0600-0039-0000 Rev D Made in the U.S.A.

March 2007 $10.00

Supersedes: 0600-0039-0000 Rev C

User’s Manual

1241 Bundy Boulevard, P.O. Box 5580, Winona, Minnesota USA 55987-5580

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507 http://www.watlow.com

Registered Company

Winona, Minnesota USA

ISO 9001

TOTAL

3 Year Warranty

CUSTOMER

SATISFACTION

Power Series

Microprocessor-Based

SCR Power Controller

U.S. English

Safety Information in this Manual

Note, caution and warning symbols appear throughout this book to draw your

attention to important operational and safety information.

A “NOTE” marks a short message to alert you to an important detail.

A “CAUTION” safety alert appears with information that is important for

protecting your equipment and performance.

A “WARNING” safety alert appears with information that is important for

protecting you, others and equipment from damage. Pay very close attention

to all warnings that apply to your application.

The ç symbol (an exclamation point in a triangle) precedes a general

CAUTION or WARNING statement.

The Ó symbol (a lightning bolt in a lightning bolt in a triangle) precedes an

electric shock hazard CAUTION or WARNING safety statement.

Technical Assistance

If you encounter a problem with your Watlow controller, see the Troubleshooting Table in the Appendix and review all of your configuration

information to verify that your selections are consistent with your application:

inputs; outputs; alarms; limits; etc. If the problem persists after checking the

above, you can get technical assistance from your local Watlow representative,

or by dialing +1 (507) 454-5300, 7:00 a.m. to 7:00 p.m. Central Standard Time.

An applications engineer will discuss your application with you.

Please have the following information available when you call:

• Complete model number • All configuration information

• User’s Manual • Diagnostic Menu readings

Warranty and return information are on the back cover of this

manual.

Your Comments

Your comments or suggestions on this manual are welcome. Please send them

to the Technical Literature Team, Watlow Winona, 1241 Bundy Boulevard,

P.O. Box 5580, Winona, Minnesota, 55987-5580 U.S.; Telephone: +1 (507) 454-

5300; fax: +1 (507) 452-4507. The Power Series User’s Manual is copyrighted

by Watlow Winona, Inc., © 2007, with all rights reserved. (2211)

