Page 1

WWW.GRIZZLY.COM

CONTRACTOR GRADE AIR COMPRESSORS

MODEL G8297/G8298/G8299

INSTRUCTION MANUAL

COPYRIGHT © 1999 BY GRIZZLY INDUSTRIAL, INC.

1821 VALENCIA ST., BELLINGHAM, WA 98227

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

Page 2

Page 3

G8297/G8298/G8299 Air Compressors

-1-

Table Of Contents

PAGE

1. SAFETY

SAFETY RULES FOR POWER TOOLS ..........................................................2-3

ADDITIONAL SAFETY INSTRUCTIONS FOR AIR COMPRESSORS................4

2. CIRCUIT REQUIREMENTS

110V OPERATION ..............................................................................................5

GROUNDING ......................................................................................................5

EXTENSION CORDS ..........................................................................................5

3. INTRODUCTION

COMMENTARY....................................................................................................6

UNPACKING ........................................................................................................7

SITE CONSIDERATIONS ....................................................................................7

PREPARING FOR USE ......................................................................................8

4. OPERATIONS

GENERAL ............................................................................................................9

STARTING ........................................................................................................10

PRESSURE REGULATOR ................................................................................10

CONNECTING TOOLS ......................................................................................11

5. MAINTENANCE

EACH USE ........................................................................................................12

AFTER FIRST 50 HOURS ................................................................................13

WEEKLY ............................................................................................................13

EVERY 300 HOURS ..........................................................................................13

PRESSURE LIMIT ADJUSTMENT ....................................................................14

6. CLOSURE................................................................................................................15

PARTS BREAKDOWN AND PARTS LISTS ................................................................16-20

TROUBLESHOOTING ......................................................................................................21

WARRANTY AND RETURNS ..........................................................................................22

Page 4

-2-

G8297/G8298/G8299 Air Compressors

Safety Instructions For Power Tools

SECTION 1: SAFETY

5. KEEP CHILDREN AND VISITORS

AWAY. All children and visitors should be

kept a safe distance from work area.

6. MAKE WORK SHOP CHILD PROOF with

padlocks, master switches, or by removing

starter keys.

7. DON’T FORCE TOOL. It will do the job

better and safer at the rate for which it was

designed.

8. USE RIGHT TOOL. Don’t force tool or

attachment to do a job for which it was not

designed.

1. KEEP GUARDS IN PLACE and in working

order.

2. REMOVE ADJUSTING KEYS AND

WRENCHES. Form habit of checking to

see that keys and adjusting wrenches are

removed from tool before turning on.

3. KEEP WORK AREA CLEAN. Cluttered

areas and benches invite accidents.

4. DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power tools in damp or

wet locations, or where any flammable or

noxious fumes may exist. Keep work area

well lighted.

For Your Own Safety Read Instruction

Manual Before Operating This Equipment

Indicates an imminently hazardous situation which, if not

avoided, WILL result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, COULD

result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, MAY

result in minor or moderate injury. It may also

be used to alert against unsafe practices.

This symbol is used to alert the user to useful information

about proper operation of the equipment.

The purpose of safety symbols is to attract your attention to possible hazardous conditions.

This manual uses a series of symbols and signal words which are intended to convey the level

of importance of the safety messages. The progression of symbols is described below.

Remember that safety messages by themselves do not eliminate danger and are not a substitute for proper accident prevention measures.

NOTICE

Page 5

G8297/G8298/G8299 Air Compressors

-3-

9. USE PROPER EXTENSION CORD. Make

sure your extension cord is in good condition. Conductor size should be in accordance with the chart below. The amperage

rating should be listed on the motor or tool

nameplate. An undersized cord will cause a

drop in line voltage resulting in loss of

power and overheating. Your extension

cord must also contain a ground wire and

plug pin. Always repair or replace extension cords if they become damaged.

Minimum Gauge for Extension Cords

10. WEAR PROPER APPAREL. Do not wear

loose clothing, gloves, neckties, rings,

bracelets, or other jewelry which may get

caught in moving parts. Non-slip footwear

is recommended. Wear protective hair covering to contain long hair.

11. ALWAYS USE SAFETY GLASSES. Also

use face or dust mask if cutting operation is

dusty. Everyday eyeglasses only have

impact resistant lenses, they are NOT safety glasses.

12. SECURE WORK. Use clamps or a vise to

hold work when practical. It’s safer than

using your hand and frees both hands to

operate tool.

LENGTH

AMP RATING 25ft 50ft 100ft

0-6 18 16 16

7-10 18 16 14

11-12 16 14 12

13-16 14 12 12

17-20 12 12 8

21-30 10 10 No

Safety Instructions For Power Tools

13. DON’T OVERREACH. Keep proper foot-

ing and balance at all times.

14. MAINTAIN TOOLS WITH CARE. Keep

tools sharp and clean for best and safest

performance. Follow instructions for lubricating and changing accessories.

15. DISCONNECT TOOLS before servicing

and changing accessories, such as blades,

bits, cutters, and the like.

16. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch is in off

position before plugging in.

17. USE RECOMMENDED ACCESSORIES.

Consult the owner’s manual for recommended accessories. The use of improper

accessories may cause risk of injury.

18. CHECK DAMAGED PARTS. Before fur-

ther use of the tool, a guard or other part

that is damaged should be carefully

checked to determine that it will operate

properly and perform its intended function.

Check for alignment of moving parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that

may affect its operation. A guard or other

part that is damaged should be properly

repaired or replaced.

19. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don’t

leave tool until it comes to a complete stop.

