Page 1

MODEL G0876

8" X 27" ENCLOSED CNC MILL

w/AUTO TOOL CHANGER

OWNER'S MANUAL

(For models manufactured since 12/22)

***Keep for Future Reference***

V2.02.23

Page 2

This manual provides critical safety instructions on the proper setup,

operation, maintenance, and service of this machine/tool. Save this

document, refer to it often, and use it to instruct other operators.

Failure to read, understand and follow the instructions in this manual

may result in fire or serious personal injury—including amputation,

electrocution, or death.

The owner of this machine/tool is solely responsible for its safe use.

This responsibility includes but is not limited to proper installation in

a safe environment, personnel training and usage authorization,

proper inspection and maintenance, manual availability and comprehension, application of safety devices, cutting/sanding/grinding tool

integrity, and the usage of personal protective equipment.

The manufacturer will not be held liable for injury or property damage

from negligence, improper training, machine modifications or misuse.

Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State

of California to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

Work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

Page 3

Table of Contents

11

10

0.1 Machine data sheet ........................................ 3

1 Safety

1.1 Safety instructions for machinery ................... 6

1.2 Additional safety for CNC mills/lathes ............ 8

1.3 Safety instructions (warning notes) ................. 9

1.4 Intended use ............

1.5 Reasonably foreseeable misuse

1.6 Possible dangers w/CNC machines ............... 12

1.7 Qualification of personnel ............................... 12

1.8 User positions ................................................ 14

1.9 Safety devices ............................................... 14

1.10 Safety check .................................................. 17

1.11 Personal protective equipment

1.12

Safety during operation

1.13

Safety during maintenance

1.14

Disconnecting/securing CNC machine

1.15 Unattended operation ...................................... 20

1.16 Accident report ............................................... 20

1.17 Electrical system ............................................. 20

1.18 Inspection deadlines .............................. 21

1.19 Clamping devices ................................. 21

1.20

Tools and tool holding fixtures .................. 21

....................................... 10

..................... 11

..................... 18

................................... 18

............................ 19

.......... 19

2 Power supply

2.1 Availability ...................................................... 22

2.2 Full-load current rating ................................... 22

2.3 Circuit information .......................................... 22

2.4 Circuit requirements for 220V ........................ 22

2.5 Connection type ............................................. 22

2.6 Grounding instructions ................................... 23

2.7 Extension cords .............................................. 23

3 Assembly and commissioning

3.1 Scope of delivery ............................................ 24

3.2 Transport ........................................................ 24

3.3 Installation and assembly ............................... 25

3.4 First commissioning ....................................... 31

3.5 Refill central lubrication system ...................... 33

3.6 Functional test and controls ............................ 35

4 General information about CNC

4.1 Compensation of geometry

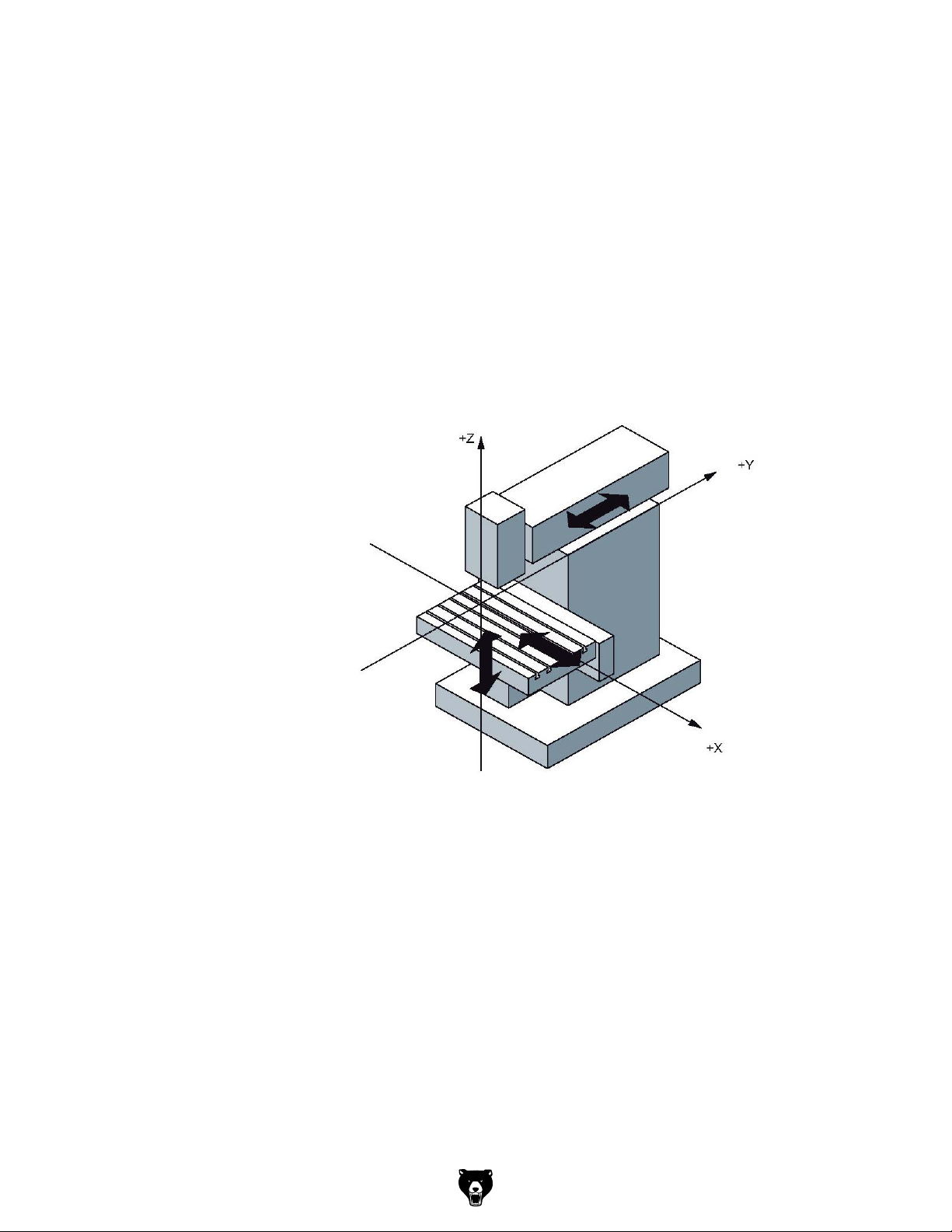

4.2 Coordinate systems on CNC machines .......... 36

4.3 NC mathmatics .............................................. 38

Trigonometric functions ................................. 39

4.4

............................. 36

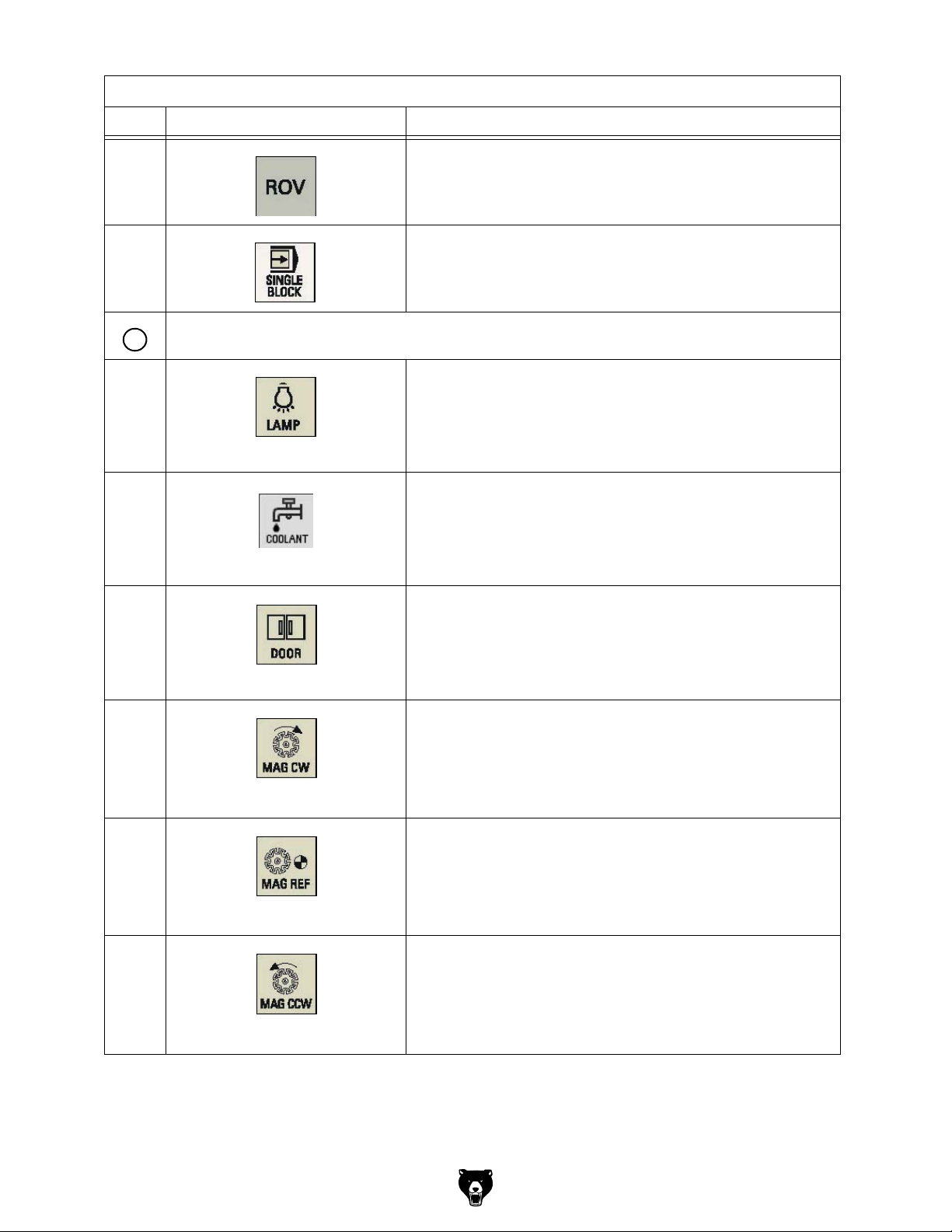

User interface, machine control panel

5

5.1

Screen arrangement ................................... 40

5.2

Elements on the front panel

5.3

Controls on the control panel ...................... 46

5.4

Protection levels .......................................... 51

6

Operation

6.1 Safety .......................................................... 53

6.2

Control and indicating elements

6.3

Operational modes

6.4 Programming ............

6.5 Operation of the machine

6.6

Operational modes

6.7

Programming

6.8

Starting the program

6.9

Central lubrication system

6.10

Data interfaces and current collection

6.11

Selecting the speed .................................. 62

7

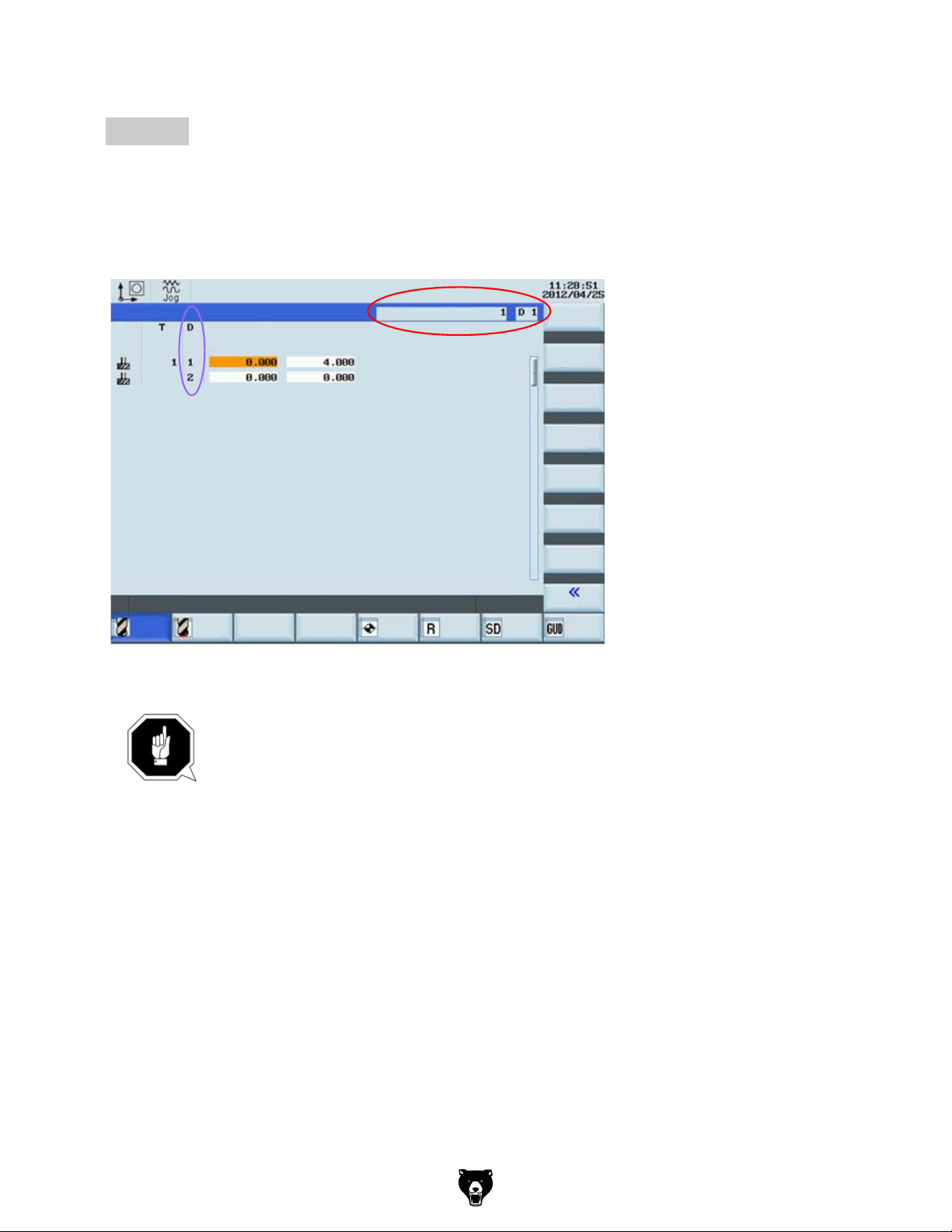

Brief instruction for 808D milling

7.1

Preparation

7.2

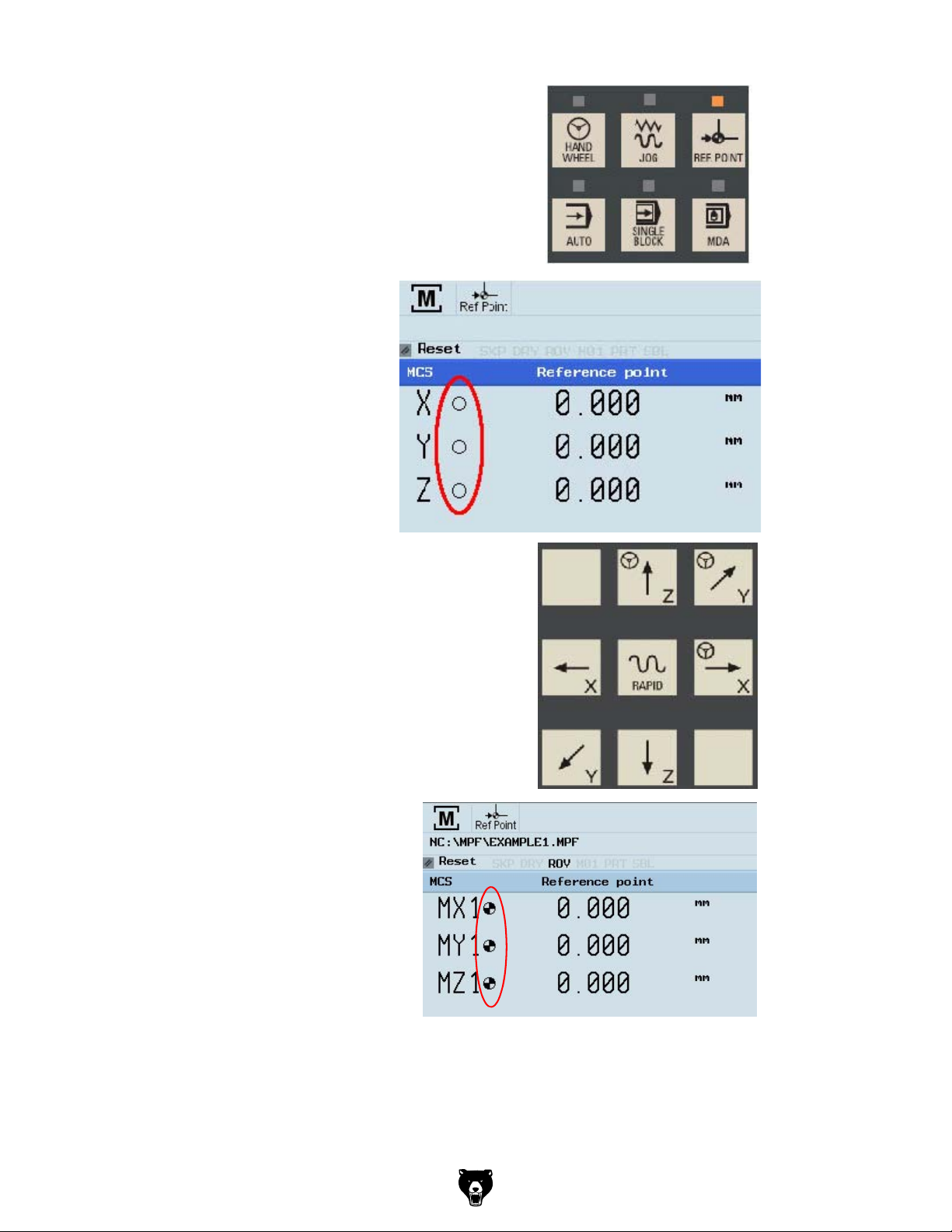

Switch on and referencing

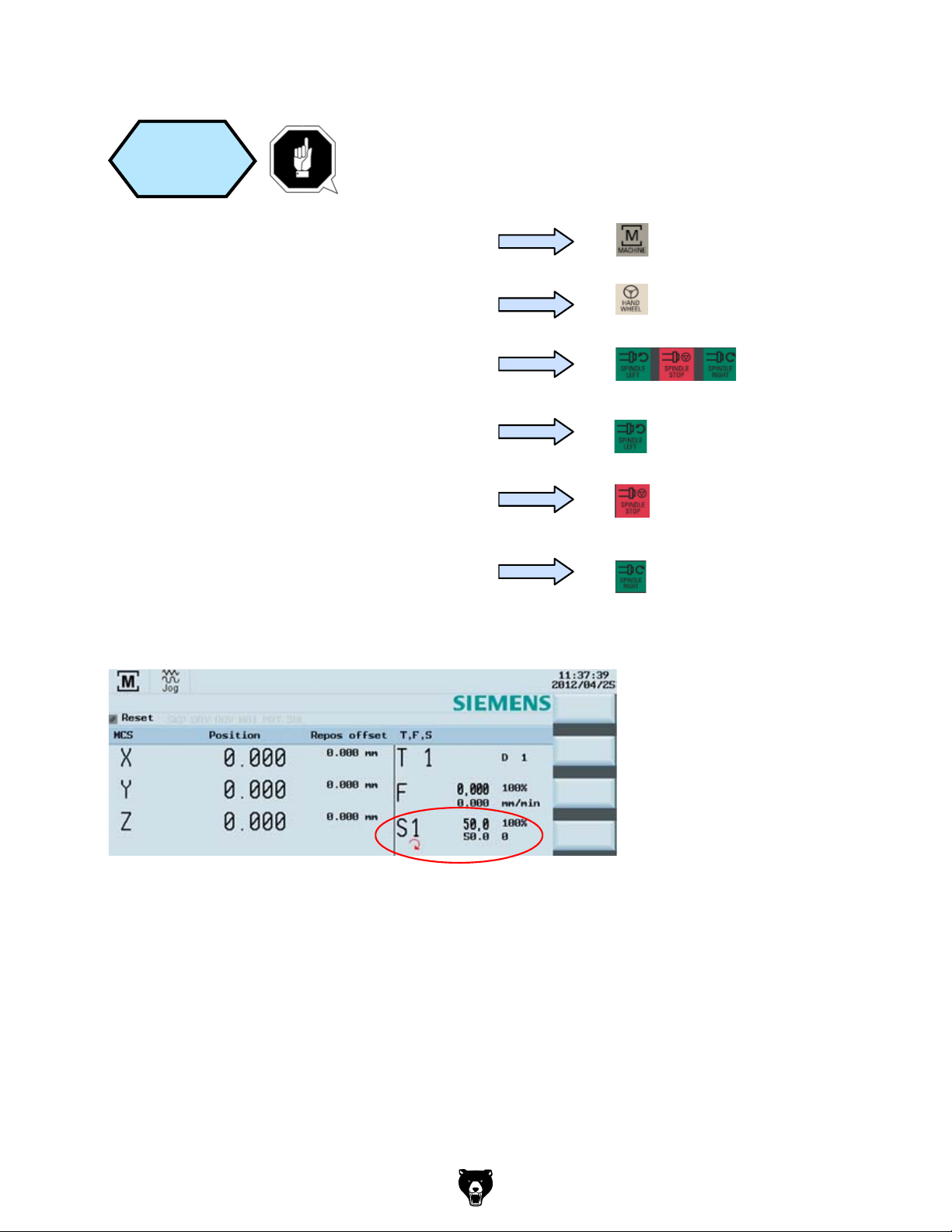

Tool Setup

7.3

Workpiece setup

7.4

7.5

Create part program: part 1

7.6

Create part program: part 2

Simulate program

7.7

Test program

7.8

7.9

Machine pieces

7.10

Program restart

Additional information: part 1

7.11

Additional information: part 2

7.12

7.13

Sample program

7.14

ISO mode

7.15

Appendix

8

M - code list, M functions

8.1

M-function for milling machines

8.2

G functions to PAL

9

Notes, messages, and errors

Sinumerik 808D

.................................................. 75

