Page 1

Installation & Maintenance Instructions

SERIES

2-WAY INTERNAL PILOT-OPERATED SOLENOID VALVES

NORMALLY OPEN OPERATION - 3/8", 1/2", OR 3/4" NPT

IMPORTANT: See separate solenoid installation and mainte nance

instr uctions for information on: Wirin g, Solenoid Temperature, Causes

of Improper Operation, Coil, or Solenoid Replacement.

DESCRIPTION

Series 8215 valves are 2-way normally open internal pilot-operated

diaphragm-type solenoid valves. Valve bodies are made of rugged

aluminum with trim and internal parts made of steel and stainless steel.

Series 8215 valves may be provided with a general purpose, explosionproof,

or watertight/explosionproof solenoid.

OPERATION

Normally Open: Valve is open when solenoid is de-energized; closed when

energized.

NOTE: No minimum operating pressure differential required.

INSTALLATION

CAUTION: Not all valves are approved for fuel gas service. Check nameĆ

plate for correct catalog number, pressure, voltage, frequency, and service.

Never apply incompatible fluids or exceed pressure rating of the valve. InĆ

stallation and valve maintenance to be performed by qualified personnel.

Future Service Considerations

Provision should be made for performing seat leakage, external leakage, and

operational tests on the valve with a nonhazardous, noncombustible fluid afĆ

ter disassembly and reassembly.

Temperature Limitations

For maximum valve ambient and fluid temperatures, refer to chart below.

Check catalog number prefix on nameplate to determine maximum

temperatures.

Construction

AC or DC

AC

DC

11.2 watts

DC

11.6 watts

Coil

Insulation

Class

F

H

F or H

F or H

Positioning

Valve is designed to perform properly when mounted in any position.

However, for optimum life and performance, the solenoid should be

mounted vertical and upright so as to reduce the possibility of foreign matter

accumulating in the solenoid base sub-assembly area.

Mounting

For mounting bracket (optional feature) dimensions, refer to Figure 1.

Piping

Connect piping to valve according to markings on valve body. Apply pipe

compound sparingly to male pipe threads only. If applied to valve threads

the compound may enter the valve and cause operational difficulty. Avoid

pipe strain by properly supporting and aligning piping. When tightening the

pipe, do not use valve or solenoid as a lever. Locate wrenches applied to

valve body or piping as close as possible to connection point.

CAUTION: To avoid damage to the valve body, DO NOT OVERTIGHTEN

PIPE CONNECTIONS. If Teflon* tape, paste, spray, or similar lubricant

is used, use extra care when tightening due to reduced friction.

Catalog

Number

Prefix

None

HT

None or

HT

None or

HB

Max.

Ambient

Te mp _F

125

140

77 77

104 104

Max.

Fluid

Te mp _F

125

140

8215

Form No.V5984R1

IMPORTANT: To protect the solenoid valve, install a strainer or filter,

suitable for the service involved, in the inlet side as close to the valve as

possible. Clean periodically depending on service conditions. See ASCO

Series 8600, 8601, and 8602 for strainers.

MAINTENANCE

WARNING: To prevent the possibility of severe

personal injury or property damage, turn off electrical

power, depressurize valve, extinguish all open flames and

avoid any type of sparking or ignition. Vent hazardous or

combustible fluid to a safe area before servicing the valve.

NOTE: It is not necessary to remove the valve from the pipeline for repairs.

Cleaning

All solenoid valves should be cleaned periodically. The time between

cleanings will vary depending on the medium and service conditions. In

general, if the voltage to the coil is correct, sluggish valve operation,

excessive noise or leakage will indicate that cleaning is required. In the

extreme case, faulty valve operation will occur and the valve may fail to open

or close. Clean valve strainer or filter when cleaning the valve.

Preventive Maintenance

1. Keep the medium flowing through the valve as free from dirt and

foreign material as possible.

2. While in service, the valve should be operated at least once a month to

insure proper opening and closing.

3. Depending on the medium and service conditions, periodic inspection

of internal valve parts for damage or excessive wear is recommended.

