Page 1

Minitrend QX, Multitrend SX and eZtrend QXe Recorders

See, Store and Send Data Securely

For the best in data acquisition, data security

and peace of mind ..

choose

Page 2

43-TV-25-30 Iss.4 GLO Dec 06 UK ii

Page 3

Table of Contents

Section 1: Preface .............................................................................. 1

Preface ...........................................................................................................1

Thank you for choosing a Honeywell X Series recorder.......................................... 1

Supplementary documentation ................................................................................. 1

Notes......................................................................................................................... 1

Trademarks............................................................................................................... 1

Safety ............................................................................................................. 2

Symbols..................................................................................................................... 2

Static Electricity........................................................................................................ 2

Protocols used in this manual ........................................................................ 3

Safety and Symbol Identification ...... ................................................. ... .................... 3

Warnings and Safety Precautions .................................................................. 3

Do’s and Don’ts......................................................................................................... 3

Hazardous Voltage.................................................................................................... 4

Section 2: Installation .........................................................................................5

Environment and Location ............................................................................ 5

Mechanical Installation .................................................................................. 6

Installation Instructions............................................................................................ 9

Electrical Installation ................................................................................... 13

Installation Category.............................................................................................. 13

Analogue Input Card.............................................................................................. 16

QXe Analogue Input (Standard) card..................................................................... 19

Analogue Output Card............................................................................................ 21

Pulse Input Card..................................................................................................... 22

Transmitter Power Supply Card............................................................................. 24

Alarm Relay Cards & Digital Input/Output Cards................................................. 24

Communications Connections ................................................................................ 28

eZtrend QXe Expansion Card................................................................................. 29

USB Devices ........................................................................................................... 29

Section 3: Overview ..........................................................................................31

Functions and Features ................................................................................ 31

Recorder Functionality........................................................................................... 33

Features.................................................................................................................. 34

Options - Hardware................................................................................................ 37

43-TV-25-30 Iss.4 GLO Dec 06 UK iii

Page 4

Section 4: Recorder Setup ............................................................................... 43

Power up .......................................................................................................43

1. Menu Access........................................................................................................ 43

2. Log On/Off .................................................... ............................................... ....... 44

3. Local Settings...................................................................................................... 44

4. Time and Date Settings........................................................................................ 45

5. Firmware Options ............................................................................................... 45

Menu Path ............................................................................................................... 45

Help..................... .............................................. ............................................... ....... 45

Main Menu .............................................................................................................. 46

Configure Menu....................................................................................................... 47

Setup Menu....................................... ....................................................................... 48

Edit Setup ... .............................................. ............................................................... 49

Edit Recording.................. ..................................................................................... 101

Layout................................................... .. ............................................... ................ 104

Passwords.............................................................................................................. 108

Settings ......... ............................................... .......................................................... 111

Alarms Menu.......................................................... ............................................... 112

Screen Menu.......................................................................................................... 113

Batch Setup/Batch Control.................................................................................... 117

Recording Menu.................................................................................................... 120

Messages Menu..................................................................................................... 122

Process Menu................. .............................................. ......................................... 125

Status Menu........................................................................................................... 127

Finish............ ............................................... .......................................................... 140

Section 5: Password Security ....................................................................... 141

Log On/Off ............................................................................................................ 141

Users and Groups.................................................................................................. 141

Administrator .............. ............................................... ........................................... 141

Password Policy.................................................................................................... 143

User Interface requirements.................................................................................. 144

Audit Trail........... .............................................. ............................................... ..... 144

Level Permissions.................................................................................................. 145

Default Password Access ...................................................................................... 147

Section 6: Screen Configuration ................................................................... 155

Process Screen Overview................... ............................................... .................... 155

Menu Bar............................................................................................................... 156

Screen Menu Bar................................................................................... ................ 157

Replay............................................... ..................................................................... 158

Chart Speeds .............................................................. ........................................... 162

Screen Activity....................................................................................................... 162

Section 7: Firmware Options ......................................................................... 167

Firmware Credit System .............................................................................167

Firmware Options.......... ....................................................................................... 168

Applying your Firmware credits . ............................................... .. ......................... 168

Remote Viewer....................................................................................................... 169

iv 43-TV-25-30 Iss.4 GLO Dec 06 UK

Page 5

Section 8: Communication .............................................................................171

Comms Configuration ............................................................................... 171

Standard Communication Interfaces ..........................................................171

Protocols............................................................................................................... 172

Hardware Installation ................................................................................. 173

Getting connected - IP Address............................................................................ 174

Local Area Network setup ............................................................. ....................... 175

Links to Remote Networks .................................................................................... 175

Data Logging and Transfer.................................................................................. 175

Comms and Trend Manager Suite ............................................................. 177

System Requirements ............................................................................................ 177

Software Installation........ .. ................................................................................... 178

Start Up............................................................................................................ ..... 179

Communications Server ............................................................................. 182

Comms Server Overview ...................................................................................... 182

Start up.......................... ........................................................................................ 182

Comms Server Setup............................................................................................. 186

Comms Database Server ............................................................................197

System Setup ......................................................................................................... 197

Modbus Capabilities: ................................................................................. 197

OPC Interface - Open Process Control ......................................................198

Web Browser .............................................................................................. 199

Internet Security Settings ........................................................................... 200

Section 9: PC Software Suite .........................................................................201

The TrendManager Pro Software Suite................................................................ 201

System Requirements ............................................................................................ 202

Section 10: Spares List ...................................................................................203

Minitrend QX Recorder........................................................................................ 203

Multitrend SX Recorder....................................................................................... . 207

eZtrend QXe Recorder.......................................................................................... 212

Section 11: Instrument Care and Maintenance .............................................217

Cleaning Instructions ................................................................................. 217

Backlights ..................................................................................................217

Operating Temperature .............................................................................. 217

Touch Screen ............................................................................................. 218

Calibration ................................................................................................. 218

Section 12: Technical Data & Specifications ................................................219

Field IO Specification ................................................................................219

Analogue Input .......................................................................................... 220

Relay Alarm/Digital Input Specification ................................................... 220

Relay/Alarm Output Card Options....................................................................... 220

Digital Input Cards............................................................................................... 221

Specification Tables ................................................................................... 223

Input Range Performance Accuracy Table........................................................... 227

LED Flash Codes.................................................................................................. 230

43-TV-25-30 Iss.4 GLO Dec 06 UK v

Page 6

Appendix A: Quality and Safety .................................................................... 231

CE Mark .....................................................................................................231

Safety ..........................................................................................................231

Appendix B: Maths Expressions ................................................................... 233

Full Maths & Script Processing ..................................................................233

Maths Credit Options............................................................................................ 233

Maths Variable and Function Tables............................................................ ......... 234

Full Maths.................................................................................................... ......... 241

Script Function Application Examples. .. ................................................. .............. 242

Maths Error Messages ....... ............................................... .................................... 246

Appendix C: Thermocouple Connections .................................................... 247

How Thermocouples work .........................................................................247

Thermocouple CJC Compensation .............................................................248

Internal Automatic .. .............................................................................................. 248

Ext 0°C Reference ................................................................................................. 249

External with a Specified Temperature .................... ............................................. 249

External Input Reference.. ............................................... ...................................... 250

Appendix D: Alarms ....................................................................................... 251

Alarms Menu.......................................................... ............................................... 251

Appendix E: Ethernet ..................................................................................... 253

Ethernet................... ............................................... ............................................... 253

Email ... ............................................... ............................................... .................... 254

General operation of the e-mail system ................................................................ 254

Appendix F: Fuzzy Logging ........................................................................... 255

Appendix G: F sub zero Sterilisation ............................................................ 259

The significance of F0........................................................................................... 259

Appendix H: Calibration ................................................................................. 261

AI Calibration and CJC Calibration ...........................................................261

Sensor Compensation .................................................................................261

Appendix I: Battery Data ................................................................................ 263

Location: Processor Board .........................................................................263

Safety Guidelines................................................................................................... 263

Appendix J: Function Codes and Memory Maps ........................................ 265

Modbus Memory Map Supplement: ...........................................................265

Totalisers ........................................................................................... .................... 265

Input Text message ................................................................................................ 265

Analogue Input Value............................................................................................ 266

Communications Input.......................................................................................... 266

Pen Values........... ......................................................................................... ......... 266

Modbus Function Codes .............................................................................267

Index ................................................................................................................ 269

vi 43-TV-25-30 Iss.4 GLO Dec 06 UK

Page 7

Section 1: Preface

Preface

Thank you for choosing a Honeywell X Series recorder

Thank you for purchasing the newest in our range of electronic data recording for Honeywell X Series Advanced Graphic Recorders.

The Minitrend QX, Multitrend SX and eZtrend QXe paperless cha rt recorders are the

latest development of the solid-state replacement for traditional paper recorders.

Many options, features and functions are available to meet a wide range of applications and

requirements including: Power, Water Treatment, Therm al Processing, Food and Beverage,

Pharmaceutical/Biotech and Manufacturing industries.

This manual explains the product functionality operation, configu ration and commun ication

as well as Safety Precautions, Installation & Wiring, Recorder Setup, Troubleshooting and

Spares List. It is recommended that the user reads the manual before installing and operating the recorder.

Supplementary document ation

Supplementary documentation to accompany these recorders are:

Table 1.1 : Supplementary documentation

Manual Part number

TrendManager Pro V5 & X Series Software Suite 43-TV-25-11

Screen Designer X Series Recorders 43-TV-25-31

Documents can be down-loaded from the web site at

www.XSeries-info.net.

Notes

• The contents of this manual are correct at the time of issue. The contents may

change at any time without prior notification. This is due to continuous developments to the recorder and it’s functionality.

• Every effort has been made to ensure the accuracy of this document, however

should there be any anomalies found, please contact your nearest Honeywell

supplier. See back page for contact addresses.

• All rights are reserved. No part of this manual should be copied or reproduced, stored on a retrieval system or transmitted in any form without the

prior permission from Honeywell International Inc.

Trademarks

• Microsoft, MS-DOS, Windows, Windows 2000, Windows XP and Windows CE are

all registered trademarks of Microsoft Corporation.

• Compact Flash and CF (logo) are trademarks of the Compact Flash Association

(CFA).

• For the purpose of this manual the

mark names or registered trademark names in every instance.

• Company names and Product names mentioned in this manual are trademarks or

registered trademarks of their individual owners.

