Page 1

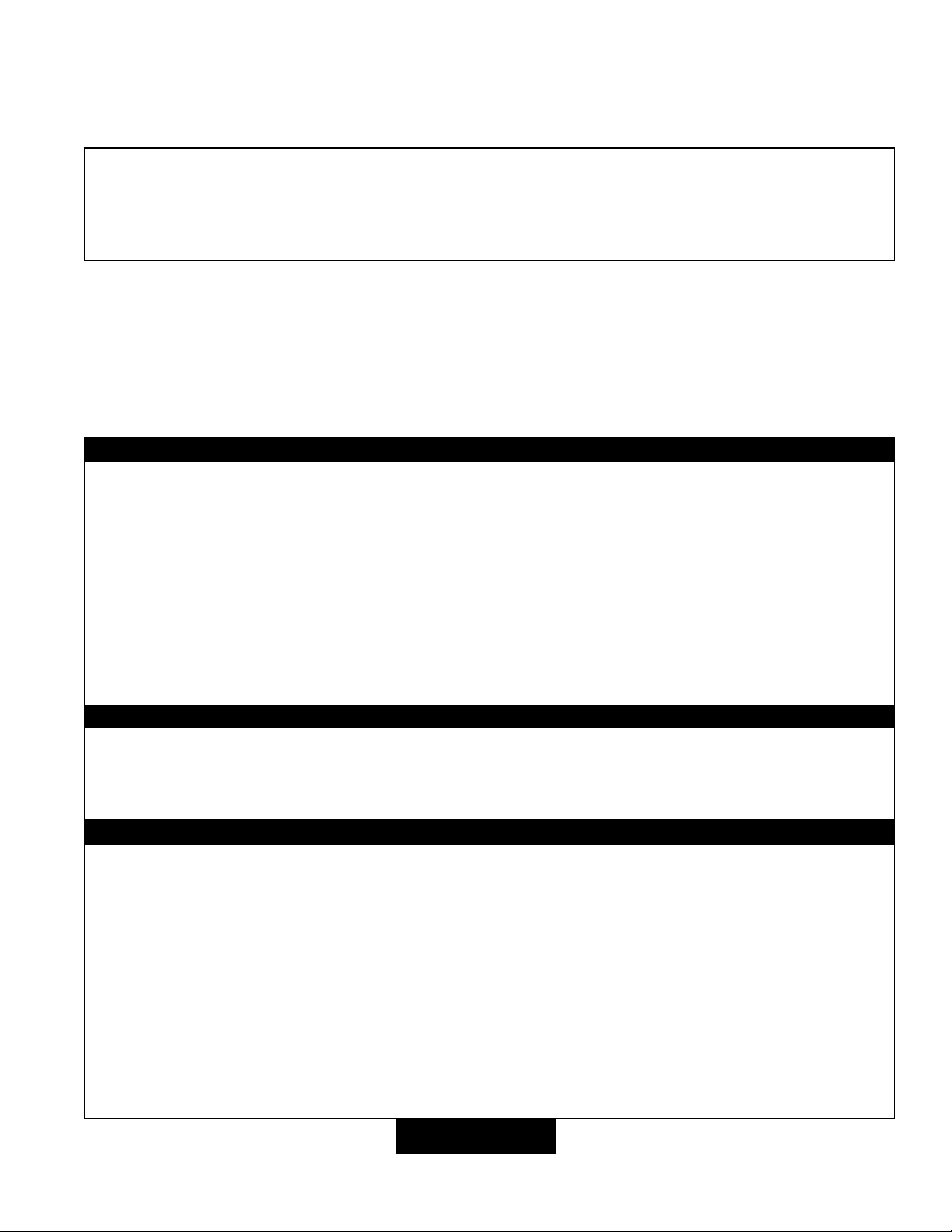

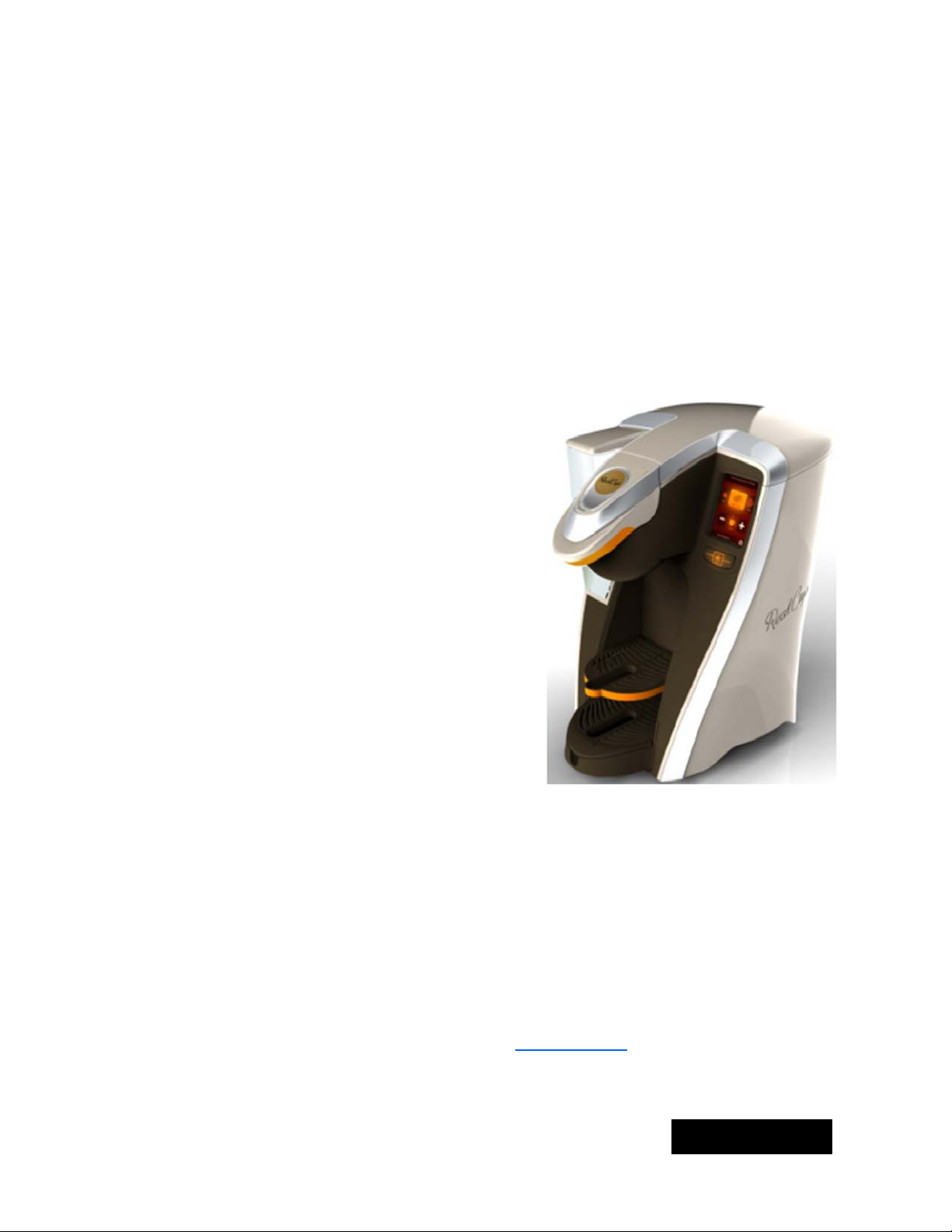

Single Cup Brewer

Table of Contents

Safety Precautions ……………………...2

Brewer Specifications …………………..3

General Information …………………….3

Model RC400

Operation Manual

Product Description …………………….4

Unpacking your brewer ………………...5

Installation ……………………………….5

Set-up ……………………………………6

Operating Instructions…………………..7

Cleaning and Maintenance …………....9

Troubleshooting………………………..10

Spare Parts List ……………………….11

Warranty ……………………………….12

Prior authorization must be obtained from GMCW

for all warranty claims.

GRINDMASTER ®

BY GMCW ™

© GMCW, 2013

Printed in Thailand

MODEL: RC400

GMCW

4003 Collins Lane

Louisville, KY 40245 USA

(502) 425-4776

(800) 695-4500 (USA & Canada only)

FAX (502) 425-4664

www.gmcw.com

1213 Form # BW-305-01

Part # 390-00005

ENGLISH

Page 2

2

Safety Precautions

Important Safety Information

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

For your safety and the safety of others, read all warnings and the operator’s manual before installing or using the

product.

DANGER: This term warns of imminent hazard that will result in serious injury or death.

WARNING: This term refers to a potential hazard or unsafe practice, which could result in serious injury.

CAUTION: This term refers to a potential hazard or unsafe practice, which could result in minor or moderate injury

or property damage.

NOTICE: This term refers to information that needs special attention or must be fully understood.

DANGER

To prevent the possibility of electrocution, burns, or other injuries and to prevent damage to your brewer, do not

immerse in water or any cleaning liquids.

Do not operate a damaged brewer. Inspect the power supply cord and water supply often. If cord or plug is damaged or worn, do not use your brewer. Turn off the water supply and disconnect the electrical power.

Turn off and unplug the brewer before cleaning or maintenance.

Risk of suffocation. The product packaging contains a plastic bag. Keep plastic bags away from children.

Disconnect power if the machine functions abnormally and notify qualified service personnel for repairs. Do not

permit non-qualified service personnel to attempt repairs. No user serviceable components inside the brewer.

Do not disassemble the brewer.

WARNING

Brew probes are sharp. To prevent injury, do not place fingers inside the brew chamber.

The brewer must only be connected to a three wire 120 VAC, 60 Hz, 15 Amp, electrical circuit.

Allow brewer to cool before cleaning or maintaining.

CAUTION

Risk of burns. The brewer uses 185°F- 200°F water that, if not properly handled, could cause burns. Do not permit children to use this appliance unless there is direct adult supervision. Keep away from pets and other animals.

For indoor use only. Do not install or use outdoors, in moving equipment, or watercraft.

Use the product for its intended purpose only. Any other usage is inappropriate and may be dangerous. The

manufacturer assumes no responsibility for injury, loss or damage resulting from improper machine use.

To avoid the risk of burns, do not operate without bezel installed.

Hot surfaces may cause burns. Do not touch the brewer while in operation.

To prevent scalding by hot water, do not open brew chamber while brewing.

To prevent scalding by hot water, do not move or tilt the brewer. Moving or tilting the brewer could result in water

spilling from the reservoir. Internal boiling is possible at high elevations. You must reduce temperature set point

below boiling point for your elevation.

To avoid scalding, use appropriate cup rest to minimize splash. Allow a minimum of 1/2” clearance between cup

rim and brewer dispense spout to prevent spills when removing a full cup. Center cup with dispense sp out while

brewing and allow brewer cycle to complete before opening brew chamber or removing cup.

To avoid pinching, keep fingers clear of brew chamber when closing.

ENGLISH

2

Page 3

3

NOTICE

For best results, remove used Real Cup™ capsule from brew chamber when brewing is complete.

Avoid spills by not removing the reservoir while Auto-Fill unit is filling; allow complete filling cycle before removing

reservoir.

A qualified professional should perform installation, maintenance and repairs.

Installation, maintenance or repairs by unqualified personnel may damage the brewer and void the manuf ac-

turer’s warranty.

This equipment must be installed in accordance with the appropriate national and local codes of the count ry and/

or region in which the appliance is installed.

Contact the manufacturer to report any malfunction of or damage to the brewer.

When turning the machine off for an extended period, be sure to evacuate the water inside the piping completely,

otherwise the water inside the machine could freeze and lead to damage or cause mold to appear.

To reduce foreign material from entering the brewer, keep brew chamber and reservoir lids closed.

To prevent accidental over filling of cup, press “BREW” to stop.

