Grieve Corporation DR4500A Installation Manual

DR4500A Truline Circular Chart

Recorder With or Without Control

Product Manual

Doc. No.: 44-45-25-30

Release: L

Last Revision Date: 8/02

Industrial Measurement and Control

WARRANTY/REMEDY

Honeywell warrants goods of its manufacture as being free of defective materials and faulty

workmanship. Contact your local sales office for warranty information. If warranted goods are

returned to Honeywell during the period of coverage, Honeywell will repair or replace without

charge those items it finds defective. The foregoing is Buyer's sole remedy and is in lieu of all other

warranties, expressed or implied, including those of merchantability and fitness for a particular

purpose. Specifications may change without notice. The information we supply is believed to be

accurate and reliable as of this printing. However, we assume no responsibility for its use.

While we provide application assistance personally, through our literature and the Honeywell web

site, it is up to the customer to determine the suitability of the product in the application.

Notices and Trademarks

Copyright 2002 by Honeywell

Release L - August, 2002

Industrial Measurement and Control

Honeywell

1100 Virginia Drive

Ft. Washington, PA 19034

DR4500 Truline is a U.S. registered trademark of Honeywell.

Other brand or product names are trademarks of their respective owners.

ii DR4500A Truline Circular Chart Recorder With or Without Control Product Manual Release L

8/02

About This Document

References

The following list identifies all documents that may be sources of reference for material discussed in this

publication.

Document Title Doc ID

How to Apply Digital Instrumentation in Severe Electrical

Noise Environments

Modbus® RTU Serial Communications User Manual 51-52-25-66

Modbus® RTU Serial Communications User Manual

Configuration Interface for DR4500

51-52-05-01

51-52-25-69

Contacts

World Wide Web

The following lists Honeywell’s World Wide Web sites that will be of interest to our customers.

Honeywell Organization WWW Address (URL)

Corporate

Industrial Measurement and Control

Telephone

Contact us by telephone at the numbers listed below.

Organization Phone Number

http://www.honeywell.com

http://www.honeywell.com/imc/

United States and Canada Honeywell

Release L DR4500A Truline Circular Chart Recorder With or Without Control Product Manual iii

8/02

1-800-423-9883 Tech. Support

1-888-423-9883 Q&A Faxback

(TACFACS)

1-800-525-7439 Service

Symbol Definitions

The following table lists those symbols used in this document to denote certain conditions.

Symbol Definition

This CAUTION symbol on the equipment refers the user to the Product Manual for

additional information. This symbol appears next to required information in the manual.

WARNING: risk of electrical shock. This symbol warns the user of a potential shock

hazard where HAZARDOUS LIVE voltages greater than 30 Vrms, 42.4 Vpeak, or 60

VDC may be accessible.

ATTENTION, Electrostatic Discharge (ESD) hazards. Observe precautions for

handling electrostatic sensitive devices

Protective Earth (PE) terminal. Provided for connection of the protective earth (green

or green/yellow) supply system conductor.

Functional earth terminal. Used for non-safety purposes such as noise immunity

improvement. NOTE: This connection shall be bonded to protective earth at the

source of supply in accordance with national local electrical code requirements.

Earth Ground. Functional earth connection. NOTE: This connection shall be bonded to

Protective earth at the source of supply in accordance with national and local electrical

code requirements.

Chassis Ground. Identifies a connection to the chassis or frame of the equipment shall

be bonded to Protective Earth at the source of supply in accordance with national and

local electrical code requirements.

iv DR4500A Truline Circular Chart Recorder With or Without Control Product Manual Release L

8/02

Contents

1. Overview ........................................................................................... 1

1.1 Introduction ........................................................................................................1

1.2 Operator Interface..............................................................................................3

1.3 Set-up Tasks......................................................................................................5

2. Installation ......................................................................................... 7

2.1 Overview............................................................................................................7

2.2 Model Number Interpretation...........................................................................13

2.3 Mounting Considerations and Overall Dimensions .........................................16

2.4 Mounting Methods ...........................................................................................17

2.5 Wiring Prerequisites.........................................................................................27

2.6 Input Wiring Procedures ..................................................................................29

2.7 Output Wiring Procedures ...............................................................................39

2.8 Option Wiring Procedures ...............................................................................45

2.9 Lockout Switch Configuration ..........................................................................54

3. Configuration................................................................................... 55

3.1 Overview..........................................................................................................55

3.2 Configuration Prompts.....................................................................................57

3.3 How To Get Started.........................................................................................60

3.4 Configuration Tips............................................................................................61

3.5 Configuration Procedure..................................................................................62

3.6 Input Set Up Group..........................................................................................64

3.7 Pen Set Up Group ...........................................................................................66

3.8 Chart Set Up Group.........................................................................................67

3.9 Time Set Up Group..........................................................................................69

3.10 Totalizer Set Up Group ....................................................................................70

3.11 Input Algorithm Set Up Group .........................................................................72

3.12 Control Set Up Group ......................................................................................73

3.13 Tuning Parameters Set Up Group ...................................................................75

3.14 SP Ramp Set Up Groups ................................................................................76

Release L DR4500A Truline Circular Chart Recorder With or Without Control Product Manual v

8/02

3.15 Timer Set Up Group ........................................................................................77

3.16 Alarms Set Up Group ......................................................................................78

3.17 Auxiliary Output Set Up Group ........................................................................80

3.18 Modbus Communications Set Up Group .........................................................81

3.19 Options Set Up Group .....................................................................................82

3.20 Event Message Configuration .........................................................................83

3.21 Lockout Set Up Group .....................................................................................86

3.22 Adjust Printing..................................................................................................87

3.23 Configuration Record Sheet ............................................................................88

4. Configuration Parameter Definitions................................................ 93

4.1 Overview..........................................................................................................93

4.2 Input Parameters Set Up Group ......................................................................94

4.3 Pen Parameters Set Up Group........................................................................98

4.4 Chart Parameters Set Up Group ...................................................................100

4.5 Time Parameters Set Up Group....................................................................103

4.6 Total Parameters Set Up Group....................................................................104

4.7 Input Algorithm Set Up Group .......................................................................106

4.8 Control Parameters Set Up Group ................................................................109

4.9 Tuning Parameters Set Up Group .................................................................119

4.10 Setpoint Ramp Set Up Group........................................................................122

4.11 Timer Set Up Group ......................................................................................124

4.12 Alarms Set Up Group ....................................................................................125

4.13 Auxiliary Output Set Up Group ......................................................................128

4.14 Modbus Communications Set Up Group .......................................................130

4.15 Options Set Up Group ...................................................................................131

4.16 Event Message Set Up Group.......................................................................133

4.17 Lockout Parameters Set Up Group ...............................................................134

4.18 Printing Characteristics Adjustments.............................................................135

5. Operation ...................................................................................... 137

5.1 Overview........................................................................................................137

5.2 Start-up ..........................................................................................................138

5.3 Monitoring Your Recorder .............................................................................142

5.4 Operator Functions........................................................................................148

5.5 Operating Modes ...........................................................................................149

5.6 Setpoints........................................................................................................151

vi DR4500A Truline Circular Chart Recorder With or Without Control Product Manual Release L

8/02

5.7 Single Setpoint Ramp....................................................................................153

5.8 Using Two Sets of Tuning Constants (PID Values).......................................156

5.9 Using Accutune II...........................................................................................159

5.10 Alarm Setpoints .............................................................................................162

5.11 Three Position Step Control Algorithm ..........................................................163

5.12 Digital Input Option (Remote Switching)........................................................164

5.13 Resetting and Displaying Totalizer Value......................................................165

5.14 Monitoring the External Event Operation ......................................................167

5.15 Maximizing Pen Life.......................................................................................168

5.16 Routine Maintenance.....................................................................................169

5.17 Installing/Replacing Chart..............................................................................170

5.18 Chart Operation .............................................................................................171

6. Setpoint Ramp/Soak Programming and Operation .......................173

6.1 Overview........................................................................................................173

6.2 Setpoint Program Contents ...........................................................................175

6.3 Drawing a Ramp/Soak Profile .......................................................................178

6.4 Entering the Setpoint Program Data..............................................................183

6.5 SP RAMP1 and SP RAMP2 Set Up Group ...................................................185

6.6 Setpoint Program Profiles Set Up Group ......................................................187

6.7 Setpoint Program Segments Set Up Group ..................................................189

6.8 Setpoint Program Event Set Up Group .........................................................192

6.9 Run/Monitor the Program ..............................................................................196

7. Input Calibration ............................................................................ 199

7.1 Overview........................................................................................................199

7.2 Restoring Factory Calibration ........................................................................200

7.3 Minimum and Maximum Range Values.........................................................202

7.4 Preliminary Information..................................................................................203

7.5 Calibration Set Up and Wiring for PV Inputs .................................................205

7.6 Calibration Procedure....................................................................................214

7.7 Printing Characteristics Adjustments.............................................................217

8. Output Calibration .........................................................................219

8.1 Overview........................................................................................................219

8.2 Current Proportional Output/Aux Out 2 and 3 Calibration.............................220

8.3 Position Proportional and Three Position Step Output Calibration ..............222

Release L DR4500A Truline Circular Chart Recorder With or Without Control Product Manual vii

8/02

8.4 Auxiliary Output Calibration ...........................................................................225

9. Troubleshooting / Service.............................................................. 227

9.1 Overview........................................................................................................227

9.2 Troubleshooting Aids.....................................................................................229

9.3 Self Diagnostics.............................................................................................231

9.4 Visual Failure Symptoms...............................................................................237

9.5 Troubleshooting Procedures .........................................................................238

10. Parts List .................................................................................... 245

10.1 Overview........................................................................................................245

10.2 Exploded Views .............................................................................................246

10.3 Miscellaneous Hardware Kit Contents ..........................................................252

10.4 Internal Cabling Data .....................................................................................253

10.5 Internal Wiring Diagram – Options Only........................................................254

A. Model DR45AR .............................................................................255

A.1 Overview........................................................................................................255

A.2 Hardware Identification..................................................................................256

A.3 Fo Reset Configuration..................................................................................258

A.4 Options Configuration....................................................................................259

A.5 Operations Additions .....................................................................................261

A.6 Configuration Worksheet Additions ...............................................................262

B. Security Lockout............................................................................ 263

B.1 Overview........................................................................................................263

C. Foreign Language Safety Instructions........................................... 265

DA2I-6056 ................................................................................................................266

DU2I-6056 ................................................................................................................267

FI2I-6056 ..................................................................................................................268

FR2I-6056.................................................................................................................269

GE2I-6056 ................................................................................................................270

GR2I-6056 ................................................................................................................271

IT2I-6056 ..................................................................................................................272

NO2I-6056 ................................................................................................................273