43-TV-25-33 GLO Iss.4 Dec 06 UK 1

and symbols will not follow their own trade-

Page 8

Safety

Safety

The X Series range of instruments is compliant with the requirements of BS EN 610101:2001 “Safety Requirements for Electrical Equipment for Measurement, Co ntrol and Laboratory Use” and UL 61010C-1 and CSA 22.2-1010.1, as options. If the eq uipment is used in

a manner not specified, the protection provided by the equipment may be impaired.

The QX and SX range of instruments is compliant to the requirements for Class 1, Div.2

Hazardous (Classified) Locations.

Symbols

One or more of the following symbols may appear on the recorder labelling.

Table 1.2 : Safety Symbols

Symbol Meaning

Caution - refer to manual for

instructions

Caution - risk of electric

shock

Direct Current

Protective conductor terminal

Earth (ground) terminal

Static Electricity

Directive 2002/96/EC

WEEE: Waste Electrical and

Electronic Equipment

Static Electricity

All circuit boards and electronic modules associated with this recorder contain components

which are susceptible to damage caused by electrostatic discharge. Should it be necessary

to handle such components, appropriate prec autions in accordance with ANSI/ESD S20.20

Electrostatic Discharge Control Program Standard, should be observed.

2 43-TV-25-30 Iss.4 GLO Dec 06 UK

Page 9

Protocols used in this manual

Protocols used in this manual

Safety and Symbol Identification

Symbol Description

Table 1.3 :

WARNING

CAUTION

NOTICE

Warnings and Safety Precautions

Do’s and Don’ts

1. Before any connections are made to the recorder, ensure the protective earth terminal

is connected to a protective conductor before applying power or any other connections.

WARNING

IMPROPER INTERRUPTION OF CONNECTIONS

Any interruption of the protective conductor outside the recorder, or disconnection of

the protective earth terminal is likely to make the recorder dang erous under some fault

conditions. Intentional interruption of the protective conductor is dangerous.

The WARNING symbol indicates a potentially

hazardous situation, which, if not avoided, could

result in death or serious injury.

This CAUTION symbol may indicates a potentially hazardous situation, which, if not avoided, may

result in property damage.

A NOTICE symbol indicates important information that must be remembered and aids in job

performance.

Failure to comply with these instructions could result in death or serious injury.

In order to comply with the requirements of safety standard EN 61010-1:2001, the

recorder should have one of the following as a disconnecting device, located within

easy reach of the operator, and be clearly labelled as the disconnecting safety device:

• A switch or circuit breaker which complies with the requirements of IEC 60947-1 and

IEC 60947-3.

• A separable coupler which can be disconnected without the use of a tool.

• A separable plug, without a locking device, to mate with a socket outlet in

the building.

2. Whenever it is likely that protection has been impaired, the recorder should be made

inoperative and secured against operation. The manufacturer's service centre should

be contacted.

43-TV-25-30 Iss.4 GLO Dec 06 UK 3

Page 10

Warnings and Safety Precautions

3. Repair is not to be attempted by a customer. Any adjustment or maintenance expected

of an operator as part of the normal operation of the product is referred to as Operational Maintenance. Any maintenance not expected of the operator is referred to as

Corrective Maintenance and is to be carried out only by authorized service personnel

or returned to an authorized repair centre.

4. Where conductive pollution such as condensation or conductive dust is present, adequate air conditioning, filtering and/or sealing must be installed.

5. This recorder contains one battery on the Processor board which must be treated and

disposed of with care. Batteries must not be short circuited. Batteries should be disposed of in accordance with local regulations, they must not be disposed of with normal

refuse.

Improper signal and supply wiring - WARNING

6.

WARNING

IMPROPER SIGNAL AND SUPPLY WIRING

Signal and supply wiring should be kept separate. Where this is impractical, shielded cables should

be used for the signal wiring. Where signal wiring is carrying, or could carry under fault conditions,

hazardous voltage (defined as >30 V rms and 42.4 V peak, or >60 Vd.c.), double insulation must

be used for all signal wiring.

Failure to comply with these instructions could result in deat h or serious injury.

7. If the equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be inadequate.

8. The protective earth terminal must remain connected (even if the recorder is isolated

from the mains supply) if any of the measuring, communications, or relay terminals are

connected to hazardous voltages.

Hazardous Voltage

Hazardous Voltages are defined by EN61010-1 as follows:

WARNING

HAZARDOUS VOLTAGE LEVELS

Voltage levels above 30V rms and 42.4V peak or 60V dc are deemed to be

"Hazardous Live". Ensure operators are not exposed to hazardous voltage levels.

Failure to comply with these instructions could result in death o r se rious injur y.

4 43-TV-25-30 Iss.4 GLO Dec 06 UK

Page 11

Section 2: Installation

Damage checks

Any damage caused to the recorder or the contents should be reported immediately to your

shipper.

Unpacking

Remove the contents, check the packaging and re move all documentation and accessories

supplied. Retain the box and any packaging for future transportation.

Contents

Check that the contents and accessories are correct against the order or Model Selection

Guide using the model number on the recorder. Contact your authorised Honeywell dis-

tributor or Honeywell immediately should there be any query.

The contents are based on Unit Model Number ordered and will vary from unit to unit. The

following list is provided as a general guide and not specific to any single unit.

• Recorder - specification as ordered (check against the Model Selection Guide)

• Mounting fixings - Mounting clamps and panel gasket

• Connector kit - mating half connectors to recorder spec. Including a CJC connector for

Thermocouple operation.

• Quick Start Guide - to get you started

• First time Password system instructions - for ESS recorders only

• CD - Viewer software + documentation

• Plastic stylus x 2 (for use with the touch screen)

• Manual (optional) - Hard copy English, French or German

• Any other items ordered as an option (Model Selection Guide)

Re-packing

NOTICE

Should the original packing be destroyed or lost, new packaging can be ordered or as a

last alternative, then ONLY pack the recorder in polystyrene granules if the recorder is

FIRST sealed in a strong plastic bag. Failure to do this will invalidate your warranty.

Environment and Location

• The recorder is designed to be mounted into a panel. See “Installation Instruc-

tions” on page 9.

• Mounting angle is unlimited. Choose a suitable location with an ideal viewing angle.

See “Mounting and Viewing Angles” on page 6.

• The location should be free from vibration.

• The environment should be of non-condensing humidity.

• The ambient temperature should be between 0C and 50C (32F to 122F).

• The relative humidity should be between 10% to 90%.

43-TV-25-30 Iss.4 GLO Dec 06 UK 5

Page 12

NOTICE

The eZtrend QXe recorder is an Emmisions Class A product. In a domestic environment this product may cause radio interference in which case the user may be required

to take adequate measures.

Mechanical Installation

Mounting and Viewing Angles

Mounting - The Minitrend QX, Multitrend SX and eZtrend QXe recorders have an unlimited mounting angle.

Mechanical Installation

Viewing - For the best view of the display the v

Minitrend QX 55from the left or right, 40looking down and 50 looking up at the recorder dis-

play.

Multitrend SX 70from the left or right, 45looking down and 55 looking up at the re-

corder display.

eZtrend QXe 45f rom the left or righ t, 10looking down and 30 looking up at the recorder display.

iewing angle should not exceed:

Panel cut-out size for the Minitrend QX and eZtrend QXe recorders

+1

- 0

138.00

(5.43”)

+1

- 0

>6.00

(0.237”)

Panel

Cut-out

138.00

(5.43”)

Panel

Cut-out

>7.00

(0.28”)

Panel

Cut-out

Figure 2.1 Minitrend QX and eZtrend QXe Panel cut-out

6 43-TV-25-30 Iss.4 GLO Dec 06 UK

Please note the recommended

spacing for adjacent mounting

Page 13

Mechanical Installation

Panel cut-out size for the Multitrend SX recorder

281.00

(11.06”)

Panel

Cut-out

>20.00

>20.00

(0.787”)

Panel

Cut-out

Figure 2.2 Multitrend SX Panel cut-out

The Minitrend QX, Multitrend SX and eZtrend QXe recorders ar e DIN Standard sizes

and should be panel mounted.

(0.787”)

Panel

Cut-out

Please note the recommended

spacing for adjacent mounting

281.00

(11.06”)