.................................................... 212

.................................................... 230

.................................................... 242

...................................... 54

..................................... 61

.............................................. 61

.................................... 61

................................................. 65

......................................... 91

....................................... 142

.............................................. 146

.......................................... 150

........................................... 156

......................................... 198

...................................... 238

......................... 41

................. 53

.................................... 54

............................ 55

.......................... 62

.......................... 71

........................ 100

........................ 116

..................... 160

...................... 180

.................. 236

........................... 239

Maintenance

11.1

Operating material

11.2

Safety

.......................................................... 244

Inspection and maintenance

11.3

Sliding door interlock switch

11.4

Cooling lubricants and tanks

11.5

...................................... 243

....................... 246

........................ 249

....................... 251

........ 62

Page 4

12

Wiring Diagrams

Wiring safety instructions

12.1

System wiring diagrams (1-2)

12.2

12.3

System wiring diagrams (3-4)

12.4

System wiring diagrams (5-6)

Handwheel wiring diagram

12.4

X/Y/Z motors wiring diagram

12.5

13

Parts

13.1

Housing

13.2

Base

Milling head

13.3

Milling table

13.4

13.5

X-Axis

13.6

Y-Axis

Z-Axis

13.7

Column

13.8

Auto tool changer

13.9

Electrical cabinet

13.10

Pneumatic system

13.11

Labels & cosmetics

13.12

14

Warranty & returns

Table of Contents (Cont.)

............................ 253

..................... 254

..................... 255

..................... 256

......................... 252

...................... 252

....................................................... 258

........................................................... 260

................................................ 261

................................................. 262

.......................................................... 263

........................................................ 264

........................................................ 265

........................................................ 266

......................................... 268

......................................... 269

....................................... 270

..................................... 271

.............................................. 272

Page 5

Customer Service #: (570) 546-9663 · To Order Call: (800) 523-4777 · Fax #: (800) 438-5901

MODEL G0876 8" X 27" ATC ENCLOSED CNC MILL

Product Dimensions:

Weight ......................................................................................................................................................................... 3080 lbs.

Width (side-to-side) x Depth (front-to-back) x Height .......................................................................................71 x 65 x 79 in.

Footprint (Length/Width) ..........................................................................................................................................110 x 86 in.

Shipping Dimensions:

Type ........................................................................................................................................................................ Wood Crate

Content .......................................................................................................................................................................... Machine

Weight .......................................................................................................................................................................... 3350 lbs.

Length x Width x Height ...............................................................................................................................80 x 72-1/2 x 85 in.

Must Ship Upright .................................................................................................................................................................Yes

Electrical:

Power Requirement ................................................................................................................................ 220V, 3-Phase, 60 Hz

Full-Load Current Rating ................................................................................................................................................... 14.1A

Minimum Circuit Size ........................................................................................................................................................... 20A

Connection Type ..................................................................................................................................................... Cord & Plug

Power Cord Length ........................................................................................................................................................ 6-1/2 ft.