PO2I-6056 ................................................................................................................274

viii DR4500A Truline Circular Chart Recorder With or Without Control Product Manual Release L

8/02

SP2I-6056.................................................................................................................275

SW2I-6056................................................................................................................276

Index ...................................................................................................277

Release L DR4500A Truline Circular Chart Recorder With or Without Control Product Manual ix

8/02

Tables

Table 1-1 Function of Keys .........................................................................................................................................4

Table 2-1 Operating Limits and Condensed Specifications.........................................................................................8

Table 2-2 Procedure to Access Components .............................................................................................................14

Table 2-3 Mounting Flush in a New Panel Cutout ....................................................................................................18

Table 2-4 Reference Data for Mounting DR4500A in Existing Panel Cutouts ......................................................... 19

Table 2-5 Mounting Flush in a Panel Using Universal Filler Kit.............................................................................. 20

Table 2-6 Mounting Flush in a Panel Using Kent Model 105M Cutout....................................................................21

Table 2-7 Procedure for Mounting Recorder with Heavy Duty Door .......................................................................22

Table 2-8 Pipe Mounting Procedure..........................................................................................................................24

Table 2-9 Mounting Flush on a Surface (of Panel or Wall).......................................................................................25

Table 2-10 Permissible Wiring Bundling..................................................................................................................28

Table 2-11 AC Line Power Wiring............................................................................................................................31

Table 2-12 Thermocouple, RTD, Radiamatic, mV, or 0–5 Vdc Input Wiring ..........................................................33

Table 2-13 4-20 mA Input Wiring............................................................................................................................. 35

Table 2-14 0-10 Volt dc Input Wiring.......................................................................................................................37

Table 2-15 4-20 mA Control Output Wiring.............................................................................................................39

Table 2-16 Position Proportional Control Output Wiring .........................................................................................41

Table 2-17 Relay Control Output Wiring..................................................................................................................43

Table 2-18 Alarm Output or Digital Input Wiring.....................................................................................................45

Table 2-19 Alarm 3 and Alarm 4 Output Wiring ......................................................................................................47

Table 2-20 Alarm 5 and Alarm 6 Output Wiring ......................................................................................................48

Table 2-21 RS485 Modbus Communications Wiring................................................................................................50

Table 2-22 4-20 mA Auxiliary Output Wiring..........................................................................................................52

Table 3-1 Configuration Tips ....................................................................................................................................61

Table 3-2 Configuration Procedure ........................................................................................................................... 62

Table 3-3 Input Group Function Prompts.................................................................................................................. 64

Table 3-4 Pen 1, 2, 3, 4 Group Function Prompts .....................................................................................................66

Table 3-5 Chart Group Function Prompts .................................................................................................................67

Table 3-6 Time Group Function Prompts ..................................................................................................................69

Table 3-7 Totalizer Group Function Prompts............................................................................................................ 70

Table 3-8 Input Algorithm Group Function Prompts ................................................................................................72

Table 3-9 Control 1 or Control 2 Group Function Prompts.......................................................................................73

Table 3-10 Tuning 1 or Tuning 2 Group Function Prompts ......................................................................................75

Table 3-11 SP Ramp 1 or 2 Group Function Prompts...............................................................................................76

Table 3-12 Timer Group Function Prompts...............................................................................................................77

Table 3-13 Priority of functions that operate relays ..................................................................................................78

Table 3-14 Alarms Group Function Prompts............................................................................................................. 79

Table 3-15 Auxiliary Output Group Function Prompts.............................................................................................80

Table 3-16 Modbus Communications Group Function Prompts ...............................................................................81

Table 3-17 Options Group Function Prompts............................................................................................................82

Table 3-18 Event Message Group Function Prompts................................................................................................83

Table 3-19 Lockout Group Function Prompts...........................................................................................................86

Table 3-20 Adjust Group Function Prompts..............................................................................................................87

Table 4-1 Input Group Definitions ............................................................................................................................ 94

Table 4-2 Pen 1, 2, 3, or 4 Group Definitions............................................................................................................98

Table 4-3 Chart Parameters Group Definitions ....................................................................................................... 100

Table 4-4 Time Parameters Group Definitions........................................................................................................103

Table 4-5 Totalizer Group Definitions ....................................................................................................................104

Table 4-6 Input Algorithm Group Definitions ......................................................................................................... 106

Table 4-7 Control 1 or 2 Group Definitions ............................................................................................................109

Table 4-8 Tuning Group Prompt Definitions...........................................................................................................119

Table 4-9 Setpoint Ramp 1 or 2 Group Definitions.................................................................................................122

Table 4-10 Timer Group Definitions....................................................................................................................... 124

x DR4500A Truline Circular Chart Recorder With or Without Control Product Manual Release L

8/02

Table 4-11 Priority of functions that operate relays .................................................................................................125

Table 4-12 Alarms Group Definitions..................................................................................................................... 126

Table 4-13 Auxiliary Output Group Definitions .....................................................................................................128

Table 4-14 Modbus Communications Group Definitions........................................................................................130

Table 4-15 Option Group Definitions......................................................................................................................131

Table 4-16 Event Message Group Definitions.........................................................................................................133

Table 4-17 Lockout Group Definitions ................................................................................................................... 134

Table 4-18 Printing Characteristics Adjustment Procedure.....................................................................................136

Table 5-1 Power Up Diagnostic Tests..................................................................................................................... 138

Table 5-2 Procedure for Testing the Displays and Keys .........................................................................................139

Table 5-3 Procedure for Starting Up the Recorder ..................................................................................................140

Table 5-4 Meaning of Indicators .............................................................................................................................143

Table 5-5 Lower Display Key Parameter Prompts..................................................................................................145

Table 5-6 Error Messages........................................................................................................................................ 146

Table 5-7 Alarm and tuning messages.....................................................................................................................147

Table 5-8 Operating Mode Definitions....................................................................................................................149

Table 5-9 Changing Operating Modes.....................................................................................................................149

Table 5-10 Procedure for Selecting Automatic or Manual Mode............................................................................150

Table 5-11 Procedure for Selecting the Setpoint Source .........................................................................................151

Table 5-12 Procedure for Changing the Local Setpoint ..........................................................................................151

Table 5-13 Procedure for Switching Between Setpoints .........................................................................................152

Table 5-14 Setpoint Selection Indication.................................................................................................................152

Table 5-15 Procedure for Configuring a Single Setpoint Ramp ..............................................................................153

Table 5-16 Procedure for Running a Setpoint Ramp ...............................................................................................154

Table 5-17 Procedure for Selecting Two Sets of Tuning Constants ........................................................................156

Table 5-18 Procedure for Setting Switchover Values..............................................................................................157

Table 5-19 Procedure for Setting Tuning Constant Values.....................................................................................157

Table 5-20 Procedure for Switching PID Sets from the Keyboard..........................................................................158

Table 5-21 Procedure for Starting Accutune II........................................................................................................159

Table 5-22 Procedure for Using Accutune for Duplex Control...............................................................................160

Table 5-23 Procedure for Displaying or Changing the Alarm Setpoints .................................................................162

Table 5-24 Procedure for Displaying the 3PSTEP Motor Position .........................................................................163

Table 5-25 Digital Input Option Action on Contact Closure...................................................................................164

Table 5-26 Procedure for Resetting the Totalizer....................................................................................................165

Table 5-27 Procedure for Displaying the Totalizer Value.......................................................................................166

Table 5-28 Maximizing Pen Life.............................................................................................................................168

Table 5-29 Cleaning the Pen Tip.............................................................................................................................169

Table 5-30 Replacing a Chart Lamp........................................................................................................................169

Table 5-31 Installing/Replacing the Chart...............................................................................................................170

Table 5-32 Remote Chart Modes.............................................................................................................................172

Table 6-1 Parameter settings for example 12-step profile .......................................................................................179

Table 6-2 Setpoint program data entry procedure ...................................................................................................183

Table 6-3 SP RAMP prompts and available selections ...........................................................................................185

Table 6-4 Setpoint Program Profiles Group Definitions .........................................................................................187

Table 6-5 Setpoint Program Segments Group Definitions ......................................................................................189

Table 6-6 Setpoint Program Event Group Definitions.............................................................................................192

Table 6-7 Segment Event relay operation requirements ..........................................................................................193

Table 6-8 Run/Monitor Functions ........................................................................................................................... 196

Table 7-1 Restoring Factory Calibration .................................................................................................................200

Table 7-2 Voltage and Resistance Equivalents for 0 % and 100 % Range Values..................................................202

Table 7-3 Disconnect the Field Wiring....................................................................................................................203

Table 7-4 Equipment Needed..................................................................................................................................204

Table 7-5 General Set Up Procedure ....................................................................................................................... 206

Table 7-6 Set Up Wiring Procedure for Thermocouple Inputs Using an Ice Bath ..................................................207

Table 7-7 Set Up Wiring Procedure for Thermocouple Inputs Using a Compensated Calibrator Method..............208

Release L DR4500A Truline Circular Chart Recorder With or Without Control Product Manual xi

8/02

Table 7-8 Set Up Wiring Procedure for Thermocouple Inputs Using the Ambient Temperature Method.............. 209

Table 7-9 Set Up Wiring Procedure for RTD Inputs...............................................................................................210

Table 7-10 Set Up Wiring Procedure for Radiamatic, Millivolts, and Volts Inputs (except 0-10 Volts) ................211

Table 7-11 Set Up Wiring Procedure for 0–10 Volt Inputs .....................................................................................212

Table 7-12 Set Up Wiring Procedure for 4–20 mA Inputs ......................................................................................213

Table 7-13 Calibration Procedure Sequence............................................................................................................214

Table 8-1 Set Up Wiring Procedure Current Proportional Output/Aux Out 2 and 3...............................................220

Table 8-2 Current Proportional Output/Aux Output 2 and 3 Calibration Procedure ............................................... 221

Table 8-3 Position Proportional and 3 Position Step Output Calibration Procedure ...............................................223

Table 8-4 Set Up Wiring Procedure Auxiliary Output ............................................................................................225

Table 8-5 Auxiliary Output Calibration Procedure..................................................................................................226

Table 9-1 Identifying the software version.............................................................................................................. 230

Table 9-2 Power-up tests .........................................................................................................................................231

Table 9-3 Displaying the test results........................................................................................................................232

Table 9-4 Error message prompts............................................................................................................................233

Table 9-5 Visual failure symptoms..........................................................................................................................237

Table 9-6 Procedure #1—Troubleshooting recorder failure symptoms...................................................................238

Table 9-7 Procedure #2—Troubleshooting pen trace failure symptoms .................................................................239

Table 9-8 Procedure #3—Troubleshooting chart rotation failure symptoms...........................................................239

Table 9-9 Procedure #4—Troubleshooting chart rotation failure symptoms...........................................................240

