Grieve Corporation BV Installation Manual

Flow Control Valves Page 7000-S-1

Installation Instructions

– Support weight of piping independently. Do not

place any Maxon Flow Control Valve in a piping

bind. Provide pipe hangers and/or special support

for related manifolds.

– Maxon connecting base and linkage assemblies

are designed to locate and/or position the

control operator for its interaction with the Flow

Control Valve assembly. They are not intended to

support the weight of the control motor. Special

provisions will be required to support the weight of

the control operators.

– Use of pipe heavier than schedule #40 can

cause interference with butterfly-type Flow Control

Valves and restrict the valve from full opening.

– Flow Control Valves provide the means to

adjust fluid and/or gas flows. They should be

installed with at least four pipe diameter lengths of

straight pipe before and after the valve. This

lessens the chance of internal flow turbulence being

set-up in the piping manifolds and control valve.

– Check fluid flow direction through “-P” and “-O”

poppet-type valves. It must flow only in direction

matching the arrow cast into valve body. If necessary, valve body may be rotated per instructions

given on page 7016.

– Install flow control valves carefully and maintain

adequate dimensional clearance to allow full

stroke and travel of the valve’s control linkage.

Internal drive mechanisms within a control motor

may be damaged if linkage is restricted as to cause

binding in high or low flow position.

CAUTION: All Flow Control Valves are designed

for throttling service only and are not intended

for tight shut-off.

– Main system shut-off should always use a

manual “leak-tight” upstream fuel cock.