Power Cord Gauge .......................................................................................................................................................12 AWG

Recommended Plug Type .................................................................................................................................................15-20

Motors:

Spindle

Horsepower ...............................................................................................................................................................3 HP

Phase .................................................................................................................................................................. 3-Phase

Amps ......................................................................................................................................................................... 6.4A

Speed ............................................................................................................................................................10,000 RPM

Type ......................................................................................................................................................................... Servo

Power Transfer .................................................................................................................................................. Belt Drive

Bearings ...................................................................................................................Shielded & Permanently Lubricated

X-Axis

Horsepower ...............................................................................................................................................................1 HP

Phase .................................................................................................................................................................. 3-Phase

Amps ......................................................................................................................................................................... 2.1A

Speed ..............................................................................................................................................................4,000 RPM

Type ......................................................................................................................................................................... Servo

Power Transfer ............................................................................................................................................... Direct Drive

Bearings ......................................................................................................................Sealed & Permanently Lubricated

Y-Axis

Horsepower ...............................................................................................................................................................1 HP

Phase .................................................................................................................................................................. 3-Phase

Amps ......................................................................................................................................................................... 2.1A

Speed ..............................................................................................................................................................4,000 RPM

Type ......................................................................................................................................................................... Servo

Power Transfer ............................................................................................................................................... Direct Drive

Bearings ......................................................................................................................Sealed & Permanently Lubricated

Model G0876 (Mfd. Since 12/22)

-3-

Page 6

Z-Axis

± 0.0008 in. (0.020 mm)

± 0.0005 in. (0.013 mm)

Horsepower ............................................................................................................................................................1.3 HP

Phase .................................................................................................................................................................. 3-Phase

Amps ............................................................................................................................................................................ 3A

Speed ..............................................................................................................................................................3,000 RPM

Type ......................................................................................................................................................................... Servo

Power Transfer ............................................................................................................................................... Direct Drive

Bearings ......................................................................................................................Sealed & Permanently Lubricated

Tool Changer

Horsepower ........................................................................................................................................................ 60 Watts

Phase .................................................................................................................................................................. 3-Phase

Amps ....................................................................................................................................................................... 0.24A

Speed ...............................................................................................................................................................1360 RPM

Type ......................................................................................................................................................................... Servo

Power Transfer .................................................................................................................................................... Gearbox

Bearings ......................................................................................................................Sealed & Permanently Lubricated

Coolant Pump

Horsepower ........................................................................................................................................................ 97 Watts

Phase .................................................................................................................................................................. 3-Phase

Amps ......................................................................................................................................................................... 0.5A

Speed ...............................................................................................................................................................2800 RPM

Type .................................................................................................................................................................... Induction

Power Transfer ............................................................................................................................................... Direct Drive

Bearings ...................................................................................................................Shielded & Permanently Lubricated

Main Specifications:

Operation Information

Max Distance Spindle to Column ............................................................................................................................. 11 in.

Max Distance Spindle to Table ..........................................................................................................................16-1/2 in.

Longitudinal Table Travel (X-Axis) ...................................................................................................................12-3/16 in.

Cross Table Travel (Y-Axis) .................................................................................................................................7-3/4 in.

Vertical Head Travel (Z-Axis) .............................................................................................................................11-3/4 in.

Position Resolution .....................................................................................................................

Repeat Position Resolution ........................................................................................................

Tool Changer Info

Type .......................................................................................................................................................... Turntable Style

Capacity .................................................................................................................................................................8 Tools

Maximum Tool Weight ............................................................................................................................................. 13 lbs

Maximum Tool Diameter with Adjacent Tool .......................................................................................................2-3/4 in.

Tool Change Average Time .............................................................................................................................6 Seconds

Table Info

Table Length ............................................................................................................................................................27 in.

Table Width ..........................................................................................................................................................8-1/4 in.

Table Thickness ...................................................................................................................................................2-3/8 in.

Table Height (from Floor/Base) ................................................................................................................................45 in.

Table Weight Capacity .........................................................................................................................................220 lbs.

Number of T-Slots ...........................................................................................................................................................3

T-Slot Size ............................................................................................................................................................... 5/8 in.

T-Slots Centers ....................................................................................................................................................2-1/2 in.

X-Axis Rapid Feed Rate ...................................................................................................................................... 400 IPM

Y-Axis Rapid Feed Rate ...................................................................................................................................... 400 IPM

Z-Axis Rapid Feed Rate ...................................................................................................................................... 400 IPM

-4-

Model G0876 (Mfd. Since 12/22)

Page 7

Spindle Info

BT30 x 45°

50 - 10,000 RPM

13 Gallons

Spindle Taper ........................................................................................................................................................... BT30

Pull Stud ..........................................................................................................................................................

Spindle Speed Range ...........................................................................................................................

Spindle Bearings (Size & Type) ...............................................................................................Angular Contact Bearings

Fluid Capacities

Coolant Capacity .............................................................................................................................................

Construction

Spindle Housing/Quill ................................................................................................................................................Steel

Table ................................................................................................................................................................... Cast Iron

Head ................................................................................................................................................................... Cast Iron

Column/Base ...................................................................................................................................................... Cast Iron

Stand ..................................................................................................................................................................Cast Iron

Paint Type/Finish ...................................................................................................................................................Enamel

Other Specifications:

Country of Origin ............................................................................................................................................................... China

Warranty ........................................................................................................................................................................... 1 Year

Approximate Assembly & Setup Time .....................................................................................................................1-1/2 Hours

Serial Number Location ..................................................................................................................................Machine ID Label

ISO 9001 Factory ..................................................................................................................................................................Yes

Features:

Siemens Sinumerk® CNC Controller

Servo Motors with Ball Screws on All Axes

Built-In Pendant/Hand Controller

Powerful 3 HP Spindle Motor

50–10,000 RPM Spindle Speeds

Easy Access to Table from 3 Sides

Hands-Free Tool Changes with 8-Position Automatic Tool Changer (ATC)

Rapid Table Speeds of Up to 400 in./min.

Heavy-Duty BT30 Spindle

Model G0876 (Mfd. Since 12/22)

-5-

Page 8

SAFETY

For Your Own Safety, Read Instruction

Manual Before Operating This Machine

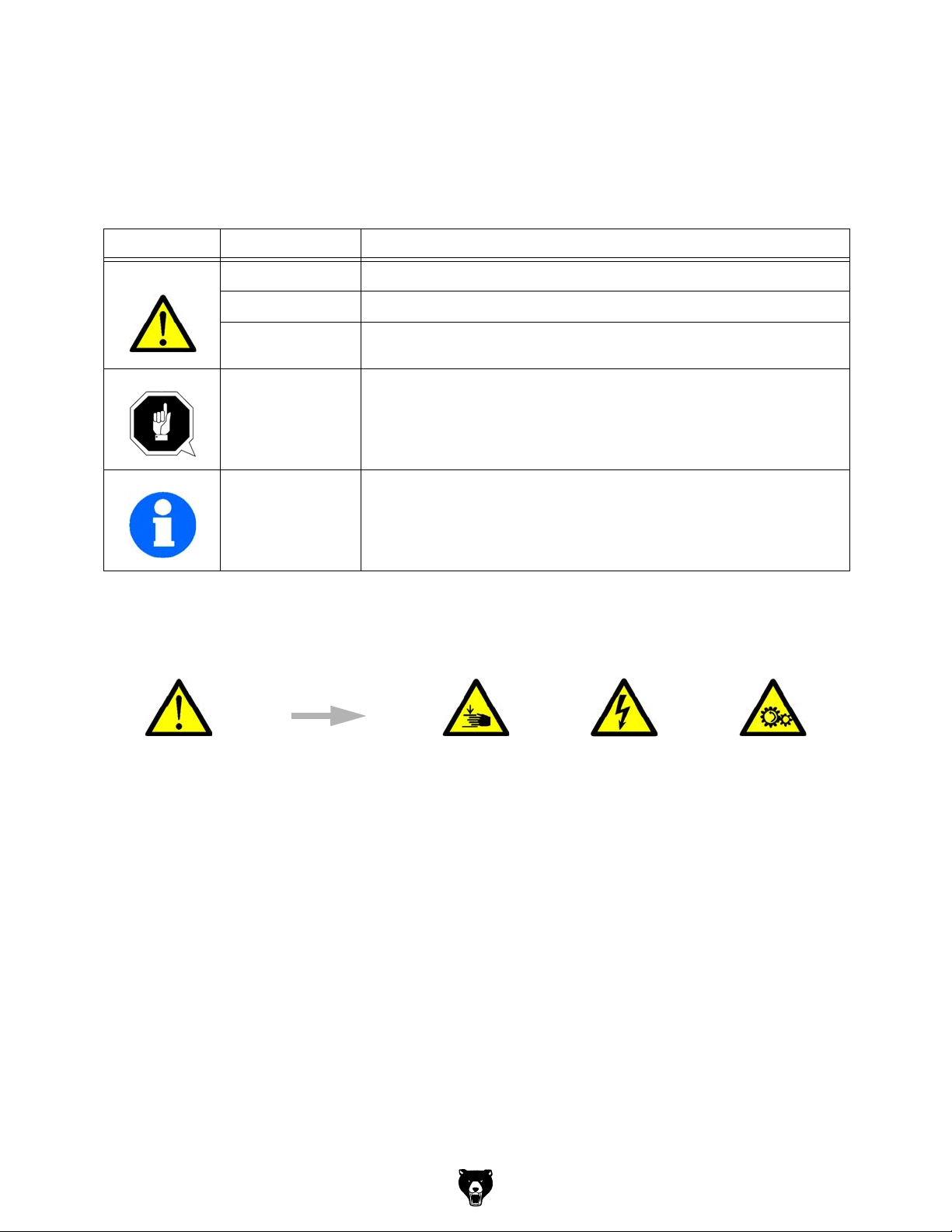

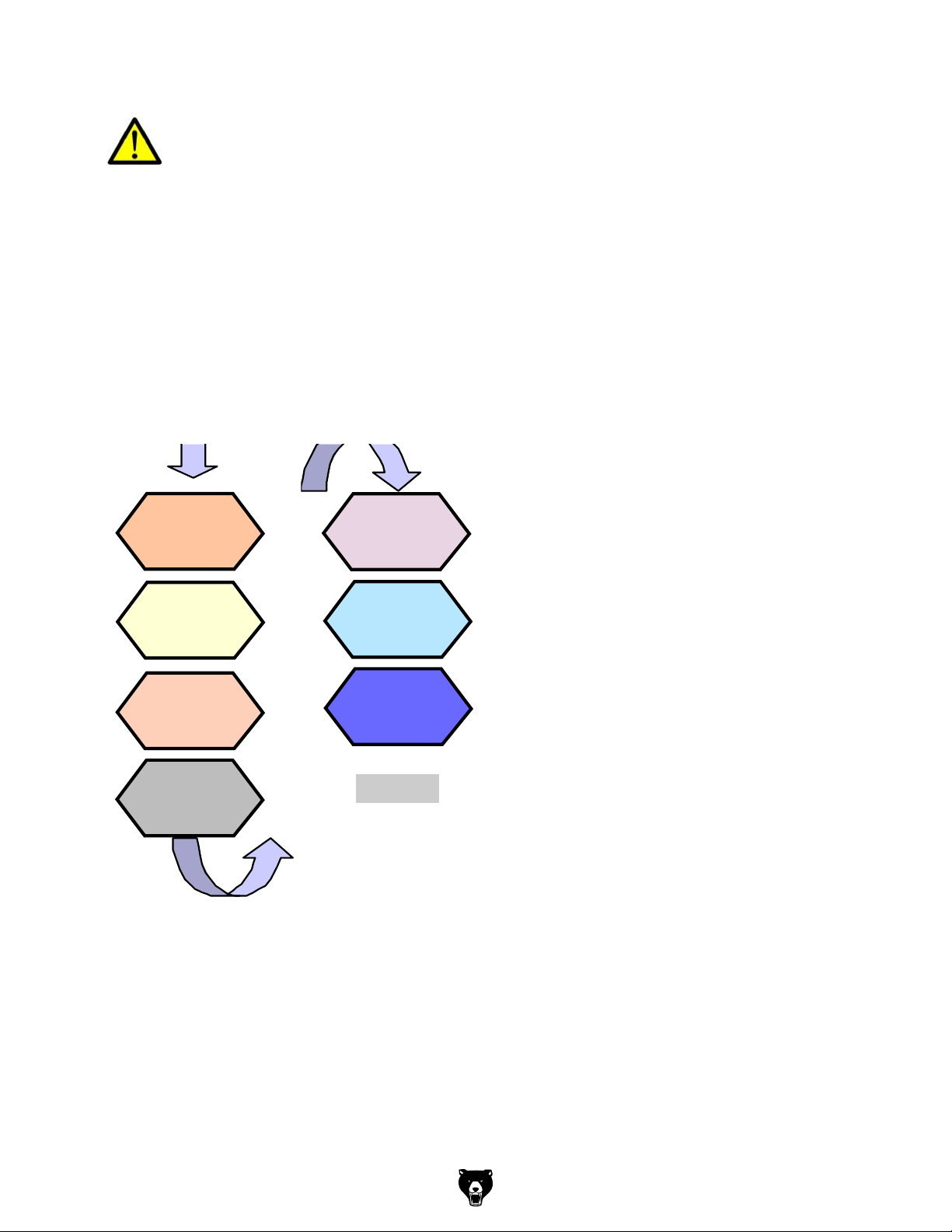

The purpose of safety symbols is to attract your attention to possible hazardous conditions.

This manual uses a series of symbols and signal words intended to convey the level of importance of the safety messages. The progression of symbols is described below. Remember that

safety messages by themselves do not eliminate danger and are not a substitute for proper

accident prevention measures. Always use common sense and good judgment.

Indicates an imminently hazardous situation which, if not avoided,

WILL result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

COULD result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

MAY result in minor or moderate injury. It may also be used to alert

against unsafe practices.

Alerts the user to useful information about proper operation of the

NOTICE

machine to avoid machine damage.

Safety Instructions for Machinery

OWNER’S MANUAL. Read and understand this

owner’s manual BEFORE using machine.

TRAINED OPERATORS ONLY. Untrained operators have a higher risk of being hurt or killed.

Only allow trained/supervised people to use this

machine. When machine is not being used, disconnect power, remove switch keys, or lock-out

machine to prevent unauthorized use—especially

around children. Make your workshop kid proof!

DANGEROUS ENVIRONMENTS. Do not use

machinery in areas that are wet, cluttered, or have

poor lighting. Operating machinery in these areas

greatly increases the risk of accidents and injury.

MENTAL ALERTNESS REQUIRED. Full mental

alertness is required for safe operation of machinery. Never operate under the influence of drugs or

alcohol, when tired, or when distracted.

