Page 1

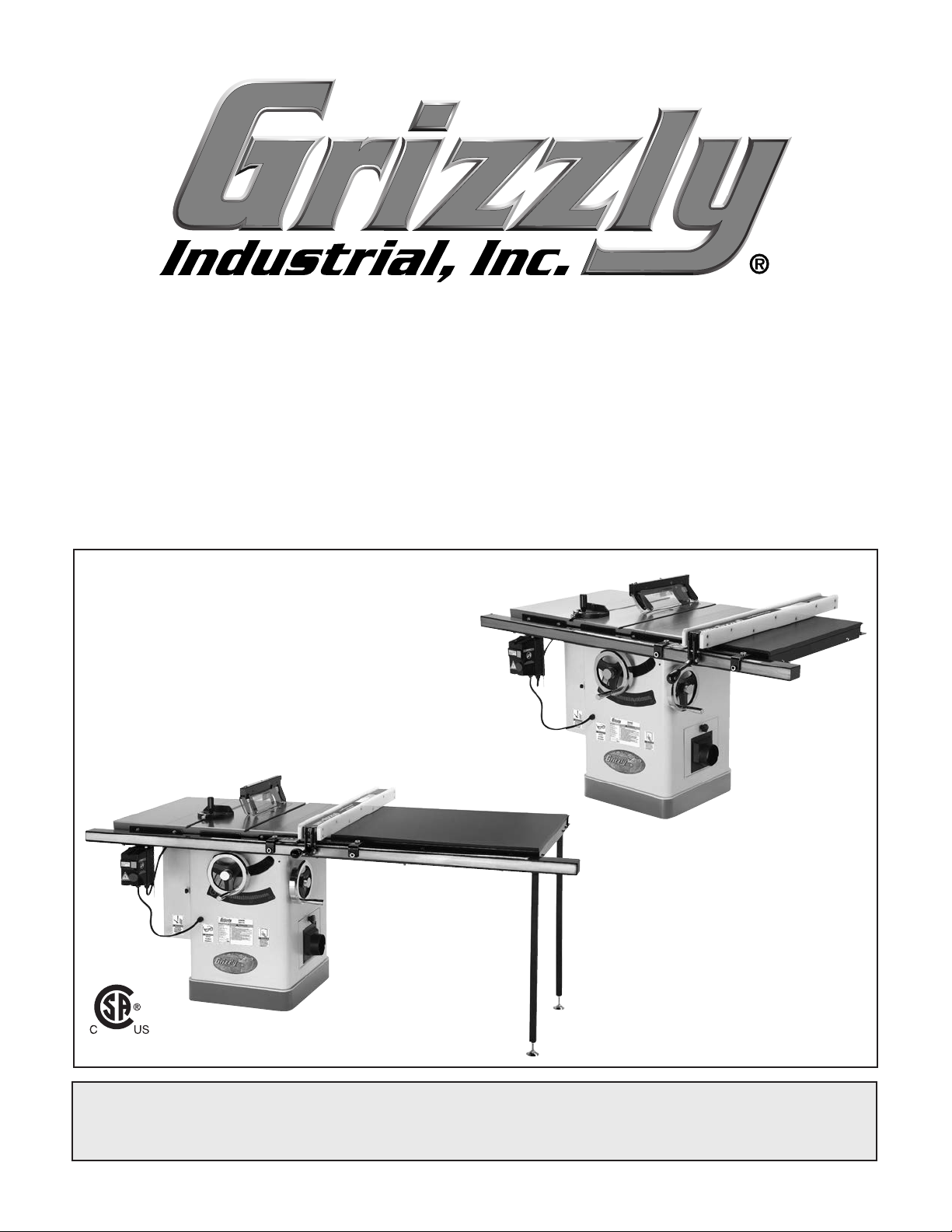

MODEL G0690/G0691

10" CABINET TABLE SAW

with RIVING KNIFE

OWNER'S MANUAL

232857

Model G0690

Model G0691

COPYRIGHT © NOVEMBER, 2008 BY GRIZZLY INDUSTRIAL, INC. REVISED MARCH, 2011 (BL)

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

(FOR MODELS MANUFACTURED SINCE 11/10) #BL11376 PRINTED IN CHINA

Page 2

This manual provides critical safety instructions on the proper setup,

operation, maintenance, and service of this machine/tool. Save this

document, refer to it often, and use it to instruct other operators.

Failure to read, understand and follow the instructions in this manual

may result in fire or serious personal injury—including amputation,

electrocution, or death.

The owner of this machine/tool is solely responsible for its safe use.

This responsibility includes but is not limited to proper installation in

a safe environment, personnel training and usage authorization,

proper inspection and maintenance, manual availability and comprehension, application of safety devices, cutting/sanding/grinding tool

integrity, and the usage of personal protective equipment.

The manufacturer will not be held liable for injury or property damage

from negligence, improper training, machine modifications or misuse.

Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State

of California to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

Work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

Page 3

Table of Contents

INTRODUCTION ............................................... 2

Manual Accuracy ........................................... 2

Contact Info.................................................... 2

Machine Description ...................................... 2

Identification ................................................... 3

G0690 Machine Data Sheet .......................... 4

G0691 Machine Data Sheet .......................... 7

SECTION 1: SAFETY ..................................... 10

Safety Instructions for Machinery ................ 10

Additional Safety for Table Saws ................. 12

Preventing Kickback .................................... 13

Protecting Yourself From Kickback.............. 13

Glossary of Terms ....................................... 14

SECTION 2: POWER SUPPLY ...................... 15

SECTION 3: SETUP ....................................... 17

Items Needed for Setup ............................... 17

Unpacking .................................................... 17

Hardware Recognition Chart ....................... 18

Inventory ...................................................... 19

Fence Inventory G0690 ............................... 20

Fence Inventory G0691 ............................... 20

Cleanup ........................................................ 21

Site Considerations ...................................... 22

Assembly ..................................................... 23

Dust Collection ............................................. 30

Power Connection........................................ 30

Test Run ...................................................... 31

Recommended Adjustments ........................ 31

SECTION 4: OPERATIONS ........................... 32

Operation Overview ..................................... 32

Basic Controls .............................................. 33

Non-Through & Through Cuts ..................... 33

Workpiece Inspection................................... 34

Blade Requirements .................................... 34

Blade Selection ............................................ 34

Blade Installation.......................................... 36

Blade Guard Assembly ................................ 37

Riving Knife .................................................. 39

Ripping ......................................................... 40

Crosscutting ................................................. 41

Miter Cuts..................................................... 41

Blade Tilt/Bevel Cuts ................................... 42

Dado Cutting ................................................ 42

Rabbet Cutting ............................................. 45

Resawing ..................................................... 47

SECTION 5: SHOP MADE SAFETY

ACCESSORIES .............................................. 50

Featherboards .............................................. 50

Push Sticks .................................................. 53

Push Blocks ................................................. 54

Narrow-Rip Auxiliary Fence & Push Block .. 55

Outfeed & Support Tables ........................... 57

Crosscut Sled............................................... 57

SECTION 6: AFTERMARKET ACCESSORIES

FROM GRIZZLY ............................................. 58

SECTION 7: MAINTENANCE ......................... 61

Schedule ...................................................... 61

Cleaning ....................................................... 61

Lubrication ................................................... 62

SECTION 8: SERVICE ................................... 63

Troubleshooting ........................................... 63

Blade Tilt Stops ............................................ 65

Miter Slot to Blade Parallelism ..................... 67

Spreader or Riving Knife Alignment ............ 68

Fence Adjustments ...................................... 69

Fence Scale Calibration ............................... 71

Miter Gauge Adjustments ............................ 72

Belt Tension & Replacement ....................... 73

SECTION 9: WIRING ...................................... 74

Wiring Safety Instructions ............................ 74

Model G0690/G0691 Wiring Diagram.......... 75

SECTION 10: PARTS ..................................... 76

Table Saw Body Breakdown........................ 76

Trunnion Assembly Breakdown ................... 78

Blade Guard Breakdown .............................. 81

Miter Gauge Breakdown .............................. 82

Fence Breakdown ........................................ 83

Model G0690 Extension Table Breakdown . 84

Model G0691 Extension Table Breakdown . 85

Labels and Cosmetic Parts Breakdown ....... 86

WARRANTY AND RETURNS ........................ 89

Page 4

INTRODUCTION

We stand behind our machines. If you have

any questions or need help, use the information

below to contact us. Before contacting, please get

the serial number and manufacture date of your

machine. This will help us help you faster.

We want your feedback on this manual. What did

you like about it? Where could it be improved?

Please take a few minutes to give us feedback.

Email: manuals@grizzly.com

We are proud to offer this manual with your new

machine! We've made every effort to be exact

with the instructions, specifications, drawings,

and photographs of the machine we used when

writing this manual. However, sometimes we still

make

Also, owing to our policy of continuous improvement, your machine may not exactly match the

manual. If you find this to be the case, and the dif-

ference between the manual and machine leaves

you in doubt,

manual update or call technical support for help.

Before calling, find the manufacture date of your

machine by looking at the date stamped into the

machine ID label (see below). This will help us

determine if the manual version you received

matches the manufacture date of your machine.

For your convenience, we

-

uals and

on our website

at

model

of

as soon as they are complete.

Manual Accuracy

an occasional mistake.

www.grizzly.com. Any updates to your

machine will be reflected in these documents

check our website for the latest

Manufacture Date

of Your Machine

post all available man

manual updates for free

Contact Info

Grizzly Technical Support

1203 Lycoming Mall Circle

Muncy, PA 17756

Phone: (570) 546-9663

Email: techsupport@grizzly.com

Grizzly Documentation Manager

P.O. Box 2069

Bellingham, WA 98227-2069

Machine Description

This table saw features a steel cabinet-type stand,

heavy-duty cast iron trunnions, and a cast iron

table that is precision hardened and ground to a

mirror-like finish.

Dust collection under the blade provides highly

effective dust removal, and the 3 HP Leeson

with triple V-belts efficiently transfers power.

Includes a camlock T-shaped fence with HDPE

face, miter gauge, quick-release spreader/blade

guard, riving knife, and table inserts for standard

and dado blades.

motor

-2-

The G0690 features 2 cast iron wings; the G0691

features an extension table with 50" rip capacity.