43-TV-25-30 Iss.4 GLO Dec 06 UK 7

Page 14

Mechanical Installation

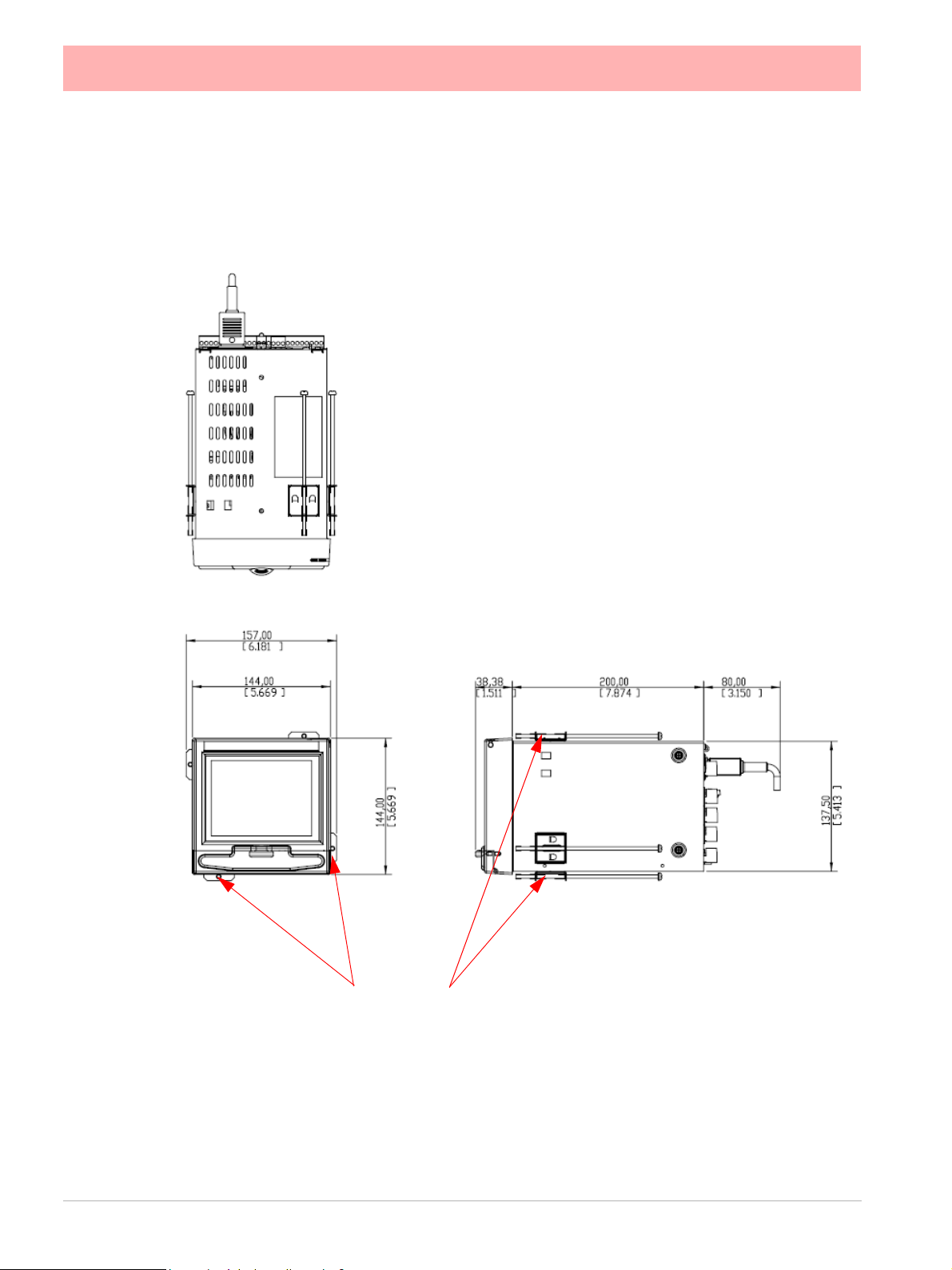

Minitrend QX Dimension details

4 Mounting clamp positions. For standard units fit only two

brackets on opposite sides of the unit, either top and bottom

or left and right slots. NEMA 4X rated recorders require all four

mounting brackets to be fitted.

Figure 2.3 Minitrend QX Recorder dimensions

8 43-TV-25-30 Iss.4 GLO Dec 06 UK

Page 15

Mechanical Installation

Mu l t i t r e n d S X Dimension details

4 Mounting clamp positions. For standard units fit only

two brackets on opposite sides of the unit, either top

and bottom or left and right slots. NEMA 4X rated recorders require all four mounting brackets to be fitted.

Figure 2.4 Multitrend SX recorder dimensions

Installation Instructions

• Minimum panel thickness = 2mm (0.078”), max = 20mm (0.78”)

• Both recorders must be inserted from the front of the panel,

• Two mounting clamps are supplied and can be fixed either on the top and bottom

sides or on the left and right sides of the case.

43-TV-25-30 Iss.4 GLO Dec 06 UK 9

Page 16

Mechanical Installation

eZ t r e n d Q X e Dimension details

4 Mounting clamp positions. For standard units fit only two

brackets on opposite sides of the unit, either top and bottom

or left and right slots. NEMA 4X rated recorders require all four

mounting brackets to be fitted.

Figure 2.5 eZtrend QXe recorder dimensions

10 43-TV-25-30 Iss.4 GLO Dec 06 UK

Page 17

Mechanical Installation

Panel Mounting Clamp Installation

The Minitrend QX, Multitrend SX and the eZtrend QXe recorders slide into the pan el

cut-out and are held in place by two (or four) pan el clamps. The panel clam ps should be fitted on diagonally opposite sides of the unit and tightened against the re ar of the panel using

two fixing screws.

The mounting clamp assembly and fitting instructions differ slightly for the two recorders.

Minitrend QX and eZtrend QXe

1. Insert the panel gasket onto the recorder so it goes between the back of the

recorder bezel and the panel. From the front p anel, place u nit in the pa nel and

push through the panel.

2. To loosen each clamp, unscrew the long screw to accommodate the panel

thickness.

3. From behind the panel, the orientation of the clamp should be with the screw

head towards the rear of the unit. See .

4. Take the first clamp and locate the two lugs on the clamp into the slots on the

unit. See .

5. Take the second clamp and do the same but in the diagonal position to the

opposite side. See Figure 2.3 on page 8.

6. Tighten the screw using a flat blade screwdriver and the clamp will secure

against the panel.

CAUTION

CONTROL UNIT DAMAGE

Do not over tighten mounting clamp screws.

Minitrend QX

Multitrend SX torque setting should be 0.5 - 0.70Nm/4.4 - 6.2lbf-in

Failure to comply with these instructions may result in product damage

Multitrend SX

1. Insert the panel gasket onto the recorder so it goes between the back of the

recorder bezel and the panel. From the front p anel, place u nit in the pa nel and

push through the panel.

2. To loosen each clamp, unscrew the long screw to accommodate the panel

thickness.

3. From behind the panel, the orientation of the clamp should be with the screw

head towards the rear of the unit. See Figure 2.2 on page 7.

4. Position the circular mounting boss in the hole on on e side of the case with the

lip of the boss inside the case. Ensure the front of the clamp is up against the

panel.

5. Fix the second clamp on the opposite side of the unit. See Figure 2.4 on

page 15.

and eZtrend QXe torque setting should be 0.5 - 0.75Nm/4.4 - 6.6lbf-in

6. Tighten the screw using a flat blade screwdriver and the clamp will secure

against the panel.

43-TV-25-30 Iss.4 GLO Dec 06 UK 11

Page 18

Mechanical Installation

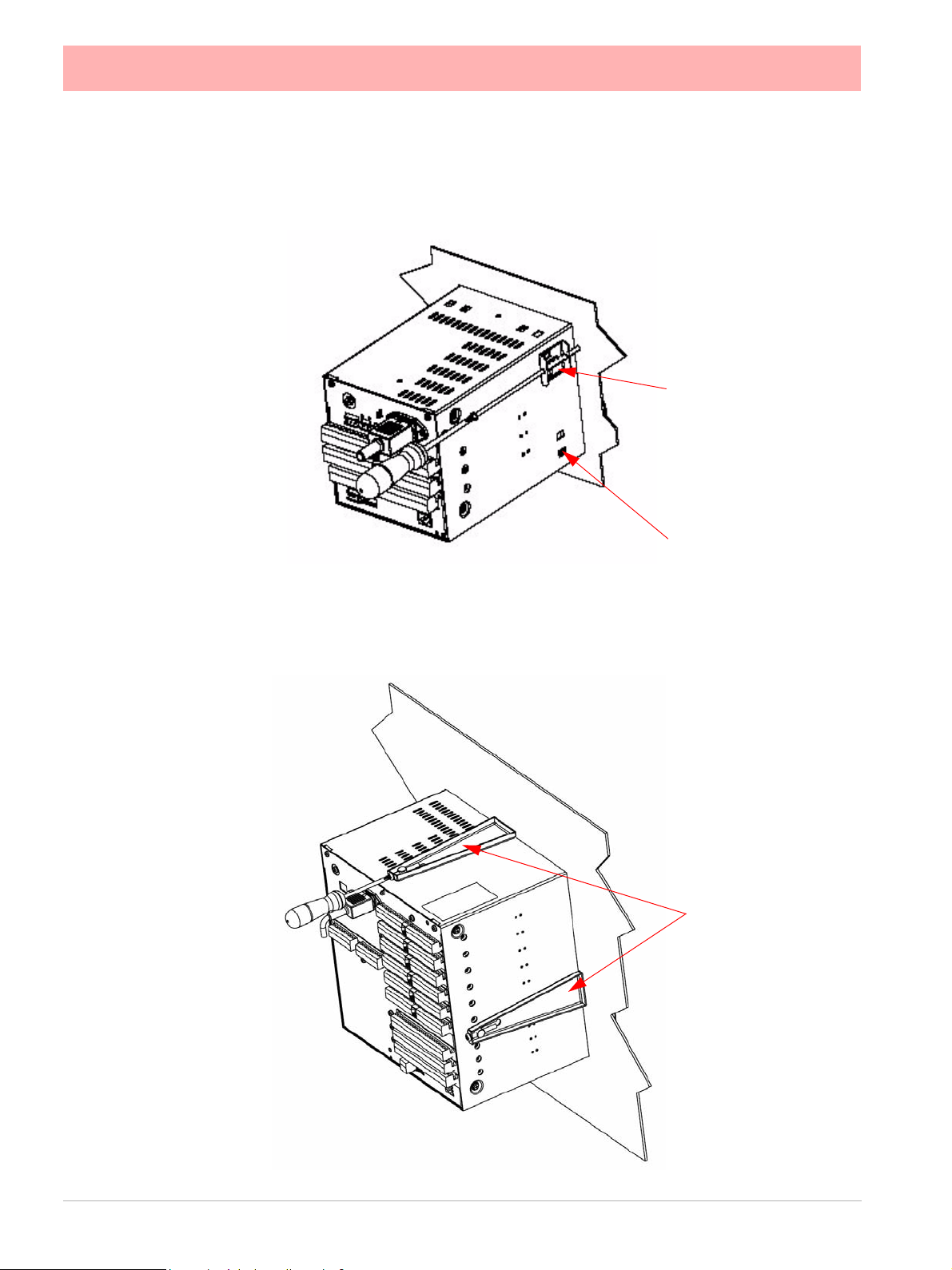

Mounting Clamp Diagram

Figure 2.1 Minitrend QX and eZt r e n d Q X e Mounting clamp

2 mounting clamp

positions required on

two opposite sides of

the recorder. Nema 4X

requires all 4 clamps to

be fitted.

Figure 2.2 Multitrend SX Mounting clamp

Mounting clamp slots

4 mounting clamp

positions (2 shown).

2 clamps are required on opposite

sides of the recorder

12 43-TV-25-30 Iss.4 GLO Dec 06 UK

Page 19

Electrical Installation

Installation Category

• Installation category - Installation category II, Pollution degree 2

• Follow National and local electrical codes for installation in a Class 1, Div.2 area.

For voltage, frequency and power refer to the appropriate Specification sheet: See “Sec-

tion 12: Technical Data & Specifications” on page 219.

Fuses

There is a fuse situated on the DC input version power supply, type 2A time-delay, this can

be replaced by the user. Replacement of fuses should be carried out by qualified service

personnel.

If the fuse should blow again there is probably a pr oblem elsewhere within the unit and the

recorder should be returned for inspection to your authorised Honeywell distributor or

Honeywell Service department.

Electrical Installation

Cables

To fully comply with the requirements of the CE Mark, all cables connected to the rear of

the unit should use screened cable terminated at both ends. A low impedance earth cable

(<50 m) must be connected to the earthing stud on the rear of the recorde r, to ensure

that the recorder is always earthed.

Before performing any installation please read the section on “Safety” on page 2.and

“Warnings and Safety Precautions” on page 3.

