Page 1

DPR 100 A - DPR 100 B

DIGITAL STRIP CHART RECORDER

PRODUCT MANUAL

Page 2

DPR 100 A - DPR 100 B

DIGITAL STRIP CHART RECORDER

PRODUCT MANUAL

Ref. : US1I-6126

Issue : 21 October 2003

Page 3

Copyright, Notices, and Trademarks

© Copyright 2000 by Honeywell Inc.

While this information is presented in good faith and believed to be

accurate, Honeywell disclaims the implied warranties of

merchantability and fitness for a particular purpose and makes no

express warranties except as may be stated in its written agreement

with and for its customer.

In no event is Honeywell liable to anyone for any indirect, special or

consequential damages. The information and specifications in this

document are subject to change without notice.

This document was prepared using Information Mapping

methodologies and formatting principles.

Information Mapping is a trademark of Information Mapping Inc.

Windows is a registered trademark of Microsoft Inc.

Modbus is a registered trademark of MODICON, Inc.

The omission of a name from this list is not to be interpreted that the

name is not a trademark.

Page 4

About This Document

Abstract

This manual describes the installation, configuration, operation, and maintenance of the Recorder.

Warranty

WARRANTY. THE FOLLOWING IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THOSE OF MERCHANTABILITY

AND FITNESS FO R PARTICULAR PURPOSE.

a) Goods/Hardware

Except as otherwise hereinafter provi ded, Honeywell warrants goods of its manufacture to be free of defective mater ials and faulty workmanship

and as conforming to applicable specifications and/or drawings. Commencing with date of shipment, Ho neywell's war ranty shal l run for the period

specified on the face hereof or, if none b e mentioned, 18 months. If warranted goods are returned to Honeywell during this period of coverage,

Honeywell will repair or replace without charge those items it finds defective.

Experimental devices (designated by the letter "X" or "E" within their part-number identification) are prototype, pre-pr oduction items that have yet to

complete all phases of prod uct-release testing; thes e items are sold "AS IS" WITH NO WARRANTY.

b) Software

Software, if listed on the face hereof and used within hardware and/or a system warranted by Honeywell, will be furnished on a medium that’s free

of defect in materials or workmanship under normal use for so long as the hardware and/or system is under warranty. During this period,

Honeywell will replace without charge any such medium it finds defective. As for the quality or performance of any software or data, they are

supplied “AS IS” WITH NO WARRANTY.

c) Services

Where hardware and/or a system is installed by Honeywell, such services are warranted against faulty workmanship for the same period (if any)

as applies to the installed items. During this concurrently r unning period, Ho neywell will correct without charge any workmanship it finds to be

faulty.

Contacts

If you encounter any problem with your recorder, please contact your nearest Sales Office. (See the

address list at the end of this manual).

An engineer will discuss your problem with you. Please have your complete model

number and serial number available. Model number and serial number are located on the

chassis nameplate.

If it is determined that a hardware problem exists, a replacement instrument or part will be shipped

with instructions for returning the defective unit. Do not return your instrument without authorization

from your Sales Office or until the replacement has been received.

Page 5

Symbol Meanings

Symbol What it means

Protective ground terminal. Provided for connection of the protective earth green (green

or green/yellow) supply system conductor.

Functional ground terminal. Used for non-safety purposes such as noise immunity

improvement.

WARNING. Risk of electric shock. This symbol warns the user of a potential shock

hazard where voltages greater than 30 Vrms, 42.4 Vpeak, or 60 Vdc may be accessible.

CAUTION. When this symbol appears on the product, see the user manual for more

information. This symbol appears next to the required information in the manual.

CE conformity

This product conforms with the protection requirements of the following European Council

Directives: 89/336/EEC, the EMC directive, and 73/23/EEC, the low voltage directive. Do

not assume this product conforms with any other “CE Mark” Directive(s).

Attention

The emission limits of EN 50081-2 are designed to provide reasonable protection against harmful

interference when this equipment is operated in an industrial environment. Operation of this equipment in a

residential area may cause harmful interference. This equipment generates, uses, and can radiate radio

frequency energy and may cause interference to radio and television reception when the equipment is used

closer than 30 meters to the antenna(e). In special cases, when highly susceptible apparatus is used in close

proximity, the user may have to employ additional mitigating measures to further reduce the electromagnetic

emissions of this equipment.

Product model number:

Serial number:

Date code:

Service department telephone

number:

Page 6

Page 7

TABLE OF CONTENTS

1. OVERVIEW ............................................................................................................................................... 1-1

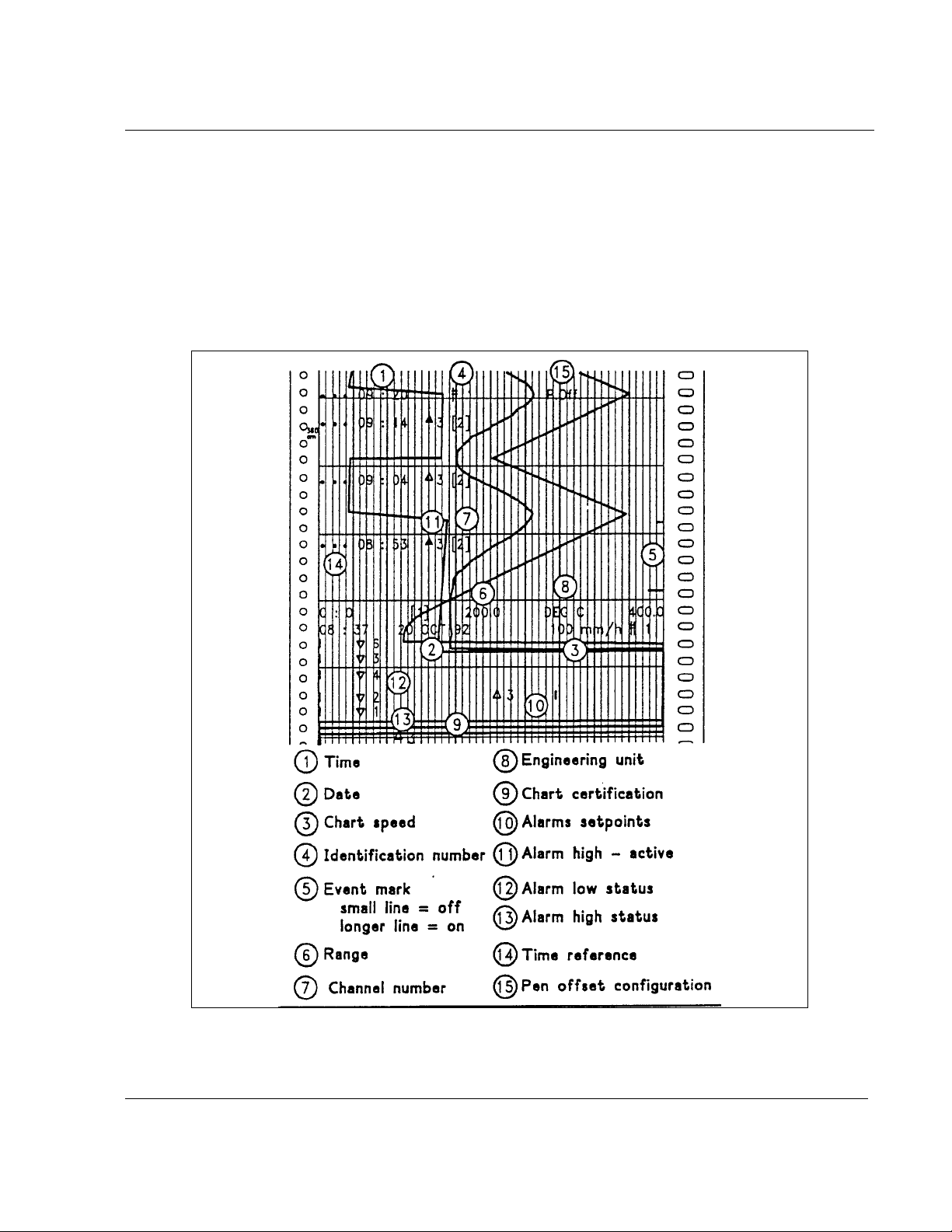

1.1 CLEAR AND FULLY DOCUMENTED CHART OF PEN RECORDER........................................ 1-1

1.1.1 Alarms are indicated clearly......................................................................................................... 1-2

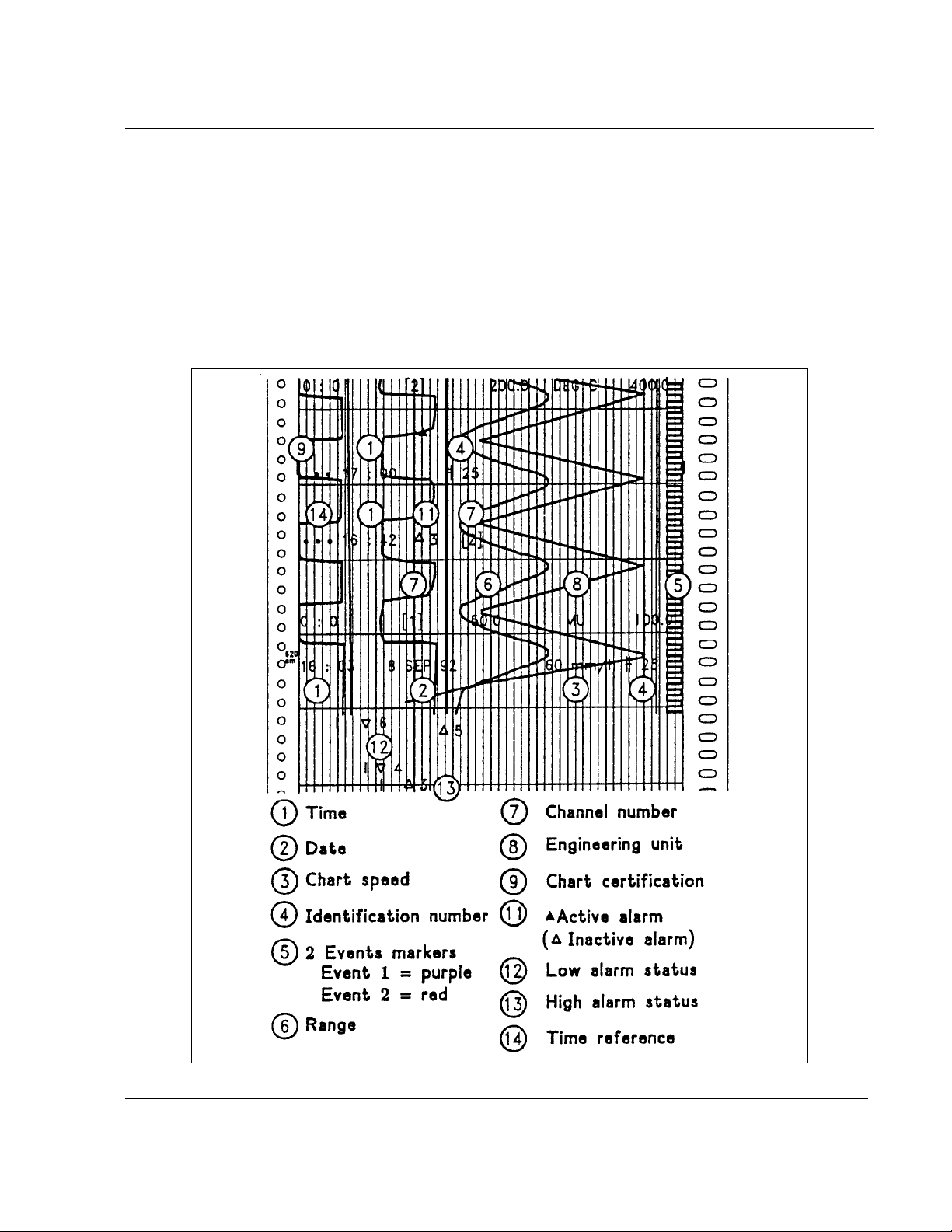

1.2 CLEAR AND FULLY DOCUMENTED CHART FOR MULTIPOINT RECORDER................... 1-3

1.2.1 Alarms are indicated clearly......................................................................................................... 1-4

