Page 1

DPR250

PRODUCT MANUAL

Issue 6 January 2004

US1I-6199

Page 2

Page 3

DPR 250

DIGITAL STRIP CHART RECORDER

PRODUCT MANUAL

Ref. : US1I-6199

Issue : 6 January 2004

Page 4

Copyright, Notices, and Trademarks

© Copyright 2000 by Honeywell Inc.

While this information is presented in good faith and believed to be accurate,

Honeywell disclaims the implied warranties of merchantability and fitness for a

particular purpose and makes no express warranties except as may be stated

in its written agreement with and for its customer.

In no event is Honeywell liable to anyone for any indirect, special or

consequential damages. The information and specifications in this document

are subject to change without notice.

This document was prepared using Information Mapping methodologies and

formatting principles.

Information Mapping is a trademark of Information Mapping Inc.

Windows is a registered trademark of Microsoft Inc.

Modbus is a registered trademark of MODICON, Inc.

The omission of a name from this list is not to be interpreted that the name is

not a trademark.

Page 5

About This Document

Abstract

This manual describes the installation, configuration, operation, and maintenance of the Recorder.

Warranty

WARRANTY. THE FOLLOWING IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THOSE OF MERCHANTABILITY

AND FITNESS FOR PARTICULAR PURPOSE.

a) Goods/Hardware

Except as otherwise hereinafter provided, Honeywell warrants goods of its manufacture to be free of defective materials

and faulty workmanship and as conforming to applicable specifications and/or drawings. Commencing with date of

shipment, Honeywell's warranty shall run for the period specified on the face hereof or, if none be mentioned, 18

months. If warranted goods are returned to Honeywell during this period of coverage, Honeywell will repair or replace

without charge those items it finds defective.

Experimental devices (designated by the letter "X" or "E" within their part-number identification) are prototype, pre-

production items that have yet to complete all phases of product-release testing; these items are sold "AS IS" WITH NO

WARRANTY.

b) Software

Software, if listed on the face hereof and used within hardware and/or a system warranted by Honeywell, will be

furnished on a medium that’s free of defect in materials or workmanship under normal use for so long as the hardware

and/or system is under warranty. During this period, Honeywell will replace without charge any such medium it finds

defective. As for the quality or performance of any software or data, they are supplied “AS IS” WITH NO WARRANTY.

c) Services

Where hardware and/or a system is installed by Honeywell, such services are warranted against faulty workmanship for

the same period (if any) as applies to the installed items. During this concurrently running period, Honeywell will correct

without charge any workmanship it finds to be faulty.

Contacts

If you encounter any problem with your recorder, please contact your nearest Sales Office. (See the

address list at the end of this manual).

An engineer will discuss your problem with you. Please have your complete model

number and serial number available. Model number and serial number are located on the

chassis nameplate.

If it is determined that a hardware problem exists, a replacement instrument or part will be shipped

with instructions for returning the defective unit. Do not return your instrument without authorization

from your Sales Office or until the replacement has been received.

World Wide Web: http://www.honeywell.com

Corporate Industrial Measurement and Control: http://www.honeywell.com/imc/

Telephone: USA & Canada Honeywell: Technical Support: 1800-423-9883

TAC FACS: 1888-423-9883

Service: 1800-525-7439

Page 6

Symbol Meanings

Symbol What it means

Protective ground terminal. Provided for connection of the protective earth green (green

or green/yellow) supply system conductor.

Functional ground terminal. Used for non-safety purposes such as noise immunity

improvement.

WARNING. Risk of electric shock. This symbol warns the user of a potential shock

hazard where voltages greater than 30 Vrms, 42.4 Vpeak, or 60 Vdc may be accessible.

CAUTION. When this symbol appears on the product, see the user manual for more

information. This symbol appears next to the required information in the manual.

CE conformity

This product conforms with the protection requirements of the following European Council

Directives: 89/336/EEC, the EMC directive, and 73/23/EEC, the low voltage directive. Do

not assume this product conforms with any other “CE Mark” Directive(s).

Attention

The emission limits of EN 61326-1 are designed to provide reasonable protection against harmful

interference when this equipment is operated in an industrial environment. Operation of this equipment in a

residential area may cause harmful interference. This equipment generates, uses, and can radiate radio

frequency energy and may cause interference to radio and television reception when the equipment is used

closer than 30 meters to the antenna(e). In special cases, when highly susceptible apparatus is used in close

proximity, the user may have to employ additional mitigating measures to further reduce the electromagnetic

emissions of this equipment.

Product model number:

Serial number:

Date code:

Service department telephone

number:

Page 7

TABLE OF CONTENTS

TABLE OF CONTENTS

1. OVERVIEW ............................................................................................................................................... 1-1

1.1 RECORDER OVERVIEW .............................................................................................................. 1-2

1.2 MODEL SELECTION GUIDE .......................................................................................................1-4

2. INSTALLATION ....................................................................................................................................... 2-1

2.1 WARNING ........................................................................................................................................ 2-2

2.2 UNPACKING .................................................................................................................................... 2-3

2.3 PANEL MOUNTING THE RECORDER ...................................................................................... 2-4

2.4 WIRING THE RECORDER............................................................................................................ 2-7

2.5 TERMINAL CONNECTIONS ........................................................................................................2-8

2.6 FITTING THE CHART ................................................................................................................. 2-15

2.7 INSTALLING THE PRINTING SYSTEM .................................................................................. 2-22

2.8 CHECK LIST.................................................................................................................................. 2-24

3. OPERATION ............................................................................................................................................. 3-1

3.1 OPERATOR INTERFACE EXPLANATIONS ............................................................................. 3-2

3.2 OPERATOR INTERFACE.............................................................................................................. 3-2

3.3 POWER UP ....................................................................................................................................... 3-3

3.4 SELECTING AND INTERPRETING RUN MODE DISPLAY................................................... 3-4

3.5 OPERATOR INITIATED ACTIONS............................................................................................. 3-9

3.6 GLOSSARY OF OPERATING TERMS ...................................................................................... 3-12

4. CONFICURATION ................................................................................................................................... 4-1

4.1 INTRODUCTION............................................................................................................................. 4-2

4.2 PARAMETERS LIST....................................................................................................................... 4-3

4.3 PRINCIPLES OF CONFIGURATION .......................................................................................... 4-4

4.4 COPY CONFIGURATION.......................................................................................................... 4-104

4.5 PRINT CONFIGURATION......................................................................................................... 4-108

4.6 CONFIGURABLE AND PRINTABLE CHARACTERS.......................................................... 4-114

INDEX............................................................................................................................................ 4-115

5. PC CONFIGURATION............................................................................................................................. 5-2

5.1 OVERVIEW ...................................................................................................................................... 5-2

5.2 INSTALLING THE SOFTWARE ON YOUR SYSTEM.............................................................. 5-2

5.3 INSTALLING THE FIRMWARE ON THE RECORDER FOR COMMS ................................ 5-3

5.4 PC - RECORDER INTERFACE.....................................................................................................5-3

5.5 CONFIGURATION UPLOAD/DOWNLOAD............................................................................... 5-4

5.6 RECORDER FIRMWARE UPGRADE ......................................................................................... 5-8

5.7 COMMUNICATION FIRMWARE UPGRADE ........................................................................... 5-8

5.8 RELAY STATE AND CONTROL.................................................................................................. 5-8

5.9 COPY LINE OPERATION.............................................................................................................. 5-9

5.10 USER ACTUATION......................................................................................................................... 5-9

i

Page 8

TABLE OF CONTENTS

6. KITS LIST .................................................................................................................................................. 6-1

7. TROUBLESHOOTING ............................................................................................................................ 7-1

7.1 PARTS LOCATION......................................................................................................................... 7-2

7.2 SYMPTOMS: .................................................................................................................................... 7-4

to 7.24........................................................................................................................................................ 7-10

8. SERVICE.................................................................................................................................................... 8-1

8.1 OPERATOR INTERFACE.............................................................................................................. 8-2

8.2 LIST OF SERVICES ........................................................................................................................ 8-5

9. PRODUCT SPECIFICATION ................................................................................................................. 9-1

10. PROMPTS TRANSLATION ................................................................................................................. 10-1

10.1 MATRICES ..................................................................................................................................... 10-2

11. CONFIGURATION WORKSHEETS .................................................................................................. 11-1

to 11.13 ............................................................................................................................................................ 11-16

SAFETY TRANSLATIONS

SALES AND SERVICE

ii

Page 9

Section 1

1.1 RECORDER OVERVIEW

1.1.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1.2 MODEL SELECTION GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1. OVERVIEW

TABLE OF CONTENTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-1

Page 10

1. OVERVIEW

1.1 RECORDER OVERVIEW

1.1.1 INTRODUCTION

This recorder is a precision measuring instrument that offers many features.

• Up to 64 analog input channels,

• Compact size: 320 mm (12.60 '') depth,

310 mm front face height x 387 mm width (12.21 '' x 15.24 ''),

278 mm x 348 mm (10.95 '' x 13.70 '') cutout,

• 250 mm chart in either roll or fanfold presentation,

• Universal power supply: 100 to 240 V ac/dc,

• IP55 front panel protection,

• Universal input with a wide choice of actuation/range,

• Option linear input,

• High accuracy: 0.05 % via field calibration,

• Easy interactive product configuration,

• Large, clear operator display,

• Fast scanning rate:

• Configurable alphanumeric chart documentation,

• Up to 64 alarm setpoints with a wide choice of alarm types,

• Event alarm: End of chart paper, sensor burnout, clock battery low, etc.,

• Up to 64 customer messages of 64 characters each,

• Standard chart illumination,

• Product configuration, service diagnostic, software upgrading via PC interface,

• Chart zoning configurable,

• Complies with IEC348 and EN61010-1 safety requirements,

• EC mark: Conformity with 73/23/EEC low voltage directive and 89/336 EEC, EMC directives,

• CSA approval (certified) LR57938

OPTIONS:

• Up to 48 alarm relay outputs,

• Up to 48 digital inputs,

• Keylock,

• 32 Maths functions,

• Communication board,

• Up to 8 4/20 mA current outputs,

• PCMCIA board driver.

2 channels = 105 ms 24 channels = 1260 ms 48 channels = 2520 ms

4 channels = 210 ms 28 channels = 1470 ms 52 channels = 2730 ms

8 channels = 420 ms 32 channels = 1680 ms 56 channels = 2940 ms

12 channels = 630 ms 36 channels = 1890 ms 60 channels = 3150 ms

16 channels = 840 ms 40 channels = 2100 ms 64 channels = 3360 ms

20 channels = 1050 ms 44 channels = 2310 ms 52 channels = 2730 ms

1-2

Page 11

1. OVERVIEW

y

p

y

V

VIV

_ _ _ _

_ _-_

p

)

p

)

1.2 MODEL SELECTION GUIDE

This table helps you to identify correctly the unit in front of you. Please refer to the product label and verify

that you have the right unit.

Select the desired key number. The mark to the right shows the selection available. A complete model

number has the requested number of digits from each table as follows:

Instructions

Select the desired Key Number. The arrow to the right marks the selection available.

A dot denotes unrestricted availabilit

A com

lete Model Number must have the designated number of digits in each table.

. A letter denotes restricted availability.

