Page 1

READ THIS FIRST

224V2 P0793224V2 SPINDLE FEED COVER V2.01.22

Model G0793

***IMPORTANT UPDATE***

For Machines Mfd. Since 01/22

and Owner's Manual Revised 02/19

For questions or help with this product contact Tech Support at (570) 546-9663 or techsupport@grizzly.com

The following changes were recently made since the owner's manual was printed:

• Oil sight glass and oil fill plug have been removed from downfeed gearbox.

• Lubrication requirement for downfeed gearbox has been revised.

• Labels & Cosmetics has been revised.

Aside from this information, all other content in the owner's manual applies and MUST be read and understood for your own safety. IMPORTANT: Keep this update with the owner's manual for future reference.

For questions or help, contact our Tech Support at (570) 546-9663 or techsupport@grizzly.com.

Revised Parts

REF PART # DES CRIPTIO N

Revised Labels

224V2

Label Removed

Lubrication

COPYRIGHT © JULY, 2022 BY GRIZZLY INDUSTRIAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

Downfeed Gearbox

The downfeed gearbox is lubricated with grease

and sealed at the factory and requires no maintenance from the user.

#JP22415 PRINTED IN CHINA

Page 2

MODEL G0793

HEAVY-DUTY DRILL PRESS

w/AUTO-FEED & L-TABLE

OWNER'S MANUAL

(For models manufactured since 02/15)

COPYRIGHT © MAY, 2015 BY GRIZZLY INDUSTRIAL, INC. REVISED FEBRUARY, 2019 (MN)

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

#BB17384 PRINTED IN CHINA

V1. 0 2 .19

Page 3

This manual provides critical safety instructions on the proper setup,

operation, maintenance, and service of this machine/tool. Save this

document, refer to it often, and use it to instruct other operators.

Failure to read, understand and follow the instructions in this manual

may result in fire or serious personal injury—including amputation,

electrocution, or death.

The owner of this machine/tool is solely responsible for its safe use.

This responsibility includes but is not limited to proper installation in

a safe environment, personnel training and usage authorization,

proper inspection and maintenance, manual availability and comprehension, application of safety devices, cutting/sanding/grinding tool

integrity, and the usage of personal protective equipment.

The manufacturer will not be held liable for injury or property damage

from negligence, improper training, machine modifications or misuse.

Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State

of California to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

Work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

Page 4

Table of Contents

INTRODUCTION ............................................... 2

Contact Info.................................................... 2

Manual Accuracy ........................................... 2

Identification ................................................... 3

Controls & Components ................................. 4

Machine Data Sheet ...................................... 5

SECTION 1: SAFETY ....................................... 7

Safety Instructions for Machinery .................. 7

Additional Safety for Drill Presses ................. 9

SECTION 2: POWER SUPPLY ...................... 10

SECTION 3: SETUP ....................................... 12

Unpacking .................................................... 12

Needed for Setup ......................................... 12

Inventory ...................................................... 12

Site Considerations ...................................... 14

Lifting & Placing ........................................... 15

Anchoring to Floor ....................................... 15

Arbor/Chuck Assembly ................................ 16

Initial Lubrication .......................................... 16

Power Connection........................................ 17

Test Run ...................................................... 18

Spindle Break-In .......................................... 20

SECTION 4: OPERATIONS ........................... 21

Operation Overview ..................................... 21

Installing/Removing Tooling ......................... 22

Depth Stop ................................................... 23

Positioning Table ......................................... 24

Spindle Speed.............................................. 24

Calculating Spindle Speed for Drilling ......... 26

Drilling Mode ................................................ 27

Auto-Feed .................................................... 28

Tapping Mode .............................................. 29

Coolant System............................................ 29

SECTION 5: ACCESSORIES ......................... 30

SECTION 6: MAINTENANCE ......................... 32

Schedule ...................................................... 32

Cleaning and Protecting .............................. 32

Lubrication ................................................... 33

Adding/Changing Coolant ............................ 36

SECTION 7: SERVICE ................................... 37

Troubleshooting ........................................... 37

Replacing Lamp Bulb ................................... 39

Adjusting Torque Limiter .............................. 39

SECTION 8: WIRING ...................................... 40

Wiring Safety Instructions ............................ 40

Wiring Overview ........................................... 41

Component Location .................................... 41

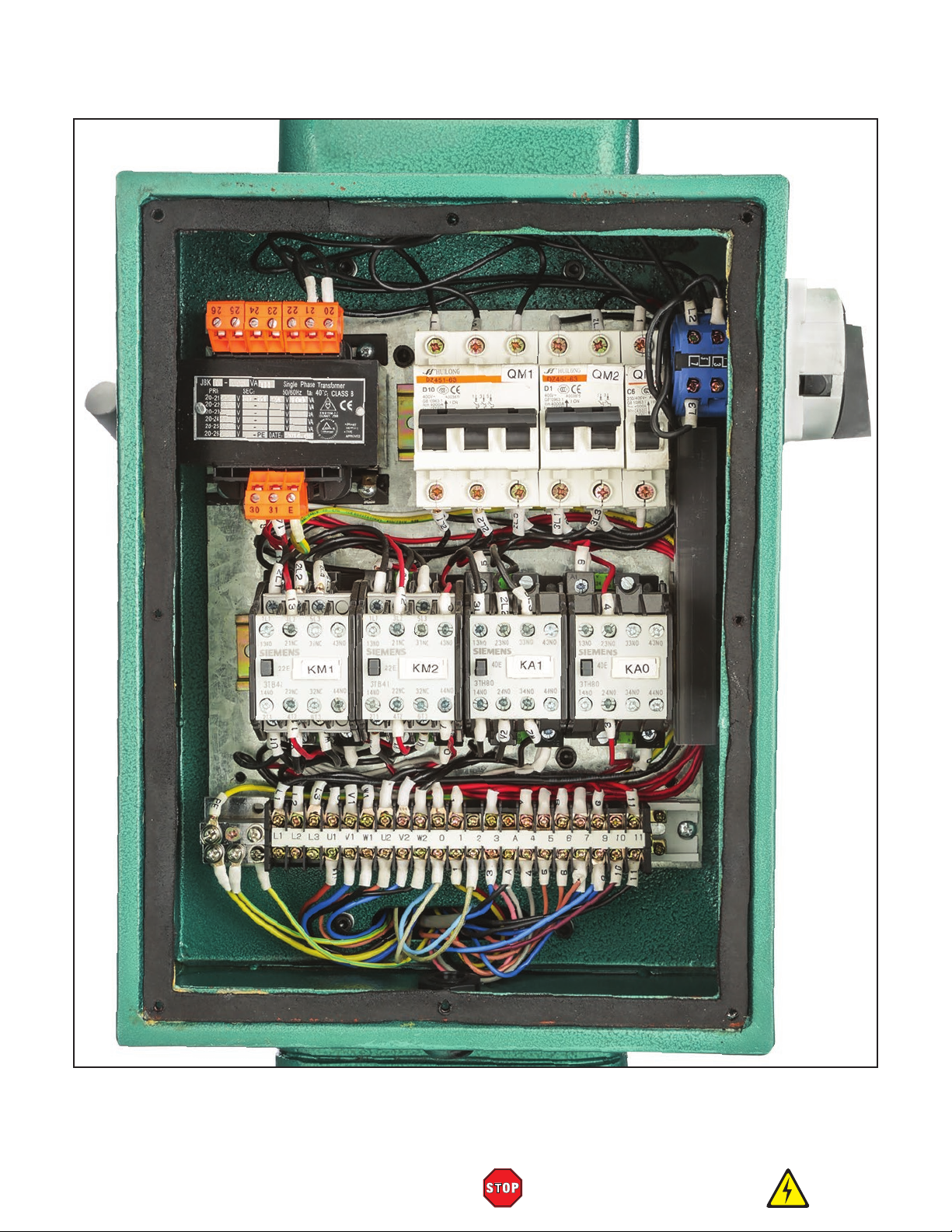

Electrical Panel Wiring ................................. 42

Electrical Panel Photo .................................. 43

Control Panel Wiring .................................... 44

Control Panel Photo ..................................... 45

Spindle Motor Wiring ................................... 46

Coolant Pump Wiring ................................... 46

SECTION 9: PARTS ....................................... 47

Table Support & Coolant ............................. 47

Gearbox ....................................................... 48

Downfeed Gearbox ...................................... 50

Headstock .................................................... 51

Electrical ...................................................... 53

Labels & Cosmetics ..................................... 54

WARRANTY & RETURNS ............................. 57

Page 5

INTRODUCTION

We are proud to provide a high-quality owner’s

manual with your new machine!