Page 6

-4-

Additional Safety Instructions For Air

Compressors

1. Operate the compressor in a well-ventilated

area free of acids, vapor, explosive gases

and flammable or unstable materials.

2. Use compressor only with air, never use

with any other type of gas.

3. Never aim the air nozzle directly at yourself

or others. The air stream can be quite forceful and can damage skin.

4. Do not pull on rubber hoses to move the

compressor.

5. Do not use compressed air for filling breath-

ing or diving apparatus. Compressed air

from this compressor cannot be used for

pharmaceutical, food or health requirements without further treatment.

6. Never transport the compressor under pres-

sure. Always make sure the pressure in the

storage tanks has been released before

loading or moving the air compressor.

7. Never attempt to adjust the pressure safety

valve on the air tanks. This is preset to 150

PSI.

Operating this equipment has the potential

to propel debris into the air which can

cause eye injury. Always wear safety glasses or goggles when operating equipment.

Everyday glasses or reading glasses only

have impact resistant lenses, they are not

safety glasses. Be certain the safety glasses you wear meet the appropriate standards of the American National Standards

Institute (ANSI).

Like all power tools, there is danger associated with the operation of air compressors. Accidents are frequently caused by

lack of familiarity or failure to pay attention.

Use this equipment with respect and caution to lessen the possibility of operator

injury. If normal safety precautions are

overlooked or ignored, serious personal

injury may occur.

No list of safety guidelines can be complete. Every shop environment is different.

Always consider safety first, as it applies to

your individual working conditions. Use

this and other machinery with caution and

respect. Failure to do so could result in

serious personal injury, damage to equip-

Page 7

G8297/G8298/G8299 Air Compressors

-5-

110V Operation

SECTION 2: CIRCUIT REQUIREMENTS

If you find it necessary to use an extension cord

with your compressor, make sure the cord is

rated Hard Service (grade S) or better. Refer to

the chart in the standard safety instructions to

determine the minimum gauge for the extension

cord. The extension cord must also contain a

ground wire and plug pin. Always repair or

replace extension cords when they become worn

or damaged.

Extension Cords

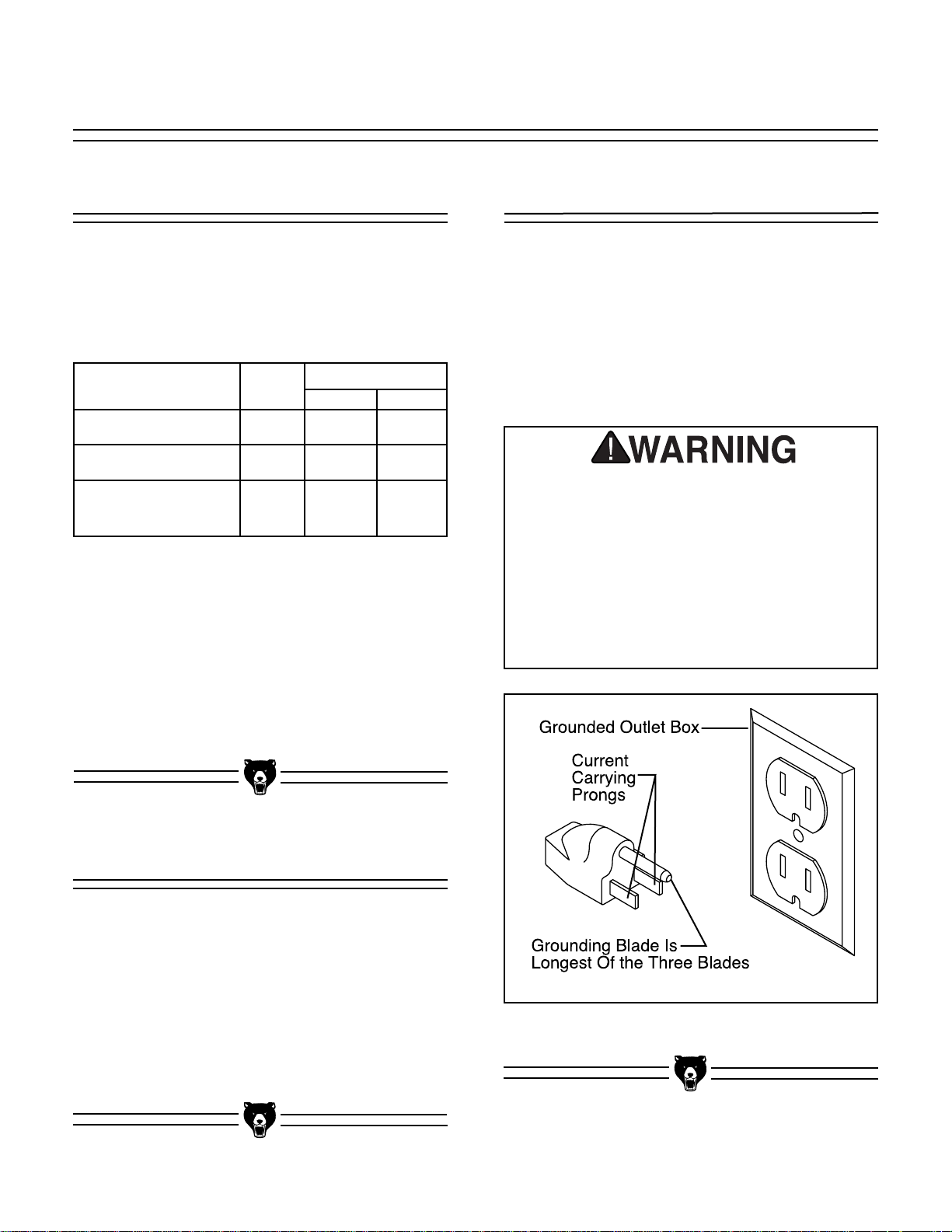

Grounding

This equipment must be grounded. Verify

that any existing electrical outlet and circuit

you intend to plug into is actually grounded. If it is not, it will be necessary to run a

separate 12 A.W.G. copper grounding wire

from the outlet to a known ground. Under

no circumstances should the grounding pin

from any three-pronged plug be removed.