Model G0690/G0691 (Mfg. 11/10+)

Page 5

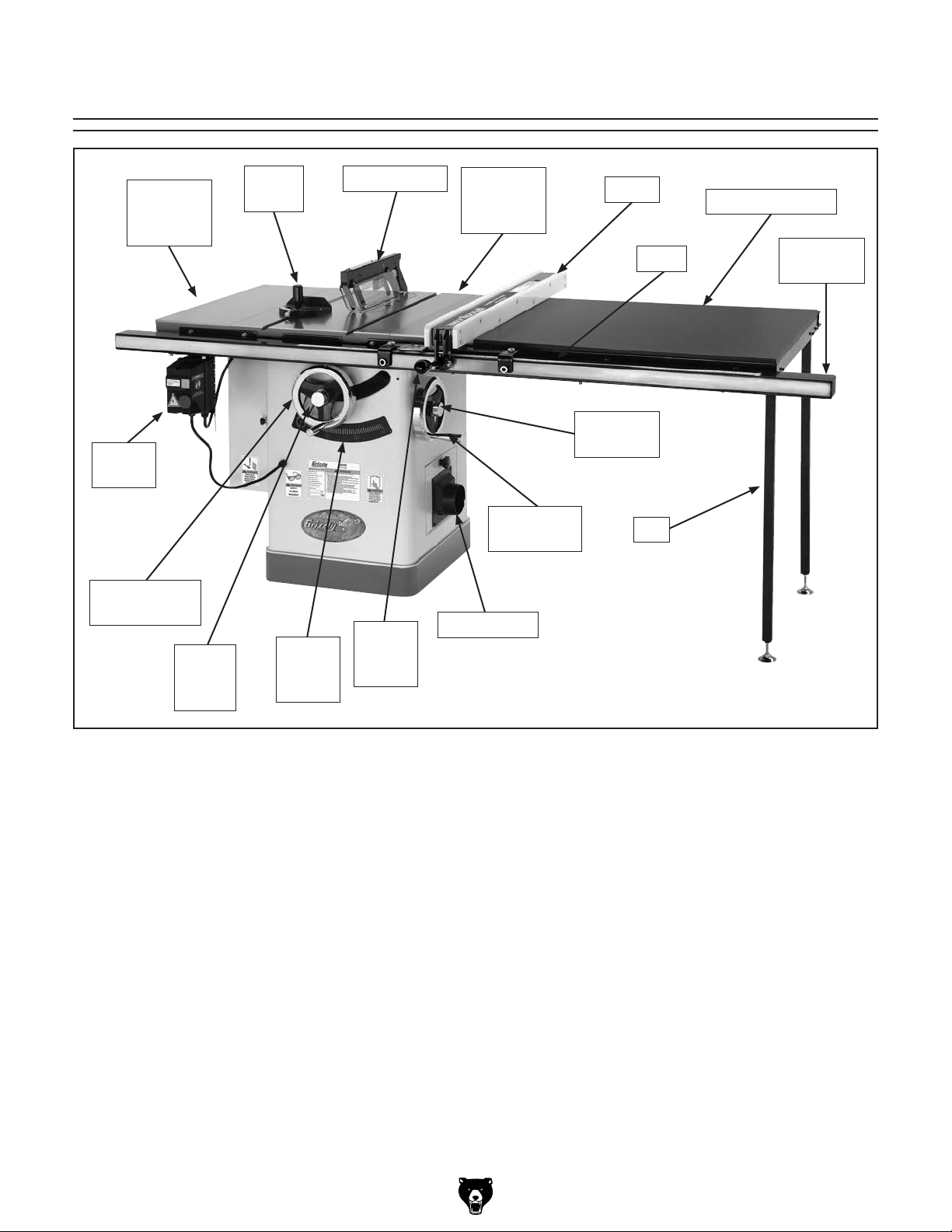

Identification

Left

Extension

Wing

On/Off

Switch

Blade Height

Handwheel

Blade

Height

Lock

Miter

Gauge

Table

Scale

Tilt

Blade Guard

Fence

Lock

Handle

Right

Extension

Wing

Blade Tilt

Handwheel

4" Dust Port

Fence

Scale

Blade Tilt

Lock

Leg

Extension Table

Front Rail

Tube

Figure 3. Identification (Model G0691 shown).

Model G0690/G0691 (Mfg. 11/10+)

-3-

Page 6

MACHINE DATA

Bearings..................................................................................................... Shielded & Permanently Lubricated

SHEET

Customer Service #: (570) 546-9663 · To Order Call: (800) 523-4777 · Fax #: (800) 438-5901

MODEL G0690 10" 3HP 220V CABINET TABLE SAW WITH

RIVING KNIFE

Product Dimensions:

Weight.............................................................................................................................................................. 507 lbs.

Width (side-to-side) x Depth (front-to-back) x Height........................................................................... 62 x 41 x 40 in.

Footprint (Length x Width)............................................................................................................................ 20 x 20 in.

Space Required for Full Range of Movement (Width x Depth).............................................................. 62 x 45-1/2 in.

Shipping Dimensions:

Carton #1

Type.................................................................................................................. Cardboard Box on Wood Skids

Content................................................................................................................................................. Machine

Weight.................................................................................................................................................... 460 lbs.

Length x Width x Height............................................................................................................. 24 x 30 x 43 in.

Must Ship Upright......................................................................................................................................... Yes

Carton #2

Type........................................................................................................................................... Cardboard Box

Content..................................................................................................................................................... Fence

Weight...................................................................................................................................................... 24 lbs.

Length x Width x Height............................................................................................................... 42 x 17 x 7 in.

Must Ship Upright.......................................................................................................................................... No

Carton #3

Type........................................................................................................................................... Cardboard Box

Content....................................................................................................................................................... Rails

Weight...................................................................................................................................................... 44 lbs.

Length x Width x Height................................................................................................................. 66 x 7 x 5 in.

Must Ship Upright.......................................................................................................................................... No

Electrical:

Power Requirement........................................................................................................... 220V, Single-Phase, 60 Hz

Prewired Voltage.................................................................................................................................................. 220V

Full-Load Current Rating..................................................................................................................................... 12.8A

Minimum Circuit Size.............................................................................................................................................. 20A

Connection Type....................................................................................................................................... Cord & Plug

Power Cord Included.............................................................................................................................................. Yes

Power Cord Length................................................................................................................................................. 6 ft.

Power Cord Gauge......................................................................................................................................... 14 AWG

Plug Included.......................................................................................................................................................... Yes

Included Plug Type................................................................................................................................................ 6-20

Switch Type.......................................................................... Magnetic Switch w/Overload Protection & Disabling Pin

Motors:

Main

Type................................................................................................................. TEFC Capacitor-Start Induction

Horsepower................................................................................................................................................ 3 HP

Phase............................................................................................................................................ Single-Phase

Amps......................................................................................................................................................... 12.8A

Speed................................................................................................................................................ 3450 RPM

Power Transfer ..................................................................................................................... Triple V-Belt Drive

-4-

Model G0690/G0691 (Mfg. 11/10+)

Page 7

Main Specifications:

Main Information

Table Saw Type..................................................................................................................................... Cabinet

Maximum Blade Diameter......................................................................................................................... 10 in.

Arbor Size................................................................................................................................................. 5/8 in.

Arbor Speed...................................................................................................................................... 4300 RPM

Maximum Width of Dado...................................................................................................................... 13/16 in.

Blade Tilt Direction....................................................................................................................................... Left

Max Blade Tilt......................................................................................................................................... 45 deg.

Maximum Depth of Cut At 90 Degrees.................................................................................................. 3-1/8 in.

Maximum Depth of Cut At 45 Degrees................................................................................................ 2-3/16 in.

Max Rip Right of Blade w/Included Fence & Rails.............................................................................. 29-1/2 in.

Max Rip Left of Blade w/Included Fence & Rails....................................................................................... 12 in.

Additional Blade Information

Included Blade Information.................................................................................................................. 10" x 40T

Riving Knife/Spreader Thickness.......................................................................................................... 0.100 in.

Required Blade Body Thickness.............................................................................................. 0.071 – 0.094 in.

Required Blade Kerf Thickness............................................................................................... 0.102 – 0.126 in.

Rim Speed at Max Blade Diameter................................................................................................. 11,300 FPM

Table Information

Floor to Table Height................................................................................................................................. 34 in.

Table Size with Extension Wings Width.................................................................................................... 40 in.

Table Size with Extension Wings Depth.................................................................................................... 27 in.

Distance Front of Table to Center of Blade......................................................................................... 17-1/4 in.

Distance Front of Table to Blade At Maximum Cut............................................................................. 12-1/4 in.

Main Table Size Thickness.................................................................................................................... 1-1/2 in.

Fence Information

Fence Type.................................................... Camlock T-Shape w/ Wraparound Rail-Mounting & HDPE Face

Fence Size Length..................................................................................................................................... 48 in.

Fence Size Width.................................................................................................................................. 4-1/8 in.

Fence Size Height................................................................................................................................. 2-1/2 in.

Fence Rail Type................................................................................................................. Square Steel Tubing

Fence Rail Length...................................................................................................................................... 62 in.

Fence Rail Width................................................................................................................................... 2-3/4 in.

Fence Rail Height........................................................................................................................................ 2 in.

Miter Gauge Information

Miter Gauge Slot Type.............................................................................................................................. T-Slot

Miter Gauge Slot Size Width..................................................................................................................... 3/4 in.

Miter Gauge Slot Size Height................................................................................................................... 3/8 in.

Construction

Table....................................................................................................................... Precision-Ground Cast Iron

Wings...................................................................................................................... Precision-Ground Cast Iron

Cabinet................................................................................................................................... Pre-Formed Steel

Trunnions............................................................................................................................................. Cast Iron

Fence Assembly................................................................................................... Steel with HDPE Side Plates

Rails........................................................................................................................................................... Steel

Miter Guage Construction............................................................................................. Cast Iron with Steel Bar

Guard............................................................................................................................. Steel and Clear Plastic

Body/Cabinet Paint.................................................................................................................... Powder Coated

Arbor Bearings.............................................................................................. Sealed & Permanently Lubricated

Other Related Information

Number of Dust Ports....................................................................................................................................... 1

Dust Port Size.............................................................................................................................................. 4 in.

Compatible Mobile Base........................................................................................................................ D2057A

Model G0690/G0691 (Mfg. 11/10+)

-5-

Page 8

Other Specifications:

Country Of Origin ............................................................................................................................................... China

Warranty ........................................................................................................................................................... 1 Year

Approximate Assembly & Setup Time .............................................................................................................. 1 Hour

Serial Number Location ............................................................................................................... ID Label on Cabinet

ISO 9001 Factory .................................................................................................................................................. Yes

CSA Certified ......................................................................................................................................................... Yes

Features:

Quick-Release Blade Guard and Spreader

Quick Release Riving Knife

Hinged Motor Cover

4" Dust Port

Heavy Duty Handwheels

Heavy Duty T-Slot Miter Gauge

Triple V-Belts

Precision-Ground Cast Iron Table

High Quality 3HP Leeson Motor

Heavy-Duty Cast Iron Trunnions

Powder Coated Paint

Camlock T-Shaped Fence with HDPE Face

Easy Glide Fence System

Knurled Knobs for Adjusting Fence

Nylon Runners Inside Fence Head Assembly

Standard and Dado Table Inserts

Recessed Screw Holding Table Insert

Included 10" x 40T Carbide-Tipped Blade

Accessories Recommended:

T24862 Long Rail Kit for G0690

-6-

Model G0690/G0691 (Mfg. 11/10+)

Page 9

MACHINE DATA

Bearings..................................................................................................... Shielded & Permanently Lubricated

SHEET

Customer Service #: (570) 546-9663 · To Order Call: (800) 523-4777 · Fax #: (800) 438-5901

MODEL G0691 10" 3HP 220V CABINET TABLE SAW WITH

LONG RAILS & RIVING KNIFE

Product Dimensions:

Weight.............................................................................................................................................................. 546 lbs.

Width (side-to-side) x Depth (front-to-back) x Height........................................................................... 82 x 41 x 40 in.

Footprint (Length x Width)............................................................................................................................ 20 x 20 in.

Space Required for Full Range of Movement (Width x Depth).............................................................. 82 x 45-1/2 in.

Shipping Dimensions:

Carton #1

Type.................................................................................................................. Cardboard Box on Wood Skids

Content................................................................................................................................................. Machine

Weight.................................................................................................................................................... 450 lbs.

Length x Width x Height............................................................................................................. 24 x 30 x 42 in.

Must Ship Upright......................................................................................................................................... Yes

Carton #2

Type........................................................................................................................................... Cardboard Box

Content..................................................................................................................................................... Fence

Weight...................................................................................................................................................... 26 lbs.

