Page 1

!

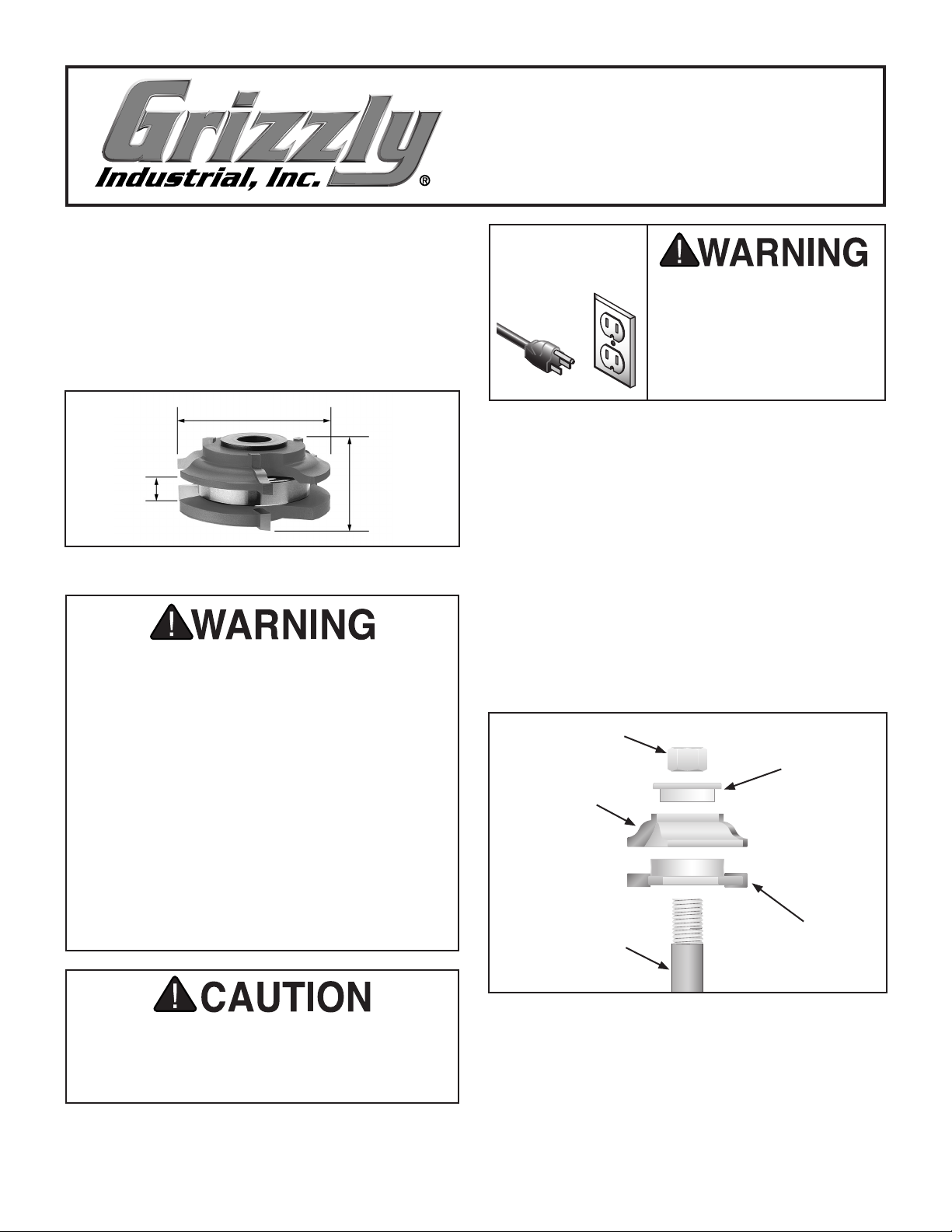

Introduction

INSTRUCTIONS FOR

C2314-C2317 REVERSIBLE

STILE AND RAIL SET

The Model C2314-C2317 Reversible Stile and Rail

Sets allow you to shape ¾" material into door stiles

and then simply reverse the cutter components to

shape the door rails. This set comes complete with

a ball bearing guide and shims.

21⁄2"

1

⁄4"

Reversible Stile and Rail Set

• Failure to follow these guidelines will result

in serious personal injury.

• Follow the safety guidelines set forth by the

manufacturer of the shaper.

• DO NOT remove guards and anti-kickback

devices from the shaper.

• ALWAYS WEAR ANSI APPROVED EYE AND

EAR PROTECTION when using this bit.