Thoroughly clean all parts. If parts are worn or damaged, install a comĆ

plete ASCO Rebuild Kit.

Causes of Improper Operation

1. Incorrect Pressure: Check valve pressure. Pressure to valve must be

within range specified on nameplate.

2. Excessive Leakage: Disassemble valve and clean all parts. If parts are

worn or damaged, install a complete ASCO Rebuild Kit.

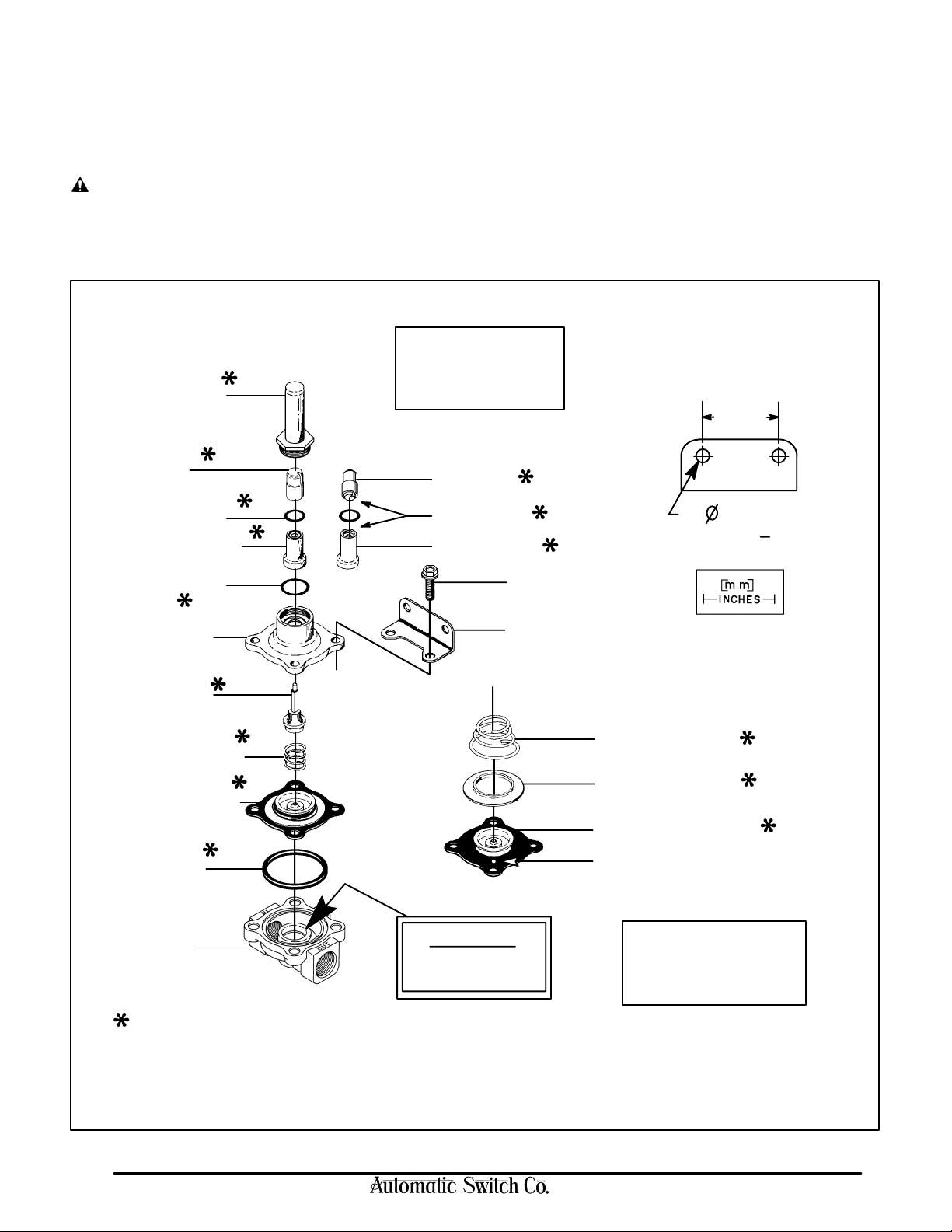

Valve Disassembly (Refer to Figure 1)

1. Remove solenoid, see separate instructions.

2. Unscrew solenoid base sub-assembly from valve bonnet

3. Remove solenoid base sub-assembly, core, plugnut gasket, plugnut

assembly and solenoid base gasket from valve bonnet.