2. INSTALLATION ....................................................................................................................................... 2-1

2.1 WARNING .............................................................................................................................................. 2-1

2.2 UNPACKING.......................................................................................................................................... 2-2

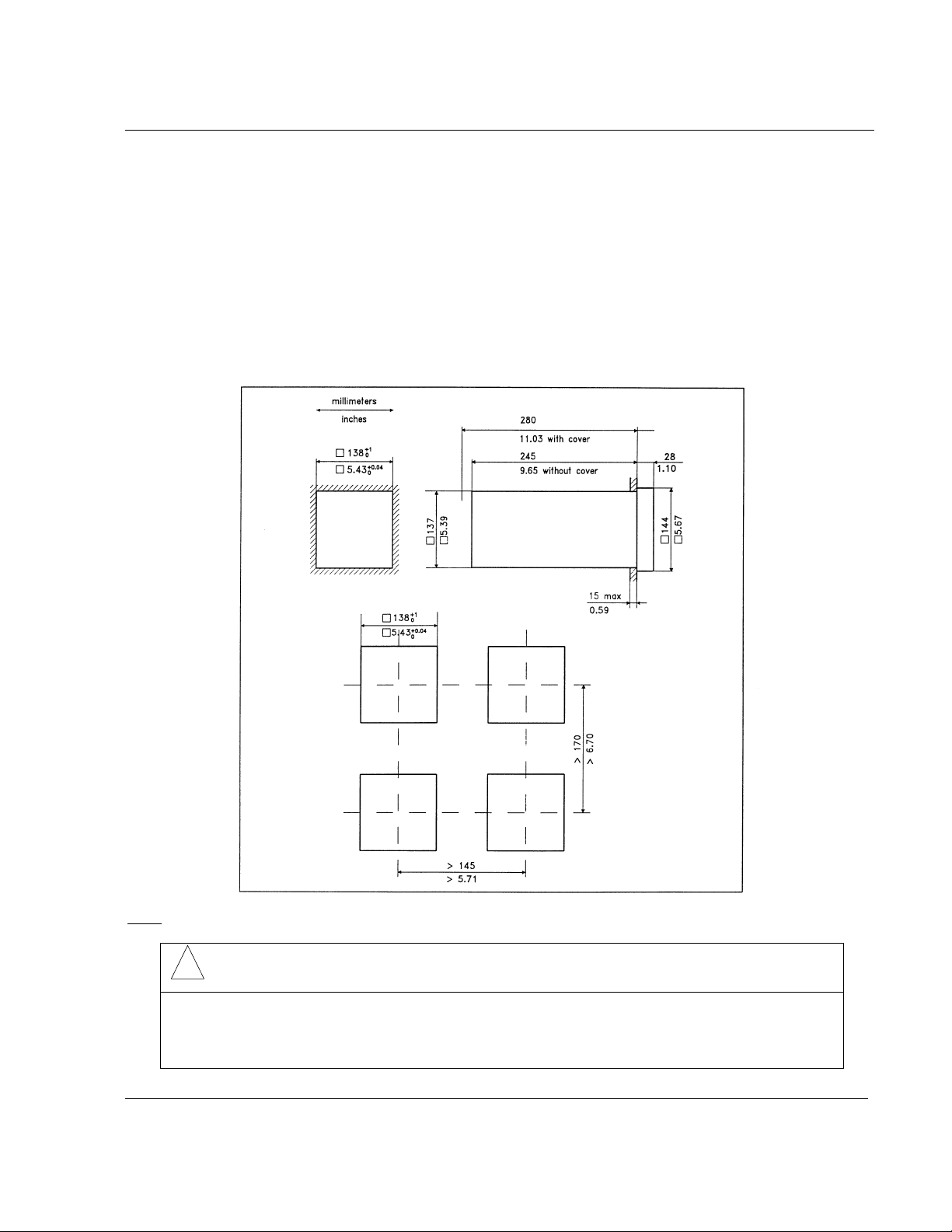

2.3 PANEL MOUNTING THE RECORDER............................................................................................ 2-3

2.3.1 Recommendations........................................................................................................................ 2-3

2.3.2 External dimensions and cut-out.................................................................................................. 2-3

2.3.3 Installing the recorder................................................................................................................... 2-4

2.4 WIRING THE RECORDER ................................................................................................................. 2-5

2.4.1 Recommendations........................................................................................................................ 2-5

2.4.2 Terminal connections................................................................................................................... 2-6

2.5 PREPARING POWER-UP.................................................................................................................... 2-7

2.5.1 Installing the printing system ....................................................................................................... 2-7

2.5.2 Fitting the roll chart.................................................................................................................... 2-12

2.5.3 Fitting the fanfold chart.............................................................................................................. 2-13

2.6 CLEANING THE PANE...................................................................................................................... 2-13

2.7 CARRIAGE CALIBRATION ............................................................................................................. 2-14

2.7.1 Chart certification....................................................................................................................... 2-14

2.7.2 Carriage calibration (or chart calibration) .................................................................................. 2-15

2.8 CHECK LIST........................................................................................................................................ 2-17

2.9 REPLACING THE INK CARTRIDGES........................................................................................... 2-17

3. CONFIGURATION................................................................................................................................... 3-1

3.1 FUNCTION KEYS ................................................................................................................................. 3-1

3.1.1 SETUP ......................................................................................................................................... 3-1

3.1.2 ENTER......................................................................................................................................... 3-1

3.1.3 INCREMENT .............................................................................................................................. 3-1

3.1.4 DECREMENT ............................................................................................................................. 3-2

3.2 MAIN MENU .......................................................................................................................................... 3-2

3.3 ALARMS................................................................................................................................................. 3-2

3.4 SPEED ..................................................................................................................................................... 3-4

3.4.1 SPEED (mm/hour) ....................................................................................................................... 3-4

3.4.2 SPEED (inches/hour) ................................................................................................................... 3-5

3.5 IDENTIFICATION ................................................................................................................................ 3-6

3.6 TIME........................................................................................................................................................ 3-7

3.7 DATE ....................................................................................................................................................... 3-8

4. MODEL SELECTION GUIDE ................................................................................................................4-1

4.1 PRODUCT IDENTIFICATION............................................................................................................ 4-1

5. PRODUCT SPECIFICATION SHEET ................................................................................................... 5-1

5.1 TECHNICAL DATA.............................................................................................................................. 5-1

5.2 ACCURACY ........................................................................................................................................... 5-4

5.3 AVAILABLE RANGES ......................................................................................................................... 5-5

5.4 DIMENSIONS......................................................................................................................................... 5-6

5.5 TERMINAL CONNECTIONS.............................................................................................................. 5-7

i

Page 8

TABLE OF CONTENTS

6. CONFIGURATION................................................................................................................................... 6-1

6.1 ANALOG INPUT CONFIGURATION................................................................................................ 6-1

6.2 RELAY OUTPUT CONFIGURATION ............................................................................................... 6-2

7. CALIBRATION ......................................................................................................................................... 7-1

7.1 FIELD CALIBRATION......................................................................................................................... 7-1

8. PC CONFIGURATION............................................................................................................................. 8-1

8.1 OVERVIEW............................................................................................................................................ 8-1

8.2 PRODUCT FEATURES ........................................................................................................................ 8-1

8.3 INSTALLATION.................................................................................................................................... 8-1

8.3.1 System Requirements................................................................................................................... 8-1

8.3.2 New installation ........................................................................................................................... 8-2

8.3.3 Upgrade old installation ............................................................................................................... 8-5

8.3.4 Uninstall....................................................................................................................................... 8-6

8.4 USE .......................................................................................................................................................... 8-7

8.4.1 Start up ......................................................................................................................................... 8-7

8.4.2 Menus........................................................................................................................................... 8-7

8.4.3 Modifying fields of parameters.................................................................................................... 8-7

8.4.4 Going from a parameter field to another one ...............................................................................8-7

8.4.5 Leaving a menu............................................................................................................................ 8-8

8.4.6 Saving modifications on a file...................................................................................................... 8-8

8.5 READ AND MODIFY PARAMETERS ............................................................................................... 8-9

8.6 DIAGNOSTIC PARAMETERS.......................................................................................................... 8-11

9. TROUBLESHOOTING ............................................................................................................................ 9-1

9.1 FAILURE SYMPTOMS AND TROUBLESHOOTING PROCEDURES ........................................ 9-1

9.2 TROUBLESHOOTING LIST ............................................................................................................... 9-1

9.2.1 Self test mode pen recorder.......................................................................................................... 9-1

9.2.2 Self test mode multipoint recorder............................................................................................... 9-5

9.2.3 Symptom: The recorder is inoperative ......................................................................................... 9-8

9.2.4 Symptom: The chart is inoperative ..............................................................................................9-8

9.2.5 Symptom: The print carriage is inoperative................................................................................. 9-9

9.2.6 Symptom: The print head is inoperative ...................................................................................... 9-9

9.2.7 Symptom: Printing incorrect color............................................................................................. 9-10

9.2.8 Symptom: Wrong date/time ....................................................................................................... 9-10

9.2.9 Symptom: The alram relay is inoperative ..................................................................................9-10

9.2.10 Symptom: Analog input out of tolerance ...................................................................................9-11

9.2.11 Symptom: Incorrect spacing between points.............................................................................. 9-11

9.2.12 Symptom: No communication with PC loader........................................................................... 9-12

9.2.13 Symptom: Printed traces are unstable ........................................................................................ 9-12

9.2.14 Symptom: Chart illumination failed........................................................................................... 9-12

10. KITS LIST ................................................................................................................................................ 10-1

10.1 ELECTRONIC PARTS ....................................................................................................................... 10-2

10.2 MECHANICAL PARTS ...................................................................................................................... 10-3

10.3 MISCELLANEOUS ............................................................................................................................. 10-4

10.4 CONSUMABLES ................................................................................................................................. 10-5

SAFETY

SALES AND SERVICE

ii

Page 9

1. OVERVIEW

1.1 CLEAR AND FULLY DOCUMENTED CHART OF PEN RECORDER

Color traces :

Pen 1 = blue

Pen 2 = red

Pen 3 = green

1-1

Page 10

1.1.1 Alarms are indicated clearly

1. OVERVIEW

1-2

Page 11

1. OVERVIEW

1.2 CLEAR AND FULLY DOCUMENTED CHART FOR MULTIPOINT RECORDER

Color traces

Channel 1 = purple Channel 4 = green

Channel 2 = red Channel 5 = blue

Channel 3 = black Channel 6 = brow n

1-3

Page 12

1.2.1 Alarms are indicated clearly

1. OVERVIEW

1-4

Page 13

2. INSTALLATION

2.1 WARNING

IMPROPER INSTALLATION

To avoid the risk of electrical shock which could cause personal injury, follow all safety

!