We

instructions, specifications, drawings, and photographs

in this manual. Sometimes we make mistakes, but

our policy of continuous improvement also means

that

you receive is

slightly different than shown in the manual

If you find this to be the case, and the difference

between the manual and machine leaves you

confused or unsure about something

check our

website for an updated version. W

current

manuals and

on our web-

site at

Alternatively, you can call our Technical Support

for help. Before calling, make sure you write down

the

from

the machine ID label (see below). This information

is required for us to provide proper tech support,

and it helps us determine if updated documentation is available for your machine.

We stand behind our machines! If you have questions or need help, contact us with the information

below. Before contacting, make sure you get the

serial number

machine ID label. This will help us help you faster.

We want your feedback on this manual. What did

you like about it? Where could it be improved?

Please take a few minutes to give us feedback.

Email: manuals@grizzly.com

Contact Info

and manufacture date from the

Grizzly Technical Support

1815 W. Battlefield

Springfield, MO 65807

Phone: (570) 546-9663

Email: techsupport@grizzly.com

Grizzly Documentation Manager

P.O. Box 2069

Bellingham, WA 98227-2069

Manual Accuracy

made every effort to be exact with the

sometimes the machine

.

,

e post

manual updates for free

www.grizzly.com.

Manufacture Date and Serial Number

Manufacture Date

Serial Number

-2-

Model G0793 (Mfd. Since 02/15)

Page 6

Identification

To reduce your risk of

serious injury, read this

entire manual BEFORE

Become familiar with the names and locations of the controls and features shown below to better understand

the instructions in this manual.

C

K

B

D

A

E

I

F

J

H

G

L

M

N

O

A. Master Power Switch

B. Lifting Eye Bolt

C. Motor

D. Speed Control Levers

E. Control Panel (see Page 4 for details)

F. Chip Guard

G. Coolant Pump

H. Automatic Drift Knob

Model G0793 (Mfd. Since 02/15)

I. Automatic Downfeed Adjustment Knob

J. Coolant Nozzle

K. Oil Sight Glass

L. Depth Stop Knob

M. Coarse Downfeed Handles

N. Table Lock Handles

O. Table Height Adjustment Crank

using machine.

-3-

Page 7

Controls & Components

Refer to Figures 1 and the following descriptions to become familiar with the basic controls and components of this machine. Understanding these items and how they work will help you understand the rest of

the manual and stay safe when operating this machine.

H

G

F

E

D

C

B

A

Figure 1. G0793 Headstock Controls and Components.

A. Spindle Stop Button: Stops spindle rotation.

B. Spindle Reverse Button: Reverses direction

of spindle rotation during tapping operations.

C. Spindle Speed/Direction Switch: Selects

high/low range for spindle speed and spindle

direction.

D. Automatic Drift: When pushed in, tooling

can be removed by returning spindle to the

"up" position.

I

J

K

L

M

N

H. Spindle Speed Levers: Used to select spin-

dle speed within selected speed range.

I. Work Lamp Switch: Turns work light ON or

OFF.

J. Depth Stop Knoba Used to set depth stop.

K. EMERGENCY STOP Button: Immediately

cuts power to motor and control panel when

pressed. Remains depressed until button is

reset by twisting clockwise.

E. Automatic Downfeed Adjustment Knob:

Selects rate of powered downfeed.

F. Master Power Switch: Enables power flow

to machine.

G. Coolant Pump Switch: Turns pump ON,

sending coolant to nozzle.

-4-

L. Drilling/Tapping Switch: Selects between

drilling and tapping modes.

M. Downfeed Engagement Lever: Engages

powered downfeed when pushed up.

When pulled down disengages powered

downfeed.

N. Spindle Start Button: Starts spindle rotation

when master power switch is set to the ON

position.

Model G0793 (Mfd. Since 02/15)

Page 8

Machine Data Sheet

MACHINE DATA

SHEET

Customer Service #: (570) 546-9663 · To Order Call: (800) 523-4777 · Fax #: (800) 438-5901

MODEL G0793 HEAVY‐DUTY DRILL PRESS WITH AUTO‐

FEED, TAPPING AND L‐TABLE

Product Dimensions:

Weight............................................................................................................................................................ 1026 lbs.

Width (side-to-side) x Depth (front-to-back) x Height..................................................................... 22 x 37 x 89-1/2 in.

Footprint (Length x Width)............................................................................................................................ 29 x 20 in.

Shipping Dimensions:

Type.......................................................................................................................................................... Wood Crate

Content........................................................................................................................................................... Machine

Weight............................................................................................................................................................ 1202 lbs.

Length x Width x Height....................................................................................................................... 90 x 28 x 45 in.

Must Ship Upright.................................................................................................................................................... No

Electrical:

Power Requirement................................................................................................................... 220V, 3-Phase, 60 Hz

Full-Load Current Rating....................................................................................................................................... 6.6A

Minimum Circuit Size.............................................................................................................................................. 15A

Connection Type....................................................................................................................................... Cord & Plug

Power Cord Included............................................................................................................................................... No

Recommended Power Cord............................................................................... "S"-Type, 4-Wire, 14 AWG, 300 VAC

Plug Included........................................................................................................................................................... No

Recommended Plug Type................................................................................................................................... 15-15

Switch Type.................................................................................................... Magnetic Switch w/Overload Protection

Recommended Phase Converter....................................................................................................................... G5844

Motors:

Coolant Pump

Main

Horsepower................................................................................................................................................. 75W

Phase.................................................................................................................................................... 3-Phase

Amps........................................................................................................................................................... 0.2A

Speed................................................................................................................................................ 1725 RPM

Type..................................................................................................................................................... Induction

Power Transfer ............................................................................................................................... Direct Drive

Bearings..................................................................................................... Shielded & Permanently Lubricated

Horsepower................................................................................................................................. 1-1/8 HP/2 HP

Phase.................................................................................................................................................... 3-Phase

Amps........................................................................................................................................................... 6.4A

Speed................................................................................................................................ 875 RPM/1725 RPM

Type........................................................................................................................................... TEFC Induction

Power Transfer ................................................................................................................................. Gear Drive

Bearings..................................................................................................... Shielded & Permanently Lubricated

Model G0793 (Mfd. Since 02/15)

-5-

Page 9

Main Specifications:

Operation Information

Swing...................................................................................................................................................... 27.5 in.

Spindle Taper............................................................................................................................................ MT#4

Spindle Travel.............................................................................................................................................. 7 in.

Max. Distance From Spindle to Column.............................................................................................. 13-3/4 in.

Max. Distance From Spindle to Table................................................................................................. 30-3/4 in.

Range of Spindle Speeds............................................................................................................. 60-1740 RPM

Drilling Capacity (Mild Steel)......................................................................................................................... 1 in

Tapping Capacity......................................................................................................................................... 1 in.

Power Down Feed Speeds..................................................................................................... 0.10mm, 0.20mm

Spindle Information

Quill Diameter.............................................................................................................................................. 3 in.

Table Information

Table Length.............................................................................................................................................. 22 in.

Table Width....................................................................................................................................... 19-1/16 in.

Vertical Table Travel.................................................................................................................................. 20 in.

Number of T-Slots............................................................................................................................................ 2

T-Slot Size................................................................................................................................................ 5/8 in.

Other Specifications:

Country of Origin ................................................................................................................................................ China

Warranty ........................................................................................................................................................... 1 Year

Approximate Assembly & Setup Time .............................................................................................................. 1 Hour

Serial Number Location ............................................................................................ Machine ID Label on Headstock

ISO 9001 Factory .................................................................................................................................................. Yes

Certified by a Nationally Recognized Testing Laboratory (NRTL) .......................................................................... No

Features:

7" of spindle travel

Recycling coolant system

2-speed power downfeed

Oil-bath gearhead

MT#4 spindle w/quick-removal feature

Spindle speeds controlled by gearhead levers

Spindle safety shield

Halogen work light

Power tapping capability

L-shaped table w/T-slots for great versatility

-6-

Model G0793 (Mfd. Since 02/15)

Page 10

SECTION 1: SAFETY

For Your Own Safety, Read Instruction

Manual Before Operating This Machine

The purpose of safety symbols is to attract your attention to possible hazardous conditions.

This manual uses a series of symbols and signal words intended to convey the level of importance of the safety messages. The progression of symbols is described below. Remember that

safety messages by themselves do not eliminate danger and are not a substitute for proper

accident prevention measures. Always use common sense and good judgment.

Indicates an imminently hazardous situation which, if not avoided,

WILL result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

COULD result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

MAY result in minor or moderate injury. It may also be used to alert

against unsafe practices.

Alerts the user to useful information about proper operation of the

NOTICE

machine to avoid machine damage.

Safety Instructions for Machinery

OWNER’S MANUAL. Read and understand this

owner’s manual BEFORE using machine.

