Page 1

Installation & Maintenance Instructions

2-WAY DIRECT-ACTING SOLENOID VALVES

NORMALLY OPEN OR NORMALLY CLOSED OPERATION

BRASS OR STAINLESS STEEL CONSTRUCTION - 1/8, 1/4, OR 3/8 NPT

Future Service Considerations.

IMPORTANT: See separate solenoid installation and maintenance

instructions for information on: Wiring, Solenoid Temperature,

Causes of Improper Operation, and Coil or Solenoid Replacement.

DESCRIPTION

Series 8262 and 8263 valves are 2-way direct-acting general service

solenoid valves. Valves bodies are of rugged brass or stainless steel.

Series 8262 or 8263 valves may be provided with a general purpose or

explosionproof solenoid enclosure. Series 8262 and 8263 valves with

suffix P" in the catalog number are designed for dry inert gas and

non-lubricated air service.

OPERATION

Normally Open: Valve is open when solenoid is de-energized; closed

when is energized.

Normally Closed: Valve is closed when solenoid is de-energized;

open when energized.

IMPORTANT: No minimum operating pressure required.

Manual Operation

Manual operator allows manual operation when desired or during an

electrical power outage. Depending upon basic valve construction,

three types of manual operators are available:

Push Type Manual Operator

To engage push type manual operator, push stem at base of valve body

upward as far as possible. Valve will now be in the same position as

when the solenoid is energized. To disengage manual operator, reĆ

lease stem. Manual operator will return to original position.

Screw Type Manual Operator

To engage screw type manual operator, rotate stem at base of the

valve body clockwise until it hits a stop. Valve will now be in the same

position as when the solenoid is energized. To disengage, rotate stem

counterclockwise until it hits a stop.

CAUTION: For valve to operate electrically, manual operator

stem must be fully rotated counterclockwise.

Stem/Lever Type Manual Operator

To engage manual operator, turn stem/lever clockwise until it hits a

stop. Valve will now be in the same position as when the solenoid is

energized. To disengage manual operator, turn stem/lever counterĆ

clockwise until it hits a stop.

CAUTION: For valve to operate electrically, manual operator

stem/lever must be fully rotated counterclockwise.

Flow Metering Devices

Valves with suffix M" in catalog number are provided with a meterĆ

ing device for flow control. Turn stem to right to reduce flow; left to

increase flow.

INSTALLATION

Check nameplate for correct catalog number, pressure, voltage,

frequency, and service. Never apply incompatible fluids or exceed

pressure rating of the valve. Installation and valve maintenance to be

performed by qualified personnel.

Note: Inlet port will either be marked I" or IN". Outlet port will be

marked 2" or OUT".

Provision should be made for performing seat leakage, external leakĆ

age, and operational tests on the valve with a nonhazardous,noncomĆ

bustible fluid after disassembly and reassembly.