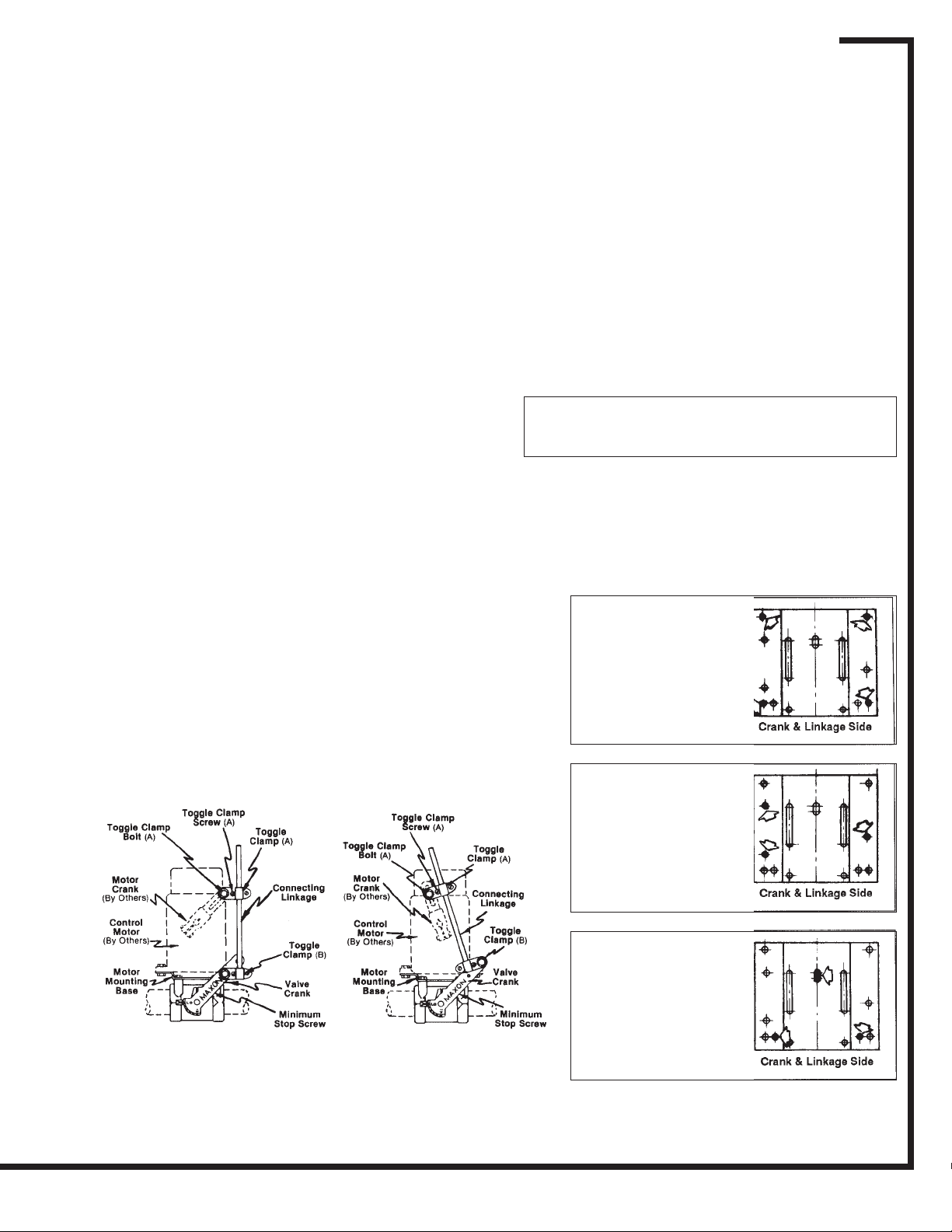

Mounting Instructions for motor operator on Series “CV” Flow Contr ol Valves

For those Series “CV” Valve assemblies furnished with

connecting base and linkage, the accompanying diagrams

illustrate mounting procedures relative to each specific type

operator.

First, mount your control motor to connecting base in

accordance with diagrams at right.

Secondly, determine if your electric operator travels

through 90° or 180° rotations. Then arrange connecting

linkage and motor crank arm as shown below for your

specific operator.

Honeywell

#M644, M744,

M941 or M944

(7616BR Crank)

Mount with four short bolts

and nuts at indicated holes.

90° Control Motor 160° – 180° Control Motor

Maxon practices a policy of continuous product improvement. It reserves the right to alter specifications without prior notice.

11/90

INDUSTRIAL COMBUSTION EQUIPMENT AND VALVES

Barber-Colman

EA50

Mount with three short bolts

and nuts at indicated holes.

Penn/Johnson

M80, M81

(MD3-600 Crank)

Mount with two short bolts

and nuts and long bolt

screwed into operator base

through slotted hole.

m

CORPORATION

MUNCIE, INDIANA, USA

Flow Control Valves Page 7000-S-1

Installation Instructions

– Support weight of piping independently. Do not

place any Maxon Flow Control Valve in a piping

bind. Provide pipe hangers and/or special support

for related manifolds.

– Maxon connecting base and linkage assemblies

are designed to locate and/or position the

control operator for its interaction with the Flow

Control Valve assembly. They are not intended to

support the weight of the control motor. Special

provisions will be required to support the weight of

the control operators.

– Use of pipe heavier than schedule #40 can

cause interference with butterfly-type Flow Control

Valves and restrict the valve from full opening.

– Flow Control Valves provide the means to

adjust fluid and/or gas flows. They should be

installed with at least four pipe diameter lengths of

straight pipe before and after the valve. This

lessens the chance of internal flow turbulence being

set-up in the piping manifolds and control valve.

– Check fluid flow direction through “-P” and “-O”

poppet-type valves. It must flow only in direction

matching the arrow cast into valve body. If necessary, valve body may be rotated per instructions

given on page 7016.

– Install flow control valves carefully and maintain

adequate dimensional clearance to allow full

stroke and travel of the valve’s control linkage.

Internal drive mechanisms within a control motor

may be damaged if linkage is restricted as to cause

binding in high or low flow position.

CAUTION: All Flow Control Valves are designed

for throttling service only and are not intended

for tight shut-off.

– Main system shut-off should always use a

manual “leak-tight” upstream fuel cock.

Mounting Instructions for motor operator on Series “CV” Flow Contr ol Valves

For those Series “CV” Valve assemblies furnished with

connecting base and linkage, the accompanying diagrams

illustrate mounting procedures relative to each specific type

operator.

First, mount your control motor to connecting base in

accordance with diagrams at right.

Secondly, determine if your electric operator travels

through 90° or 180° rotations. Then arrange connecting

linkage and motor crank arm as shown below for your

specific operator.

Honeywell

#M644, M744,

M941 or M944

(7616BR Crank)

Mount with four short bolts

and nuts at indicated holes.

