Page 1

MODEL G0822

VARIABLE-SPEED MILLING

MACHINE w/POWER FEED

MANUAL INSERT

For Machines Mfd. Since 6/17

The Model G0822 essentially the same machine as the Model G0802, but the G0822 is equipped with a

variable-speed 3-phase motor and an inverter/VFD (variable-frequency drive), which allows the machine to

operate on a single-phase power supply. Except for the differences noted in this insert, all other content in

the Model G0802 owner's manual applies to this machine.

: To reduce the risk of serious injury, you MUST read and understand this insert—and

the entire Model G0802 manual—BEFORE assembling, installing, or operating this machine!

If you have any further questions about this manual insert or the differences between the Model G0822

and the Model G0802, contact our Technical Support at (570) 546-9663 or email techsupport@grizzly.com.

COPYRIGHT © AUGUST, 2017 BY GRIZZLY INDUSTRIAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

#JH18959 PRINTED IN CHINA

Page 2

Controls &

To reduce your risk of

serious injury, read this

entire manual BEFORE

Components

using machine.

A. Power Button (Green): Illuminates when

machine is connected to power. Starts spindle rotation when pressed.

Note: Spindle switch must be engaged in

either the FORWARD/REVERSE position for

machine to begin spindle rotation.

B. Spindle Direction Switch: Toggles between

FORWARD (left), NEUTRAL (center), and

REVERSE (right).

C. Digital Readout: Displays spindle RPM.

Refer to the Figure below and the following

descriptions to become familiar with the basic

controls and components of this machine.

Understanding these items and how they work will

help you better understand the rest of the manual

and reduce your risk of injury when operating this

machine.

Downfeed Controls

A

Figure 1. G0822 control panel.

B

ED

C

F

D. OFF Button: Stops spindle rotation.

E. E-Stop Button: Cuts power to the spindle

motor and remains depressed until reset.

Twist clockwise to reset.

F. Variable-Speed Dial: Controls spindle speed

from 100–600 RPM (low) to 425–2500 RPM

(high), depending on High/Low position of

V-belt.

-2-

Model G0822 (Mfd. Since 06/17)

Page 3

Changing High/Low

Belt Position

The G0822 features two belt positions for High

(425–2500 RPM) and Low (100–600 RPM) spindle

speed operation.

To change belt position:

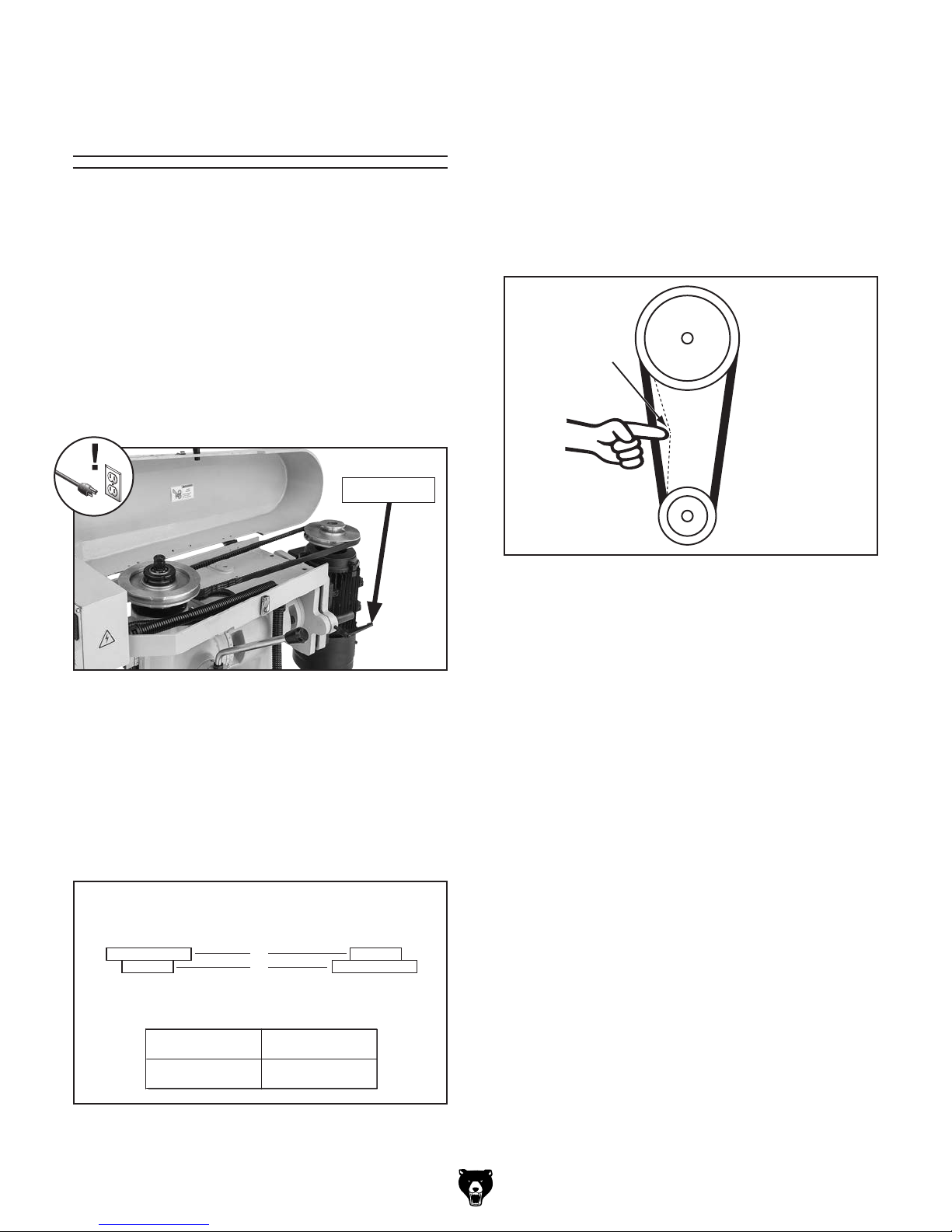

1. DISCONNECT MACHINE FROM POWER!

2. Open V-belt cover.

3. Support motor with one hand and loosen

motor lock shown in Figure 2.