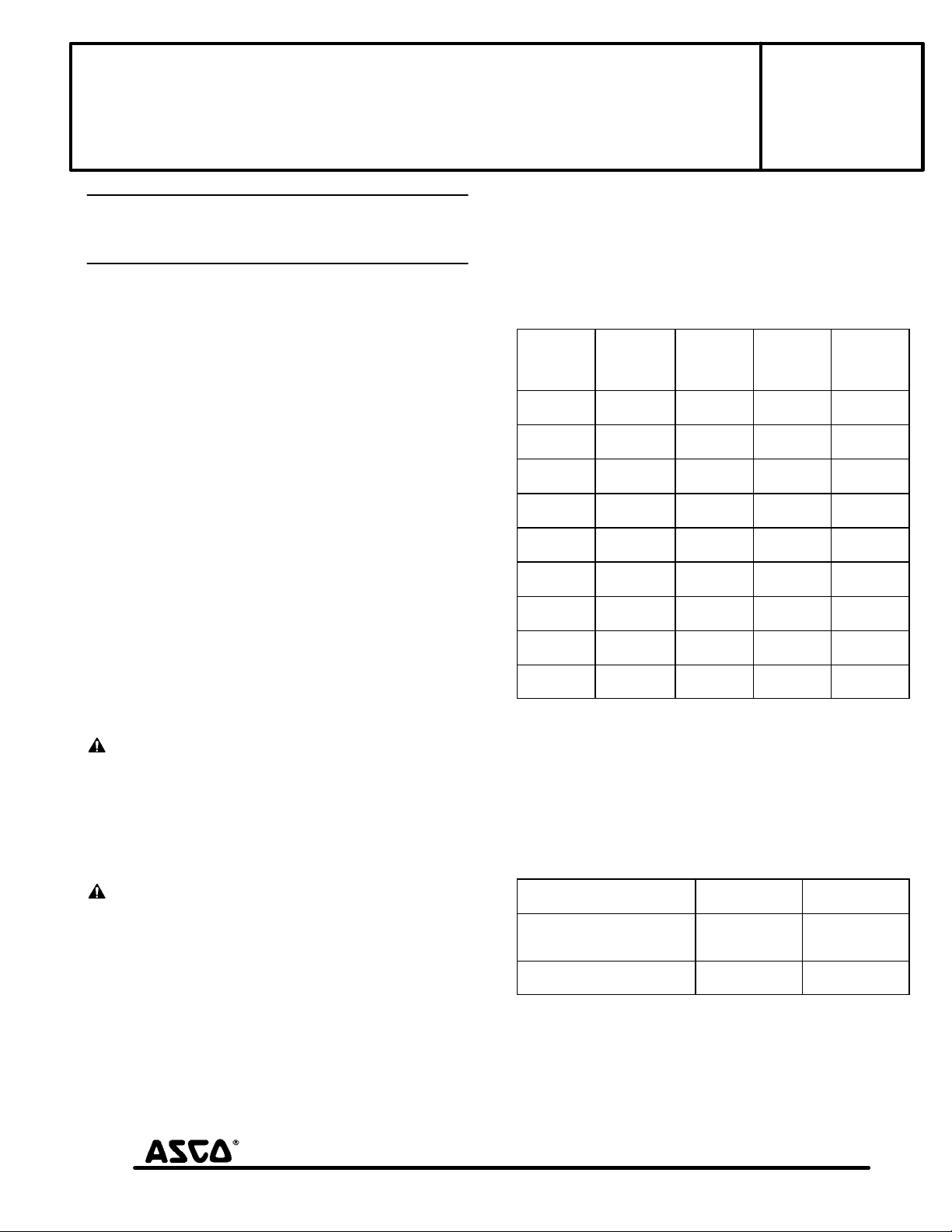

Temperature Limitations

For maximum valve ambient and fluid temperatures, refer to charts

below. Check catalog number, coil prefix, suffix, and watt rating on

nameplate to determine the maximum temperatures.

Catalog

Wattage

6, 10.5,

12.4

6,10.5

12.4

6,10.5,

12.4

9,10.7

9.7

11.2

16.7

17.1

17.1

Number

Coil

Prefix

none,ĂDA or

S

DF, FT

or SF

HT H 140 180

none, DP or

SP

none, FT or

HT

none, FT or

HT

none, DP or

SP

none, KP

SP or SD

HB, KB SS

or SV

Catalog Nos.8262B200 and 8262 C200 AC construction only and

Catalog Nos.8262B214 and 8262 D200 AC and DC construction are

limited to 140F fluid temperature.

Valves with Suffix V or W that are designed for AC service and norĆ

mally closed operation are for use with No. 2 and 4 fuel oil service.

These valves have the same maximum temperatures per the above

table except Suffix W valves are limited to a maximum fluid temperaĆ

ture of 140F.

Listed below are valves with Suffix V in the catalog number that are

acceptable for higher temperatures.

Catalog Number

Coil Prefix

FT8262, HB8262

FT8263, HB8263

8262G, 8263G

HT or HB 8262G

HT or HB 8263G

*The only exception is the 8262G and 8263G series (Class F coil) at 50

Hertz rated 11.1 and 17.1 watts are limited to 210F fluid temperature.

Positioning

This valve is designed to perform properly when mounted in any posiĆ

tion. However, for optimum life and performance, the solenoid

should be mounted vertically and upright to reduce the possibility of

foreign matter accumulating in the solenoid base sub-assembly area.

SERIES

8262

8263

Form No.V5256R9

Coil

Class

A 77 180

F 125 180

F 77 180

A, F

or H

A, F

or H

F 77 200

F 125 180

H 140 180

Max. Ambient

Temp.F

Max.

Ambient

Temp. F

77 120

77 150

Max. Fluid

Temp.F

125 250*

140 250

Max.

Fluid

Temp. F

MM All Rights Reserved.

50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

Printed in U.S.A.

Page 1 of 4

Page 2

Valves with suffix P" in the catalog number must be mounted with

the solenoid vertical and upright.

Mounting

Refer to Figure 2 for mounting dimensions.

Piping

Connect piping or tubing to valve according to markings on valve

body. Inlet port will either be marked I" or IN". Outlet port will be

marked 2" or OUT". Wipe the pipe threads clean of cutting oils.

