Page 1

0600-0032-0013 Rev D

January 2003 $15.00

User ’s Manual

Series F4P

96mm x 96mm Process Controller (1/4 DIN)

with Guided Setup and Programming

1241 Bundy Boulevard, Winona, Minnesota USA

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507 http://www.watlow.com

English

Registered Company

Winona, Minnesota USA

Page 2

Safety Information

We use note, caution and warning symbols throughout this book to draw your

attention to important operational and safety information.

A “NOTE” marks a short message to alert you to an important detail.

A “CAUTION” safety alert appears with information that is important for protecting

your equipment and performance. Be especially careful to read and follow all

cautions that apply to your application.

A“WARNING” safety alert appears with information that is important for protecting

you, others and equipment from damage. Pay very close attention to all warnings

that apply to your application.

The safety alert symbol, ç (an exclamation point in a triangle) precedes a general

CAUTION or WARNING statement.

The electrical hazard symbol, Ó (a lightning bolt in a triangle) precedes an electric

shock hazard CAUTION or WARNING safety statement.

Technical Assistance

If you encounter a problem with your Watlow controller, review your configuration

information to verify that your selections are consistent with your application:

inputs; outputs; alarms; limits; etc. If the problem persists after checking the

configuration of the controller, you can get technical assistance from your local

Watlow representative (see back cover), or in the U.S., dial +1 (507) 494-5656

between 7 a.m. and 5 p.m., Central Standard Time (CST). Ask for for an Applications

Engineer. Please have the following information available when calling:

• Complete model number • All configuration information

• User’s Manual • Diagnostic menu readings

Your Comments

We welcome your comments or suggestions on this user’s manual. Please send them

to: Technical Writer, Watlow Winona, 1241 Bundy Blvd., P.O. Box 5580, Winona,

Minnesota, USA 55987-5580; telephone: +1 (507) 454-5300; fax: +1 (507) 452-4507.

© Copyright 2003 by Watlow Winona, Inc. All rights reserved. (2328)

ç

CAUTION or

WARNING

Ó

Electrical

Shock Hazard

CAUTION or

WARNING

Page 3

Watlow Series F4P Table of Contents ■ i

Operating the Controller

Chapter 1: Introduction . . . . . . . . . . . . . . . . . 1.1

Setup Steps . . . . . . . . . . . . . . . . . . . . . . . .1.2

Chapter 2: Operating from the Front Panel . .2.1

Keys, Displays and Lights . . . . . . . . . . . . .2.2

Guided Programming . . . . . . . . . . . . . . . .2.3

Custom Main Page . . . . . . . . . . . . . . . . . .2.3

Auto and Manual Operation . . . . . . . . . . .2.3

Troubleshooting, Alarms and Errors . . . . .2.4

Programming the Controller

Chapter 3: Operations Page . . . . . . . . . . . . . .3.1

Alarm Set Points . . . . . . . . . . . . . . . . . . . .3.1

To Clear an Alarm or Error . . . . . . . . . . . .3.1

Autotune PID . . . . . . . . . . . . . . . . . . . . . . .3.2

Edit PID . . . . . . . . . . . . . . . . . . . . . . . . . . .3.2

Multiple PID Sets . . . . . . . . . . . . . . . . . . . .3.3

Cascade . . . . . . . . . . . . . . . . . . . . . . . . . .3.3

Chapter 4: Setup Page . . . . . . . . . . . . . . . . . .4.1

Parameter Setup Order . . . . . . . . . . . . . . .4.1

Customizing the Main Page . . . . . . . . . . .4.2

Static Messages . . . . . . . . . . . . . . . . . . . .4.2

Chapter 5: Factory Page . . . . . . . . . . . . . . . .5.1

Security . . . . . . . . . . . . . . . . . . . . . . . . . . .5.1

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . .5.3

Calibration . . . . . . . . . . . . . . . . . . . . . . . . .5.3

Chapter 6: Parameters . . . . . . . . . . . . . . . . . .6.1

Pages, Menus and Parameters . . . . . . . . .6.1

Main Page . . . . . . . . . . . . . . . . . . . . . . . . .6.2

Operations Page Parameter Table . . . . . .6.4

Setup Page Parameter Table . . . . . . . . . .6.11

Factory Page Parameter Table . . . . . . . . .6.26

Chapter 7: Features . . . . . . . . . . . . . . . . . . . .7.1

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.2

Control Methods . . . . . . . . . . . . . . . . . . . .7.5

Other Features . . . . . . . . . . . . . . . . . . . . .7.9

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.10

Advanced Features . . . . . . . . . . . . . . . . . .7.12

Features in Enhanced Series F4P Controller

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.15

Installation and Wiring

Chapter 8: Installation and Wiring . . . . . . . . .8.1

Wiring the F4P Controller . . . . . . . . . . . . .8.5

Communications

Chapter 9: Communications . . . . . . . . . . . . . .9.1

Exception Responses . . . . . . . . . . . . . . . .9.1

Modbus Registers (Alphabetical) . . . . . . .9.2

Modbus Registers (Numerical) . . . . . . . . .9.11

Appendix

Specifications . . . . . . . . . . . . . . . . . . . . . .A.2

Ordering Information . . . . . . . . . . . . . . . . .A.3

Declaration of Conformity . . . . . . . . . . . . .A.4

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . .A.5

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A.8

Software Map . . . . . . . . . . . . . . . . . . . . . .A.13

About Watlow and Warranty Information

. . . . . . . . . . . . . . . . . . . . . . Inside Back Cover

Series F4P: Table of Contents

T

A downloadable electronic copy of this user manual is available free of charge through Watlow's web