Serious injury may occur.

In the event of an electrical short, grounding

reduces the risk of electric shock by providing a

path of least resistance to disperse electric current. These machines are equipped with power

cords having an equipment-grounding conductor.

See Figure 1. The outlet must be properly

installed and grounded in accordance with all

local codes and ordinances.

This family of air compressors is wired for

110/120V, single phase operation only. The chart

below shows the maximum amperage draw and

recommended fusing level for each of the

machines.

Figure 1. Grounded plug configuration.

G8297

G8298

G8299 (2 Motors)

2.0

2.5

2.5

2.0

11

17

17

11

15

20

20

15

Model

Amperage

HP

Max

Fuse

It is generally best to operate a compressor on a

dedicated circuit, i.e. a circuit where there are no

other electrical appliances plugged in. The dual

motors on the G8299 should be plugged into separate circuits. The fuse requirements above

assume the use of a circuit breaker or a slowblow fuse. If an unusual load does not exist and

the compressor still breaks the circuit, contact a

qualified electrician or our service department.

Page 8

-6-

G8297/G8298/G8299 Air Compressors

SECTION 3: INTRODUCTION

We are proud to offer the Grizzly Models

G8297/8298/8299 Contractor Grade Air

Compressors. These compressors are part of the

growing Grizzly family of heavy-duty machinery

for the contractor and professional user. When

used according to the guidelines set forth in this

manual, you can expect years of trouble-free,

enjoyable operation and proof of Grizzly’s commitment to customer satisfaction.

These compressors are designed to suit the

needs of the professional contractor who requires

a reliable air source on the job site. The G8297 is

a 2.0 HP unit with a 4.25 gallon tank capacity and

delivers 4.2 CFM@90 PSI. The G8298 is similar

to the G8297 with the 2.5 HP motor which provides 5.8 CFM. The dual motor 4.5 HP G8299

delivers 10 CFM with a 9.0 gallon tank capacity.

The G8299 is conveniently portable with a wheel

built into the tank system.

We are also pleased to provide this manual with

your new air compressor. It was written to guide

you through assembly, review safety considerations, and cover general operating procedures. It

represents our effort to produce the best documentation possible. If you have any comments

regarding this manual, please write to us at the

address below:

Grizzly Industrial, Inc.

C

/

O Technical Documentation

P.O. Box 2069

Bellingham, WA 98227-2069

Most importantly, we stand behind our machines.

If you have any service questions or parts

requests, please call or write us at the location

listed below.

Grizzly Industrial, Inc.

1203 Lycoming Mall Circle

Muncy, PA 17756

Phone: (570) 546-9663

Fax: (800) 438-5901

E-Mail: techsupport@grizzly.com

Web Site: http://www.grizzly.com

The specifications, drawings, and photographs

illustrated in this manual represent the Models

G8297/8298/8299 as supplied when the manual

was prepared. However, owing to Grizzly’s policy

of continuous improvement, changes may be

made at any time with no obligation on the part of

Grizzly. Whenever possible, though, we send

manual updates to all owners of a particular tool

or machine. Should you receive one, we urge you

to insert the new information with the old and

keep it for reference.

To operate this, or any power tool, safely

and efficiently, it is essential to become as

familiar with its characteristics as possible.

The time you invest before you begin to use

your air compressor will be time well spent.

DO NOT operate this machine until you are

completely familiar with the contents of this

manual. Make sure you read and understand all of the safety procedures. If you do

not understand something, DO NOT operate

the machine.

Commentary

Page 9

-7-

Unpacking

This air compressor is shipped from the manufacturer in a carefully packed carton. If you discover the machine is damaged after you’ve

signed for delivery, and the truck and driver are

gone, you will need to file a freight claim with the

carrier. Save the containers and all packing materials for possible inspection by the carrier or its

agent. Without the packing materials, filing a

freight claim can be difficult. If you need assis-

tance determining whether you need to file a

freight claim, or with the procedure to file one,

please contact our Customer Service.

When taking the air compressor to a job site, the

most important consideration is access to an

adequate and properly fused power supply. Refer

to Section 2: Circuit Requirements for the needs

for your particular compressor.

Also make sure the compressor is not operating

in an environment where there are any explosive,

flammable or caustic fumes or gases. A clear and

well-ventilated area is best for its safe operation.

Place the compressor on a solid and level surface. Make sure that the hoses you attach to supply your pneumatic device will be unrestricted in

movement and not subject to being run over by

vehicles or punctured by any other sharp objects

in the area.

And since air compressors are often used for a

sustained period of time, sometimes in restricted

areas, it is also best to wear ear protection to

avoid the long-term exposure to the sound of the

electric motor and piston.

NOTICE

The machine should always be run in the

positions shown on the cover of this manual. Never run the G8299 when it is standing

upright on its wheel and support frame.

Also never continue to operate the machine

if it has fallen over on its side. The motor

will not receive adequate oil flow in these

positions, and continued operation can

Page 10

-8-

Before using your Grizzly Air Compressor, follow

these steps before the first use:

1. Remove all packing materials and the pro-

tective plastic plugs from the cylinder head

and oil plug. Do not remove the yellow cap

underneath the black plastic cover of the

pressure switch housing.