Ke

KEY NUMBER

250 mm Strip Chart Recorder D25

TABLE I - Lower Rack Analog Inputs Selection Availability

Input Card 1 None 0 _ _ _ _ _ _ _

Input Card 2 None _ 0 _ _ _ _ _ _

Input Card 3 None _ _ 0 _ _ _ _ _

Input Card 4 None _ _ _ 0 _ _ _ _

Input Card 5 None _ _ _ _ 0 _ _ _

Input Card 6 None _ _ _ _ _ 0 _ _

Input Card 7 None _ _ _ _ _ _ 0 _

Input Card 8 None _ _ _ _ _ _ _ 0

Number

D25

(Slot A) 4 Linear Inputs (Channel 1 to 4) L _ _ _ _ _ _ _

(Slot B) 4 Linear Inputs (Channel 5 to 8) _ L _ _ _ _ _ _

(Slot C) 4 Linear Inputs (Channel 9 to 12) _ _ L _ _ _ _ _

(Slot D) 4 Linear Inputs (Channel 13 to 16) _ _ _ L _ _ _ _

(Slot E) 4 Linear Inputs (Channel 17 to 20) _ _ _ _ L _ _ _

(Slot F) 4 Linear Inputs (Channel 21 to 24) _ _ _ _ _ L _ _

(Slot G) 4 Linear Inputs (Channel 25 to 28) _ _ _ _ _ _ L _

(Slot H) 4 Linear Inputs (Channel 29 to 32) _ _ _ _ _ _ _ L

- _ _ _ _ _ _ _ _ - _ _ _ _ _ _ _ _ -

-

4 Universal In

4 Universal In

4 Universal Inputs (Channel 9 to 12)

4 Universal Inputs (Channel 13 to 16)

4 Universal Inputs (Channel 17 to 20)

4 Universal Inputs (Channel 21 to 24)

4 Universal Inputs (Channel 25 to 28)

4 Universal Inputs (Channel 29 to 32)

I II III IV

_ _ _

II

Description

uts (Channel 1 to 4

uts (Channel 5 to 8

U _ _ _ _ _ _ _

_ U _ _ _ _ _ _

_ _ U _ _ _ _ _

_ _ _ U _ _ _ _

_ _ _ _ U _ _ _

_ _ _ _ _ U _ _

_ _ _ _ _ _ U _

_ _ _ _ _ _ _ U

-_-

1-3

Page 12

1. OVERVIEW

TABLE II - Upper Rack Digital Inputs/Outputs

Analog Inputs/Outputs Selection

None 0 _ _ _ _ _ _ _

4 Linear Inputs (Channel 33 to 36) L _ _ _ _ _ _ _

Slot J 4 Universal Inputs (Channel 33 to 36) U _ _ _ _ _ _ _

6 Alarm Relay Outputs (Alarm 1 to 6) A _ _ _ _ _ _ _

6 Digital Inputs (Digital 1 to 6)

None _ 0 _ _ _ _ _ _

4 Linear Inputs (Channel 37 to 40) _ L _ _ _ _ _ _

Slot K 4 Universal Inputs (Channel 37 to 40) _ U _ _ _ _ _ _

6 Alarm Relay Outputs (Alarm 7 to 12) _ A _ _ _ _ _ _

6 Digital Inputs (Digital 7 to 12)

None _ _ 0 _ _ _ _ _

4 Linear Inputs (Channel 41 to 44) _ _ L _ _ _ _ _

Slot L 4 Universal Inputs (Channel 41 to 44) _ _ U _ _ _ _ _

6 Alarm Relay Outputs (Alarm 13 to 18) _ _ A _ _ _ _ _

6 Digital Inputs (Digital 13 to 18)

None

4 Linear Inputs (Channel 45 to 48)

Slot M 4 Universal Inputs (Channel 45 to 48)

6 Alarm Relay Outputs (Alarm 19 to 24)

6 Digital Inputs (Digital 19 to 24)

None

4 Linear Inputs (Channel 49 to 52)

Slot N 4 Universal Inputs (Channel 49 to 52)

6 Alarm Relay Outputs (Alarm 25 to 30)

6 Digital Inputs (Digital 25 to 30)

None _ _ _ _ _ 0 _ _

4 Linear Inputs (Channel 53 to 56) _ _ _ _ _ L _ _

Slot P 4 Universal Inputs (Channel 53 to 56) _ _ _ _ _ U _ _

6 Alarm Relay Outputs (Alarm 31 to 36) _ _ _ _ _ A _ _

6 Digital Inputs (Digital 31 to 36)

None _ _ _ _ _ _ 0 _

4 Linear Inputs (Channel 57 to 60) _ _ _ _ _ _ L _

Slot Q 4 Universal Inputs (Channel 57 to 60) _ _ _ _ _ _ U _

6 Alarm Relay Outputs (Alarm 37 to 42) _ _ _ _ _ _ A _

6 Digital Inputs (Digital 37 to 42) _ _ _ _ _ _ D _

4 Current Outputs (Output 1 to 4)

None _ _ _ _ _ _ _ 0

4 Linear Inputs (Channel 61 to64) _ _ _ _ _ _ _ L

Slot R 4 Universal Inputs (Channel 61 to 64) _ _ _ _ _ _ _ U

6 Alarm Relay Outputs (Alarm 43 to 48) _ _ _ _ _ _ _ A

6 Digital Inputs (Digital 43 to 48) _ _ _ _ _ _ _ D

4 Current Outputs (Output 5 to 8)

D _ _ _ _ _ _ _

_ D _ _ _ _ _ _

_ _ D _ _ _ _ _

_ _ _ 0 _ _ _ _

_ _ _ L _ _ _ _

_ _ _ U _ _ _ _

_ _ _ A _ _ _ _

_ _ _ D _ _ _ _

_ _ _ _ 0 _ _ _

_ _ _ _ L _ _ _

_ _ _ _ U _ _ _

_ _ _ _ A _ _ _

_ _ _ _ D _ _ _

_ _ _ _ _ D _ _

_ _ _ _ _ _ C _

_ _ _ _ _ _ _ C

Availability

D25

1-4

Page 13

(

(

)

p

TABLE III - Options Selection

Communications None 0 _ _

Universal Communication

RS232/422/485) ASCII/Modbus RTU

Ethernet Interface 2 _ _

PCMCIA None _ 0 _

PCMCIA Interface

Math None _ _ 0

Math Package

TABLE IV - Door and Case Options

Grey Door, Glass Window, with Latch, Standard Case 0

Grey Door, Glass Window, with Key Lock, Standard Case 1

Grey Door, Plastic Window, with Latch, Standard Case 2

Grey Door, Plastic Window, with Key Lock, Standard Case 3

Grey Door, Glass Window, with Latch, Black Case A

Grey Door, Glass Window, with Key Lock, Black Case B

Grey Door, Plastic WIndow, with Latch, Black Case C

Grey Door, Plastic Window, with Key Lock, Black Case D

Black Door, Glass Window, with Latch, Black Case E

Black Door, Glass Window, with Key Lock, Black Case F

(Note 6)

1. OVERVIEW

D25

1 _ _

d

_ A _

_ _ A

Grey Door, Plastic Window, Latch and Black Portable Case 4

TABLE V - Miscellaneous

None

None _ 0 _ _

Test Report (Calibration Certificate)

Certificate of Conformance

None _ _ 0 _

Product Configuration

Product Configuration with User Defined Actuation

User Defined Actuation

None _ _ _ 0

CSA Approval/NRTL/C

TABLE VI - Specials

None 00

Special ST #

TABLE VII - Language/Prompts/Manuals

Product Information on CD

English E

French F

German G

Italian Prom

Spanish S

Consult Ft. Washington

ts/English Manual I

(Note 5)

(Note 3)

(Note 3)

(Note 3)

(Note 4)

0 _ _ _

_ A _ _

_ B _ _

_ _ A _

_ _ B _

_ _ U _

_ _ _ C

XX

0

c

1-5

Page 14

1. OVERVIEW

RESTRICTIONS

Restriction

Letter Table Table

c

d

Available Only With Not Available With

Selection Selection

V

_ _ _ _ _ _ _ L, _ _ _ _ _ _ _ U,

II

_ _ _ _ _ _ _ A, _ _ _ _ _ _ _ D,

_ _ _ C

_ _ _ _ _ _ _ C

DPR 250

Notes:

A 250 ohm resistor is required for ma input actuation's. Order the required

1.

quantity using Part Number 46181080-503. See Parts Price Book for pricing.

Consult Customer Services for pricing and availability.

2.

Customer must complete "Configuration Worksheets" and attach to order or

3.

send to Customer Service. (Reference Product Manual)

NRTL/C indicates product safety compliance approval by a Nationally Recognized

4.

Testing Laboratory of which UL and CSA are both OSHA accredited NRTL's.

Not available with Portable Case option.

It is recommended that the Product Configuration (Table V) option be ordered

5.

when ordering the Calibration Certificate otherwise the certificate will be based

on the factory default configuration.

PCMCIA Flash Memory Cards must be ordered separately.

6.

PCMCIA Memory Cards are ATA Type II compatible and stored data is

accessible using SDA software (P/N 045501) or TrendManager Pro V5, TMPCON5.

1-6

Page 15

2. INSTALLATION

TABLE OF CONTENTS

Section Page

2.1 WARNING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2 UNPACKING

2.3 PANEL MOUNTING THE RECORDER

2.3.1 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.3.2 External dimensions and cut-out

2.3.3 Installing the recorder

2.4 WIRING THE RECORDER

2.4.1 Recommendations

2.5 TERMINAL CONNECTIONS

2.5.1 Digital input signals. (DI)

2.5.2 Relay outputs. (DO)

2.5.2.1 Removing the alarm card to change NC to NO contacts

2.6 FITTING THE CHART

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . 2-7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . ... . .. . . . . . . . 2-10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . .. . . . . . 2-11

. . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

. . . . . .. . . . . .. . . 2-12

2.6.1 Chart cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.6.2 Cleaning the rod and lubricating the carriage bushings

2.7 INSTALLING THE PRINTING SYSTEM

2.8 CHECK LIST . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

. . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . 2-22

2-1

. . . . . . . . . . . . . . . . . . 2-21

Page 16

2. INSTALLATION

2.1 WARNING

WARNING

IMPROPER INSTALLATION

To avoid the risk of electrical shock that could cause personal injury, follow all safety notices in

!

! POWER SUPPLY

Ensure the source voltage matches the voltage of the power supply before turning on the power. (In the

rear of the recorder, near to the connector of the power supply)

! PROTECTIVE GROUNDING

Make sure to connect the protective grounding to prevent an electric shock before turning on the power.

Do not operate the instrument when protective grounding or fuse might be defective.

To avoid a potential shock hazard, never cut off the internal or external grounding wire or disconnect the

protective grounding terminal

! NECESSITY OF PROTECTIVE GROUNDING

To avoid a potential shock hazard, never cut off the internal or external protective grounding wire or

disconnect the wiring of protective grounding terminal.

! FUSE

To prevent a fire, make sure to use the fuse with specified standard (current voltage, type). Before

replacing the fuse, turn off the power and disconnect the power source. Do not use a different fuse or

short-circuit the fuse holder.

! DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable liquids or vapours. Operation of any

electrical instrument in such an environment constitutes a safety hazard.

! NEVER TOUCH THE INTERIOR OF THE INSTRUMENT

Inside this instrument there are areas of high voltage; therefore, never touch the interior if the power

supply is connected. This instrument has an internal changeable system; however, internal inspection

and adjustments should be performed by qualified personnel only.

! If the equipment is used in a manner not specified by the manufacturer, the protection provided by the

equipment may be impaired.

! Do not replace any component (or part) not explicitly specified as replaceable by your supplier.

! INSTALL INDOOR ONLY

this documentation.

Protective earth terminal. Provided for connection of the protective earth supply system

conductor.