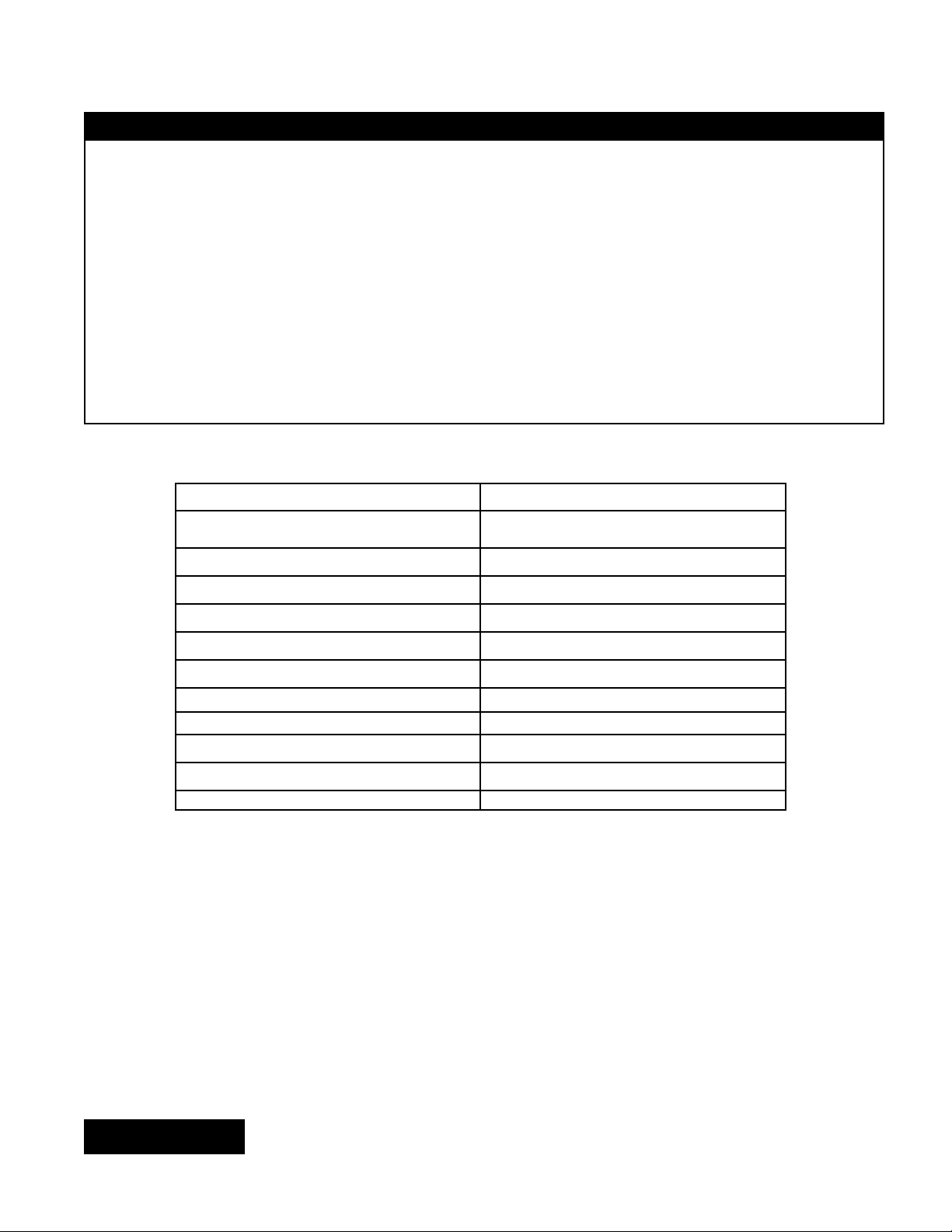

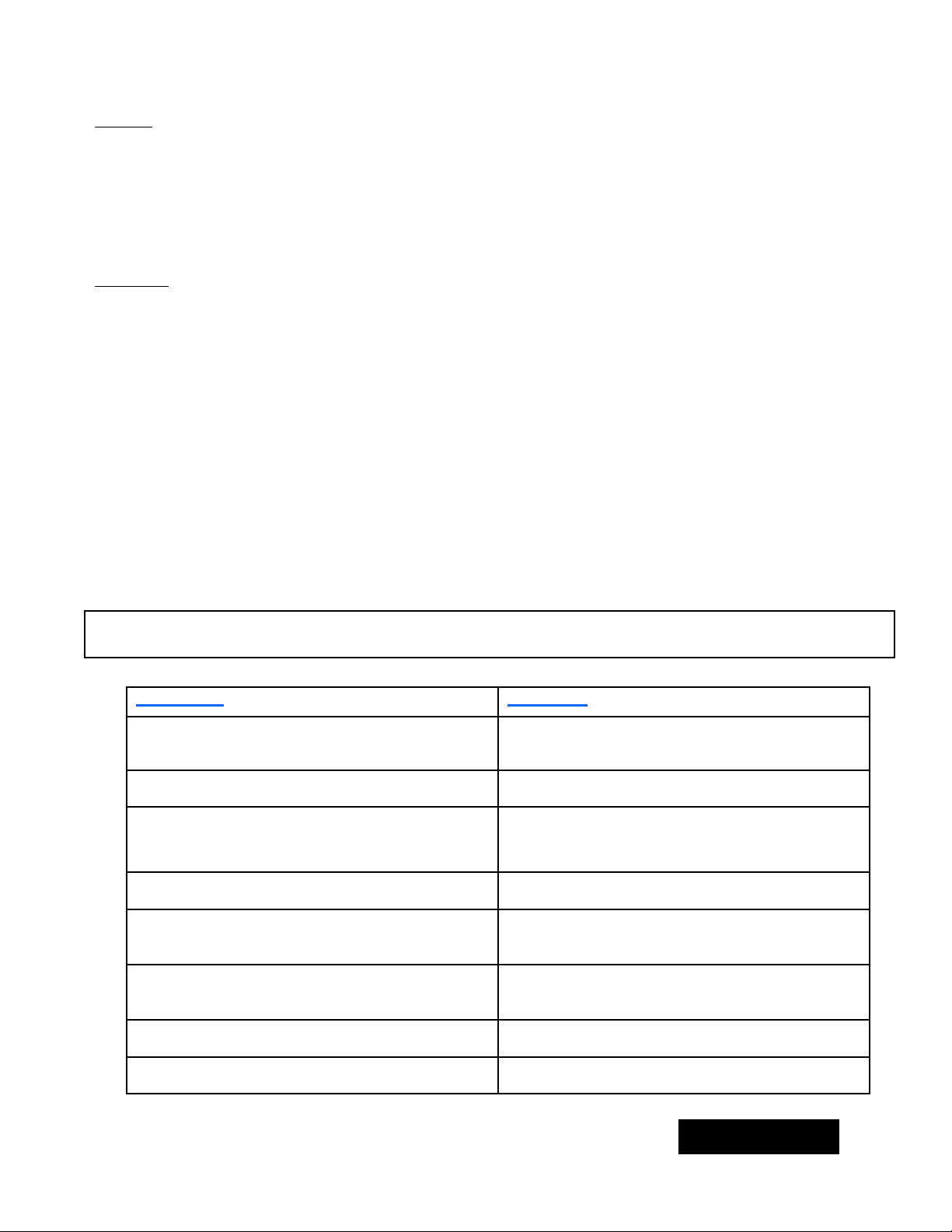

Brewer Specifications

Model RC400

Dimensions (H x W x D) 15.7” (40 cm) x 10.8” (28 cm) x 14.8” (38

cm)

Shipping Weight 18.7 LBS (8.5 kg)

Machine Weight 15.3 LBS (6.9 kg)

Reservoir Capacity 72 fl. oz. (2.1 L)

Voltage 120 VAC

Phase 1

Frequency 60 Hz

Power 1.55 KW

Current 13 Amps

No. of Heaters 1

NEMA Plug 5-15P

General Information

This operating manual includes instructions for using and maintaining your coffee brewer; keep this manual readily

available.

After unpacking your brewer, check to ensure that your machine has not been damaged during shipping and includes all components. Notify your service representative regarding any questions or concerns before installing.

Please note that packaging material can be dangerous. Keep away from children. Discard promptly.

During various stages of operation, you may hear normal operating sounds that are unfamiliar. The following noi ses

are normal:

Buzzing/Clicking - Heard when the water pump energizes and/or the three way valve opens and closes to dis-

pense water or direct water to reservoir.

Popping – A damaged Real Cup™ capsule could result in a popping sound.

Pulsating/Whirring – Under normal operating conditions, an internal air pump activates at the end of a brewing

cycle and you will hear it while energized.

ENGLISH

3

Page 4

4

Water running or gurgling – On a pour over installation, you will hear gurgling when reservoir is empty before the end

of a brew cycle. On an auto fill installation, you will hear this sound as the brewer automatically refills.

Do not use a damaged Real Cup™ capsule or re-insert a capsule that has be en previously been inserted & re-

moved. This may result in coffee grounds and unwanted material inside the brew chamber and the drinki ng cup or

mug. Damage to Real Cup™ capsule may be around the edge of the foil seal or denting and deforming the entire

Real Cup™ capsule.

To ensure food safety and proper operation, clean machine regularly following the daily and weekly cleaning instructions. Cleaning and water evacuation instructions are found in the Cleaning and Maintenance Section of this manual.

When turning off the machine for an extended period, be sure to evacuate the water inside the piping completely.

Otherwise, the water inside the machine could freeze and lead to damage or cause mold to appea r.

Water pipe connections and fixtures directly connected to a potable water supply shall be sized, installed and maintained in accordance with federal, state and local codes. This product requires an approved back flow prevention

device, such as a double check valve, to be installed between the machine and the water supply.

To prevent foreign material from entering the brewer, keep brew chamber and reservoir lid cl osed.

To ensure proper operation of the electronic controls, do not use reverse osmosis, distilled or de-ionized water.

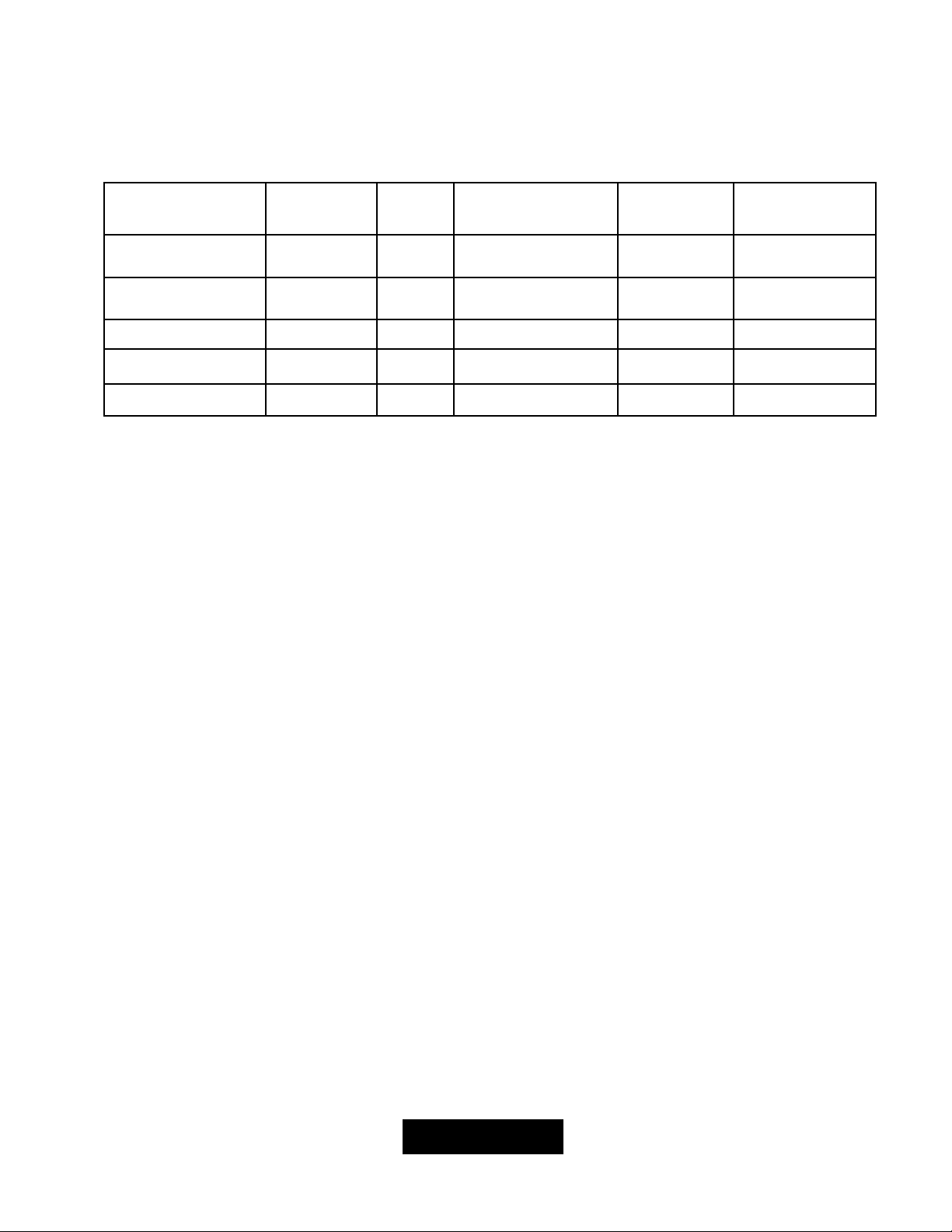

The RC400 brewer hot water temperature is factory set at 195

o

F (90.6o C). If you brewer is operated above 4000

feet in elevation, set point adjustment may become necessary. If the brewer reservoir fogs or experiences hot water

dripping into the reservoir this indicates the set point must be lowered. In addition, if the set point is too high, you

could experience less than expected brew volumes.

Recommended

Set Point

o

C)

(

200 (93) 0 191 (88) 5000 (1524) Denver/

198 (92) 1000 (305) 189 (87) 6000 (1828) Colorado Springs

196 (91) 2000 (610) 187 (86) 7000 (2134) Santa Fe

195 (90) 3000 (915) Calgary 185 (85) 8000 (2438)

193 (89) 4000 (1219)

Elevation ft(M) City Recommended

o

F

Set Point

o

C)

(

Elevation ft(M) City

o

F

Albuquerque

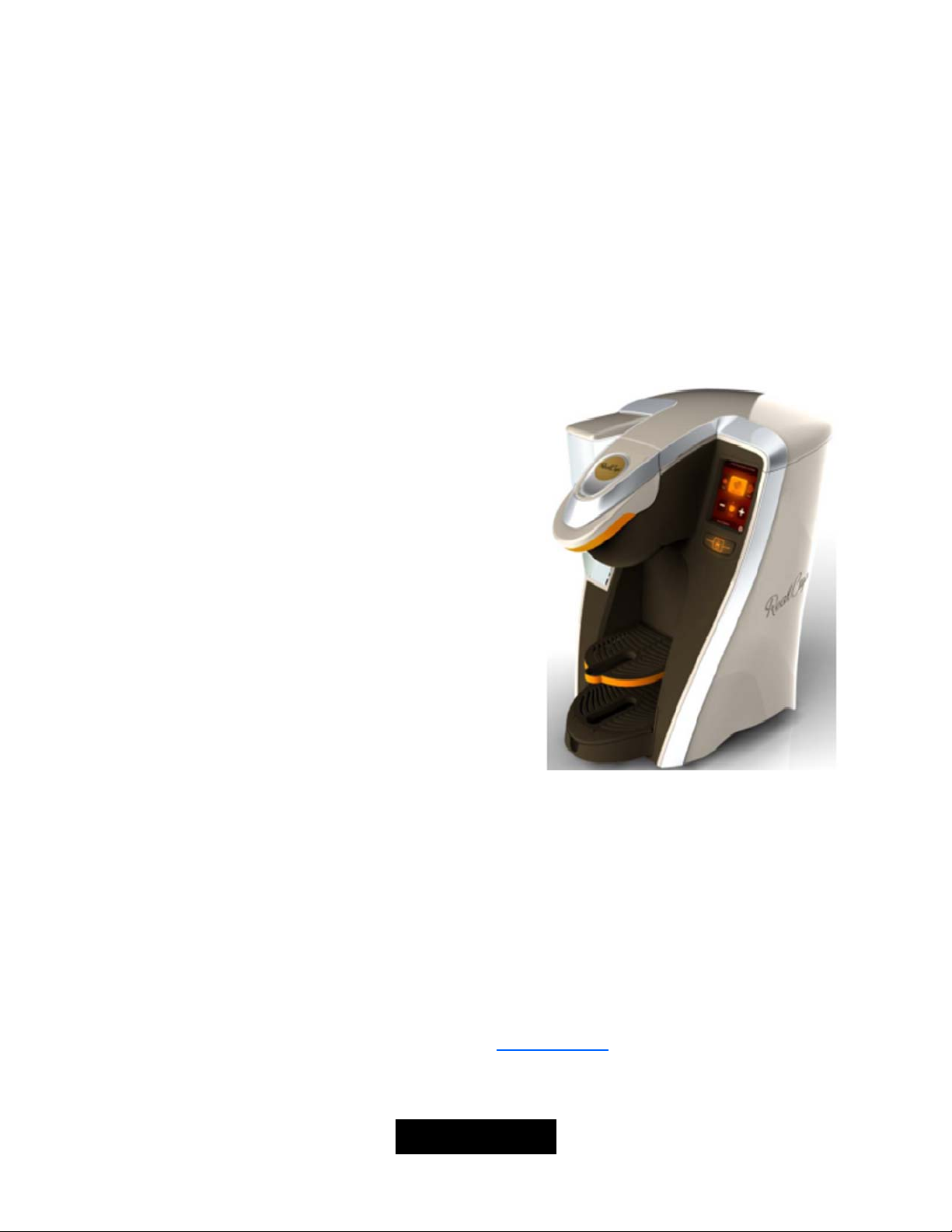

Product Description

Thank you for purchasing the RealCup™ RC400 brewer. This brewer is a digitally controlled commercial/residential

coffee brewer that brews one cup at a time. The brewer is designed for optimal use with RealCup™ capsules and is

compatible with Keurig®* K-Cup®* capsules.

The Single Cup brewer can be plumbed into a potable water supply. If a water line is not available, the brewer can

be used as a pour over brewer. The brewer requires a dedicated 15 amp, 120V, 60 Hz power source. If the brewer

is plumbed, it will refill the reservoir itself automatically. If used as a pour over brewer, manually refill the reservoir

as necessary.

The operating principle of this machine is that a user places a coffee mug on the drip tray (or foldaway tray), then

places a fresh RealCup™ capsule in the brew chamber. The user then closes the chamber and selects, from the

*RealCup™brandhasnoaffiliationwithK‐Cup®orKeurigInc.Keurig®andK‐Cup®areregisteredtrademarksofKeurigInc.

ENGLISH

4

Page 5

5

user interface screen, their beverage and size choice. Once these selections are made, the BREW button is

pressed. The brewer is designed to dispense 4 (118), 6 (177), 8 (237), 10 (296), 12 (355) and 16 (473) fluid ounces

(ml). Actual dispensed volume is approximately 10% less to allow for addition of milk, cream or sweetener if desire d.