2. Screw the air filter(s) into the cylinder

head(s).

3. Place the oil dipstick into the opening of the

casing and check the oil level in the motor

crankcase. See Figure 2. Each motor

requires approximately 100 cc or 3.5 fluid

ounces of compressor oil (ISO 100 or SAE

30W viscosity, non-detergent). Make certain the oil is at the full indicator level on the

dipstick.

Operating this equipment has the potential

to propel debris into the air which can

cause eye injury. Always wear safety glasses or goggles when operating equipment.

Everyday glasses or reading glasses only

have impact resistant lenses, they are not

safety glasses. Be certain the safety glasses you wear meet the appropriate standards of the American National Standards

Institute (ANSI).

Operating this equipment has the potential

for hearing damage to occur, especially if

operated for a long period of time. Use

ANSI (American National Standards

Institute) approved ear muff or ear plugs

when using this equipment. Always wear

proper hearing protection, cotton balls or

tissue paper in the ear canal do not provide

adequate noise reduction.

Fig 2. Oil sump and dipstick.

4. Make sure drain valve(s) on the air tanks is

closed.

5. Make sure the power switch is in the OFF

position, fully pushed in. Connect the power

cord(s) to a properly protected power

source.

NOTICE

The machine should never be run without a

full oil reservoir. The oil provides lubrication to the cylinder rings which deliver the

compressed air. Severe damage to the

internal parts can occur if there is not adequate oil flow. Check the oil level frequently, and change the oil on a regular sched-

Page 11

G8297/G8298/G8299 Air Compressors

-9-

SECTION 4: OPERATIONS

The pump produces compressed air which goes

into the air tanks through the delivery pipe and

the check valve. When the air pressure arrives at

the factory pre-set level of 135 PSI, the pressure

switch shuts off the electrical current to the axial

electric pump. At the time it shuts off, it discharges the air held in the pump cylinder to the

delivery pipe. This allows the pump to be depressurized so it can easily restart. When the pressure in the air tanks falls below the minimum factory set pressure of 105 PSI, the pump cycles

again to build the pressure back up. The pressure

switch is supplied with a discharge valve with

delayed closing, which reduces the strain on the

pump and the motor during startup.

The compressor is operating correctly when there

is a bleed of air every time the motor is switched

off. You will notice an audible air discharge each

time the pump motor stops. On these compressors, the pump will cycle first to minimize the

amperage draw and will bleed off air through the

cold-start valve. The valve will stay open until

approximately 20 PSI is reached in the air tanks

at which time it closes to allow full pressurization

of the tanks.

For the G8299 with the dual motors, both motors

can be started simultaneously for rapid pressurization. As with the G8298, the 2.5 HP pump is fitted with a cold-start valve which will stay open

until approximately 20 PSI is reached in the

tanks. This will allow the compressor to lubricate

properly without straining the motor and pump.

Depending on the volume of the air usage, it is

often adequate to recharge the system during

operation using only the 2 HP pump taking

advantage of its lower RPM and quieter operation.

General

Fig 3. Pressure safety relief valve.

All of the compressors are equipped with a 150

PSI safety relief valve which will discharge air

from the tanks if for any reason they should

become over-pressured. See Figure 3. These

are preset valves and are not adjustable.

Relief Valve

Fig 4. Thermal protection typical placement.

Thermal

Overload

Switch

These compressors are also equipped with thermal overload breakers which will trip if there is

excessive load on the motors which causes a

heat buildup. In the event the breaker shuts the

compressor down, wait a few minutes for the unit

to cool down, then press the reset button shown

in Figure 4.

Page 12

-10-

G8297/G8298/G8299 Air Compressors

After the compressor has fully pressurized the

tanks, turn the red knob on the pressure regula-

tor (See Figure 6) to set the pressure needed for

the air tool you will be using. Consult the manual

which accompanied your air tool to determine

what pressure setting is required for optimal operation. The gauge on the regulator will indicate the

pressure which will be delivered through the air

line.

Pressure Regulator

Make sure the compressor switch is in the OFF

position (the red button on top of the control box

should be in the fully depressed position, see

Figure 5) before connecting to the power supply.

Close the drain cock on the tanks. Pull the switch

to the ON position.

Starting

Fig 5. G8299 starting switches and gauge.

Check the tank pressure gauge to see that the

tank pressure gets up to approximately 120-130

PSI.

Tank

Gauge

On/Off

Switches

Fig 6. Pressure regulator and gauge.

Always wear safety glasses and use

extreme caution when working around

compressed air. The force of the air stream

can cause small bits of debris to become

airborne and cause potential injury to the

eyes or other parts of the body. Never let

the full force of the air stream come in

direct contact with the skin as it can cause

abrasions or bruising.

Page 13

G8297/G8298/G8299 Air Compressors

-11-

Make sure the compressor model you use has

sufficient cubic feet per minute (CFM) output for

the air tool you plan to connect. Most air tools will

have an air requirement stated in terms of a specific CFM at a specific pressure (PSI). Most common is a rating at 90 PSI. Consult the chart below

to determine the output of your compressor

model.

Connecting Tools

Notes

G8297

G8298

G8299

2.0

2.5

4.5

4.2

5.8

10

4.25 gal

4.25 gal

9.0 gal

Model

HP

CFM

@ 90 PSI

Tank

Cap.

The compressor should put out a higher CFM

than the tool requires. If connecting multiple tools

which will be used simultaneously, then the CFM

for each tool should be added together and compared to the compressor output value.