TRAINED OPERATORS ONLY. Untrained operators have a higher risk of being hurt or killed.

Only allow trained/supervised people to use this

machine. When machine is not being used, disconnect power, remove switch keys, or lock-out

machine to prevent unauthorized use—especially

around children. Make your workshop kid proof!

DANGEROUS ENVIRONMENTS. Do not use

machinery in areas that are wet, cluttered, or have

poor lighting. Operating machinery in these areas

greatly increases the risk of accidents and injury.

MENTAL ALERTNESS REQUIRED. Full mental

alertness is required for safe operation of machinery. Never operate under the influence of drugs or

alcohol, when tired, or when distracted.

ELECTRICAL EQUIPMENT INJURY RISKS.

You can be shocked, burned, or killed by touching

live electrical components or improperly grounded

machinery. To reduce this risk, only allow qualified

service personnel to do electrical installation or

repair work, and always disconnect power before

accessing or exposing electrical equipment.

DISCONNECT POWER FIRST.

nect machine from power supply BEFORE making adjustments, changing tooling, or servicing

machine. This prevents an injury risk from unintended startup or contact with live electrical components.

EYE PROTECTION. Always wear ANSI-approved

safety glasses or a face shield when operating or

observing machinery to reduce the risk of eye

injury or blindness from flying particles. Everyday

eyeglasses are NOT approved safety glasses.

Always discon-

Model G0793 (Mfd. Since 02/15)

-7-

Page 11

WEARING PROPER APPAREL. Do not wear

clothing, apparel or jewelry that can become

entangled in moving parts. Always tie back or

cover long hair. Wear non-slip footwear to reduce

risk of slipping and losing control or accidentally

contacting cutting tool or moving parts.

HAZARDOUS DUST. Dust created by machinery

operations may cause cancer, birth defects, or

long-term respiratory damage. Be aware of dust

hazards associated with each workpiece material. Always wear a NIOSH-approved respirator to

reduce your risk.

HEARING PROTECTION. Always wear hearing protection when operating or observing loud

machinery. Extended exposure to this noise

without hearing protection can cause permanent

hearing loss.

REMOVE ADJUSTING TOOLS. Tools left on

machinery can become dangerous projectiles

upon startup. Never leave chuck keys, wrenches,

or any other tools on machine. Always verify

removal before starting!

USE CORRECT TOOL FOR THE JOB. Only use

this tool for its intended purpose—do not force

it or an attachment to do a job for which it was

not designed. Never make unapproved modifications—modifying tool or using it differently than

intended may result in malfunction or mechanical

failure that can lead to personal injury or death!

AWKWARD POSITIONS. Keep proper footing

and balance at all times when operating machine.

Do not overreach! Avoid awkward hand positions

that make workpiece control difficult or increase

the risk of accidental injury.

CHILDREN & BYSTANDERS. Keep children and

bystanders at a safe distance from the work area.

Stop using machine if they become a distraction.

GUARDS & COVERS. Guards and covers reduce

accidental contact with moving parts or flying

debris. Make sure they are properly installed,

undamaged, and working correctly BEFORE

operating machine.

FORCING MACHINERY. Do not force machine.

It will do the job safer and better at the rate for

which it was designed.

NEVER STAND ON MACHINE. Serious injury

may occur if machine is tipped or if the cutting

tool is unintentionally contacted.

STABLE MACHINE. Unexpected movement during operation greatly increases risk of injury or

loss of control. Before starting, verify machine is

stable and mobile base (if used) is locked.

USE RECOMMENDED ACCESSORIES. Consult

this owner’s manual or the manufacturer for recommended accessories. Using improper accessories will increase the risk of serious injury.

UNATTENDED OPERATION. To reduce the

risk of accidental injury, turn machine OFF and

ensure all moving parts completely stop before

walking away. Never leave machine running

while unattended.

MAINTAIN WITH CARE. Follow all maintenance

instructions and lubrication schedules to keep

machine in good working condition. A machine

that is improperly maintained could malfunction,

leading to serious personal injury or death.

DAMAGED PARTS. Regularly inspect machine

for damaged, loose, or mis-adjusted parts—or

any condition that could affect safe operation.

Immediately repair/replace BEFORE operating

machine. For your own safety, DO NOT operate

machine with damaged parts!

MAINTAIN POWER CORDS. When disconnecting cord-connected machines from power, grab

and pull the plug—NOT the cord. Pulling the cord

may damage the wires inside. Do not handle

cord/plug with wet hands. Avoid cord damage by

keeping it away from heated surfaces, high traffic

areas, harsh chemicals, and wet/damp locations.

EXPERIENCING DIFFICULTIES. If at any time

you experience difficulties performing the intended operation, stop using the machine! Contact our

Technical Support at (570) 546-9663.

-8-

Model G0793 (Mfd. Since 02/15)

Page 12

Additional Safety for Drill Presses

Serious injury or death can occur from getting clothing, jewelry, or long hair entangled in

rotating spindle or bit/cutting tool. Contact with rotating bit/cutting tool can result in severe cuts

or amputation of fingers. Flying metal chips can cause blindness or eye injuries. Broken bits/

cutting tools, unsecured workpieces, chuck keys, or other adjustment tools thrown from rotating

spindle can strike nearby operator or bystanders with deadly force. To reduce the risk of these

hazards, operator and bystanders MUST completely heed hazards and warnings below.

EYE/FACE/HAND PROTECTION. Flying chips

created by drilling can cause eye injuries or blindness. Always wear a face shield in addition to

safety glasses. Always keep hands and fingers

away from drill bit/cutting tool. Avoid awkward

hand positions, where a sudden slip could cause

hand to move into bit/cutting tool.

AVOIDING ENTANGLEMENT. DO NOT wear

loose clothing, gloves, or jewelry. Tie back long

hair. Keep all guards in place and secure. Always

allow spindle to stop on its own. DO NOT stop

spindle using your hand or any other object.

REMOVING ADJUSTMENT TOOLS. Chuck key,

wrenches, and other tools left on machine can

become deadly projectiles when spindle is started.

Remove all loose items or tools used on spindle

immediately after use.

CORRECT SPINDLE SPEED. Using wrong spindle speed can cause bits/cutting tools to break

and strike operator or bystanders. Follow recommended speeds and feeds for each size/type of

bit/cutting tool and workpiece material.

SECURING BIT/CUTTING TOOL. Firmly secure

bit/cutting tool in chuck so it cannot fly out of

spindle during operation or startup.

DRILLING PREPARATION. To avoid loss of drilling

control or bit breakage, only drill into a flat surface

that is approximately perpendicular to bit. Clear

table of all objects before starting spindle. Never

start spindle with bit pressed against workpiece.

SECURING TABLE AND HEADSTOCK. To avoid

loss of control leading to accidental contact with

tool/bit, tighten all table and headstock locks

before operating drill press.

WORKPIECE CONTROL. An unsecured

workpiece may unexpectedly shift, spin out of control, or be thrown if bit/cutting tool "grabs" during

operation. Clamp workpiece to table or in tablemounted vise, or brace against column to prevent

rotation. NEVER hold workpiece by hand during

operation. NEVER start machine with bit/cutting

tool touching workpiece; allow spindle to gain full

speed before drilling.

INSPECTING BIT/CUTTING TOOL. Damaged

bits/cutting tools may break apart during operation

and hit operator or bystanders. Dull bits/cutting

tools increase cutting resistance and are more

likely to grab and spin/throw workpiece. Always

inspect bits/cutting tools for sharpness, chips, or

cracks before each use. Replace dull, chipped, or

cracked bits/cutting tools immediately.

Like all machines there is danger associated

with this machine. Accidents are frequently

caused by lack of familiarity or failure to pay

attention. Use this machine with respect

and caution to lessen the possibility of

operator injury. If normal safety precautions

are overlooked or ignored, serious personal

injury may occur.

Model G0793 (Mfd. Since 02/15)

No list of safety guidelines can be complete.

Every shop environment is different. Always

consider safety first, as it applies to your

individual working conditions. Use this and

other machinery with caution and respect.

Failure to do so could result in serious personal injury, damage to equipment, or poor

work results.

-9-

Page 13

SECTION 2: POWER SUPPLY

Before installing the machine, consider the availability and proximity of the required power supply

circuit. If an existing circuit does not meet the

requirements for this machine, a new circuit must

be installed. To minimize the risk of electrocution,

fire, or equipment damage, installation work and

electrical wiring must be done by an electrician or

qualified service personnel in accordance with all

applicable codes and standards.

or equipment damage

may occur if machine is

not properly grounded

and connected to power

The full-load current rating is the amperage a

machine draws at 100% of the rated output power.

On machines with multiple motors, this is the

amperage drawn by the largest motor or sum of all

motors and electrical devices that might operate

at one time during normal operations.

