Page 1

P200E Shuttle & RAPS200E

Airpot/Shuttle Brewer Series

Operation and Instruction Manual

Installation

WARNING: ELECTRIC SHOCK HAZARD!

INSTALLATION OF THIS APPLIANCE SHOULD BE PERFORMED BY

QUALIFIED SERVICE PERSONNEL ONLY. IMPROPER

INSTALLATION COULD RESULT IN ELECTROCUTION.

See rough-in drawings in this manual for dimensions and locations of

electric and water input.

Set-Up/Position

1) Remove the brewer from the packing material and attach its legs.

2) Position the brewer on a strong, stable table or counter. Check

the level front to back and side to side. Adjust the legs to the

correct level.

IMPORTANT:

THE PERSON INSTALLING THIS APPLIANCE IS RESPONSIBLE

FOR ENSURING THAT ELECTRIC AND WATER CONNECTIONS

MEET THE REQUIREMENTS OF THE NATIONAL ELECTRIC

CODE, NATIONAL PLUMBING CODE, AND ANY LOCAL

ORDINANCES.

Water Hook-up

1) Water inlet (supply) fitting is located at rear of unit.

2) Use 1/4" copper or flexible water line to prevent strain. Do not use low temperature plastic tubing. The connection

is 1/4" flare.

3) Water line pressure must be from 30 to 70 psi.

4) Hot (up to 160F) or cold water may be used. Hot water offers faster recovery between brews, (Use cold water only

if in-line water filters are implemented before the brewer).

5) Install a shut-off valve near the brewer.

6) Installing a filtering system can improve the taste of brewed coffee and extend the life of the brewer. If your water

has high calcium (lime), chlorine, or iron content, this is especially important. The filter should be the lime inhibiting

type if cold water is used. Contact our Customer Service Department to select the filter for your conditions.

© Grindmaster Corporation, 1996

Printed in the U.S.A.

1004 FORM # AM-308-06

Part # A090-085

Prior authorization must be obtained from

Grindmaster for all warranty claims.

Table of Contents

Installation and Start-up ......................................1-2

Operation ............................................................3

Adjustments ..........................................................4-5

Cleaning ..........................................................5-6

Service ............................................................7

Troubleshooting

Filling Problems .................................... 8

Heating Problems ................................. 9

Brewing Problems ................................ 10

Exploded View for P200-E ....................................11

Exploded View for P200 (G version)......................12

Exploded View for RAPS200-E..............................13

Exploded View for RAPS200 (G version) ..............14

Rough-In Drawing for P200-E................................15

Rough-In Drawing for RAPS200-E ........................

16

Wiring Diagram for P200E/RAPS200-E ..........17

Grindmaster Corporation™

4003 Collins Lane

Louisville, KY 40245 USA

(502) 425-4776 (800) 695-4500

(800) 568-5715 (Technical Service Only)

FAX (502) 425-4664

www.grindmaster.com

!

Page 2

Page 3

Page 2

P200/RAPS200 Brewers

Installation (con't.)

Electric hook-up

1) The electric ratings for your brewer are printed on its nameplate. Typical electric ratings

are: 120V, 1.65 kW, 15 Amp, 1 phase.

2) The brewer should be connected to its own circuit with a fused disconnect switch or a

circuit breaker near the brewer.

3) Electrical connection is made with power cord with NEMA 5-15P grounded plug (supplied) to

120V, 15 Amp wall socket. Certain models may be equipped with a NEMA 5-20P cordset and

plug.

WARNING

ELECTROCUTION HAZARD

NEVER USE THE GROUND CONDUCTOR AS A NEUTRAL. DO NOT USE GROUND

ELIMINATING ADAPTORS. UNIT MUST BE PROPERLY GROUNDED.

Start-up

Connect water line and turn water valve on. Check for leaks. Plug in power cord (supplied) to 120,

15 Amp (20 Amp for some models, see rating plate on unit) wall outlet.

Once the brewer is full of water, it will take 15 to 35 minutes to heat. The “READY” LAMP will light when

water has reached the set temperature.