Consideration should also be given to the type of

usage. A nailer or staple gun uses air in short

bursts and it is easier for the compressor to maintain pressure. A paint sprayer or grinder tends to

use a more continuous stream of air as these

tools are run for longer time periods. It is always

better to oversize a compressor to allow for variation in the type of usage and the number of tools

to be powered. Air tools being operated with

insufficient air volume will not perform their function satisfactorily.

Connect the tool using a good quality air line with

an adequate length to reach from the compressor

to the point of use. Quick-connect couplers are a

good option for fast and sure connection of tools

and air hoses. Make certain the air hose will not

be placed in a position where it can become constricted or cut by a sharp object. Having a hose

run over by heavy vehicles may not cause an

immediate leak, but it will shorten the life of the

hose.

Page 14

G8297/G8298/G8299 Air Compressors

SECTION 5: MAINTENANCE

Regular periodic maintenance on your Air

Compressor will ensure its optimum performance. Make a habit of inspecting your compressor each time you use it. Check the following

items:

1. Check oil level. See Figure 7.

Each Use

Fig 7. Checking oil level with dipstick.

-12-

Fig 8. Typical location of drain cocks.

2. Drain tanks of any condensation by open-

ing the drain cocks on the bottom of both

tanks. See Figure 8. Depending upon the

amount of use and the weather conditions,

a certain amount of condensed water may

be released. For longevity of the compressor seals and the air tools you connect, it is

best to keep the tanks free of water. The

tanks are best drained if the drain cocks are

opened when the system is pressurized.

Once water has stopped coming out, you

can close the drain cocks.

3. Clean off cylinder head cooling fins of any

dirt which might hamper air flow.

4. Check for worn or damaged cords and

plugs.

5. Check for any other condition that could

hamper the safe operation of this machine.

Always wear safety glasses and use

extreme caution when working around

compressed air. The force of the air stream

can cause small bits of debris to become

airborne and cause potential injury to the

eyes or other parts of the body. Never let

the full force of the air stream come in

direct contact with the skin as it can cause

abrasions or bruising.

Page 15

G8297/G8298/G8299 Air Compressors

-13-

Weekly

Every 300 Hours

If the compressor is used on a regular daily basis,

perform the following checks each week:

1. Rinse the air filter foam element in water.

2. Check for loose bolts or fittings.

After every 300 hours or 3 months of regular

operation, perform the following maintenance

items:

1. Change compressor motor oil.

2. Rinse the air filter foam element in water.

3. Check for air leaks and correct as needed.

4. Clean cylinder head fins for proper cooling.

5. Check for loose bolts or fittings.

After First 50 Hours

After the first 50 working hours, or 30 days,

whichever comes first, replace the oil in the

motor with compressor oil (use ISO 100 or SAE

30W viscosity, non-detergent type).

Also after this initial operation period, check to

make sure that all the fittings are tight. Remove

the air filter foam element (See Figure 9) and

rinse it out in water. Allow it to dry and reinstall.

Blow out any accumulated dirt between the cylinder cooling fins.

Fig 9. Air filter cover and foam element.

Page 16

Do not remove the pressure switch cover

with the machine plugged in to power.

When the cover is off, the electrical connections are uncovered and can be a

source of electrical shock. Make the adjustments progressively until the desired level

is reached, and disconnect from power

each time you turn the adjusting nut.

Serious personal injury can occur.

-14-

G8297/G8298/G8299 Air Compressors

Pressure Limit

Adjustment

The compressor is delivered with pressure switch

settings which turn the compressor pump off

when it reaches a tank pressure of 135 PSI, and

turn it back on when it reaches 105 PSI. Normally

these settings should not require any adjustment.

In the event it becomes necessary to change, first

make certain the compressor is disconnected

from the power source. Then remove the black

plastic cover below the On/Off switch. This is

done by removing the rubber plug on top of the

housing and inserting a Phillips

®

screwdriver. See

Figure 10.

Fig 10. Removing pressure switch cover.

The hex nut on the top of the exposed switch is

used to adjust the pressure limits. See Figure 11.

Turn it clockwise to increase the pressure and

counterclockwise to reduce. This will move both

the maximum pressure shutoff point and the minimum pressure turn-on point simultaneously.

These limits are not separately adjustable. Do not

exceed a maximum cutoff pressure of 145 PSI.

After adjusting, replace the cover and reconnect

to the power source.

Fig 11. Adjusting nut on pressure switch.

Adjusting Nut

For the G8299, it is possible to control which

motor comes on first by adjusting these pressure

limits. The machine is set from the factory so the

2 HP pump comes on first to minimize amperage

draw. If this is not acceptable, adjust the limits on

the 2 HP higher, and set the limits on the 2.5 HP

lower so they will operate in reverse of the factory setting.

Page 17

G8297/G8298/G8299 Air Compressors

-15-

The following pages contain general machine

data, parts diagrams/lists, troubleshooting guide

and Warranty/Return information for your Model

G8297/8298/8299 Air Compressor.

If you need parts or help in assembling your

machine, or if you need operational information,

we encourage you to call our Service

Department. Our trained service technicians will

be glad to help you.

If you have comments dealing specifically with

this manual, please write to our Bellingham,

Washington location using the address in Section

3 Introduction. The specifications, drawings, and

photographs illustrated in this manual represent

the Model G8297/8298/8299 Air Compressor as

supplied when the manual was prepared.

However, due to Grizzly’s policy of continuous

improvement, changes may be made at any time

with no obligation on the part of Grizzly.

Whenever possible, though, we send manual

updates to all owners of a particular tool or

machine. Should you receive one, add the new

information to this manual and keep it for reference.