ç

Safety Alert

CAUTION or

WARNING

∫

Electrical

Shock Hazard

CAUTION or

WARNING

Chapter 1: Overview . . . . . . . . . . . . . . . . .1.1

Chapter 2: Installation . . . . . . . . . . . . . . . .2.1

Dimensions . . . . . . . . . . . . . . . . . . . .2.2

Mounting the Power Series . . . . . . . . .2.2

Enclosure Guidelines . . . . . . . . . . . . .2.3

Harsh Environments . . . . . . . . . . . . . .2.3

Removing the Power Series . . . . . . . .2.4

Maintaining the Power Series . . . . . . .2.4

Output Rating Curves . . . . . . . . . . . . .2.5

Chapter 3: Wiring . . . . . . . . . . . . . . . . . . .3.1

Torque Guidelines . . . . . . . . . . . . . . .3.1

Input Wiring . . . . . . . . . . . . . . . . . . . .3.2

Line Power/Output Wiring . . . . . . . . . .3.4

Wiring Example . . . . . . . . . . . . . . . . .3.6

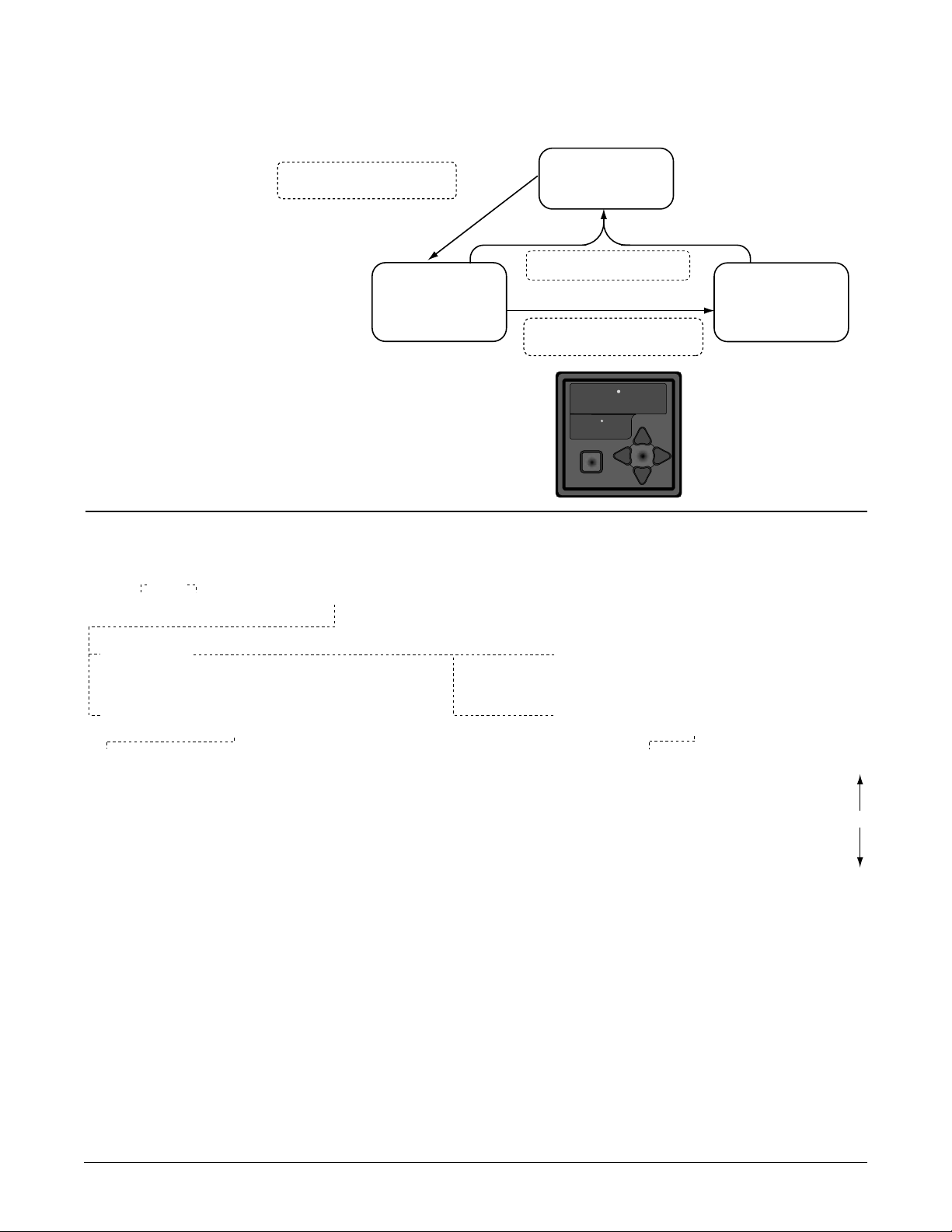

Chapter 4: Navigation and Software . . . . .4.1

Keys and Displays . . . . . . . . . . . . . . .4.1

Navigation . . . . . . . . . . . . . . . . . . . . .4.2

Software Map . . . . . . . . . . . . . . . . . . .4.3

Chapter 5: Control Methods and Features .5.1

Zero Cross . . . . . . . . . . . . . . . . . . . . .5.1

Phase Angle . . . . . . . . . . . . . . . . . . . .5.2

Other Features . . . . . . . . . . . . . . . . . .5.6

Input . . . . . . . . . . . . . . . . . . . . . . . . .5.6

Alarms . . . . . . . . . . . . . . . . . . . . . . . .5.7

Communications . . . . . . . . . . . . . . . .5.8

Retransmit . . . . . . . . . . . . . . . . . . . . .5.9

Fast Start Guide . . . . . . . . . . . . . . . . .5.10

Chapter 6: Parameters . . . . . . . . . . . . . . 6.1

Display Loop . . . . . . . . . . . . . . . . . . .6.1

Setup Page . . . . . . . . . . . . . . . . . . . .6.5

Factory Page . . . . . . . . . . . . . . . . . . .6.14

Factory Mode . . . . . . . . . . . . . . . . . . .6.20

Appendix . . . . . . . . . . . . . . . . . . . . . . . . .A.1

Troubleshooting . . . . . . . . . . . . . . . .A.2

Troubleshooting Alarms and Errors . .A.4

Checking and Replacing Fuses . . . . .A.6

Power Series Backup . . . . . . . . . . . . .A.7

Modbus™ Register Numbers . . . . . . .A.8

Product Specifications . . . . . . . . . . . .A.9

Ordering Information . . . . . . . . . . . . .A.10

Index . . . . . . . . . . . . . . . . . . . . . . . . .A.11

Prompt Index . . . . . . . . . . . . . . . . . . .A.13

CE Declaration of Conformity . . . . . . .A.14

Warranty and Returns Policy . . .back cover

T

Power Series

Table of Contents

Table of Contents Watlow Power Series ■ i

ii ■ Watlow Power Series Table of Contents

1

Overview, Chapter 1 Watlow Power Series ■ 1.1

Chapter One

Overview

Introduction

The Power Series is a state-of-the-art microprocessor-based Silicon Controlled Rectifier

(SCR) power controller intended for controlling industrial heaters. This product is based on

one package with several configurations that include single phase, three phase, and single

phase-multizone capabilities. Each package configuration has a specific current rating

depending on the number of phases switched. The switching capabilities include 65 to 250A

rms at 50°C from 24 to 600V~ depending on the configuration or model number selected. See

page 1.2 for additional information on the Power Series configuration options.

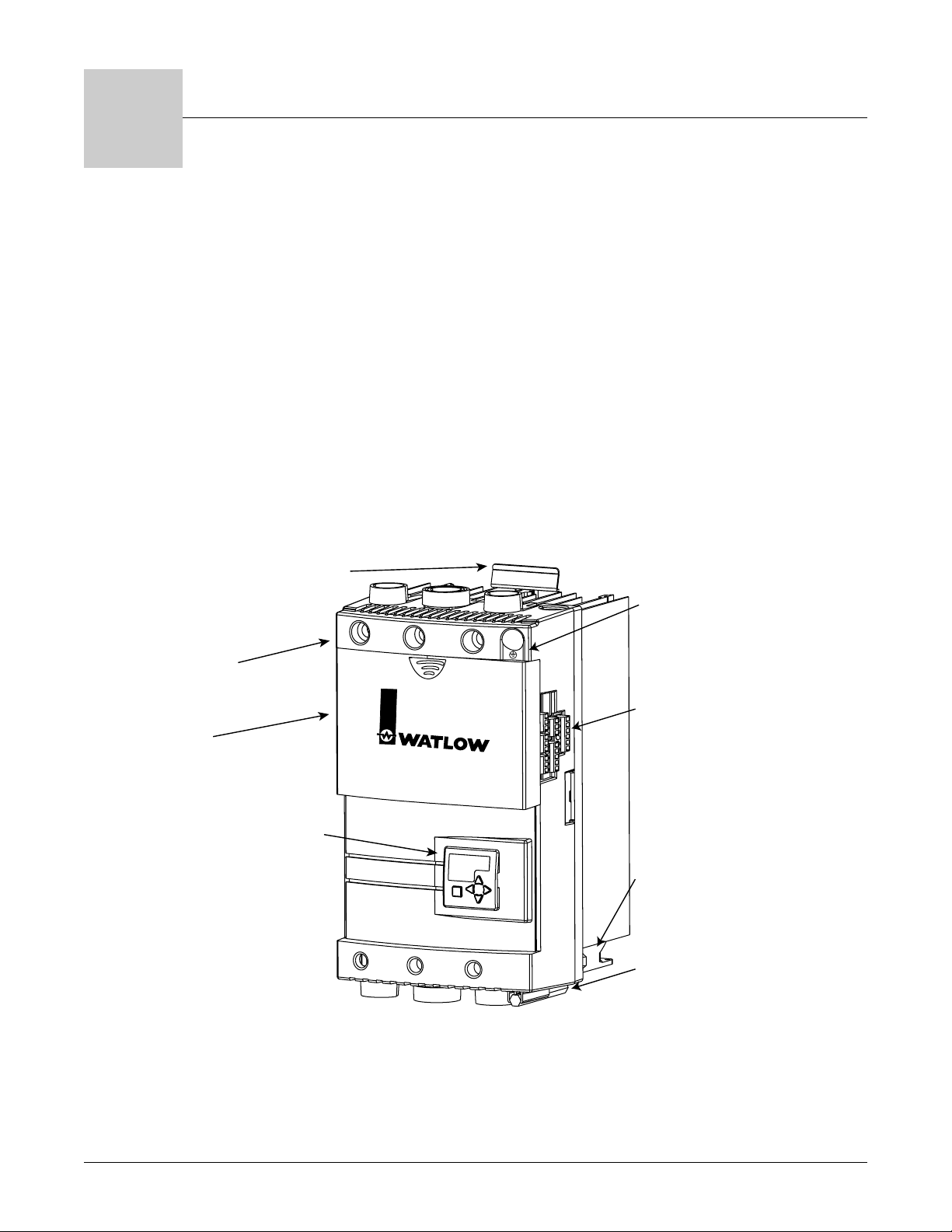

Figure 1.1 — Power Series features.

Removable Mounting Plate

Power Series snaps on a premounted, removable plate.

Terminal Cover

Electrically touch-safe

package.

Fuse Cover

Slides up and down for fuse

maintenance and covers the

high voltage components.

Digital Programmer/Display

For controller configuration,

setup, and monitoring features.

1

2

Power Series

Solid State Power Control

Ground Lug

Built in, designed for easy

3

ground connections.

I/O Port

Input, retransmit

output, communications,

and alarms.

On-Board Fan

A fan is integrated into

the package on forced

air cooled models to

eliminate separate power

connection for fan.

4

5

6

Allen Wrench

Used to torque terminals

1 to 6 and ground lug.

Single Phase

This configuration can be purchased with any or all the features available on the Power

Series. The only limitations are the features selected by the customer upon purchase. It has

the highest current rating of all configurations since it is only switching one phase of the ac

line. It is intended for resistive heaters, but can also be used on transformer connected loads

in the phase angle firing mode.

Three Phase, Two-Leg Configuration

This configuration is intended for zero cross firing into a stable resistive heater, i.e.,

nichrome element. Typically, a three phase, three-wire delta or ungrounded wye/star connected heater is most often used where only two of the three V~ line phases are switched.

The third phase is a direct connection through a bussbar on board the Power Series and is

controlled by the previous two phases. For this reason, a two-leg configuration should not be

used for three phase grounded wye/star connected heaters. (For heaters that are required to

be three phase grounded wye/star connected, see “Three Phase, Three-Leg Configuration”

section below.)

Because this configuration does not allow phase angle firing, it should not be used on

transformer coupled heaters and less stable resistance heaters such as silicon carbide,

molybdenum disilicide, carbon graphite, or tungsten lamp heaters. This may cause

premature heater failure or nuisance fuse blowing.

Heater current monitoring and kVA options are available with a three phase, two-leg configuration via the heater diagnostics option. Phase angle firing, including current limiting and

heater bakeout, is not available.

Three Phase, Three-Leg Configuration

There are two Power Series configurations that include six SCR control. All features are

available in these configurations.

The three-leg version is intended for phase angle firing into a transformer connected load or

direct connection to heating that requires soft start and/or current limiting.

The four-wire configuration is intended for zero cross firing into a four-wire wye connected

nichrome/resistive heater.

Single Phase, Multizone Configuration

This configuration is available in two and three single phase zones. Back-to-back SCRs are

used and all of the features of a single phase unit are available. (Note that there is only one

alarm relay and all zones in the controller must use the same control method.) This configuration is intended for applications with multiple command signals from independent control

zones. The multizone platform offers reduced panel space compared to using multiple single

phase power controllers.