ELECTRICAL EQUIPMENT INJURY RISKS.

You can be shocked, burned, or killed by touching

live electrical components or improperly grounded

machinery. To reduce this risk, only allow qualified

service personnel to do electrical installation or

repair work, and always disconnect power before

accessing or exposing electrical equipment.

DISCONNECT POWER FIRST.

nect machine from power supply BEFORE making adjustments, changing tooling, or servicing

machine. This prevents an injury risk from unintended startup or contact with live electrical components.

EYE PROTECTION. Always wear ANSI-approved

safety glasses or a face shield when operating or

observing machinery to reduce the risk of eye

injury or blindness from flying particles. Everyday

eyeglasses are NOT approved safety glasses.

Always discon-

-6-

Model G0876 (Mfd. Since 12/22)

Page 9

WEARING PROPER APPAREL. Do not wear

clothing, apparel or jewelry that can become

entangled in moving parts. Always tie back or

cover long hair. Wear non-slip footwear to reduce

risk of slipping and losing control or accidentally

contacting cutting tool or moving parts.

HAZARDOUS DUST. Dust created by machinery

operations may cause cancer, birth defects, or

long-term respiratory damage. Be aware of dust

hazards associated with each workpiece material. Always wear a NIOSH-approved respirator to

reduce your risk.

HEARING PROTECTION. Always wear hearing protection when operating or observing loud

machinery. Extended exposure to this noise

without hearing protection can cause permanent

hearing loss.

REMOVE ADJUSTING TOOLS. Tools left on

machinery can become dangerous projectiles

upon startup. Never leave chuck keys, wrenches,

or any other tools on machine. Always verify

removal before starting!

USE CORRECT TOOL FOR THE JOB. Only use

this tool for its intended purpose—do not force

it or an attachment to do a job for which it was

not designed. Never make unapproved modifications—modifying tool or using it differently than

intended may result in malfunction or mechanical

failure that can lead to personal injury or death!

AWKWARD POSITIONS. Keep proper footing

and balance at all times when operating machine.

Do not overreach! Avoid awkward hand positions

that make workpiece control difficult or increase

the risk of accidental injury.

CHILDREN & BYSTANDERS. Keep children and

bystanders at a safe distance from the work area.

Stop using machine if they become a distraction.

GUARDS & COVERS. Guards and covers reduce

accidental contact with moving parts or flying

debris. Make sure they are properly installed,

undamaged, and working correctly BEFORE

operating machine.

FORCING MACHINERY. Do not force machine.

It will do the job safer and better at the rate for

which it was designed.

NEVER STAND ON MACHINE. Serious injury

may occur if machine is tipped or if the cutting

tool is unintentionally contacted.

STABLE MACHINE. Unexpected movement during operation greatly increases risk of injury or

loss of control. Before starting, verify machine is

stable and mobile base (if used) is locked.

USE RECOMMENDED ACCESSORIES. Consult

this owner’s manual or the manufacturer for recommended accessories. Using improper accessories will increase the risk of serious injury.

UNATTENDED OPERATION. To reduce the

risk of accidental injury, turn machine OFF and

ensure all moving parts completely stop before

walking away. Never leave machine running

while unattended.

MAINTAIN WITH CARE. Follow all maintenance

instructions and lubrication schedules to keep

machine in good working condition. A machine

that is improperly maintained could malfunction,

leading to serious personal injury or death.

DAMAGED PARTS. Regularly inspect machine

for damaged, loose, or mis-adjusted parts—or

any condition that could affect safe operation.

Immediately repair/replace BEFORE operating

machine. For your own safety, DO NOT operate

machine with damaged parts!

MAINTAIN POWER CORDS. When disconnecting cord-connected machines from power, grab

and pull the plug—NOT the cord. Pulling the cord

may damage the wires inside. Do not handle

cord/plug with wet hands. Avoid cord damage by

keeping it away from heated surfaces, high traffic

areas, harsh chemicals, and wet/damp locations.

EXPERIENCING DIFFICULTIES. If at any time

you experience difficulties performing the intended operation, stop using the machine! Contact our

Technical Support at (570) 546-9663.

Model G0876 (Mfd. Since 12/22)

-7-

Page 10

Additional Safety for CNC Mills/Lathes

You can be seriously injured or killed by getting clothing, jewelry, or long hair entangled with

rotating cutter/spindle. You can be severely cut or have fingers amputated from contact with

rotating cutters. You can be blinded or struck by broken cutting tools, metal chips, workpieces,

or adjustment tools thrown from the rotating spindle with great force. To reduce your risk of

serious injury when operating this machine, completely heed and understand the following:

UNDERSTAND ALL CONTROLS. Make sure

you understand the function and proper use of all

controls before starting. This will help you avoid

making mistakes that result in serious injury.

AVOIDING ENTANGLEMENT. DO NOT wear

loose clothing, gloves, or jewelry, and tie back

long hair. Keep all guards in place and secure.

Always allow spindle to stop on its own. DO NOT

stop spindle using your hand or any other object.

EYE INJURIES. Operator and bystanders MUST

wear ANSI-approved safety glasses to help protect eyes from thrown metal shards and chips.

USE CORRECT SPINDLE SPEED. Follow recommended speeds and feeds for each size and

type of cutting tool. This helps avoid tool breakage

during operation and ensures best cutting results.

INSPECT CUTTING TOOL. Inspect cutting tools

for sharpness, chips, or cracks before each use.

Replace dull, chipped, or cracked cutting tools

immediately.

UNATTENDED MACHINE. Operator MUST be

present to immediately stop machine in case of

malfunction to prevent injury to bystanders and

machine damage.

POWER DISRUPTION. In event of power outage

during operation, turn spindle switch OFF to avoid

a possible sudden startup once power is restored.

SECURE WORKPIECE TO TABLE. Clamp workpiece to table or secure in a vise mounted to table,

so workpiece cannot unexpectedly shift or spin

during operation. NEVER hold workpiece by hand

during operation.

DISCONNECT POWER FIRST. To reduce risk of

electrocution or injury from unexpected startup,

make sure mill/drill is turned OFF, disconnected

from power, and all moving parts have come to

a complete stop before changing cutting tools or

starting any inspection, adjustment, or maintenance procedure.

CLEAN MACHINE SAFELY. Metal chips or shavings can be razor sharp. DO NOT clear chips

by hand or compressed air that can force chips

farther into machine—use a brush or vacuum

instead. Never clear chips while spindle is turning.

PROPERLY MAINTAIN MACHINE. Keep

machine in proper working condition to help

ensure that it functions safely and all guards and

other components work as intended. Perform routine inspections and all necessary maintenance.

Never operate machine with damaged or worn

parts that can break or result in unexpected movement during operation.

SAFE OPERATING LOCATION. DO NOT place

machine where it can be exposed to rain or moisture. Exposure to water creates a shock hazard

and will reduce life of machine.

-8-

Model G0876 (Mfd. Since 12/22)

Page 11

1.3 Safety instructions (warning notes)

1.3.1 Classification of hazards

We classify the safety warnings into different categories. The table below gives an overview of

the classification of symbols (ideogram) and the warning signs for each specific danger and its

(possible) consequences.

Symbol Warning alert Definition / consequence

DANGER!

WARNING!

CAUTION!

ATTENTION!

In case of specific dangers, we replace the pictogram with

INFORMATION

Impending danger that will cause serious injury or death to people.

A danger that can cause serious injury or death.

A danger or unsafe procedure that can cause personal injury or damage to

property.

Situation that could cause damage to the CNC-machine and products and

other types of damage.

No risk of injury to people.

Practical tips and other important or useful information and notes.

No dangerous or harmful consequences for people or objects.

general danger by a

warning of

Model G0876 (Mfd. Since 12/22)

injury to hands, hazardous electrical

voltage,

rotating

parts.

-9-

Page 12

1.3.2 Other pictograms

Activation forbidden! Do not step into the

machine!

Wear protective boots! Use ear protection! Wear protective glasses! Read the operating instruc-

Warning: suspended loads! Warning of oxidizing sub-

stances!

Protect the environment! Contact address

Do not extinguish with

water!

Caution, danger of explo-

sive substances!

Access forbidden!

tion before commissioning!

Warning: danger of slip-

ping!

1.4 Intended use

WARNING!

In the event of improper use of the CNC machine

will endanger personnel,

the CNC machine and other material property of the operating company will be

endangered,

the correct function of the CNC machine may be affected.

The CNC machine is designed and manufactured to be used for milling and drilling cold metals

or other non-flammable materials or materials that do not constitute a health hazard by using

commercial milling and drilling tools.

Using this machine it is possible to perform dry processing as well as processing by using cool-

ing lubricants.

The limit values of the balances of the tools need to be observed.

fixtures“ on page 21

The CNC machine must only be installed and operated in a dry and well-ventilated place.

The CNC machine is designed and manufactured to be used in a non-explosive environment.

If the CNC machine is used in any way other than described above or modified without the

approval of Grizzly Industrial, Inc., then the CNC machine is being used improperly.

We will not be held liable for any damages resulting from any operation which is not in accordance with the intended use.

"Cooling lubricants“ on page 243

"Tools and tool holding

express

-10 -

Model G0876 (Mfd. Since 12/22)

Page 13

We expressly point out that the guarantee or CE conformity will expire, if any constructive, tech-

nicolor procedural changes are not performed by Grizzly Industrial, Inc.

It is also part of intended use that you

the limits of performance of the CNC machine are observed,

the operating manual is observed,

the inspection and maintenance instructions are observed.

WARNING!

Severe injuries due to non-intended use.

It is forbidden to make any modifications or alternations to the operation values of the

CNC machine. They could endanger the personnel and cause damage to the CNC

machine.

1.5 Reasonably foreseeable misuse

Any other use other than that specified under "Intended use" or any use beyond the described

use shall be deemed as non-intended use and is not permissible.

Any other use has to be discussed with the manufacturer.

It is only allowed to process metal, cold and non-inflammable materials with the milling

machine.

In order to avoid misuse, it is necessary to read and understand the operating instructions

before first commissioning.

Operators must be qualified.

1.5.1 Avoiding misuse

Use of suitable cutting tools.

Adapting the speed adjustment and feed to the material and workpiece.

Clamp workpieces firmly and vibration-free.

ATTENTION!

The workpiece is always to be fixed by a machine vice, jaw chuck or by another

appropriate clamping tool such as for the clamping claws.

WARNING!

Risk of injury caused by flying workpieces.

Clamp the workpiece in the machine vice. Make sure that the workpiece is firmly clamped in the

machine vice and that the machine vice is firmly clamped onto the machine table.

Use cooling and lubricating agents to increase the durability of the tool and to improve the

surface quality.

Clamp the cutting tools and workpieces on clean clamping surfaces.

Sufficiently lubricate the machine.

Correctly adjust the bearing clearance and the guidings.

ATTENTION!

Do not use the drill chuck as a milling tool. Never clamp a milling cutter into a drill

chuck. Use a collet chuck with collets for the end mill.

Model G0876 (Mfd. Since 12/22)

-11-

Page 14

1.6 Possible dangers caused by the CNC machine

The CNC machine has been tested for operational safety. The construction and type are state

of the art.

Nevertheless, there is a residual risk as the CNC machine operates with

rotating parts,

electrical voltage and currents,

compressed air,

rapid moves.

We have used construction resources and safety techniques to minimize the health risk to personnel resulting from these hazards.

If the CNC machine is used and maintained by personnel who are not duly qualified, there may

be a risk resulting from incorrect or unsuitable maintenance of the lathe.

INFORMATION

Everyone involved in the assembly, commissioning, operation and maintenance must

be duly qualified,

and strictly follow these operating instructions.

In the event of improper use

there may be a risk to personnel,

there may be a risk of damage to the CNC machine and other material values,

the correct function of the CNC machine may be affected.

Always switch off the CNC machine and disconnect it from the mains, when cleaning or maintenance work is carried out.

WARNING!

The CNC machine may only be operated with functional safety devices. Disconnect the

CNC machine immediately, whenever you detect a failure in the safety devices or when

they are not fitted!

All additional parts of the machine which had been added by the customer need to be

equipped with the prescribed safety devices.

This is your responsibility being the operating company!

1.7 Qualification of personnel

1.7.1 Target group

This manual is addressed to

the operating companies,

operators having sufficient specialist knowledge,

the maintenance personnel.

Therefore, the warning notes refer to both, operation and maintenance personnel of the CNC

machine.

Determine clearly and explicitly who will be responsible for the different activities on the CNC

machine (operation, setting up, maintenance and repair). Please note the name of the responsible person into an operators´s log.

INFORMATION

Unclear responsibilities constitute a safety risk!

Always lock the main switch after switching off the CNC machine. This will prevent it from being

used by unauthorized persons.

The qualifications of the personnel for the different tasks are mentioned below:

-12-

Model G0876 (Mfd. Since 12/22)

Page 15

Operator

The operator has been instructed by the operating company regarding the assigned tasks and

possible risks in case of improper behaviour. Any tasks which need to be performed beyond the

operation in standard mode must only be performed by the operator, if so indicated in these

instructions and if the operator has been expressively commissioned by the operating company.

Qualified electrician

With professional training, knowledge and experience as well as knowledge of respective

standards and regulations, qualified electricians are able to perform work on the electrical system and recognise and avoid any possible dangers.