We have included some important safety measures that are essential to this machine’s operation. While most safety measures are generally

universal, Grizzly reminds you that each workshop is different and safety rules should be considered as they apply to your specific situation.

We recommend you keep a copy of our current

catalog for complete information regarding

Grizzly's warranty and return policy. If you need

additional technical information relating to this

machine, or if you need general assistance or

replacement parts, please contact the Service

Department listed in Section 3: or Introduction.

Additional information sources are necessary to

realize the full potential of this machine. Trade

journals, woodworking magazines, and your local

library are good places to start.

SECTION 6: CLOSURE

The Model G8297/8298/8299 Air Compressors

are specifically designed for air tool operation.

DO NOT MODIFY AND/OR USE THIS

MACHINE FOR ANY OTHER PURPOSE.

Modifications or improper use of this tool

will void the warranty. If you are confused

about any aspect of this machine, DO NOT use

it until you have answered all your questions.

Serious personal injury may occur.

Like all power tools, there is danger associated with operating this equipment.

Accidents are frequently caused by lack of

familiarity or failure to pay attention. Use

this tool with respect and caution to lessen

the possibility of operator injury. If normal

safety precautions are overlooked or

ignored, serious personal injury may

occur.

Operating this equipment has the potential

for flying debris to cause eye injury.

Always wear safety glasses or goggles

when operating equipment. Everyday

glasses or reading glasses only have

impact resistant lenses, they are not safety

glasses. Be certain the safety glasses you

wear meet the appropriate standards of the

American National Standards Institute

(ANSI).

Page 18

-16-

G8297/G8298/G8299 Air Compressors

001 P8297001 Guard

002 P8297002 Screw M4.2 x 13

003 P8297003 Motor Flange

004 P8297004 Fan 155mm Dia.

005 P8297005 Screw M6 x 135

006 P8297006 Bearing 17 x 40 x 12

007 P8297007 Rotor

008 P8297008 Bearing 25 x 52 x 15

009 P8297009 Stator

010 P8297010 Compressor Casing

011 P8297011 Screw M8 x 35

012 P8297012 Screw M8 x 25

013 P8297013 Eccentric

014 P8297014 Connecting Rod

015 P8297015 Snap Ring 15mm

016 P8297016 Gasket

017 P8297017 Screw M4.2 x 13mm

018 P8297018 Casing Cover

019 P8297019 Oil Dipstick

020 P8297020 Piston 50mm Dia

021 P8297021 Snap Ring 12mm

022 P8297022 Piston Pin

023 P8297023 50mm Ring Set

023A P8297023A 50mm Ring Set

023B P8297024B 50mm Ring Set

024 P8297024

3

⁄8'' Elbow

025 P8297025 Cylinder Head

026 P8297026 Valve Plate

027 P8297027 Valve

028 P8297028 Nut M8

029 P8297029 Cylinder Gasket

030 P8297030 Screw M4.2 x 6.5

031 P8297031 Condensator

032 P8297032 M8 Hex Nut

033 P8297033 Valve Gasket

034 P8297034 Valve Plate

035 P8297035 Valve Gasket

036 P8297036 Valve Gasket

037 P8297037 Micro Switch

038 P8297038 Air Filter

039 P8297039 Screw M6 x 45

040 P8297040 Cylinder 50mm Dia

041 P8297041 Connector

042 P8297042 Air Pressure

043 P8297043 Pressure Gauge

044 P8297044 Connector

045 P8297045 Pressure Gauge

046 P8297046 Cable

047 P8297047 Pressure Reducer

048 P8297048 Non-Return Valve

049 P8297049 Hose, Rilsan

050 P8297050 Connecting Pipe

051 P8297051 Tank 16 liter

053 P8297053 Sticker

054 P8297054 Screw

055 P8297055 Support

056 P8297056 Washer 6mm

057 P8297057 Drain Cock

1

⁄4''

058 P8297058 Knob

Ref. # Part # Description Ref. # Part # Description

PARTS LIST G8297 AIR COMPRESSOR

Page 19

G8297/G8298/G8299 Air Compressors

-17-

Page 20

-18-

G8297/G8298/G8299 Air Compressors

001 P8298001 Guard

002 P8298002 Screw M4.2 x 13

003 P8298003 Motor Flange

004 P8298004 Fan 155mm Dia.

005 P8298005 Screw M6 x 135

006 P8298006 Bearing 17 x 40 x 12

007 P8298007 Rotor

008 P8298008 Bearing 25 x 52 x 15

009 P8298009 Stator

010 P8298010 Compressor Casing

011 P8298011 Screw M8 x 35

012 P8298012 Screw M8 x 25

013 P8298013 Eccentric

014 P8298014 Connecting Rod

015 P8298015 Snap Ring 15mm

016 P8298016 Gasket

017 P8298017 Screw M4.2 x 13mm

018 P8298018 Casing Cover

019 P8298019 Oil Dipstick

020 P8298020 Piston

021 P8298021 Snap Ring 12mm

022 P8298022 Piston Pin

023 P8298023 Ring Set

023A P8298023A Ring Set

023B P8298024B Ring Set

024 P8298024

3

⁄

8'' Elbow

025 P8298025 Cylinder Head

026 P8298026 Valve Plate

027 P8298027 Valve

028 P8298028 Nut M8

029 P8298029 Cylinder Gasket

030 P8298030 Screw M4.2 x 6.5

031 P8298031 Condensator

032 P8298032 M8 Hex Nut

033 P8298033 Valve Gasket

034 P8298034 Valve Plate

035 P8298035 Valve Gasket

036 P8298036 Valve Gasket

037 P8298037 Micro Switch

038 P8298038 Air Filter

039 P8298039 Screw M6 x 45

040 P8298040 Cylinder

041 P8298041 Drain Cock

1

⁄

4''