Motor Lock

6. Loosen motor lock, pull motor away from

machine with moderate force to tension

V-belt.

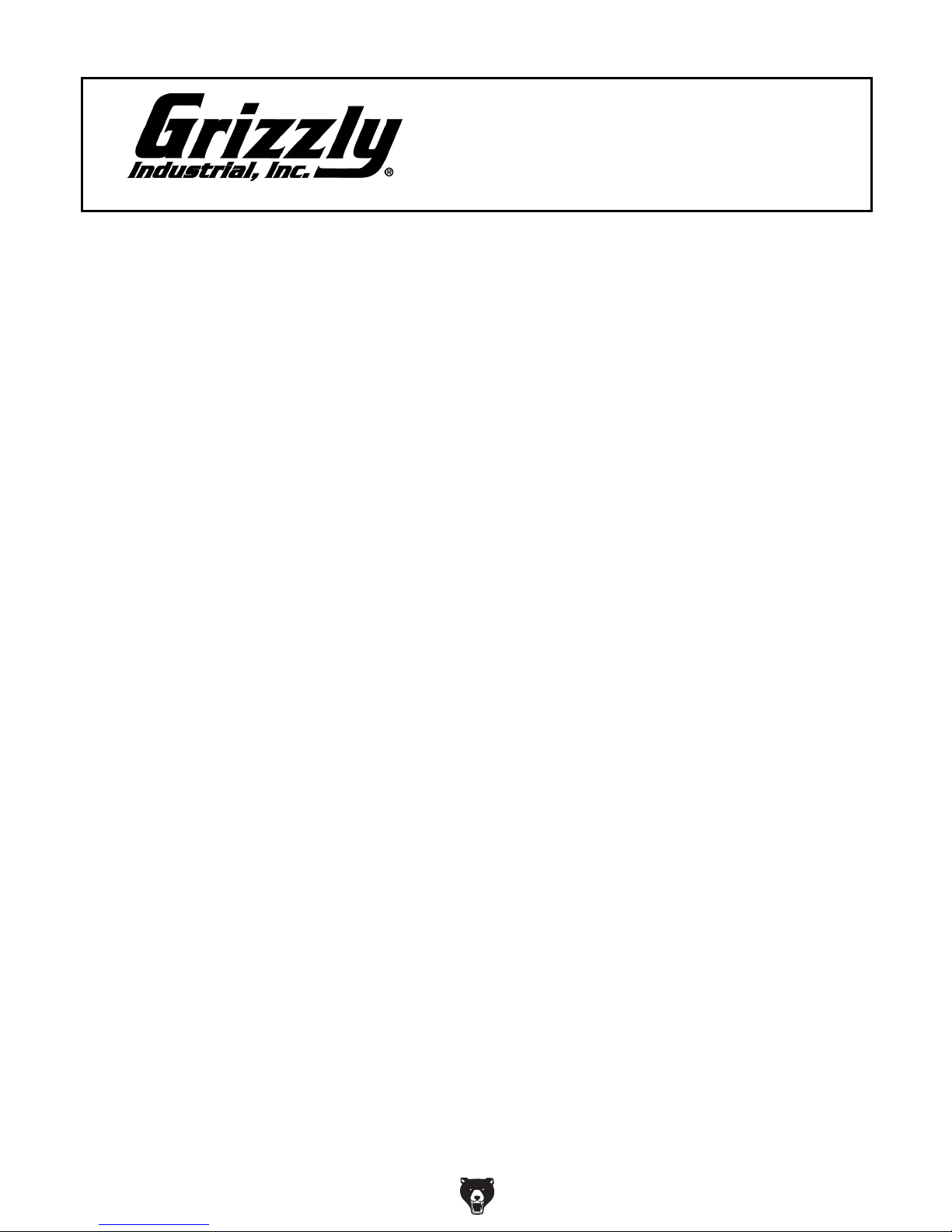

7. Check V-belt tension by applying moderate

pressure on belt with your finger between two

pulleys (see Figure 4). The proper amount

of belt deflection for this machine is approximately

Deflection

½"

1

⁄2".

Pulley

Pulley

Figure 2. V-belt position overview.

4. Press motor toward front of headstock to

release tension on V-belt, then tighten motor

lock to prevent it from re-tensioning belts.

5. Refer to V-belt configuration chart in Figure 3

and position V-belt on appropriate pulleys for

desired spindle speed.

Spindle

Pulley

A

B

Motor

Pulley

SPINDLE R.P.M.

Figure 4. Checking V-belt deflection for proper

tension.

8. Close V-belt cover before beginning

operations.

A B

100–600 425–2500

Figure 3. V-belt configuration chart.

Model G0822 (Mfd. Since 06/17)

-3-

Page 4

MACHINE DATA

SHEET

Customer Service #: (570) 546-9663 · To Order Call: (800) 523-4777 · Fax #: (800) 438-5901

MODEL G0822 VARIABLE‐SPEED MILLING MACHINE WITH

POWER FEED

Product Dimensions:

Weight.............................................................................................................................................................. 810 lbs.