All connections to the unit are made via the rear panel, the layou t of which is sh own in Fig-

ure 2.3 on page 14

Note: The eZtrend QXe

to the recorder case using a low impedance bond. Also avoid use of a length of wire between

the cable screen and the recorder case.

Analogue Input card (Slot A). Cable screen must be well connected

Signal Wiring

WARNING

ENSURE SAFETY EARTH CONNECTION

Always ensure the unit is connected to safety earth when connecting to an AC or DC

supply.

Failure to comply with these instructions could result in death or serious injury.

Your recorder is intended for pa nel-mount u se, and only the fro nt face is intended to be

exposed to the operator. Disconnection from the supply MUST be mad e possible by

means of a switch, circuit breaker or other means of supply isolation.

The disconnection device must be included in the panel installation , clearly marke d, in

close proximity to the recorder, and within easy reach of the operator. The protective earth

terminal must remain connected (even if the recorder is isolated from the mains supply) if

any of the analogue or relay terminals are connected to hazardou s voltage.

43-TV-25-30 Iss.4 GLO Dec 06 UK 13

Page 20

Electrical Installation

CAUTION

UNIT DAMAGE CONTROL

To protect against component failures the user should fit an external fuse for the DC

input power supply. The value should be 4A, time delay, high breaking capacity, minimum 60Vdc.rated.

Failure to comply with these instructions may result in product damage

WARNING

HAZARDOUS VOLTAGES

When using the recorder as portable equipment the optional rear cover must be fitted

when hazardous voltages are connected.

Failure to comply with these instructions could result in death or serious injury.

AC Power

AC supply is connected via the standard configuration IEC chassis plug on the rear panel,

100 - 250 Vac, 50-60 Hz (40 VA Minitrend QX, eZtrend QXe and 60VA Multitrend

SX). Absolute limits 90V-132Vac (110V) and 180V-264Vac (240V)

24V AC/DC Power / 48V AC Power

For the Minitrend QX and the Multitrend SX the supply range is 24V DC +/- 10% (absolute limits are 20V to 55V DC). Also accepts 20 to 30V AC. Power to the D.C.variant is

connected via a rectangular 3-way connector as identified in Figure 2.3 on page 14 for the

Minitrend QX and Figure 2.4 on page 15 for the Multitrend SX.

The eZtrend QXethe supply range is 24V DC +/- 10% (absolute limits are 20 V to 30V DC).

Also accepts 20 to 25V AC.

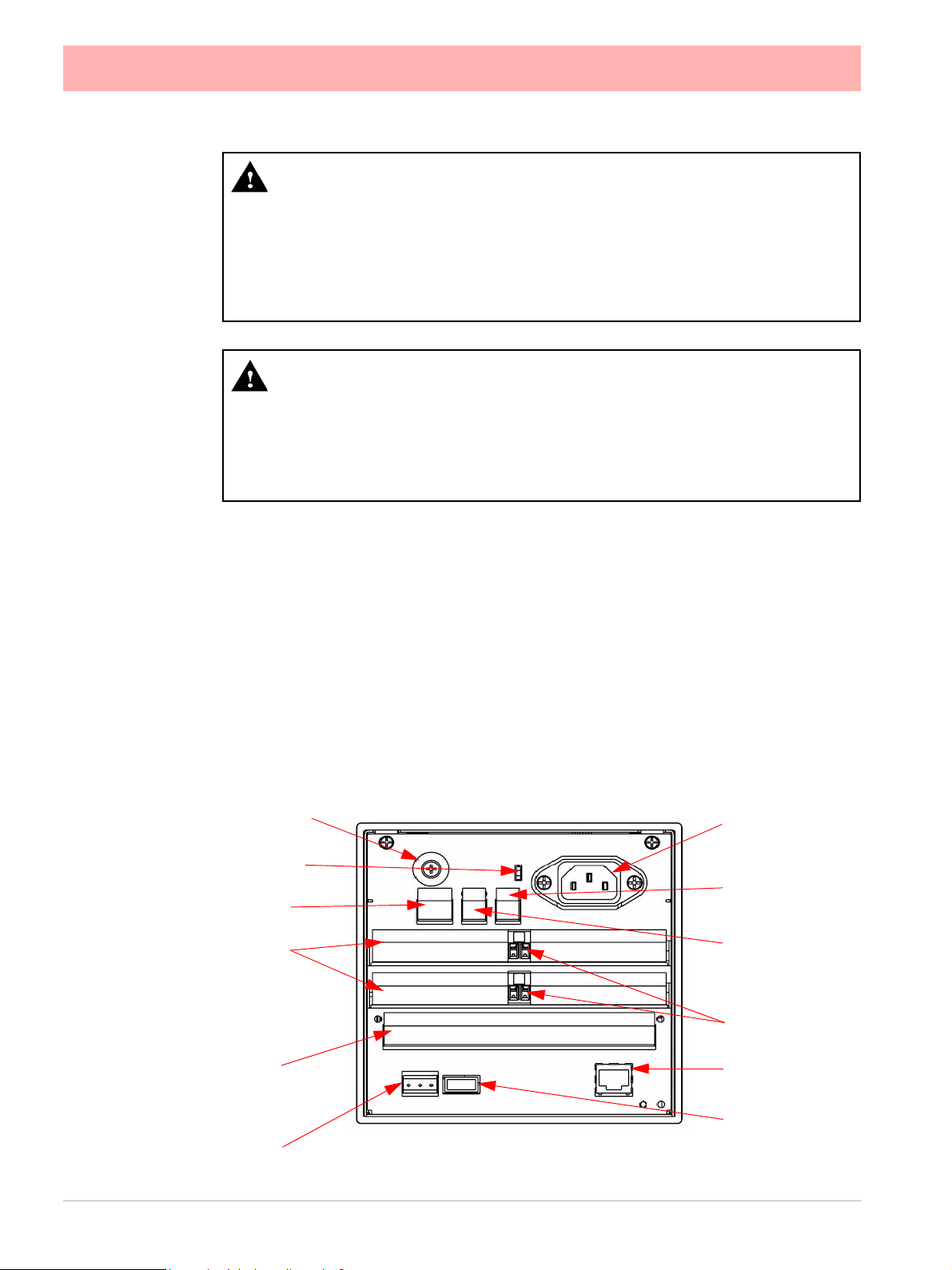

Earth screw (ground)

Wire seal provision

24V DC/AC Input

Analogue Input /

Analogue Output

/ or Pulse Input

Slot A

Slot B

AC supply

100 - 250 VAC

SPNC Relay

24V TX Power

Supply Output

CJC Sensor

Alarm Relay or

Digital I/O

Slot G

RS485

14 43-TV-25-30 Iss.4 GLO Dec 06 UK

Figure 2.3 Minitrend QX Connector diagram

Ethernet

USB Host

Page 21

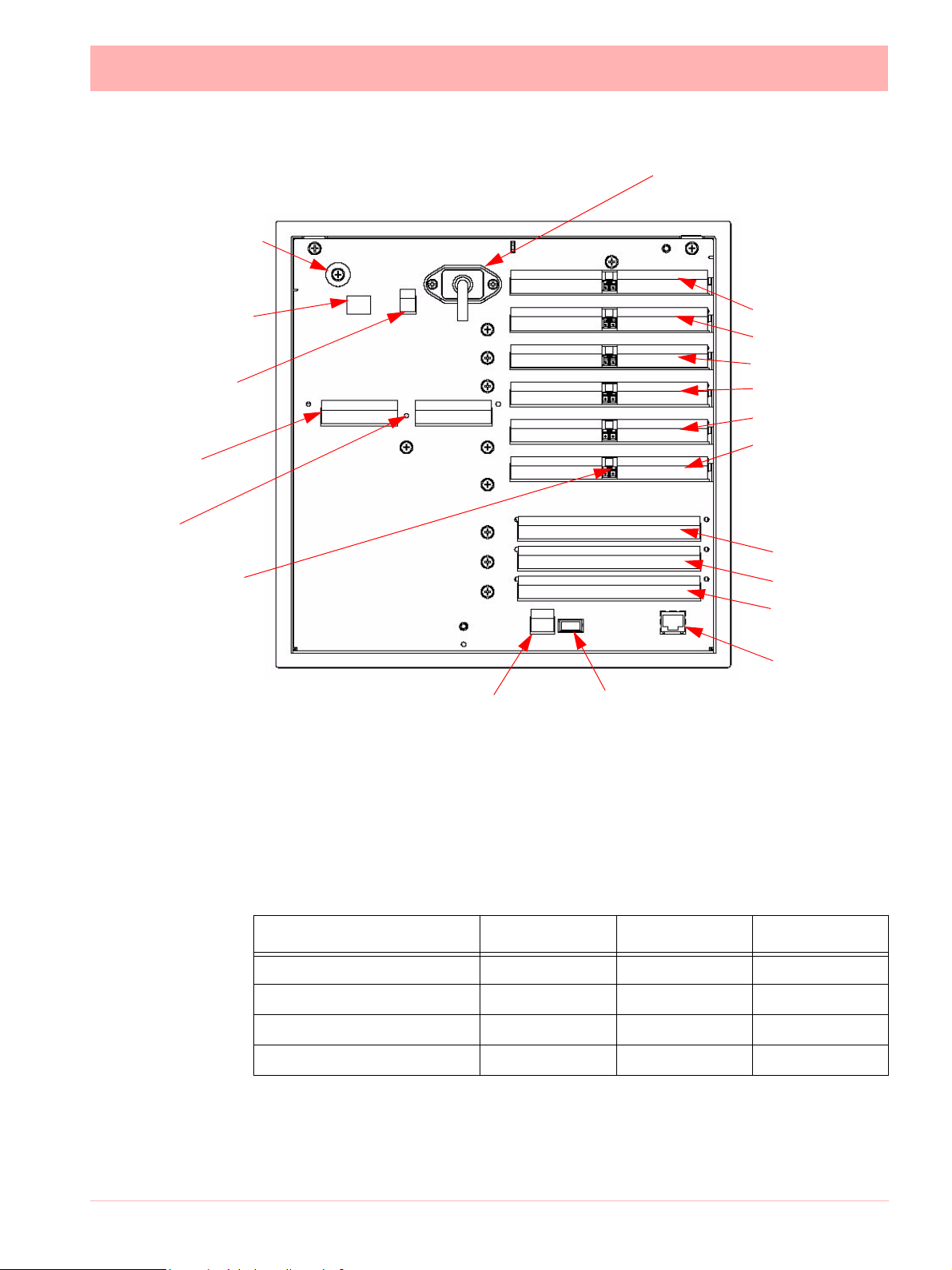

Electrical Installation

AC supply

100 - 250 VAC

Earth screw

(ground)

24V DC/AC Input

SPNC

Relay

24V TX

Power Supply

Output

LED

CJC Sensor

position in the

middle of the

Analogue Input

connector.