site: http://www.watlow.com/literature/prodtechinfo

Page 4

ii ■ Table of Contents Watlow Series F4P

Notes

Page 5

Watlow Series F4P Introduction ■ 1.1

1

Chapter One: Introduction

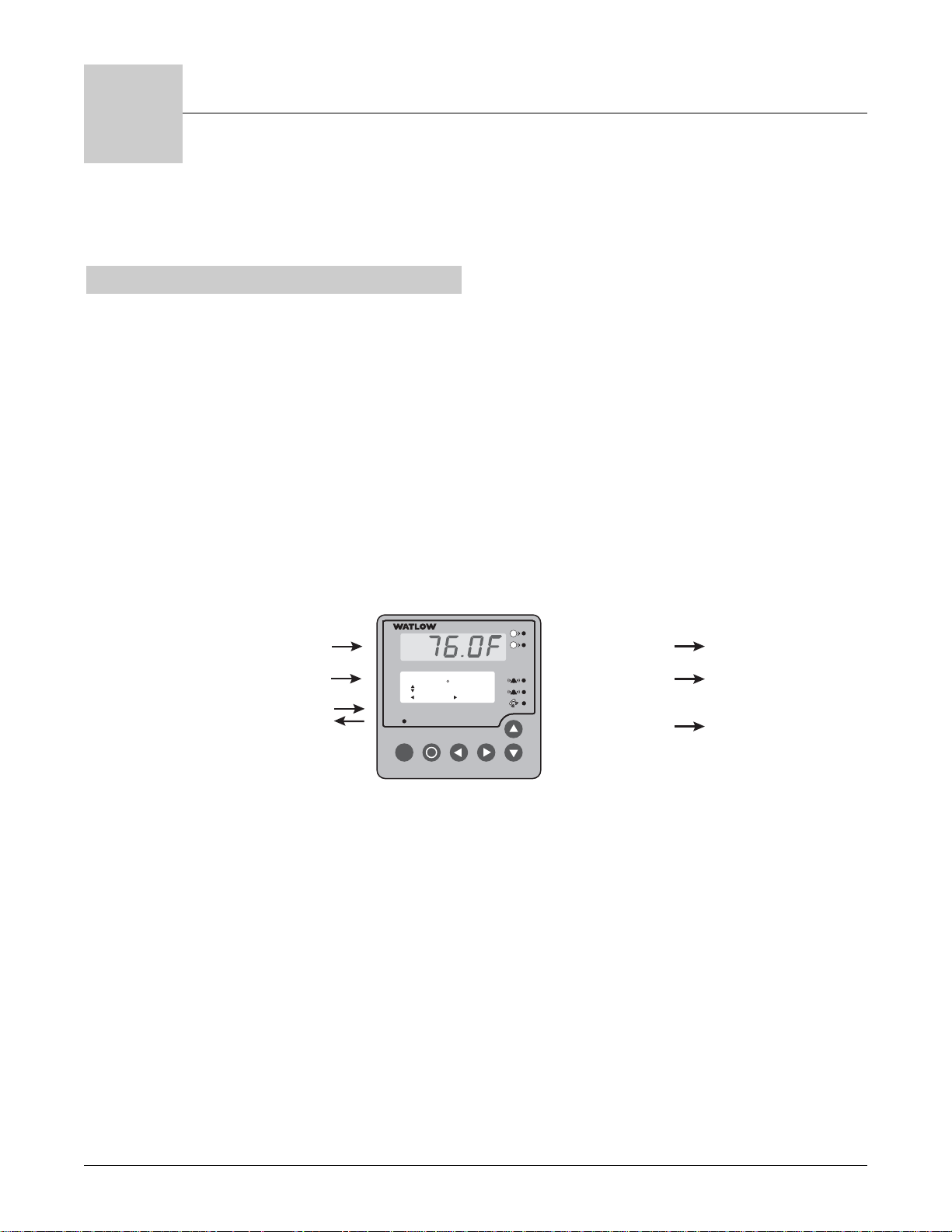

Inputs and Outputs

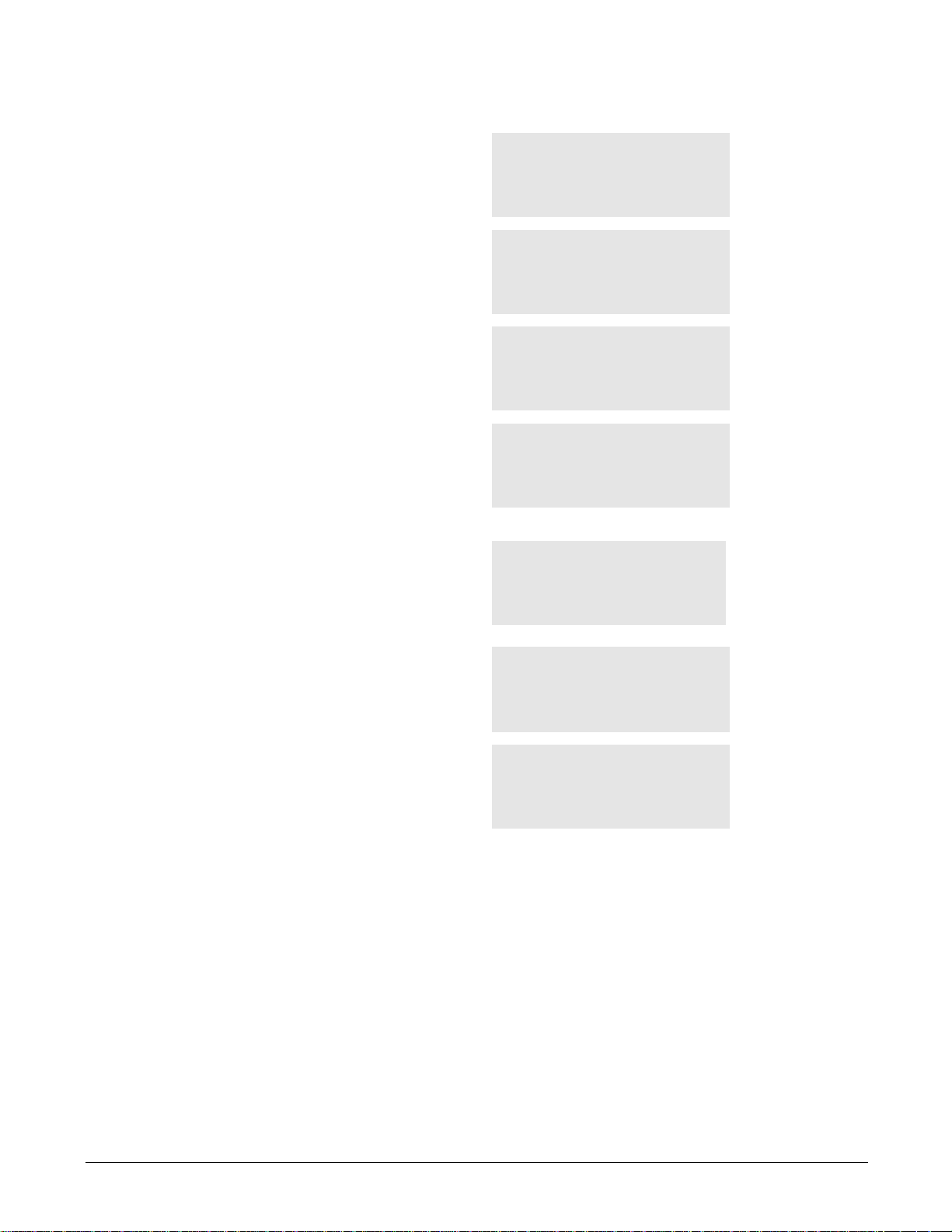

Figure 1.1 — Series F4P Inputs and Outputs (Standard, 1 input, F4P _ - _ _ AA - _ _ _ _; and Enhanced, 3 inputs, F4P _ _ _ AB - _ _ _ _ ).

1B

1A

Watlow’s Series F4P, 96mm by 96mm (1/4 DIN)

Temperature/Process controllers are easy to set up, program and operate in the most demanding applications.

The F4P Temperature/Process controller includes:

• four-line, high resolution LCD display;

• guided setup software;

• context-sensitive information key;

• 16-bit microprocessor;

• universal and digital inputs.

F

4

1A

1B

1 or 3 Universal Analog Inputs

4 Digital Inputs

1 Communication Input/Output

…Alarm1 Lo Deviation

–1

F

Adjusts Value

Back Next

2 Control Outputs

1

2 Alarm Outputs

2

2 Retransmit Outputs

(optional)

ˆ

å

Page 6

1.2 ■ Introduction Watlow Series F4P

Setup Steps

The

ˆˆ

Key

During all these steps, the Information Key will summon

helpful definitions and setup tips. Just position the cursor next to the item you want to know more about, then

press the key. Press it again to return to your task.

See Chapter 3, Operations Page.

4

Establish a set point for static set point

control.

See Chapter 3, Operations Page.

3

Tune the system and set alarm set points.

Learn to navigate the software in Chapter 2,

Operating from the Front Panel, and then go to

Chapter 4, Setup Page. For background, you may

also want to refer to Chapter 7, Features. (This

step may not be necessary if the Series F4P is

already installed in the equipment.)

2

Configure the controller to suit your

application.

See Chapter 8, Installation and Wiring. (This

step will not be necessary if the Series F4P is

already installed in equipment.)

1

Install and wire the controller.

How to do itWhat to do

Your Series F4P may arrive as an independent unit or

already installed in other equipment. The steps below

may or may not apply to all units. The Series F4P software can be locked with different types of security. See

Chapter 5, Factory Page.