! POWER SUPPLY

Ensure the source voltage matches the voltage of the power supply before turning on the power.

! PROTECTIVE GROUNDING

Make sure to connect the protective grounding to prevent an electric shock before turning on the power.

! NECESSITY OF PROTECTIVE GROUNDING

To avoid a potential shock hazard, never cut off the internal or external protective grounding wire or

disconnect the wiring of protective grounding terminal.

! DEFECT OF PROTECTIVE GROUNDING AND FUSE

Do not operate the instrument when protective grounding or fuse might be defective.

! FUSE

To prevent a fire, make sure to use the fuse with specified standard (current voltage, type). Before

replacing the fuse, turn off the power and disconnect the power source. Do not use a different fuse

or short-circuit the fuseholder.

! DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable liquids or vapors. Operation of any

electrical instrument in such an environment constitutes a safety hazard.

! NEVER TOUCH THE INTERIOR OF THE INSTRUMENT

Inside this instrument there are areas of high voltage; therefore, never touch the interior if the

power supply is connected. This instrument has an internal changeable system; however, internal

inspection and adjustments should be done by qualified personnel only.

! EXTERNAL CONNECTION

To ground securely, connect the protective grounding before connecting to measurement or control

unit.

! If the equipment is used in a manner not specified by the manufacturer, the protection provided by

the equipment may be impaired.

! Do not replace any component (or part) not explicitly specified as replaceable by your supplier.

notices in this documentation.

Protective earth terminal. Provided for connection of the protective earth supply system

conductor.

Failure to comply with these instructions could result in death or serious injury

2-1

Page 14

2.2 UNPACKING

Remove the accessories and check them against the figure below.

2. INSTALLATION

1. Ink cartridge(s) (A) or ink wheel (B)

2. Fuse (Spare) (Use only 1 A T. fuses)

3. Roll (R) or fanfold (Z) chart

4. Mounting brackets with nuts

5. Operator manual

6. Front label

NOTE: In case of missing item, please contact your nearest sales office.

2-2

Page 15

2. INSTALLATION

2.3 PANEL MOUNTING THE RECORDER

2.3.1 Recommendations

This recorder is designed to operate under specific conditions. If you need more information, refer to

the product specification sheet.

2.3.2 External dimensions and cut-out

Prepare panel cut-out as detailed below:

: Maximum panel thickness 15 mm

Note

!

CAUTION

The maximum temperature inside the cabinet should not exceed the ambient conditions

specific to the recorders. The recorder must be mounted into a panel to limit operator

access to the rear terminals.

Failure to comply with these instructions may result in product damage

2-3

Page 16

2.3.3 Installing the recorder

To install the recorder, follow the figures below:

Mounting brackets

2. INSTALLATION

Mounting angle limits

2-4

Page 17

2. INSTALLATION

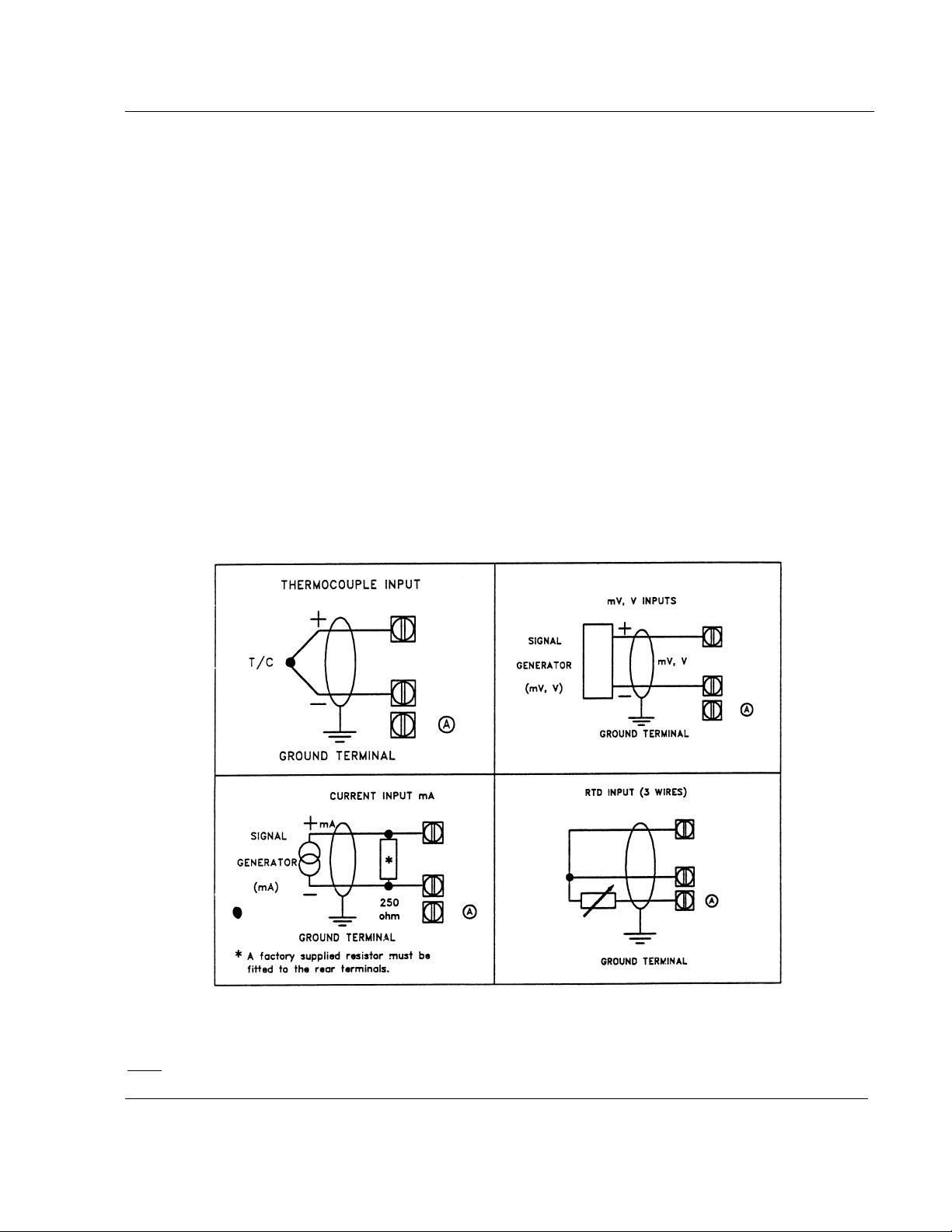

2.4 WIRING THE RECORDER

2.4.1 Recommendations

# All wiring must be in accordance with local norms and carried out by authorized experienced

personnel.

# The ground terminal must be connected before any other wiring (and disconnected last).

# A switch in the main power supply wiring is required near the equipment.

# If an external fuse is used to protect the line supply to the recorder, the fuse should match the

recorder fuse rating (fuse type) as well as for the fuseholder.

# Sensor wiring should be run as far as possible from power wiring.

# To reduce stray pick-up, we recommend the use of twisted pair sensor wiring.

# EMI effects can be further reduced by the use of shielded cable sensor wiring. The shield must be

connected to the ground terminal:

: Terminal (A) is only used for RTD. (See diagrams above.)