Apply pipe compound sparingly to male pipe threads only. If applied

to valve threads, the compound may enter the valve and cause operaĆ

tional difficulty. Avoid pipe strain by properly supporting and alignĆ

ing piping. When tightening the pipe, do not use valve or solenoid as

a lever. Locate wrenches applied to valve body or piping as close as

possible to connection point.

IMPORTANT: To protect the solenoid valve, install a strainer or filĆ

ter suitable for the service involved, in the inlet side as close to the

valve as possible. Clean periodically depending on service condiĆ

tions. See ASCO Series 8600, 8601 and 8602 for strainers.

MAINTENANCE

WARNING: To preventĂ the possibility of death,

serious injury or property damage, turn off electrical

power, depressurize valve, and vent fluid to a safe area

before servicing the valve.

NOTE: It is not necessary to remove the valve from the pipeline for

repairs.

Cleaning

All solenoid valves should be cleaned periodically. The time between

cleanings will vary depending on the medium and service conditions.

In general, if the voltage to the coil is correct,sluggish valve operation,

excessive noise or leakage will indicate that cleaning is required. In

the extreme case, faulty valve operation will occur and the valve may

fail to open or close. Clean strainer or filter when cleaning the valve.

Preventive Maintenance

Keep the medium flowing through the valve as free from dirt and

foreign material as possible.

While in service, the valve should be operated at least once a

month to insure proper opening and closing.

Depending on the medium and service conditions, periodic

inspection of internal valve parts for damage or excessive wear is

recommended. Thoroughly clean all parts. If parts are worn or

damaged, install a complete ASCO Rebuild Kit.

Causes of Improper Operation

Incorrect Pressure: Check valve pressure. Pressure to valve must

be within range specified on nameplate.

Excessive Leakage: Disassemble valve (see Maintenance) and

clean all parts. If parts are worn or damaged, install a complete

ASCO Rebuild Kit.