Slots A - F

Analogue Input/

Analogue Output/

or Pulse Input

Slot A

Slot B

Slot C

Slot D

Slot E

Slot F

Alarm Relay

or

Digital I/O

Slot G

Slot H

Slot I

Ethernet

RS485 USB Host

Figure 2.4 Multitrend SX Rear p anel

Card and Slot positions

Table 2.1 : Card priority positions

Cards

Analogue Input card A, B A, B, C, D, E, F A*, B (option)

Analogue Output card B E, F Pulse Input card A, B A, B, C, D, E, F Alarm Relay or Digital I/O card G G, H, I G

“QXe Analogue Input (Standard) card” on page 19

43-TV-25-30 Iss.4 GLO Dec 06 UK 15

Minitrend QX Multitrend SX eZtrend QXe

Page 22

Electrical Installation

Earth screw

(ground)

Analogue Input

card (option)

Slot B

CJC Sensor

24V TX Power

Supply Output /

RS485 port /

USB Host card

(option)

Wire seal provision

24Vdc TX

RS485

20 to 30VDC / 20 to 25VAC Input

Instrument power (option)

AC supply

100 - 250 VAC

Alarm Relay or

Digital I/O

Slot G (option)

USB

ETHERNET

Analogue Input /

Ethernet connection

card (std) - Slot A

Figure 2.5 eZtrend QXe Rear panel

Analogue Input Card

Each Analogue Input card has up to 8 input channels for th e Minitrend QX and the Multitrend SX and up to 6 channels for the eZtrend

way screw terminal plugs that fit into a PCB header on the rear of the unit. The 2- way CJC

sensor should remain fitted in the central 2-way header.

The Minitrend QX

can have two analogue input cards fitted giving up to 16 input channels

(2 x 8 channel cards). The slot positions are A & B, these are identified on the rear p anel on

the back of the unit. Either slot can be used, it is recommended that slot A is used if only one

card is fitted.

The Multitrend SX can have up to 6 analogue input cards fitted, up to 48 inpu t channels.

The slot positions A, B, C, D, E or F; these are identified on the rear panel. PC boards are

fitted in order, slot ”A” starts from the top.

The eZtrend

QXe can use this card as an additional Analogue Input card fitted in Slot B,

providing up to 6 more channels. This card would be used after using the 3 or 6 channel

standard eZtrend

QXe Analogue Input card which is fitted in Slot A, see “QXe Analogue

Input (Standard) card” on page 19.

QXe. Connections are made via 2 x 12-

To fit this option card into the eZtrend QXe recorder you will require an expansion card to

interface to the recorder. See “QXe Analogue Input (Standard) card” on page 19.

16 43-TV-25-30 Iss.4 GLO Dec 06 UK

Page 23

Electrical Installation

WARNING

HAZARDOUS VOLTAGES

Insulation from channel to channel: Normally a channe l can be sa fely conn ected to a

hazardous voltage up to 300V AC common mode* with respect to earth. However,

where a channel is connected to a safety low voltage circuit, an immediately adjacent

channel must be adequately insulated from hazardous voltages between 150V AC

and 300V AC max. This insulation should comprise of at least 1.5mm air gap, or a barrier rated greater than 1400V AC. This is to ensure that protection of the safety low

voltage circuit is fully maintained.

*Common Mode voltage is a voltage applied between the whole channel and earth,

not between pins on a channel. 300V AC is permitted at M easurement Category CAT

ll (Overvoltage Category ll)

Failure to comply with these instructions could result in death or serious injury.

NOTICE

For 12 and 24-way connectors; torque setting 0.4 Nm/3.5lbf-in. Do not over tighten.

Recommended wire size for termination connector is 22-12 AWG (American Wire

gauge) equivalent to 22-14 SWG (Standard Wire Gauge). AWG metric 0.6426-

2.052mm in diameter or SWG metric 0.71 - 2.03mm in diameter.

Analogue Input Channel Numbers

Analogue Input cards are either 4, 6 or 8 channels with a full length connector taking up 8

channels even if only 4 or 6 are operational.

Table 2.2 :

Minitrend QX and Multitrend SX Analogue Input card

Card Position

Channel number 1 to 8 9 to 16 17 to 24 25 to 32 33 to 40 41 to 48

Slot A Slot B Slot C Slot D Slot E Slot F

Table 2.3 :

Card 3 CH. 6 CH. 9 CH. 12 CH.

A 1-3 1-6 1-3 1-6

B 9-14 9-14

eZtrend QXe Analogue Input cards

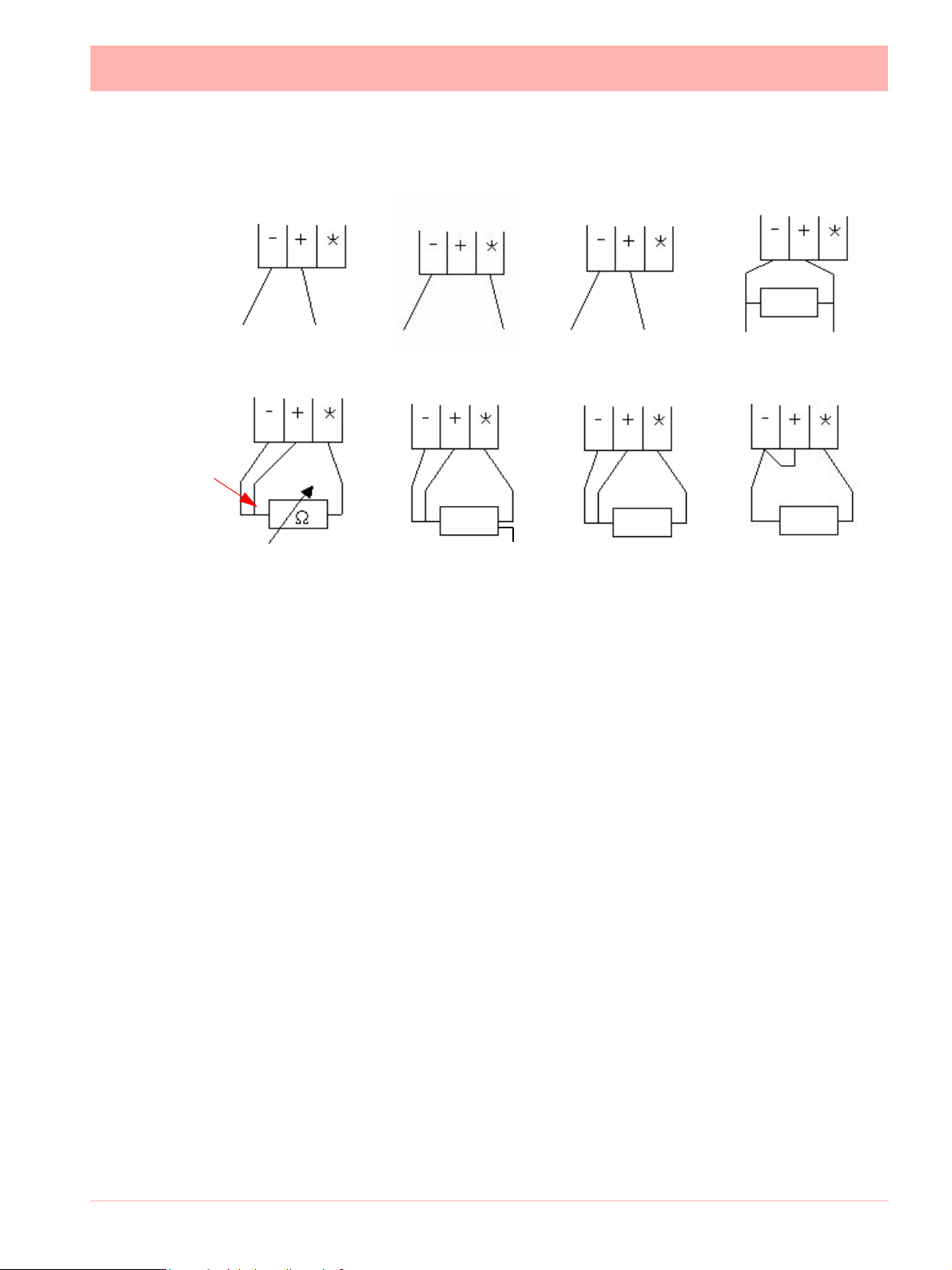

Analogue Input Connection Details

Current Input

For Current (mA) Input fit a 10

analogue connector. Figure 2.7 on page 19 shows a 10

nel 5 for a current (mA) input.

resistor across the + and - pins of the 12-way mating half

(±0.1%) resistor fitted to chan-

43-TV-25-30 Iss.4 GLO Dec 06 UK 17

Page 24

Electrical Installation

Thermocouples

Ensure polarity of thermocouple is correct.

Resistance Thermometers

If using 2 wire R/T the + and - terminals must be linked together. See Figure 2.7 on

page 19.

Analogue Input Signal Wiring

CAUTION

CONTROL UNIT DAMAGE

Do not apply a hazardous live voltage between + and - pins within a channel. ( eg. 60V

maximum on voltage ranges, 5V maximum on millivolts ranges). Do not apply a voltage

above 1.2V to the * pin.

Failure to comply with these instructions may result in product damage

Figure 2.6 Analogue Input connector

CJC

CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8

This Analogue Input card can be used as an option to add up to 6 more Analogue Input

channels for the eZtrend QXe

numbers 9 to 14. The standard fit Analogue Input card is fitted in slot A with up to 6 channels

(channels numbers 1 to 6).

To fit this option card into the eZtrend QXe recorder you will require an expansion card to

interface to the recorder. See “QXe Analogue Input (Standard) card” on page 19.

recorder. This will fit into Slot B and will display as channel

18 43-TV-25-30 Iss.4 GLO Dec 06 UK

Page 25

Electrical Installation

Figure 2.7 Input signal wiring

+ve optional

connection

Active Burnout

Volts/mV

-ve +ve

Ohms

Recorder setup will be required if wiring changes are made for Active Burnout Thermocouples. See “*Thermocouple Wiring Changes.” on page 55.

Thermocouple Active Burnout status can be viewed in the Main Menu > Status >Diagnostics

> Analogue Input screen, Input column. The Health Watch/Maintenance firmware option

must be active to access the Maintenance and Diagnostic buttons. See “Diagnostics” on

page 133.