Width (side-to-side) x Depth (front-to-back) x Height........................................................................... 45 x 41 x 68 in.

Footprint (Length x Width)............................................................................................................................ 21 x 28 in.

Space Required for Full Range of Movement (Width x Depth).............................................................. 59 x 39-1/2 in.

Shipping Dimensions:

Type.......................................................................................................................................................... Wood Crate

Content................................................................................................................................................. Machine/Stand

Weight.............................................................................................................................................................. 914 lbs.

Length x Width x Height....................................................................................................................... 40 x 37 x 74 in.

Must Ship Upright................................................................................................................................................... Yes

Electrical:

Power Requirement........................................................................................................... 220V, Single-Phase, 60 Hz

Full-Load Current Rating....................................................................................................................................... 6.4A

Minimum Circuit Size.............................................................................................................................................. 15A

Connection Type....................................................................................................................................... Cord & Plug

Power Cord Included.............................................................................................................................................. Yes

Power Cord Length................................................................................................................................................. 6 ft.

Power Cord Gauge......................................................................................................................................... 14 AWG

Plug Included.......................................................................................................................................................... Yes

Included Plug Type................................................................................................................................................ 6-15

Switch Type.................................................................................................................... ON/OFF Push Button Switch

Inverter (VFD) Type.................................................................................................................................. Delta VFD-E

Inverter (VFD) Size............................................................................................................................................... 2 HP

-4-

Motors:

Main

Horsepower................................................................................................................................................ 2 HP

Phase.................................................................................................................................................... 3-Phase

Amps........................................................................................................................................................... 6.4A

Speed.................................................................................................................................................... Variable

Type........................................................................................................................................... TEFC Induction

Power Transfer ............................................................................................................................... V-Belt Drive

Bearings..................................................................................................... Shielded & Permanently Lubricated

Model G0822 (Mfd. Since 06/17)

Page 5

Main Specifications:

Operation Info

Spindle Travel.............................................................................................................................................. 3 in.

Max Distance Spindle to Column.......................................................................................................... 5-1/4 in.

Max Distance Spindle to Table.................................................................................................................. 11 in.

Longitudinal Table Travel (X-Axis)...................................................................................................... 14-1/4 in.

Longitudinal Leadscrew (X-Axis)............................................................................................................... 36 in.

Cross Table Travel (Y-Axis)......................................................................................................................... 6 in.

Cross Leadscrew (Y-Axis)................................................................................................................... 14-3/4 in.

Vertical Table Travel (Z-Axis).................................................................................................................... 11 in.

Vertical Leadscrew (Z-Axis)....................................................................................................................... 17 in.

Turret or Column Swivel (Left /Right)..................................................................................................... 45 deg.

Head Tilt (Left/Right).............................................................................................................................. 45 deg.

Drilling Capacity for Cast Iron...................................................................................................................... 1 in.

Drilling Capacity for Steel......................................................................................................................... 3/4 in.

End Milling Capacity................................................................................................................................. 3/4 in.

Face Milling Capacity................................................................................................................................... 3 in.

Table Info

Table Length.............................................................................................................................................. 26 in.

Table Width........................................................................................................................................... 6-1/8 in.

Table Thickness.................................................................................................................................... 1-3/4 in.

Table Height (from Floor/Base)........................................................................................................... 17-3/4 in.

Number of T-Slots............................................................................................................................................ 3

T-Slot Size................................................................................................................................................ 1/2 in.

T-Slots Centers...................................................................................................................................... 1-5/8 in.

X-Axis Table Power Feed Rate................................................................................................... 0 – 3-3/8 FPM

X/Y-Axis Travel per Handwheel Revolution.............................................................................................. 0.1 in.

Z-Axis Travel per Handwheel Revolution................................................................................................. 0.1 in.

Spindle Info

Spindle Taper............................................................................................................................................... R-8

Number of Vertical Spindle Speeds...................................................................................................... Variable

Range of Vertical Spindle Speeds........................................... 100 – 600 RPM (Low), 425 – 2500 RPM (High)

Quill Diameter....................................................................................................................................... 2.950 in.

Drawbar Thread Size....................................................................................................................... 7/16-20 TPI

Drawbar Length................................................................................................................................... 11-5/8 in.

Spindle Bearings......................................................................................................... Tapered Roller Bearings

Construction

Spindle Housing/Quill........................................................................................................................... Cast Iron

Table.................................................................................................................................................... Cast Iron

Head.................................................................................................................................................... Cast Iron

Column/Base....................................................................................................................................... Cast Iron

Base..................................................................................................................................................... Cast Iron

Stand.......................................................................................................................................................... Steel

Paint Type/Finish...................................................................................................................................... Epoxy

Other Specifications:

Country of Origin ................................................................................................................................................ China

Warranty ........................................................................................................................................................... 1 Year

Approximate Assembly & Setup Time .............................................................................................................. 1 Hour

Serial Number Location .................................................................................................................................. ID Label

ISO 9001 Factory .................................................................................................................................................. Yes

Certified by a Nationally Recognized Testing Laboratory (NRTL) .......................................................................... No

Model G0822 (Mfd. Since 06/17)