The full-load current is not the maximum amount

of amps that the machine will draw. If the machine

is overloaded, it will draw additional amps beyond

the full-load rating.

If the machine is overloaded for a sufficient length

of time, damage, overheating, or fire may result—

especially if connected to an undersized circuit.

To reduce the risk of these hazards, avoid overloading the machine during operation and make

sure it is connected to a power supply circuit that

meets the specified circuit requirements.

For your own safety and protection of

Note: Circuit requirements in this manual apply to

a dedicated circuit—where only one machine will

be running on the circuit at a time. If machine will

be connected to a shared circuit where multiple

machines may be running at the same time, consult an electrician or qualified service personnel to

ensure circuit is properly sized for safe operation.

This machine is prewired to operate on a power

supply circuit that has a verified ground and meets

the following requirements:

A power supply circuit includes all electrical

equipment between the breaker box or fuse panel

in the building and the machine. The power supply circuit used for this machine must be sized to

safely handle the full-load current drawn from the

machine for an extended period of time. (If this

machine is connected to a circuit protected by

fuses, use a time delay fuse marked D.)

Availability

Electrocution, fire, shock,

supply.

Full-Load Current Rating

Circuit Requirements for 220V

Nominal Voltage .........20 8V, 22 0V, 23 0V, 24 0V

Cycle .......................................................... 60 Hz

Phase .................................................... 3-Phase

Power Supply Circuit ......................... 15 Amps

Plug/Receptacle ............................NEMA 15 -15

Cord ........“ S”-Type, 4-Wire, 14 AWG, 300 VAC

Full-Load Current Rating at 220V .... 6.6 Amps

-10 -

property, consult an electrician if you are

unsure about wiring practices or electrical

codes in your area.

Model G0793 (Mfd. Since 02/15)

Page 14

We do not recommend using an extension cord

with this machine.

cord, only use it if absolutely necessary and only

on a temporary basis.

Extension cords cause voltage drop, which can

damage electrical components and shorten motor

life. Voltage drop increases as the extension cord

size gets longer and the gauge size gets smaller

(higher gauge numbers indicate smaller sizes).

Any extension cord used with this machine must

be in good condition and contain a ground wire

and matching plug/receptacle. Additionally, it must

meet the following size requirements:

Improper connection of the equipment-grounding

wire can result in a risk of electric shock. The

wire with green insulation (with or without yellow

stripes) is the equipment-grounding wire. If repair

or replacement of the power cord or plug is necessary, do not connect the equipment-grounding

wire to a live (current carrying) terminal.

Check with a qualified electrician or service personnel if you do not understand these grounding

requirements, or if you are in doubt about whether

the tool is properly grounded. If you ever notice

that a cord or plug is damaged or worn, disconnect it from power, and immediately replace it with

a new one.

Serious injury could occur if you connect

process. DO NOT connect to power until

Grounding Instructions

This machine MUST be grounded. In the event

of certain malfunctions or breakdowns, grounding

reduces the risk of electric shock by providing a

path of least resistance for electric current.

The power cord and plug specified under “Circuit

Requirements for 220V”

has an equipment-grounding wire and a grounding prong. The plug must only be inserted into

a matching receptacle (outlet) that is properly

installed and grounded in accordance with all

local codes and ordinances (see figure below).

No adapter should be used with plug. If

plug does not fit available receptacle, or if

process. DO NOT connect to power until

on the previous page

GROUNDED

15-15 RECEPTACLE

15-15 PLUG

Current

Carrying

Grounding Pin

Prongs

Serious injury could occur if you connect

machine to power before completing setup

instructed later in this manual.

Extension Cords

Figure 2. Typical 15-15 plug and receptacle.

machine to power before completing setup

instructed later in this manual.

machine must be reconnected for use on a

different type of circuit, reconnection must

be performed by an electrician or qualified

service personnel, and it must comply with

all local codes and ordinances.

Model G0793 (Mfd. Since 02/15)

If you must use an extension

Minimum Gauge Size ...........................14 AWG

Maximum Length (Shorter is Better).......50 ft.

-11-

Page 15

SECTION 3: SETUP

This machine was carefully packaged for safe

transport. When unpacking, separate all enclosed

items from packaging materials and inspect them

for shipping damage.

,

please

IMPORTANT:

you are completely satisfied with the machine and

have resolved any issues between Grizzly or the

shipping agent. You MUST have the original pack-

aging to file a freight claim. It is also extremely

helpful if you need to return your machine later.

Keep children and pets away

from plastic bags or packing

materials shipped with this

The following is a list of items shipped with your

machine. Before beginning setup, lay these items

out and inventory them.

If any non-proprietary parts are missing (e.g. a

nut or a washer), we will gladly replace them; or

for the sake of expediency, replacements can be

obtained at your local hardware store.

Unpacking

If items are damaged

call us immediately at (570) 546-9663.

Save all packaging materials until

SUFFOCATION HAZARD!

Inventory

Inventory (Figure 3): Qty

A. Drill Chuck B16 3–16mm ............................ 1

B. Drill Chuck Arbor MT#4–B16 ...................... 1

C. Spindle Sleeve MT#4–MT#3 ...................... 1

D. Spindle Sleeve MT#4–MT#2 ...................... 1

E. Bottle for Oil ............................................... 1

F. Drift Key ...................................................... 1

G. Chuck Key .................................................. 1

H. Toolbox (not shown) ................................... 1

machine.

Needed for Setup

The following are needed to complete the setup

process, but are not included with your machine.

Description Qty

• Additional People ....................................... 1

• Safety Glasses ........................ 1 Per Person

• Cleaner/Degreaser ..................... As Needed

• Disposable Shop Rags ............... As Needed

• Forklift ......................................................... 1

• Lifting Sling (Rated 1500 lbs. Minimum) ..... 1

• Steel Bar Stock 1" x 3' ................................ 1

-12-

A

G

F

Figure 3. Toolbox inventory.

CB

D

E

NOTICE

If you cannot find an item on this list, carefully check around/inside the machine and

packaging materials. Often, these items get

lost in packaging materials while unpacking or they are pre-installed at the factory.

Model G0793 (Mfd. Since 02/15)

Page 16

The unpainted surfaces of your machine are

coated with a heavy-duty rust preventative that

prevents corrosion during shipment and storage.

This rust preventative works extremely well, but it

will take a little time to clean.

Be patient and do a thorough job cleaning your

machine. The time you spend doing this now will

give you a better appreciation for the proper care

of your machine's unpainted surfaces.

There are many ways to remove this rust preventative, but the following steps work well in a wide

variety of situations. Always follow the manufacturer’s instructions with any cleaning product you

use and make sure you work in a well-ventilated

area to minimize exposure to toxic fumes.

Before cleaning, gather the following:

• Disposable rags

• Cleaner/degreaser (WD•40 works well)

• Safety glasses & disposable gloves

• Plastic paint scraper (optional)

Basic steps for removing rust preventative:

1.

2.

3.

4.

Many cleaning solvents

work in a well-ventilated

Cleanup

Gasoline and petroleum

products have low flash

points and can explode

or cause fire if used to

clean machinery. Av oid

using these products

to clean machinery.

Put on safety glasses.

Coat the rust preventative with a liberal

amount of cleaner/degreaser, then let it soak

for 5–10 minutes.

Wipe off the surfaces. If your cleaner/degreas-

er is effective, the rust preventative will wipe

off easily. If you have a plastic paint scraper,

scrape off as much as you can first, then wipe

off the rest with the rag.

are toxic if inhaled. Only

area.

NOTICE

Avoid harsh solvents like acetone or brake

parts cleaner that may damage painted surfaces. Always test on a small, inconspicuous location first.

T23692—Orange Power Degreaser

A great product for removing the waxy shipping grease from the non-painted parts of the

machine during clean up.

Repeat Steps 2–3 as necessary until clean,

then coat all unpainted surfaces with a quality

metal protectant to prevent rust.

Model G0793 (Mfd. Since 02/15)

-13-

Page 17

Site Considerations

Weight Load

Refer to the

of your machine. Make sure that the surface upon

which the machine is placed will bear the weight

of the machine, additional equipment that may be

installed on the machine, and the heaviest workpiece that will be used. Additionally, consider the

weight of the operator and any dynamic loading

that may occur when operating the machine.

Space Allocation

Consider the largest size of workpiece that will

be processed through this machine and provide

enough space around the machine for adequate

operator material handling or the installation of

auxiliary equipment. With permanent installations,

leave enough space around the machine to open

or remove doors/covers as required by the maintenance and service described in this manual.

See below for required space allocation.

Physical Environment

Extreme conditions for this type of machinery are

Place this machine near an existing power source.

other hazards. Make sure to leave enough space

Shadows, glare, or strobe effects that may distract

or impede the operator must be eliminated.