Thermocouples

-ve

4-wire R/T

+ve

R/T

Passive Burnout

Thermocouples

-ve

3-wire R/T

+ve

R/T

Current

10R

-ve +ve

2-wire R/T

R/T

For the eZtrend QXe

the link between positive (+) and negative (-).

recorder Active Burnout is not available. Ohms measurements must have

CJC Connectors

The CJC connector resides between channel 4 and channel 5 on the Analogue Input card.

For information on connecting the CJC sensor, see Figure 2.6 on page 18.

For the eZtrend QXe

recorder this is available on the Analogue Input card (option).

QXe Analogue Input (Standard) card

The eZtrend QXe is fitted with a standar d Analogue Input card in Slot A, with up to 6 chan-

nels. The card is also fitted with an Ethernet port as standard. Connection is made via 1 x

18-way screw terminal plugs that fit into a PCB header on the rear of the unit. To fit up to a

further 6 analogue input channels, see “Analogue Input Card” on page 16

43-TV-25-30 Iss.4 GLO Dec 06 UK 19

Page 26

Electrical Installation

Figure 2.8 eZtrend QXe Analogue Input card (std) - Slot A

1 2 3 4 5 6 7 8 9 10 11 12

- +

CH.1 CH.2 CH.3 CH.4 CH.5 CH.6

- +

*

- +

*

- +

*

13 14 15 16 17 18

- +

*

*

- +

*

WARNING

HAZARDOUS VOLTAGES

Insulation from channel to channel: Normally a channel can be safely connected to a

hazardous voltage up to 150V AC common mode* with respect to earth. However,

where a channel is connected to a safety low voltage circuit (i.e. is accessible for operators to touch), any channel within the same 'input bank' must be limited at all time s

to a maximum of 55Vac or 140Vdc**. This is to ensure that protection of the safety low

voltage circuit is fully maintained.

The inputs are divided into two banks: inputs 1 to 3 are one bank, and inputs 4 to 6 (if

fitted) are another bank. A voltage of up to 150V AC common mod e can be applied on

one bank as long as any safety low voltage circuits are on the other bank. The recorder

is protected against accidental connection of a voltage up to 240V AC common mo de

which might occur as a temporary fault condition, provided there are no safety low voltage circuits connected to the same input bank as the channel with the fault.

*Common Mode voltage is a voltage applied between the whole channel and earth,

not between pins on a channel.

** this reduces to 33Vrms or 70Vdc if any channel within the input bank is configured

as an ohms or R/T measurement.

Failure to comply with these instructions could result in death or serious injury.

20 43-TV-25-30 Iss.4 GLO Dec 06 UK

Page 27

Electrical Installation

CAUTION

CONTROL UNIT DAMAGE

Do not apply a hazardous live voltage between + and - pins within a channel (e.g . 60V

maximum on voltage ranges, 5V maximum on millivolts ranges).

The * pin should be connected only as part of ohms or R/T me asurements. Ohm s and

R/T measurements share a common connection (* pin) with all channels in the same

bank (the inputs are divided into two banks: inputs 1 to 3 are one bank, and inputs 4 to

6, if fitted, are another bank). To avoid damage, ensure t hat a channel selected as ohms

or R/T remains floating, i.e. the sensor is not connected to any external voltage.

Alternatively, if an ohms or R/T sensor must be biased to an external voltage, ensure

that the other two channels within the same input bank a re floating or are biased to the

same voltage (i.e. - inputs of all three channels connected to the same voltage).

Failure to comply with these instructions may result in product damage

Analogue Output Card

Not available on the eZtrend QXe recorder.

The Analogue Output card connections are made via 1 x 12- way screw te rminal plug that

fits into a PCB header on the rear of the unit.

The Analogue Output card position for the Minitrend QX

page 14, and Figure 2.4 on page 15 for the Multitrend SX.

is shown in Figure 2.3 on

WARNING

HAZARDOUS VOLTAGES

Insulation from channel to channel: Normally a channel can be safely connected to a

hazardous voltage up to 300V AC common mode* with respect to earth. However,

where a channel is connected to a safety low voltage circuit, an i mmedi ately adjace nt

channel must be adequately insulated from hazardous voltages betwe en 150V AC and

300V AC max. This insulation should comprise of at least 1.5mm air gap, or a barrier

rated greater than 1400V AC. This is to ensure that protection of the safety low voltag e

circuit is fully maintained.

*Common Mode voltage is a voltage applied between the whole channel and earth, not

between pins on a channel. 300V AC is permitted at Measurement Category CAT ll

(Overvoltage Category ll)

Failure to comply with these instructions could result in death or serious injury.

43-TV-25-30 Iss.4 GLO Dec 06 UK 21

Page 28

Electrical Installation

Analogue Output Channel Numbers

The Analogue Output cards are eith er 2 or 4 ch annels using a connector that on ly takes up

half the length of the connector slot. Looking from the rear of the unit the Analogue Out connector is on the left of the Analogue slot with a blanking plate on the right.

Table 2.4 :

Analogue Output card

Card Position

Channel number 9 to 12 33 to 36 41 to 44

Slot B Slot E Slot F

Analogue Output Connection Details

Output 1 Output 2 Output 3

1 2 3 4 5 6 7 8 9 10 11 12

Loop -

Loop +NCLoop -

Loop +

Loop -

NC

Loop +NCLoop -

Output 4

Loop +

NC

NC = Not

connected

Pulse Input Card

The Pulse Input card connections are made via 1 x 12-way screw terminal plugs that fits

into a PCB header on the rear of the unit.

The Pulse Input card position for the Minitrend QX

and Figure 2.4 on page 15 for the Multitrend SX.

The Pulse Input card is not available on the eZtrend QXe

O option card has 4 channels that can be set as pulse inputs (channels 1 to 4). Th e operating frequency for pulse inputs on the Digital I/O card is 1kHz max.

Input: Low < 1V, High >4V to <50V DC (8V to 50V p-p AC) or Volt free input: Low = short

circuit, High = open circuit.

22 43-TV-25-30 Iss.4 GLO Dec 06 UK

is shown in Figure 2.3 on page 14,

recorder, however, the 8 Digital I/

Page 29

Electrical Installation

WARNING

HAZARDOUS VOLTAGES

Insulation from channel to channel: Normally a channel can be safely connecte d to a

hazardous voltage up to 300V AC common mode* with respect to earth. However,

where a channel is connected to a safety low voltage circuit, an immediately adjacent

channel must be adequately insulated from hazardous voltages between 150V AC

and 300V AC max. This insulation should comprise of at least 1.5mm air gap, or a barrier rated greater than 1400V AC. This is to ensure that protection of the safety low

voltage circuit is fully maintained.

*Common Mode” voltage is a voltage applied between the whole channel and earth,

not between pins on a channel. 300V AC is permitted at Measurement Category CAT

ll (Overvoltage Category ll)

Failure to comply with these instructions could result in death or serious injury.

Pulse Input Channel Numbers

The Pulse Input card has channels using a connector that only takes up half the length of

the connector slot. Looking from the rear of the unit th e Pulse Input connector is o n the right

of the slot with a blanking plate on the left.

Table 2.5 :

Pulse Input card

Card Position

Channel number 1 to 4 9 to 12 17 to 20 25 to 28 33 to 36 41 to 44

Slot A Slot B Slot C Slot D Slot E Slot F

Pulse Input Connection Details

Do not connect anything to terminals marked NC (Not Connected). For F requency and Voltage levels see “Specification Tables” on page 223.

Channel 1 Channel 2 Channel 3 Channel 4

- + NC - + NC - + NC - + NC

43-TV-25-30 Iss.4 GLO Dec 06 UK 23

Page 30

Electrical Installation

Transmitter Power Supply Card

The Minitrend QX Transmitter power supply option is

24V DC 200 mA and is fitted to the power supply card

within the unit. Connection is made via a 2-way connector

at the rear of the unit, the mating half is supplied with this

option. For connector position see Figure 2.3 on

page 14. The 24V transmitter power supply is not isolat-

ed from the recorder, and is not referenced to ground.

The Multitrend SX

the power supply card within the unit. Connectio n is made via two 10-way connectors, see

Figure 2.4 on page 15, mating halves su pplied with this option. The Multitrend SX trans-

mitter power supply is isolated from the recorder.

A red LED light will illuminate when there is voltage on the connectors. The LED is situated

between the two connectors at the back of the unit. Figure 2.4 on page 15.

The eZtrend QXe has a 24V DC 130mA Transmitter Power Supply card that can be fitted

as an option. Connection is made via a 2-way connector at the rear of the unit, the mating

half is supplied with this option. For connector position see Figure 2.3 on page 14. The

24V transmitter power supply is not isolated from the recorder, and is not referenced to

ground. The option card also has an RS485 Modbus port and a USB port.

Recommended wire size for termination connector 22-12 AWG (22-14 SWG).

Transmitter power supply option is 24V DC 1 A and is fitted below

24V 0V

Minitrend 24V DC TXP

24V

Figure 2.9 Transmitter Power Supply card for the Multitrend SX recorder

LED

0V

Alarm Relay Cards & Digital Input/Output Cards

The Alarm Relay Cards and the Digital Input/Output Cards are both option s available for

the Minitrend QX, Multitrend SX and the eZtrend QXe recorders.

To fit these option cards into the eZtrend QXe recorder it requires an expansion card to

interface to the recorder. See “QXe Analogue Input (Standard) card” on page 19.

All Alarm Relay card outputs provide 240V AC isolation channel to chann el and channe l to

recorder. Digital Input/Outputs will provide isolation to 100V AC test voltage (not for mains

connection).

All digital inputs have volt free contacts, and are sampled at 10Hz max.

24 43-TV-25-30 Iss.4 GLO Dec 06 UK

Page 31

Electrical Installation

The Minitrend QX and the eZtrend QXe reco rders have only one slot available for digital

inputs and relay outputs for either a 4 or 8 channel Alarm Relay card or an 8 or 16 chann el

Digital I/O card fitted in slot G, the position is identified on the rear panel. The 16 channel

Digital I/O card is not available on the eZtrend QXe recorders.

The Multitrend SX can have up to three Alarm Relay cards fitted in any combination of

Alarm Relay card or Digital I/O cards. The fir st Alarm Relay card or Digital I/O card is fitted

in slot G, any additional cards will locate in positions H and I.

WARNING

HAZARDOUS VOLTAGES

Digital Input/Output card channels must not be connected to any hazardous live voltages (no higher than 30V AC rms or 60V DC).