-5-

Page 6

Electrical Cabinet Diagram

Circuit Board

Sensor

Start

DCM

04

FOR/REV

DRO

0

0

1

DCM

SN161209

1

3

1

1

3

4

M2

1

4

3

2

4

3

Stop

E-Stop

Hot

Hot

6-15 Plug

Ground

G

X-Axis Power Feed

GND

Motor 220V

ACM

Potentiometer

10V

AVI

To Motor Fan To Motor

Ground

10V

PE

Ground

L2

N2

DELTA VFD-E

AVI

ACM

DCM

MOTOR MICRO DRIVER

1

L1

N1

1

1

8

L

N

CHINT

Circuit

Breaker

NS2-25

Motor Start

Contactor

Siemens 3TB41 24V

NXB-63

20-25A

CHINT

3

0

L2

L2

N2

N2

2

L1

L1

N1

N1

PE

8

L1

N1

W1

V1

U1

M2

M1

PE

DCM

4

L2

5

4

3

N2

L

2

N

1

DCM

M2

0

M1

PE

PE

JBK5-63

Transformer

HH52PL

5

0

DCM

0

5

L2

L2

5

4

N2

3

N2

2

L

2

N

1

DCM

0

M2

0

M1

PE

PE

PE

-6-

Work Light

Model G0822 (Mfd. Since 06/17)

Page 7

Main

123

132

133

32

131

124

33

125

21

35

33

36

105

32

33

32

130

122

45

34

31

87

121

26

38

31

105

129

126

37

30

9

25

57

84

127

39

29

40

83

125

19

24

16

91

89

88

128

133

41

15

74

66

26

42

21

16

19

65

43

7

11

10

16

14

90

13

77

13

23

63

48

92

26

13

15

13

73

65

60

65

15

20

13

9

106-1

106-3

106-4

102-5

57

87

33

106

102-8

102-9

107

106-2

102-7

108

109

110

79

70

72

98

96

99

97

69

21

72

73

67

7

57

61

62

54

15

55

16

51

114

113

112

113

7

56

74

56

19

56

19

18

112

13

59

19

111

17

35

102-1

111

111

2

100

102-6

82

83

111

102

102-2

84

105

101

103

80

104

81

102-3

102-4

39

31

32

8

7

6

Model G0822 (Mfd. Since 06/17)