Length x Width x Height............................................................................................................... 42 x 17 x 7 in.

Must Ship Upright.......................................................................................................................................... No

Carton #3

Type........................................................................................................................................... Cardboard Box

Content....................................................................................................................................................... Rails

Weight...................................................................................................................................................... 66 lbs.

Length x Width x Height................................................................................................................. 67 x 7 x 5 in.

Must Ship Upright.......................................................................................................................................... No

Electrical:

Power Requirement........................................................................................................... 220V, Single-Phase, 60 Hz

Prewired Voltage.................................................................................................................................................. 220V

Full-Load Current Rating..................................................................................................................................... 12.8A

Minimum Circuit Size.............................................................................................................................................. 20A

Connection Type....................................................................................................................................... Cord & Plug

Power Cord Included.............................................................................................................................................. Yes

Power Cord Length................................................................................................................................................. 6 ft.

Power Cord Gauge......................................................................................................................................... 14 AWG

Plug Included.......................................................................................................................................................... Yes

Included Plug Type................................................................................................................................................ 6-20

Switch Type.......................................................................... Magnetic Switch w/Overload Protection & Disabling Pin

Motors:

Main

Type................................................................................................................. TEFC Capacitor-Start Induction

Horsepower................................................................................................................................................ 3 HP

Phase............................................................................................................................................ Single-Phase

Amps......................................................................................................................................................... 12.8A

Speed................................................................................................................................................ 3450 RPM

Power Transfer ..................................................................................................................... Triple V-Belt Drive

Model G0690/G0691 (Mfg. 11/10+)

-7-

Page 10

Main Specifications:

Main Information

Table Saw Type..................................................................................................................................... Cabinet

Maximum Blade Diameter......................................................................................................................... 10 in.

Arbor Size................................................................................................................................................. 5/8 in.

Arbor Speed...................................................................................................................................... 4300 RPM

Maximum Width of Dado...................................................................................................................... 13/16 in.

Blade Tilt Direction....................................................................................................................................... Left

Max Blade Tilt......................................................................................................................................... 45 deg.

Maximum Depth of Cut At 90 Degrees.................................................................................................. 3-1/8 in.

Maximum Depth of Cut At 45 Degrees................................................................................................ 2-3/16 in.

Max Rip Right of Blade w/Included Fence & Rails.................................................................................... 50 in.

Max Rip Left of Blade w/Included Fence & Rails....................................................................................... 12 in.

Additional Blade Information

Included Blade Information.................................................................................................................. 10" x 40T

Riving Knife/Spreader Thickness.......................................................................................................... 0.100 in.

Required Blade Body Thickness.............................................................................................. 0.071 – 0.094 in.

Required Blade Kerf Thickness............................................................................................... 0.102 – 0.126 in.

Rim Speed at Max Blade Diameter................................................................................................. 11,300 FPM

Table Information

Floor to Table Height................................................................................................................................. 34 in.

Table Size with Extension Wings Width.............................................................................................. 74-3/4 in.

Table Size with Extension Wings Depth.................................................................................................... 27 in.

Distance Front of Table to Center of Blade......................................................................................... 17-1/4 in.

Distance Front of Table to Blade At Maximum Cut............................................................................. 12-1/4 in.

Main Table Size Thickness.................................................................................................................... 1-1/2 in.

Fence Information

Fence Type.................................................... Camlock T-Shape w/ Wraparound Rail-Mounting & HDPE Face

Fence Size Length..................................................................................................................................... 48 in.

Fence Size Width.................................................................................................................................. 4-1/8 in.

Fence Size Height................................................................................................................................. 2-1/2 in.

Fence Rail Type................................................................................................................. Square Steel Tubing

Fence Rail Length...................................................................................................................................... 62 in.

Fence Rail Width................................................................................................................................... 2-3/4 in.

Fence Rail Height........................................................................................................................................ 2 in.

Miter Gauge Information

Miter Gauge Slot Type.............................................................................................................................. T-Slot

Miter Gauge Slot Size Width..................................................................................................................... 3/4 in.

Miter Gauge Slot Size Height................................................................................................................... 3/8 in.

Construction

Table....................................................................................................................... Precision-Ground Cast Iron

Wings...................................................................................................................... Precision-Ground Cast Iron

Cabinet................................................................................................................................... Pre-Formed Steel

Trunnions............................................................................................................................................. Cast Iron

Fence Assembly................................................................................................... Steel with HDPE Side Plates

Rails........................................................................................................................................................... Steel

Miter Guage Construction............................................................................................. Cast Iron with Steel Bar

Guard............................................................................................................................. Steel and Clear Plastic

Body/Cabinet Paint.................................................................................................................... Powder Coated

Arbor Bearings.............................................................................................. Sealed & Permanently Lubricated

-8-

Other Related Information

Number of Dust Ports....................................................................................................................................... 1

Dust Port Size.............................................................................................................................................. 4 in.

Compatible Mobile Base........................................................................................................................ D2057A

Model G0690/G0691 (Mfg. 11/10+)

Page 11

Other Specifications:

Country Of Origin ............................................................................................................................................... China

Warranty ........................................................................................................................................................... 1 Year

Approximate Assembly & Setup Time .............................................................................................................. 1 Hour

Serial Number Location ............................................................................................................... ID Label on Cabinet

ISO 9001 Factory .................................................................................................................................................. Yes

CSA Certified ......................................................................................................................................................... Yes

Features:

Quick-Release Blade Guard and Spreader

Quick Release Riving Knife

Hinged Motor Cover

4" Dust Port

Heavy Duty Handwheels

Heavy Duty T-Slot Miter Gauge

Triple V-Belts

Precision-Ground Cast Iron Table

High Quality 3HP Leeson Motor

Heavy-Duty Cast Iron Trunnions

Powder Coated Paint

Camlock T-Shaped Fence with HDPE Face

Easy Glide Fence System

Knurled Knobs for Adjusting Fence

Nylon Runners Inside Fence Head Assembly

Standard and Dado Table Inserts

Recessed Screw Holding Table Insert

Extension Table and Long Rails enable 50" Rip Capacity

Sturdy Steel Legs with Adjustable Feet

Included 10" x 40T Carbide-Tipped Blade

Model G0690/G0691 (Mfg. 11/10+)

-9-

Page 12

SECTION 1: SAFETY

For Your Own Safety, Read Instruction

Manual Before Operating This Machine

The purpose of safety symbols is to attract your attention to possible hazardous conditions.

This manual uses a series of symbols and signal words intended to convey the level of importance of the safety messages. The progression of symbols is described below. Remember that

safety messages by themselves do not eliminate danger and are not a substitute for proper

accident prevention measures. Always use common sense and good judgment.

Indicates an imminently hazardous situation which, if not avoided,

WILL result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

COULD result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

MAY result in minor or moderate injury. It may also be used to alert

against unsafe practices.

This symbol is used to alert the user to useful information about

NOTICE

proper operation of the machine.

Safety Instructions for Machinery

OWNER’S MANUAL. Read and understand this

owner’s manual BEFORE using machine.

TRAINED OPERATORS ONLY. Untrained operators have a higher risk of being hurt or killed.

Only allow trained/supervised people to use this

machine. When machine is not being used, disconnect power, remove switch keys, or lock-out

machine to prevent unauthorized use—especially

around children. Make workshop kid proof!

DANGEROUS ENVIRONMENTS. Do not use

machinery in areas that are wet, cluttered, or have

poor lighting. Operating machinery in these areas

greatly increases the risk of accidents and injury.

MENTAL ALERTNESS REQUIRED. Full mental

alertness is required for safe operation of machinery. Never operate under the influence of drugs or

alcohol, when tired, or when distracted.

ELECTRICAL EQUIPMENT INJURY RISKS. You

can be shocked, burned, or killed by touching live

electrical components or improperly grounded

machinery. To reduce this risk, only allow qualified

service personnel to do electrical installation or

repair work, and always disconnect power before

accessing or exposing electrical equipment.

DISCONNECT POWER FIRST.

nect machine from power supply BEFORE making

adjustments, changing tooling, or servicing machine.

This prevents an injury risk from unintended startup

or contact with live electrical components.

EYE PROTECTION. Always wear ANSI-approved

safety glasses or a face shield when operating or

observing machinery to reduce the risk of eye

injury or blindness from flying particles. Everyday

eyeglasses are not approved safety glasses.

Always discon-

-10 -

Model G0690/G0691 (Mfg. 11/10+)

Page 13

WEARING PROPER APPAREL. Do not wear

clothing, apparel or jewelry that can become

entangled in moving parts. Always tie back or

coverlonghair.Wearnon-slipfootweartoavoid

accidentalslips,whichcouldcauselossofworkpiececontrol.

hAzARdOus dusT. Dust created while using

machinery may cause cancer, birth defects, or

long-term respiratory damage. Be aware ofdust

hazardsassociatedwitheachworkpiecematerial,

andalwayswearaNIOSH-approvedrespiratorto

reduceyourrisk.

hEARING PROTECTION. Always wear hearing protection whenoperating or observing loud

machinery. Extended exposure to this noise

withouthearingprotection can cause permanent

hearingloss.

REMOVE AdJusTING TOOLs. Tools left on

machinery can become dangerous projectiles

uponstartup.Neverleavechuckkeys,wrenches,

or any other tools on machine. Always verify

removalbeforestarting!

INTENdEd usAGE. Only use machine for its

intendedpurposeandnever makemodifications

not approved by Grizzly. Modifying machine or

using it differently than intended may result in

malfunctionormechanicalfailurethatcanleadto

seriouspersonalinjuryordeath!

AWKWARd POsITIONs. Keep proper footing

andbalanceatalltimeswhenoperatingmachine.

Donotoverreach!Avoidawkwardhandpositions

that make workpiececontrol difficult or increase

the

riskofaccidentalinjury.

ChILdREN & BYsTANdERs. Keepchildrenand

bystandersatasafedistancefromtheworkarea.

Stopusingmachineiftheybecomeadistraction.

FORCING MAChINERY.Donotforce machine.

Itwill do the job safer and betterattheratefor

whichitwasdesigned.

NEVER sTANd ON MAChINE. Serious injury

may occur if machine is tipped or if the cutting

toolisunintentionallycontacted.

sTABLE MAChINE. Unexpectedmovementduring operation greatly increases risk of injury or

lossofcontrol.Beforestarting,verifymachineis

stableandmobilebase(ifused)islocked.

usE RECOMMENdEd ACCEssORIEs.Consult

thisowner’smanualorthemanufacturerforrecommended accessories. Using improper accessorieswillincreasetheriskofseriousinjury.

uNATTENdEd OPERATION. To reduce the

risk of accidental injury, turn machine off and

ensure all moving parts completely stop before

walking away. Never leave machine running

whileunattended.

MAINTAIN WITh CARE.Followallmaintenance

instructions and lubrication schedules to keep

machine in good working condition. A machine

that is

leadingtoseriouspersonalinjuryordeath.

ChECK dAMAGEd PARTs. Regularly inspect

machine for any condition that may affect safe

operation.Immediatelyrepairorreplacedamaged

ormis-adjustedpartsbeforeoperatingmachine.

MAINTAIN POWER CORds. When disconnecting cord-connected machines from power, grab

andpulltheplug—NOTthecord.Pullingthecord

may damage the wires inside. Do not handle

cord/plugwithwethands.Avoidcorddamageby

keepingitawayfromheatedsurfaces,hightraffic

areas,harshchemicals,andwet/damplocations.

improperly maintained could malfunction,

GuARds & COVERs.Guardsandcoversreduce

accidental contact with moving parts or flying

debris. Make sure they are properly installed,

undamaged,andworkingcorrectly.