Crank & Linkage Side

11/90

Barber-Colman

EA50

Mount with three short bolts

and nuts at indicated holes.

Penn/Johnson

M80, M81

(MD3-600 Crank)

Mount with two short bolts

and nuts and long bolt

90° Control Motor 160° – 180° Control Motor

Maxon practices a policy of continuous product improvement. It reserves the right to alter specifications without prior notice.

screwed into operator base

through slotted hole.

INDUSTRIAL COMBUSTION EQUIPMENT AND VALVES

Crank & Linkage Side

Crank & Linkage Side

m

CORPORATION

MUNCIE, INDIANA, USA

Page 7000-S-2 Flow Control Valves

Adjusting Instructions

Notice: Only generalized instructions can be provided

here. Detailed adjusting instructions are provided with

each individual Maxon burner and/or mixer system.

General Instructions

Important: Do not discard packing materials

until all loose items are accounted for.

To prevent damage in transit, some connecting

base and linkage components may be packed

separately and shipped loose with your new Maxon

Flow Control Valve.

The Flow Control Valve is normally only a part of

your complete combustion system. Additional pipe

train accessories and control components may be

required for a complete system installation.

Read complete instructions before proceeding,

and familiarize yourself with all the system’s

equipment components. Verify that your equipment

has been installed in accordance with the original

manufacturer’s current instructions.

CAUTION: Initial adjustment and light-off of

burner systems should be undertaken only by

trained and experienced personnel familiar with

combustion systems, with control/safety

circuitry, and with knowledge of the overall

installation. Instructions provided by the

company and/or individuals responsible for the

manufacture and/or overall installation of

complete system incorporating Maxon burners

take precedence over these provided by Maxon.

If Maxon instructions conflict with any codes or

regulations, contact Maxon Corporation before

attempting start-up.

For initial adjustment and/or burner start-up:

1. Close all burner fuel valves and cocks. Make

preliminary adjustments to fuel gas regulators.

2. Check all electric circuitry. Verify that all

control devices and interlocks are operable and

functioning within their respective settings/

ranges. Be sure all air and fuel manifolds are

tight and that test ports are plugged if not being

used.

3. Check that any air handling dampers are

properly positioned and locked into operating

positions.

4. Disconnect the automatic control motor’s

linkage from your control valve’s operating crank

arm by loosening the control motor’s connecting

rod from the burner’s toggle linkage.

Initial adjustment should only be

accomplished during a “manual” control

mode.

5. Start all system-related fans and blowers.

Check for proper motor rotation and impeller

direction. Verify that all control interlocks are

working. Allow air handling equipment to run for

adequate purge of your manifolds.

CAUTION: Do not by-pass control panel timers

typically controlling sequential operations.

6. With MICRO-RATIO

air and fuel valves, the minimum differential

pressure setting is initially established with

the air valve only.

A. By disconnecting the linkage between the air

butterfly valve and interconnected fuel

valve(s), the minimum and maximum limits of

travel on the air valve may be determined.

For example, a combustion system may

need the air valve to be 15° open for the

“minimum” setting and the “maximum”

requirements are satisfied with the air valve

open to 60°. By marking these points on the

air valve’s indicating strip, you are ready to

reconnect the SYNCHRO Fuel Valve’s

linkage to the air valve.

B. The next step involves adjusting the

connecting linkage between the air valve

and the fuel valve(s) so that each fuel valve

travels its full quadrant range (i.e. from

minimum to maximum), while the air valve

swings from its pre-determined minimum and

maximum positions.

C. With Series “CV” Valves and Series “Q”

adjustable-gradient Flow Control Valves,

the minimum flow position is set by their

minimum stop screw. This adjustable stop is

located on the side of the screw carrier of

Series “Q” Valves and at the base of crank

arm of Series “CV” Valves. Screwing “in” on

the minimum stop screw produces a physical

stop on the quadrant’s travel that prohibits

valve from being completely closed off.

®

Valve combinations of

m

CORPORATION

MUNCIE, INDIANA, USA

Maxon practices a policy of continuous product improvement. It reserves the right to alter specifications without prior notice.

INDUSTRIAL COMBUSTION EQUIPMENT AND VALVES