5

1

4

3

78

-7-

Page 8

Main Parts List

REF PART # DESCRIPTION REF PART # DESCRIPTION

1 P0822001 BASE 77 P0822077 X-AXIS GIB

2 P0822002 COLUMN 78 P0822078 CABINET BASE

3 P0822003 CAP SCREW M14-2 X 50 79 P0822079 OIL PAN

4 P0822004 LOCK WASHER 14MM 80 P0822080 HEX BOLT M10-1.5 X 45

5 P0822005 FLAT WASHER 14MM 81 P0822081 FLAT WASHER 10MM

6 P0822006 ELEVATION LEADSCREW NUT 82 P0822082 CLUTCH

7 P0822007 CAP SCREW M6-1 X 20 83 P0822083 COMPRESSION SPRING 24 X 15

8 P0822008 ELEVATION LEADSCREW 84 P0822084 SPACER

9 P0822009 MACHINE KEY 6 X 6 X 20 87 P0822087 CAP SCREW M6-1 X 12

10 P0822010 THRUST BEARING 51204 88 P0822088 X-AXIS GRADUATED DIAL (LEFT)

11 P0822011 ELEVATION BEARING BASE 89 P0822089 STEEL BALL 5MM

13 P0822013 BALL BEARING 6004-2RS 90 P0822090 COMPRESSION SPRING 4 X 12

14 P0822014 ELEVATION GEAR 12T 91 P0822091 CAP SCREW M6-1 X 8

15 P0822015 TABBED WASHER 20MM 92 P0822092 CLUTCH

16 P0822016 SPANNER NUT M20-1.5 96 P0822096 MACHINE KEY 5 X 5 X 16

17 P0822017 TABLE BASE CASTING 97 P0822097 CAP SCREW M8-1.25 X 16

18 P0822018 GIB 98 P0822098 LIMIT STOP

19 P0822019 GIB ADJUSTMENT SCREW M6-1 X 38 99 P0822099 LIMIT STOP SLIDE NUT M8-1.25

20 P0822020 CROSS LEADSCREW 100 P0822100 REAR COLUMN COVER

21 P0822021 MACHINE KEY 5 X 5 X 20 101 P0822101 PHLP HD SCR M6-1 X 12

23 P0822023 LEADSCREW BRACKET 102 P0822102 POWER FEED ASSEMBLY AS-235

24 P0822024 THRUST BEARING 51104 102-1 P0822102-1 POWER FEED BODY

25 P0822025 INT THREADED TAPER PIN 8 X 25 102-2 P0822102-2 POWER FEED ADAPTER GEAR

26 P0822026 CAP SCREW M6-1 X 20 102-3 P0822102-3 DETENT SLEEVE

29 P0822029 GRADUATED DIAL 102-4 P0822102-4 COMPRESSION SPRING 1.5 X 17 X 25.5

30 P0822030 KNOB BOLT M5-.8 X 12, KN 102-5 P0822102-5 POWER FEED GRADUATED DIAL

31 P0822031 HANDWHEEL TYPE-8 155D X 16B-S X M10-1.5 102-6 P0822102-6 RETAINING COLLAR

32 P0822032 HANDLE W/O SHAFT 22 X 75, 12 102-7 P0822102-7 LIMIT SWITCH ASONG V52 AN

33 P0822033 SHOULDER SCREW M10-1.5 X 12, 12 X 68 102-8 P0822102-8 LIMIT SWITCH MOUNTING BRACKET

34 P0822034 ELEVATION CRANK 102-9 P0822102-9 PHLP HD SCR M3-.5 X 30

35 P0822035 EXT RETAINING RING 17MM 103 P0822103 FLAT WASHER 6MM

36 P0822036 COMPRESSION SPRING 20 X 20 104 P0822104 LOCK WASHER 10MM

37 P0822037 ELEVATION HANDLE CLUTCH 105 P0822105 SET SCREW M6-1 X 10

38 P0822038 SET SCREW M6-1 X 16 106 P0822106 LED WORKLAMP ASSEMBLY

39 P0822039 ADJUSTMENT NUT 1-1/4 X 20 106-1 P0822106-1 LAMP BODY

40 P0822040 X-AXIS GRADUATED DIAL (RIGHT) 106-2 P0822106-2 BULB LED 24V MR16 1W(3)

41 P0822041 BUSHING 106-3 P0822106-3 LENS COVER

42 P0822042 CAP SCREW M6-1 X 25 106-4 P0822106-4 CAP SCREW M5-.8 X 25

43 P0822043 ADAPTER SLEEVE 107 P0822107 STRAIN RELIEF TYPE-3 M20-1.5

45 P0822045 ELEVATION SHAFT 108 P0822108 POWER CORD 14G 3W 72" 5-15P

48 P0822048 GEAR SHAFT SLEEVE 109 P0822109 MOTOR CORD 14G 5W 48"

51 P0822051 ELEVATION GEAR 12T 110 P0822110 SWITCH CORD 14G 3W 24"

54 P0822054 SPLASH GUARD 111 P0822111 STRAIN RELIEF TYPE-5 M24-1.5

55 P0822055 CROSS LEADSCREW NUT 112 P0822112 BUTTON HD CAP SCR M6-1 X 10

56 P0822056 CAP SCREW M5-.8 X 25 113 P0822113 WAY COVER HOLDER

57 P0822057 FLAT WASHER 6MM 114 P0822114 WAY COVER

59 P0822059 SADDLE 121 P0822121 ONE-SHOT OILER ASSEMBLY

60 P0822060 WAY WIPER (REAR) 122 P0822122 PIPE CONNECTOR M8-1 X 25

61 P0822061 WAY WIPER (FRONT) 123 P0822123 FLAT WASHER 8MM

62 P0822062 CAP SCREW M5-.8 X 12 124 P0822124 OIL DISTRIBUTOR 4-PORT M8-1

63 P0822063 X-AXIS SCALE INDICATOR 125 P0822125 TUBING CONNECTOR M8-1 X 8

65 P0822065 ADJUSTABLE HANDLE M8-1.25 X 35 126 P0822126 OIL DISTRIBUTOR 5-PORT M8-1

66 P0822066 Y-AXIS GIB 127 P0822127 TUBING SHEATH HNL 4-600

67 P0822067 LONGITUDINAL LEADSCREW NUT 128 P0822128 RIGHT-ANGLE FITTING M8-1 X 8

69 P0822069 LONGITUDINAL LEADSCREW 129 P0822129 PIPE JOINT M8-1

70 P0822070 WORK TABLE 130 P0822130 STRAIGHT COUPLING M8-1

72 P0822072 X-AXIS LEADSCREW BRACKET 131 P0822131 TUBING (NYLON)

73 P0822073 CAP SCREW M6-1 X 45 132 P0822132 FLAT WASHER 6MM

74 P0822074 INT THREADED TAPER PIN 8 X 50 133 P0822133 CAP SCREW M6-1 X 20

-8-

Model G0822 (Mfd. Since 06/17)

Page 9

Headstock

292

207

224

225

244

245

246

248

252

247

248

249

250

251

253 254

255

228

262

294

297

226

263

256

298

227

242

261

293

296

243

257

223

295

206

284

229

220

258

211

222

214

213

212

302

219

218

217

216

215

201

221

288

286

285

266

291

202

269

260

259

287

289

210

209

203

283

282

230

267

231

290

232

291

268

271

270

234

235

204

272

273

274

238

233

236

281

278

240 241

237

205-1

205-3

205-2

205

275

239

205-3

280

279

277

276

264

Model G0822 (Mfd. Since 06/17)

264

265

208

299

301

300

-9-

Page 10

Headstock Parts List

REF PART # DESCRIPTION REF PART # DESCRIPTION

201 P0822201 SPINDLE HEAD 251 P0822251 HANDWHEEL TYPE-21 115D X 12B-K X M18-2.5

202 P0822202 ROCKER ARM BRIDGE 252 P0822252 SET SCREW M5-.8 X 16

203 P0822203 MOTOR BRACKET 253 P0822253 HANDLE W/O SHAFT 18 X 65, 8

204 P0822204 MOTOR MOUNTING PLATE 254 P0822254 HANDLE 58L, M6-1 X 10, 10 OD

205 P0822205 MOTOR 2 HP 220V 3-PH 255 P0822255 QUILL LOCK SCREW M8-1.25 X 125

205-1 P0822205-1 MOTOR FAN COVER 256 P0822256 LOCK SET (OUTER)

205-2 P0822205-2 MOTOR FAN 257 P0822257 SPACER

205-3 P0822205-3 BALL BEARING 6205ZZ 258 P0822258 LOCK SET (INNER)