Page 7

Watlow Series F4P Operating from the Front Panel ■ 2.1

Chapter Two: Navigation and

Operating from the Front Panel

Displays and Indicator Lights . . . . . . . . . . . . . . . . .2.2

Guided Programming . . . . . . . . . . . . . . . . . . . . . . .2.3

Custom Main Page . . . . . . . . . . . . . . . . . . . . . . . . .2.3

Auto and Manual Operation . . . . . . . . . . . . . . . . . .2.3

Troubleshooting Alarms and Errors . . . . . . . . . . . . .2.4

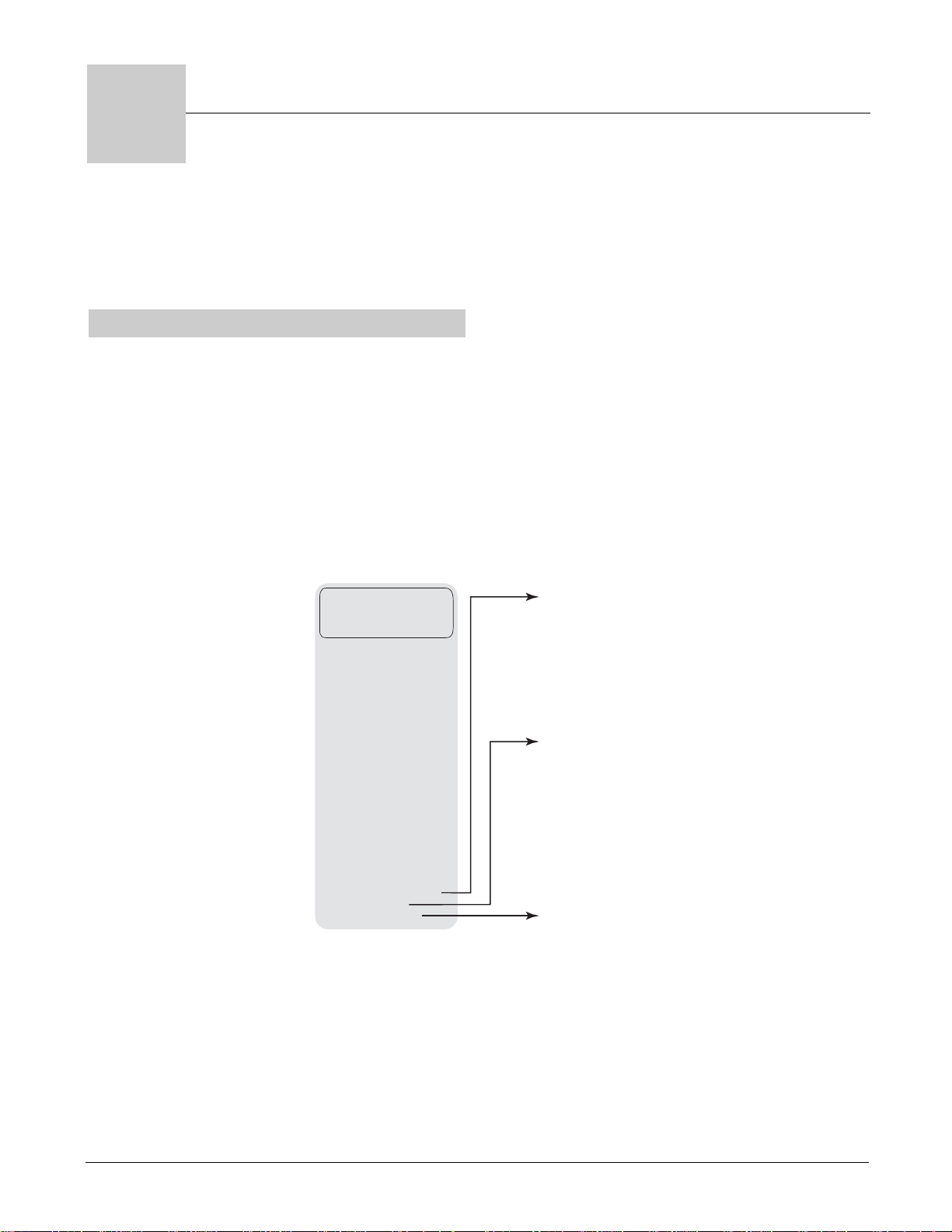

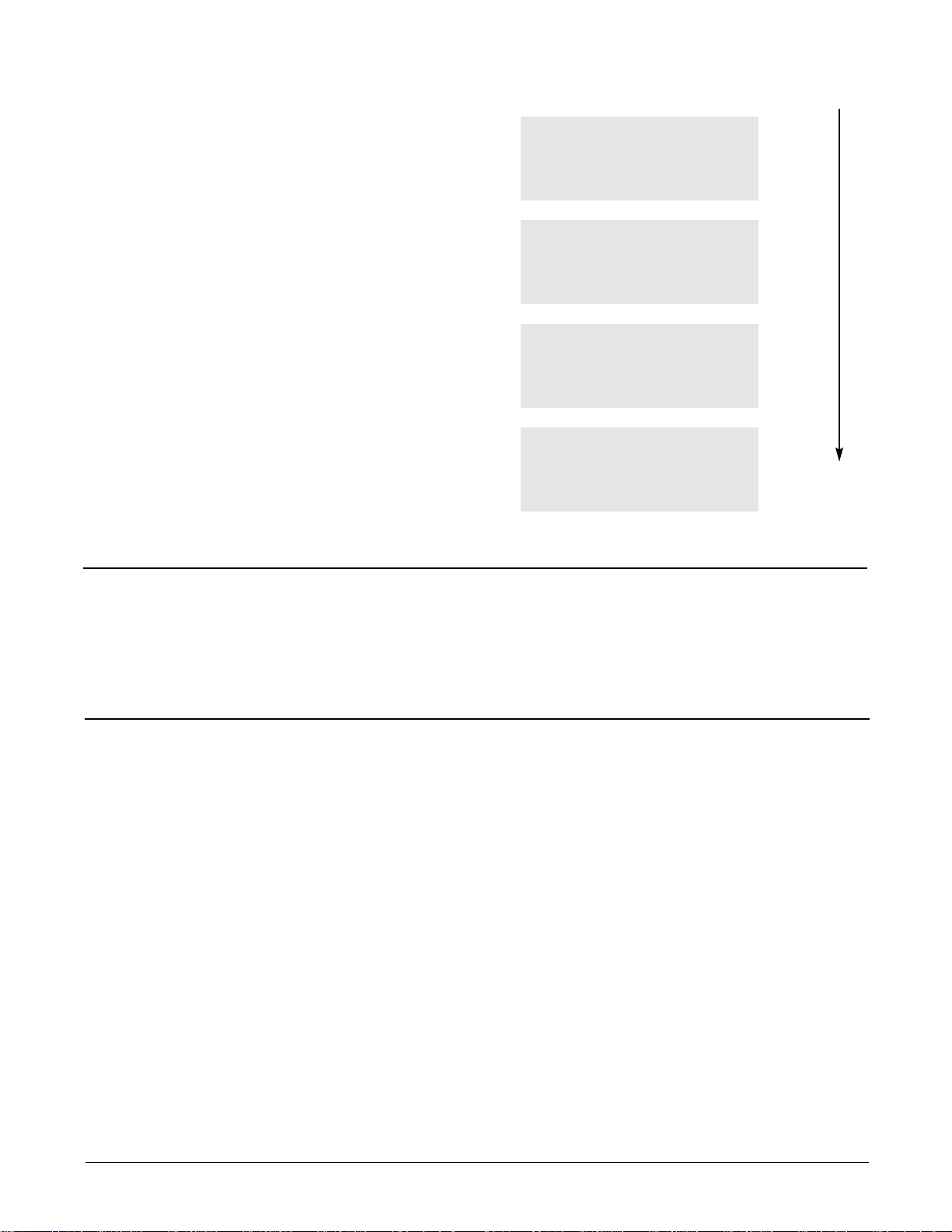

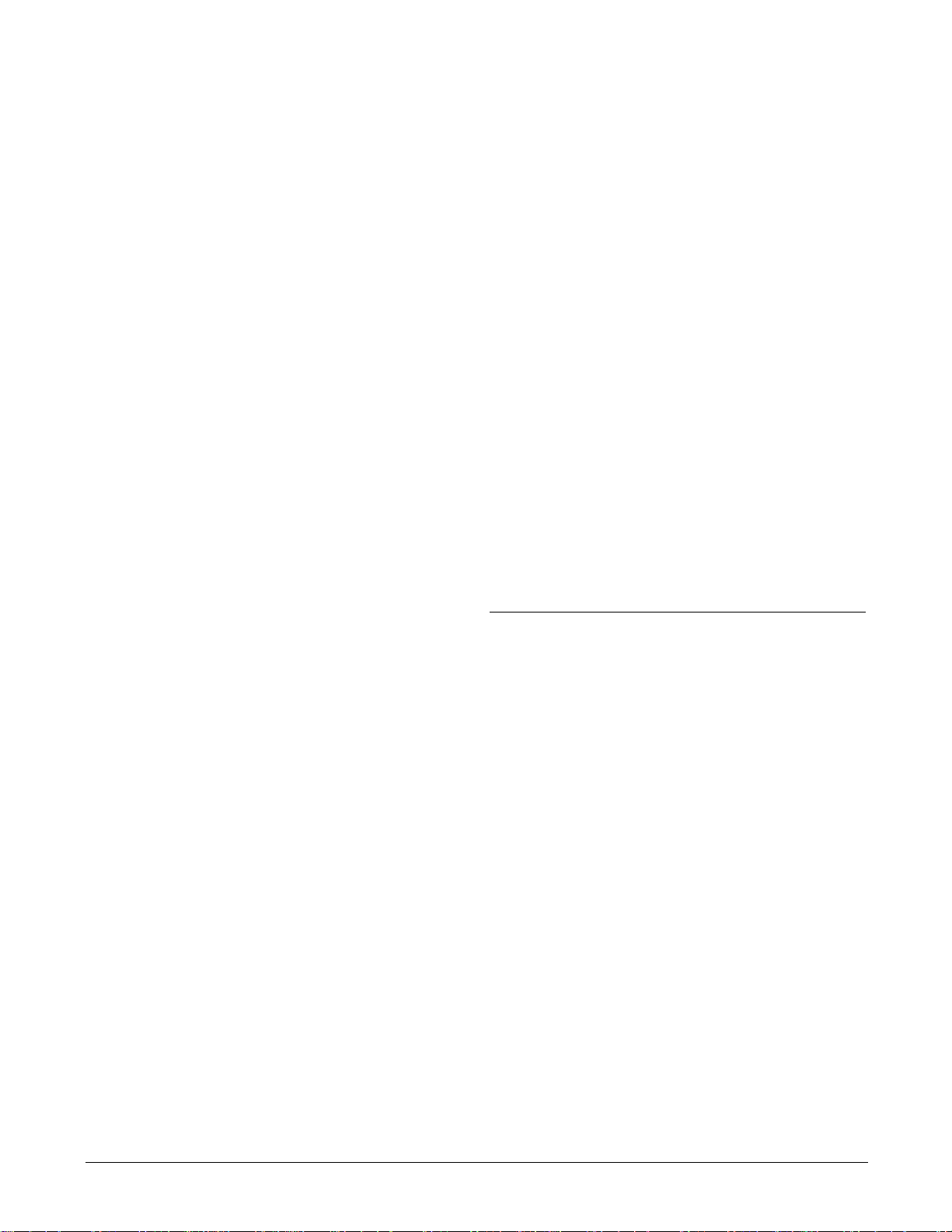

Figure 2.1 — Page Navigation.

Series F4P software is organized into four sections called

“pages.” The Main Page is the central, default page that

displays status information on the lower display. To get

to the other pages, you must begin in the Main Page.

✔ Note: Access to the software is limited while the con-

troller is autotuning (Setup and Factory pages are not

accessible).

2

Main Page_____

The Main Page presents

error messages, static

messages and the status

of inputs, outputs and

depending on the Custom

Main Page, parameter

settings in the Setup

Page.

Scroll to the bottom of the

Main Page to reach the

other pages.

When you exit the Setup

or Factory Page, the

controller prompts you to

restore the old settings or

save the new ones.

Input 1 Error

Input 2 Error

Input 3 Error

Alarm 1 Condition

Alarm 2 Condition

Tune Status 1

Input 1 Value

In 1 ■■■■

Input 2 Value

Set Point 1

Set Point 2

Digital Set Point

Power 1A

1A% ■■

Power 1B

1B% ■■■

Digital Ins 1234

Active PID Set

Message 1

Message 2

Message 3

>Go to Operations

Go to Setup

Go to Factory

Operations Page

Autotune PID

Edit PID

Alarm Set Point

PID Crossover

Ramp to Set Point

Control Set Points

Setup Page

System

Analog Inputs

Digital Inputs

Control Outputs

Alarm Outputs

Retransmit Outputs

Communications

Custom Main Page

Static Message

Factory Page

Set Lockout

Diagnostic

Test

Calibration

Page 8

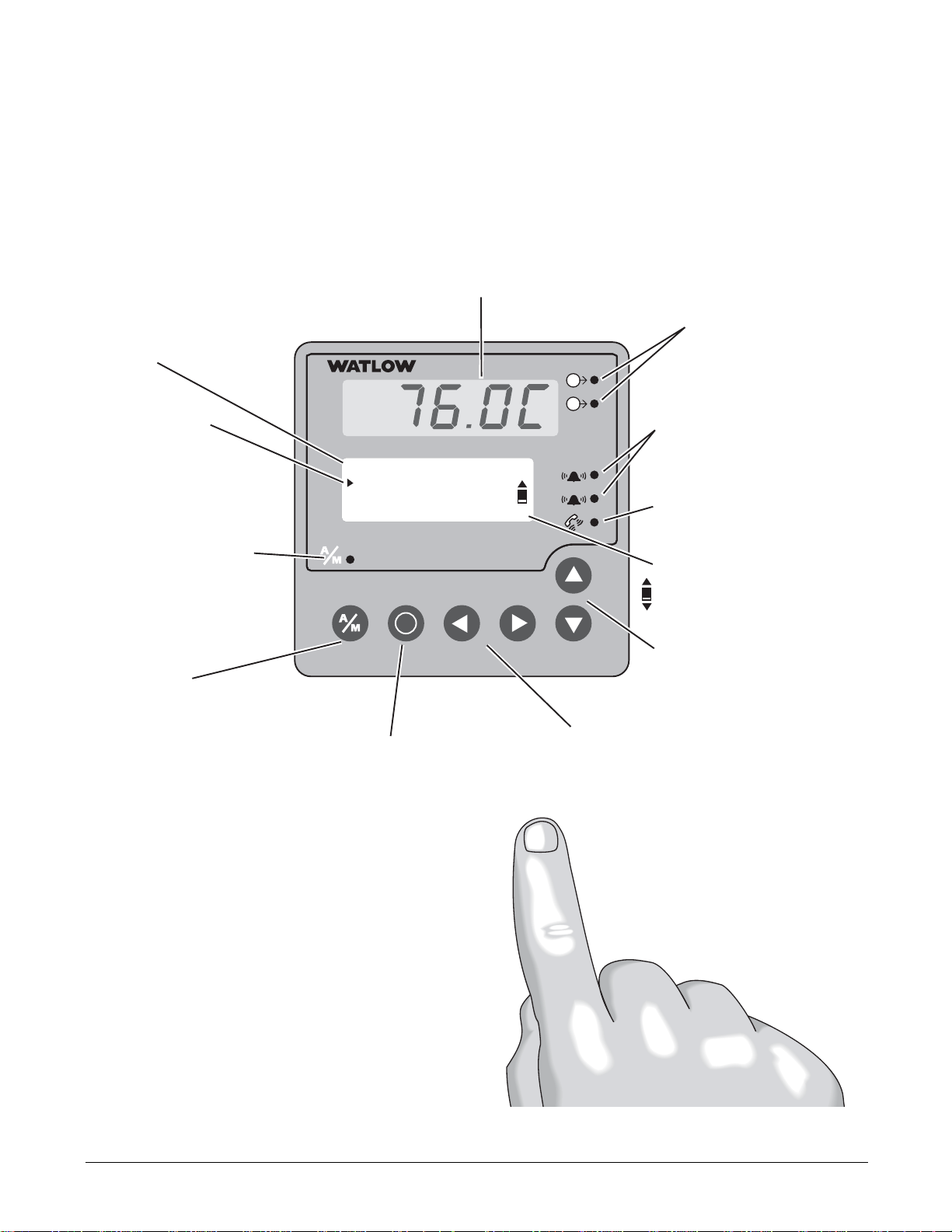

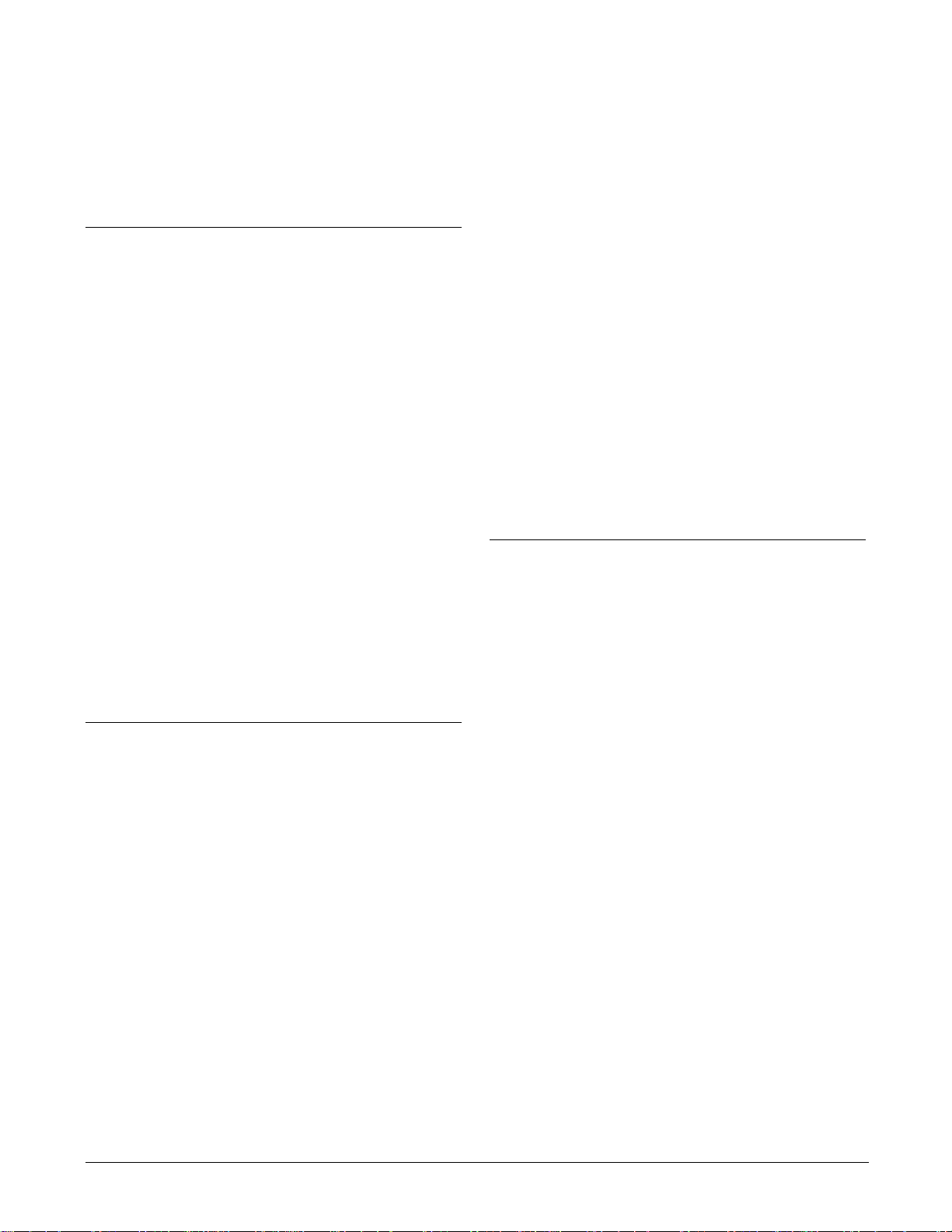

Keys, Displays and Lights

Figure 2.2 — Series F4P Displays and Indicator Lights.