Model G0690/G0691 (Mfg. 11/10+)

EXPERIENCING dIFFICuLTIEs. If at any time

youexperiencedifficultiesperformingtheintendedoperation,stopusingthemachine!Contactour

TechnicalSupportat(570)546-9663.

-11-

Page 14

Additional Safety for Table Saws

HAND POSITIONING. Never purposely touch a

saw blade during operation. Always keep hands/

fingers out of the blade path; place them where

they cannot slip into the blade accidentally. Never

reach around, behind, or over the blade. Touching

a spinning saw blade will cause serious laceration

or amputation injuries.

BLADE GUARD. Use the blade guard for all

“through cuts” for which it can be used. (A through

cut is an operation where the blade cuts completely through the top of the workpiece.) Make sure

the blade guard is installed and adjusted correctly;

promptly repair or replace it if damaged. Always

re-install blade guard immediately after operations

that require its removal. Operating saw with the

blade guard removed greatly increases the risk of

severe laceration or amputation injuries from accidental blade contact.

RIVING KNIFE. Use the riving knife for all “nonthrough cuts” for which it can be used. (A nonthrough cut is an operation where the blade does

not cut through the top of the workpiece.) Make

sure the riving knife is aligned and positioned correctly; and promptly repair or replace it if damaged.

Using the riving knife incorrectly will increase the

risk of kickback or accidental blade contact.

FENCE. Make sure the fence remains properly

adjusted and parallel with the blade. Always lock

the fence in place before using. Using or adjusting

the fence incorrectly will increase risk of kickback.

PUSH STICKS/BLOCKS. Use push sticks or push

blocks whenever possible to keep your hands farther away from the blade while cutting; in the event

of an accident these devices will often take damage that would have happened to hands/fingers.

CUT-OFF PIECES. Never use your hands to move

cut-offs away from the blade while the saw is running. If a cut-off becomes trapped between the

blade and table insert, turn the saw OFF and allow

the blade to completely stop before removing it.

BLADE ADJUSTMENTS. Adjusting the blade

height or tilt during operation increases the risk of

crashing the blade and sending metal fragments

flying with deadly force at the operator or bystanders. Only adjust the blade height and tilt when the

blade is completely stopped and the saw is OFF.

CHANGING BLADES. Always disconnect power

before changing blades. Changing blades while

the saw is connected to power greatly increases

the injury risk if saw is accidentally powered up.

KICKBACK. Kickback occurs when the saw blade

ejects the workpiece back toward the operator.

Know how to reduce the risk of kickback, and learn

how to protect yourself if it does occur.

FEEDING WORKPIECE. Feeding the workpiece

incorrectly will increase risk of kickback. Never

start the saw with a workpiece touching the blade;

allow the blade to reach full speed before cutting.

Only feed the workpiece against the direction of

blade rotation. Always use some type of guide

(fence, miter gauge, sliding table or sled, etc.) to

feed the workpiece in a straight line. Never back a

workpiece out of a cut or try to move it backwards

or sideways after starting a cut. Feed cuts all the

way through to completion. Never perform any

operation “freehand” (making a cut without using a

fence, miter gauge, or other guide).

-12-

DAMAGED SAW BLADES. Never use blades

that have been dropped or otherwise damaged.

Damaged blades can fly apart and strike the operator with shards of metal.

DADO AND RABBET OPERATIONS. DO NOT

attempt dado or rabbeting operations without

first reading those sections in this manual. Dado

and rabbeting operations require special attention

because they must be performed with the blade

guard removed.

CUTTING CORRECT MATERIAL. Never cut

materials not intended for this saw; only cut natural

and man-made wood products, laminate covered

wood products, and some plastics. Cutting metal,

glass, stone, tile, etc. increases the risk of operator

injury due to kickback or flying particles.

Model G0690/G0691 (Mfg. 11/10+)

Page 15

Preventing Kickback

Below are tips to avoid the most common

causes of kickback:

• Only cut workpieces with at least one smooth

and straight edge. DO NOT cut warped,

cupped or twisted wood.

• Never attempt freehand cuts. If the workpiece

is not fed parallel with the blade, kickback will

likely occur. Always use the rip fence or miter

gauge to support the workpiece.

• Make sure the spreader or riving knife is

aligned with the blade. A misaligned spreader

or riving knife can cause the workpiece to

catch or bind, increasing the chance of kickback. If you think that your spreader or riving

knife is not aligned with the blade, check it

immediately!

Statistics show that most common accidents among table saw users can be

linked to kickback. Kickback is typically

defined as the high-speed expulsion of

stock from the table saw toward its operator. In addition to the danger of the operator or others in the area being struck by

the flying stock, it is often the case that

the operator’s hands are pulled into the

blade during the kickback.

Protecting Yourself

From Kickback

Even if you know how to prevent kickback, it

may still happen. Here are some tips to protect yourself if kickback DOES occur:

• Take the time to check and adjust the rip

fence parallel with the blade; otherwise, the

chances of kickback are extreme.

• The spreader or riving knife maintains the

kerf in the workpiece, reducing the chance of

kickback. Always use the riving knife for all

non-through operations, unless a dado blade

is installed. Always use the spreader with the

blade guard for all through cuts.

• Feed cuts through to completion. Anytime

you stop feeding a workpiece in the middle

of a cut, the chance of kickback is greatly

increased.

• Keep the blade guard installed and in good

working order. Only remove it when performing non-through cuts and immediately

re-install the blade guard when finished.

Remember, always use the riving knife for all

non-through operations, unless a dado blade

is installed.

• Stand to the side of the blade during every cut.

If kickback does occur, the thrown workpiece

usually travels directly in front of the blade.

• Wear safety glasses or a face shield. In the

event of kickback, your eyes and face are the

most vulnerable part of your body.

• Never, for any reason, place your hand

behind the blade. Should kickback occur,

your hand will be pulled into the blade.

• Use a push stick to keep your hands farther

away from the moving blade. If kickback

occurs, the push stick will most likely take

the damage that your hand would have

received.

• Use featherboards or anti-kickback devices

to prevent or slow down kickback.

• Make multiple, shallow passes when performing a non-through cut. Making a deep

non-through cut will greatly increase the

chance of kickback.

Model G0690/G0691 (Mfg. 11/10+)

-13-

Page 16

Glossary of Terms

The following is a list of common definitions, terms and phrases used throughout this manual as they relate

to this table saw and woodworking in general. Become familiar with these terms for assembling, adjusting

or operating this machine. Your safety is VERY important to us at Grizzly!

Arbor: A metal shaft extending from the drive

mechanism that is the mounting location for the

saw blade.

Bevel Edge Cut: A cut made with the blade tilted

to an angle between 0˚ and 45˚ to cut a beveled

edge onto a workpiece. Refer to Page 42 for

more details.

Blade Guard Assembly: Metal or plastic safety

device that mounts over the saw blade. Its function is to prevent the operator from coming into

contact with the saw blade. Refer to Page 37

for more details.

Crosscut: Cutting operation in which the cross-

cut fence is used to cut across the shortest

width of the workpiece. Refer to Page 41 for

more details.

Dado Blade: Blade or set of blades that are used

to cut grooves and rabbets. Refer to Page 59

for more details. The saw and arbor are not

intended to safely use a larger dado blade.

Dado Cut: Cutting operation that uses a dado

blade to cut a flat bottomed groove into the face

of the workpiece. Refer to Page 42 for more

details.

Featherboard: Safety device used to keep the

workpiece against the rip fence and against

the table surface. Refer to Page 50 for more

details.

Kerf: The resulting cut or gap in the workpiece

after the saw blade passes through during a

cutting operation.

Kickback: An event in which the workpiece is

propelled back towards the operator at a high

rate of speed.

Non-Through Cut: A cut in which the blade does

not cut through the top of the workpiece. Refer

to Page 33 for more details.

Parallel: Being an equal distance apart at every

point along two given lines or planes (i.e. the

rip fence face is parallel to the face of the saw

blade).

Perpendicular: Lines or planes that intersect and

form right angles (i.e. the blade is perpendicular

to the table surface).

Push Stick: Safety device used to push the

workpiece through a cutting operation. Used

most often when rip cutting thin workpieces.

Refer to Page 53 for more details.

Rabbet: Cutting operation that creates an L-shaped

channel along the edge of the workpiece. Refer

to Page 45 for more details.

Rip Cut: Cutting operation in which the rip fence

is used to cut across the widest width of the

workpiece. Refer to Page 40 for more details.

Riving Knife: Metal plate located behind the

blade. It maintains the kerf opening in the wood

when performing a cutting operation. Refer to

Page 39 for more details.

Straightedge: A tool used to check the flatness,

parallelism, or consistency of a surface(s).

Thin Kerf Blade: A blade with a kerf or thickness

that is thinner than a standard blade cannot be

used on this saw.

Through Cut: A cut in which the blade cuts com-

pletely through the workpiece. Refer to Page

33 for more details.

-14-

Model G0690/G0691 (Mfg. 11/10+)

Page 17

SECTION 2: POWER SUPPLY

Before installing the machine, consider the availability and proximity of the required power supply

circuit. If an existing circuit does not meet the

requirements for this machine, a new circuit must

be installed. To minimize the risk of electrocution,

fire, or equipment damage, installation work and

electrical wiring must be done by an electrican or

qualified service personnel in accordance with all

applicable codes and standards.

Electrocution, fire, or

equipment damage may

occur if machine is not

correctly grounded and

connected to the power

The full-load current rating is the amperage a

machine draws at 100% of the rated output power.

On machines with multiple motors, this is the

amperage drawn by the largest motor or sum of all

motors and electrical devices that might operate

at one time during normal operations.

The full-load current is not the maximum amount

of amps that the machine will draw. If the machine

is overloaded, it will draw additional amps beyond

the full-load rating.

If the machine is overloaded for a sufficient length

of time, damage, overheating, or fire may result—

especially if connected to an undersized circuit.

To reduce the risk of these hazards, avoid overloading the machine during operation and make

sure it is connected to a power supply circuit that

meets the requirements in the following section.

For your own safety and protection of

Note: The circuit requirements listed in this manual apply to a dedicated circuit—where only one

machine will be running at a time. If this machine

will be connected to a shared circuit where multiple machines will be running at the same time,

consult a qualified electrician to ensure that the

circuit is properly sized for safe operation.

A power supply circuit includes all electrical

equipment between the breaker box or fuse panel

in the building and the machine. The power supply circuit used for this machine must be sized to

safely handle the full-load current drawn from the

machine for an extended period of time. (If this

machine is connected to a circuit protected by

fuses, use a time delay fuse marked D.)