206 P0822206 BELT HOUSING BASE 259 P0822259 SET SCREW M6-1 X 8 CONE-PT

207 P0822207 BELT HOUSING COVER 260 P0822260 SET SCREW M6-1 X 8

208 P0822208 SPINDLE R8 261 P0822261 QUILL DOG

209 P0822209 BEARING COVER 262 P0822262 SET SCREW M6-1 X 10

210 P0822210 TAPERED ROLLER BEARING 30207 263 P0822263 COMPRESSION SPRING 11 X 48

211 P0822211 SPINDLE SLEEVE 264 P0822264 DEPTH STOP LIMIT NUT M12-1

212 P0822212 TAPERED ROLLER BEARING 30206 265 P0822265 LEADSCREW

213 P0822213 TABBED WASHER 30MM 266 P0822266 T-BOLT M10-1.5 X 40

214 P0822214 SPANNER NUT M30-1.5 267 P0822267 FLAT WASHER 10MM

215 P0822215 INT RETAINING RING 75MM 268 P0822268 HEX NUT M10-1.5

216 P0822216 BALL BEARING 6009ZZ 269 P0822269 T-BOLT M10-1.5 X 40

217 P0822217 BALL BEARING 6009ZZ 270 P0822270 FLAT WASHER 10MM

218 P0822218 SPINDLE COVER 271 P0822271 HEX NUT M10-1.5

219 P0822219 PHLP HD SCR M5-.8 X 12 272 P0822272 T-BOLT M10-1.5 X 40

220 P0822220 SHAFT 273 P0822273 FLAT WASHER 10MM

221 P0822221 SPINDLE PULLEY 274 P0822274 HEX NUT M10-1.5

222 P0822222 SPANNER NUT M42 X 1.5 275 P0822275 DOWEL PIN 14 X 55

223 P0822223 SPANNER NUT M42 X 1.5 276 P0822276 COMPRESSION SPRING 11 X 48

224 P0822224 SPINDLE RETURN NUT M18-1.5 277 P0822277 BUSHING

225 P0822225 SET SCREW M6-1 X 10 278 P0822278 ADJUSTABLE HANDLE M8-1.25 X 25

226 P0822226 RETURN SPRING COVER (LEFT) 279 P0822279 FLAT WASHER 8MM

227 P0822227 CLUTCH 280 P0822280 HEX BOLT M8-1.25 X 20

228 P0822228 COMPRESSION SPRING 25 X 33 281 P0822281 MACHINE KEY 8 X 8 X 35

229 P0822229 GEAR 48T 282 P0822282 STUD-SE M12-1.75 X 155, 12

230 P0822230 MACHINE KEY 6 X 6 X 15 283 P0822283 HEX NUT M12-1.75

231 P0822231 GEAR SHAFT 284 P0822284 RETAINING RING

232 P0822232 TORSION SPRING 32 X 80 285 P0822285 MAGNETIC BEAD

233 P0822233 RETURN SPRING COVER (RIGHT) 286 P0822286 SENSOR BRACKET

234 P0822234 OIL CUP 8MM 287 P0822287 SENSOR

235 P0822235 CAP SCREW M5-.8 X 20 288 P0822288 CAP SCREW M4-.7 X 16

236 P0822236 EXT RETAINING RING 19MM 289 P0822289 HEX BOLT M6-1 X 35

237 P0822237 HANDLE HUB 290 P0822290 MOTOR PULLEY

238 P0822238 CAP SCREW M8-1.25 X 25 291 P0822291 SET SCREW M8-1.25 X 10

239 P0822239 HEX NUT M10-1.5 292 P0822292 V-BELT V13 X 1395

240 P0822240 HANDLE SHAFT M10-1.5 X 240 293 P0822293 BELT HOUSING HINGE

241 P0822241 HANDLE M10-1.5 X 24 X 32 (PLASTIC) 294 P0822294 CAP SCREW M6-1 X 12

242 P0822242 GEAR SHAFT 295 P0822295 CAP SCREW M6-1 X 12

243 P0822243 MACHINE KEY 4 X 4 X 20 296 P0822296 COVER HINGE 40 X 40

244 P0822244 THRUST BEARING 51102 297 P0822297 FLAT HD SCR M5-.8 X 12

245 P0822245 SHAFT SLEEVE 298 P0822298 CONTROL PANEL ASSEMBLY

246 P0822246 CAP SCREW 299 P0822299 SET SCREW M5-.8 X 6

247 P0822247 THRUST BEARING 51102 300 P0822300 SET SCREW M5-.8 X 6

248 P0822248 HEX NUT M14-1.5 THIN 301 P0822301 DRAWBAR 7/16-20

249 P0822249 GRADUATED DIAL 302 P0822302 SEAL

250 P0822250 KNOB BOLT M5-.8 X 12 KN

-10 -

Model G0822 (Mfd. Since 06/17)