Alarm Relay Card channels

Alarm Relay Card channels can be connected to hazardous voltages up to 300V AC,

at Measurement Category CAT II (Overvoltage Category II)

Failure to comply with these instructions could result in death or serious injury.

NOTICE

For 12 and 16-way connectors; torque settin g 0. 4 Nm/3.5lb-in. Do not over tighten.

Recommended wire size for termination connector is 22-12 AWG (22-14 SWG)

4 and 8 Alarm Relay Cards

The 24-way connector for the Alarm Relay Card, connects to 3 A, 240 VAC SPCO relays.

The pin-outs for 4 and 8 relay Alarm Relay cards are numbered from left to right and they

read as follows for each channel; NC (normally closed), C (common), NO (norm ally open ).

Devices driven by the relays are connected via two 12-way screw terminal plugs.

The last two channels, 7&8, 23&24 or 39&40, can be used as digital inputs, connect across

Common (C) and Normally Open (NO).

CAUTION

IMPROPER MAINS SWITCHING

For 8 channel Alarm Relay cards.

Switching mains on the normally-open contact on cha nnels 7 and 8 is not recommended,

as surges and spikes on the mains supply could cause damage to the input circuitry.

The normally-closed contact is unaffected, and can be used like all the other channels.

A Form C dry contact relay is used for this type of card. The inputs are designed to accept

“Dry contact, no volt inputs”. The relays should be used for non-inductive loads only where

a device requires a voltage to operate it, such as a 12 Volt buzzer, connect it to the normally

open (NO) contacts (unless the fail-safe setting is activated).

The maximum voltage which may be used with the alarm relays is 240V

43-TV-25-30 Iss.4 GLO Dec 06 UK 25

Page 32

Electrical Installation

Alarm Relay Channel Numbers

The Alarm Relay cards are either 4 or 8 channels with a full length connector taking up 8

channels even though the cards only operate on 4 channels or 8 ch annels. The 8 channels

Alarm Relay card has 2 digital inputs available on the last 2 channels. There are no Digital

Inputs available on the 4 channels Alarm Relay card.

Table 2.6 :

Alarm Relay card 4 channel Alarm Relay card 8 channel

Card

position

Slot G 1 to 4 N/A Slot G 1 to 8 7 & 8

Slot H 17 to 20 N/A Slot H 17 to 24 23 & 24

Slot I 33 to 36 N/A Slot I 33 to 40 39 & 40

Channel

number

Figure 2.10 Alarm Relay Card connector details

Digital

Inputs

Card

position

Channel

number

Digital

Inputs

CH 1 CH 2 CH 3 CH 4 CH 5 CH 6 CH 7 CH 8

NC C NO NC C NO NC C NO NC C NO NC C NO NC C NO NC C NO NC C NO

Relay contacts position

NC = Normally Closed

C = Common

NO = Normally Open

Channels 7 and 8 can

be set as Digital Inputs.

(Use C and NO)

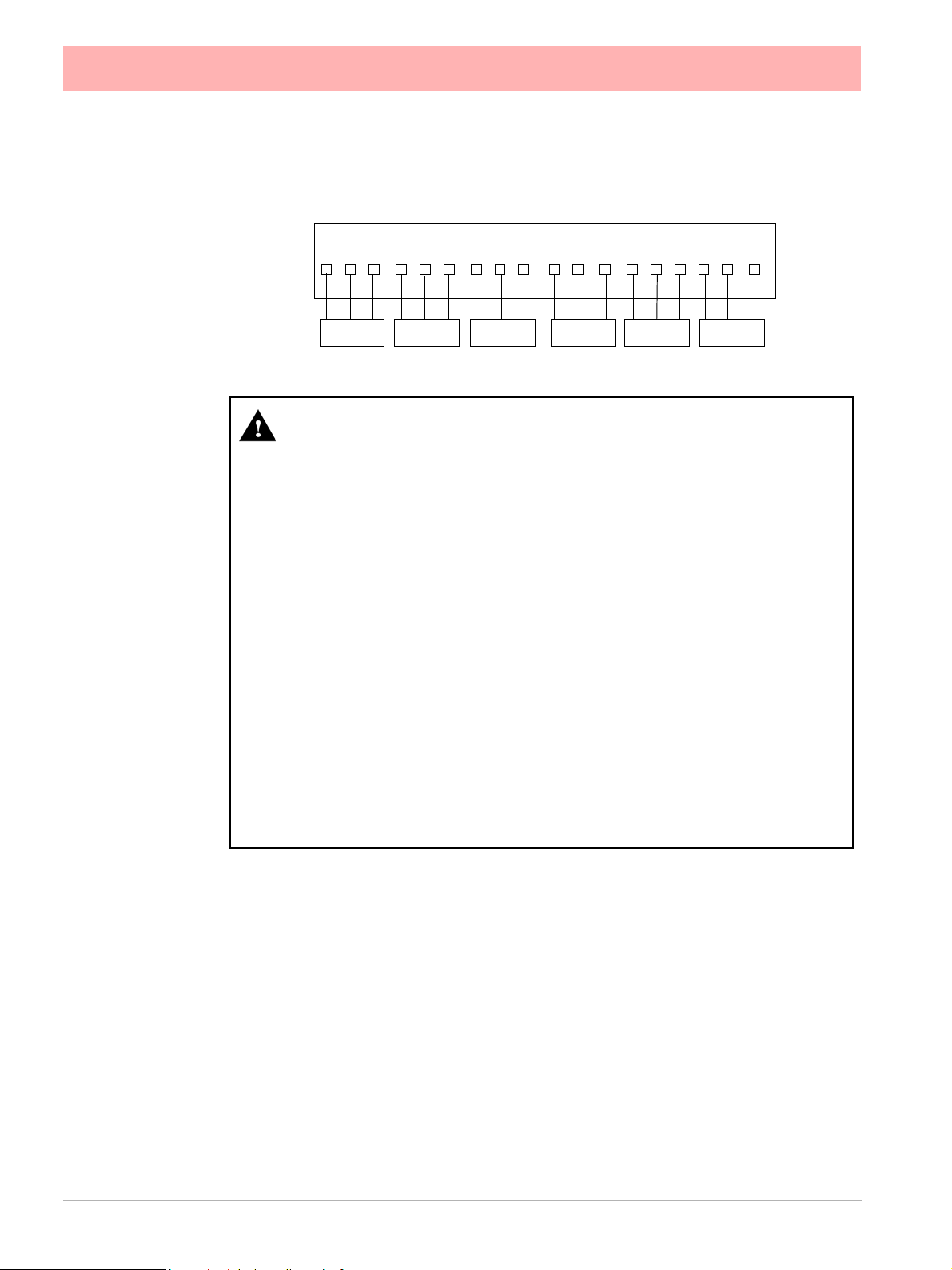

8 and 16 Digital Input/Output Card

The 16 channel Digital I/O card is not available on the eZtrend QXe recorders.

The

Digital Input/Output Card has 1A 24V DC rated relays th at are con nected via two 16-

way connectors, the left connector for the first 8 channels and right connector for the second

8 channels. The pin-outs for 8 and 16 I/O cards are labelled from left to right, 1 to 16 on the

left side and 17 to 32 on the right. Each channel can be se t up as an input o r an output. For

output the relay is normally open type.

A Form A dry contacts relay is used for this type of card. The inputs are designed to accept

“Dry contact, no volt inputs”.

26 43-TV-25-30 Iss.4 GLO Dec 06 UK

Page 33

Electrical Installation

NOTICE

For Digital Inputs, short together the 2 pins of the channels with a switch or a relay.

Pulse Inputs

The 8 and 16 Digital I/O option card has 4 channels that can be set as pulse inputs (first 4

channels). The operating frequency for pulse inputs on the Digital I/O card is 1kHz max.

Input: Low < 1V, High >4.5V to <10V DC (9V to 20V p-p AC) or Volt free input: Low = short

circuit, High = open circuit.

.

Figure 2.11 Digital Input/Output card connector details

CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

NO C NO C NO C NO C NO C NO C NO C NO C NO C NO C NO C NO C NO C NO C NO C NO C

CH9 CH10 CH11 CH12 CH13 CH14 CH15 CH16

NO = Normally Open

C = Common

Digital Input Card Channel Numbers

The Digital input cards are either 8 or 16 channels with a full length connector taking up 16

channels even if only 8 channels are in operation. Both the digital input cards can be used

as a relay card if required.

Table 2.7 :

Digital Input card 8 channel

Card

position

Channel

number

Digital Input card 16

channel

Card

position

Channel

number

Slot G 1 to 8 Slot G 1 to 16

Slot H 17 to 24 Slot H 17 to 32

Slot I 33 to 40 Slot I 33 to 48

The 16 channel Digital I/O card is not available on the eZtrend QXe.

43-TV-25-30 Iss.4 GLO Dec 06 UK 27

Page 34

Electrical Installation

Communications Connections

Ethernet

The Ethernet port is fitted to all X Series recorders as standard and uses a standard RJ45

Ethernet connection. After connect ion , se lec t th e Eth er n et p or t fr om th e Com ms menu and

select the required protocol from the Protocol menu eg.Modbus.

2468

8 7 6 5 4 3 2 1

RD-

RJ45 Pin 1 is to the right

from the rear of the unit

RD+

TD-

TD+

24V DC Instrument Power Input

24V DC instrument power is available on all X Series recorders as an option. It is connected using 3- way connector , mating half is supplied. Diagram shows a view looking from the

rear of the unit.

1735

A

1 2 3

+ - GND

B

eZtrend QXe Comms card

An option card is available with RS485 Modbus port and USB device connections. The card

can be purchased and fitted at any time. The RS485 connection uses a 3-way connector.

The card also has connection for 24V DC Transmitter Power Supply, see “Transmitter

Power Supply Card” on page 24.

To fit this option card into the eZtrend QXe recorder you will require an expansion card to

interface to the recorder. See “QXe Analogue Input (Standard) card” on page 19.

Figure 2.12 eZtrend QXe Comms card

24V DC TX

Power Supply

28 43-TV-25-30 Iss.4 GLO Dec 06 UK

RS485

Modbus port

USB Host

Page 35

Electrical Installation

RS485 Minitrend QX and Multitrend SX recorders.

The RS485 port is fitted as standard as a part of the processor

card and uses a 3-way connection.

After connection, select the RS485 port from the Comms

menu and select the required protocol from the Protocol menu

eg. Modbus. Diagram shows a view looking from the rear of

the unit. See “Comms Services Menu” on page 73.