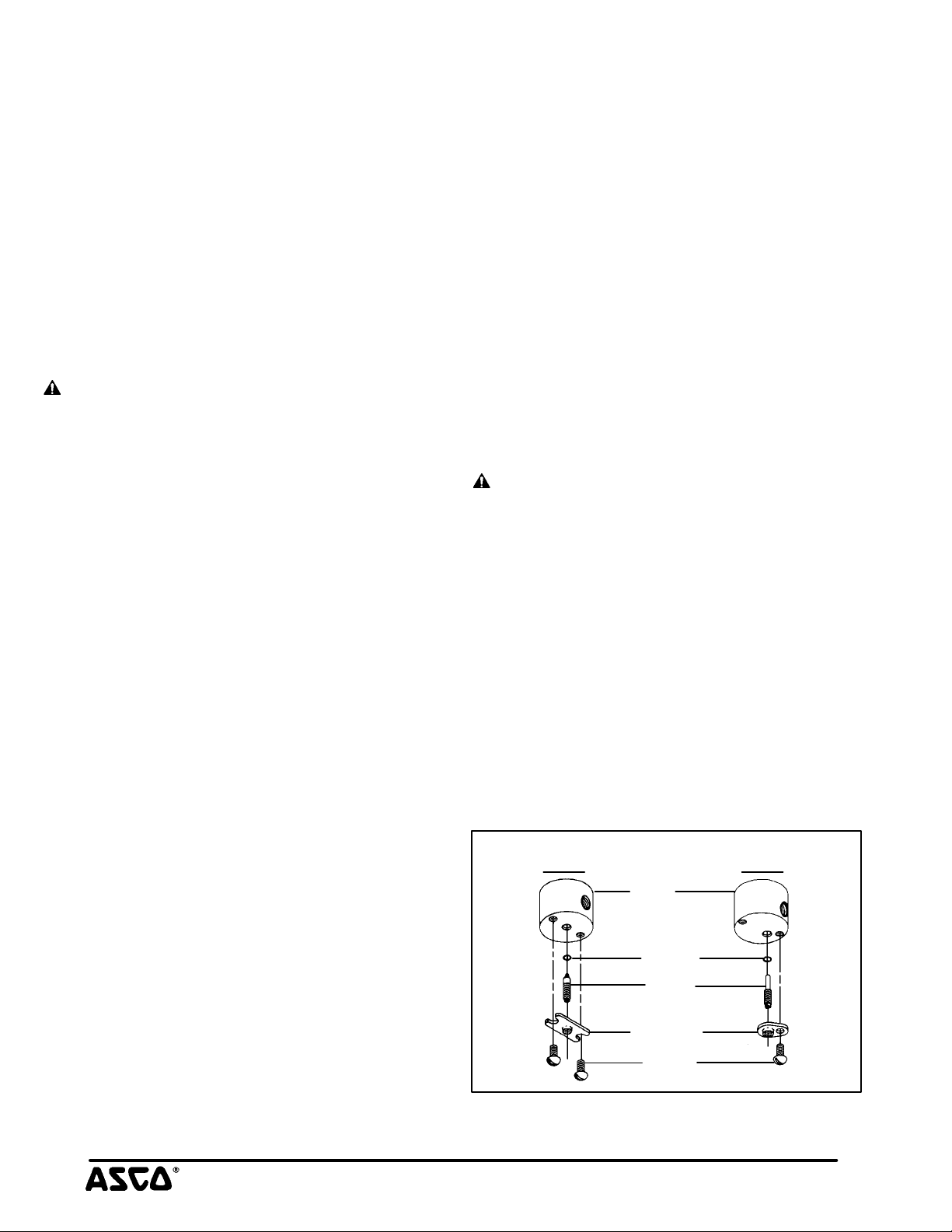

Valve Disassembly

1. Disassemble valve using exploded views for identification of parts.

2. Remove solenoid, see separate instructions.

3. Unscrew solenoid base sub-assembly or valve bonnet with

special wrench adapter supplied in ASCO Rebuild Kit. For

wrench adapter only, order No. K218948. Remove core

assembly, core spring, and solenoid base gasket from valve

body. For normal maintenance on Series 8263 valves it is not

necessary to remove valve seat. See Figure 1 for metering or

manual operator constructions.

4. For normally open construction (Figure 3) remove end cap, or

manual operator, (not shown) end cap gasket, disc holder

spring, and disc holder assembly.

5. All parts are now accessible to clean or replace. If parts are worn

or damaged, install a complete ASCO Rebuild Kit.

Valve Reassembly

1. Use exploded views for identification, orientation and placement

of parts.

2. Lubricate all gaskets with DOW CORNING 111 Compound

lubricant or an equivalent high-grade silicone grease.

3. For normally open construction (Figure 3), install disc holder

assembly, disc holder spring, end cap gasket and end cap or

manual operator. For valves with 1/8 NPT, torque end cap or

manual operator to 90ñ 10 in-lbs [10,2 ± 1,1 Nm]. For all othĆ

er valves torque end cap or manual operator to 175 ± 25 in-lbs

[19,8 ± 2,8 Nm].

4. For Series 8263 apply a small amount of LOCTITE PST pipe

sealant to threads of valve seat (if removed). Follow manufacĆ

turers instructions for application of pipe sealant. Then install

valve seat and torque to 75 ± Ă10 in-lbs [8,5 ± 1,1 Nm].

5. Replace solenoid base gasket, core assembly with core spring

and solenoid base sub-assembly or plugnut/core tube sub-asĆ

sembly and valve bonnet. Note: For core assemblies with interĆ

nal type core springs, install wide end of core spring in core asĆ

sembly first, closed end of core springĂ protrudes from top of

core assembly.

6. For 1/8 NPT valve constructions, Torque valve bonnet to 90 ± Ă10

in-lbs [10,2 ± 1,1 Nm]. Torque solenoid base sub-assembly to

175 ± 25 in-lbs [19,8 ± 2,8 Nm].

7. Install solenoid, see separate solenoid instructions. Then make

electrical hookup to solenoid.

WARNING: To prevent theĂ possibility of death,

serious injury or property damage, check valve for

proper operation before returning to service. Also perĆ

form internal seat and external leakage tests with a

nonhazardous, noncombustible fluid.

8. Restore line pressure and electrical power supply to valve.

9. After maintenance is completed, operate the valve a few times

to be sure of proper operation. A metallic click signifies the soĆ

lenoid is operating.

ORDERING INFORMATION

FOR ASCO REBUILD KITS

Parts marked with an asterisk (*) in the exploded view are supplied in

Rebuild Kits. When Ordering Rebuild Kits for ASCO valves, order

the Rebuild Kit number stamped on the valve nameplate. If the numĆ

ber of the kit is not visible, order by indicating the number of kits reĆ

quired, and the Catalog Number and Serial Number of the valve(s)

for which they are intended.

Metering

Device

body

(1/8 NPT only)

O-ring

stem

retainer

screw

Figure 1. Metering and manual operator constructions.

Manual

Operator

Page 2 of 4 Form No.V5256R9

50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

Page 3

Torque Chart

Bonnet wrench supplied in ASCO Rebuild Kits.

For bonnet wrench only order No. K218948.