Page 11

Electrical Components & Accessories

Electrical Components

3/L2

20

OFF

Test

401

5/L3

ON

QF1

CHINT

NXB-83

C2

402

A1

1L1

3L2 5L3

13NO 21NC

KA Contactor

Siemens 3TB41 24V

22E

14NO 22NC 32NC 44NO

2T1 4T2 6T3

403

1/L1

21 22 13 14

25

23

20-25A

NS2-25

CHINT

2/T1 4/T2 6/T3

405

406

429

434

433

427

432

31NC 43NO

407

A2

E&E HH52P-L

24V %A

MOTOR MICRO DRIVER

DELTA VFD-E

MI2

MI4

MI6

MI1

MI3

MI5

U

T1

GND

PE 0 220 230 380 400

KA

430

S

R

L2

L1

DCM

DCM

24V

DCM

VT2W

T3

Transformer

426

T

L3

AFM

MCM

ACI

ACM

AVI

ACM

AVI

B1+B2

JBK5-40VA

0 24

435

MO1

10V

10V

404

RB

RCRA

GND

428

TC

408

416

418

419

420

409

Potentiometer

421

424

Control Panel

DRO

FOR/REV Switch

1

NC

2

E-Stop

2

1NC

412

Sensor Circuit Board

425

2

NC

1

413

417

422

410

415

431

Start Button

Stop Button

2

414

423

411

1NC

REF PART # DESCRIPTION REF PART # DESCRIPTION

401 P0822401 ON/OFF SWITCH CHINT NS2-25 20-25A 419 P0822419 HEX WRENCH 5MM

402 P0822402 CIRCUIT BREAKER CHINT NXB-83 C2 420 P0822420 HEX WRENCH 4MM

403 P0822403 CONTACTOR SIEMENS 3TB41 24V 421 P0822421 HEX WRENCH 3MM

404 P0822404 MICRO VFD DELTA VFD-E 422 P0822422 WRENCH 12 X 14MM OPEN-ENDS

405 P0822405 TERMINAL BAR 1P 423 P0822423 WRENCH 17 X 19MM OPEN-ENDS

406 P0822406 TERMINAL BAR (GROUNDING) 1P 424 P0822424 SCREWDRIVER FLAT #2

407 P0822407 RELAY E & E HH52P-L 24V 5A 425 P0822425 SCREWDRIVER PHILLIPS #2

408 P0822408 TRANSFORMER BEJING AOHENGA JBK5-40VA 426 P0822426 ADAPTER MT#3-MT#2

409 P0822409 SPINDLE DIGITAL READOUT SN161209 427 P0822427 DRILL CHUCK ARBOR R8-B16

410 P0822410 FOR/REV SWITCH 428 P0822428 SPINDLE SLEEVE R8-MT#3

411 P0822411 ON BUTTON 429 P0822429 CHUCK KEY

412 P0822412 POTENTIOMETER 430 P0822430 DRILL CHUCK B16 1-13MM

413 P0822413 E-STOP BUTTON 431 P0822431 BOTTLE FOR OIL

414 P0822414 OFF BUTTON 432 P0822432 T-BOLT M12-1.75 X 55

415 P0822415 SENSOR CIRCUIT BOARD 433 P0822433 FLAT WASHER 12MM

416 P0822416 ELECTRICAL BOX 434 P0822434 HEX NUT M12-1.75

417 P0822417 TOOLBOX 435 P0822435 DRIFT KEY

418 P0822418 HEX WRENCH 6MM

Model G0822 (Mfd. Since 06/17)

-11-

Page 12

G0822 Machine Labels B

(11/09/16)

• Label is actual size

• Label must be made of

oil-resistant material

***These labels must have individual letters/numbers. Do not print with clear background.

grizzly.com

***

G0822

***

To reduce risk of death

or serious injury, read

manual BEFORE using

machine.

To get a new manual, call

(800) 523-4777 or go to

www.grizzly.com.

WARNING!

K

CO

H

S

/Y

RU

J

NI

!D

RAZA

H

rew

op

tc

e

n

noc

s

iD

,

s

tne

m

tsu

jda

e

r

o

feb

ro

,ec

nan

e

t

n

iam

.

e

c

ivr

es

Always keep this

cover closed

during operation.

PINCH

HAZARD!

WARNING!

COLOR CODES

GRIZZLY BEIGE

PANTONE 7527 C

WARNING!

ENTANGLEMENT

HAZARD!

Tie back long hair, roll up

long sleeves, and remove

loose clothing, jewelry, or

gloves to prevent getting

caught in moving parts.

Always wear

ANSI-approved safety

glasses and face shield

when using this

machine.

EYE/FACE INJURY

HAZARD!

G0822 Machine Labels B

(11/09/16)

• Label is actual size

• Label must be made of

oil-resistant material

***These labels must have individual letters/numbers. Do not print with clear background.

grizzly.com

***

To reduce risk of death

or serious injury, read

manual BEFORE using

machine.

To get a new manual, call

(800) 523-4777 or go to

www.grizzly.com.

WARNING!

K

C

OHS/

YRU

J

N

I

!D

RAZ

AH

r

e

wop t

c

e

n

n

oc

si

D

,s

t

n

emts

uj

d

a

er

o

f

e

b

r

o ,

e

cn

a

netn

ia

m

.

e

c

i

v

res

Always keep this

cover closed

during operation.

PINCH

HAZARD!

WARNING!

COLOR CODES

GRIZZLY BEIGE

PANTONE 7527 C

WARNING!

ENTANGLEMENT

HAZARD!

Tie back long hair, roll up

long sleeves, and remove

loose clothing, jewelry, or

gloves to prevent getting

caught in moving parts.

Always wear

ANSI-approved safety

glasses and face shield

when using this

machine.

EYE/FACE INJURY

HAZARD!

(11/09/16)

• Label is actual size

• Label must be made of

oil-resistant material

(11/09/16)

• Scale = 1:1

(unless otherwise noted)

• Labels MUST be made of

chemical-resistant material

• Lubricant: Use Grizzly T23962

Machine Oil or ISO 68 equivalent.

• To operate pump, pull handle six

times every 4 hours of use.

COLOR CODES

GRIZZLY LOGO RED

PANTONE 711C or RAL 3020

PANTONE 151 C or RAL 2005

WARNING

NOTICE

PANTONE 3005 C or RAL 5005

(11/09/16)

• Label is actual size

• Label must be made of

oil-resistant material

To reduce risk of death

or serious injury, read

manual BEFORE using

machine.