This machine is prewired to operate on a 220V

power supply circuit that has a verified ground and

meets the following requirements:

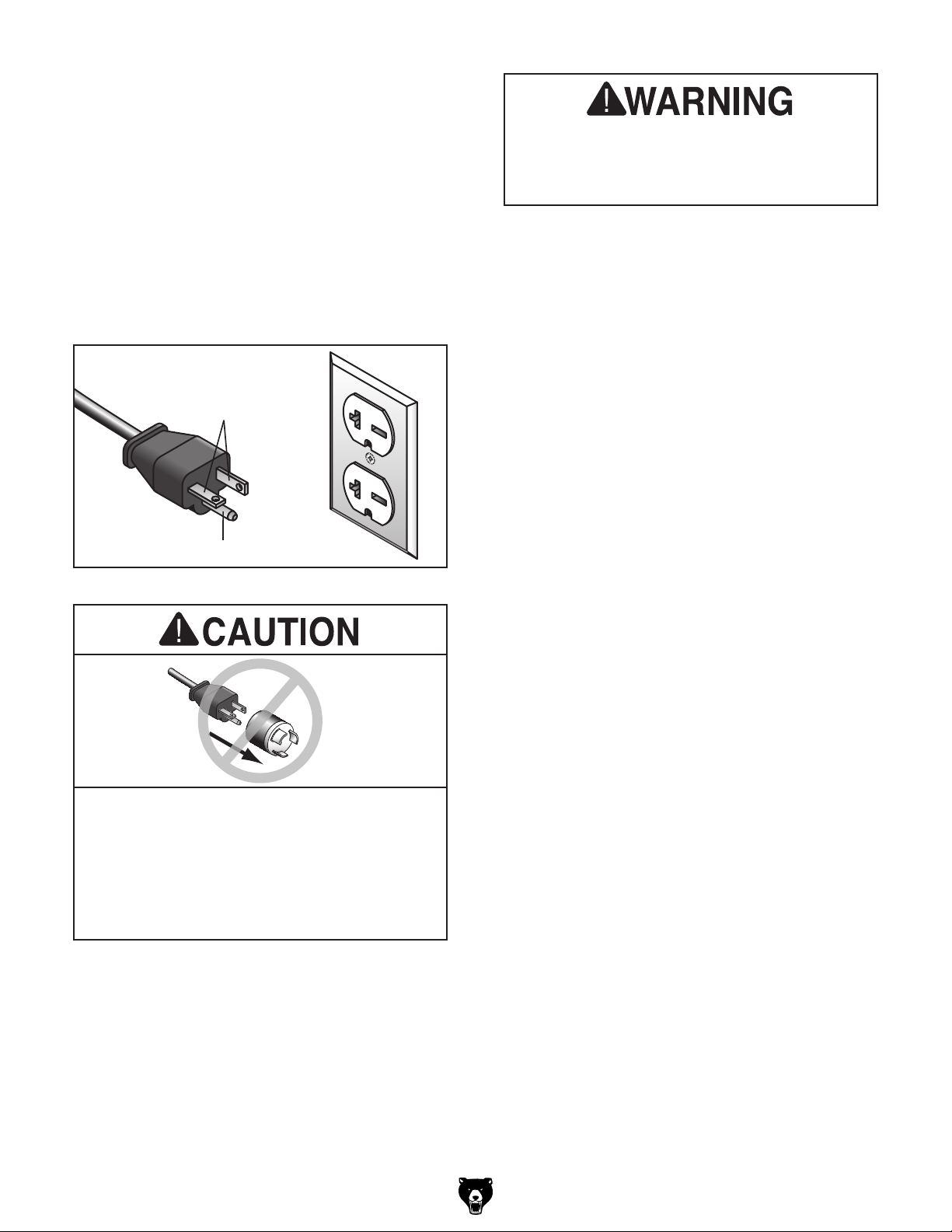

Availability

supply.

Full-Load Current Rating

Circuit Information

property, consult an electrician if you are

unsure about wiring practices or electrical

codes in your area.

Full-Load Current Rating at 220V .. 12.8 Amps

Model G0690/G0691 (Mfg. 11/10+)

Circuit Requirements for 220V

Nominal Voltage .............................. 220V/240V

Cycle ..........................................................60 Hz

Phase ........................................... Single-Phase

Circuit Rating ...................................... 20 Amps

Plug/Receptacle ............................. NEMA 6-20

-15-

Page 18

We do not recommend using an extension cord

with this machine.

cord, only use it if absolutely necessary and only

on a temporary basis.

Extension cords cause voltage drop, which may

damage electrical components and shorten motor

life. Voltage drop increases as the extension cord

size gets longer and the gauge size gets smaller

(higher gauge numbers indicate smaller sizes).

Any extension cord used with this machine must

contain a ground wire, match the required plug

and receptacle, and meet the following requirements:

Grounding Instructions

This machine MUST be grounded. In the event

of certain malfunctions or breakdowns, grounding

reduces the risk of electric shock by providing a

path of least resistance for electric current.

Improper connection of the equipment-grounding

wire can result in a risk of electric shock. The

wire with green insulation (with or without yellow

stripes) is the equipment-grounding wire. If repair

or replacement of the power cord or plug is necessary, do not connect the equipment-grounding

wire to a live (current carrying) terminal.

Check with a qualified electrician or service personnel if you do not understand these grounding

requirements, or if you are in doubt about whether

the tool is properly grounded. If you ever notice

that a cord or plug is damaged or worn, disconnect it from power, and immediately replace it with

a new one.

This machine is equipped with a power cord that

has an equipment-grounding wire and a grounding plug (similar to the figure below). The plug

must only be inserted into a matching receptacle

(outlet) that is properly installed and grounded in

accordance with all local codes and ordinances.

No adapter should be used with the

required plug. If the plug does not fit the

available receptacle, or the machine must

GROUNDED

6-20 RECEPTACLE

Current Carrying Prongs

6-20 PLUG

Serious injury could occur if you connect

the machine to power before completing the

setup process. DO NOT connect to power

until instructed later in this manual.

Grounding Prong

Figure 4. Typical 6-20 plug and receptacle.

be reconnected for use on a different type

of circuit, the reconnection must be made

by a qualified electrician and comply with all

local codes and ordinances.

-16 -

Extension Cords

If you must use an extension

Minimum Gauge Size ...........................12 AWG

Maximum Length (Shorter is Better).......50 ft.

Model G0690/G0691 (Mfg. 11/10+)

Page 19

SECTION 3: SETUP

Your machine was carefully packaged for safe

transportation. Remove the packaging materials

from around your machine and inspect it. If you

discover any damage, please call us immediately

at (570) 546-9663

Save the containers and all packing materials for

possible inspection by the carrier or its agent.

Otherwise, filing a freight claim can be difficult.

When you are completely satisfied with the condition of your shipment, inventory the contents.

Lifting heavy machinery

or parts without proper

assistance or equipment

Items Needed for

Setup

The following items are needed to complete the

setup process, but are not included with your

machine:

Description Qty

• Safety Glasses for Each Person ................ 1

• Degreaser or Solvent for Cleaning ..... Varies

• Disposable Rags for Cleaning ............ Varies

• Straightedge ............................................... 1

• Level ........................................................... 1

• Dust Collection System .............................. 1

• 4" Dust Hose .............................................. 1

• 4" Hose Clamp ........................................... 1

• Assistant for Lifting ..................................... 1

• Needle Nose Pliers .................................... 1

• Wrench or Socket 17mm ............................ 1

• Wrenches or Sockets 13mm ...................... 2

• Wrench or Socket 10mm ............................ 1

• Wrench 14mm ............................................ 1

• Adjustable Wrench ..................................... 1

Unpacking

for advice.

may result in strains, back

injuries, crushing injuries,

or property damage.

To reduce the risk of serious

injury, read and understand

this entire document before

using the machine!

Model G0690/G0691 (Mfg. 11/10+)

-17-

Page 20

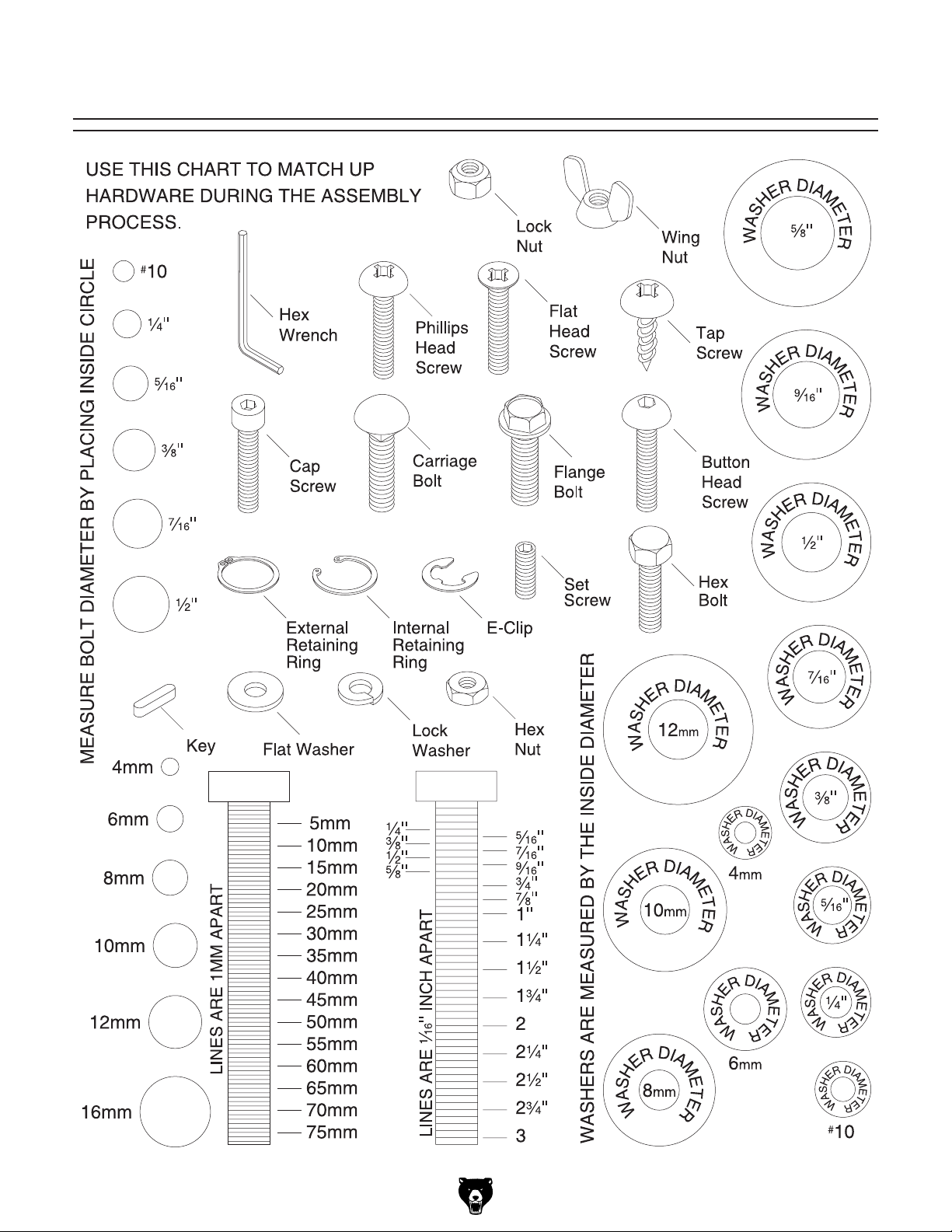

Hardware Recognition Chart

-18-

Model G0690/G0691 (Mfg. 11/10+)