Unpacking Your Brewer

1. Place carton on a table or a stable, firm surface.

2. Open the box. Do not use sharp objects to open the box. Doing so could cause damage to the brewer.

3. Remove enclosed protective materials, printed information, and the brewer.

4. Record the serial number inside the back cover of this manual.

5. After unpacking, check to ensure that your machine has not been damaged duri ng shipping and includes all

components.

6. Notify your service representative regarding any questions or concerns before installing.

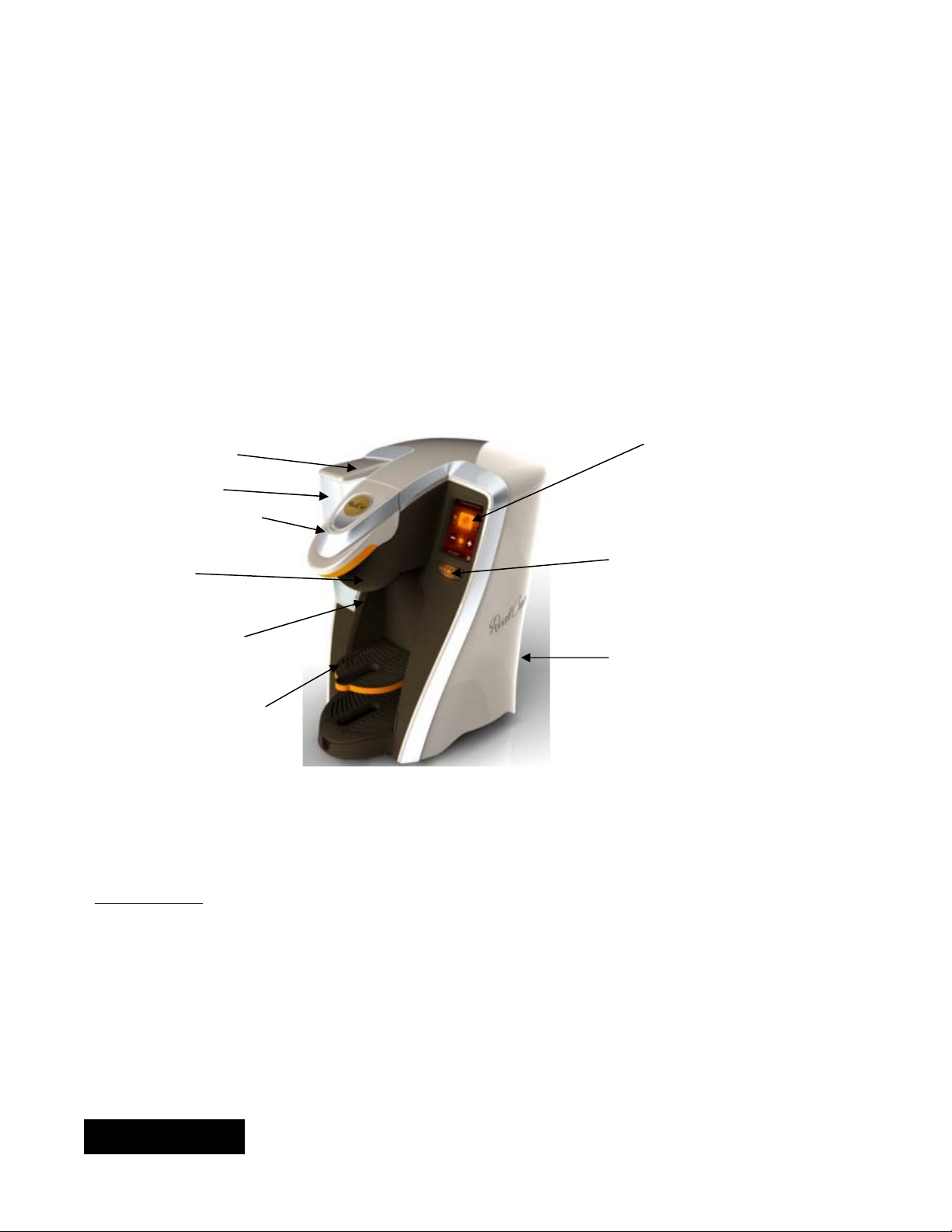

RC400 Features

Screen

Reservoir Lid

Reservoir

Brew Chamber Lid

Brew Button

Bezel

Reservoir LED

Power Switch

Pull Down Tray

(Back side of brewer)

Installation

Where to Install

Brewer should be installed on a firm, stable, level surface. Keep away from pets. Provide supervision for unat-

tended children and assistance for others that require help to operate the brewer.

*RealCup™brandhasnoaffiliationwithK‐Cup®orKeurigInc.Keurig®andK‐Cup®areregisteredtrademarksofKeurigInc.

ENGLISH

5

Page 6

6

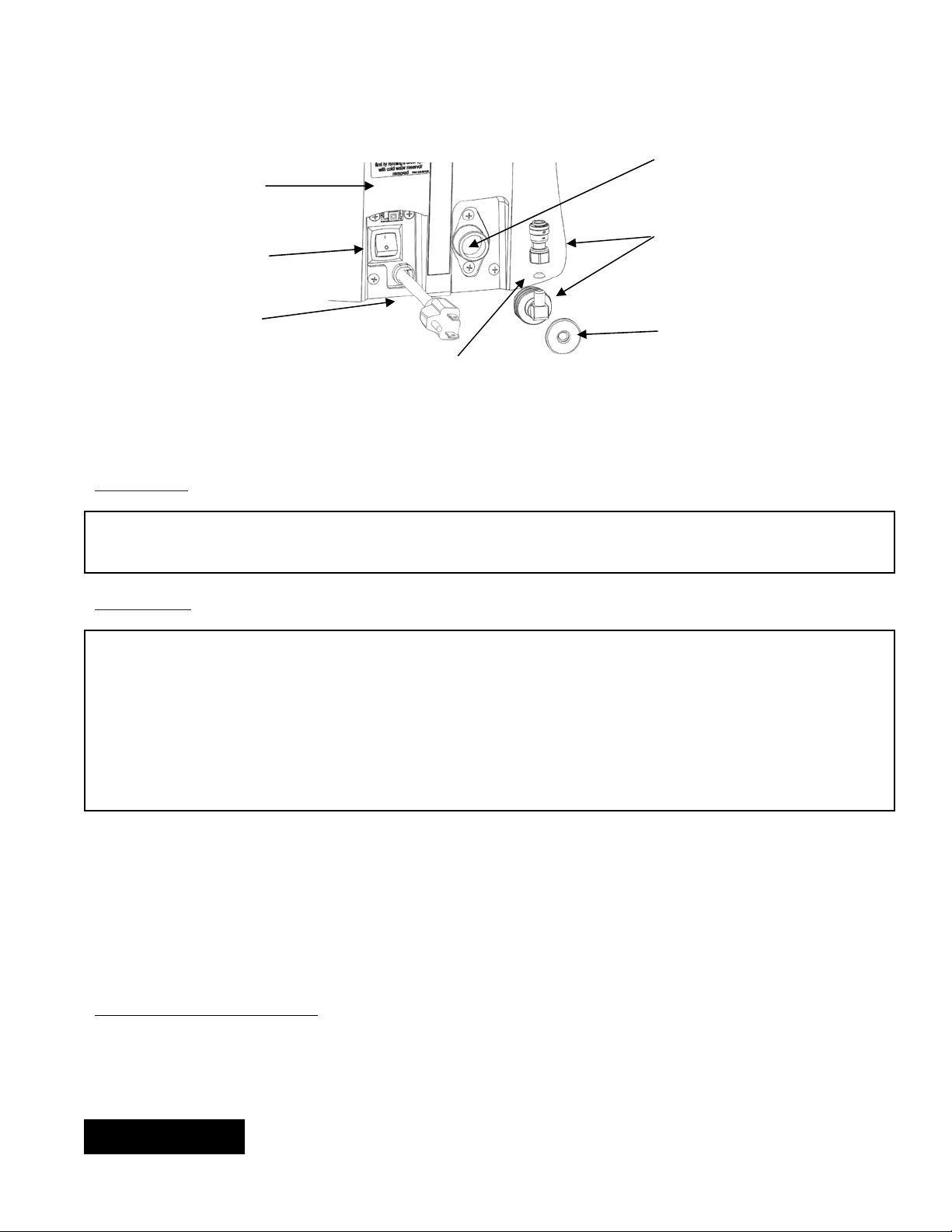

Drain Tube Cover

Power Switch

Power Cord

Water Supply

NOTICE: The brewer is designed to operate with water pressures from 10 psig up to 100 psig. Grindmaster re-

quires the use of an external water filter such as Water Filter Kit P/N 250-00034. The filter mounts on the rear surface of the brewer.

Water and Power Inlets

Grommet

Water Inlet

Adapter (Auto-Fill ONLY)

Valve Cap (Pour Over ONLY)

Power Supply

WARNING

Disconnect power if the machine functions abnormally and notify qualified service personnel for repairs. Do not per-

mit non-qualified service personnel to attempt repairs.

No user serviceable components inside the brewer. Do not disassemble brewer.

Notice

This appliance is equipped with a three wire power cord. A dedicated three wire 120V, 15A NEMA 5-15 electrical

circuit must be used.

1. A dedicated 120 VAC, 60 Hz, 15 Amp, type 5-15, electrical circuit is required for proper operation.

2. Always unplug machine before servicing or maintaining the machine.

3. Place power switch in OFF position and plug power cord into the dedicated three wire 120V, 15A NEMA 515 electrical circuit

Set-Up

Priming the internal heating tank

NOTE: The brewer will not operate until the tank is primed.

Please follow these procedures to ensure proper installation.

ENGLISH

6

Page 7

7

Pour Over version Auto-Fill version

1. Ensure that the water inlet valve cap supplied with the

machine is installed on the water inlet valve to prevent

leaking.

2. Open reservoir lid. 2. Open water service valve.

1. Plumb water to the fill valve located on the back of

the brewer. A ¼” female flare x ¼” tube adapter as

well as a ¼” flare x hose adapter provided with the

brewer. Do not use reverse osmosis water.

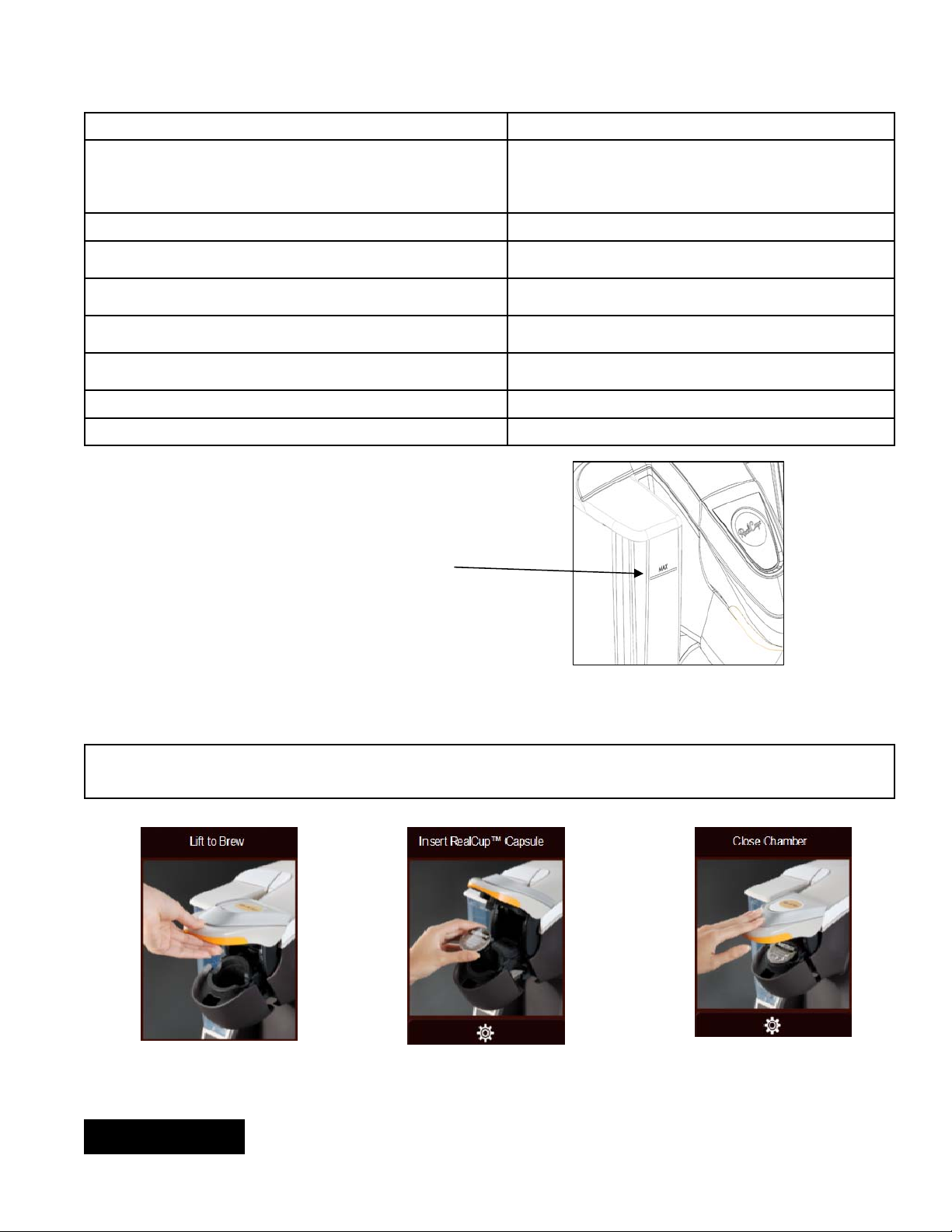

3. Fill reservoir with tap or bottled water to the level indicated on reservoir. Do not use distilled water.

4. Plug unit into a 120V/15 amps receptacle. Turn main

power switch to ON.

5. Place a cup in the drip tray of the unit to collect the water from the priming operation.

6. The screen will display "Prime Brewer". Press BREW

button until water flows into cup.

7. Refill the reservoir to the appropriate level. 7. Allow brewer to reach brewing temperature.

8. Allow brewer to reach brewing temperature.

Note: Auto-Fill ONLY:

The water is supplied directly to the unit and

the water fill level marking is not used.

Operation is not affected by the water being

below the fill line.

3. Plug unit into a 120V/15 amp receptacle. Turn

main power switch to ON.

4. Reservoir will automatically fill.

5. Place a cup in the drip tray of the unit to collect the

water from the purging operation.

6. The screen will display "Prime Brewer". Press

BREW button until water flows into cup.

Fill Level

Operating Instructions

WARNING Brew probes are sharp. To prevent injury, do not place fingers inside the brew chamber. To prevent

accidental overflow, press “BREW” to stop.

