Page 1

GRINDMASTER CRATHCO SYSTEMS, INC.

Crathco®Post Mix Beverage Dispensers

Operation and Instruction Manual

Model PM4-B & PM45-B

TABLE OF CONTENTS

Warnings and Safety Precautions..................2

Installation ..................................................3-5

Operating and Adjustments.........................5-7

Care and Cleaning......................................7-9

Maintenance Service ................................9-10

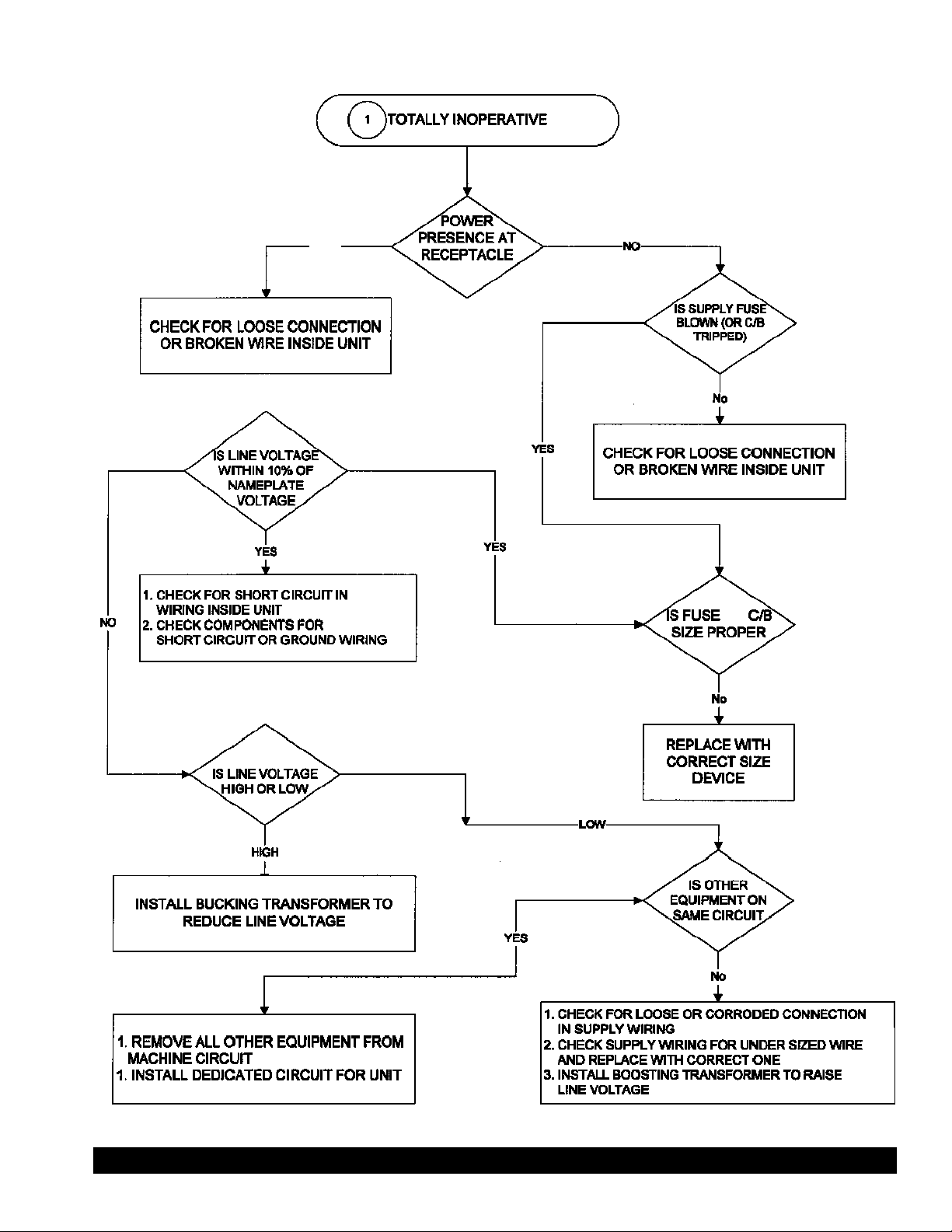

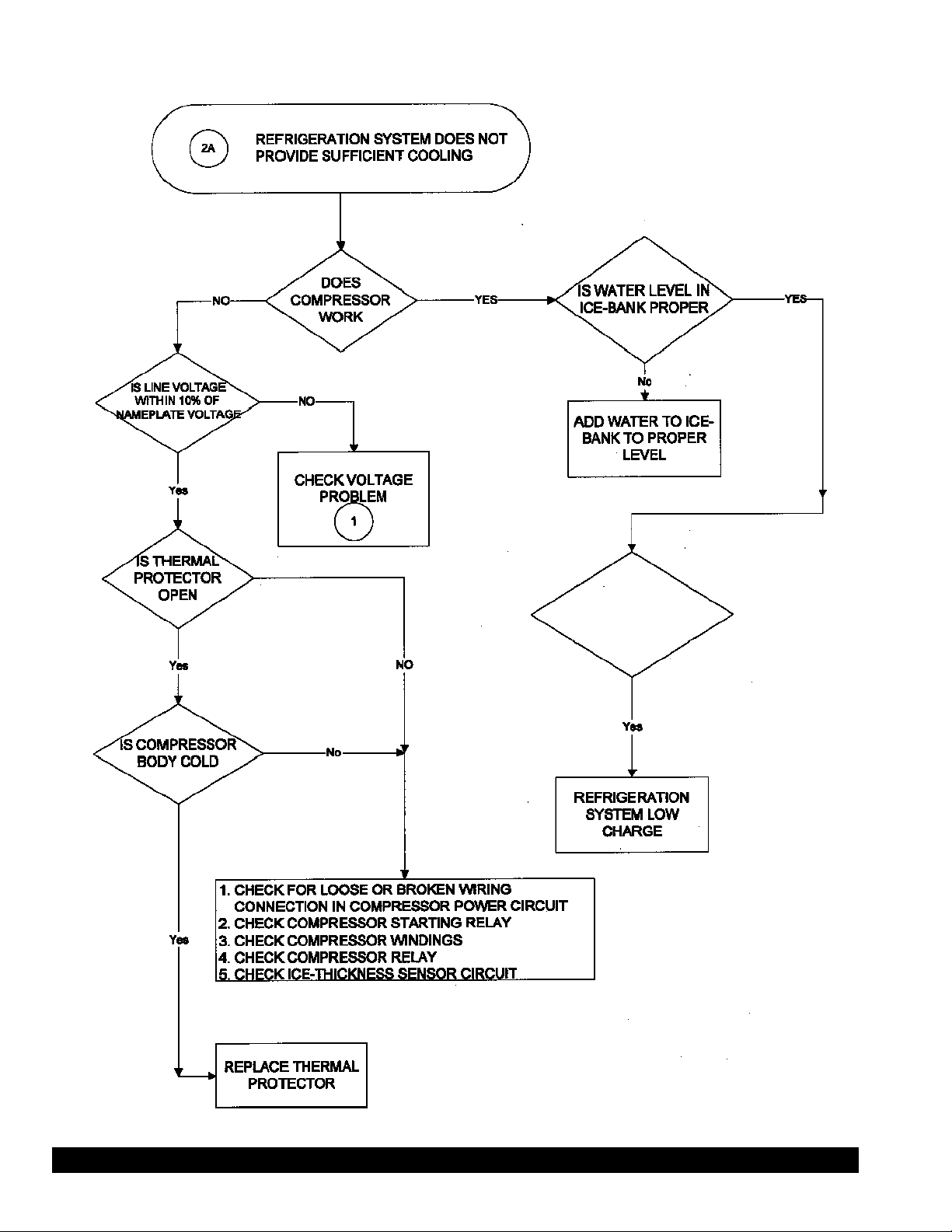

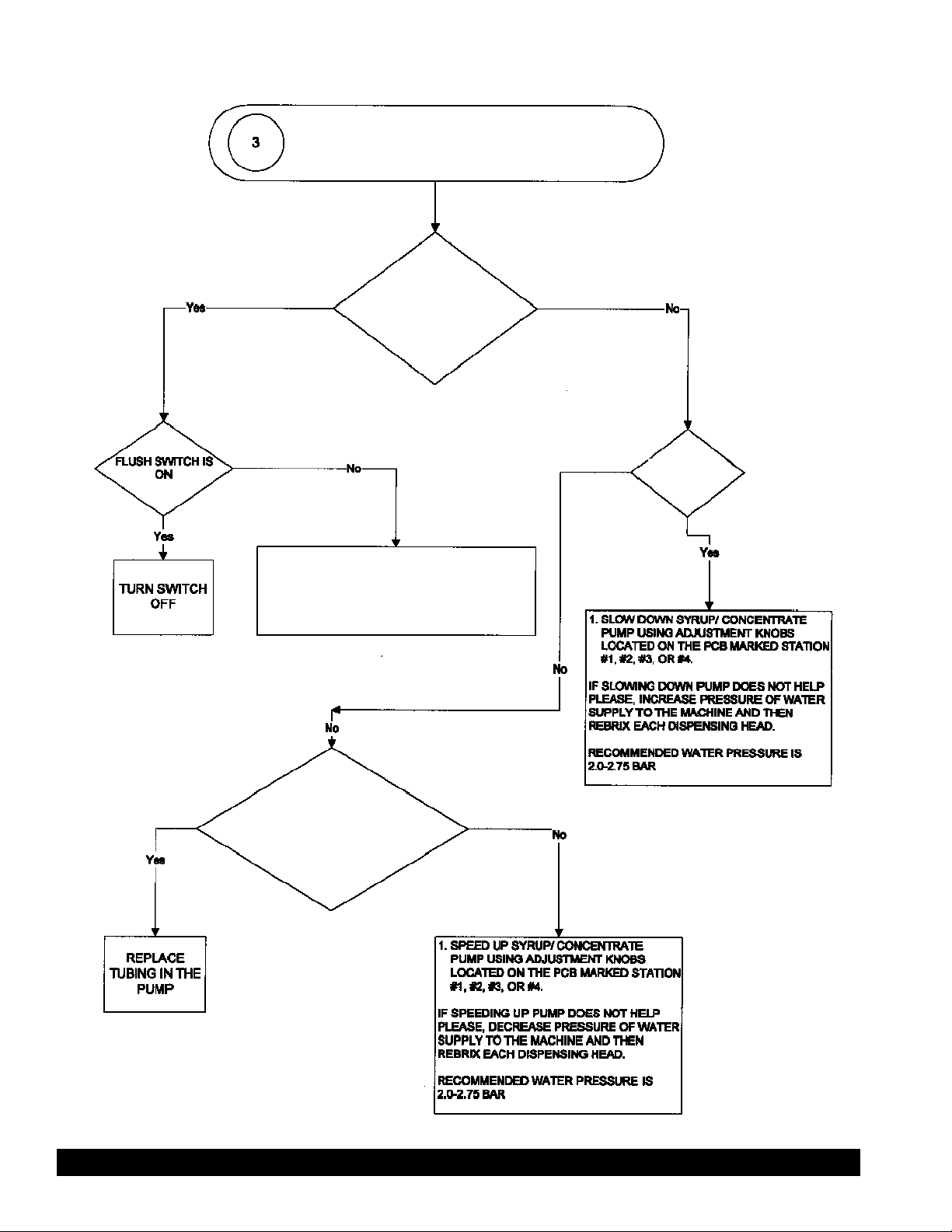

Troubleshooting.......................................11-16

Exploded Views ......................................17-23

for

Electrical Diagrams.................................24-25

Refrigeration Diagram..................................26

Prior authorization must be obtained

from Grindmaster Crathco Systems for all warranty claims.

