Install correct fuses or circuit breakers.

1. Reduce load on motor.

2. Clean out motor to provide normal air circulation.

1. Inspect connections on motor for loose or shorted terminals or

worn insulation.

2 Correct the low voltage conditions.

3. Install correct fuses or circuit breakers.

4. Reduce load on motor.

Slow down the rate of movement of the workpiece into wheel.

1. Make sure machine is securely mounted on a solid surface.

2. Use a holding device to firmly retain the workpiece.

3. Dress the grinding wheel.

4. Use softer wheel, or reduce the feed rate.

1. Dress the grinding wheel.

2. Use a holding device to firmly retain the workpiece.

1. Try a wheel which is softer style or a coarser grit.

2. Slow down the rate of movement of the workpiece into wheel.

3. Add optional coolant system or introduce coolant by hand.

1. Slow down the rate of movement of the workpiece into wheel.

2. Wheel too soft for the material being ground, select harder bond.

3. Replace the wheel.

4. Dress the wheel.

5. Consult manufacturer of grinding wheel.

1. Wheel too hard for the material being ground, select softer bond.

2. Increase the rate of movement of the workpiece into wheel.

3. Dress the wheel.

4. Add optional coolant system or introduce coolant by hand.

Page 13

G9717 6" Grinder

-12-

Ref# Part# Description

001 P9717001 WHEEL COVER LH OUTER

002 P9717002 WHEEL NUT LH

003 P9717003 WHEEL DISC

004 P9717004 SPARK BREAKER

005 P9717005 EYESHIELD

006 P9717006 WHEEL COVER LH INNER

007 P9717007 TOOL REST LH

008 P6202 BALL BEARING 6202ZZ

009 P9717009 BEARING HOUSING

010 P9717010 ROTOR

011

PWRCRD110L POWER CORD 110V W/PLUG

012 P9717012 STATOR

013 P9717013 WAVY WASHER

014 P9717014 STRAIN RELIEF

015 P9717015 MOUNTING PLATE

016 P9717016 MOTOR BODY

017A P9717017A WARNING LABEL

017B P9717017B NAMEPLATE LABEL

018 P9717018 WHEEL COVER RH INNER

019 P9717019 WHEEL RIM GUARD

020 P9717020 TOOL REST RH

021 P9717021 GRINDING WHEEL 60 GRIT

022 P9717022 WHEEL FLANGE

Ref# Part# Description

023 P9717023 WHEEL NUT RH

024 P9717024 WHEEL COVER RH OUTER

025 P9717025 BASE

026 P9717026 SWITCH PROTECTOR

027 P9717027 SWITCH

029 P9717029 CAPACITOR

030 P9717030 BASE PLATE

031 P9717031 RUBBER FOOT

032 P9717032 GRINDING WHEEL 30 GRIT

034 PW02M FLAT WASHER 5MM

035 PLW01M LOCK WASHER 5MM

036 PS05M PHLP HD SCR M5-.8 x 8

037 PS07M PHLP HD SCR M4-.7 X 8

038 PN06M HEX NUT M5-0.8

039 P9717039 PHLP HD SCR M5-.8 X 45

040 PS09M PHLP HD SCR M5-.8 X 10

041 P9717041 PHLP HD SCR M5-.8 X 13

042 PB06M HEX BOLT M8-1.25 X 12

043 PW01M FLAT WASHER 8MM

044 PLW04M LOCK WASHER 8MM

044 PB18M HEX BOLT M6-1 X 15

045 PW03M FLAT WASHER 6MM

Page 14

G9717 6" Grinder

-13-

Page 15

G9717 6" Grinder

-14-

Grizzly Industrial, Inc. warrants every product it sells for a period of

11 yyeeaarr

to the original purchaser from

the date of purchase. This warranty does not apply to defects due directly or indirectly to misuse, abuse,

negligence, accidents, repairs or alterations or lack of maintenance. This is Grizzly’s sole written warranty

and any and all warranties that may be implied by law, including any merchantability or fitness, for any particular purpose, are hereby limited to the duration of this written warranty. We do not warrant or represent

that the merchandise complies with the provisions of any law or acts unless the manufacturer so warrants.