Note

2-5

Page 18

2.4.2 Terminal connections

2. INSTALLATION

2-6

Page 19

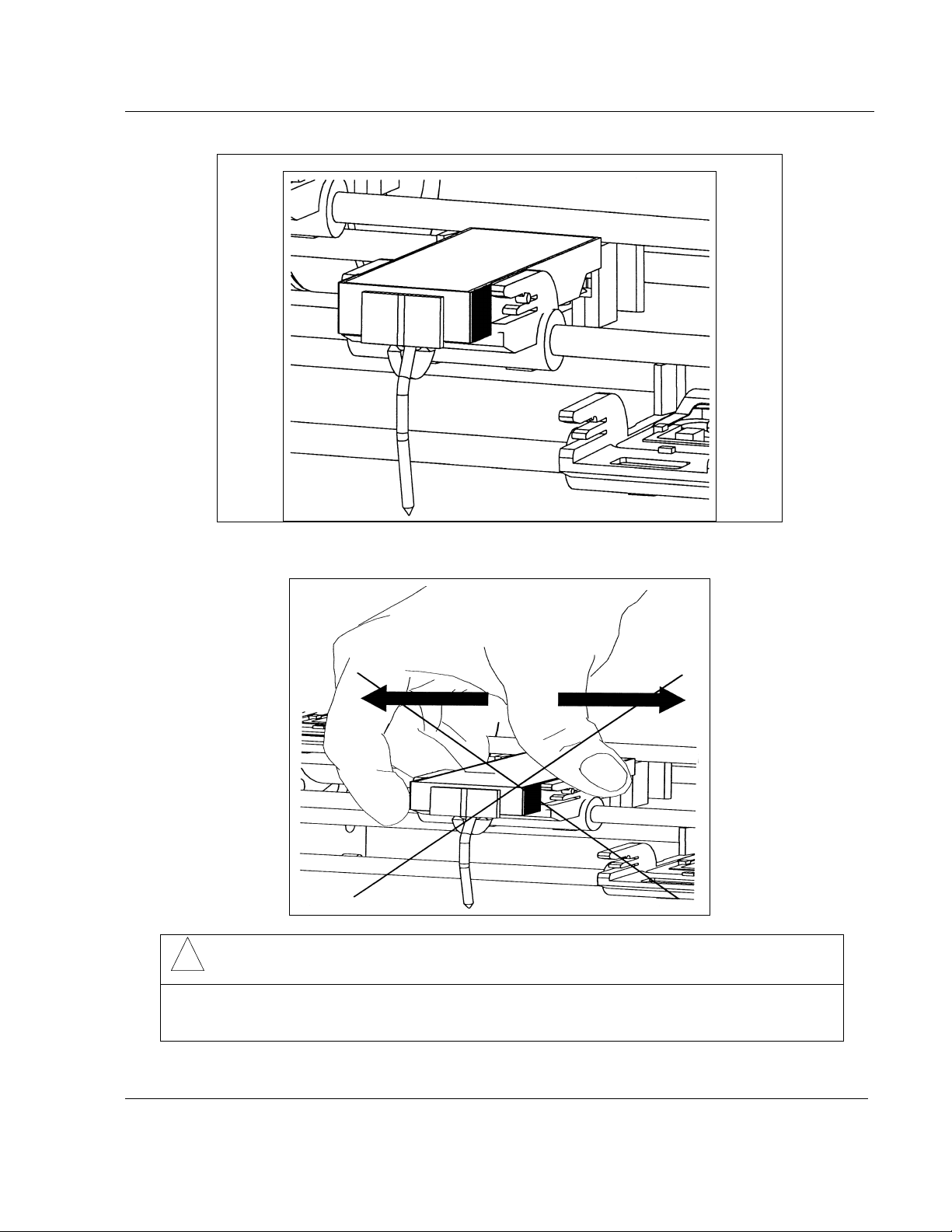

2.5 PREPARING POWER-UP

2.5.1 Installing the printing system

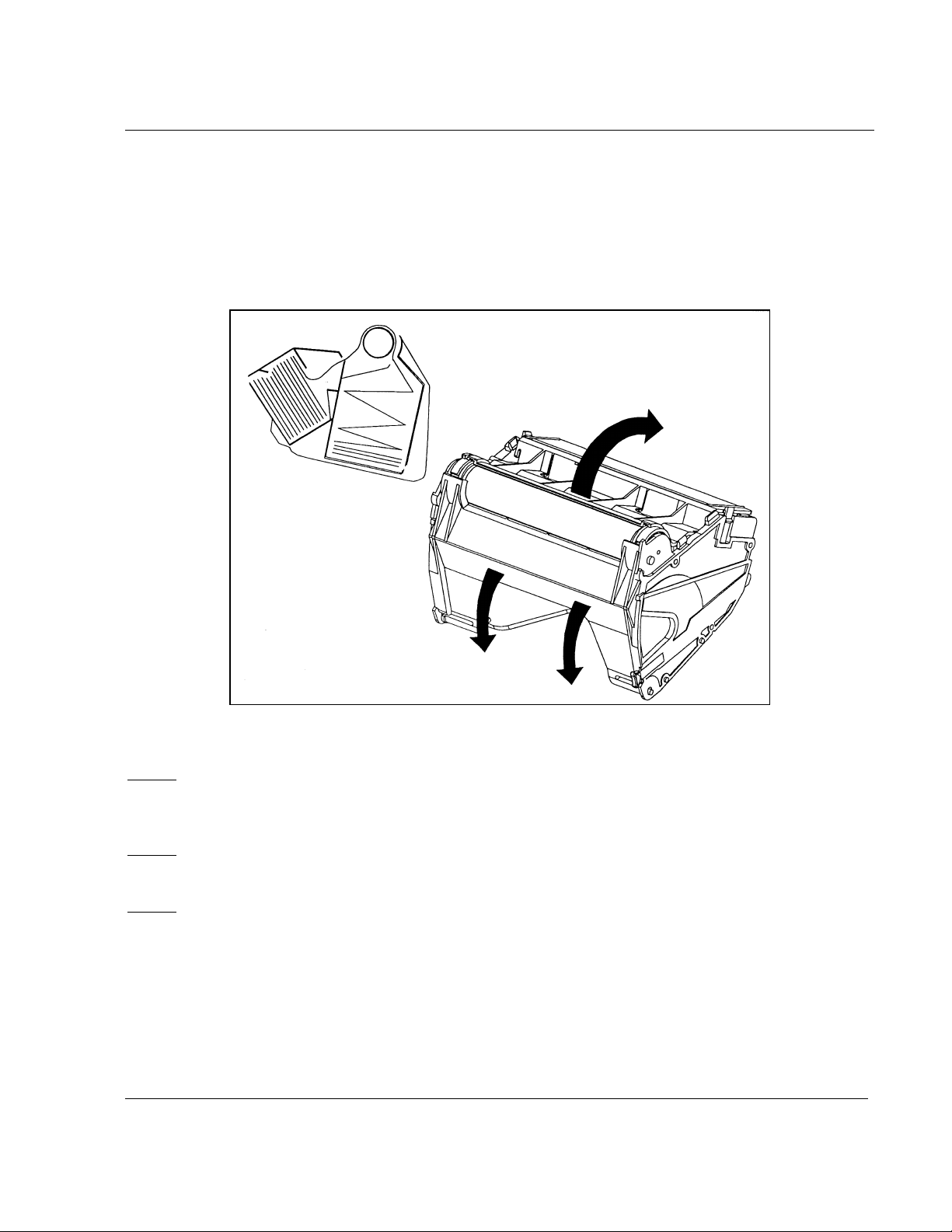

Remove the chart cassette from the chassis as shown below:

2. INSTALLATION

2-7

Page 20

If you have a pen recorder, proceed as shown below:

Open the front display after having removed the chart cassette.

2. INSTALLATION

Insert the pen cartridges.

2-8

Page 21

2. INSTALLATION

Inserted pen cartridges

!

CAUTION

Do not move the print head mechanism when the recorder is working.

Failure to comply with these instructions may result in product damage

2-9

Page 22

If you have a multipoint recorder, proceed as shown below:

Open the front scale after having removed the chart cassette.

2. INSTALLATION

Insert the ink wheel.

: The ink wheel should be inserted and rotated counter-clockwise until ratchet engages.

Note

2-10

Page 23

2. INSTALLATION

!

CAUTION

Do not move the print head mechanism when the recorder is working.

Failure to comply with these instructions may result in product damage

2-11

Page 24

2. INSTALLATION

2.5.2 Fitting the roll chart

Open the chart cassette as shown below and install the chart using the figure on the cassette.

Note 1

If required, the chart cassette can be cleaned with a damp cotton cloth.

Note 2

Note 3

: To maintain print quality, the print carriage guide rods should be cleaned at six-monthly

intervals with a dry cotton cloth. Lubricant should NOT be used.

: On completion, close the front scale(s) before reinserting the chart cassette in the printing

position.

: After a change of paper it is recommended to check the chart with calibration and to adjust it

if necessary (Refer to section 2.7 CARRIAGE CALIBRATION).

2-12

Page 25

2. INSTALLATION

2.5.3 Fitting the fanfold chart

• Open the chart cassette as shown below and install the chart using the figure on the cassette.

• Place the fanfold chart in the upper compartment with the folds in the vertical plane and the slots

on the right hand side.

• Pull out 4 folds of paper and then close the rear metal cover.

Note 1

If required, the chart cassette can be cleaned with a damp cotton cloth.

Note 2

Note 3

: To maintain print quality, the print carriage guide rods should be cleaned at six-monthly

intervals with a dry cotton cloth. Lubricant should NOT be used.

: On completion, close the front scale(s) before reinserting the chart cassette in the printing

position.

: After a change of paper it is recommended to check the chart with calibration and to adjust it

if necessary (Refer to section 2.7 CARRIAGE CALIBRATION).

2.6 CLEANING THE PANE

It is recommended to clean the recorder pane with a soft cloth and the following products:

• Light soapy water

• Methylated spirit

2-13

Page 26

2.7 CARRIAGE CALIBRATION

2.7.1 Chart certification

ON PEN RECORDER

2. INSTALLATION

Figure 2-1

If the trace of one or several pens are not correctly on 0 % or 100 % (see ref. A, fig. 2-1) of the chart,

make a carriage calibration.

ON MULTIPOINT RECORDER

Figure 2-2

If the trace is not correctly on 0 % or 100 % (see ref. B, fig. 2-2) of the chart, make a carriage

calibration.

2-14

Page 27

2. INSTALLATION

2.7.2 Carriage calibration (or chart calibration)

This operation allows the 0 % and 100 % calibration of the traces on the paper.

• The CALIBRATION mode is "hidden" and can only be accessed by a special combination of

Function Keys when in the RUN mode.

• To enter the CALIBRATION mode, press both

print the channel numbers.

For a one-pen recorder: available channel number is 1 only.

For a two-pen recorder: available channel numbers are 1 and 2.

For a three-pen recorder: available channel numbers are 1, 2 and 3.

For a multipoint recorder: available channel numbers are 1, 2, 3, 4, 5 and 6.

When printing completed, the pointer will be positioned on channel 1.

On a multipoint recorder, the chart calibration is made once for all channels, whatever the channel you

choose.

ENTER

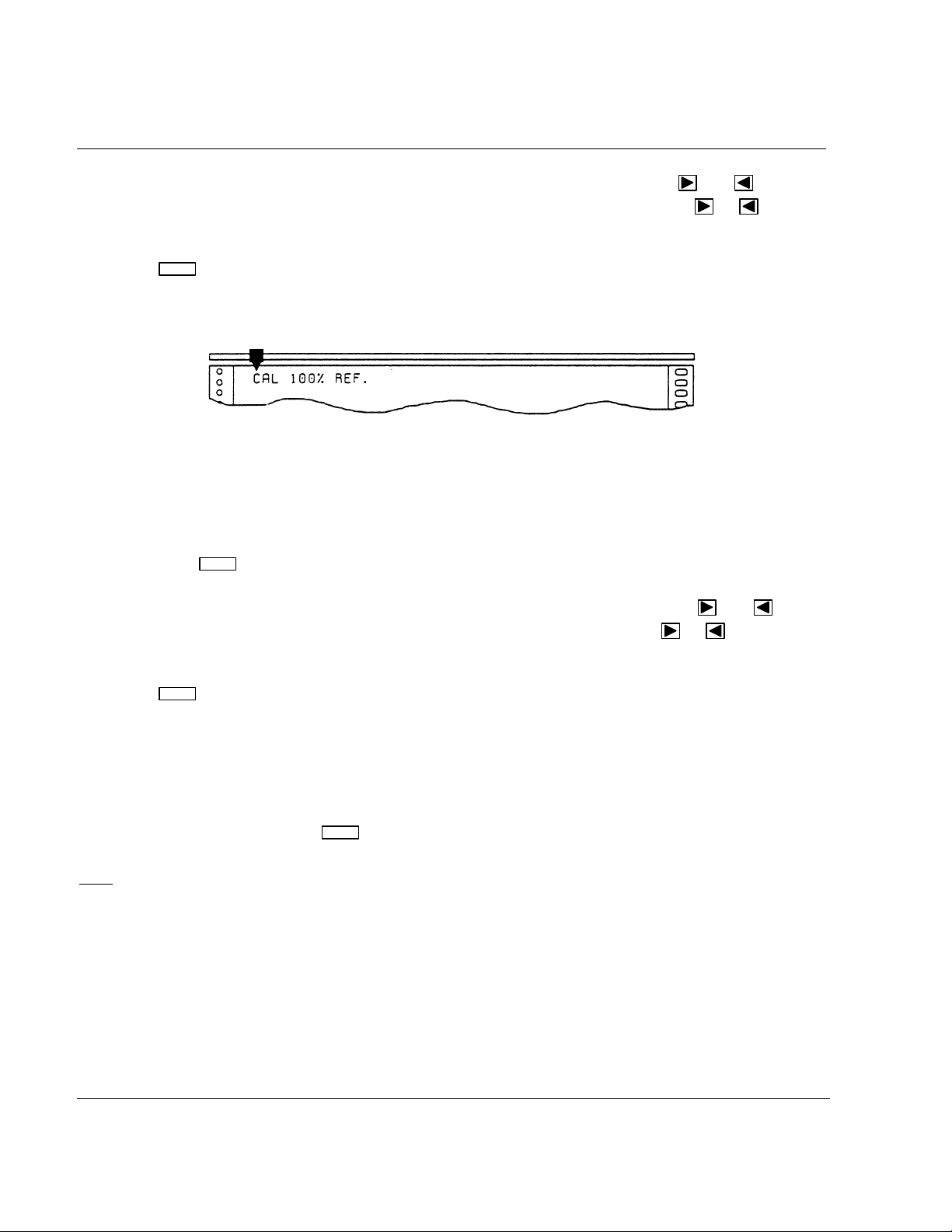

• Press

Now the recorder prints a message indicating that it will calibrate the 0 % of the chart on the chosen

channel.

to confirm your choice (your choice will be highlighted).

and FOR 10 SECONDS and the recorder will

NOTICE

The sensor MUST either be disconnected, or the input voltage shall not change of more than

25 % of the span during the whole operation.