Table 9-10 Procedure #5—Troubleshooting pen failure symptoms........................................................................240

Table 9-11 Procedure #6—Troubleshooting keyboard and/or display failure symptoms .......................................240

Table 9-12 Procedure #7—Troubleshooting current proportional output failure symptoms...................................241

Table 9-13 Procedure #8—Troubleshooting position proportional output failure symptoms .................................241

Table 9-14 Procedure #9—Troubleshooting relay output failure symptoms...........................................................242

Table 9-15 Procedure #10—Troubleshooting current/time or time/current failure symptoms ................................ 242

Table 9-16 Procedure #11—Troubleshooting the auxiliary output .........................................................................243

Table 9-17 Procedure #12—Troubleshooting external alarm function failure symptoms.......................................243

Table 9-18 Procedure #13—Troubleshooting Modbus communications ................................................................243

Table 10-1 Door assembly parts..............................................................................................................................246

Table 10-2 Chart plate assembly parts.....................................................................................................................247

Table 10-3 Basic recorder parts without options ..................................................................................................... 249

Table 10-4 Recorder parts associated with options .................................................................................................251

Table 10-5 Miscellaneous hardware kit...................................................................................................................252

Table A-1 Fo RESET group function prompts........................................................................................................258

Table A-2 Options group function prompts, continued from Section 3/Table 3-17 ................................................259

Table A-3 Option group definitions, continued from Section 4/Table 4-15............................................................ 260

xii DR4500A Truline Circular Chart Recorder With or Without Control Product Manual Release L

8/02

Figures

Figure 1-1 Operator Interface ...................................................................................................................................... 3

Figure 1-2 Set-up Tasks...............................................................................................................................................5

Figure 2-1 Model Number Interpretation ..................................................................................................................13

Figure 2-2 DR4500A Recorder Hardware Components Versus “Table” Selections ................................................. 15

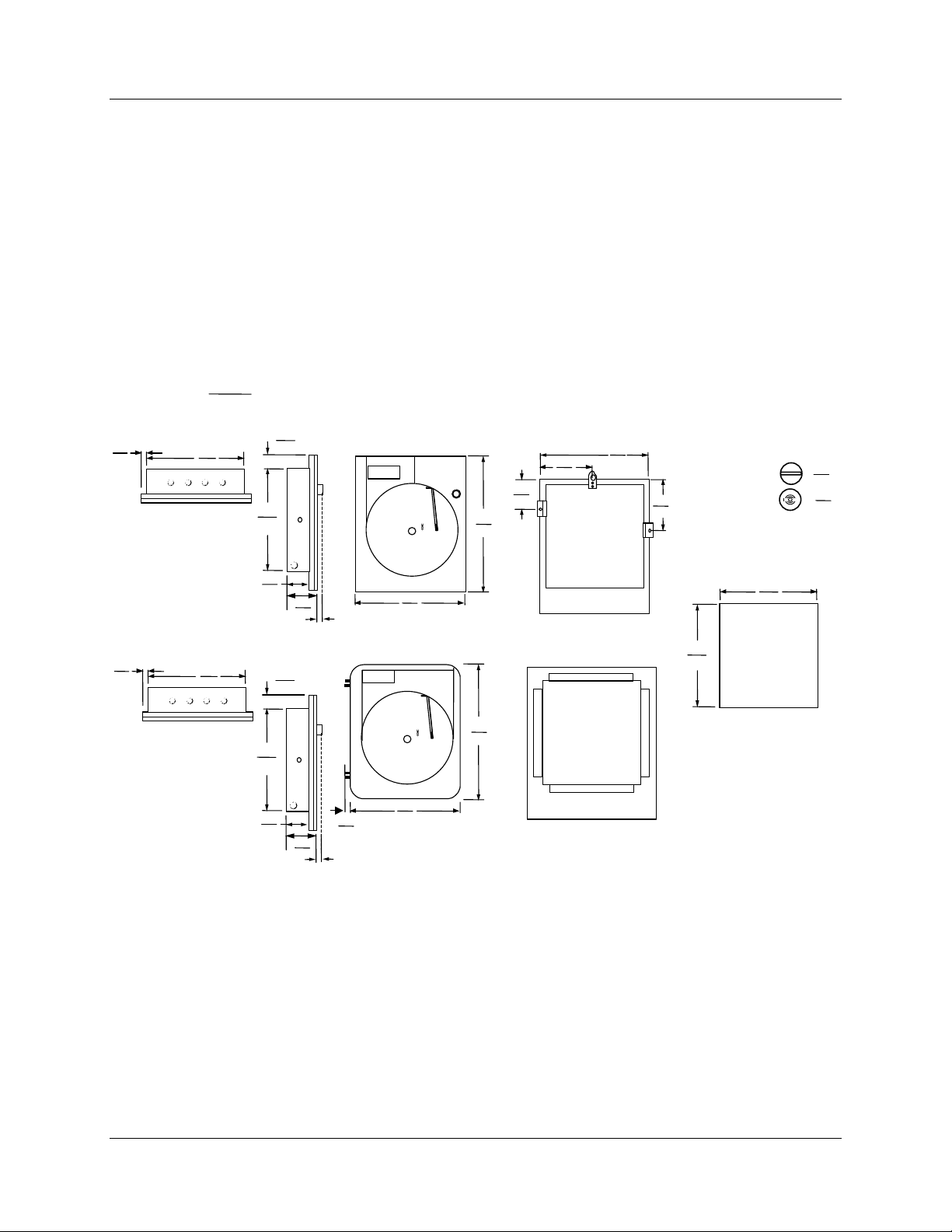

Figure 2-3 Overall Dimensions .................................................................................................................................16

Figure 2-4 How to Remove Knockouts ..................................................................................................................... 17

Figure 2-5 Mounting Flush in a New Panel Cutout ...................................................................................................18

Figure 2-6 Mounting in a Panel Using Universal Filler Kit ......................................................................................20

Figure 2-7 Mounting in a Panel using Kent Model 105M Cutout.............................................................................21

Figure 2-8 Panel Mounting Recorder with Heavy Duty Door...................................................................................23

Figure 2-9 Pipe Mounting Brackets...........................................................................................................................24

Figure 2-10 Mounting Flush on a Surface (of Panel or Wall) ...................................................................................26

Figure 2-11 Ferrite Filter Locations and Shield Wiring (CE Mark)..........................................................................30

Figure 2-12 AC Line Power Wiring ..........................................................................................................................32

Figure 2-13 Thermocouple, RTD, Radiamatic, mV, or 0–5 Vdc Input Wiring.........................................................34

Figure 2-14 4-20 mA Input Wiring............................................................................................................................36

Figure 2-15 0-10 Volt dc Input Wiring...................................................................................................................... 38

Figure 2-16 4-20 mA Control Output Wiring (or Aux Out #2 and #3 Wiring) .........................................................40

Figure 2-17 Position Proportional Control Output or Three Position Step Wiring....................................................42

Figure 2-18 Relay Control Output Wiring................................................................................................................. 44

Figure 2-19 Alarm Output or Digital Input Wiring ...................................................................................................46

Figure 2-20 Alarm outputs #3, 4, 5, and 6 wiring......................................................................................................49

Figure 2-21 RS485 Modbus Communications Wiring .............................................................................................. 51

Figure 2-22 4-20 mA Auxiliary Output #1 Wiring....................................................................................................53

Figure 2-23 S1 Lockout Switch Location..................................................................................................................54

Figure 3-1 DR4500A Prompt Hierarchy ...................................................................................................................57

Figure 5-1 Operator Interface .................................................................................................................................. 142

Figure 5-2 Deviation Bargraph................................................................................................................................144

Figure 6-1 Ramp/Soak Profile Example..................................................................................................................178

Figure 7-1 Location of the Input Connections on the Input Boards ........................................................................ 203

Figure 7-2 Location of Jumper Positions W1/MA and W3 on the Input Boards.....................................................205

Figure 7-3 Calibration Set Up Diagram for Thermocouple Inputs Using an Ice Bath.............................................207

Figure 7-4 Calibration Set Up Diagram for Thermocouple Inputs Using a Compensated Calibrator Method........ 208

Figure 7-5 Calibration Set Up Diagram for Thermocouple Inputs using the Ambient Temperature Method .........209

Figure 7-6 Calibration Set Up Diagram for RTD Inputs .........................................................................................210

Figure 7-7 Calibration Set Up Diagram for Radiamatic, Millivolts, and Volts Inputs (except 0-10 Volts) ............211

Figure 7-8 Calibration Set Up Diagram for 0–10 Volt Inputs .................................................................................212

Figure 7-9 Calibration Set Up Diagram for 4–20 mA Inputs ..................................................................................213

Figure 8-1 Test Equipment Connections for Calibrating Current Proportional Output...........................................220

Figure 8-2 Test Equipment Connections for Calibrating Auxiliary Output.............................................................225

Figure 10-1 Door assembly .....................................................................................................................................246

Figure 10-2 Chart plate assembly ............................................................................................................................ 247

Figure 10-3 Basic recorder components without options ........................................................................................248

Figure 10-4 Recorder components associated with options.....................................................................................250

Figure 10-5 Internal cabling for DR4500A Truline recorder...................................................................................253

Figure 10-6 Internal diagram for DR4500A Truline recorder – options only..........................................................254

Figure A-1 DR45AR with one input........................................................................................................................256

Figure A-2 DR45AR with two to four inputs .......................................................................................................... 257

Release L DR4500A Truline Circular Chart Recorder With or Without Control Product Manual xiii

8/02

1.1 Introduction

Function

The DR4500A Truline Recorder is a one to four-channel microprocessor-based circular chart recorder. Its

"one-pen" stylus printhead produces up to four analog traces and prints alphanumeric chart data on a blank

heat-sensitive chart. All four traces share the same time line reference which the Truline prints. This

eliminates the error caused by pen alignment offsets in conventional pen designs. Since the Truline prints

the chart and generates the analog traces at the same time, there is no error due to variations in chart size

caused by changes in temperature and humidity.

In addition to printing chart records, the Truline recorder alternately displays process variable values for all

channels in the selected engineering units.

Models with up to four input channels accept inputs from any one of a variety of sensors or transmitters

within the configurable range limits.

The Truline is also available with one or two independent digital controllers and setpoint programmers.

CE Conformity (Europe)

Indicated models of this product are in conformity with the protection requirements of the following

European Council Directives: 73/23/EEC, the Low Voltage Directive, and 89/336/EEC, the EMC

Directive. Conformity of this product with any other “CE Mark” Directive(s) shall not be assumed.

1. Overview

Deviation from the installation conditions specified in this manual, and the special conditions for CE

conformity in Subsection 2.1, may invalidate this product’s conformity with the Low Voltage and EMC

Directives.