After “READY” LAMP is lit, portion volume may now be checked. Insert the brew basket and place

Shuttle/Airpot under the brew basket. Brew at least one batch at half and full volume to check for

proper volumes. Remember that when brewing coffee, the level will be lower. The water must be hot

to check for proper levels.

If adjustments are needed, see the Adjustments section of this manual.

WARNING: HOT LIQUID HAZARD

DO NOT TRANSPORT BREWER WITHOUT DRAINING WATER TANK FIRST.

!

!

WARNING

ELECTROCUTION HAZARD

Page 4

Page 3

Operation

CAUTION: HOT LIQUID HAZARD

WATER USED FOR BREWING COFFEE IS VERY HOT. USE CAUTION

WHEN BREWING, POURING, OR TRANSPORTING COFFEE. ACCIDENTAL

SPILLS MAY RESULT IN SEVERE BURNS.

1) Place an empty, warm Shuttle under the brew head. Turn on the warmer once a Shuttle is

in place, or place an empty 1.9L to 3.0L airpot under the brewing head. Choose one size airpot

to minimize risk of brewing too large of volume in smaller container.

2) Remove the brew basket and line it with a paper filter. Paper size is 13 x 5 (Filter # BB1.5WP).

3) Place ground coffee in the filter basket. Your coffee supplier can help you select the right

amount of coffee and grind. Coffee brewing experts recommend between 6.5 and 8 ounces

of coffee per gallon of water for most applications. A full Shuttle is 1.5 gallons.

4) Slide the basket into the brewer, making sure the spout lines up with the top of the Shuttle or

Airpot.

5) Check that the correct batch size is selected. Check the “READY” light

. If lit, press

START.

6) Brew time is about 5 minutes for Shuttles and 4 minutes for 3.0L Airpots. After the brew, allow

the coffee to drip for 1 to 2 minutes.

CAUTION: HOT LIQUID HAZARD

COFFEE BASKET CONTAINS VERY HOT WATER UNTIL THE DRIP IS

COMPLETED. EARLY REMOVAL OF A DRIPPING BASKET COULD RESULT IN

BURNS.

7) Dump the grounds from the basket and rinse for the next brew. Coffee is ready to serve.

8) The Shuttle may be placed on remote warming stations. Use caution when moving a

full Shuttle or Airpot.

P200/RAPS200 Brewers

Page 5

Page 4

Adjustments

WARNING: ELECTRIC SHOCK HAZARD

DANGEROUS ELECTRIC VOLTAGES ARE PRESENT NEAR ADJUSTABLE

COMPONENTS. ALL ADJUSTMENTS SHOULD BE PERFORMED BY

QUALIFIED SERVICE PERSONNEL ONLY.

All adjustable components are located under the top cover. To access these parts:

1) Unplug the brewer.

2) Remove the screw fastening the top cover. Remove the top cover.

Brew Volume Adjustment

The brew volume of the P200/RAPS200 brewer is controlled by its timer. The batch size is directly

proportional to the timer setting. The timer adjustment is located under the top cover.

There will always be a small variation (+/- 5%) in level from batch to batch.

Before making the timer adjustment, do the following:

1) Brew a batch of water to determine where the level falls. Using a stop watch, determine

the current brew time. Measure the volume of water.

2) To determine the desired time setting, use the following formula:

desired brew volume

desired brew time = _________________ X current brew time

current brew volume

Timer Adjustment

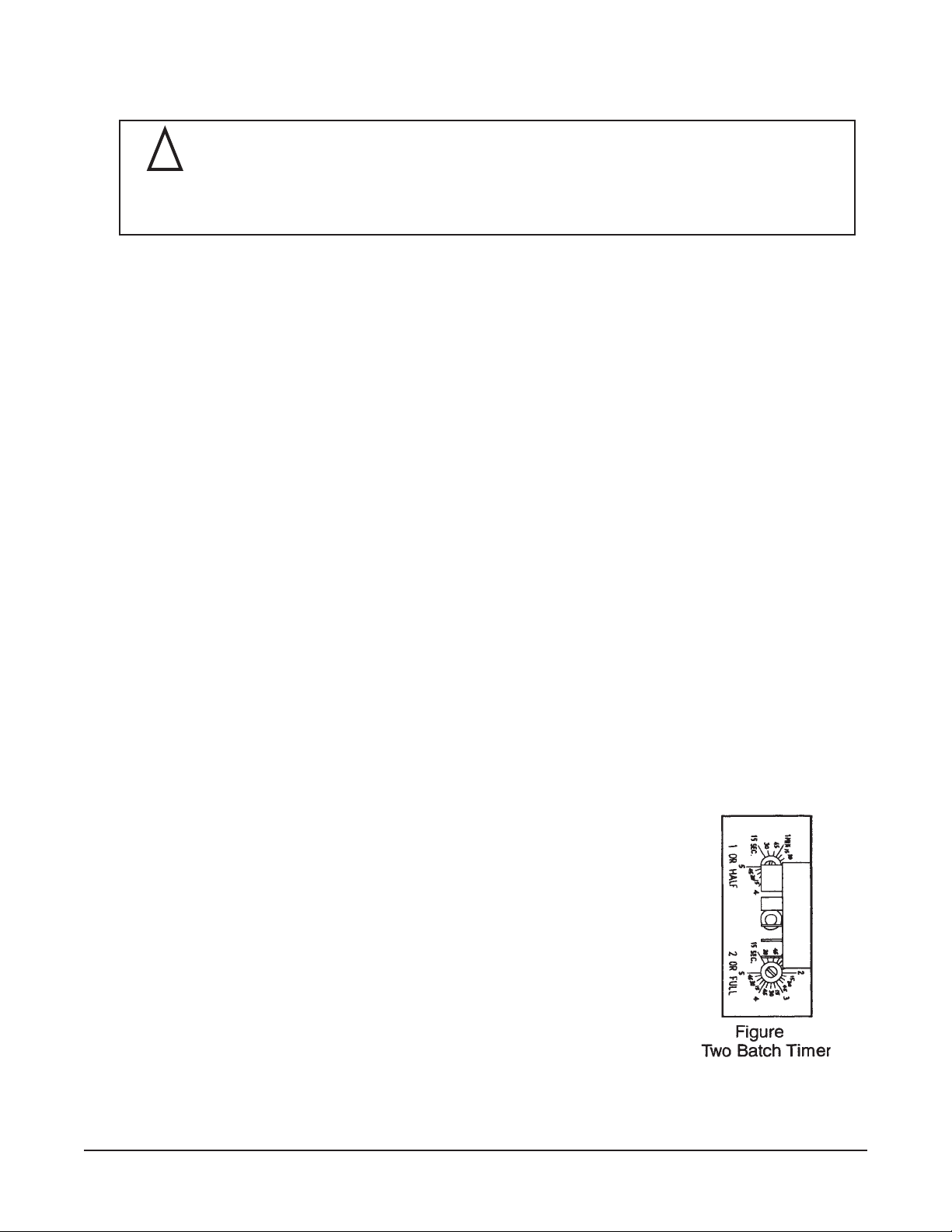

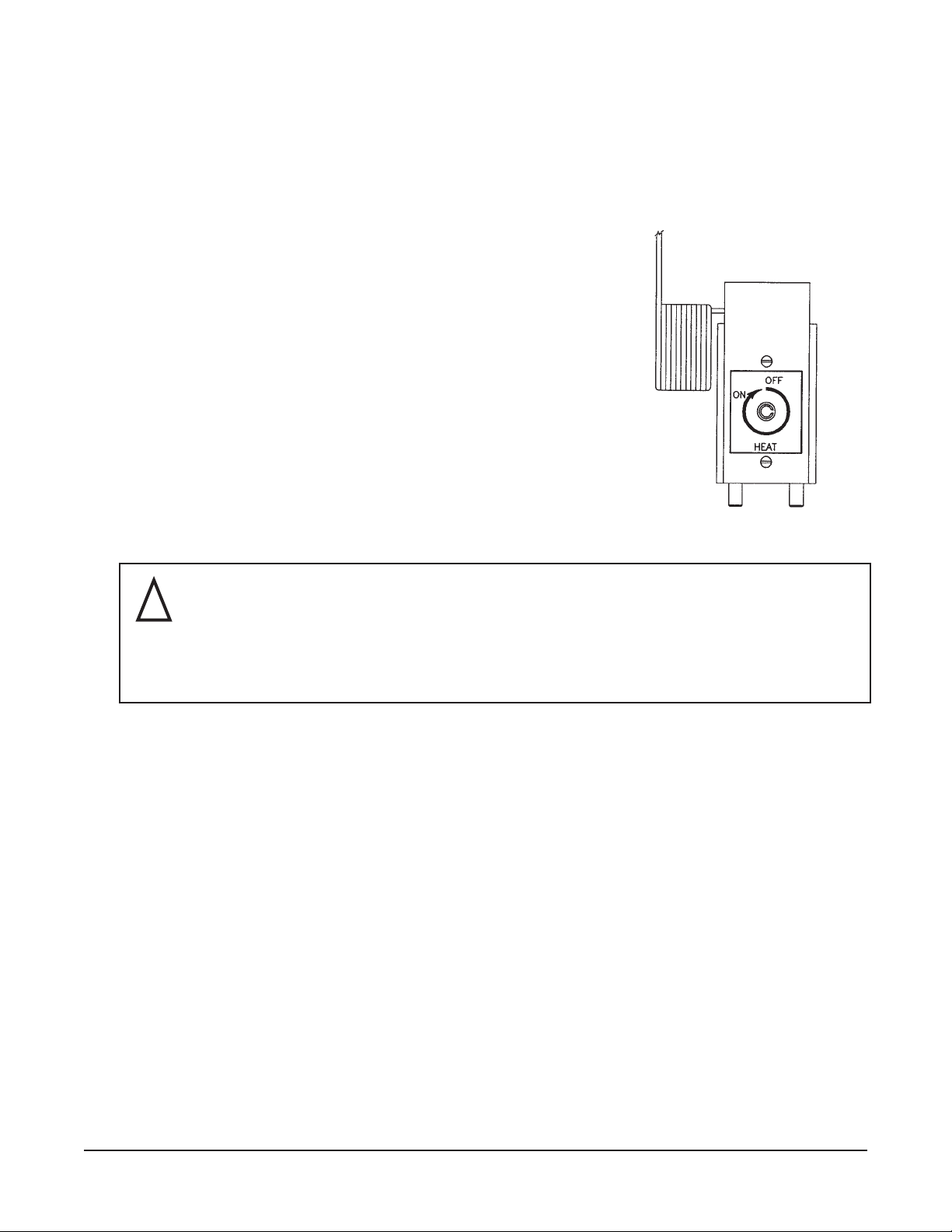

Two Batch Timer with Knob Adjustment, See Figure A:

1) This timer is adjustable from 15 seconds to 5 minutes. Locate the

adjustment knobs under the top cover.

2) Set this timer by adjusting the knob. The batch selector switch

picks the adjustment potentiometer which the timer will see.

P200/RAPS200 Brewers

A

!

Page 6

Page 5

Thermostat Adjustment

The thermostat controls the water temperature in the tank. Factory setting is 195 degrees F. This

is the ideal temperature for brewing coffee. Water should never boil in the tank. If water is

boiling in the tank, adjust the temperature appropriately.

Standard Mechanical Thermostat:

1) Shut off power and unplug brewer.

2) Open cover, locate thermostat mounted on tank. (Refer to Figure B).

3) Turn the shaft counter clockwise to increase temperature,

clockwise to decrease temperature.

4) If the maximum temperature adjustment needs to be increased,

insert a small flat screwdriver into the shaft.Turn the calibration

screw counter clockwise to increase the maximum temperature.

5) Reinstall top cover with screw then plug unit in, return to use.