In no event shall Grizzly’s liability under this warranty exceed the purchase price paid for the product and

any legal actions brought against Grizzly shall be tried in the State of Washington, County of Whatcom.

We shall in no event be liable for death, injuries to persons or property or for incidental, contingent, special, or consequential damages arising from the use of our products.

To take advantage of this warranty, contact us by mail or phone and give us all the details. We will then

issue you a “Return Number’’, which must be clearly posted on the outside as well as the inside of the carton. We will not accept any item back without this number. Proof of purchase must accompany the merchandise.

The manufacturers reserve the right to change specifications at any time because they constantly strive to

achieve better quality equipment. We make every effort to ensure that our products meet high quality and

durability standards and we hope you never need to use this warranty.

Please feel free to write or call us if you have any questions about the machine or the manual.

Thank you again for your business and continued support. We hope to serve you again soon.

WWAARRRRAANNTTYY AANNDD RREETTUURRNNSS

Page 16

G9717 6" Grinder

-15-

WWAARRRRAANNTTYY CCAARRDD

NAME_______________________________________________ PHONE NUMBER___________________

STREET________________________________________________________________________________

CITY_______________________________STATE_________ZIP ___________________________________

MODEL# _________________ INVOICE#_________________

The following information is given on a voluntary basis. This information will be used for marketing purposes to help

Grizzly develop better products. Your name will be included in our mailing

lliisstt

only. It will not be sold to other com-

panies. of course, all information is strictly confidential.

11..

How did you find out about us?

__Advertisement __Friend __Website

__Catalog __Card deck __Other____________________

22..

Do you think your machine represents good value? __YES __NO

33..

Would you allow us to use your name as a reference for Grizzly customers in your area? __YES __NO

((NNoottee::

Your

nnaammee

will be used a maximum of three

ttiimmeess..))

44..

To which of the following publications do you subscribe? Check all that apply.

__Home Shop Machinist __Rifle Magazine Other ________________

__Projects in Metal __Hand Loader Magazine

__Modeltec __Precision Shooter

__Live Steam __RC Modeler

__Shotgun News __Model Airplane News

55..

What is your annual household income?

__$20,000-$30,000 __$50,001-$60,000 __$80,000-$90,000

__$30,001-$40,000 __$60,001-$70,000 __+$90,000

__$40,001-$50,000 __$70,001-$80,000

66..

To which age group do you belong?

__20-30 __41-50 __61-70

__31-40 __51-60 __+70

77..

Which of the following machines or accessories do you own? Check all that apply.

__Engine Lathe __Abrasive Cutoff __Sheet Metal Machine

__Band Saw (Metal) __Arc Welder __Other _____________________________

__Band Saw (Wood) __Oxy/Ac. Outfit

__Milling Machine __Air Compressor

__Bench Grinder __Drill Press

88..

How many of the machines you checked in Question 7 are Grizzly machines? ______________________

99..

Which of the following tooling and accessories do you own? Check all that apply.

__Milling Vises __Collet Closer __Digital Readout

__Indexing Head __Taper Attachment __Tool Post Grinder

__Rotary Table __Boring Head __Other _________________________________________

1100..

In the space below, list three tools you would like Grizzly to carry.

1111..

Of all the mail order metalworking company’s you have purchased from, how do you rate Grizzly in terms of overall customer satisfaction?

__The best __Above average __Average

__Below average __The worst

1122..

Comments_______________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

________________________________________________________________________________________________

CUT ALONG DOTTED LINE

Page 17

FOLD ALONG DOTTED LINE

FOLD ALONG DOTTED LINE

GGRRIIZZZZLLYY IINNDDUUSSTTRRIIAALL,, IINNCC..

PP..OO.. BBOOXX 22006699

BBEELLLLIINNGGHHAAMM,, WWAA 9988222277--22006699

Place

Stamp

Here

TAPE ALONG EDGES--PLEASE DO NOT STAPLE

Name_______________________________

Street_______________________________

City______________State______Zip______

Send a Grizzly Catalog to a friend:

Loading...

Loading...