ATTENTION

The emission limits of EN 61326 are designed to provide reasonable protection against

harmful interference when this equipment is operated in an industrial environment. Operation

of this equipment in a residential area may cause harmful interference. This equipment

generates, uses, and can radiate radio frequency energy and may cause interference to radio

and television reception when the equipment is used closer than 30 meters (98 feet) to the

antenna(e). In special cases, when highly susceptible apparatus is used in close proximity, the

user may have to employ additional mitigating measures to further reduce the electromagnetic

emissions of this equipment.

Microprocessor controlled recording and printing

Both the chart and printhead are driven by stepper motors controlled by the microprocessor with

configurable chart speed through the keypad.

You can configure various "printed" chart data such as range marking in engineering units, digital values

for process variables, and trace identification. This data plus printed time lines and engineering units of

scale eliminate the need to maintain an inventory of a variety of preprinted charts.

The Truline recorder uses a dot fill technique from a microprocessor algorithm to produce a continuous

analog trace of a process variable.

Release L DR4500A Truline Circular Chart Recorder With or Without Control Product Manual

8/02

1

Overview

Introduction

Digital controller

The DR4500A recorder controller includes an integral microprocessor-based, single or dual loop PID

controller with optional setpoint program. A variety of output types, including a duplex variation for heat

cool applications, lets you select the output that is right for your final control element. Accutune II lets you

automatically tune your loops.

You can configure the control action as On-Off, PID-A, PID-B, PD with manual reset, or Three Position

Step. English language prompts guide you through the entry of all the controller's configurable parameters.

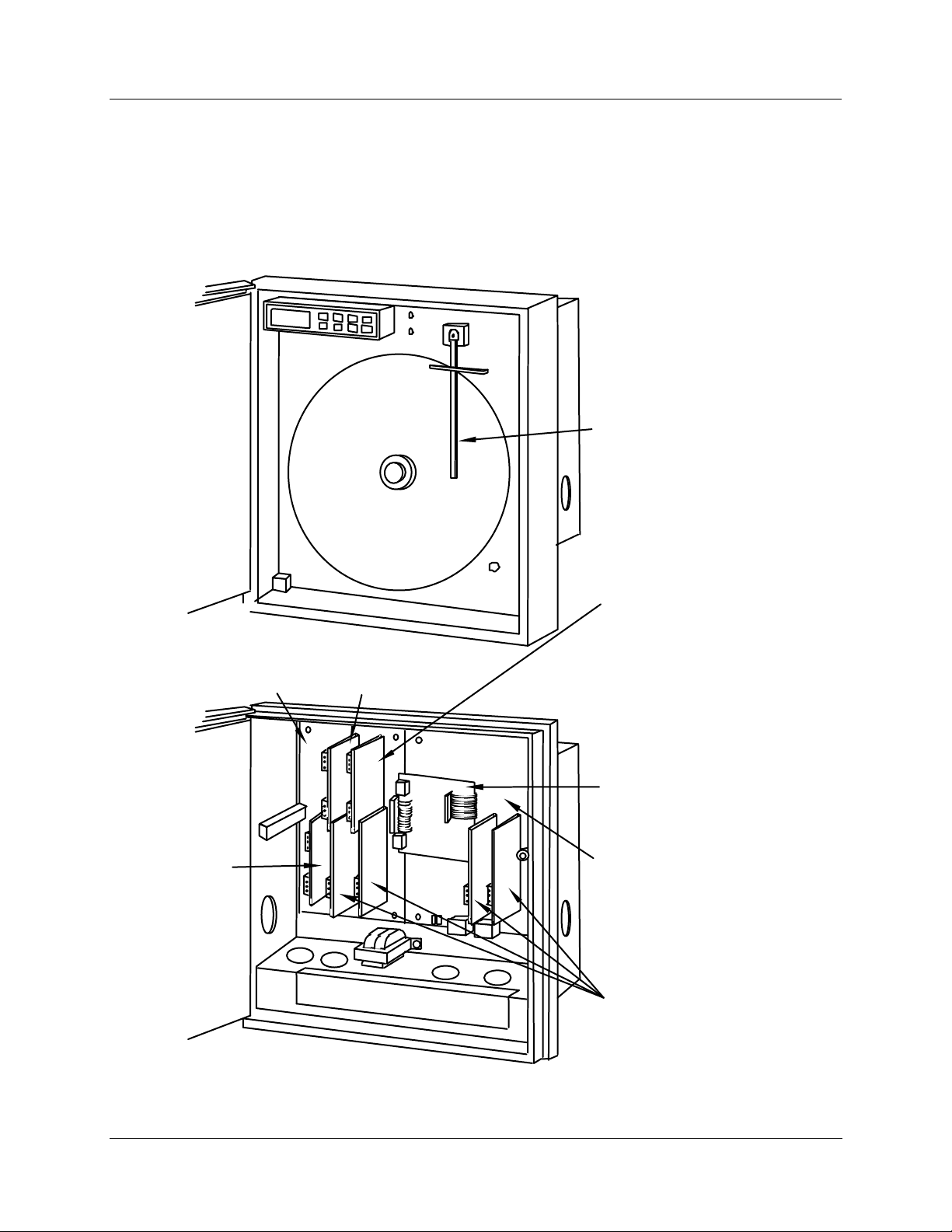

Construction

The DR4500A recorder is housed in a molded case which can be panel or surface mounted. A glass or

acrylic windowed door (A UL and FM approved NEMA4X door is also available )protects the internal

components while allowing easy access to the chart and operator interface. An optional external keypad

that allows operator selections without opening the door is available.

Circuitry is partitioned on printed circuit boards for ease of service.

Power, input, and output wiring connect to terminations inside the case. Knockouts in the sides and bottom

of the case accept conduit connections for convenient wire entry.

2 DR4500A Truline Circular Chart Recorder With or Without Control Product Manual Release L

8/02

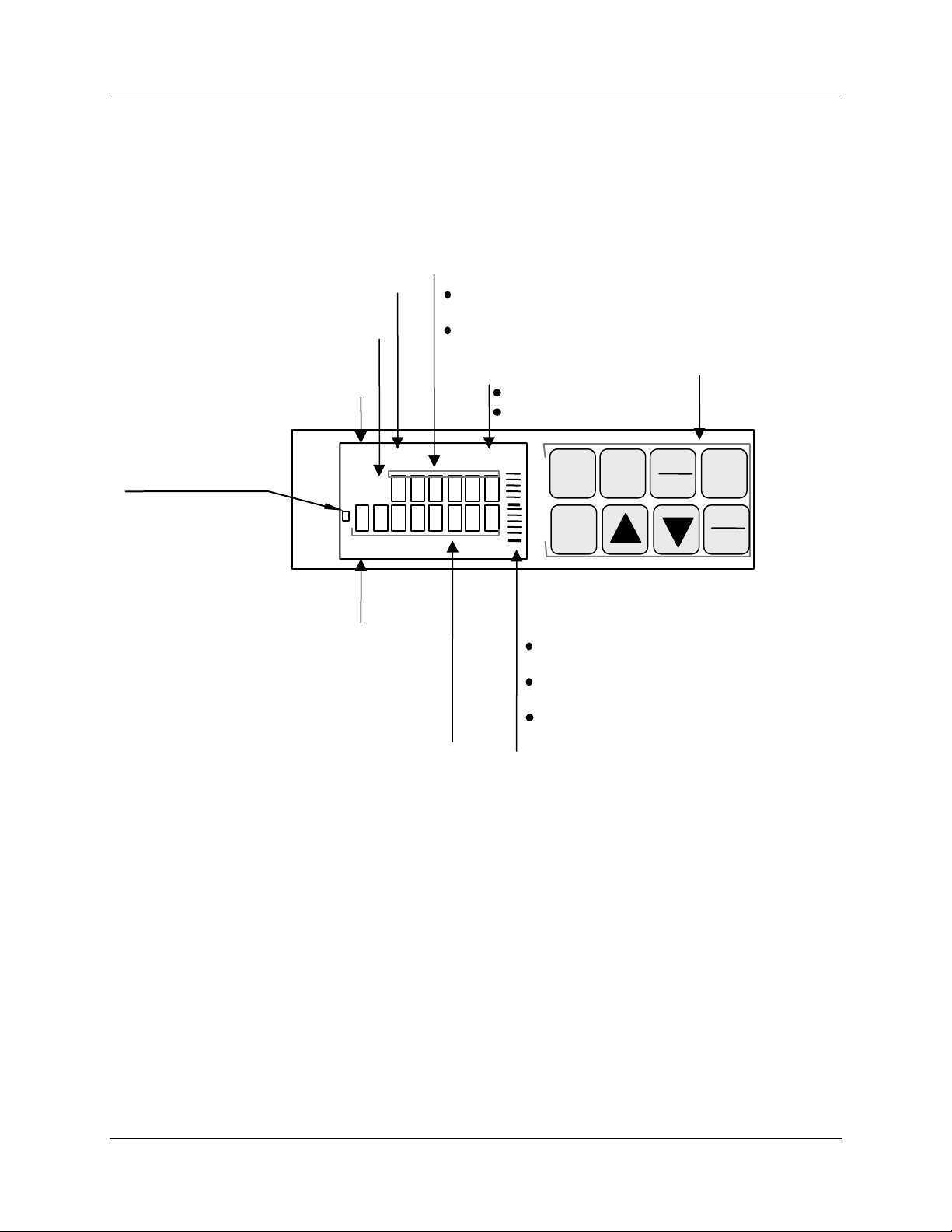

1.2 Operator Interface

Operator interface

Figure 1-1 shows the operator interface and defines the displays and indicators. The function of the keys is

described in Table 1-1.

Indicates temperature units of PV Upper Display - six characters

PV displayed is for channel

1, 2, 3, or 4

Alarm condition exists for

alarm 1 or 2, when lit.

ALM

CHN

Remote set point or

2nd set point is active,

when lit. Blinks when

2nd setpoint or remote

setpoint is attained

through remote switch

RSP

OUT

12 FC

1234

12

Operator Interface

Normal operation - Displays process

variable (PV) for selected channels.

Configuration mode - Displays selection or

parameter value.

Indicates controller mode:

MAN = Manual

Keypad /

Key functions

A = Automatic

MAN

FUNC

LOWR

DISP

MAN

AUTO

CHART

%

SET

UP

RUN

HOLD

Overview

Control relay 1 or 2 is

ON, when lit.

Lower Display - eight characters

• Normal operation - Displays selectable

operating parameters and values. Indicates

diagnostic error messages, alarm condition

for alarms 3-6, Accutune in progress.

• Configuration mode - Displays function

group and parameters.

Bargraph - deviation (±10% of span)

Center green bar indicates PV is within

±1% of control setpoint

Next small bar will light if PV is between

±1% but less than ±2% in deviation.

If PV is equal to or greater than ±10%

deviation, the green bar plus all ten small

green bars will light.