4. Remove bonnet screws, valve bonnet, disc holder sub-assembly, disc

holder spring, diaphragm/spring sub-assembly and body gasket.

5. All parts are now accessible for cleaning or replacement. If parts are

worn or damaged, install a complete ASCO Rebuild Kit.

Valve Reassembly

1. Lubricate plugnut gasket, solenoid base gasket, and body gasket with

a light coat of DOW CORNINGr 200 Fluid lubricant or an

equivalent high-grade silicone fluid.

2. Position body gasket and diaphragm/spring sub-assembly in valve

body. Locate the bleed hole in diaphragm/spring sub-assembly

approximately 45_ from valve outlet.

NOTE: Should diaphragm/spring sub-assembly become disassembled, be sure to replace the diaphragm/spring support with lip

facing upward toward the valve bonnet.

3. Position disc holder spring and disc holder sub-assembly on diaphĆ

ragm/spring sub-assembly.

4. Replace valve bonnet and bonnet screws on valve body. Hand thread

screws a few turns into valve body; then torque bonnet screws in a crissĆ

cross manner 70 ± 8 in-lbs [8,0 ± 0,9 Nm].

*DuPont's Registered Trademark

e

ASCO Valves

MCMXCI All Rights Reserved.

1 of 2

50-60 Hanover Road, Florham Park, New Jersey 07932

Page 2

5. Install solenoid base gasket, plugnut assembly, plugnut gasket core

(small end up), and solenoid base sub-assembly. For DC

Construction, be sure plugnut assembly and core are installed with

mated ends together.

6. Torque solenoid base sub-assembly to 175 ± 25 in-lbs

[19,8 ± 2,8 Nm].

7. Replace solenoid (see separate instructions) and make electrical hookĆ

up.

WARNING: To prevent the possibility of severe

personal injury or property damage, check valve for proper

operation before returning to service. Also perform

internal seat and external leakage tests with a nonhazardĆ

ous, noncombustible fluid.

8. Restore line pressure and electrical power supply to valve.

9. After maintenance is completed, operate the valve a few times to be

sure of proper operation. A metallic click" signifies the solenoid is opĆ

erating.

ORDERING INFORMATION

FOR ASCO REBUILD KITS

Parts marked with a asterisk (*) in the

exploded views are supplied in Rebuild Kits.

S When Ordering Rebuild Kits for ASCO Valves, order the Rebuild Kit

number stamped on the valve nameplate.+

+If the number of the kit is not visible, order by indicating the number of

kits required, and the Catalog Number and Serial Number of the valve(s)

for which they are intended.

solenoid base

sub-assembly

core (AC)

(small end up)

plugnut gasket

plugnut assembly

(AC)

solenoid base

gasket

valve bonnet

disc holder

sub-assembly

disc holder spring

diaphragm/spring

sub-assembly

Torque solenoid base

sub-assembly to

_

+

175 25 in-lbs

_

+

[19,8 2,8 Nm]

core (DC)

mated ends

plugnut (DC)

bonnet screw (4)

mounting bracket

two positions

(optional feature)

Partial view of

mounting bracket

(optional)

[42.1]

1.656

[ 7.1]

.281 diameter

2 mounting holes

diaphragm spring

diaphragm spring

support

diaphragm assembly

body gasket

valve body

Supplied in ASCO Rebuild Kit

Figure 1. Series 8215 Valve Without Solenoid.

ASCO Valves

bleed hole

( see note )

CAUTION

Do not damage

valve seat

NOTE: Locate bleed hole 45 from valve outlet.

_

50-60 Hanover Road, Florham Park, New Jersey 07932

Torque bonnet screws

in a crisscross manner

_

+

to 70 8 in-lbs

_

+

[8,0 0,9 Nm]

2 of 2Form No.V5984R1

Loading...

Loading...