Failure to comply with these instructions could result in death or serious injury

2-2

Page 17

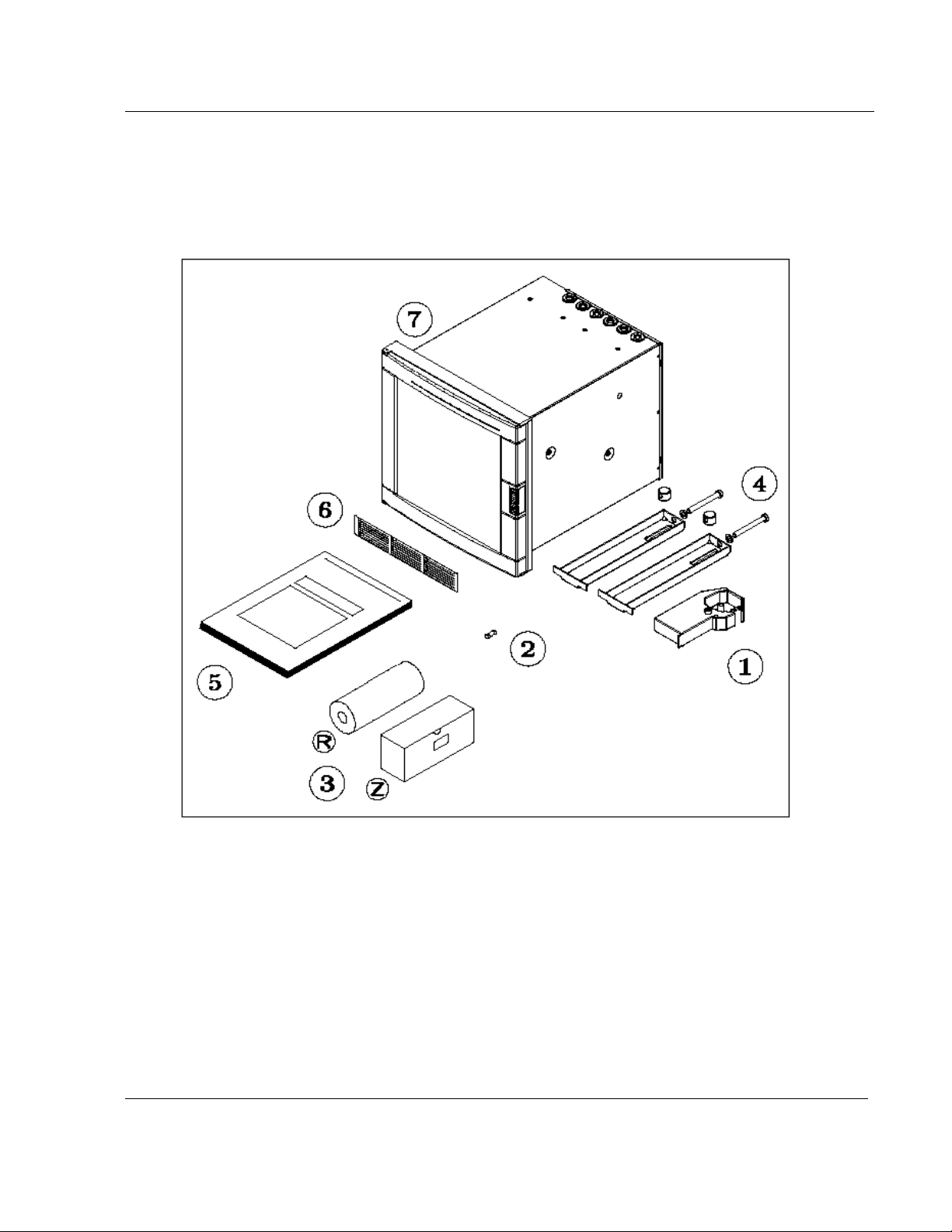

2.2 UNPACKING

Remove the accessories and check them against the figure below.

2. INSTALLATION

1. Ribbon cartridge

2. Fuse (Spare) (Use only 3.15 A T. fuses for

Europe or 3.2 A T. fuses for U.S.)

3. Roll (R) and fanfold (Z) chart

NOTE: In the event that any items are missing, please contact your nearest sales office.

4. Mounting brackets with nuts

5. Product manual or CD

6. Front label

7. Recorder

2-3

Page 18

2. INSTALLATION

2.3 PANEL MOUNTING THE RECORDER

2.3.1 Recommendations

This recorder is designed to operate under specific conditions. If you need more information, refer to the

product specification sheet.

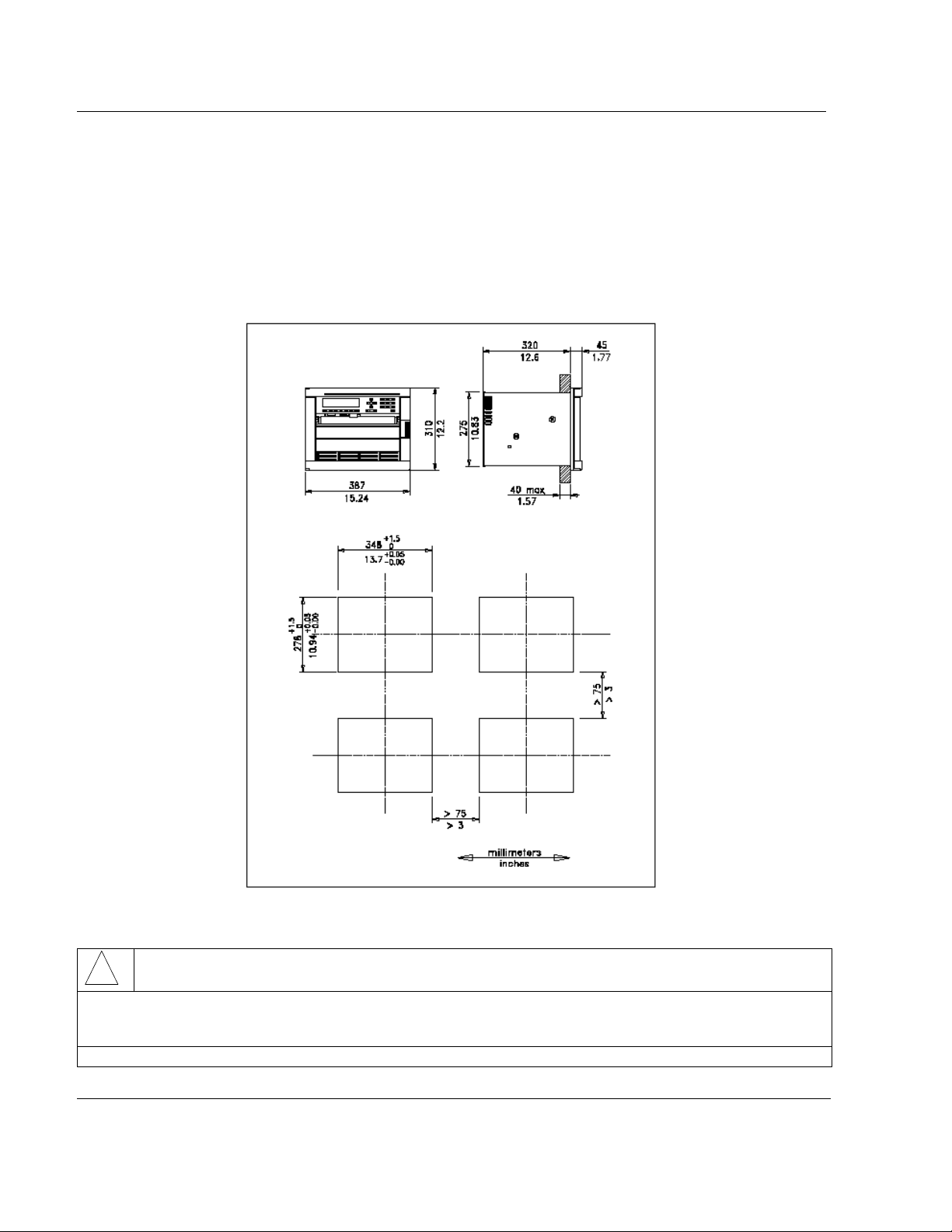

2.3.2 External dimensions and cut-out

Prepare panel cut-out as detailed below:

Note: Maximum panel thickness 40 mm (1.5 '')

CAUTION

!

The maximum temperature inside the cabinet should not exceed the ambient conditions specific for the

recorders. The recorder must be mounted into a panel to limit operator access to the rear terminals.

Failure to comply with these instructions may result in product damage

2-4

Page 19

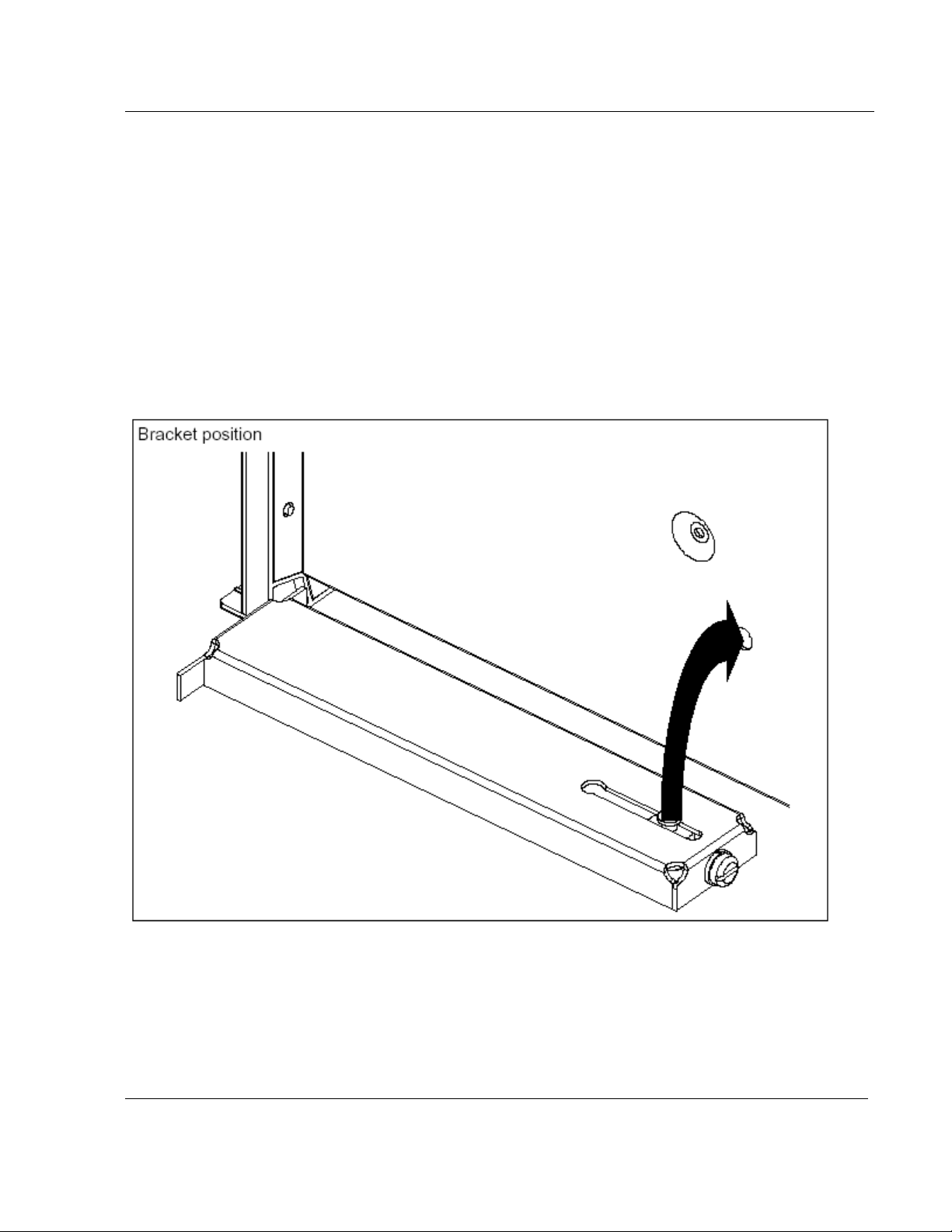

2.3.3 Installing the recorder

To install the recorder, follow the figures below:

1. Remove rear cover and wire access holes.

2. Insert recorder through the panel cutout

3. Attach mounting brackets to the sides of the recorder

4. Tighten the mounting screws

2. INSTALLATION

2-5

Page 20

2. INSTALLATION

2-6

Page 21

2.4 WIRING THE RECORDER

2.4.1 Recommendations

• All wiring must be in accordance with local electrical codes and should be carried out by

authorized experienced personnel.

• The ground terminal must be connected before any other wiring (and disconnected

last).

• A switch in the main supply is recommended near the equipment.

• If an external fuse is used to protect the electrical circuit to the recorder, the fuse

should match the recorder fuse rating (fuse type) as well as for the fuse holder.

• Sensor wiring should be run as far as possible from power wiring. (motors, contactors,

alarms, etc.)

• To reduce stray pick-up, we recommend the use of a twisted pair sensor wiring.

• EMI effects can be further reduced by the use of shielded cable sensor wiring. The

shield must be connected to the ground terminal.

• The use of spade terminals on all wiring is recommended.