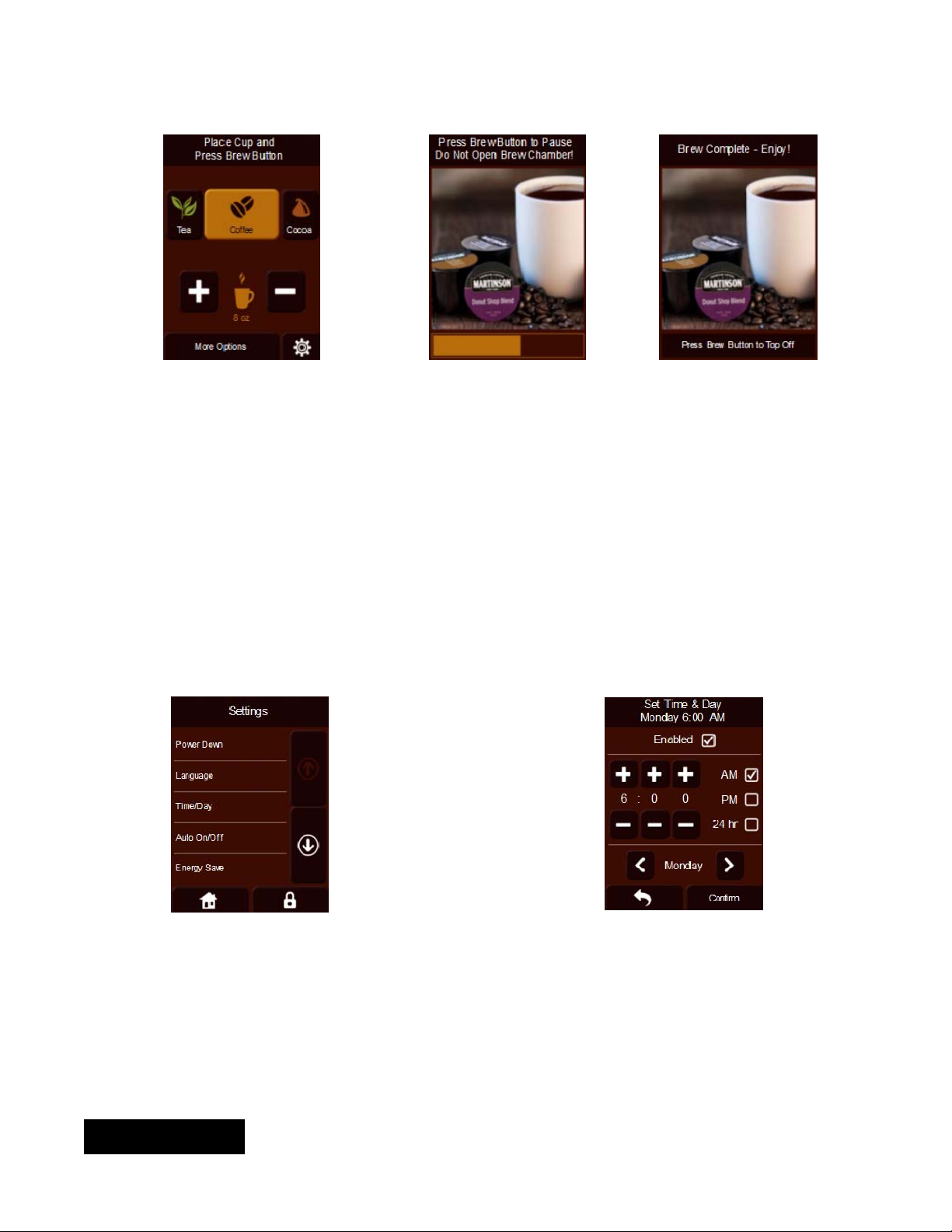

Step 1 – Lift brew chamber lid Step 2 – Insert RealCup™ capsule Step 3 – Close brew chamber

ENGLISH

7

Page 8

8

Step 4 – Select settings

Step 5 – Place cup & press

brew button

Step 6 – Remove RealCup™

capsule and enjoy

Brew Button Color

RED-BLUE-GREEN: Color start up sequence.

RED: Pulses during heating cycle. Light flashes if there is a fault.

YELLOW: Steady on when brew chamber is open.

GREEN: Steady on when ready to brew or at end of brew. Pulses while brewing.

ORANGE: Fresh capsule must be loaded before brewing.

Topping off the brew – After step 5 is completed, if more hot water is desired, press and hold the brew button until

the desired extra hot water is dispensed. When proper hot water level is achieved, release brew button.

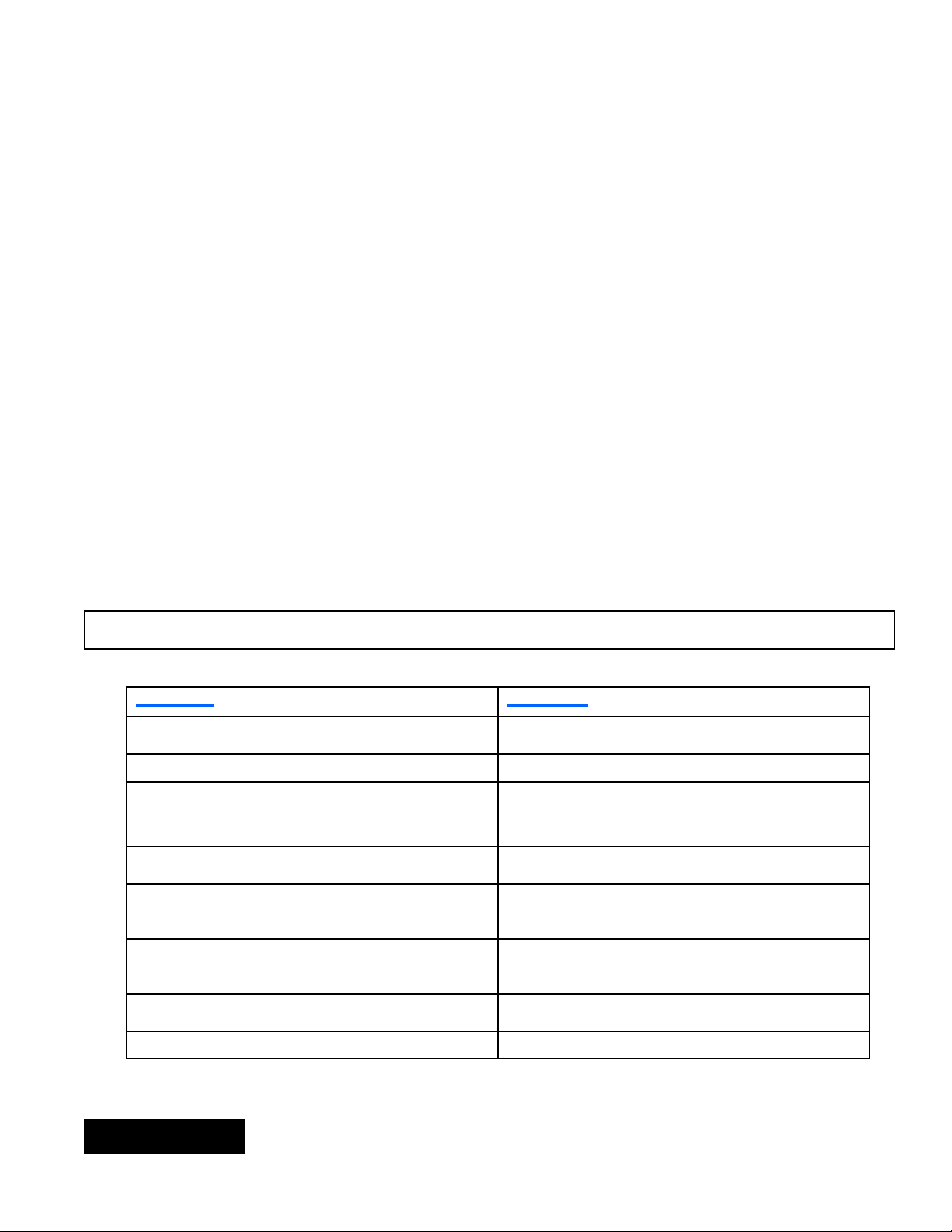

Setting Screens

Set up Screen: Provides access to Language

changes, Time/Day set up, Auto On/Off changes,

Energy Save, de-scaling brewer, Service Contact, and reset factory defaults (ONLY FOR SERVICE PERSONNEL). Home button at bottom left

returns user to “Lift to Brew” screen. The lock

button at lower right enters the advanced setting

screens (pass code protected). If password is lost

a factory reset must be performed.

ENGLISH

There are six usable setting screens. The

screens are Language, Set Time & Day, Turn

brewer on at, Turn brewer off at, Energy Save,

and Service Contact. The arrow button at the

bottom left allows going back to basic settings

screen, on previous page, without saving

changes. The Confirm button allows going back

to basic settings screen, on previous page, and

saves changes.

8

Page 9

9

Screens Types

There are three types of screens:

1. Lift to Brew (“HOME”) screen with rotating product and ingredient images.

2. Process related screens. These images provide an instruction for the user and/or provide status of an

internal process that needs to take place before the user proceeds to brew a beverage.

Lift to Brew

Heating Please Wait

Press Brew Button to Pause

Brewing Complete

Insert Real-Cup™ capsule

Close Brew Chamber

3. Action related screens: The action related screens require the user to perform an action. If this action is

not performed, the brewer will not properly function.

Prime Brewer

Refill Water Tank

Make Sure Water Tank Is Properly Positioned

Error: Brew Chamber Opened

Water Flow Error

Water Too Hot

Water Not Heating

If the actions screen has a red exclamation

mark, call service provider. If it is yellow,

user action is required

Cleaning and Maintenance

WARNING Brew probes are sharp. To prevent injury, do not place fingers inside the brew chamber. To reduce

foreign material from entering the brewer, keep brew chamber and reservoir lids closed.

Cleaning:

NOTE: When cleaning the unit do not use cleansers, liquid bleach, powders or any other substance that contains

chlorine. These products promote degradation of plastic parts. Use of these products will void the warranty.

Empty the drip tray and reservoir tank as needed and wash in a solution of dish detergent and water, rinse thor-

oughly.

All external parts can be cleaned with a soft, damp cloth. Do not use any abrasives. They will scratch the external

surfaces. Do not immerse machine in water. Do not place brewer into a dishwasher.

ENGLISH

9

Page 10

10

Draining:

Descaling

This action will clear water from the brewer.

1. Power off brewer. Allow brewer to cool. Close water supply valve (Auto-Fill only) and disconnect water

line.

2. Remove and empty reservoir.

3. Place a cup under the brew chamber, hold down reservoir detection switch and start a brew sequence.

4. Continue brew sequence until water stops flowing into the cup or until Water Flow Error is displayed.

:

Close water supply valve (Auto-Fill models only), empty reservoir, empty brew chamber.

Fill reservoir with 72 oz. of distilled white vinegar.

Using the 12 oz. cycle, operate brewer until "Fill Reservoir" notification appears.

Power off brewer – Empty reservoir and rinse thoroughly. Allow brewer to remain off for 3 hours before peforming Step 5.

Remove back panel, uncap and drain tank. Recap and replace back panel.

Fill reservoir with fresh water and return to brewer.

Flush brew chamber with 12 oz of fresh water. Close brew chamber when finished.

Power on brewer, open water supply valve (Auto-Fill models only).

Follow on screen instructions and prime brewer.

Allow brewer to reach brewing temperature.

Proceed with 12 oz brews until water returns to normal smell and taste.

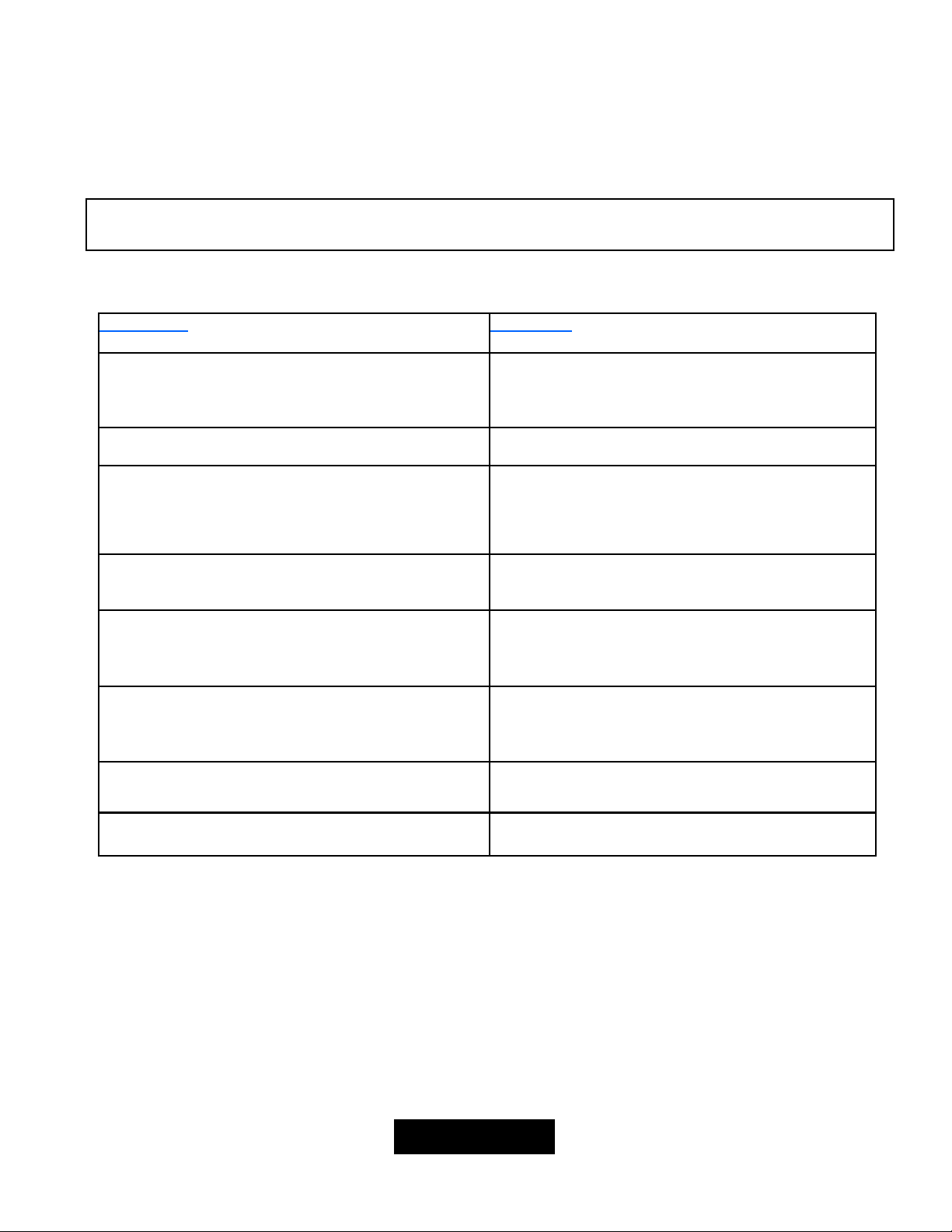

Troubleshooting

WARNING Brew probes are sharp. To prevent injury, do not place fingers inside the brew chamber.

PROBLEM SOLUTION

No power Verify unit is plugged into a 120V/15 amp rated

outlet and power switch is in the ON position.

Refill water tank (Pour Over model ONLY) Add water to proper level on reservoir.

Refill water tank (Auto-Fill model ONLY) Make sure that the water shut off valve is opened.

Turn brewer off and restart, using power switch at

rear of brewer.

Brew volume is less than normal Adjust volume of beverage on screen. If error per-

sists, perform descaling procedure.

Water drips from machine when not brewing Ensure reservoir tank is not filled above maximum

fill level. Perform descaling procedure. Call service technician.

Water drips from machine (Pour Over model

ONLY).

Water leaks from machine while brewing Remove d rain tube cover and verify that the drain

Red light flashes continuously Contact service company/technician.