1B

1A

2.2 ■ Operating from the Front Panel Watlow Series F4P

Upper Display

Displays Channel 1 actual

process values during

operation. Displays error

information if errors occur.

Lower Display

Guides setup and operation, displays

status information.

Cursor (>):

Points to the selected

parameter or present value.

Moves via the Up, Down,

Right and Left keys.

Auto/Manual Status Light

(Indicates mode status):

• Lit when in manual mode.

• Blinks for 10 seconds after

key pressed, while user

can change mode.

• Not lit during automatic

mode.

Auto/Manual Key

Press to toggle between auto

(closed-loop) and manual

(open-loop) control.

Information Key

Press for tips and definitions,

press again to return to the

original task.

Main Page___________

Go to Operations

Go to Setup

Go to Factory

i

F

4

1A

1B

1

Left and Right Keys

Press Right key to select the

item to the right of the cursor

(>) and proceed to the next

screen. Press Left key to

move left or exit.

2

Active Output Status Lights

Lit when the corresponding

controller channel output is

active.

Alarm Output Status Lights

Lit during an alarm state.

Communications Status

Light

Blinks when the controller

sends or receives data.

Scroll Bar

Indicates that more information exists above or below.

Use Up and Down keys.

Up and Down Keys

Press to move the cursor (>),

increase or decrease a value

or change a letter in a name.

To Clear an Alarm or Error

In an alarm condition, the alarm

status light will be lit. An alarm

message will appear on the Main

Page if configured to do so. To

silence the alarm, move the cursor

to the alarm message and press the

Right key. A message will confirm

the alarm silencing, and the alarm

status light will turn off.

After correcting the condition that

caused the error or alarm, return to

the error or alarm message on the

Main Page, and press the Right key

again. A message will confirm that

the alarm is unlatched.

Page 9

Watlow Series F4P Operating from the Front Panel ■ 2.3

Guided Programming

The Series F4P software guides users through most

tasks. To accomplish a task, simply proceed through the

sequence of parameters. For each parameter, choose the

appropriate option or establish the value, then press the

Right key to proceed to the parameter on the next

screen. The task is complete when you return to the initial menu.

1. Use

> or < to move the cursor to select an item

in a list.

2. Press the Right key

...

3. Enter the value and make a choice.

4. Press

. again.

5. Repeat until you return to the original list.

To change a specific, single parameter, proceed through

the parameter sequence without changing values until

you reach that parameter, then make your change. After

changing the value, you may back out of the sequence by

pressing the Left key or continue on through the

sequence by pressing the Right key. When you exit the

page, you must choose to Save Changes or Restore

Values.

.

.

.

Choose Cycle Time:__

>Variable Burst

Fixed Time

Choose Function:____

>Heat

Cool

Choose to Setup:____

>Control Output 1A

Control Output 2A

Main Page___________

Go to Operations

>Go to Setup

Go to Factory

Custom Main Page

The Main Page shows error messages; input and output

status; and allows access to controller software. You can

customize the Main Page to display chosen information

by going to the Setup Page, Custom Main Page Menu.

(See Chapter 4, Setup Page, for instructions.)

Auto and Manual Operation

The Series F4P controller can function as a static set

point controller (auto mode); or the user can directly

control the outputs (manual mode).

In the static set point mode, the Series F4P can only be

operated in a closed-loop configuration.

The Auto/Manual Indicator Light is on when the con-

troller is in manual mode. To toggle between manual and

auto mode, first press the Auto/Manual key

å , then con-

firm your selection in the lower display. The indicator

light will flash after you press

å until you confirm your

choice or 10 seconds have elapsed. While in manual mode

you can adjust the output power level for process outputs

or turn relay or open collector outputs on or off.

çWARNING: Only authorized and qualified personnel

should change the set point on the controller. Failure to

comply with these recommendations may result in damage to equipment and property and injury to personnel.

Static Set Point Control

When the Series F4P is in static set point mode:

• The Upper Display shows the actual process temperature of input 1.

• The Lower Display shows the default or user-configured Main Page.

To operate the Series F4P as a static set point controller,

select SP1 in the Main Page then use the Up and Down

keys to adjust the set point.

Limits may be placed on the set point in the Set Point

Low Limit and Set Point High Limit parameters (Setup

Page > Analog Input 1).

✔ Note: All control activity stops when you enter the

Setup Page, Analog Input, Digital Input, Control Output,

Alarm Output and Retransmit menus.

✔ Note: See also differential set point and ratio set

point.

Page 10

2.4 ■ Operating from the Front Panel Watlow Series F4P

• Process value must return to normal by

more than the hysteresis value to be

cleared.

• Configure alarm type, sides, hysteresis,

logic and set points.

• Correct cause of input error.

• Check the alarm output function.

• Alarm latched.

• Alarm output not configured correctly.

• Analog input(s) in error condition.

• Input may be in error condition.

• Alarm won’t clear.

(To clear the alarm, correct the

alarm condition. If the alarm

is latched, press

. with the

cursor at the alarm message on

the Main Page.)

• Turn on alarm annunciation.• Alarm annunciation is set to off.

• Exit Diagnostic mode.• Controller in Diagnostic mode.

• Configure alarm type, sides, hysteresis, logic

and set points.

• Alarm output not configured.

• Verify that silencing function is required.

Disable if not required.

• Alarm silencing is enabled.

Alarms

• Alarm won’t occur.

• Return controller to factory for repair.• Serial port of controller is defective.

• Verify or replace serial cable.• Serial cable is open or not wired correctly.

• Check converter box wiring and its documentation.

• Termination and/or pull up of bus required.

• Check computer communications port settings and verify PC communications.

• Computer communications port incorrectly

set up or defective.

• Converter must be half duplex.

• Check converter box wiring and settings.

• EIA-232 to EIA-485 converter incorrectly

set or wired.

• Verify correct connections and test wiring

paths.

• Communications wiring reversed, shorted

or open.

• Look for a break in the daisy chain.• Unit-to-unit daisy chain disconnected.

• Check Communications Setup Menu and set

to correct baud rate. Be sure it is Modbus

RTU protocol.

• Baud rate parameter incorrectly set or

incorrect protocol. Use Modbus RTU, 8 data

bits, no parity and 1 stop bit.

• Check Communications Setup Menu and set

to correct address.

• Address parameter incorrectly set.

Communications

• Unit will not

communicate.

• Measure power for required level. Check

part number for input power required.

• Check wire size.

• Check for bad connections.

• Input power incorrect.

• Check switches, fuses, breakers, interlocks,

limits, connectors, etc. for energized conditions and proper connection.

• Power to unit off.

• Fuse blown.

• Breaker tripped.

• Safety Interlock door switch, etc., activated.

• Separate system limit control latched.

• Wiring open.

Power

• No displays.

Corrective ActionProbable Cause(s)Indication

Troubleshooting

Page 11

Watlow Series F4P Operating from the Front Panel ■ 2.5

• Return to factory for evaluation.• Component failure.

Upper [Atod`]

Lower !Timeout x

(x is 1 to 3)

• Repair or replace sensor.

• Reverse sensor wiring connections.

Red lead is usually negative for tc.

• Set analog input to match sensor.

• Check sensor isolation. Inputs 2 and

3 are not isolated from each other.

• Sensor open.

• Sensor wired backwards. Display

decreases as process increases.

• Input type set to wrong sensor.

• Ground loop

Upper [SEnhi]

Lower !Input Sensor x+

(x is 1 to 3)

• Repair or replace sensor.

• Reverse sensor wiring connections.

Red lead is usually negative for tc.

• Set analog input to match sensor.

• Check sensor isolation. Inputs 2 and

3 are not isolated from each other.

• Sensor shorted (RTD).

• Sensor wired backwards. Display

decreases as process increases.

• Input type set to wrong sensor.

• Ground loop

Upper [SEnLo]

Lower !Input Sensor x-

(x is 1 to 3)

• Repair or replace sensor.

• Reverse sensor wiring connections.

Red lead is usually negative for tc.

• Set analog input to match sensor.

• Check sensor isolation. Inputs 2 and

3 are not isolated from each other.

• Sensor open.

• Sensor wired backwards. Display

decreases as process increases.

• Input type set to wrong sensor.

• Ground loop

Upper [A-dhi]

Lower !Input x AtoD+

(x is 1 to 3)

• Repair or replace sensor.

• Reverse sensor wiring connections.

Red lead is usually negative for tc.

• Set analog input to match sensor.

• Check sensor isolation. Inputs 2 and

3 are not isolated from each other.

• Sensor shorted (RTD).

• Sensor wired backwards. Display

decreases as process increases.

• Input type set to wrong sensor.

• Ground loop

Upper [A-dLO]

Lower !Input x AtoD

(x is 1 to 3)

Input Errors

(Upper Display shows error code

for input 1 only. Lower Display

shows additional errors. Input

2 and 3 error messages appear

in Lower Display. Alarm

Output Indicator is lit.)

• Tune PID set.

• Check power limit settings.

• Replace fuse or reset circuit breaker.

• Reposition sensor to accurately measure process.

• Check slidewire settings.

• PID values set incorrectly.

• Power limit set incorrectly.

• Open fuse or circuit breaker on energy

source.

• Incorrect sensor location in the process.

• Slidewire (if used) settings incorrect.

• Process will not reach set

point.

• Check operation mode. Automatic is

closed loop, manual is open loop.

• Check power limit settings.

• Check sensor, repair or replace.

• Check outputs, repair or replace.

• Check output settings.

• Check system wiring.

• Controller in manual operation mode

(percent power).

• Power limit set incorrectly.

• Thermocouple shorted.

• Shorted power switching device.

• Output set incorrectly (heat vs. cool).

• System wired incorrectly.

• Process runs away (too high or

too low).

• Check power limit settings.

• Tune PID set.

• Use correct PID set.

• Power limit set incorrectly.

• PID values set incorrectly.

• Incorrect PID set active.

Controllability

• Process will not

stabilize.

• Check alarm logic setting and output

wiring.

• Alarm logic setting incorrect or output

wired incorrectly.

• Alarm output action is

reversed.

Corrective ActionProbable Cause(s)Indication

Page 12

2.6 ■ Operating from the Front Panel Watlow Series F4P

• Add power line filter for input power.

• Return controller to factory for repair.

• Noise on power line.

• Component failure.

• Checksum error in

Cycle device power.

• Press any key. All parameters will default.

• Module changed.• Module change. Defaults will

occur. Accept with any key.

• Replace incorrect module with retransmit module.