2. INSTALLATION

2-7

Page 22

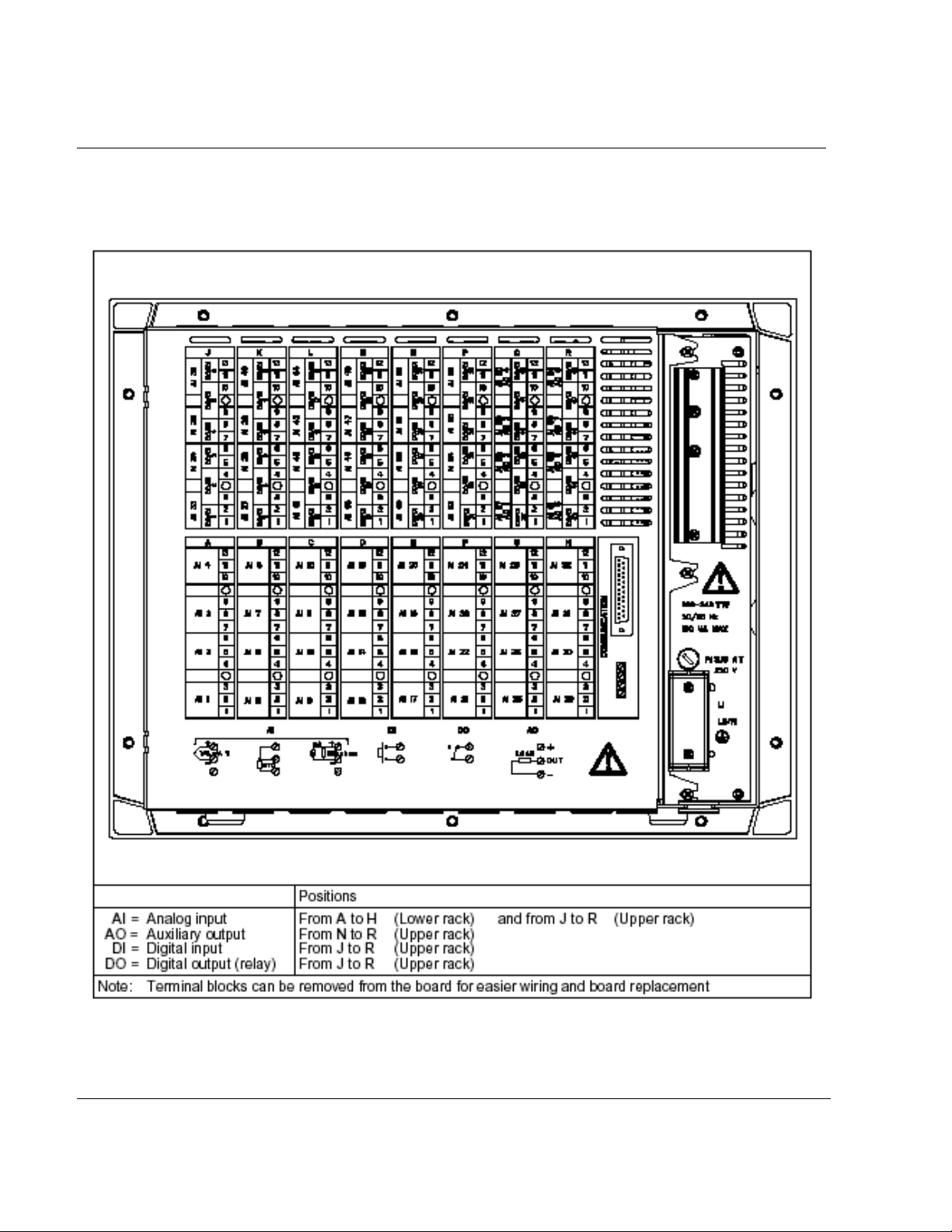

2.5 TERMINAL CONNECTIONS

2. INSTALLATION

2-8

Page 23

2. INSTALLATION

Note: Terminal (A) is only used for RTD. (See diagrams above)

CAUTION

!

Unwired configured channel terminals should be shorted.

Failure to comply with these instructions may result in product damage

2-9

Page 24

2. INSTALLATION

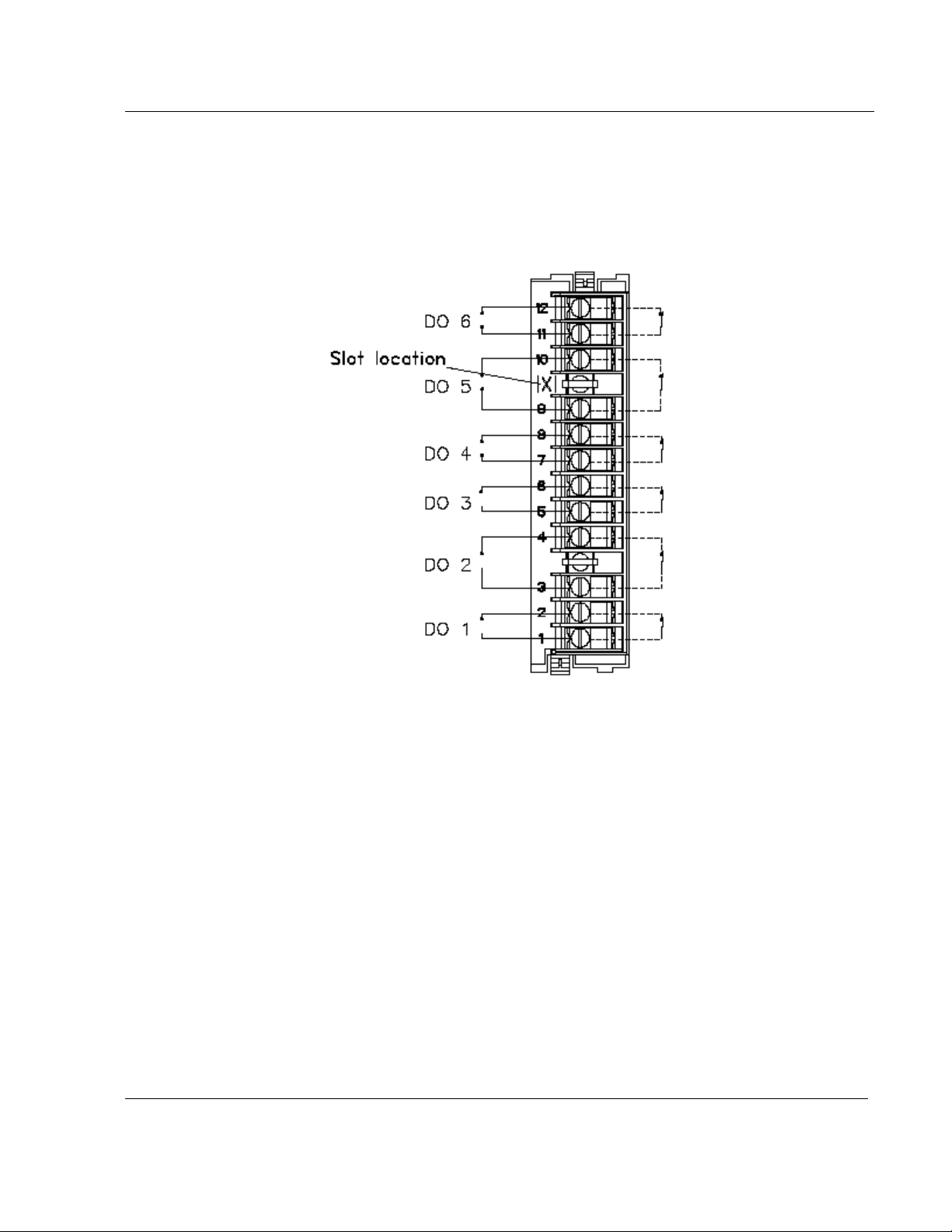

2.5.1 Digital input signals. (DI)

If an optional digital input board is installed, connect the wiring as shown in Figure 2-1.

Slot location X = J to P

Figure 2-1 Digital input signal wiring (DI)

If 2 digital input boards are fitted, repeat the above procedure for the second board.

Note: Use dry contacts, voltage free, designed to switch 5 mA at 5 V.

Up to 36 digital inputs allowed.

2-10

Page 25

2. INSTALLATION

2.5.2 Relay outputs. (DO)

If an optional relay board is installed, connect the wiring as shown in Figure 2-2.

Slot location X = J to P

Figure 2-2 Relay output wiring (DO)

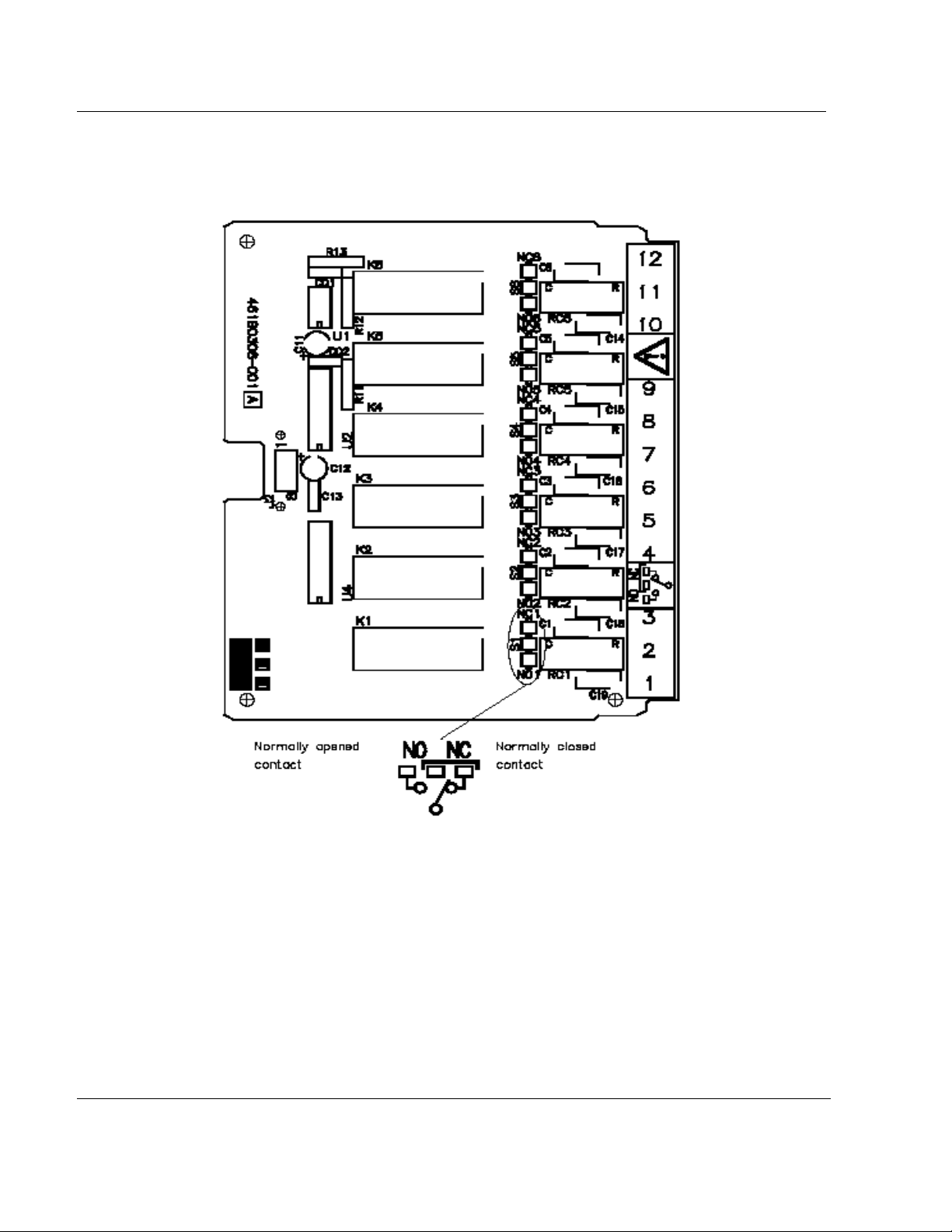

All the relays are factory configured de-energized in alarm. The contacts are factory configured normally

closed by a jumper per output on the alarm relay board.

If you need to change this function for normally opened output:

• Turn off power.