Heater Diagnostics

Heater diagnostics is a key feature of the Power Series SCR power controller. Heater

diagnostics may include all or only some of the features that require heater current

monitoring, depending on the model selected. Heater current monitoring is only available

with heater diagnostics installed on the controller. The features dependent on heater current monitoring are heater bakeout, current limiting, heater current and kVA monitoring,

retransmit, and heater monitoring alarms such as open heater, heater out of tolerance, load

balance, and shorted SCR detection/error. Heater diagnostics must also be installed if you

need phase angle control with current limit.

1.2 ■ Watlow Power Series Overview, Chapter 1

Chapter Two

Installation

Installation, Chapter 2 Watlow Power Series ■ 2.1

2

The following two chapters will explain how to install the Power Series

controller. Watlow power controllers are thoroughly tested before leaving the

factory, so the Power Series controller is ready to install when you receive it.

Chapters 2 and 3 describe the steps required to install the Power Series

controller. Refer to Chapter 2 for mounting information and Chapter 3 for input,

power, and load wiring of the Power Series.

Before beginning installation, read through these chapters to gain an understanding of the entire installation. Consider the installation carefully. Plan the

power, load, and input signal wiring before mounting the Power Series. Also

consider the cabinet space, controller dimensions, wire bending radius, and airflow. Use good wiring practices to minimize electrical noise problems.

∫

WARNING:

To avoid potential electric

shock and other hazards,

all mounting and wiring

for the Power Series must

conform to the National

Electric Code (NEC) and

other locally applicable

codes.

Power Series Wire Bending Radius at Base Current and Ambient

Temperature Rating and Replacement Semiconductor Fuses

Minimum recommended wire sizes are based on the NEC 30°C ambient with not

more than three current carrying conductors in raceway or cable, while also

considering the Power Series 50°C enclosure temperature and semiconductor

fuse rating. Use copper conductors only.

The terminal lug wire range for all Power Series amperages is 350 MCM to 6

AWG. The recommended terminal torque is 180 in.-lbs. (20 Nm.). Refer to page

3.1 for torque guidelines.

NOTE: Ground must be

wired with the same size

wire as line and load

connections to a ground

of sufficient current

carrying capacity.

NOTE: Integral semiconductor fuses do not

qualify as branch circuit

protection.

Power Series

Current (Amps)

Minimum

Recommended Wire

Size (90C) (AWG)

Wire Bending

Radius

mm inches

Semiconductor

Fuse Rating

(Amps)

Watlow Replacement

fuse P/N

Bussmann

Replacement Fuse

P/N

65 6 51 2.0 100 0802-0102-0100 170M1317

80 4 76 3.0 125 0802-0102-0125 170M1318

85 4 76 3.0 125 0802-0102-0125 170M1318

90 4 76 3.0 125 0802-0102-0125 170M1318

100 3 76 3.0 160 0802-0102-0160 170M1319

105 3 76 3.0 160 0802-0102-0160 170M1319

120 2 89 3.5 160 0802-0102-0160 170M1319

125 2 89 3.5 160 0802-0102-0160 170M1319

140 1 114 4.5 200 0802-0102-0200 170M1320

155 1/0 140 5.5 200 0802-0102-0200 170M1320

160 1/0 140 5.5 250 0802-0102-0250 170M1321

165 1/0 140 5.5 250 0802-0102-0250 170M1321

185 2/0 152 6.0 250 0802-0102-0250 170M1321

200 3/0 165 6.5 250 0802-0102-0250 170M1321

250 4/0 178 7.0 315 0802-0102-0315 170M1322

2.2 ■ W atlow Power Series Installation, Chapter 2

Mounting the Power Series Controller

NOTE: The Power Series controller must be mounted vertically. When multiple units are used in one cabinet, it is

best that they are mounted side-by-side when possible. If they are mounted one above the other, adequate spacing

and airflow must be provided. See Enclosure Guidelines on page 2.3.

1. Determine the panel location for mounting the Power Series controller and punch or drill holes for the

4 mounting screws per the drawing below. The mounting plate can be used as a template.

2. Attach the Power Series mounting plate using 4 screws (customer supplied, #10 screw minimum, 1/4

inch screw maximum).

3. Align the heads of the shoulder screws on the back of the Power Series heat sink with the key slots on

the mounting plate. Push the unit in, and then down until it snaps into place. Mounting is complete.

Figure 2.2c — Installing the controller.Figure 2.2b — Mounting plate dimensions.

Figure 2.2a — Power Series dimensions.

Power Series Dimensions

Add a 9-in. clear-

ance dimension to

help develop the

chimney cooling

effect. This should

be on the top and

bottom of the Power

Series mounting.

Power Series Top View

Power Series Front View

1

23

200 mm

(7.9 in.)

Power Series

Solid State Power Control

354 mm

(14.0 in.)

191 mm

(7.5 in.)

45 6

Power Series Mounting Plate

Mounting Holes (4)

7mm

(0.27 in.)

Key Slots

102mm

(4.00 in.)

151mm

(5.93 in.)

Release Tab

178mm

(7.00 in.)

39mm

(1.53 in.)

25mm

(0.97 in.)

Installation, Chapter 2 Watlow Power Series ■ 2.3

Enclosure Guidelines

The Power Series must be mounted in a suitable electrical enclosure. It must

have adequate wire bending space and cooling. The maximum ambient

temperature in the enclosure must not exceed 50°C (122°F) for name plate

rating. For other output ratings and enclosure ambient temperatures, see output

rating curves on pages 2.5 and 2.6.

To maintain the proper cooling, the enclosure must be large enough to dissipate

the heat generated by the Power Series, or there must be some form of active

cooling.

1. Air circulation — fans bring air into the bottom of the enclosure and louver

plates to allow the air to exit the top of the enclosure. Filters are not

recommended as they can become plugged and block air flow. To maintain

80 percent of the CFM of a fan, the outlet must be four times the area of the

fan inlet. Ensure that each Power Series is within an unobstructed

airstream.

2. Vortex coolers operate on compressed air and provide good cooling on a

sealed enclosure, but are noisy and consume a lot of air.

3. Cabinet air conditioners work well on sealed enclosures.

4. Heat pipe coolers work well on sealed enclosures, but do not provide as

much cooling as vortex coolers or air conditioners.

To determine how much cooling is required:

1. Determine the amperage load on the Power Series. Multiply the amperage by

1.2 and then by the number of phases controlled. This is the output power

dissipated by the SCRs in watts. Add the watts dissipated by the controller’s

power supply (21W) and multiply the total power in watts by 3.41 to get

BTUs per hour. Vortex coolers, heat pipe coolers, and air conditioner cooling are

rated in BTUs removed.

2. Add up the watts generated by other electronics in the enclosure and

multiply by 3.41 to get BTUs per hour.

3. Add up the total BTUs inside the enclosure and pick a cooling device that will

remove that amount of BTUs.

4. For fan cooled enclosures, enclosure and fan manufacturers usually have

free software programs and application notes to help size the fans for

enclosures. If necessary, contact the Application Engineers at Watlow

Controls for assistance.

Harsh Environment

The Power Series meets standards UL508, Pollution degree 3 for safety which

states: “Conductive pollution occurs or non-conductive pollution occurs which

becomes conductive due to condensation which is to be expected.” However,

Watlow recommends that the Power Series be used in a clean, dry environment

to ensure long-term reliability.

2.4 ■ Watlow Power Series Installation, Chapter 2

Removing the Power Series

Controller

1. To release the Power Series controller from the mounting plate, press in on

the release tab at the top of the mounting plate.

2. When the release tab is in, push up on the controller from the bottom to

release it from the mounting plate. Beware of sharp edges on the heat

sink when you push upward. This will take some force!

Maintaining the Power Series

• Cleaning: The heatsink fins must be kept clean for proper cooling and the

printed circuit board should be free of conductive residue condensation.

• Calibration: Not normally necessary. See pages 6.15-6.16 for data restore

and backup.

• Retorquing: See page 3.1 for torque guidelines.