Page 21

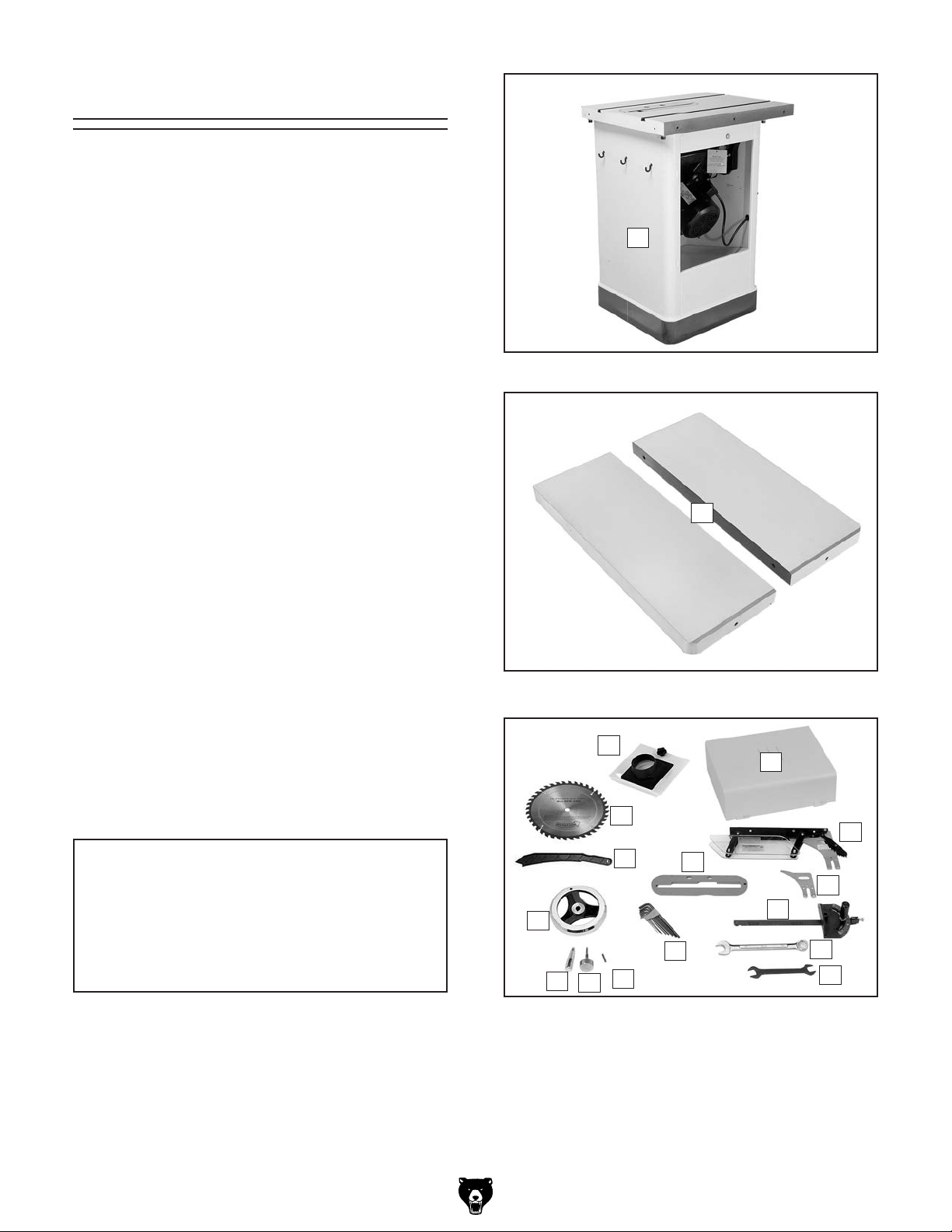

Inventory

The following is a list of items shipped with your

machine. Before beginning setup, lay these items

out and inventory them.

If any non-proprietary parts are missing (e.g. a

nut or a washer), we will gladly replace them; or

for the sake of expediency, replacements can be

obtained at your local hardware store.

Box Contents: (Figures 5–7) Qty

A. Main Table Saw Unit .................................. 1

B. Extension Wings ........................................ 2

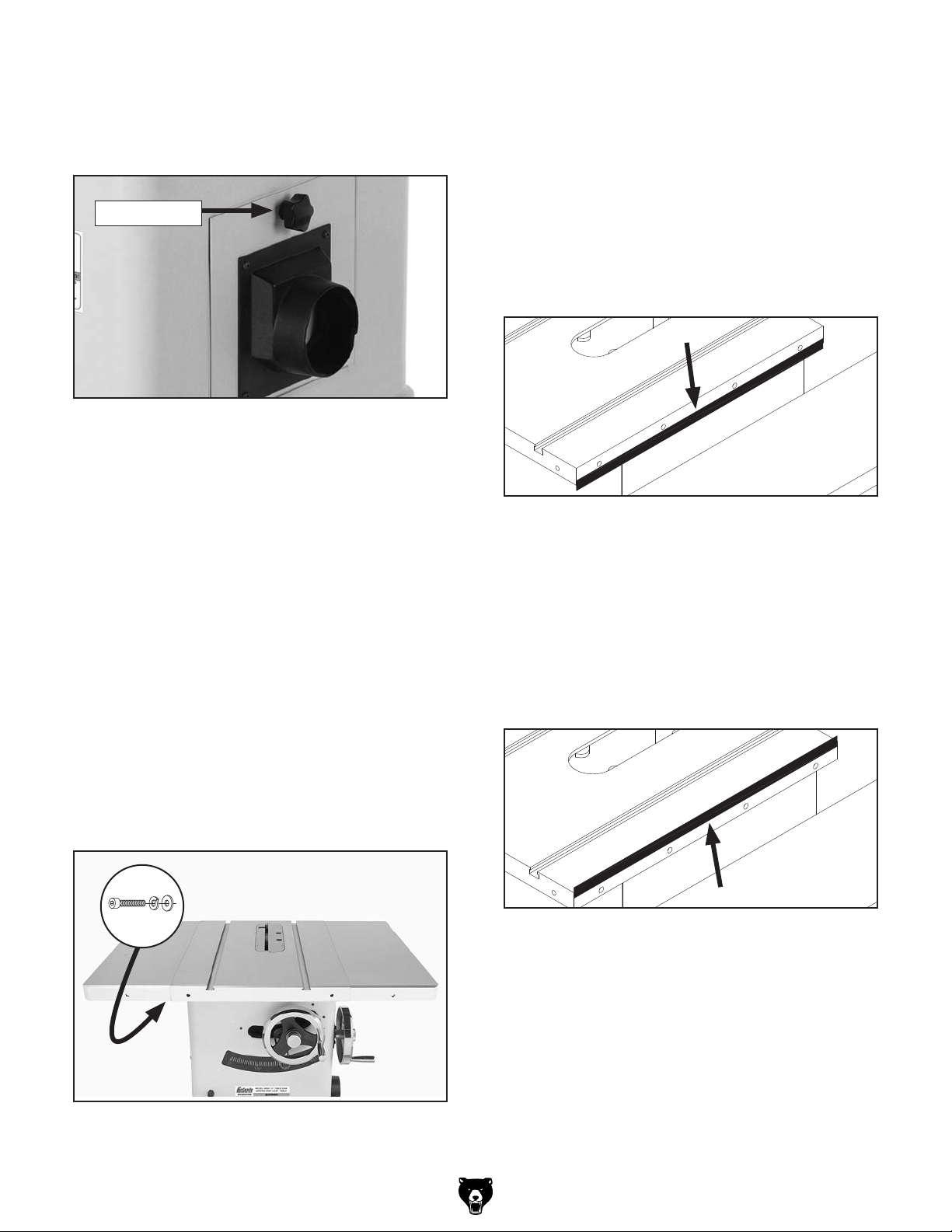

C. Dust Port .................................................... 1

D. Door ............................................................ 1

E. Blade Guard Assembly .............................. 1

F. Riving Knife ................................................ 1

G. Miter Gauge ................................................ 1

H. Wrench 27mm ............................................ 1

I. Wrench 22/24mm ....................................... 1

J. Dado Table Insert ....................................... 1

K. Hex Wrench Set (Eight Pieces) 1.5-8mm ... 1

L. Key 5 x 5 x 40 ............................................ 1

M. Handwheel Lock Knob ............................... 1

N. Handwheel Handle ..................................... 1

O. Handwheel ................................................. 1

P. Push Stick .................................................. 1

Q. Saw Blade 10" x 40T .................................. 1

A

Figure 5. Main table saw unit.

B

Figure 6. Extension wings.

Hardware (Not Shown)

Phillips Head Screw M6-1 x 12 (Mag Switch) .... 1

Hex Bolts M6-1 x 12 (Mag Switch) .................... 2

Lock Washers 6mm (Mag Switch) ..................... 3

Flat Washers 6mm (Mag Switch) ...................... 3

Qty

NOTICE

If you cannot find an item on this list, carefully check around/inside the machine and

packaging materials. Often, these items get

lost in packaging materials while unpacking or they are pre-installed at the factory.

Model G0690/G0691 (Mfg. 11/10+)

C

Q

P

O

M

L

N

Figure 7. Component inventory.