MODEL PM4-B

480 Neponset Street

Canton, MA 02021 USA

(617) 828-1250

FAX (617) 828-9617

www.grindmaster.com

Grindmaster Crathco Systems, Inc., 2000

PRINTED IN THE USA

0700 Form # CC-398-03

Part # 9408

Page 2

WARNING LABELS AND SAFETY PRECAUTIONS

OPERATOR'S SAFETY PRECAUTIONS

1. Read and understand the operating instructions in this manual thoroughly.

2. Note all warning labels. If any of the warning labels are missing or damaged replace them immediately.

3. Keep operating area clean.

Located on the top of the condenser shroud and on the rear panel.

INTRODUCTION

The GRINDMASTER CORPORATION dispenser is a unique, self contained, counter top style unit with high

capacity self-adjusting cooling systems. Both cooling systems: patented cabinet cooling system and ice-bank

water cooling system do not require manual adjustment or settings. There are no Electromechanical thermostats

to control the cooling systems.

The cabinet cooling system is a frost-free system that maintains not only desired temperature, but also a constant

humidity level in the cabinet with exception to the time when the cabinet door is open.

The dispensing buttons are located on the front panel, and are easily accessible by the operator. The system is

powered with safe 24 VDC as well as a water inlet solenoid valve and an electronic controller.

The machine has accessible modular construction and has been designed to be simple, yet effective, to provide

many years of trouble-free operation.

Page 2 Crathco® Post Mix Beverage Dispensers

Page 3

INSTALLATION

Installation Notice

A water filter is recommended for the water supply to the dispenser, especially in areas where water contains a

high level of minerals such as calcium or other solids. Over long periods of time, calcium deposits build on

heat-exchanger coils and will lower the cooling capacity of the system. Calcium build up will also occur on the

strainers enclosed in the dispensing valves.

The cooling system is provided with copper coils, designed to last the life of the dispenser. However, some

chemicals in treated or not treated water, specifically chlorine and sulfur (sulfide) may shorten the life of the coils.

The initial investment in the filtering system will pay for itself in quality and by ensuring longer life for the

machine.

Unpacking

1. With the unit upright, remove staples from the box at the very bottom around perimeter of the box and on the

top of the box.

2. Open the top of the box and remove the accessory box.

3. Slide the box tube upward exposing the machine.

4. Remove supporting corners and front supporting block.

5. The unit must have the legs installed upon removal from the packaging. Legs are supplied in the acces-

sory kit (box on top of the machine in the packaging.)

Failure to install the legs will cause the dispenser refrigeration system to work improperly and burn out as

well as possibly damage the water inlet valve.

6. Support all 4 sides, lift and place in an appropriate area. (See location below)

Installing Your Unit

CAUTION: DO NOT ALTER OR DEFORM THE PLUG IN ANY WAY!

!

ALTERING OR DEFORMING THE PLUG MAY DAMAGE UNIT AND WILL VOID WARRANTY!

1. Location

Position dispenser in a well-ventilated area indoors. Avoid exposure to direct sunlight and/or heat caused

by radiation. Ambient room temperature must be in the range of 60Þ - 90ÞF (15-32ÞC). Do not install unit

in an enclosed area where heat build up could be a problem.

Note: Air flow direction and spacing required on Figure B page 4.

2. Plumbing

Connect the dispenser to cold, potable water source suitable for drinking.

Do not install unit on a water softener/softening line. For proper operation incoming supply water pressure

must be in the range 29 psig (2 - 2.75 bar), therefore a water pressure regulating valve is recommended.

3. Electrical

This unit is supplied with a 6” (2m) long 2 wire plus ground power cord. The PM45-B connector is suitable

for standard single phase 220V/50Hz power supply. PM4-B models should be connected to a 115V 60 Hz

power supply. This cord exits the unit out the bottom of the base and should be routed per National Electric

Code.

Crathco® Post Mix Beverage Dispensers Page 3

Page 4

WARNING: Only a qualified service technician should service internal electrical components.

Installing Your Unit (cont.)

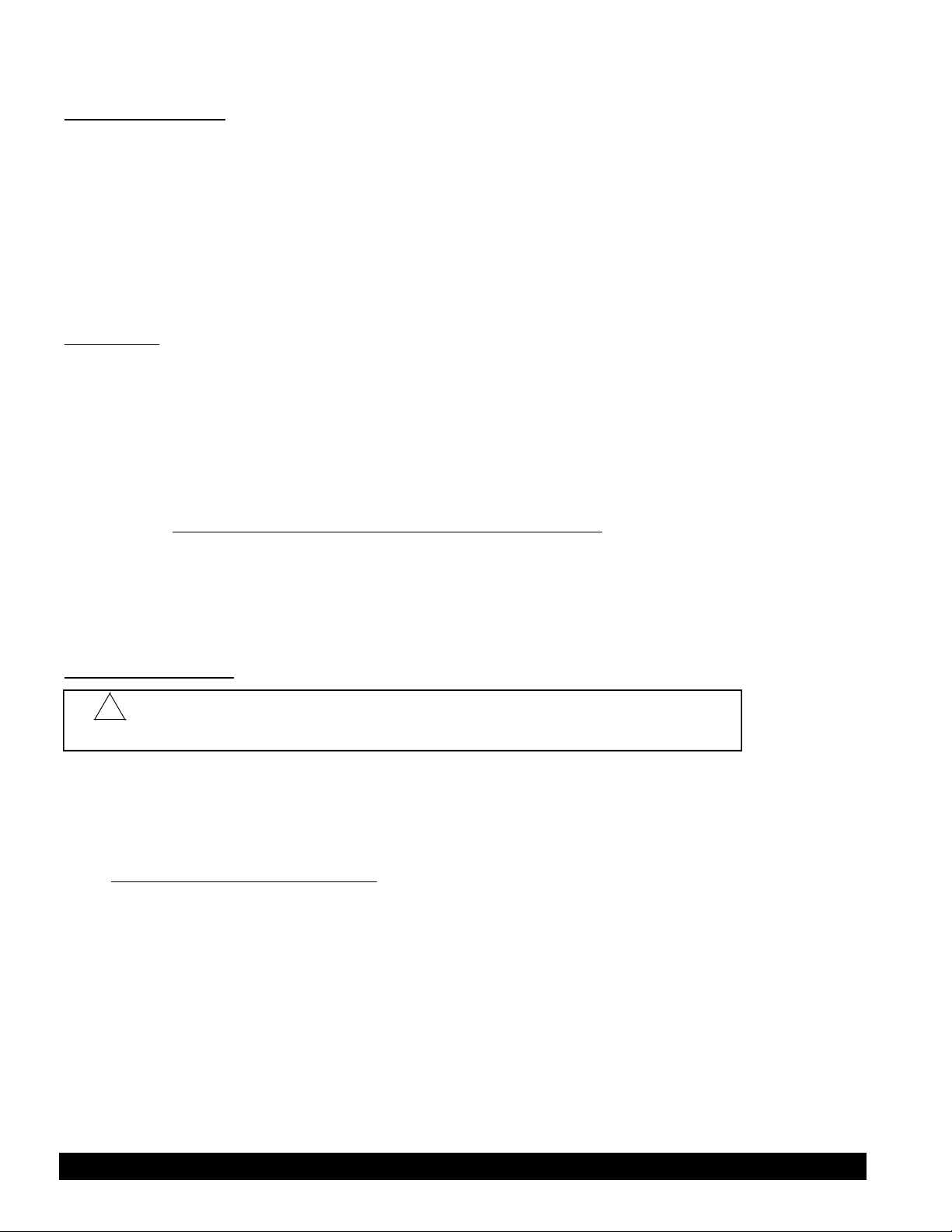

4. Water Hook-up.

It is recommended to provide water connection to the dispenser from a dedicated

water line. Without this, consistent water pressure necessary to sustain proper brix

levels may not be maintained due to water surges caused by other water-consuming equipment, such as dishwashing machines, other dispensing equipment, coffee

machines etc!

The water line supply should be at least 3 2/5” (8 mm) internal diameter and must

be rated for 217 psig (15 bar) pressure at 70ÞF (21°C) water temperature.

Install a water pressure regulator gauge at the inlet to the machine and set it to

29 Psig (2 bar). The water pressure regulator gauge, is included in the Accessory

Box. It is important that the gauge is installed accordingly. (See figure A) Failure to

comply will damage the gauge and render it inoperable.

Filling the Ice bank with Water

1. Remove the rear upper panel from the dispenser.

(Figure A)

2. Find the Ice Tank Plug (round black rubber plug

about 1” (2.5 cm) diameter) on the top of the ice

Back of unit

Ice Tank Plug

bank cover and remove it.

Water Level

3. Use the water hose or funnel to fill the tank with cold

tap water (18 liters.)