Machine Data Sheet for the weight

Children or untrained people

may be seriously injured by

this machine. Only install in an

access restricted location.

The physical environment where the machine is

operated is important for safe operation and longevity of machine components. For best results,

operate this machine in a dry environment that is

free from excessive moisture, hazardous chemicals, airborne abrasives, or extreme conditions.

generally those where the ambient temperature

range exceeds 41°–104°F; the relative humidity

range exceeds 20%–95% (non-condensing); or

the environment is subject to vibration, shocks,

or bumps.

Electrical Installation

Make sure all power cords are protected from

traffic, material handling, moisture, chemicals, or

around machine to disconnect power supply or

apply a lockout/tagout device, if required.

Lighting

Lighting around the machine must be adequate

enough that operations can be performed safely.

37 "

-14-

Wall

30" minimum for

maintenance

Figure 5. Minimum working clearances.

Model G0793 (Mfd. Since 02/15)

22"

Page 18

Lifting & Placing

get help from other people

Anchoring machinery to the floor prevents tipping

or shifting and reduces vibration that may occur

during operation, resulting in a machine that runs

slightly quieter and feels more solid.

If the machine will be installed in a commercial or

workplace setting, or if it is permanently connected (hardwired) to the power supply, local codes

may require that it be anchored to the floor.

If not required by any local codes, fastening the

machine to the floor is an optional step. If you

choose not to do this with your machine, we recommend placing it on machine mounts, as these

provide an easy method for leveling and they have

vibration-absorbing pads.

Lag shield anchors with lag screws (see below)

are a popular way to anchor machinery to a concrete floor, because the anchors sit flush with the

floor surface, making it easy to unbolt and move

the machine later, if needed. However, anytime

local codes apply, you MUST follow the anchoring

methodology specified by the code.

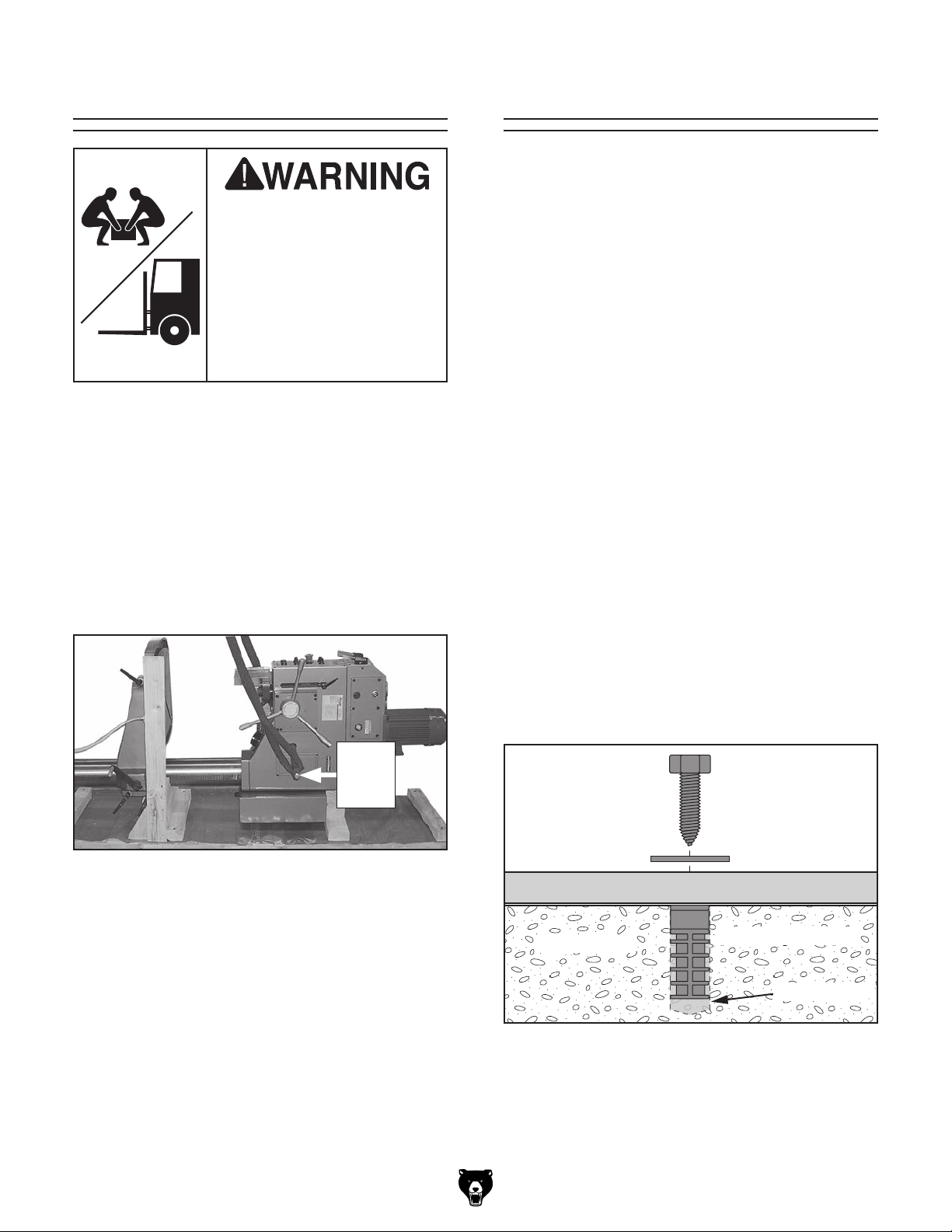

HEAVY LIF T!

Straining or crushing injury

may occur from improperly

lifting machine or some of

its parts. To reduce this risk,

and use a forklift (or other

lifting equipment) rated for

weight of this machine.

To lift and place drill press:

1. Place shipping crate near final machine

mounting location.

2. Remove top portion of crate from shipping

pallet, secure ends of a properly rated lifting

sling around each side of bar placed through

lifting holes, and attach it securely to your

power lifting equipment (see Figure 6).

Anchoring to Floor

Number of Mounting Holes ............................ 4

Diameter of Mounting Hardware ...................1"

Anchoring to Concrete Floors

Bar In

Lifting

Figure 6. Sling around bar in lifting hole.

3. Unbolt machine from pallet.

4. With another person to help to steady

machine, lift it just enough to clear pallet and

any floor obstacles, then place it in its final

position.

Model G0793 (Mfd. Since 02/15)

Hole

Lag Screw

Flat Washer

Machine Base

Concrete

Figure 7. Popular method for anchoring

machinery to a concrete floor.

Lag Shield Anchor

Drilled Hole

-15-

Page 19

Arbor/Chuck

An arbor is included for the drill chuck that

comes with this machine. The following procedure

describes how to install the arbor in the chuck.

After the arbor is installed in the drill chuck, it

is very difficult to separate the assembly. If you

would like to use a different chuck in the future,

we recommend obtaining a new arbor.

IMPORTANT: DO NOT

and arbor assembly

AFTER

the test run.

To join drill chuck and arbor:

1.

clean drill

2.

3.

4.

5. Attempt to separate drill chuck and arbor by

hand —if they separate, repeat Steps 3–4.

Assembly

install the drill chuck

into the spindle until

Use acetone or lacquer thinner to

chuck and arbor mating surfaces, especially

the bore.

Retract chuck jaws completely into chuck.

Insert small end of arbor into chuck.

Hold assembly by the arbor and tap chuck

onto a block of wood with medium force, as

illustrated below.

Initial Lubrication

GEARBOXES MUST

BE FILLED WITH OIL!

OIL MAY NOT BE

SHIPPED WITH MACHINE!

Refer to Lubrication Section

for Correct Oil Type.

To prevent spillage, this machine was shipped

from the factory without any oil or coolant in it.

The headstock and gearbox oil reservoirs must

be properly filled with oil before the drill press

can be operated for the first time. In addition, the

coolant pump reservoir must be filled properly

before operation. Refer to the Lubrication section, beginning on Page 33, for details on how to

check and add oil or coolant.

Damage caused by running drill press without oil in reservoirs is not covered under

warranty.

Figure 8. Installing arbor into chuck.

-16 -

If pump is running, ball valve is open, and

no coolant is flowing from coolant nozzle,

this is an indication of inadequate coolant

levels in reservoir. Immediately turn pump

OFF! Running pump without adequate coolant can lead to pump damage, which will not

be covered under warranty.