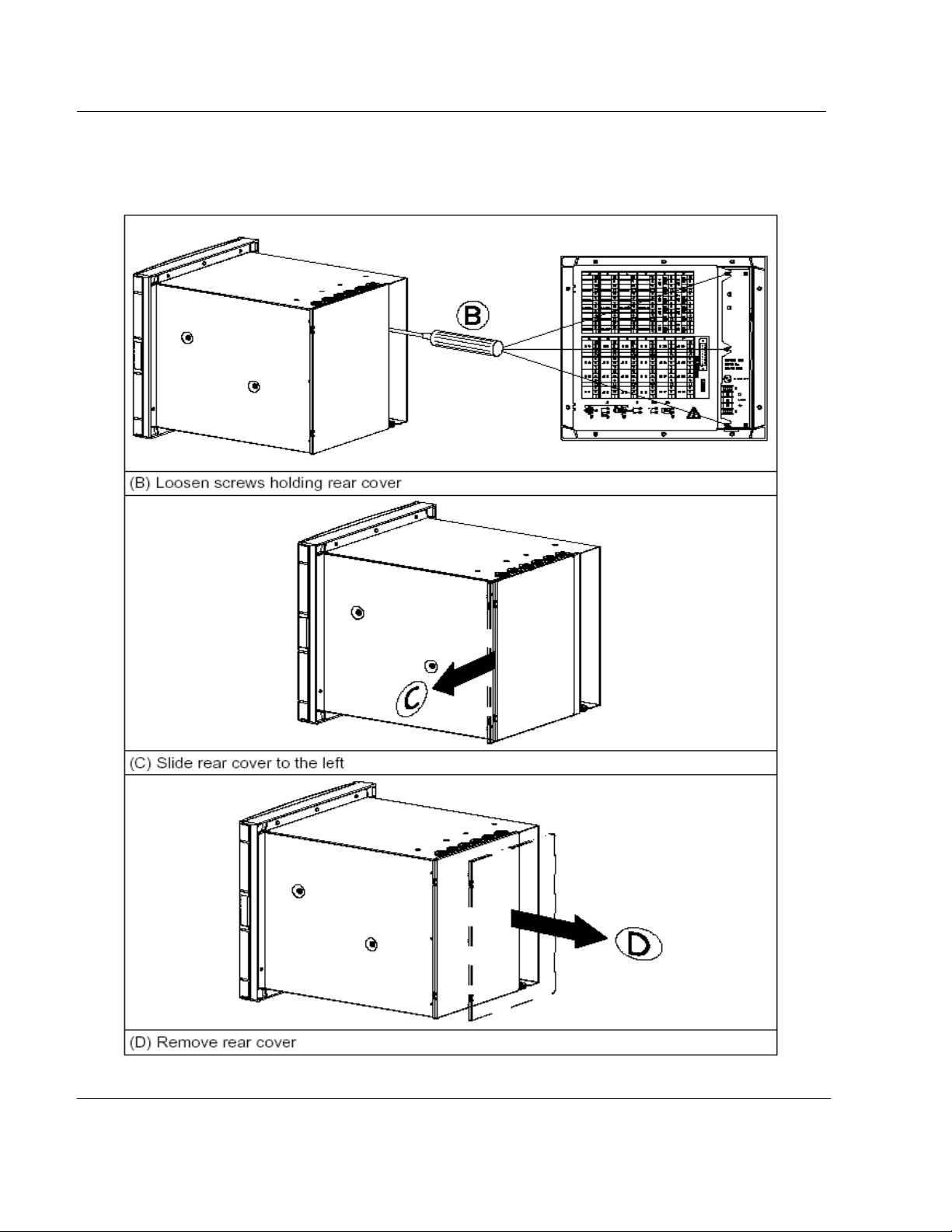

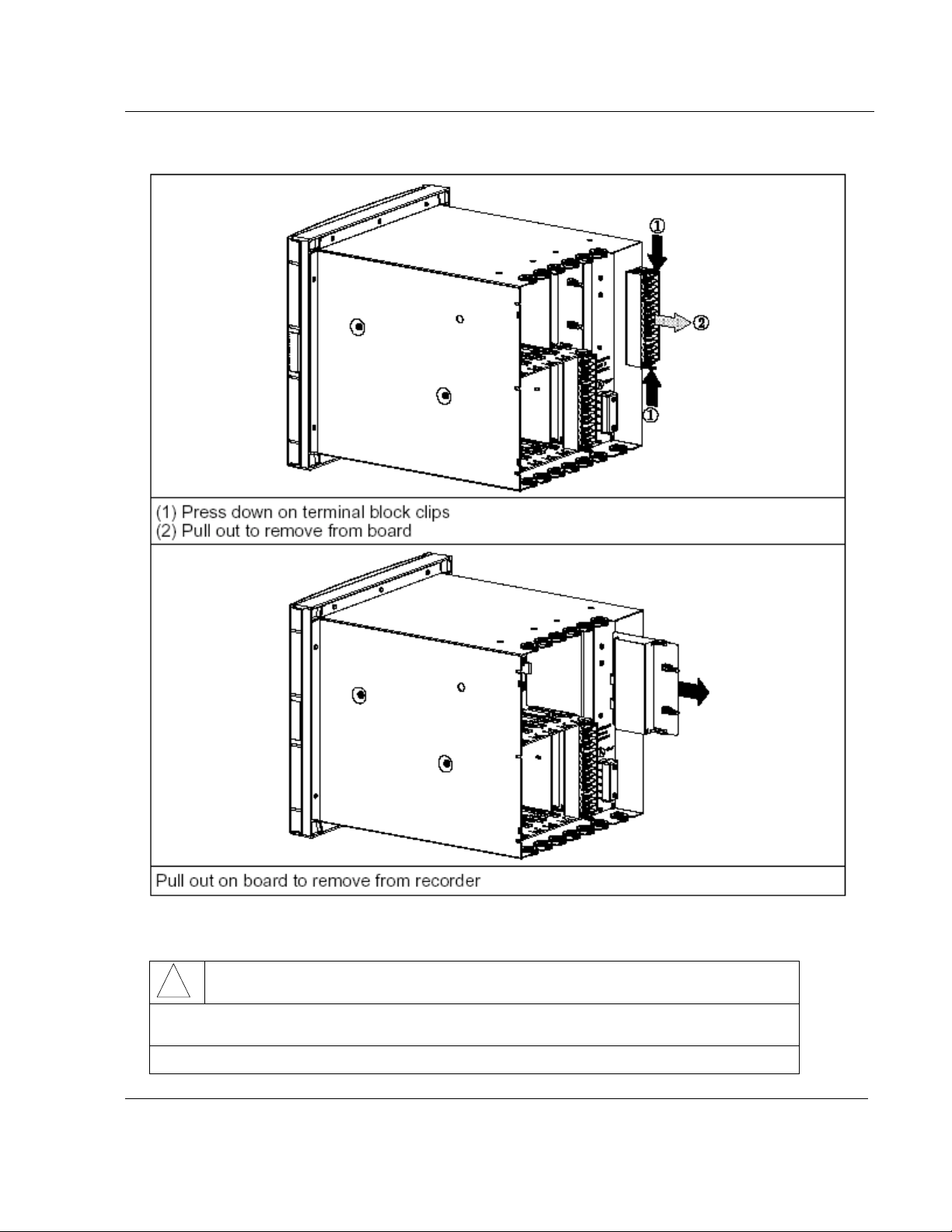

• Remove the rear terminal cover plate and remove the relay board, see page 2-11.

• Move the jumper from the location NC (for normally closed) to the location NO (for normally

opened).

• Up to 36 alarm outputs allowed.

2-11

Page 26

2.5.2.1 Removing the alarm card to change NC to NO contacts

(A) Turn off power.

2. INSTALLATION

2-12

Page 27

2. INSTALLATION

Use ground strap to avoid electrostatic damage to board.

CAUTION

!

Use ground strap to avoid electrostatic damage to board.

Failure to comply with these instructions may result in product damage

2-13

Page 28

2. INSTALLATION

All the relays are factory configured de-energized in alarm. The contacts are factory configured normally

closed by a jumper for each output on the alarm relay board.

If you need to change this function:

• Move the jumper from the location NC (for normally closed) to the location NO (for normally

opened)

2-14

Page 29

2.6 FITTING THE CHART

2. INSTALLATION

2-15

Page 30

2. INSTALLATION

2.6.1 Chart cassette

Open the chart cassette as shown below and install the chart using the figure on the cassette.

1 = First action - Press in on both tabs to release chart cassette

2 = Second action - Pull out on the tabs to remove cassette

2-16

Page 31

2. INSTALLATION

2-17

Page 32

2. INSTALLATION

2-18

Page 33

2. INSTALLATION

2-19

Page 34

2. INSTALLATION

Note: If the recorder is powered, and the message "NO PAPER" is indicated on the display, carefully check

again that the cassette assembly and chart are correctly installed.

NOTICE

Reset the paper length (if configured) after installing the new chart. See section 3.2

"OPERATOR INTERFACE".

Length 35 m (115 ft) or less to provide sufficient warning that the paper is near its end.

2-20

Page 35

2. INSTALLATION

2.6.2 Cleaning the rod and lubricating the carriage bushings

The print carriage bushings are factory lubricated and should not normally require further maintenance.

However, in a dusty environment, you should have to clean the print carriage rod periodically.

Also, whenever the print carriage rod is found sticky or dirty, you have to clean it.

The procedure for cleaning and lubricating is explained below:

1. Power off the recorder.

2. Clean the rod with a dry, lint free cotton cloth.

3. Move the carriage to the center of the rod.

4. Apply a thin ring of grease around the rod, at each side of the carriage (as shown above).

5. Move the carriage from right to left four or five times.

6. Wipe off any excess grease from the rod with a dry, lint free cotton cloth.

CAUTION

!

Never use any solvent to clean the rod.

Please, use only lubricant "Dow Corning white EP grease or equivalent" which may be ordered as

part number: "Lubricant kit 46210096-501".

Failure to comply with these instructions may result in product damage

NOTE:

The color ribbon axis (50 mm long), which keeps maintained the color ribbon, must be cleaned with a dry

cotton cloth each time you replace the color ribbon.

2-21

Page 36

2. INSTALLATION

2.7 INSTALLING THE PRINTING SYSTEM

Before doing it, please remove the chart cassette from the chassis as indicated page 2-15.

The recorder automatically moves the print carriage to the correct position for the installation of the ink

ribbon cartridge by:

CAUTION

!

Do not attempt to install the ribbon cartridge while the chart cassette is in place.

Failure to comply with these instructions may result in product damage

2-22

Page 37

2. INSTALLATION

2-23

Page 38

2. INSTALLATION

2.8 CHECK LIST

Your recorder should now be ready to configure and use. If you are having problems check the

following

1. Have you connected the ground terminal ?

2. Have you connected the sensor(s) correctly? (Wire type, polarity, etc.)

3. Have you tightened all terminal screws?

4. Have you installed the ink ribbon cartridge? (See figures on page 2-22)

5. Have you installed the chart correctly? (See figures on page 2-15)

6. Have you closed the display?

7. Have you fitted the chart cassette in the recorder?

8. Have you replaced the rear cover?

9. Have you switched ON the power switch?

2-24

Page 39

3. OPERATION

TABLE OF CONTENTS

Section Page

3.1 OPERATOR INTERFACE EXPLANATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2 OPERATOR INTERFACE

3.3 POWER UP

3.3.1 Power up display sequence

3.4 SELECTING AND INTERPRETING RUN MODE DISPLAY

3.4.1 INTRODUCTION

3.4.2 How to select a display type

3.4.3 How to explain displays in run mode

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.1.1 Display test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.1.2 Measure initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.4.3.1 For a selection either on the upper display and/or on the lower display . . . . . . 3-7

3.4.3.2 Exception: For selections on the 2 displays with the same display type. . . . . . 3-9

3.4.3.3 LOCK displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . 3-9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

. . . . . . . . . . . . . . . . . . . . 3-6

3.5 OPERATOR INITIATED ACTIONS

3.5.1 Hold display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.5.2 Printer action

3.5.3 RESET display

3.5.4 Alarm acknowledgment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.6 GLOSSARY OF OPERATING DISPLAY MESSAGES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3-1

. . . . . . . . . . . . . . . . . . . . . . . 3-14

Page 40

3. OPERATION

3.1 OPERATOR INTERFACE EXPLANATION

This section describes the various actions which an operator can initiate through the keyboard, and explains

how to interpret the displays in the different modes of operation available.

3.2 OPERATOR INTERFACE

DISPLAY AND KEYPAD: The display gives a clear indication of action prompts by means of two lines of 16

characters and the keypad consists of 23 keys.