042 P8298042 Tank

043 P8298043 Knob

044 P8298044 Connector

045 P8298045 Valve

1

⁄4''

046 P8298046 Non-Return Valve

047 P8298047 Connecting Pipe

049 P8298049 Screw

050 P8298050 Hex Nut M6

051 P8298051 Washer 6mm

052 P8298052 Support

053 P8298053 Screw M6 x 30

054 P8298054 Cable

055 P8298055 Pressure Gauge

056 P8298056 Pressure Reducer

057 P8298057 Hose, Rilsan

058 P8298058 Connector

059 P8297059 Air Pressure

060 P8297060 Pressure Gauge

061 P8297060 Connector

Ref. # Part # Description Ref. # Part # Description

PARTS LIST G8298 AIR COMPRESSOR

Page 21

G8297/G8298/G8299 Air Compressors

-19-

Page 22

-20-

G8297/G8298/G8299 Air Compressors

041 P8299041 Air Pressure

042 P8299042 Connecting Pipe

043 P8299043 Non-return valve

044 P8299044 Knob 22mm

046 P8299046 Tank Assembly

047 P8299047 Washer 8mm

048 P8299048 Support

049 P8299049 Hex Nut M8

050 P8299050 Wheel

051 P8299051 Pipe

052 P8299052 Hex Nut M6

053 P8299053 Screw

054 P8299054 Pressure Reducer

055 P8299055 Pressure Gauge

056 P8299056 Nipple

1

⁄4''

057 P8299057 Air Pressure

058 P8299058 Cable

059 P8299059 Valve

060 P8299060 Drain Cock

1

⁄4''

Ref. # Part # Description

PARTS LIST G8299 AIR COMPRESSOR

The G8299 utilizes the 2 HP motor from the G8297 and the 2.5 HP motor from the G8298. The part

numbers are as referenced for those components on the previous pages.

Page 23

G8297/G8298/G8299 Air Compressors

-21-

SYMPTOM

Pump Motor Will Not

Start

Pump Motor Starts; But

Fuses Blow or Circuit

Breakers Trip

Low Pressure At The

Tool

Low Pressure At The

Tanks

Compressor Knocking

Air Leaks From Pressure

Switch

Air Is Dirty Or Has

Excessive Moisture

Motor Runs Hot

Pressure Relief Valve

Stays Open And Motor

Won’t Stop Running

POSSIBLE CAUSE

1. Low voltage.

2. Open circuit in motor, switch or

cord.

3. Tank already pressurized.

4. Thermal overload switch.

1. Short circuit in line cord or plug.

2. Short circuit in motor or loose

connections.

3. Incorrect fuses or circuit breakers in power line.

1. Air leaks in flexible hoses.

2. Pressure gauge bad

3. Pressure regulator bad.

1. Air leaks in tanks or delivery

pipes.

2. Drain cock open

3. Safety valve releasing below

150 PSI.

4. Air filter clogged.

5. Gaskets leaking

6. Worn rings.

1. Improper oil level.

2. Air filter clogged.

3. Piston assembly loose.

1. Faulty check valve.

2. Faulty pressure switch.

1. Tanks not drained.

2. Delivery pipes are dirty.

1. Cooling Fins Dirty.

2. Air filter clogged.

1. Faulty pressure switch, unit is

trying to overpressure the tank

2. Faulty pressure relief valve.

CORRECTIVE ACTION

1. Check power line for proper voltage.

2. Inspect all lead connections on motor, switch and

cord for loose or open connections.

3. Motor will not start if tank pressure is too high.

4. Thermal overload switch has tripped, wait for motor

to cool, then reset switch by pressing red button.

1. Inspect cord or plug for damaged insulation and

shorted wires.

2. Inspect all connections on motor for loose or shorted

terminals or worn insulation.

3. Install correct fuses or circuit breakers.

1. Check air hoses and all connections for leaks.

2. Check pressure in line with known good gauge.

3. Adjust pressure regulator, if no improvement inspect

regulator for leaks or replacement.

1. Check air tanks, pipes and all connections for leaks.

2. Close drain cock.

3. Replace safety valve.

4. Inspect and clean air filter.

5. Check gaskets on cylinder head assembly, repair or

replace as needed.

6. Inspect and replace pump piston rings.

1. Check oil level and add oil.

2. Inspect and clean air filter.

3. Inspect and repair piston and connecting rod.

1. Clean dirt or debris from rubber membrane of check

valve after removing top nut.

2 Repair or replace pressure switch.

1. Open drain cocks on both tanks and make certain all

condensation water is drained out.

2. Remove delivery pipes, clean out and replace.

1. Clean cylinder head fins and also remove any accumulated dirt or grease from motor area.

2. Inspect and clean air filter.

1. Turn compressor off, unplug from power supply,

drain tank. DO NOT USE until switch is repaired or

replaced.

2. Relief valve is relieving pressure too early, test pressure relief and repair or replace,

TROUBLESHOOTING

Page 24

-22-

G8297/G8298/G8299 Air Compressors

Grizzly Industrial, Inc. warrants every product it sells for a period of 1 year to the original purchaser from

the date of purchase. This warranty does not apply to defects due directly or indirectly to misuse, abuse,

negligence, accidents, repairs or alterations or lack of maintenance. This is Grizzly’s sole written warranty

and any and all warranties that may be implied by law, including any merchantability or fitness, for any particular purpose, are hereby limited to the duration of this written warranty. We do not warrant or represent

that the merchandise complies with the provisions of any law or acts unless the manufacturer so warrants.