Model G0793 (Mfd. Since 02/15)

Page 20

or equipment damage

may occur if machine is

not properly grounded

and connected to power

30 31 E

U2 V2 W2 0 1 2 3 A 4 5 6 7 9 10 11

Master Power Switch

L

7

531

8 4

6 2

R

TC

Transformer

JBK5-100VATH

CanSen

LW26-20

ON

OFF

QM3

14

14

C6

DZ451-63

ON

OFF

QM2

D1

DZ451-63

ON

OFF

QM1

D10

DZ451-63

L1

L2

L3

L3L2L1

L2

L1

L3

A1

1L1

13NO 21NC 31NC 43NO

14NO 22NC 32NC 44NO

3L2 5L3

2T1 4T2 6T3

A2

KM1 Contactor

Siemens 3TB41 24V

A1

1L1

13NO 21NC 31NC 43NO

14NO 22NC 32NC 44NO

3L2 5L3

2T1 4T2 6T3

A2

KM2 Contactor

Siemens 3TB41 24V

2L1 ZL3

A1

13NO 23NO 33N0 43NO

14NO 24N0 34N0 44NO

A2

KA1 Contactor

Siemens 3TH80 24V

A1

13NO 23NO 33N0 43NO

14NO 24N0 34NO 44NO

A2

KA0 Contactor

Siemens 3TH80 24V

2L1

2L1

2L2

2L2

ZL3

ZL3

9

11

119

U1

U1

V1

V1

W1

W1

0

0

0

0

0

PE

6

6

5

5 643

3

4

6

2L2

2L2

3L1

3L1

3L3

3L3

2L1

2L1

ZL3

ZL3

3L3

3L1

U2U2V2V2W2

W2

12 13

13

12

1

1

0

U2 V2 W2

11

7

7

1

6

7

0

9

10

5

4

A3

2

Power Connection

Before the machine can be connected to the

power source, an electrical circuit and connection device must be prepared per the POWER

SUPPLY section in this manual; and all previous setup instructions in this manual must be

complete to ensure that the machine has been

assembled and installed properly.

Note About Extension Cords: Using an incor-

rectly sized extension cord may decrease the life

of electrical components on your machine. If you

must use an extension cord, refer to Extension

Cords on Page 11 for more information.

To connect power cord to drillpress:

1. Press EMERGENCY stop button on control

panel, turn master power switch OFF, then

remove electrical panel cover, as shown in

Figure 9.

2. Thread power cord through strain relief shown

in Figure 9.

Electrocution, fire, shock,

supply.

3. Connect ground wire to terminal on ground-

ing plate. Then connect incoming hot wires to

L1, L2, and L3 terminals (see Figure 10).

Note About Phase Converters: If using a

phase converter to supply power, only connect the manufactured leg or "wild wire" to the

"L2" terminal. The L2 line can handle power

fluctuations because it bypasses sensitive

electrical components and is wired directly to

the motor.

Ground Wire

PE

Connected

PE

PE

For phase

converter wild

wire (if used)

Incoming

Power Cord

Figure 10. Incoming ground and hot wires

4. Make sure wires have enough slack between

strain relief and terminal connections so they

are not pulled tight or stretched, then tighten

strain relief to secure cord.

connected.

Note: The strain relief must be tightened

against the outer jacket of the cord. Avoid

over-tightening the strain relief or it may

crush the cord and cause a short.

L1 L2 L3

L1 L2 L3 U1 V1 W1

L1 L2 L3

PE

Hot Wires

Connected

U1 V1

W1

U1 V1 W1

Incoming Power

Strain Relief

Figure 9. Electrical box with panel cover

removed.

Model G0793 (Mfd. Since 02/15)

5. Test strain relief to ensure it is properly tight-

ened by pulling cord from outside box with

light-to-moderate force. When strain relief is

properly tightened, cord will not move inside

cabinet.

6. Install NEMA 15-15 plug on other end of

power cord per plug manufacturer's instructions.

7. Re-install main electrical panel cover.

-17-

Page 21

3. Turn master power switch to ON position.

To avoid unexpected start-up, keep

Emergency Stop Reset button pressed in

until instructed otherwise in Test Run.

8. Insert power cord plug into a matching power

supply receptacle. The machine is now connected to the power source.

Test Run

Once the preceding setup procedures are complete, test run your machine to make sure it runs

properly and is ready for regular operation.

The test run consists of verifying the following: 1)

The motor powers up and runs correctly, 2) the

motor rotates in the correct direction (machine

is not wired out of phase), 3) the EMERGENCY

STOP button stops spindle rotation, 4) the chip

guard safety feature works correctly, and 5) the

coolant system works correctly.

If, during the test run, you cannot easily locate

the source of an unusual noise or vibration, stop

using the machine immediately, then review

Troubleshooting on Page 37.

4. Press EMERGENCY STOP button, then twist

it clockwise so it pops out. When button pops

out, switch is reset and ready for operation

(see Figure 11).

Spindle

Master Power

Switch

Coolant

Pump

Switch

Spindle

Stop

Button

Figure 11. Controls for testing the drill press.

5. Verify machine is operating correctly by turn-

ing spindle speed/direction switch to L1 position and pressing spindle start button (see

Figure 11).

— When operating correctly, machine runs

smoothly with little or no vibration or rubbing noises.

Speed/Direction

Switch

EMERGENCY

STOP Button

Spindle

Start

Button

BIOLOGICAL & POISON

HAZARD!

Use the correct personal protection equipment

when handling coolant.

Follow federal, state,

and fluid manufacturer

requirements for proper

disposal.

To test run machine:

1. Make sure all tools and objects used during

setup are cleared away from machine.

2. Make sure machine is properly lubricated

(see Page 33).

— Investigate and correct strange or unusu-

al noises or vibrations before operating

machine further. Always stop machine and

disconnect from power before investigating or correcting potential problems.

6. Verify oil is flowing through headstock by

examining oil-flow sight glass for oil movement (see Page 34).

7. Verify spindle rotates from right to left (as

standing in front of machine). This is correct

direction of rotation for L1 setting on spindle

speed/direction switch.

-18-

Model G0793 (Mfd. Since 02/15)

Page 22

Due to high voltage and risk of serious

shock involved, we strongly recommend

this procedure be done by an electrician or

qualified service personnel.

— If spindle rotates from left to right (as stand-

ing in front of machine), phase polarity of

incoming power supply is reversed. Stop

spindle and DISCONNECT MACHINE

FROM POWER! Remove electrical panel

cover, swap wires at L1 and L3 terminals

(see Figure 12) then re-install electrical

panel cover and reconnect machine to

power.

10. Attempt to start spindle rotation. Spindle

should not start.

— If spindle rotation does start with chip

guard open, safety switch is not operating

correctly. This safety feature must operate properly before continuing operation.

Turn master power switch to OFF position,

disconnect machine from power, and call

Tech Support for help.

11. Close chip guard.

12. Aim coolant nozzle into trough, and use cool-

ant pump switch on control panel to start

pump (see Figure 11 on Page 18).

If pump is running, ball valve is open, and

no coolant is flowing from coolant nozzle,

this is an indication of inadequate coolant

levels in reservoir. Immediately turn pump

OFF! Running pump without adequate coolant can lead to pump damage, which will not

be covered under warranty.

L1 and L3

Terminals

Figure 12. Location of L1 and L3 terminals for

incoming power.

8. Press EMERGENCY STOP button to turn

machine OFF, then, without resetting the

EMERGENCY STOP button, try to restart

spindle rotation. Spindle should not start.

— If spindle rotation does start with

EMERGENCY STOP button pressed in,

EMERGENCY STOP button safety is not

operating correctly. This safety feature

must operate properly before continuing

operation. Turn master power switch to

OFF position, disconnect machine from

power, and call Tech Support for help.

9. Twist EMERGENCY STOP to reset, and

press Spindle Stop Button. Open chip guard

to activate safety switch, which should prevent the spindle from starting.

13. Open ball valve (see Figure 13). Verify cut-

ting fluid flows from nozzle, then turn pump

OFF and close ball valve.

Ball Valve

Figure 13. Location of coolant ball valve.

Congratulations! The test run is complete. Perform

the following Spindle Break-In procedure.

Model G0793 (Mfd. Since 02/15)

-19 -

Page 23

Spindle Break-In

The spindle break-in procedure distributes lubrication

reduce the risk

of early

if there are any "dry" spots

or areas where lubrication has settled in the bearings. You

efore

placing

for the

first time when the machine is new or if it has

been sitting idle for longer than 6 months.

Always start the spindle break-in at the lowest

speed to minimize wear if there

Allow the spindle to run long enough to warm up

and distribute the bearing grease, then incrementally increase spindle speeds and repeat this process at each speed until reaching the maximum

spindle speed. Following the break-in procedure

in this progressive manner helps minimize any

potential wear that could occur before lubrication

is fully distributed.

throughout the bearings to

bearing failure

must complete this procedure b

operational loads on the spindle

are dry spots.