Qualified electricians have been specially trained for the working environment, in which they are

working and know the relevant standards and regulations.

Qualified personnel

Thanks to professional training, knowledge and experience as well as knowledge of relevant

regulations the qualified personnel is able to perform the assigned tasks and to independently

recognise and avoid any possible dangers themselves.

Instructed person

Instructed persons were instructed by the operating company regarding the assigned tasks and

any possible risks of improper behaviour.

1.7.2 Authorized personnel

INFORMATION

Sufficient expertise is required for working on the CNC machine. No one must work on

the machine without having the necessary training, not even for a short while.

We recommend the use of the CNC software SinuTrain as an aid for training and

operation.

SinuTrain made by Siemens is the perfect software-supplement for the G0876 CNC Mill.

This training software supports the rapid training for the operation of the control Sinumerik

808D. Employees having little CNC-experience can learn the basics of the DIN-programming

by using SinuTrain and are finally able to write and test programs using SINUMERIK 808D.

Please find SinuTrain and further information on the website of Siemens.

http://www.cnc4you.siemens.com

WARNING!

Inappropriate operation and maintenance of the CNC machine constitutes a danger to

the personnel, objects and the environment.

Only authorized personnel may operate the CNC machine !

Persons authorized to operate and maintain should be trained technical personnel and

instructed by the ones who are working for the operating company and for the manufacturer.

The operating company must

train the personnel,

instruct the personnel in regular intervals (at least once a year) on

- all safety standards that apply to the CNC machine,

- operation of the CNC machine,

- generally accepted engineering standards.

- possible emergency situations,

Model G0876 (Mfd. Since 12/22)

-13-

Page 16

check the personnel‘s knowledge level,

document training/instruction in a operation book,

require personnel to confirm participation in training/instructions by means of a signature,

check whether the personnel is working safety and risk-conscious and observes the operat-

ing instructions.

define and document the inspection deadlines for the machine.

The operator must

be specially trained in handling and programming the CNC machine,

know and understand the program sequence and the effects of the individual process

parameters,

keep an operator‘s log,

before taking the machine in operation

- have read and understood the operating manual,

- be familiar with all safety devices and instructions.

For work on the following CNC machine parts there are additional requirements:

Electric components or operating materials: Must only be worked on by a qualified electri-

cian or person working under the instructions and supervision of a qualified electrician.

1.8 Operator positions

The operator position is in front of the CNC machine at the sight window or on the machine control panel.

1.9 Safety devices

Use the CNC machine only with properly functioning safety devices.

Stop the CNC machine immediately, if a safety device fails or is faulty or becomes ineffective.

It is your responsibility!

If a safety device has been activated or has failed, the drilling machine must only be used if you

the cause of the fault has been eliminated,

you have verified that there is no danger to personnel or objects.

Obligations of

the operator

Additional

requirements

regarding the

qualification

WARNING!

If you bypass, remove or deactivate a safety device in any other way, you are

endangering yourself and other personnel working with the CNC machine. The possible

consequences are:

injuries due to tools, workpieces or fragments hereof which are flying off at high

speed,

contact with rotating or moving parts,

fatal electrocution,

pulling-in of clothes.

The CNC machine features the following safety devices:

a lockable main switch,

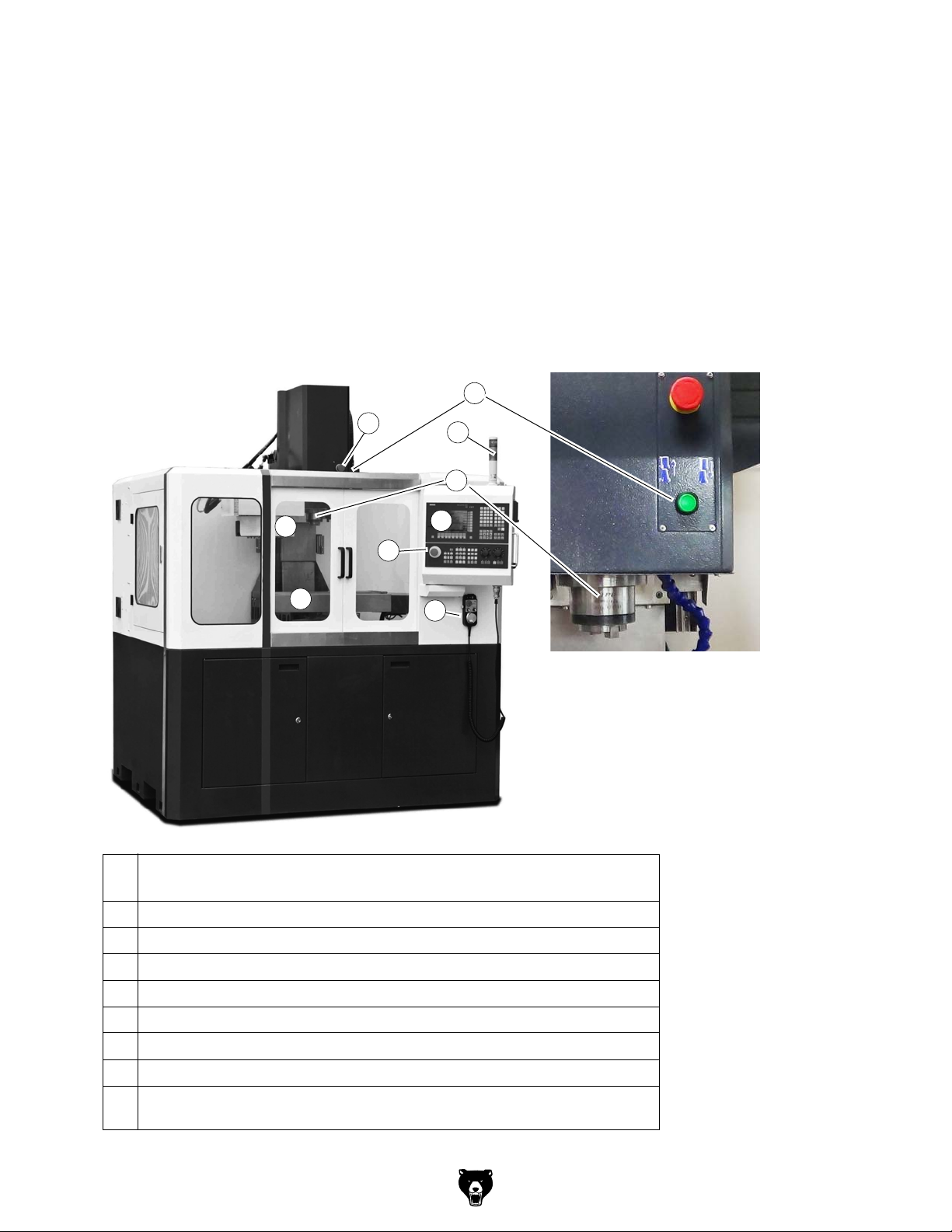

One EMERGENCY STOP push-button on the machine control panel, the milling head and

on the electronic handwheel,

A locked, separating protective equipment around the CNC milling machine with sight win-

dows made of break-proof Makrolon.

Locking switch on the separating safety devices.

-14-

Model G0876 (Mfd. Since 12/22)

Page 17

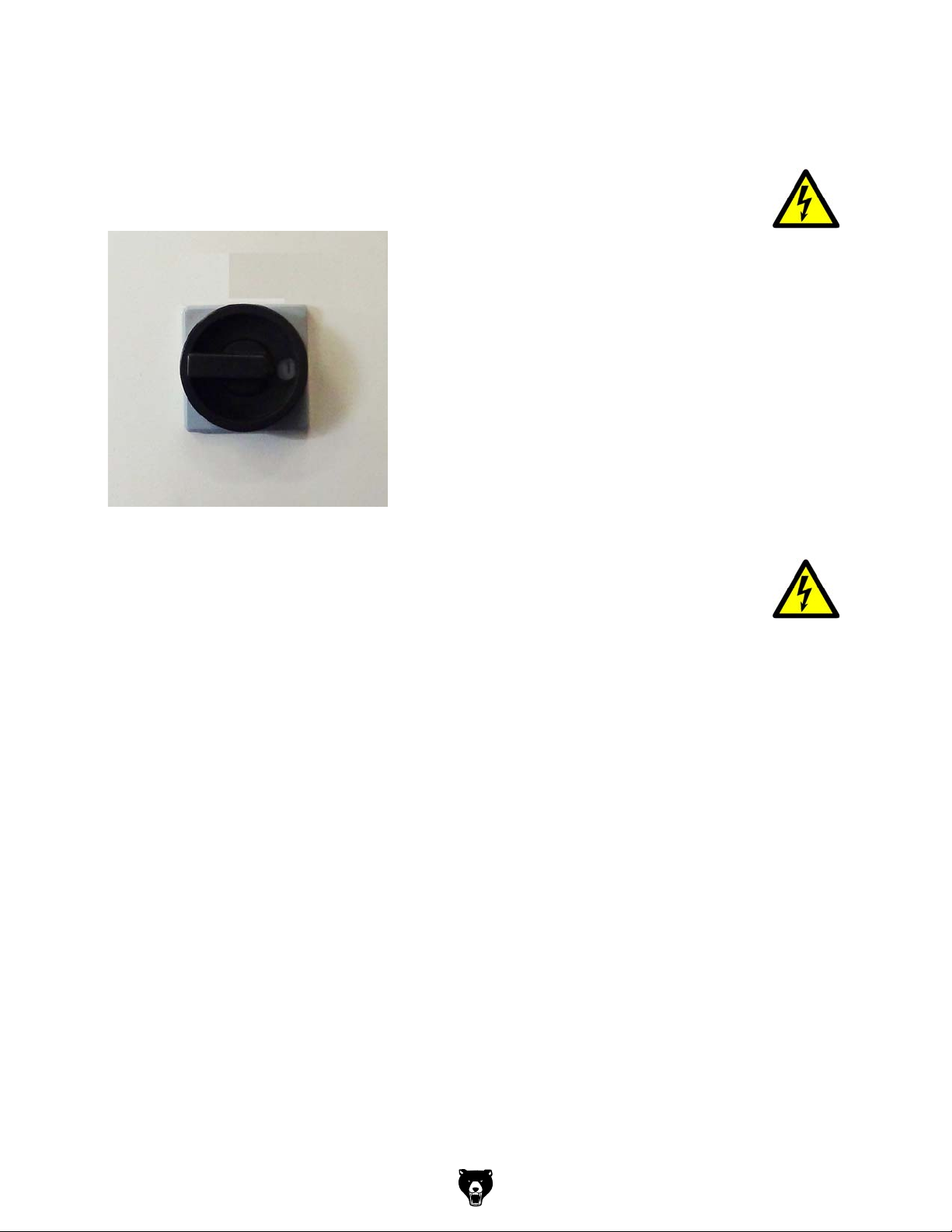

1.9.1 Lockable main switch

In the "0" position, the lockable main switch can be secured against accidental or non-authorised switching on by means of a padlock.

The power supply is interrupted by switchingoff the main plug.

Except for the areas marked by the pictogram in the margin. In these areas there might be voltage, even if the main switch is switched-off.

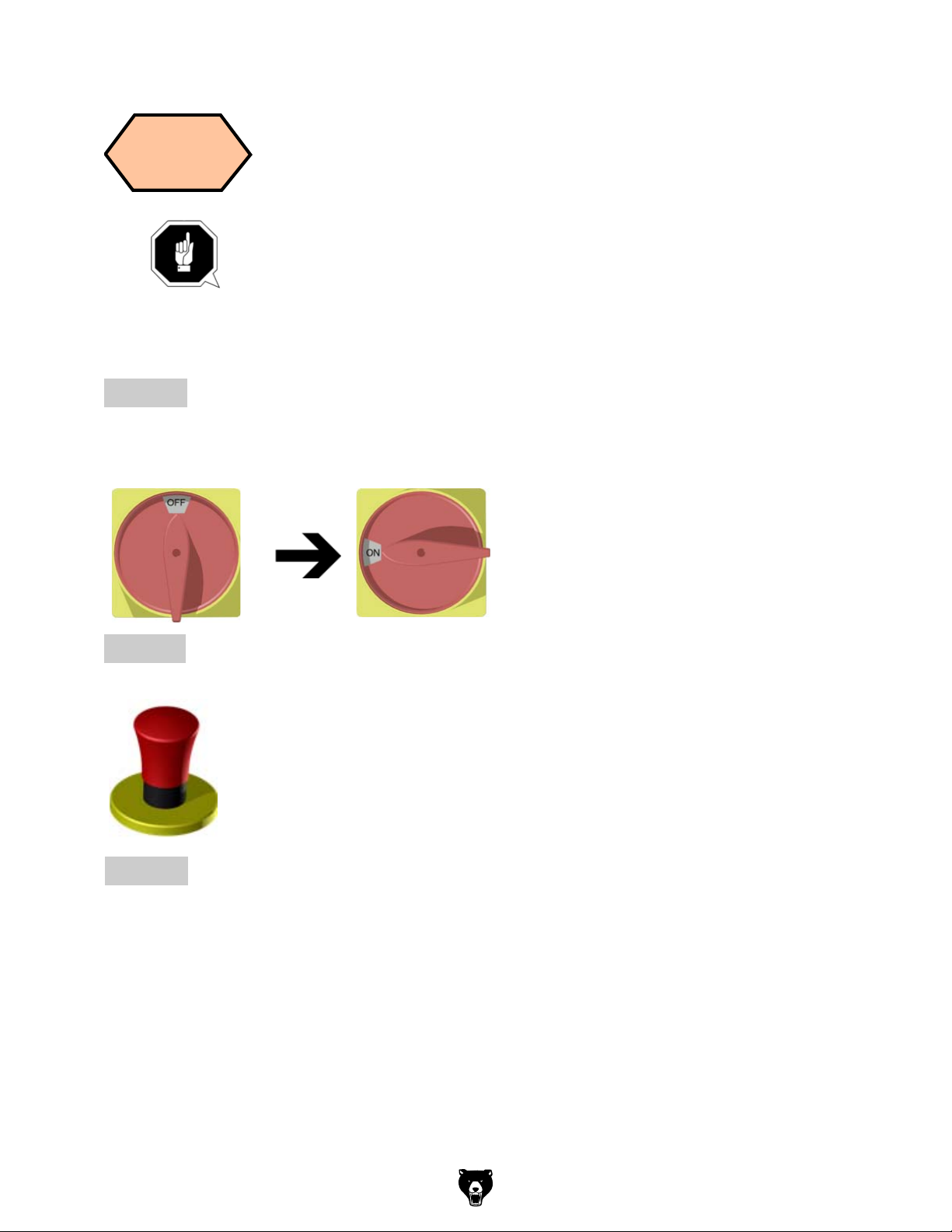

Img.1-1: Main switch

WARNING!