1 2 3

+A -B GND

SPNC Relay Minitrend QX and Multitrend SX recorders.

(Single Pole Normally Closed). 2-way connector. This is a fail safe

relay which means if the power goes off the relay closes and can be

set to trigger an alarm. So should the power fail the relay is in a “fail

safe” condition. Diagram shows a view looking from the rear of the

unit. Either pins can be Common or Normally closed.

NOTE: Once the recorder is powered up, if there are no active alarms associated with the

“Fixed Relay”, the contacts will open. When the alarm is on they will close.

1 2

eZtrend QXe Expansion Card

This is an interface card that is required when fitting the following option cards:

• Analogue Input card in Slot B (up to 6 channels)

• Four Relay output card

• 8 Relay/2 Digital Inputs card (6 fixed Outputs/2 Configurable DI/DO)

• 8 Configurable Digital Inputs/Discrete 24V Output card

• Comms card (24Vdc Transmitter Power Supply, Rear USB Port, RS485 Comms Port)

USB Devices

For a full list of the latest compatible USB devices, go to: www.XSeries-info.net

Print Support

Print Support is a firmware option that can be activated using the credit system, refer to the

Options item in “Credits” on page 92.

Not all printers will be compatible with the print support feature on the recorder. The guidelines are they must be a USB printer that shows as a standard PCL (Printer Command Language). The system will not support multi function devices or printers that require specific

drivers. Avoid photo printers and printers that allow stand alone operation with cameras or

media specific printers such as pictbridge.

There isn’t a constant factor to which printers work and tho se that wont. We recommend that

you follow the guidelines outlined here and plug it in and see.

Examples of printers that are compatible with the system are:

• HP Deskjet 995C • HP Photosmart 7760 • HP DeskJet 895Cxi

• HP Laserjet 1022n • HP Laserjet 1300 • HP Deskjet 970Cxi

• HP Deskjet 450cbi

To set up your printer configuration go to “Printer Menu” on page 98.

43-TV-25-30 Iss.4 GLO Dec 06 UK 29

Page 36

Electrical Installation

Keyboards

All keyboards are native USB keyboards. Local keyboard layouts are not supported; all keyboards are recognised as US layout (QWERTY).

Cordless keyboards and mice are not supported:

• Dell Model # SK-8115 Keyboard • IBM ACC42 with USB hubs

• Dell Model # C-BG17-Dual Cordless

Keyboard and Mouse Combination

• Logitech Model # LX300 Cordless

Keyboard and Mouse Combination

• IBM SK-8815 with USB hubs

• IBM SK-8806 with USB hubs

Barcode Reader

Most USB barcode readers emulate keyboards and cause no recognition prob lems. Exa mples of tested barcode readers are:

• Peninsula Phoenix 2 • Wasp - WWR 2905 Pen Scanner

• Quick Scan QS2500

• Barcode Traders LC4400 Series

30 43-TV-25-30 Iss.4 GLO Dec 06 UK

Page 37

Section 3: Overview

Functions and Features

.

Up to 16 Analogue Inputs

for the Minitrend QX, 48

for the Multitrend SX and

up to 12 for the eZtrend

QXe

• mA (external shunt)

• ohms

• Volts

• mV

• Thermocouple

• RTD

QX - Up to 4 Analogue Outputs

SX - Up to 8 Analogue Outputs

QX - Up to 8 Pulse Inputs

SX - Up to 24 Pulse Inputs

QX - Up to 8 Relay Alarm Outputs

SX - Up to 24 Relay Alarm Outputs

QXe - Up to 8 Relay Alarm Outputs

Data Storage media:

• QX/SX Compact Flash - up

to 4Gb

• USB ports for keyboard,

mouse and storage

QX - Up to 192 “soft alarms” 6 per pen

SX - Up to 576 “soft alarms” 6 per pen

QXe - Up to 144 “soft alarms” 6 per pen

QX - Up to 32 Totalisers (1 per

pen)

QXe - Up to 24 Totalisers (1

per pen)

SX - Up to 96 Totalisers (1 per

pen)

Fast Scanning Mode

(QX = 8 Inputs,

SX = 16 inputs)

24V Power Supply

24V Transmitter Power Supply

QX - Up to 16 Digital Inputs /

24V Outputs

SX - Up to 48 Digital Inputs /

24V Outputs

QXe - Up to 8 Digital Inputs /

24V Outputs

Crystal Clear Display

• Minitrend QX has a 5.5” Digital Colour LCD (TFT), QVGA Resolution (320 x 240 pixels)

• Multitrend SX has a 12.1” Digital Colour LCD (TFT), SVGA Resolution (800 x 600 pix-

els)

•

• Clear and intuitive operation, Industrial rugged Touch Screen with rapid navigation

• Industrial rugged Touch Screen with rapid navigation

• Custom build screens in the recorder or using Screen Designer (not

QX/SX

Common Relay Output

Communications:

• FTP, TCP/IP

• RS485 Modbus (slave

• 10/100 Ethernet, Web and Email

• USB ports for keyboard and mouse

• OPC Server

• RS485 Modbus (slave) QXe

) QX/SX

Key:

Standard

Option

eZtrend QXe has a 5” Digital Colour LCD (TFT), QVGA Resolution (320 x 240 pixels)

eZtrend QXe)

43-TV-25-33 GLO Iss.4 Dec 06 UK 31

Page 38

Functions and Features

Comprehensive Connectivity

• 10/100 Ethernet (DHCP), Web, OPC Server and E-mail

• FTP and TCP/IP

• RS485 Modbus Protocol (A Comms option card and expansion card are required for the

eZtrend QXe recorder).

• USB ports for keyboard, mouse and printer (Rear port is an option for the eZtrend QXe).

Data Storage

• On-board non-volatile Flash memory - up to 2GB for Minitrend QX and the Multi-

trend SX

, - up to 400MB for eZtrend QXe.

• Removable Compact Flash and USB storage (

See “Storage Media Format” on

page 120.) for formatting information of Compact Flash cards and USB keys).

Compact Flash not available

• No moving parts - all solid state flash memory

for the eZtrend QXe.

Security Stringent - Total Data integrity

• Password Protection - 21CFR Part 11

• ESS - Extended Security System

Plus..

• Health Watch for preventative maintenance

• Remote Access - Advanced Software Data Analysis at your PC

• Independent Chart and Logging speeds

• Global Language Support

• Rapid review and replay of data at recorder

• Approvals - CE, CSA, UL.

• NEMA 4X

/ IP66 option.

Minitrend QX and Multitrend SX also have FM approval.

• Up to 50Hz (20 msec) Logging, 10Hz (100mS for eZtrend QXe.

• Up to 16 Analogue Inputs for the Minitrend QX

• Up to 48 Analogue Inputs for the Multitrend SX

• Up to 12 Analogue Inputs for the eZtrend QXe

• Remote Viewer via the recorder web page

• Events

• Batch

• Print Support

• Counters

32 43-TV-25-30 Iss.4 GLO Dec 06 UK

Page 39

Functions and Features

Recorder Functionality

• X Series recorders provide flexible electronic data acquisition and recording in a high

functionality instrument. Minitrend QX

5.5” QVGA display and the Multitrend SX is a large 12.1” diagonal display format

recorder. The eZtrend QXe is a DIN standard 144mm format recorder with a 5” QVGA dis-

play.

is a DIN standard 144mm format recorder with a

• The Minitrend QX

Analogue inputs and the eZtrend QXe

expandable non-volatile flash memory available plus additional removable storage media.

• All recorders use digital colour TFT LCD screens to provide easy to read displays with wide

viewing angles for the best all around data viewing.

• The touch screen operator interface provides fast, easy access to the recorder menus making set up and data analysis quick and efficient. Navigation through the menus and text

entry are direct and intuitive.

Example of a recorder menu path from the Main Menu to change the Pen Scale configuration with clear rapid navigation

has up to 16 Analogue inputs, and the Multitrend SX has up to 48

has up to 12 Analogue inputs. 70Mb to 400MB of

43-TV-25-30 Iss.4 GLO Dec 06 UK 33

Page 40

Functions and Features

Features

Display

• 5.5” Colour Active TFT for the Minitrend QX and 12.1” Colour Active TFT for the

Multitrend SX and 5” Colour Active TFT for the eZtrend QXe - with more than

256,000 colours makes it easy to interpret process data and take action with the intuitive

bar charts, digital values, trends or customised displays. A screen saver function can be set

from 1 to 720 minutes to extend the life of the backlight.

• Touch Screen - the heavy duty durable touch screen provides easy data entry and rapid

navigation though the menus.

• Help Files - A complete contextual help system can be accessed and visualised on the

screen of the recorder.

Communications

• Ethernet Connectivity - the Ethernet (DHCP standard) connection, with support for various protocols, provides comprehensive connectivity to local area networks (LANs). The

standard Ethernet interface makes networking of the recorder to a LAN or the world wide

web fast and convenient. Dynamic Host Configuration Protocol (DHCP) automatically

acquires the settings (IP address) for network communications from a DHCP server.

• RS485 Modbus - the RS485 connection allows process data to be transferred to other

devices, or to record data received in MODBUS RTU protocol (slave mode only). (A

Comms option card and expansion card are required for the eZtrend QXe recorder).

• Simple Network Time Protocol (SNTP) - The recorder can be synchronised over the ethernet network via a SNTP client or synchronise other recorders via a Server.

• Web Server - with the recorder connected to a LAN, all process variables, alarm and messages can be viewed from an internet browser; values are automatically refreshed.

Data Storage

Internal Data Storage - 70MB to 1850MB of expandible internal non-volatile flash memory

is available for data storage and chart history (replay of data on the display).

Internal memory / Logging rate = 1 sec

Type Pens 70MB 180MB 400MB 890MB 1850MB

QX, SX

QXe

QX, SX

QXe

QX, SX 32 6d 15d 34d 75d 155d

SX 48 4 10d 22d 50d 103d

SX 96 2 5d 11d 25d 51d

8824days

24days

16

16

12d

12d

61d

30.5d-68.5d

137d

-

137d

68.5d

301d

-

150d

-

622d

-

311d

-

34 43-TV-25-30 Iss.4 GLO Dec 06 UK

Page 41

Functions and Features

Data Export - Removable compact flash and USB flash storage device provides multiple data storage

alternatives. Data is stored in a secure binary encrypted format, with the recorder’s configurations, providing added security of the data files. (Compact Flash is not available for the eZtrend QXerecorder).

Removable Compact flash and

USB flash storage devices