• 7 function keys that enable you to start immediate action. See table below.

FUNCTION KEYS

F1 HOLD PRINT RESET ACK DISPLAY F2

Immediate

action key

configurable

To hold the

display on a

current

channel.

Use !and

"keys to

change the

channel.

To choose an

Immediate printing

action.

The choices are:

- Inhibit/Printing

- Reset paper length

- Change speed/ int 2

to speed/ int 1

- Print date & time

- Snap shot trace

- Chart advance

- Change group B to

A

- Change group A+B

to B

- Snap shot logic

- Snap shot math

- Start archive/stop

archive

- Remove PCMCIA

- Math

- Occurrence

- Reset

PCMCIA

To

Acknowledge

all latching

alarm relays

To choose the

display type in

run mode or to

escape

from

configuration

to run mode

NOTE: The function keys are used in run mode and they control the contents of the display and other

functions. In case of a power loss the configuration is unchanged.

• #$!" : THESE KEYS ARE USED FOR PRODUCT CONFIGURATION.

• SET UP: To move to configuration mode or to return from parameter configuration to the sub-

matrix.

• ENTER: To confirm your selected action.

• An ALPHANUMERIC keypad with either capital and small print letters, digits or special characters.

Immediate

action key

configurable

3-2

Page 41

3. OPERATION

The keypad is designed to simplify the way to configure your parameters.

Two kinds of parameters are possible:

1. Parameters in which you only have to enter digits (eg: CHART SPEED) or to enter a letter (COPY

function). Both cases, the keyboard will automatically be configured correctly.

2. Parameters which need every possible ASCII characters defined in the recorder (eg: MESSAGE).

When you confirm the action to enter configuration mode, a triangle in the right hand bottom corner of

your display is lit. It indicates that you are in capital letter mode. Depending on the type of characters

you wish to enter, you will have to press the F2 key. Then it will automatically shift to the next group of

characters (digits, small print letters, special characters, capital letters) indicated on the display by a

triangle. Then you will be able to select the way you wish to write the text.

3-3

Page 42

3. OPERATION

You will find in the table below the different letters associated to each key:

Digits

1 ABC abc

2

3

4

5

6

7

8 VWX vwx

9

0 , -

Capital

letters

DEF def Ä Ö Ü

GHI ghi

JKL jkl

MNO mno

PQR pqr

STU stu

YZ yz

Space Space Space

Note: The selection can also be made with the ! and " keys in the same way as for parameters

containing a list of choices.

Small

print

letters

Special characters

Ω

°

A

Ampere

V

Volt

C

Celsius F Fahrenheit

ñ Ñ

/

*

- +

±

[ ] ( ) { }

. , ; : ! ?

=

≠

" _ # $

m

milli

\

K

kilo

√ ∑ φ

< >

µ

micro

M

mega

≤ ≥

% &

n

nano

∫ ˆ

Å

.

G

giga

3-4

Page 43

3. OPERATION

3.3 POWER UP

WARNING

Before powering up, check your recorder is correctly installed. See section 2, "INSTALLATION".

!

Failure to comply with these instructions could result in death or serious injury

3.3.1 Power up display sequence

After powering up, check the messages appear on the displays in the following order:

3.3.1.1 Display test

Check that all dots for each character, commas and triangle marks are lit.

Upper display shows:

INITIALIZATION

If the communication board is present,

Upper display shows:

INITIALIZATION

Lower display shows:

COMMUNICATION

3.3.1.2 Measure initialization

Upper display shows:

INITIALIZATION

Lower display shows:

MEASURE

During a few seconds, the recorder reads and analyzes every inputs. After these operations of initialization,

input values appear on the 2 displays in run mode.

3-5

Page 44

3. OPERATION

3.4 SELECTING AND INTERPRETING RUN MODE DISPLAY

3.4.1 INTRODUCTION

The recorder allows you to choose between a lot of display types when in the normal scanning mode. At the

end of the power display sequence (see section 3-5, "POWER UP"), the display will be in the scanning

mode, in the display type you have selected in the configuration matrix of the display (Parameters: DISPLAY

HI, DISPLAY LO).

To select another display type (for the lower and/or the upper display), use the DISPLAY key (See next

section 3.4.2 ) or use the configuration mode.

3.4.2 How to select a display type

• The immediate action keys are not available if you are in configuration mode.

• The selection of the DISPLAY key is lost at the power off.

• Press the DISPLAY key. Then you can read:

DISPLAY HI

The upper display is flashing.

DISPLAY LO

• The ! and " keys allow you to select the desired display. Confirm your choice by pressing

the ENTER key.

According to your choice, you may obtain:

DISPLAY HI

ANALOG INPUTS

or

Electrical input signal

DISPLAY LO

ANALOG INPUTS

• The ! and " keys allow you to select the desired display mode on the lower display.

Electrical input signal

3-6

Page 45

3. OPERATION

NOTICE

In particular cases, you may be allowed to select a display type or a parameter only in the upper

display. See section 3.4.3.3, "LOCK displays".

3.4.3 How to explain displays in run mode

3.4.3.1 For a selection either on the upper display and/or on the lower display

ANALOG INPUTS

•

Analog input numbers, measured values and sensor engineering units will be displayed.

AN 0 1 1 2 4 . 2 o C

AN = mnemonic for analog input

• Two printed channels on the same display

0 1 2 4 . 2 & 2 4 . 3

01: channel number

24.2: channel value of channel 1

24.3: channel value of channel 2

Note that the second channel number is incremented by 1 from the first channel number.

If, for example, the first channel is not configured, no value will be displayed, e.g.

0 3 & 2 4 7 . 2

• COMMUNICATION CHANNELS

COM 0 1 2 5 4 . 9

• COM = mnemonic for communication channel

3-7

Page 46

3. OPERATION

• ALARMS

For each operated alarm, alarm number, alarm state, relay number, relay state, channel type and channel

number will be displayed.

AL 0 4 " - RL 0 6 _ - AN 1 1

AL 0 4 "- RL 0 6 _ - MA 1 2

AL 0 4 "- RL 0 6 _ - CO 0 1

" active _ inactive . = missing

AL = mnemonic for alarm

RL = mnemonic for relay

AN = mnemonic for analog input

MA = mnemonic for maths results

CO = mnemonic for comm. Channels

• SPEED IN USE

In the trend mode, speed number, value and unit will be displayed.

SP 1 1 5 0mm / h

SP 1 or SP 2 = mnemonic for speed 1 or speed 2

In tabular mode, interval name, time and unit will be displayed.

INT 1 1 0 m i n

INT1 or INT2 = mnemonic for interval 1 or interval 2

• DATE AND TIME

Day, month, year, hour "h" and minutes will be displayed.

2 5 FEB 9 6 1 1 h 1 3

3-8

Page 47

3. OPERATION

3.4.3.2 Exception: For selections on the 2 displays with the same display type

In this case the upper display shows odd numbers and the lower one shows even numbers.

For example:

AN 0 1 1 2 4 . 2 oC

AN 0 2 5 4 4 . 7 oC

If a channel is not configured or does not exist, when previous or next channel is correct, then display mode

and channel number are only displayed. See the examples below:

Only channel 01 is not correct:

AN 0 1

AN 02 1 4 . 1 oC

Only channel 06 is not correct:

AN 0 5 7 4 . 3 oC

AN 0 6

3.4.3.3 LOCK displays

In this case you are allowed to select a display mode only in the upper display.

• MATHS RESULTS

MA 2 0 TAG NAME

1 . 3 2 E + 1 2 UNITS

The upper display shows the tag name

The lower display shows the value and unit of maths results.

To display maths results, the maths option is required

3-9

Page 48

3. OPERATION

• TAG NAME AND TRACE

LOCK displays mean that the 2 displays are necessary to keep information together.

TAG NAME

0 1 2 5 8 . 1 UNITS _

The upper display shows the channel name.

The lower display shows number, value, unit and indicator of the alarm.

If the channel is in alarm status and if the alarm parameter (See EVENTS matrix, ONE ALARM ON

parameter) is not valid, then the "A" indicator appears on the last digit of the display. On the contrary units

are displayed and the alarm number is displayed just after, as follows

If ALARM and EVENTS are ON:

TAG NAME AL 1 2

0 1 2 5 8 . 1 U N I T S "

• TRACES IN ALARM

The upper display shows the name of the display type "TRACE IN ALxx-yy" and the display interval of the

lower display.

TRACE IN AL x x - y y

# # # # # # # # # # # # # # # #

The lower display shows the trace status of alarm.

"xx" - "yy" takes values from "01 to 16" or "17 to 24".

# = you may have:

" active _ inactive . = missing

3-10

Page 49

• LOGICAL INPUT STATUS

The 2 displays are necessary.

3. OPERATION

DI XX - - - > Y Y

# # # # # # # # # # # # # # # #

The upper display shows the name of the display type "DI" and the display interval of the lower display.

The lower display shows the digital input status.

"xx" - "yy" takes values from "01 to 16" or "17 to 24".

# = you may have:

" contact closed _ contact opened . = missing

3.5 OPERATOR INITIATED ACTIONS

3.5.1 Hold display

The HOLD key allows you to stop the scanning action while displaying current value of the selected channel

(upper display only).

The selection of the HOLD key is lost at the power off.

In case of locked displays, see section 3.4.3.3, "LOCK displays".

Then press HOLD key, the HOLD message appears on the upper display during a few seconds. And the

current value is displayed with two lit triangle marks, as shown below:

HOLD

0 1 2 4 5 . 5 UNITS

" "

These two triangle marks allow you to scan the other channels.

NOTE: Some display types do not allow you to use the HOLD key, like DATE/TIME, SPEED.

3-11

Page 50

3.5.2 Printer action

The PRINT key allows you to choose between various actions.

Press PRINT key and the upper display shows during a few seconds:

BASIC ACTION

and just after:

3. OPERATION

PRINT MENU

INHIBIT PRINTING

or

RESET PAPER LENG

SPEED / INT 2

or

SPEED / INT 1

PRINT DATE & TIME

SNAP SHOT TRACE

CHART ADVANCE

The chart advances as long as the

ENTER key is pressed.

CHG GROUP B

CHG GROUP A + B

SNAP SHOT LOGIC

or

CHG GROUP A

or

CHG GROUP B

3-12

Page 51

3. OPERATION

SNAP SHOT MATH

START ARCHIVE STOP ARCHIVE

or

REMOVE PCMCIA

Only when PCMCIA option is installed.

Press ENTER and use ! or " to choose the display type.

3.5.3 RESET display

Only when MATH OPTION is configured.

RESET MATH #

RESET ALL MATHS

RESET OCCURRENCE

RESET ALL OCCUR

RESET PCMCIA

Only when PCMCIA option is installed.

3.5.4 Alarm acknowledgment

Pressing ACK key is only allowed for alarms you have configured in acknowledgment mode.

This acknowledgment is only available

• f the lower display shows alternately:

REQUEST ACK NOW

and the display type,

- if the ACK key is active.

(See ACK KEY parameter in the MMI sub-matrix)

3-13

Page 52

3.6 GLOSSARY OF OPERATING DISPLAY MESSAGES

• ENTERING IN THE IMMEDIATE ACTION MODE

3. OPERATION

BASIC ACTION

• DISPLAY CHOICE

DISPLAY HI

DISPLAY LO

• DISPLAY MODE CHOICE

ANALOG INPUTS

2 PVS TRACE

MATH RESULTS

Electrical input signal

Process value in engineering unit

Only when MATH OPTION is configured.

COMM RESULTS

Only when COMM OPTION is configured.

ALARM STATUS

SPEED IN USE

3-14

Page 53

3. OPERATION

DATE & TIME

TRACE & TAG

TRACE IN ALARM

LOGIC STATES

• ACK MESSAGES

REQUEST ACKNOW

ACKNOWLEDGMENT

• INFORMATION MESSAGES

NO PAPER

END PAPER

BATTERY FAIL

ONE ALARM ON

BURNOUT

PRT INHIBIT

3-15

Page 54

OVER FLOW SPEED

3. OPERATION

SHED TIME

PCMCIA FULL

PCMCIA BAD

PCMCIA NOT INIT

PCMCIA PENDING

REMOVE PCMCIA

Only when COMM option is configured.

Only when PCMCIA option is configured.