Figure 1-1 Operator Interface

.

Release L DR4500A Truline Circular Chart Recorder With or Without Control Product Manual 3

8/02

Overview

Operator Interface

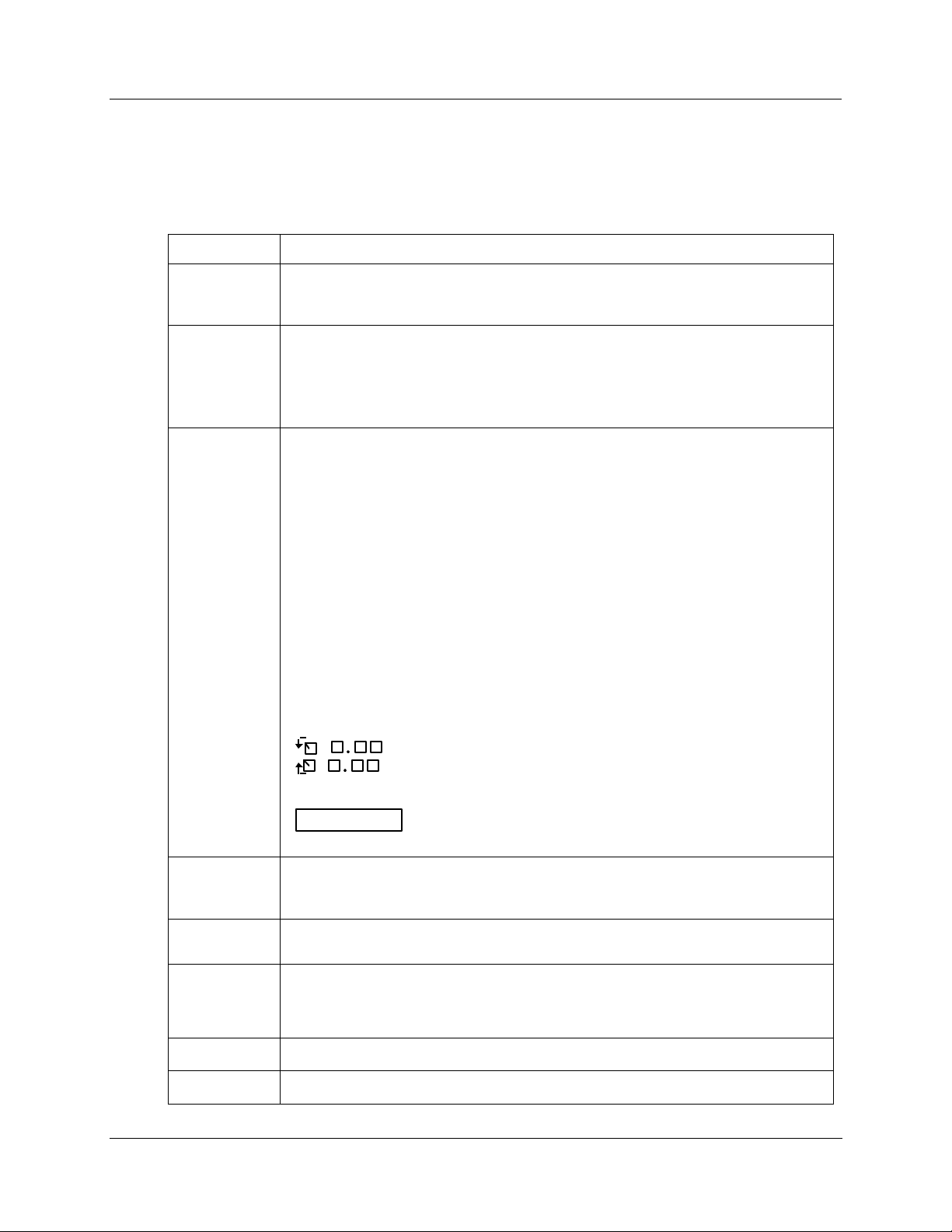

Key functions

Table 1-1 shows each key on the operator interface and defines its function.

Key Function

Table 1-1 Function of Keys

SET

UP

FUNC

LOWR

DISP

• Places the controller in the Configuration Set Up group select mode. Sequentially

displays Set Up groups and allows the FUNC key to display individual functions in

each Set Up group.

• Used in conjunction with the SET UP key to select the individual functions of a

selected Configuration Set Up group.

• Used to toggle between SP1 and SP2.

• Used during field calibration procedure.

• Selects an operating parameter to be shown in the lower display:

OUT = Output Value (estimated motor position for 3 Position Step)

SP = Local Setpoint 1

SPN = Current setpoint for setpoint rate applications

2SP = Local Setpoint 2

RSP = Remote Setpoint

1IN = Input 1 (if Loop 1 is a derived PV)

2IN = Input 2

3IN = Input 3

4IN = Input 4

DEV = Deviation

EU = PV Engineering Units

RH = % RH Value

PIDSETX = Tuning Parameter Set X=1 or 2

RAMP = Minutes remaining in Setpoint Ramp

#RA = Minutes remaining in SP Prog Ramp

#SK = Minutes remaining in SP Prog Soak

RECYC = Number of recycles left in SP Program

= Time remaining in Timer function

= Time elapsed in Timer function

TUNExXXX = Accutune II indicator. x = 1 or 2

ATTENTION

The lower display can be configured to scroll through the operating

parameters.

MAN

AUTO

• Alternately selects:

AUTO Lower display automatically displays setpoint value in engineering units.

MAN Lower display automatically indicates output in %.

CHART

• Used to stop printing operation and move pen to outer limit for chart change.

Display will revert to date and time.

RUN

• Alternate action switch initiates or holds the Setpoint Ramp or Setpoint Program.

HOLD

• In configuration mode, restores the original value or selection if you do not want to

enter a change you are making to a parameter.

▲

▼

• Increases the setpoint, output, or configuration values displayed.

• Decreases the setpoint, output, or configuration values displayed.

4 DR4500A Truline Circular Chart Recorder With or Without Control Product Manual Release L

8/02

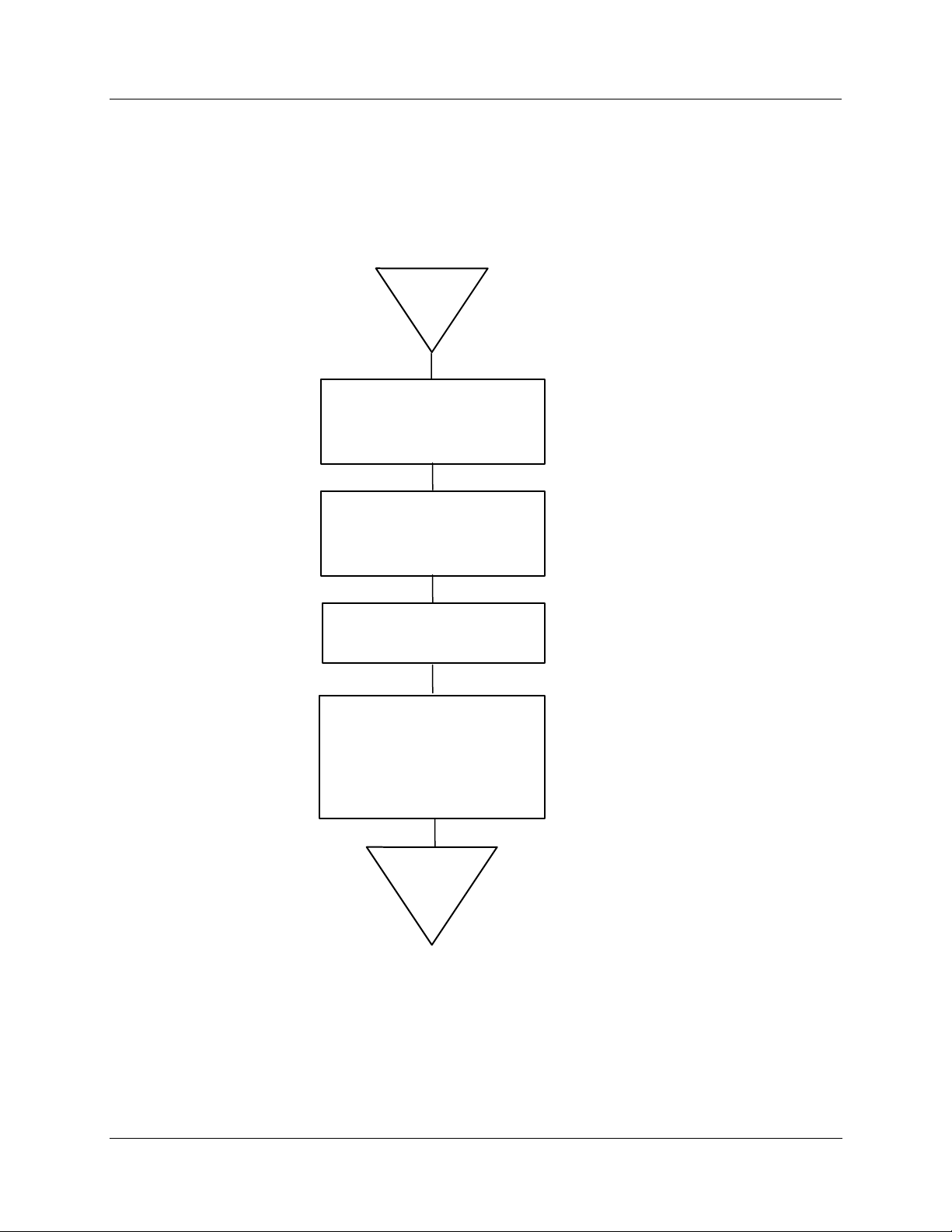

1.3 Set-up Tasks

Major set-up tasks

As shown in Figure 1-2, there are four major tasks that you must complete to "Set Up" the DR4500A

recorder for operation. For easy reference the section numbers for each task are shown.

START

1.

Determine your recorder's

hardware components and

software functions

Mount the recorder flush in

2.

a panel, or on the surface

of a panel or a wall

Overview

Set-up Tasks

See Section 2

See Section 2

3.

Connect the power and

input/output wiring.

Follow the simple keystroke

4.

See Section 2

sequences and English

language prompts to

See Sections 3 & 4

"configure" the functional

characteristics of your

recorder.

Ready for

Operation

For Model DR45AR, also see Appendix A

21402

Figure 1-2 Set-up Tasks

Release L DR4500A Truline Circular Chart Recorder With or Without Control Product Manual 5

8/02

Overview

Set-up Tasks

6 DR4500A Truline Circular Chart Recorder With or Without Control Product Manual Release L

8/02

2.1 Overview

Introduction

Installation of the DR4500A Recorder consists of mounting and wiring the recorder according to the

instructions given in this section.