If Pour Over model, ensure the water inlet valve is

capped with the cap that has been provided with

the brewer.

line is properly plugged

ENGLISH

10

Page 11

11

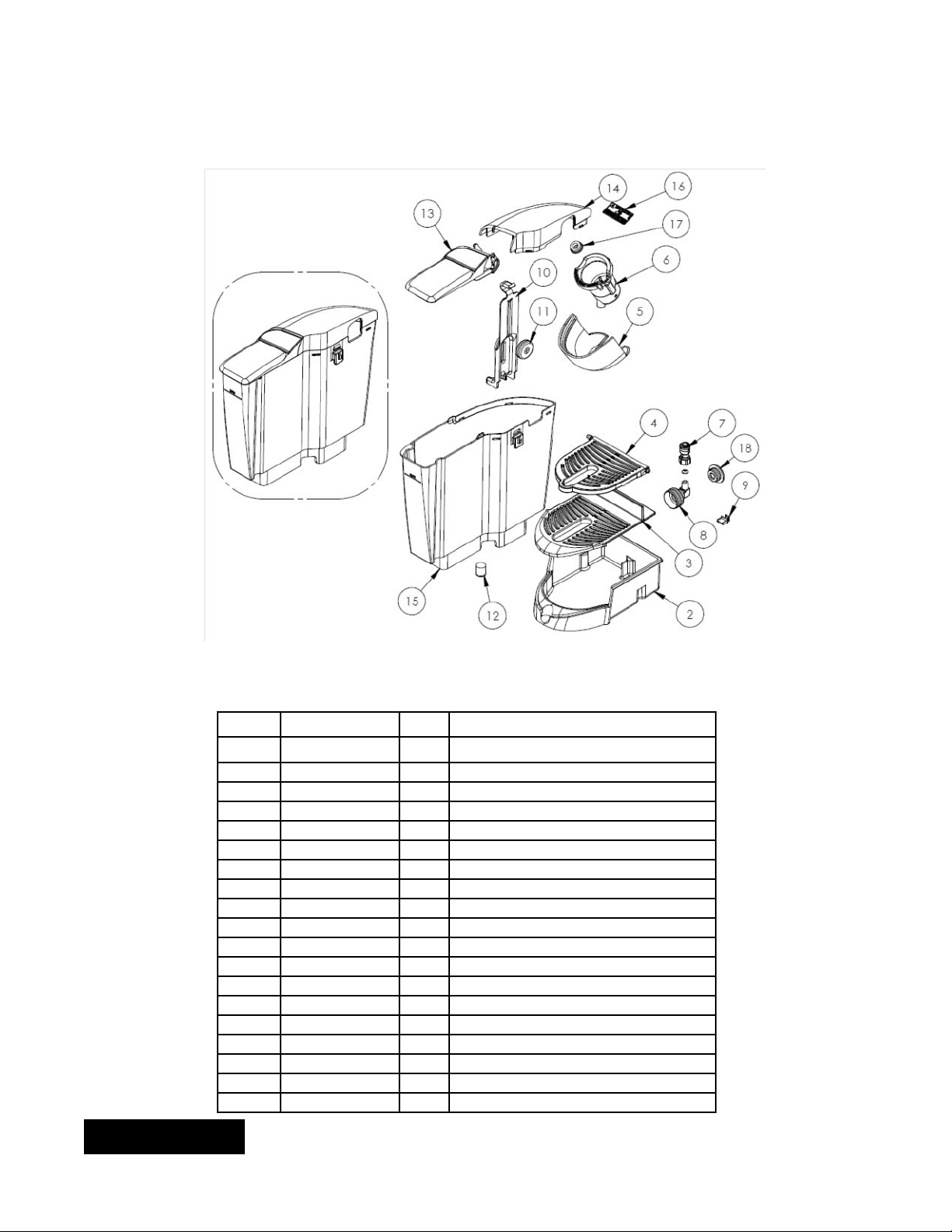

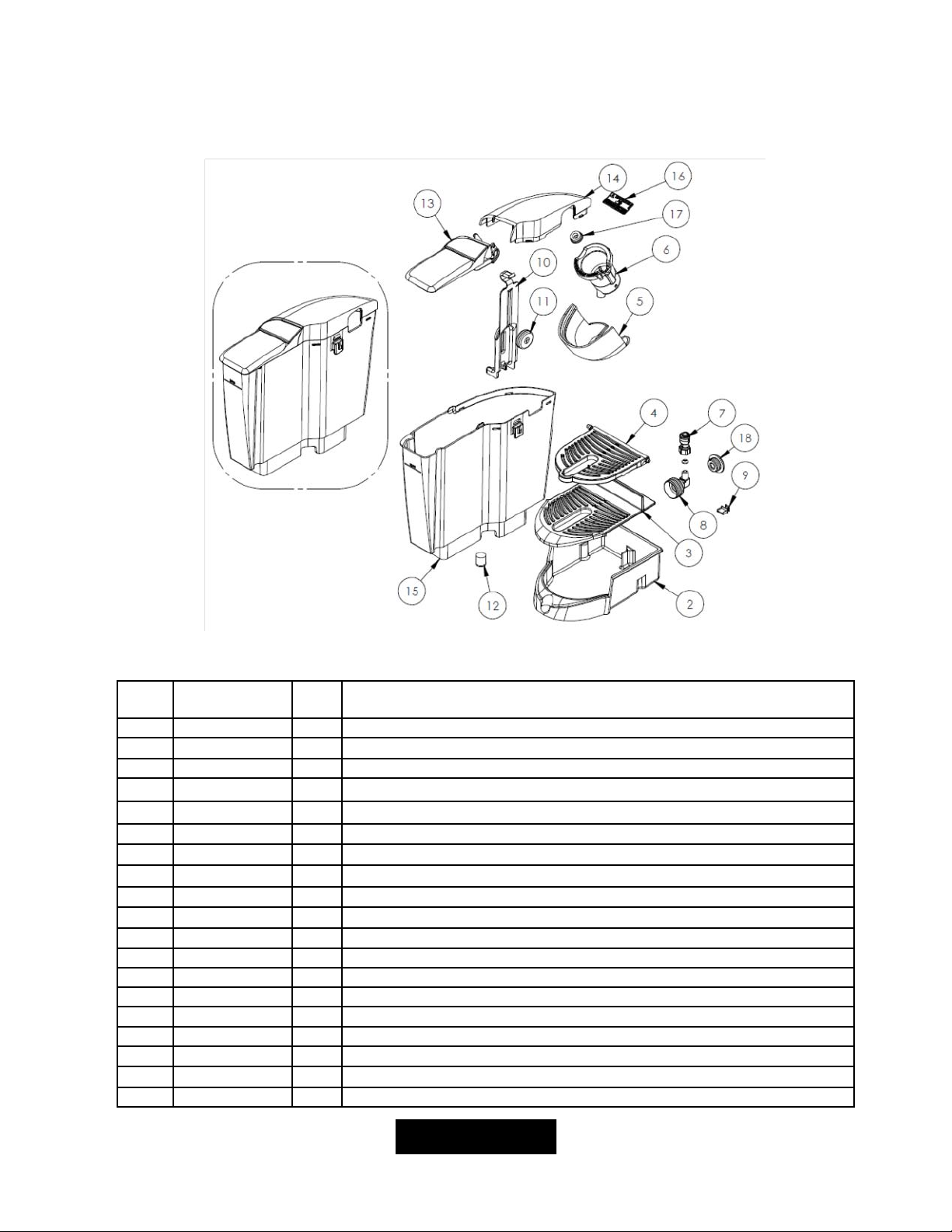

Exploded View Drawing

Spare Parts List

Item # Part Number Qty Description

1 230-00001 1 Reservoir sub-assembly

2 210-00030 1 Drip Tray- single Cup

3 210-00031 1 Grid- Single Cup

4 230-00004 1 Flip down grid sub-assembly

5 210-00004 1 Bezel

6 230-00015 1 Capsule holder sub-assembly

7 359-00003 1 Fitting, MUR-LOK 1/4", 1/4" Flare

8 359-00031 1 Fitting, Assy, 1/4 FL X 3/4 HS, BRS

9 B256A 1 Cover, USB Port

10 210-00052 1 Float guide

11 230-00021 1 Float assembly

12 280-00001 1 Valve, DW15 Check

13 210-00230 1 Reservoir cover assembly

14 210-00233 1 Lid- stationary

15 210-00051 1 Reservoir

16 380-00020 1 Label , Warning, Hot Liquid

17 210-00017 1 Seal-Capsule upper

18 210-00235 1 Cap, Molded inlet valve

19 359-00115 1 Gasket , 1/ 4" S AE fl are

ENGLISH

11

Page 12

12

Warranty

Prior authorization must be obtained from GMCW for all warranty claims.

Product Warranty for USA and Canada Effective October 1, 2013

New machines that have been manufactured by or for Grindmaster Corp. and its subsidiaries (“Grindmaster”) and

all parts thereof are conditionally warranted to the original user by Grindmaster to be free from defects in material

and workmanship (existing at the time of manufacture and appearing during the stated warranty period) under normal use and service as follows:

90-day replacement and 2-year limited parts warranty

During the 90-day replacement warranty period, Grindmaster will immediately ship a replacement machine to the

customer at no charge upon notice of a claim and will provide reasonable means for the failed machine to be returned to Grindmaster as Grindmaster’s expense. During the 2-year limited parts warranty, Grindmaster will immediately ship replacement parts to the customer at no charge.

Warranty Period

If your machine was purchased from Mother Parker’s Tea & Coffee (“Mother Parker’s”) and:

proof of installation is provided, the warranty period runs from the, earlier of, the date of installation or 9

months from the date the machine was transferred to Mother Parker’s inventory;

no proof of installation is provided, the warranty period runs from the date the machine was transferred to

Mother Parker’s inventory.

If your machine was purchased directly from Grindmaster and:

proof of installation is provided, the warranty period runs from the, earlier of, the date of installation or 9

months from the date the machine shipped from the Grindmaster facility;

no proof of installation is provided, the warranty period runs from date the machine was shipped from the

Grindmaster facility.

A customer must give prompt notice to and obtain prior authorization from Grindmaster for any warranty claim.

Grindmaster may be reached via telephone at (800-695-4500) or by writing to P.O. Box 35020, Louisville, KY

40232-5020.

This warranty is subject to the following conditions, terms and exclusions:

Warranty does not apply to machines or any part thereof which have been subject to any accident, abuse,

misuse, neglect, alteration, use on incorrect voltage, improper ventilation, damage caused in transit, improper installation or operation, improper maintenance or repair, wearable rubber parts, poor water conditions, machine adjustments, temporary non-functioning conditions, fire, flood, electrical surge or acts of

God.

Warranty is in lieu of all other warranties expressed or implied. In no event shall Grindmaster be liable for

consequential or incidental damages.

The model and serial number of the unit (shown on the serial plate) shall be supplied to Grindmaster upon

request.

ENGLISH

12

Page 13

13

Warranty (continued):

At its option, Grindmaster may provide instructions to the customer to dispose of a failed machine replaced

under the 90-day warranty in the field rather than provide means for such machine to be shipped to Grindmaster.

Replacement parts provided under the 2-year warranty will be shipped to customer free of charge. Upon

request by Grindmaster, some warranty parts are to be shipped at Grindmaster’s expense to the Grindmaster Factory Service Center designated in the RGA confirmation. If the customer fails to return parts or

upon inspection the warranty claim is deemed invalid, Grindmaster will bill customer for the replacement

parts previously shipped.

The dealers, distributors, employees and agents of Grindmaster are not authorized to modify this warranty or to

add warranties that are binding to Grindmaster. Neither written nor oral statements by such individuals establish

warranties and thus should not be relied upon.

This will establish your warranty rights. The purchaser’s redress against Grindmaster for the breach of any obligation arising from the sale of this equipment, whether derived from warranty or elsewhere, shall be limited to repair,

replacement or refund at Grindmaster’s discretion.

For technical assistance please call 855-869-2802™

For future reference, write serial number here:

GRINDMASTER ® BY GMCW

4003 Collins Lane, Louisville, KY 40245 USA www.gmcw.com

ENGLISH

13

Page 14

Modelo RC400

Infusor para una sola taza

Índice

Precauciones de seguridad .................. 15

Especificaciones del infusor ................. 16

Información general .............................. 17

Manual de uso

Descripción del producto ...................... 18

Desembalaje del infusor ....................... 19

Instalación ............................................ 19

Configuración ....................................... 20

Instrucciones de uso ................................ 22

Limpieza y mantenimiento .................... 25

Solución de problemas ......................... 26

Lista de piezas de repuesto .................. 27

Garantía ................................................ 28

Para realizar cualquier reclamación de garantía,

se debe obtener una autorización previa por

parte de GMCW.

GRINDMASTER®

DE GMCW™

© GMCW, 2013

Impreso en Tailandia

MODELO: RC400

Conserve este manual del usuario para poder

consultarlo en el futuro.

GMCW

4003 Collins Lane

Louisville, KY 40245, Estados Unidos

(502) 425-4776

(800) 695-4500 (Estados Unidos y Canadá únicame nte)

FAX: (502) 425-4664

www.gmcw.com

Formulario 1213 n.º BW-305-01

Pieza n.º 390-00005

Español

Page 15

15

Precauciones de seguridad

Información importante sobre seguridad

Este es el símbolo de alerta de seguridad. Se utiliza para advertirle sobre posibles peligros de lesiones personales.

Para evitar posibles lesiones o la muerte, obedezca todos los mensajes de seguridad que tengan este símbolo.

Para proteger su seguridad y la seguridad de los demás, lea todas las advertenc ias y el manual del operador

antes de instalar o utilizar el producto.

PELIGRO: Este término advierte un peligro inminente que provocará lesiones graves o la muerte.

ADVERTENCIA: Este término se refiere a un peligro posible o a una práctica poco segura, que podrían dar co mo

resultado lesiones graves.

PRECAUCIÓN: Este término se refiere a un peligro posible o a una práctica poco segura, que podrían dar como

resultado lesiones leves o moderadas o daños a la propiedad.

AVISO: Este término se refiere a la información que requiere especial atención y que debe comprenderse

plenamente.

PELIGRO

Para evitar posibles casos de electrocución, quemaduras u otras lesiones e impedir que el infusor se dañe, no lo

sumerja en agua ni en líquidos de limpieza.

No opere un infusor averiado. Controle el cable de alimentación y el suministro de agua con frecuencia. Si el cable

o el enchufe están dañados o desgastados, no utilice el infusor. Apague el suministro de agua y desconecte la

energía eléctrica.

Apague y desenchufe el infusor antes de la limpieza o el mantenimiento.

Riesgo de asfixia. El embalaje del producto contiene una bolsa de plástico. Mantenga las bol sas de plástico fuera

del alcance de los niños.

Si la máquina funciona de manera anormal, desconecte la energía eléctrica y notifique al personal de

mantenimiento calificado para que realice las reparaciones pertinentes. No permita que personal de

mantenimiento no calificado intente hacer reparaciones. El infusor no contiene compon entes que el usuario pueda

reparar. No lo desmonte.

ADVERTENCIA

Las sondas de infusión son filosas. Para evitar lesiones, no coloque los dedo s en el interior de la cámara de

infusión.

El infusor solo debe conectarse a un circuito eléctrico de 120 V CA, 60 Hz y 15 A de tres hilos.

Antes de la limpieza o el mantenimiento, deje enfriar el infusor.