4. Stop filling water once water is flowing from overflow

1.5 cm below top

cover

Water Level Gauge

Overflow

Drain

drain.

5. Look at the water level gauge (tank drain clear hose

attached to the insulated refrigeration line in upright

position.) The water level in the tank is equal to the

Air Out

›

›

›

water level in the water gauge and should be about

1.5 cm below ice bank cover. *(see Figure B)

6. Replace rubber plug and rear upper panel.

7. Turn the power switch ON.

(Figure B)

›››

Air In

Minimum Air Space Requirements

Top 12”

*To assure the proper operation of the dispenser, the water level in the

ice bank must be kept at the full fill level explained above. Water level

Sides 2”

Back 4”

in the ice bank should be checked every couple of months.

WARNING: Do not remove the water level gauge from its position unless you want to drain the water

from the ice bank.

Note: If the water level in the ice bank falls substantially (about 2”/5 cm), the refrigeration system will stop

operating. Before this happens, the loss of cabinet cooling will be observed.

Page 4 Crathco® Post Mix Beverage Dispensers

Page 5

Installation (cont.)

POWER SUPPLY: 220 VAC 50 Hz 115/60Hz

COMPRESSOR: HP: 1/4, (630 Kcal, 2500 BTUH)

REFRIGERANT: R134a 260 grams/9.1 oz.

DESIGN LOW PRESSURE: Max. 9.5 BAR; 140 PSIG

DESIGN HIGH PRESSURE: Max. 16.3 BAR; 240 PSIG

SYSTEM TYPE: CAPILLARY TUBE, HERMETIC

IDLE POWER CONSUMPTION .5A .8A

RUN POWER CONSUMPTION 4A, 5A (MAX) 7A, 8A (MAX)

FUSE SIZE 6 A Slow Blow Controller

DISPENSING RATIO 50 ML/SEC

SUPPLY WATER PRESSURE 2 - 2.7 BAR; 29-40 PSIG

WORKING AMBIENT TEMPERATURE 15.5°C - 32.2°C 60-90ÞF(guaranteed performance)

PRODUCT STORAGE CAPACITY NOM. 4 LITERS (FOUR 1L TETRAPACK)

Specifications: PM45-B PM4-B

OPERATING AND ADJUSTMENTS

Explanation of terms

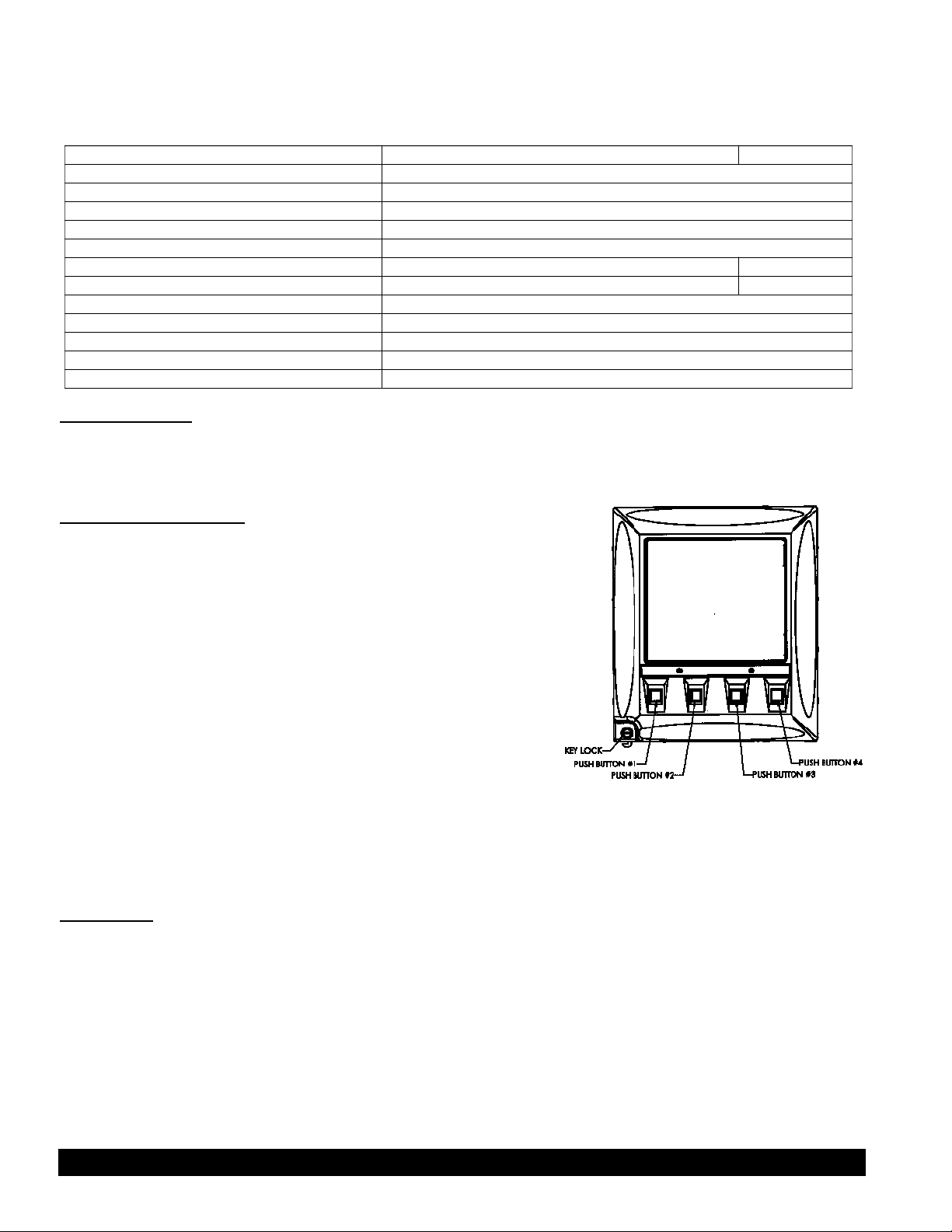

All descriptions related to dispensing heads, dispensing buttons,

pump motors such as: push button #1, dispensing head #2, pump

motor #3 etc. are used in relation to the front of the machine. This

relates also to all components inside of the machine that are

symmetrically positioned. (See Figure C)

For example:

Push button #1 - Far left positioned dispensing push button.

Push button #4 - Far right positioned dispensing push button.

Dispensing head #3 - All components involved when dispensing

caused by depressed push button #3.

Pump motor #4 - Pump motor that works when push button #4 was depressed and is positioned inside the

machine in line with push

button.

(Figure C)

Brix Setup

If initial concentrate brix is 60 and required mixing ratio is 6+1/6:1 (6 ounces water to one part concentrate),

then brix of ready to drink mixture of a concentrate and water should be 10.

To measure brix level, a refractometer is used to show sucrose content in a drink by measuring change of the light

diffraction in the water caused by change of viscosity due to sucrose content.

The correct ratio is achieved by controlling water and a concentrate flow to the mixing device, in this case mixing

chamber. Brix on each dispensing head is preset in the factory. In the field, the brix needs to be fine-tuned to the

Crathco® Post Mix Beverage Dispensers Page 5

Page 6

correct value with the use of a refractometer. Setting brix by taste is an acceptable method and usually gives

+ 0.5-0.8 brix error.

Brix Setup (cont.)

Mixing water with a concentrate in this dispenser was designed at the following conditions:

1. The initial temperature of a concentrate (syrup) used in the dispenser should be 39-41ÞF (4-5°C).

2. The initial temperature of the water supplied by the dispenser cooling system is 39ÞF (4°C).

3. The static water pressure should be set to 29PSIG.

The pressure regulator gauge should show 29PSIG (2 bar) when there is no water flow.

It is very important to apply the concentrate at the noted temperature since a concentrate changes its viscosity

when it cools down. A dramatic change of the viscosity (thickness of concentrate) causes the pumps capacity to

change resulting in the need to readjust the brix level.

The machine provides cooling to keep syrups or concentrates in the correct temperature. If the initial temperature

of syrup or concentrate is the room temperature when the brix is set, after approximately one hour the syrup or

concentrate will be cooled down to 39-41ÞF (4-5ÞC). As a result your brix setting will change. Therefore it is recommended that syrup or concentrate should be refrigerated prior to setting brix.

Brix Set Procedure

The brix number for given flavors is shown in the table. If the table does not include information for a particular

flavor, temporarily use the taste method and request information from a concentrate supplier.

Assuming that correct temperature of orange concentrate is applied

to the first dispensing head and syrups are applied to the remaining

dispensing heads proceed as follows:

1. Set the water pressure to 2 bar (29 Psig) static.

2. Depress chosen dispensing push button and hold until water

from the dispensing nozzle changes color.

3. Release push button. Depress push button again dispensing

drink into the cup.