• Wrong module in retransmit 2 slot.• Retransmit 2 Module Error!

Only process modules

supported.

• Replace incorrect module with retransmit module.

• Wrong module in retransmit 2 slot.• Retransmit 1 Module Error!

Only process modules

supported.

• Check for correct installation of module.

• Module not seated correctly in slot.• Verify the module.

• Check for correct installation of module.

• Module installed incorrectly or in

wrong slot.

• Module not allowed

• Replace output module.• Output module failure.• Output 1A

• Output 1B

• Output 2A

• Output 2A

• Move module to correct input slot.

• Move module to correct input slot.

• Input module 2 or 3 is in input 1 slot.

• Input module 1 is in input 2 or 3 slot.

• Verify Input 1

• Verify Input 2 or 3

• Replace module or return controller

to factory for repair

• Amodule has lost its programming ID. • Incorrect ID!

• Contact factory for further information and diagnosis.

• Component failure. • Unknown Error!

Record this number. Contact

the factory.

• Add filter to AC power line and verify

unit is power by AC voltage.

• Controller can’t detect zero cross point.

Noise is present on AC power line or

unit is not powered by AC voltage.

• Zero Cross Failure!

Switched to Fixed

Time control.

System Errors

(Upper Display shows error

numbers. Lower Display messages indicate cause and

action to take.)

• Check wiring and process valve for

compatibility.

• Process valve is wired incorrectly or incompatible.

Upper

Lower Slidewire time out

• Increase slidewire time out value.

• Replace process valve.

• Increase slidewire time out value.

• Check wiring and process valve for

compatibility.

• Slidewire time out value set too short.

• Slidewire valve is stuck or not

responding.

• Process valve is wired incorrectly or incompatible.

Upper

Lower Slidewire time out

• Return to factory for evaluation.• Component failure.

Upper

Lower !Input x Error

(x is 1 to 3)

Corrective ActionProbable Cause(s)Indication

Page 13

Watlow Series F4P Operating from the Front Panel ■ 2.7

• Repair heating/cooling circuits.

• Check circuit breakers, switches,

heater elements, compressor.

• Heater/cooling non-functional.

• Replace sensor.• Sensor shorted.

• Replace relay.• Output relay open or shorted.

• Place sensor near source.• Sensor not properly located

• Check all wiring and components.

• Turn the controller off, then on again.

Open Loop Detect

(Upper Display shows error

code for input 1 only. Lower

Display shows additional

errors.

Upper: [oPLP`]

Lower: Open Loop

• Return controller to factory for repair.• Controller has failed.• Flash memory Failed.

Return controller to the

Factory.

• Return controller to factory for repair.• Controller has failed.• RAM Test Failed!

Return controller to the

Factory.

• Turn the controller off, then on again.

If problem persists, power line filter is

required.

• Power line noise has corrupted memory.• Checksum Error!

Parameter memory.

• Checksum Error!

Unit Config memory

• Checksum Error!

Profile memory.

• Normal operation following flash update of firmware.

• Controller firmware has been updated.• Firmware change.

Parameters are initializing.

• Return controller to factory for repair.• Power was interrupted during a flash

update or there is a component failure.

• Flash Memory Failed!

Return controller to the

Factory.

• Return controller to factory for repair.• Component failure.• RAM Test Failed!

Return controller to the

Factory.

• Should not appear in the field. Call

the factory if you get this message.

• Controller powered up for the first time.• First power-up.

Parameters are initializing.

• This is normal upon module change.• Input or output module was changed.• Module change.

All parameters are initializing.

Corrective ActionProbable Cause(s)Indication

Page 14

2.8 ■ Operating from the Front Panel Watlow Series F4P

Notes:

Page 15

Watlow Series F4P Operations Page ■ 3.1

Chapter Three: Operations Page

Alarm Set Points . . . . . . . . . . . . . . . . . . . . . . . . . . .3.1

Autotune PID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.2

Edit PID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.2

Multiple PID Sets . . . . . . . . . . . . . . . . . . . . . . . . . . .3.3

Cascade Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.3

This chapter explains how to establish alarm set points,

autotune and manually tune and establish cascade control through the Operations Page of the software.

To configure the alarm outputs, go to the Setup Page of

the software (see related information in the Parameters

Chapter).

For the alarm clearing procedure, go to the Troubleshooting Alarms and Errors table in the Navigation and

Operating from the Front Panel Chapter.

For background information about alarms; proportional,

integral and derivative control; and cascade, see the Features Chapter.

Alarm Set Points

The Series F4P includes two alarm outputs, which can be

programmed as process, deviation or rate alarms.

Process alarms notify the operator when process values

exceed or fall below Alarm Low and Alarm High Set

Points. Deviation alarms notify the operator when the

process has deviated from the set point beyond the deviation limits. Rate alarms are triggered by a change in

temperature or process value that is faster than the selected rate.

For more information, see the Features Chapter. To set

up the alarms, see the Setup Chapter.

Alarm set points are the points at which alarms switch

on or off, depending on the alarm setting. Alarm set

points can be viewed or changed in the Alarm Set Point

Menus (Operations Page).

The Alarm High Set Point defines the high value that,

if exceeded, will trigger an alarm. This value must be

higher than the alarm low set point and lower than the

high limit of the sensor range.

The Alarm Low Set Point defines the low value that, if

exceeded, will trigger an alarm. This value must be lower

than the alarm high set point and higher than the low

limit of the sensor range.

The Alarm Low Deviation defines the deviation value

on the low side of set point at which the alarm will be

triggered.

The Alarm High Deviation defines the deviation value

on the high side of set point at which the alarm will be

triggered.

✔ Note: You may want to set up the alarms with names

that will identify the alarm conditions. See the Setup

Page.

To Clear an Alarm or Error

In an alarm condition, the alarm status light will be lit.

An alarm message will appear on the Main Page if configured to do so. To silence an alarm, the Silencing option

in the Alarm Output menu (Setup Page) must be enabled. To silence the alarm, move the cursor to the alarm

message and press the Right key. Amessage will confirm

the silencing of the alarm, and the alarm status light will

turn off. After correcting the condition that caused the

error or alarm, return to the error or alarm message on

the Main Page, and press the Right key again. Amessage

will confirm that the alarm is unlatched.

3

Page 16

3.2 ■ Operations Page Watlow Series F4P

Autotune PID

In autotuning, the controller automatically selects the

PID parameters for optimal control, based on the thermal response of the system. In the Series F4P, five sets of

PID values are available. Default PID values exist for all

PID sets, although these values typically do not provide

optimal control. PID values can be auto-tuned or adjusted manually. When autotuning is complete, the PID values will be stored in the Edit PID Menu.

Set point changes for remote, ratio and differential control are ignored until autotuning is complete.

Autotuning Procedure

Autotuning is initiated from the Operation Menu.

1. Before initiating auto-tune, go to the System Menu

(Setup Page), and establish the Autotune Set Point

to a percentage of set point. This percentage is based

on your knowledge of the system and how much

overshoot or undershoot there is likely to be in on-off

control.

Select to display Tune Status in the Custom Main

Page Menu.

2. Go to the Main Page and adjust set point.

3. Go to the Autotune PID Menu (Operations Page) and

choose the PID set in which to store the values. You

must exit back to Main Page with the left arrow. A

message will be displayed on the Main Page during

the autotuning process.

4. When autotuning is complete, the controller will

store the values for optimum control in the specified

PID set.

For additional information about autotuning and proportional, integral and derivative control, see the Features

Chapter.

✔ Note: While the controller is autotuning, only the Op-

eration Page of the software can be entered.

ç

CAUTION: Choose an autotune set point value that will

protect your product from possible damage from overshoot

or undershoot during the autotuning oscillations. If the

product is sensitive, select the autotune set point very

carefully to prevent product damage.

Edit PID

The Edit PID Menu is useful when Auto-tune PID does

not provide adequate control. Each of the PID parameters can be adjusted manually:

Proportional Band: Define a band for PID control, entered in degrees or units. Lower values increase gain,

which reduces droop but can cause oscillation. Increase

the proportional band to eliminate oscillation.

Integral (Reset): Define the integral time in minutes

per repeat; define reset in repeats per minute. Set repeats per minute if units are U.S.; minutes per repeat if

units are SI.

Derivative (Rate): Define the derivative (rate) time in

minutes. Large values prevent overshoot but can cause

sluggishness. Decrease if necessary.

Dead Band: Define the dead band in degrees or units.

Heating dead band shifts the set point down. Cooling

dead band shifts the set point up. For more information,

see the Features Chapter.

For background information, see Chapter 7, Features.

Manual Tuning Procedure

1. Apply power to the Series F4P and establish a set

point on the Main Page.

2. Establish Cycle Time in the Control Output Menu

(Setup Page), as required. Typical cycle times are 1.0

second for an SSR and 5.0 seconds for a mechanical

relay. Faster cycle times sometimes achieve the best

system control. However, if a mechanical contactor or

solenoid is switching power to the load, a longer cycle time may be desirable to minimize wear on the

mechanical components. Experiment until the cycle

time is consistent with the desired quality of control.

3. Go to the Edit PID Menu (Operations Page), and

choose the channel and PID set. Establish values for

the PID parameters: Proportional Band, 5; Integral

(Reset), 0; Derivative (Rate), 0; and Autotune, Tune

Off. Tuning begins when you choose a PID set.

4. When the system stabilizes, watch the value of Input

1 on the Main Page. If this value fluctuates, increase

the proportional band setting until it stabilizes. Adjust the proportional band in 3° to 5° increments, allowing time for the system to stabilize between adjustments.

5. When Input 1 has stabilized, watch the percent power on the Main Page. It should be stable, ±2%. At

this point, the process temperature should also be

stable, but it will exhibit droop (stabilized below set

point). The droop can be eliminated with integral (reset).

Page 17

Watlow Series F4P Operations Page ■ 3.3

6. Start with an integral setting of 99.9 minutes and allow 10 minutes for the process temperature to get to

set point. If it has not, decrease the setting by half

and wait another 10 minutes. Then halve the setting

again and wait another 10 minutes until the process

value equals the set point. If the process becomes unstable, the integral value is too small. Increase it until the process stabilizes.

7. Increase Derivative/Rate to 0.10 minute. Then increase the set point by 11° to 17°C. Watch the system's approach to the set point. If the process value

overshoots the set point, increase Derivative/Rate to

0.50 minute.

Increase the set point by 11° to 17°C and watch the

approach to the new set point. If you increase

Derivative/Rate too much, the approach to the set

point will be very sluggish. Repeat as necessary until

the system rises to the new set point without overshoot or sluggishness.

For additional information about the burst fire feature,

manual tuning and PID control, see the Features Chapter.

Multiple PID Sets

Environmental chambers, ovens and furnaces typically

have different thermal requirements at high and low

temperatures or pressures. To accommodate this, the Series F4P can store five different PID sets.

Multiple Tuning Procedure

To autotune multiple PID sets, follow the Autotuning

procedure above for each PID set. When autotuning is

finished for one set, proceed with another.

Cascade

Cascade control is available on enhanced (F4P _ - _ _ AB

- _ _ _ _) Series F4P controllers. For background information about cascade control, see the Features Chapter.

Select cascade control through the Analog Input 3 Menu

(Setup Page), and choose Process Cascade or Deviation

Cascade. To set the range for the inner loop set point,

Process Cascade uses Low and High Range settings that

are independent of set point; Deviation Cascade uses Deviation Low and High settings that are deviations from

the primary set point.