PRECAUCIÓN

Riesgo de quemaduras. El infusor utiliza agua a una temperatura de 185 °F a 200 °F, por lo que, si no se o pera de

manera adecuada, podría provocar quemaduras. No permita que los niños usen este aparato, a menos que estén

bajo la supervisión directa de un adulto. Manténgalo fuera del alcance de mascotas y otros animales.

El infusor es solo apto para uso en interiores. No lo instale ni lo utilice al aire libre, en equipos en movimiento ni en

embarcaciones.

Utilice el producto únicamente para los fines previstos. Cualquier otro uso es inadecuado y puede ser peligroso. El

fabricante no asume ninguna responsabilidad por lesiones, pérdidas o daños que se produzcan a partir del uso

incorrecto de la máquina.

Para evitar el riesgo de quemaduras, no opere el infusor sin el bisel instalado.

Las superficies calientes pueden provocar quemaduras. No toque el infusor mientras esté en funcionamiento.

Para evitar quemaduras con agua caliente, no abra la cámara de infusión durante la preparación.

Para evitar quemaduras con agua caliente, no mueva ni incline el infusor. Mover o inclinar el infusor podría

ocasionar que se derrame agua del depósito. Es posible que se produzca ebullición interna a altitudes elevadas.

Español

15

Page 16

16

Debe disminuir el punto de ajuste de temperatura por debajo del punto de ebullición según la altitud a la que se

encuentre.

Para minimizar las salpicaduras y evitar quemaduras, utilice el apoyo adecuado. Para evitar derrames cuando retire

una taza llena, deje un espacio de ½” como mínimo entre el borde de la taza y la boquilla vertedora del infuso r.

Durante la preparación, coloque la taza en el centro, debajo de la boquilla vertedora, y deje que finalice el ciclo del

infusor antes de abrir la cámara de infusión o de retirar la taza.

Mantenga los dedos alejados de la cámara de infusión cuando la cierre, para evit ar pellizcos.

AVISO

Para obtener mejores resultados, retire la cápsula RealCup™ usada de la cámara de infusión cuando haya

finalizado la preparación.

Para evitar derrames, no retire el depósito mientras se esté llenando la unidad de llenado automático. Deje finalizar

el ciclo de llenado antes de extraer el depósito.

Solo un profesional calificado debe realizar la instalación, el mantenimiento y las reparaciones.

La instalación, el mantenimiento o las reparaciones por parte de personal no calificado pueden dañar el infusor y

anular la garantía del fabricante.

Este equipo debe instalarse de acuerdo con los códigos nacionales y locales correspondientes que rijan en el país

o en la región donde se instale el aparato.

Comuníquese con el fabricante para informar cualquier mal funcionamiento o avería del infu sor.

Cuando apague la máquina durante un período prolongado, asegúrese de retirar el agua del interior de los tubos

por completo; de lo contrario, el agua podría congelarse dentro de la máquina y provocar daños o la aparición de

moho.

Para reducir el ingreso de materiales extraños en el infusor, mantenga cerradas las tapas de la cámara de infusión

y del depósito.

Para evitar que la taza se desborde accidentalmente, pulse el botón de infusión para detener la preparación.

Especificaciones del infusor

Modelo RC400

Dimensiones (alto x ancho x profundidad) 15.7” (40 cm) x 10.8” (28 cm) x

Peso de envío 18.7 lb (8.5 kg)

Peso de la máquina 15.3 lb (6.9 kg)

Capacidad del depósito 72 onzas líquidas (2.1 L)

Voltaje 120 V CA

Fase 1

Frecuencia 60 Hz

Potencia 1.55 KW

Corriente 13 A

Cant. de calentadores 1

Enchufe NEMA 5-15P

14.8” (38 cm)

Español

16

Page 17

17

Información general

Este manual de uso incluye instrucciones para utilizar y realizar el mantenimiento del infusor. Guarde este manual a

mano.

Después de desembalar el infusor, compruebe que no haya sufrid o daños durante el envío y que incluya todos los

componentes. Si tiene alguna pregunta o inquietud antes de instalar el infusor, notifique al representante de servi cio

al cliente.

Tenga en cuenta que el material de embalaje puede ser peligroso. Manténgalo fuera del alcance de los niños y

deséchelo de inmediato.

Durante varias de las etapas de uso, es posible que oiga sonidos normales del funcionamiento que no le resulten

familiares. Los siguientes sonidos son normales:

Zumbido/chasquido: Se produce cuando se activa la bomba de agua o cuando la válvula de tres vías se abre y

se cierra para dispensar agua o para enviar agua al depósito.

Estallido: Cuando se daña una cápsula RealCup™, esto podría generar un sonido de estallido.

Pulsación/silbido: En condiciones normales de funcionamiento, se produce este sonido cuan do se activa una

bomba de aire interna al final de un ciclo de preparación.

Flujo de agua/gorgoteo: En una instalación para verter por encima, se puede oír un gorgoteo cuand o el

depósito está vacío antes del final de un ciclo de preparación. En una instalación de llenado automático, se

puede oír este sonido cuando se llena el infusor automáticamente.

No utilice una cápsula RealCup™ dañada, ni vuelva a introducir una cápsula que se haya introducido y retirado

anteriormente. Esto puede producir que queden granos de café y materiales no deseados en el interior de la

cámara de infusión y en la taza o jarra. Los daños en la cápsula RealCup™ pueden presentarse alrededor del borde

de la tapa de aluminio o pueden ser abolladuras y deformaciones en toda la cá psula RealCup™.

Para garantizar la seguridad de los alimentos y un funcionamiento adecuado, limpie la máquina de manera regular,

de acuerdo con las instrucciones de limpieza diaria y semanal. Las instrucciones de limpieza y evacuación del agua

se encuentran en la sección “Limpieza y mantenimiento” de este manual.

Cuando apague la máquina durante un período prolongado, asegúrese de vaciar el agua del interior de los tubos

por completo. De lo contrario, el agua que quede en el interior de la máquina podría congelarse y provocar d años o

la aparición de moho.

Los accesorios y las conexiones de la tubería de agua que estén conectados directamente a un suministro de agua

potable deben ser del tamaño indicado en los códigos federales, estatales y locales, y deben instalarse y

mantenerse de acuerdo con ellos. Este producto requiere que se instale un dispositivo antirretorno aprobado, como

una válvula de retención doble, entre la máquina y el suministro de agua.

Para evitar que ingresen materiales extraños en el infusor, mantenga cerradas las tapa s de la cámara de infusión y

del depósito.

Para garantizar el funcionamiento adecuado de los controles electrónicos, no utilice agua de ósmo sis inversa,

destilada o desionizada.

La configuración de fábrica de la temperatura del agua caliente del infusor RC400 es de 195 °F (90.6 °C). Si se

utiliza el infusor a más de 4000 pies de altitud, es posible que sea necesario modificar el punto de ajuste. Si el

depósito del infusor se empaña o si gotea agua caliente en el dep ósito, esto indica que se debe bajar el punto de

ajuste. Además, si el punto de ajuste es demasiado elevado, podría obtener volúmenes de infusión menores de los

esperados.

Español

17

Page 18

18

Punto de ajuste

recomendado en °F (°C)

200 (93) 0

198 (92) 1000 (305)

196 (91) 2000 (610)

195 (90) 3000 (915) Calgary 185 (85) 8000 (2438)

193 (89) 4000 (1219)

Altitud en ft (m) Ciudad Punto de ajuste

recomendado en °F (°C)

191 (88) 5000 (1524) Denver/Albuquerque

189 (87) 6000 (1828) Color ado Springs

187 (86) 7000 (2134) Santa Fe

Altitud en ft (m) Ciudad

Descripción del producto

Gracias por adquirir el infusor RealCup™ RC400. Esta máquina es un infusor comercial/residencial con control

digital, que permite preparar una taza a la vez. El infusor está diseñado para que se utilice de manera óptima con

las cápsulas RealCup™ y es compatible con las cápsulas Keurig®* K-Cup®*.

El infusor para una sola taza se puede instalar de manera fija a un suministro de agua potable. Si no hay un sistema

de suministro de agua disponible, el infusor puede utilizarse como infusor para verter por encima. El infusor requiere

una fuente de energía exclusiva de 15 A, 120 V y 60 Hz. Si el infusor está instalado de manera fija, se llenará el

depósito automáticamente. Si se utiliza como infusor para verter por encima, llene el depósito manualmente según

sea necesario.

El principio de funcionamiento de esta máquina es el siguiente: el usuario coloca una taza para café en la bandeja

escurridora (o plegable) y, luego, introduce una cápsula RealCup™ nueva en la cámara de infusión. A continua ción,

el usuario cierra la cámara y selecciona su bebida y el tamaño que desea en la pantalla de la i nterfaz del usuario.

Después de realizar estas selecciones, pulsa el botón de infusión. El infusor está diseñado para dispensar 4, 6, 8,

10, 12 y 16 onzas líquidas (118, 177, 237, 296, 355 y 473 ml). El volumen que realmente se dispensa es

aproximadamente un 10% menor para permitir el agregado de leche, crema o endulzante, si se desea.

*LamarcaRealCup™notieneafiliaciónalgunaconK‐Cup®oKeurigInc.Keurig®yK‐Cup®sonmarcascomercialesregistradas

deKeurigInc.

Español

18

Page 19

19

Desembalaje del infusor

1. Coloque la caja sobre una mesa o sobre una superficie estable y firme.

2. Abra la caja. No utilice objetos punzantes para abrir la caja, ya que esto podría dañar el infusor.

3. Retire los materiales de protección incluidos, la información impresa y el infusor.

4. Registre el número de serie que se encuentra en la contratapa de este manual.

5. Después de desembalar el infusor, compruebe que no haya sufrid o daños durante el envío y que incluya

todos los componentes.

6. Si tiene alguna pregunta o inquietud antes de instalar el infusor, notifique al representante de servicio al

cliente.

Características del modelo RC400

Pantalla

Tapa del depósito

Depósito

Tapa de la

cámara de infusión

Botón de infusión

Bisel

LED del depósito Interruptor de encendido

(Parte posterior del infusor)

Bandeja

desplegable

Instalación

Lugar de instalación

El infusor debe instalarse en una superficie firme, estable y nivelada.

Manténgalo fuera del alcance de las mascotas.

Supervise a los niños y brinde asistencia a las demás personas que necesiten ayuda para utilizar el infusor.

*LamarcaRealCup™notieneafiliaciónalgunaconK‐Cup®oKeurigInc.Keurig®yK‐Cup®sonmarcascomercialesregistradas

deKeurigInc.

Español

19

Page 20

20

Tapa del tubo de drenaje

Interruptor de encendido

Cable

Suministro de agua

AVISO: El infusor está diseñado para funcionar con presiones de agua de 10 a 100 psig. El infusor Grindmaster

requiere el uso de un filtro de agua externo, como el kit de filtros de agua P/N 250-00034. El filtro se instala en la

superficie posterior del infusor.

Entradas de agua y energía

Arandela aislante

Entrada de agua

Adaptadores (SOLO modelo de

llenado automático)

Capuchón de válvula (SOLO

modelo para verter por encima)

Suministro de energía

ADVERTENCIA

Si la máquina funciona de manera anormal, desconecte la energía eléctrica y notifique al personal de

mantenimiento calificado para que realice las reparacione s pertinentes. No permita que personal de mantenimiento

no calificado intente hacer reparaciones.

El infusor no contiene componentes que el usuario pueda reparar. No lo de smonte.

Aviso

Este aparato está equipado con un cable de tres hilos. Se debe utilizar un circuito eléctrico exclusivo de tres hilos

NEMA 5-15 de 120 V y 15 A.

1. Para que el funcionamiento sea correcto, se requiere un circuito eléctrico exclusivo de 120 V CA, 60 Hz y

15 A, tipo 5-15.

2. Siempre desenchufe la máquina antes de que se realicen reparaciones o el mantenimiento del aparato.

3. Coloque el interruptor de encendido en la posición OFF (Apagado) y enchufe el cable al circuito eléctrico

exclusivo de tres hilos NEMA 5-15 de 120 V y 15 A

.

Configuración

Cebado del tanque de calentamiento interno

NOTA: El infusor no funcionará hasta que el tanque se haya cebado.

Para asegurarse de que la instalación sea correcta, siga estos procedimientos.

Español

20

Page 21

21

Versión para verter por encima Versión de llenado automático

1. Asegúrese de que el capuchón de la válvula de entrada

de agua, proporcionado con la máquina, esté instalado en

la válvula de entrada de agua para evitar filtraciones.

2. Abra la tapa del depósito. 2. Abra la válvula del suministro de agua.

1. Conecte el agua a la válvula de llenado que se

encuentra en la parte posterior del infusor. El infusor

incluye una tuerca abocinada hembra de ¼” con

adaptador de tubo de ¼”, además de una tuerca

abocinada hembra de ¼” con adaptador de

manguera. No utilice agua de ósmosis inversa.

3. Llene el depósito con agua corriente o embotellada

hasta el nivel indicado en el depósito. No utilice agua

destilada.

4. Enchufe la unidad en un tomacorriente de 120 V/15 A.

Coloque el interruptor de encendido principal en la

posición ON (Encendido).

5. Coloque una taza en la bandeja escurridora de la

unidad para recoger el agua de la operación de cebado.

6. La pantalla mostrará “Prime Brewer” (Cebar infusor).

Pulse el botón de infusión hasta que el agua comience a

verterse en la taza.

7. Vuelva a llenar el depósito hasta el nivel

correspondiente.

8. Deje que el infusor llegue a la temperatura de infusión.

Nota:

SOLO modelo de llenado automático:

El agua se suministra directamente a la unidad, y no se

utiliza la marca del nivel de llenado de agua.

funcionamiento no se ve afectado si el agua está por

debajo de la línea de llenado.

Nivel de llenado

3. Enchufe la unidad en un tomacorriente de

120 V/15 A. Coloque el interruptor de encendido

principal en la posición ON (Encendido).

4. El depósito se llenará de manera automática.

5. Coloque una taza en la bandeja escurridora de la

unidad para recoger el agua de la operación de

purga.

6. La pantalla mostrará “Prime Brewer” (Cebar

infusor). Pulse el botón de infusión hasta que el agua

comience a verterse en la taza.

7. Deje que el infusor llegue a la temperatura de

infusión.

El

Español

21

Page 22

22

Instrucciones de uso

ADVERTENCIA Las sondas de infusión son filosas. Para evitar lesiones, no coloque los dedos en el i nterior de

la cámara de infusión. Para evitar derrames accidentales, pulse el botón de infusión para detener la preparación.

Paso 1: Levante la tapa

de la cámara de

infusión.

Paso 4: Seleccione los

ajustes.

Paso 2: Introduzca la

cápsula RealCup™.

Paso 5: Coloque la taza y pulse

el botón de infusión.

Paso 3: Cierre la cámara de

infusión.

Paso 6: Retire la cápsula RealCup™… ¡y disfrute!

Español

22

Page 23

23

Color del botón de infusión

ROJO, AZUL Y VERDE: Colores de la secuencia de comienzo.

ROJO: Titila durante el ciclo de calentamiento. La luz destella si hay alguna falla.

AMARILLO: La luz queda encendida de manera continua cuando está abierta la cámara de infusión.

VERDE: La luz queda encendida de manera continua cuando el infusor está li sto para comenzar la infusión o al

finalizarla. Titila durante la preparación.

NARANJA: Se debe colocar una cápsula nueva antes de la preparación.