4. Measure a brix level. If the brix is too rich (higher number

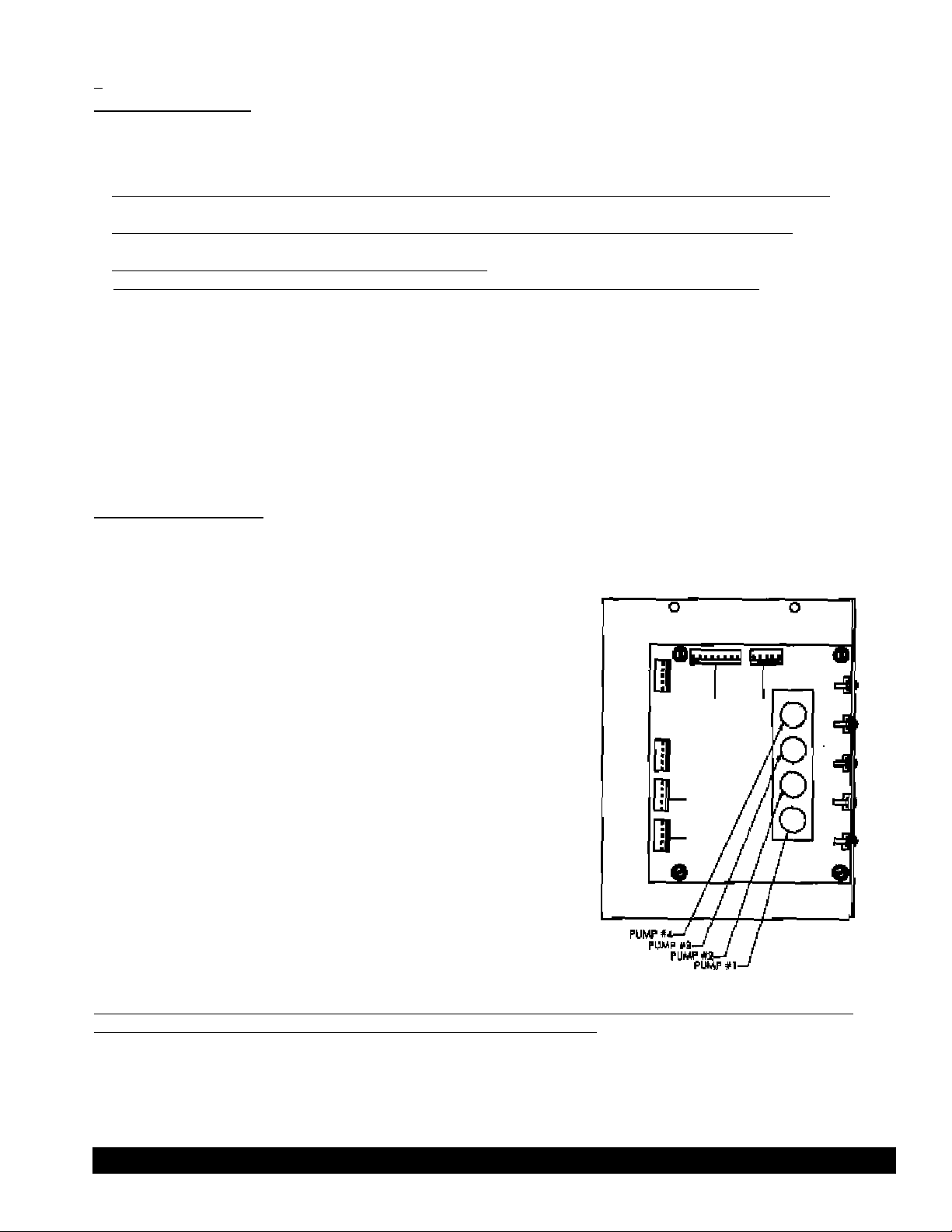

than expected) the concentrate pump needs to be slowed

down by turning corresponding potentiometer on the controller

board counterclockwise (potentiometer called Pump #1 on the

controller board corresponds with push button #1 and so on.)

The controller board can be found on the right hand side in the front

of the machine behind the splash panel. If potentiometer is already

all the way to the left, the water pressure must be increased

assuming that a concentrate temperature is at 39-41ÞF (4-5° C). Please, note that water pressure change will

cause brix change on other dispensing heads if they were set previously. (See figure D)

(Figure D)

If brix is too weak the pump speed must be increased by turning the corresponding potentiometer clockwise.

If there is problem setting up brix, refer to brix problem troubleshooting.

Page 6 Crathco®Post Mix Beverage Dispensers

Page 7

Once the brix is set, use the same flavor set up on each dispensing head. The flavor used on a particular

dispensing head can be changed if the brix and viscosity of the syrup remains the same.

Dispenser Operation Tips

1. To dispense the drink, depress and hold dispensing push button as long as needed.

2. After dispensing 2 liters consecutively allow a 15-30 second idling time before next usage.

3. Keep dispenser door closed and do not allow it to be open for a longer time than necessary.

4. Avoid a concentrate spillage inside the cabinet. If spillage occurs, clean immediately. If spillage is left

unattended, over time it will dry out and be difficult to clean.

Care and Cleaning

Flushing the Dispensing System.

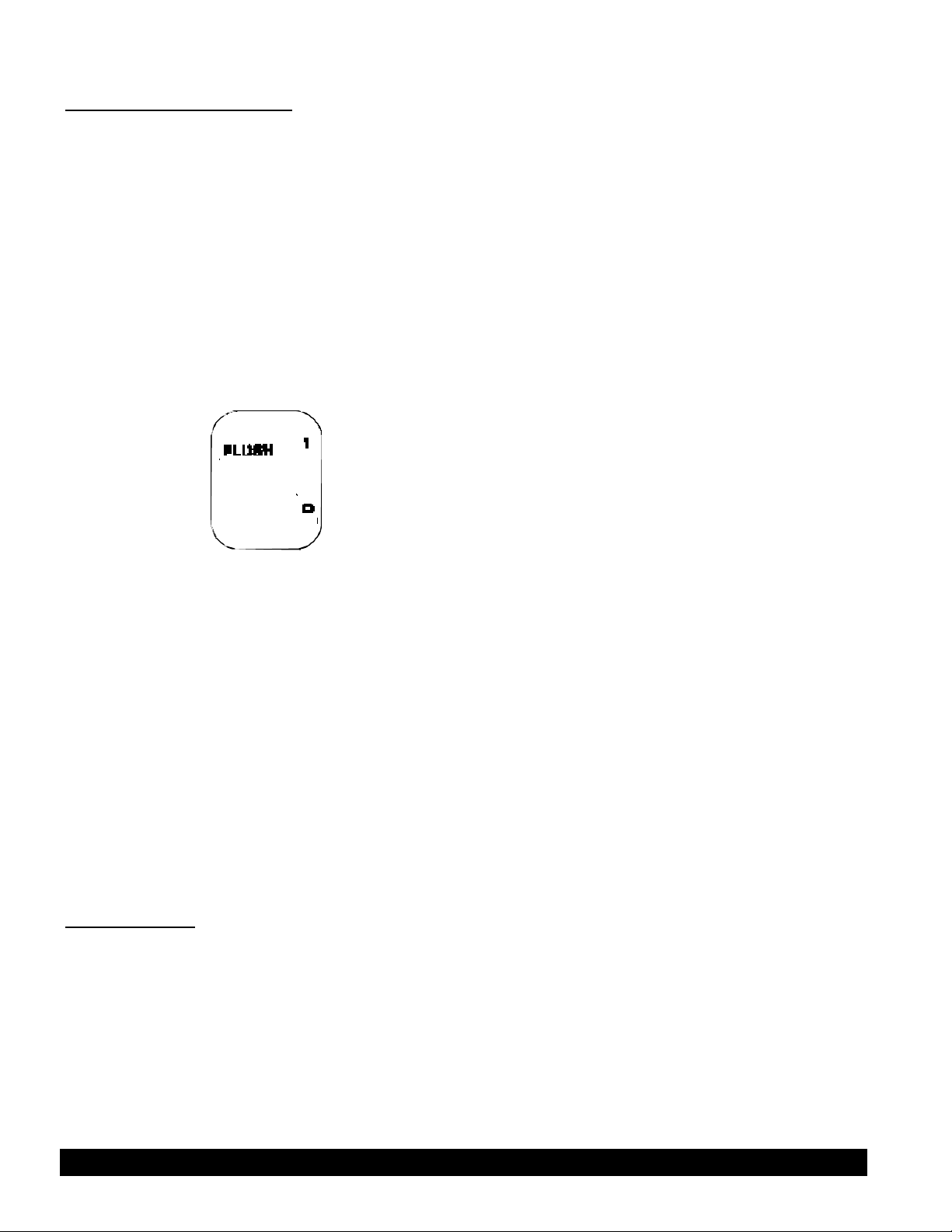

1. Open the door cabinet and turn the flush switch to the FLUSH

Dispense

FLUSH

position. The flush switch is located on the inside wall of the

door and is labeled:

(Figure E)

By turning the switch to the FLUSH position the product pumps are disabled. The machine now can

dispense water only.

2. Close the door and depress the far left dispensing switch for 30 seconds. Repeat this operation with all

remaining dispensing switches.

3. Open the door and turn the flush switch to the DISPENSE position.

The flushing operation rinses the mixing chamber, static mixer, and dispensing nozzle. The flushing

operation is required every day at closing or when the machine will not be in use for more than four hours.

Note: Flushing the dispensing system does not cause loss of cooling capacity.