Read the preinstallation information, check the model number interpretation and become familiar with your

model selections, then proceed with installation.

What’s in this section?

This section contains the following information:

2.1 Overview 7

2.2 Model Number Interpretation 13

2. Installation

Topic See Page

2.3 Mounting Considerations and Overall Dimensions 16

2.4 Mounting Methods 17

2.5 Wiring Prerequisites 27

2.6 Input Wiring Procedures 29

2.7 Output Wiring Procedures 39

2.8 Option Wiring Procedures 45

2.9 Lockout Switch Configuration 54

Pre-installation information

If the recorder has not been removed from its shipping carton, inspect the carton for damage and remove

the recorder. Inspect the unit for any obvious shipping damage and report any damage due to transit to the

carrier.

Make sure a bag containing mounting hardware is included in the carton with the recorder.

Check that the model number shown on the chart plate agrees with what you have ordered.

CE Conformity special conditions (Europe)

Braid shielded twisted pair cables are required for all Analog I/O, Process Variable, RTD, Thermocouple,

dc millivolt, low level signal, 4-20 mA, and relay output circuits. Supplementary bonding of the recorder

enclosure to a local ground, using a 3/4” braided copper conductor, is required. Ferrite suppression filters

and capacitor filters (see Subsection 2.5 for Wiring Prerequisites) shall be installed on all cables connected

to the recorder/controller.

Refer to document 51-52-05-01, How to Apply Digital Instrumentation in Severe Electrical Noise

Environments, for additional installation guidance.

Release L DR4500A Truline Circular Chart Recorder With or Without Control Product Manual 7

8/02

Installation

Overview

Operating limits and condensed specifications

We recommend that you review and adhere to the operating limits listed in Table 2-1 when you install your

recorder.

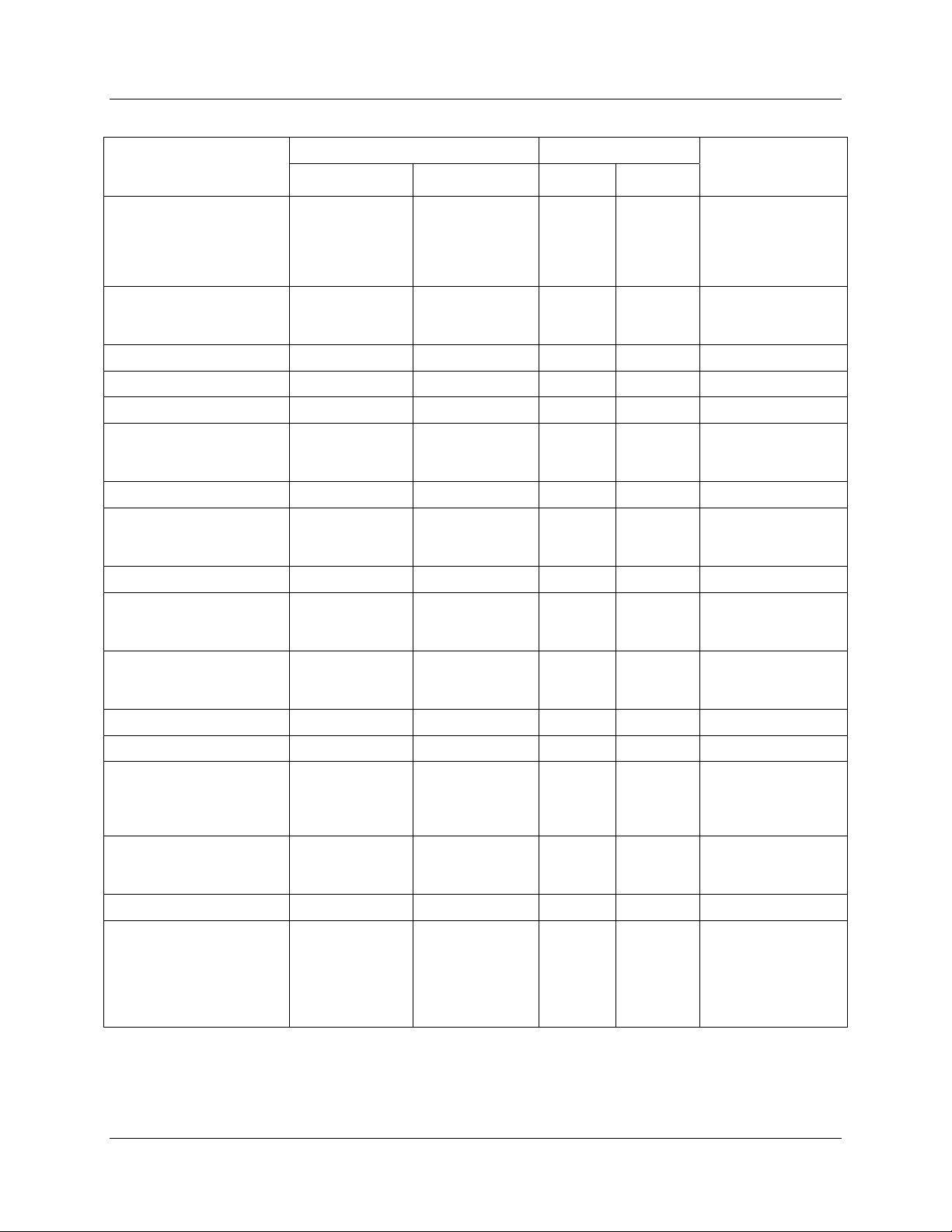

Table 2-1 Operating Limits and Condensed Specifications

Condition Specifications

Ambient Temperature

Relative Humidity

Vibration

Frequency

Acceleration

Mechanical Shock

Acceleration

Duration

Power

Power Consumption

Digital Indication

Accuracy

Minimum Input Span

Input Impedance

Source Impedance

Sampling Rate

Input Filter

Digital Displays

Indicators

Deviation Bargraph

Controller Modes of

Operation

Transmitter Supply

Voltage

32 °F to 131 °F (0 °C to 55 °C)

5 % to 90 % RH at 40 °C (104 °F)

0 to 200 Hz

0.2 g

5 g

30 ms

102 Vac to 132 Vac 50/60 Hz

204 Vac to 264 Vac 50/60 Hz

20 VA maximum

1 digit

Range is fully configurable with span limitation of the operating range selected.

4-20 mA dc: 250 ohms

0-10 Vdc: 200K ohms

All others: 10 Megohms

RTD: 100 ohms per lead maximum

Each input sampled 3 times a second (1 or 2 inputs); 3 times in 2 seconds (3 or 4

inputs).

Software: Single pole low pass section with selectable time constants (off to 120

seconds).

Vacuum fluorescent, alphanumeric.

A six-digit display dedicated to the process variable.

Alternate information displayed during configuration mode.

An eight-digit display shows key selected operating parameters. Also provides

guidance during configuration.

Channel PV display (CHN 1, 2, 3, or 4)

Alarm status (ALM 1, 2)

Controller Output (OUT 1, 2)

Remote Setpoint (RSP)

Temperature unit (F or C) or Engineering Units

Controller’s mode (A or MAN)

21 segment, color coded deviation bargraph:

Green (large) = On Control

Green (small) = Deviation to ± 10 % of PV

Manual Operation

Automatic with local setpoint

Automatic with remote setpoint

22 Vdc to 26 Vdc at input terminals (50 mA dc at 24 Vdc)

8 DR4500A Truline Circular Chart Recorder With or Without Control Product Manual Release L

8/02

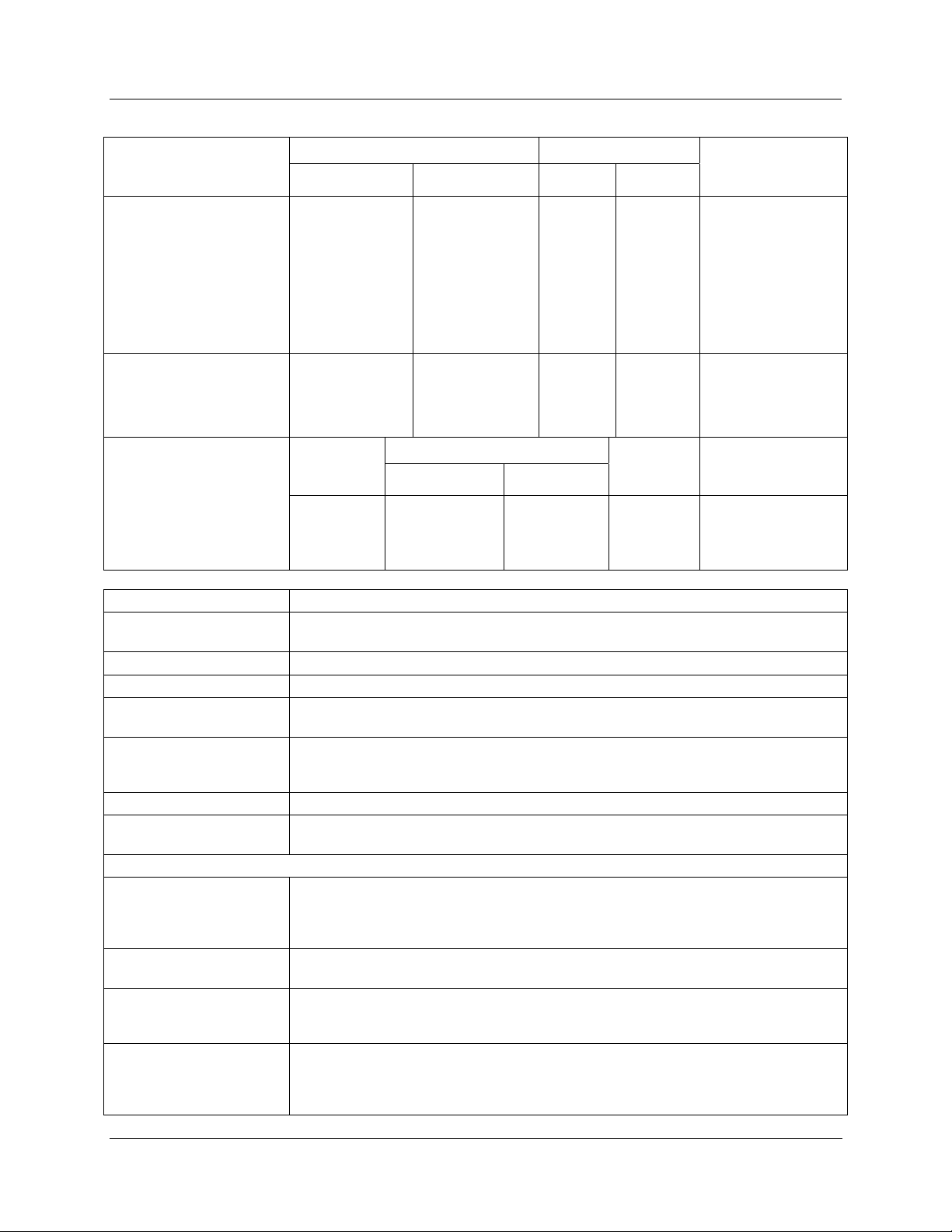

Condition Specifications

Controller Output1

(Optional)

Auxiliary Output

(Optional)

Installation

Overview

• On-Off or Time Proportional

One SPST electromechanical relay. Control action can be set for direct or reverse;

N.O. or N.C. contact selectable.