Agregado de la infusión: Después de haber realizado el paso 5, si desea más agua caliente, pulse el botón de

infusión y manténgalo presionado hasta que se dispense la cantidad de agua caliente adicional que desee.

Cuando se alcance el nivel de agua caliente adecuado, suelte el botón de infu sión.

Pantallas de configuración

Pantalla de configuración: Permite cambiar el

idioma, configurar el día y la hora, cambiar el

encendido/apagado automático, establecer el

ahorro de energía, realizar el procedimiento de

desincrustación del infusor, ver la información

del contacto de servicio al cliente y restablecer

los valores de fábrica (SOLO PARA EL

PERSONAL DE MANTENIMIENTO). El botón

de inicio que se encuentra en la parte inferior

izquierda permite que el usuario regrese a la

pantalla “Lift to Brew” (Levantar para preparar).

El botón de bloqueo que se encuentra en la

parte inferior derecha permite ingresar a las

pantallas de configuración avanzada

(protección con contraseña). Si se pierde la

contraseña, se debe realizar un

restablecimiento de fábrica.

Español

Existen seis pantallas de configuración utilizables.

Las pantallas son Language (Idioma), Set Time &

Day (Configuración de día y hora), Turn brewer on

at (Hora de encendido del infusor), Turn brewer

off at (Hora de apagado del infusor), Energy Save

(Ahorro de energía) y Service Contact

(Información del contacto de servicio al cliente). El

botón de flecha que se encuentra en la parte

inferior izquierda permite volver a la pantalla de

configuración básica, en la página anterior, sin

guardar los cambios. El botón

“Confirm” (Confirmar) permite volver a la pantalla

de configuración básica, en la página anterior, y

guardar los cambios.

23

Page 24

24

Tipos de pantallas

Existen tres tipos de pantallas:

1. Lift to Brew [Levantar para preparar] (“INICIO”): pantalla con imágenes rotatorias de productos e

ingredientes.

2. Pantallas relacionadas con procesos: Estas imágenes brindan instrucciones para el usuario o informan

el estado de un proceso interno que debe realizarse antes de que el usuario pueda continuar con la

preparación de una bebida.

Lift to Brew (Levantar para preparar)

Heating Please Wait (Calentando; espere)

Press Brew Button to Pause (Pulsar botón de infusión para pausar)

Brewing Complete (Infusión terminada)

Insert RealCup™ capsule (Introducir cápsula RealCup™)

Close Brew Chamber (Cerrar cámara de infusión)

3. Pantallas relacionadas con acciones: Las pantallas relacionadas con acciones requieren que el usuario

realice una acción. Si no se realiza esta acción, el infusor no funcionará de manera a decuada.

Prime Brewer (Cebar infusor)

Refill Water Tank (Llenar tanque de agua)

Make Sure Water Tank Is Properly Positioned (Verificar que el tanque de agua esté en la posición

correcta)

Error: Brew Chamber Opened (Error: Cámara de infusión abierta)

Water Flow Error (Error de flujo de agua)

Water Too Hot (Agua demasiado caliente)

Water Not Heating (No se está calentando el agua)

Critical Fault (Falla grave)

Si las pantallas de acciones presentan un signo de

exclamación rojo, llame al proveedor de servicios.

Si es amarillo, se requiere una acción por parte del

usuario.

Español

24

Page 25

25

Limpieza y mantenimiento

ADVERTENCIA Las sondas de infusión son filosa s. Para evitar lesiones, no coloque los dedos en el

interior de la cámara de infusión. Para reducir el ingreso de materiales extraños en el infuso r, mantenga

cerradas las tapas de la cámara de infusión y del depósito.

Limpieza:

NOTA: Cuando limpie la unidad, no utilice productos de limpieza, cloro líquido, productos en polvo ni ninguna otra

sustancia que contenga cloro. Estos productos favorecen la degradación de las piezas de plástico. El uso de

estos productos anulará la garantía.

Vacíe la bandeja escurridora y el tanque del depósito, según sea necesario; luego, lávelos en una solución de

detergente y agua y enjuáguelos bien.

Todas las piezas externas se pueden limpiar con un paño suave y húmedo. No utilice abrasivos, ya que estos

rayarán las superficies externas. No sumerja la máquina en agua. No coloqu e el infusor en un lavavajillas.

Drenaje:

Desincrustación:

Esta acción eliminará el agua del infusor.

1. Apague el infusor. Deje que se enfríe. Cierre la válvula de suministro de agua (opción de llen ado

automático únicamente) y desconecte el sistema de suministro de agua.

2. Retire y vacíe el depósito.

3. Coloque una taza debajo de la cámara de infusión, mantenga pulsado el interruptor de detec ción de

depósito y comience una secuencia de preparación.

4. Continúe la secuencia de preparación hasta que deje de verterse agua en la taza o hasta q ue aparezca la

pantalla Water Flow Error (Error de flujo de agua).

5. Retire el panel posterior, destape el conducto de desagüe y drene el tanque. Vuelva a colocar la tapa y el

panel posterior.

Cierre la válvula de suministro de agua (modelos de llenado automático únicam ente) y vacíe el depósito y la

cámara de infusión.

Llene el depósito con 72 oz de vinagre blanco destilado.

Cuando utilice el ciclo de 12 oz, opere el infusor hasta que aparezca la notificación “Fill Reservoir” (Llenar

depósito).

Apague el infusor, vacíe el depósito y enjuáguelo bien. Deje el infusor apagado durante 3 horas antes de

realizar el paso 5.

Retire el panel posterior, quite la tapa y drene el tanque. Vuelva a colocar la tapa y el panel posterior.

Llene el depósito con agua dulce y colóquelo nuevamente en el infuso r.

Purgue la cámara de infusión con 12 oz de agua dulce. Cuando finalice, cierre la cámara de infusión.

Encienda el infusor y abra la válvula de suministro de agua (modelos de llenado automático únicamente).

Siga las instrucciones de la pantalla y cebe el infusor.

Deje que el infusor llegue a la temperatura de infusión.

Continúe con infusiones de 12 oz hasta que el agua vuelva a tener el aroma y el sabor normal es.

Español

25

Page 26

26

Solución de problemas

ADVERTENCIA Las sondas de infusión son filosas. Para evitar lesiones, no coloque los dedos en el interior de

la cámara de infusión.

PROBLEMA

Falta de energía eléctrica Verifique que la unidad esté enchufada en un

Llenado del tanque de agua (SOLO modelo para verter

por encima)

Llenado del tanque de agua (SOLO modelo de llenado

automático)

Volumen de infusión menor de lo normal Ajuste el volumen de la bebida en la pantalla. Si el error

Caída de gotas de agua de la máquina cuando no se

está realizando una preparación

Caída de gotas de agua de la máquina (SOLO modelo

para verter por encima)

Filtraciones de agua de la máquina durante una

preparación

SOLUCIÓN

tomacorriente con clasificación de 120 V/15 A y que el

interruptor de encendido esté en la posición ON

(Encendido).

Agregue agua hasta el nivel adecuado en el depósito.

Asegúrese de que esté abierta la válvula de paso de

agua. Apague el infusor y reinícielo con el interruptor de

encendido que se encuentra en la parte posterior del

infusor.

persiste, realice el procedimiento de desincrustación.

Asegúrese de que el tanque del depósito no supere el

nivel de llenado máximo. Realice el procedimiento de

desincrustación. Llame a un técnico de mantenimiento.

En el caso del modelo para verter por encima,

asegúrese de que la válvula de entrada de agua tenga

colocada la tapa que se proporciona con el infusor.

Retire la tapa del tubo de drenaje y verifique que el

conducto de desagüe esté conectado correctamente.

Destello continuo de la luz roja Comuníquese con la compañía o el técnico de

mantenimiento.

Español

26

Page 27

27

Diagrama detallado de las piezas

Lista de piezas de repues-

N.º de

artículo

1 230-00001 1 Subunidad de depósito

2 210-00030 1 Bandeja escurridora para una sola taza

3 210-00031 1 Rejilla para una sola taza

4 230-00004 1 Subunidad de rejilla abatible

5 210-00004 1 Bisel

6 230-00015 1 Subunidad de portacápsulas

7 359-00003 1 Conexión MUR-LOK de ¼” y tuerca abocinada de ¼”

8 359-00031 1 Conexión de montaje con tuerca abocinada de ¼” y acople de manguera de ¾”

9 B256A 1 Tapa del puerto USB

10 210-00052 1 Guía del flotador

11 230-00021 1 Unidad de flotador

12 280-00001 1 Válvula de retención DW15

13 210-00230 1 Unidad de tapa del depósito

14 210-00233 1 Tapa fija

15 210-00051 1 Depósito

16 380-00020 1 Etiqueta de advertencia de líquido caliente

17 210-00017 1 Sello de cápsula superior

18 210-00235 1 Tapa de válvula de entrada moldeada

19 359-00115 1 Junta de tuerca abocinada SAE de ¼”

Número de pieza Cant. Descripción

Español

27

Page 28

28

Garantía

Para realizar cualquier reclamación de garantía, se debe obtener una autorización previa por parte de GMCW.

Garantía del producto para Estados Unidos y Canadá Vigencia a partir del 1 de octubre de 2013

Las nuevas máquinas fabricadas por o para Grindmaster Corp. y sus filiales (“Grindmaster”) y todas sus piezas

tienen una garantía condicional de Grindmaster para el usuario original, que indica que no tienen defectos de

materiales ni de mano de obra (con existencia en el momento de la fabricación o con aparición durante el período

de garantía establecido) en condiciones normales de uso y mantenimiento, según lo indicado a continuación:

Garantía de reemplazo de 90 días y garantía limitada de 2 años para las piezas

Durante el período de garantía de reemplazo de noventa (90) días, Grindmaster enviará de inmediato y sin cargo

alguno una máquina de reemplazo al cliente después de recibir el aviso de una reclamación y proporcionará

medios razonables para que la máquina defectuosa se devuelva a Grindmaster a cargo de Grindmaster. Durante

la garantía limitada de dos (2) años para las piezas, Grindmaster enviará de inmediato las piezas de repuesto al

cliente sin cargo alguno.

Período de garantía

Si la máquina se adquirió en Mother Parker’s Tea & Coffee (“Mother Parker’s”) y:

si se proporciona un comprobante de instalación, el período de garantía abarca desde la fecha de

instalación o desde los nueve (9) meses posteriores a la fecha en que la máquina se trasladó al inventario

de Mother Parker’s, lo que haya sucedido antes;

si no se proporciona un comprobante de instalación, el período de garantía abarca desde la fecha en que

la máquina se trasladó al inventario de Mother Parker’s.

Si la máquina se adquirió directamente a Grindmaster y:

si se proporciona un comprobante de instalación, el período de garantía abarca desde la fecha de

instalación o desde los nueve (9) meses posteriores a la fecha en que la máquina se envió de las

instalaciones de Grindmaster, lo que haya sucedido antes;

si no se proporciona un comprobante de instalación, el período de garantía abarca desde la fecha en que

la máquina se envió de las instalaciones de Grindmaster.

El cliente debe avisar de inmediato y obtener autorización previa de Grindmaster para realizar cualquier

reclamación de garantía. Puede comunicarse con Grindmaster por teléfono al (800-695-4500) o por correo a la

dirección postal P.O. Box 35020, Louisville, KY 40232-5020.

Esta garantía está sujeta a los siguientes términos, condiciones y exclusiones:

La garantía no se aplica a las máquinas o sus piezas que hayan sido objeto de cualquier accidente,

abuso, mal uso, negligencia, alteración, uso de voltaje incorrecto, ventilación inadecuada, daños durante

el transporte, instalación u operación incorrectas, mantenimiento o reparaciones inadecuados, piezas de

goma propensas al desgaste, malas condiciones del agua, ajustes de la máquina, condiciones temporales

de falta de funcionamiento, incendios, inundaciones, subida de tensión o sucesos fortuitos.

La garantía reemplaza a todas las demás garantías expresas o implícitas. En ningún caso Grindmaster

será responsable por daños consecuentes o incidentales.

Español

28

Page 29

29

Garantía (continuación)

Se deben proporcionar a Grindmaster el modelo y el número de serie de la unidad (que se encuentran en

la placa de serie) cuando se lo solicite.

A su propia discreción, Grindmaster puede brindar instrucciones para que el cliente deseche en su área la

máquina defectuosa que se haya reemplazado en virtud de la garantía de noventa (90) días, en lugar de

proporcionar los medios para que se envíe dicha máquina a Grindmaster.

Las piezas de repuesto que se proporcionen en virtud de la garantía de dos (2) año s se enviarán al cliente

de forma gratuita. A petición de Grindmaster, algunas piezas de garantía deberán ser enviadas a cargo de

Grindmaster al Factory Service Center (Centro de servicio de fábrica) de Grindmaster designado en la

confirmación de la Autorización de Devolución de Bienes (RGA, por sus siglas en inglés). Si el cliente no

devuelve las piezas o si, después de la inspección, la reclamación de garantía se considera no válida,

Grindmaster facturará al cliente por las piezas de repuesto que se hayan enviado previamente.

Los vendedores, distribuidores, empleados y agentes de Grindmaster no están autorizados a modificar esta

garantía ni a agregar garantías que sean vinculantes para Grindmaster. Asimismo, las declaraciones escritas u

orales que realicen dichos individuos no establecen garantías y, por lo tanto, no se debe depe nder de ellas.

Esto establecerá sus derechos de garantía. La compensación que el comprador recibirá de Grindmaster por el

incumplimiento de cualquier obligación que surja de la venta de este equipo, ya sea derivada de la garantía o de

cualquier otro modo, se limitará a la reparación, el reemplazo o el reembolso del producto, a discreción de

Grindmaster.

Para obtener asistencia técnica, llame al 855-869-2802™.

A los fines de futuras consultas, escriba el número de serie aquí:

GRINDMASTER ® DE GMCW

4003 Collins Lane, Louisville, KY 40245 Estados Unidos www.gmcw.com

Infusor para una sola taza, modelo RC400

Español

29

Page 30

Modèle RC400

Infuseur une tasse

Manuel d’instructions

Table des matières

Instructions de sécurité…………….…….. 31

Spécifications de la cafetière…...….…….. 32

Informations générales………….……..…. 32

Description du produit……………….…… 33

Déballage de votre cafetière….…..….….. 34

Installation……………………….….…….. 34

Préparation…………….….………………. 35

Mode d'emploi……………………...…….. 36

Nettoyage et entretien……………………. 38

Dépannage…………………….………….. 39

Liste des pièces de rechange……….…….. 40

Une autorisation préalable doit être obtenue auprès

de GMCW pour toute réclamation de garantie.

GRINDMASTER ®

par GMCW ™

© GMCW, 2013

Imprimé en Thailande

Modèle RC400

GMCW

4003 Collins Lane

Louisville, KY 40245 USA

(502) 425-4776

(800) 695-4500 (USA & Canada uniquement)

FAX (502) 425-4664

www.gmcw.com

1213 Formulaire # BW-305-01

Elément # 390-00005

Français

Page 31

31

Instructions de sécurité

Information de sécurité importante

Ceci est un symbole d’alerte de sécurité. Il est utilisé pour vous alerter de dangers potentiels de ble ssures person-

nelles. Respectez tous les messages de sé curit é qui suivent ce symbole pour éviter des blessures ou la mort.

Pour votre sécurité et la sécurité des autres, lisez tous les avertissements et le manuel d'instruction avant

d’installer et d’utiliser le produit.