Dangerous voltage even if the main switch is switched off.

The areas marked by the pictogram might contain live parts, even if the main switch is switched

off.

Model G0876 (Mfd. Since 12/22)

-15-

Page 18

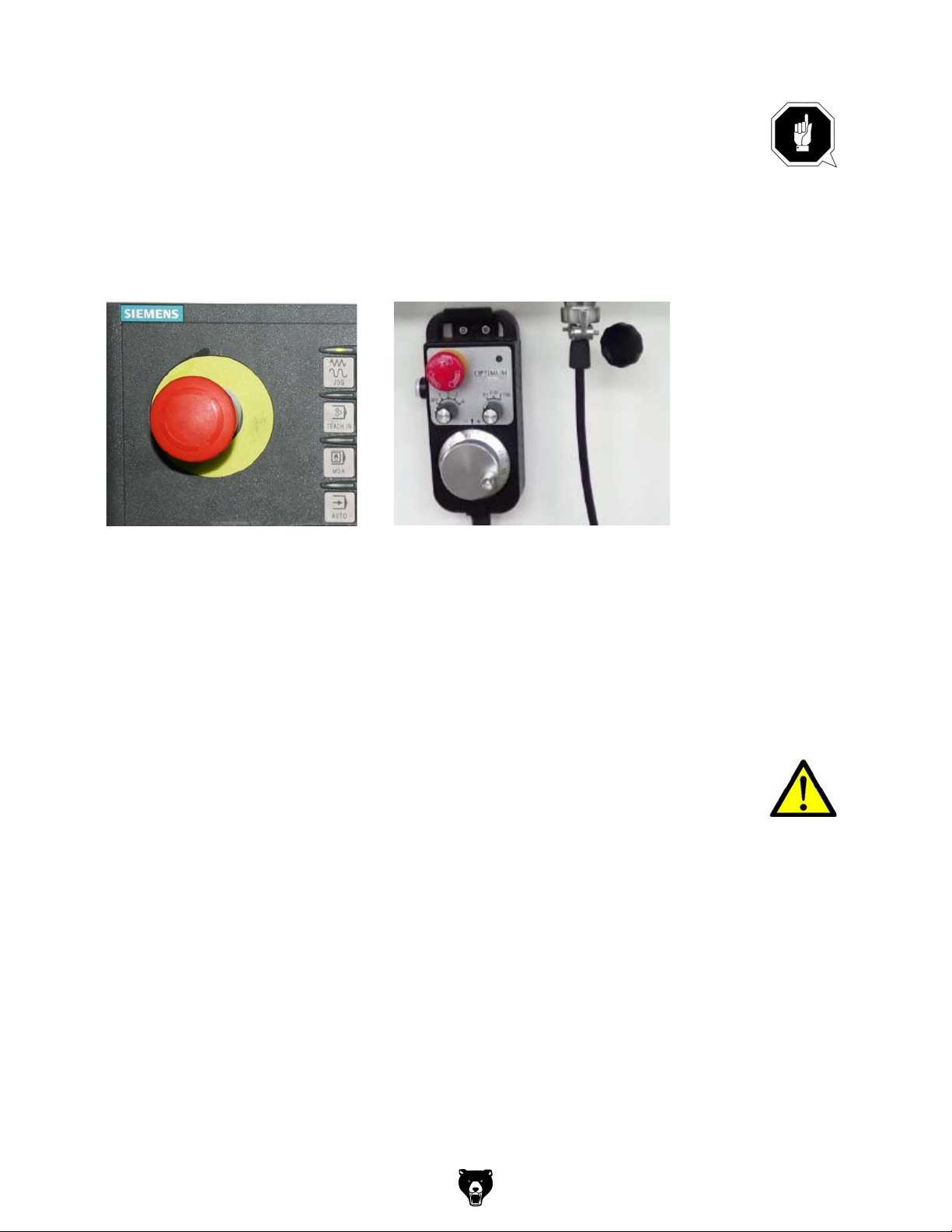

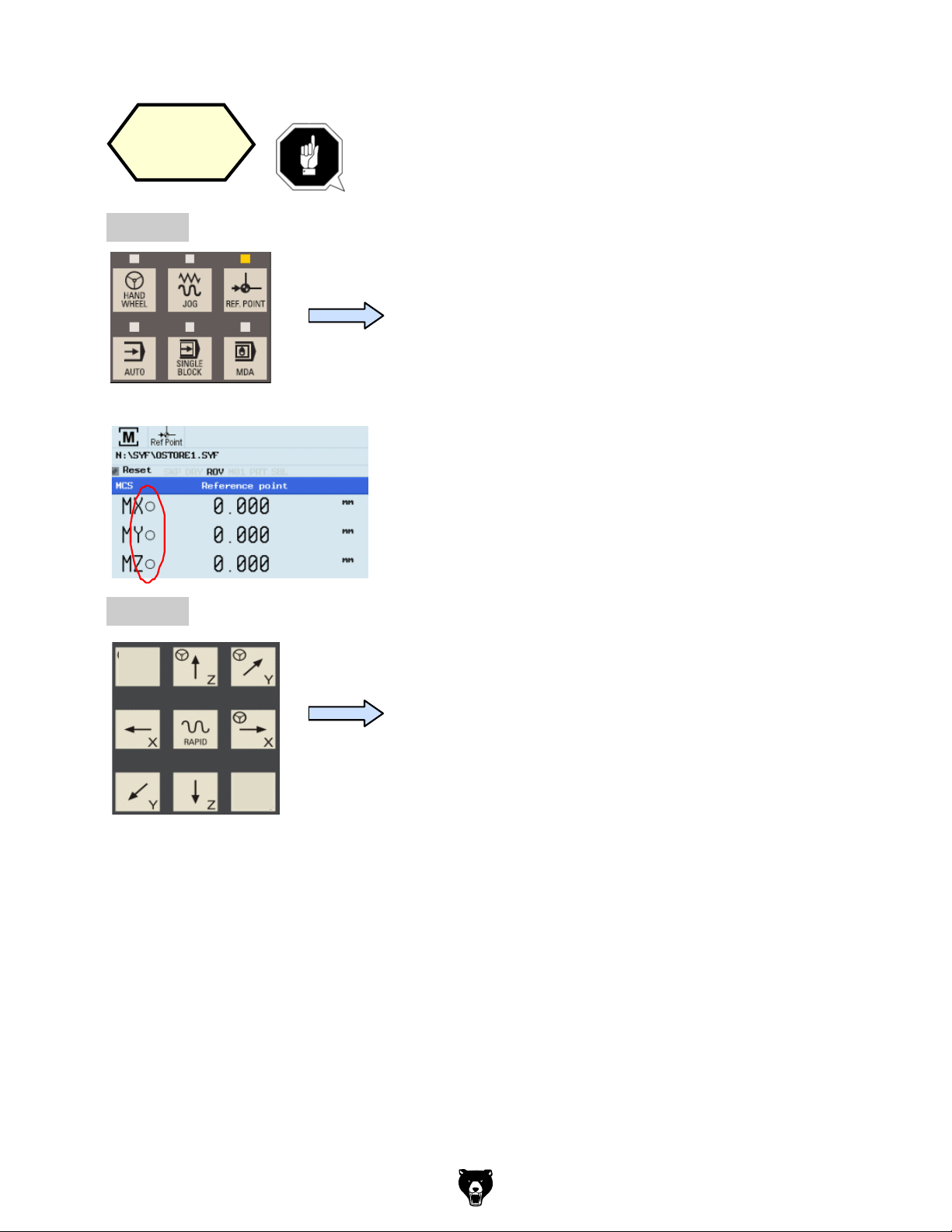

1.9.2 Emergency stop button

ATTENTION!

The EMERGENCY STOP push button immediately stops the operation of the CNC

machine.

Press the EMERGENCY STOP button only if there is a risk! If this push button is

actuated in order to switch off the CNC machine in the standard operation the tool or

workpiece might get damaged.

After having actuated the EMERGENCY STOP button, turn the knob of the particular push

button to the right in order to restart the machine.

Img.1-2: Emergency-stop push button

1.9.3 Control technical protection

WARNING!

If you bypass a controller you endanger yourself and other persons working on the CNC

machine.

injuries due to tools, workpieces or fragments hereof which are flying off at high

speed,

contact with rotating parts,

fatal electrocution,

pulling-in of clothes.

If you temporarily bypass a controller in exceptional cases (e.g. during electrical repairs), you

must continuously monitor the CNC machine.

-16 -

Model G0876 (Mfd. Since 12/22)

Page 19

1.9.4 Polycarbonate windows

Polycarbonate viewing window in chip protection, must be visual inspected by the customer

responsible personnel at regular intervals to guarantee the operational safety of the CNC

machine.

Polycarbonate viewing panes are subject to an ageing process and are classified as wear

parts.

The aging of polycarbonate windows can not be detected by visual inspection. It is therefore

necessary to replace the polycarbonate windows after a certain time.

Prolonged exposure from polycarbonate windows to cutting fluids can lead to accelerated aging, i.e. deterioration of the mechanical properties (brittleness). Coolant vapours, detergents,

greases and oils or other corrosive substances from the operator side can also lead to a deterioration of the polycarbonate windows. The result in reduced impact resistance of the polycarbonate windows.

"Cleaning and replacing of the polycarbonate windows“ on page 248

1.9.5 Prohibition, warning and mandatory labels

INFORMATION

All warning and mandatory signs must be legible. They must be checked regularly.

1.10 Safety check

Check the CNC machine at least once per shift. Inform the person responsible immediately of

any damage, defects or changes in the operating function.

Check all safety devices

at the beginning of each shift (when the machine is operated continuously),

once per day (during one-shift operation),

once per week (when operated occasionally),

after all maintenance and repair work.

Check that prohibition, warning and information signs and the labels on the CNC machine

are legible (clean them, if necessary)

and complete (replace them, if necessary).

INFORMATION

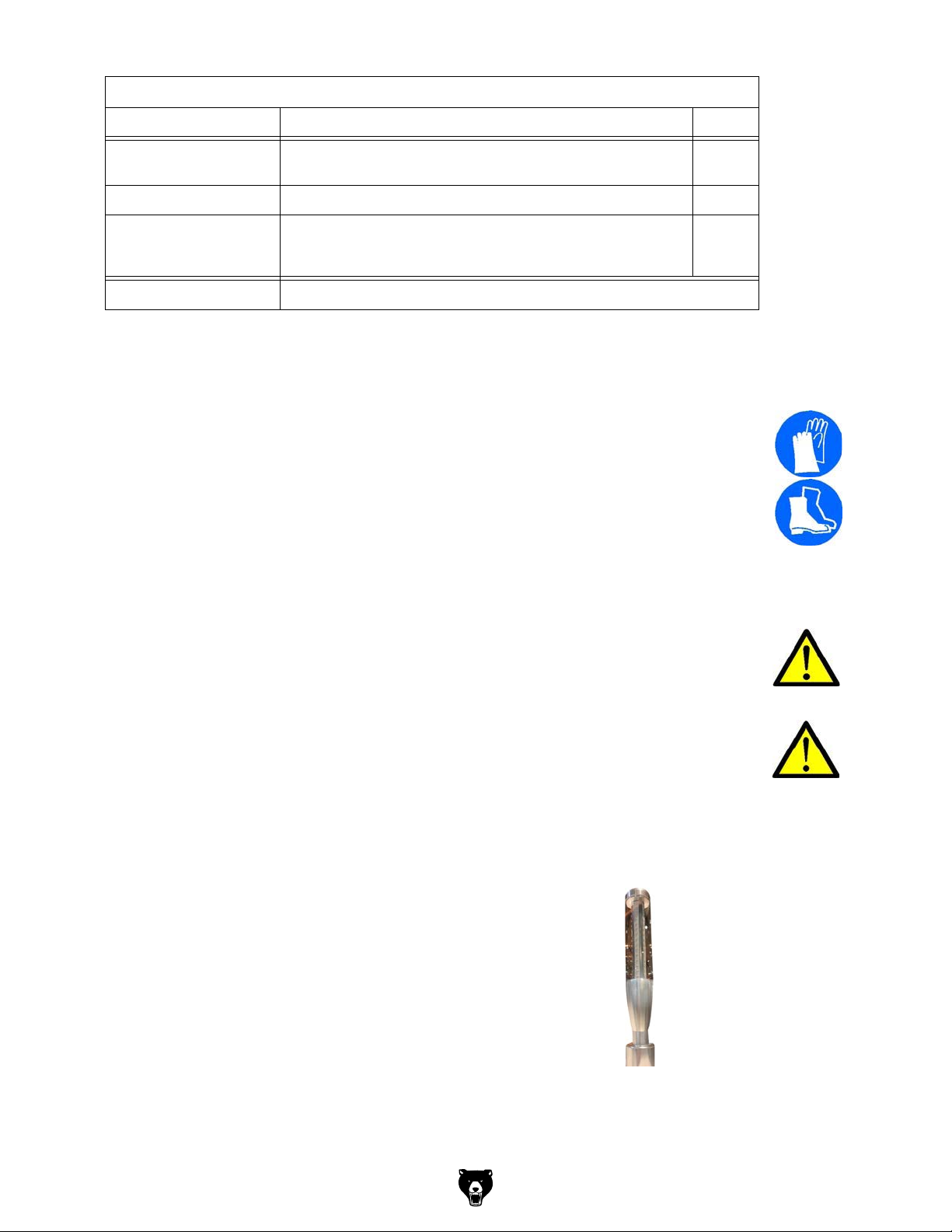

Organise the checks according to the following table;