• Unplug shaper before installing or

cutter.

• Always inspect workpiece for cracks, knots,

or other imperfections that could cause the

workpiece to kick or shatter while milling.

• Always feed the workpiece against the cut

ter rotation.

1"

adjusting

-

Always disconnect power

to the machine when set

ting up or making adjust

ments. Failure to do this

may result in serious per

sonal injury.

-

-

-

Cutting Rails

For safety and best results, we recommend using

a shaper with adjustable fences and a miter gauge.

These instructions are only intended for setting up

the cutter for counterclockwise rotation.

To cut the rail ends:

1. UNPLUG THE SHAPER!

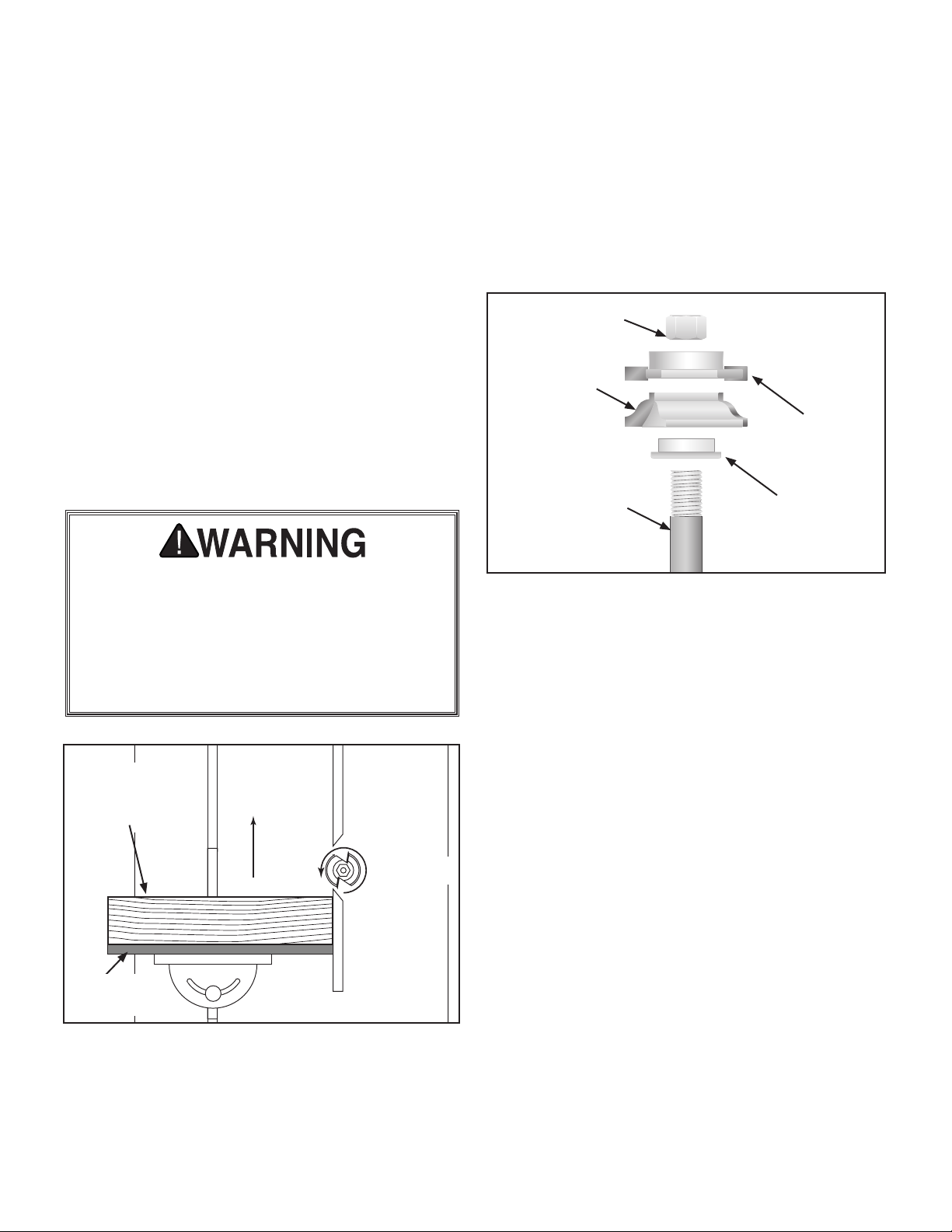

2. Slide the flat cutter, bearing side up, over the

spindle as shown in Figure A

Spindle Nut

Profile

Cutter

Spindle

.