Washing Parts

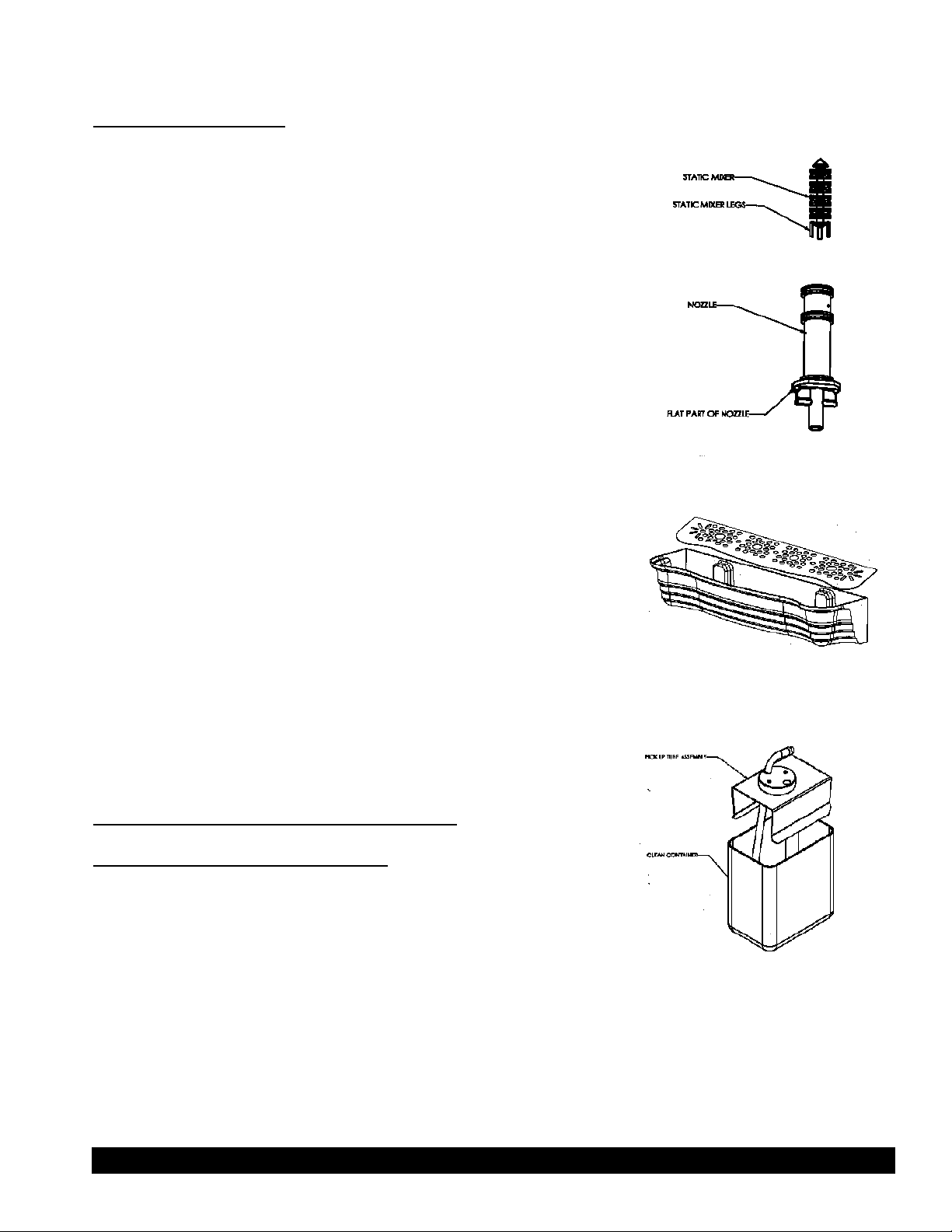

Parts such as the dispensing nozzle, static mixer and pick up tube assembly must be washed consistently every

week to remove possible product build up. This will help to assure the correct mixing and dispensing of product

especially when the product contains a pulp.

Removal of these parts does not require use of any tools. This is a simple hand operation and requires luke warm

water and dishwashing detergent.

1. Flush dispensing system first.

Crathco® Post Mix Beverage Dispensers Page 7

Page 8

Washing Parts (cont.)

2. Remove the dispensing nozzle from the machine by turning it 90° to the

left or right side, pulling it down. If there is a

problem pulling it down, turn the nozzle with quick short left to right and

back motions pulling it down at the same time. Make

sure that the nozzle is in the proper position. The flat part of the thin round

plate should be between

screw heads. Remove product pick up tubes from the product containers.

Note: Static mixer is inside the nozzle. If static mixer is lost, the product will not

mix properly. (See Figure F.)

3. Turn the dispensing nozzle upside down and remove static mixer.

Repeat the same with all remaining nozzles.

- - - -

4. Wash the parts with water mixed with hand dishwashing detergent.

5. Rinse all parts thoroughly, put static mixers into nozzle leg first and

install them back in the machine by inserting

into mixing chambers and locking

in positions. Failing to lock in position may cause dispensing nozzle with the

static mixer to be pushed rapidly out of the mixing chamber by the 29

Psig

(2

bar)

water

pressure and splash all surrounding with

mixed product. Replace product pick up

tubes.

Note: Wash on a regular basis the drip tray and the drip tray grill separately. (see figure G)

Sanitizing and Cleaning Dispensing System

Product Pumps System Cleaning

(Figure F)

(Figure G)

The product pumps system cleaning assures the performance of the pumping system and cleans the inside walls of tubing.

The product used is very thick (6+1 concentration or more) and will build up

a layer of sucrose and pulp mixture on the inside walls of tubing. This build up

narrows the inside diameter of the tubes and will restrict the product flow and

will slowly offset the brix. Proper cleaning of the pump system will help prevent and correct this condition.

1. Remove the product containers from the dispensing cabinet. Replace each container with any clean contain-

er (same capacity as product container) filled with warm water (40-45°C) and insert product pick up tubes

Page 8 Crathco® Post Mix Beverage Dispensers

(Figure H)

Page 9

into clean container. (see figure H)

2. Close the cabinet door and dispense the warm water the same way, as it would be a product. Dispensing

should last for no longer than 90 seconds.

3. Repeat the above for all remaining dispensing stations.

Washing Parts

Proceed as described in “Wash Parts” without flushing.

Sanitizing

Prepare sanitizing solution per instruction on the package changing the strength of the solution to be equivalent to

6+1 e.g. If instruction calls to dilute contents of the sanitizer package in 4 liters of water use only 0.6 liters of the

water for the solution. Fill the clean container that was used for tubing cleaning with the sanitizing solution.

1. Install container with sanitizer solution in the cabinet and connect pump tubing to product pick up tube assembly.

2. Close the cabinet door and depress dispensing switch corresponding with position of the container with

sanitizing solution for 15 seconds.

3. Wait 3 minutes.

4. Lift the pick up tubes assembly to be above the sanitizing solution and depress the same dispensing switch

for 2 seconds to avoid sanitizer spillage inside of the cabinet. Rinse the pick up tube assembly and connect it

back to the pump tubing.

5. Replace the container containing the sanitizing solution with the product container.

6. Depress dispensing switch. Keep dispensing product until 200 ml is dispensed with correct brix.

7. Repeat steps 1 to 6 for all remaining stations.

8. Turn the flush switch to FLUSH and depress each dispensing switch for 4 seconds.

Note: Do not skip any sanitizing procedure step.

Flushing

Proceed as described in Flushing the Dispensing System. Flushing

time is only 4 seconds.

Preventing Unauthorized Dispensing During “Off

Hours”

After system flushing, do not turn the flush switch to the DISPENSE

position. Lock the door and remove the key from the lock. This will

allow dispensing cold water only. (See figure I)

Note: Turn the flush switch to DISPENSE when resuming operation

the next day.

Back of unit

Ice Tank Plug

Water Level 1.5

cm below top

cover

Water Level

Gauge

Overflow

Drain

Air Out

›

›

›

(Figure I)

›

(Figure J)

Air In

›

›

Crathco®Post Mix Beverage Dispensers l Page 9

Page 10

MAINTENANCE

Daily:

System Flushing (See pages 7-8)

Weekly:

System flushing and washing (See pages 8-9)

MAINTENANCE (cont.)

Biweekly:

Sanitizing (See page 8-9). Ice bank water level check up. (See figure J)

Note: Make sure that water level in the drain tube is even with tank overflow outlet.

Monthly:

1. Check the condenser for dust build up. If necessary clean the condenser with a bristle brush.

2. After sanitizing, remove dispensing base assembly and wipe off the interior of the cabinet with a cloth

dampened in sanitizer.

3. Check the platform of the dispensing base assembly and clean it using sanitizer solution. Replace

dispensing base assembly.

4. Clean cabinet cooling system drain with a small bottle brush and sanitizer solution.

5. Check water level to ensure it is maintained at aproper fill level (See page 4). Filling the ice bank with water.

Every half of the year:

1. Replace all pump tubing. If pumps are loosing their capacity and adjusting pump speed does not correct the

problem, replace tubing on a more frequent basis.

2. Remove cabinet cooling system and wash it. Remove cooling fan prior to washing. If necessary separate the

cooling coil from the plastic shroud and wash them separately. Rinse

thoroughly both parts. Wipe off plastic shroud with dry cloth. Replace the

cooling system.

Every two years:

Inspect pump housings and pump rollers. Clean inside pump housings.

Merchandiser Bulb Replacement

WARNING: Disconnect machine from branch electrical supply before

changing the light bulb.

1. Remove merchandiser graphic by pushing its edge towards the center

of the merchandiser causing it to bow.

2. Repeat the same with clear plastic graphic reinforcement.

3. Remove the old light bulb by gently turning the lightbulb 1/4 turn to the

left and pulling the bulb from the socket. (See figure K)

4. Install the new bulb by lining up the pins on either end of the bulb parallel with the socket opening.

5. Gently insert both ends of the bulb into the socket and turn the bulb 1/4 turn to the right until the bulb locks

into place.

6. Replace the merchandiser photo and cover.

(Figure K)

Page 10 Crathco®Post Mix Beverage Dispensers

Page 11

TROUBLESHOOTING

WARNING: Only a qualified service technician should perform Electrical and mechanical adjust-

ments of repairs. Always disconnect power before attempting any maintenance procedures.

UNIT DISPENSES POOR BRIX DRINK

OR SYRUP/CONCENTRATE ONLY

IS

THE DOOR

MERCHANDISER

LIGHT ON

Crathco® Post Mix Beverage Dispensers Page 11

Page 12

Post Mix Beverage Dispensers

TROUBLESHOOTING (con’t.)

YES

Page 12 Crathco®

Page 13

TROUBLESHOOTING (con’t.)

DOES

ICE-BANK HAVE NO

ICE OR PARTIAL ICE

AROUND

COIL

Crathco®Post Mix Beverage Dispensers Page 13

Page 14

Post Mix Beverage Dispensers

TROUBLESHOOTING (con’t.)

Page 14 Crathco®

1. THERE IS RESTRICTION IN WATER

SUPPLY LINE OR IN THE COOLING COIL

2. POSSIBLE RESTRICTION AT THE SUCTION

SIDE OF THE WATER PUMP OR AT THE

DISCHARGE IN THE INSIDE OF THE

WATER

Page 15

TROUBLESHOOTING (con’t.)

UNIT DISPENSES POOR BRIX DRINK

OR SYRUP/CONCENTRATE ONLY

UNIT DISPENSES

SYRUP/CONCENTRATE

ONLY

IS DRINK

TOO RICH

1. CHECK CORRESPONDING

SOLENOID VALVE FOR POWER

SUPPLY OR MALFUNCTION

2. CHECK INLET SOLENOID VALVE FOR

POWER SUPPLY OR MALFUNCTION

TUBING IN PUMP HAS

OPERATED LONGER THAN 6

MONTHS OR WAS USED

EXCESSIVELY

Crathco® Post Mix Beverage Dispensers Page 15

Page 16

TROUBLESHOOTING (con’t.)