Then press

ENTER

to start the 0 % calibration.

2-15

Page 28

2. INSTALLATION

Now the pointer will take up the current 0 % calibration position. If necessary, the

be used to position the pen to 0 %. The chart will advance by one line each time the

pressed and the recorder will reprint its mechanical references and be positioned on its new value.

ENTER

• Press

to confirm the new 0 % carriage calibration.

Now the recorder prints a message indicating that the 100 % of the span will be calibrated:

and keys can

or keys are

• To adjust the carriage calibration keep the input terminals open or keep the sensor connected, but

be sure that the voltage given by this sensor have not changed from more than 25 % of the span

since the 0 % calibration.

ENTER

• Then press

to start the 100 % calibration.

Now the pointer will take up the current 100 % calibration position. If necessary, the

can be used to position the pen to 100 %. The chart will advance each time the

and keys

or keys are

pressed.

ENTER

• Press

to confirm the new 100 % calibration.

Calibration is now complete and the recorder will reprint the calibration menu.

• At this point, if necessary, the recorder will print again the channel numbers to allow you to select

another channel to calibrate.

SETUP

• To return to RUN mode, the

key should be pressed for a few seconds.

: If the difference between the 100 % and 0 % reference signals is under 25 %, then only the

Note

carriage calibration is made; otherwise the operation will be considered as a full "field calibration".

In case of faulty operation, you would have to provide again a complete field calibration (note that, if

you have a PC LOADER, you can find back the factory calibration only by changing the configured

range and coming back to the previous one).

2-16

Page 29

2.8 CHECK LIST

1 Have you connected the ground terminal?

2 Have you connected the sensor(s) correctly? (Wire type, polarity, etc.)

3 Have you tightened all terminal screws?

4 Have you installed the ink cartridge(s) or wheel?

(See figures on pages 2-8 to 2-13.)

5 Have you installed the chart correctly?

(See figures on pages 2-14 and 2-15.)

2. INSTALLATION

6 Have you closed the front scale?

7 Have you fitted the chart cassette in the recorder?

8 Have you programmed the right scale with your PC Loader?

2.9 REPLACING THE INK CARTRIDGES

• Remove the chart cassette. The print carriage stops to allow you to replace the ink cartridges.

• Open the front scale.

• For the pen recorders:

- Pull the ink cartridge forward and remove from its housing.

- The new ink cartridge must be fully pushed home.

• For the multipoint recorder:

- Hold the print carriage with the left hand and pull the ink wheel to the right and remove from

its support.

- The new ink wheel should be inserted and rotated counter-clockwise until ratchet engages.

• Close the front scale.

• Reinsert the chart cassette in printing position.

: When pen recorders are not used for long periods of time, it is recommended that the ink

Note

cartridges be removed and capped.

2-17

Page 30

2. INSTALLATION

2-18

Page 31

3.1 FUNCTION KEYS

3. CONFIGURATION

3.1.1 SETUP

SETUP

The key has three functions.

• Entering CONFIGUR ATI ON main menu from the RUN mode.

• Exiting CONFIGU R AT I ON main menu to normal RUN mode.

• Exiting CONFIGURATION sub-menus (ALARMS, SPEED, ID, TIME, DATE) to return to the main

menu.

3.1.2 ENTER

ENTER

The key allows confirmation of your choice of a sub-menu or a parameter.

3.1.3 INCREMENT

The

• Advancing chart in run mode. The chart advances unt i l the key is released.

key has 2 functions:

• Moving the pointer in confi guration mode.

The

Note

key has no effect. If you w ant to move the pointer to t he l eft, use the

key moves the pointer to the right and pl aces i t at the sub-menu or parameter to be changed.

: When the pointer is placed eit her on t he l ast sub-menu or on the last parameter t o t he ri ght, this

key.

3-1

Page 32

3. CONFIGURATION

3.1.4 DECREMENT

The

Note: When the pointer is pl aced ei t her on the first sub-menu or on the first parameter to the left, this

key has no effect. If you w ant to move the pointer to t he ri ght , use the

3.2 MAIN MENU

The recorder automatically prints any m odi fication to the configurat i on.

• To access the main menu, press

The recorder will print the main menu:

key moves the pointer to the lef t and places it at the sub-menu or param et er to be changed.

key.

SETUP

for a few seconds.

When printing completed, the pointer will be positioned at the ALARMS sub-menu. If there is no

action, the recorder returns to the RU N mode after a few minutes.

• Press

wish to modify.

• Note 1

• Note 2

return to RUN mode.

to move the pointer to the right and place on the desired sub-menu or parameter you

: To return to the normal RUN m ode, press the

: When existing configuration mode, the recorder will reprint its mechanical references and

SETUP

key for a few seconds.

3.3 ALARMS

• When the pointer is positioned at ALARMS:

3-2

Page 33

• Press

3. CONFIGURATION

ENTER

to confirm your choice and the recorder prints the ALARMS sub-menu:

The printed numbers refer to ALARMS numbers. F or ex am pl e, the digit 1 represents alarm number 1.

• Press

• Press

or to point to the desired al arm num ber.

ENTER

to confirm your choice. (Your choice will be highlighted)

The pen carriage moves to indicate the posit i on of the alarm setpoint on the scale.

• Pressing

• Press

or modifies the pen position from initial position to the new required position.

ENTER

to confirm the new value. The content of ALARMS sub-menu will be reprinted.

IMPORTANT

: Unless modified by PC and configuration software, t he standard alarm configuration is

shown below.

• For a One-pen recorder: Alarm numbers are 1 and 2.

• For a Two-pen recorder: Alarm numbers are 1, 2, 3 and 4.

• For a Three-pen recorder: Alarm numbers are 1 to 6.

• For a Multipoint recorder: Alarm numbers are 1 to 6.

:

Note

• The alarm type (High or Low) is pre-configured but may be m odi f ied via PC and configuration

software.

PEN RECORDER MULTIPOINT RECORDER

ALARM

NUMBER

TYPE PEN ALARM

TYPE CHANNEL

NUMBER

1 Low Pen 1 1 High Channel 1

2 High Pen 1 2 High Channel 2

3 Low Pen 2 3 High Channel 3

4 High Pen 2 4 High Channel 4

5 Low Pen 3 5 High Channel 5

6 High Pen 3 6 High Channel 6

3-3

Page 34

Alarm type and set point are printed each t i m e the recorder is powered.

3. CONFIGURATION

High Alarm ON

High Alarm OFF

Low Alarm ON

Low Alarm OFF

• The operation can be repeated for other ALARMS or the ALARMS sub-menu can be left by pressing

SETUP

the

key for a few seconds, so that you will return to the main menu.

3.4 SPEED

This menu permits configuration of chart speed #1. Selection of units (mm/ or inches per hour) and

chart speed #2 are pre-configured as defined in your order.

3.4.1 SPEED (mm/hour)

• When the pointer is positi oned at SPEED 1:

• Press

ENTER

and the recorder prints current speed #1:

When printing completed, the pointer will be positioned at the leading digit, in this case 0.

• Press

or to select the position of digit to be changed.

For example, position the poi nt er on the digit 3. The minim um speed i s 10 m m /h and maximum speeds

are 6000 mm/h for pen recorders and 1500 mm/h for the multipoint.

ENTER

• Press

to confirm your choice of position and the recorder will print the choice of values

which can be selected. (Your choice will be highlighted).

3-4

Page 35

3. CONFIGURATION

In this example, the pointer will be positioned at the current value, in this case 3.

• Press

• Press

• At this point, if necessary, the position of t he nex t digit to be changed can be made and follow ed

by selection of value.

• To return to the main menu, the

3.4.2 SPEED (inches/hour)

• When the pointer is positi oned at SPEED 1:

or to move the pointer t o t he desi red v al ue, for example 1.

ENTER

to confirm the change and the new speed of 160 mm/h will be printed.

SETUP

key should be pressed for a few seconds.

• Press

ENTER

and the recorder prints current speed #1:

When printing completed, the pointer will be positioned at the leading digit, in this case 0.

• Press

or to select the posit i on of digit to be changed, for exam pl e 0 . T he m i nimum speed is

0.5 inch/h and the maximum speeds are 240 inch/h for the pen recorders and 60 inch/h for the

multipoint.

ENTER

• Press

to confirm your choice and the recorder print s choi ce of value which can be selected.

(Your choice will be highlighted)

• Press

• Press

or to move the pointer t o t he desi red v al ue, for example 2.

ENTER

to confirm your choice and the new speed of 20.75 inch/h will be printed.

• At this point, if necessary, the position of t he nex t digit to be changed can be made and follow ed

by selection of value.

• To return to the main menu, the

SETUP

key should be pressed for a few seconds.

: Choices available for least signi f i cant digit are 0 or 5 only.

Note

3-5

Page 36

3. CONFIGURATION

3.5 IDENTIFICATION

This menu permits configuration of a speci fic ID (1 to 99) for t he recorder.

• When the pointer is positioned at ID (IDENTIF I CAT I O N OR ADDRESS NUMBER):

ENTER

• Press

and the recorder prints the current identifi cation number:

When printing completed, the pointer will be positioned at the leading digit, in this case 1.

• Select the digit t o be changed by pressing

ENTER

• Press

to confirm your selection (Your choice will be highlighted) and the recorder prints

or , for example 7.

choice of values which may be select ed.

When printing completed, the pointer will be positioned to the current value, in this case 7.

• Press

• Press

or to position the pointer to the desired value, for exampl e 4 .

ENTER

to confirm your choice and the new identification 14 will be printed.

• At this point, the sel ection of the next digit requi ri ng m odi fication can be made.

• To return to the main menu, the

SETUP

key should be pressed for a few seconds.

3-6

Page 37

3.6 TIME

• When the pointer is positi oned at T I M E:

3. CONFIGURATION

ENTER

Press

to confirm your choice and the recorder prints t he current time:

When printing completed, the pointer will be positioned at the leading digit, in this case 2.

• Press

or to choose the position you w i sh to modify, for example 1.

: It is recommended that t he l east significant position i n m inute units be set last to ensure a

Note

precise time configuration.

ENTER

• Press

to confirm your choice (Your choice will be highlighted) and the recorder prints choice

of values which may be selected.

When printing completed, the pointer will be positioned at the current value, in this case 1.

• Press

• Press

or to choose another value, for ex am pl e 2 .

ENTER

to confirm your choice and the new time of 22:47 will be printed.

Note

: The internal recorder clock is corrected/modi f i ed w hen

ENTER

is pressed.

• A this point, if necessary , the position of the next di git to be changed can be made, followed by

selection of value.

SETUP

• To return to the main menu, the

key should be pressed for a few seconds.