To get a new manual, call

(800) 523-4777 or go to

www.grizzly.com.

WARNING!

(11/09/16)

• Label is actual size

• Label must be made of

oil-resistant material

To reduce risk of death

or serious injury, read

manual BEFORE using

machine.

To get a new manual, call

(800) 523-4777 or go to

www.grizzly.com.

WARNING!

INJURY/SHOCK

HAZARD!

Disconnect power

before adjustments,

maintenance, or

service.

Always keep this

cover closed

during operation.

PINCH

HAZARD!

WARNING!

WARNING!

ENTANGLEMENT

HAZARD!

Tie back long hair, roll up

long sleeves, and remove

loose clothing, jewelry, or

gloves to prevent getting

caught in moving parts.

(11/09/16)

• Label is actual size

• Label must be made of

oil-resistant material

To reduce risk of death

or serious injury, read

manual BEFORE using

machine.

To get a new manual, call

(800) 523-4777 or go to

www.grizzly.com.

WARNING!

Always keep this

cover closed

during operation.

PINCH

HAZARD!

WARNING!

WARNING!

ENTANGLEMENT

HAZARD!

Tie back long hair, roll up

long sleeves, and remove

loose clothing, jewelry, or

gloves to prevent getting

caught in moving parts.

(11/09/16)

• Label is actual size

• Label must be made of

oil-resistant material

To reduce risk of death

or serious injury, read

manual BEFORE using

machine.

To get a new manual, call

(800) 523-4777 or go to

www.grizzly.com.

WARNING!

WARNING!

ENTANGLEMENT

HAZARD!

Tie back long hair, roll up

long sleeves, and remove

loose clothing, jewelry, or

gloves to prevent getting

caught in moving parts.

• Label is actual size

• Label must be made of

oil-resistant material

COLOR CODES

GRIZZLY LOGO RED

PANTONE 711C or RAL 3020

PANTONE 151 C or RAL 2005

WARNING

NOTICE

PANTONE 3005 C or RAL 5005

• Label is actual size

• Label must be made of

oil-resistant material

501

WARNING!

To reduce risk of death

or serious injury, read

manual BEFORE using

machine.

To get a new manual, call

(800) 523-4777 or go to

www.grizzly.com.

502

Labels

503 504

WARNING!

ENTANGLEMENT

HAZARD!

Tie back long hair, roll up

long sleeves, and remove

loose clothing, jewelry, or

gloves to prevent getting

caught in moving parts.

EYE/FACE INJURY

HAZARD!

Always wear

ANSI-approved safety

glasses and face shield

when using this

machine.

505

INJURY/SHOCK

HAZARD!

Disconnect power

before adjustments,

maintenance, or

service.

506

WARNING!

PINCH

HAZARD!

Always keep this

cover closed

during operation.

502

• Lubricant: Use Grizzly T23962

Machine Oil or ISO 68 equivalent.

• To operate pump, pull handle six

times every 4 hours of use.

511

512

510

508

509

507

MODEL G0822

VS MILLING MACHINE

w/POWER FEED

Specifications

Power Requirement: 220V, 1-Ph, 15A, 60 Hz

Motor: 2 HP, 220V, 3-Ph, 6.4A

Max. Distance Spindle-to-Column: 5-1/4"

Max. Distance Spindle-to-Table: 11"

Spindle Travel: 3"

Spindle Taper: R-8

Drawbar Thread Size: 7/16"-20

Spindle Speeds: (Variable) 100–2500 RPM

Longitudinal Table Travel: 14-1/4"

Cross Table Travel: 6"

Vertical Table Travel: 11"

Head Tilt: 45° Left/Right

Turret Swivel: 45° Left/Right

Weight: 810 lbs.

To reduce the risk of serious personal injury while using this machine:

1. Read and understand owner’s manual before starting.

2. Always wear approved safety glasses AND a face shield.

3. Only plug power cord into a grounded outlet.

4. Disconnect power before setting up, adjusting, or servicing.

5. Tie back long hair, roll up sleeves, and DO NOT wear loose

clothing, gloves, or jewelry.

6. Keep all guards in place and covers closed during operation.

7. Never use hands to secure workpiece to table during

operation—use clamps or a vise.

8. Avoid positioning hands where they could slip into rotating bits.

9. Never attempt to slow or stop spindle with hands or tools.

10. Always use proper feeds and speeds for operation and workpiece.

11. Never leave machine running unattended.

12. DO NOT expose to rain or use in wet locations.

13. Prevent unauthorized use by children or untrained users.

Mfd. for Grizzly in China

Date

S/N

502

REF PART # DESCRIPTION REF PART # DESCRIPTION

501 P0822501 READ MANUAL LABEL 507 P0822507 MACHINE ID LABEL

502 P0822502 ELECTRICITY LABEL 508 P0822508 TOUCH-UP PAINT, GRIZZLY GREEN

503 P0822503 ENTANGLEMENT HAZARD LABEL 509 P0822509 GRIZZLY.COM LABEL

504 P0822504 EYE/FACE INJURY HAZARD LABEL 510 P0822510 MODEL NUMBER LABEL

505 P0822505 DISCONNECT POWER LABEL 511 P0822511 LUBRICATION NOTICE

506 P0822506 PINCH HAZARD LABEL 512 P0822512 TOUCH-UP PAINT, GRIZZLY BEIGE

-12-

Model G0822 (Mfd. Since 06/17)

Loading...

Loading...