Page 16 Crathco® Post Mix Beverage Dispensers

Page 17

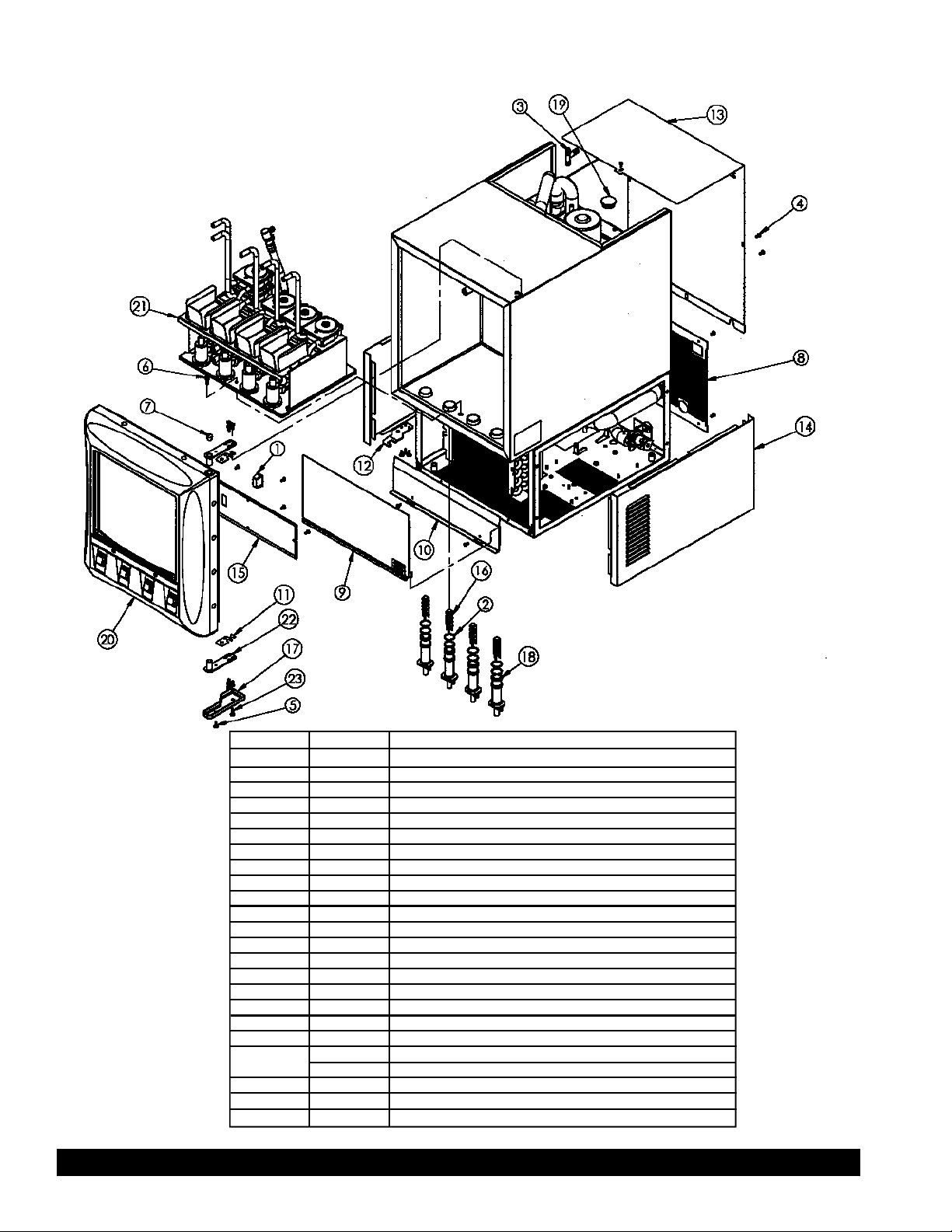

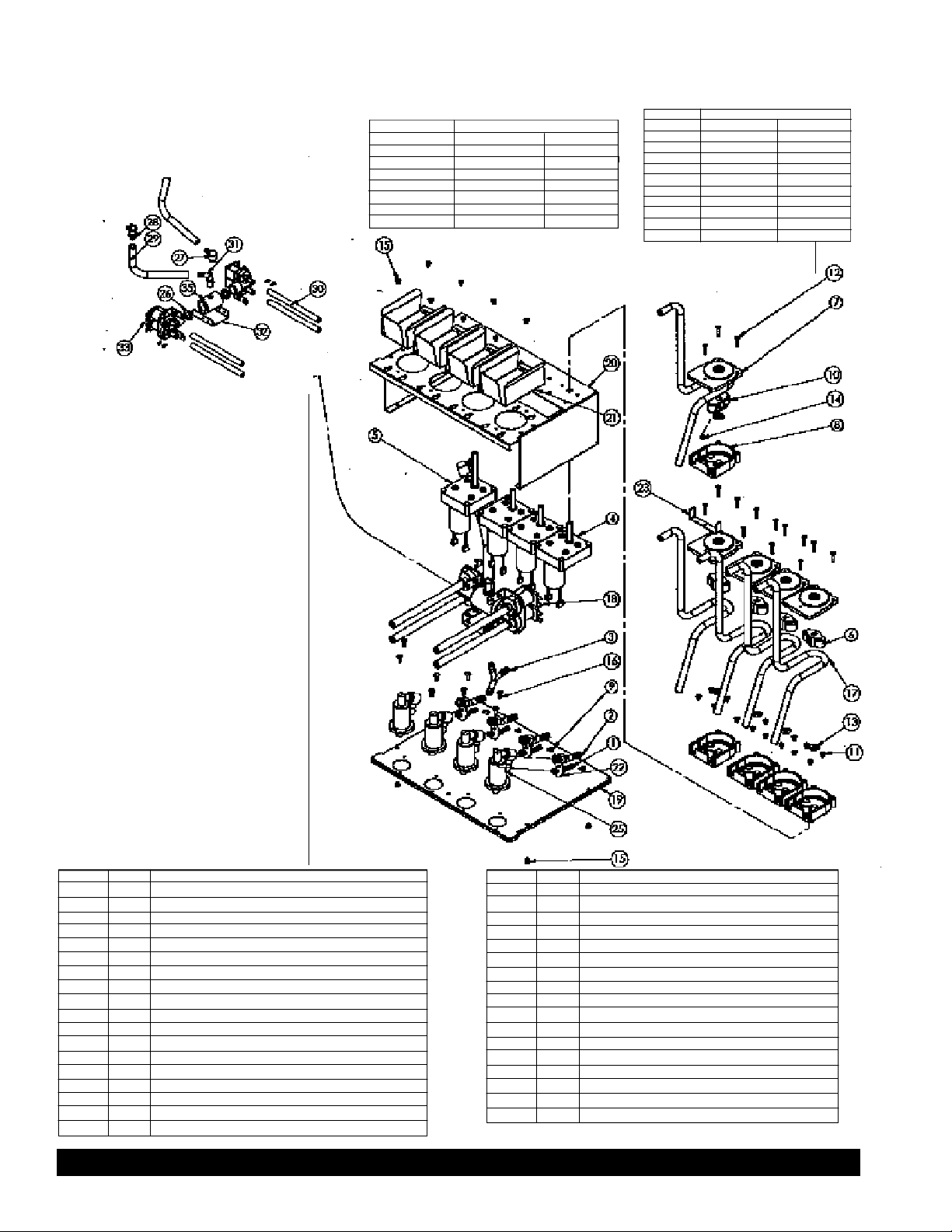

FINAL ASSEMBLY EXPLODED

ITEM P/N DESCRIPTION

1 3373 SWITCH, ROCKER

2 9105 O-RING, .864 ID X .070 W

3 9108 FITTING, 3/8 X 3/8 X /38 BARB PLASTIC TEE

4 9137 SCREW, 8-32 X 3/8 TAPTITE II SS BLACK

5 0069 SCREW, 8-32 X 1/2 PH TR HD TYPE F 410 SS

6 9110 SCREW, 8-32 X 5/8 PLAIN THUMB SS

7 9126 PLUG, HEYCO 2633

8 9304 PANEL, BACK LOWER

9 9307 PANEL, UPPER SPLASH

10 9308 PANEL, LOWER SPLASH

11 9311 SPACER, HINGE

12 9315 PLATE, DOOR GUIDE

13 9316 PANEL, BACK UPPER

14 9319 PANEL, SIDE

15 9322 PANEL, ACCESS

16 9803 MIXER, STATIC

17 9811 COVER, HINGE

18 9814 NOZZLE

19 9193 PLUG, ICEBANK LID

20 9213 MERCHANDISER DOOR ASSEMBLY, STD

21 9214 DISPENSING PLATFORM ASSEMBLY

22 9204 HINGE ASSEMBLY, DOOR

23 0073 SCREW, #10 PN HD PH ZINC

9233 MERCHANDISER ASSEMBLY

Crathco® Post Mix Beverage Page 17

Page 18

CONDENSING UNIT EXPLODED VIEW

31

ITEM P/N DESCRIPTION

1 1828 GROMET, COMPRESSOR 3250

2 1830 WASHER, COMPRESSOR

3 1831 CLIP, COMPRESSOR

4 9506 VALVE, INLET 2.2 GPM 24VDC

5 9517 TRANSFORMER 220VAC TO 28VAC, 150VA

9532 TRANSFORMER 115VAC TO 28VAC

6 3250 COMPRESSOR 240/220V 50 Hz

3247 COMPRESSOR 115V/60Hz

7 3371 CONDENSER

8 9521 BALLAST, LAMP F8T5 P/N 61118

8218 BALLAST, 120V

9 9522 RELAY, 12VDC COIL

10 9205 CONTROLLER ASSEMBLY

11 1000 SILENCER, FAN BLADE

12 1459 CONDENSER FAN BLADE

13 1584 FAN MOTOR 220V

1336 FAN MOTOR 115V

14 0055 NUT, FAN MOUNTING

15 9702 DRIER, SPORLAN C-03S

16 0057 NUT KEPS, 8-32

17 3370 BRACKET, CONDENSER FAN

18

ITEM P/N DESCRIPTION

18 9411 SCREW, #8 X 1/2 HEX HD SELF DRILL ZINC

19 9137 SCREW, 8-32 X 3/8 TAPTITE II SS BLACK

20 1783 POWER CORD, 1.5 M (NOT SHOWN) 220V

1072 POWER CORD 18-3 115V

21 9503 HARNESS, TRANSFORMER TO CONTROLLER 28 VAC (NOT SHOWN; SEE NOTE 1)

22 9507 HARNESS, COMPRESSOR RELAY COIL (NOT SHOWN; SEE NOTE 1)