3-7

Page 38

3.7 DATE

• When the pointer is positi oned at DATE:

3. CONFIGURATION

ENTER

• Press

to confirm your choice and the recorder prints the current date:

When printing completed, the pointer will be positioned at the leading position, in this case 1.

• Press

• Press

or to choose the position you w i sh to modify, in this ex am pl e 8.

ENTER

to confirm your choice. (Your choice will be highlighted)

The recorder prints the range of values which may be select ed.

When printing completed, the pointer will be positioned at the current value, in this case 8.

• Press

• Press

or to choose another value, for ex am pl e 9 .

ENTER

to confirm your choice and the new date will be printed: 19 FEB 93.

• At this point, if necessary, the position of t he nex t digit to be changed can be made and follow ed

by selection of value.

• To return to the main menu, the

SETUP

key should be pressed for a few seconds.

3-8

Page 39

4. MODEL SELECTION GUIDE

g

p

_ _ _ _ _

-

_ _ _ _ _ _

-

_

-_-

-_-_-

_ _ _ _ _

-

V

_ _ _

_ _

g

g

p

3

g

g

g

4.1 PRODUCT IDENTIFICATION

Instructions

Select the desired Key Number. The arrow to the right marks the selections available.

Make one selection each from Tables I throu

A com

lete Model Number must have the designated number of digits in each table.

h IX.

Key Numbers

I II III IV V VI VII

_ _

_

III IX

KEY NUMBER Selection Availability

Description

1 Pen

Recor der De

Deg. C 1 Scale to Input 1 DA101

. F DA111

2 Pen Deg. C 2 Scales to Inputs 1 and 2 DA102

Recor der De

3 Pen Deg. C 3 Scales to In

Recor der De

. F DA112

uts 1, 2, and

DA103

. F DA113

3 Channel Deg. C 1 Scale 0 to 100 Linear DB103

Recor der De

. F DB113

6 Channel Deg. C 1 Scale 0 to 100 Linear DB106

Recor der De

. F DB116

4-1

Page 40

4. MODEL SELECTION GUIDE

g

0

0

0

0

0

0

0

p

0

0

0

0

p

5

5

5

5

3

t

0

0

0

0

(

)

0

0

6

Availability

DB1 _ _

DA1 _ _

0101010101

1122333366

TABLE I RANGE/SCALE

Table 1 Specify 6 digits

Format 1 per Input

None 0

T/C Deg. C De

J -50 to 150 -100 to 300 A

J 0 to 400 0 to 800 B

J 0 to 800 0 to 1500 C

K 0 to 400 0 to 800 D

K 0 to 800 0 to 1500 E

K 0 to 1200 0 to 2400 F

Upscale K 0 to 1400 0 to 2500 X

Burnout N 0 to 400 0 to 800 G

N 0 to 800 0 to 1500 H

N 0 to 1200 0 to 2400 I

N 0 to 1400 0 to 2500 Y

S 0 to 1600 0 to 3000 J

R 0 to 1600 0 to 3000 Q

T -100 to 200 -150 to 400 K

0 to 150 0 to 300 L

T

T 50 to 150 100 to 300 M

-50 to 50 -60 to 140 7

RTD Pt -50 to 150 -100 to 300 N

Burnout 100 0 to 100 0 to 200 P

Fixed -200 to 200 -300 to 400 R

Upscale 0 to 400 0 to 800 S

. F

TABLE I RANGE/SCALE, continued

Linear

mV 0 to 1

0 to 2

0 to 10

Linear U

scale 10 to 5

0 to 5

Scale Burnout 0 to 10

0 to 1

0 to 2

0 to 5

10 to 5

0 to 10

T

U

V

W

Z

Only V 0 to 1 0 to 1 1

scale 0 to

U

Burnout 1 to

V Burnou

0 to 1

0 to

1 to

0 to 1

2

4

Fixed Down

Note 4, 6

mA Burnout 0 to 2

Fixed 4 to 2

0 to 2

4 to 2

5

Downscale 4 to 20 SQRT 4 to 20 SQRT 8

Special Range 9

4-2

Page 41

4. MODEL SELECTION GUIDE

)

r

A _ _

)

rB _ _

)

rC _ _

)

rD _ _

rE _ _

rF _ _

rG _ _

rH _ _

_

_

_

_

_

_

_

_

_

_

_

_

_

_

p

_

_

(

)

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_ _ A

_ _

_ _

_ _

_ _

p

_ _

_ _

_ _

_ _

_ _

_ _

Availability

DB1 _ _

DA1 _ _

0101010101

1122333366

TABLE II CHART SPEED Selection

Multivoltage 50 Hz (85 to 264 V

Multivoltage 50 Hz (85 to 264 V

Units Multivoltage 60 Hz (85 to 250 V

FrequencyMultivoltage 60 Hz (85 to 250 V

24 Vac/dc 50 Hz mm/h

24 Vac/dc 60 Hz inch/h

48 Vac/dc 50 Hz mm/h

48 Vac/dc 60 Hz inch/h

mm/hr Inch/hr

10 0.5 _ A _

20 0.75

30 1

50 2

60 3

100 4

120 5

150 6

Preset 180 7 _ I _

S

eed 1 200 8

Note 5

Preset 60 3

S

eed 2 100 4

240 10

300 15

360 20

600 25

720 30

1200 40

1500 60

1800 90

3600 120

4800 180

6000 240

5 0.2 _ _ 0

10 0.5

20 0.75

30 1

50 2

120 5

150 6

180 7

200 8

240 10

Chart

Speed

mm/h

inch/h

mm/h

inch/h

B

C

D

E

F

G

H

J

K

L

M

N

P

Q

R

S

T

U

V

B

C

D

E

F

G

H

I

J

K

4-3

Page 42

4. MODEL SELECTION GUIDE

_ _ M

5

_ _

p

2

_ _ P

_ _ Q

T

2

(

)

5

ccccccccc

c

DB1 _ _ Availability

DA1 _ _

TABLE II CHART SPEED, continued Selection

mm/hr Inch/hr

300 15 _ _ L

360 20

Preset 600 2

eed

S

TABLE III ALARMS (Note 1)

None 0

6 Relays - 2 Configured (Channel #1) 1

2 Relays - 2 Configured (Channel #1) 2

6 Relays - 4 Configured (Channels #1 and #2) 4

6 Relays - 6 Configured (2 on Each Channel) 5

6 Relays - (One High Alarm SP on Each Channel) 6

720 30

1200 40

1500 60

0101010101

1122333366

N

_ _ R

TABLE I V LOGIC INPU

None 0

2 Remote L1: Print Inhibit Switch A

Contacts L2: Change Speed 1 to Speed 2

2 Remote L1: Print Inhibit Switch B

Contacts L2: Event Marks

2 Remote L1: Print Inhibit Switch C

Contacts L2: Event Trace

2 Remote L1: Event Trace 1

Contacts L2: Event Trace

TABLE V CHART CASSETTE

Standard Chart: 0-100 Linear Roll R

(50 divisions) Fan Fold Z

TABLE VI DOOR AND CASE

Dark Gray Door with Latch, Plastic Window 1

Dark Gray Door Key Lock, Plastic Window 2

Portable Case

Note 2

D

dddddddddd

4-4

Page 43

4. MODEL SELECTION GUIDE

r

r

(

)

_ _ _

(

)

(

)

DB1 _ _ Availability

DA1 _ _

TABLE VII OPTIONS

None 0 _ _ _ _

Pen Offset A _ _ _ _

Rear Cove

Pen Offset and Rear Cover P _ _ _ _

UL/CSA Approval R _ _ _ _

UL/CSA Approval and Rear Cove

UL/CSA Approval and Pen Offset T _ _ _ _

UL/CSA Approval, Pen Offset and Rear Cover

None _ 0 _ _ _

Power Supply for Transmitter 24 Vdc (50 mA max)

None _ _ 0_ _

Chart Illumination _ _ C _ _

Certificate of Conformance (F2474) _ _ D _ _

Certificate of Calibration _ _ E _ _

Certificate of Conformance & Chart Illumination _ _ F _ _

Certificate of Calibration & Chart Illumination

TABLE VII OPTIONS (Continued) Selection

None _ _ _ 0 0

Remote Compensation Box Input (60 deg C All Inputs) _ _ _ 0 E

Mounting of Scale Ordered Separately

Mounting of Scale Ordered Separately

Remote Compensation Box Input (60 deg C All Inputs) _ _ _ H E

Mounting of Scale Ordered Separately

Note 4

Note 4

Note 4

Plus

Plus

Selection

G _ _ _ _

S _ _ _ _

U _ _ _ _

_ B _ _ _

_ _ G _ _

H 0

0101010101

1122333366

1122333366

TABLE VIII Specials

None 0 0 0

ST Number (Consult Honeywell IM&C Representative) X X X

TABLE IX Manuals

English EN

French FR

German GE

Italian IT

Spanish SP

Swedish SW

Dutch DU

English: U.S. Format

US

4-5

Page 44

4. MODEL SELECTION GUIDE

d

Note 1: Alarm output: "N.C." contact. Can be changed to "N.O." Alarms are configured 1 High and 1 Low on each

channel except for Selection 6 which is configured as High Alarm on each channel. The Alarm Setpoint

Value can be changed from the front key panel.

Note 2: Portable case with dark gray door, plastic window, latch, rear main switch. IEC main plug connector

and rear cover. (Not available with UL/CSA Approval.)

Note 3: Consult Factory.

Note 4: For chart range and scale configuration different than what is specified in Table I, specify Table VII

option _ _ _ H0 and complete the following table. For mV, V, and mA the input signal can be selected

within the range actuation limits (minimum range is 20%). For T/C and RTD ranges the chart range

and scale can be selected within the range actuation limits (minimum chart range is 20%). Refer to

the DPR 100 A/B scales list for available scales. The information in the table is to be entered in the

free form section of the order. Multipoint units come with a single scale.

Note 5: Speed 1 can be changed from the front key panel.

Note 6: The units are built with Universal input and are delivered with 250 ohm resistors to convert input

current signal 4-20 mA into 1-5 volts dc.***

Table for Table VII Option _ _ _ H0

Pen # Multipoint Input* Burnout** Chart Scale

(DA1XX) Channel # Signal Range Eng. Unit** Range Item #

(DB1XX)

11

22

33

4

5

6

* For mV, V, and mA, the input signal can be scaled within the actuation limits (minimum input scaling is 20%).

** Burnout is factory set as indicated in Table I. Burnout on 4-20 mA and the 0-10 volt range is fixed at downscale

burnout. All other ranges burnout can be set per customer request except RTD's which is fixed at upscale

burnout.

*** Engineering Units is 5 characters maximum.

RESTRICTIONS

Restriction Letter Available Only With Not Available With

Table Selection Table Selection

R _ _ _ _ , S _ _ _ _

c VII T _ _ _ _ , U _ _ _ _

G _ _ _ _ , P _ _ _ _

50 deg C maximun temperature limit

4-6

Page 45

5.1 TECHNICAL DATA

Technical data

Analog inputs

Pen recorder 1, 2 or 3 continuous traces. Pen 1 also prints all chart documentation.

Multipoint recorder 1 up 6 channels. Inputs are scanned by relays, galvanically isolated and

Signal source Thermocouple with individual cold junction compensation.