• Diagnostic Messages

BAD CARRIAGE DISP

BAD REFERENCE

BAD EEPROM BACKPLANE

3-16

Page 55

4. CONFIGURATION

TABLE OF CONTENTS

Section Page

4.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2 PARAMETERS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.3 PRINCIPLE OF CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.4 COPY CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-105

4.4.1 Introduction

4.4.2 Configuration

4.4.3 WARNING

4.5 PRINT CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-110

4.5.1 Introduction

4.5.2 Configuration

4.5.3 Information about printing

4.5.4 WARNING

4.6 CONFIGURABLE AND PRINTABLE CHARACTERS . . . . . . . . . . . . . . . . . . . . . . . . 4-116

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-117

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-105

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-105

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-109

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-110

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-111

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-115

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-115

4-1

Page 56

4. CONFIGURATION

4.1 INTRODUCTION

The recorder can be configured - using the front keyboard or by using the PC configurator and L.P.C.S.

When using the keyboard there are two possible levels of password that can be configured. Password 1

provides limited configuration access as shown on the configuration sheet (See page 4-92). Password 2

provides full configuration of all parameters (See page 4-93).

Page 4-1 provides a key to each explanation for the individual parameters.

To begin configuration you only need to press SET UP. The recorder will indicate "CONFIGURATION", "

ACCESS" and wait for a password to be entered if one has been programmed. If no password has been

programmed the recorder will display the "READ/WRITE", "ANALOG INPUT" position (see programming

matrix). You can now use the LEFT or RIGHT side arrows to select the sub-matrix you want to configure

(i.e. ANALOG INPUT, CHART, ALARM etc.) or the UP or DOWN arrows to select the READ/WRITE,

COPY, PRINT CONF or SERVICE matrices and then use the LEFT or RIGHT arrow to enter into one of

these sub-matrices. When you have selected the sub-matrix that you want to configure you only need to

press ENTER to begin configuration of this sub-matrix.

Each sub-matrix such as ANALOG INPUT has a number of parameters associated with it that need to be

configured in order to set up that parameter and channel. Each parameter needs to be configured for each

input. To exit from the configuration mode press DISPLAY or SET UP keys.

4-2

Page 57

SUB-MATRIX PARAMETER CLASSIFICATION

NAME OF THE

FUNCTION

DEFINITION:

HOW TO MODIFY IT:

POSSIBLE VALUES:

SEE ALSO:

EXAMPLE:

NOTE:

NOTICE

4. CONFIGURATION

IMPORTANCE OF THE PARAMETER

NAME OF THE

PARAMETER

EXPLAIN THE ROLE OF THE PARAMETER

BY SELECTING OR ENTERING A NEW VALUE I.E. USING

! # KEYS

THE

LIST OF POSSIBLE VALUES OR LIMITS

The configuration of parameters with the classification “!!“ stops the

acquisition as well as the operation of alarm supervision.

Leaving the configuration mode resets the memory buffer and the alarm status

is defined again, and the chart speed changes back to the configured value.

Occurrence value is reset.

! CAN BE CHANGED IN RUN MODE

!! STOP OF ACQUISITIONS

! WITH PASSWORD 1 OR 2

!! ONLY WITH PASSWORD 2

4-3

Page 58

4. CONFIGURATION

4.2 PARAMETERS LIST

$ ANALOG INPUT page 4-6

$ CHART page 4-20

$ ALARM page 4-31

$ DIGITAL page 4-47

$ MESSAGES page 4-57

$ PRINTER page 4-60

$ CHART DOC page 4-69

$ MMI page 4-77

$ EVENTS page 4-84

$ MISCELLANEOUS page 4-88

$ PERIODIC REPORT page 4-96

$ CURRENT 4/20 mA page 4-102

4-4

Page 59

4.3 PRINCIPLE OF CONFIGURATION

4. CONFIGURATION

4-5

Page 60

4. CONFIGURATION

4-6

Page 61

4. CONFIGURATION

SUB - MATRIX ANALOG INPUT

Configuration of analog input parameters

PARAMETERS SENSOR page 4-7

RANGE page 4-12

EXT COMP page 4-13

FILTER page 4-14

LOW VALUE page 4-15

HIGH VALUE page 4-15

STD MATH page 4-16

DIFF WITH page 4-17

BURNOUT page 4-18

LOW ADJUST page 4-19

HIGH ADJUST page 4-19

4-7

Page 62

SUB-MATRIX PARAMETER CLASSIFICATION

ANALOG INPUT

DEFINITION:

HOW TO MODIFY IT:

POSSIBLE VALUES:

SEE ALSO:

NOTE:

4. CONFIGURATION

SENSOR

Basic: sensor type used on each channel.

Select a new sensor. Press ENTER. With keys # ! select the right sensor type

and press ENTER

T/C INT COMP: The sensor is a directly connected thermocouple and the cold junction

compensation of the recorder is used.

T/C EXT COMP: Thermocouple sensor is directly connected to a remote temperature

compensation box *.

* See parameter EXT COMP to configure temperature or analog channels (see page 4-

14) used to measure the external cold junction.

RTD: Sensor is a directly connected RTD or variable resistance device.

TR NL 0-5V: Sensor is a temperature transmitter signal range of 0-5V which is not

linear with temperature.

TR NL 1-5V: Sensor is a temperature transmitter signal range of 1-5V which is not

linear with temperature.

TR NL 0-20mA : Sensor is a temperature transmitter signal range of 0-20mA which is

not linear with temperature.

TR NL 4-20mA: Sensor is a temperature transmitter signal range of 4-20mA which is

not linear with temperature.

LINEAR: Sensor is a transmitter output which is linear with process variable.

SPECIAL: Special sensor connected. Must be specified by special order,

or created using PC application software.

NO ENTRY: No sensor connected or unused input.

RANGE to select the required input range.

Changing the sensor type will automatically change RANGE, LOW

VALUE, HIGH VALUE into predefined values.

Which is dependent on:

1) The type of analog input board installed (linear or universal)

2) If the input type is a directly connected temperature sensor.

The access to all sensors is possible only with an universal input board.

T/C INT COMP and RTD sensors are not accessible with a linear input

board.

!! !!

4-8

Page 63

SUB-MATRIX PARAMETER CLASSIFICATION

ANALOG INPUT

DEFINITION:

HOW TO MODIFY IT:

POSSIBLE VALUES:

4. CONFIGURATION

RANGE

DISPLAY ACTUATION RANGE

For directly connected temperature sensors and non-linear temperature

transmitters, the actuation selection defines the linearization routine used

to produce a linear chart scale. For linear transmitters, the selection simply

defines the transmitter's range/span.

The choice of actuation offered by the recorder during configuration will

depend upon sensor selected. The ranges allowed will depend on whether

you have selected Thermocouple, Linear or Non Linear or RTD.

Select a new actuation using the # or !arrows and press ENTER

Depends on the type of sensor connected. Possible selections are listed

below.

!! !!

4-9

Page 64

4. CONFIGURATION

AVAILABLE RANGES

LINEAR

DISPLAY

RANGE

DISPLAY

RANGE

mV: mV:

0/10 mV 0, 10 mV -50/150 C

-10/10 mV -10, 0, 10 mV -58/302 F

0/ 20 mV 0, 20 mV 0/100 C

-20/20 mV -20, 0, 20 mV 32/212 F

0/50 mV 0, 50 mV 0/200 C

-50/50 mV -50, 0, 50 mV 32/392 F

10/50 mV 10, 50 mV 0/400 C

0/100 mV 0, 100 mV 32/752 F

-100//100 mV -100, 0, 100 mV -200/800 C

0/500 mV 0, 500 mV -328/1472 F

-500/500 mV -500, 0, 500 mV

Volt: Volt: 320 C

0/1 V 0, 1 V 608 F

-1/1 V -1, 0, 1 V

0/2 V 0, 2 V Ni 508 ohms: Ni 508 ohms:

-2/2 V -2, 0, 2 V 150 C

0/5 V 0, 5 V 302 F

-5/5 V -5, 0, 5 V

1/5 V 1, 5 V Cu 10 ohms: Cu 10 ohms:

0/10 V 0, 10 V 250 C

-10/10 V -10, 0, 10 V 482 F

Pt 100 Ω at 0 ° C Pt 100 Ω at 0 ° C:

-50, 0, 150°C

-58, 0, 302

0, 100°C**

32, 212°F**

0, 200°C

32, 392°F

0, 400°C

32, 752°F

-200, 0, 800°C

-328, 0, 1472°F

°F

Ni 50 ohms: Ni 50 ohms:

-80, 0, 320°C

-112, 0, 608°F

-80, 0, 150°C

-112, 0, 302°F

-20, 0, 250°C***

-4, 0, 482°F***

mA: mA: Ohms: Ohms:

0/20 mA 0, 20 mA*

4/20 mA 4, 20 mA*

0/200 Ω 0, 200 Ω

0/2000 Ω 0, 2000 Ω

* The mA inputs have to be connected on a 250 Ω input resistor across the input terminals.

** Accuracy: 0.25 %

*** Accuracy: 0.5 %

RTD / OHMS

JIS: JIS:

-50/150 C

-58/302 F

0/100 C

32/212 F

0/200 C

32/392 F

0/400 C

32/752 F

-200/500 C

-328/932 F

DISPLAY

RANGE

-50, 0, 150°C

-58, 0, 302°F

0, 100°C**

32, 212°F**

0, 200°C

32, 392°F

0, 400°C

32, 752°F

-200, 0, 500°C

-328, 0, 932°F

4-10

Page 65

4. CONFIGURATION

AVAILABLE RANGES (continued)

THERMOCOUPLES

DISPLAY RANGE DISPLAY RANGE DISPLAY RANGE

J: J: S: S: U: U:

-50/150 C

-50/150 C

-58/302 F

0/400 C

32/752 F

-200/870 C

-328/1598 F

0/400 C

L: L: 32/752 F

-50/150 C

-58/302 F

0/400 C

32/2552 F

-200/870 C

-328/1598 F

0, 1400 C

K: K: T: T: 32/2552 F 32, 2552 oF

0/400 C

32/752 F

0/800 C

32/1472 F

0/1200 C

32/2192 F

-200/400 C

-200/1370 C

-328/2498 F

PR20-40: PR20-40:

R: R:

-20/1760 C

-4/3200 F

B: B:

40/1820 C 400, 1820

104/3308 F 752, 3308oF

-50, 0, 150°C

-50, 0, 150°C

-58, 0, 302°F

0, 400°C

32, 752°F

-200, 0, 870°C

-328, 0, 1598°F

-50, 0, 150°C

-58, 0, 302°F

0, 400°C

32, 2552°F

-200, 0, 870°C

-328, 0, 1598°F

0, 400°C

32, 752°F 0, 800°C

32, 1472°F

0, 1200°C

32, 2192°F

-200, 0, 1370°C

-328, 0, 2498°F

-20, 0, 1760°C

-4, 0, 3200°F

0/1600 C

0/1600 C

32/2912 F

-20/1760 C

-4/3200 F

50/150 C

N: N: 122/302 F

0/800 C

32/1472 F

0/1200 C

32/752 F

-200/1300 C

-328/2372 F

-50/150 C

58/302 F

0/150 C

32/302 F

50/150 C

122/302 F

-328/752 F

PR20 1800C

PR20 3272 F

0, 1600°C

0, 1600°C

32, 2912°F

-20, 0, 1760°C

-4, 0, 3200°F

0, 400°C

32, 752°F

0, 800°C

32, 1472°F

0/1200°C

32, 752°F

-200, 0,1300°C

-328, 0, 2372°F

-50, 0, 150°C

-58, 0, 302°F

0, 150°C

32, 302°F

50, 150°C

122, 302°F

-200, 0, 400°C

-328, 0, 752°F

50/150 C

-50/150 C

-58/302 F

0/150 C

32/302 F

-200/400 C

-328/752 F

NiMo: NiMo:

0/1400 C

32/2192 F

Moco: Moco:

Reference

W-W26: W-W26: Range

-20/2320 C

-4/4208 F

W5-W26: W5-W26:

-20/2320 C

-4/4208 F

50, 0, 150°C

-50, 0, 150°C

-58, 0, 302°F

0, 150°C

32, 302°F

50, 150°C

122, 302°F

-200, 0, 400°C

-328, 0, 752°F

0, 1400°C

32, 2192°F

0, 1400°C

-20, 0, 2320°C 500, 2100°C

-4, 0, 4208 °F 932, 3812 °F

-20, 0, 2320°C 0, 1800°C

-4, 0, 4208°F 32, 3272°F

0, 1800°C 600, 1800°C

32, 3272°F 1110, 3300°F

o

C

400, 1820 °C

752, 3308 °F

4-11

Page 66

SUB-MATRIX PARAMETER CLASSIFICATION

ANALOG INPUT

NOTE:

NOTICE

4. CONFIGURATION

RANGE

For non-linear signals TR NL 0 - 5 V, 1 - 5 V, 0 - 20 mA, 4 - 20 mA, 1 to

5 VDC or 4 to 20 mA or 0 to 5 VDC or 0 to 20 mA, the transmitter range

must be identical to the range shown in the previous tables.