• Software backup and refresh: Not necessary; see page A.7, Power Series

Backup.

NOTE: All Power Series controllers have been 100 percent tested before shipment. The

records of these tests are on file for recall if necessary.

Figure 2.4 — Removing the controller.

ç

CAUTION:

You may want to use a

large screwdriver to

press in on the release

tab while you are pushing

on the controller to avoid

potential injury to your

hands.

Power Series Output Rating Curves

Fan Cooled

All curves are at 100% on with 90°C rated load wire and line wire connected. Note that each chart is slightly different on the amperage scale. The safe operating region is from 1 amp up to the specific curve for the

output amperage code selected. For example: F25 Single Phase is rated up to 200 amps at 50°C; F30 Single

Phase is rated for 250 amps at 50°C. See page 2.6 for Natural Convection Cooled output rating curves.

3 Phase, 3-Leg and 3-Zone Multizone

Fan Cooled at 100% On

70 17080

25

30

35

40

45

50

55

60

Current (Amps) into a Resistive Load

90 100 110 120 130 140 150 160

F20 F25

F30

Enclosure Internal

Ambient Temperature °C

3 Phase, 2-Leg and 2-Zone Multizone

Fan Cooled at 100% On

100 210110

25

30

35

40

45

50

55

60

Current (Amps) into a Resistive Load

120 130 140 150 160 170 180 190 200

F20 F25 F30

Enclosure Internal

Ambient Temperature °C

Single Phase Fan Cooled at 100% On

110 220120

25

30

35

40

45

50

55

60

Current (Amps) into a Resistive Load

230130 240140 250150 260160 170 180 190 200 210

Enclosure Internal

Ambient Temperature °C

F20 F25 F30

Watlow Power Series Installation ■ 2.5

Power Series Output Rating Curves

Natural Convection

All curves are at 100% on and with 90°C rated load wire and line wire connected. Note that each chart is

slightly different on the amperage scale. The safe operating region is from 1 amp up to the specific curve for

the output amperage code selected. For example: N25 Single Phase is rated up to 140 amps at 50°C; N30

Single Phase is rated for 165 amps at 50°C.

3 Phase, 3-Leg and 3-Zone Multizone

Natural Convection at 100% On

25

30

35

40

45

50

55

60

65

Current (Amps) into a Resistive Load

N20 N25 N30

Enclosure Internal

Ambient Temperature °C

60 14070 80 90 100 110 120 13050

3 Phase, 2-Leg and 2-Zone Multizone

Natural Convection at 100% On

25

30

35

40

45

50

55

60

65

Current (Amps) into a Resistive Load

60 14070 80 90 100 110 120 130

N20 N25 N30

Enclosure Internal

Ambient Temperature °C

Single Phase Natural Convection at 100% On

25

30

35

40

45

50

55

60

65

Current (Amps) into a Resistive Load

80 21090 100 110 120 130 140 150 170 180 190 200160

N20 N25 N30

Enclosure Internal

Ambient Temperature °C

2.6 ■ Installation Watlow Power Series

Chapter Three

Wiring

Wiring the Power Series Controller

Wiring options depend on the model number. Check the terminal designation stickers on the

right side of the controller and compare your model number to those shown here and with

the model number breakdown in the Appendix (page A.10) of this manual.

Chapter 3 illustrates how to wire the inputs and outputs for all options. Refer to Figure 3.1

for terminal torque guidelines.

Torque Guidelines

• Properly torque terminals by holding for 30 seconds to allow for wires to settle and

minimize loosening due to cold flow.

• Re-torque all terminals after 48 hours.

• Establish a maintenance program to re-torque line and load terminations every 3-6

months.

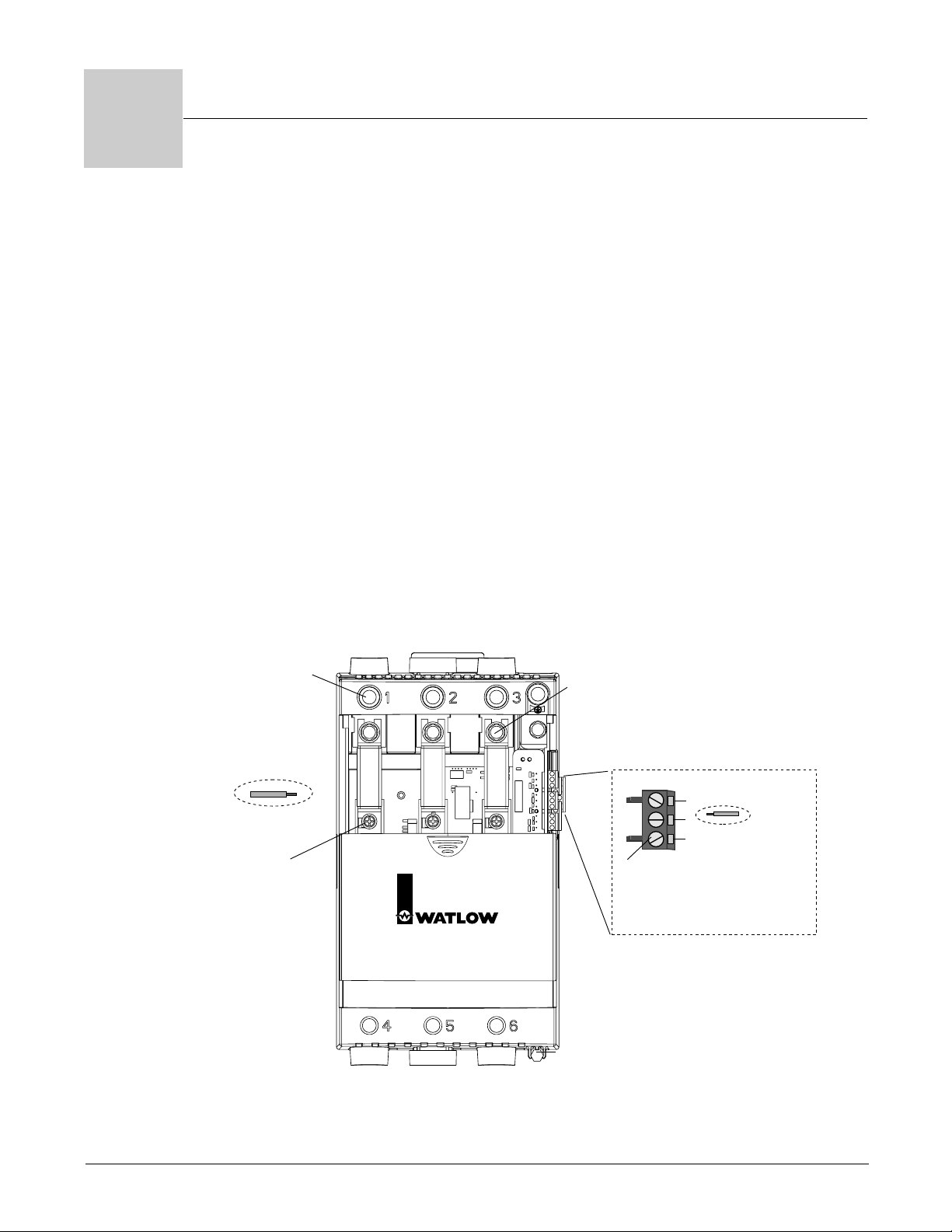

Figure 3.1 — Torque and wire stripping.

3

Wiring, Chapter 3 Watlow Power Series ■ 3.1

Terminals 1 - 6

and Ground Lug

Torque to

180 in.-lbs.

(20 Nm.)

with 3/8 inch

Allen wrench

provided.

Fuse

Strip wires

1-1/8 inch (30mm)

#3 Phillips

Screws for Fuse

Mounting

For models

PXX-F20X-XXXX

PXX-N20X-XXXX

Torque to

26 in.-lbs. (2.93 Nm.)

For models

PXX-F25X-XXXX

PXX-N25X-XXXX

PXX-F30X-XXXX

PXX-N30X-XXXX

Torque to

44 in.-lbs. (4.95 Nm.)