J

K

D

E

F

G

H

I

-19 -

Page 22

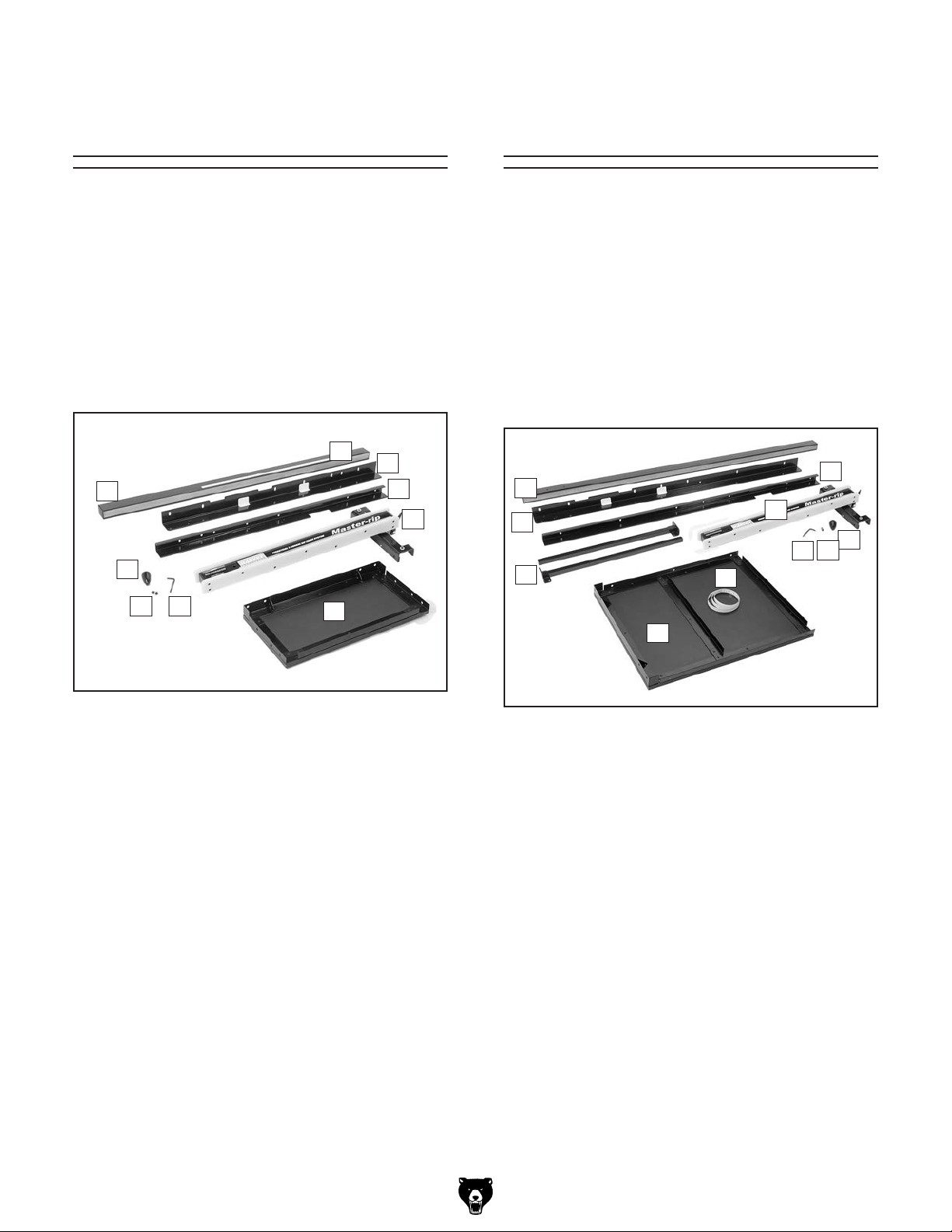

Fence Inventory

Fence Inventory

G0690

Components Qty

A. Front Rail Rectangular Tube 62" ................ 1

B. Front Rail Tape Scale ................................. 1

C. Front Rail 50" .............................................. 1

D. Rear Rail 50" .............................................. 1

E. Fence Assembly ......................................... 1

F. Fence Handle ............................................. 1

G. Rear Rail Foot M12-1.75 ............................. 1

H. Hex Wrench 6mm ....................................... 1

I. Extension Table 27" x 13

A

F

3

⁄4" ....................... 1

B

C

D

E

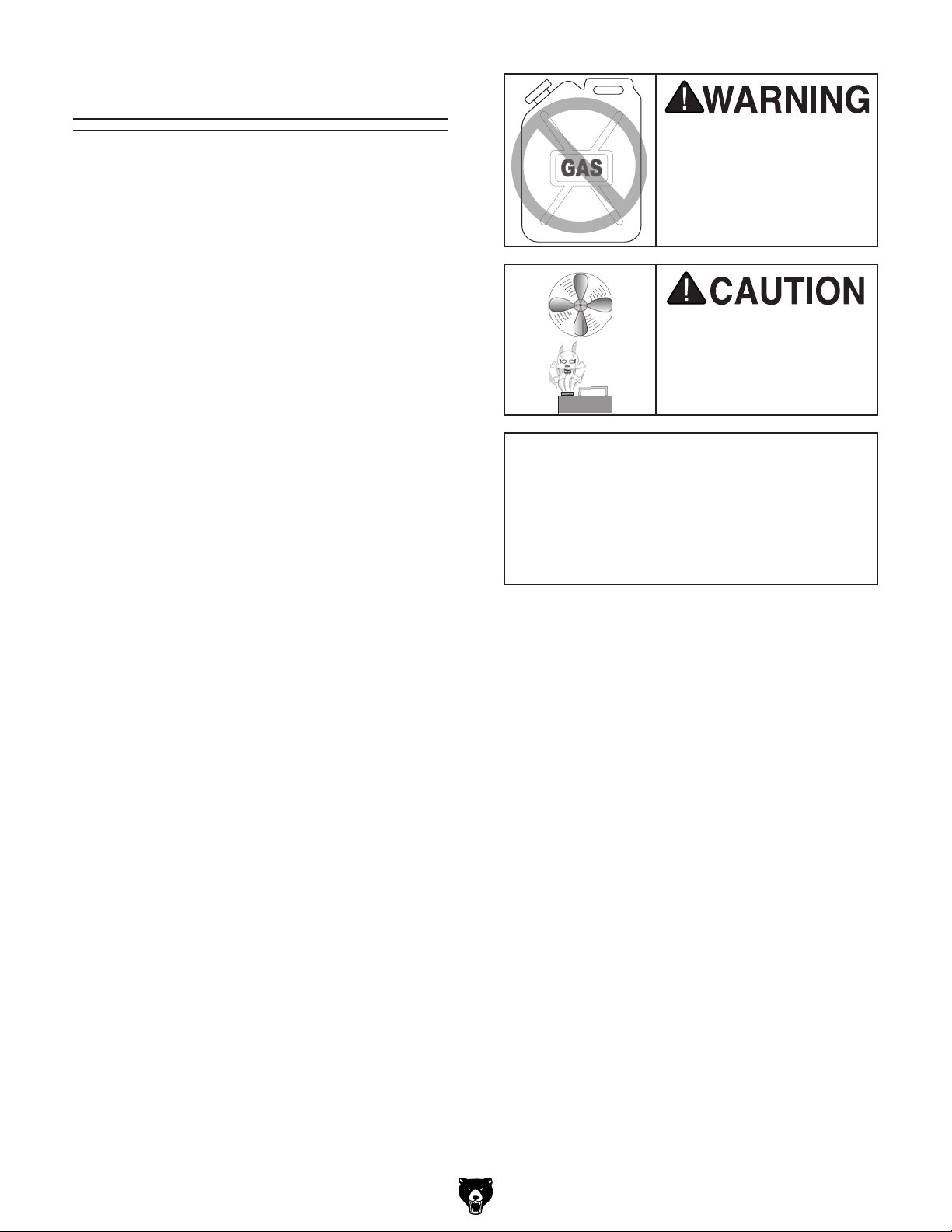

G0691

Components Qty

A. Front Rail Rectangular Tube 82" ................ 1

B. Front Rail 70" .............................................. 1

C. Rear Rail 70" .............................................. 1

D. Fence Assembly ......................................... 1

D. Fence Handle ............................................. 1

F. Rear Rail Foot ............................................ 1

G. Hex Wrench 6mm ....................................... 1

H. Front Rail Tape Scale ................................. 1

I. Extension Table .......................................... 1

J. Legs ............................................................ 2

C

A

B

J

H

D

E

F

G

GIH

Figure 8. Inventory needed to install the fence

on the Model G0690.

Hardware and Tools (Not Shown) Qty

Cap Screws M6-1 x 16 (Front Rail/Tube) .......... 3

Flat Washers 6mm (Front Rail/Tube) ................ 3

Lock Washers (Front Rail/Tube) ........................ 3

Hex Bolts M8-1.25 x 40 (Front & Rear Rails) .... 6

Flat Washers 8mm (Front & Rear Rails) ......... 14

Lock Washers 8mm (Front & Rear Rails) .......... 8

Hex Nuts M8-1.25 (Front & Rear Rails) ............. 6

Hex Bolts

Hex Bolts M8-1.25 x 30 (Extension Table) ........ 4

Hex Nuts M8-1.25 (Extension Table) ................. 4

Flat Washers 8mm (Extension Table) ............... 8

Lock Washers 8mm (Extension Table) .............. 4

5

⁄16"-18 x 1" (Rear Rail) ...................... 2

I

Figure 9. Inventory needed to install the fence

on the Model G0691.

Hardware and Tools (Not Shown) Qty

Feet w/Bolts & Hex Nuts ........................... 2 Sets

Cap Screws M6-1 x 16 (Front Rail/Tube) .......... 5

Flat Washers 6mm (Front Rail/Tube) ................ 5

Lock Washers (Front Rail/Tube) ........................ 5

Hex Bolts M8-1.25 x 40 (Front & Rear Rails) .... 6

Flat Washers 8mm (Front & Rear Rails) ......... 14

Lock Washers 8mm (Front & Rear Rails) .......... 8

Hex Nuts M8-1.25 (Front & Rear Rails) ............. 6

Hex Bolts

Hex Bolts M8-1.25 x 30 (Extension Table) ........ 6

Hex Nuts M8-1.25 (Extension Table) ................. 6

Flat Washers 8mm (Extension Table) ............. 12

Lock Washers 8mm (Extension Table) .............. 6

Cap Screws M8-1.25 x 20 (Legs) ...................... 4

Flat Washers 8mm (Legs) ................................. 4

Lock Washers 8mm (Legs) ............................... 4

Hex Nuts M8-1.25 (Legs) ................................... 4

5

⁄16"-18 x 1" (Rear Rail) ...................... 2

-20-

Model G0690/G0691 (Mfg. 11/10+)

Page 23

The unpainted surfaces of your machine are

coated with a heavy-duty rust preventative that

prevents corrosion during shipment and storage.

This rust preventative works extremely well, but it

will take a little time to clean.

Be patient and do a thorough job cleaning your

machine. The time you spend doing this now will

give you a better appreciation for the proper care

of your machine's unpainted surfaces.

There are many ways to remove this rust preven

tative, but the following steps work well in a wide

variety of situations. Always follow the manufac

turer’s instructions with any cleaning product you

use and make sure you work in a well-ventilated

area to minimize exposure to toxic fumes.

Before cleaning, gather the following:

•

•

•

•

Basic steps for removing rust preventative:

1.

2.

3.

4.

metal protectant to prevent rust.

Gasoline or products

Many cleaning solvents

ed amounts are inhaled.

Avoid chlorine-based solvents, such as

Cleanup

with low flash points can

explode or cause fire if

used to clean machinery. Avoid cleaning with

these products.

are toxic if concentrat-

Disposable Rags

Cleaner/degreaser (WD•40 works well)

Safety glasses & disposable gloves

Plastic paint scraper (optional)

Put on safety glasses.

Coat the rust preventative with a liberal

amount of cleaner/degreaser, then let it soak

for 5–10 minutes.

Wipe off the surfaces. If your cleaner/degreas-

er is effective, the rust preventative will wipe

off easily. If you have a plastic paint scraper,

scrape off as much as you can first, then wipe

off the rest with the rag.

-

-

Only work in a well-ventilated area.

NOTICE

acetone or brake parts cleaner, that may

damage painted surfaces. Test all cleaners

in an inconspicuous area before using to

make sure they will not damage paint.

Repeat Steps 2–3 as necessary until clean,

then coat all unpainted surfaces with a quality

Model G0690/G0691 (Mfg. 11/10+)