DANGER: Ce terme indique un danger de mort ou de blessure grave.

AVERTISSEMENT: Ce terme fait référence à un danger potentiel ou une pratique dangereuse, qui pourrait

entraîner des blessures graves.

ATTENTION: Ce terme fait référence à un danger potentiel ou une pratique dangereuse, qui pourrait entraîner des

blessures mineures ou modérées ou des dégâts matériels.

REMARQUE: Ce terme fait référence à une information qui nécessite une attention spéciale ou doit être

pleinement comprise.

DANGER

Pour éviter les risques d’électrocution, de brûlures, ou autres blessures et pour éviter d’endommager votre infuseur, ne pas l’immerger dans l’eau ou dans d’autres liquides nettoyants.

Ne pas faire fonctionner un infuseur endommagé. Contrôler régulièrement le cordon d’alimentation électrique et

le tuyau d’alimentation en eau. Si le cordon ou la fiche sont endommagés ou usés, ne pas utiliser l'infuseur. Fermer l’alimentation d'eau et débrancher électriquement.

Eteindre et débrancher l'infuseur avant le nettoyage et l’entretien.

Risque d’étouffement. L’emballage du produit contient un sac plastique. Garder les sacs plastique s hors de portée des enfants.

Débrancher si l’appareil fonctionne anormalement et contacter un professionnel qualifié pou r la réparation. Ne

pas autoriser une personne non qualifiée à effectuer les réparations. Pas de réparation possible à l'intérieur de

l'infuseur. Ne pas démonter l'infuseur.

AVERTISSEMENT

Les sondes d'infusion sont tranchantes. Pour éviter les blessures ne pas mettre les doigts à l’intérieur de la cavité

d'infusion. L'infuseur doit être uniquement branchée à un circuit électrique 120 VAC, 60 Hz, 15 A avec terre.

Laisser refroidir l'infuseur avant le nettoyage ou l’entretien.

ATTENTION

Risques de brûlures. L'infuseur utilise de l'eau à 185°F- 200°F si bien que, si il n'est pas utilisé correctement, il peut

entraîner des brûlures. Ne pas laisser des enfants utiliser cet appareil sans la supervision d'un adulte. Maintenir l'appareil hors de portée d'animaux.

Utilisation à l'intérieur uniquement. Ne pas installer ou utiliser à l'extérieur, sur des équipements mobiles, ou flottants.

N'utiliser l'appareil que pour les fins auxquelles il a été conçu. Tout autre usage est inapproprié et peut être dangereux. Le fabriquant décline toute responsabilité pour blessure, perte ou endommagement dus à une mauvaise utilisation.

Pour éviter les risques de brûlures, ne pas utiliser sans que le capot soit en place.

Des surfaces chaudes peuvent entraîner des brûlures. Ne pas toucher à l'infuseur pendant son utilisation.

Pour ne pas se brûler avec l'eau chaude, ne pas ouvrir la cavité d'infusion pendant le cycle.

Pour ne pas se brûler avec l'eau chaude, ne pas bouger ou incliner l'appareil. En bougeant ou inclinant l'infuseur,

l'eau pourrait se déverser du réservoir. En haute altitude, une ébullition interne est possible. Vous devez réduire la

température de consigne en-dessous du point d'ébullition de cette altitude.

Pour éviter de se brûler, utiliser une tasse appropriée pour minimiser les éclaboussures. Laisser un minimum de 1/2”

d'espace entre le rebord de la tasse et le bec de distribution de l'infuseur pour que la tasse ne déverse pas quand on

la retire. Centrer la tasse sous le bec de distribution pendant l'écoulement et laisser le cycle d'infusion se terminer

avant d'ouvrir la cavité d'infusion ou de retirer la tasse.

Pour éviter de se pincer, éloigner les doigts de la cavité d'infusion pendant la fermeture.

Français

31

Page 32

32

REMARQUE

Pour de meilleurs résultats, enlever la capsule Real Cup™ usagée de la cavité d'infusion quand le cycle est

terminé.

Ne pas retirer le réservoir pendant que l'unité d'Auto-remplissage se remplit pour éviter des déversements;

attendre la fin du cycle de remplissage avant d'enlever le réservoir.

Toute intervention d'entretien ou de réparation doit être faite par un professionnel qualifié.

L'installation, l'entretien ou les réparations par du personnel non qualifié pourrait endommag er l'infuseur et

annulerait la garantie du fabricant.

Cet équipement doit être installé conformément aux normes locales et nationales propres au pays et / ou à la

région où l'appareil est installé.

Contacter le fabricant pour tout dysfonctionnement ou endommagement de l'appareil.

Quand l'appareil est éteint pendant une longue période, s'assurer qu'il n'y a plus d'eau à l'intérieur des tuyaux.

L'eau pourrait geler et entraîner des détériorations ou l'apparition de moisissures.

Pour éviter que des corps étrangers n'entrent dans l'infuseur, maintenir les couvercles du réservoir et de la cavité

d'infusion fermés.

En cas de débordement accidentel de la tasse, appuyer sur “INFUSER” pour arrêter.

Spécifications de l'infuseur

Modèle RC400

Dimensions (H x L x P) 15.7” (40 cm) x 10.8” (28 cm) x 14.8” (38

cm)

Poids à l'expédition 18.7 LBS (8.5 kg)

Poids Machine 15.3 LBS (6.9 kg)

Capacité du réservoir 72 fl. oz. (2.1 L)

Tension 120 VAC

Phase 1

Fréquence 60 Hz

Puissance 1.55 KW

Intensité 13 Amps

Nombre de résistances 1

Prise NEMA 5-15P

Informations générales

Ce manuel d'instructions comprend les instructions d'utilisation et d'entretien de votre infuseur; gardez ce manuel à

disposition.

Après avoir déballé votre infuseur, assurez-vous que votre appareil n'a pas été endommagé pendant le transport et

qu'il comprend tous les composants. Contacter le service après-vente pour tou t e question ou problème avant

l'installation.

Merci de noter que les matériaux d'emballage peuvent être dangereux. Maintenez-les hors de portée des enfants.

Évacuez-les rapidement.

Pendant les différentes étapes de fonctionnement, vous pourrez entendre des sons de fonctionneme nt normaux qui

ne vous sont pas familiers. Les bruits suivants sont normaux:

Bourdonnement / Clic - entendu lorsque la pompe à eau s'active et / ou la vanne à trois voies s'ouvre et se ferme

pour distribuer de l'eau ou remplir le réservoir.

Pop – une capsule Real Cup™ endommagée pourrait entraîner un bruit sec.

Vibration / vrombissement - Dans les conditions normales de fonctionnement, une pompe à air interne se met en

marche à la fin du cycle d'infusion et vous l'entendrez lorsqu'elle est active.

Français

32

Page 33

33

Ecoulement d'eau ou gargouillement - Sur une installation à infuseur verseuse, vous entendrez des

gargouillements quand le réservoir est vide avant la fin d'un cycle d'infusion. Sur une installation à

remplissage automatique, vous entendrez ce son quand la cafetière se remplit automatiquement.

Ne pas utiliser de capsules Real Cup™endommagées. L'utilisation de capsules Real Cup™endommagées risquerait

d'entraîner des grains de café ou des matières indésirables dans la cavité d'infusion et dans la tasse. La capsule

Real Cup™ peut être abîmée autour de l'opercule ou l'ensemble de la capsule Real Cup™ peut être bosselée ou

déformée.

Pour assurer la sécurité alimentaire et le bon fonctionnement, nettoyer la machine régulièrement en suivant les

instructions de nettoyages quotidien et hebdomadaire. Les instructions de nettoyage et d'évacuation de l'eau se

trouvent dans la section Nettoyage et Entretien de ce manuel.

Quand l'appareil est éteint pendant une longue période, s'assurer qu'il n'y a plus d'eau à l'intérieur des tuyaux. L'eau

pourrait geler et entraîner des détériorations ou l'apparition de moisissures.

Les raccords et accessoires des tuyaux d'eau directement connectés sur une conduite d'eau potable doivent être

conformes, au niveau de la taille, de l'installation et de l'entretien, aux normes fédérales, d'État et locales. Ce

produit nécessite un dispositif de prévention de reflux homologué, tel qu'un clapet anti-retour double, à installer entre

la machine et l'alimentation en eau.

Pour éviter que des corps étrangers n'entrent dans la cafetière, maintenir les couvercles du réservoir et de la

chambre d'infusion fermés.

Pour assurer le bon fonctionnement des contrôles électroniques, ne pas utiliser l 'osmose inverse, l'eau distillée ou

déminéralisée.

La température de l'eau chaude de la cafetière à capsule RC400 est réglée en usine à 195

o

F (90.6o C). Si vous

utilisez votre infuseur au-delà de 4000 pieds d'altitude, un ajustement de consigne peut être nécessaire. Si de la

vapeur sort du réservoir ou si des gouttes d'eau chaude tombent dans le réserv oir, c'est que la consigne de

température doit être baissée. De plus, si la consigne de température est trop haute, vous pourriez obtenir moins de

volume infusé.

Consigne

recommandée

o

F (oC)

200 (93) 0 191 (88) 5000 (1524) Denver/

198 (92) 1000 (305) 189 (87) 6000 (1828) Colorado Springs

196 (91) 2000 (610) 187 (86) 7000 (2134) Santa Fe

195 (90) 3000 (915) Calgary 185 (85) 8000 (2438)

193 (89) 4000 (1219)

Altitude

en pieds(M)

Ville Consigne

recommandée

o

F (oC)

en pieds (M)

Altitude

Ville

Albuquerque

Description du produit

Merci d'avoir choisi l'infuseur une tasse à usage commercial/domestique Grindmaster par GMCW. L'infuseur une

tasse est un infuseur à usage commercial ou domestique à commande numé rique qui prépare une tasse à la fois.

L'infuseur est conçu pour une utilisation optimale avec les capsules RealCup ™ et est compatible avec les capsules

Keurig ® * K-Cup ® .

L'infuseur une tasse peut être raccordé à une source d'eau potable. Si une ligne d'eau n'est pas disp onible,

l'infuseur peut être utilisé comme un infuseur verseuse. L'infuseur requiert une alimentation 15 A, 120V, 60 Hz. Si

l'infuseur est raccordé, le remplissage du réservoir se fera automatiquement. Sinon, un remplissage ma nuel du

réservoir sera nécessaire.

Principe d'utilisation de cette machine :

L'utilisateur place une tasse à café sur le plateau d'égouttage (ou plateau escamotable) et une capsule Real Cu p™

dans la cavité d'infusion. Il ferme ensuite la cavité d'infusion. Puis il sélectionne, à partir de

*

*LamarqueRealCup™n'estpasaffiliéeàK‐Cup®ouKeurigInc.Keurig®etK‐Cup®sontdesmarquesdéposéesdeKeurigInc.

Français

33

Page 34

34

l'écran d'interface utilisateur, la boisson et les réglages de format. Une fois ces sélections faites, il appuie sur le

bouton INFUSER. L'infuseur une tasse est conçu pour des doses de 4 (118), 6 (177), 8 (237), 10 (296), 12 (355)

and 16 (473) onces liquides (ml). Le volume dosé réel est d'environ 10% de moins pour permettre l'addition de lait,

de crème ou d'édulcorant, si désirée.

Déballage de votre infuseur

1. Mettre le carton sur une table ou sur une surface ferme et stable

2. Ouvrir la boîte. Ne pas utiliser d'objets tranchants pour ouvrir la boîte, ils risqueraient d'abîmer l'infuseur.

3. Retirer les matériaux de protection, les notices imprimées et l'infuseur.

4. Noter le numéro de série à l'intérieur de la couverture arrière de ce manuel.

5. Après le déballage, vérifier que votre appareil n'a pas été endommagé pendant le transport et comp rend

tous les composants.

6. Informer votre représentant du service après-vente en cas de questions ou de préoccupations avant

l'installation

Caractéristiques du RC400

Couvercle du reservoir

Couvercle de la cavité d'infusion

Reservoir

Capot

LED du réservoir

Plateau réglable

Écran

Bouton INFUSER

Interrupteur d'alimentation

(à l'arrière de l’infuseur )

Installation

Où l'installer

L'infuseur doit être installé sur une surface ferme, stable et de niveau.

Surveiller les enfants et assister ceux qui ont besoin d'aide pour faire fonctionner l'infuseur.

*La marque RealCup™ n'est pas affiliée à K-Cup® ou Keurig Inc. Keurig ® et K-Cup ® sont des marques déposées de Keurig Inc.

Tenir à l'écart des animaux de compagnie.

Français

34

Page 35

35

Couvercle du tube de drainage

Interrupteur d'alimentation

Cordon d'alimentation

Alimentation en eau

REMARQUE: L'infuseur est conçu pour fonctionner avec de s pressions d'eau allant de 10 psig à 100 psig.

Grindmaster recommande l'utilisation d'un filtre à eau externe tel que le kit de filtres à eau P/N 250-00034. Le filtre

se monte sur la face arrière de l'infuseur.

Prises d'eau et électriques

Passe-fil

Prises d'eau

Adaptateur (infuseur à remplissage

automatique seulement)

Bouchon de valve

(infuseurs verseuses seulement)

Alimentation électrique

AVERTISSEMENT

Couper l'alimentation si la machine fonctionne anormalement et informer le personnel de maintenance qualifié pour

les réparations. Ne pas laisser du personnel non qualifié effectuer des réparations.

Pas de composants réparables à l'intérieur de l'infuseur. Ne pas dé monter l'infuseur.

Remarque

Cet appareil est équipé d'un cordon d'alimentation à trois broches. Un circuit électriqu e 120V 15A NEMA 5-15 avec

terre doit être utilisé.

1. Un circuit électrique 120 VAC, 60 Hz, 15 A, de type 5-15, est nécessaire au bon fonctionnement.

2. Toujours débrancher la machine avant l'entretien ou la maintenance de l'appareil.

3. Placer l'interrupteur d'alimentation en position OFF et brancher le cordon d'alimentation sur un circuit

électrique 120V 15A NEMA 5-15 avec terre

Préparation

Amorçage de la cuve de chauffage interne

REMARQUE: L'infuseur ne fonctionnera pas tant que le réservoir n'est pas amor cé.

Merci de suivre ces procédures pour assurer une bonne installation.

Français

35

Page 36

36

Version pour infuseur verseuse Version à remplissage automatique

1. Assurez-vous que le bouchon de valve d'admission d'eau

fourni avec la machine est installé sur la vanne d'entrée

d'eau pour empêcher les fuites.

2. Ouvrez le couvercle du réservoir. 2. Ouvrez la vanne de service d'eau.

1. Branchez l'eau à la vanne de remplissage située à

l'arrière de la cafetière. Un adaptateur raccord femelle

conique ¼ " x tube ¼" ainsi qu'un adaptateur conique

1/4" x tuyau sont fournis avec la cafetière. N'utilisez

pas d'eau osmosée.

3. Remplissez le réservoir avec de l'eau du robinet ou de

l'eau en bouteille jusqu'au niveau indiqué sur le réservoir. Ne

pas utiliser d'eau distillée.

4. Branchez l'appareil sur une prise 120V/15 A. Mettez l'interrupteur principal sur ON.

5. Placer une tasse sur le plateau d'égouttage de l'appareil

pour recueillir l'eau de l'opération d'amorçage.

6. L'écran affichera "Prime Brewer", appuyez sur le bouton

INFUSER jusqu'à ce que l'eau s'écoule dans la tasse.