Field calibration A channel field calibration - 0% and 100% span - may be made to certify

Burnout T/C, mV, Volt, factory set to upscale (configurable to downscale or none).

5. PRODUCT SPECIFICATION SHEET

individually configurable to any listed actuation.

Line resistance up to 1000 ohms T/C, mV, mA, Volt

RTD Pt 100 3-wire connections, lead resistance per wire 40 Ω balanced.

input sensor loop.

RTD: inherent upscale.

mA: inherent downscale

Scanning time

Input impedance 10 Mohm for T/C, mV inputs,

Stray rejection

Logic inputs (option)

Actions

Scales

Pen

Mpt

Recording span

Scaling Per input, an analog scale is printed on the chart with the engineering unit.

mV, V, mA : 330 ms

Pen:

2 seconds at 10-60 mm/h (T/C or RTD)

1 second at 60-300 mm/h (T/C or RTD)

0.33 second at > 330 mm/h or if one linear input is selected

Multipoint:

5 seconds for 6 channels

> 1 Mohm for volt inputs.

Series mode ≥ 60 dB.

Common mode at 250 Vac ≥ 130 db.

Up to 2-dry contact input s (1.5 mA – 12Vdc)

Change chart speed 1 to speed 2

Print inhibit

Event marking :

- Pen : pen 1 used as operation marker on the right side of the chart

– Mpt : 2 traces maximum on the right side of the chart. (L

= red)

1 = purple, L2

1 analog scale per pen in accordance with the input range

1 analog scale, 0 to 100 linear.

Each input can be configured differently.

Pen offset Distance between pens: 2 mm

Chart definition: 1 step = 0.2 mm

Pen carriage speed 1 second full scale

5-1

Page 46

5. PRODUCT SPECIFICATION SHEET

Technical data

Chart length

Pen trace

Pen

Multipoint

Chart speed 1 or 2 chart speeds, fully configurable, selected by a logic input.

Speed setting Pen: 10 to 6000 mm/h (.5 to 240"/h).

Stepping chart motor Resolution 0.12 mm

Alarms (Option)

Pen 1, 2, 3 or Mpt 3 CH

Mpt (6CH)

Hysteresis

Outputs

Rating contact

Power supply

To transmitters

Power consumption

Clock timer

Format

Power interruption

Accuracy

Packaging

Weight

Front face

Depth

Front window

Front protection

Lock

Cut out

Construction

Optional

Mounting Panel mounting ± 30° from horizontal.

Wiring Rear screw terminals. Terminal modules are plugged on the instrument.

Fanfold 18 m (as DIN 16230)

Roll 24 m

1400 m per pen

250 m per color

Speed 1: fully adjustable per step of 1 mm/h, within limit

Speed 2: choice as per the model selection guide

Mpt: 10 to 1500 mm/h (.5 to 60"/h)).

2 alarm setpoints per channel, (factory set* 1 low, 1 high)

1 alarm setpoint per channel, (factory set* high)

0.5 % to 99 % of scale (factory set at 0.5 %)

Up to 6 alarm relays output contacts

1 SPST normally closed contact (may be configured into normally open

contact)

2 A, 250 VAC on resistive loads

* Other selections configured by PC

85 to 264 Vac, 50/60 Hz or 24 or 48 Vac/dc (+10 –15 % nominal)

24 Vdc, 50 mA max. (optional) (75 mA available from 100V)

3 pens: 30 VA max.

Mpt: 30 VA max.

Year, month, hour, minute can be set

Battery back-up time of 10 years with 3 years off power

-5

± 10

Pen: 3.5 kg

Mpt: 3.5 kg

144 x 144 mm according to DIN 43718

245 mm/9.7" behind panel, including terminals and line protection cover.

Polycarbonate

IP54 (IEC 529) – optionally IP55

Latch or key (DIN 43832-N)

DIN 138 x 138 mm

Silicon - free

Chart illumination

Rear terminal cover

5-2

Page 47

5. PRODUCT SPECIFCATION SHEET

Technical data

Writing

Pen

Multipoint

Noise immunity This product is in conformity with the protection requirements of the

Safety protection

Electrical insulation

Input to input

Input to ground

Input to line voltage

Line voltage to ground

Alarm relay to ground

Logic input to ground

Temperature

Ambient 0 to 50° C (32 to 122°C) with fan fold paper.

1 cartridge per pen, fibre tip, 1400 m of trace per color (blue, red,

green).

1 print wheel, 6 colors, 250 m of trace per color (purple, red, black,

green, blue, brown).

following European council directives:

• 73/23/EEC – Low Voltage directive

• 89/336/EEC – EMC Directive

Conformity of this product with any other “CE Mark” Directive(s) shall

not be assumed.

EMC Classification:

• EN 50081-2-1993 Electromagnetic Compatibility – General

Emission Standard, Part 2: Industrial Environment.

EN 50082-2-1995 Electromagnetic Compatibility – General Immunity

Standard, Part 2: Industrial Environment

Complies with IEC 414, 348 and 1010-1 installation category 2 for

personal protection.

Designed to meet UL and CSA C22.2, N142 standard (CSA approved)

Test voltage 280 Vac for 1 min (except for RTD input).

Test voltage 2.1 kVdc for 1 min.

Test voltage 2.1 kVdc for 1 min.

Test voltage 2.1 kVdc for 1 min.

Test voltage 2.1 kVdc for 1 min.

Test voltage 500 Vdc for 1 min.

0 to 60° C (32 to 140°C) with roll paper.

Optionally 0 to 60° C (32 to 140° F)

Storage -40 to 70° C (32 to 158° F)

10 to 90 % RH non condensing

Humidity

Roll

Fan fold

Vibrations Frequency:

10 to 90 % RH non-condensing

15 to 80 % RH non condensing

10 to 60 Hz – amplitude 0.07 mm

60 to 150 Hz- acceleration 1g

5-3

Page 48

5. PRODUCT SPECIFICATION SHEET

5.2 ACCURACY

Accuracy

Reference conditions

Temperature

Humidity

Line voltage nominal

Source resistance

Series mode

Common mode

Frequency nominal

Accuracy A/D converter accuracy: 0.25 % of selected input range * (IEC873).

Rated limits and associated drifts

Parameter Rated limits Influence on accuracy

Temperature 0 to 50° C

Supply voltage 85 to 264 V No influence

Source resistance T/C, mV

RTD

Humidity 10 to 90 % RH at 25°

Long-term stability 0.1 % per year

Vibrations 1.25 mm at 0 t 14 Hz

Extreme conditions

Operating

Temperature 0 to 60° C (32 to 140° F)

Humidity 10 to 90 % RH non-condensing

Storage

Temperature -40 to 70° C (-40 to 158° F)

Humidity 5 to 95 % RH non-condensing

* Refer to "Available ranges" table for exceptions

23° C ±2° C (73° F ±3° F)

65 % ±5 % RH

±1 %

0 Ω

0 V

0 V

±1 %

For a 4/20 mA input, you must add the resistor accuracy.

Cold junction accuracy: 0.5° C

Chart resolution: 0.2 mm

0.1 % per 10° C of

(32 to 122° F)

Cold junction

0.3° C/10° C

6 µV per 100 Ω of line

resistance, 1000 Ω

0.1° C per Ω in each

wire balanced leads,

40 Ω max.

0.1 % max.

C

1 g at 14 to 250 Hz

change

max.

5-4

Page 49

5. PRODUCT SPECIFICATION SHEET

5.3 AVAILABLE RANGES

Available ranges

Thermocouples

° C ° F

J -50 to 150

0 to 400

0 to 800

K 0 to 400

0 to 800

0 to 1200

0 to 1400

N (Nicrosil Nisil) 0 to 400

0 to 800

0 to 1200

0 to 1400

R 0 to 1600 0 to 3000

S 0 to 1600 0 to 3000

T -100 to 200

0 to 150

50 to 150

Note: Provision to accept T/C input for remote compensation box at

fixed temperature of 50° C or 60° C.

RTD's Pt100

(Alpha = 0.00385)

MV and Volt 0 to 10 mV

0 to 20 mV

0 to 50 mV

10 to 50 mV

0 to 100 mV

mA

* Accuracy = 1° C or 1.8° F

0 to 20 mA or 4 to 20 mA linear

4 to 20 mA SQRT

Input resistor 250 ohms required

-50 to 50*

-50 to 150*

0 to 100*

-200 to 200

0 to 400

-100 to 300

0 to 800

0 to 1500

0 to 800

0 to 1500

0 to 2400

0 to 2500

0 to 800

0 to 1500

0 to 2400

0 to 2500

-150 to 400

0 to 300

100 to 300

-60 to 140*

-100 to 300*

0 to 200*

-300 to 400

0 to 800

0 to 1 V

0 to 5 V

1 to 5 V

0 to 10 V

5-5

Page 50

5.4 DIMENSIONS

DIMENSIONS

5. PRODUCT SPECIFICATION SHEET

5-6

Page 51

5.5 TERMINAL CONNECTIONS

5. PRODUCT SPECIFICATION SHEET

5-7

Page 52

5. PRODUCT SPECIFCATION SHEET

5-8

Page 53

6. CONFIGURATION

6.1 ANALOG INPUTS CONFIGURATION

The analog input boards are hardware configured at the factory to match the specifi ed actuation type.

This hardware configuration only requires change i f a m aj or change i n actuation type is required via the

configuration jack connector.

• Configure the range(s) via t he j ack connector

(See section 9 : PC Confi guration, paragraph 9.5 "Read and modif y parameters")

• Check if the new range(s) need a hardware change on t he anal og i nput board (See figure

below)

• If so, remove power from the recorder.

• Remove the analog input term i nal bl ock.

• Change the switch position(s) with a small screw driver. (See figure below)

Push the switch completely on the high or low position.

• During the initialisation of the recorder, the relays will be in the de-energized state. (Alarm

state)

Analog input hardware configuration

6-1

Page 54

6. CONFGURATION

6.2 Analog input hardware configuration RELAY OUTPUT CONFIGURATION

All the relays are factory confi gured to be de-energized under alarm conditions.

Each relay is factory set for NC ( norm al l y cl osed) operation by a jumper on the alarm board.

If you need to reverse this operation. (See figure below)

• 5 Remove the alarm relay board. (See CK 110)

• 5 Move the jumper from the NC location (normally cl osed) to the NO location ( norm al l y open).

Jumpers configuration

6-2

Page 55

7. CALIBRATION

7.1 FIELD CALIBRATION

This menu allows the 0% and 100% calibration of each input.

!

CAUTION

The recorder should have been powered for at least 15 minutes and requires provision of

accurate signal source to match actuation/range.

Failure to comply with these instructions may result in product damage

• Verify the alignment of the 0% actuation range limit with the 0% on the chart. If wrong

alignment, undo the securing screws of the scale, reposition the scale and tighten the screws.

• The CALIBRATION menu is "hidden" and can only be accessed by a special combination of

Function Keys while in the RUN mode.

To enter the CALIBRATION mode, press both

• recorder will print the channel numbers :

! and " FOR 10 SECONDS and the

For a one-pen recorder : available channel number is 1 only.

For a two-pen recorder : available channel numbers are 1 and 2.