When tuning a cascade system, the inner loop must be

tuned first. The inner loop comprises outputs 1A and 1B

and the Analog Input 1 sensor, which usually measures

the energy source temperature. The output device controls a power switching device, which in turn switches

the heating and cooling. The set point for the inner loop

is generated by the outer loop. For Process Cascade, this

will have a range between the Cascade Low Range and

Cascade High Range.

Cascade Setup Procedure

1. First, configure Analog Input 3, Cascade Low Range

and Cascade High Range.

Go to the Analog Input 3 Menu (Setup Page). Choose

Process or Deviation Cascade. Deviation Cascade references Channel 1 set point allowing a range above and

below the current control set point. For Process Cascade

control of a heat/cool or cool only system, set the Cascade

Low Range to a value slightly lower than the lowest

temperature desired in the chamber. For heat-only systems, set the Cascade Low Range to a value slightly lower than the ambient temperature; otherwise the heat

output will never turn fully off.

For heat/cool or heat only systems , set the Cascade

High Range to a value slightly higher than the highest

temperature desired in the chamber. For cool-only

systems, set the Cascade High Range to a value slightly

higher than the ambient temperature; otherwise the

cooling will never fully turn off.

2. Next, configure the controller to tune and display data

for the outer loop. To view Inner Loop Set Point in the

upper display, go to the Setup Page, Custom Main Page

Menu, select the Inner Set point as one of the parameters, P1 to P16, to be displayed in the Main Page.

To also view Analog Input 3 in the upper display, go to

the Setup Page, Process Display Menu, and choose Alternating. Under Set Display Time, choose a duration

for the display of the Input 1 and Input 3 variables.

Cascade Autotuning Procedure

1. Go to Setup Page, Custom Main Page Menu. Choose

Tune Status 1 and Tune Status 2 to appear as 2 of the

16 parameters that can be displayed on the Main Page.

The Main Page will now display the status of the autotuning process.

2. Autotune the inner loop. Go to the Autotune PID Menu

(Operations Page), and select Cascade Inner-loop.

Choose Cascade Inner Loop PID Set 1 to 5, where PID

values will be stored after autotuning. Autotuning begins when you choose the PID set. While autotuning,

the F4 controller will control the energy source in an

on-off mode to a temperature equal to the Cascade High

Range setting x Channel 1 Autotune Set Point. For best

results, use proportional control only on the inner loop.

Page 18

3.4 ■ Operations Page Watlow Series F4P

3. Next, autotune the outer loop. Go to the Autotune PID

Menu (Operations Page). Choose Cascade Outer Loop,

then choose Outer Loop PID set 1 to 5, where PID values will be stored after autotuning. Autotuning begins

when you choose the PID set. While autotuning, the

outer loop will be controlled in an on-off mode at a set

point equal to static set point x Ch 1 Autotune Set

Point. In most cases, the autotuning feature will tune

for acceptable control. If not, manually tune the outer

loop (step 4 below). Before manually tuning, record the

values generated by the autotuning feature.

4. To manually tune the outer loop, go to the Edit PID

Menu (Operations Page). Choose Cascade Outer Loop,

then choose Outer Loop PID set 1 to 5. Begin manual

tuning by setting the Proportional Band to 5, Integral

(Reset) to 0, and Rate to 0. Establish the desired set

point and let the system stabilize. When the system

stabilizes, watch the Inner Loop Set Point on the Main

Page. If this value fluctuates, increase the proportional

band until it stabilizes. Adjust the proportional band

in 3° to 5° increments, allowing time for the system to

stabilize between adjustments.

5. When Input 1 has stabilized, watch the percent power

on the Main Page. It should be stable, ±2%. At this

point, the process temperature should also be stable,

but it will exhibit droop (stabilized below set point).

The droop can be eliminated with Integral (reset).

6. Start with an integral setting of 99.9 minutes, and allow 10 minutes for the process temperature to come up

to set point. If it has not, decrease the setting by half

and wait another 10 minutes. Then halve the setting

again and wait another 10 minutes until the process

value equals the set point. If the process becomes

unstable, the integral value is too small. Increase it

until the process stabilizes.

Page 19

Watlow Series F4P Setup Page ■ 4.1

Chapter Four: Setup Page

Parameter Setup Order . . . . . . . . . . . . . . . . . . . . . .4.1

Customizing the Main Page . . . . . . . . . . . . . . . . . .4.2

Static Messages . . . . . . . . . . . . . . . . . . . . . . . . . . .4.2

4

This chapter explains how to configure the controller

software through the Setup Page menus. Setup Page parameters affect the way the controller responds to your

application, which parameters and functions are visible

in other pages, and the way information is displayed on

the Main Page. Set up the controller properly to provide

a sound foundation for settings in other pages.

For ranges, defaults and other information about specific

parameters, see the Parameters Chapter. Record your

settings in the Parameter Setup Record, also in that

chapter.

For background information about inputs, outputs,

alarms and other features, see the Features Chapter.

Parameter Setup Order

Initial configuration of the Series F4P is best done in the

following order:

1. Go to the System Menu (Setup Page) to configure:

• PID units — SI (Integral, Derivative) or U.S. (Reset, Rate);

• Celsius or Fahrenheit scales;

• display of units in the controller’s upper display;

• Autotune set point;

• open-loop detection warnings; and

• controller response to a power outage.

2. Go to other menus on the Setup Page to configure:

• Analog Input x (1 to 3);

• Digital Input x (1 to 4);

• Control Output x (1A, 1B);

• Alarm Output x (1 or 2);

• Retransmit Output x (1 or 2);

• Communications; and

• Custom Main Page and Custom Messages.

3. Go to the Operations Page to tune the PID sets.

4. Go to the Operations Page to set the alarm set

points.

After this initial configuration, the most frequent

changes will be to the Operations Page (alarm set points

and PID sets).

If the Series F4P is already installed in an environmental chamber, oven, furnace or other equipment, most parameters will already be configured and access to the

Setup Page may be limited (see Chapter 5, Factory

Page).

Changing Setup Page parameters may change other parameters. In some cases, a change in one parameter will

affect the defaults of others. To see how all the pages,

menus and parameters are grouped, see the software

map on the inside back cover of this manual.

✔ Note: For more information about how parameter set-

tings affect the controller’s operation, see the Features

Chapter.

çWARNING: Only authorized and qualified personnel

should change the factory-default settings, which may

cause changes in other settings. Failure to comply with

this recommendation may result in damage to equipment

and property and injury to personnel.

Page 20

4.2 ■ Setup Page Watlow Series F4P

Customizing the Main Page

Up to 16 lines can be added to the Main Page to display

status and information from the controller.

Go to the Custom Main Page Menu on the Setup Page.

The first screen will prompt you to choose one of the 16

lines to customize. "P1 Parameter" is the first line; "P16

Parameter" is the 16th. After choosing this line by pressing ., select a parameter to monitor.

Your choices are listed under Custom Main Page in the

Setup Page Parameter Table in this chapter.

Figure 4.2 — Example of Parameters on the Custom Main

Page.

Input1 26°C

PID Set 1

Power1A 0%

Power1B 55%

DigitalIn _234

Choose P:1 Display_ _

>None

Input 1 Value ■

Input 1 Value bar ▼

Choose:_ _ _____

>P1 Parameter

P2 Parameter ■

P3 Parameter ▼

Static Messages

Digital inputs can be configured to display a message

that the user enters. The message is displayed on the

Main Page when the digital input is active.

This feature could, for instance, display “DOOR OPEN” if

an oven door is not closed all the way.

Page 21

Watlow Series F4P Factory Page ■ 5.1

Chapter Five: Factory Page

Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.1

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.3

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.3

5

Security

The Series F4P allows users to set separate security

levels for the Static Set Point prompt on the Main Page,

for all menus on the Operations Page, as well as for the

Setup Page and Factory Page. Four levels of security are

available:

• Full Access (operators can enter and change

settings);

• Read Only (operators can read but not change

settings);

• Password (operators can enter and change settings

after entering a password); and

• Hidden (operators cannot see the menu or page — it

is not displayed). Set Point settings cannot be

Hidden.

✔ Note: Full Access is the default for all menus. Unless

you change the level of access, operators will be able to

read and change every setting in every menu in the

Series F4P software.

How to Set Lockout Levels

Using the Lockout Menu, you can limit access to the

following menus and pages:

• Set Point on Main Page

• Operations Page Autotune PID

• Operations Page Edit PID

• Operations Page Alarm Set Point

• Setup Page

• Factory Page

Choose the item to lock out, press .. and choose the level

of access: Full, Read Only, Password or Hidden. If you

choose Password, you must set the password — see

below.

✔ Note: For more information about how parameter

settings affect the controller’s operation, see the Features

Chapter.

ç CAUTION: Only authorized and qualified personnel

should be allowed to perform preventive and corrective

maintenance on this unit.

…Lock>Autotune PID___

Full Access

Read Only

>Password

.

…Factory>Set Lock___

Set Point

>Oper. Autotune PID ■

Oper. Edit PID ▼

.

Main>Factory________

>Set Lockout

Diagnostic

Test

Page 22

5.2 ■ Factory Page Watlow Series F4P

Enter a Password

If you try to set password security before any password

has been established, a pop-up message will give you the

opportunity to enter one. Use the . , , , > and < keys

to enter a four-character password, which can consist of

letters, numbers or both. After entering and confirming

the password, re-enter the chosen menu or page and

select Password Security. Record your password and keep

it secure.

Confirm Password:

_ _ _ _

▲▼ Adjusts Char

< Back >Next

Enter New Password:

_ _ _ _

▲▼ Adjusts Char

< Back >Next

Must reset lock

after setting the

password

■ ■ ■ Press any key!■ ■ ■

>

No Password!

Set Password?

▼ No ▲ Yes

■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■

Use a Password

To enter a password-protected area, users must enter the

password. If an incorrect password is entered, a pop-up

message will tell you it is invalid and you may try again.

When the password is correct, choose again to enter the

menu or page of your choice.

Change a Password

The Change Password parameter is near the end of the

list under Set Lockout on the Factory Page. To change a

password, you must first enter the old password for

confirmation.

Enter Password:

_ _ _ _

▲▼ Adjusts Char

< Back >Next

.

…Factory>Set Lock___

Setup ▲

Factory ■

>Change password ▼

Invalid, Re-Enter:____

▲▼ Adjusts Char

< Back >Next

Page 23

Watlow Series F4P Factory Page ■ 5.3

Diagnostics

Diagnostic Menu parameters (on the Factory Page)

provide information about the controller unit that is

useful in troubleshooting. For example, the Out1A

parameter will identify what type of output has been

selected for Output 1A.

Select the parameter by pressing the Right Key . . The

information will appear on the Lower Display.

Some of the parameters in the Diagnostic Menu provide

information for factory use only.

To reset all parameters to their original factory values,

use the Full Defaults parameter under the Test Menu.

Test

This menu allows you to test outputs, test the displays

(upper, lower and status lights), and cause the controller

to revert to the defaults set at the factory. Reverting to

factory defaults will erase all preset software and the

controller will return to U.S. PID units (Reset and Rate)

and the Fahrenheit temperature scale.

Calibration

The Calibration Menu on the Factory Page allows

calibration of inputs and outputs. Calibration procedures

should be done only by qualified technical personnel with

access to the equipment listed in each section.

Before beginning calibration procedures, warm up the

controller for at least 20 minutes.

Restore Factory Values

Each controller is calibrated before leaving the

factory. If at any time you want to restore the factory

input calibration values, use the last parameters in the

menu: Restore Input x (1 to 3) Calibration. Press ... No

special equipment is necessary.