23 9508 HARNESS, COOLING FAN (NOT SHOWN; SEE NOTE 1)

24 9509 HARNESS, FILL VALVE (NOT SHOWN; SEE NOTE 1)

25 9510 HARNESS, DISPENSE SWITCH (NOT SHOWN; SEE NOTE 1)

26 9512 HARNESS, DISPENSING CABINET (NOT SHOWN; SEE NOTE 1)

27 9514 HARNESS, TRANSFORMER TO TERMINAL BLOCK (NOT SHOWN; SEE NOTE 1)

28 9504 HARNESS, FLUSH SWITCH (NOT SHOWN; SEE NOTE 1)

29 9516 LEADS, LIGHT ASSEMBLY (NOT SHOWN; SEE NOTE 1)

30 9515 HARNESS, TERM BLOCK TO COMP. AND RELAY (NOT SHOWN; SEE NOTE 1)

31 8213 SWITCH, DOUBLE POLE ON/OFF

32 9166 GROMMET, SNAP IN HEYCO

33 9530 HARNESS, PWR SWITCH TO PWR CORD(NOT SHOWN; SEE NOTE1)

19

NOTES:

1) ALL HARNESS HOOK UP LOCATIONS

ARE DETAILED IN WIRING DIAGRAM P/N 9165

Page 18 Crathco® Post Mix Beverage Dispensers

Page 19

DISPENSING BASE EXPLODED VIEW

REPLACEMENT PUMP KITS MAY BE ORDERED AS FOLLOWS:

P/N 9400 KIT PERSTALTIC PUMP SINGLE

ITEM P/N QTY

6 9134 1

7 9135 1

8 9136 1

11 9160 4

12 9161 3

13 9162 1

17 9177 1

P/N 9401 KIT PERSTALTIC PUMP DUAL

ITEM P/N QTY

6 9134 1

7 9135 2

8 9136 2

10 9141 1

11 9160 4

12 9161 6

13 9162 2

14 9163 1

17 9177 2

23 9334 1

ITEM P/N DESCRIPTION

1 9103 FITTING, ELBOW 45 1/4 X BARB

2 9123 FITTING, ELBOW 45 3/8 X BARB DOUBLE O’ RING

3 9124 FITTING, Y BARB X 1/4 ID

4 9132 GEAR MOTOR, SHORT SHAFT 24V DC NOM

5 9133 GEAR MOTOR, LONG SHAFT 24V DC NOM

6 9134 ROLLER ASSY, SYRUP, PERISTALTIC PUMP

7 9135 COVER, ANKO PERIST, PUMP 810

8 9136 HOUSING, ANKO PERIST, PUMP 810 REAR

9 9137 SCREW, 8-32 X 3/8 TAPTITE II SS BLACK

10 9141 ROLLER ASSY, JUICE TOP PUMP, PERISTALTIC

11 9160 SCREW, 8-32 X 5/16 PH PN HD SS

12 9161 SCREW, 6-32 X 3/4 SS PH PH

13 9162 WASHER, SPACER, PUMP HOUSING

14 9163 SET SCREW, ANKO PUM PROLLER

15 9164 SCREW, 8-32 X 1/4 PH PN HD 18-8 SS

16 0069 SCREW, 8-32 X 1/2 PH TR HD TY PE F 410 SS

17 9177 TUBING NORPRENE, 810 ANKO PERISTALTIC PUMPS

18 9212 DUAL VALVE ASSEMBLY

ITEM P/N DESCRIPTION

19 9312 BASE, DISPENSING

20 9314 SHELF, DISPENSING

21 9324 BRACKET, TETRA PACK HOLDER

22 9330 BRACKET, FITTINGS HOLDER

23 9334 BRACKET, PERIST PUMP RETAINER

24 9513 HARNESS, DISPENSING PLATFORM (NOT SHOWN)

25 9816 CHAMBER, MIXING

26 9104 GASKET, MANIFOLD

27 9118 FITTING, 3/8" ID CPC ELBOW W/SHUTOFF

28 9119 FITTING, 3/8" ID CPC STRAIGHT

29 9153 TUBING, 3/8" ID INNERBRAIDED PV C

30 9143 TUBE, 1/4 X 1/8 WALL TY GON (B-44-4X)

31 9190 FITTING, 1/4 NPT X 3/8 BARB ELBOW

32 9328 BRACKET, DUAL WATER VALVE

33 9502 VALVE DUAL OUTLET, 1.0 GPM 24V DC COIL

34 9511 HARNESS, DAISY JUMPER (NOT SHOWN)

35 9806 MANIFOLD, DUAL VALVE

Crathco® Post Mix Beverage Page 19

Page 20

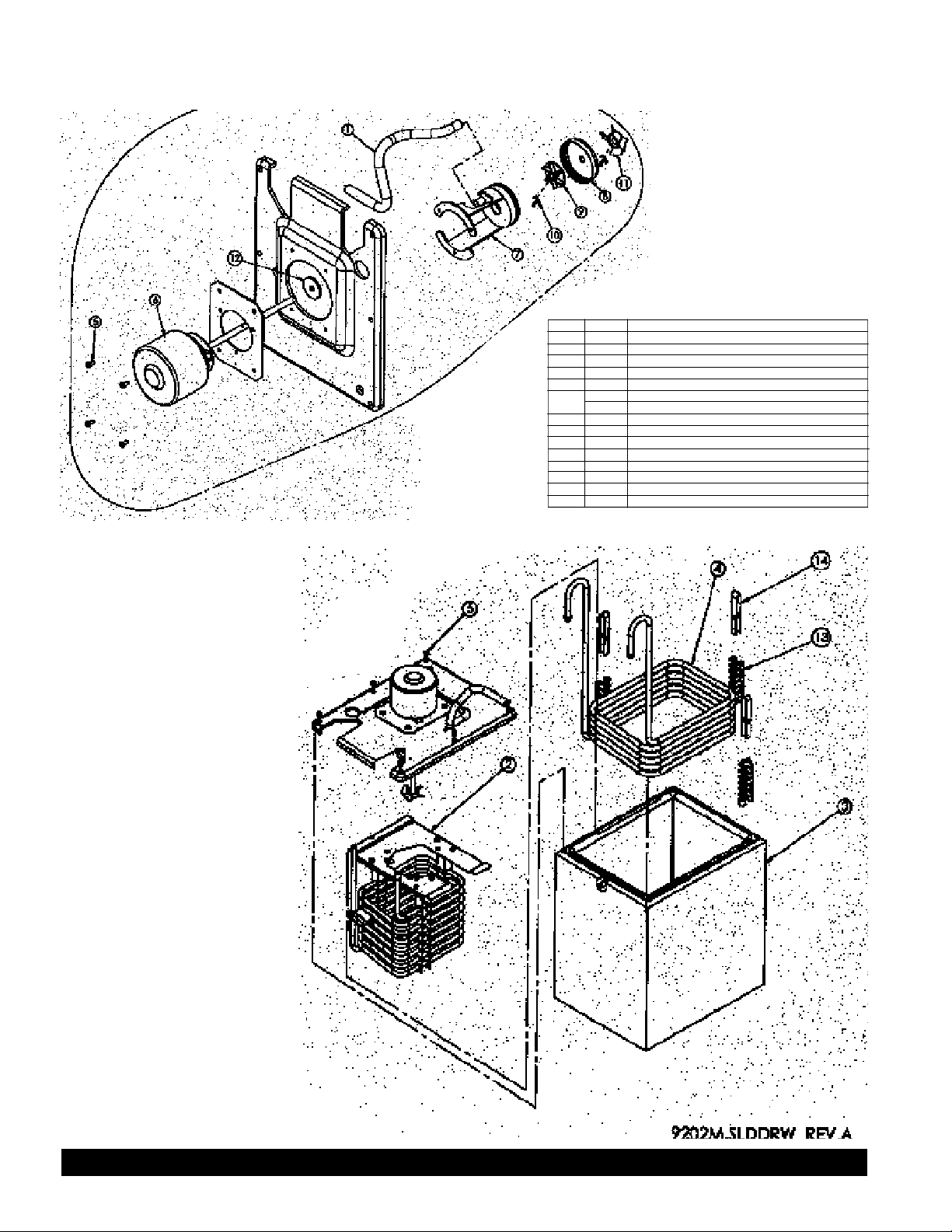

REFRIGERATION SYSTEM EXPLODED VIEW

ITEM P/N DESCRIPTION

1 9137 SCREW, 8-32 X 3/8 TAPTITE II SS BLACK

2 9109 TUBING, 3/8 D X 1/16 WALL TY GON B-44-4X

3 9153 TUBING, 3/8 D INNERBRAIDED PVC

4 9201 CONDENSING UNIT ASSEMBLY 220V

9227 CONDENSING UNIT ASSEMBLY 115V

5 9202 ICE-BANK ASSEMBLY 220V

9228 ICE-BANK ASSEMBLY 115V

6 9703 ACCUMULATOR, 1 3/16 OD X 8"

Page 20 Crathco® Post Mix Beverage Dispensers

Page 21

EVAPORATOR ASSEMBLY/CABINET COOLING PUMP EXPLODED VIEW

ITEM P/N DESCRIPTION

1 9413 TUBING, 3/8 D X 1/16 WALL TYGON

2 9203 EVAPORATOR ASSEMBLY, ICE-BANK

3 9225 TANK FOAMED, ICE-BANK

4 9701 COIL, WATER COOLING HEAT EXCHANGER

5 9411 SCREW, 8-32 X 3/8 TAPTITE II SS BLACK

6 9500 MOTOR AGITATOR 220V 50Hz

9531 MOTOR AGITATOR 115V/60Hz

7 9818 HOUSING, WATER PUMP

8 9819 CLOSURE, WATER PUMP

9 9817 IMPELLER

10 9127 P/N COTTER, .062 DA X 1"