Bushing

Flat

Cutter

These shaper bits have sharp edges. Use care

while removing the waxy protective coating.

Never turn on the shaper with the protective

coating still on the bit.

Figure A. Set-up for cutting rails.

3. Place the bushing into the hole in the profile cut-

ter and slide both onto the spindle.

4. Thread the spindle nut against the bushing and

tighten it with a wrench.

-1-

Page 2

5. Use a straightedge to align the fences with the

edge of the guide bearing.

Cutting Stiles

6. Align the bottom edge of the shaper cutter with

the top, or slightly below the top of the table.

7. Before turning the shaper ON, place a test rail

on against the miter gauge finished face up and

slide it against the fence.

Note—We recommend using a back-up piece of

wood behind the rail to prevent tear-out.

8. Turn ON the shaper and slide the miter gauge

and test rail through the shaper cutter as shown

in Figure B.

Note—The workpiece must always be fed

against the cutter rotation and the full depth of

profile should be made in one pass to ensure a

precise cut.

These instructions are intended for

COUNTERCLOCKWISE spindle operation only.

DO NOT operate the shaper in the clockwise

direction to make a climb cut. If this warning

is ignored, the workpiece can kick forward,

and may pull the hand into the shaper cutter,

causing severe injury or death!

To cut the stile edges:

1. Unplug the shaper!

2. Place the bushing into the hole in the profile cut-

ter from the bottom, as shown in Figure C,

slide both onto the spindle.

Spindle Nut

Profile

Cutter

Flat

Cutter

Spindle

Figure C. Set-up for cutting stiles.

3. Slide the flat cutter, bearing side up, over the

spindle as shown in Figure C

4. Thread the spindle nut against the bushing and

tighten it with a wrench.

Bushing

.

and

RAIL

WORKPIECE

FACE UP

BACK-UP

BOARD

Figure B. Cutting the ends of rails.

9. Rotate the board and cut the edge, and then the

other end, maintaining the face-up position.

FEED

ROTATION

5. Check the alignment of the fences with the edge

of the guide bearing with a straightedge. This

should already be aligned from Step 5 of

Rails.

6. Align the bottom edge of the shaper cutter with

the top, or slightly below the top of the table.

7. Turn ON the shaper and slide a test stile, face

up, through the shaper cutter.

Note—The workpiece must always be fed

against the cutter rotation and the full depth of

profile should be made in one pass to ensure a

precise cut.

8. Turn ON the shaper and slide a test stile, face

up, through the shaper cutter.

9. Place the test stile and rail together to check for

a smooth fit

-2-

.

Cutting

Page 3

Adjustments

If the test pieces are not flush (Figure D) then check

the following:

Improper Height Adjustment Shown

NOTICE

If you have never used this type of machine

or equipment before, WE STRONGLY RECOM

MEND that you read books, trade magazines,

or get formal training before beginning any

projects. Regardless of the content in this

instruction sheet, Grizzly Industrial will not

be held liable for accidents caused by lack of

training.

-

Figure D. Improperly fitting stile and rail.

—If the bottom edge lines up, but the top does

not, make sure the thickness of the stile mate

rial is the same as the rail material.

—If both the top and bottom edges do not line

up as shown in Figure D, adjust the height

of the shaper spindle, or fine tune the cutter

height by placing the included metal shims

between the bushing and the profile cutter.

—If the panel wont slide into the groove in the

stile and rails, place a metal shim between

the guide bearing and the profile cutter as

shown in Figure E

.

We stress the importance of working with good qual

ity material and insuring that all pieces are machined

the same and that all ends and edges are cut square.

Follow all recommended safety procedures and

always test your setup using sample pieces.

If this is your first time performing panel door con

struction, start simple by making a square door.

Doors having more intricate designs, such as arched,

tombstone or curved panels, should only be done

when you are confident of your ability. If your proj

ect requires curved pieces then freehand shaping

will be necessary. Remove the fence(s) and always

incorporate the use of a starting pin or block to sup

port the workpiece as it is initially fed into the cutter.

Always use some type of jig or hold-down device to

make the operation safer and to avoid having your

hand in close proximity to the spinning cutter.

Figure F is a sample of how all the stile and rail

pieces should fit together.

-

-

-

-

SHIM

Insert Shim

When Joint Is

Too Tight

Figure E. Adjustment to fit panel.

Figure F. Stile and rail assembly.

-3-

Loading...

Loading...