F is used for

°Fahrenheit ; C is used for °Celsius.

!! !!

4-12

Page 67

4. CONFIGURATION

SUB-MATRIX PARAMETER CLASSIFICATION

ANALOG INPUT

DEFINITION:

EXT COMP

The thermocouple sensor is directly connected to a remote temperature

compensation box. Then the connections are made with copper

lead wires. Two types of wiring are possible:

1) At a fixed temperature compensation box with temperature

configurable from 0 up to 80

2) On variable temperature compensation box. We use 1 channel to

measure the temperature of the box.

1) Fixed temperature compensation box

o

C (32 to 176oF).

!! !!

HOW TO MODIFY IT:

NOTICE

2) Variable temperature compensation box

1) Fixed Temperature: Enter a new temperature value in engineering

unit. Choose between VALUE 0 and 80.

2) Variable Temperature: Select the channel used to measure the

temperature of the box.

This parameter is just taken into account if the corresponding channel is

configured with T/C EXT COMP. For T/C INT COMP, RTD and LINEAR, this

parameter has no effect whatever the entered value.

4-13

Page 68

SUB-MATRIX PARAMETER CLASSIFICATION

ANALOG INPUT

DEFINITION:

HOW TO MODIFY IT:

POSSIBLE VALUES:

4. CONFIGURATION

FILTER

You may wish to apply a filter to noisy signals. However if pulses, square

waves or other rapidly changing inputs are to be displayed and recorded

without damping, choose 0 filter value.

Enter a numeric value.

0-99 seconds

0 = No filter

10 = 10 seconds

!! !

NOTICE

All the alarms or maths functions configured on a filtered analog input are

affected by the filter delay. Be mindful with the filter action for the channels on

which a "rate of change" alarm is configured: the filter can suppress the alarm

action.

4-14

Page 69

4. CONFIGURATION

SUB-MATRIX PARAMETER CLASSIFICATION

ANALOG INPUT

DEFINITION:

HOW TO MODIFY IT:

POSSIBLE VALUES:

NOTICE

NOTICE

LOW VALUE

Engineering value corresponding to low limit of the selected input

actuation range.

Enter a numeric value.

Up to 4 digits plus optional sign.

[-9999 ... 9999]

Modification is not allowed for any directly connected temperature sensors, as

this would adversely affect the linearization.

Modification is only possible when the sensor is:

- LINEAR or SPECIAL

- RTD and the range is 0, 200 Ohms or 0, 2000 Ohms

For linear and non-linear transmitters choose the value in engineering

units, which corresponds to the low range limit of the transmitter.

SUB-MATRIX PARAMETER CLASSIFICATION

ANALOG INPUT

DEFINITION:

HOW TO MODIFY IT:

POSSIBLE VALUES:

NOTICE

NOTICE

HIGH VALUE

Engineering value corresponding to high limit of the selected input actuation

range.

Enter a numeric value.

Up to 4 digits plus optional sign.

[-9999 ... 9999]

Modification is not allowed for any directly connected temperature sensors, as

this would adversely affect the linearization.

Modification is only possible when the sensor is:

- LINEAR or SPECIAL

- RTD and the range is 0, 200 Ohms or 0, 2000 Ohms

For linear and non-linear transmitters choose the value in engineering

units, which corresponds to the low range limit of the transmitter.

!! !

!! !

4-15

Page 70

SUB-MATRIX PARAMETER CLASSIFICATION

ANALOG INPUT

DEFINITION:

HOW TO MODIFY IT:

POSSIBLE CHOICES:

SEE ALSO:

NOTE:

4. CONFIGURATION

STD MATH

2 mathematical functions are included as standard in the recorder.

These functions apply only to analog inputs.

Select the maths function.

NO OPT MATH: No maths function configured.

SQUARE ROOT: Square root applies to analog input.

CHANNEL DIFF: Difference between the current analog input and the one

configured in "DIFF WITH".

DIFF WITH in this sub-matrix for CHANNEL DIFF.

1) For SQUARE ROOT the formula is:

!! !!

Smin = min. sensor input value

Smax = max. sensor input value

S = current sensor input value

Available for linear inputs

2) For CHANNEL DIFF, the formula is:

PV = PV

A and B are any analog input.

A - PVB

4-16

Page 71

SUB-MATRIX PARAMETER CLASSIFICATION

ANALOG INPUT

DEFINITION:

HOW TO MODIFY IT:

POSSIBLE CHOICES:

NOTE:

4. CONFIGURATION

DIFF WITH

Second channel used when STD MATH = CHANNEL DIFF

Select a new value.

ANALOG # i (i = 1 ... 64)

NONE

The software will only allow selection of pre-configured input.

For the difference between 2 channels, it is recommended to take

first the highest channel reference and subtract from the other channel.

Example:

You want to make a difference between channels 7 and 12:

make ch12 minus ch7.

!! !!

4-17

Page 72

SUB-MATRIX PARAMETER CLASSIFICATION

ANALOG INPUT

DEFINITION:

HOW TO MODIFY IT:

POSSIBLE CHOICES:

NOTE:

!

CAUTION

Failure to comply with these instructions may result in product damage

4. CONFIGURATION

BURNOUT

Allows you to define the safety backup position to activate alarms (if

configured) in case of sensor burnout. The trace can go either on the right

(high) or on the left (low).

Select new text.

NO BURNOUT: No burnout.

B OUT LOW: Burnout configured low scale. Display shows [-9999]

B OUT HIGH: Burnout configured high scale. Display shows [9999]

FIX LOW: Value fixed low. (mA) Not configurable

FIX HIGH: Value fixed high. (RTD/OHMS) Not configurable

FIX NONE: Undefined value. Not configurable (Linear sensors)

0 to 10 V / - 5 to 5 V / -1 to 1 V / -500 to 500 mV

- For some sensors (mA, RTD, Volts), burnout is not configurable but fixed

and display will show FIX LOW, FIX HIGH or FIX NONE.

The value will be out of range (low, high or undefined). The "BURNOUT" event

is only activated with the B OUT LOW or B OUT HIGH configuration.

- For RTD/OHMS sensors, a third wire burnout cannot be detected: the output

value will be undefined.

For configurable burnout, be aware that a current pulse of 0.125 mA will

occur regularly as part of the burnout detection and may disturb other

devices connected to the same sensor. For an application with another

controller connected on the same current loop, please remove the

burnout detection on your recorder.

!! !!

4-18

Page 73

SUB-MATRIX PARAMETER CLASSIFICATION

ANALOG INPUT

DEFINITION:

HOW TO MODIFY IT:

POSSIBLE CHOICES:

EXAMPLE:

4. CONFIGURATION

LOW ADJUST

HIGH ADJUST

Zero adjust and span adjust are values used to calibrate a temperature loop.

Otherwise choose 0 Value = Factory Calibration

Adjustments are made directly in Engineering unit to the input range.

(ex.: 5 = 5

Enter a numeric value.

Up to 3 digits including negative sign and decimal point.

[-99 ... +99]

LOW ADJUST will be added to the 0% of the considered range.

HIGH ADJUST will be added to the 100% of the considered range, so the

calibration is changed.

o

C)

!! !

4-19

Page 74

4. CONFIGURATION

4-20

Page 75

SUB – MATRIX CHART

PARAMETERS

Configuration of chart range and format

TRACE page 4-21

DESTINATION page 4-21

FORMAT page 4-22

MIN RANGE 1 page 4-22

MAX RANGE 1 page 4-23

RG 1 COLOR page 4-23

MIN RANGE 2 page 4-24

MAX RANGE 2 page 4-24

RG 2 COLOR page 4-25

ENG UNIT page 4-25

TAG NAME page 4-26

RANGE USED page 4-26

0% ZONE page 4-27

100% ZONE page 4-27

SUB DIV page 4-28

GROUP DEF page 4-29

4. CONFIGURATION

4-21

Page 76

SUB-MATRIX PARAMETER CLASSIFICATION

CHART

DEFINITION:

HOW TO MODIFY IT:

POSSIBLE CHOICES:

NOTICE

4. CONFIGURATION

TRACE

Defines the variable to be printed on the chart or stored on the PCMCIA

memory card (None, Analog input 1... 24, Comm input 1 ... 24, maths input

1 ... 24).

Select a new value.

NO TRACE

ANALOG # i (i = 1 ... 64)

COMM # i (i = 1 ... 32)

MATH # i (i = 1 ... 32)

The software will only allow selection of a pre-configured analog input.

!! !!

SUB-MATRIX PARAMETER CLASSIFICATION

CHART

DEFINITION:

HOW TO MODIFY IT:

POSSIBLE CHOICES:

DEFAULT VALUE:

DESTINATION

Determines where to print or copy charts.

Select a new value.

ON PAPER

ON FILE *

PAPER & FILE *

* FILE: this corresponds to the trace storage on a PCMCIA memory card.

ON PAPER

!! !!

4-22

Page 77

SUB-MATRIX PARAMETER CLASSIFICATION

CHART

DEFINITION:

POSSIBLE CHOICES:

4. CONFIGURATION

FORMAT

Format used for the printing of trend, range and information, and the display of

trace value.

XXXXX (no decimal point) 10000

XXX.X (1/10) 100.0

XX.XX (1/100) 10.00

X.XXX (1/1000) 1.000

AUTOMATIC: Automatically displays and prints the measured value based on

the accuracy of the recorder and the available number of digits on the display.

IE ACCURACY = 0.1% on selected ranges.

! !!

SUB-MATRIX PARAMETER CLASSIFICATION

CHART

DEFINITION:

HOW TO MODIFY IT:

POSSIBLE VALUES:

EXAMPLE:

MIN RANGE 1

Lower limit of chart range 1.

Enter a numeric value.

Up to 8 digits for analog inputs, maths results and comm. results.

Including negative sign and decimal point.

!! !

4-23

Page 78

4. CONFIGURATION

SUB-MATRIX PARAMETER CLASSIFICATION

CHART

DEFINITION:

HOW TO MODIFY IT:

POSSIBLE VALUES:

EXAMPLE:

MAX RANGE 1

Upper limit of chart range 1

Enter a numeric value.

Up to 8 digits for analog inputs, maths results and comm. results.

Including negative sign and decimal point.

!! !

SUB-MATRIX PARAMETER CLASSIFICATION

CHART

DEFINITION:

HOW TO MODIFY IT:

POSSIBLE VALUES:

RG1 COLOR

Color of range 1.

Select a new color

BLACK

BLUE

PURPLE

GREEN

BROWN

RED

BLACK THICK

BLUE THICK

PURPLE THICK

GREEN THICK

BROWN THICK

RED THICK

! !

4-24

Page 79

4. CONFIGURATION

SUB-MATRIX PARAMETER CLASSIFICATION

CHART

DEFINITION:

HOW TO MODIFY IT:

POSSIBLE VALUES:

EXAMPLE:

MIN RANGE 2

Lower limit of chart range 2.

Enter a numeric value.

Up to 8 digits for analog inputs, maths results and comm. results.

Including negative sign and decimal point.

!! !

SUB-MATRIX PARAMETER CLASSIFICATION

CHART

DEFINITION:

HOW TO MODIFY IT:

POSSIBLE VALUES:

EXAMPLE:

MAX RANGE 2

Upper limit of chart range 2

Enter a numeric value.

Up to 8 digits for analog inputs, maths results and comm. results.

Including negative sign and decimal point.

!! !

4-25

Page 80