General check

Equipment Check OK

Protective housing Switching function, firmly bolted and not damaged

Signs,

Markers

Sight window

Installed and legible

Check for mechanical damage (scratches, cracks).

cracks,

"Polycarbonate windows" on page 17

Date: checked by (signature):

Model G0876 (Mfd. Since 12/22)

-17-

Page 20

Functional check

KOk c e hCtnempiuqE

EMERGENCY STOP

push button

Switch cabinet cooling The cabinet cooling must be running.

Separating protective

equipment around the

CNC machine

After actuating an EMERGENCY STOP push button the CNC

machine must be switched off.

If the protective equipment is open it must not be possible to

start program.

Date: checked by (signature):

1.11 Personal protective equipment

For certain work personal protective equipment is required.

Protect your face and your eyes: Wear a safety helmet with facial protection when performing

work where your face and eyes are exposed to hazards.

Wear protective gloves when handling pieces or tools with sharp edges.

Wear safety shoes when you assemble, disassemble or transport heavy components.

Use ear protection if the noise level (emission) in the workplace exceeds 80 dB (A).

Before starting work make sure that the required personal protective equipment is available at

the work place.

CAUTION!

Dirty or contaminated personnel protective equipment can cause illness. It must be

cleaned after each use and at least once a week.

1.12 Safety during operation

WARNING!

Before activating the CNC machine, ensure that this will not endanger other persons or

cause damage to equipment.

Avoid any unsafe work methods:

The instructions mentioned in these operating instructions have to be strictly observed dur-

ing assembly, operation, maintenance and repair.

Do not work on the CNC machine, if your concentration is reduced, for example, because

you are taking medication.

Stay on the CNC machine until the program is termi-

nated.

The running program can be identified by means of

the signal lamp.

- Green light: Program run active

- Yellow light: Malfunction

- Red light: Actuated emergency stop push button

Img.1-3: Signal lamp

Safely and firmly clamp the workpiece in place, before switching the CNC machine on.

Never change the dosing of the coolant supply during operation.

-18-

Model G0876 (Mfd. Since 12/22)

Page 21

Never open the sliding door of the separating protective unit when the CNC

program is

running.

WARNING!

When chipping magnesia materials (aluminum-/magnesium alloys), spontaneously

inflammable or explosive particles (powder, dust, chips) might be generated, which

might cause a fire and/or explosion.

Magnesium is a dangerous material. In case of a fire with magnesium, only use

appropriate and admitted extinguishing agents. Never extinguish using water. If

burning magnesium is extinguished with water, this might lead to dangerous reactions

(hydrogen gas). Water would be decomposed in its components hydrogen (H) and

oxygen (O).

Only the following extinguishing agents are permissible:

solid extinguishing agent of fire class D (fires involving metals)

dry covering salts for magnesium

a mixture of sand and cast chips

argon (Ar) or nitrogen (N

)

2

If fine mist and smoke is generated at the workplace, suction units must be provided in

order to avoid the accumulation of ignitable mixtures and emissions.

We provide information about the specific dangers when working with and on the CNC machine

in the descriptions for these types of work.

1.13 Safety during maintenance

Inform the operators in good time of any maintenance and repair works.

Report all safety-relevant changes and performance characteristics of the CNC machine. Any

changes must be documented, the operating instructions updated and machine operators

instructed accordingly.

1.14 Disconnecting and securing the CNC machine

Turn off the main switch of the CNC machine before starting any maintenance or repair work.

Use a padlock to prevent the switch from being turned on without authorization and keep the

key in a safe place.

All machine parts as well as all dangerous voltages are switched off.

Excepted are only the positions which are marked with the adjoining pictogram. These positions

may be live, even if the main switch is switched off.

Place a warning sign on the CNC machine.

WARNING!

Live parts and moves of machine parts can injure you or others dangerously!

Proceed with extreme care if you cannot switch off

switch due to required works (e.g. functional control).

Model G0876 (Mfd. Since 12/22)

-19 -

Page 22

1.14.1 Using lifting equipment

WARNING!

The use of unstable lifting and load suspension equipment that might break under load

can cause severe injuries or even death. Observe the accident prevention regulations

issued by your Employers Liability Insurance Association or other supervisory

authorities responsible for your company.

Check that the lifting and load-suspension equipment are of sufficient load-bearing

capability and are in perfect condition.

Fasten the loads carefully.

Never walk under suspended loads!

1.14.2 Mechanical maintenance work

Remove or install protection safety devices before starting or after completing any maintenance work; this include:

covers,

safety instructions and warning signs,

grounding cables.

If you remove protective or safety devices, re-fit them immediately after the completing the

work.

Check if they are working properly!

1.15 Unattended Operation

CNC machines are designed for unattended operation. However, it may not be safe to let your

machining process run unmonitored. As it is the shop owner’s responsibility to set up the

machine safely and use best practice machining techniques, it is also their responsibility to

manage the progress of these methods. The machining process must be monitored to prevent

damage in case of a hazardous situation.

For example, if there is a risk of fire due to the machined material, an appropriate fire suppression system must be installed to reduce the risk of harm to personnel, equipment and the building. Have a specialist supplier install monitoring tools, before allowing machines to run

unattended.

It is especially important to select monitoring equipment that can immediately perform an appropriate action without human intervention to prevent an accident, should a problem be detected.

1.16 Accident report

Inform your supervisors immediately in the event of accidents, possible sources of danger

and any actions which almost led to an accident (near misses).

There are many possible causes for "near misses".

The sooner they are notified, the quicker the causes can be eliminated.

INFORMATION

We provide information about the specific dangers when working with and on the CNC machine

in the descriptions for these types of work.

1.17 Electrical system

Have the machine and/or the electric equipment checked regularly. Immediately eliminate all

defects such as loose connections, defective wires, etc.

-20-

Model G0876 (Mfd. Since 12/22)

Page 23

A second person must be present during work on live components to disconnect the power in

the event of an emergency. Disconnect the machine immediately if there is a malfunction in the

in case of failure of the power supply!

The operator of the machine must ensure that the electrical systems and operating equipment

are inspected with regards to their proper condition, namely,

by a qualified electrician or under the supervision and direction of a qualified electrician,

prior to initial commissioning and after modifications or repairs, prior to recommissioning

and at certain intervals.

The deadlines must be set so that arising, foreseeable defects can be detected in a timely manner.

The relevant electro-technical rules must be followed during the inspection.

The inspection prior to initial commissioning is not required if the operator receives confirmation from the manufacturer or installer that the electrical systems and operating equipment comply with the accident prevention regulations, see conformity declaration.

Permanently installed electrical systems and operating equipment are considered constantly

monitored if they are continually serviced by qualified electricians and inspected by means of

measurements in the scope of operation (e.g. monitoring the insulation resistance).

1.18 Inspection deadlines

Define and document the inspection deadlines for the machine.

1.19 Clamping devices for workpieces and tools

ATTENTION!

Attention when taking over existing clamping devices. Pleased thoroughly check that

the clamping device is appropriate for your CNC machine.

Only use clamping devices with a complete inherent rigidity.

Contact the manufacturer of the clamping device regarding the reuse of clamping

devices after damage to the clamping device due to collisions.

Correctly insert the workpiece and make sure that the machine is proper working

condition.

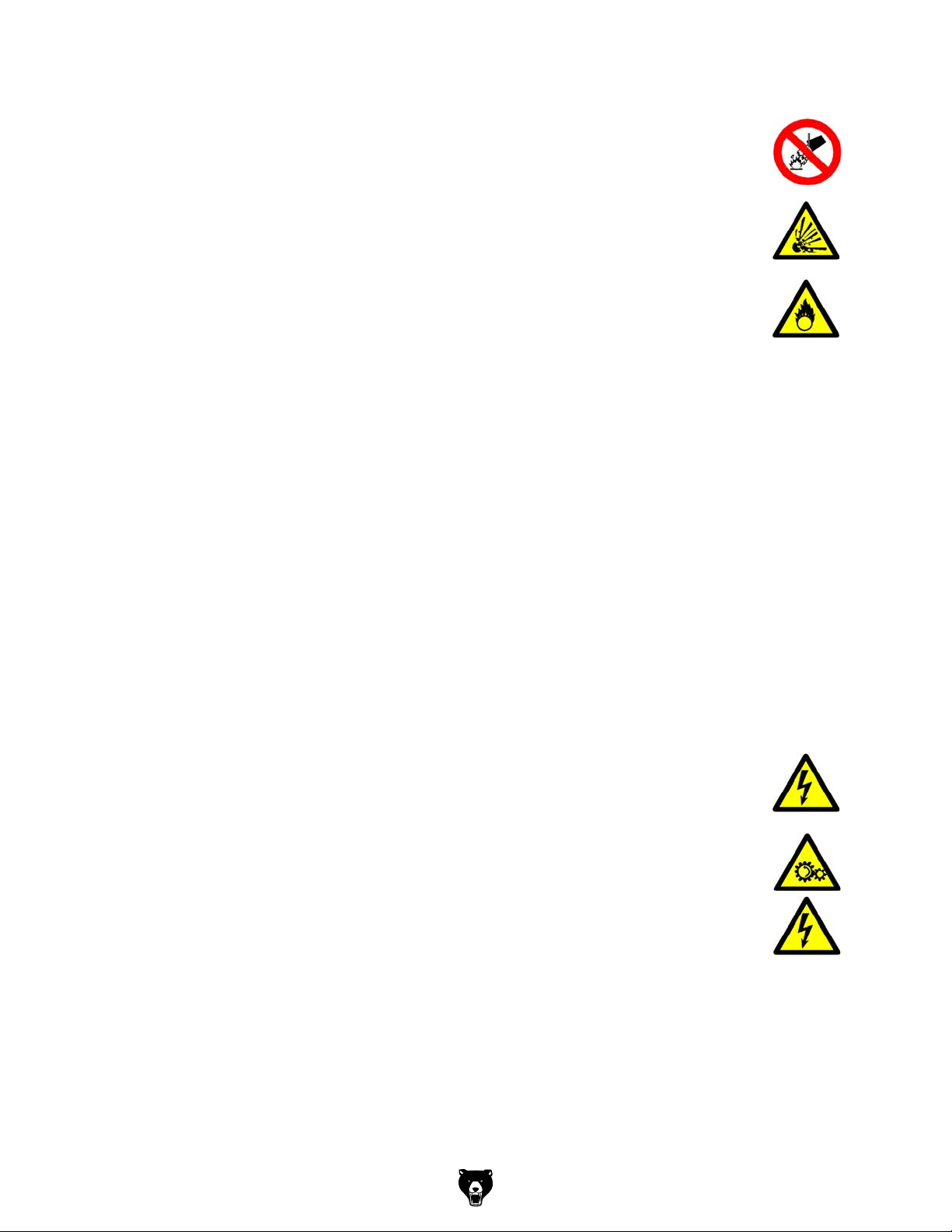

1.20 Tools and tool holding fixtures

CAUTION !

When using tools with larger diameters or at higher speeds!

The balancing of the tools has to amount to

0 - 6000 min

from a speed of 6000 min

according to DIN / ISO 1940.

-1

- G 6,3

-1

- G 2,5

Model G0876 (Mfd. Since 12/22)

-21-

Page 24

POWER SUPPLY

Before installing the machine, consider the availability and proximity of the required power supply

circuit. If an existing circuit does not meet the

requirements for this machine, a new circuit must

be installed. To minimize the risk of electrocution,

fire, or equipment damage, installation work and

electrical wiring must be done by an electrician or

qualified service personnel in accordance with all

applicable codes and standards.

or equipment damage

may occur if machine is

not properly grounded

and connected to power

The full-load current rating is the amperage a

machine draws at 100% of the rated output power.