-21-

Page 24

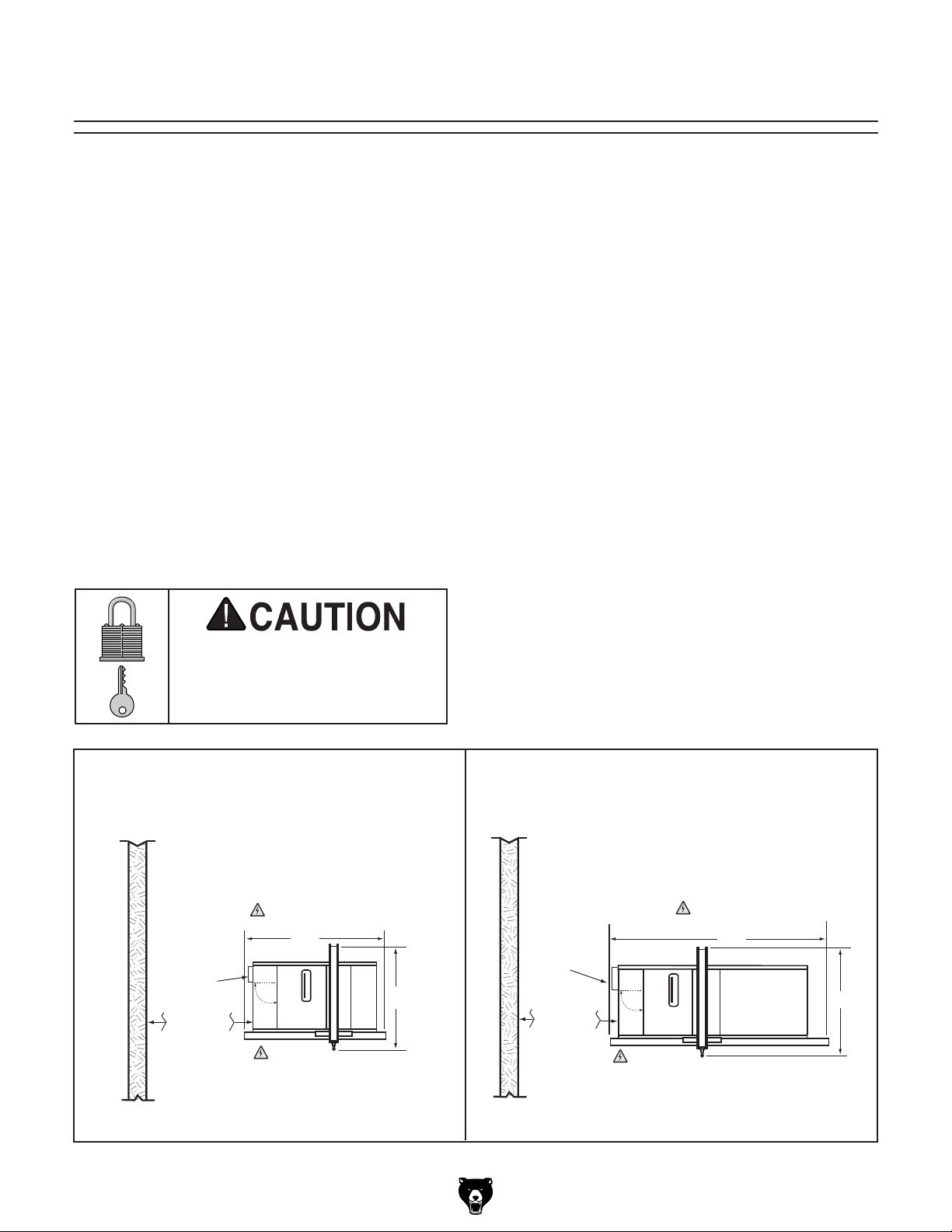

Site Considerations

Weight Load

Physical Environment

Place this machine near an existing power source.

Shadows, glare, or strobe effects that may distract

Wall

Min. 30"

Access

Door

Swing at 90º

= Power Connection

45½"

G0691

82"

Refer to the Machine Data Sheet for the weight

of your machine. Make sure that the surface upon

which the machine is placed will bear the weight

of the machine, additional equipment that may be

installed on the machine, and the heaviest workpiece that will be used. Additionally, consider the

weight of the operator and any dynamic loading

that may occur when operating the machine.

Space Allocation

Consider the largest size of workpiece that will

be processed through this machine and provide

enough space around the machine for adequate

operator material handling or the installation of

auxiliary equipment. With permanent installations,

leave enough space around the machine to open

or remove doors/covers as required by the maintenance and service described in this manual.

See below for required space allocation.

Children or untrained people

may be seriously injured by

this machine. Only install in an

access restricted location.

The physical environment where the machine is

operated is important for safe operation and longevity of machine components. For best results,

operate this machine in a dry environment that is

free from excessive moisture, hazardous chemicals, airborne abrasives, or extreme conditions.

Extreme conditions for this type of machinery are

generally those where the ambient temperature

range exceeds 41°–104°F; the relative humidity

range exceeds 20–95% (non-condensing); or the

environment is subject to vibration, shocks, or

bumps.

Electrical Installation

Make sure all power cords are protected from

traffic, material handling, moisture, chemicals,

or other hazards. Make sure to leave access to

a means of disconnecting the power source or

engaging a lockout/tagout device, if required.

Lighting

Lighting around the machine must be adequate

enough that operations can be performed safely.

or impede the operator must be eliminated.

-22-

Wall

Swing at 90º

Access

Door

Min. 30"

G0690

= Power Connection

62"

Figure 10. Minimum working clearances.

45½"

G0691

= Power Connection

Access

Door

Swing at 90º

Wall

Min. 30"

Model G0690/G0691 (Mfg. 11/10+)

82"

45½"

Page 25

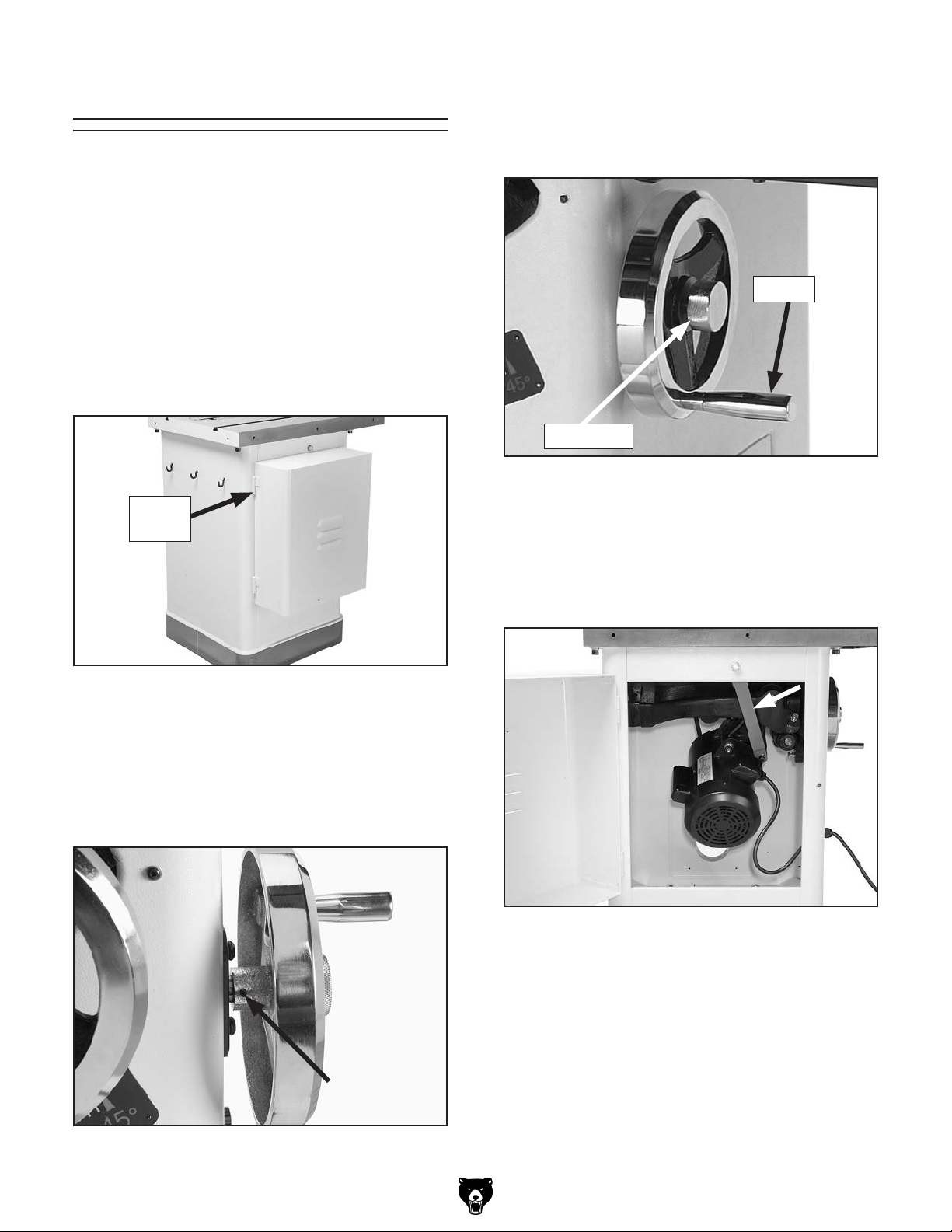

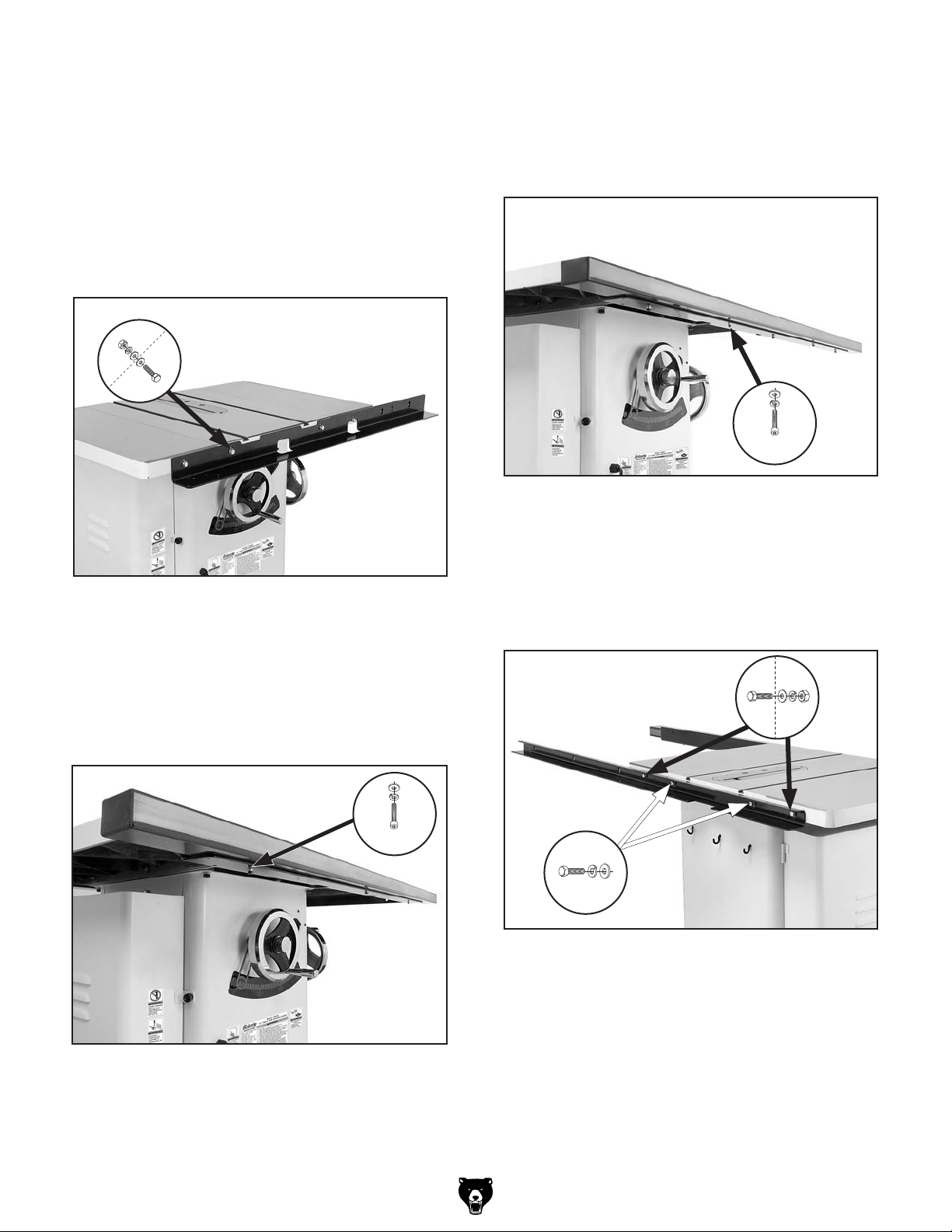

Assembly

Assembly steps are the same for the Model

G0690 and G0691 except where noted. Assembly

consists of installing minor components, the extension wings, front and rear rails, extension table,

and the legs (Model G0691 only).