Figure B

P200/RAPS200 Brewers

Cleaning

WARNING: BURN HAZARD

HOT LIQUIDS AND SURFACES ARE PRESENT IN THIS EQUIPMENT. TO

AVOID BURNS, USE CAUTION WHEN CLEANING. RINSE HOT PARTS

WITH COLD WATER BEFORE CLEANING. USE GLOVES OR A HEAVY

CLOTH WHEN REMOVING HOT PARTS FROM BREWER.

After Each Brew:

1) Dispose of grounds and rinse brew basket.

2) Rinse Shuttles and Airpots before reuse.

Every Day:

1) Wash brew basket with warm soapy water.

2) Remove spray head located above brew basket, using gloves or a heavy towel. Wash off coffee

oils and clean any plugged holes.

3) Clean Shuttles and Airpots with warm soapy water and a brush or towel.

4) Wipe exterior of brewer with a damp cloth. Do not use abrasives which will scratch surface.

5) If the Shuttle is to be left on the warmer all night, fill it with water to avoid coffee oil burn-in.

!

Page 7

Page 6

Weekly or Bi-Weekly, Depending on Use (P200 Only):

1) Fill Shuttle with one gallon of hot water.

2) Pour the recommended concentration of urn cleaner into the Shuttle liners (Excessive amounts

of cleaner will attack the stainless steel).

Urn cleaners that have been used successfully:

DIP-IT, manufactured by Economics Laboratories, Inc.

4 Corporate Park Drive

White Plains, NY 10604

OXYLITE, manufactured by Avril, Inc., Syndet Division

601 N. Third Street

Reading, PA 19601

3) Scrub the liner interior with a plastic bristle brush.

4) Remove the knurled nut at the top of the gauge glass and clean the glass with a small

bottle brush.

5) Pour out the contents of the Shuttle.

6) Remove the handle assembly of the Shuttle faucet by unscrewing the plastic bonnet.

7) Gently wash the faucet seat cup with a soft cloth and warm soapy water.

8) Wash the faucet shank with a bottle brush.

9) Clean the warmer and bottom of Shuttle surfaces. These surfaces must be clean for

proper heat transfer.

10) Polish the exterior of the brewer with stainless steel cleaner. Use the appropriate

cleaner for brass, copper, or vinyl if these optional finishes are provided.

P200/RAPS200 Brewers

Page 8

Page 7

P200/RAPS200 Brewers

To Drain The Water Tank

CAUTION: HOT LIQUIDS / BURN HAZARD

WATER IN TANK IS VERY HOT. USE CAUTION WHEN DRAINING TANK.

ACCIDENTAL SPILLS MAY RESULT IN SEVERE BURNS.

1) Shut off power to brewer.

2) Remove the top panel.

3) Remove the warmer shelf.

4) Pinch or clamp the tube from fill valve to tank (near tank entry on bottom).

5) Disconnect rubber tube from outlet barb on fill valve.

6) Pull tube through the brewer body so that it exits at the bottom.

7) Place tube over drain and release clamp.

To Remove The Heater

1) Disconnect power and remove top cover of brewer.

2) Disconnect wire leads to heater.

3) Remove tank cover by loosening retaining nuts. Remove heater from cover.

4) Replace heater with sealing washers in same configuration. When tightening nuts, hold

element so it does not twist.

5) Replace tank cover.

6) Replace heater wires. Be sure all electrical connections are secure.

7) Replace top cover of brewer and connect power cord to outlet.

Service

The rest of this manual contains information to help the service person who is working on this

equipment. This section has information on performing common service tasks.

Page 9

Page 8

Troubleshooting: Filling, Heating, and Brewing

Overfilling

watertank even

when power is off.

Fill valve not sealing

properly.

Fill valve installed

backwards.

Water entering tank

continuously, usually

slowly.

Disassemble valve and clean out

dirt. Valve may need new plunger

if seal is worn.

Problem Possible Cause Service Check Remedy

Filling Problems

The filling system consists of the following components:

• Liquid Level Control, located behind the brewer front panel.

• Liquid Level Probes, located on the tank top, secured by wing nut, under the top cover

• Fill Valve, located behind the front panel.

P200/RAPS200 Brewers

Tank does not refill.

No power at

equipment.