• On-Off Duplex or Time Proportional Duplex

Two SPST electromechanical relays. Control action can be set for direct or reverse;

N.O. or N.C. contact selectable.

• Current Proportional

21 mA dc maximum into a negative or positive grounded or non-grounded load of 0

to 1000 ohms. Output range can be set between 4 and 20 mA, and as direct or

reverse action.

Resolution: 10 bits

Accuracy: 0.5 % full scale

FM Approved Output (optional)

• Position Proportional and Three Position Step

Two SPST electromechanical relays operate motor having a 100 ohm to 1000 ohm

slidewire.

• Current/Time Duplex and Time/Current Duplex

Variation of time proportional duplex for Heat/Cool applications. Time proportional

output (heat or cool) is a SPST electromechanical relay. Current proportional output

(heat or cool) is a 4-20 mA signal that can be fed into a negative or positive

grounded load of 0 to 1000 ohms and is operational over 50 % of range or the

entire range.

Time Proportional Relay Resolution: 4.4 mSec

Relay Contact Ratings:

Resistive Load: 5 A @ 120 Vac, 2.5 A @ 240 Vac

Inductive Load: 50 VA @ 120 Vac or 240 Vac

Cycle Time: 1 second to 120 seconds

Current Proportional:

Resolution: 10 bits

Accuracy: 0.5 % full scale

21 mA dc maximum into a negative or positive grounded load of 0 to 1000 ohms. The

range can be set between 0 to 21 mA. It can be configured to represent any one of 12

control parameters.

Resolution: 12 bits over 0 to 21 mA

Accuracy: 0.2 % of full scale

Temperature Stability: 0.03 % F.S./°C

Release L DR4500A Truline Circular Chart Recorder With or Without Control Product Manual 9

8/02

Installation

Overview

2

Actuations

Thermocouples3

B

E

E (low)

J

J (low)

K

K (low)

NNM (Ni Ni Moly)

NIC (Nicrosil-Nisil)

R

S

T

T (low)

W5W26

W5W26 (low)

°F °C ± °F ± °C

105 to 3300

105 to 150

150 to 500

500 to 1000

1000 to 3300

–454 to 1832

–454 to –202

–202 to 1832

–200 to 1100 –129 to 593

0 to 1600 –18 to 871

20 to 770 –7 to 410

–320 to 2500

–320 to 0

0 to 2500

–20 to 1000 –29 to 538

32 to 2500

32 to 500

500 to 2500

0 to 2372 –18 to 1300

0 to 3100

0 to 500

500 to 3100

0 to 3100

0 to 500

500 to 3100

–300 to 700 –184 to 371

–200 to 600 –129 to 316

0 to 4200

0 to 600

600 to 3600

3600 to 4200

0 to 2240

0 to 600

600 to 2240

Range Reference Accuracy Types of Input

41 to 1816

41 to 66

66 to 260

260 to 538

538 to 1815

–270 to 1000

–270 to –130

–130 to 1000

–196 to 1371

–196 to –18

–18 to 1371

0 to 1371

0 to 260

260 to 1371

–18 to 1704

–18 to 260

260 to 1704

–18 to 1704

–18 to 260

260 to 1704

–18 to 2315

–18 to 316

316 to 1982

1982 to 2315

–18 to 1227

–18 to 316

316 to 1227

Radiamatic 1400 to 3400 760 to 1871

RTD

Platinum

100 ohms

200 ohms (high)5

200 ohms (low)

5

500 ohms

–300 to 900

32 to 752

32 to 392

–300 to 900

–184 to 482

0 to 400

0 to 200

–184 to 482

Temp Stability ±

Degrees Error Per 1

Degree ∆T

42.00

14.00

3.00

1.50

18.00

1.00

23.00

7.70

1.70

0.80

10.00

0.55

2.00

2.00

0.50

0.20

0.70

0.35

0.50 0.30 0.20

0.40 0.22 0.06

0.20 0.11 0.04

1.25

0.60

0.70

0.35

0.18

0.09

0.30 0.16 0.05

0.75

0.50

0.40

0.30

0.09

0.07

1.0 0.55 0.01

2.00

1.00

2.00

1.00

1.10

0.55

1.10

0.55

0.25

0.13

0.23

0.13

0.60 0.35 0.07

0.40 0.22 0.07

1.40

1.30

1.60

1.10

1.00

0.77

0.70

0.90

0.60

0.55

0.17

0.17

0.29

0.14

0.10

1.00 0.55 0.10

0.40

0.30

0.20

0.20

0.22

0.16

0.12

0.11

0.05

0.05

0.05

0.05

10 DR4500A Truline Circular Chart Recorder With or Without Control Product Manual Release L

8/02

Installation

Overview

2

Actuations

Linear

Milliamperes dc

Millivolts dc

Volts dc

Relative Humidity

Platinum 100 ohm

Wet/Dry Bulb*

Wet/Dry Input

% RH4

Range Reference Accuracy Types of Input

°F °C ± °F ± °C

4 to 20

0 to 10

10 to 50

1 to 5 (can be

calibrated

0 to 5)

0 to 10

–130 to 392

—

—

—

—

–90 to 200

0.10 %

0.05 %

0.05 %

0.05 %

0.10 %

0.30

Dry Bulb Range Measured

% RH

0 to <20

20 to 100

°F °C

–103 to 212

35 to 40

>40 to 100

100 to 212

–75 to 100

2 to 4

>4 to 38

38 to 100

—

—

—

—

0.03

Reference

Accuracy

2 % RH

2 % RH

1 % RH

1 % RH

Temp Stability ±

Degrees Error Per 1

Degree ∆T

0.004 %/°F

0.004 %/°F

0.004 %/°F

0.004 %/°F

0.004 %/°F

0.03

Temp. Stability

53 °F to 104 °F/

12 °C to 40 °C

0.11 % RH/°F

0.11 %RH/°F

0.06 % RH/°F

0.03 % RH/°F

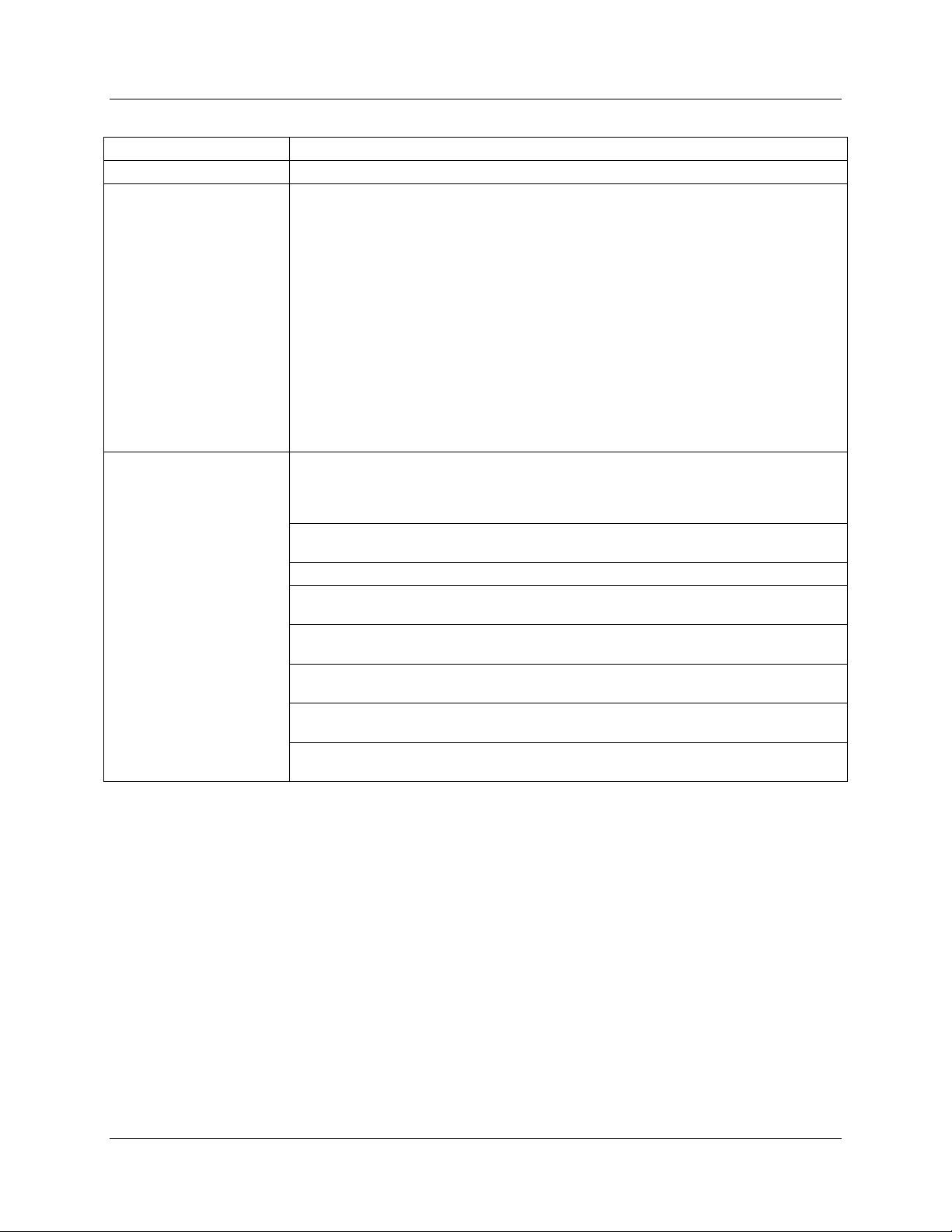

Condition Specifications

Case Molded, foamed-Noryl** with gasketed door.

A UL and FM approved NEMA4X door is also available.

Chart

Wiring Connections

12-inch (304.8 mm) diameter chart. Plain thermal-sensitive paper.

Terminals inside the case.

Color Case: Black

Door (standard): Caribbean Blue, Black, or Gray

Approval Bodies U.L. Approval depending on model. CSA Approval. Consult Model Selection Guide for

information.

FM approved for Class I, Div. 2, Groups A, B, C, D areas depending on model.

Weight

13.2 lbs (6 kg)

Mounting Panel, 2-inch pipe, or surface mounted. Some adapter kits available for existing panel

cutouts.