Thermocouple Input Procedure

Equipment

•Type J reference compensator with reference

junction at 32°F/0°C, or type J thermocouple

calibrator to 32°F/0°C.

• Precision millivolt source, 0 to 50mV minimum

range, 0.002mV resolution.

Input x (1 to 3) Setup and Calibration

Inputs 2 and 3 appear only if the controller is the

enhanced version (F4P _ - _ _ AB - _ _ _ _).

1. Connect the correct power supply to terminals 1, 2

and 3 (see the Wiring Chapter and the Appendix).

2. Connect the millivolt source to input 1 terminals 62

(-) and 61 (+), input 2 terminals 58 (-) and 57 (+), or

input 3 terminals 56 (-) and 55 (+), with copper wire.

3. Enter 50.000mV from the millivolt source. Allow at

least 10 seconds to stabilize. Press the Right Key .

once at the Calibrate Input x (1 to 3) prompt

(Factory Page). At the 50.00mV prompt press . once

and to store 50.00mV press the Up Key > once.

4. Enter 0.000mV from the millivolt source. Allow at

least 10 seconds to stabilize. At the 0.00mV prompt

press . once and to store 0.00mV press > once.

5. Disconnect the millivolt source and connect the

reference compensator or thermocouple calibrator to

input 1 terminals 62 (-) and 61 (+), input 2 terminals

58 (-) and 57 (+), or input 3 terminals 56 (-) and 55

(+). With type J thermocouple wire, if using a

compensator, turn it on and short the input wires.

When using a type J calibrator, set it to simulate

32°F/0°C. Allow 10 seconds for the controller to

stabilize. Press . once at the Calibrate Input x (1 or

2) prompt (Factory Page). At the 32°F Type J prompt

press . once and to store type J thermocouple

calibration press > once.

6. Rewire for operation and verify calibration.

Page 24

5.4 ■ Factory Page Watlow Series F4P

RTD Input Procedure

Equipment

•1kΩ decade box with 0.01Ω resolution.

Input x (1 to 3) Setup and Calibration

1. Connect the correct power supply to terminals

1, 2 and 3 (see the Wiring Chapter and the

Appendix).

2. Short Input 1 terminals 60, 61 and 62; Input 2

terminals 54, 57 and 58; or Input 3 terminals

52, 55 and 56 together with less than 0.1Ω.

Press the Right Key . once at the Calibrate

Input x (1 to 3) prompt. At the Ground prompt

press . once and to store ground input press

the Up Key > once.

3. Short Input 1 terminals 60 and 61; Input 2

terminals 54 and 57; or Input 3 terminals 52

and 55 together with less than 0.5Ω. Press .

once at the Calibrate Input x (1 to 3) prompt.

At the Lead prompt press . once and to store

lead resistance press > once.

4. Connect the decade box to Input 1 terminals 60

(S2), 61 (S1) and 62 (S3); Input 2 terminals 54

(S2), 57 (S1) and 58 (S3); or Input 3 terminals

52 (S2), 55 (S1) and 56 (S3), with 20- to 24gauge wire.

5. For 100Ω RTD, enter 15.00Ω. For 500Ω or 1kΩ

RTD, enter 240.00Ω. Allow at least 10 seconds

to stabilize. Press . once at the Calibrate

Input x (1 to 3) prompt (Factory Page). At the

15.00Ω or 240.00Ω* RTD prompt press . once

and to store the 15.00Ωor 240.00Ωinput press >

once.

6. For 100Ω RTD, enter 380.00Ω. For 500Ω or 1kΩ

RTD, enter 6080.00Ω. Allow at least 10 seconds

to stabilize. Press . once at the Calibrate

Input x (1 to 3) prompt. At the 380.0Ω or

6080.00Ω* RTD prompt press . once and to

store the 380.00Ω or 6080.00Ω input press >

once.

7. Rewire for operation and verify calibration.

Slidewire Feedback Input Procedure

Equipment

•1kΩ decade box with 0.01Ω resolution.

Input 3 Setup and Calibration

Input 3 appears only if the controller is the enhanced

version (F4P _ - _ _ AB - _ _ _ _).

1. Connect the correct power supply to terminals

1, 2 and 3 (see the Wiring Chapter and the

Appendix).

2. Connect the decade box to Input 3 terminals 55

(S1) and 56 (S3), with 20- to 24-gauge wire.

3. Enter 15.00Ω. on the decade box. Allow at least

10 seconds to stabilize. Press . once at the

Calibrate Input 3 prompt (Factory Page). At the

15.00Ω SlWr prompt press . once and to store

the 15.00Ω input press > once.

4. Enter 1000.00Ω. from the decade box. Allow at

least 10 seconds to stabilize. Press . once at

the Calibrate Input 3 prompt. At the 1000.00Ω

SlWr prompt press . once and to store the

380.00Ω or 6080.00Ω input press > once.

5. Rewire for operation and verify calibration.

Voltage Process Input Procedure

Equipment

• Precision voltage source, 0 to 10V minimum range,

with 0.001V resolution.

Input x (1 to 3) Setup and Calibration

Inputs 2 and 3 appear only if the controller is the

enhanced version (F4P _ - _ _ AB - _ _ _ _).

1. Connect the correct power supply to terminals 1, 2

and 3 (see the Wiring Chapter and the Appendix).

2. Connect the voltage source to input 1 terminals 59

(+) and 62 (-), input 2 terminals 53 (+) and 58 (-) or

input 3 terminals 51 (+) and 56 (-).

3. Enter 0.000V from the voltage source to the

controller. Allow at least 10 seconds to stabilize.

Press the Right Key . once at the Calibrate Input 1

prompt. At the 0.000V prompt press . once and to

store the 0.000V input press the Up Key > once.

✔

NOTE:

You need the equipment listed and technical skills.

Controllers come calibrated from the factory. Recalibrate

only for other agency requirements or if temperatures

aren’t accurate as verified by another calibrated

instrument.

*The tenth digit of your model number, F4XX-XXXX-

X

XXX, determines what prompts appear and what

input resistance values to use for RTD calibration. Refer

to the Ordering Information in the Appendix.

Page 25

Watlow Series F4P Factory Page ■ 5.5

4. Enter 10.000V from the voltage source to the

controller. Allow at least 10 seconds to stabilize.

Press . once at the Calibrate Input 1 prompt. At

the 10.000V prompt press . once and to store the

10.000V input press > once.

5. Rewire for operation and verify calibration.

Current Process Input Procedure

Equipment

• Precision current source, 0 to 20mA range, with

0.01mA resolution.

Input x (1 to 3) Setup and Calibration

Inputs 2 and 3 appear only if the controller is the

enhanced version (F4P _ - _ _ AB - _ _ _ _).

1. Connect the correct power supply to terminals 1, 2

and 3 (see the Wiring Chapter and the Appendix).

2. Connect the current source to input 1 terminals 60

(+) and 62 (-), input 2 terminals 54 (+) and 58 (-), or

input 3 terminals 52 (+) and 56 (-).

3. Enter 4.000mA from the current source to the

controller. Allow at least 10 seconds to stabilize.

Press the Right Key . once at the Calibrate Input 1

prompt. At the 4.000mAprompt press . once and to

store 4.000mA press the Up Key > once.

4. Enter 20.000mA from the current source to the

controller. Allow at least 10 seconds to stabilize.

Press . once at the Calibrate Input 1 prompt. At

the 20.000mA prompt press . once and to store

20.000mA press > once.

5. Rewire for operation and verify calibration.

Process Output Procedure

Equipment

• Precision volt/ammeter with 3.5-digit resolution.

Output 1A Setup and Calibration

1. Connect the correct power supply to terminals 1, 2

and 3 (see the Wiring Chapter and the Appendix).

Milliamperes

2. Connect the volt/ammeter to terminals 42 (+) and 43

(-).

3. Press the Right Key . at the Calibrate Output 1A

prompt. At the 4.000mAprompt press . once. Use

the Up Key > or the Down Key < to adjust the

display to the reading on the volt/ammeter. The

controller should stabilize within one second. Repeat

until the volt/ammeter reads 4.000mA. Press . to

store the value.

4. Press the Right Key . at the Calibrate Output 1A

prompt. At the 20.000mAprompt press . once. Use

the Up Key > or the Down Key < to adjust the

display to the reading on the volt/ammeter. The

controller should stabilize within one second. Repeat

until the volt/ammeter reads 20.000mA. Press . to

store the value.

Volts

5. Connect the volt/ammeter to terminals 44 (+) and 43

(-).

6. Press the Right Key . at the Calibrate Output 1A

prompt. At the 1.000V prompt press . once. Use the

Up Key > or the Down Key < to adjust the display

to the reading on the volt/ammeter. The controller

should stabilize within one second. Repeat until the

volt/ammeter reads 1.000V. Press . to store the

value.

7. Press the Right Key . at the Calibrate Output 1A

prompt. At the 10.000V prompt press . once. Use

the Up Key > or the Down Key < to adjust the

display to the reading on the volt/ammeter. The

controller should stabilize within one second. Repeat

until the volt/ammeter reads 10.000V. Press . to

store the value.

8. Rewire for operation and verify calibration.

Output 1B Setup and Calibration

1. Connect the correct power supply to terminals 1, 2

and 3 (see the Wiring Chapter and the Appendix).

Milliamperes

2. Connect the volt/ammeter to terminals 39 (+) and 40

(-).

3. Press the Right Key . at the Calibrate Output 1B

prompt. At the 4.000mAprompt press . once. Use

the Up Key > or the Down Key < to adjust the

display to the reading on the volt/ammeter. The

controller should stabilize within one second. Repeat

until the volt/ammeter reads 4.000mA. Press . to

store the value.

4. Press the Right Key . at the Calibrate Output 1B

prompt. At the 20.000mAprompt press . once. Use

the Up Key > or the Down Key < to adjust the

display to the reading on the volt/ammeter. The

controller should stabilize within one second. Repeat

until the volt/ammeter reads 20.000mA. Press . to

store the value.

Volts

5. Connect the volt/ammeter to terminals 41 (+) and 40

(-).

6. Press the Right Key . at the Calibrate Output 1B

prompt. At the 1.000V prompt press . once. Use the

Up Key > or the Down Key < to adjust the display

to the reading on the volt/ammeter. The controller

should stabilize within one second. Repeat until the

volt/ammeter reads 1.000V. Press . to store the

value.

Page 26

5.6 ■ Factory Page Watlow Series F4P

7. Press the Right Key . at the Calibrate Output 1B

prompt. At the 10.000V prompt press . once. Use

the Up Key > or the Down Key < to adjust the

display to the reading on the volt/ammeter. The

controller should stabilize within one second. Repeat

until the volt/ammeter reads 10.000V. Press . to

store the value.

8. Rewire for operation and verify calibration.

Retransmit Output Procedure

Equipment

• Precision volt/ammeter with 3.5-digit resolution.

Retransmit 1 Setup and Calibration

1. Connect the correct power supply to terminals 1, 2

and 3 (see the Wiring Chapter and the Appendix).

Milliamperes

2. Connect the volt/ammeter to terminals 50 (+) and 49

(-).

3. Press the Right Key . at the Calibrate

Rexmit 1 prompt. At the 4.000mAprompt press .

once. Use the Up Key > or the Down Key < to

adjust the display to the reading on the

volt/ammeter. The controller should stabilize within

one second. Repeat until the volt/ammeter reads

4.000mA. Press . to store the value.