No water at

equipment.

Water strainer

clogged.

No power to level

control.

Level control faulty.

Electrodes faulty.

Fill valve faulty.

Overfilling

watertank only

when power is on.

High electrode coated

with lime or faulty.

Missing or faulty

connection of C

terminal on level

control to metal

enclosure.

Fill valve connected to

heat terminal on level

control.

Liquid level control is

faulty.

Jumper HI terminal on

level control to metal

enclosure stops fill.

Jumper from C

terminal to metal body

stops fill.

Check connections.

Jumper from HI to C

or metal enclosure

does not stop fill.

Remove electrode assembly and

clean both probes. If this does not

work, replace assembly.

Make secure connection of C to

metal body.

Connect black lead for valve to

FILL on level control.

Replace level control.

Nothing operates.

Crack water inlet

fitting.

Water pressure

before strainer but

not after.

Tank fills only when

probe wire is

disconnected from HI

terminal on level

control.

120V is across FILL

and N on level

control, but no fill.

Check main switch or circuit

breaker, brewer's circuit breaker or

power switch if provided.

Make sure all water supply line

valves are open.

Remove and clean or replace

strainer's mesh.

If no voltage, check for loose or

broken wires.

If no 120V at FILL terminal, replace

level control.

Replace electrodes. If no remedy,

check for improper wiring or level

probe tip touching metal.

Disassemble valve and clean or

replace plunger if frozen. If plunger

is OK, coil may need replacement.

If arrow on valve is pointing toward

water inlet, remove valve and install

correctly.

Look for direction of

arrow on valve body.

Check for 120V AC

across H and N

terminals on level

control

Disconnect probe

wire to HI terminal on

level control. Check

for 120V at FILL

terminal.

Page 10

Page 9

Troubleshooting: Filling, Heating, and Brewing (con’t.)

Tank does not

heat.

Thermostat faulty or

out of calibration.

Heater faulty.

Make sure thermostat

is turned on.

Check resistance

across elements with

wires disconnected.

Recalibrate thermostat. If no remedy or thermostat does not cycle,

replace thermostat.

If resistance is much different than 7

to 10 ohms, replace heater.

Problem Possible Cause Service Check Remedy

Heating Problems

The heating system consists of the following components:

• Thermostat, located on the tank or on the front of top control panel under top cover.

• Heating Element, located on top of tank under top cover.

Recovery time is very

long.

Heater faulty. See above. See above.

P200/RAPS200 Brewers

If you still need help, call our Service Department at (800) 568-5715, press 2 (Monday through

Friday, 8 a.m. - 6 p.m. EST) or an authorized service center in your area. Please have the model

and serial numbers ready so that accurate information can be given.

Prior authorization must be obtained from Grindmaster Technical Services Department for all

warranty claims.

Page 11

Page 10

Troubleshooting: Filling, Heating, and Brewing (con’t.)

Brewing Problems

The brewing system consists of the following components:

• Start and Stop switches, located on the front control panel.

• Brew Timer, located in the top control section under the top cover.

Brew volume too

large or too small.

Timer out of adjustment.

Pressure not adequate at brewer.

Spray head clogged.

Timer faulty.

Compare timer setting

to factory setting

chart.

Check water flow before

removing strainer.

Visual

Check if brew time

matches timer setting

and if timer can be

adjusted.

Adjust timer.

Clean or rinse strainer at fill valve.

Clean all holes.

Replace timer.

Problem Possible Cause Service Check Remedy

Brew volume erratic.

(there is always some

small variation from

batch to batch)

Timer faulty.

Pressure fluctuations

at brewer.

Measure brew time for

inconsistencies.

Check pressure at

brewer inlet.

If time is different from batch to

batch, replace timer.

Plumb water line so its pressure is

not influenced by other appliances.

Brew will not

start.

Tripped circuit

breaker.

Brew valve faulty.

Stop switch faulty.

Start switch faulty.

Timer faulty.

Check to see if circuit

breaker tripped or

popped out.

Check 120V across

brew valve.

Check for continuity

across stop switch

when not pressed.