Fuse

Power Series

Solid State Power Control

Fuse

5/16 inch Bolts

for Fuse Mounting

Torque to 44 in.-lbs.

(4.95 Nm.)

Controller Connectors

Strip wires

0.24 in. (6mm)

Torque to 8 in.-lbs. (0.9 Nm.) using

a 1/8 inch (2.5 mm) blade screwdriver.

Accepts 12-22 AWG or 2 No. 22-18

AWG wires.

Allen Wrench

(Flat surface must be against the case.)

3.2 ■ Watlow Power Series Wiring, Chapter 3

ç∫

WARNING:

To avoid damage to

property and equipment,

and/or injury or loss of

life, use National Electric

Code (NEC) standard

wiring practices to install

and operate the Power

Series. Failure to do so

could result in damage,

and/or injury or death.

NOTE:

Input, retransmit and

communications external

terminals have been

designed for protection in

case of direct contact in

accordance with Europpean Standard EN50178.

NOTE:

Insure ground is wired

with the same size wire

as line and load

connections to a ground

of sufficient current

carrying capacity. (Refer

to Chapter 2, p. 2.1,

Power Series Wire

Bending Radius at Base

Current and Ambient

Temperature Rating.)

NOTE:

Torque and wire strip

guidelines:

• Control wiring 1 thru

23.

• Strip wire to 0.24 inch

(6mm). Torque to 8 in.lbs. ( 0.9 Nm).

• Hold torque for 30

seconds to allow for

wiring settling and cold

flow. Re-torque after

48 hours.

• All line connections

should be re-torqued

every 3-6 months.

Input Wiring

Figure 3.2a – Control Power and Alarm Wiring

Figure 3.2b – Retransmit Wiring

Figure 3.2c – Communications Wiring

Power Series

6

5

4

3

2

1

11

10

9

8

7

14

13

12

17

16

15

20

19

18

23

22

21

External Connector

COMMS

7 8

485 T/R +

(Common)

9 10 11

232 TRAN (EIA/TIA-232 Transmit Out)

232 REC (EIA/TIA-232 Receive In)

485 T/R -

RETRANSMIT

DC 10V/20mA

Power Series

6

5

4

3

2

1

11

10

9

8

7

14

13

12

17

16

15

20

19

18

23

22

21

External Connector

12 13 14

I

V

+

+

(Current Out, 4 to 20mA)

(Common)

(Voltage Out, 0 to 10V)

Power Series

External Connector

Relay Internal to Power Series

NC

C

NO

L1

L2

L1

L2

208 or 240V~

(Alarm Common)

(Alarm

Normally Open)

(Alarm

Normally Closed)

Unused

120V~

6

5

4

3

2

1

11

10

9

8

7

14

13

12

17

16

15

20

19

18

23

22

21

CONTROLLER

POWER SUPPLY

85 to 265V~ 55VA

L1

Neutral

ALARM

250V~ 3A

1 2 3 4 5 6

Wiring, Chapter 3 Watlow Power Series ■ 3.3

Figure 3.3a – Single Zone Input Wiring

Figure 3.3b – 2-Zone Input Wiring

Figure 3.3c – 3-Zone Input Wiring

Power Series

6

5

4

3

2

1

11

10

9

8

7

14

13

12

17

16

15

20

19

18

23

22

21

External Connectors

21 22 23

INPUT 1

18 19 20

INPUT 2

15 16 17

INPUT 3

I

V

+

+

(Current In, 4 to 20mA)

(Common)

(Voltage In, 0 to 10V)

I

V

+

+

(Current In, 4 to 20mA)

(Common)

(Voltage In, 0 to 10V)

I

V

+

+

(Current In, 4 to 20mA)

(Common)

(Voltage In, 0 to 10V)

NOTE:

Successful installation

requires four steps:

• Choose the controller’s

hardware configuration

and model number

(Appendix);

• Install the controller

(Chapter Two);

• Wire the controller

(Chapter Three); and

• Configure the controller

(Chapters Four, Five

and Six).

ç∫

WARNING:

To avoid damage to

property and equipment,

and/or injury or loss of

life, use National Electric

Code (NEC) standard

wiring practices to install

and operate the Power

Series. Failure to do so

could result in damage,

and/or injury or death.

Power Series

External Connector

INPUT 1

+

(Voltage In, 0 to 10V)

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

V

+

(Current In, 4 to 20mA)

I

21 22 23

(Common)

Power Series

External Connectors

INPUT 1

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

21 22 23

INPUT 2

18 19 20

+

(Voltage In, 0 to 10V)

V

+

(Current In, 4 to 20mA)

I

(Common)

+

(Voltage In, 0 to 10V)

V

+

(Current In, 4to 20mA)

I

(Common)

3.4 ■ Watlow Power Series Wiring, Chapter 3

Line Power/Output Wiring

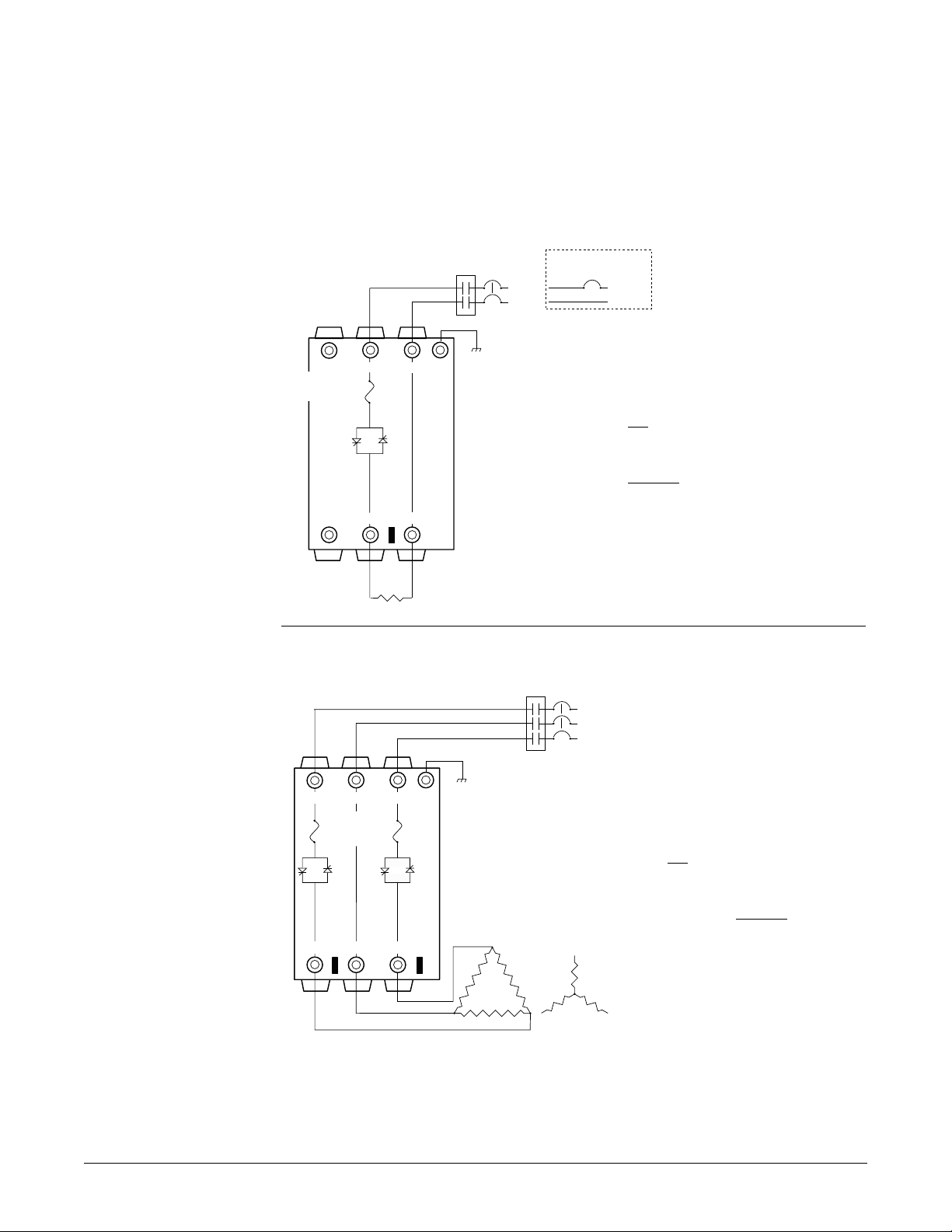

Figure 3.4a – Single Phase Output Wiring

(Model PC1X-XXXX-XXXX)

Figure 3.4b – 3 Phase, 2-Leg, 4 SCR Output Wiring

(Model PC2X-XXXX-XXXX)

NOTE: Our illustrations illustrate circuit breakers for branch circuit protection. Fuses can

also be used.