To perform spindle break-in procedure:

1. Set drilling/tapping switch to "drilling" position

(see Figure 14).

Speed

Control

Levers

Drilling/

Spindle

Speed/

Direction

Switch

Spindle

Stop Button

Figure 14. Drilling/tapping switch.

2. Run spindle at 60 RPM for 10 minutes (see

Setting Spindle Speed on Page 25 for

details on how to change speeds).

Tapping

Switch

Spindle

Start Button

Complete the spindle bearing break-in procedure to prevent rapid wear and tear of

spindle components once the drill press is

placed into operation.

DO NOT perform this procedure independently of the Test Run section. The drill

press could be seriously damaged if the

controls are set differently than instructed

in that section.

-20-

3. Reverse spindle rotation direction and run

spindle for an additional 10 minutes.

4. Run spindle for 5 minutes in each direction

of spindle rotation. Run following speeds: 90,

120, 260, 600, 1220, and 1740 RPM. Make

sure to only increase speeds in the order

shown.

Congratulations! Spindle break-in is complete. We

recommend changing the headstock and gearbox

oil before operating the machine further (refer to

Lubrication on Page 33).

Model G0793 (Mfd. Since 02/15)

Page 24

SECTION 4: OPERATIONS

The purpose of this overview is to provide the novice machine operator with a basic understanding

of how the machine is used during operation, so

the

discussed later

in this manual

Due to the generic nature of this overview, it is

not

more about specific operations,

manual,

training from experienced

machine operators

outside of this manual by reading "how-to" books,

trade magazines, or websites.

To reduce your risk of

serious injury, read this

entire manual BEFORE

Keep hair, clothing, and

ing parts at all times.

Entanglement can result

in death, amputation, or

using machine.

To reduce risk of eye or face injury from

flying chips, always wear approved safety

glasses and a face shield when operating

this machine.

Operation Overview

machine controls/components

are easier to understand.

intended to be an instructional guide. To learn

read this entire

seek additional

, and do additional research

To complete a typical operation, the operator

does the following:

jewelry away from mov-

severe crushing injuries!

If you are not experienced with this type

of machine, WE STRONGLY RECOMMEND

that you seek additional training outside of

this manual. Read books/magazines or get

formal training before beginning any projects. Regardless of the content in this section, Grizzly Industrial will not be held liable

for accidents caused by lack of training.

Model G0793 (Mfd. Since 02/15)

1. Examines workpiece to make sure it is suit-

able for drilling.

2. Puts on required safety glasses and face

shield.

3. Firmly secures workpiece to table using vise

or T-slot clamps.

4. Installs correct cutting tool for operation.

5. Adjusts table to correct height, then locks it in

place.

6. Connects machine to power, and turns mas-

ter power switch ON.

7. Selects spindle RPM and direction with spin-

dle speed levers and spindle speed/direction

switch. Then presses Spindle Start button.

8. Begins drilling.

9. When finished, presses Spindle Stop button

and disconnects machine from power.

-21-

Page 25

Installing/Removing

Tooling

This machine has an MT#4 spindle for installing tooling. It is also equipped with an automatic

drift for easy removal of tooling (see Figure 16).

Additionally, a drift key is included to manually

remove the tooling from the spindle, if needed.

The Model G0793 includes the following spindle

tools (see Figure 15):

A. B16 Drill Chuck w/MT#4–R-8 Arbor. Refer

to Arbor/Chuck Assembly on Page 16.

B. MT#4–MT#3 Spindle Sleeve. Used for MT#3

tools and will accommodate tools with a tang.

It also has a drift key slot for tool removal.

C. MT#4–MT#2 Spindle Sleeve. Used for MT#2

tools and will accommodate tools with a tang.

It also has a drift key slot for tool removal.

Installing Tapered Tooling

1. DISCONNECT MACHINE FROM POWER!

2. Clean tooling and spindle tapers to ensure

proper seating.

3. Insert MT#4 tooling into spindle, and maneuver tang (see Figure 15) until it engages with

slot at end of spindle.

4. Use rubber or wooden mallet to seat tooling

into spindle by firmly tapping from bottom.

Note: If installing a drill chuck, make sure to

retract jaws to prevent damage to chuck.

Removing Tooling with Automatic

Drift

1. DISCONNECT MACHINE FROM POWER!

2. Lower spindle with coarse downfeed handle

until you can press in automatic drift knob

(see Figure 16).

D. Drift Key: Use for tool removal.

Tang

A

D

Figure 15. Drill chuck, arbor, spindle sleeves,

and drift key included with Model G0793.

Cutting tools are sharp and

can easily cause laceration

injuries. Always protect

your hands with leather

gloves or shop rags when

handling cutting tools.

B C

Drift Key Slot

Automatic

Drift Knob

Figure 16. Location of automatic drift knob.

Leaving the automatic drift knob pressed in

can result in the arbor coming free the next

time it is inserted into the spindle sleeve.

An improperly installed arbor can become

a projectile and result in serious injury to

operator or others nearby. Always verify

arbor is correctly installed before beginning

drilling operations.

-22-

Model G0793 (Mfd. Since 02/15)

Page 26

3. While holding tooling, raise spindle to origi-

nal position. Tooling should automatically

release from spindle.

Depth Stop

4. Pull automatic drift knob to OUT position.

Removing Tooling Manually

1. DISCONNECT MACHINE FROM POWER!

2. Lower quill and rotate spindle by hand until

drift key holes in spindle and quill are aligned

(see Figure 17).

Drift Key

Hole

Quill

This drill press includes a depth stop for drilling

multiple holes to the same depth.

To set depth stop:

1. DISCONNECT MACHINE FROM POWER!

2. Adjust table height so workpiece is close to

tooling.

3. Mark side of workpiece at intended cutting

depth (see Figure 19 ).

Workpiece

Scrap Wood

Drill Bit

Workpiece

Depth

Mark

Table

Figure 17. Spindle and quill drift key holes

aligned.

3. Insert drift key into aligned holes and allow

quill to rise, trapping drift key.

4. Use rubber or wooden mallet to softly tap end

of key while holding arbor/chuck assembly

until it separates from spindle (see Figure

18).

Figure 19. Depth stop mark on workpiece.

4. Secure workpiece and scrap wood to table

with a clamp or vise.

5. Lower spindle until tip of bit is even with mark.

6. Loosen depth stop knob and position so it

rests on downfeed engagement lever, then

tighten depth stop knob (see Figure 20).

Depth Stop

Knob

Downfeed

Engagement

Lever

Figure 18. Using drift key to remove arbor.

Model G0793 (Mfd. Since 02/15)

Figure 20. Setting depth stop knob.

-23-

Page 27

7. Return spindle to up position.

Note: Drill a hole into scrap stock before drill-

ing into any workpiece to ensure the depth

has been set correctly. If necessary, repeat

Ste ps 1–7.

Positioning Table

The table for this drill press moves vertically and

rotates 360 degrees around the column to accommodate larger workpieces.

Raising/Lowering Table

1. Remove all objects from table surface.

2. Loosen lock handles shown in Figure 21.

3. Adjust table height by rotating height adjust-

ment crank (see Figure 21).

Spindle Speed

Using the correct spindle speed is important for

safe and satisfactory results, as well as maximizing tool life.

To set the spindle speed for your operation, you

will need to: 1) Determine the best spindle speed

for the operation, and 2) configure the spindle

speed levers to produce the required spindle

speed.

Determining Spindle Speed

Many variables affect the optimum spindle speed

to use for any given operation, but the two most

important are the recommended cutting speed

for the workpiece material and the diameter of

the cutting tool, as noted in the formula shown in

Figure 22.

Lock

Handles

Height

Adjustment

Crank

Figure 21. Location of column lock handles and

height adjustment crank.

Rotating Table

1. Remove all objects from table surface.

2. Loosen lock handles (see Figure 21).

3. Push table to desired location, and guide rack

on side of column will follow.

4. Tighten lock handles.

*Recommended

Cutting Speed (FPM) x 12

Tool Dia. (in inches) x 3.14

Spindle

=

Speed

(RPM)

*Double if using carbide cutting tool

Figure 22. Spindle speed formula for mill/drills.

Cutting speed, typically defined in feet per minute

(FPM), is the speed at which the edge of a tool

moves across the material surface.

A recommended cutting speed is an ideal speed

for cutting a type of material in order to produce

the desired finish and optimize tool life.

The books Machinery’s Handbook or Machine

Shop Practice, and some internet sites, provide excellent recommendations for which cutting

speeds to use when calculating the spindle speed.

These sources also provide a wealth of additional

information about the variables that affect cutting

speed and they are a good educational resource.

Also, there are a large number of easy-to-use

spindle speed calculators that can be found on

the internet. These sources will help you take into

account the applicable variables in order to determine the best spindle speed for the operation.