Check 120V between

S.S. and N on timer

when start is pressed.

Check 120V between H

and N on timer. If OK,

check for 120V between

BREW and N on timer

after pressing start.

Reset or replace breaker.

If 120V is across brew valve, but brew

valve doesn't open, replace coil or valve.

If no continuity, replace switch.

If start switch does not provide 120V

start signal, replace switch.

If no 120V BREW output from timer,

replace timer.

Spray head will not

stop dripping water.

(spray heads normally

drip slightly after

brew)

Boiling tank.

Limed up Fill valve.

If drip is from right side,

check for water from

overflow outlet at top of

tank.

Visual check of valve.

Turn down thermostat. If that doesn't

cure, check for faulty thermostat or

heater relay.

Clean valve. Valve seal or entire

valve may need replacement.

P200/RAPS200 Brewers

Page 12

Page 11

P200/RAPS200 Brewers

Exploded View for the P200-E

ITEM

DESCRIPTION PART

#

Page 13

Page 12

P200/RAPS200 Brewers

Exploded View for the P200 (G version only)

ITEM

DESCRIPTION PART #

Page 14

Page 13

P200/RAPS200 Brewers

Exploded View for the RAPS200-E

ITEM

DESCRIPTION PART #

Page 15

Page 14

P200/RAPS200 Brewers

Exploded View for the RAPS200 (G version only)

ITEM

DESCRIPTION PART #

Page 16

Page 15

P200/RAPS200 Brewers

Rough-In Drawing for the P200-E

Page 17

Page 16

P200/RAPS200 Brewers

Rough-In Drawing for the RAPS200-E

Page 18

Page 17

P200/RAPS200 Brewers

Wiring Diagram for P200-E/RAPS200-E

Page 19

Page 20

WARRANTY

for P200/RAPS200 Series

GENERAL WARRANTY INFORMATION

Grindmaster maintains the highest standard of quality control in the manufacturing of American Metal Ware

products. We use the finest components and materials, and employ quality engineering standards and

tests. The P200E Brewer is warranted for a period of one year from date of shipment. This warranty will

include parts and labor but will not cover transportation and shipping charges and will be limited to equipment sold to commercial purchasers and installed in the continental U.S.A., Hawaii, Alaska and Canada.

EXCEPTIONS

Coverage is not included for labor needed or caused by:

• Adjustments of temperature or flow rates or timers. These adjustments are covered in

the technical manual provided and subject to user preferences.

• This warranty does not cover maintenance consumable parts such as o-rings, seat cups,

washers. These are subject to NORMAL wear or everyday usage and are a responsibility

of the user.

• Accident

• Improper installation

• Neglect or abuse

• Excessive lime/mineral content of water used

• Cleaning of any category. Cleaning is a user's responsibility.

• All warranties are null and void if muriatic or any other form of hydrochloric acid is used

for cleaning or deliming our equipment.

NOTE: THIS WARRANTY SUPERSEDES ANY OTHER WARRANTY. ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING THE WARRANTIES OR MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE OR USE, ARE HEREBY EXCLUDED AND DISCLAIMED.

HOW TO OBTAIN WARRANTY SERVICES

Call Grindmaster Service Department toll free at 1-800-695-4500 for technical services or write to:

Grindmaster Factory Service Center, P.O. Box 35020, Louisville, KY 40232. In order to receive warranty

service, you must provide the serial number of the machine requiring service along with a description of

the problem. Service will be arranged through one of our authorized local service centers or our factory

service center. Transportation is the user's responsibility. Should it become necessary to transport your

machine to a service center, make sure it is properly packaged to avoid in-transit damage, which is not

covered by this warranty.

No field, outside or service station work is covered by this warranty without prior authorization

by Grindmaster's Service Dept.

Printed in the U.S.A.

© Grindmaster Corporation, 1996

EFFECTIVE MARCH 1, 1996

Grindmaster Corporation™

4003 Collins Lane

Louisville, KY 40245 USA

(800) 695-4500 • (502) 425-4776

FAX: (502) 425-4664

www.grindmaster.com

Loading...

Loading...