For a three-pen recorder : available channel numbers are 1, 2 and 3.

For a multipoint recorder : available channel numbers are 1, 2, 3, 4, 5 and 6.

When printing completed, the pointer will be positioned on channel 1.

• Press

• Press ENTER to confirm your choice. (Your choice will be highlighted)

Now the recorder prints a message indicating that a reference source corresponding to the 0 % of the

range on the chosen channel should be connected :

! or " to select the channel number you wish to calibrate.

7-1

Page 56

7. CALIBRATION

NOTICE

The source MUST correspond to the 0 and 100 % actuation input limits (total input

range) for the channel and take into account the effect of cold junction temperature and

thermocouple actuations.

• If you need to adjust the carriage calibration and analog calibration, connect your 0 % reference

signal.

Then press ENTER to start the 0 % calibration.

Now the pointer will take up the current 0 % calibration position. If necessary, the

keys can be used to position the pen to 0 %. Chart will advance by one line each time the

! or " keys are pressed. Each time the ! or " keys are pressed, the recorder will

reprint its mechanical references and be positioned on its new value.

• Press ENTER to confirm the new 0 % calibration.

It can take some seconds for the A/D converter to be calibrated.

Now the recorder prints a message indicating that a reference source corresponding to 100 %

of the range on the chosen channel should be connected :

• If you need to adjust the carriage calibration and analog calibration, connect your 100 %

reference signal.

Then press ENTER to start the 100 % calibration.

Now the pointer will take up the current 100 % calibration position. If necessary, the

" keys can be used to position the pen to 100 %. Chart will advance by one line each time

the

! or " keys are pressed.

• Press ENTER to confirm the new 100 % calibration.

Calibration is now complete and the recorder will reprint the calibration menu.

• At this point, if necessary, the position of the next channel to be changed can be made and

followed by selection of value.

• To return to RUN mode, the SETUP key should be pressed for a few seconds.

Note: If the difference between the 100 % and 0 % reference signals is under 25 % of the full

span, then the analog calibration is canceled, only a carriage calibration has been made

during this operation.

Extended values for thermocouple K and N are :

K 1400 oC = 55.824 mV

N 1400 oC = 51.067 mV

N 2500 oF = 50.026 mV

! and "

! and

7-2

Page 57

8. PC CONFIGURATION

8.1 OVERVIEW

You have just received your application software package. This tool has been designed to modify,

upload/download and store the recorder configuration.

8.2 PRODUCT FEATURES

The main functions of this software are :

• Reading the configuration of your recorder.

• Preparing or modifying the configuration from your PC.

• Downloading configuration from your PC to the recorder.

• Retrieving configuration stored on hard disk.

• Saving configuration on hard disk.

• Diagnostics.

8.3 INSTALLATION

8.3.1 System Requirements

A PC AT Compatible personal computer with

• A Serial Communication card: RS232 as serial port 1

• A hard disk

• A color or B/W monitor

• A mouse optional

• Upto 625 KB RAM Free

8-1

Page 58

8. PC CONFIGURATION

8.3.2 New Installation

Insert the PC Loader CD into the CD drive. The setup is launched automatically. Run Setup.exe in case

the setup does not launch automatically. If you don’t have Administrator privilege, the setup will

prompt to select Administrator user or enter the Administrator Password. Otherwise it will give

“Kernel.error”.(This is necessary to update the Registry Settings properly).

8-2

Page 59

8. PC CONFIGURATION

Please ensure you have adequate disk space on C:\ and click Next> to proceed with the installation.

Please note that PCLoader can only be installed in C:\ .

The progress of the installation is displayed.

8-3

Page 60

Click Finish to complete the installation

8. PC CONFIGURATION

8-4

Page 61

8. PC CONFIGURATION

8.3.3 Upgrade old installation

Insert the PC Loader CD into the CD drive. The setup is launched automatically. Run Setup.exe in case

the setup does not launch automatically. If you don’t have Administrator privilege, the setup will

prompt to select Administrator user or enter the Administrator Password. Otherwise it will give

“Kernel.error”.(This is necessary to update the Registry Settings properly).

If an older/similar version of PCLoader is already installed, the installation wizard will prompt you with

the following options.

Select Overwrite to directly overwrite the older version and upgrade to the new version without

running the set up twice.

Note: If any recorder configuration files are saved in the older PCLoader version you will be prompted

“Setup has found .cnf file. Do you want to retain them?”

Select “Yes” to retain the configuration files in their respective directories inside C:\PCLoader directory

and to continue installation.

Select “No” to delete the configuration files along with the other files and to continue installation.

8-5

Page 62

8. PC CONFIGURATION

8.3.4 Uninstall

Select Start>Settings>ControlParel\Add & Remove Programs, then select PCLoader

or

Insert the PC Loader CD into the CD drive. The setup is launched automatically. Run Setup.exe in case

the setup does not launch automatically.

Select Remove to uninstall the older version of PCLoader. You will be asked to confirm you want to

delete the old files.

Note: If any recorder configuration files are saved in the older PCLoader version you will be prompted

“Setup has found .cnf file. Do you want to retain them?”

Select “Yes” to retain the configuration files in their respective directories inside C:\PCLoader directory

and to delete non-configuration files.

Select “No” to delete the configuration files along with the other files.

To install the new version see New Installation.

If you don’t have Administrator privilege, the setup will prompt to select Administrator user or enter

the Administrator Password. Otherwise it will give “Kernel.error”.(This is necessary to update the

Registry Settings properly).

8-6

Page 63

8.4 USE

8.4.1 Startup

8. PC CONFIGURATION

To launch PCLoader, double-click the PCLoader icon

Start>Programs>PCLoader>DPR100.

8.4.2 Menus

The software is based on the use of menu bars. To confirm a menu, you have three methods :

• Placing the cursor on the chosen menu, then press ENTER

• Pressing the highlighted key letter of the menu's name.

• Using the mouse.

8.4.3 Modifying fields of parameters

Some menus may allow the modification of parameter's values. There are two kinds of

modifications

according to the type of parameters.

• Selective modification : When placing the index on the chosen parameter, you can modify it by

pressing the

type.

• Modifying with the alphanumeric keyboard : in this case, position the cursor on the chosen

parameter and type the required value.

! or " keys to scroll through allowed values. Most modifications are of this

on your Desktop or alternately, select

8.4.4 Going from a parameter field to another one

• Press

• Press

Each time the cursor points to a field, a "help" message is displayed on the bottom line of the

screen.

$ or ENTER to access to the next field.

% to access to the previous field.

8-7

Page 64

8. PC CONFIGURATION

8.4.5 Leaving a menu

To leave a menu, you have two options :

• To leave the present menu and validate your screen modifications in the PC memory

(RAM), press F10 key.

• To leave the present menu without saving modifications, press ESC key.

8.4.6 Saving modifications on a file

Use the corresponding menu to save your modification on a file

NOTICE

After powering up or if the set-up key has been pressed, the recorder cannot communicate

during the initialization.

8-8

Page 65

8.5 "READ AND MODIFY" PARAMETERS

ANALOG INPUTS

SENSOR

ACTUATION

BURN OUT

ENG. LIST

RANGE MIN*

RANGE MAX*

SCALE MIN*

Defines the sensor type for the

selected channel.

Defines the actuation (and range)

for the selected channel. Provides

selection of actuation, range and

engineering units for all directly

connected temperature sensors

and non-linear temperature

transmitters. The actuations

offered will depend on the sensor

selected. Provides selection of

input range for linear transmitters.

Defines the type of burnout per

channel.

Represents the engineering units

of the input channel. Modification

is possible for linear and special

inputs.

Establishes in absolute units the

value corresponding to 0 % of the

selected linear input.

Establishes in absolute units the

value corresponding to 100 % of

the selected linear input.

Defines the 0 % of the paper

scale. Defines in engineering

units the value corresponding to

the range min for linear inputs.

DESCRIPTION HOW TO MODIFY THE

8. PC CONFIGURATION

CURRENT VALUE

Select the desired type by

the

! or " keys.

The transition of RTD or NO Input

in another sensor type requires a

new calibration of cold junction,

and is only possible for the users

who have the access code which

authorize it. The cold junction

calibration will be made in the

diagnostic mode.

Select the desired actuation by

! or " keys.

the

For SQUARE ROOT extraction,

the formula is :

PV=[(S-Smin)(HV2 -LV2)/(SmaxSmin) +LV2]1/2

HV = range max

LV = range min

Smin =min sensor input value

Smax = max sensor input value

S = current sensor input value

Select the desired type by

the [ or ] keys. For RTD, the type

is fixed at UPSCALE.

For 0-20 mA and 4-20 mA

ranges, the type is fixed at

DOWNSCALE.

Type the desired units and then

press ENTER

Type the desired value and then

press ENTER

Type the desired value and then

press ENTER

Type the desired value and then

press ENTER

8-9

Page 66

8. PC CONFIGURATION

ANALOG INPUTS

SCALE MAX*

FILTER

Defines the 100 % of the paper

scale. Defines in engineering

units the value corresponding to

the range max for linear inputs.

Defines the filter (in seconds) to

be applied on the inputs.

* NOTE : (Range max - range min) must correspond at least to 20 % of (actuation max-

actuation min) for linear inputs.

(Scale max - scale min) must correspond at least to 20 % of (range max-range

min) for other inputs.

ANALOG ALARMS

CHANNEL

SETPOINT

TYPE

HYSTERESIS

Identifies the input channel to be

assigned to each alarm.

Identifies the setpoint value for each

alarm.

Identifies the alarm type, ie NONE,

HIGH or LOW.

The value chosen will estqblish the

switching hysteresis of the alarm and

output relay.

Alarms switch "on" at the configured

setpoint vqlue. The value at which an

alarm will switch "off" depends upon

the hysteresis.

The hysteresis value will be added to

low alarm setpoints, or subtracted

from high alarm setoints.

Alarm hysteresis is expressed in

percent of the total input range.

DESCRIPTION HOW TO MODIFY THE

LOGIC INPUTS

LOGIC INPUTS 1

LOGIC INPUTS 2

Specifies the action of logic

input #1.

Specifies the action of logic

input #2.

DESCRIPTION HOW TO MODIFY THE

Type the desired value and then

press ENTER

Type the desired value (from 0

to 99) and then press ENTER

CURRENT VALUE

Select the desired channel by

the

! or " keys.

Type the desired value and

then press enter

Select the desired type by the

! or " keys.

Type the desired value and

then

press ENTER

CURRENT VALUE

Select the desired action by

the

! or " keys.

Select the desired action by

the

! or " keys.

8-10

Page 67

UNIT

SPEED 1

SPEED 2

DISTANCE BETWEEN

TWO PRINTINGS

PEN OFFSET (One, two

ot three pen recorder)

ADDRESS NUMBER

POWER LINE

FREQUENCY

8. PC CONFIGURATION

PRINTER PARAMETERS

DESCRIPTION HOW TO MODIFY THE

CURRENT VALUE

Defines the chart speed units. Select the desired units by

the

! or " keys.

Defines the value of chart speed

1.

Defines the value of chart speed

2.

Defines the gap between routine

printing of time, date, speed and

ranges.

Enable/disable pen offset

correction.