-24-

Model G0793 (Mfd. Since 02/15)

Page 28

Setting Spindle Speed

The chart below explains how to position the

spindle speed/direction switch and spindle speed

levers to set the desired spindle speed.

The spindle speed/direction switch can be set to

speed 1 or 2 for both left and right spindle directions. The direction of the spindle does not factor

into the spindle speed.

Note: If the levers will not move to the desired

position, rotate the spindle by hand while applying

pressure on the lever. When the gear teeth align,

the lever will move into place.

Change spindle speed ONLY when spindle

is completely stopped. Otherwise, machine

damage could occur.

With the spindle completely stopped, position the

spindle speed levers and spindle speed/direction

switch (see Figure 23) to set the spindle speed.

Spindle Speed Chart

Spindle

Speed

60 RPM 1 A D

90 RPM 1 A E

120 RPM 2 A D

130 RPM 1 A F

150 RPM 1 B D

180 RPM 2 A E

215 RPM 1 B E

260 RPM 2 A F

300 RPM 2 B D

310 RPM 1 B F

415 R PM 1 C D

440 RPM 2 B E

600 RPM 1 C E

625 RPM 2 B F

830 RPM 2 C D

870 RPM 1 C F

1220 RPM 2 C E

1740 RPM 2 C F

Spindle

Speed

Switch

Speed

Lever

A–C

Speed

Lever

D–F

Spindle Speed

Lever D–F

Figure 23. Spindle speed controls.

Spindle Speed

Lever A–C

Spindle

Speed/Direction

Switch

Model G0793 (Mfd. Since 02/15)

-25-

Page 29

Calculating Spindle Speed for Drilling

Using the Drilling Speed Chart

The chart shown in Figure 24 is intended as

a guide only. Always follow the manufacturer's

speed recommendations if provided with your

drill bits, cutters, or hole saws. Exceeding the

recommended speeds may be dangerous to the

oper ator.

The speeds shown here are intended to get you

started. The optimum speed will always depend

on various factors, including tool diameter, drilling

pressure, material hardness, material quality, and

desired finish.

Often, when drilling materials other than wood,

some type of lubrication is necessary.

Lubrication Suggestions

Wood ...........................................................None

Plastics ............................................Soapy Water

Brass ...............................Water-Based Lubricant

Aluminum ..................... Paraffin-Based Lubricant

Mild Steel ............................. Oil-Based Lubricant

Larger bits turning at slower speeds tend

to grab the workpiece aggressively. This

can result in the operator's hand being

pulled into the bit or the workpiece being

thrown with great force. Always clamp the

workpiece to the table to prevent injuries.

-26-

Figure 24. Drilling speed chart.

Model G0793 (Mfd. Since 02/15)

Page 30

Drilling Mode

2. Clamp workpiece to table, and adjust depth

stop for needed depth of cut.

This drill press is designed for vertical drilling

and tapping operations. For repeated drilling

at the same depth, there is a power downfeed

mechanism.

Overloading tools or using excessive spindle speeds may cause parts or broken tools

to hit operator, resulting in serious impact

injuries.

To drill a workpiece:

1. Refer to Controls & Components on Page 4

to understand control functions.

Master Power

Switch

Drilling/Tapping

Switch

Note: Drilling with quill fully extended can

cause tool chatter. For maximum spindle

rigidity, keep spindle retracted into headstock

as far as possible.

3. Put on safety glasses, a face shield, and

close chip guard.

4. Turn drilling/tapping switch left to select "drilling" mode (see Figure 25).

5. Refer to Calculating Spindle Speed for

Drilling on Page 26, and choose closest

available spindle RPM.

6. Turn master power switch to ON position.

7. Ensure EMERGENCY STOP button is not

pushed in.

8. Press Spindle Start button and begin drilling

operation.

Spindle Start

Button

Figure 25. Controls for drilling.

Model G0793 (Mfd. Since 02/15)

-27-

Page 31

Auto-Feed

This drill press comes with automatic downfeed

control for repeated drilling operations at the

same depth. The automatic downfeed only works

in the drilling mode.

Stay clear of coarse downfeed handles while

using automatic downfeed. When depth

stop triggers lower elevation limit switch,

handles spin rapidly as spindle returns to

its starting position. Failure to stay clear of

handles may result in injury.

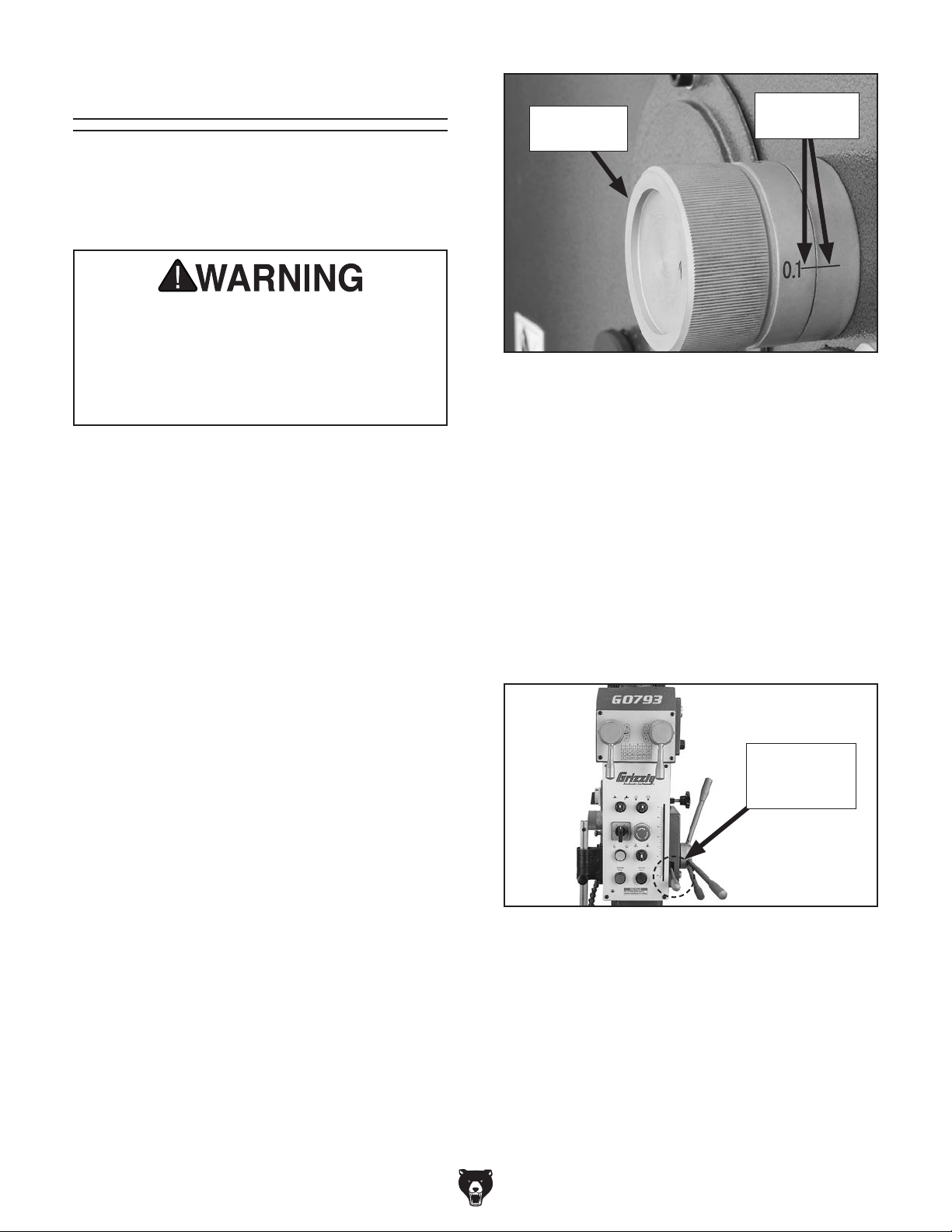

Adjustment

Knob

Figure 26. Automatic downfeed adjustment

knob.

5. Reconnect machine to power.

Downfeed

Option Lines

To operate automatic powered downfeed:

1. DISCONNECT MACHINE FROM POWER!

2. Turn drilling/tapping switch left to select "drill-

ing" mode.

3. Set spindle depth stop (refer to Page 23 if

necessary).

4. Match lines on adjustment knob (see Figure

26) to select automatic powered downfeed

option as follows:

• 0.2 = 0.20mm of downfeed/rotation.

• 0.1 = 0.10mm of downfeed/rotation.

• 0.0 disengages downfeed mechanism.

6. Turn master power switch to ON position,

ensure EMERGENCY STOP button is not

pressed in, and press Spindle Start button.