In no event shall Grizzly’s liability under this warranty exceed the purchase price paid for the product and

any legal actions brought against Grizzly shall be tried in the State of Washington, County of Whatcom.

We shall in no event be liable for death, injuries to persons or property or for incidental, contingent, special, or consequential damages arising from the use of our products.

To take advantage of this warranty, contact us by mail or phone and give us all the details. We will then

issue you a “Return Number’’, which must be clearly posted on the outside as well as the inside of the carton. We will not accept any item back without this number. Proof of purchase must accompany the merchandise.

The manufacturers reserve the right to change specifications at any time because they constantly strive to

achieve better quality equipment. We make every effort to ensure that our products meet high quality and

durability standards and we hope you never need to use this warranty.

Please feel free to write or call us if you have any questions about the machine or the manual.

Thank you again for your business and continued support. We hope to serve you again soon.

WARRANTY AND RETURNS

Page 25

10. Which benchtop tools do you own? Check all that apply.

___1" x 42" Belt Sander ___6" - 8" Grinder

___5" - 8" Drill Press ___Mini Lathe

___8" Table Saw ___10" - 12" Thickness Planer

___8" - 10" Bandsaw ___Scroll Saw

___Disc/Belt Sander ___Spindle/Belt Sander

___Mini Jointer

___Other__________________________________________________

11. How many of the machines checked above are Grizzly? ____________

12. Which portable/hand held power tools do you own? Check all that apply.

___Belt Sander ___Orbital Sander

___Biscuit Joiner ___Palm Sander

___Circular Saw ___Portable Planer

___Detail Sander ___Saber Saw

___Drill/Driver ___Reciprocating Saw

___Miter Saw ___Router

___Other__________________________________________________

13. What machines/supplies would you like Grizzly Industrial to carry?

___12" Table Saw ___Radial Arm Saw

___12" Jointer ___Panel Saw

___Combination Planer/Jointer ___Brass Hardware

___Paint & Finishing Supplies ___Lumber

___Contractor’s Supplies

___Other__________________________________________________

14. What new accessories would you like Grizzly Industrial to carry?

___Builders Hardware ___Hand Tools

___Fasteners ___Wood Components

___Other__________________________________________________

15. What other companies do you purchase your tools and supplies from?

__________________________________________________________

__________________________________________________________

16. Do you think your purchase represents good value?

___Yes ___No

17. Would you recommend Grizzly Imports to a friend?

___Yes ___No

18. Would you allow us to use your name as a reference for Grizzly customers

in your area? Note: We never use names more than three times.

___Yes ___No

19. Comments:_________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

1. How did you learn about us?

___Advertisement ___Friend

___Catalog ___Card Deck

___World Wide Web

___Other__________________________________________________

2. Which of the following magazines do you subscribe to.

___American Woodworker ___Practical Homeowner

___Cabinetmaker ___Shop Notes

___Family Handyman ___Today’s Homeowner

___Fine Homebuilding ___WOOD

___Fine Woodworking ___Wooden Boat

___Home Handyman ___Woodshop News

___Journal of Light Construction ___Woodsmith

___Old House Journal ___Woodwork

___Popular Mechanics ___Woodworker

___Popular Science ___Woodworker’s Journal

___Popular Woodworking ___Workbench

___Other__________________________________________________

3. Which of the following woodworking/remodeling shows do you watch?

___Backyard America ___The New Yankee Workshop

___Home Time ___This Old House

___The American Woodworker ___Woodwright’s Shop

___Other__________________________________________________

4. What is your annual household income?

___$20,000-$29,999 ___$60,000-$69,999

___$30,000-$39,999 ___$70,000-$79,999

___$40,000-$49,999 ___$80,000-$89,999

___$50,000-$59,999 ___$90,000 +

5. What is your age group?

___20-29 ___50-59

___30-39 ___60-69

___40-49 ___70 +

6. How long have you been a woodworker?

___0 - 2 Years ___8 - 20 Years

___2 - 8 Years ___20+ Years

7. How would you rank your woodworking skills?

___Simple ___Advanced

___Intermediate ___Master Craftsman

8. What stationary woodworking tools do you own? Check all that apply.

___Air Compressor ___Panel Saw

___Band Saw ___Planer

___Drill Press ___Power Feeder

___Drum Sander ___Radial Arm Saw

___Dust Collector ___Shaper

___Horizontal Boring Machine ___Spindle Sander

___Jointer ___Table Saw

___Lathe ___Vacuum Veneer Press

___Mortiser ___Wide Belt Sander

___Other__________________________________________________

9. How many of your woodworking machines are Grizzly? _____________

Name ____________________________________________________________________________________

Street ____________________________________________________________________________________

City ______________________________________________________________State________Zip_________

Phone Number_______________________E-Mail_______________________FAX________________________

MODEL # ______________________________Order #______________________________________________

The following information is given on a voluntary basis. It will be used for marketing purposes to help us develop better products and services. Of

course, all information is strictly confidential.

WARRANTY CARD

Page 26

FOLD ALONG DOTTED LINE

FOLD ALONG DOTTED LINE

GRIZZLY INDUSTRIAL, INC.

P.O. BOX 2069

BELLINGHAM, WA 98227-2069

TAPE ALONG EDGES--PLEASE DO NOT STAPLE

Name_______________________________

Street_______________________________

City______________State______Zip______

Send a Grizzly Catalog to a friend:

Loading...

Loading...