Part Name

Torque value

Inch-Pounds Newton-Meters

Torque value

valve bonnet

bonnet gasket

plugnut/core tube

sub-assembly

core spring

(see note)

core assembly

body gasket

valve body

(1/8 NPT brass or

stainless steel)

mounting bracket

(stainless steel

construction only)

(see note)

valve body

(1/4 NPT

brass)

solenoid base

sub-assembly

valve bonnet

valve seat

+_+_

175 25 19,8 2,8

+_

90 10

+_+_

75 10 8,5 1,1

solenoid base

sub-assembly

core assembly

core spring

body gasket

valve body

(1/4 NPT

stainless steel)

mounting bracket

+_

10,2 1,1

(1/8 NPT brass)

Series 8262

Indicates Parts Supplied

in ASCO Rebuild Kits.

solenoid base

sub-assembly

(see note)

core assembly

body gasket

valve seat

valve body

(brass or

stainless steel)

Series 8263

Note:

Wide end of core spring in core first,

closed end protrudes from top of core.

Figure 2. Series 8262 and 8263, normally closed construction.

50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

Page 3 of 4Form No.V5256R9

Page 4

Disassembly and Reassembly of Stem /Lever Type Manual

Operator (Refer to Figure 3)

NOTE: There are two stem/lever manual operator constructions.

They are identified by the location of the core spring as internal or

external spring construction.

1. Unscrew solenoid base sub-assembly from manual operator

body.

2. Unscrew manual operator body from valve body. Then remove

body gasket and stem retainer.

3. Slip stem/spacer sub-assembly with stem gasket from manual

operator body. Remove core assembly with core spring from

center of manual operator body.

4. All parts are now accessible for cleaning or replacement.

Lubricate gaskets per Valve Reassembly step 2.

5. Position core assembly with core spring into base of manual

operator body. Then install stem/spacer sub-assembly into

manual operator body to engage with core assembly.

6. Reinstall stem retainer on body and stem/spacer sub-assembly.

IMPORTANT: The spacer on the stem/spacer sub-assembly must

be inside of the stem retainer for internal spring construction and

outside the stem retainer for external spring construction.

7. Replace body gasket and install manual operator assembly in

valve body. Torque manual operator body to 175 ± 25 in-lbs

[19,8 ± 2,8 Nm].

8. Replace solenoid base gasket and solenoid base sub-assembly.

Torque solenoid base sub-assembly to 175 ± 25 in-lbs [19,8

± 2,8 Nm].

9. Check manual operator for proper operation. Turn stem clockĆ

wise and counterclockwise; stem should turn freely without

binding.

External Spring

Construction

solenoid base

manual

operator

body

stem

gasket

stem/spacer

sub-assembly

core assembly

body gasket

valve body

Indicates Parts Supplied

In ASCO Rebuild Kits

Note:

Wide end of core spring in core first, closed

end protrudes from top of core.

Spacer location for

external spring

construction

sub-assembly

solenoid base

gasket

stem gasket

stem retainer

core spring

External

spacer

stem retainer

Internal Spring

Construction

Internal

core spring

(see note)

Spacer location for

internal spring

construction

spacer

Important: Spacer must be inside of stem retainer

for internal spring construction and outside of stem

retainer for external spring construction.

solenoid base

sub-assembly

mounting bracket

(optional feature)

4 positions

2 self-tapping

screws provided

(see note 4)

valve bonnet

bonnet gasket

plugnut/core tube

sub-assembly

core spring

(see note 3)

core assembly

body gasket

valve body

(see note 2)

(Port 3 plugged)

disc holder assembly

disc

disc spring

mounting bracket

optional feature

(see note 1)

1/8 NPT-Stainless Steel

core spring

(see note 3)

core assembly

body gasket

valve body

(see note 2)

(Port 3 plugged)

disc holder assembly

disc spring

body gasket

end cap

Notes:

1.

For mounting, a flat surface must be provided

across the entire length of the bracket. The

valve body becomes secure to bracket when

bracket is tightened into position.

2.

Body inverted for in-line piping. Inverted 1 is

valve inlet and inverted 2 is valve outlet.

3.

Wide end of core spring in core first, closed

end protrudes from top of core.

4.

Bonnet wrench supplied in ASCO Rebuild Kit.

For bonnet wrench only order No. K218948.

body gasket

end cap

1/4 NPT-Brass

Indicates Parts Supplied

In ASCO Rebuild Kits

Figure 3. Stem/lever type manual operators Figure 4. Series 8262, normally open construction.

Page 4 of 4 Form No.V5256R9

50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

Loading...

Loading...