NOTE:

Successful installation

requires four steps:

• Choose the controller’s

hardware configuration

and model number

(Appendix);

• Install the controller

(Chapter Two);

• Wire the controller

(Chapter Three); and

• Configure the controller

(Chapters Four, Five

and Six).

ç∫

WARNING:

To avoid damage to

property and equipment,

and/or injury or loss of

life, use National Electric

Code (NEC) standard

wiring practices to install

and operate the Power

Series. Failure to do so

could result in damage,

and/or injury or death.

NOTE:

Torque and wire strip

guidelines:

• Connections 1 thru 6,

and ground lug

• Strip wire 1-1/8 in.

(30mm). Torque to 180

in.-lbs. (20 Nm).

• Hold torque for 30

seconds to allow for

wiring settling and cold

flow. Re-torque after

48 hours.

• All load connections

should be re-torqued

every 3-6 months.

çCAUTION: Figure 3.4a shows the

Watlow-recommended output wiring

using the internal bussbar as a

return current path and with ref. 2

not connected. Should a user choose

a non-recommended wiring scheme,

then ref. 2 or the internal bussbar

must be connected to the

appropriate line or neutral. Failure

to follow these guidelines could

cause damage to the Power Series.

çCAUTION: Figure 3.4b shows the

Watlow-recommended output wiring

using the internal bussbar as a

return current path and with ref. 1

and 3 not connected. Should a user

choose a non-recommended wiring

scheme, then ref. 1 or ref. 3 or the

internal bussbar must be connected

to the appropriate line. Failure to

follow these guidelines could cause

damage to the Power Series.

L1

L2

Contacts

Heater

5

120V~

and 277V~

L1

L2

L3

6

L1

Neutral

4

240V~

and above

Limit Control Contacts

(If Required)

1 3

On-board

Semiconductor

Fuse

4 5 6

2

Heater

Gnd

Internal Bussbar

ref.2

Limit Control

2

1 3

On-board

Semiconductor

Fuses

Internal Bussbar

4 5 6

ref.1 ref.3

Gnd

(If Required)

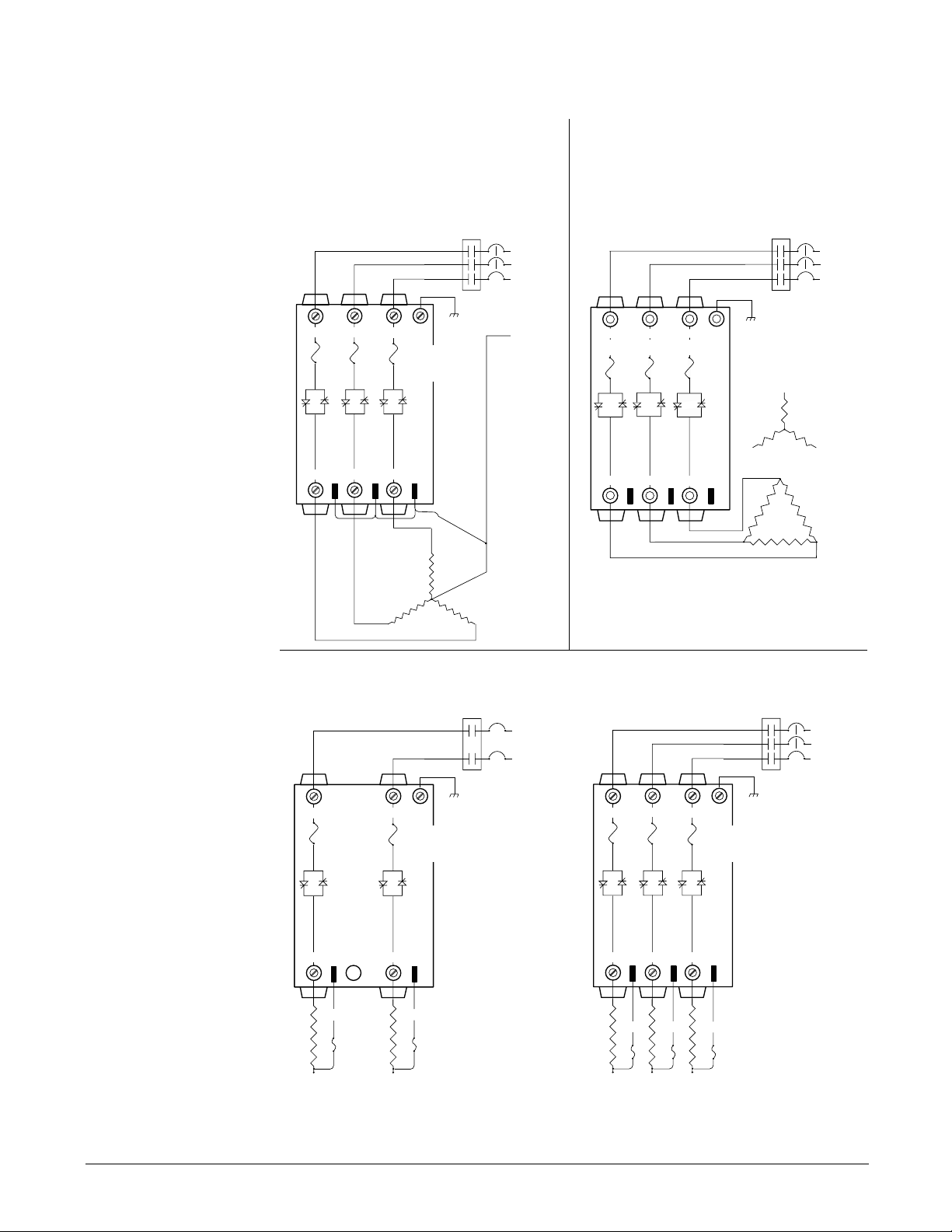

Figure 3.5c – **Multizone Output Wiring

(Models PC8X-XXXX-XXXX and PC9X-XXXX-XXXX)

Figure 3.5a – 3 Phase, 3-Leg,

6 SCR, Output Wiring for

4-Wire Wye Application

(Model PC4X-XXXX-XXXX)

Figure 3.5b – 3 Phase, 3-Leg, 6

SCR Output Wiring

(Model PC3X-XXXX-XXXX)

Wiring, Chapter 3 Watlow Power Series ■ 3.5

ç∫

WARNING:

To avoid damage to

property and equipment,

and/or injury or loss of

life, use National Electric

Code (NEC) standard

wiring practices to install

and operate the Power

Series. Failure to do so

could result in damage,

and/or injury or death.

ç

WARNING:

Install high or low

temperature limit control

protection in systems

where an over

temperature fault

condition could present a

fire hazard or other

hazard. Failure to install

temperature limit control

protection where a

potential hazard exists

could result in damage to

equipment, property and

injury to personnel.

NOTE:

For reference connections

1 to 3, use QC 0.250 in.

wide and 0.032 in. thick

compatible connection

which is fully insulated

with nylon and has a metal

grip ring.

For 14-16 AWG: Molex/ETC

AA-5261; 3M MNG14250DFIX C-54-503X or

equivalent.

**NOTE:

Models PC8 and PC9 control legs are isolated so that they may be wired from phase-to-phase inside delta or phase-to-

neutral, independent of how the other legs are wired.