11 9131 PROPELLOR

12 9404 WASHER, 1.25 OD X .310 ID X .120 THK NYLON

13 9318 BRKT, SPACER WATER LINE

14 9327 STRIP, COIL RETAINING

Crathco® Post Mix Beverage Page 21

Page 22

UPPER CABINET EXPLODED VIEW

ITEM P/N DESCRIPTION

1 9505 FAN, COOLING 20-27 VDC

2 9718 COIL, CABINET COOLING

3 9813 SHROUD, CABINET COOLING

4 9137 SCREW, 8-32 X 3/8 TAPTITE II SS BLACK

5 9519 HARNESS, COOLING FAN EXTENSION

6 9138 SCREW, #8 X 1 1/2 PH PN HD ZINC PL

7 9109 TUBING, 3/8 ID X 1/16 WALL TYGON

8 9140 SCREW, 8-32 X 1/2 PH TR HD TY PE F 410 SS

9 9217 CABINET COOLING SYSTEM

10 9313 BRACKET, RETAINER

11 9815 BUSHING

12 9411 SCREW, #8 X 1/2 HEX HD SELF DRILL

Page 22 Crathco® Post Mix Beverage Dispensers

Page 23

MERCHANDISER EXPLODED VIEW

ITEM P/N DESCRIPTION ITEM P/N DESCRIPTION

1 9128 BEARING, HINGE 9 9528 STARTER

2 9167 KEYED DOOR LOCK 10 9529 HARNESS, LIGHT KIT (NOT SHOWN)

3 9173 FEATHER FASTNER-FASTEX, TRUSSHEAD 11 9800 GASKET DOOR, PVC

4 9323 PANEL, GASKET RETAINING 12 9807 MERCHANDISER, DOOR

5 9511 HARNESS, DAISY JUMPER (NOT SHOWN) 13 9809 COVER PLEXI, GRAPHIC

6 9524 LAMP, F8T5 FLUORESCENT 14 9821 GRAPHIC

7 9525 HOLDER, MINI-BI PIN 15 9411 SCREW, #8 X 1/2 HEX HD SELF DRILL ZINC

8 9527 SWITCH, DISPENSING

ACCESSORY KIT EXPLODED VIEW

ITEM P/N DESCRIPTION

16 9170 MANUAL (NOT SHOWN) FRENCH

9408 MANUAL (NOT SHOWN) ENGLISH

17 9211 PICK UP TUBE ASSEMBLY, SYRUP

18 9812 HOLDER, DUAL PICK UP TUBE

19 9106 PICK UP TUBE CONCENTRATE

20 9326 BRACKET, PICK-UP TUBE

21 0069 SCREW, 8-32 X 1/2 PH TR HD TYPE F 410 SS

22 9216 PICK UP TUBE ASSEMBLY, JUICE

23 9325 GRILL, DRIP PAN

24 9192 LEG, 2 1/2" CHROME

25 9808 DRIP TRAY

Crathco® Post Mix Beverage Page 23

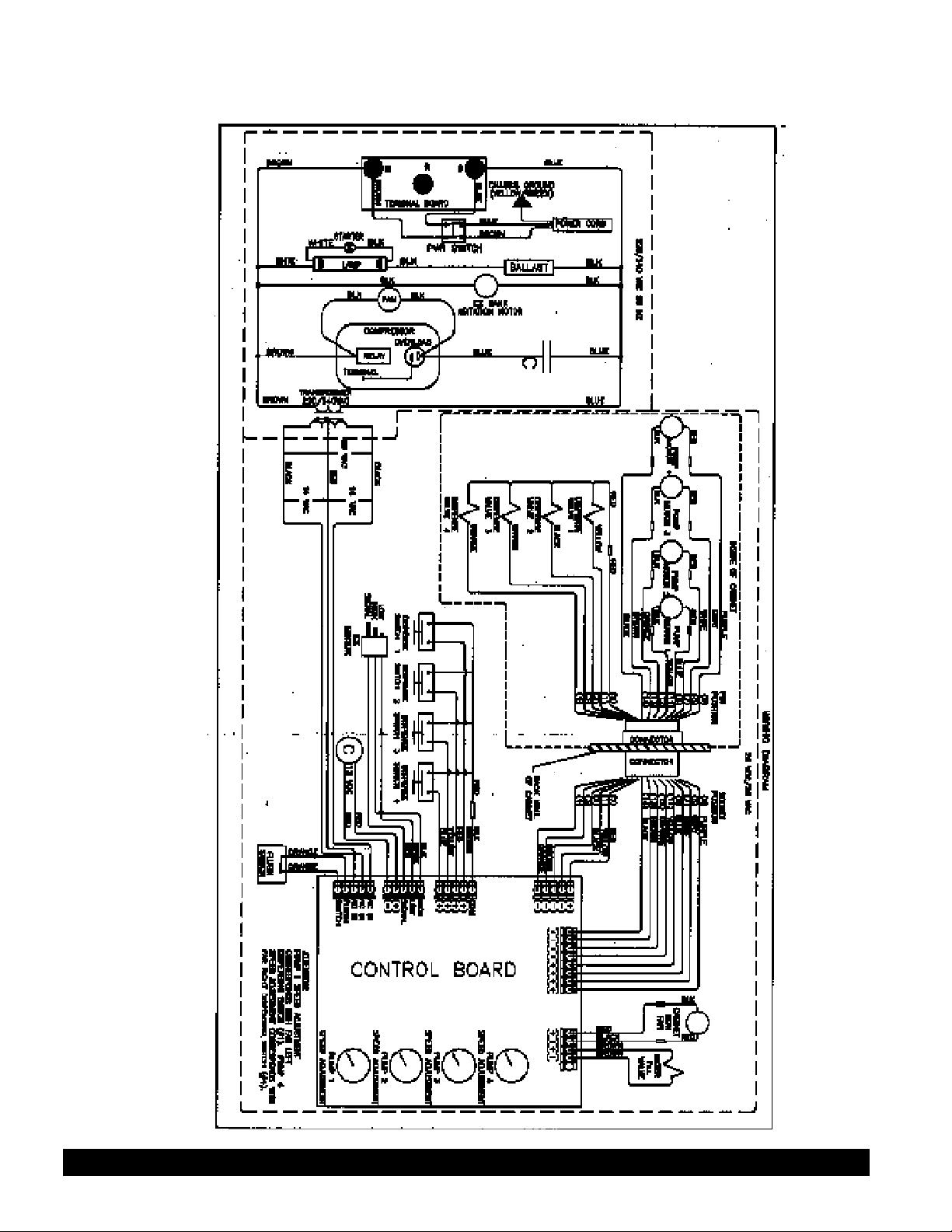

Page 24

Page 24 Crathco® Post Mix Beverage Dispensers

Page 25

Crathco® Post Mix Beverage Page 25

Page 26

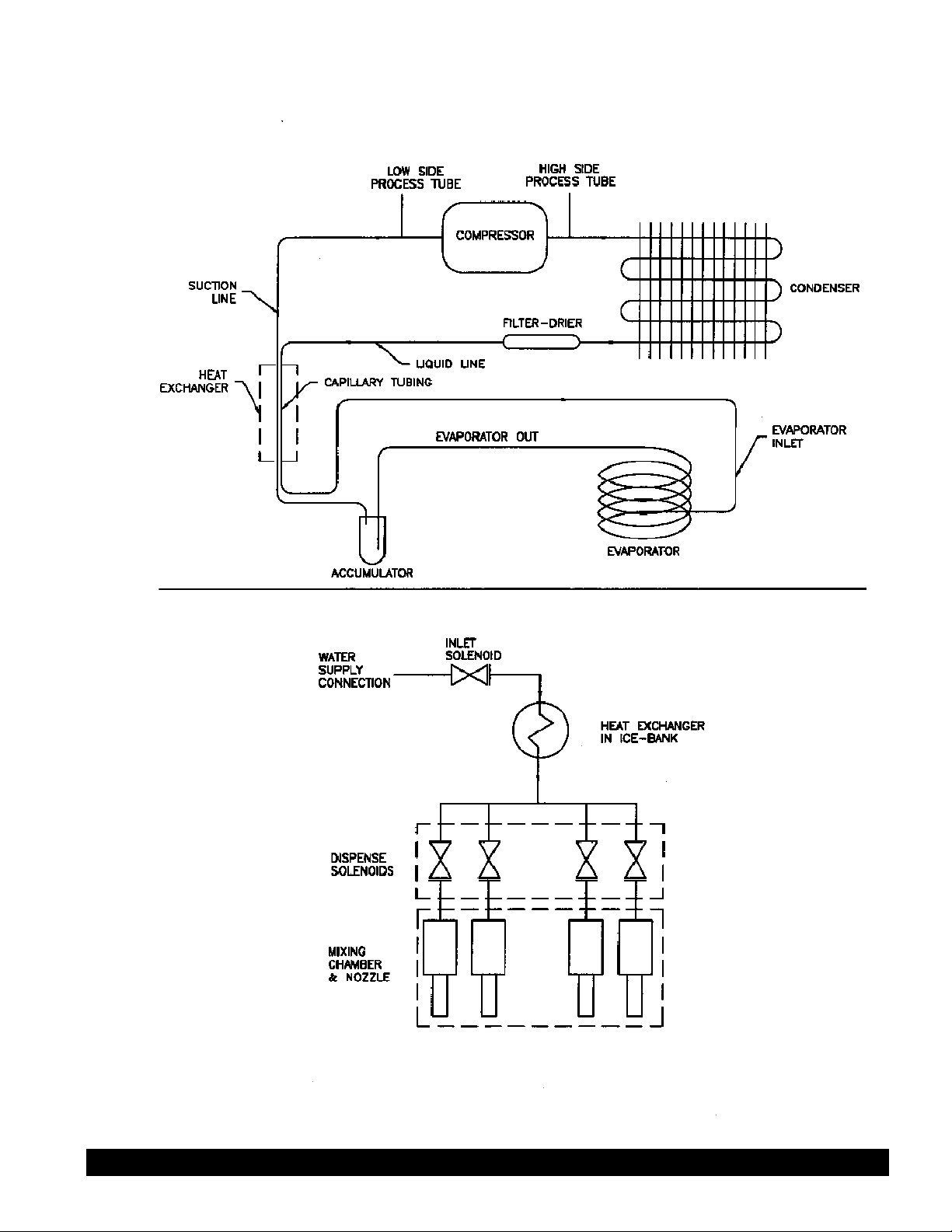

REFRIGERATION DIAGRAM

PLUMBING DIAGRAM

Page 26 Crathco® Post Mix Beverage Dispensers

Loading...

Loading...