4. Press the Right Key . at the Calibrate Rexmit 1

prompt. At the 20.000mAprompt press . once. Use

the Up Key > or the Down Key < to adjust the

display to the reading on the volt/ammeter. The

controller should stabilize within one second. Repeat

until the volt/ammeter reads 20.000mA. Press . to

store the value.

Volts

5. Connect the volt/ammeter to terminals 48 (+) and 49

(-).

6. Press the Right Key . at the Calibrate Rexmit 1

prompt. At the 1.000V prompt press . once. Use the

Up Key > or the Down Key < to adjust the display

to the reading on the volt/ammeter. The controller

should stabilize within one second. Repeat until the

volt/ammeter reads 1.000V. Press . to store the

value.

7. Press the Right Key . at the Calibrate Rexmit 1

prompt. At the 10.000V prompt press . once. Use

the Up Key > or the Down Key < to adjust the

display to the reading on the volt/ammeter. The

controller should stabilize within one second. Repeat

until the volt/ammeter reads 10.000V. Press . to

store the value.

8. Rewire for operation and verify calibration.

Retransmit 2 Setup and Calibration

1. Connect the correct power supply to terminals 1, 2 and

3 (see the Installing and Wiring Chapter and the

Appendix).

Milliamperes

2. Connect the volt/ammeter to terminals 47 (+) and 46

(-).

3. Press the Right Key . at the Calibrate Rexmit 2

prompt. At the 4.000mAprompt press . once. Use

the Up Key > or the Down Key < to adjust the

display to the reading on the volt/ammeter. The

controller should stabilize within one second. Repeat

until the volt/ammeter reads 4.000mA. Press . to

store the value.

4. Press the Right Key . at the Calibrate Rexmit 2

prompt. At the 20.000mAprompt press . once. Use

the Up Key > or the Down Key < to adjust the

display to the reading on the volt/ammeter. The

controller should stabilize within one second. Repeat

until the volt/ammeter reads 20.000mA. Press . to

store the value.

Volts

5. Connect the volt/ammeter to terminals 45 (+) and 46

(-).

6. Press the Right Key . at the Calibrate Rexmit 2

prompt. At the 1.000V prompt press . once. Use the

Up Key > or the Down Key < to adjust the display

to the reading on the volt/ammeter. The controller

should stabilize within one second. Repeat until the

volt/ammeter reads 1.000V. Press . to store the

value.

7. Press the Right Key . at the Calibrate Rexmit 2

prompt. At the 10.000V prompt press . once. Use

the Up Key > or the Down Key < to adjust the

display to the reading on the volt/ammeter. The

controller should stabilize within one second. Repeat

until the volt/ammeter reads 10.000V. Press . to

store the value.

8. Rewire for operation and verify calibration.

Page 27

Watlow Series F4P Parameters ■ 6.1

Chapter Six: Parameters

Pages, Menus and Parameters . . . . . . . . . . . . . . . .6.1

Main Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.2

Operations Page Parameter Table . . . . . . . . . . . . .6.4

Operations Page Parameter Record . . . . . . . . . . . .6.10

Setup Page Parameter Table . . . . . . . . . . . . . . . . .6.11

Setup Page Parameter Record . . . . . . . . . . . . . . . .6.23

Custom Main Page Parameter Record . . . . . . . . . .6.25

Factory Page Parameter Table . . . . . . . . . . . . . . . .6.26

6

Pages, Menus and Parameters

The Series F4P parameters are arranged into four

groups, or pages: Main; Operations, Setup and Factory.

See the chapters about each page for additional information. The Features Chapter provides information about

features, such as alarms, and the parameters that apply

to them.

Only active parameters will appear on the controller. If,

for instance, Output 1B is set to Off, no other output 1B

parameters will appear.

Changing some parameters will force changes to other

parameter settings. The safest and most efficient way to

configure the Series F4P controller for the first time is to

configure the parameters in the Setup Page in the order

in which they appear.

It may also be helpful for you to make copies of the Parameter Records for each of the pages, as well as the

Custom Main Page Record, then record your settings for

future reference.

✔ Note: If the Series F4P is already installed in an oven,

furnace or other equipment, most parameters will already be

configured and access to the Setup Page may be limited

(locked).

✔ Note: To see how all the pages, menus and parameters

are grouped, see the software map on the inside back cover

of this manual.

✔ Note: For more information about how parameter settings

affect the controller’s operation, see the Features Chapter.

Page 28

6.2 ■ Parameters Watlow Series F4P

✔ Note: For more information about how parameter settings affect

the controller’s operation, see the Features Chapter.

Modbus

Register

Range read/write Conditions for

Parameter Description (Modbus Value) Default (I/O, Set) Parameters to Appear

[Defaults de-

pend on the

control type

selected

and settings in

Setup>Custom Main

Page.]

None

Input 1 [value]

Input 1 Value bar

[graph]

Input 2 [value]

Input 2 Value bar

[graph]

Input 3 [value]

Input 3 Value bar

[graph]

Dgt. [digital] Diff. [dif-

ferential] Value

CTL SP [Differential

Set Point]

Set Differential

Dgt. [digital] Ratio

Value

CTL SP [Ratio Set

Point]

Set Ratio

Digital Set Point

Remote Set Point 2

Remote Set Point 3

Target Set Point

[cascade] Inner Set

Point

Set Point 1

Set Point 1 bar [graph]

% Power 1A

% Power 1B

% Power 1A bar [graph]

% Power 1B bar [graph]

Tune Status 1

Digital Inputs

Parameter x (1 to 16)

View customized parameter list.

Alarm x (1 to 2) Condition

Input x (1 to 3) Error

Main Page

Main Page

Main Page Parameters

Page 29

Watlow Series F4P Parameters ■ 6.3

✔ Note: For more information about how parameter settings affect the

controller’s operation, see the Features Chapter.

Main Page Parameter Table Modbus

Register

Range read/write Conditions for

Parameter Description (Modbus Value) Default (I/O, Set) Parameters to Appear

Go to Factory

Set security settings, calibrate and restore factory

settings, perform diagnostics, test outputs.

Go to Setup

Set up inputs and outputs, configure the system, design the Main

Page, configure alarms,

configure communication,

and define static messages.

Go to Operations

Auto-tune PID sets, edit

PID parameters, select

alarm set points, select

PID crossover, select

ramp to set point, select

control set points, and

mode.

Page 30

6.4 ■ Parameters Watlow Series F4P

✔ Note: For more information about how param-

eter settings affect the controller’s operation, see

the Features Chapter.

* None of the B parameters are active if both outputs are set to cool or heat.

Modbus

Register

Range read/write Conditions for

Parameter Description (Modbus Value) Default (I/O, Set) Parameters to Appear

Operations Page Parameters

Active: Always.* Based on deci-

mal setting.

1A 1B Set

500 550 [1]

510 560 [2]

520 570 [3]

530 580 [4]

540 590 [5]

r/w

25°F

14°C

0 to 30000

0.0 to 3000.0

0.00 to 300.00

0.000 to 30.000

(0 to 30000) in integer,

tenths, hundredths or

thousandths

Proportional Band x (A or

B)

Define the proportional

band for PID control.

Main > Operations > Edit PID > PID Set Channel 1 > PID Set x (1 to 5)

PID Set x (1 to 5)* (Optional Inner Loop)

Main > Operations > Edit PID

Edit PID

Active if Analog Input 3 Control

Type is set to Cascade.

Outer loop is Input Channel 3.

343

r/w

Tune Off (0)Tune Off (0)

Outer Loop PID Set 1 (1)

Outer Loop PID Set 2 (2)

Outer Loop PID Set 3 (3)

Outer Loop PID Set 4 (4)

Outer Loop PID Set 5 (5)

Cascade Outer Loop

Select which PID parameters will be automatically tuned.

Active if Analog Input 3 Control

Type is set to Cascade.

Inner loop is Input Channel 1.

305

r/w

Tune Off (0)Tune Off (0)

Inner Loop PID Set 1 (1)

Inner Loop PID Set 2 (2)

Inner Loop PID Set 3 (3)

Inner Loop PID Set 4 (4)

Inner Loop PID Set 5 (5)

Cascade Inner Loop

Select which PID parameters will be automatically tuned.

Main > Operations > Autotune PID > Cascade

Autotune PID Cascade

Active if controller is in auto

(closed-loop) mode.

307

r/w

OffHeat Only (0)

Cool Only (1)

Heat and Cool (3)

Autotune PID Type

Select which output to

autotune.

Active if controller is in auto

(closed loop) mode.

305

r/w

Tune Off (0)

Tune Off (0)

PID Set 1 (1)

PID Set 2 (2)

PID Set 3 (3)

PID Set 4 (4)

PID Set 5 (5)

Channel 1 Autotune

Select which PID parameters will be automatically

tuned.

Main > Operations > Autotune PID

Autotune PID

Page 31

Watlow Series F4P Parameters ■ 6.5

✔ Note: For more information about how parameter set-

tings affect the controller’s operation, see the Features

Chapter.

* None of the B parameters are active if both outputs are

set to cool or heat.

Operations Page Parameter Table Modbus

Register

Range read/write Conditions for

Parameter Description (Modbus Value) Default (I/O, Set) Parameters to Appear

Active if Control Type (Analog

Input 3) is set to Cascade, PID

Units (Setup Page) is set to SI

and Proportional Band is not

set to 0.*

1A 1B Set

2601 2611 [1]

2621 2631 [2]

2641 2651 [3]

2661 2671 [4]

2681 2691 [5]

r/w

0 minutes0.00 to 99.99 minutes

(0 to 9999)

Integral x (A or B)

Set the integral time in

minutes.

[or]

Active if Control Type (Analog

Input 3) is set to Cascade.*

1A 1B Set

2600 2610 [1]

2620 2630 [2]

2640 2650 [3]

2660 2670 [4]

2680 2690 [5]

r/w

25°F

14°C

0 to 30000

0.0 to 3000.0

0.00 to 300.00

0.000 to 30.000

(0 to 30000) in integer,

tenths, hundredths or

thousandths

Proportional Band x (A or

B)

Define the proportional

band for PID control.

Main > Operations > Edit PID > Cascade Outer Loop PID Set X (1 to 5)

Cascade Outer Loop PID Set x (1 to 5)

* None of the B parameters are active if both outputs are set to cool or heat.

Active if Proportional Band is set

to 0 and one output is set to

heat and the other to cool

(Setup Page).* Based on dial

setting.

1A 1B Set

507 557 [1]

517 567 [2]

527 577 [3]

537 587 [4]

547 597 [5]

r/w

30 to 30000

0.0 to 3000.0

0.00 to 300.00

0.000 to 30.000

(0 to 30000) in integer,

tenths, hundredths or

thousandths

Hysteresis x (A or B)

Define the process variable change from the set

point required to re-energize the output (in onoff mode).

Active if Proportional Band is not

set to 0 and one output is set to

heat and the other to cool

(Setup Page).* Based on decimal

setting.

1A 1B Set

505 555 [1]

515 565 [2]

525 575 [3]

535 585 [4]

545 595 [5]

r/w

00 to 30000

0.0 to 3000.0

0.00 to 300.00

0.000 to 30.000

(0 to 30000) in integer,

tenths, hundredths or

thousandths

Dead Band x (A or B)

Define the effective shift

in the heating and cooling set points to prevent

conflict.

Active if PID Units (Setup Page)

is set to U.S. and Proportional

Band is not set to 0.*

1A 1B Set

504 554 [1]

514 564 [2]

524 574 [3]

534 584 [4]

544 594 [5]

r/w

0.00 minutes0.00 to 9.99 minutes

(0 to 999)

Rate x (A or B)

Set the rate time.