çCAUTION: Do not connect ref.

connections with PC3 models. Failure to

follow this guideline could cause damage

to the Power Series.

L1

L2

L3

Limit Control

Contacts

2

1 3

Gnd

On-board

Semiconductor

Fuses

(If Required)

N

L1

L2

L3

Limit Control

Contacts

2

1 3

On-board

Semiconductor Fuses

Gnd

(If Required)

6

4 5 6

ref.1 ref. 2 ref. 3

4 5 6

5

4

Heater

L1

L2

L3

Limit Control

Contacts

(If Required)

1 3

Gnd

On-board

Semiconductor

Fuses

L1

L1

Limit Control

Contacts

(If Required)

2

1 3

Gnd

On-board

Semiconductor

Fuses

4

ref.1 ref. 3

PC8

6

4 5

ref.1 ref. 2 ref. 3

PC9

6

Heater

1

L2

Heater

2

L2

2 Independent,

Single Phase

Heaters

Heater

1

L2 L3

Heater

2

Heater

3

L1

3 Independent,

Single Phase

Heaters

3.6 ■ Watlow Power Series Wiring, Chapter 3

Wiring Example

Figure 3.6 - System wiring example.

Recommended fusing options to meet 200KA SCCR. All other untested combinations are

defaulted to 5KA per UL508A and NEC guidelines.

ç∫

WARNING:

To avoid damage to

property and equipment,

and/or injury or loss of

life, use National Electric

Code (NEC) standard

wiring practices to install

and operate the Power

Series. Failure to do so

could result in damage,

and/or injury or death.

ç

WARNING:

Install high or low

temperature limit control

protection in systems

where an over

temperature fault

condition could present a

fire hazard or other

hazard. Failure to install

temperature limit control

protection where a

potential hazard exists

could result in damage to

equipment, property and

injury to personnel.

NOTE: Our wiring

example illustrates

circuit breakers for

branch circuit protection.

Fuses can also be used.

Power Series Model Fuse Rating Watlow Fuse P/N Bussmann Fuse P/N

PC1X-N20 160 0808-0102-0160 170M1319

PC1X-N25 200 0808-0102-0200 170M1320

PC1X-N30 250 0808-0102-0250 170M1321

PC1X-F20 160 0808-0102-0160 170M1319

PC1X-N25 250 0808-0102-0250 170M1321

PC1X-N30 315 0808-0102-0315 170M1322

PC2(8)X-N20 125 0808-0102-0125 170M1318

PC2(8)X-N25 160 0808-0102-0160 170M1319

PC2(8)X-N30 160 0808-0102-0160 170M1319

PC2(8)X-F20 160 0808-0102-0160 170M1319

PC2(8)X-F25 250 0808-0102-0250 170M1321

PC2(8)X-F30 250 0808-0102-0250 170M1321

PC3(4,9)X-N20 100 0808-0102-0100 170M1317

PC3(4,9)X-N25 125 0808-0102-0125 170M1318

PC3(4,9)X-N30 160 0808-0102-0160 170M1319

PC3(4,9)X-F20 125 0808-0102-0125 170M1318

PC3(4,9)X-F25 200 0808-0102-0200 170M1320

PC3(4,9)X-F30 200 0808-0102-0200 170M1320

Line

Neutral

Fuse

High Limit

Controller

1 3

Semiconductor

Zero Cross Fired

Power Series

4 5 6

2

On-board

Fuses

3Ø, 2-leg

Gnd

Neutral

Line

High

Limit

Contactor

Circuit Breakers

Overtemp.

Indicator

Fuse

Reset

Switch

Line

Fuse

11

(+)

3

5

Series 93

Thermocouple Input

Process Output

93BA-1FA0-00RR

4 to 20mA

Retransmit to Monitor

Output Operation

Control Power

Neutral

12

9 +

10 -

Three Phase

Resistive Heater

Chapter Four

Navigation and Software

Keys and Displays

This chapter explains keys, displays and navigation skills. You’ll also find a complete

software map.

Navigation and Software, Chapter 4 Watlow Power Series ■ 4.1

4

Figure 4.1 — Power Series keys and displays.

Alarm Indication LED:

Lit when an alarm is

active.

Upper Display:

Indicates operating

levels - requested

current, line voltage or

power feedback levels

for the parameter in the

lower display.

Lower Display:

Indicates the

parameter whose

value appears in the

upper display.

***8

***8

Increment/Decrement

Keys: Moves to next or

previous submenu if at

the top item of a menu, or

increments/decrements

current menu item.

Home Key:

Returns to the Display

Loop if in any other

page or menu, or in

the Display Loop,

moves between like

prompts of different

zones or phases.

Small LED:

Blinks with

communications

activity.

Left/Right Keys: Moves

to the next or previous

item in a submenu.

Navigating the Power Series

Choose a page (Setup or Factory) and press its key sequence. The page appears in the lower

display.

PressÎ or Ó to find a specific menu in a page. The menu appears in the upper display and

the page remains in the lower display.

Press ® to enter the list of parameters in the menu displayed. The menu’s parameters

appear in the lower display and the values in the upper display. To go backward through the

parameter list press ¬ .

PressÎ or Ó to select a value, either alpha or numeric, within a specific parameter.

Setup Page - for

setting up the

control, alarms,

retransmit, and

communications.

Factory Page for calibration

and diagnostic

information.

Display Loop for monitoring

parameters and

adjusting manual/digital input,

and for clearing

alarms if they are

latched.

4.2 ■ Watlow Power Series Navigation and Software, Chapter 4

NOTE:

The Load Activity Indicator in the Display Loop indicates different things, dependent on whether heater

diagnostics is installed. With heater diagnostics installed, it indicates load current has been detected.

Without heater diagnostics installed, it indicates the SCRs are being gated and line voltage is present.

• Setup Page: From Display Loop, press ± and ¬ keys together for 2 sec.

• Factory Page:

• Display Loop: From Setup or Factory Page, press the ± key.

***8

***8

***8

***8

From Setup Page, press ± and ¬ and ® keys together for 2 sec

***8

***8

algo

SEt

***8

FCty

-–-

load

Navigation

¨[````]¨[````]¨[load]¨[freq]¨

Single-Zone Single-Phase

¬®[In``] or [In|c] or [In|u] ¬®[`Out]¬®[`Hbt]¬%%% ®[`UoL]¬®[`Cur]¬®[`HUa]

Multi-Zone [```] Three-Phase [```]

%%%% [2one]

%%%%%%% [PHAS]

Display Loop

Use the Increment/Decrement keys ( Ó Î ) to select a Zone or Phase

within the Display Loop. The Zone/Phase appears in the upper display.

Use the Left/Right arrow keys ( ¬ ® ) to select a parameter within a Zone or Phase.

The parameter appears in the bottom display.

Use the Increment/Decrement keys (

Ó Î ) to select a value, either alpha or

numeric, within a parameter. The value appears in the upper display.

Use the Home key ( ± ) to toggle between Zones/Phase 1, 2, or 3 sequentially.

(#)

Î

Ó

Display Zone

Selection

Display Phase

Selection

(#)

Î

Ó

(code) (code)

Active Alarms

(if any)

[```1] Zone 1 [```1] Phase 1

[2one] % ¨[In1`] or [In|`c1] or [In|`u1] ¨[Out1]¨[Hbt1]¨[UoL1]¨[Cur1]¨[HUa1]¨% [`ph5] % ¨[UoL1]¨[Cur1]¨

%Î% ±% ±% ±% ±% ±% ±% ±% ±% Î% ±% ±%

% Ó%%%%%% Ó%

[```2] Zone 2 [```2] Phase 2

[2one] % ¨[In2`] or [In|`c2] or [In|`u2] ¨[Out2]¨[Hbt2]¨[UoL2]¨[Cur2]¨[HUa2]¨% [`ph5] % ¨[UoL2]¨[Cur2]¨[`HUa]¨

% Î% ±% ±% ±% ±% ±% ±% ±% ±%% Î% ±% ±%

% Ó%%%%%% Ó

[```3] Zone 3 [```3] Phase 3

[2one] % ¨[In3`] or [[In|`c3] or [In|`u3] ¨[Out3]¨[Hbt3]¨[UoL3]¨[Cur3]¨[HUa3]¨% [`ph5] % ¨[UoL3]¨[Cur3]¨

%Î% ±% ±% ±% ±% ±% ±% ±% ±% Î% ±% ±%

% Ó%%%%%% Ó

%

Navigation and Software, Chapter 4 Watlow Power Series ■ 4.3

NOTE: For an explanation of the parameters in the Display Loop, range information, Modbus address, and conditions for

the parameter to appear, see pp. 6.1-6.4, Chapter Six, Parameters.