On machines with multiple motors, this is the

amperage drawn by the largest motor or sum of all

motors and electrical devices that might operate

at one time during normal operations.

The full-load current is not the maximum amount

of amps that the machine will draw. If the machine

is overloaded, it will draw additional amps beyond

the full-load rating.

If the machine is overloaded for a sufficient length

of time, damage, overheating, or fire may result—

especially if connected to an undersized circuit.

To reduce the risk of these hazards, avoid overloading the machine during operation and make

sure it is connected to a power supply circuit that

meets the specified circuit requirements.

For your own safety and protection of

Note: Circuit requirements in this manual apply to

a dedicated circuit—where only one machine will

be running on the circuit at a time. If machine will

be connected to a shared circuit where multiple

machines may be running at the same time, consult an electrician or qualified service personnel to

ensure circuit is properly sized for safe operation.

This machine is prewired to operate on a power

supply circuit that has a verified ground and meets

the following requirements:

A power supply circuit includes all electrical

equipment between the breaker box or fuse panel

in the building and the machine. The power supply circuit used for this machine must be sized to

safely handle the full-load current drawn from the

machine for an extended period of time. (If this

machine is connected to a circuit protected by

fuses, use a time delay fuse marked D.)

Availability

Electrocution, fire, shock,

supply.

Full-Load Current Rating

Circuit Requirements for 220V

Nominal Voltage .........208V, 220V, 230V, 240V

..........................................................60 Hz

Cycle

Phase

Power Supply Circuit

Plug/Receptacle

Cord

.................................................... 3-Phase

......................... 20 Amps

........................... NEMA 15 -20

........“S”-Type , 4-Wire, 12 AWG, 300 VAC

Full-Load Current Rating at 220V ...14 .1 Amps

-22-

property, consult an electrician if you are

unsure about wiring practices or electrical

codes in your area.

Model G0876 (Mfd. Since 12/22)

Page 25

We do not recommend using an extension cord

with this machine.

cord, only use it if absolutely necessary and only

on a temporary basis.

Extension cords cause voltage drop, which can

damage electrical components and shorten motor

life. Voltage drop increases as the extension cord

size gets longer and the gauge size gets smaller

(higher gauge numbers indicate smaller sizes).

Any extension cord used with this machine must

be in good condition and contain a ground wire

and matching plug/receptacle. Additionally, it must

meet the following size requirements:

Improper connection of the equipment-grounding

wire can result in a risk of electric shock. The

wire with green insulation (with or without yellow

stripes) is the equipment-grounding wire. If repair

or replacement of the power cord or plug is necessary, do not connect the equipment-grounding

wire to a live (current carrying) terminal.

Check with a qualified electrician or service personnel if you do not understand these grounding

requirements, or if you are in doubt about whether

the tool is properly grounded. If you ever notice

that a cord or plug is damaged or worn, disconnect it from power, and immediately replace it with

a new one.

Serious injury could occur if you connect

process. DO NOT connect to power until

Grounding Instructions

This machine MUST be grounded. In the event

of certain malfunctions or breakdowns, grounding

reduces the risk of electric shock by providing a

path of least resistance for electric current.

The power cord and plug specified under “Circuit

Requirements for 220V”

has an equipment-grounding wire and a grounding prong. The plug must only be inserted into

a matching receptacle (outlet) that is properly

installed and grounded in accordance with all

local codes and ordinances (see figure below).

No adapter should be used with plug. If

plug does not fit available receptacle, or if

process. DO NOT connect to power until

on the previous page

GROUNDED

15-20 RECEPTACLE

15-20 PLUG

Current

Carrying

Grounding Pin

Blades

Serious injury could occur if you connect

machine to power before completing setup

instructed later in this manual.

Extension Cords

Typical 15-20 plug and receptacle.

machine to power before completing setup

instructed later in this manual.

machine must be reconnected for use on a

different type of circuit, reconnection must

be performed by an electrician or qualified

service personnel, and it must comply with

all local codes and ordinances.

Model G0876 (Mfd. Since 12/22)

If you must use an extension

Minimum Gauge Size ...........................10 AWG

Maximum Length (Shorter is Better).......50 ft.

-23-

Page 26

3 Assembly and commissioning

INFORMATION

The CNC-machine is delivered pre-assembled. It is delivered in a transport box.

3.1 Scope of delivery

Compare the delivery volume with the attached packing list.

Check the status of the CNC machine immediately upon receipt and claim possible damages at

the last carrier also if the packing is not being damaged. In order to ensure claims towards the

freight carrier we recommend you to leave the machines, devices and packing material for the

time being in the status at which you have determined the damage or to take photos of this status. Please inform us about any other claims within six days after receipt of delivery.

Check if all parts are firmly seated.

3.2 Transport

WARNING!

Severe or fatal injuries may occur if the machine or parts of the machine tumble or fall

down from the forklift truck or from the transport vehicle. Follow the instructions and

information on the transport box:

Centers of gravity

Load suspension points

(Marking of positions for the load

suspension point)

Prescribed transportation position

(Marking of the top surface)

Means of transport to be used

Weights

WARNING!

The use of damaged lifting and load suspension equipment without sufficient load

capacity that might break under load can cause severe injuries or even death.

Check that the lifting and load suspension equipment has sufficient load capacity and

that it is in perfect condition.

Observe the accident prevention regulations.

Fasten the loads carefully.

Never walk under suspended loads!

Check the substructure. The substructure must bear the load.

Disassemble the lateral parts of the wooden box.

The CNC machine is lifted and transported with an appropriate handling device to the instal-

lation place by means of a fork-lift truck.

Disassemble the clamping bolts which are used to fix the machine on the pallet.

-24-

Model G0876 (Mfd. Since 12/22)

Page 27

Lift the CNC machine carefully from the pallet of the transportation box by means of a crane

or a fork-lift truck.

"Total weight on page 3.

Bring the CNC machine with an appropriate handling device, e.g. Electric pallet truck or

fork-lift truck at their firm position.

Make sure that no add-on-pieces are damaged or cause paintwork is damaged during

transport.

WARNING!

The use of unstable lifting and load suspension equipment that might break under load

can cause severe injuries or even death.

3.3 Installation and assembly

3.3.1 Requirements regarding the installation site

Organize the working area around the CNC machine according to the local safety regulations.

The working area for operating, maintenance and repair must not be restricted.

INFORMATION

The main switch of the CNC machine must be freely accessible.

Model G0876 (Mfd. Since 12/22)

-25-

Page 28

3.3.2 Installation plan

Connection compressed air

3.3.3 Machine mounting

1641

Electrical supply connection

530530152

Anchor-free assembly

Align the CNC machine with a machine spirit level. The slope deviation of all levels must not

exceed 0.04/1000mm.

Adjust the height by screwing in or screwing out of the levelling screw. Screwing in the lev-

elling screw causes that the rubber plate lifts itself as on the drawing from the same element.

Fix the height adjustment by the the jackscrew with the help of the counternut.

Check the alignment of the machine after a few days of usage.

-26-

Model G0876 (Mfd. Since 12/22)

Page 29

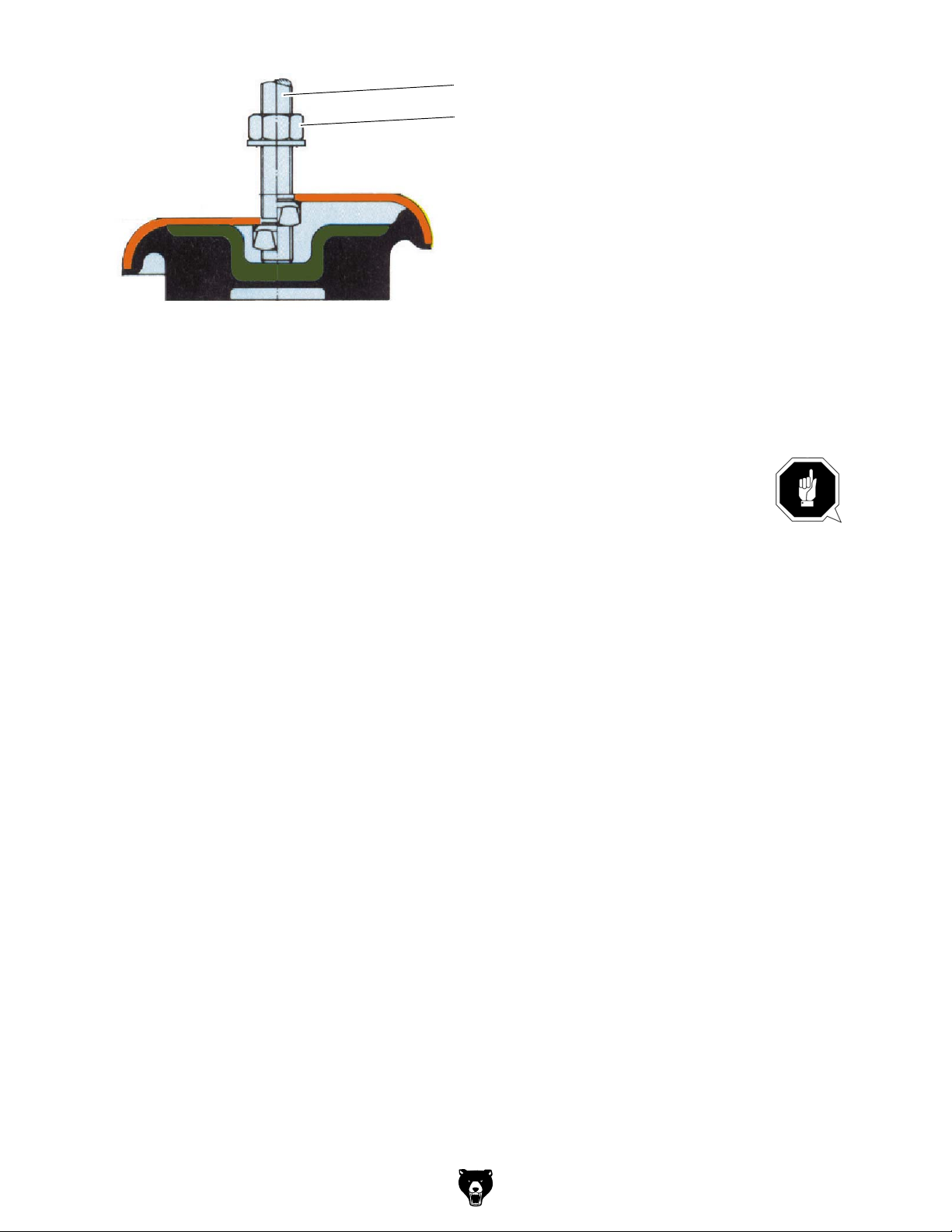

Jackscrew

Counternut

Img.3-1: Oscillating element

Anchored assembly

Use the anchored assembly in order to attain a firm connection to the ground. An anchored

assembly is always reasonable if parts are manufactured to the maximum capacity of the CNC

machine.

ATTENTION!

An insufficient rigidity of the substructure leads to superposition of vibrations between

the CNC machine and the substructure (natural frequency of the components). Critical

speeds and moves in the axis with displeasing vibrations are rapidly achieved in case of

insufficient rigidity of the whole system and will lead to bad milling results.

Check the correct alignment of the machine after a few days of usage.

3.3.4 Corrosion protection

A corrosion protection is applied on the machine table and on the guiding surfaces for trans-

port and storage. Remove the anti-corrosive agent from the CNC machine before first commissioning. Therefore, we recommend you to use paraffin.

Model G0876 (Mfd. Since 12/22)

-27-

Page 30

3.3.5 Electrical connection

Check the fusing (fuse) of your electrical supply according to the technical instructions

regarding the total connected power of the milling machine.

Firmly connect the machine.

CAUTION!

Install the connection cable of the machine in such a way that people will not stumble

over it.

Please verify if the type of current, voltage and protection fuse correspond to the values specified. A protective earth ground wire connection must be available.

With an internal EMC filter the leakage current of the frequency converter of milling spindle is

greater than 3.5 mA. We ask for due attention while executing machine tests within

the framework of industrial safety guidelines.

ATTENTION!

When delivered the machine is equipped with a plug for electrical connection. It only

serves for acceptance and test purposes. In order to operate the machine it is necessary

to remove this plug and to connect the machine directly with a power supply.

Firmly connect the CNC machine to the terminal box. It is not allowed to connect the machine

using a standard 16A CEE plug, since the stray current of the frequency converter is exceeding the admissible value of 3.5mA.

ATTENTION!

Depending on the quality of the network, there is a risk of machine malfunctions under

extreme conditions. If necessary and in order to exclude retroactive effects on the

internal power supply system, the operator should install a line filter on the machine.

Therefore, at workplaces with lots of powerful consumers, it might also be necessary to

use a system for network compensation. Please consult your electricity supplier

regarding this.

ATTENTION!

Frequency converters (drive regulators) might trigger the Fl circuit breaker of your

electrical supply. In order to avoid malfunction, an Fl circuit breaker switch sensitive to

pulse current or to universal current may be required.

ATTENTION!

Ensure that all 3 phases (L1, L2, L3) and the ground wire are connected correctly.

The neutral conductor (N) of its power supply is not connected.

-28-

Model G0876 (Mfd. Since 12/22)

Page 31

3.3.6 Current in the Protective Earth Ground Wire