OPTIONS

Alarm Output Two, four, or six relays available.

Relay Contact Ratings:

First Relays, Resistive Load: 1 A @ 120 Vac, 1/2 A @ 240 Vac

Relays 3 through 6, Resistive Load: 5 A @ 120 Vac, 2.5 A @ 240 Vac

Digital Input +20 Vdc source for external dry contact or isolated solid state contacts. Selects one

configured input.

Totalizers One to four totalizers depending on model.

Eight digit “totals” with multiplier on digital display; 14 digit totalization printout on

chart.

RS485 Modbus RTU

Communications

Baud rate: 300, 600, 1200, 2400, 4800, 9600,19,200, 38,400

Protocol: RS485 Modbus RTU Communications

Length of Link: 4000 ft (1,219 m) maximum

Link Characteristics: Two-wire, multidrop

Release L DR4500A Truline Circular Chart Recorder With or Without Control Product Manual 11

8/02

Installation

Overview

Condition Specifications

Calculations

Miscellaneous

calculation available on DR45AR, Math function.

F

o

• FM Approved 4-20 mA Control Output

• A UL and FM approved NEMA4X door

• Door Lock

• External Keypad

• Chart Illumination

• U.L. Listing, CSA Approval, FM Class I Div. 2

• Control with Accutune II Tuning capability

• Math

• Glass or Acrylic Window

• Configuration Lockout Switch

• Customer ID Tag (30 characters maximum)

• Pulse output counter alarm function on DR45AW model

CE Conformity (Europe) This product is in conformity with the protection requirements of the following

European Council Directives: 73/23/EEC, the Low Voltage Directive, and 89/336/EEC,

the EMC Directive. Conformity of this product with any other “CE Mark” Directive(s)

shall not be assumed.

Product Classification Class 1: Permanently connected, Panel/Surface Mounted Industrial Control Equipment

with protective earthing (grounding). (EN 61010-1)

Enclosure Rating

Installation Category

(Overvoltage Category)

Panel/Surface Mounted Equipment, IP 54. (ref. IEC 529)

Category II: Energy-consuming equipment supplied from the fixed installation. Local

level appliances, and Industrial Control Equipment. (EN 61010-1)

Pollution Degree Pollution Degree 2: Normally non-conductive pollution with occasional conductivity

caused by condensation. (ref. IEC 664-10

EMC Classification Group 1, Class A, ESM Equipment (EN 55011, emissions),

Industrial Equipment (EN 50082-2, immunity)

Method of EMC

Technical File (TF)

Assessment

Declaration of

Document #51197639-000

Conformity

*IEC Alpha (α) = 0.00385 Ω/Ω/°C

**Registered Trademark—General Electric Co.

1

Not all controller outputs are available on all models of the Truline Recorder.

Consult Model Selection Guide for information.

2

Not all Input Actuations are available on all models of the Truline Recorder.

Consult Model Selection Guide for information.

3

Includes reference junction calibration of ±0.01 degrees using standard “ice bath” method of calibration. Factory

calibration at reference ± 1.2 °F. Note that factory calibration may vary by as much as ± 10 microvolts or ± 0.3 ohms

for RTDs, which means recalibration may be required to achieve stated accuracy.

4

The RH calculation is inoperative when temperature goes below 32 °F (0 °C) or above 212 °F (100 °C). However,

the dry bulb temperature will be monitored to –103 °F (–75 °C). Accuracy stated is for Classic Series Recorder only,

and does not include remaining system accuracies.

5

Only available with Model DR45AR.

12 DR4500A Truline Circular Chart Recorder With or Without Control Product Manual Release L

8/02

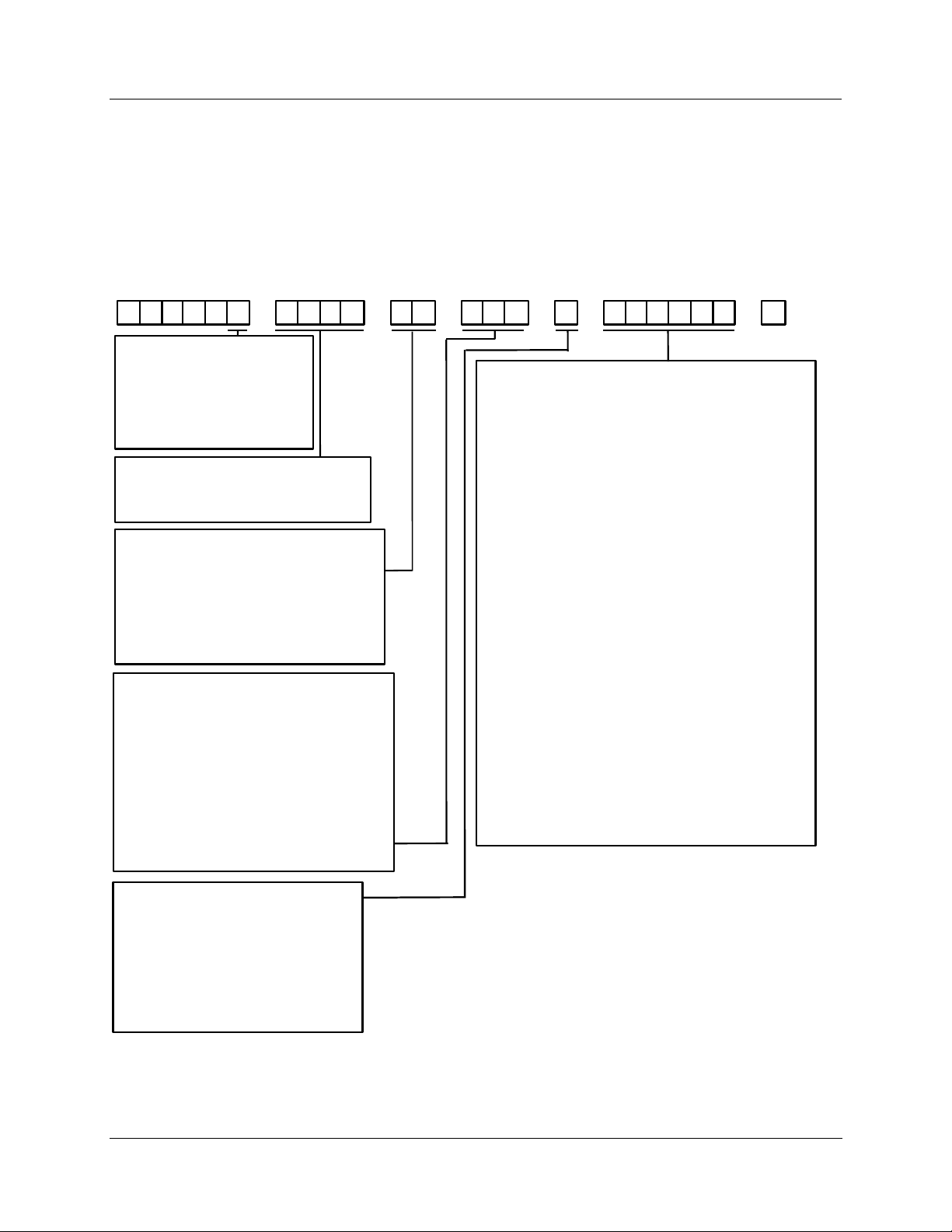

Model Number Interpretation

2.2 Model Number Interpretation

Model number

The model number interpretation is shown in Figure 2-1. Write the model number into the spaces provided

and compare it to the model number interpretation. This information will also be useful when you wire

your recorder. The example on the next page will help you to decode the model.

Table 1 Table 2 Table 3 Table 4 Table 5Key Number

DR45A 00

Key Number

T

=

Standard Recorder

R

=

Relay expansion Recorder

W

=

Flow Recorder

H

=

HTST

P

=

Pasteurization Recorder - Flow

S

=

Safety Thermal Limit Recorder

Input Actuation (Note 1)

0

None

=

1

T/C, RTD, Radiamatic , mV, 0–5V, 4–20mA

=

3

0–10 Vdc

=

External Output

0 0

= None

1 0

= 1 Control Output

1 1

= 2 Control Outputs

4 0

= 1 Control w/SP Programming

4 4

= 2 Controls w/SP Programming

5 0

= Pulse Output

6 0

= 1 Control Output with FM Approval

6 6

= 2 Control Outputs with FM Approval

External Interface

0 – –

= None

1 – –

= Auxiliary 4-20 mA Output

3 – –

= RS485 Modbus RTU**

4 – –

= RS485 Modbus RTU ** plus Auxiliary Output

– 0 –

= Standard Pen

– 1 –

= Abrasion Resistant Pen

– – 0

= None

– – 1

= 2 Alarm Outputs/2 Digital Inputs

– – 2

= 4 Alarm Outputs/2 Digital Inputs

– – 3

= 6 Alarm Outputs/2 Digital Inputs

– – 4

= 1 Alarm/1 Timer/2 Digital Inputs **

**Only available with key number DR45AT, AR, AW

––––– –

Hardware Options

0 - - - - 1 - - - - E - - - - F - - - - 5 - - - - 6 - - - - -

L - - - - 9 - - - - P - - - - R - - - - S - - - - -

- 0 - - - -

- A - - - -

- K - - - -

- - 0 - - -

- - L - - -

- - M - - -

- - N - - -

- - - 0 - -

- - - K - -

- - - L - -

- - - M - -

- - - N - -

- - - P - -

- - - R - - FM approved - Class 1, Div. 2, Groups A, B, C, D

- - - U - -

- - - - 0 -

- - - - T -

- - - - B -

- - - - C -

- - - - D -

- - - - E -

- - - - - 0

- - - - - 1

Gray door / Glass window

=

Gray door / Acrylic window

=

Gray door / Glass window and keypad

=

Gray door / Acrylic window and keypad

=

Blue door / Glass window

=

Blue door / Acrylic window

=

Black door / Glass window

=

Black door / Acrylic window

=

NEMA4X door / Glass window

=

NEMA4X door / Acrylic window

=

NEMA4X HTST door

=

Standard door latch

=

Keyed latch

=

Door lock with key

=

No illumination

=

Configuration lockout / Chart plate seal

=

Configuration Lockout / Chart plate seal / Illumination

=

Chart illumination

=

No approvals

=

CE Mark

=

CE Mark + UL + CSA certification

=

CE Mark + FM approval

=

CE Mark + UL + FM / CSA certification

=

UL listing + CSA certification

=

=

UL listing + CSA certification + FM approval

=

No I.D. Tag

=

Customer I.D. Tag (30 characters maximum)

=

Certificate of Conformance (F3391)

=

Custom Calibration / Test Report (F3399)

=

Certificate of Conformance + I.D. Tag

=

Customer Calibration + I.D. Tag

=

None

=