NOTES:

What you see in each Page and in each Menu are factory set, depending on the options and settings of your controller.

The input signal method indicator will change depending on the input signal method chosen — digital, current, or volts.

Current operating parameters may be modified at any time with the use of the keypad or communications port.

The Display Loop is

used to monitor

parameters and adjust

manual/digital input,

and to clear alarms if

they are latched.

***8

***8

Press Home and Left Keys together

for 2 seconds to enter the Setup

Menus from the Display Loop.

Setup Page Menus

±¬

Display Loop

±±

Press Home Key from any menu to

return to the Display Loop.

% ±¬®

Press Home, Left and Right Keys all

together for 2 seconds to enter the

Factory Menus from the Setup Menus.

Factory Page Menus

4.4 ■ Watlow Power Series Navigation and Software, Chapter 4

**NOTE: These menus and display prompts are only viewable in the Factory Mode using a password.

NOTE: For an explanation of the parameters in the Setup Page, (range information, Modbus address, and conditions for the

parameter to appear), see Chapter Six, Parameters, pp. 6.5-6.14; for information on the Factory Page, see pp. 6.14-6.22.

[dAta] System Data Manipulation

[FctY]% ¨[baup]¨[dflt]¨[rEst]¨[nUOl]¨

%Î

%Ó

[`Loc] Global/Menu Lockouts

[[FctY]% ¨[gloc]¨[`Ctr]¨[`OPt]¨[`Alr]¨[COm]¨[retr]¨[`CIn]¨[C|`rtr]¨[dAta]¨[diAg]¨

%Î

%Ó

[InFo] Unit Information

[FctY]% ¬®[`sn–]¬®[`sn_]¬®[date]¬®[HUEr]¬®[SUEr]¬®[sbld]¬®[ratU]¬®[rata]¬®[2onC]¬®[`Opt]¬®[```Ç]¬®

Î

%Ó

%%% ¬®[Hrs_]¬®[Hrs–]¬®[HIÇ`]¬®[sdÇ`]¬®[AlÇ`]

[diAg] Diagnostics

[[FctY]% ¨[``Ad]¨[Cnts]¨[l!A1]¨[l!A2]¨[l!A3]¨[l@A1]¨[l@A2]¨[l@A3]¨[l#A1]¨[l#A2]¨[l#A3]¨

Î

%Ó%

¨[retr]¨[`UAL]¨[``In]¨[dIsp]

%%

[`pw] Factory Password

[FctY]

% ¨[`pw]¨[fcty]¨

%

Î

%Ó

[CIn1] Calibrate Analog Input Signal Zone 1**

[FctY] % ¬®[nnA_]¬®[nnA–]¬®[UoL_]¬®[UoL–]¬®[Cala]¬®

%

Î

%Ó

[CIn2] Calibrate Analog Input Signal Zone 2**

[FctY] % ¬®[nnA_]¬®[nnA–]¬®[UoL_]¬®[UoL–]¬®[Cala]¬®

%

Î

%Ó

[CIn3] Calibrate Analog Input Signal Zone 3**

[FctY] % ¬®[nnA_]¬®[nnA–]¬®[UoL_]¬®[UoL–]¬®[Cala]¬®

%

Î

%Ó

[Crtr] Calibrate Retransmit**

[FctY]% ¬®[nnA_]¬®[nnA–]¬®[UoL_]¬®[UoL–]¬®[Calr]¬®

%Î

Factory Page Menus

Use the Increment/Decrement keys ( Ó Î ) to select a menu

within the Factory Page. The menu appears in the upper display.

Use the Left/Right arrow keys (

¬ ® ) to select a parameter

within a menu. The parameter appears in the bottom display.

Use the Increment/Decrement keys ( Ó Î ) to select a value,

either alpha or numeric, within a parameter. The value appears

in the upper display.

*NOTE: This prompt will only appear in [Ctr1], and if the controller is 3 phase.

Setup Page Menus

[algo] Control Algorithm

[`set]

% ¨[algo]¨[`ftb]¨[``UC]¨

%Î% Î

%Ó% Óv

%

[Ctr1] Setup Control Zone 1

% ¬®[``In]¬®[%dflt]¬®[nna_]¬®[nna–]¬®[Uol_]¬®[Uol–]¬®[lrn|``A]¬®[bl`U]¬®[lrn|``U]¬®[type]¬®[rate]¬®[soft]¬®[rdly]¬®

[`set]

%Î

%Ó

[Opt1] Setup Options Zone 1

[`set]

% ¬®[`Hbo]¬®[Min]¬®[`HbC]¬®[`Cli]¬®[`Cla]¬®[tol_]¬®[toL–]¬®[Indf]¬®[1Cur]¬®

%Î

%Ó

[Ctr2] Setup Control Zone 2

[`set]

% ¬®[``In]¬®[dflt]¬®[nna_]¬®[nna–]¬®[Uol_]¬®[Uol–]¬®[lrn|``A]¬®[bl`U]¬®[lrn|``U]¬®[rate]¬®[soft]¬®

Î

%

%Ó

[Opt2] Setup Options Zone 2

[`set]

% ¬®[`Hbo]¬®[Min]¬®[`HbC]¬®[`Cli]¬®[`Cla]¬®[tol_]¬®[toL–]¬®[Indf]¬®[1Cur]¬®

%Î

%Ó

[Ctr3] Setup Control Zone 3

[`set]

% ¬®[``In]¬®[dflt]¬®[nna_]¬®[nna–]¬®[Uol_]¬®[Uol–]¬®[lrn|A]¬®[bl`U]¬®[lrn|``U]¬®[rate]¬®[soft]¬®

Î

%

%Ó

[Opt3] Setup Options Zone 3

[`set]

% ¬®[`Hbo]¬®[Min]¬®[`HbC]¬®[`Cli]¬®[`Cla]¬®[tol_]¬®[toL–]¬®[Indf]¬®[1Cur]¬®

%Î

%Ó

[`aLr] Setup Alarms Configuration

[`set]

% ¬ ®[A|``l9c]¬®[glbl]¬®[Open]¬®[`tol]¬®[``Ot]¬®[`aLÇ]¬®[Line]¬®[p|bal]¬®[lbal]¬®[ldif]¬®[freq]¬®

%Î

%Ó

% %%% ¨ [C|``wd]¨[``OU]¨[``UC]

[COm] Setup Comms Configuration

[`set]

% ¨[addr]¨[baUd]¨[`wd]¨[`seC]¨[pwr]¨

%Î

%Ó

[retr] Setup Retransmit Configuration

[`set]

% ¬®[`Cfg]¬®[type]¬®[pha5]¬®[2one]¬®[Cur_]¬®[Cur–]¬®[HUa_]¬®[HUa–]¬®[rt|``C_]¬ ®[rt|``C–]¬ ®[rt|``U_]¬ ®[rt|``U–]¬ ®

%Î

%Ó

[cont] Î [`OFF] Î [`ftb] Î Urtb] Î [pH2t]

Use the Increment/Decrement keys ( Ó Î ) to select a menu

within the Setup Page. The menu appears in the upper display.

Use the Left/Right arrow keys (

menu. The parameter appears in the bottom display.

Use the Increment/Decrement keys (

or numeric, within a parameter. The value appears in the upper display.

¬ ® ) to select a parameter within a

Ó Î ) to select a value, either alpha

*

Loading...

Loading...